Patents

Literature

2509 results about "Alkaline catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

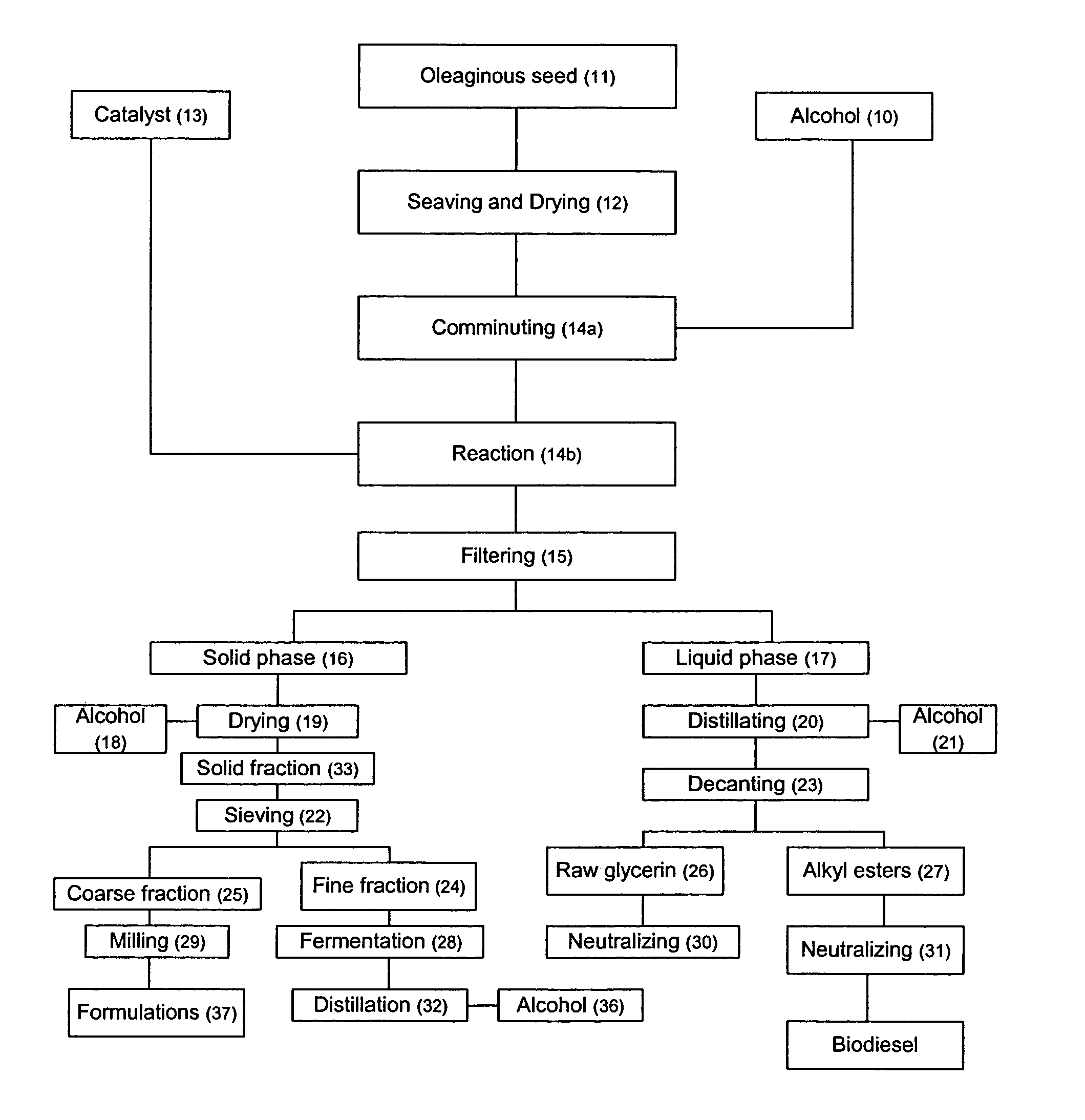

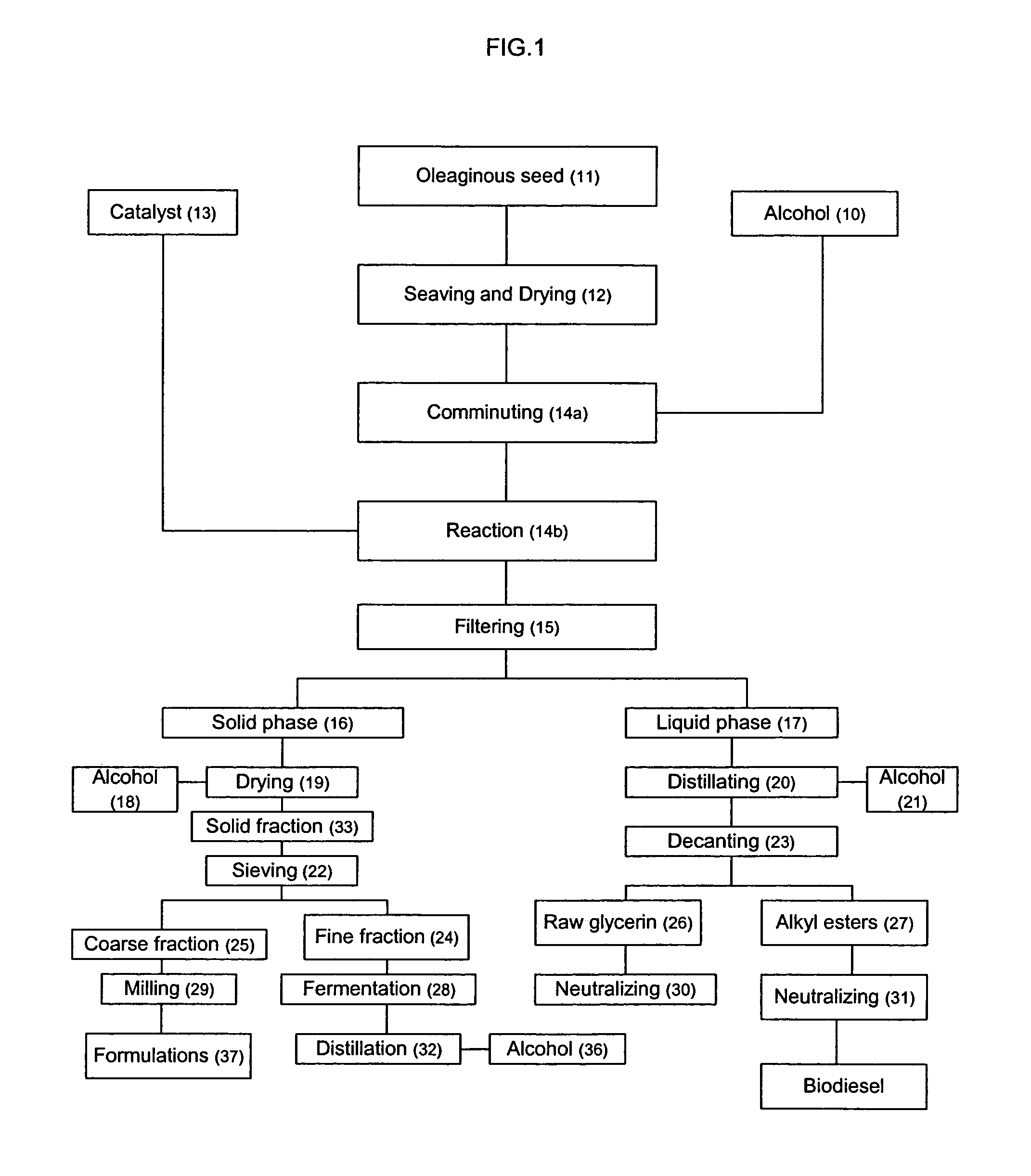

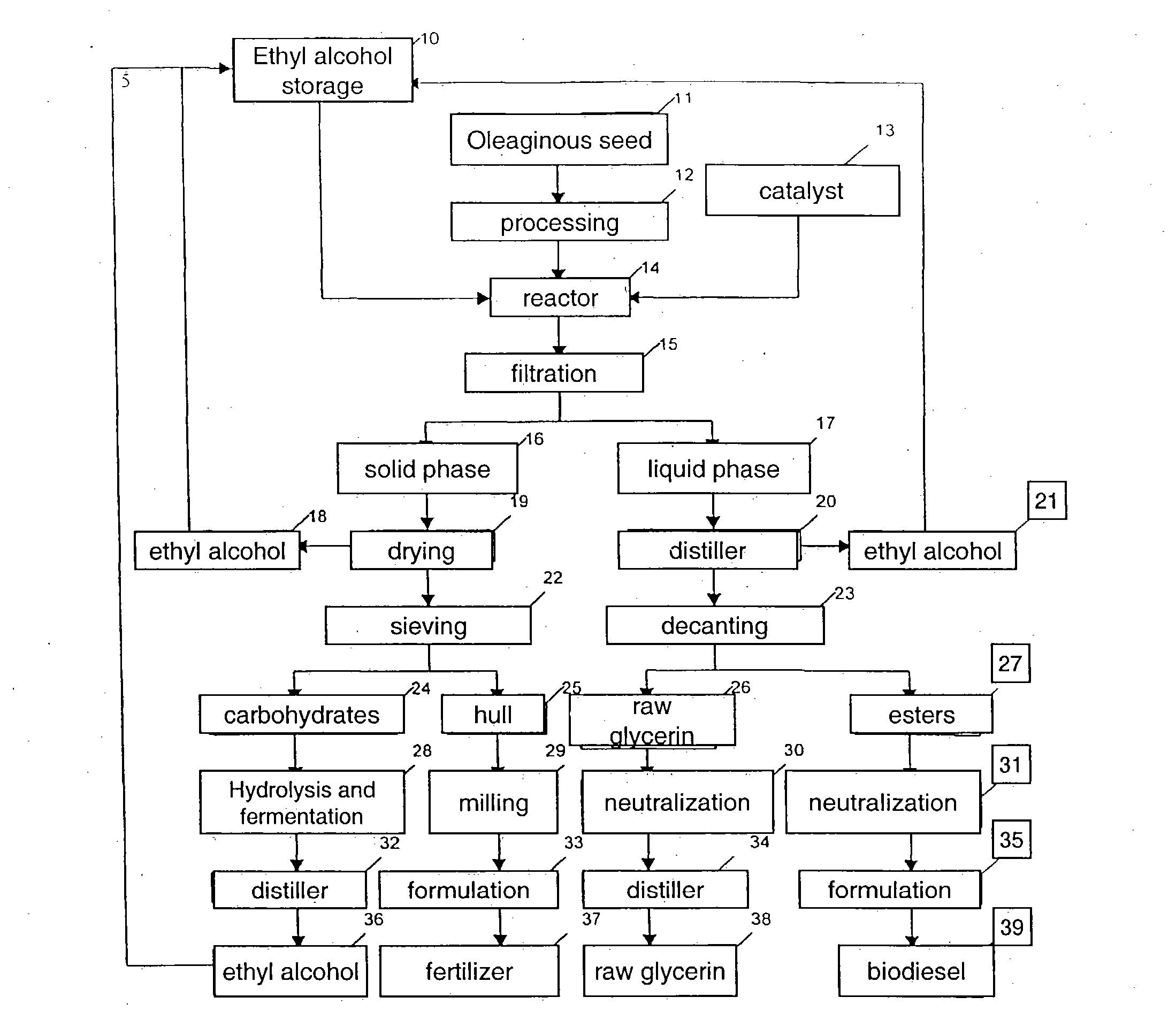

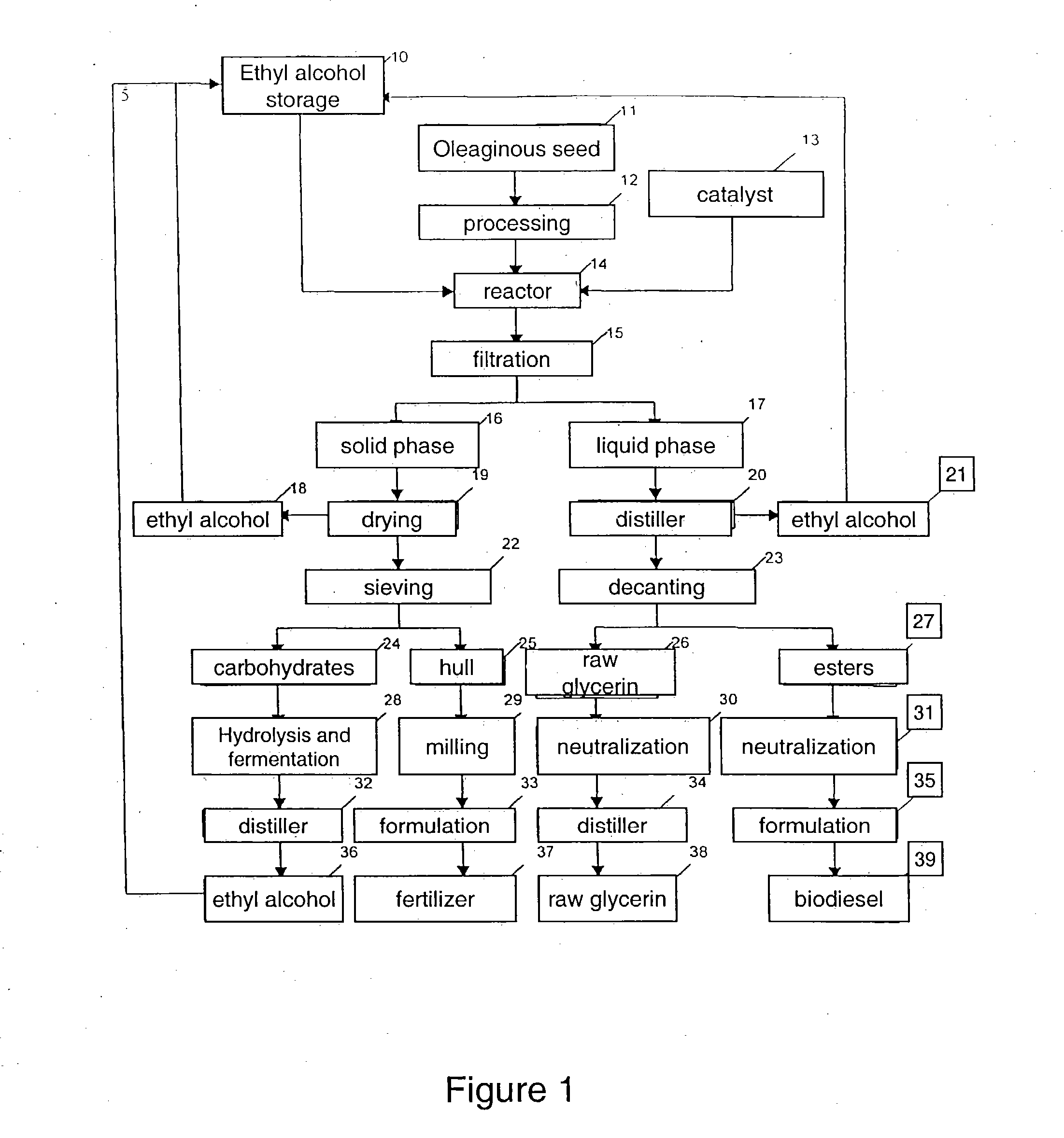

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

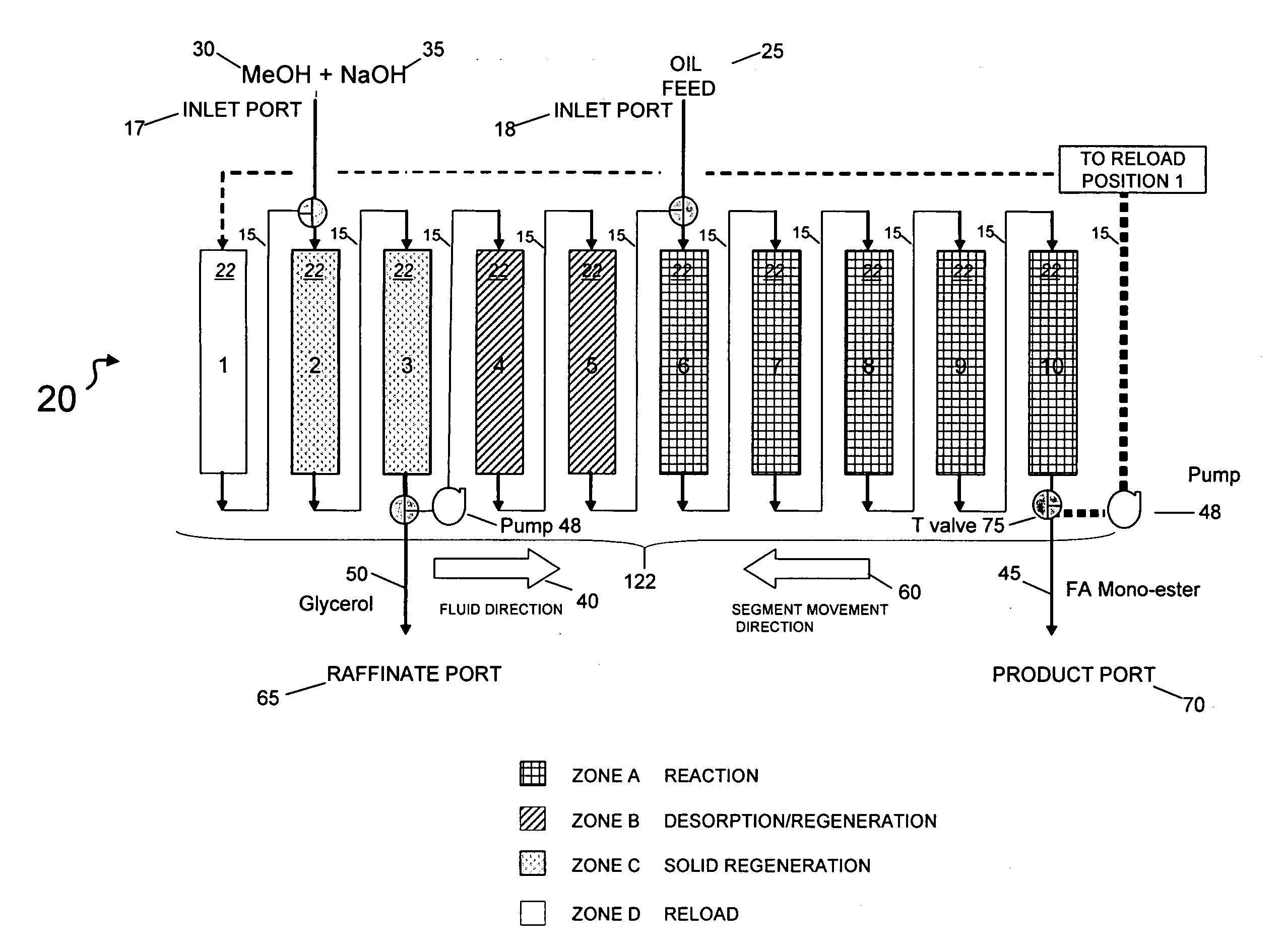

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel

ActiveUS20070158270A1Reduce contentLow costFatty oils/acids recovery from wasteFatty acid esterificationBiodieselAlcohol

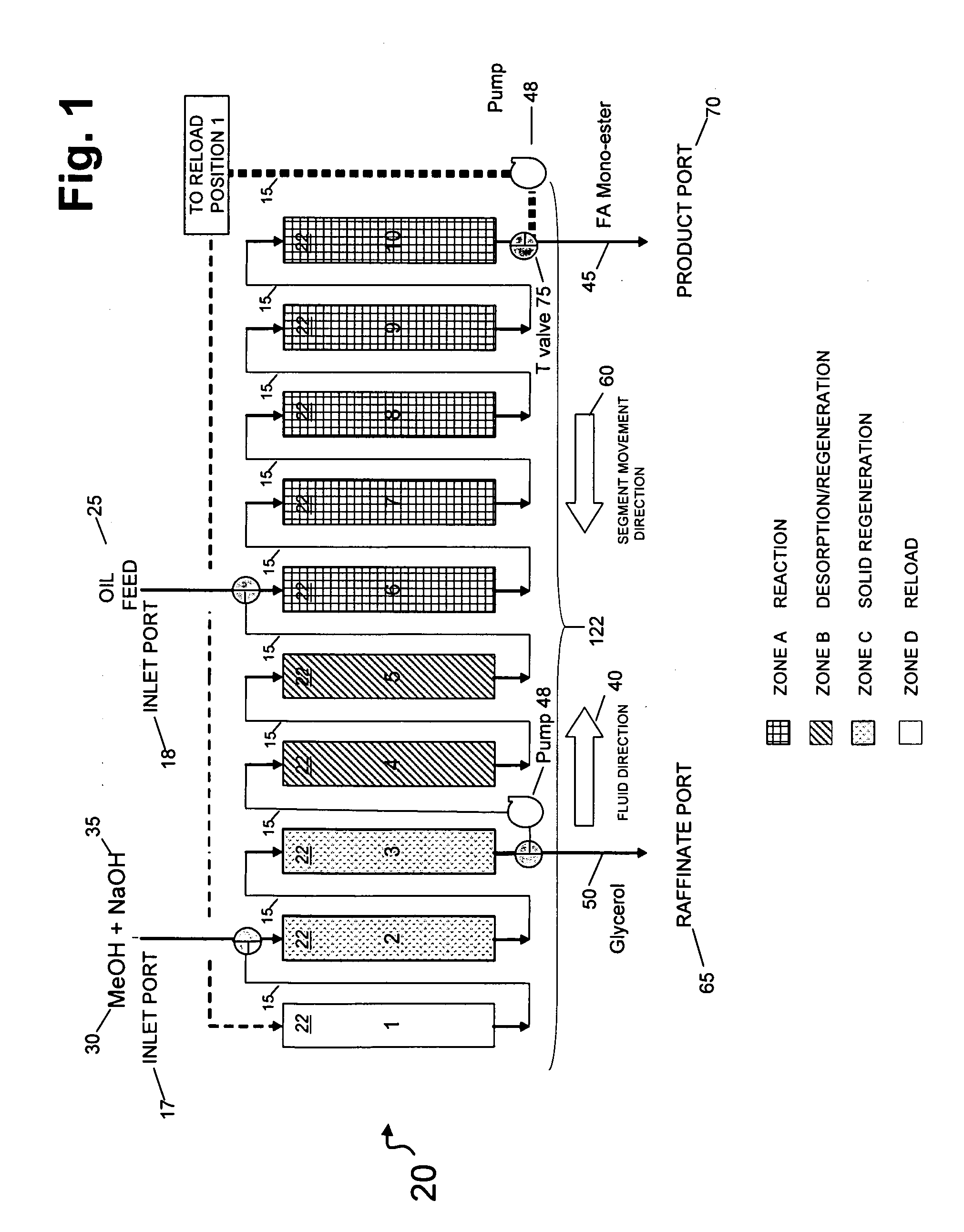

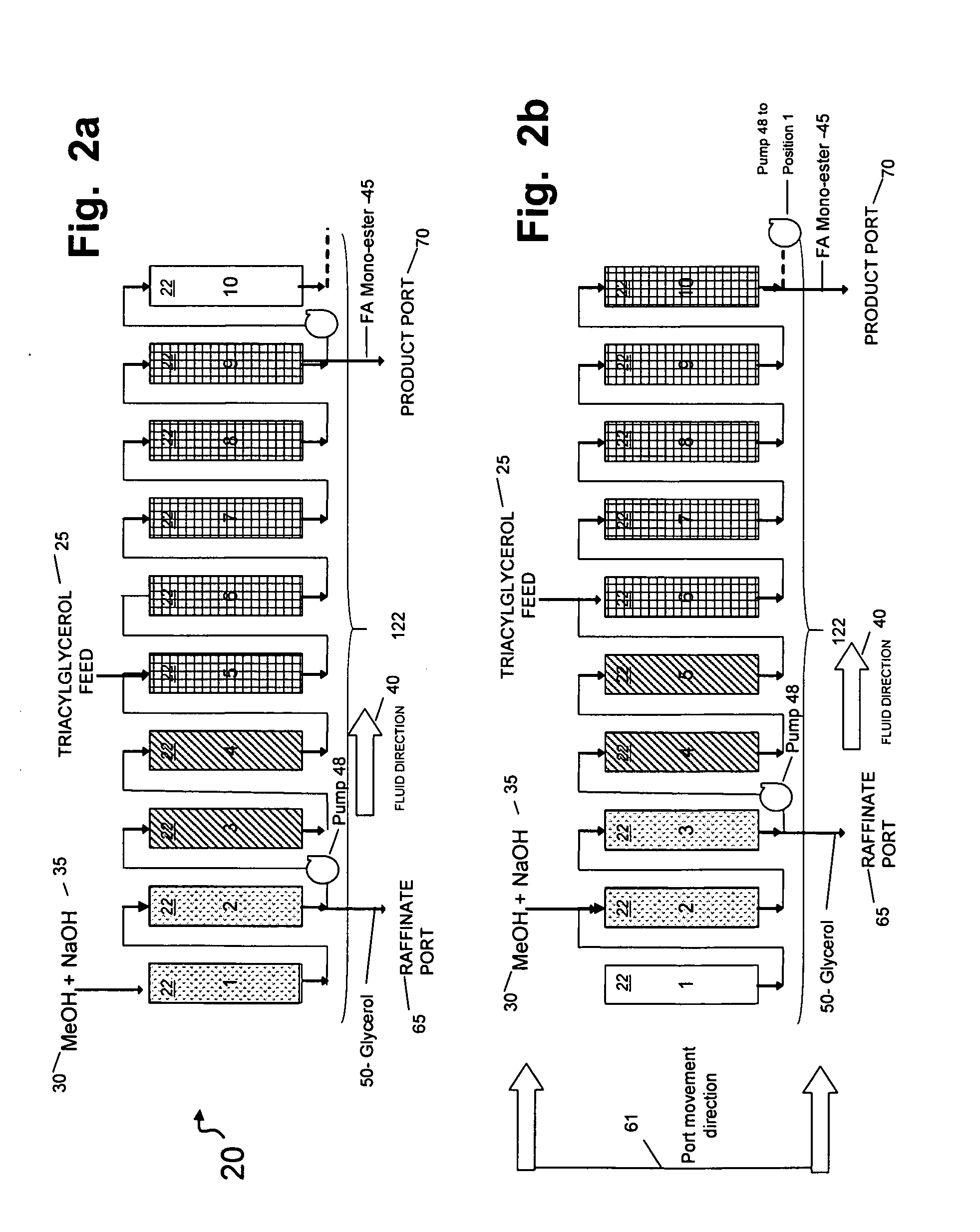

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel from a triacylglycerol feedstock is described. In an exemplary method, the triacylglycerol feedstock is continuously contacted with a catalytic chromatographic bed comprising a first (solid phase) basic catalyst through a first port of a simulated moving bed chromatographic apparatus. A monohydric alcohol and optional second (mobile phase) basic catalyst is continuously contacted with the catalytic chromatographic bed through a second port and pumped in a first direction toward the triacylglycerol feedstock to contact the triacylglycerol in a reaction zone of the catalytic chromatographic bed where the fatty acid monoester and glycerol coproduct are formed. The fatty acid monoester is removed from the reaction zone through a product port of the simulated moving bed apparatus. Segments of the catalytic chromatographic bed are incrementally moved in a second direction, opposite the first direction, and the glycerol is removed from a raffinate port located opposite the product port of the apparatus.

Owner:ARCHER DANIELS MIDLAND CO

Method of producing fatty acid lower alkylester from fat and oil

InactiveUS6090959AImprove reaction efficiencySimplify eliminate needFatty acid esterificationFatty acids production/refiningAlcoholTransesterification

In a method of producing a fatty acid lower alkylester according to the invention, a fat & oil and a lower alcohol are caused to react with each other in the presence of a catalyst, in which triglyceride contained in the fat & oil undergoes a transesterification. The catalyst to be used in the reaction is a solid basic catalyst consisting essentially of a potassium compound and iron oxide, of a calcium compound and iron oxide, or of a potassium compound and zirconium oxide. It is possible to produce the fatty acid lower alkylester at a high reaction efficiency by this method as well as to simplify or eliminate the need of catalyst separation and recovery processes.

Owner:GREENTECH SOLUTION

Process for producing biodiesel

InactiveUS20050011112A1Fatty oils/acids recovery from wasteFatty acid esterificationBiodieselSolid fraction

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds, comprising a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

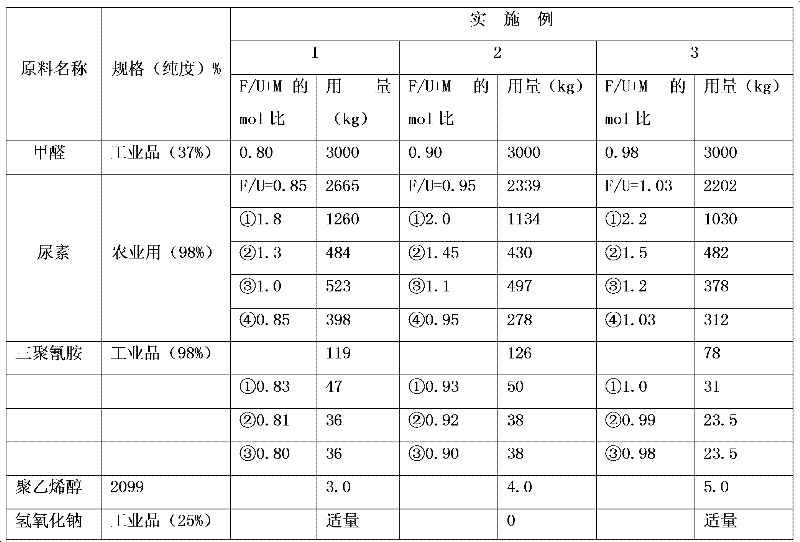

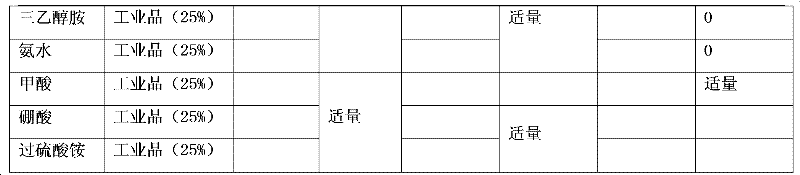

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

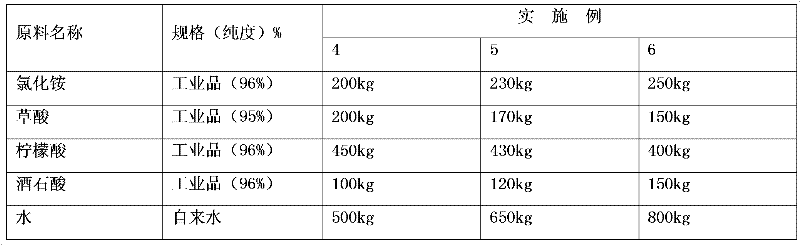

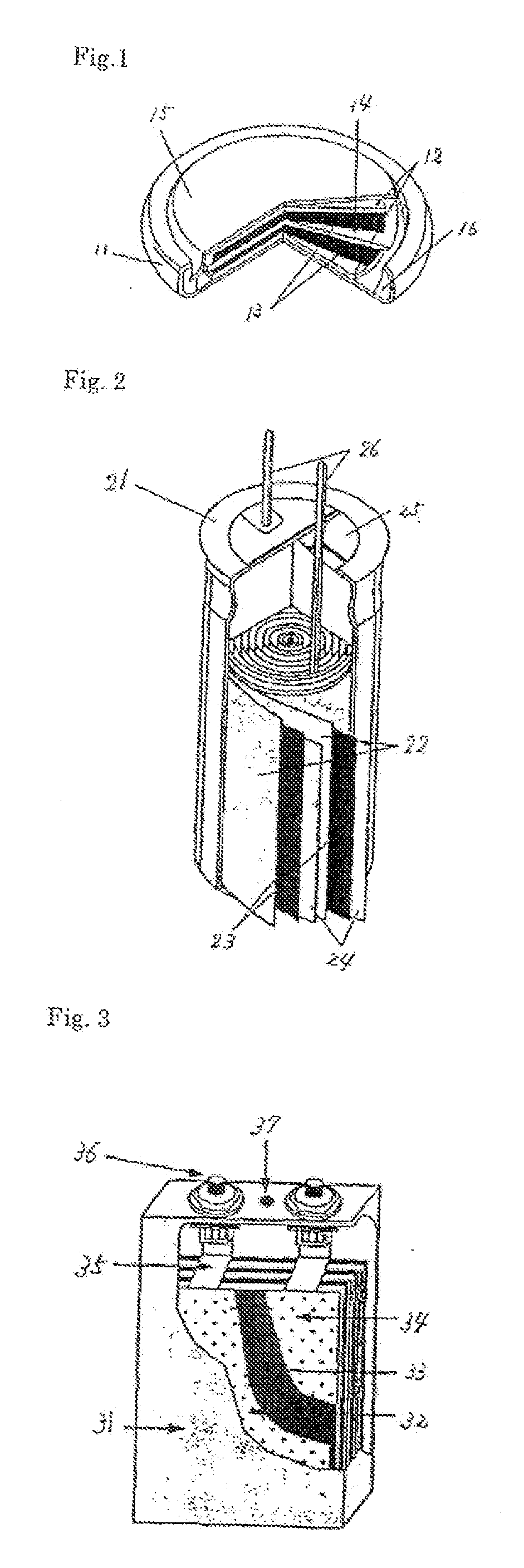

Carbon aerogels for supercapacitors and method of manufacturing the same

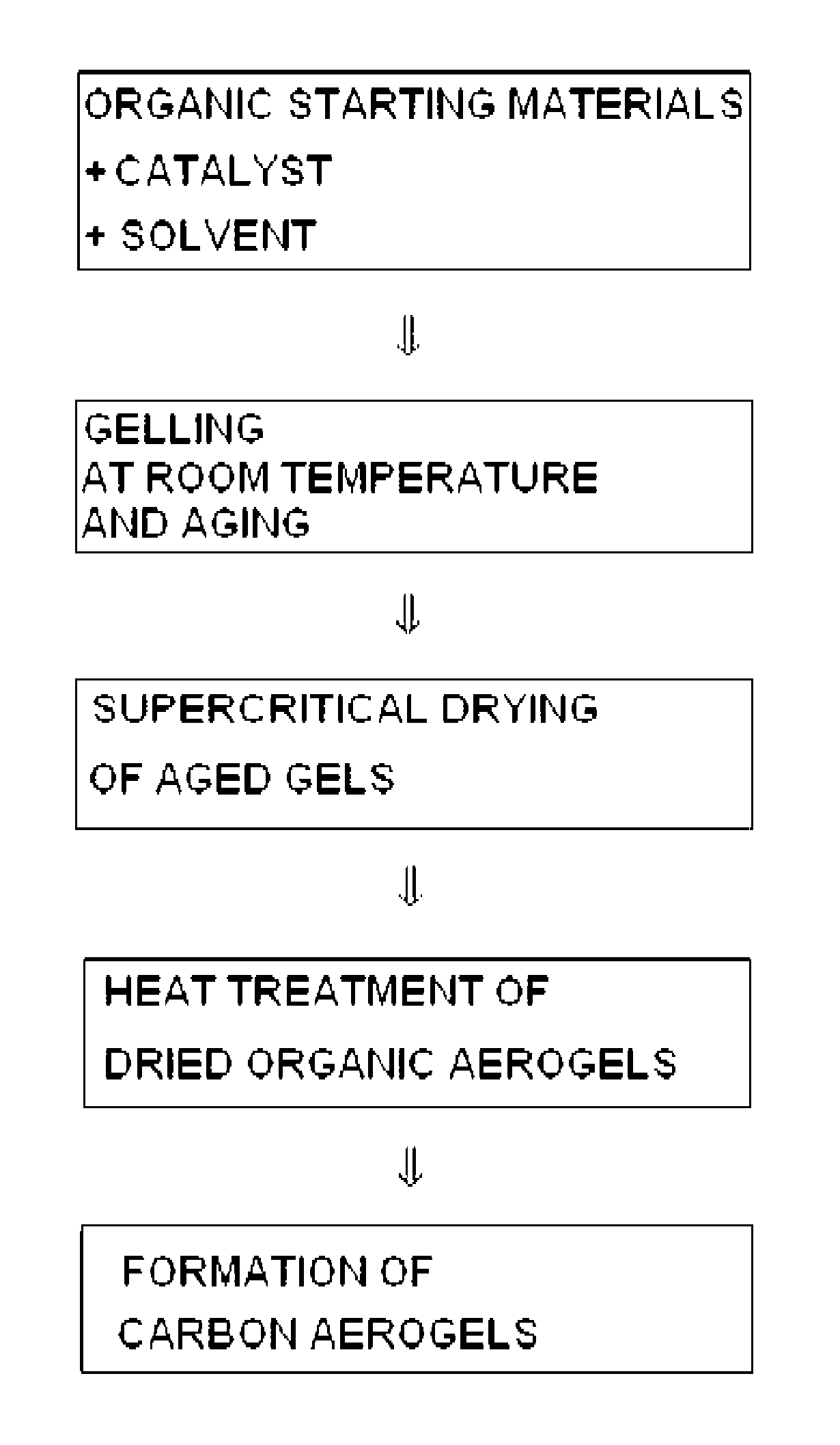

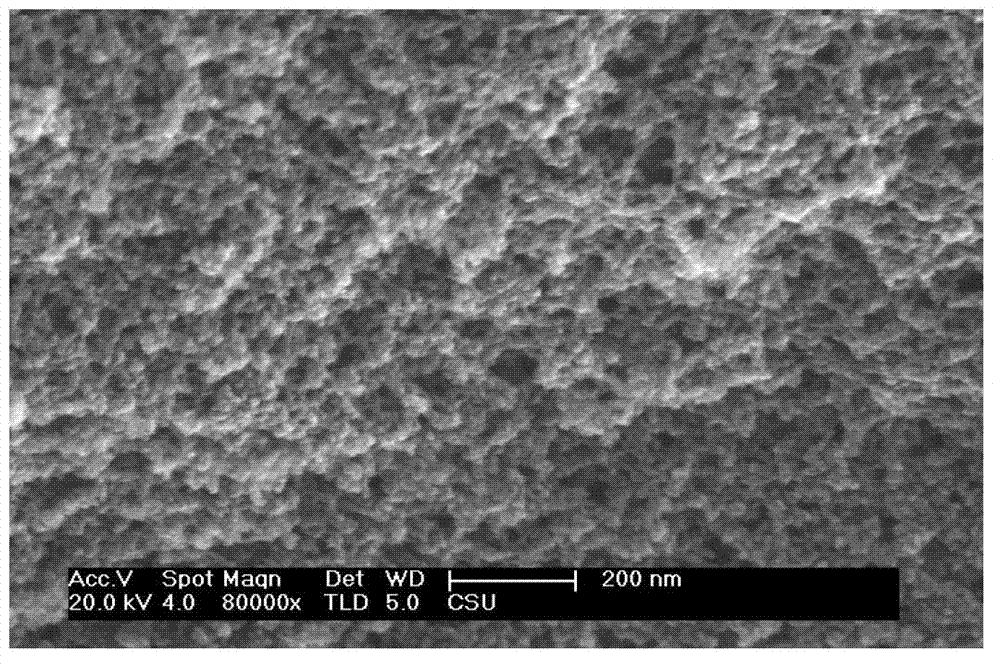

InactiveUS8480930B2Large specific surface areaShort processConductive materialNon-conductive material with dispersed conductive materialSupercritical dryingFurfural

A method for preparing carbon aerogels and carbon aerogels obtained therefrom are disclosed. The method for preparing carbon aerogels comprises: mixing organic starting materials including phloroglucinol and furfural with a solvent capable of dissolving the organic materials in a predetermined ratio to form a sol solution; adjusting pH of the sol solution adequately by using an acidic or basic catalyst, gelling the sol solution at room temperature under atmospheric pressure, and aging the resultant gels; substituting the solvent in thus obtained gels with liquid carbon dioxide, followed by drying in a supercritical state, to form organic aerogels; and pyrolyzing the organic aerogels in an electric furnace under inert atmosphere to obtain carbon aerogels. Particularly, the gels are formed at room temperature in a short period of time by adequately adjusting pH of the sol solution. Therefore, the method provides improved time efficiency and energy efficiency as compared to existing methods for preparing gels. Additionally, the method allows supercritical drying while avoiding a need for an additional solvent substitution, thereby simplifying the overall process. Further, the method enables preparation of carbon aerogels for supercapacitors having a high specific surface area and high capacitance even in the absence of additional activation step.

Owner:KOREA INST OF SCI & TECH

Preparation method of silicon dioxide super-hydrophobic thin film and super-hydrophobic material

InactiveCN103359954AImprove surface hydrophobicityImprove stabilityOther chemical processesCoatingsAdhesion forcePtru catalyst

The invention provides a preparation method of a silicon dioxide super-hydrophobic thin film. The preparation method comprises the following steps of: step one. preparing alkaline colloidal sol, namely mixing orthosilicate ester, a basic catalyst, a solvent and water to prepare the SiO2 alkaline colloidal sol; step two. adding hexamethyl disilazane to the SiO2 alkaline colloidal sol for reaction to obtain modified SiO colloidal sol; and step three. coating the modified SiO colloidal sol on the surface of a substrate, and drying to obtain the silicon dioxide super-hydrophobic thin film. The invention also provides a super-hydrophobic material. The silicon dioxide super-hydrophobic thin film prepared by the method has strong adhesion force with a substrate and a good dewatering effect; complicated equipment is not needed; the process is simple; the preparation cycle is shortened; the cost is saved; and the application range is wide.

Owner:BYD CO LTD

Composition for film formation, method of film formation, and silica-based film

InactiveUS20020189495A1Group 4/14 element organic compoundsPlastic/resin/waxes insulatorsDecompositionSilicon dioxide

A composition for film formation capable of forming a silica-based coating film having low water absorption and dielectric constant of 2.1 or lower and useful as an interlayer insulating film material in semiconductor devices, etc. The composition contains: (A) a product of hydrolysis and condensation obtained by hydrolyzing and condensing at least one silane compound selected from the group consisting of compounds represented by formula (1), compounds represented by formula (2), and compounds represented by formula (3) in the presence of a basic catalyst and water, <paragraph lvl="0"><in-line-formula>RaSi(OR1)4-a (1) < / in-line-formula>wherein R represents a hydrogen atom, a fluorine atom, or a monovalent organic group, R1 represents a monovalent organic group, and a is an integer of 1 or 2, <paragraph lvl="0"><in-line-formula>Si(OR2)4 (2) < / in-line-formula>wherein R2 represents a monovalent organic group, <paragraph lvl="0"><in-line-formula>R3b(R4O)3-bSi-(R7)d-Si(OR5)3-cR6c (3) < / in-line-formula>wherein R3 to R6 may be the same or different and each represents a monovalent organic group, b and c may be the same or different and each is a number of 0 to 2, R7 represents an oxygen atom, a phenylene group, or a group represented by -(CH2)n-, wherein n is an integer of 1 to 6, and d is 0 or 1; (B) a compound compatible with or dispersible in ingredient (A) and having a boiling point or decomposition temperature of from 250 to 450° C.; and (C) an organic solvent.

Owner:JSR CORPORATIOON

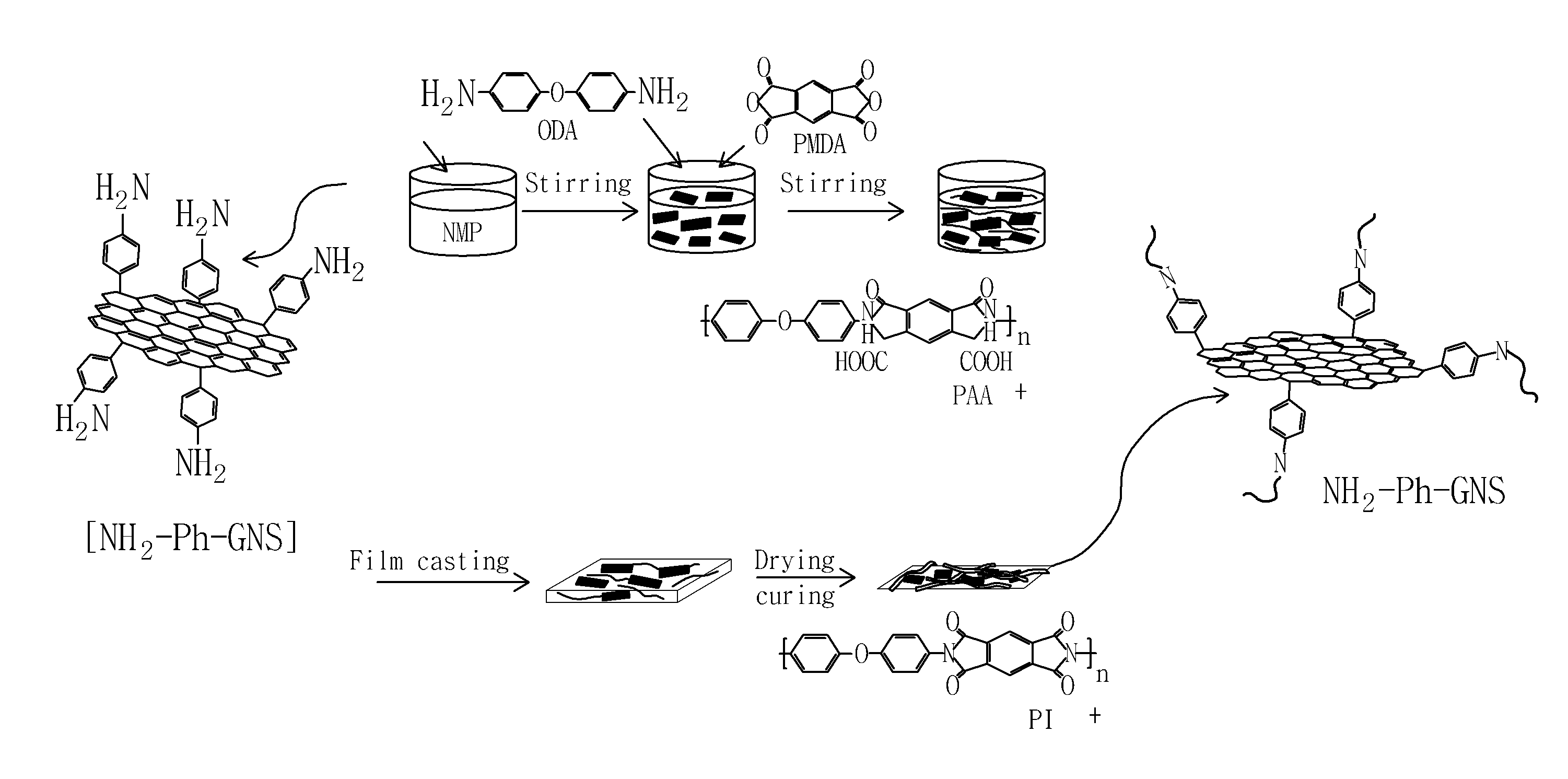

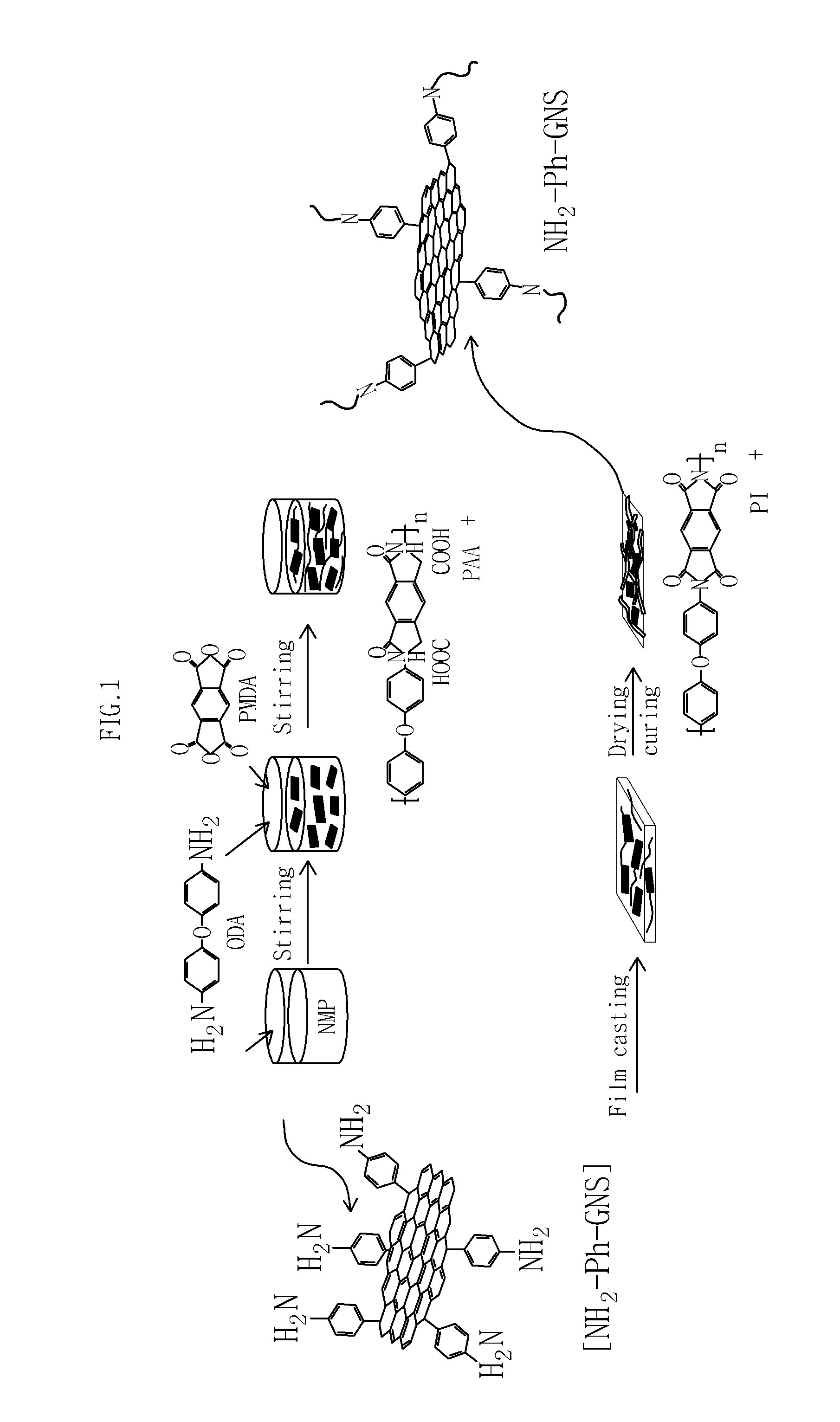

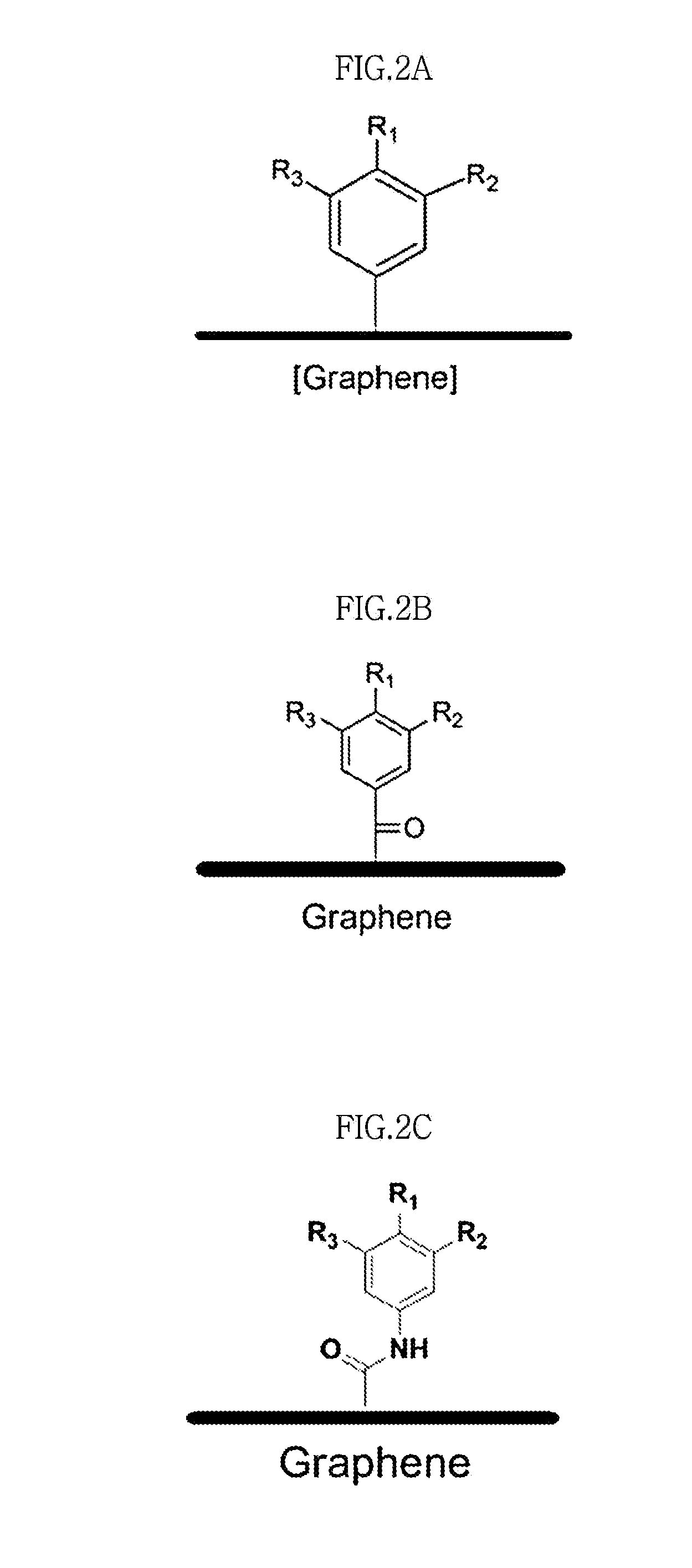

Polyimide-graphene composite material and method for preparing same

ActiveUS20140121350A1Improve mechanical propertiesImprove conductivityThin material handlingPolymer scienceGraphene

The present disclosure relates to a polyimide-graphene composite material and a method for preparing same. More particularly, it relates to a polyimide-graphene composite material prepared by adding modified graphene and a basic catalyst during polymerization of a polyimide precursor so as to improve mechanical strength and electrical conductivity and enable imidization at low temperature and a method for preparing same.

Owner:KOREA INST OF SCI & TECH

Method for preparing phenolic aldehyde adhesive based on lignin phenolized liquid and application thereof

InactiveCN101260283AImprove liquidityGood storage stabilityAldehyde/ketone condensation polymer adhesivesThermal insulationResin adhesive

The invention provides a preparation method for phenolic adhesive based on lignin phenolization liquid and application thereof. Under the condition of normal pressure heating or thermalcatalysis, phenol is taken as liquefaction reagent, lignin is added, the temperature is raised to 90 to 150 DEG C, the thermal insulation liquefaction reaction is made to cool to obtain a lignin liquefaction product; basic catalyst and formaldehyde are directly added into the liquefaction liquid, the temperature is raised to 70 to 97 DEG C under normal pressure to react for 1 to 3 hours, the reaction is terminated when the viscosity is measured to meet the preset requirement, and low-free formaldehyde environmental protection type phenolic adhesive based on lignin phenolization liquid is obtained. The adhesive obtained by the invention has lower cost and lower content of free formaldehyde than the prior phenolic resin adhesive. The plywood pressed by using the adhesive obtained by the invention has good bonding performance.

Owner:HUANGSHAN UNIV

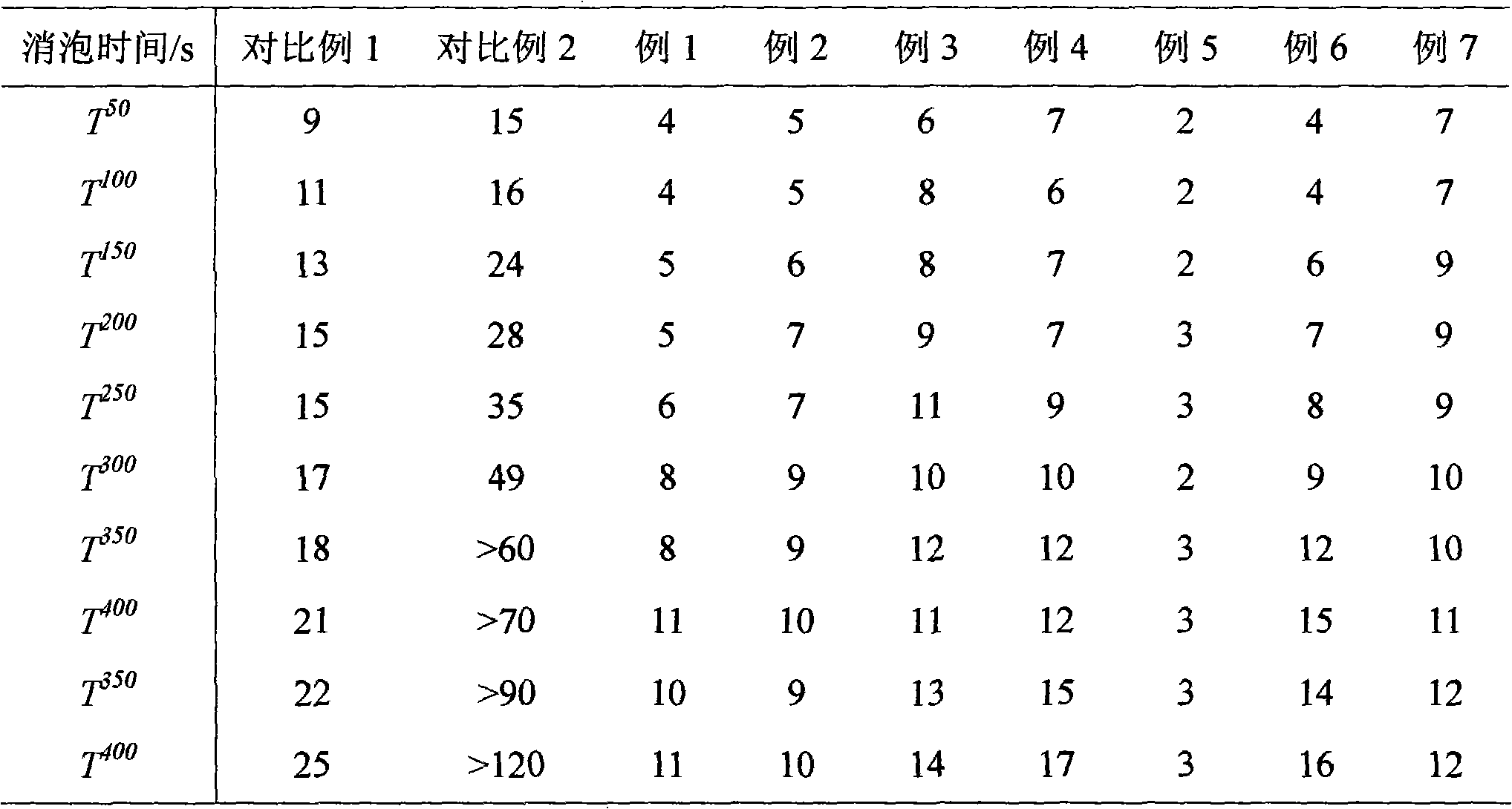

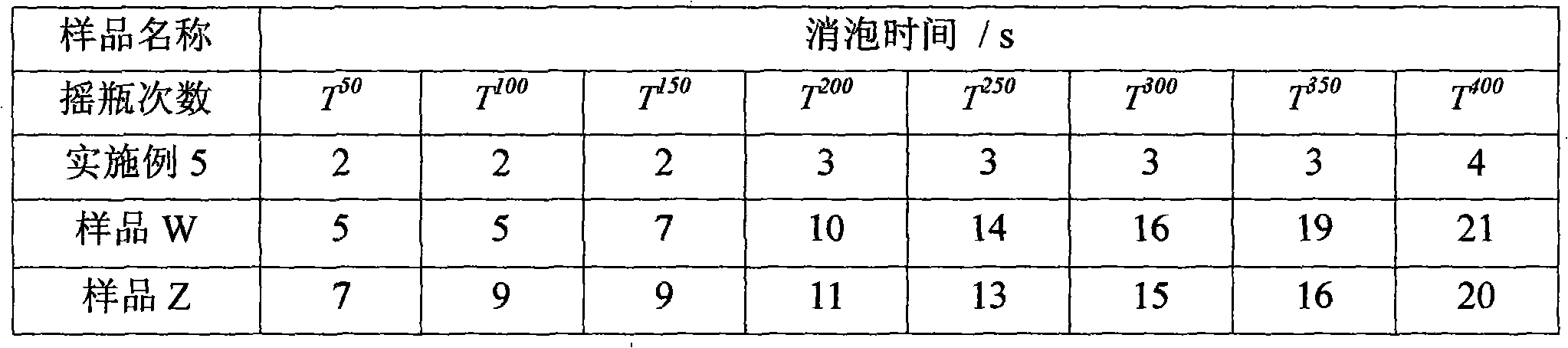

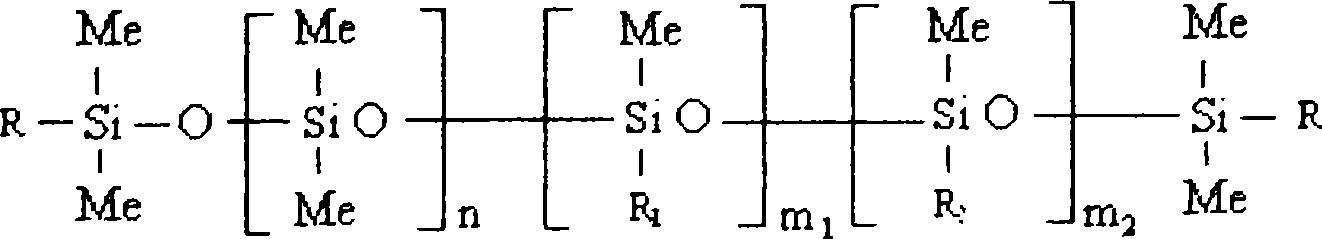

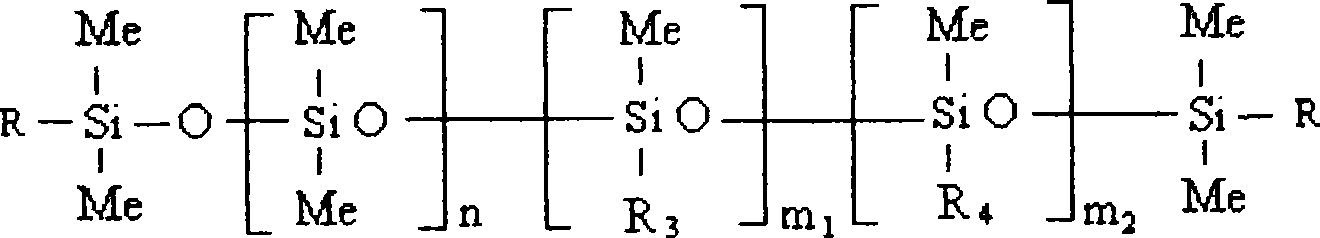

Method for preparing defoaming agent composition

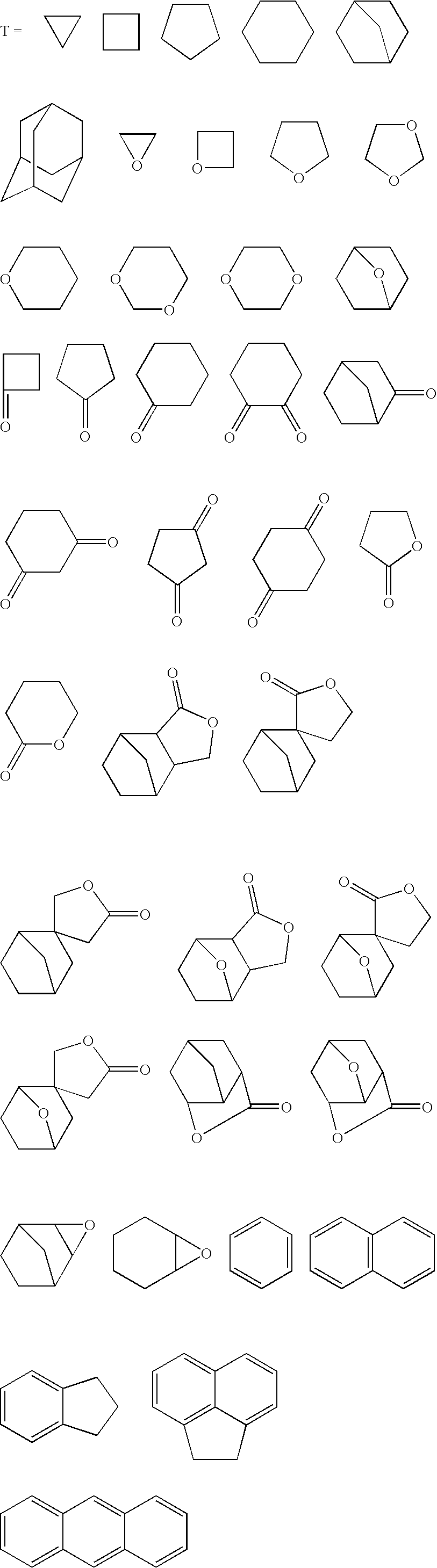

The invention discloses a method for preparing a defoaming agent composition, belonging to the technical field of fine chemical preparation. The invention provides a defoaming agent composition widely used for removing harmful foams in industrial production. The defoaming agent composition comprises the following components: (1) polysiloxane RaSiO(4-a) / 2; (2) a coupling agent; (3) fine filler particles such as silicon dioxide and the like; (4) organic silicon resin; (5) polyether modified polysiloxane MDx(CH3GSiO)yM, wherein M is chain link R'2SiO1 / 2, D is chain link R'2SiO2 / 2, G is polyether radical-(CH2)z(EO)g(PO)hR'' and (6) an alkaline catalyst. The preparation method comprises the following steps: (1) heating the polysiloxane and the coupling agent together in a stirring machine, adding the alkaline catalyst to carry out a polymerization reaction at the temperature of 40-140 DEG C; (2) after crosslinking the mixture, adding the organic silicon resin and the polyether modified polysiloxane, carrying out a reaction again for 1-7 h at the temperature of 80-140 DEG C, and then adding the fine filler particles to mix uniformly, carrying out a reaction for 1-6 h at temperature of 90-180 DEG C; (3) after finishing the reaction, keeping the mixture for 0.1-1.5 h at the vacuum degree of -0.01 to -0.08 MPa, and finally, cooling to the room temperature to obtain white active materials that are defoaming agent compositions.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Silicon-containing film-forming composition, silicon-containing film, silicon-containing film-bearing substrate, and patterning method

ActiveUS20080026322A1Sufficient etching resistanceImprove accuracyPhotosensitive materialsSemiconductor/solid-state device manufacturingAmmonium compoundsPtru catalyst

A silicon-containing film is formed from a heat curable composition comprising (A-1) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of an acid catalyst and removing the acid catalyst, (A-2) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of a basic catalyst and removing the basic catalyst, (B) a hydroxide or organic acid salt of lithium, sodium, potassium, rubidium or cesium, or a sulfonium, iodonium or ammonium compound, (C) an organic acid, and (D) an organic solvent. The silicon-containing film allows an overlying photoresist film to be patterned effectively.

Owner:SHIN ETSU CHEM IND CO LTD

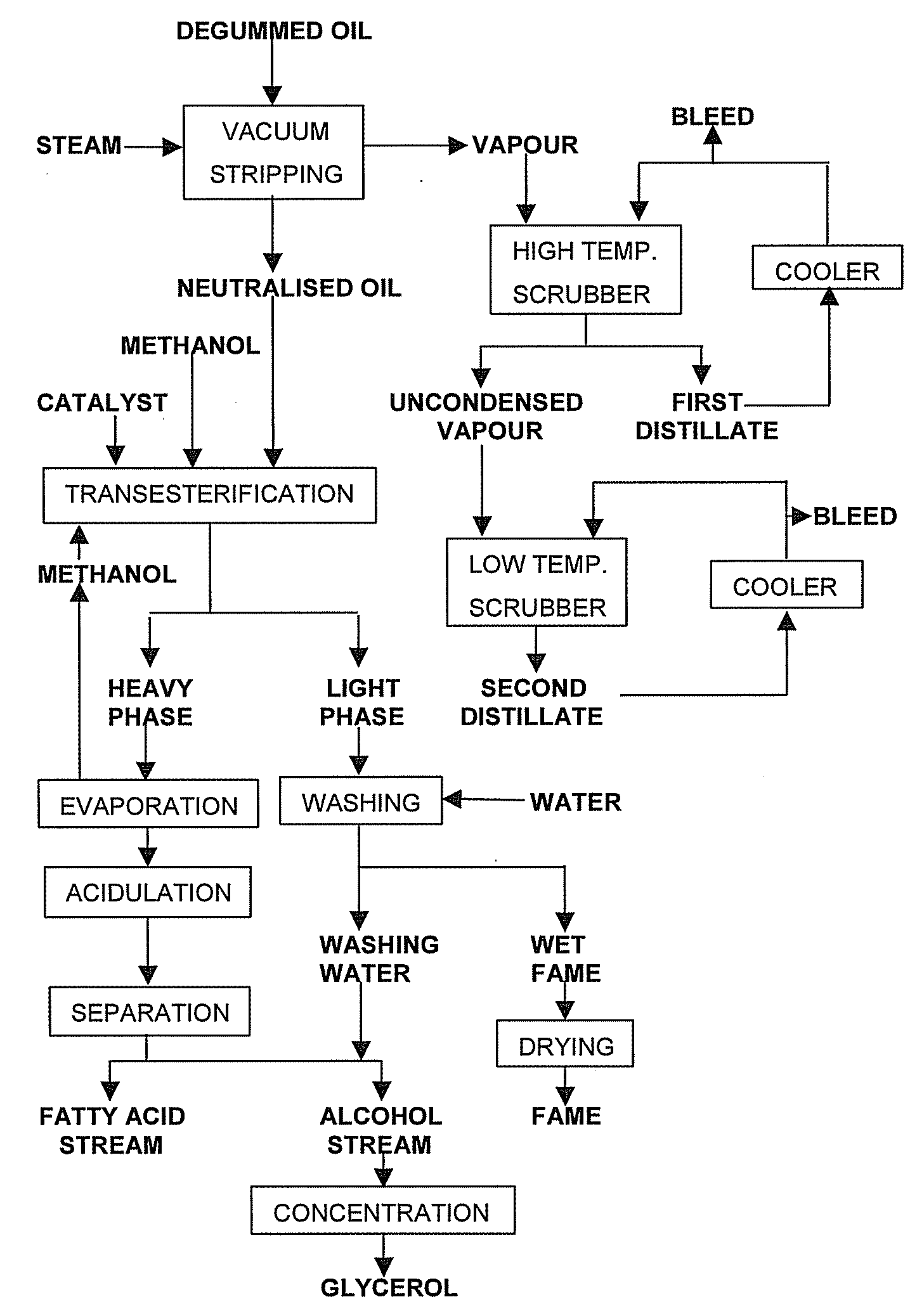

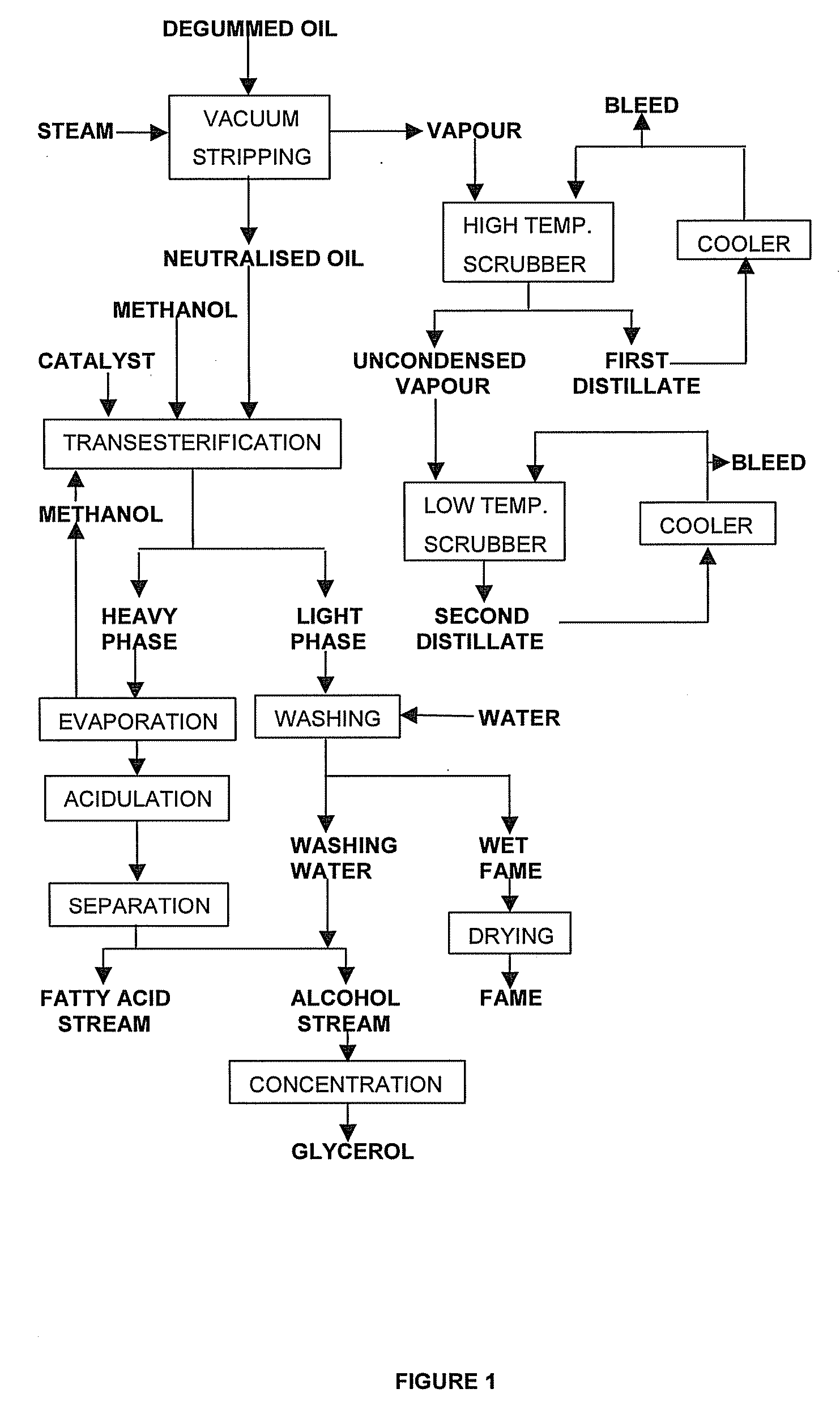

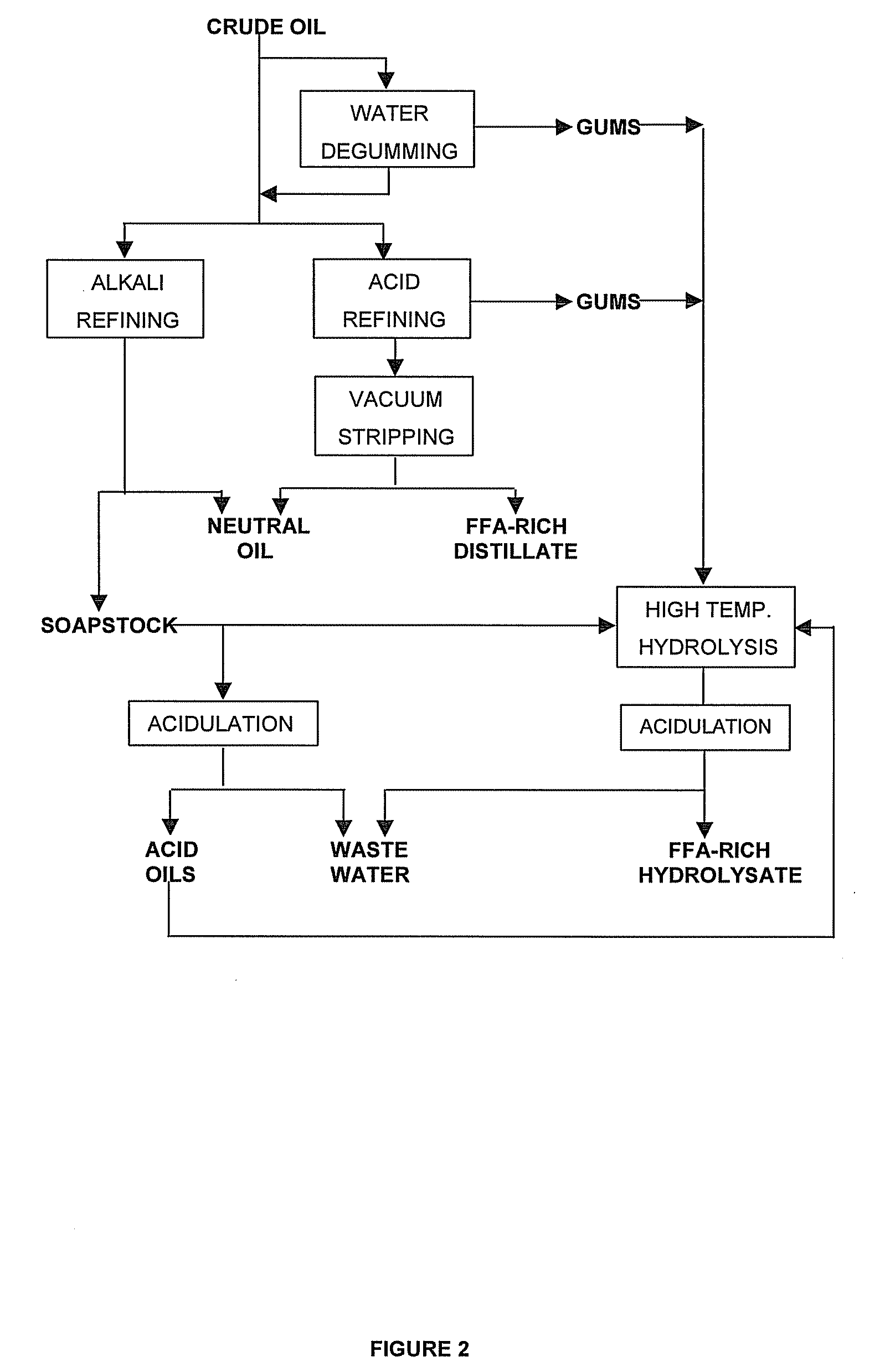

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

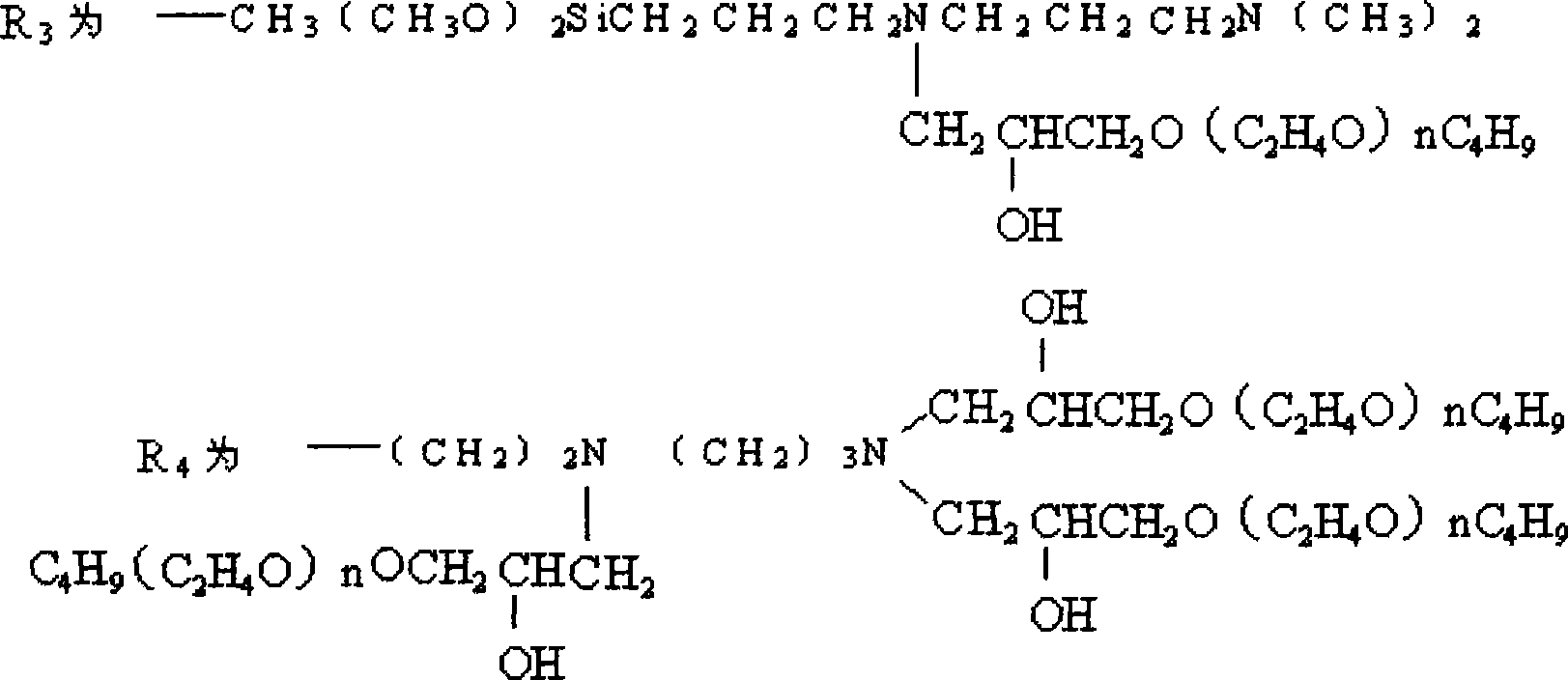

Method for preparing durable hydrophilic polyether modified amino polysiloxane soft agent

The invention discloses a method for preparing a perdurable hydrophilic polyether modified amino-polysiloxane softener. The method is characterized by comprising the following steps: octamethylcy-clotetrasiloxane and amino silane coupling agents with different structures are used as raw materials; with a bulk polymerization method, under the analysis of an alkali catalyst, firstly, an amino organic polysiloxane softener with high ammonia value is generated through ring-opening polymerization; and secondly, on the basis of the amino organic polysiloxane softener, amidogen is subjected to etherifying modification, thereby synthesizing the hydrophilic polyether modified amino-polysiloxane softener with good hand feeling and hydrophilic property. The prepared softener keeps the hydrophilic property and simultaneously improves the softness of hydrophilic silicon oil so that the hand feeling of textile can reach the hand feeling of the prior linearity amino silicon oil after the textile is treated by the softener and the treated textile can keep the hydrophilic property permanently.

Owner:SHAOXING UNIVERSITY

Melamine modified polyvinylalcohol formal foam, preparation and uses thereof

InactiveCN101508747AIncrease dosageImprove mechanical propertiesAbsorbent padsFiltration separationFoaming agentAdjuvant

The invention relates to a melamine modified polyvinyl formal foam material and a preparation method thereof. The foam material is prepared by proportionally mixing and reacting among polyvinyl alcohol, melamine, formaldehyde, an acidic catalyst, a basic catalyst, an emulsifier, a foaming agent, a pore former, an adjuvant and the like. The foam material has the advantages of simple preparation process, adjustable aperture ratio, high mechanical strength and good temperature resistance, and can be widely used as medical sponge, filtering material, sound insulation protection material, wiping and dedusting material and biological carrier material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Synthesis of higher polyol fatty acid polyesters by transesterification

InactiveUS6504003B1Process economyHigh degree of esterificationEsterified saccharide compoundsSugar derivativesPolyesterTrans esterification

A process for synthesizing polyol fatty acid polyesters comprising the steps of (1) mixing ingredients comprising (a) unesterified first polyol having hydroxyl groups, (b) second polyol esterified with fatty acids, (c) basic catalyst, and (d) emulsifying agent to form a mixture of ingredients; (2) reacting the mixture of ingredients at a temperature sufficient to obtain a transesterification reaction products and by-products; and (3) removing at least a portion of the by-products from the transesterification reaction mixture; and (4) further heating the transesterification reaction products and ingredients from step (3) at a temperature and for a time sufficient to esterify at least about 50% of the hydroxyl groups of the first polyol.

Owner:THE PROCTER & GAMBLE COMPANY

Process for the production of monoglyceride based on the glycerolysis of methyl ester

InactiveUS6127561AAvoid pollutionFatty acid chemical modificationPreparation by ester-hydroxy reactionMonoglycerideDistillation

The invention discloses a process for the production of monoglycerides by glycerolysis of methyl ester derived from animal or vegetable fat and oils which includes mixing a surplus of 0.1 to 3 moles of glycerols in relation to methyl ester, subjecting the reaction mixture to a reaction temperature between 130 to 160 at a vacuum of 200 to 400 mbar, adding of alkaline catalysts, stopping the reaction by fast cooling of the reaction mixture and the destruction of the alkaline catalyst when the quantity of glycerides has reached a concentration of mono and diglyceride of 40 to 60%, leaving the catalyst in the reaction mixture to catalyse the reaction downstream in a reactor, separating the surplus methyl ester and glycerol by distillation and stopping the reaction by fast cooling of the reaction mixture with reactor and the destruction of the alkaline catalyst when the quantity of glycerides has reached a concentration of 40 to 60% and the ratio of concentrations of mono and diglyceride lies between 3 to 10.

Owner:GLOBAL PALM PROD

Composition for film formation, method of film formation, and silica-based film

InactiveUS6800330B2Group 4/14 element organic compoundsPlastic/resin/waxes insulatorsDecompositionSilicon dioxide

A composition for film formation capable of forming a silica-based coating film having low water absorption and dielectric constant of 2.1 or lower and useful as an interlayer insulating film material in semiconductor devices, etc. The composition contains: (A) a product of hydrolysis and condensation obtained by hydrolyzing and condensing at least one silane compound selected from the group consisting of compounds represented by formula (1), compounds represented by formula (2), and compounds represented by formula (3) in the presence of a basic catalyst and water,wherein R represents a hydrogen atom, a fluorine atom, or a monovalent organic group, R<1 >represents a monovalent organic group, and a is an integer of 1 or 2,wherein R<2 >represents a monovalent organic group,wherein R<3 >to R<6 >may be the same or different and each represents a monovalent organic group, b and c may be the same or different and each is a number of 0 to 2, R<7 >represents an oxygen atom, a phenylene group, or a group represented by -(CH2)n-, wherein n is an integer of 1 to 6, and d is 0 or 1; (B) a compound compatible with or dispersible in ingredient (A) and having a boiling point or decomposition temperature of from 250 to 450° C.; and (C) an organic solvent.

Owner:JSR CORPORATIOON

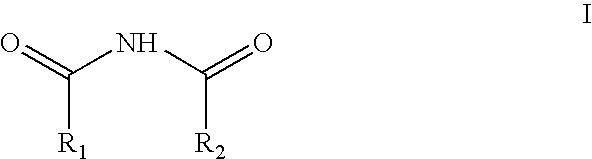

Method and reagents for N-alkylating ureides

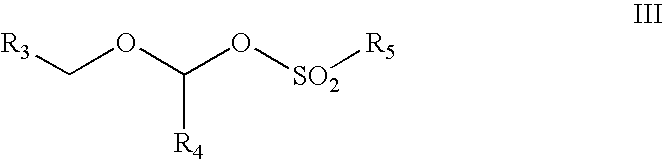

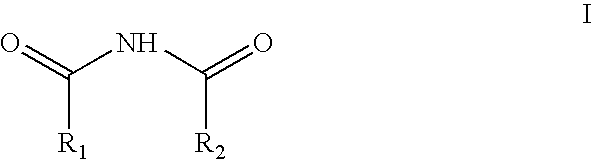

InactiveUSRE38934E1Reduce usageLow applicabilityUrea derivatives preparationBiocideGlutethimideEthosuximide

A method of N-alkoxyalkylating ureides according to the invention comprises reacting a ureide of structure I with an alkylating agent of structure III in the presence of a basic catalyst in an aprotic reaction medium. The ureide may be a 5,5-disubstituted barbituric acid, or it may be phenytoin, glutethimide, and ethosuximide. The alkylating agent is an ester of a sulfonic acid. The base may be a hydride or amine. A preferred process comprises N-alkoxyalkylating 5,5-diphenyl-barbituric acid with methoxymethyl methanesulfonate in the presence of di-isopropyl ethyl amine and isolating the resultant N,N′-bismethoxymethyl-5,5-diphenyl-barbituric acid. The invention also contemplates the novel compounds N-methoxymethyl-5,5-diphenylbarbituric acid, N-methoxymethyl ethosuximide, and N-methoxymethyl glutethimide, and a method comprising administering them to a patient.

Owner:TARO PHARMA INDS

Manufacturing method of silica sol and obtained silica sol

A process for preparing high-granularity Si sol includes such steps as heating the SiO2 dispersed water, stirring while adding alkaline catalyst and metallic Si powder, hydrolytic reaction at pH=7-14 to obtain active silicic acid micro-particles, and quickly adsorbing the micro-particles by SiO2 seed particles to become target sol. Its advantages are high speed and controllable and uniform granularity.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

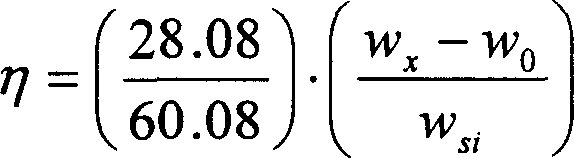

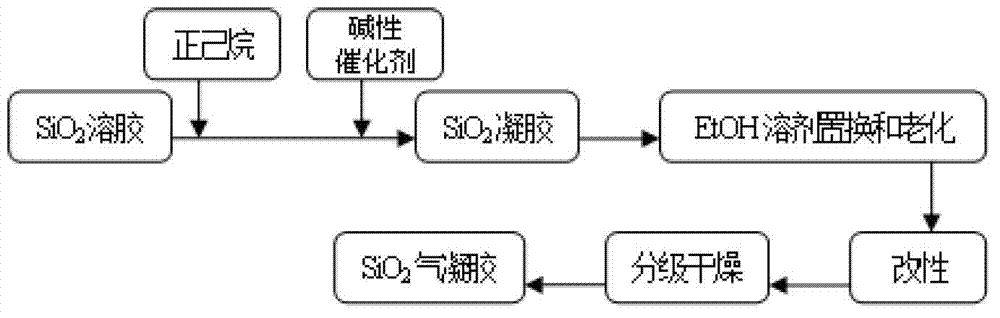

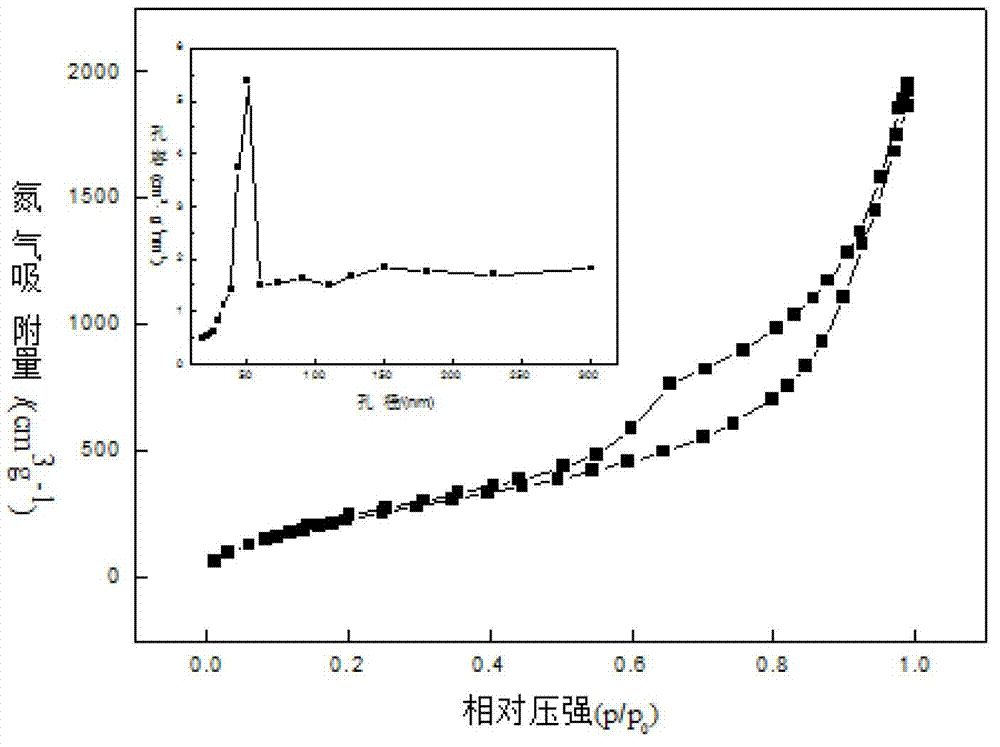

Ambient pressure drying method for rapidly preparing SiO2 aerogel

ActiveCN102951650AReduce performanceOmit the replacement processSilicon compoundsSupercritical dryingApparent density

The invention discloses an ambient pressure drying method for rapidly preparing SiO2 aerogel. Part of an alcohol solvent is replaced with a solvent with low surface tension; silica-alkoxides, the non-replaced alcohol solvent, an acidic catalyst, a basic catalyst and the solvent with the low surface tension are prepared into sol according to a certain proportion, after alcogel containing the solvent with the low surface tension is formed, ageing and surface modification processes are carried out, and then, ambient pressure drying is directly carried out, so that the complex solvent exchanging step is omitted, and the SiO2 aerogel is prepared within 30h. By using the method, not only are the defects such as high equipment investment, low efficiency, high cost of the traditional supercritical drying process overcome, but also the problems of long period, high using cost for solvent exchanging and the like in the traditional ambient pressure drying process are solved, and the prepared SiO2 aerogel has the characteristics of low surface density, large specific area, large pore volume and the like.

Owner:卢斌

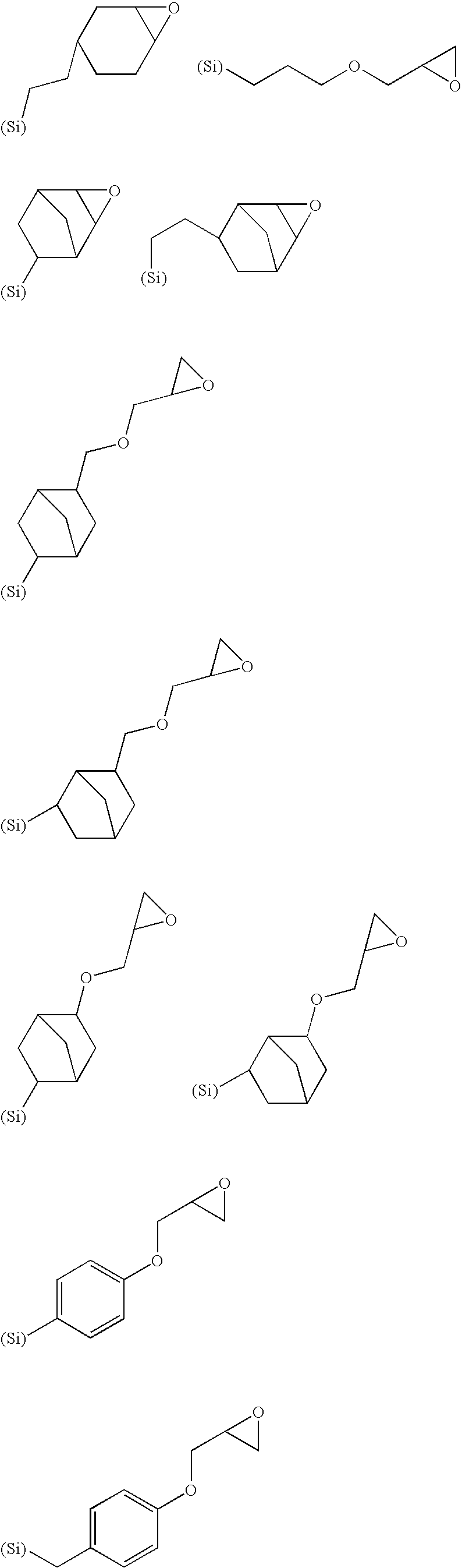

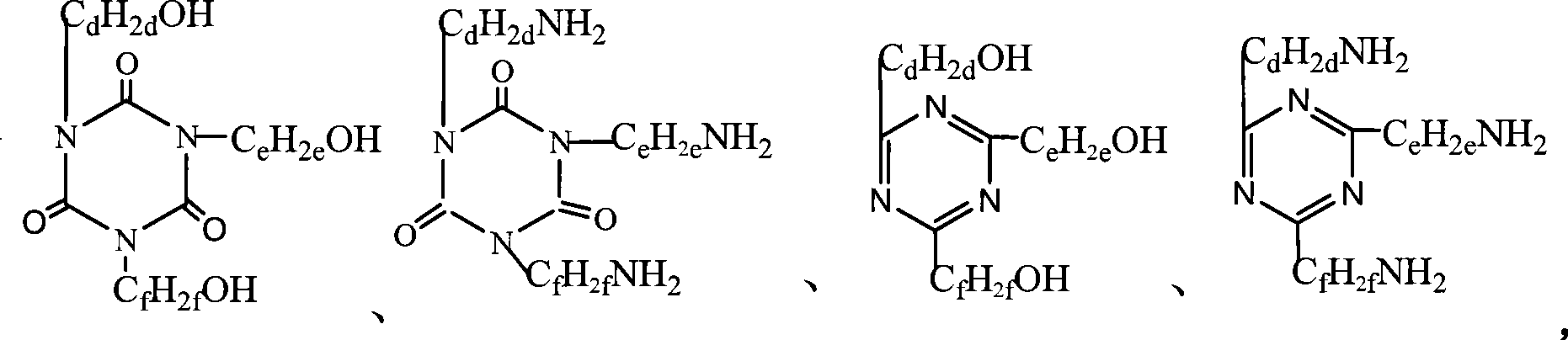

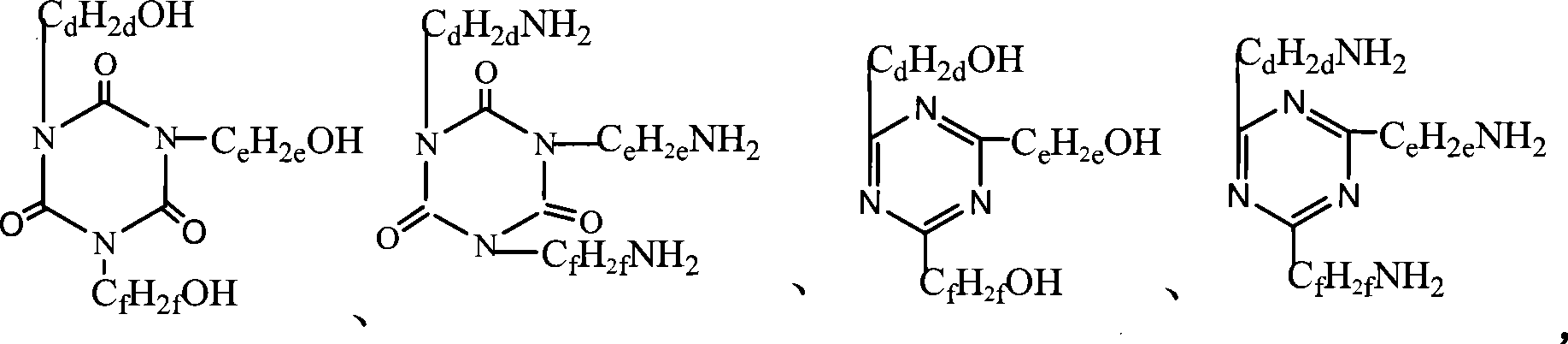

Preparation of hyperbranched polymer and hyperbranched epoxy resin

The invention relates to a preparation method for a hyperbranched epoxy resin. The preparation method comprises the following steps: (1) preparing a hyperbranched polymer with a functional end group; (2) carrying out the reaction of the hyperbranched polymer and chloroepoxy propane under the action of a ring opening catalyst to obtain an addition product; and (3) carrying out the ring closing reaction of the obtained addition product in an organic solvent and under the reaction of a basic catalyst to generate the hyperbranched epoxy resin, wherein the hyperbranched polymer is prepared under the action of the catalyst through the reaction of a first monomer and a second. Polybasic amine, polyol or the mixture thereof is taken as the first monomer; polyatomic acid, anhydride or the mixture thereof is taken as the second monomer; the dosage mol ratio of the first monomer to the second monomer is 1:0.3 to 2.5; and the first monomer at least comprises a heat resistant six-membered compound which is more than or equal to 1 percent of the total mol number of the first monomer. The prepared hyperbranched epoxy resin has low viscosity, high heat resistance, and the reinforcing and plasticizing functions for a common epoxy resin. The hyperbranched epoxy resin can be widely applied to the fields of electronic packaging, functional adhesives, and the like.

Owner:苏州海博特树脂科技有限公司

Producing fuel and specialty chemicals from glyceride containing biomass

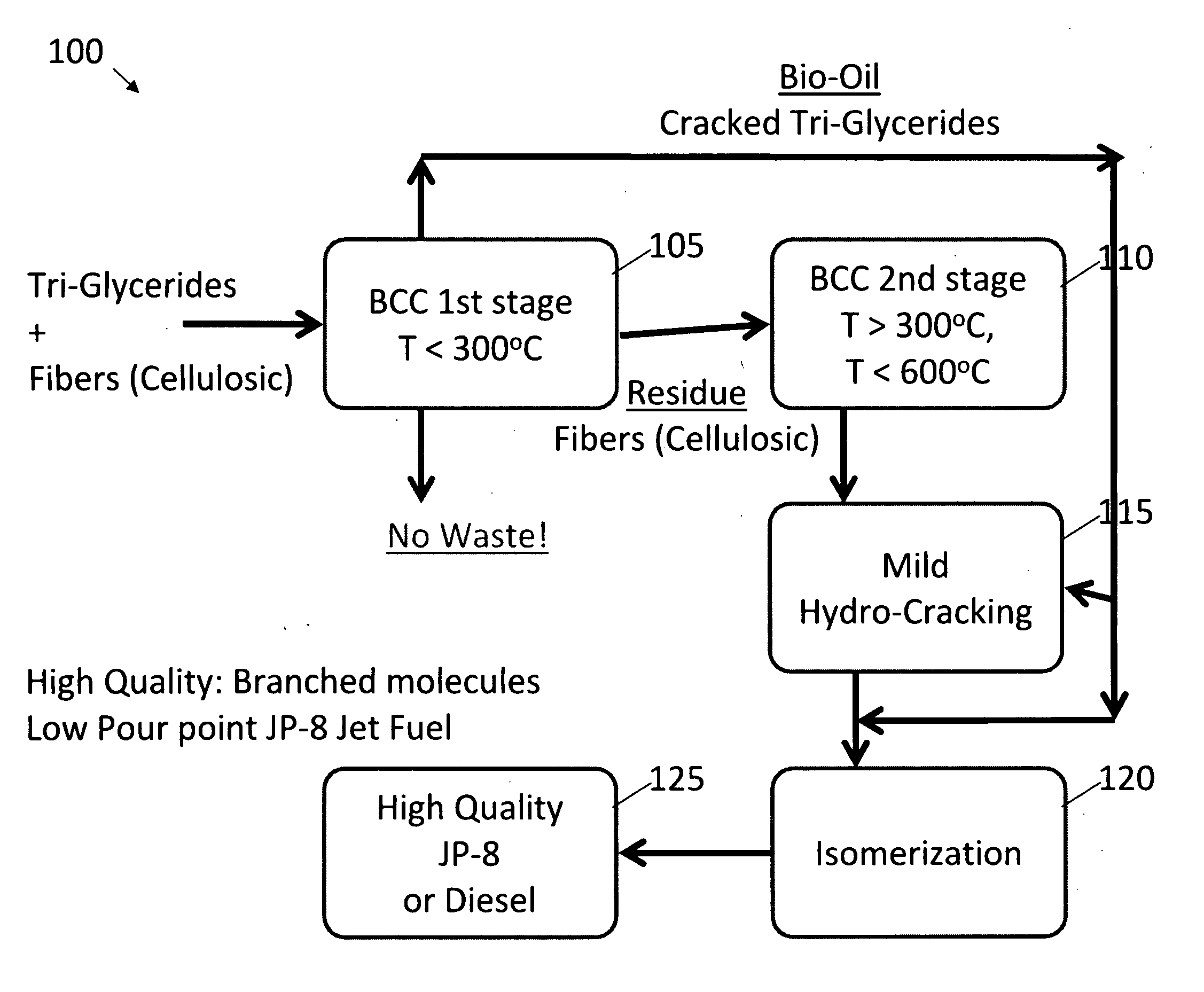

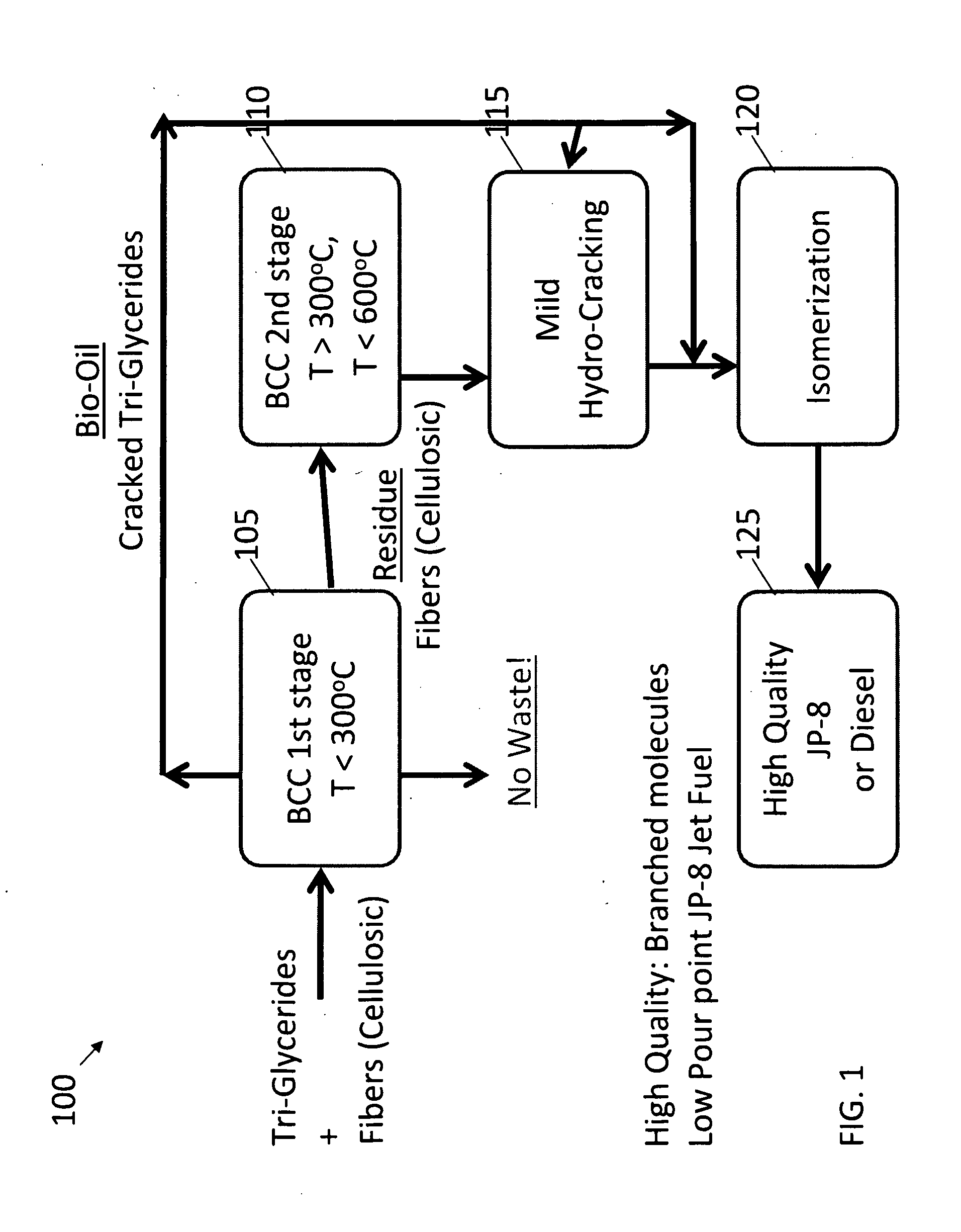

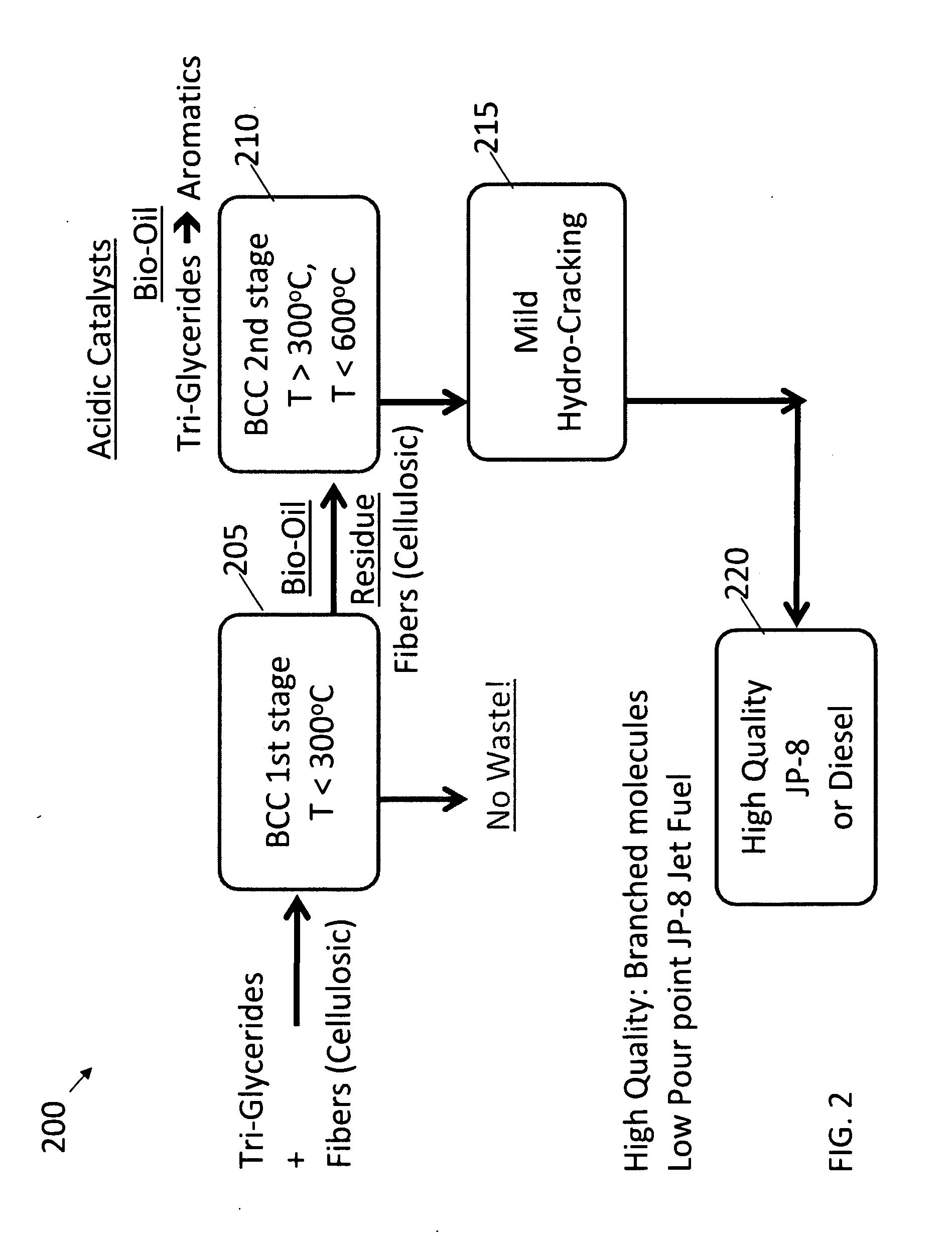

InactiveUS20110197496A1Improve usabilityIncreases value and utilityCatalytic crackingRefining to change hydrocarbon structural skeletonCelluloseSpeciality chemicals

A method for catalytically cracking a triglyceride-containing biomass can include the steps of (i) catalytically cracking triglycerides in a biomass-catalyst mixture, at a temperature below about 300° C., to produce a first oil and a cellulosic portion and (ii) catalytically cracking cellulose in the cellulosic portion, at a temperature between about 300 and about 600° C., to produce a second oil. Another method for catalytically cracking a triglyceride-containing biomass includes catalytically cracking triglycerides in a biomass-catalyst mixture, at a temperature between about 300 and about 600° C., where the catalyst comprises an acidic or basic catalyst, to produce an oil comprising aromatics.

Owner:INAERIS TECH

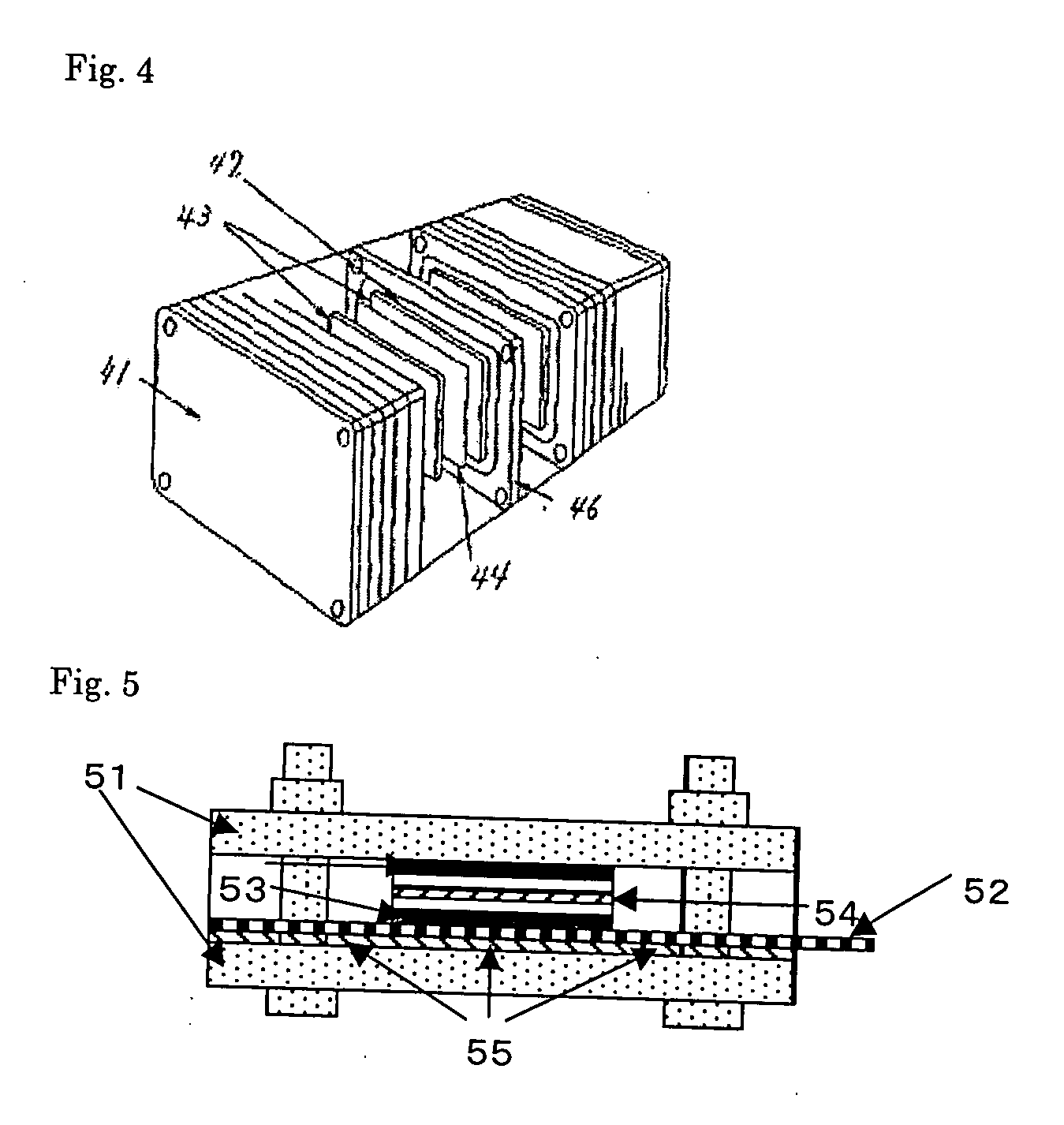

Electric double layer capacitor

ActiveUS20080094777A1Enhanced electrostatic capacity per volumeHybrid capacitor electrolytesCarbon compoundsActivated carbonHydrogen atom

An electric double-layer capacitor comprising an electrode containing an activated carbon, an electrolytic solution containing an electrolyte and a separator, wherein the electrolyte is an imidazolium salt represented by the following formula (1) (wherein R and R′ each independently represent alkyl group having 1 to 6 carbon atoms, R1 to R3 each independently represent hydrogen atom or alkyl group having 1 to 6 carbon atoms and X− represents a counter ion), and the activated carbon is produced by carbonizing an organic aerogel obtained by polymerizing a phenolic compound having at least one hydroxyl group in its molecule with an aldehyde compound in an aqueous solvent in the presence of a basic catalyst.

Owner:SUMITOMO CHEM CO LTD

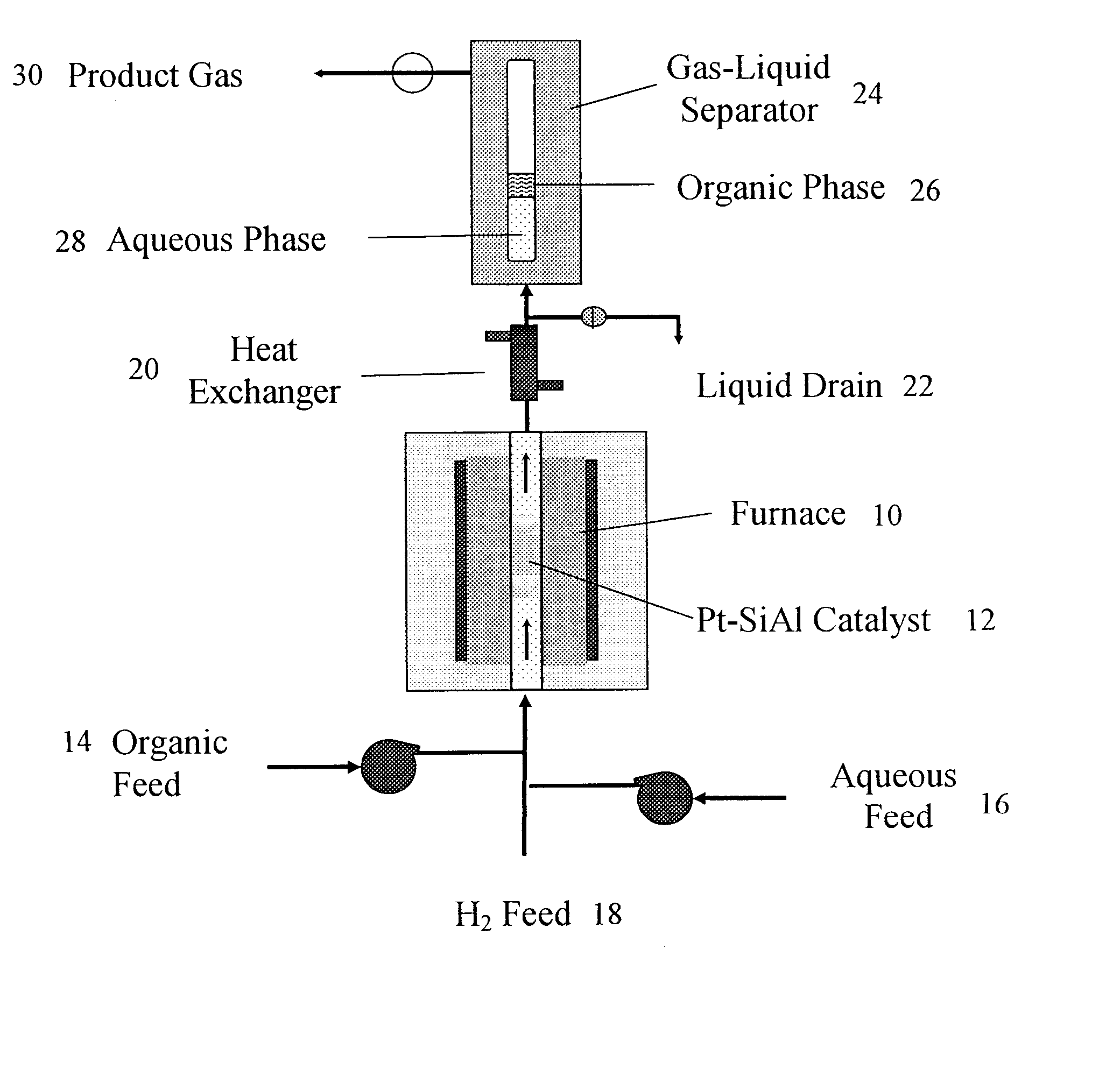

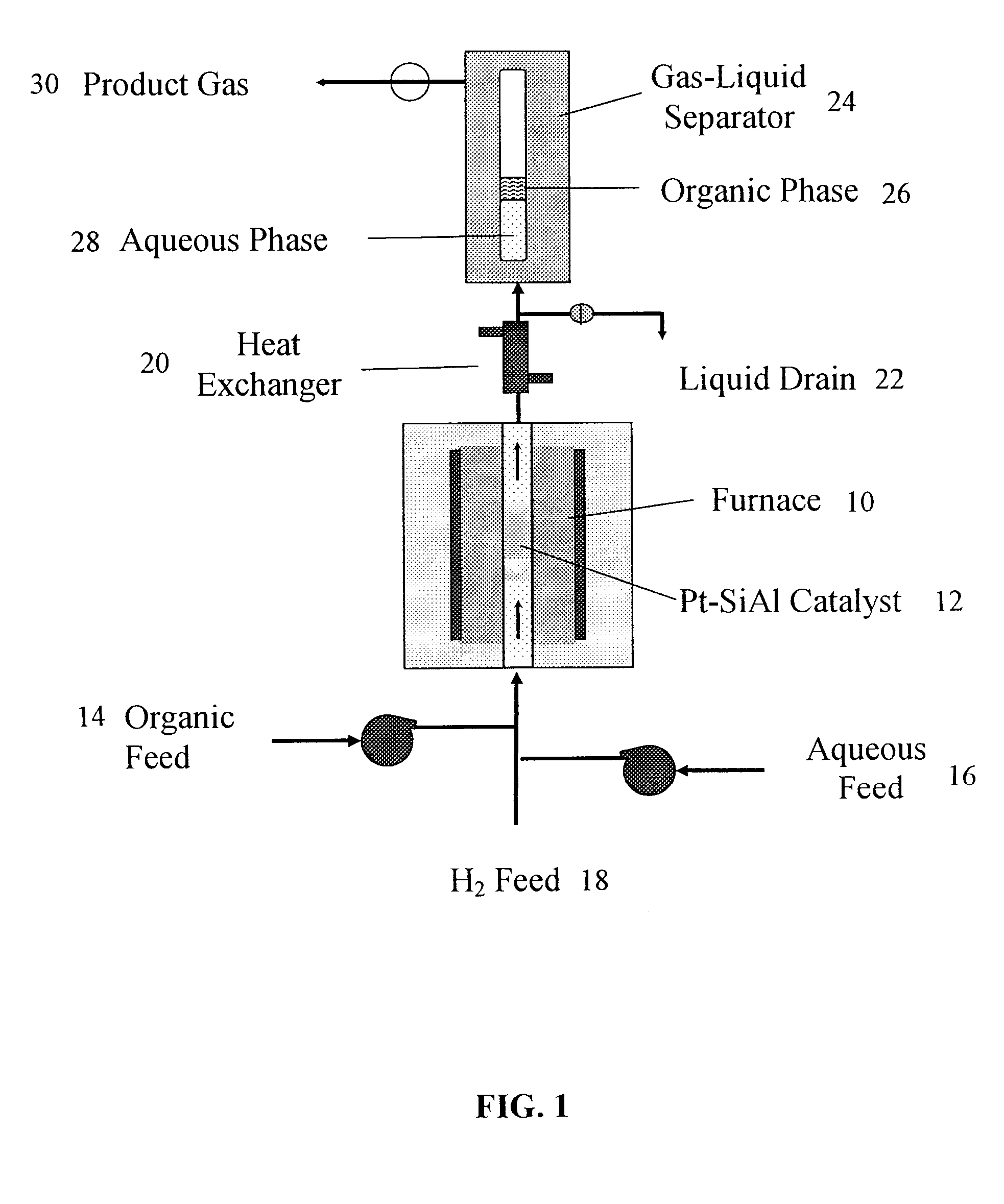

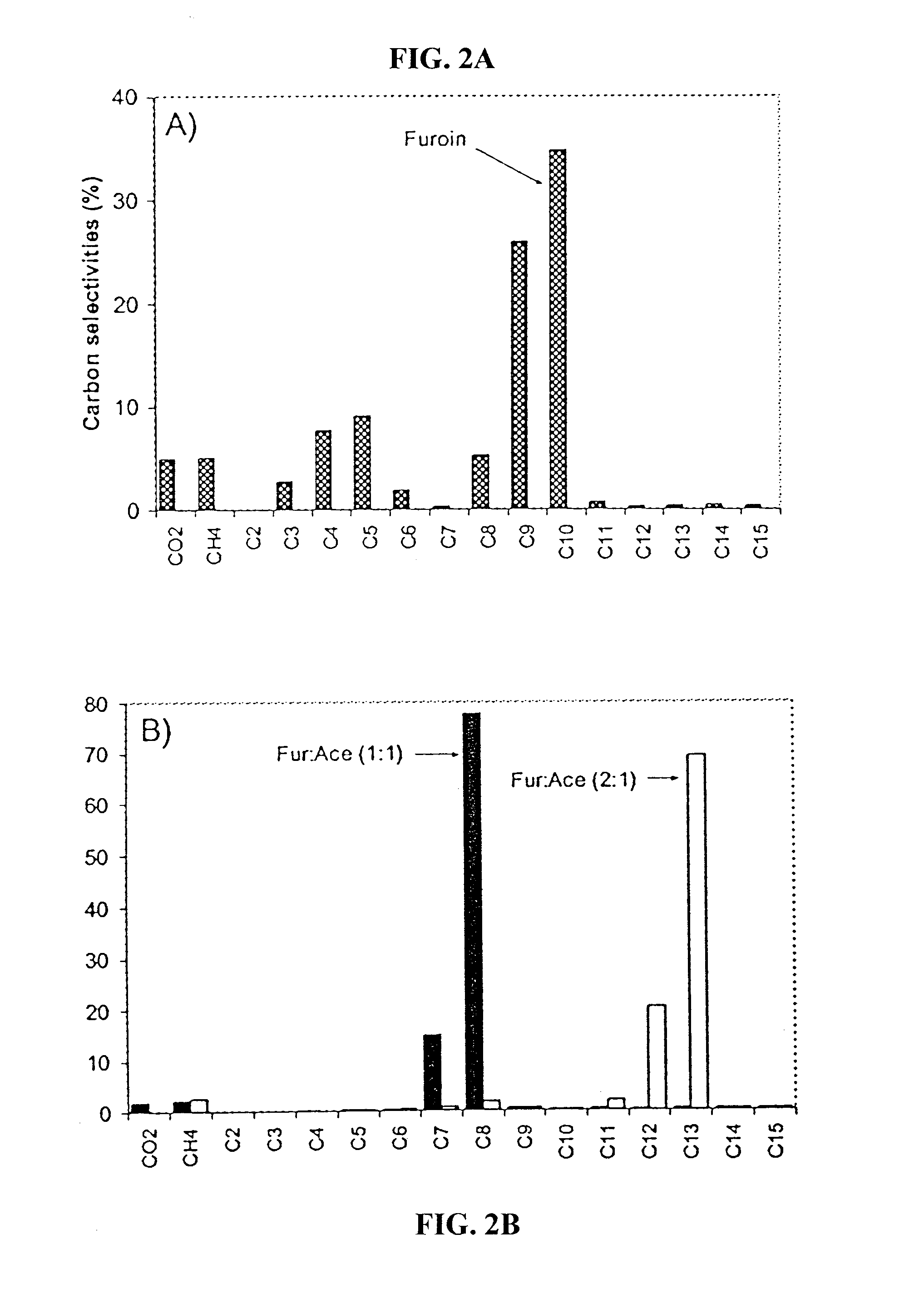

Stable, aqueous-phase, basic catalytsts and reactions catalyzed thereby

ActiveUS20080058563A1Hydrocarbon by hydrogenationHydrocarbon purification/separationHydrogenation reactionEther

A catalytic process for converting biomass-derived carbohydrates to liquid alkanes, alkenes, and / or ethers is described. The process uses combinations of self- and crossed-aldol condensation reactions, dehydration reactions, and hydrogenation reactions, over specified metal-containing catalysts, to yield alkane, alkene, and ether products from carbohydrate reactants.

Owner:WISCONSIN ALUMNI RES FOUND

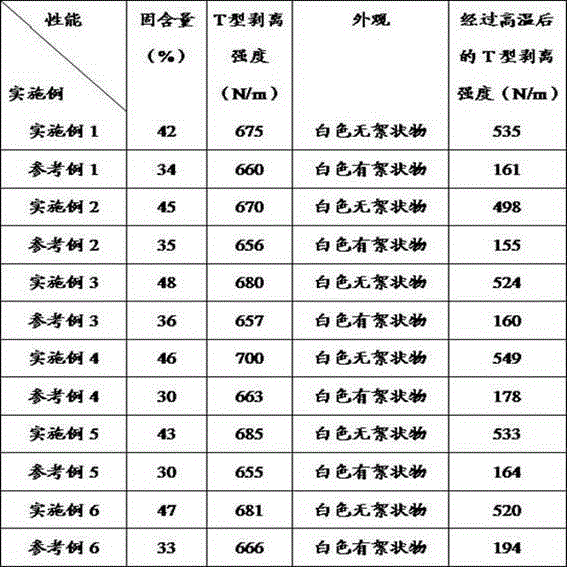

High-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and preparation method thereof

The invention discloses a high-bonding-strength and high-temperature-resisting phenolic resin modified polyurethane adhesive and a preparation method thereof. The preparation method comprises the following steps of: synthesizing modified phenolic resin, preparing polyurethane prepolymer, synthesizing modified polyurethane prepolymer, and synthesizing the modified polyurethane adhesive, wherein the step of synthesizing the modified phenolic resin is carried out by adding methoxyl dimethylbenzene monomer and phenols in phenolic resin to react under the effect of an acid catalyst, cooling the mixture, and then adding a basic catalyst, solvent and formaldehyde in the mixture for dehydration reaction under vacuum until the mixture is transparent, thus obtaining the modified phenolic resin; the step of preparing the polyurethane prepolymer is carried out by adding polyisocyanates and polyester polyol in the modified phenolic resin for reacting; the step of synthesizing the modified polyurethane prepolymer is carried out by modifying the polyurethane prepolymer through the modified phenolic resin to obtain the modified polyurethane prepolymer; and the step of synthesizing the modified polyurethane adhesive is carried out by adding water to the modified polyurethane prepolymer, and dispersing the modified polyurethane prepolymer through dispersing agent, and finally adding neutralizing agent, cross-linking agent and chain extender into the dispersed modified polyurethane prepolymer to obtain the modified aqueous polyurethane adhesive. The preparation method disclosed by the invention is simple, and improves the bonding strength and high temperature resistance of the polyurethane adhesive.

Owner:高金技术产业集团有限公司

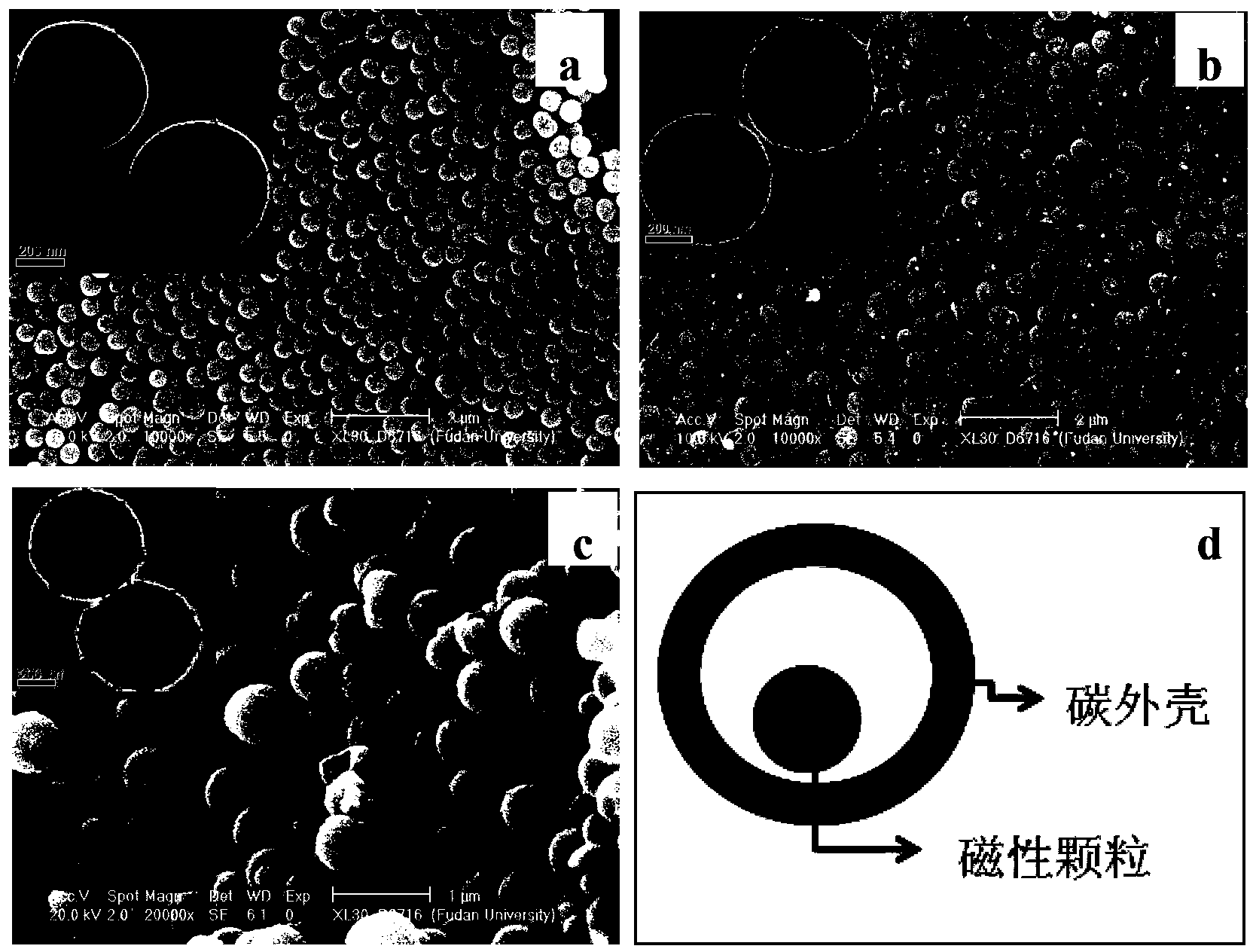

Magnetic polymer/carbon-based microsphere material with core-shell structure and preparation method thereof

ActiveCN103657545AStrong magnetic responseEasy to prepareMagnetic materialsMicroballoon preparationChemical synthesisNanoreactor

The invention belongs to the field of advanced nano composite materials, and relates to a magnetic polymer / carbon-based microsphere material with a core-shell structure and a preparation method thereof. The preparation method comprises the steps of: by adopting a sol-gel chemical synthesis method, in an alcohol water phase, in the presence of an alkali catalyst, wrapping polymer resin macromolecule layer outside a magnetic nano particle to obtain a magnetic macromolecule microsphere with a core-shell structure, carbonizing the polymer resin macromolecule layer through high temperature roasting to obtain a magnetic carbon-based microsphere material with the core-shell structure; adding a macromolecule surfactant during preparation, removing a surfactant by carbonizing through roasting to obtain a magnetic carbon-based microsphere material with a cavity, which is of a core-shell structure. The composite microsphere has stronger magnetic responsiveness, and the surface of the composite microsphere can be further functionalized and a large quantity of hydrophobic substances are absorbed; the magnetic microsphere material with the cavity, which is of a core-shell structure, can be used in a nano reactor, drug sustained release, and large-capacity adsorption and separation. The preparation method is simple, is easily available in raw materials, and suitable for amplified production.

Owner:FUDAN UNIV

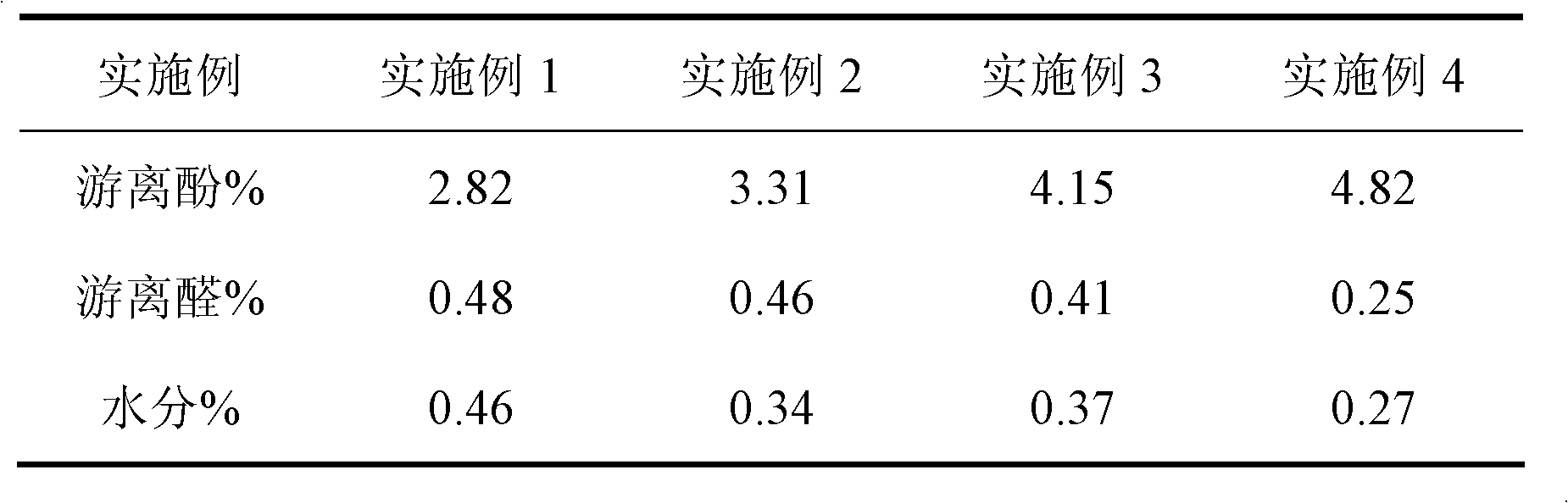

Method for preparing thermoset phenolic resin and method for preparing conductive slurry

ActiveCN102585125AReduce contentHigh reactivityNon-conductive material with dispersed conductive materialSolubilitySlurry

The invention provides a method for preparing thermoset phenolic resin and a method for preparing conductive slurry. The method for preparing the thermoset phenolic resin comprises the following steps of: firstly weighing phenol, a part of methanal, and a mixed alkaline catalyst and reacting for several hours in a reaction flask at 50-90 DEG C; adding the residual methanal to the reaction flask to react; adding acid for neutralizing, and carrying out extraction separation; heating and vacuumizing for removing agents, adding an organic solvent for dissolving to obtain a thermoset phenolic resin solution. According to the method for preparing the thermoset phenolic resin, with the mixed alkaline as a catalyst, backflow reaction is performed for a period of time and then the acid is added for neutralizing; then the organic solvent with very low water solubility is added to carry out extraction separation; then, the solvents are removed in vacuum by heating; and finally the organic solvent is added for dissolving to obtain the thermoset phenolic resin solution with a certain solid content. In addition, a conductive filler, organic diluent and other additives are added to the prepared thermoset phenolic resin solution at the same time to obtain the low-temperature conductive slurry which has the advantages of high conductivity, extremely high adhesion strength and stable electric performance and is suitable for screen printing.

Owner:广州三则电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com