Patents

Literature

345results about How to "Efficient introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for tissue removal and for delivery of a therapeutic agent or bulking agent

InactiveUS7806871B2Efficient removalMinimize damageInfusion syringesMedical devicesSurgeryMedical device

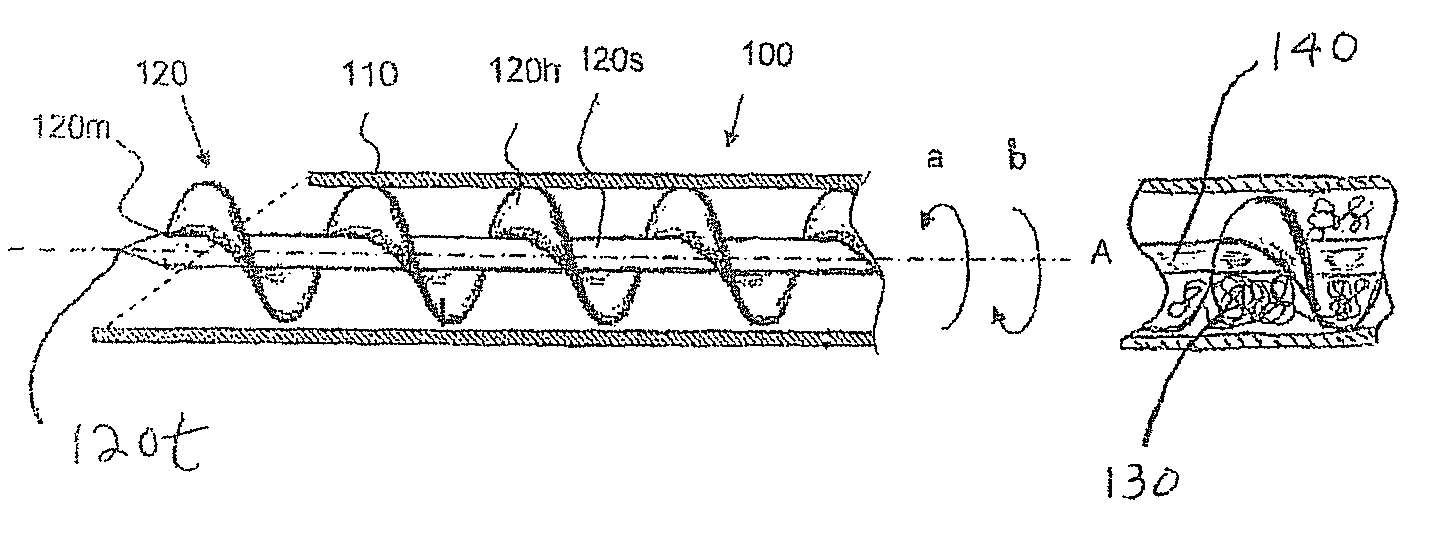

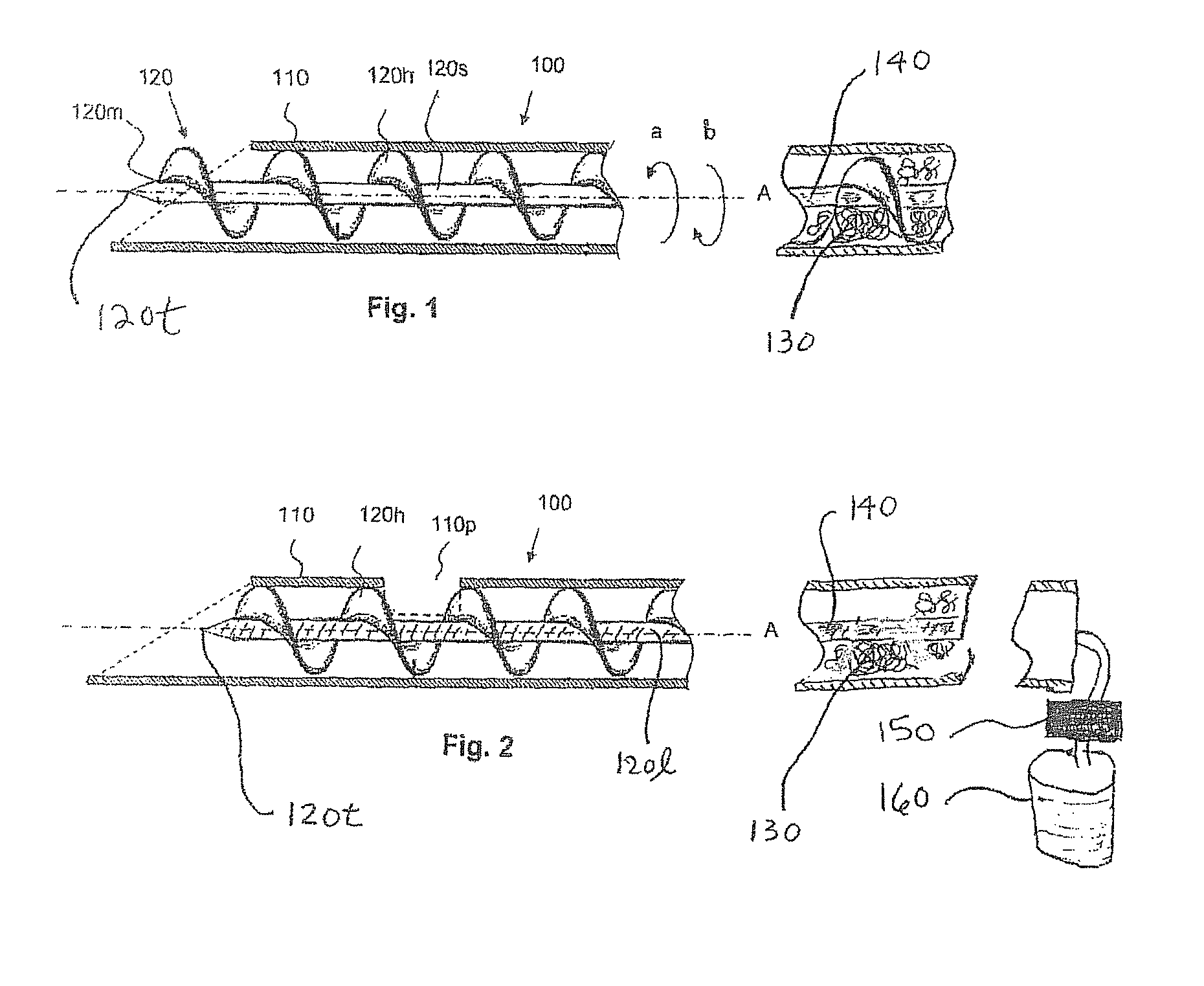

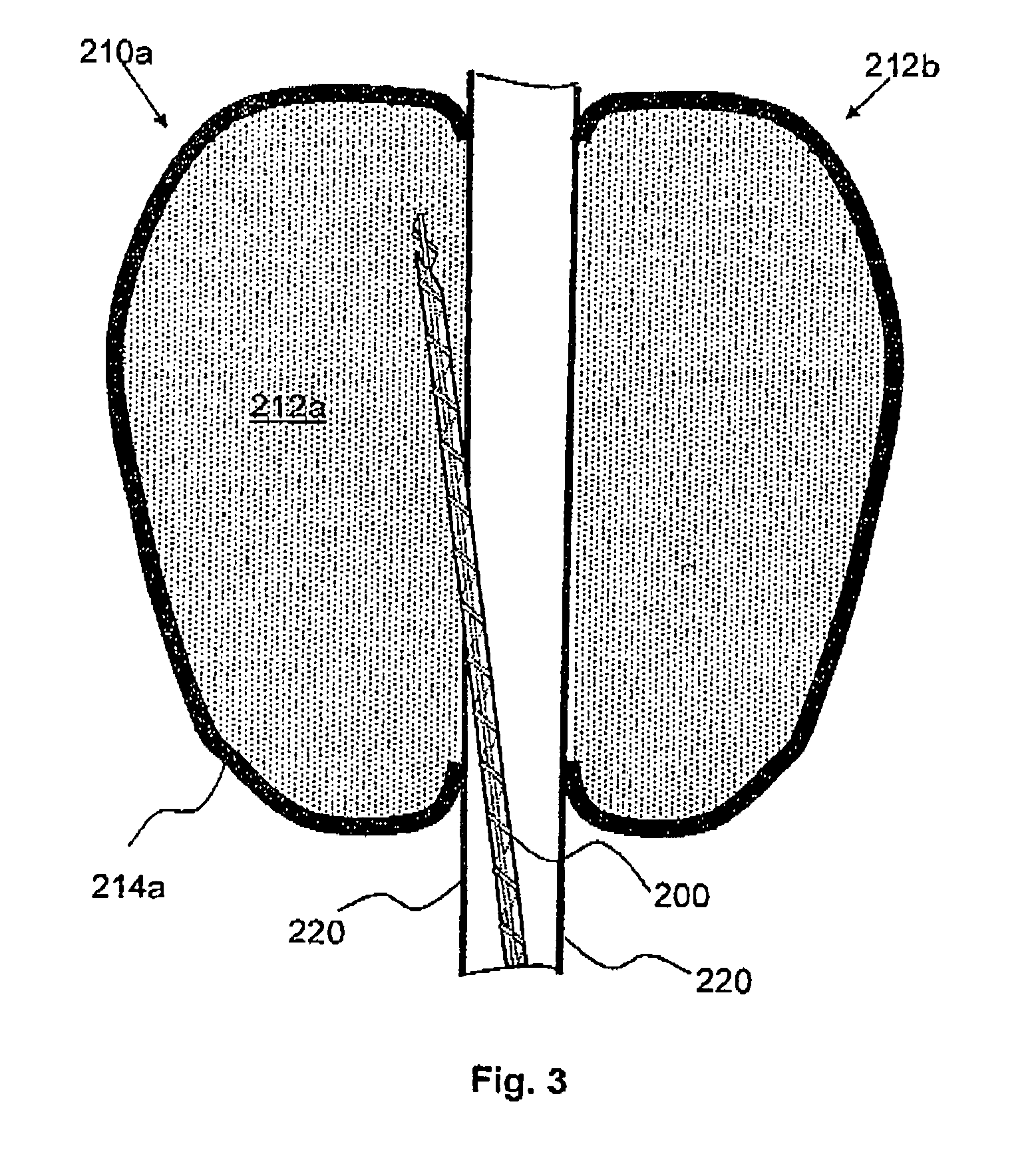

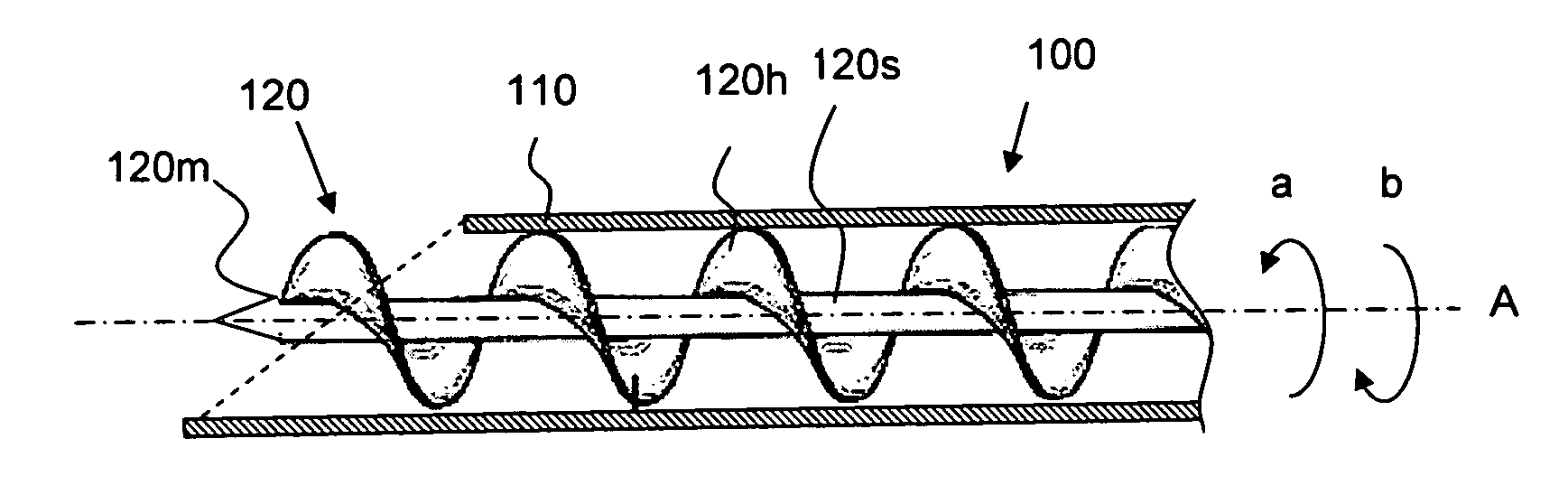

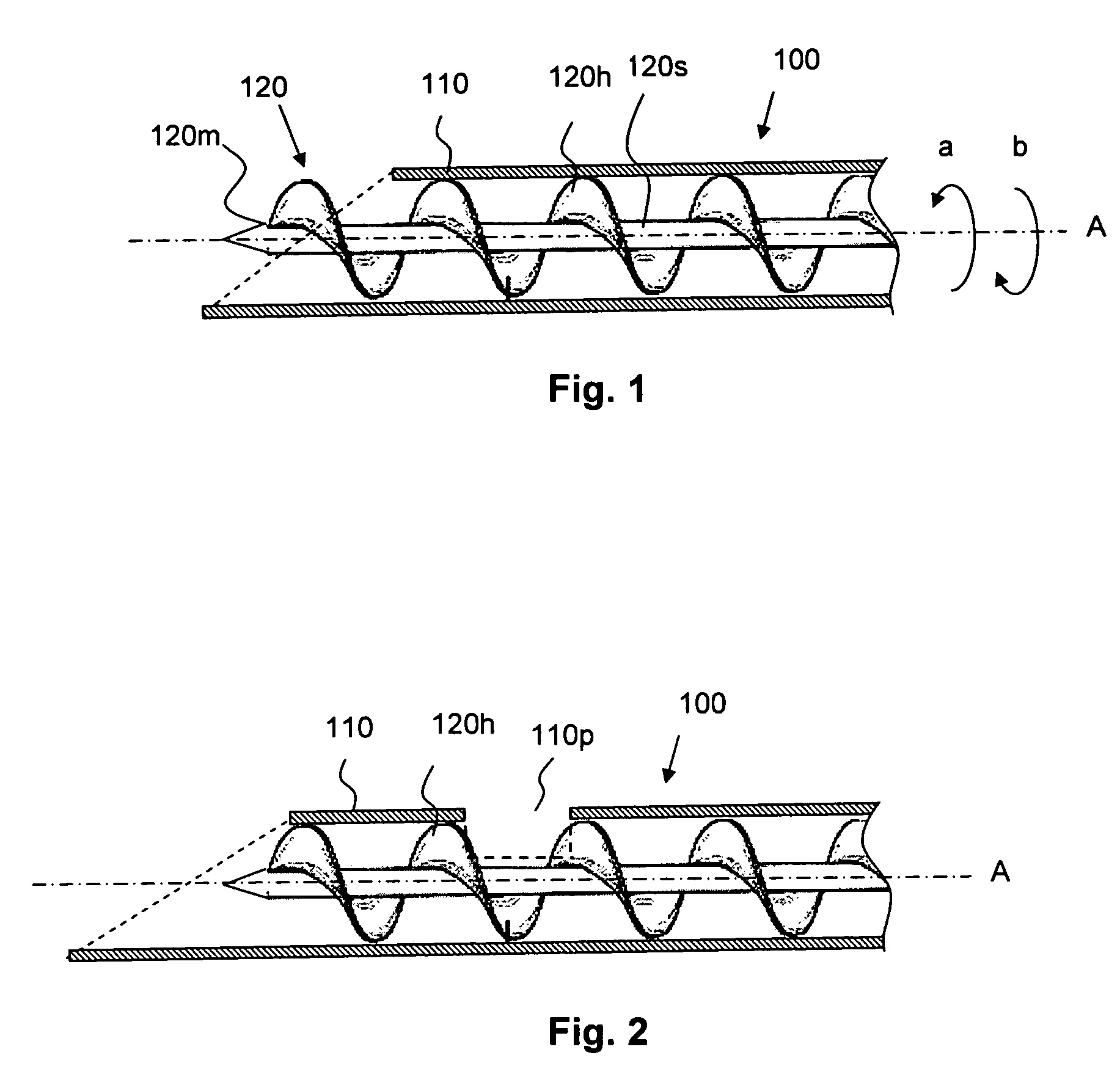

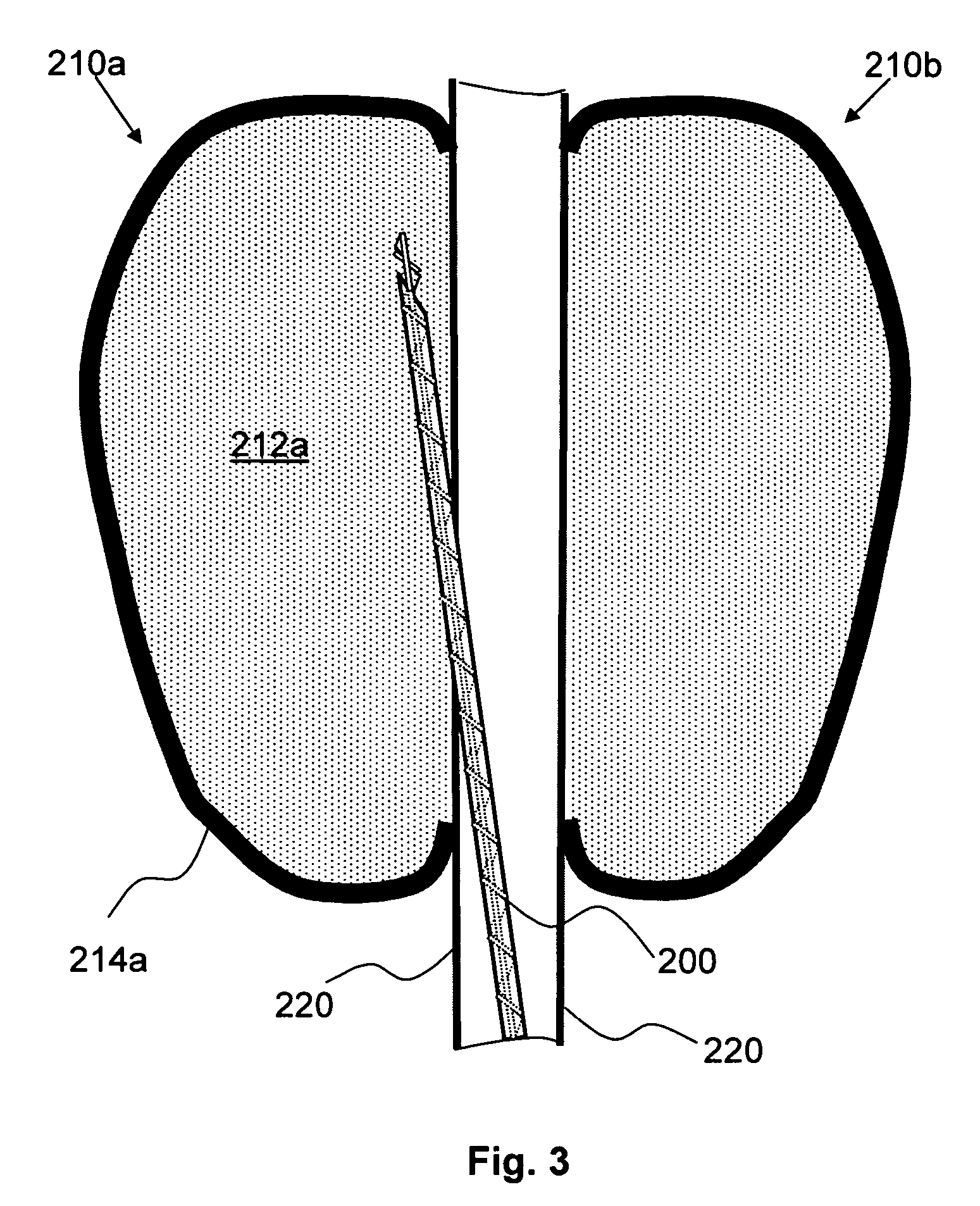

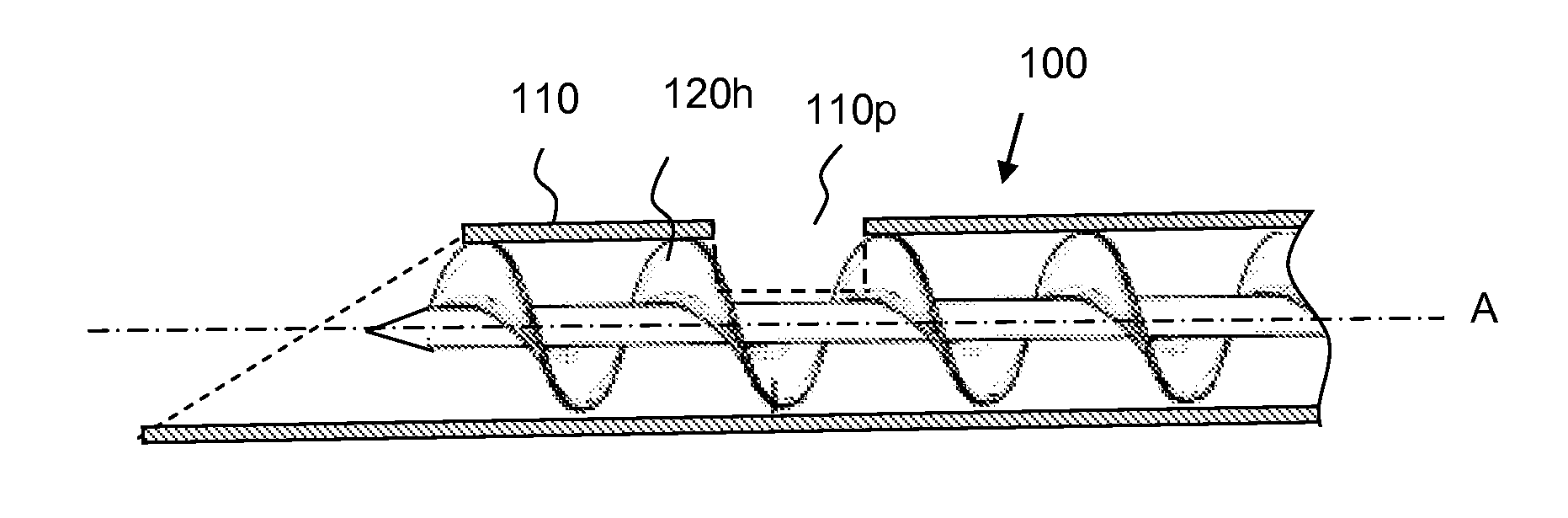

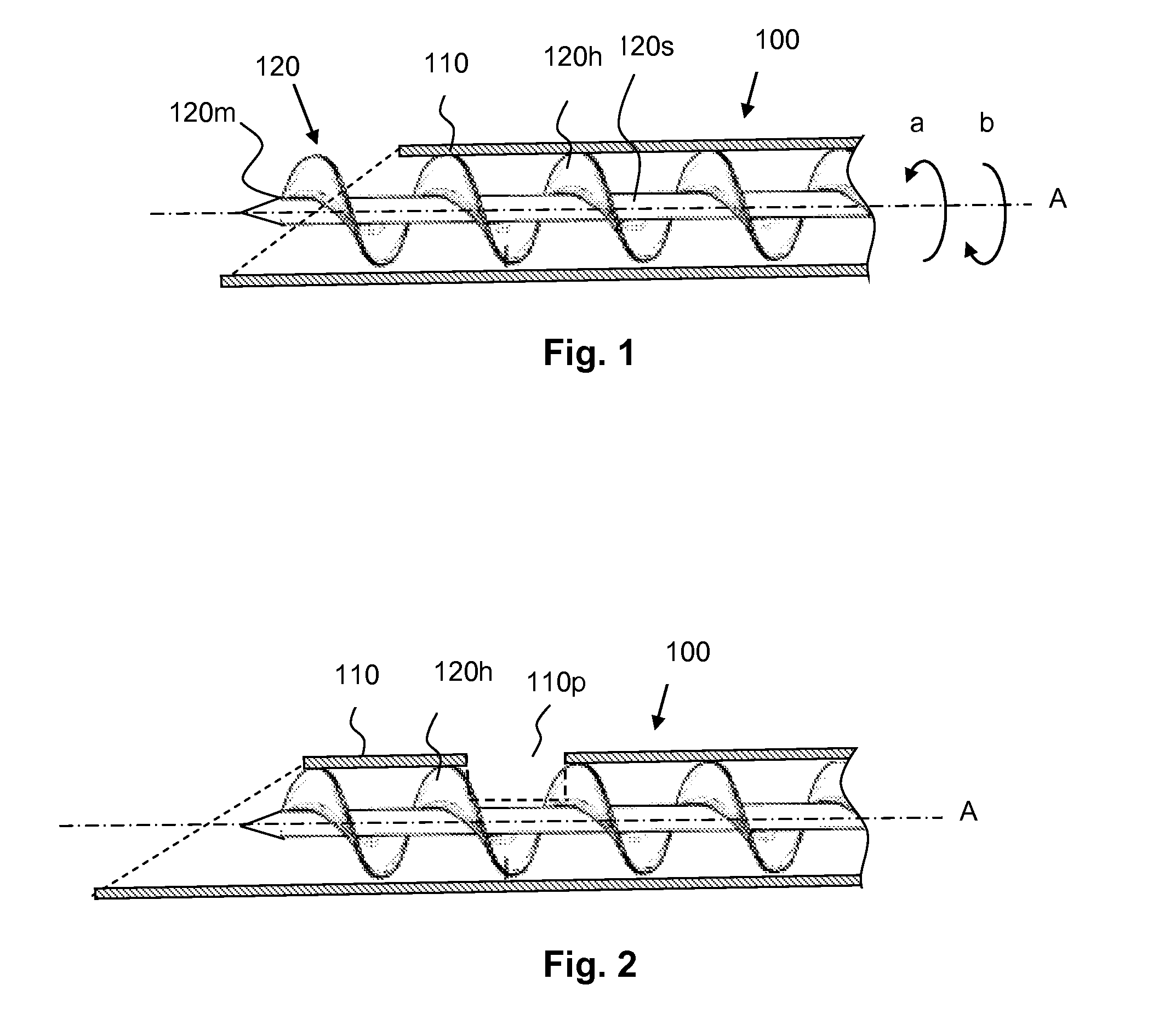

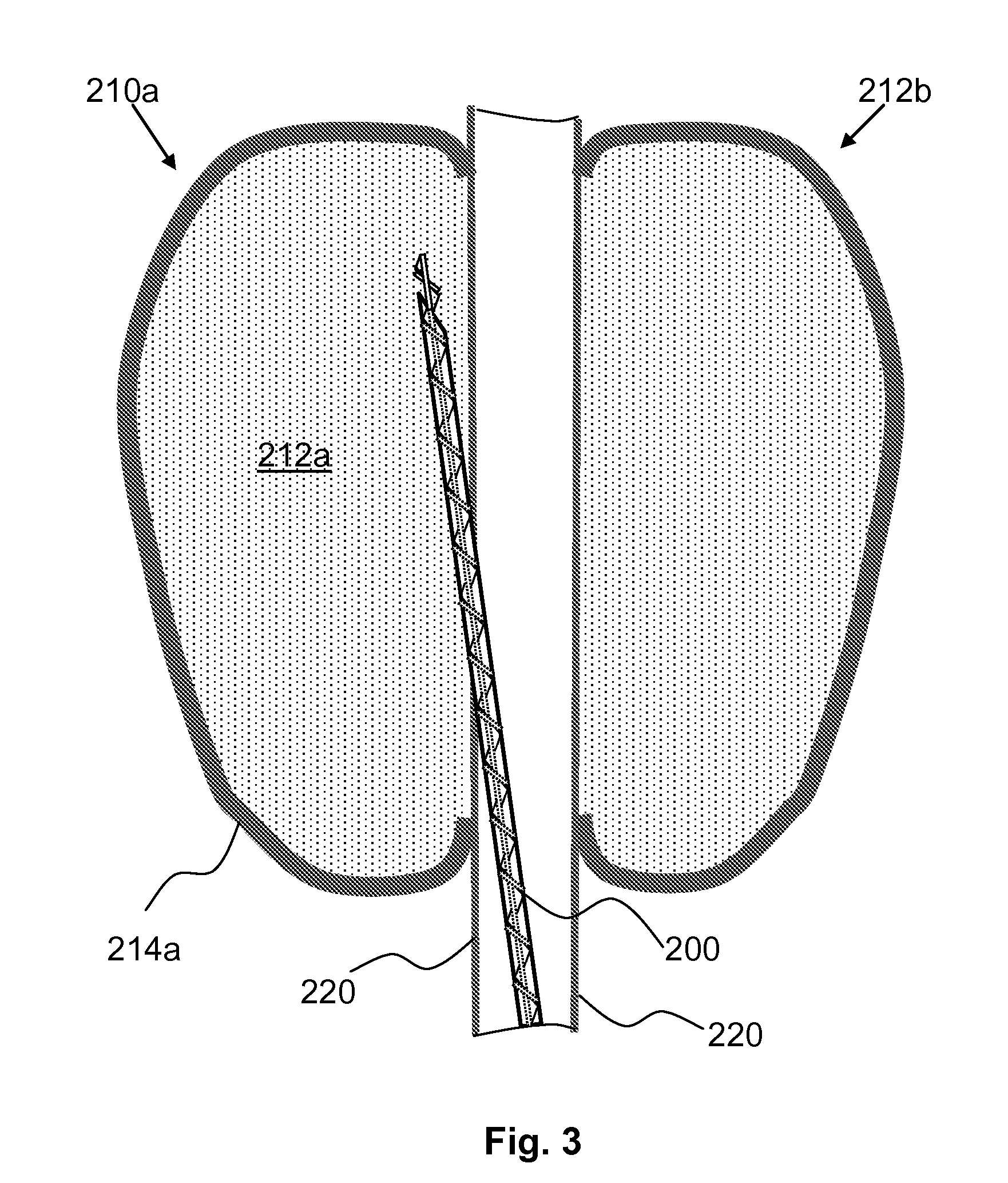

According to an aspect of the present invention, a medical device is provided, which comprises the following: (a) a hollow elongate body (e.g., a elongate cylinder, such as a needle) having distal and proximal ends; and (b) a rotatable member comprising a tissue morselizer and an elongate shaft (e.g., an auger-like tissue-drilling bit). The device (i) advances material (e.g., morselated tissue) toward the proximal end of the hollow elongate body when the shaft is rotated in a first direction, and (ii) advances material (e.g., a therapeutic agent and / or a bulking agent) toward the distal end of the hollow elongate body when the shaft is rotated in a second direction that is opposite the first direction. The invention also provides a method of treatment for morselizing and removing tissue from within the patient and creating a void within the patient and introducing a therapeutic agent and / or a bulking agent into the void.

Owner:BOSTON SCI SCIMED INC

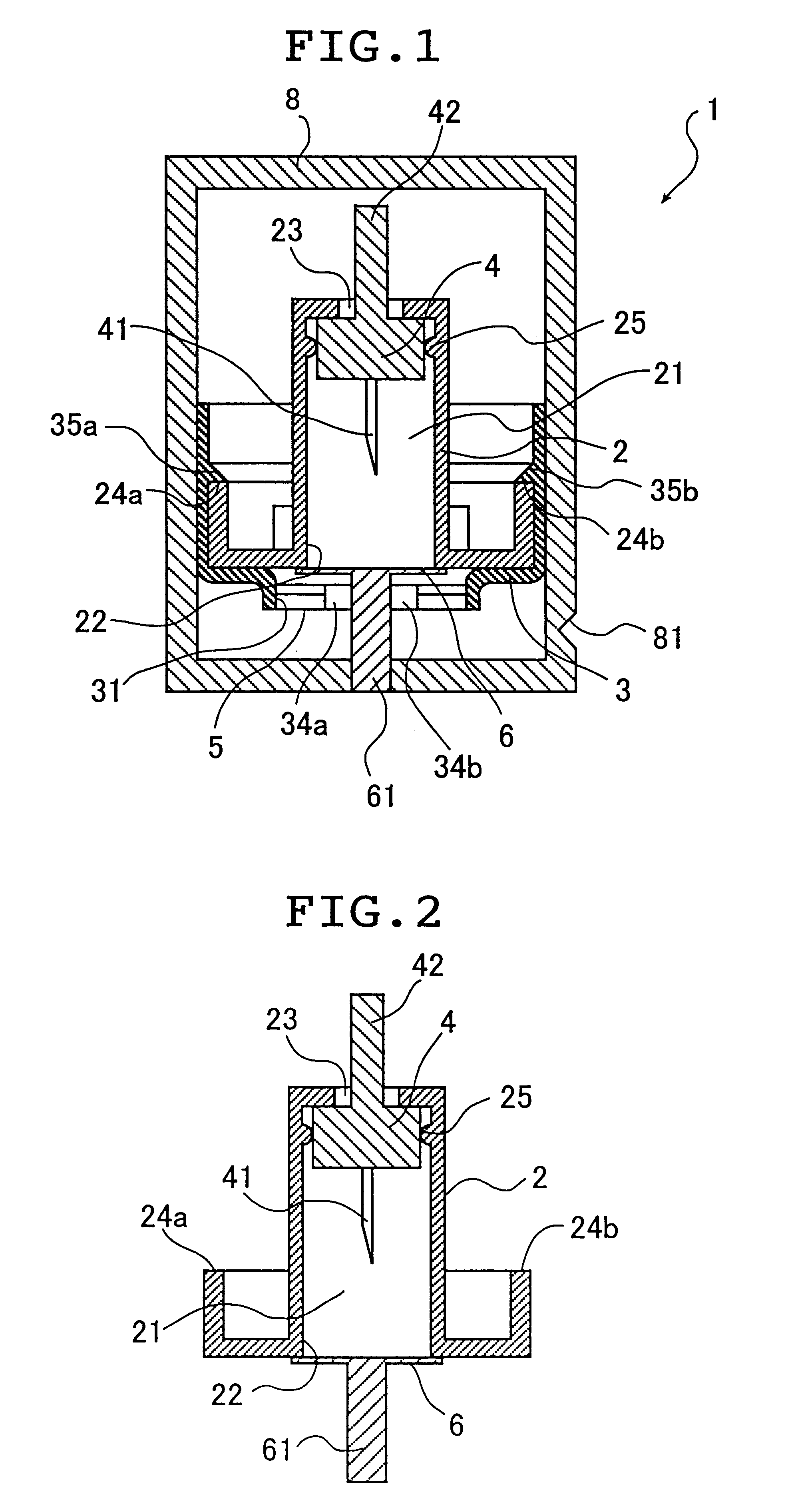

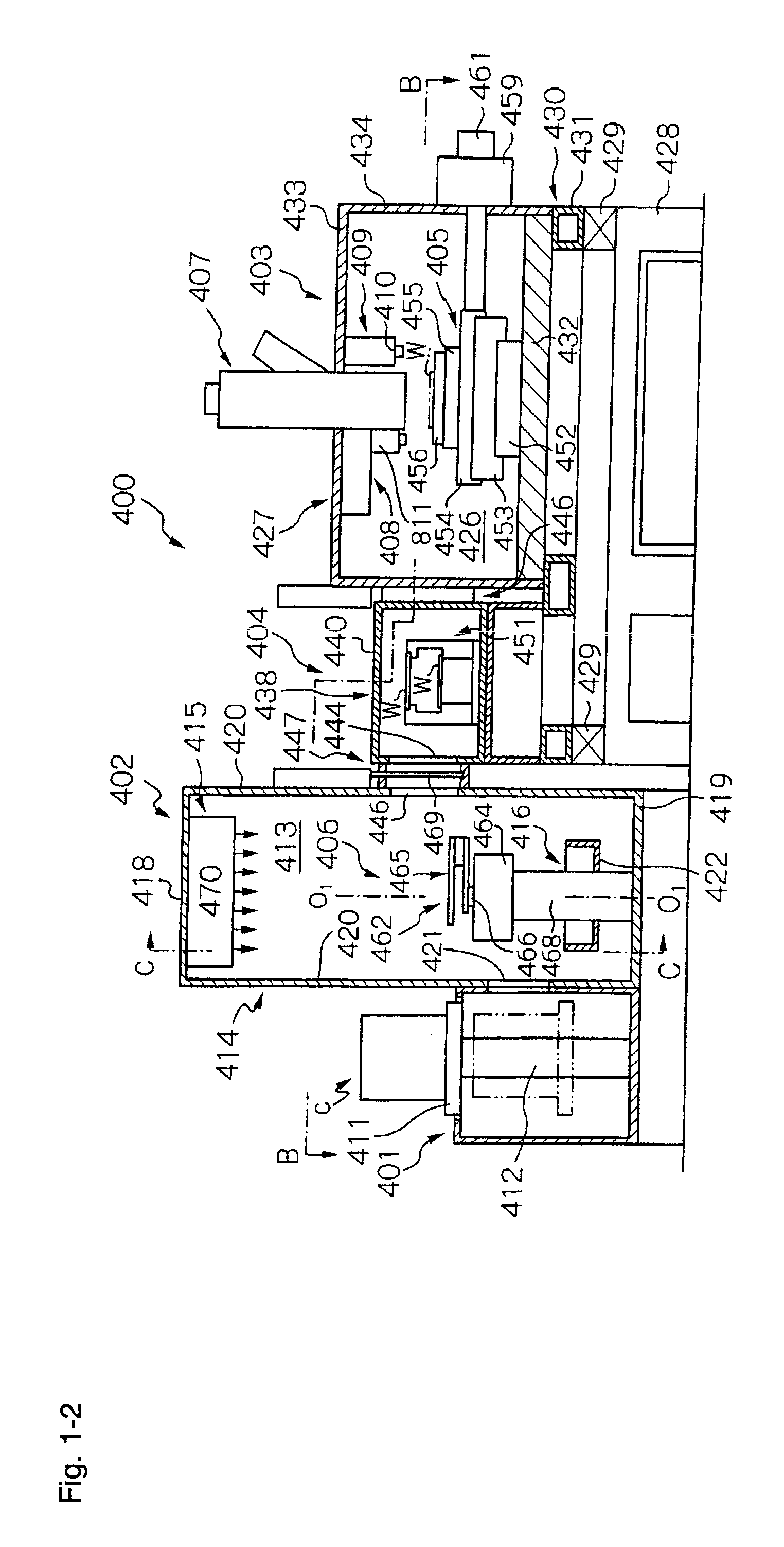

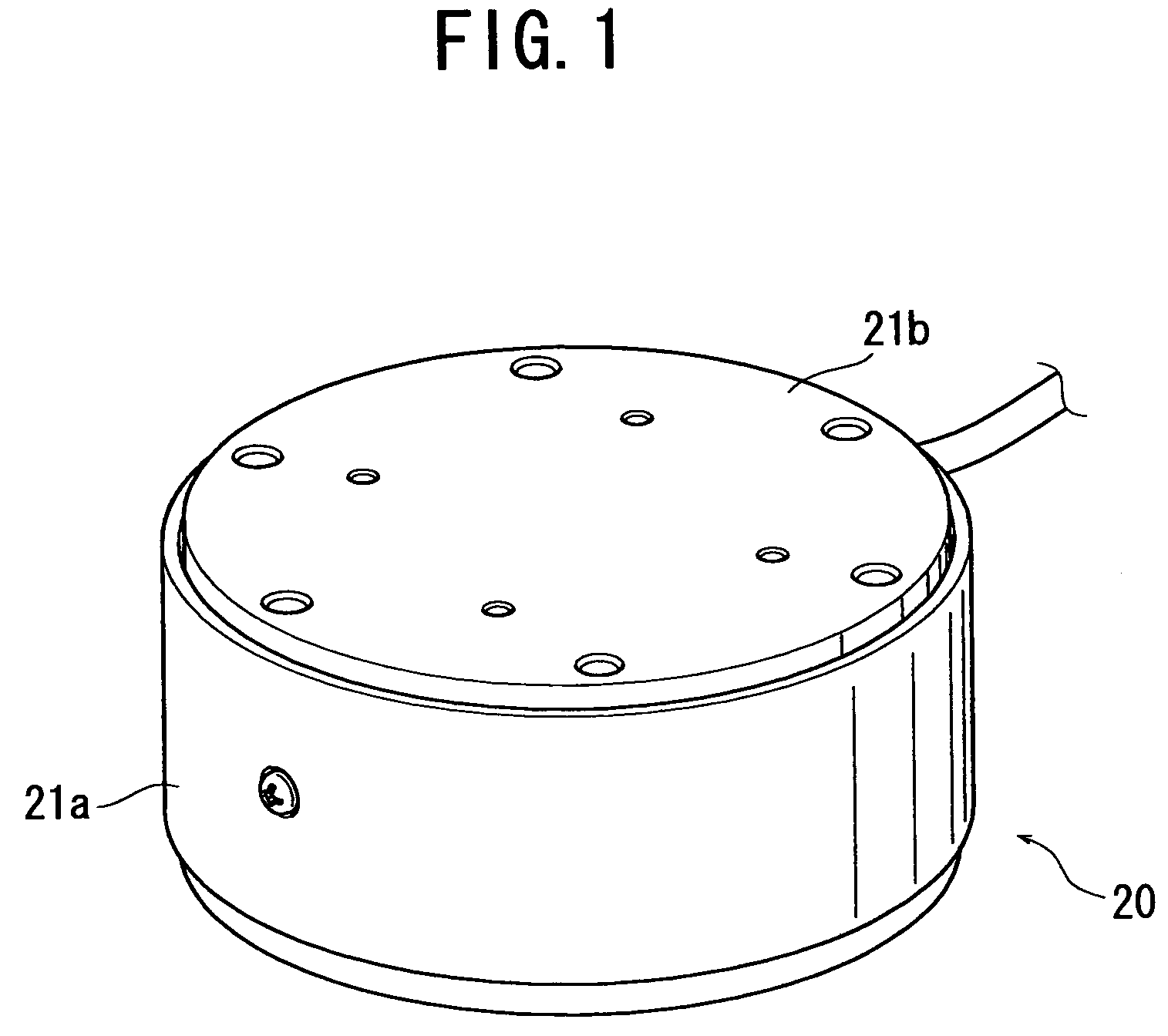

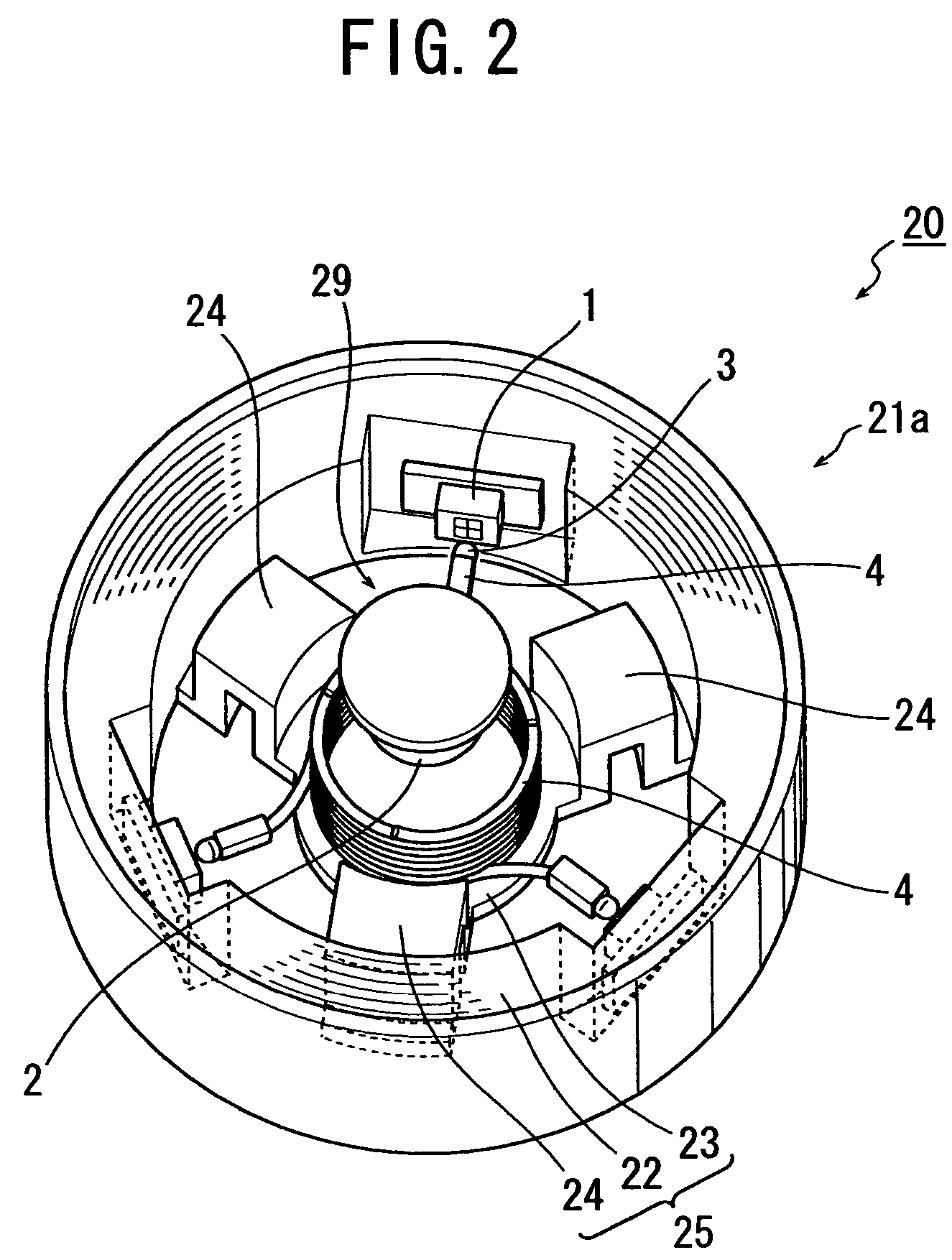

Assembly having lancet and means for collecting and detecting body fluid

An assembly to be detachably mounted on a body fluid monitoring system is provided. The assembly has a lancet and a device for collecting and detecting a body fluid. The lancet has a puncture needle. In this assembly, the puncture needle is maintained in sterilized conditions until its use, and the sterilization can be conducted with no adverse effects on the detection device. A readily sterilizable lancet unit and a body fluid-collecting and detecting unit adapted for use in such an assembly as well as a body fluid-monitoring system including such an assembly are also provided. The assembly comprises a first housing having a sleeve which movably accommodates the lancet in its interior, and a second housing having the body fluid detection device. The first housing and the second housing share an opening. The lancet is sterilized before the assembly. The body fluid-collecting and detecting section has a body fluid guide on the periphery of the inlet.

Owner:TERUMO KK

Method and device for tissue removal and for delivery of a therapeutic agent or bulking agent

InactiveUS20060253069A1Efficient removalMinimizing collateral damageMedical devicesVaccination/ovulation diagnosticsSurgeryMedical device

According to an aspect of the present invention, a medical device is provided, which comprises the following: (a) a hollow elongate body (e.g., a elongate cylinder, such as a needle) having distal and proximal ends; and (b) a rotatable member comprising a tissue morselizer and an elongate shaft (e.g., an auger-like tissue-drilling bit). In the devices of the present invention, the elongate shaft is disposed within the hollow elongate body and cooperates with the hollow elongate body to (i) advance material (e.g., morselated tissue) toward the proximal end of the hollow elongate body when the shaft is rotated in a first direction, and (ii) advance material (e.g., a therapeutic agent and / or a bulking agent) toward the distal end of the hollow elongate body when the shaft is rotated in a second direction that is opposite the first direction. According to another aspect of the invention a method of treatment is provided that comprises: (a) inserting the a medical device like that above into the tissue of a patient; (b) morselizing and removing tissue from within the patient while rotating the shaft in a first direction, thereby creating a void within the patient; and (c) introducing a therapeutic agent and / or a bulking agent into the void.

Owner:BOSTON SCI SCIMED INC

Method and device for tissue removal and for delivery of a therapeutic agent or bulking agent

InactiveUS20110021976A1Efficient removalMinimize damageVaccination/ovulation diagnosticsMedical devicesMedical deviceBiomedical engineering

According to an aspect of the present invention, a medical device is provided, which comprises the following: (a) a hollow elongate body (e.g., a elongate cylinder, such as a needle) having distal and proximal ends; and (b) a rotatable member comprising a tissue morselizer and an elongate shaft (e.g., an auger-like tissue-drilling bit). In the devices of the present invention, the elongate shaft is disposed within the hollow elongate body and cooperates with the hollow elongate body to (i) advance material (e.g., morselated tissue) toward the proximal end of the hollow elongate body when the shaft is rotated in a first direction, and (ii) advance material (e.g., a therapeutic agent and / or a bulking agent) toward the distal end of the hollow elongate body when the shaft is rotated in a second direction that is opposite the first direction. According to another aspect of the invention a method of treatment is provided that comprises: (a) inserting the a medical device like that above into the tissue of a patient; (b) morselizing and removing tissue from within the patient while rotating the shaft in a first direction, thereby creating a void within the patient; and (c) introducing a therapeutic agent and / or a bulking agent into the void.

Owner:BOSTON SCI SCIMED INC

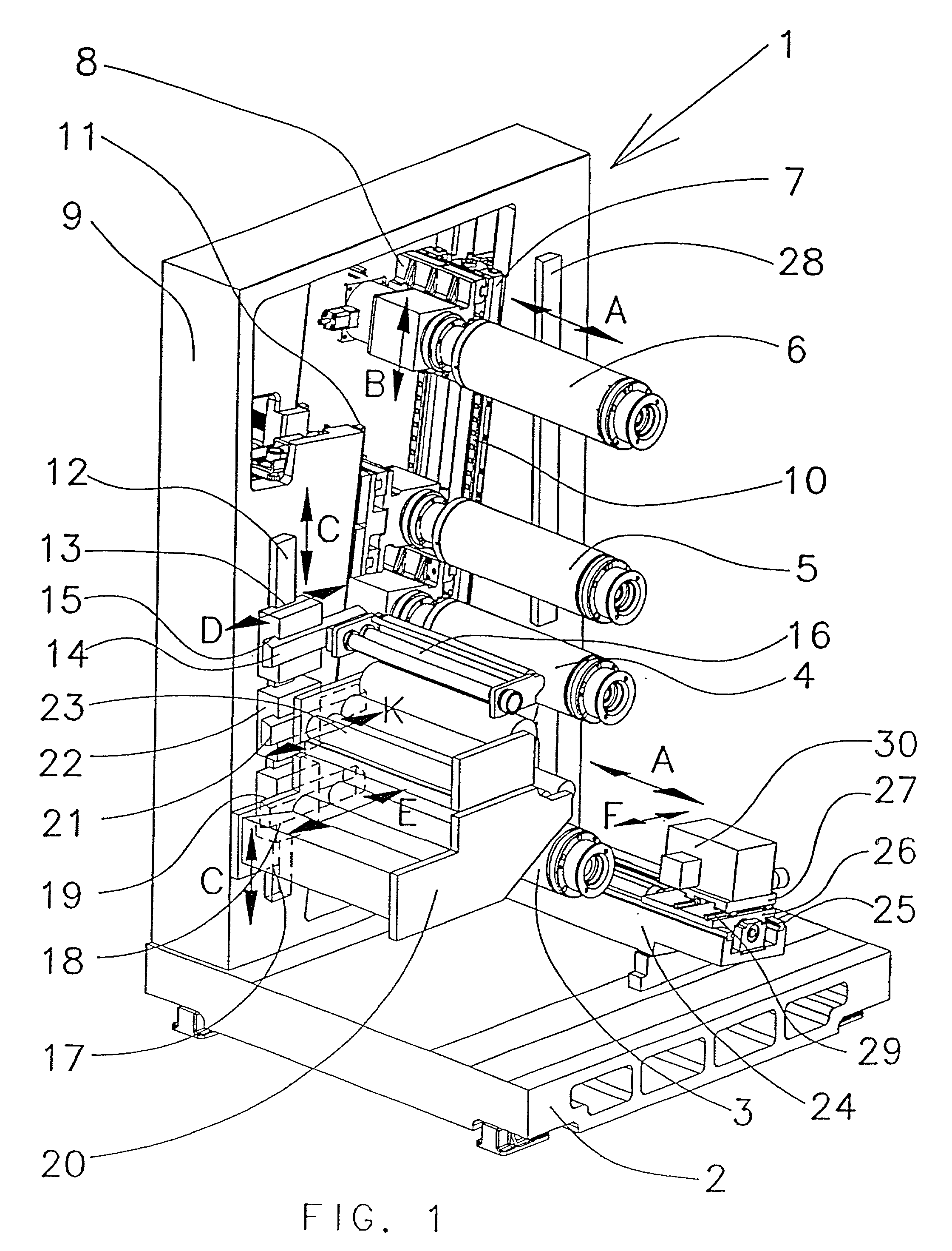

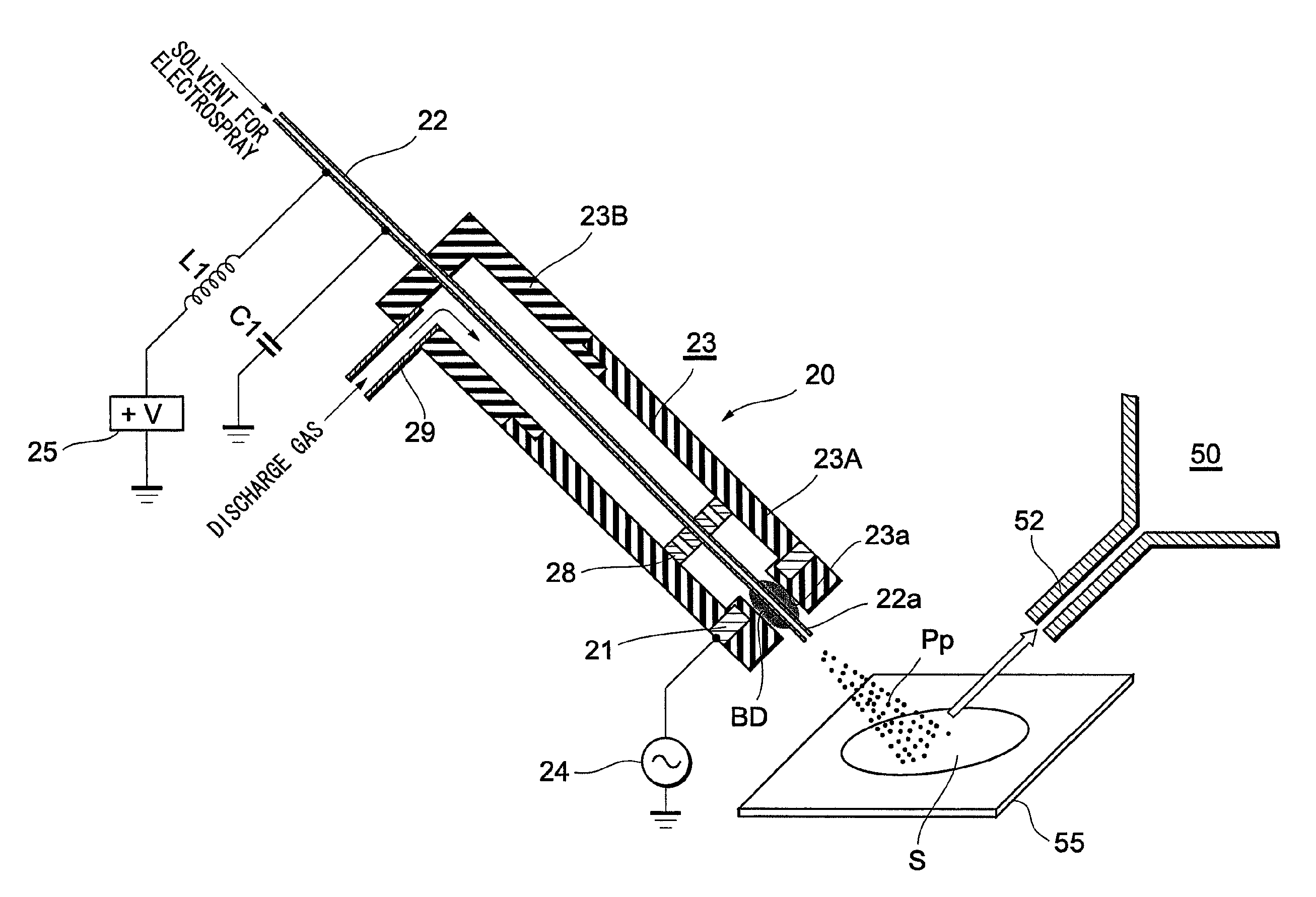

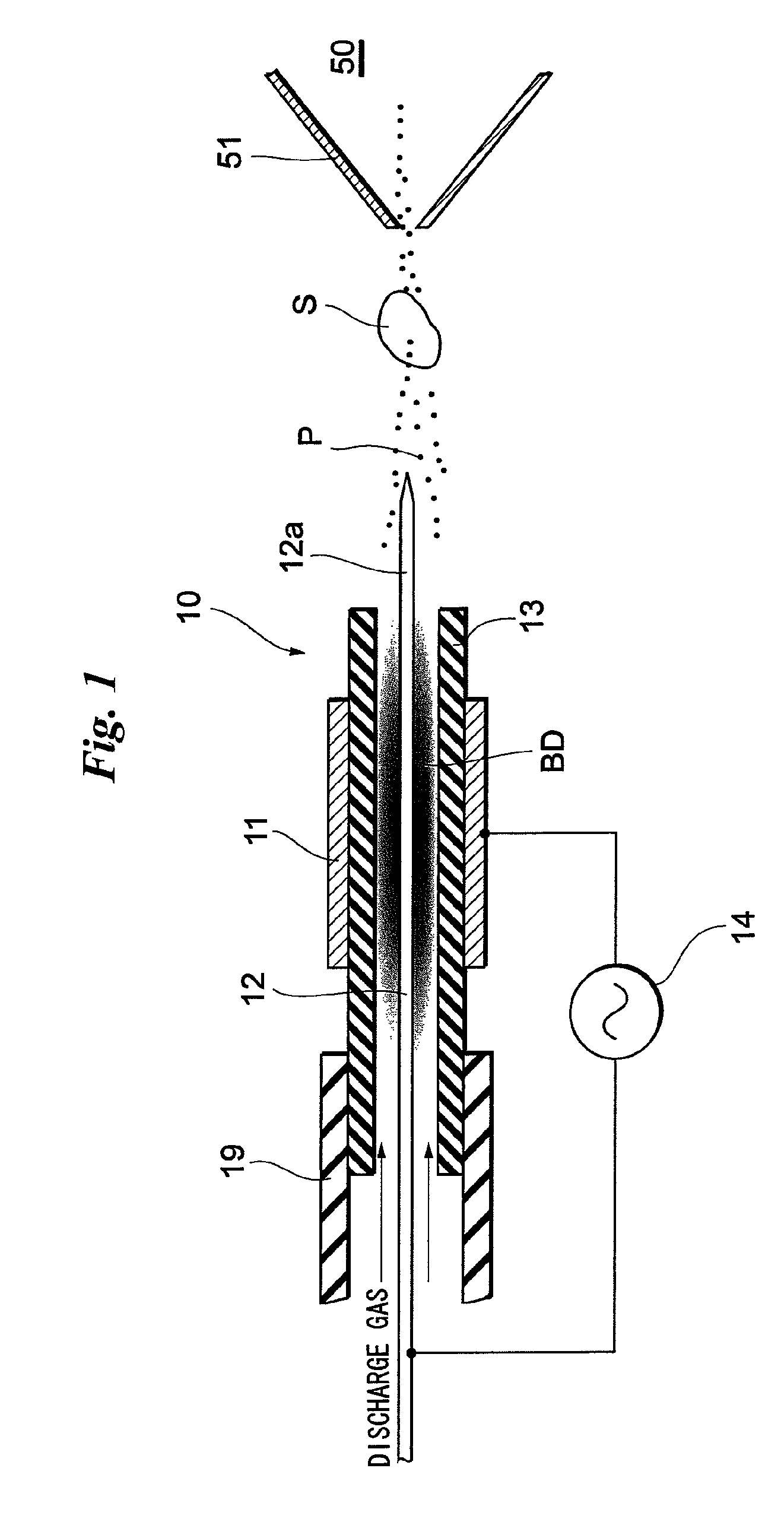

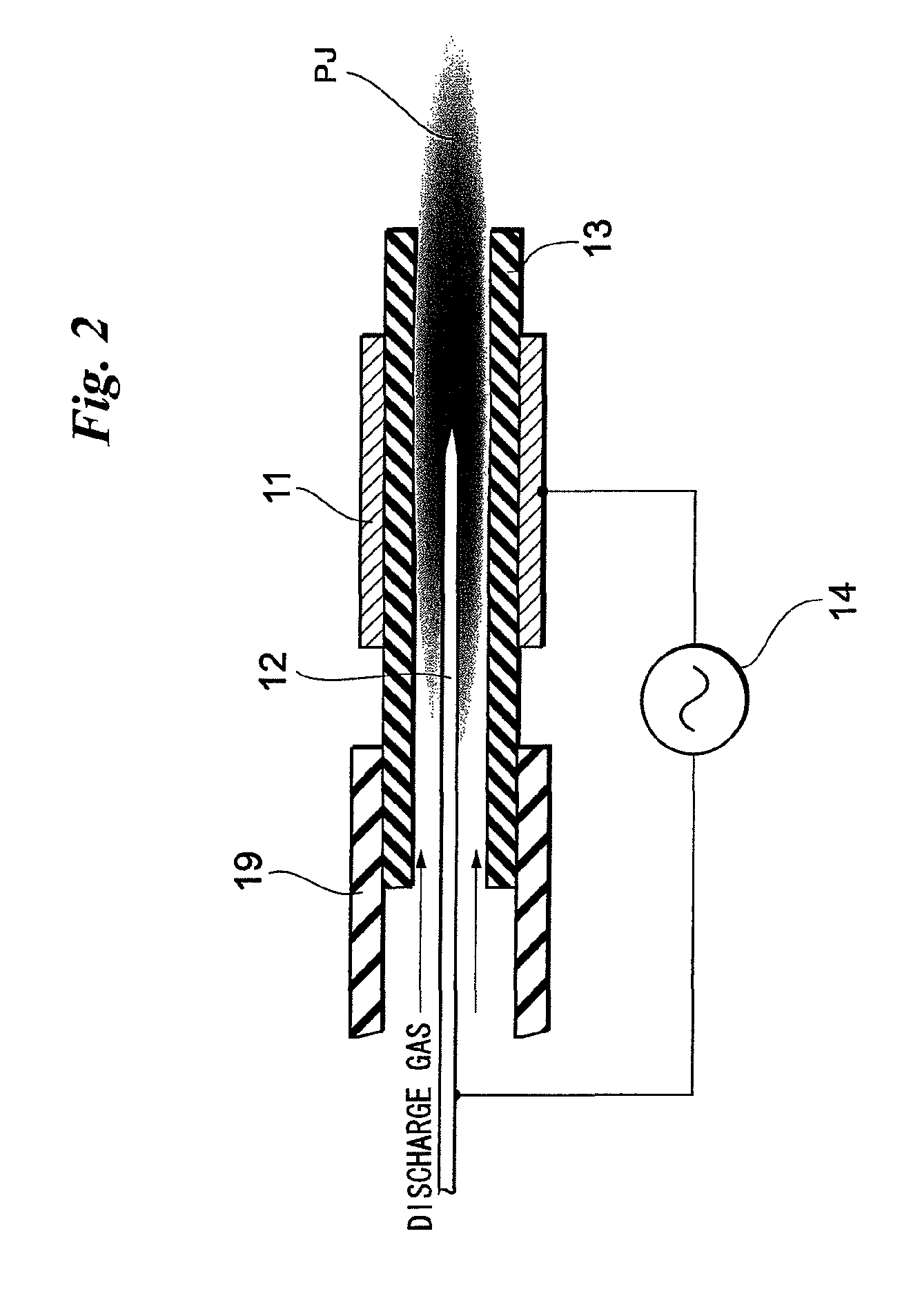

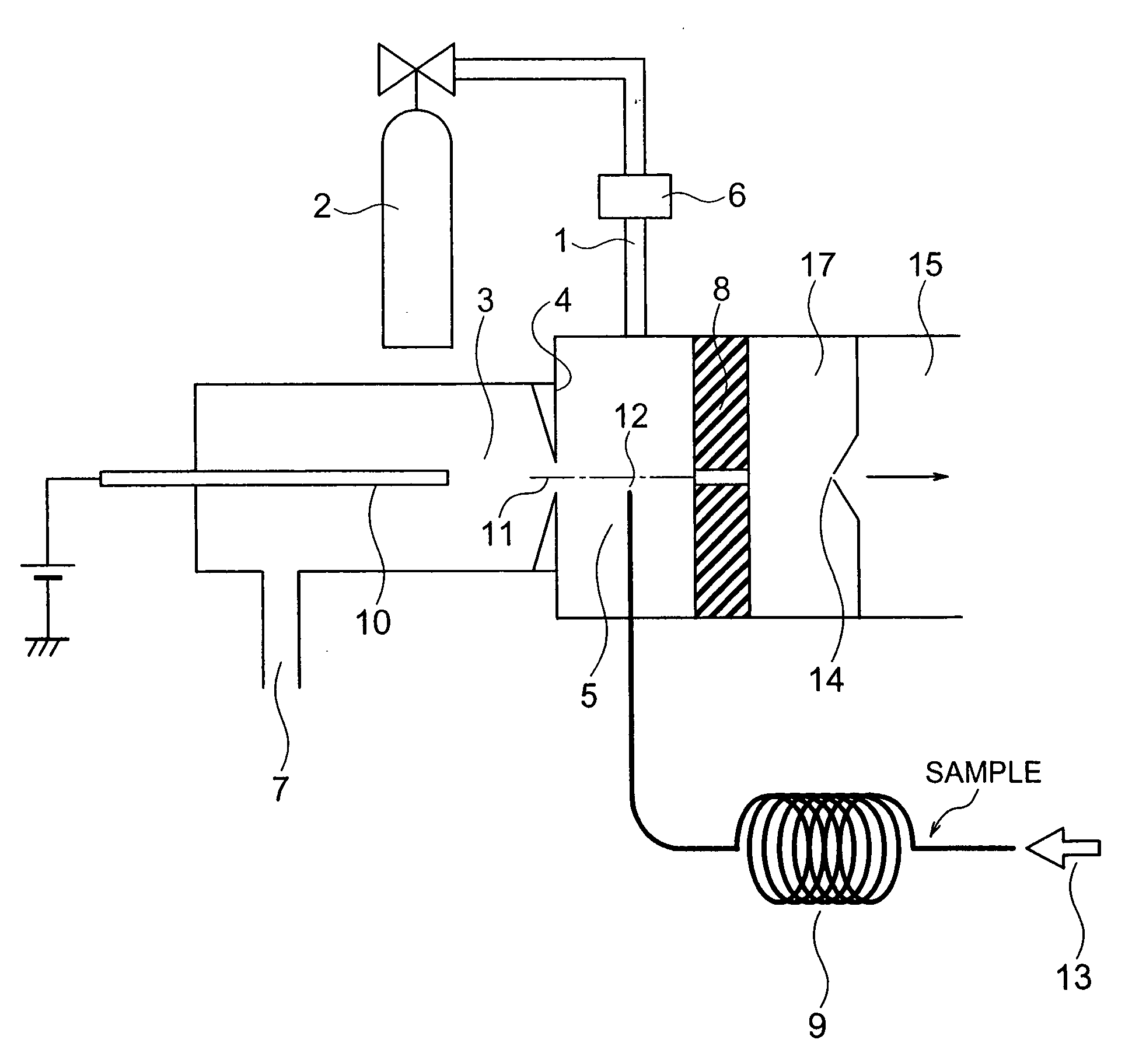

Ionization analysis method and apparatus

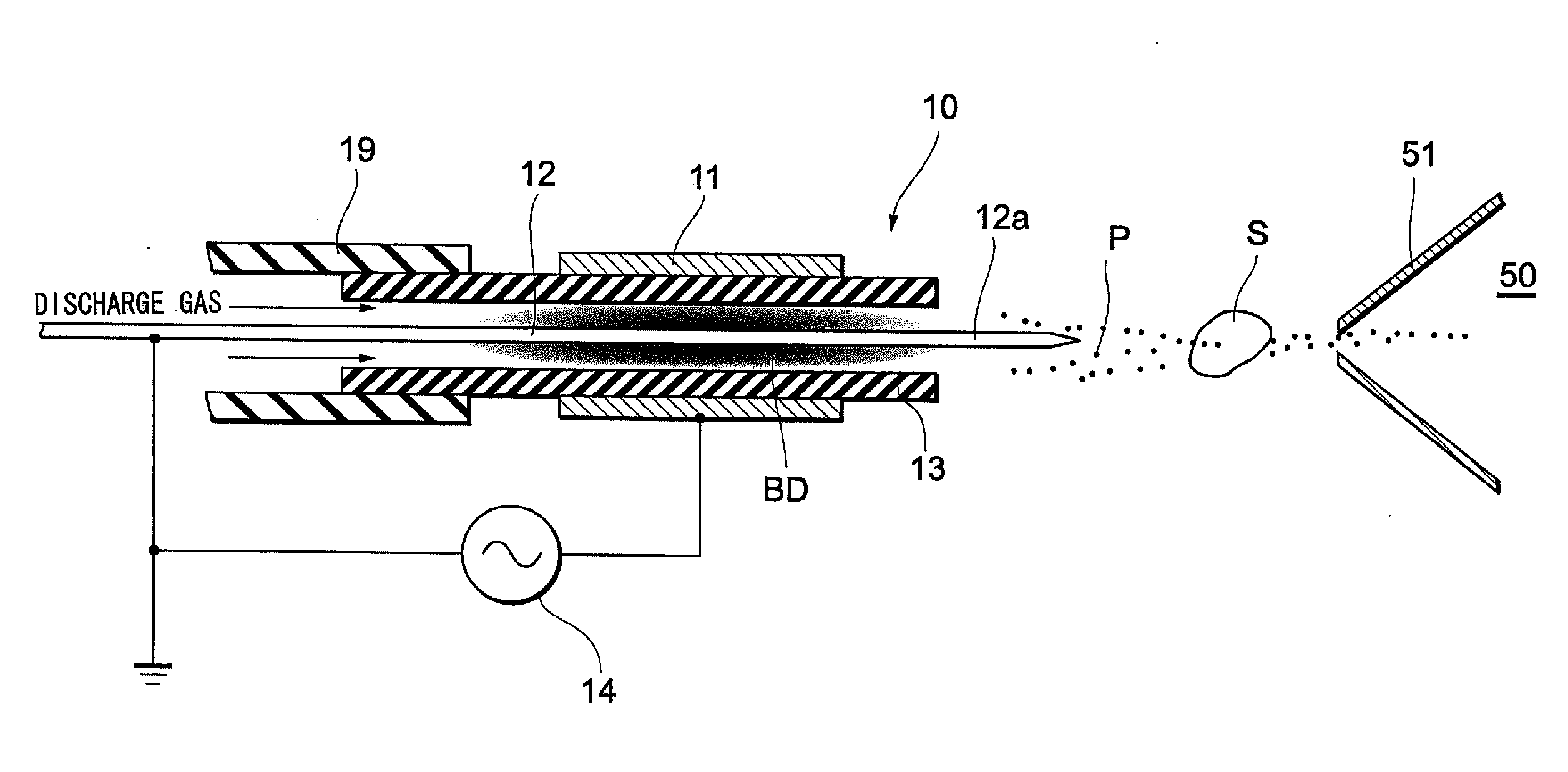

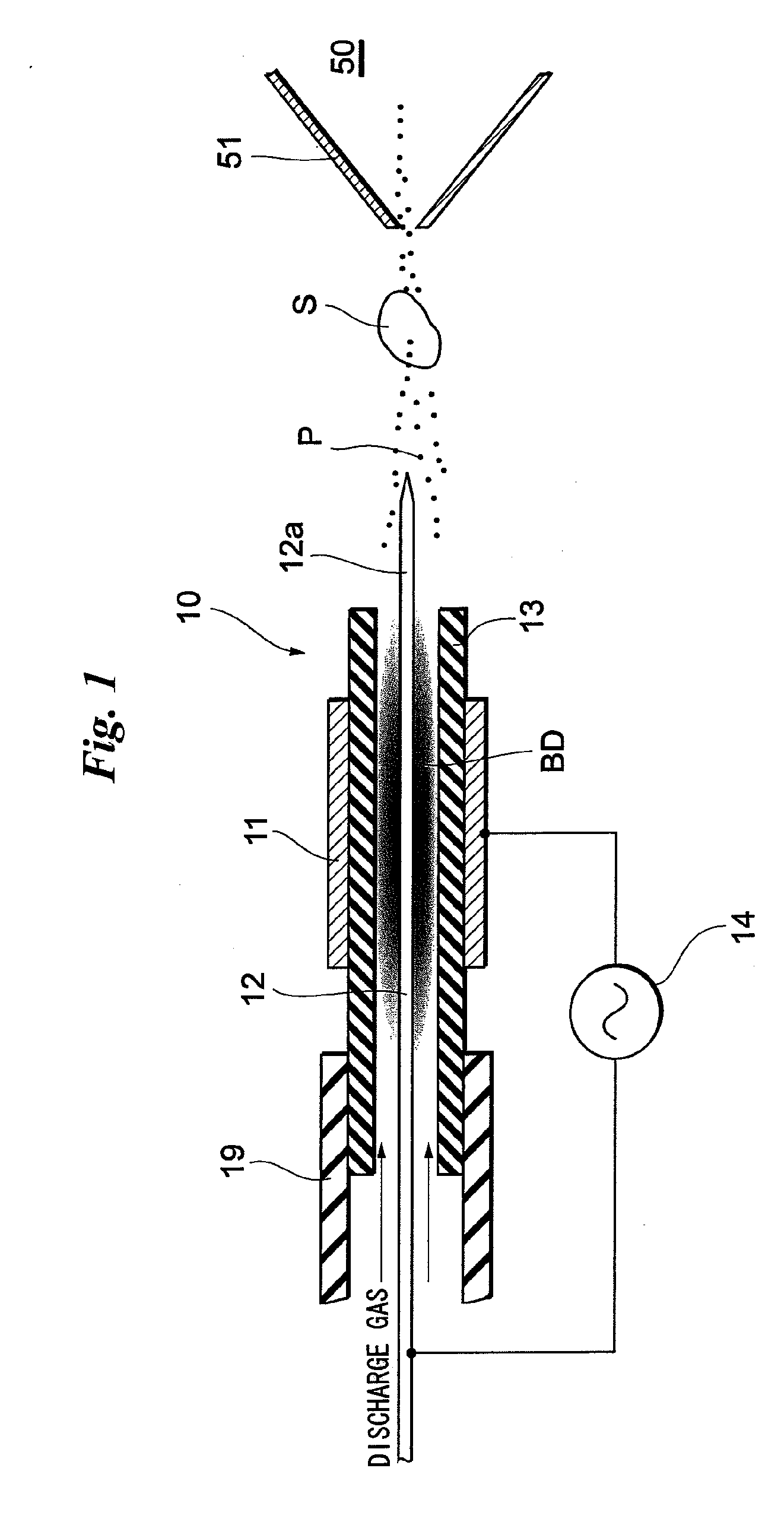

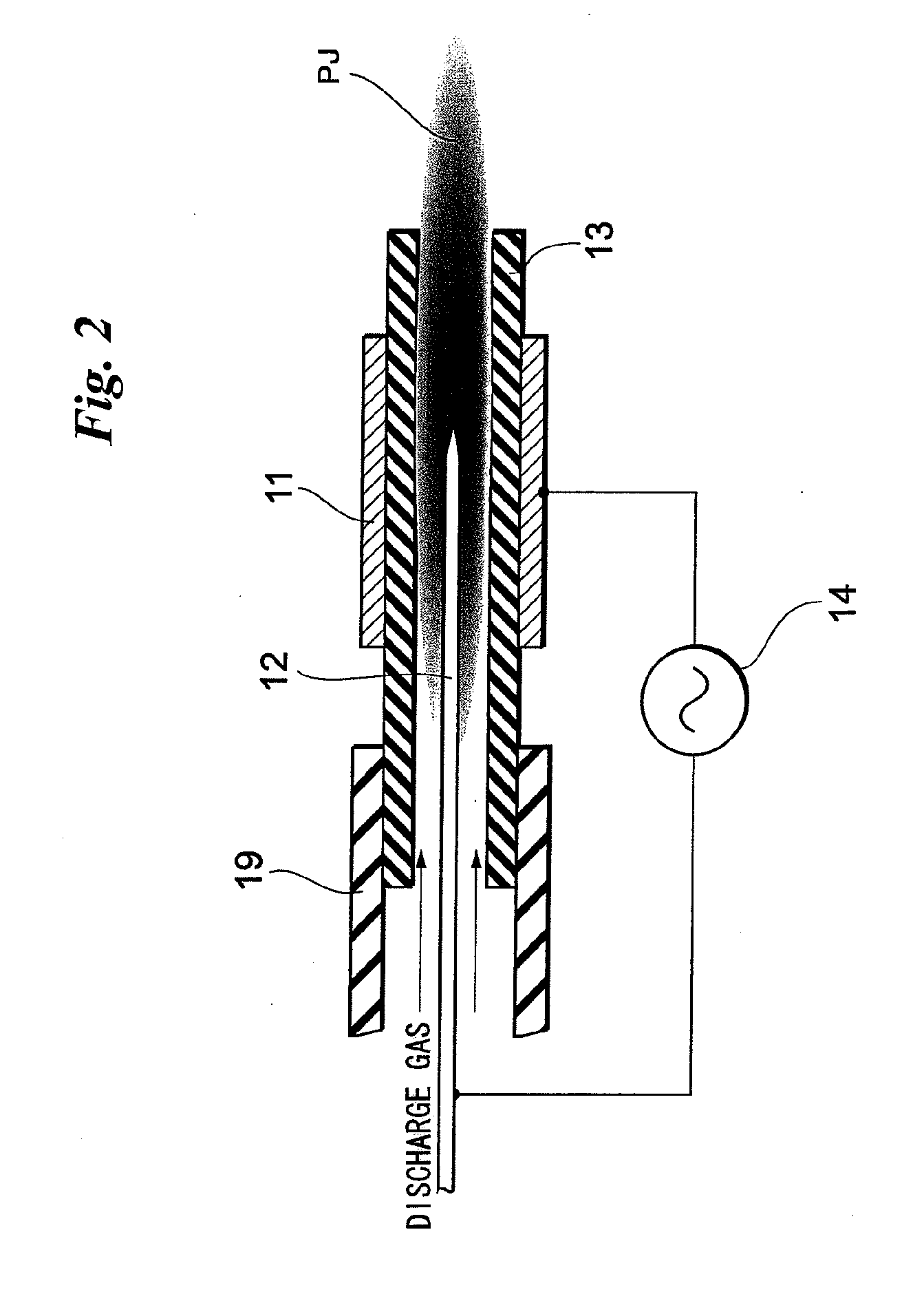

ActiveUS20110108726A1Ultra high sensitivitySufficient ion intensityParticle separator tubesMaterial analysis by optical meansPlasma jetElectron temperature

It is arranged so that ions can be analyzed accurately and with high sensitivity. A first electrode 11 is provided on the outer periphery of a dielectric cylindrical body 13 and a second electrode 12 is placed inside the cylindrical body 13 leaving a clearance between itself and the inner surface of the cylindrical body 13. When an AC high voltage is impressed across the first electrode 11 and second electrode 12, a barrier discharge occurs within the cylindrical body 13. When a distal end portion 12a of the second electrode 12 projects outwardly from the distal end of the cylindrical body 13, a thermal equilibrium plasma P having a low electron temperature is generated outwardly of the distal end of the cylindrical body 13 without a plasma jet ascribable to the barrier discharge emerging outwardly from the distal end of the cylindrical body 13. By exposing a sample S to the thermal equilibrium plasma P, particles (atoms, molecules) desorbed from the sample S undergo soft ionization without being decomposed or polymerized. The ions generated are introduced to a mass analyzer 50.

Owner:UNIVERSITY OF YAMANASHI

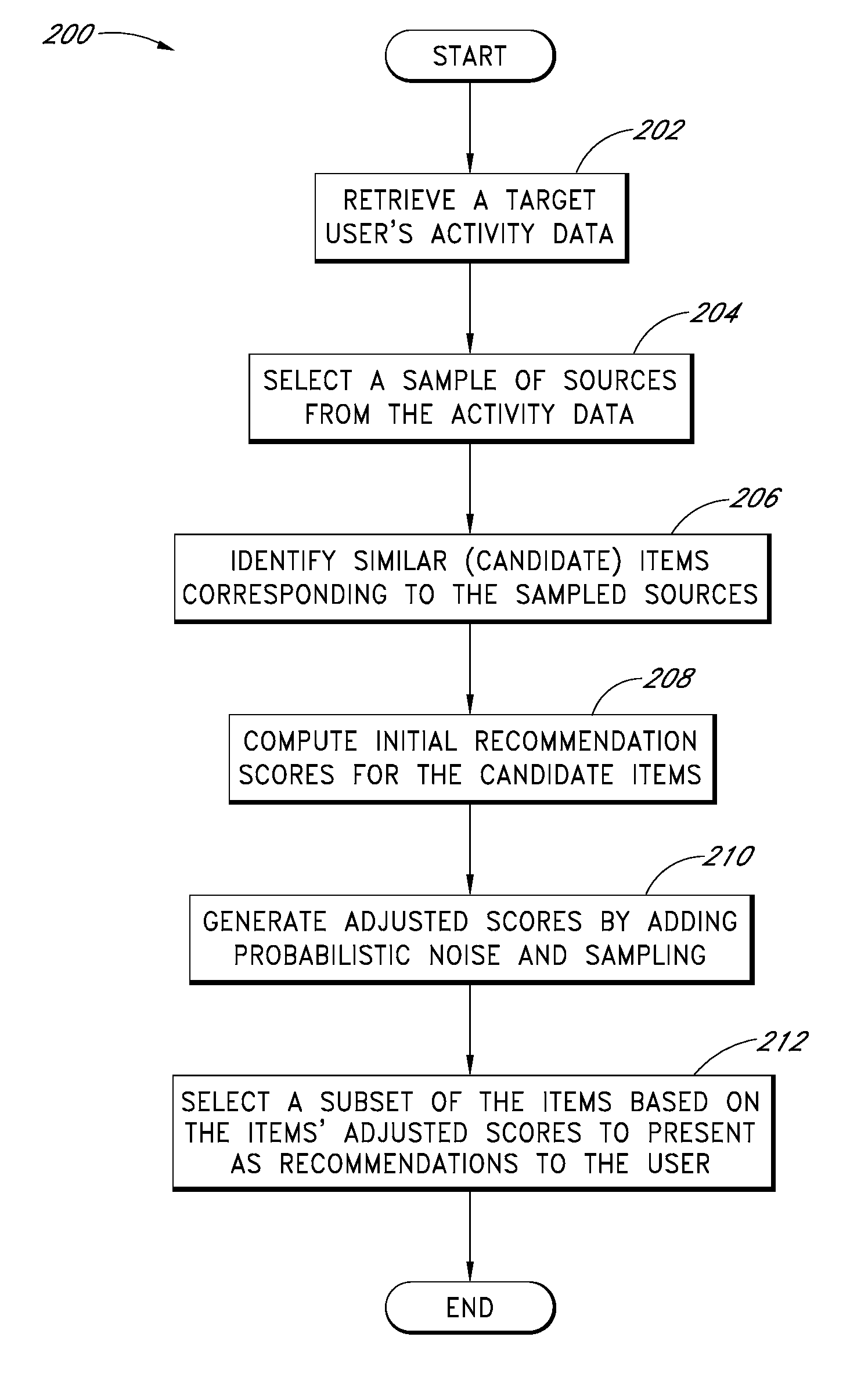

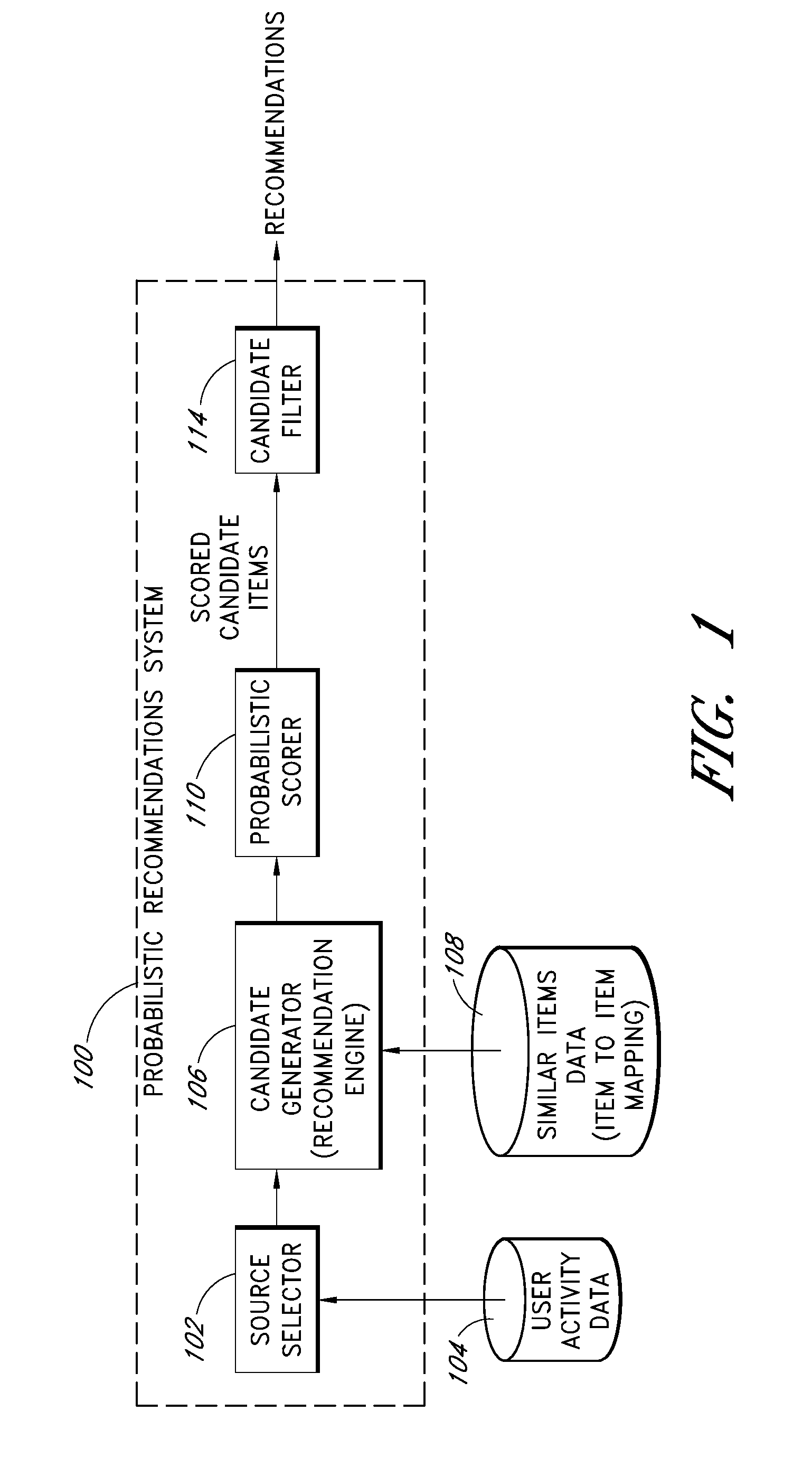

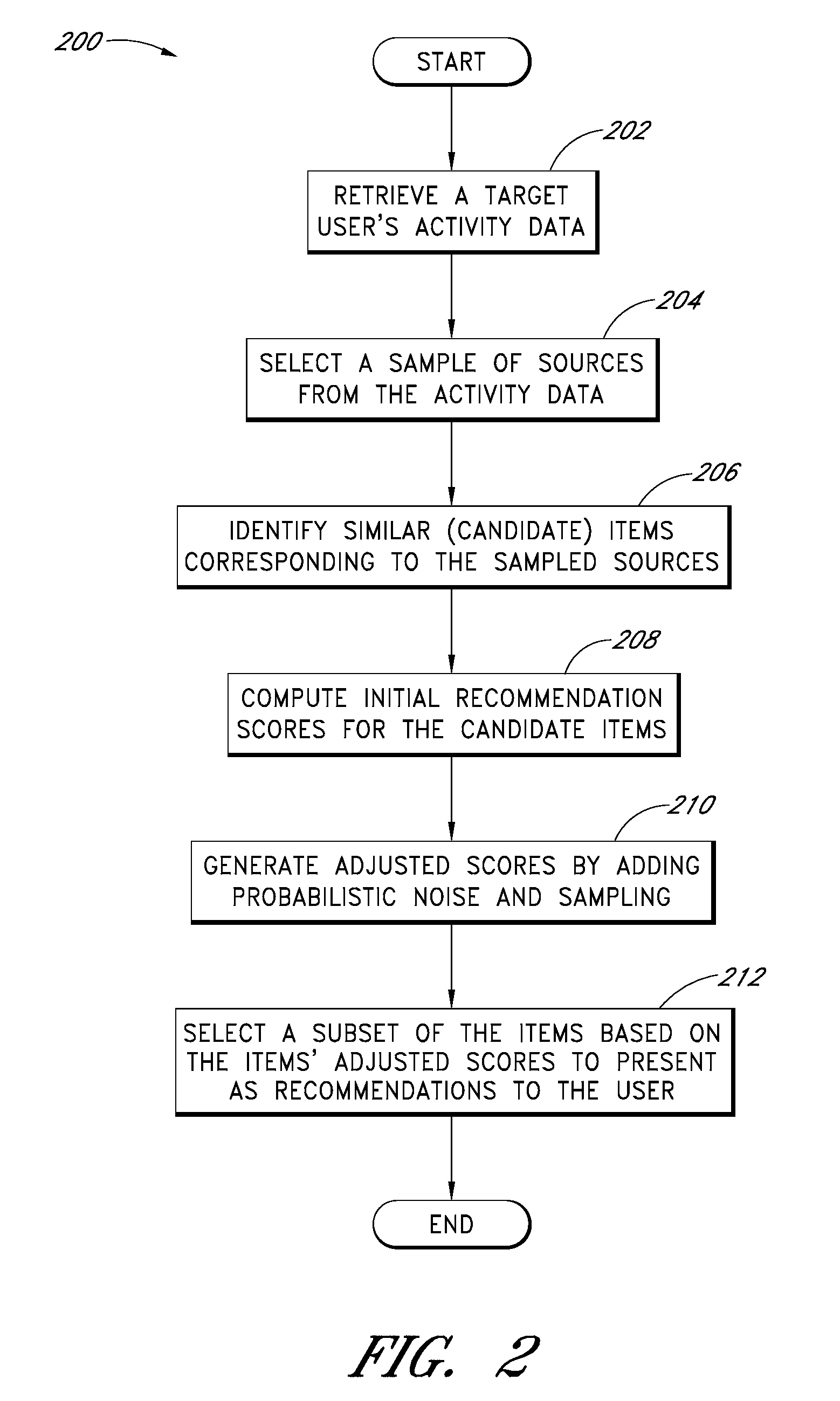

Probabilistic recommendation system

InactiveUS8301623B2Big burden to solveEfficient introductionDigital data information retrievalDigital data processing detailsProbabilistic methodControl manner

A recommendations system uses probabilistic methods to select, from a candidate set of items, a set of items to recommend to a target user. The methods can effectively introduce noise into the recommendations process, causing the recommendations presented to the target user to vary in a controlled manner from one visit to the next. The methods may increase the likelihood that at least some of the items recommended over a sequence of visits will be useful to the target user. Some embodiments of the methods are stateless such that the system need not keep track of which items have been recommended to which users.

Owner:AMAZON TECH INC

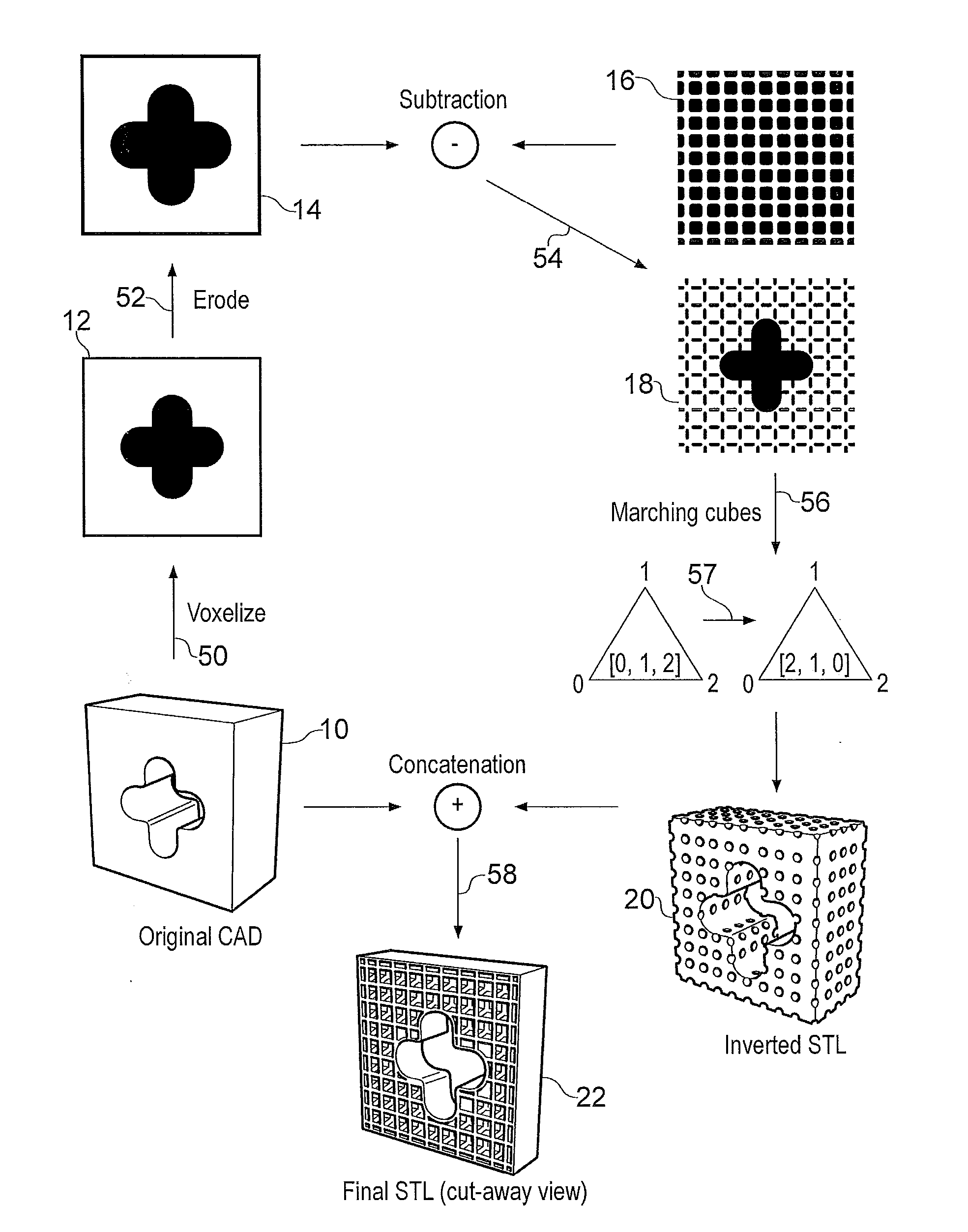

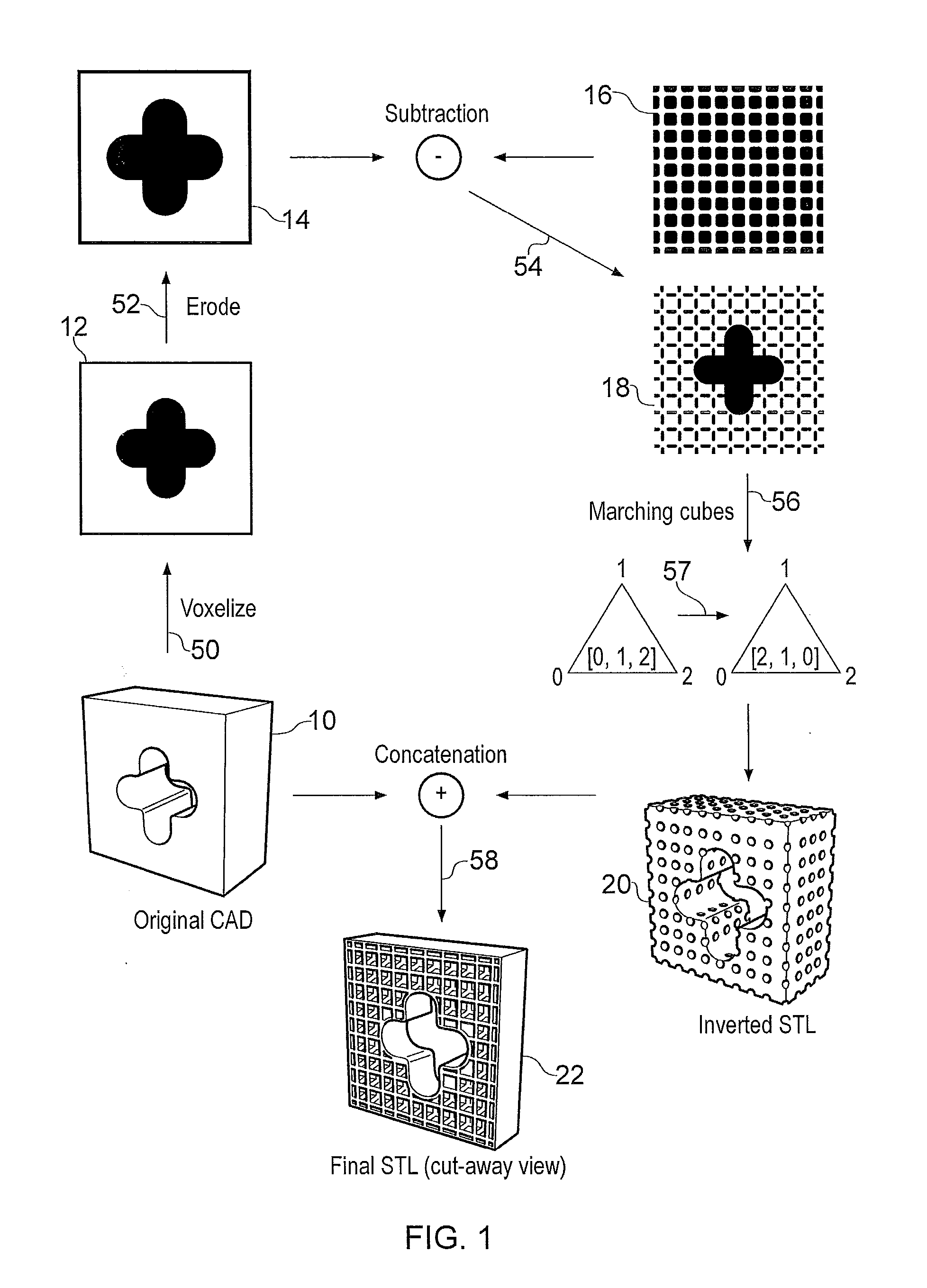

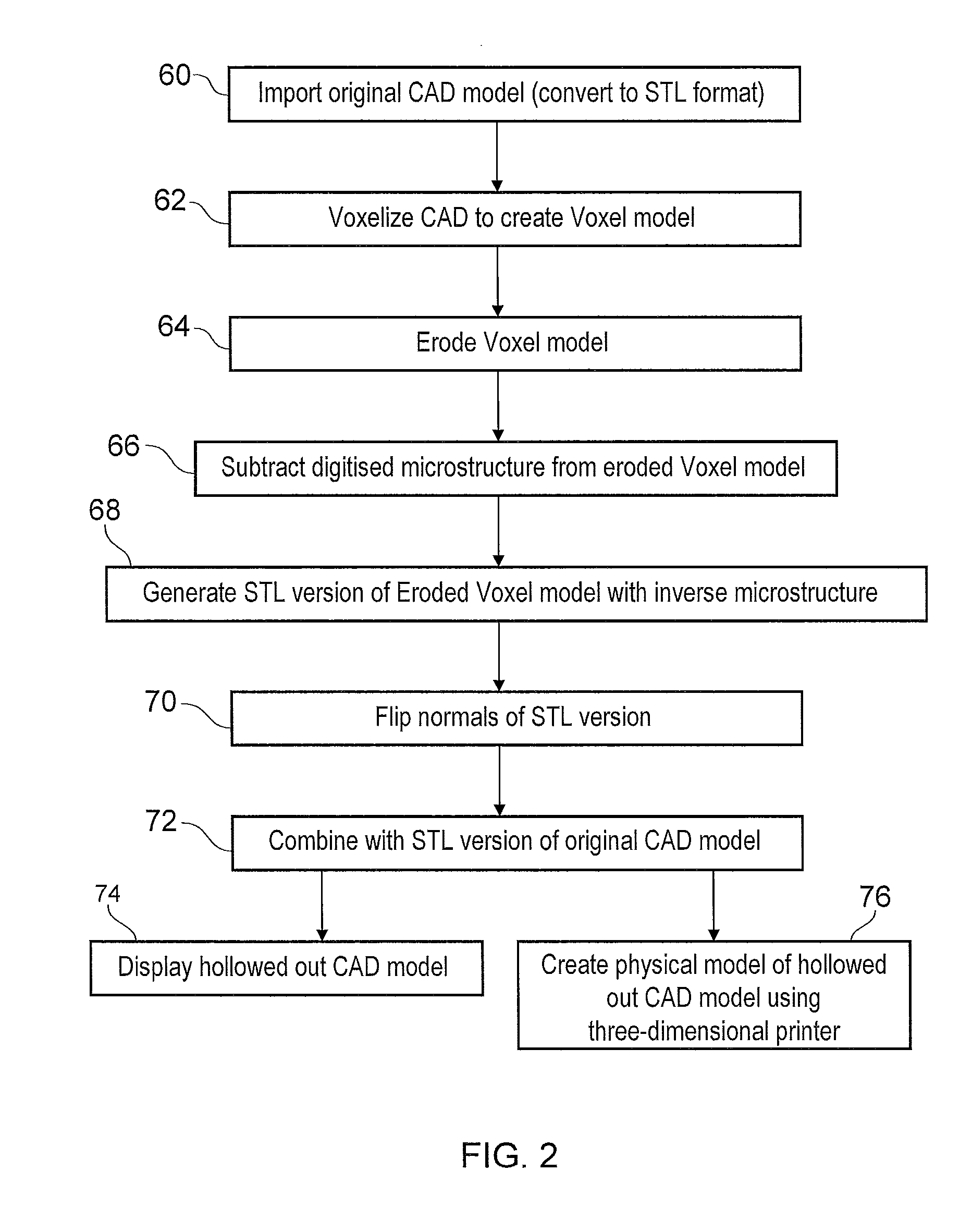

Image processing method and method of three-dimensional printing incorporating the same

ActiveUS20110205583A1Improve robustnessEfficient introductionAdditive manufacturing apparatusDesign optimisation/simulationMicrostructureComputer graphics (images)

A method for preparing image data for three-dimensional printing in which a digitised (e.g. voxelized) representation of a virtual three-dimensional object (e.g. CAD model) is eroded to create an internal volume for the object. Subsequently, a vector-based surface representation of this internal volume is generated and simply combined with a corresponding vector-based surface representation of the original virtual three-dimensional object to yield a hollowed out model in a format suitable for three-dimensional printing.A microstructure may be introduced into the interior of the hollowed out model, e.g. by extracting a volume corresponding to the inverse of that microstructure from the eroded digitised representation.

Owner:SYNOPSYS INC

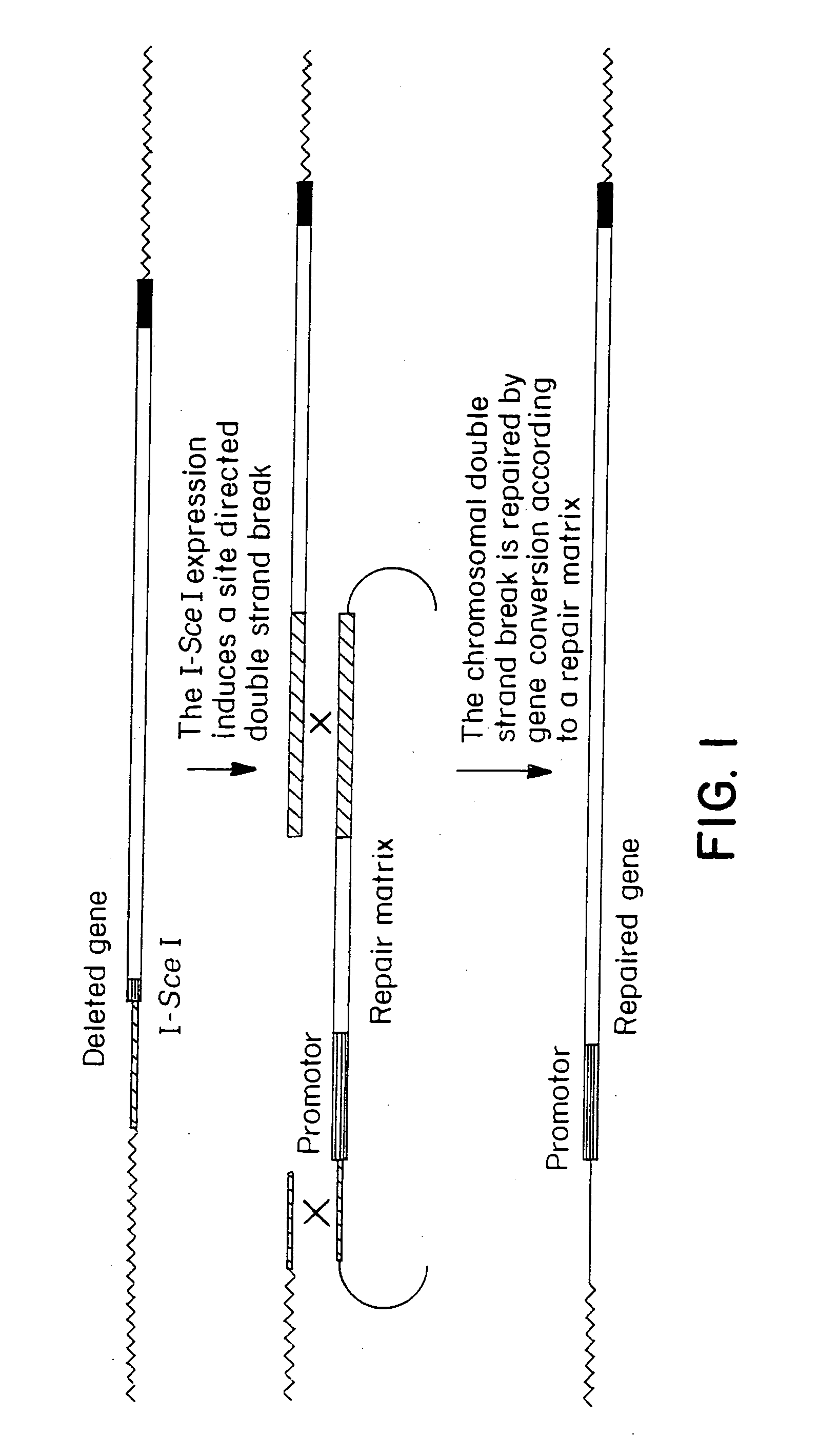

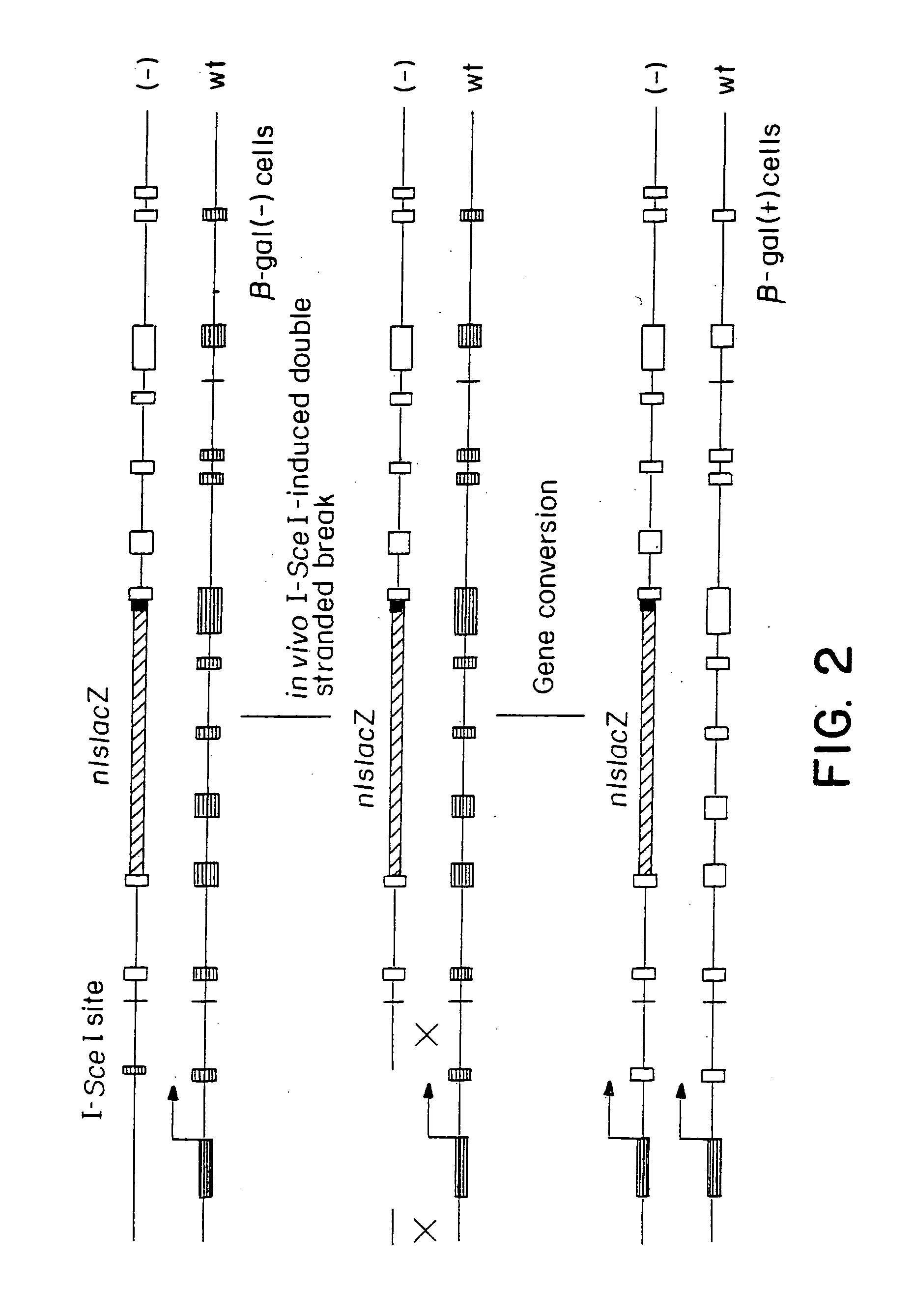

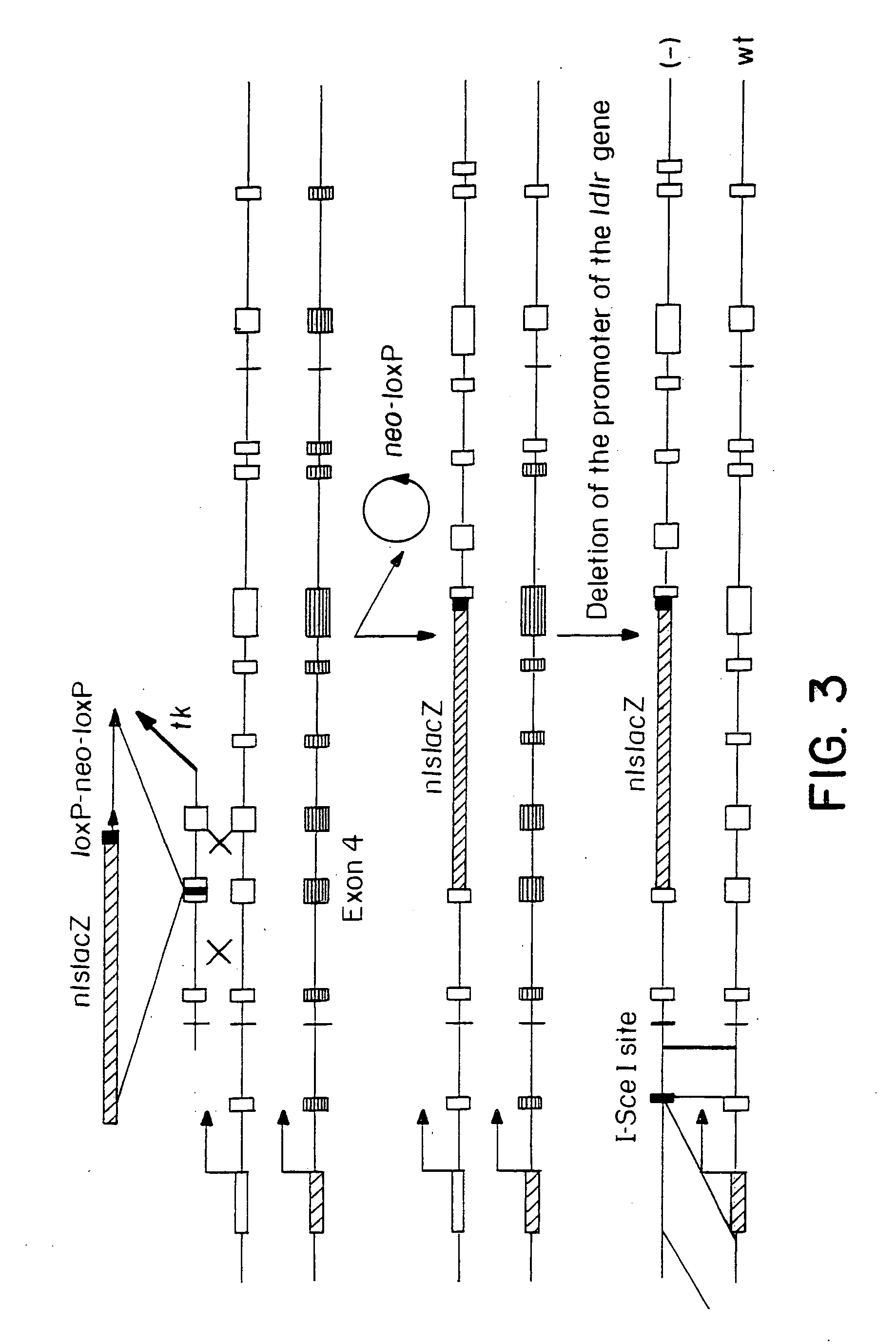

Gene repair involving the induction of double-stranded DNA cleavage at a chromosomal target site

InactiveUS20070141038A1Highly efficient recombinational eventEfficient introductionOrganic active ingredientsBiocideDouble strandLiving cell

Methods of modifying, repairing, attenuating and inactivating a gene or other chromosomal DNA in a cell are disclosed. Also disclosed are methods of treating or prophylaxis of a genetic disease in an individual in need thereof. Further disclosed are chimeric restriction endonucleases.

Owner:INST PASTEUR +1

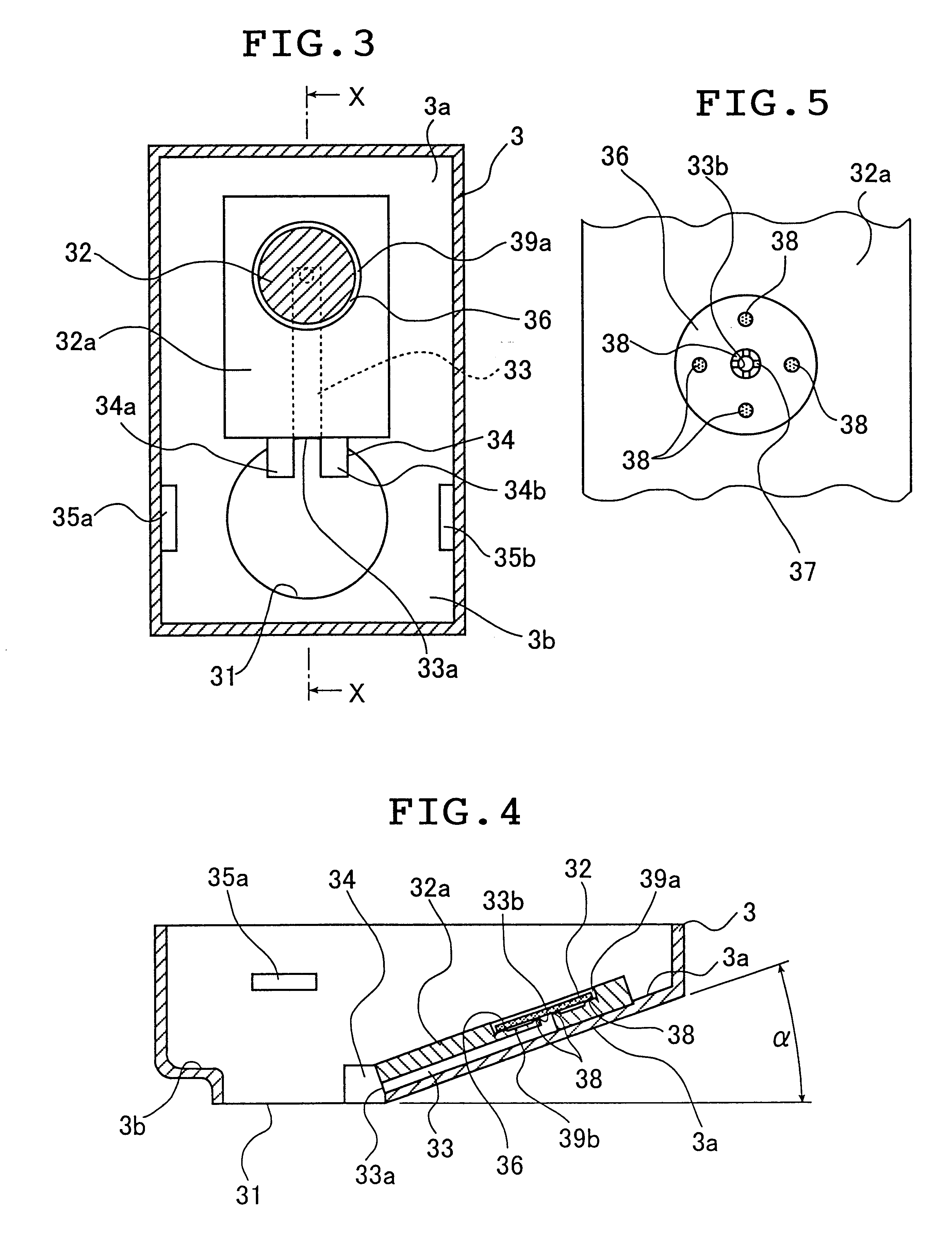

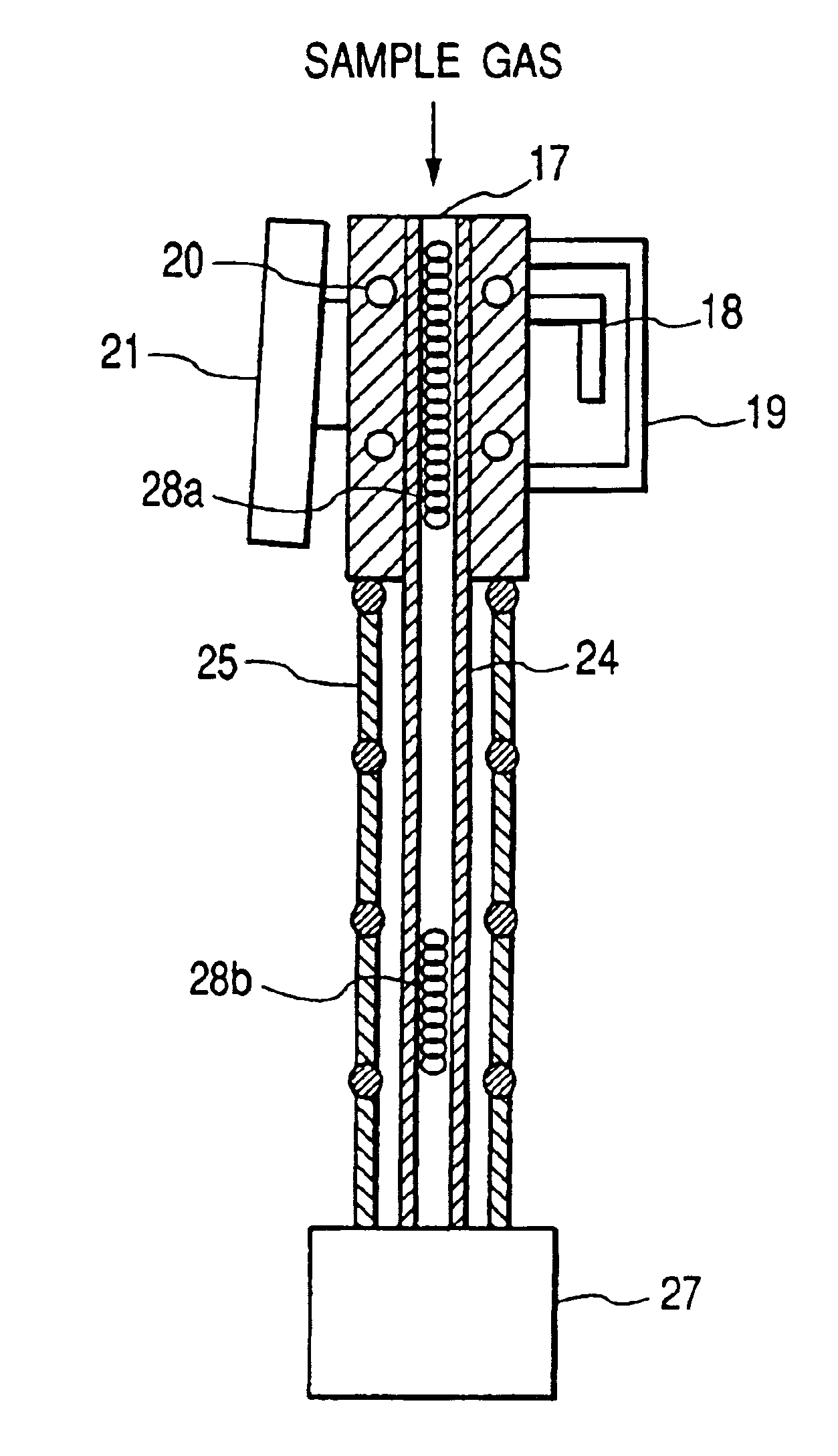

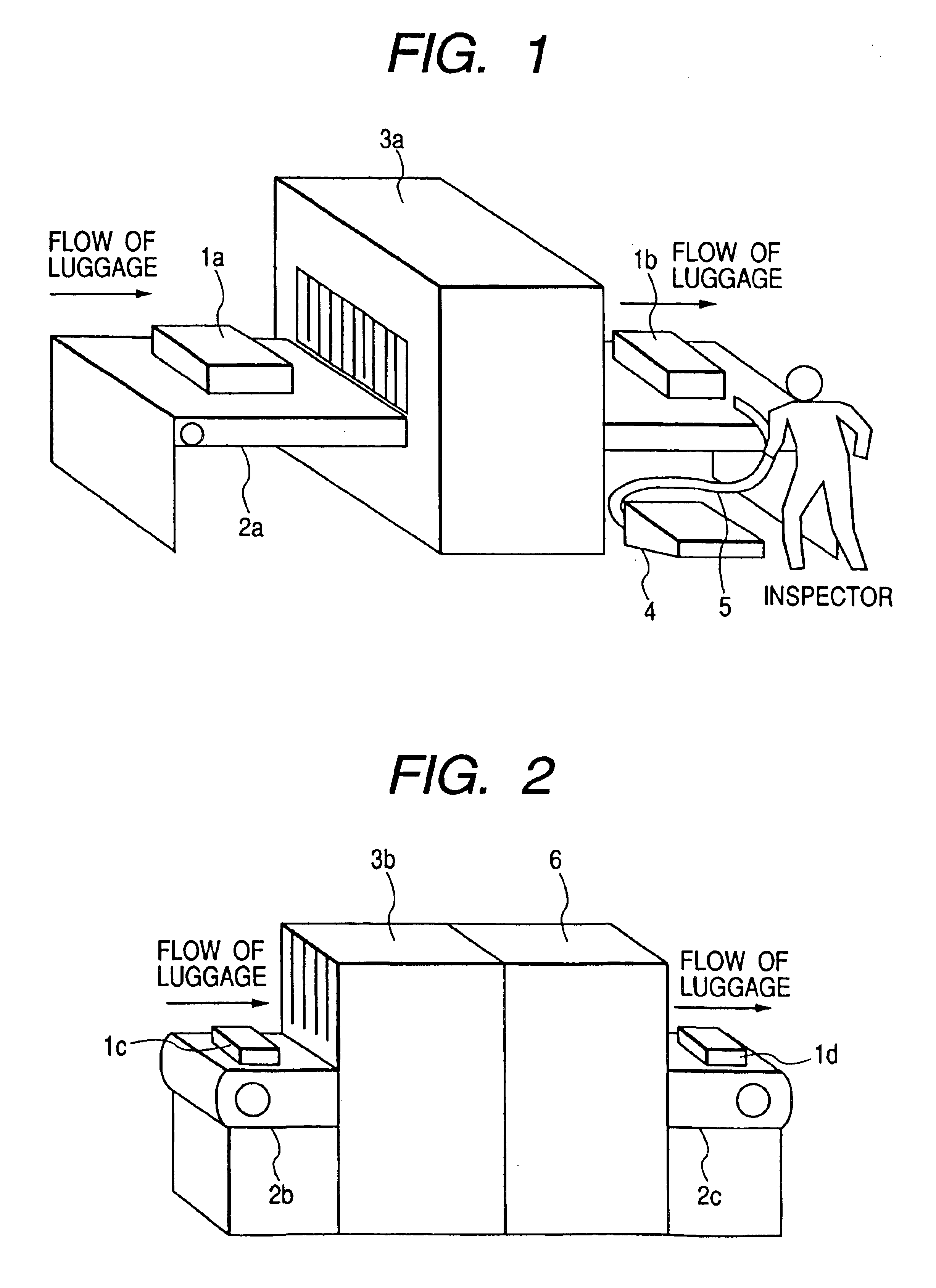

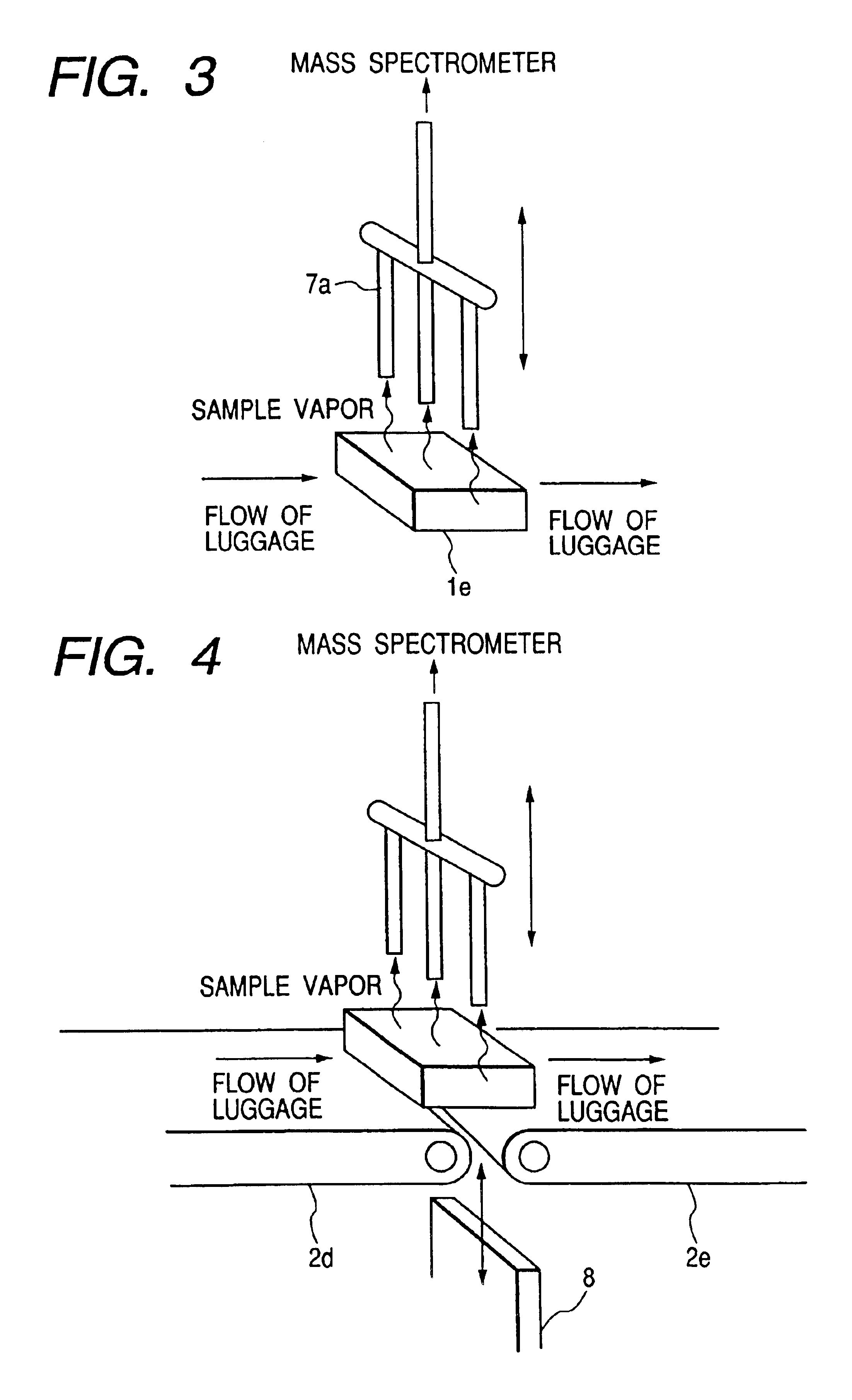

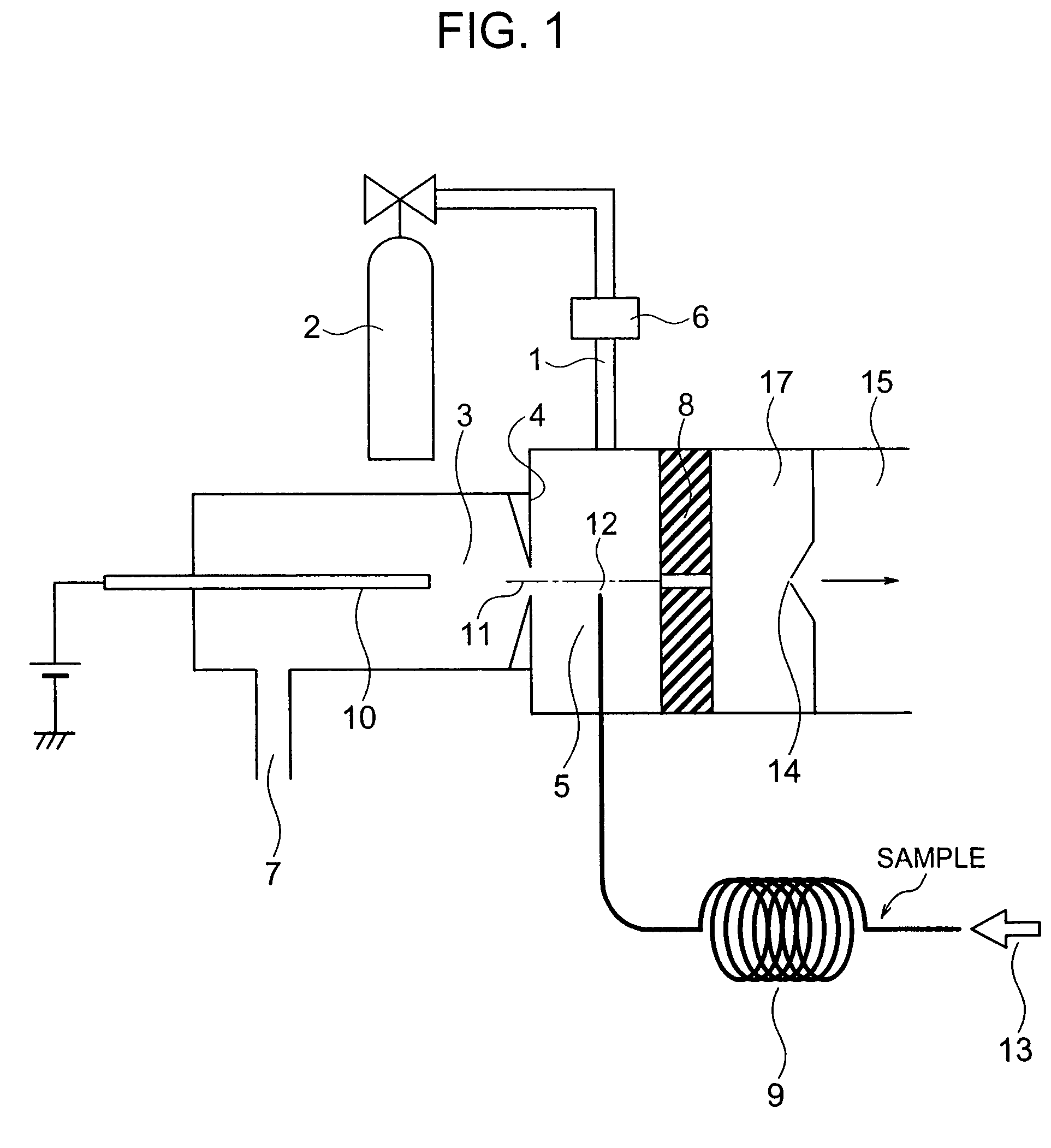

Explosive detection system and sample collecting device

InactiveUS6840120B2Efficient ionizationHigh detection sensitivityMaterial analysis using wave/particle radiationSamples introduction/extractionCorona dischargeX-ray

An explosive detection system includes an X-ray inspection apparatus, a mover for moving an object to be inspected to the X-ray inspection apparatus, a sample introduction probe for sampling a gas sample from the object to be inspected, a pipe for introducing the sampled gas into a corona discharge region and for subjecting the sampled gas to negative corona discharge to ionize the sampled gas and to generate negative ions. A mass spectrometer is provided to analyze the mass of the negative ions of the sampled gas and to provide results thereof. Inspection by the X-ray inspection apparatus is performed in relation to sampling of the gas sample, and explosive detection system inspects whether or not an explosive is present in the object to be inspected, from the analysis results of the sampled gas.

Owner:HITACHI LTD

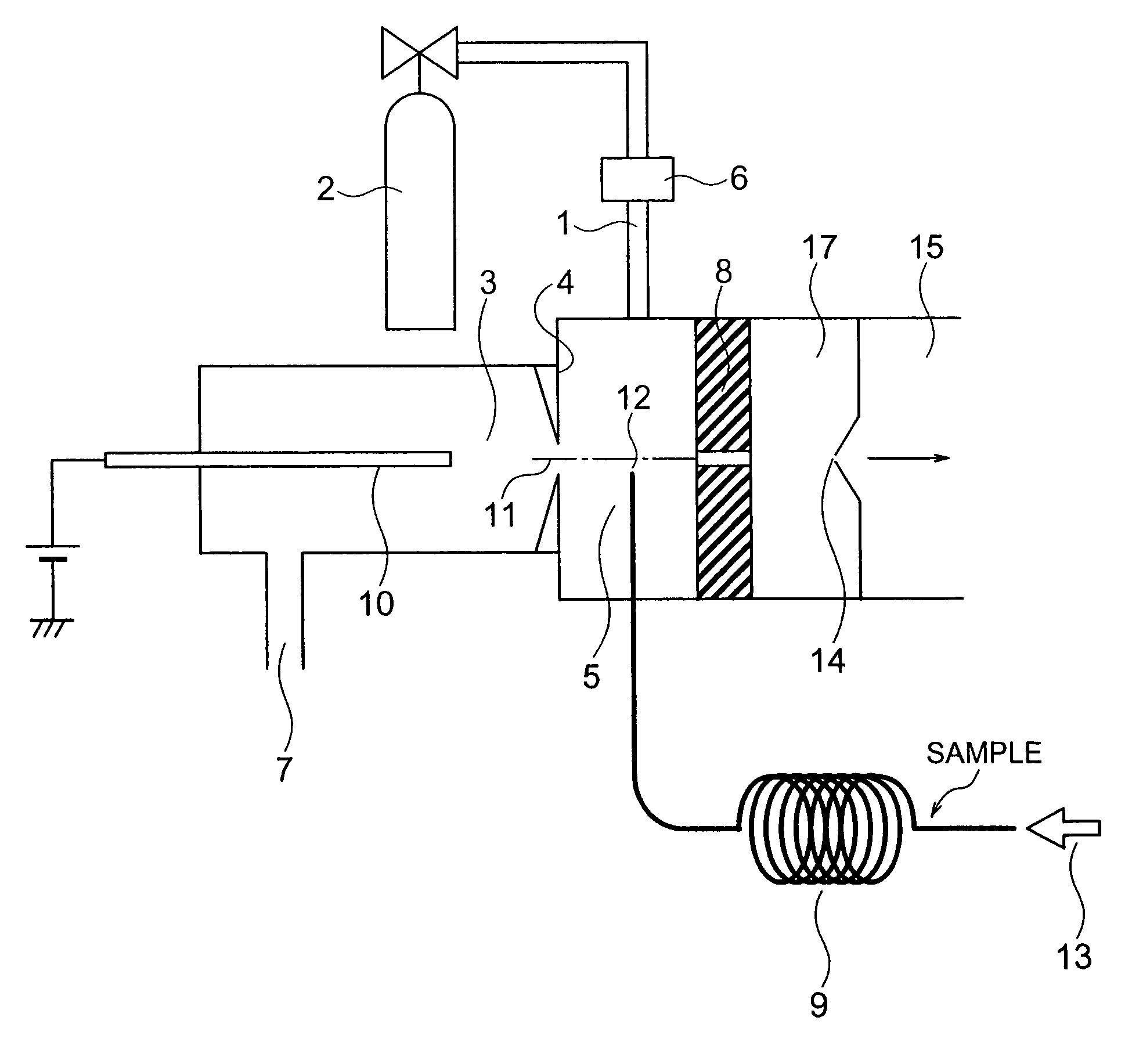

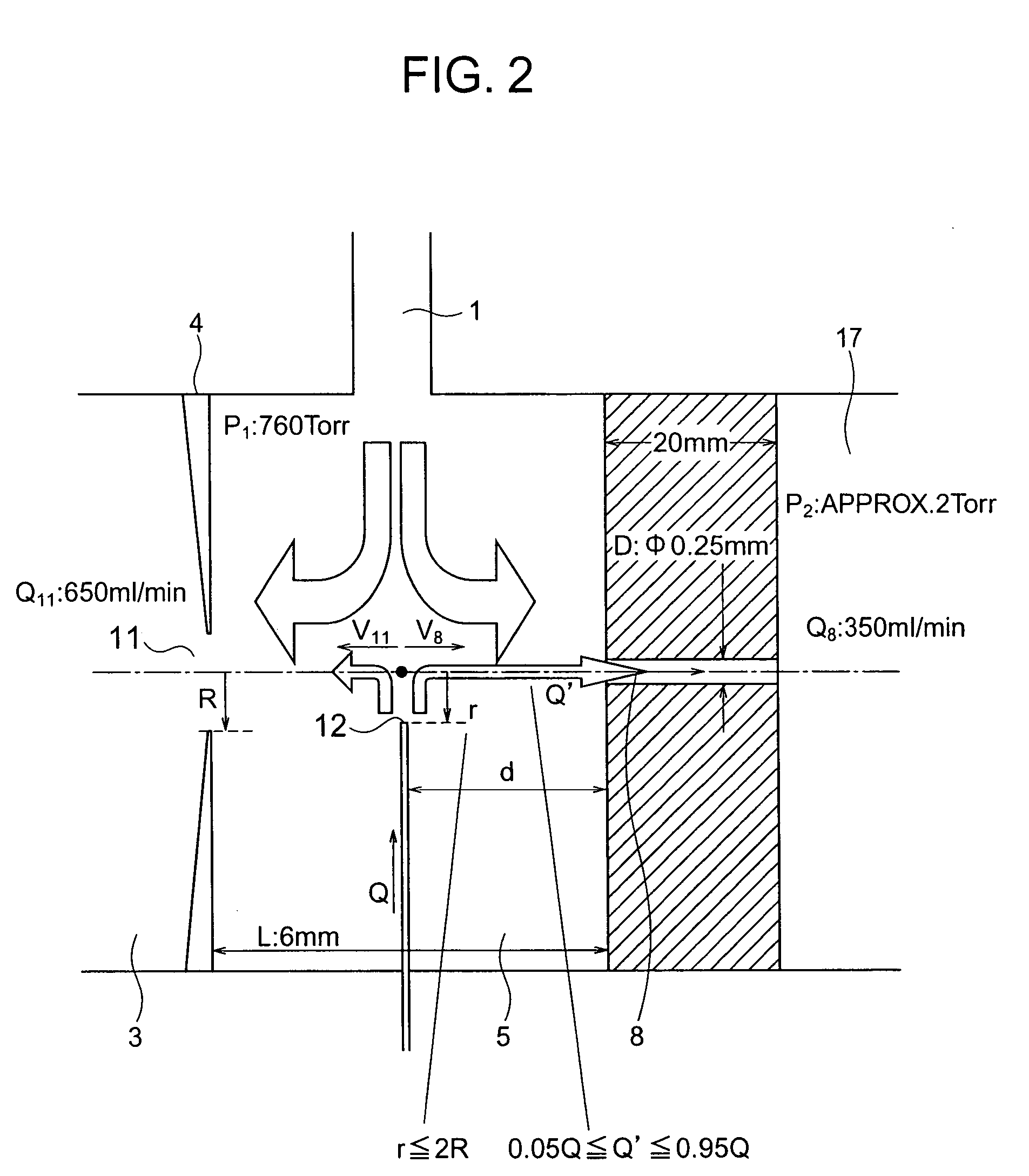

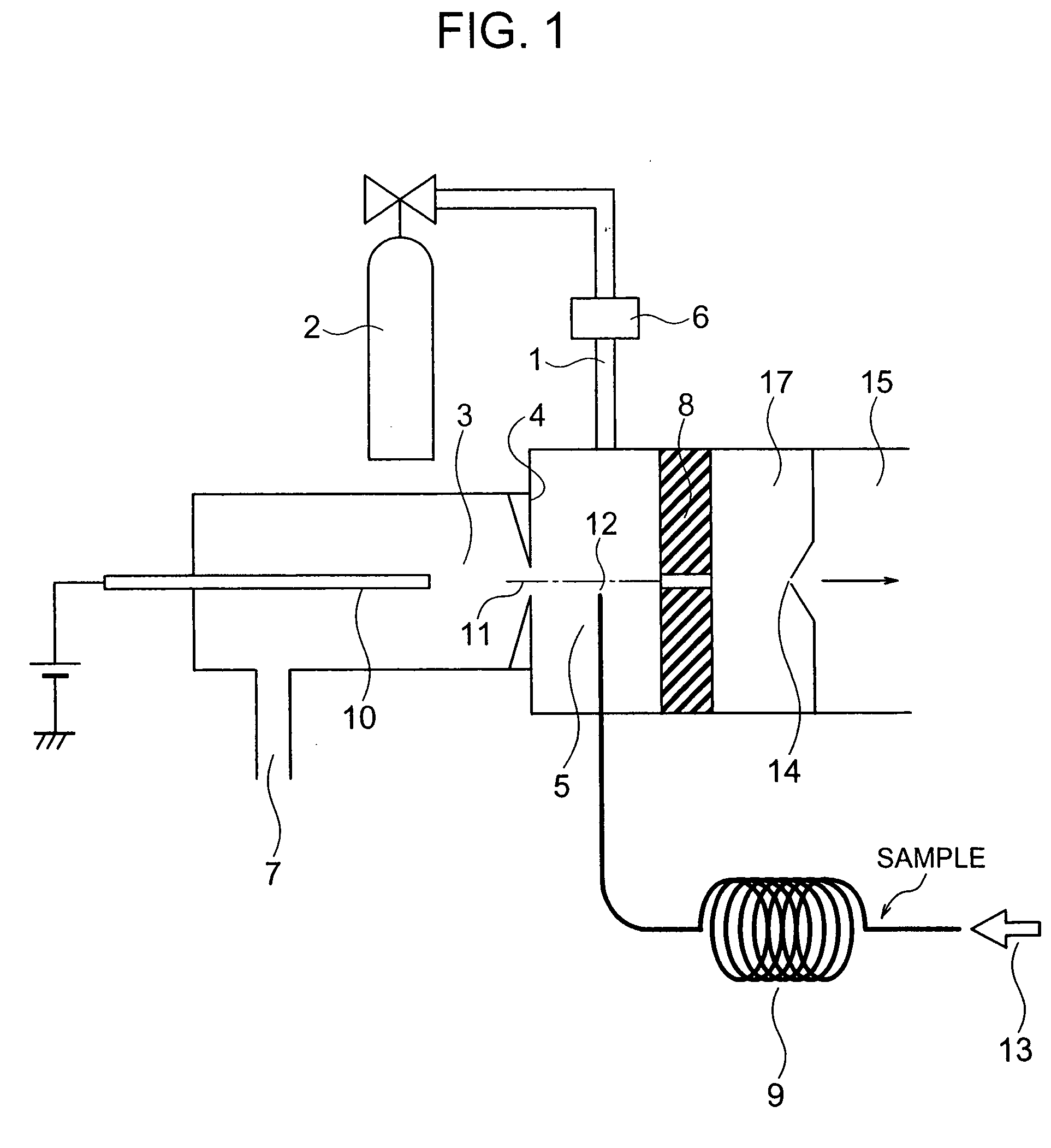

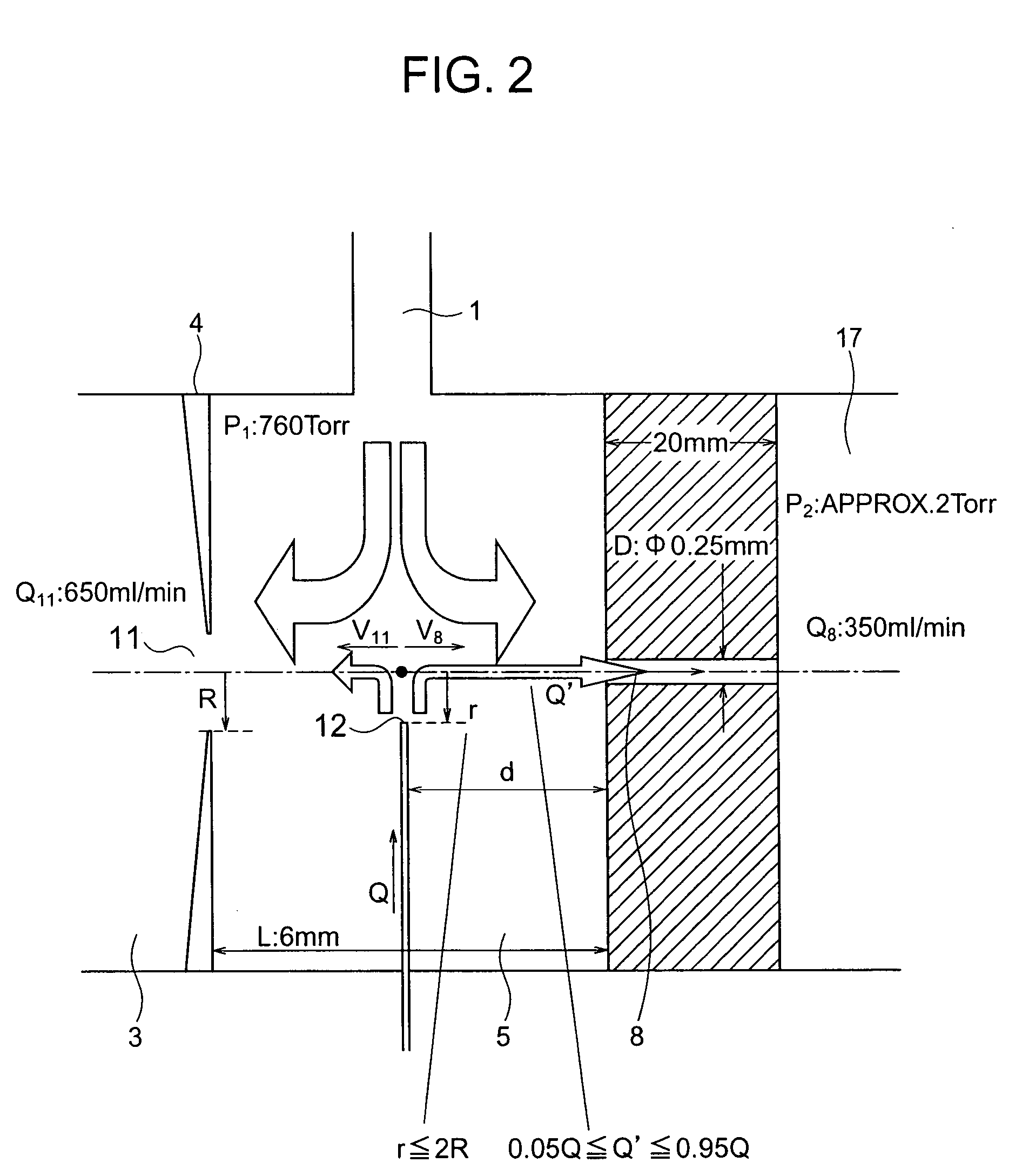

Mass chromatograph

ActiveUS7064320B2Easily contaminatedHigh sensitivity analysisComponent separationMaterial analysis by electric/magnetic meansMass analyzerIonization

A mass spectrometer has an atmospheric pressure chemical ionization source that includes a first ionization portion including a needle electrode, for generating a primary ion by discharge of the needle electrode a primary ion introduction aperture, and a second ionization portion including an introduction aperture, for generating a sample ion by the reaction between the primary ion and the sample gas introduced from an end of a column of gas chromatography, a sample ion movement aperture; and a mass analysis portion; wherein the end is arranged at a position satisfying the relation r≦2R where R is a radius of an inner diameter of the aperture and r is a distance between an axis connecting the center of the aperture and the center of the aperture, and the end.

Owner:HITACHI LTD

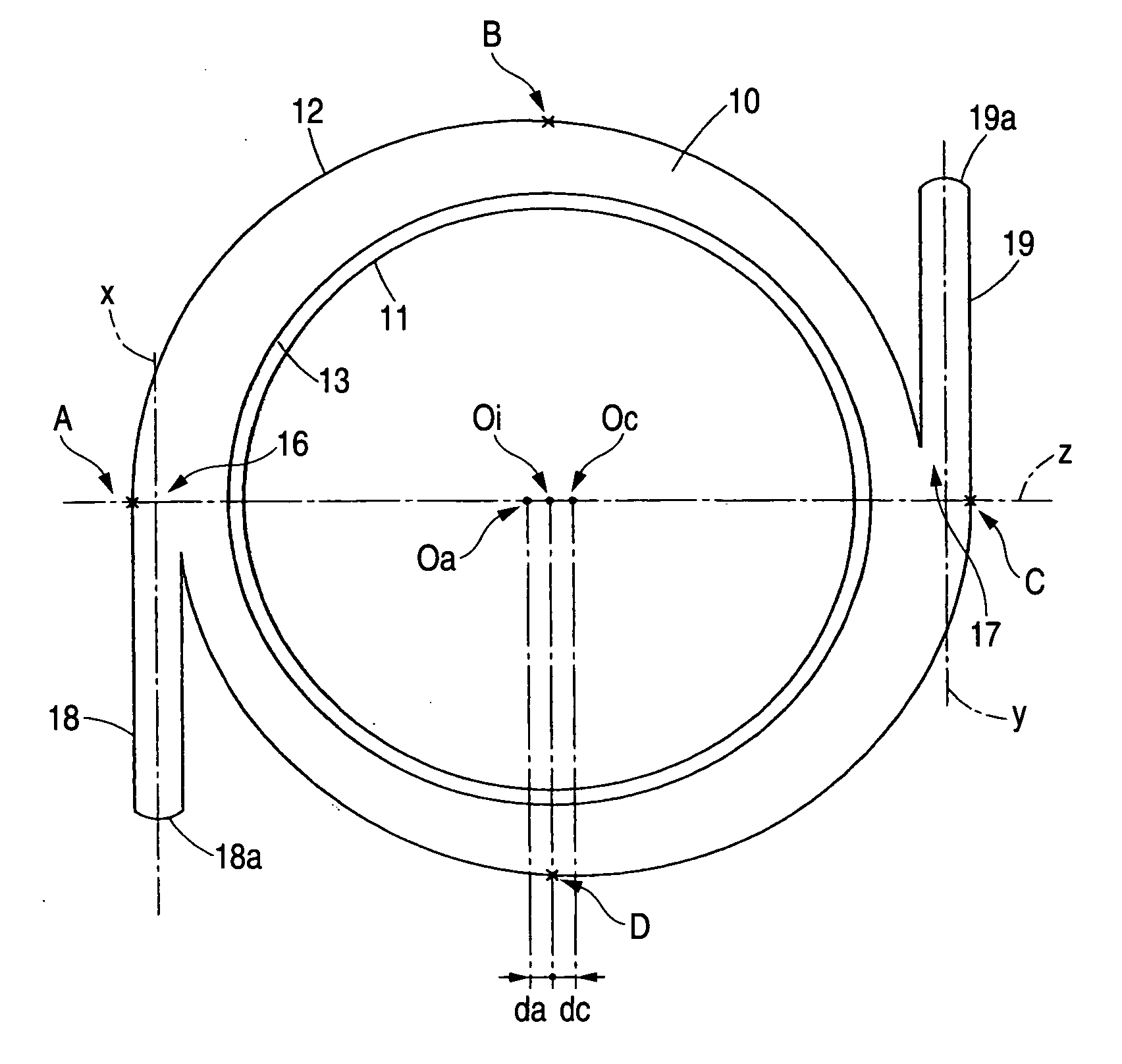

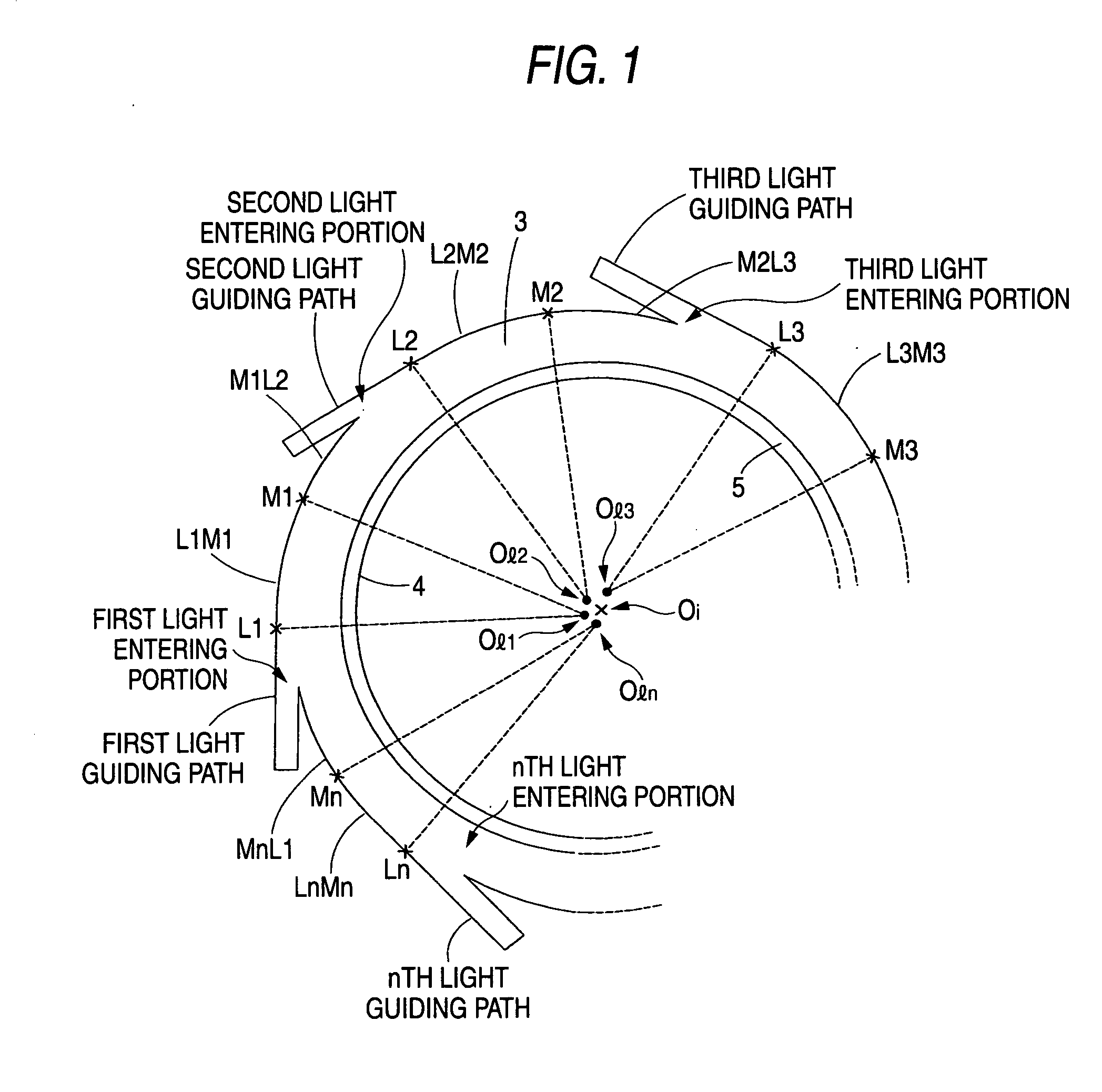

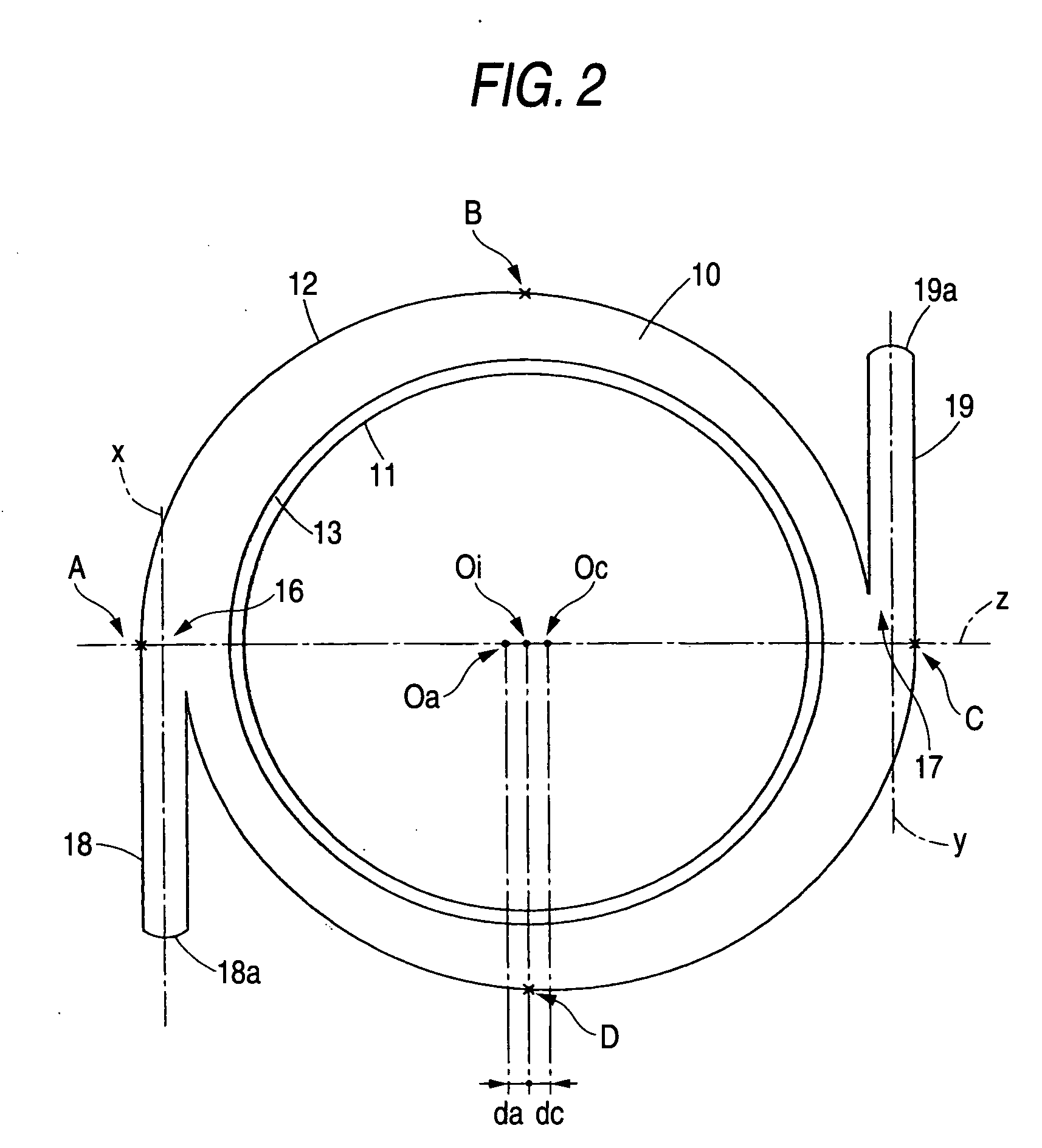

Ring-shaped light emitting unit

InactiveUS20060171137A1High light utilization rateSimple structureMeasurement apparatus componentsMachines/enginesLight guideLight-emitting diode

A ring-shaped light emitting unit including a ring-shaped light guiding member having a light emitting surface which is continuous along an extending direction thereof, and n light guiding paths for guiding light of a light source into the ring-shaped light guiding member, the n light guiding paths being continuously connected to portions of an outer periphery of the ring-shaped light guiding member at positions rotationally symmetrical about a center of the ring-shaped light guiding member as a reference, wherein an inner periphery of the ring-shaped light guiding member is a substantially perfectly round circle in a plan view, and the outer periphery of the ring-shaped light guiding member has a shape in which circular arcs of a plurality of substantially perfectly round circles are continuously connected in a plan view, excluding light entering portions.

Owner:TOYODA GOSEI CO LTD

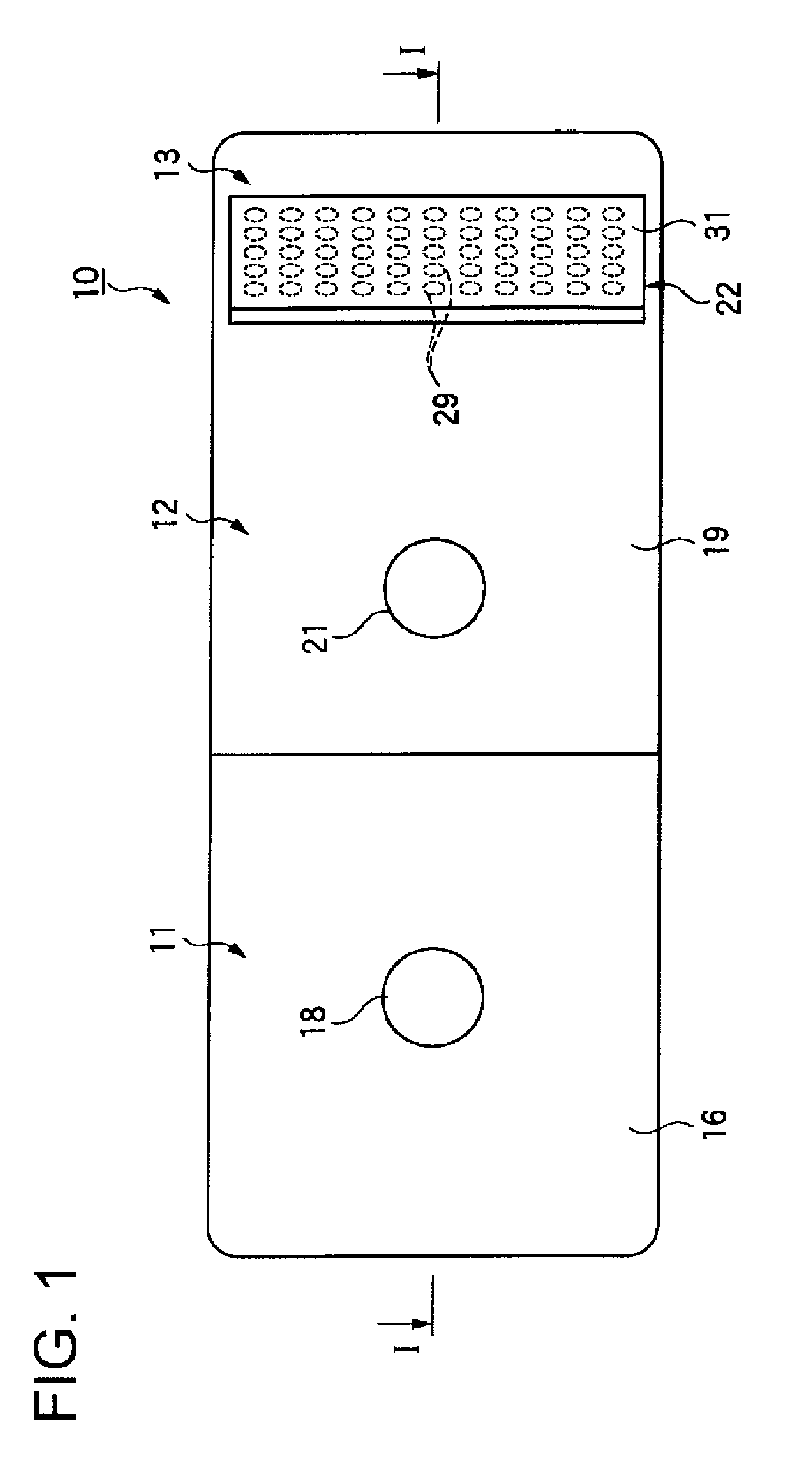

Vehicular lamp

InactiveUS7775697B2Reduce directivityEfficient introductionNon-electric lightingLighting support devicesLight guideEngineering

Owner:KOITO MFG CO LTD

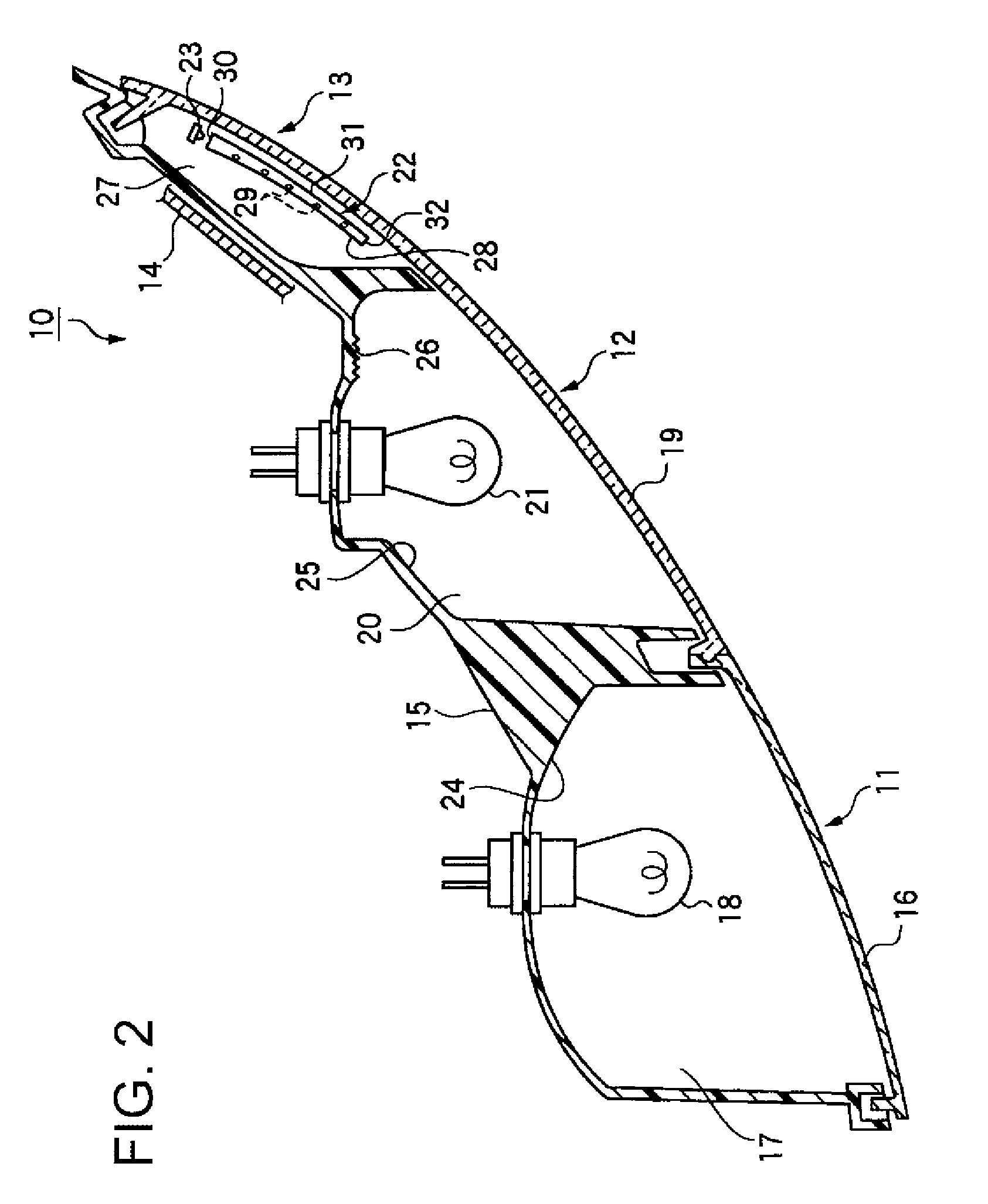

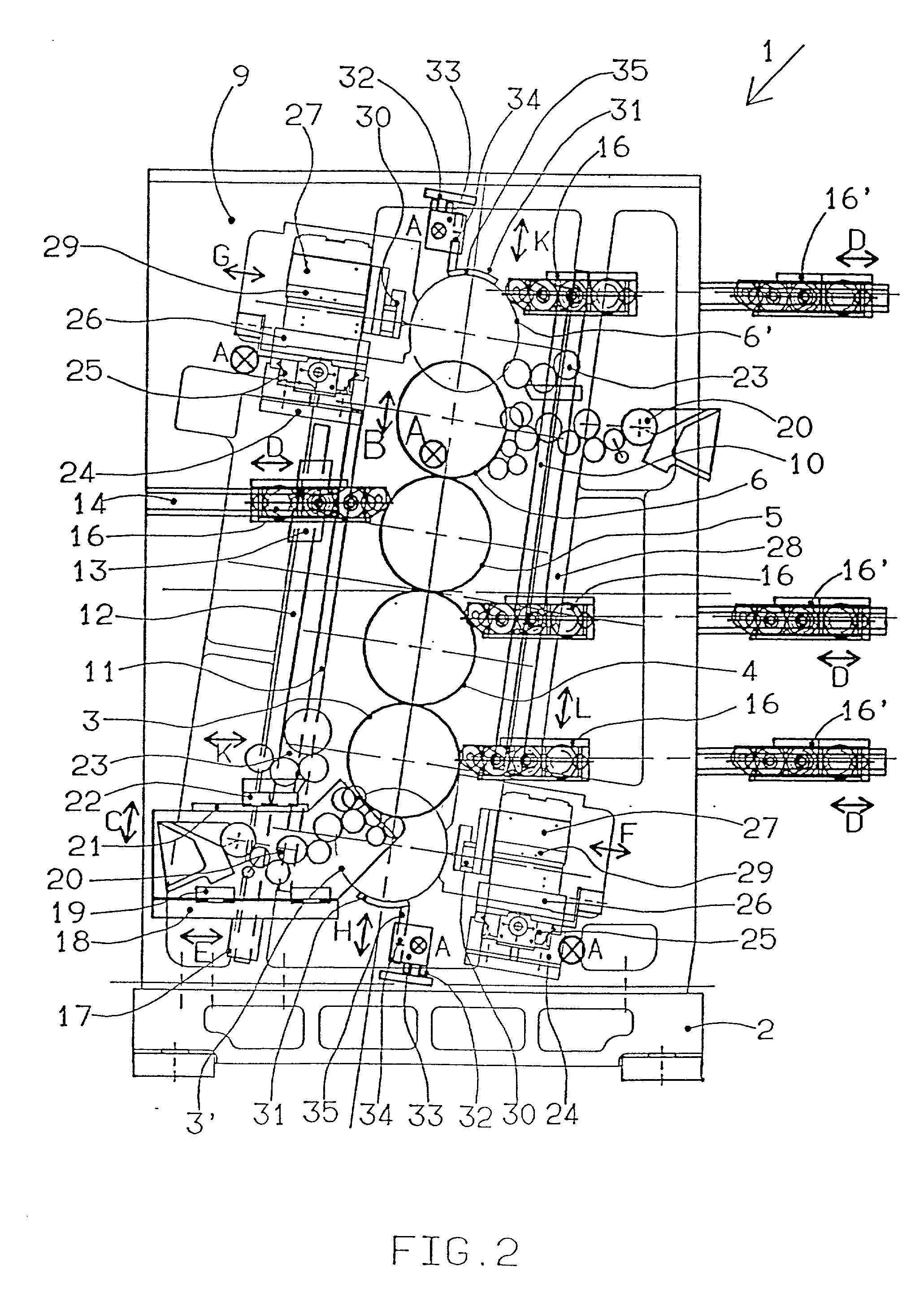

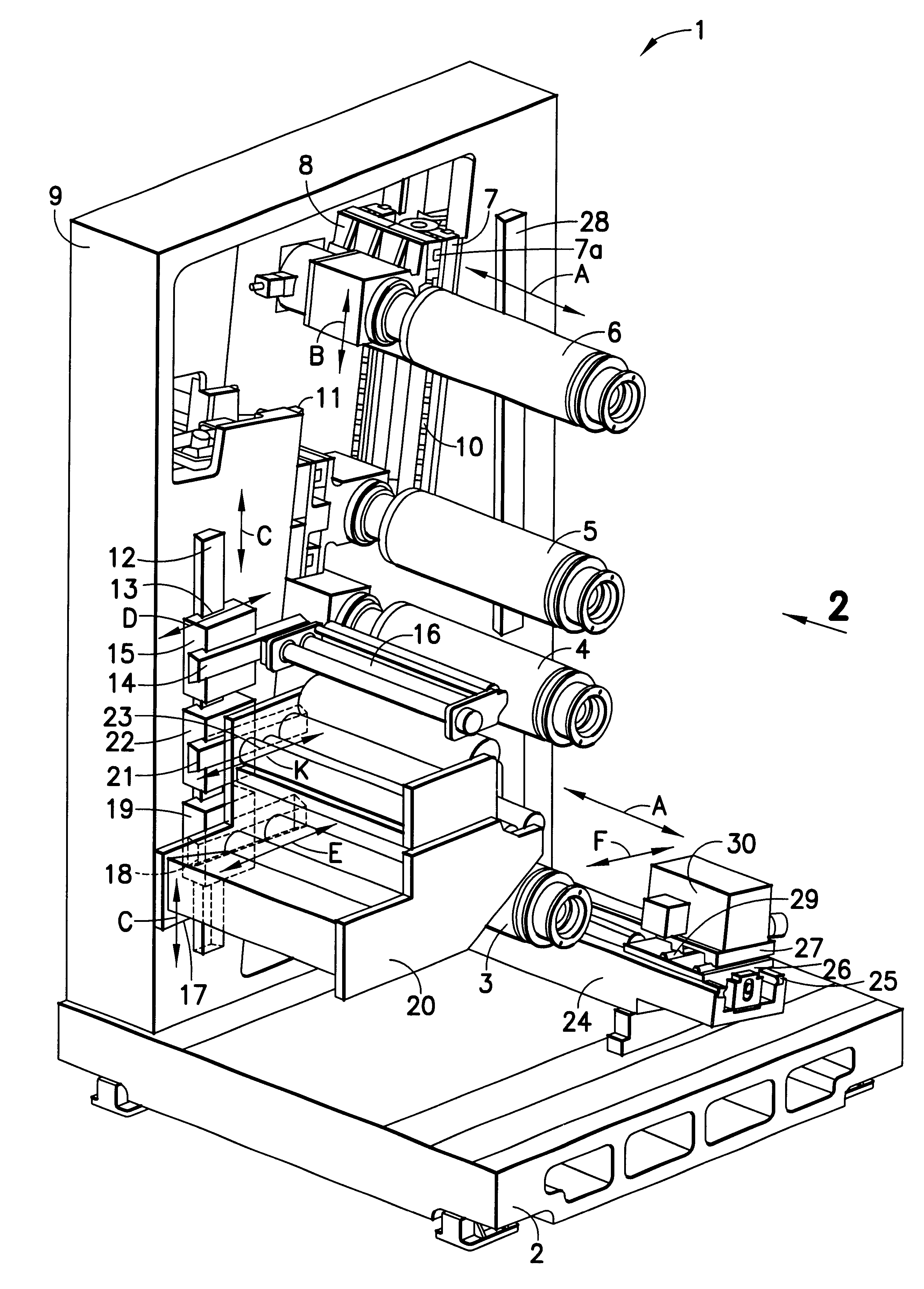

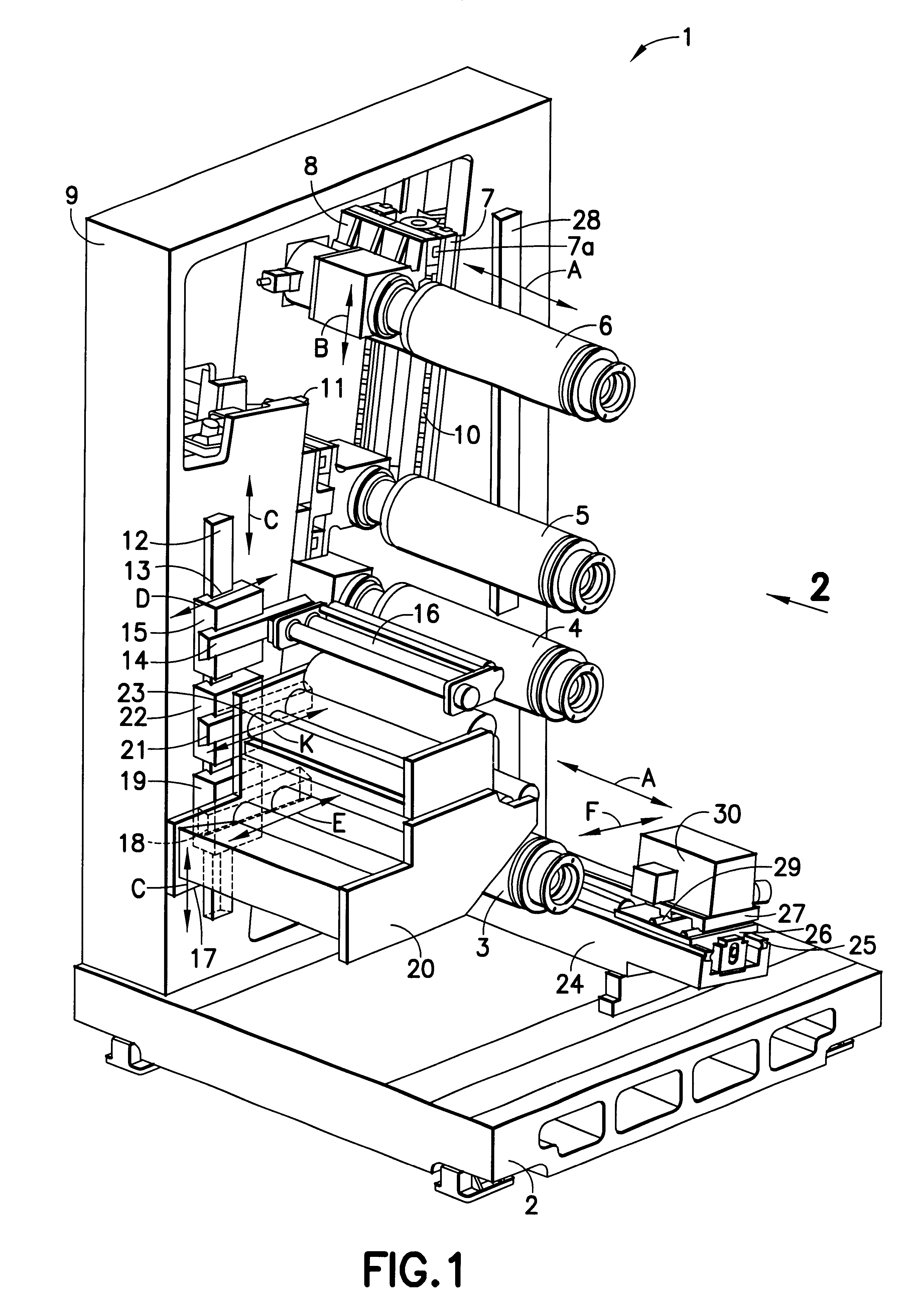

Printing unit for a rotary printing machine with cross slide

InactiveUS20010035104A1Long constructionEfficient introductionCylinder pressesAddressographsEngineeringPrinting press

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

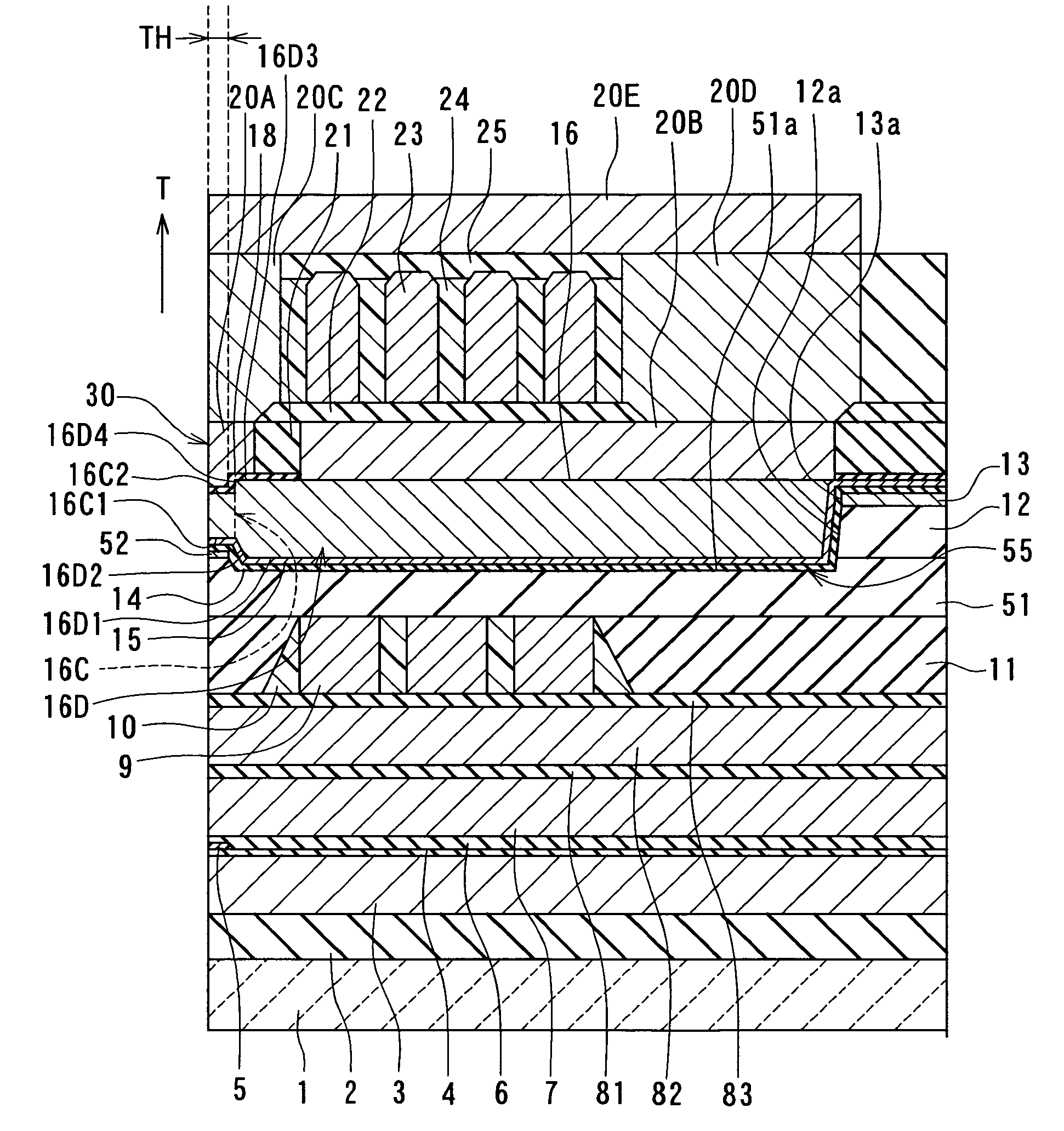

Magnetic head for perpendicular magnetic recording and method of manufacturing same

ActiveUS7375925B2Avoid problemsForming accuratelyConstruction of head windingsRecord information storageElectrical and Electronics engineeringEngineering

A pole layer incorporates: a first portion having an end face located in a medium facing surface; and a second portion having a thickness greater than that of the first portion. A surface of the first portion closer to a substrate is located farther from the substrate than a surface of the second portion closer to the substrate. A surface of the first portion farther from the substrate is located closer to the substrate than a surface of the second portion farther from the substrate. At least a portion of the pole layer is placed in an encasing groove formed in a region extending from a first encasing layer through a second encasing layer to a nonmagnetic metal layer.

Owner:HEADWAY TECH INC

Ionization analysis method and apparatus

ActiveUS8253098B2High sensitivityReduce the temperatureMaterial analysis by optical meansIon sources/gunsElectron temperaturePlasma jet

An ionization apparatus comprises a first electrode provided on the outer periphery of a dielectric cylindrical body and a second cylindrical electrode placed inside at a center of the cylindrical body. When an AC high voltage is impressed across the first electrode and the second cylindrical electrode, a barrier discharge occurs within the cylindrical body. A distal end portion of the second cylindrical electrode projects outwardly from the distal end of the cylindrical body, a thermal equilibrium plasma P having a low electron temperature is generated outwardly from the distal end of the cylindrical body without a plasma jet ascribable to the barrier discharge emerging outwardly from the distal end of the cylindrical body. By exposing a sample S to the thermal equilibrium plasma P, particles (atoms, molecules) desorbed from the sample S undergo soft ionization without being decomposed or polymerized.

Owner:UNIVERSITY OF YAMANASHI

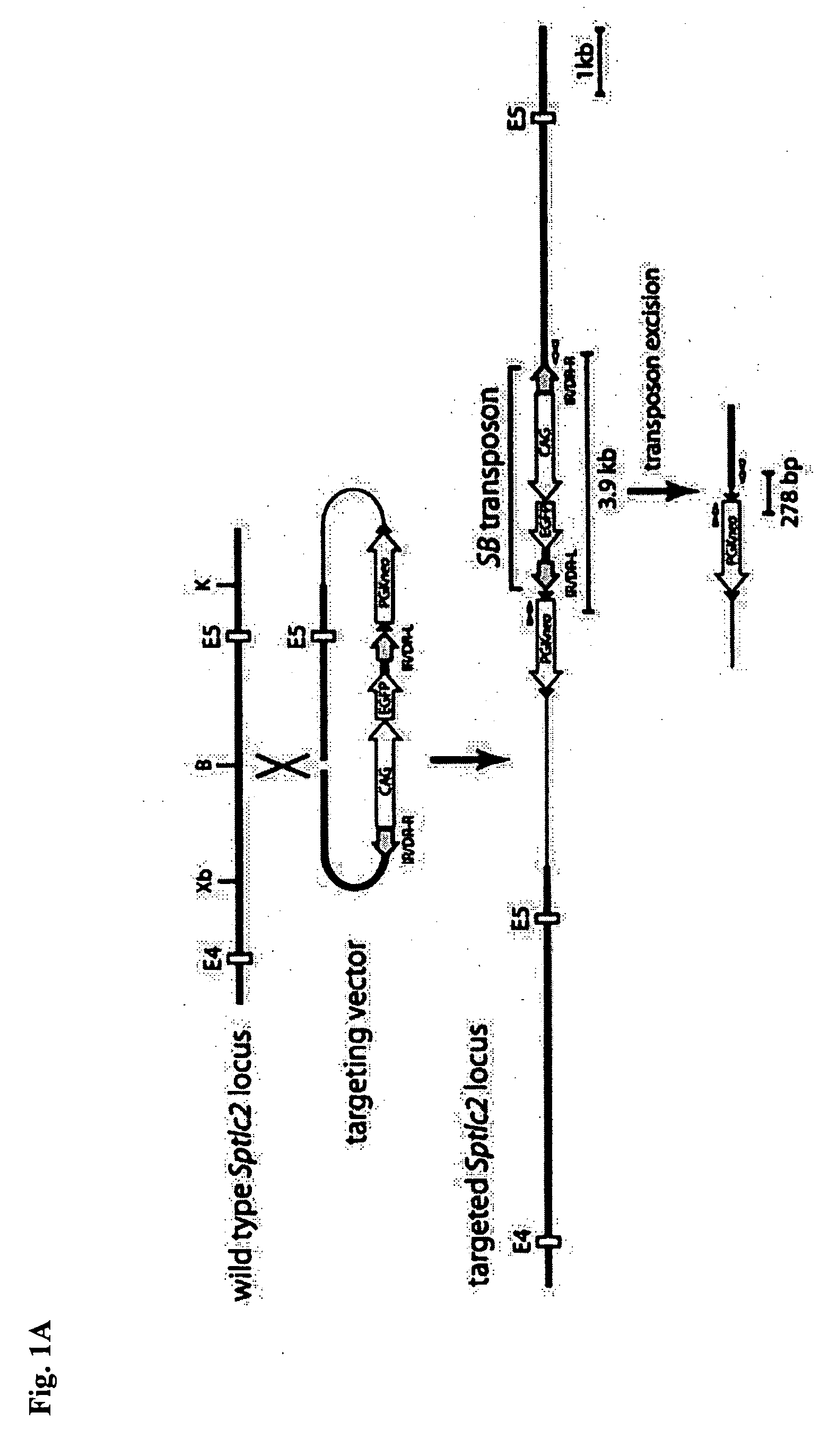

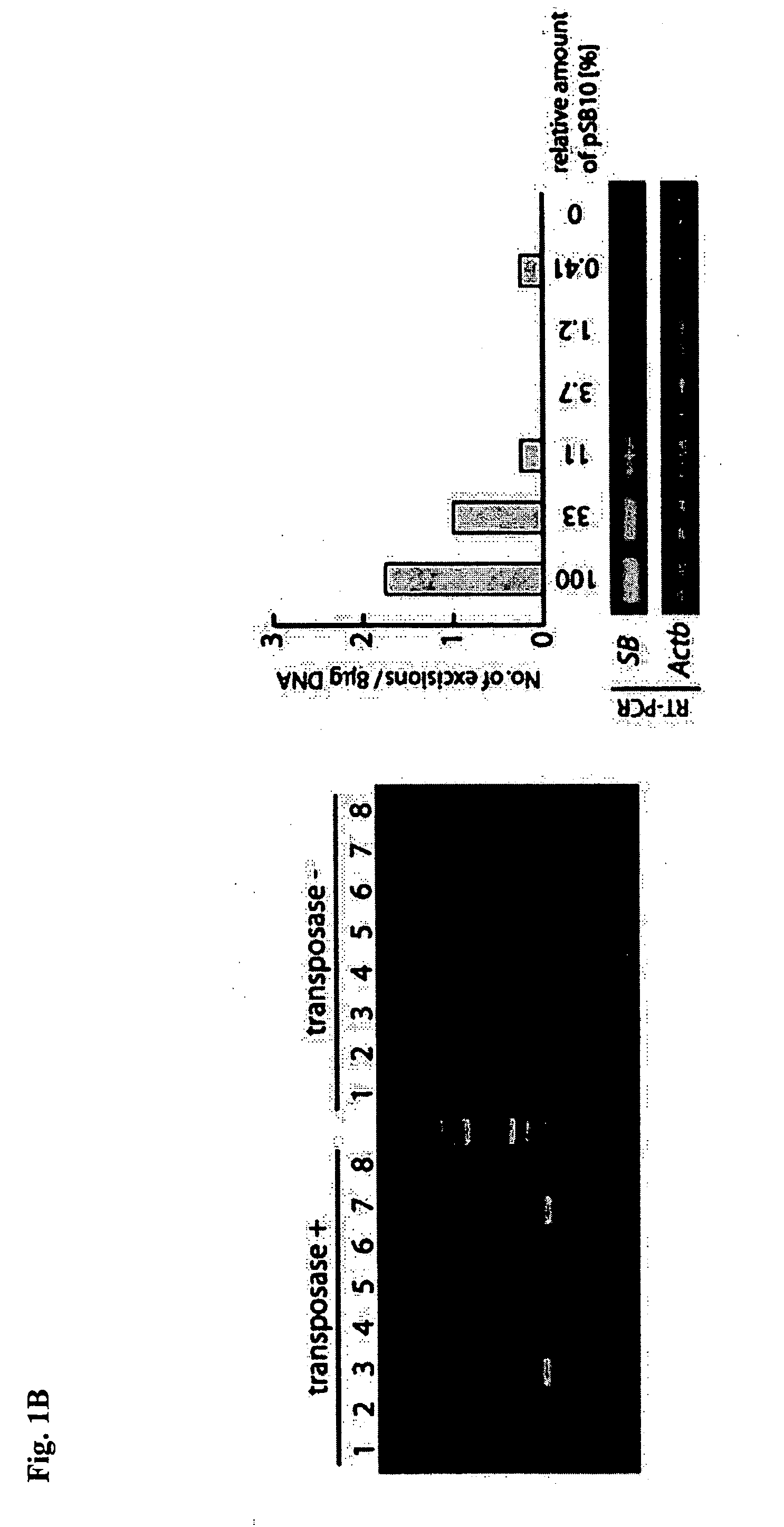

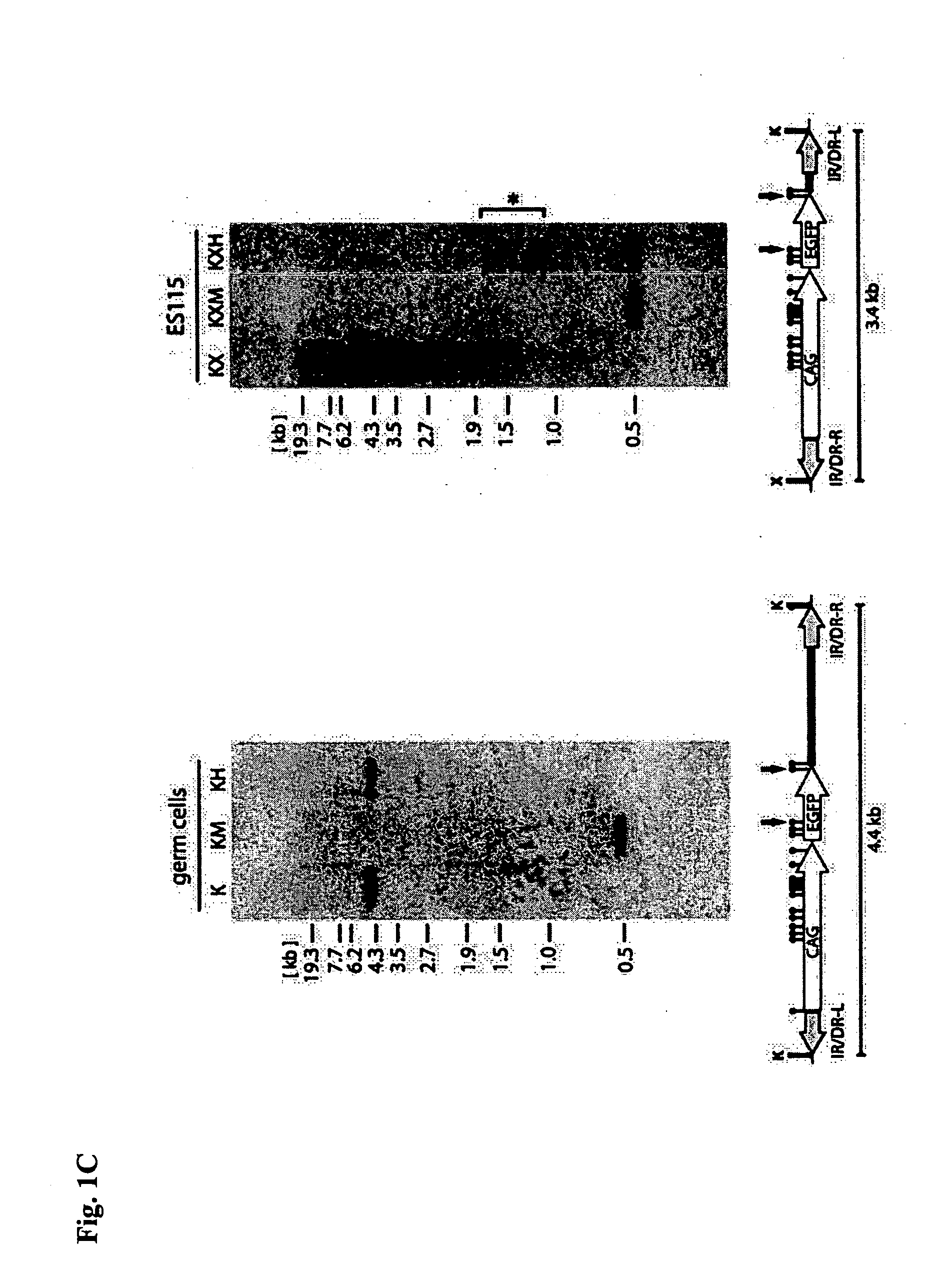

Method of preparing transgenic organism with use of methylation and system therefor

InactiveUS20070022485A1Improve conversion efficiencyEfficient productionAnimal cellsHydrolasesGene conversionOrganism

A technique for efficiently introducing a foreign gene into cells with the use of transposons. In particular, a technique for efficiently preparing a transgenic organism with the use of a transposon having its transposition activity strikingly enhanced through methylation of a sequence containing the transposon. The methylation is retained even after incorporation in a genome, and now can be utilized in actual gene incorporation in a genome. This technique can realize strikingly efficient gene transformation as compared with the a method of preparing a transgenic organism with the use of conventional transposons.

Owner:JAPAN SCI & TECH CORP

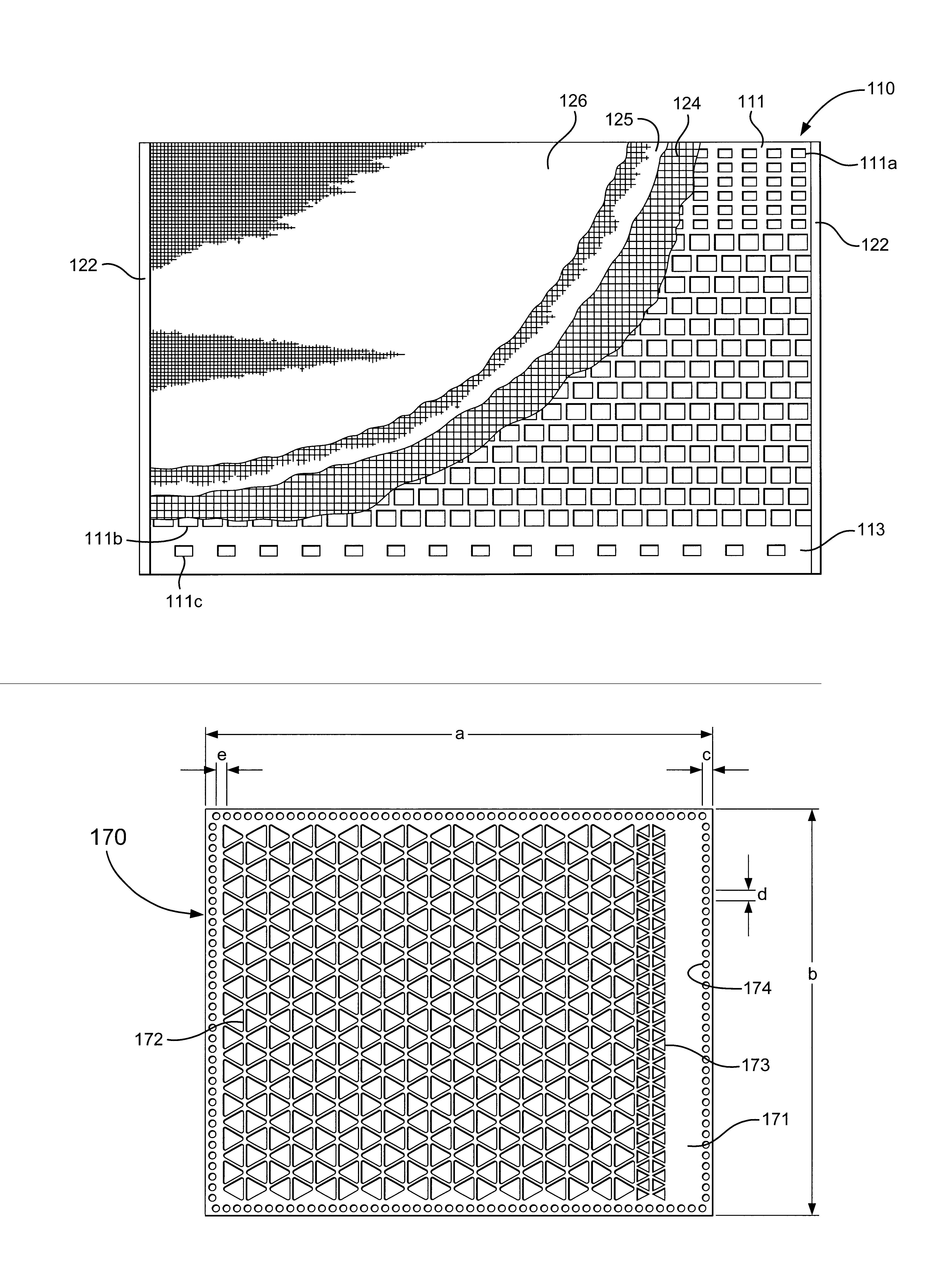

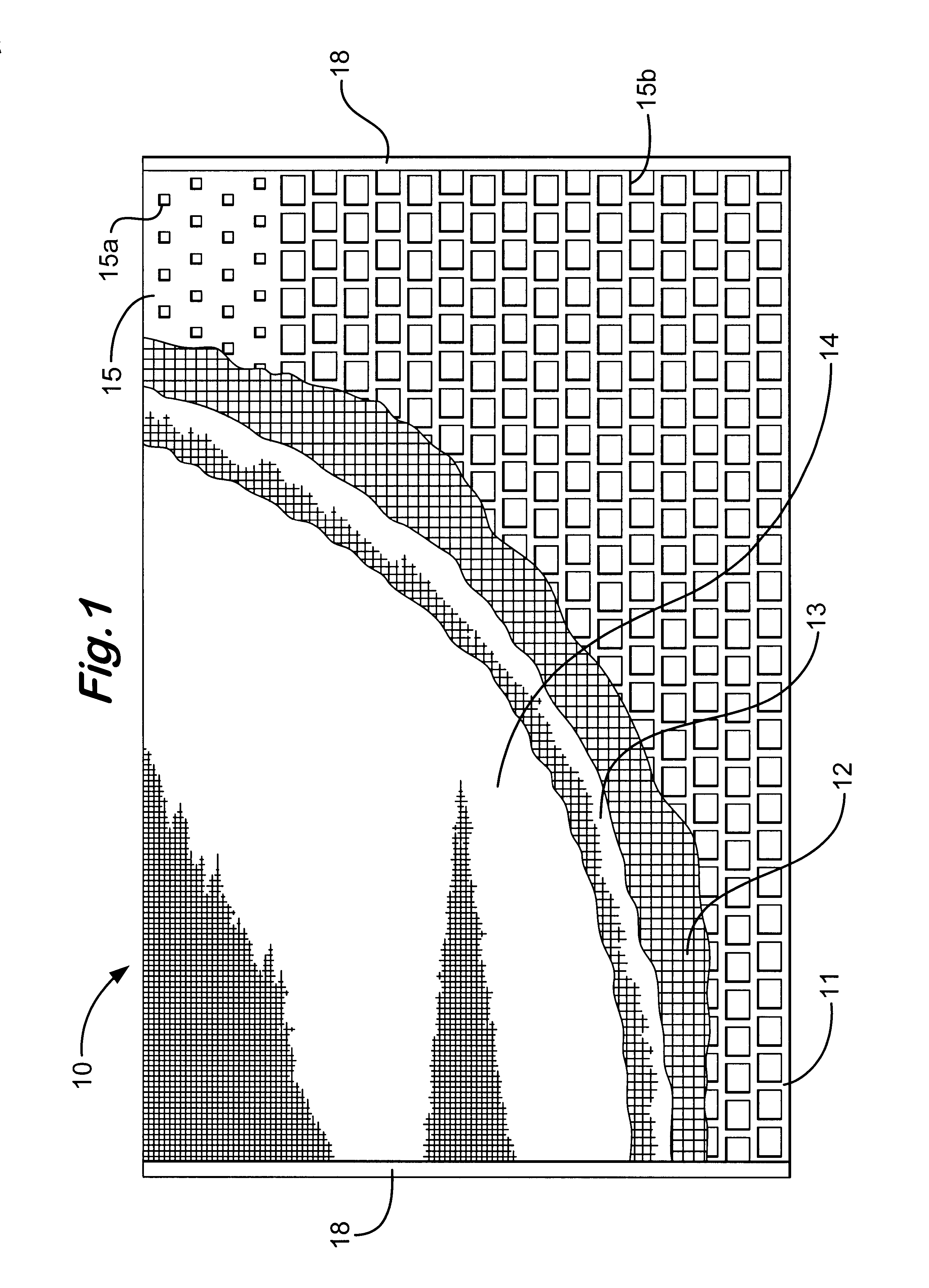

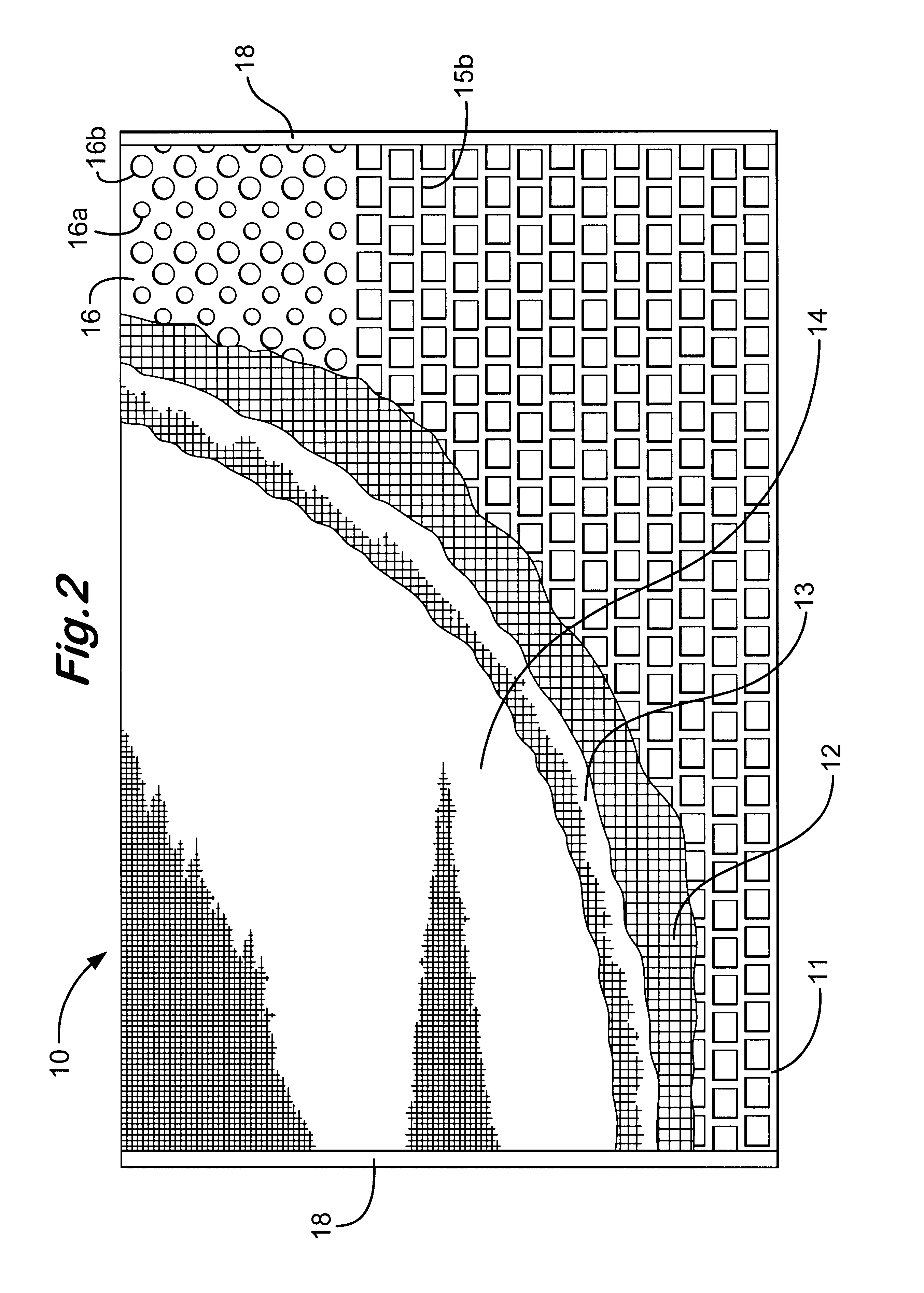

Screen support and screens for shale shakers

InactiveUS6601709B2Efficient introductionGuaranteed effective sizeSievingScreeningShale shakersBiomedical engineering

A support for a screen assembly for a vibratory separator, a screen assembly with such a support, a vibratory separator with one or more such screen assemblies, and a method of using such a screen assembly, such a support having a body, a first series of holes through the body each hole having a first opening size as viewed from above, a second series of holes through the body each hole with a second opening size as viewed from above, the second series of holes at a selected area of the body and the support positionable in a vibratory separator so that the selected area is adjacent a selected location with respect to the vibratory separator, and the second opening size smaller than the first opening size and / or the second series of holes with holes spaced apart differently than the holes of the first series of holes; and in one aspect, a plastic grid with such hole series for fusing together layers of screening material.

Owner:VARCO I P INC

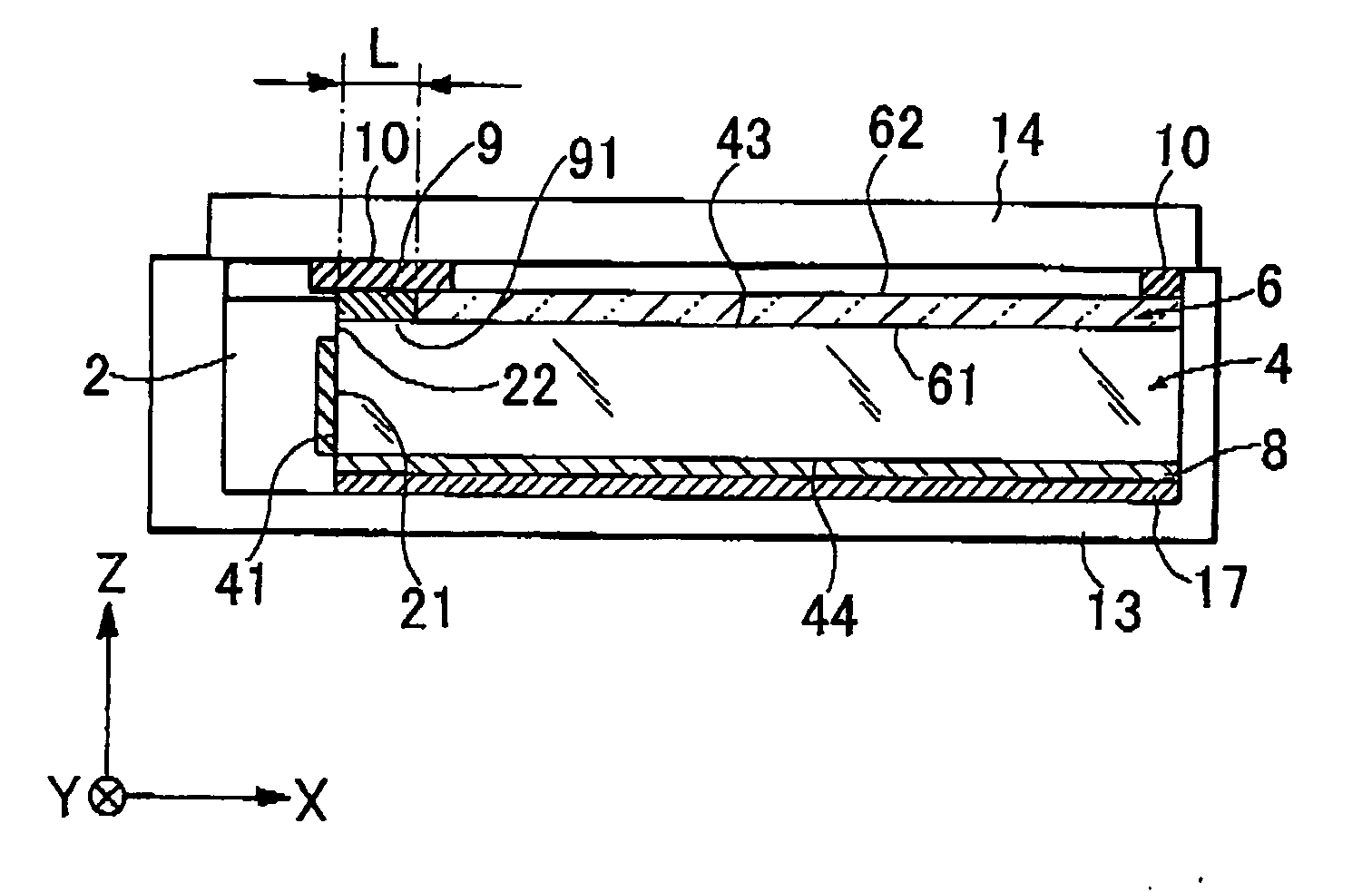

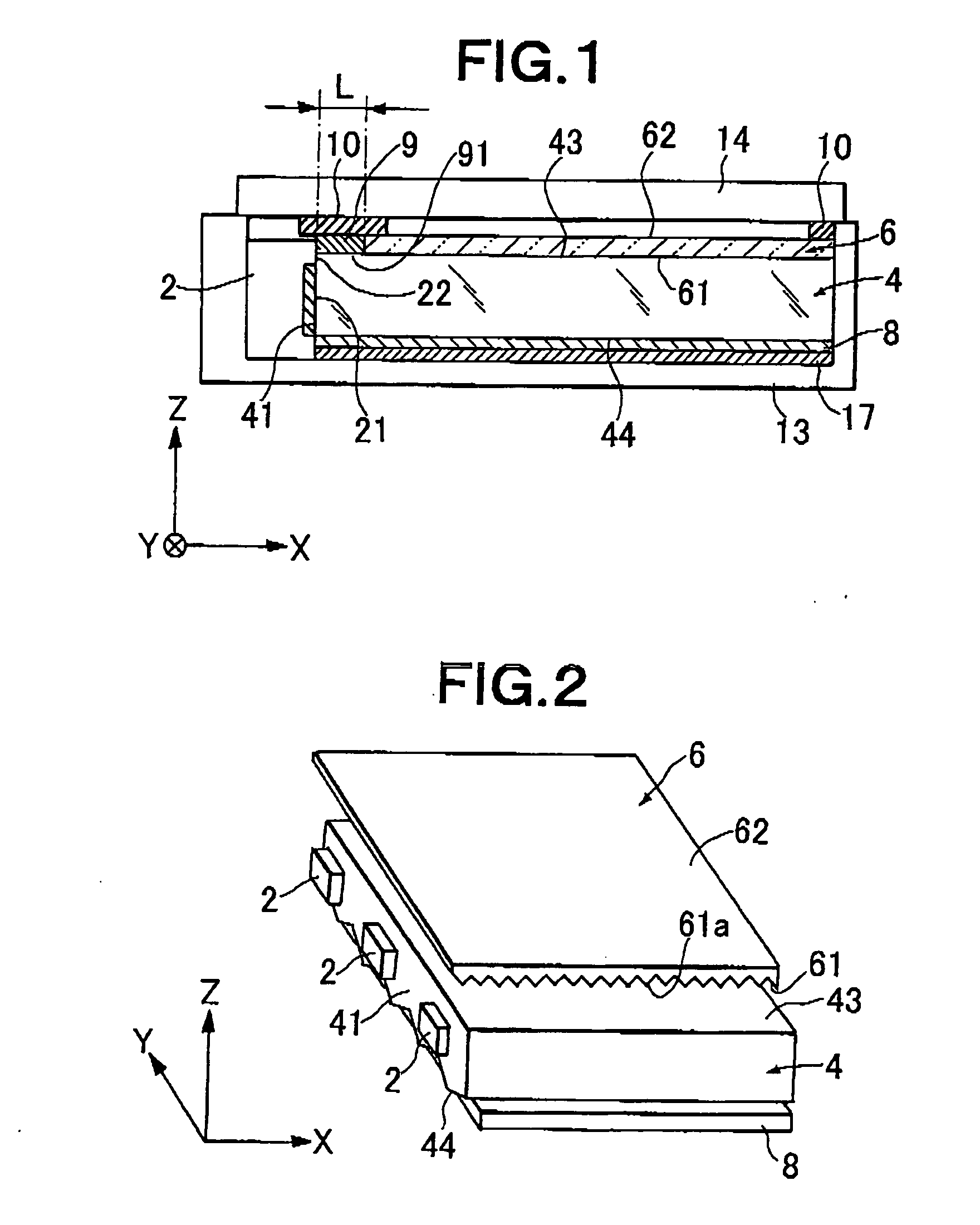

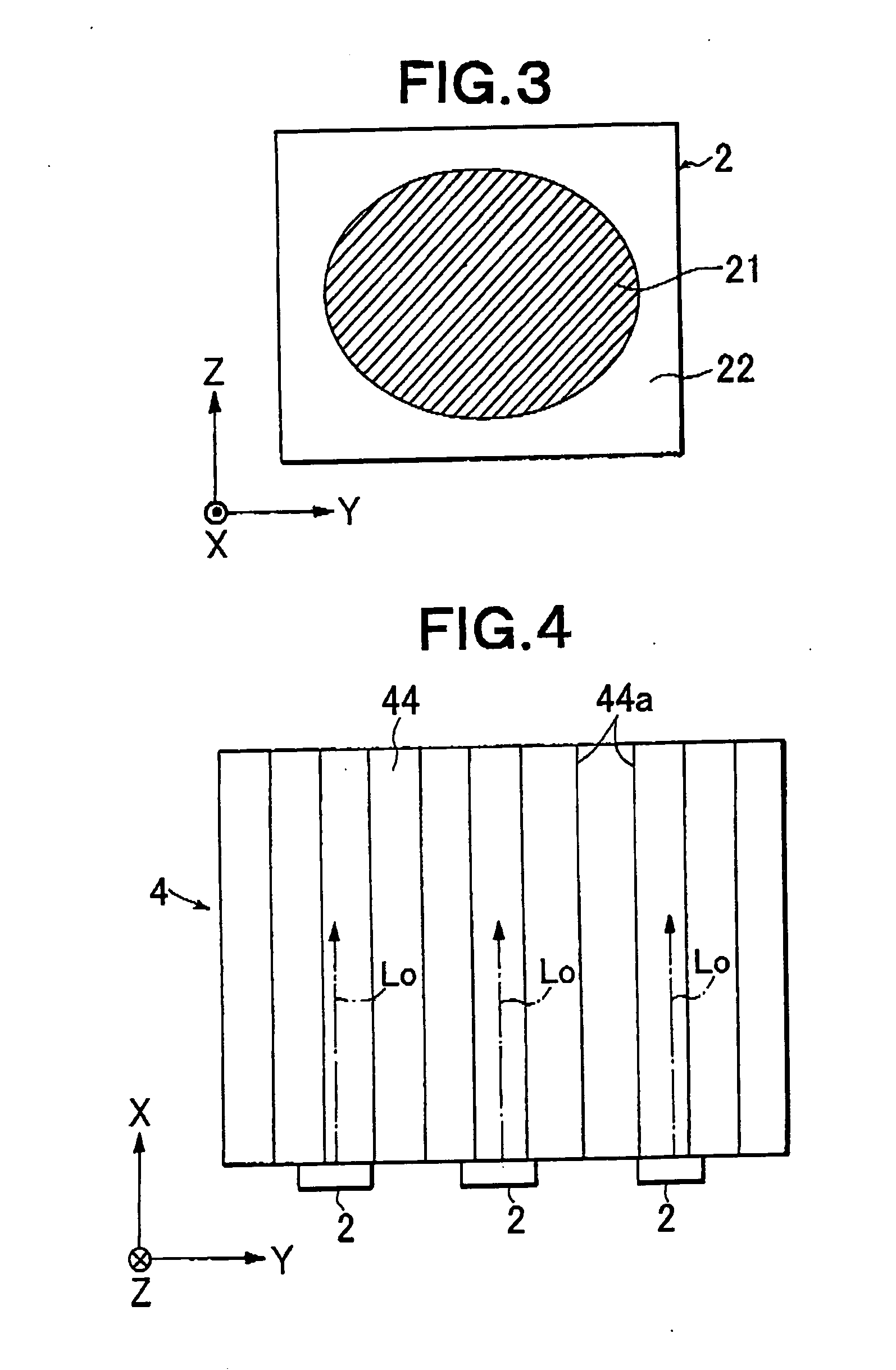

Area light source

InactiveUS20060056200A1Efficient introductionQuality improvementMechanical apparatusPlanar/plate-like light guidesLight guideOptoelectronics

An area light source comprising an LED primary light source (2), a plate-like light guide (4) and a light deflector (6) is provided with a direct light incoming prevention means closed of a light-blocking member (9). The light guide (4) has a light incoming end face (41) and a light outgoing face (43) and guides a light emitted from the LED primary light source (2). The light deflector (6) is arranged adjacently to the light outgoing face (43) and has a light entering face (61) and a light exiting face (62). The direct light incoming prevention means prevents a light, which is emitted from the LED primary light source (2), from entering into the light deflector (6) without passing through the light guide (4). The light-blocking deflector (9) is disposed on a first region of the light outgoing face (43) which is located near the edge of the light incoming end face side of the light outgoing face (4). The surface of the light-blocking member (9) facing the light outgoing face (43) is a diffusing reflective surface. The light deflector (6) is disposed on a second region of the light outgoing face (43) where the light-blocking member (9) is not arranged.

Owner:MITSUBISHI RAYON CO LTD

Mass chromatograph

ActiveUS20060054806A1Easily contaminatedHigh sensitivity analysisComponent separationSamples introduction/extractionIonizationMass spectrometric

A mass spectrometer has an atmospheric pressure chemical ionization source that includes a first ionization portion including a needle electrode, for generating a primary ion by discharge of the needle electrode a primary ion introduction aperture, and a second ionization portion including an introduction aperture, for generating a sample ion by the reaction between the primary ion and the sample gas introduced from an end of a column of gas chromatography, a sample ion movement aperture; and a mass analysis portion; wherein the end is arranged at a position satisfying the relation r≦2R where R is a radius of an inner diameter of the aperture and r is a distance between an axis connecting the center of the aperture and the center of the aperture, and the end.

Owner:HITACHI LTD

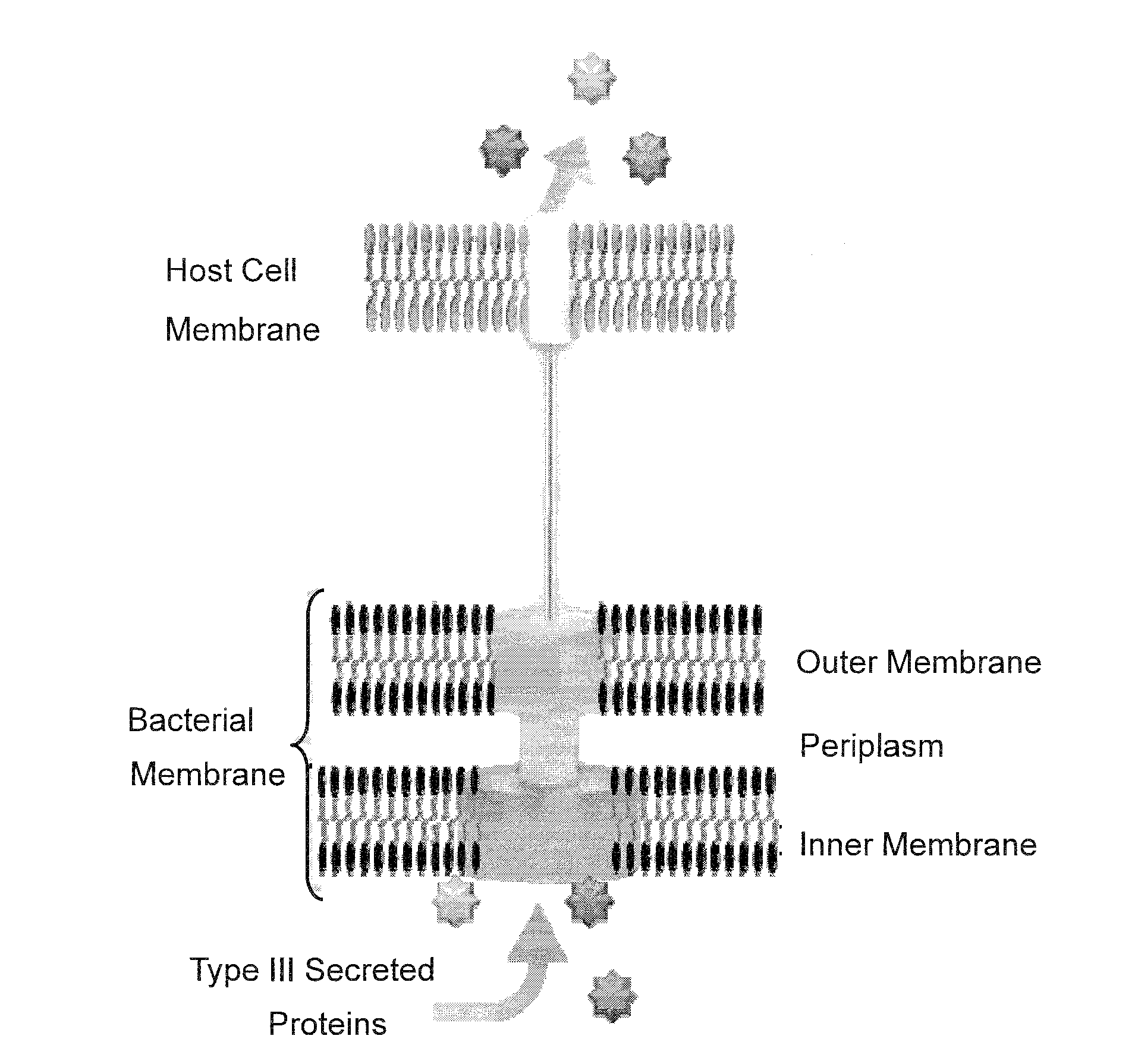

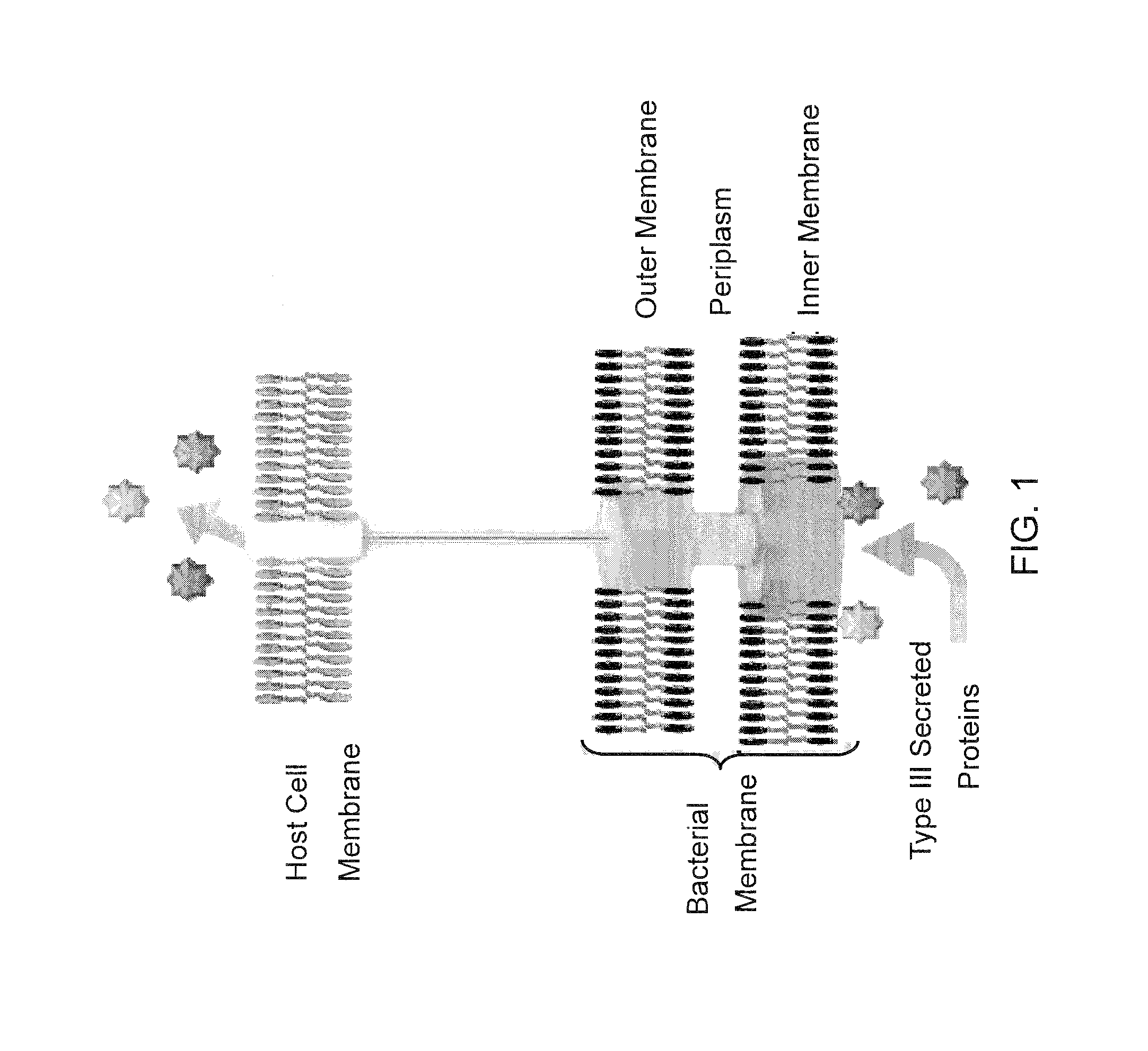

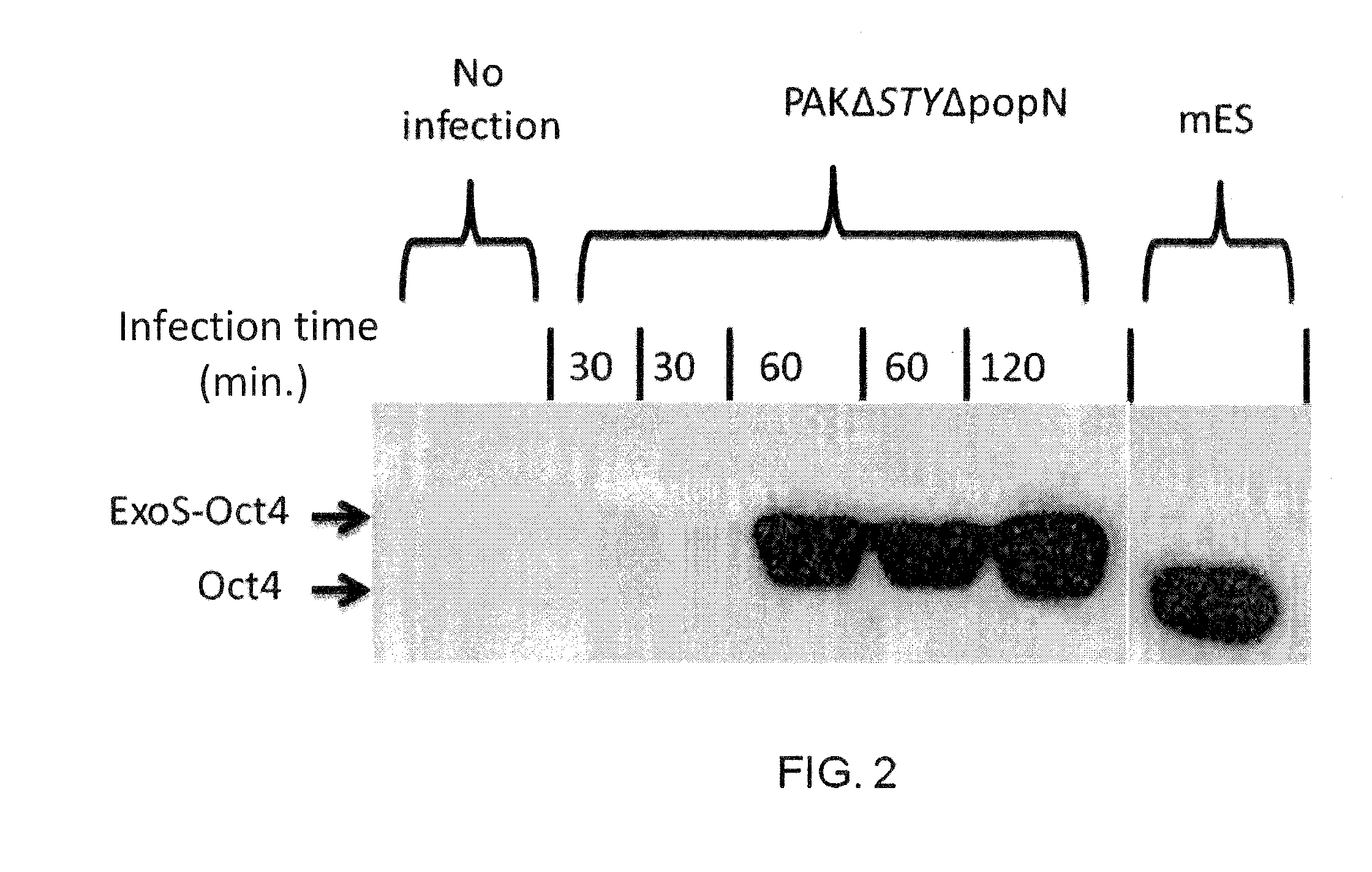

Bacterial Mediated Delivery of Nuclear Protein Into Pluripotent and Differentiated Cells

ActiveUS20120021517A1Reduce host cell toxicityEfficient systemSugar derivativesBacteriaDirected differentiationType three secretion system

A modified P. aeruginosa type III secretion system has been developed that efficiently delivers selected proteins into a host cell. In one example, a functional nuclear Cre Recombinase is injected into embryonic stem (ES) cells and can be used to induce pluripotent stem (iPS) cells. This method of in vitro lineage directed differentiation prevents insertional mutagenesis and provides a route to selected stem cell renewal and cell-based therapies.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

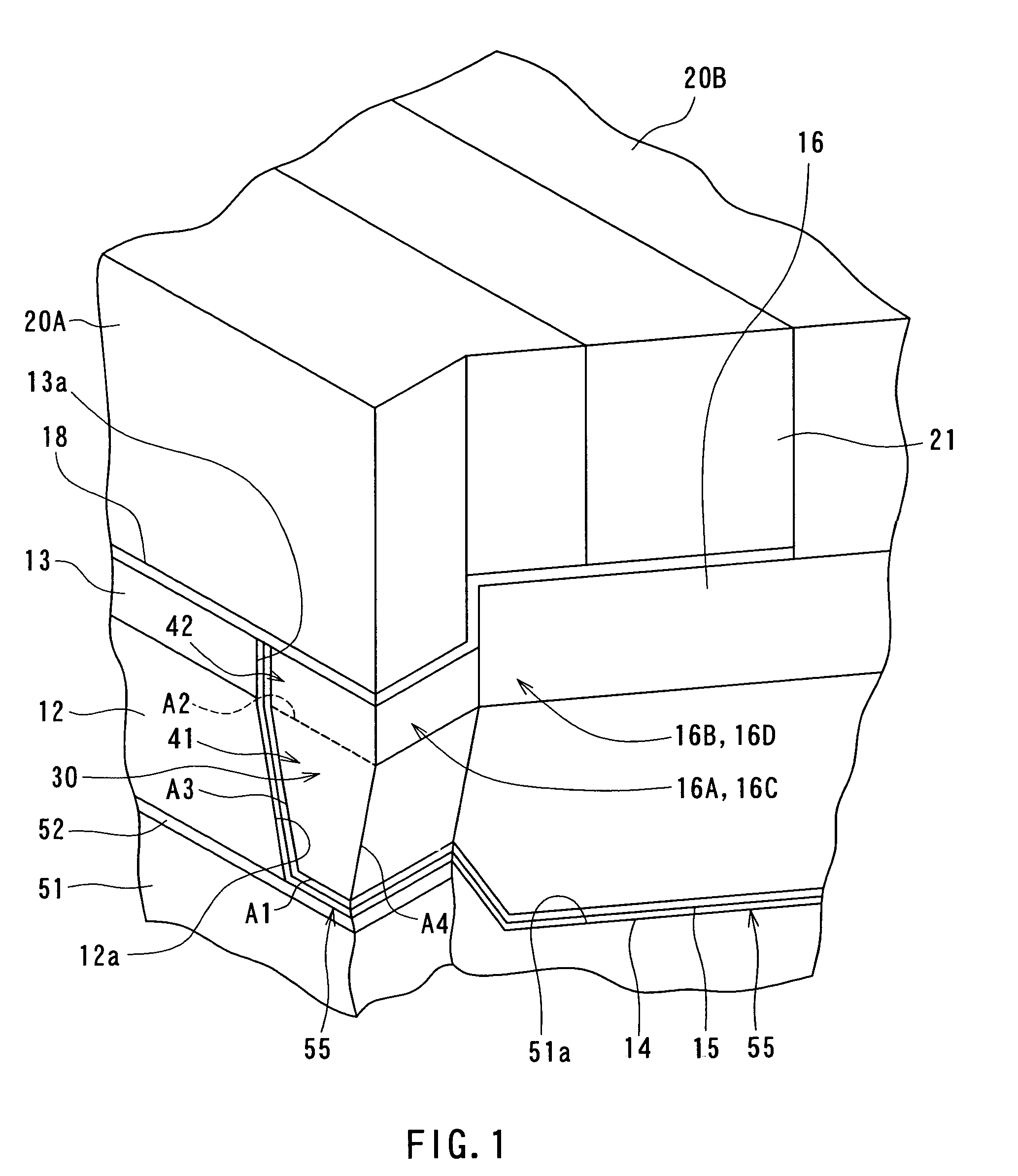

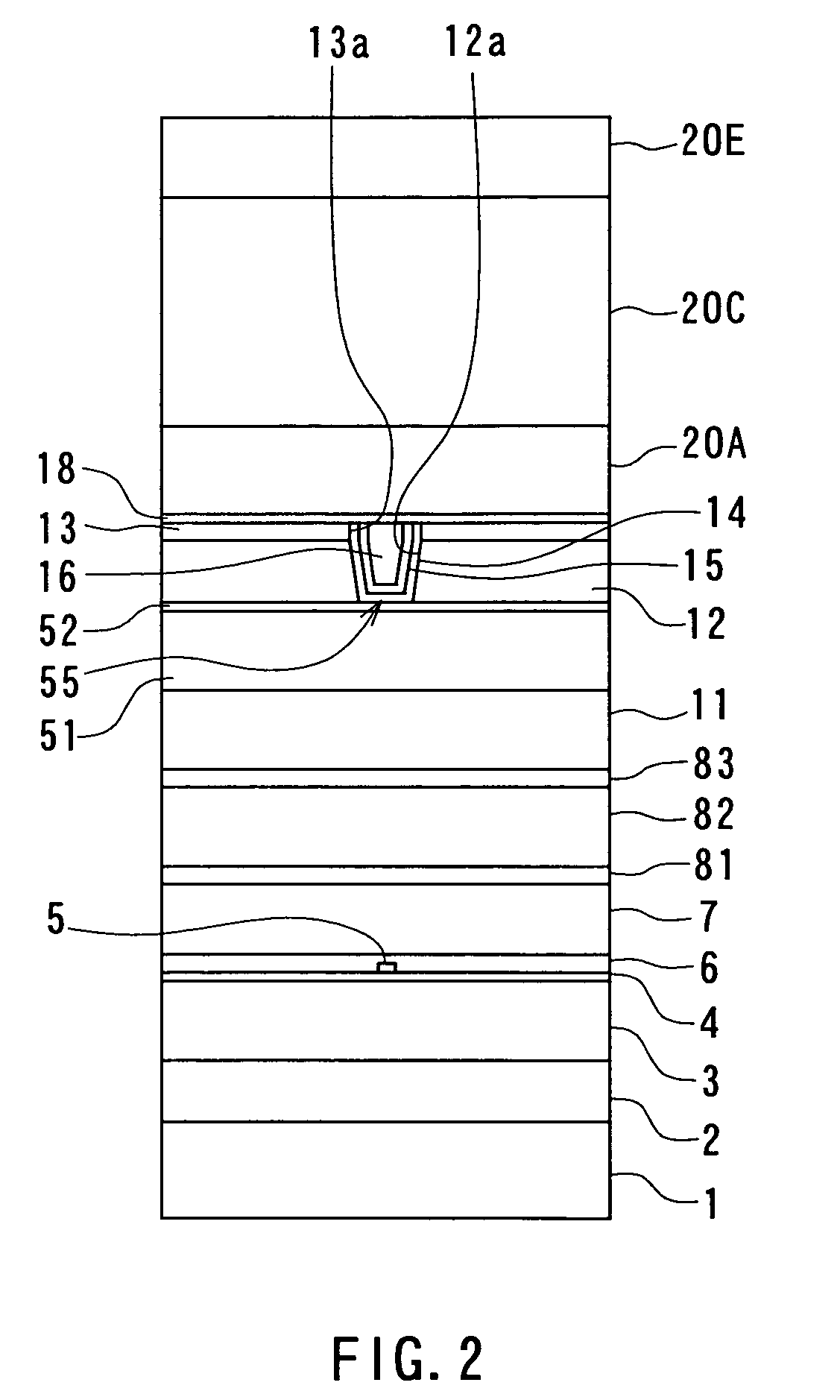

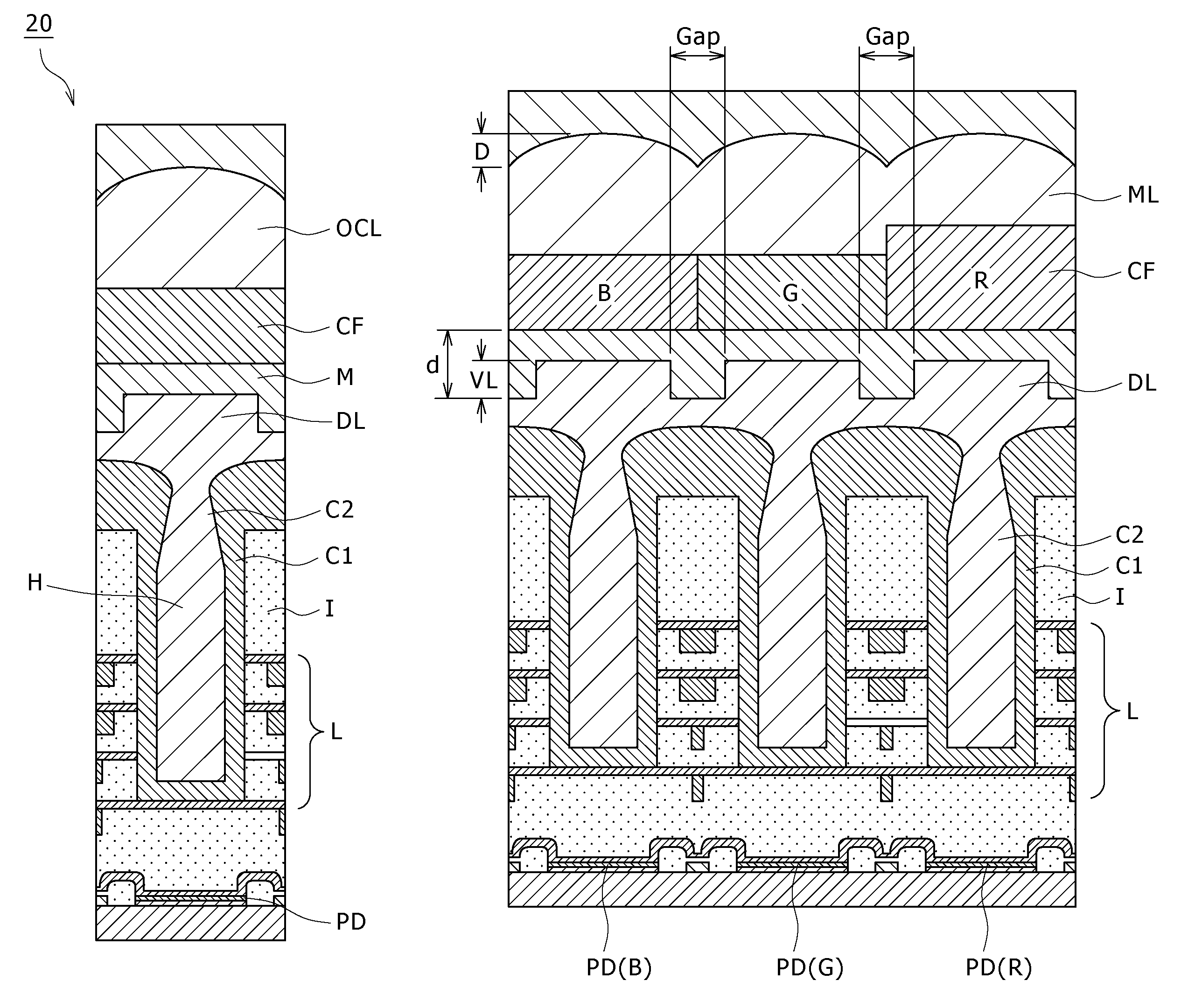

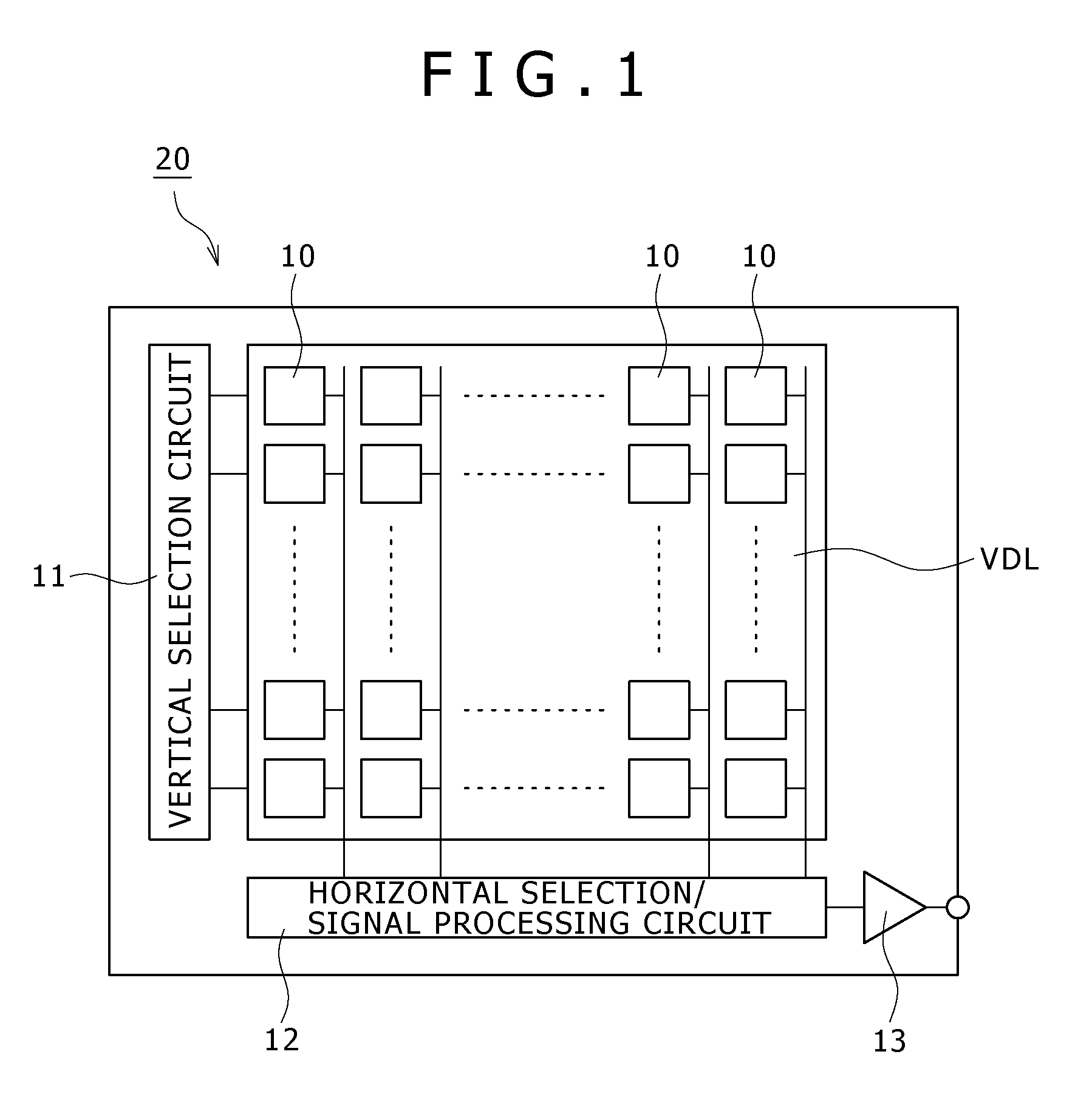

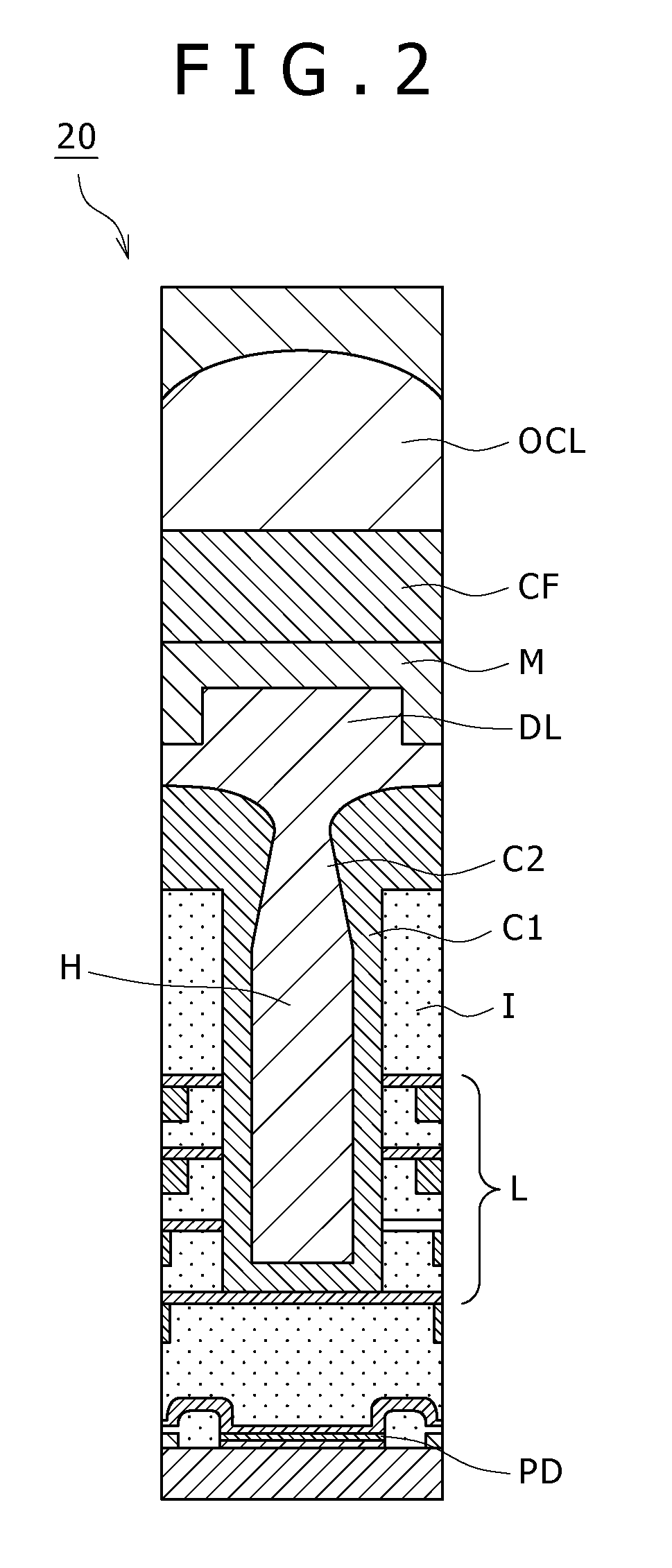

Solid-state image pickup device, method of manufacturing the same and electronic apparatus

ActiveUS8222705B2Small sizeEfficient introductionTransistorTelevision system detailsEngineeringPartial filling

Disclosed herein is a solid-state image pickup device including: a trench formed in an insulating film above a light-receiving portion; a first waveguide core portion provided on an inner wall side of the trench; a second waveguide core portion filled in the trench via the first waveguide core portion; and a rectangular lens formed of the same material as that of the second waveguide core portion and provided integrally with the second waveguide core portion.

Owner:SONY SEMICON SOLUTIONS CORP

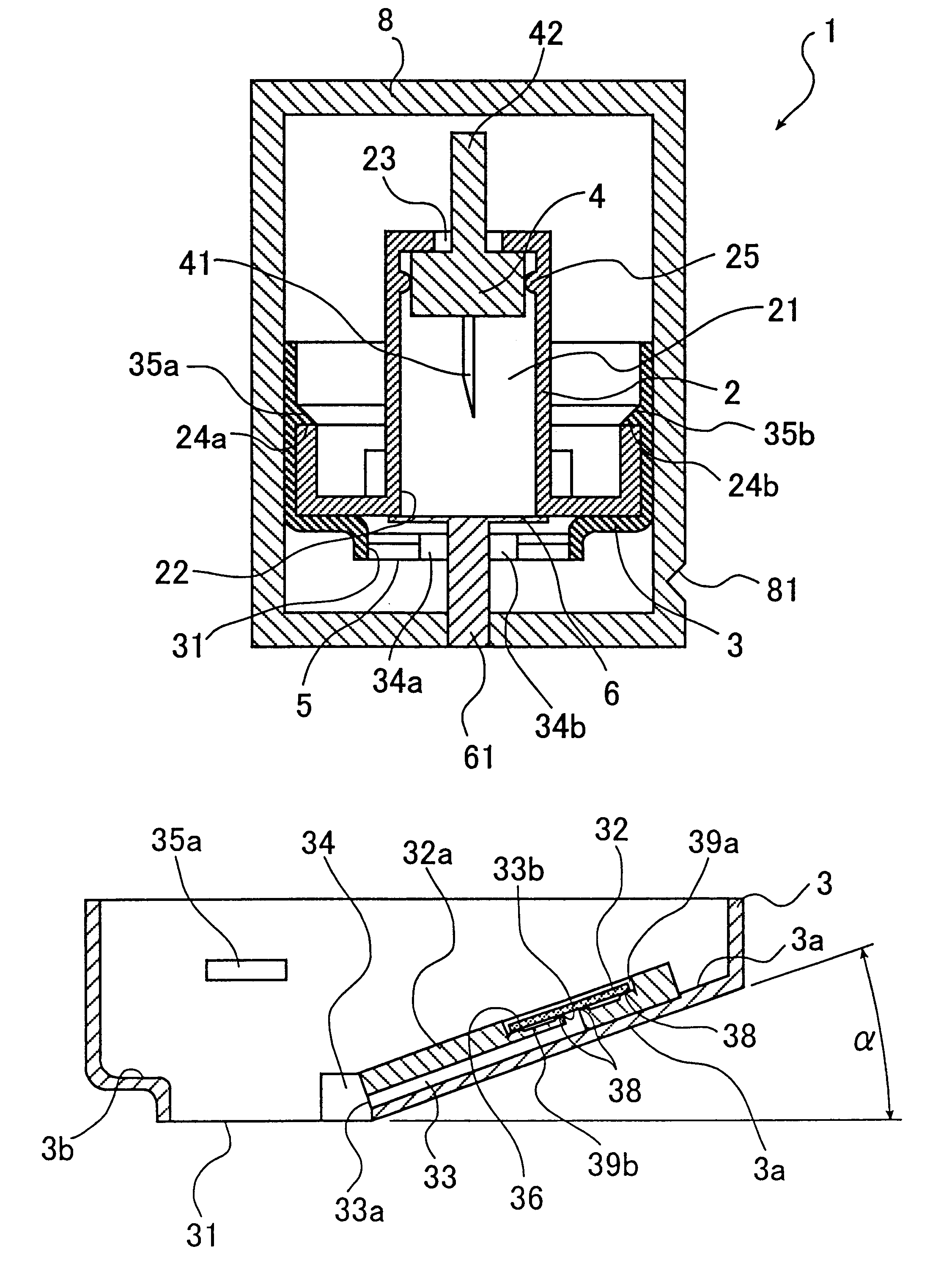

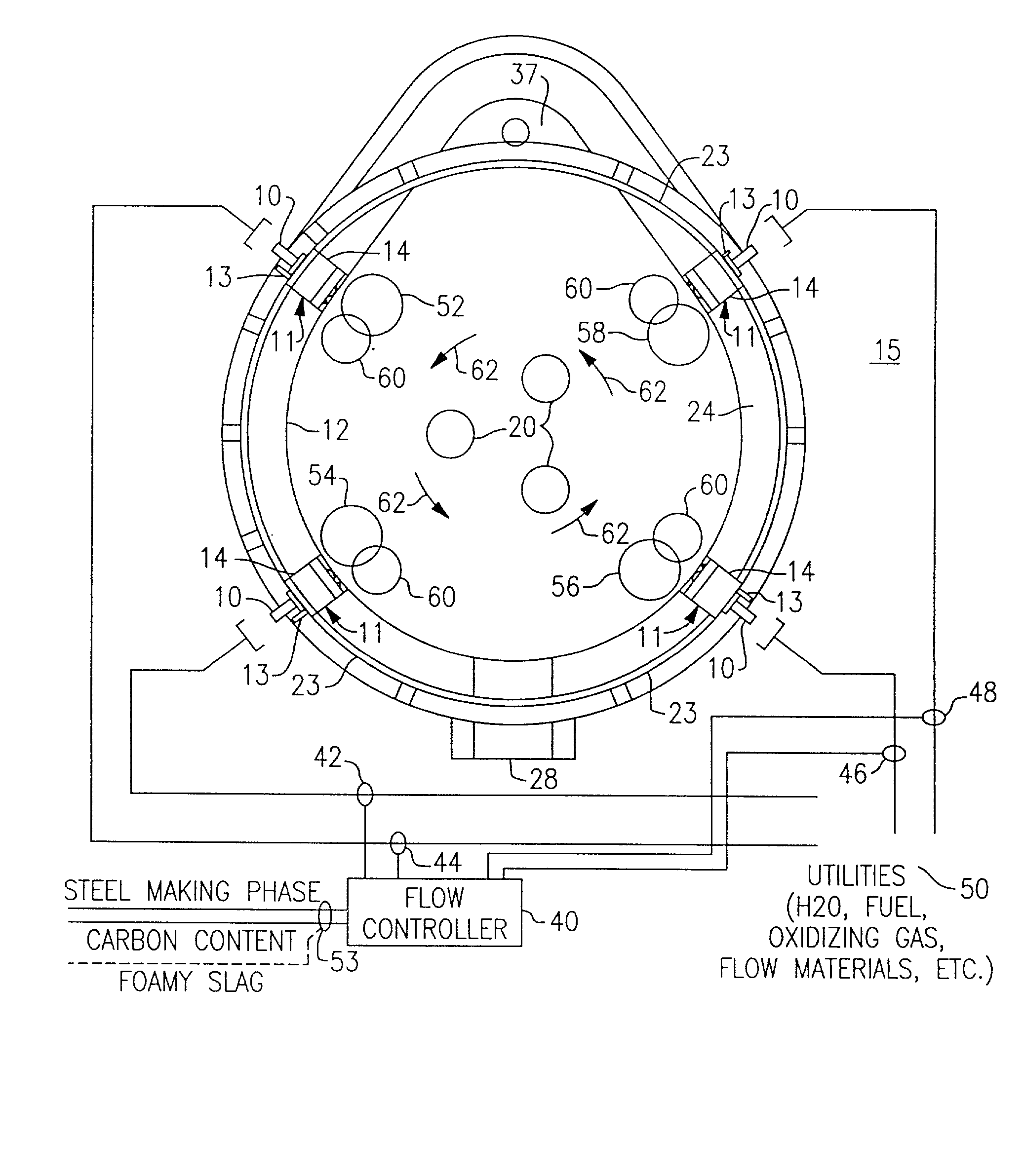

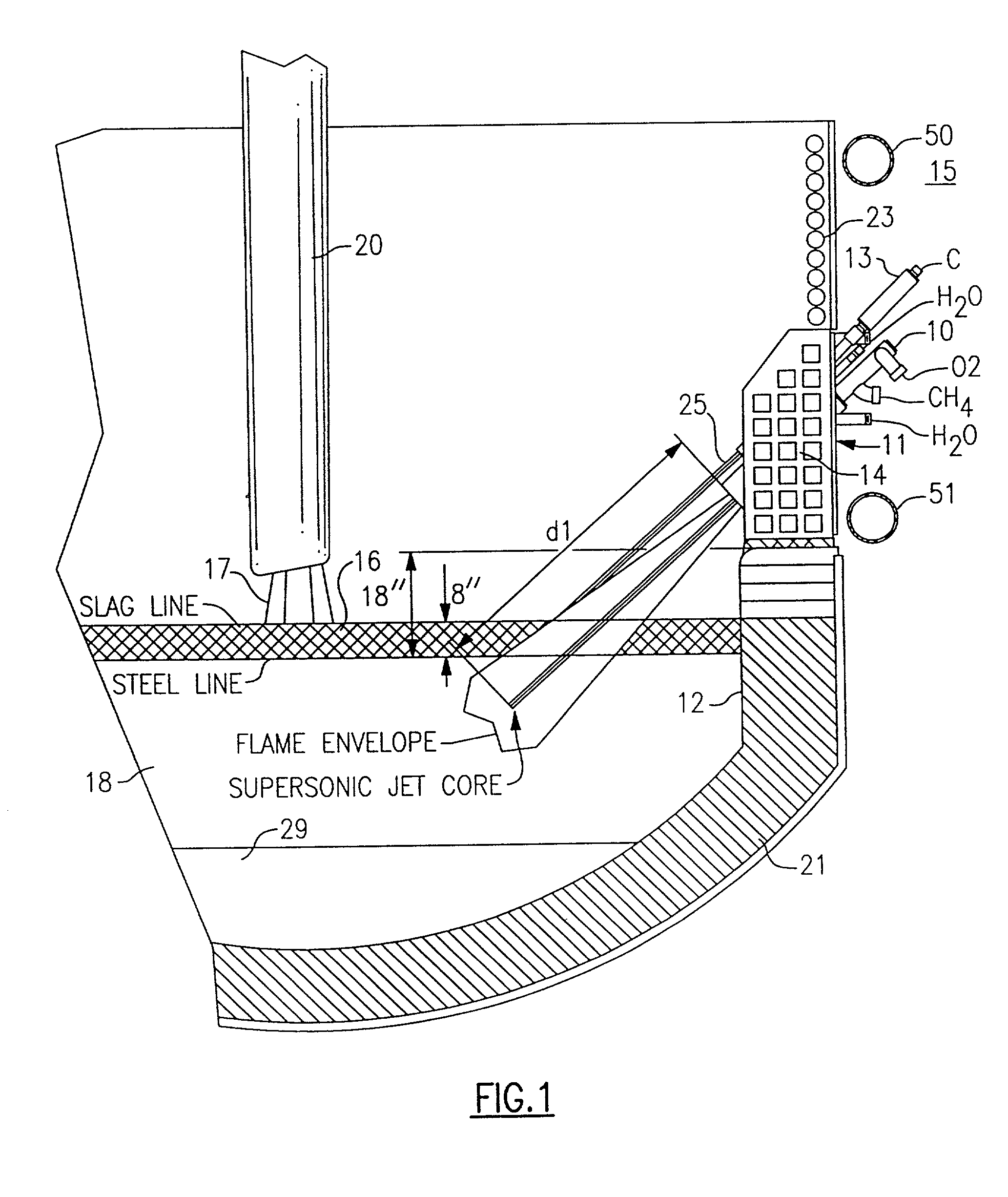

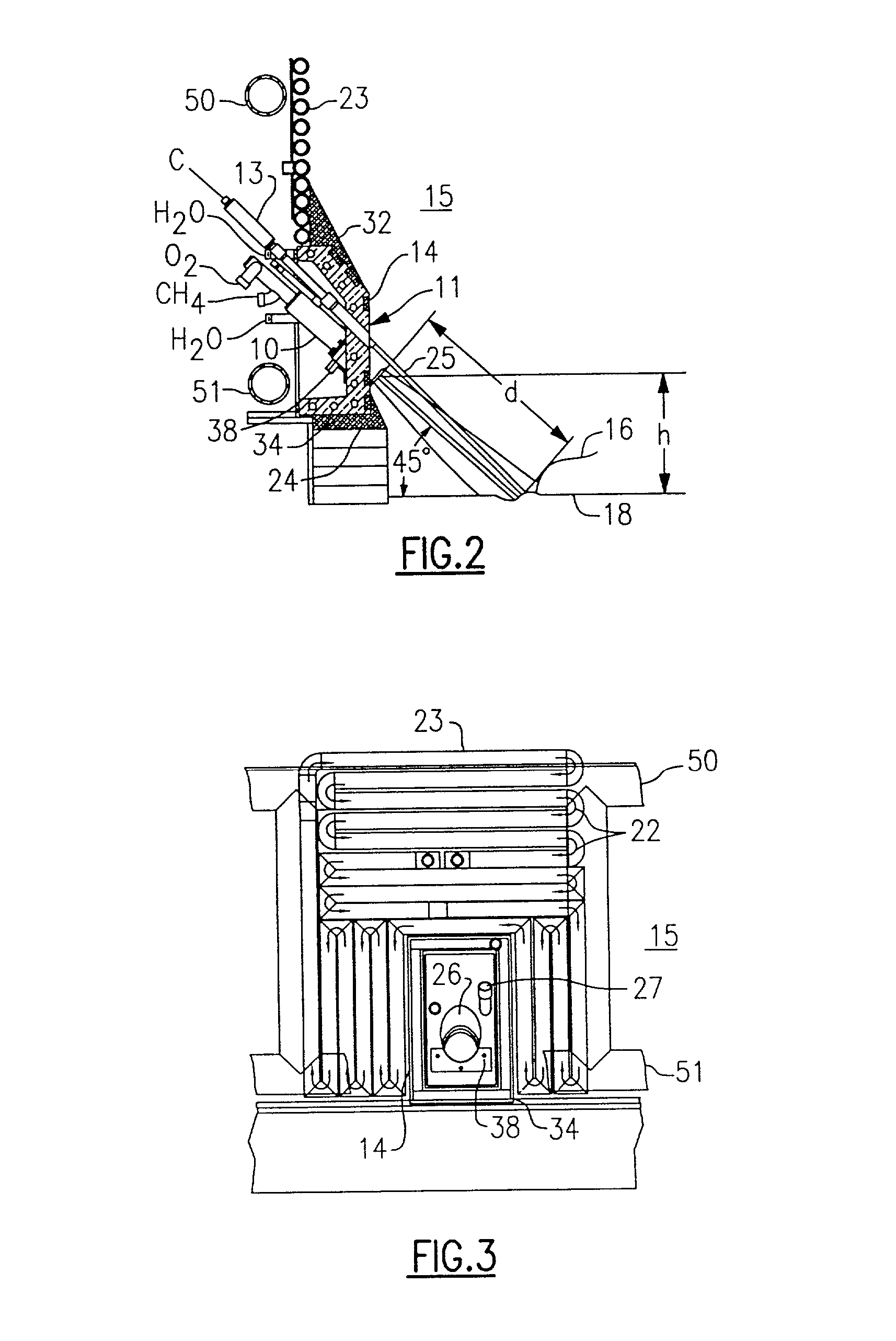

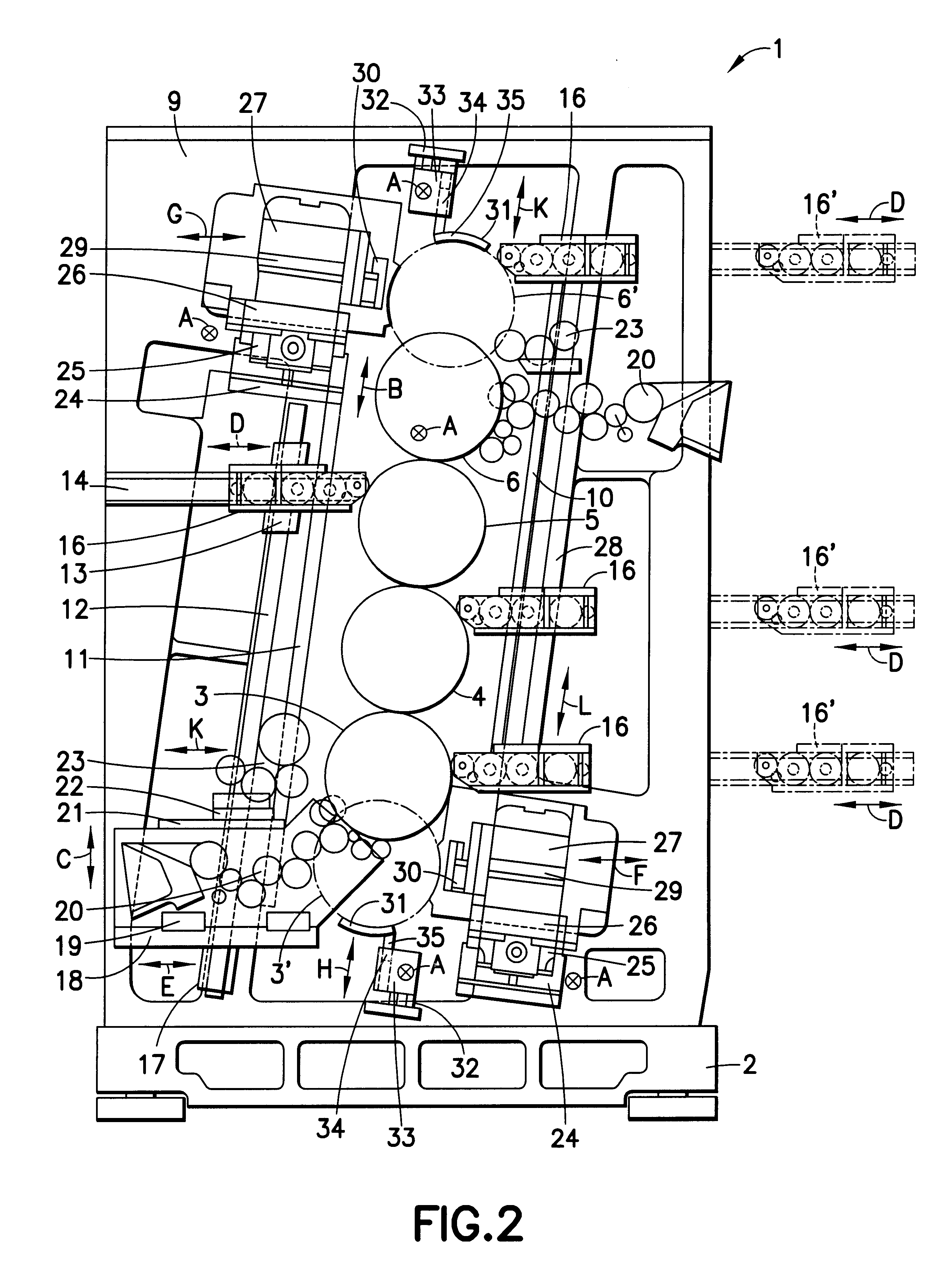

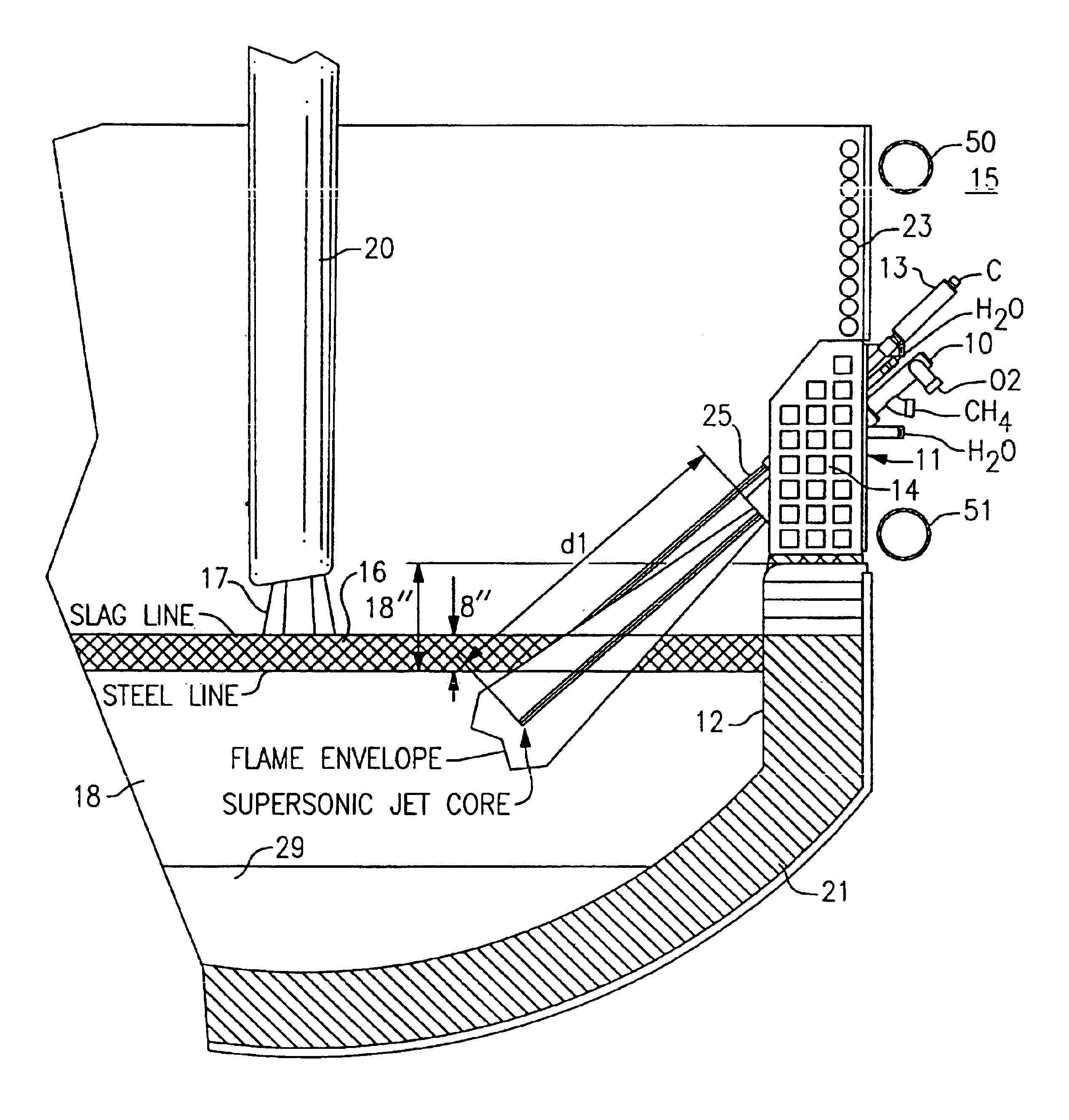

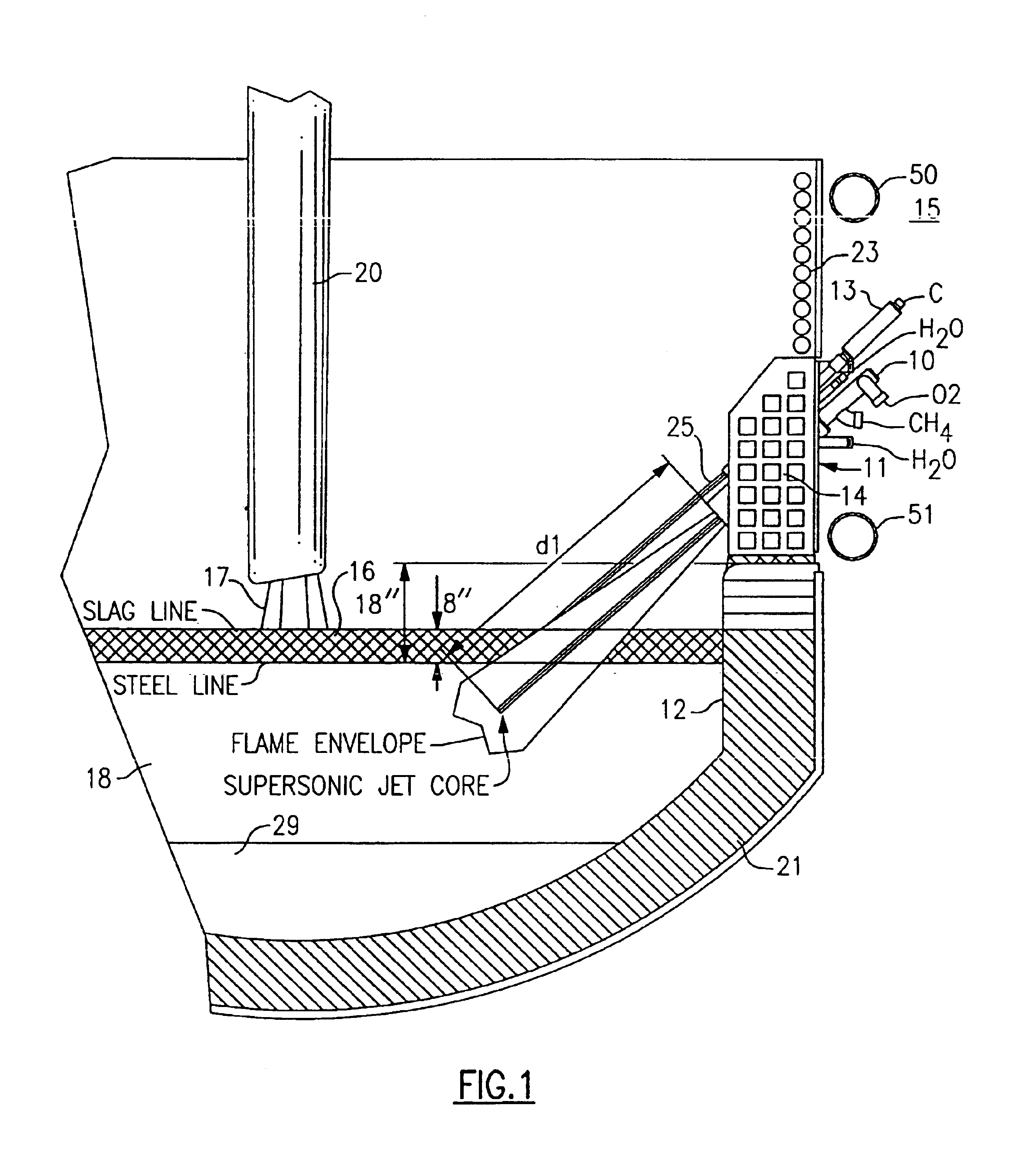

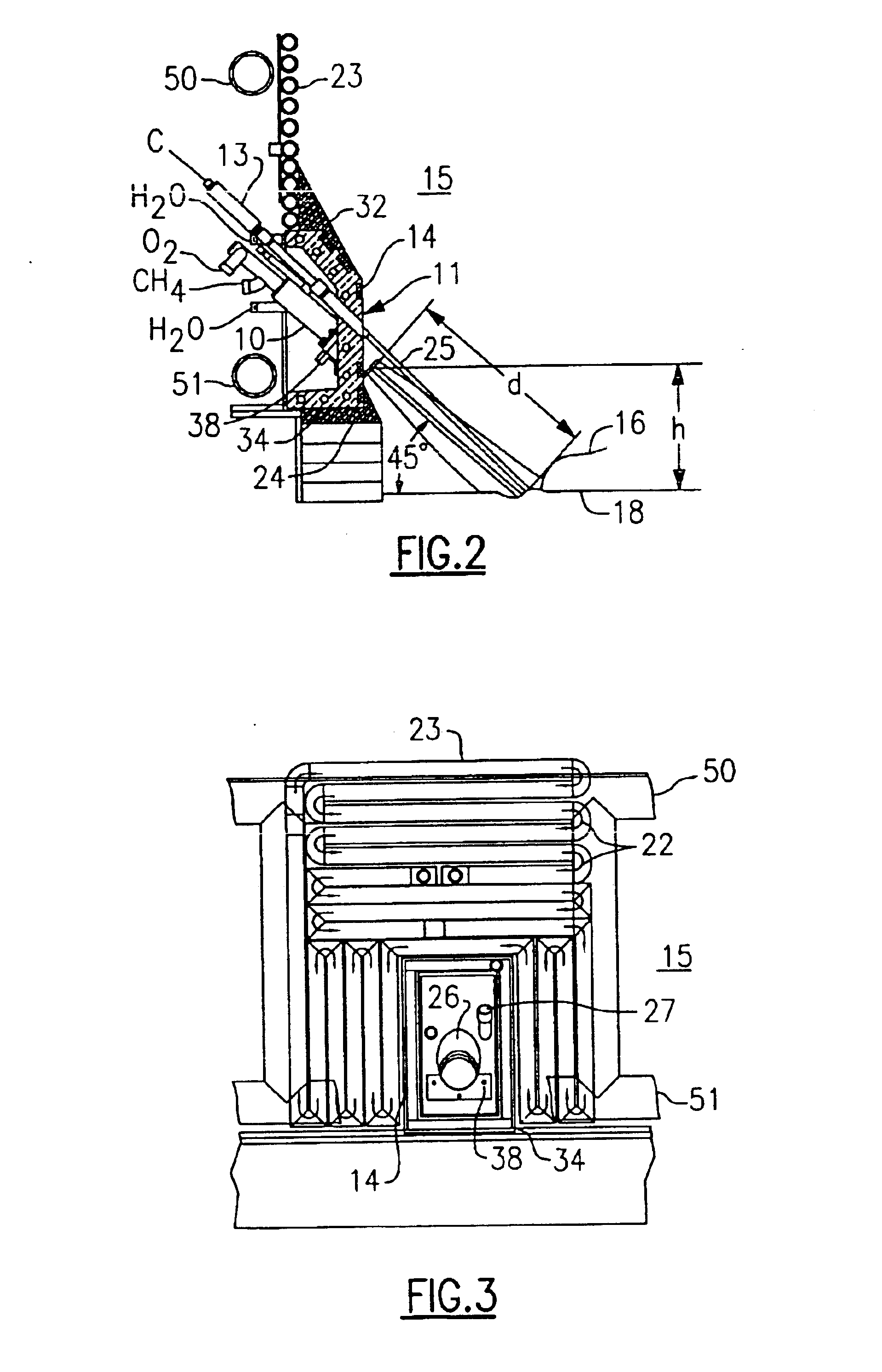

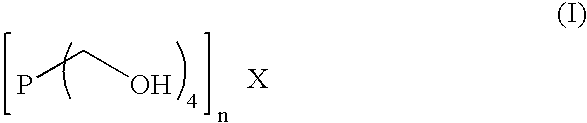

Method for particulate introduction for metal furnaces

InactiveUS20030000338A1Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

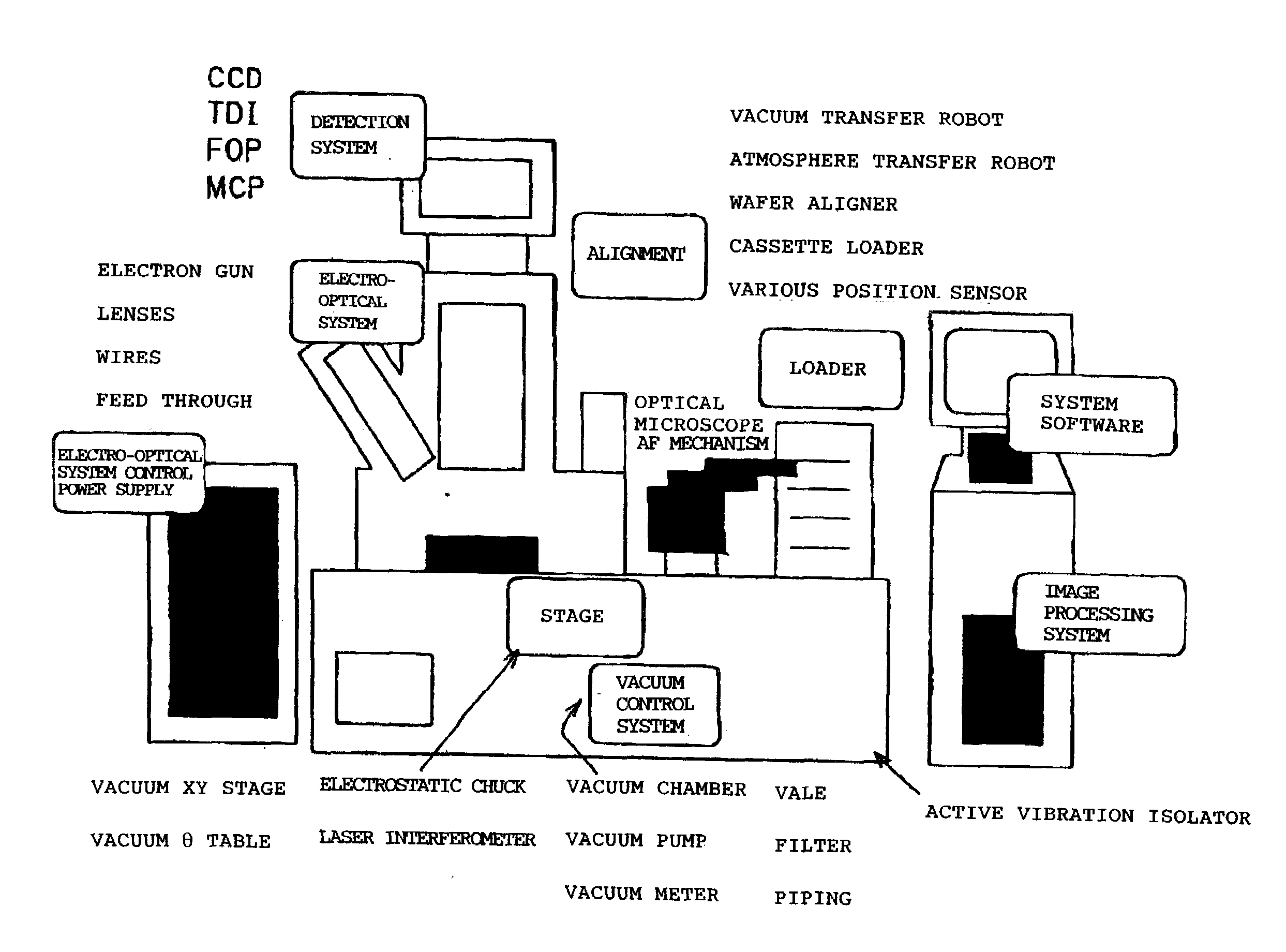

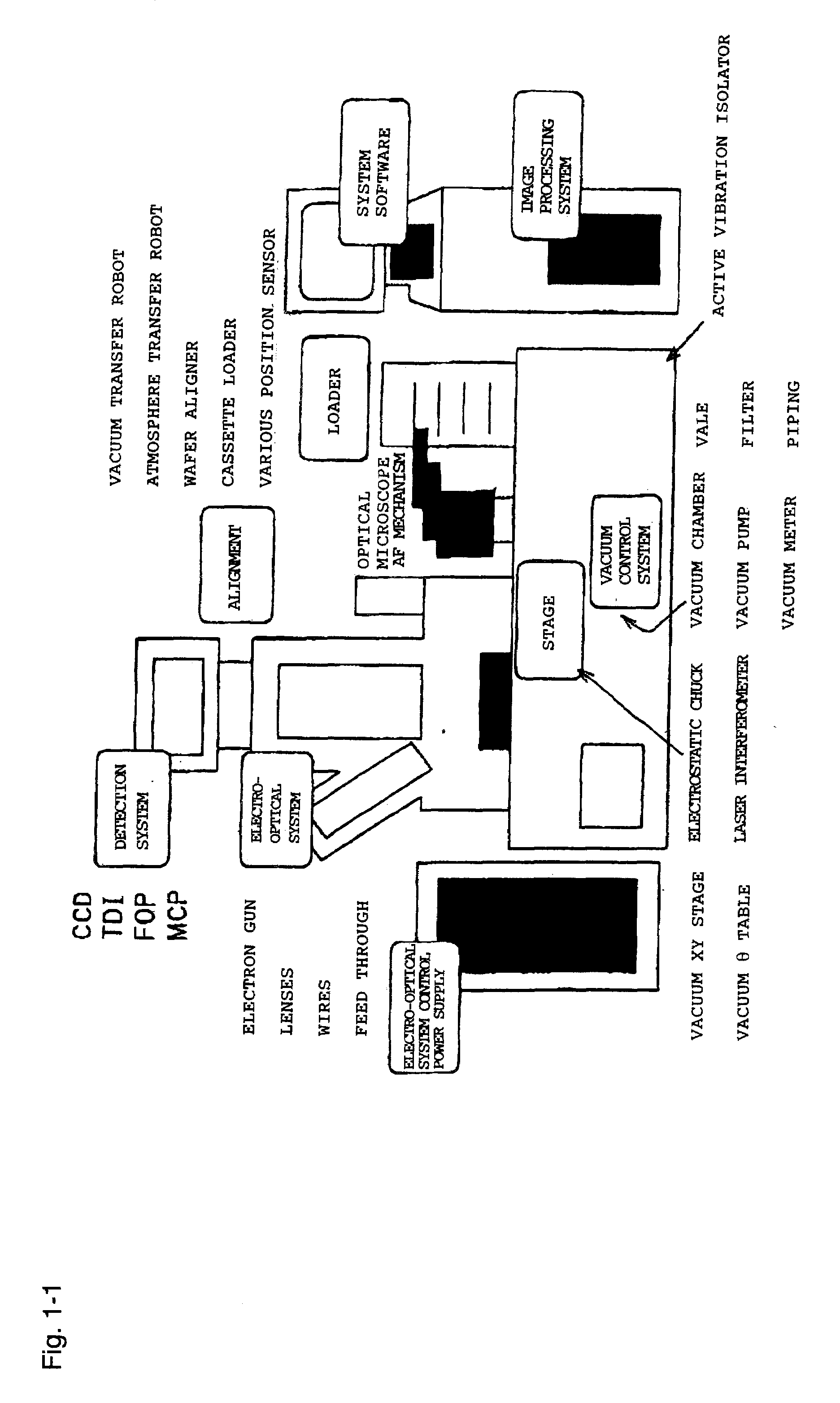

Detector and inspecting apparatus

ActiveUS20090224151A1Efficiently introduceEfficiently emitMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementTime lossElectric signal

An inspecting apparatus for reducing a time loss associated with a work for changing a detector is characterized by comprising a plurality of detectors 11, 12 for receiving an electron beam emitted from a sample W to capture image data representative of the sample W, and a switching mechanism M for causing the electron beam to be incident on one of the plurality of detectors 11, 12, where the plurality of detectors 11, 12 are disposed in the same chamber MC. The plurality of detectors 11, 12 can be an arbitrary combination of a detector comprising an electron sensor for converting an electron beam into an electric signal with a detector comprising an optical sensor for converting an electron beam into light and converting the light into an electric signal. The switching mechanism M may be a mechanical moving mechanism or an electron beam deflector.

Owner:EBARA CORP

Optical displacement sensor

InactiveUS7491957B2Efficient introductionRadiation pyrometryInvestigating moving sheetsMiniaturizationOptical fiber cable

An optical displacement sensor structure includes a plurality of light receiving elements and a plurality of optical fibers together with one light source, wherein light emitted from the one light source is efficiently introduced into the plurality of optical fibers from the circumferences of the optical fibers, well kept inside the optical fibers while transmitting therethrough, and exits out from the end face of one end portion of each optical fiber so as to impinge on each light receiving element. This structure, with only one light source, provides a plurality of optical displacement sensors thus reducing power consumption without suffering a problem of light loss and successfully enables downsizing.

Owner:MINEBEA CO LTD

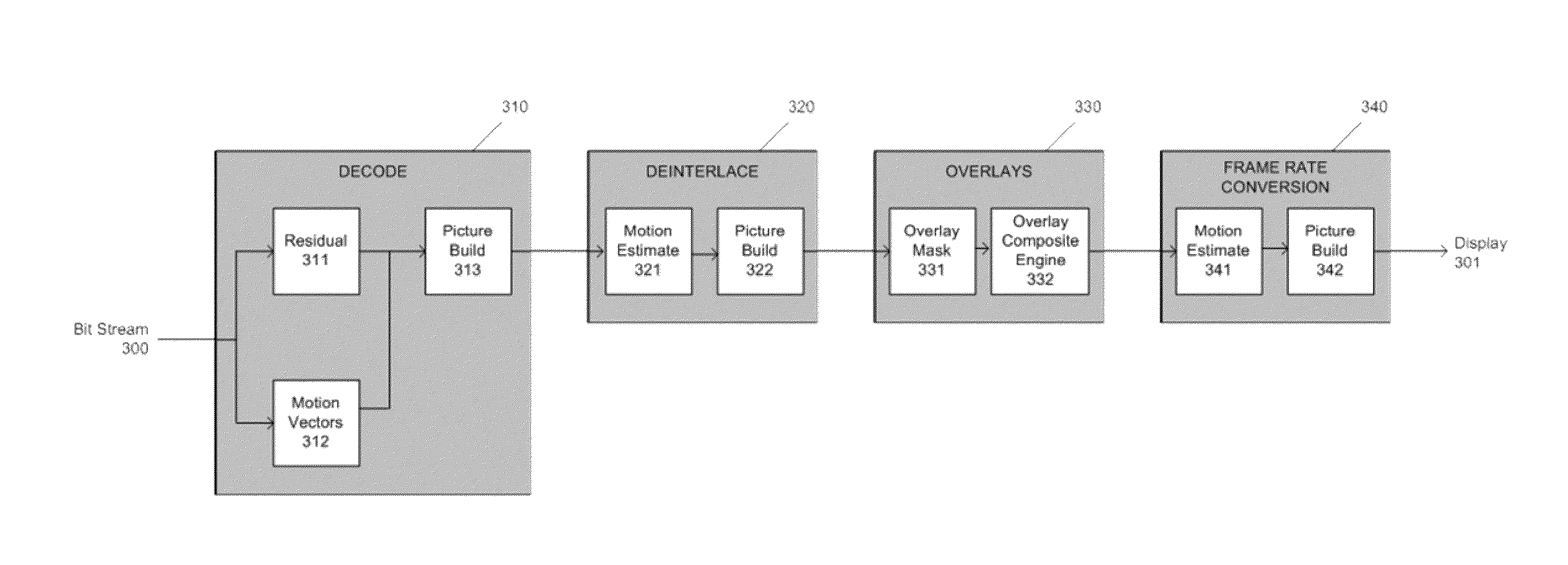

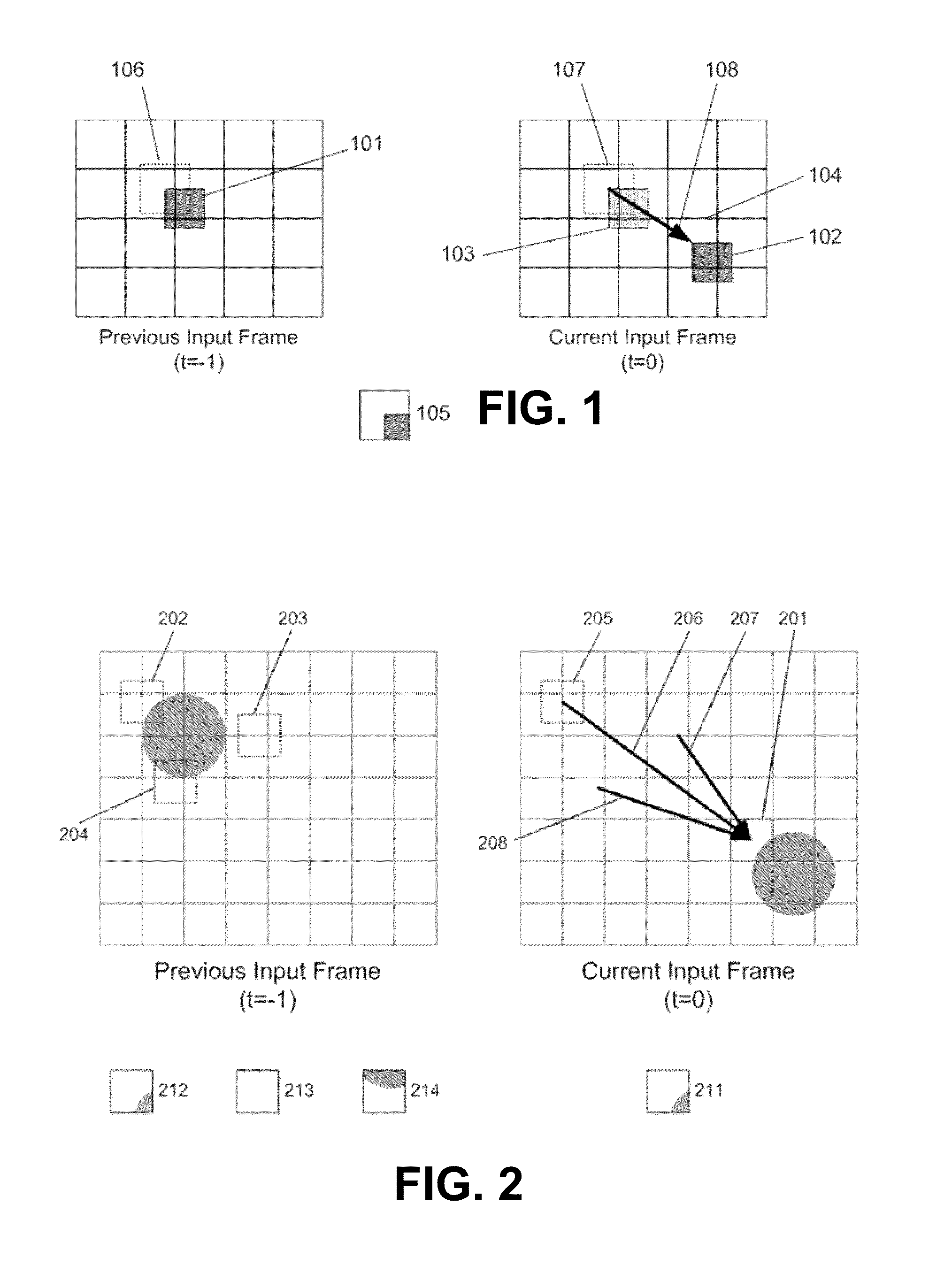

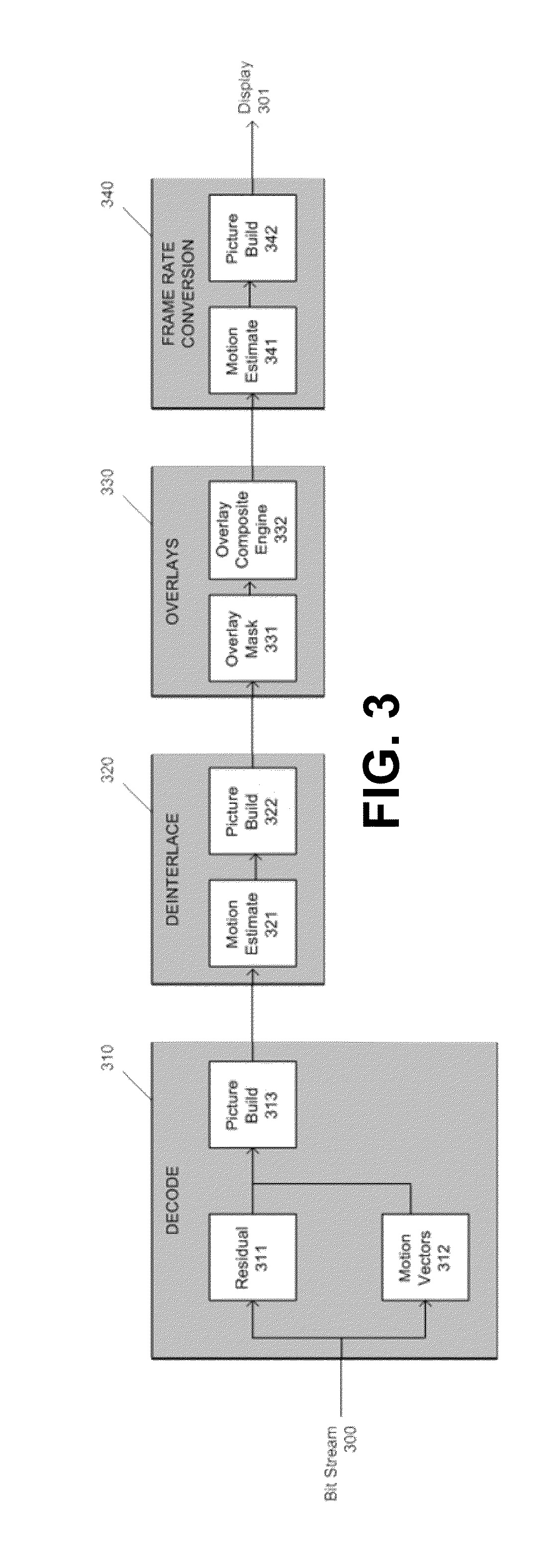

External vectors in a motion estimation system

ActiveUS20130101041A1Quality improvementImprove efficiencyColor television with pulse code modulationColor television with bandwidth reductionA-weightingMotion vector

A method and apparatus for motion estimation in a sequence of video images is provided. Each field or frame in a sequence of video images is sub-divided into a plurality of blocks. Each block in each video field or frame has assigned to it a set of candidate motion vectors. The vector which produces a best match to a block in a previous field or frame, from the set of candidate motion vectors, is assigned to that block thus forming the motion vector field for the current video field or frame using the selected vector. The set of candidate motion vectors assigned to a block include one or more candidate vectors derived from an external source vector field and each such vector from an external source vector field is assigned a weighting that biases towards or away from the selection of that vector.

Owner:IMAGINATION TECH LTD

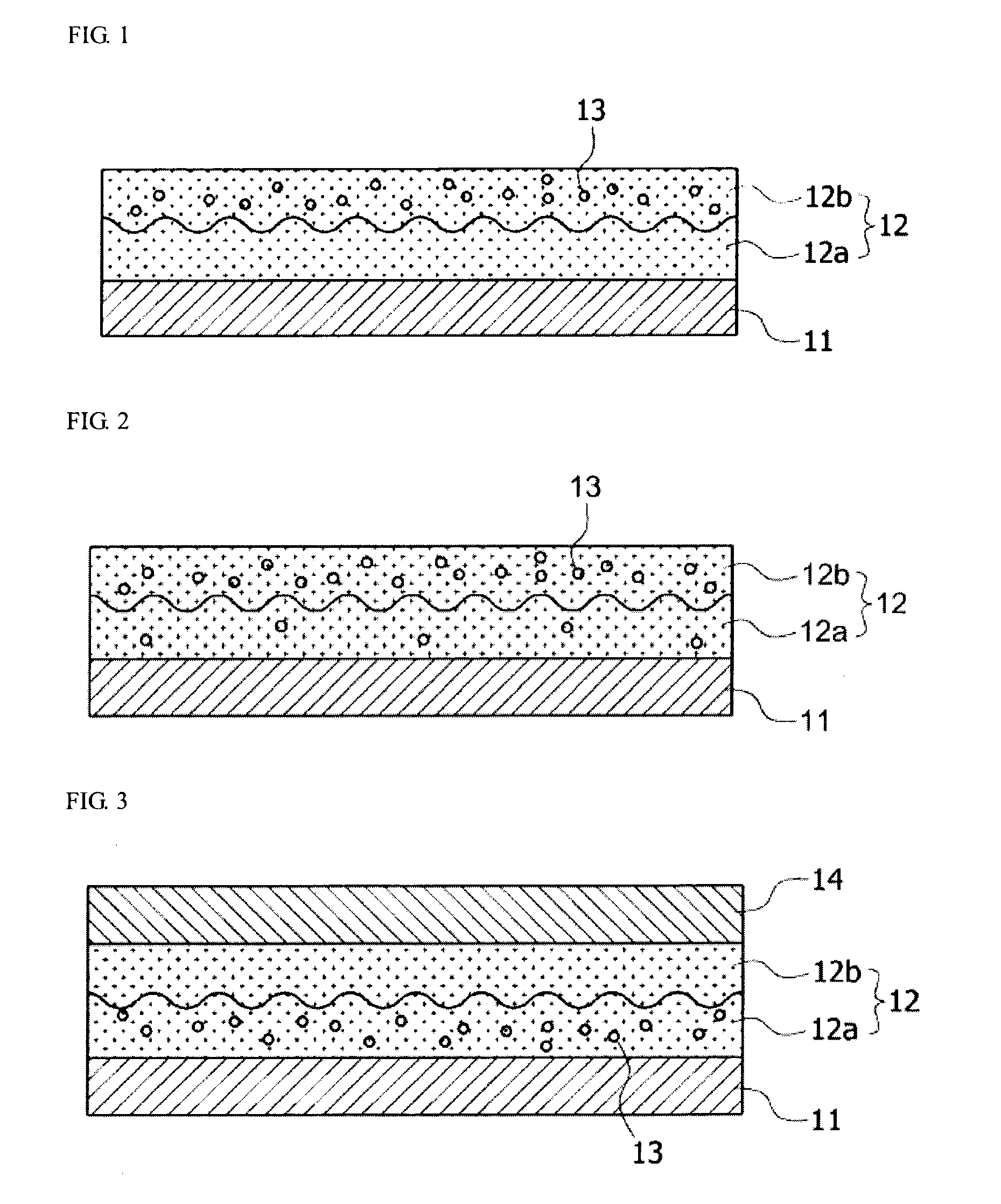

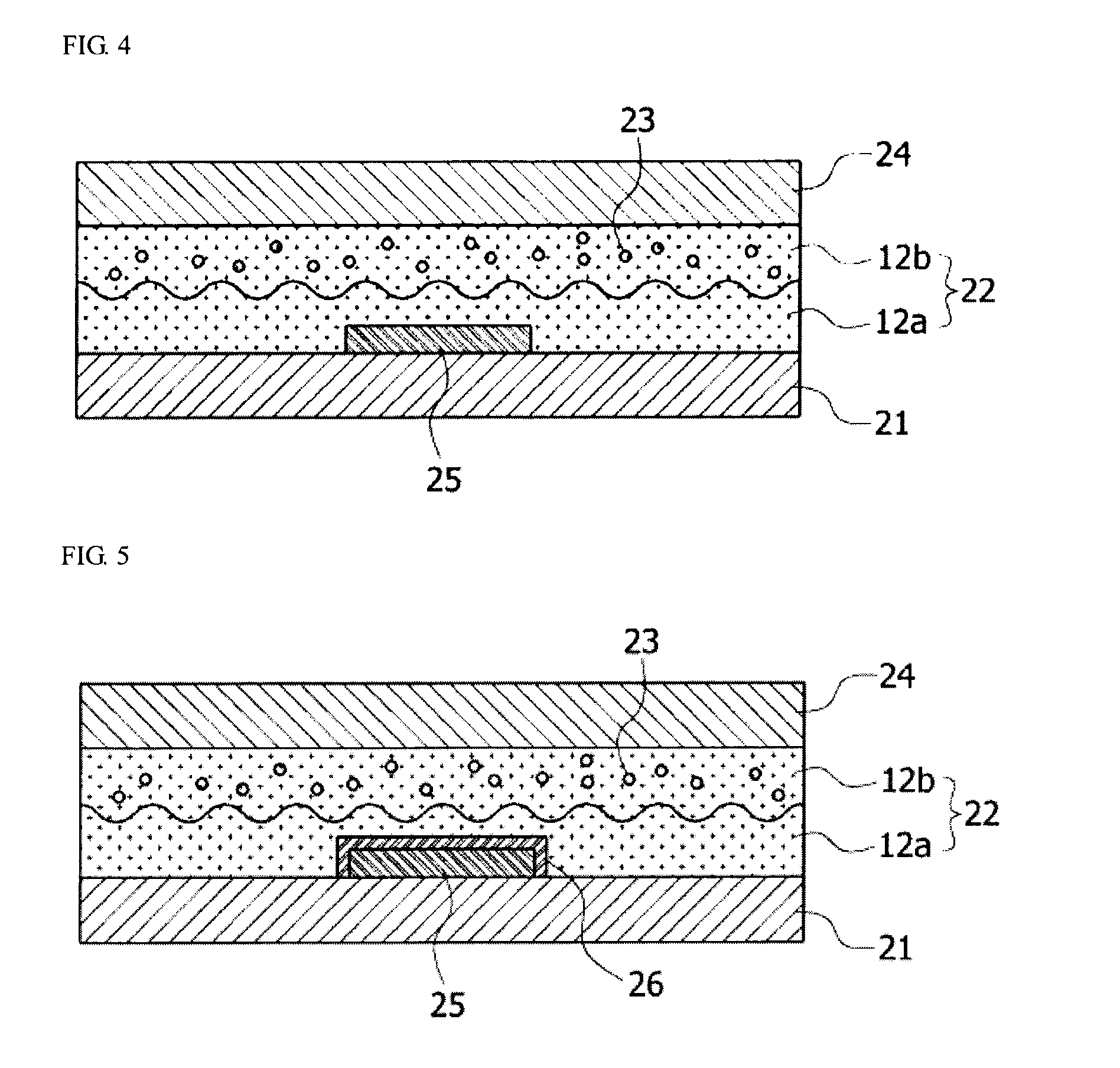

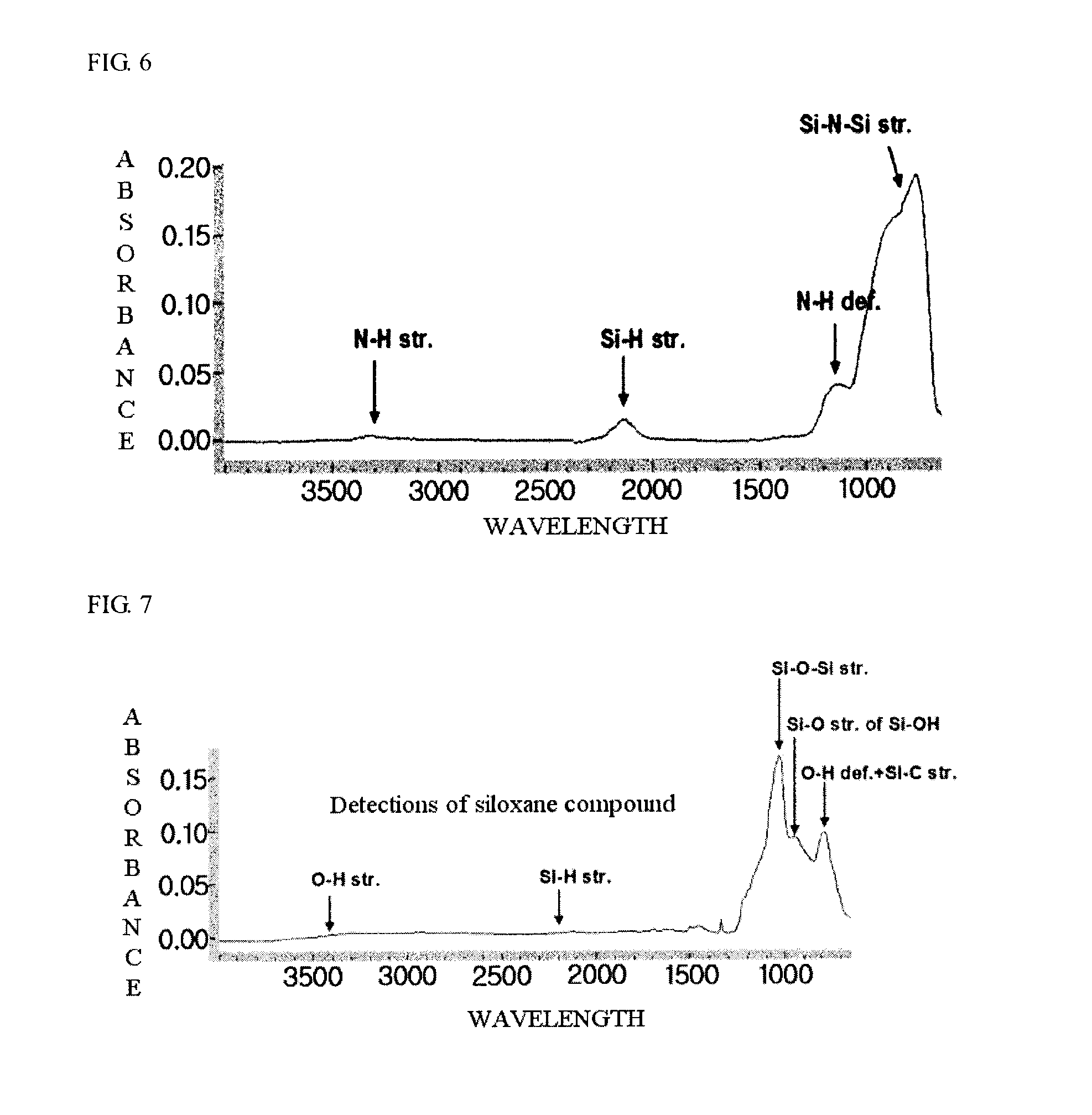

Adhesive film and method of encapsulating organic electrode device using the same

ActiveUS20130240862A1Prevent moisture penetrationEffectively introduce a moisture-reactive absorbentNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsChemistryHot-melt adhesive

An adhesive film, and a product and method of encapsulating an organic electronic device (OED) using the same are provided. The adhesive film serves to encapsulate the OED and includes a curable hot-melt adhesive layer including a curable resin and a moisture absorbent, and the curable hot-melt adhesive layer includes a first region coming in contact with the OED upon encapsulation of the OED and a second region not coming in contact with the OED. Also, the moisture absorbent is present at contents of 0 to 20% and 80 to 100% in the first and second regions, respectively, based on the total weight of the moisture absorbent in the adhesive layer.

Owner:LG CHEM LTD

Printing unit for a rotary printing machine with cross slide

InactiveUS6502509B2Long constructionEfficient introductionCylinder pressesAddressographsPrinting pressMechanical engineering

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

Method for particulate introduction for metal furnaces

InactiveUS6805724B2Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

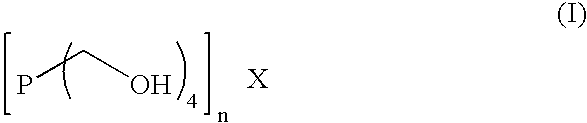

Method and composition to decrease iron sulfide deposits in pipe lines

InactiveUS20050263739A1Easily determineSlow rateBiocideDetergent mixture composition preparationSolventAqueous solution

The levels of iron sulfide present in a conduit, such as a pipeline, are reduced by contacting the conduit, on an inner surface, with a composition obtained from an aqueous solution containing at least one compound of Formula (I) and at least one amine or corresponding ammonium derivative in the presence of a solvent, wherein X is an anion of valency n. Preferably, the pH of the solution is about 8. Alternatively, the method employs a composition comprising tris(hydroxymethyl)phosphine (TRIS) and at least one amine or corresponding ammonium derivative. The amine preferably is ammonia or a primary alkylamine. The compositions readily complex and thereby dissolve deposits of iron(II) sulfide, removing them from the conduit.

Owner:GREENES ENERGY GROUP

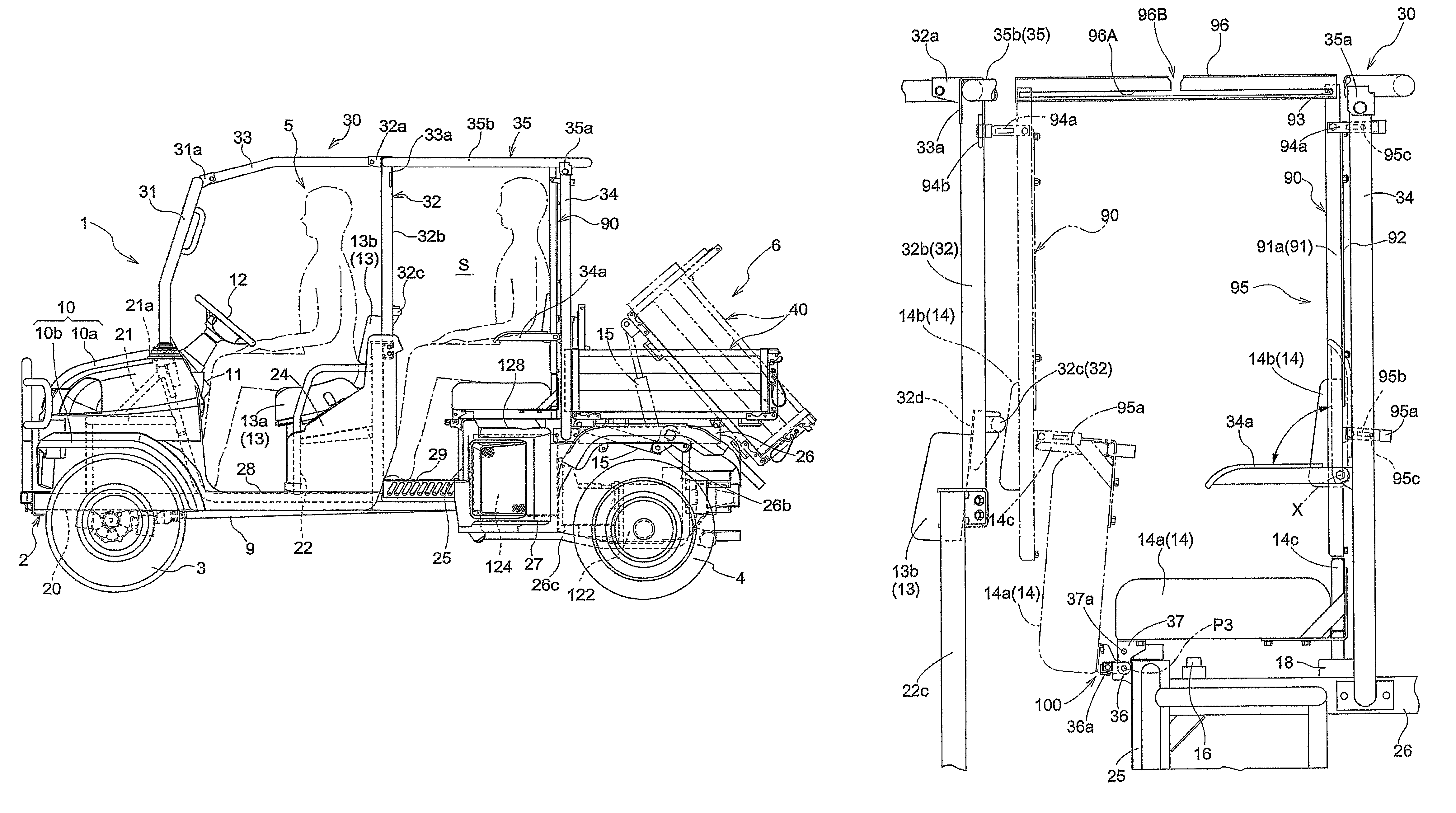

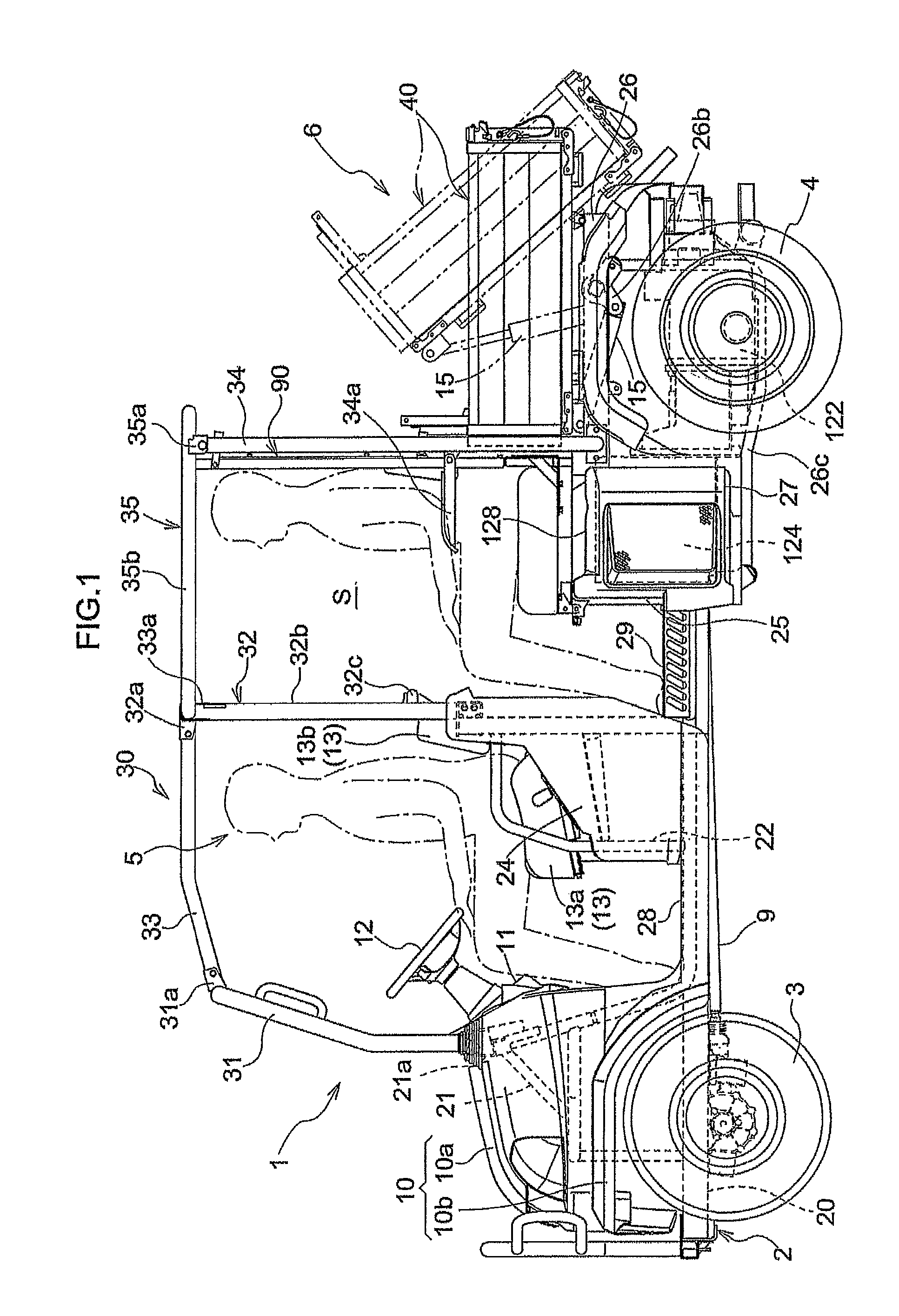

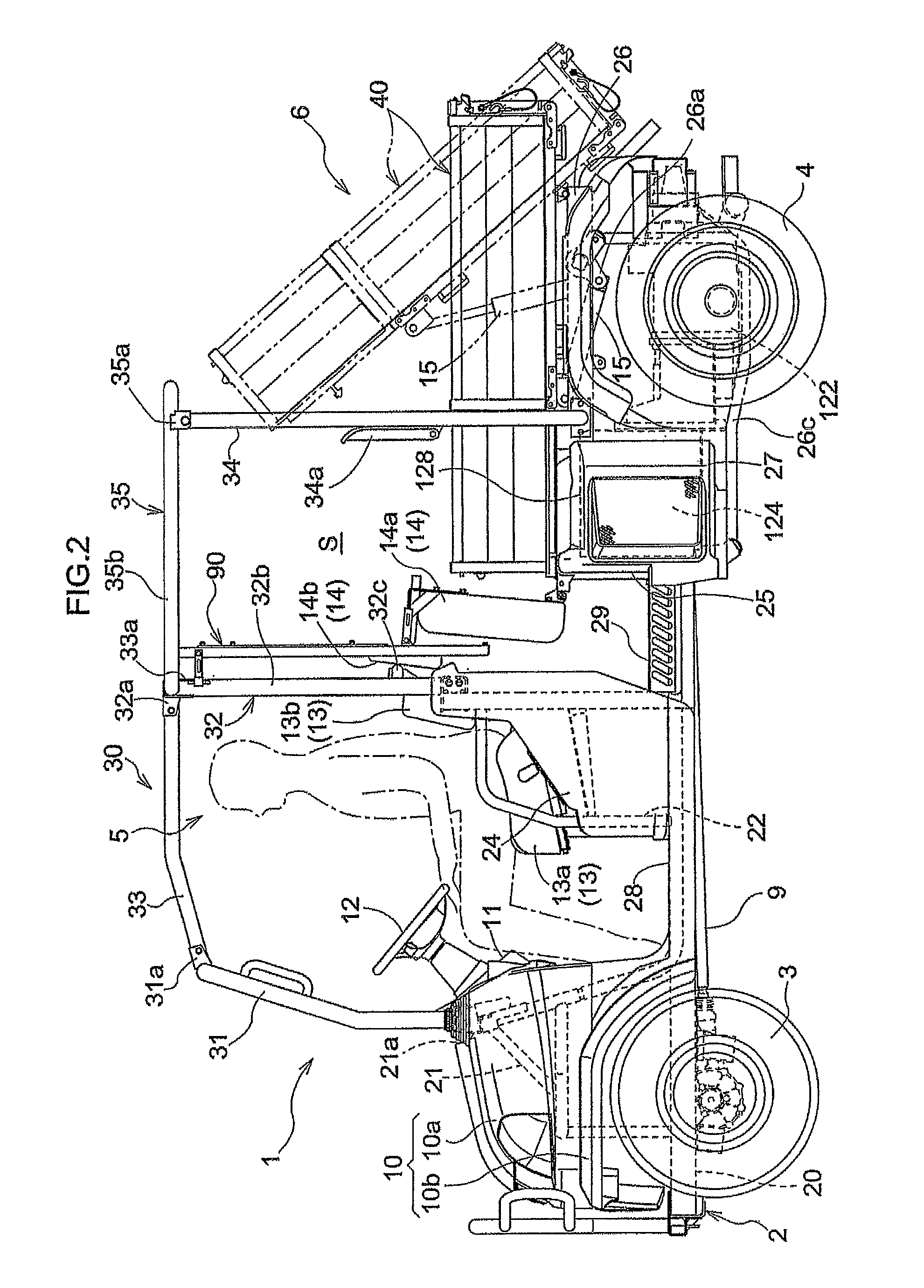

Work vehicle

ActiveUS8376441B2Easy to operateInspection troublesomePedestrian/occupant safety arrangementUnderstructuresRolloverDriver/operator

A pick-up style work vehicle includes a rollover protection structure (ROPS), a seat section including a forward driver's seat and a rear seat, and a rear seat posture changing mechanism for changing the rear seat in its position between a first posture where the rear seat is in a non-use condition and a second posture where the rear seat is in a use condition. A fore / aft length of the rear seat in the first posture is shorter than the fore / aft length of the rear seat in the second posture. The work vehicle also includes a partitioning member for partitioning the seat section from a space behind the seat section with the partitioning member being supported by the ROPS. The partitioning member is movable with being supported by the ROPS between a rearwardly displaced position immediately behind the rear seat and a forwardly displaced position moved forward from the rearwardly displaced position.

Owner:KUBOTA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com