Method for preparing multilevel porous carbon base composite phase change material

A technology of composite phase change materials and carbon materials, which is applied in the field of preparation of multi-level porous carbon-based composite phase change materials, can solve the problems of low utilization rate of heat storage, small specific surface area, poor heat transfer performance, etc., and achieve a wide temperature range , Excellent heat transfer performance, and the effect of improving heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of metal-organic framework template materials:

[0028] Dissolve 3.06 g of terephthalic acid and 10.89 g of zinc nitrate nonahydrate in 360 ml of DMF to prepare a homogeneous solution, stir magnetically for 30 mins, add 14.4 g of triethylamine to the solution, and stir at room temperature for 30 min, a solid product was obtained. After the reaction, it was filtered and washed repeatedly, and dried at 120 °C for 24 h to obtain the metal-organic framework template material MOF-5.

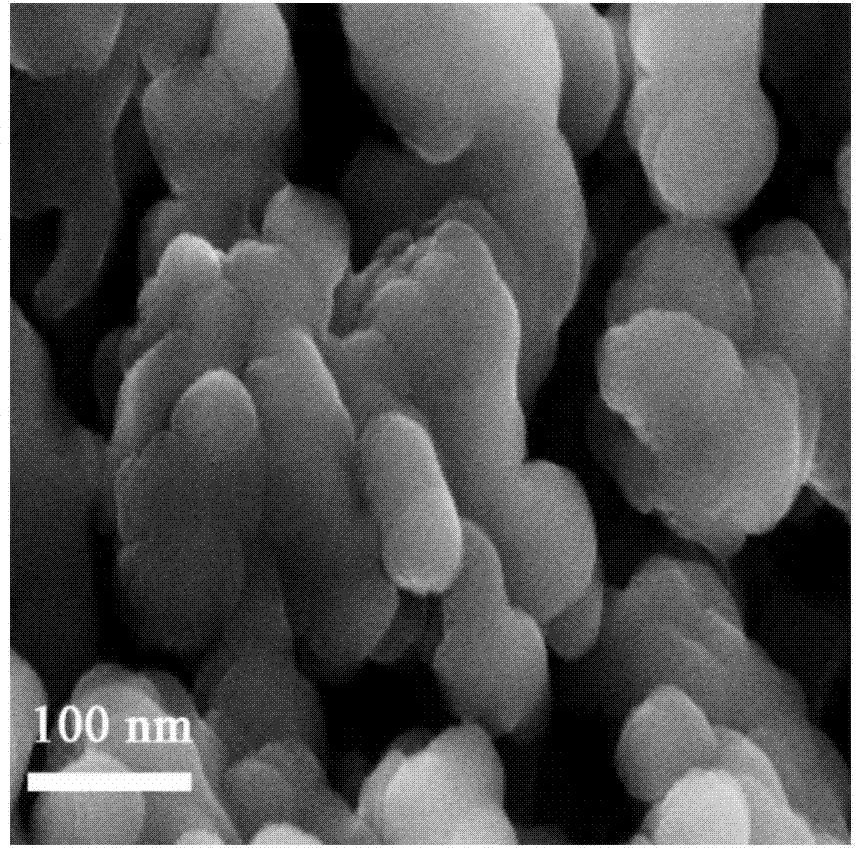

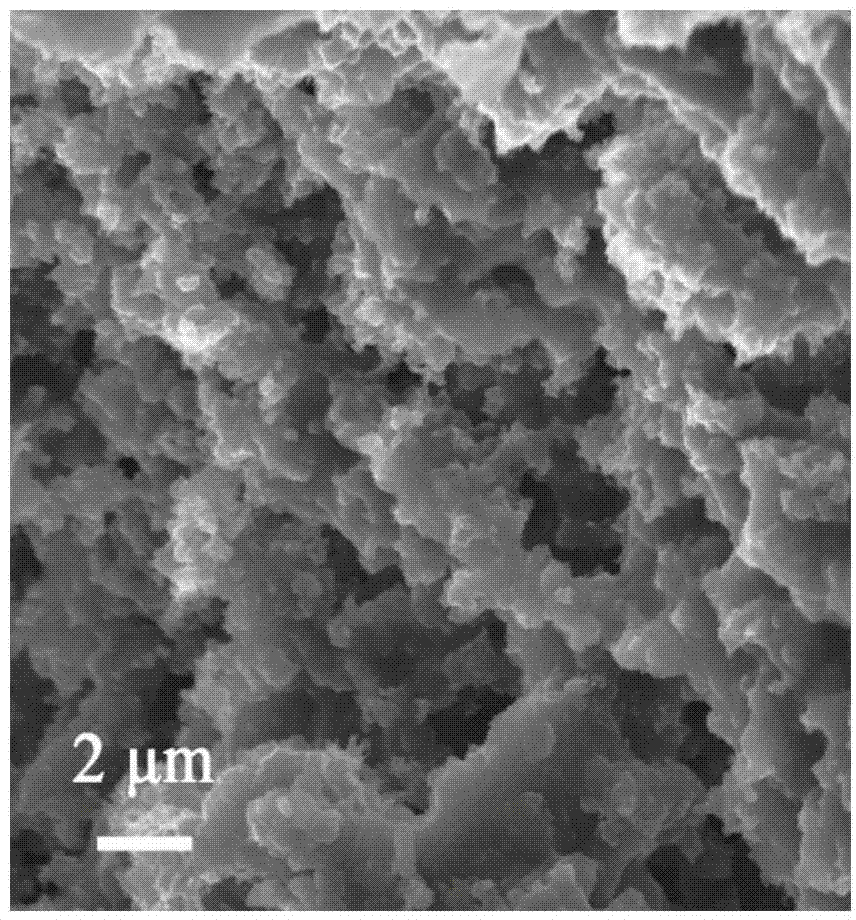

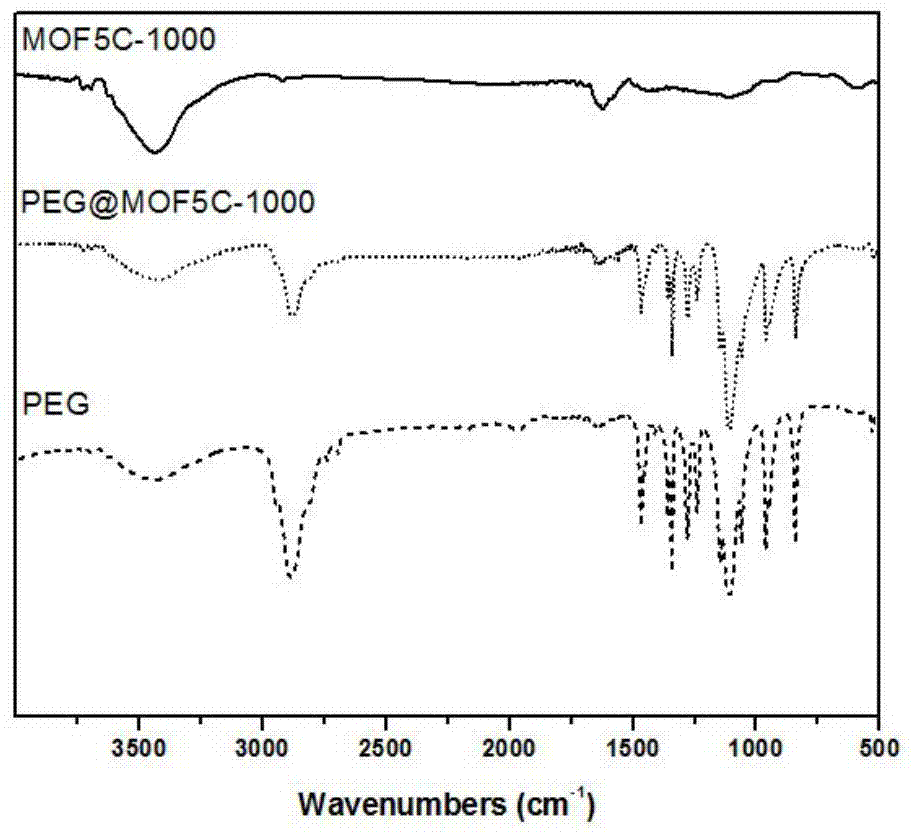

[0029] (2) Preparation of multi-level porous carbon materials:

[0030] Put metal-organic framework material MOF-5 powder into a porcelain boat and transfer it to a tube furnace. First pass nitrogen gas for 30 mins, and then raise the temperature to 1000 °C at a rate of 5 °C / min under the protection of an inert gas. o C and kept for 6 h, then naturally cooled to room temperature, washed several times with 1 mol / L hydrochloric acid solution, then washed with deionized water unt...

Embodiment 2

[0034] (1) Preparation of metal-organic framework template materials:

[0035]Dissolve 3.06 g of 2-aminoterephthalic acid and 10.89 g of zinc nitrate nonahydrate in 360 ml of DMF to prepare a homogeneous solution, stir magnetically for 30 mins, and add 2.7 ml of 30 wt% H 2 o 2 and 14.4 g of triethylamine were stirred at room temperature for 30 min to obtain a solid product. After the reaction, it was filtered and washed repeatedly with DMF and methanol, and dried at 120 °C for 24 h to obtain the metal-organic framework template material IRMOF-3.

[0036] (2) Preparation of multi-level porous carbon materials:

[0037] Put the metal-organic framework material IRMOF-3 powder into a porcelain boat and transfer it to a tube furnace. First pass nitrogen gas for 30 mins, and then raise the temperature to 1000 °C at a rate of 5 °C / min under the protection of an inert gas. o C and kept for 6 h, then naturally cooled to room temperature, washed several times with 1 mol / L hydrochlori...

Embodiment 3

[0041] (1) Preparation of metal-organic framework template materials:

[0042] Dissolve 3.0 g of TDBTM and 10.89 g of zinc nitrate nonahydrate in 360 ml of DMF to prepare a homogeneous solution, stir magnetically for 30 mins, add 14.4 g of triethylamine to the solution, and stir at room temperature for 30 min to obtain solid product. After the reaction, the chloroform was filtered and washed several times, and dried at 80 °C for 24 h to obtain the metal-organic framework template material Zn-TPBTM.

[0043] (2) Preparation of multi-level porous carbon materials:

[0044] Put the metal-organic framework material Zn-TPBTM powder into a porcelain boat and transfer it to a tube furnace, first pass nitrogen gas for 30 min, and then raise the temperature to 1000 °C at a rate of 5 °C / min under the protection of an inert gas. o C and kept for 6 h, then naturally cooled to room temperature, washed several times with 1 mol / L hydrochloric acid solution, then washed with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com