Patents

Literature

166results about How to "Prevent moisture penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming insulation film

InactiveUS7582575B2Reduce trafficReduce volumeSolid-state devicesSemiconductor/solid-state device manufacturingPlasma reactionResidence time

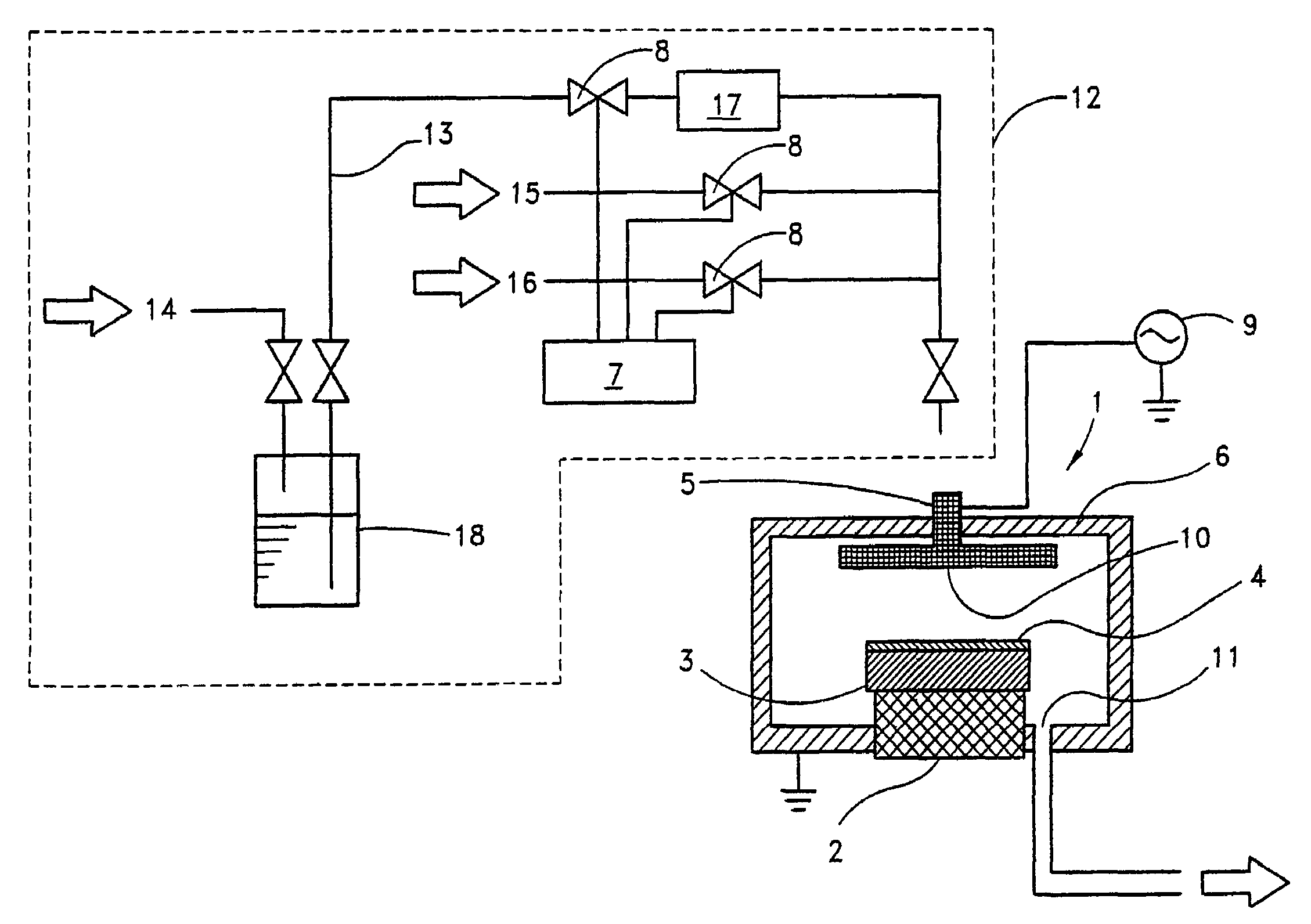

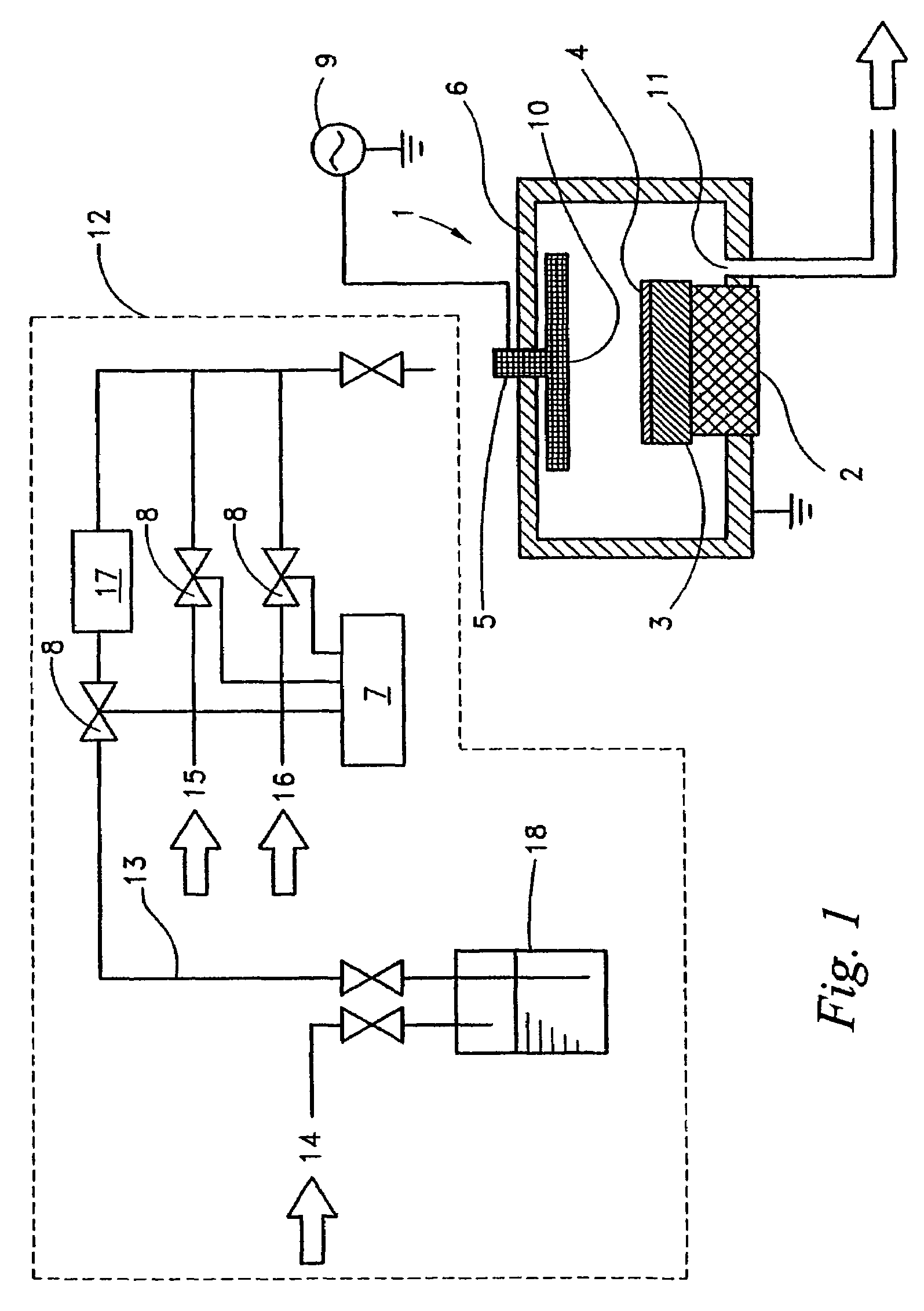

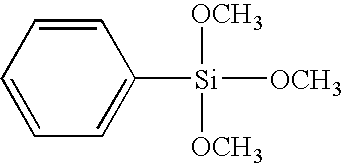

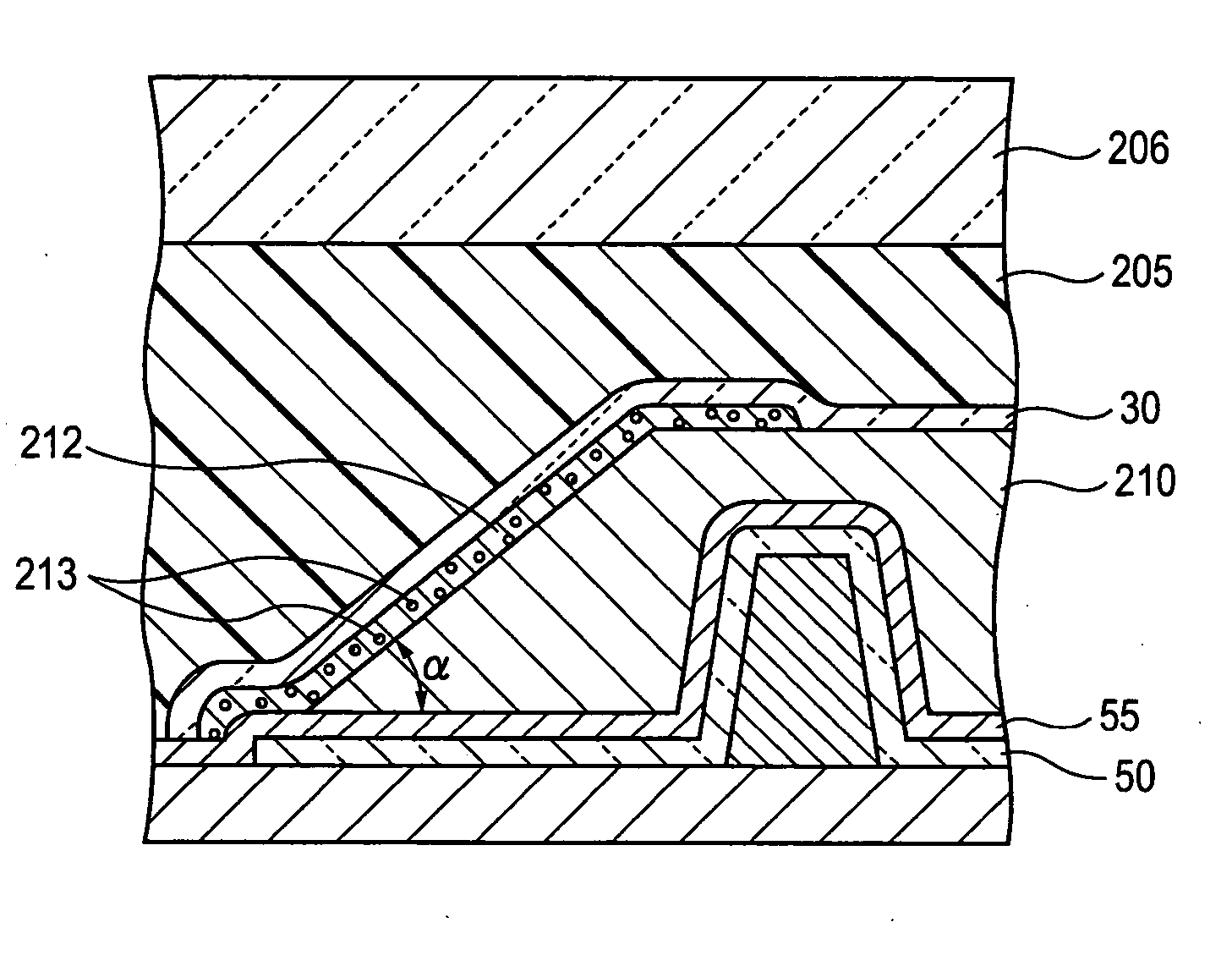

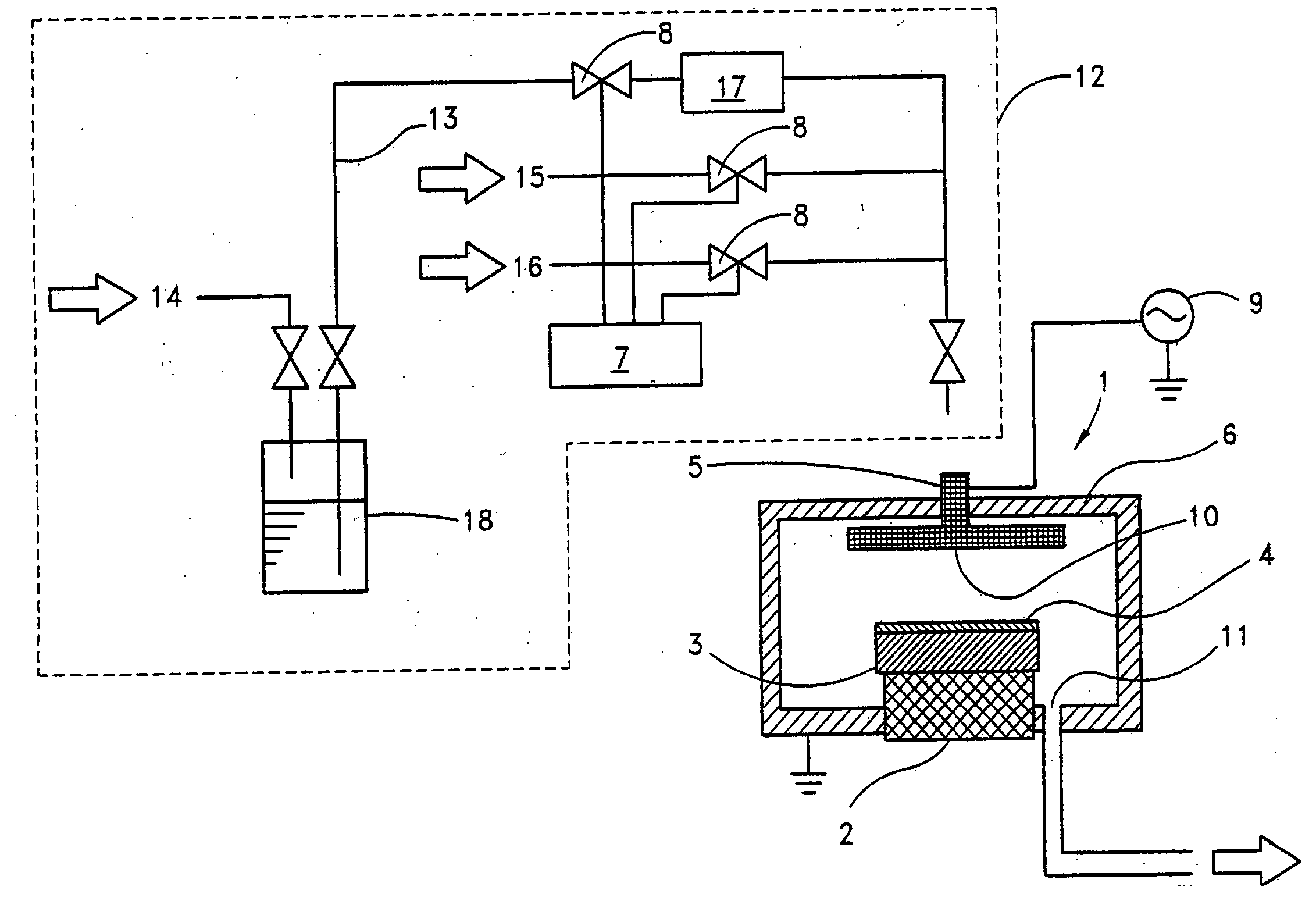

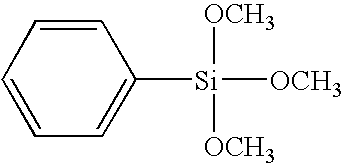

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

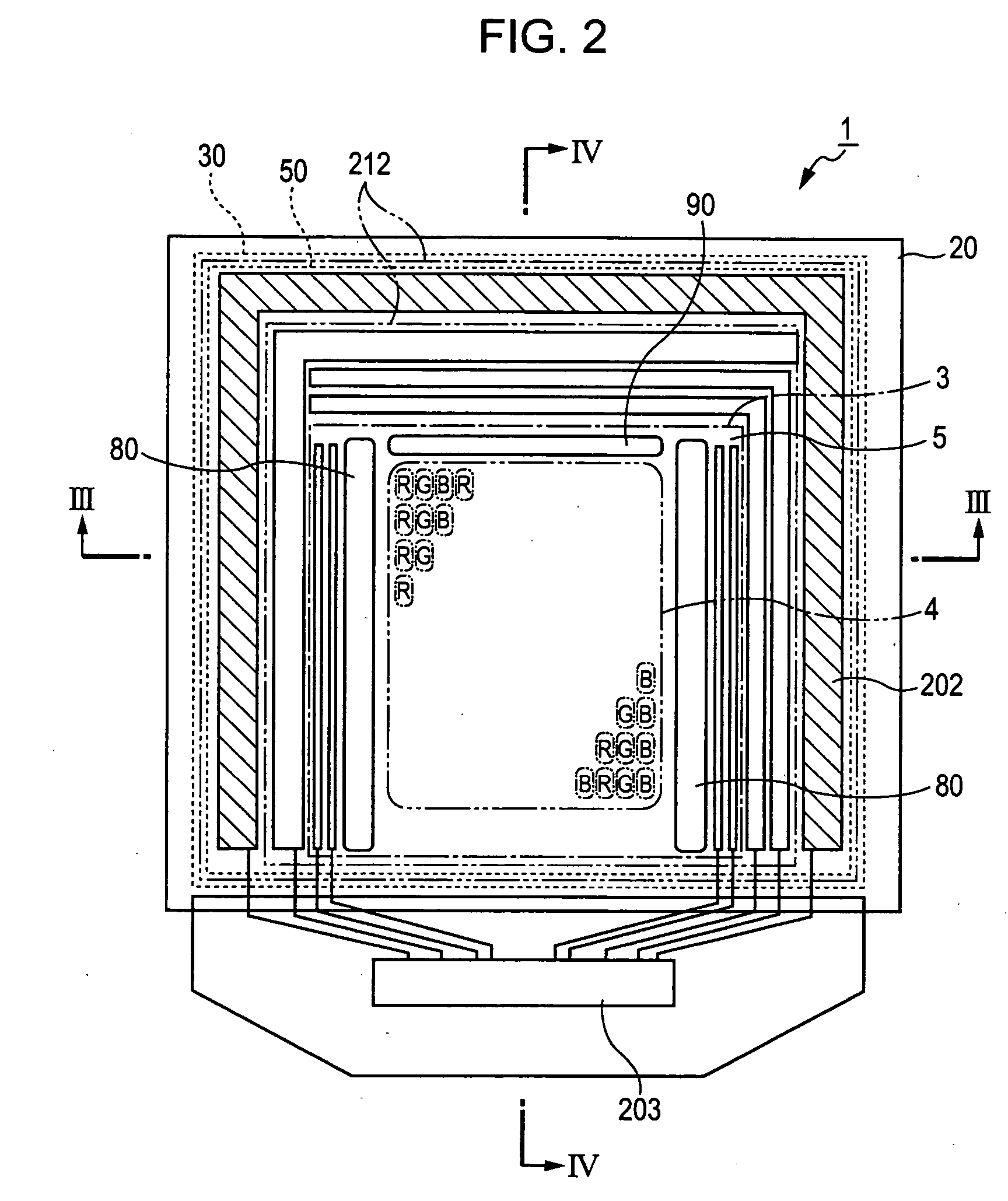

Light-emitting device, method for manufacturing light-emitting device, and electronic apparatus

ActiveUS20060158111A1Prevent moisture penetrationPrevent penetrationDischarge tube luminescnet screensLayered productsEngineeringProtection layer

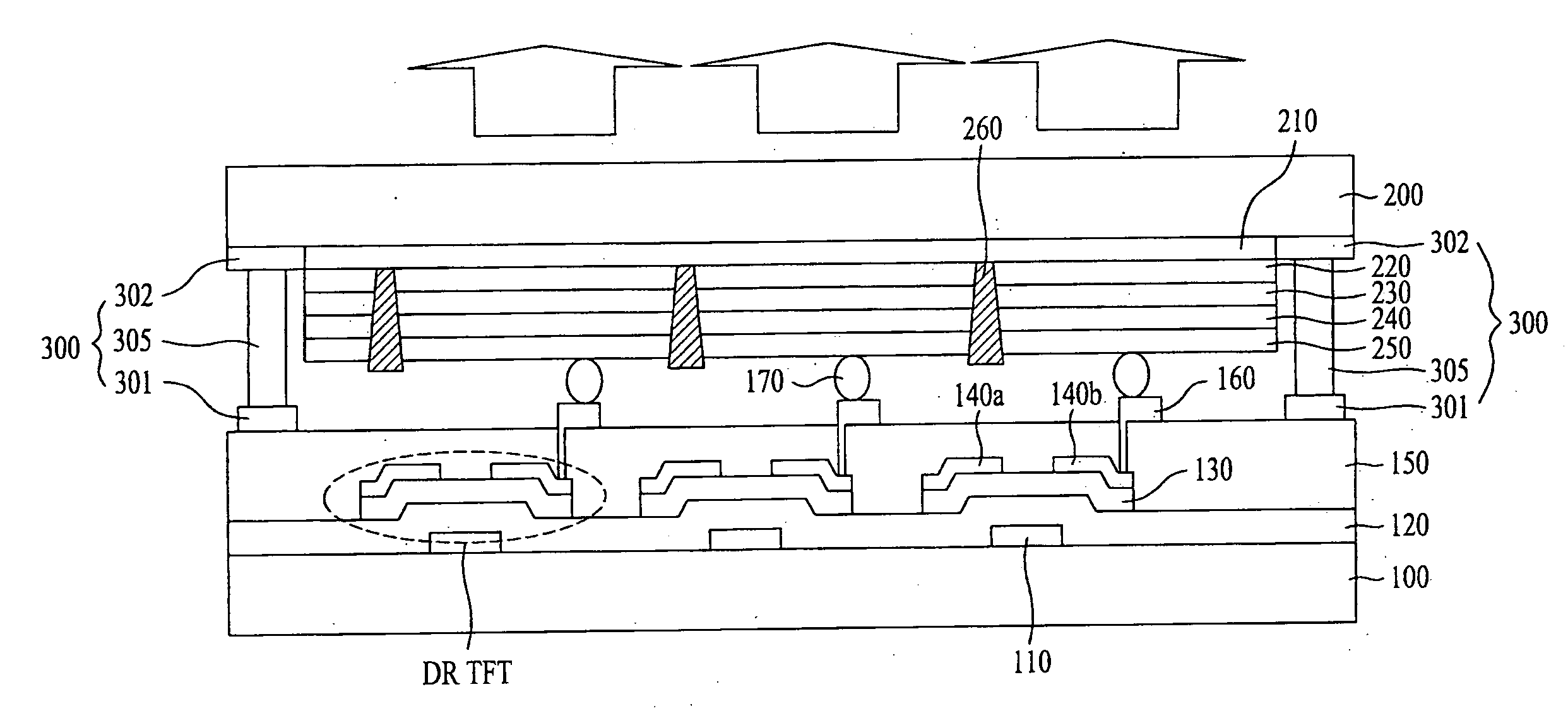

A light-emitting device includes a base; a plurality of first electrodes; a partition having a plurality of openings located at positions corresponding to the first electrodes; organic functional layers each arranged in the corresponding openings; a second electrode covering the partition and the organic functional layers; an organic buffer layer covering the second electrode; a gas barrier layer covering the organic buffer layer; and an intermediate protective layer, disposed between the organic buffer layer and the gas barrier layer, having an elasticity which is greater than that of the organic buffer layer and which is less than that of the gas barrier layer. These layers and electrodes are arranged on or above the base.

Owner:SEIKO EPSON CORP

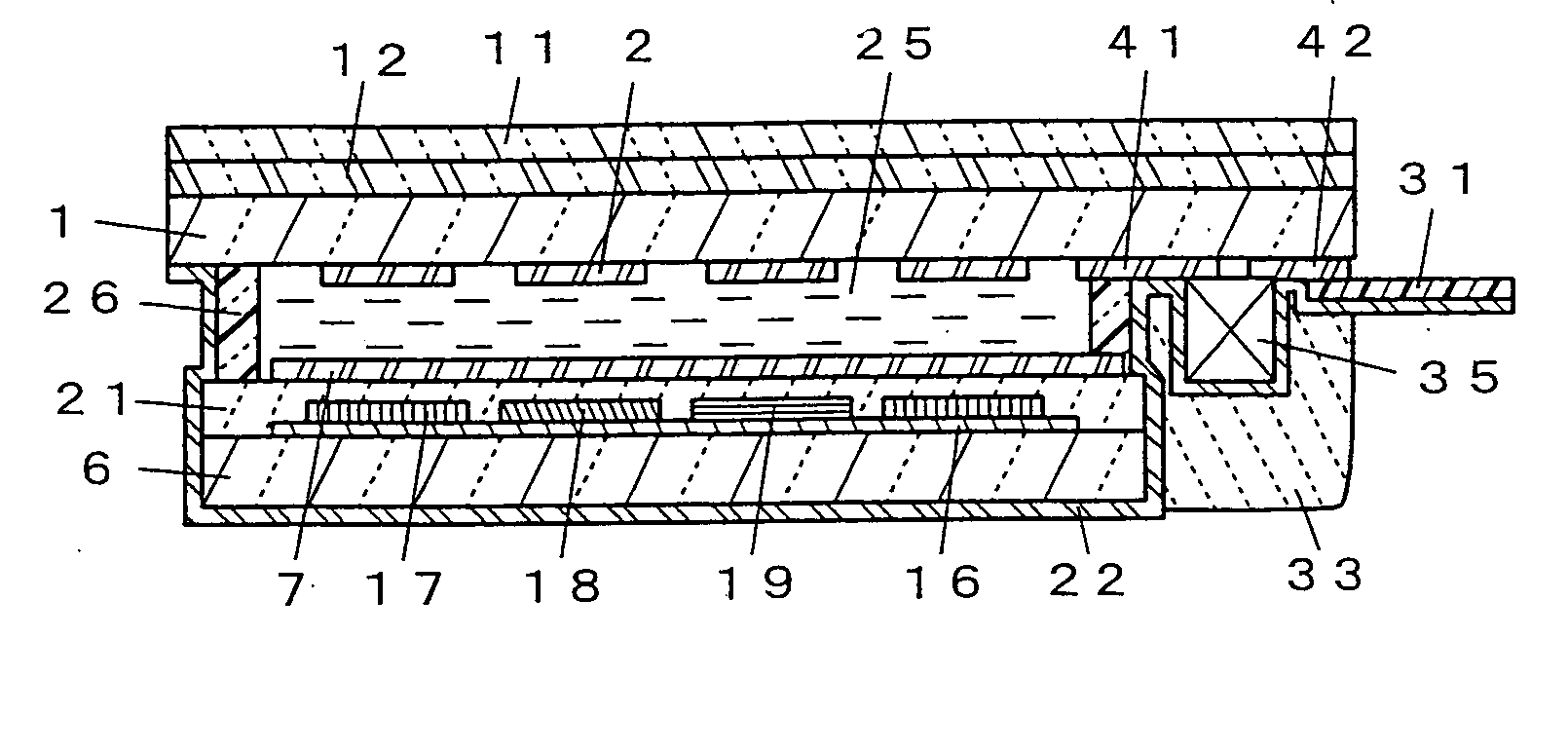

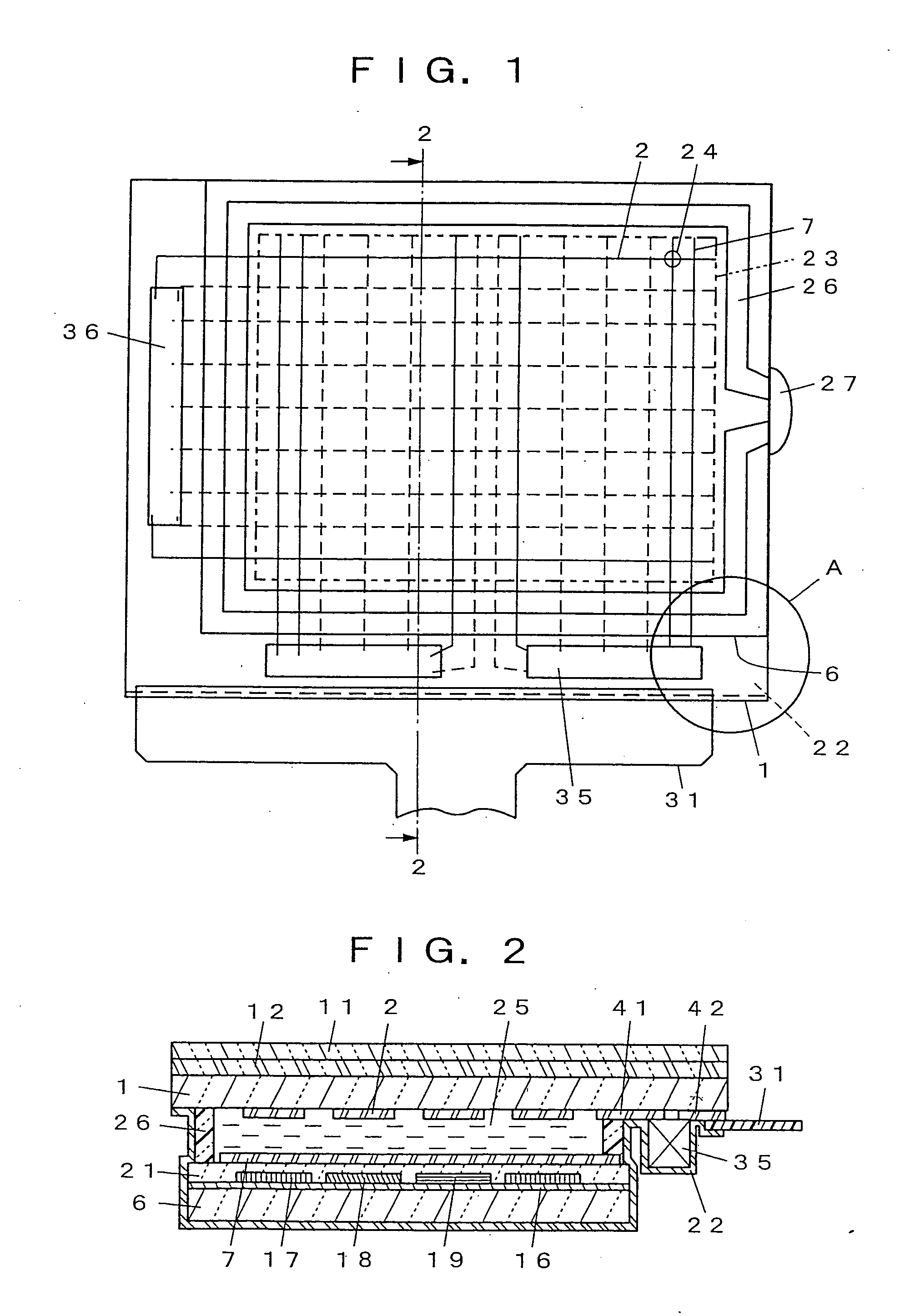

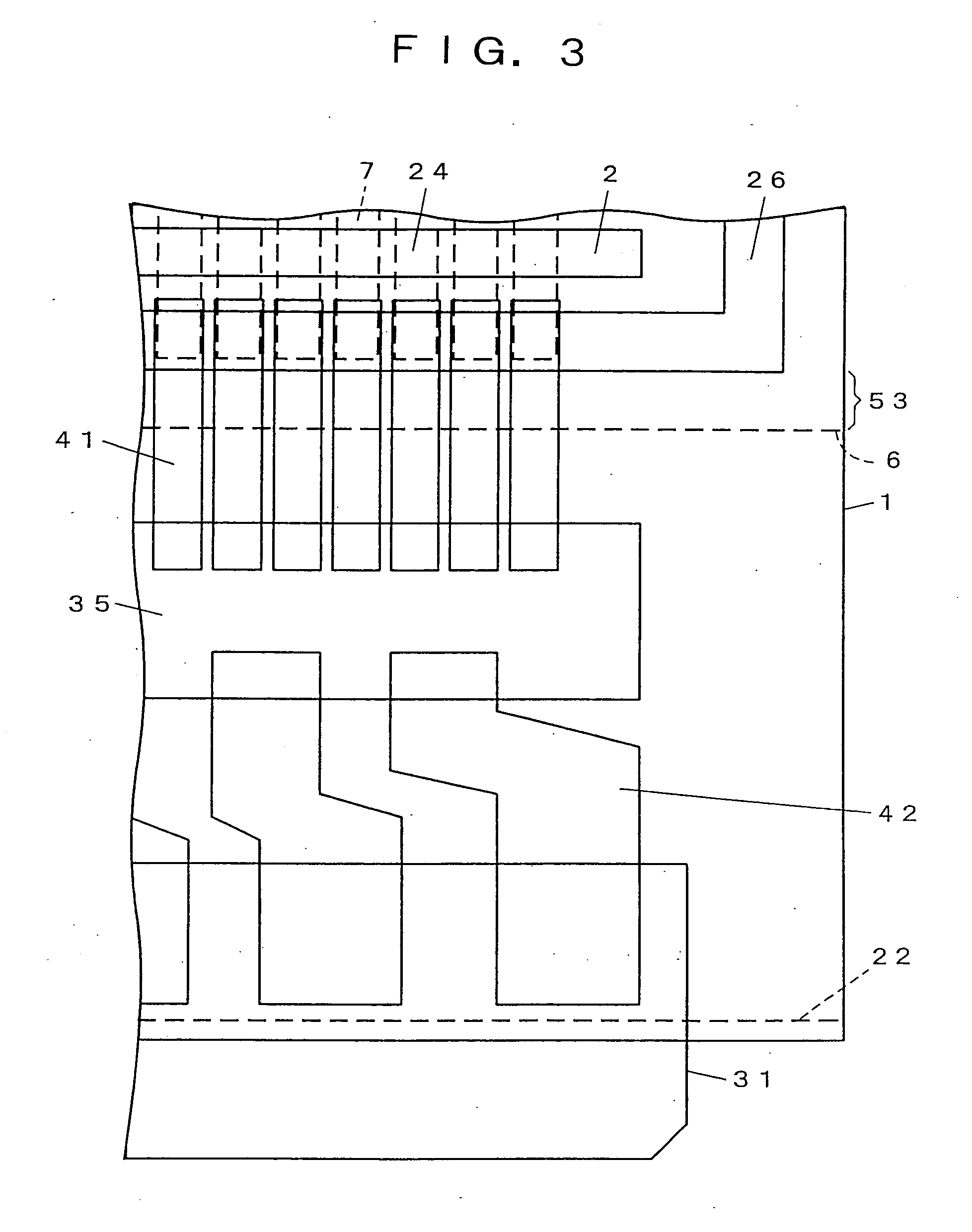

Liquid crystal display panel and its manufacturing method

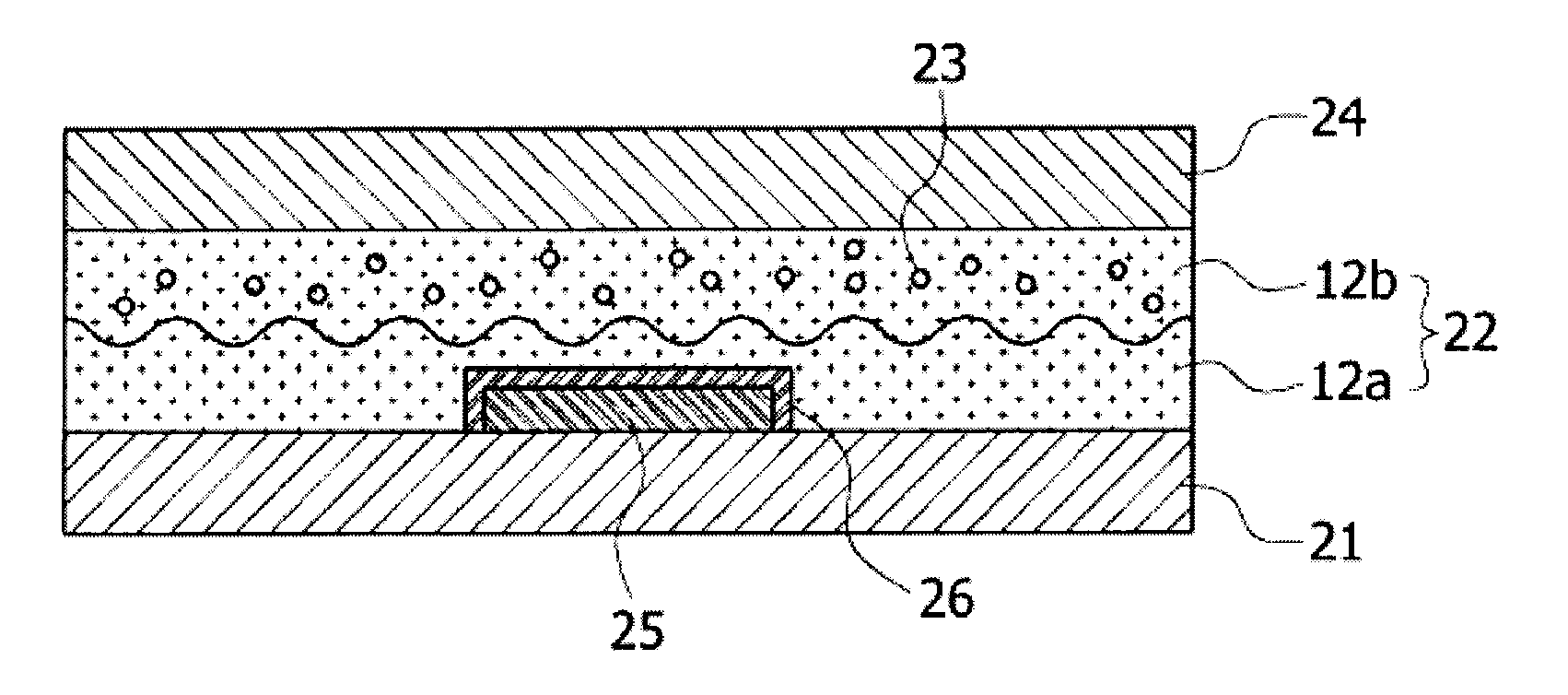

InactiveUS20040046909A1Resistance temperatureAvoid radiationStatic indicating devicesNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display panel, in which a first substrate (1) and a second substrate (6) are opposed to each other with a predetermined gap provided therebetween, a liquid crystal layer (25) is sealed in the gap with a sealant (26), pixel portions are formed by electrodes (2, 7), the electrodes being provided on the first substrate (1) and on the second substrate (6) to oppose to each other via the liquid crystal layer (25), and lead electrodes (41) for applying electric signals to the electrodes (2, 7) forming the pixel portions are provided at least on the first substrate (1), wherein a thin film insulating layer (22) being an insulating covering member is provided to cover at least portions of the lead electrodes (41) outside the sealant (26) and overlap with a portion of the second substrate (6).

Owner:CITIZEN WATCH CO LTD

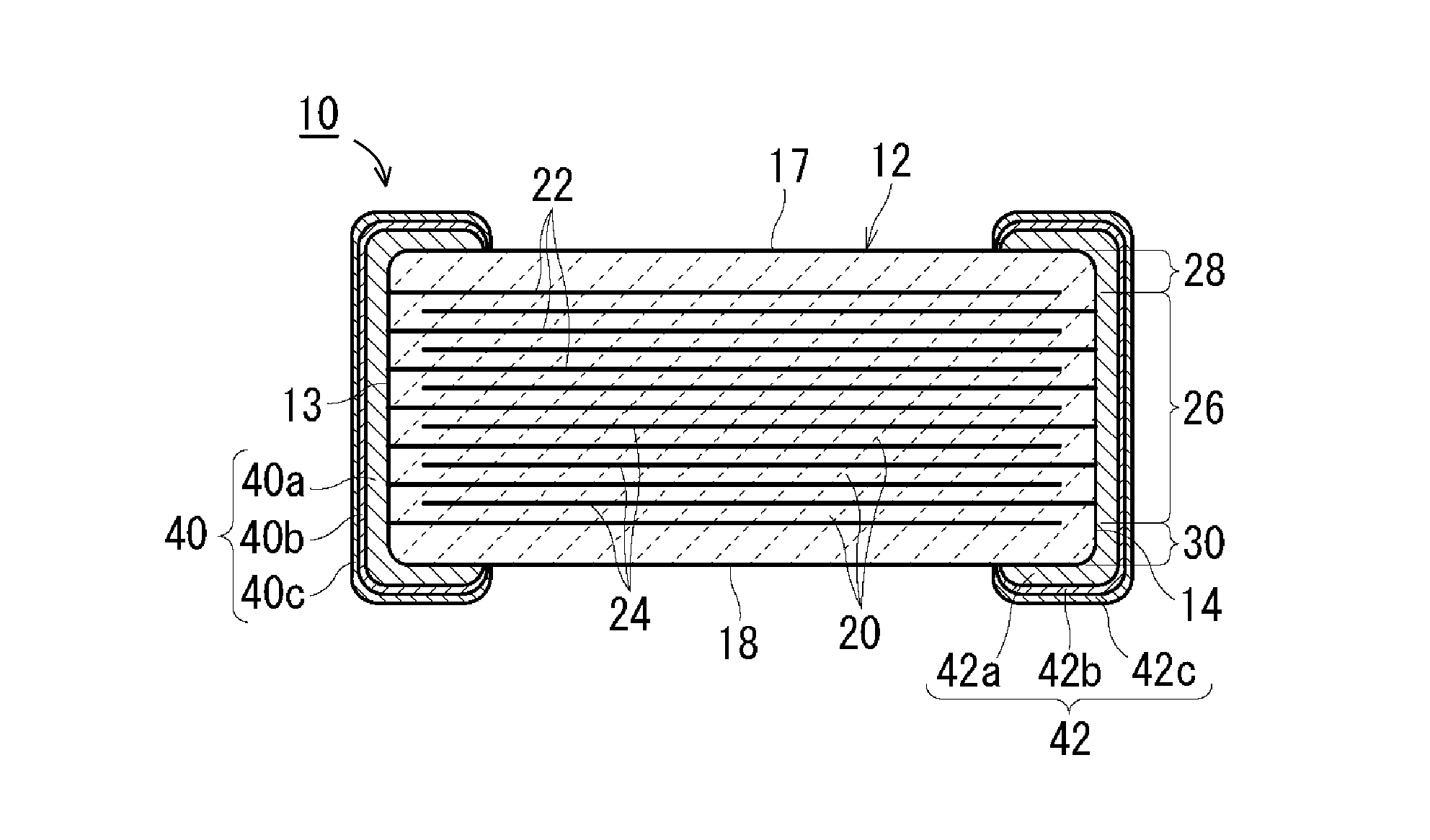

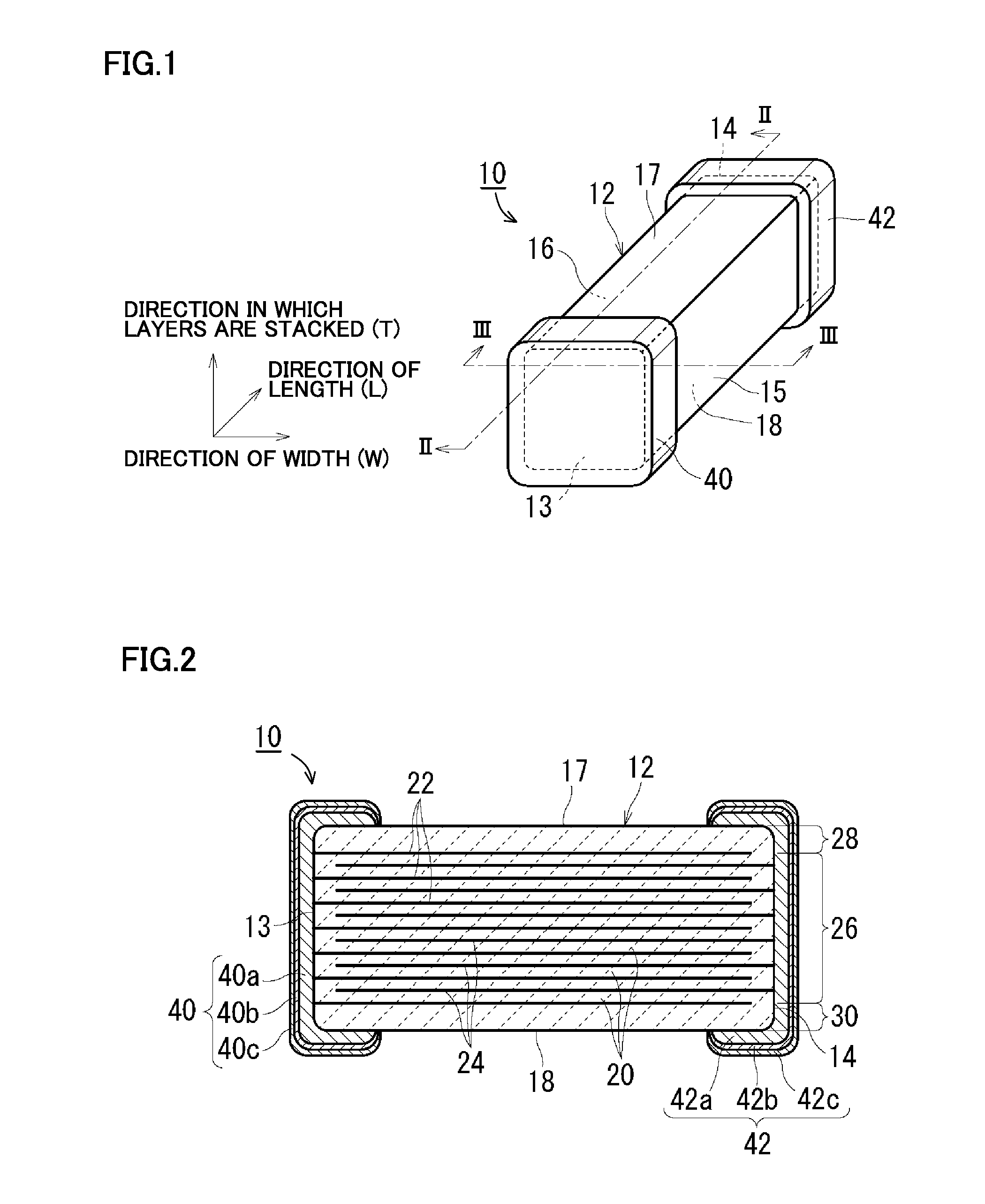

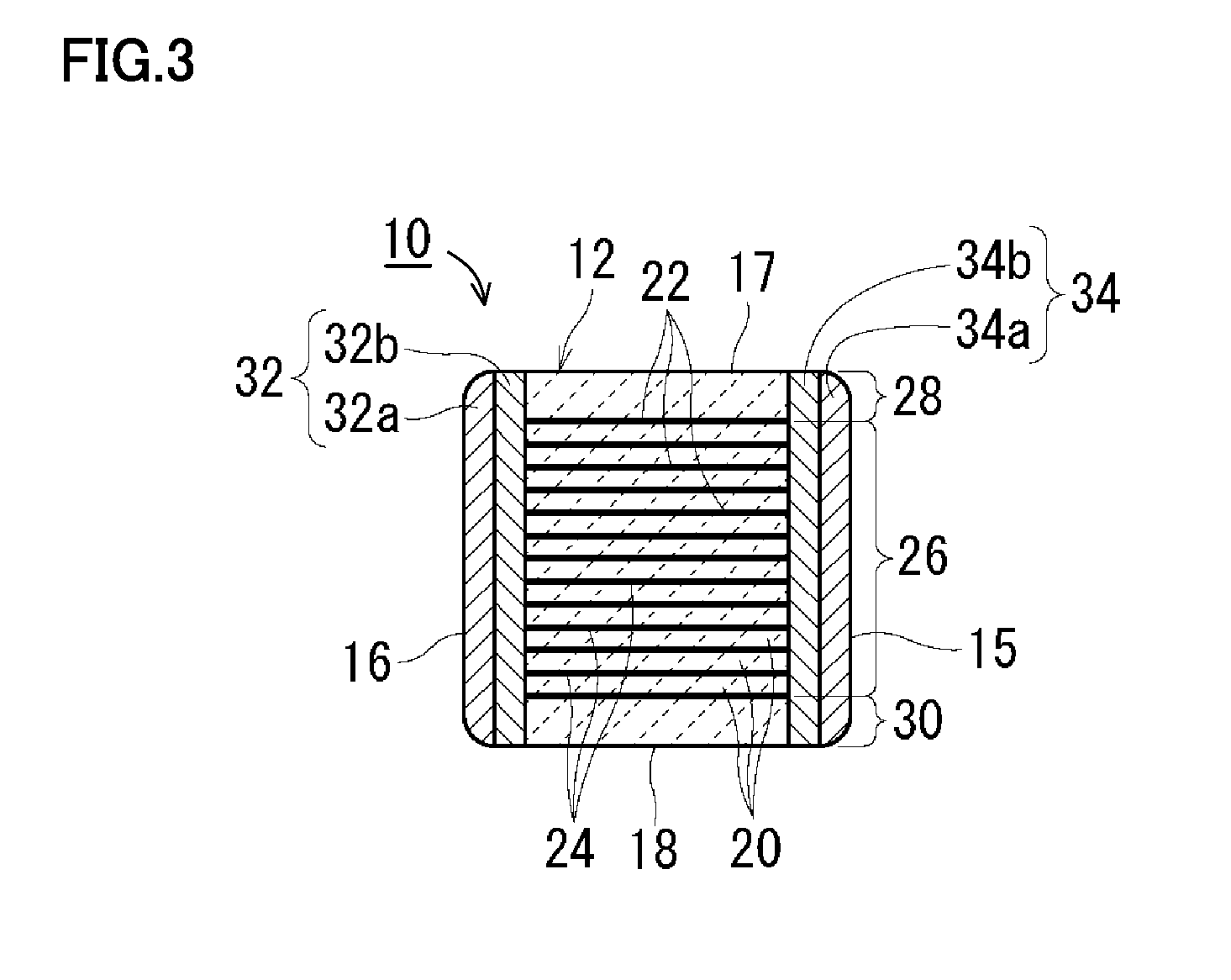

Multilayer ceramic capacitor

ActiveUS20150340155A1Reduce moistureImprove moisture resistanceFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

A multilayer ceramic capacitor includes a ceramic body and external electrodes provided on opposite end surfaces of the ceramic body. The ceramic body includes an inner layer portion including a plurality of ceramic layers defining inner layers and a plurality of first and second internal electrodes each disposed at an interface of adjacent ones of the ceramic layers defining the inner layers, outer layer portions sandwiching the inner layer portion in a direction in which the layers are stacked, and side margin portions sandwiching the inner layer portion and the outer layer portions in a widthwise direction. The side margin portion includes pores that decrease in number along a direction from inside to outside of the ceramic body.

Owner:MURATA MFG CO LTD

Method for forming insulation film

InactiveUS20060110931A1Reduce distanceIncrease film densitySolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryRadio frequency

A method for forming an insulation film on a semiconductor substrate by plasma reaction includes: vaporizing a silicon-containing hydrocarbon having a Si—O bond compound to provide a source gas; introducing the source gas and a carrier gas without an oxidizing gas into a reaction space for plasma CVD processing; and forming an insulation film constituted by Si, C, O, and H on a substrate by plasma reaction using a combination of low-frequency RF power and high-frequency RF power in the reaction space. The plasma reaction is activated while controlling the flow of the reaction gas to lengthen a residence time, Rt, of the reaction gas in the reaction space.

Owner:ASM JAPAN

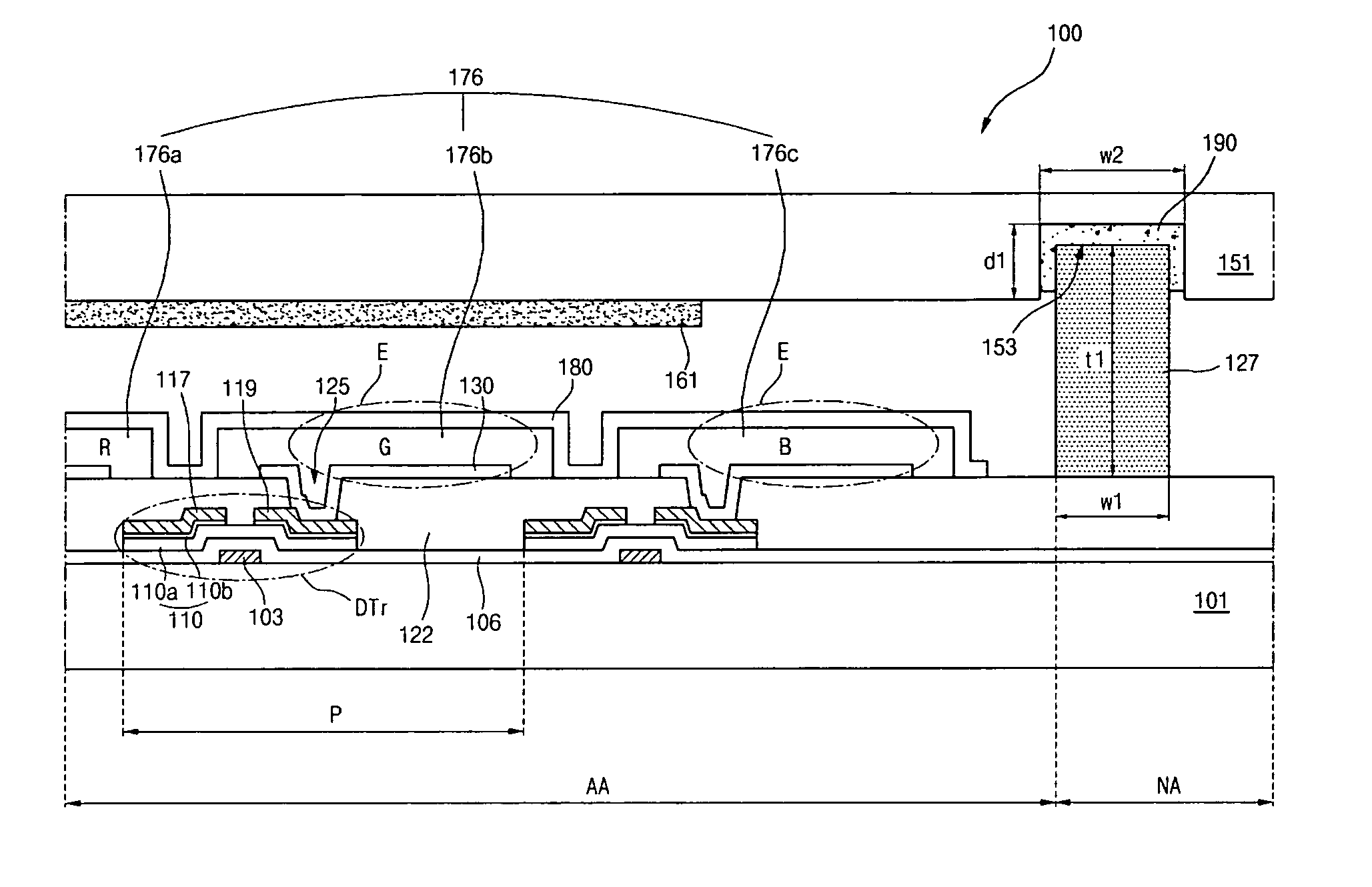

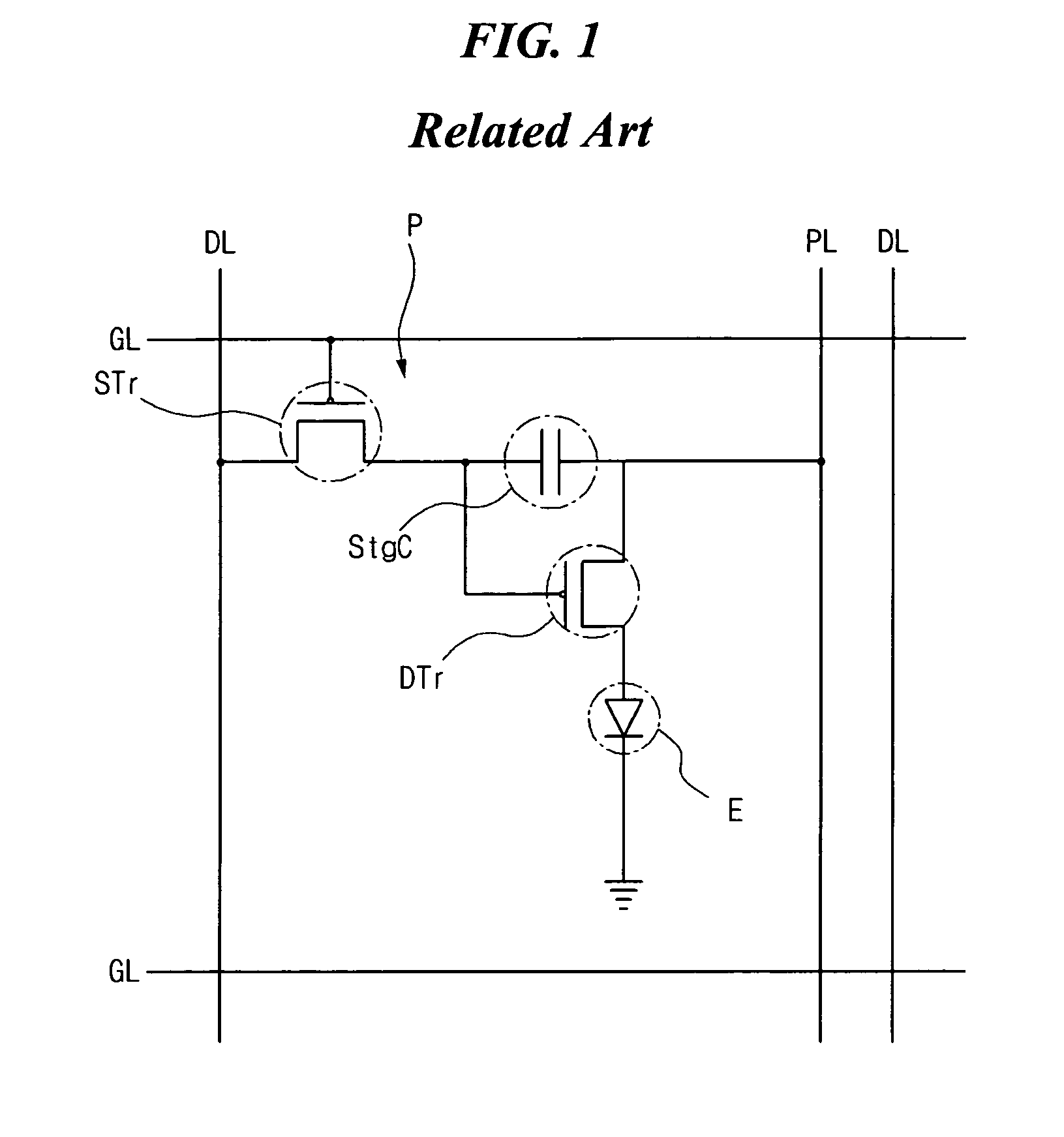

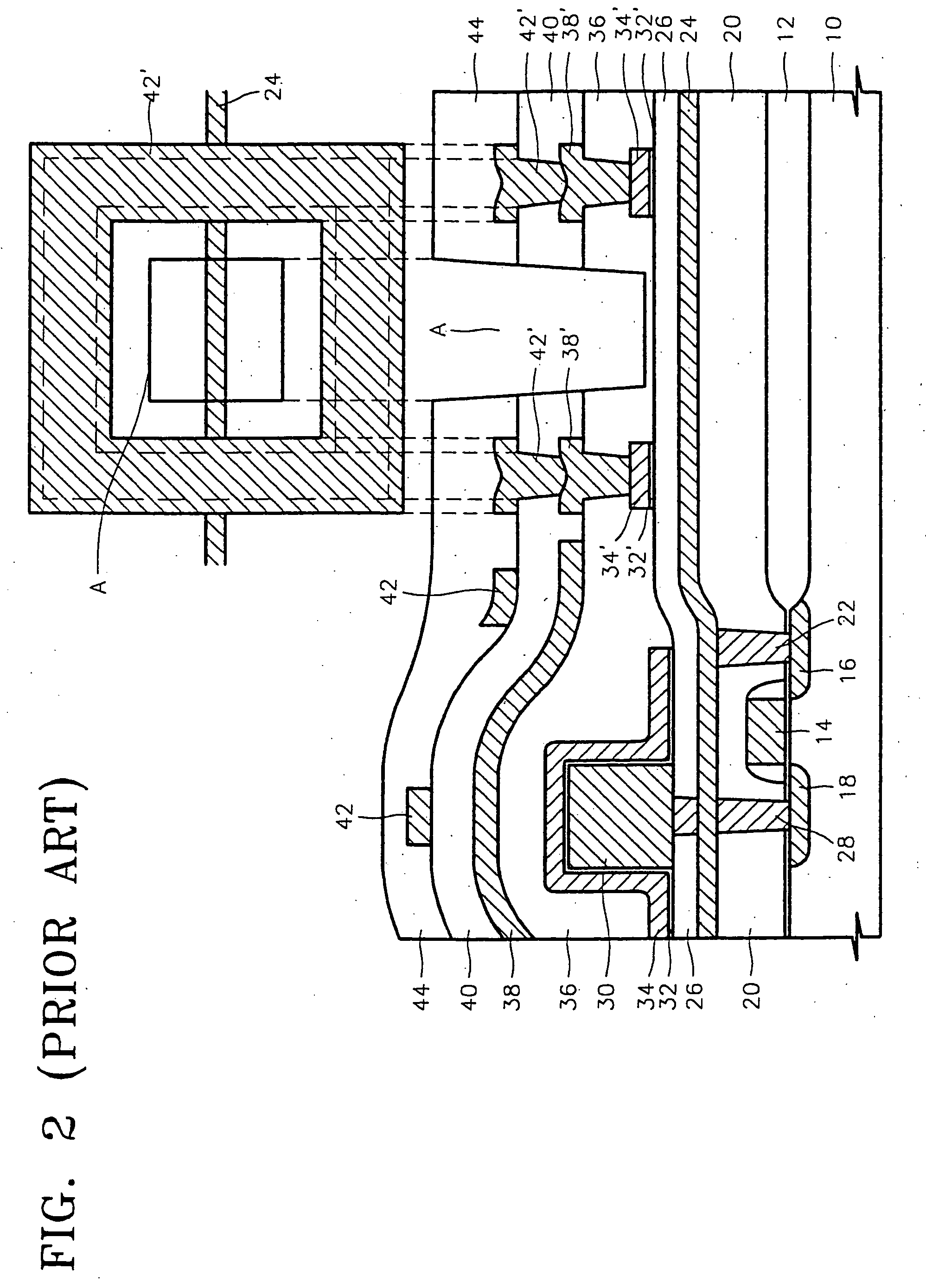

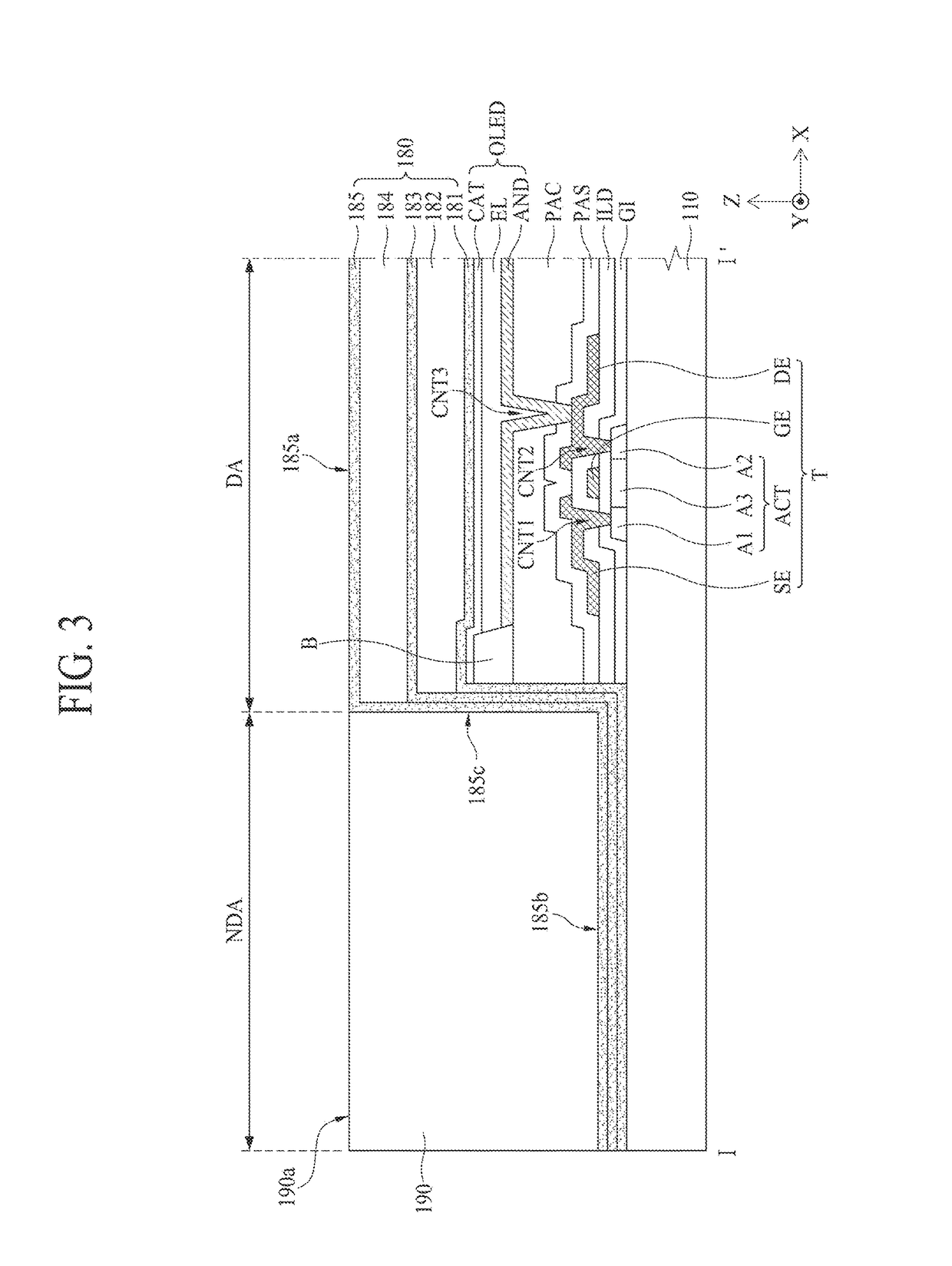

Organic light emitting display device and method of manufacturing the same

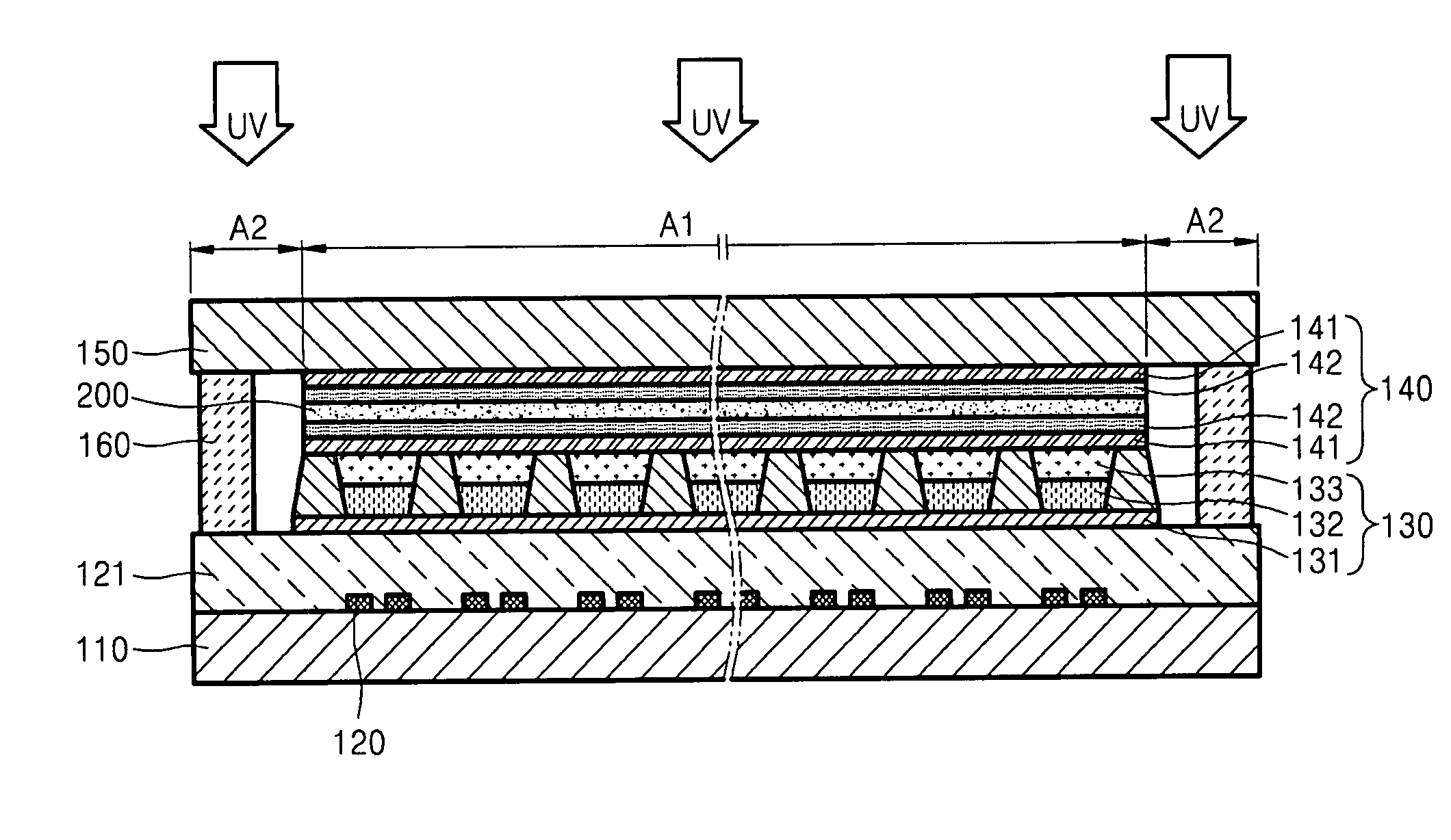

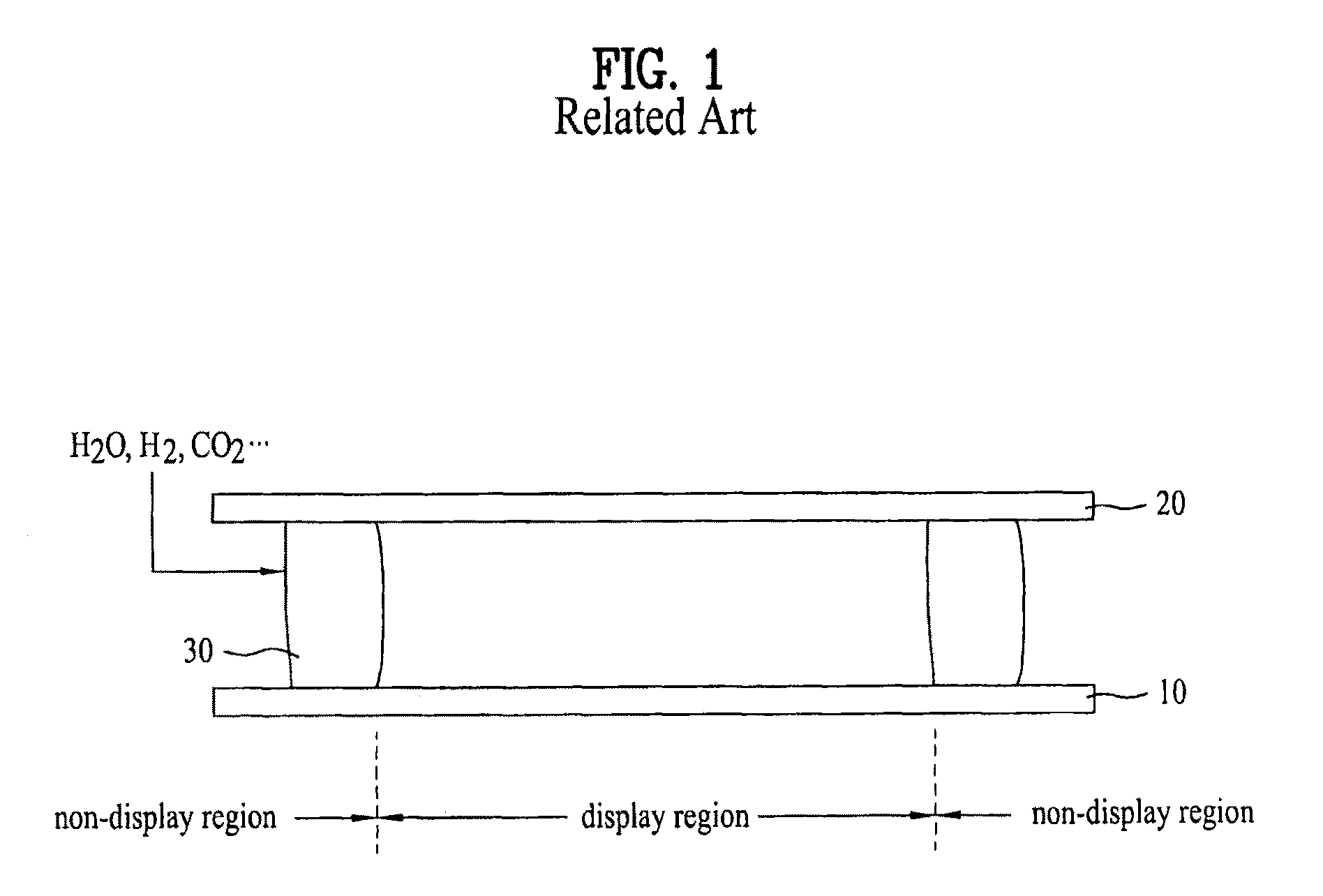

ActiveUS20080297042A1Prevent penetrationPrevent moisture penetrationDischarge tube luminescnet screensLamp detailsDisplay deviceOptoelectronics

An organic light emitting display device that is capable of preventing the permeation of moisture by changing a sealing structure, thereby preventing the degradation of pixels and thus improving look-and-feel characteristics and a method of manufacturing the same are disclosed. The organic light emitting display device includes a first substrate and a second substrate being opposite to each other, the first substrate and the second substrate having a display region defined in the middle thereof and a non-display region defined at the edge thereof, respectively, a plurality of gate lines and data lines formed at the display region on the first substrate, the gate lines and the data lines crossing each other to define a pixel region, a thin film transistor formed at each of the intersections between the gate lines and data lines, an organic light emitting layer formed on the second substrate corresponding to the pixel region, and first and second electrodes located above and below the organic light emitting layer and a sealing structure connected between the first and second substrates, such that the first and second substrates are bonded to each other by the sealing structure, for preventing the permeation of moisture and gas.

Owner:LG DISPLAY CO LTD

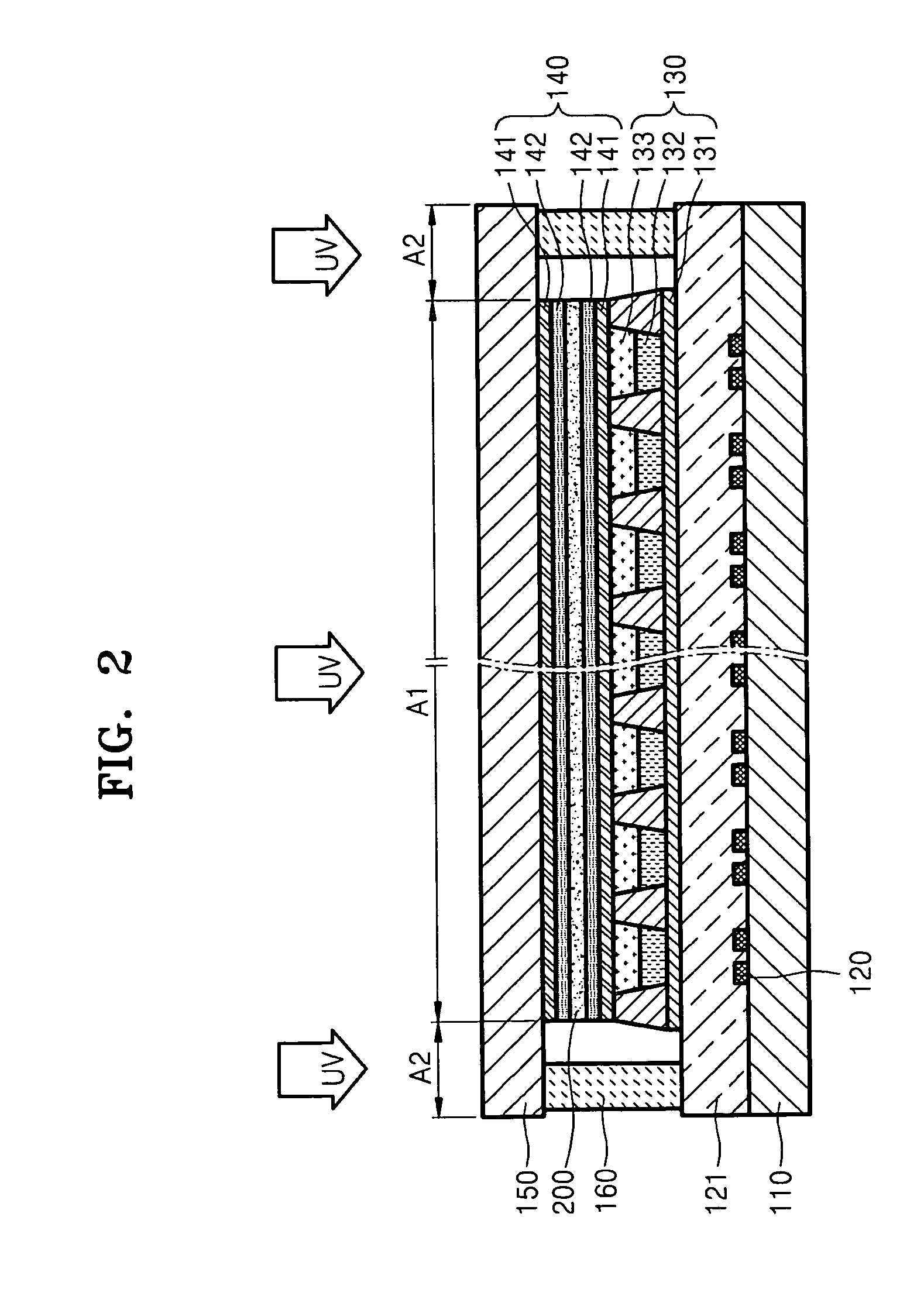

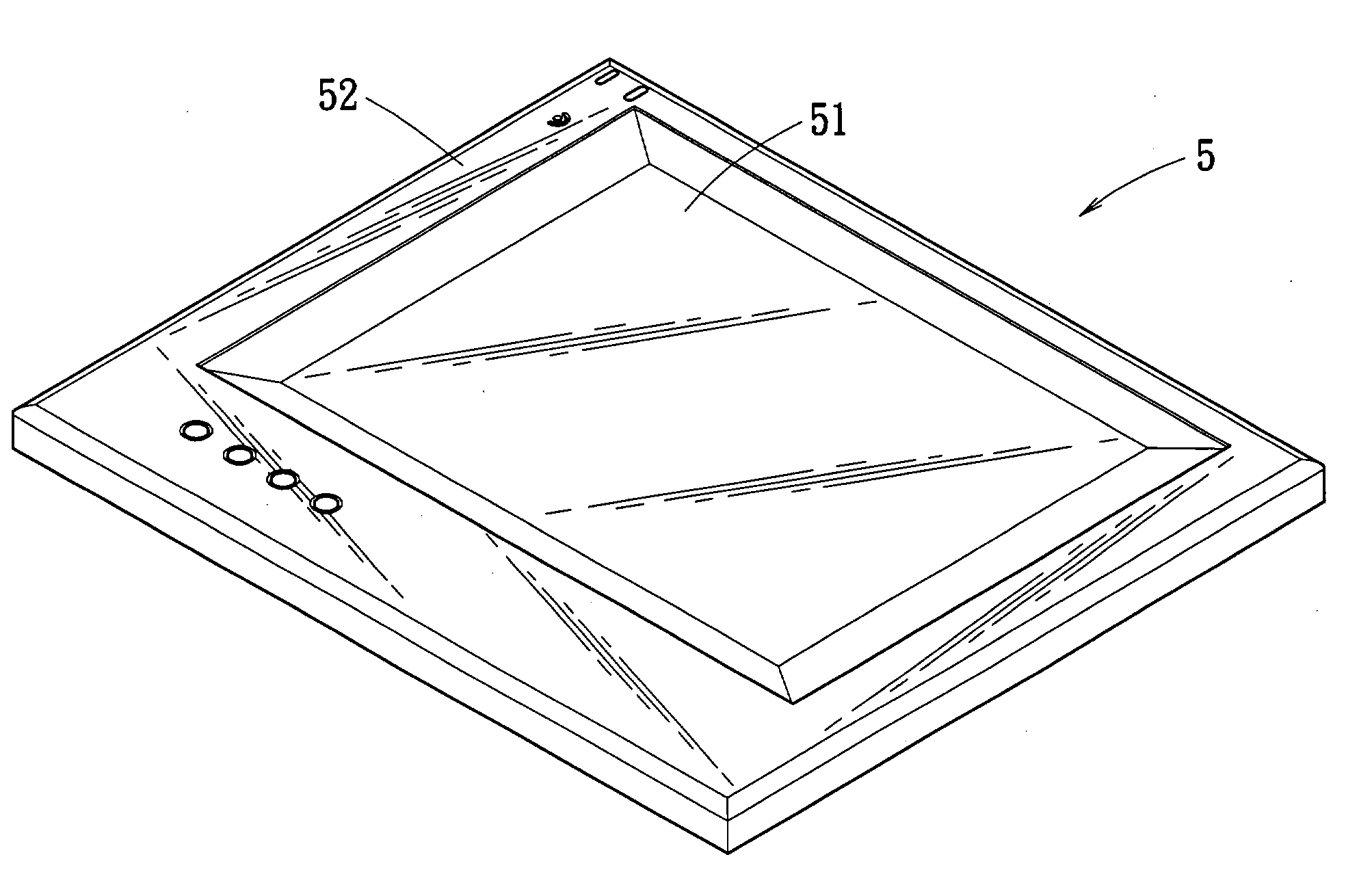

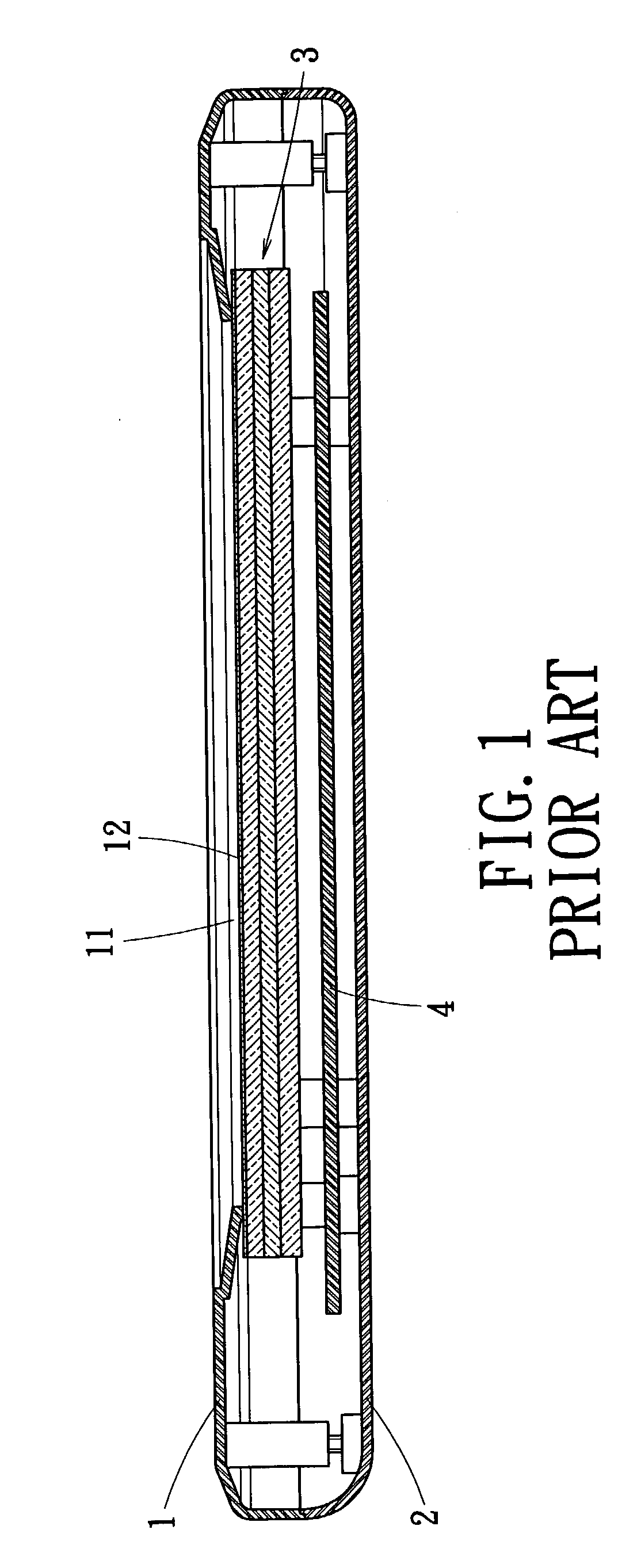

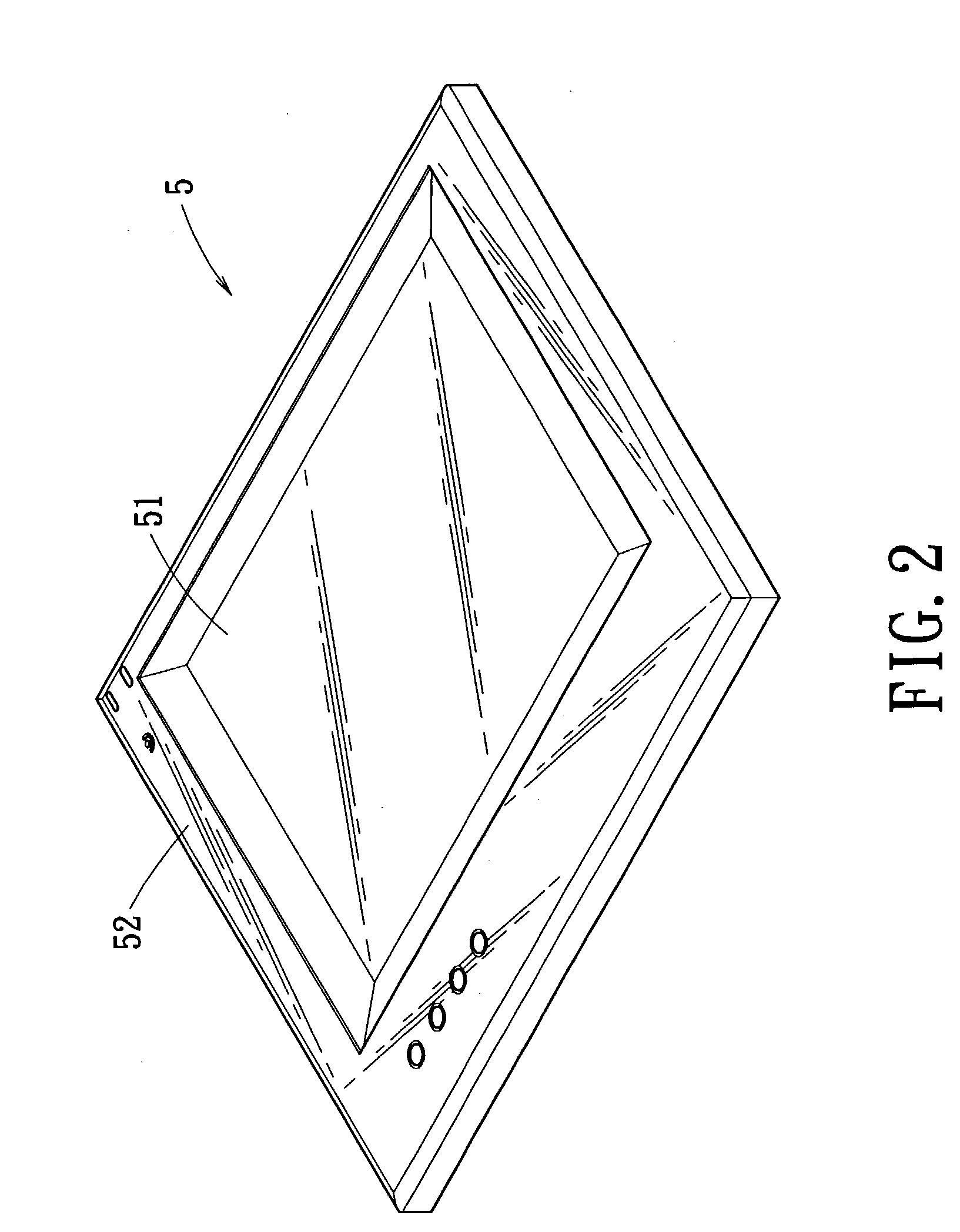

Organic light emitting display providing ultraviolet ray protection and method of manufacturing same

ActiveUS20070182314A1Prevent moisture penetrationPreventing oxygen penetrationDischarge tube luminescnet screensElectroluminescent light sourcesAdhesiveUltraviolet

An organic light emitting display including an ultraviolet protecting layer and a method of manufacturing the same include a lower substrate; an ultraviolet hardening adhesive formed on the lower substrate; a driving unit and a light emitting unit deposited on the lower substrate and surrounded by the ultraviolet hardening adhesive; an encapsulation layer covering the driving unit and light emitting unit and preventing moisture and oxygen penetration from an outside; an upper substrate arranged on the encapsulation layer facing the lower substrate and fixed by the ultraviolet hardening adhesive; and an ultraviolet ray blocking film formed in a region to block the driving unit and the light emitting unit from being irradiated by UV rays radiated to harden the ultraviolet hardening adhesive. The ultraviolet ray blocking film is disposed in the encapsulation layer or on the upper substrate to protect the driving unit and light emitting unit from ultraviolet rays.

Owner:SAMSUNG DISPLAY CO LTD

Touch panel display device

InactiveUS20040164966A1Easy to produceLow costCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceTouchscreen

A touch panel display device that is easily produced with a lower cost and has moisture-proof and dust-proof properties includes an upper casing, a lower casing, a touch control module and a circuit board. The upper casing includes a display part and a remaining part surrounding the display part. The lower casing is mounted corresponding to the upper casing to define a space therein. The touch control module is located under a bottom of the upper casing in the defined space. The circuit board is located between the touch control module and the lower casing in the defined space. The display part and the remaining part of the upper casing are integrally formed in a single body with no gap or slit there between. A bottom of the display part is correspondingly attached to a top of the touch control module.

Owner:AMTEK SYST

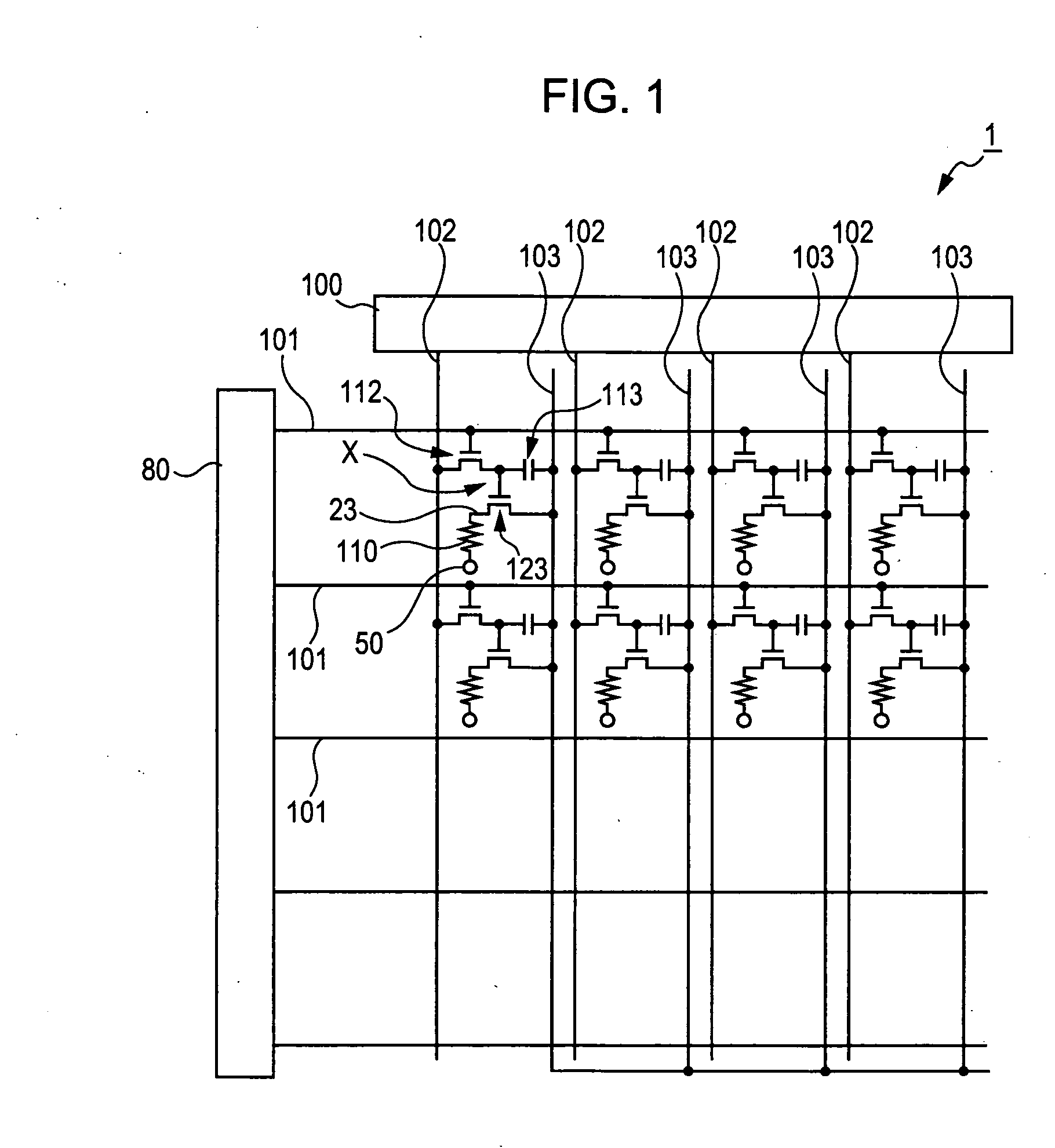

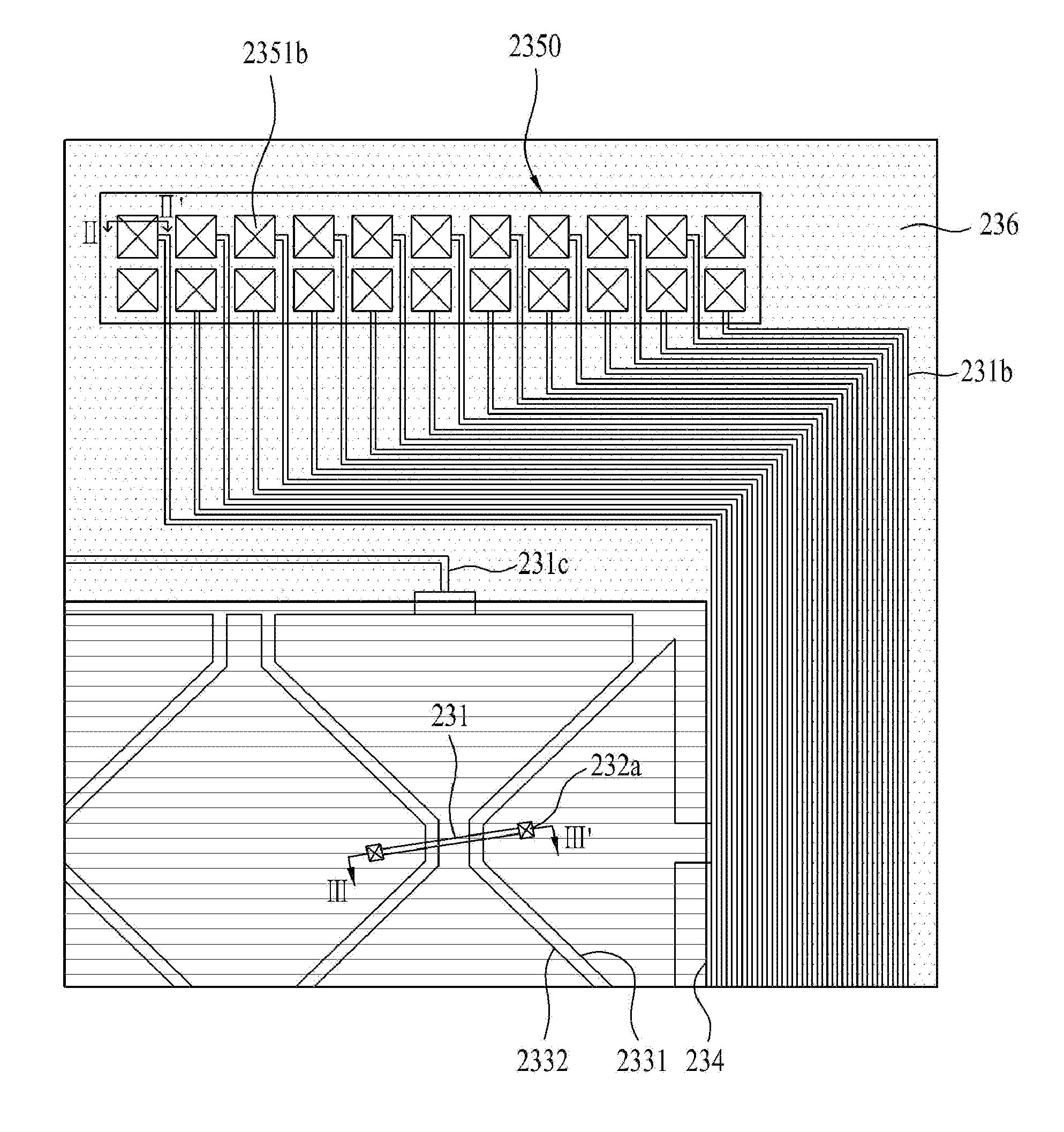

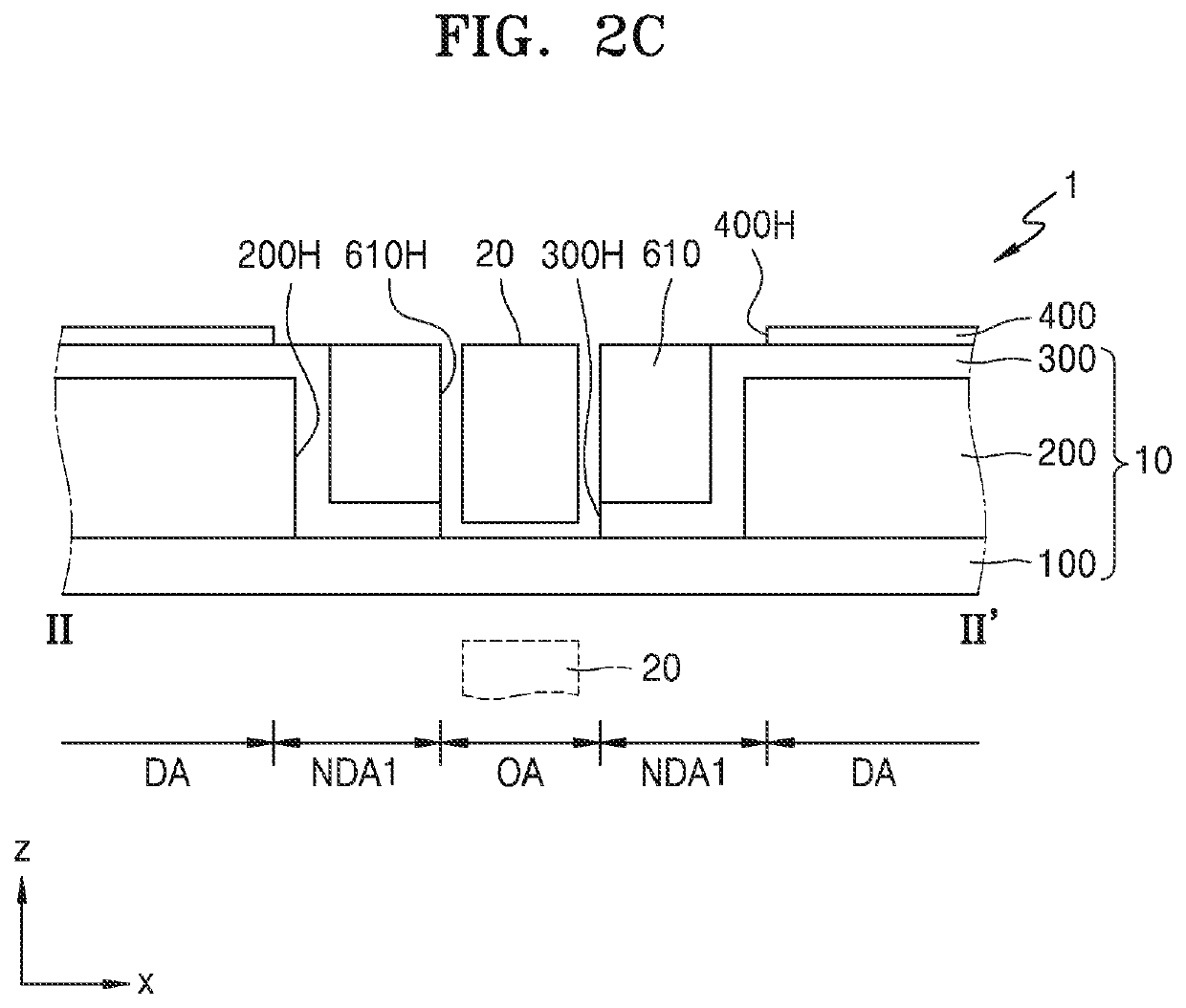

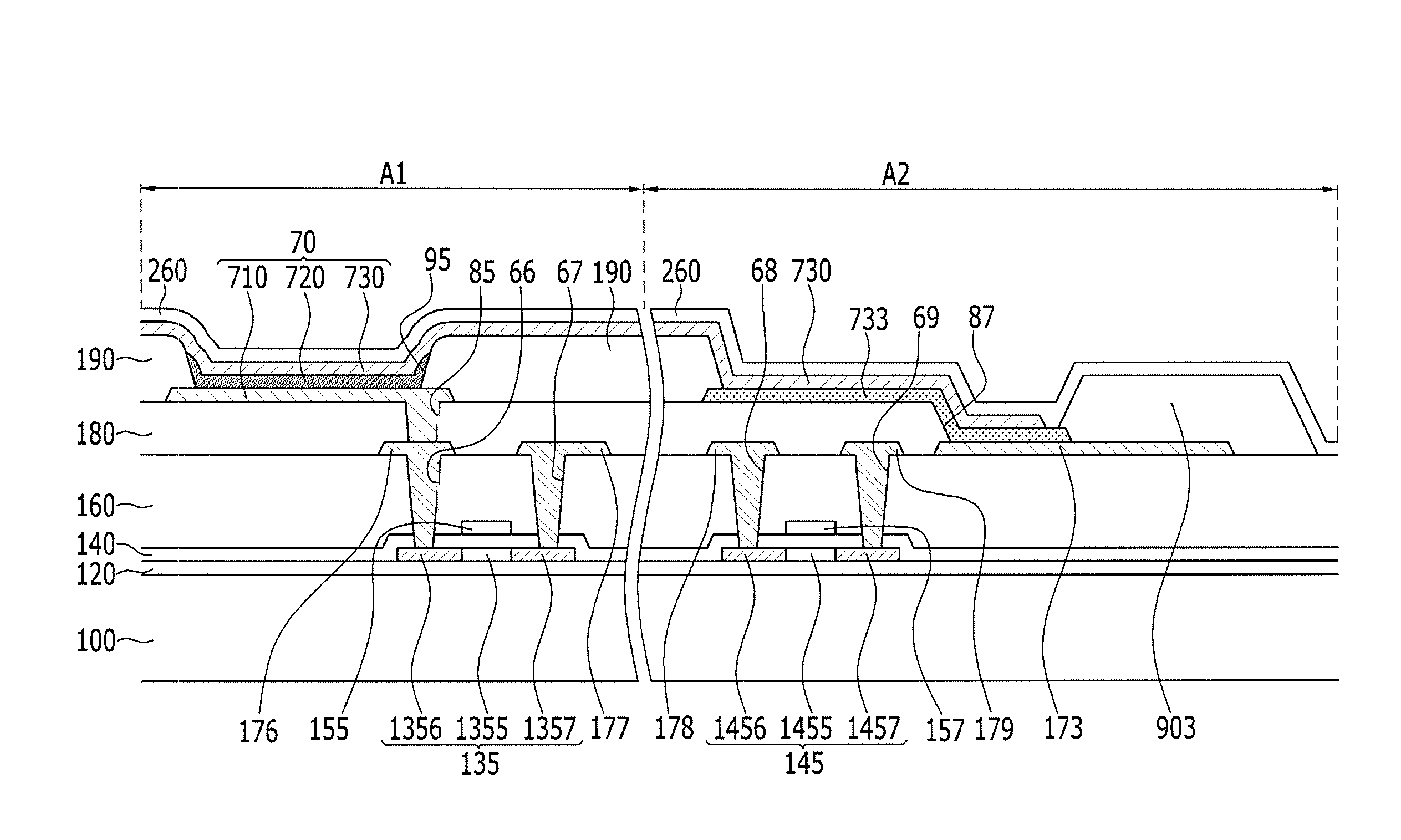

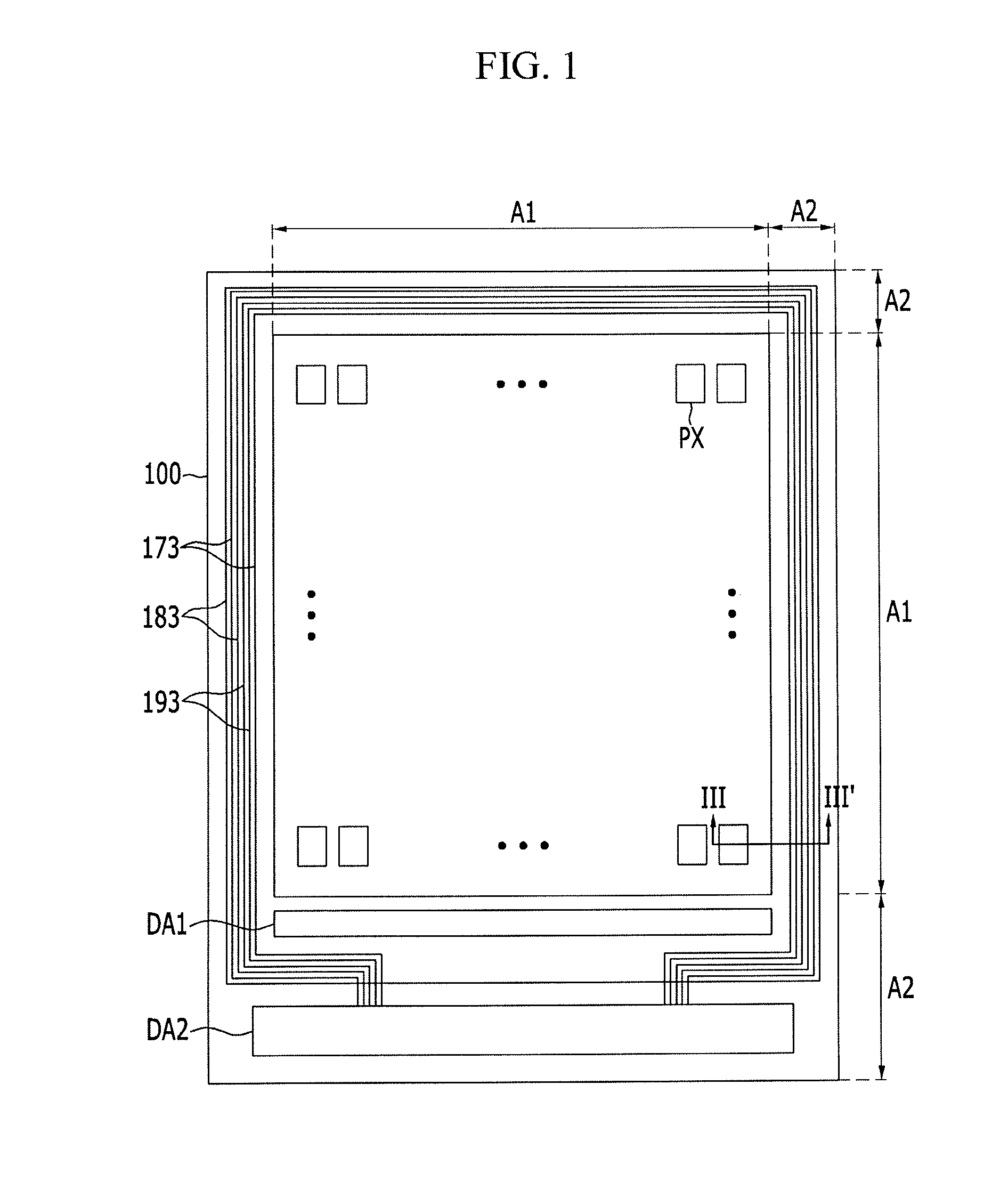

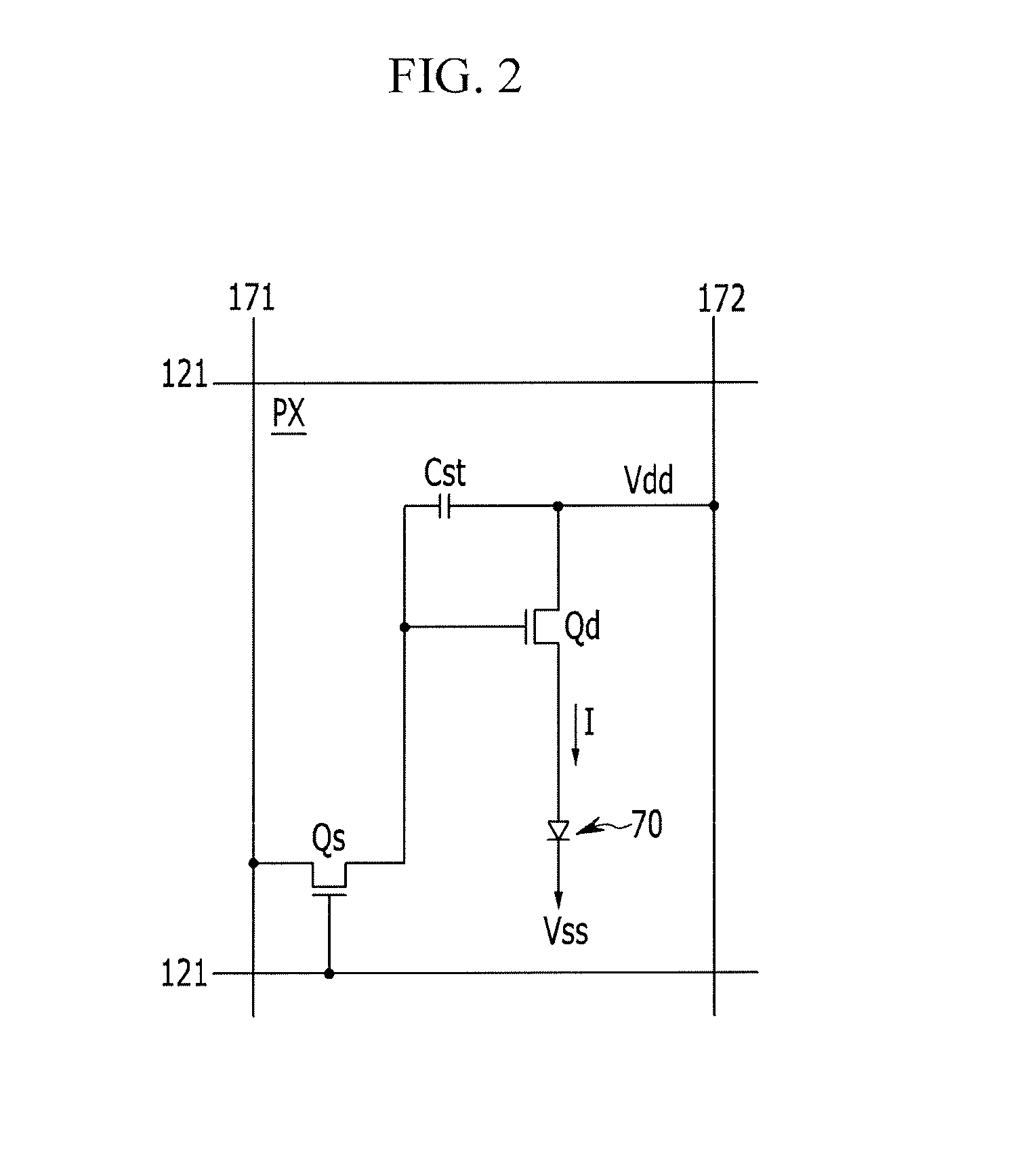

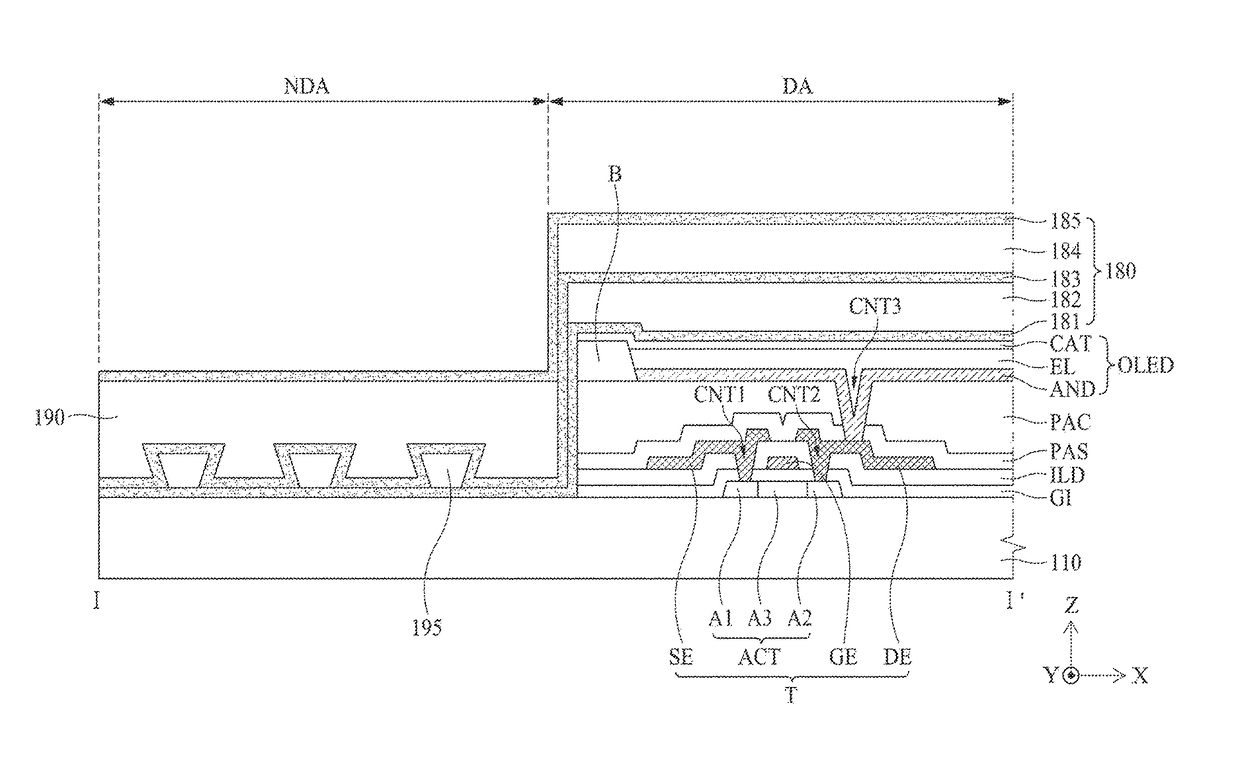

Organic Light Emitting Display

ActiveUS20140078077A1Prevent moisture penetrationLayered productsElectrical equipmentOptoelectronicsElectrode array

Disclosed is an organic light emitting display an organic light emitting display that can efficiently prevent permeation of moisture in a structure including an in-cell touch electrode array, the uppermost layer of the second buffer layer contacting the sealant between the dead region adjacent to the touch pad portion and the touch pads is an inorganic film.

Owner:LG DISPLAY CO LTD

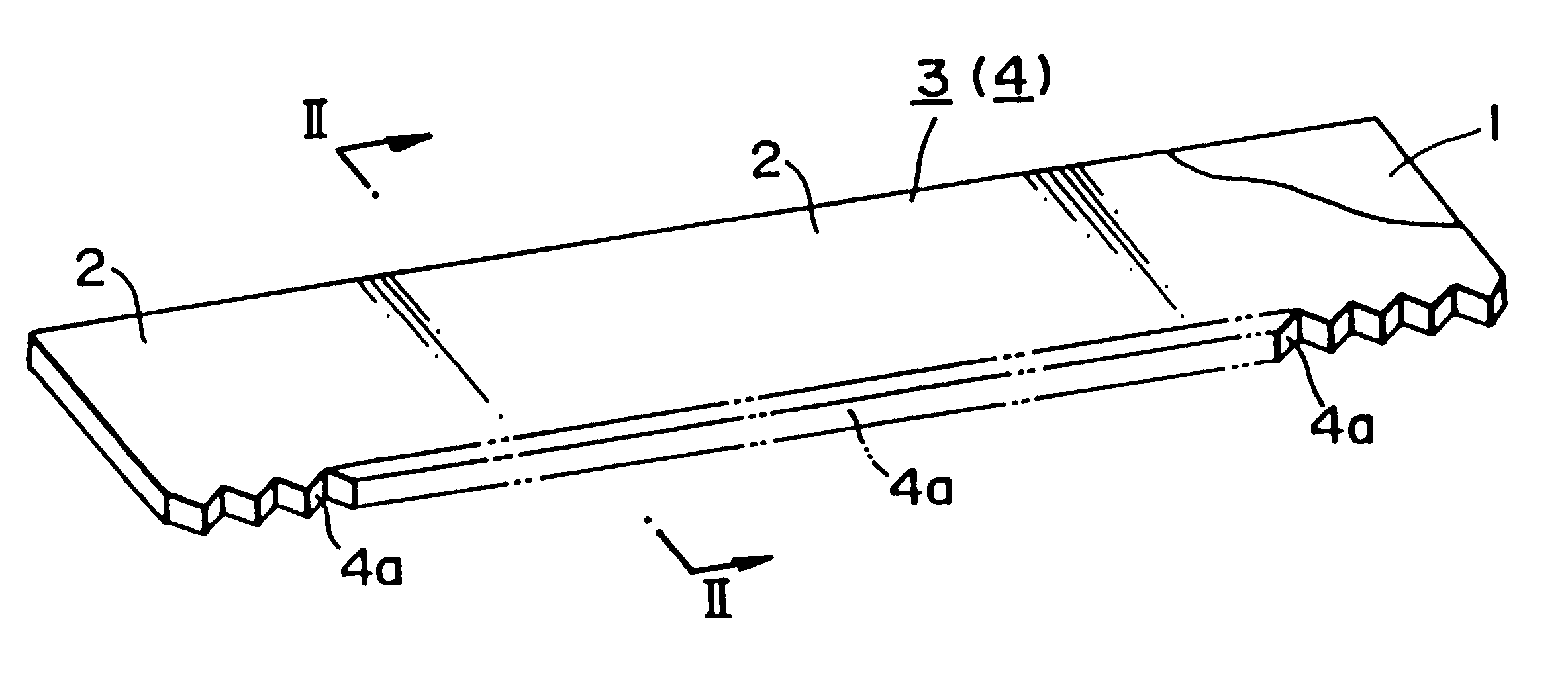

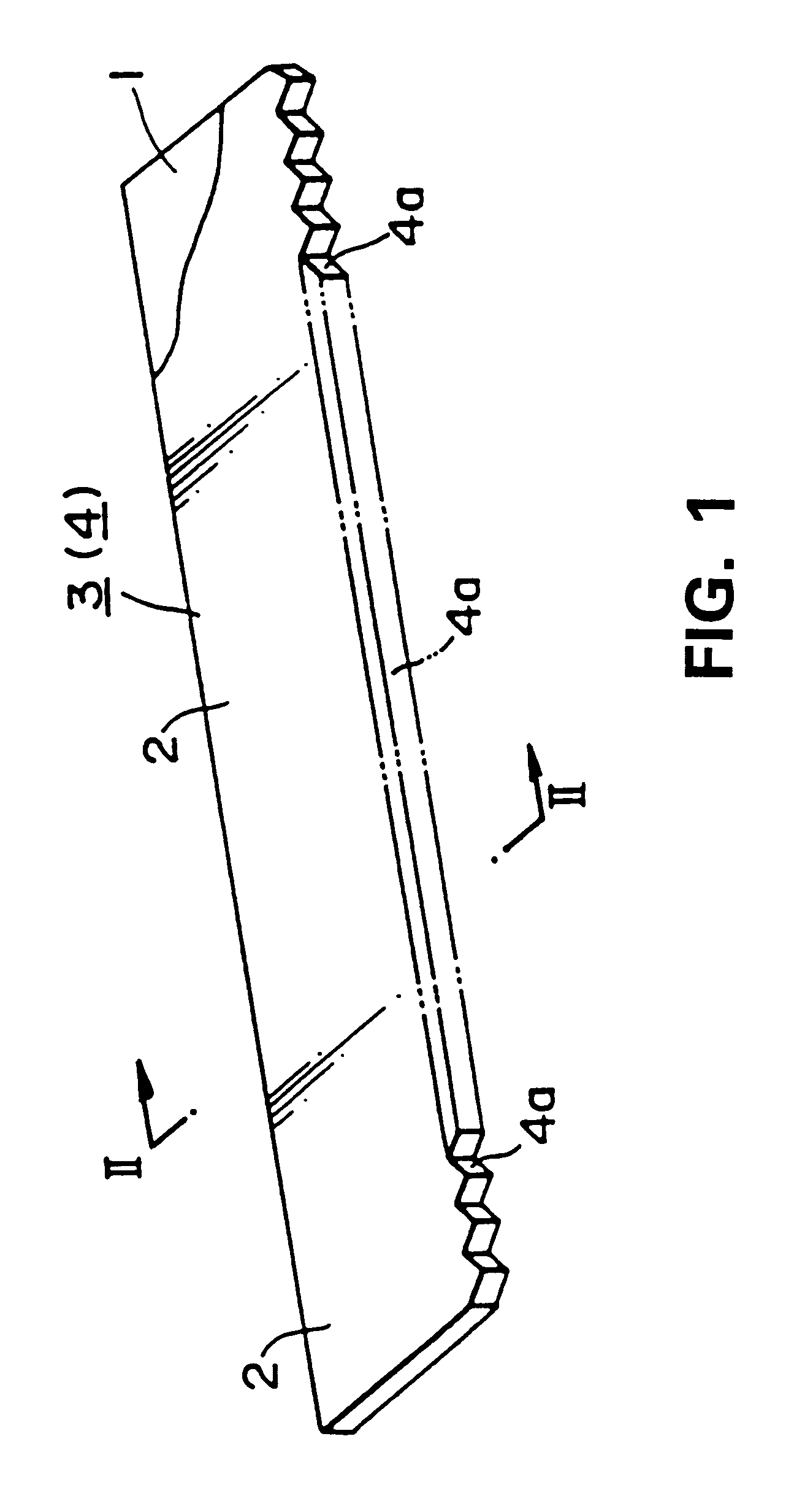

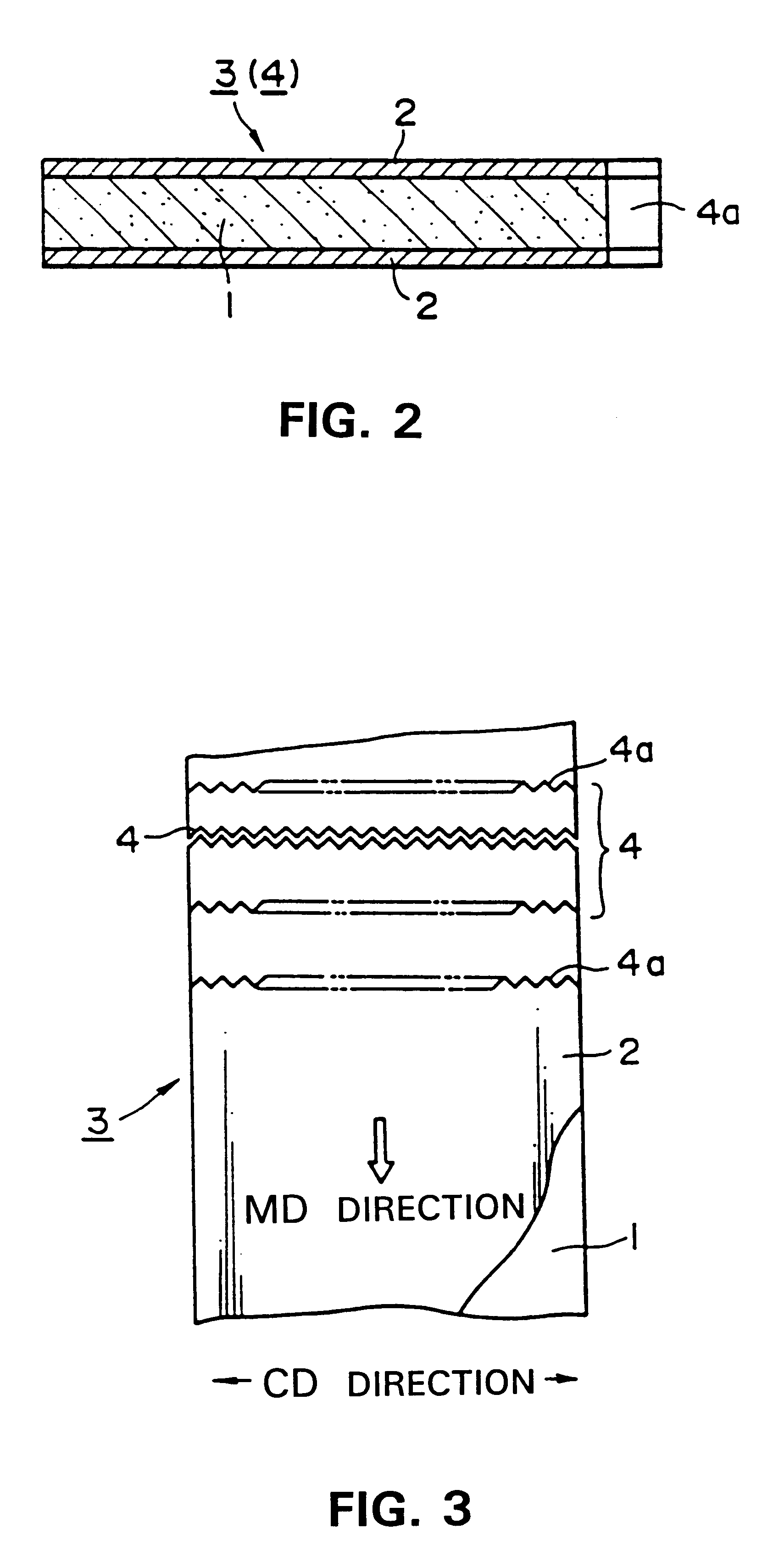

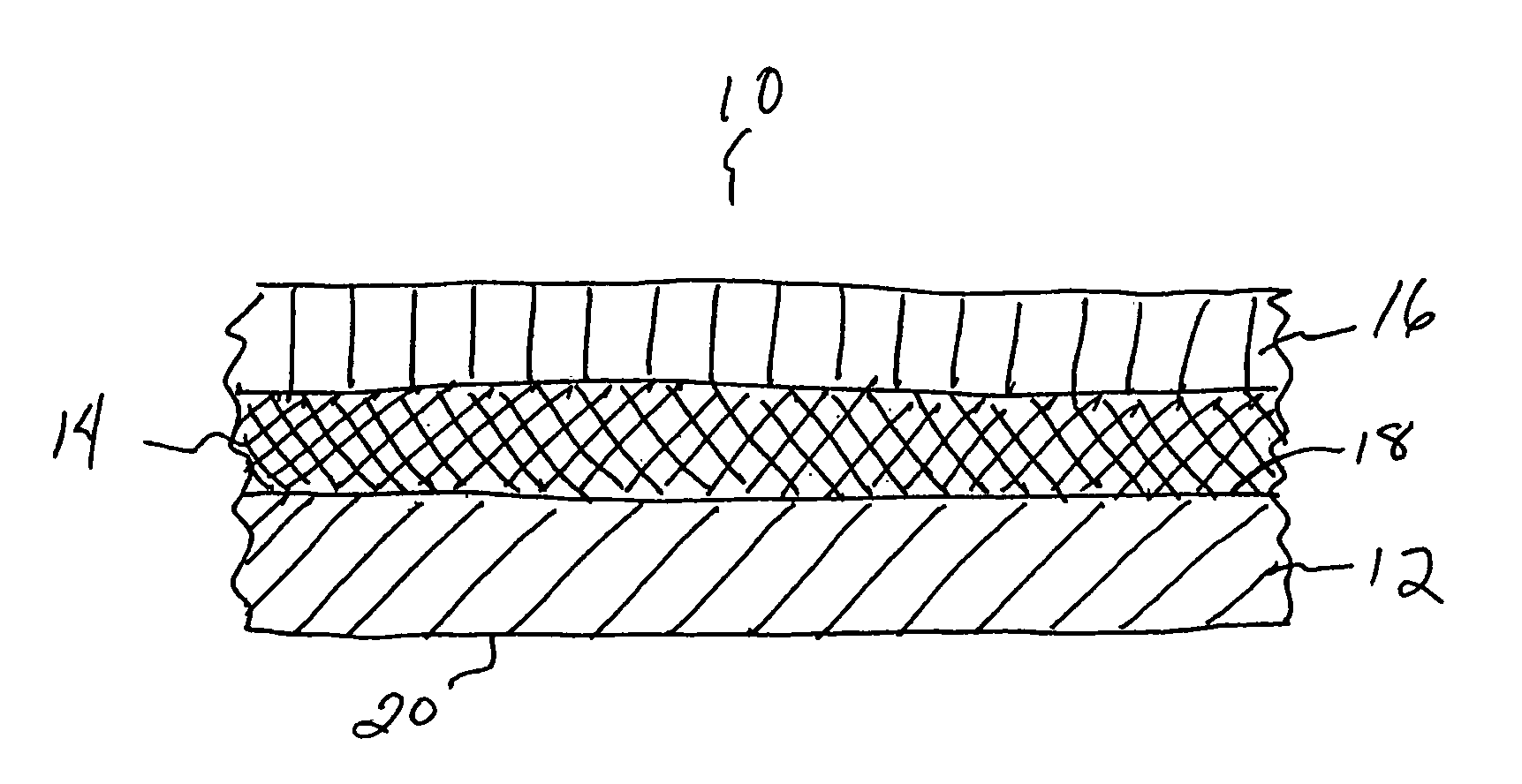

Vulcanized fiber sheet having a serrated cutting edge, a carton having said sheet adhered thereto, and a method of adhesion thereof

InactiveUS6173876B1Increase elasticityImprove rigidityBox making operationsFlat article dispensingMetallic foilFiber

The present invention is a sheet having a serrated cutting edge attached to a carton case containing a roll of a cooking sheet such as a synthetic resin film, paper sheet and metallic foil, the sheet having a serrated cutting edge used for cutting the cooking sheet. The sheet having a serrated cutting edge is made of a vulcanized fiber. A moisture-proof film of a synthetic resin is formed on the two surfaces of a vulcanized fiber blank in order to make the most of the rigidity and elasticity which are advantages of the vulcanized fiber and decreases moisture absorption which is a disadvantage thereof. The invention also is a carton to which the sheet having a serrated cutting edge is adhered to as well as to a method of adhering the sheet having a serrated cutting edge to the carton by utilizing the moisture-proof film and ultrasonic adhesion.

Owner:OJI PAPER CO LTD

Display panel

ActiveUS20200106045A1Prevent moisture penetrationSolve the real problemSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:SAMSUNG DISPLAY CO LTD

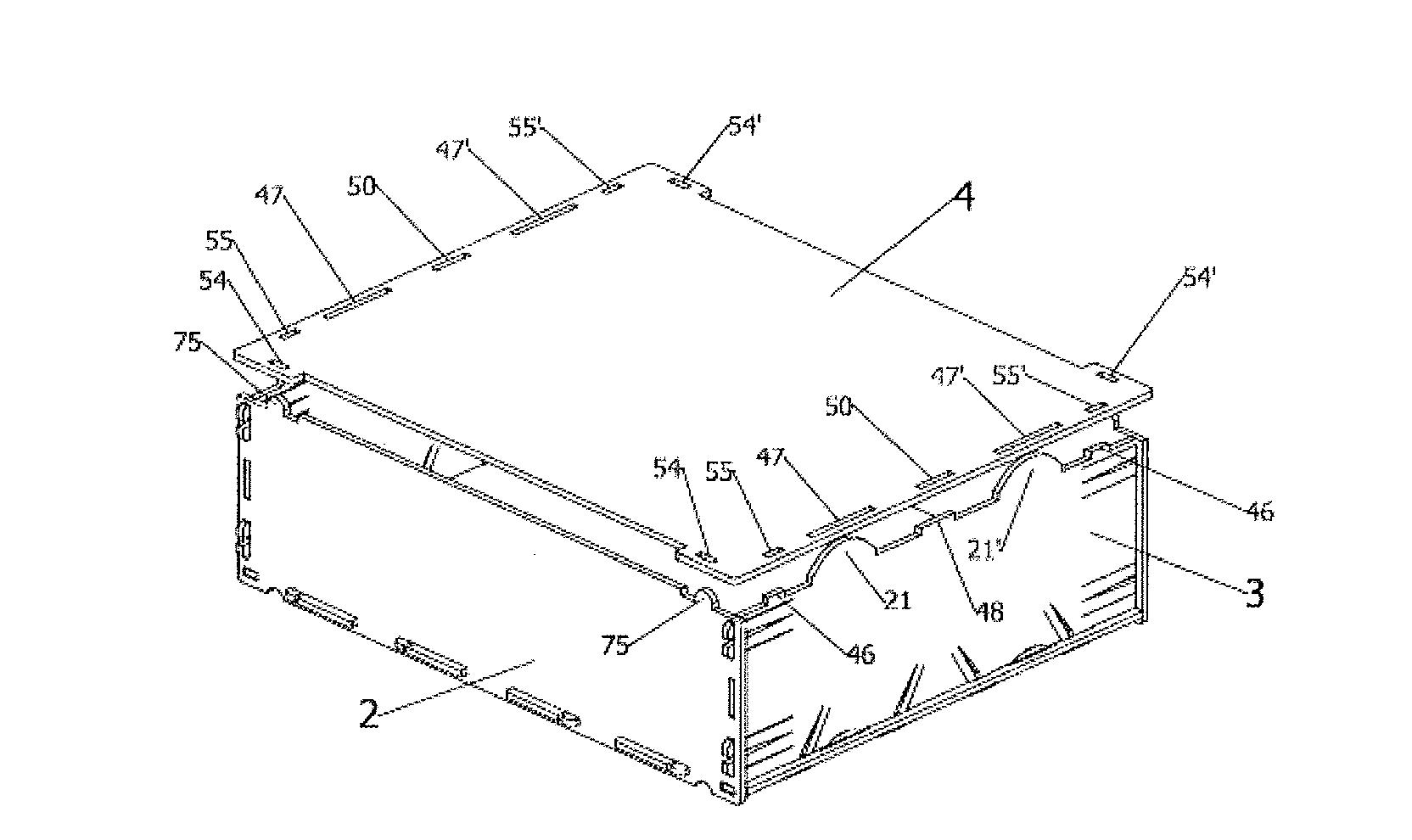

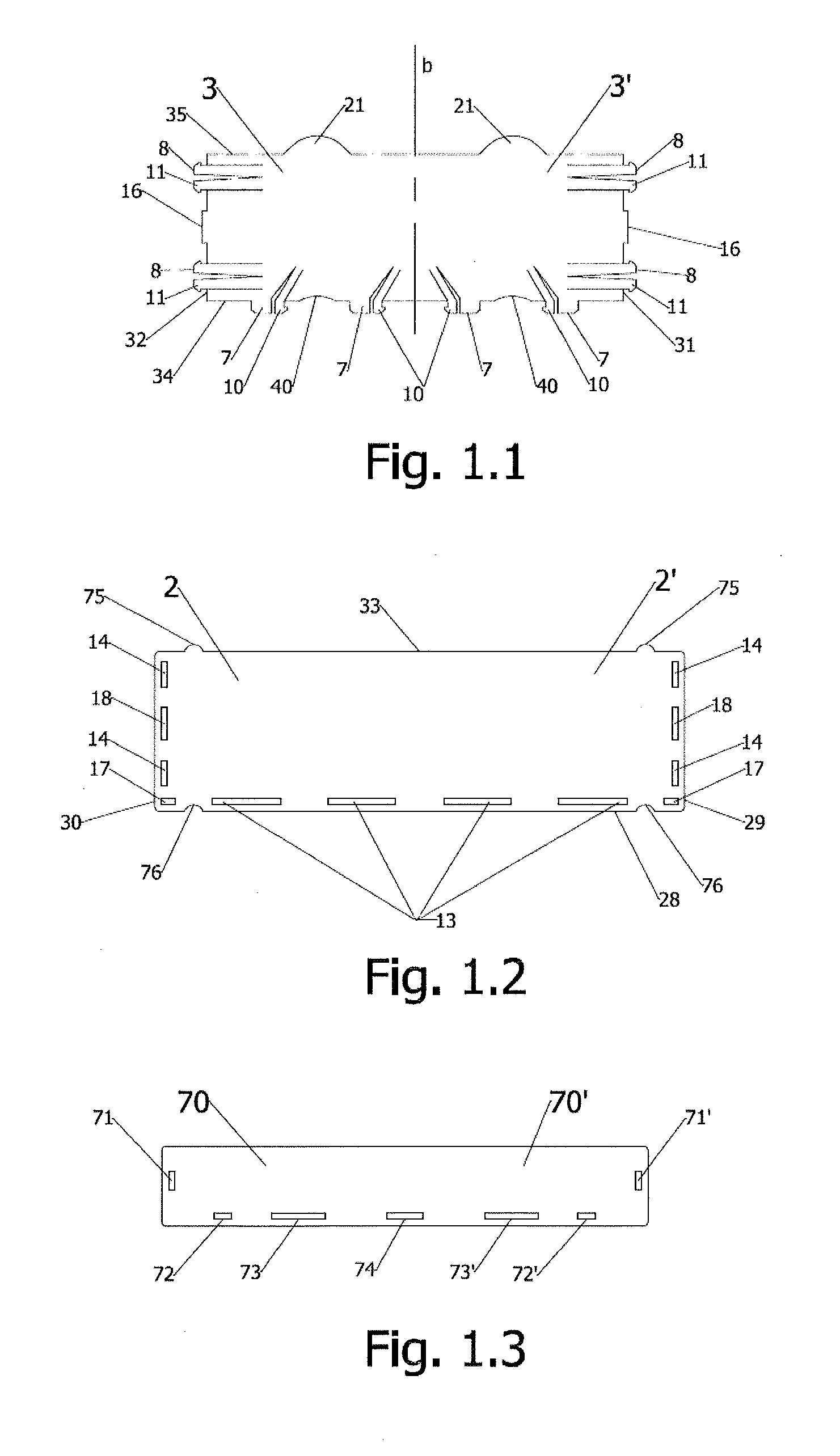

Self-assemblable container for generic use and manufacturing method thereof

ActiveUS20110309072A1Ensure structural stabilityAvoid disassemblyBoxes/cartons making machineryPaper-makingNatural resinMoisture penetration

The present invention refers to a self-assemblable container, preferably manufactured from ecologic materials such as standard fiberboard, comprising as its main structural elements a bottom, two longitudinal sides and two transverse sides of a basically rectangular shape having cauterized perimetrical faces to prevent moisture penetration into the structural elements that make up the container, thus providing long term structural stiffness to the perimetrical faces of the container's structural elements comparable to that of the fiberboard surface. Each of the main structural elements comprises in one side adjacent to another corresponding main structural element, tensile-resistant flexible tabs or receiving slots, the other corresponding main structural element in said side adjacent to the first main structural element respectively comprising slots or flexible tensile resistant tabs, said main structural elements being assembled together by the insertion of the flexible tabs into the receiving slots. In addition, the container may comprise an antisagging brace, a lid and / or two transverse laths. The invention also refers to a method of manufacturing the structural elements of a self-assemblable container by means of perimetrical laser cutting that by reason of the extremely high cutting temperature causes a reaction of the natural resins contained in the raw material and the resulting perimetrical cauterization.

Owner:COMPANIA DE PATENTES DEL PACIFICO

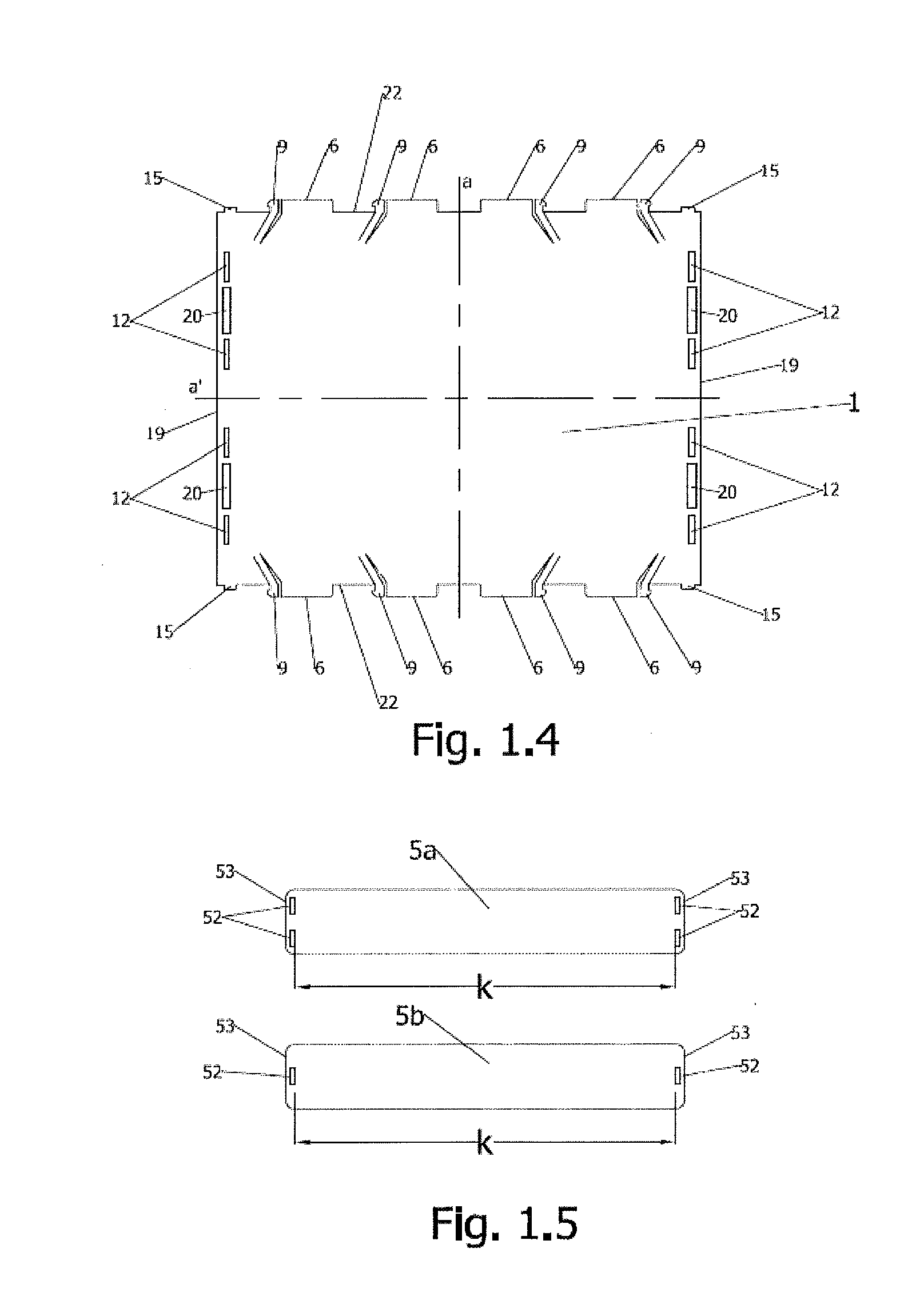

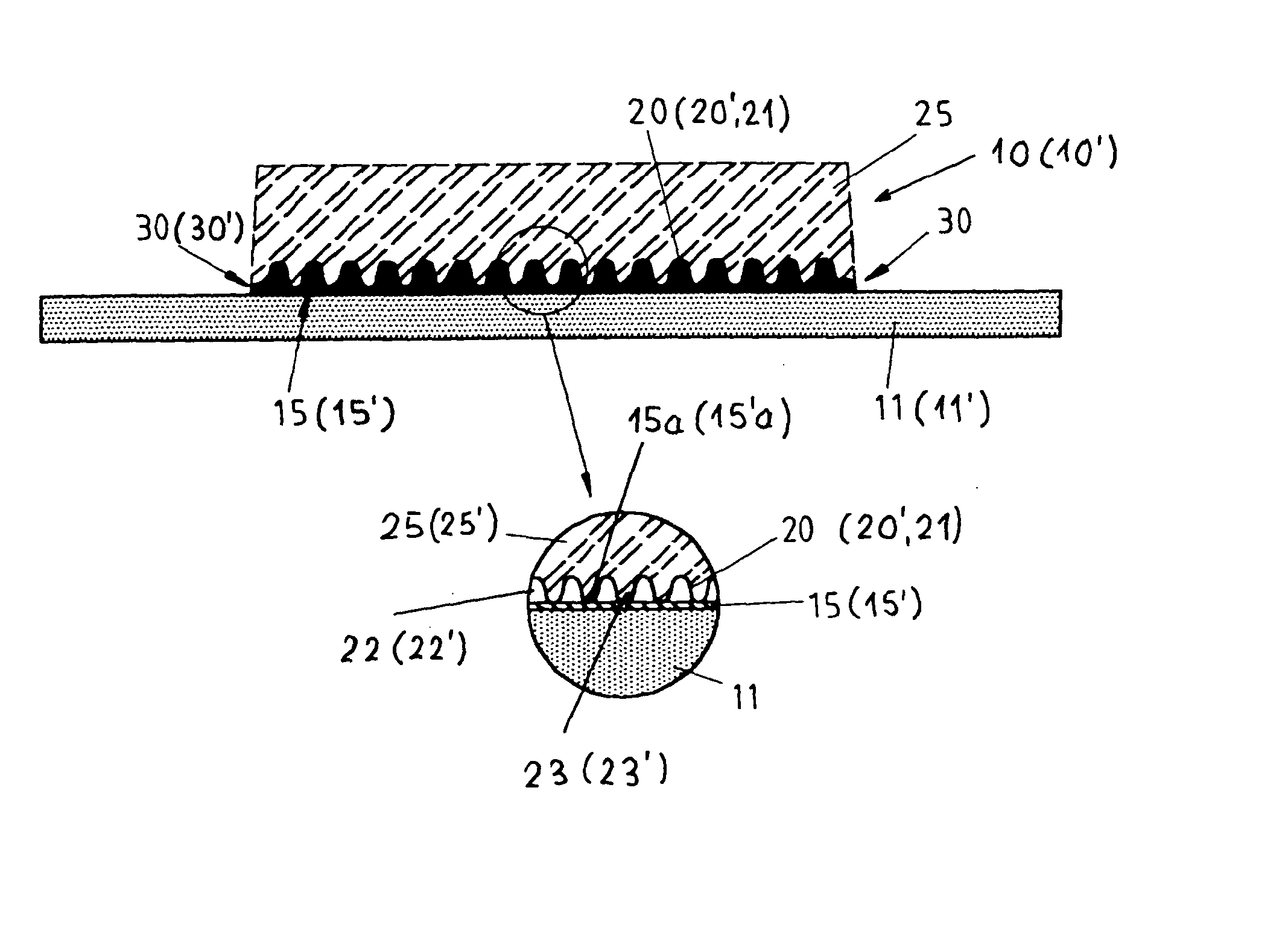

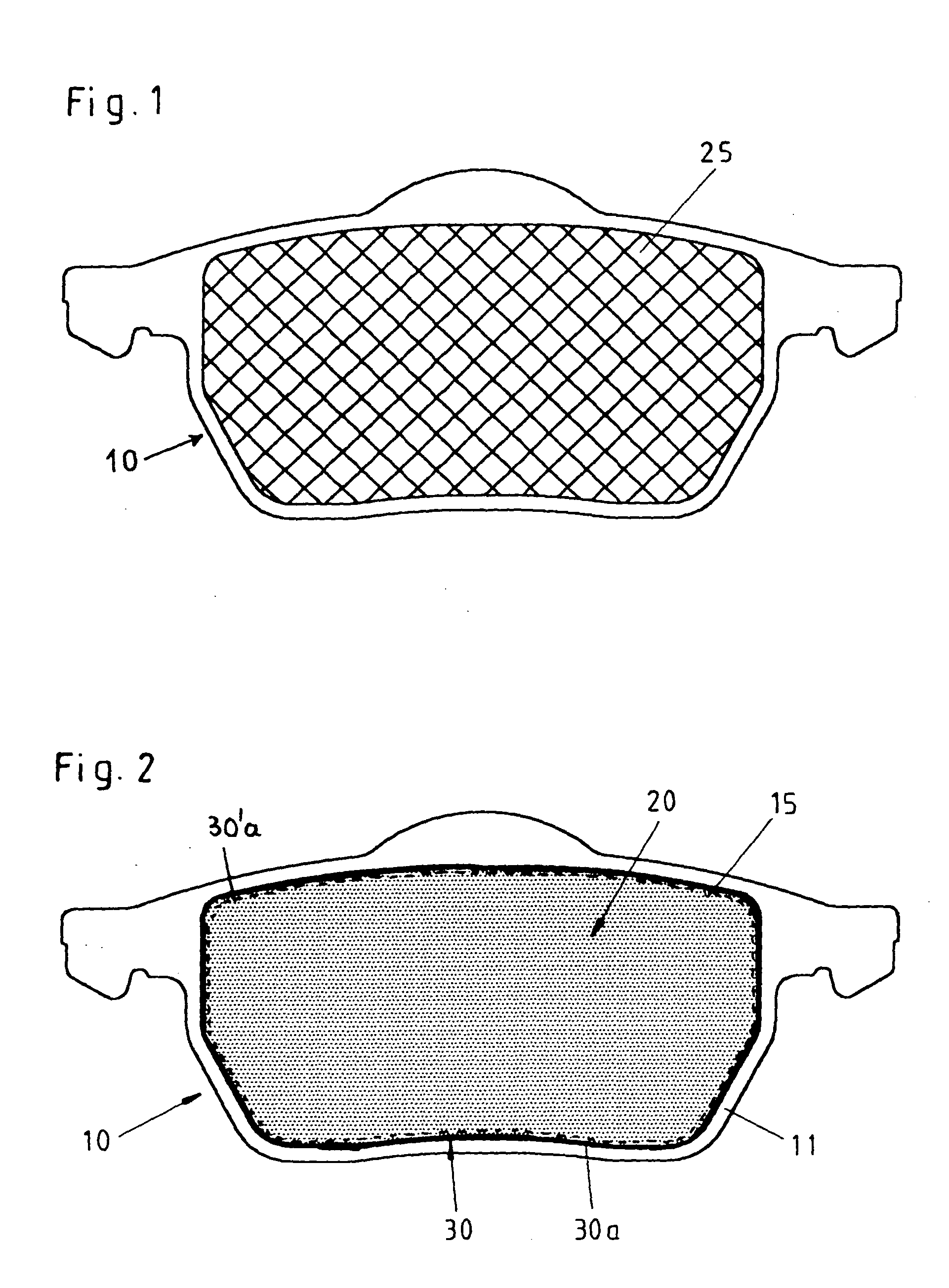

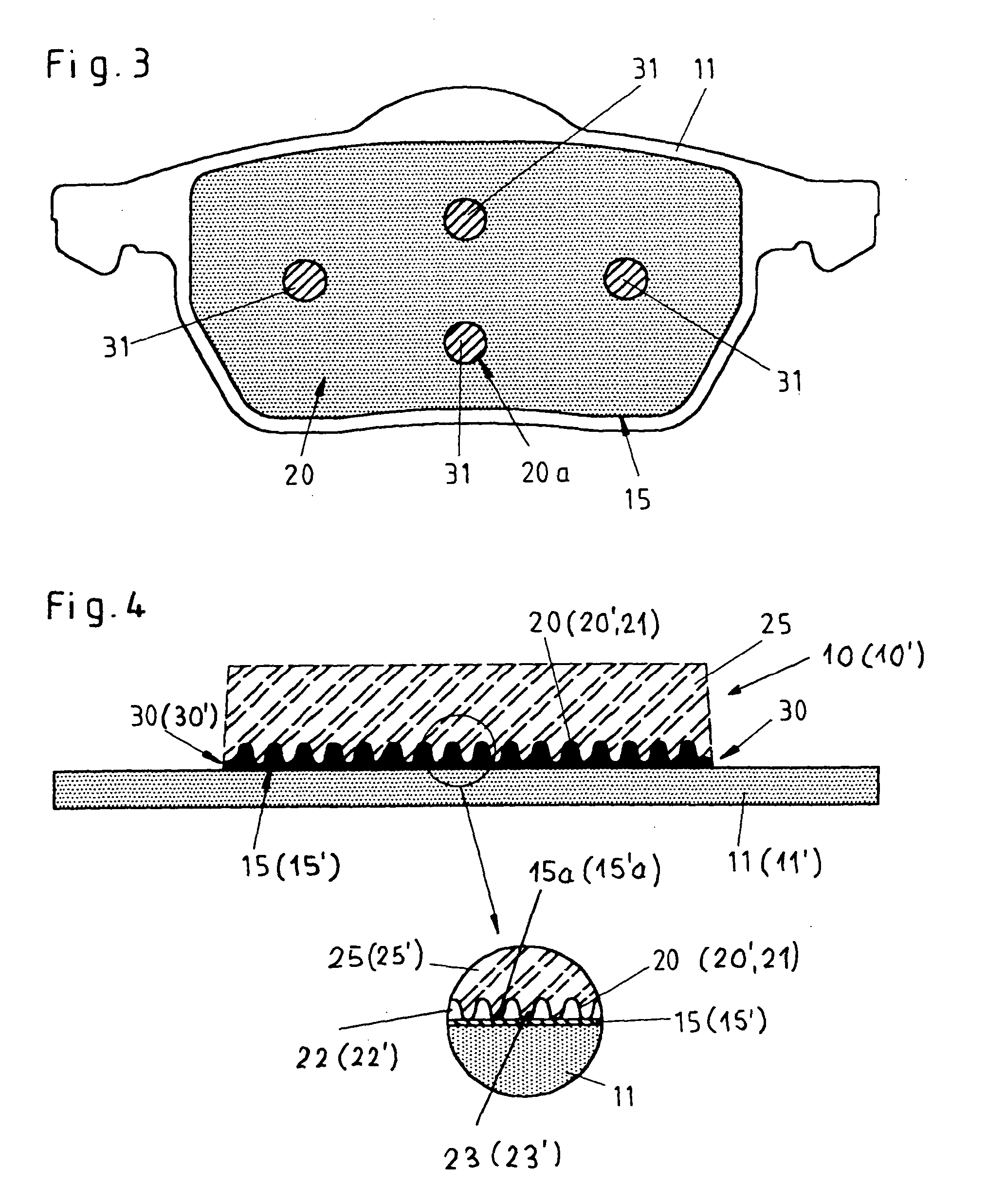

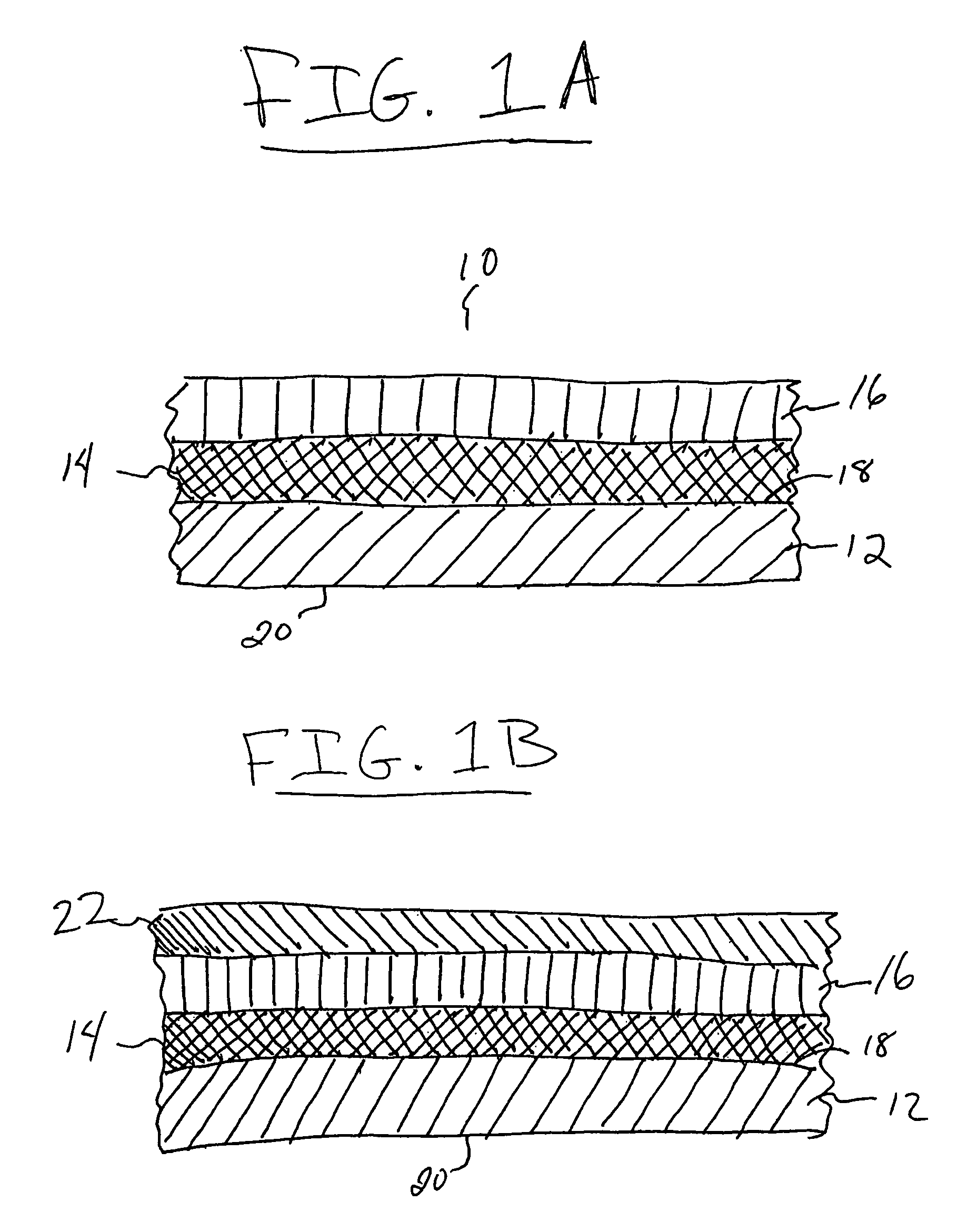

Lining, in particular friction lining for disc brakes

InactiveUS20040099493A1Improve strength propertiesMaintain propertiesNoise/vibration controlFriction liningSynthetic materialsMetal sheet

The lining or functional body (10) consists a carrier (11) in form of a ground plate, for example a carrier plate or a carrier sheet, of a thin-walled rough ground carrier (15; 15') made of a metal sheet or of another appropriate material placed on the carrier (11; 11'), of a rough ground (20') made of a support base (20; 20'; 21) sintered on the surface (15a; 15'a) of the rough ground carrier (15; 15') which is turned away from the lining carrier (11; 11'), this support base being made of single moulded bodies (22') with undercuts, recesses or the like which are positively and frictionally connected with the rough ground carrier (15; 15'), and of a functional block (25; 25') fixed on the rough ground carrier (15; 15') with the rough ground (20'), this functional block being made of a friction material, a synthetic material, in particular of such a synthetic material which is not appropriate to be glued together or to be applied in another manner, for example of a polymer or teflon, whereby the rough ground carrier (15; 15') is fixed on the lining carrier (11; 11') by means of a welded, riveted or glued joint (30; 30') or other connecting procedures, such as engraving.

Owner:HONEYWELL BREMSBELAG GMBH

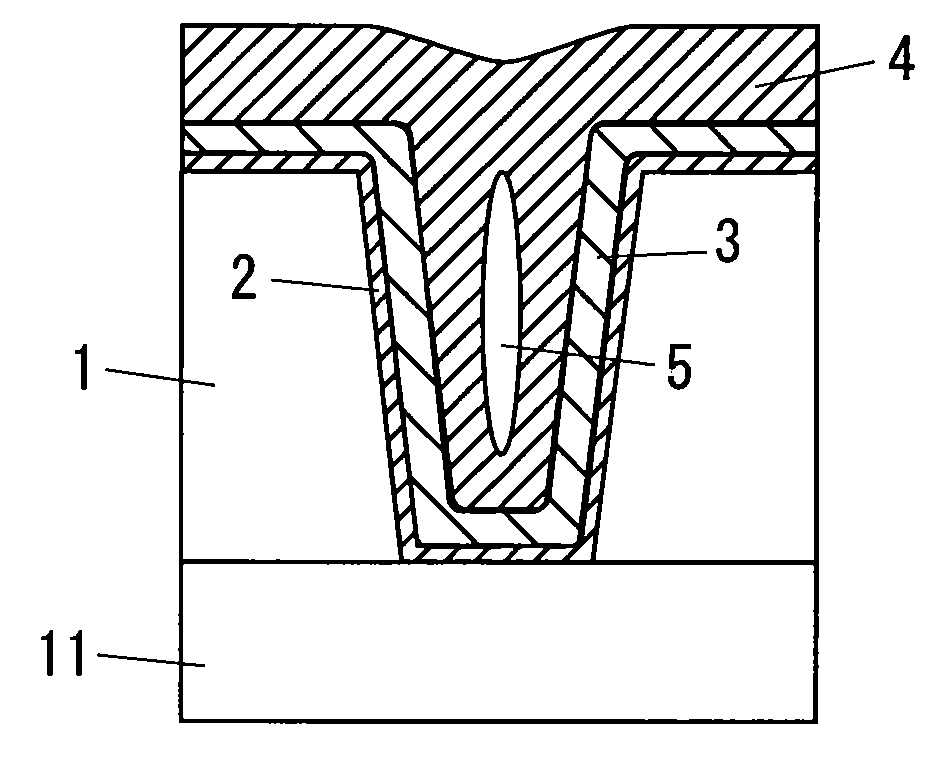

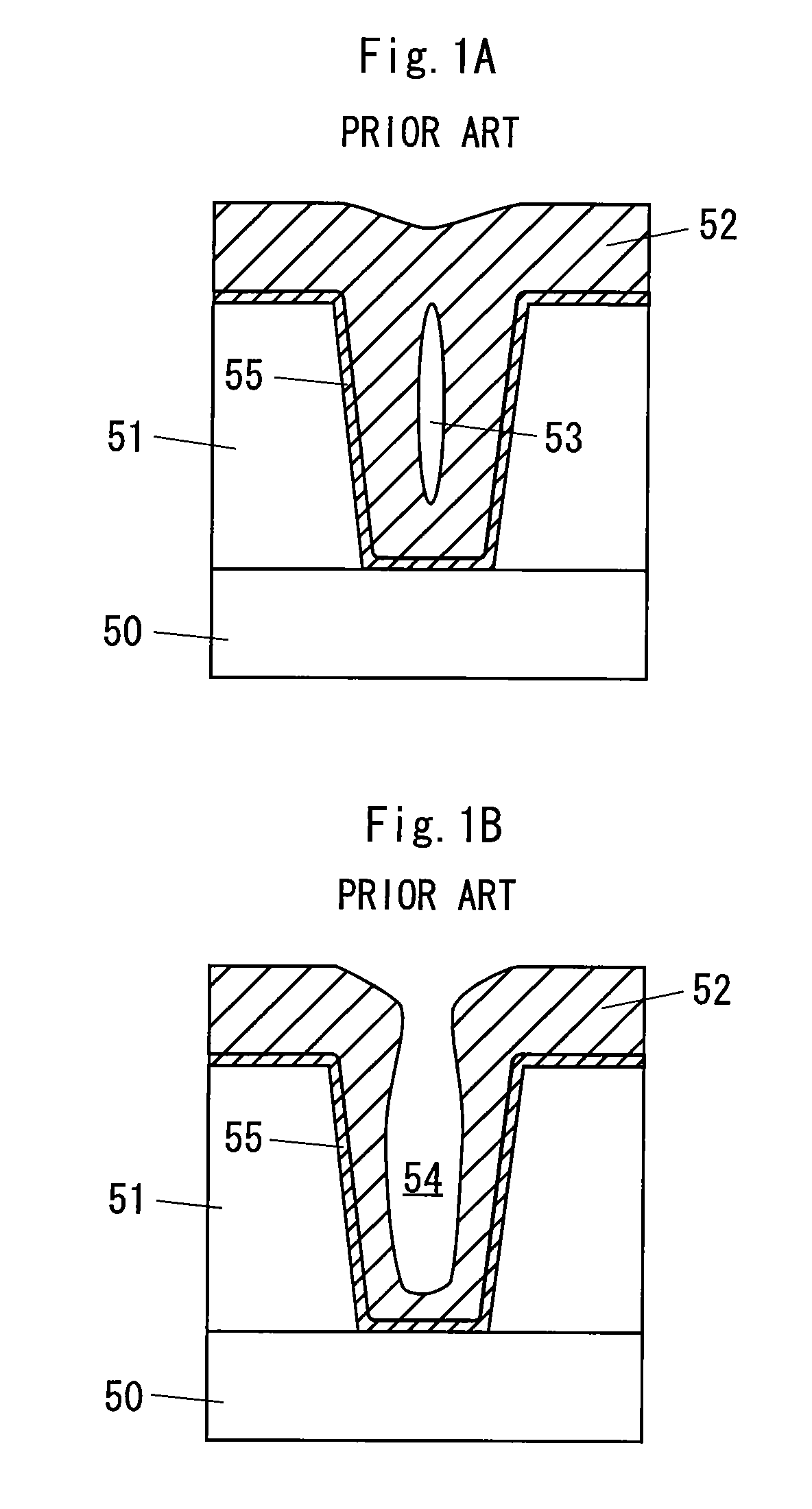

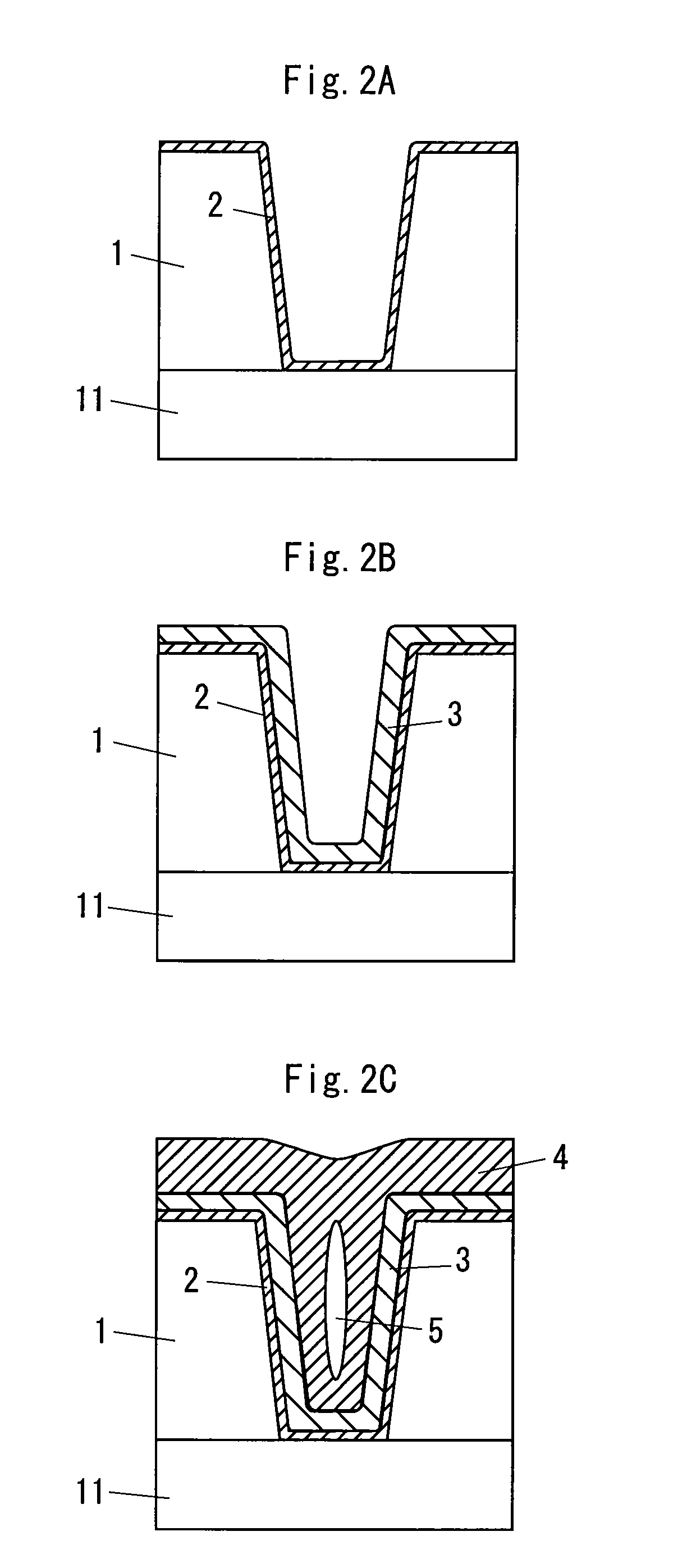

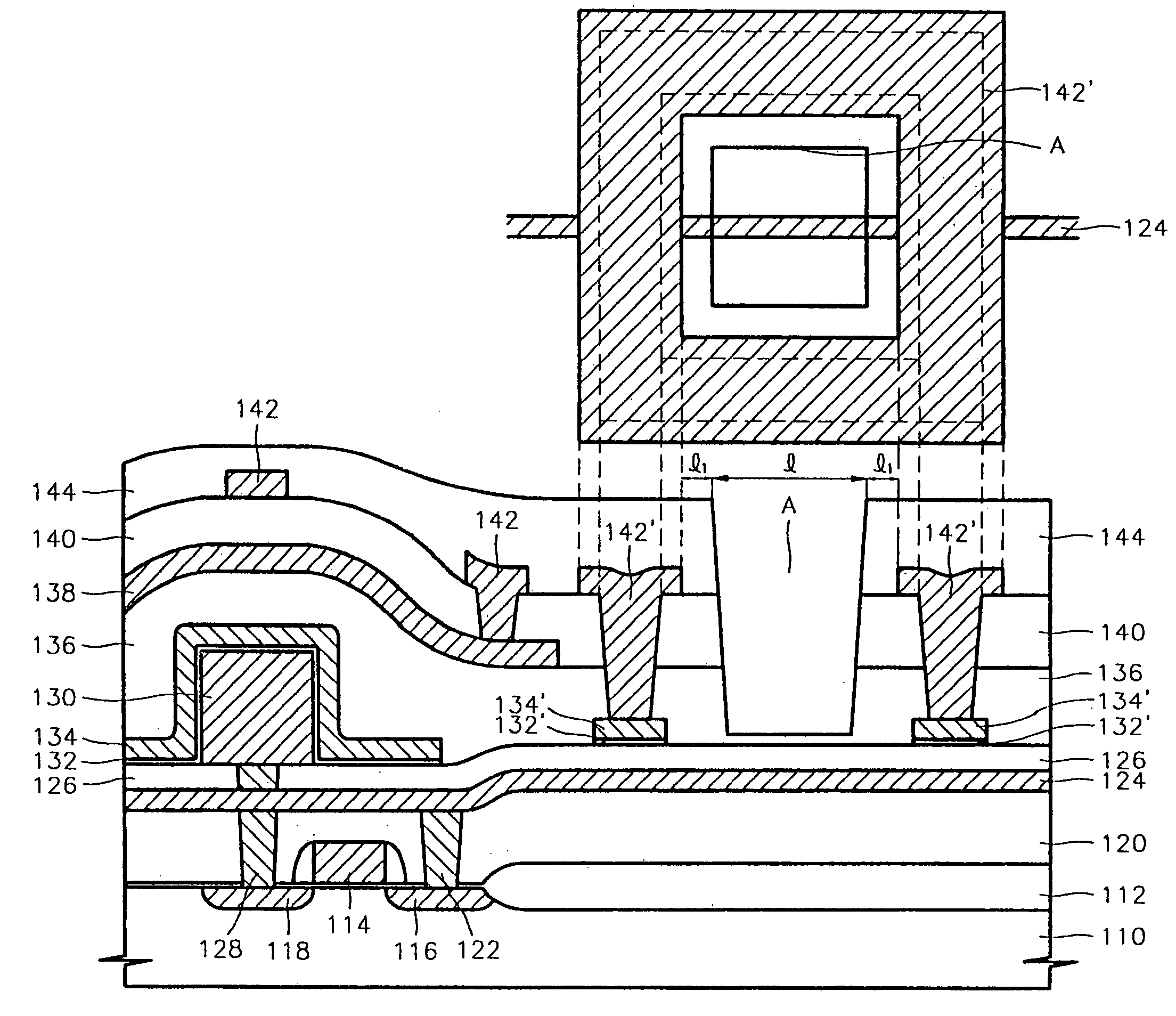

Method For Manufacturing Semiconductor Device

InactiveUS20080160783A1Eliminate voidsPrevent moisture penetrationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMoisture

A method for manufacturing semiconductor device according to the present invention comprises a first film forming step of forming, on a concave and convex portion formed by an element on a semiconductor substrate, an oxidation preventive layer which prevents permeation of moisture into the element; a second film forming step of forming, on this oxidation preventive layer, an expansion layer which can be oxidized and expanded by a heat treatment in an oxidation atmosphere; a third film forming step of forming, on this expansion layer, an insulating film which can be fluidized by the heat treatment in the oxidation atmosphere; and an expansion step of subjecting, to the heat treatment in the oxidation atmosphere, the semiconductor substrate on which the oxidation preventive layer, the expansion layer and the insulating film have been formed, to fluidize the insulating film and to oxidize and expand the expansion layer, thereby eliminating bubbles generated in the insulating film.

Owner:IHI CORP

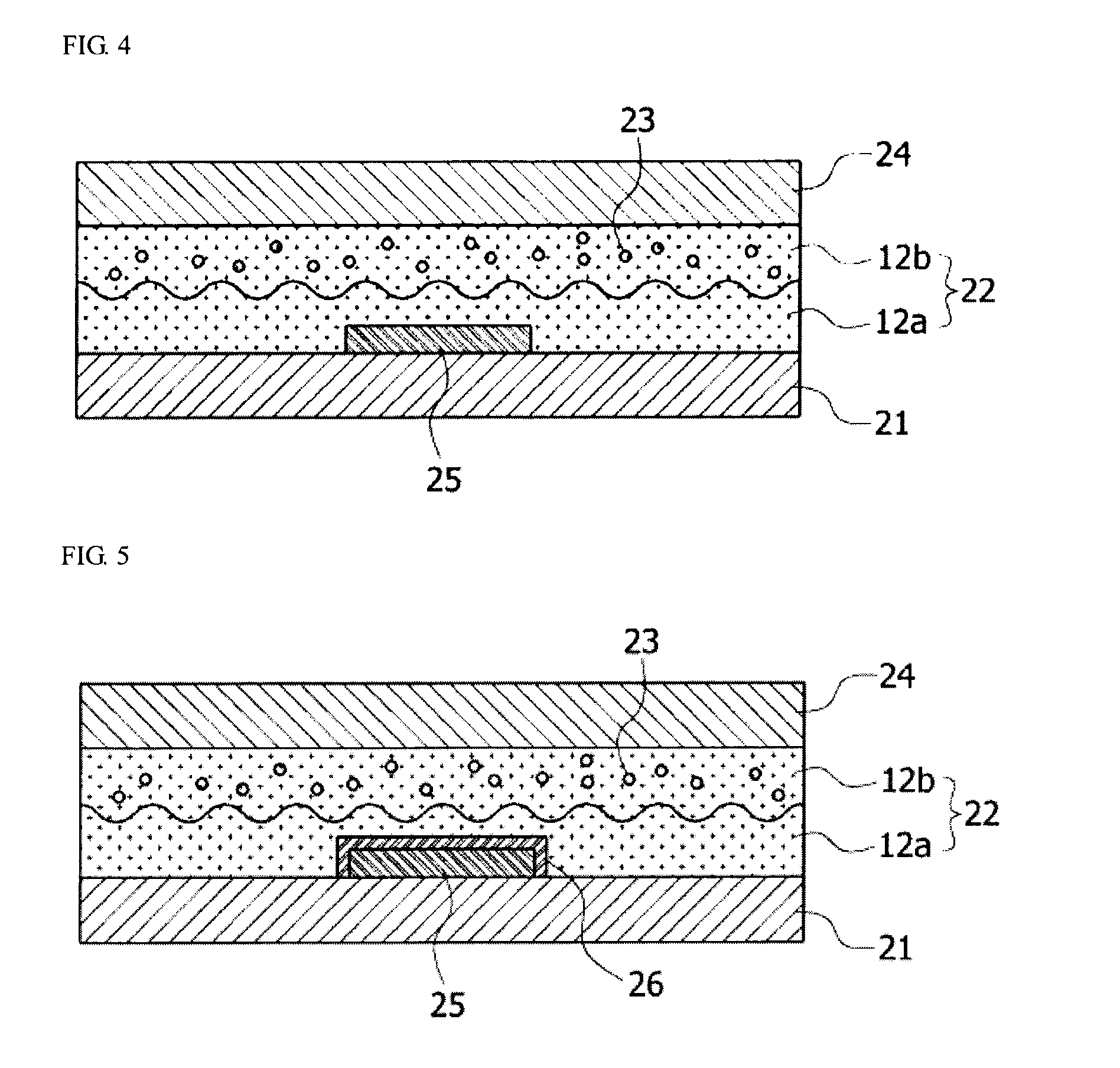

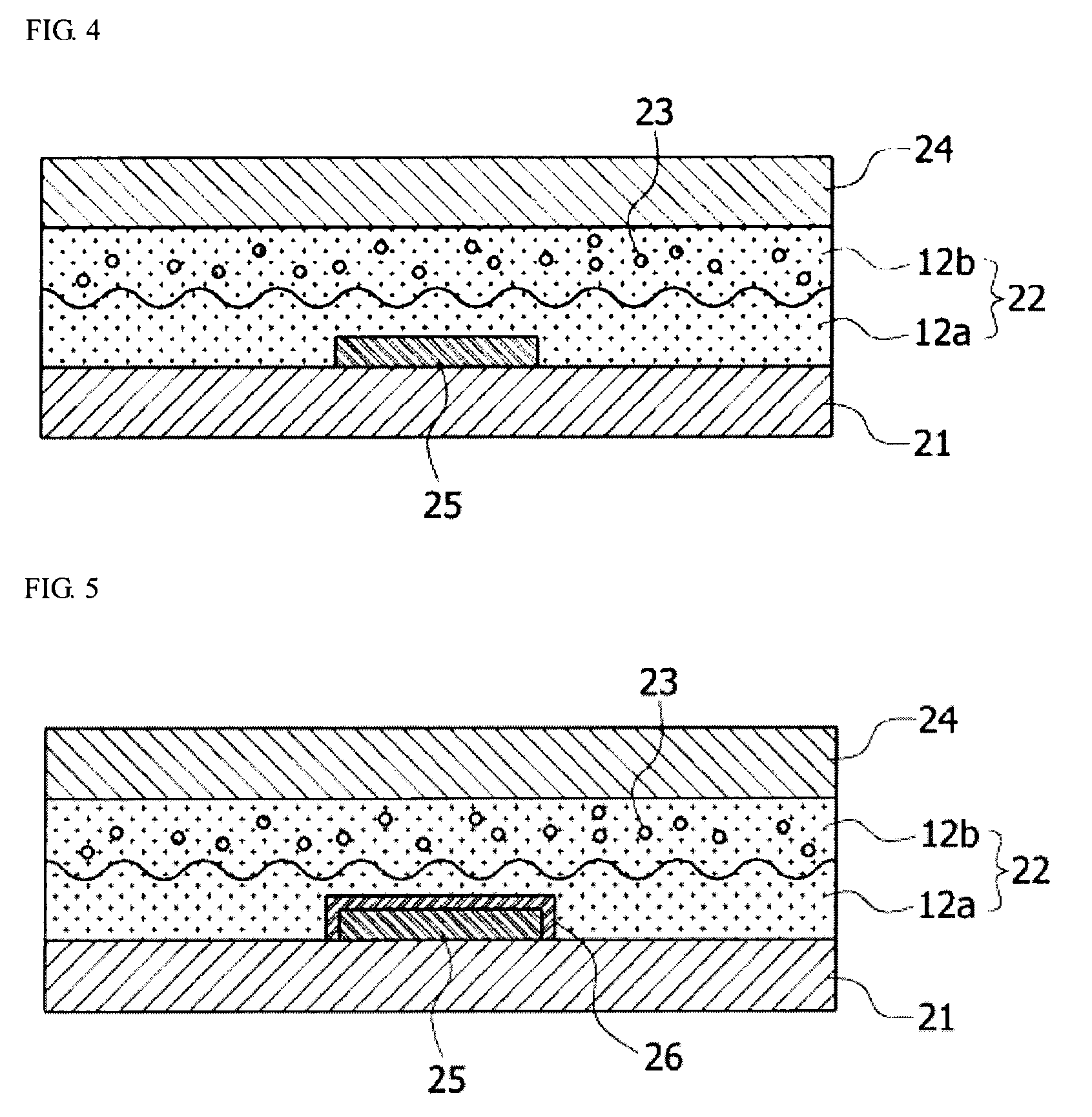

Adhesive film and method of encapsulating organic electrode device using the same

ActiveUS20130240862A1Prevent moisture penetrationEffectively introduce a moisture-reactive absorbentNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsChemistryHot-melt adhesive

An adhesive film, and a product and method of encapsulating an organic electronic device (OED) using the same are provided. The adhesive film serves to encapsulate the OED and includes a curable hot-melt adhesive layer including a curable resin and a moisture absorbent, and the curable hot-melt adhesive layer includes a first region coming in contact with the OED upon encapsulation of the OED and a second region not coming in contact with the OED. Also, the moisture absorbent is present at contents of 0 to 20% and 80 to 100% in the first and second regions, respectively, based on the total weight of the moisture absorbent in the adhesive layer.

Owner:LG CHEM LTD

Organic light emitting diode display

ActiveUS20150041791A1Prevent and reduce damagePrevent moisture penetrationElectroluminescent light sourcesSolid-state devicesDisplay deviceLight-emitting diode

An organic light emitting diode (OLED) display includes a substrate including a pixel area and a surrounding peripheral area. The pixel area includes at least one pixel including an organic light emitting element. The OLED display includes a common voltage line disposed in the peripheral area and configured to transmit a common voltage to the pixel area, a barrier rib disposed on the substrate and covering one side of the common voltage line, a protection member covering another side of the common voltage line, at least one thin film transistor (TFT) disposed in the pixel area, a first electrode disposed in the pixel area and connected to the at least one TFT, an organic emission layer disposed on the first electrode, a second electrode disposed on the organic emission layer and connected to the common voltage line, and an encapsulation layer disposed on the protection member and the second electrode.

Owner:SAMSUNG DISPLAY CO LTD

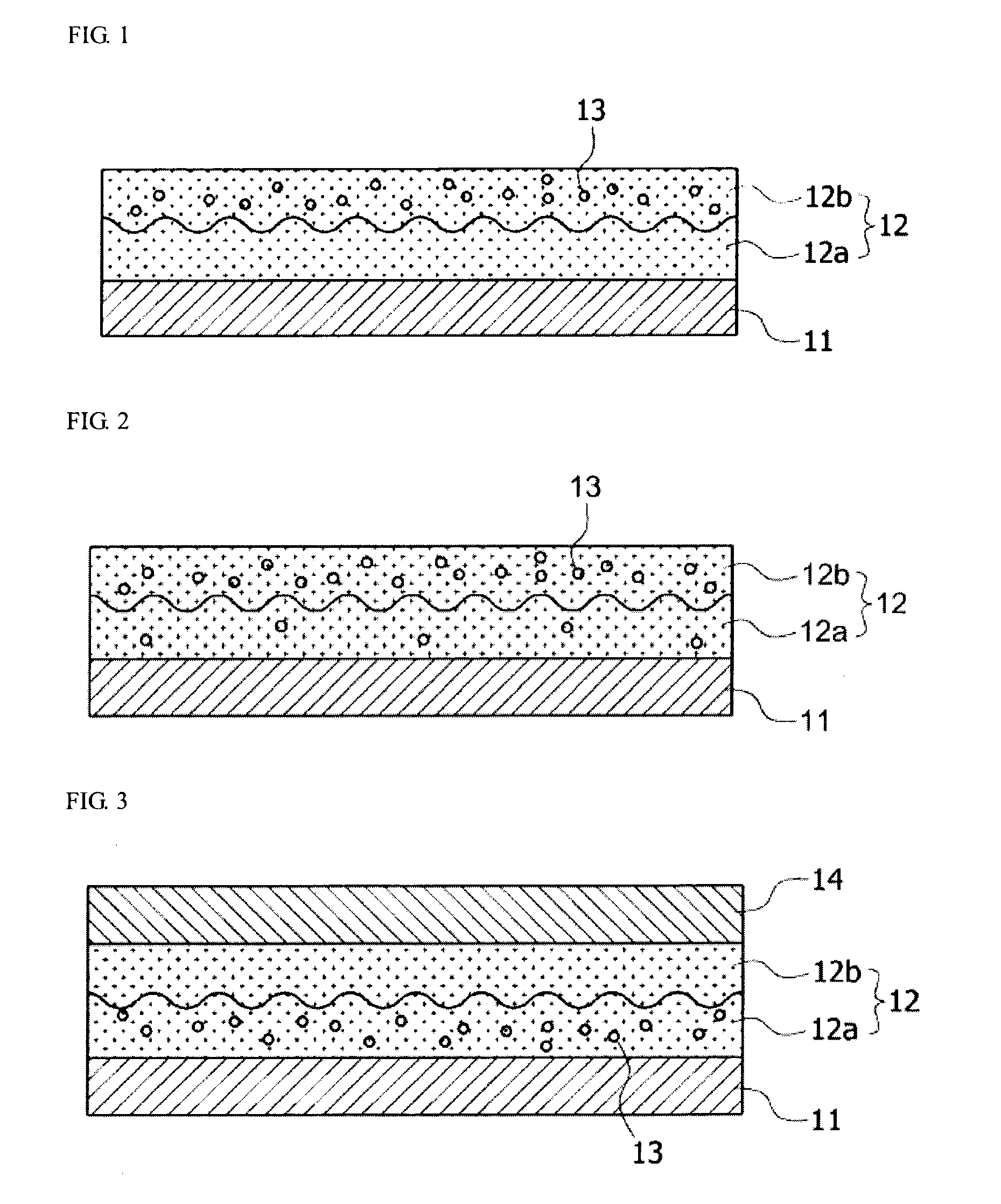

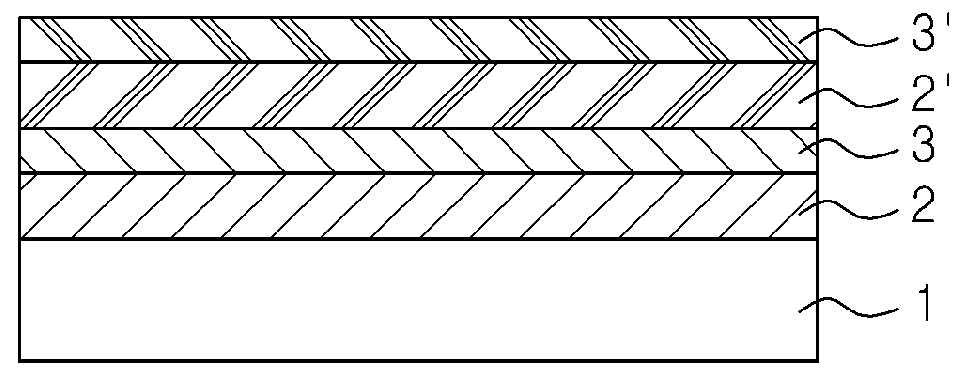

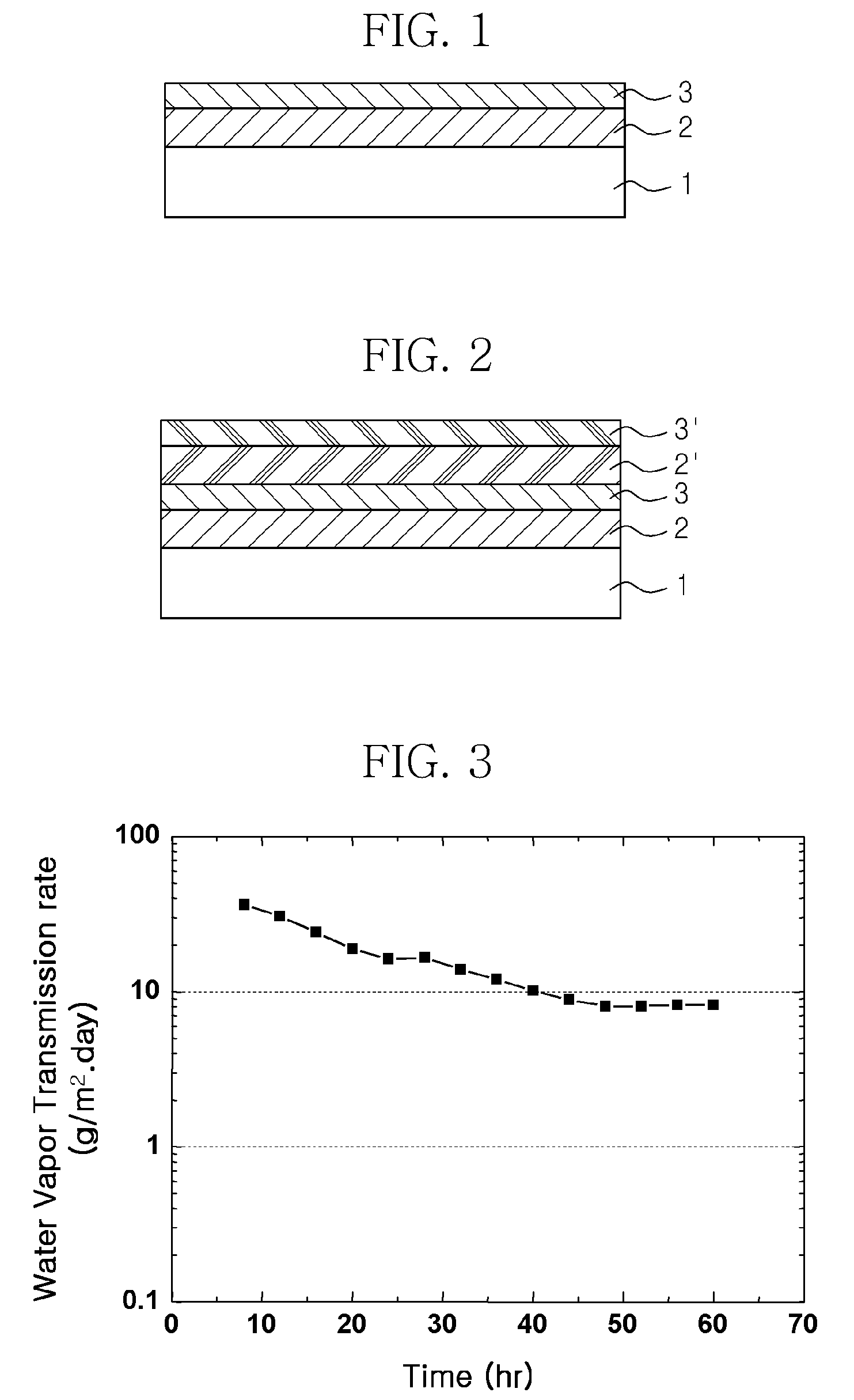

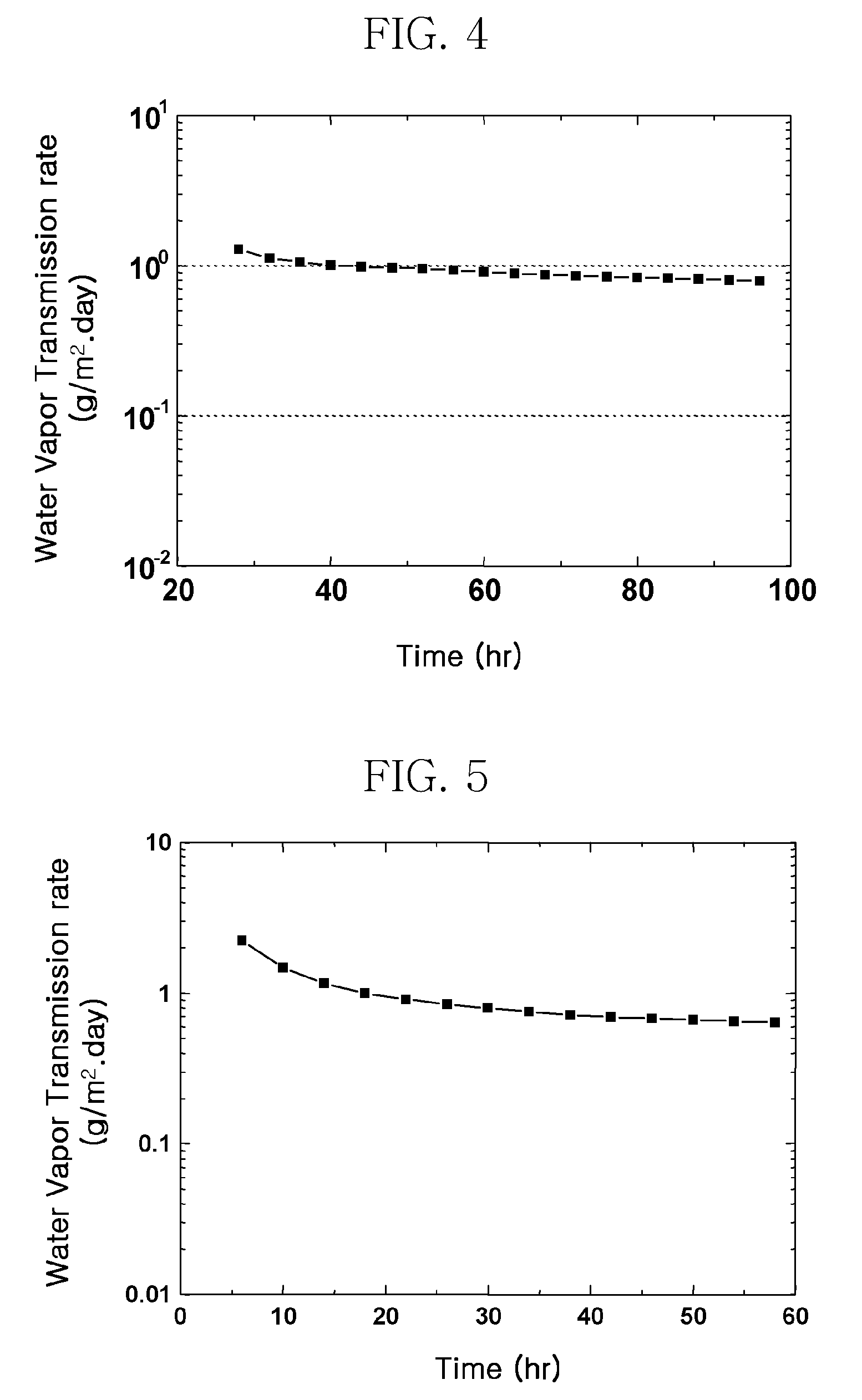

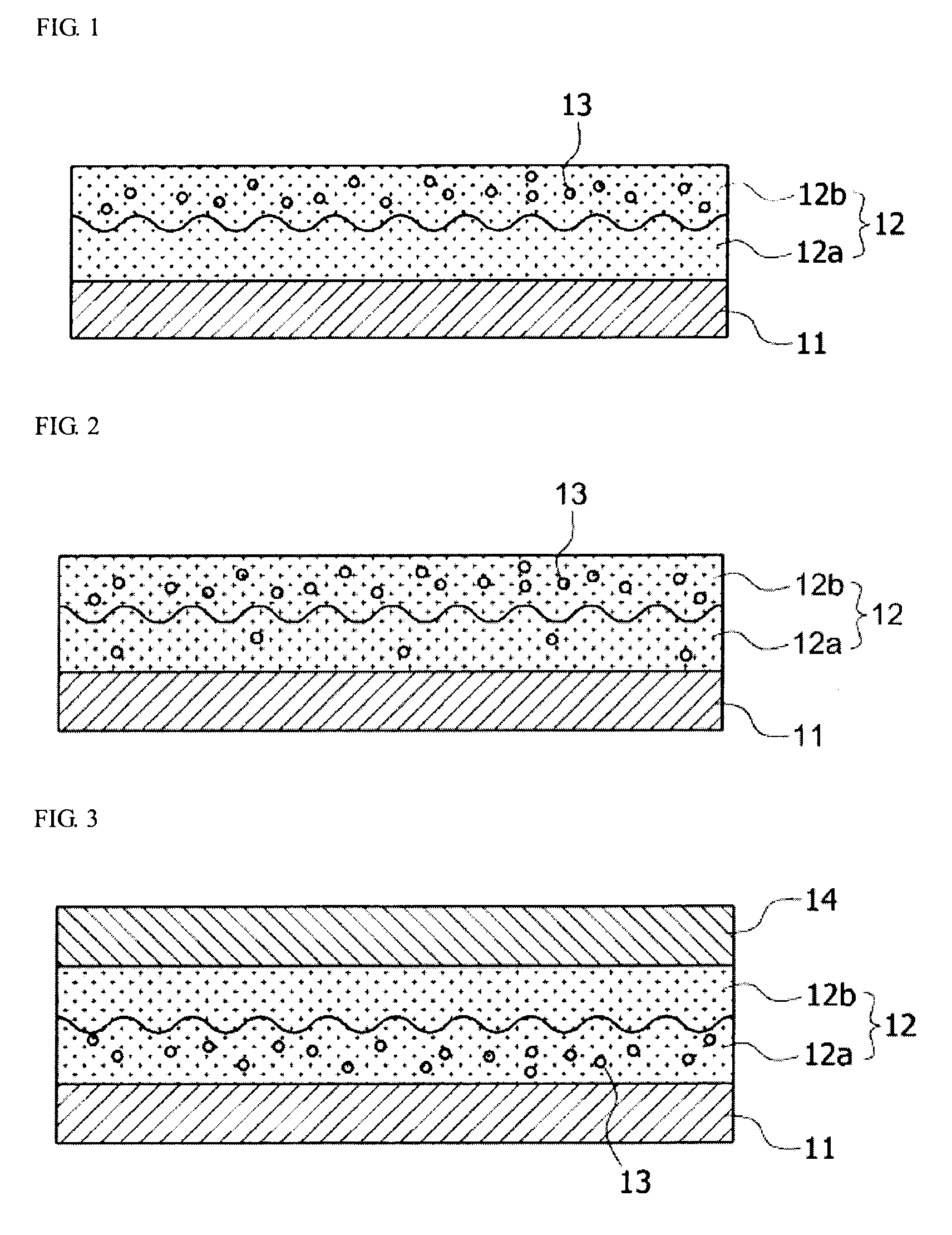

Protective film and encapsulation material comprising the same

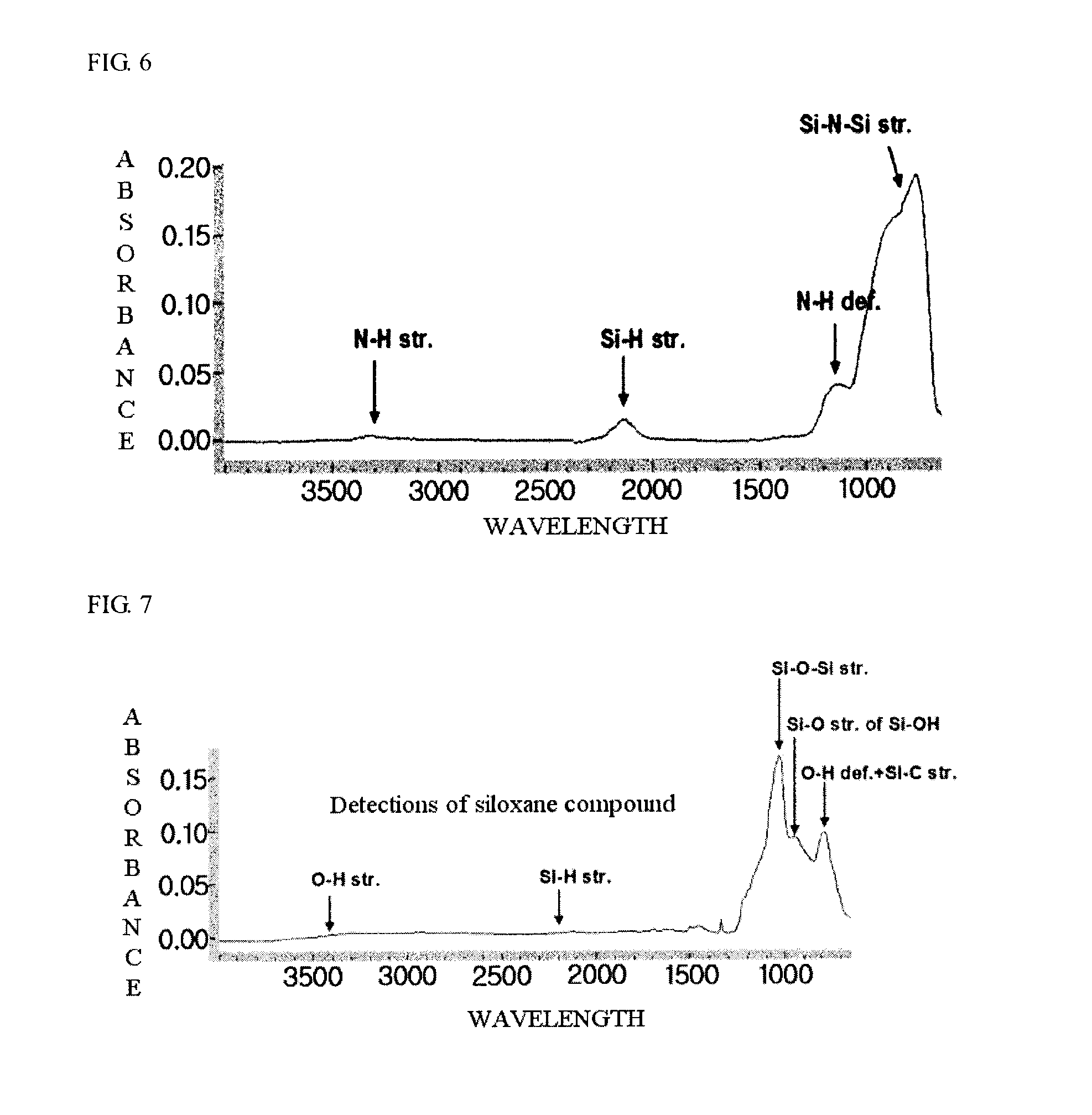

ActiveUS20090252975A1Prevent moisture penetrationIncrease flexibilitySynthetic resin layered productsCoatingsOptical transmittancePolysilazane

Disclosed herein is a protective film. The protective film is produced by alternate coating of a polysilazane-based polymer and a flexible polysiloxane-based polymer. The polysilazane-based polymer is cured at low temperature to form silica, thereby achieving high hardness and high light transmittance. The protective film has improved interfacial adhesion between the respective coating films, which prevents permeation of moisture and oxygen. In addition, the protective film can be easily produced by low-temperature wet processes. Also disclosed herein is an encapsulation material comprising the protective film.

Owner:CHEIL IND INC +1

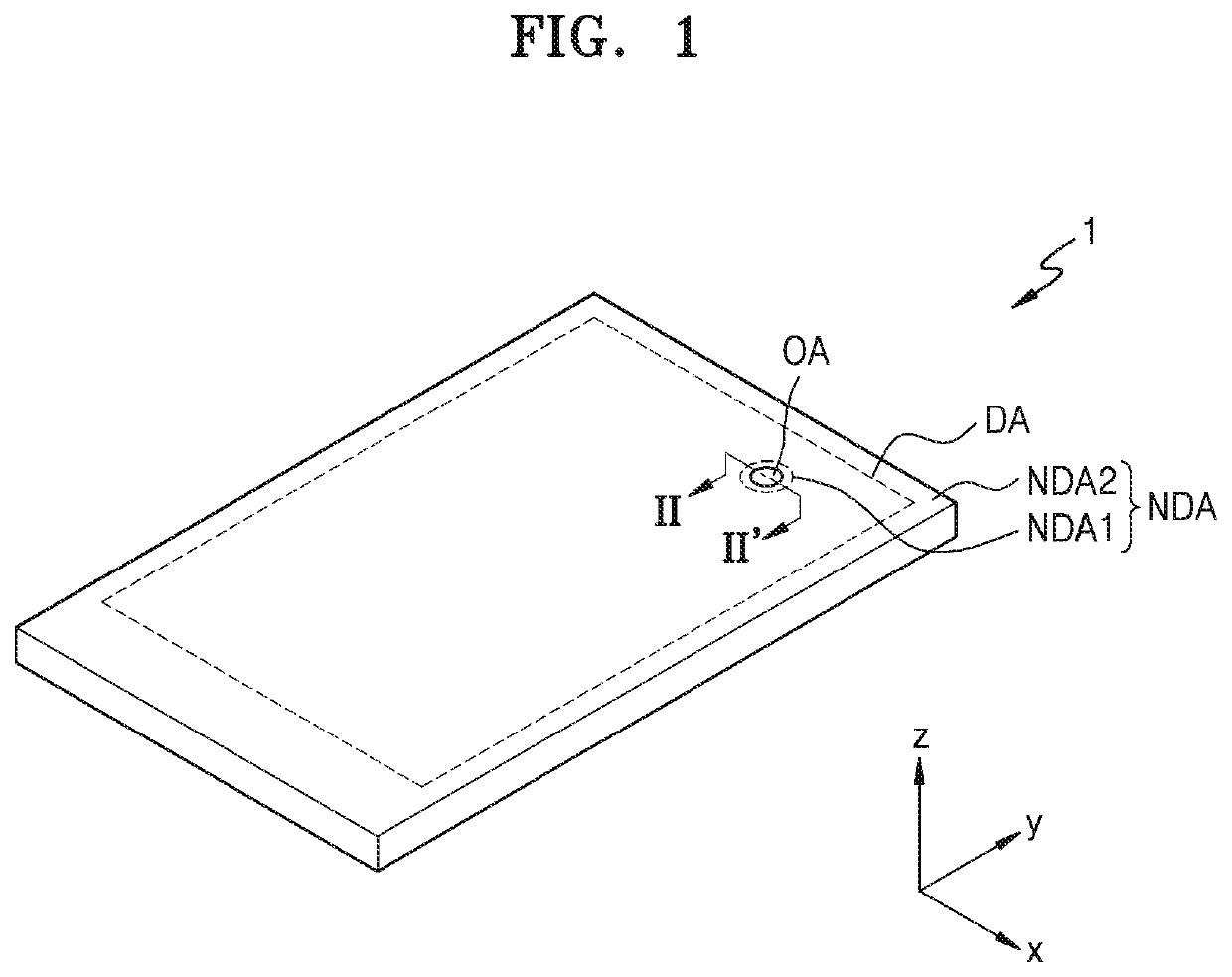

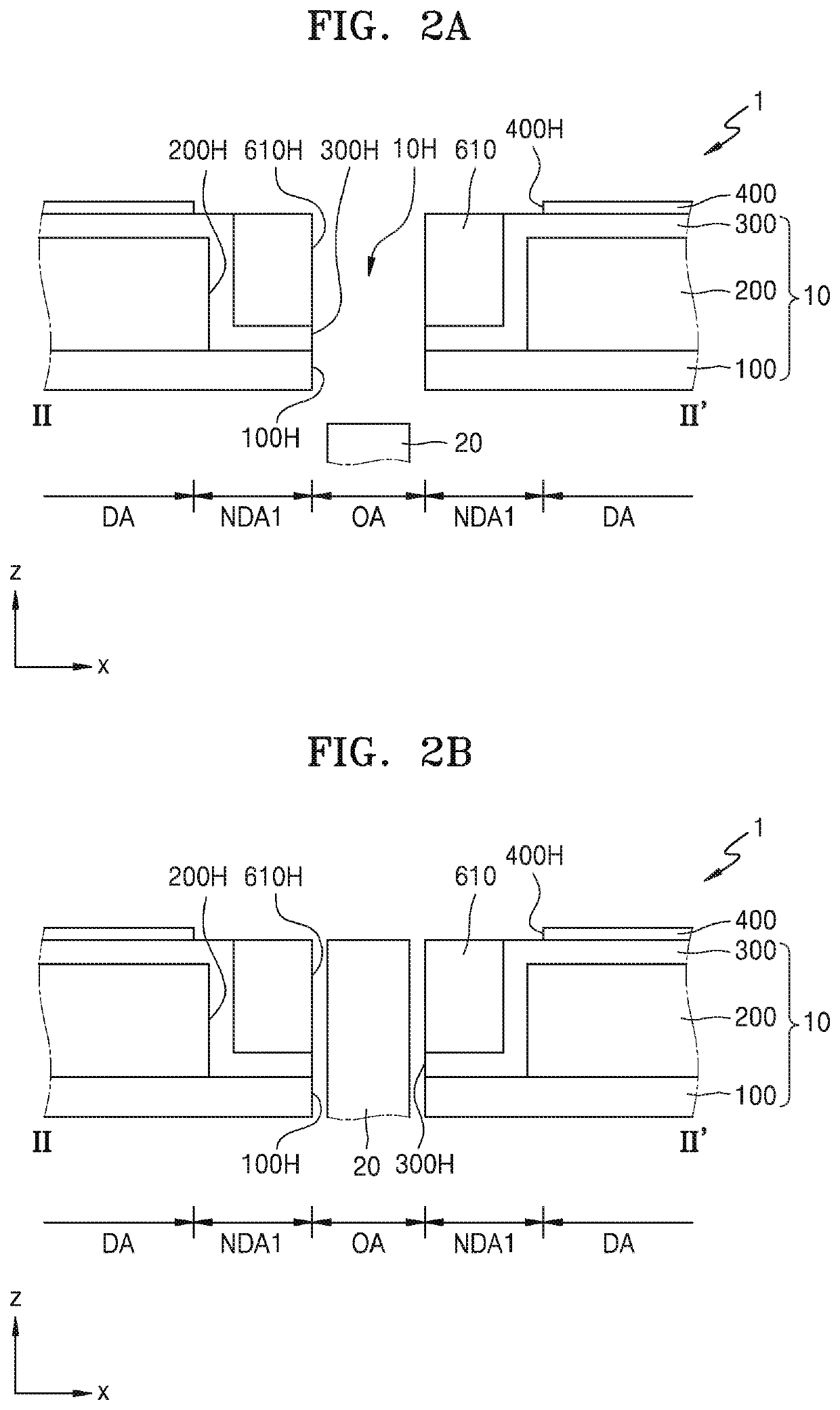

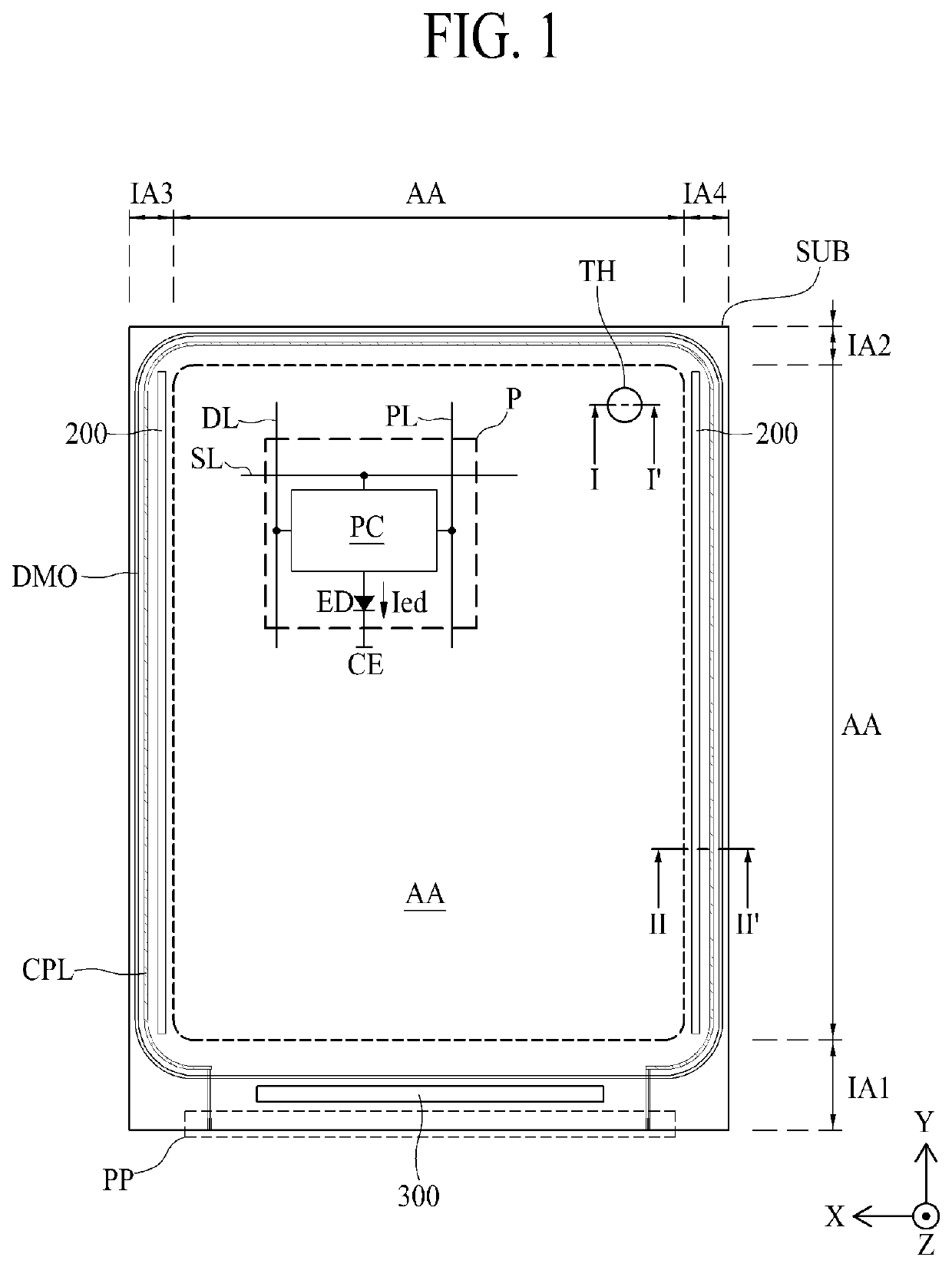

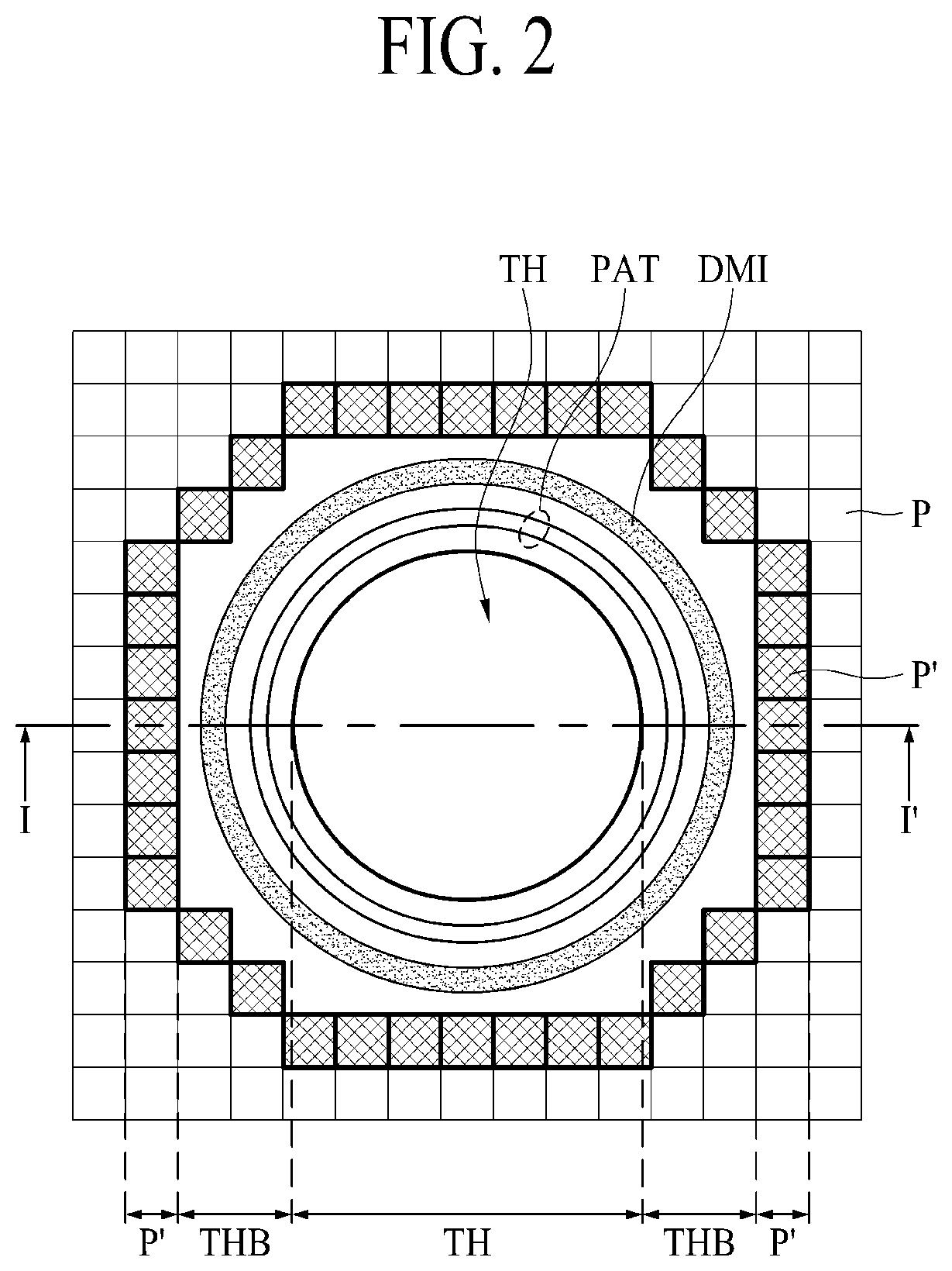

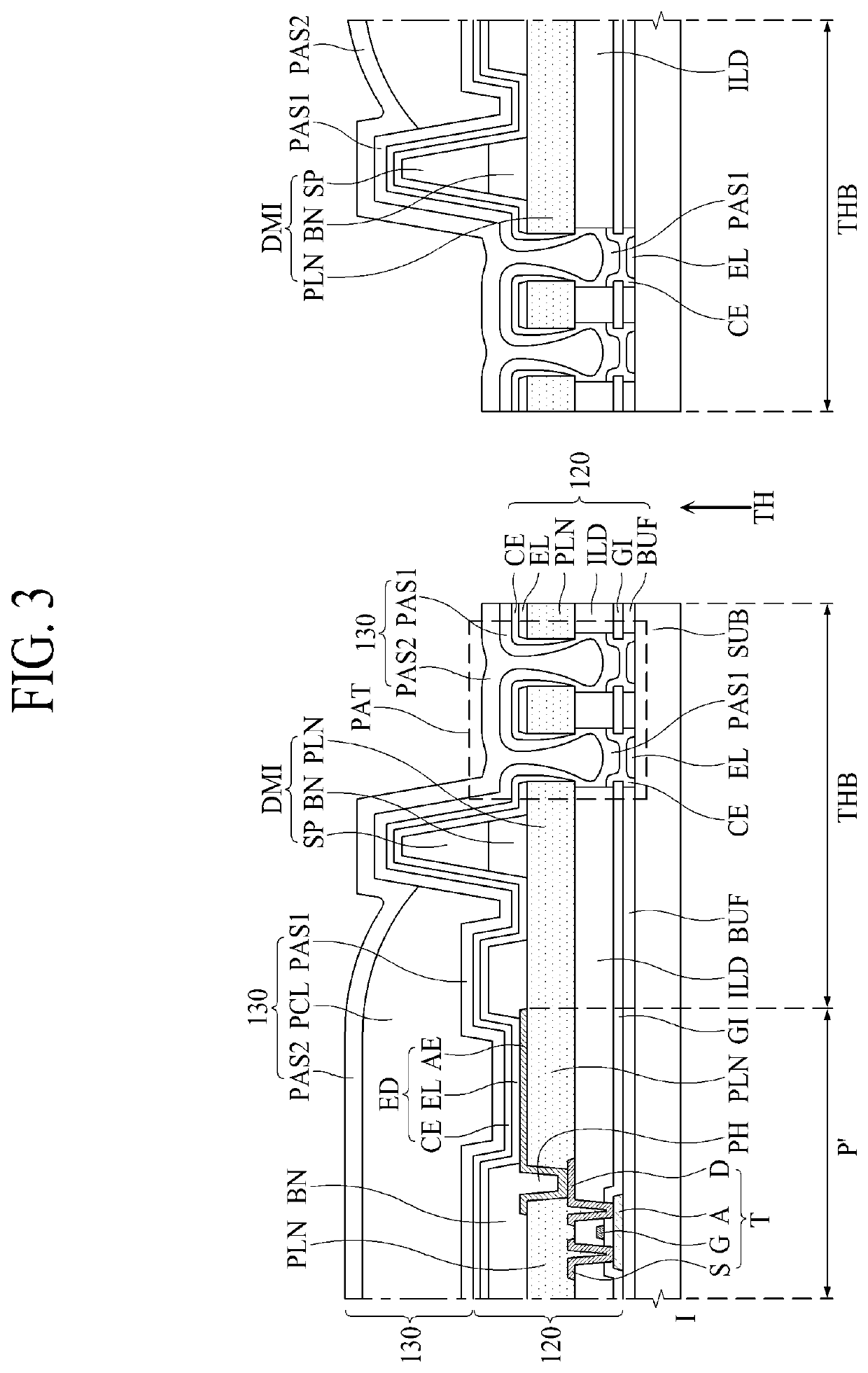

Electroluminesence Display Having Through-Hole In Display Area

ActiveUS20200176520A1Prevent moisture penetrationDisplay areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringMaterials science

Disclosed is an electroluminescence display device having a through-hole in a display area thereof. The electroluminescence display device includes a substrate, a display area, a non-display area, a through-hole, an inner dam, and a concave-convex pattern. In the display area, a plurality of pixels, each of which includes a light emitting element that displays an image and a driving element that drives the light emitting element, are disposed on the substrate. The non-display area surrounds the display area on the substrate. The through-hole is disposed in the display area and does not include the substrate, the light emitting elements, and the driving elements. The inner dam surrounds the through-hole. The concave-convex pattern surrounds the through-hole between the through-hole and the inner dam.

Owner:LG DISPLAY CO LTD

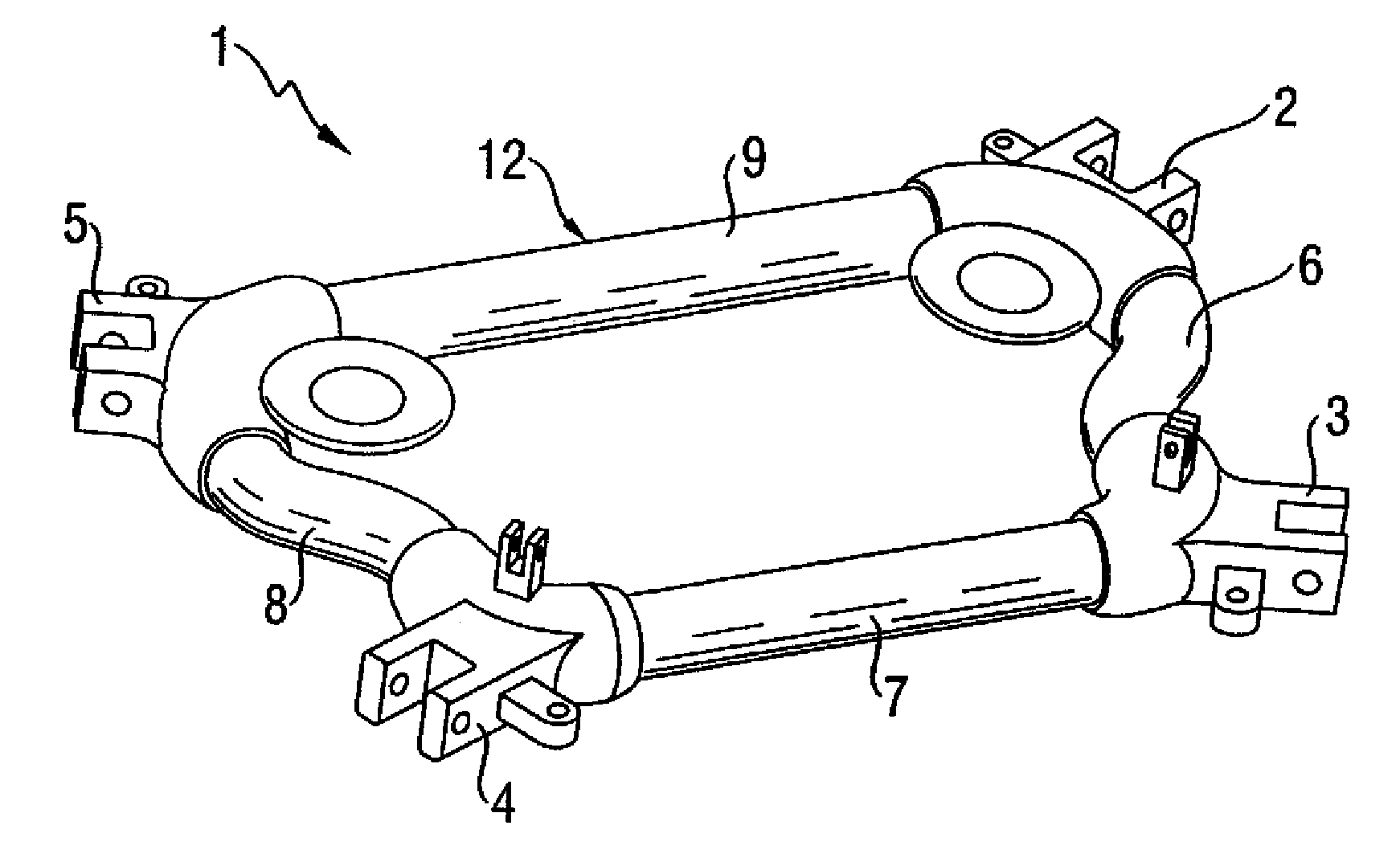

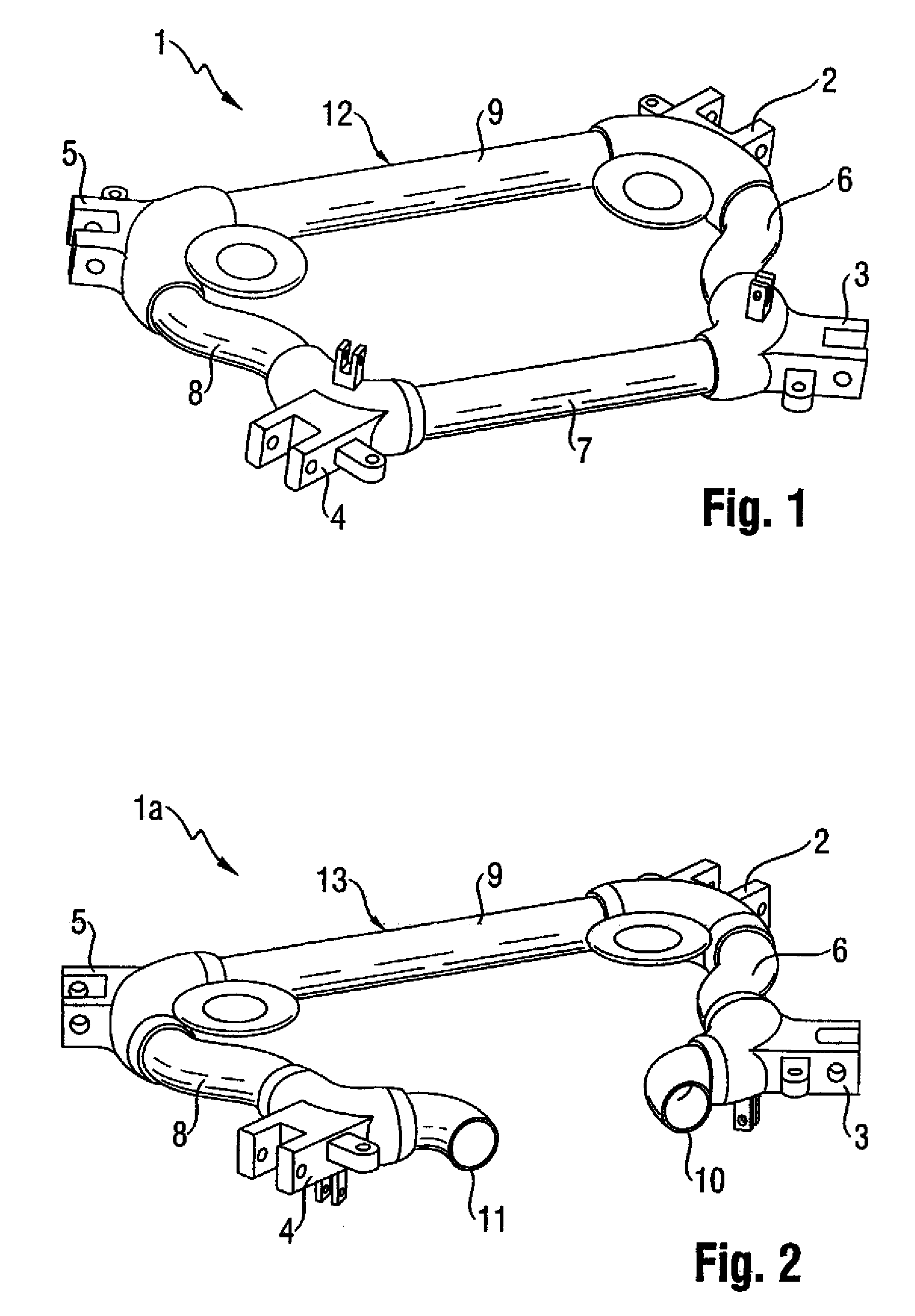

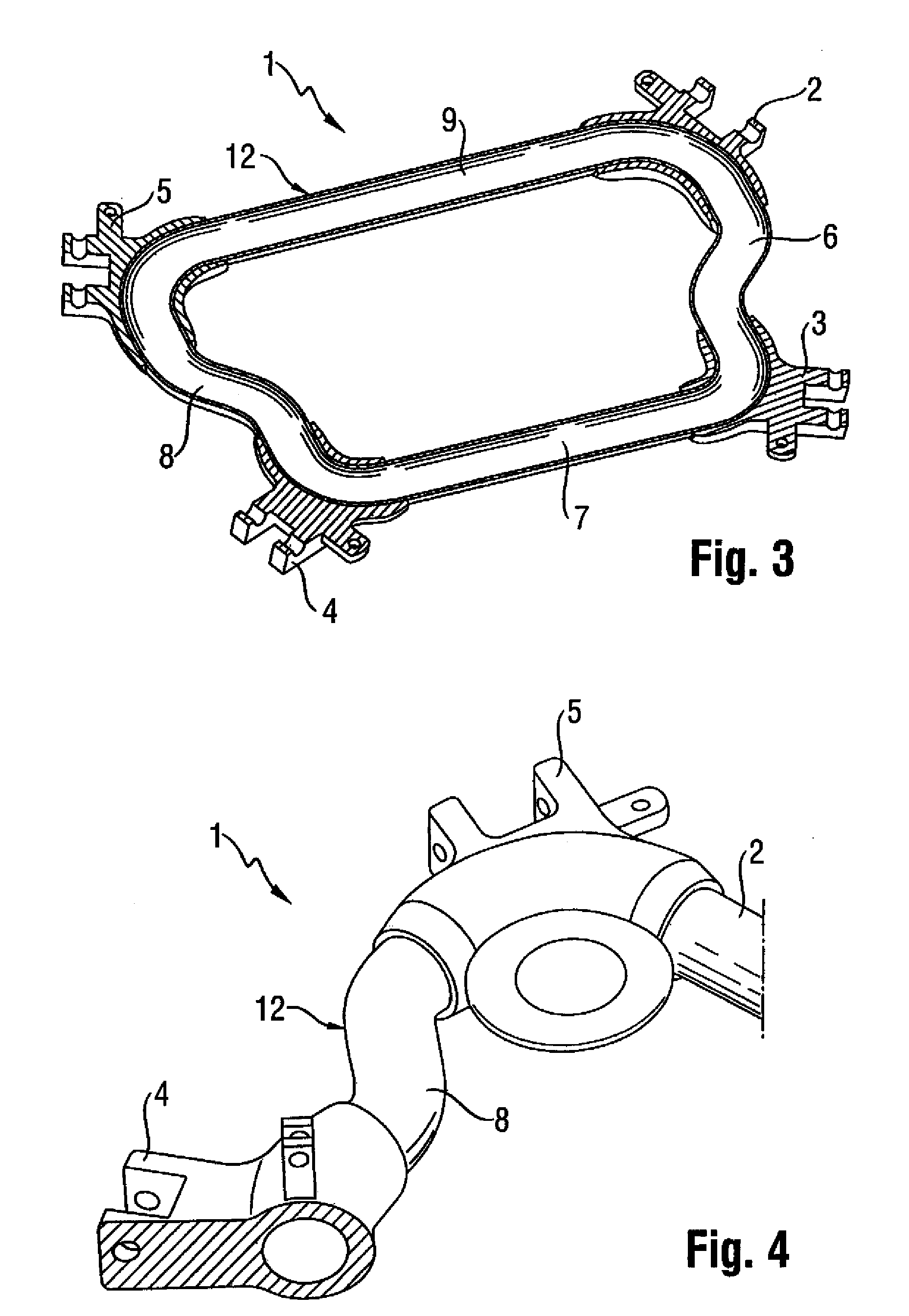

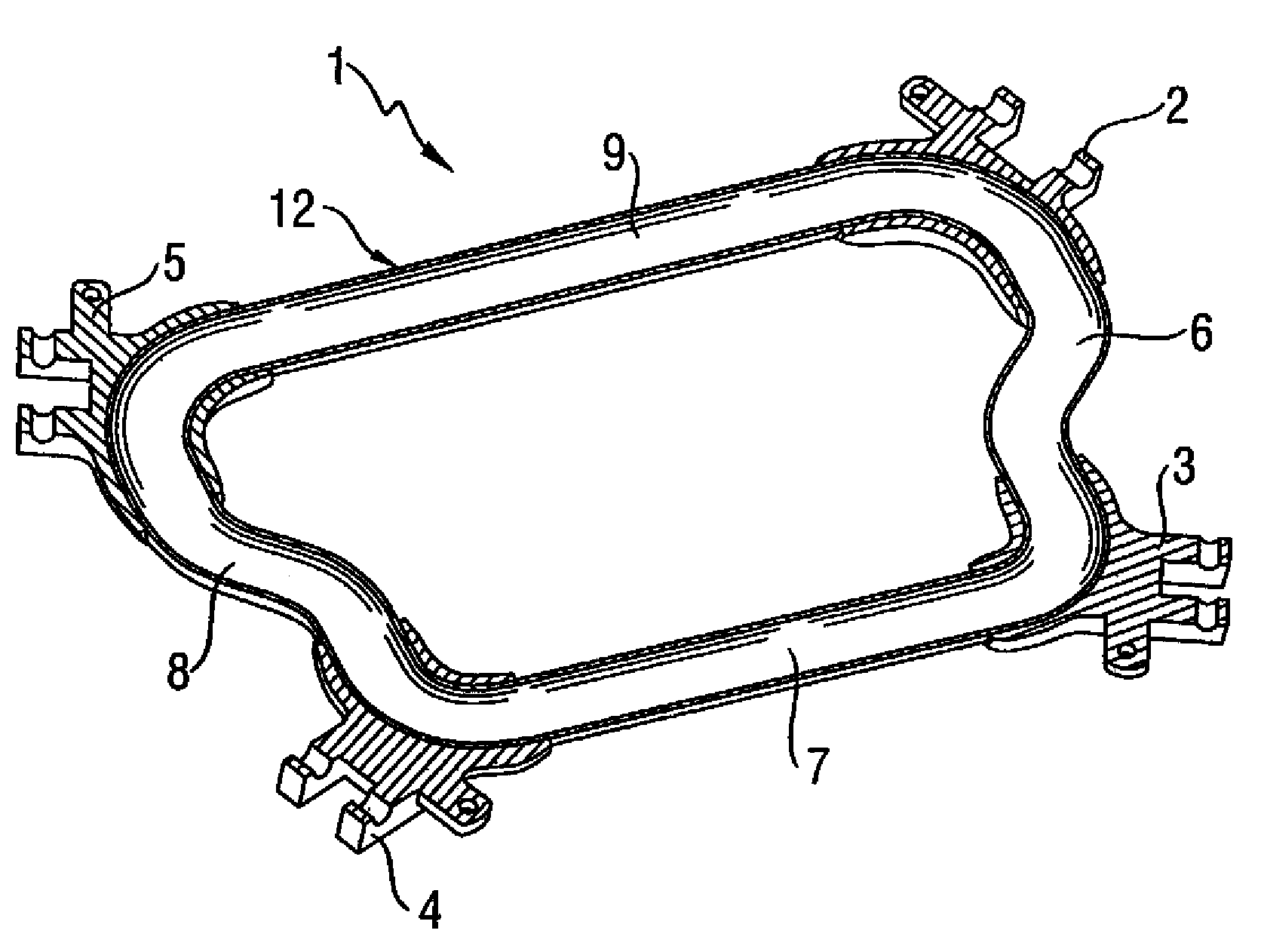

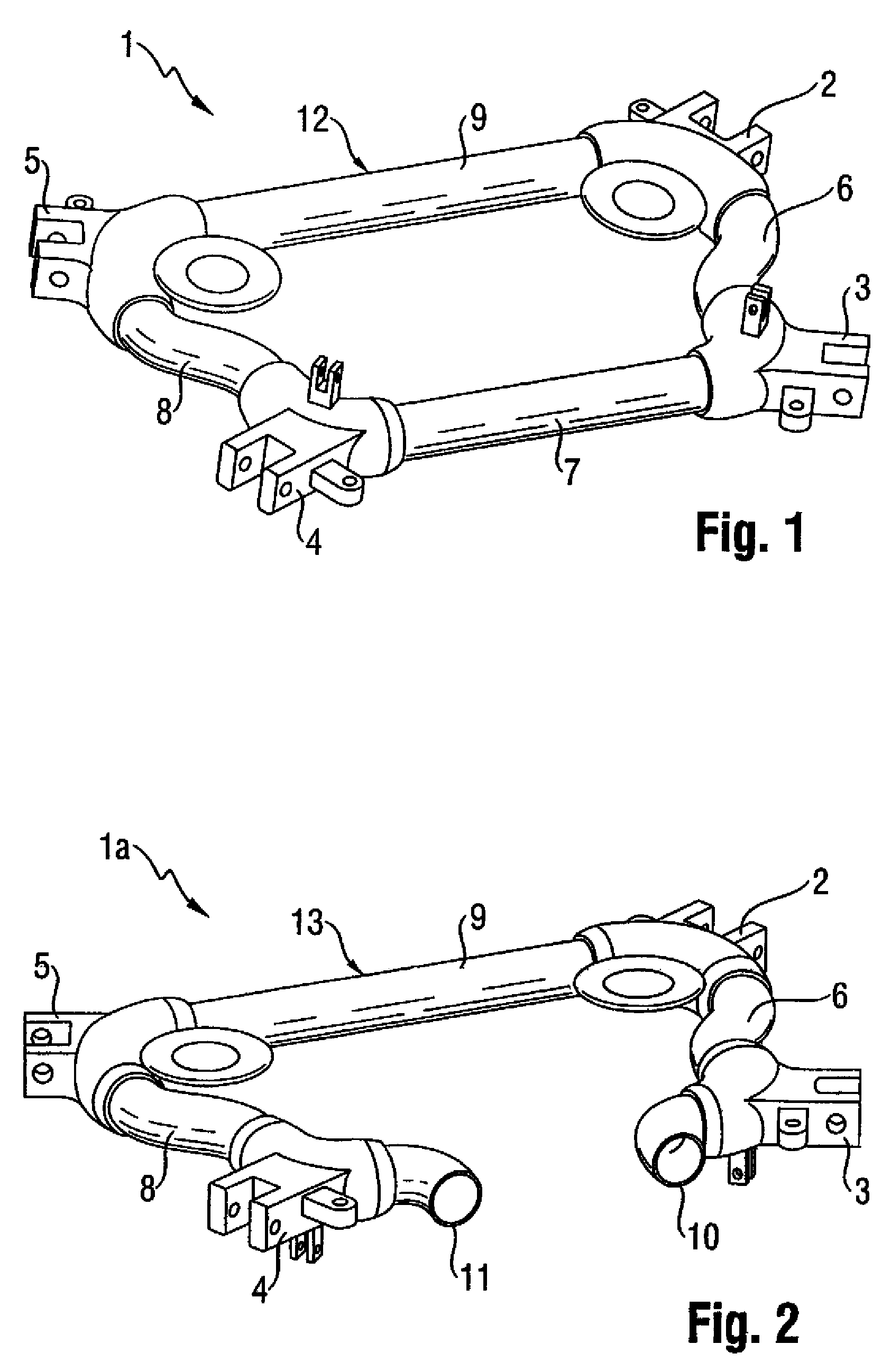

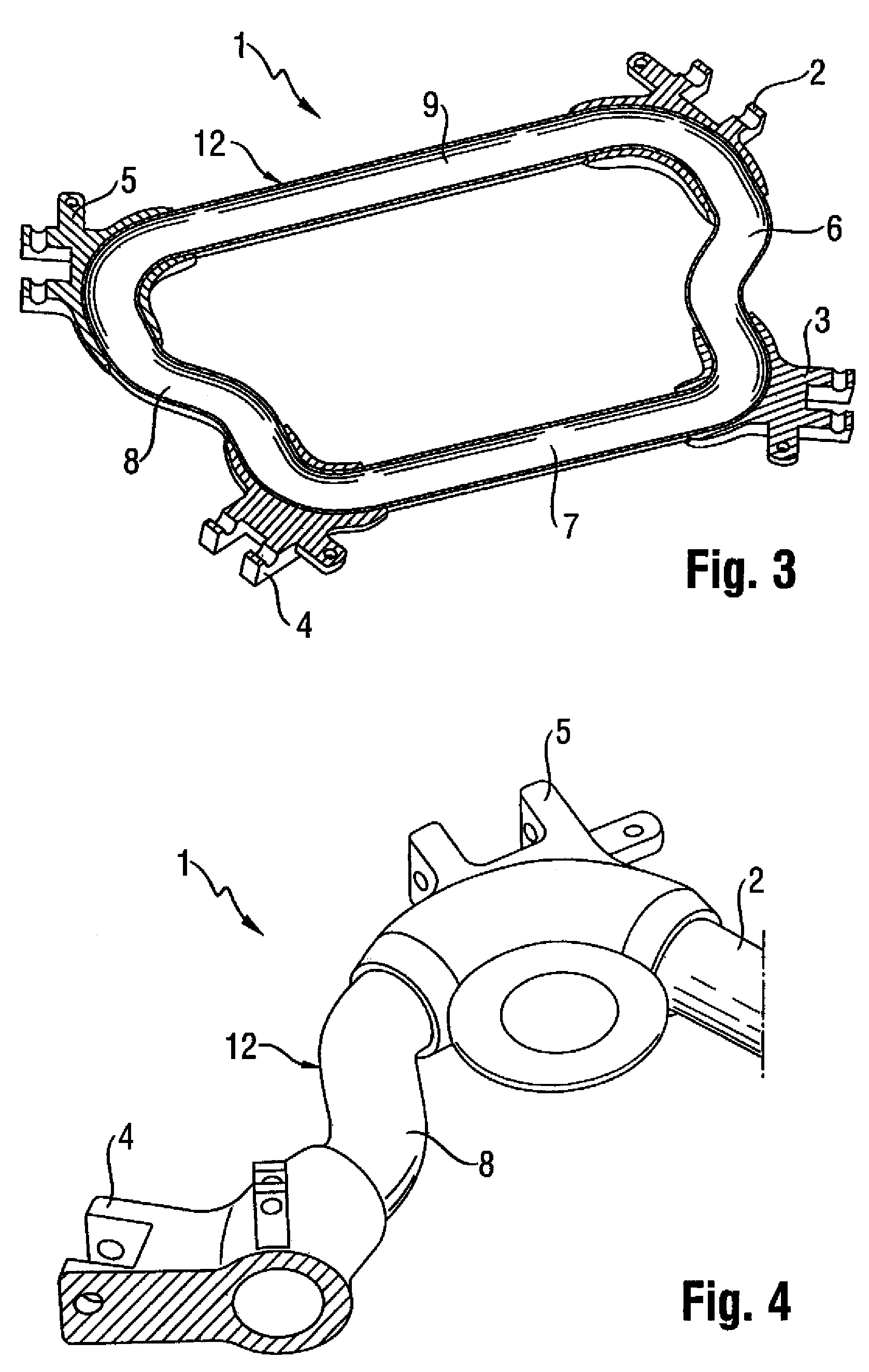

Method of making a subframe of a motor vehicle, and subframe for a motor vehicle

InactiveUS20080265626A1Reduce material costsProportion of aluminum is decreasedVehicle seatsVehicle body-frame connectionsMobile vehicleVehicle frame

In a method of making a subframe of a motor vehicle profile elements made of hollow sections of steel are placed in a casting tool. Subsequently, aluminum material is filled into the casting tool to casting around the profile elements so as to form plural cast nodes on the profile elements in spaced-apart relationship.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

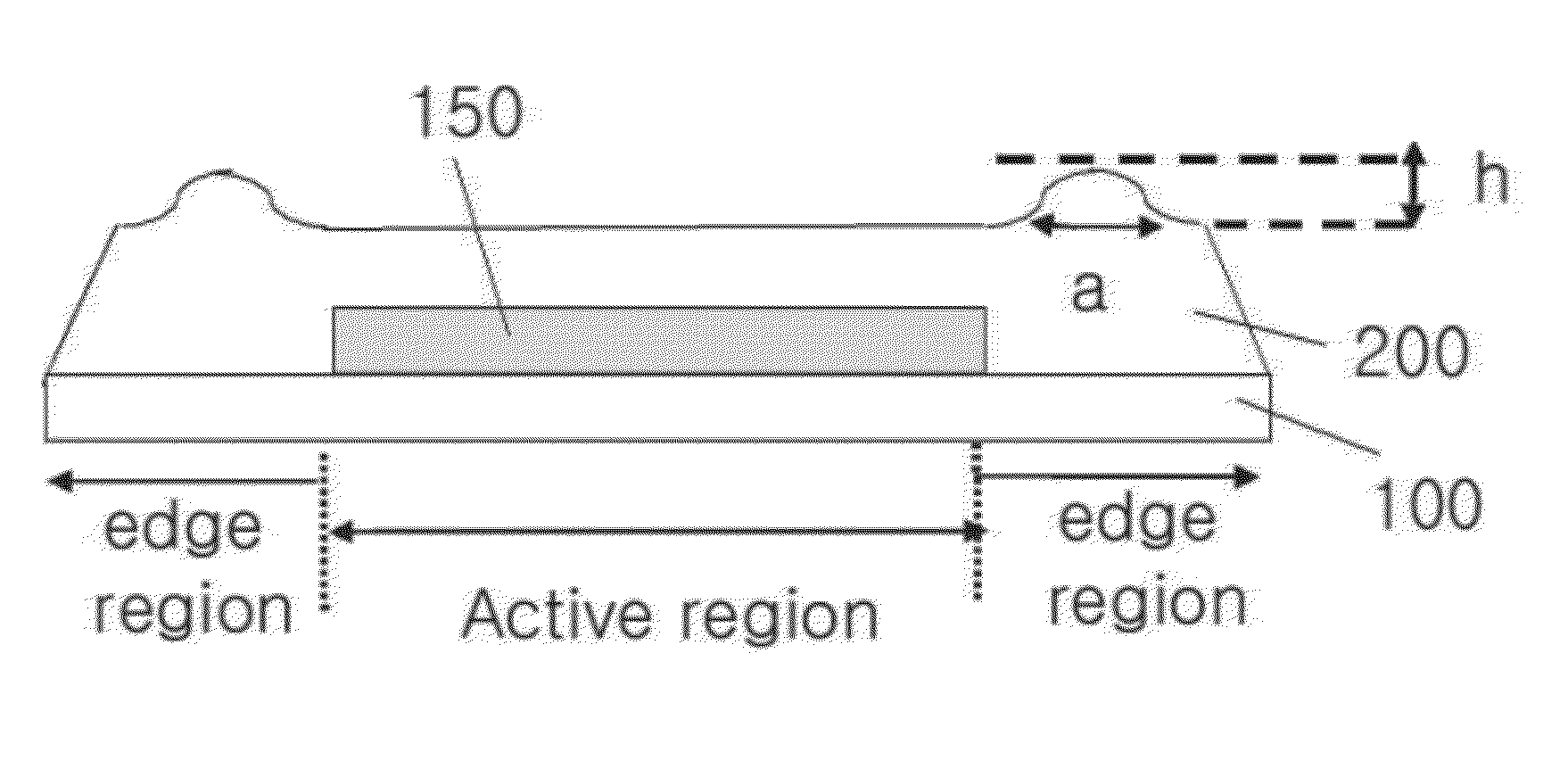

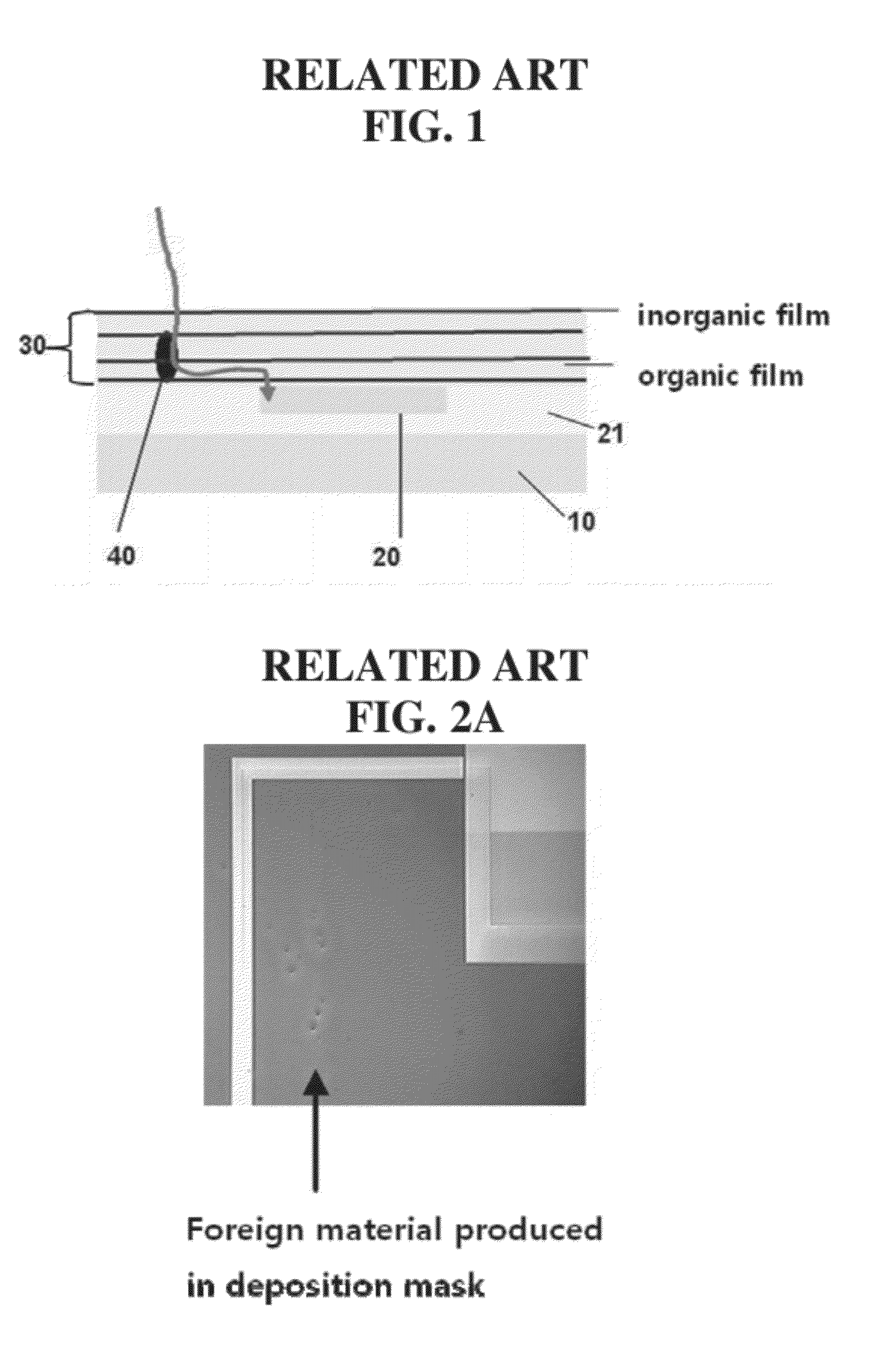

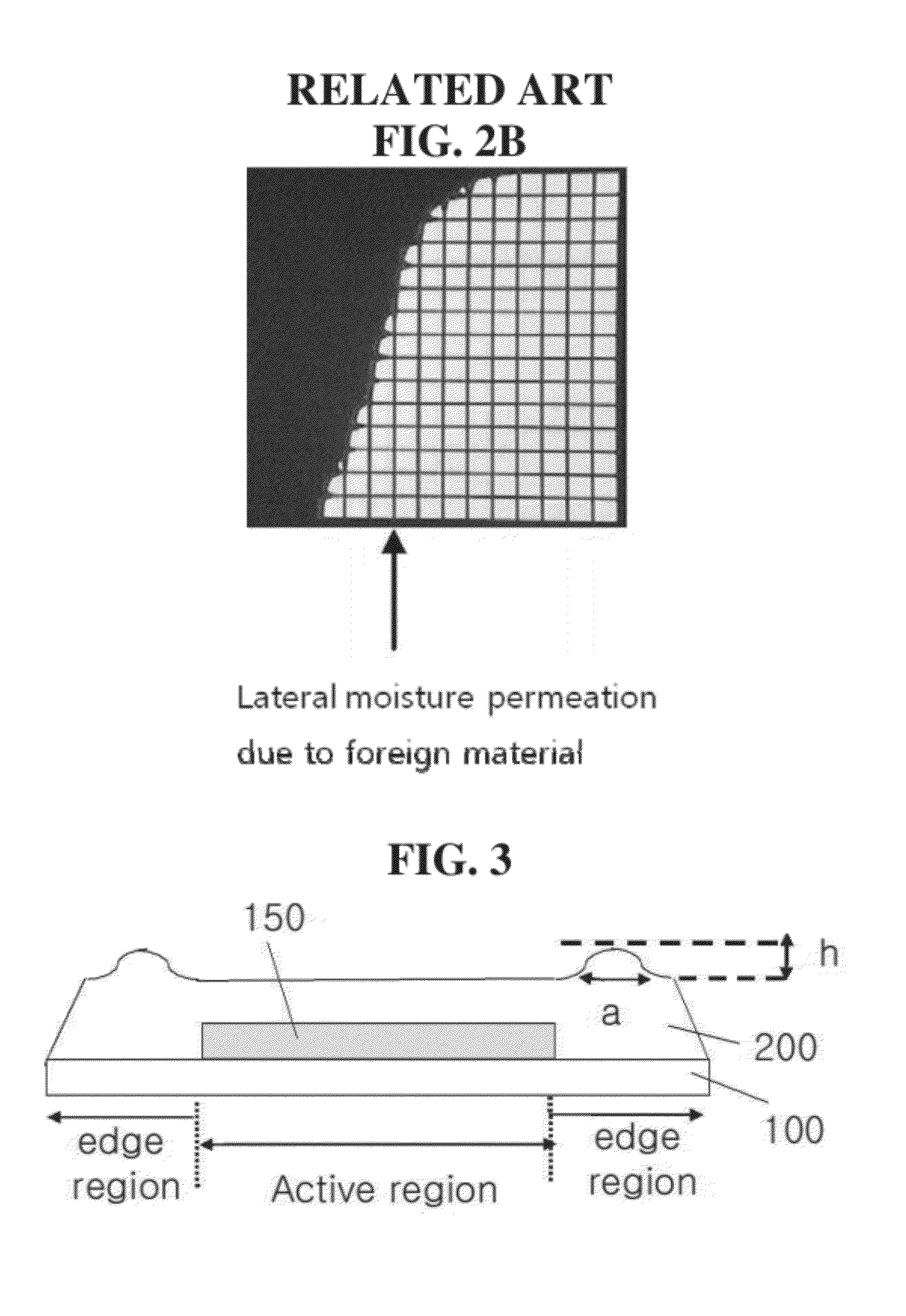

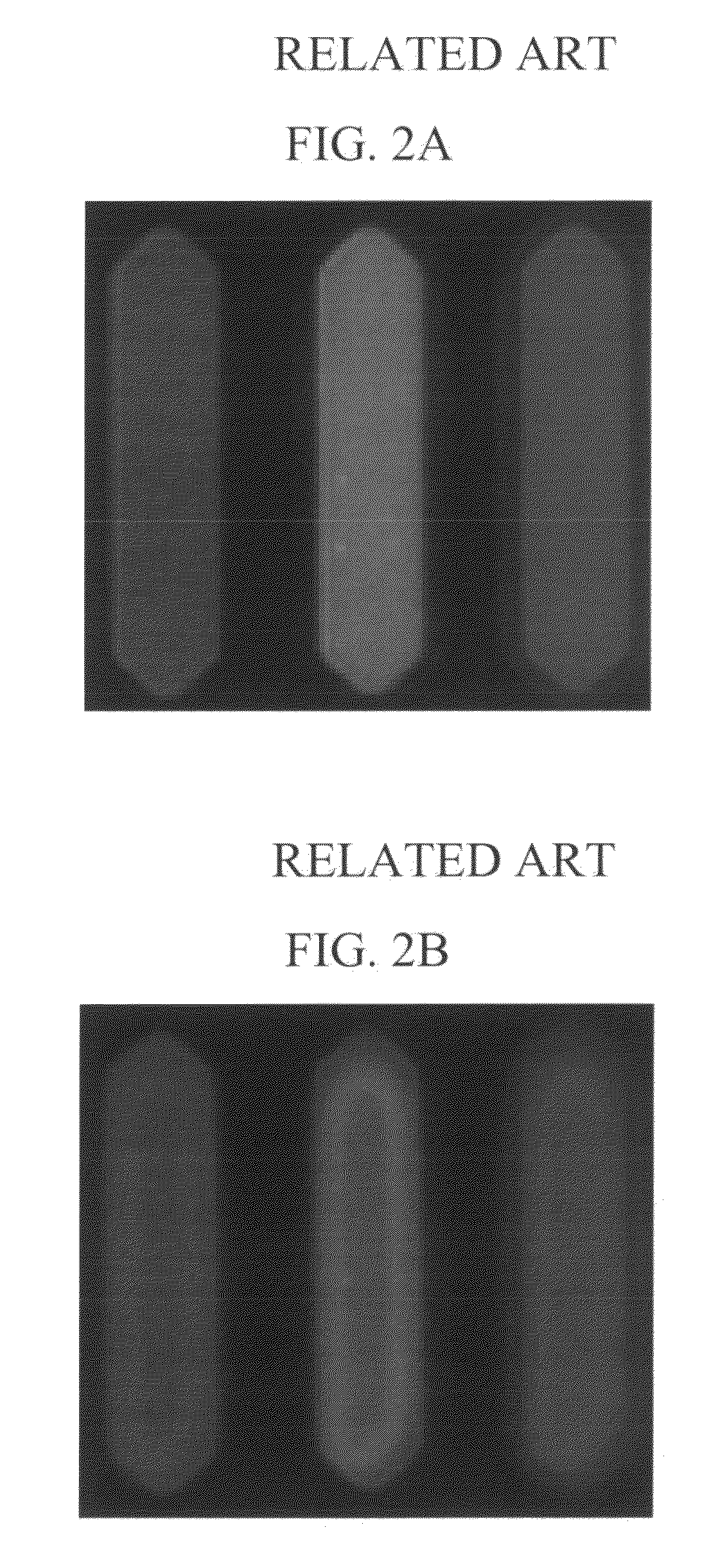

Organic Light Emitting Display Device and Method for Manufacturing the Same

ActiveUS20120313516A1Improve lifespanPrevent permeation of moistureDischarge tube luminescnet screensSemiconductor/solid-state device detailsEdge regionForeign matter

Present invention is for an organic light emitting display device in which permeation of exterior moisture can be prevented, dark defects caused by foreign materials can be improved and lifespan can thus be improved by changing the structure and manufacturing method of thin film encapsulation layer, and a method for manufacturing the same, the organic light emitting display device includes the edge region of the thin film encapsulation layer is thicker than the active region thereof and the thin film encapsulation layer includes a plurality of organic film and a plurality of inorganic film, the organic film and the inorganic film being laminated one on top of the other.

Owner:LG DISPLAY CO LTD

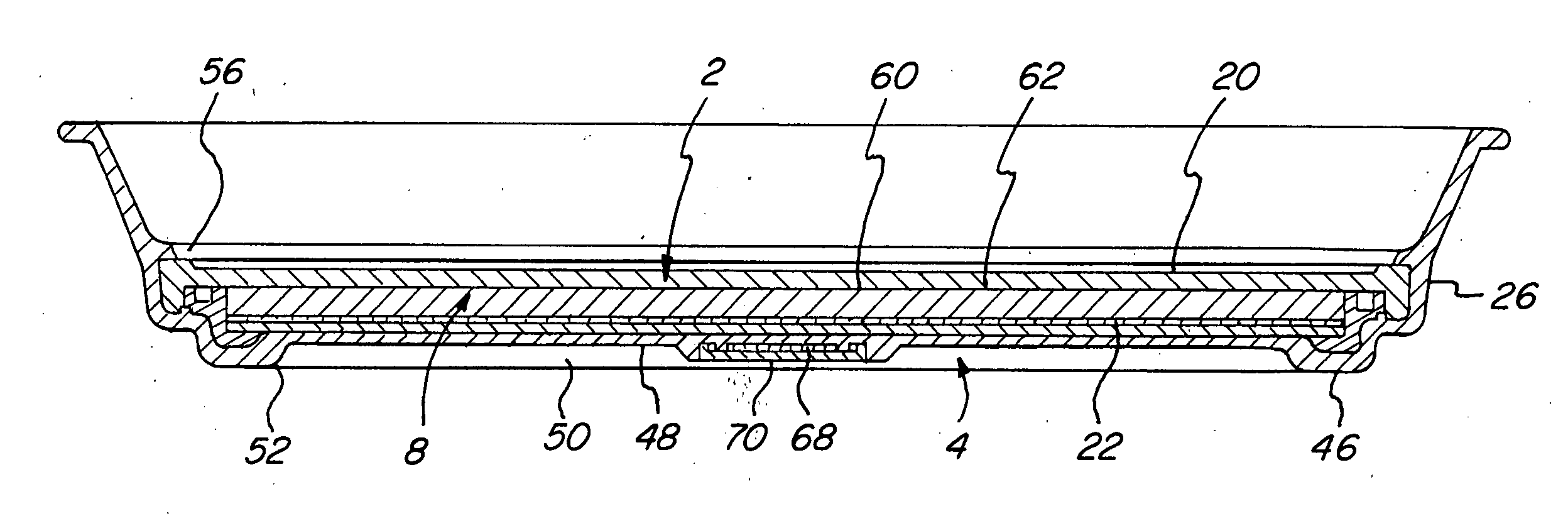

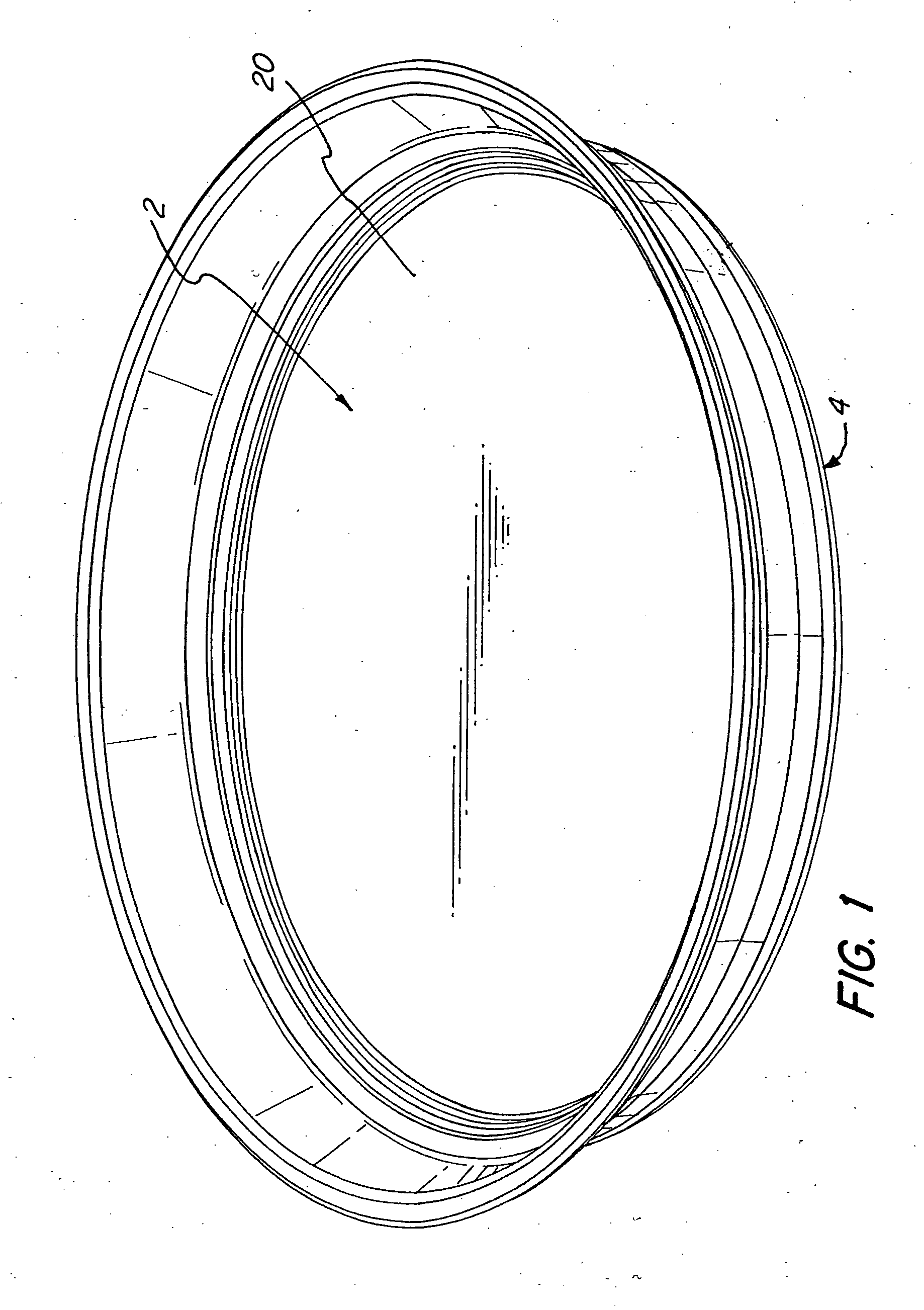

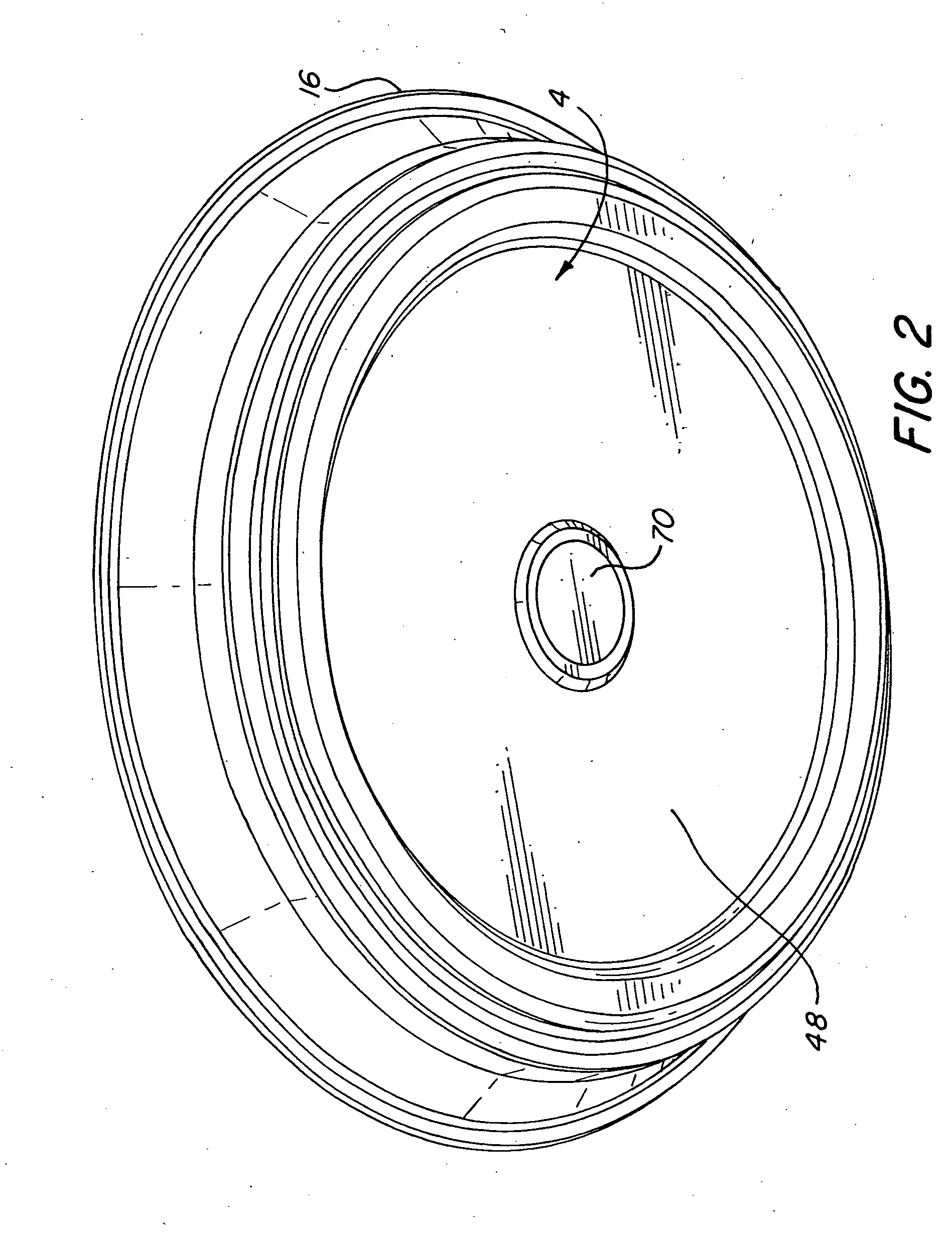

Induction heated server and method of making

InactiveUS20090188909A1Easy to reachPrevent moisture penetrationCooking-vessel materialsMetal working apparatusMoisture penetrationEngineering

An induction heatable server comprises a base element having a bottom wall and a peripheral wall defining an upwardly opening cavity in which are disposed a heat retentive disc and a ring member which is bonded to the peripheral wall. A top element extends over the ring member and seals the cavity. The top element is bonded to the peripheral wall of the base element and the ring member to preclude moisture penetration into the cavity.

Owner:NEWSTAR BUSINESS CREDIT +1

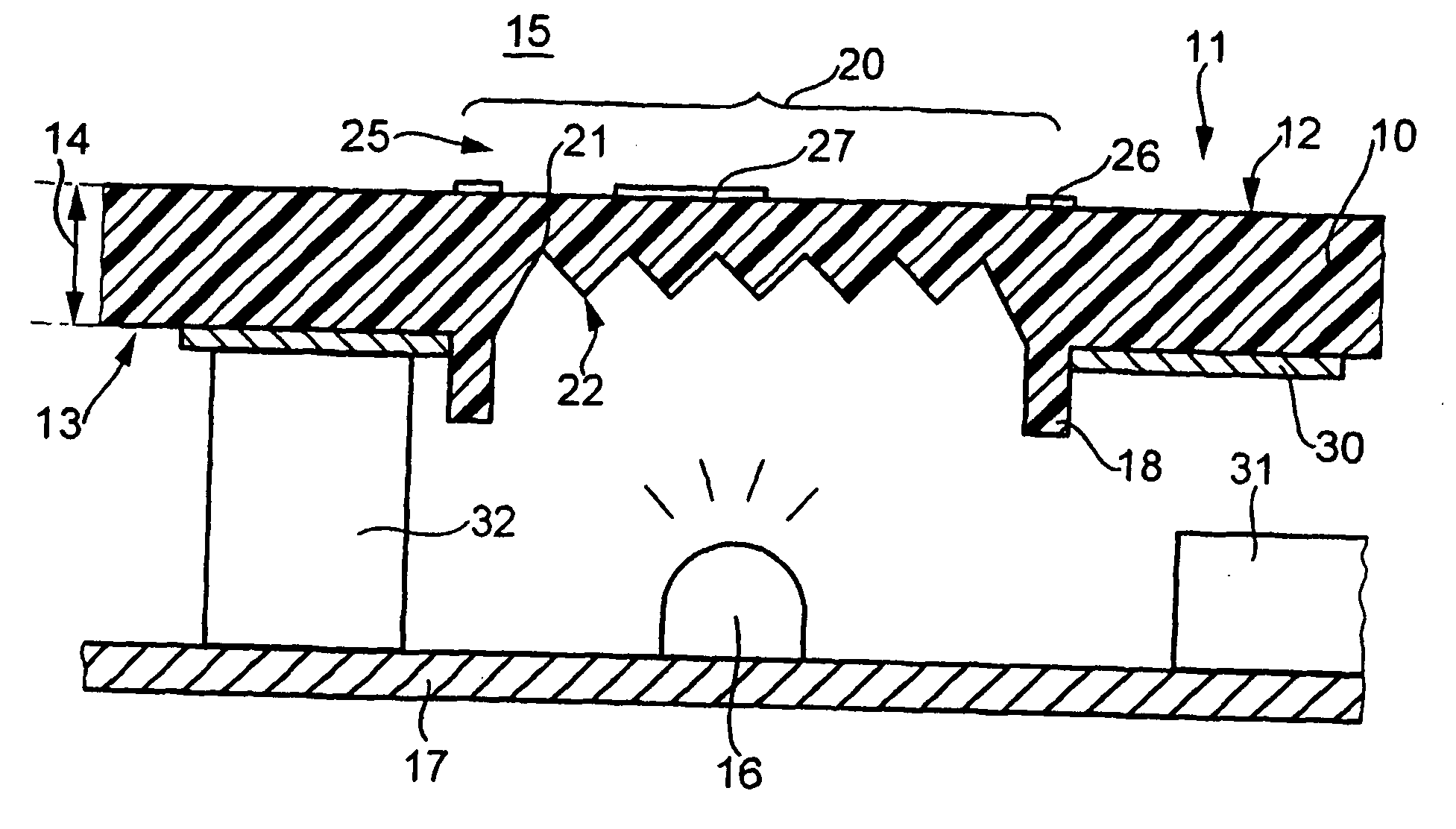

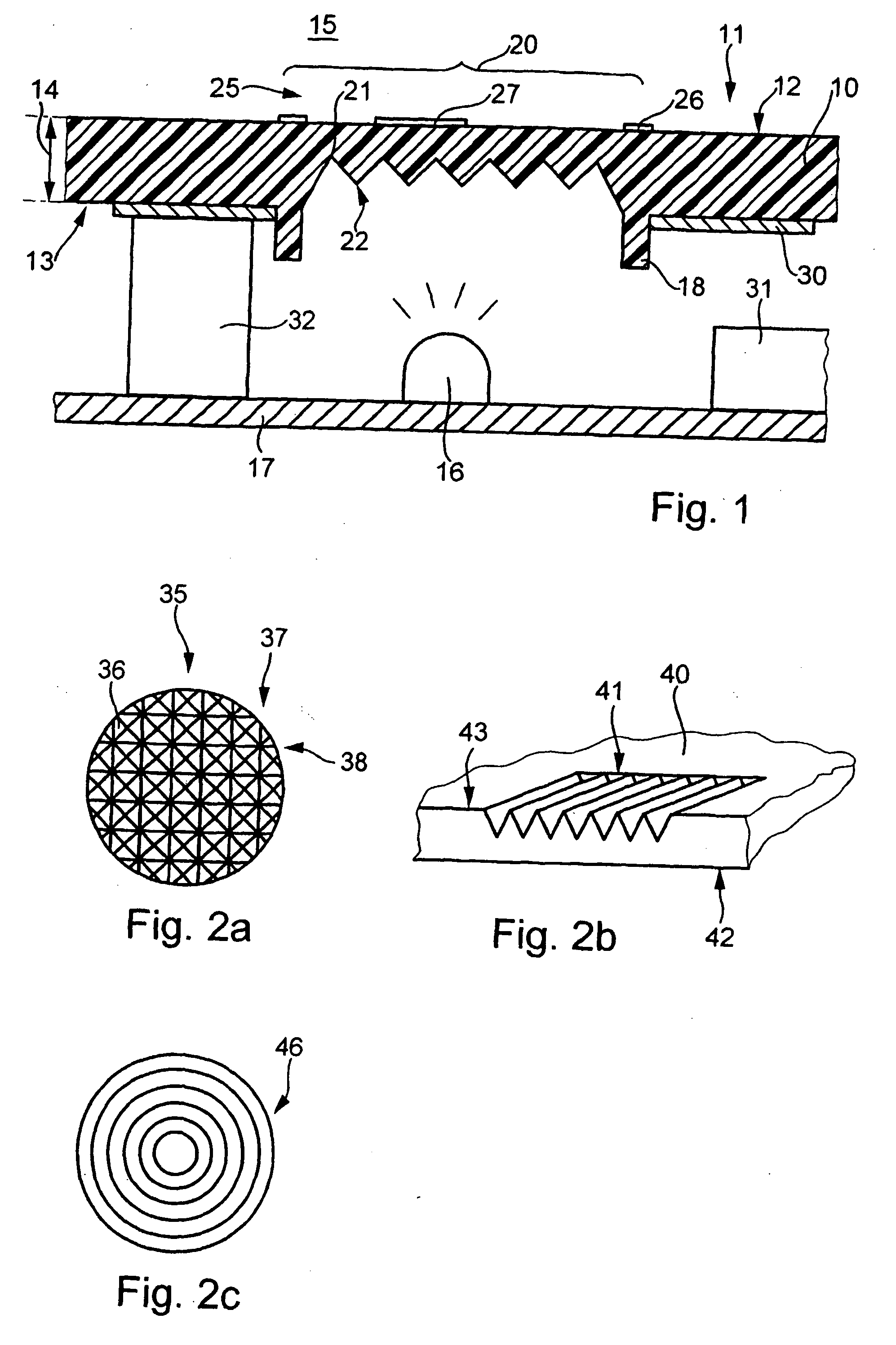

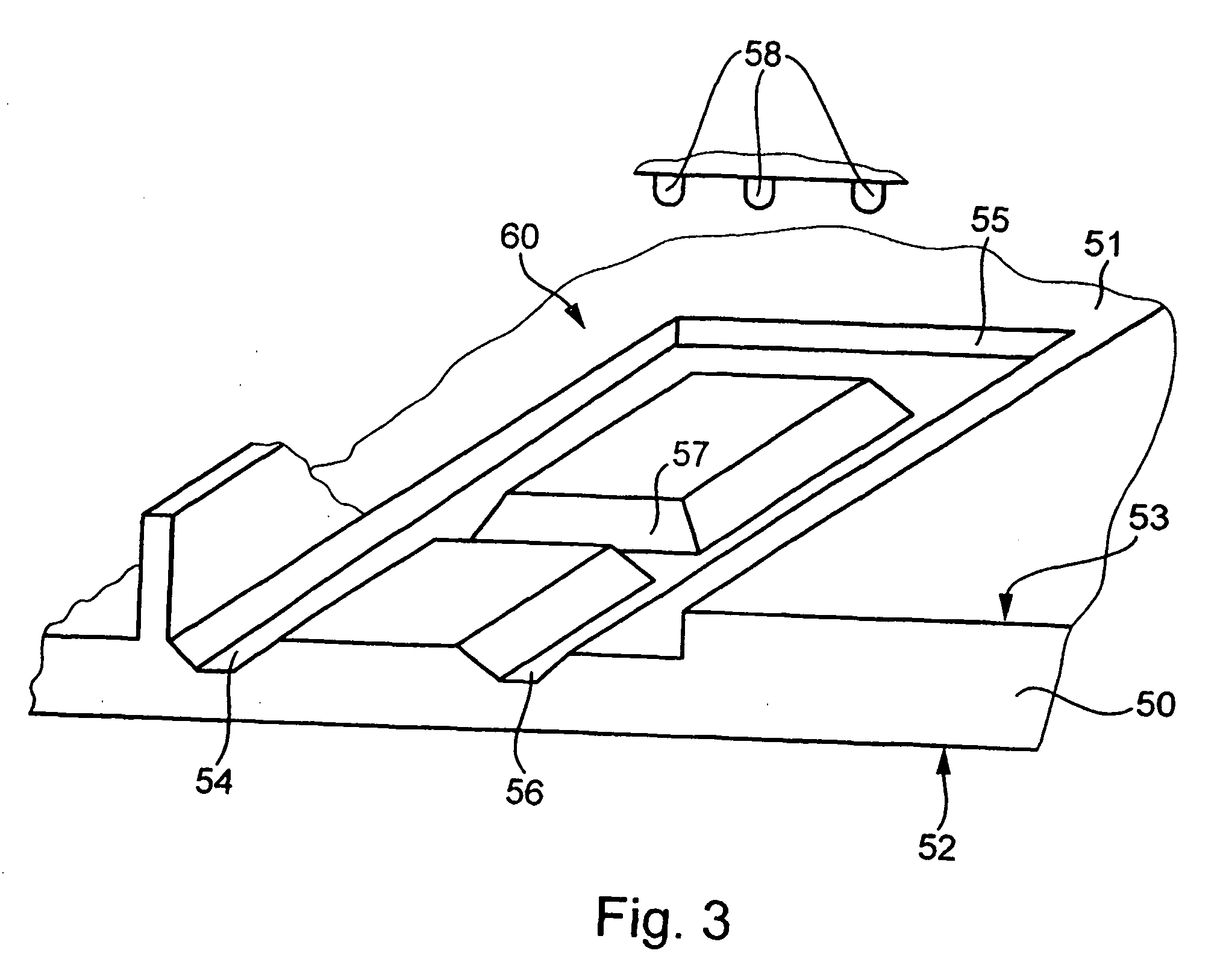

Electrical household appliance equipped with a control device and a display device

InactiveUS20060089732A1Large wall thicknessImprove stabilityDomestic stoves or rangesTableware washing/rinsing machine detailsDisplay deviceLight-emitting diode

One embodiment of the invention concerns an electrical household apparatus, for example a washing machine, equipped with a control device in the form of a panel, said panel comprising a display device for providing visual data to the user. Said panel (10) is made of a material which is substantially opaque when it has a normal thickness (14). One area specific to the display device (15) comprises at least one transparency zone (20) wherein the thickness of the panel material is reduced relative to the thickness of the material outside said transparency zone such that light from a light source (16), for example a light-emitting diode, located behind the panel may pass through said transparency zone. Such a configuration provides backlighted panels having a closed surface. In another embodiment, the control device is in the form of a turning knob (70, 80).

Owner:E G O CONTROL SYST

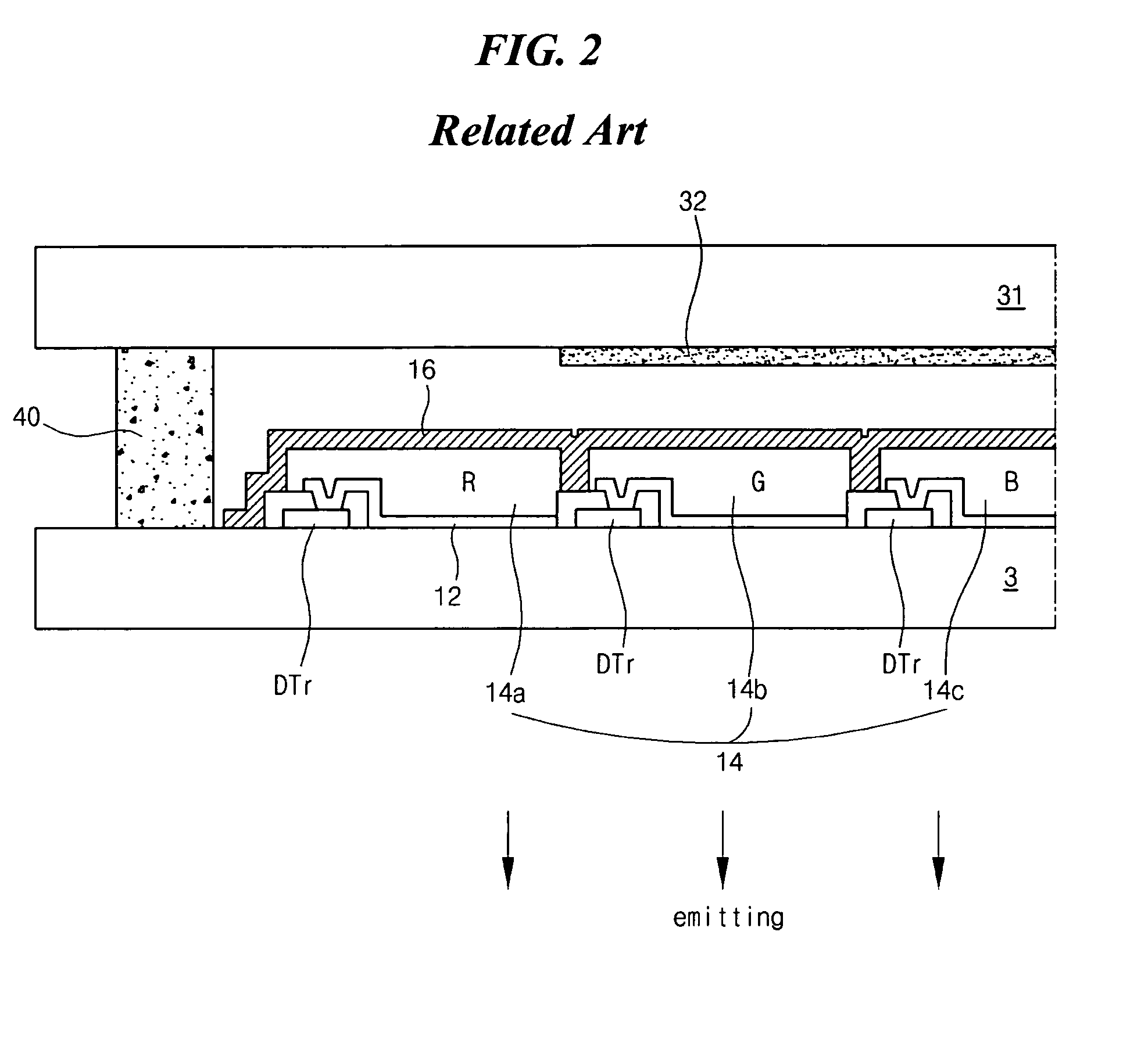

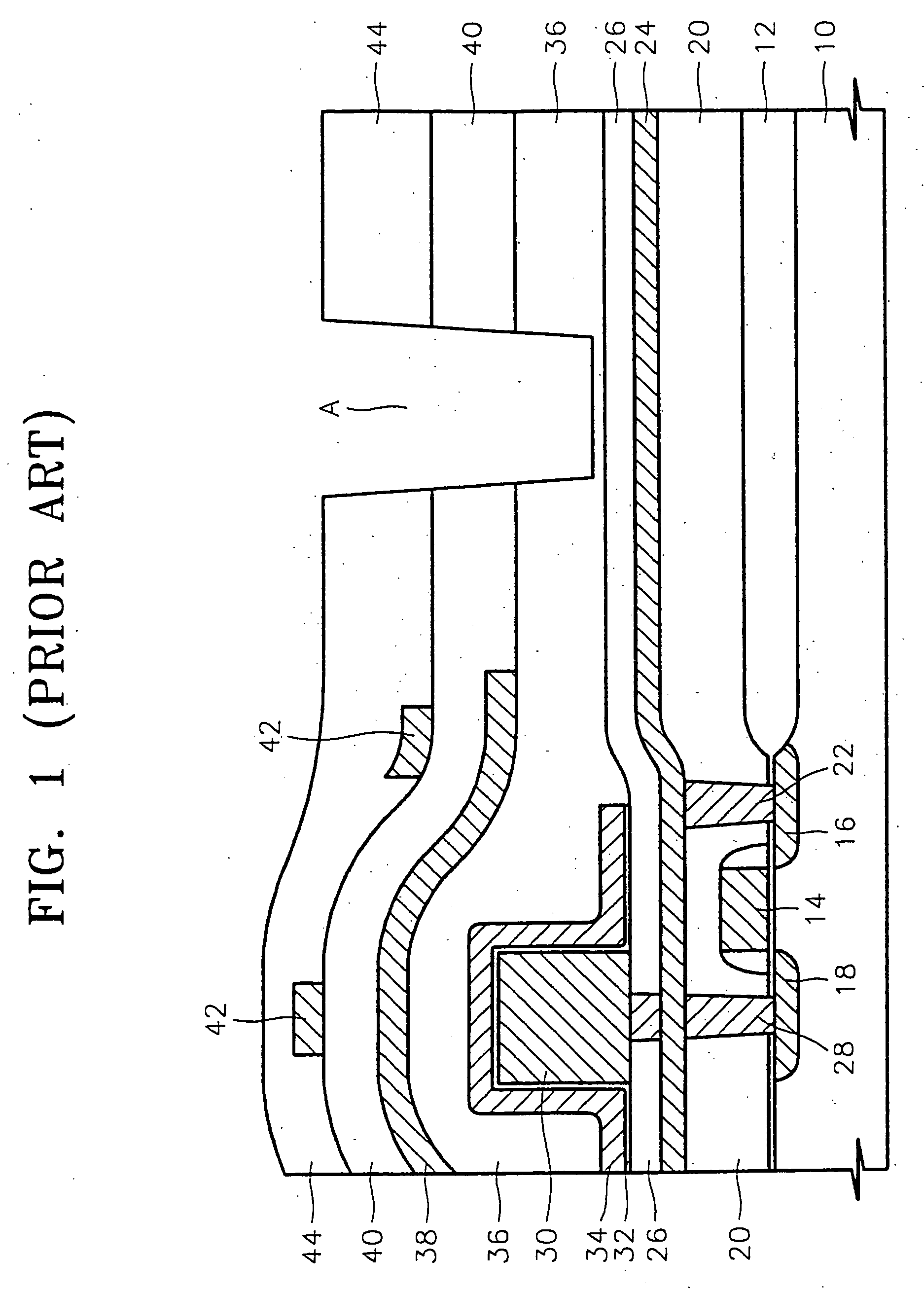

Organic electroluminescent display device and method of fabricating the same

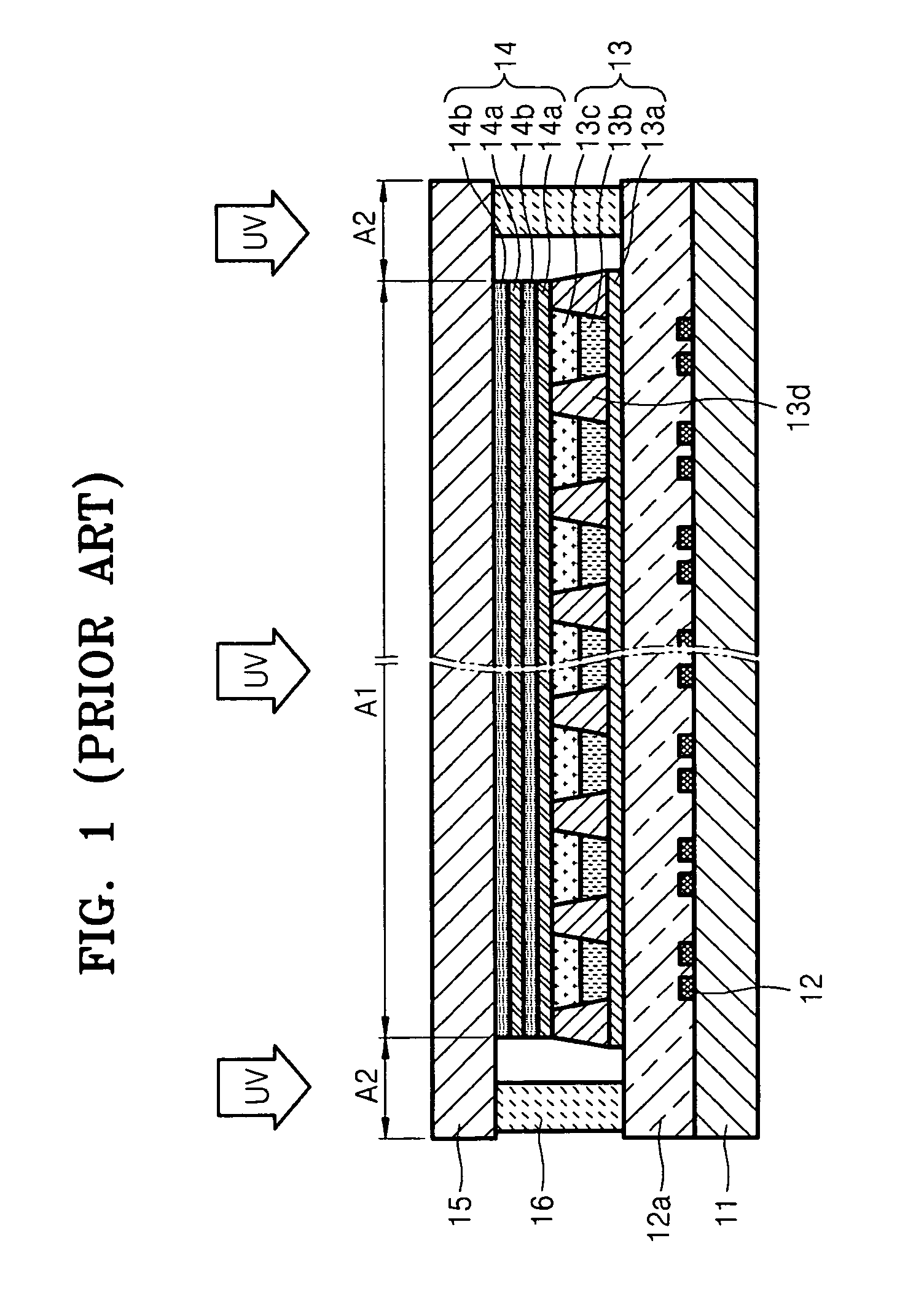

ActiveUS20070285007A1Prevent moisture penetrationPrevents moisture penetrating into the organic electroluminescent diodeDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceLight-emitting diode

An organic electroluminescent display (OELD) device includes first and second substrates facing each other and having a display region and a non-display region on a periphery of the display region, an organic electroluminescent diode in the display region of the first substrate, a protrusion formed with a first thickness and a first width in the non-display region of the first substrate, a groove formed with a first depth and a second width in the non-display region of the second substrate, wherein the protrusion is inserted into the groove, a seal pattern formed between the protrusion and the groove.

Owner:LG DISPLAY CO LTD

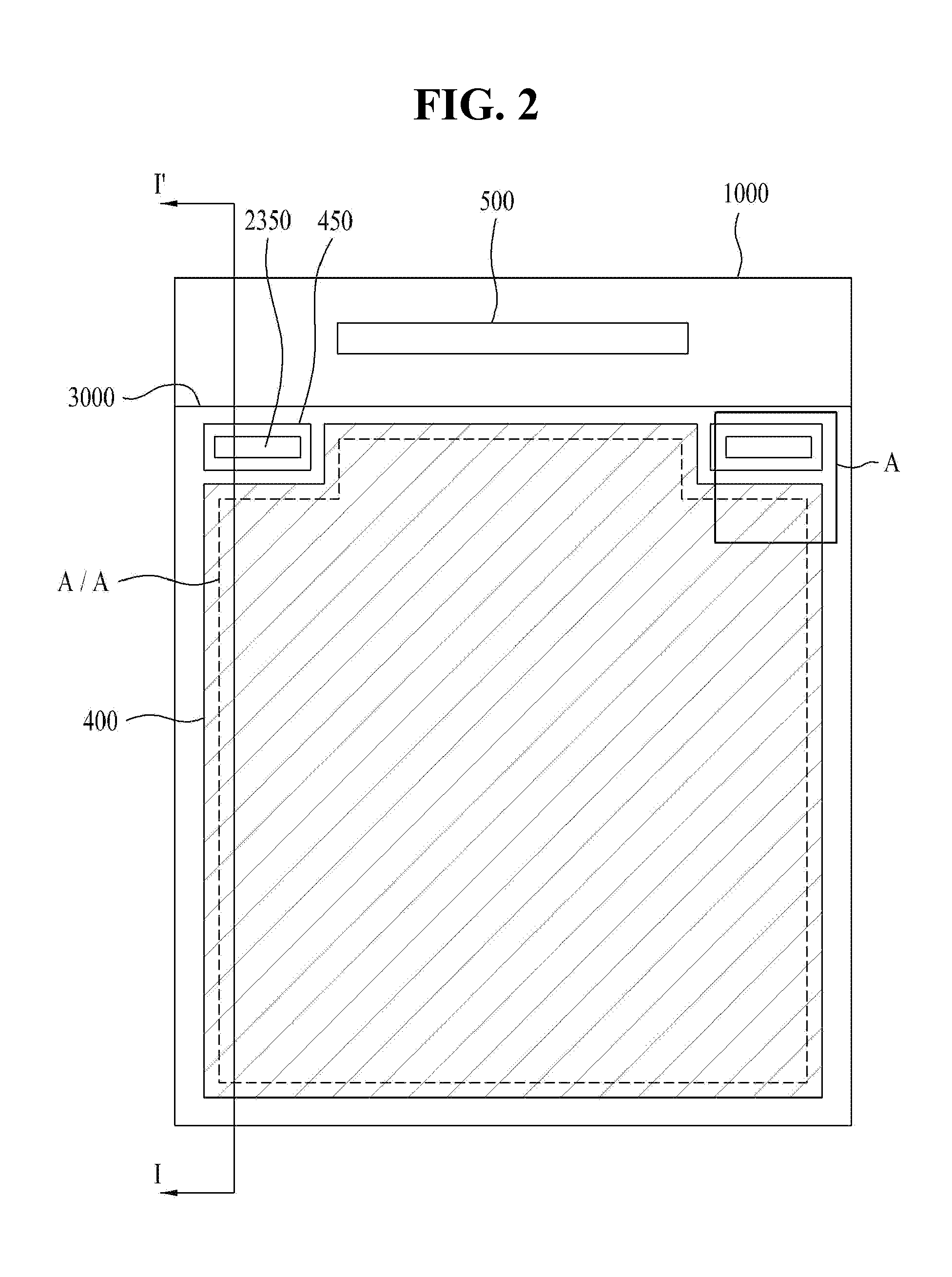

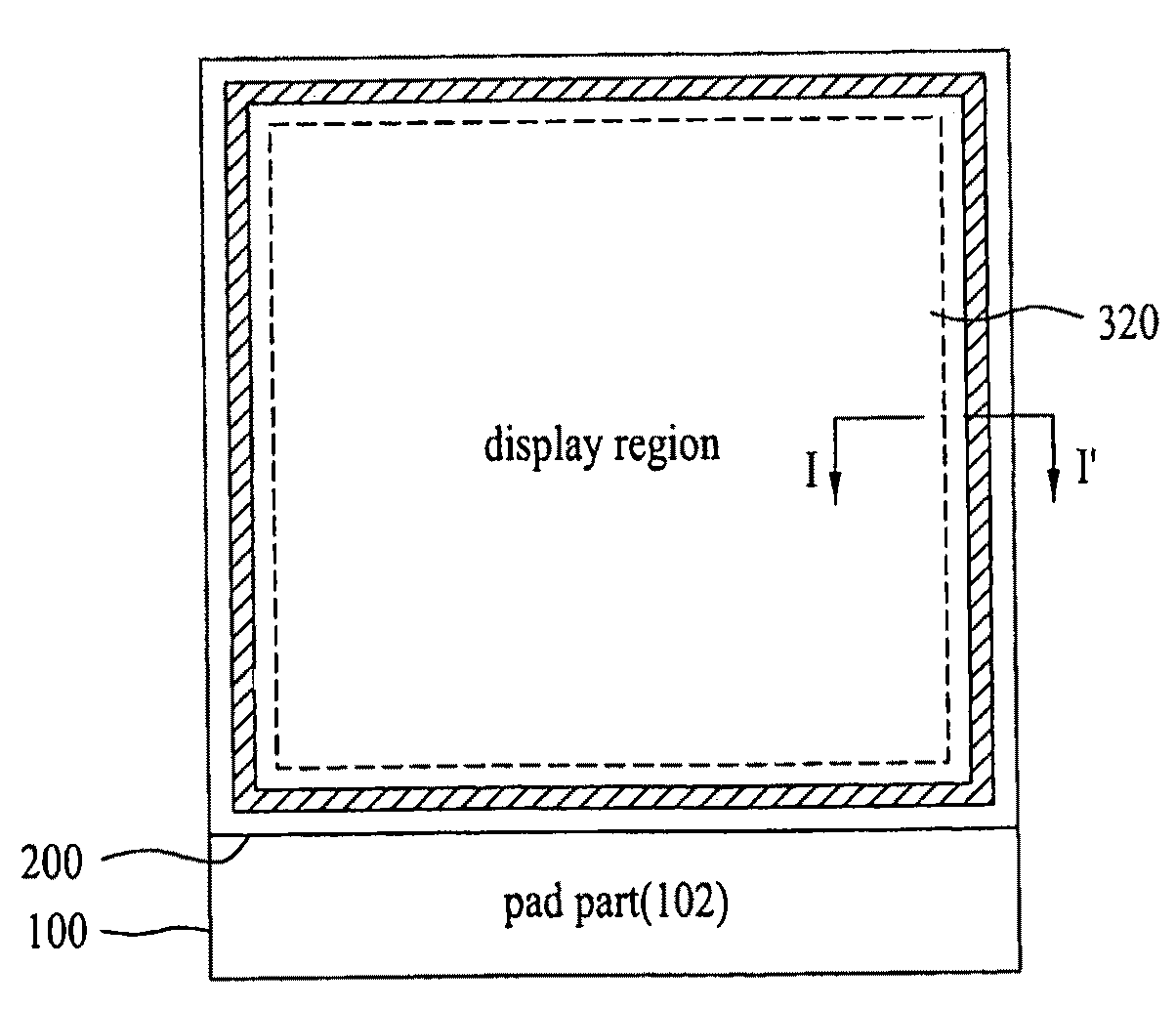

Organic light emitting display device and method of manufacturing the same

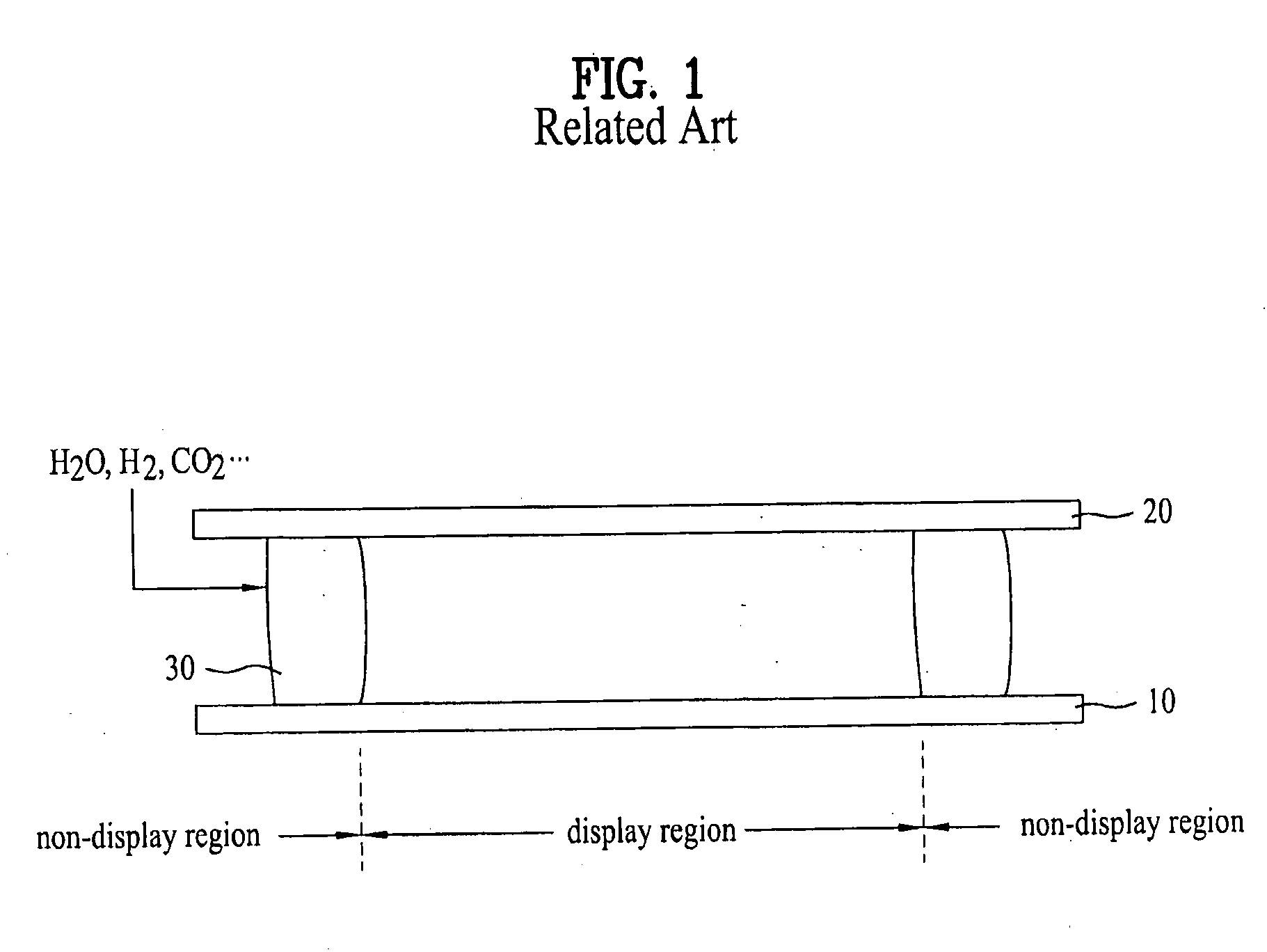

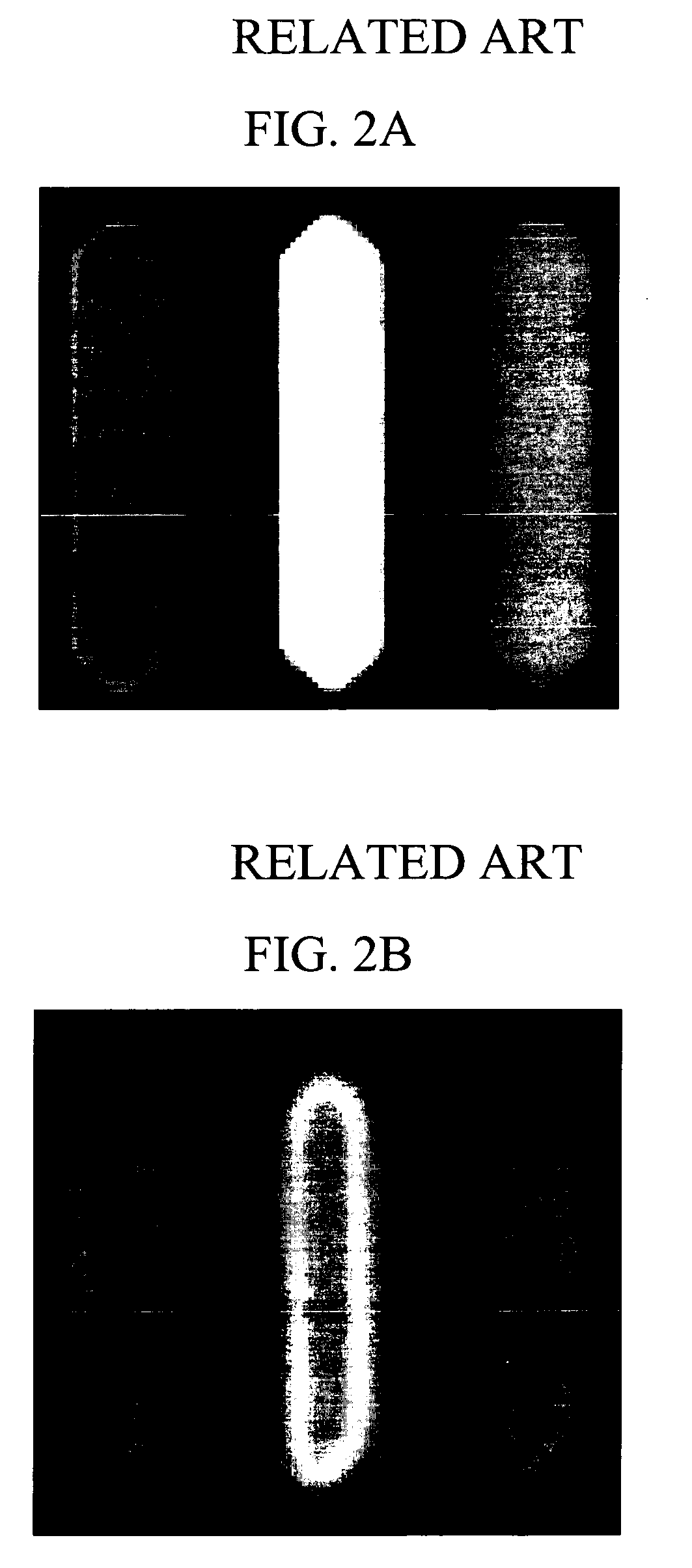

ActiveUS7990060B2Prevent moisture penetrationAvoid degradationDischarge tube luminescnet screensLamp detailsDisplay deviceOptoelectronics

An organic light emitting display device that is capable of preventing the permeation of moisture by changing a sealing structure, thereby preventing the degradation of pixels and thus improving look-and-feel characteristics and a method of manufacturing the same are disclosed. The organic light emitting display device includes a first substrate and a second substrate being opposite to each other, the first substrate and the second substrate having a display region defined in the middle thereof and a non-display region defined at the edge thereof, respectively, a plurality of gate lines and data lines formed at the display region on the first substrate, the gate lines and the data lines crossing each other to define a pixel region, a thin film transistor formed at each of the intersections between the gate lines and data lines, an organic light emitting layer formed on the second substrate corresponding to the pixel region, and first and second electrodes located above and below the organic light emitting layer and a sealing structure connected between the first and second substrates, such that the first and second substrates are bonded to each other by the sealing structure, for preventing the permeation of moisture and gas.

Owner:LG DISPLAY CO LTD

Method of making a subframe of a motor vehicle, and subframe for a motor vehicle

InactiveUS7971887B2Reduce material costsProportion of aluminum is decreasedVehicle seatsVehicle body-frame connectionsVehicle frameMotorized vehicle

In a method of making a subframe of a motor vehicle profile elements made of hollow sections of steel are placed in a casting tool. Subsequently, aluminum material is filled into the casting tool to casting around the profile elements so as to form plural cast nodes on the profile elements in spaced-apart relationship.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

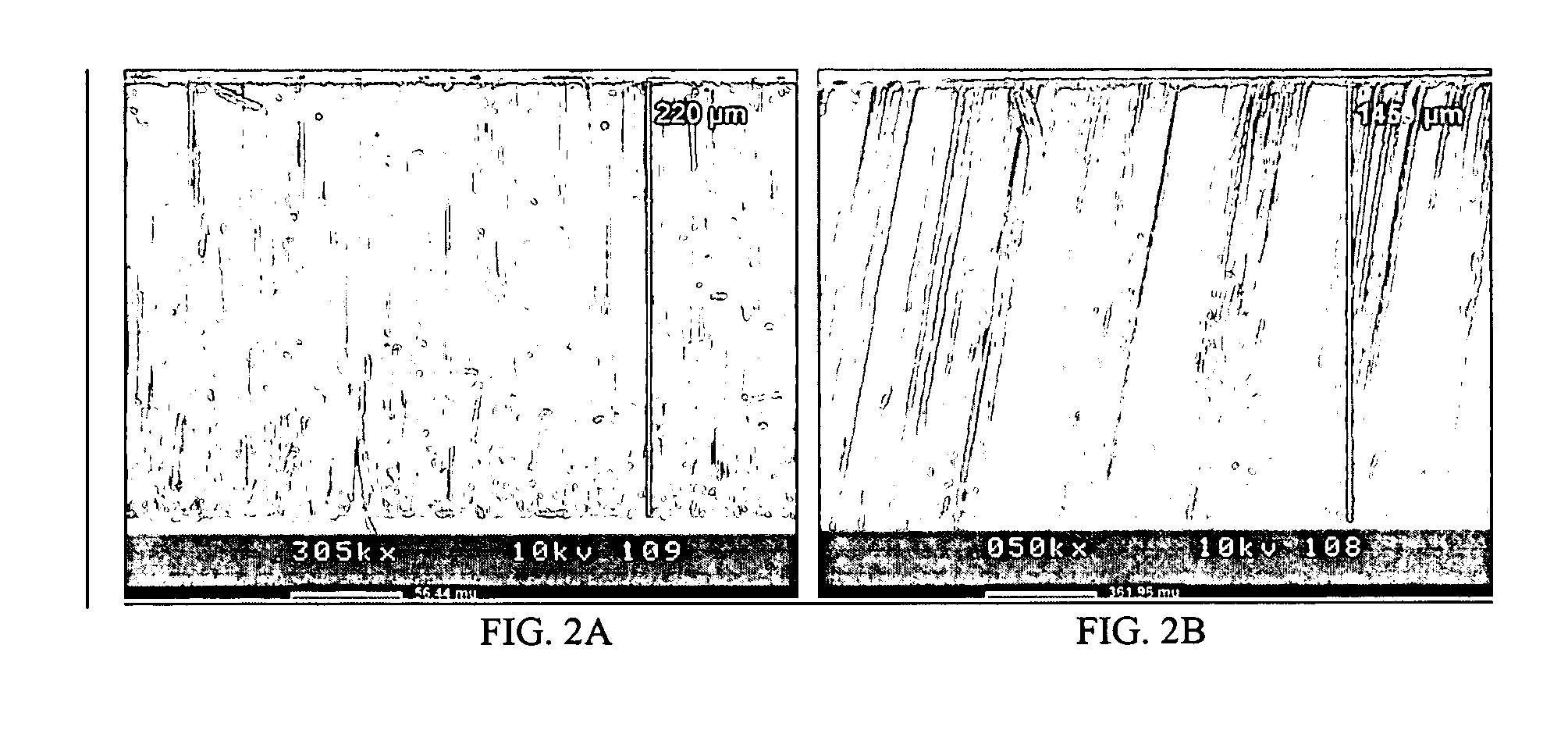

Semiconductor device capable of preventing moisture-absorption of fuse area thereof and method for manufacturing the fuse area

InactiveUS20050221539A1Efficient cuttingPrevent moisture penetrationTransistorSemiconductor/solid-state device detailsDevice materialMoisture absorption

A fuse area of a semiconductor device capable of preventing moisture-absorption and a method for manufacturing the fuse area are provided. When forming a guard ring for preventing permeation of moisture through the sidewall of an exposed fuse opening portion, an etch stop layer is formed over a fuse line. A guard ring opening portion is formed using the etch stop layer. The guard ring opening portion is filled with a material for forming the uppermost wiring of multi-level interconnect wirings or the material of a passivation layer, thereby forming the guard ring concurrently with the uppermost interconnect wiring or the passivation layer. Accordingly, permeation of moisture through an interlayer insulating layer or the interface between interlayer insulating layers around the fuse opening portion can be efficiently prevented by a simple process. In addition, the etch stop layer is also formed under the fuse opening portion so that an insulating layer remaining on the fuse line can be controlled to have a predetermined thickness when forming the fuse opening portion, thereby improving the cutting efficiency of fuses.

Owner:SAMSUNG ELECTRONICS CO LTD

Flexible display device

ActiveUS20170346041A1Prevent moisture penetrationAvoid crackingSemiconductor/solid-state device detailsSolid-state devicesFlexible displayLight-emitting diode

A flexible display device includes a base substrate defining a display area and a non-display area; a thin film transistor in the display area of the base substrate; an organic light emitting diode on and connected with the thin film transistor; an encapsulation layer on the organic light emitting diode; and a crack preventing portion in the non-display area defined by the base substrate.

Owner:LG DISPLAY CO LTD

Multi-layer radiation detector and related methods

ActiveUS7772558B1Prevent moisture penetrationImprove spatial resolutionMaterial analysis by optical meansRadiation intensity measurementResin coatingScintillator

The present invention provides radiation detectors and related methods, including methods of making radiation detectors and devices, as well as methods of performing radiation detection. A radiation detector includes a first resin coating formed on at least a surface of the substrate and an additional layer, such as a scintillator layer, formed on the resin coating.

Owner:RADIATION MONITORING DEVICES

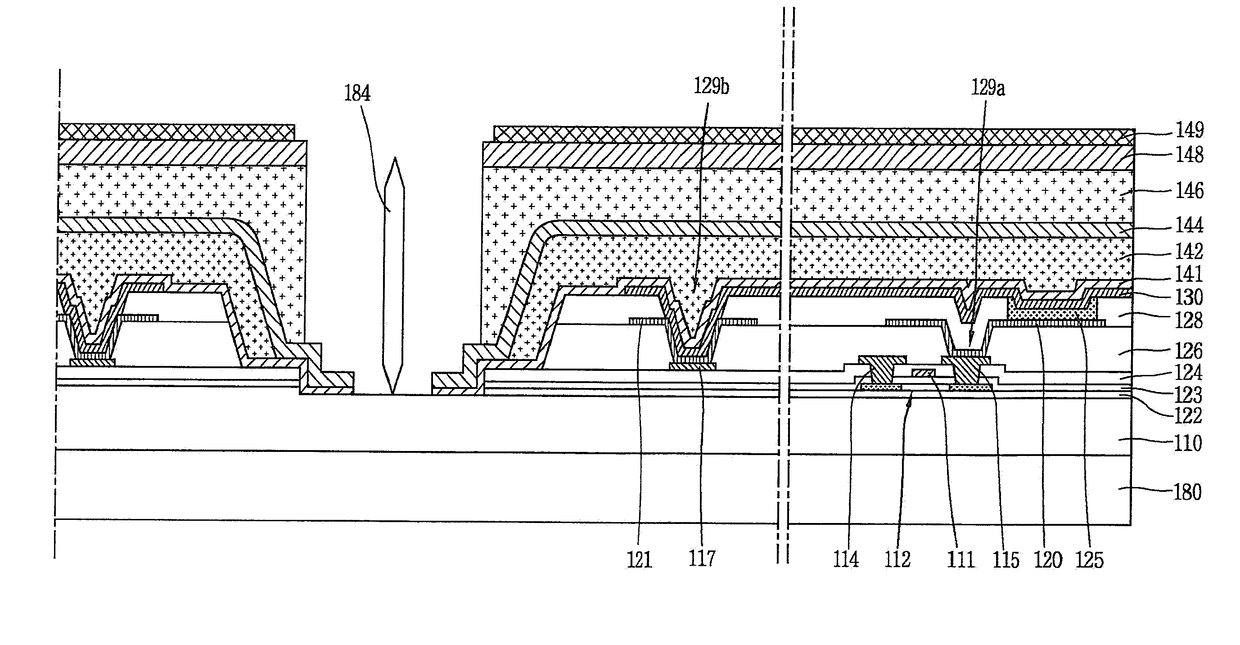

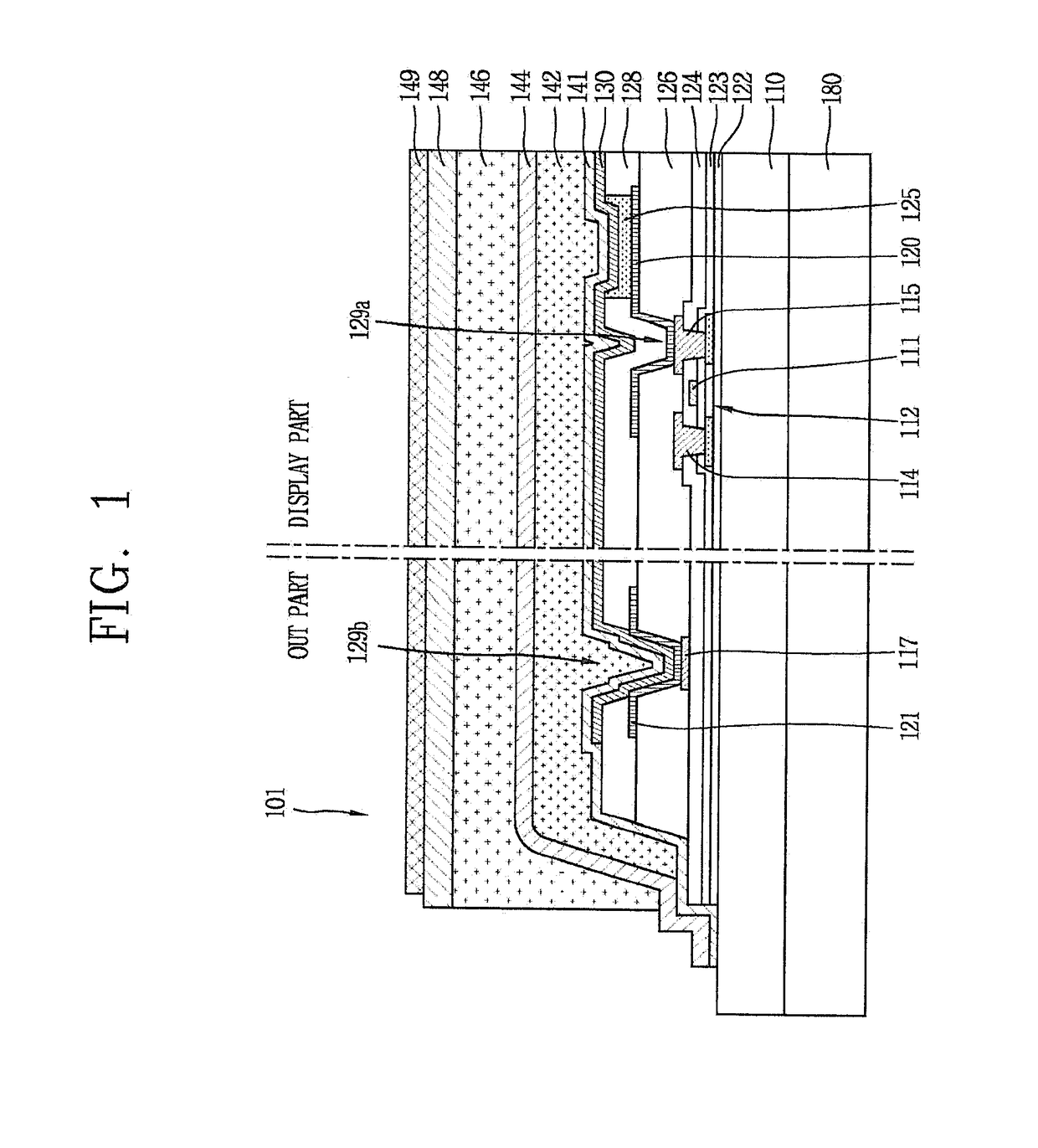

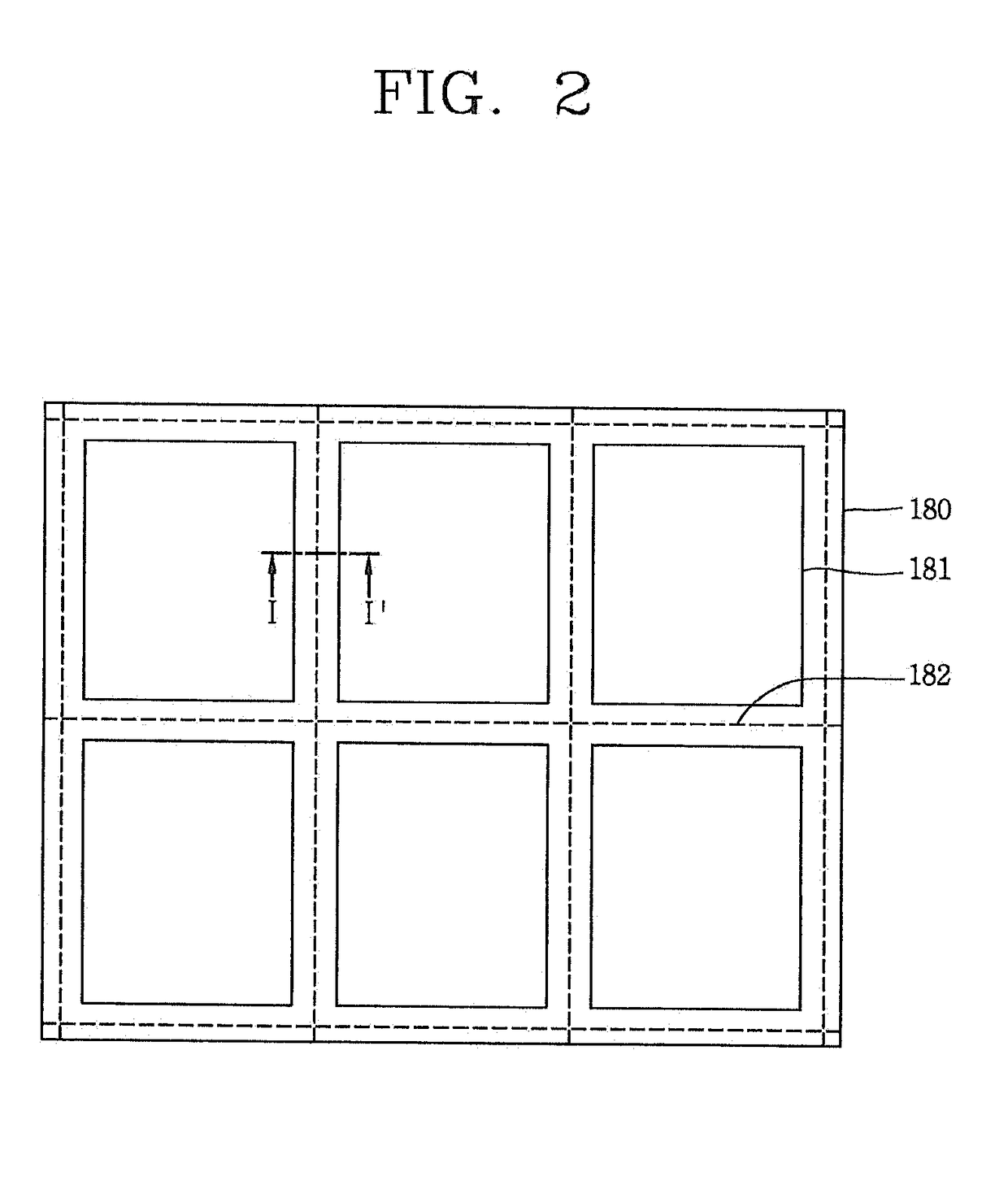

Organic light emitting display device and method of fabricating the same

ActiveUS20170084883A1Prevent moisture penetrationAvoid crackingFinal product manufactureElectroluminescent light sourcesDisplay deviceOptoelectronics

The present disclosure relates to an organic light emitting display device including a substrate having an outer part and a display part, a driving thin film transistor on each of a plurality of pixel regions within the display part of the substrate, a pixel electrode on each pixel region of the display part, an organic light emitting unit on each pixel region of the display part to emit light, a common electrode on the organic light emitting unit and a bank layer to apply a signal to the organic light emitting layer, and a first passivation layer, an organic insulating layer and a second passivation layer on the outer part and the display part, wherein the first passivation layer and the second passivation layer are removed from the outermost region of the outer part, so that the substrate is exposed to the outside.

Owner:LG DISPLAY CO LTD

Adhesive film and method of encapsulating organic electrode device using the same

ActiveUS8742411B2Prevent moisture penetrationEffectively introduce a moisture-reactive absorbentNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsMoistureHot-melt adhesive

An adhesive film, and a product and method of encapsulating an organic electronic device (OED) using the same are provided. The adhesive film serves to encapsulate the OED and includes a curable hot-melt adhesive layer including a curable resin and a moisture absorbent, and the curable hot-melt adhesive layer includes a first region coming in contact with the OED upon encapsulation of the OED and a second region not coming in contact with the OED. Also, the moisture absorbent is present at contents of 0 to 20% and 80 to 100% in the first and second regions, respectively, based on the total weight of the moisture absorbent in the adhesive layer.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com