Patents

Literature

2865 results about "Supercritical fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A supercritical fluid (SCF) is any substance at a temperature and pressure above its critical point, where distinct liquid and gas phases do not exist. It can effuse through solids like a gas, and dissolve materials like a liquid. In addition, close to the critical point, small changes in pressure or temperature result in large changes in density, allowing many properties of a supercritical fluid to be "fine-tuned".

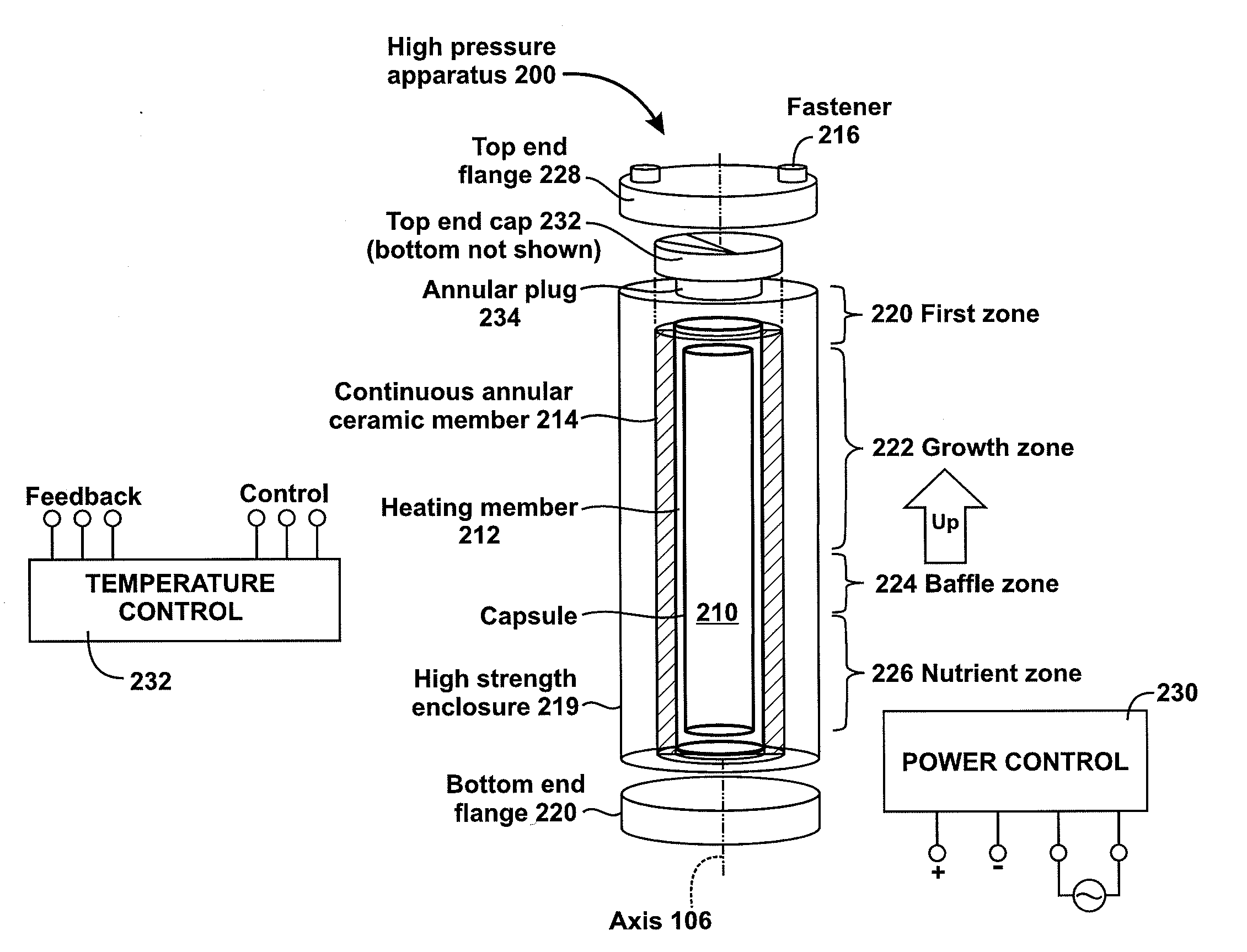

High pressure apparatus and method for nitride crystal growth

ActiveUS20090301387A1Simple and cost-effective to manufactureIncrease pressureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

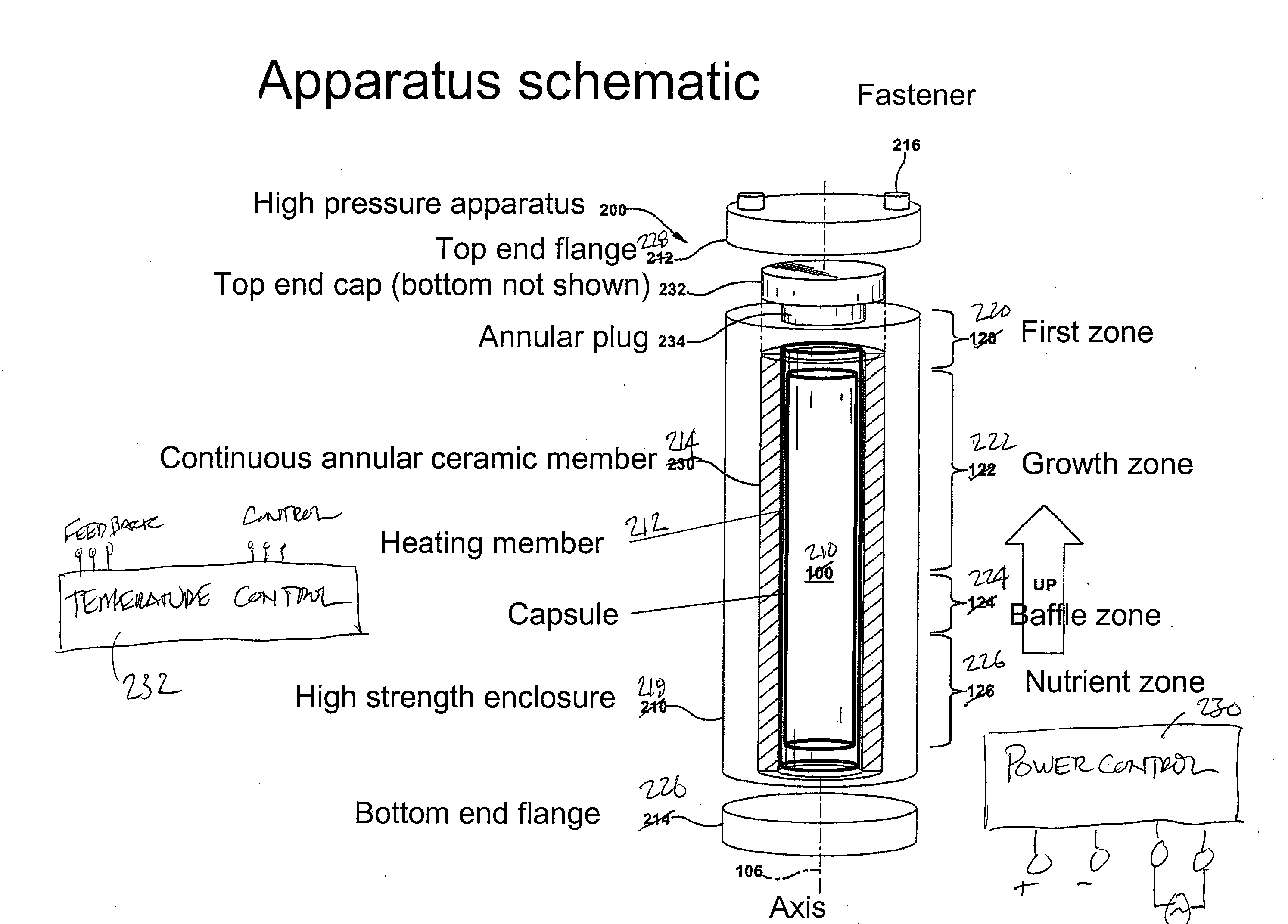

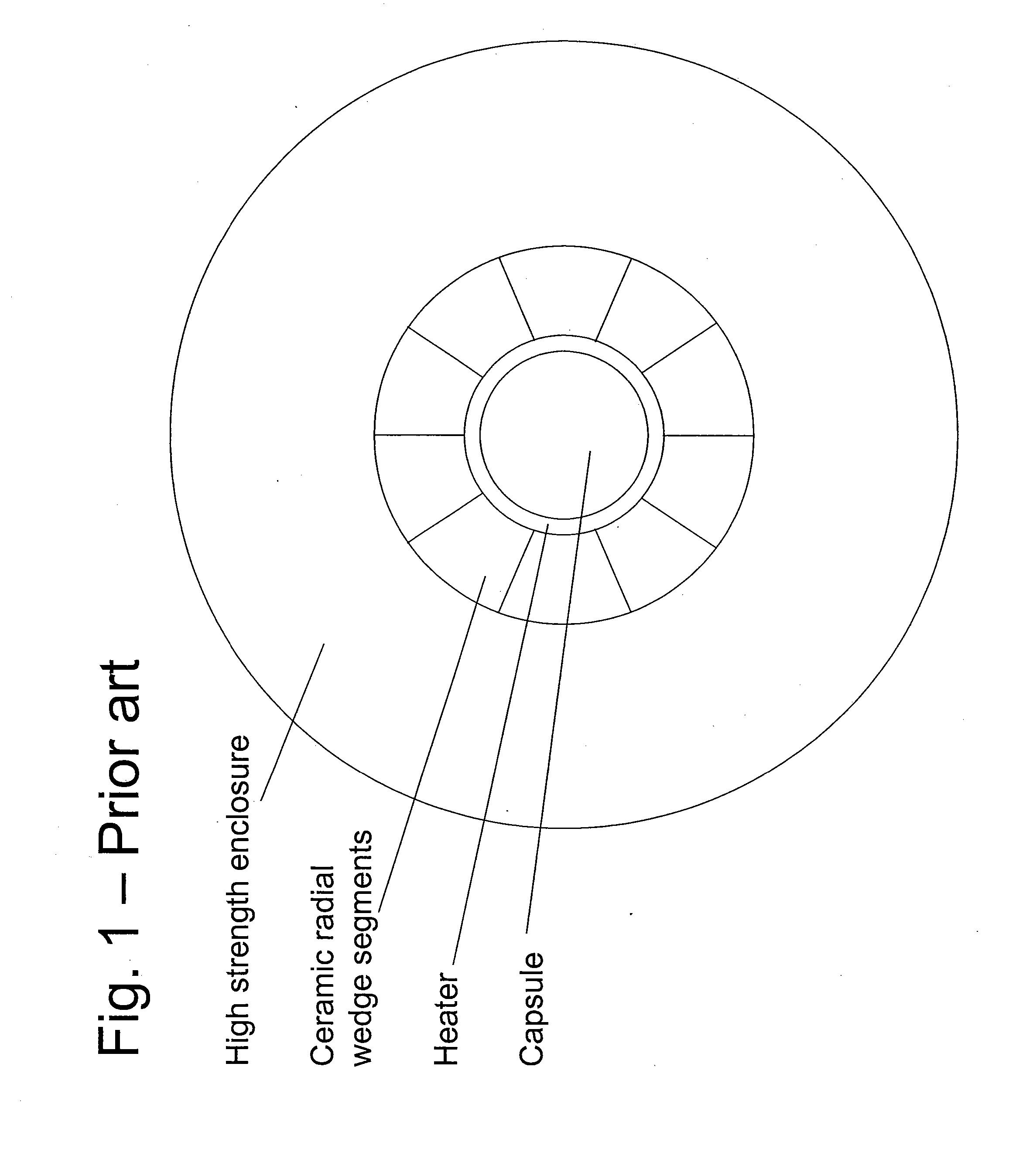

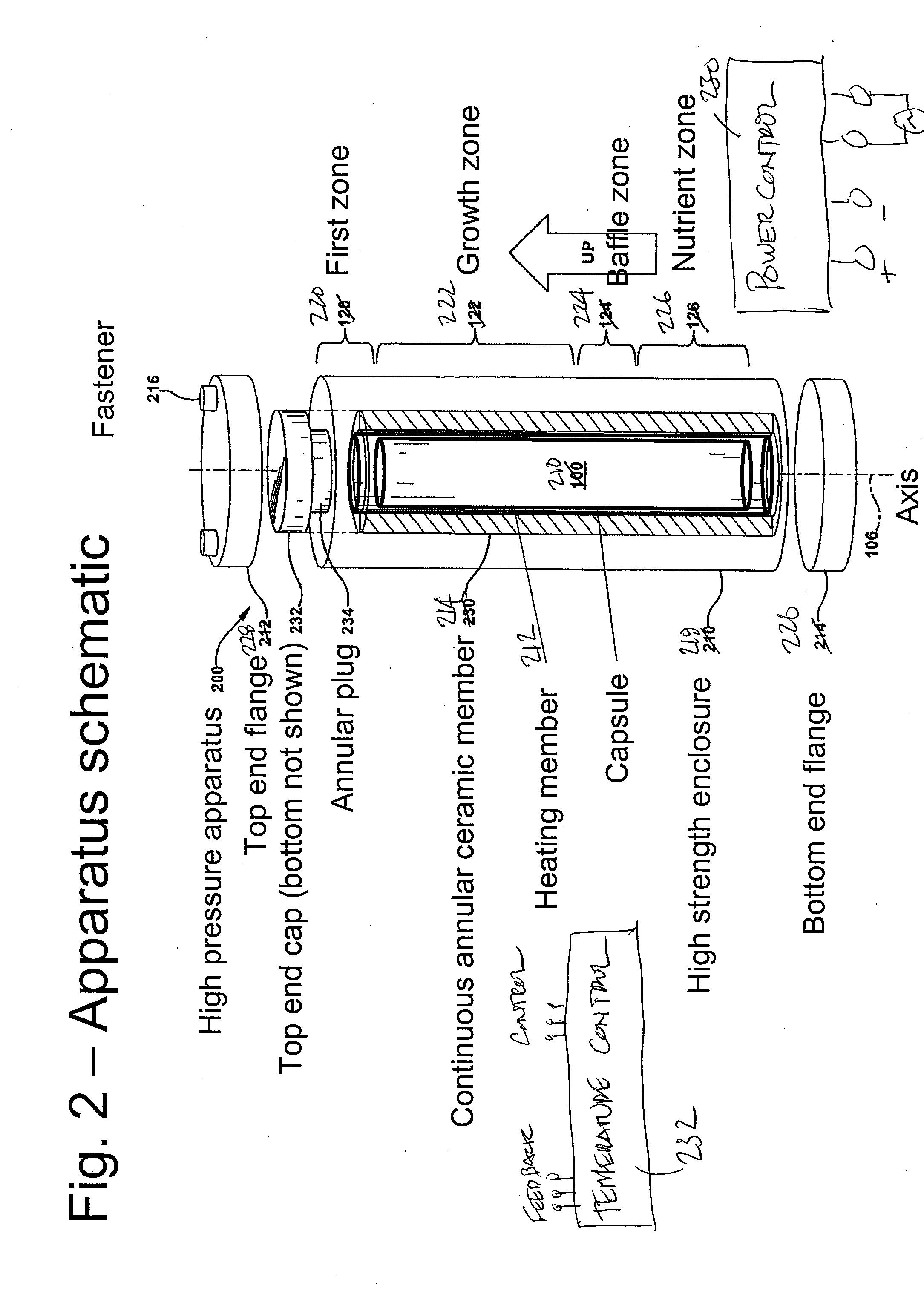

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. IN a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

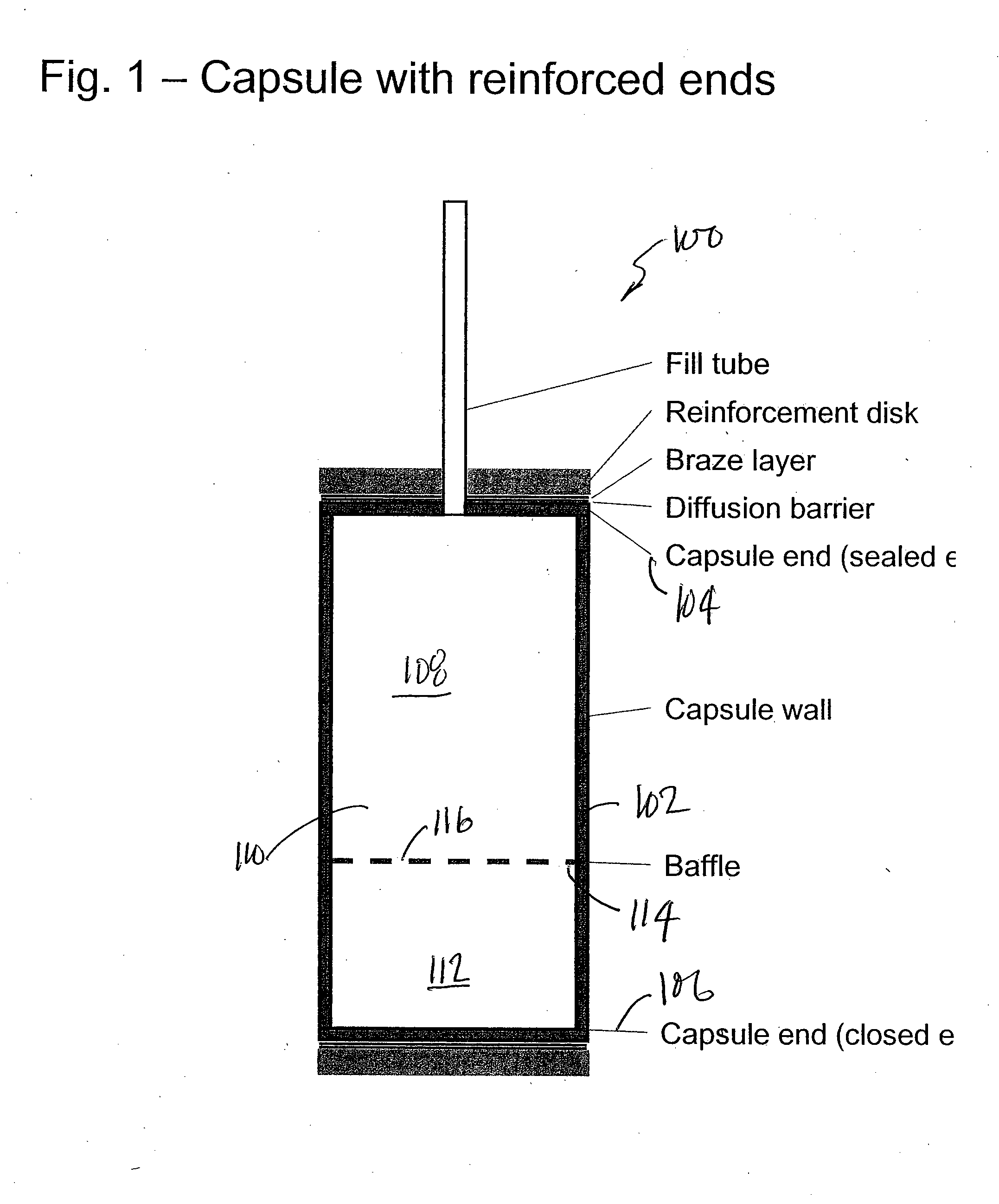

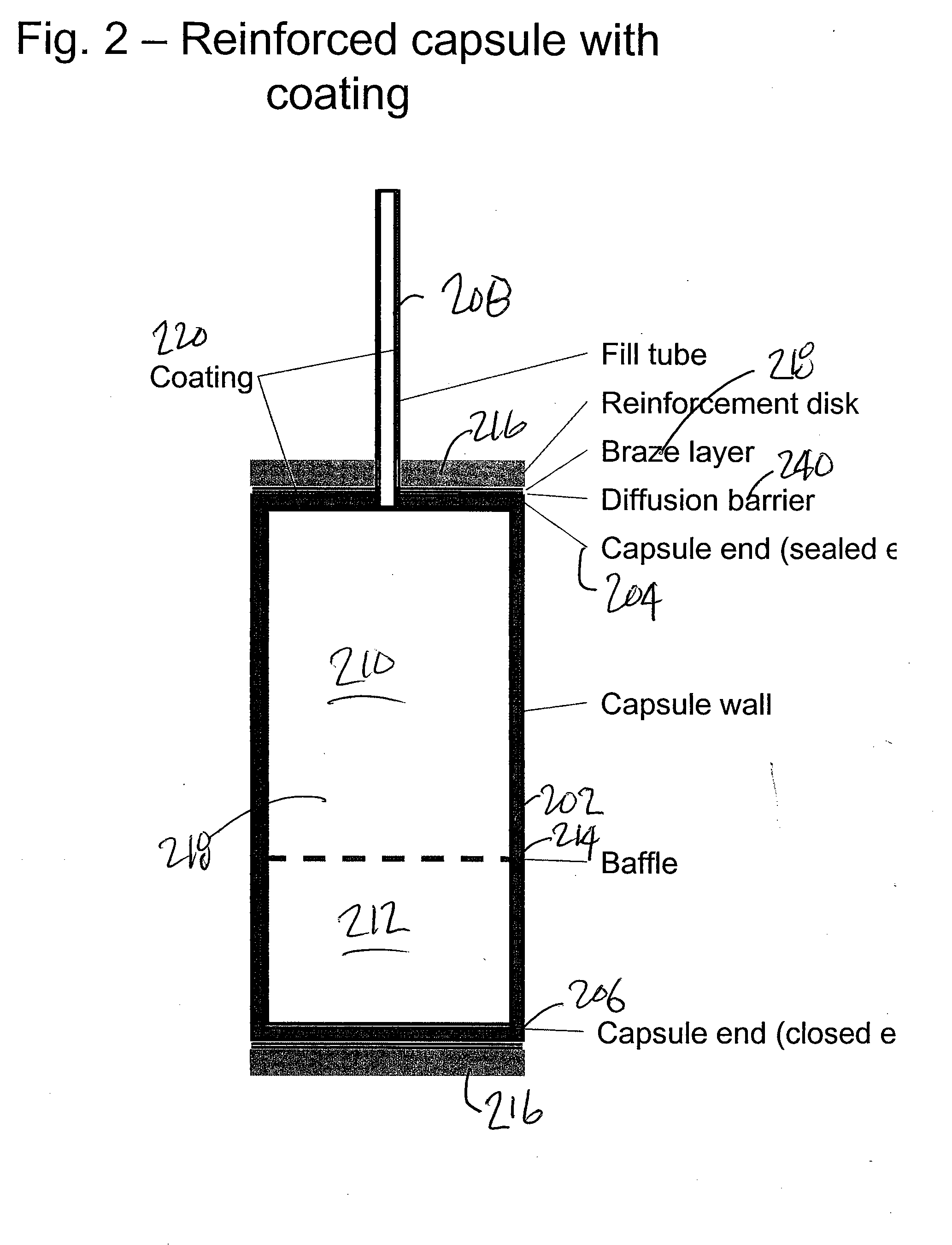

Capsule for high pressure processing and method of use for supercritical fluids

InactiveUS20090301388A1Large deformationImprove structural strengthPolycrystalline material growthFrom normal temperature solutionsHigh pressureBiology

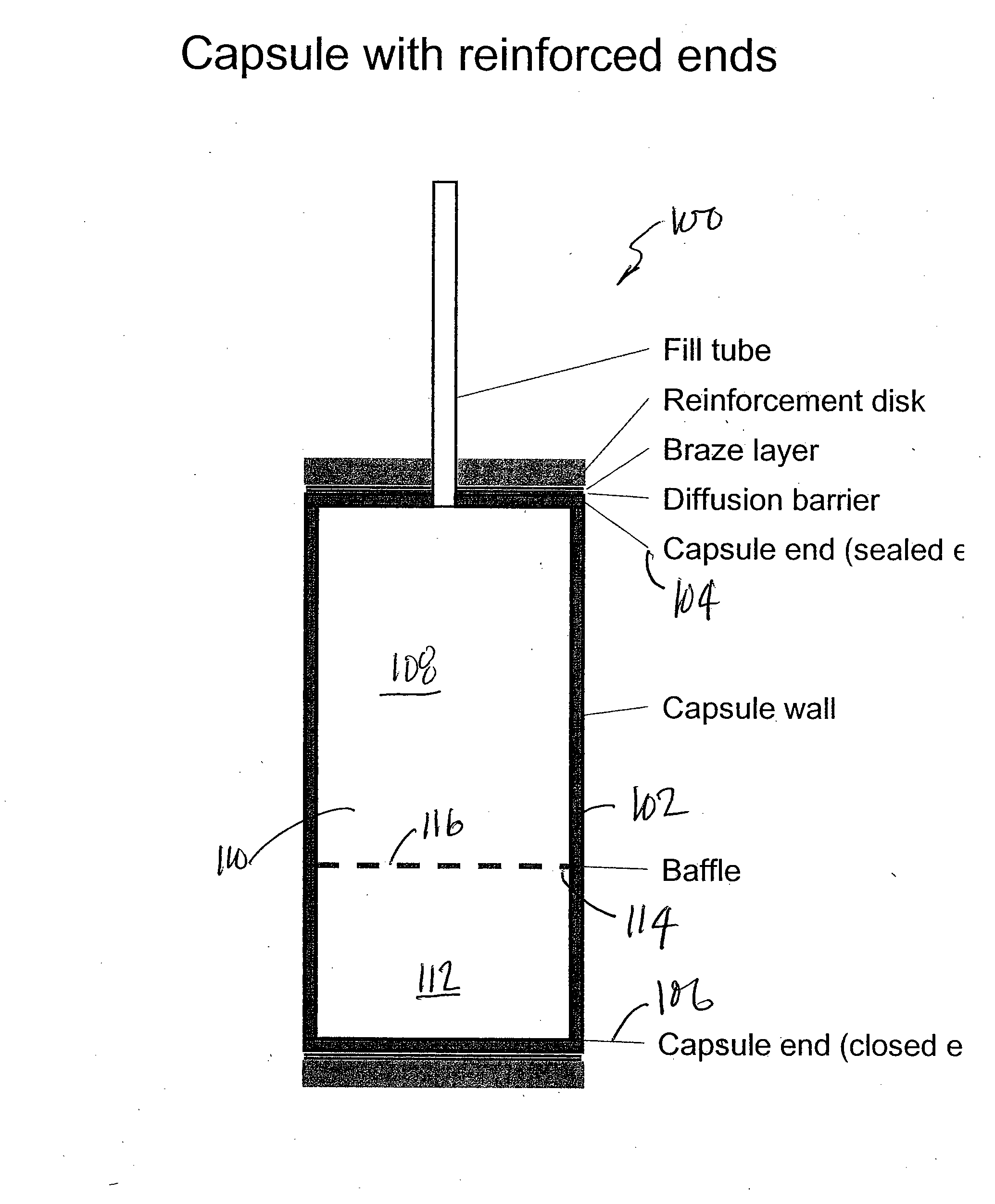

An improved capsule for processing materials or growing crystals in supercritical fluids. The capsule is scalable up to very large volumes and is cost effective according to a preferred embodiment. In conjunction with suitable high pressure apparatus, the capsule is capable of processing materials at pressures and temperatures of 0.2-8 GPa and 400-1500° C., respectively. Of course, there can be other variations, modifications, and alternatives.

Owner:SORAA

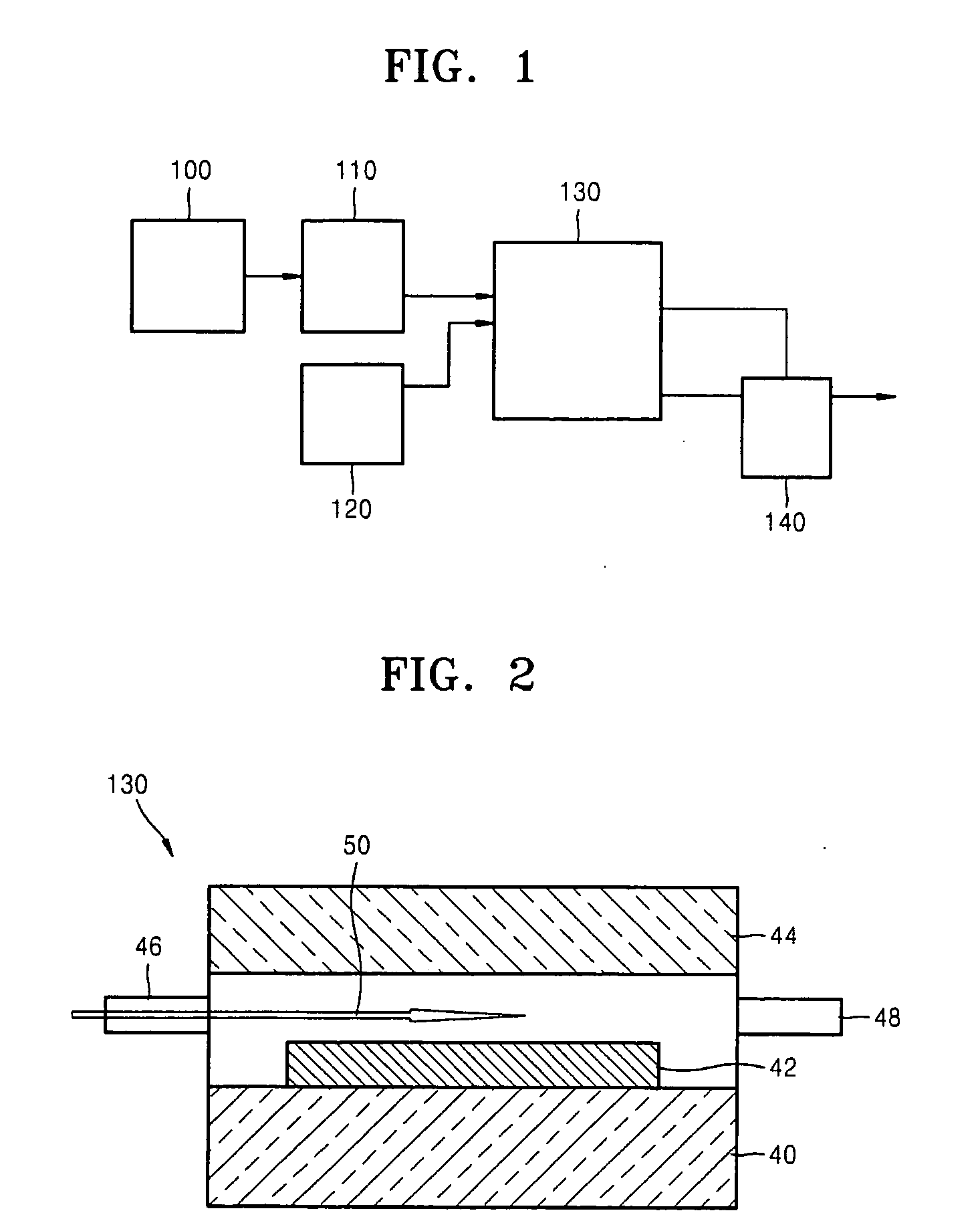

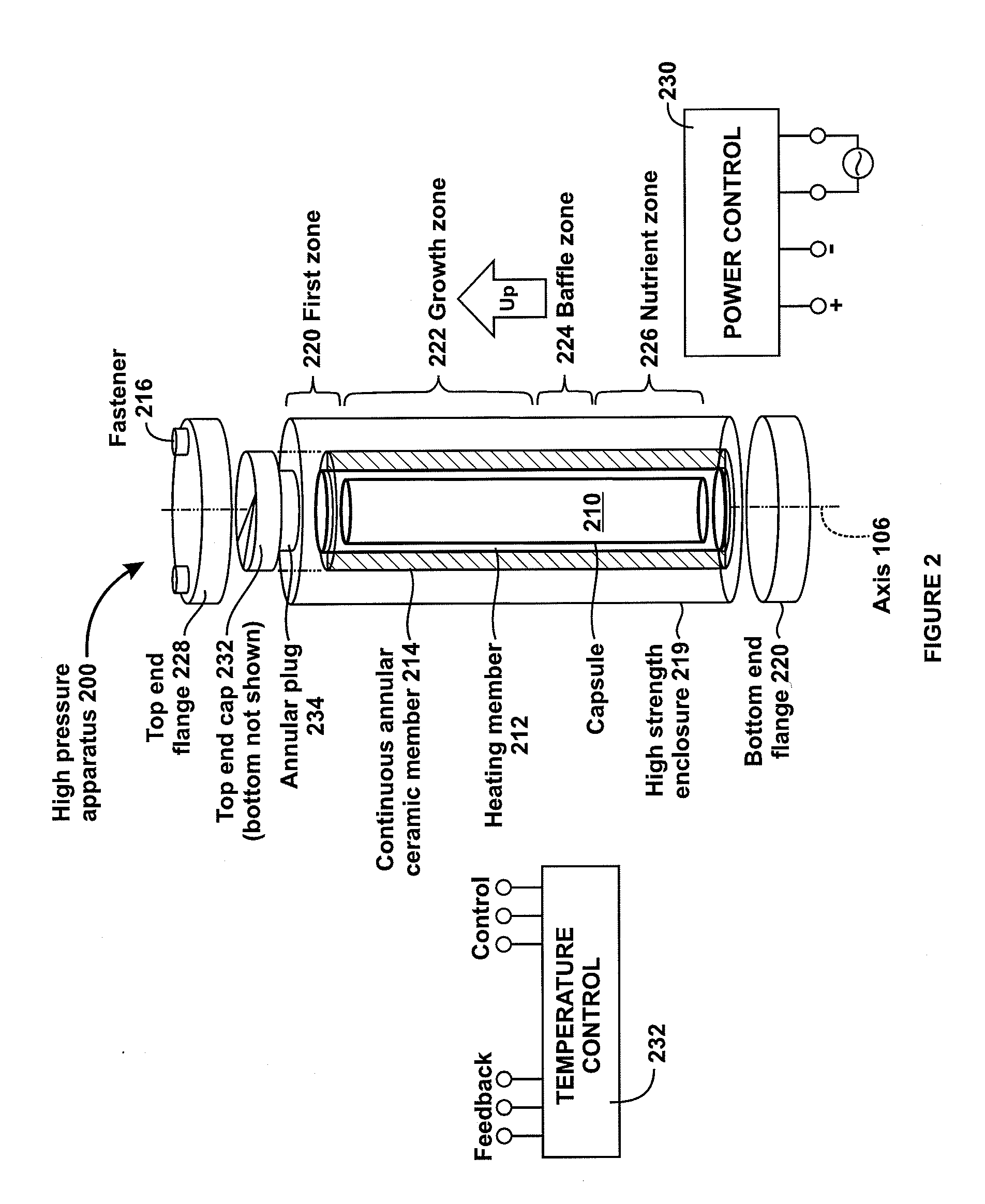

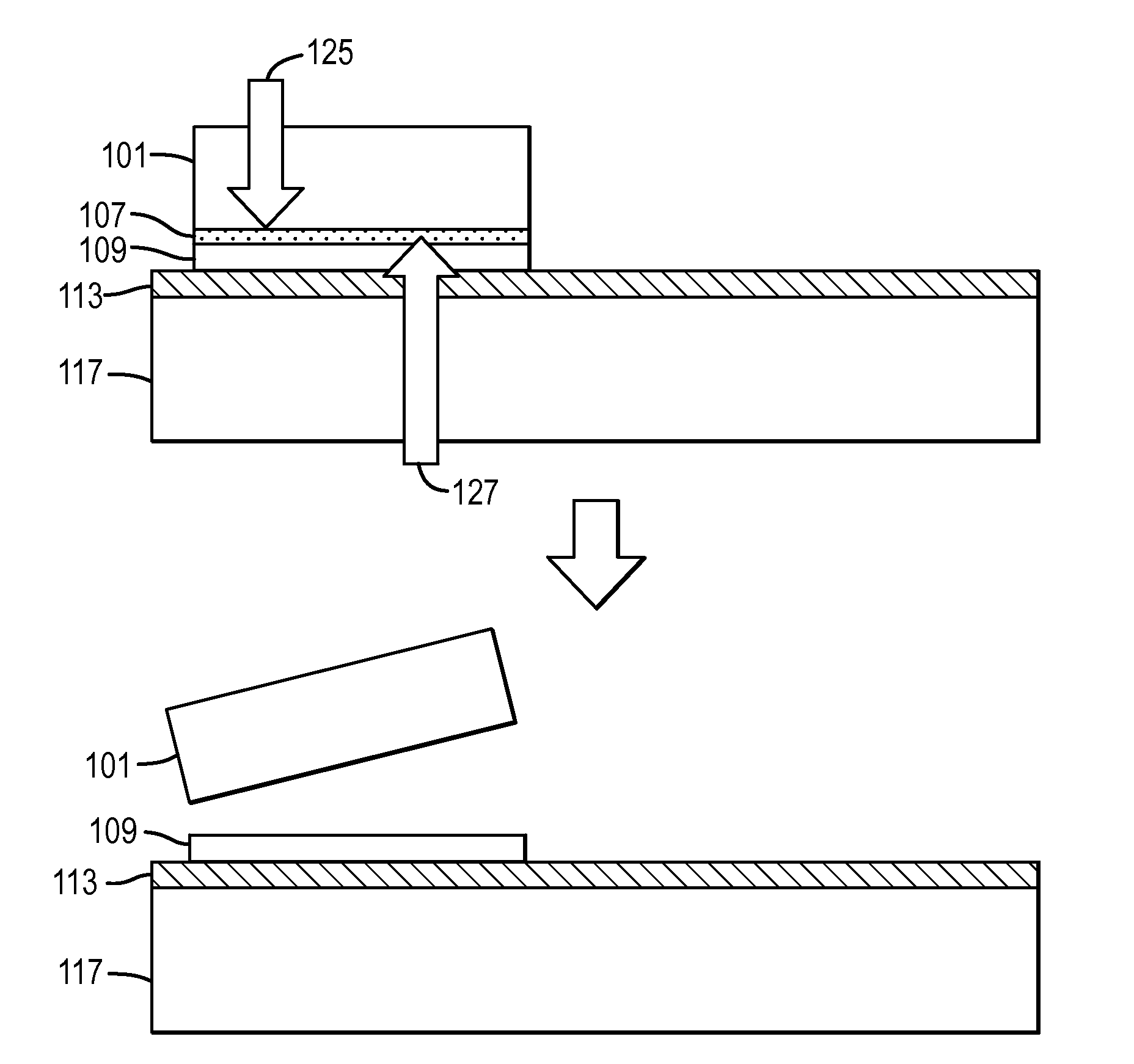

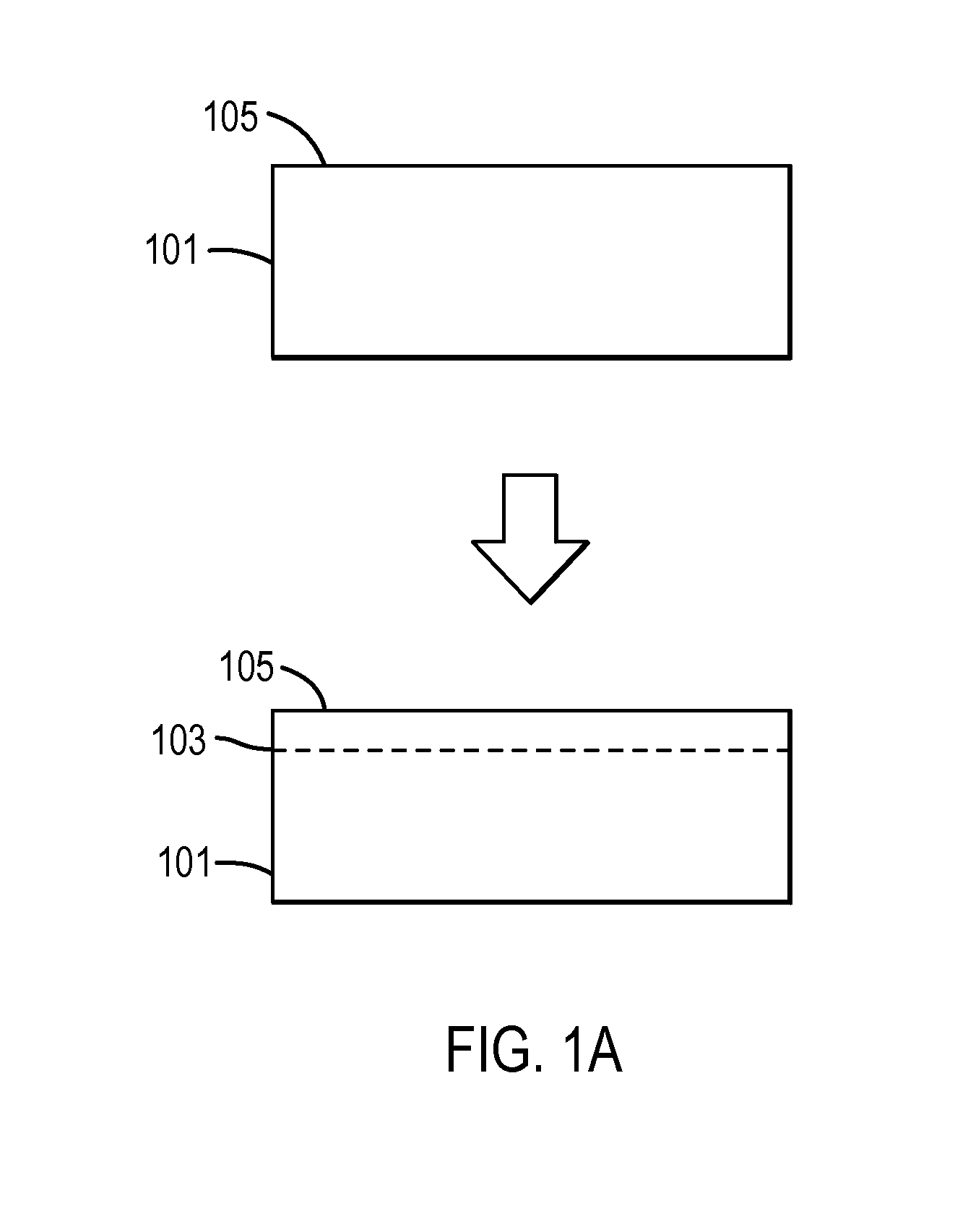

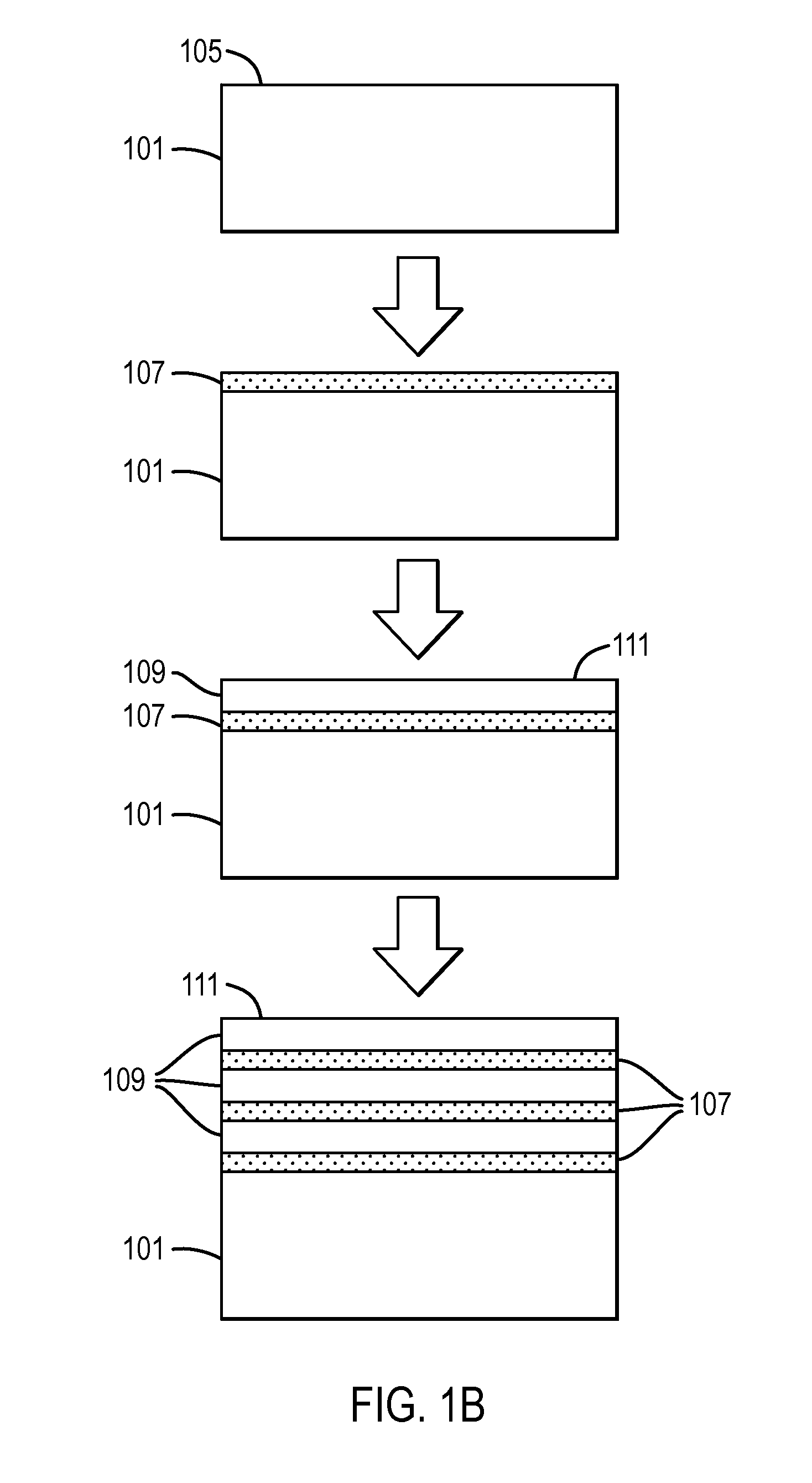

Material layer forming apparatus using supercritical fluid, material layer forming system comprising the same and method of forming material layer

InactiveUS20100092679A1Pretreated surfacesSemiconductor/solid-state device manufacturingInternal pressureEngineering

Provided are a material layer forming apparatus using a supercritical fluid, a material layer forming system including the apparatus, and a method of forming a material layer using the system. The material layer forming system may include a high pressure pump supplying a supercritical fluid to a precursor storage container and the material layer forming apparatus, and maintaining the internal pressure of the precursor storage container, a reactant material storage container at a pressure such that the supercritical fluid is in a supercritical state, and a material layer forming apparatus. The material layer forming system may further include a pressure gauge adjusting the pressure of the material layer forming apparatus. The precursor of the precursor storage container may be supplied to the material layer forming apparatus using the supercritical fluid.

Owner:SAMSUNG ELECTRONICS CO LTD

High pressure apparatus and method for nitride crystal growth

ActiveUS20090320744A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids. In a specific embodiment, the present apparatus includes a capsule, a heater, at least one ceramic ring but can be multiple rings, optionally, with one or more scribe marks and / or cracks present. In a specific embodiment, the apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. In a specific embodiment, the apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SLT TECH

Precision surface treatments using dense fluids and a plasma

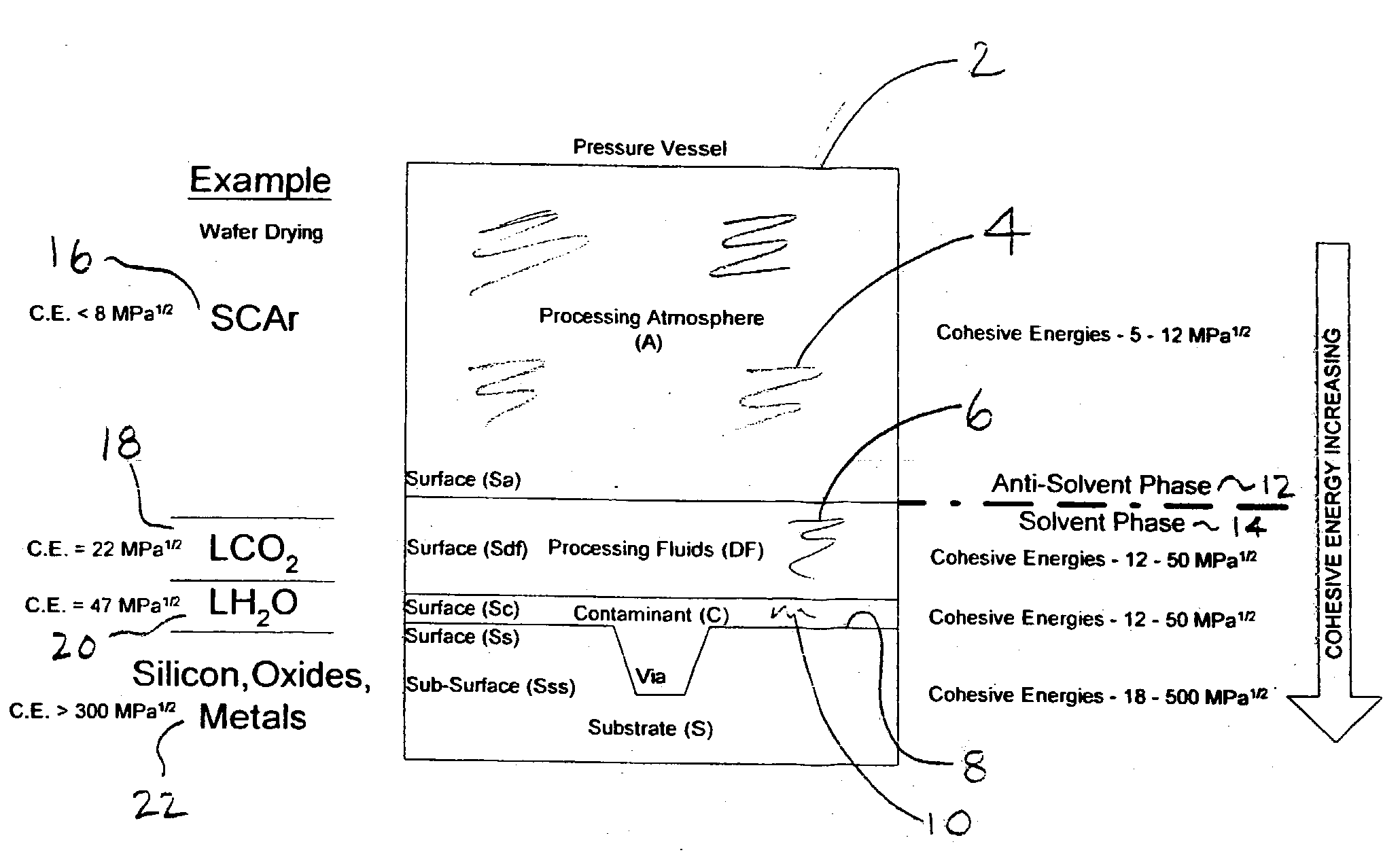

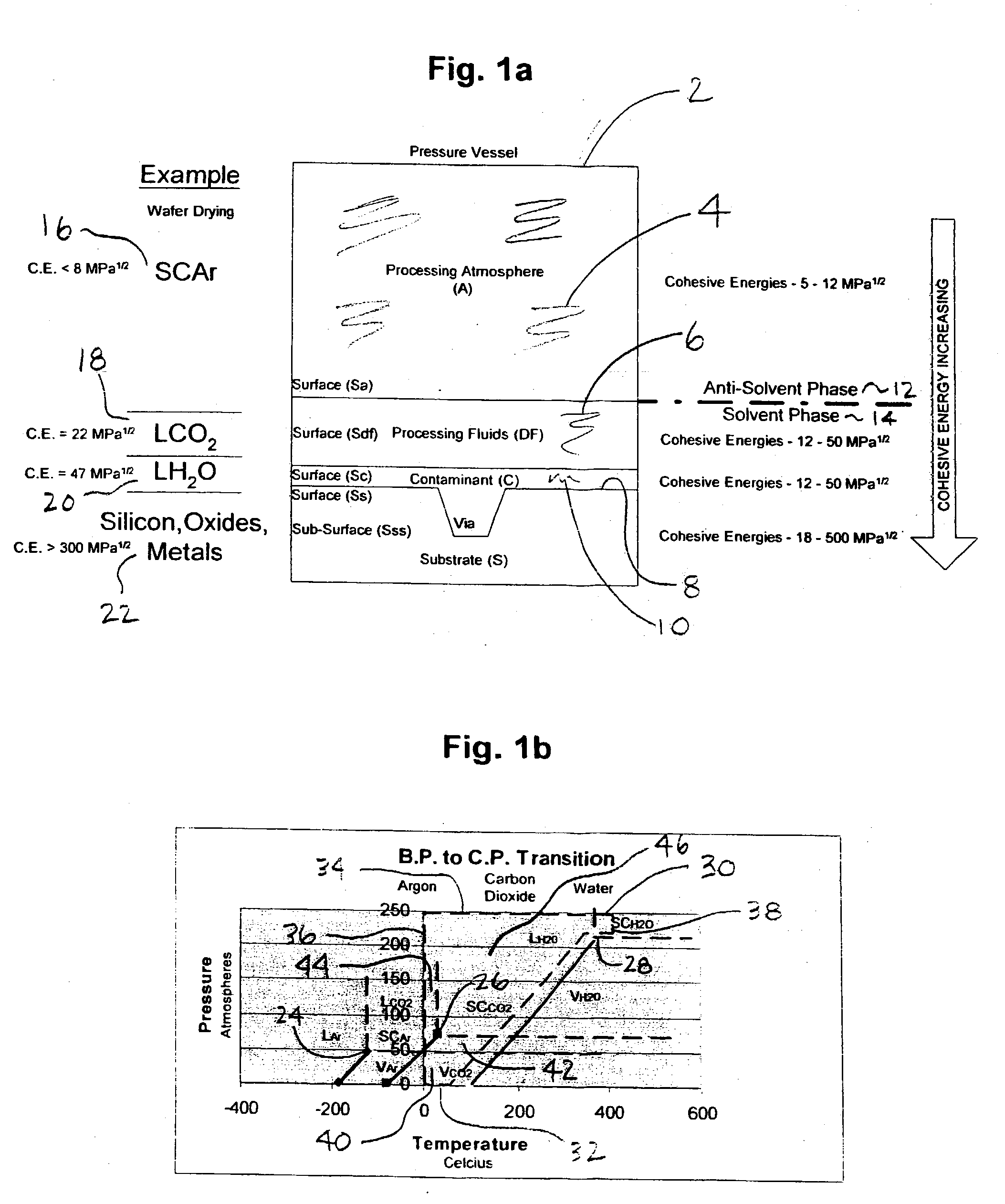

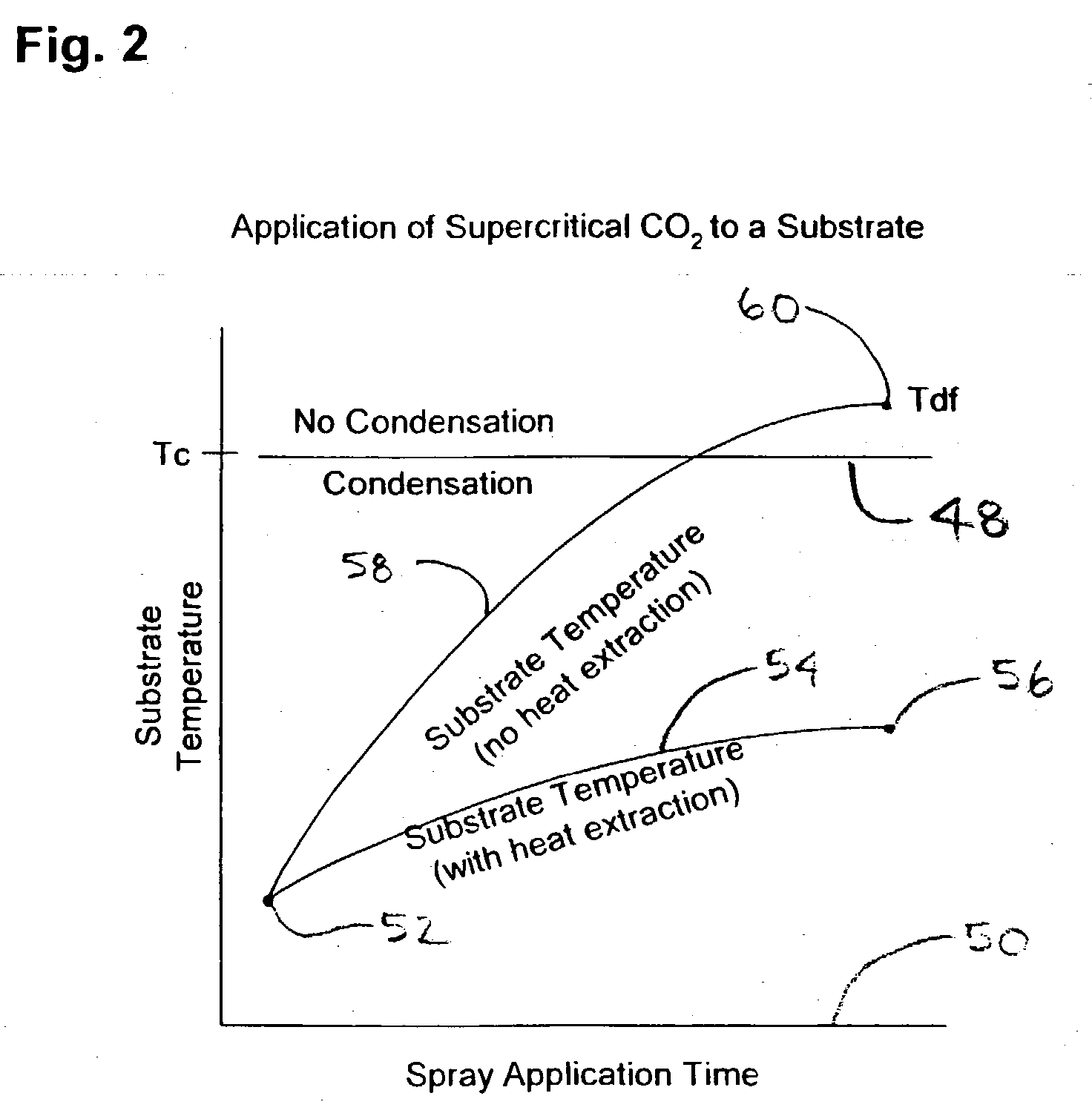

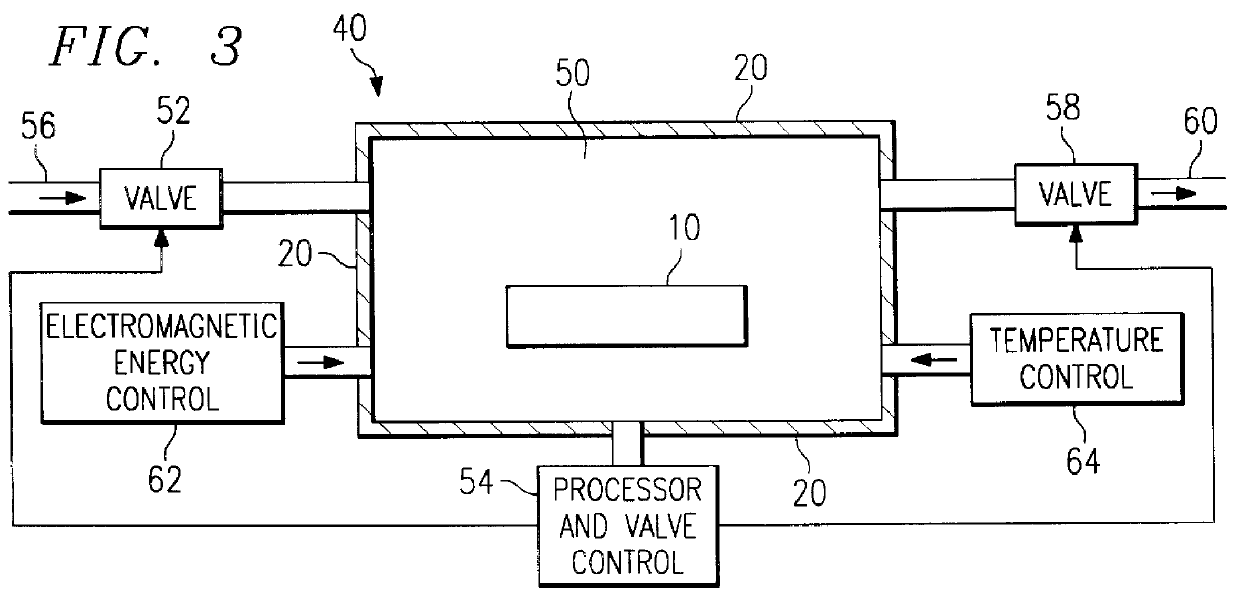

InactiveUS20040003828A1Reduce the temperatureEasy to separateElectric discharge tubesElectrostatic cleaningSolventSolid phases

The present invention is a method, process and apparatus for selective cleaning, drying, and modifying substrate surfaces and depositing thin films thereon using a dense phase gas solvent and admixtures within a first created supercritical fluid antisolvent. Dense fluids are used in combination with sub-atmospheric, atmospheric and super-atmospheric plasma adjuncts (cold and thermal plasmas) to enhance substrate surface cleaning, modification, precision drying and deposition processes herein. Moreover, conventional wet cleaning agents such as hydrofluoric acid and ammonium fluoride may be used with the present invention to perform substrate pre-treatments prior to precision drying and cleaning treatments described herein. Finally, dense fluid such as solid phase carbon dioxide and argon may be used as a follow-on treatment or in combination with plasmas to further treat a substrate surface.

Owner:JACKSON DAVID P

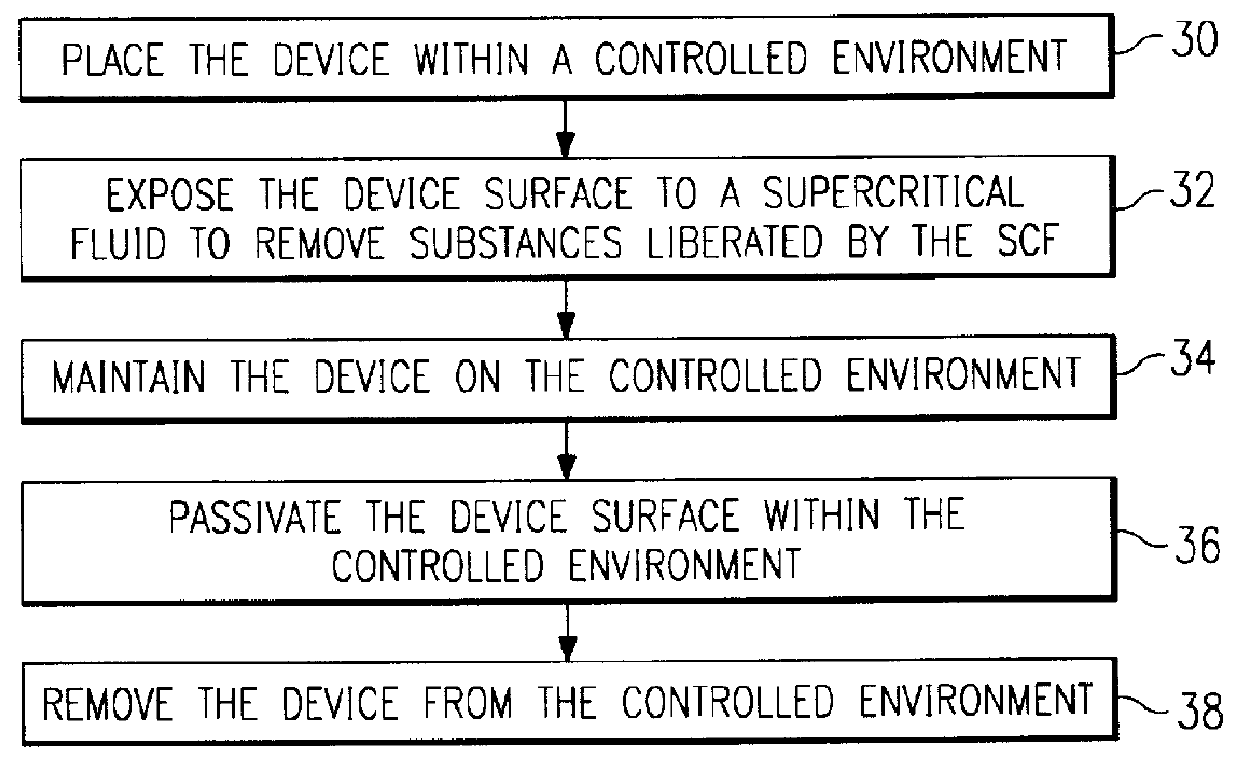

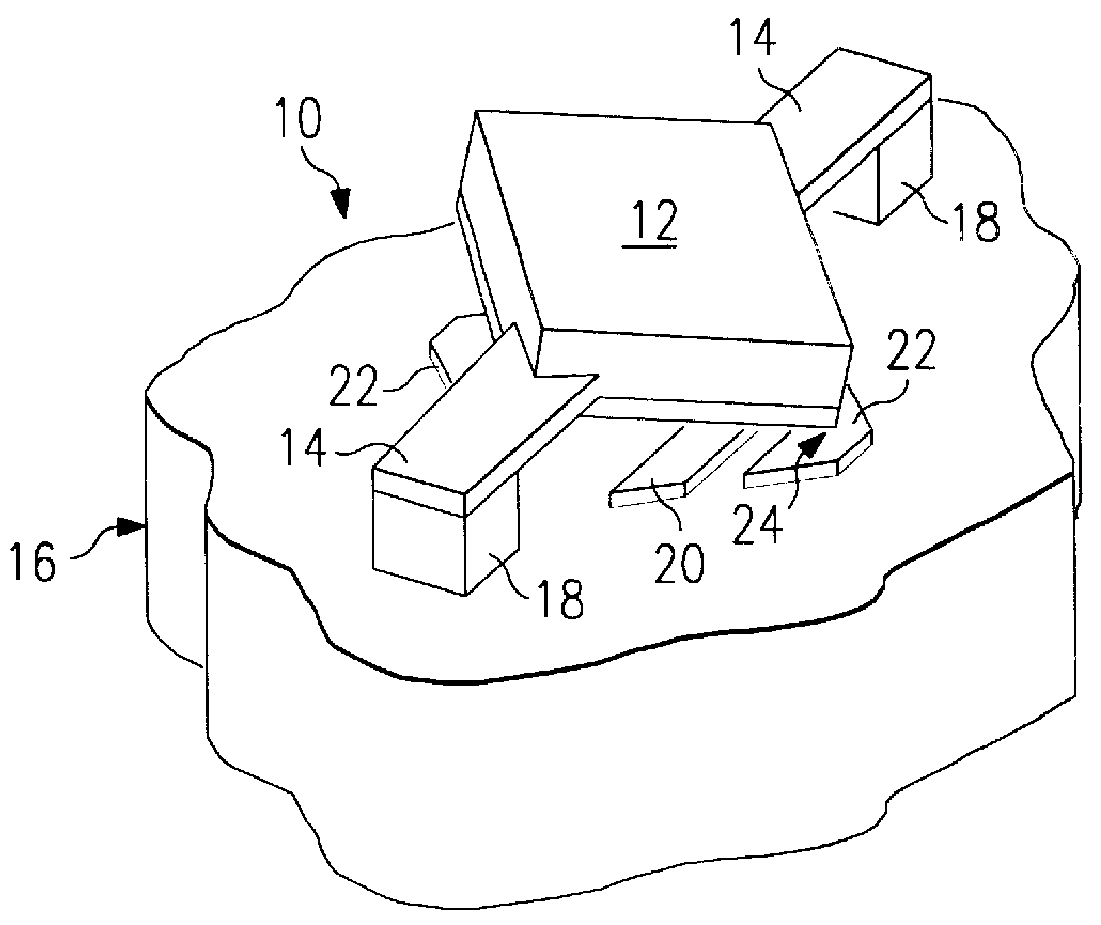

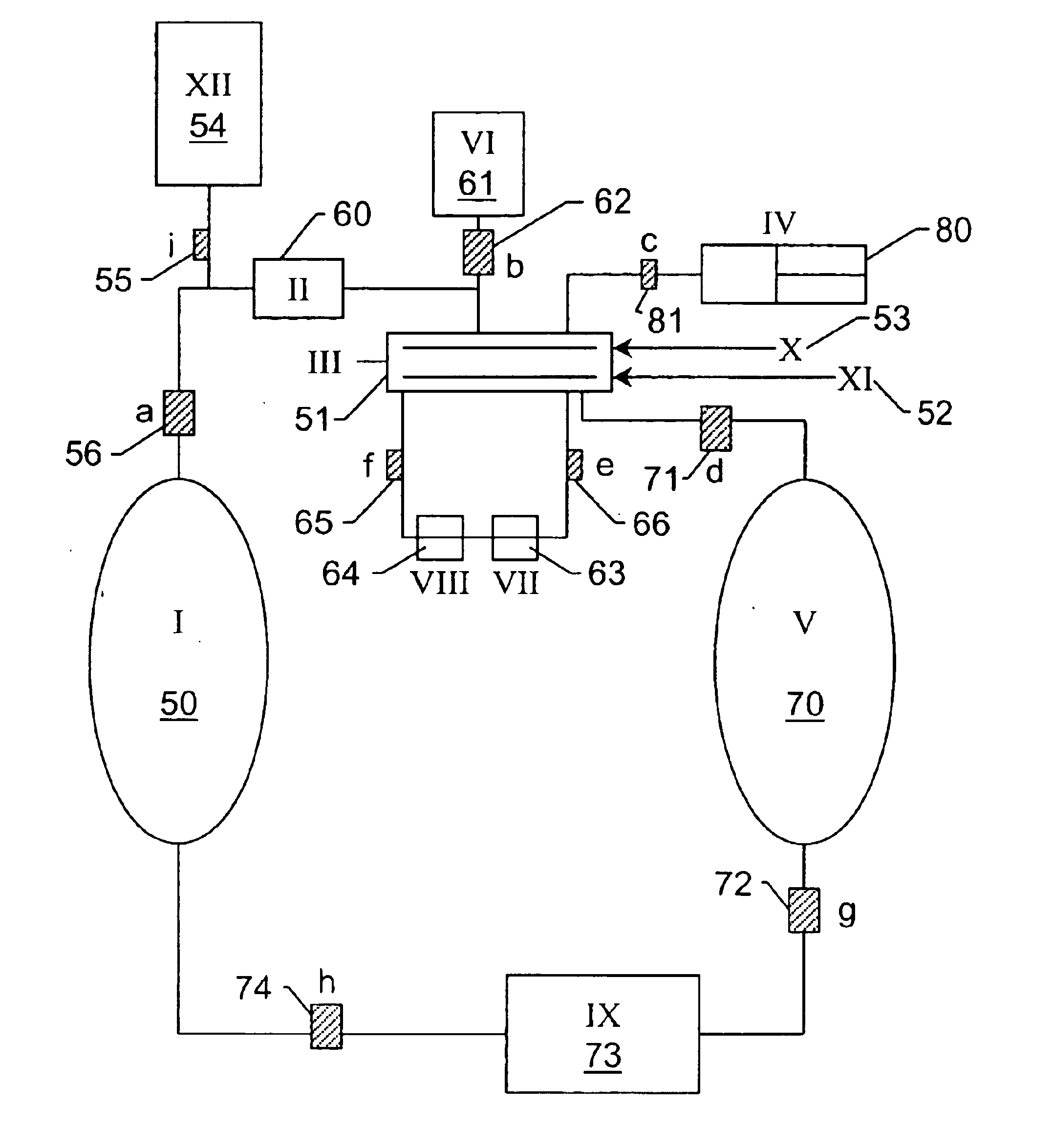

Method of cleaning and treating a semiconductor device including a micromechanical device

InactiveUS6024801ADecorative surface effectsSemiconductor/solid-state device manufacturingChemical compoundEngineering

A method of cleaning and treating a device, including those of the micromechanical (10) and semiconductor type. The surface of a device, such as the landing electrode (22) of a digital micromirror device (10), is first cleaned with a supercritical fluid (SCF) in a chamber (50) to remove soluble chemical compounds, and then maintained in the SCF chamber until and during the subsequent passivation step. Passivants including PFDA and PFPE are suitable for the present invention. By maintaining the device in the SCF chamber, and without exposing the device to, for instance, the ambient of a clean room, organic and inorganic contaminants cannot be deposited upon the cleaned surface prior to the passivation step. The present invention derives technical advantages by providing an improved passivated surface that is suited to extend the useful operation life of devices, including those of the micromechanical type, reducing stiction forces between contacting elements such as a mirror and its landing electrode. The present invention is also suitable for cleaning and passivating other surfaces including a surface of semiconductor wafers, and the surface of a hard disk memory drive.

Owner:TEXAS INSTR INC

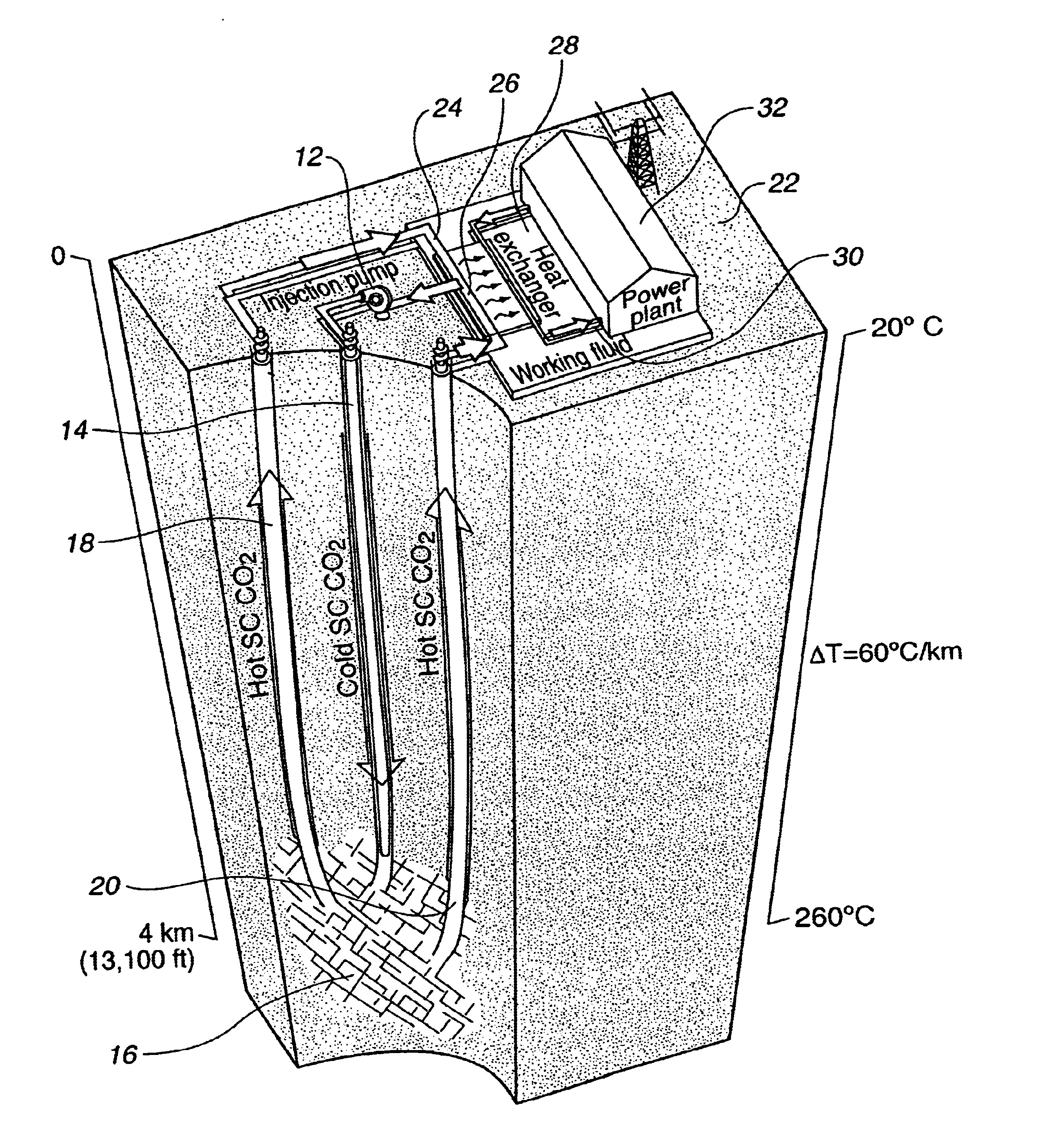

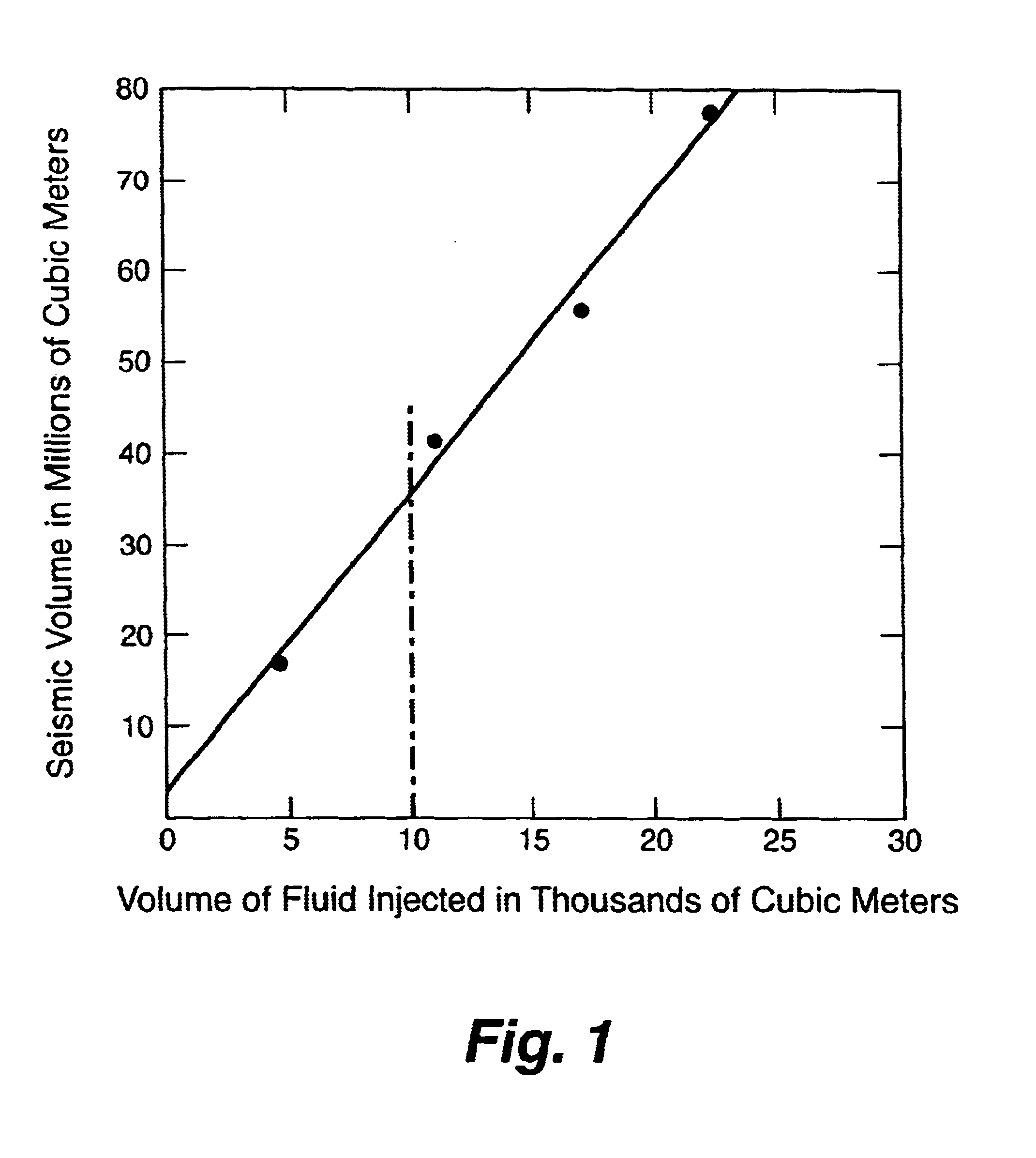

Geothermal energy production with supercritical fluids

InactiveUS6668554B1Other heat production devicesGeothermal energy generationProcess engineeringCarbon dioxide

There has been invented a method for producing geothermal energy using supercritical fluids for creation of the underground reservoir, production of the geothermal energy, and for heat transport. Underground reservoirs are created by pumping a supercritical fluid such as carbon dioxide into a formation to fracture the rock. Once the reservoir is formed, the same supercritical fluid is allowed to heat up and expand, then is pumped out of the reservoir to transfer the heat to a surface power generating plant or other application.

Owner:RGT UNIV OF CALIFORNIA LOS ALAMOS NAT LAB +1

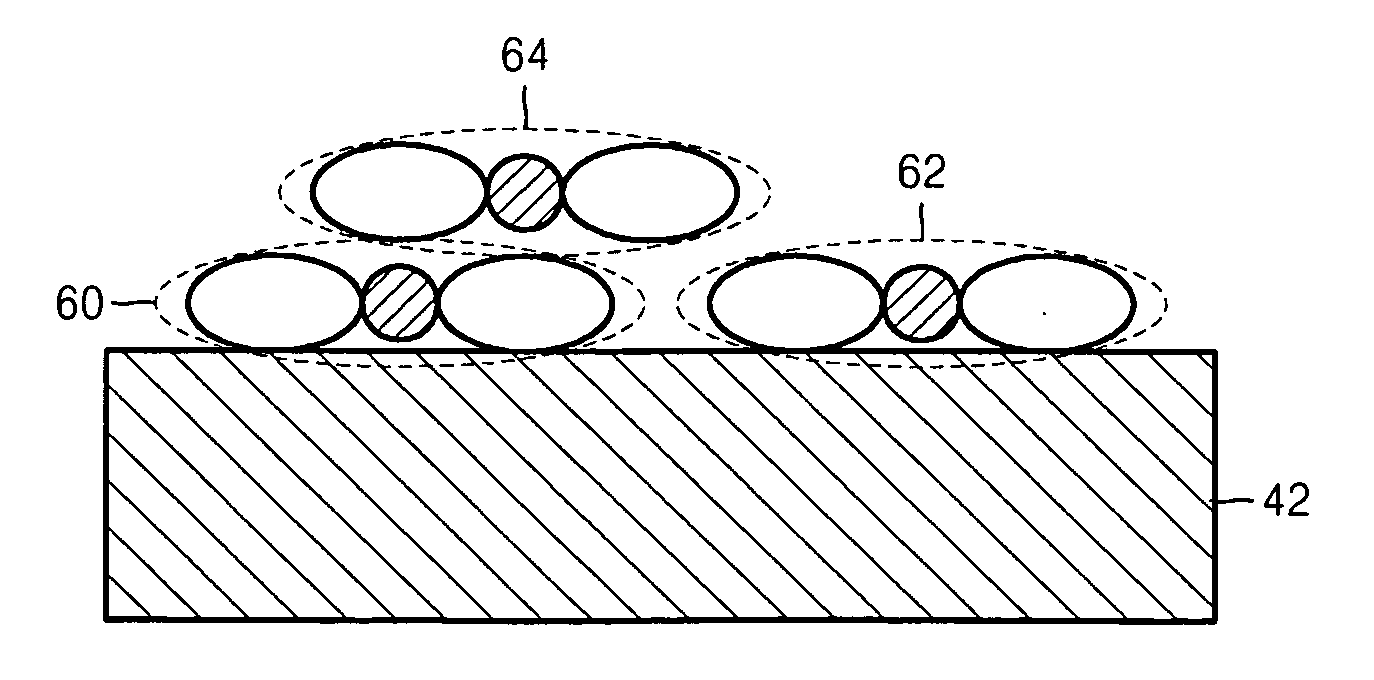

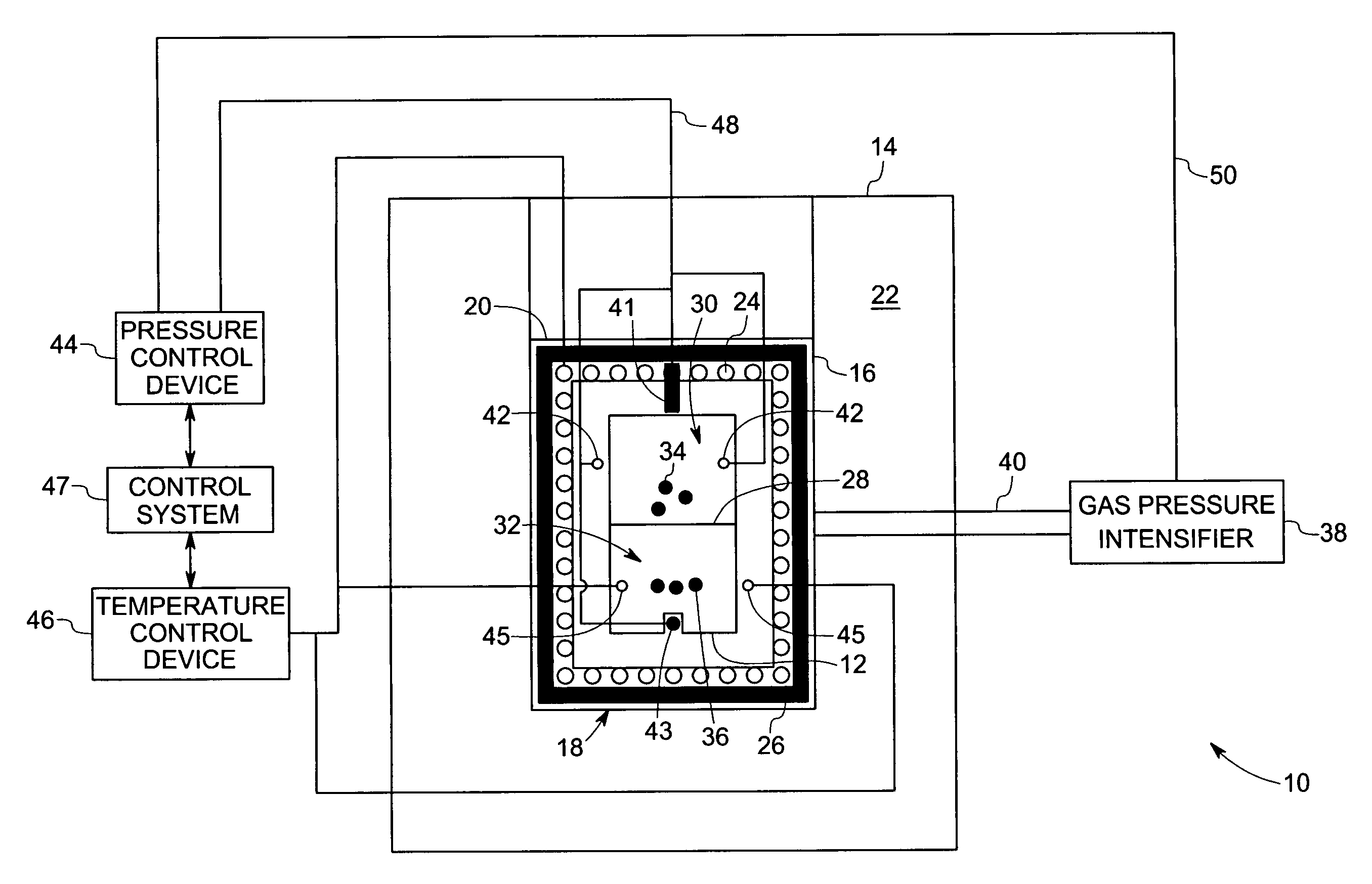

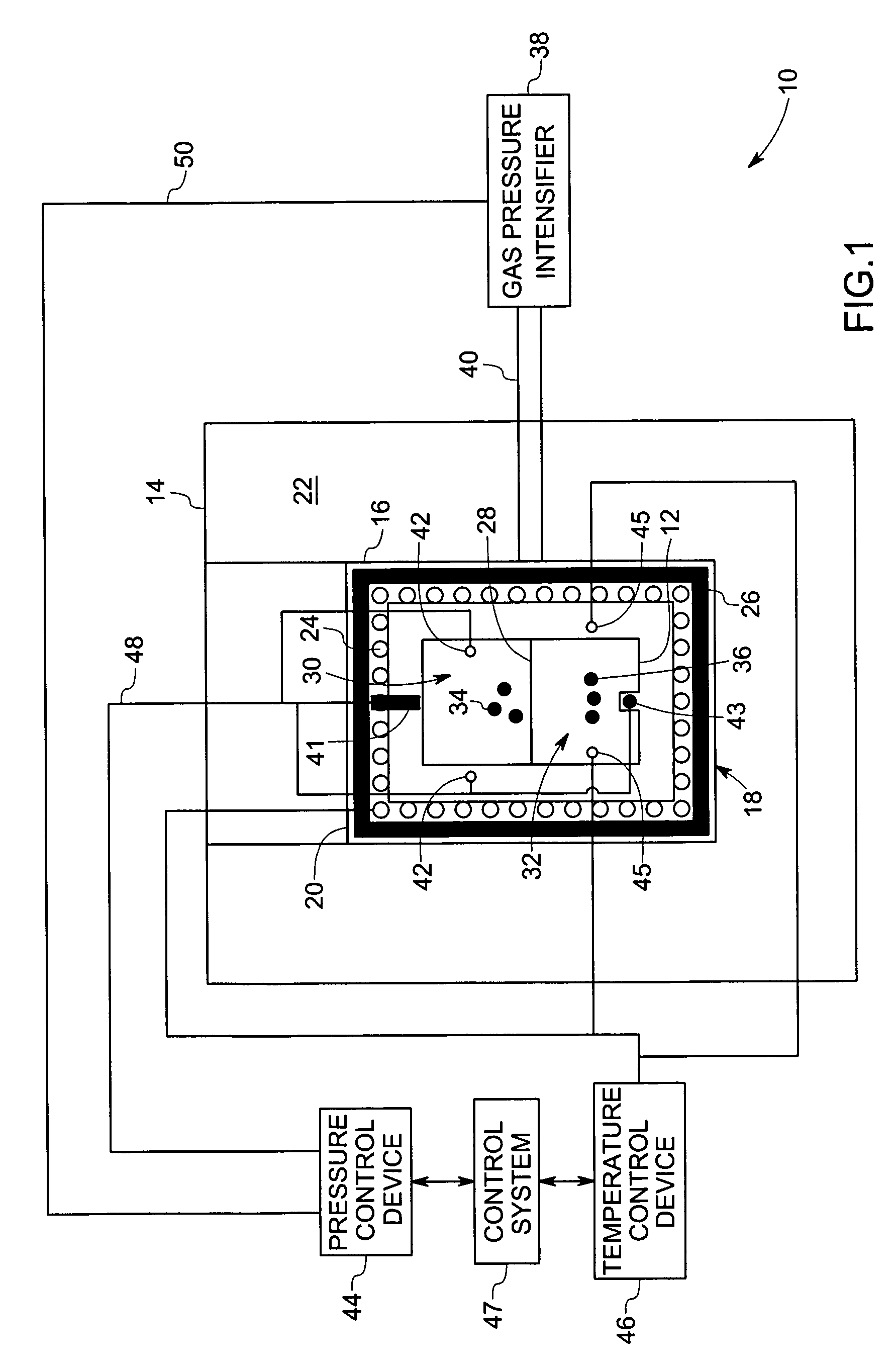

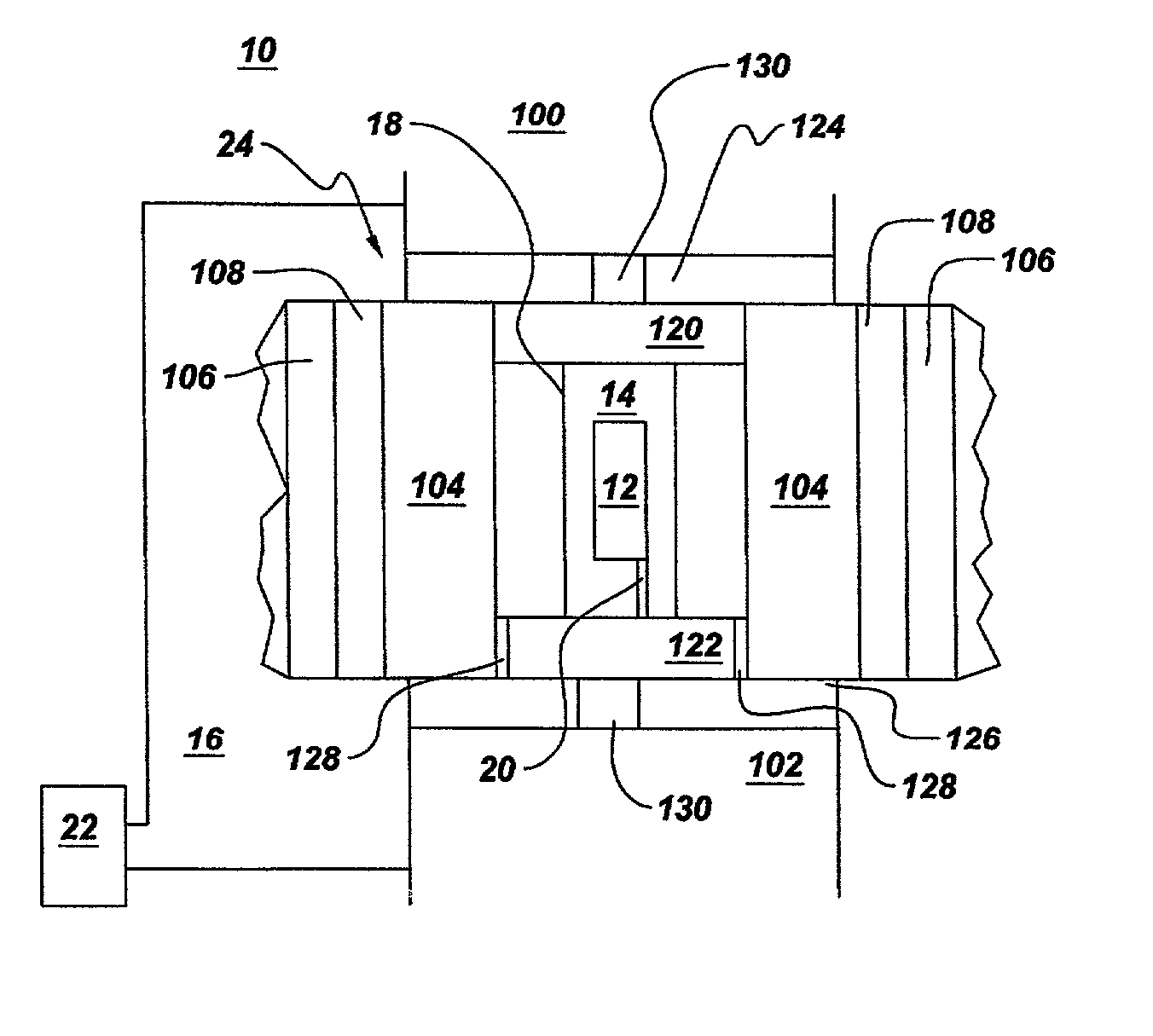

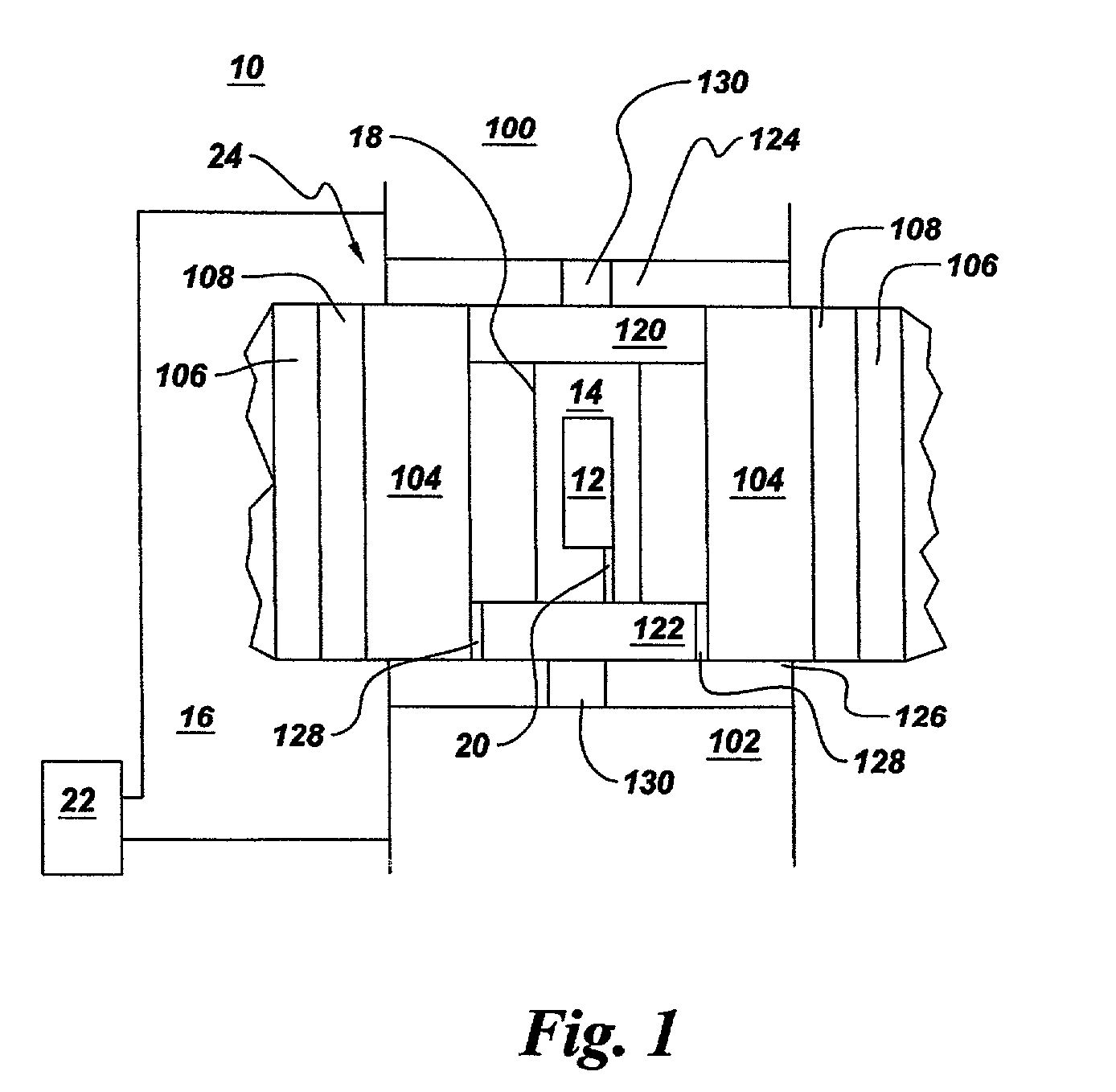

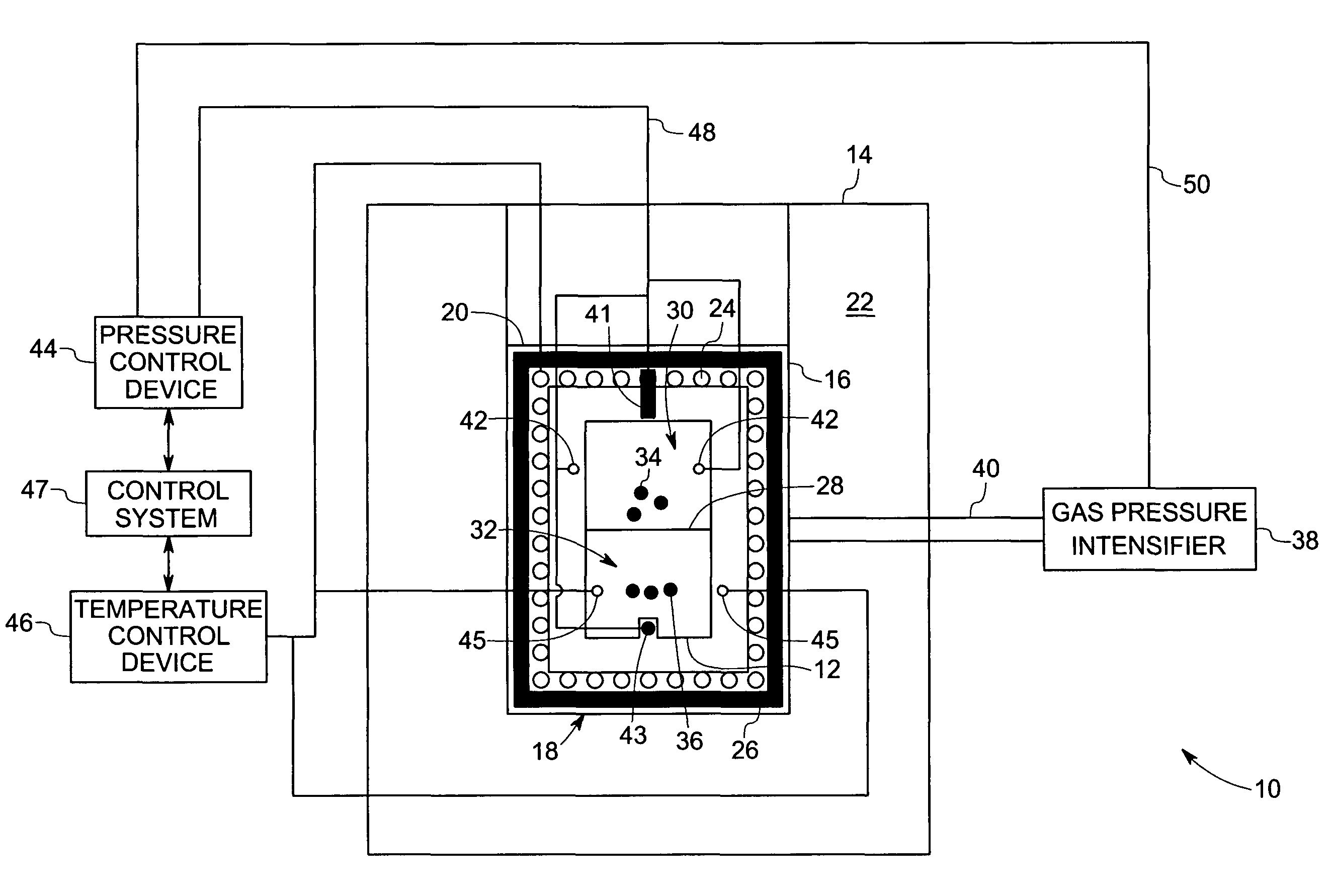

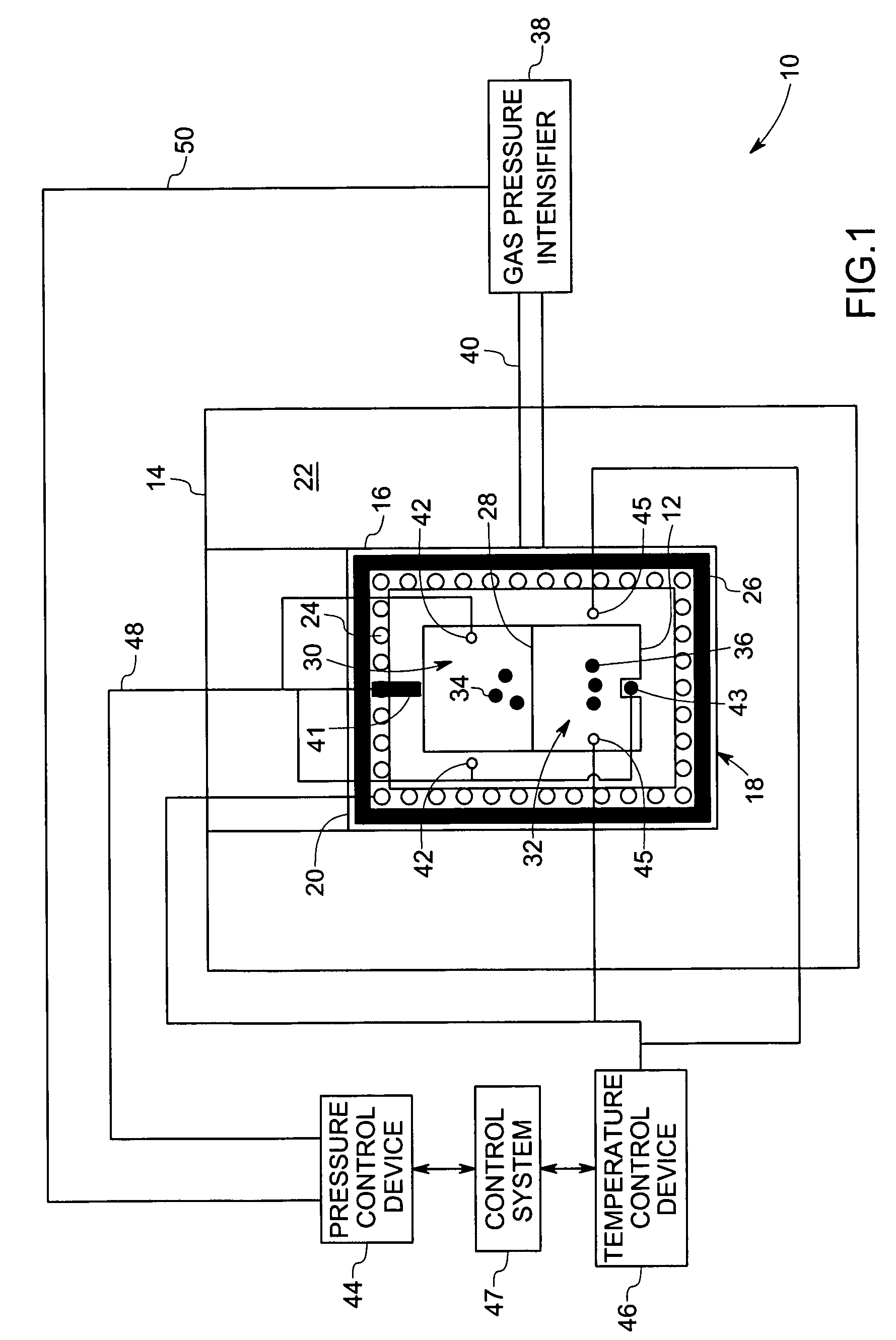

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS20060177362A1After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

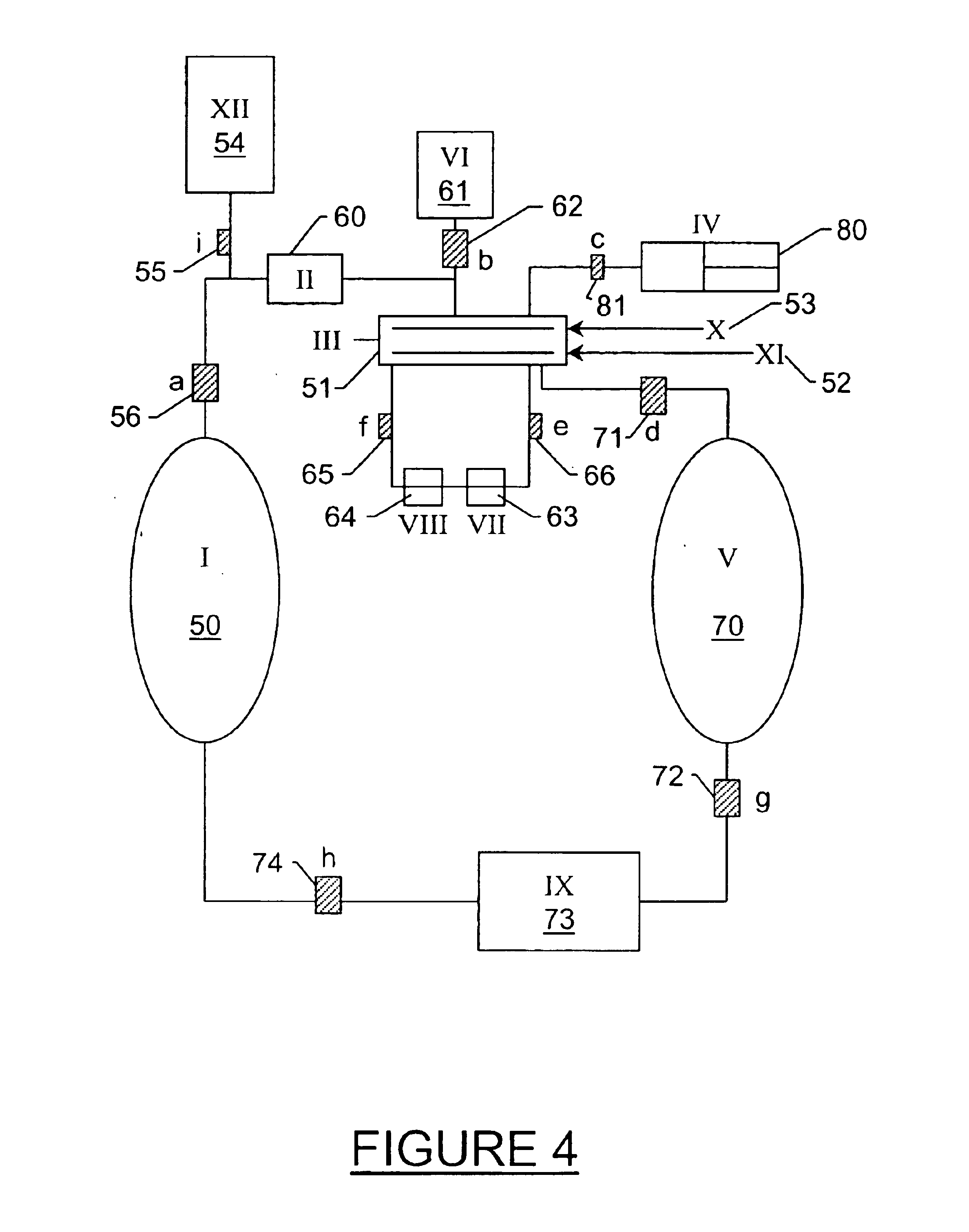

Apparatus and methods for processing semiconductor substrates using supercritical fluids

InactiveUS6848458B1Ease in introductionHigh removal rateSemiconductor/solid-state device manufacturingElectrostatic cleaningLiquid stateCompound (substance)

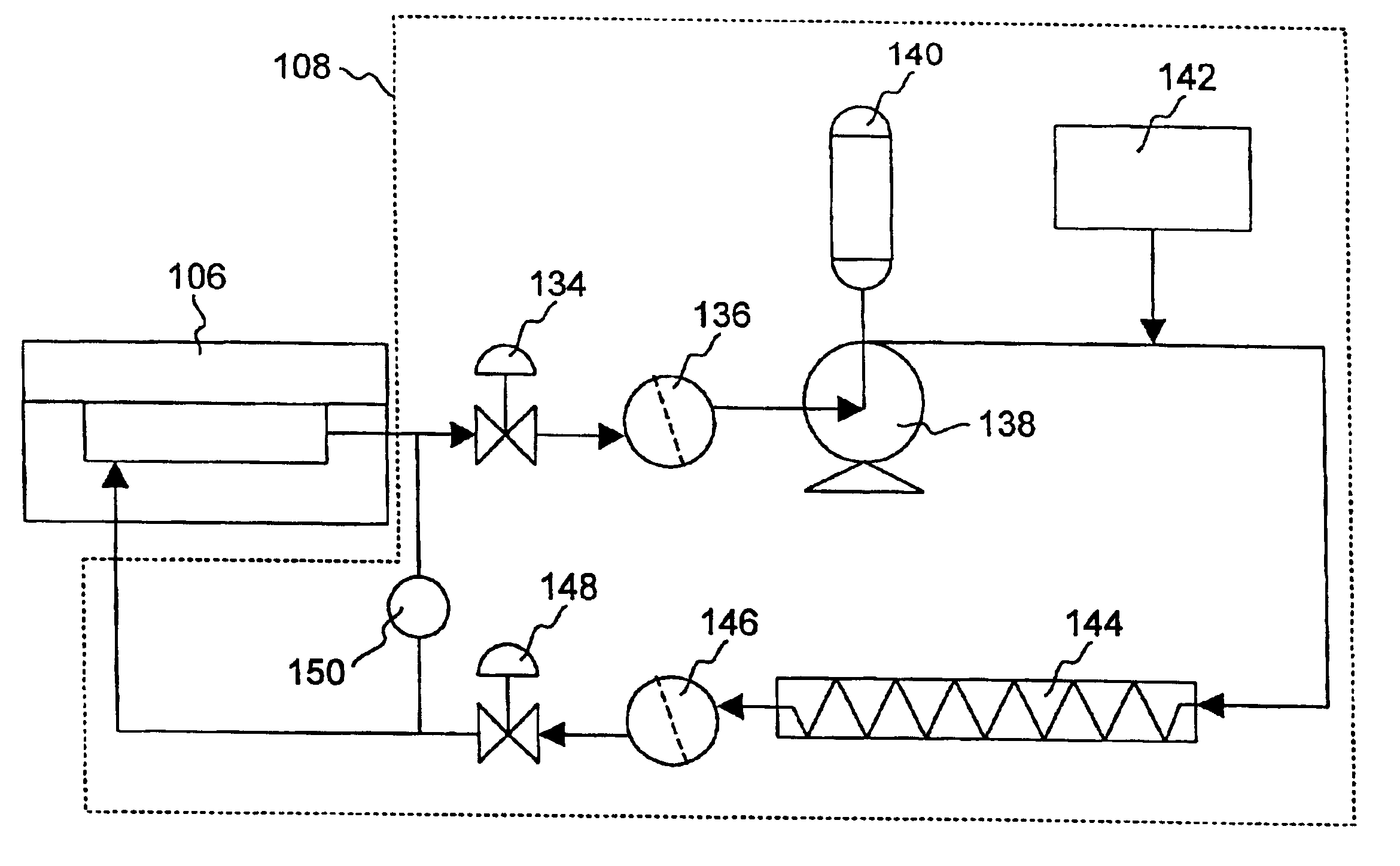

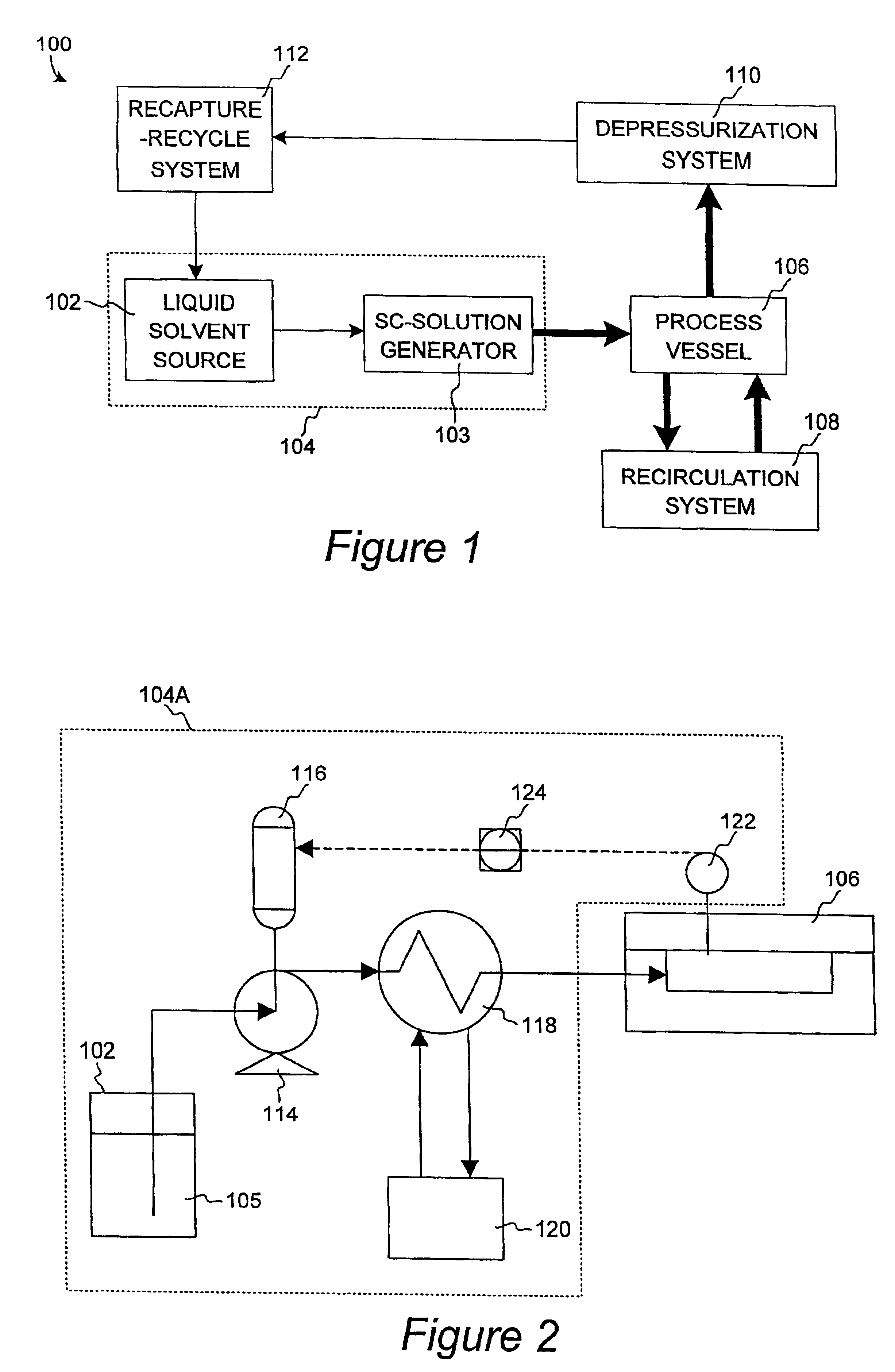

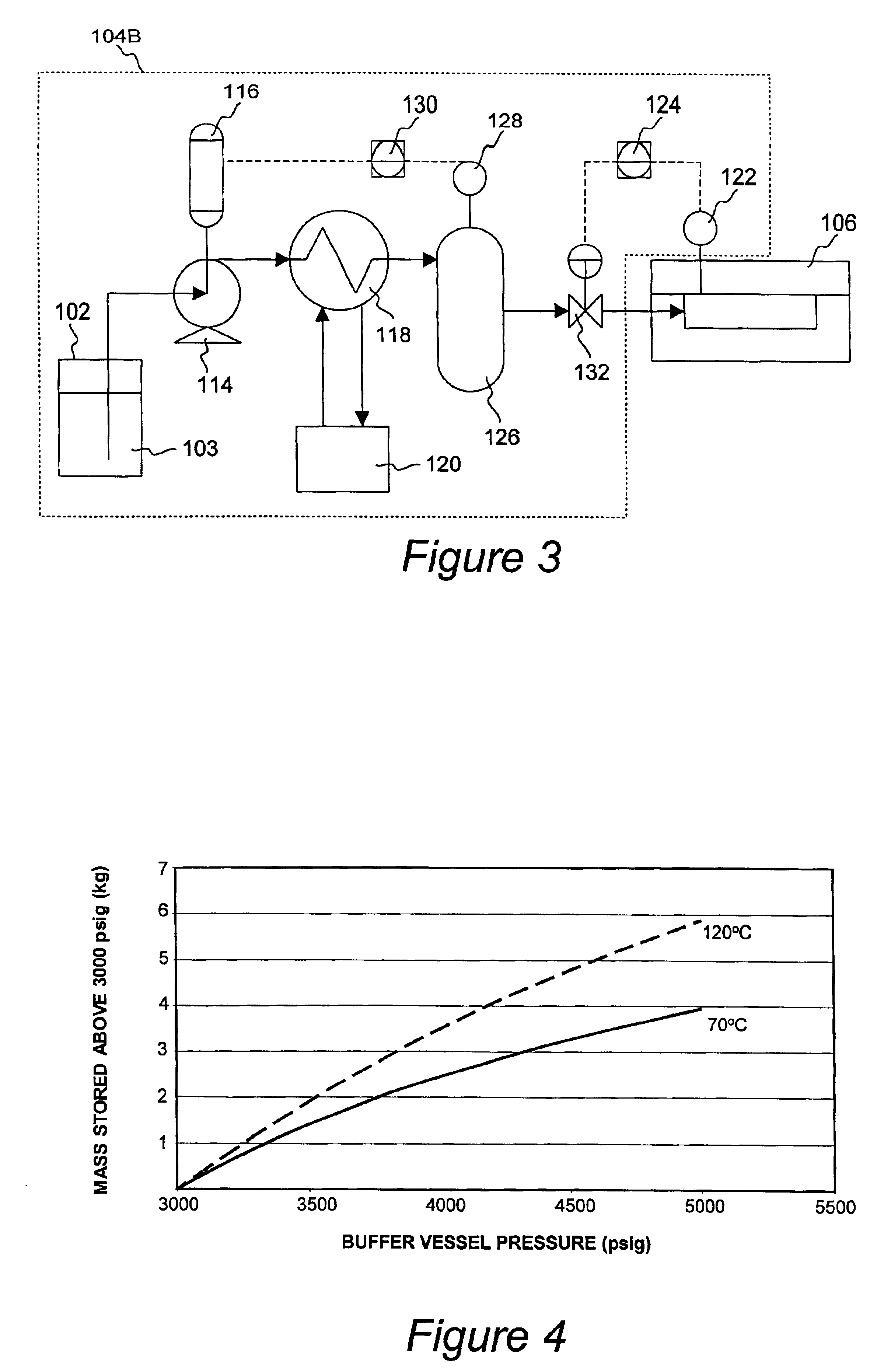

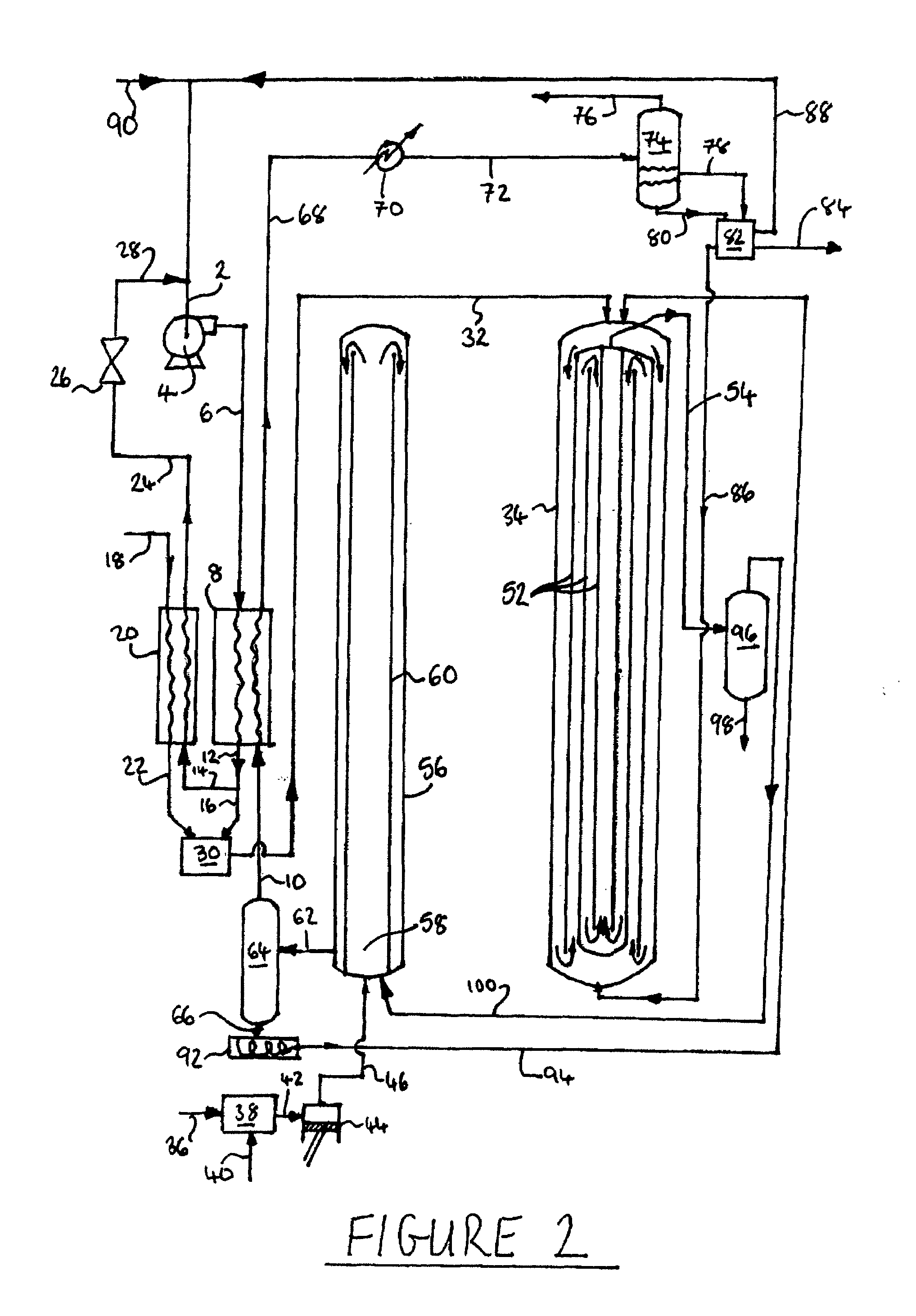

The present invention pertains to a system for cleaning wafers that includes specialized pressurization, process vessel, recirculation, chemical addition, depressurization, and recapture-recycle subsystems, as well as methods for implementing wafer cleaning using such a system. A solvent delivery mechanism converts a liquid-state sub-critical solution to a supercritical cleaning solution and introduces it into a process vessel that contains a wafer or wafers. The supercritical cleaning solution is recirculated through the process vessel by a recirculation system. An additive delivery system introduces chemical additives to the supercritical cleaning solution via the solvent delivery mechanism, the process vessel, or the recirculation system. Addition of chemical additives to the sub-critical solution may also be performed. The recirculation system provides efficient mixing of chemical additives, efficient cleaning, and process uniformity. A depressurization system provides dilution and removal of cleaning solutions under supercritical conditions. A recapture-recycle system introduces captured-purified solvents into the solvent delivery mechanism.

Owner:NOVELLUS SYSTEMS

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

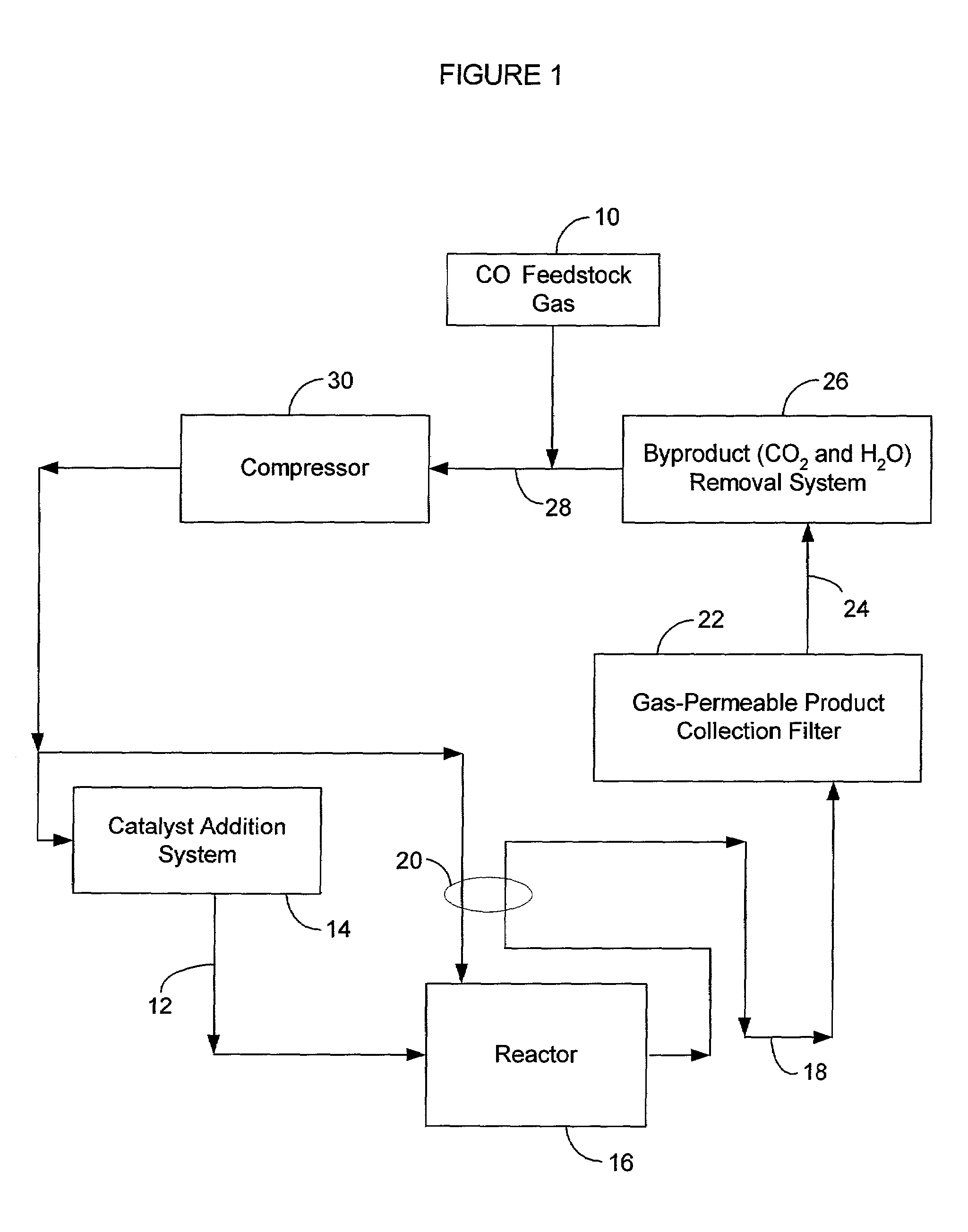

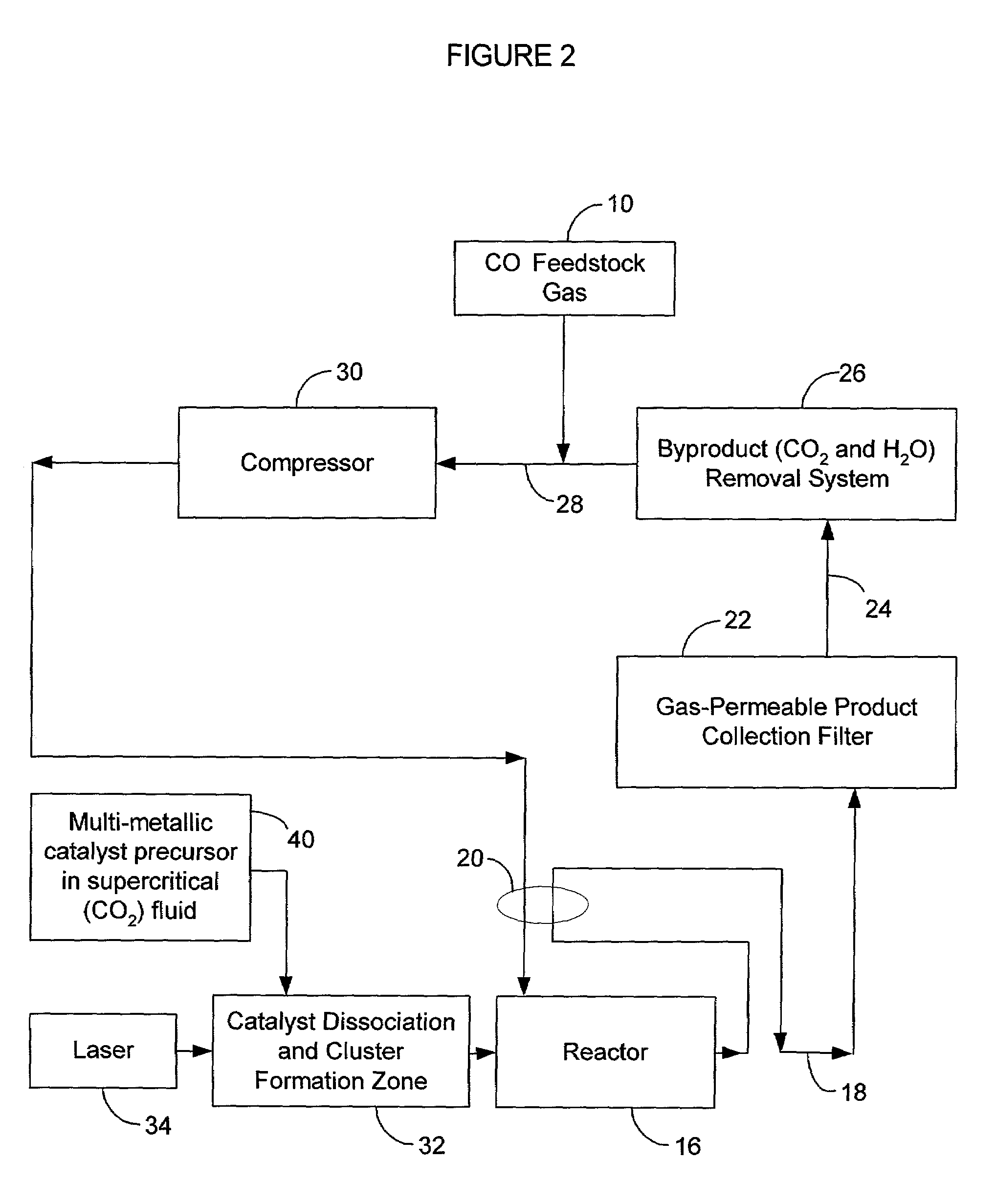

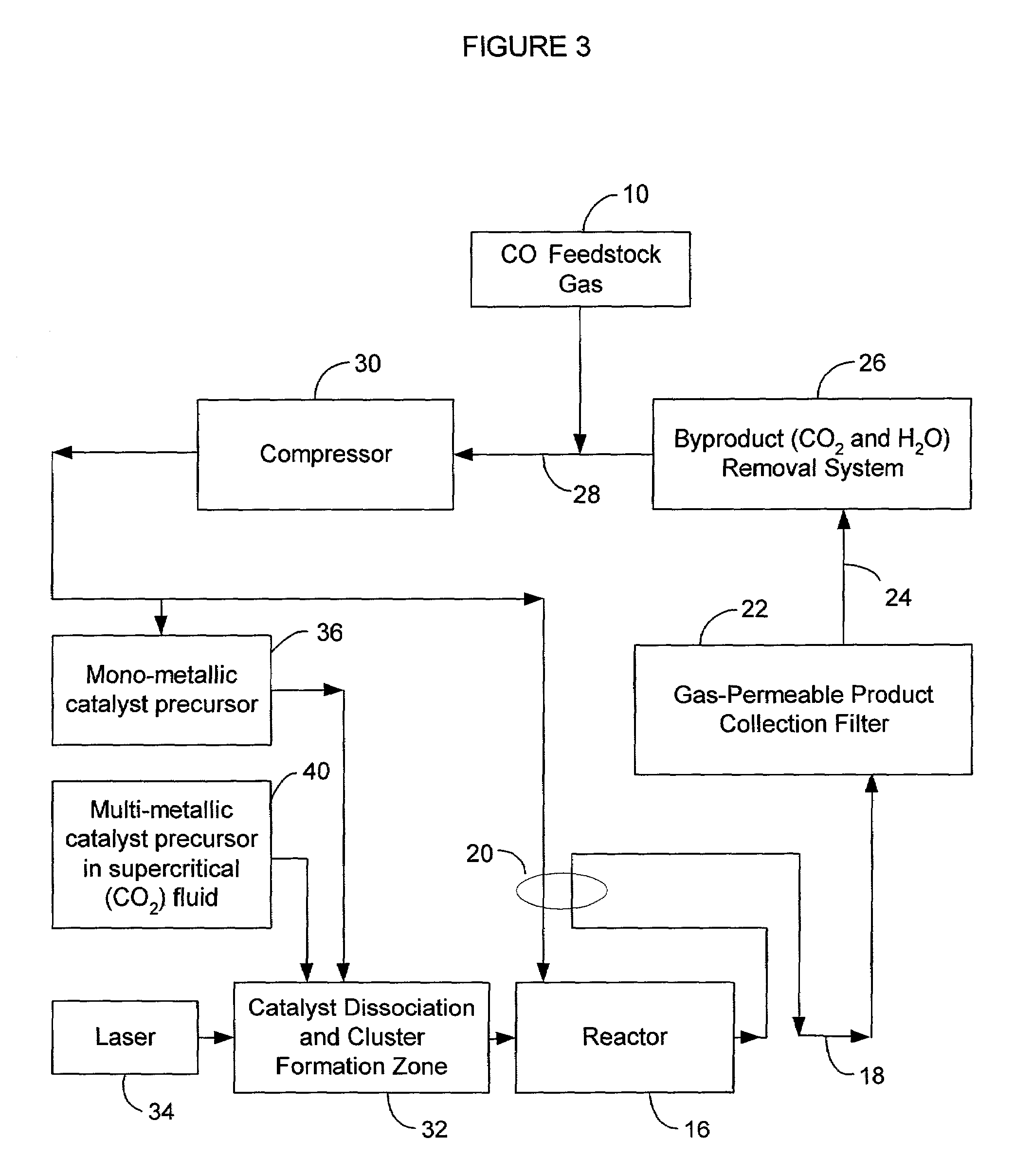

Process utilizing seeds for making single-wall carbon nanotubes

InactiveUS7052668B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFullerenesMetal catalystGas phase

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

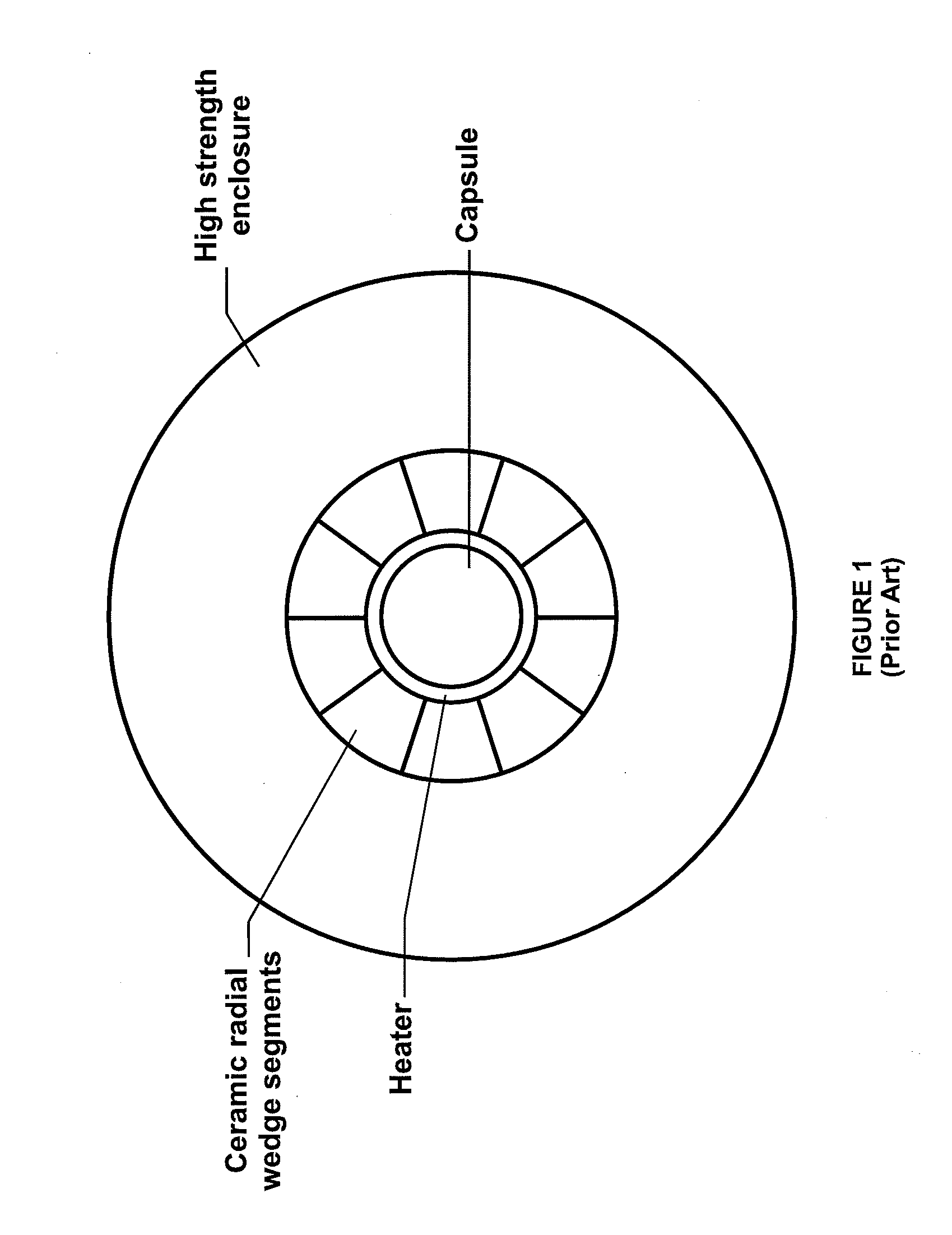

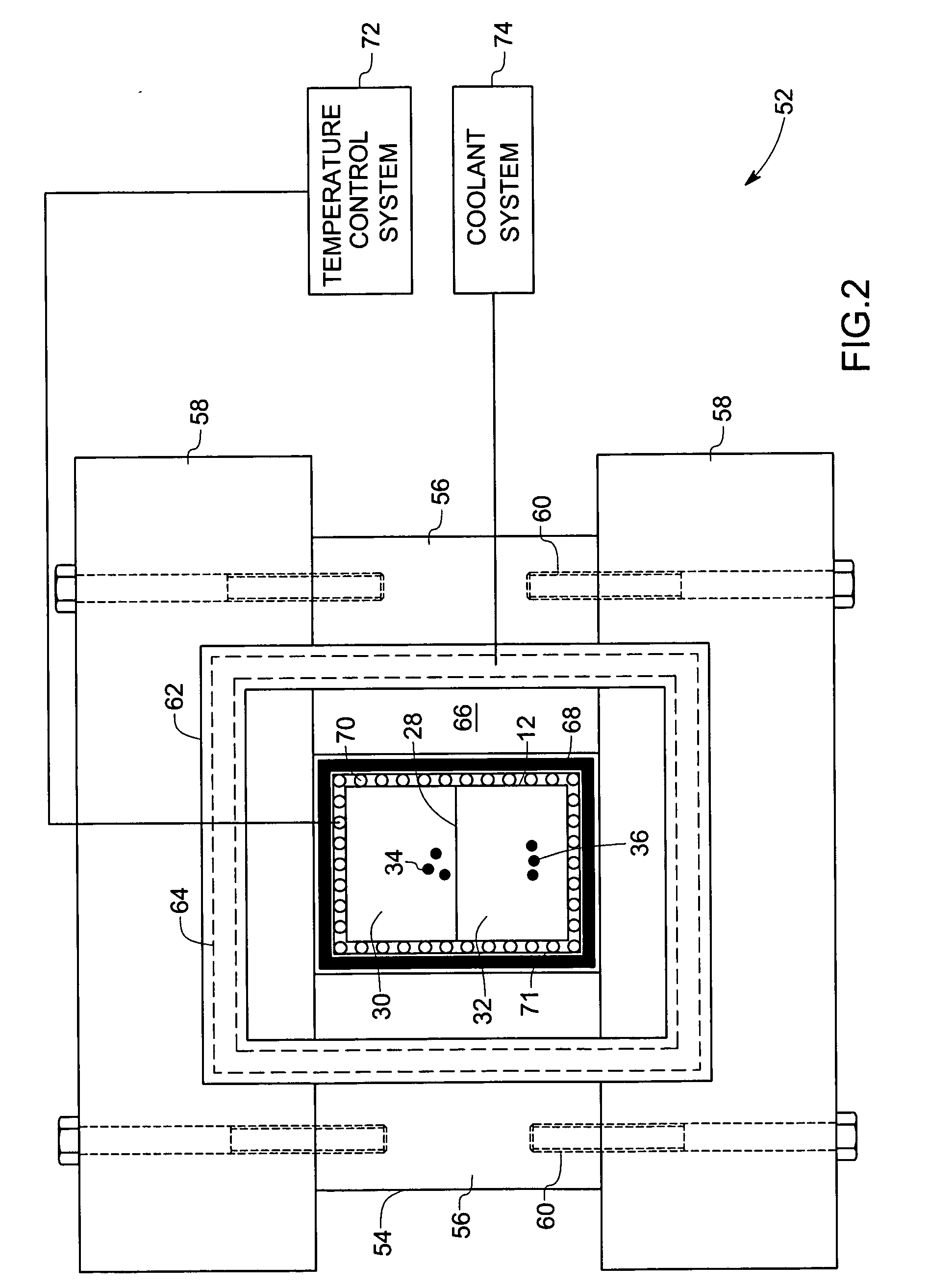

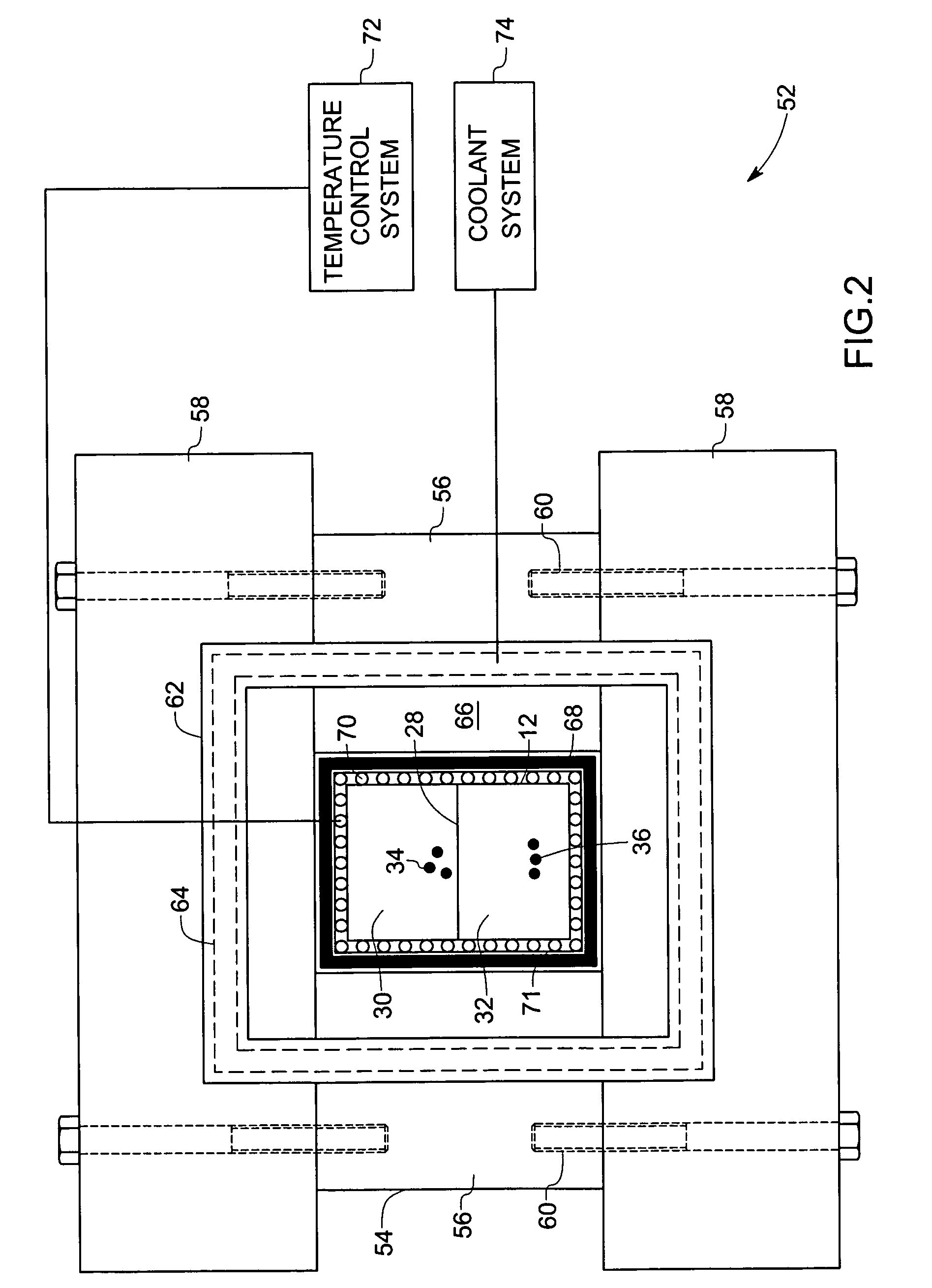

Pressure vessel

InactiveUS20030140845A1Prevent escapeAvoid creatingFrom gel statePolycrystalline material growthTemperature controlPressure transmission

A pressure vessel for processing at least one material in a supercritical fluid. The pressure vessel includes a self-pressurizing capsule for containing at least one material and the supercritical fluid in a substantially air-free environment, a pressure transmission medium surrounding the capsule for maintaining an outer pressure on the capsule, at least one heating element insertable in the pressure transmission medium such that the heating element surrounds the capsule, a temperature measurement means for measuring a temperature of the capsule, a temperature controller for controlling the temperature and providing power to the heating element, a restraint to contain and hold in place the capsule, the pressure transmission medium, and the heating element, and at least one seal between the restraint and the pressure transmission medium for preventing escape of the pressure transmission medium. Methods of using the pressure vessel, processing a material at high temperature and high pressure in the presence of a supercritical fluid within the capsule are also described.

Owner:SORAA

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

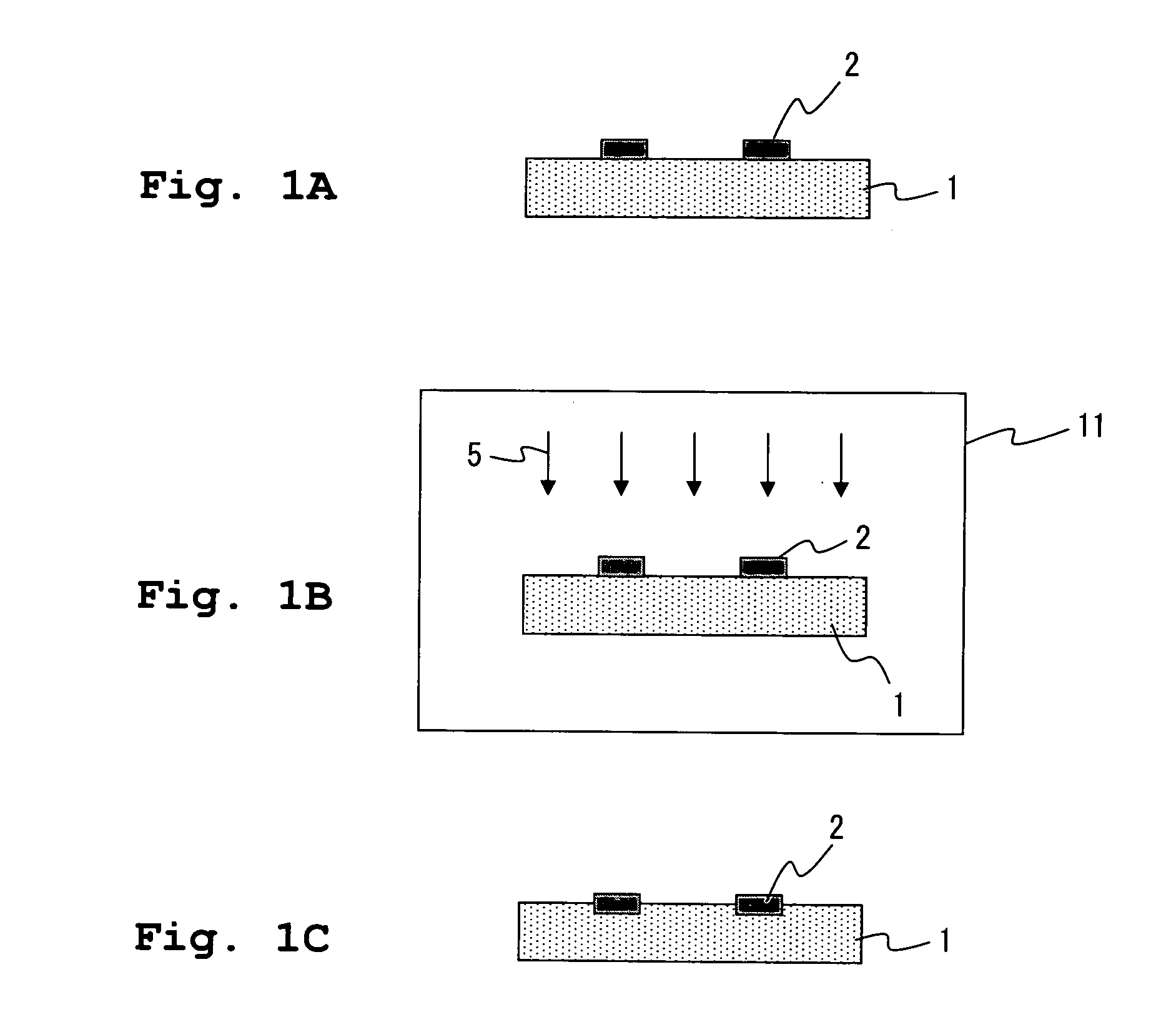

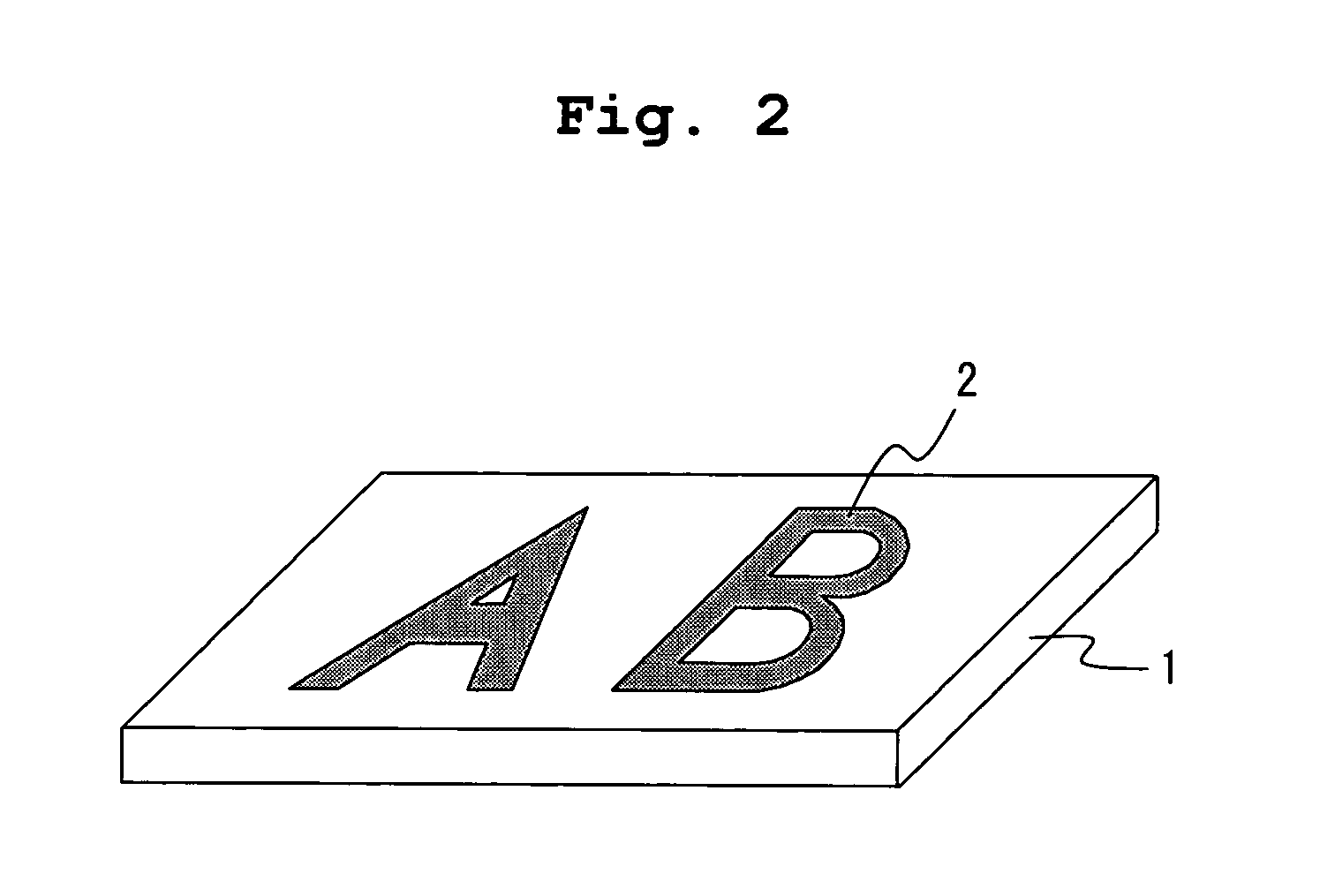

Method for modifying surface of polymer substrate, method for forming plated film on polymer substrate, method for producing polymer member, and coating member

InactiveUS20060257633A1Decorative surface effectsDuplicating/marking methodsPolymer sciencePolymer substrate

A method for modifying the surface of a polymer substrate is provided, which includes applying a permeating substance to predetermined region on the surface of the polymer substrate, and bringing a supercritical fluid into contact with the surface of the polymer substrate to which the permeating substance has been applied to cause the permeating substance to permeate into the polymer substrate. This method makes it possible to selectively (partially) modify a portion of the surface of the polymer substrate by an easier method.

Owner:HITACHT MAXELL LTD

Method for preparing heat-resisting alumina-silox aerogel thermal-protective composite material

The invention discloses a method for preparing a heat-resisting alumina-silox aerogel thermal-protective composite material, which comprises the following steps: (1) preparing Al2O3 sol; (2) preparing SiO2 sol; (3) preparing Al2O3-SiO2 sol, (4) preparing SiC coating-containing reinforcing fibers; (5) mixing the SiC coating-containing reinforcing fiber felts or fiber prefabricated members and the Al2O3-SiO2 sol; (6) aging; and (7) carrying out drying treatment by using supercritical fluid. The operating temperature of the Al2O3-SiO2 aerogel composite material prepared by the method can reach 1,200 DEG C; and therefore, the Al2O3-SiO2 aerogel composite material has good heat-insulating property and good mechanical property.

Owner:NAT UNIV OF DEFENSE TECH

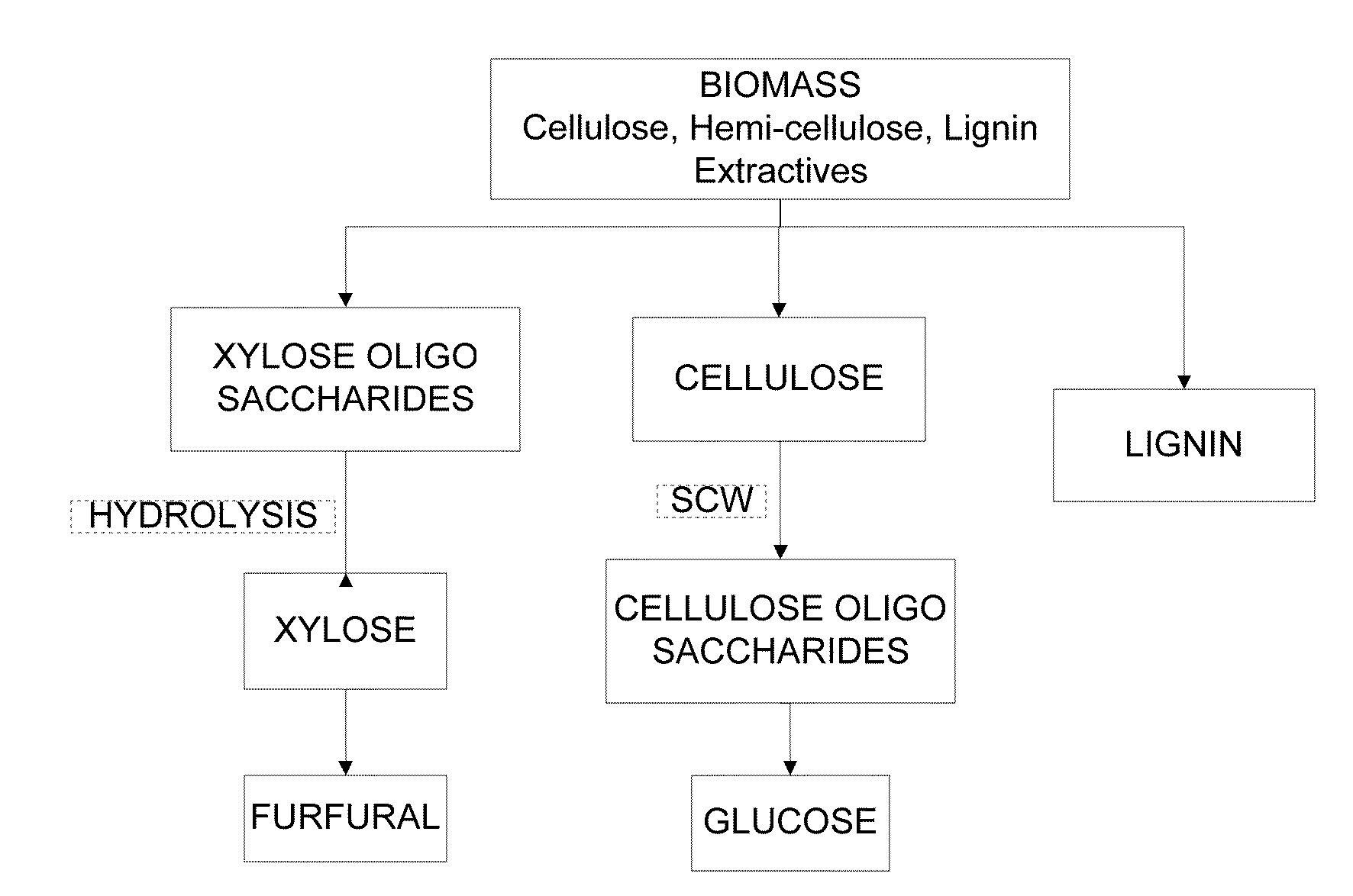

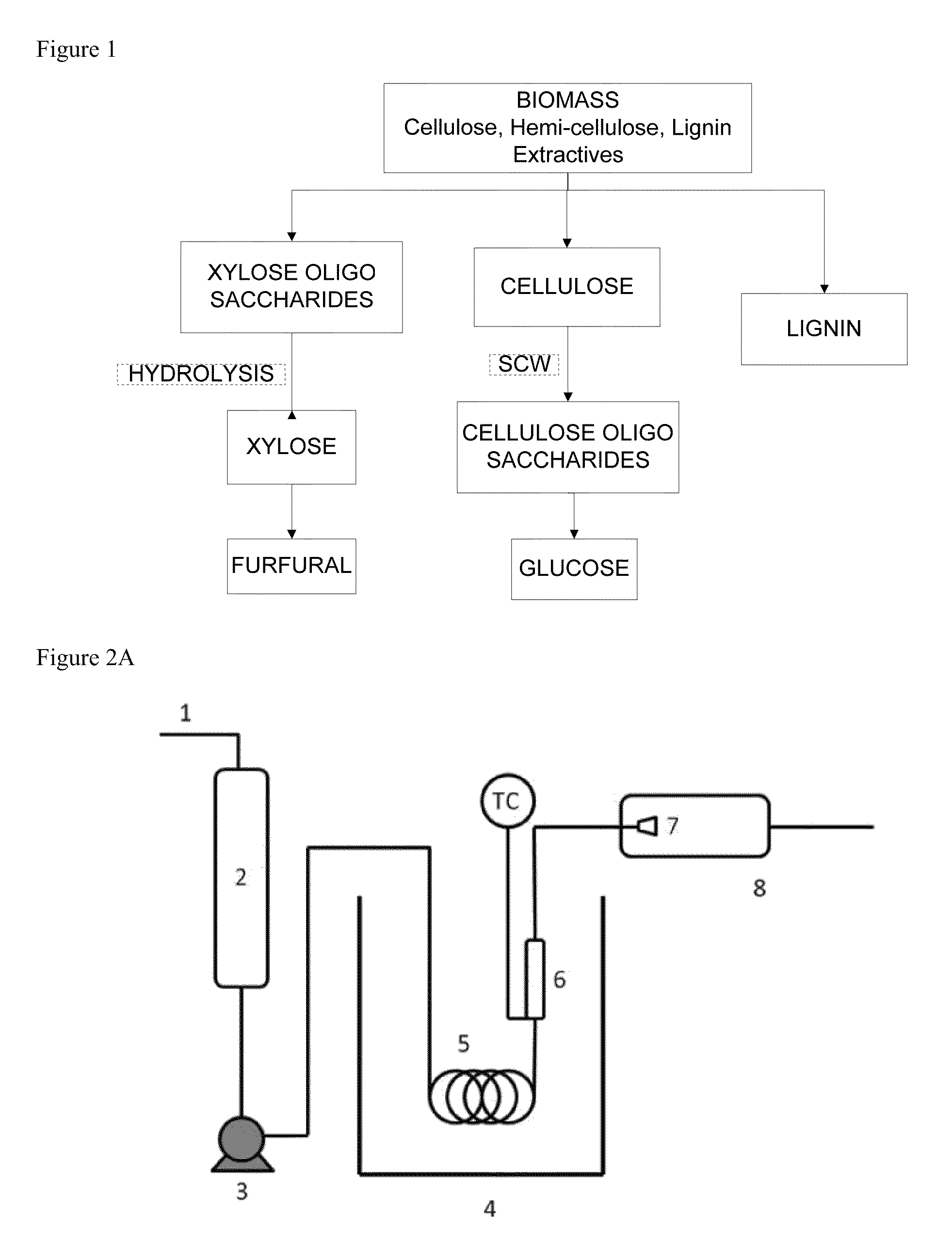

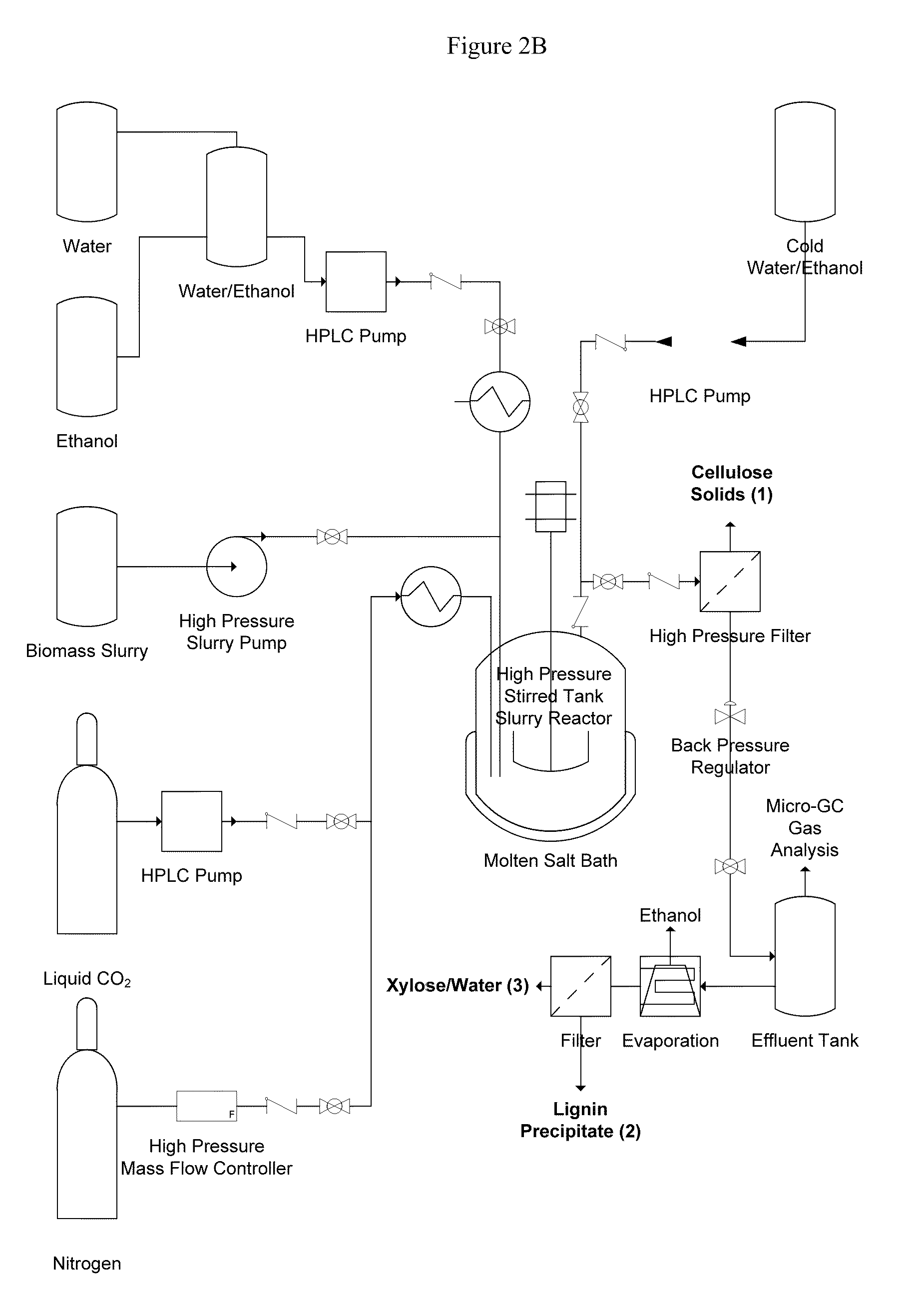

Nano-catalytic-solvo-thermal technology platform bio-refineries

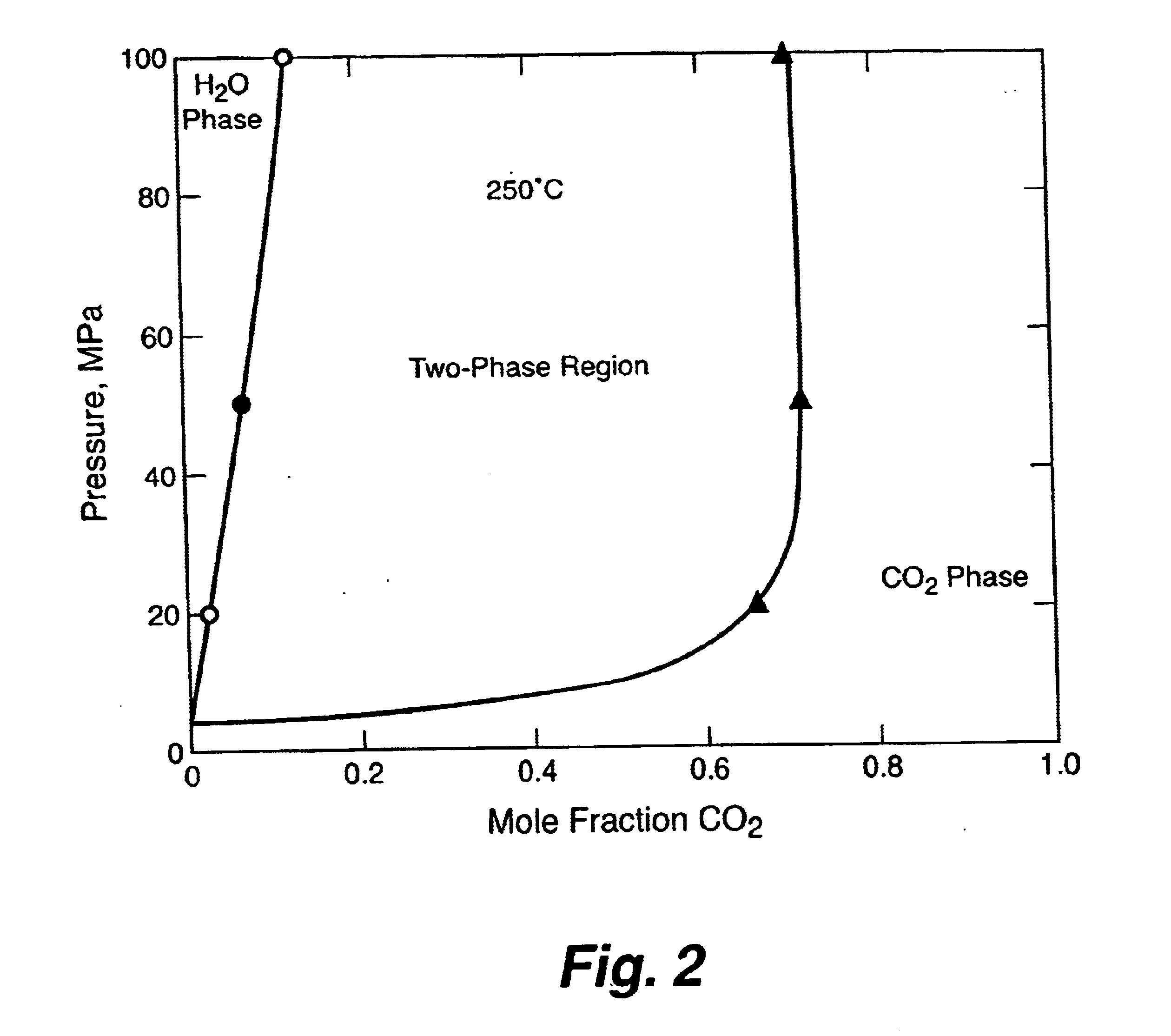

Methods of making glucose and / or furfural from biomass require one or more supercritical fluids that may be used to process biomass, cellulose from the biomass, and / or xylose from the biomass. Examples of supercritical fluids for use in processing biomass include ethanol, water, and carbon dioxide at a temperature and pressure above the critical points for ethanol and carbon dioxide but at a temperature and / or pressure below that of the critical point for water. A supercritical fluid containing carbon dioxide and water may be used to convert cellulose to glucose or convert xylose to furfural. The fluid has a temperature and pressure above the critical point of carbon dioxide, but at least one of the temperature and pressure is below the critical point for water.

Owner:RENMATIX INC

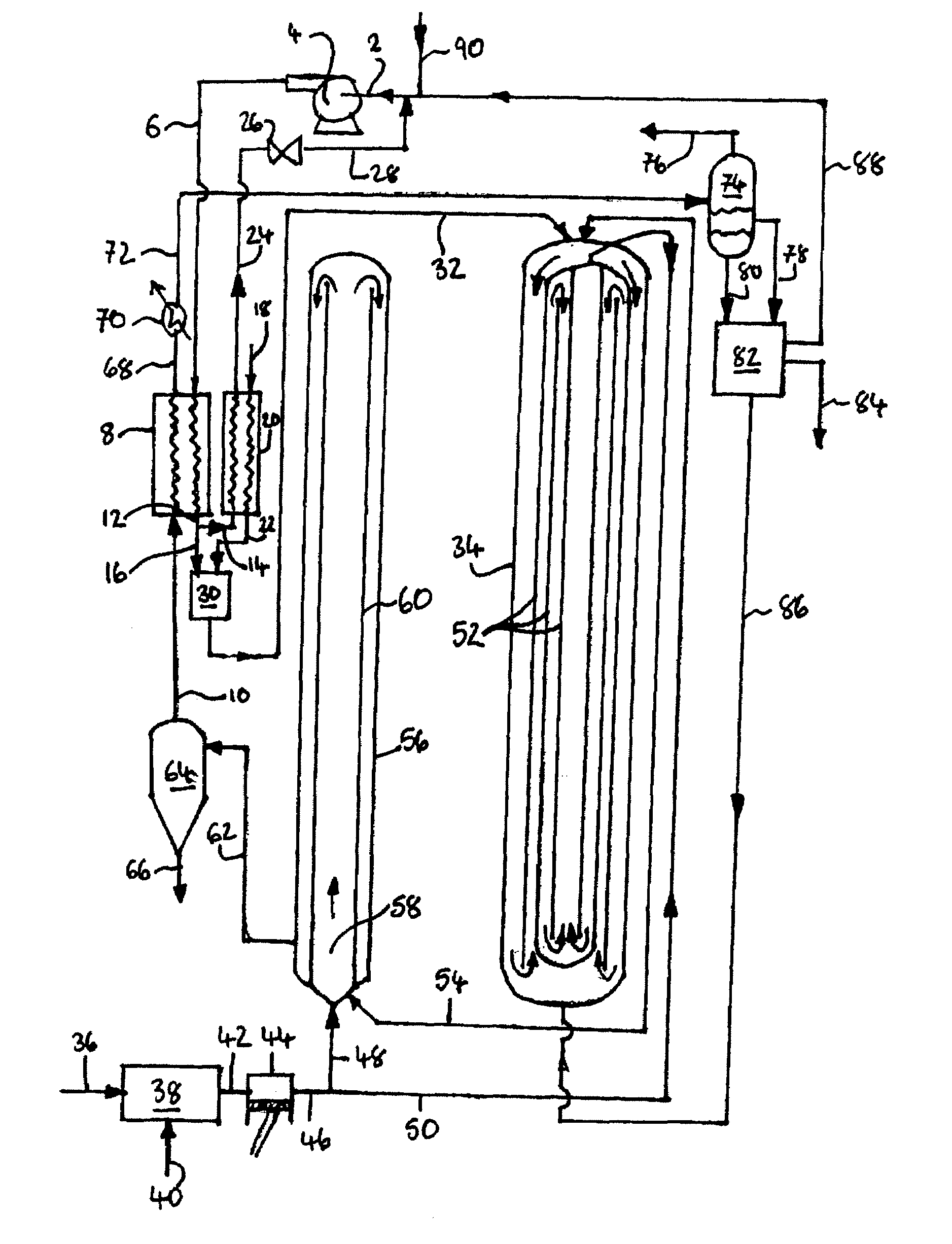

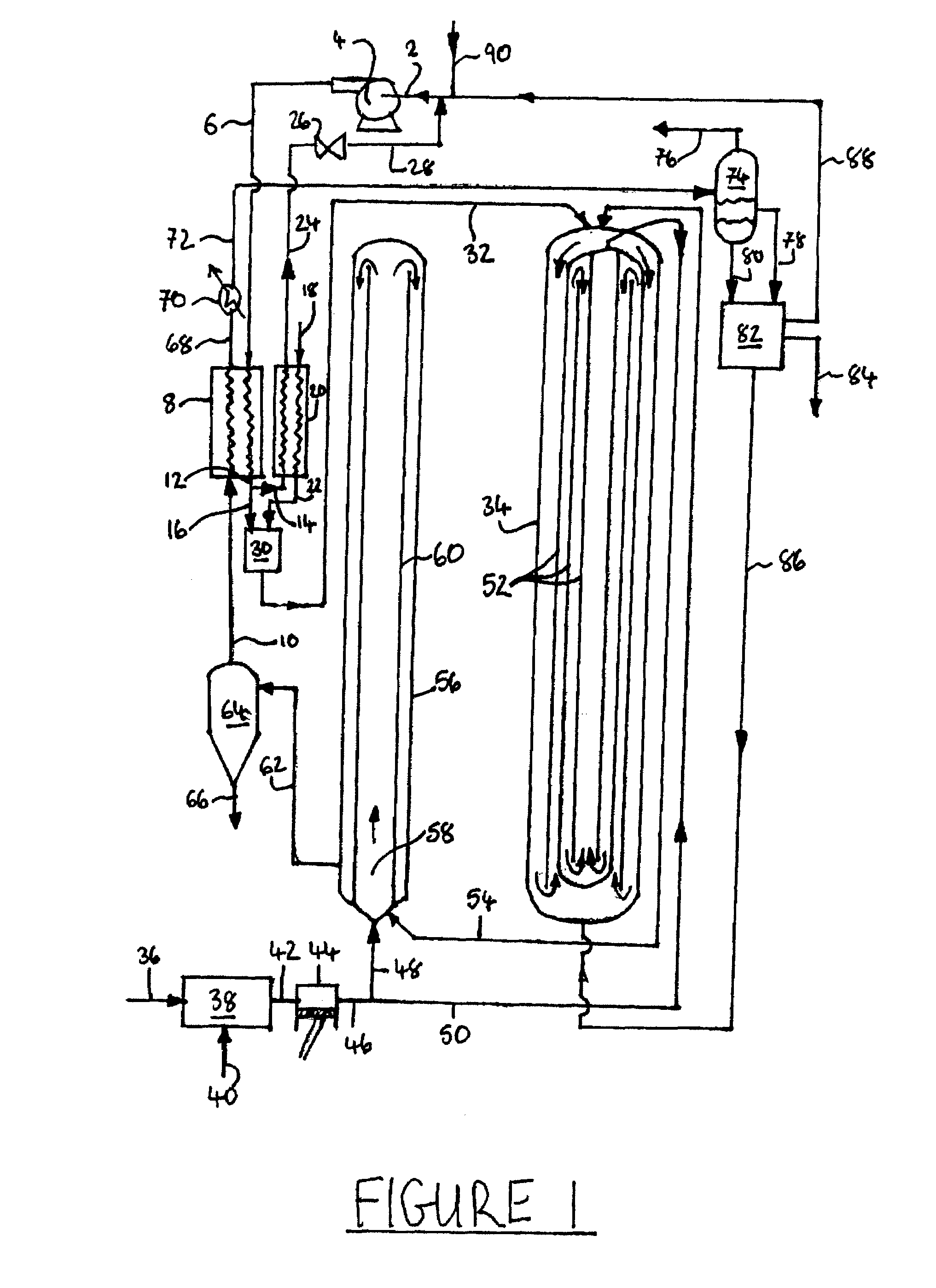

Process and apparatus for upgrading coal using supercritical water

Coal is converted into hydrocarbon compounds using supercritical water. The process involves two stages; a first stage in which carbonaceous material is reacted with supercritical water at above 850K to produce a first supercritical fluid reaction mixture comprising hydrocarbon compounds; and a second stage in which hydrocarbon compounds are extracted from coal mixed with at least a portion of the first supercritical fluid at a temperature within a range of from the supercritical temperature of water to about 695K. Char from the second stage is finely divided and may be either be used outside the process, e.g. in a coal fired power station or a gasifier, or used as at least a portion of the carbonaceous material used in the first stage.

Owner:AIR PROD & CHEM INC

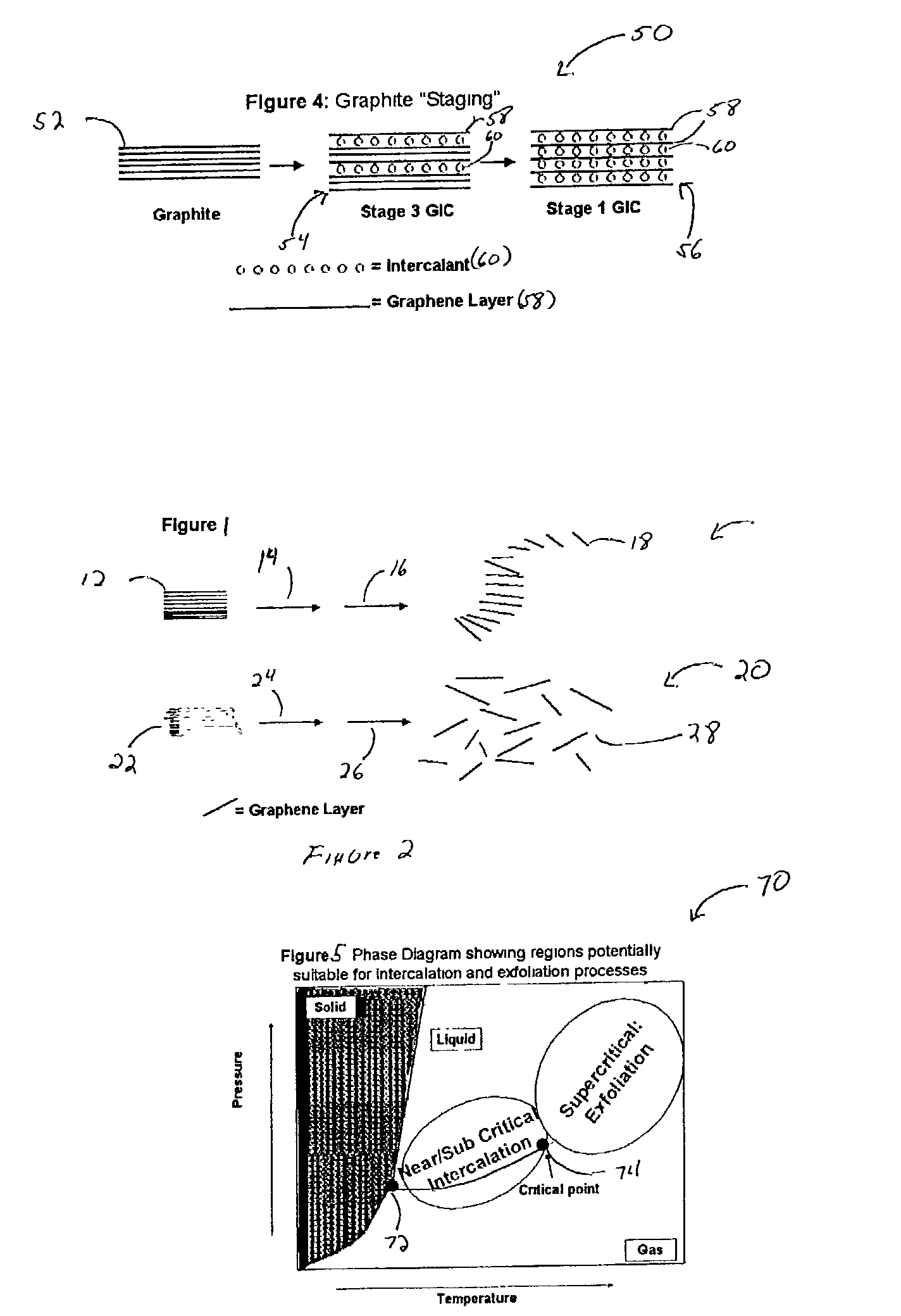

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

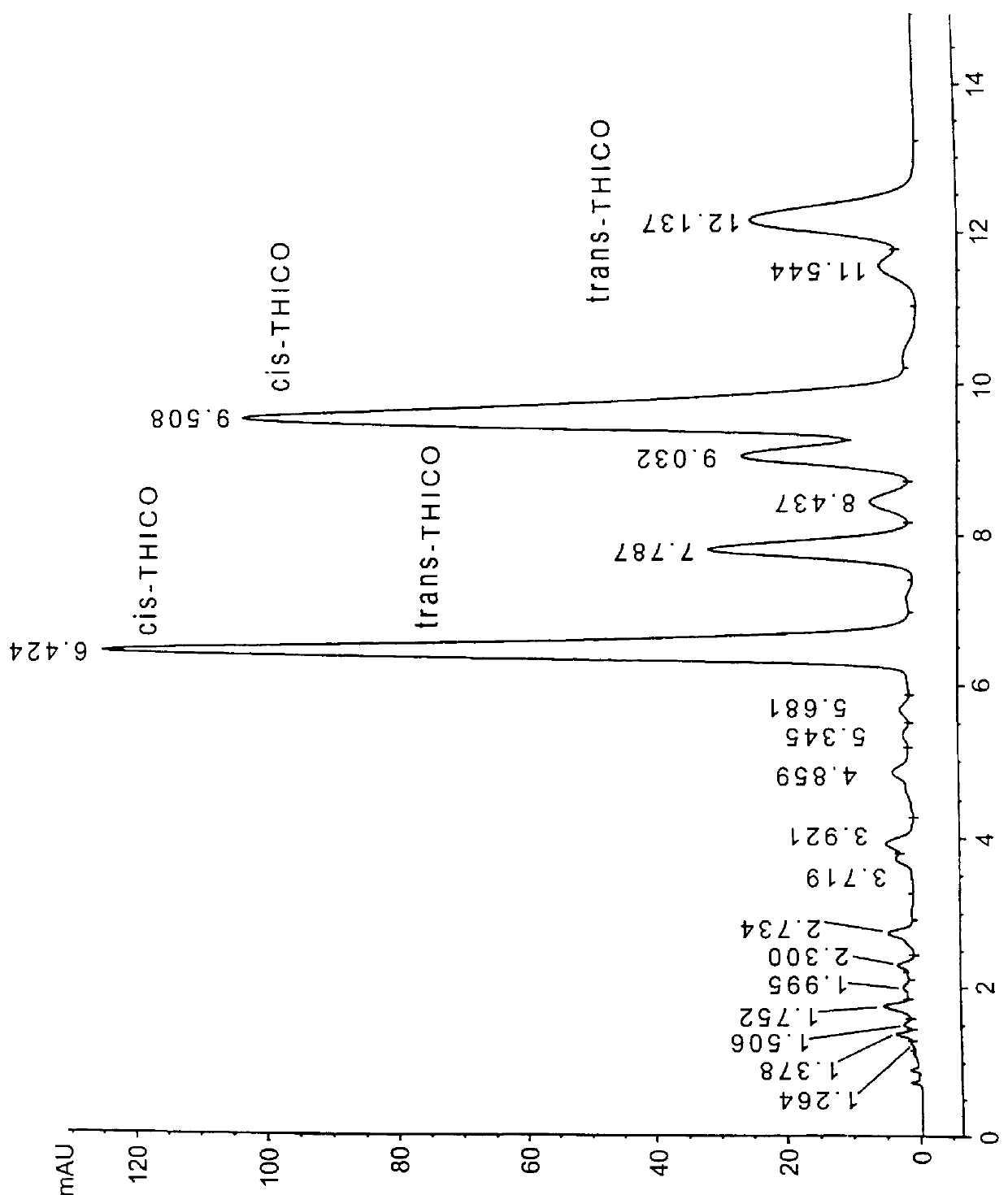

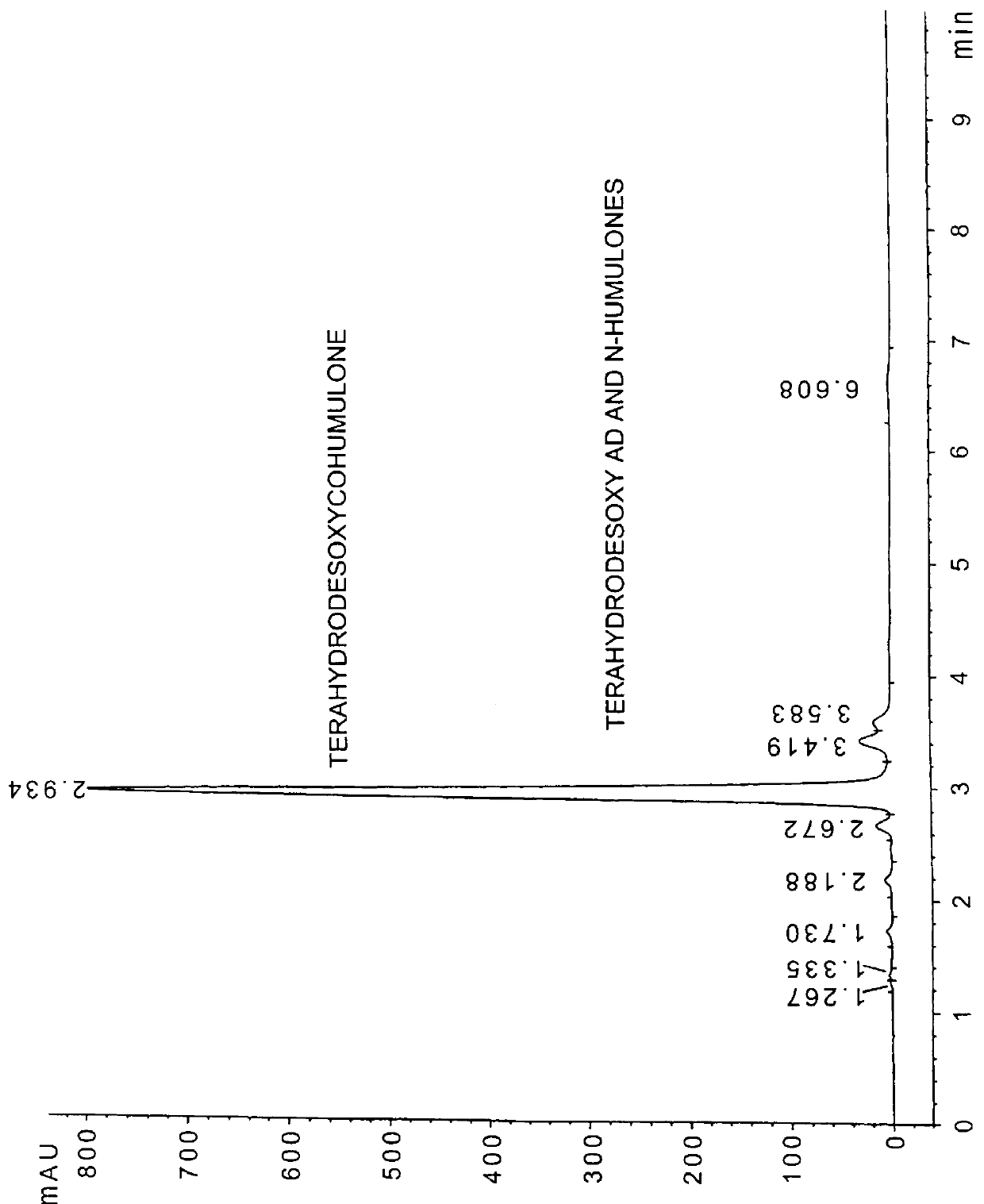

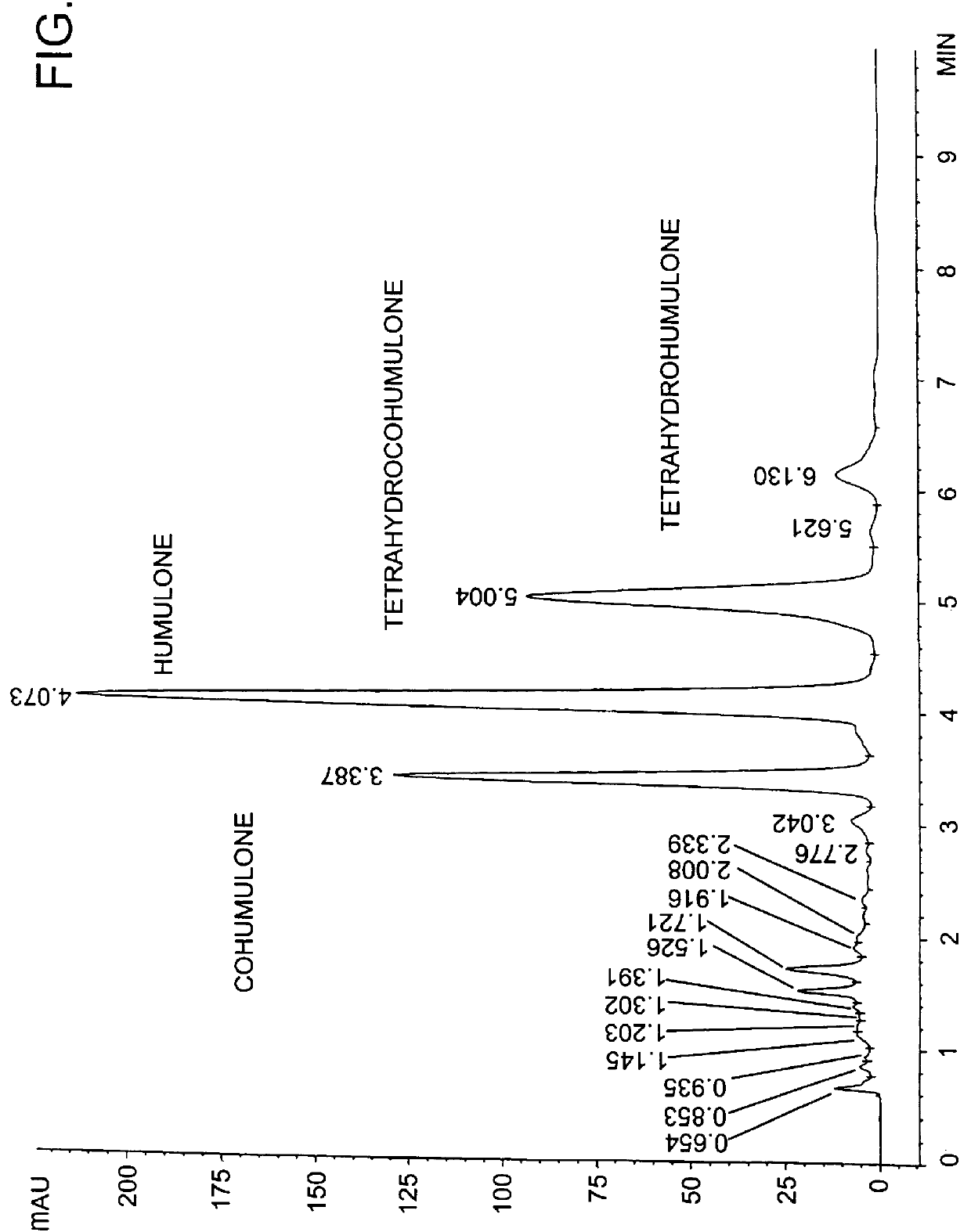

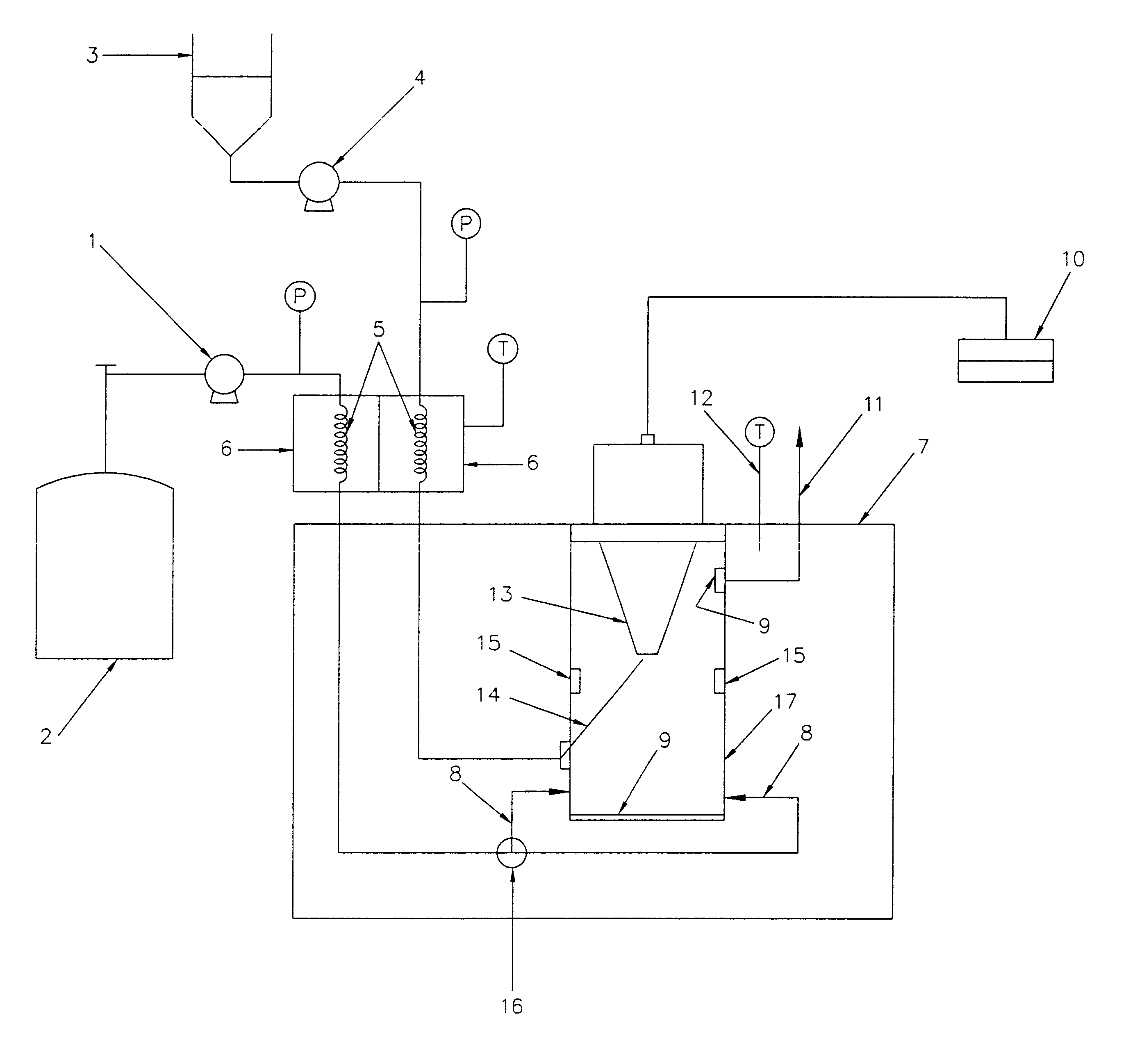

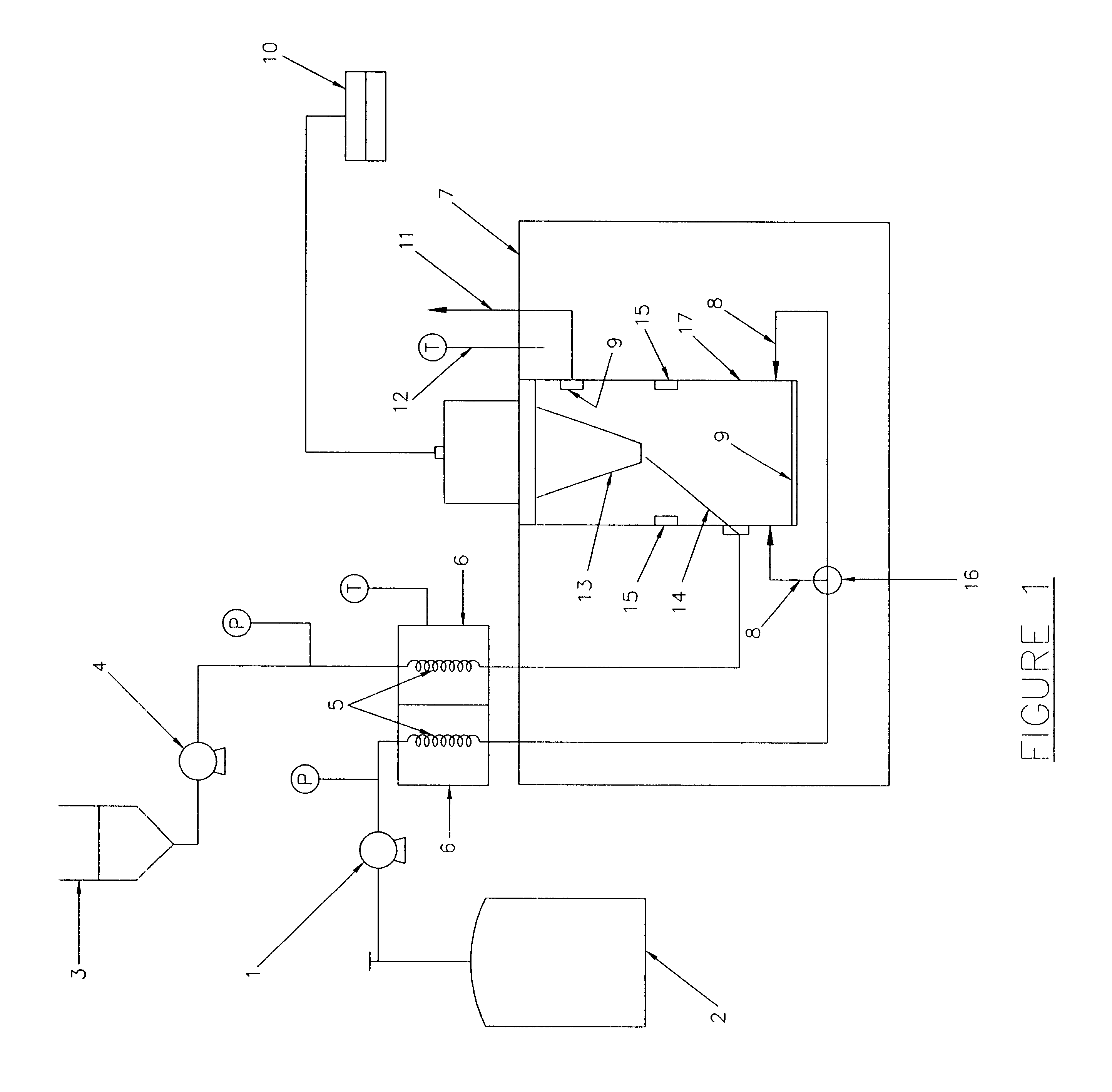

Hydrogenation of hop soft resins using CO2

InactiveUS6020019AEncourage the formation of desoxytetrahydro-alpha-acidsOrganic compound preparationCarbonyl compound preparationAlcoholCO2 - Carbon dioxide

Carbon dioxide is used as a reaction solvent in the hydrogenation of organic compounds. The carbon dioxide is preferably a liquid or a supercritical fluid. The hydrogenation method can be used advantageously in methods for making tetrahydroiso-alpha-acids from alpha-acids, iso-alpha-acids, or beta-acids. If beta-acids are used to make tetrahydroiso-alpha-acids, an acidic lower alcohol is preferably added to the carbon dioxide reaction medium to act as a promoter.

Owner:MILLER BREWING COMPANY

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

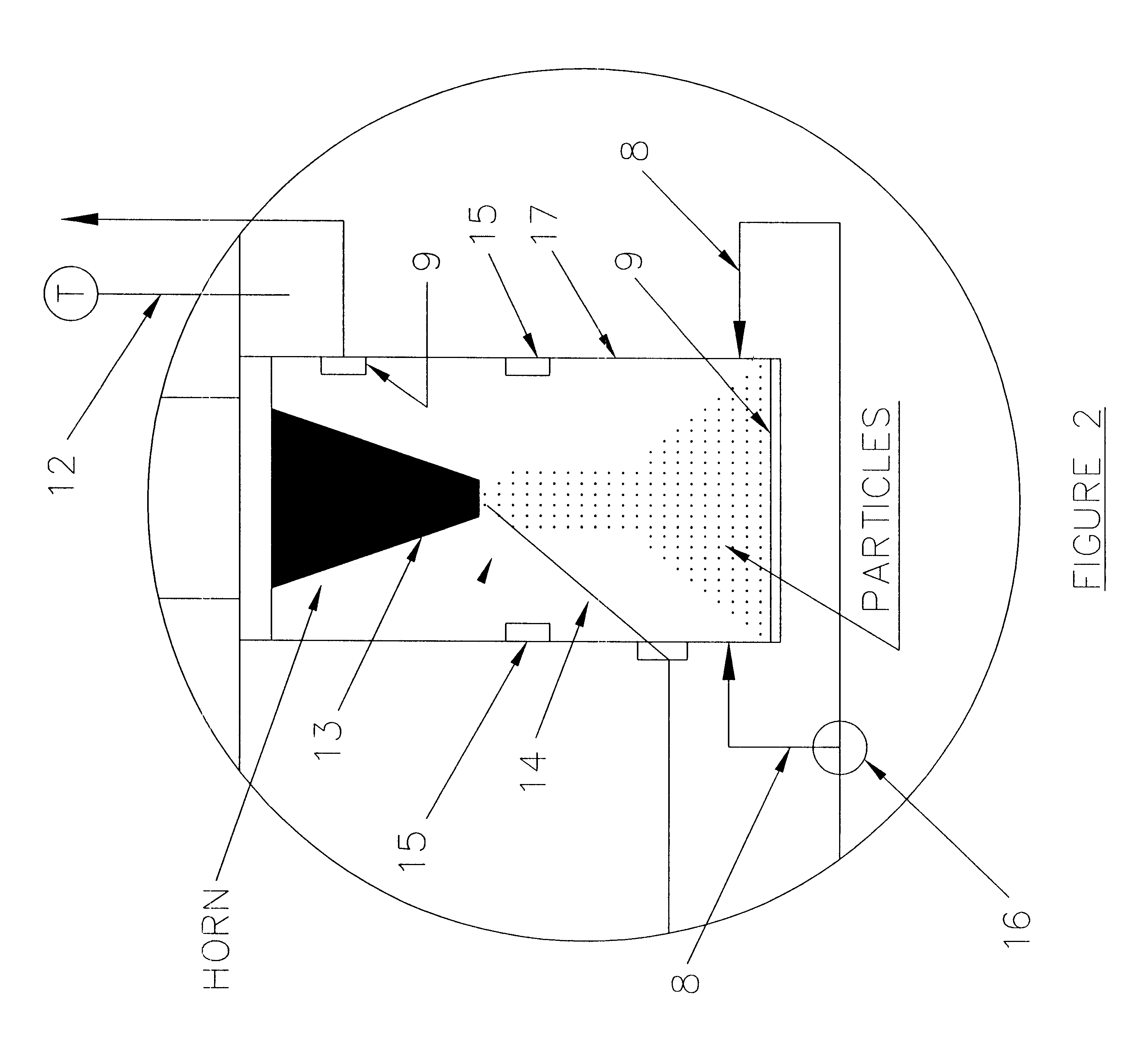

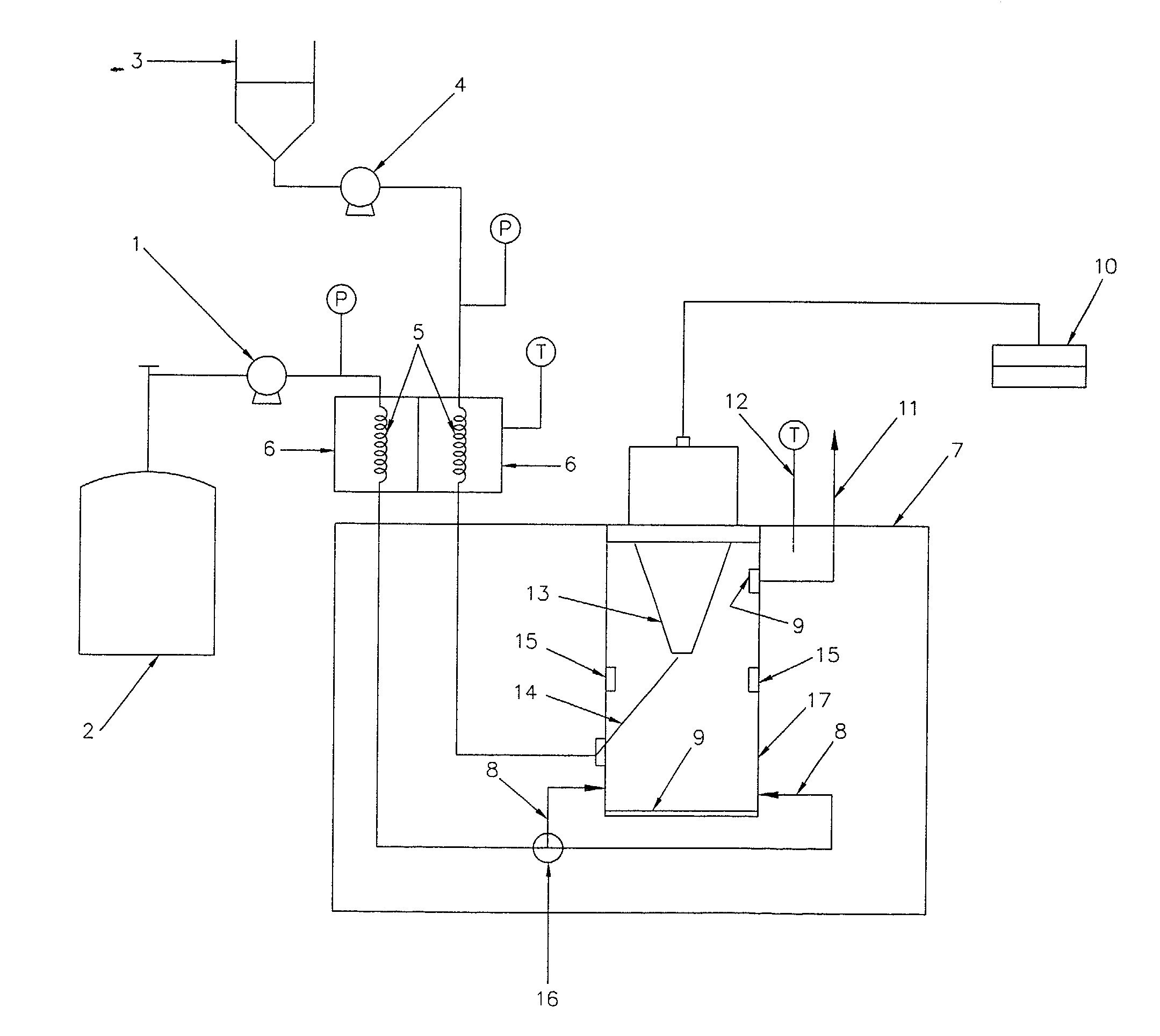

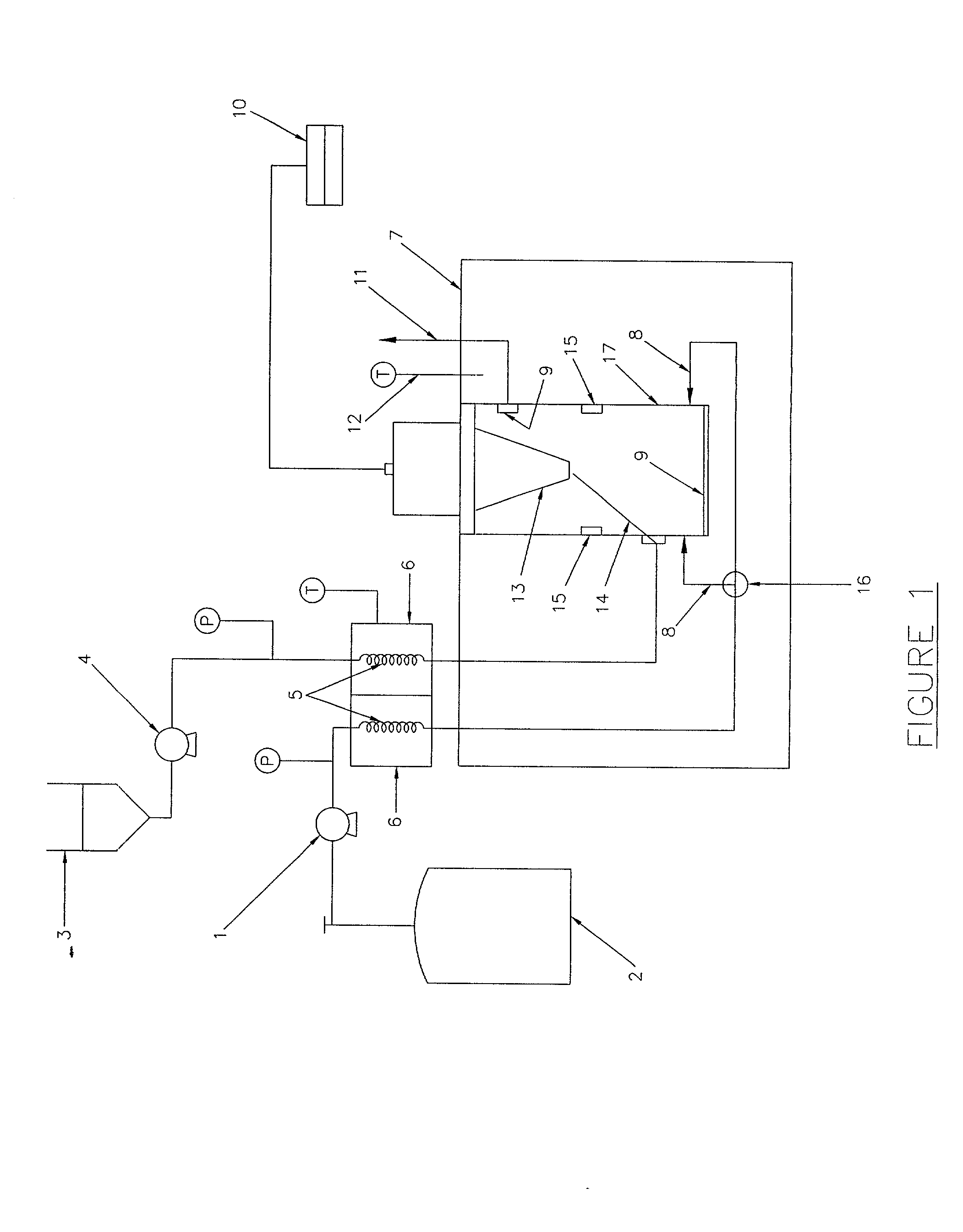

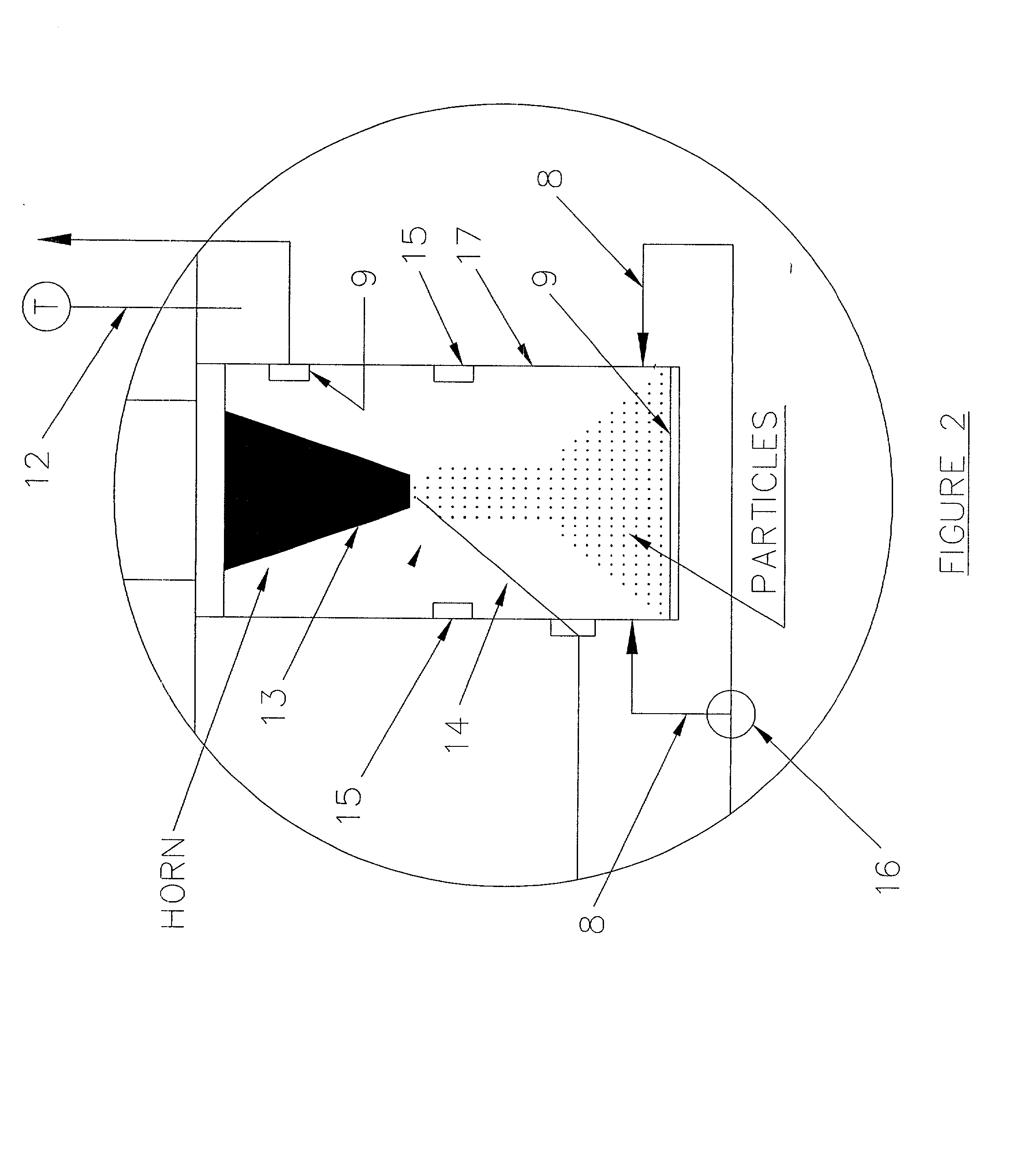

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

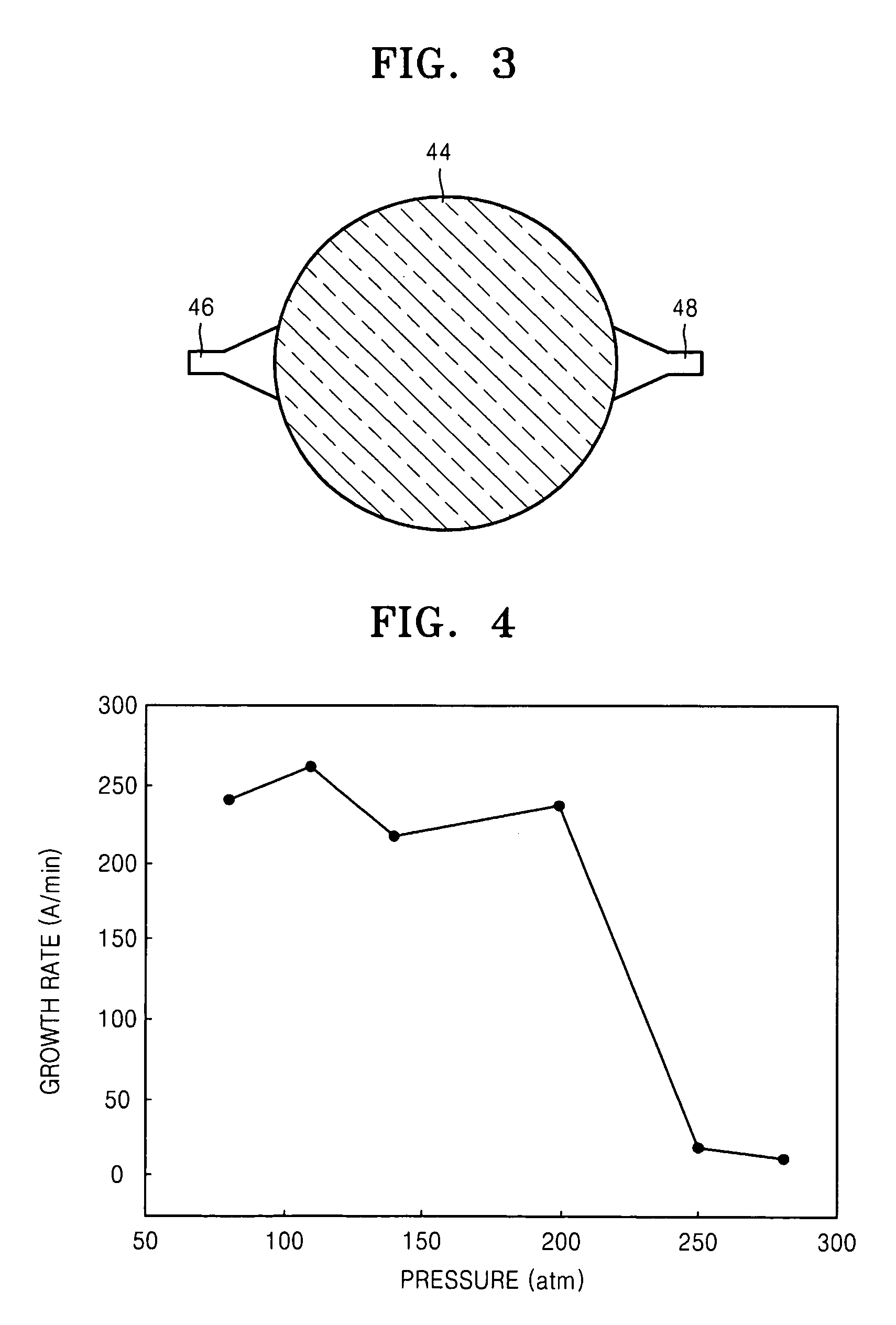

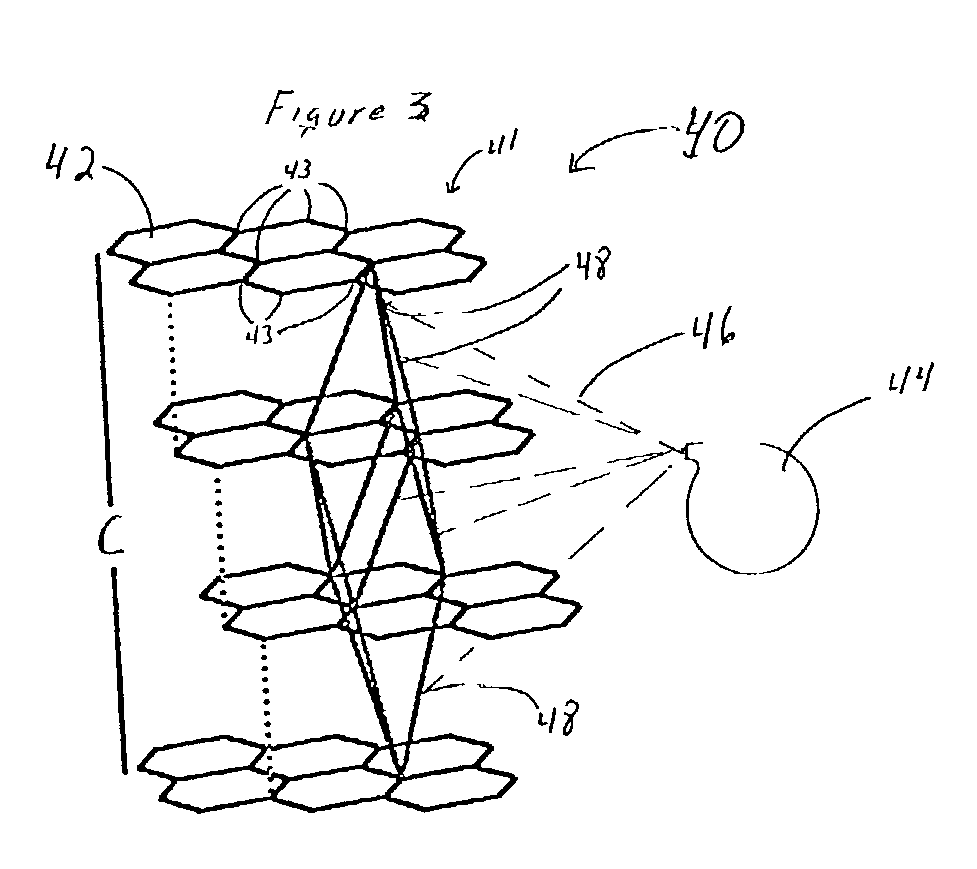

Large area nitride crystal and method for making it

Techniques for processing materials in supercritical fluids including processing in a capsule disposed within a high-pressure apparatus enclosure are disclosed. The disclosed techniques are useful for growing crystals of GaN, AlN, InN, and their alloys, including InGaN, AlGaN, and AlInGaN for the manufacture of bulk or patterned substrates, which in turn can be used to make optoelectronic devices, lasers, light emitting diodes, solar cells, photoelectrochemical water splitting and hydrogen generation devices, photodetectors, integrated circuits, and transistors.

Owner:SLT TECH

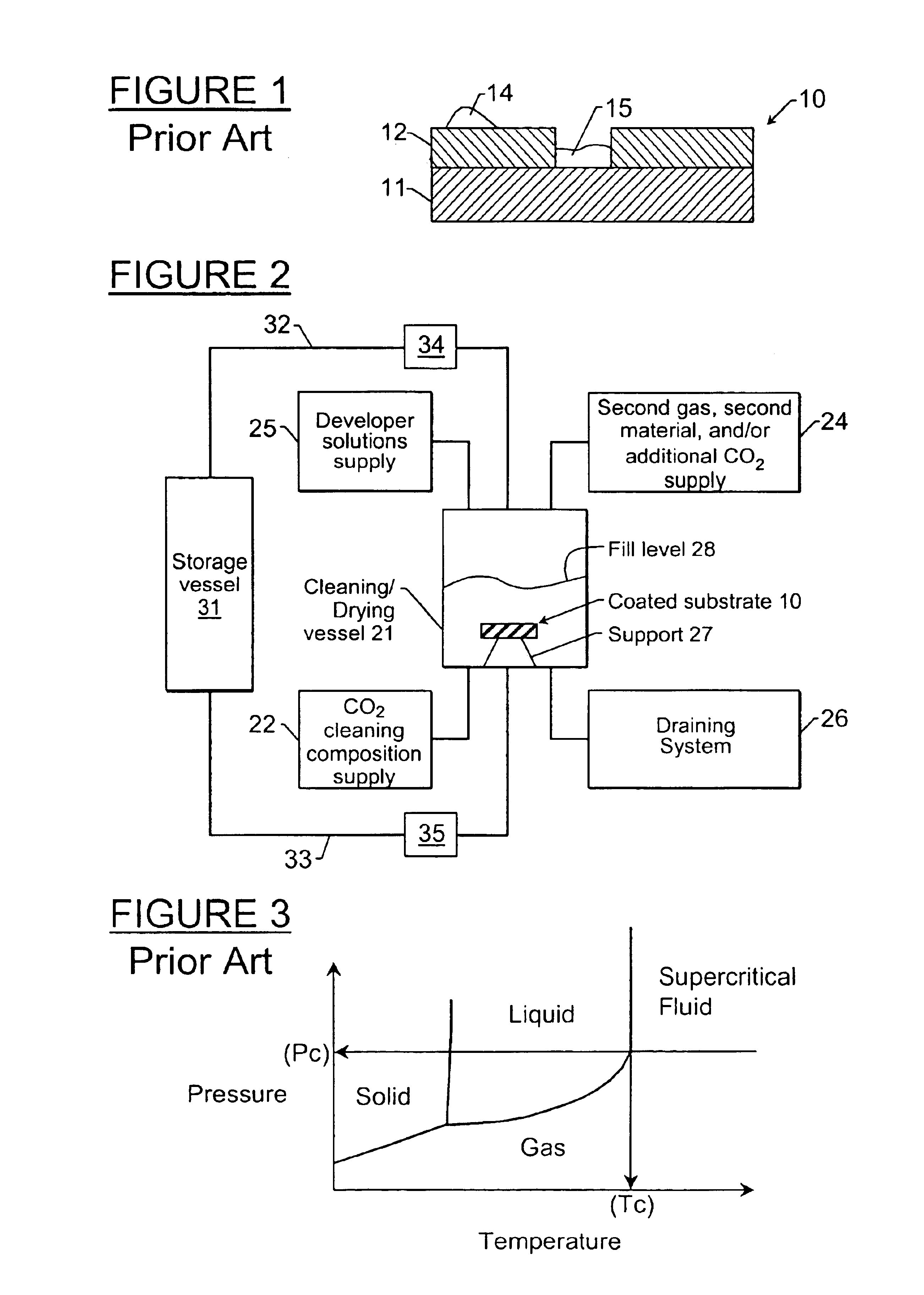

Supercritical fluid cleaning of semiconductor substrates

InactiveUS20030125225A1Inorganic/elemental detergent compounding agentsSurface-active detergent compositionsChemical reactionSURFACTANT BLEND

Chemical formulations and methods for removing unwanted material, such as unexposed photoresist, metal oxides, CMP residue, and the like, from semiconductor wafers or other substrates. The formulations utilize a supercritical fluid-based cleaning composition, which may further include (I) co-solvent(s), (II) surfactant(s), (III) chelating agent(s), and / or (IV) chemical reactant(s).

Owner:ADVANCED TECH MATERIALS INC

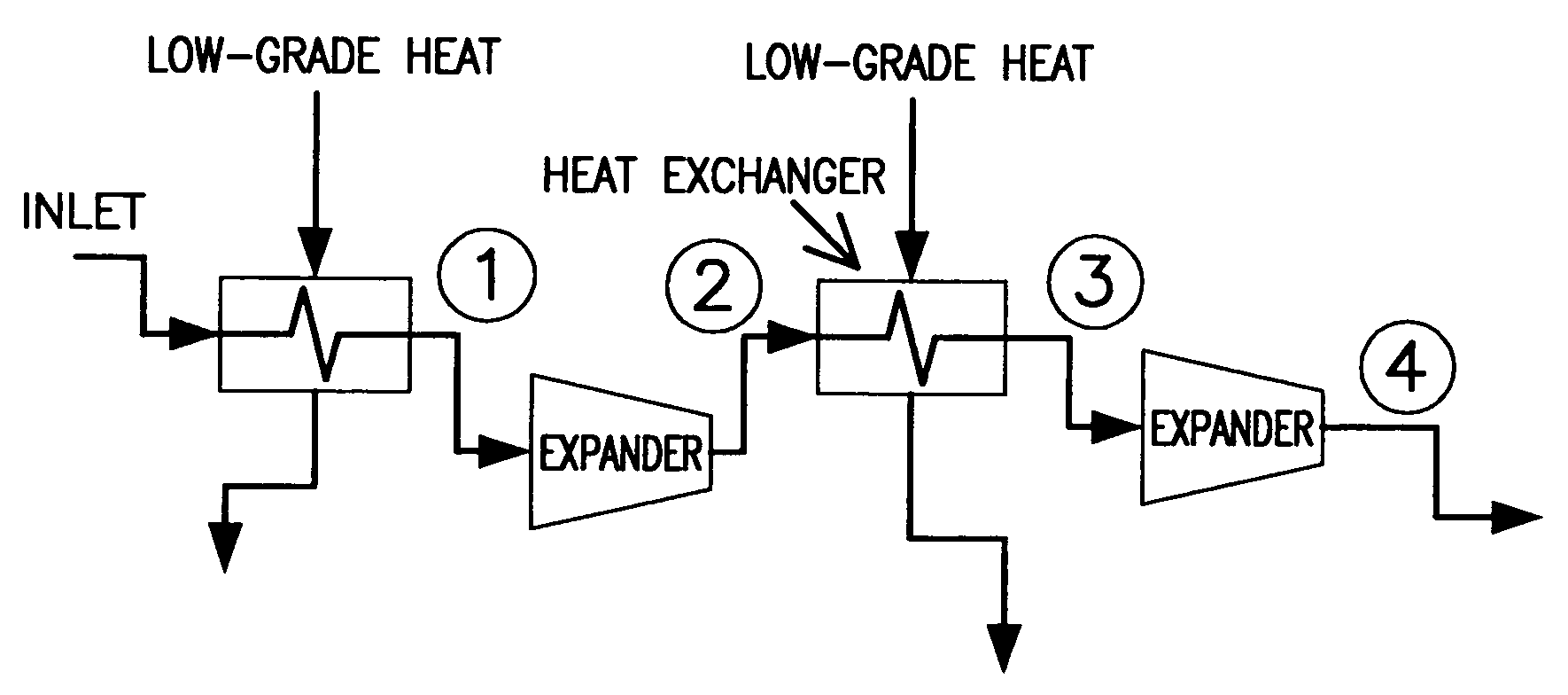

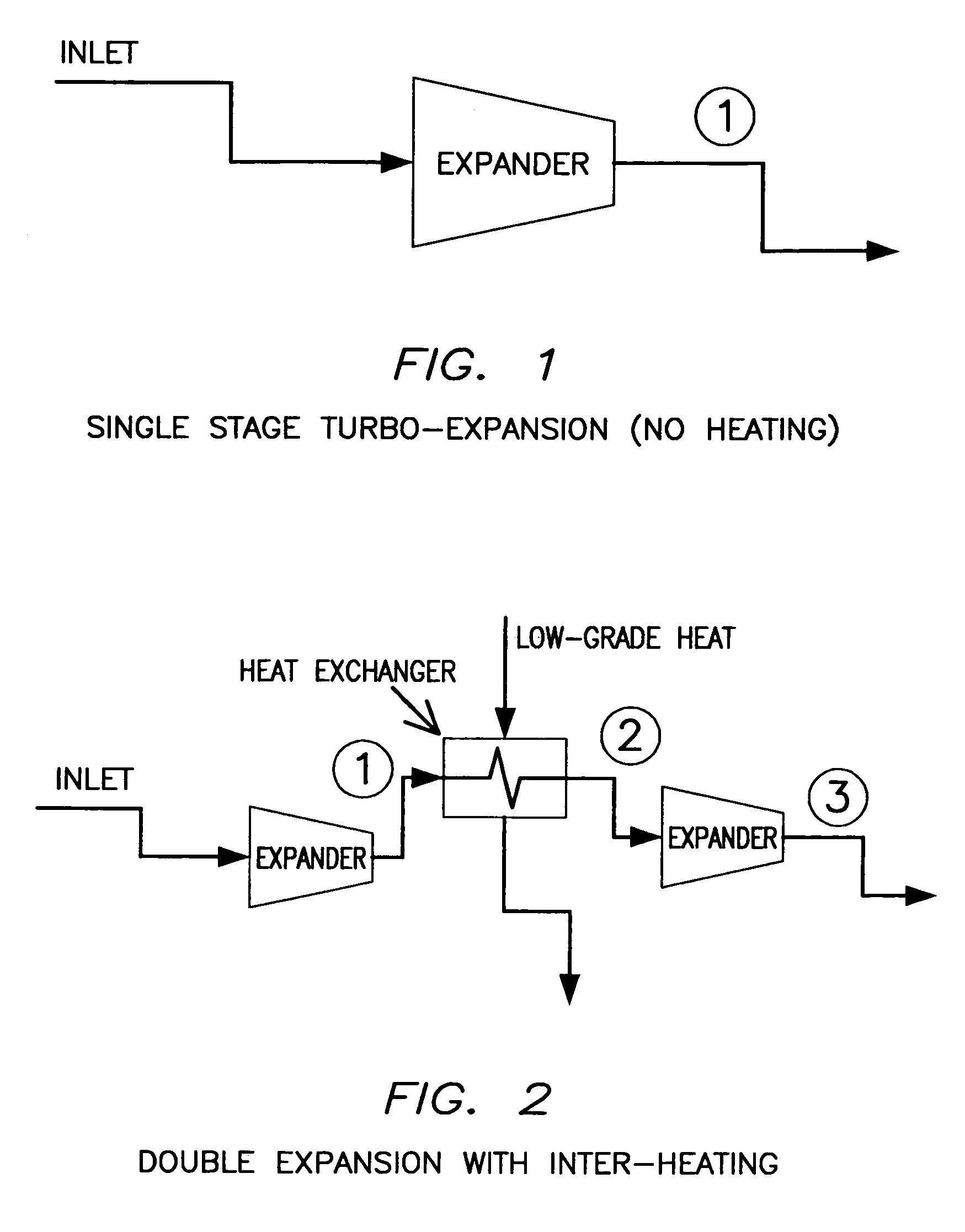

Energy recovery during expansion of compressed gas using power plant low-quality heat sources

A method of recovering energy from a cool compressed gas, compressed liquid, vapor, or supercritical fluid is disclosed which includes incrementally expanding the compressed gas, compressed liquid, vapor, or supercritical fluid through a plurality of expansion engines and heating the gas, vapor, compressed liquid, or supercritical fluid entering at least one of the expansion engines with a low quality heat source. Expansion engines such as turbines and multiple expansions with heating are disclosed.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

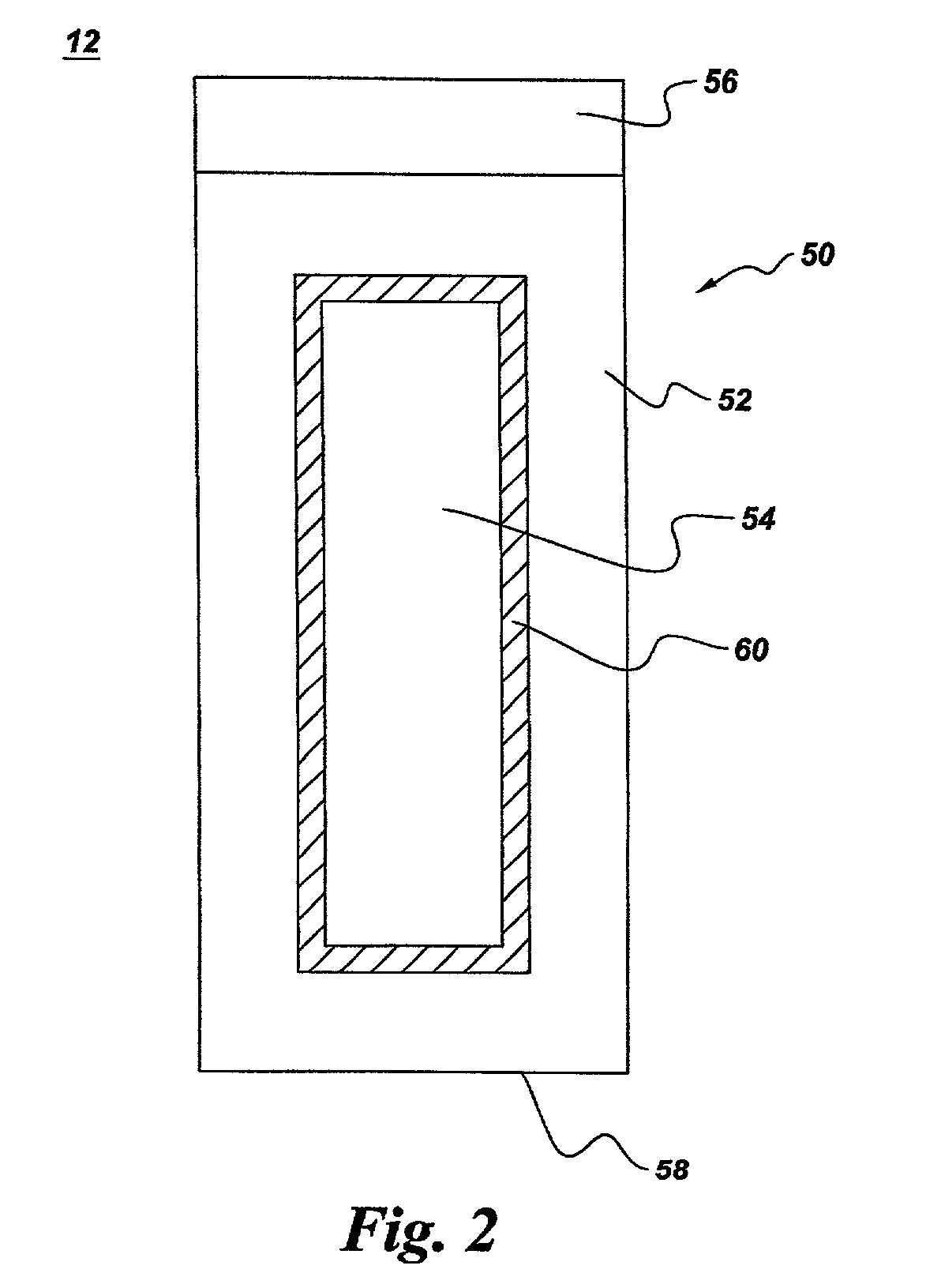

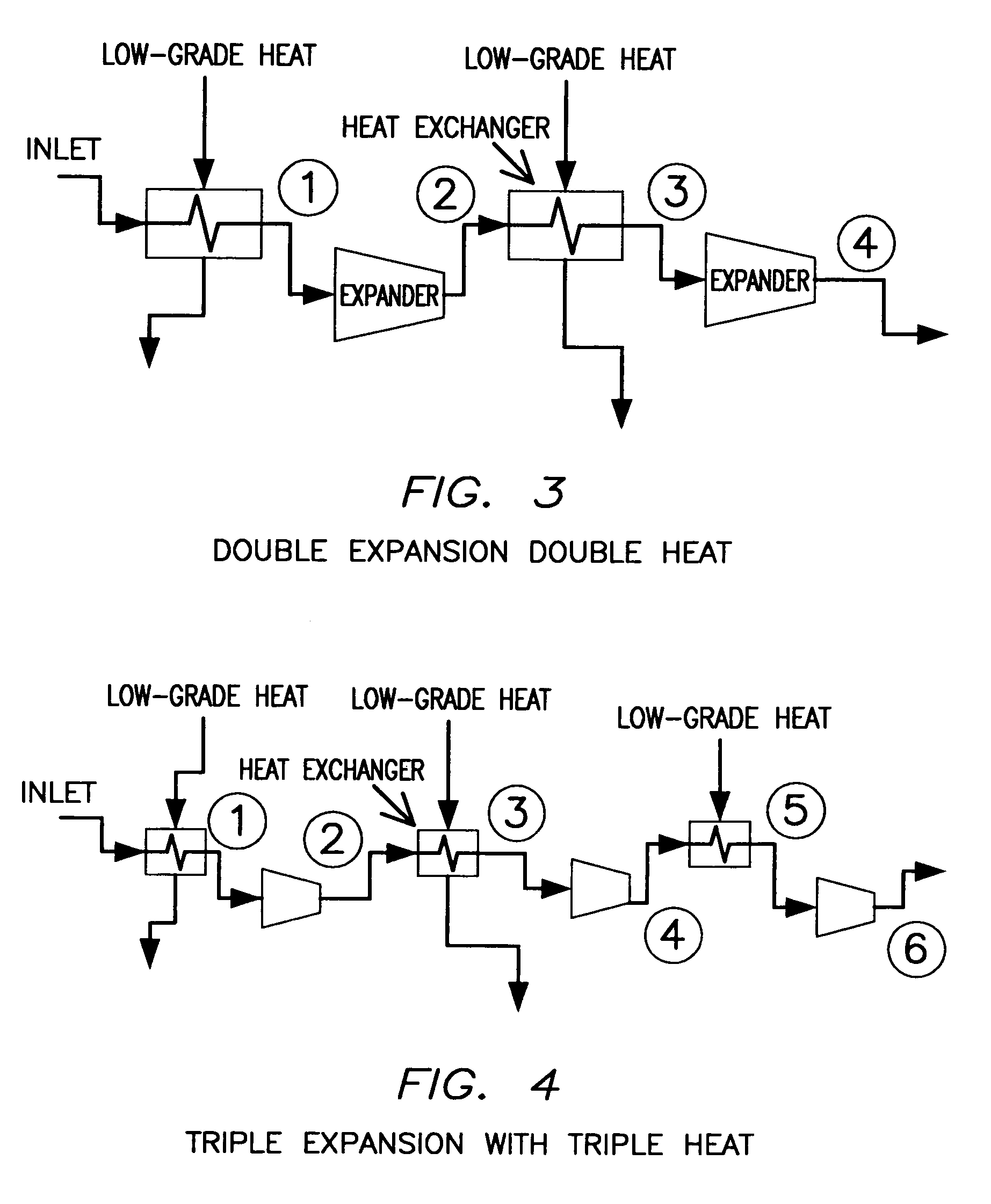

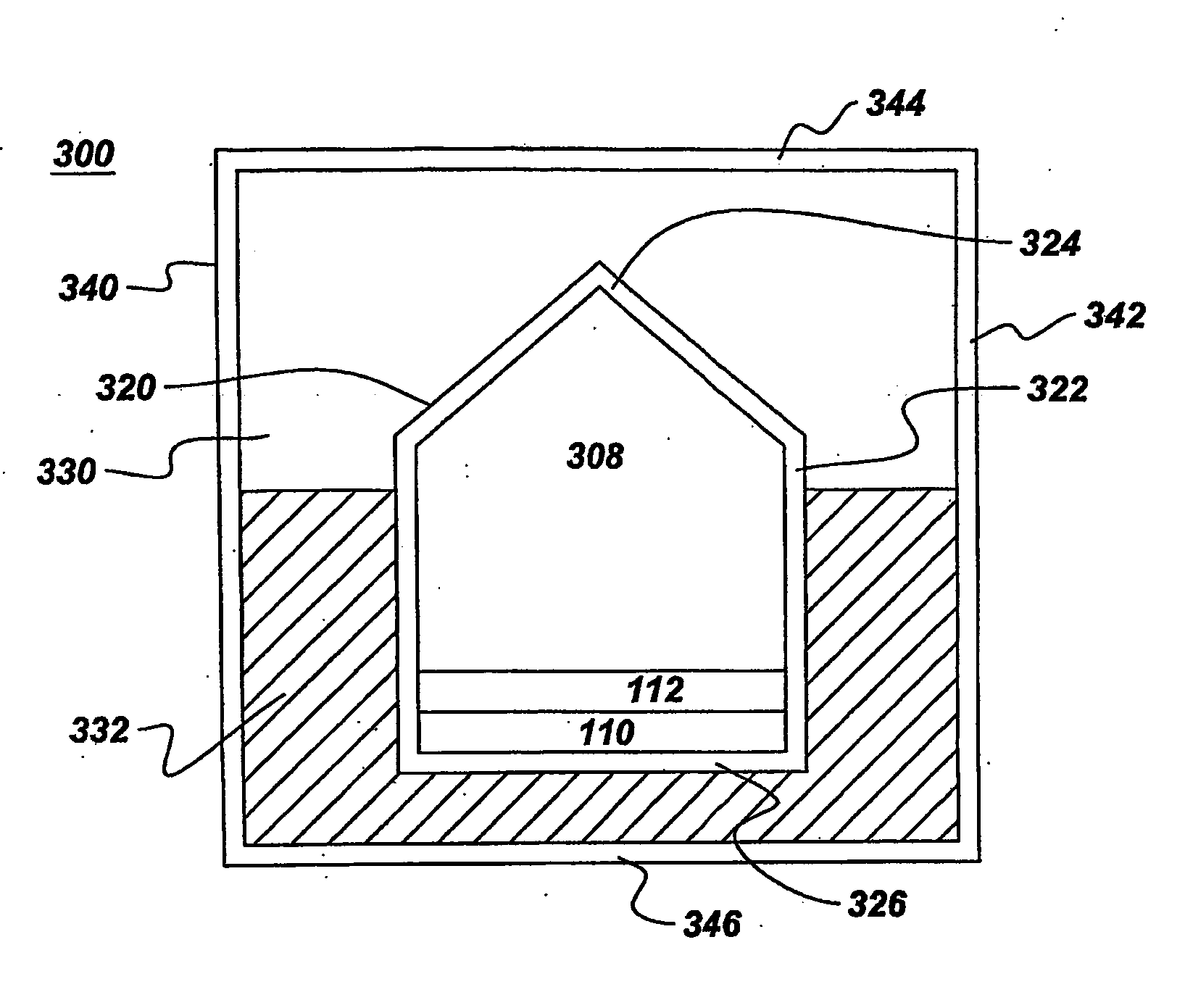

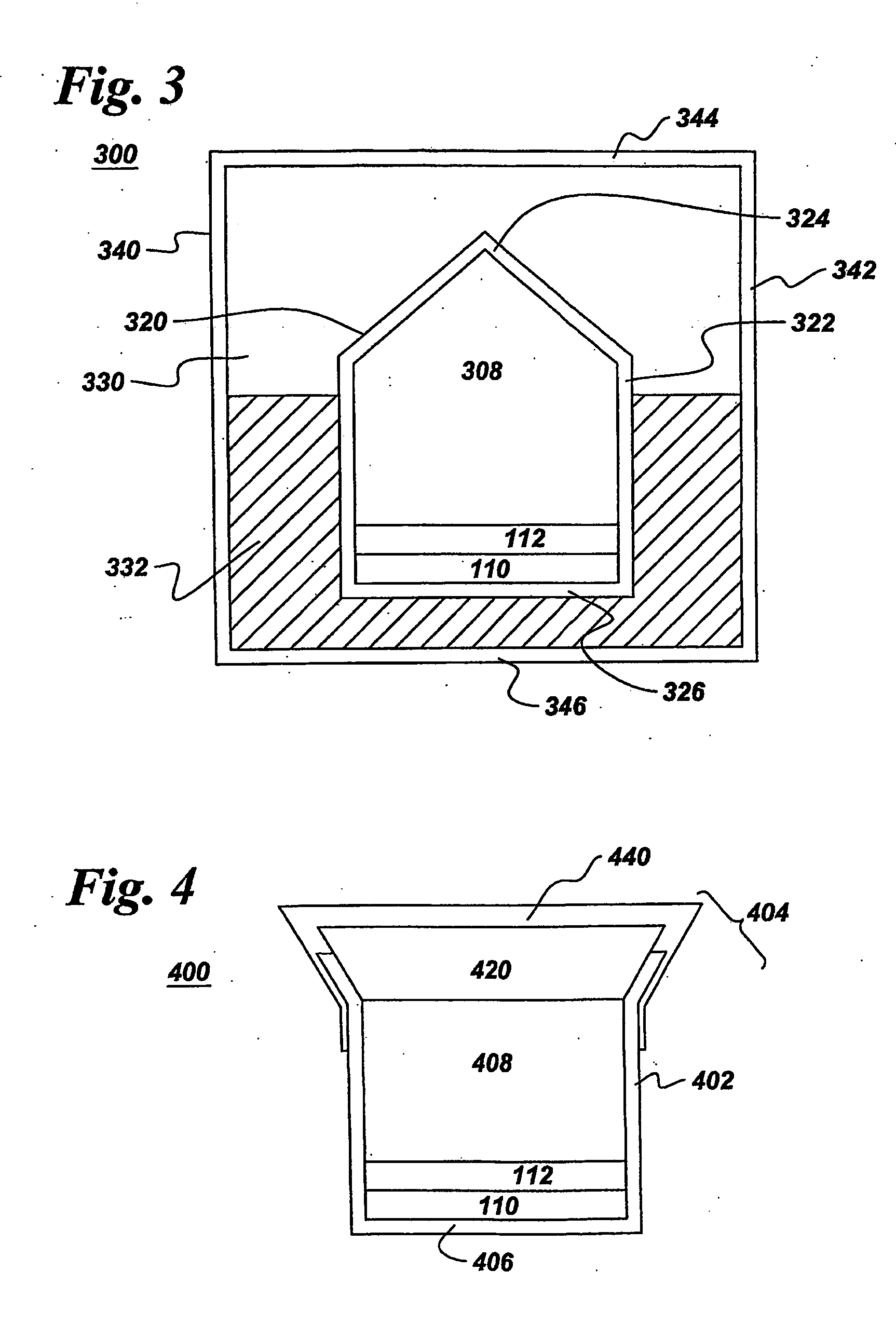

High temperature high pressure capsule for processing materials in supercritical fluids

InactiveUS20050152820A1From normal temperature solutionsUltra-high pressure processesHigh pressureSolvent

A capsule for containing at least one reactant and a supercritical fluid in a substantially air-free environment under high pressure, high temperature processing conditions. The capsule includes a closed end, at least one wall adjoining the closed end and extending from the closed end; and a sealed end adjoining the at least one wall opposite the closed end. The at least one wall, closed end, and sealed end define a chamber therein for containing the reactant and a solvent that becomes a supercritical fluid at high temperatures and high pressures. The capsule is formed from a deformable material and is fluid impermeable and chemically inert with respect to the reactant and the supercritical fluid under processing conditions, which are generally above 5 kbar and 550° C. and, preferably, at pressures between 5 kbar and 80 kbar and temperatures between 550° C. and about 1500° C. The invention also includes methods of filling the capsule with the solvent and sealing the capsule, as well as an apparatus for sealing the capsule.

Owner:SLT TECH

Apparatus for processing materials in supercritical fluids and methods thereof

ActiveUS7704324B2After-treatment apparatusUltra-high pressure processesHigh intensityPressure difference

An apparatus and method for processing materials in supercritical fluids is disclosed. The apparatus includes a capsule configured to contain a supercritical fluid, a high strength enclosure disposed about the capsule and a sensor configured to sense pressure difference between an interior and an exterior of the capsule. The apparatus also includes a pressure control device configured to adjust pressure difference of the capsule in response to the pressure difference sensed by the sensor. The apparatus further includes at least one dividing structure disposed within the capsule that divides the capsule into a seed growing chamber and a nutrient chamber.

Owner:SLT TECH

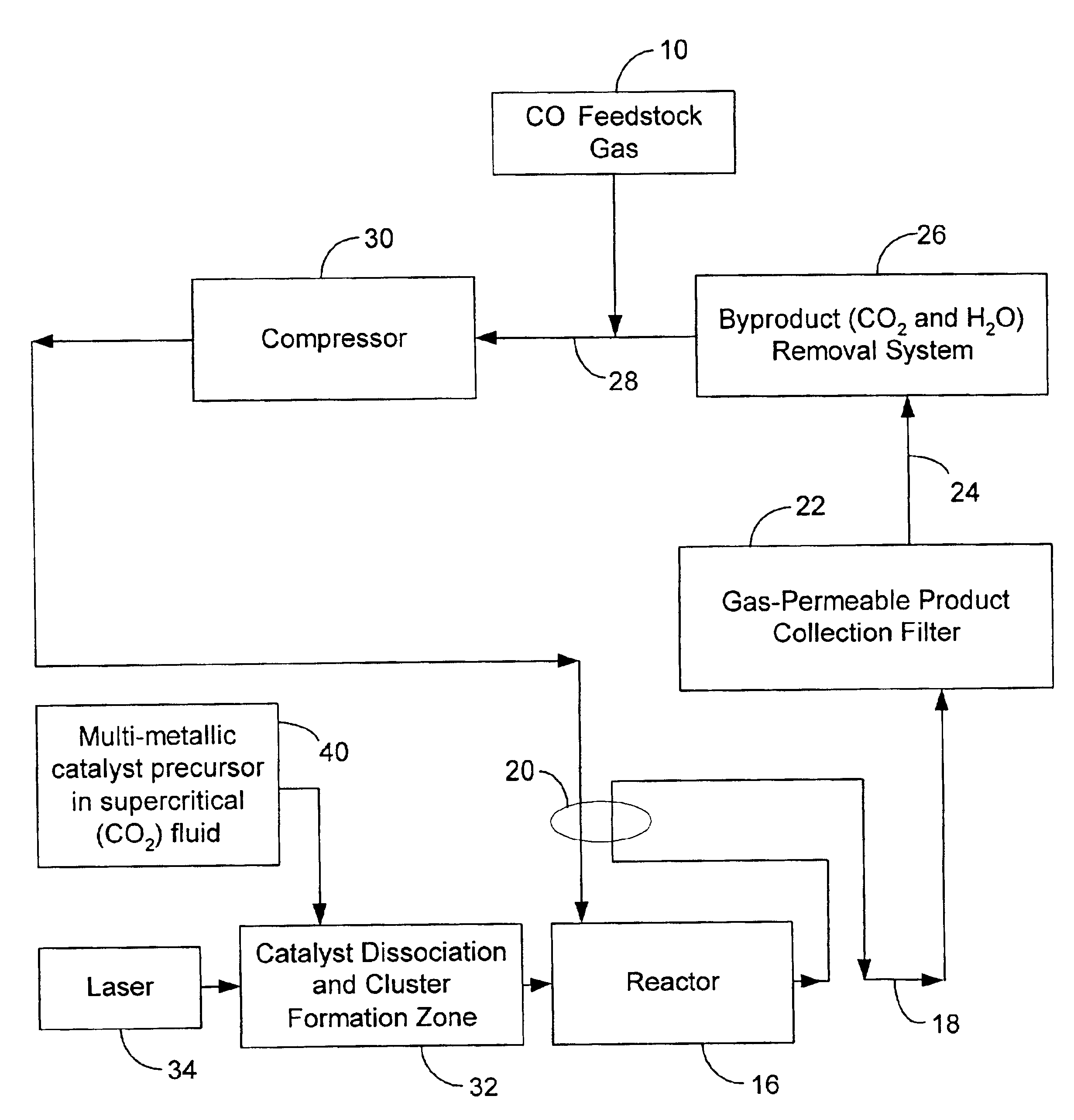

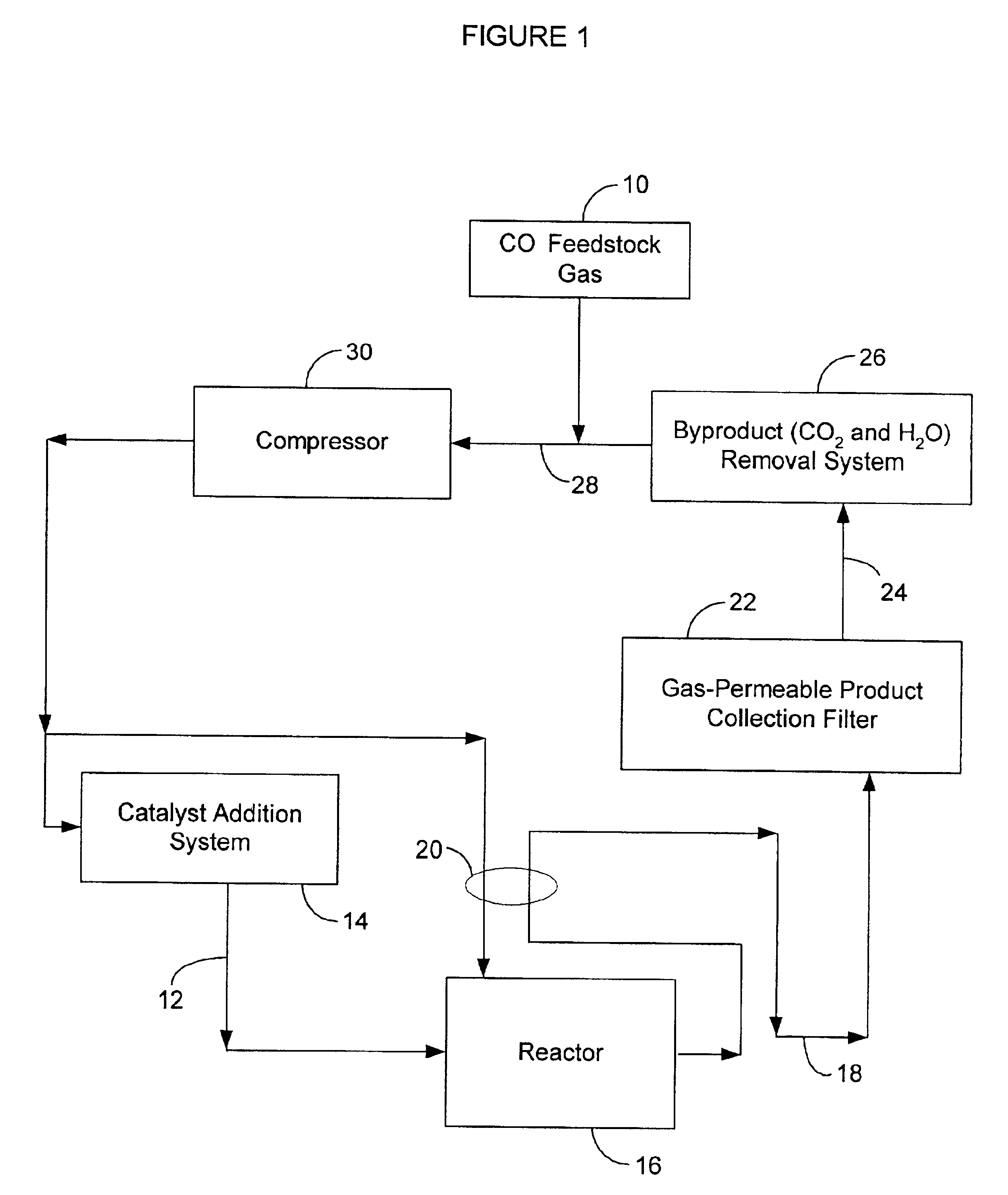

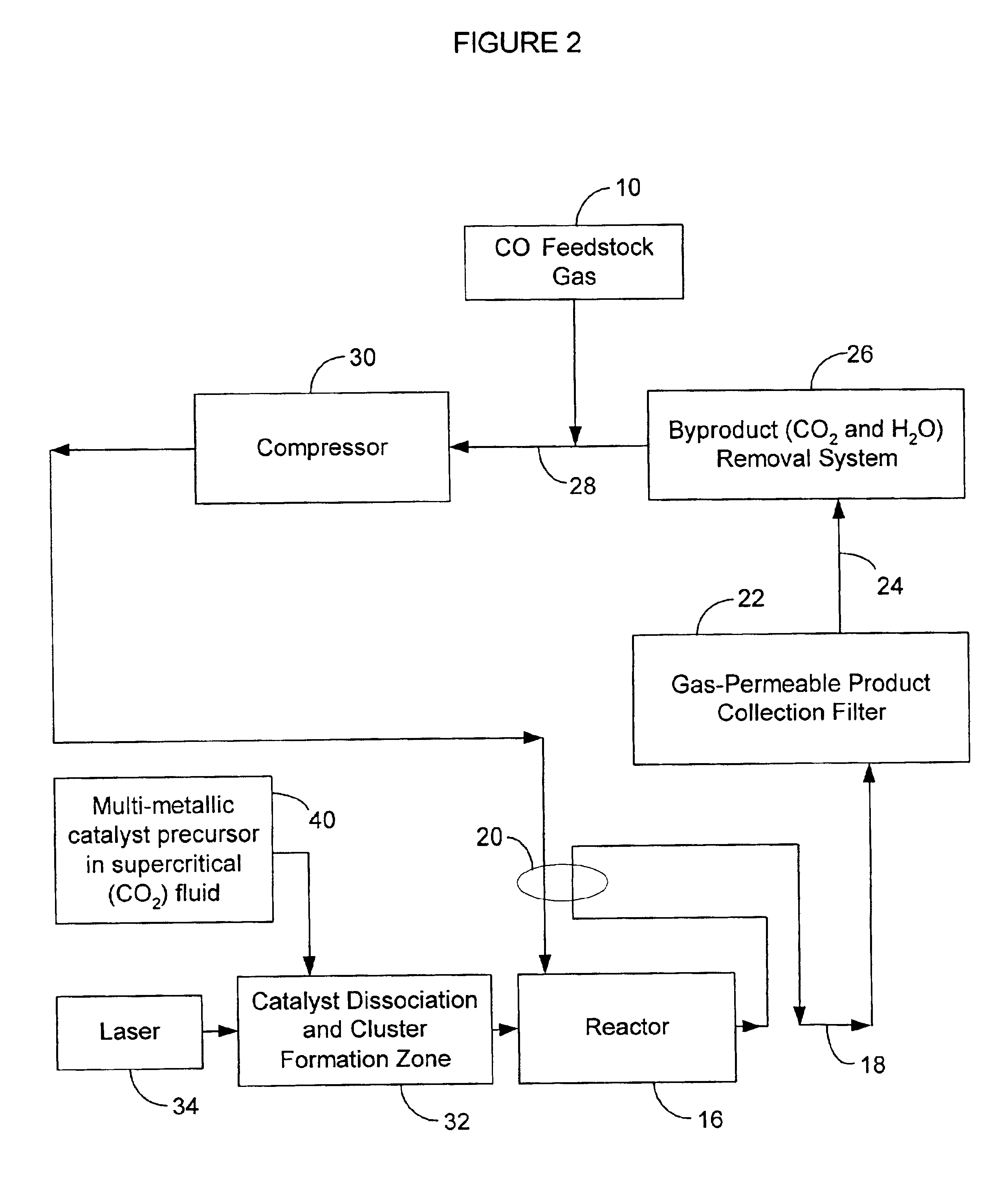

Process utilizing pre-formed cluster catalysts for making single-wall carbon nanotubes

InactiveUS6913789B2Facilitates nucleation phaseFaster and more reproducible and stable clusteringMaterial nanotechnologyFibre chemical featuresGas phaseMetal catalyst

A gas-phase method for producing high yields of single-wall carbon nanotubes with high purity and homogeneity is disclosed. The method involves using preformed metal catalyst clusters to initiate and grow single-wall carbon nanotubes. In one embodiment, multi-metallic catalyst precursors are used to facilitate the metal catalyst cluster formation. The catalyst clusters are grown to the desired size before mixing with a carbon-containing feedstock at a temperature and pressure sufficient to initiate and form single-wall carbon nanotubes. The method also involves using small fullerenes and preformed sections of single-wall carbon nanotubes, either derivatized or underivatized, as seed molecules for expediting the growth and increasing the yield of single-wall carbon nanotubes. The multi-metallic catalyst precursors and the seed molecules may be introduced into the reactor by means of a supercritical fluid. In addition the seed molecules may be introduced into the reactor via an aerosol or smoke.

Owner:RICE UNIV

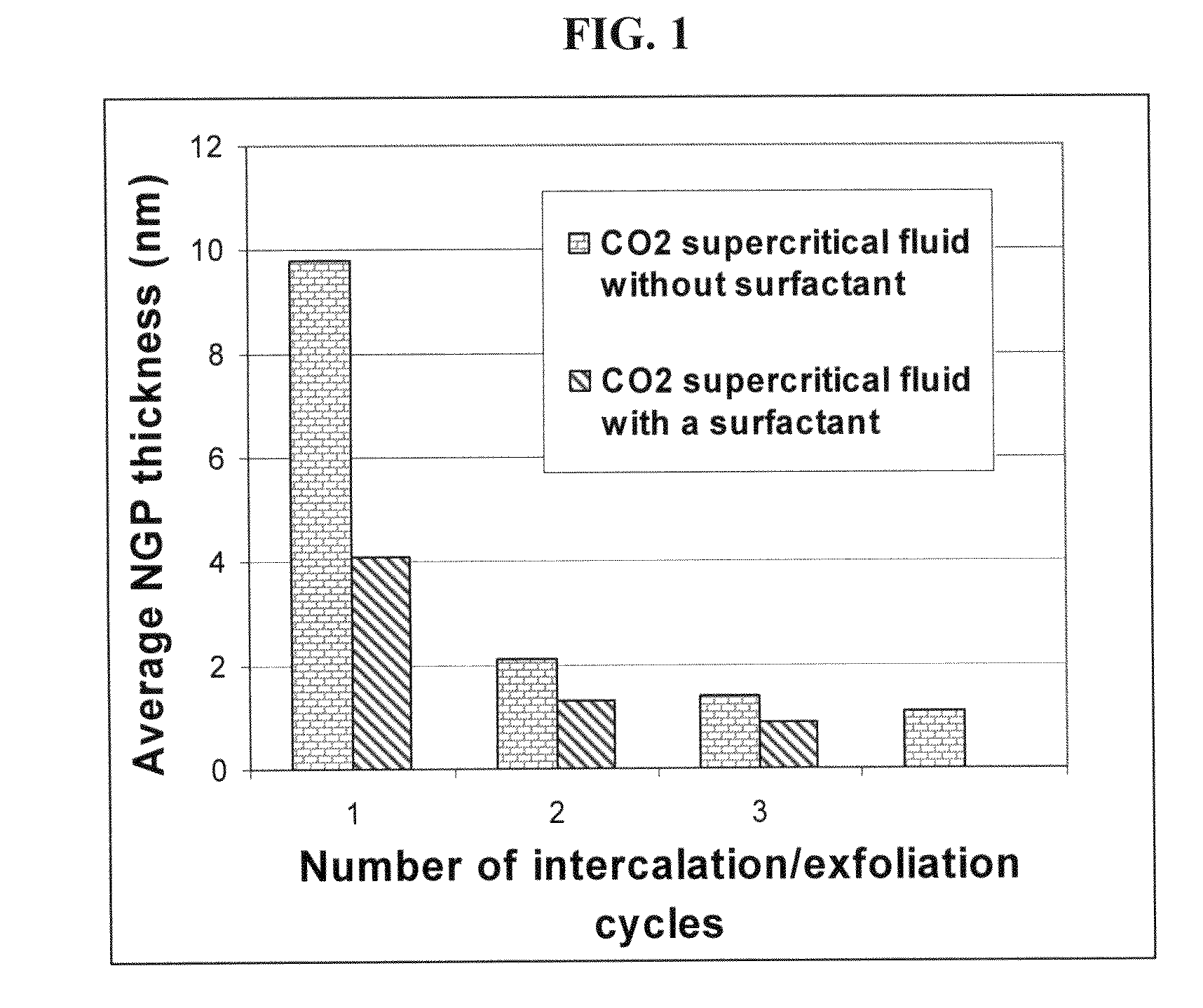

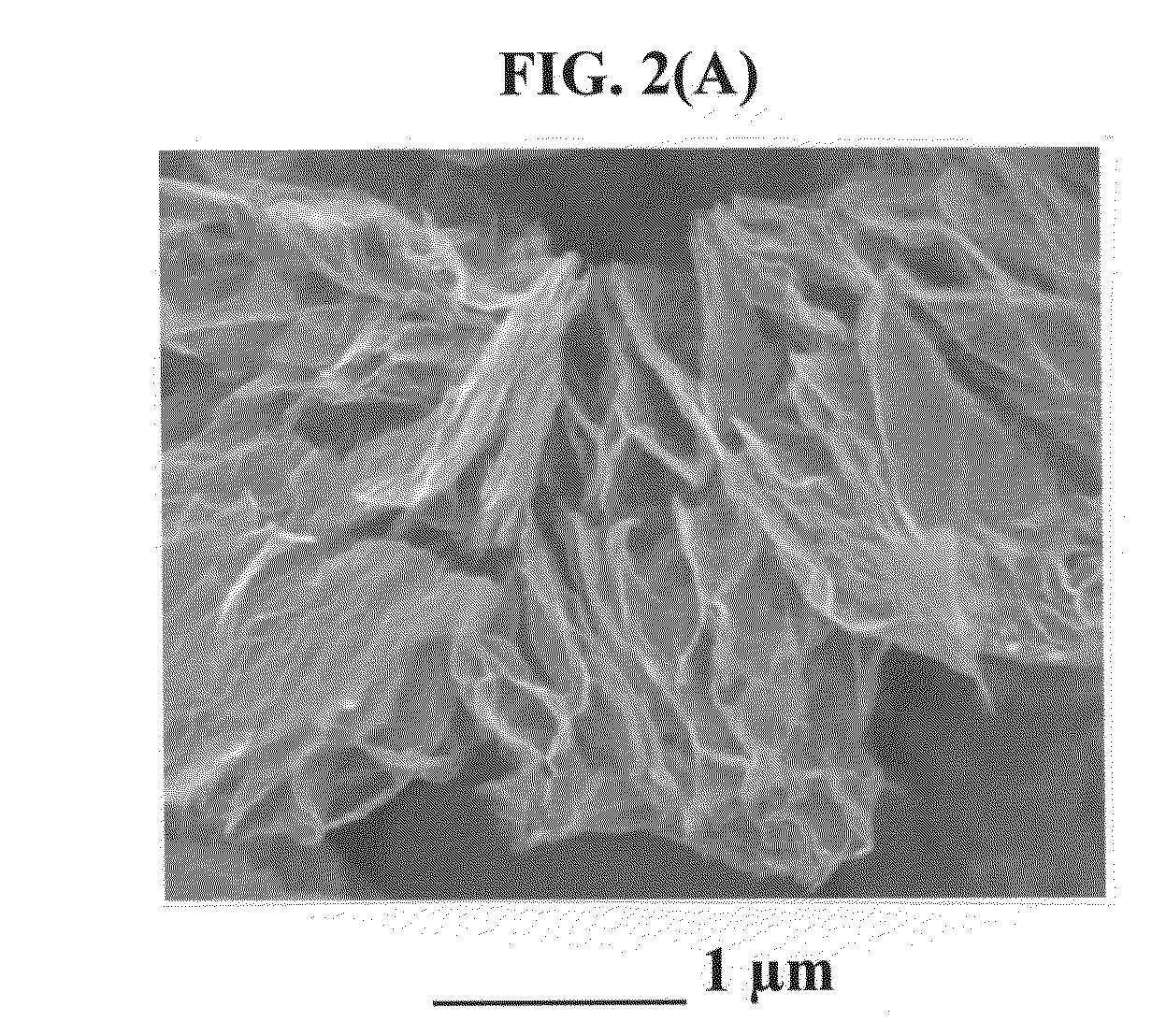

Supercritical fluid process for producing nano graphene platelets

ActiveUS20100044646A1Improve conductivityPigmenting treatmentNon-metal conductorsDisplay deviceSolar cell

The present invention provides a process for producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The process comprises: (i) subjecting a graphitic material to a supercritical fluid at a first temperature and a first pressure for a first period of time in a pressure vessel and then (ii) rapidly depressurizing the fluid at a fluid release rate sufficient for effecting exfoliation of the graphitic material to obtain the NGP material. Conductive NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposite for electromagnetic wave interference (EMI) shielding and static charge dissipation, etc.

Owner:GLOBAL GRAPHENE GRP INC

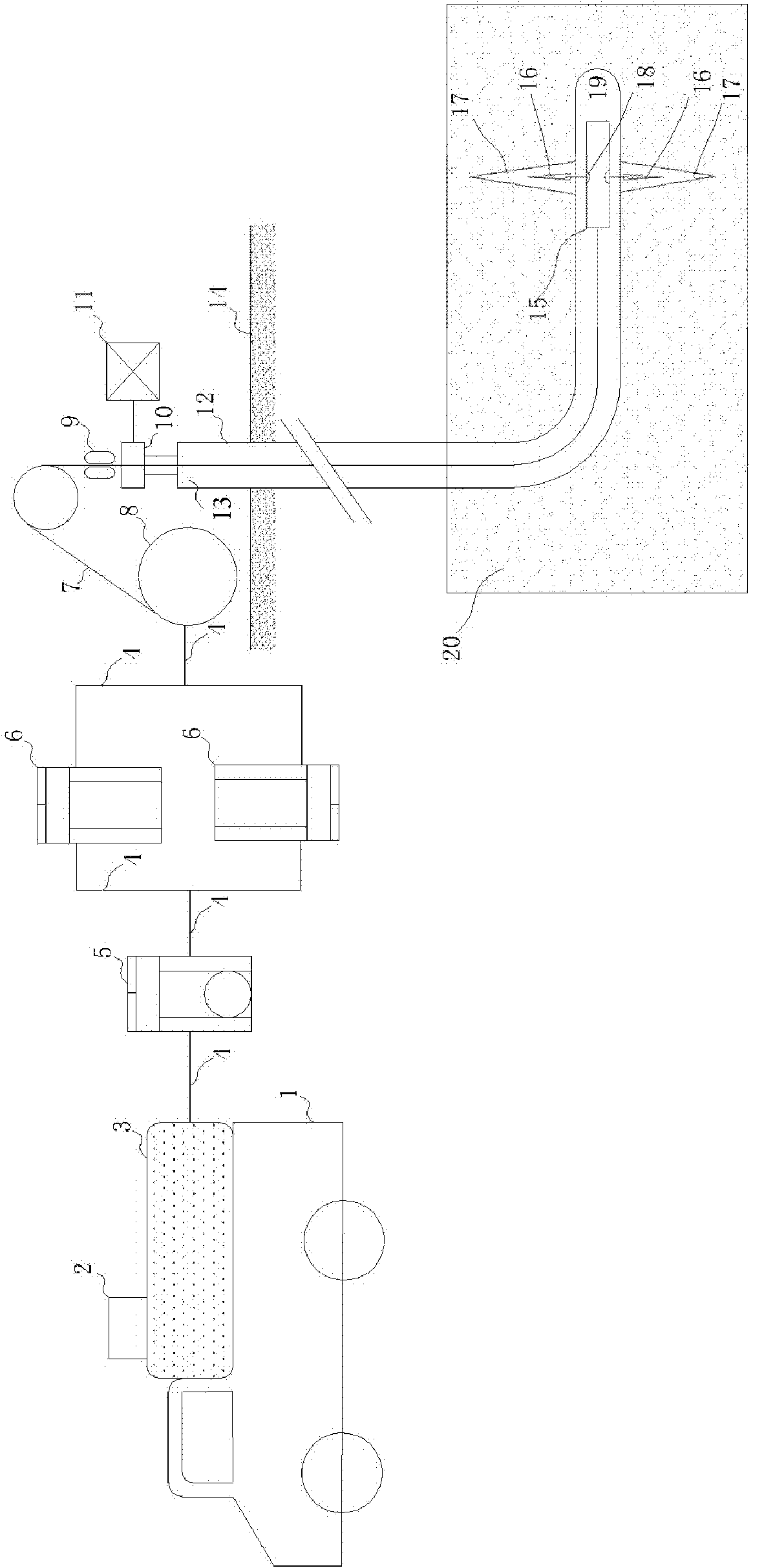

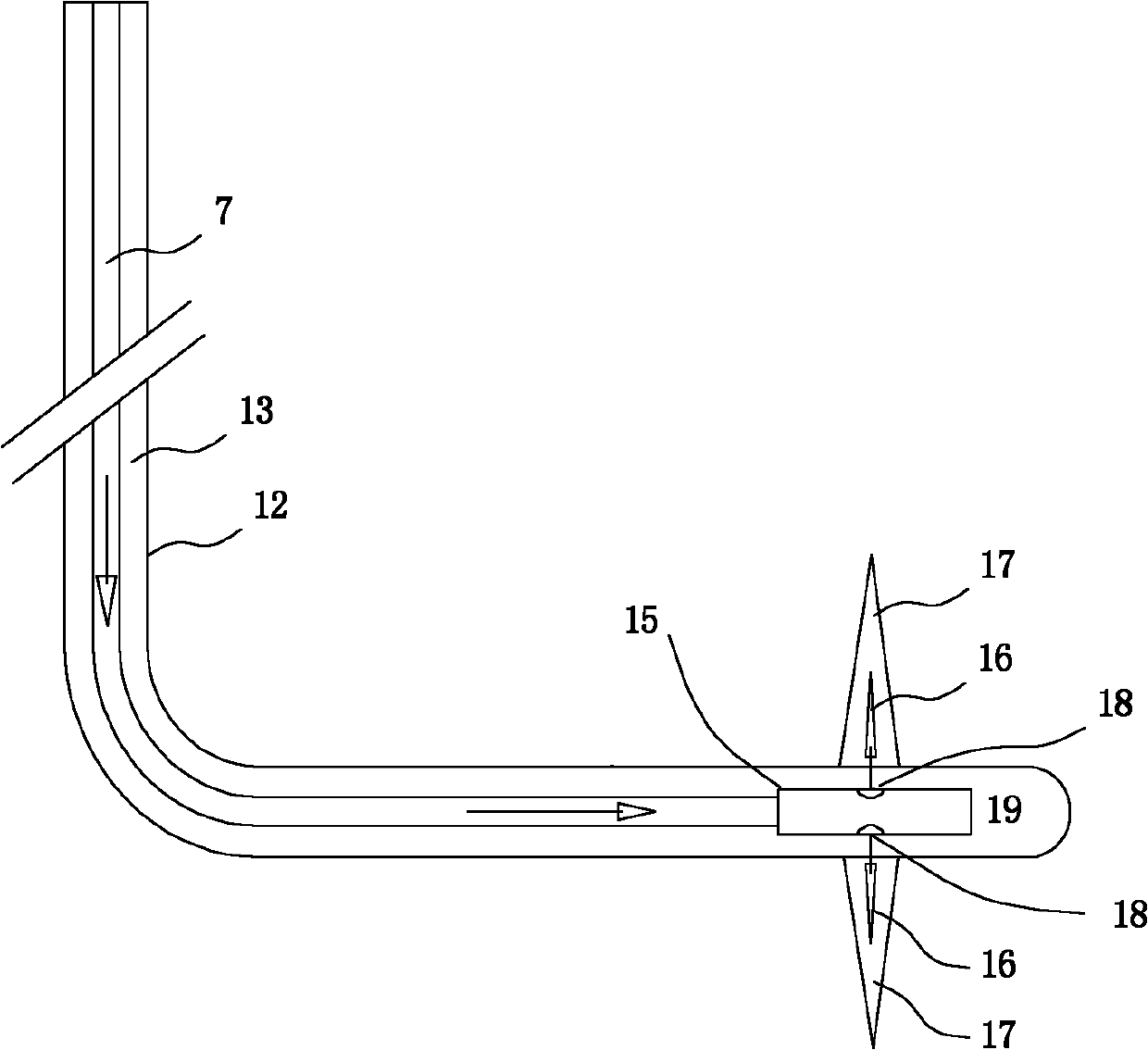

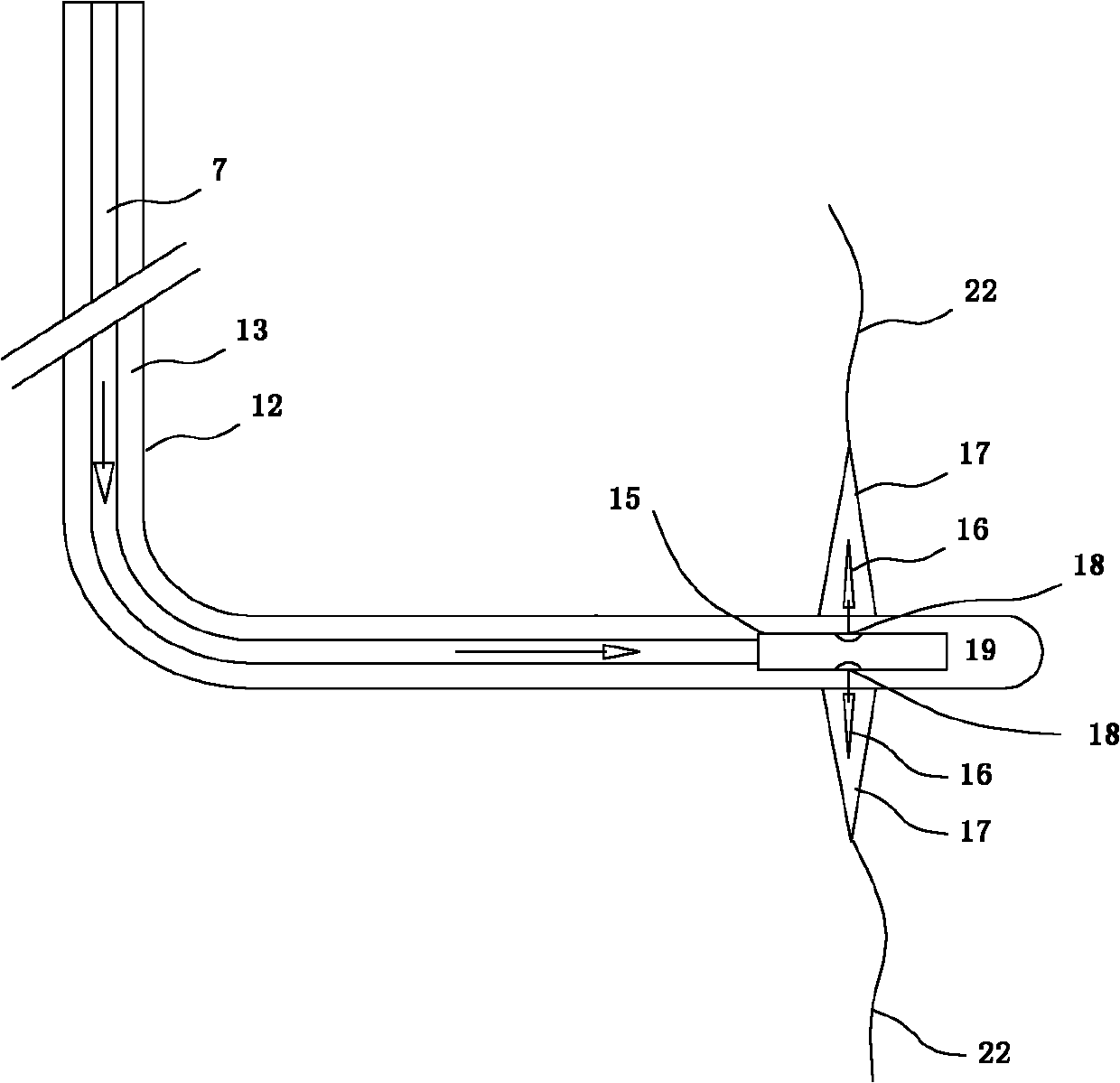

Coiled tubing supercritical CO2 jet fracturing method

ActiveCN102168545AJet rock breaking efficiency is highRock breaking threshold pressure is lowLiquid/gas jet drillingFluid removalWater basedFracturing fluid

The invention relates to a coiled tubing supercritical CO2 jet fracturing method. The method is used for performing jet fracturing on oil well reservoirs by taking supercritical CO2 as fracturing fluid. By the method, a supercritical CO2 fluid is used as the fracturing fluid to perform the jet fracturing; a supercritical CO2 sand jet perforating hole can reduce system pressure; the pressure needed by fissure extension can be further reduced by the characteristics of low viscosity and high dispersion performance of the supercritical CO2 fluid; most importantly, the supercritical CO2 jet fracturing does not pollute the reservoirs, but the supercritical CO2 can further improve the oil and gas recovery ratio after entering the reservoirs; the return discharge is not needed after the fracturing is completed; when the stage-by-stage jet fracturing is performed by using the coiled tubing, a tube pillar can be lifted or put down without mineshaft pressure relieving, the operation process is reduced and the operation cost is reduced, so that the method is extremely suitable for fracturing modification of unconventional oil-gas reservoirs such as thick oil reservoirs, low permeability and super-low permeability oil-gas reservoirs, shale gas reservoirs, coal bed methane reservoirs and the like of which the effects are low by using the conventional water-based fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Methods for transferring supercritical fluids in microelectronic and other industrial processes

InactiveUS6905555B2Decorative surface effectsSemiconductor/solid-state device manufacturingVolumetric Mass DensityPressure vessel

A method of displacing a supercritical fluid from a pressure vessel (e.g., in a microelectronic manufacturing process), with the steps of: providing an enclosed pressure vessel containing a first supercritical fluid (said supercritical fluid preferably comprising carbon dioxide); adding a second fluid (typically also a supercritical fluid) to said vessel, with said second fluid being added at a pressure greater than the pressure of the first supercritical fluid, and with said second fluid having a density less than that of the first supercritical fluid; forming an interface between the first supercritical fluid and the second fluid; and displacing at least a portion of the first supercritical fluid from the vessel with the pressure of the second, preferably fluid while maintaining the interface therebetween.

Owner:MICELL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com