Sodion-embedded manganese dioxide nanometer sheet electrode as well as preparation method and application of electrode

A technology of manganese dioxide and sodium ions, which is applied in the field of nanomaterials and electrochemistry, can solve problems such as unsatisfactory energy density and no redox peaks observed, and achieve a product that is conducive to market promotion, good cycle stability, and good diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

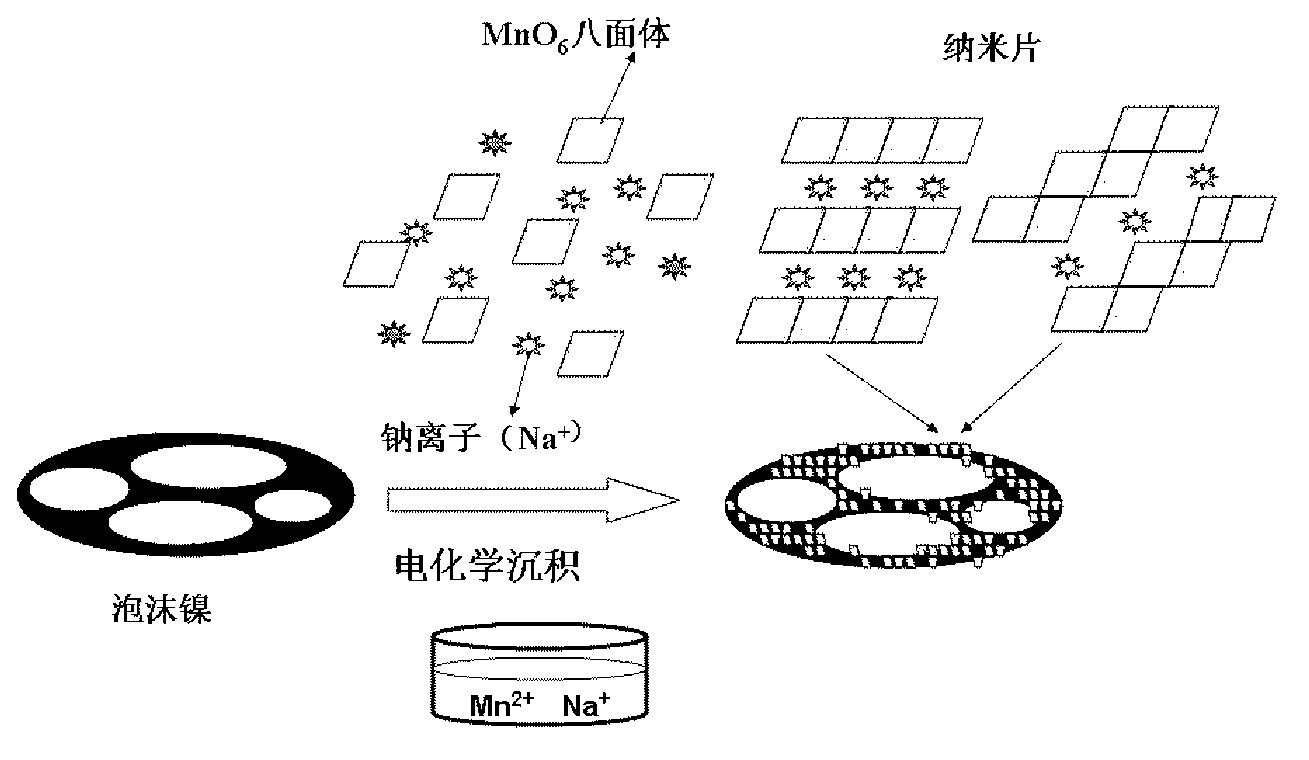

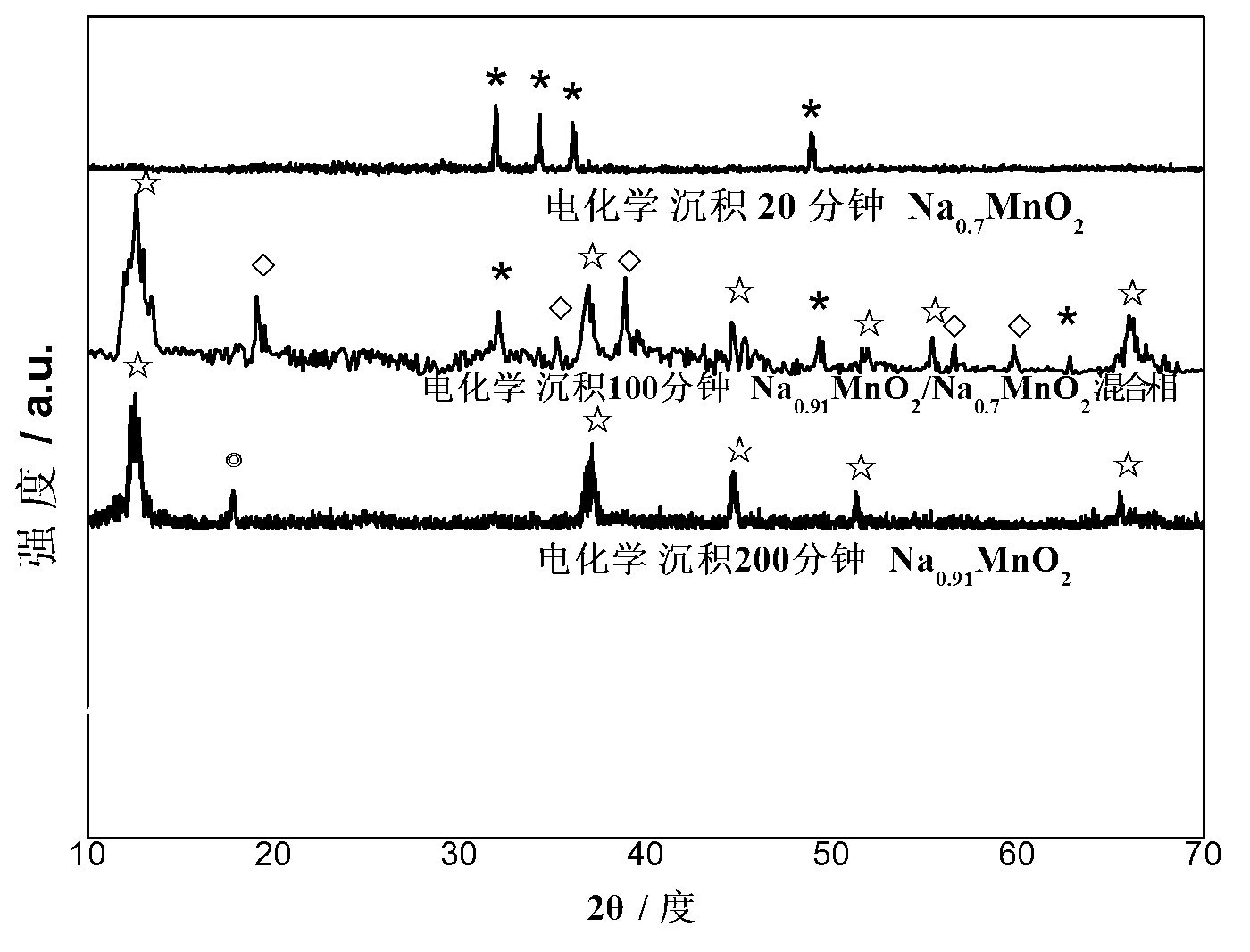

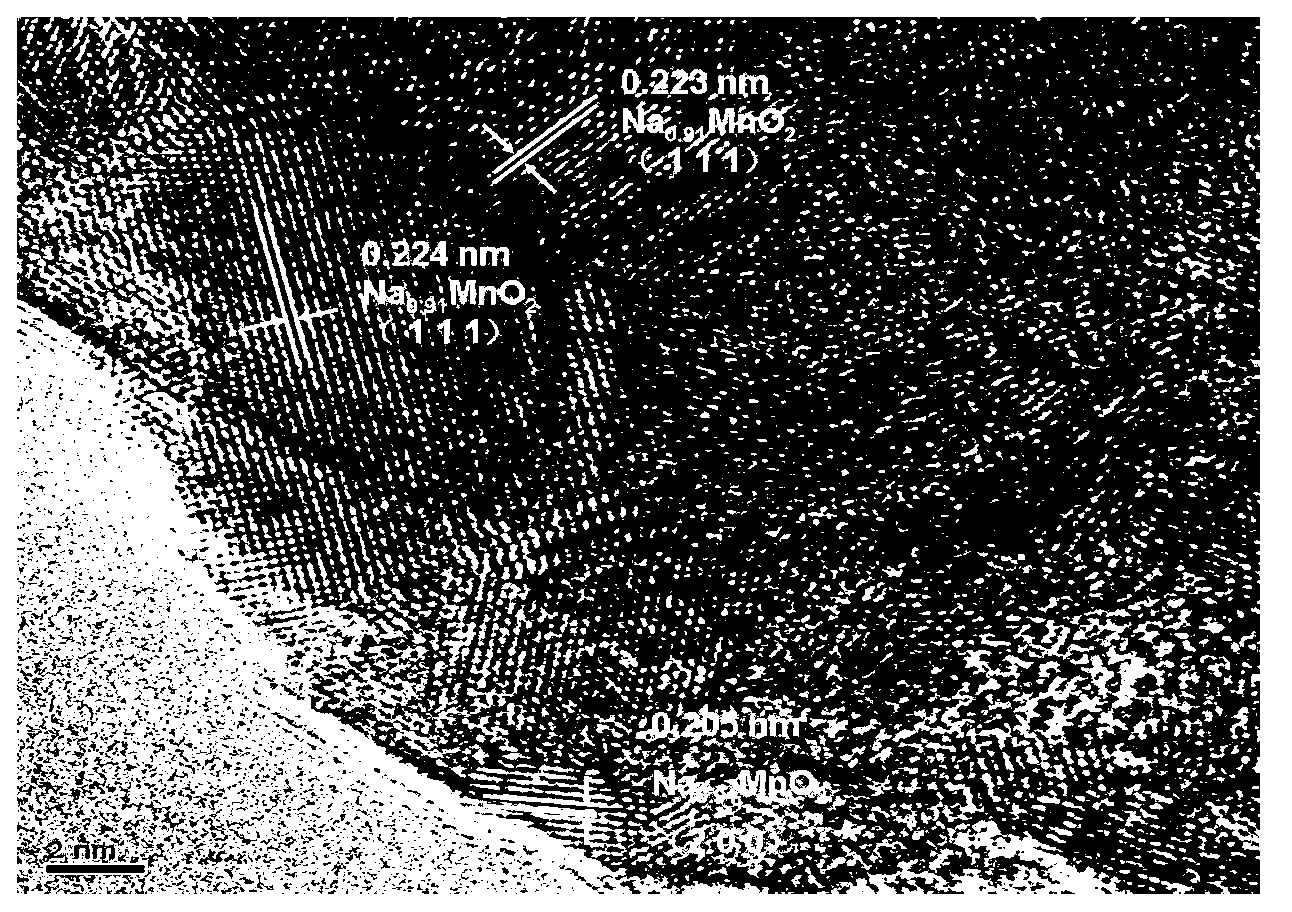

[0035] Preparation of Sodium Ion Intercalated Manganese Dioxide Na by Electrochemical Deposition 0.91 MnO 2 A nanosheet electrode, comprising the steps of:

[0036] 1) Use foamed nickel as the electrode substrate, first soak the foamed nickel in 2mol / L dilute sulfuric acid for 20 minutes, take it out and wash it twice with deionized water under ultrasonic (60KHz), 20 minutes each time, Then dry the washed foam nickel substrate for subsequent use;

[0037] 2) Take sodium sulfate and manganese acetate at a molar ratio of 50:1, and mix them to form electrochemical deposition precursor solutions with concentrations of 1mol / L and 0.02mol / L, respectively;

[0038] 3) The electrochemical deposition platform was built by the three-electrode method, and the nickel foam substrate pretreated in step 1) was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode;

[0039] 4) Immerse...

Embodiment 2

[0048] Preparation of Sodium Ion Intercalated Manganese Dioxide Na by Electrochemical Deposition 0.91 MnO 2 / Na 0.7 MnO 2 A nanosheet electrode, comprising the steps of:

[0049] 1) Use foamed nickel as the electrode substrate, first soak the foamed nickel in 2mol / L dilute sulfuric acid for 20 minutes, take it out and wash it twice with deionized water under ultrasonic (60KHz), 20 minutes each time, Then dry the washed foam nickel substrate for subsequent use;

[0050] 2) Take sodium sulfate and manganese acetate at a molar ratio of 50:1, and mix them to form electrochemical deposition precursor solutions with concentrations of 1mol / L and 0.02mol / L, respectively;

[0051] 3) The electrochemical deposition platform was built by the three-electrode method, and the nickel foam substrate pretreated in step 1) was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode;

[...

Embodiment 3

[0058] Preparation of Sodium Ion Intercalated Manganese Dioxide Na by Electrochemical Deposition 0.7 MnO 2 The preparation method of nano sheet electrode, it comprises the steps:

[0059] 1) Use foamed nickel as the electrode substrate, first soak the foamed nickel in 2mol / L dilute sulfuric acid for 20 minutes, take it out and wash it twice with deionized water under ultrasonic (60KHz), 20 minutes each time, Then dry the washed foam nickel substrate for subsequent use;

[0060] 2) Take sodium sulfate and manganese acetate at a molar ratio of 50:1, and mix them to form electrochemical deposition precursor solutions with concentrations of 1mol / L and 0.02mol / L, respectively;

[0061] 3) The electrochemical deposition platform was built by the three-electrode method, and the nickel foam substrate pretreated in step 1) was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com