High-performance graphene/cellulose composite hydrogel and aerogel and preparation methods thereof

A composite hydrogel and composite aerogel technology, applied in the field of material science, can solve the problems of limiting the application of graphene, easy agglomeration and difficult dispersion of graphene, and achieve excellent mechanical properties, good thermal stability, and prevent agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

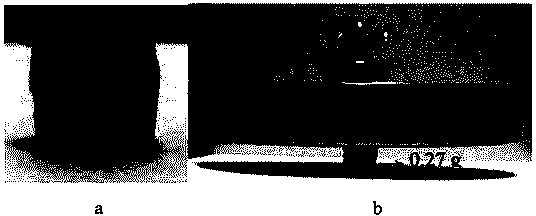

Image

Examples

Embodiment 1

[0039] (1) Add 15g of ionic liquid into a 25ml three-necked flask, and heat the oil bath to 80°C. When the ionic liquid was completely dissolved, 0.45 g of graphite oxide (prepared by the improved Hummers method) was added, the mixture was stirred for 0.5 h, and then the three-neck flask was transferred into a cell disruptor and ultrasonicated for 10 min. Then 1.8 g of ascorbic acid was added, and the mixture was stirred at 80° C. for 24 h. A reduced graphene oxide ionic liquid solution with a graphene oxide concentration of 2.6 wt% was obtained.

[0040] (2) Add 20g of ionic liquid into a 50ml three-neck flask, and heat the oil bath to 80°C. When the ionic liquid was completely dissolved, 1.2 g of softwood pulp (after ball milling) was added under magnetic stirring, and nitrogen gas was passed (5 min). Then stir at 80°C until the cellulose is completely dissolved. A cellulose ionic liquid solution with a cellulose mass fraction of 6% was obtained.

[0041] (3) Add 0.23 g ...

Embodiment 2

[0043] (1) Add 15g of ionic liquid into a 25ml three-necked flask, and heat the oil bath to 110°C. When the ionic liquid was completely dissolved, 0.45 g of graphite oxide was added, the mixture was stirred for 0.5 h, and then the three-neck flask was transferred to an ultrasonic cleaner, 100 W, 60 ° C for 3 h. Then 1.8 g of ascorbic acid was added, and the mixture was stirred at 80° C. for 24 h. A reduced graphene oxide ionic liquid solution with a graphene oxide concentration of 2.6 wt% was obtained.

[0044](2) 24g of ionic liquid was added into a 50ml three-neck flask, and the oil bath was heated to 110°C. When the ionic liquid was completely dissolved, 1.2 g of cellulose was added under magnetic stirring, and nitrogen gas was passed (5 min). Then stir at 110°C until the cellulose is completely dissolved.

[0045] (3) Add 0.046 g of the reduced graphene oxide ionic liquid solution in (1) to the cellulose solution in (2), and stir the mixture at 110° C. for 30 min. Tran...

Embodiment 3

[0049] (1) Add 15g of ionic liquid into a 25ml three-necked flask, and heat the oil bath to 110°C. When the ionic liquid was completely dissolved, 0.3 g of graphite oxide was added, the mixture was stirred for 0.5 h, and then the three-neck flask was transferred to an ultrasonic cleaner, 80 W, 60 ° C for 4 h. Then 1.2 g of ascorbic acid was added, and the mixture was stirred at 80° C. for 24 h. A reduced graphene oxide ionic liquid solution with a graphene oxide concentration of 2.6 wt% was obtained.

[0050] (2) 24g of ionic liquid was added into a 50ml three-neck flask, and the oil bath was heated to 110°C. When the ionic liquid was completely dissolved, 1.2 g of cellulose was added under magnetic stirring, and nitrogen gas was passed (5 min). Then stir at 110°C until the cellulose is completely dissolved.

[0051] (3) Add 0.66 g of the reduced graphene oxide ionic liquid solution in (1) to the cellulose solution in (2), and stir the mixture at 110° C. for 30 min. Transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com