Patents

Literature

34 results about "Human material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

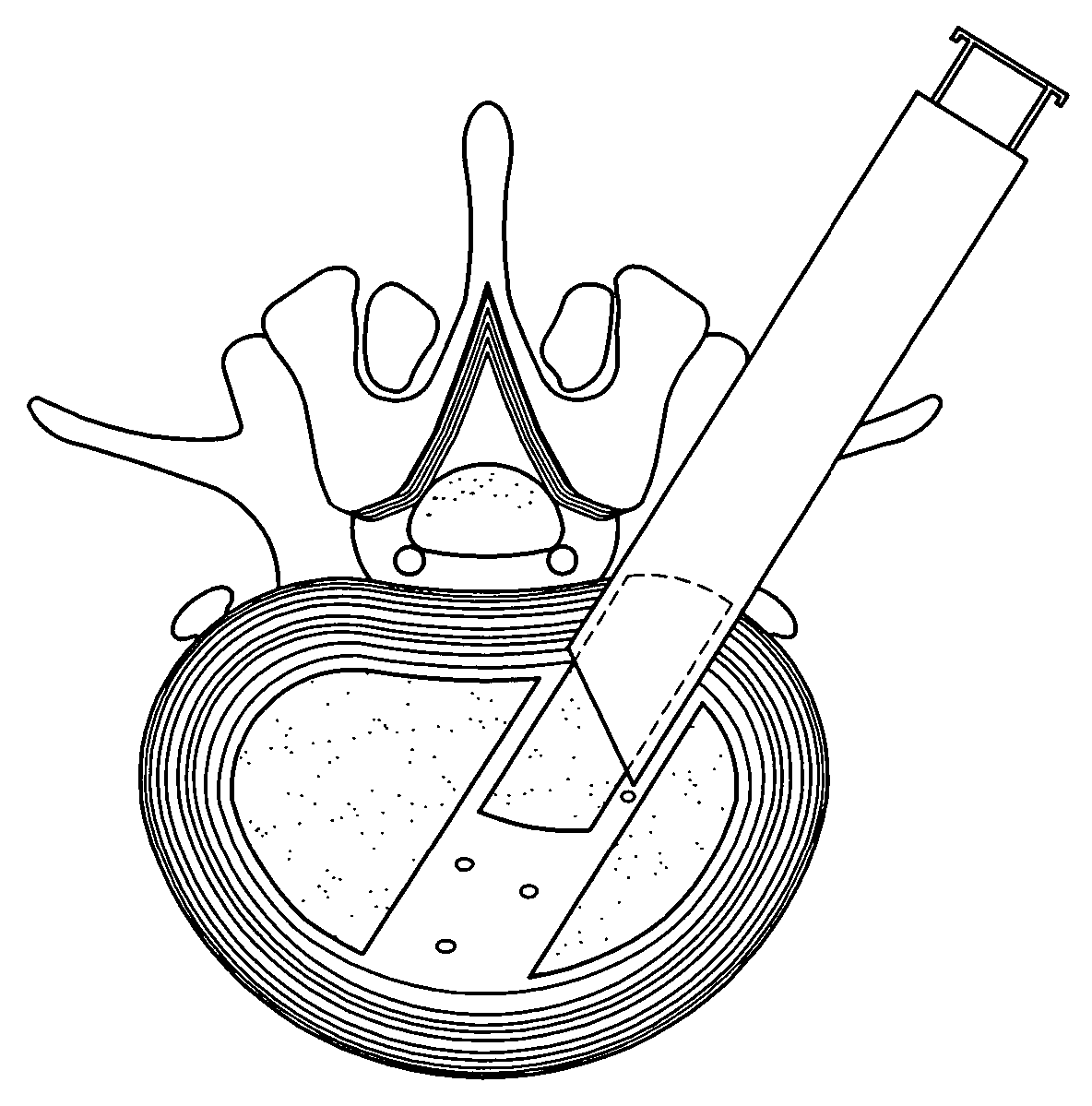

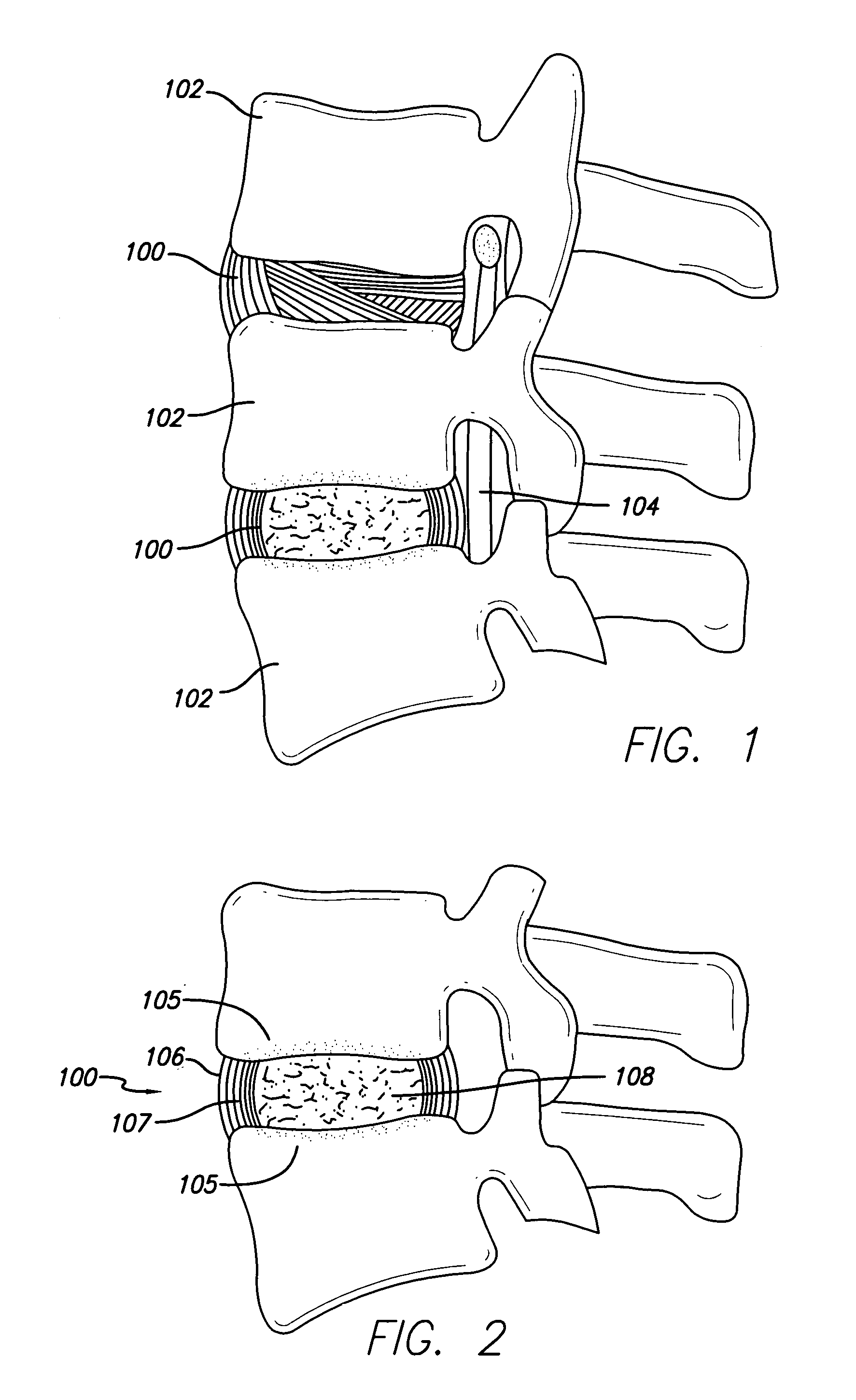

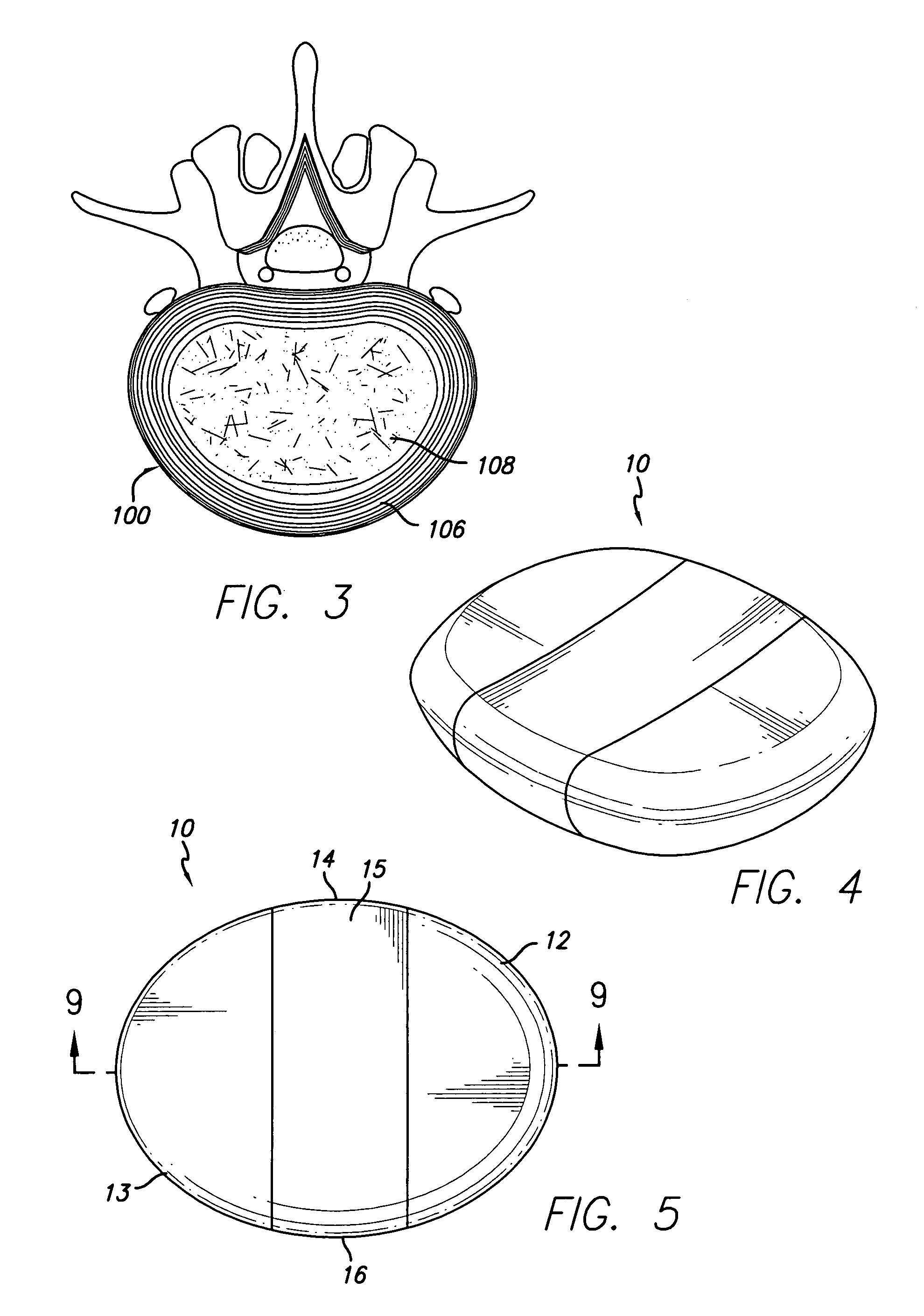

Implant material for minimally invasive spinal interbody fusion surgery

InactiveUS20060106462A1Easily be inserted into positionInternal osteosythesisBone implantSpinal columnHydroxyapatite ceramics

An implant device for spinal interbody fusion surgery has a shape substantially similar to a human excavated disc space, and includes a first modular end section, at least one modular middle section disposed adjacent to the first modular end section, a second modular end section disposed adjacent to the modular middle section and wherein when the first end section, the middle section and the second end section are placed adjacent to each other, the implant device has a shape with is substantially oval, viewed from top, and a cross section which is bi-convex. The preferred embodiment of the implant device is manufactured from human bone material that has been formed into the shape of the modular components. Alternative embodiments are manufactured from non-human material such as hydrooxyapetite, ceramics, coral and other biodegradable material. Non-resorptable plastic and metal can be used as internal structural members of the implant modules.

Owner:TSOU PAUL M

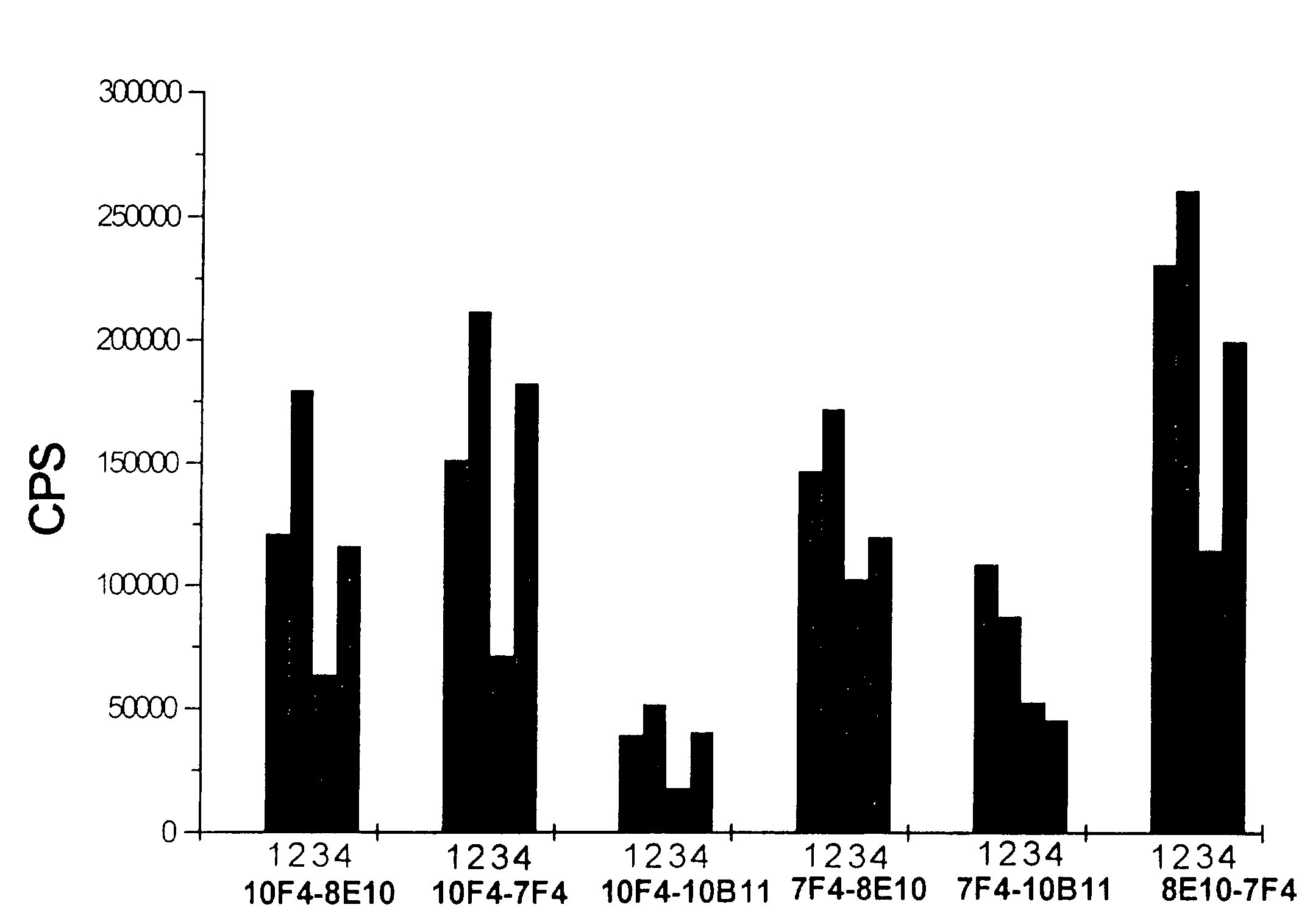

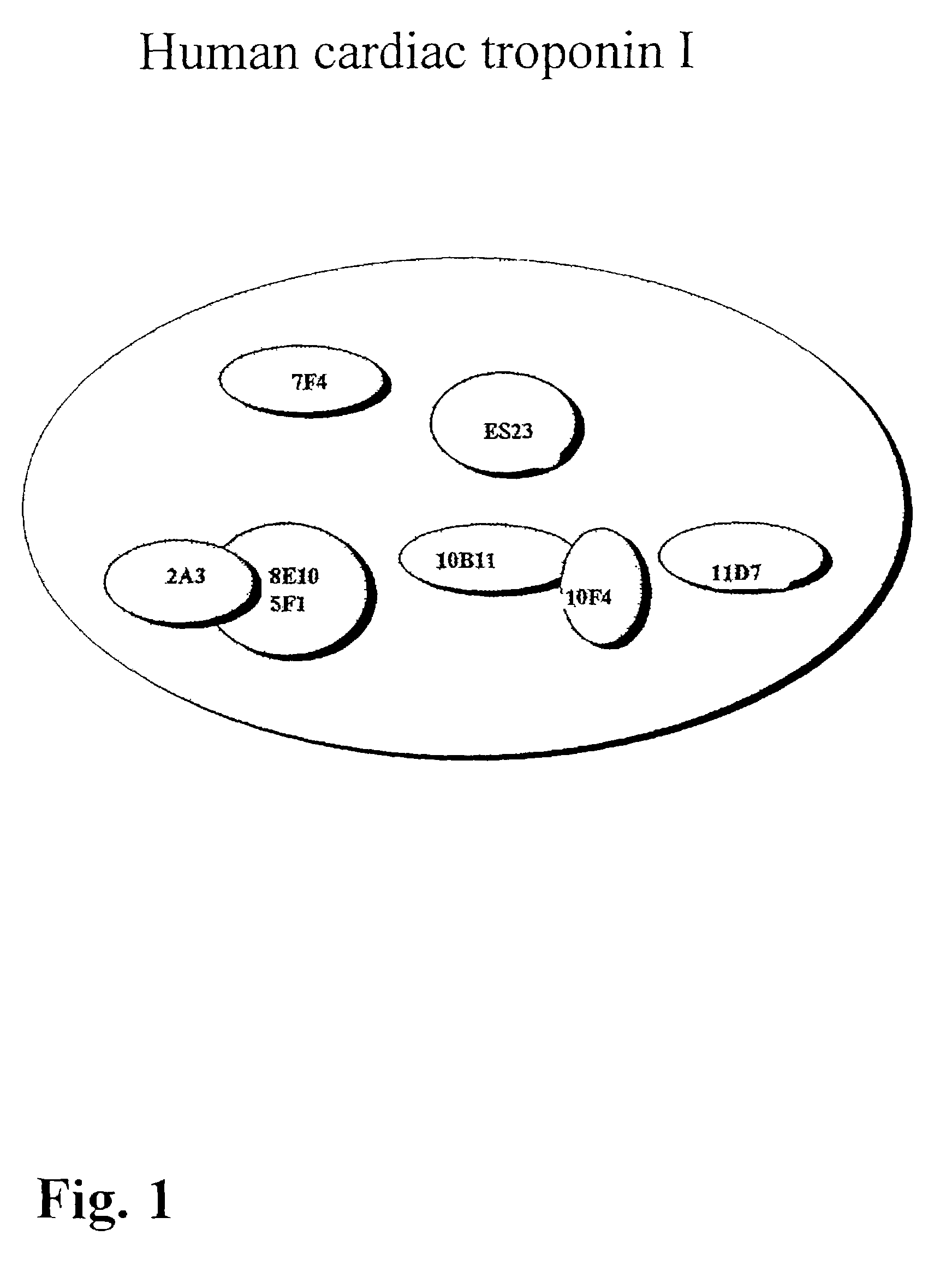

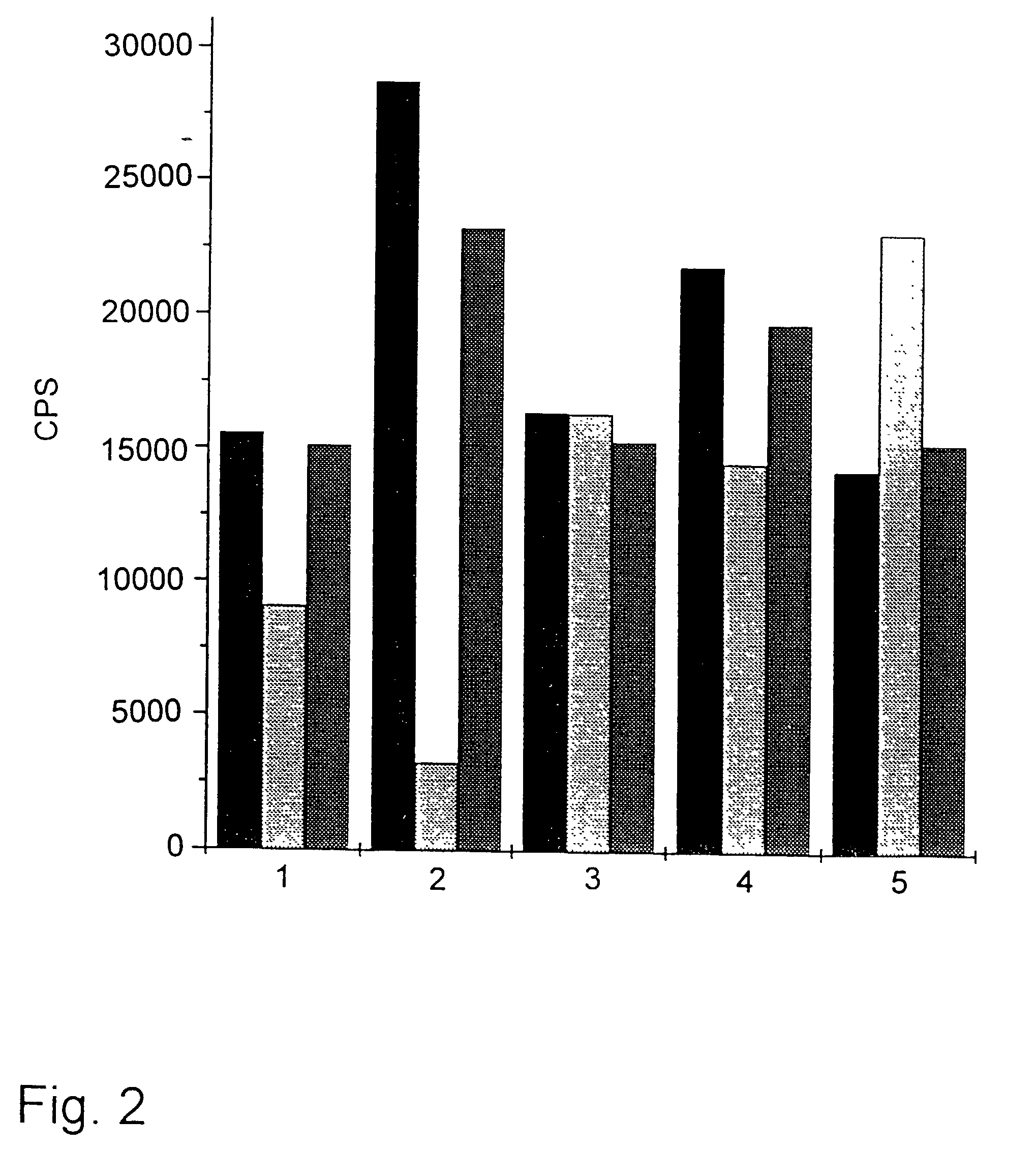

Method and kit for the diagnosis of troponin I

InactiveUS7285418B2High affinityIncrease exposurePeptide/protein ingredientsChemiluminescene/bioluminescenceSerum igeTroponin I binding

The invention provides a method for assaying for troponin I in a sample such as serum, the method comprising a determination of the troponin I concentration in a sample using a standard preparation that comprises a complete native troponin complex. One exemplary assay for troponin I concentration according to the invention is an immunoassay. Further contemplated in the method is a step comprising contacting the sample with a Ca2+-binding agent. Another aspect of the invention is the standard preparation comprising a complete native troponin complex. Yet another aspect of the invention is a kit for use in the assay method comprising the standard preparation, a detectable label, and a troponin I binding partner, such as an anti-troponin I antibody. All aspects of the invention are usefully practiced using human materials, such as a human troponin complex, and / or human sources for samples.

Owner:HYTEST LTD

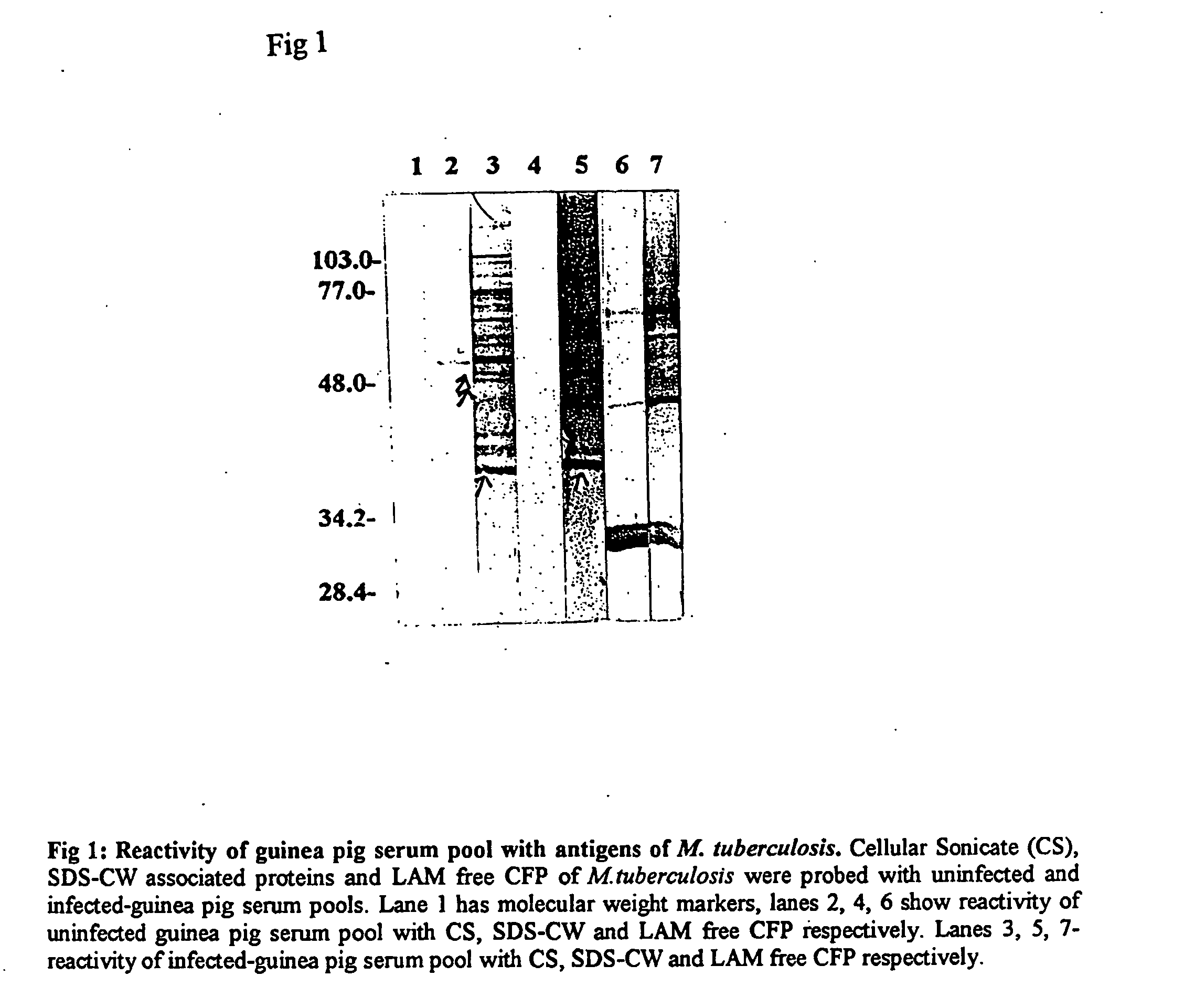

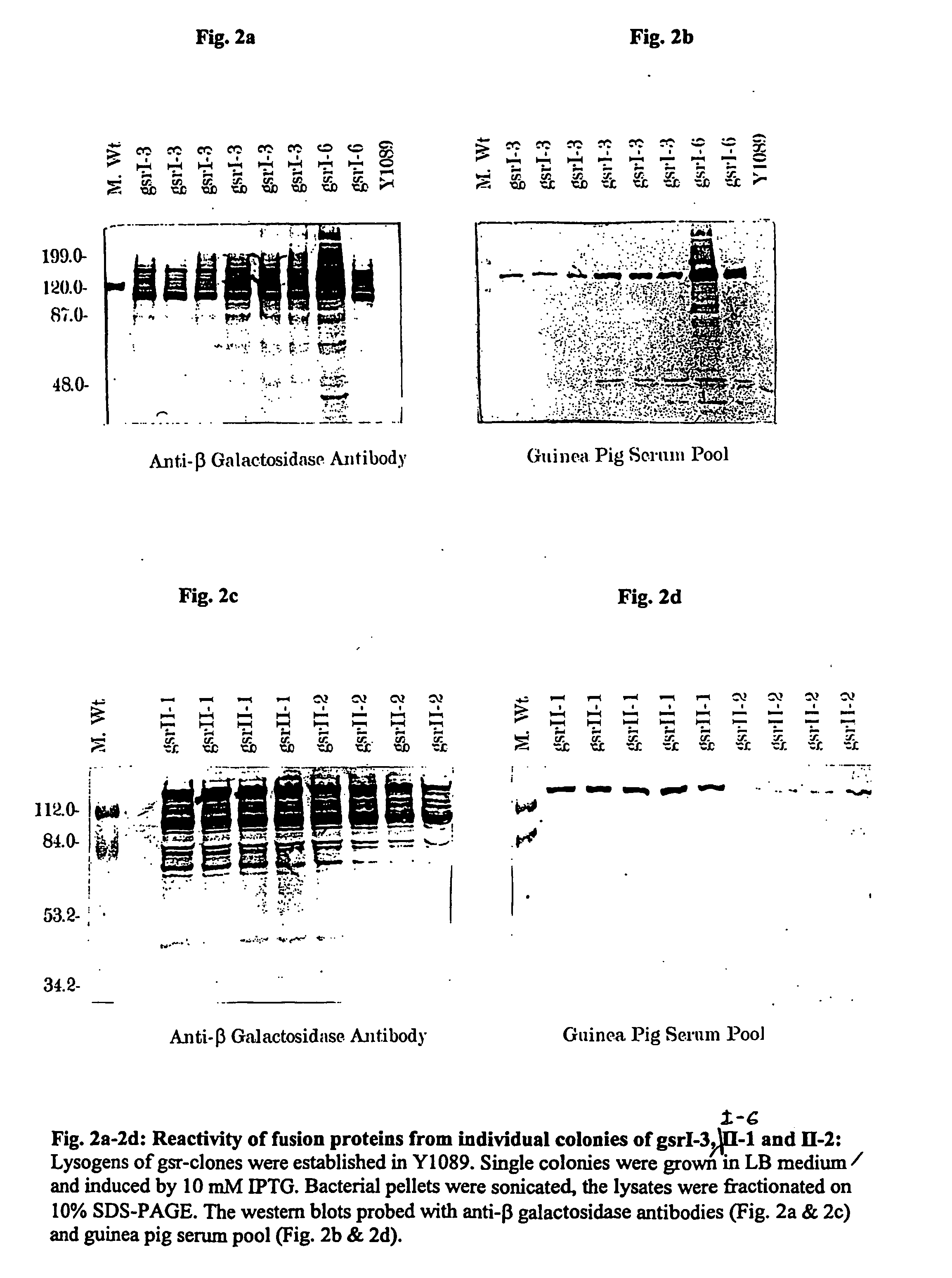

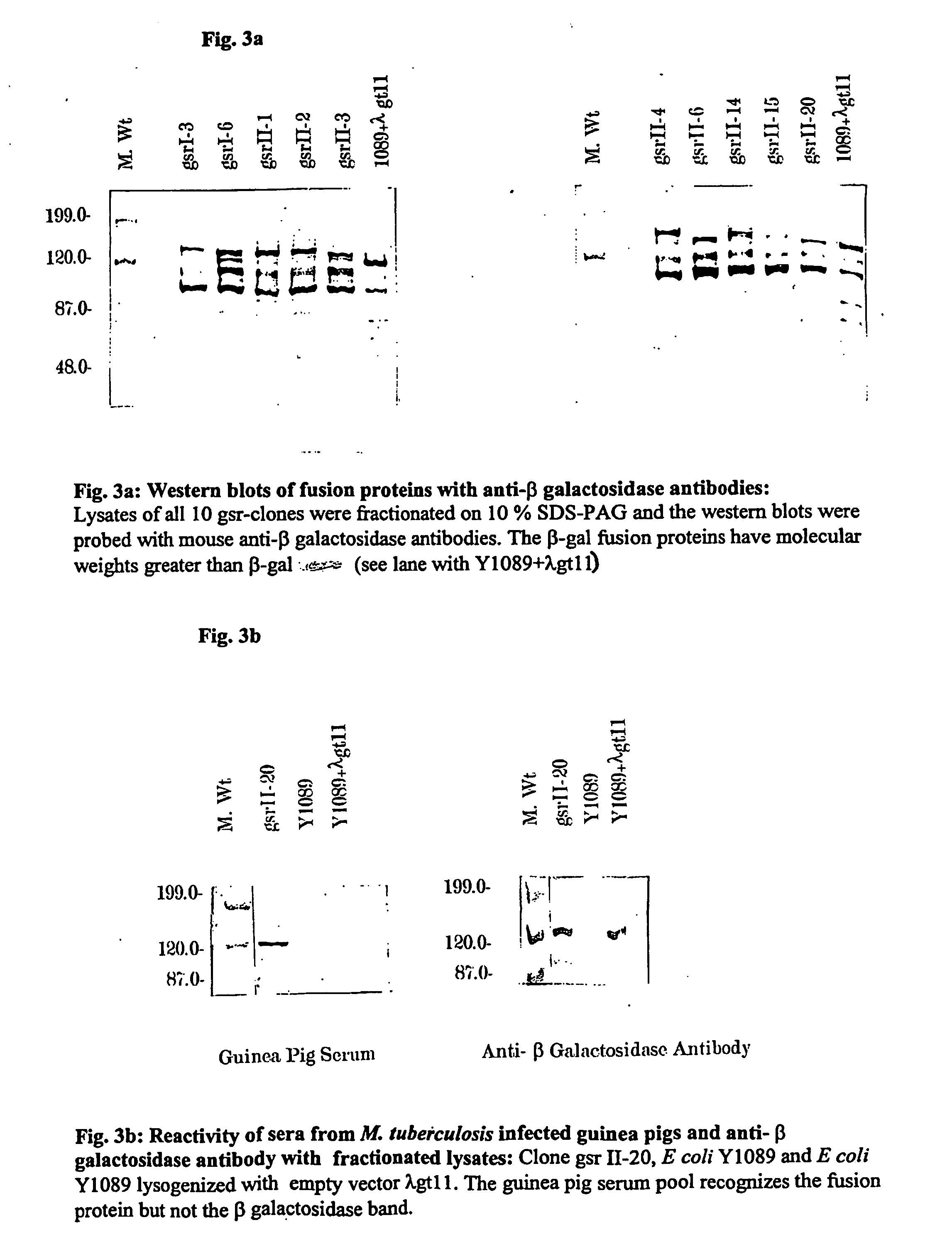

Mycobacterial proteins as early antigens for serodiagnosis and vaccines

In view of the paucity of human material available to study the immunological events occurring after inhalation of virulent bacilli, but prior to development of clinical TB, the present invention is based in part on studies of aerosol infected rabbits. The present inventors reasoned that by 3-5 weeks post-infection, the sera from infected rabbits would contain antibodies to the antigens being expressed by the in vivo bacteria.

Owner:NEW YORK UNIV

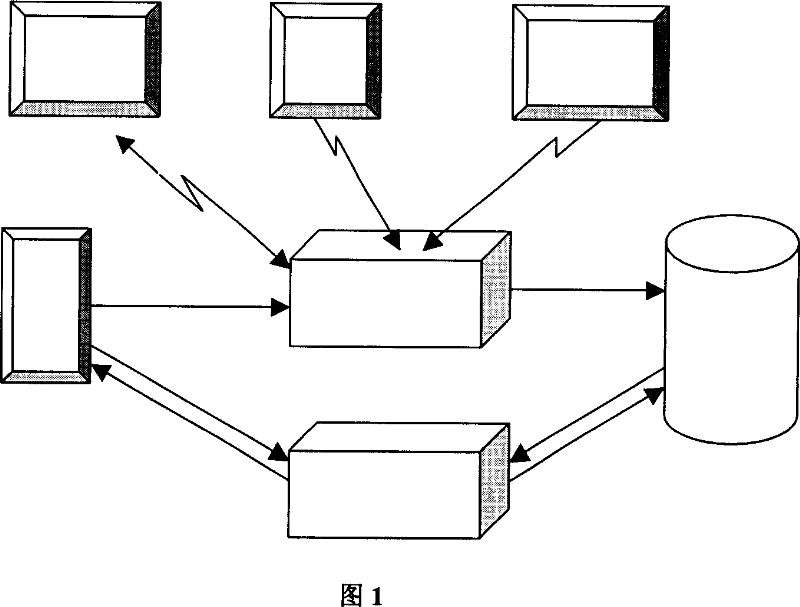

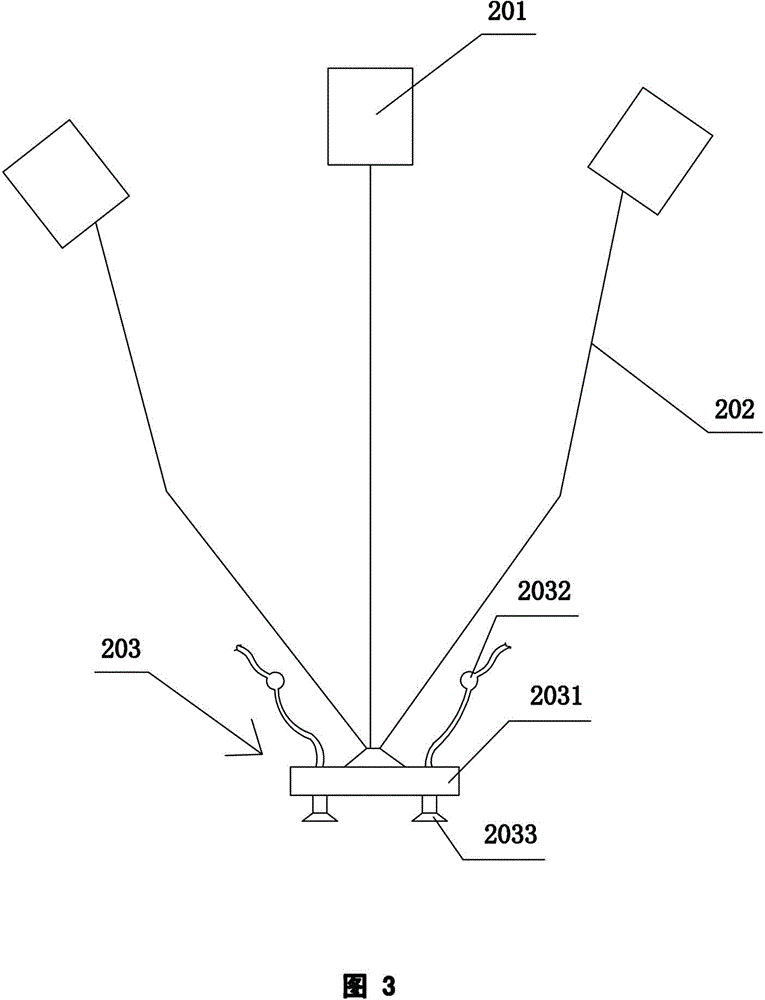

Synthesis examination system and method for container harbor resource operation efficiency

InactiveCN101042744AImprove production efficiencyEnergy efficient ICTTechnology managementEvaluation systemComputer science

This invention discloses one container harbor materials operation efficiency integral evaluation system and its method, which comprises back bench database, middle application servo and terminal and the method comprises the following steps: it uses information technique and data dig technique to get container mechanic operation efficiency from terminal and tracing multiple mechanic instant status and energy consumption situation; storing the collected data through wireless network through middle servo into back database; middle servo program analyzes and predicts the service programs through refine data to get essence data relative to operation cost and human materials for management use.

Owner:SHANGHAI PUDONG INTERNATIONAL CONTAINER TERMINALS LIMITED

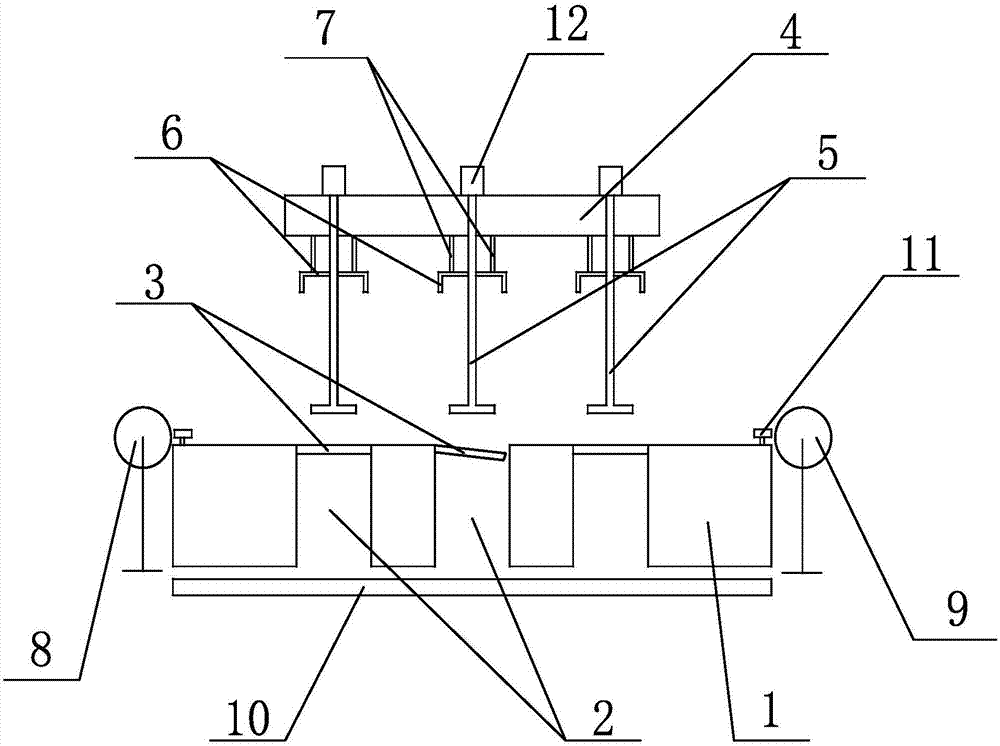

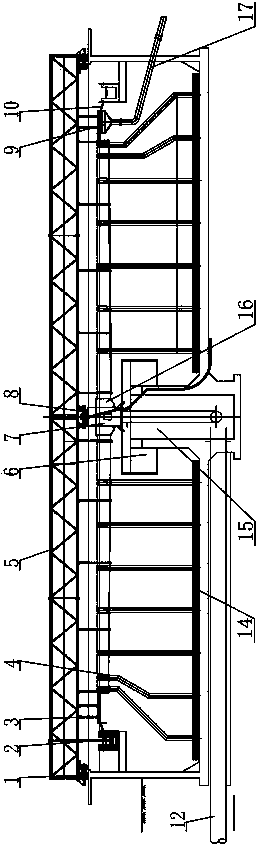

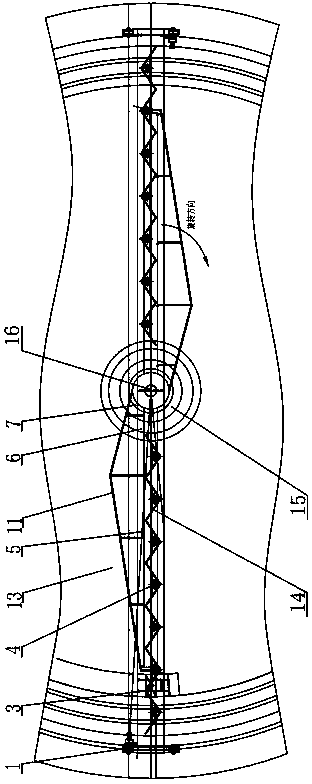

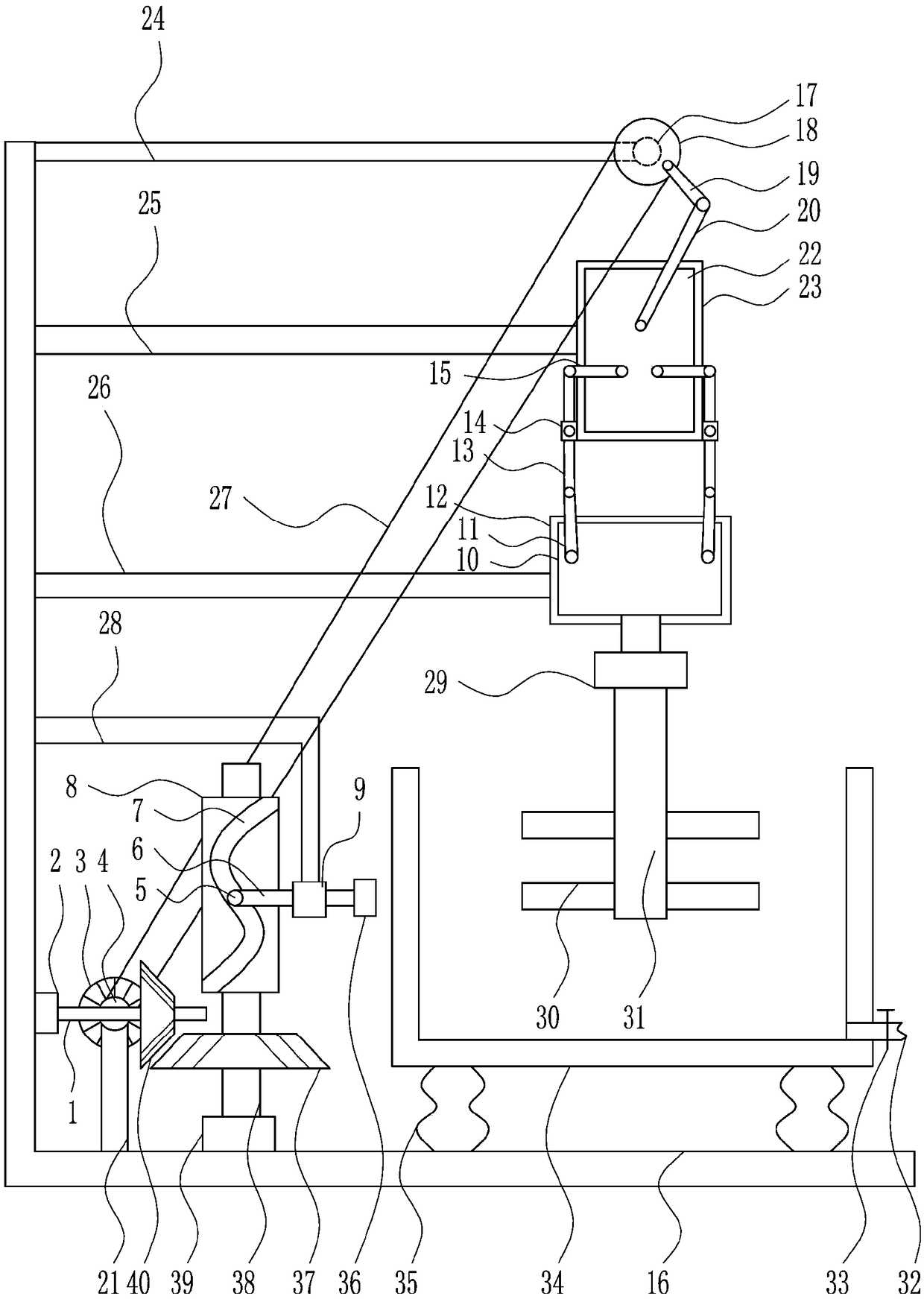

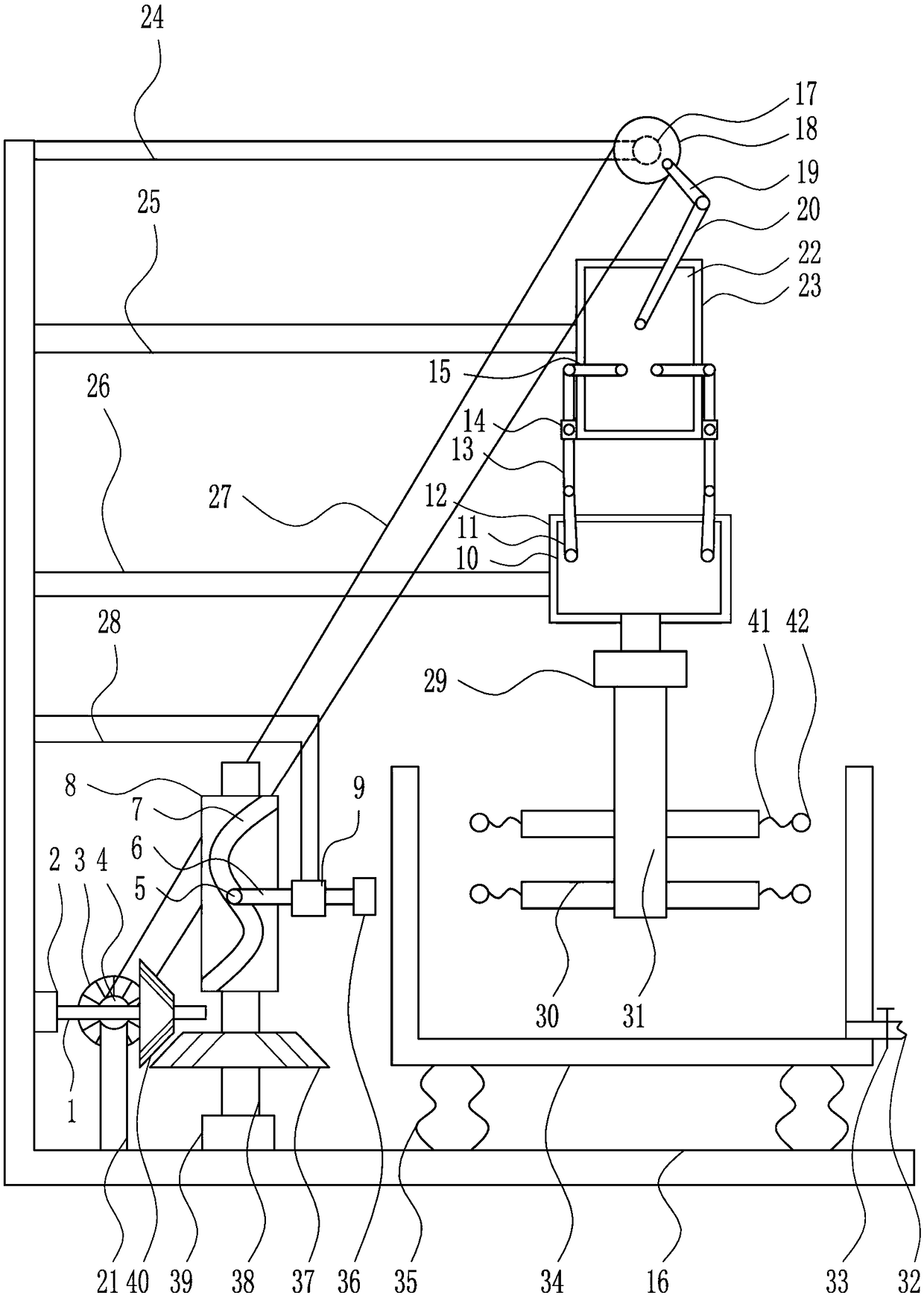

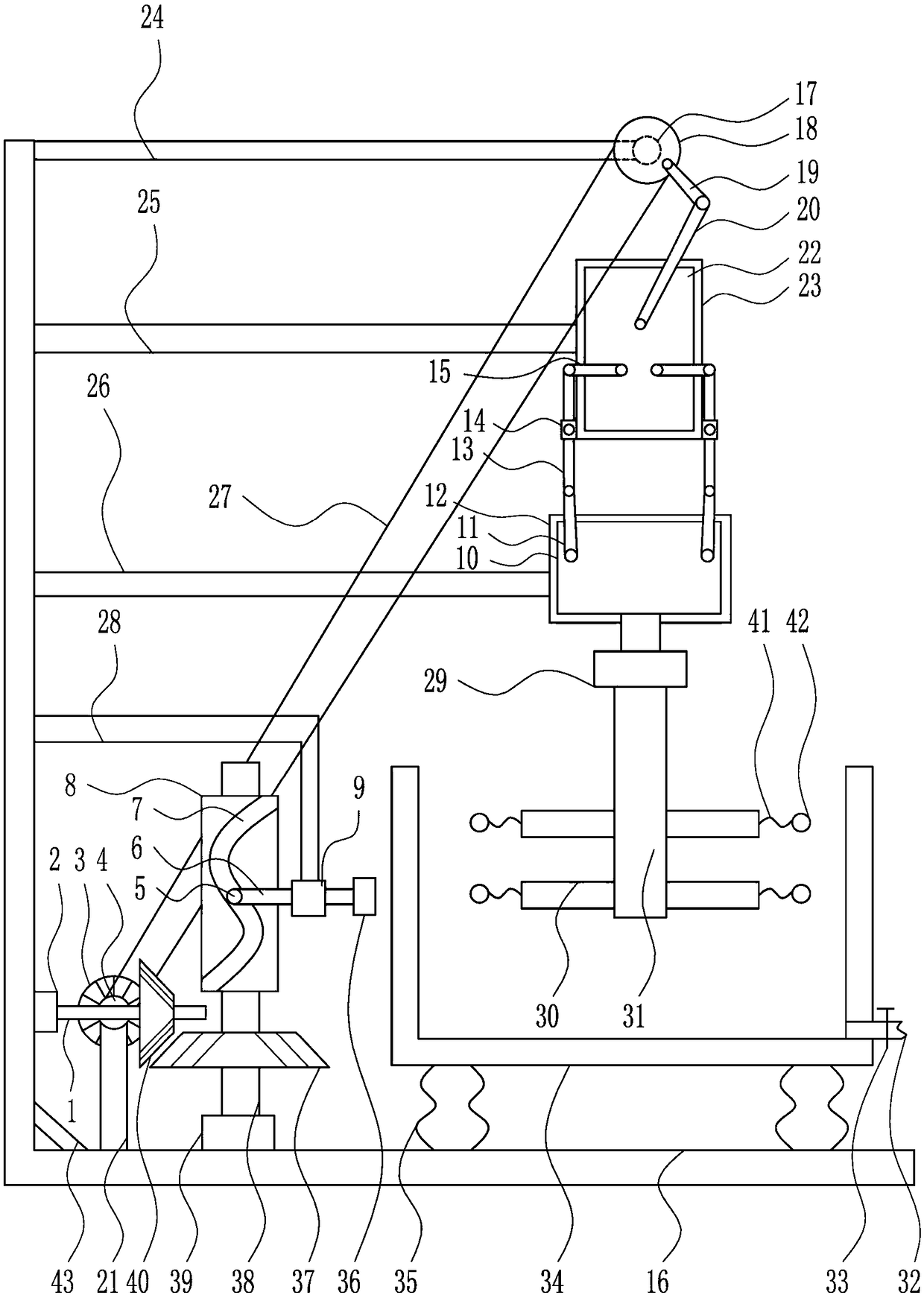

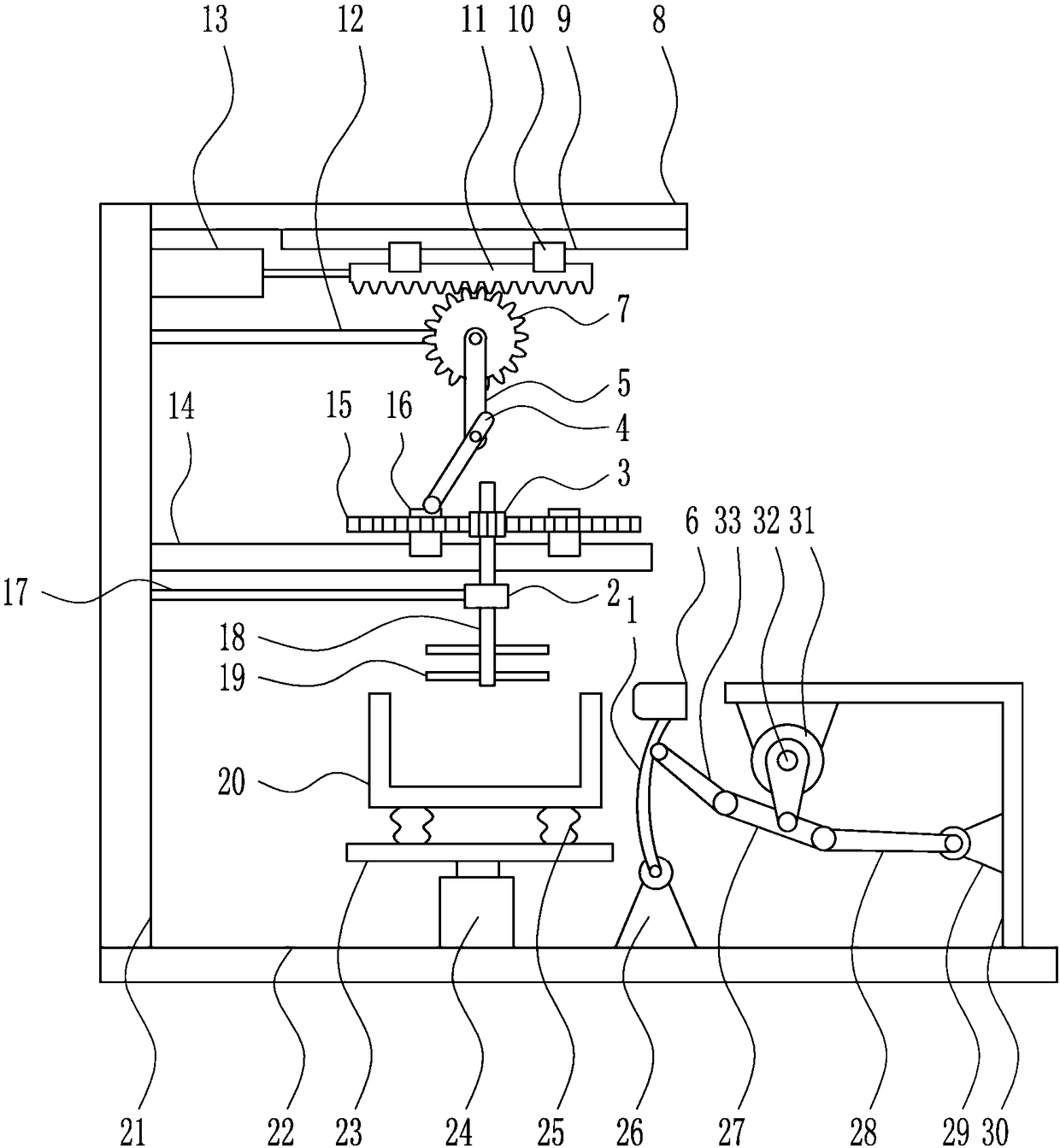

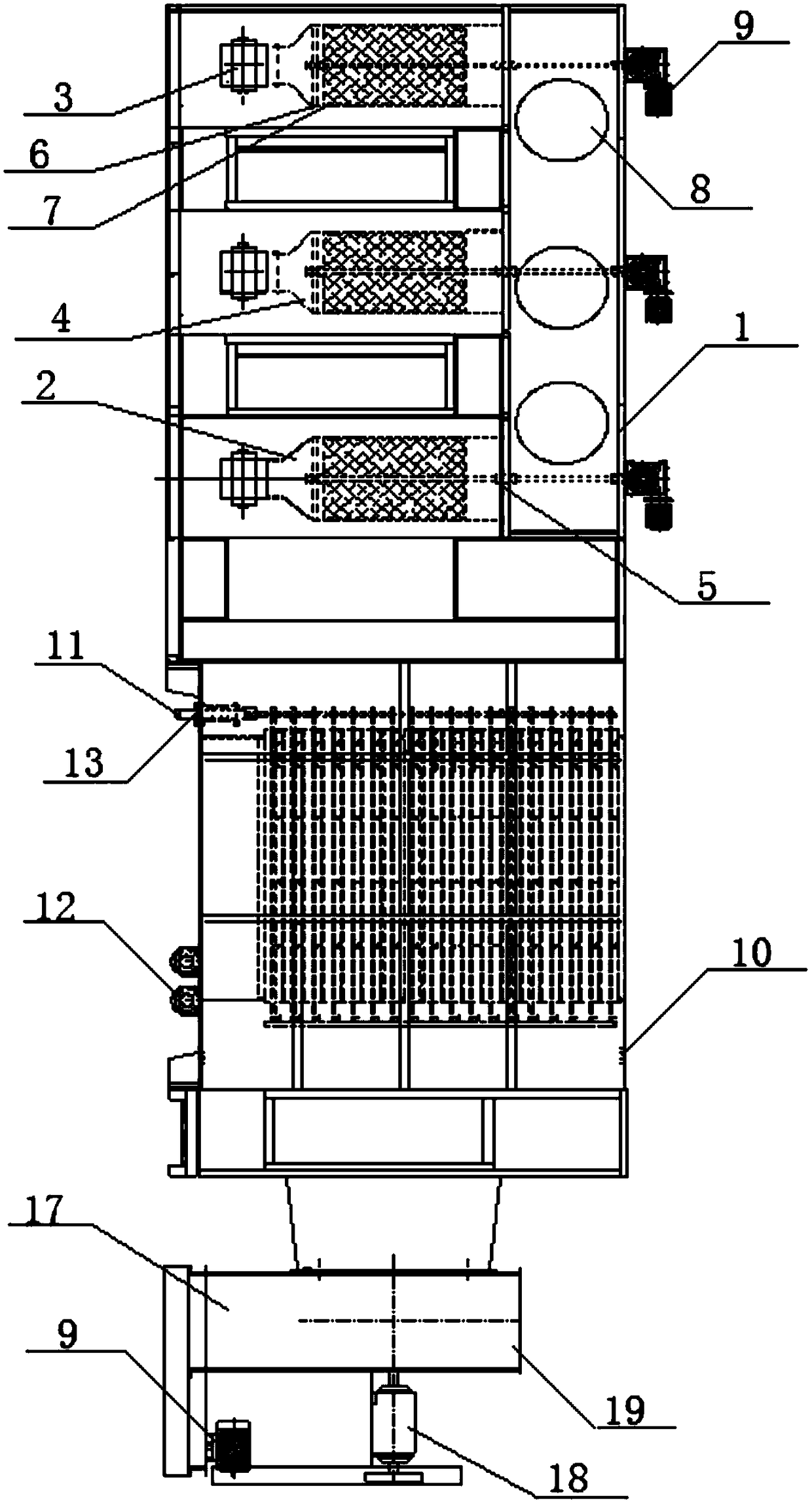

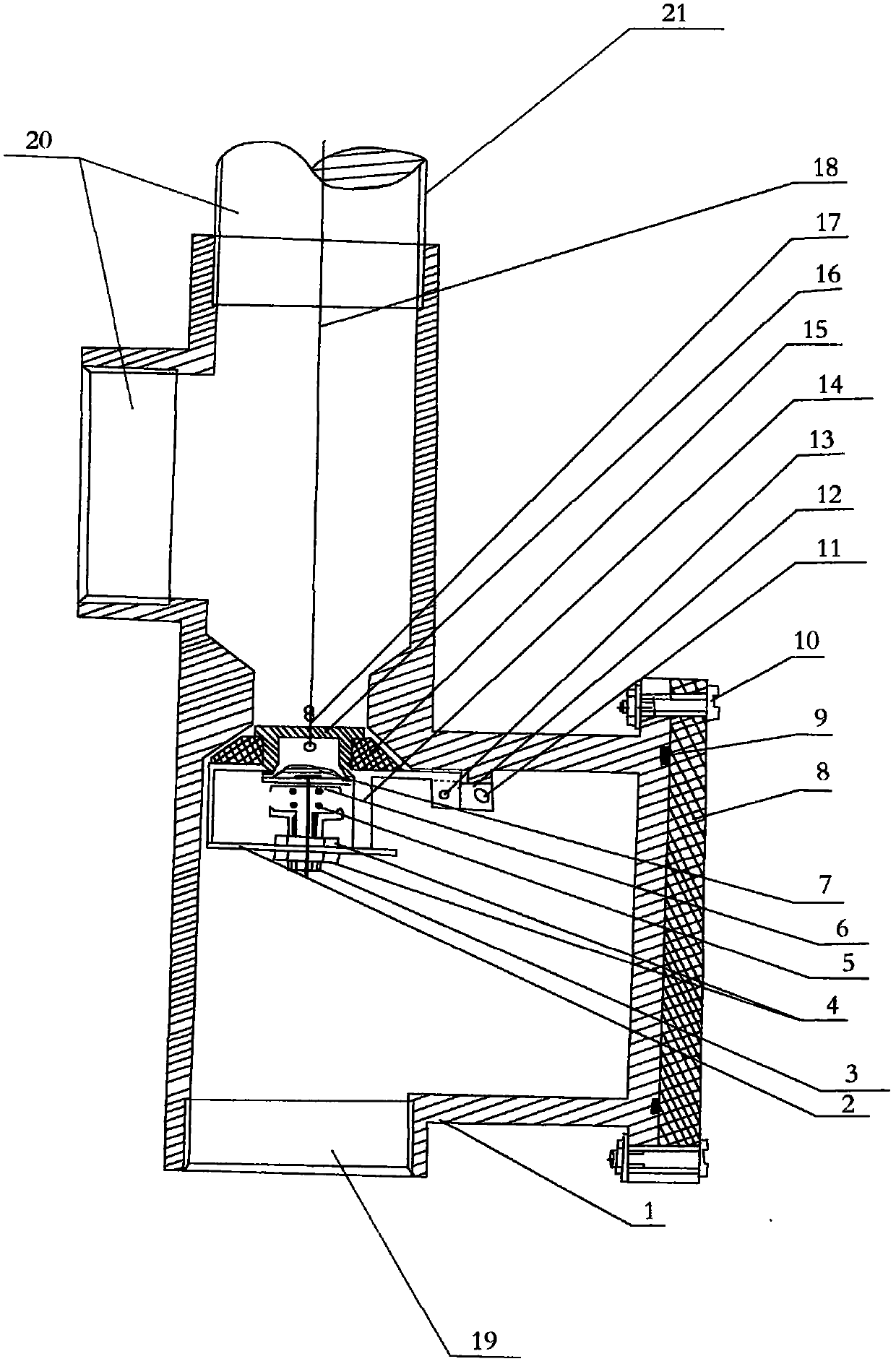

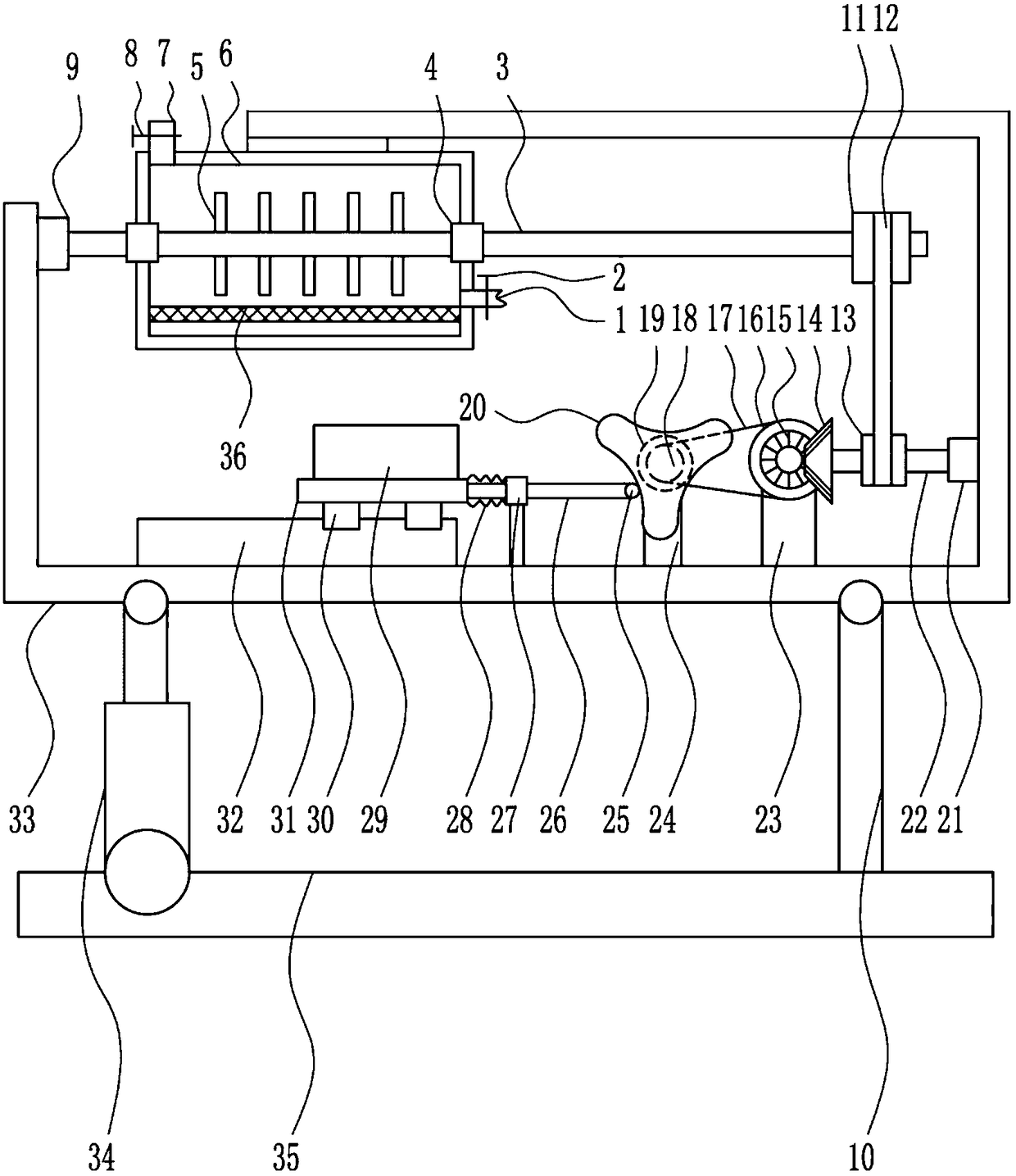

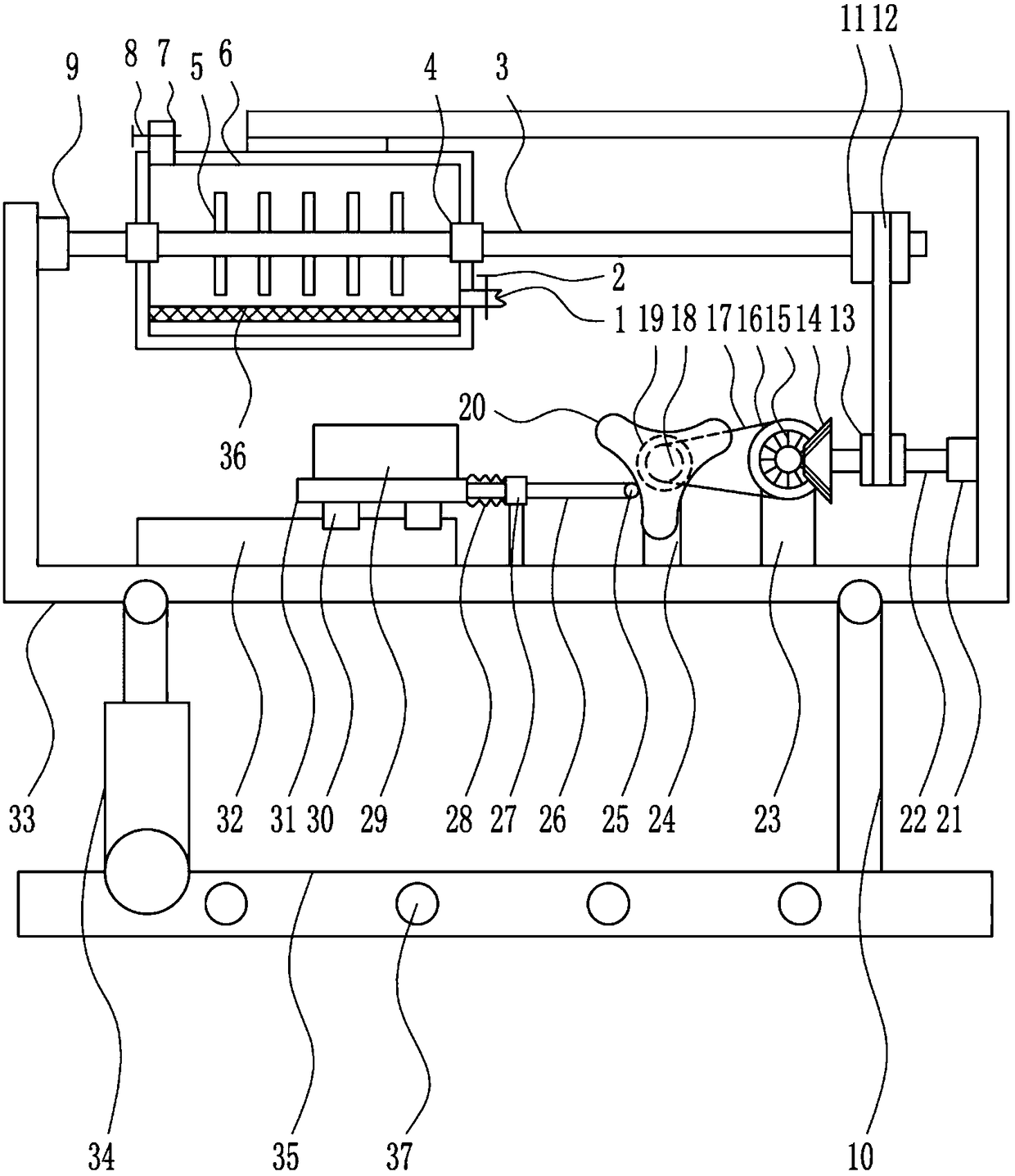

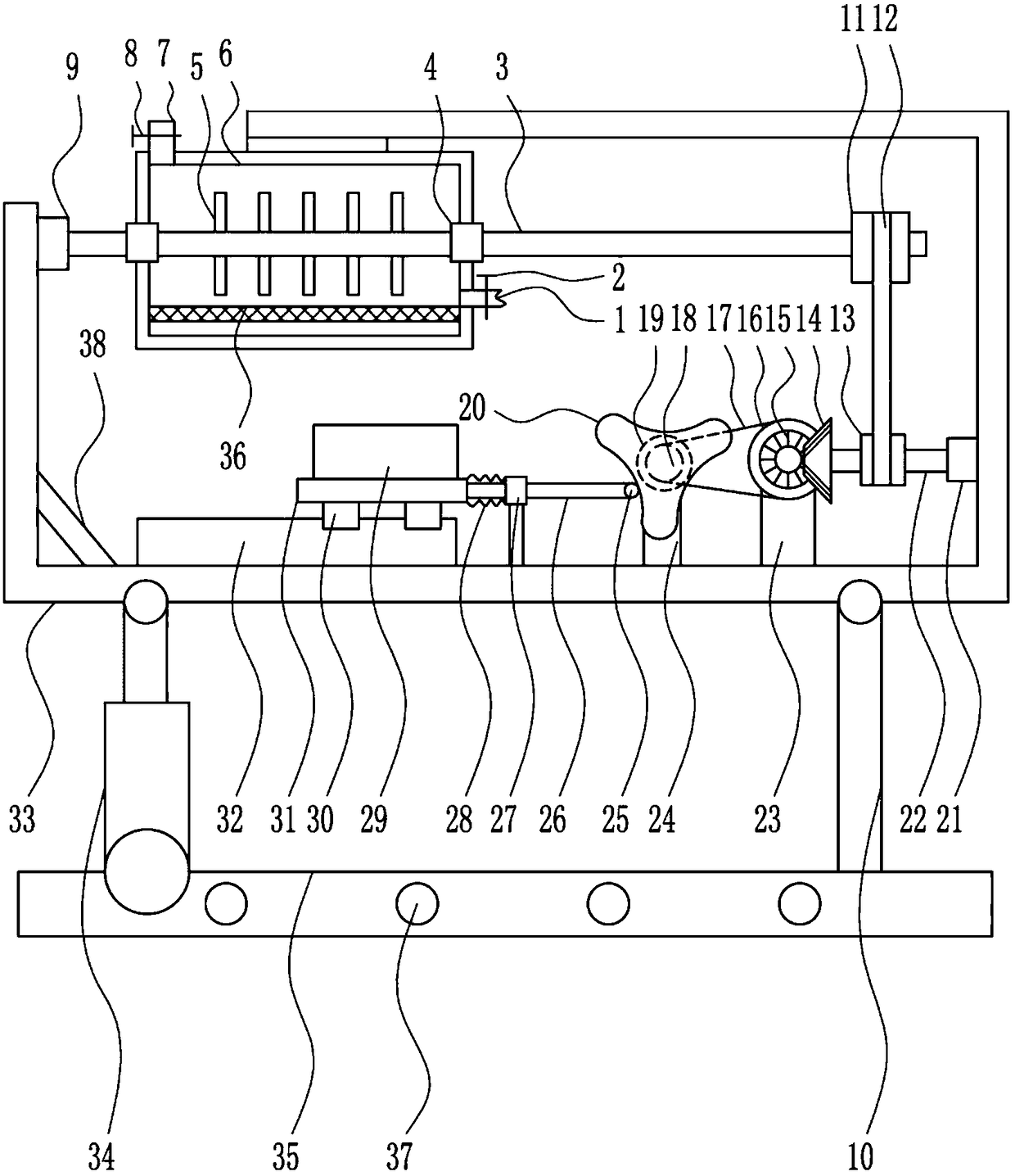

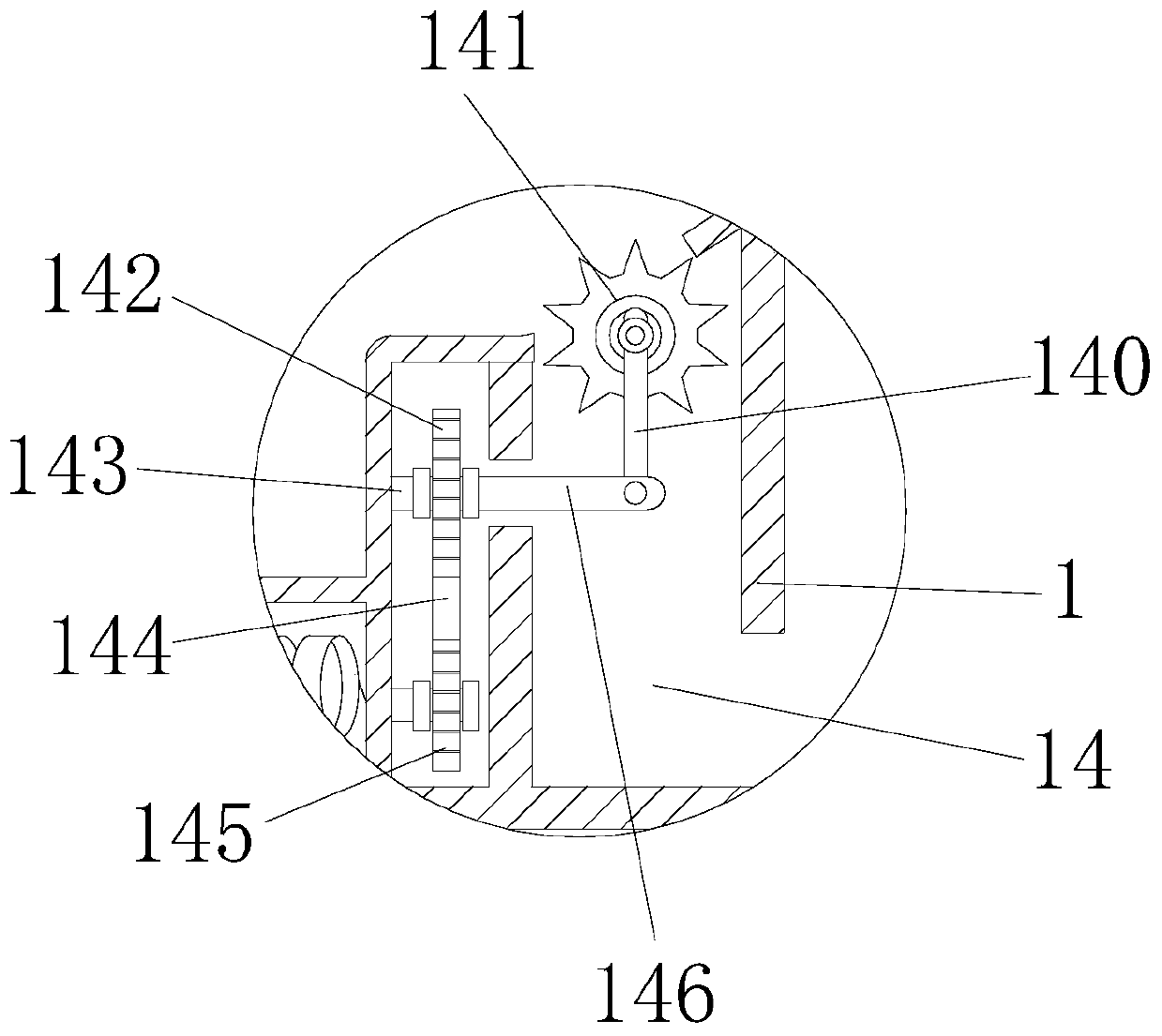

High-efficiency shoe material processing device

InactiveCN107136652ARealize continuous and uninterrupted workReduce labor intensityShoemaking devicesHeelsEngineeringMaterials processing

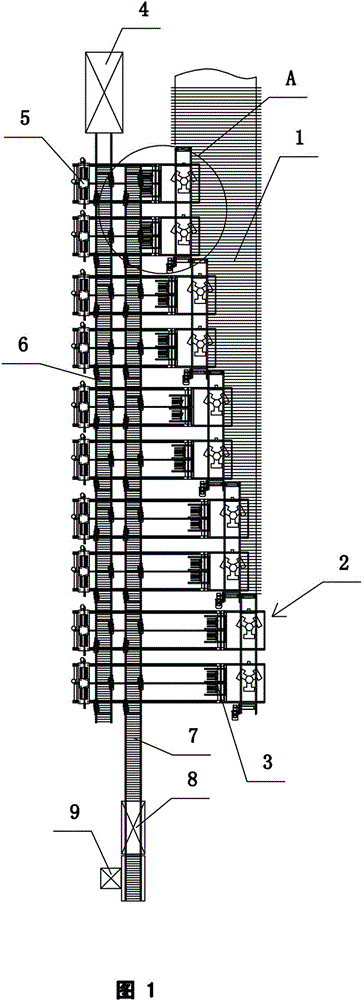

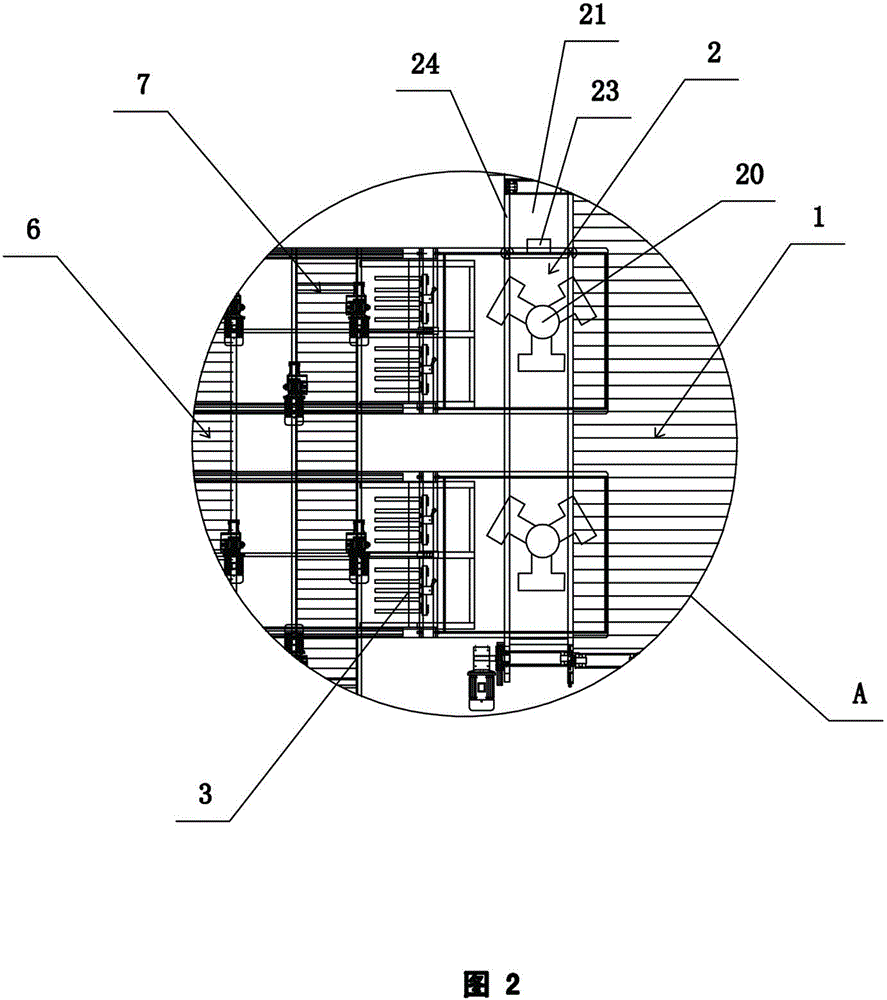

The invention discloses a high-efficiency shoe material processing device. The device comprises a molding platform, a plurality of through holes are formed in the molding platform, rotating tables are arranged in the through holes, lifting mechanisms are arranged below the rotating tables, and the lifting mechanisms drive the rotary tables to move vertically; a molding mechanism is arranged above the molding platform, and a plurality of molding modules are arranged on the molding mechanism; each cutting module comprises a telescopic pressing rod and a molding die which is arranged on the pressing rod in a sleeving mode, and the molding dies and the molding mechanism are connected through telescopic rods; a grinding wheel is arranged between every two adjacent molding modules, and the grinding wheels are connected with the molding mechanism through connecting rods. According to the molding machine, raw materials can be separated automatically from dies after the raw materials are cut, and people do not need to take out the raw materials from the molding dies, so that the labor intensity of workers is reduced; meanwhile, after molding is completed, the edges of the dies can be polished, so that burrs are removed, the molding quality of shoe materials is improved, and the efficiency of the subsequent process is improved easily.

Owner:四川丹露鞋业有限公司

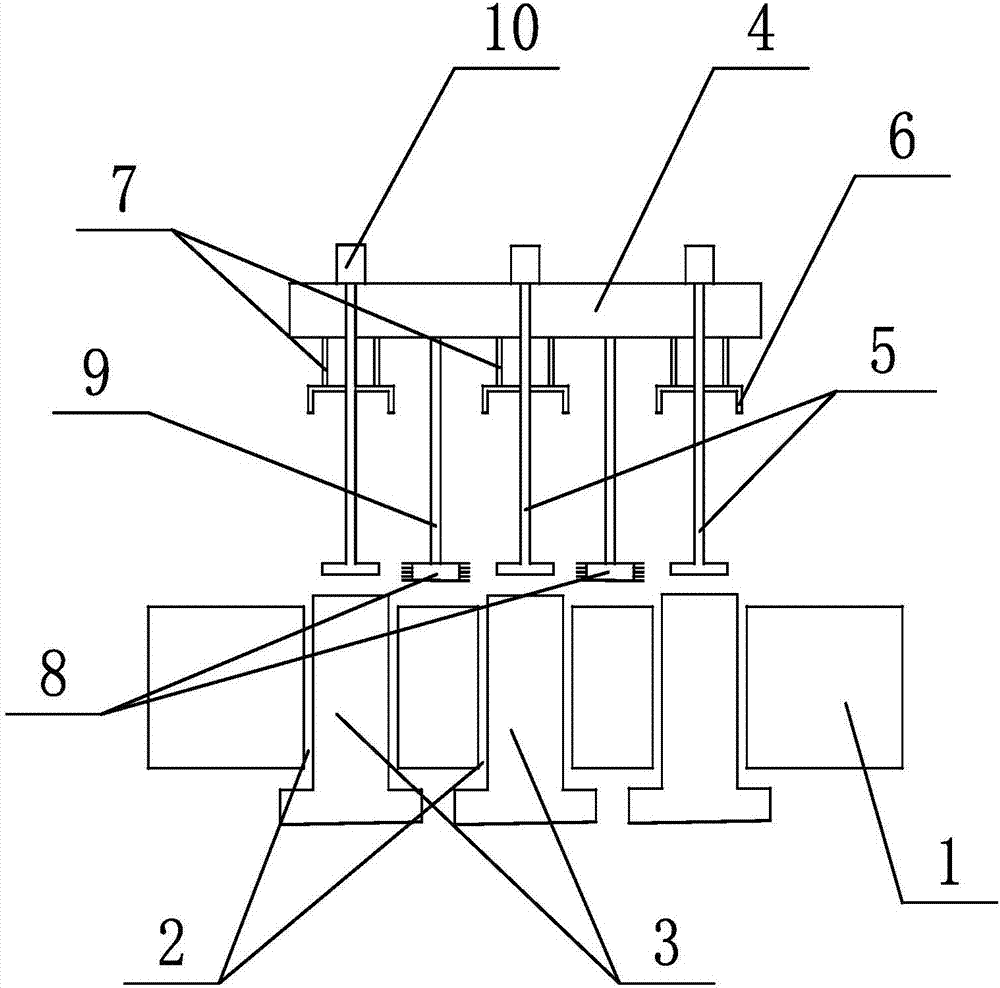

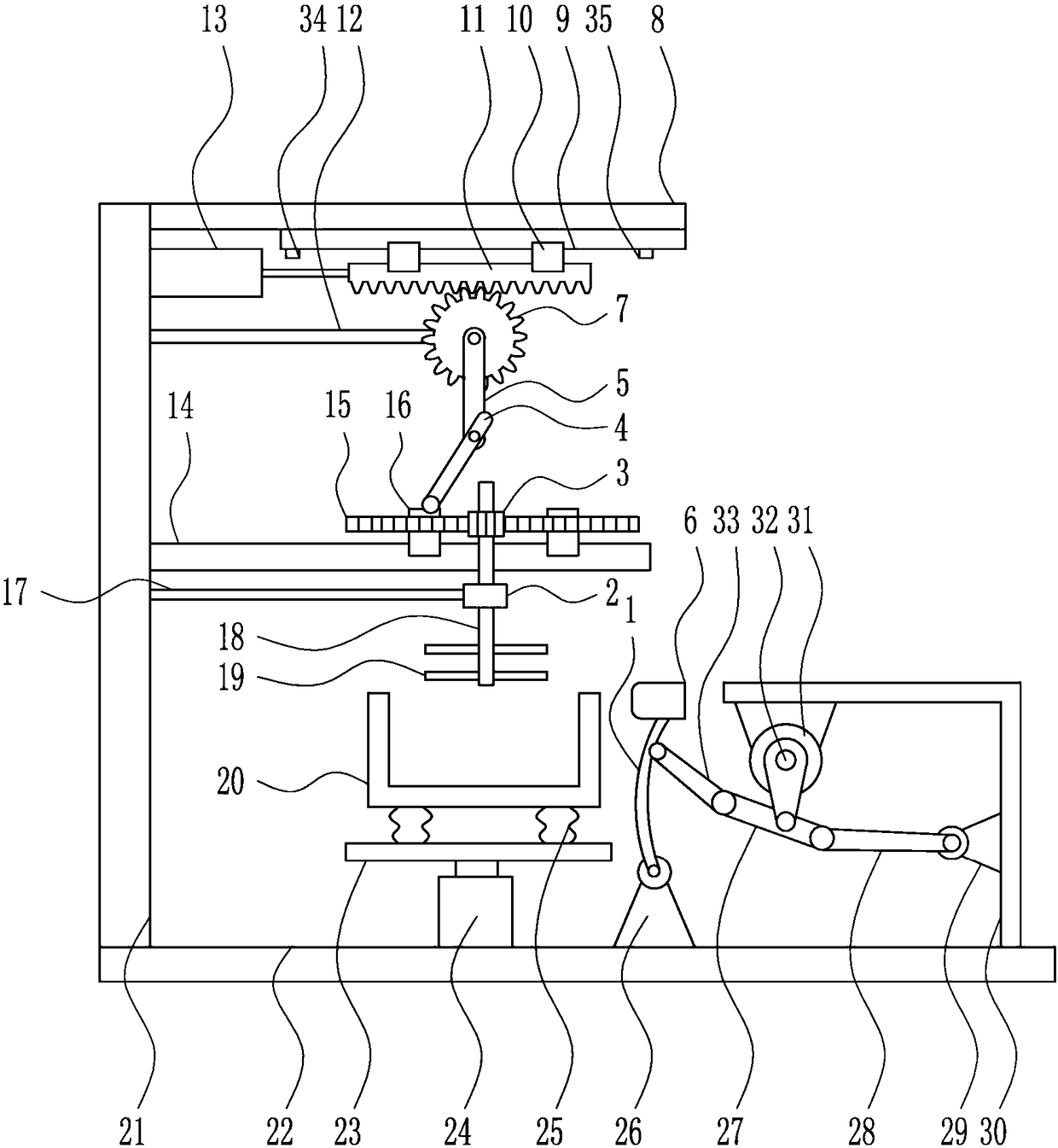

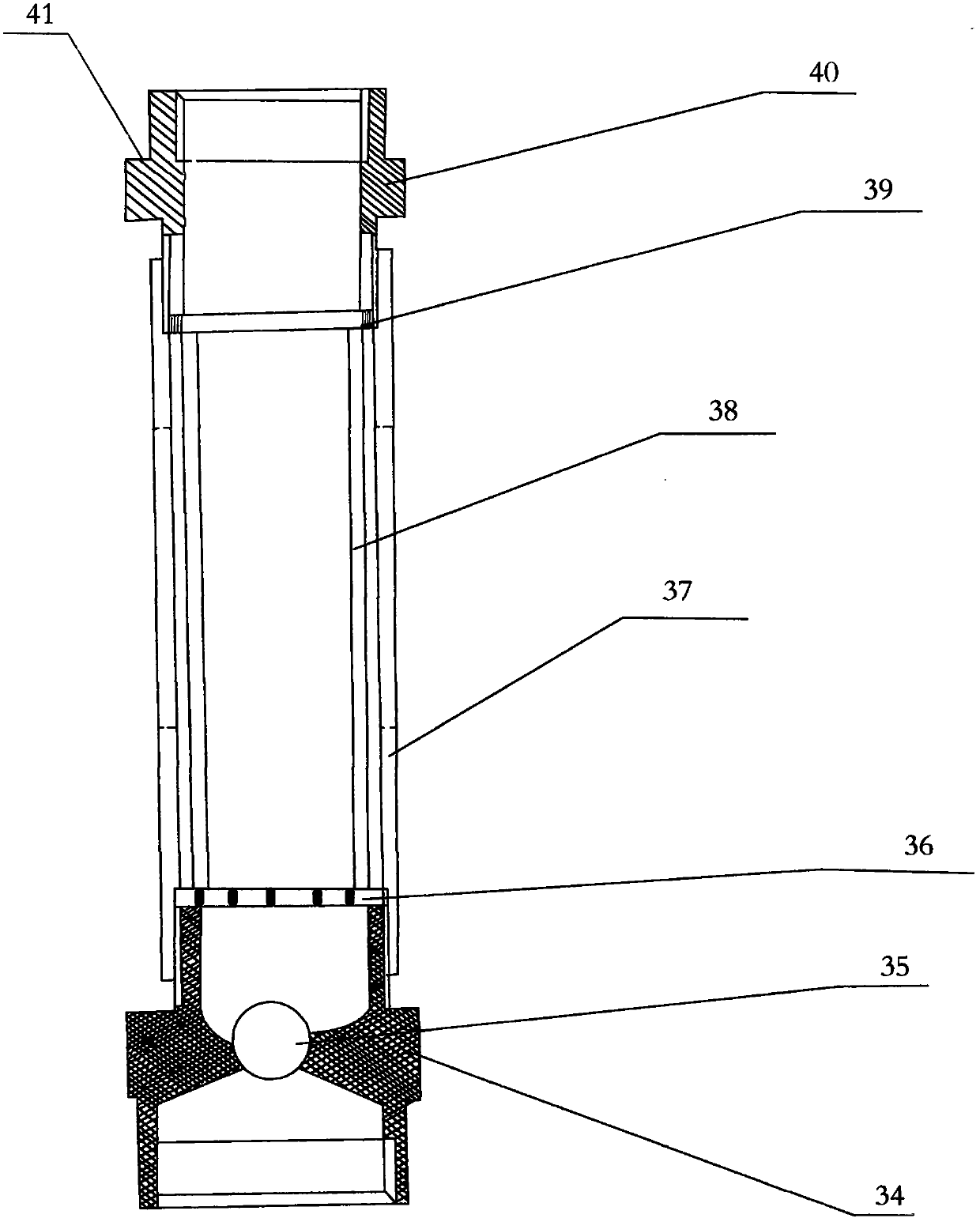

Shoe material cutting device capable of improving quality

InactiveCN107319688AReduce labor intensityDeburringEdge grinding machinesShoemaking devicesEngineeringUltimate tensile strength

The invention discloses a shoe material cutting device capable of improving quality, comprising a die-cutting platform, the die-cutting platform is provided with a plurality of through holes, a rotating platform is arranged in the through holes, a lifting mechanism is arranged under the rotating platform, and the lifting mechanism drives the rotation The platform moves up and down; a die-cutting mechanism is provided above the die-cutting platform, and a plurality of die-cutting groups are arranged on the die-cutting mechanism. The mold and the die-cutting die are connected with the die-cutting mechanism through telescopic rods; a grinding wheel is arranged between two adjacent die-cutting groups, and the grinding wheel is connected with the die-cutting mechanism through a connecting rod. The die cutting machine of the present invention not only enables the raw materials to be separated from the mold automatically after the cutting is completed, it is not necessary to manually take the raw materials out of the cutting die, which reduces the labor intensity of the workers. At the same time, after the die cutting, it can Grinding the edge can remove the burr, improve the cutting quality of the shoe material, and help improve the efficiency of the subsequent process.

Owner:四川丹露鞋业有限公司

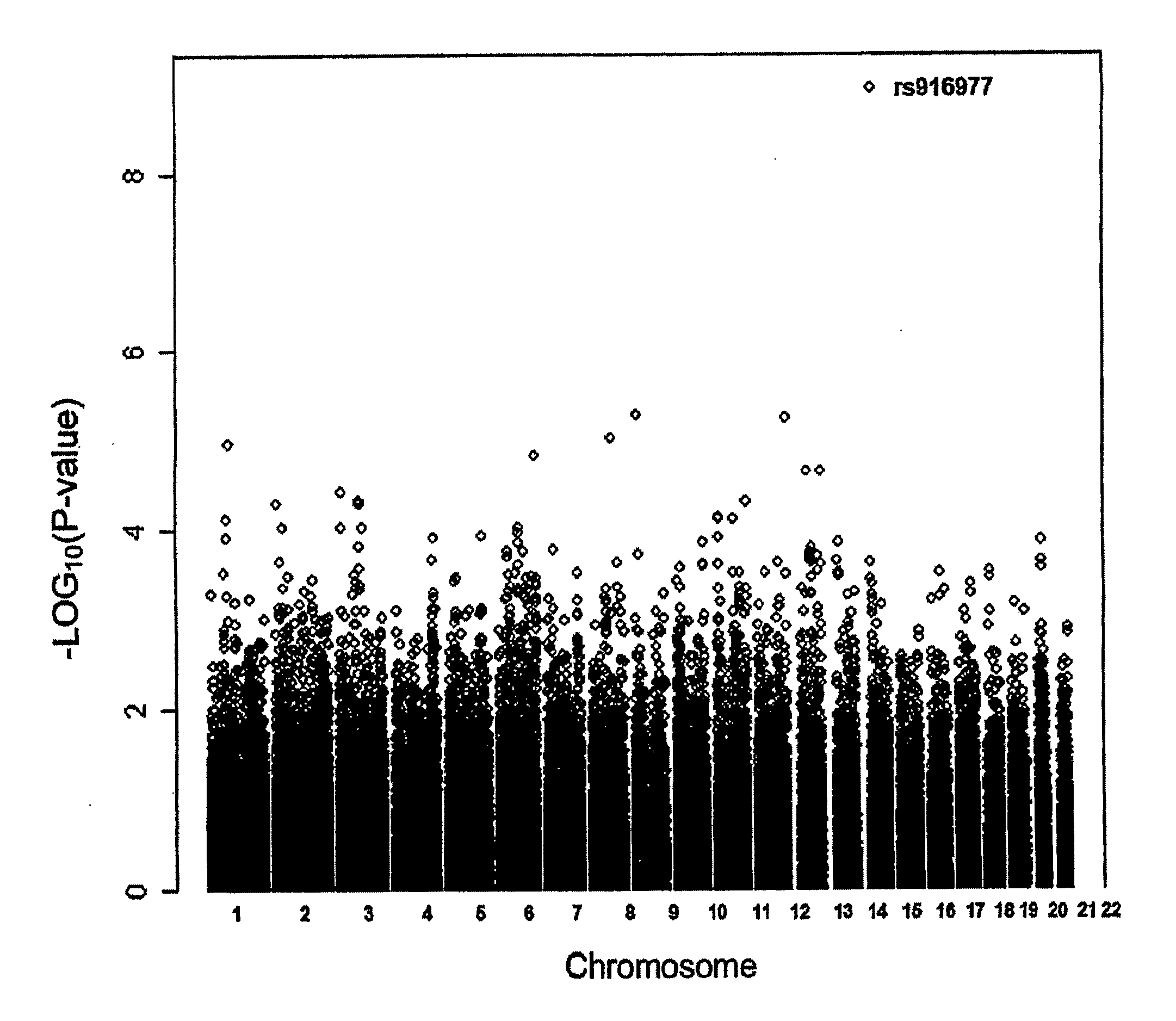

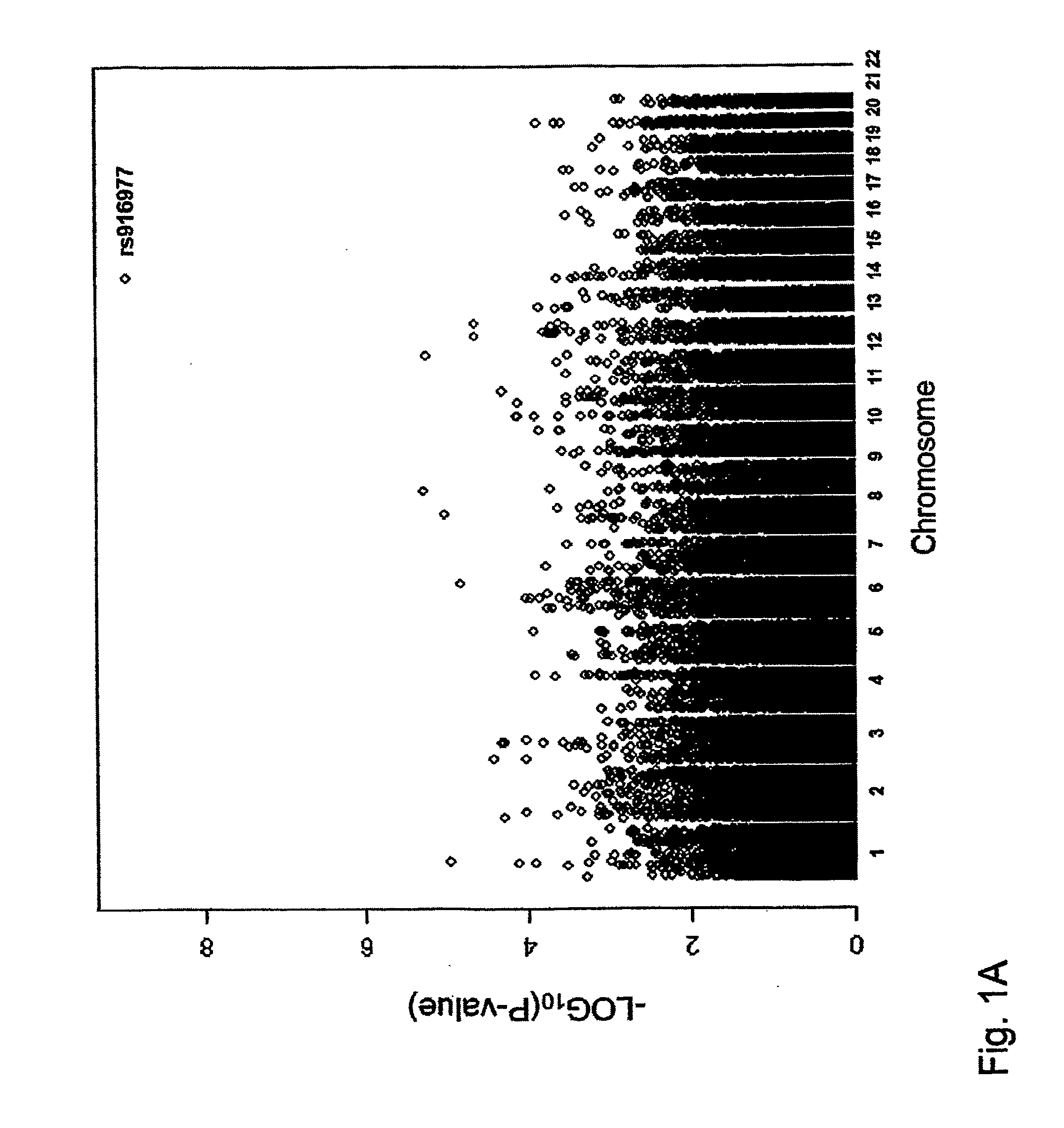

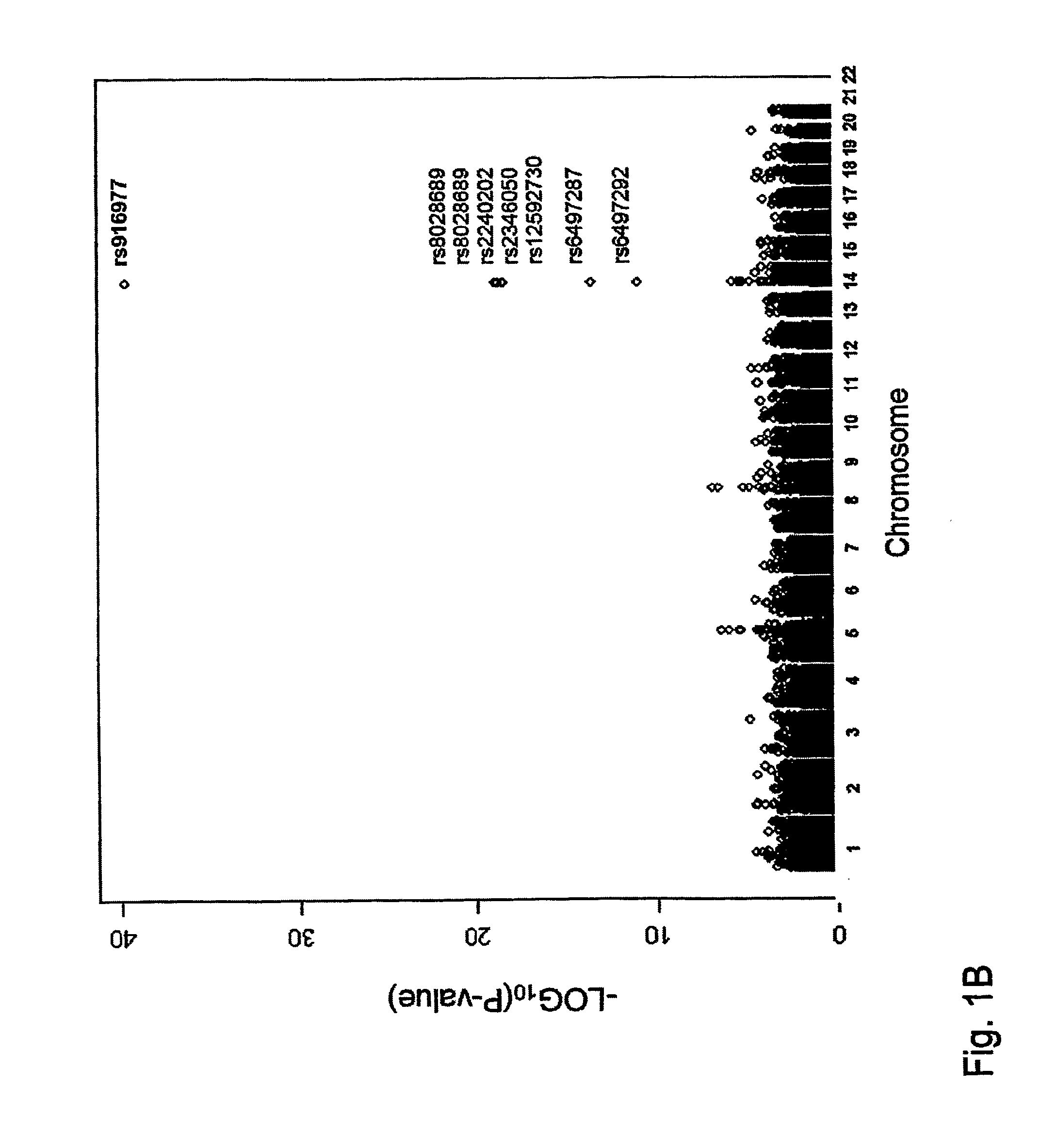

Method to predict iris color

The invention comprises a method to predict iris color of a human from a nucleic acid / protein sample comprising assaying for one or more polymorphisms in the region 5′ proximal of the OCA2 gene up to and including the HERC2 gene on chromosome 15 between basepairs 26018062 and 26240890 according to NCBI build 36 or Ensemble Homo sapiens version 46.36h and on basis of the results from the assay predicting the eye color of a human e.g. an unknown person (such as perpetrators and / or victims of crime, missing persons etc.) in forensic and other applications of human identification. Said polymorphisms preferably are selected from the group consisting of rs916977, rs8028689, rs6497287, rs8041209, rs6497292, rs2240202, rs2346050, rs12592730, rs7183877, rs2240204, rs8039195, rs16950979, rs16950987, rs1667394, and rs1635168 or any marker in close physical distance to said markers and consequently in genetic linkage in the region of chromosome 15 between basepairs 26018062 and 26240890 according to NCBI build 36 or Ensemble Homo sapiens version 46.36h. Said polymorphisms are analysed from human material such as human body fluids (e.g. blood, saliva, semen etc.) or other human body parts (e.g. hairs, organs, etc) or from material obtained from whole bodies. The invention further comprises primers and probes, and a kit for the assay. The invention includes application of the genetic eye color prediction using said markers or their combinations (haplotypes) for forensic and other purposes of human identification such as to identify or trace unknown persons e.g. perpetrators and / or victims of crime, missing persons etc.

Owner:ERASMUS UNIV MEDICAL CENT ROTTERDAM ERASMUS MC

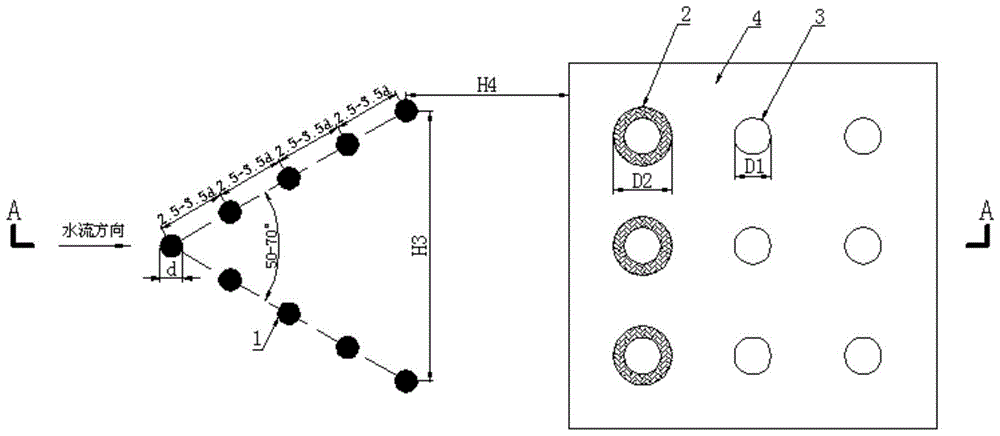

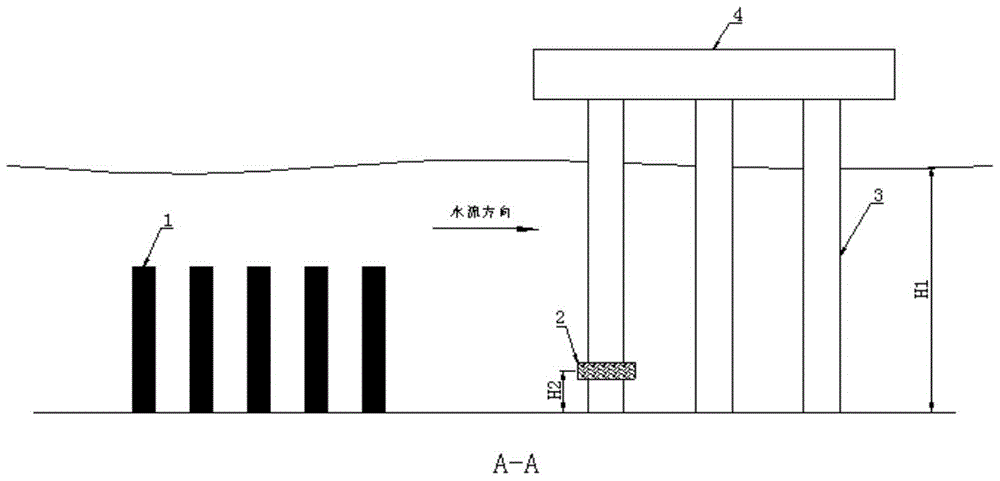

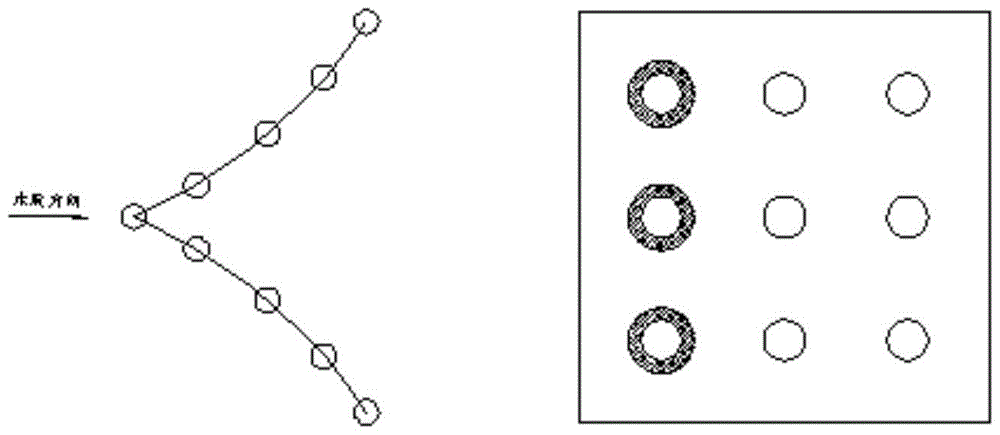

A kind of pile foundation scour protection measure method

ActiveCN104213586BReduce turbulent intensityReduce local scourProtective foundationWater flowEngineering

The invention discloses a method for protection against pile foundation scour, which comprises the combined use of two methods of pile front row piles and retaining ring surrounding the group piles, wherein the front row piles are set in front of the pile group to deviate from the pile group piles In the direction of the high-speed water flow in front, the row of piles that reduces the water flow velocity in the wake area where the pile group is located and reduces the turbulent strength of the vortex system around the pile group; A wheel retainer for weakening the downflow and the strength of the horseshoe vortex is set on the top. The method of the invention improves the reliability of pile foundation scour protection, and enhances the stability and safety of infrastructure such as bridges and offshore platforms; at the same time, it is convenient for construction and strong in practicability. It saves time and effort, reduces the consumption of manpower and materials, and is economical.

Owner:SOUTHEAST UNIV

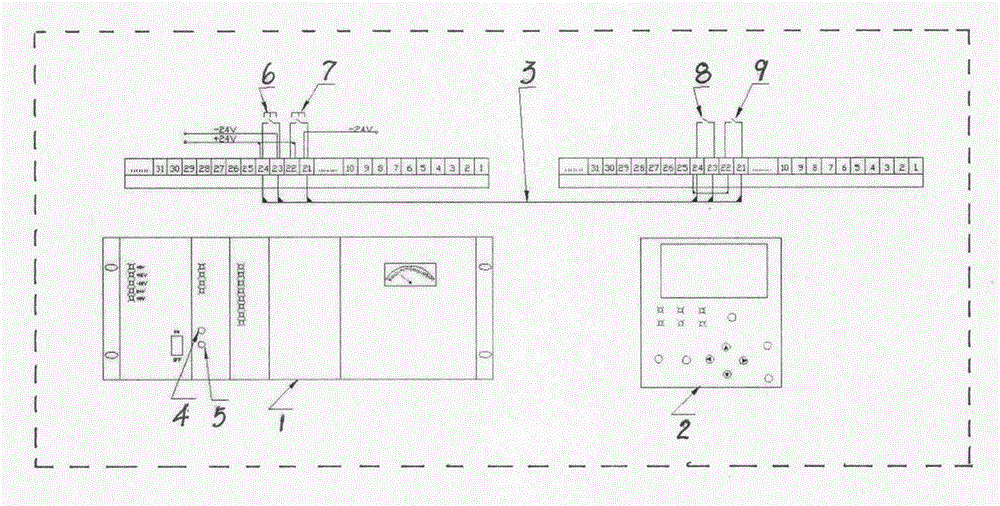

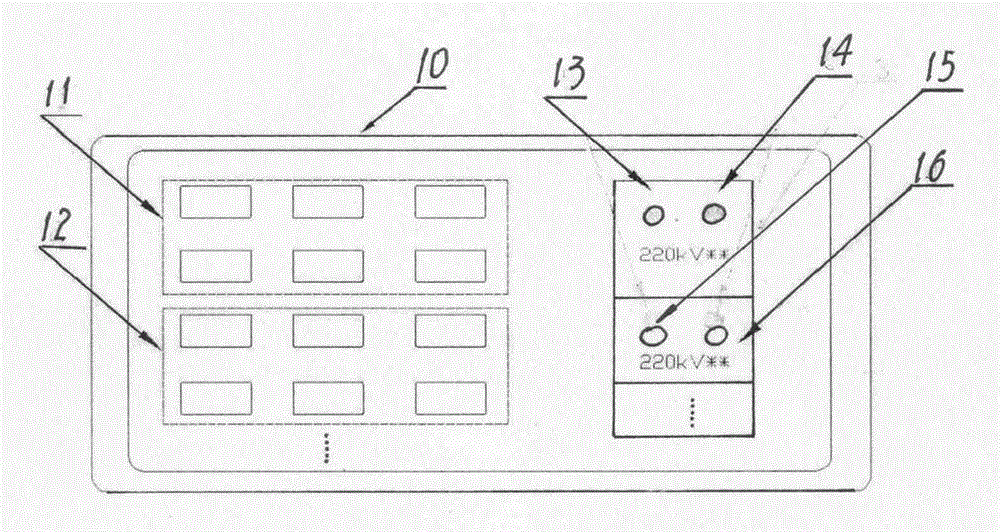

Method for realizing high frequency channel test and signal reset

InactiveCN103605011AGuaranteed uptimeSafe and stable operationElectrical testingTransceiverRemote control

A method for realizing high frequency channel test and signal reset is provided. The method comprises the following steps that: channel test contacts and signal reset contacts of a high-frequency transceiver with a high-frequency channel interval in each substation are led to a detection control device of a corresponding interval and are corresponding to remote control contacts of the detection control device; an interface is constructed in a scheduling-end monitoring machine operating system, one channel test button and one signal reset button are defined corresponding to each interval in the interface; in the interface of the scheduling-end monitoring machine operating system, the validity of access is checked according to the channel test buttons of the interface; high-frequency channel abnormality is simulated, and the high-frequency transceiver is made to act, and then, the abnormality is made to vanish, and then, the signal reset button is pressed, and the validity of access is checked; and the high frequency channel test and signal reset of corresponding intervals can be realized through remote operation. The method is advantageous in simplicity, intuitiveness in vision, convenient operation and easiness in grasp, and can assist in improving work efficiency, avoiding the waste of human material and financial resources, and ensuring safe and stable operation of a power grid.

Owner:STATE GRID CORP OF CHINA +1

Sealing structure for sludge collecting cylinder and central post of sludge scraping suction dredger

ActiveCN102743904BPrevent leakageExtend your lifeSettling tanks feed/dischargeSedimentation settling tanksAbnormal tissue growthRubber ring

The invention discloses a sealing structure between a mud collection cylinder and a center column of a scraper and suction mud machine. A rubber ring is fixed on the outer peripheral surface of the center column through flanges and fasteners, and the bottom wall of the mud collection cylinder is directly placed on the rubber ring. On the upper surface, the two are compressed by internal and external pressure to realize dynamic sealing during rotation. The present invention utilizes the bottom surface of the bottom wall of the mud collecting cylinder and the upper surface of the rubber ring to be frictionally and rotationally sealed, the contact surface is relatively large, and the water level in the pool and the mud level difference of the mud collecting tank are used to compress and seal, so a good dynamic sealing effect can be obtained to prevent Leakage of clean water. And it is not easy to wear, which effectively improves the life of the seal. The joints of the upper and lower layers of rubber rings in the present invention are staggered, which not only prevents sludge from leaking from the joints, but also facilitates maintenance, greatly reduces the consumption of manpower and material resources, and has significant economic value.

Owner:江苏通用环境工程有限公司

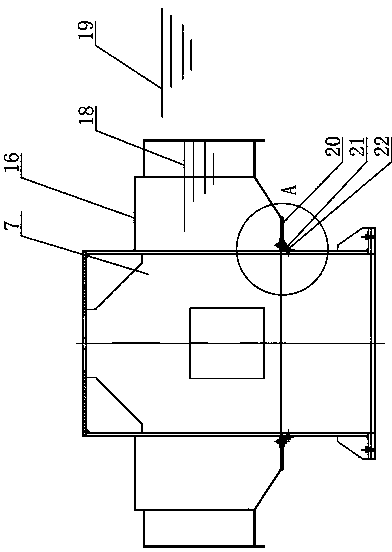

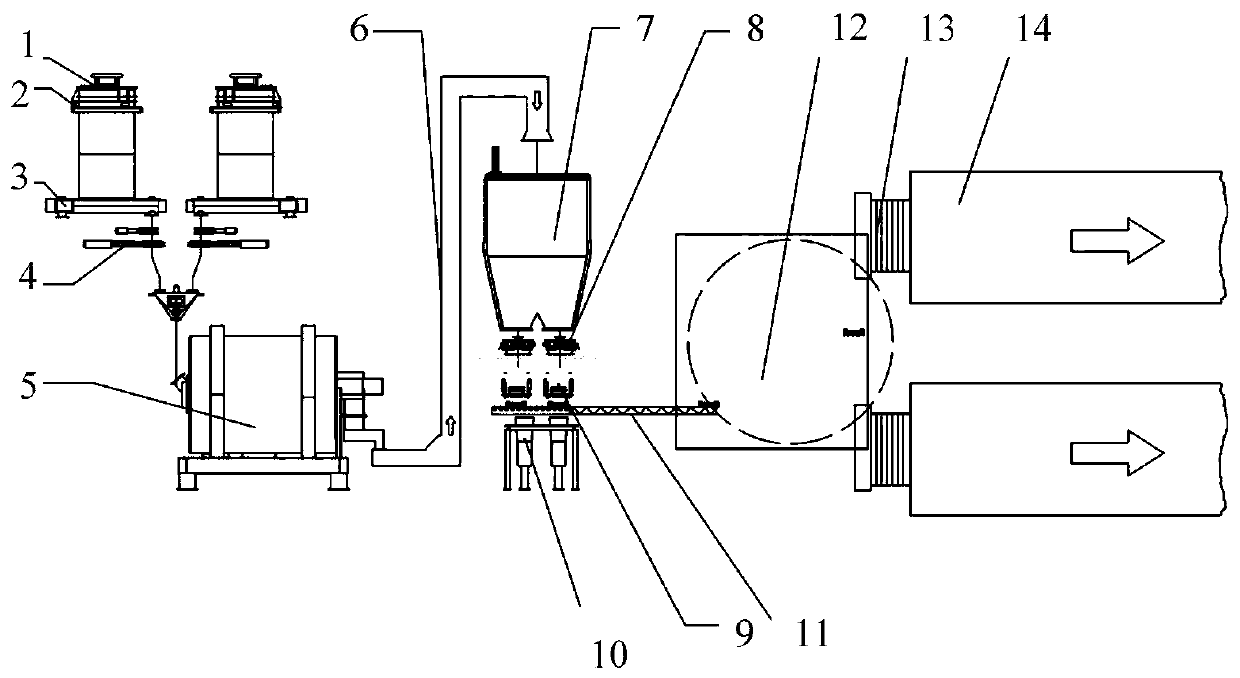

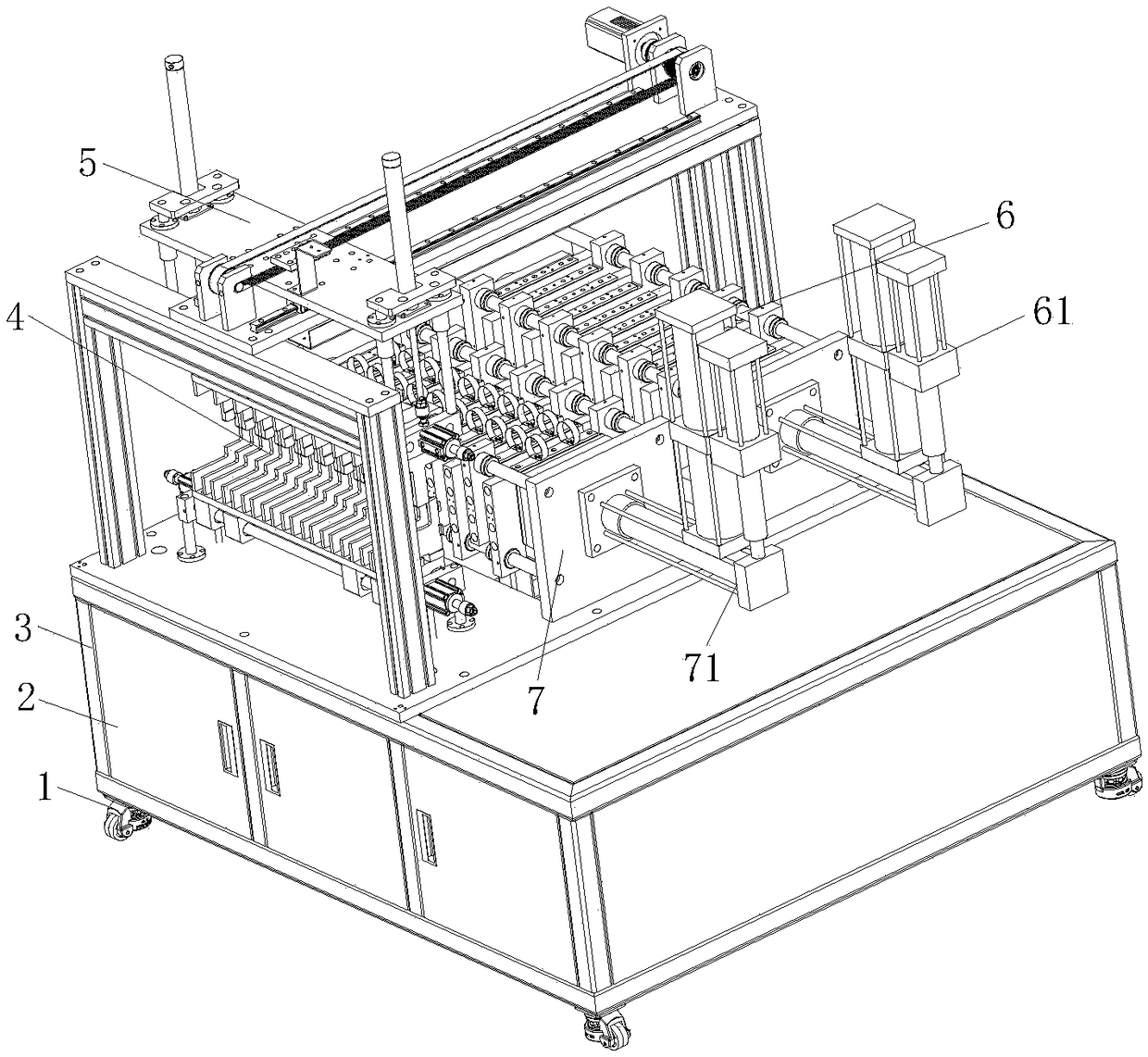

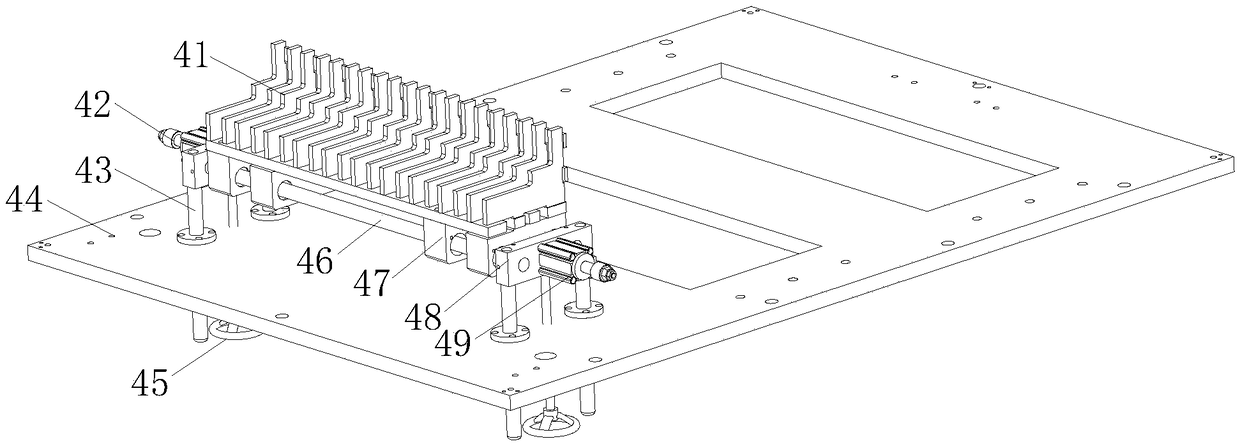

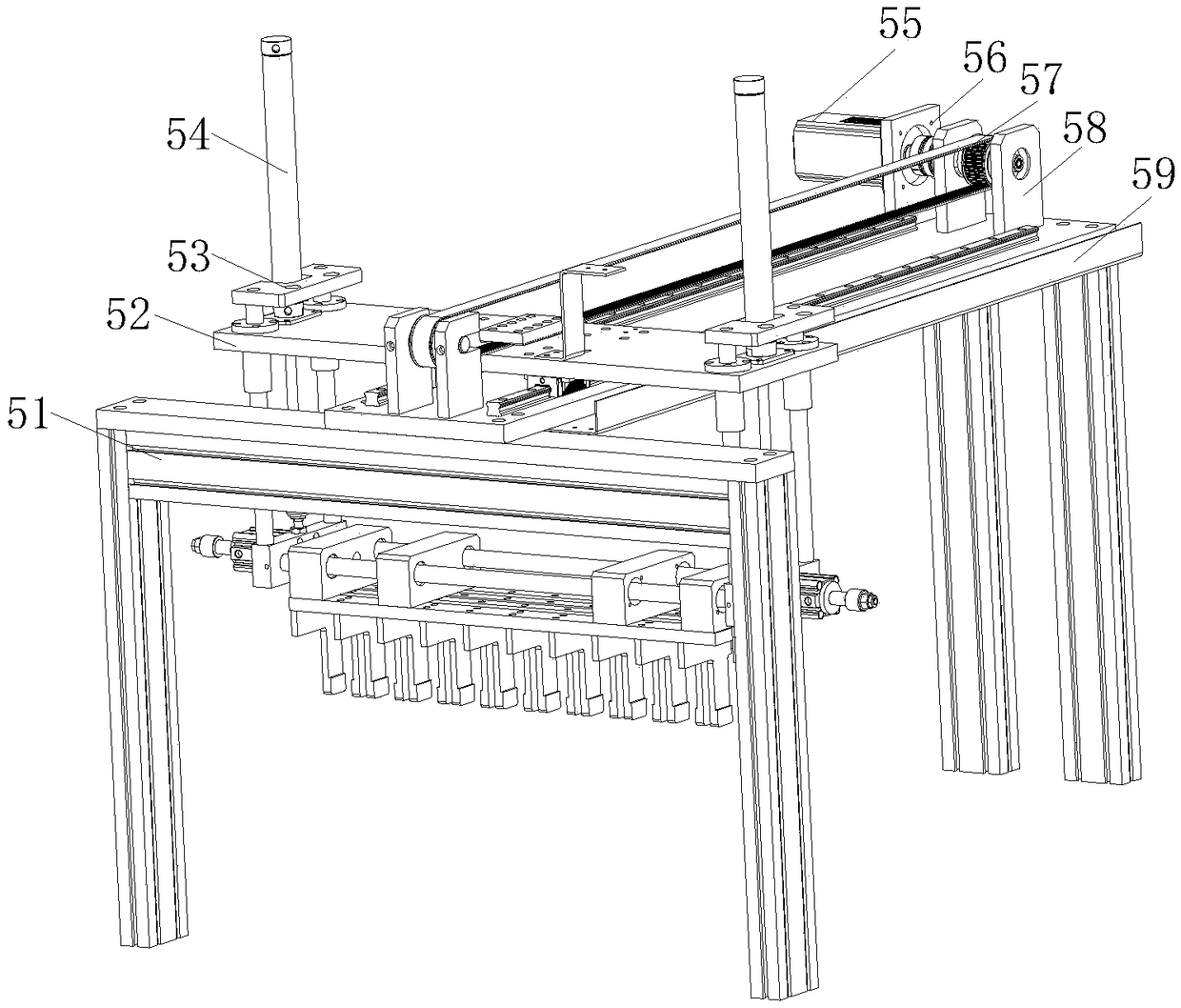

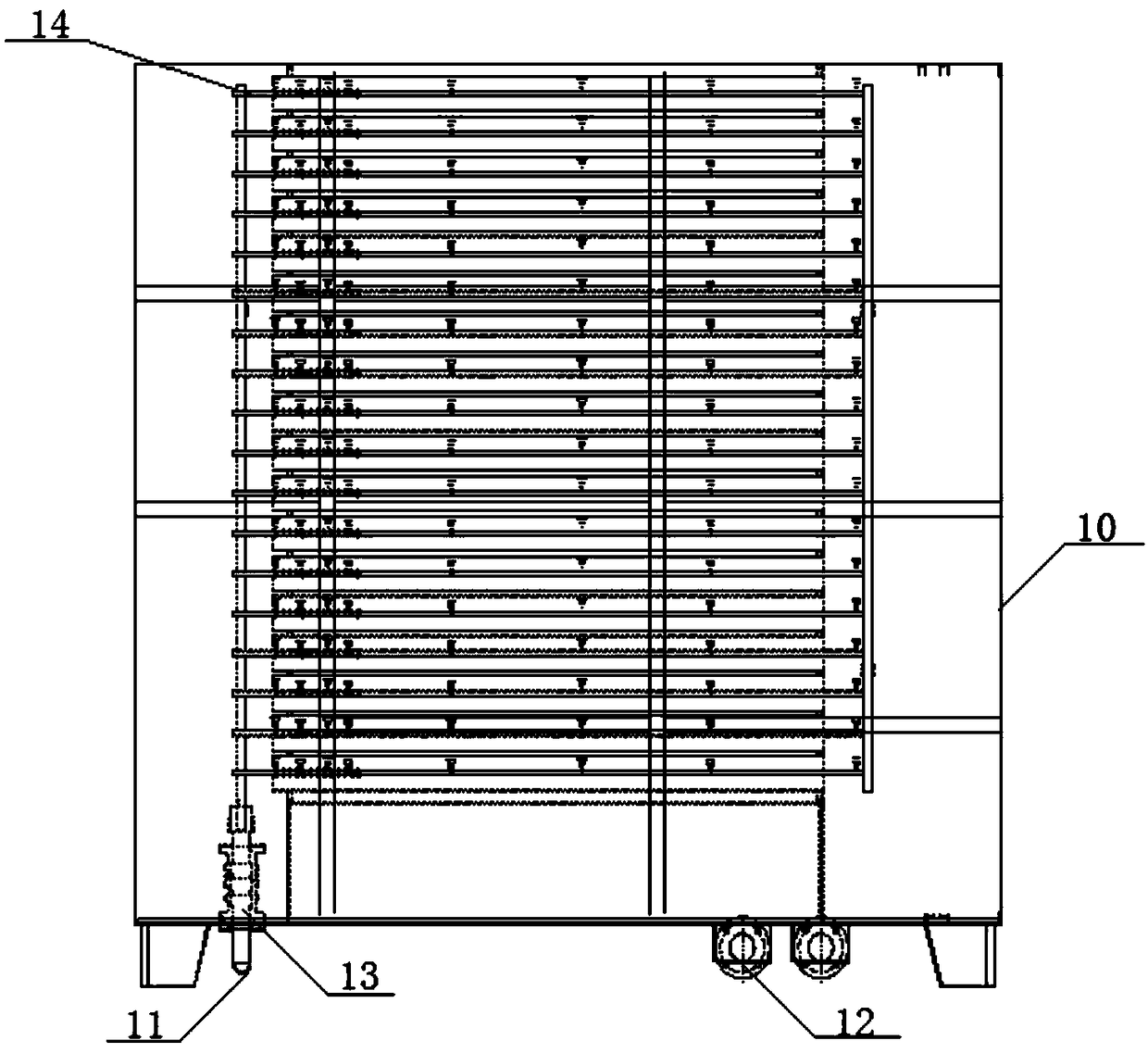

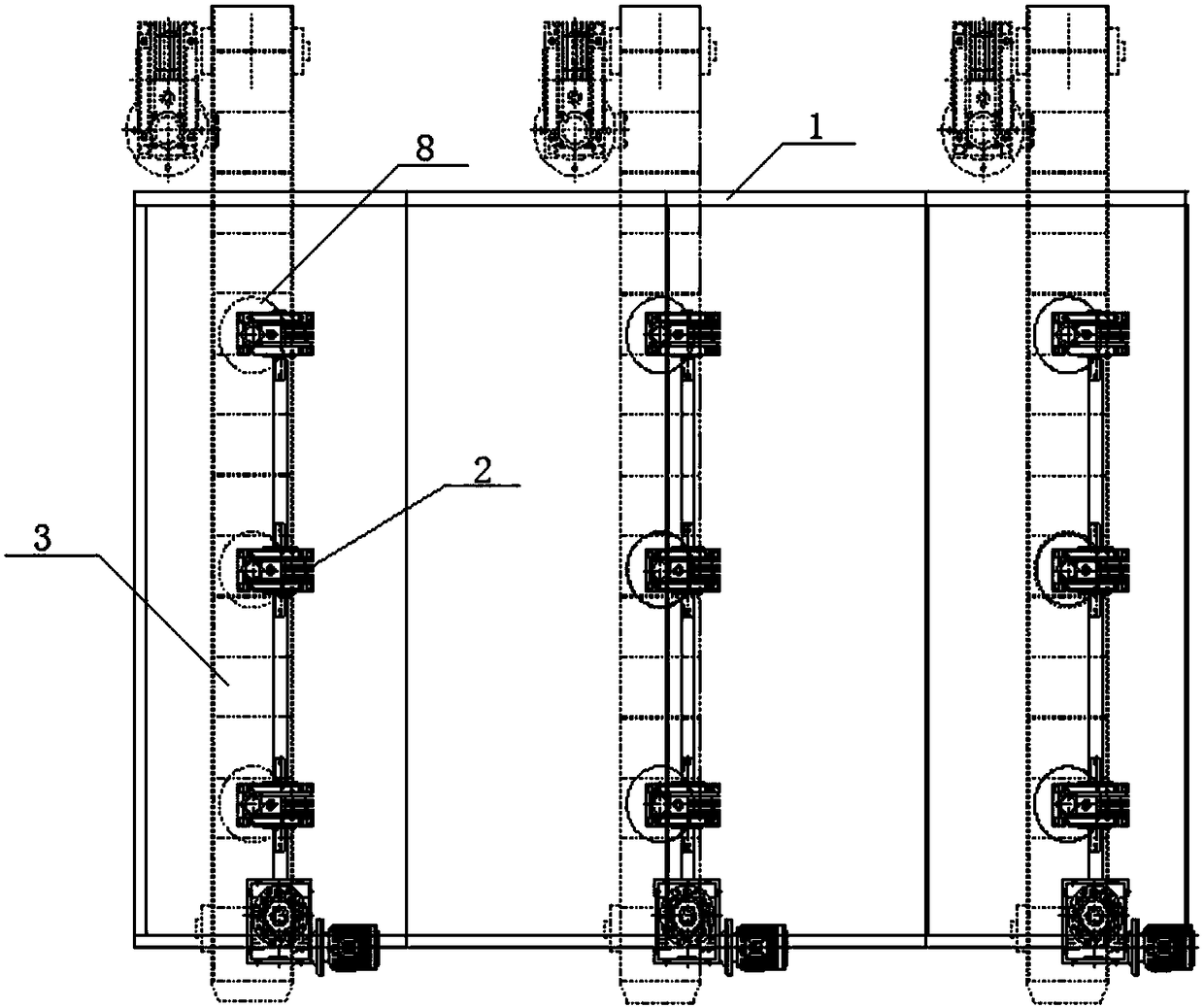

A working method of a material conveying and feeding system

ActiveCN108249174BSave manpower and material resourcesSave spaceCell electrodesFinal product manufactureRobotic armEngineering

Owner:GEM WUXI ENERGY MATERIAL CO LTD +1

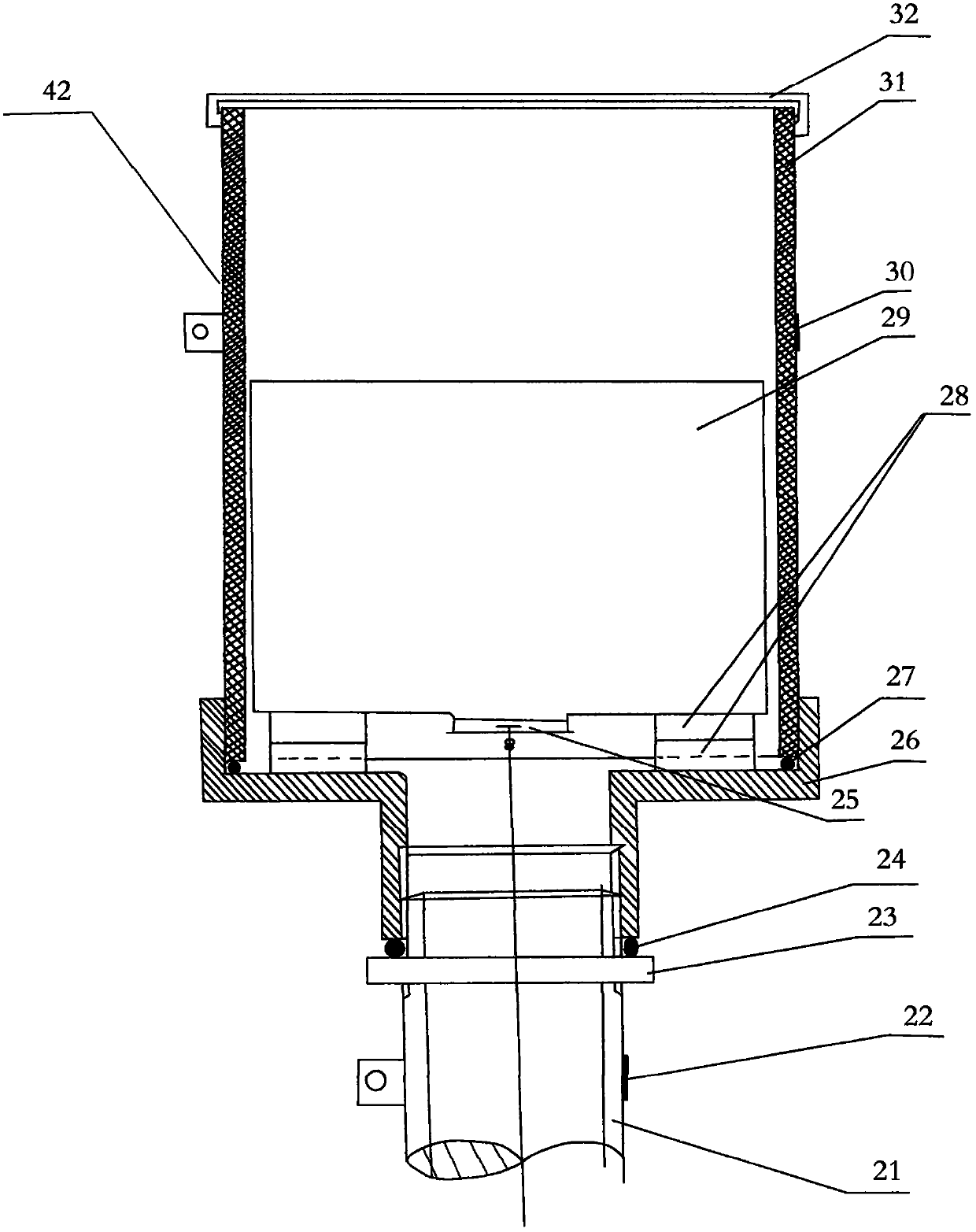

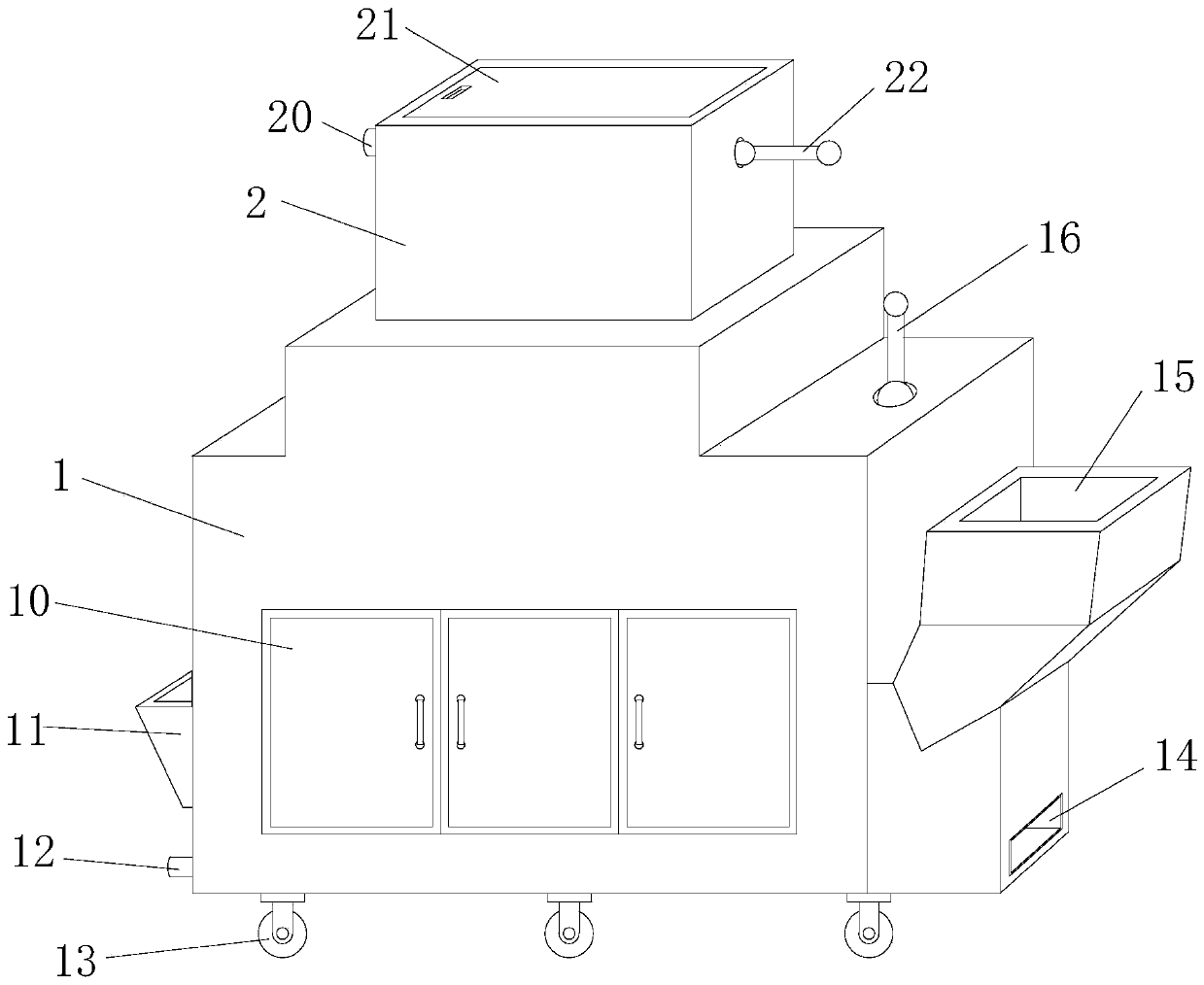

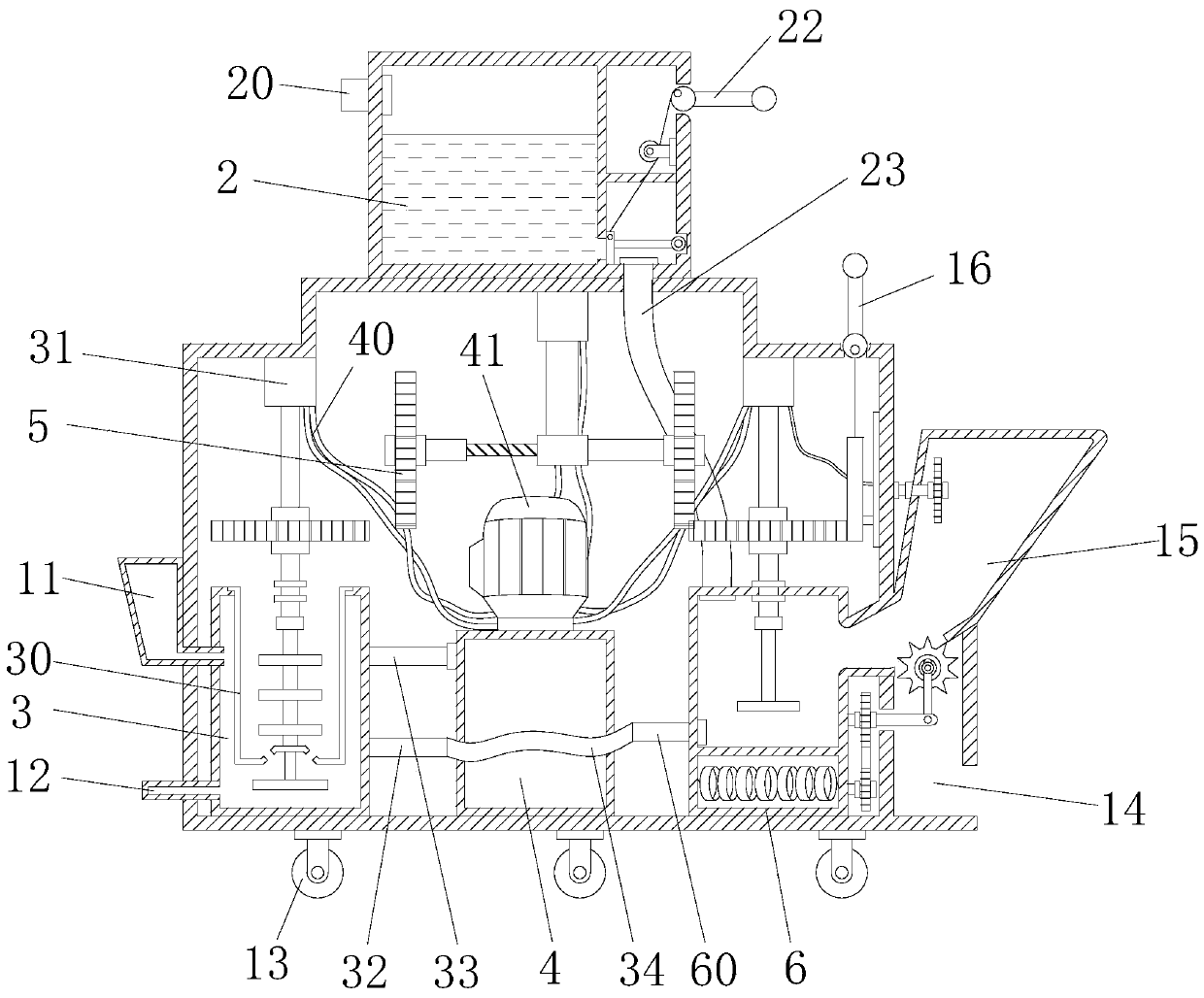

A high-efficiency preparation device for disinfectant for animal husbandry

ActiveCN106139984BEasy to operateEasy to useShaking/oscillating/vibrating mixersTransportation and packagingDisinfectantEngineering

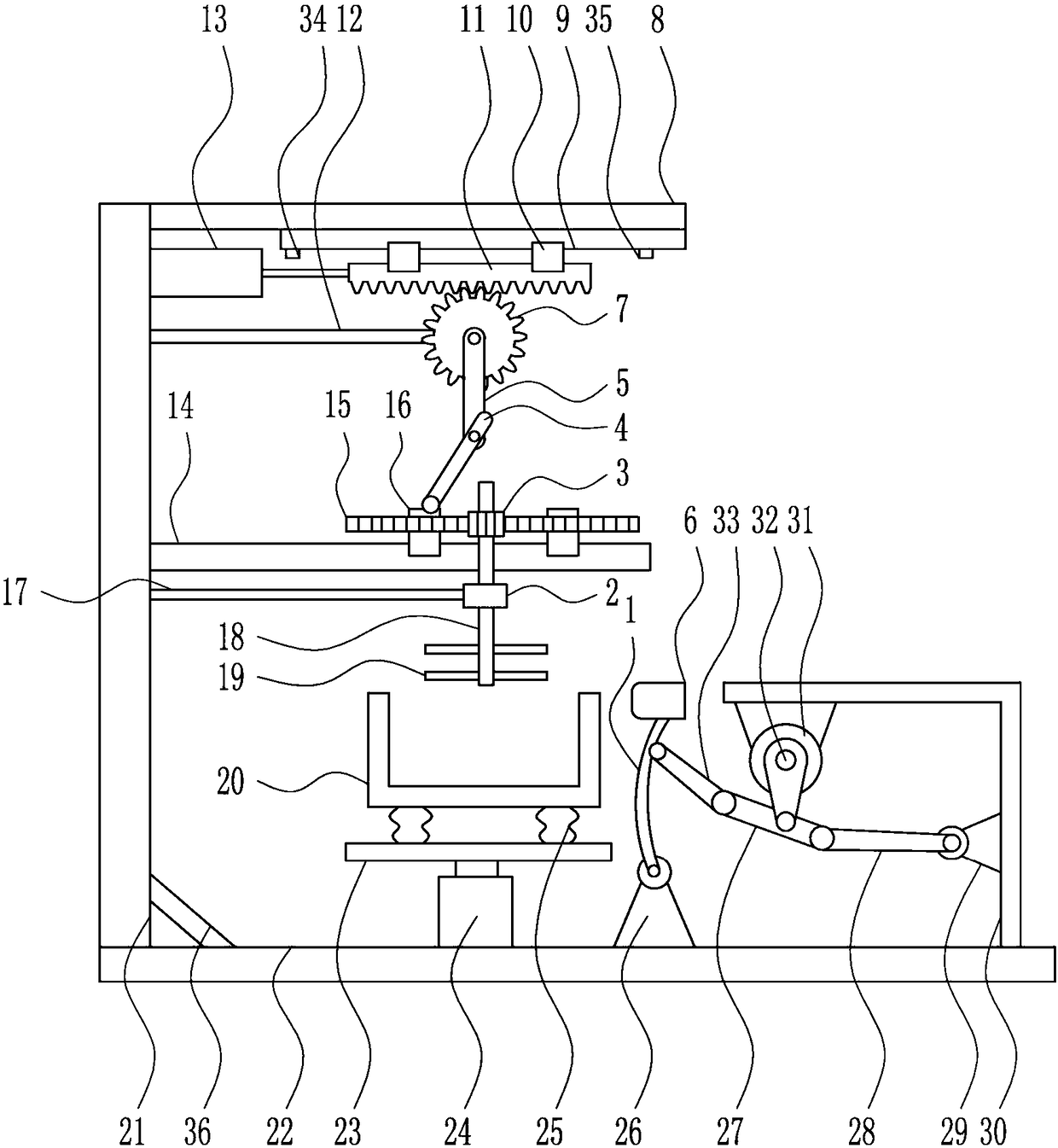

The invention relates to a disinfectant preparation device for animal husbandry, in particular to a high-efficiency preparation device for disinfectant liquid for animal husbandry. The technical problem to be solved by the present invention is to provide a high-efficiency preparation device for animal husbandry disinfectant that is easy to operate, fast in preparation, time-saving and labor-saving. In order to solve the above technical problems, the present invention provides such a high-efficiency preparation device for animal husbandry disinfectant, which includes a first rotating shaft, a first bearing seat, a first bevel gear, a small pulley, a block, a moving rod, and a cylindrical cam , guide sleeve, first slider, first connecting rod, first slide rail, etc., the left wall in the mounting frame is sequentially provided with first connecting rods from top to bottom. The invention achieves the effects of convenient operation, fast preparation, time-saving and labor-saving, low manufacturing cost, reasonable structure, easy maintenance, convenient use, less manpower and material resources input, and lower cost.

Owner:正大食品(徐州)有限公司

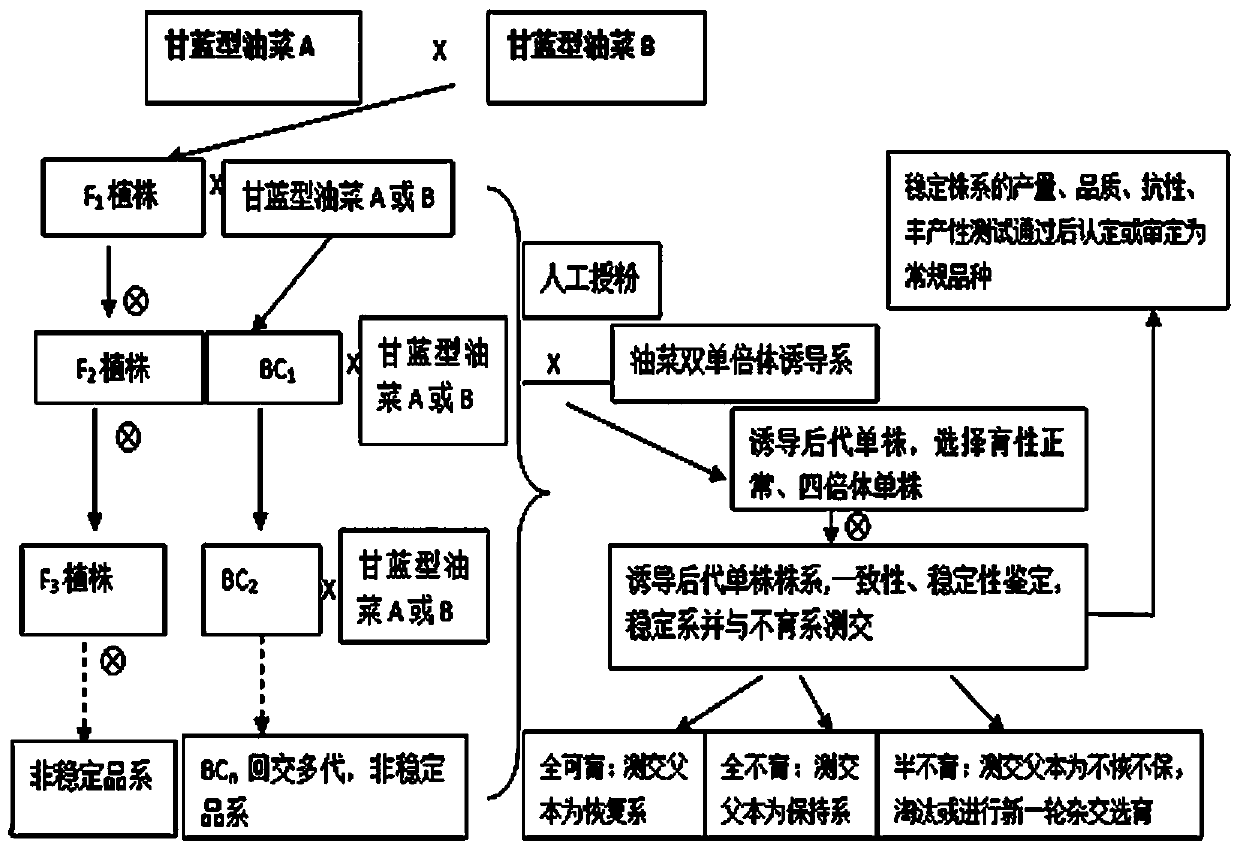

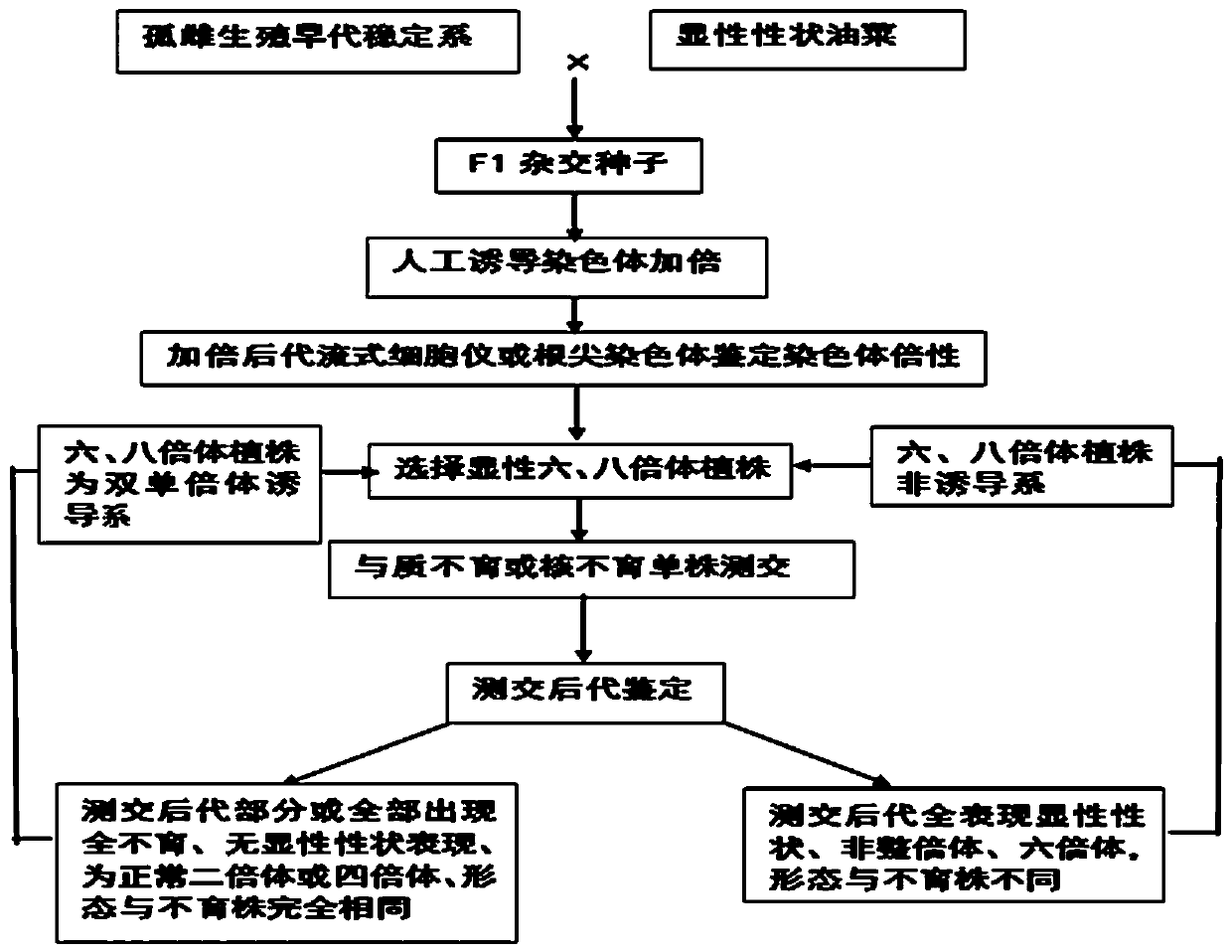

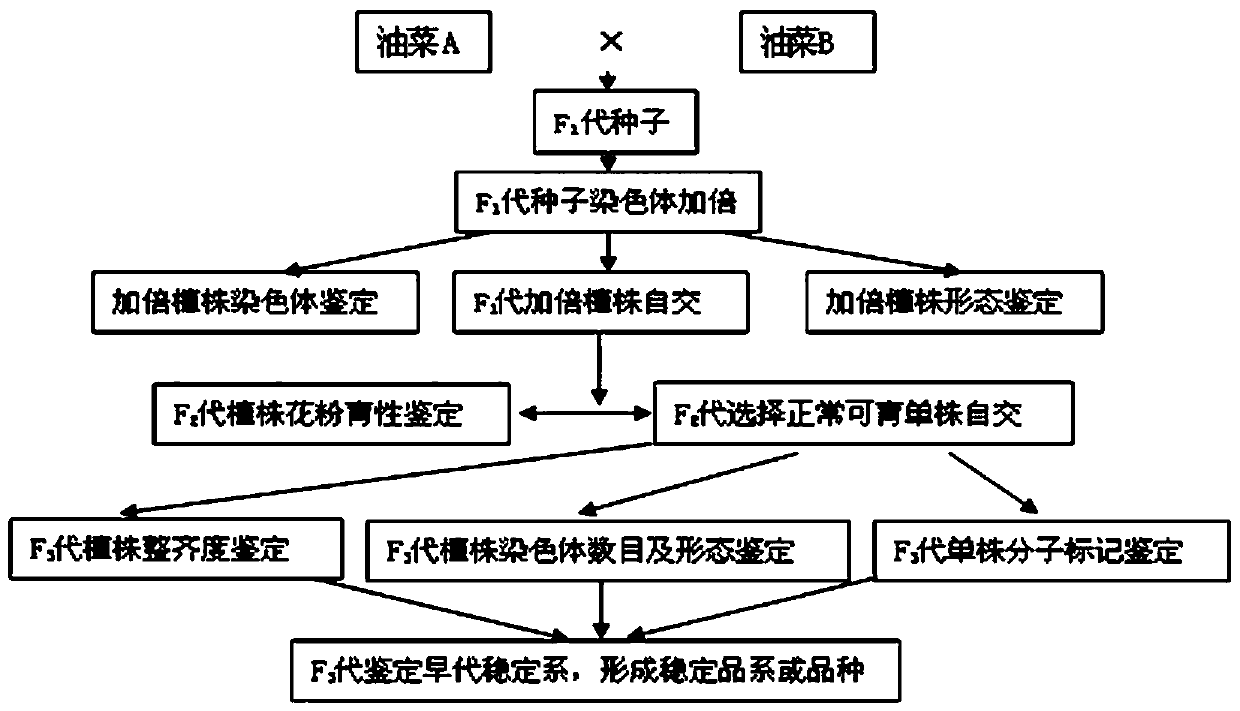

Method for Breeding Brassica napus Varieties and Rapeseed Rapeseed Double Haploid Inducer Lines

InactiveCN106069720BHigh speedImprove efficiencyPlant tissue culturePlant genotype modificationBrassicaPollination

The method for breeding Brassica napus varieties and materials of rapeseed double haploid induction lines of the present invention includes: 1) determining the target traits of Brassica napus restorer lines, maintainer lines, and conventional varieties; 2) combining two or more Brassica napus hybridization or aggregation hybridization with target traits; 3) Pollination of hybrid or backcross progeny with double haploid induction line of rapeseed; 4) Stability identification of induced progeny; 5) Test cross identification or yield, resistance of stable progeny Identification; 6) Formation of stable restorer lines and maintainer lines into hybrid breeding groups or formation of conventional varieties. The invention can quickly, efficiently and large-scalely obtain rapeseed materials or conventional varieties with application value in breeding, and lay a solid foundation for genetic breeding of Brassica napus, innovation of breeding resources, selection of conventional varieties of rapeseed, and breeding of new hybrid rapeseed varieties. The method of the invention can greatly improve the breeding speed and efficiency of hybrid varieties or conventional varieties of Brassica napus, and reduce manpower and material resources.

Owner:CHENGDU ACAD OF AGRI & FORESTRY SCI

Material mixing and stirring device for recycling livestock and poultry pollutants in animal husbandry

ActiveCN106110992BEasy to operateEasy to useTransportation and packagingMixer accessoriesEngineeringAnimal husbandry

The invention relates to a material mixing and stirring device, in particular to a material mixing and stirring device for recycling livestock and poultry pollutants used in animal husbandry. The technical problem to be solved by the present invention is to provide a material mixing and stirring device for recycling livestock and poultry pollutants used in animal husbandry, which is easy to operate, fast in stirring, time-saving and labor-saving. In order to solve the above-mentioned technical problems, the present invention provides such a material mixing and agitating device for recycling livestock and poultry pollutants used in animal husbandry, which includes a first swing rod, a bearing, a first gear, a second swing rod, a third swing rod, Rubber hammer, second gear, fixed plate, second connecting rod, rotating rod, stirring rod, stirring frame, left frame, base plate, support plate, etc., the left frame is arranged in sequence from left to right on the top of the base plate. The invention achieves the effects of convenient operation, fast stirring, time-saving and labor-saving, low manufacturing cost, reasonable structure, easy maintenance and repair, convenient use, reduced manpower and material resources input, and reduced cost.

Owner:冠县华冠资产运营有限公司

A vertical pressurizing machine

ActiveCN106299452BReduce vibrationImprove work efficiencyAssembling battery machinesFinal product manufactureEngineeringHuman material

Owner:DONGGUAN ZEHENG MACHINERY

A kind of dust removal and exhaust gas purification treatment equipment

ActiveCN106039900BAvoid time-consuming and labor-intensive deficienciesPrevent leakageCombination devicesDispersed particle filtrationExternal storageHazardous substance

Owner:江苏蓝博环保机械有限公司

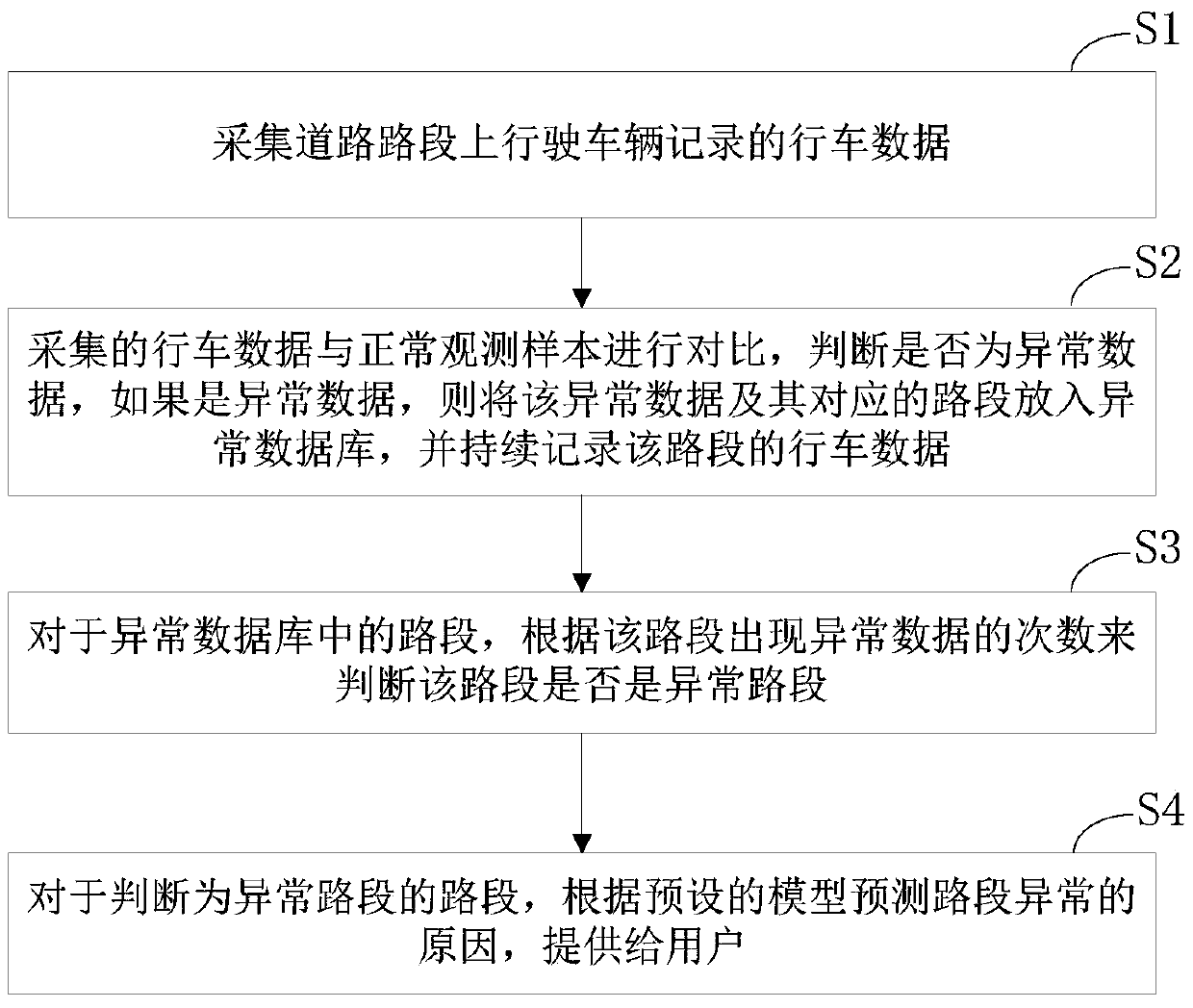

A method and device for predicting road conditions based on big data

ActiveCN106910334BSave manpower and material resourcesEasy maintenanceDetection of traffic movementData acquisitionPath condition

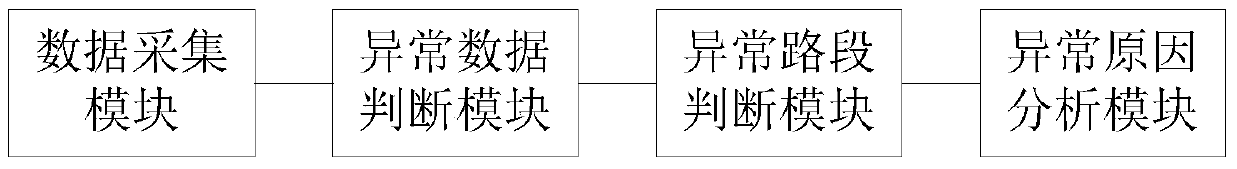

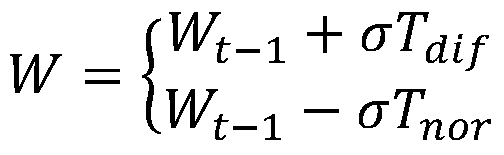

The present invention discloses a method and device for predicting road section conditions based on big data. The method collects driving data recorded by vehicles traveling on road sections, compares the collected driving data with normal observation samples, and judges whether it is abnormal data. If If it is abnormal data, put the abnormal data and the corresponding road section into the abnormal database, and continuously record the driving data of the road section; for the road section in the abnormal database, judge whether the road section is abnormal according to the number of abnormal data in the road section Road section: For a road section judged as an abnormal road section, the reason for the abnormal road section is predicted according to the preset model, and provided to the user. The device of the present invention includes a data acquisition module, an abnormal data judgment module, an abnormal road section judgment module and an abnormal cause analysis module. The method and device of the present invention can accurately predict the condition of road sections through the analysis of big data, saving manpower and material resources.

Owner:ALIBABA GRP HLDG LTD

Ceramic tile full-automatic packaging production line

ActiveCN103129766BFast sortingImprove work efficiencyPackaging automatic controlShock-sensitive articlesProduction lineControl system

Owner:FUJIAN MINJIE MACHINERY

High level liquid control device

ActiveCN106979368BWide range of usesGood water control effectOperating means/releasing devices for valvesCheck valvesEngineeringScrew thread

The invention relates to a high-level liquid control device, which is characterized in that the valve body is made of plastic, the lower end is a water inlet of an internal thread, the outer end is a hexagonal screw head, the side of the lower end has an oblate hole with the same width as the valve body, and the upper and lower ends It is a semicircle with edges around it, and there is a groove along the surface. There are symmetrically distributed screw holes corresponding to the blind plate on the inner side of the groove. There is a 60° positive tapered sealing port on the inner upper side. Line and the center line of the valve body are on the same straight line, there is a flat protrusion with a hole in the middle of the upper end of the oblate hole, the outer arm of the oblate hole has a round boss, and there is a threaded protrusion in the middle The cylindrical countersunk through hole has a blind hole on the inner wall of the opposite side. The beneficial effect of the present invention is that the present invention is widely used, has a good water control effect, can save a lot of manpower and material resources, has a long service life, and is not easily damaged. Maintenance is simple.

Owner:刘广和

A pa12 gear-driven drying device for injection molding

The invention relates to a PA12 drying device for the injection molding process, in particular to a PA12 gear-driven drying device for the injection molding process. The technical problem to be solved by the present invention is to provide a PA12 gear-driven drying device for injection molding process with convenient operation, thorough drying, time-saving and labor-saving. In order to solve the above technical problems, the present invention provides such a PA12 gear-driven drying device for injection molding, which includes a discharge pipe, a first electric control valve, a first rotating shaft, a first bearing seat, a stirring rod, a drying box, The feed pipe, the second electric control valve, the second bearing seat, the support rod, etc.; the left side of the top of the bottom plate is hingedly connected to the cylinder, and the right side of the top of the bottom plate is provided with a support rod. The invention achieves the effects of convenient operation, thorough drying, time-saving and labor-saving, low manufacturing cost, reasonable structure, easy maintenance, convenient use, reduced manpower and material resources input, and improved work efficiency.

Owner:中山市启元五金制品有限公司

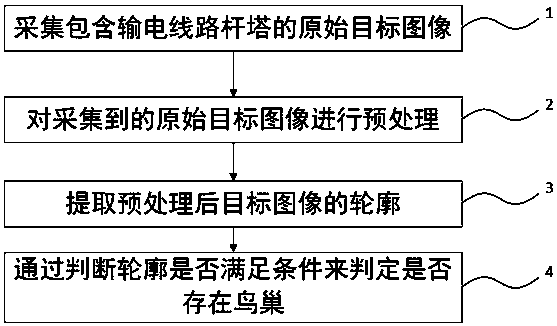

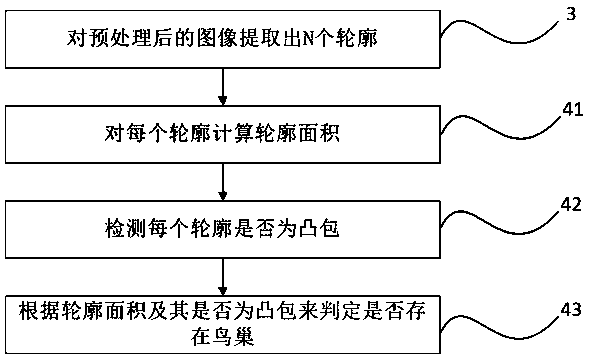

A method for detecting bird's nest of transmission line towers

The invention discloses a bird's nest detection method for power transmission line towers, which includes collecting original target images including power transmission line towers; preprocessing the collected original target images; extracting the contours of the preprocessed target images; and judging whether the contours meet conditions. Determine whether there is a bird's nest. If the contour area is greater than the set threshold and the contour is a non-convex hull, then it is determined that the contour is a bird's nest. Based on the image contour, the invention has a simple and efficient algorithm, can effectively detect the bird's nest on the power transmission line, and saves manpower and material resources.

Owner:中国科学院自动化研究所(洛阳)机器人与智能装备创新研究院

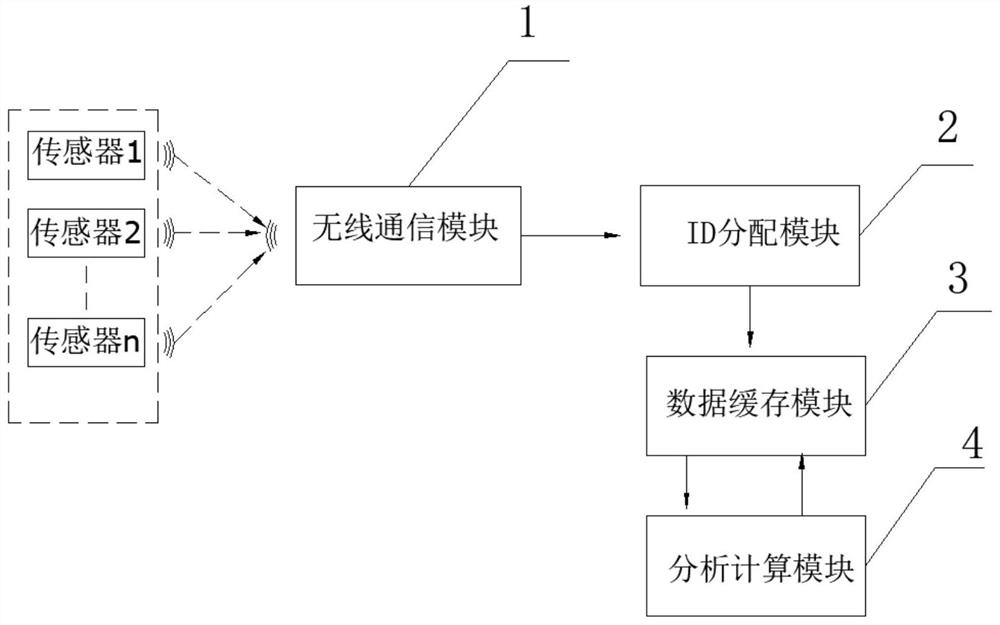

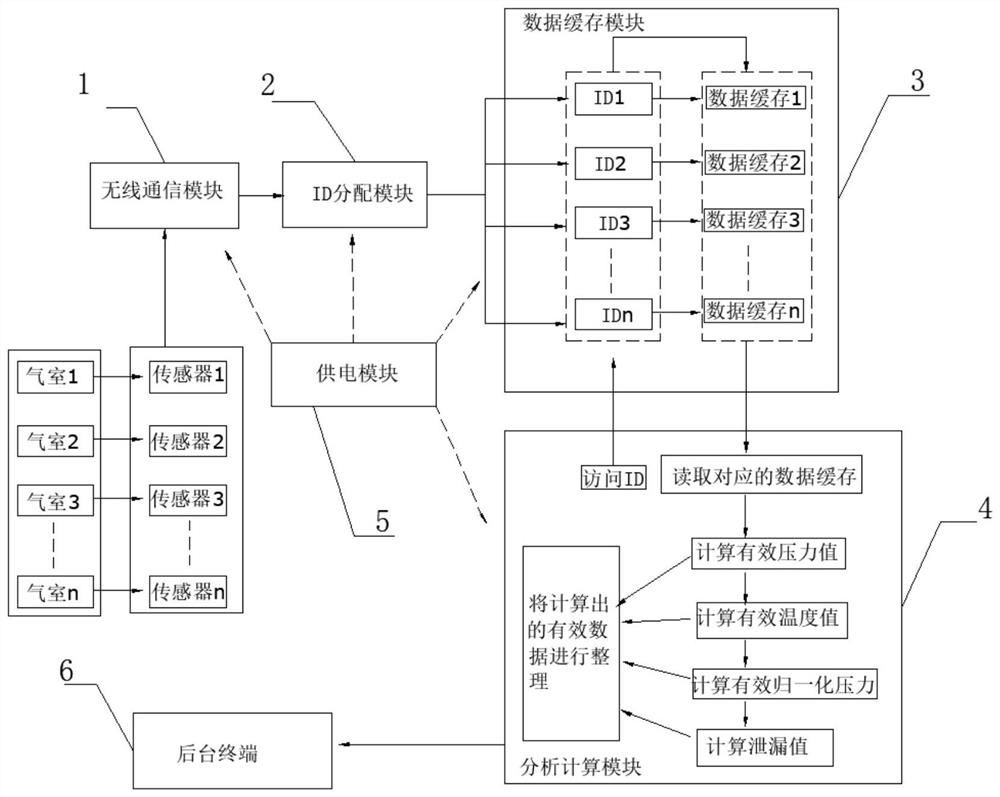

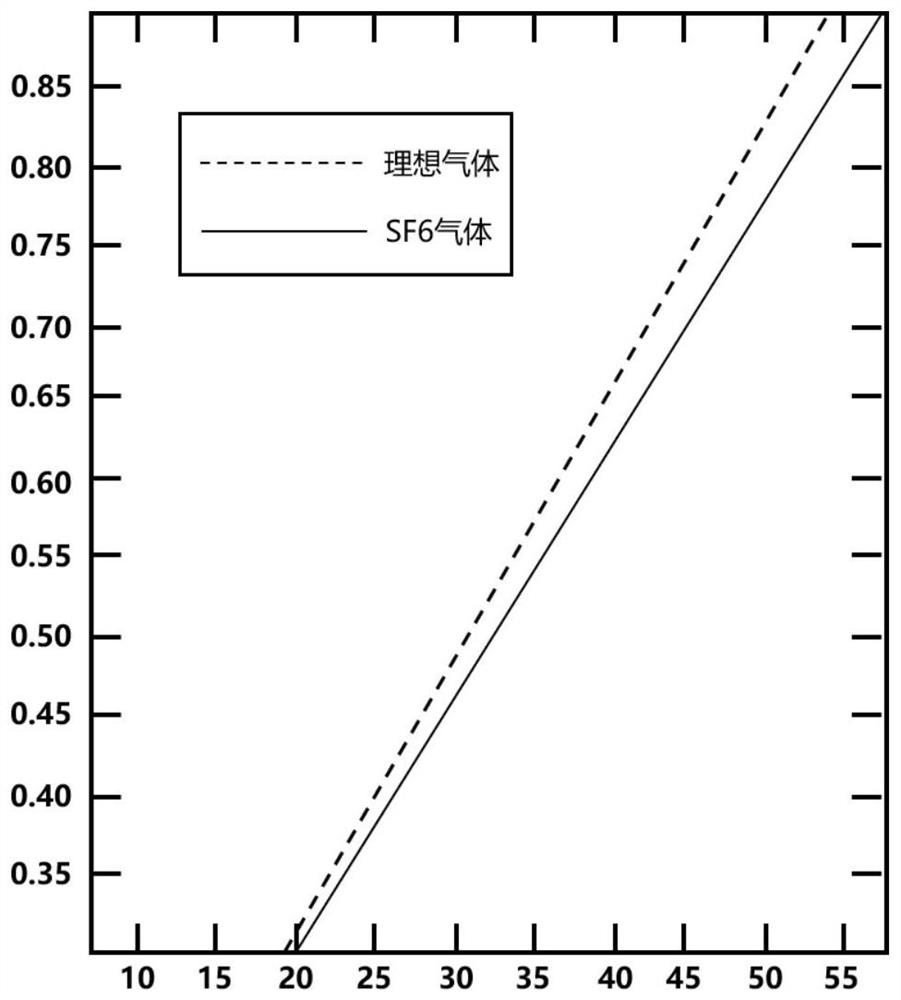

SF6 comprehensive collection and analysis device

InactiveCN113654709AGuaranteed accuracyReduce mistakesMeasurement of fluid loss/gain rateDigital data information retrievalComputer moduleParallel computing

The invention provides an SF6 comprehensive collection and analysis device, which comprises a plurality of sensors, a wireless communication module, an ID distribution module, a data caching module, an analysis and calculation module and a power supply module, wherein the wireless communication module receives data collected by the sensors and analyzes the data, the ID distribution module can receive the analyzed data transmitted by the wireless communication module and distributes and marks the data according to the ID of the data, the data caching module receives the data marked by the ID distribution module and performs regional caching on the data according to the ID, and the calculation and analysis module accesses the cache data of the corresponding area through the ID, obtains the data needing to be measured and collected through calculation and analysis, and sends the data to a background terminal. The SF6 comprehensive collection and analysis device can automatically collect data of SF6 in a gas chamber and calculate and analyze the data to obtain required data values, so that waste and errors of manpower and material resources in manual measurement and calculation are reduced.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

A high-performance orthodontic bite and its preparation method

The invention provides a high-performance orthodontic bite and a preparation method thereof, which is prepared from the following raw materials in parts by weight: 60-80 parts of silica gel, 10-30 parts of modified nano filler, and organosiloxane modified butyl styrene 10-20 parts of rubber, 10-25 parts of maleic anhydride grafted hydrogenated styrene-butadiene block co-extract, 1-5 parts of vulcanizing agent, and 1-3 parts of crosslinking agent. According to the test results, the rubber bite prepared by the present invention has good mechanical strength, and the compression permanent deformation test results show that the rubber bite has good deformation resistance and good resilience. The method has simple process and convenient operation, can save a large amount of manpower and material resources, is low in cost, produces no toxic irritating smell during the preparation process, is safe and environment-friendly, and the obtained chew has high resilience and strong bite resistance. Therefore, the method of the present invention has wide application prospects in the field of chewing gum.

Owner:苏州多美新健康科技有限公司

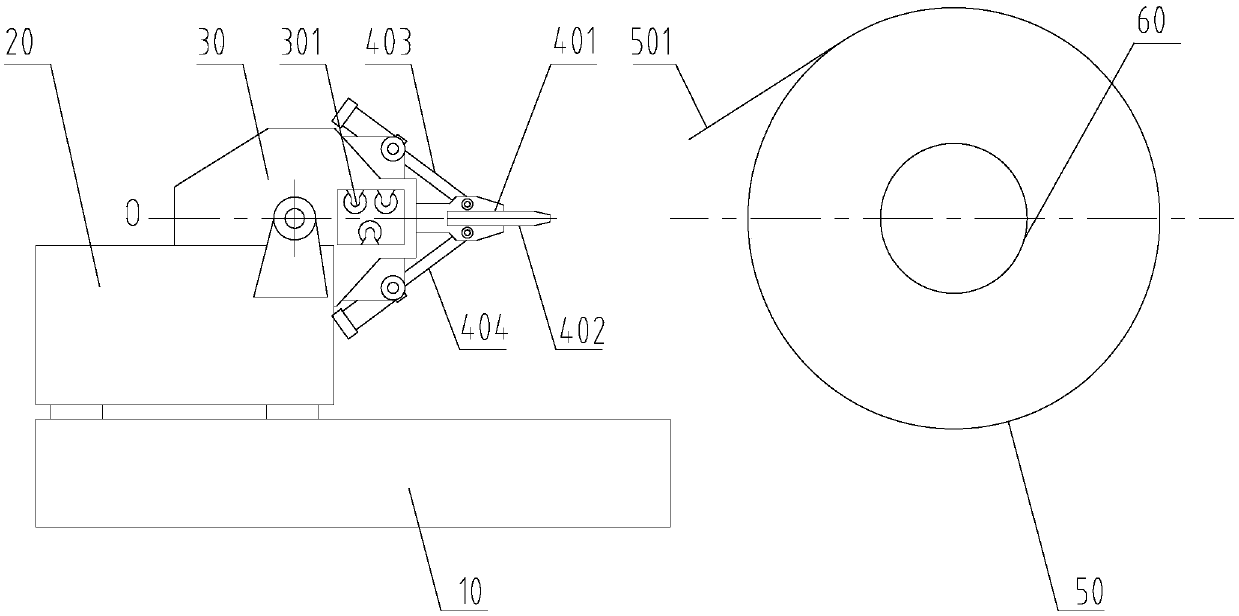

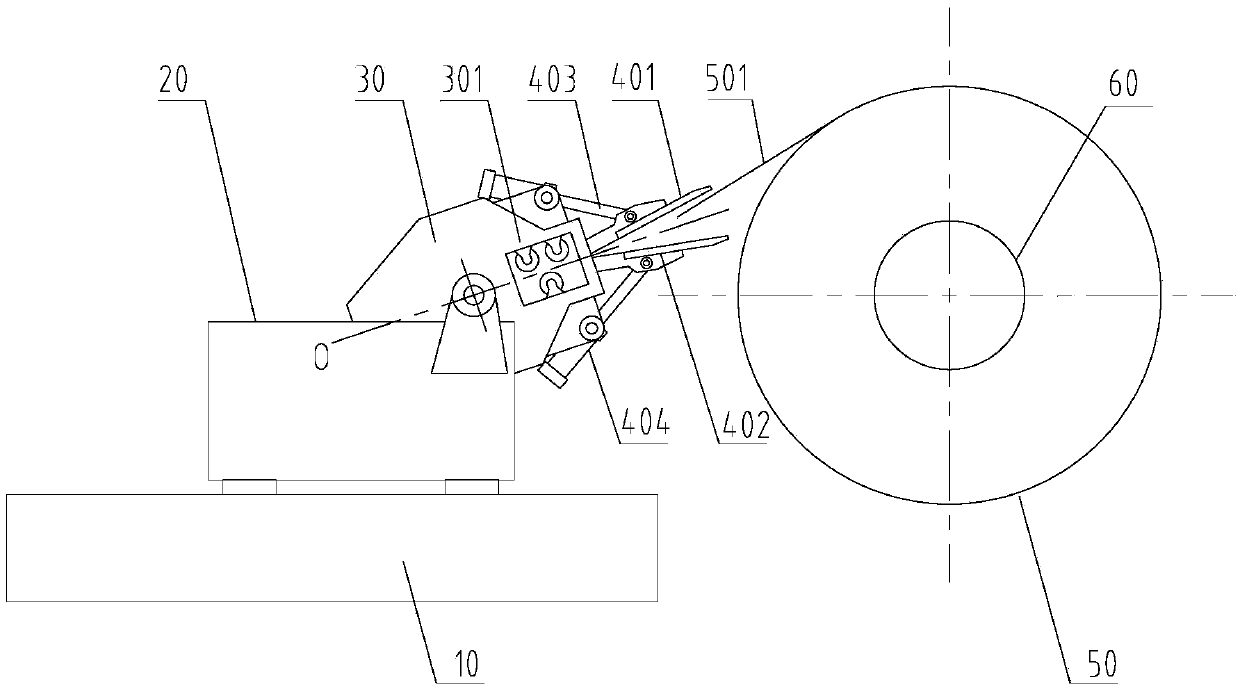

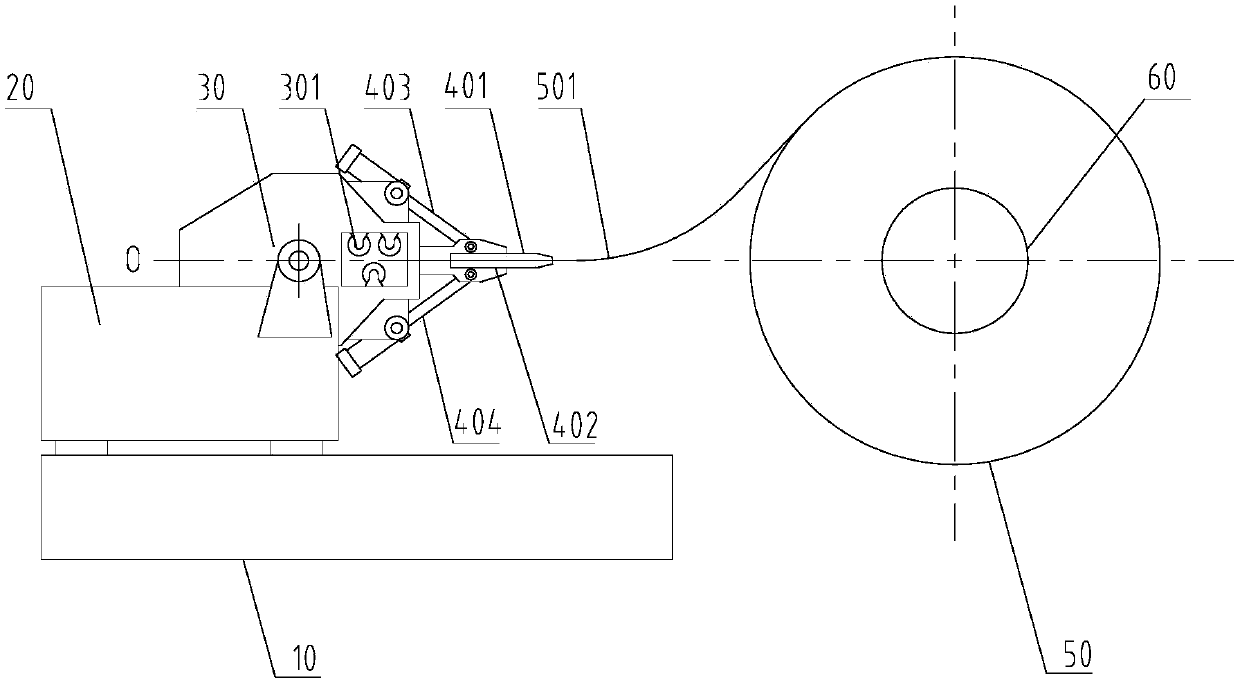

Coil material introduction machine and coil material introduction method

The invention discloses a tape material introduction machine and a tape material introduction method. The tape material introduction machine includes a base, a material introduction roller set arranged on the base, and a material introduction part, and the material introduction part caters to the coil. The protruding section of the belt is used to guide the protruding section into the set of leading rollers along the material leading part. Compared with the manual introduction method in the prior art, the tape material introduction machine obviously improves efficiency, saves manpower and material resources, and improves the safety factor of operators.

Owner:DALIAN FIELD HEAVY MACHINERY MFG CO LTD

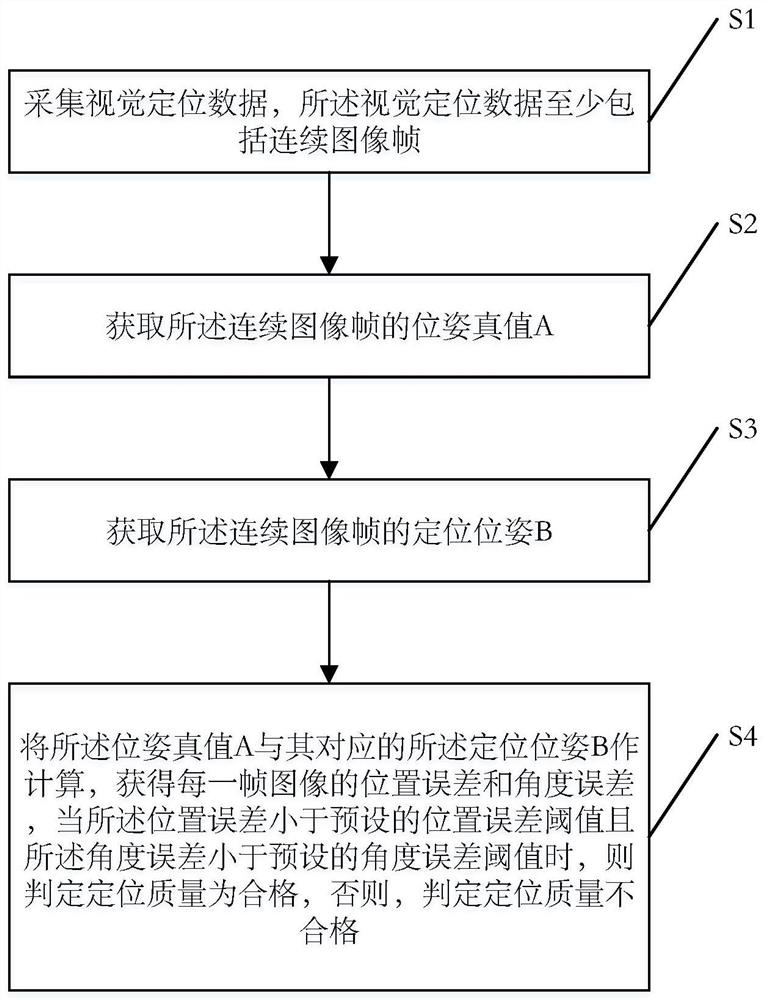

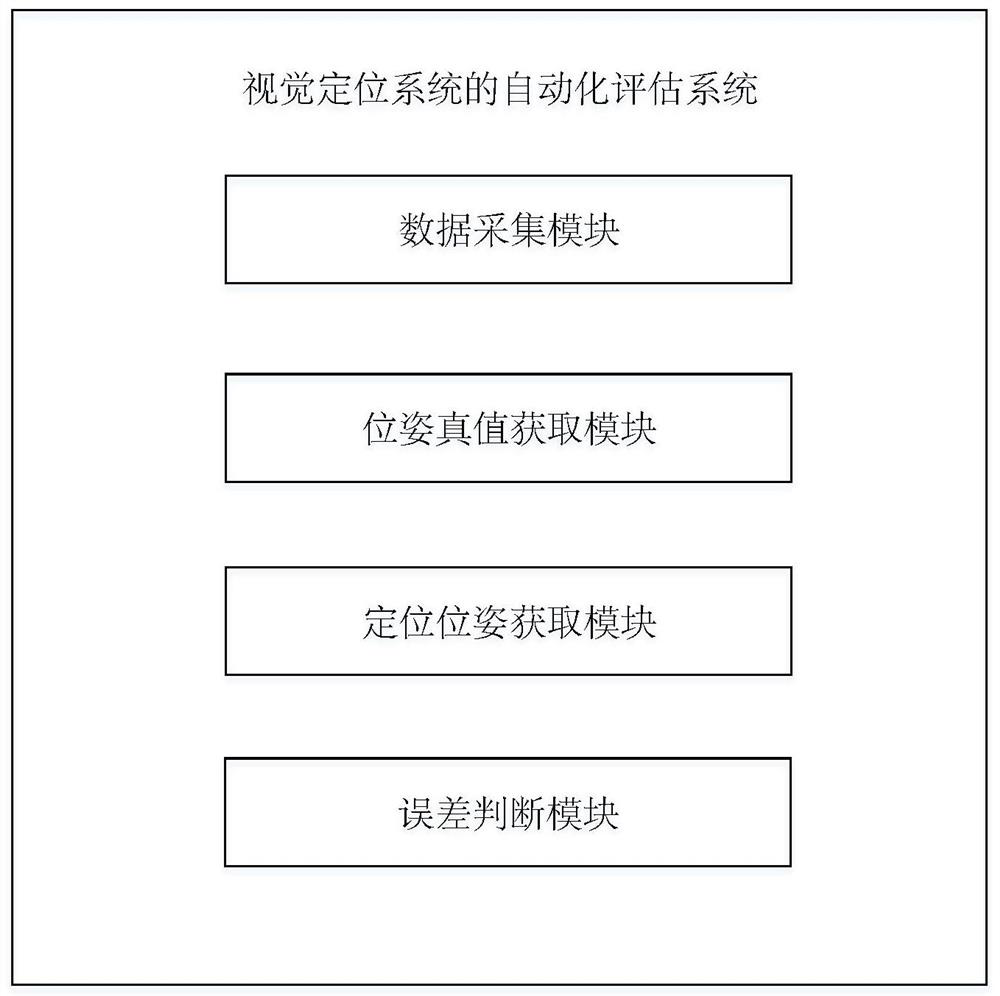

Automatic evaluation method and system for visual positioning system

The embodiment of the invention provides an automatic evaluation method and system for a visual positioning system. In one method, the method includes obtaining consecutive image frames as visual localization data; obtaining a pose true value A of the continuous image frame; acquiring a positioning pose B of the continuous image frames; and calculating the pose truth value A and the positioning pose B corresponding to the pose truth value A to obtain a position error and an angle error of each frame of image, and when the position error is smaller than a preset position error threshold value and the angle error is smaller than a preset angle error threshold value, determining that the positioning quality is qualified, otherwise, determining that the positioning quality is unqualified. According to the method, the quality of the positioning result is completely and automatically evaluated, the result is reliable, the requirements for application scenes, operation modes and equipment are low, and manpower and material resources are saved.

Owner:SHICHEN INFORMATION TECH SHANGHAI CO LTD

A stirring linkage extraction device for rare earth processing

ActiveCN108085485BFast processImprove the efficiency of agitated extractionProcess efficiency improvementElectricityWater storage tank

The invention discloses a stirring linkage extraction device for rare earth processing. A transmission gear, a fixed support main rod, a first controller, a second transmission gear, a connecting rod, and a transmission screw rod. The rare earth mixing drum is provided with a rare earth discharge pipe, a rare earth stirring device, a water injection port, an electric heating wire, The feed inlet, the rare earth stirring device is provided with a third controller, a second stirring gear, a second stirring paddle, and a second stirring device main shaft, so that when the equipment is in use, the rare earth can be stirred by two steps. The extraction work is carried out automatically. There is a water tank on the top of the body, which does not require additional water injection. At the same time, the electric heating wire and the stirring device cooperate with each other to accelerate the process of rare earth extraction, improve the efficiency of rare earth stirring and extraction, and save manpower and material resources.

Owner:GANZHOU QICHANG NEW MATERIAL CO LTD

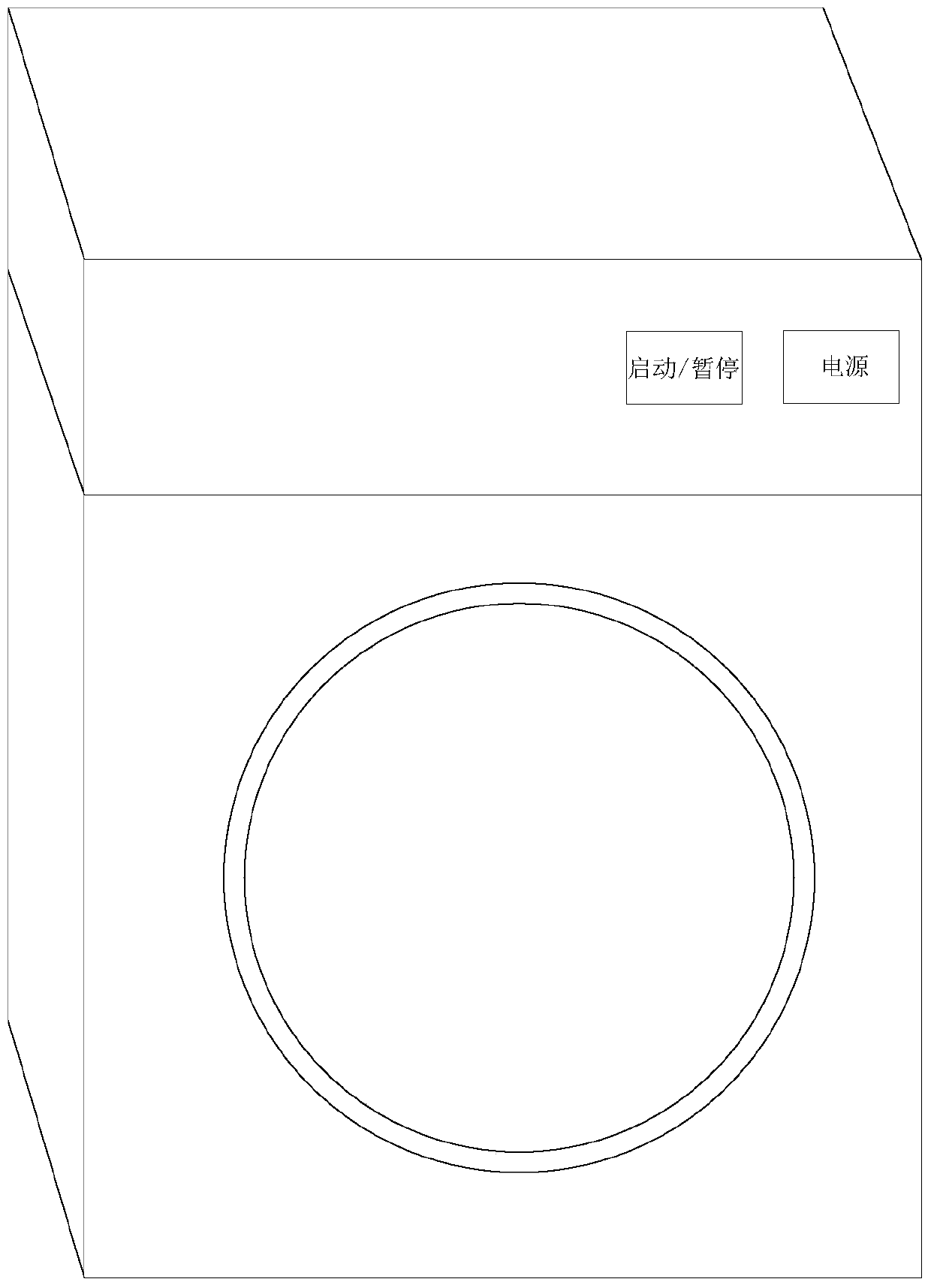

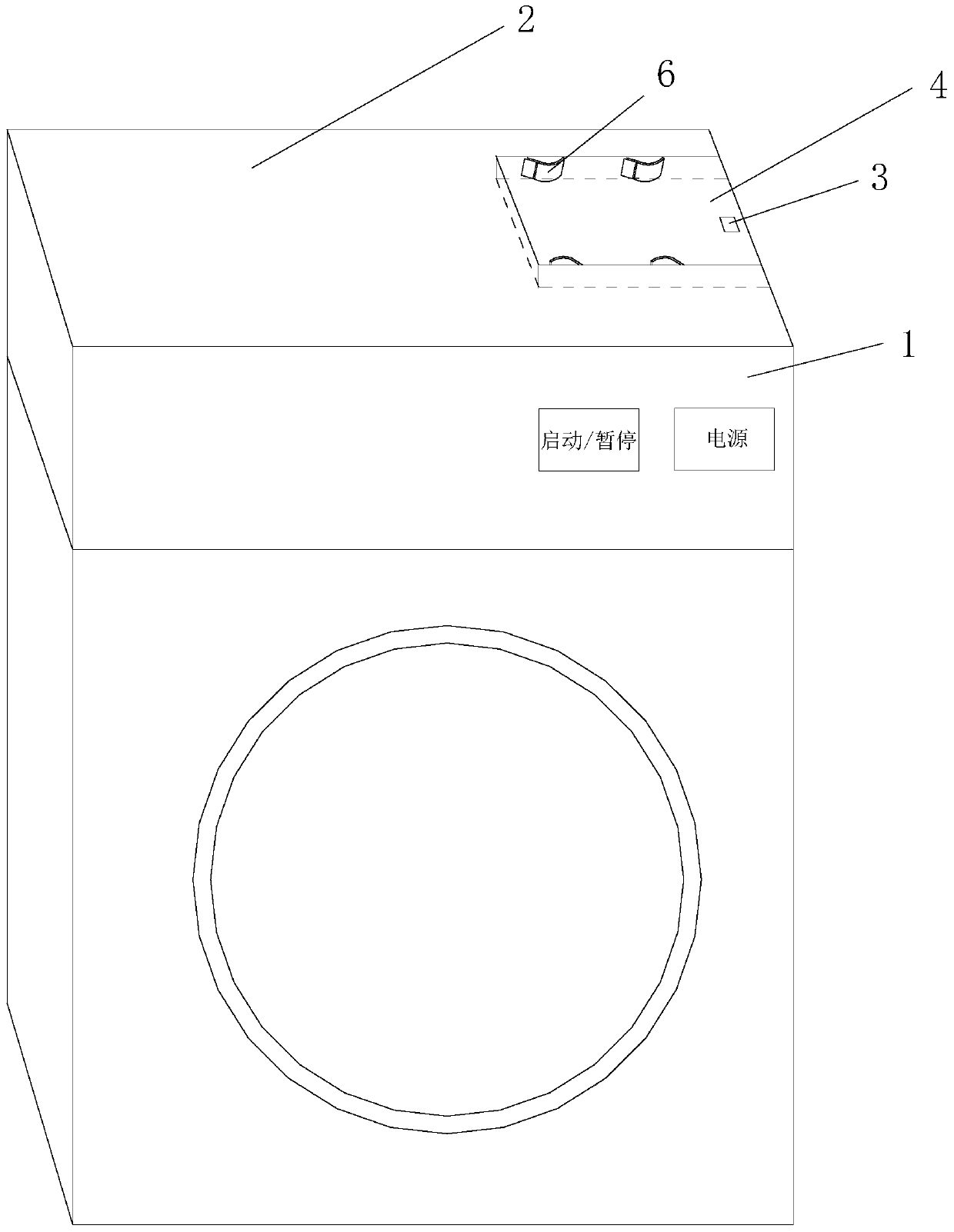

A washing machine and its control method

ActiveCN106930041BGood lookingElegant appearanceOther washing machinesControl devices for washing apparatusKey pressingEngineering

Owner:CHONGQING HAIER ROLLER WASHING MASCH CO LTD

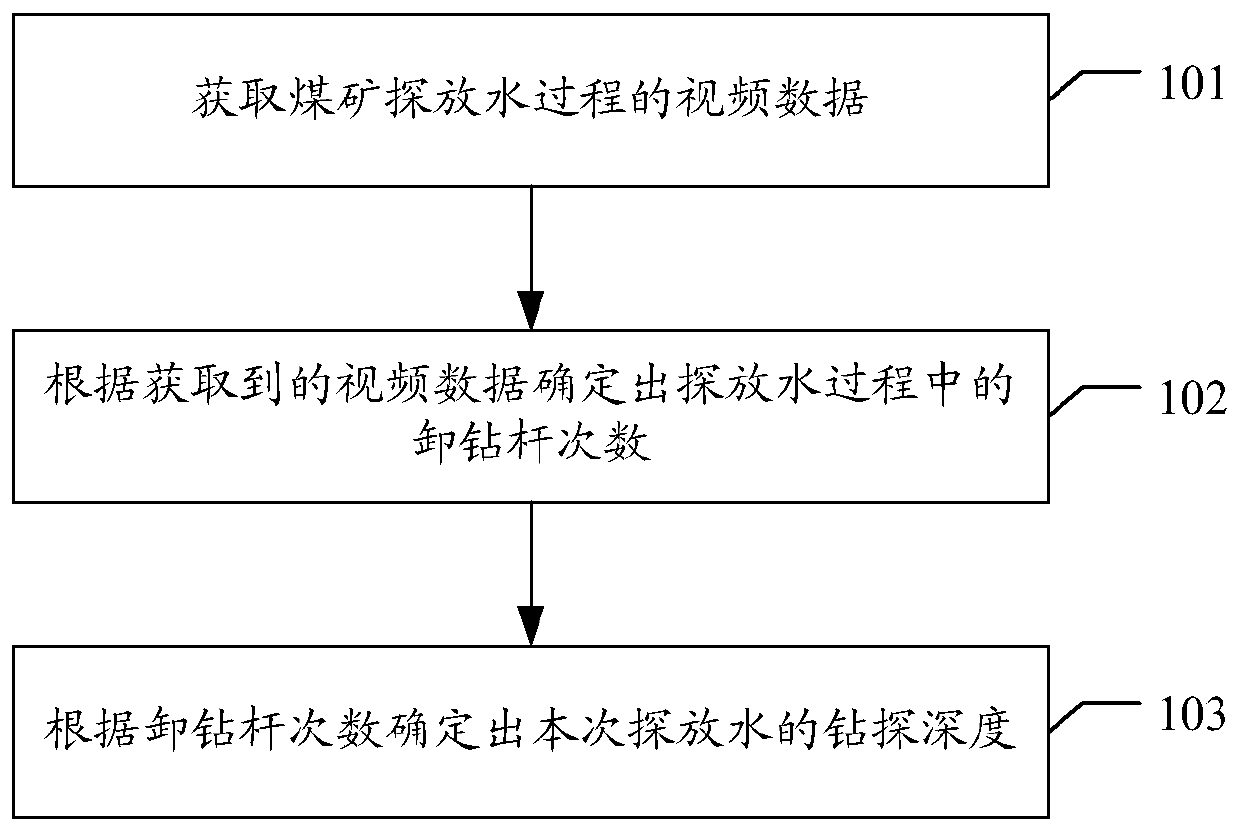

Coal mine water exploration and discharge intelligent monitoring method, device, computer equipment and storage medium

ActiveCN108764032BTo achieve the purpose of automatic monitoringImprove monitoring effectImage enhancementData processing applicationsComputer scienceHuman material

The invention discloses an intelligent monitoring method, device, computer equipment and storage medium for coal mine water exploration and drainage, wherein the method includes: acquiring video data of the coal mine water exploration and drainage process; determining the number of drill pipe unloading during the water exploration and drainage process according to the acquired video data; Determine the drilling depth of this water exploration and discharge according to the number of unloading drill pipes. Applying the scheme of the present invention can improve the monitoring effect and save manpower and material resources.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

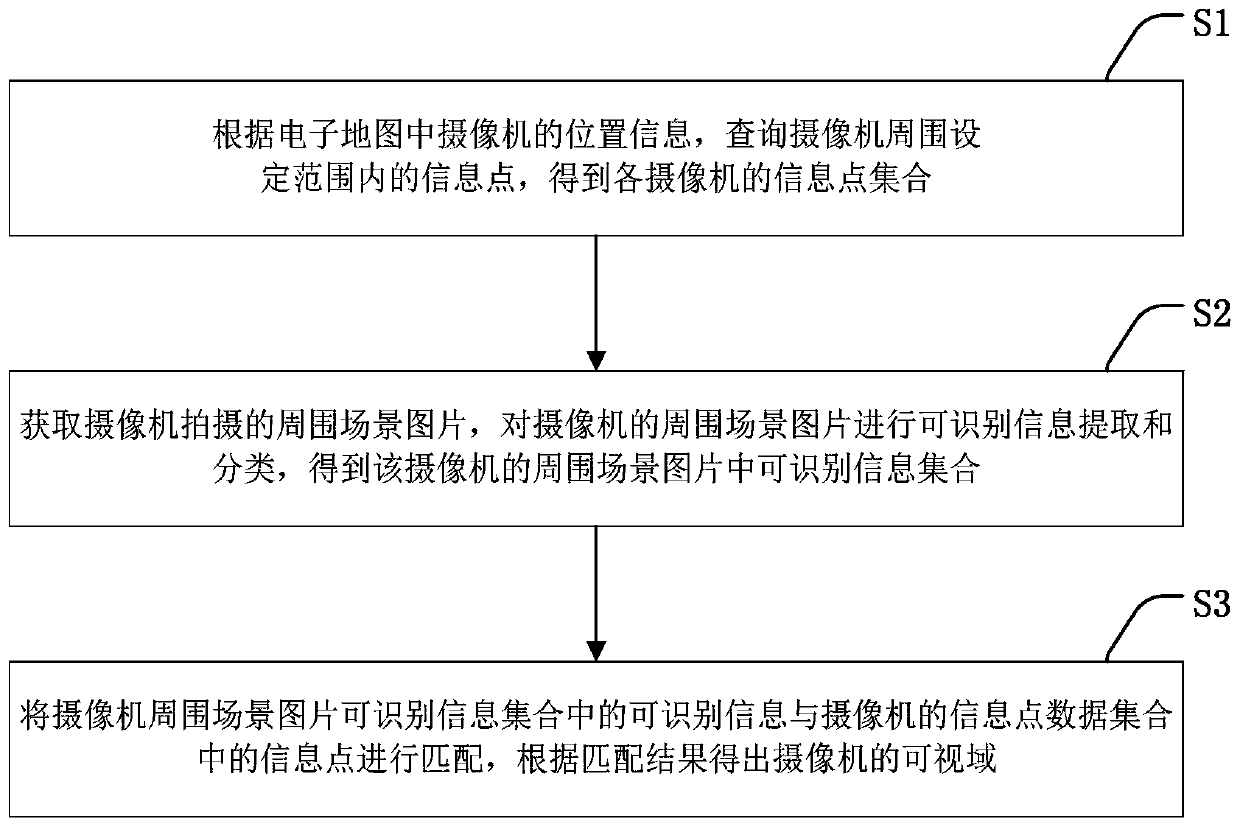

A method and device for automatically confirming the field of view of a camera

ActiveCN106331618BAutomatic drawing fastSave manpower and material resourcesCharacter and pattern recognitionClosed circuit television systemsVisual field lossComputer science

The invention discloses a method and device for automatically confirming the visual field of a camera. By querying the information point data around the camera and calculating the set of information points within the preset distance range of the camera, the picture of the scene around the camera sent by the camera is received. , and extract and analyze the information in the scene picture around the camera to obtain the identifiable information set in the scene around the camera, and combine the identifiable information in the identifiable information set in the scene around the camera with the information points within the preset distance range of the camera The information points in the set are matched, and the visual field of the camera is obtained according to the matching result. The device of the present invention includes an information point acquisition module, an identifiable information acquisition module and a visual domain acquisition module. The method and device of the present invention can quickly and automatically draw the visual field of each camera in the electronic map, saving manpower and material resources.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com