Method for preparing super-hydrophobic silica aerogel at normal pressure

A silicon dioxide and super-hydrophobic technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of restricting silicon dioxide aerogel, high equipment material requirements, restricting the popularization and use, etc., to achieve a simple and dangerous process. Low-response, parameter-adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

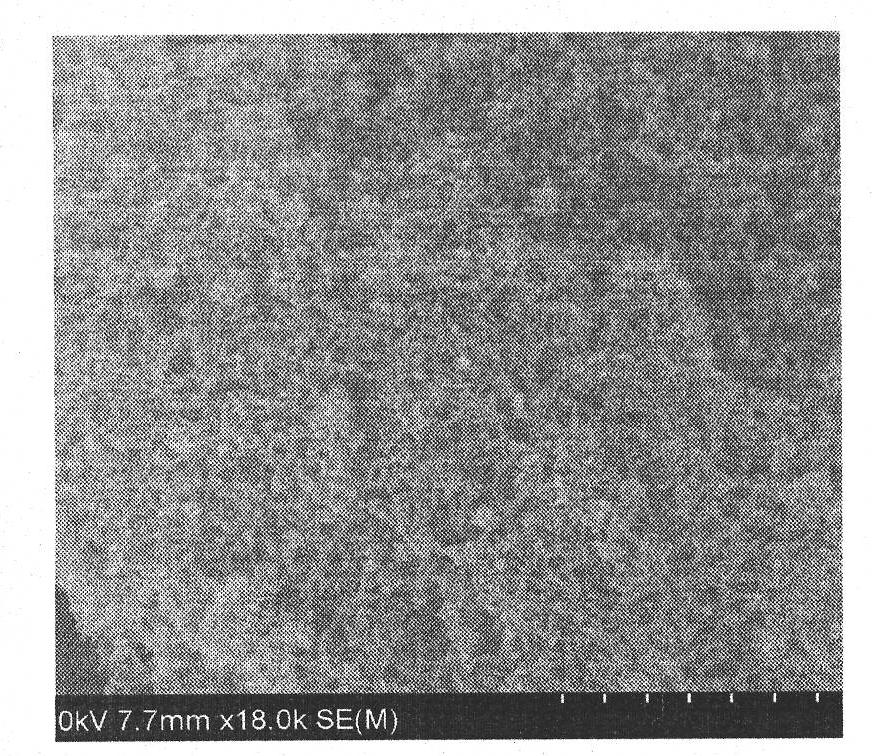

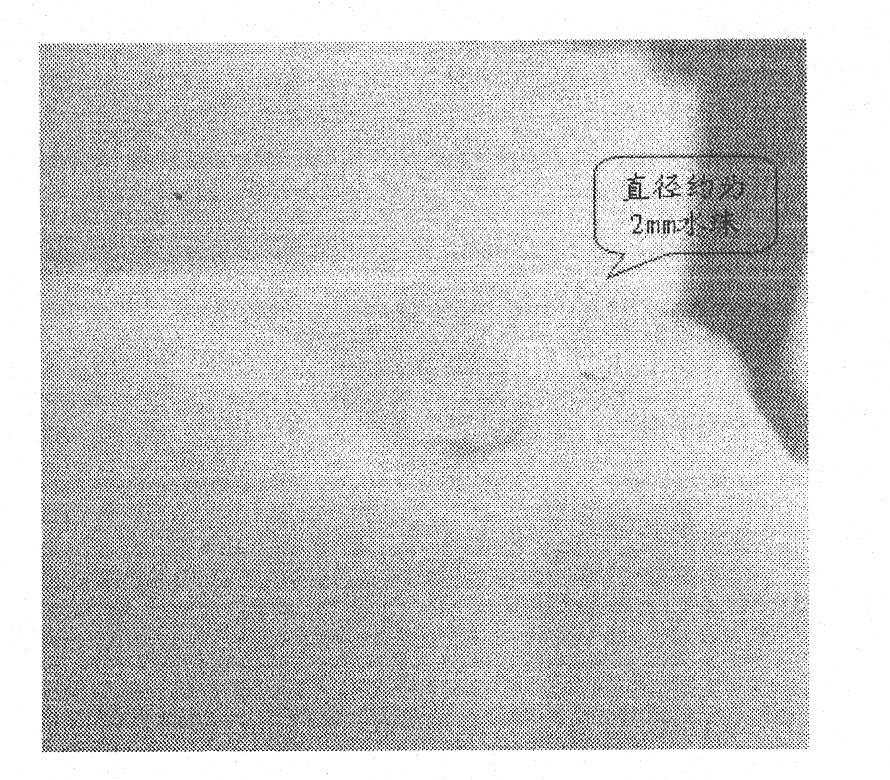

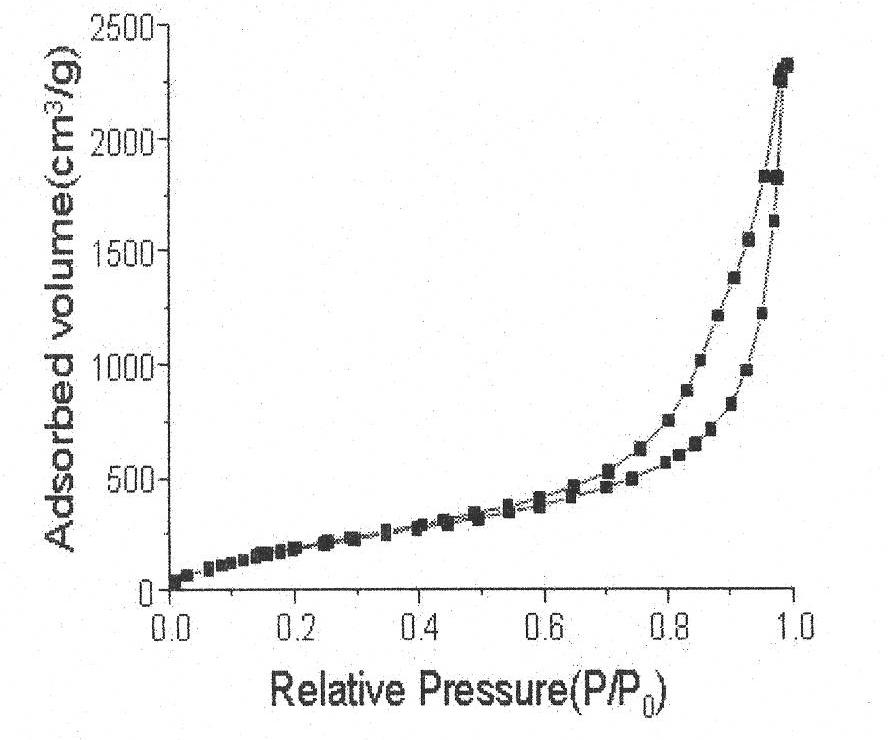

example 1

[0020] Prepare a sodium silicate aqueous solution with a mass ratio of 23%, then adjust the pH value to 1 with concentrated hydrochloric acid, and obtain a gel after standing in an environment of 50°C for 30 minutes, and then use deionized water, ethanol, n-hexane and volume ratio in sequence The mixed solutions of 20% n-hexane and trimethylchlorosilane were treated for 24 hours respectively, and finally dried at 150° C. to obtain silica airgel. The specific surface area of the resulting silica airgel is 543m 2 / g, the pore volume is 3.43cm 3 g -1 , the internal pore diameter is 25.3nm.

example 2

[0022] Take 3.03g of sodium silicate aqueous solution with a mass ratio of 23%, adjust the pH value to 1 with concentrated hydrochloric acid, then add 2.08g of deionized water, and obtain a gel after standing at 50°C for 3 hours, and then use deionized A mixed solution of ionic water, ethanol, n-hexane and 20% by volume of n-hexane and trimethylchlorosilane was treated for 24 hours respectively, and finally dried at 150° C. to obtain a silica airgel. The specific surface area of the resulting silica airgel is 572m 2 / g, the pore volume is 2.03cm 3 g -1 , the internal pore diameter is 14.1nm.

example 3

[0024] Take 3.03g of sodium silicate aqueous solution with a mass ratio of 23%, adjust the pH value to 1 with concentrated hydrochloric acid, then add 4.16g of deionized water, and obtain a gel after standing at 15°C for 40 hours, and then use A mixed solution of ionic water, ethanol, n-hexane and 20% by volume of n-hexane and trimethylchlorosilane was treated for 24 hours respectively, and finally dried at 150° C. to obtain a silica airgel. The specific surface area of the silica airgel is 582m 2 / g, the pore volume is 2.5cm 3 g -1 , the internal pore diameter is 17.3nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Internal aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com