Patents

Literature

1763results about How to "Ensure structural stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

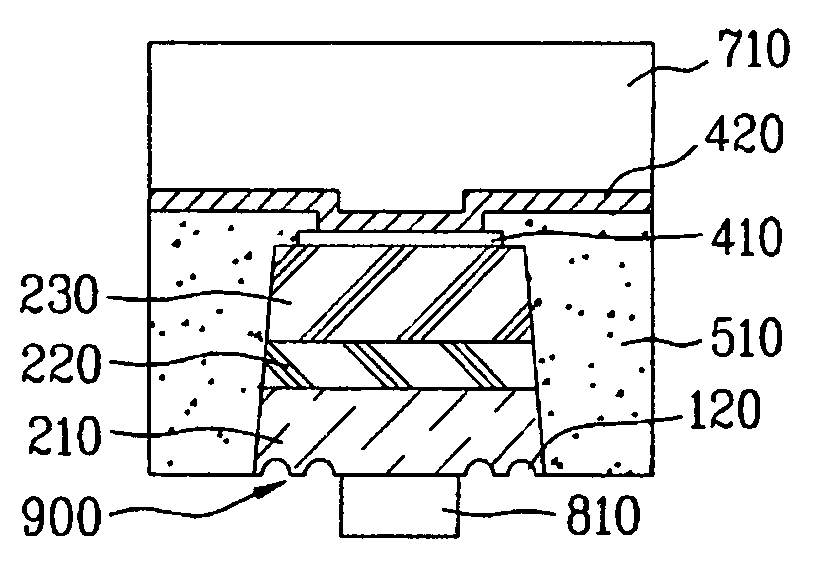

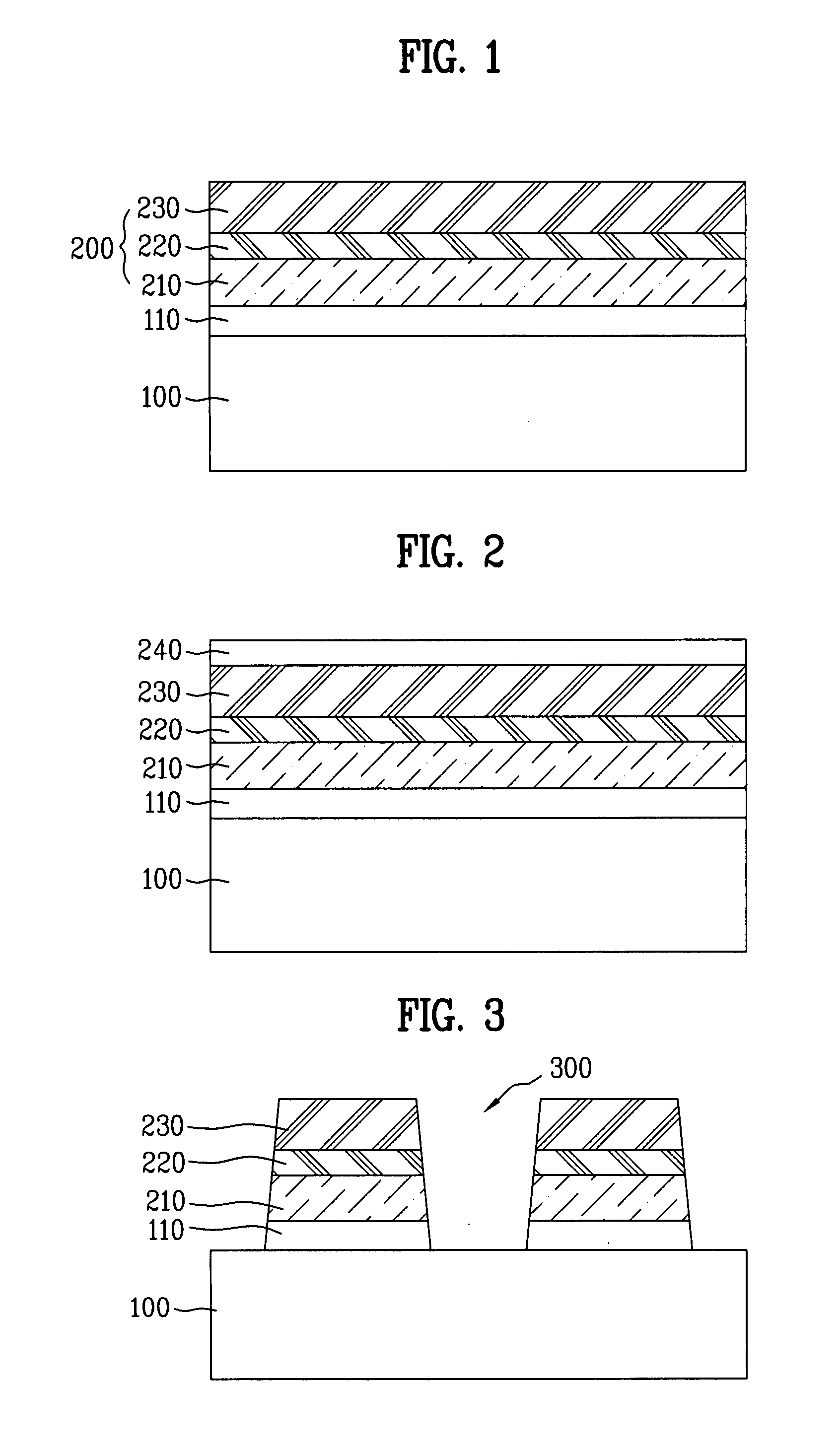

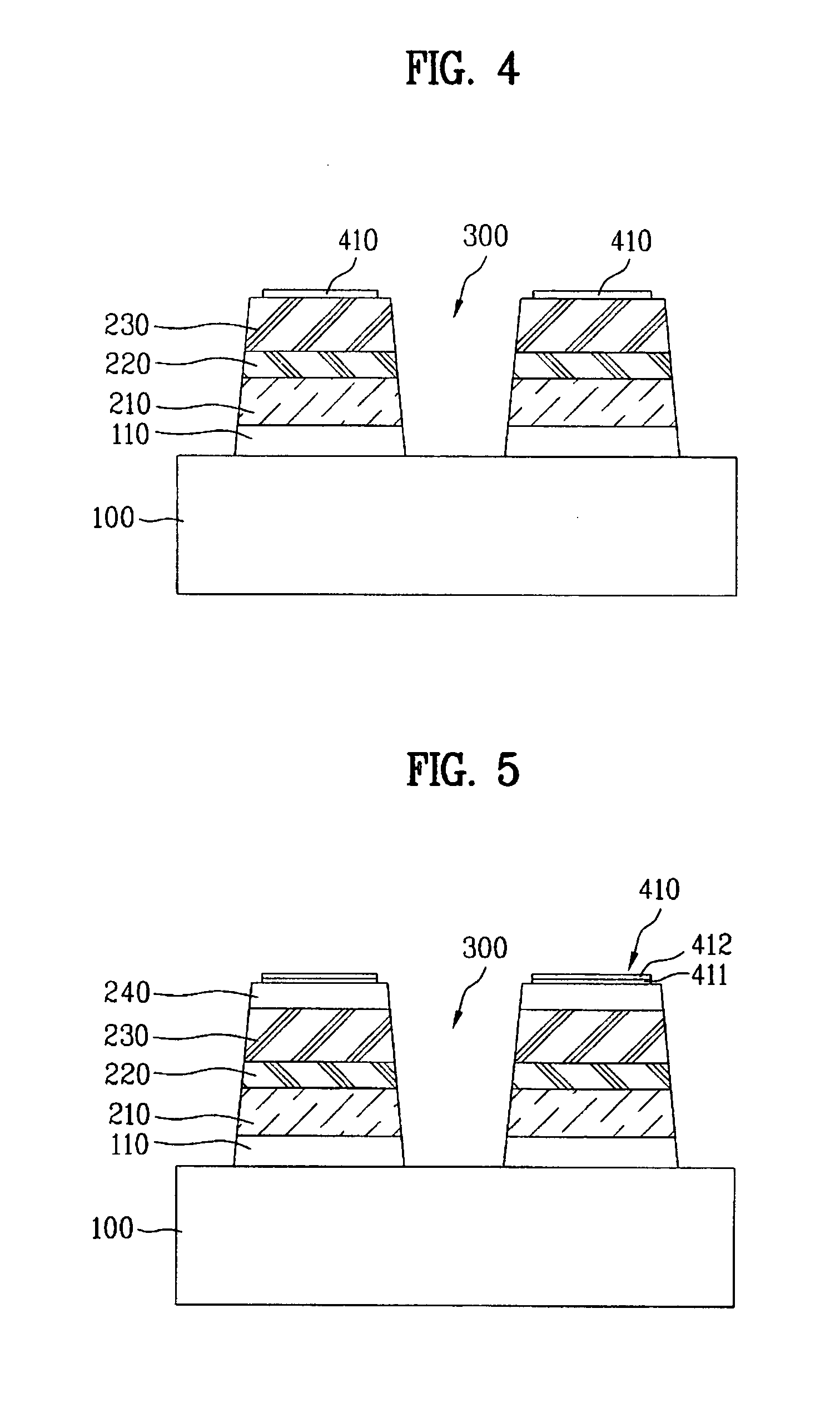

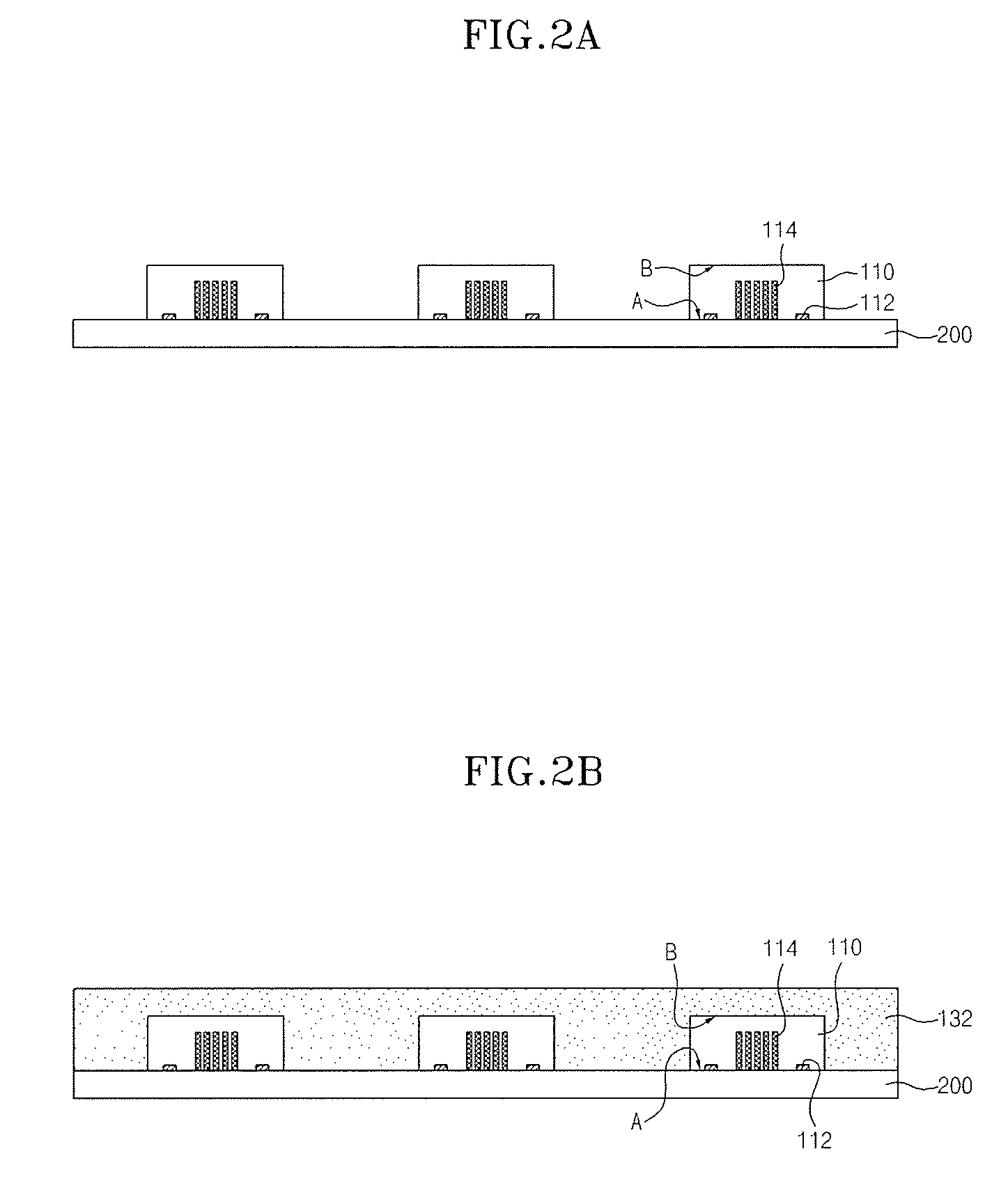

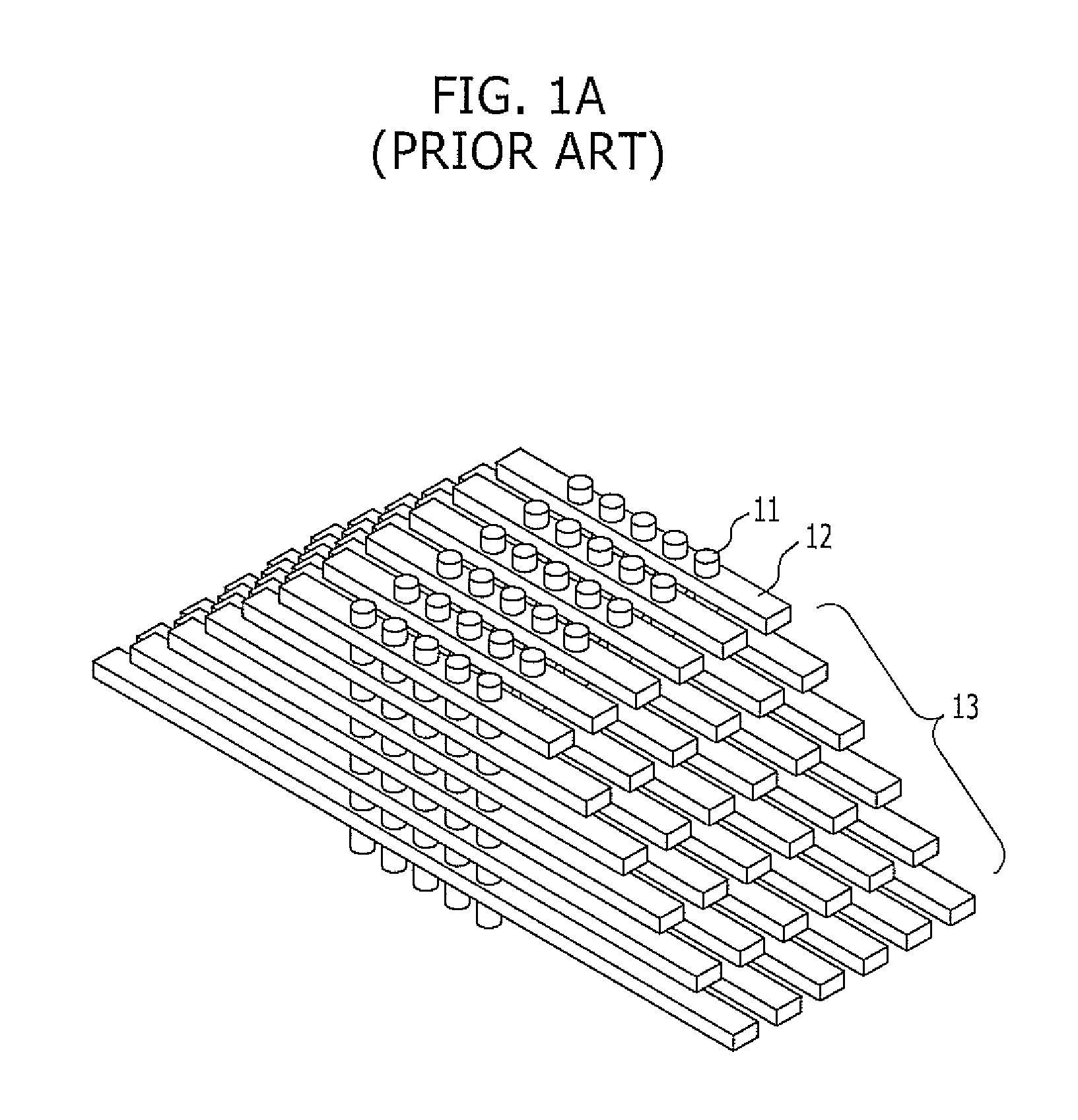

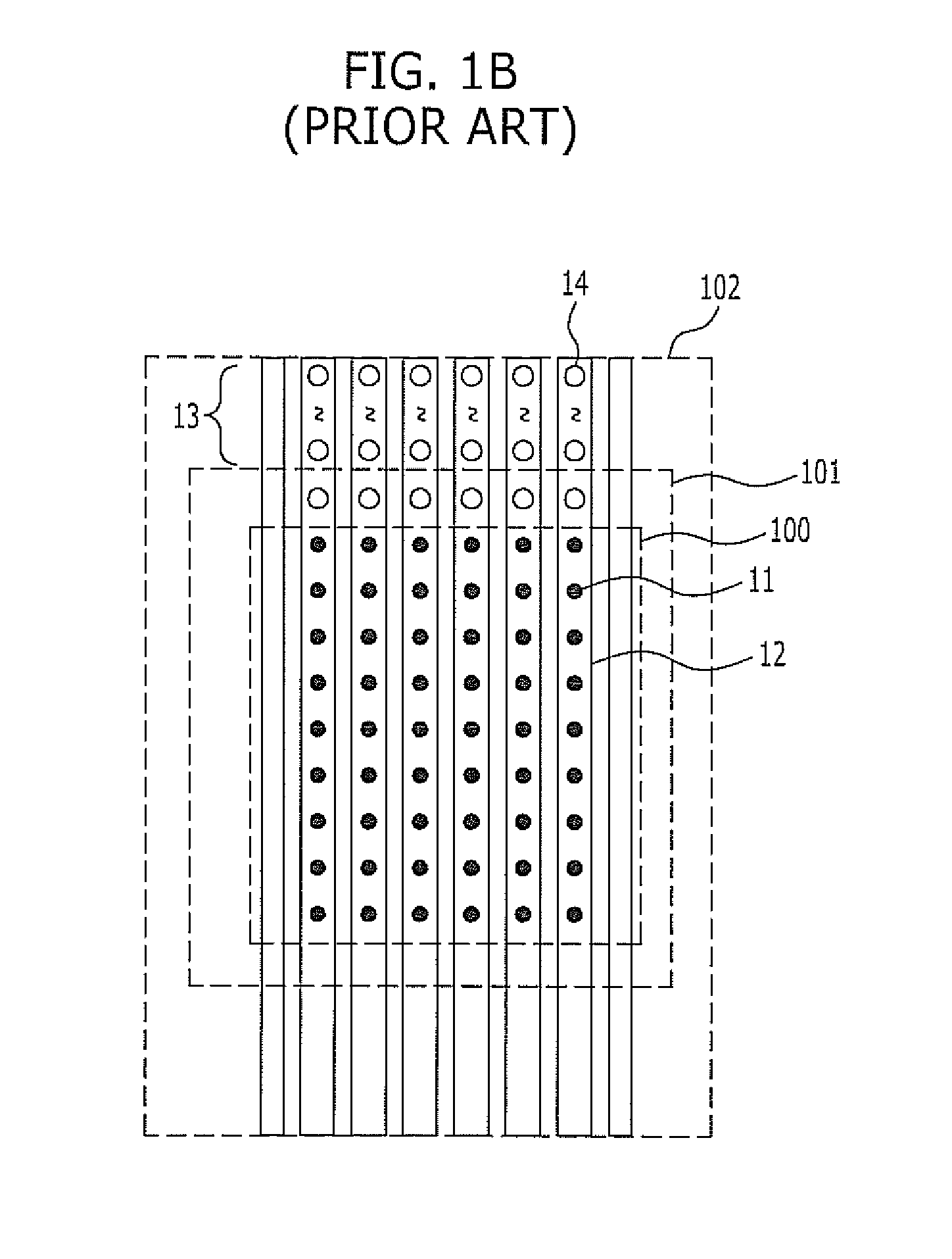

Light Emitting Diode having vertical topology and method of making the same

ActiveUS20070295952A1Efficient implementationEnsure structural stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesStress waveSemiconductor

An LED having vertical topology and a method of making the same is capable of improving a luminous efficiency and reliability, and is also capable of achieving mass productivity. The method includes forming a semiconductor layer on a substrate; forming a first electrode on the semiconductor layer; forming a supporting layer on the first electrode; generating an acoustic stress wave at the interface between the substrate and semiconductor layer, thereby separating the substrate from the semiconductor layer; and forming a second electrode on the semiconductor layer exposed by the separation of the substrate.

Owner:SUZHOU LEKIN SEMICON CO LTD +1

Supporting structure and display device

ActiveCN110767096AImprove bending resistanceBending Resistance GuaranteeCasings with display/control unitsPhotovoltaic energy generationDisplay deviceEngineering

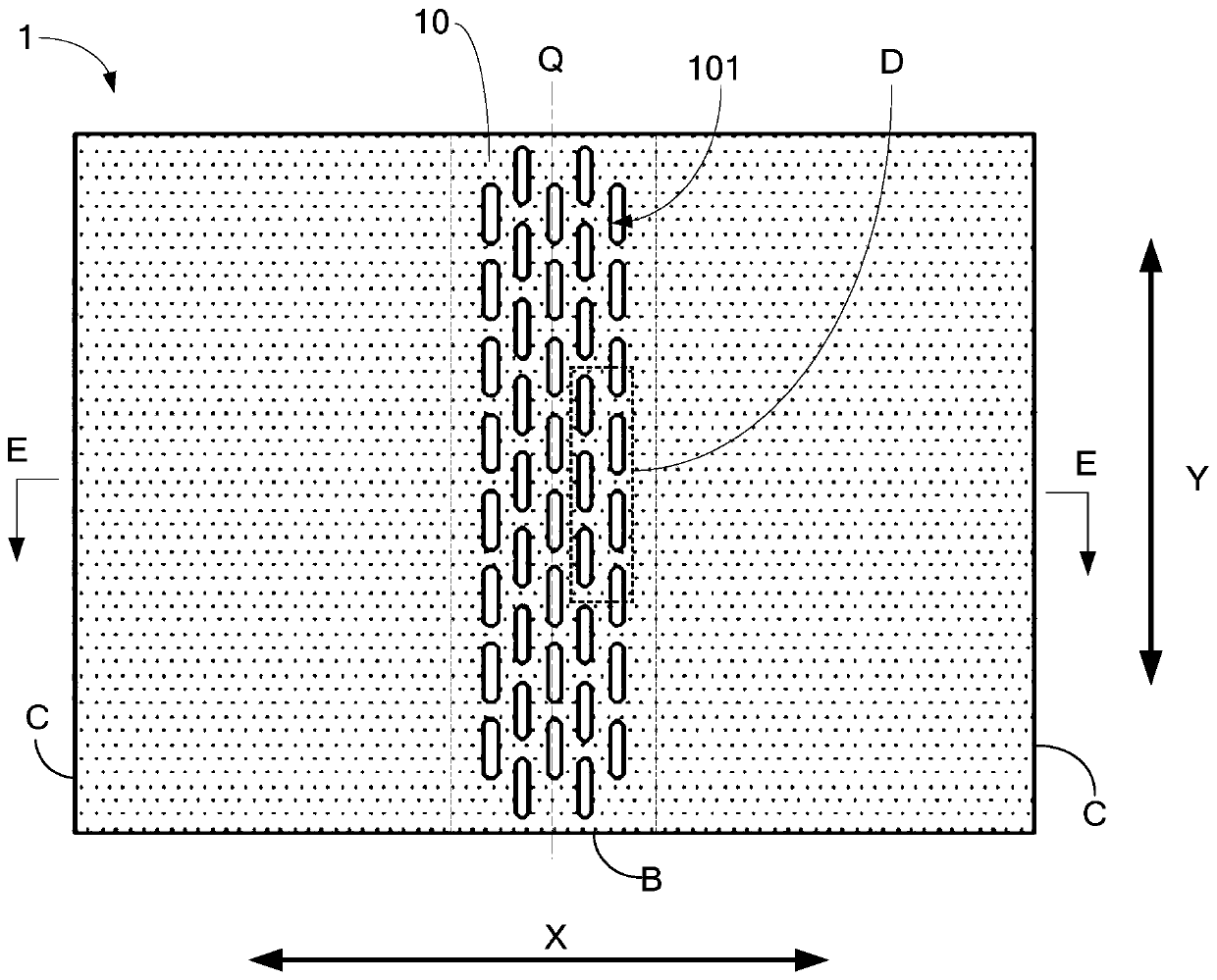

The application relates to a supporting structure and a display device. The supporting structure is arranged at one side of a flexible display panel, the flexible display panel comprises a bendable area, a bending axis corresponding to the bendable area extends on a first direction, wherein the supporting structure comprises a hollow-out area with a positive projection capable of completely covering the bendable area on the display panel, the hollow-out area comprises a first part formed with multiple first hollow-out holes, second parts located at two opposite sides of the first part on the first direction, wherein multiple second hollow-out holes are formed on the second parts; a specific value of the total area of multiple second hollow-out holes and the total area of the second parts is different from that of the total area of multiple first hollow-out holes and the first part, thereby guaranteeing the structure stability of the supporting structure and enhancing the shock resistance and bending resistance of the flexible display panel.

Owner:BOE TECH GRP CO LTD

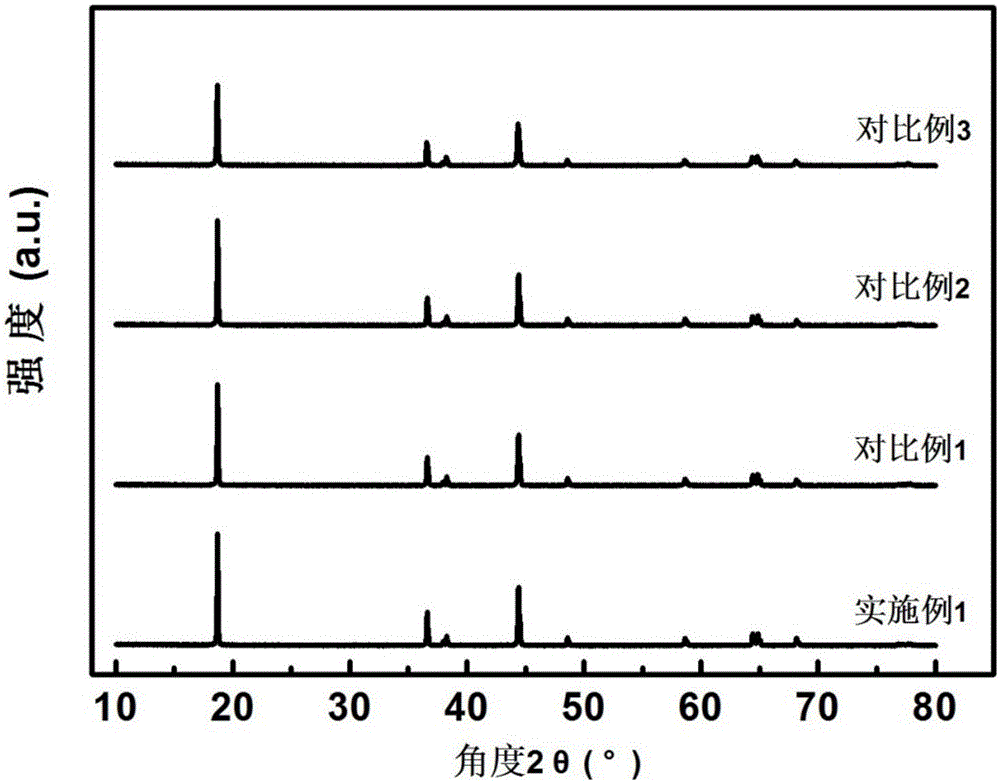

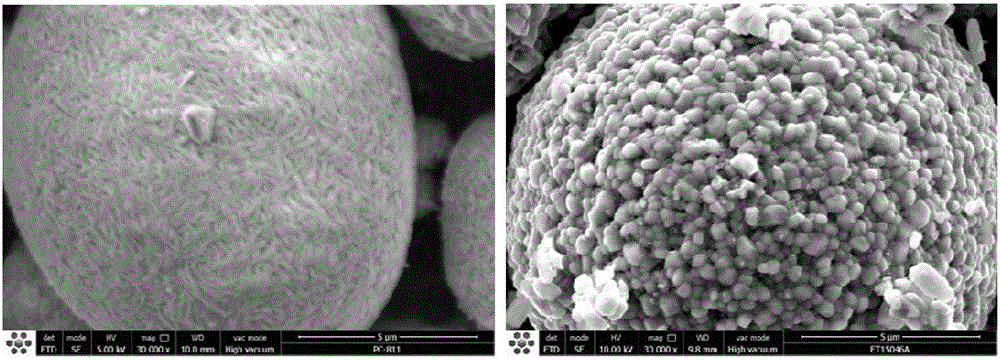

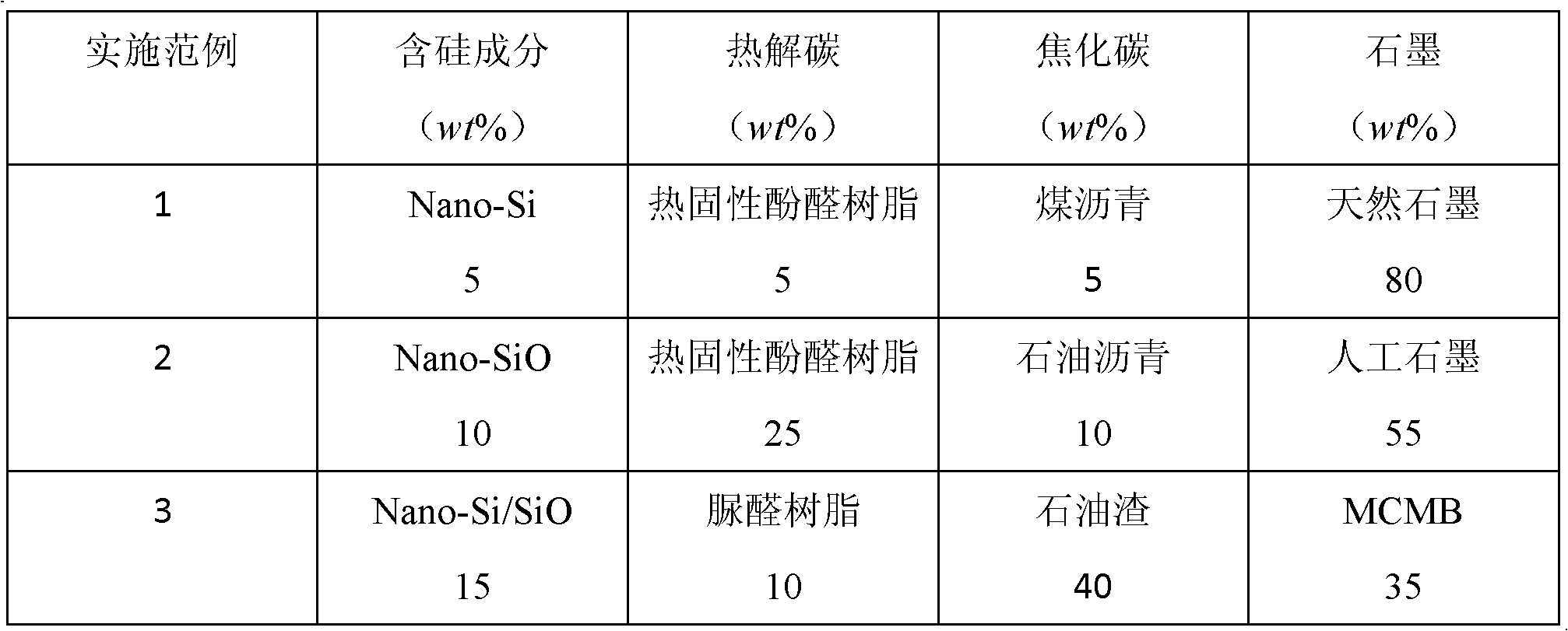

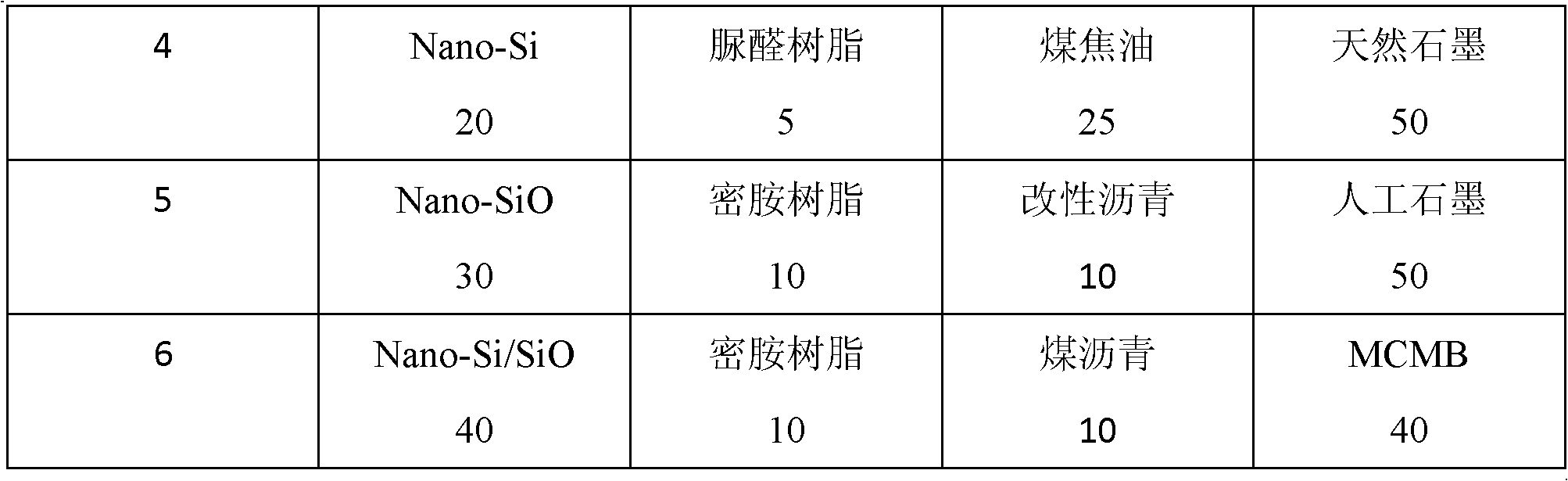

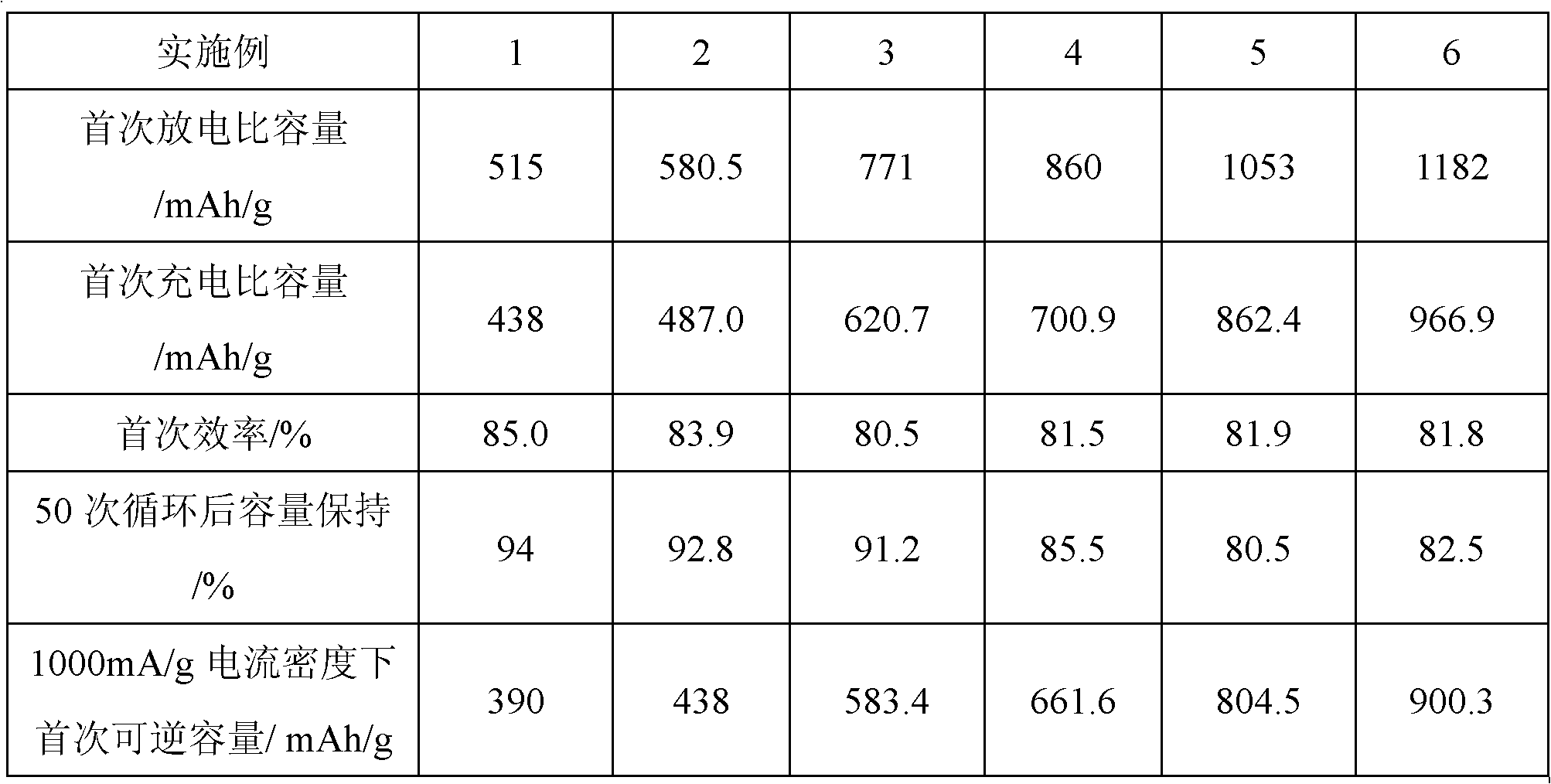

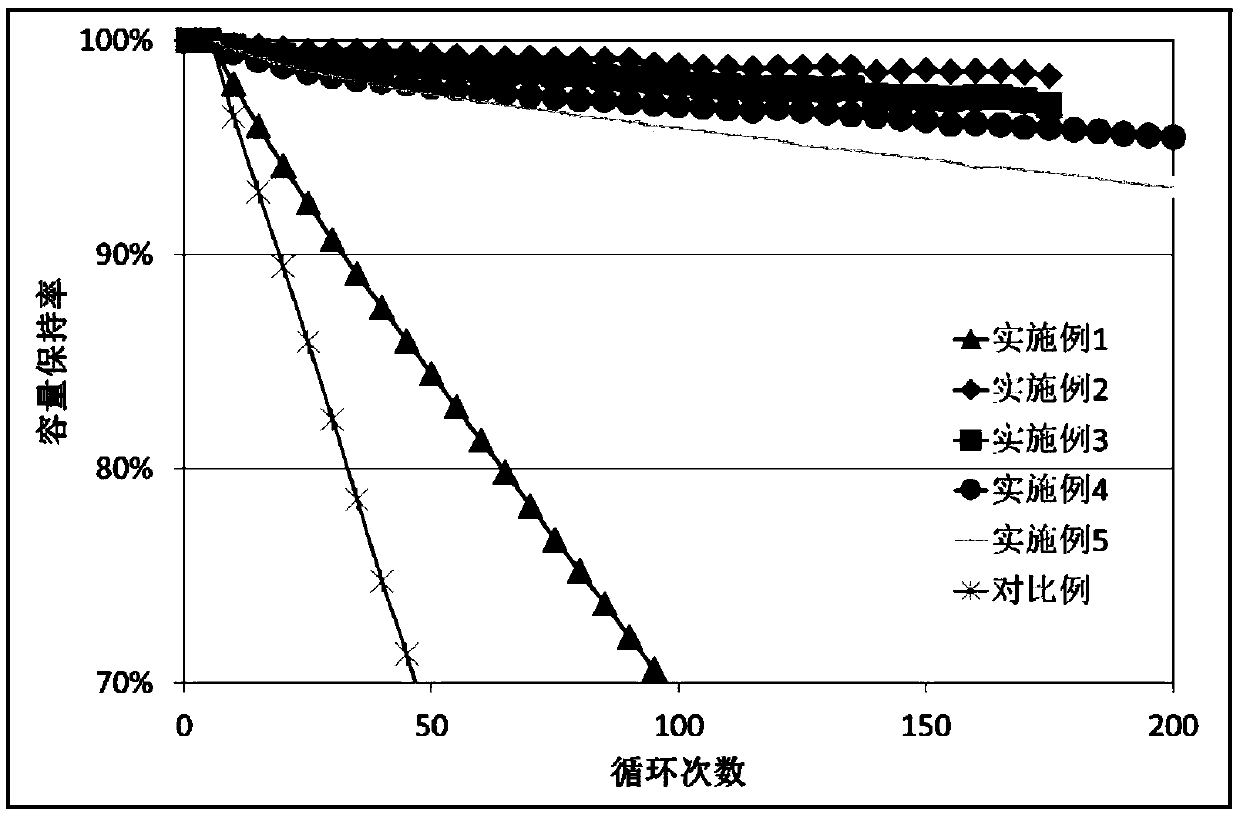

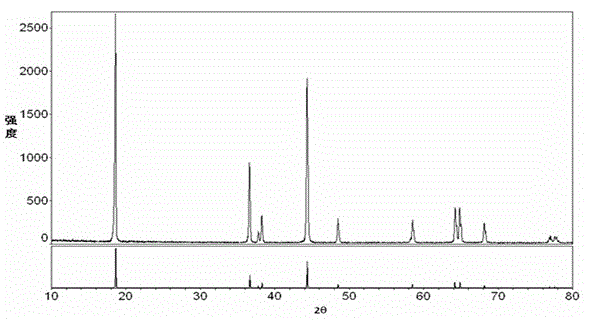

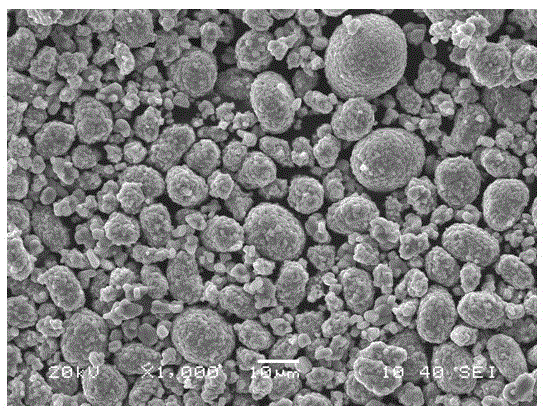

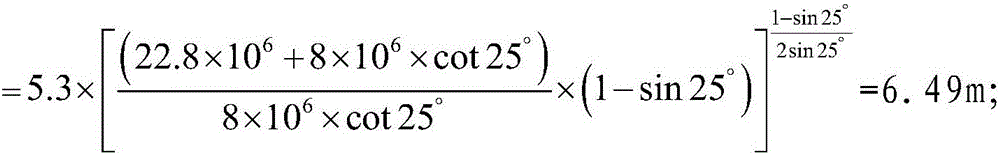

Lithium ion battery composite anode material and preparation method thereof

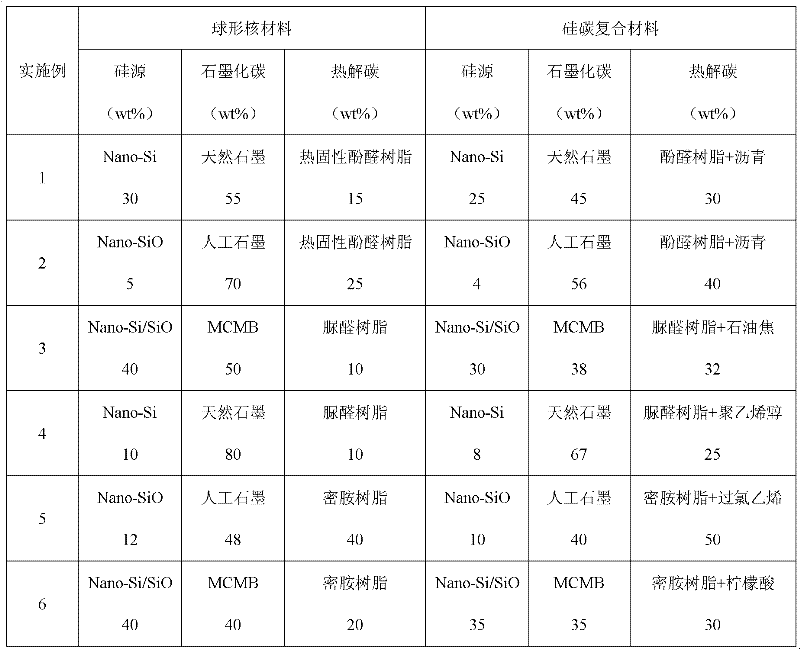

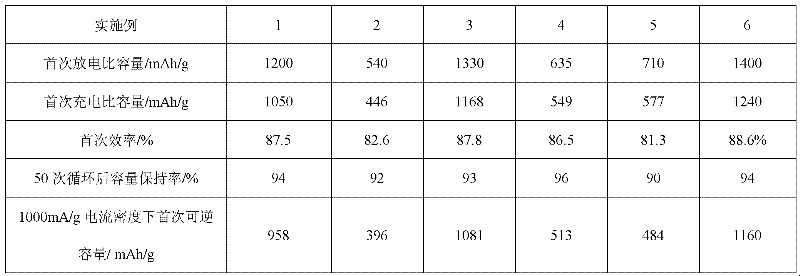

The invention discloses a lithium ion battery silicon carbon composite anode material and a preparation method thereof. The material is prepared by twice spray drying and once sintering. The preparation method comprises the following steps of: 1) dissolving an organic carbon source in an appropriate amount of solvent, adding a silicon source and a dispersing agent for dispersing suspension uniformly, adding graphitized carbon for dispersing the suspension for a certain period of time, and performing primary spray drying on the uniformly dispersed suspension to obtain a spherical nucleus material; and 2) dissolving the organic carbon source in the appropriate amount of the solvent, adding the prepared spherical nucleus material, dispersing the suspension uniformly, performing secondary spray drying on the uniformly dispersed suspension to obtain powder, transferring the powder into a protective atmosphere for sintering, and performing furnace cooling on the powder to obtain the lithium ion battery composite anode material. The preparation method is simple and practicable and has high practicality; and the prepared silicon carbon composite material has the advantages of large reversible capacity, designable capacity, high cycle performance, high rate capability, high tap density and the like.

Owner:CENT SOUTH UNIV

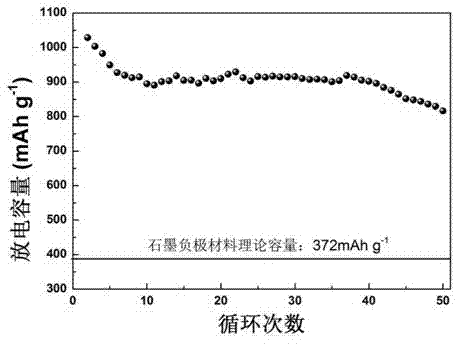

Modified composite material containing silicon-base material, preparation method thereof, and application thereof in lithium ion battery

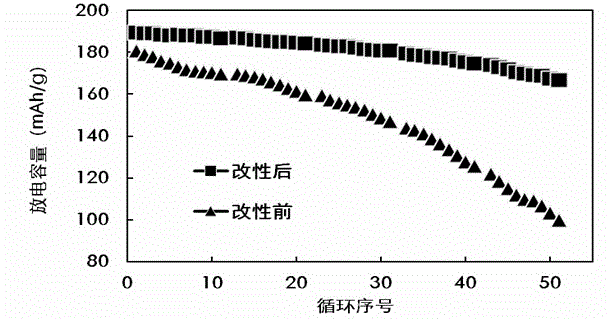

PendingCN109301184AImprove performanceEasy to crushMaterial nanotechnologyCell electrodesStructural stabilitySide reaction

The invention discloses a modified composite material containing silicon-base material, a preparation method thereof, and an application thereof in a lithium ion battery. The composite material includes a silicon-base core and a modifying layer covering same. The modifying layer includes a polymer covering film and a nano-conductive material embedded therein. The modified composite material not only can isolate an electrolyte to inhibit side reactions of the electrolyte on the surface of the material, thus improving overall performance of the battery, but also can improve electric conductivityand improve structural stability due to the unique structure by embedding the nano-conductive material in the polymer. Tension is absorbed by means of deformation, so that problems of breaking and pulverization and stripping of the electrode during processing and use of the silicon-base negative material are solved. The problems of pulverization and stripping of the electrode due to large expansion during charge / discharge processes of the silicon-base material are solved, thus stabilizing the structure of the electrode and improving cycle performance of the cell.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

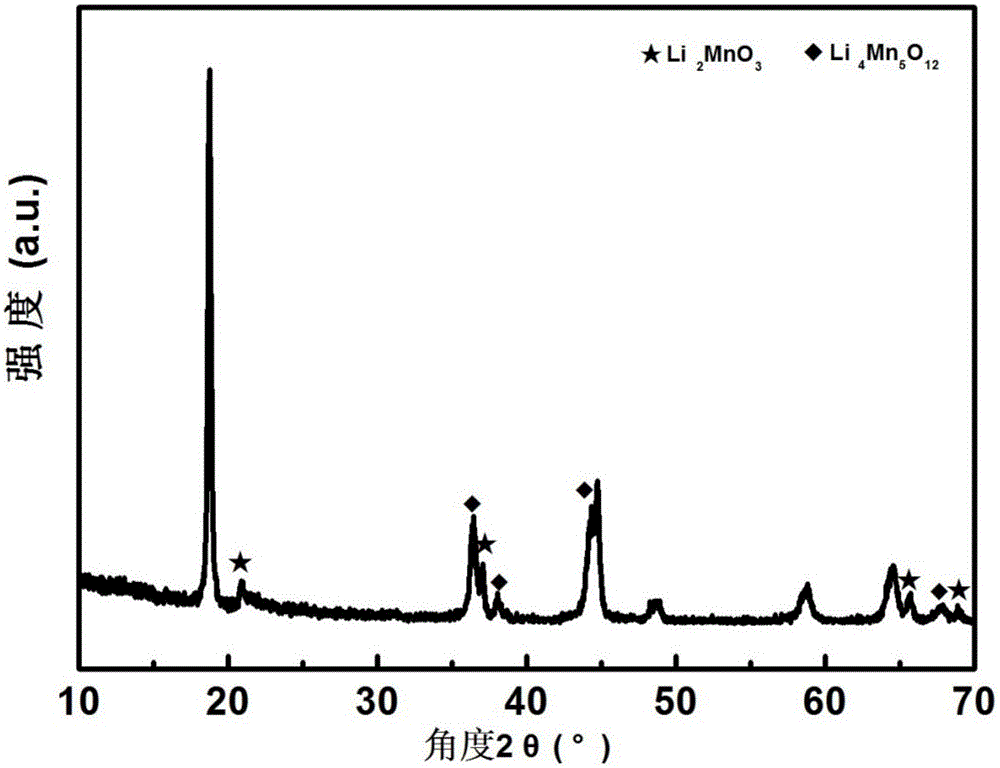

Polycrystal high-nickel positive electrode material used for lithium ion battery and preparation method for polycrystal high-nickel positive electrode material

InactiveCN105958062AExtended storage timeReduce lithiumCell electrodesSecondary cellsSodium-ion batteryLithium-ion battery

Disclosed is a polycrystal high-nickel positive electrode material used for a lithium ion battery. The polycrystal high-nickel positive electrode material comprises a base material with a layered structure and a coating layer which is arranged outside the base material and has a spinel structure; the general formula of the base material is LiNi<1-x-y>Co<x>M<y>O<2>, wherein M is at least one kind of Mn and Al; the coating layer is lithium manganese oxide; the mass percentage of the total impurity lithium on the surface of the base material is less than 0.085% based on the total mass percentage of the base material; the preparation method for the positive electrode material comprises the following steps of weighing Ni<1-x-y>Co<x>M<y>(OH)<2>, and mixing with a lithium source, then carrying out thermal treatment, cooling, crushing and sieving to obtain the base material; measuring the content of the residual impurity Li<2>CO<3> and LiOH on the surface of the base material, adding into the metal Mn compound according to the measurement result, and carrying out low-temperature thermal treatment in an oxygen atmosphere to obtain the polycrystal high-nickel positive electrode material used for the lithium ion battery. The polycrystal high-nickel positive electrode material provided by the invention has the advantages of low material alkalinity, low inflatable degree, excellent processing property and cycling performance, and the like.

Owner:HUNAN SHANSHAN NEW ENERGY CO LTD

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

InactiveCN109103441AImprove overall performanceStable electrode structureNegative electrodesSecondary cellsSolventCharge and discharge

The invention discloses a modified composite material containing a silicon base material, which comprises a silicon base core and a polymer cladding layer covering the surface of the core, and a preparation method and use thereof in a lithium ion battery. The method comprises the steps of : 1) adding a polymer into a liquid solvent and dispersing to obtain a slurry; 2) adding a silicon-based material or a mixture of that silicon-based material and the carbon material into the slurry and mixing the solid and liquid; 3) removing the solvent to obtain a modified composite material containing a silicon-based material. As the polymer coat layer is introduced on the surface of the silicon base core, so that the electrolyte can be isolated and the side reaction of the electrolyte on the surface of the silicon base core can be prevented; the method can also improve the crushing, electrode pulverization and peeling of the silicon-based negative electrode material in the process of processing and using, and reduce the electrode crushing and peeling caused by the huge volume expansion of the silicon-based material in the process of charging and discharging, so as to achieve the purpose of stabilizing the electrode structure and improving the cell cycle performance.

Owner:JIANGSU TAFEL NEW ENERGY TECH CO LTD +2

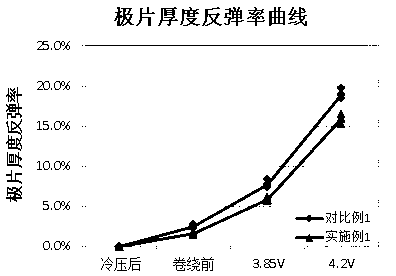

Lithium ion battery cathode and lithium ion battery

ActiveCN103326027AReduce expansionImprove adhesionSecondary cellsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryBattery cell

The invention discloses a lithium ion battery cathode. The lithium ion battery cathode comprises a cathode current collector and a cathode active-substance layer coated on the cathode current collector. The cathode active-substance layer comprises a cathode active-substance, a conductive agent, a polymer thickening agent, a water emulsion-type polymer binder and a water soluble polymer binder. The water soluble polymer binder is polyethyleneimine. A weight ratio of the water emulsion-type polymer binder to the water soluble polymer binder is in a range of (10: 90)-(90: 10). The lithium ion battery cathode can obviously improve the adhesion between the cathode active-substance layer and the cathode current collector and among particles in the cathode active-substance layer thereby improving structure stability of the cathode active-substance layer in long-term battery cycle and reducing a use amount of the polymer binders having electrochemical inertia, reducing a battery volume expansion ratio in cycle, and improving low temperature, multiplying power, cycle performances and energy density of a polymer lithium ion battery. The invention also discloses a lithium ion battery.

Owner:NINGDE AMPEREX TECH

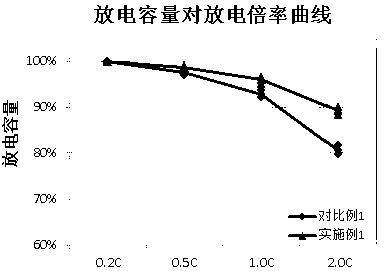

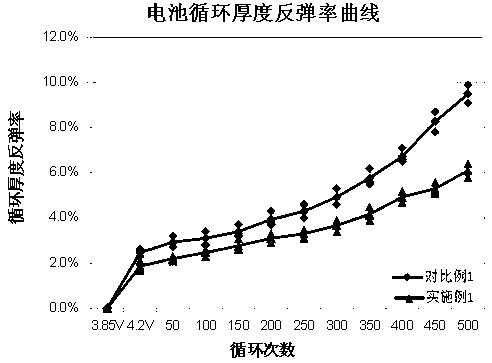

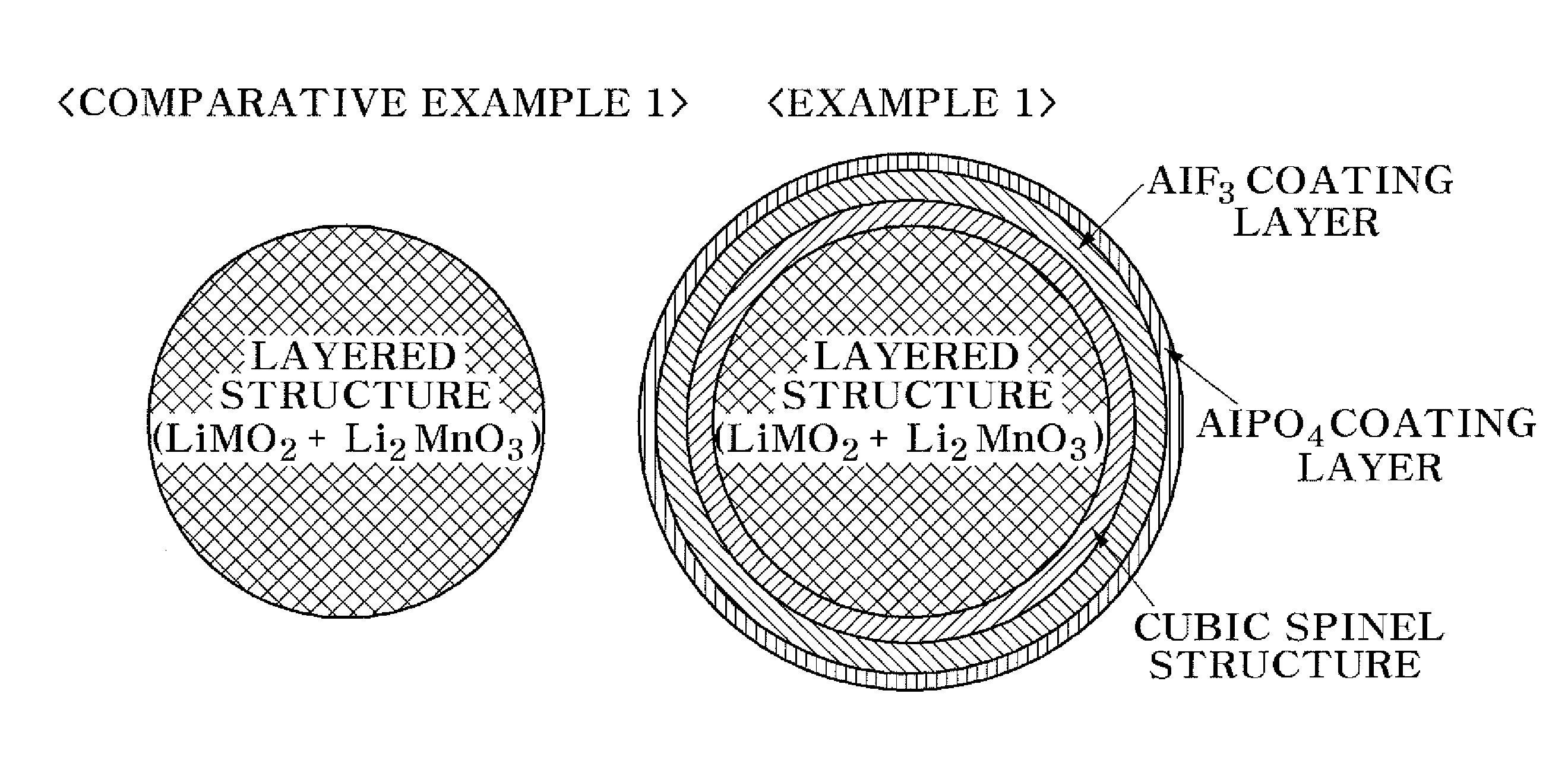

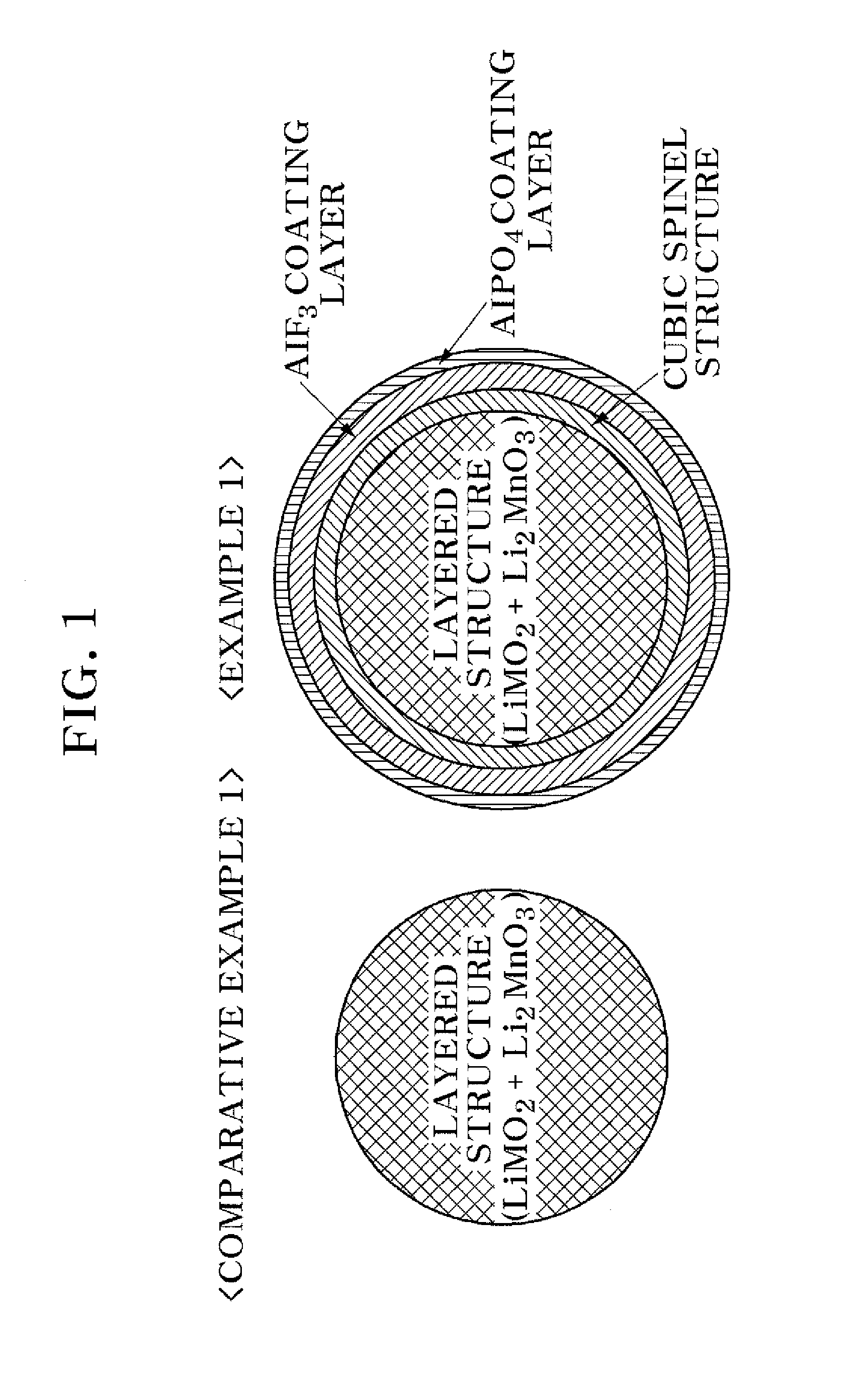

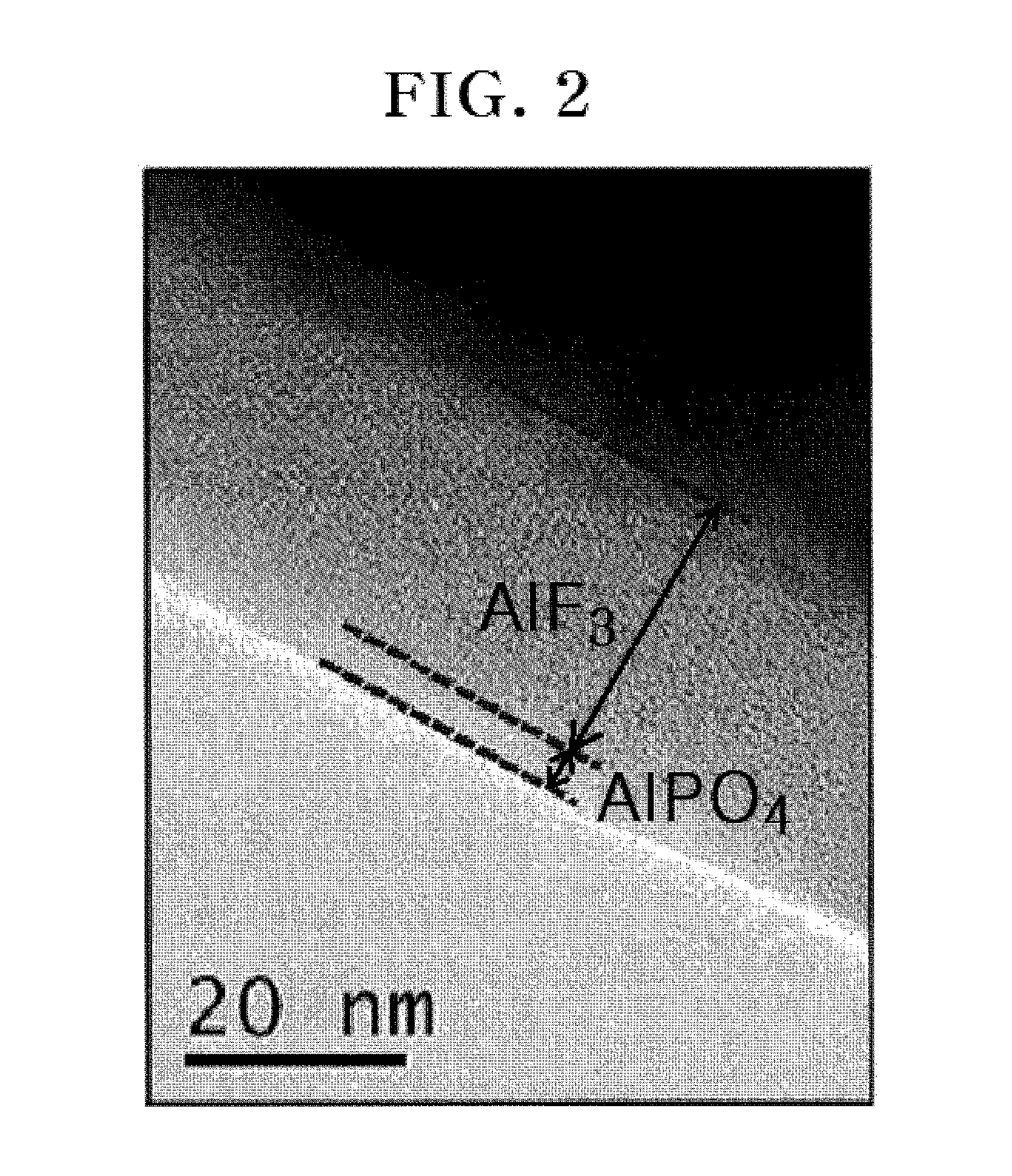

Cathode active material, method for preparing the same, and lithium secondary batteries including the same

ActiveUS20140162127A1Improve thermal stabilityLarge capacityElectrode manufacturing processesPositive electrodesPhosphateManganese

The present invention relates to a cathode active material for a lithium secondary battery, a method for preparing the same, and a lithium secondary battery including the same, and provides a cathode active material including: a lithium manganese-excess layered structure composite oxide represented by Formula Li[Lix-z(NiaCobMnc)1-x]O2-yFy (here, a+b+c=1, 0.05≦x≦0.33, 0≦y≦0.08, and 0<z≦0.05); a metal fluoride coating layer coated on a surface of the composite oxide; and a metal phosphate coating layer coated on the metal fluoride coating layer.

Owner:SAMSUNG SDI CO LTD

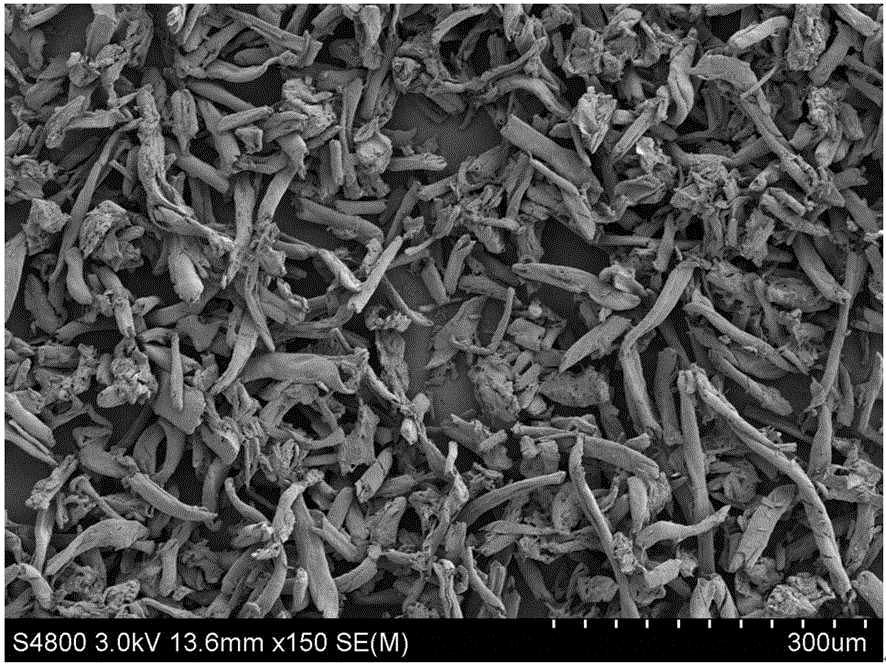

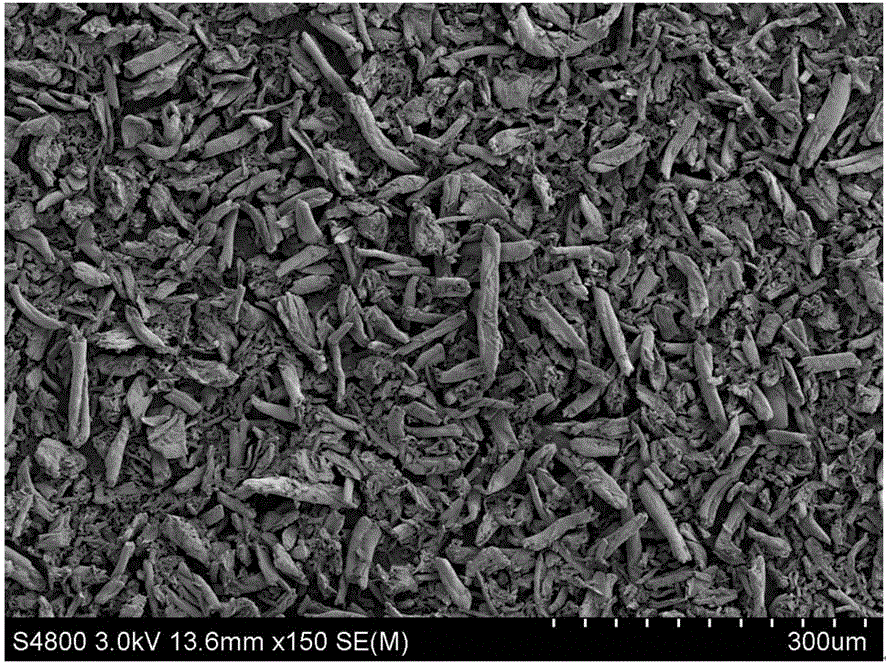

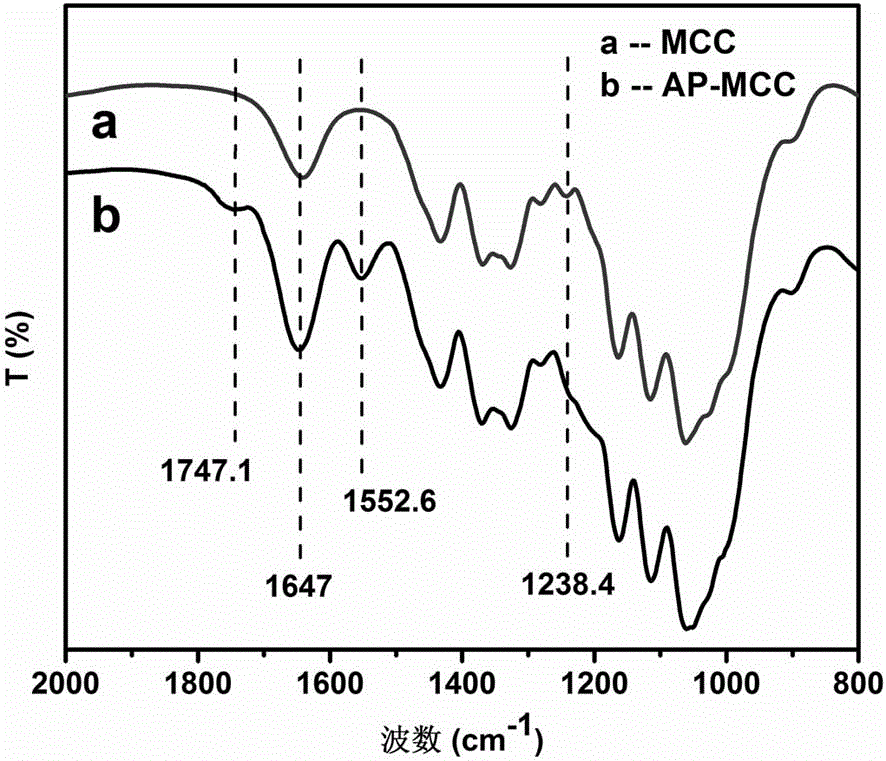

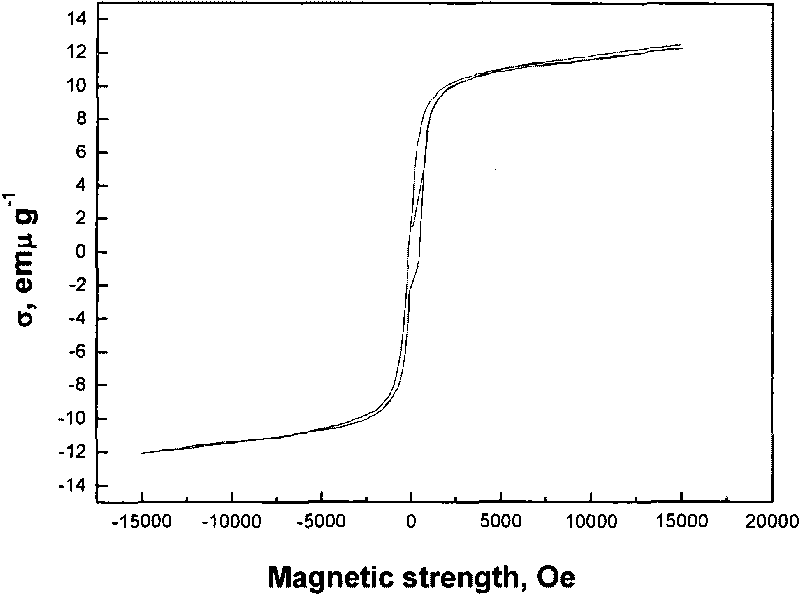

Cellulose-based magnetic aerogel material and preparation method thereof

ActiveCN104479174AHigh activityHigh specific surface propertiesOrganic/organic-metallic materials magnetismCelluloseFreeze-drying

The invention discloses a cellulose-based magnetic aerogel material and a preparation method thereof. The method comprises the following steps: carrying out chemical modification, thereby obtaining high-activity amphoteric cellulose; firmly combining the amphoteric cellulose and a graphene oxide through electrostatic interaction and hydrogen bonding forces and the like to build a framework of the aerogel material. Disperse loading of a magnetic nano ferroferric oxide can be achieved by virtue of the advantages of high surface activity and super-large specific surface area; the structure uniformity and the stability of the magnetic aerogel of the amphoteric cellulose are ensured through the steps of cross-linking, freeze-drying and the like; the characteristics of high specific surface properties, good affinity, biodegradability and the like of the cellulose are kept by the magnetic aerogel; and the magnetic aerogel obtains high surface activity and superparamagnetic property, has the advantages of low cost, high strength, amphoteric characteristic, biocompatibility and the like, has the characteristics of high specific surface area, high loading capacity, high surface activity, intelligent positioning and the like, and has significant adsorption capacity on pollutants such as heavy metal ions and organic molecules.

Owner:HAIMEN ZHUOWEI TEXTILE CO LTD

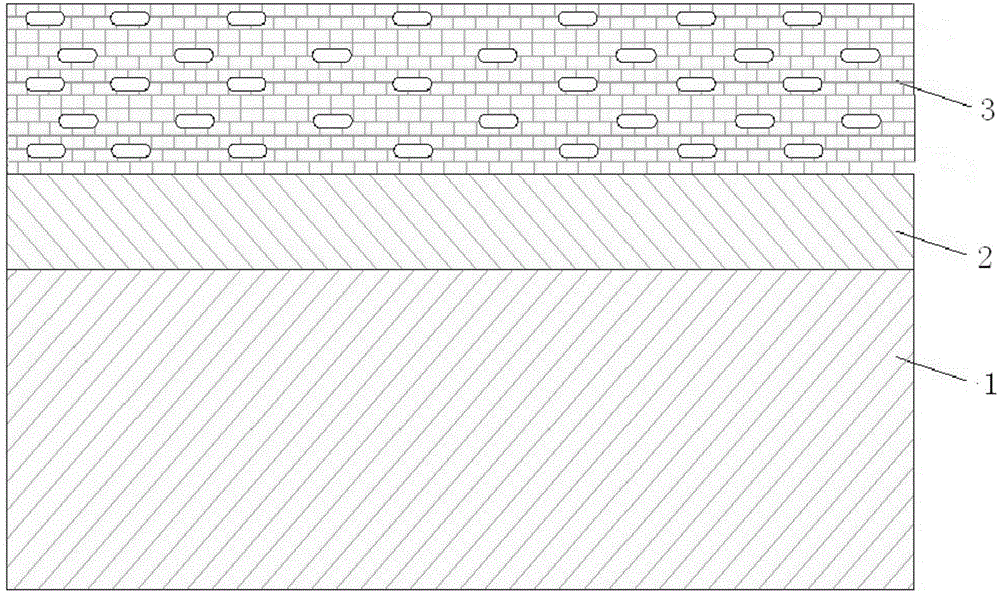

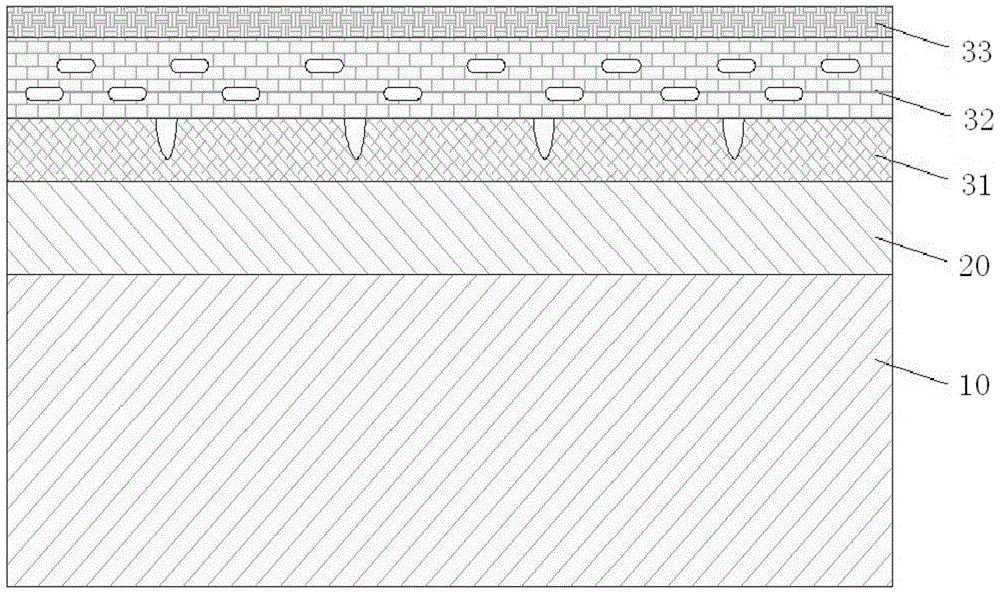

Multi-layer thermal barrier coating and forming method thereof

ActiveCN104451519AIncreased strain toleranceHigh crack resistanceMolten spray coatingEfficient propulsion technologiesThermal barrier coatingPlasma sprayed

The invention relates to a multi-layer thermal barrier coating. The coating comprises a base body, a binding layer and a ceramic top layer which are sequentially arranged from bottom to top, wherein the ceramic top layer consists of a vertical-crack-containing ceramic bottom layer with different microstructures, a porous intermediate ceramic layer and a compact ceramic top layer, which are sequentially arranged from bottom to top; the invention further provides a forming method of the multi-layer thermal barrier coating; the forming method comprises the following steps: providing the base body and the binding layer; forming the vertical-crack-containing ceramic bottom layer on the upper surface of the binding layer by plasma spraying; forming the porous intermediate ceramic layer on the upper surface of the vertical-crack-containing ceramic bottom layer by virtue of plasma spraying; forming the compact ceramic top layer on the upper surface of the porous intermediate ceramic layer by virtue of plasma spraying. The multi-layer thermal barrier coating containing different microstructures is formed by the vertical-crack-containing ceramic bottom layer, the porous intermediate ceramic layer and the compact ceramic top layer which are sequentially arranged from bottom to top, so that the multi-layer thermal barrier coating has a thermal cycle service life which multiple times that of the existing thermal barrier coating.

Owner:EAST CHINA UNIV OF SCI & TECH

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Chip capacitor

InactiveUS20070279841A1High strengthEnsure structural stabilityFixed capacitor terminalsCapacitor housing/encapsulationEngineeringMoisture resistance

A chip capacitor which can be miniaturized with structural stability. In the chip capacitor, a capacitor device has a cathode layer formed on an outer surface thereof and an anode wire is protruded from a portion thereof. A cathode lead is electrically connected to the cathode layer. An anode lead is electrically connected to the anode wire through a weld reinforcement. A molding is configured to cover the capacitor device in such a way that the cathode and anode leads are only partially exposed. Protrusions are protruded from outer surfaces of the cathode and anode leads, respectively, thereby forming steps on the outer surfaces thereof. In the chip capacitor, the leads and molding are bonded with much greater strength, thus more structurally robust. Also, this prevents external moisture from penetrating inside the chip capacitor, thereby significantly enhancing moisture resistance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

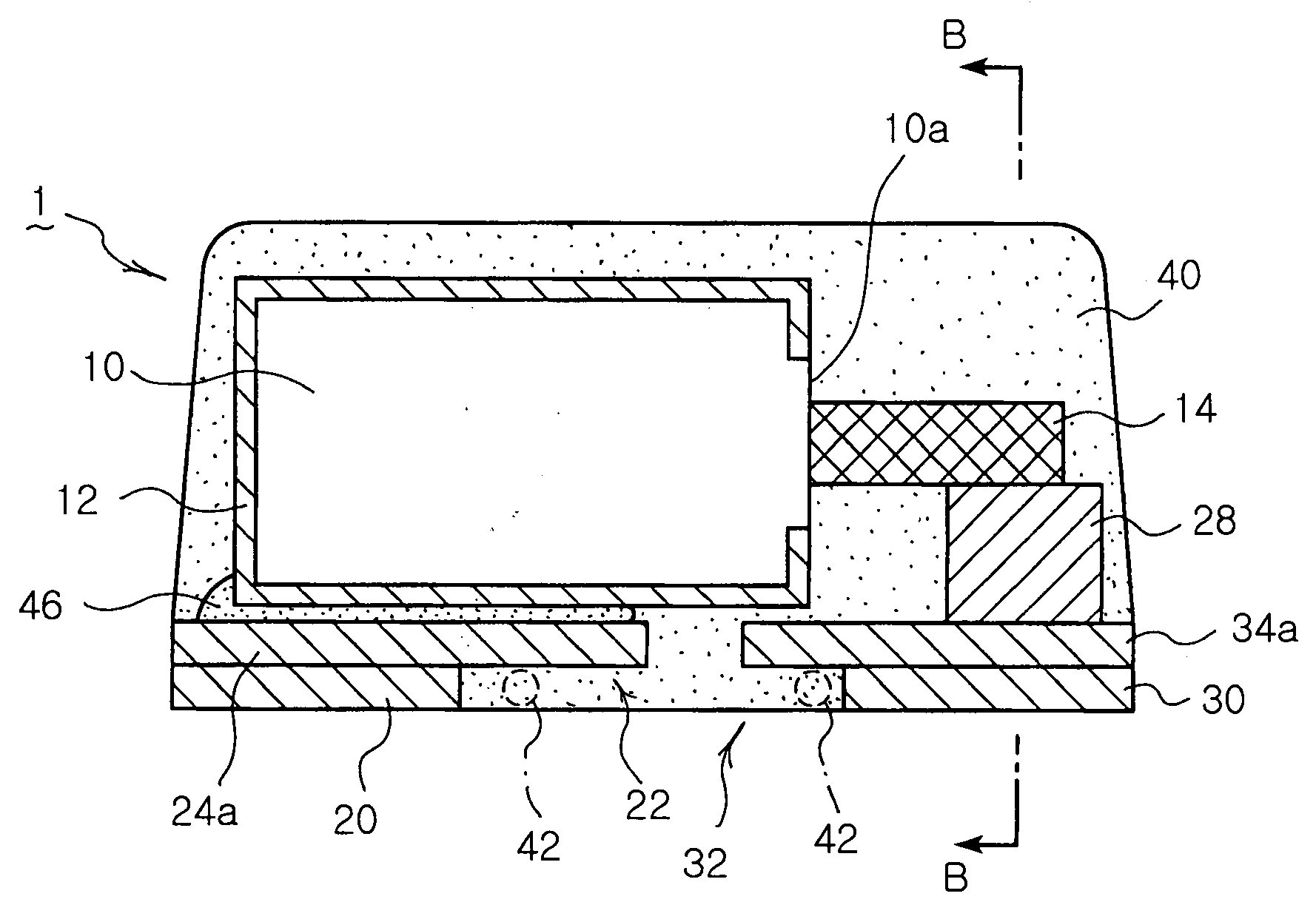

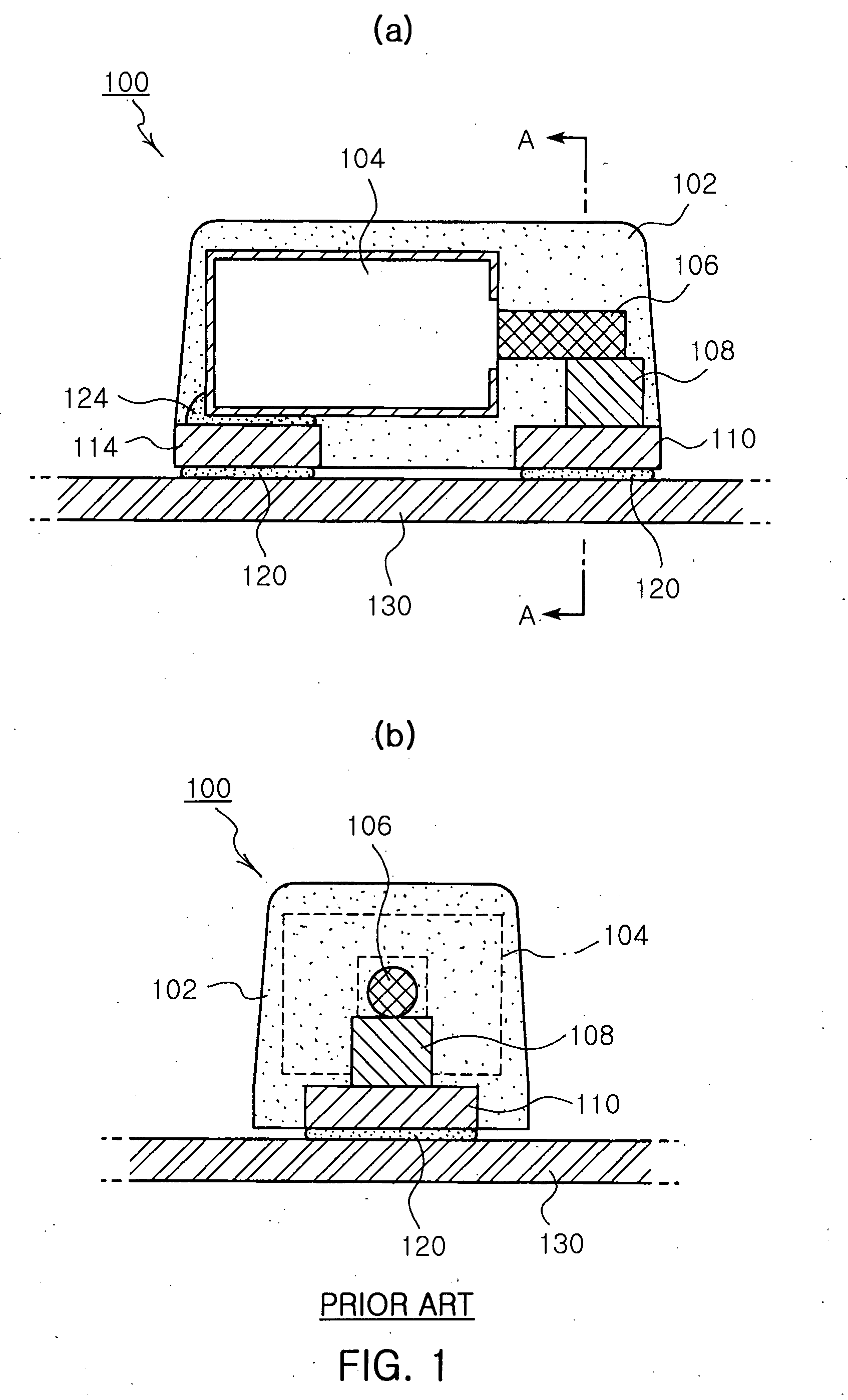

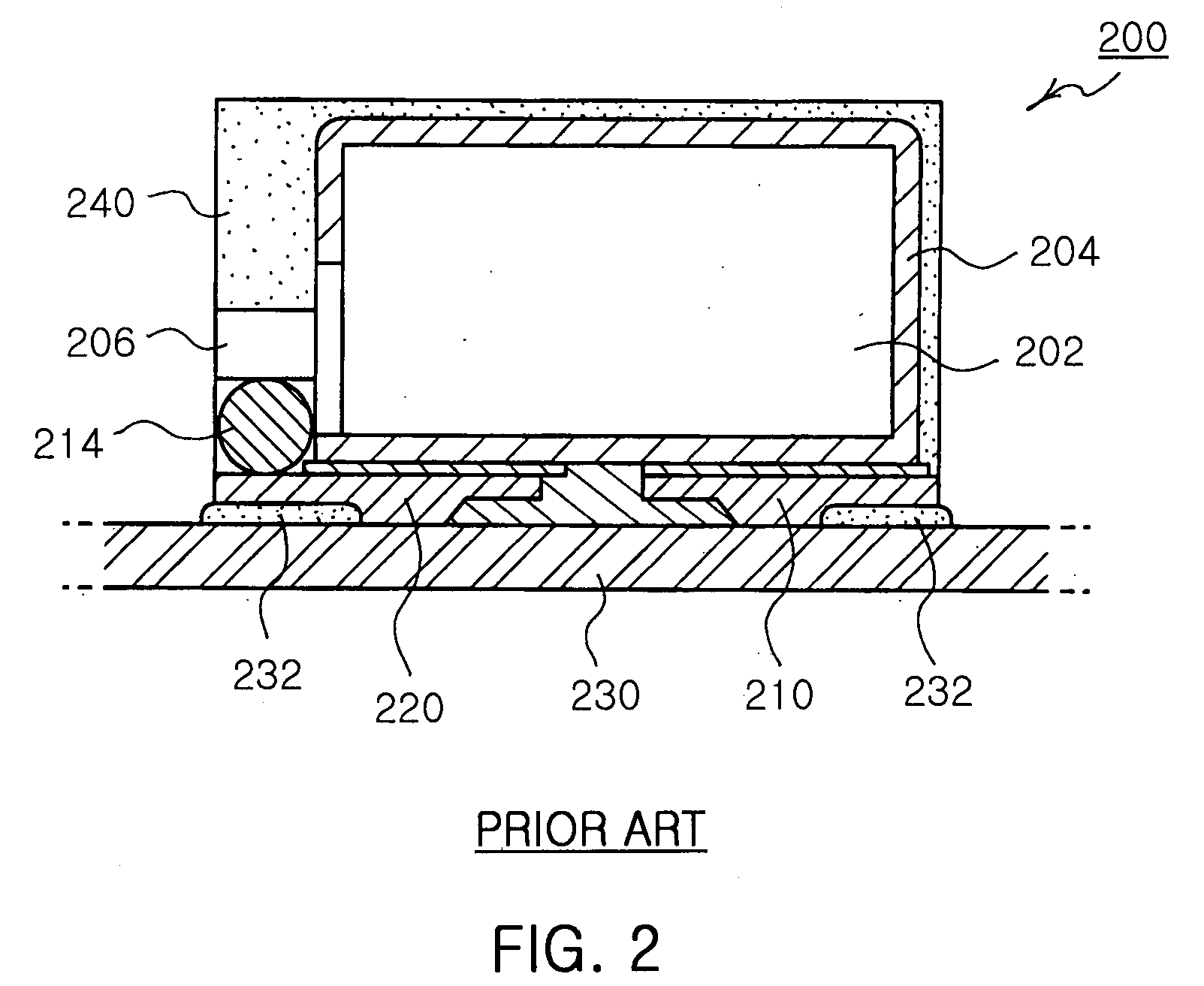

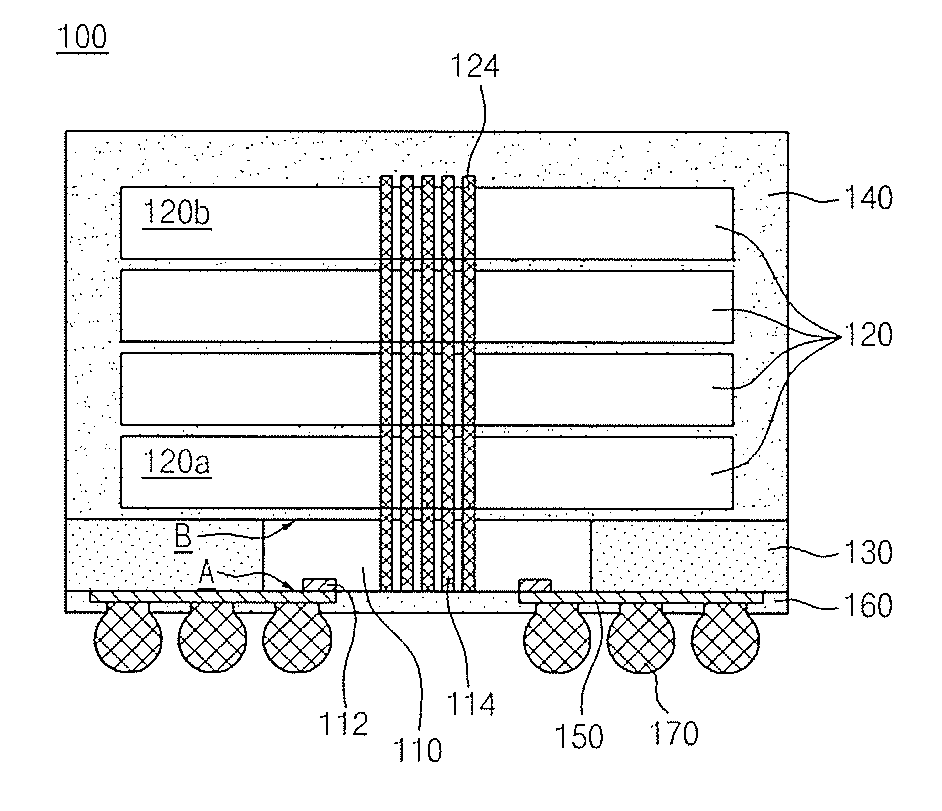

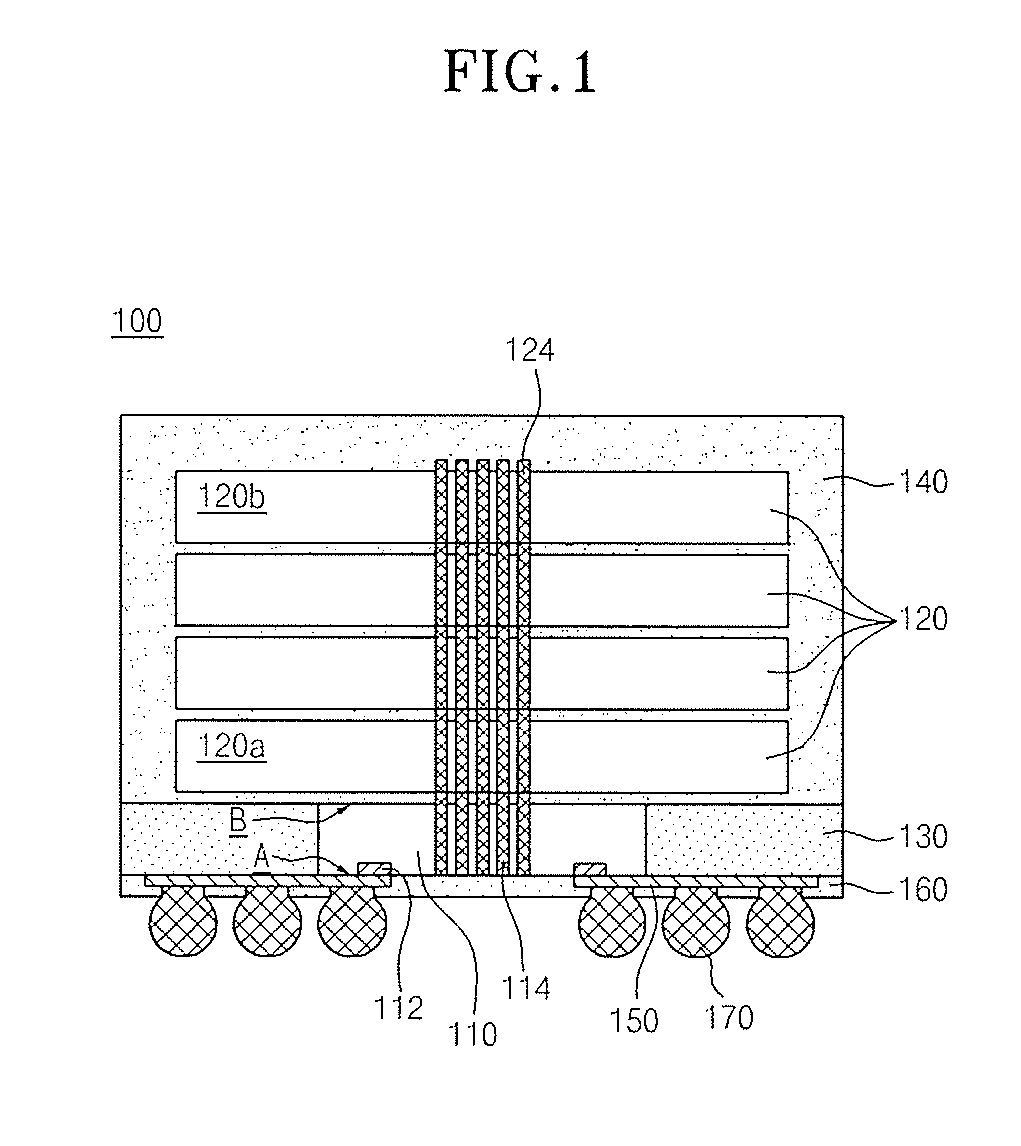

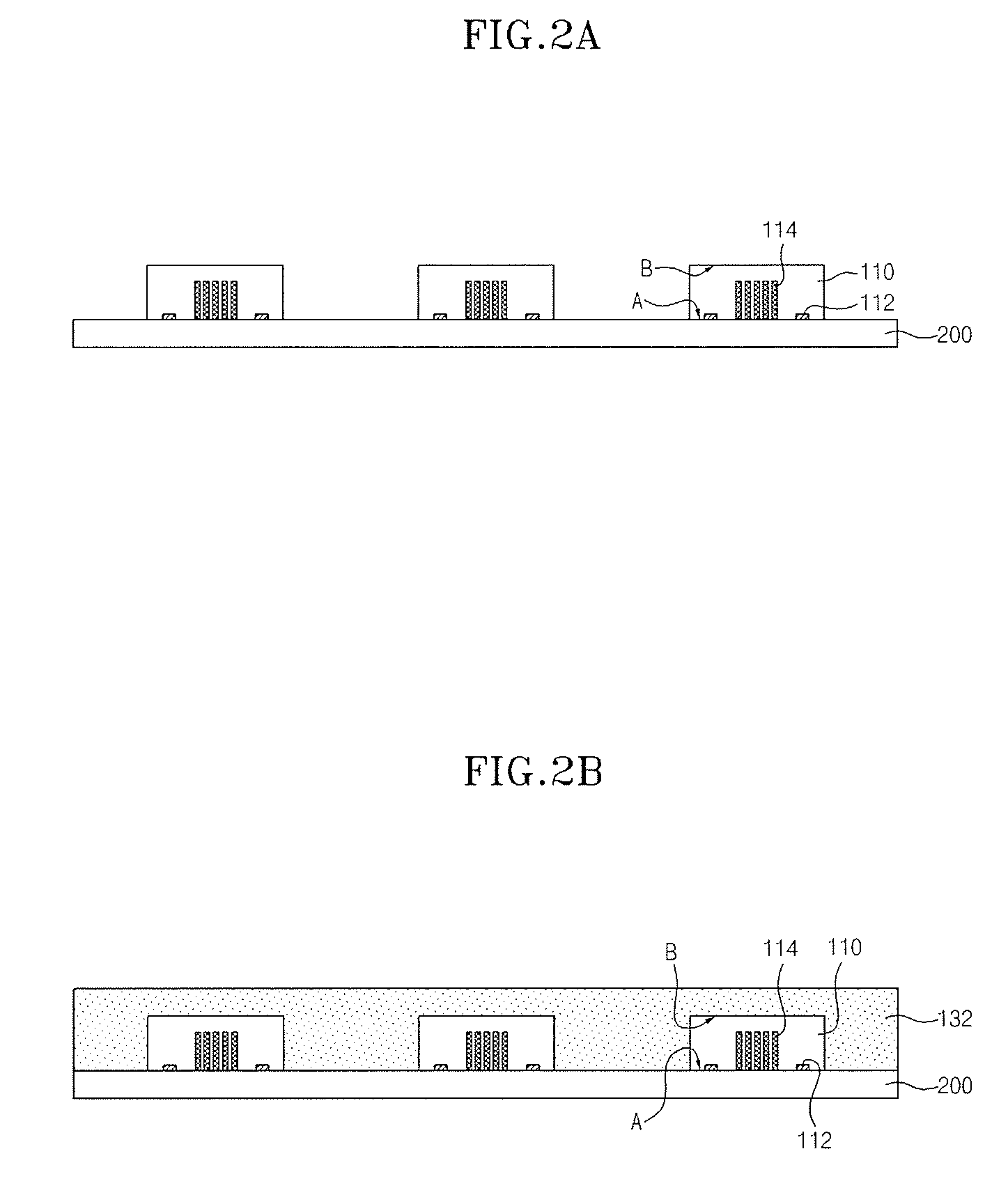

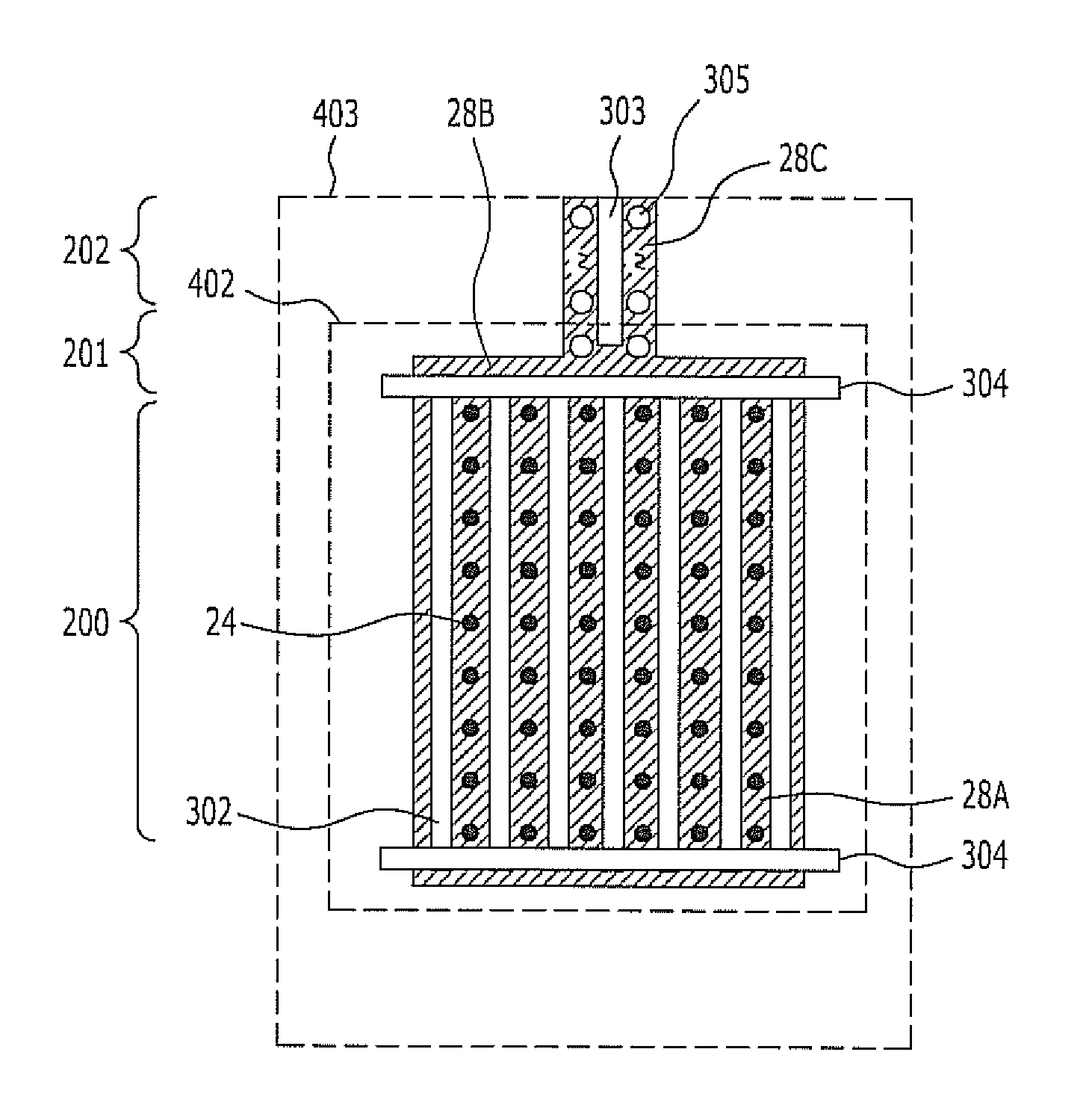

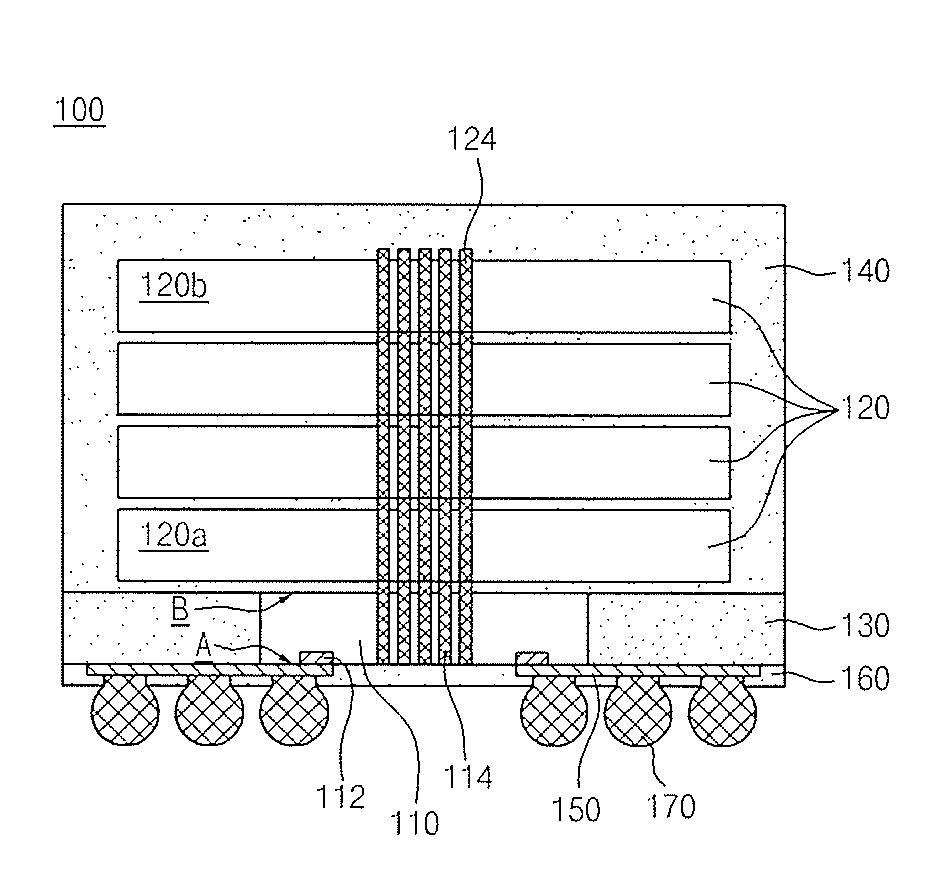

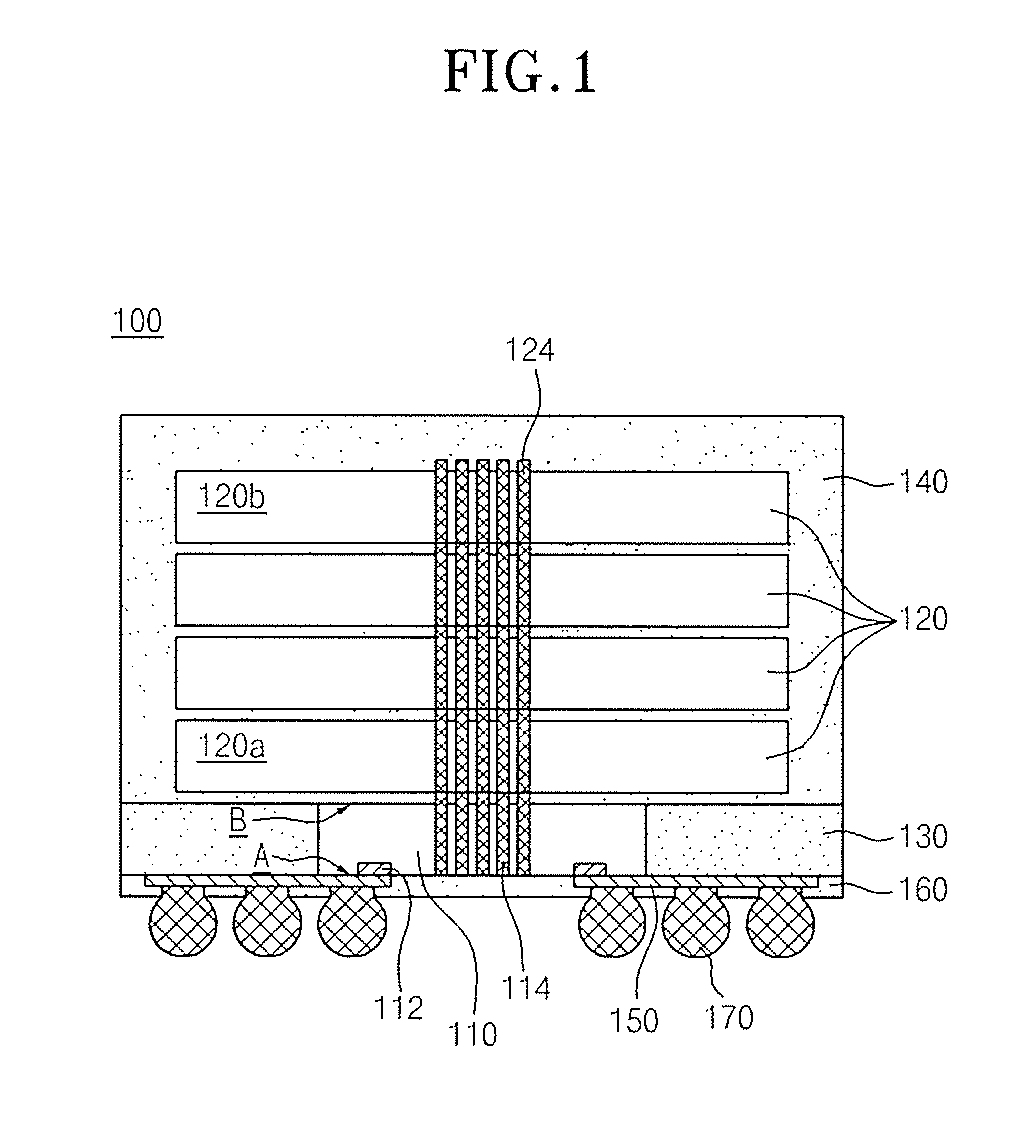

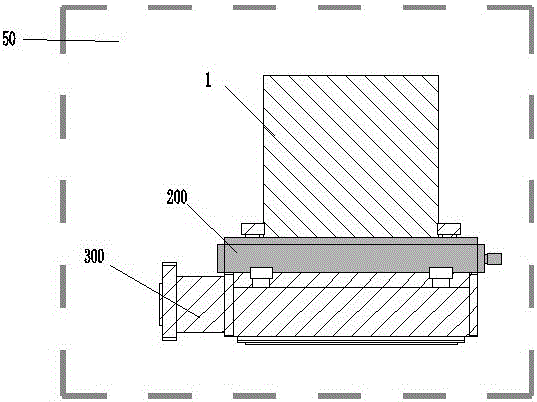

Stack package

ActiveUS20110156233A1Ensure structural stabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrode

A stack package includes a first semiconductor chip possessing a first size and one or more second semiconductor chips possessing a second size greater than the first size. The first semiconductor chip has a first surface on which bonding pads are disposed, a second surface which faces away from the first surface, and first through-electrodes which pass through the first surface and the second surface. The one or more second semiconductor chips are stacked on the second surface of the first semiconductor chip and have second through-electrodes which are electrically connected to the first through-electrodes. A molding part abuts one or more side surfaces of the first semiconductor chip such that a total size including the first size and a size of the molding part is equal to or greater than the second size.

Owner:SK HYNIX INC

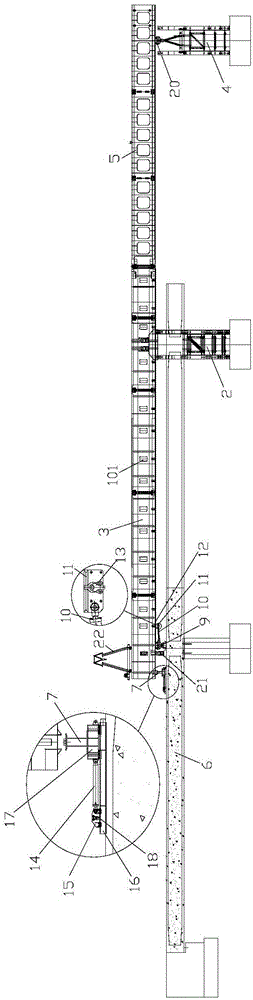

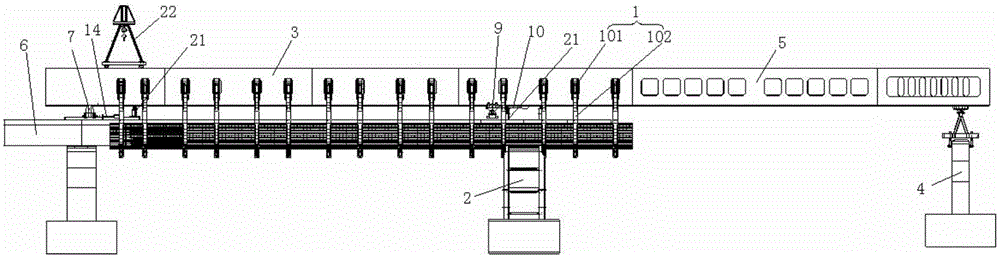

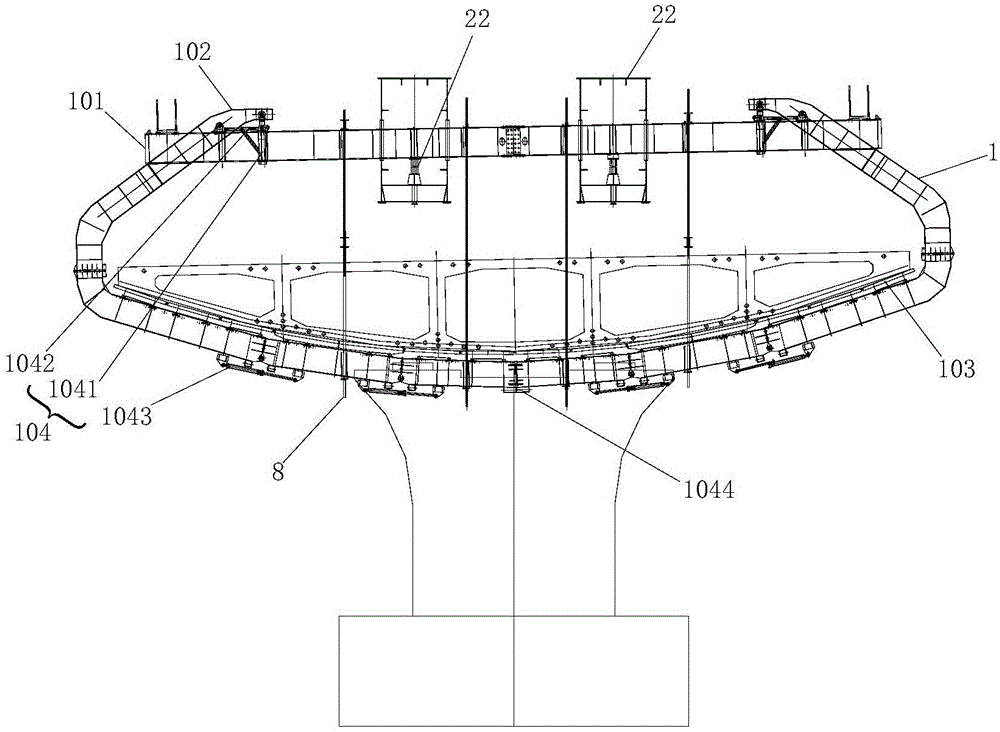

Upward moving type movable formwork for continuous box girder construction

InactiveCN105155423ALow costSpeed up the construction progressBridge erection/assemblyStructural stabilityEngineering

The invention discloses an upward moving type movable formwork for continuous box girder construction. The upward moving type movable formwork comprises a box girder body construction mold, a main beam, a nose beam and a rear sliding beam. The bottom of the box girder body construction mold is unfolded for box girder form removal or the bottom of the box girder body construction mold is closed so that a box girder can be poured. The main beam is supported on a middle supporting leg of the box girder and used for bearing the box girder body construction mold and driving the box girder body construction mold to move in the longitudinal direction of the box girder. The nose beam is supported on a front supporting leg of the box girder and used for guiding the main beam moving in the longitudinal direction of the box girder. The rear sliding beam is supported on the poured molded box girder and used for assisting the main beam in moving in the longitudinal direction of the box girder and being adjusted to be bent in the transverse direction of the box girder. The box girder body construction mold is suspended on the main beam, the nose beam is arranged at the advancing end of the main beam, and the rear sliding beam is arranged at the rear end of the main beam. Whole box girder pouring construction and mold movement are finished on the supporting legs and the poured molded box girder, the box girder body construction mold is opened from the bottom to form a folding span-crossing structure, and therefore the structural stability and safety of the whole formwork are guaranteed.

Owner:CCFEB CIVIL ENG

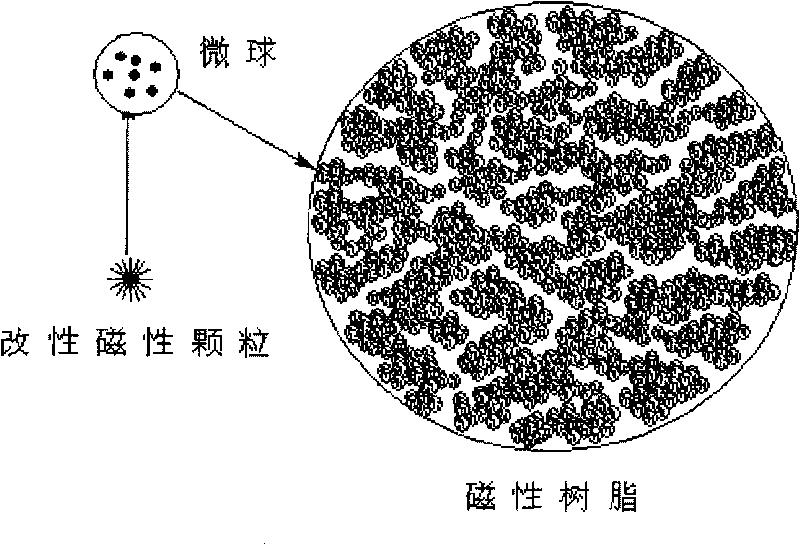

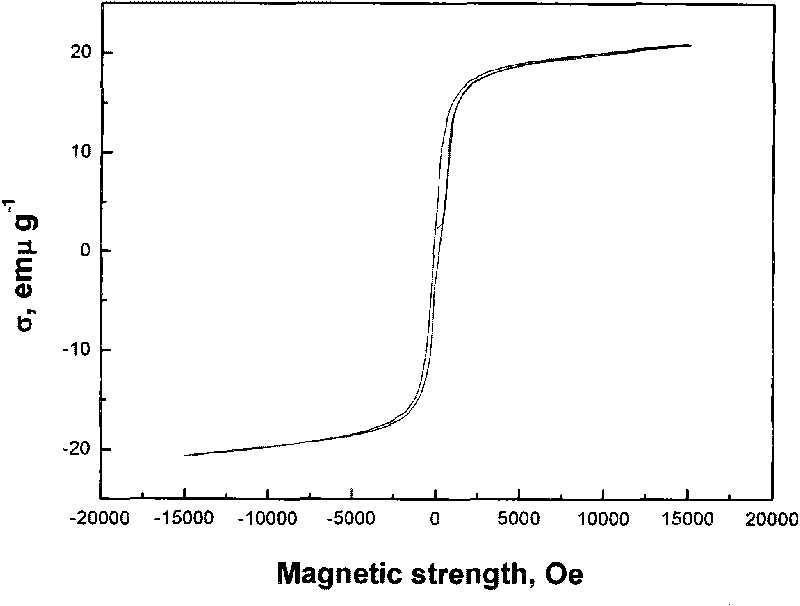

Magnetic cation exchange resin catalyzer and preparation method and application thereof

ActiveCN101733152AStrong magnetismEasy to wrap and fixOrganic-compounds/hydrides/coordination-complexes catalystsParticulatesHydration reaction

The invention relates to a magnetic cation exchange resin catalyzer and a preparation method and application thereof. In the method, nanometer magnetic metal oxide and long-chain fatty acid are mixed in the water the pH of which is 9-12, the pH is regulated to 4-5, and modified nanometer magnetic particulate is obtained after the nanometer magnetic metal oxide and the long-chain fatty acid react; monomer, evocating agents, crosslinking agents and pore-foaming agents are mixed with the modified nanometer magnetic particulate which accounts for 5-65% of the total weight of the monomer and the crosslinking agents, magnetic resin is obtained after polymerization, and the catalyzer is obtained through sulphur reaction of the magnetic resin. The catalyzer can be used for catalyzing olefin hydration reaction, ether hydrolysis reaction, esterification reaction, etherealization reaction, condensation reaction or aromatic hydrocarbon alkylation reaction in a magnetic reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

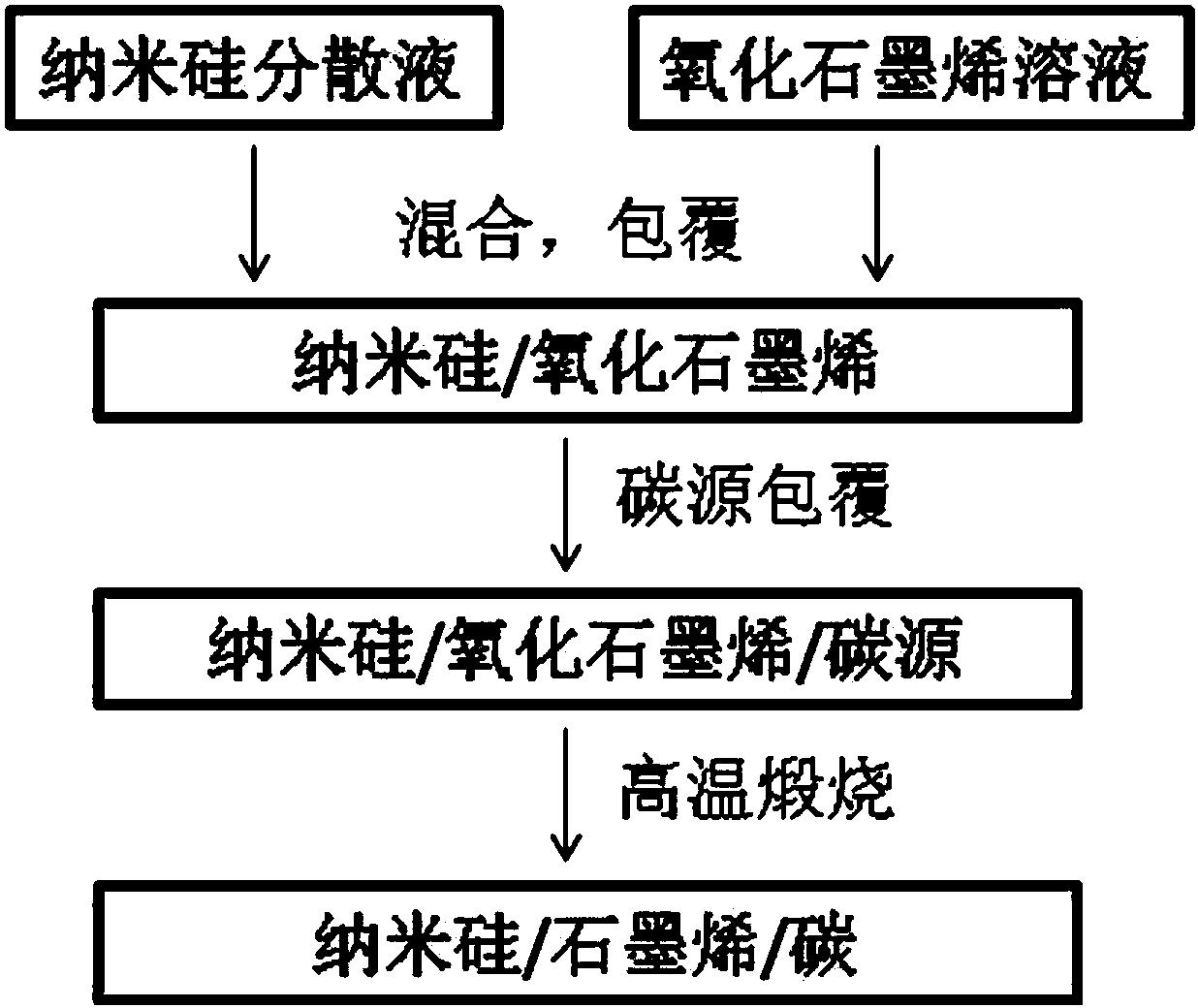

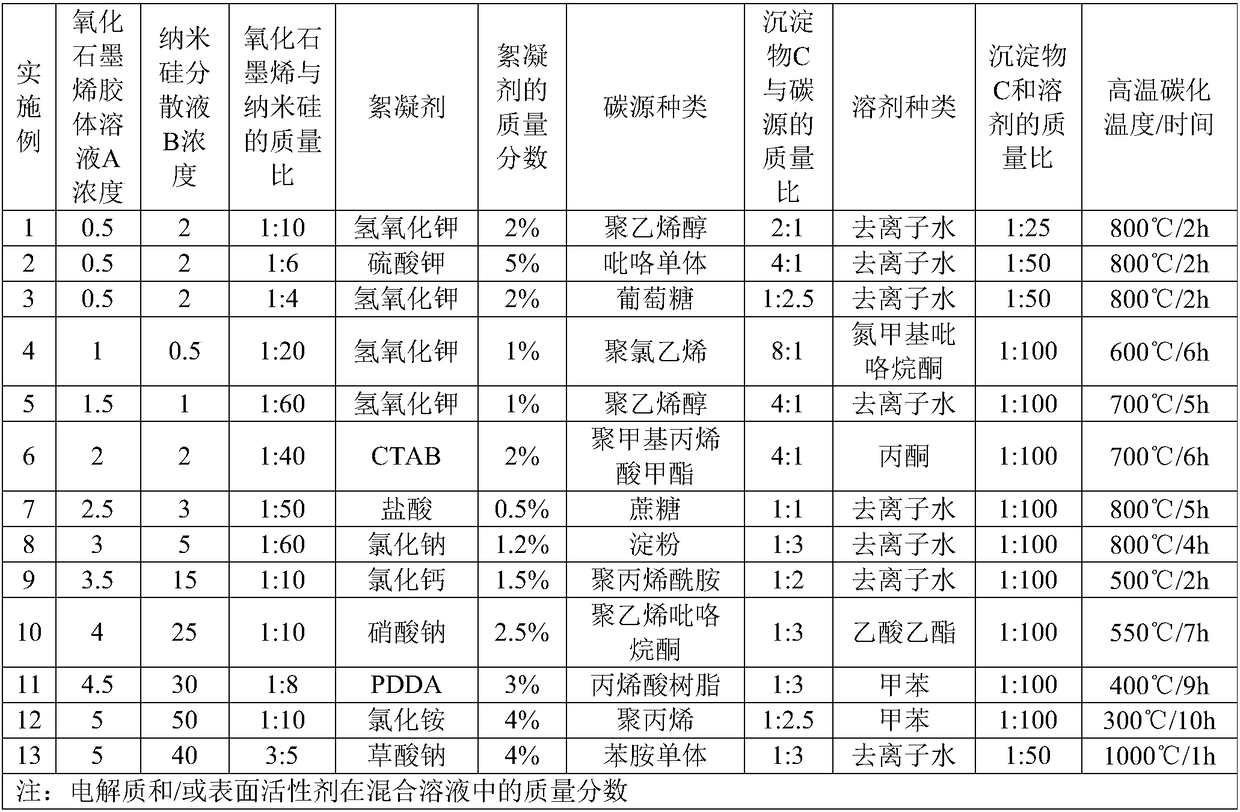

Graphene composite material and preparation method thereof

ActiveCN108232139AConducive to inhibiting damageAvoid reunionMaterial nanotechnologyCell electrodesLithium-ion batteryStructural stability

The invention discloses a graphene composite material and a preparation method thereof. The graphene composite material has a multi-level core shell coating structure, wherein the nanometer silicon isused as the core, the graphene is used as the first coating layer, the carbon is used as the second coating layer, the surface of the nanometer silicon is coated with the graphene, and the surface ofthe graphene is coated with the carbon. The graphene has high conductivity, mechanical strength and flexibility, and provides a conductive network, an elastic space and a folded structure for the nanometer silicon, thereby being good for inhibiting the damage caused by the volume expansion of the silicon; the carbon can maintain the internal structure stability of the composite material, and prevent the composite electrode material from agglomerating and falling down. The composite electrode material has better stability and conductivity performance when being used for a lithium ion battery.The preparation method is simple in reaction and easy to control, and has a extensive application prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

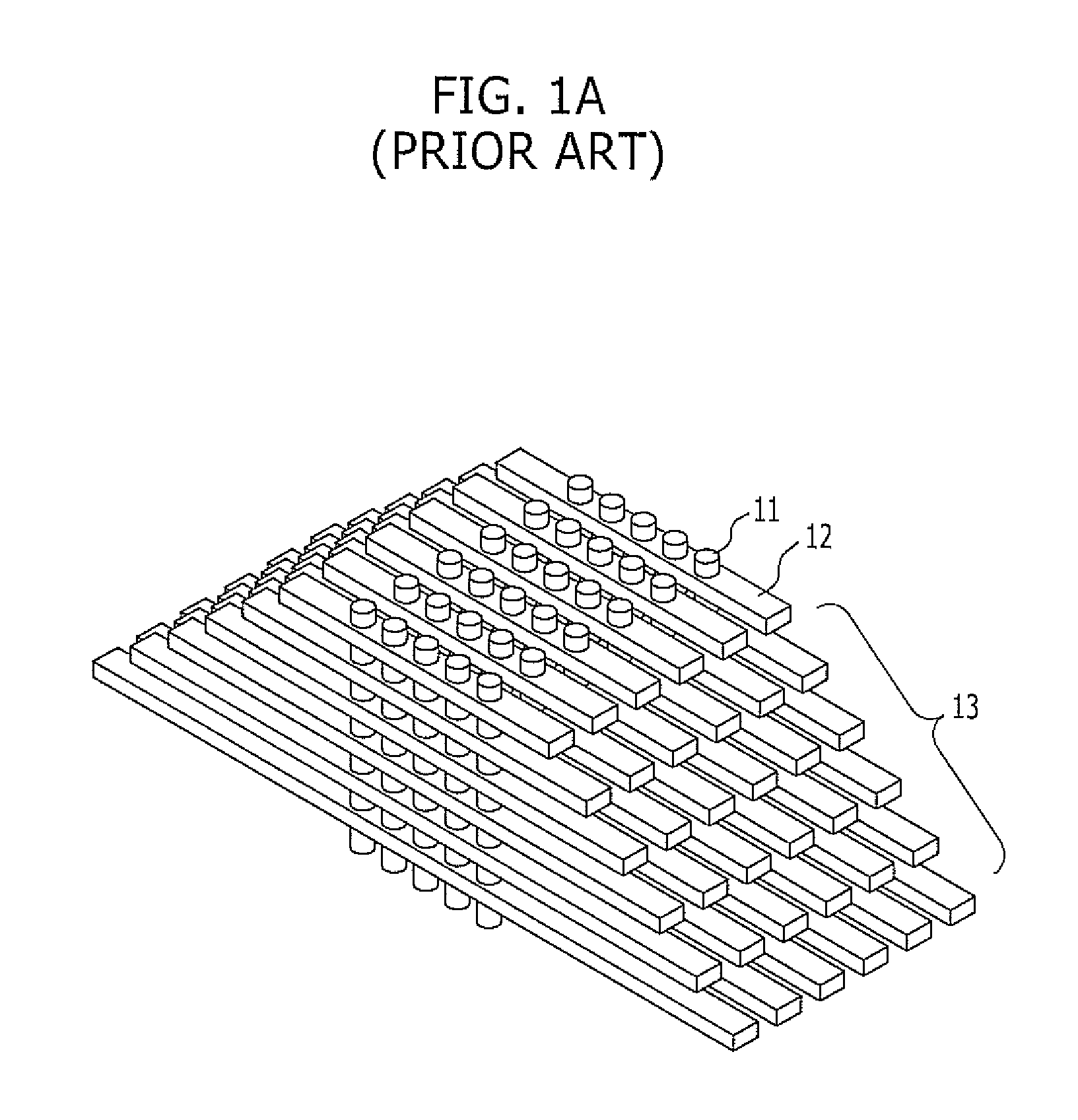

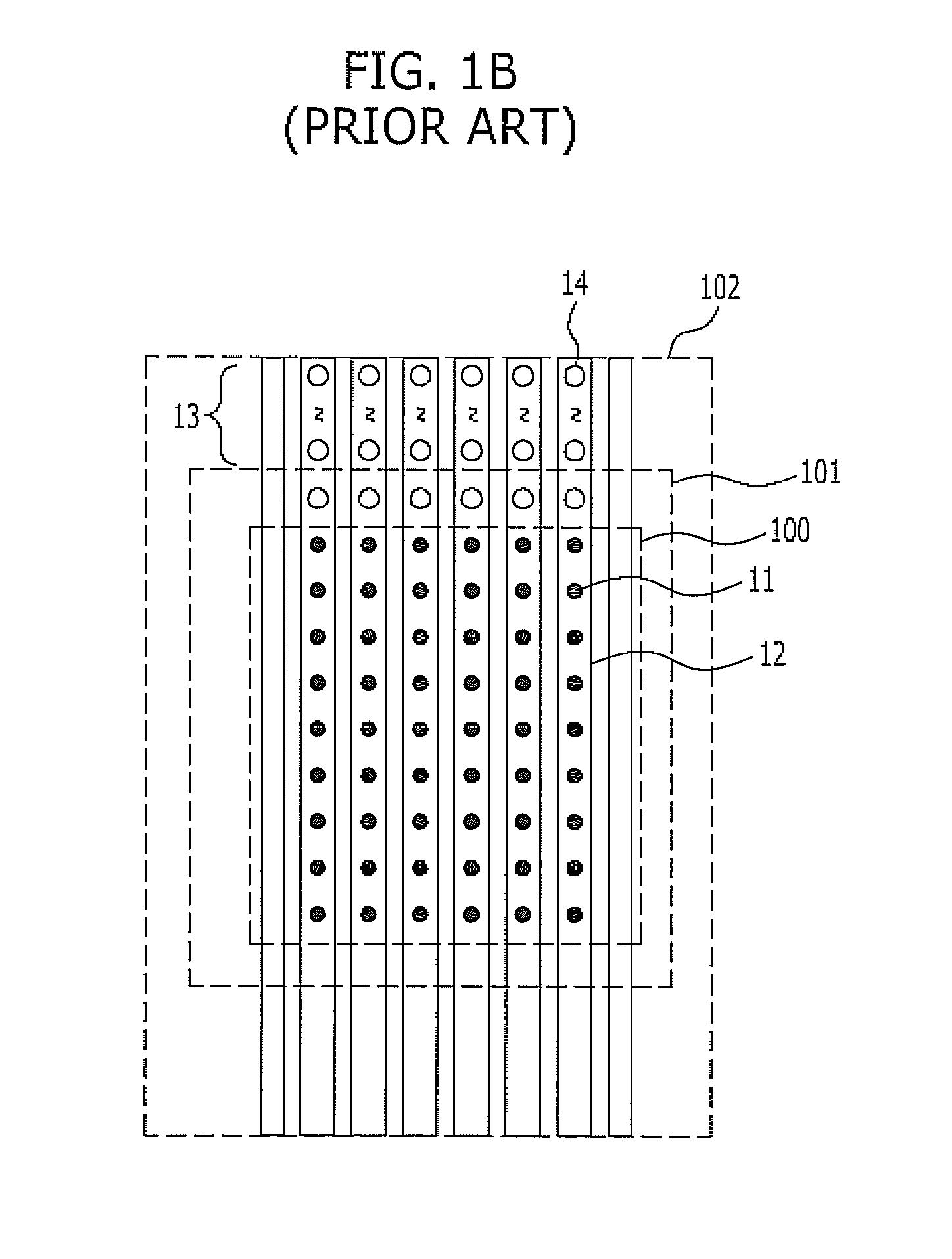

Nonvolatile memory device and method for fabricating the same

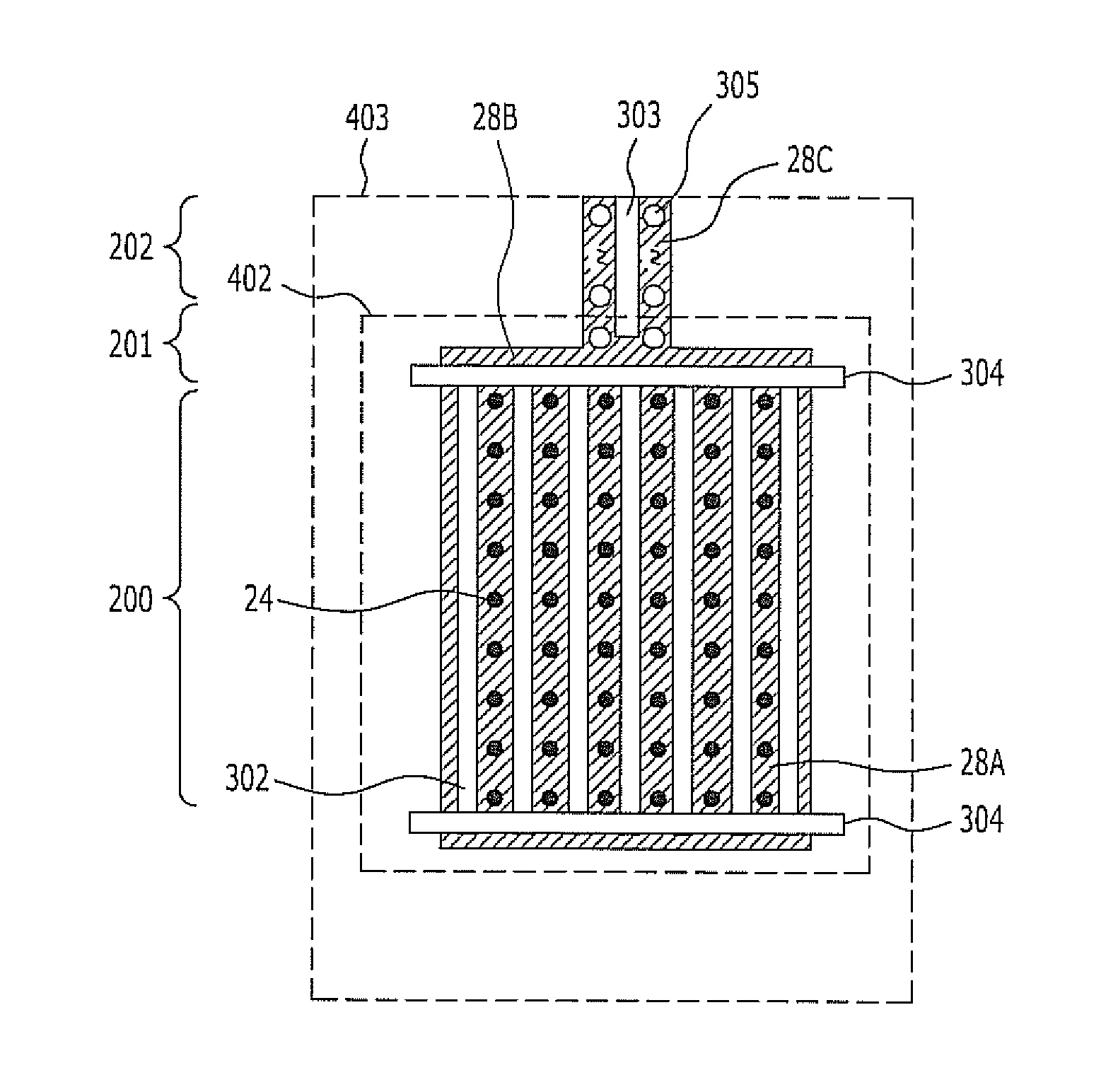

ActiveUS8456909B2Ensure structural stabilitySolid-state devicesRead-only memoriesDielectric layerComputer science

Provided are a nonvolatile memory device and a method for fabricating the same, which can secure the structural stability of a three-dimensional nonvolatile memory device. The nonvolatile memory device includes one or more columnar channel plugs, a plurality of word lines and a plurality of dielectric layers stacked alternately to surround the columnar channel plug, a memory layer disposed between the word line and the columnar channel plug, a plurality of word line connection portions, each of the word line connection portions connecting ends of word lines of a common layer from among the plurality of word lines, and a plurality of word line extension portions extending from the word line connection portions.

Owner:SK HYNIX INC

Stack package

ActiveUS8110910B2Ensure structural stabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectrode

A stack package includes a first semiconductor chip possessing a first size and one or more second semiconductor chips possessing a second size greater than the first size. The first semiconductor chip has a first surface on which bonding pads are disposed, a second surface which faces away from the first surface, and first through-electrodes which pass through the first surface and the second surface. The one or more second semiconductor chips are stacked on the second surface of the first semiconductor chip and have second through-electrodes which are electrically connected to the first through-electrodes. A molding part abuts one or more side surfaces of the first semiconductor chip such that a total size including the first size and a size of the molding part is equal to or greater than the second size.

Owner:SK HYNIX INC

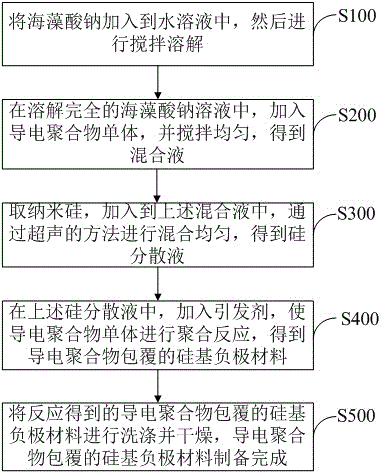

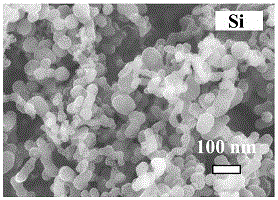

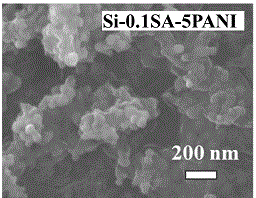

Conductive polymer-coated silicon-based negative electrode material and preparation method thereof

ActiveCN106229495AImprove electrochemical performanceAlleviate volume effectCell electrodesSecondary cellsConductive polymerUltrasound method

The invention discloses a conductive polymer-coated silicon-based negative electrode material and a preparation method thereof. The method comprises the following steps of adding sodium alginate to a water solution, and then stirring and dissolving the sodium alginate; adding a conductive polymer monomer to the completely dissolved sodium alginate solution and stirring evenly; adding taken nanometer silicon to a mixed solution and mixing evenly through an ultrasound method to obtain a silicon dispersion liquid; adding an initiator to the silicon dispersion liquid and carrying out polymerization reaction on the conductive polymer monomer to obtain the conductive polymer-coated silicon-based negative electrode material; and carrying out washing and drying and finishing preparation of a final product. A three-dimensional mesh structure is built by the conductive polymer, so that the conductive polymer-coated silicon-based negative electrode material has conductivity and also provides a certain accommodation space for volume expansion of the silicon; and the silicon is embedded into the mesh structure, so that the volume effect of the silicon is effectively relieved. Furthermore, the hydroxyl-containing sodium alginate is introduced, so that the structure stability of the overall silicon-based negative electrode material is strengthened.

Owner:SHENZHEN UNIV

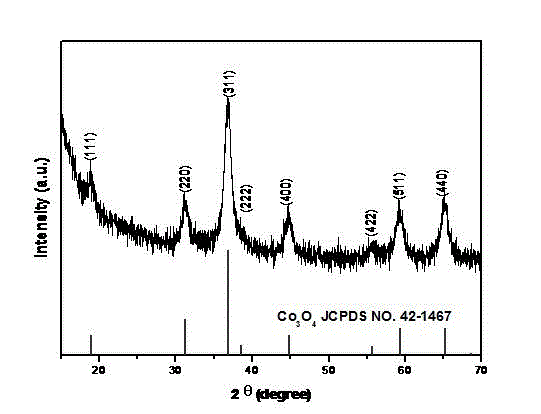

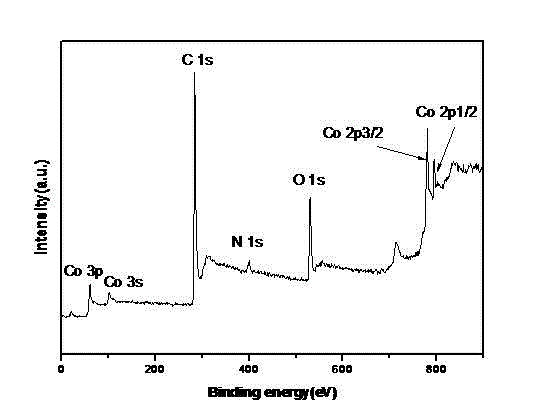

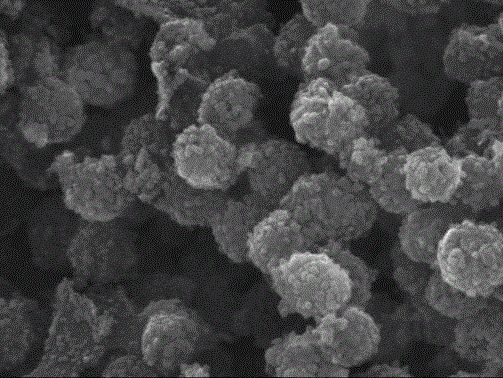

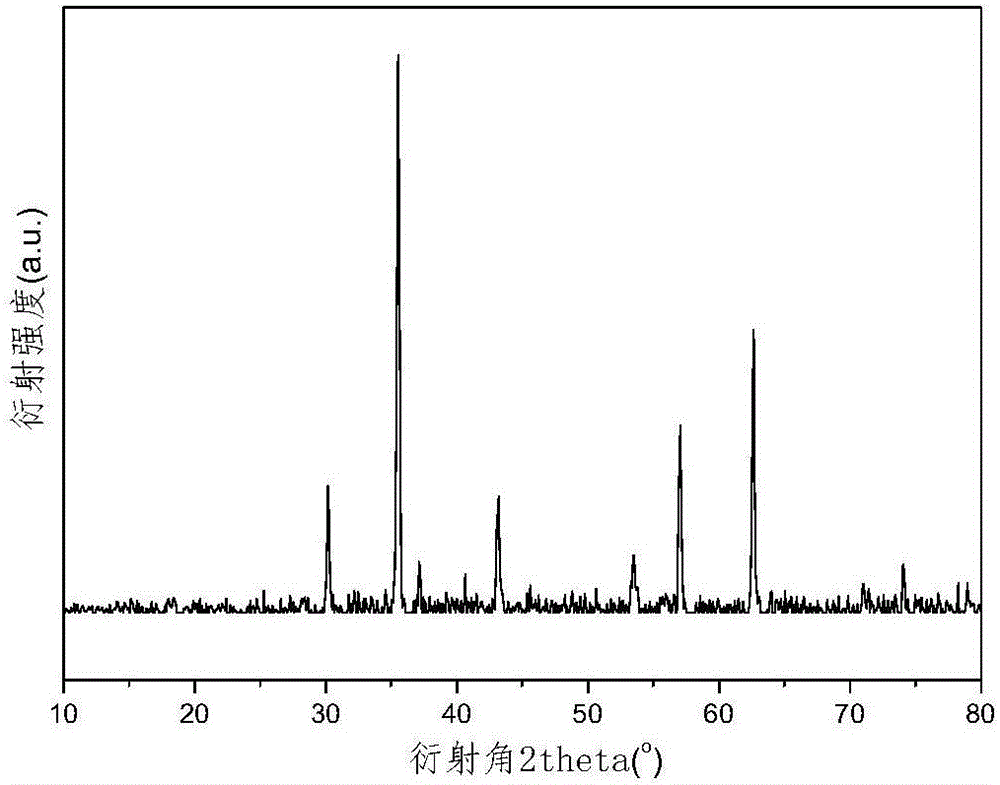

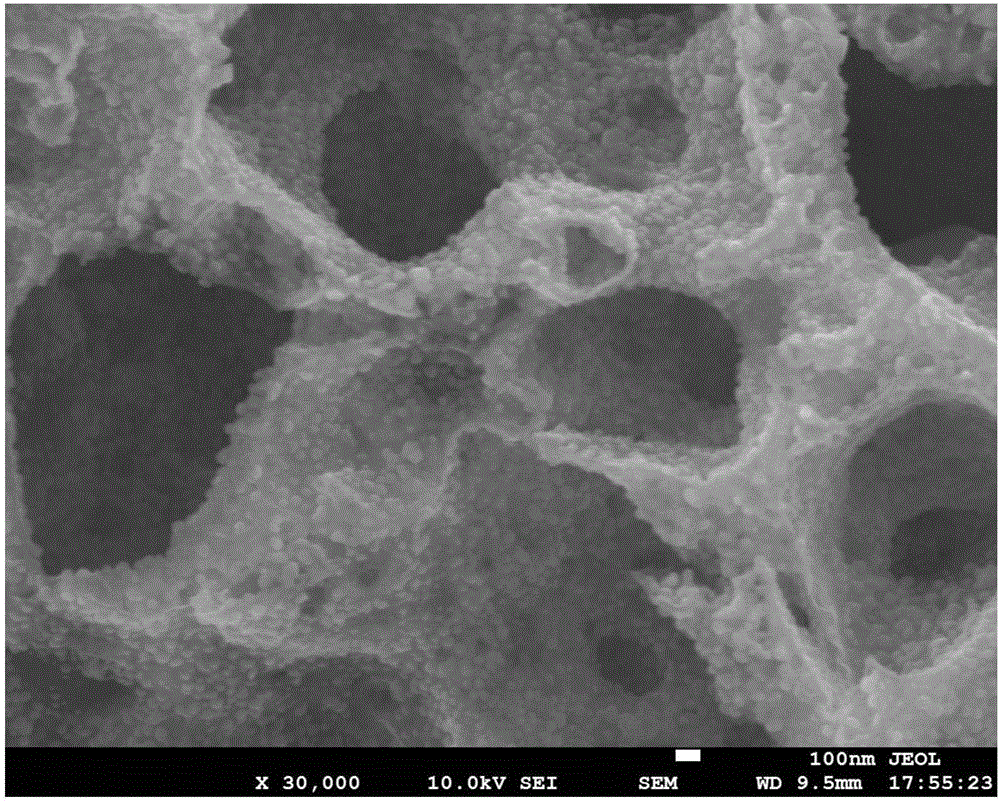

Nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and preparation method thereof

InactiveCN104966824AShorten the diffusion distanceImprove mobilityCell electrodesSecondary cellsPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on chitosan and derivatives thereof and a preparation method thereof and belongs to the fields of electrochemistry and new energy resource materials. According to the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite anode material based on the chitosan and the derivatives thereof and the preparation method thereof, firstly the chitosan and the derivatives thereof are taken as carbon source and nitrogen source precursors, a hard template carbonization method is adopted to prepare nitrogen-doped porous carbon spheres; then a mild hydrothermal method is adopted to load cobaltous oxide nano particles to the nitrogen-doped porous carbon spheres, and then the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material is obtained. The material synthesizes the structural features of the nitrogen-doped porous carbon spheres and the small-size effect advantages of the cobaltous oxide nano particles, and due to the expression of the synergistic effect of the nitrogen-doped porous carbon spheres and the cobaltous oxide nano particles, the prepared material shows higher reversible specific capacity, better cycling stability and more excellent large rate discharge performance than a commercial graphite material when used as a lithium ion battery anode material. The method is strong in operability, preparation conditions are mild, the requirement for equipment is not rigorous, and the preparation method is suitable for industrial production; the nitrogen-doped porous carbon sphere and cobaltous oxide nano-composite material prepared by the method has potential application value in electrochemistry fields including lithium ion batteries, supercapacitors and the like.

Owner:HUBEI ENG UNIV

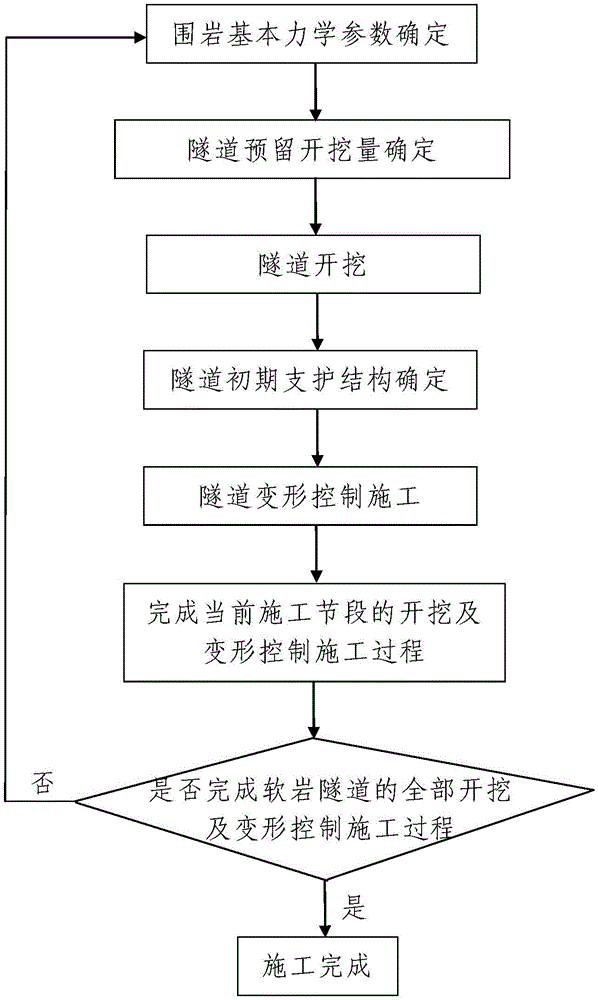

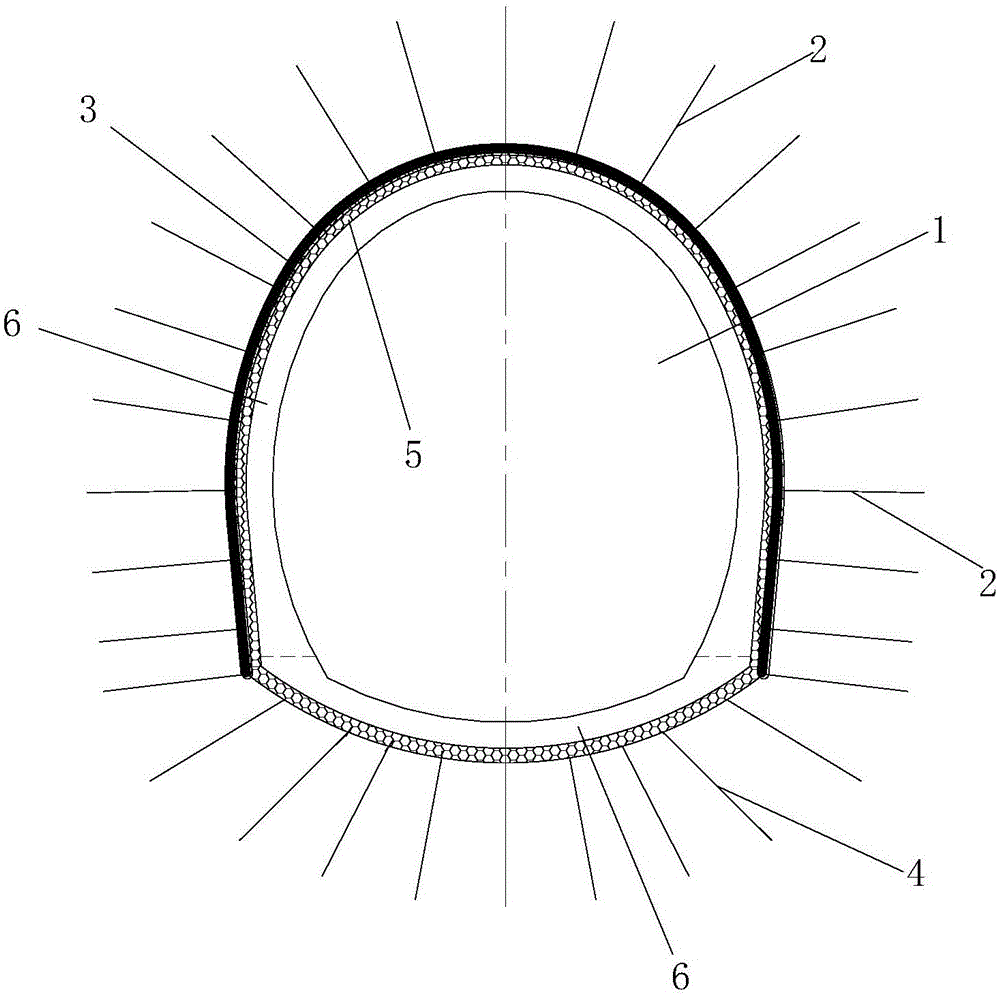

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

Carbon-coated hollow ferriferrous oxide and application thereof

The invention discloses carbon-coated hollow ferriferrous oxide and an application thereof. The preparation method of the carbon-coated hollow ferriferrous oxide comprises the following steps of: (1) adding a ferric salt into a solvent and dissolving the ferric salt, wherein the solvent is a mixture of water and ethanol; implementing a hydrothermal reaction in a sealed hydrothermal kettle for 20-30hours at 100-250 DEG C, and separating to obtain a ferric oxide deposit; and (2) uniformly mixing the ferric oxide deposit with a reducing carbon source, wherein the reducing carbon source is one substance or a combination of multiple substances selected from carbon powder, glucose, polyethylene, acetylene black and starch; and implementing an insulating reaction for 0.5-4hours in a muffle at 200-1000 DEG C, to obtain the carbon-coated hollow ferriferrous oxide. The carbon-coated hollow ferriferrous oxide, used as a lithium ion battery negative electrode material, can remarkably improve electrical conductivity and keeps a stable structure, so that a comparatively high capacity retention ratio is still guaranteed after several charge-discharge cycles.

Owner:ZHEJIANG UNIV OF TECH

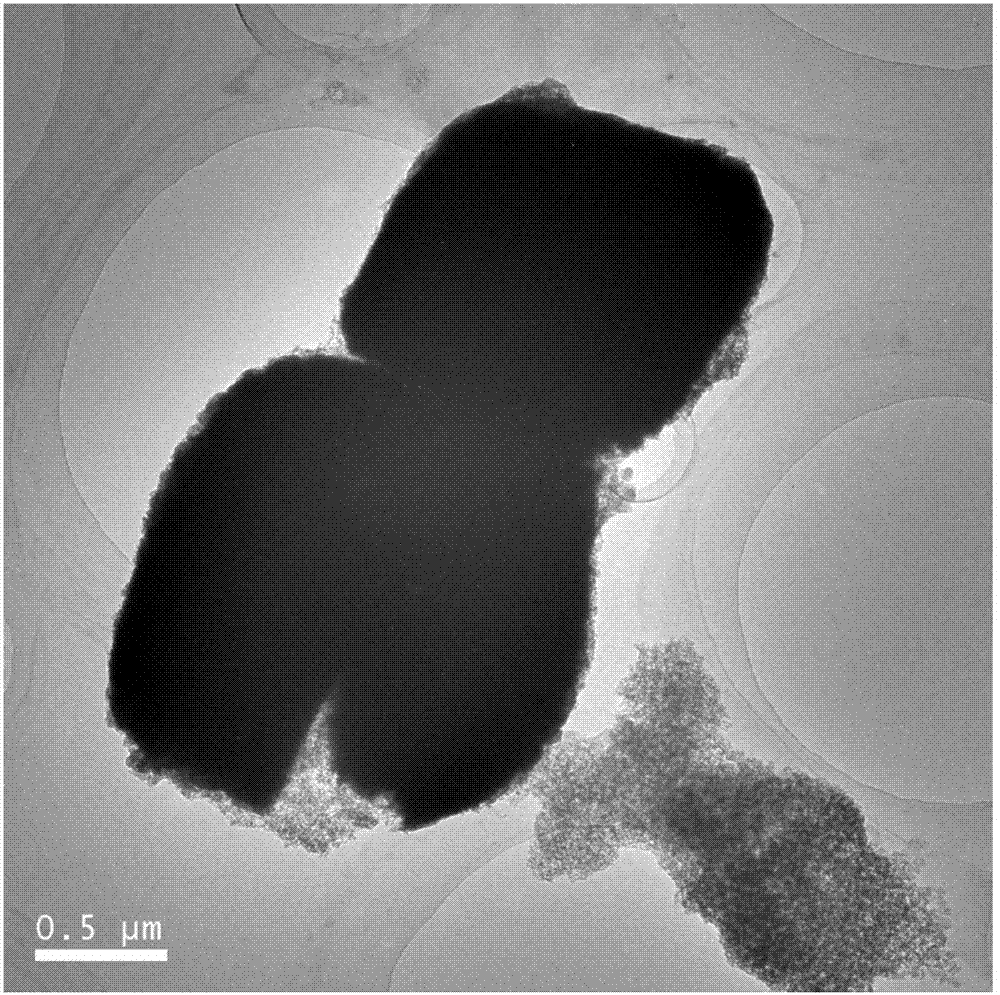

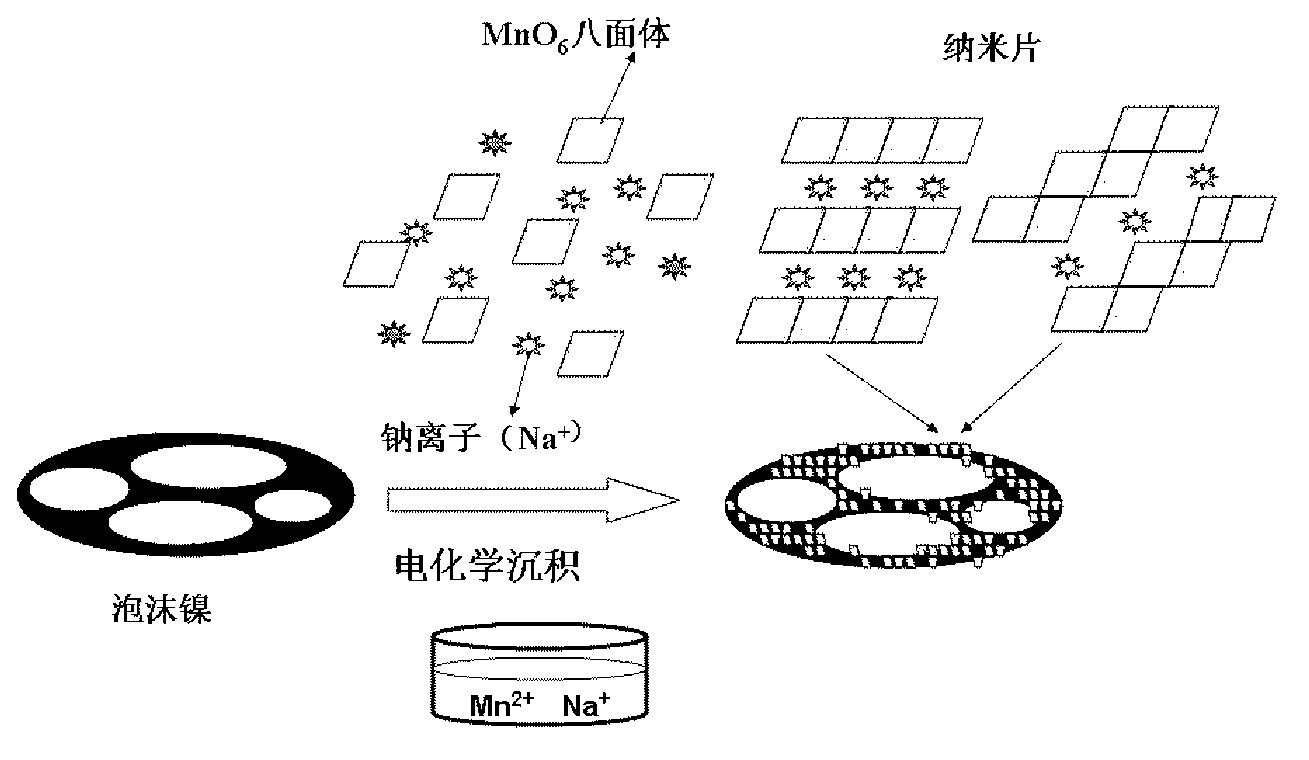

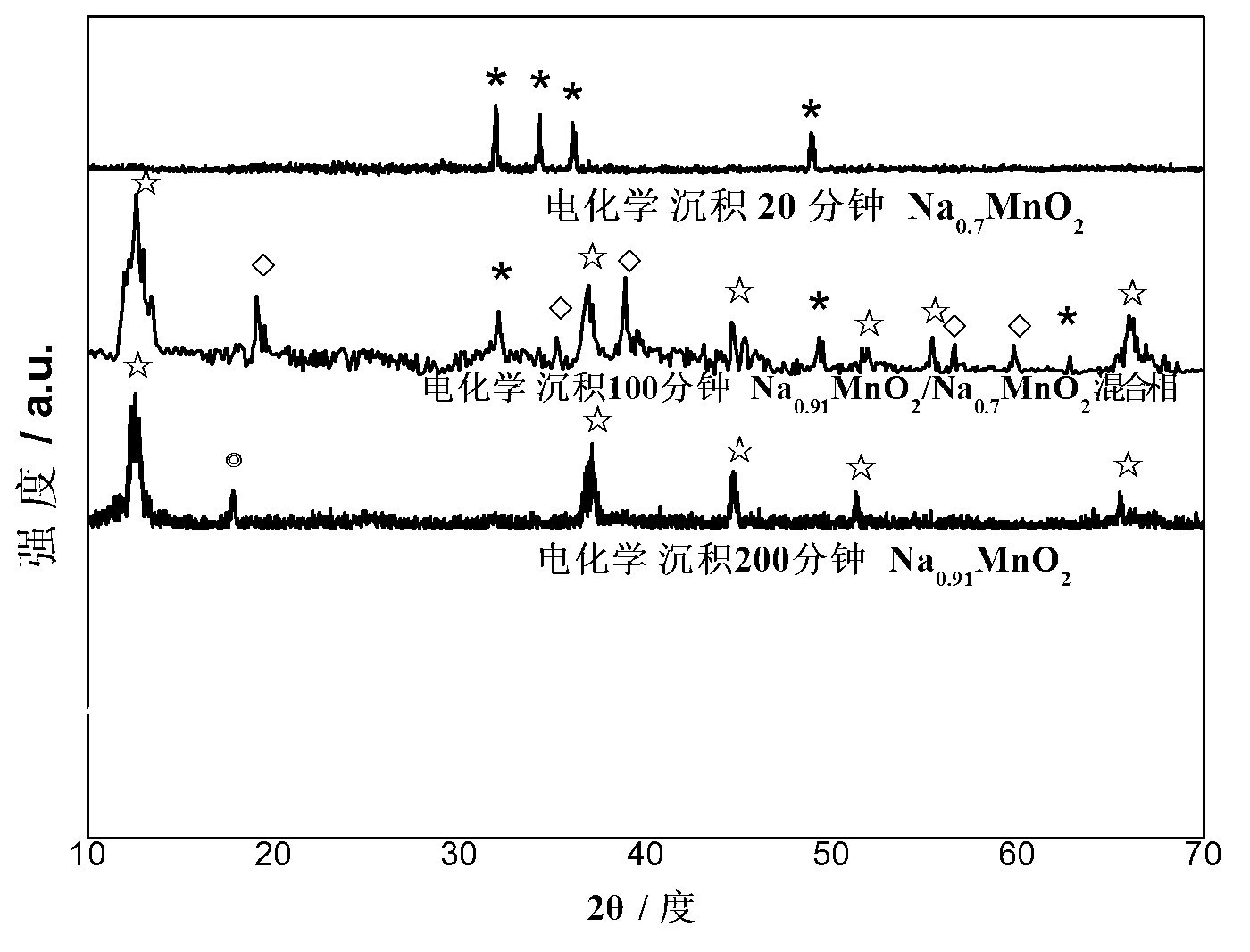

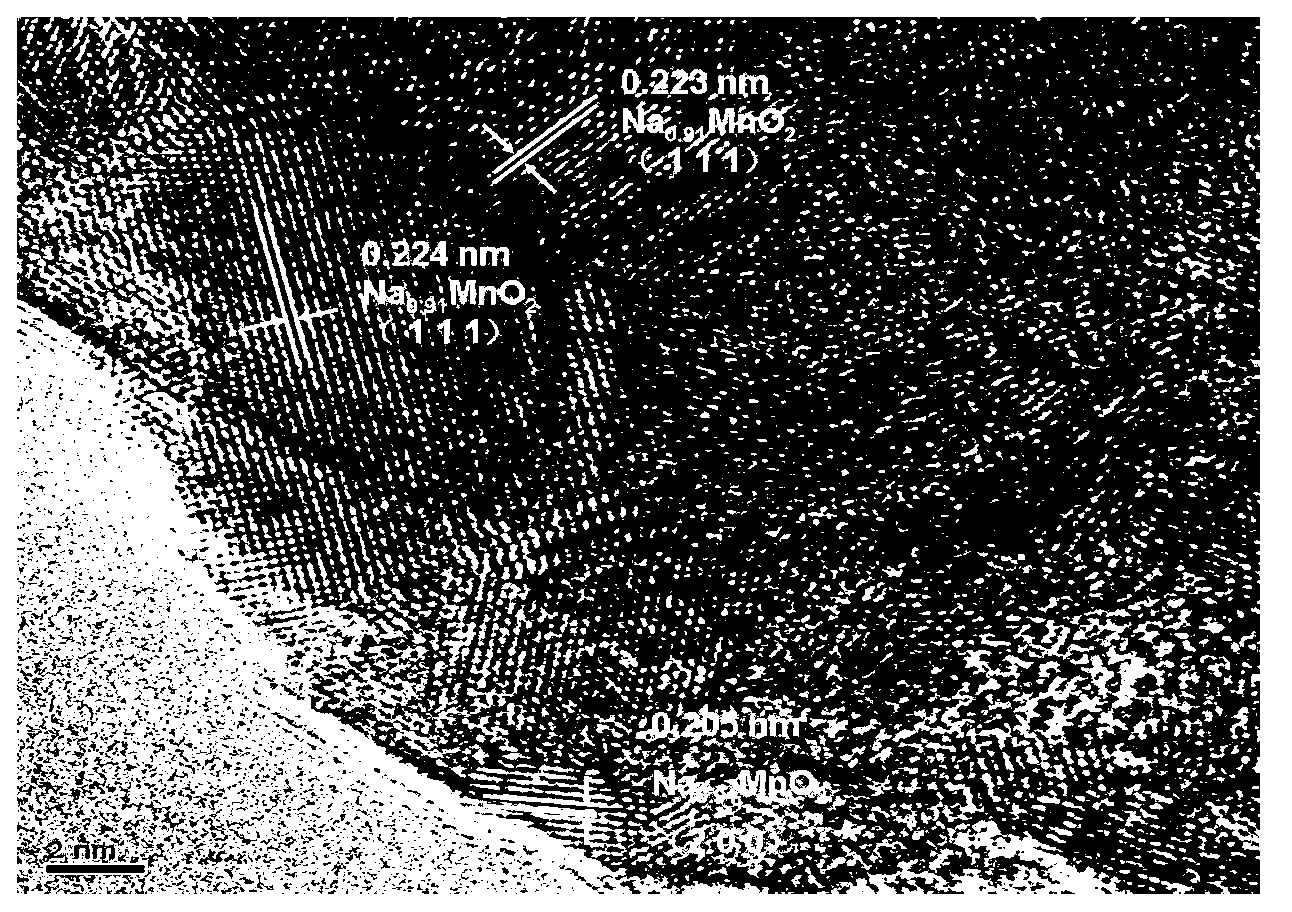

Sodion-embedded manganese dioxide nanometer sheet electrode as well as preparation method and application of electrode

ActiveCN103065806AImprove conductivityEnsure structural stabilityHybrid capacitor electrodesHybrid/EDL manufactureMANGANESE ACETATEStopped work

The invention relates to a sodion-embedded manganese dioxide nanometer sheet electrode as well as a preparation method and an application of the electrode. The electrode can be used as the active material of a supercapacitor and comprises sodion-embedded manganese dioxide nanometer sheets evenly distributed on the surface of a foamed nickel substrate. The preparation method comprises the following steps of: (1) mixing sodium sulfate and manganese acetate to prepare an electrochemical deposition precursor solution; (2) setting up an electrochemical deposition platform through a three-electrode method and taking the foamed nickel substrate after pretreatment as a working electrode, a platinum electrode as a counter electrode and a saturated calomel electrode as a reference electrode; (3) soaking the electrodes in the electrochemical deposition precursor solution at same depth; (4) opening an electrochemical workstation, setting the working electrode to the anode, setting the working mode to a timing potential mode, and starting up the electrochemical workstation; (5) taking out and washing the working electrode after the electrochemical workstation stops working; and (6) drying to obtain the sodion-embedded manganese dioxide nanometer sheet electrode. The sodion-embedded manganese dioxide nanometer film electrode as well as the preparation method and the application of the electrode disclosed by the invention have the characteristics of simple technique, mild reaction condition and excellent electrochemical performance of materials.

Owner:WUHAN UNIV OF TECH

Nonvolatile memory device and method for fabricating the same

ActiveUS20120170368A1Ensure structural stabilitySolid-state devicesRead-only memoriesDielectric layerComputer science

Provided are a nonvolatile memory device and a method for fabricating the same, which can secure the structural stability of a three-dimensional nonvolatile memory device. The nonvolatile memory device includes one or more columnar channel plugs, a plurality of word lines and a plurality of dielectric layers stacked alternately to surround the columnar channel plug, a memory layer disposed between the word line and the columnar channel plug, a plurality of word line connection portions, each of the word line connection portions connecting ends of word lines of a common layer from among the plurality of word lines, and a plurality of word line extension portions extending from the word line connection portions.

Owner:SK HYNIX INC

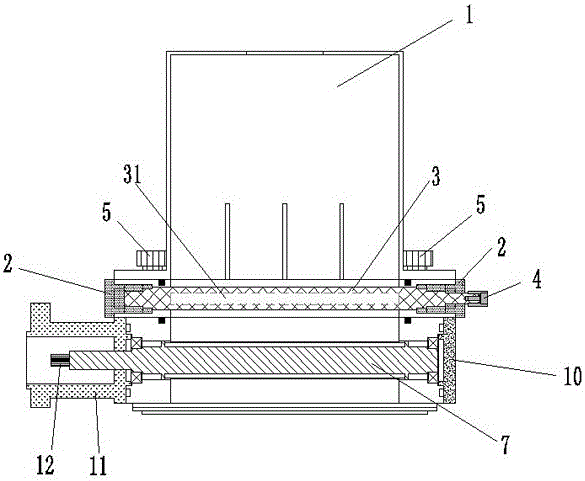

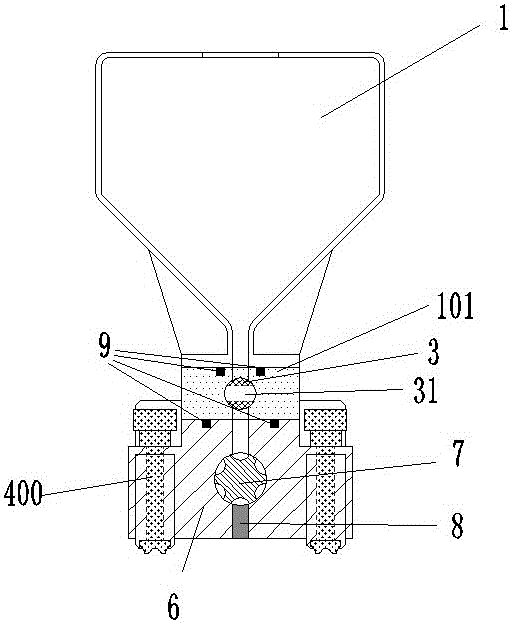

3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device and equipment

PendingCN106696260AReduce splashReduce wasteAdditive manufacturing apparatus3D object support structuresLinkage conceptMental detachment

The invention relates to a 3D (three-dimensional) printing powder delivery and paving linkage type bidirectional powder paving device. The 3D printing powder delivery and paving linkage type bidirectional powder paving device comprises a worktable, a powder paving driving device, and a powder paving device, wherein the powder paving device is of a powder delivery and paving linkage structure and comprises a powder bin, a powder falling closing area, a quantitative powder delivery area and a powder paving part; the powder falling closing area is arranged at the bottom part of the powder bin, and a powder falling closing shaft is arranged in the powder falling closing area; a detachment and installation structure is arranged between an end cap of the powder bin and the bottom part of the powder bin; a powder bin pressing rotary button is arranged above a roller cylinder in the quantitative powder delivery area and is used for fixing the powder bin and the roller cylinder, a quantitative powder delivery roller is arranged in the quantitative powder delivery area, a powder falling port is arranged under the quantitative powder delivery roller, and the roller cylinder is detachably connected with the bottom part of the powder bin; a powder delivery and paving separation structure is arranged between the powder delivery and paving linkage structure and the powder paving driving device; the powder paving part is arranged at both sides of the roller cylinder, and each side is provided with a scraping knife. The 3D printing powder delivery and paving linkage type bidirectional powder paving device has the advantages that the whole structure is stable, the efficiency is improved by double scraping knives, the bidirectional powder paving function is realized, the aligning process of powder delivery and powder paving in working is not needed, the powder control accuracy is high, and the powder lifting and snapping are avoided; the structure is simple, and the detachment and cleaning are convenient.

Owner:安徽泰尔控股集团有限公司

Porous graphene supported carbon coated iron oxide nanoparticle composite material and preparation method thereof

ActiveCN106207121AAlleviate volume changesHigh lithium storage capacityCell electrodesWater bathsPorous graphene

The invention belongs to the technical field of lithium ion battery materials, and specifically relates to a porous graphene supported carbon coated iron oxide nanoparticle composite material and a preparation method thereof. The porous graphene supported carbon coated iron oxide nanoparticle composite material is prepared from the following steps: (1) directly preparing graphene oxide with graphite ore as a raw material by using a closed oxidation method; (2) preparing a ferric salt aqueous solution, wherein the specific steps are as follows: weighing and dissolving cetyl trimethyl ammonium bromide in water to obtain a clear cetyl trimethyl ammonium bromide solution, adding a ferric salt, stirring until the ferric salt is completely dissolved, and adding an ammonia solution to prepare the ferric salt aqueous solution; and (3) stirring and ultrasonic mixing the graphene oxide solution with the ferric salt aqueous solution, placing the mixture in a water bath kettle, reacting at 80-100 DEG C for 0.5-5h, stewing at a room temperature, removing clear liquid, freeze drying a head product, and carrying out heat treatment on the head product in an inert atmosphere to obtain the porous graphene supported carbon coated iron oxide nanoparticle composite material.

Owner:SHANXI UNIV

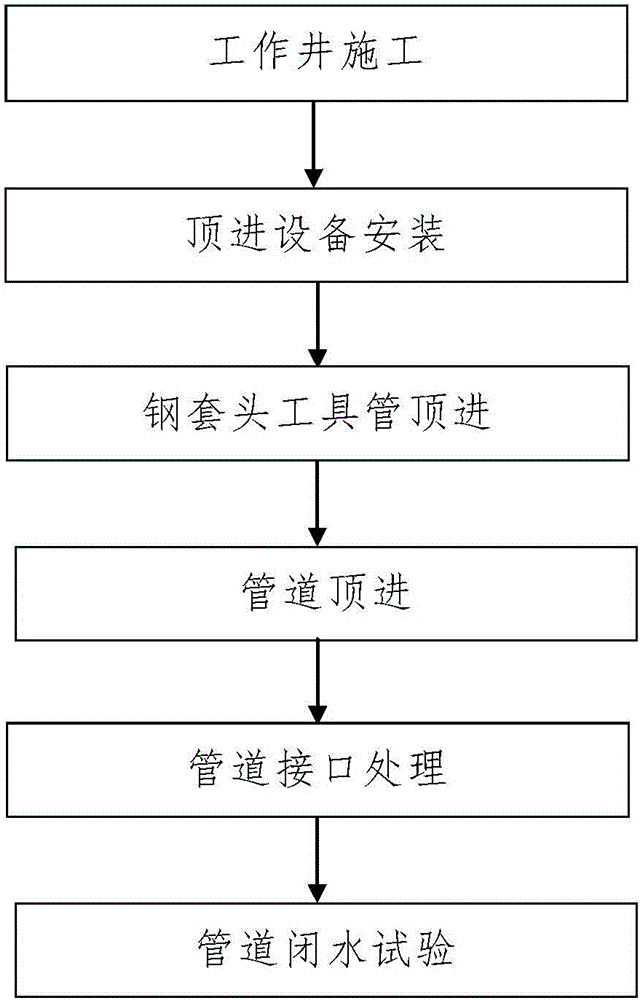

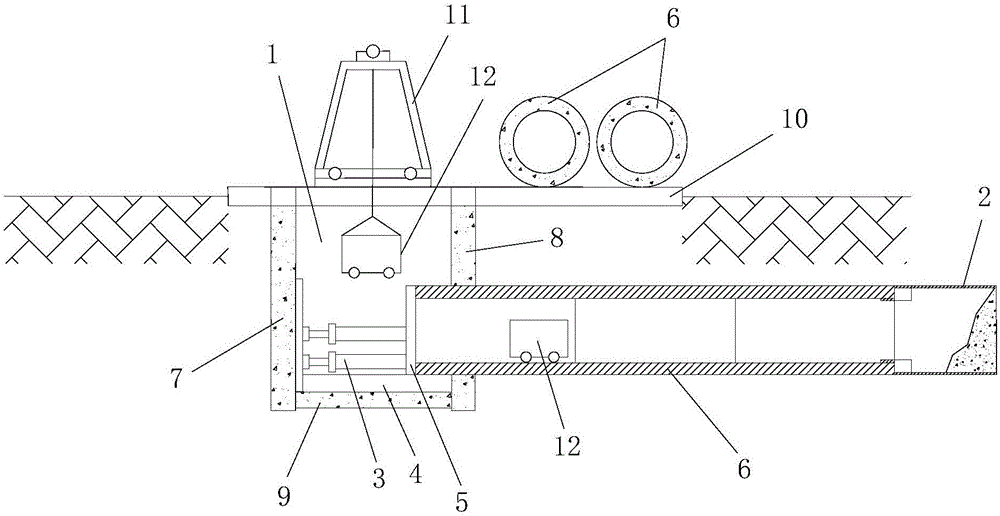

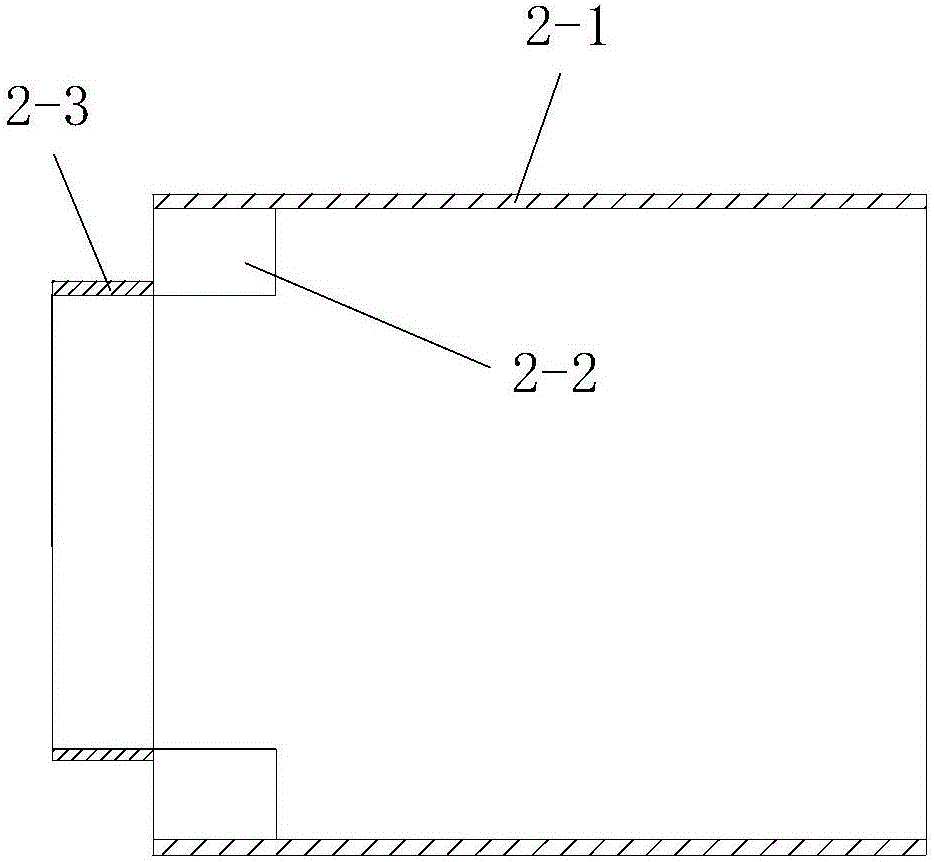

Pipe-jacking construction method for mealy sand stratum

ActiveCN106369223AThe method steps are simpleReasonable designPipe laying and repairEngineeringUnderground pipeline

The invention discloses a pipe-jacking construction method for a mealy sand stratum. The pipe-jacking construction method for the mealy sand stratum comprises the steps that firstly, a working well is constructed, specifically, the working well used for jacking a constructed underground pipeline is constructed, the constructed underground pipeline is formed by splicing a plurality of pipeline assembly sections from front to back, and a steel bushing head tool pipe comprises a steel sleeve, a supporting ring mounted on the inner side of the rear end of the steel sleeve, and an insertion opening fixed to the supporting ring; secondly, jacking equipment is mounted, specifically, the jacking equipment is mounted at the bottom of the inner side of the working well; thirdly, the steel bushing head tool pipe is jacked through the process that the steel bushing head tool pipe is hoisted in place, the steel bushing head tool pipe is jacked, and manual intra-pipe earth cutting is conducted; fourthly, the pipeline is jacked, specifically, the multiple pipeline assembly sections of the constructed underground pipeline are jacked from front to back; fifthly, a pipeline port is treated; and sixthly, a closed water test for the pipeline is conducted. According to the pipe-jacking construction method for the mealy sand stratum, the steps are simple, the design is reasonable, construction is easy and convenient, and the using effect is good; and a pipe-jacking construction process of the mealy sand stratum can be completed easily, conveniently and rapidly, and the construction process is safe and reliable.

Owner:中铁二十局集团第五工程有限公司

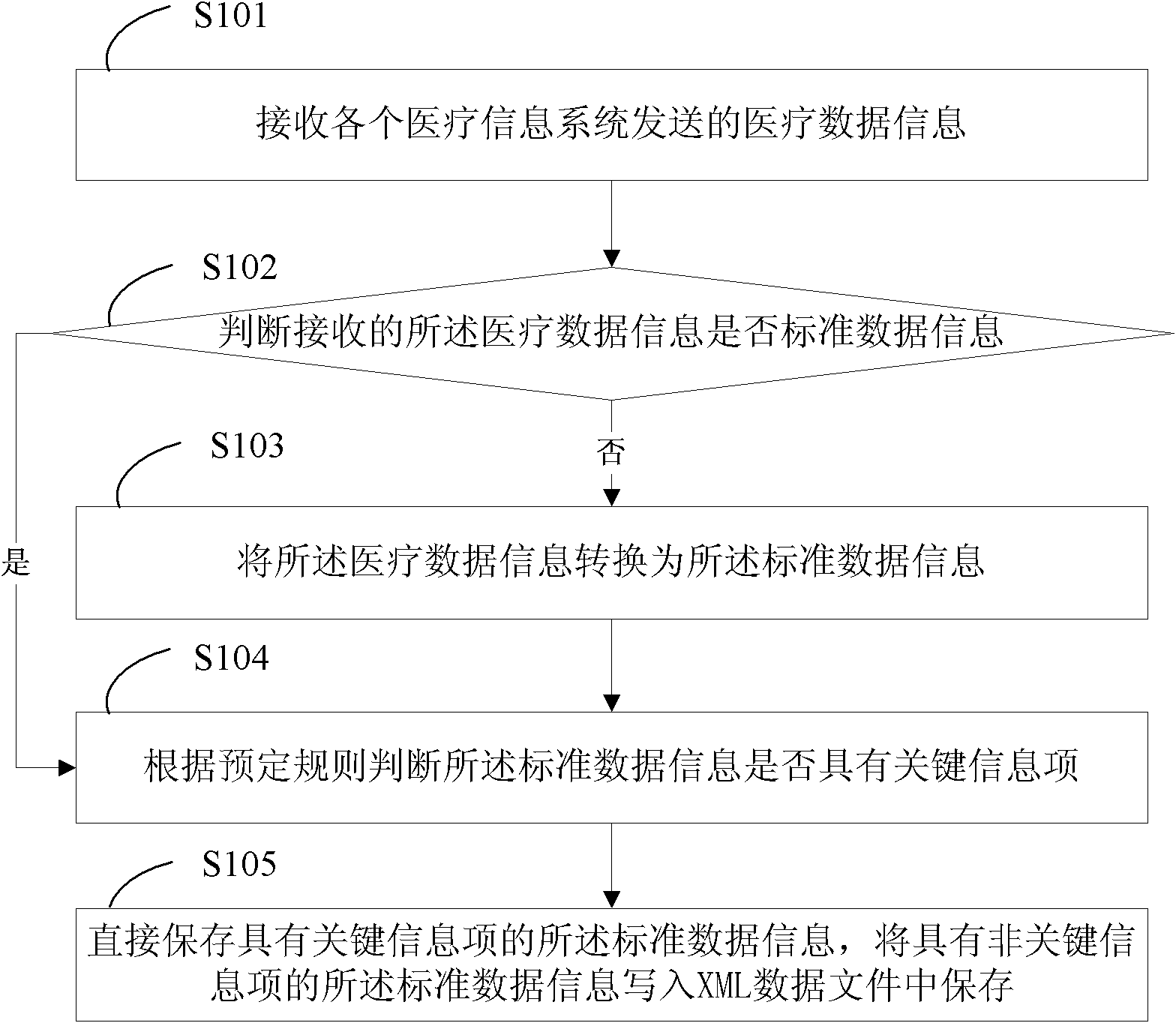

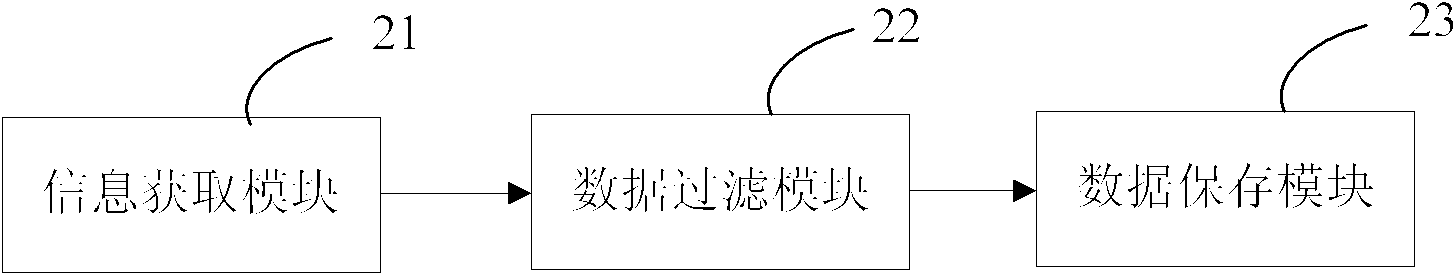

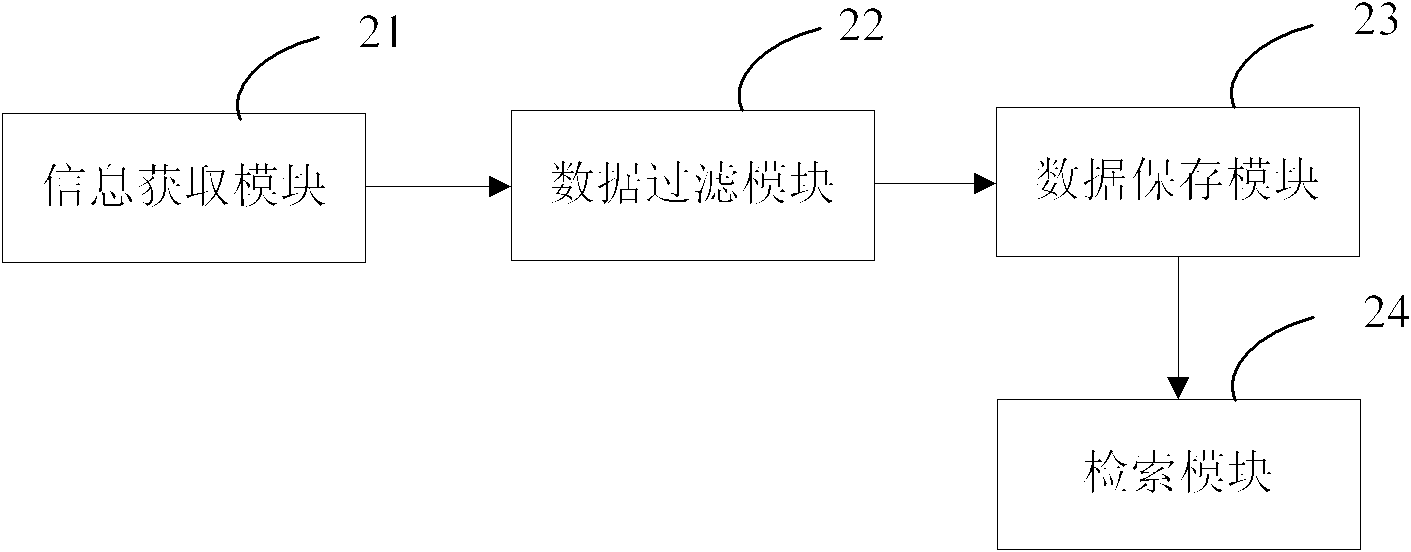

Medical data information processing method and system

InactiveCN102054032ARealize centralized storageEasy to interactData processing applicationsSpecial data processing applicationsGeographic information systemData science

The invention provides a medical data information processing method and system. The method comprises the following steps: receiving medical data information transmitted by each medical information system; if the medical data information is not standard data information, converting the medical data information into the standard data information, wherein the standard data information at least has preset message formats, information items and medical terms; judging whether the standard data information has key information items according to preset rules; if so, directly saving the standard data information; and if not, writing the standard data information in an XML (extensible markup language) data file, and saving. The medical data information processing method and system provided by the invention can realize the centralized information management and information sharing of different medical information systems.

Owner:GUANGZHOU HUITONG COMP

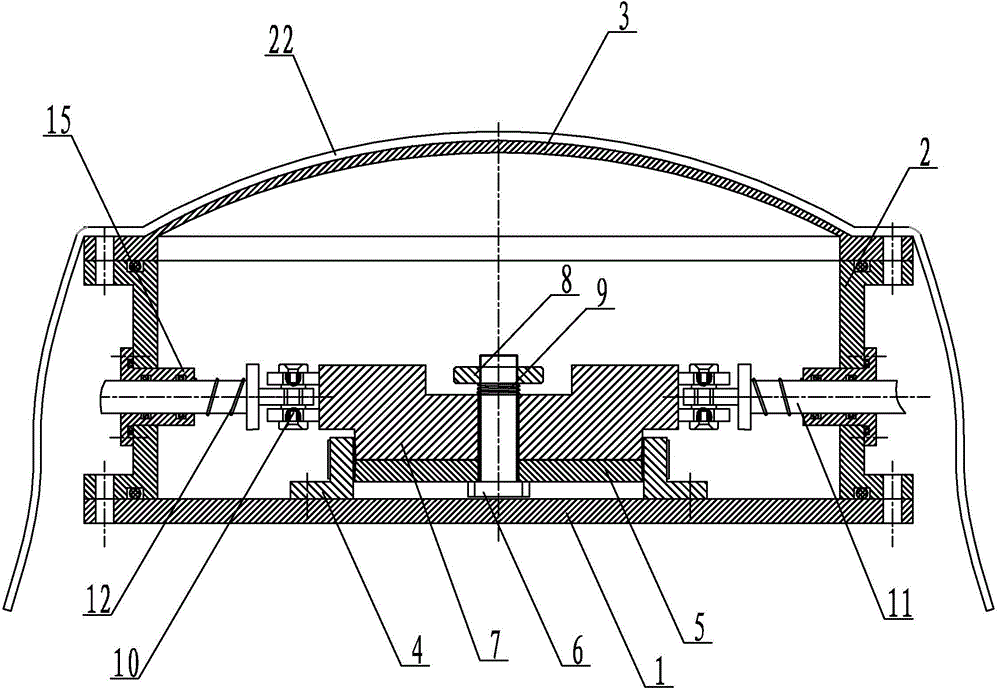

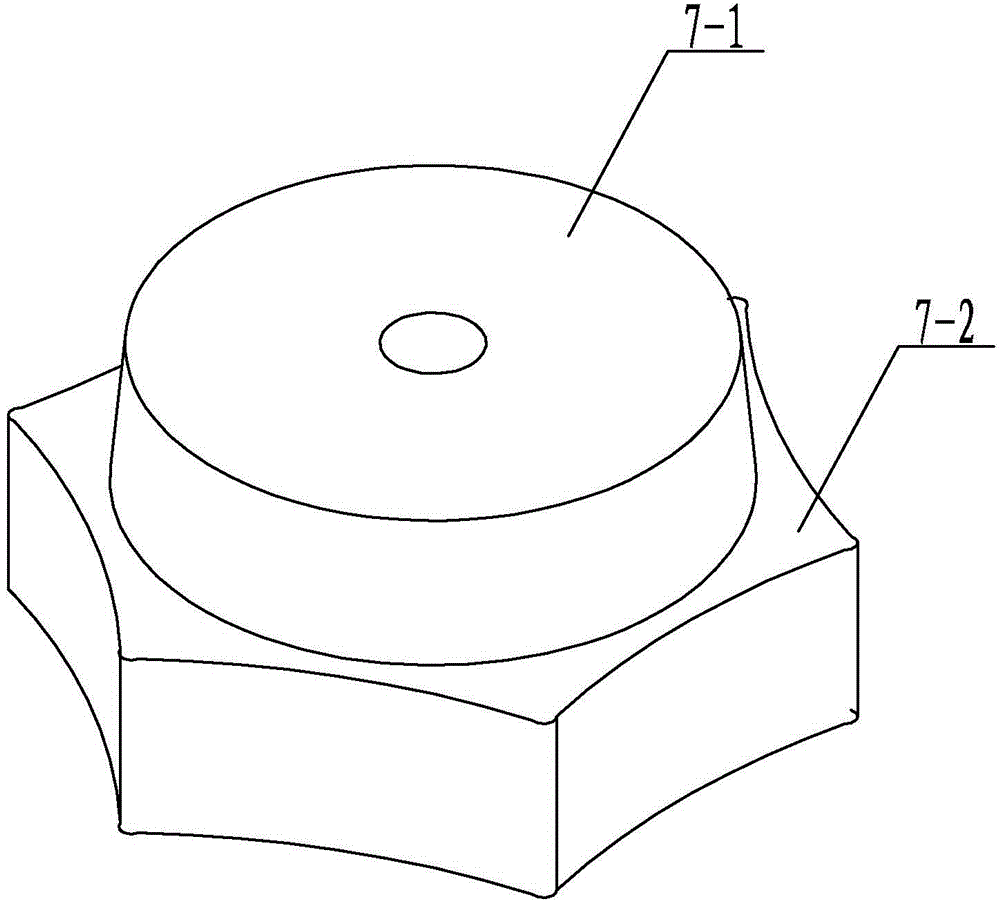

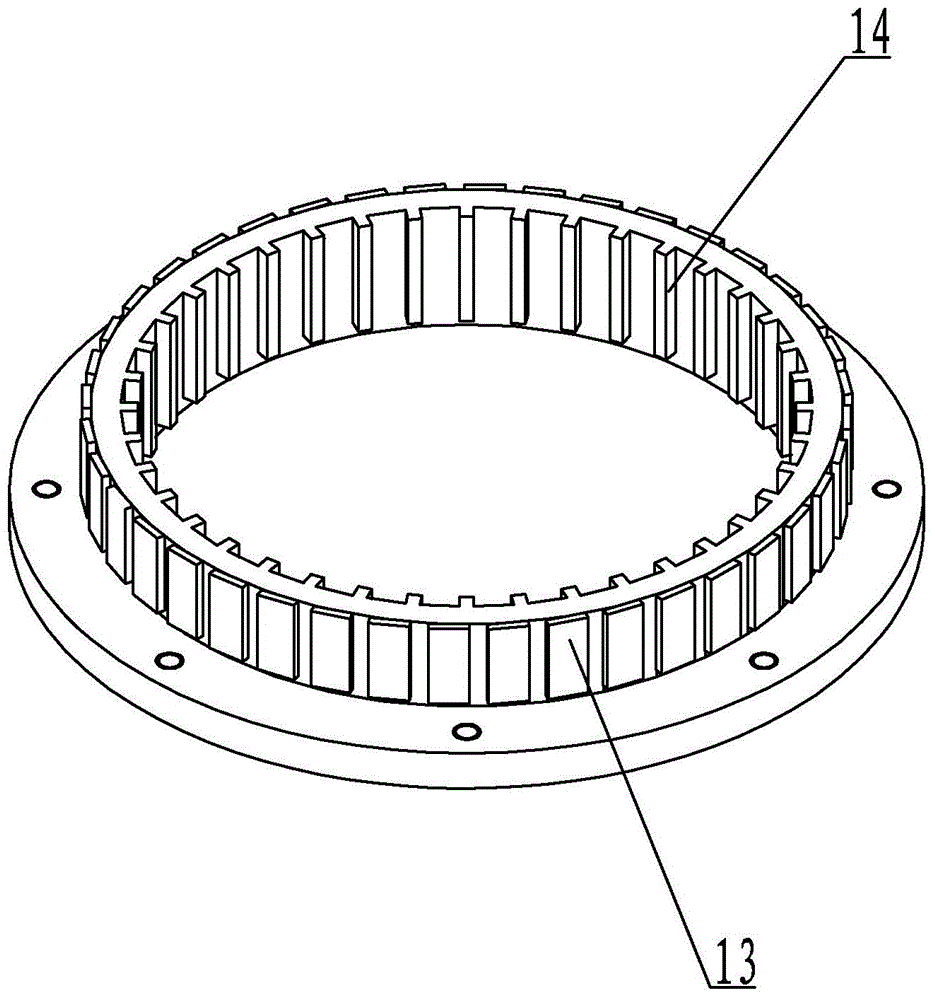

Machine jellyfish driven by embedded type cylindrical motor

ActiveCN104149953AEffectively control the movement positionAchieve continuous advancementPropulsive elements of non-rotary typeElectricityAbdominal cavity

The invention relates to a machine jellyfish, in particular to a machine jellyfish driven by an embedded type cylindrical motor. The problem that an existing bionic jellyfish robot is limited in moving range, small in effective water spraying size and small in driving force and is not suitable for a complex water flow environment in nature is solved. A mechanical abdominal cavity end cover, a sleeve and a bottom disc base of the machine jellyfish are in sealing connection from top to bottom in sequence. A cylindrical traveling wave ultrasonic motor is arranged on the bottom disc base. A transmission cam is located in the middle of the cylindrical traveling wave ultrasonic motor. A plurality of piezoelectric ceramic pieces are evenly distributed on the outer cylinder wall of the cylindrical traveling wave ultrasonic motor. A plurality of rectangular bosses which are arrayed vertically are evenly distributed on the inner cylinder wall of the cylindrical traveling wave ultrasonic motor. The other end of each arm pushing force rod is connected with a multi-joint arm. Each arm pushing force rod and the sleeve are connected through a pushing force rod guiding flange. An auxiliary spring is arranged between each pushing force guiding flange and an arm pushing force rod close to one side of a double-idler-wheel part. The machine jellyfish is used for unmanned underwater carrying.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com