Patents

Literature

2046 results about "Apatite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apatite is a group of phosphate minerals, usually referring to hydroxylapatite, fluorapatite and chlorapatite, with high concentrations of OH⁻, F⁻ and Cl⁻ ions, respectively, in the crystal. The formula of the admixture of the three most common endmembers is written as Ca₁₀(PO₄)₆(OH,F,Cl)₂, and the crystal unit cell formulae of the individual minerals are written as Ca₁₀(PO₄)₆(OH)₂, Ca₁₀(PO₄)₆F₂ and Ca₁₀(PO₄)₆Cl₂.

Enhanced purification of antibodies and antibody fragments by apatite chromatography

ActiveUS20090187005A1Peptide/protein ingredientsPeptide preparation methodsApatiteAntibody fragments

Methods are disclosed for use of apatite chromatography, particularly without reliance upon phosphate gradients, for purification or separation of at least one intact non-aggregated antibody, or at least one immunoreactive antibody fragment, from an impure preparation. Integration of such methods into multi-step procedures with other fractionation methods are additionally disclosed.

Owner:BIO RAD LAB INC

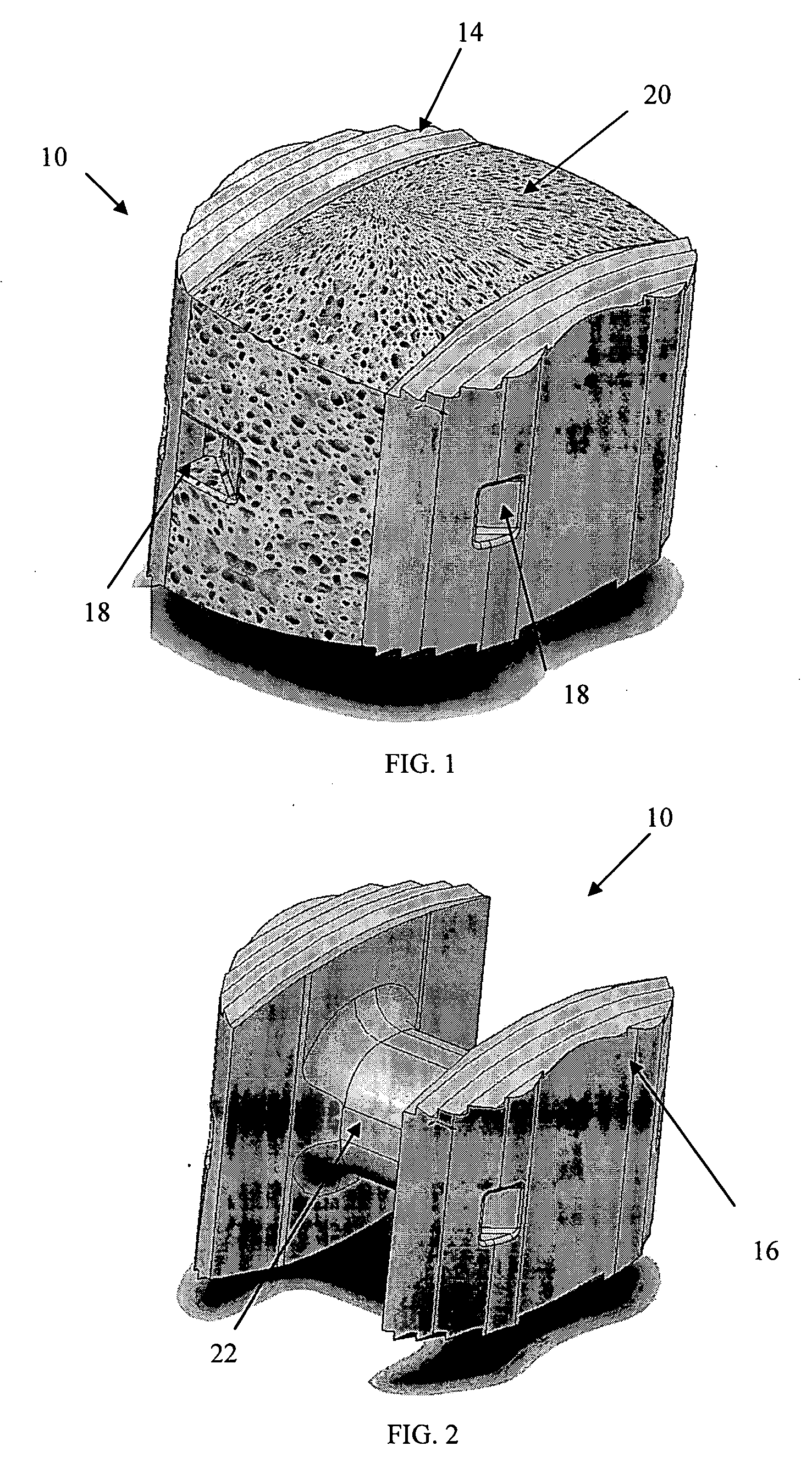

Radiolucent bone graft

An improved bone graft is provided for human implantation, bone graft includes a substrate block of high strength biocompatible material having a selected size and shape to fit the anatomical space, and a controlled porosity analogous to natural bone. The substrate block may be coated with a bio-active surface coating material such as hydroxyapatite or a calcium phosphate to promote bone ingrowth and enhanced bone fusion. Upon implantation, the bone graft provides a spacer element having a desired combination of mechanical strength together with osteoconductivity and osteoinductivity to promote bone ingrowth and fusion, as well as radiolucency for facilitated post-operative monitoring. The bone graft may additionally carry one or more natural or synthetic therapeutic agents for further promoting bone ingrowth and fusion.

Owner:AMEDICA A DELAWARE

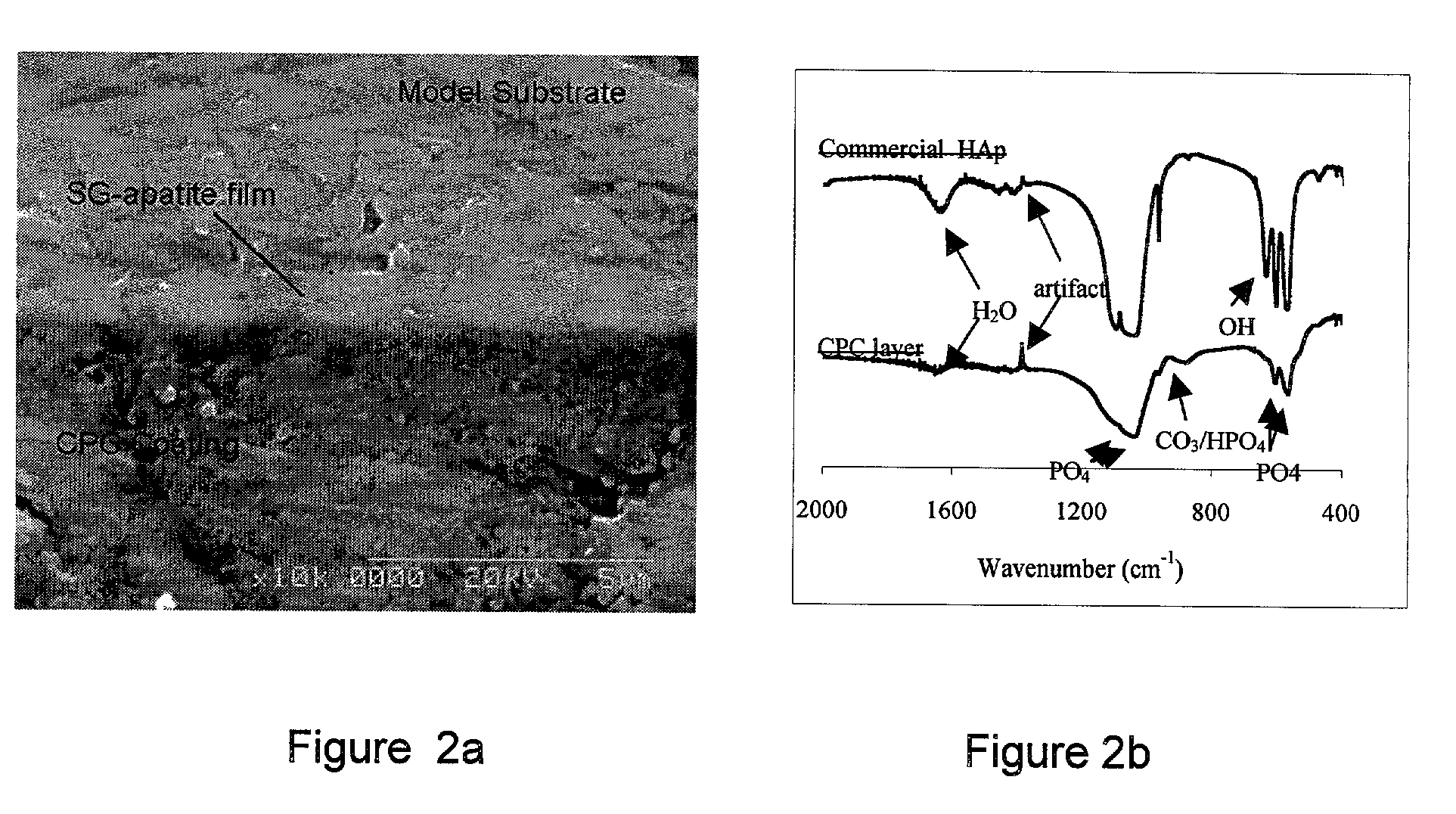

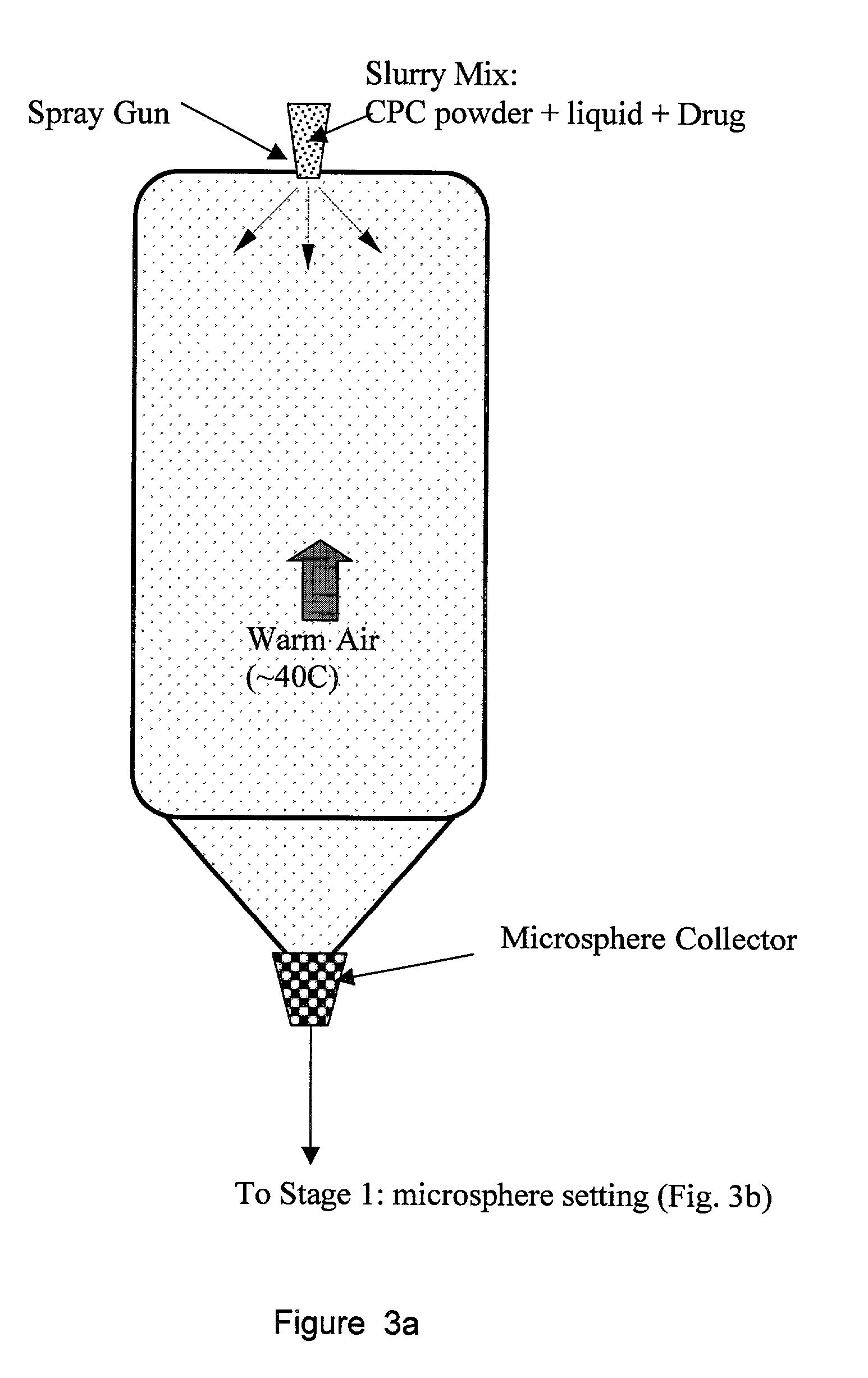

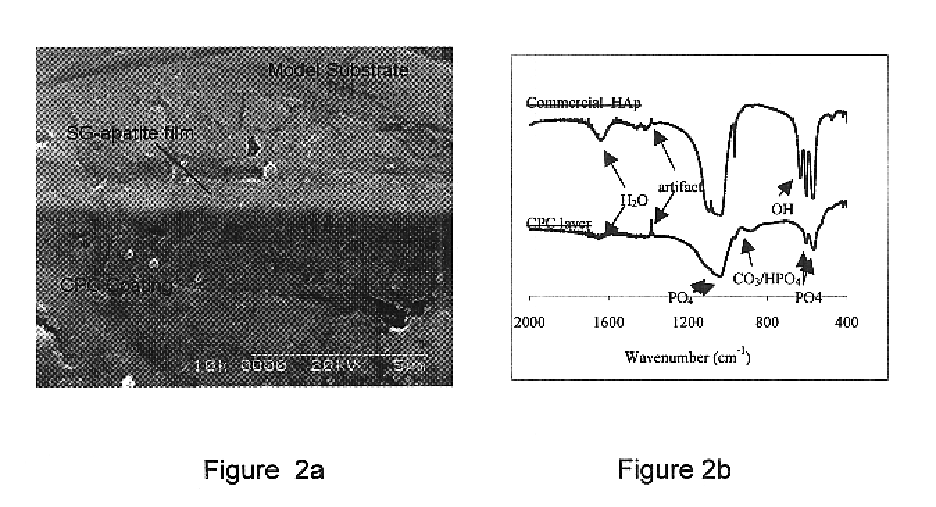

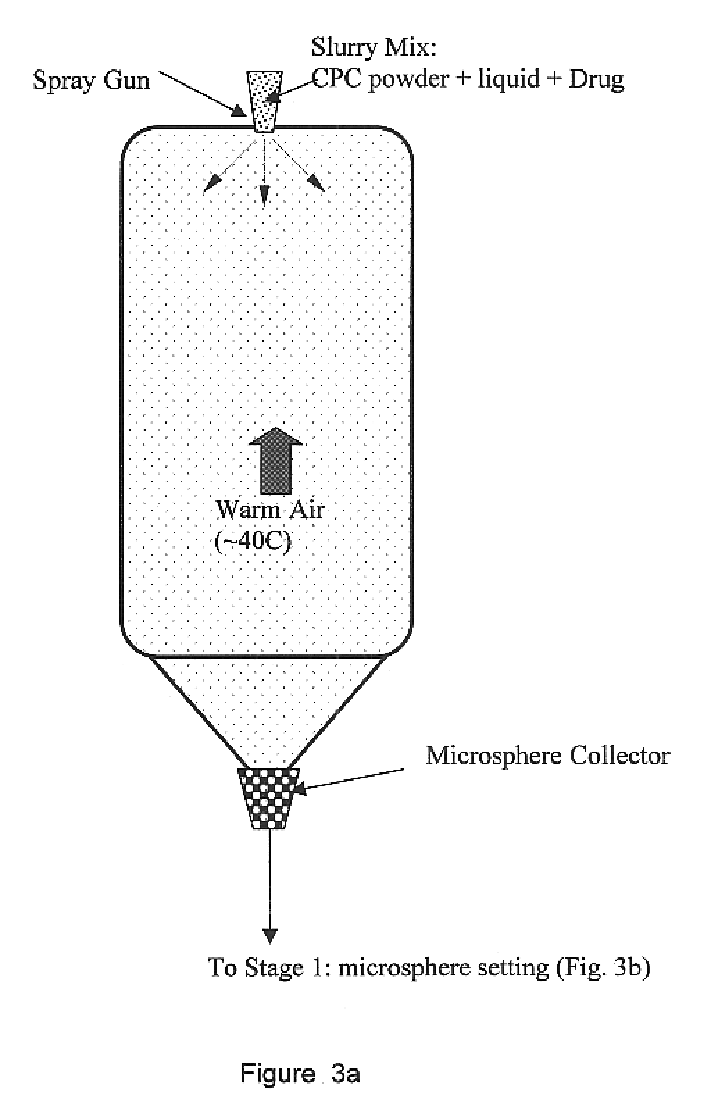

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS20020155144A1Improve relationshipImprove interface strengthPowder deliveryOrganic active ingredientsGene deliverySide effect

Owner:THE UNIV OF BRITISH COLUMBIA

Bioceramic compositions

InactiveUS6972130B1Good biocompatibilityEasy to processBiocideInorganic phosphorous active ingredientsDiseaseDelivery vehicle

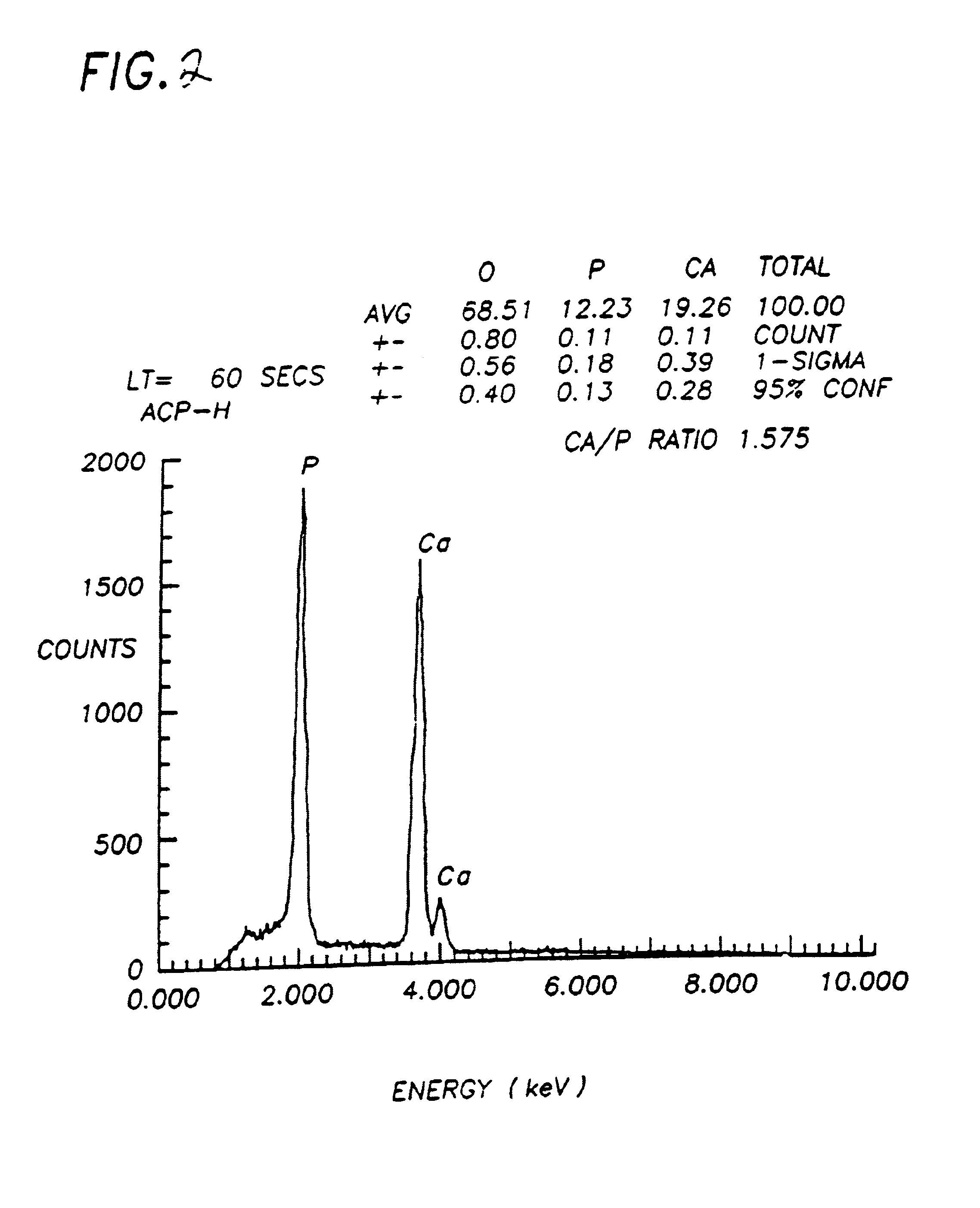

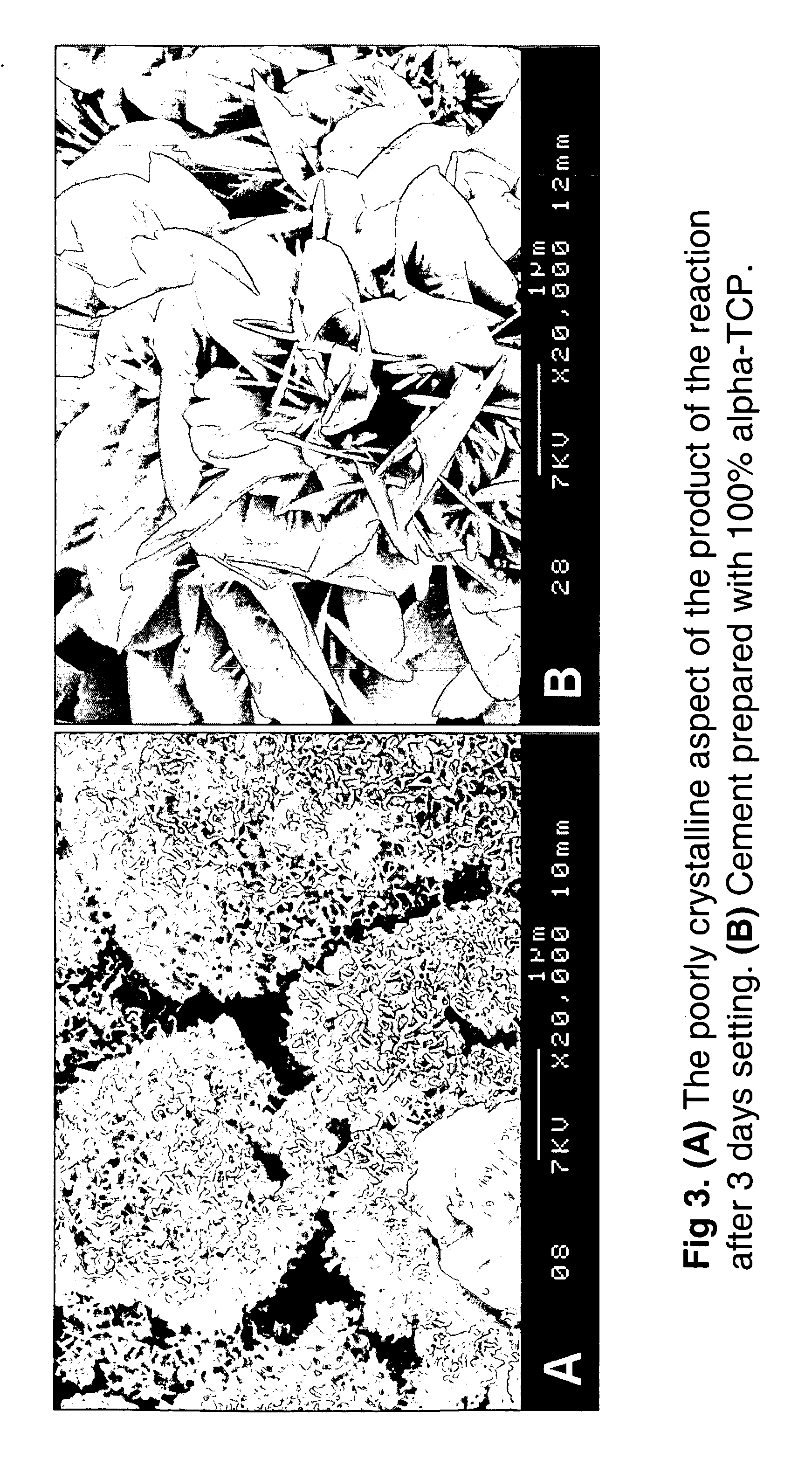

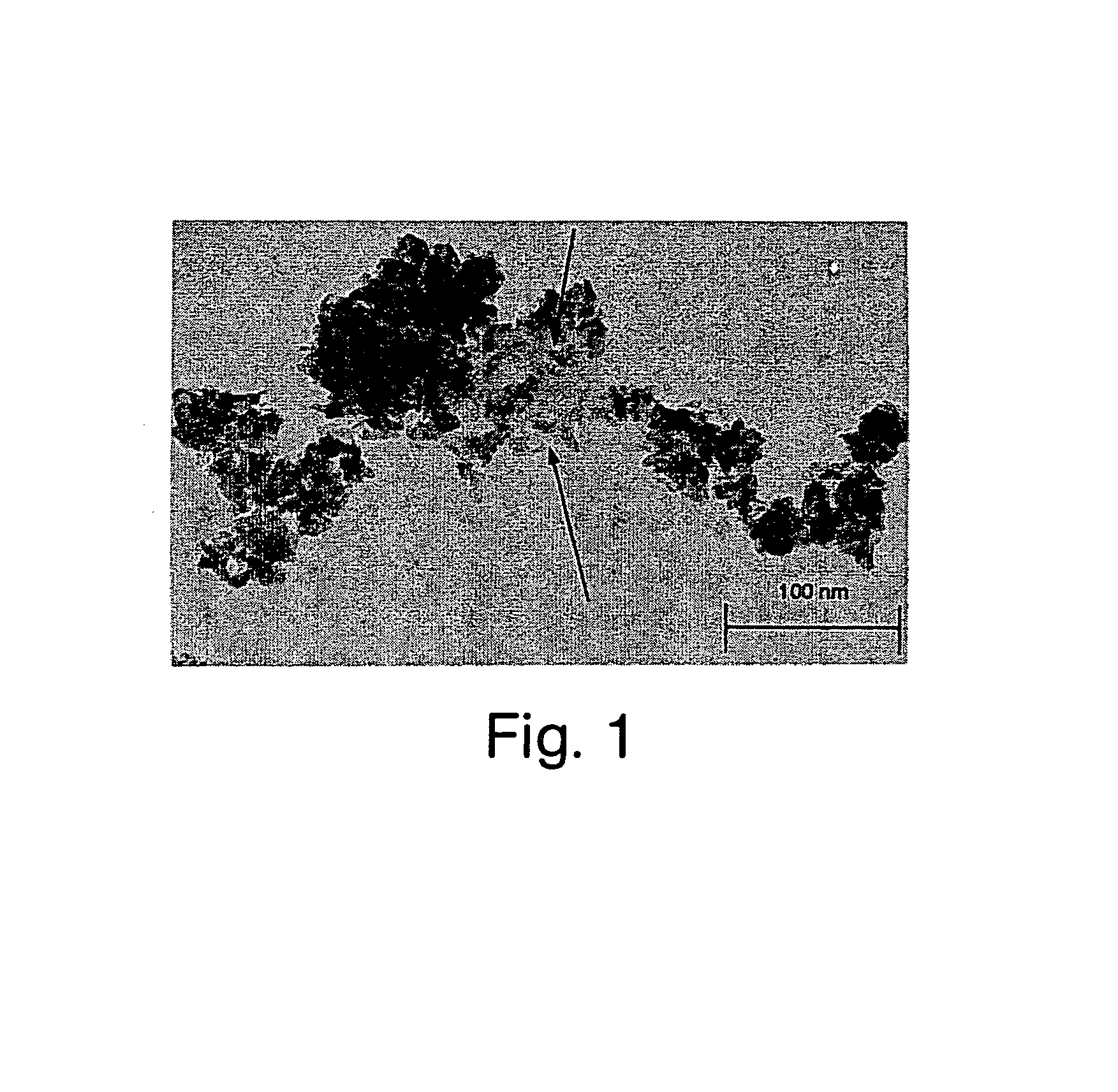

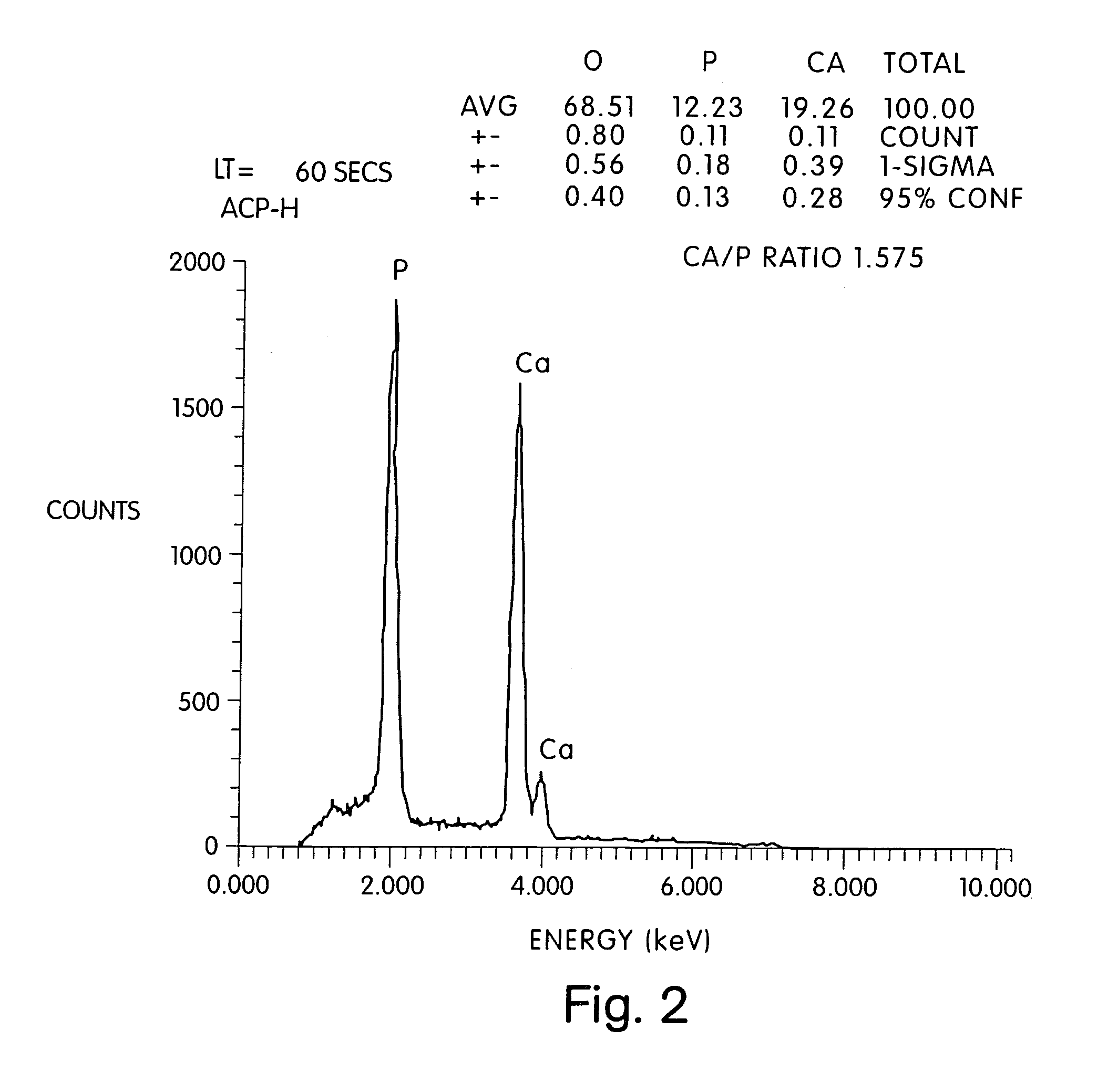

The present invention provides a synthetic, poorly crystalline apatite (PCA) calcium phosphate containing a biologically active agent and / or cells (preferably tissue-forming or tissue-degrading cells). The compositions provided by the present invention are useful for a variety of in vivo and in vitro applications, including drug delivery (for example, to bony sites, the central nervous system, intramuscular sites, subcutaneous sites, interperitoneal sites, and occular sites) tissue growth (preferably bone or cartilage) osseous augmentation, and methods of diagnosing disease states by assaying tissue forming potential of cells isolated from a host. The invention also provides methods of preparing delivery vehicles, of altering delivery vehicle characteristics, and of delivering biologically active agents to a site. The invention further provides in vitro cell culture systems and cell encapsulation materials. The invention is useful for both medical and veterinary applications.

Owner:LIFE SCI ENTERPRISES

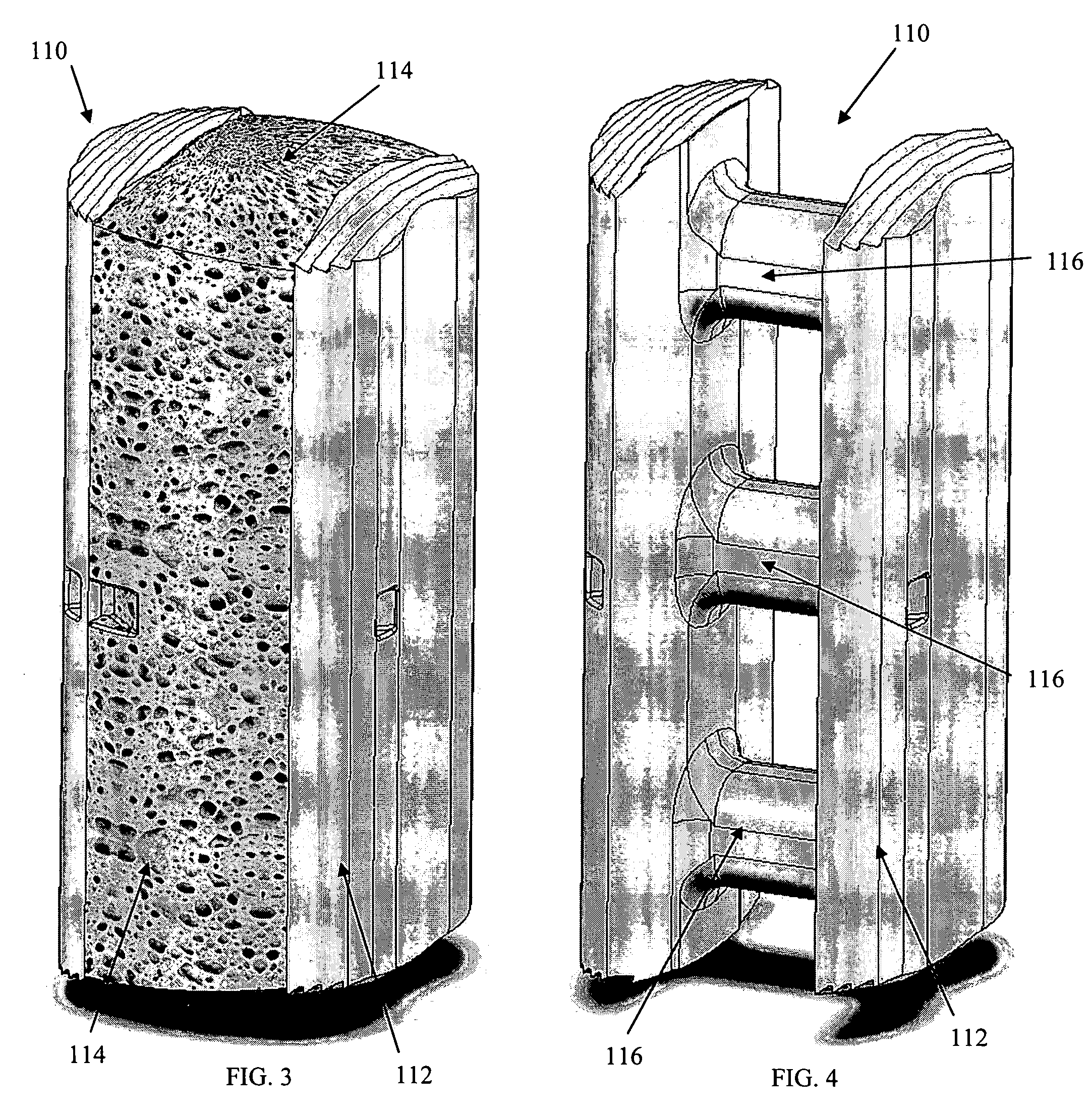

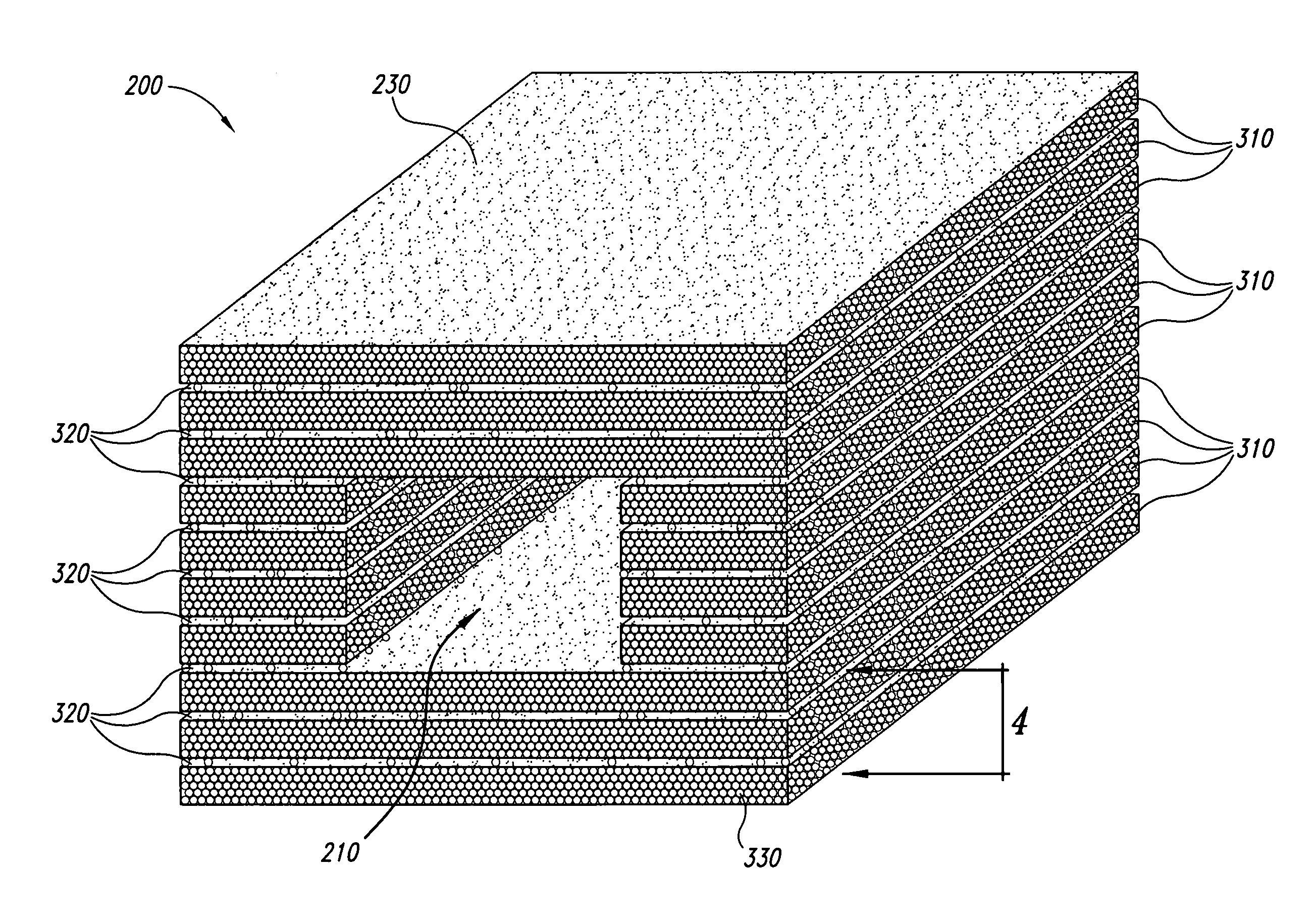

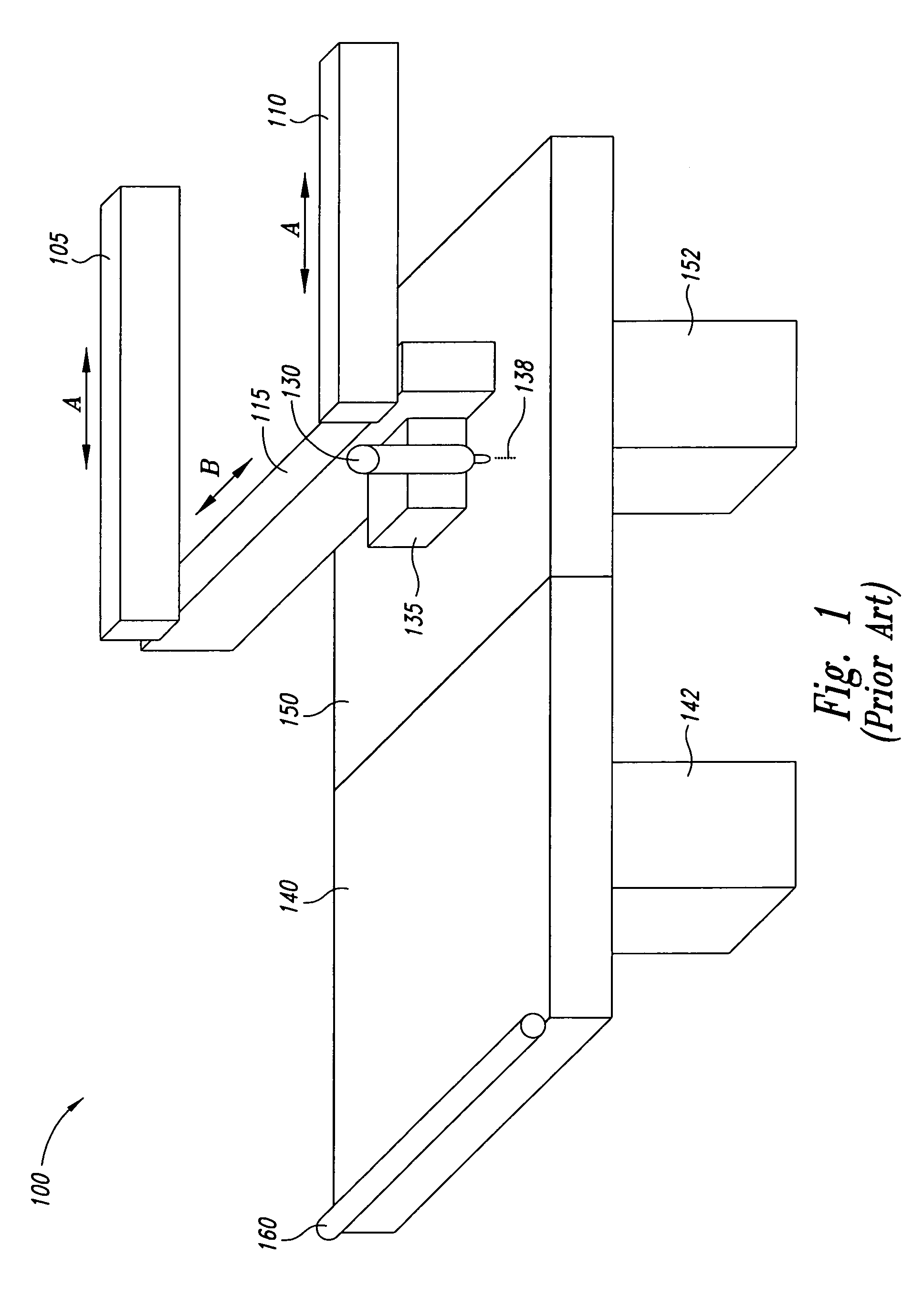

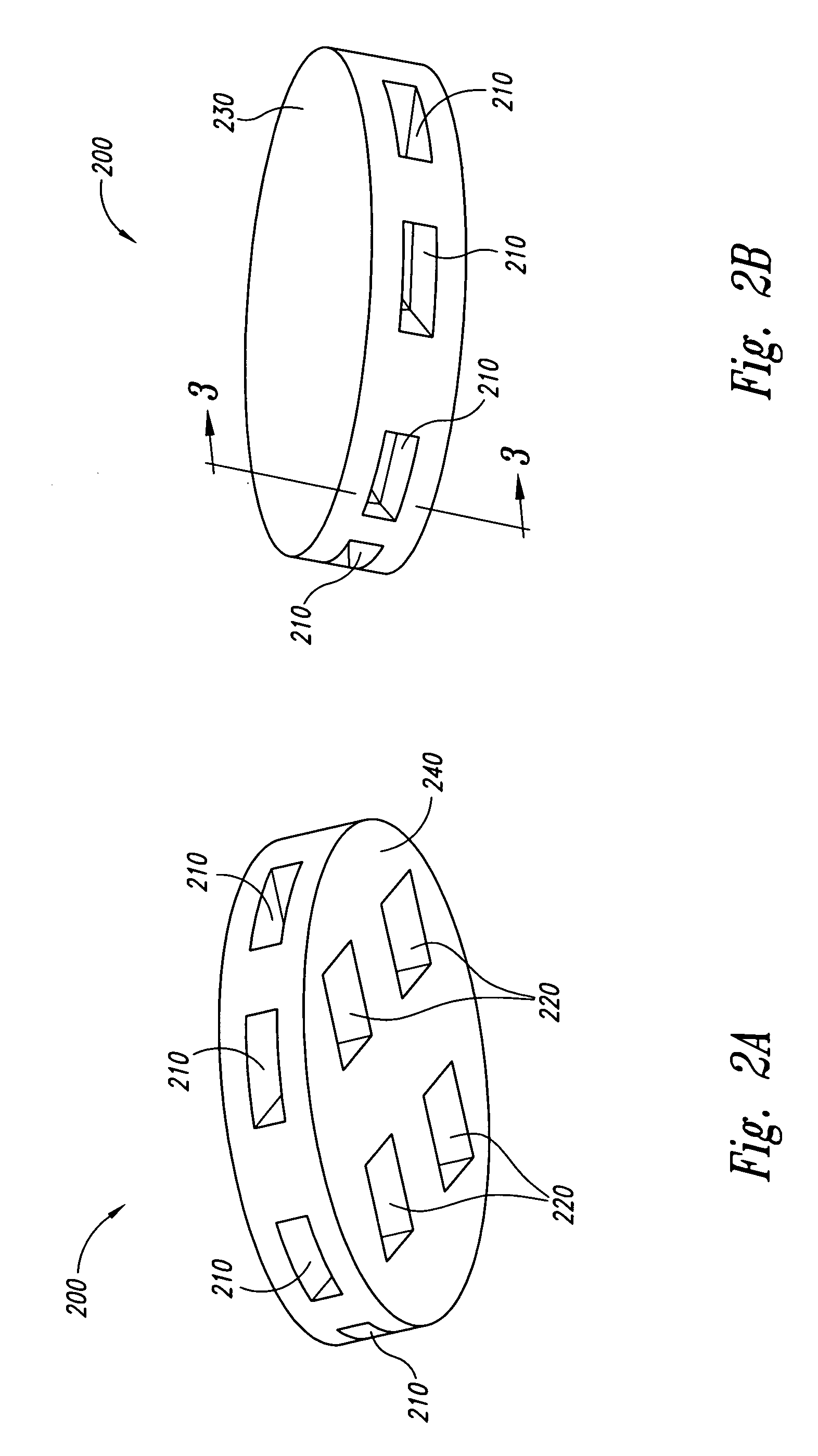

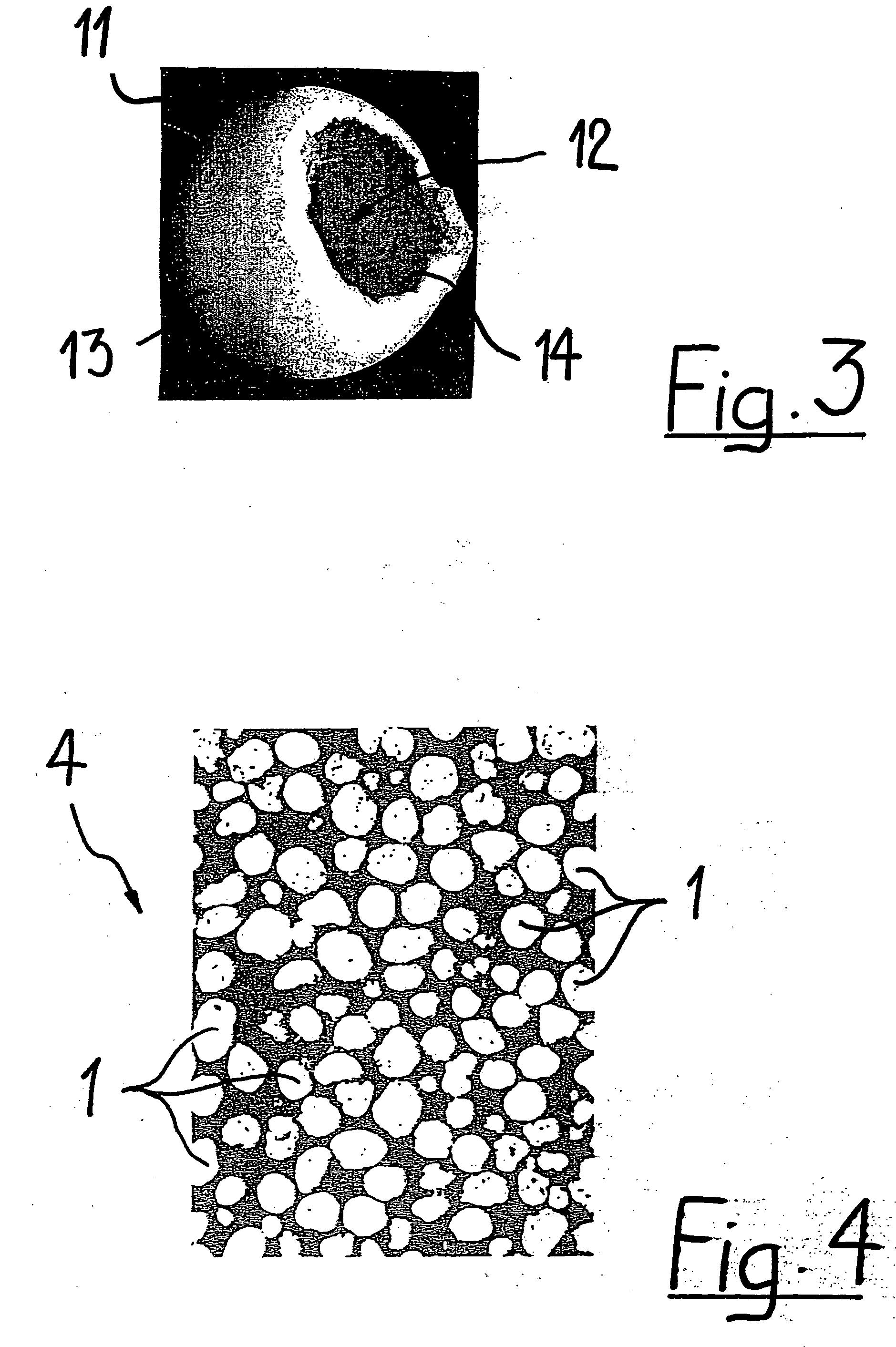

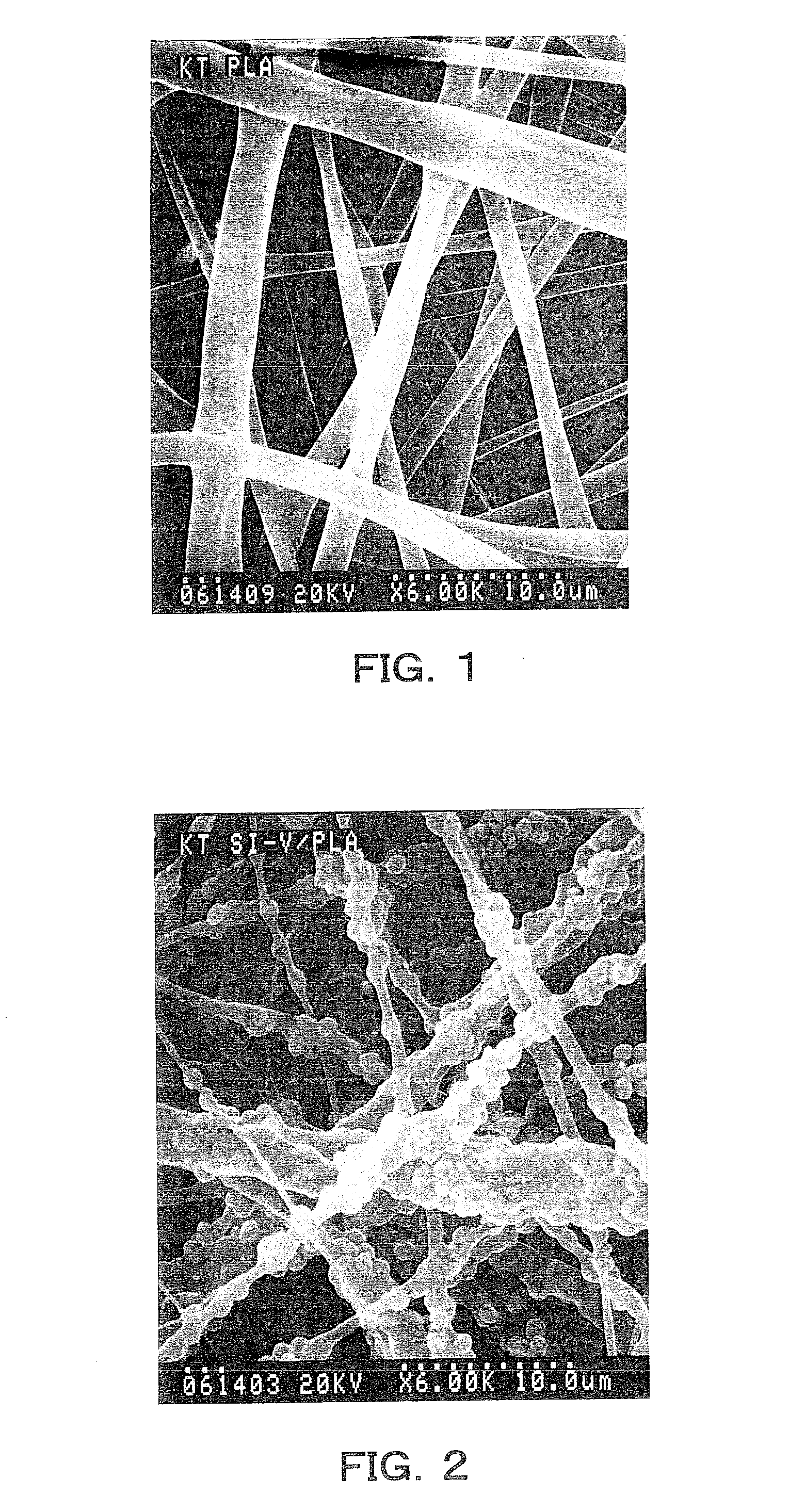

Method and apparatus for engineered regenerative biostructures such as hydroxyapatite substrates for bone healing applications

An engineered regenerative biostructure (erb) for implantation into a human body as a bone substitute, which includes an internal microstructure, mesostructure and / or macrostructure to provide improved bone in-growth, and methods for making the erb. Under one aspect of the invention, the biostructure has resorbable and nonresorbable regions. Under another aspect of the invention, the biostructure is constructed of hydroxyapatite, tricalcium phosphate and / or demineralized bone. Under yet another aspect of the invention, the porous biostructure is partially or fully infused with a resorbable, nonresorbable or dissolvable material.

Owner:THEKEN SURGICAL LLC

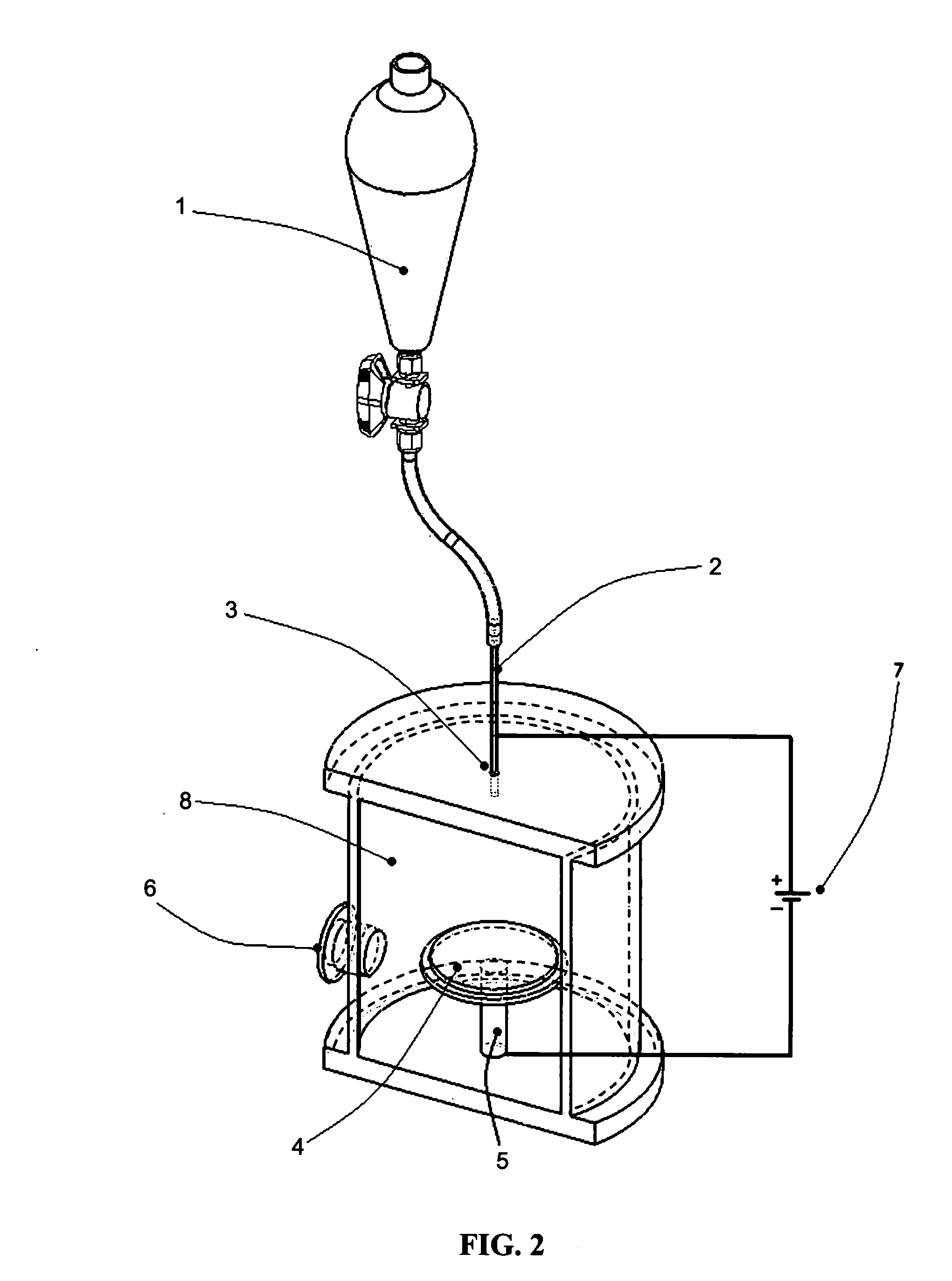

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS6730324B2High strengthEasy to makePowder deliveryOrganic active ingredientsGene deliverySide effect

This invention relates to novel room-temperature process for obtaining calcium phosphate, in particular hydroxyapatite, coatings and microspheres that encapsulate drugs, proteins, genes, DNA for therapeutical use. The coatings and microspheres are designed to perform a defined biological function related to drug delivery, such as gene therapy through gene delivery. A novel method for encapsulation, and subsequent controlled release of therapeutically active agents from such biofunctional coatings and microspheres is disclosed. Such coatings and microspheres are useful for side-effects free, long-term, targeted, controlled release and delivery of drugs, proteins, DNA, and other therapeutic agents.

Owner:THE UNIV OF BRITISH COLUMBIA

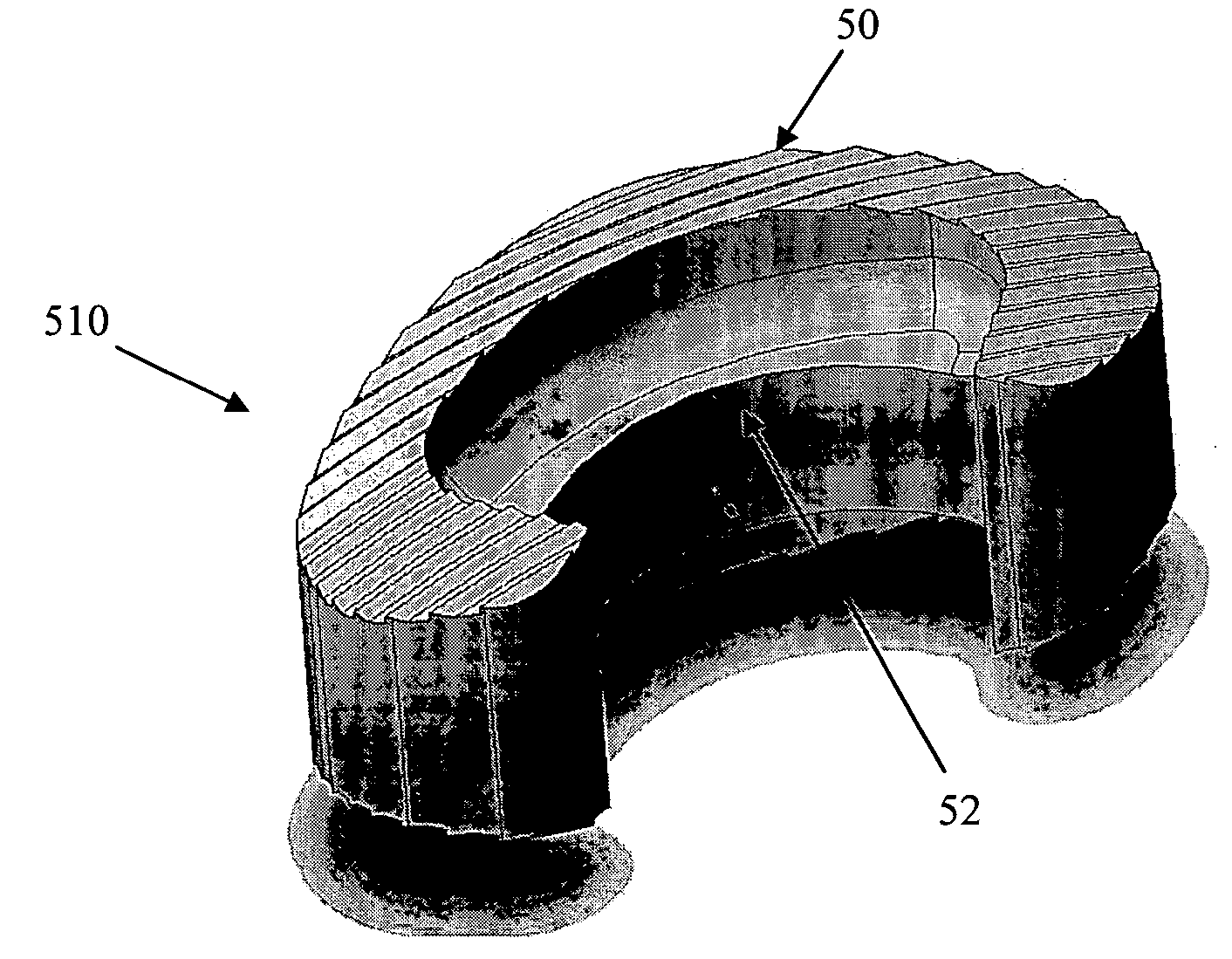

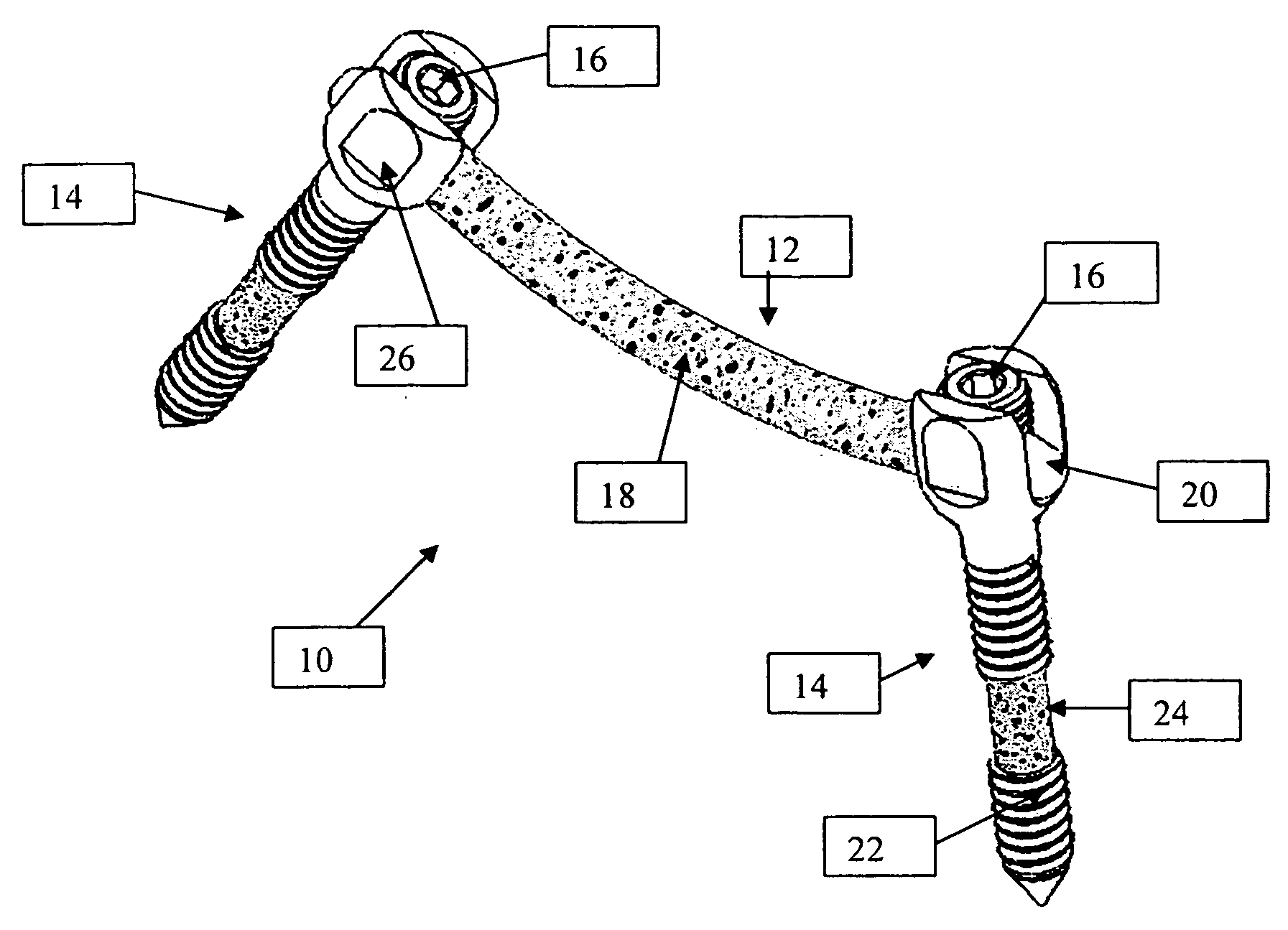

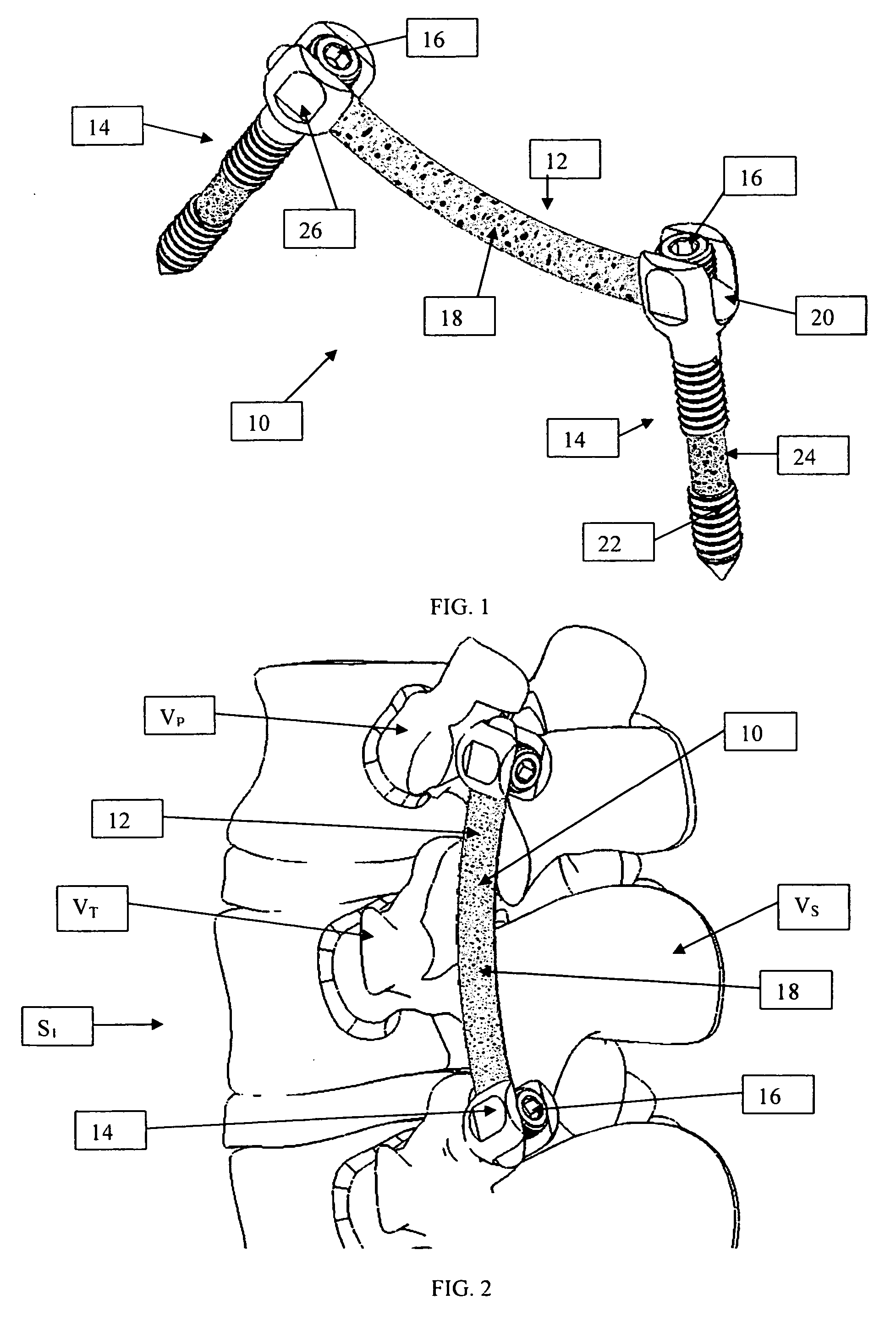

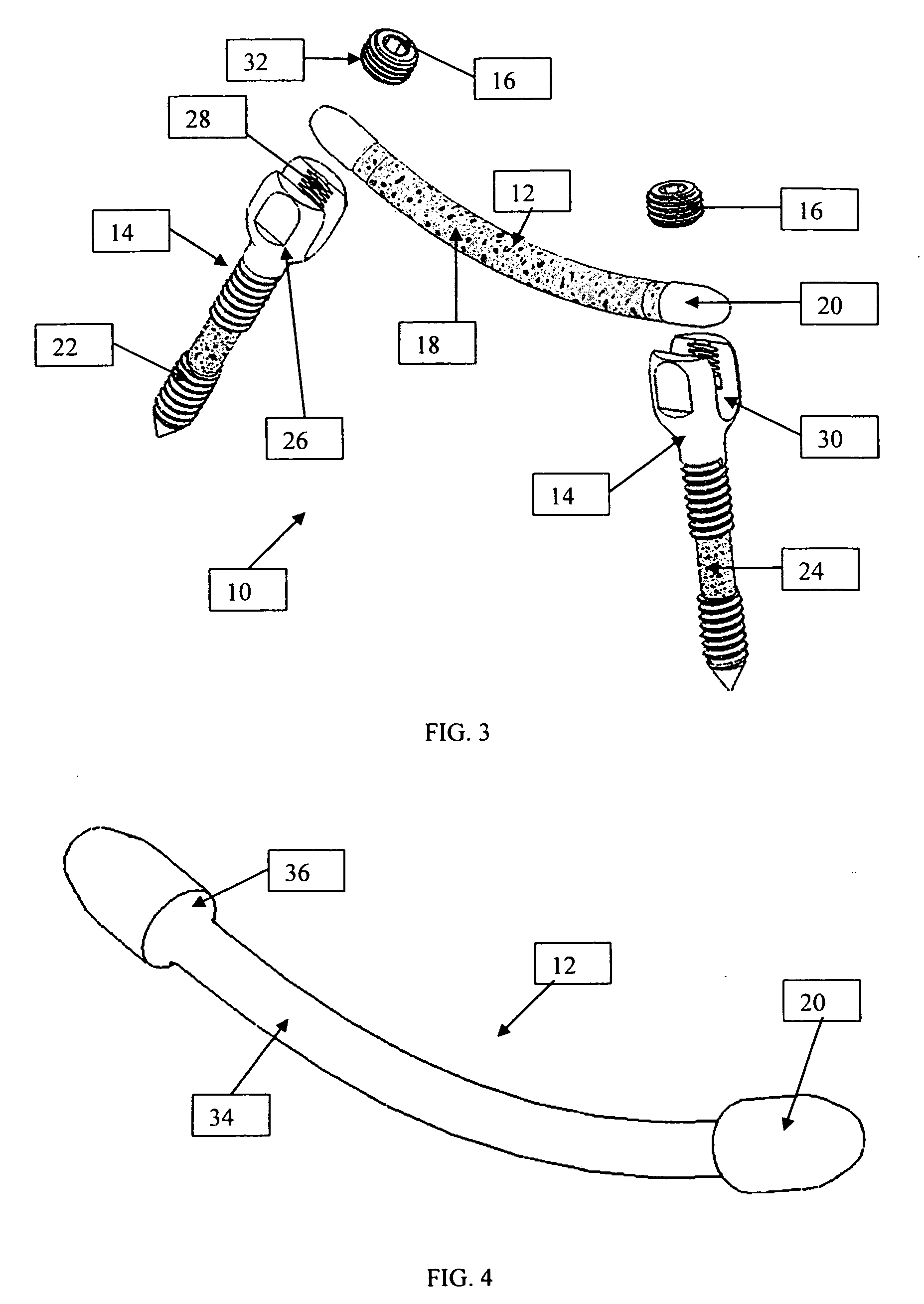

Osteoconductive spinal fixation system

InactiveUS20060276788A1High strengthHigh mechanical strengthSuture equipmentsInternal osteosythesisPorositySpinal column

An improved spinal fixation system is provided for human implantation, including a set of screws with interconnecting rods for implantation into the pedicle and between two adjacent vertebrae or a plate with screws for fixating two adjacent vertebrae. The screws, rods, and plates include a substrate portion of high strength biocompatible material and a controlled porosity analogous to natural bone. The substrate portion may be coated with a bio-active surface coating material such as hydroxyapatite or a calcium phosphate to promote bone ingrowth and enhanced bone fusion. Upon implantation, the fixation system provides a desired combination of mechanical strength together with osteoconductivity and bio-activity to promote bone ingrowth and fusion, as well as radiolucency for facilitated post-operative monitoring. The fixation system may additionally carry one or more natural or synthetic therapeutic agents for further promoting bone ingrowth and fusion.

Owner:AMEDICA A DELAWARE

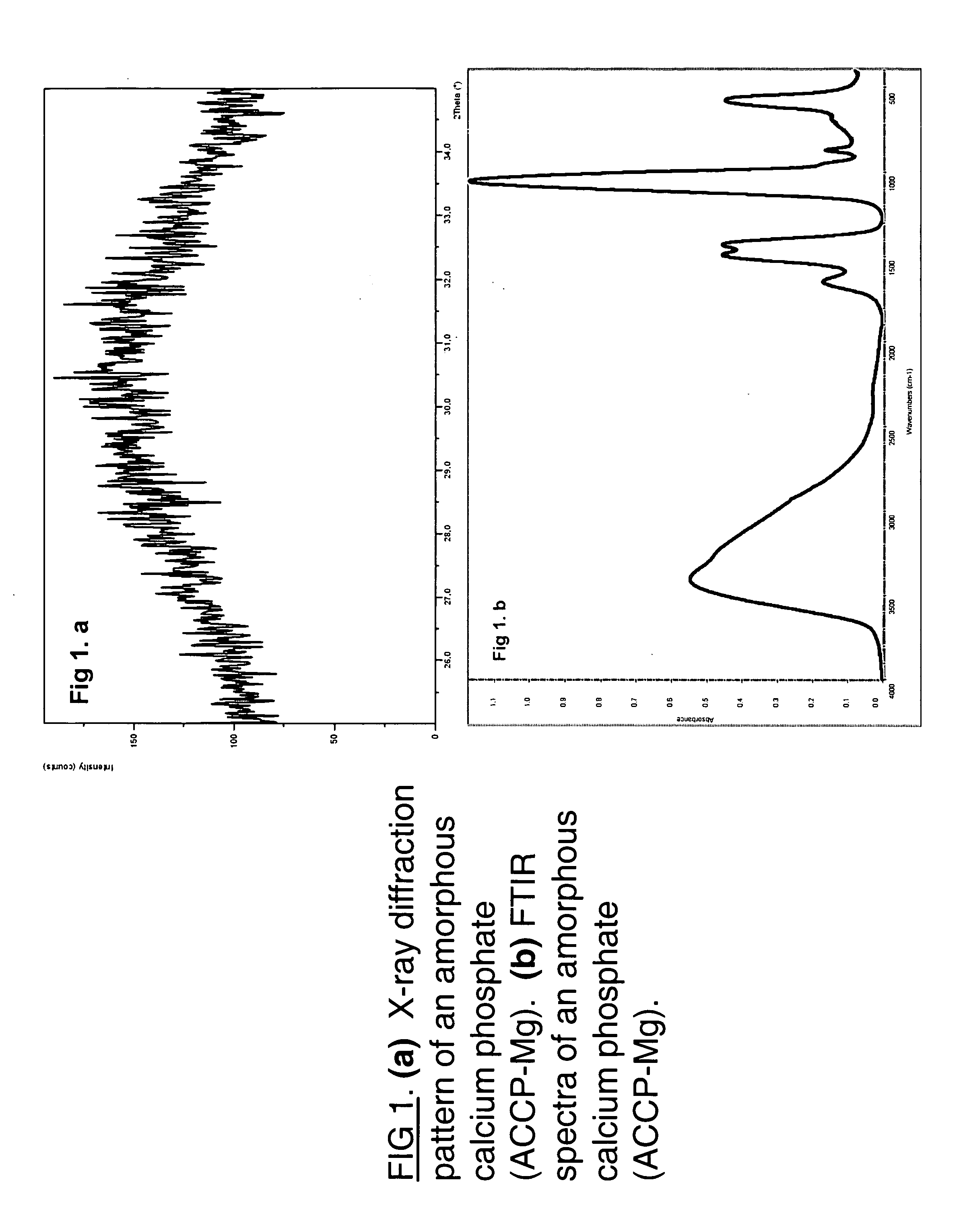

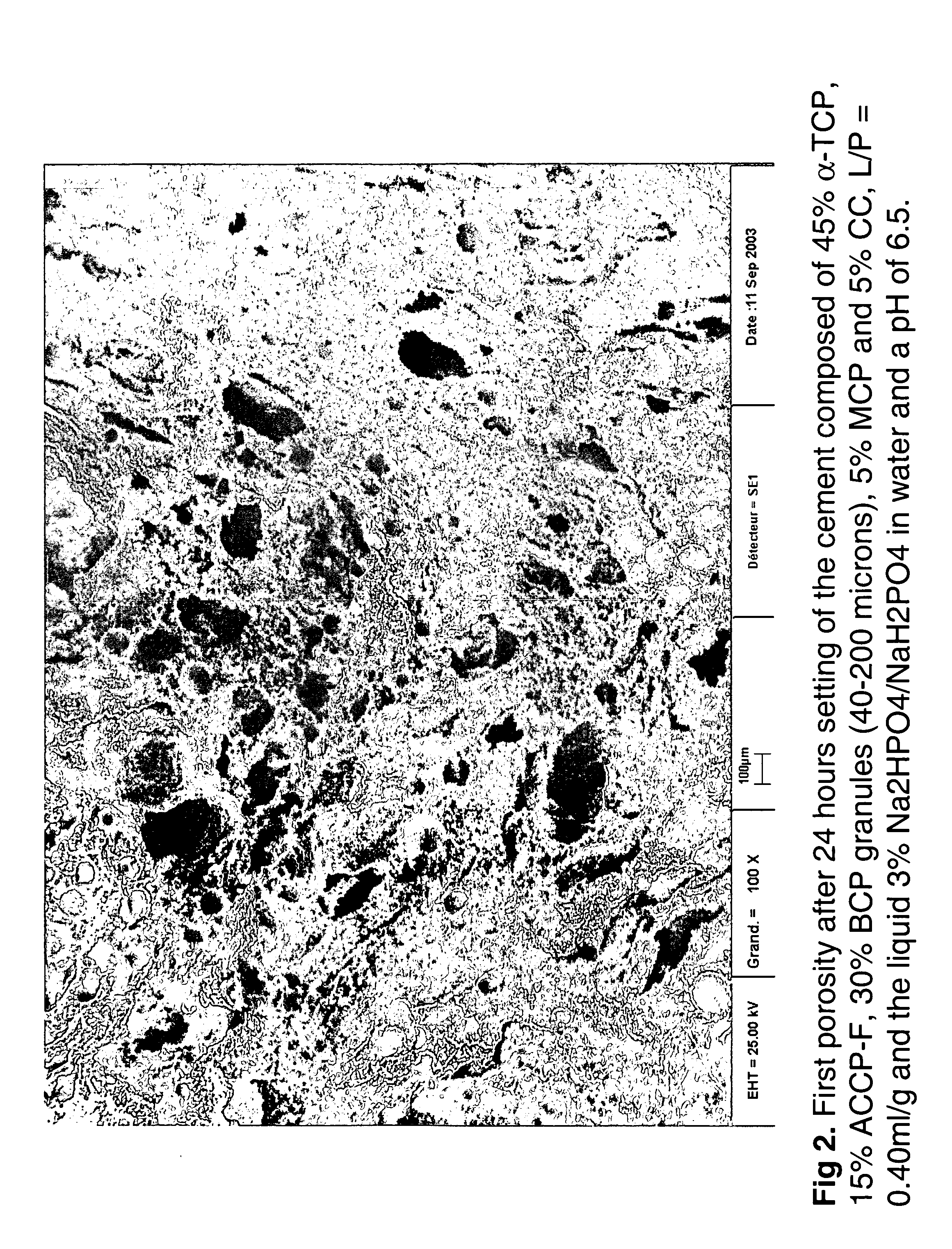

Macroporous, resorbable and injectible calcium phosphate-based cements (MCPC) for bone repair, augmentation, regeneration, and osteoporosis treatment

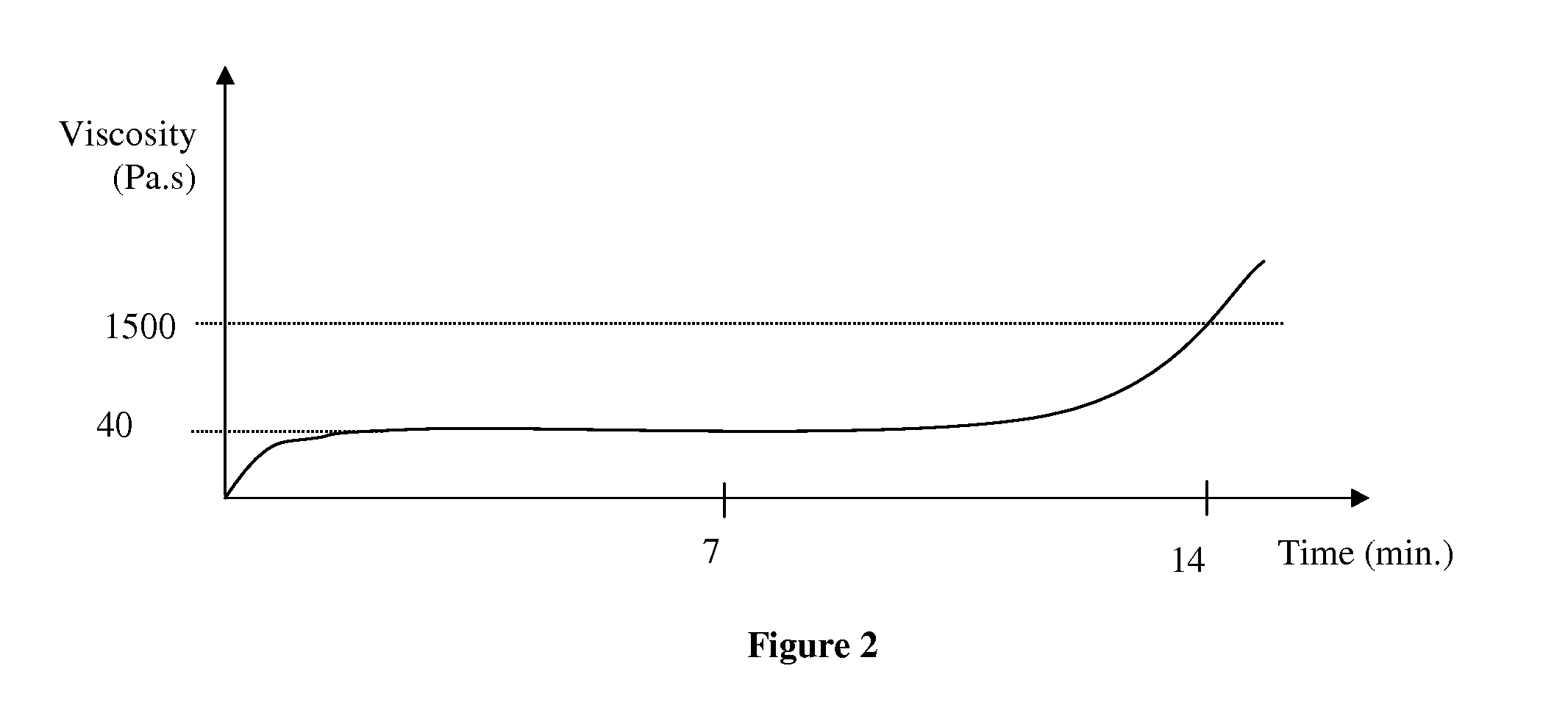

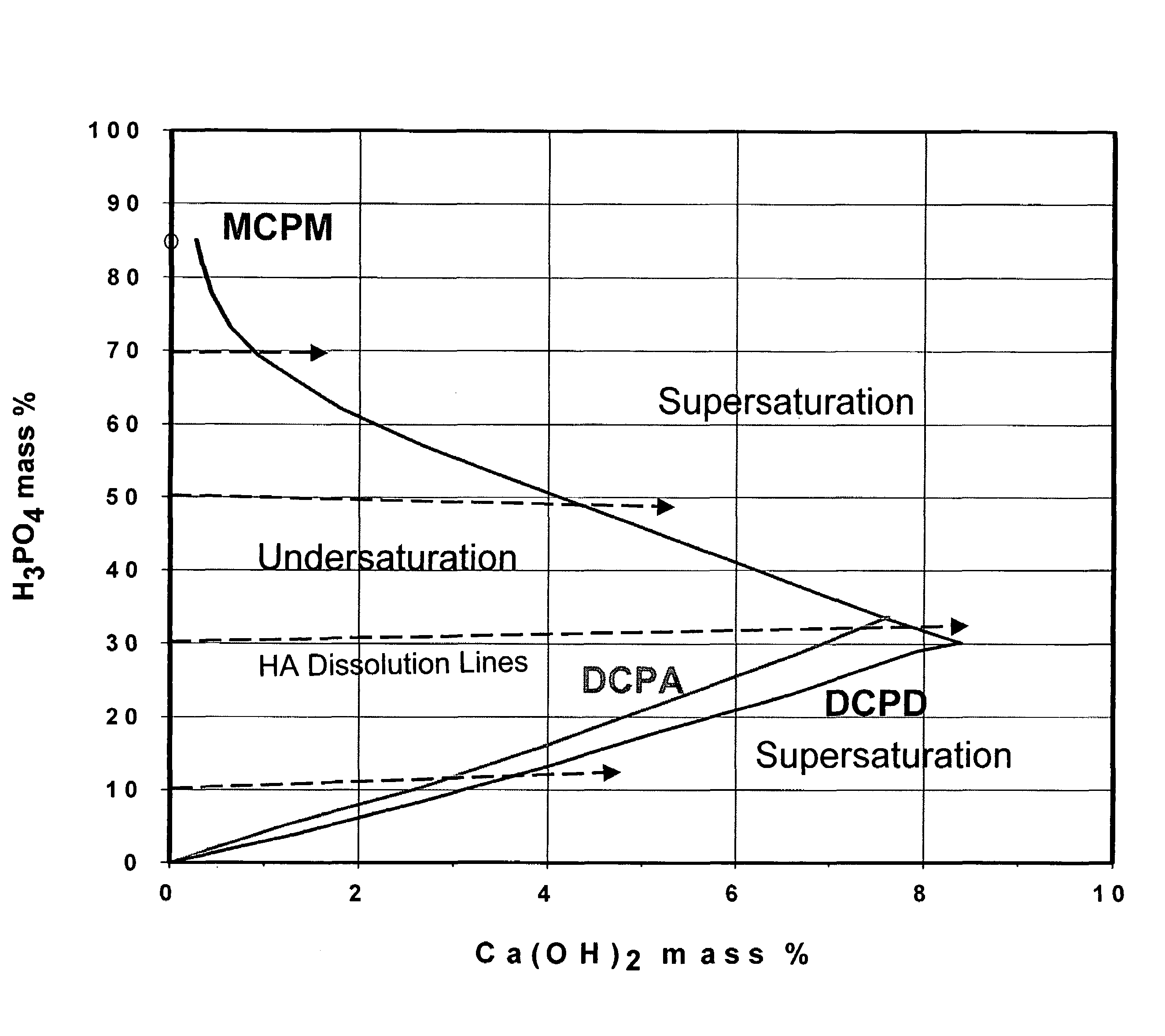

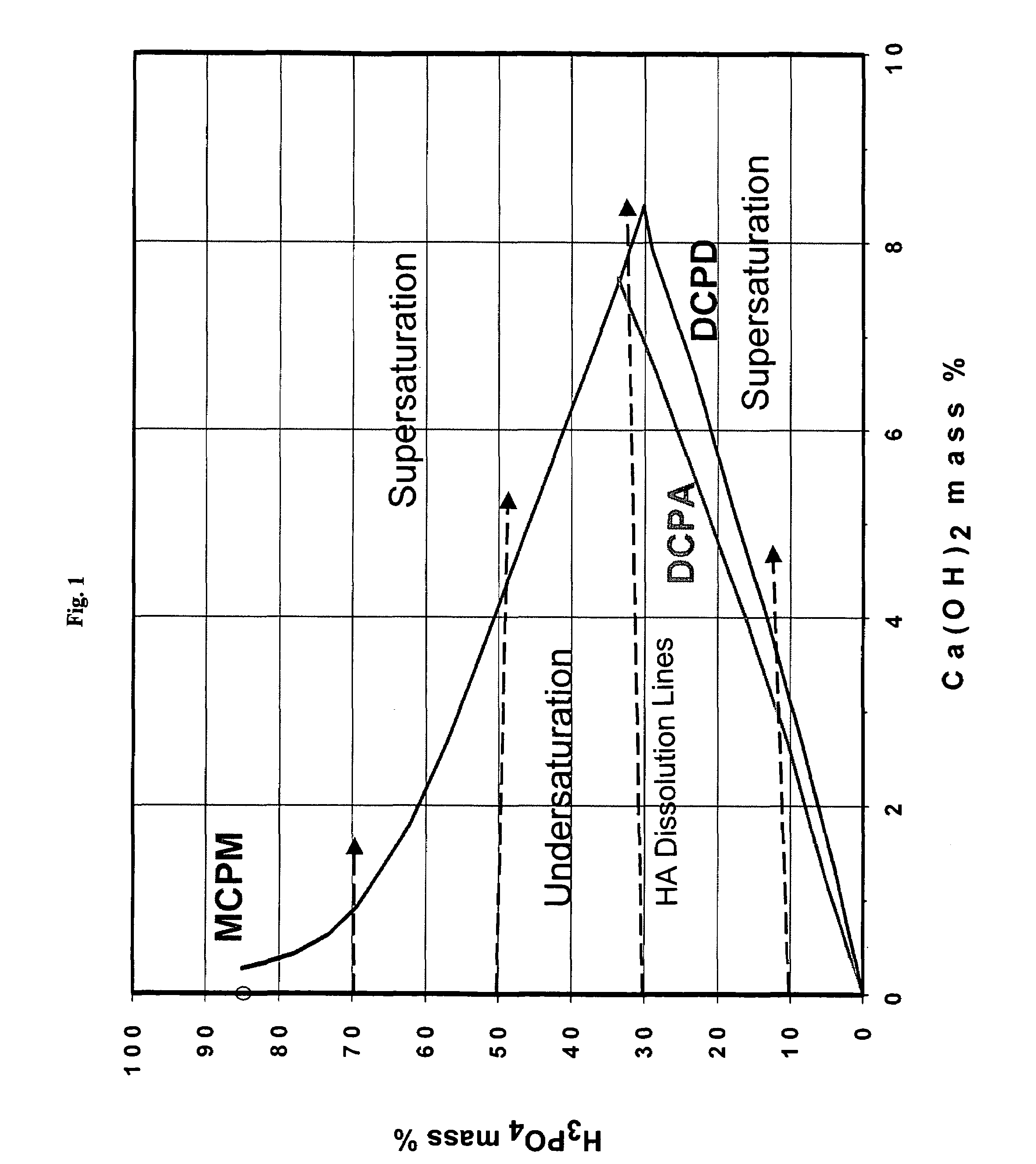

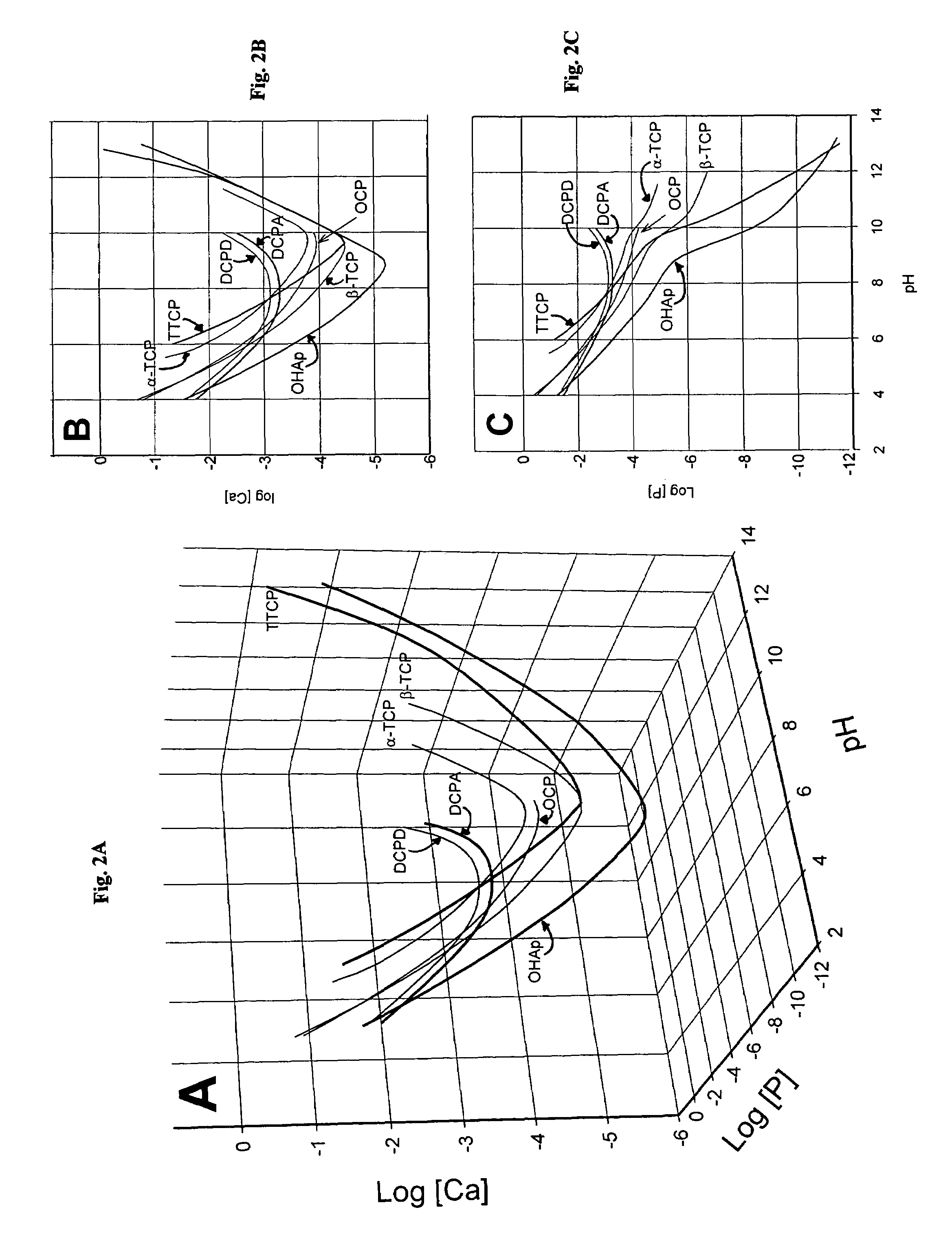

ActiveUS20050199156A1Easy to controlSurgical adhesivesOther chemical processesApatitePhosphoric acid

A composition and method for producing interconnective macroporous, resorbable and injectable calcium phosphate-based cements (MICPCs). The composition of the invention sets to poorly crystalline apatitic calcium phosphate after mixing a powder component and an aqueous solution. The multiphasic calcium phosphate components in the cement resorb at different rates allowing the timely replacement by new bone. The interconnected macroporosity in the cement allows for vascularization, entrapment of growth factors, cell colonization and tissue ingrowth. This MICPC can be used for dental and medical applications relating to bone repair, augmentation, reconstruction, regeneration, and osteoporosis treatment, and also for drug delivery, and as scaffolds for tissue engineering.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

Hydroxyapatite coated nanostructured titanium surfaces

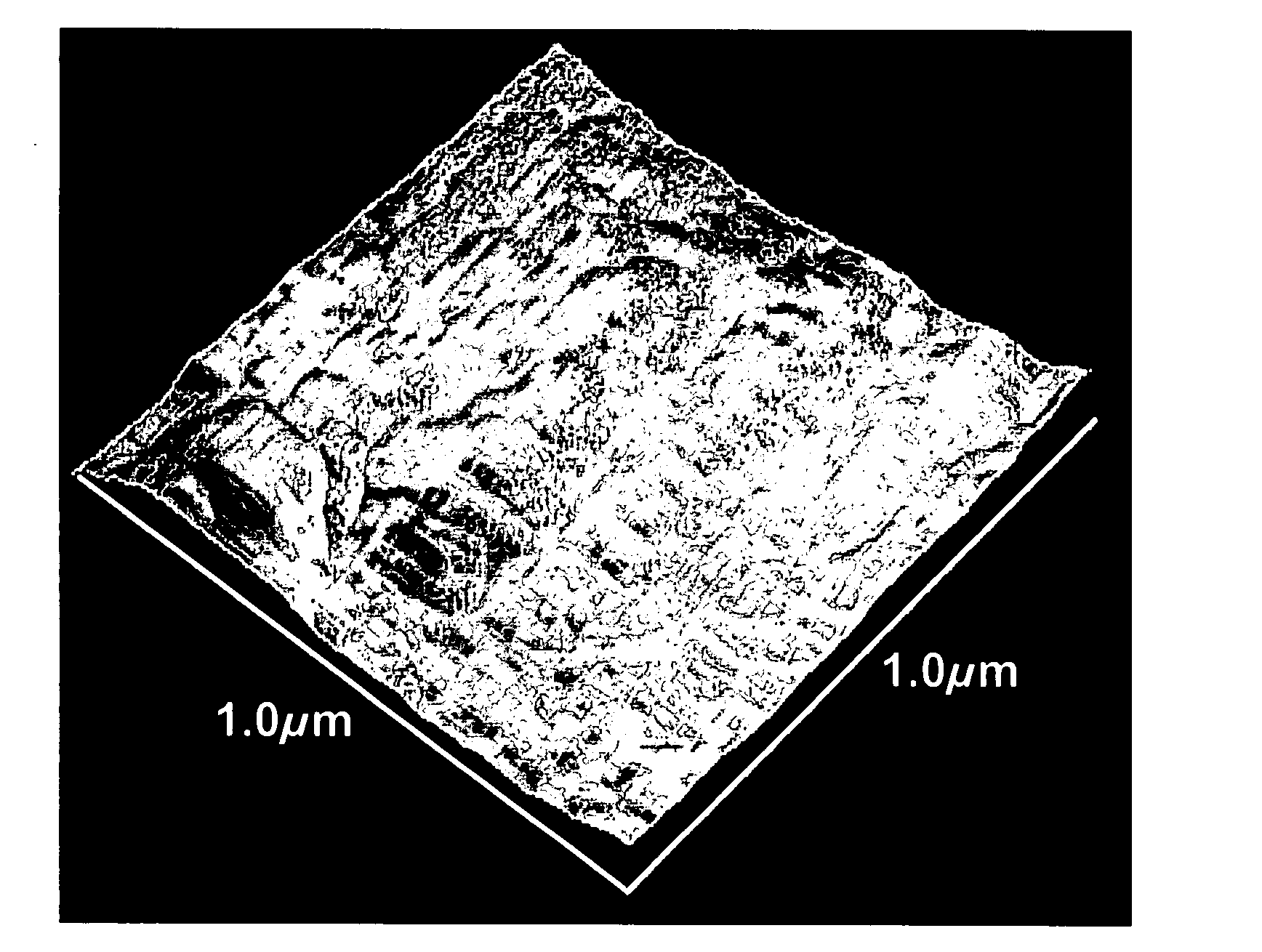

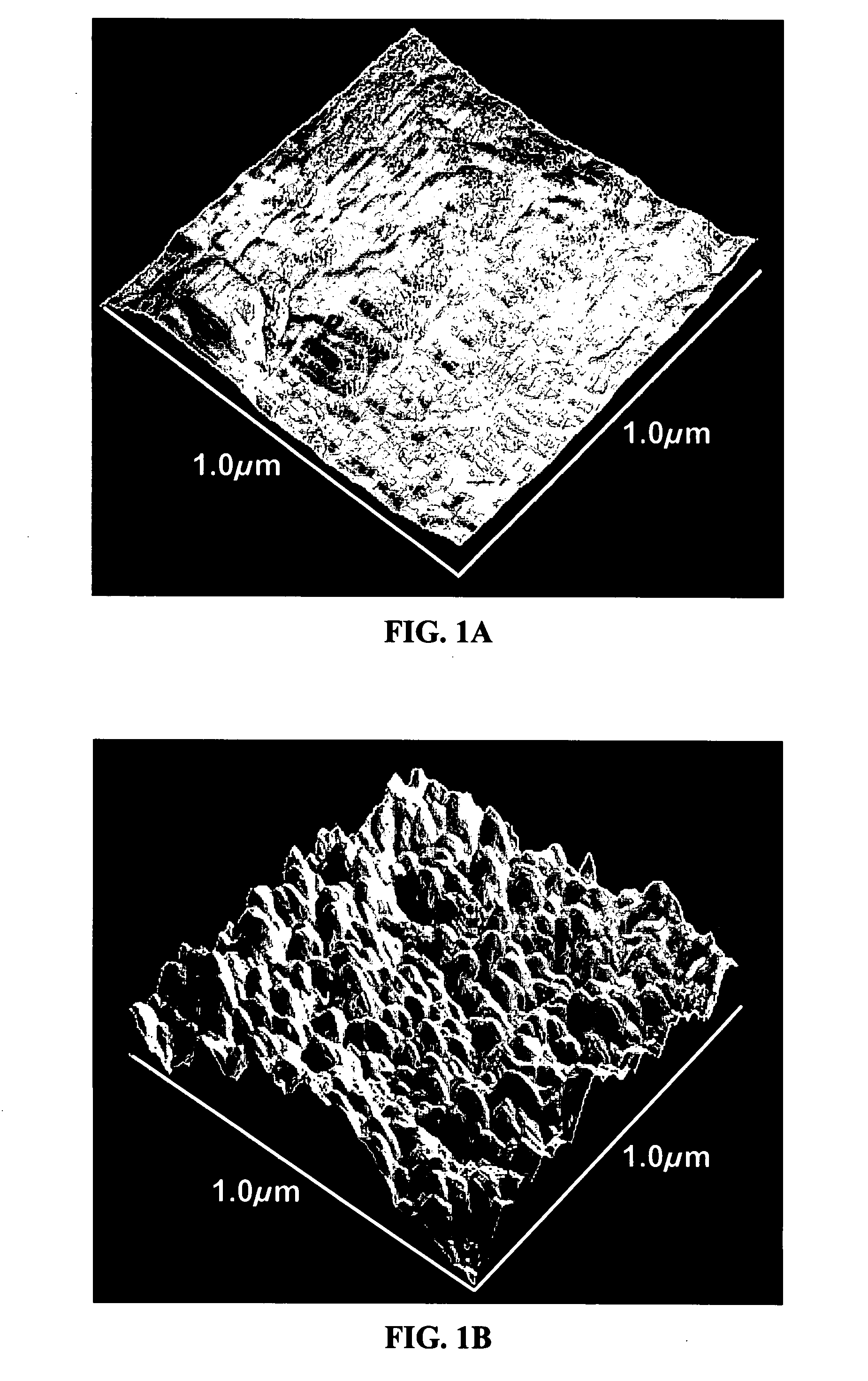

InactiveUS20090035722A1Improve adhesionPromote accumulationDental implantsImpression capsOsteoblast adhesionApatite

Nanotubular structured titanium (Ti) substrates have been coated with nanoparticulate hydroxyapatite (nano-HA). The nano-HA surface is highly adherent to the nanotubular Ti surface and is free of microparticles. The nano-HA coated nanotubular Ti surface promotes osteoblast cell adhesion and is particularly suitable for orthopedic and dental implants where deposition of osteoblasts and other proteins is important in bone formation.

Owner:METASCAPE

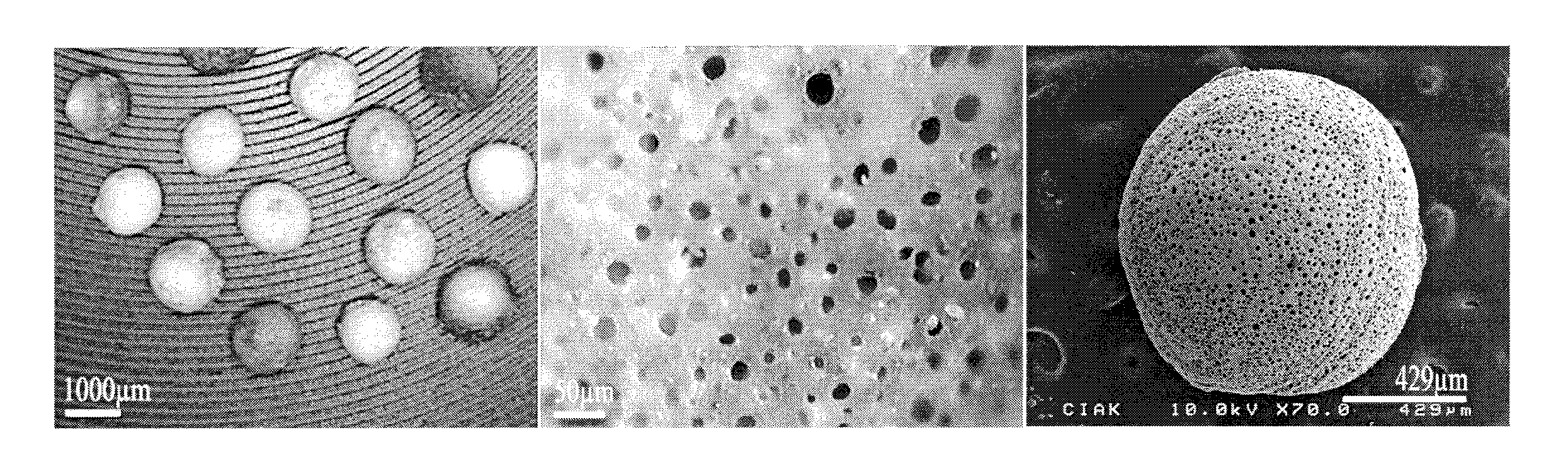

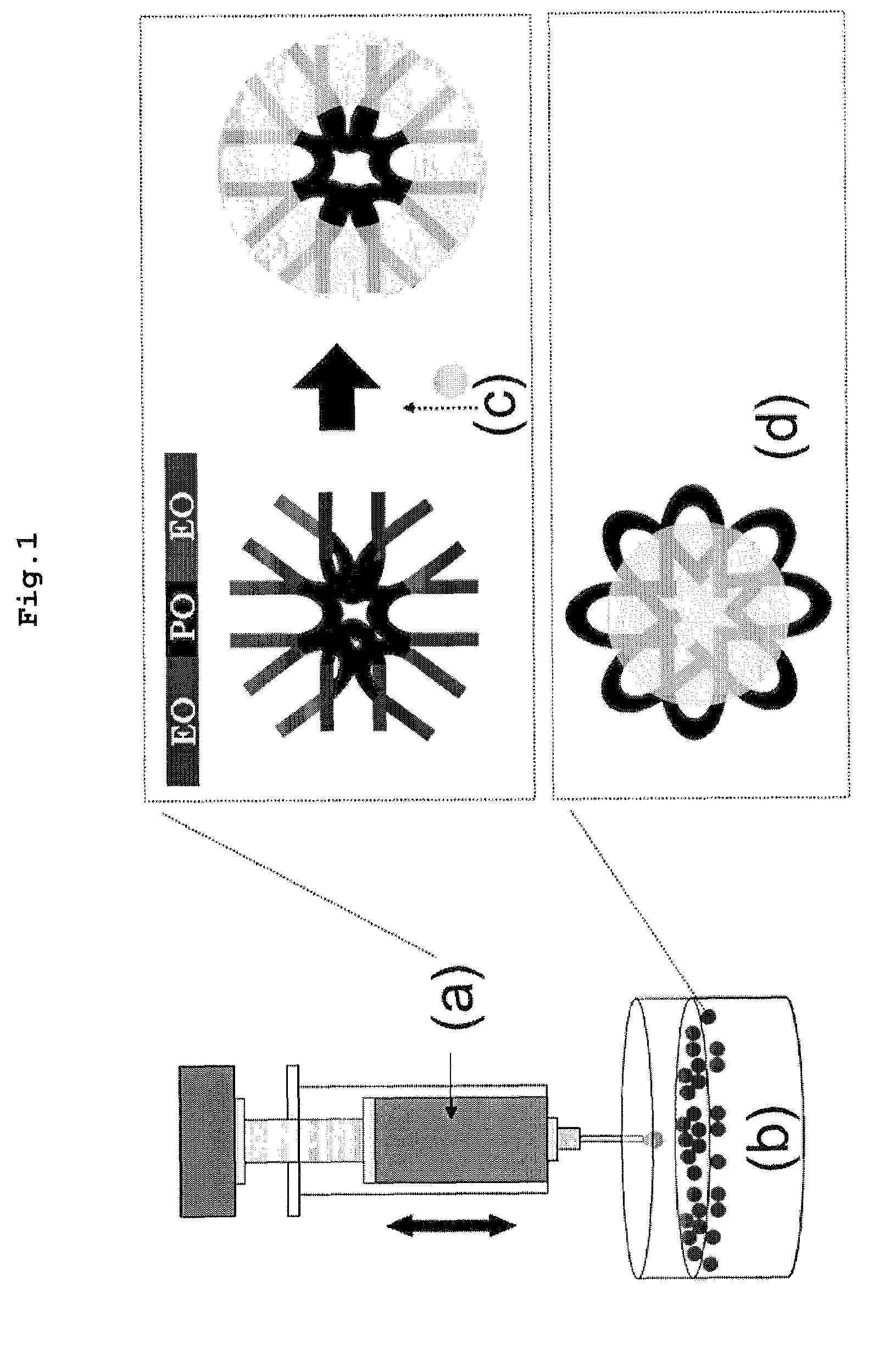

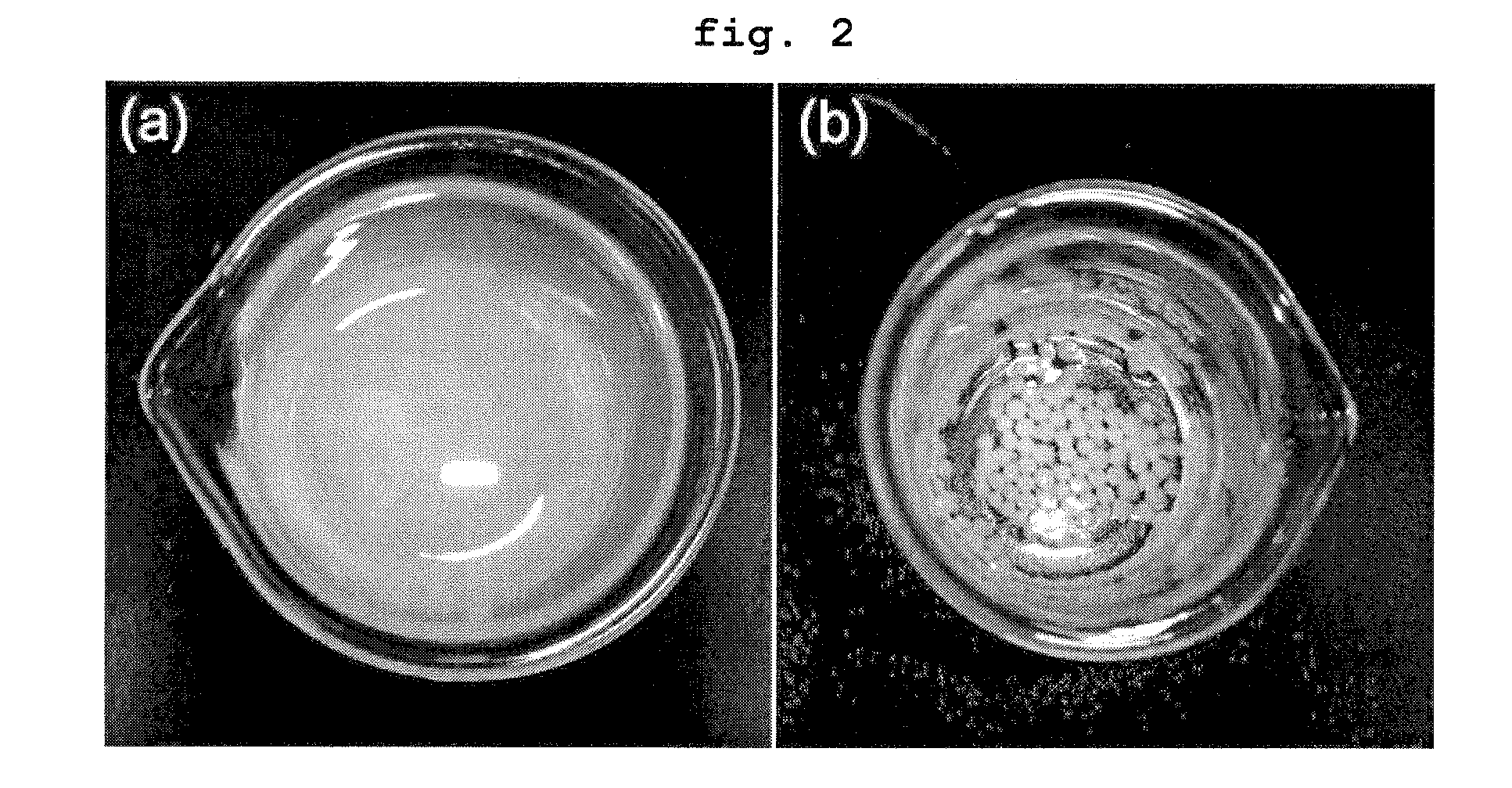

Porous material having hierarchical porous structure and preparation method thereof

Disclosed are porous ceramic balls with a hierarchical porous structure ranging in size from nanometers to micrometers, and preparation methods thereof. Self-assembly polymers and sol-gel reactions are used to prepare porous ceramic balls in which pores ranging in size from ones of nanometers to tens of micrometers are hierarchically interconnected to one another. This hierarchical porous structure ensures high specific surface areas and porosities for the porous ceramic balls. Further, the size and distribution of the pores can be simply controlled with hydrophobic solvent and reaction time. The pore formation through polymer self-assembly and sol-gel reactions can be applied to ceramic and transition metals. Porous structures based on bioceramic materials, such as bioactive glass, allow the formation of apatite therein and thus can be used as biomaterials of bioengineering, including bone fillers, bone reconstruction materials, bone scaffolds, etc.

Owner:KOREA INST OF MATERIALS SCI

Absorbable implants and methods for their use in hemostasis and in the treatment of osseous defects

ActiveUS20060013857A1Lower potentialMinimally inhibit osteogenesis and subsequent bone healingSurgical adhesivesSkeletal disorderBarium saltApatite

Two (or more), -component, body-implantable, absorbable, biocompatible, putty, and non-putty hemostatic tamponades for use in surgery. Component 1 is a finely powdered bulking material, preferably less than 50 microns, e.g. the calcium, magnesium, aluminum, or barium salts of saturated or unsaturated carboxylic acids containing about 6 to 22 carbon atoms, hydroxyapatite, DBM, polyglycolide, polylactide, poldioxinones, polycaprolactones, absorbable glasses, gelatin, collagens, mono, and polysaccharides starches. Component 2, a dispersing vehicle, may be esters unsubstituted and N-substituted pyrrolidones of C8-C18 monohydric alcohols with C2-C6 aliphatic monocarboxylic acids; C2-C18 monohydric alcohols with polycarboxylic acids; C8-C30 monohydric alcohols; tocopherol and esters thereof with C2-C10 aliphatic monocarboxylic acids or polycarboxylic acids; absorbable 10-14C hydrocarbons; free carboxylic acids such as oleic, capric, and lauric; dialkyl ethers and ketones; alkyl aryl ethers and ketones, polyhydroxy compounds and esters and ethers thereof; (ethylene oxide / propylene oxide copolymers), oils e.g. olive oil, castor oil and triglycerides.

Owner:ABYRX

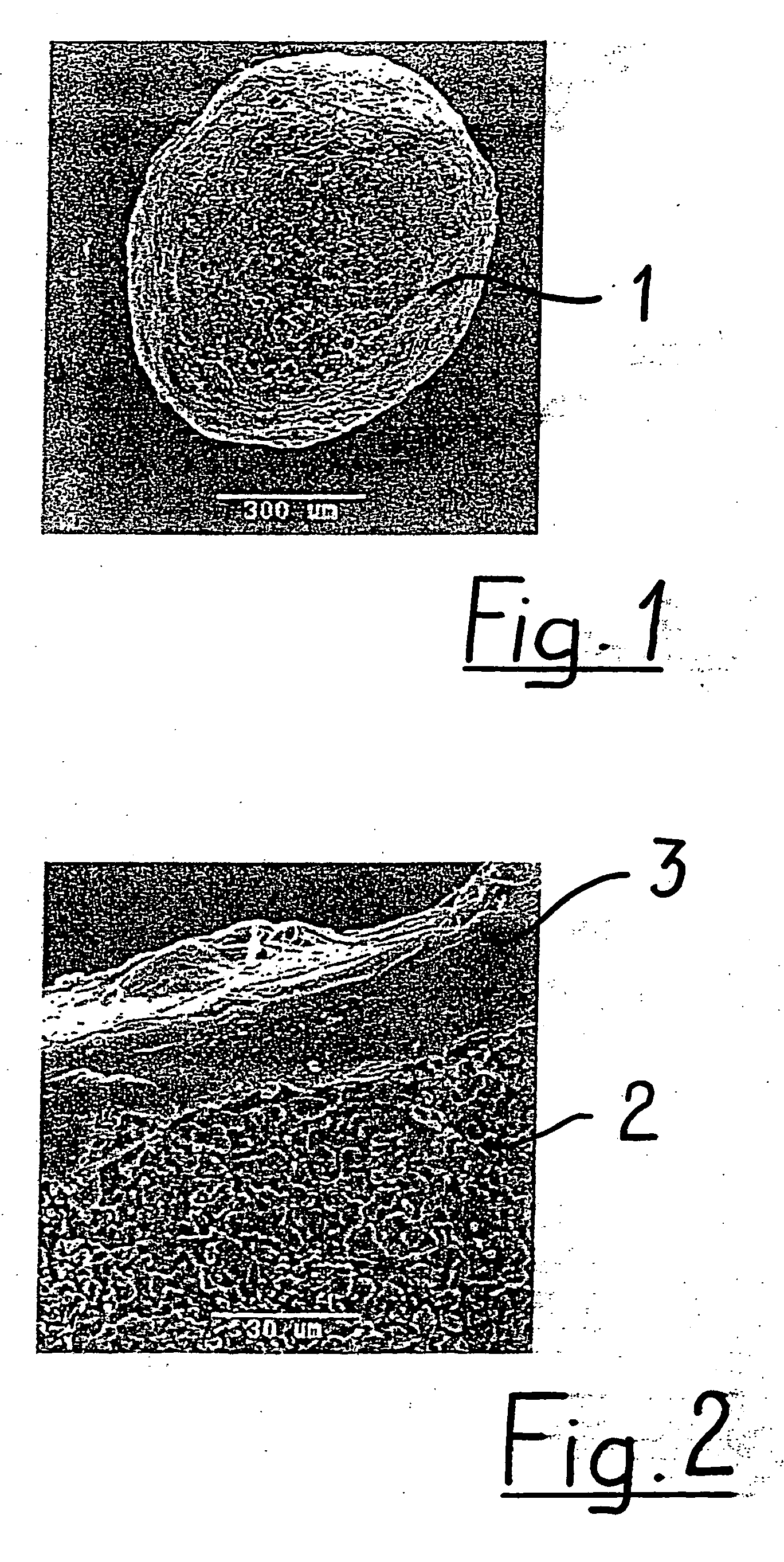

Porous biocompatible implant material and method for its fabrication

a biocompatible and biodegradable implant for a cavity in a bone of a living organism is made of a biocompatible and biodegradable granules which are selected from the group including biopolymers, bioglasses, bioceramics preferably calcium sulfate, calcium phosphate such as monocalcium phosphate monohydrate, monocalcium phosphate anhydrous, dicalcium phosphate dihydrate, dicalcium phosphate anhydrous, tetracalcium phosphate, calcium orthophosphate phosphate, α-tricalcium phosphate, β-tricalcium phosphate, apatite such as hydroxyapatite, or a mixture thereof. The biocompatible and biodegradable granules are provided with a coating, which comprises at least one layer of a biocompatible and biodegradable polymer which is selected from the group including poly((α-hydroxyesters), poly(orthoesters), polyanhydrides, poly(phosphazenes), poly(propylene fumarate), poly(ester amides), poly(ethylene fumarate), polylactide, polyglycolide, polycaprolactone, poly(glycolide-co-trimethylene carbonate), polydioxanone, co-polymers thereof and blends of those polymers. The biocompatible and biodegradable implants are obtained by fusing together the polymer-coated granules through polymer-linkage of the polymer coatings of neighboring granules.

Owner:COLLAGEN MATRIX

Composite heavy metal polluted soil conditioner as well as application and application method thereof

ActiveCN104046361AImprove fertilityContinuous Enhancement RepairContaminated soil reclamationOrganic fertilisersApatiteSlag

The invention discloses a composite heavy metal polluted soil conditioner as well as application and an application method thereof. The soil conditioner comprises the following components: plant ash, calcium magnesium phosphate, quicklime, zeolite and organic fertilizers at a weight ratio of (0.3-1.1):(0.1-1.2):(0.4-2.1):(0.1-0.6):(0.008-0.06):(0.4-1.2). Through inorganic components such as quicklime, calcium magnesium phosphate and phosphate in hydroxyapatite as well as potassium carbonate in the plant ash, the soil conditioner can be used for fixing heavy metals in polluted soil and improving the fertility of the polluted soil in combination with organic manures such as the plant ash and the organic fertilizers so as to continuously intensify the restoration of the polluted soil, has the advantages of relatively-high stability, good environmental friendliness and low cost, can be used for inactivating and restoring various heavy metal polluted soil, especially has a good restoration effect on soil pollution caused by waste slag discharged by industrial and mining enterprises, can be used for realizing the treatment goal without generating secondary pollution, and is liable to realize large-area popularization.

Owner:SICHUAN UNIV

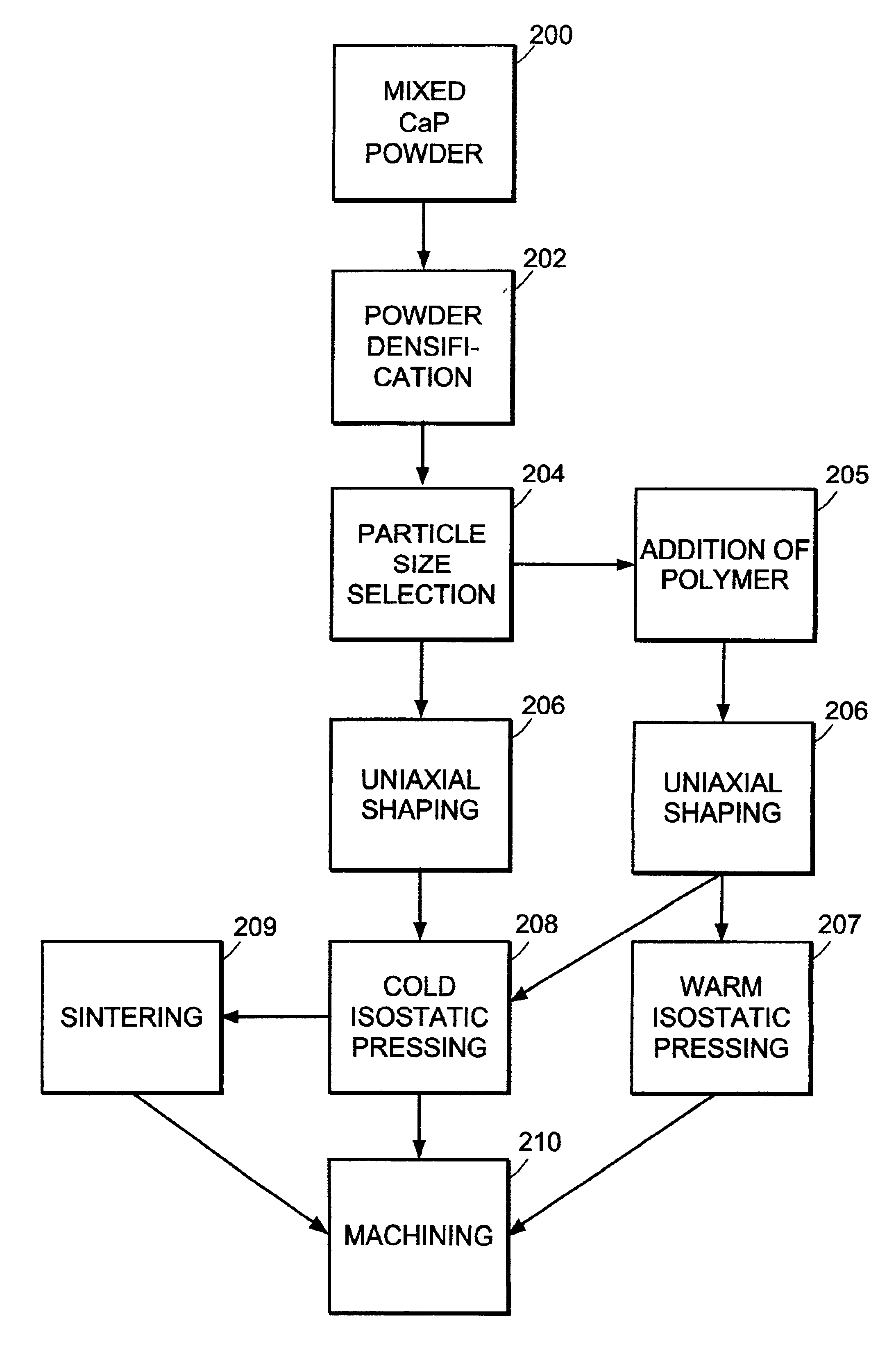

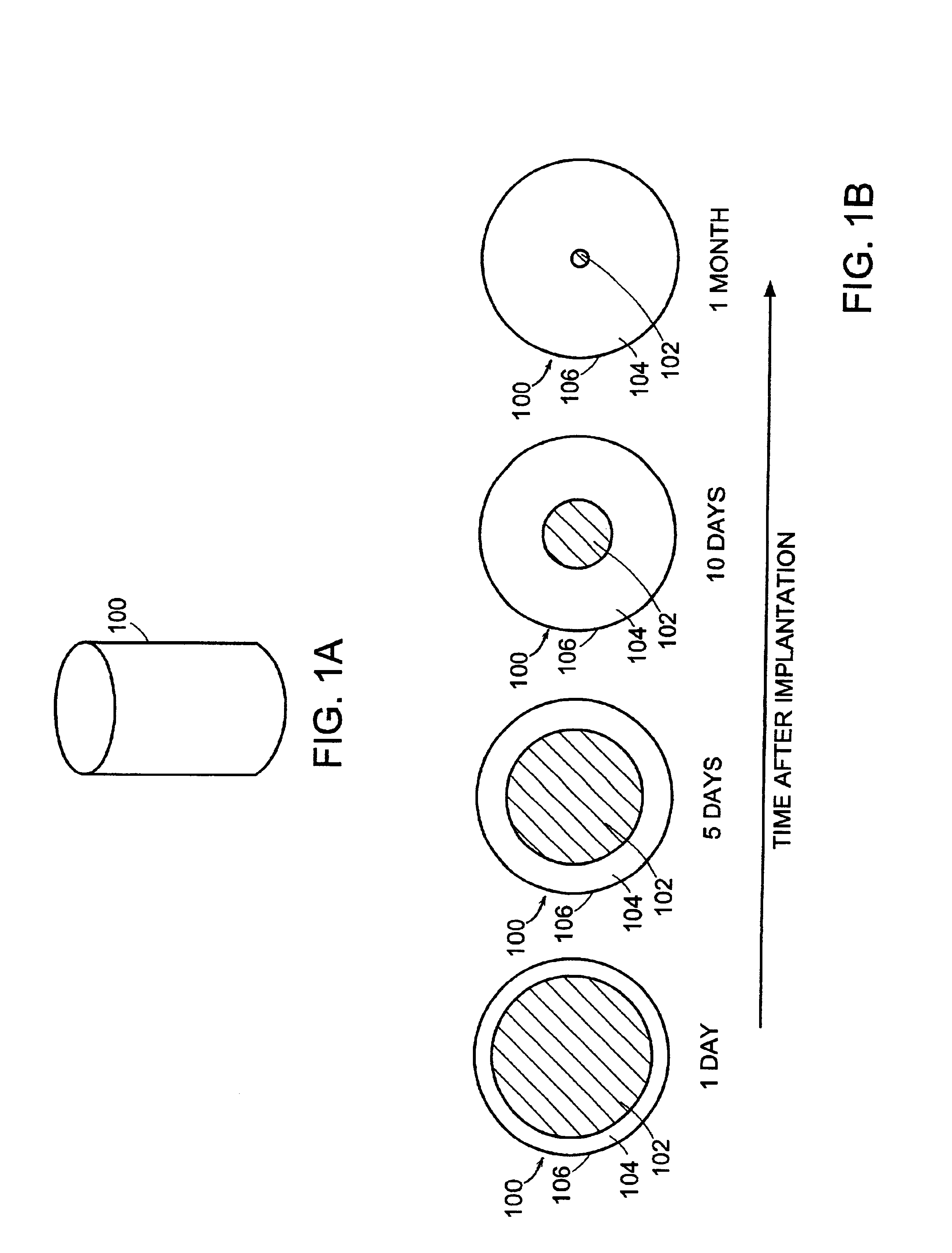

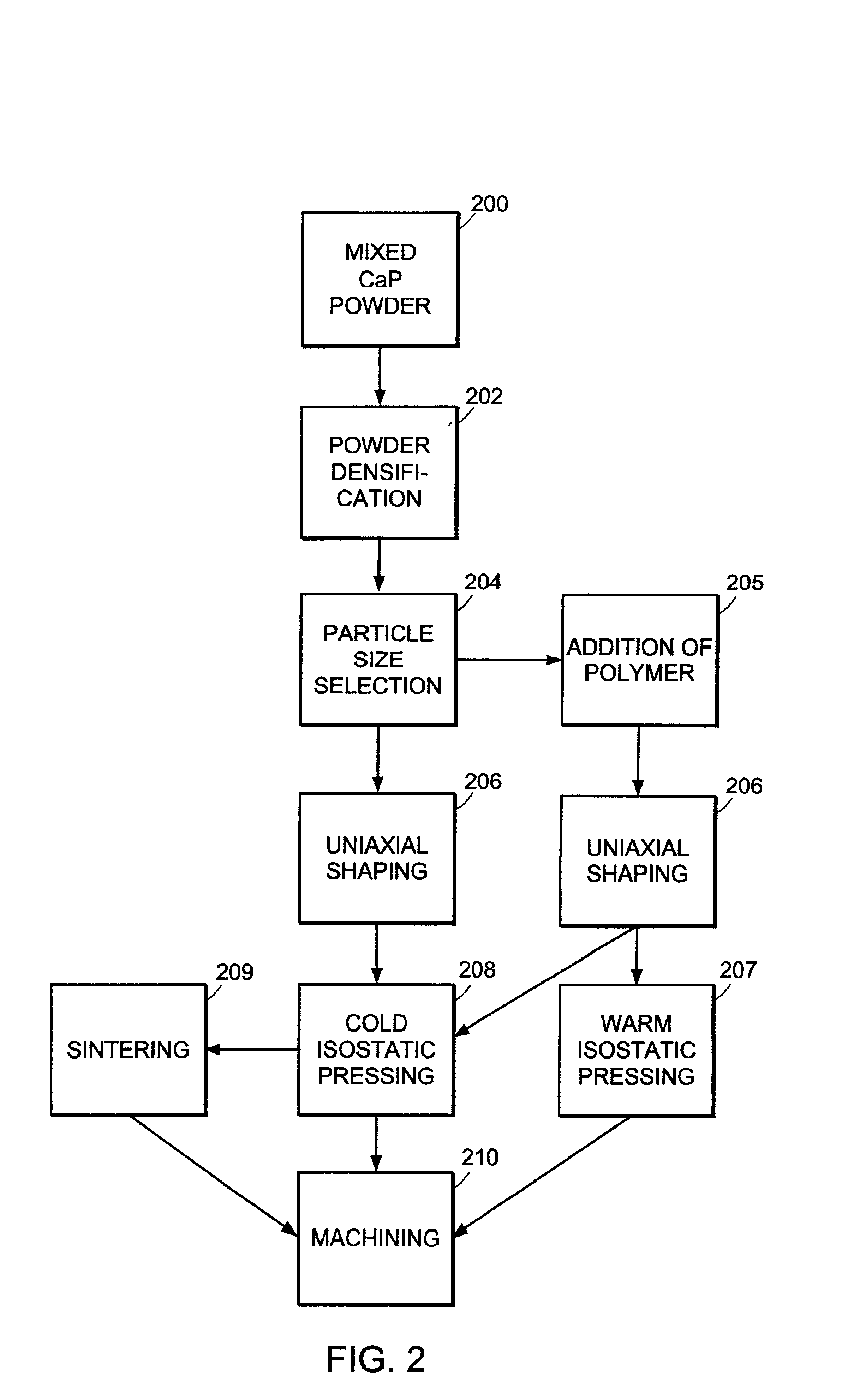

Machinable preformed calcium phosphate bone substitute material implants

InactiveUS6840961B2Process stabilitySlows natural bone growthBiocideSurgical adhesivesCalcium biphosphateNatural bone

The present invention provides machinable calcium phosphate bone substitute material implants having mechanical properties comparable to those of natural bone. The implants include intimately mixed solid precursor materials that react under physiological conditions to form poorly-crystalline hydroxyapatite and eventually are remodeled into bone in vivo. The implants can include a biocompatible polymer to increase density and strength and control resorbability.

Owner:ETEX

Apatite-coated solid composition

InactiveUS6344209B1Efficient use ofImprove efficiencyOrganic active ingredientsPowder deliveryApatiteBiodegradable polymer

An apatite-coated solid composition which contains a biodegradable polymer and an apatite-coated solid composition which contains a biodegradable polymer and a medicinal substance have properties of sustained release and of osteoconductive activity.

Owner:TAKEDA PHARMA CO LTD

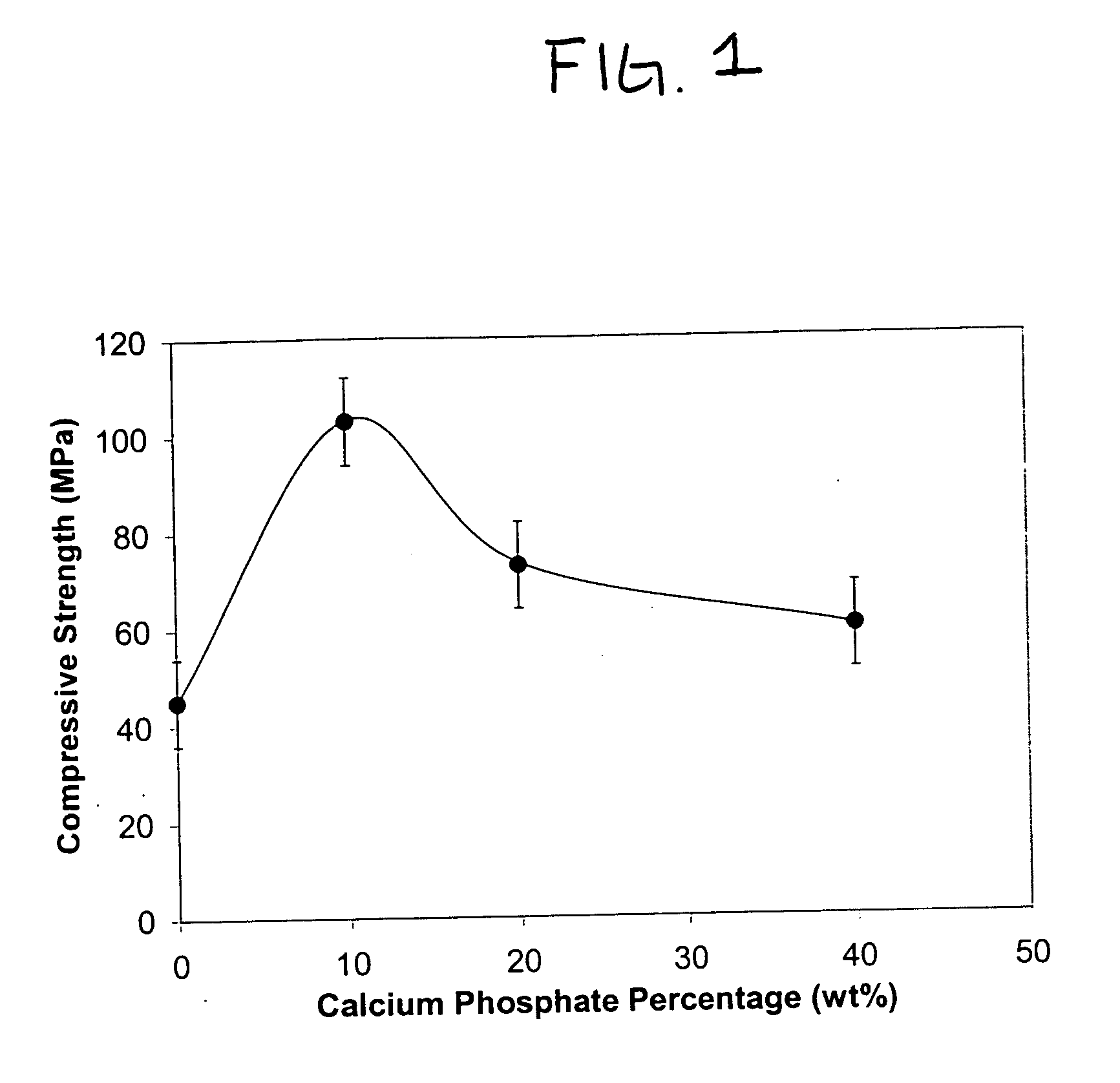

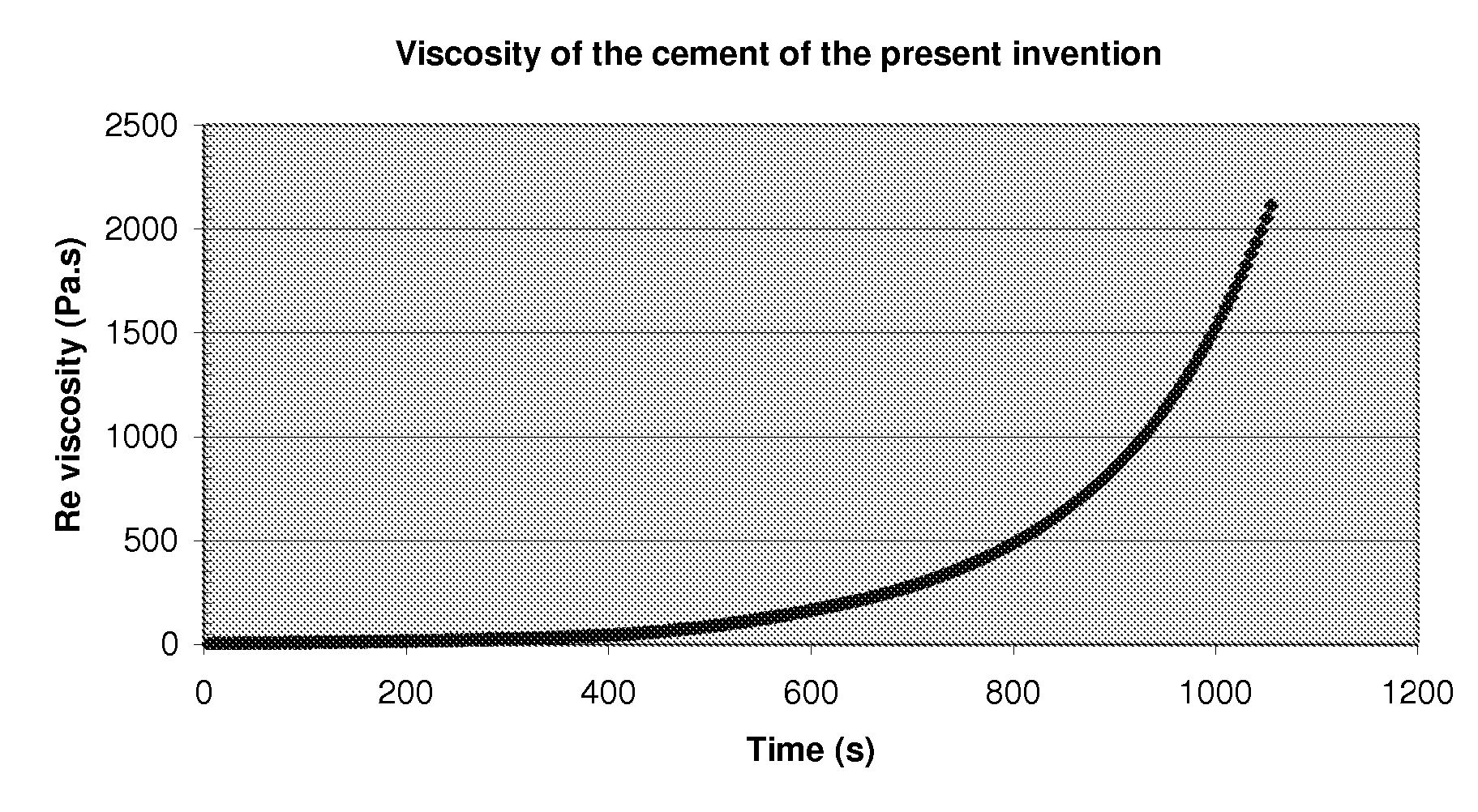

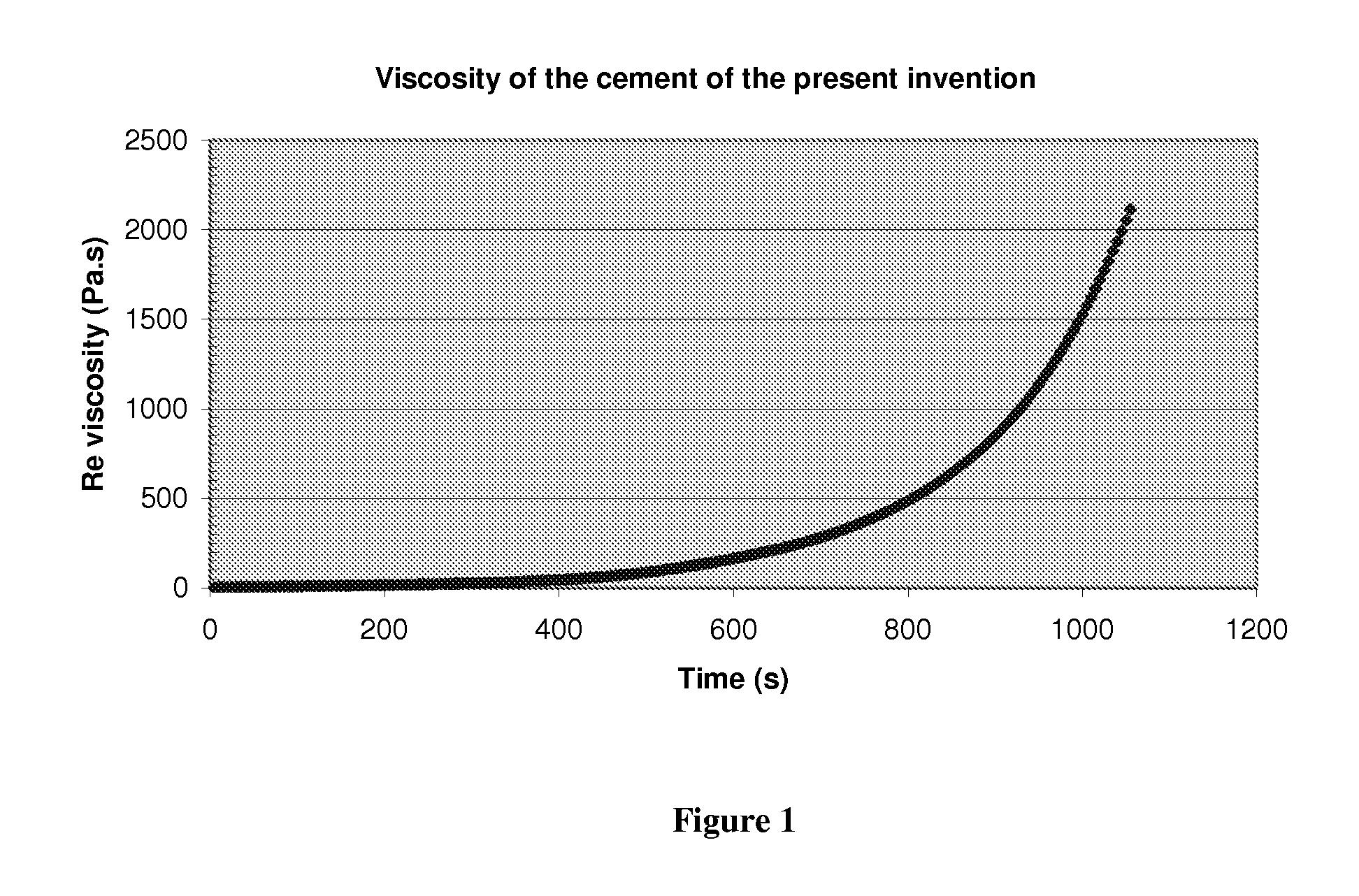

High strength biological cement composition and using the same

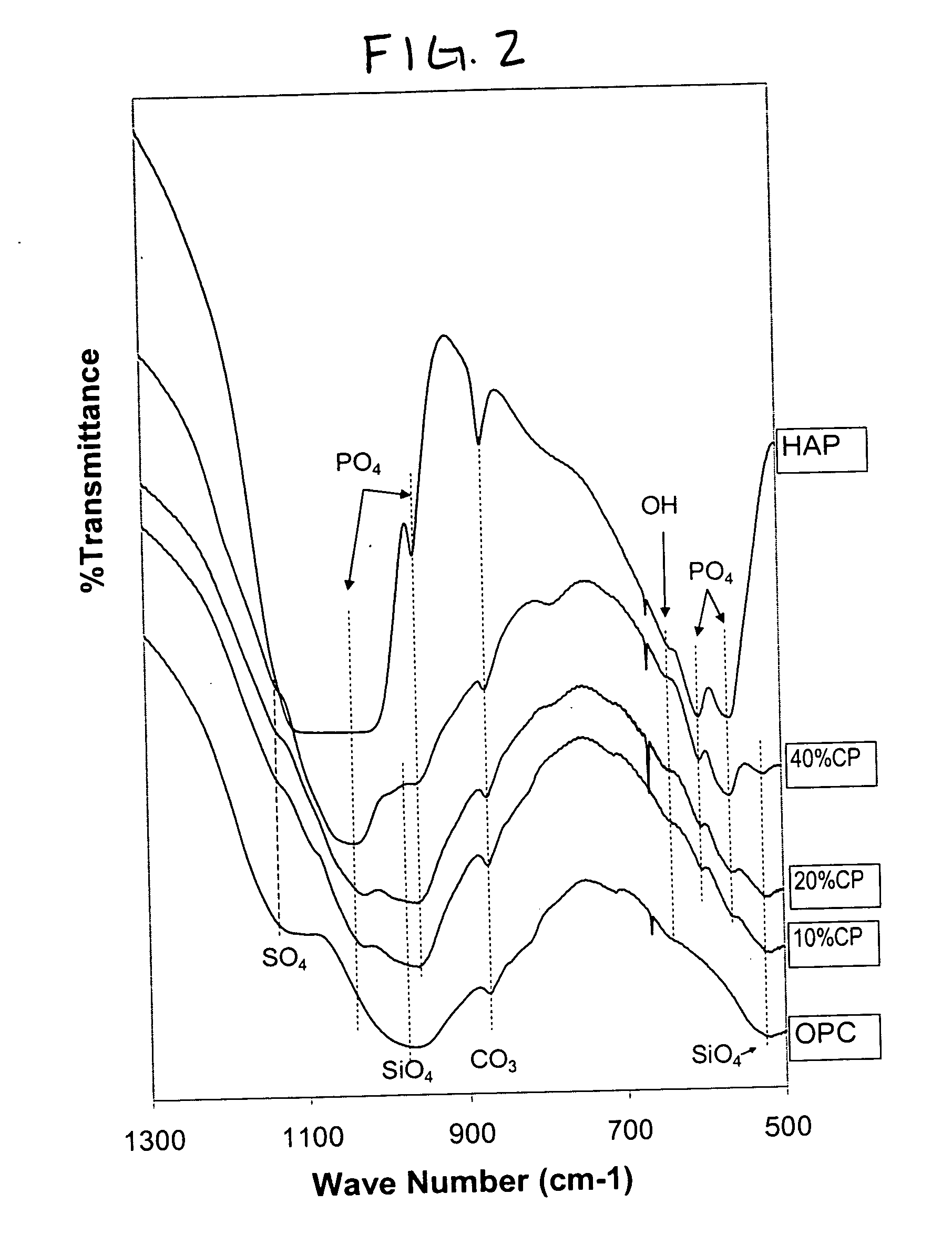

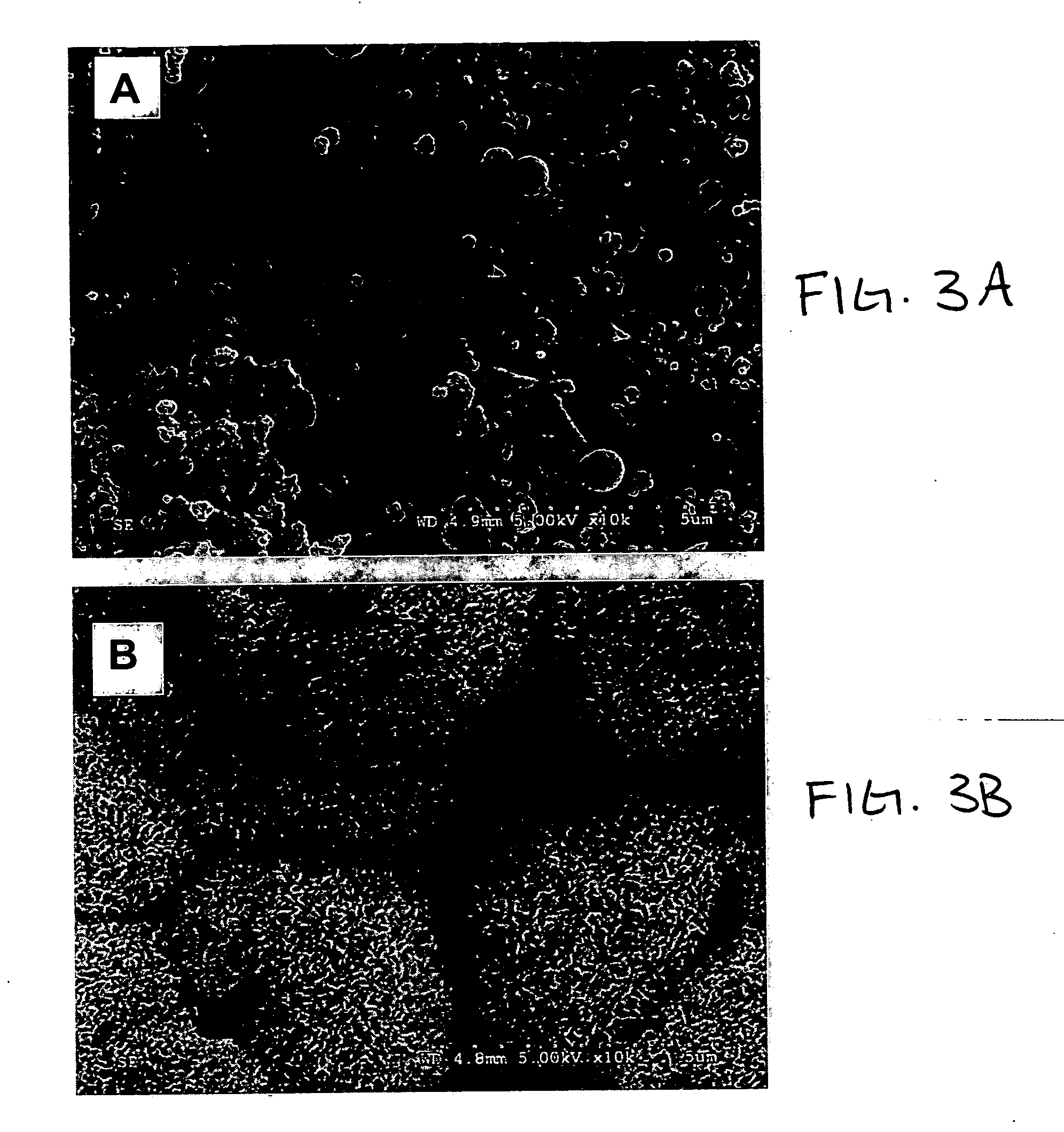

ActiveUS20070098811A1High mechanical strengthImprove biological activityBiocideSurgical adhesivesCalcium silicateApatite

A hydraulic cement for biomedical applications. The cement sets in-situ, hardening when exposed to water to produce nano-dispersed composite of calcium-silicate-hydrate gel mixed with hydroxyapatite. In comparison with prior cements, the composition provides high biocompatibility, high bioactivity and high biomechanical strength, due to the composite structure of the calcium silicate hydrate reinforced with co-precipitated particles of hydroxyapatite. Biocompatibility is also increased due to an absence of aluminum and magnesium in the composition. The cement is suitable for variety of applications, including dental implants, bone fixation, and bone repair.

Owner:INNOVATIVE BIOCERAMIX

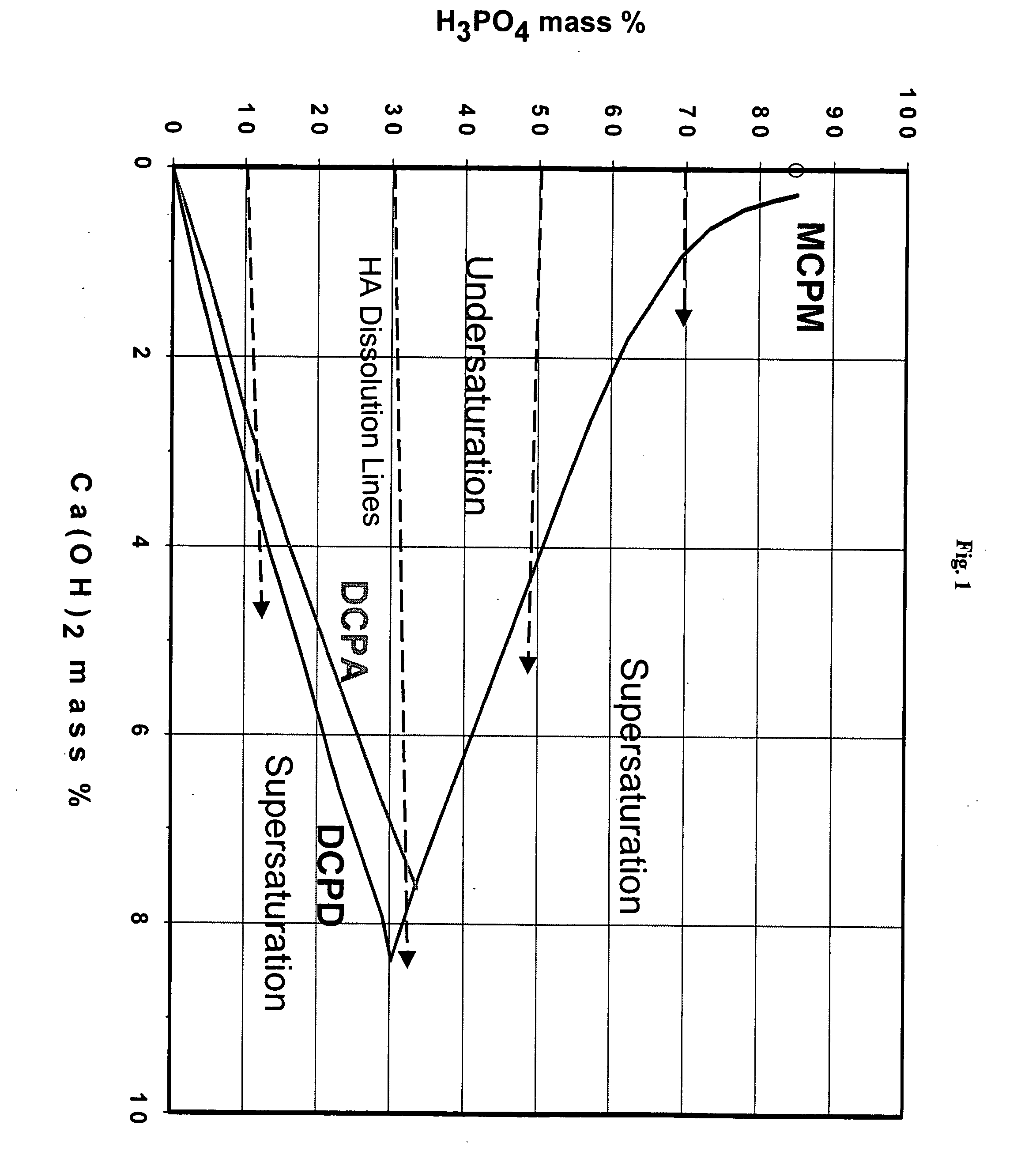

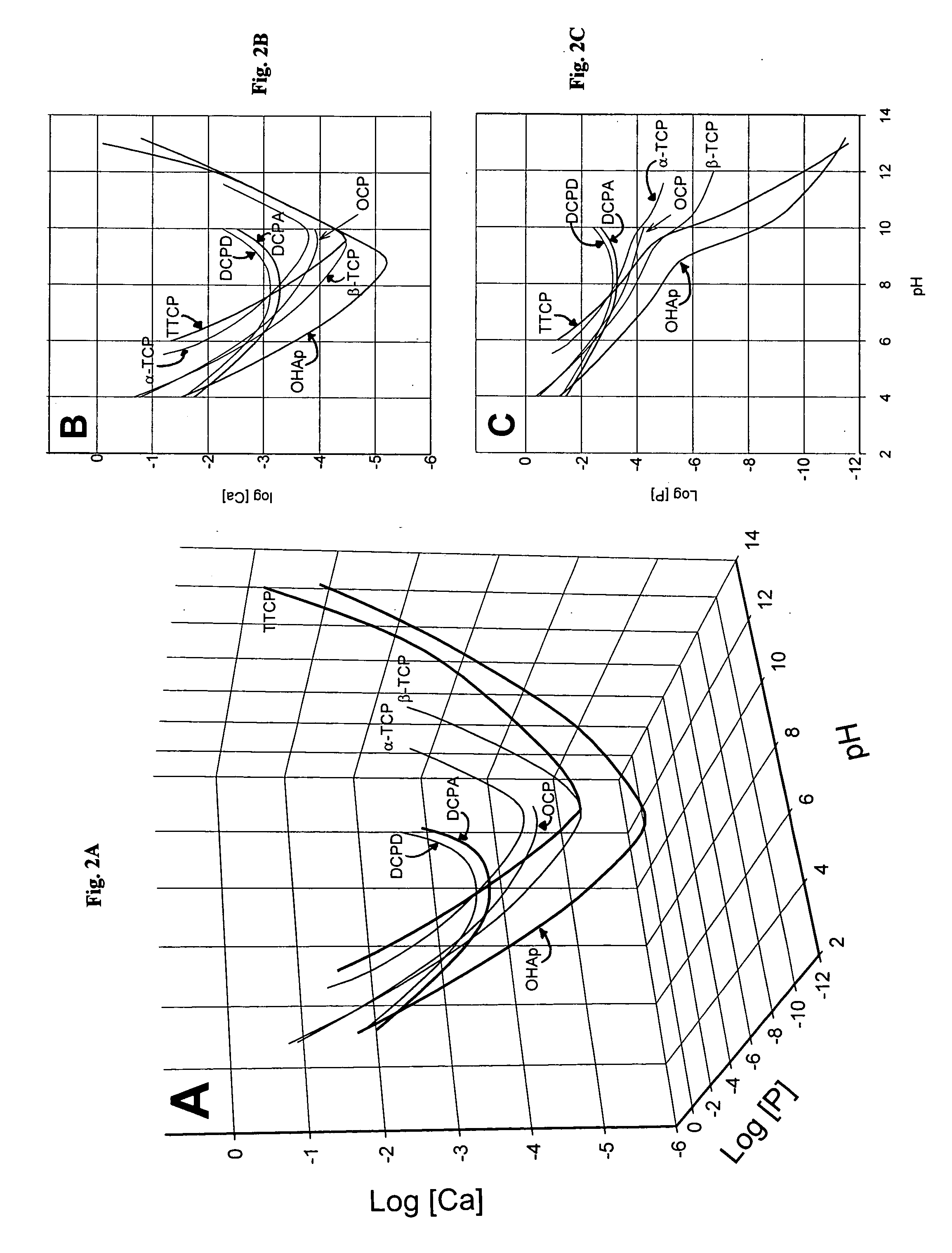

Rapid-hardening calcium phosphate cement compositions

InactiveUS20050074415A1Resist erosionEasy and fast setupCosmetic preparationsBiocideCalcium biphosphateApatite

A bone or dental implant material in the form of a paste includes a mixture of calcium phosphate and / or calcium-containing powders and a solution that is (1) an acidic calcium phosphate solution saturated with respect to one or more calcium phosphate compounds, (2) a concentrated acid solution, or (3) salt solutions with a cationic component other than calcium. The paste is stable, resistant to washout and will form hydroxyapatite and harden relatively rapidly to a cement.

Owner:ADA FOUND

Coating film for building material

A building material and a method for coating a substrate for the building material with a coating film having a variety of functions relating to an environment such as mildew resistance, deodorization, antibacterial activity and air purification in addition to the anti-staining effect by having an excellent hydrophilicity. The method for coating the substrate for a building material comprises the steps of; coating a coating material comprising a hydrophilic polymer and a photocatalyst on the substrate, and drying the coating material to form a coating film containing the photocatalyst, wherein the hydrophilic polymer is at least one selected from the group consisting of methyl silicate, liquid glass, colloidal silica, poly(meth)acrylate, and polytetrafluoroethylene graft-polymerized with sulfonic acid, and the photocatalyst is at least one selected from the group consisting of titanium oxide coated with zeolite, titanium oxide coated silica and titanium oxide coated with apatite.

Owner:NICHIHA CORP

Composite material for porous material and gel use thereof

InactiveCN1644221AImprove stabilityGood adhesionProsthesisCalcium biphosphateAlpha-tricalcium phosphate

A composition of porous material and gel for preparing artificial bone is prepared from collagen and porous material chosen from alpha-tricalcium phosphate / hydroxy apatite, beta-tricalcium phosphate / hydroxy apatite-coral, calcium phosphate / hydroxy apatite, calcium carbonatel tricalcium phosphate, etc.

Owner:徐小良

Method for preparing hydroxyapatite composite and biocompatible material

A method for preparing a hydroxyapatite composite is disclosed. This method comprises alternately soaking a matrix which has been made hydrophilic at least on its surface, in a calcium ion aqueous solution containing calcium ions and substantially free of phosphate ions and in a phosphate ion aqueous solution containing phosphate ions and substantially free of calcium ions to securely form hydroxyapatite at least on the surface of the matrix. Also disclosed is a biocompatible material composed of the hydroxyapatite composite obtained by the method.

Owner:NOF CORP +1

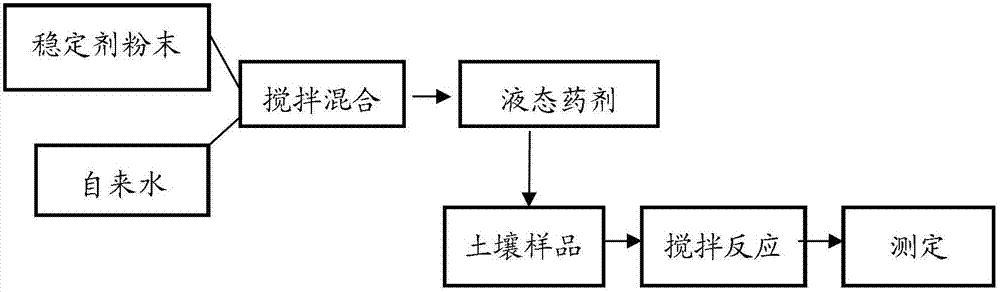

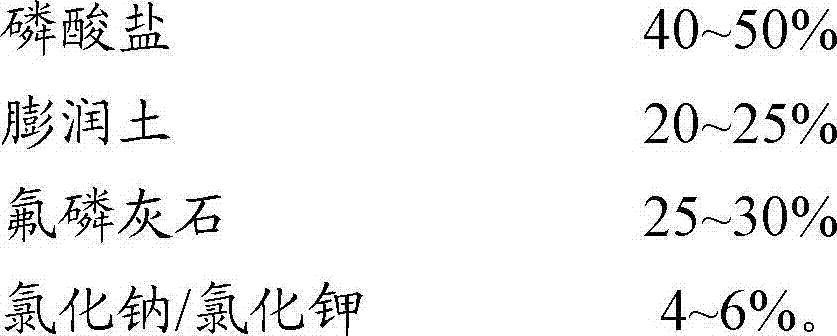

Heavy metal stabilizing agent and method for treating heavy metal contaminated soil by using same

ActiveCN102965116ACaptureHarmlessContaminated soil reclamationOrganic fertilisersSodium BentoniteApatite

The invention discloses a heavy metal stabilizing agent and a method for treating heavy metal contaminated soil by using the heavy metal stabilizing agent. The heavy metal stabilizing agent is prepared from the following raw materials in percentage by weight: 40 to 50 percent of phosphate, 20 to 25 percent of bentonite, 25 to 30 percent of fluor apatite and 4 to 6 percent of sodium chloride / potassium chloride. When the heavy metal stabilizing agent is used for treating the contaminated soil, the heavy metal stabilizing agent and water are mixed together to form a suspension, then the suspension is added into the heavy metal contaminated soil, and the suspension and the heavy metal contaminated soil are fully mixed. The heavy metal stabilizing agent has high stability for treating soil, and the technical problem that the conventional curing agent and curing method cause reverse dissolution easily is solved.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

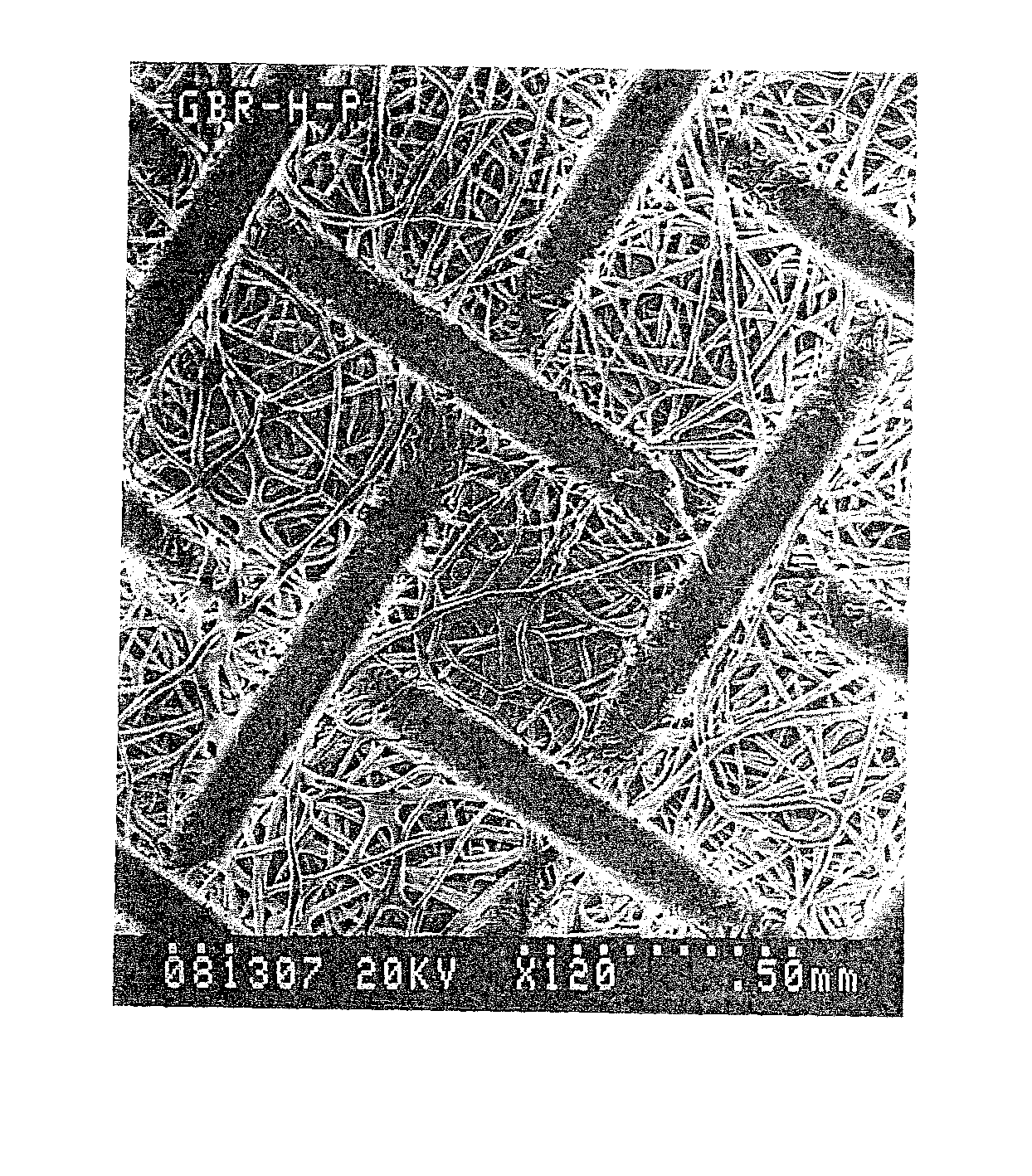

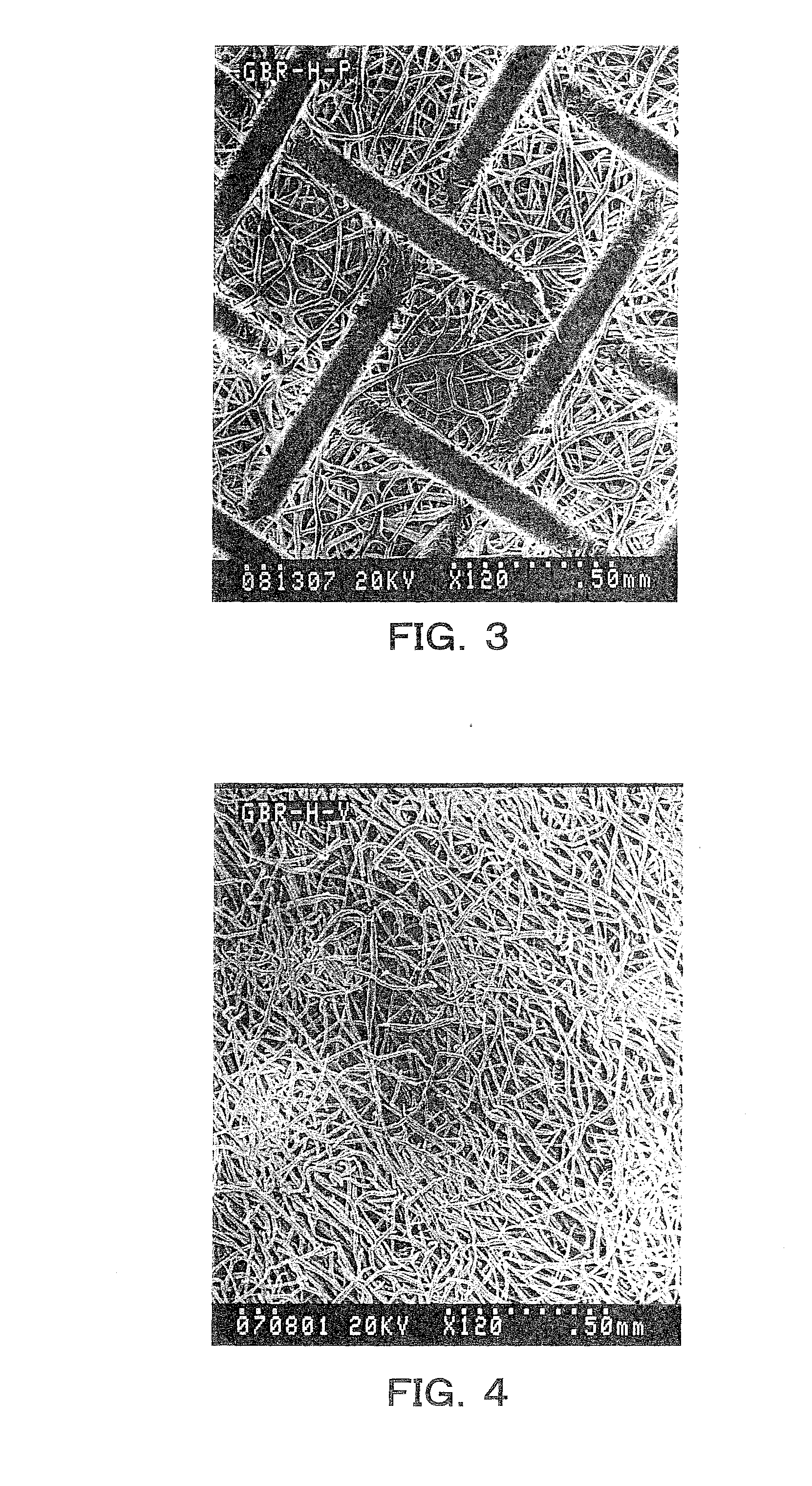

Guided bone regeneration membrane and manufacturing method thereof

InactiveUS20100119564A1Improve cell affinityImproving osteogenic abilityBiocideElectric discharge heatingManufacturing technologySimulated body fluid

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +2

Method for preparing hydroxylapatite/polylactic acid composite biological coating on surface of magnesium alloy

The invention belongs to the field of a biomaterial, in particular to a preparation method for hydroxyapatite / polylactic acid composite biological coat on magnesium alloy surface, and solves the problem that an electrolytic deposition hydroxyapatite (HA) coat is not quite compact through sealing treatment of polylactic acid, so that the composite coat can improve corrosion resistance of magnesiumalloy in human body fluid remarkably, and biological degradability of the composite coat is used for adjusting service cycle of the magnesium alloy in vivo. The preparation method is as follows: the magnesium alloy is subjected to electrolytic deposition in water solution consisting of calcium salt, dihydrogen phosphate or hydrogen phosphate or other additives, so as to obtain a mixture coat of several calcium phosphates; the mixture coat is treated by alkali metal hydroxide solution and then transformed into an even HA coat; the HA coat is soaked in polylactic acid solution and subjected to the sealing treatment; and finally the HA coat is dried to obtain the hydroxyapatite / polylactic acid composite coat. The preparation method which combines biological activity of the HA and biological degradability of the polylactic acid organically is used for corrosion protection of the magnesium alloy in biotic environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

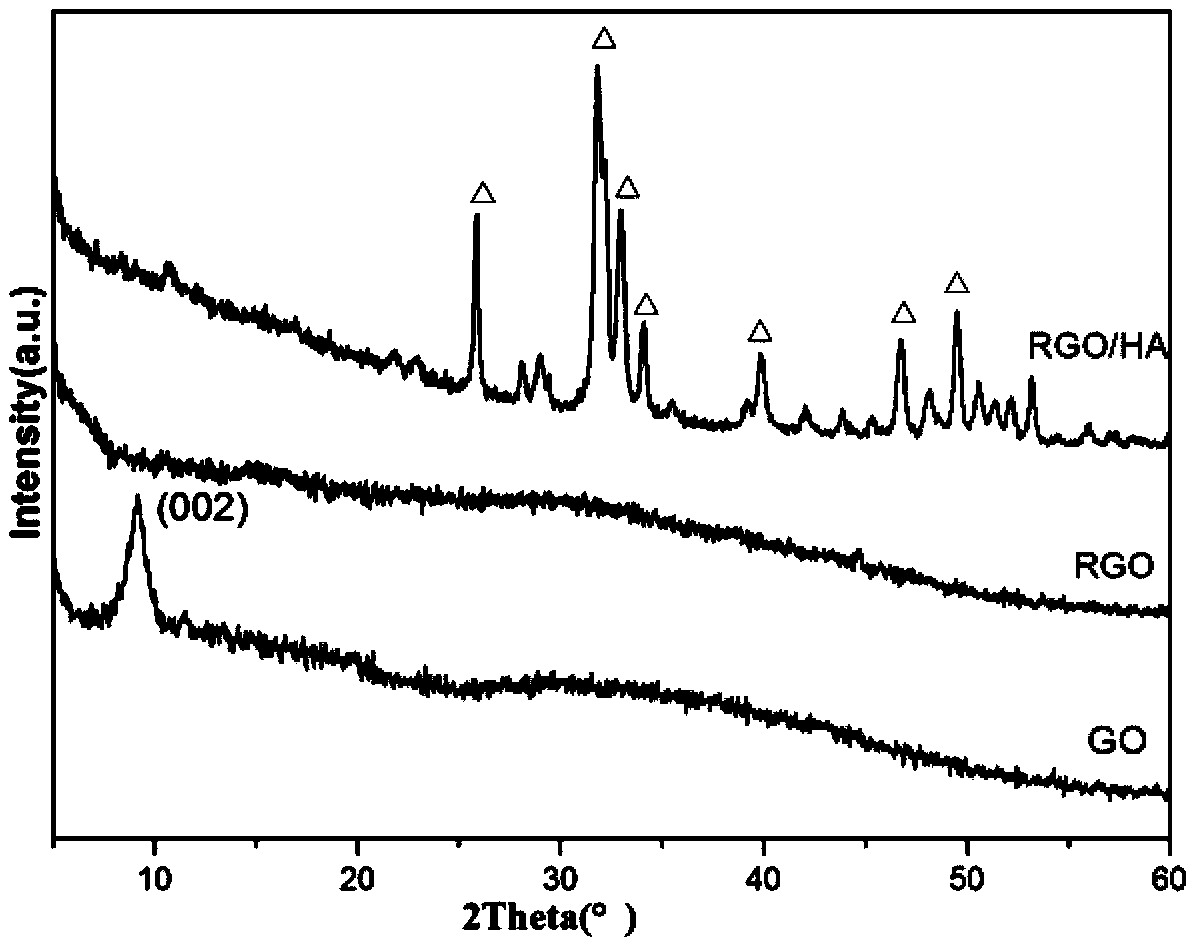

Preparation method of grapheme/hydroxyapatite composite material

InactiveCN103420364AGood biocompatibilityHigh activityCarbon compoundsPhosphorus compoundsApatitePhosphate ion

A preparation method of a grapheme / hydroxyapatite composite material comprises the following steps: uniformly mixing oxidized grapheme with the concentration of 0.5-5 mg / ml and a solution or a turbid liquid with the calcium ion concentration of 0.01-3.0 mol / L to obtain a first mixed solution; adding a solution I with the phosphate anion concentration of 0.01-2.0 mol / L to the first mixed solution according to the molar ratio of calcium to phosphorus is (1.5-2.0) to 1, and uniformly mixing the solution I and the first mixed solution under the action of magnetic mixing; adjusting the pH to be 8-14 through a pH adjusting agent to obtain a second mixed solution; transferring the second mixed solution to a reaction kettle; carrying out hydro-thermal treatment for 1-12 hours at the temperature of 160-240 DEG C; cooling the second mixed solution until the temperature of the second mixed solution is the room temperature; cleaning, freezing and drying to obtain the grapheme / hydroxyapatite composite material. The preparation method is environment-friendly, simple and beneficial to large-scale production. The prepared grapheme / hydroxyapatite composite material has the advantages of good mechanical property as well as high electrical conductivity, adsorbability, biocompatibility and osteogenic activity.

Owner:SOUTHWEST JIAOTONG UNIV

Polymer cement for percutaneous vertebroplasty and methods of using and making same

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

Hydroxylapatite coating magnesium alloy medical inner implantation material and method of preparing the same

The invention relates to a hydroxyapatite coating magnesium alloy medical implantation material and a preparation method thereof. The hydroxyapatite coating magnesium alloy medical implantation material is characterized in that: the surface of a magnesium alloy substrate is attached with a hydroxyapatite coating layer. The preparation method of the hydroxyapatite coating magnesium alloy medical implant material can adopt the bionic solution growing method, the ion beam deposition method, the coating and sintering process, the plasma spray method, the discharge plasma sintering method or the electrophoresis deposition method. The magnesium alloy material with the hydroxyapatite coating structure which is provided by the invention can effectively slow down the degradation rate of the magnesium alloy; at the same time, the coating layer can not only have great tissue compatibility, but can also be conductive to connective tissue attachment and the growth of the bone tissues, improve the bone healing rate and shorten the healing time.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

Rapid-hardening calcium phosphate cement compositions

InactiveUS7294187B2Easy and fast setupShorten hardening timeBiocideCosmetic preparationsCalcium biphosphateApatite

Owner:ADA FOUND

Make-up composition

InactiveUS20050191328A1Improved sebum control benefitGood spreadabilityCosmetic preparationsBody powdersApatiteZinc

Disclosed is a make-up composition comprising by weight: from about 1% to about 20% of a sebum solidifying powder comprising a base substance having a hydroxyapatite coated on the base substance, and a zinc oxide fixed to the coating layer of the hydroxyapatite, wherein the zinc oxide is from about 15% to about 25% by weight of the sebum solidifying powder; from about 1% to about 10% of an inorganic oil absorbing powder having an oil absorbency of at least about 200 ml / 100 g wherein the weight ratio of the sebum solidifying powder to the inorganic oil absorbing powder is from about 1:1.5 to about 20:1; and a suitable carrier.

Owner:THE PROCTER & GAMBLE COMPANY

Technique for separating mineral from weak magnetic separation iron tail sand

InactiveCN101219412AProduction process specificationLow costElectrostatic separationFlotationApatiteNon magnetic

The invention relates to a method used for separating minerals from weak magnetic iron tails, which is divided into six stages: primary sorting of strong magnetic minerals, separation of strong magnetic minerals, separation of weak magnetic minerals, separation of non-magnetic minerals, treatment of ore pulp water during the ore dressing process and treatment of finish tail sand. According to the magnetic susceptibility differences, specific gravitydifferences and floating differeces between minerals, magnetite, vanadium titano-magnetite, mixed ore of apatite and xenotime and hematite feldspar concentrate can be separated from the weak magnetic iron by using techniques of crude separation with a strong magnetic separator, refine separation with a weak magnetic separator, gravity separation, floatation, electric separation, etc. The method has advantages of standard production technique, low cost for industrialized production, great variety of separated minerals, stable quality and high separating efficiency, thereby having significant social and economic benefits.

Owner:冯云善

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com