Patents

Literature

8170results about "Silica" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

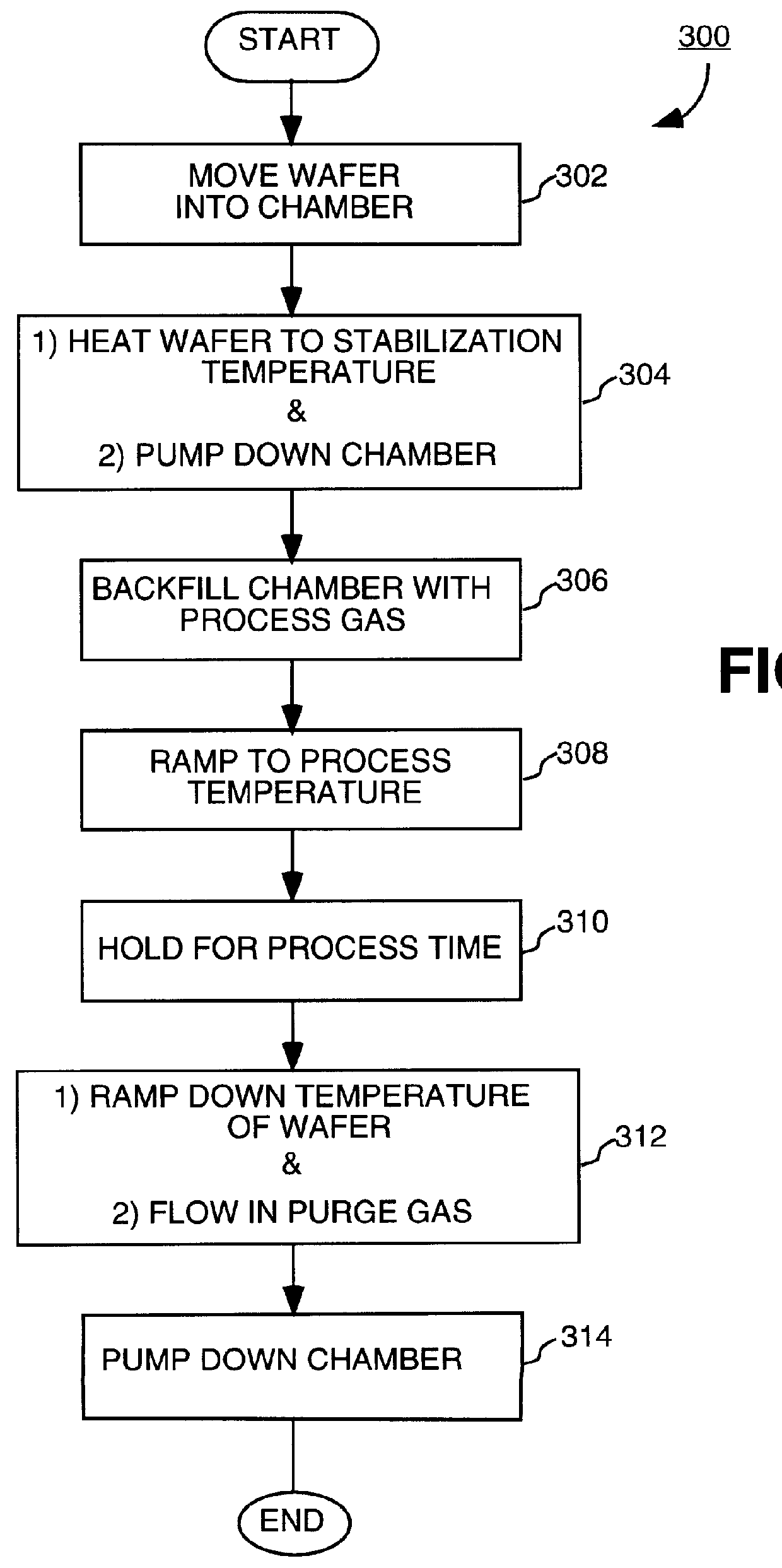

Plasma curing process for porous silica thin film

InactiveUS6558755B2Low dielectric constantHigh elastic modulusSilicaSemiconductor/solid-state device manufacturingSilicon dioxideHeat treated

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The costing is plasma cured for between about 15 and about 120 seconds at a temperature less than or about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically loss than or about 475° C., and the annealing time is typically no more than or about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

Plasma curing process for porous low-k materials

InactiveUS6913796B2Improving elastic modulusImproving material hardnessSilicaLayered productsHardnessMaterials science

Low dielectric constant porous materials with improved elastic modulus and hardness. The process of making such porous materials involves providing a porous dielectric material and plasma curing the porous dielectric material to produce a plasma cured porous dielectric material. Plasma curing of the porous dielectric material yields a material with improved modulus and hardness. The improvement in elastic modulus is typically greater than or about 50%, more typically greater than or about 100%, and more typically greater than or about 200%. The improvement in hardness is typically greater than or about 50%. The plasma cured porous dielectric material can optionally be post-plasma treated. The post-plasma treatment of the plasma cured porous dielectric material reduces the dielectric constant of the material while maintaining an improved elastic modulus and hardness as compared to the plasma cured porous dielectric material. The post-plasma treated, plasma cured porous dielectric material has a dielectric constant between about 1.1 and about 3.5 and an improved elastic modulus and hardness.

Owner:DOW CORNING CORP

Method for Removal of Carbon From An Organosilicate Material

Described herein is a method for removing at least a portion of the carbon-containing species within an organosilicate (OSG) film by treating the OSG film with a chemical, such as but not limited to an oxidizer, exposing the OSG film to an energy source comprising ultraviolet light, or treating the OSG film with a chemical and exposing the OSG film to an energy source.

Owner:VERSUM MATERIALS US LLC

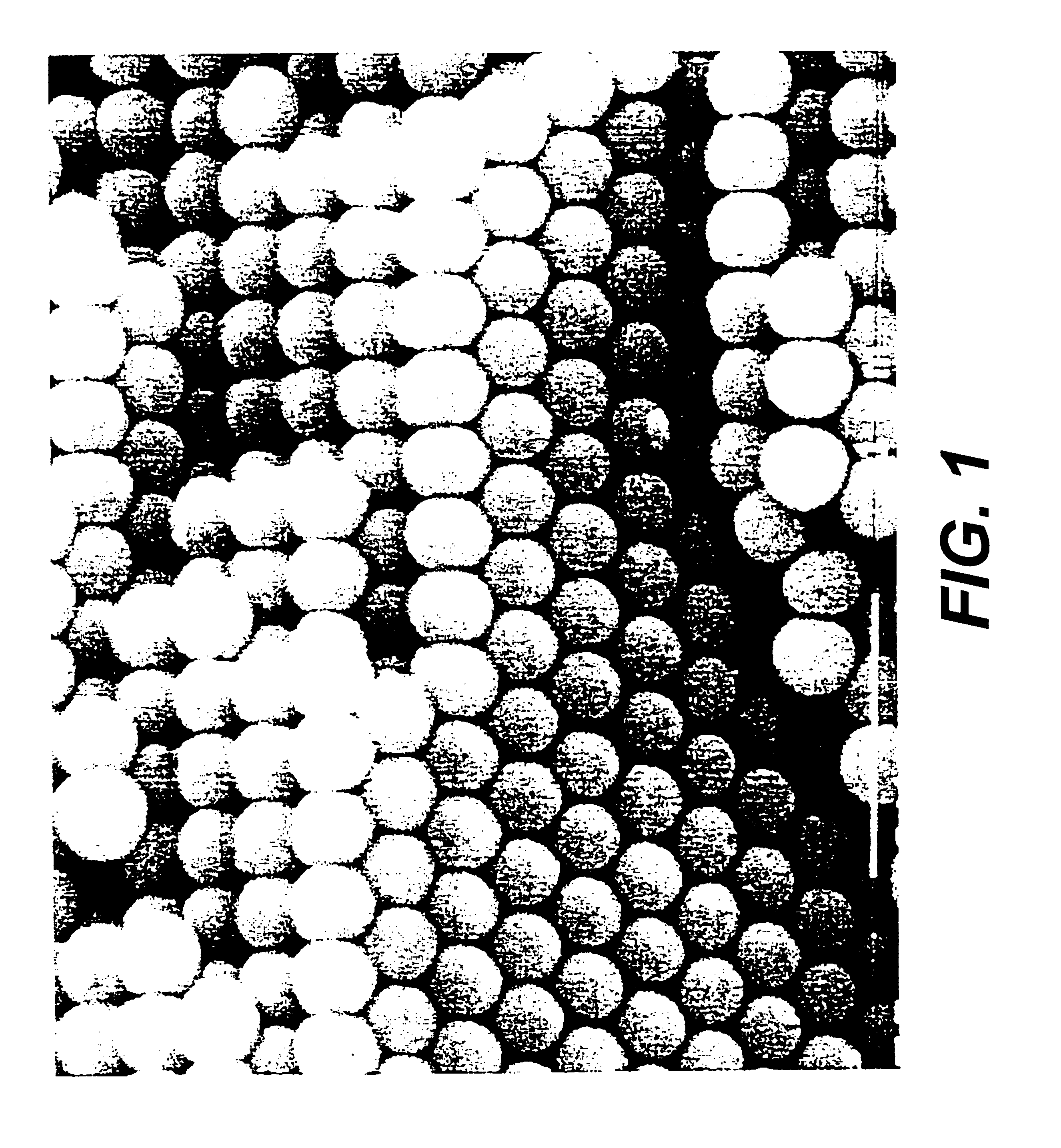

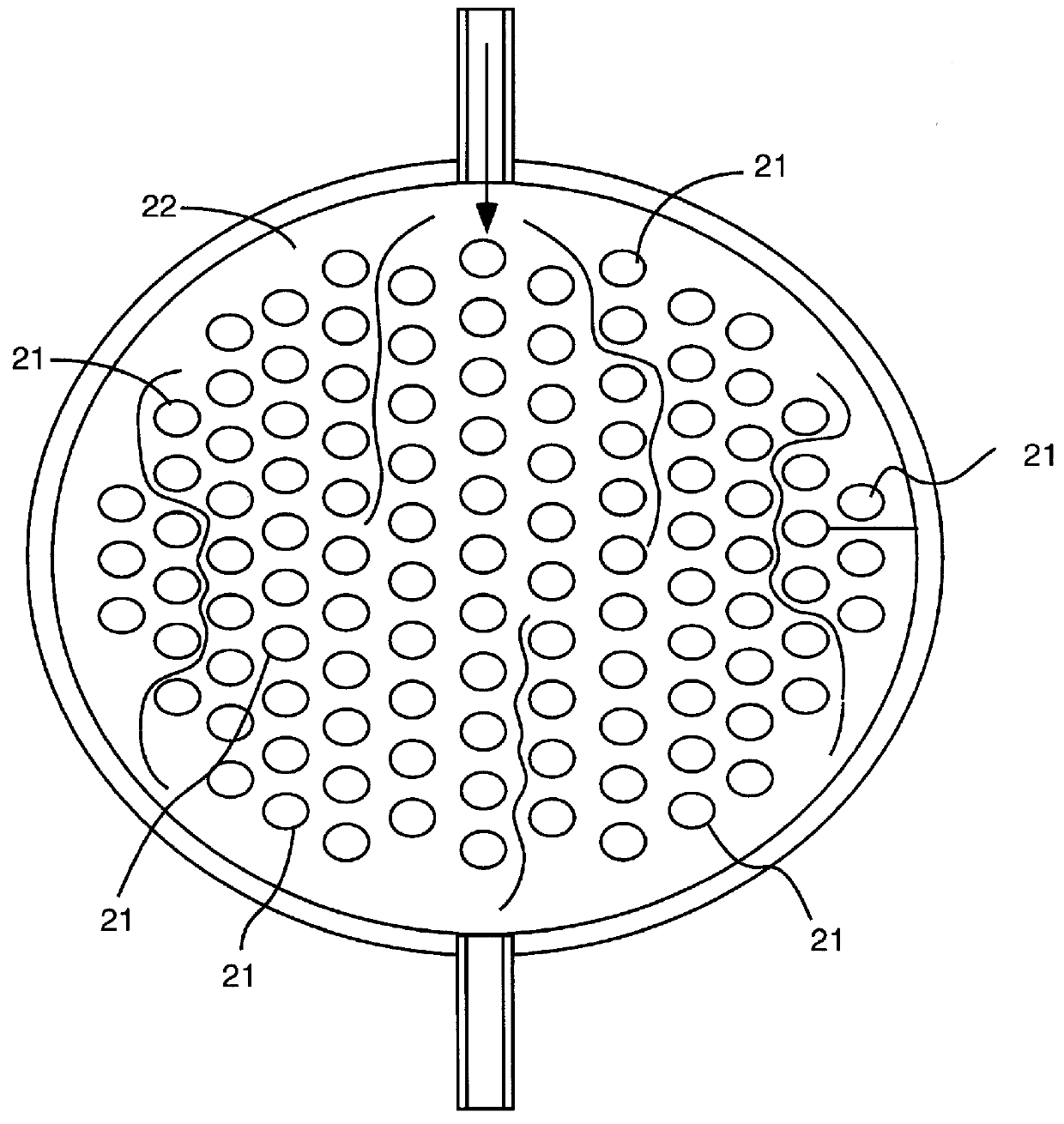

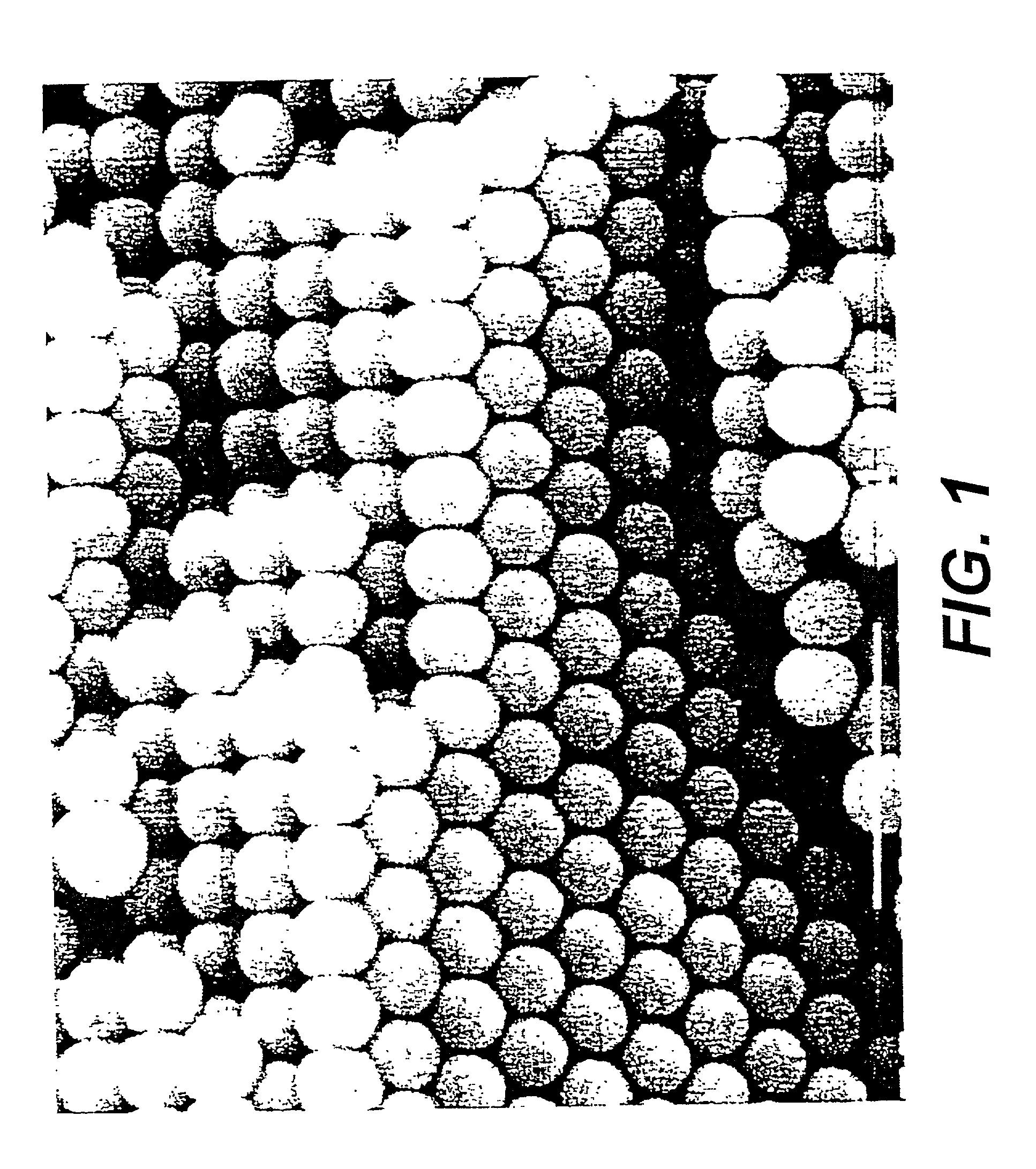

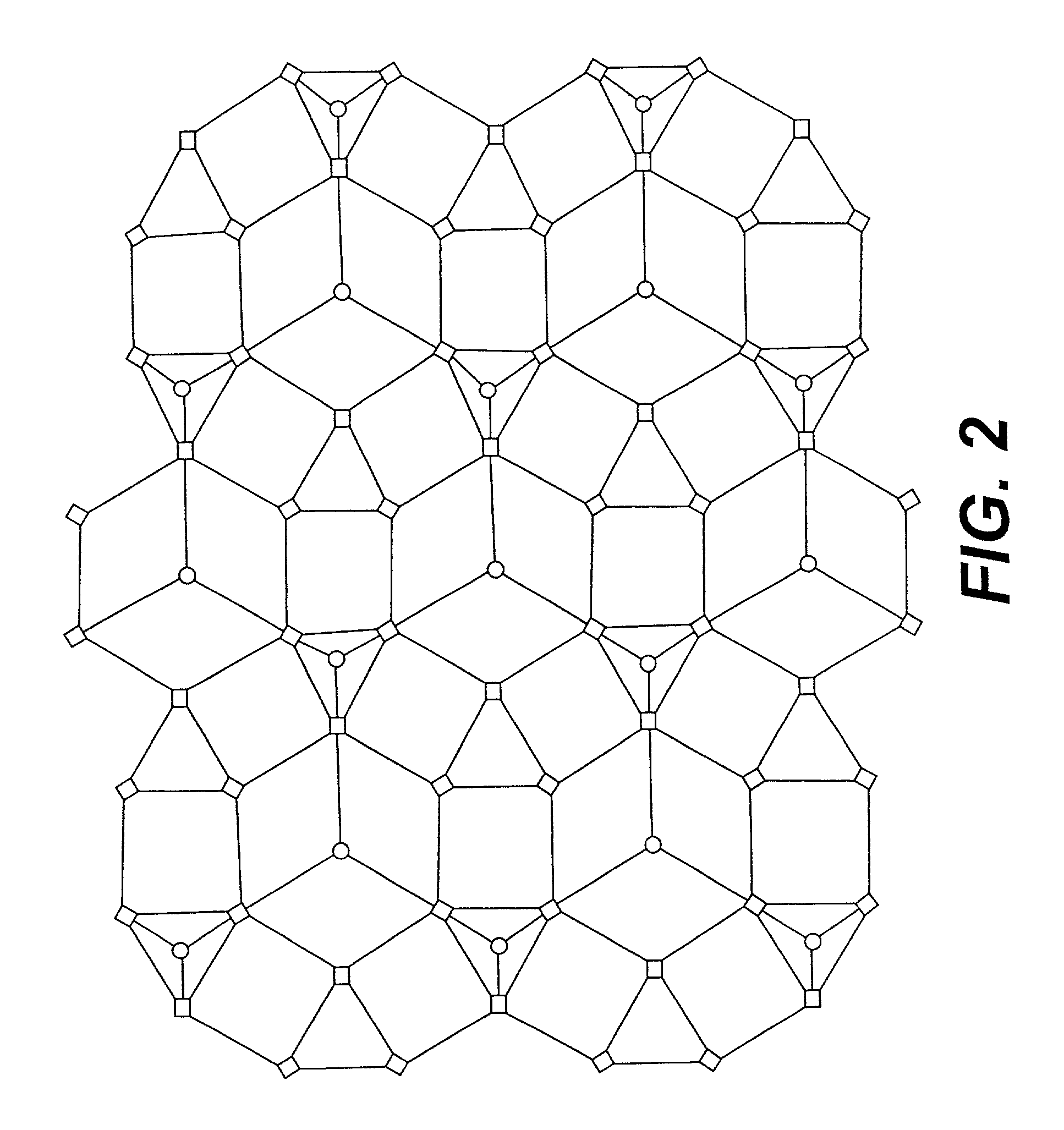

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS6261469B1Low melting pointEasily de-infiltrateSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ALLIEDSIGNAL INC

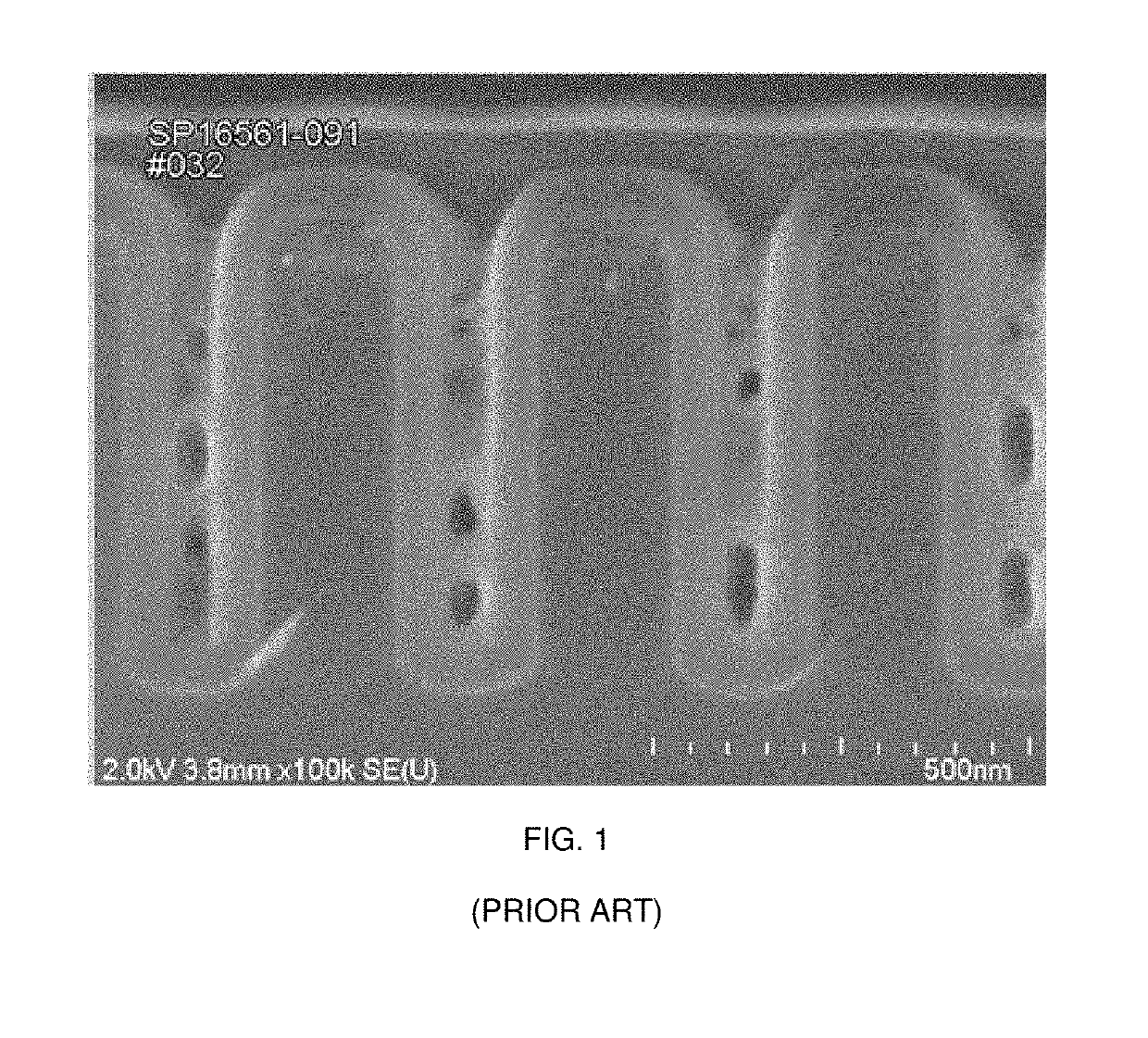

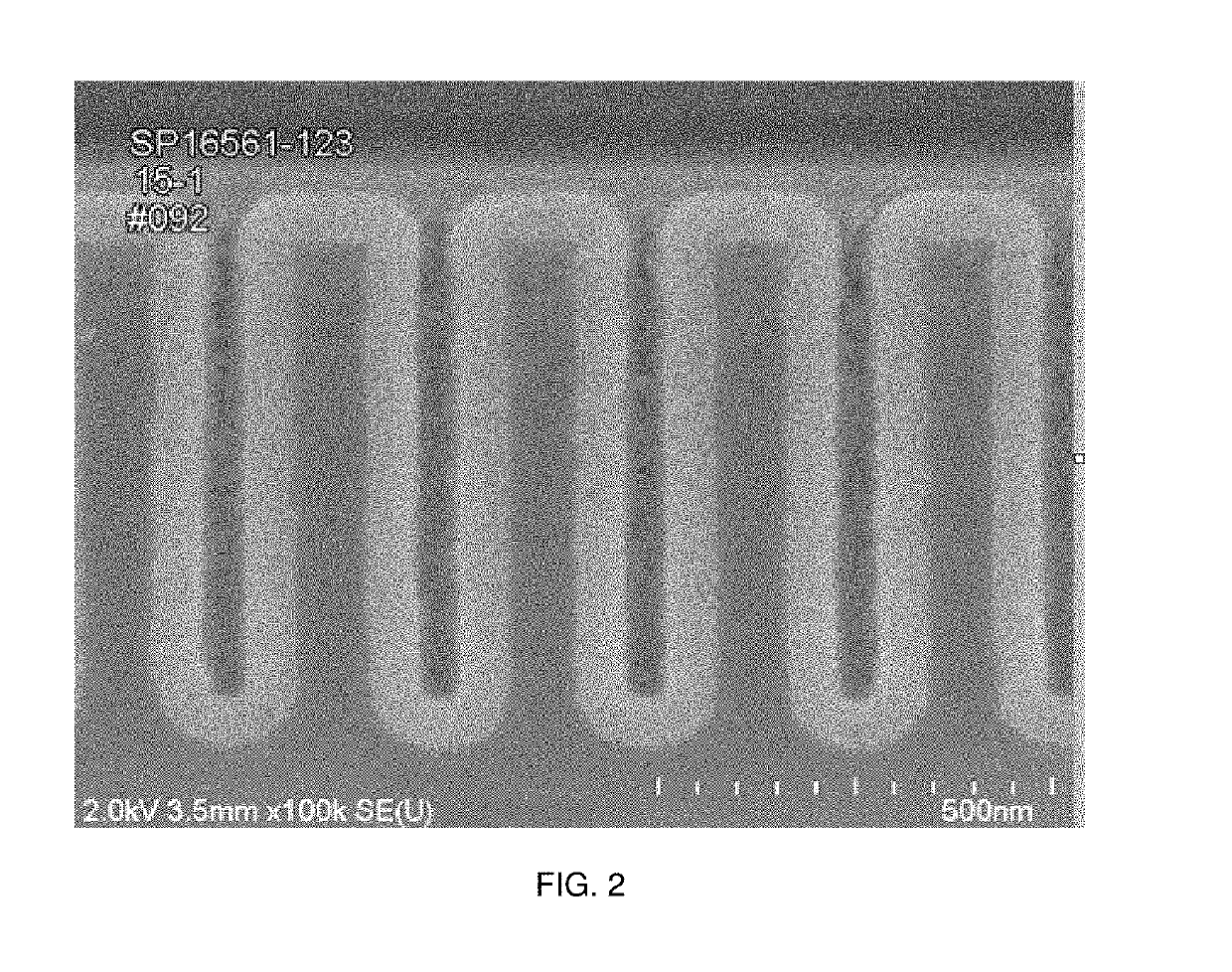

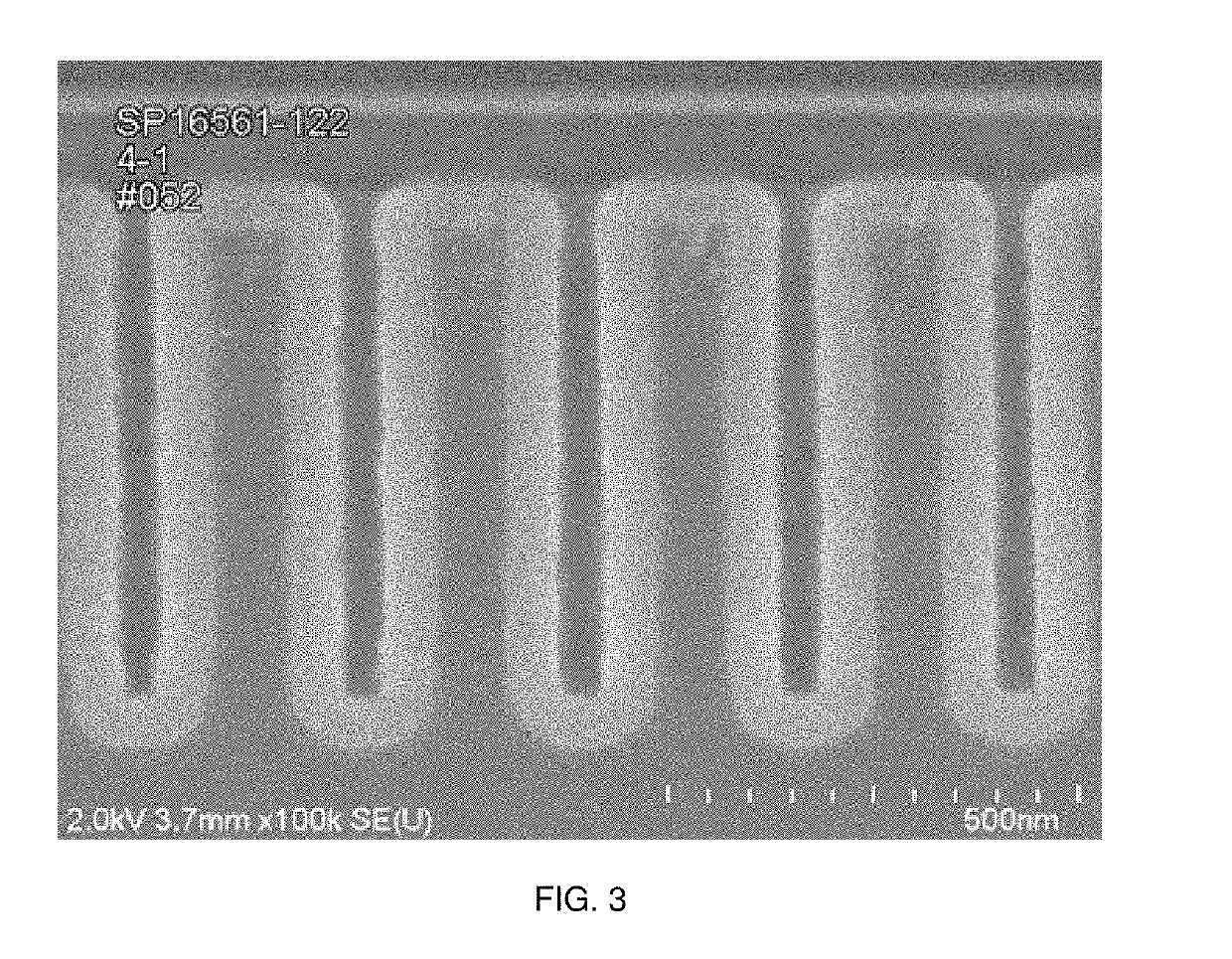

Precursors and flowable CVD methods for making low-K films to fill surface features

A method for depositing a silicon-containing film, the method comprising: placing a substrate comprising at least one surface feature into a flowable CVD reactor which is at a temperature of from about −20° C. to about 400° C.; introducing into the reactor at least one silicon-containing compound having at least one acetoxy group to at least partially react the at least one silicon-containing compound to form a flowable liquid oligomer wherein the flowable liquid oligomer forms a silicon oxide coating on the substrate and at least partially fills at least a portion of the at least one surface feature. Once cured, the silicon oxide coating has a low k and excellent mechanical properties.

Owner:VERSUM MATERIALS US LLC

Method and apparatus for insitu vapor generation

A method of forming an oxide on a substrate. According to the method of the present invention a substrate is placed in a chamber. An oxygen containing gas and a hydrogen containing gas are then fed into the chamber. The oxygen containing gas and the hydrogen containing gas are then caused to react with one another to form water vapor in the chamber. The water vapor then oxidizes the substrate.

Owner:APPLIED MATERIALS INC

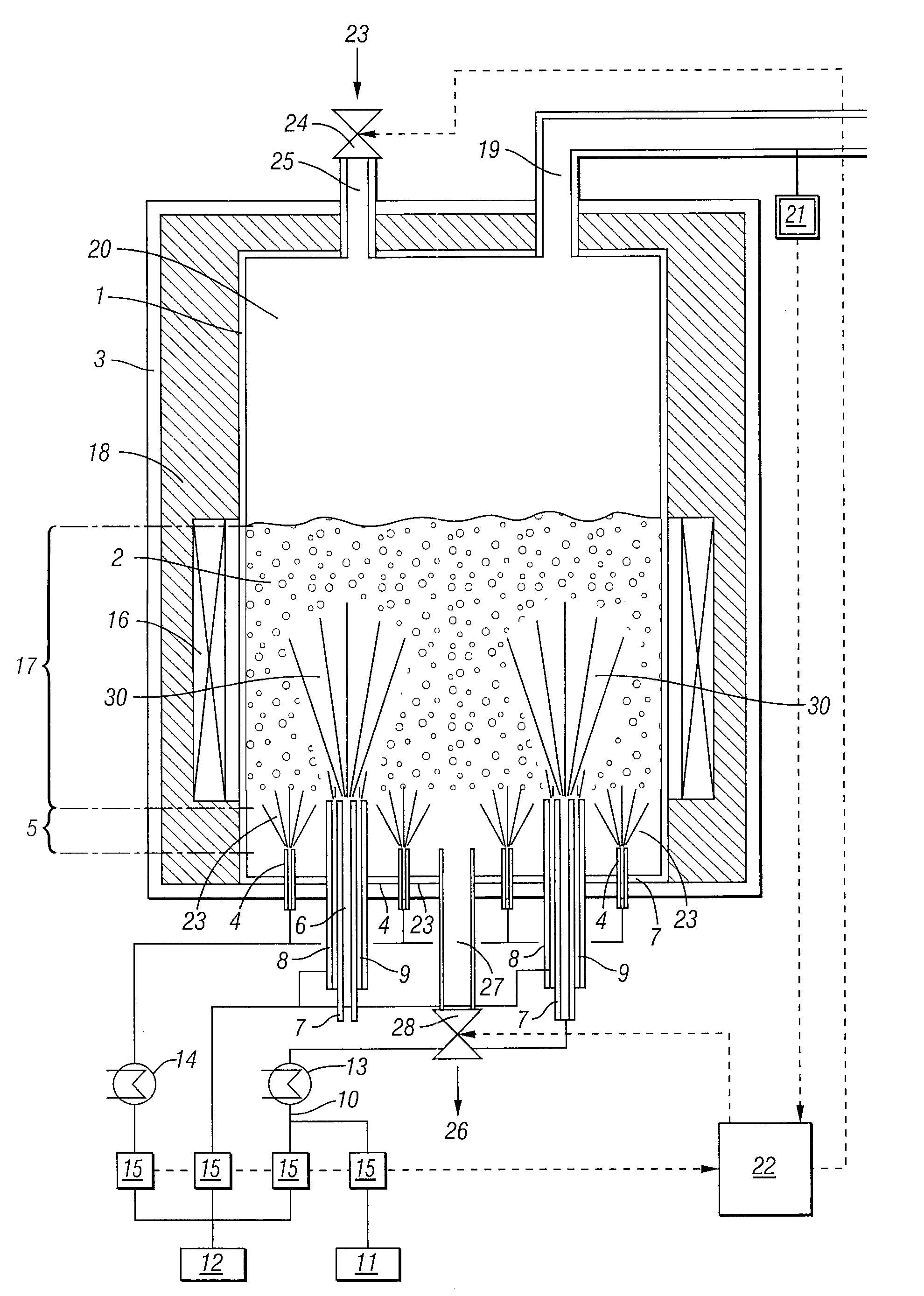

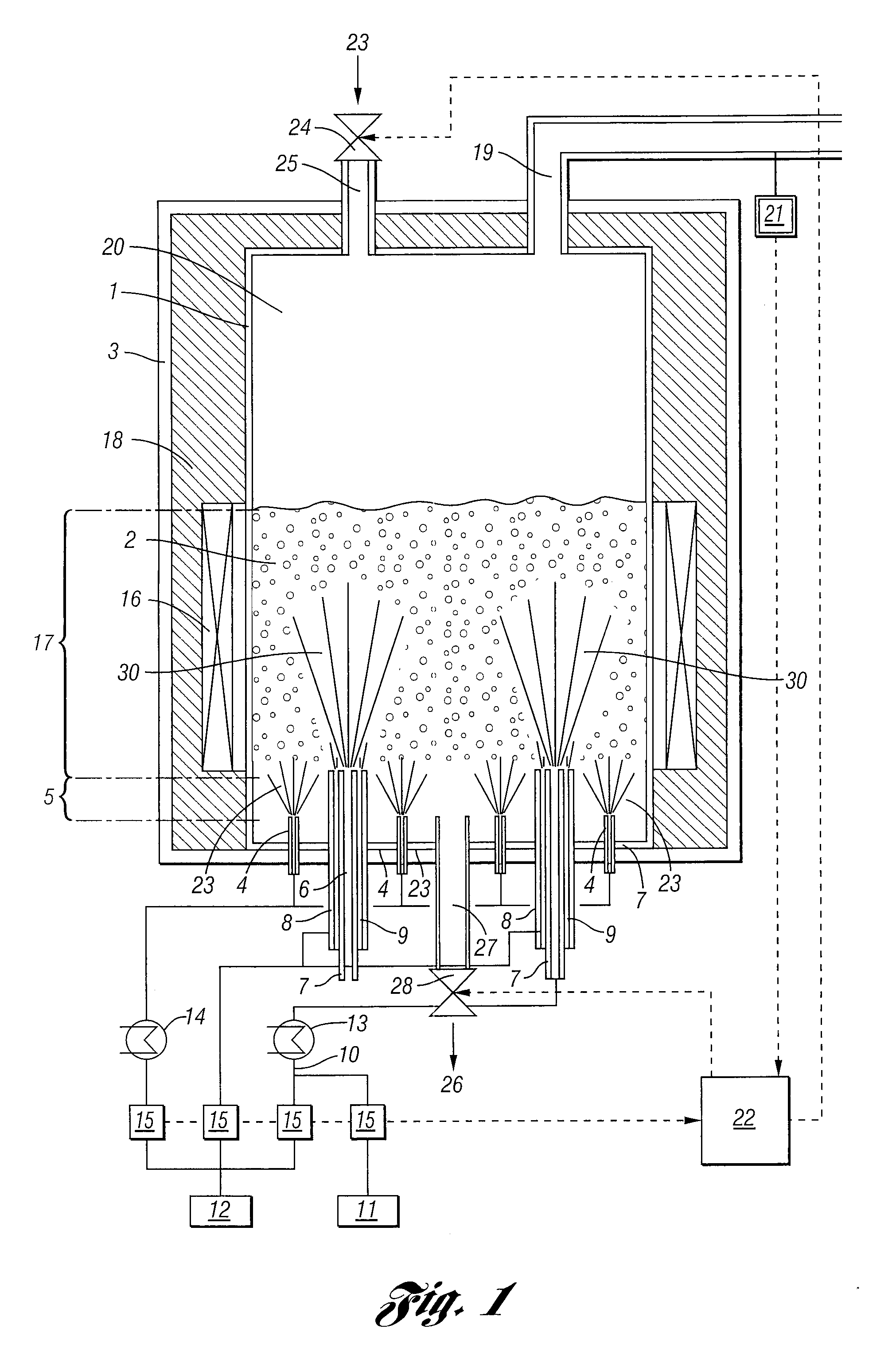

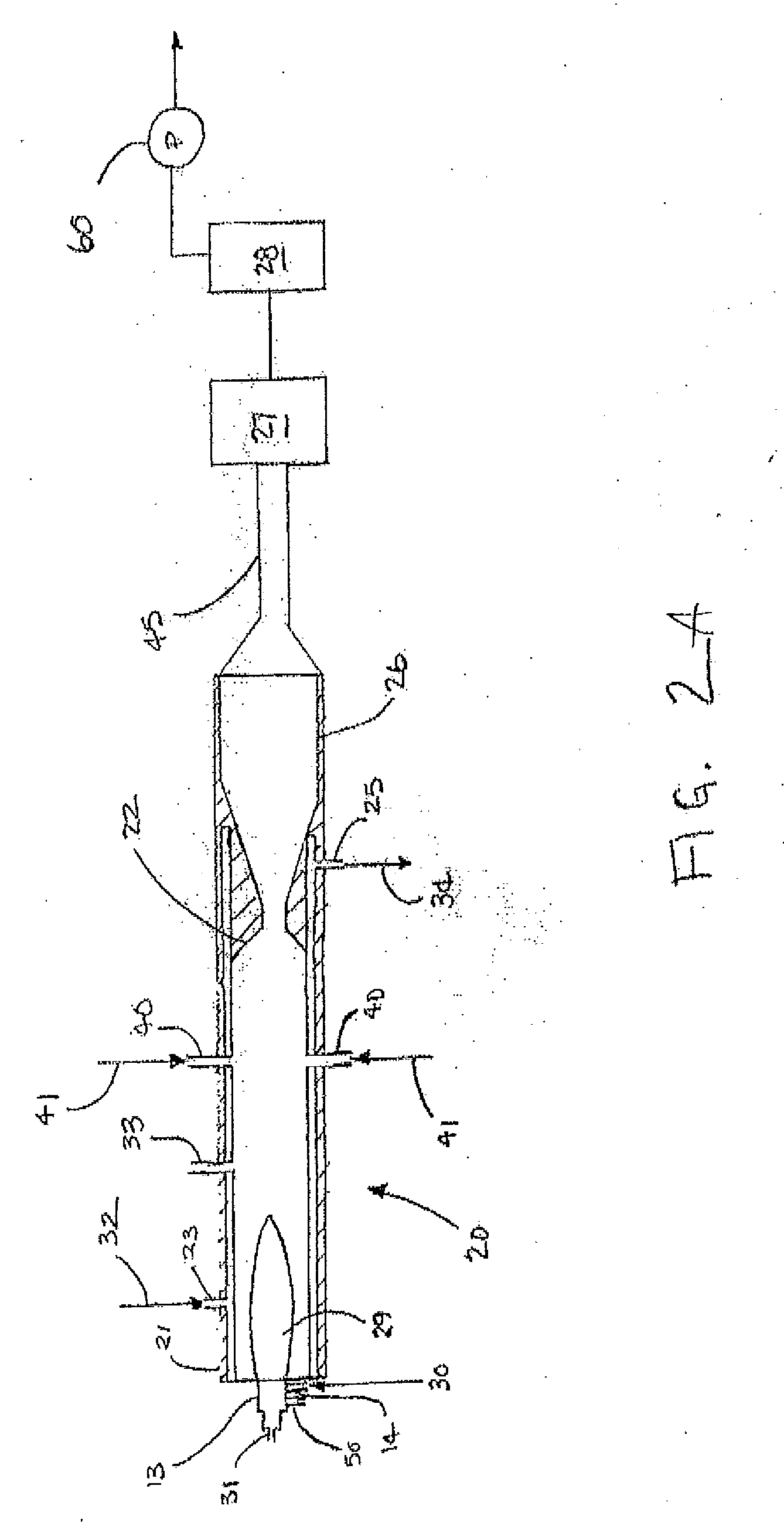

Process For The Continuous Production Of Polycrystalline High-Purity Silicon Granules

ActiveUS20080299291A1Efficient heatingLong operating campaignPolycrystalline material growthLiquid surface applicatorsFluidized bedReaction zone

High-purity polysilicon granules are prepared by depositing reaction gas on silicon granules in a fluidized bed reactor having:a reactor space comprising at least two zones lying one above the other, the lower zone weakly fluidized by introduction of a silicon-free gas into silicon granules in the lower zone by a plurality of individual dilution gas nozzles, and a second, reaction zone directly abutting the lower zone,the reaction zone heated via its outwardly bounding wall,introducing silicon-containing reaction gas as a vertical high speed gas jet into the reaction zone by reaction gas nozzle(s), forming local reaction gas jets surrounded by bubble-forming fluidized bed, gas decomposing leading to particle growth,wherein the reaction gas has fully or almost fully reacted to chemical equilibrium conversion before reaching the wall or bed surface.

Owner:WACKER CHEM GMBH

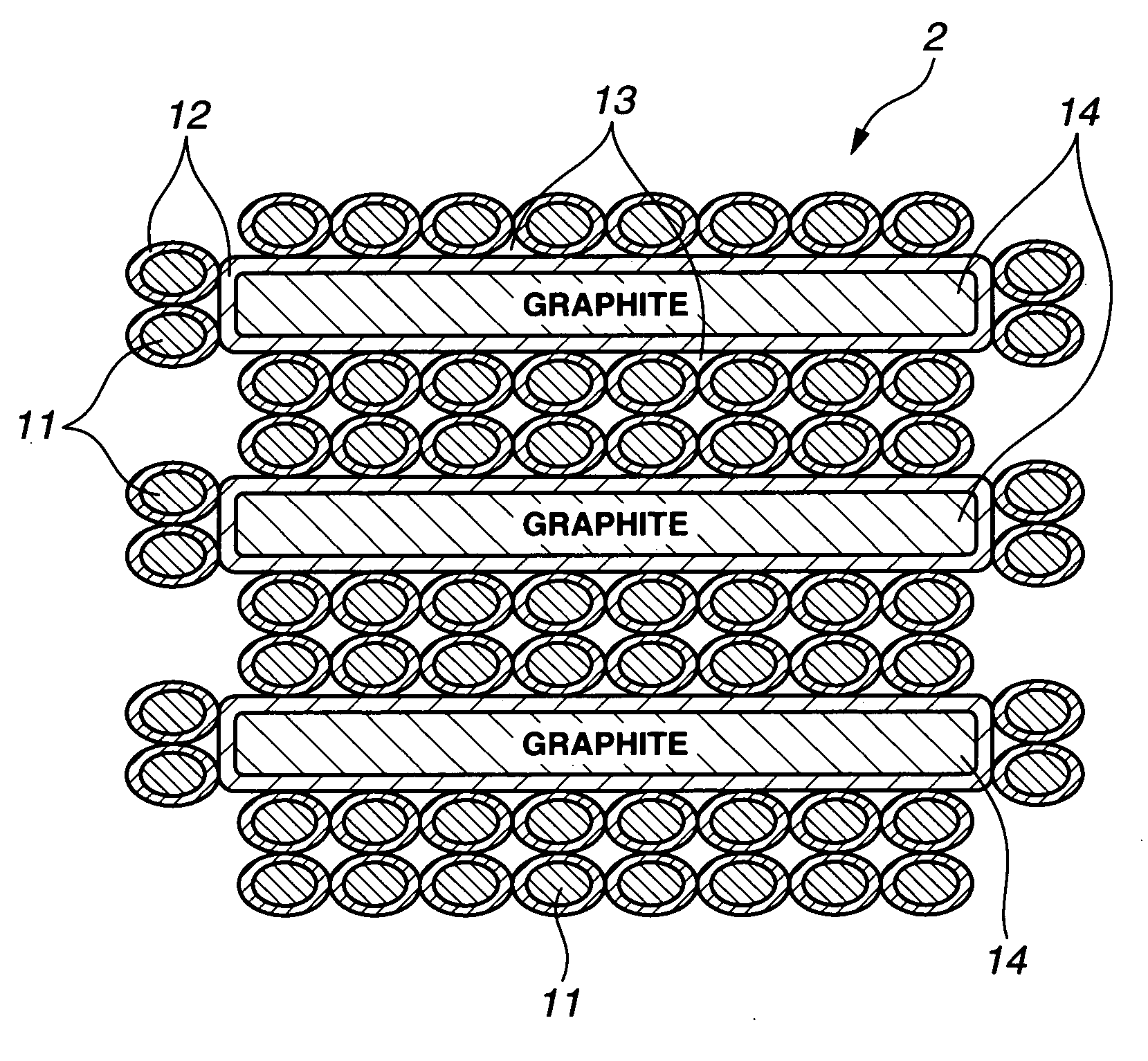

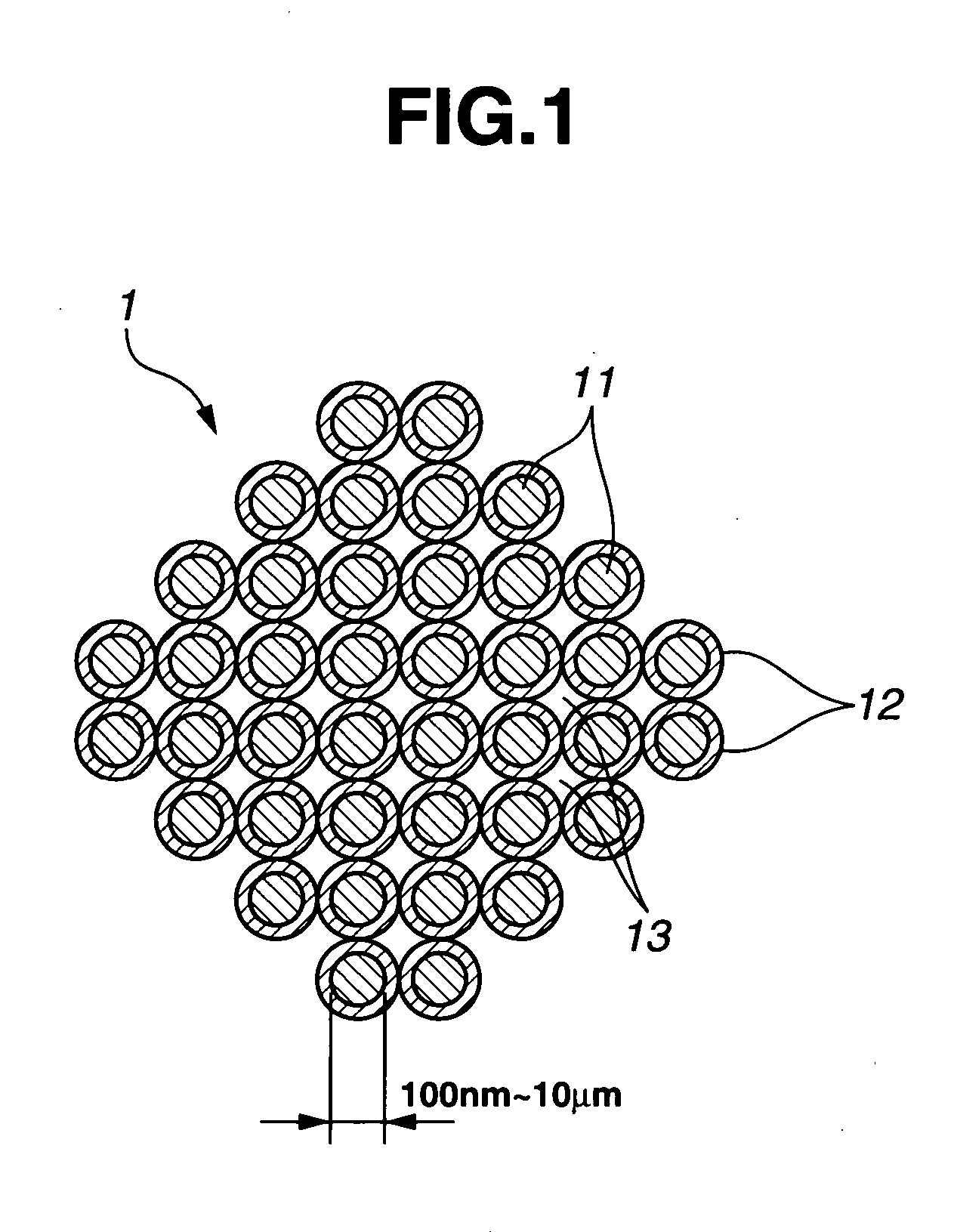

Silicon composite particles, preparation thereof, and negative electrode material for non-aqueous electrolyte secondary cell

ActiveUS20050214644A1Improve cycle performanceMinimize changesSilicaNitrogen compoundsSilicon alloyInorganic compound

Silicon composite particles are prepared by sintering primary fine particles of silicon, silicon alloy or silicon oxide together with an organosilicon compound. Sintering of the organosilicon compound results in a silicon-base inorganic compound which serves as a binder. Each particle has the structure that silicon or silicon alloy fine particles are dispersed in the silicon-base inorganic compound binder, and voids are present within the particle.

Owner:SHIN ETSU CHEM IND CO LTD

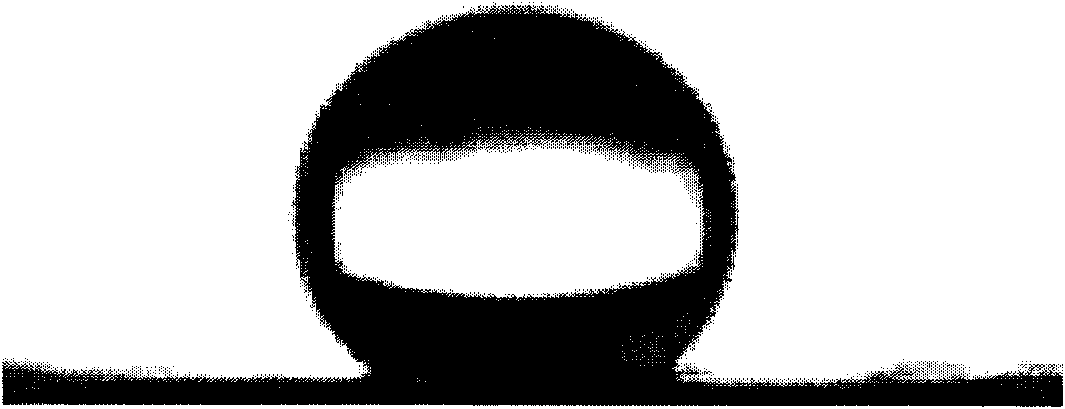

Processing compositions and method of forming the same

ActiveUS20060110542A1Increased durabilityImprove conditionsPigmenting treatmentFouling preventionSilica particleAdditive ingredient

A method for processing compositions, compositions obtained by such a process and methods of use are disclosed for forming a detachable and renewable protective coating which is substantially transparent. The inventive process compositions are produced by making a highly concentrated dispersion of hydrophobically modified silica particles in the presence of an optional, yet preferable, disilazane derivative under high shear conditions. These process compositions are intended to be further diluted to final treatment compositions, optionally while adding other functional ingredients.

Owner:EVONIK OPERATIONS GMBH

Precipitated silica product, dentifrices containing same, and processes

InactiveUS7255852B2Reduce the possibilityIncrease volumeCosmetic preparationsPigmenting treatmentSilica particleAntimicrobial action

Owner:EVONIK OPERATIONS GMBH

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20060233692A1Simplified and advantageous mannerReduce productionSolar heating energyMaterial nanotechnologyHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

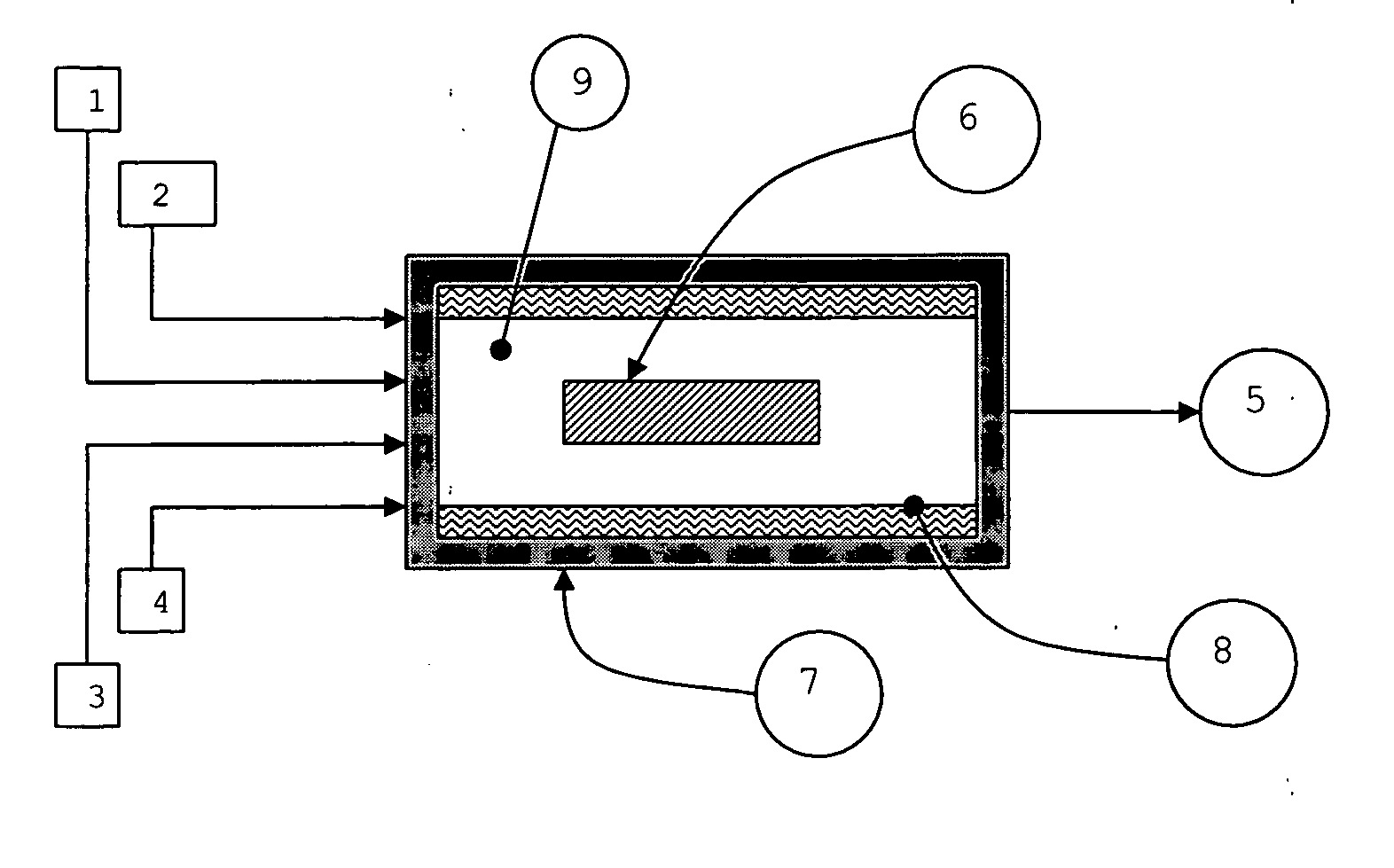

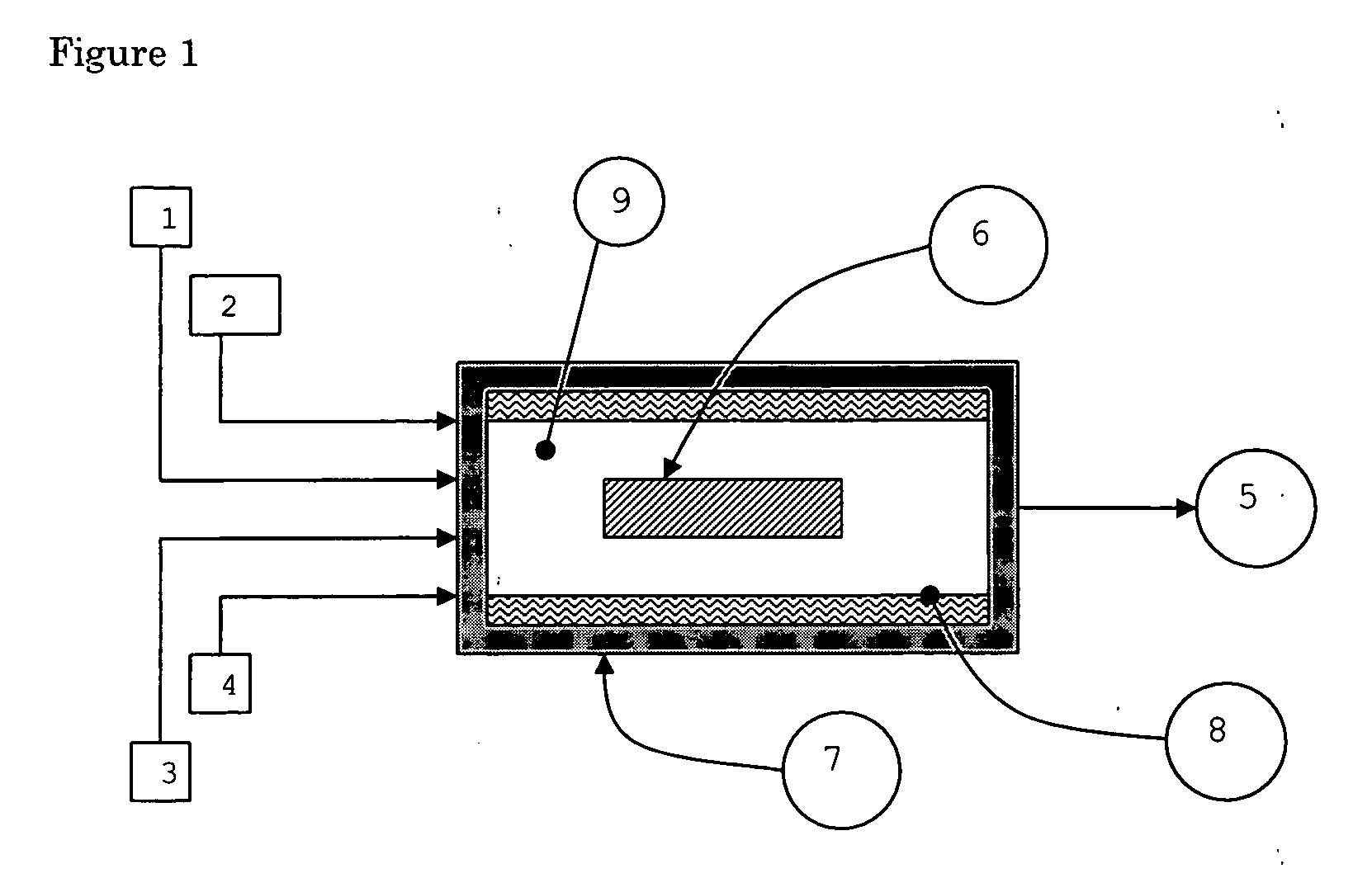

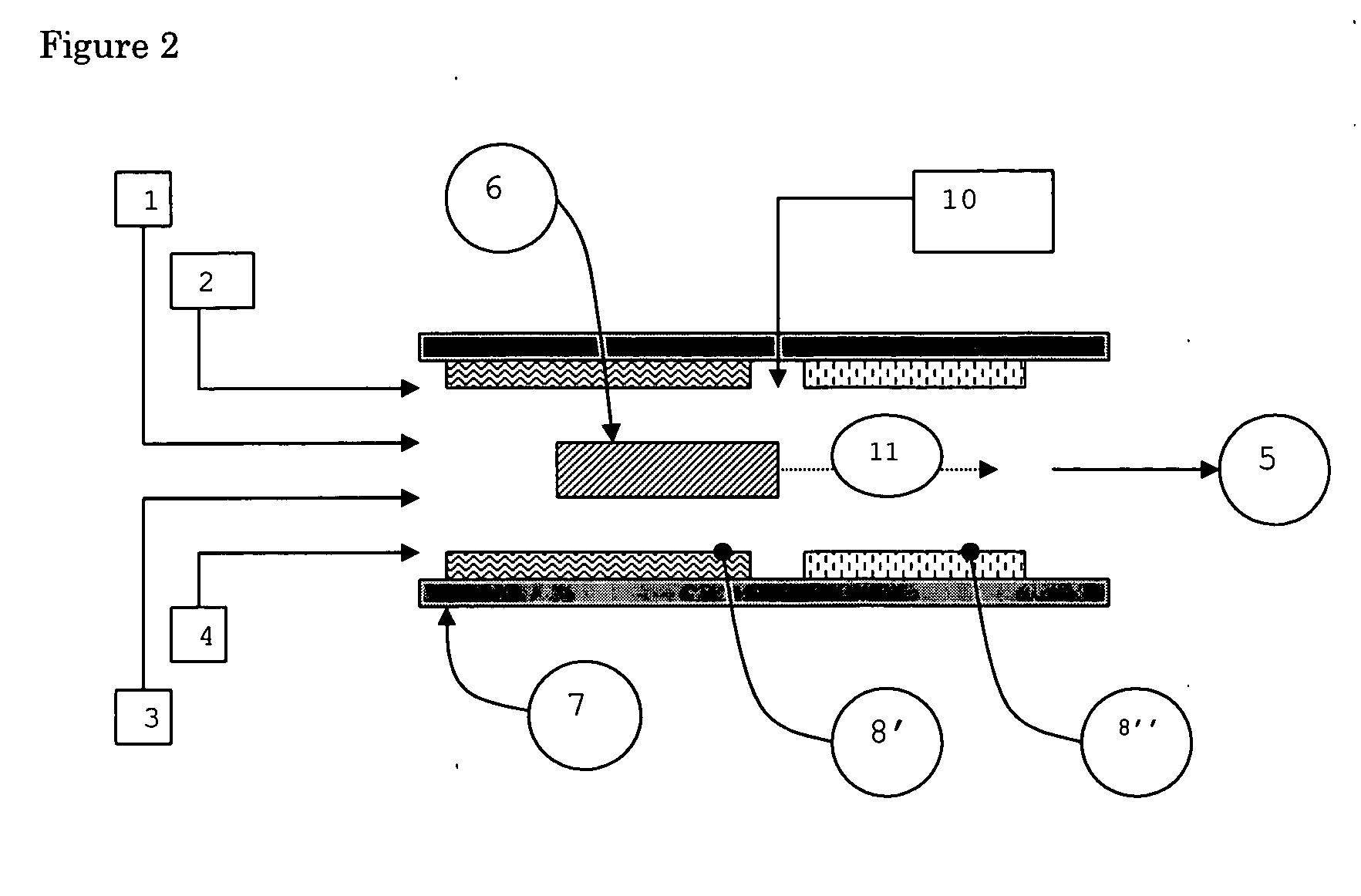

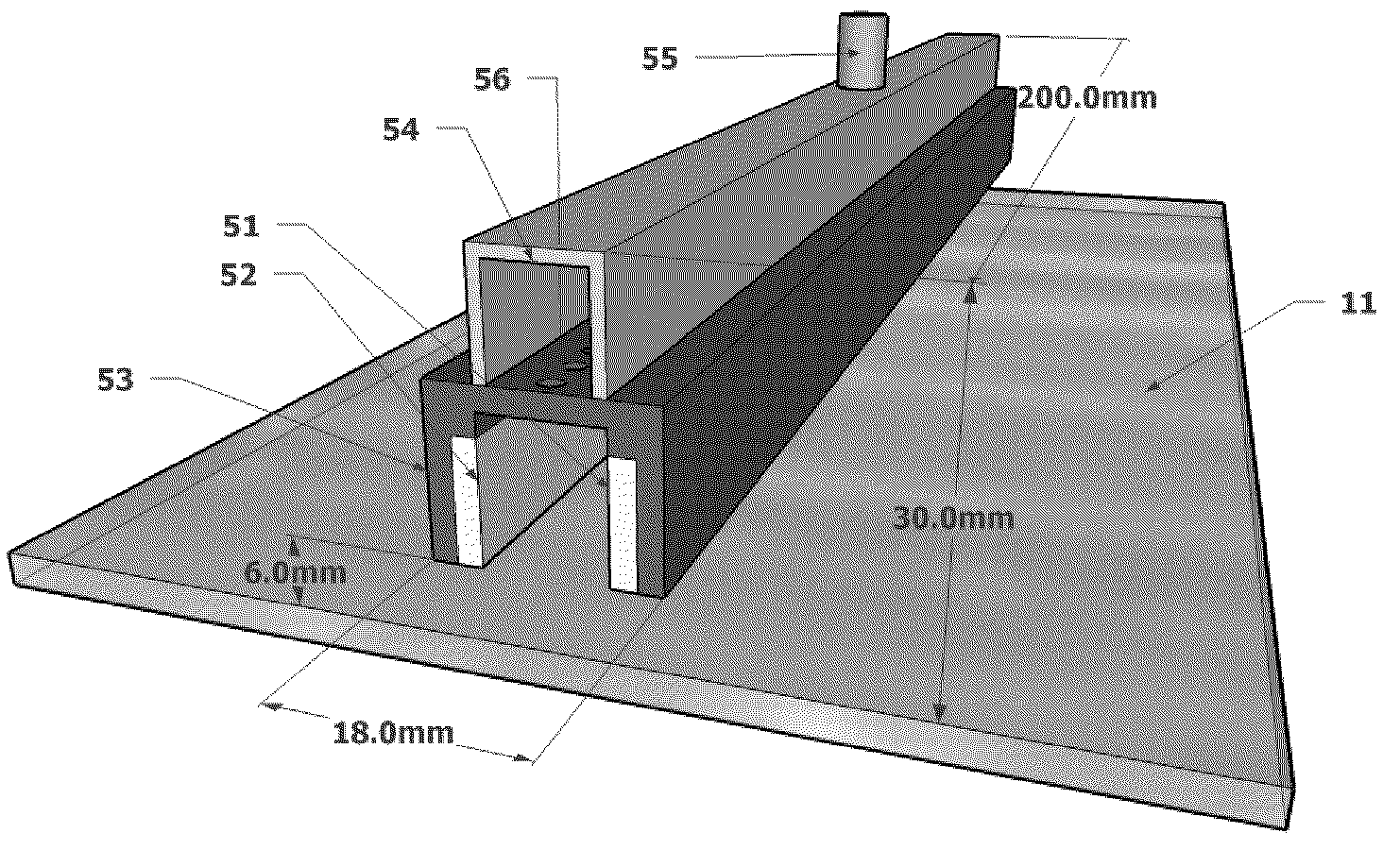

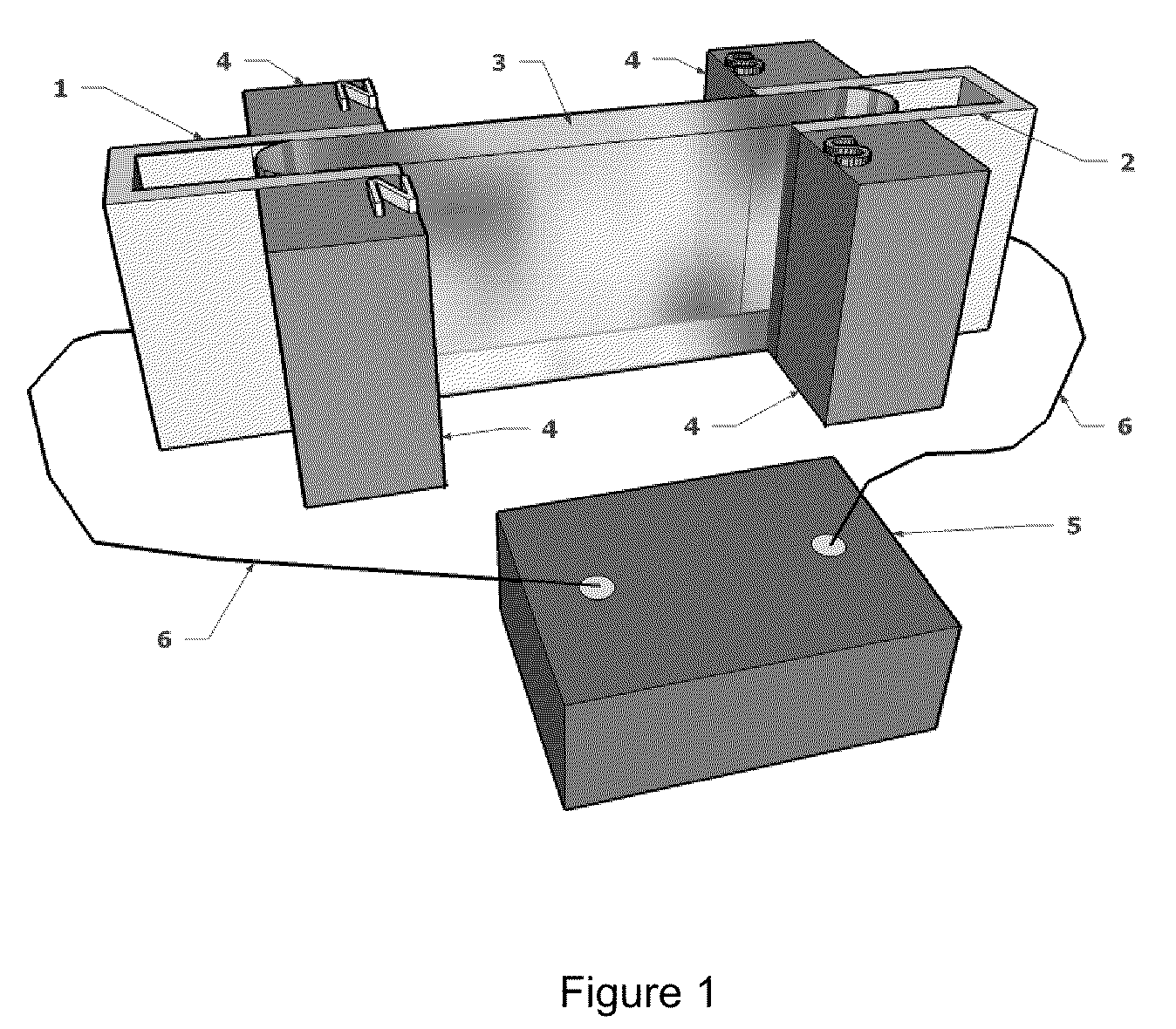

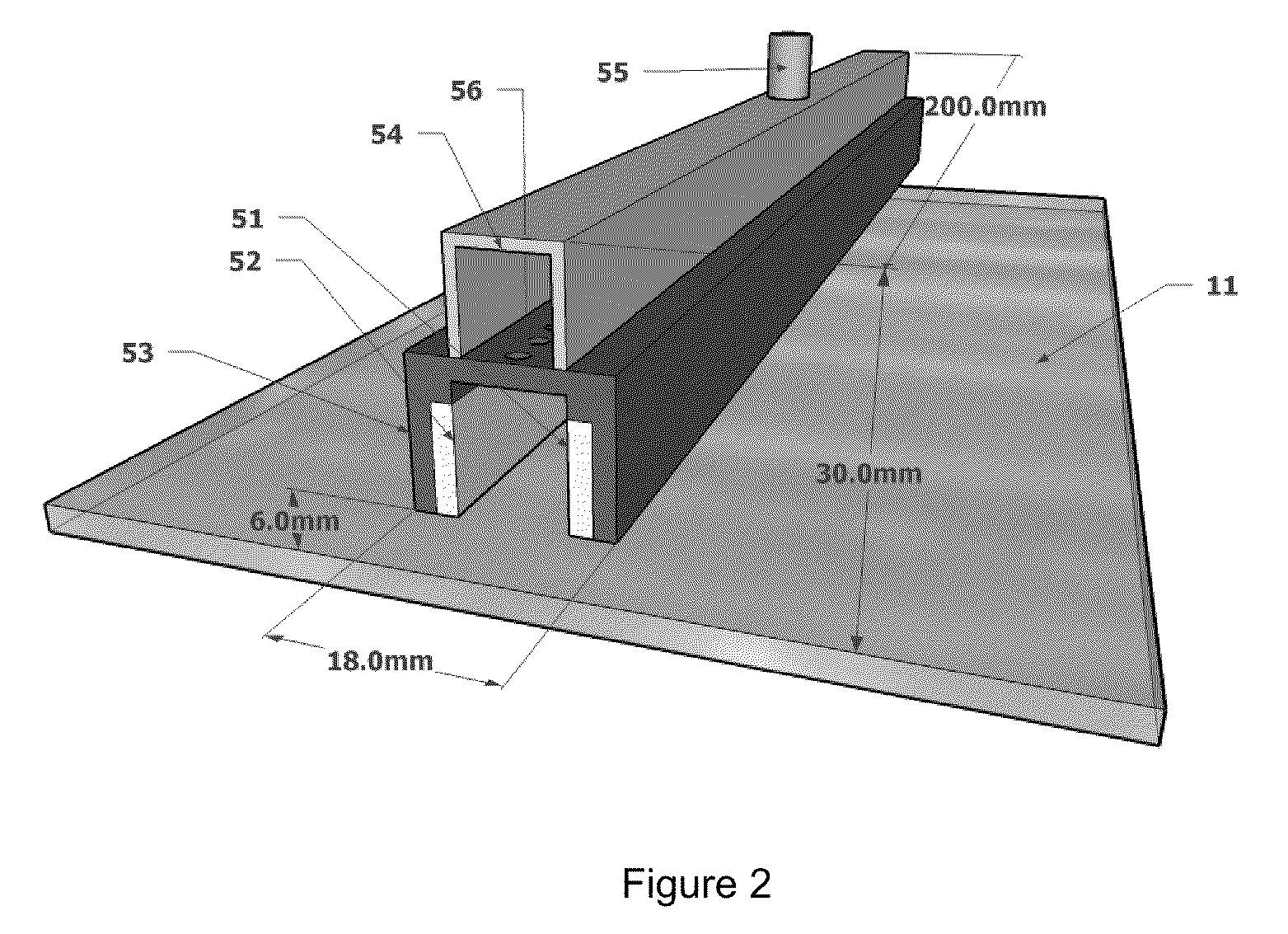

Plasma source and methods for depositing thin film coatings using plasma enhanced chemical vapor deposition

ActiveUS20100028238A1Stable and uniform and long plasmaSilicaElectric discharge tubesGas phaseFilm-coated tablet

The present invention provides novel plasma sources useful in the thin film coating arts and methods of using the same. More specifically, the present invention provides novel linear and two dimensional plasma sources that produce linear and two dimensional plasmas, respectively, that are useful for plasma-enhanced chemical vapor deposition. The present invention also provides methods of making thin film coatings and methods of increasing the coating efficiencies of such methods.

Owner:AGC FLAT GLASS NORTH AMERICA INC +1

Method for preparing silicon dioxide silica aerogel composite material by drying in atmosphere pressure

InactiveCN101318659ALow thermal conductivityIncrease added valueSilicaThermal insulationPipeline transport

The invention discloses a method for preparing a silicon dioxide aerogel composite material at the condition of normal pressure and drying, which comprises the steps as following: (1) silicon dioxide sol and a reinforcing material are compounded and placed statically to form plural gel, and then ageing treatment is carried out to the plural gel; (2) a modifying agent is used for the hydrophobic modification of the aged plural gel, and then ambient pressure drying is carried out for the modified plural gel to obtain the silicon dioxide aerogel composite material at the condition of normal pressure and drying. The silicon dioxide aerogel composite material prepared by the method of the invention has extremely low coefficient of heat conductivity, which greatly increases the added value of the reinforcing materials such as corpus fibrosum, the product can be widely applied to thermal insulation and sound insulation of buildings, thermal insulation and sound insulation in the industrial pipeline transportation, and the like, and expands the application field of silicon dioxide and the corpus fibrosum.

Owner:绍兴纳诺气凝胶新材料研发中心有限公司 +2

Method for quick-speed preparing aerogel by hydro-thermal synthesis at low cost

InactiveCN101456569AReduce surface tensionIntegrity guaranteedSilicaAlkali metal silicatesReaction temperatureHydrothermal synthesis

The invention discloses a method for preparing aerogel materials by combining hydrothermal synthesis technology and sol-gel technology. The prepared aerogel comprises one or more of alumina aerogel, silica aerogel, zirconia aerogel and titania aerogel. The method comprises the following steps: mixing a reactant and a structure-directing agent according to certain proportion, and adding a pH value control agent to adjust the pH value; sealing hydrothermal reaction equipment, heating the mixture to be between 50 and 280 DEG C, making the mixture stand for 0 to 72 hours, raising the temperature to be between 60 and 300 DEG C, and continuously reacting for 0.1 to 72 hours; and cooling gel, taking out the gel, drying the gel and obtaining the aerogel. Compared with the prior art, the method has low reaction temperature and pressure, small equipment investment and simple and controllable technology, reduces potential safety hazards, greatly improves the preparation speed of the aerogel, saves the production cost, and is favorable to realize commercial mass production.

Owner:纳诺科技有限公司 +1

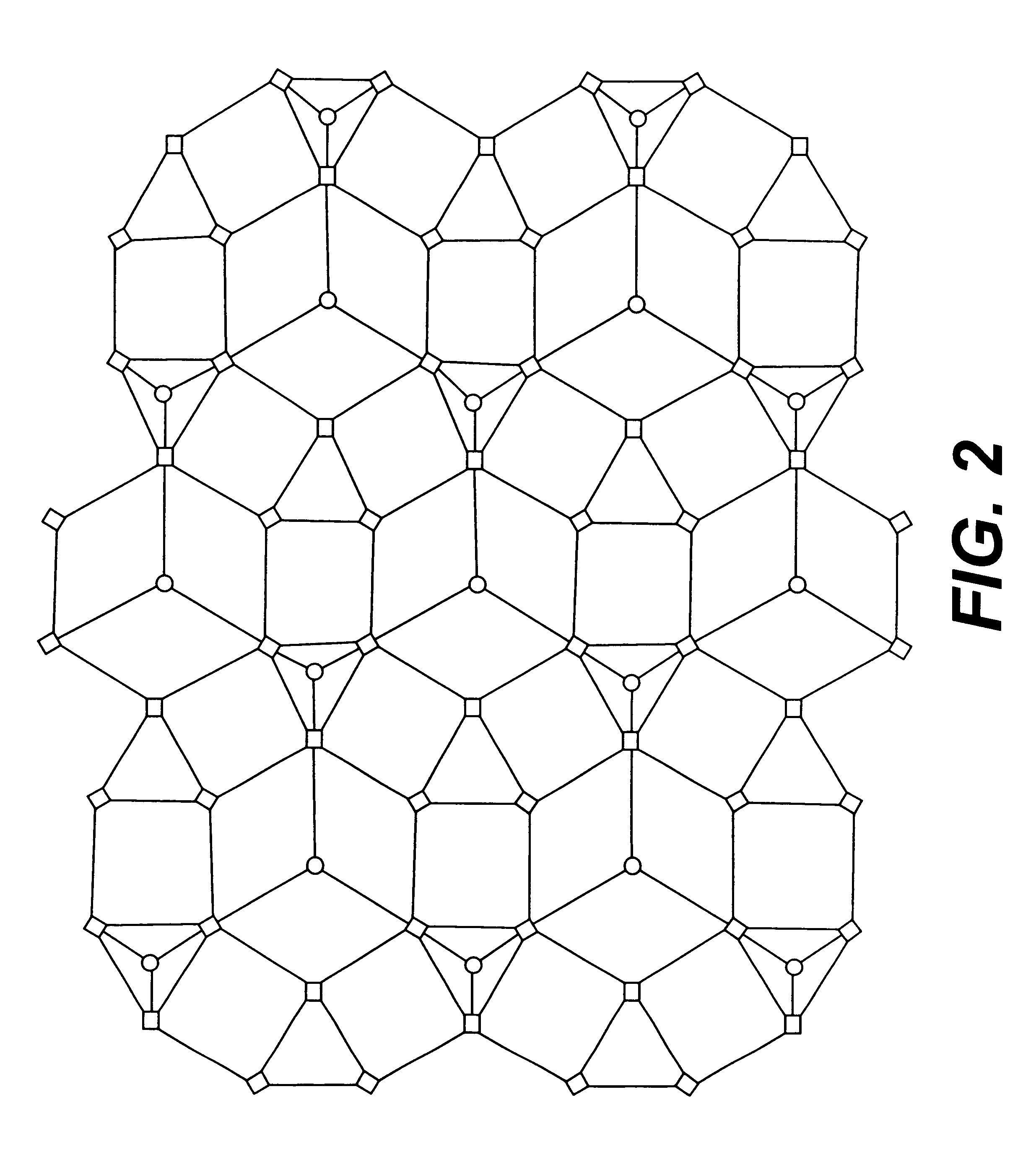

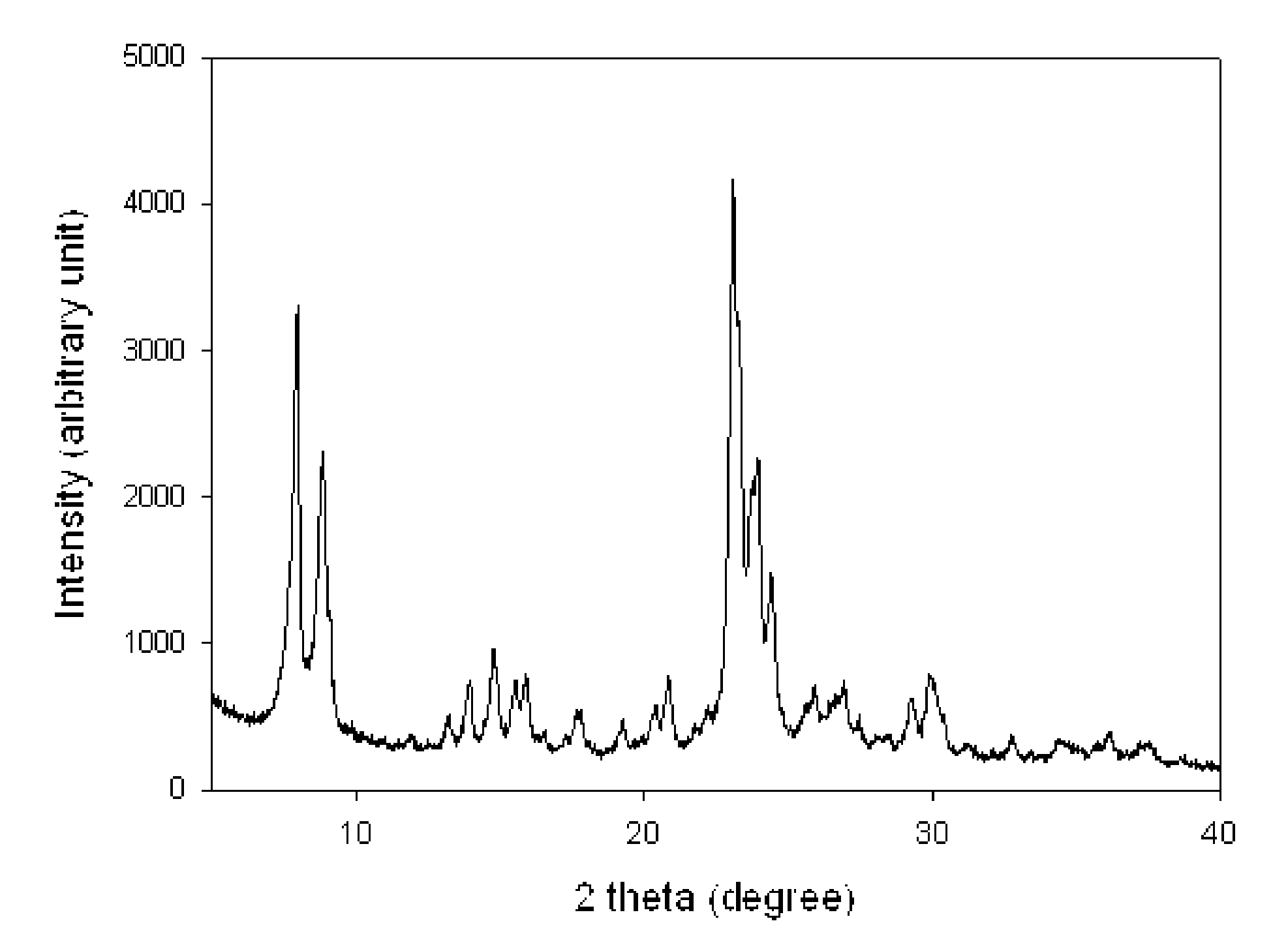

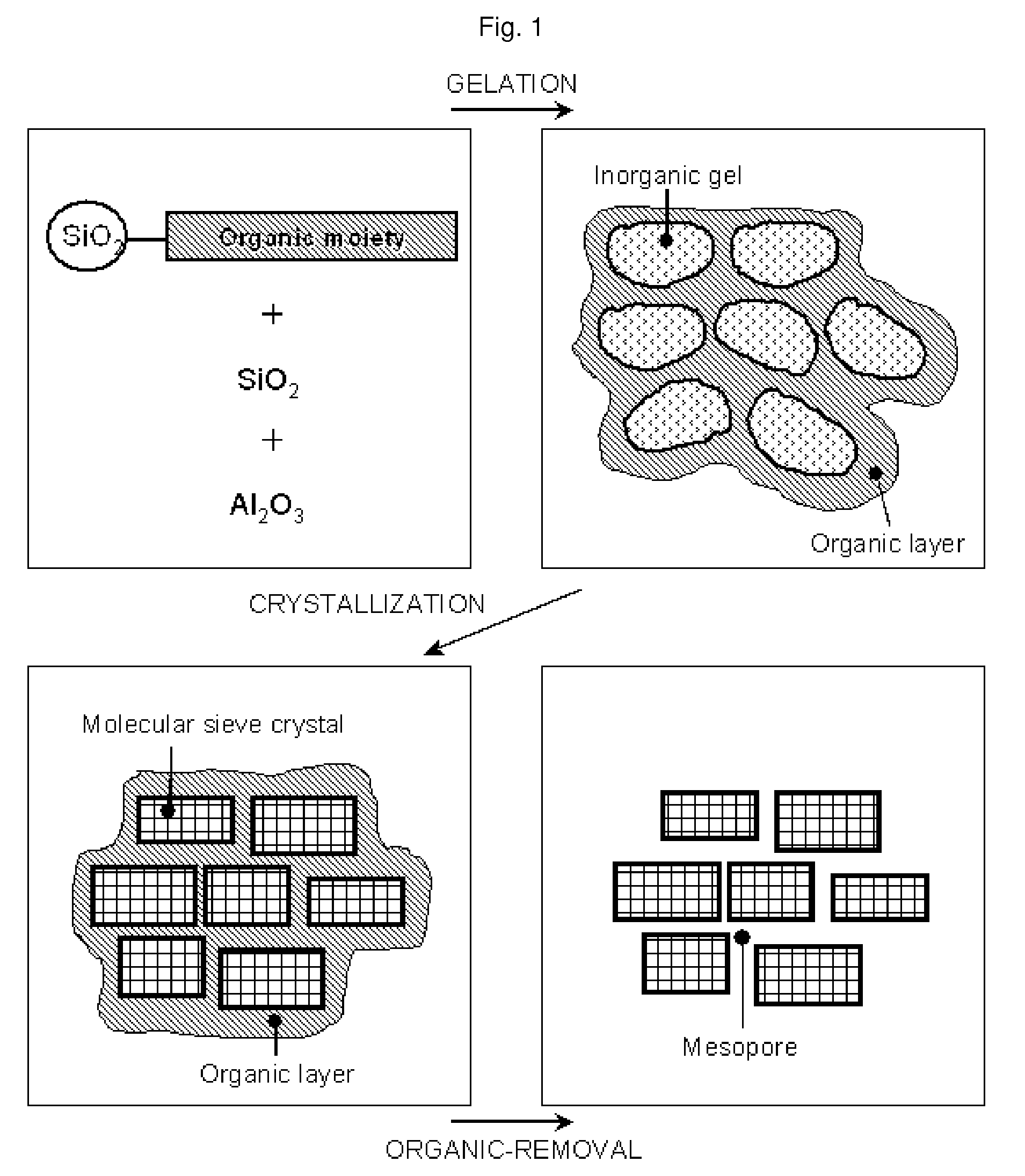

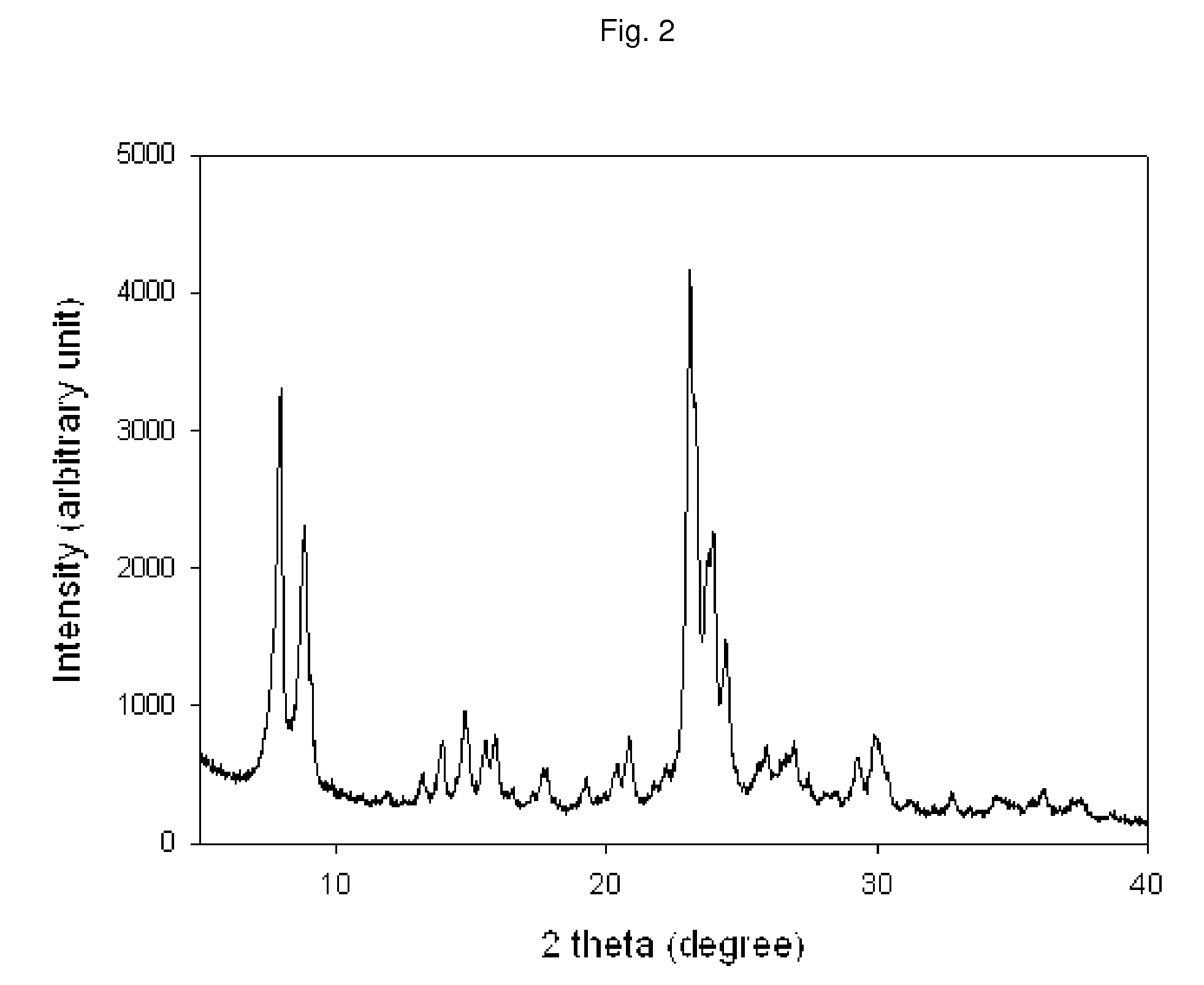

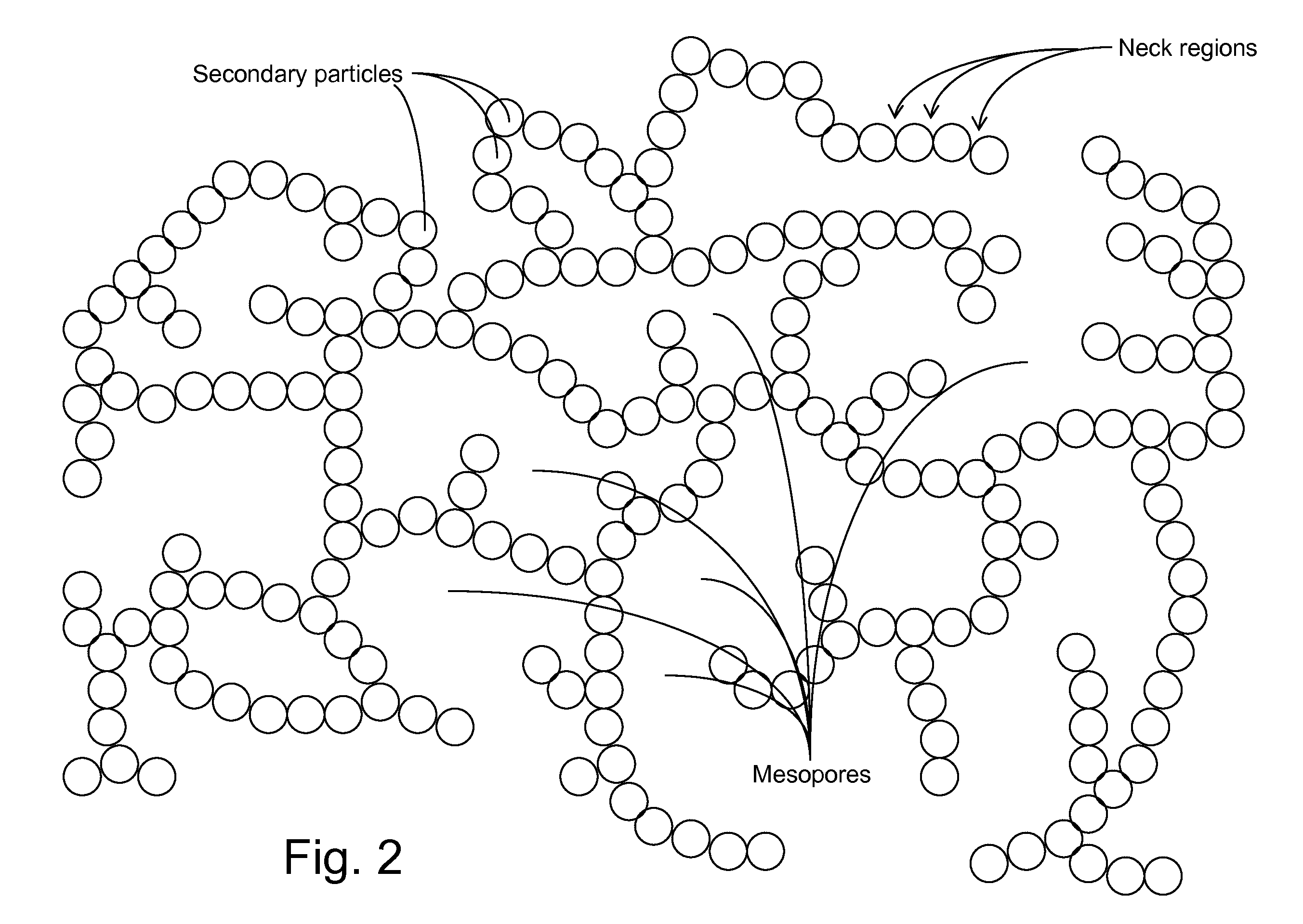

Method of the preparation of microporous crystalline molecular sieve possessing mesoporous frameworks

InactiveUS7785563B2Facilitate diffusion and adsorptionImprove overall utilizationAluminium compoundsSilicaMolecular sieveChemical treatment

The present invention relates to a method of preparing a microporous crystalline molecular sieve having mesoporous skeleton, comprising following steps: (a) adding a meso-SDA (meso-Structure Directing Agent) into a gel composition of synthesizing molecular sieve, (b) subjecting the mixture obtained in the above step (a) to crystallization by a hydrothermal reaction, a microwave reaction, a dry-gel synthesis, etc., and (c) removing selectively organic materials from the resulted material obtained in the above step (b) by a calcination or a chemical treatment. Molecular sieve having mesoporous skeleton synthesized by the present invention exhibits, as compared with conventional zeolite, a good molecule diffusion ability and a greatly improved catalytic activity.

Owner:KOREA ADVANCED INST OF SCI & TECH

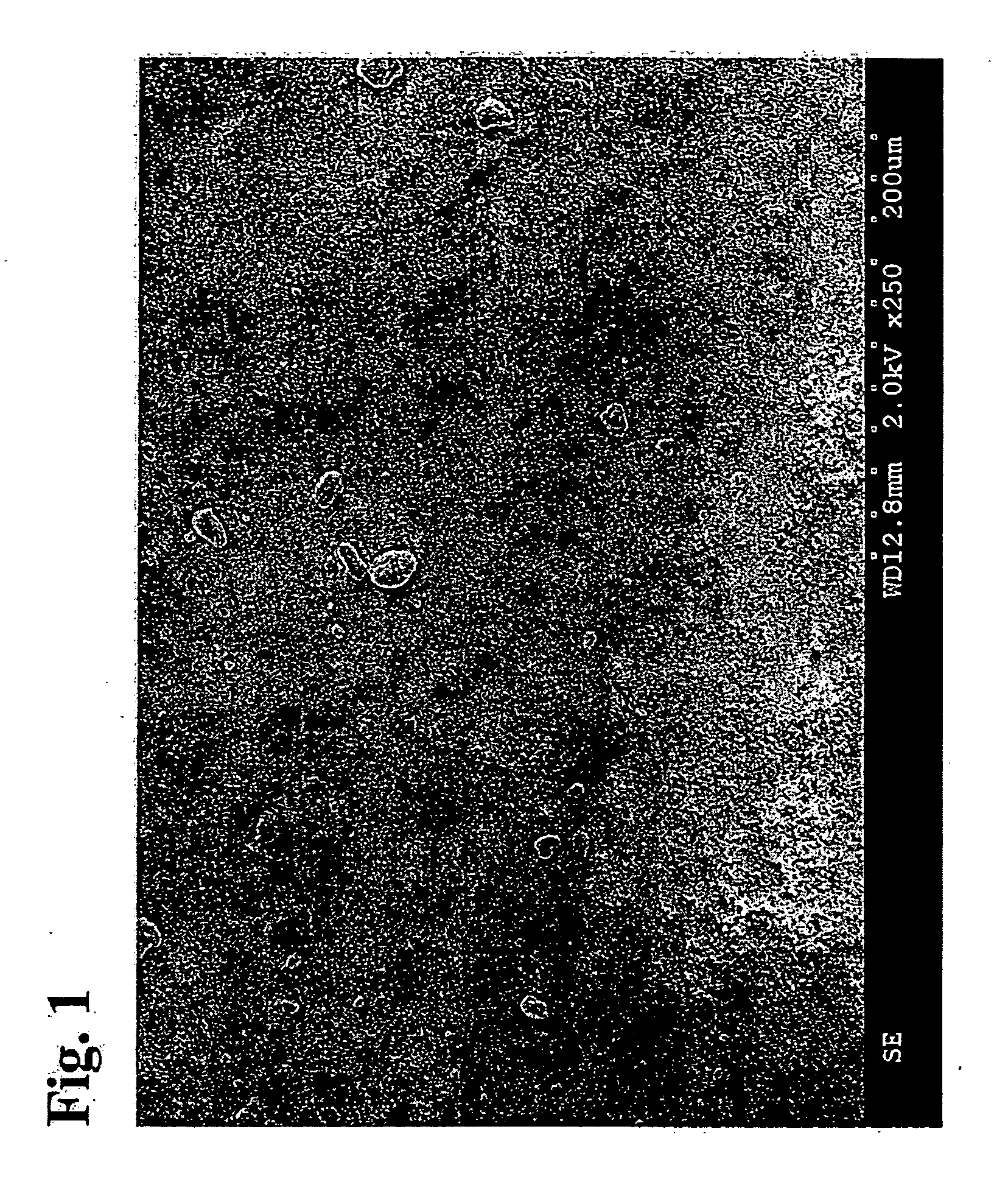

Porous silica having substance carried thereon

InactiveUS20070003492A1Improve adsorption capacityMild desorbabilityCosmetic preparationsBiocideMentholSilicon dioxide

The present invention relates to a substance-supporting porous silica, wherein a porous silica supports a substance selected from the group consisting of menthols, volatile substances, thermal substances, plant polyphenols and organic colorants.

Owner:TAIYO KAGAKU CO LTD +1

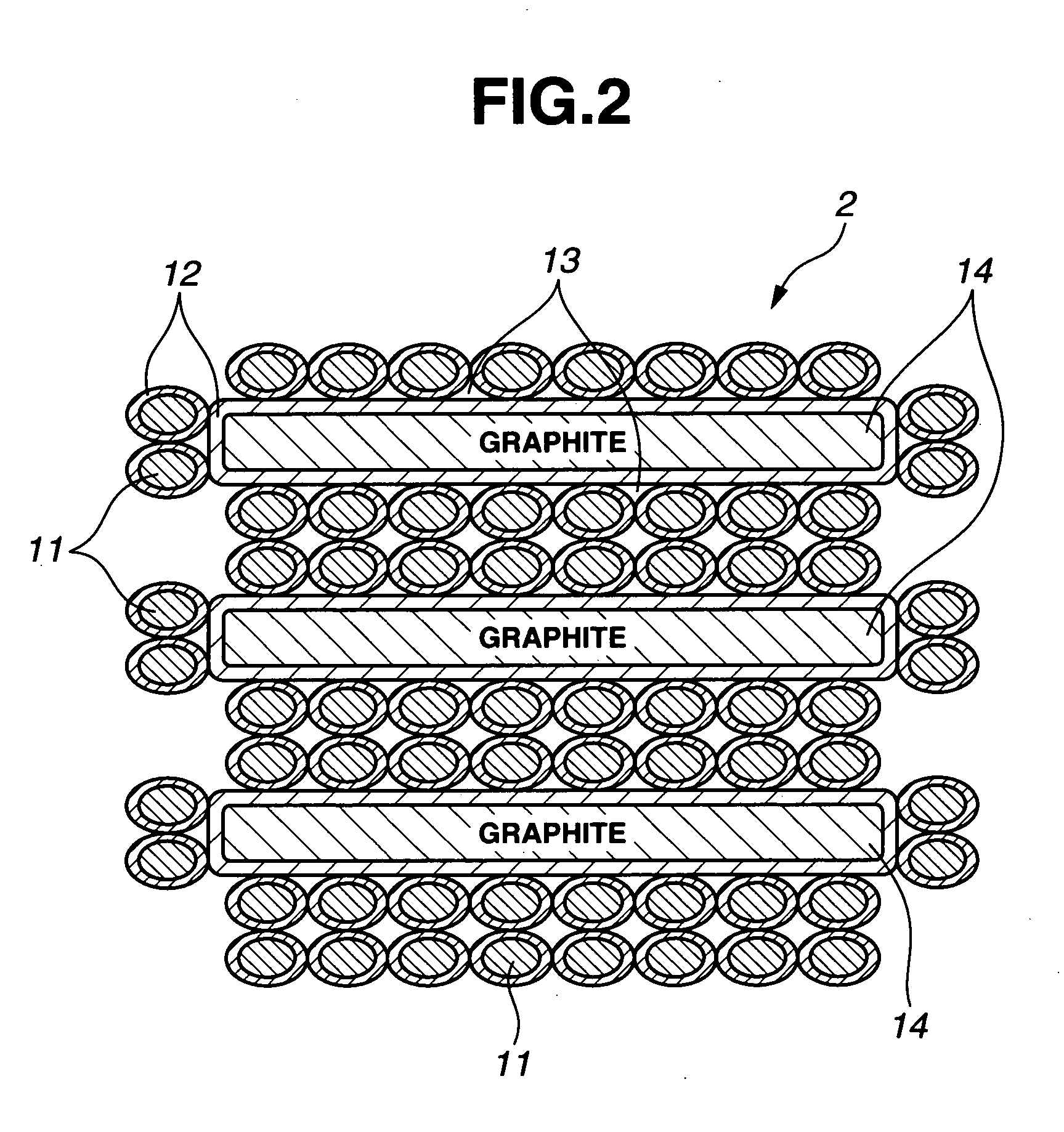

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

Silica aerogel material and preparation method thereof

The invention provides a novel silica aerogel material which is diaphanous, adiabatic, heat-retaining and noise-proof and a preparation method of the silica aerogel material. The silica aerogel material has the advantages of being high in tenacity strength, high in transparency, flawless, light in mass, low in density, especially big in block and the like. The silica aerogel material besides can be used in the field of energy saving buildings such as glass curtain walls, doors and windows which are heat-retaining, adiabatic and noise-proof, can be further used in the fields such as aerospace, petroleum and petrochemical, new energy resources, ships and refrigeration, and has good application prospect.

Owner:海鹰空天材料研究院(苏州)有限责任公司

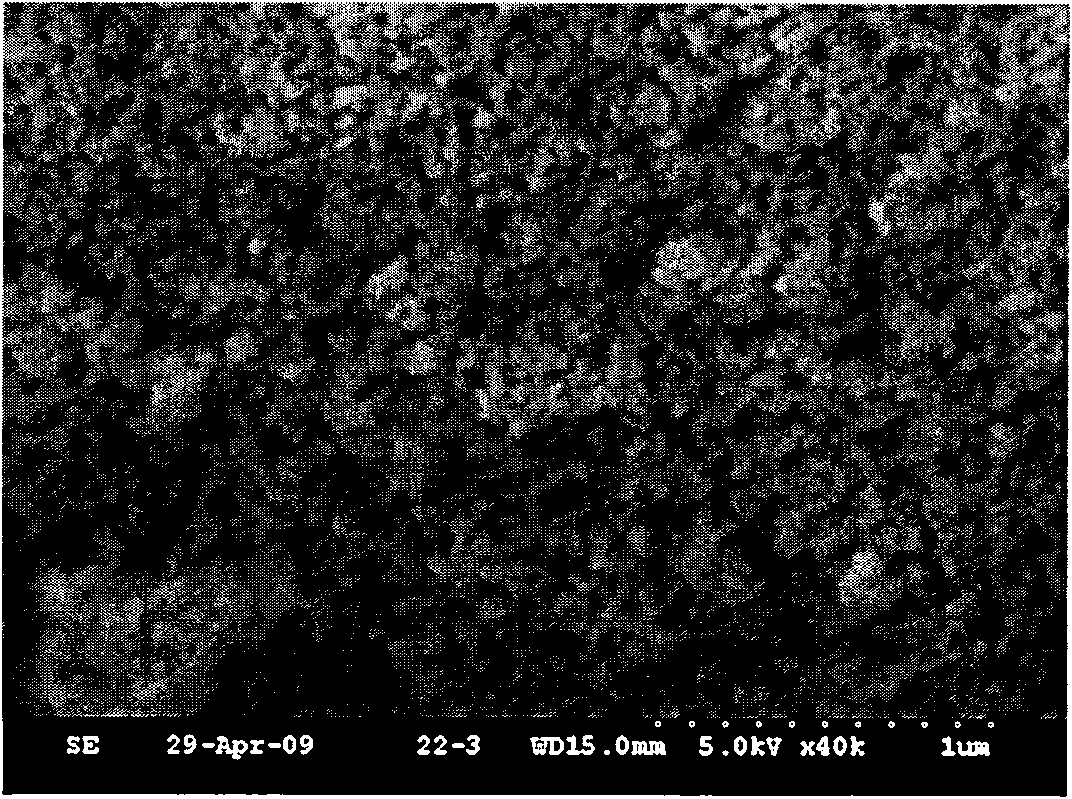

Raspberry-type metal oxide nanostructures coated with ceo2 nanoparticles for chemical mechanical planarization (CMP)

InactiveUS20120077419A1Efficient processCost-effective and convenient processMaterial nanotechnologySilicaCeo2 nanoparticlesWater soluble

Raspberry-type coated particles comprising a core selected from the group consisting of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof with a core size of from 20 to 100 nm wherein the core is coated with CeCO2 particles having a particle size below 10 nm; process for preparing raspberry type coated particles comprising the steps of i) providing a mixture containing: a) core particles selected from the group of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof, with a particle size of from 20 to 100 nm; b) a water soluble Ce-salt and c) water; ii) adding an organic or inorganic base to the mixture of step i) at temperatures of from 10 to 90° C. and iii) aging the mixture at temperatures of from 10 to 90° C.; and polishing agents containing the particles and their use for polishing surfaces.

Owner:BASF AG

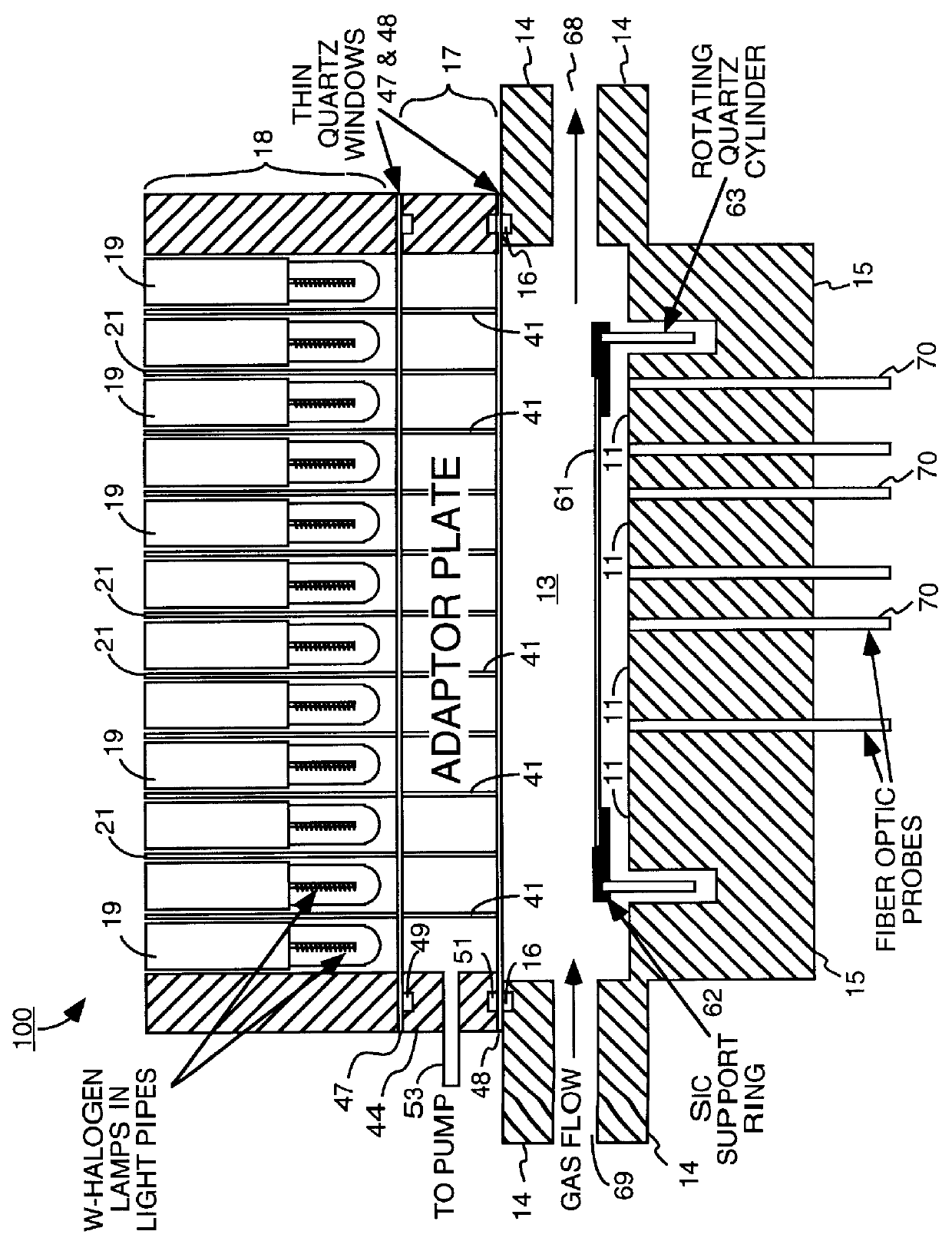

Plasma curing process for porous silica thin film

InactiveUS20010038919A1High elastic modulusLow dielectric constantSilicaPretreated surfacesSilicon dioxideMaterials science

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The coating is plasma cured for between about 15 and about 120 seconds at a temperature less than about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically less than about 475° C., and the annealing time is typically no more than about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

Highly Porous Ceramic Oxide Aerogels Having Improved Flexibility

Ceramic oxide aerogels having improved flexibility are disclosed. Preferred embodiments exhibit high modulus and other strength properties despite their improved flexibility. The gels may be polymer cross-linked via organic polymer chains to further improve strength properties, without substantially detracting from the improved flexibility. Methods of making such aerogels are also disclosed.

Owner:UNITED STATES GOVERNMENT ADMINISTRATOR OF NASA +1

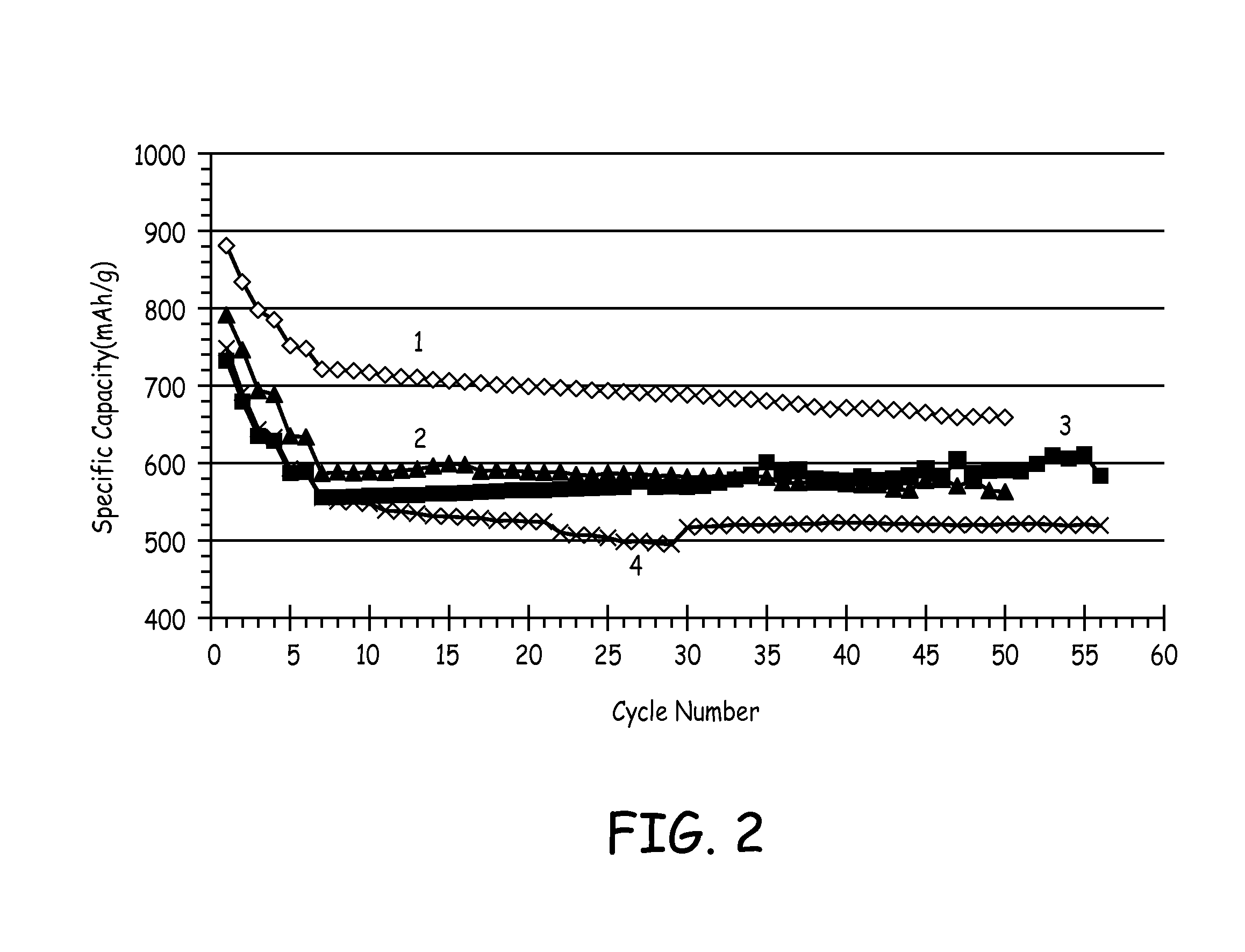

Silicon-based active materials for lithium ion batteries and synthesis with solution processing

Silicon based anode active materials are described for use in lithium ion batteries. The silicon based materials are generally composites of nanoscale elemental silicon with stabilizing components that can comprise, for example, silicon oxide-carbon matrix material, inert metal coatings or combinations thereof. High surface area morphology can further contribute to the material stability when cycled in a lithium based battery. In general, the material synthesis involves a significant solution based processing step that can be designed to yield desired material properties as well as providing convenient and scalable processing.

Owner:IONBLOX INC

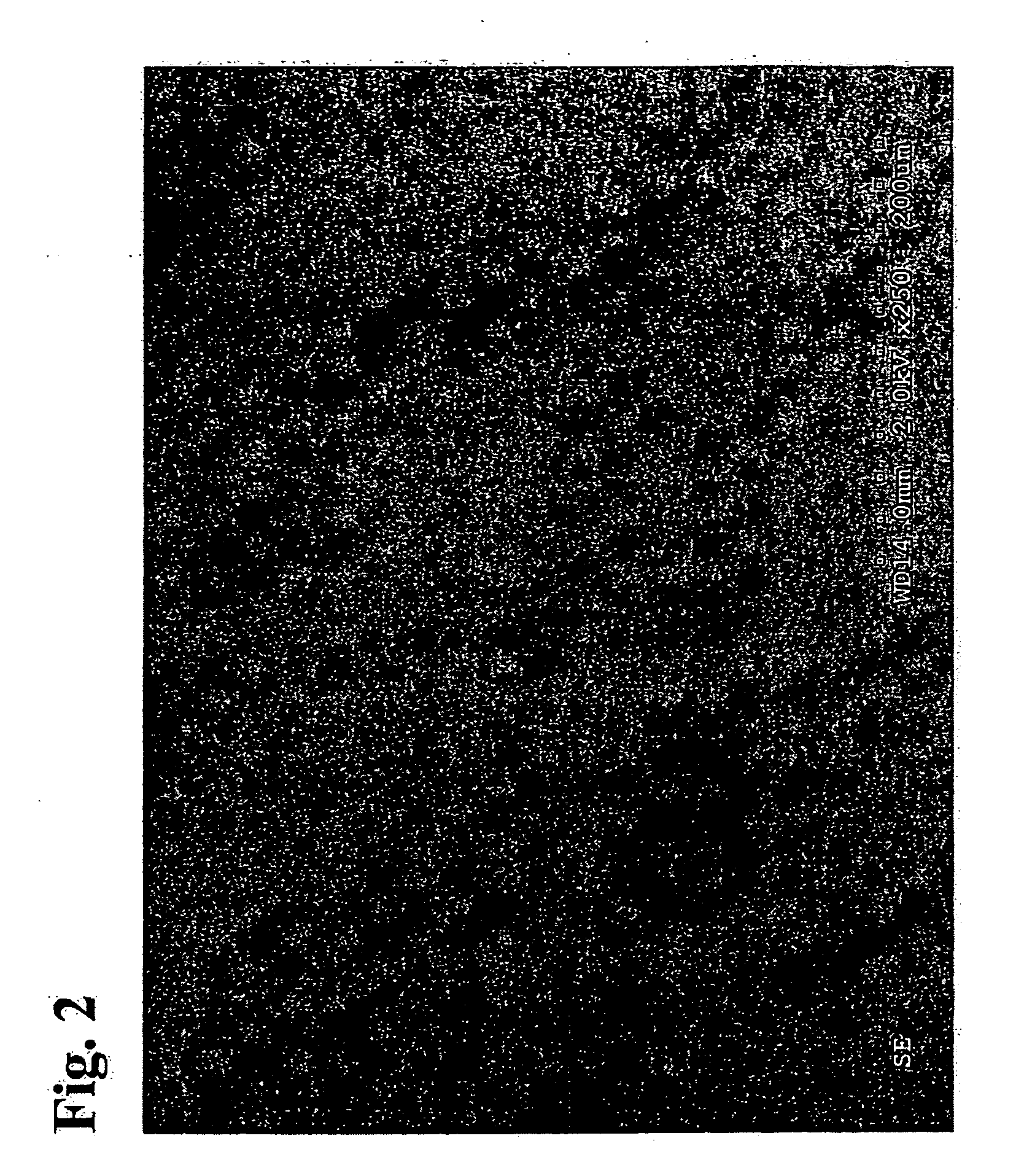

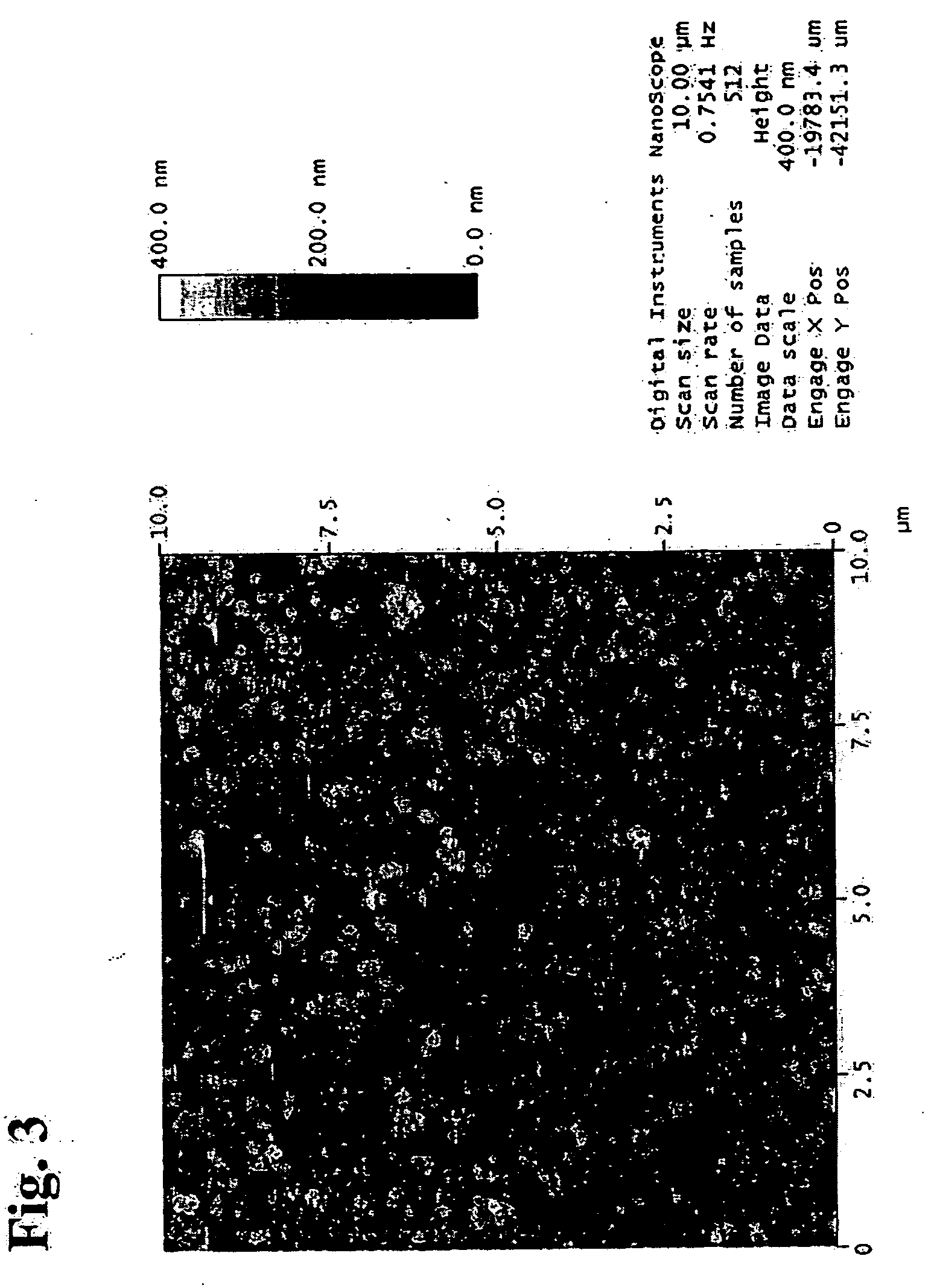

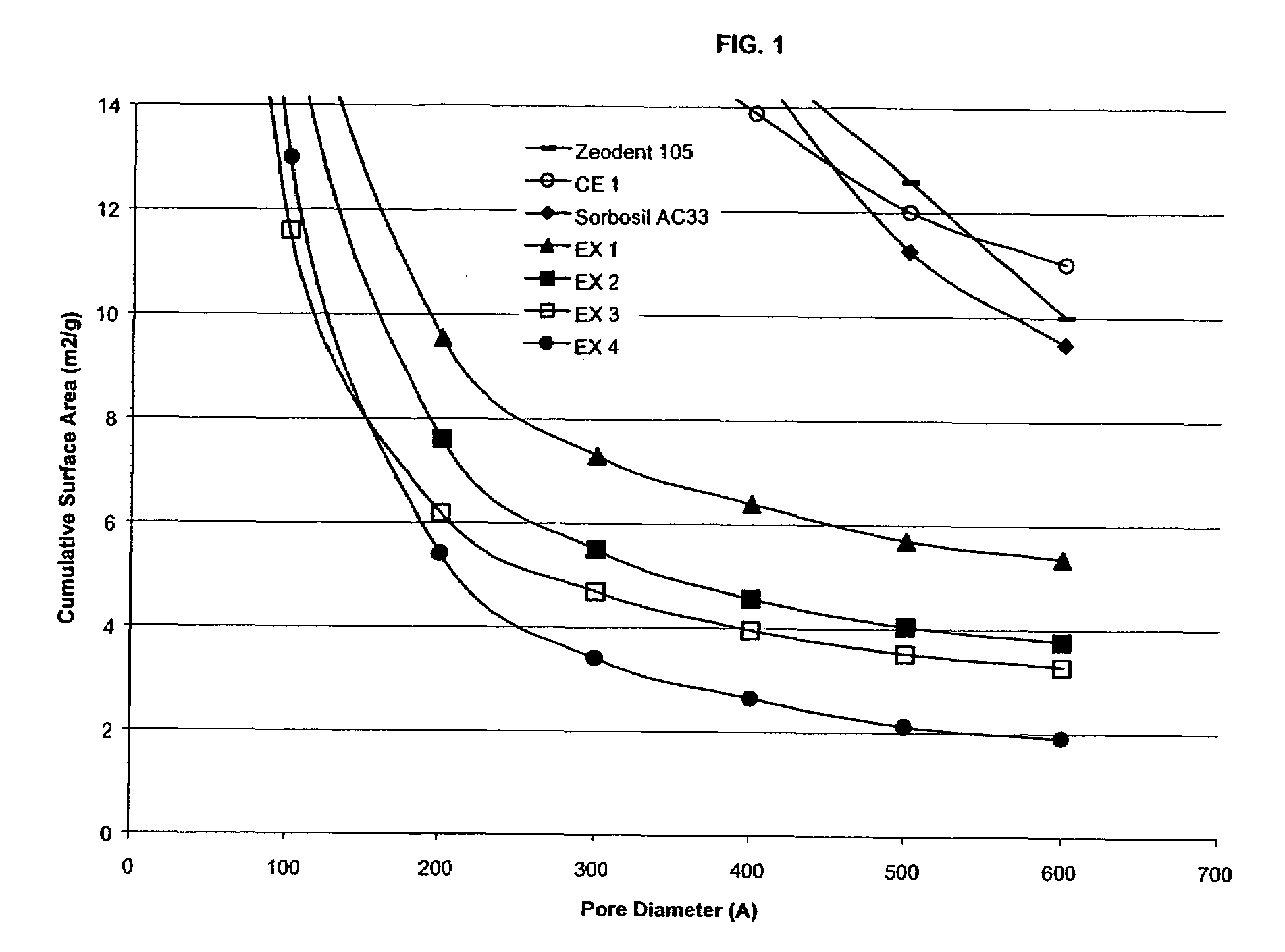

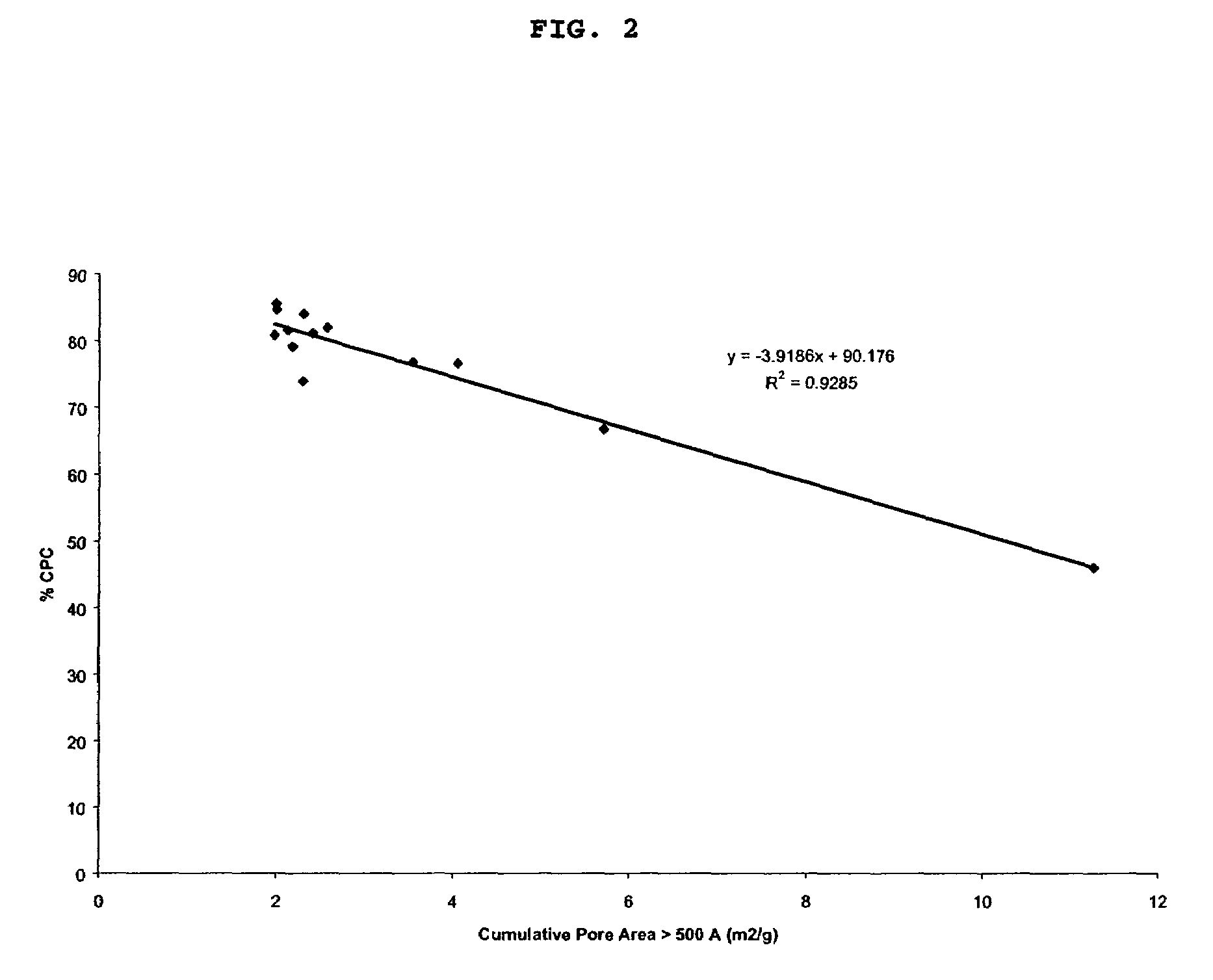

Precipitated silica materials exhibiting high compatibility with cetylpyridinium chloride

ActiveUS7438895B2Increase volumeImprove compatibilityCosmetic preparationsBiocideAntimicrobial actionSilica particle

Precipitated silica comprising porous silica particles having a cumulative surface area for all pores having diameters greater than 500 Å of less than 6 m2 / g, as measured by mercury intrusion, and a percentage cetylpyridinium chloride (% CPC) Compatibility of greater than about 85%. The precipitated silica product is especially well-adapted for use in dentifrices containing cetylpyridinium chloride, which do not attach to the low surface area silica product in a meaningful level and thus remain available for antimicrobial action. Processes for making the silica product including the introduction of sodium sulfate powder during different process steps in order to enhance such a compatibility with CPC are provided.

Owner:EVONIK OPERATIONS GMBH

Preparation method for hydrophobic silica aerogel

The present invention discloses a preparation method for hydrophobic silica aerogel with industrial waterglass as a raw material, which comprises the following steps: diluting the industrial waterglass with water; neutralizing with an acid to obtain hydrosol; allowing the hydrosol to stand and age for 8-48 hours at normal temperature so as to form hydrogel; replacing the water in the hydrogel with anhydrous ethanol; allowing the hydrogel to react with organosilane compounds; performing surface modification and simultaneous solvent exchange with n-hexane; suction-filtering; washing; allowing to stand at normal temperature to obtain white hydrophobic silica aerogel powder. The preparation method has simple process and low cost, and the prepared aerogel has porous network-like structure which features a low density and a high specific surface area.

Owner:SHENZHEN UNIV

Silicon dioxide aerogel material and preparation method thereof

The invention relates to a silicon dioxide aerogel material and a preparation method thereof. The method comprises the following steps: by using water glass as silicon source, adding an acid-containing organic solvent free of chlorine ions and fluorine ions to generate a precipitate of sodium ions, potassium ions and other metal salt ions, filtering to remove the precipitate to obtain high-purity silica sol, carrying out a sol-gel process, aging, acidifying, modifying, and drying to obtain the silicon dioxide aerogel material. The acidification before modification enhances the surface reaction activity of the silicon gel, thereby obviously enhancing the modification effect and efficiency. The method has the advantages of low cost and simple and efficient technique, is beneficial to mass high-efficiency production, is free of chlorine ions and fluorine ions in the whole technical process, and enhances the equipment operation safety and reliability; and the product can be used for heat preservation and thermal insulation of nuclear power and liquefied natural gas equipment and pipelines with higher requirement for corrosion resistance, and can also be used for thermal insulation in the field of aerospace, petrochemical engineering, track transportation, ships, automobiles, construction and the like.

Owner:浙江圣润纳米科技有限公司

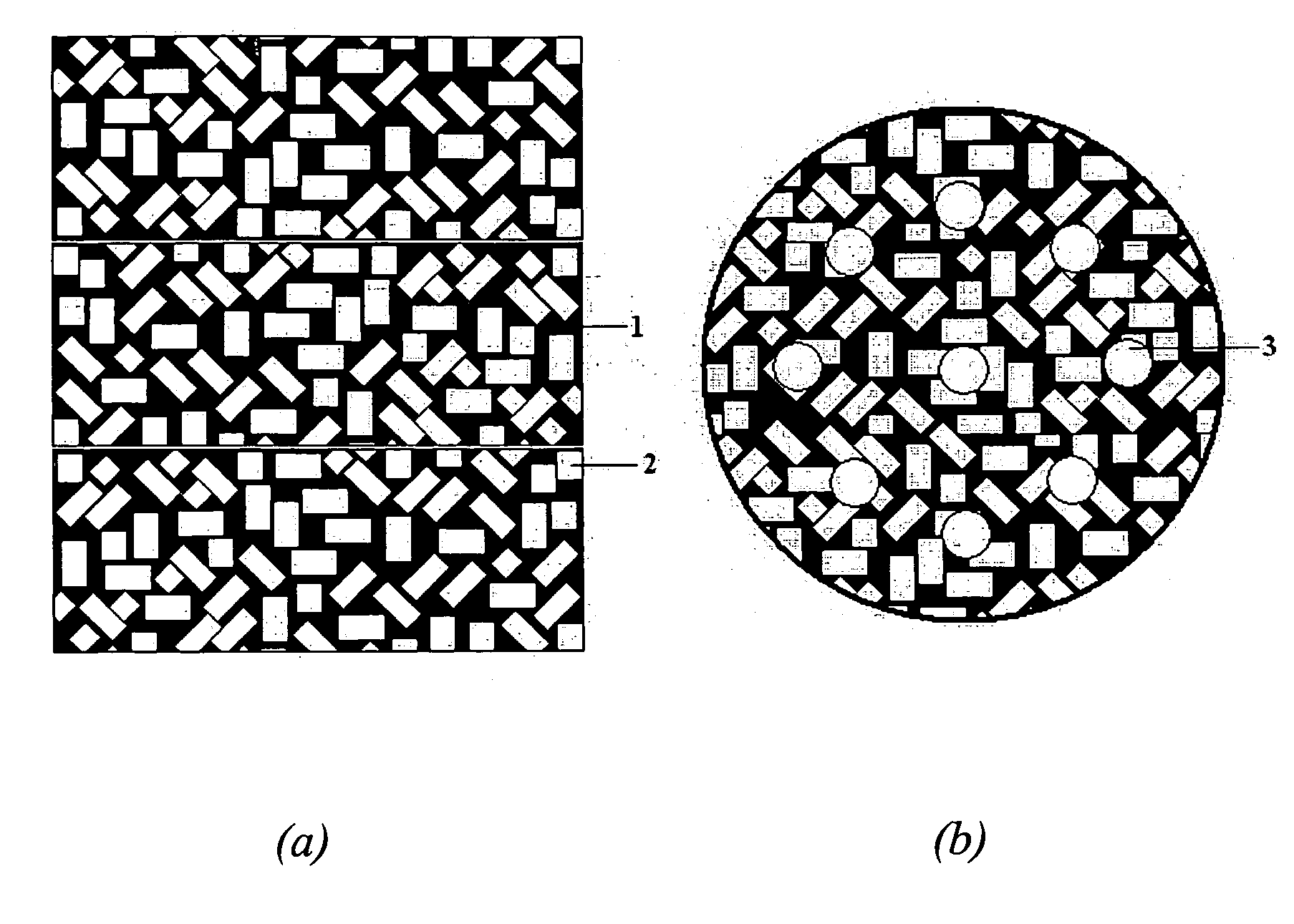

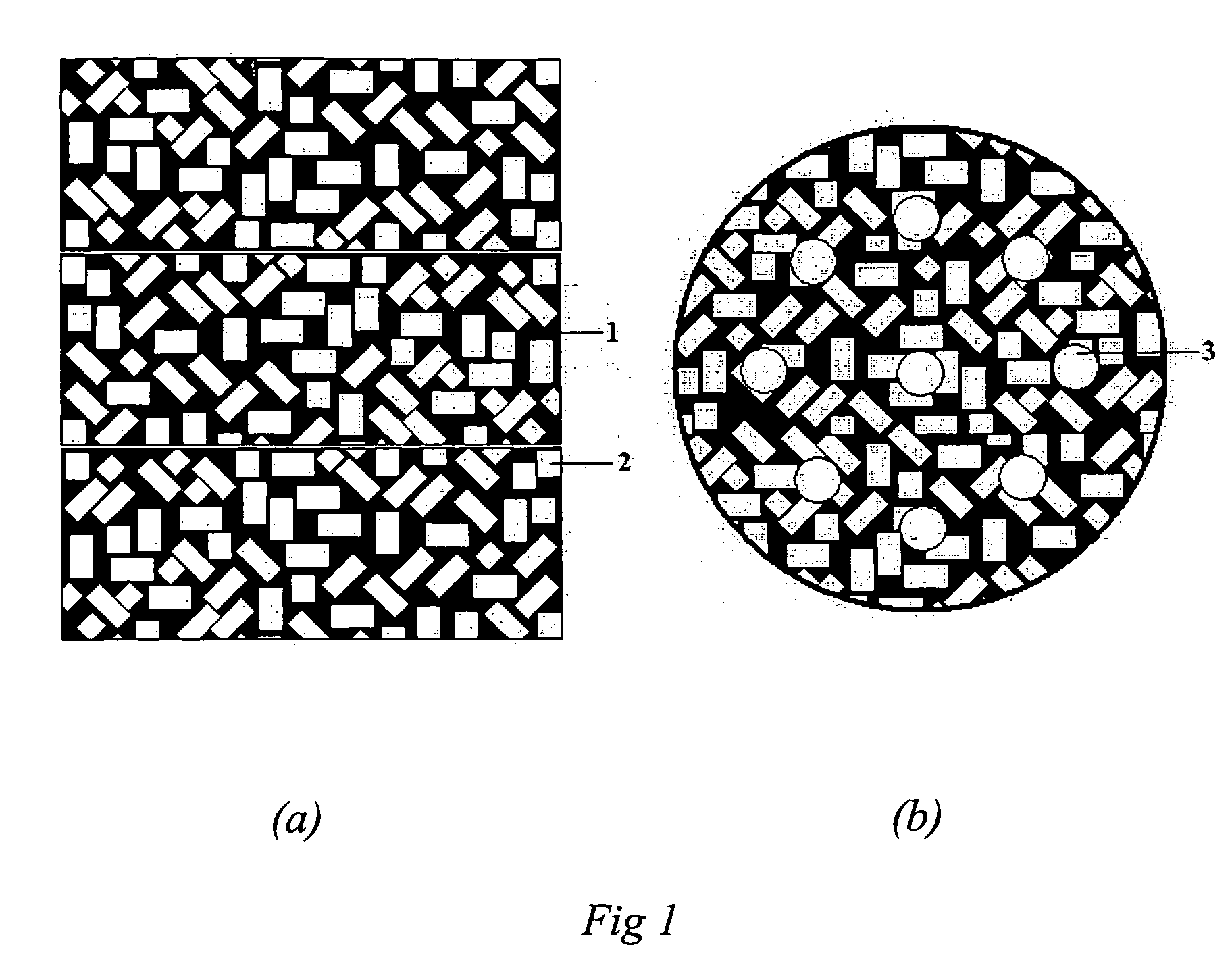

Three dimensionally periodic structural assemblies on nanometer and longer scales

InactiveUS20010019037A1Increase volumeEasy to useSilicaPaper/cardboard articlesChromatographic separationThermoelectric materials

This invention relates to processes for the assembly of three-dimensional structures having periodicities on the scale of optical wavelengths, and at both smaller and larger dimensions, as well as compositions and applications therefore. Invention embodiments involve the self assembly of three-dimensionally periodic arrays of spherical particles, the processing of these arrays so that both infiltration and extraction processes can occur, one or more infiltration steps for these periodic arrays, and, in some instances, extraction steps. The product articles are three-dimensionally periodic on a scale where conventional processing methods cannot be used. Articles and materials made by these processes are useful as thermoelectrics and thermionics, electrochromic display elements, low dielectric constant electronic substrate materials, electron emitters (particularly for displays), piezoelectric sensors and actuators, electrostrictive actuators, piezochromic rubbers, gas storage materials, chromatographic separation materials, catalyst support materials, photonic bandgap materials for optical circuitry, and opalescent colorants for the ultraviolet, visible, and infrared regions.

Owner:ZAKHIDOV ANVAR +7

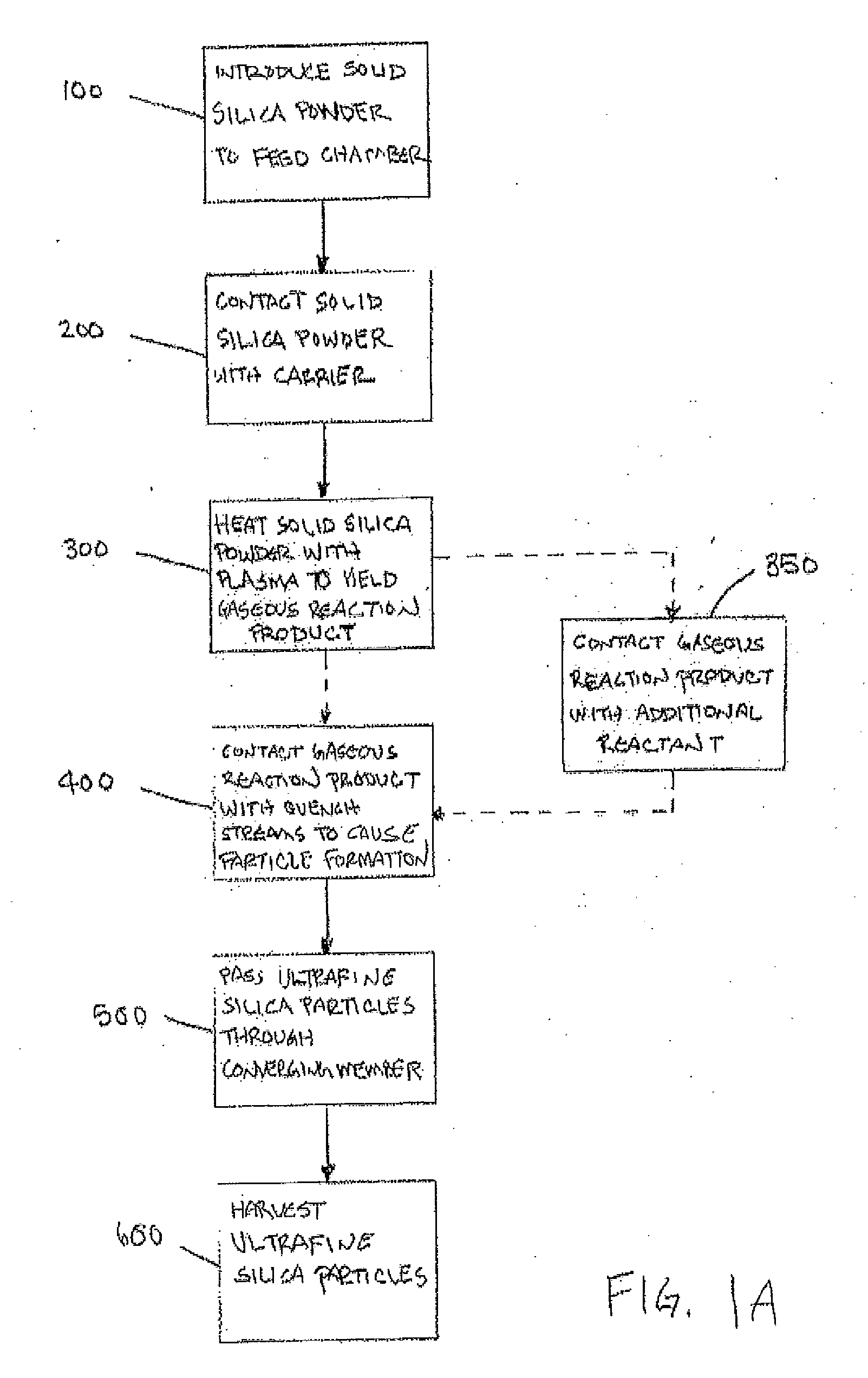

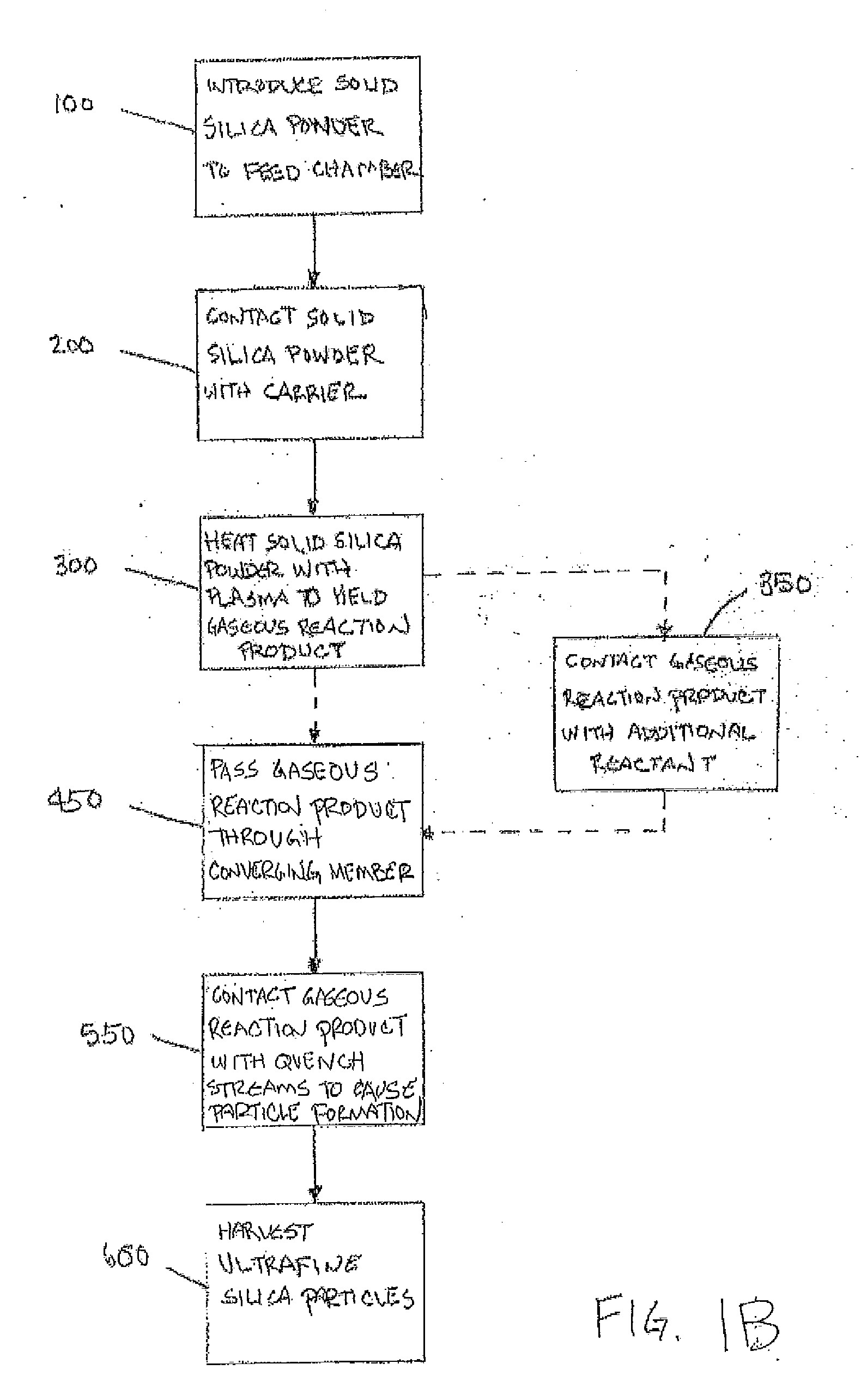

Method and apparatus for the production of ultrafine silica particles from solid silica powder and related coating compositions

Owner:PPG IND OHIO INC

Method for preparing super-hydrophobic silica aerogel at normal pressure

The invention discloses a method for preparing super-hydrophobic silica aerogel at the normal pressure by taking an inorganic silicon source or an organic silicon source as a raw material. The method comprises the following steps: taking the inorganic silicon source or the organic silicon source as the raw material, then mixing the raw material with a solvent and a catalyst, and obtaining wet gel through a process of sol-gel, and then carrying out ageing, solvent replacement, surface modification and ambient pressure drying on the obtained wet gel to obtain the silica aerogel with low-density, high specific table and super hydrophobicity. The invention realizes the ambient pressure drying of the wet gel, avoids the equipment investment when the conventional supercritical drying is adopted, greatly improves the safety of the production, has simple operation, good properties and controllability of the products, and is suitable for large-scale production.

Owner:DALIAN UNIV OF TECH

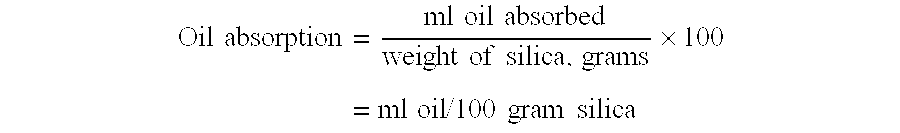

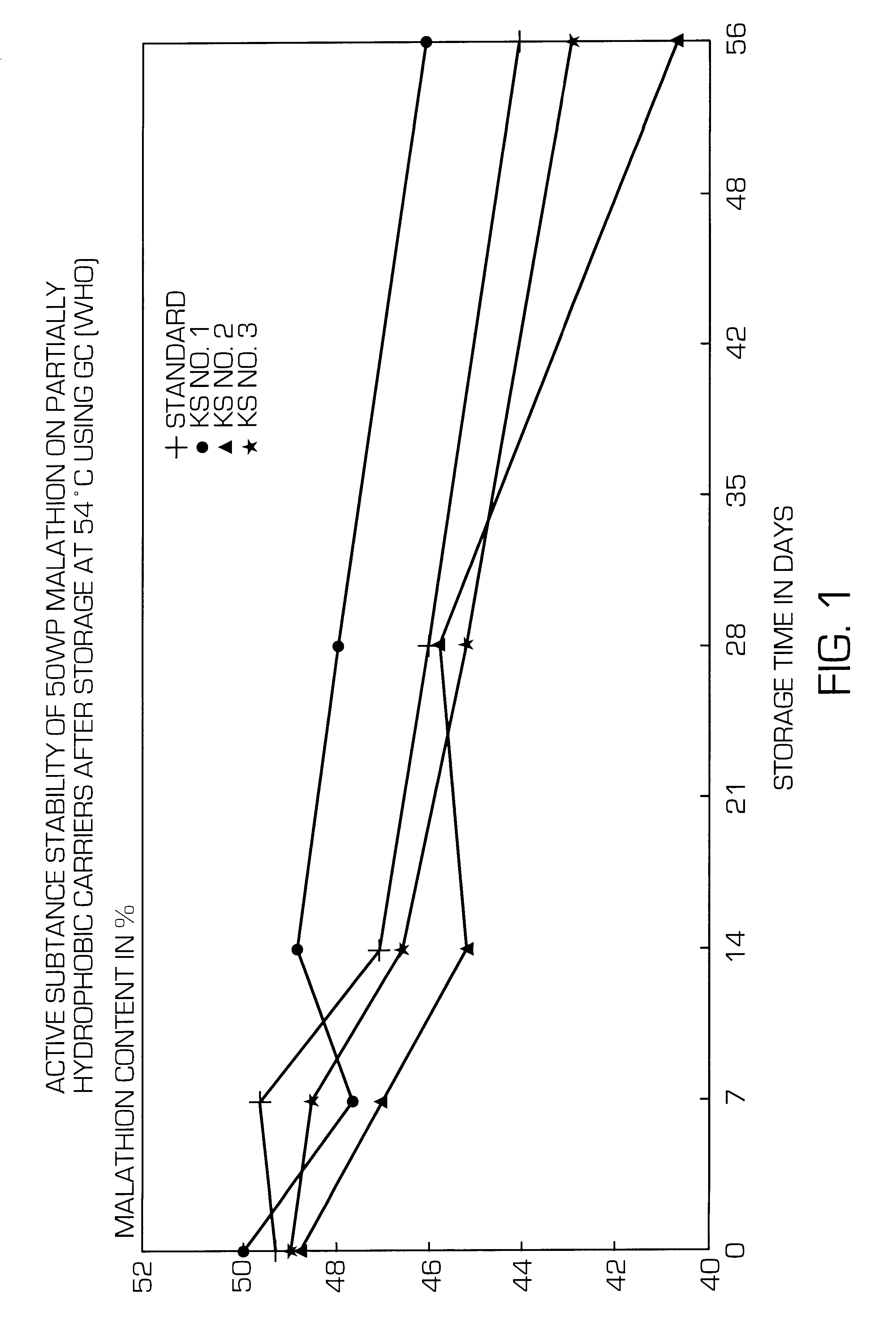

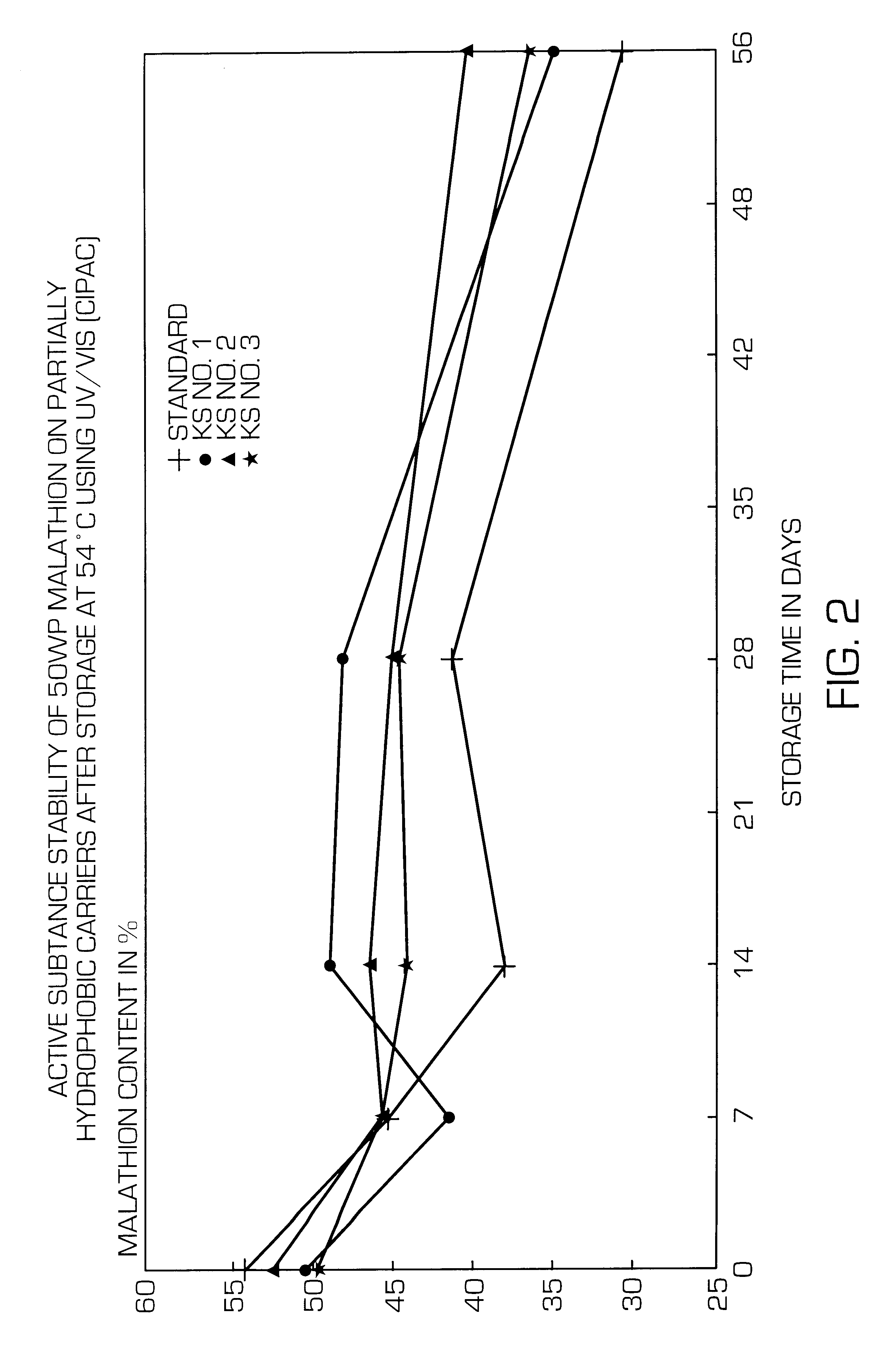

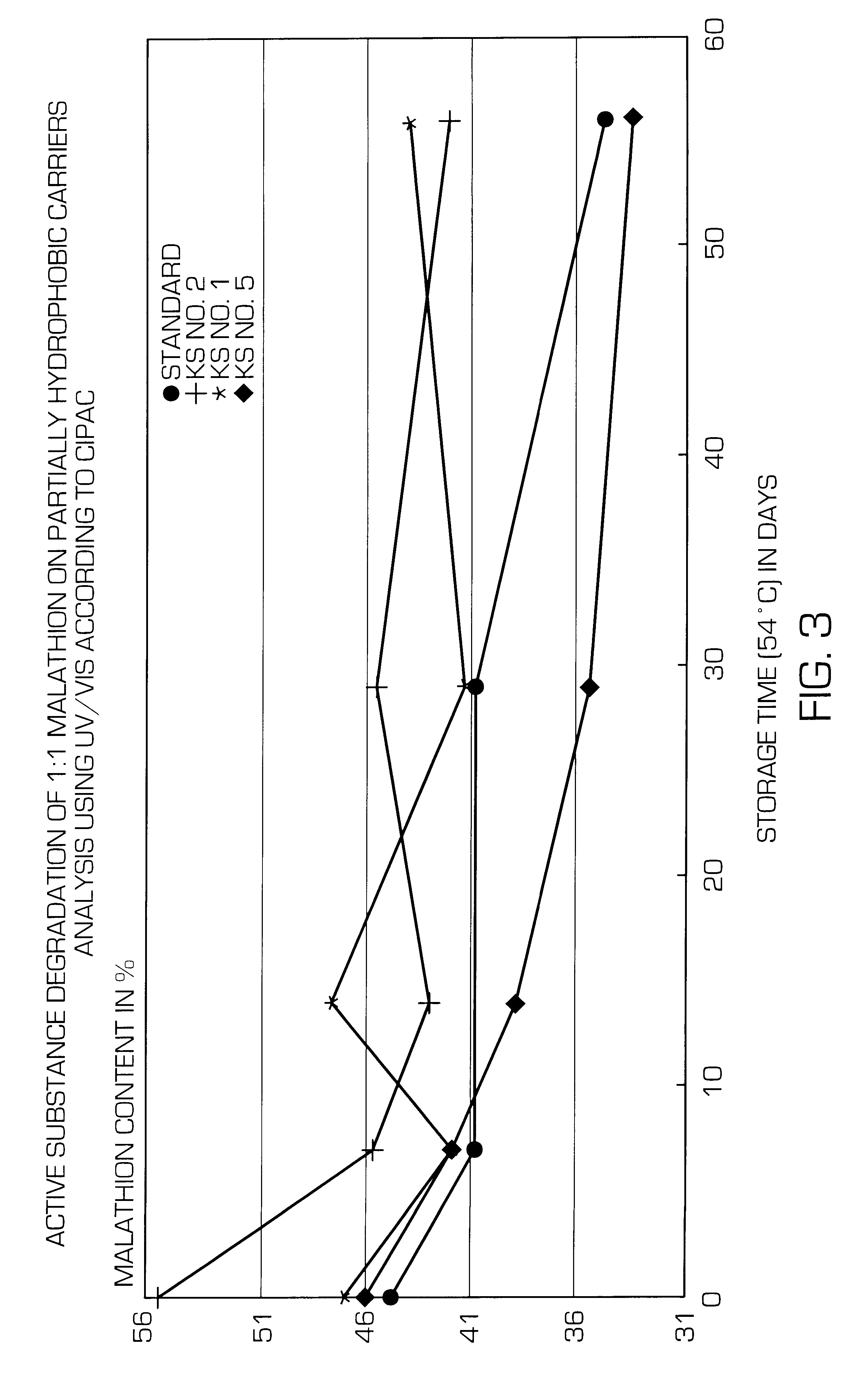

Partially hydrophobic precipitated silicas

A partially hydrophobic precipitated silica having a methanol wettability of 10 to 49%, in particular with a DBP uptake on a dry basis of greater than 250 g / 100 g and a mean particle size of 1 to 12 mum and / or a carbon content of 0.3 to 1.85% and / or a loss on drying of 2.6 to 10.0% and / or a pH value of 5.5 to 10.0, is prepared by mixing the amount of water-repellent agent with the precipitated silica suspension at very short residence time and low pH value, filtering off the solid substance, washing free of salt, drying, post-treating thermally and milling. The partially hydrophobic precipitated silica can be used in active substance formulations and active substance formulations of hydrolysis-sensitive substance and in defoaming agents.

Owner:EVONIK DEGUSSA GMBH

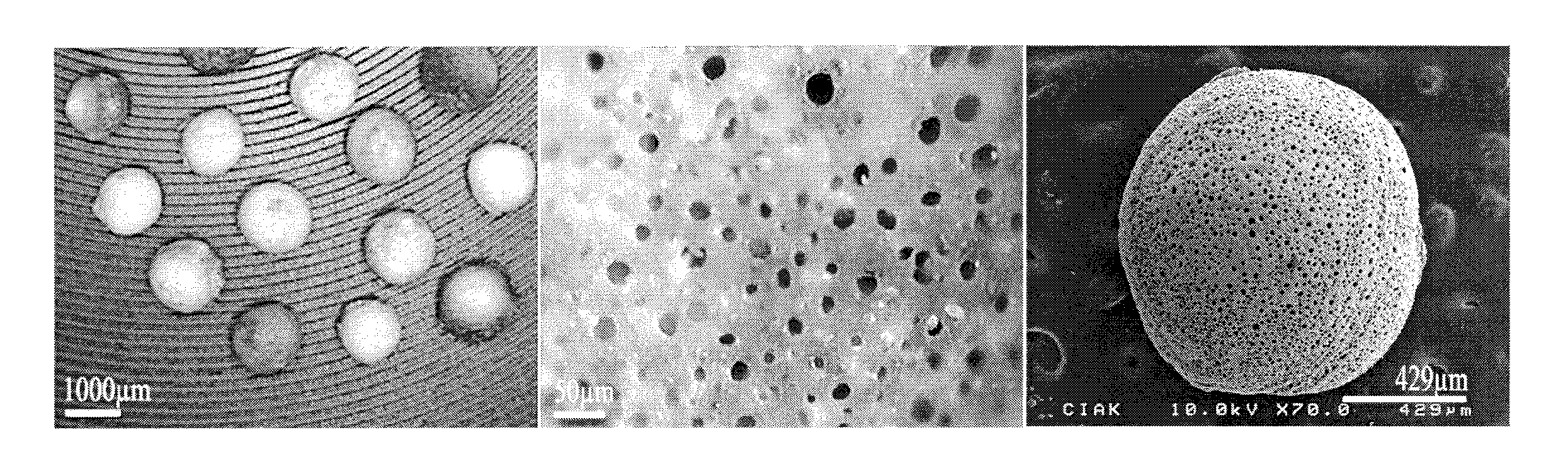

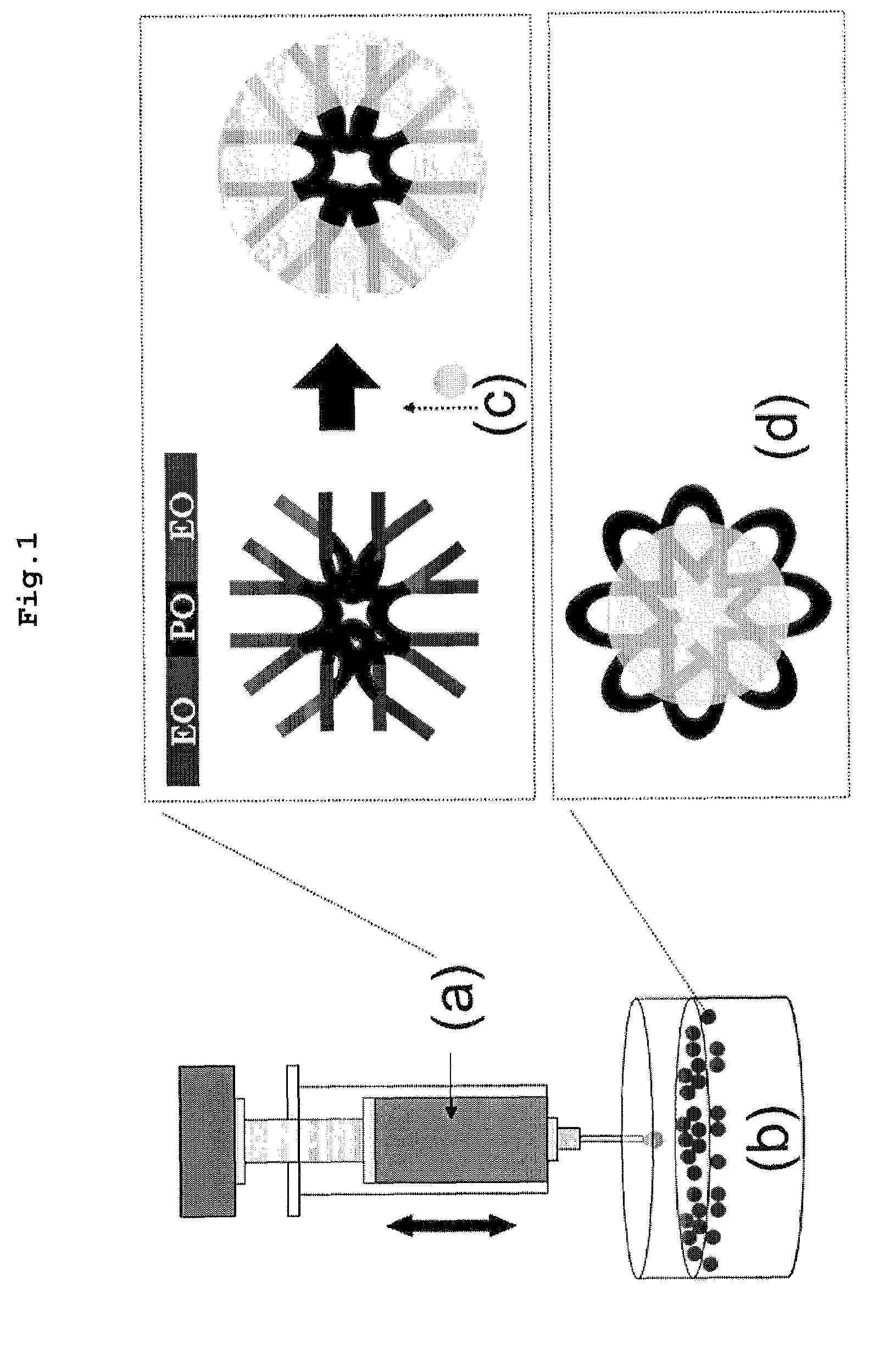

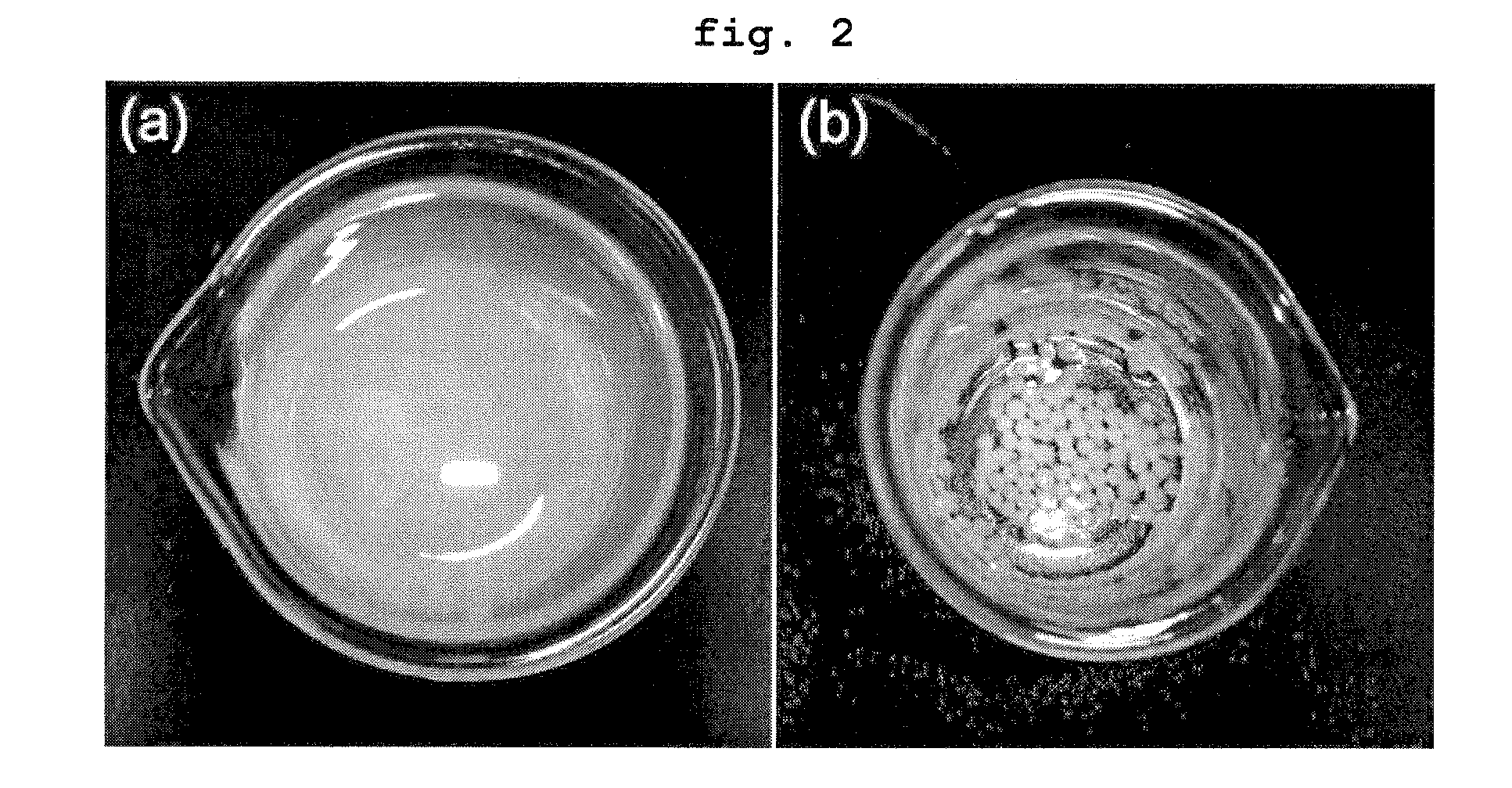

Porous material having hierarchical porous structure and preparation method thereof

Disclosed are porous ceramic balls with a hierarchical porous structure ranging in size from nanometers to micrometers, and preparation methods thereof. Self-assembly polymers and sol-gel reactions are used to prepare porous ceramic balls in which pores ranging in size from ones of nanometers to tens of micrometers are hierarchically interconnected to one another. This hierarchical porous structure ensures high specific surface areas and porosities for the porous ceramic balls. Further, the size and distribution of the pores can be simply controlled with hydrophobic solvent and reaction time. The pore formation through polymer self-assembly and sol-gel reactions can be applied to ceramic and transition metals. Porous structures based on bioceramic materials, such as bioactive glass, allow the formation of apatite therein and thus can be used as biomaterials of bioengineering, including bone fillers, bone reconstruction materials, bone scaffolds, etc.

Owner:KOREA INST OF MATERIALS SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com