Manganese nickel cobalt composite lithium-inserting oxide and manufacturing method thereof

A technology of composite oxides and composite hydroxides, which is applied in the direction of lithium oxides;/hydroxides, nickel compounds, cobalt compounds, etc., can solve the problems of capacity loss and other problems, and achieve a small cycle decline rate, which is beneficial to popularization and improvement The effect of working voltage platform and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The manganese nitrate of 0.5mol, the nickel nitrate of 0.5mol and the cobalt nitrate of 0.05mol are mixed to make 300 milliliters of brown-black mixed solution with molar ratio Mn:Ni:Co=1:1:0.1, and the temperature of the control solution is 35°C , add dropwise 2.5M sodium hydroxide solution at a stirring speed of 250red / min until the pH of the solution is 9.5, stop stirring, filter to obtain a yellow-green precipitate, and then place the precipitate in a drying oven at 400°C Dry for 5 hours to obtain a black product. Wash the product three times with distilled water at 50-60°C, then filter, add 60 grams of lithium nitrate and 50 ml of distilled water to the filter residue, mix, slowly dry, press into discs, and place in Roasting in an air furnace at 750°C for 24 hours, pulverizing after cooling, and passing through a 200-mesh sieve to obtain a manganese-nickel-cobalt composite lithium intercalation oxide powder of brown-black lithium-ion battery cathode material.

[00...

Embodiment 2

[0025] Mix the manganese nitrate of 0.51mol, the nickel nitrate of 0.5mol and the cobalt nitrate of 0.1mol to make 500 milliliters of the brown-black mixed solution of molar ratio Mn: Ni: Co=1.02: 1: 0.2, control solution temperature to be 50 ℃ , under the condition of stirring speed of 300red / mind, add 2M lithium hydroxide solution dropwise until the pH value of the solution is 10, stop stirring, filter to obtain a yellow-green precipitate, and then dry the precipitate in a drying oven at 550°C After 2 hours, the black product was fully mixed with 31.5g of ground lithium carbonate, pressed into discs and then roasted in an oxygen furnace at 900°C for 16 hours. After cooling, it was pulverized and passed through a 200-mesh sieve to obtain a black lithium-ion battery positive electrode. Material Manganese nickel cobalt composite lithium intercalation oxide powder.

[0026] The obtained material was analyzed with an IRIS Advantage 1000 ICP-AES type plasma emission spectrometer, ...

Embodiment 3

[0028] Except that the amount of cobalt nitrate is 0.15mol, molar ratio Mn: Ni: Co=1.02: 1: 0.3, the pH value when the precipitation terminates is 12 and the amount of lithium carbonate is 33.5g, other conditions are all identical with embodiment two, Manganese-nickel-cobalt composite lithium-intercalation oxide powder, which is a positive electrode material for lithium-ion batteries, is obtained.

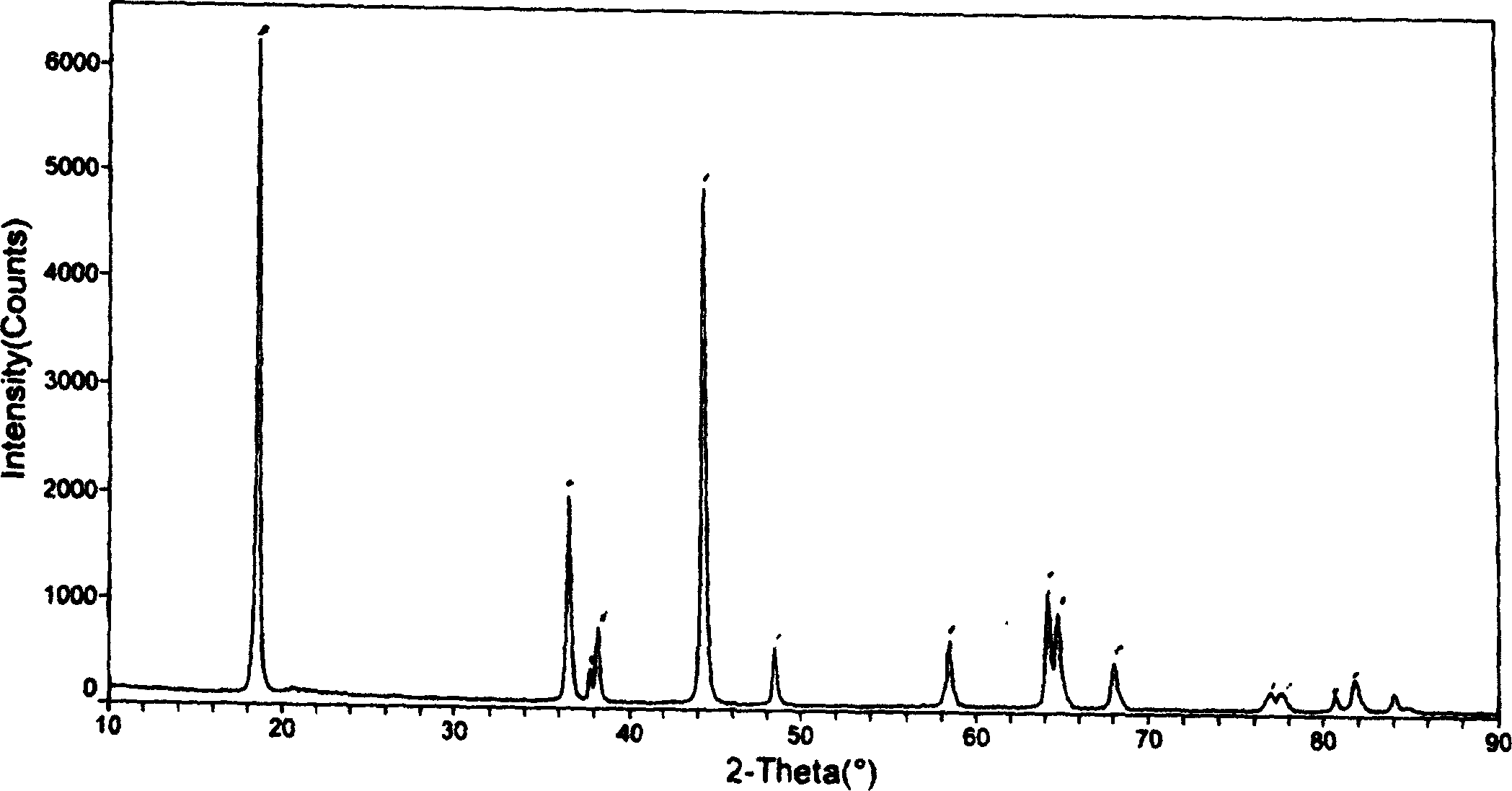

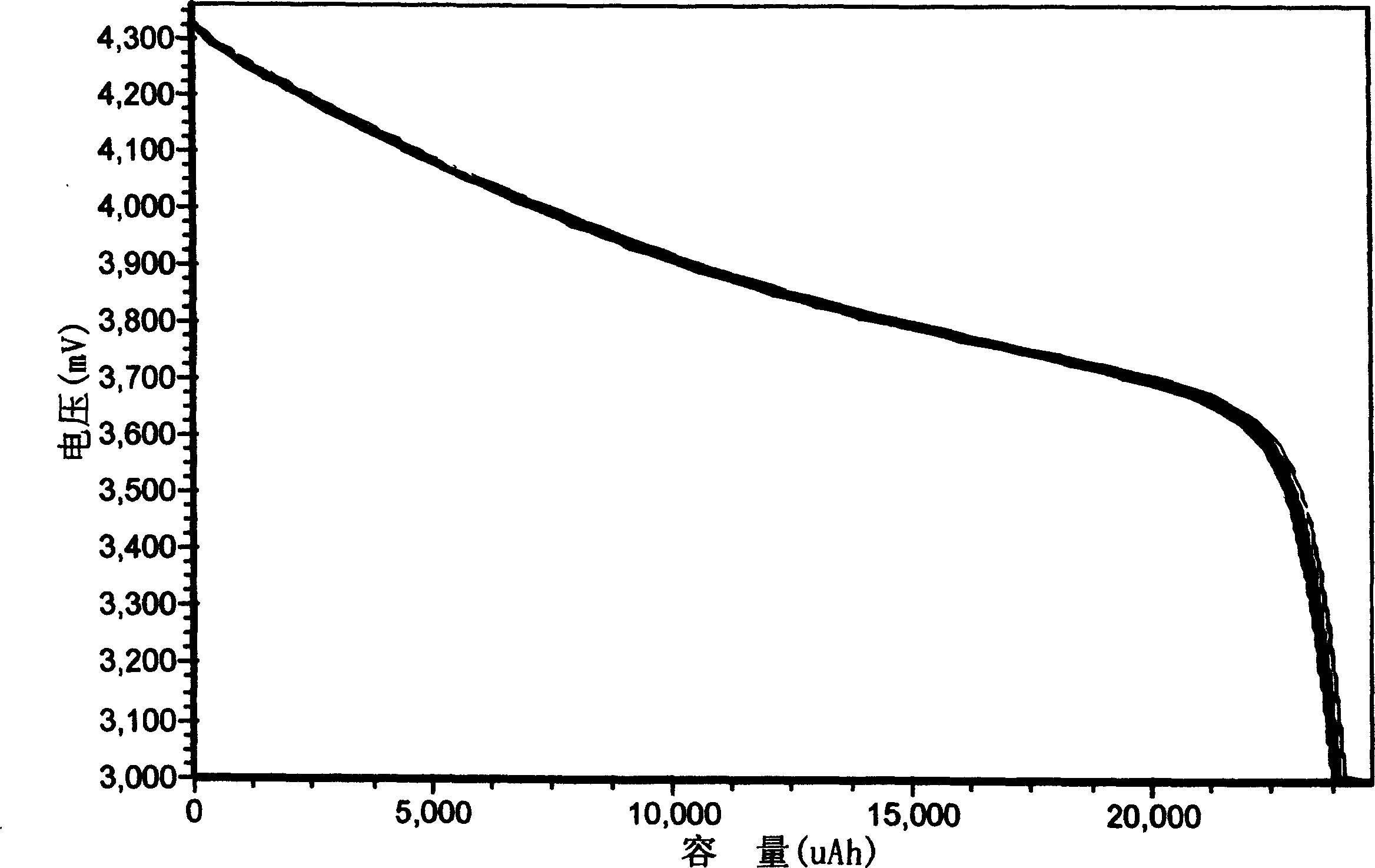

[0029] The obtained material is analyzed with an IRIS Advantage 1000 ICP-AES type plasma emission spectrometer, and the contents of Li, Mn, Ni and Co are respectively 4.36%, 24.94%, 25.49% and 7.45%; The particle size analysis was carried out by the instrument, and the median diameter was 6.23 μm. Carry out XRD test, the result shows that crystal structure is hexagonal system. The obtained material was used as the positive electrode, and the metal lithium sheet was used as the negative electrode to assemble an experimental battery. The charge and discharge test was carried out in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com