Method for preparing TPU foamed beads by continuous extrusion foaming

A technology of foaming beads and extrusion foaming, which is applied in the field of continuous extrusion foaming to prepare TPU foaming beads, which can solve the problems of environmental protection and production safety, the smell of aromatic foaming agents, and the high shrinkage rate of products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

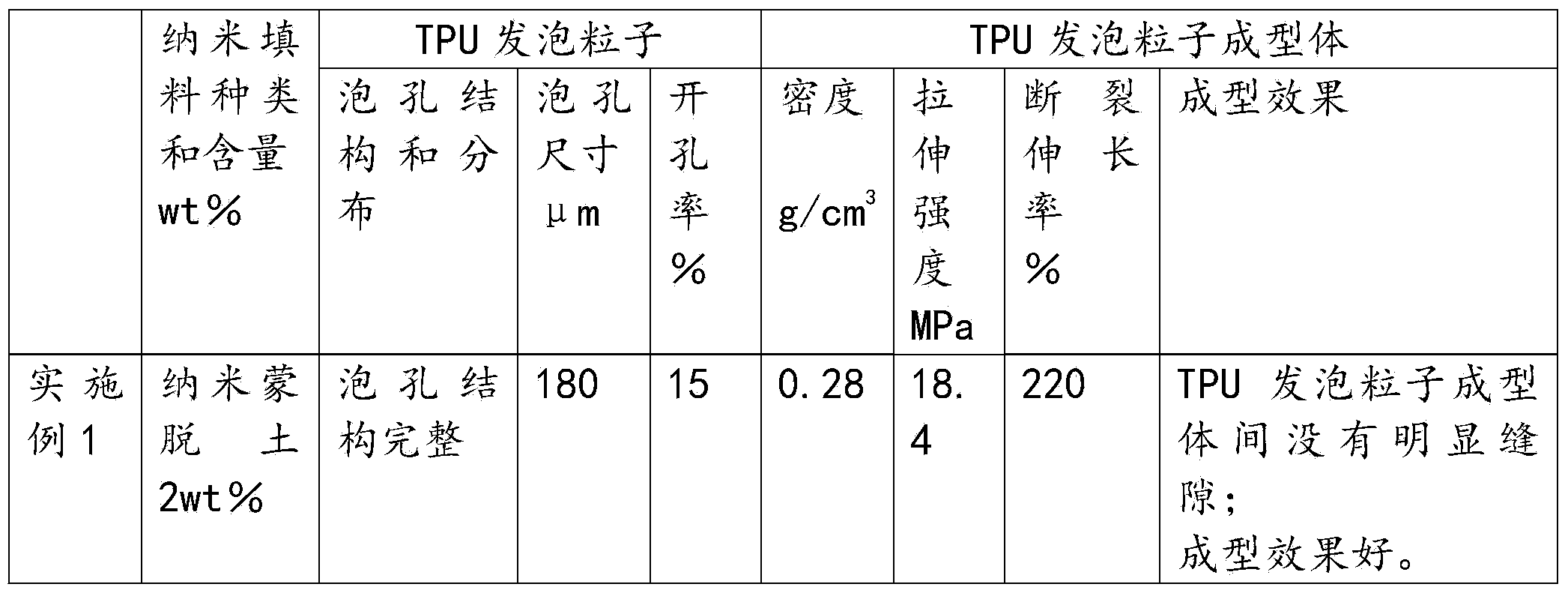

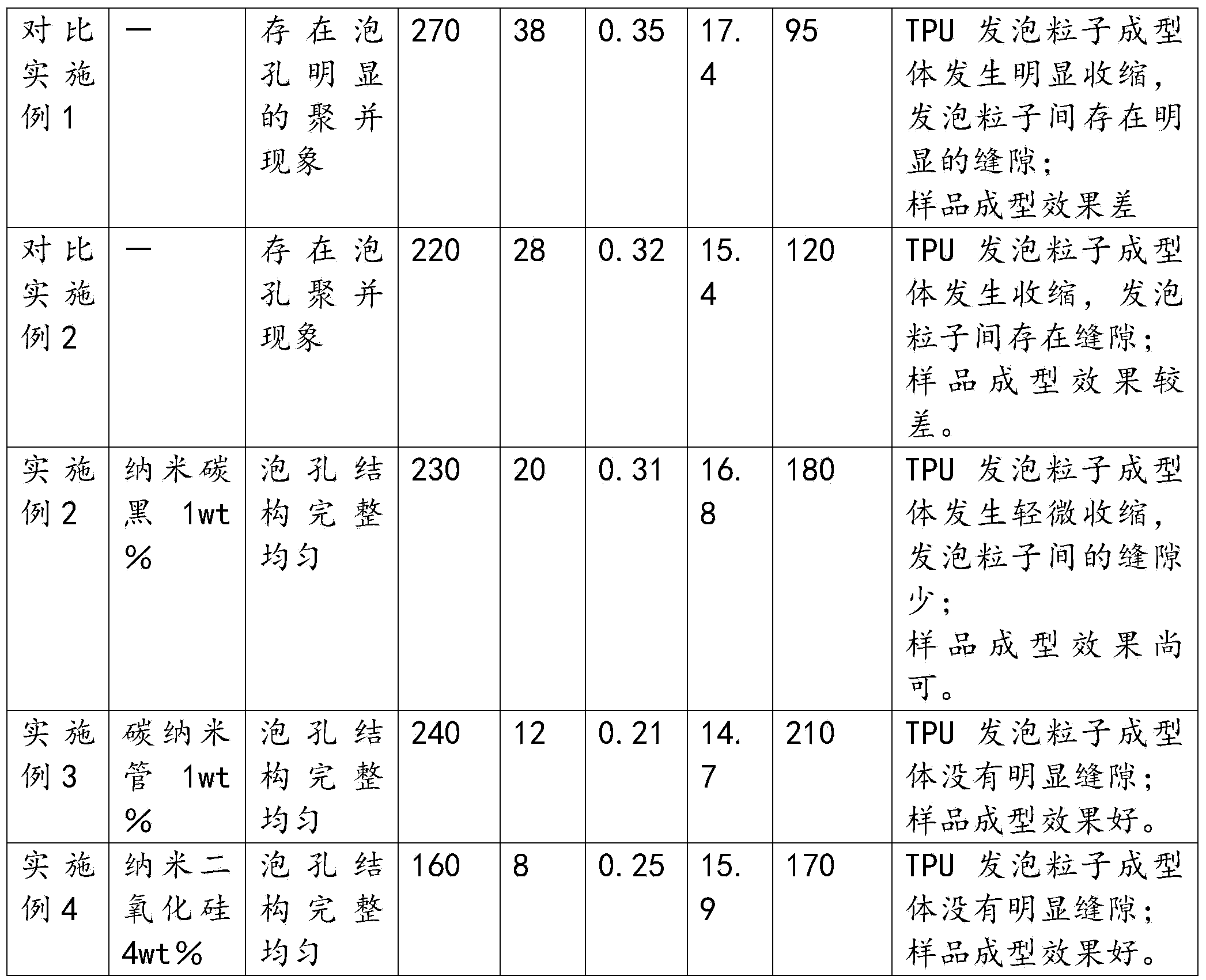

Embodiment 1

[0033] Mix the pickled and alcoholized nano-montmorillonite (the content is 2wt%, the organic matter content of nanomaterials is 15wt%) with TPU particles, and add the mixture to the barrel of the first extruder, and the temperature range is 160-180- The screw heating at 200-185-160°C melts the TPU particles, and the supercritical CO with a pressure of 8-30MPa 2 Injected into the end of the first extruder to spread the high pressure fluid into the polymer melt. The polymer high-pressure fluid melt is injected into the second extruder through a melt pump, and the polymer high-pressure fluid melt is gradually cooled through the second extruder with a temperature range of 160-155-150-145-140-135°C.

[0034] The cooled polymer high-pressure fluid is extruded and foamed through the die of the extruder, and the foamed strips are cut into regular-sized TPU foamed particles by the underwater granulation system. The TPU expanded particles are molded by steam compression molding equipm...

Embodiment 2

[0041] Except adding sulfonated nano-carbon black (the content is 1 wt%, and the organic matter content of the nano-material is 20 wt%), other operations are the same as in Example 1. As shown in Table 1, the cell structure of the prepared TPU expanded particles is complete and uniform, the average cell size is 230 μm, the porosity is 20%, and the density of the TPU expanded particle molded body is 0.31 g / cm 3 , The tensile strength of expanded particles is 16.8MPa, and the elongation at break is 180%. The molded body of TPU foamed particles shrinks slightly, there are few gaps between the foamed particles, and the molding effect of the sample is acceptable.

Embodiment 3

[0043] Except for the addition of sulfonated carbon nanotubes (the content is 1 wt%, and the organic matter content of the nanomaterial is 30 wt%), other operations are the same as in Example 1. As shown in Table 1, the cell structure of the prepared TPU expanded particles is complete and uniform, the average cell size is 240 μm, the porosity is 12%, and the density of the TPU expanded particle molded body is 0.21 g / cm 3 , The tensile strength of expanded particles is 14.7MPa, and the elongation at break is 210%. The TPU expanded particle molding has no obvious gaps, and the sample molding effect is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Average cell size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com