Manufacturing method of silica sol and obtained silica sol

A manufacturing method and technology of silica sol, which is applied in the field of silica sol, can solve the problems of limited particle size of silica sol, high performance requirements of production equipment, uneven particle size, etc., and achieve low equipment performance requirements, low cost, and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

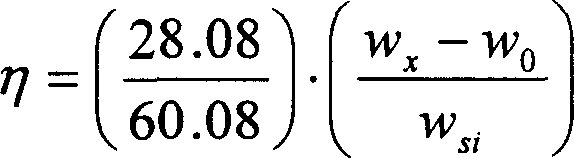

Method used

Image

Examples

Embodiment 1

[0023] In a 2000 ml four-neck flask equipped with a reflux device, dilute 200 g of silica sol with a solid content (silica particles) of 30% (mass) and a particle diameter of 40 to 50 nm with 1000 ml of water to SiO 2The mass concentration is about 5%. Stirring and heating are started, and another 6g of NaOH solid is weighed and dissolved with a small amount of water to form a solution with a concentration of about 10%. When the temperature rises to 85°C, start to add the commercially available 200-300 mesh silicon powder while adding the NaOH solution. NaOH was added at a rate to keep the pH of the system in the range of 9.0 to 10.0; the silicon powder was added at a rate to keep the reaction temperature not exceeding 90° C., and a total of 220 g (catalyst: silicon powder=1:37) silicon powder was added. After adding all the NaOH and silicon powder, keep the temperature and react for 5 hours, then keep stirring, cool to below 60°C and filter. The obtained silica sol index is ...

Embodiment 2

[0027] Using the same conditions as in Example 1, the difference is: the use of solid content is 20%, and the particle diameter is 300g of silica sol diluted to SiO with 10000 milliliters of water. 2 The mass content is about 0.6%; NaOH is dissolved in water to make the concentration about 2% before adding. Finally obtained silica sol index is as follows:

[0028] SiO 2 Mass content: 3.0% SiO 2 Particle size: 5~20nm

[0029] Viscosity (20°C): 1.4mp a ·s Silica fume utilization rate: 80%

Embodiment 3

[0031] Using the same conditions as in Example 1, the difference is: using silica sol with a particle size of 10-15 nm as the seed liquid; dissolving NaOH in water to a concentration of about 20% before adding. Finally obtained silica sol index is as follows:

[0032] SiO 2 Mass content: 35.0% SiO 2 Particle size: 20~30nm

[0033] Viscosity (20°C): 10.5mp a ·s Silica fume utilization rate: 89%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com