Preparation method of hybrid graphene gel/phase-change heat-conducting composite material

A graphene gel, phase change heat conduction technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of uneven dispersion, easy stacking, etc., achieve good repeatability, improve thermal conductivity, and improve thermal conductivity. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

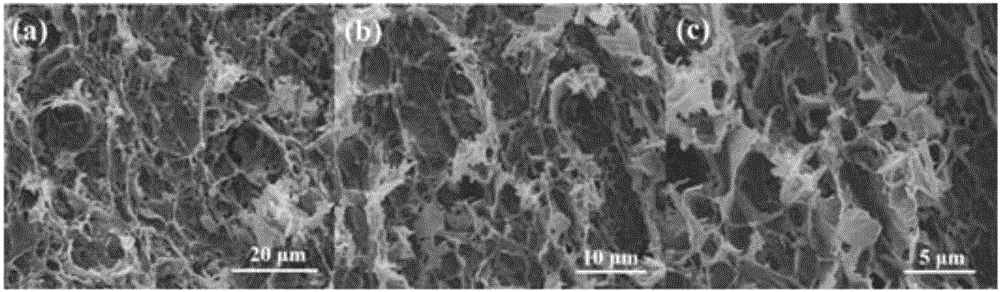

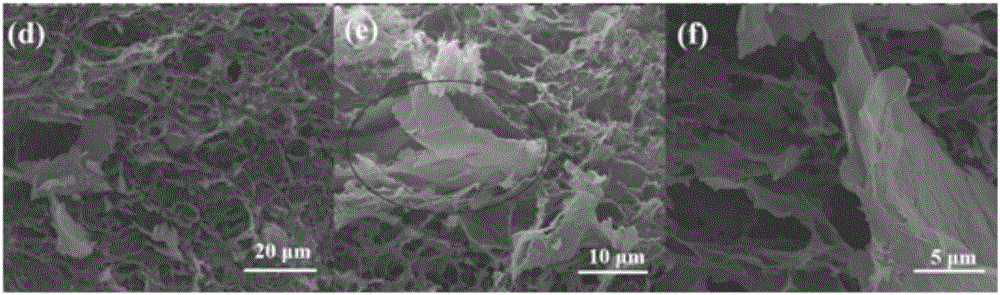

Embodiment 1

[0036] (1) Dissolve graphite oxide in water, stir for 60 minutes, and ultrasonicate for 2 hours to prepare a graphene oxide solution with a certain concentration, the concentration range is 4mg / ml;

[0037] (2) Take 50ml of graphene oxide solution and place it in a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 24 hours. After the reaction, the graphene columnar body was taken out, and vacuum freeze-dried for 24 hours using a vacuum freeze dryer to obtain a graphene gel.

[0038] (3) Place hexadecanoic acid as the phase change material and the graphene gel in a vacuum oven for vacuuming. After maintaining under vacuum for 1 hour, heat at 80° C. to melt the phase change material, and take it out after 2 hours. The excess phase change material is filtered out, and the hybrid graphene gel phase change composite material is obtained after the sample is cooled to room temperature.

Embodiment 2

[0040] (1) Dissolve graphite oxide in water, stir for 60 minutes, and ultrasonicate for 2 hours to prepare a graphene oxide solution with a certain concentration, the concentration range is 4mg / ml;

[0041] (2) Take 50ml of graphene oxide solution, add a certain amount of graphene nanosheets (the mass ratio of graphene oxide to graphene nanosheets is 4:1), stir for 30min, and ultrasonicate for 2h to obtain graphene oxide / graphene solution .

[0042] (3) Put it in a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 24 hours. After the reaction, the graphene column was taken out, and vacuum freeze-dried for 24 hours using a vacuum freeze dryer to obtain a hybrid graphene gel.

[0043](4) Place hexadecanoic acid as the phase change material and the graphene gel in a vacuum oven for vacuuming. After maintaining under vacuum for 1 hour, heat at 80° C. to melt the phase change material, and take it out after 2 hours. The excess phase change material is filtered ...

Embodiment 3

[0046] (1) Dissolve graphite oxide in water, stir for 60 minutes, and ultrasonicate for 2 hours to prepare a graphene oxide solution with a certain concentration, the concentration range is 4mg / ml;

[0047] (2) Take 50ml of graphene oxide solution, add a certain amount of graphene nanosheets (the mass ratio of graphene oxide to graphene nanosheets is 2:1), stir for 30min, and ultrasonicate for 2h to obtain graphene oxide / graphene solution .

[0048] (3) Put it in a reaction kettle, and conduct a hydrothermal reaction at 180° C. for 24 hours. After the reaction, the graphene column was taken out, and vacuum freeze-dried for 24 hours using a vacuum freeze dryer to obtain a hybrid graphene gel.

[0049] (4) Place hexadecanoic acid as the phase change material and the graphene gel in a vacuum oven for vacuuming. After maintaining under vacuum for 1 hour, heat at 80° C. to melt the phase change material, and take it out after 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com