Patents

Literature

236 results about "Hydroxyapatite coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

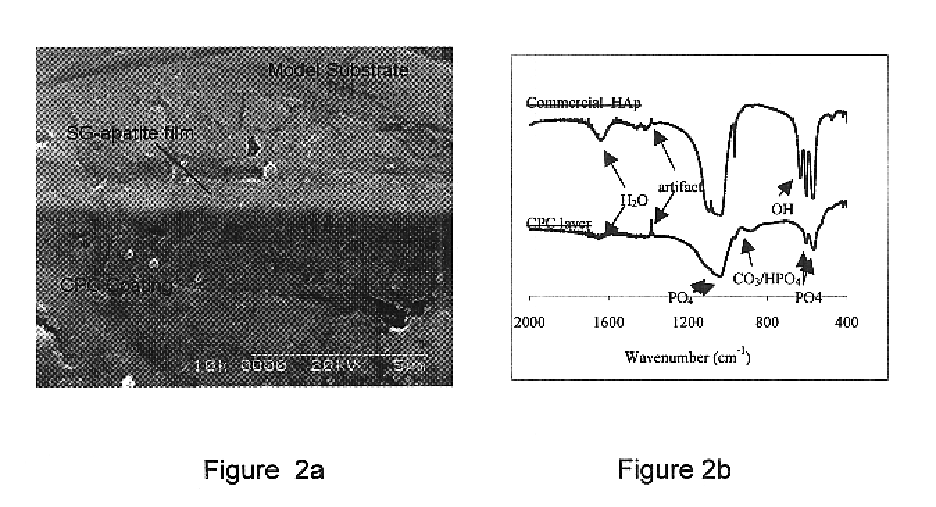

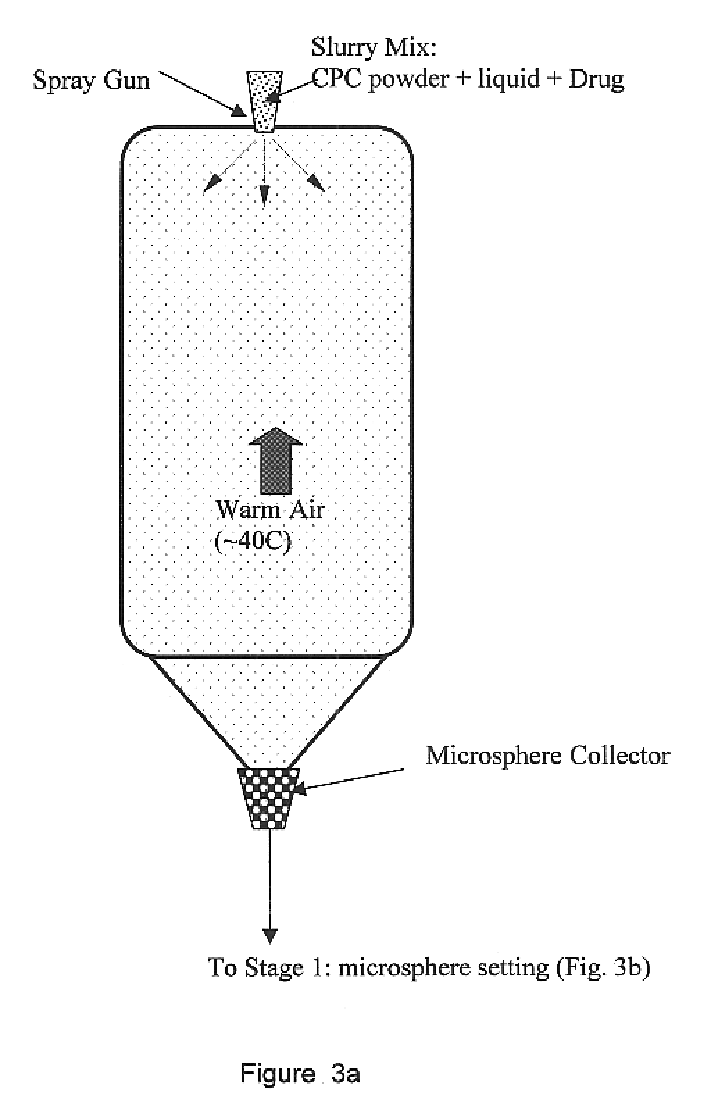

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS20020155144A1Improve relationshipImprove interface strengthPowder deliveryOrganic active ingredientsGene deliverySide effect

Owner:THE UNIV OF BRITISH COLUMBIA

Biofunctional hydroxyapatite coatings and microspheres for in-situ drug encapsulation

InactiveUS6730324B2High strengthEasy to makePowder deliveryOrganic active ingredientsGene deliverySide effect

This invention relates to novel room-temperature process for obtaining calcium phosphate, in particular hydroxyapatite, coatings and microspheres that encapsulate drugs, proteins, genes, DNA for therapeutical use. The coatings and microspheres are designed to perform a defined biological function related to drug delivery, such as gene therapy through gene delivery. A novel method for encapsulation, and subsequent controlled release of therapeutically active agents from such biofunctional coatings and microspheres is disclosed. Such coatings and microspheres are useful for side-effects free, long-term, targeted, controlled release and delivery of drugs, proteins, DNA, and other therapeutic agents.

Owner:THE UNIV OF BRITISH COLUMBIA

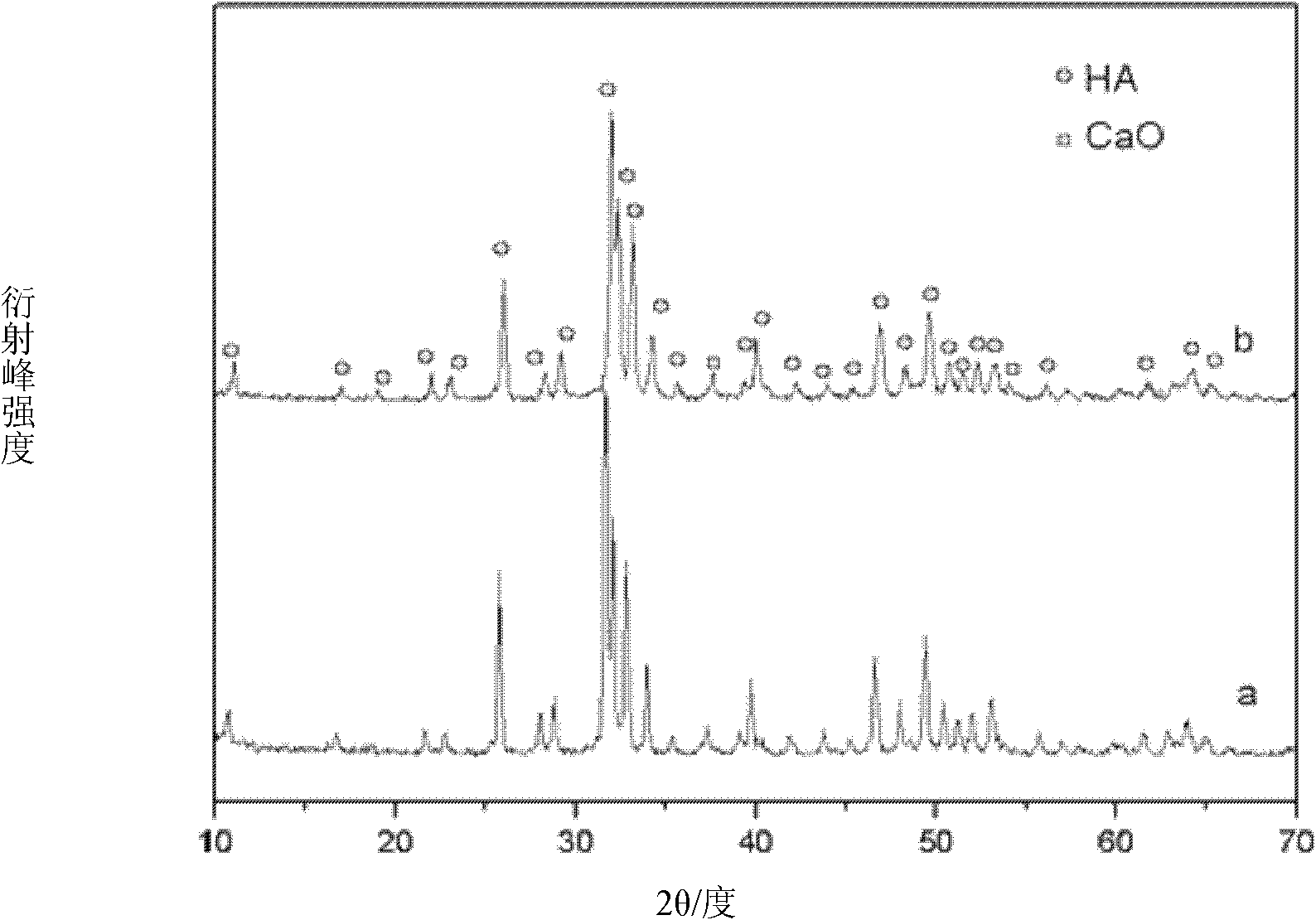

Hydroxylapatite coating magnesium alloy medical inner implantation material and method of preparing the same

The invention relates to a hydroxyapatite coating magnesium alloy medical implantation material and a preparation method thereof. The hydroxyapatite coating magnesium alloy medical implantation material is characterized in that: the surface of a magnesium alloy substrate is attached with a hydroxyapatite coating layer. The preparation method of the hydroxyapatite coating magnesium alloy medical implant material can adopt the bionic solution growing method, the ion beam deposition method, the coating and sintering process, the plasma spray method, the discharge plasma sintering method or the electrophoresis deposition method. The magnesium alloy material with the hydroxyapatite coating structure which is provided by the invention can effectively slow down the degradation rate of the magnesium alloy; at the same time, the coating layer can not only have great tissue compatibility, but can also be conductive to connective tissue attachment and the growth of the bone tissues, improve the bone healing rate and shorten the healing time.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH +1

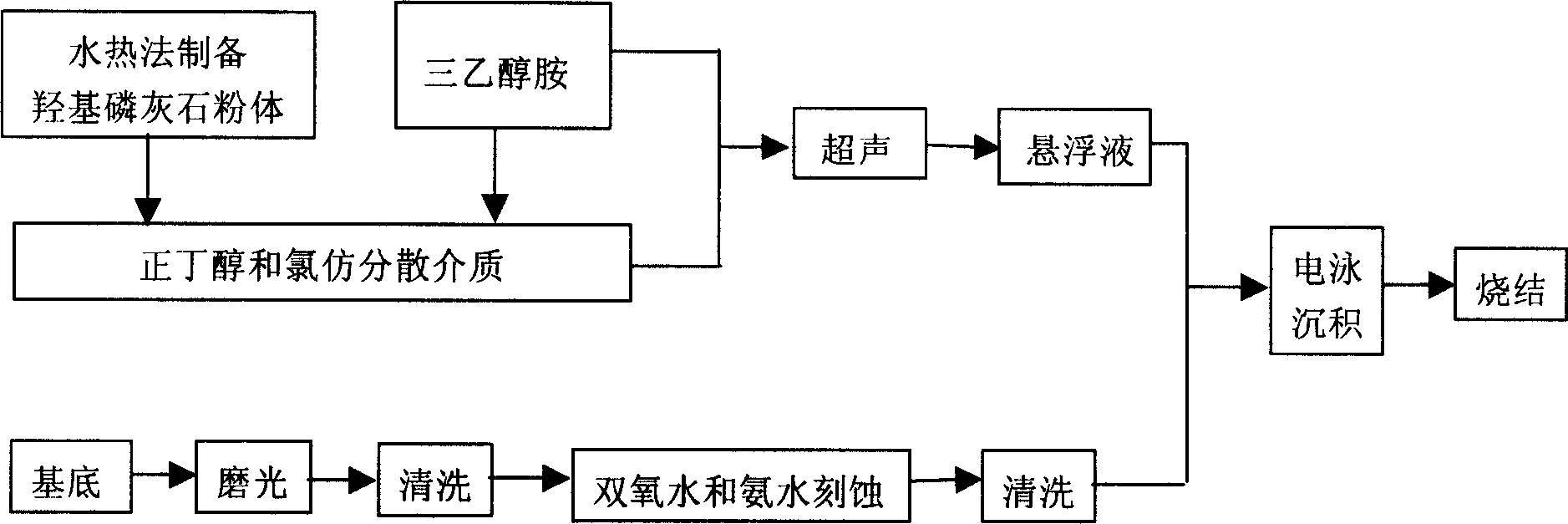

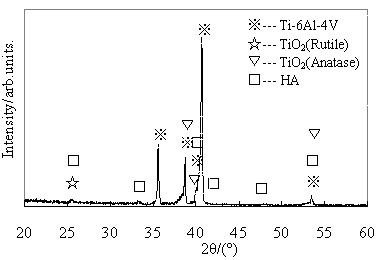

Method of preparing electrophoretic deposited hydroxyl apatite coating on Ti or Ti alloy surface

This invention relates to a method for preparing hydroxyapatite coating layer on the surface of Ti or Ti alloy by electrophoretic deposition, which comprises the steps of: (1) adding hydroxyapatite powders and triethanolamine into a mixed dispersing medium of n-butonol and chloroform at a volume ratio of 8~2:1, and ultrasonicating; (2) using medical pure Ti or Ti alloy (Ti6Al4V) pretreated with a mixed solution of hydrogen peroxide and concentrated ammonia solution at a volume ratio of 1:1 as the cathode, and Pt sheet or graphite electrode as the anode; (3) performing electrophoretic deposition at an electric field strength of 30 V / cm for three times (30 s for each time) to obtain hydroxyapatite coating layer; and (4) performing thermal treatment at 680-800 deg.C for 2 h to improve the bonding strength of the coating layer. The method has such characteristics as no staleness, high stability, short deposition time, simple process and high bonding strength.

Owner:FUJIAN NORMAL UNIV

Method for polylactic acid high polymer material surface modified hydroxyapatite coating

InactiveCN102504311AAchieve chemical bondingGood osteoinductivityCoatingsProsthesisPolymer scienceApatite

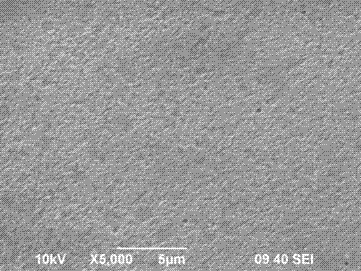

The invention discloses a method for a polylactic acid high polymer material surface modified hydroxyapatite coating, and aims to design a method for the polylactic acid high polymer material surface modified hydroxyapatite coating, which has the advantages of simple and feasible preparation method, low cost and suitability for surface modification of various degradable polylactic acid high polymer material scaffolds. The method for the polylactic acid high polymer material surface modified hydroxyapatite coating comprises the following steps of: soaking a polylactic acid high polymer material with the molecular weight of 10,000-200,000 in an activating solution for activating, covalently introducing -OH, -COOH or -NH2 active groups onto the surface, soaking the activated polylactic acid high polymer material in a Ca<2+> ionic solution, soaking in a PO4<3-> alkaline solution, and repeatedly circulating the steps for 3-50 times to grow a layer of uniform and compact hydroxyapatite coating on the surface of the material finally. The method is environment-friendly, has the advantages that the coating preparation period is short and the cost is low, and is suitable for preparing degradable biological material hydroxyapatite coatings.

Owner:HENAN NORMAL UNIV

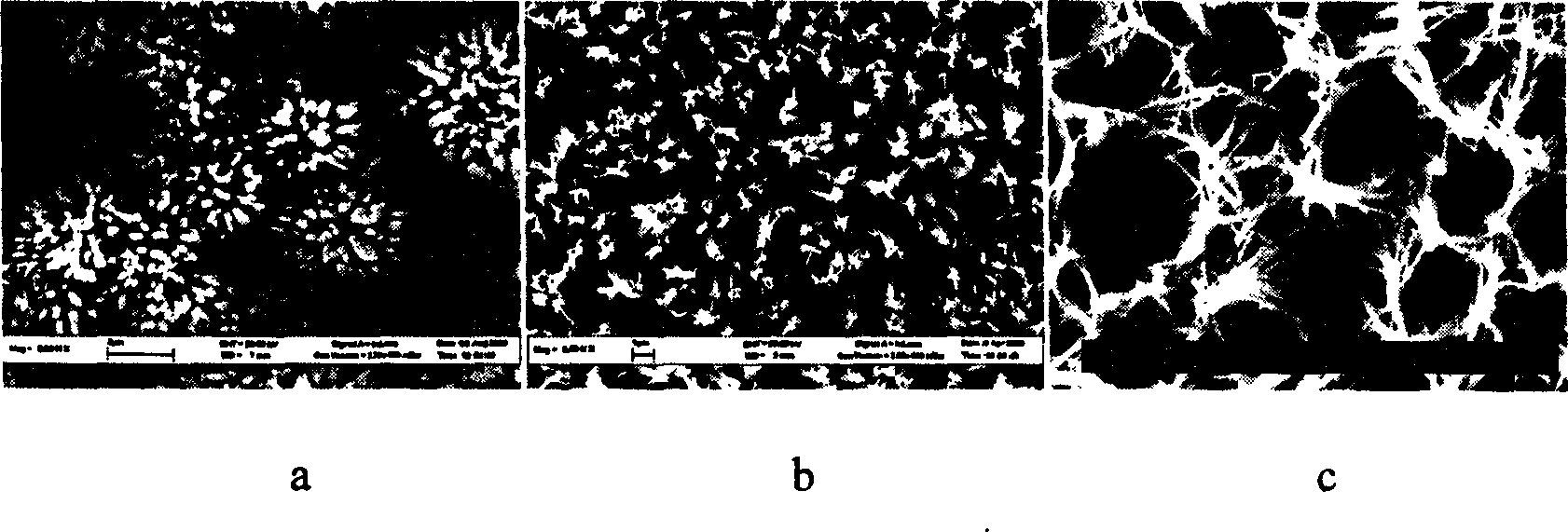

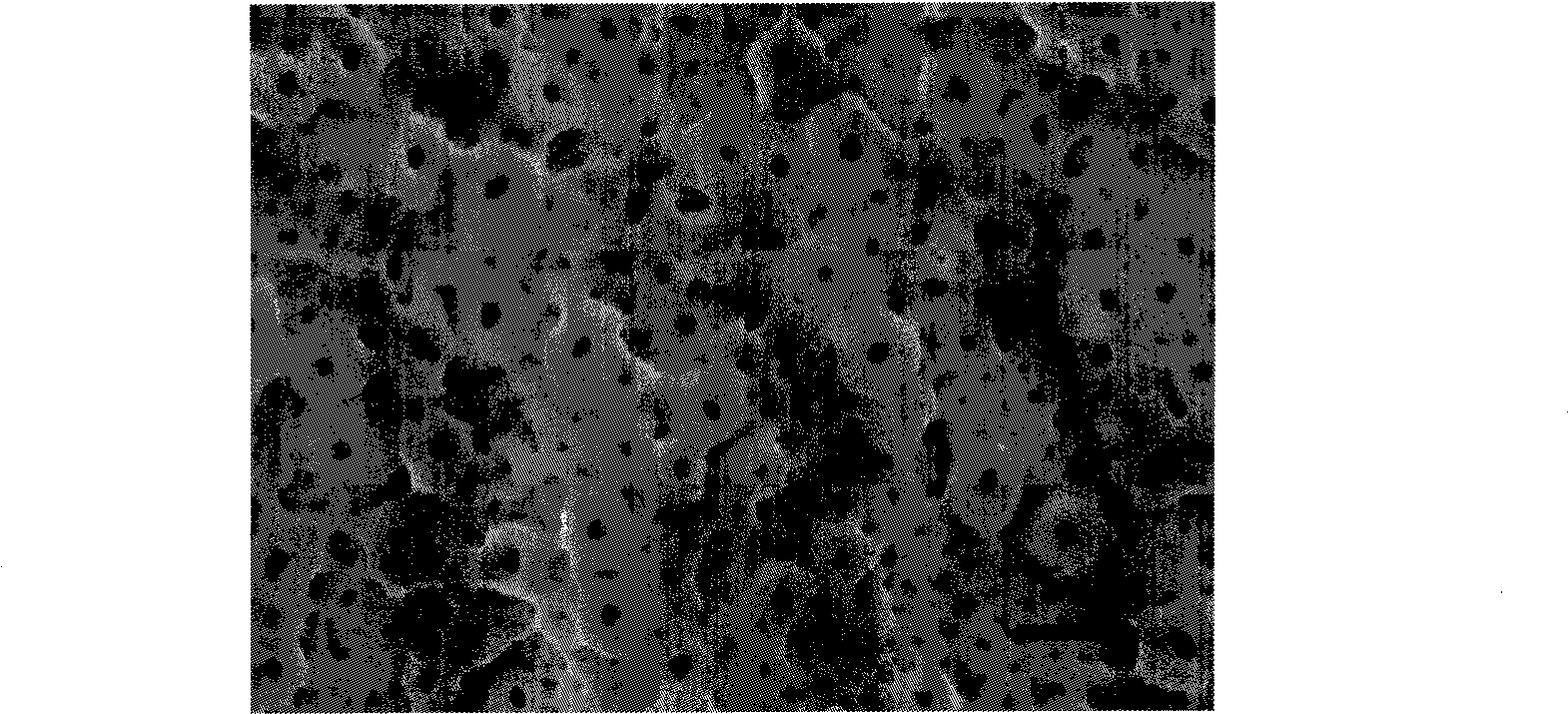

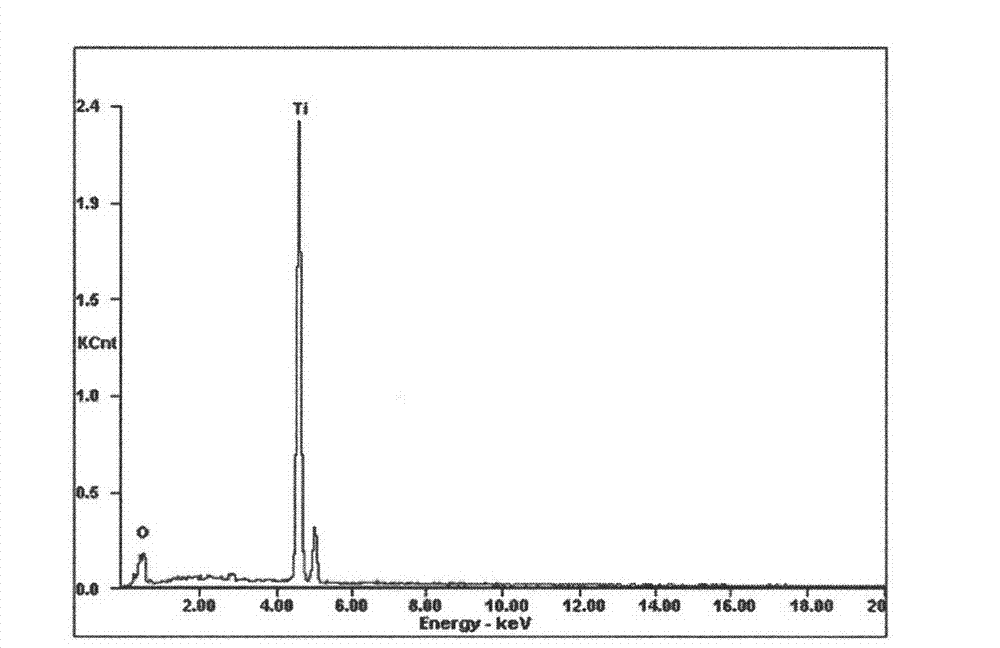

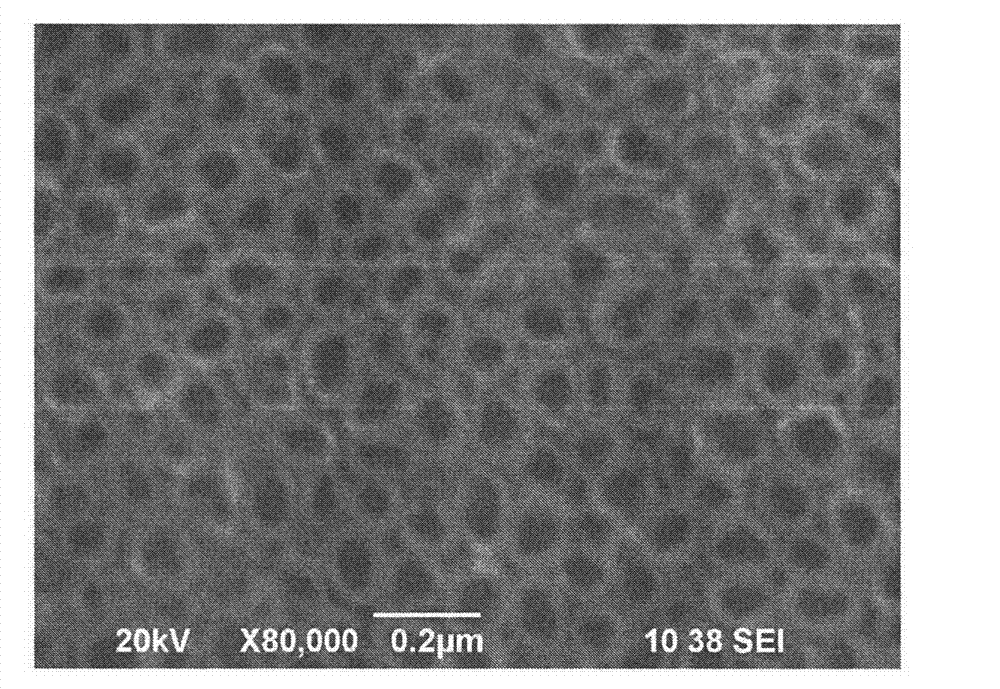

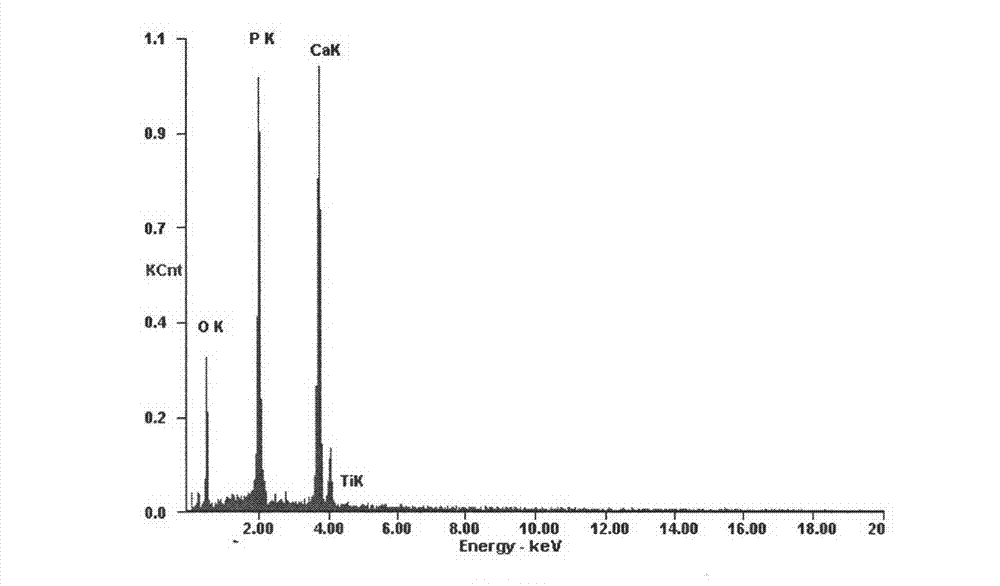

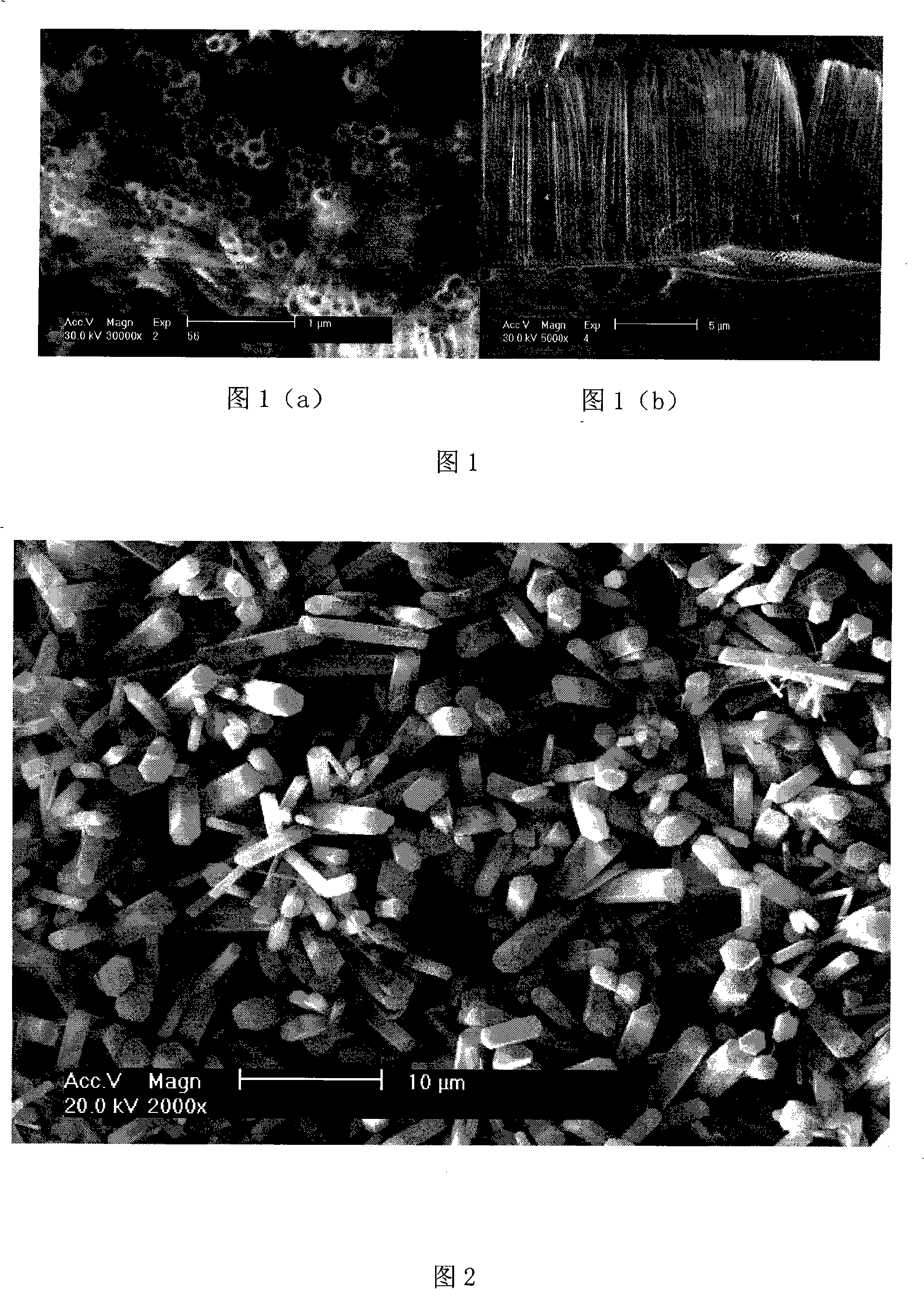

Electrochemical preparing method for nano ordered hydroxy apatite coating

ActiveCN1587442AGood biocompatibilityImprove biological activityElectrolytic inorganic material coatingApatiteBiocompatibility Testing

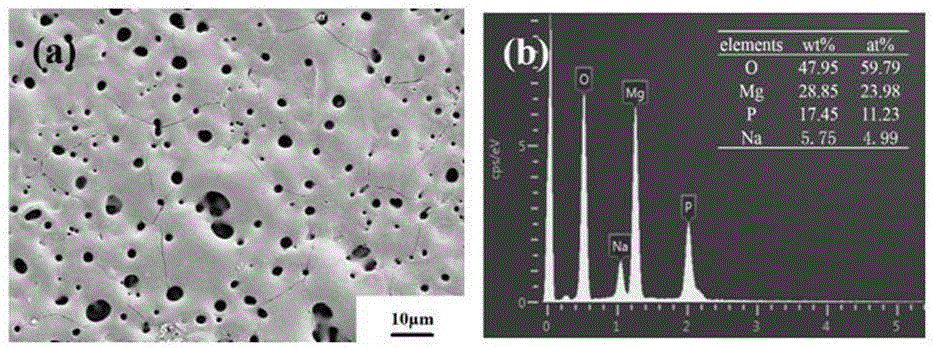

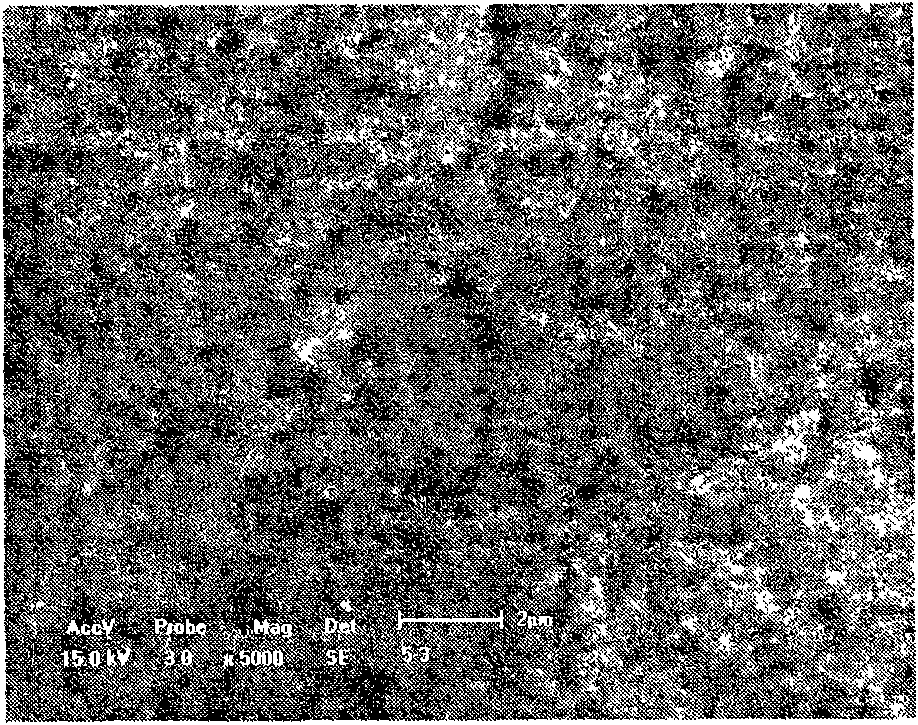

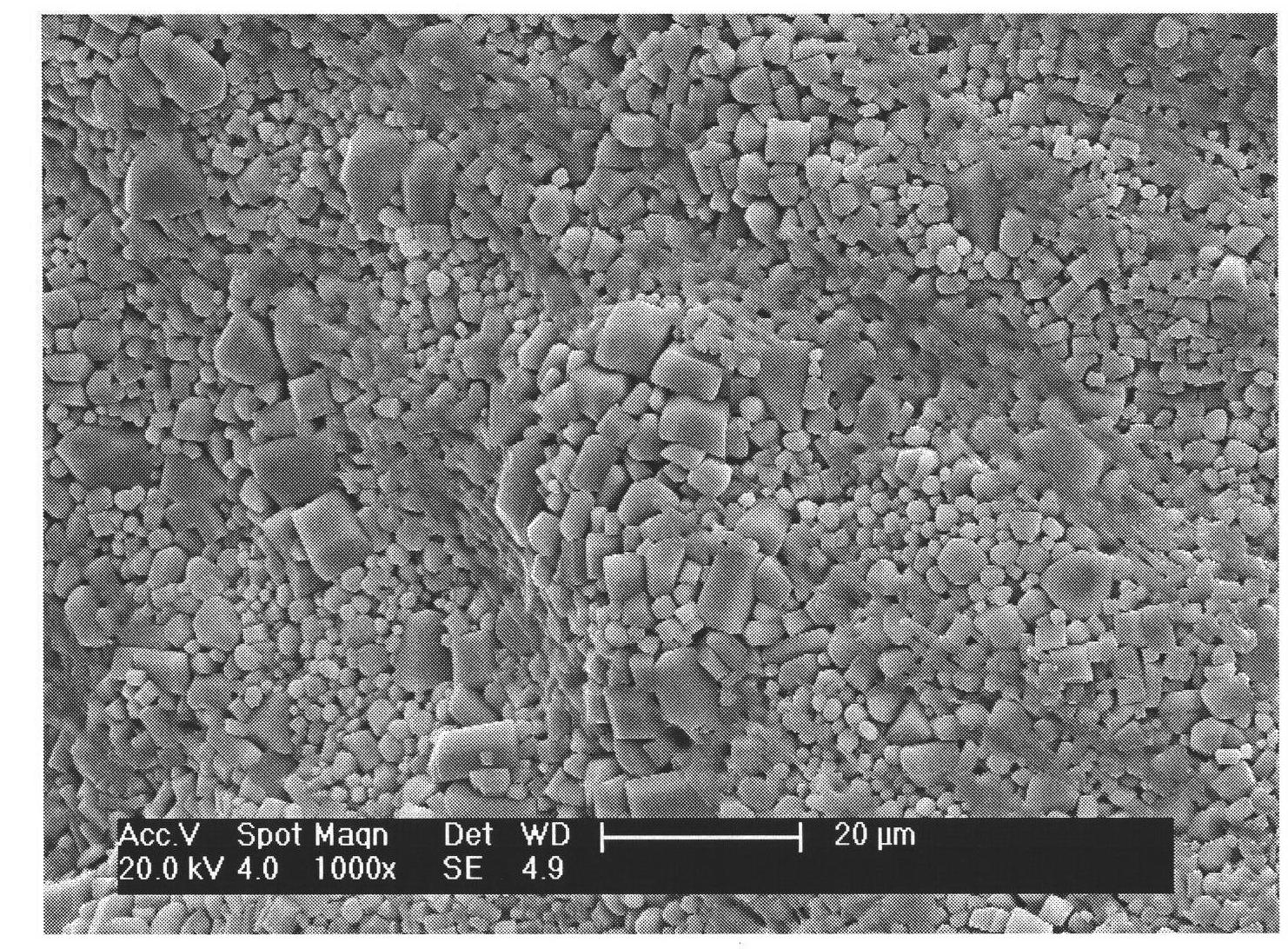

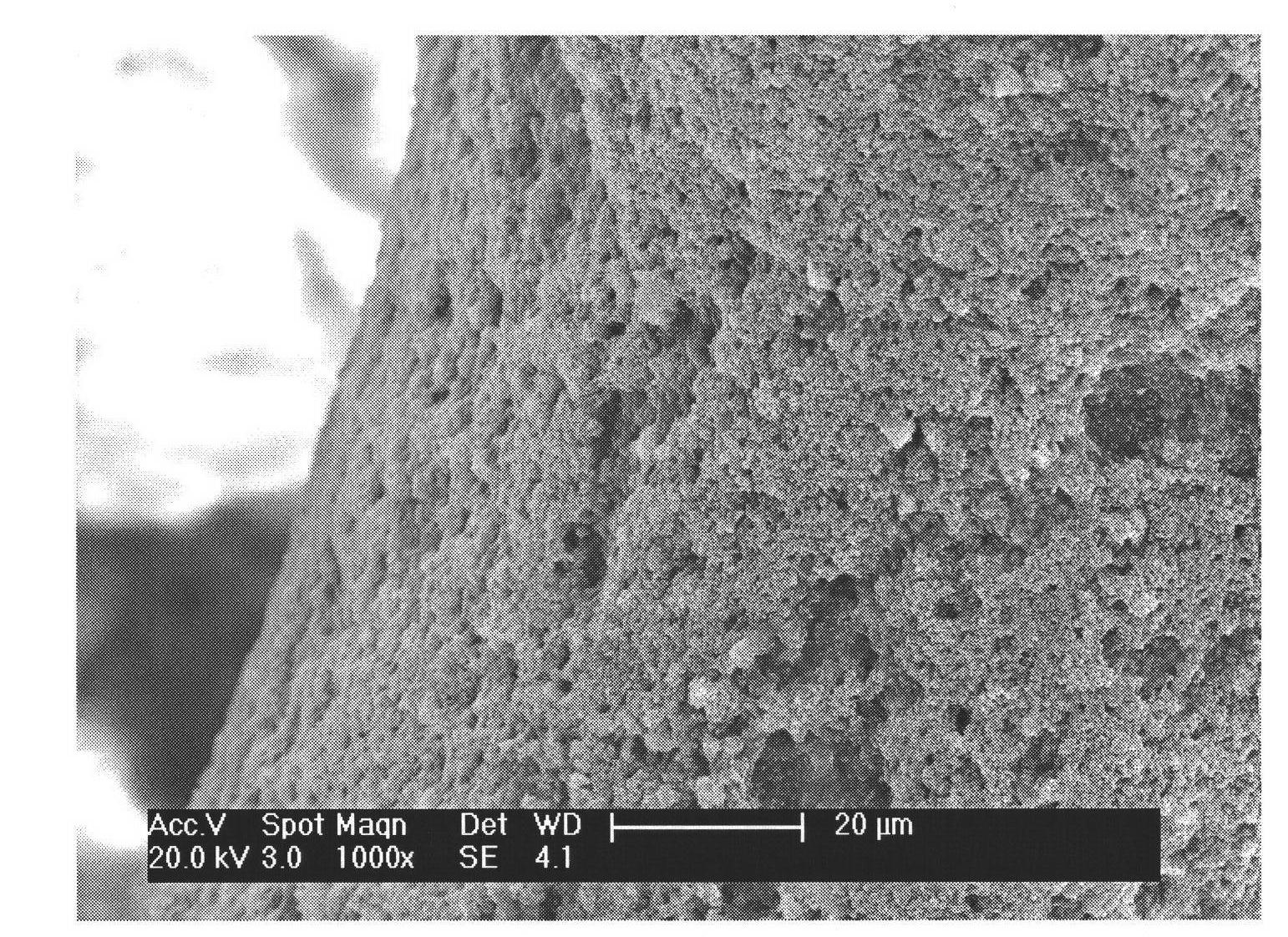

The present invention relates to electrochemical deposition process of preparing nanometer ordered hydroxyapatite coating on the surface of medical metal material. Cathode electrochemical deposition onto surface of Ti or Ti alloy is performed with electrodeposition solution containing Ca ion of 1E(-4) to 1E(-3) mol / L and LH2PO4 ion of 0.5E(-4) to 1E(-3) mol / L and in voltage of 1-20 V and current of 0.1-10 mA / sq cm. By means of controlling the electrochemical deposition parameters for forming nanometer hydroxyapatite coating, nanometer hydroxyapatite crystal particles may have different aggregate forms to form different secondary microscopic structures, blossom cluster shaped, upstanding or microspore. The form controllable nanometer hydroxyapatite material is biological material with different topologic structure and homogeneous chemical property, and is expected to have raised biocompatibility and bioactivity in clinical application.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD +1

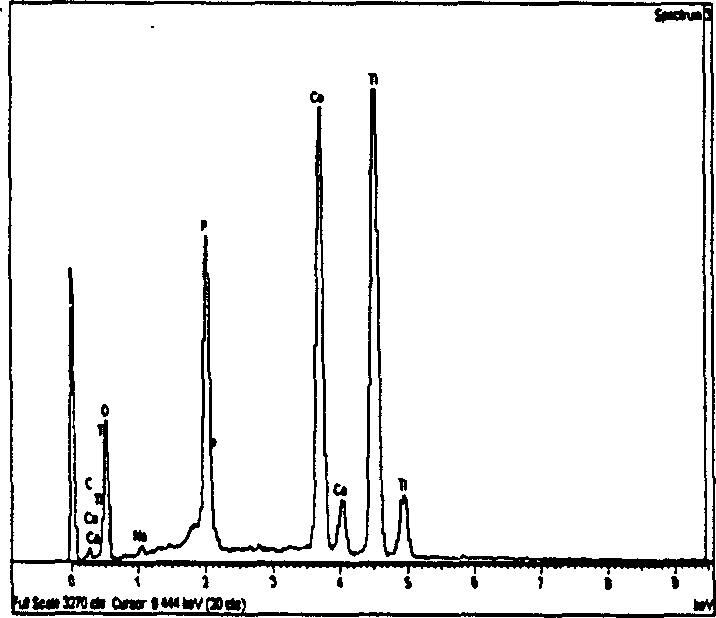

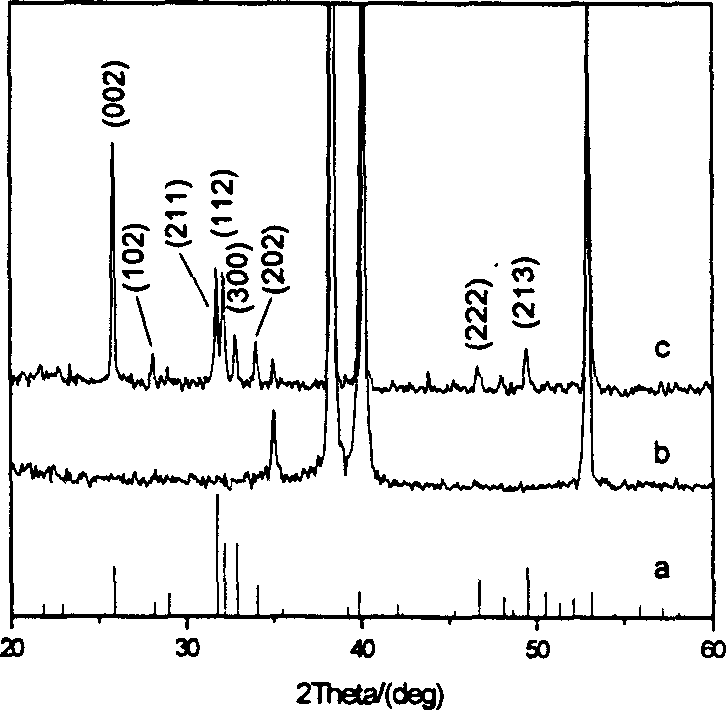

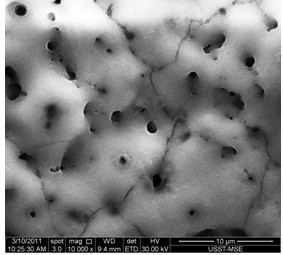

Titanium or titanium alloy with surface bioactive layer and preparation method thereof

InactiveCN101545109AHigh bonding strengthSimple processSurface reaction electrolytic coatingSuperimposed coating processApatiteHydroxyapatite coating

The invention relates to titanium or a titanium alloy with a surface bioactive layer and a preparation method thereof. In the titanium or the titanium alloy with the surface bioactive layer, the surface bioactive layer is a gradient coating, an inner layer is a ceramic membrane with a porous structure, and an outer layer is a hydroxyapatite coating. The preparation method comprises the following steps that: the titanium or the titanium alloy is subjected to micro-arc anode oxidation to form the porous ceramic membrane containing titanium dioxide and amorphous calcium and phosphorus on the surface; then, hydroxyapatite is synthesized in situ on the surface of the porous ceramic membrane containing the calcium and the phosphorus by using primary hydro-thermal synthesis; and in a secondary hydro-thermal reaction, the existing hydroxyapatite in the coating forms a new core in a hydroxyapatite nucleate to make the coating further grow to finally form the titanium or the titanium alloy with the surface bioactive layer. The preparation method as well as the titanium and the titanium alloy have the advantages of simple manufacturing process, short production period, low cost, high bonding strength of the surface bioactive layer of a product, good bioactivity and the like; and the product can be used for medical implantation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A kind of preparation method of carbon/carbon composite material containing silicon hydroxyapatite coating

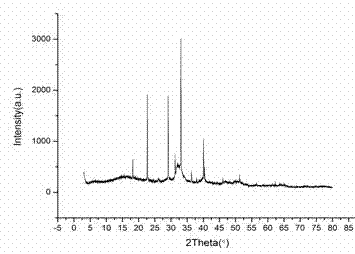

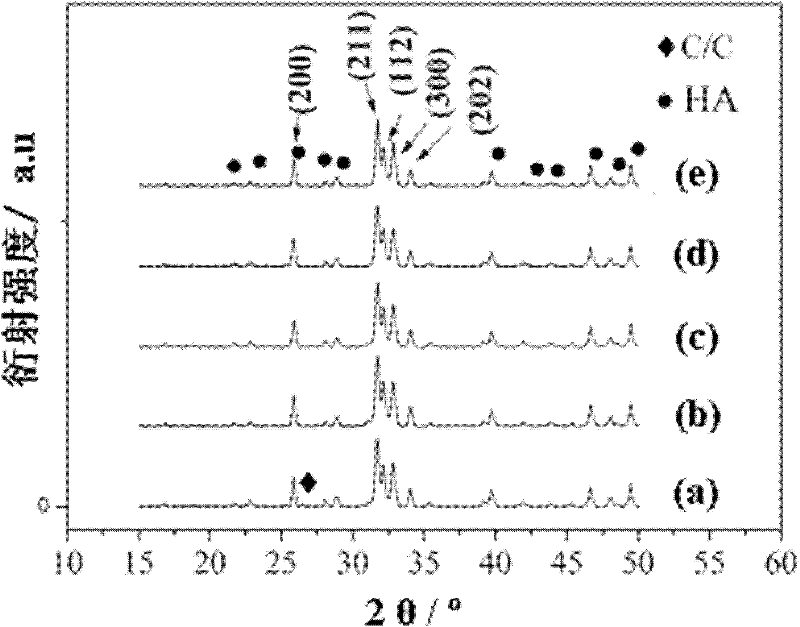

InactiveCN102260863AHigh crystallinityHigh hardnessLiquid/solution decomposition chemical coatingProsthesisCarbon compositesCritical load

The invention provides a preparation method of a silicon-containing hydroxyapatite coating of a carbon / carbon composite material. The preparation method comprises the following steps: placing a low-density carbon / carbon composite material in a hydrothermal kettle containing a sodium perchlorate solution for hydrothermal treatment, and then washing with distilled water and drying the carbon / carboncomposite material; placing the treated carbon / carbon composite material in a flowable aqueous solution containing calcium nitrate and ammonium dihydrogen phosphate, and precipitating out a calcium hydrophosphate coating on the surface of the carbon / carbon composite material through an ultra-high frequency electromagnetic induced heating method; then placing the calcium hydrophosphate coating of the carbon / carbon composite material in the hydrothermal kettle containing an ammonia water aqueous solution for hydrothermal treatment so as to obtain the hydroxyapatite coating of the carbon / carbon composite material; and subsequently, placing the hydroxyapatite coating of the carbon / carbon composite material in the hydrothermal kettle containing a sodium silicate aqueous solution for hydrothermal treatment again so as to obtain the silicon-containing hydroxyapatite coating of the carbon / carbon composite material. By using the method, the silicon-containing hydroxyapatite coating with good crystallinity, high bonding strength up to critical load 143 N and Vickers hardness 2.3 can be prepared on the surface of the low-density carbon / carbon composite material.

Owner:SHAANXI UNIV OF SCI & TECH

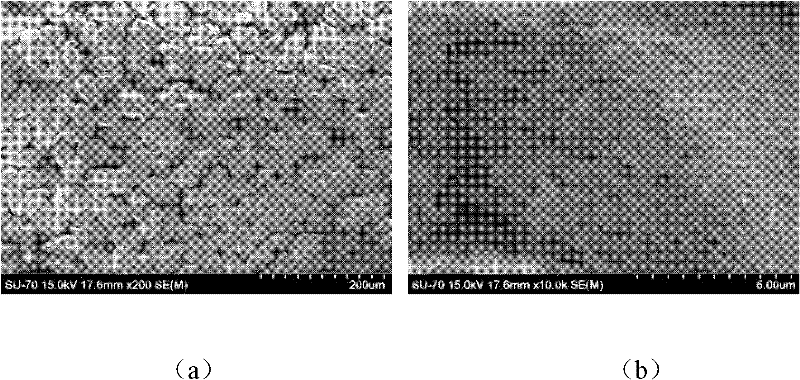

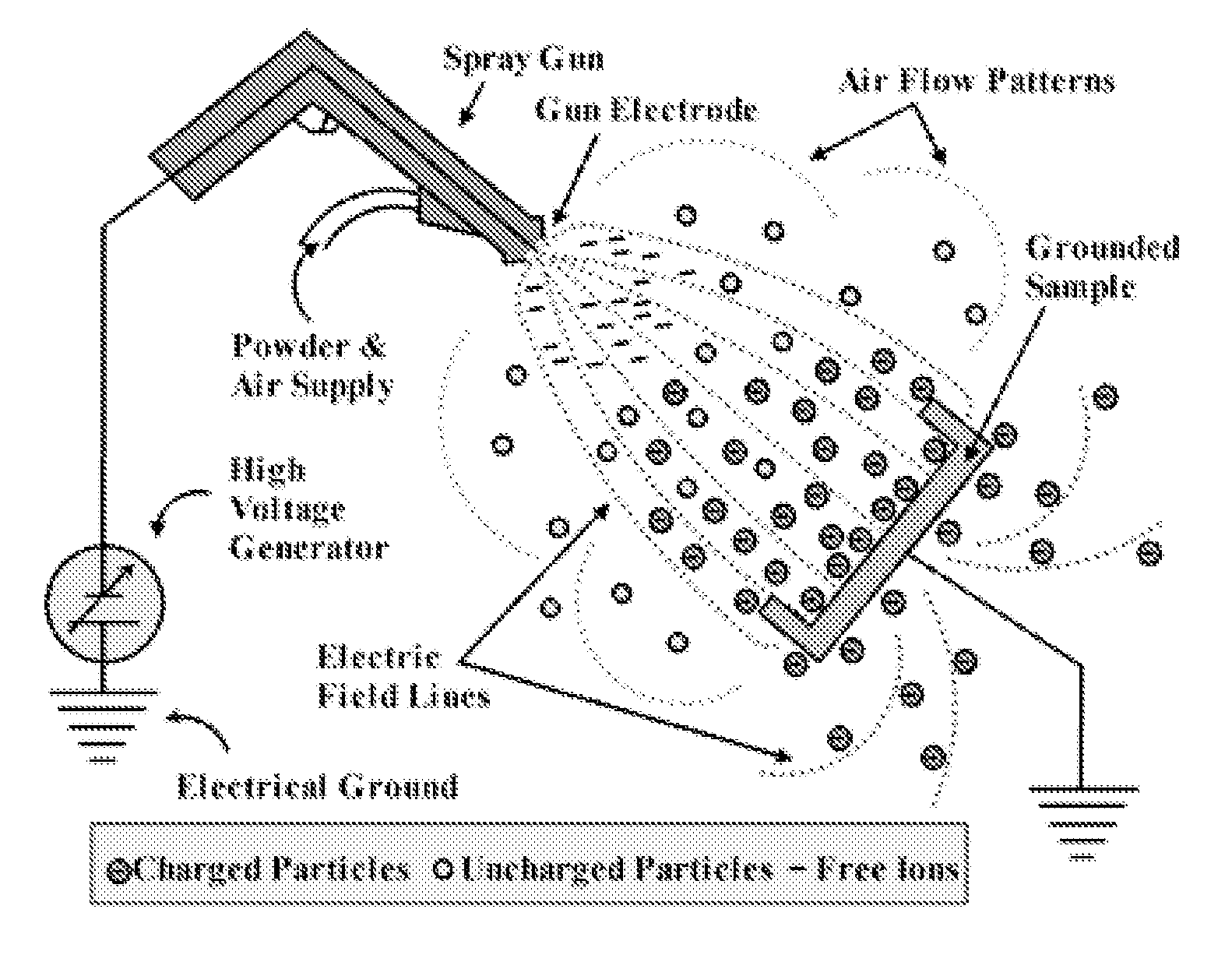

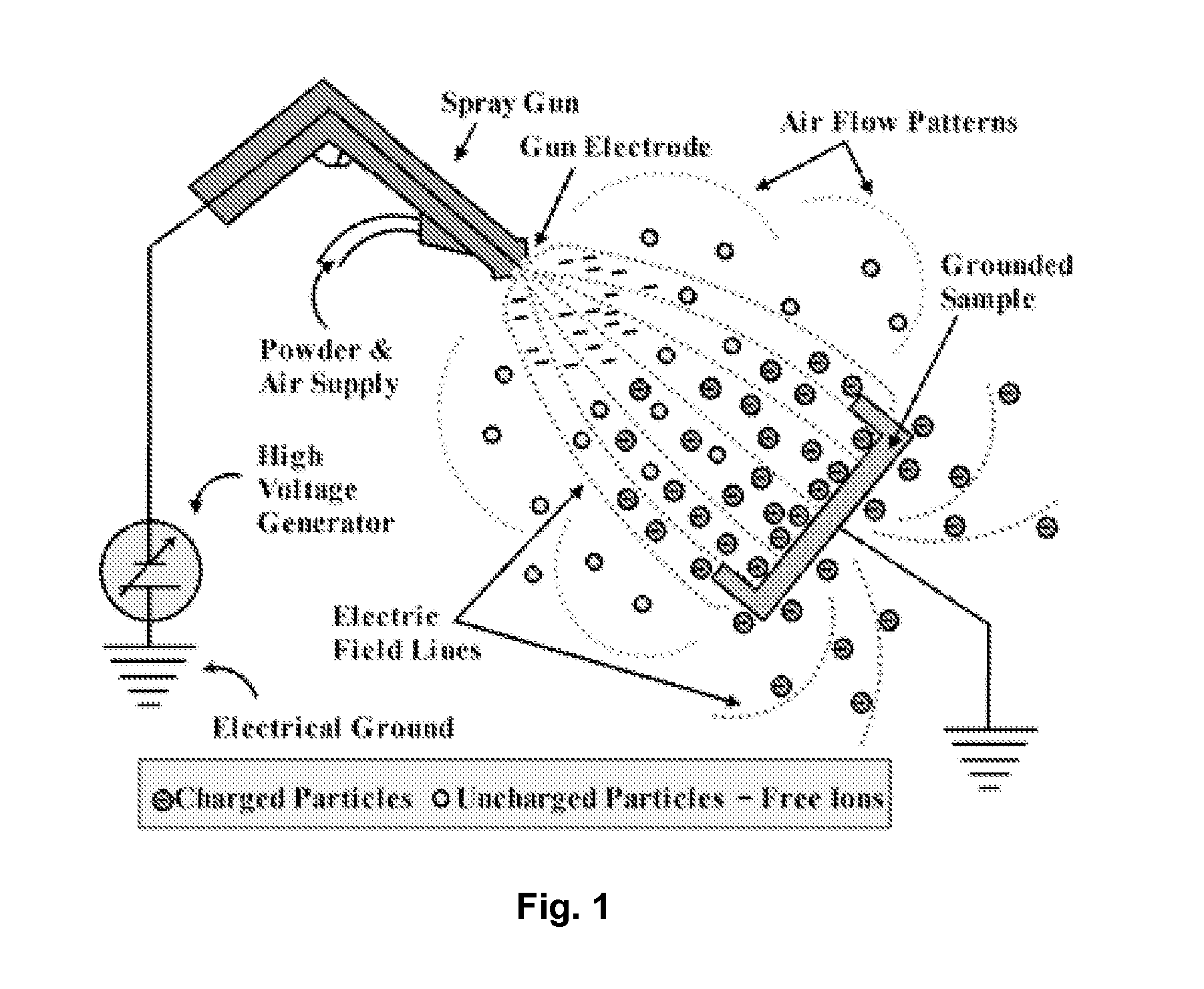

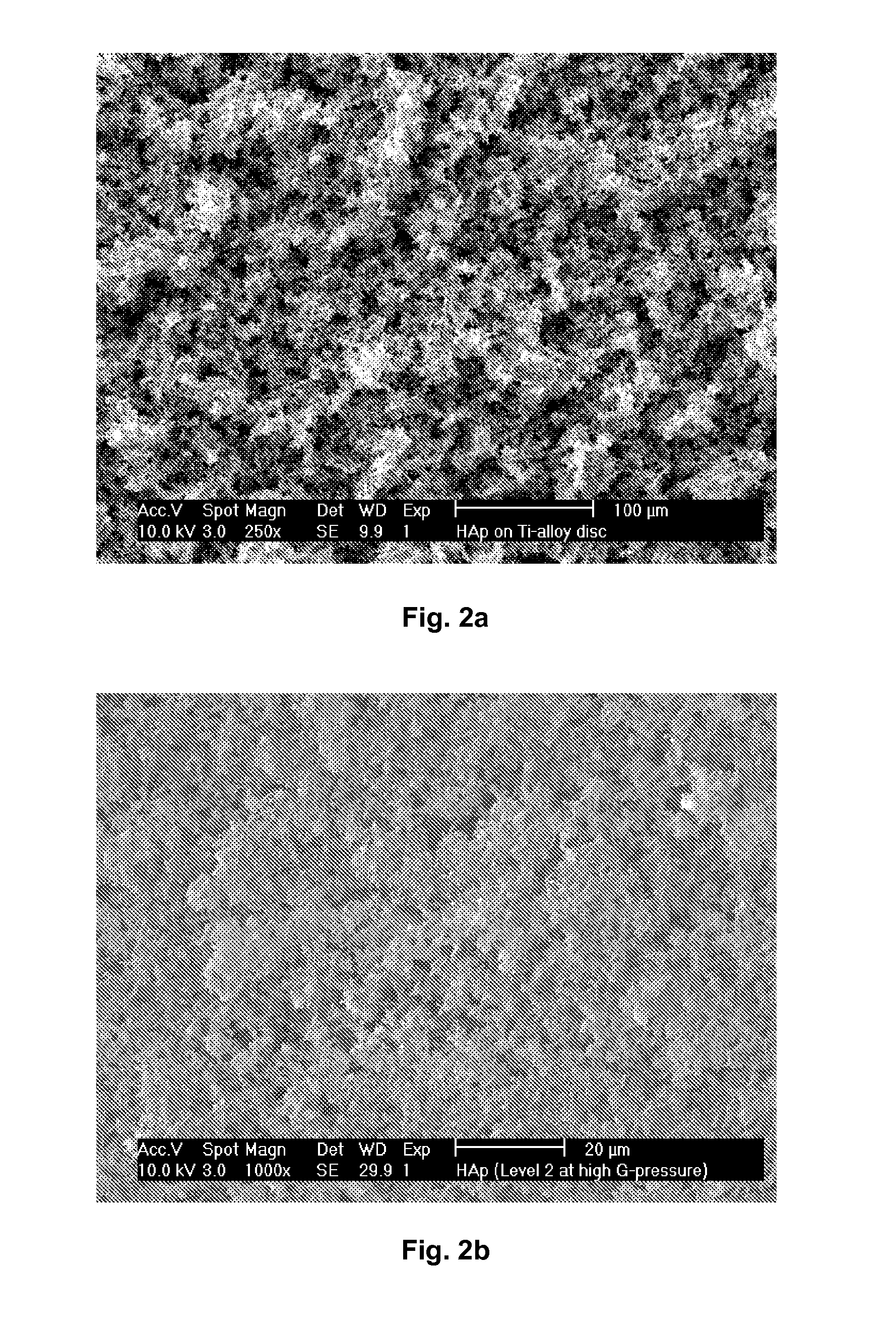

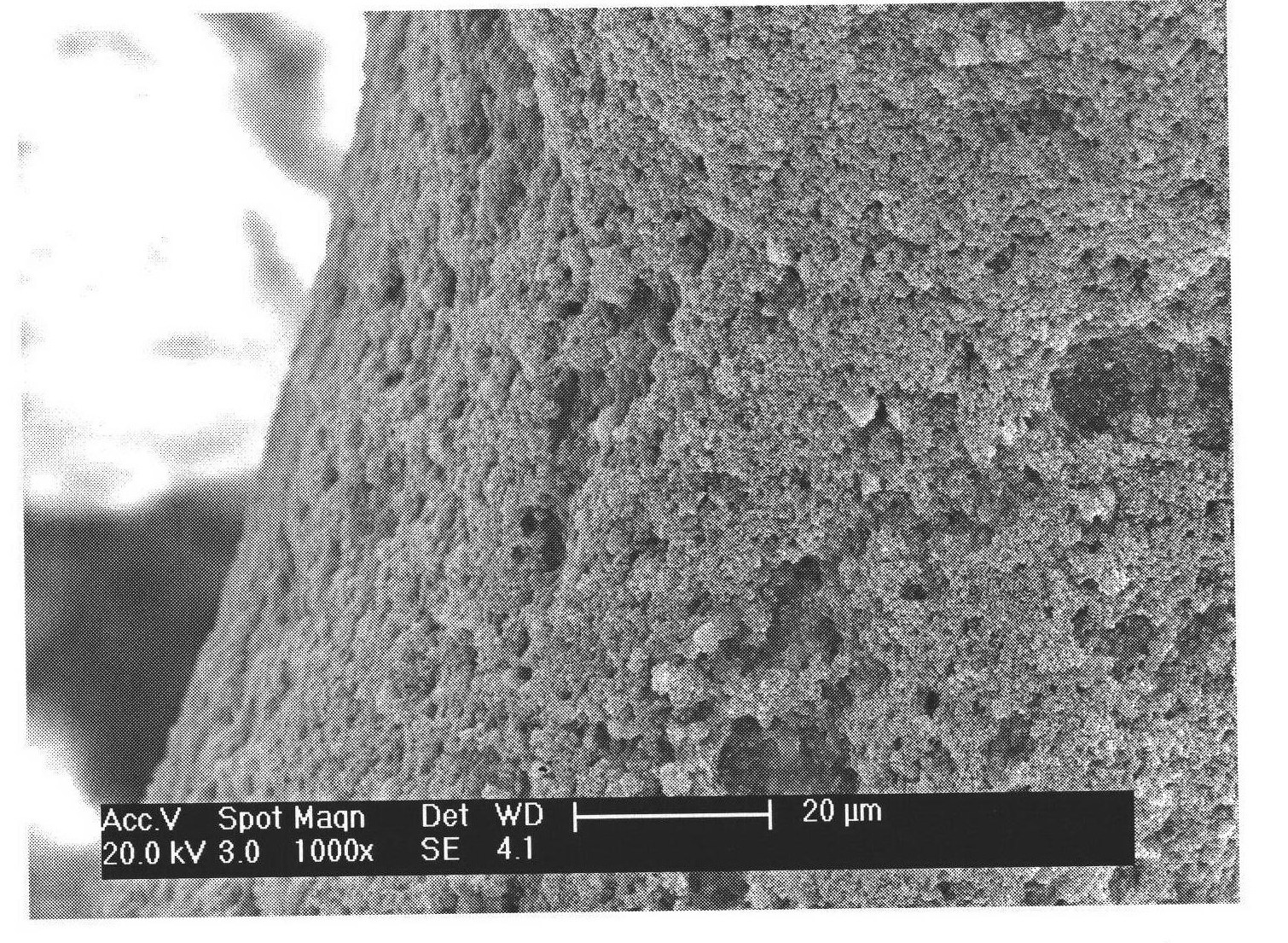

Nanostructured Hydroxyapatite Coating for Dental and Orthopedic Implants

ActiveUS20120276336A1Reduces HAp dissolutionIncrease deposition rateSpecial ornamental structuresPharmaceutical delivery mechanismOsseointegrationApatite

A high-strength coating for dental and orthopedic implants utilizing hydroxyapatite (HAp) nanoparticles provides for a high level of osseointegration through a range of surface pore sizes in the micro- to nanoscale. Zinc oxide (ZnO) nanoparticles may be incorporated with the HAp nanoparticles to form a composite coating material, with ZnO providing infection resistance due to its inherent antimicrobial properties. A textured surface, consisting of “islands” of roughly square coating structures measuring about 250 μm on a side, with spacing of 50-100 μm therebetween, may further promote the osseointegration and antimicrobial properties of the implant coating.

Owner:P&S GLOBAL HLDG LLC +1

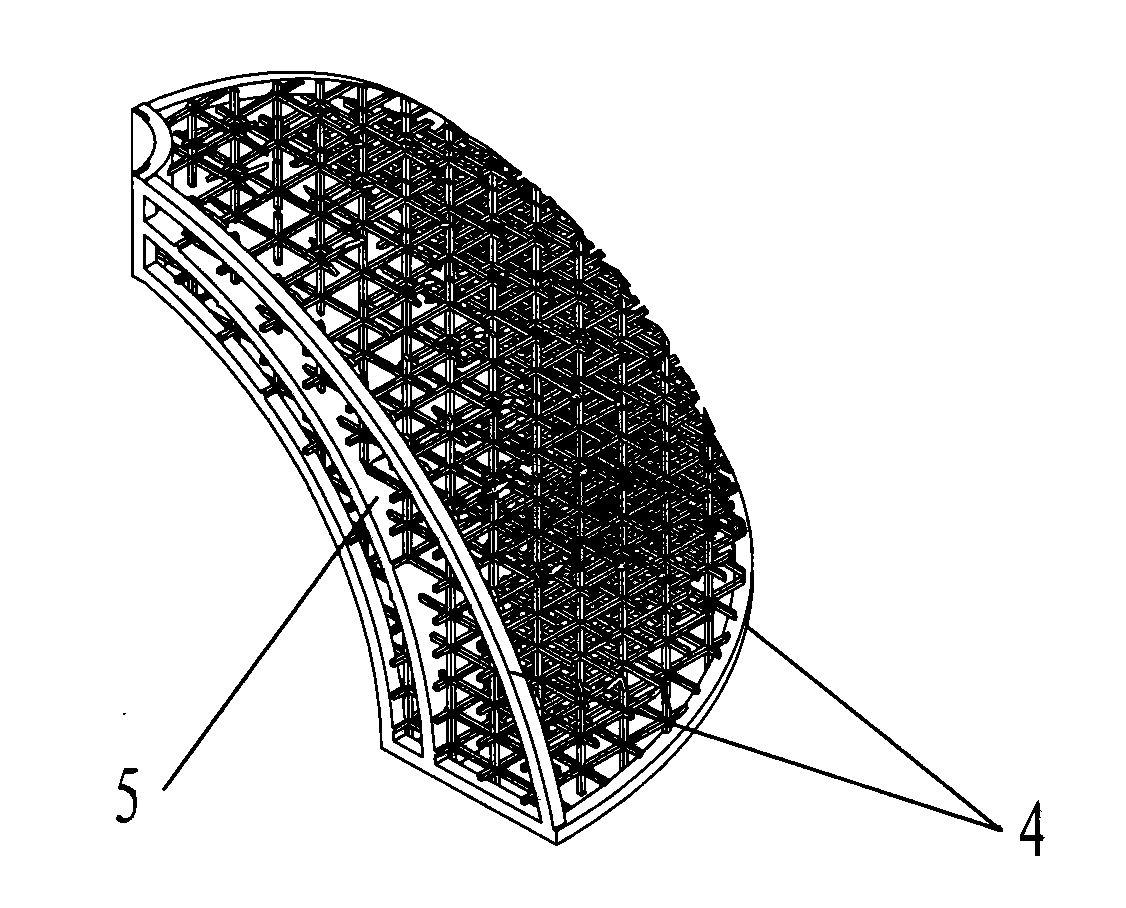

Porous, controllable and low-modulus bone defect repair bracket and preparation method thereof

ActiveCN103751840APromote ingrowthSolve the interface stress problemElectrolytic inorganic material coatingProsthesisApatiteRapid prototyping

The invention discloses a porous, controllable and low-modulus bone defect repair bracket which consists of a porous, controllable and low-modulus titanium alloy bracket and a biological activity coating on the surface of the titanium alloy bracket. The invention further discloses a preparation method of the bone defect bracket. The method comprises the steps that the low-modulus and porous titanium alloy bracket in a controllable internal microstructure is prepared by a quick forming technique; a uniform hydroxyapatite coating and a strontium doped hydroxyapatite coating are prepared on the surface of the bracket in the controllable microstructure; an electrolyte with certain concentration is prepared; a potential is controlled in an electrolytic bath of a three-electrode system; and pulse electrochemical deposition is performed. The elastic modulus of the prepared titanium alloy bracket is equivalent to that of a bone; the prepared hydroxyapatite coating or strontium doped hydroxyapatite coating is combined with a titanium alloy well; the concentration of strontium is controllable; and an implant provided with the biological activity coating can be used for a bone defect of a massive bearing part clinically.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

Method for preparing hydroxyapatite bioactive coating

The invention discloses a method for preparing a hydroxyapatite bioactive coating, and aims to solve the technical problem that the bonding strength of carbon nano-tubes and a matrix material in a hydroxyapatite bioactive coating prepared by the conventional preparation method is low. The technical scheme is that the method comprises the following steps of: introducing the carbon nano-tubes onto the surface of the matrix material in an in-situ growth mode, and electrodepositing a hydroxyapatite coating, so that the bottoms of the carbon nano-tubes are combined with the matrix material in the in-situ growth mode, and the carbon nano-tubes are distributed in the hydroxyapatite coating to achieve a wild phase effect. A method for forming effective combination of the carbon nano-tubes and the matrix material in the hydroxyapatite coating is constructed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

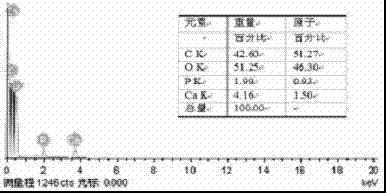

Method for preparing similar bone bioactivity coatings medical material by galvano-chemistry method

InactiveCN101156963AThe preparation process conditions are simpleEfficient preparation process conditionsElectrolytic inorganic material coatingElectrolysisApatite

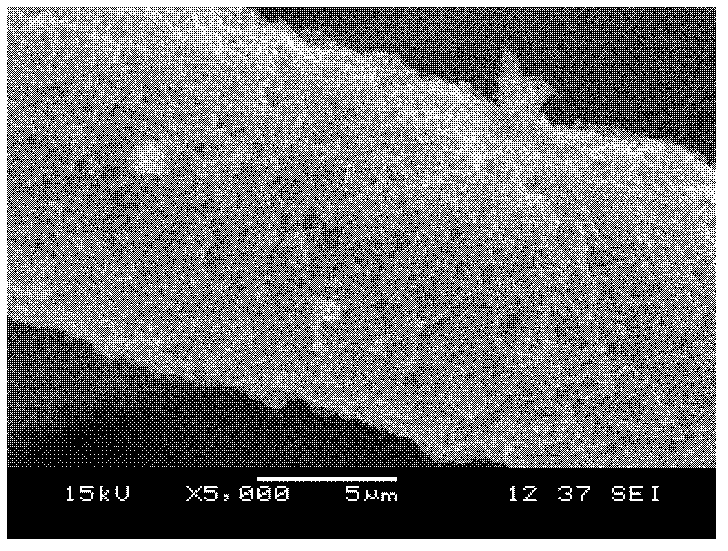

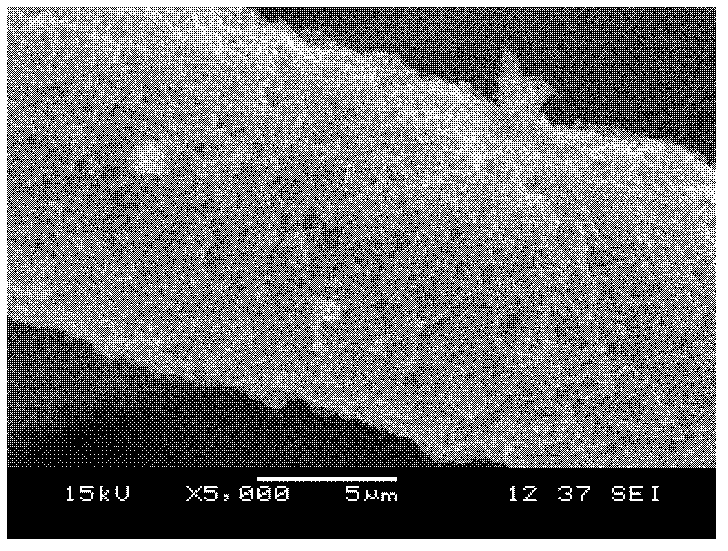

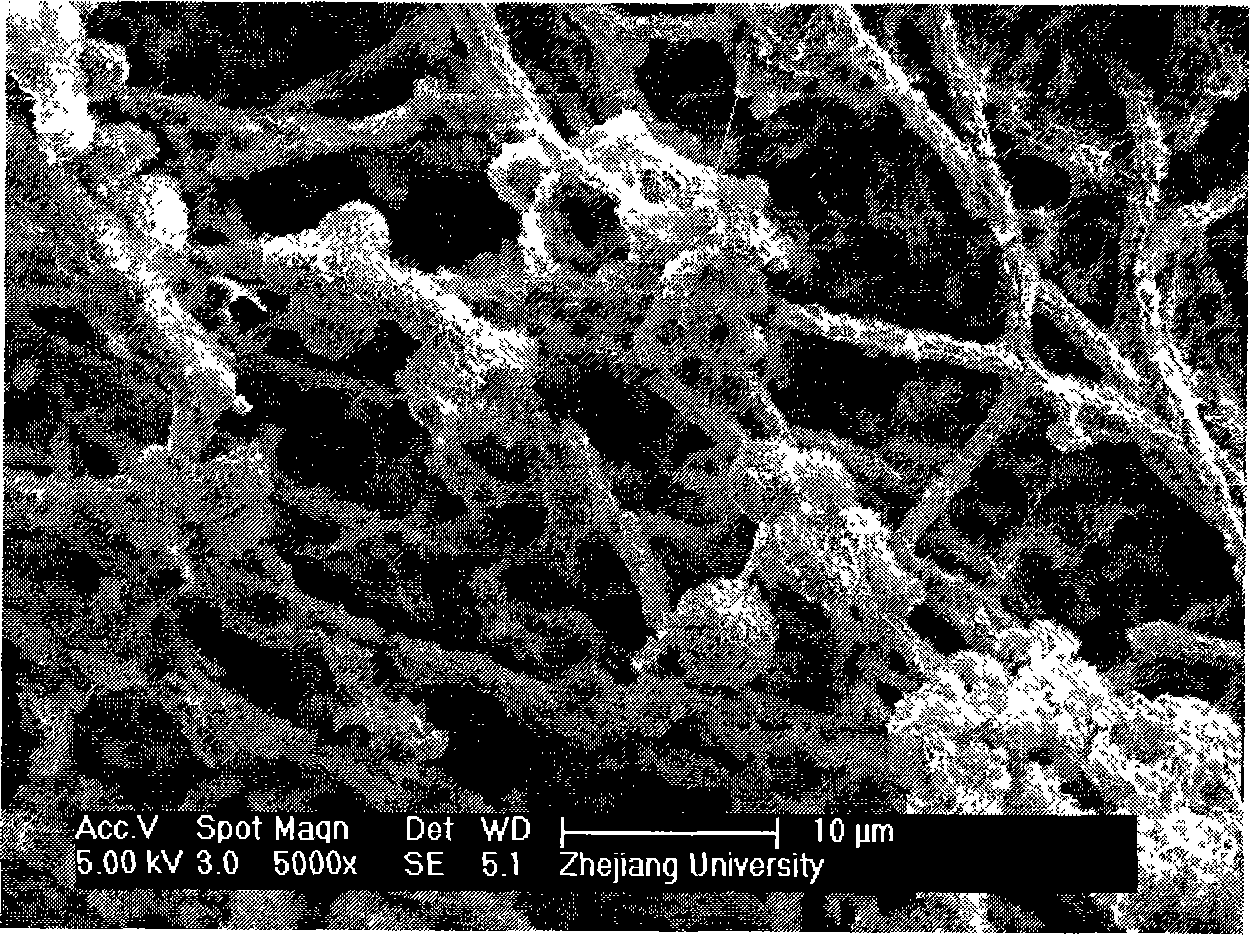

The invention discloses bone-like bioactive coating medical material which is prepared by adopting an electrochemical method. The invention adopts an electrolytic deposition method and imitates the forming process of a natural bone. Electrolyte solution contains calcium, a phosphorous compound and bone matrix collagen, a medical metal transplant body is taken as a working electrode, platinum is taken as a reference electrode, the electrode reaction causes partial pH value of the electrolyte solution around the medical metal transplant body to ascend, thereby leading collagen to be gelatinized, in cooperation with the deposition of calcium phosphate mineral, the bone-like bioactive coating is formed on the medical metal surface. Through the adoption of the invention method, the bioactive coating acquired on the surface of the metal transplant body is similar to the natural bone in the component and the structure, and has favorable biological activity, thus the disadvantages that the biological activity of the business use hydroxyapatite coating is limited, the required curing time is long, etc. are solved. The preparation process of the invention is simple, highly effective and easy to be industrialized.

Owner:ZHEJIANG UNIV

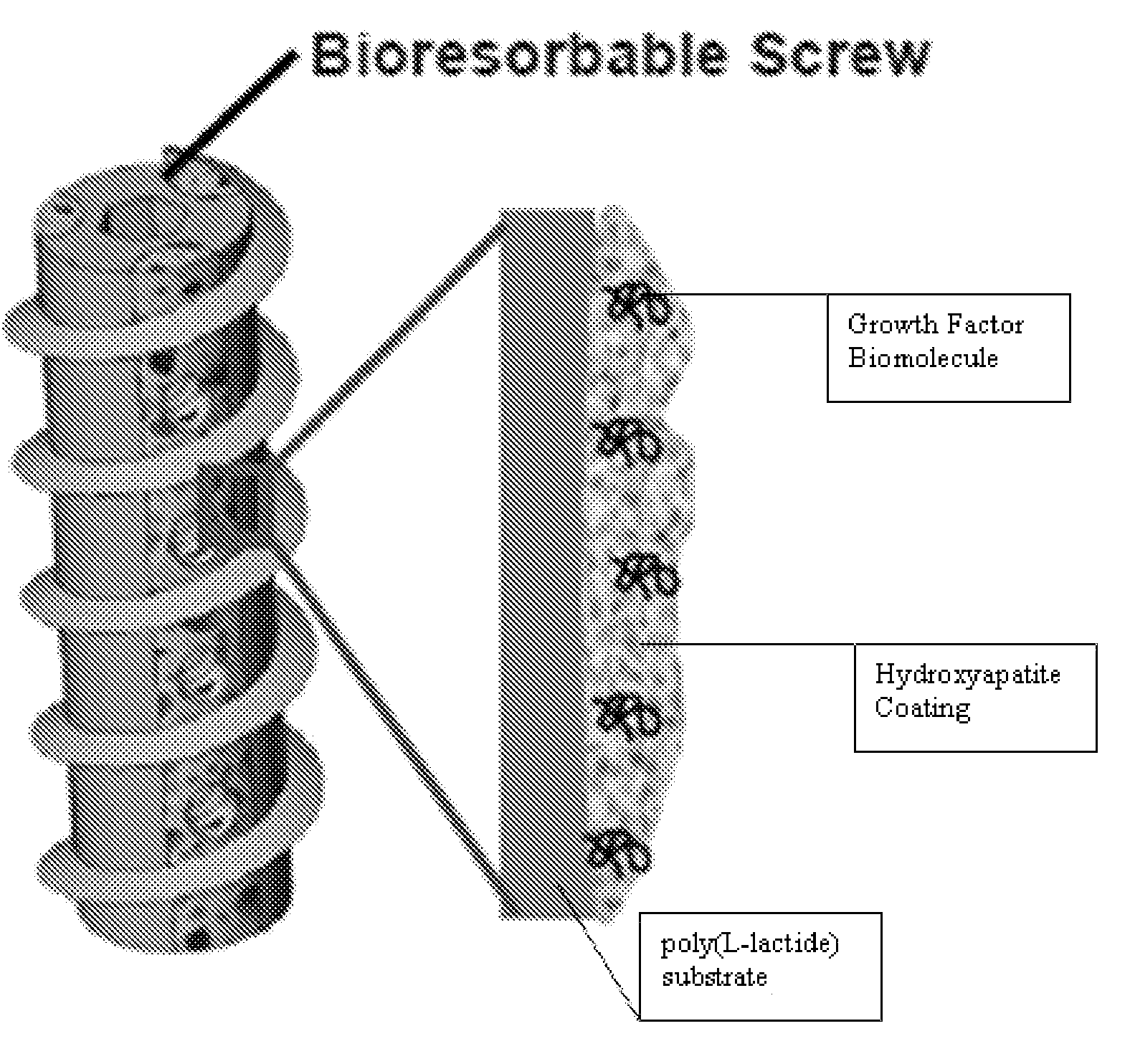

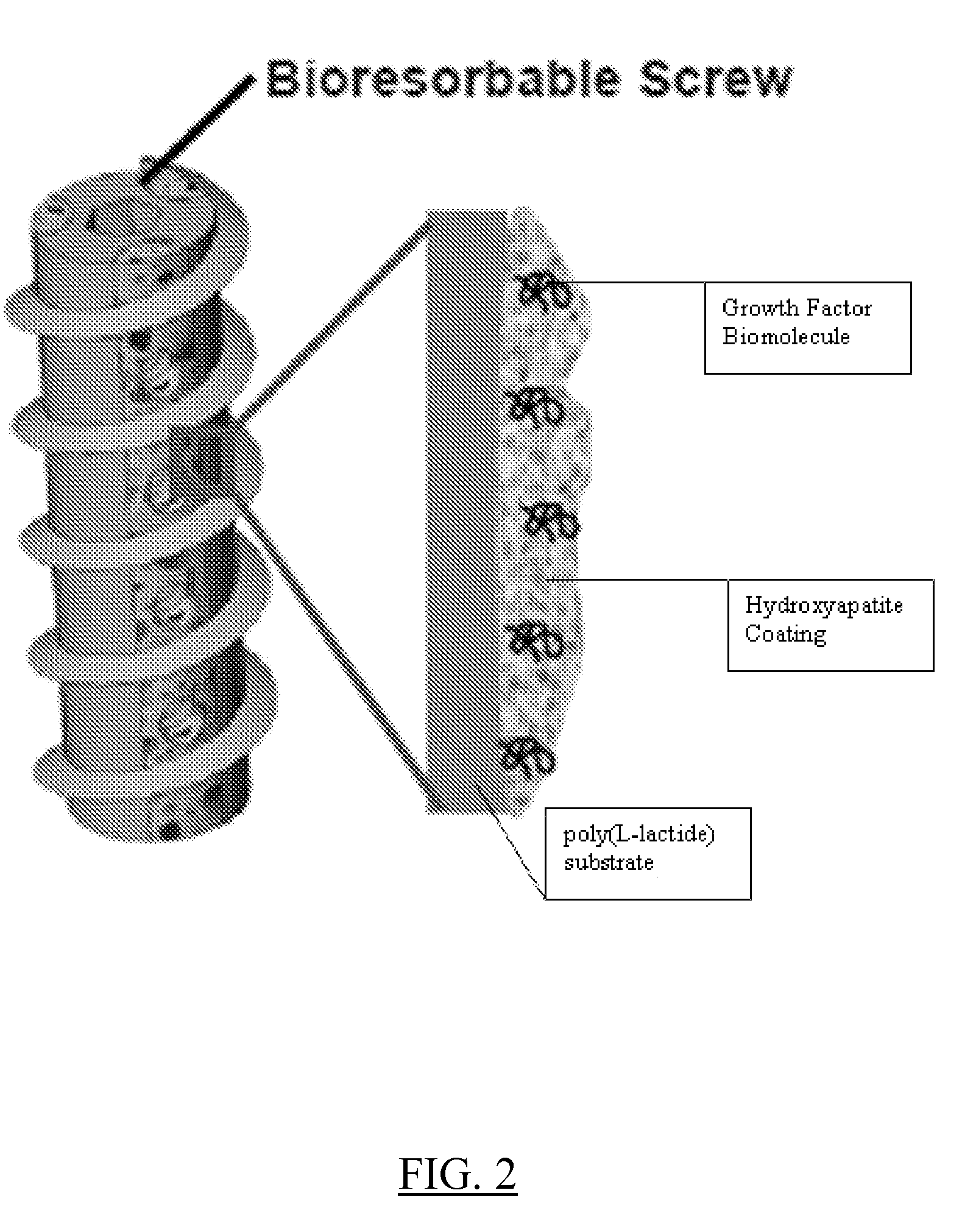

Controlled release of biopharmaceutical growth factors from hydroxyapatite coating on bioresorbable interference screws used in cruciate ligament reconstruction surgery

Controlled release of biopharmaceutical growth factors from a hydroxyapatite coating on a bioresorbable interference screw used in cruciate ligament reconstruction surgery on a human. Biologically active scaffolds, such as interference bone screws used for ligament fixation, made by growing calcium phosphate-based hydroxyapatite coatings on bioresorbable poly(α-hydroxy ester) scaffolds that provide controlled mineral dissolution and controlled release of bone morphogenetic protein-2. The biologically active scaffold provides improved bioavailability of BMP-2 growth factor that in turn provides enhanced graft-bone healing in the tibial bone tunnel. The coating method uses surface hydrolysis and modified simulated body fluid incubation which does not require solvent or heat and is conducted at room temperature.

Owner:WISCONSIN ALUMNI RES FOUND

Personalized carbon/carbon composite artificial bone and preparation method thereof

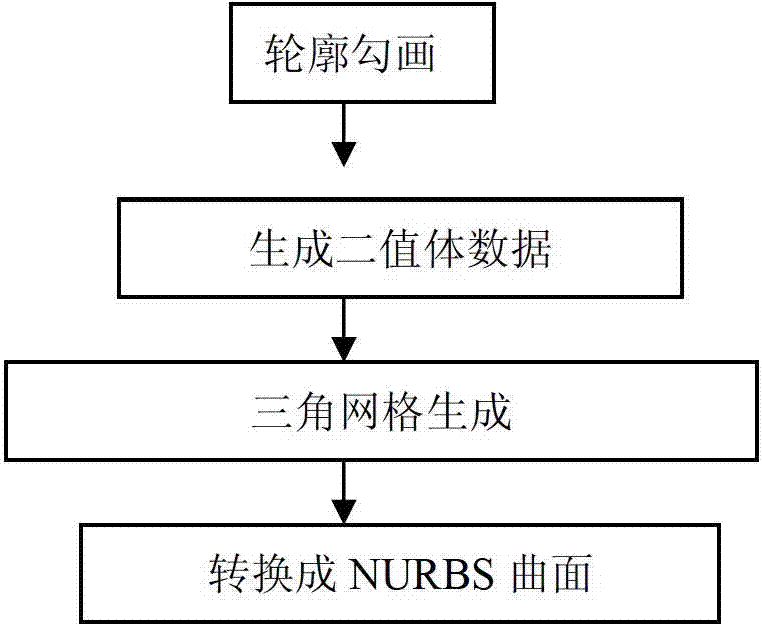

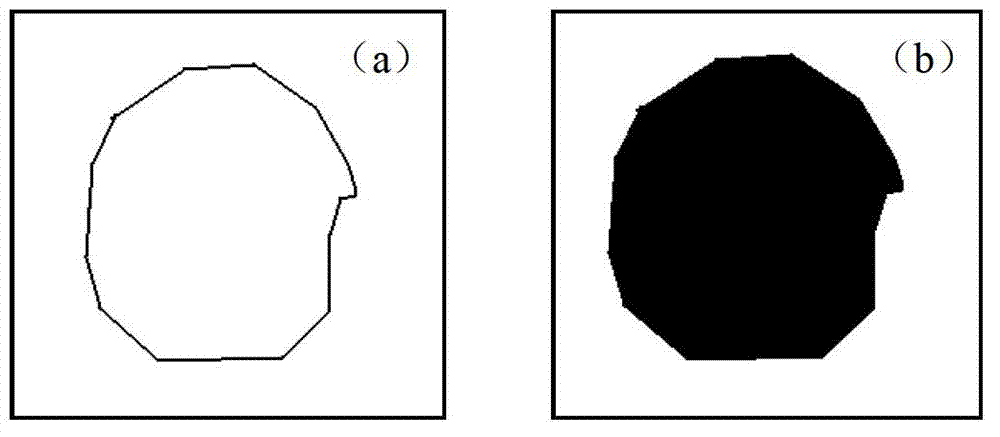

The invention relates to a personalized carbon / carbon composite artificial bone and a preparation method of the personalized carbon / carbon composite artificial bone, wherein specific steps are as follows: a. choosing carbon-fiber reinforced carbon matrix as a raw material; b. performing an artificial bone outline by collection of computerized tomography (CT) images, converting the collected artificial bone outline into a non-uniform rational B-spline surface, processing the carbon / carbon composite to form the carbon / carbon composite artificial bone; c. filling argon into a vacuum glow discharge chamber to perform plasma pretreatment on the surface of the carbon-fiber reinforced carbon matrix, placing the processed carbon-fiber reinforced carbon matrix into alcohol solution to perform ultrasonic washing; d. spraying a hydroxyapatite coating onto the surface of the washed carbon-fiber reinforced carbon matrix to form the carbon / carbon composite. According to the personalized carbon / carbon composite artificial bone and preparation method of the personalized carbon / carbon composite artificial bone provided by the invention, the hydroxyapatite coating is sprayed onto the surface of the carbon / carbon composite, the surface activity of the carbon / carbon composite is improved and the release of carbon granules can be decreased effectively.

Owner:倪昕晔

Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy

InactiveCN104888271AGood biocompatibilitySimple processMetallic material coating processesProsthesisCalcium nitrate tetrahydrateCalcium phosphate coating

The invention relates to a method for preparing a strontium-containing hydroxyapatite coating on the surface of a biodegradable magnesium alloy. The method comprises the following steps: polishing a magnesium alloy matrix to remove a surface oxidation layer, and cleaning; preparing a hydrothermal solution from calcium nitrate tetrahydrate, EDTA-2 Na, sodium dihydrogen phosphate dihydrate and strontium nitrate; and placing the well treated magnesium alloy matrix into the hydrothermal solution for hydrothermal reaction to obtain the strontium-containing hydroxyapatite coating, a biomimetic calcium phosphate coating, wrapping the magnesium alloy matrix. Compared with the prior art, as the hydrothermal method is adopted to prepare hydroxyapatite, not only is the degradation rate of the magnesium alloy in a human body effectively slowed down, but also the biocompatibility of the magnesium alloy is further improved. As strontium element is added into the hydroxyapatite coating, and as one of trace elements of the human body, strontium has the functions of promoting bone formation and inhibiting bone breakage, both the biological activity and the biocompatibility are improved.

Owner:TONGJI UNIV

Preparation method of hydroxyapatite bioactive coating doped with trace elements

The invention belongs to the technical field of biomedical composite materials, in particular to a preparation method of a hydroxyapatite bioactive bionic coating containing trace elements. The method comprises the following steps of: firstly, reacting raw materials for preparing hydroxyapatite containing the trace elements according to the proportion at a certain temperature to obtain a suspension; and then transmitting the suspension as a precursor liquid to a high-temperature area of plasma flame and directly spraying the suspension on a biomedical metal substrate to form the hydroxyapatite coating containing the trace elements. The invention has simple process and low production cost; and the obtained hydroxyapatite coating contains the trace elements such as silicon, magnesium and the like closer to human bony bionic components and has better osteogenesis capability and important application value.

Owner:SICHUAN UNIV

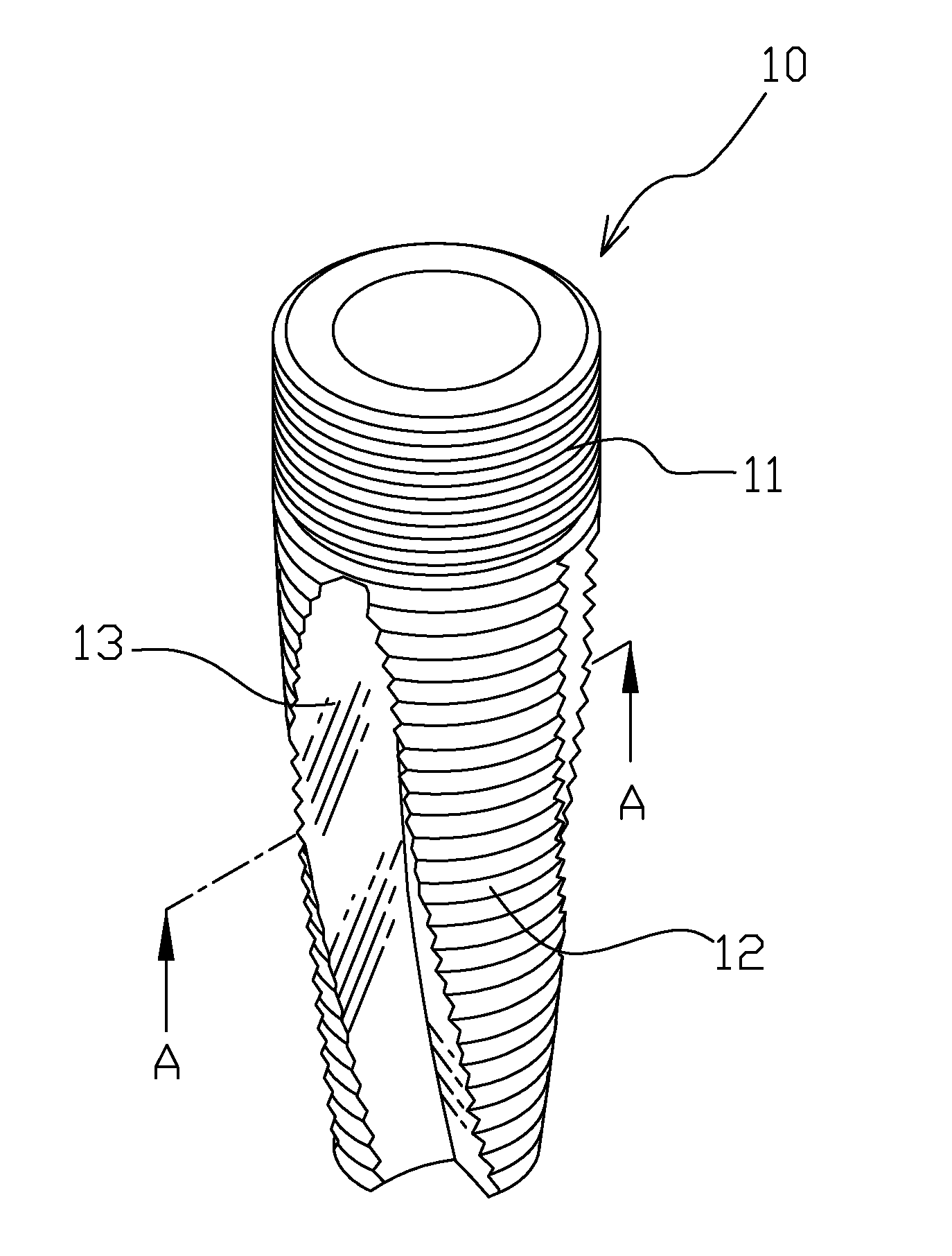

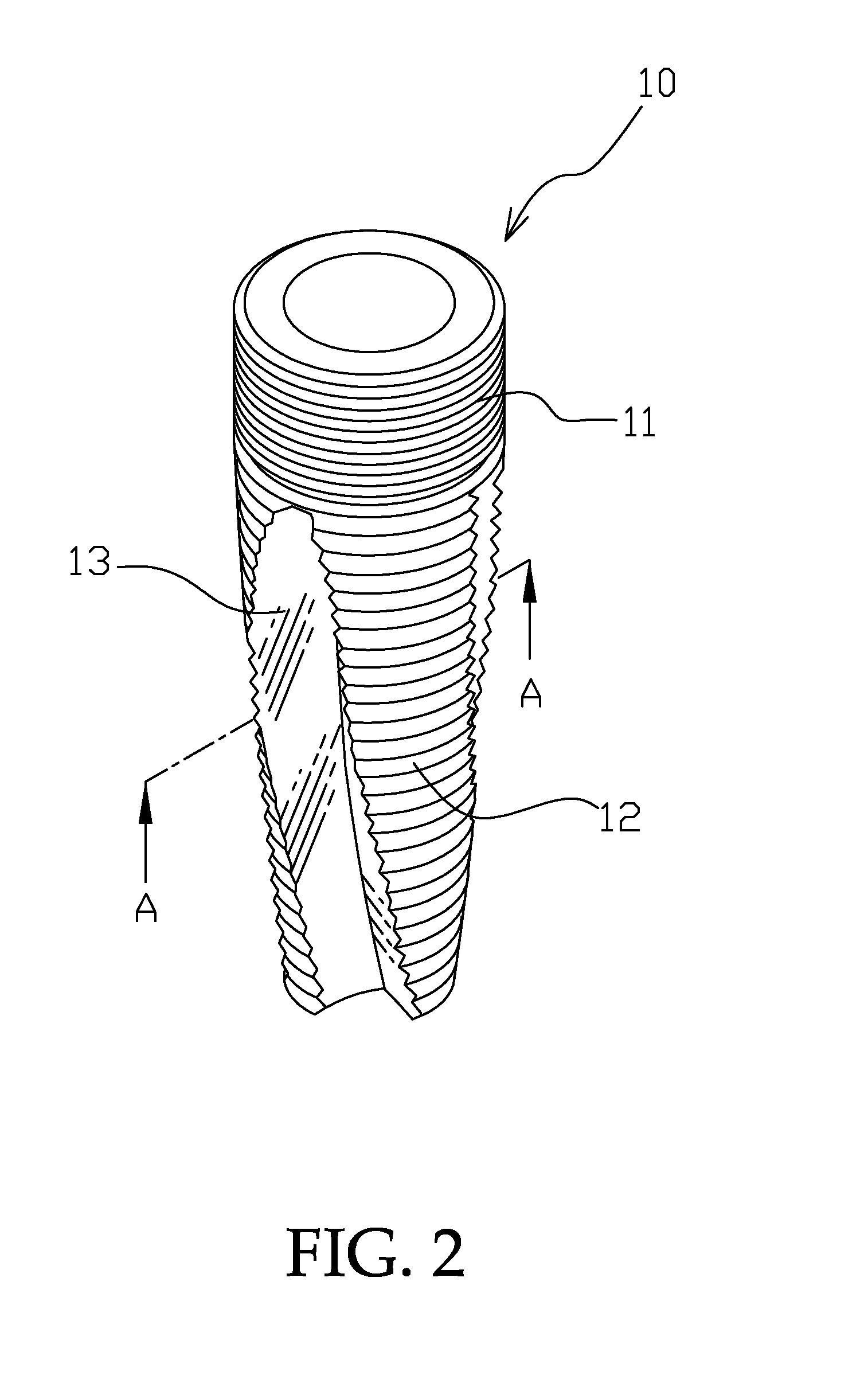

Implant root for tooth implanting

InactiveUS20110033826A1Increase the areaIncrease spacingDental implantsHydroxyapatite coatingDenture base

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treated surfaces extending from the bottom to the top of the implant root of the coarse threaded portion each being treated with a roughened coating (for example, covered with a hydroxyapatite coating) and extending in the whole length of the coarse threaded portion and each extending in the vertical direction. The areas of the roughened coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

Hydrophobic composite biological activity coating on surface of pure-magnesium or magnesium alloy and preparation method of hydrophobic composite biological activity coating

InactiveCN105420789AImprove compactnessGood biocompatibilityAnodisationProsthesisMicro arc oxidationMagnesium phosphate

The invention relates to the technical field of surface treatment of bio-medical metal materials, in particular to a hydrophobic composite biological activity coating on the surface of pure-magnesium or magnesium alloy and a preparation method of the hydrophobic composite biological activity coating. The method includes the technical processes of preparing a micro-arc oxidation coating on the surface of a magnesium matrix material firstly, preparing a hydroxyapatite coating on the basis of the micro-arc oxidation coating to form a composite active coating, and carrying out hydrophobic treatment on the composite active coating finally to form the hydrophobic composite biological activity coating. The hydrophobic composite biological activity coating on the surface of the magnesium alloy is composed of magnesium oxide, magnesium phosphate and hydroxyapatite and has a compact layer ranging from 5 micrometers to 10 micrometers and a band-shaped hydroxyapatite array, the contact angle of the coating and simulated body fluid is larger than 90 degrees, and the coating shows hydrophobicity. The hydrophobic composite biological activity coating has the beneficial effects of high corrosion resistance, good biocompatibility, good bone induction capacity and the like, and has the wide application prospect.

Owner:FUZHOU UNIV

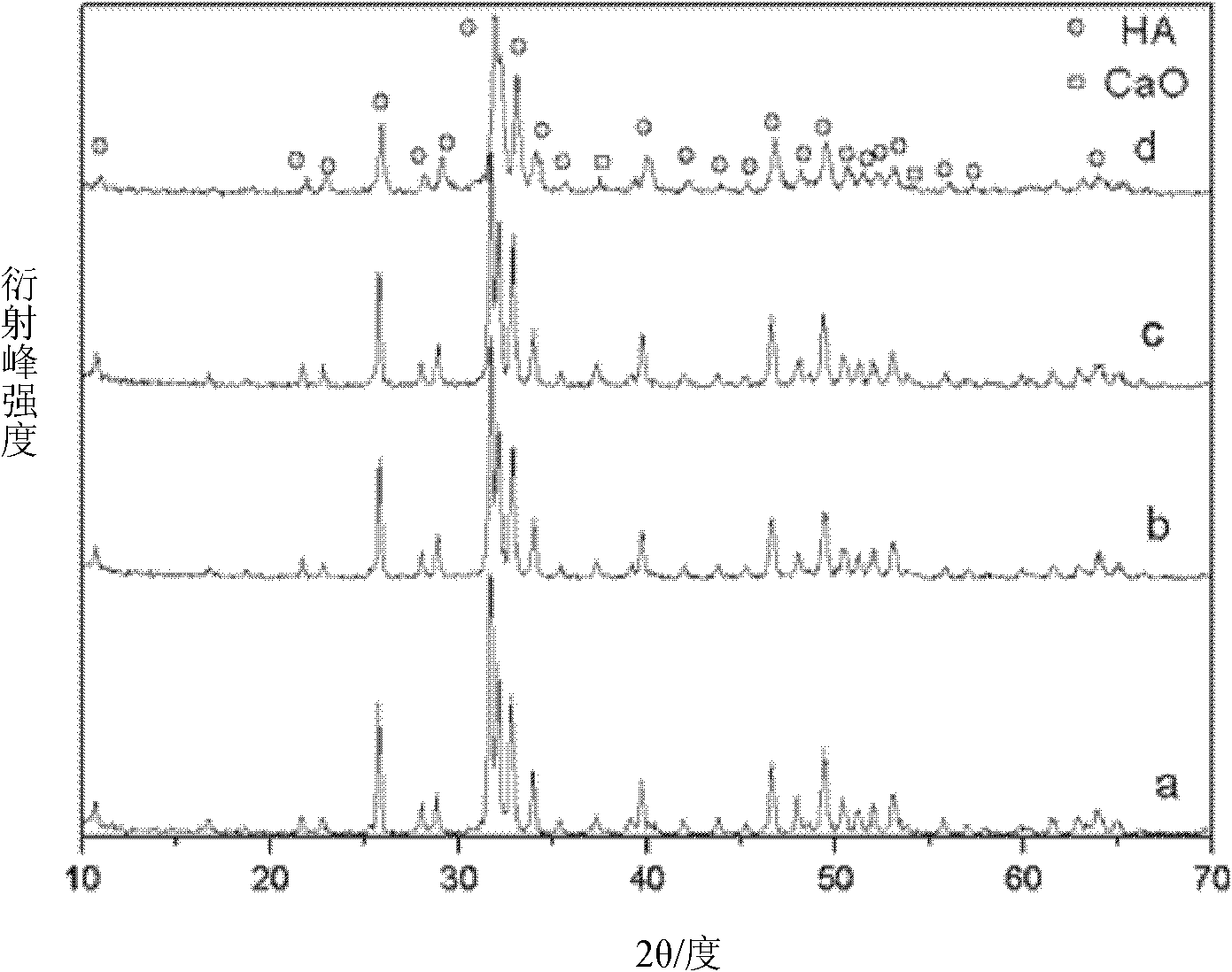

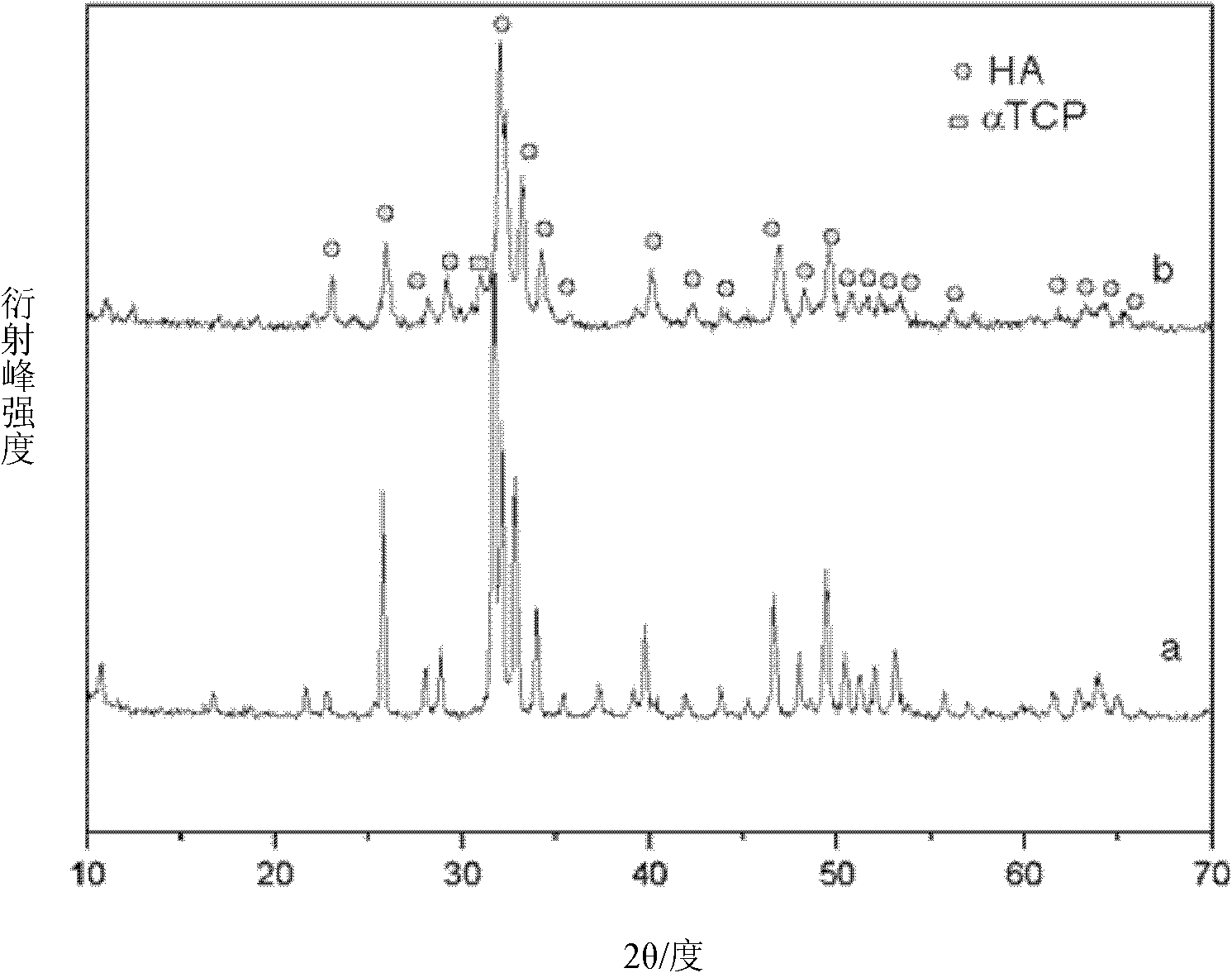

Post-treatment method for plasma spraying hydroxyapatite coating

InactiveCN1483480AIncrease contentHigh crystallinityCoatingsHigh volume manufacturingHydroxyapatite coating

The present invention relates to an aftertreatment method of plasma spray-coated hydroxypatite coating, and is characterized by that the hydroxyapatite coating product obtained by adopting plasma spray-wating process is placed in a container connected with the steam generator, then said steam in the container is heated or (and) pressurized to make the hydroxyapatite coating product undergo the process of treatment for 2-6 hr. under the moist steam whose temp. is 100 deg.C-300 deg.C and pressure is 1-3 atms, then said hydroxyapatite coating product can be taken out and placed into the baking oven with 100-150 deg.C and baked for 0.5-2 hr. so as to implement its aftertreatment.

Owner:SICHUAN UNIV

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

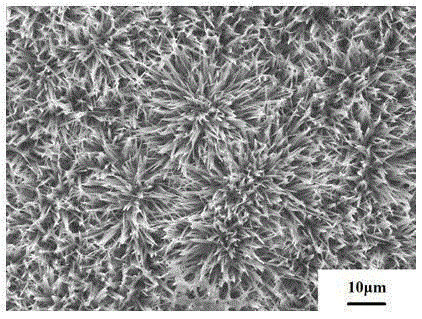

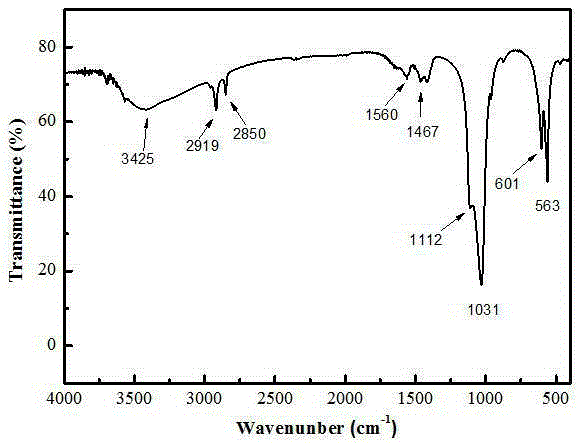

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

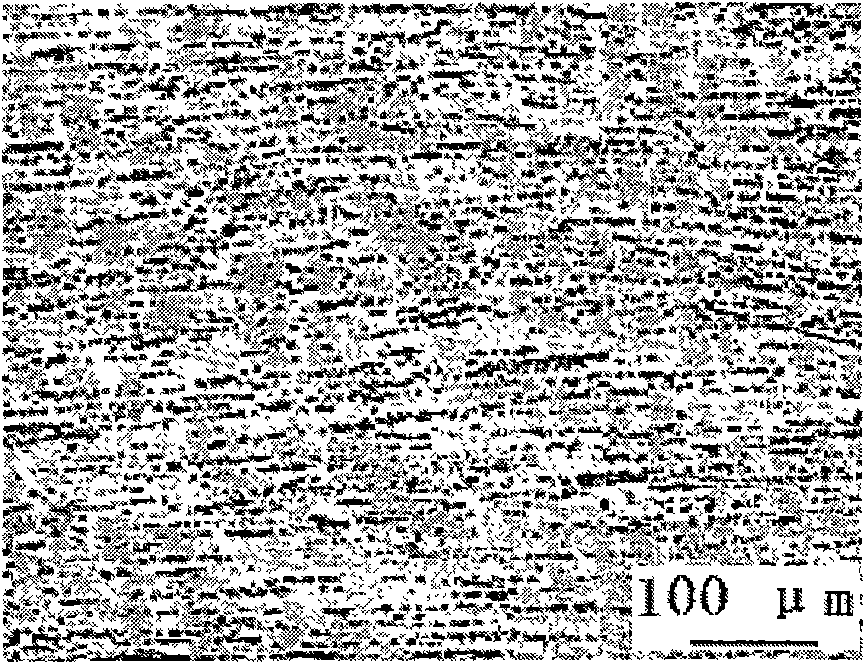

Mg-Zn-Sr alloy biomaterial of hydroxyapatite coating and preparation method thereof

The invention discloses an Mg-Zn-Sr alloy biomaterial of a hydroxyapatite coating, which belongs to the technical field of materials. The material consists of a magnesium alloy matrix and the hydroxyapatite coating, wherein the magnesium alloy matrix comprises the following components in percentage by weight: 2 to 6 percent of Zn, 0.5 to 2 percent of Sr and the balance of magnesium; the hydroxyapatite coating comprises the following components in percentage by weight: 1.8 to 5.4 percent of Zn, 0.45 to 1.8 percent of Sr, 5 to 14.95 percent of hydroxyapatite and the balance of magnesium; and the thickness of the hydroxyapatite coating is 0.1 to 0.3 micron. The HA biological coating is deposited on the alloy surface by a reasonable process; and close to the human skeleton, the biomaterial has high specific strength and specific stiffness, can be automatically degraded and absorbed by the human body, and does not produce long-term stimulation effect on an organism.

Owner:NORTHEASTERN UNIV

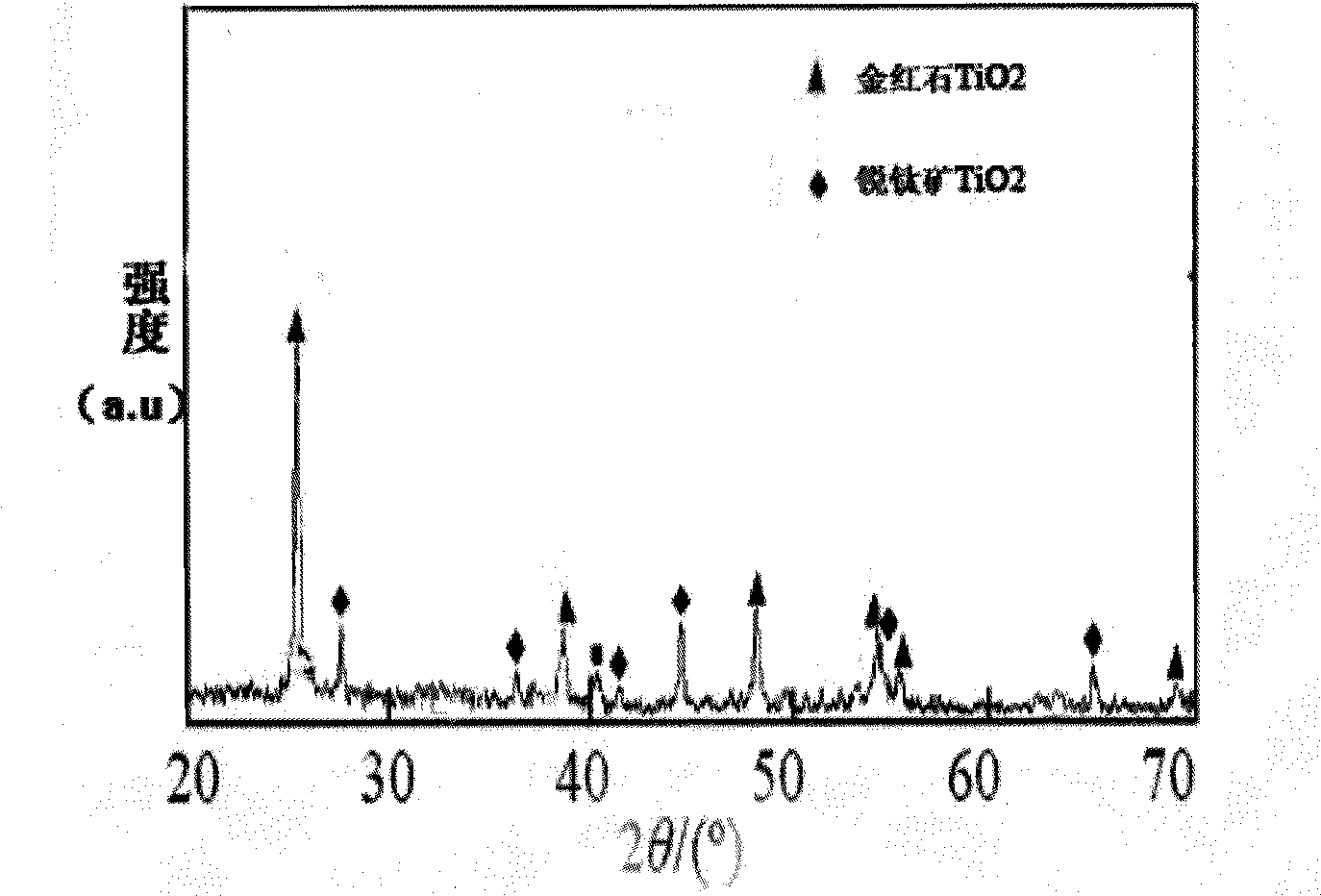

Titanium dioxide-hydroxyapatite gradient coating of medical titanium or titanium alloy surface and preparation method

InactiveCN102330086AImprove the problem of coating peelingPromote exfoliationSuperimposed coating processProsthesisMicro arc oxidationHydroxyapatite coating

The invention discloses a titanium dioxide-hydroxyapatite gradient coating of a medical titanium or titanium alloy surface and a preparation method. The inner layer of the titanium dioxide-hydroxyapatite gradient coating is a composite layer of the titanium dioxide and the hydroxyapatite while the outer layer of the titanium dioxide-hydroxyapatite gradient coating is a hydroxyapatite coating. The preparation method comprises the following steps of: using titanium or titanium alloy as anode and metal stainless steel as cathode; carrying out microarc oxidation on the titanium or titanium alloy by using a direct current pulse power supply; after forming a porous structure containing titanium dioxide and amorphous calcium and phosphorus on the surface of the titanium or titanium alloy, coating the hydroxyapatite on the surface; and finally obtaining the titanium dioxide-hydroxyapatite gradient coating. The porous structure formed after the microarc oxidation is beneficial for improving the bonding strength of a titanium or titanium alloy substrate and the costing; the titanium dioxide layer formed by the microarc oxidation has a transitional effect on the performance so that the residual stress between the substrate and a hydroxyapatite bioactive coating can be reduced. The preparation method has the advantages of simplicity and convenience in operation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

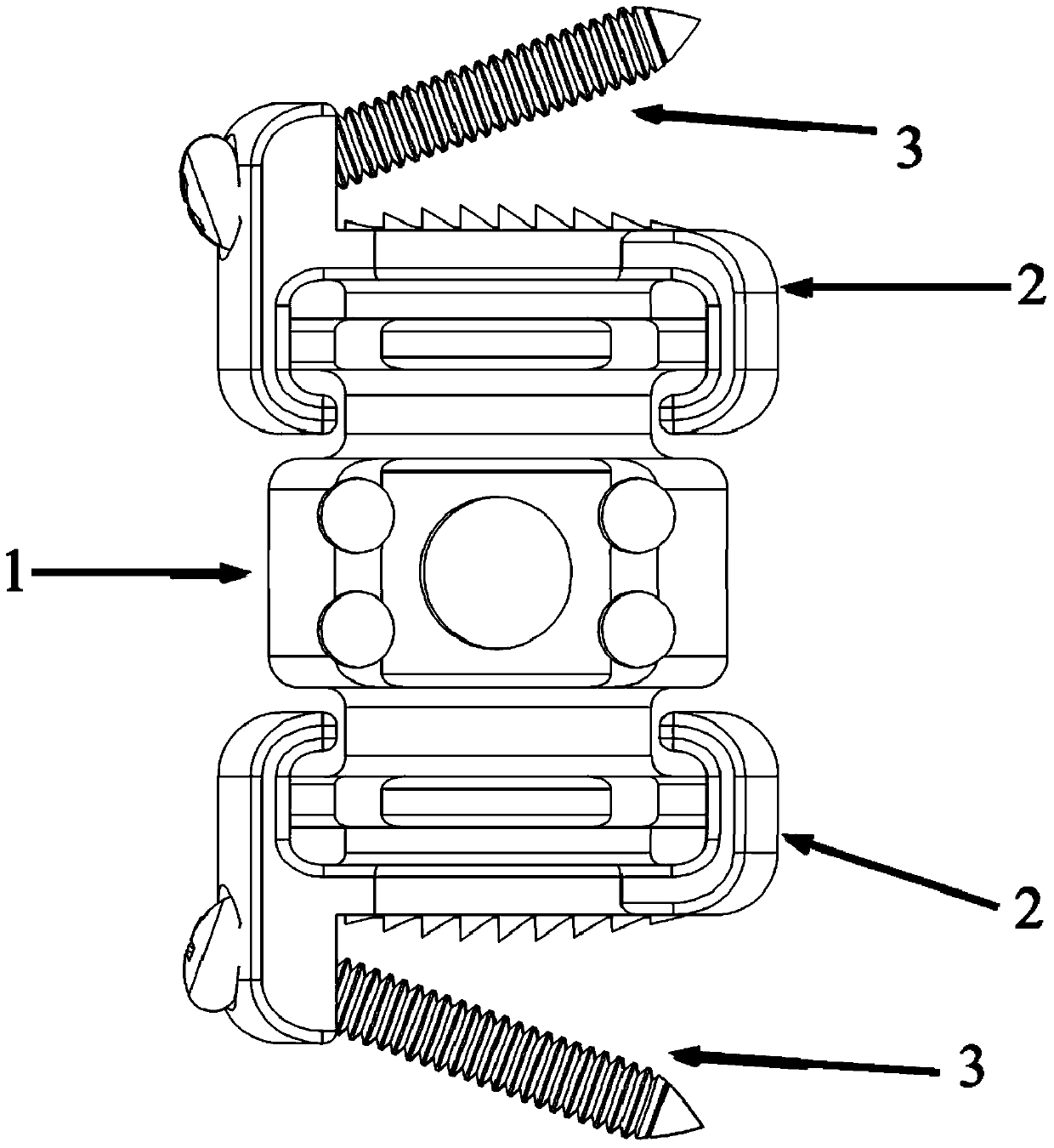

Dislocation prevention type non-fusion artificial cervical vertebra and intervertebral disc system

ActiveCN103800101ADistribute stressRelieve pressureSpinal implantsCoatingsGynecologyLamina terminalis

The invention discloses a dislocation prevention type non-fusion artificial cervical vertebra and intervertebral disc system comprising a vertebra body component and two end plate components, wherein the end plate components are connected to the upper end and the lower end of the vertebra body component respectively through a dome joint structure and L-type dislocation prevention structures on the front side and the rear side. End plate fixing screws are arranged on the two end plate components respectively. After corpectomy, the system can play a role in supporting at once, the motion function of the normal cervical vertebra is replaced through own interbody connecting parts, stress of the cervical vertebra can be dispersed in the motion process, internal stress of adjacent segment intervertebral discs and zygapophyseal joints can be reduced, and degeneration, which is caused by fusion, of the adjacent segments can be effectively prevented. In addition, stable bony fusion can be achieved through bone grafting and a hydroxyapatite coating on the surface of the system. The operation difficulty is small, trauma is small, and the system is convenient to popularize. Due to the fact that the dislocation prevention positions of the system are arranged, long-period stability can be achieved after the operation.

Owner:XI AN JIAOTONG UNIV

Method for surface modification of dental implant

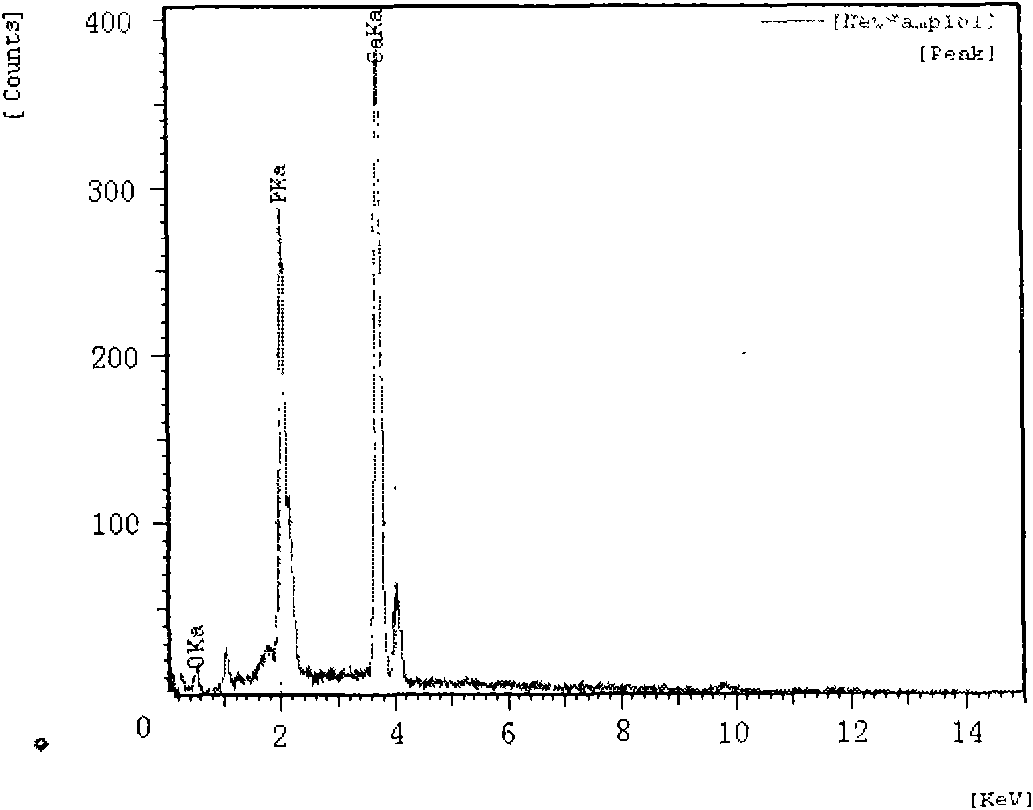

InactiveCN103361702AEvenly distributedUniform pore sizeImpression capsSurface reaction electrolytic coatingBiocompatibility TestingDrug biological activity

The invention mainly discloses a method for surface modification of a metal titanium dental implant. A titanium dioxide / hydroxyapatite composite coating with biocompatibility and biological activity is prepared on the surface of the dental implant by using a multi-electrode method; and the technology is suitable for modifying most of medical metal surfaces. The method mainly comprises the following steps of: (1) ultrasonically cleaning a mechanical face threaded titanium dental implant through ultrapure water, acetone and absolute ethyl alcohol and then drying; (2) uniformly arranging and distributing a titanium dioxide nanotube array with consistent aperture size on an anodic oxide layer of the implant as a buffer layer by using the multi-electrode method; (3) electrodepositing the hydroxyapatite coating in a calcium phosphate electric deposition solution by using the multi-electrode method to prepare the prepared hydroxyapatite coating which is uniformly distributed and has high purity and better biological activity; and (4) processing the material obtained by the process through high-temperature vacuum sintering. The titanium dioxide / hydroxyapatite composite coating prepared by the steps has better bonding strength and superior biological activity, so that the dental implant subjected to surface modification has a broader and longer-range application prospect.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation method of biodegradable magnesium alloy surface-modified hydroxyapatite coating

InactiveCN103446627AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a preparation method of a biodegradable magnesium alloy surface-modified hydroxyapatite coating. The method specifically comprises the following steps: cutting the magnesium alloy into samples; polishing the samples by aluminum oxide water-resistant abrasive paper to remove surface oxide layers of the magnesium alloy; sequentially ultrasonic-cleaning with deionized water and absolute ethyl alcohol for 5-30 minutes, and drying at room temperature; preparing a conversion liquid by adopting sodium dihydrogen phosphate dihydrate and calcium nitrate tetrahydrate; controlling the molar ratio of calcium and phosphorus at (1:1)-(2:1), the concentration of Ca<2+> at 0.01-0.2M and the P<5+> concentration at 0.01-0.2M; placing pre-treated matrix sample in the conversion liquid to be soaked for 5-100 hours to obtain a calcium and phosphorus coating; preparing the hydroxyapatite coating through the calcium and phosphorus coating by adopting a thermal treatment process: soaking the samples in calcium and phosphorus liquor for 24-72 hours; taking out and directly placing in a Muffle furnace; carrying out thermal treatment at 250-350 DEG C for 2-5 hours; detecting performance. According to the method provided by the invention, the samples taken out from the calcium and phosphorus liquor are placed in the Muffle furnace for direct thermal treatment, so that the method is simpler and easier to operate and control, and the samples can be converted into the hydroxyapatite coating to achieve a considerable corrosion resistant effect.

Owner:TONGJI UNIV

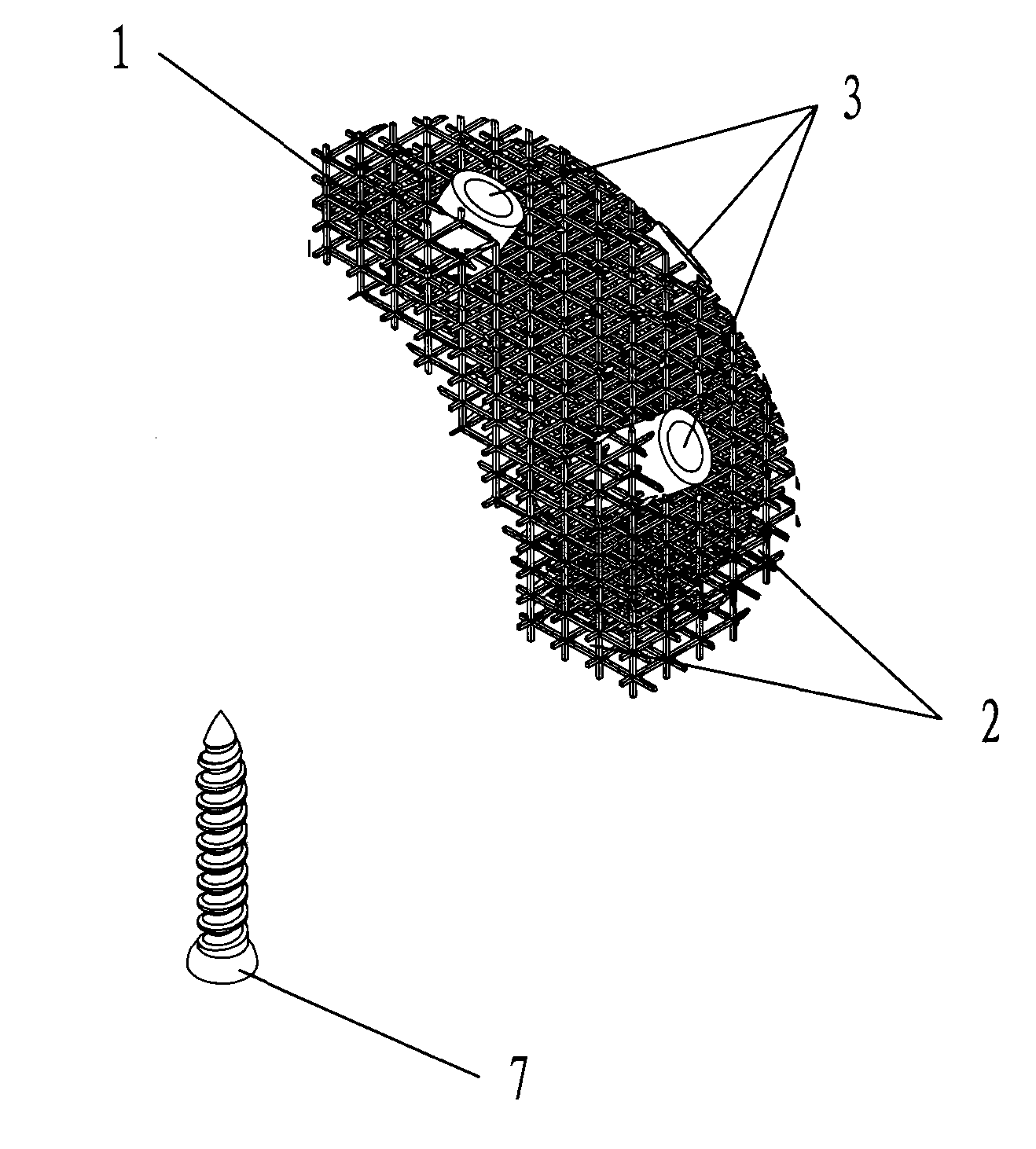

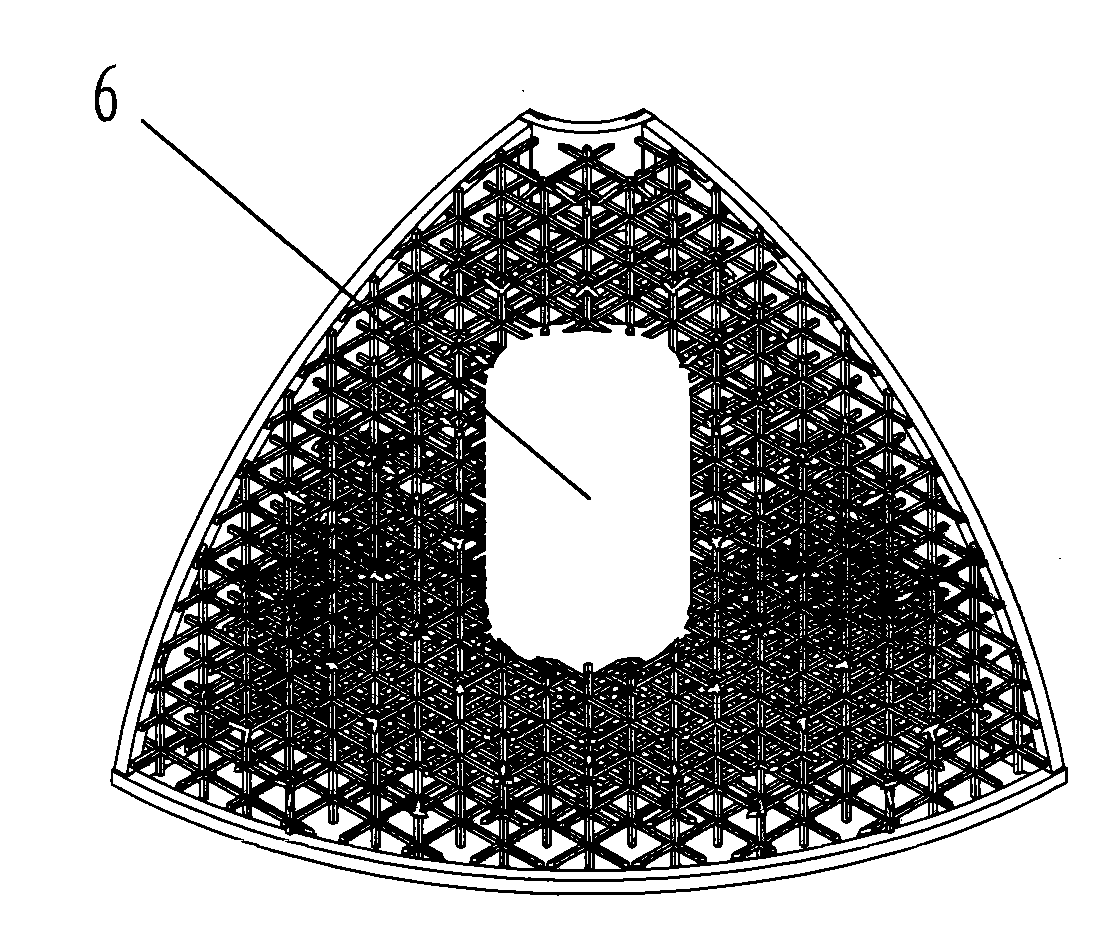

Acetabular bone deformity filler

InactiveCN102113924APromote ingrowthPrevent long-term looseningJoint implantsAcetabular cupsHydroxyapatite coatingMedicine

The invention relates to an acetabular bone deformity filler which comprises a bone deformity filler, a screw hole, reinforcing ribs and a reinforcing plate and is made into a three-dimensional porous dictyosome structure by adopting medical metals or biological ceramics. The surface and the interior of the three-dimensional porous dictyosome are provided with a plurality of mutually communicated pore canals, the acetabular bone deformity filler is provided with a screw hole in a suitable position and also provided with a bone-planting hole for containing bone-planting particles or bone meal in a suitable position, all or partial surface of the acetabular bone deformity filler is provided with a hydroxyapatite coating, and the acetabular bone deformity filler can be effectively prevented from loosening for a long time when external osseous tissue permeates and grows in the three-dimensional porous dictyosome and melts and grows with the bone-planting particles or the bone meal filled in the bone-planting hole into a whole after operational planting.

Owner:BEIJING AKEC MEDICAL

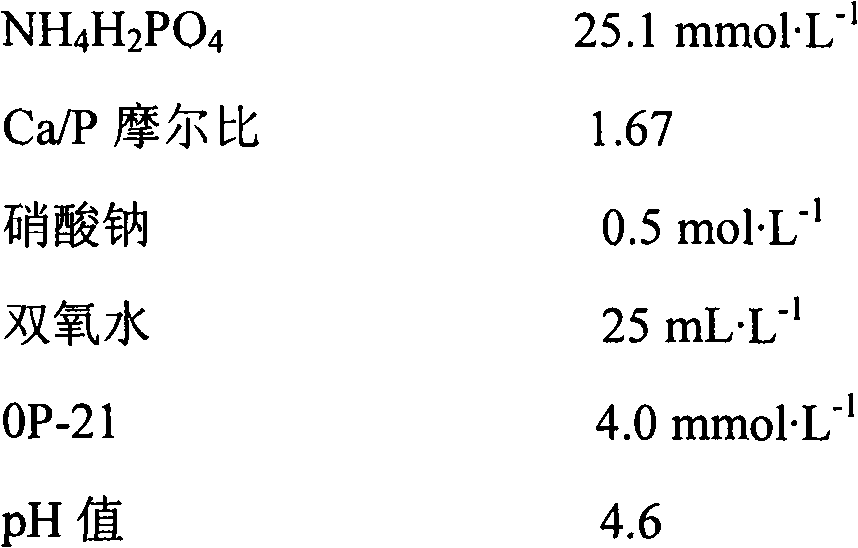

Electrodeposition preparation method for biomedical titanium base hydroxyapatite composite material

InactiveCN103014801ASimple operation processEasy to controlElectrolytic inorganic material coatingSupporting electrolyteApatite

The present invention discloses a preparation method for electrodeposition of a hydroxyapatite coating on the surface of titanium or a titanium alloy. The method comprises: adopting a pretreated titanium substrate or a pretreated titanium alloy substrate as a cathode, adopting a platinum-plated titanium mesh as an anode, heating an electroplating solution to a constant temperature of 40-80 DEG C, and adopting a constant current manner or a constant potential manner under a magnetic stirring condition to carry out electrodeposition, wherein a current density is 1.0-50.0 mA.cm<-2>, a deposition potential is 1.0-10.0 V, the electroplating solution comprises 20.2-80.0 mmol.L<-1> of Ca<2+> and 10.0-50.0 mmol.L<-1> of H2PO4<->, a Ca / P molar ratio is 1.6-2.0, a supporting electrolyte concentration is 0.1-1.0 mol.L<-1>, and the pH value is 4.2-5.0. According to the present invention, the hydroxyapatite coating prepared through electrodeposition by using the constant current manner or the constant potential manner has characteristics of fine crystal, smooth surface, strong bonding force with the substrate, good biological activity and mechanical property. The preparation method for the titanium base hydroxyapatite composite material has characteristics of mild reaction condition, avoidance of influence on material biological activity by a high temperature treatment, simple process, and low equipment investment, wherein a series of problems caused by expensive equipment and complex operation of the existing method are overcome with the preparation method.

Owner:TIANJIN XUANZHEN BIOMEDICAL TECH DEV

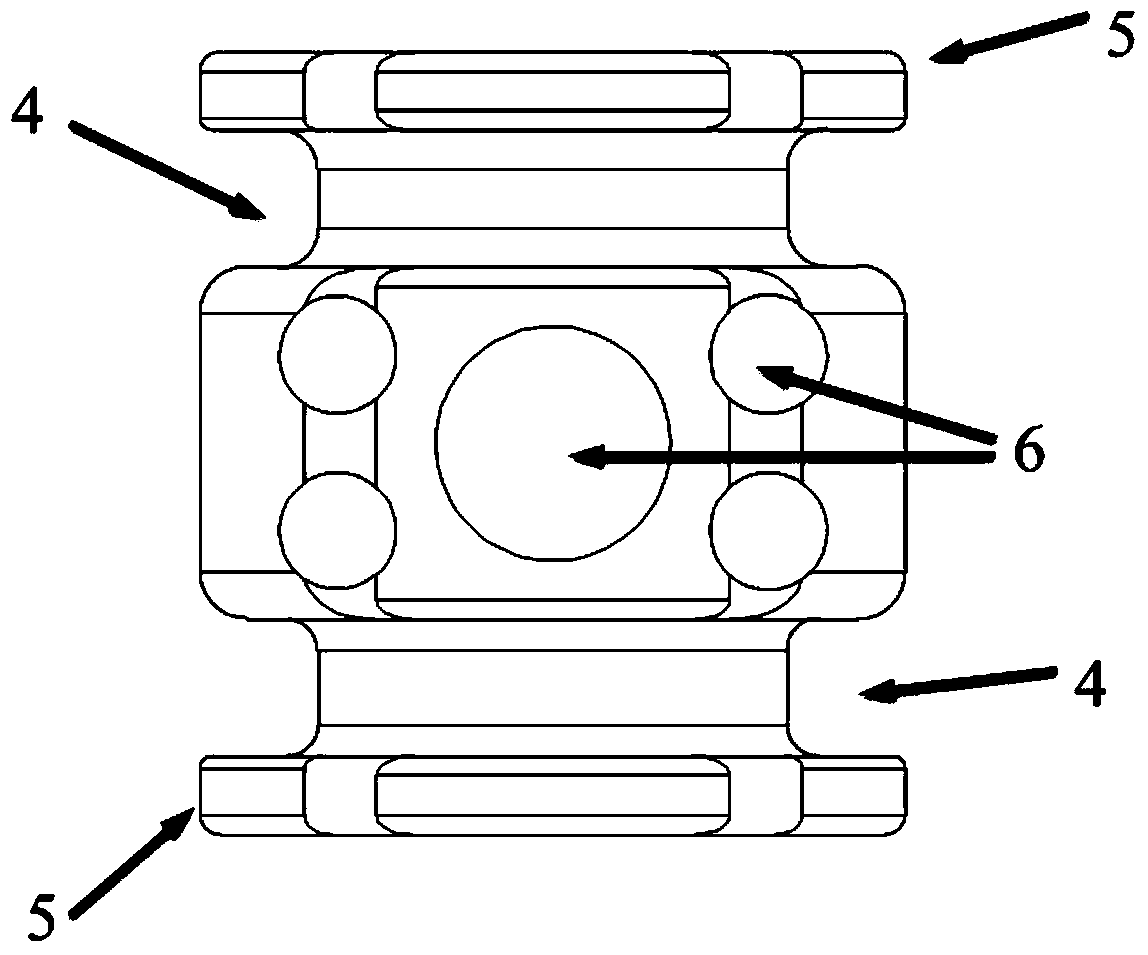

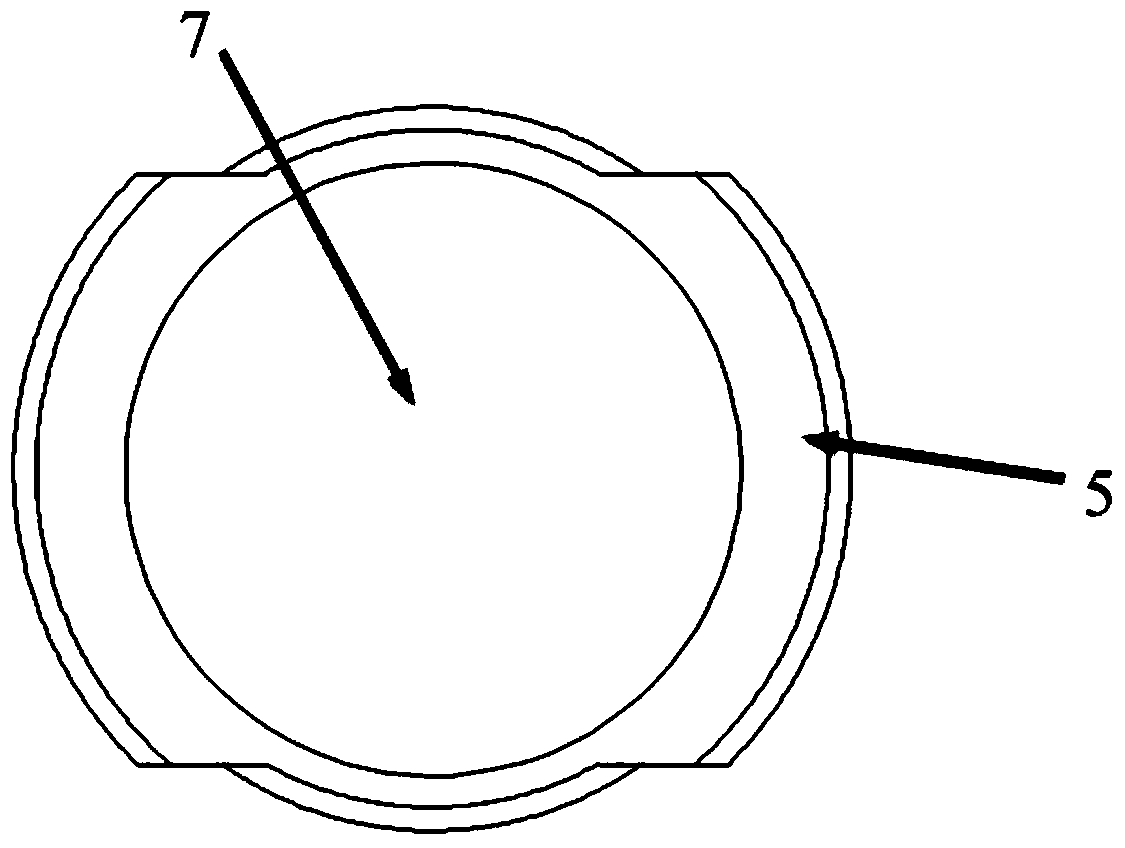

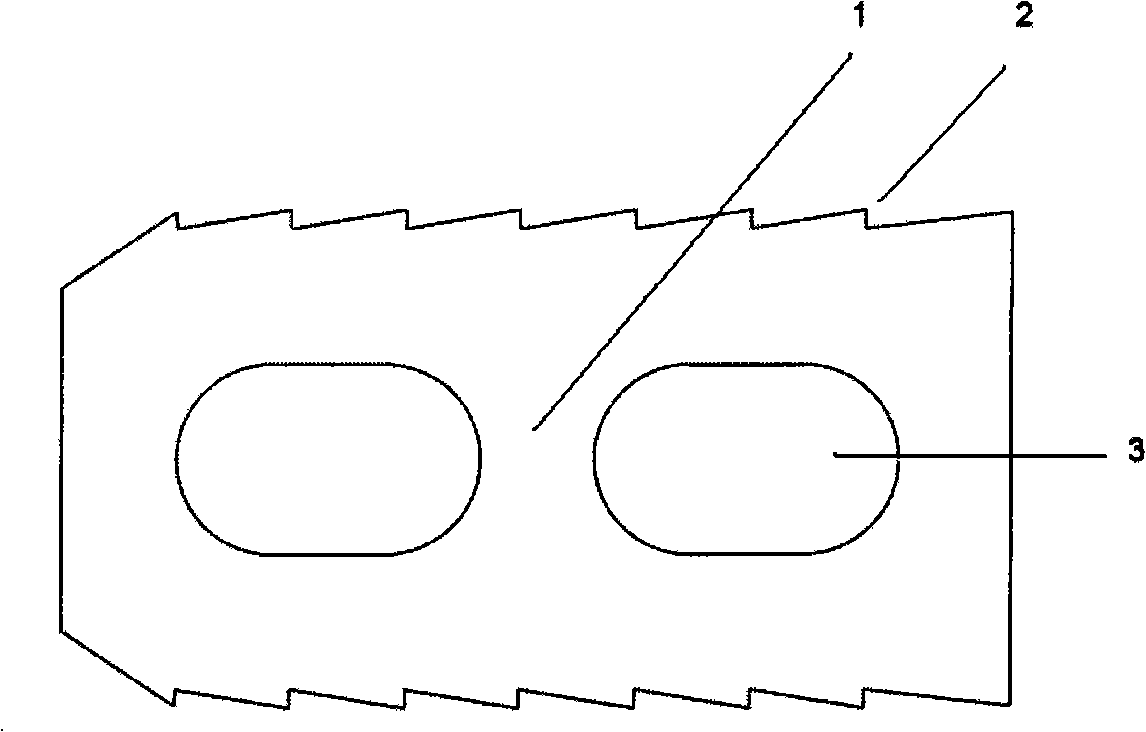

Intervertebral fusion device and method of preparing the same

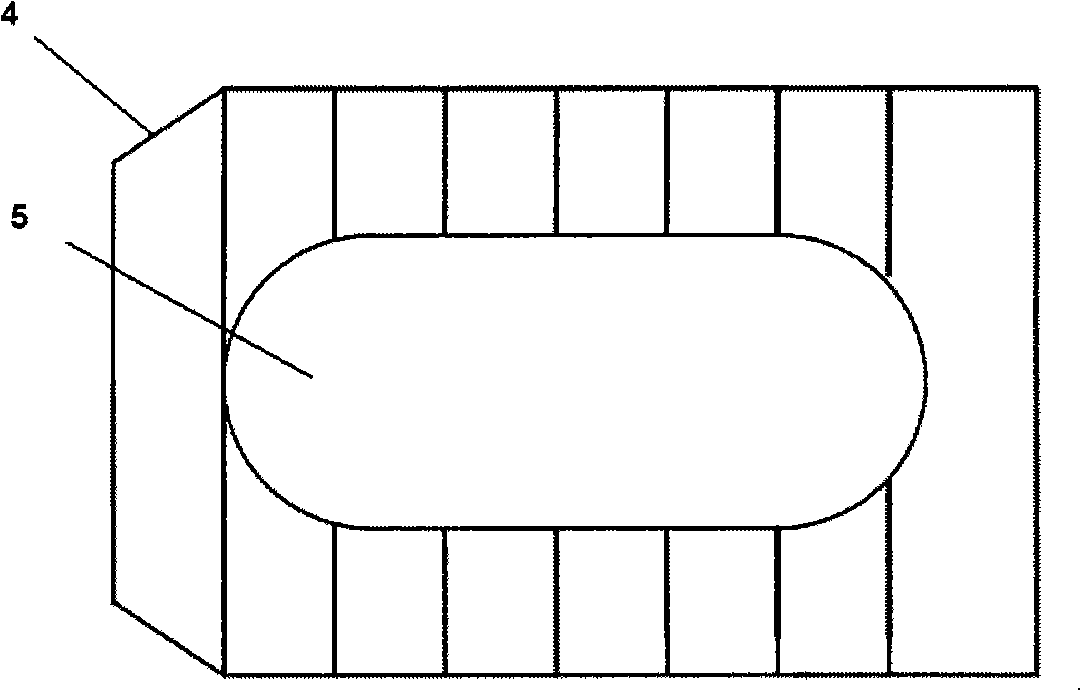

InactiveCN101254140AReasonable shape and structureReasonable design structureInternal osteosythesisSpinal implantsCarbon compositesSpinal cage

The invention provides an interbody fusion cage for posterior lumbar spinal surgery and a preparation method thereof, and belongs to the application field of biomedical composite materials. The rectangular interbody fusion cage has side surface drainage through-holes, end surface chamfers, and triangle toothed structures on the upper and the bottom surfaces. The preparation method comprises the following steps of profiling the interbody fusion cage with carbon / carbon composite material as target, and preparing hydroxyapatite coating layers on the upper and the bottom surfaces of the interbody fusion cage sequentially by sandblasting pretreatment, plasma spraying, vacuum heat treatment and simulated body fluid immersion. The interbody fusion cage prepared by the inventive method has the advantages of novel material, advanced preparation method, reasonable structural design and good osteoconductivity function.

Owner:SHANDONG UNIV

Preparation method of calcium phosphate ceramics/chitosan-hydroxyapatite composite coating porous material

InactiveCN101829358AHighlight substantive featuresSignificant progressCoatingsProsthesisMass ratioApatite

The invention provides a method for preparing a calcium phosphate ceramics / chitosan-hydroxyapatite composite coating porous material, which comprises steps of: selecting porous calcium phosphate ceramics with hole size of 300-600 microns and of a net-shaped hole structure, adding nano-hydroxyapatite in chitosan acetum with the mass percent of 0.5-5 percent to prepare a suspension, coating the surface of the porous calcium phosphate ceramics, and carrying out crosslinking process to obtain the calcium phosphate ceramics / chitosan-hydroxyapatite composite coating porous material, wherein the mass ratio of the hydroxyapatite to the chitosan in the chitosan-hydroxyapatite suspension is (6-1):(1-5). The invention has the technical scheme that a chitosan-hydroxyapatite coating is prepared on the porous calcium phosphate ceramics, thereby enhancing the surface bioactivity of the porous material; the coating is an organic-inorganic composite material and integrates the advantages of the chitosan and the hydroxyapatite, and the constitution of the surface of the material can be conveniently adjusted according to the actual need, thereby endowing the porous material with better combination property.

Owner:SUZHOU PULIN BIO TECH

Process for preparing titanium-based hydroxylapatite/titanium oxide nanotube composite coating

InactiveCN101311328AHigh bonding strengthReduce residual stressSurface reaction electrolytic coatingSuperimposed coating processWater bathsTio2 nanotube

The invention discloses a method for preparing titanium base hydroxy apatite or titanium oxide nano tube composite coating, comprising the following steps: the pure titanium is taken as an anode while a platinum plate is taken as a cathode; in the dimethyl sulfoxide solution containing HF with the weight percent of 1 to 4 percent, under the voltage of 20 to 70 V, the pure titanium and the platinum plate are oxidized for 2 to 10 hours in the water bath with the temperature of 10 to 30 DEG C; then, a titanium oxide nano tube array film is arranged in aqueous solution which contains 0.1 to 0.5mol per liter of CaC12, 0.1 to 0.5 mol per liter of NaH2PO4 and 0.2 mol per liter of EDTA. The PH value of the solution is adjusted by NaOH to be 4 to 6. Under the condition of the temperature of 100 to 200 DEG C and hydrothermal reaction of 2 to 10 hours, the hydroxyapatite is induced to be crystallized and deposited on the surface of the array film of the nano tube and a novel hydroxyapatite coating layer which takes the array film of the titanium oxide nano tube as a buffer layer is formed. The method is characterized by taking the array film of the titanium oxide nano tube as the buffer layer, which reduces the residual stress caused by mismatch of coefficient of heat expansion of the hydroxyapatite and the titanium base and enhances the binding strength of the coating layer and the base interface.

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com