Graphene composite material and preparation method thereof

A graphene and graphene-coated technology, applied in nanotechnology for materials and surface science, electrical components, electrochemical generators, etc., can solve problems such as cumbersome operation, difficult industrial production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

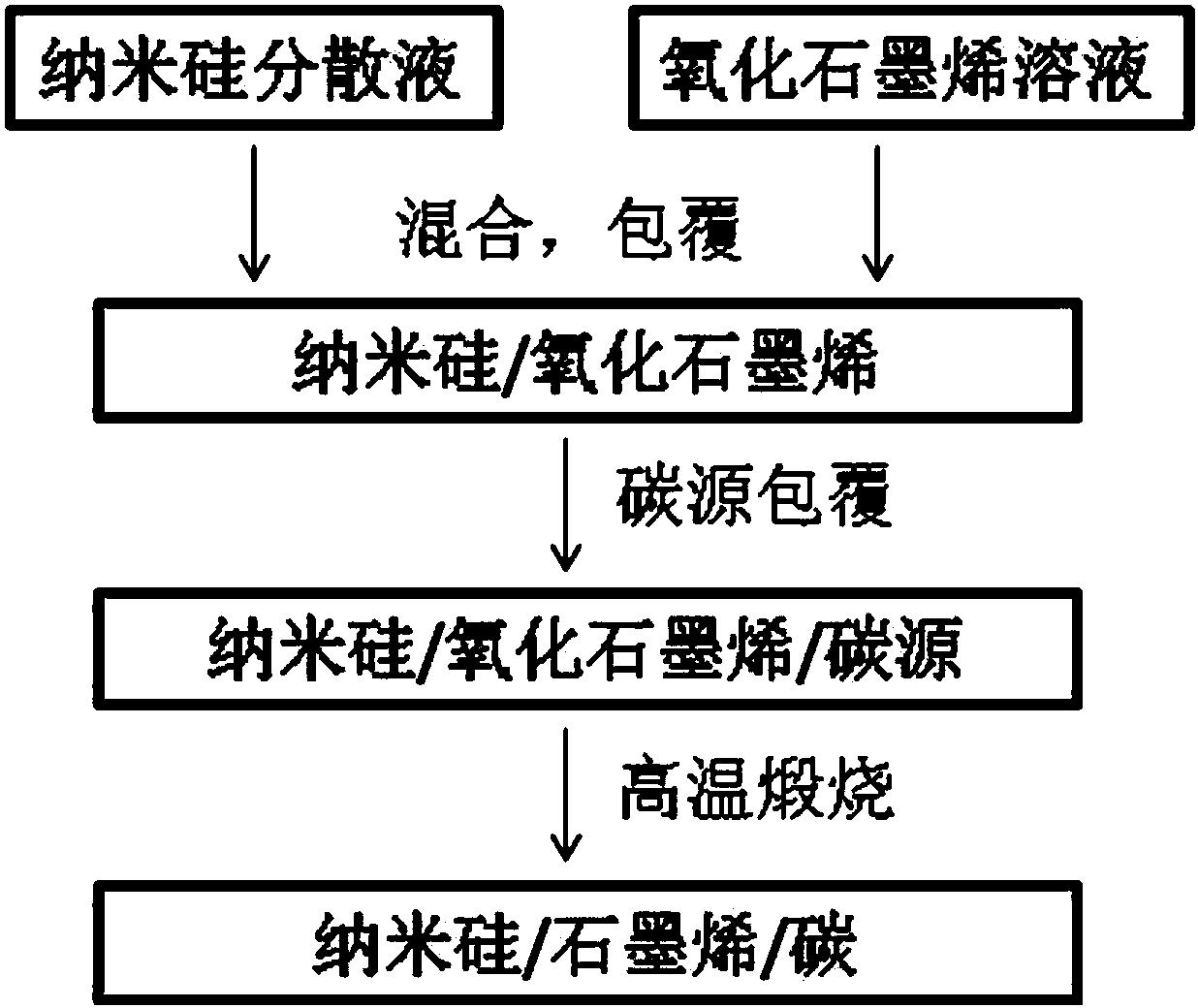

Method used

Image

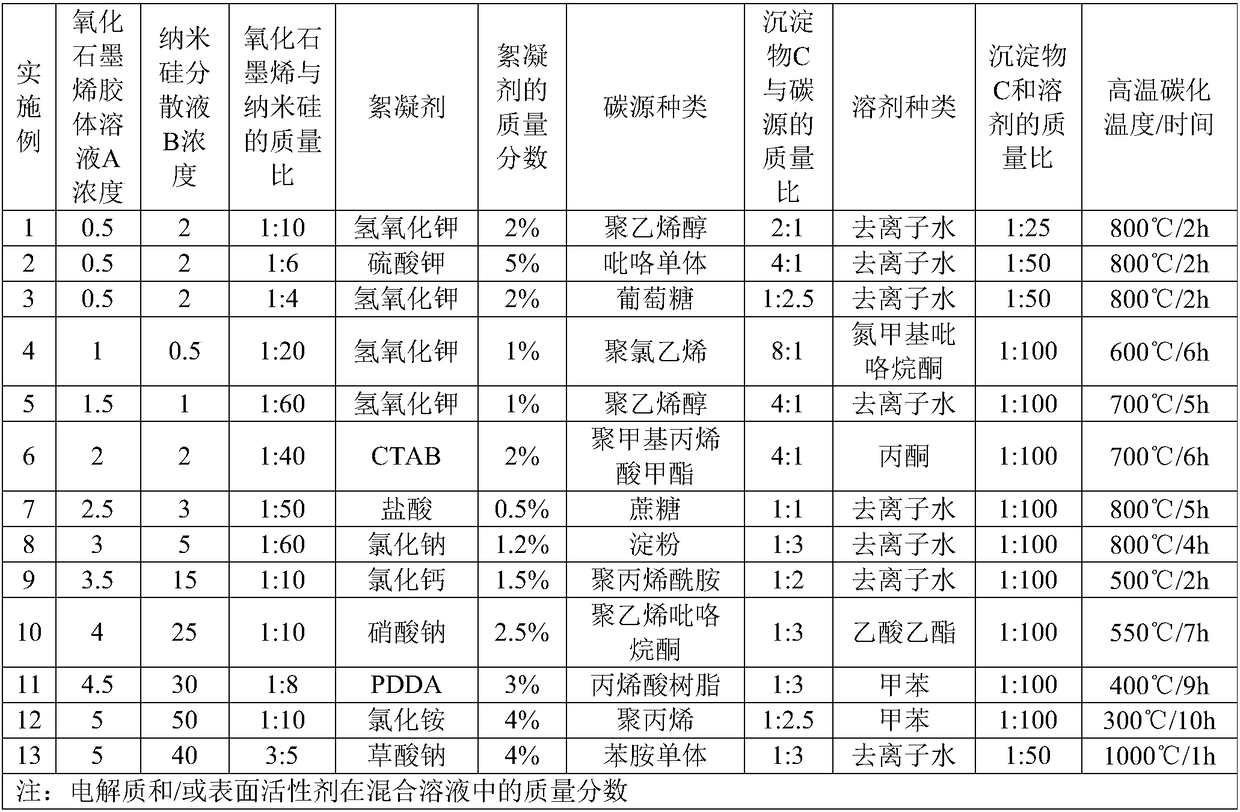

Examples

preparation example 1

[0052] Preparation of Graphene Oxide Colloidal Solution A

[0053] 0.1g-10g of graphene oxide was added to 2000ml of deionized water, and placed in an ultrasonic cleaner for ultrasonic dispersion for 10min under 100W power, to prepare a graphene oxide colloidal solution A with a graphene oxide concentration of 0.05-5mg / mL.

[0054] Specifically, for example, 1 g of graphene oxide was added to 2000 ml of deionized water, and placed in an ultrasonic cleaner for ultrasonic dispersion for 10 min at a power of 100 W to prepare a graphene oxide colloidal solution A with a graphene oxide concentration of 0.5 mg / mL.

preparation example 2

[0056] Preparation of nano-silicon dispersion B

[0057] Disperse 0.025g-25g of nano-silicon with a particle size of 50nm in 500ml of deionized water, and disperse it ultrasonically for 1 hour at a power of 100W to prepare nano-silicon dispersion B with a nano-silicon concentration of 0.05-50mg / mL.

[0058] Specifically, for example, disperse 1 g of nano-silicon with a particle size of 50 nm in 500 ml of deionized water, and disperse it ultrasonically for 1 hour under a power condition of 100 W to prepare a nano-silicon dispersion B with a nano-silicon concentration of 2 mg / mL.

Embodiment 1

[0060] 200mL preparation example 1 prepared graphene oxide concentration is 0.5mg / mL graphene oxide colloidal solution A and 500mL preparation example 2 preparation nano-silicon concentration is 2mg / mL nano-silicon dispersion B mixed and sonicated for 10min minutes, Stir for 1h, add potassium hydroxide, continue stirring for 2h, flocculation and precipitation occur in the mixed solution, after centrifugation and washing, prepare precipitate C (i.e. nano-silicon particles coated with graphene oxide); 0.4g precipitate C and 10g of a mass fraction of 2% polyvinyl alcohol aqueous solution was mixed and ball milled for 4h to obtain a precipitate D (i.e., polyvinyl alcohol-coated graphene oxide-coated nano-silicon particles), which was freeze-dried at -50°C; Solid, under the protection of argon, carbonized at 800 °C for 2 hours at a high temperature to prepare nano-silicon / graphene / carbon composite electrode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com