Graphene conductive ink and preparation method thereof

A conductive ink and graphene technology, applied in the field of materials, can solve the problems of poor conductivity, unstable conductivity and easy agglomeration of conductive ink, and achieve the effects of stable conductivity, excellent product performance and easy dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

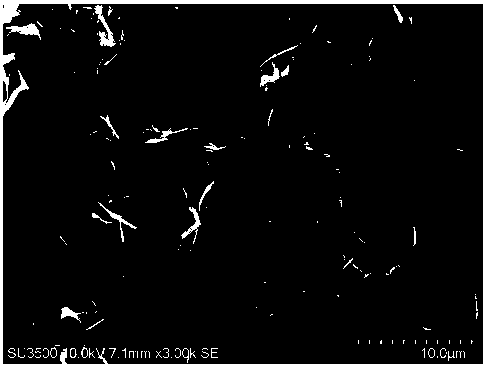

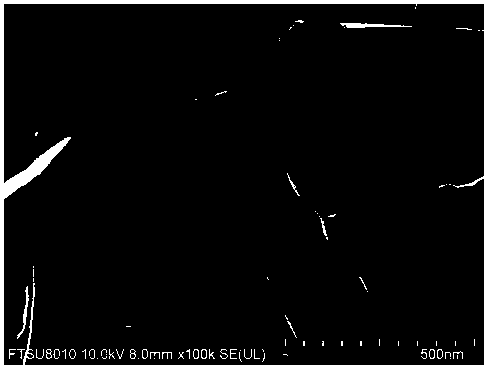

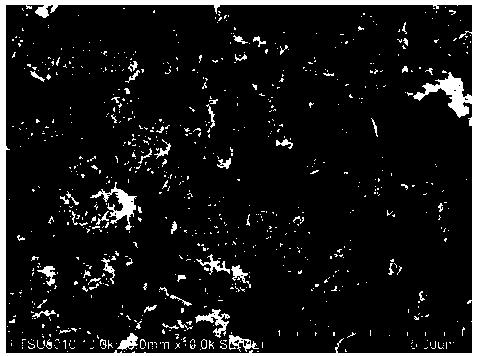

Image

Examples

preparation example Construction

[0035] A preparation method of graphene conductive ink, comprising the following steps.

[0036] Step 1: Add graphene, cyclohexanone, isophorone, ethylene glycol monobutyl ether, N-methylpyrrolidone, K-30, BYK104S into the dispersion cylinder and disperse with a high-speed disperser, stir and disperse evenly to obtain Initially dispersed graphene dispersion;

[0037] Step 2: Grinding the graphene dispersion with a ball mill, using 1 zirconia ball, grinding until the graphene slurry is ground to a fineness of less than to obtain a coarsely ground graphene slurry;

[0038] Step 3: Add conductive carbon black XE2-B, cellulose acetate butyrate, N-methylpyrrolidone, BYK104S, acrylic resin, and fumed silica to the coarsely ground graphene slurry, and disperse with a high-speed disperser to obtain Graphene slurry;

[0039] Step 4: Grinding the graphene slurry with a nano-sand mill until the fineness of the slurry is ground to within, to obtain finely ground graphene slurry;

[004...

Embodiment example 1

[0044] Implementation case 1: In this embodiment, the mass ratio of each raw material is: 18 parts of few-layer graphene of Shenzhen Guochuang Jiawei Graphene Technology Co., Ltd., 15 parts of acrylic resin, 3 parts of cellulose acetate butyrate, cyclohexane 20 parts of ketone, 10 parts of isophorone, 3 parts of K-30 polyvinylpyrrolidone, 10 parts of N-methylpyrrolidone, 11 parts of ethylene glycol monobutyl ether, 3 parts of adhesion promoter, KH-560 silane coupling 3 parts of agent, 1 part of leveling agent, 2 parts of BYK104S, 1 part of fumed silica.

[0045] A kind of graphene conductive ink provided by the present invention, the preparation steps are as follows: mix 10 parts of graphene with 20 parts of cyclohexanone, 10 parts of isophorone, 11 parts of ethylene glycol monobutyl ether, 5 parts of N-methylpyrrolidone , 3 parts of K-30, and 1 part of BYK104S were added to the dispersion cylinder and dispersed for 30 minutes with a high-speed disperser at 1000 rpm, stirred a...

Embodiment example 2

[0050] Implementation case 2: In this implementation plan, the mass ratio of each raw material is: 12 parts of few-layer graphene from Shenzhen Guochuang Jiawei Graphene Technology Co., Ltd., 6 parts of conductive carbon black XE2-B, 15 parts of acrylic resin, and butyl acetate 3 parts of acid cellulose, 20 parts of cyclohexanone, 10 parts of isophorone, 3 parts of K-30 polyvinylpyrrolidone, 10 parts of N-methylpyrrolidone, 11 parts of ethylene glycol monobutyl ether, 3 parts of adhesion promoter 1 part, 3 parts of KH-560 silane coupling agent, 1 part of leveling agent, 2 parts of BYK104S, 1 part of fumed silica.

[0051] A kind of graphene conductive ink provided by the present invention, the preparation steps are as follows: mix 12 parts of graphene with 20 parts of cyclohexanone, 10 parts of isophorone, 11 parts of ethylene glycol monobutyl ether, 5 parts of N-methylpyrrolidone , 3 parts of K-30, and 1 part of BYK104S were added to the dispersion cylinder and dispersed for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com