Patents

Literature

135results about How to "The preparation process conditions are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

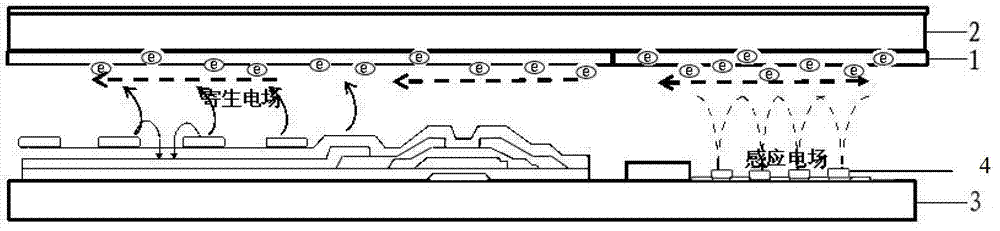

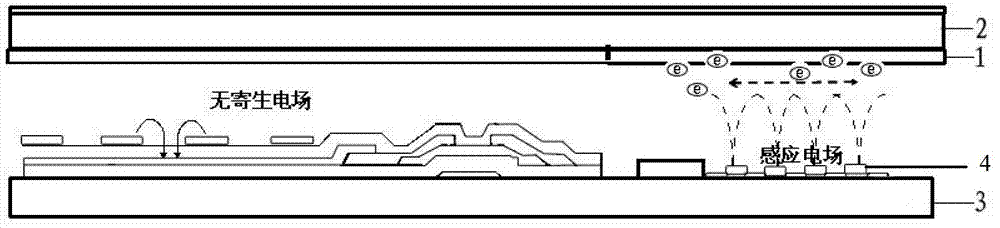

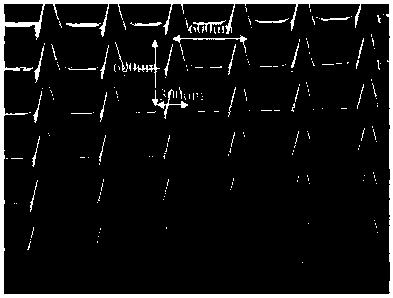

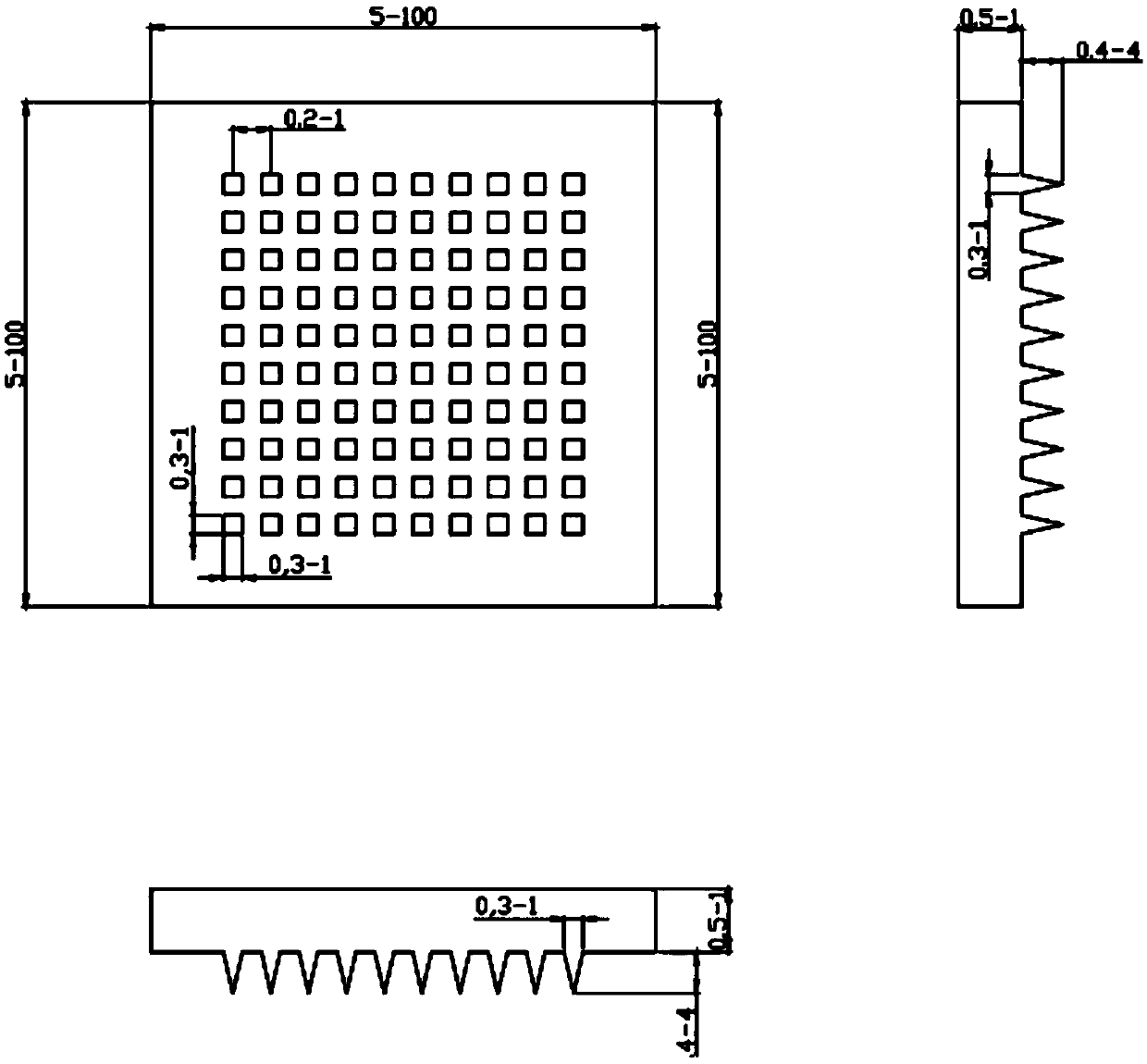

Macromolecular soluble microneedle used for cutaneous penetration of polypeptide and protein medicines and preparation method of macromolecular soluble microneedle

InactiveCN105078880AHigh concentrationThe preparation process conditions are simplePeptide/protein ingredientsPharmaceutical delivery mechanismSide effectHigh volume manufacturing

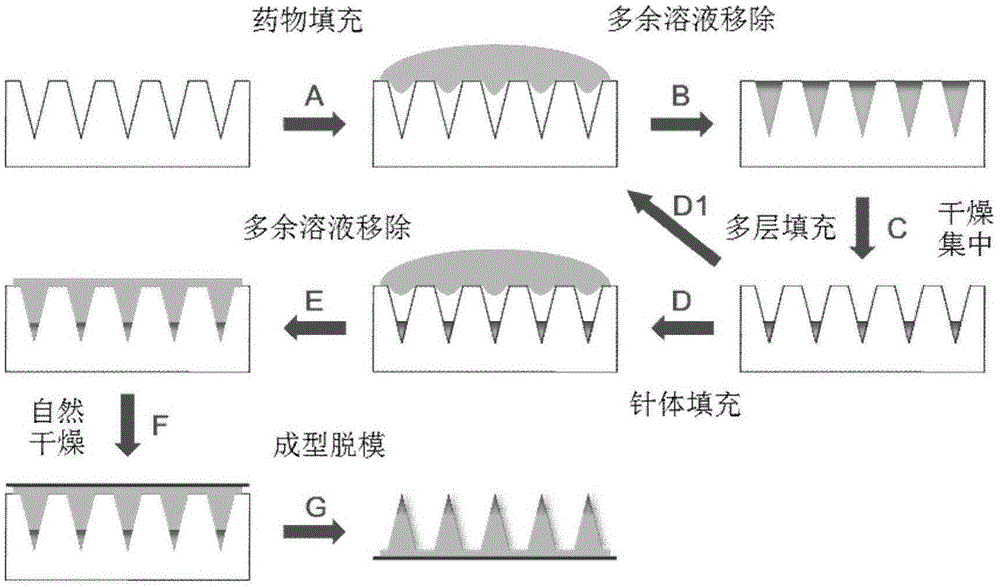

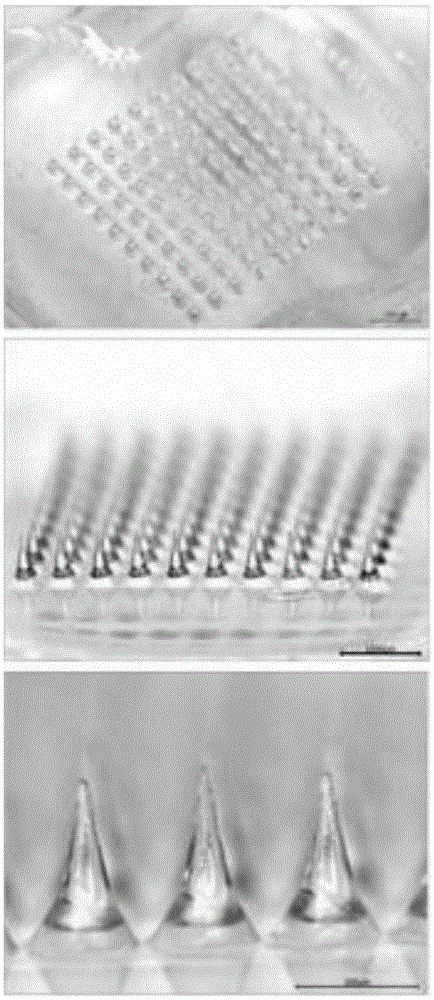

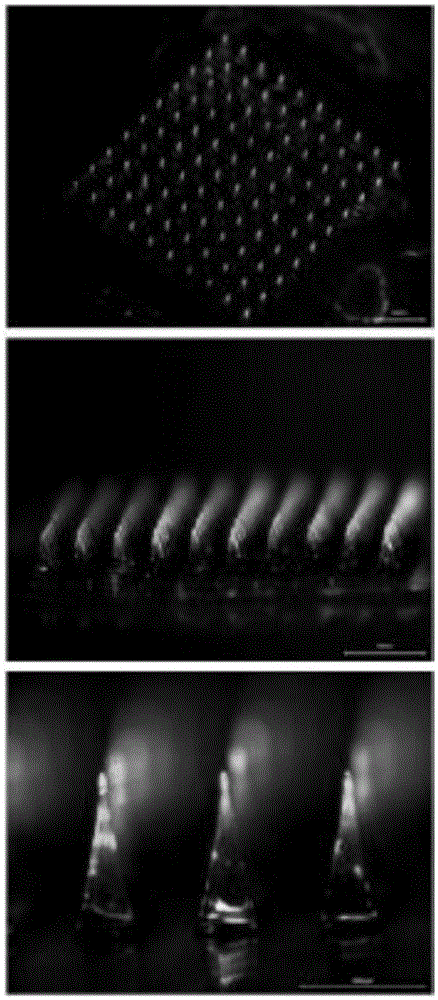

The invention discloses a macromolecular soluble microneedle used for polypeptide and protein medicines. The macromolecular soluble microneedle comprises a base as well as a needle body on the base and a needle point on the needle body, wherein the base and the needle body are made of a mixture of a high polymer material and a stabilizer; and solid active peptide or protein medicines are embedded into the needle point. The concentration degree of the medicines embedded in the needle point of the macromolecular soluble microneedle is relatively high, and nearly no residual medicines exist on the bottom of the needle body, so that the administration efficiency and the administration accuracy are greatly improved; in addition, the part entering the subcutaneous tissue of the needle body can rapidly dissolve, and further degrade to be completely absorbed by the tissues without toxic or side effects, so that the possible needle breaking risk existing in the microneedle made of other materials such as metal, glass and silicon is avoided. The preparation method of the macromolecular soluble microneedle is carried out under simple technological conditions, is low in price, and suitable for volume production, and the macromolecular soluble microneedle can be widely applied to the field of cutaneous penetration of macromolecular medicines.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing active carbon carrying precious metal catalyst

InactiveCN102658133AReduce usageAvoid acid and alkaliSulfonic acid preparationMetal/metal-oxides/metal-hydroxide catalystsEthylene diamineActivated carbon

The invention discloses a method for preparing an active carbon carrying precious metal catalyst. The method comprises the following steps of: immersing an active carbon carrier into an ethylene diamine tetraacetic acid disodium salt (EDTA disodium salt for short) aqueous solution for pretreatment; then mixing the pretreated active carbon carrier and water to prepare carbon slurry; adding a nitrate solution or chlorate aqueous solution which contains precious metal into the carbon slurry, and stirring at the temperature between 25 and 90 DEG C for 2 to 6 hours; adding an alkaline aqueous solution under the condition of the temperature between 25 and 80 DEG C, adjusting the pH value of the reaction solution until the pH value is 6 to 9; stirring at the constant temperature between 25 and 80 DEG C for 0.5 to 4 hours, thus obtaining slurry; and post-treating the slurry, thus obtaining the active carbon carrying precious metal catalyst. According to the method, acid and alkaline are not used during pretreatment of the active carbon carrier, so that environment friendliness is realized; during preparation of the catalyst, any auxiliary catalyst is not added, so that the cost is saved, and the process is simplified; the preparation process is simple in condition; the requirement on equipment is low; and industrialization is facilitated.

Owner:杭州凯大催化金属材料股份有限公司

Method for preparing superfine groundnut oil

ActiveCN101433244AThe preparation process conditions are simpleAroma production is easy to controlEdible oils/fatsNeutral proteaseHydrolysate

The invention discloses a method for preparing fragrant peanut oil, which comprises the following steps: 1) a raw material is pretreated, wherein a peanut raw material is selected, is mixed with water, then is soaked, and then is subjected to coarse grinding and fine grinding; 2) complex enzyme is hydrolyzed, wherein the complex enzyme with neutral protease or alkali protease and flavor enzyme is selected to perform hydrolysis on the pretreated peanut raw material; 3) auxiliary materials are added, wherein reducing sugar, amino acid and peanut oil are added into a hydrolysate of the peanut raw material obtained through the treatment in step 2); 4) fragrance is generated through a thermal reaction, wherein the hydrolysate of the peanut raw material and the auxiliary materials are stirred evenly, then are transferred into a high pressure reaction kettle to be heated, and then are cooled to room temperature; and 5) the fragrant peanut oil is prepared, wherein a reaction liquid obtained after the treatment in step 4) is added with refined peanut oil, is quickly stirred first, and then is slowly stirred under certain temperature conditions, and water and impurities are removed through centrifugal separation to obtain the fragrant peanut oil product. The method can obtain flavor precursors of the fragrant peanut oil, namely amino acid and small peptide through the hydrolysis of the peanut raw material by the complex enzyme, and form the peanut oil with peanut fragrance flavor through the heating.

Owner:嘉里特种油脂(上海)有限公司

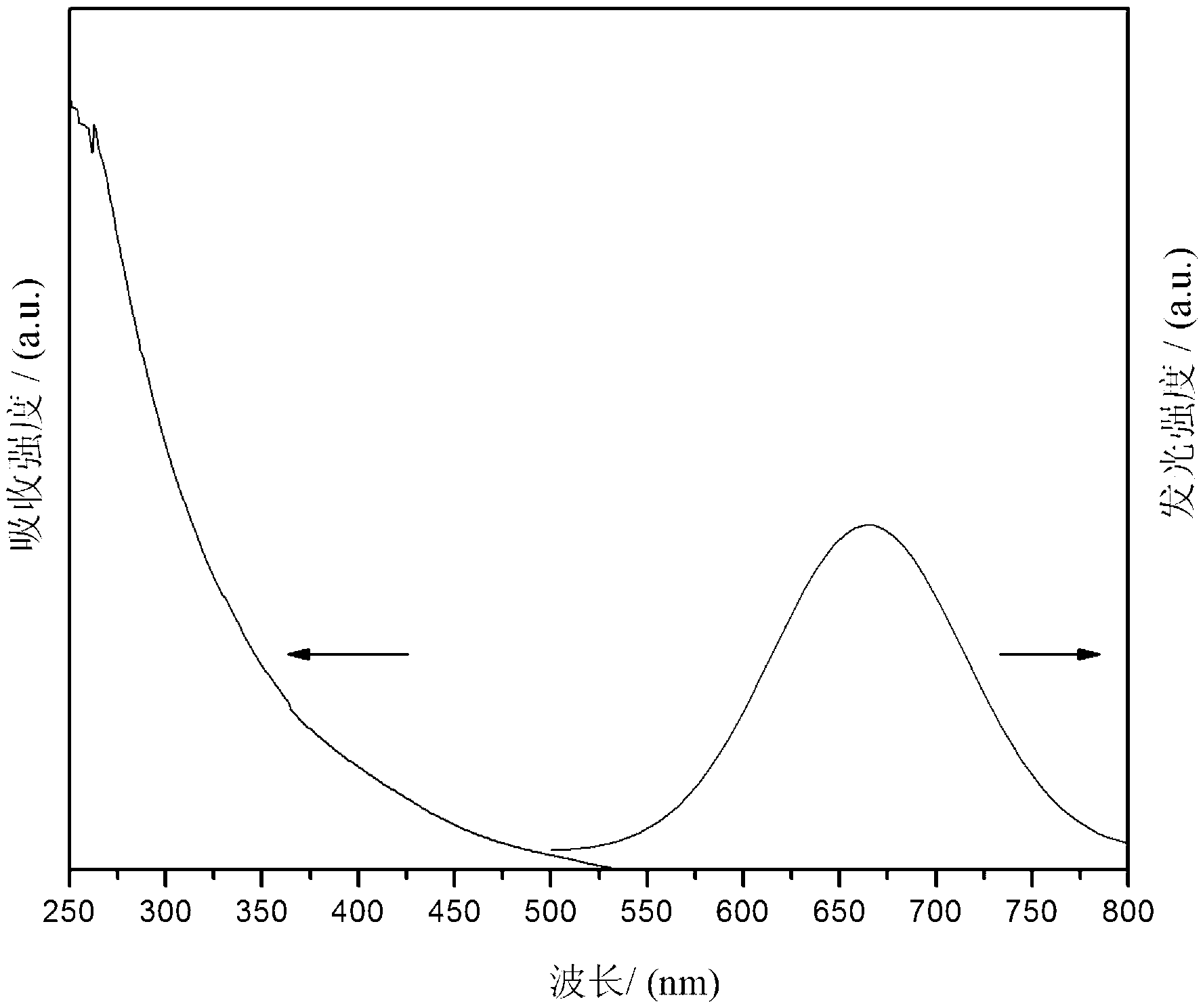

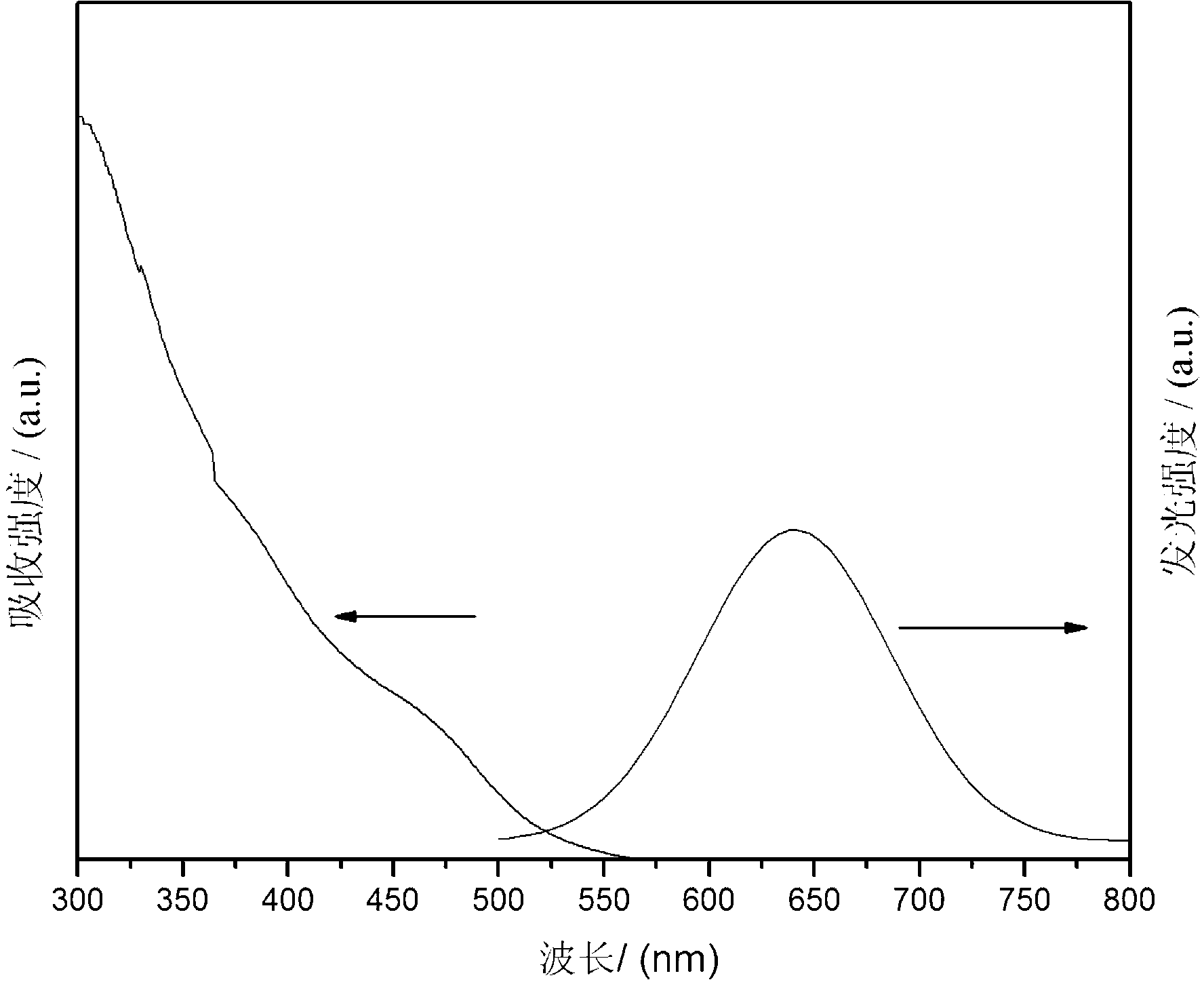

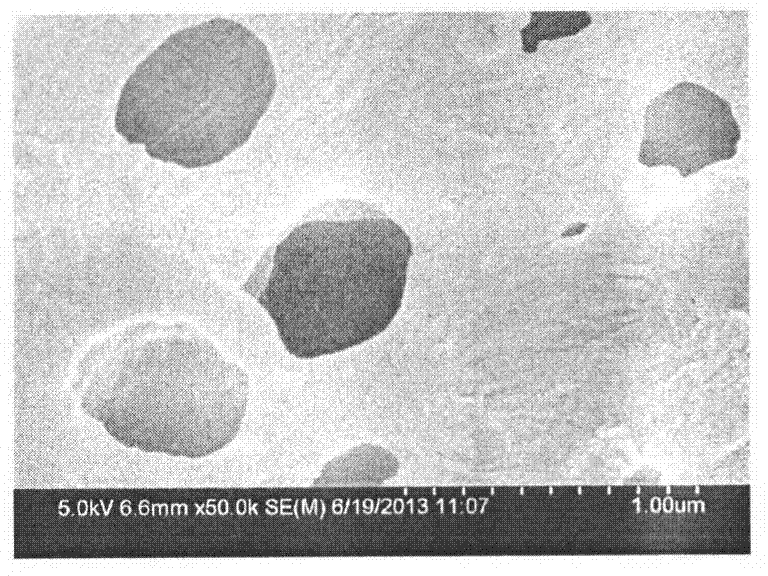

Method for preparing mononuclear AgInS2 quantum dot

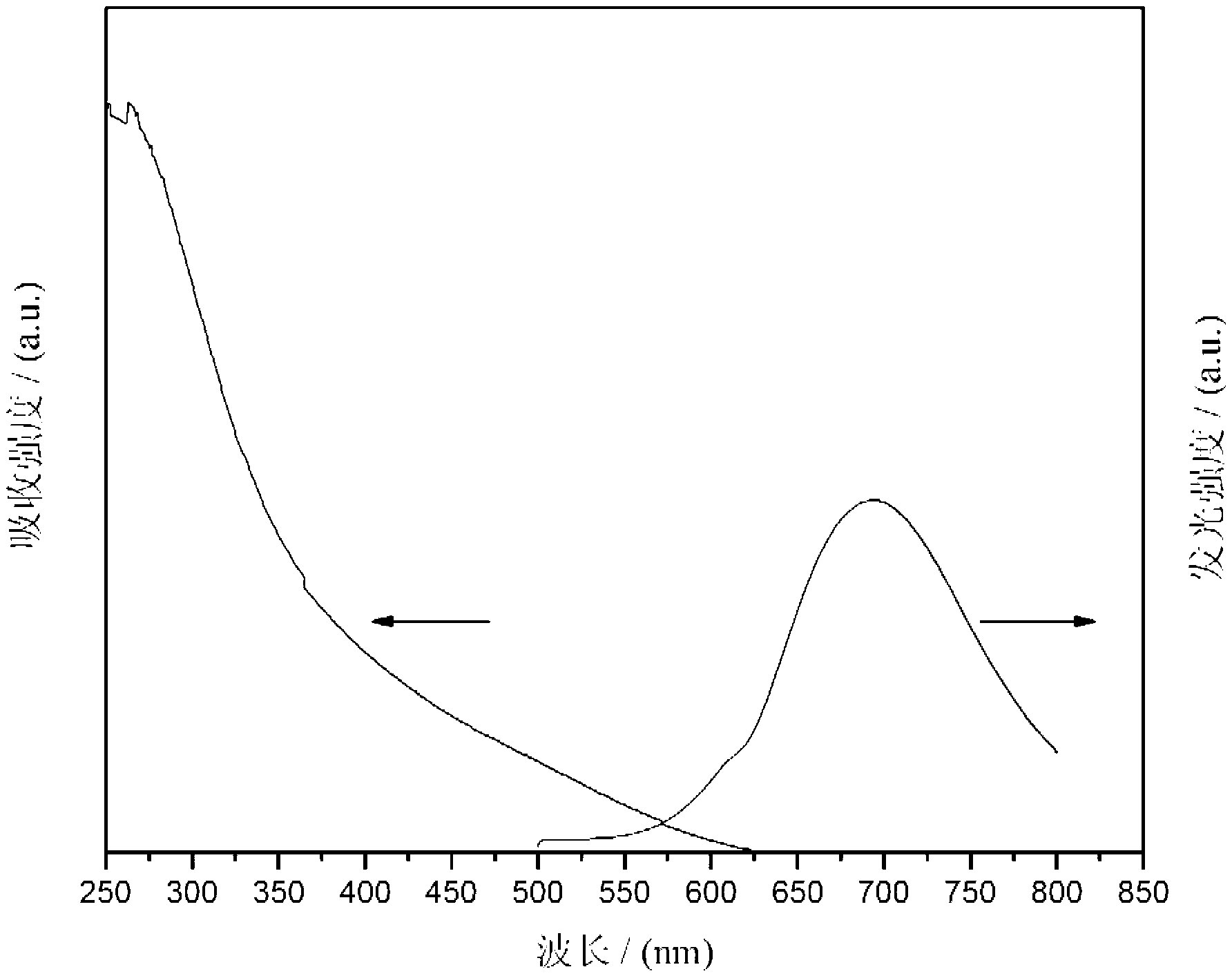

ActiveCN103265949AReduce the temperatureHigh fluorescence quantum yieldLuminescent compositionsQuantum yieldSolvent

The invention discloses a method for preparing mononuclear AgInS2 quantum dots, comprising the following steps of: (1) adding AgNO3, InCl3, oleic acid, dodecyl mercaptan and solvent octadecene in a reaction container, to obtain an Ag and In precursor mixed liquor; (2) adding sulfur powder into oleylamine, and heating until the sulfur powder is fully dissolved, to obtain an S precursor solution; (3) under protection of argon, heating the Ag and In precursor mixed liquor from room temperature to 50-80 DEG C, and maintaining for 10-60min, in order to discharging air; and then raising temperature to 100-120 DEG C, maintaining for 1-5min, and injecting the S solution, wherein a mol ratio of Ag to S is 1:2, and reaction time is 5-90min; (4) sampling, and dissolving a sample into hexane, to obtain a AgInS2 quantum dot solution; and (5) adding waterless ethanol into the AgInS2 quantum dot solution obtained in the step (4), and centrifugally separating to obtain the mononuclear AgInS2 quantum dots. The method of the invention further raises fluorescent quantum yield of the mononuclear AgInS2 quantum dots prepared by a thermal injection method, in order to reach practical application requirement.

Owner:WENZHOU UNIVERSITY

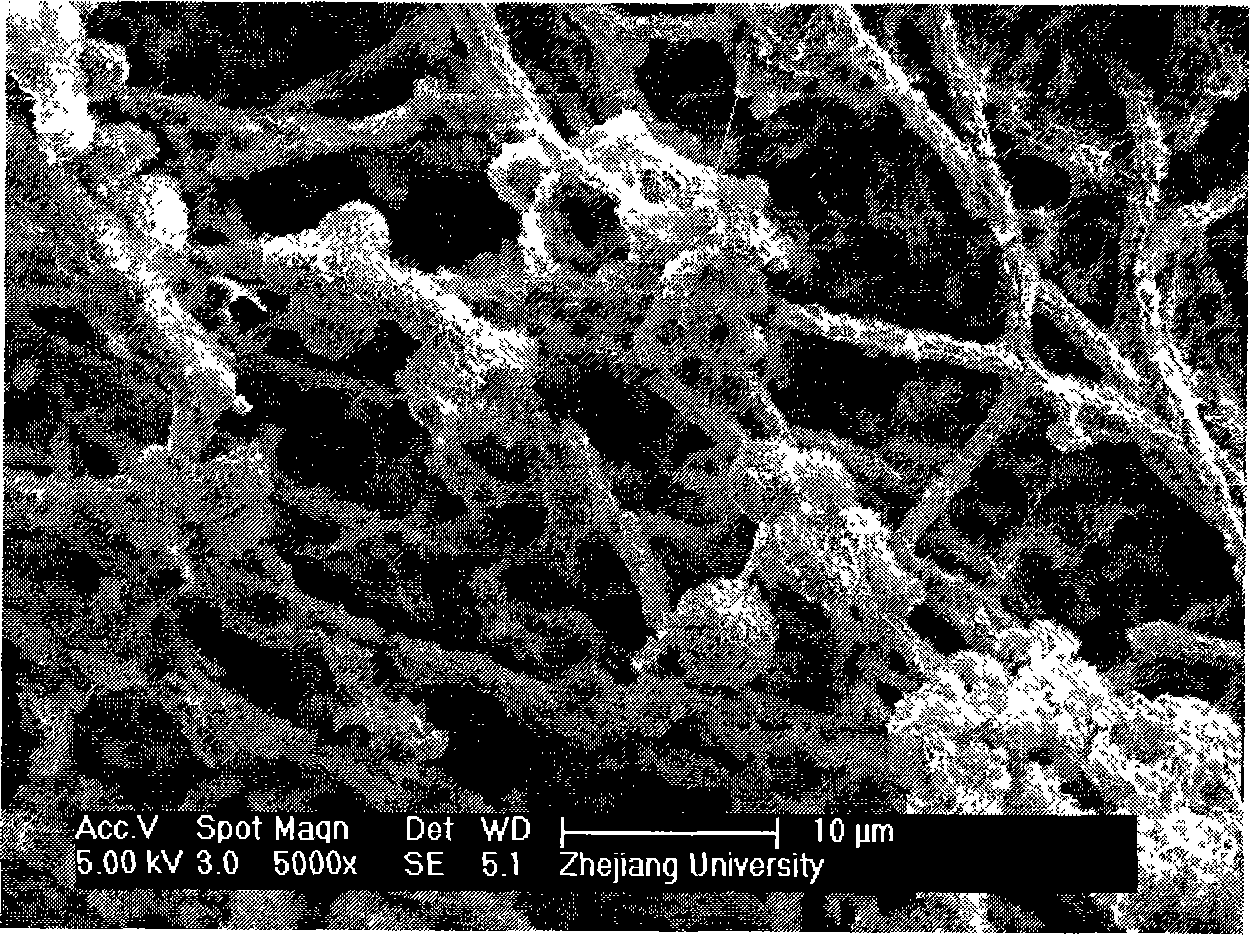

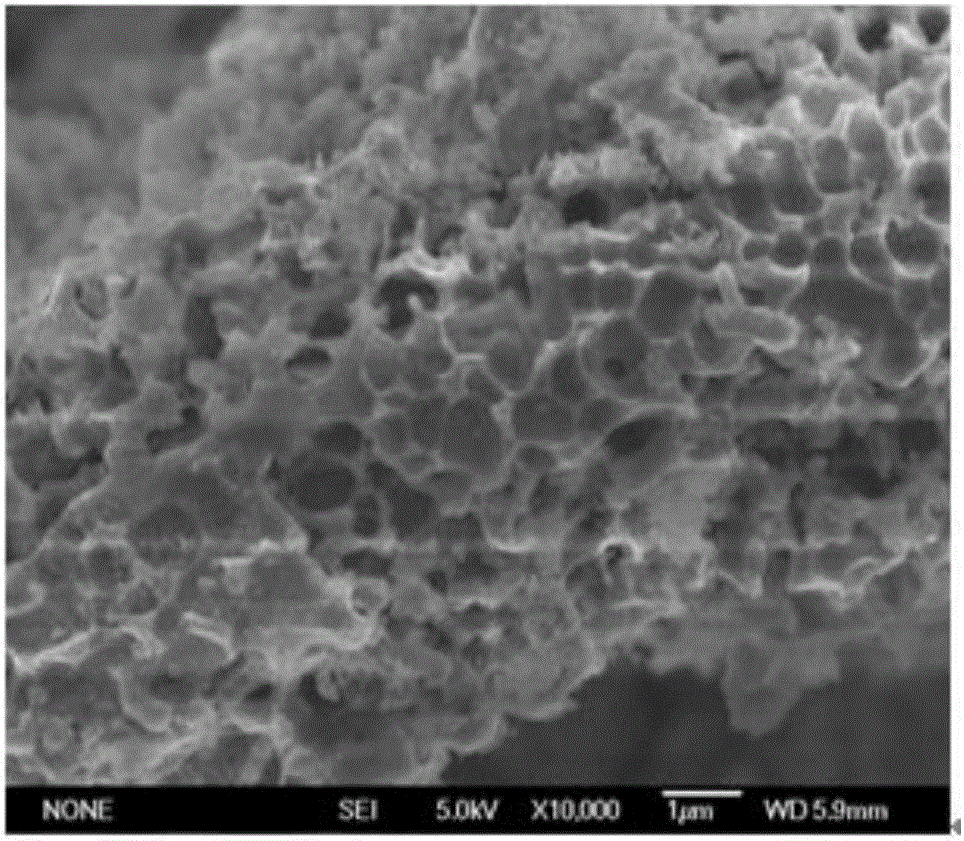

Method for preparing similar bone bioactivity coatings medical material by galvano-chemistry method

InactiveCN101156963AThe preparation process conditions are simpleEfficient preparation process conditionsElectrolytic inorganic material coatingElectrolysisApatite

The invention discloses bone-like bioactive coating medical material which is prepared by adopting an electrochemical method. The invention adopts an electrolytic deposition method and imitates the forming process of a natural bone. Electrolyte solution contains calcium, a phosphorous compound and bone matrix collagen, a medical metal transplant body is taken as a working electrode, platinum is taken as a reference electrode, the electrode reaction causes partial pH value of the electrolyte solution around the medical metal transplant body to ascend, thereby leading collagen to be gelatinized, in cooperation with the deposition of calcium phosphate mineral, the bone-like bioactive coating is formed on the medical metal surface. Through the adoption of the invention method, the bioactive coating acquired on the surface of the metal transplant body is similar to the natural bone in the component and the structure, and has favorable biological activity, thus the disadvantages that the biological activity of the business use hydroxyapatite coating is limited, the required curing time is long, etc. are solved. The preparation process of the invention is simple, highly effective and easy to be industrialized.

Owner:ZHEJIANG UNIV

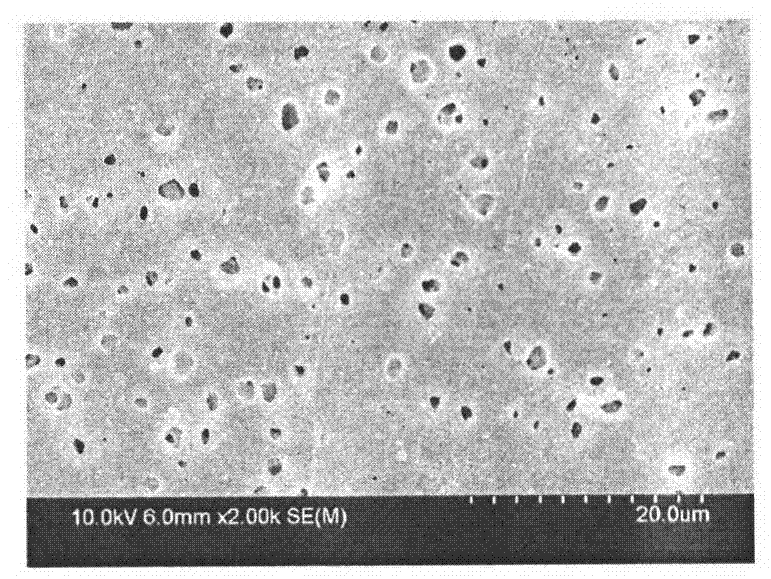

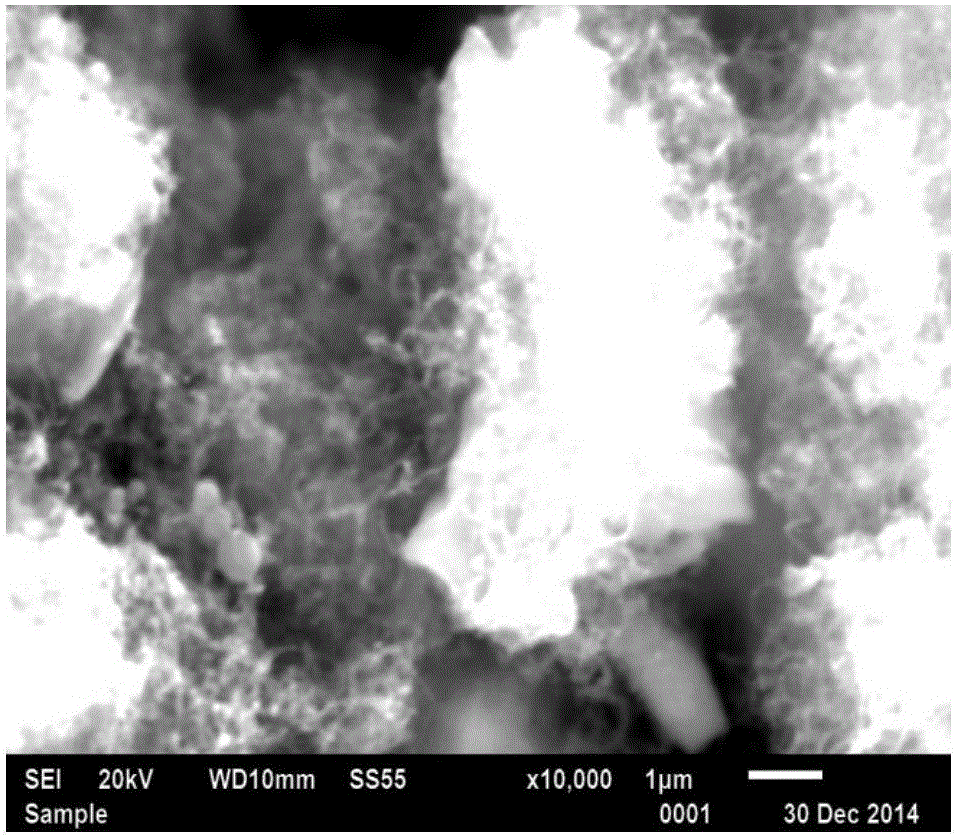

Multi-walled composite conductive carbon nanotube-polyvinylidene fluoride ultrafiltration membrane and preparation method thereof

InactiveCN103785305AImprove hydrophilicityImprove conductivitySemi-permeable membranesUltrafiltrationCarbon nanotube

The invention provides a multi-walled composite conductive carbon nanotube-polyvinylidene fluoride ultrafiltration membrane and a preparation method thereof. The multi-walled composite conductive carbon nanotube-polyvinylidene fluoride ultrafiltration membrane is prepared from polyvinylidene fluoride, N-N-dimethylacetamide and multi-walled carbon nanotubes. According to the conductive ultrafiltration membrane, the insulated polyvinylidene fluoride serves as a film-forming matrix, the carboxylated multi-walled carbon nanotubes serve as a nano conductive filler, the multi-walled carbon nanotubes are uniformly dispersed in the matrix by adopting an ultrasonic dispersion method, and the multi-walled composite conductive carbon nanotube-polyvinylidene fluoride ultrafiltration membrane is prepared by adopting a wet-phase inversion method. Because the carbon nanotubes have the extremely high conductivity, the conductive performance of the composite membrane is well improved due to the addition of the carbon nanotubes, and the strength and the hydrophilicity of the membrane are enhanced. Therefore, the membrane can be effectively prevented from being polluted during water treatment, and the service life of the membrane is prolonged. The preparation method and a process flow are simple, the operation is convenient, the cost is low, equipment is not required to be transformed, and the operability is high.

Owner:TIANJIN POLYTECHNIC UNIV

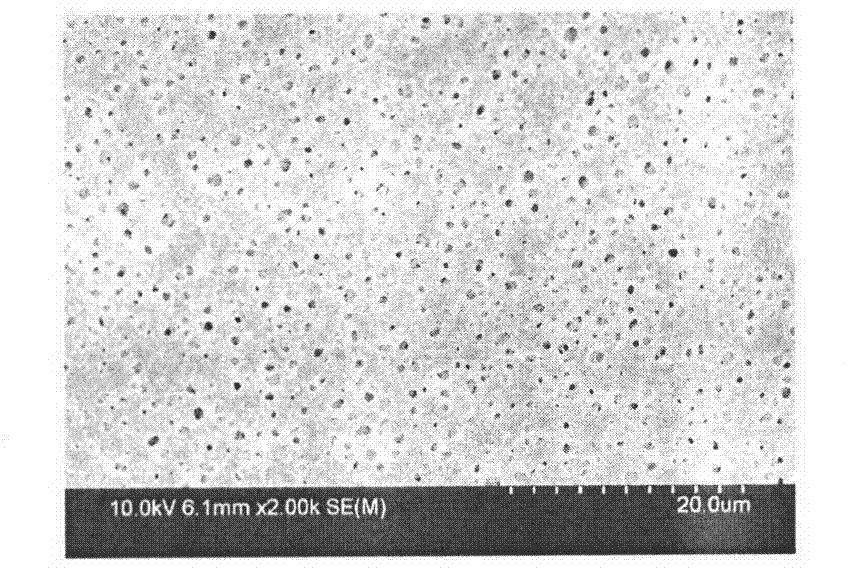

Method for preparing porous silicon carbon nanotube composite negative electrode material of lithium ion battery by diatomite

InactiveCN105845911AUnique pore structurePore structure retentionCell electrodesSecondary cellsCarbon compositesPtru catalyst

The invention relates to a method for preparing a porous silicon carbon nanotube composite negative electrode material of a lithium ion battery by diatomite. The method is characterized in that the diatomite is a silicon source, comprises the steps of preparing porous silicon, preparing a porous silicon matrix surface supported catalyst precursor and preparing a porous silicon carbon nanotube composite material, has the advantages of availability in raw material, low cost, clearness in morphology of the prepared porous silicon, high capacity of the silicon carbon composite material, cycle stability, high production efficiency, low cost and the like, and is suitable for industrial production. Under the test in which current density is 100mA / g, the initial reversible specific capacity of a negative electrode, prepared from the material, of the lithium ion battery reaches 1,529.1mAh / g, the reversible specific capacity reaches 885.4mAh / g after circulation of 40 times, and the subsequent cycle capacity is almost unchanged; and through the rate performance test, the reversible specific capacity is restored to about 800mAh / g when the current density is restored to 100mA / g, and the test shows that the material is high in connection tightness performance.

Owner:NORTHEAST DIANLI UNIVERSITY

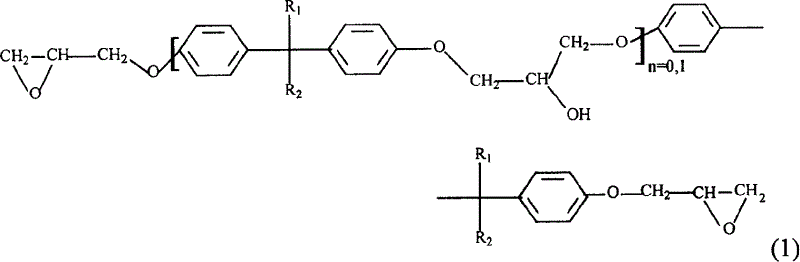

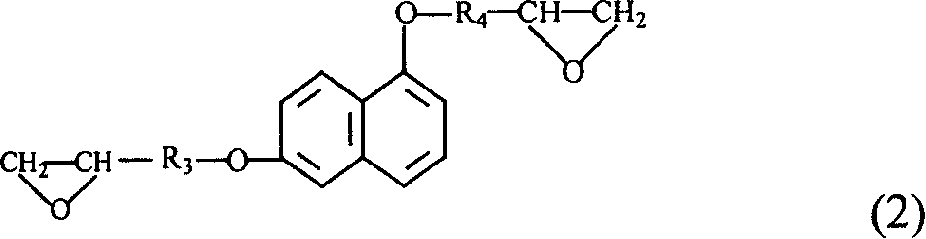

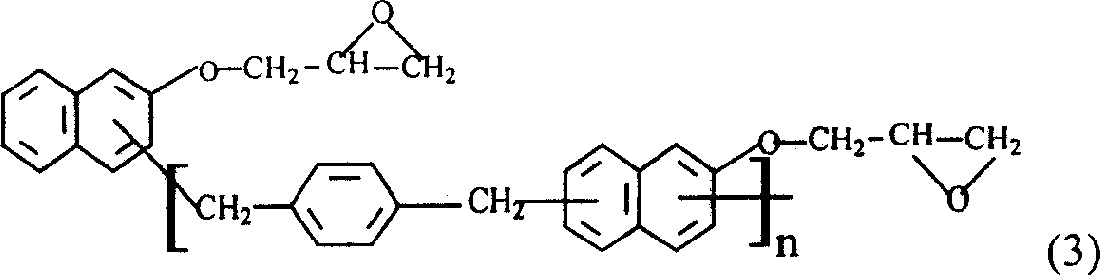

Modified epoxy resin adhesive and its preparation process

InactiveCN1670106AResistant to bendingThe preparation process conditions are simpleEpoxy resin adhesivesEpoxideProper weights

The invention discloses a thermosetting multi-component modified epoxy binder for using in the middle between IC cores and insulating underlay base boards and its preparation process, which belongs to the electronic device packaging technical field. The said binding agent is made of combined modified epoxide resin, latent curing agent, filler and addition auxiliary agent in a correct proportion, wherein the combined modified epoxide resin is made of bisphenol ethylene oxide resin as the main resin, alicyclic rings and naphthalene epoxide resin as the modified resin, the said latent curing agent is aromatic terminal group amine or alicyclic ring terminal group amine, the said filler is inorganic powder prepared by tensioactive treatment, the said addition auxiliary agent contains toning agent, accelerating agent, flame retardant and phenols curing agent. The said binding agent in the invention has many advantages such as high glass transition temperature, high adhesive property, high heat resistance, middle-and-low graded curing temperature and short curing time.

Owner:徐良衡

Degradable nanometer composite material for biological and medical use

A nanometer-grade medical decomposable composite material and its preparation method. By different Ca / P, different crystallizing states in the inorganic phase, the composite material adjusts decomposing rate, recombines with decomposable polymer, thus the biological decomoposing rate of the whole composite material is adjustable. The inorganic phase is selected from one or two of amorphous calcium phosphate, ª‡- tricalcium phosphate, ª‰- tricalcium phosphate, phosphorite and calcium phosphate dibasic. The preparation method comprises selecting organic solvents for uniformly dispersing calciumphosphate powder in a decomposable polymer matrix, then obtaining nanometer-grade composite material.

Owner:ZHEJIANG UNIV

Technique of preparing superfine groundnut oil from peanut rough material

InactiveCN101176489AThe preparation process conditions are simpleAroma production is easy to controlEdible oils/fatsFood preparationFlavorNeutral protease

The invention relates to an aromatic peanut oil preparation craft with peanuts as the materials, comprising the following steps that: firstly, pretreatment of the materials: peanut materials are chosen, mixed and immersed into water successively and then are grinded roughly, and then the materials are grinded finely; secondly, hydrolysis of the compound enzyme: after the pretreatment, the peanut materials are hydrolyzed by the compound enzyme of the neutral protease and the flavor enzyme; thirdly, addition of accessories: after the treatments of the procedures, reduction sugar, amino acid and peanut oil are added into the hydrolysate of the peanut materials; fourthly, thermal reaction to produce an aromatic smell: the hydrolysate of the peanut materials and the accessories are moved into a high pressure reaction kettle to be heated and then be cooled to an ambient temperature; fifthly, prepartion of the aromatic peanut oil: refined peanut oil is added into the reaction liquid after the treatment of the fourth step, the mixture is agitated quickly and then is agitated slowly at a certain temperature, water and impurities are removed by centrifugal separation, and at last the aromatic peanut oil is obtained. The invention has the advantages that: the amino acid and small peptides which are the flavor precursor of the aromatic peanut oil can be obtained by compound enzyme hydrolyzing the peanut materials and then are heated to produce the peanut oil with peanut aromatic flavor.

Owner:嘉里特种油脂(上海)有限公司

Milk nutrition bar

ActiveCN101999465ANutritional diversityReduce volumeMilk preparationFood flavorConjugated linoleic acid

The invention relates to a milk nutrition bar prepared from the following components in percentage by weight: 10-20 percent of albumen powder, 5-25 percent of milk powder, 5-25 percent of malt extract powder, 6-15 percent of sirup, 4-8 percent of cream, 8-22 percent of flavor substance, 2-6 percent of water retention agent, 1-4 percent of oligose, 0.5-6 percent of conjugated linoleic acid and 0.2-0.8 percent of lecithin. The milk nutrition bar provided by the invention has the advantages of whole nutrition, good taste, low production cost, high production efficiency, portability, and the like, has a certain action on helping a dinner to effectively control the weight and shape the figure and can satisfy the health needs of various crowds.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of palladium-platinum bimetallic catalyst

InactiveCN103071486AHigh activityExtend your lifeOrganic compound preparationAmino compound preparationActivated carbonPlatinum

The invention relates to a preparation method of a palladium-platinum bimetallic catalyst. The preparation method is characterized by using active carbon as a carrier, pretreating the active carbon respectively by hydrochloric acid and nitric acid before preparation, then simultaneously loading palladium and platinum on the pretreated active carbon, and adding an activating agent into the active carbon with palladium and platinum for reduction to finally obtain the palladium-platinum bimetallic catalyst. According to the invention, the preparation method is simple; and the obtained palladium-platinum bimetallic catalyst disclosed herein has the advantages of high activity, long life, etc, and is especially suitable for preparing o-phenylenediamine by solvent-free hydrogenation.

Owner:JIANGSU YANGNONG CHEM GROUP +1

Method for preparing liposoluble tea polyphenol

ActiveCN101270108AThe preparation process conditions are simpleSugar derivativesFatty substance preservation using additivesOrganic solventWater soluble

The present invention relates to a preparation method of fat-soluble tea polyphenol and aims to expand the use of the tea polyphenol by using the water-soluble tea polyphenol as raw material to prepare the fat-soluble tea polyphenol. In the preparation method, carbon acylation is used for preparing the fat-soluble tea polyphenol. More accurately, the preparation of the fat-soluble tea polyphenol causes no loss of phenolic hydroxyl of the raw material of tea polyphenol. Thus the product has improved fat-solubility and original antioxidant properties. The product can be dissolved in oil, fat and organic solvents but can not be dissolved in water. The antioxidant free group and anti-lipid overoxidation performance are similar to the tea polyphenol. The present invention also relates to a preparation method and conditions therefore for the esterification of class formation of catechin through carbon acylation. And the fat-soluble tea polyphenol has the performances that are superior to the products of the same class in the prior art.

Owner:SHANGHAI JIAODA ONLLY CO LTD +1

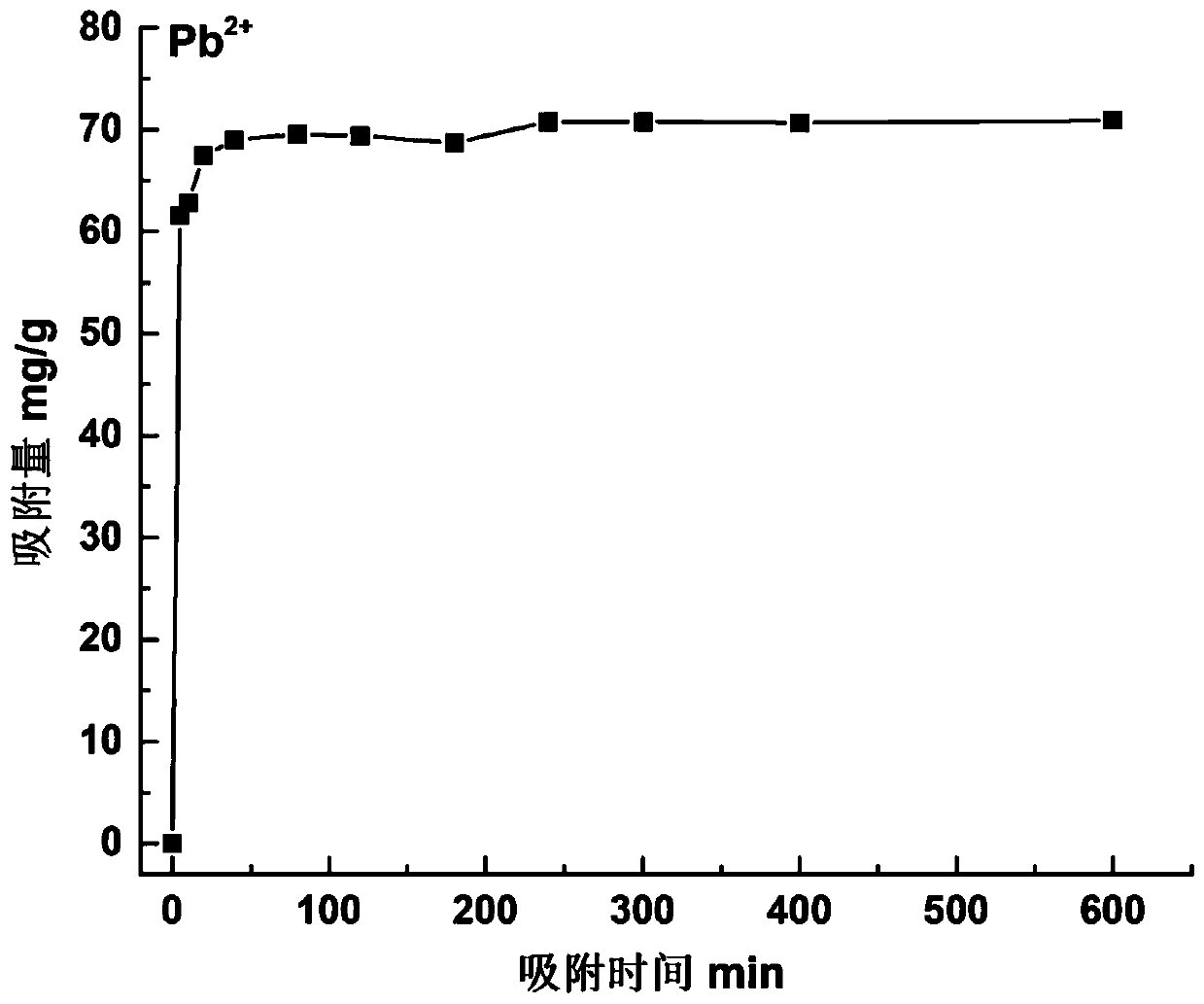

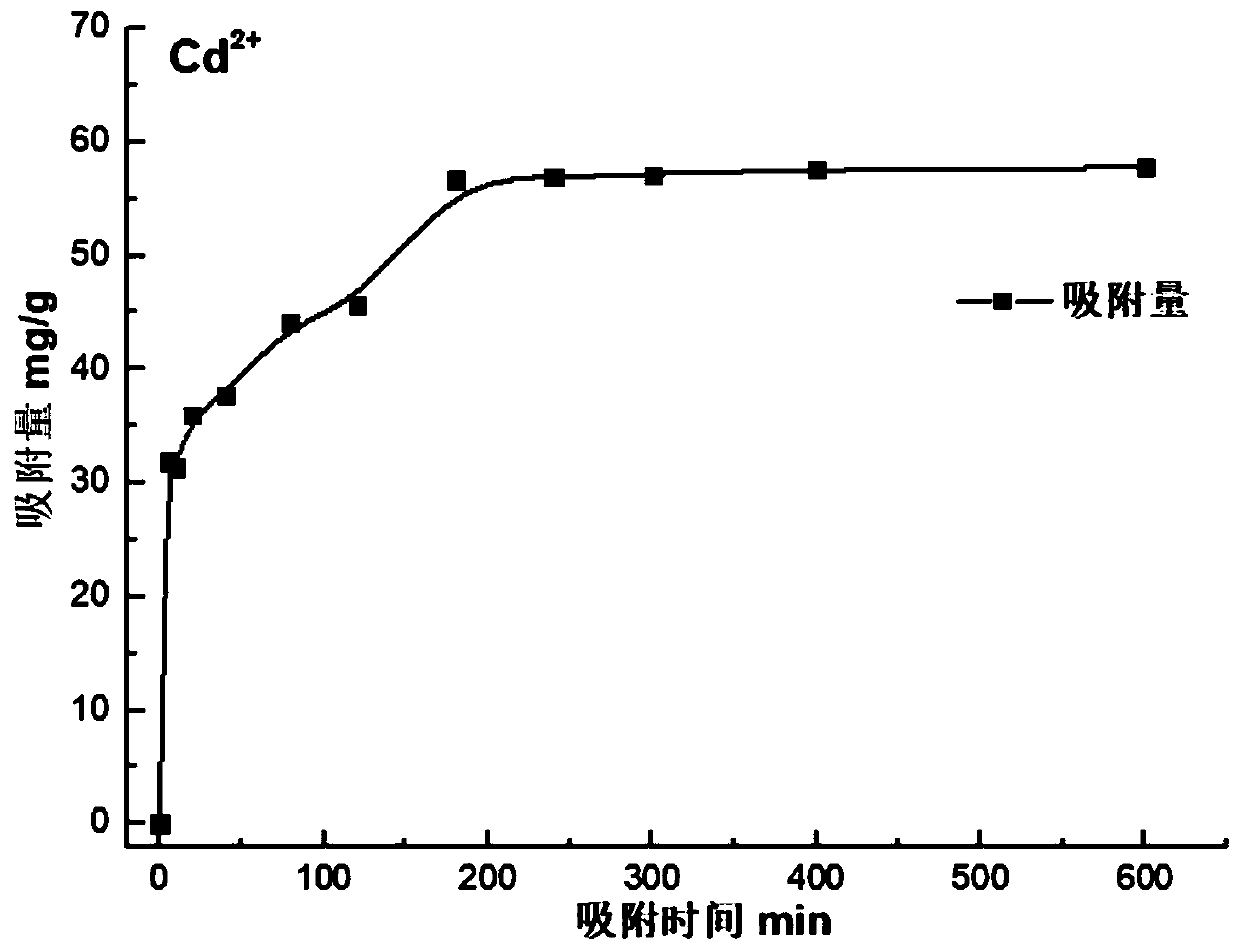

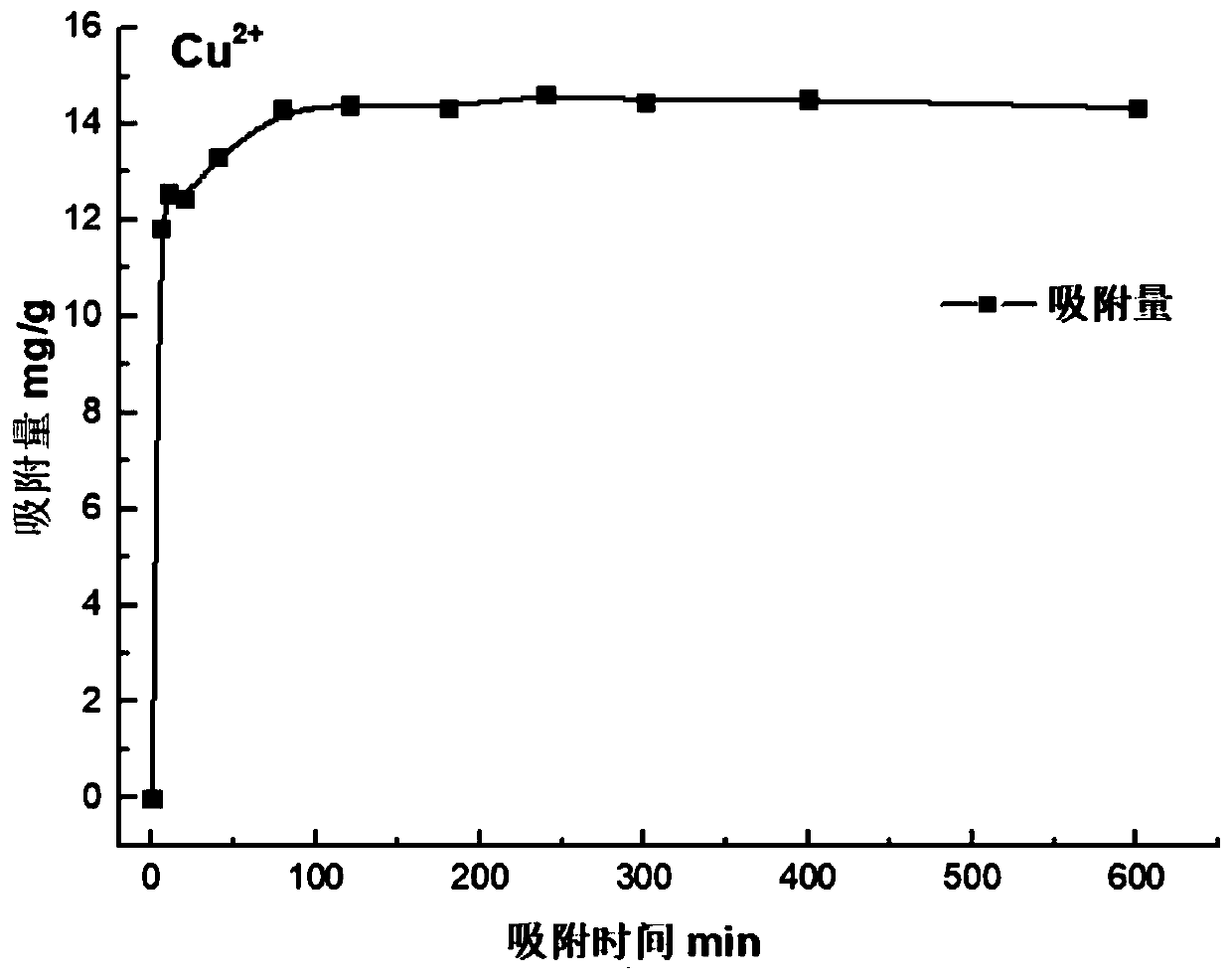

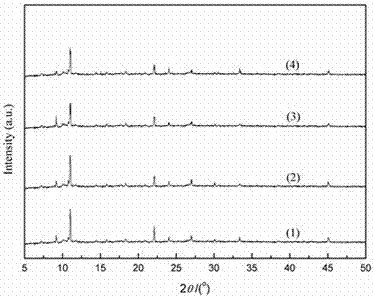

Geopolymer adsorption material and preparation method thereof

ActiveCN110041016AImprove adsorption capacityRealize resource utilizationOther chemical processesAluminium silicatesResource utilizationSlurry

The invention provides a geopolymer adsorption material and a preparation method thereof. The geopolymer adsorption material is prepared from the following raw materials in parts by weight: 15-35 parts of fly ash, 65-85 parts of metakaolin, 40-120 parts of water glass, 2-30 parts of sodium hydroxide and 30-90 parts of deionized water. The preparation method comprises the following steps that all the raw materials are uniformly mixed to obtain slurry, the slurry is injected into a mould to be alternately cured at a temperature of 80 DEG C and under a room temperature condition, and therefore, the geopolymer adsorption material is obtained. According to the geopolymer adsorption material and the preparation method thereof provided by the invention, the fly ash, the metakaolin and the like are taken as the raw materials to prepare the geopolymer adsorption material with high adsorption performance and low cost; on one hand, a new material is provided for removing heavy metal ions in sewage; on the other hand, the resource utilization of industrial waste can be realized, and the geopolymer adsorption material has a good application prospect.

Owner:CHINA AGRI UNIV

Method for synthesizing metal-organic framework material Co-MOF-71

InactiveCN107099038AUniform grain sizeImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionReactive siteMetal-organic framework

The invention relates to successful preparation of a Co-MOF-71 nano-material. According to the invention, preparation process conditions are optimized; the prepared Co-MOF-71 nano-material is uniform in crystal grain size and has good stability; and when Co utilizes the acidic catalysis reaction of MOF framework metal ions, the metal ions are active sites and the supporting points of a framework, and metal ions undergo coordination in the process of catalysis. The prepared Co-MOF-71 material has high metal content and completely exposed metal sites; more Lewis acid site Co-MOF-71 materials can be provided; and the material is beneficial for total activation of reactant molecules and has good catalytic activity.

Owner:NINGXIA UNIVERSITY

High-impedance material, and display substrate black matrix and liquid crystal display apparatus containing same

InactiveCN102827526AIncrease resistanceHigh optical density (OD) valueCoatingsNon-linear opticsLiquid-crystal displayAdhesive

The invention provides a high-impedance material which is composed of the following components by weight percent: 10 to 30 % of bonding resin, 20 to 50 % of an opacifier, 30 to 65 % of a solvent and 0.03 to 0.2 % of an adhesive modifier. The high-impedance material provided by the invention can be used for preparing a black matrix (BM) which can play a role of isolation. By applying the black matrix to a liquid crystal display apparatus, induced charges generated due to electric field change at electrode lead areas on both sides of a lower substrate are enabled to gather and bound at the edge of an upper-side BM area at the instant of power on, and do not diffuse and leak into an inner side, so that situations of white lines on both sides of ADS products can be thoroughly resolved.

Owner:BOE TECH GRP CO LTD +1

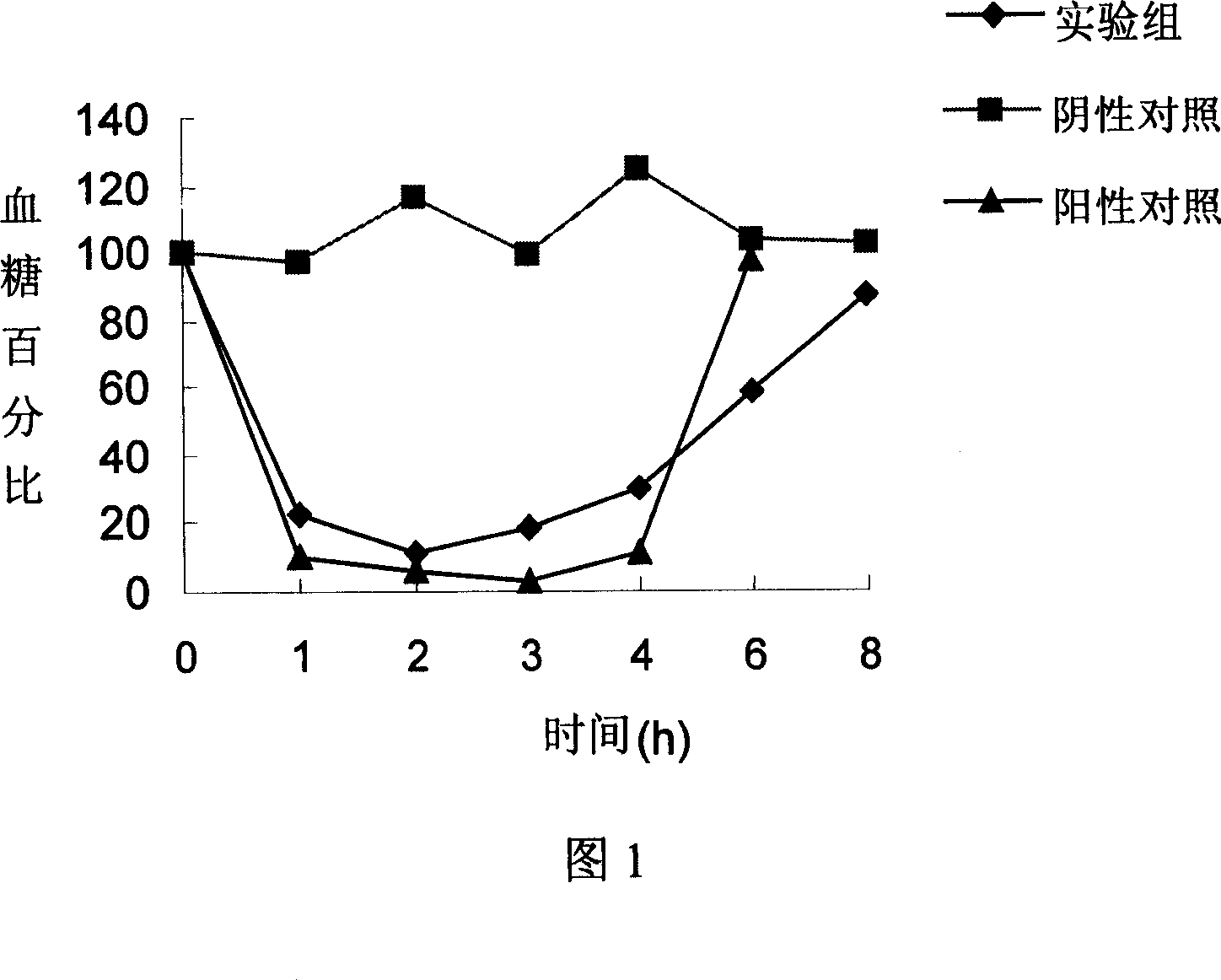

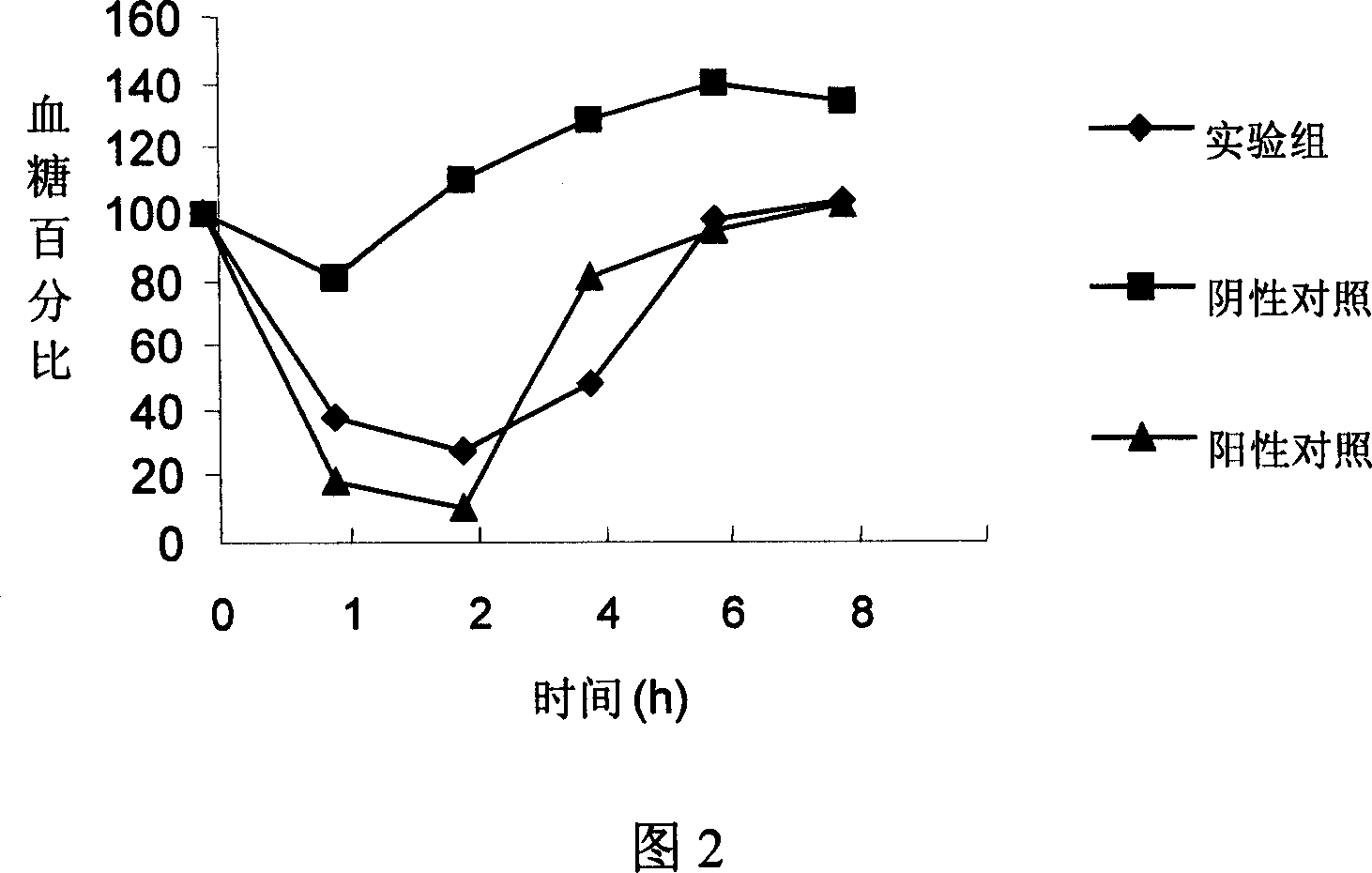

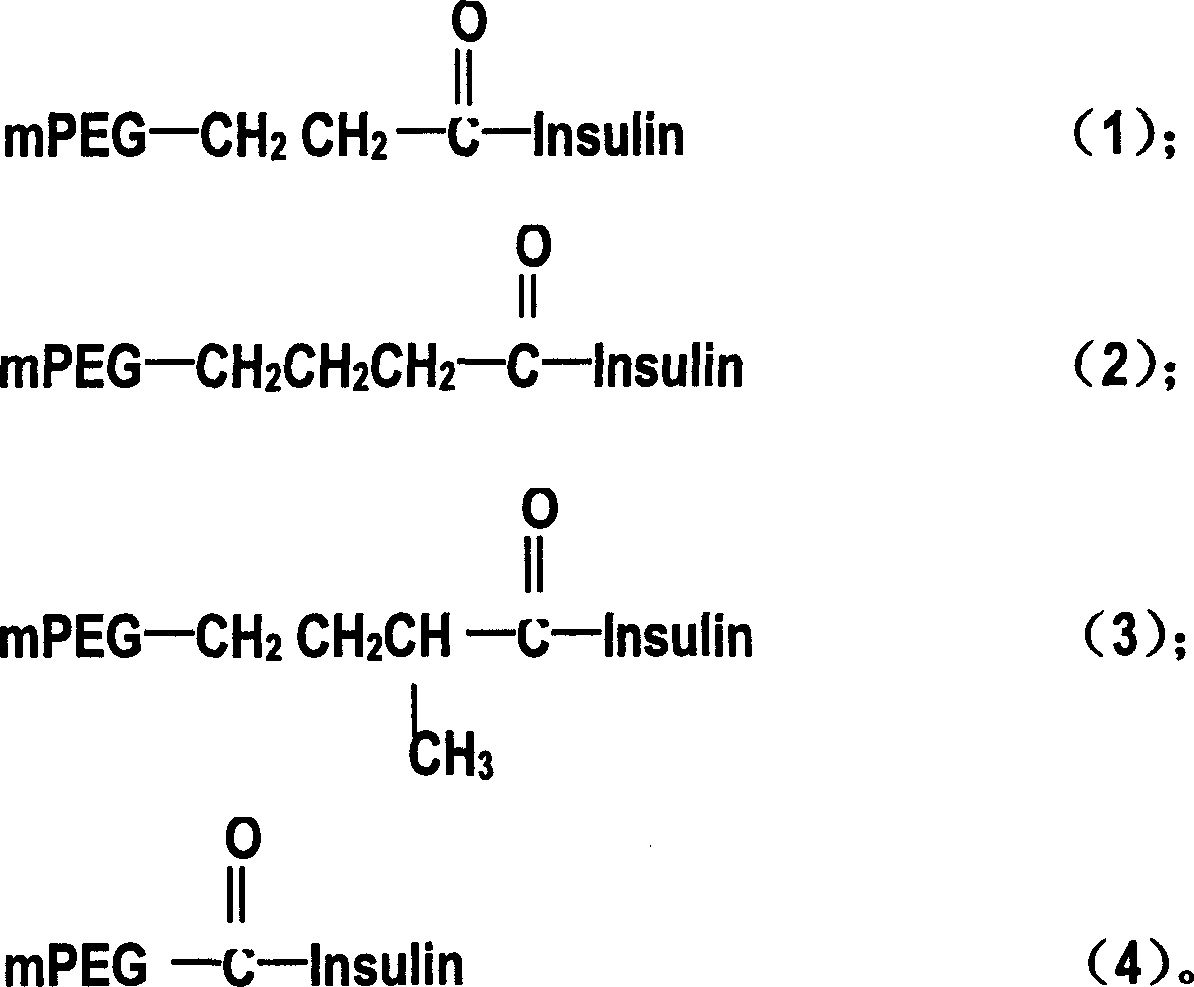

Oral insulin compound medicine preparation and its preparing method

ActiveCN101062408AReduce degradationPrevent drug loading capacity from decreasingPeptide/protein ingredientsMetabolism disorderCalcium biphosphateMonomethoxypolyethylene glycol

The invention discloses an oral insulin complexing preparation, which is characterized by the following: allocating 1-15% insulin raw material, 50-97% stable protecting agent, 1-15% carrying medicine carrier, 1-20% absorption promoting agent; setting the stable protecting agent as one or several of carbowax and casein, protamine, albumin and protease inhibitor; setting the carrying medicine carrier as calcium phosphate salt; setting the absorption promoting agent as one or several of salicylic acid, cholate and fatty acid; setting the insulin raw material as human retooling insulin or human retooling insulin chemical trimmed by single methoxy carbowax derivant. This invention also relates to a preparing method of oral insulin complexing preparation. This invention can increase biostability of human retooling insulin and can resist degradation of gastrointestinal tract enzyme.

Owner:TONGHUA GOLDEN-HORSE PHARM IND CO LTD

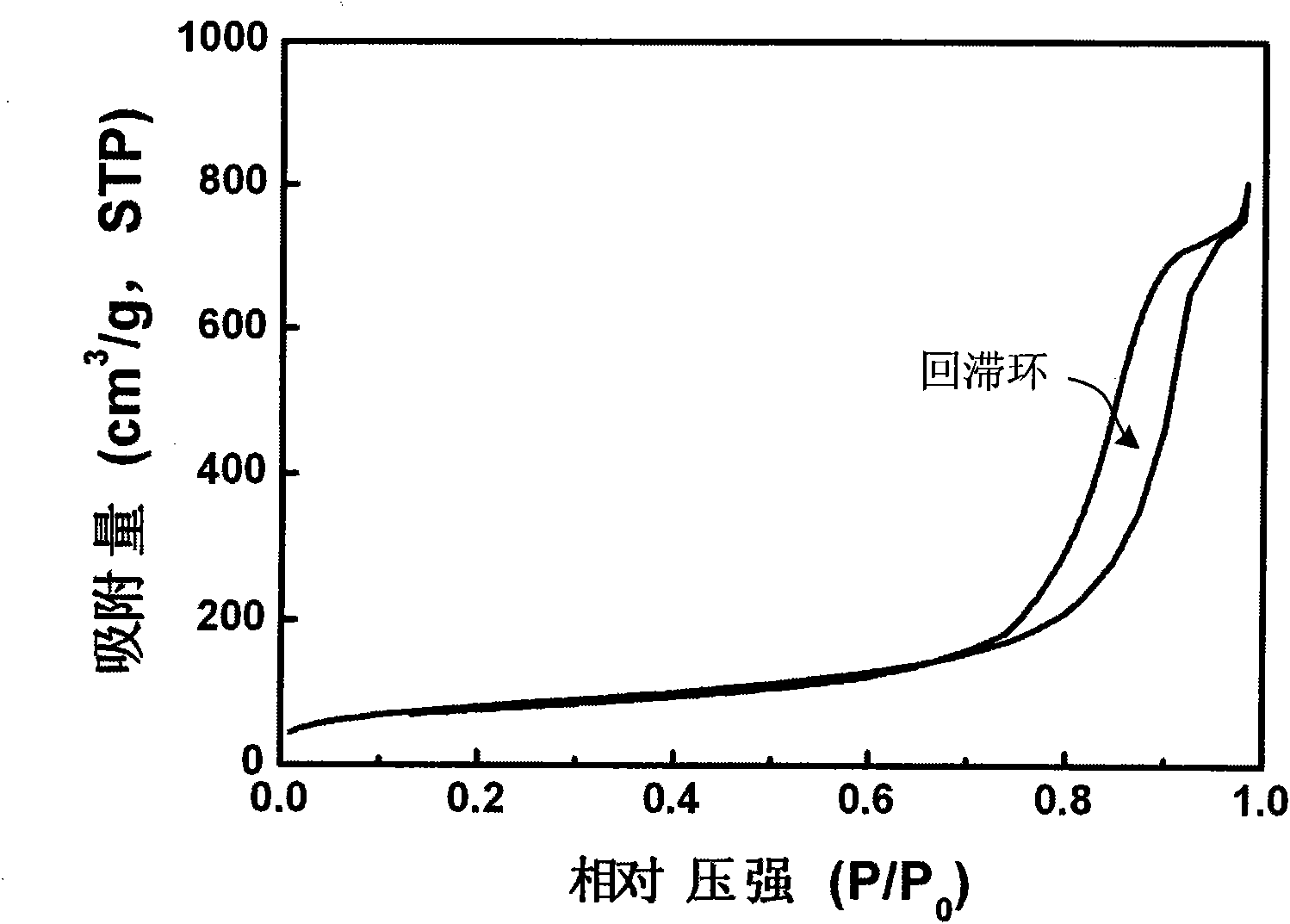

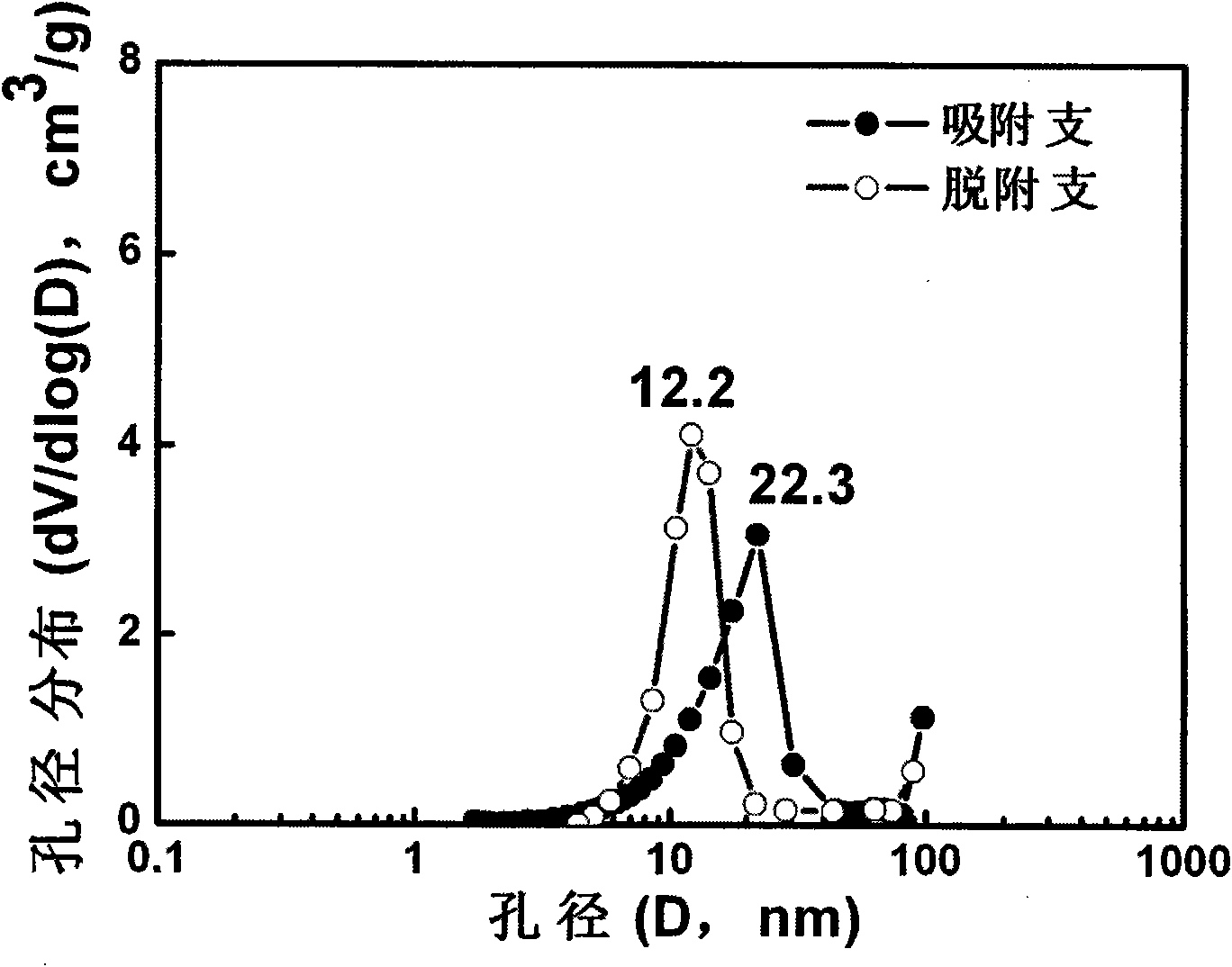

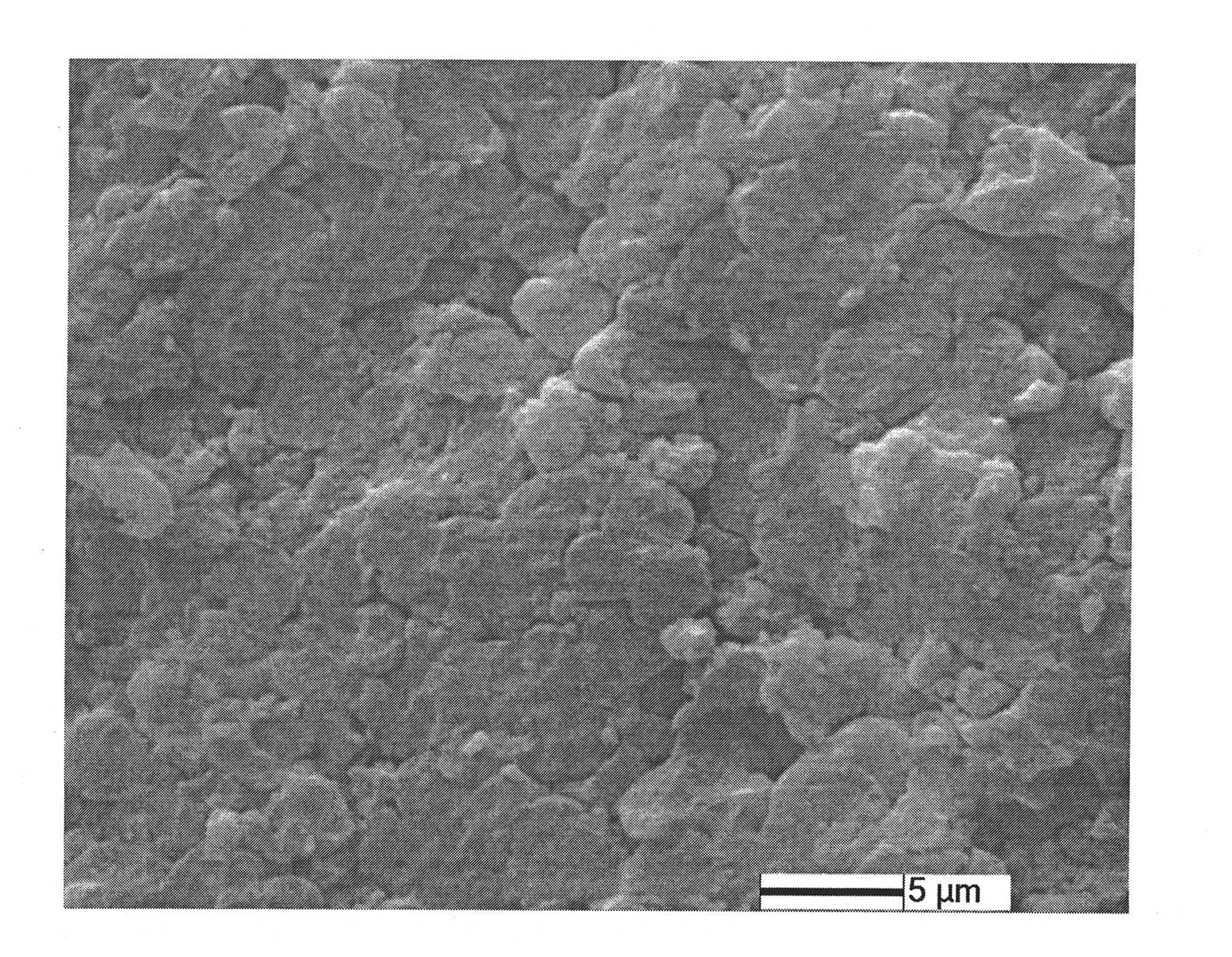

Silica-based porous bulk for heat insulating material and coating-dry pressing preparation method thereof

InactiveCN101974314AHigh porosityHigh compressive strengthOther chemical processesHeat-exchange elementsPorosityCoated surface

The invention discloses a silica-based porous bulk for heat insulating material and a coating-dry pressing preparation method thereof. The preparation method comprises the following steps of: preparing porous silica powder through the hydrolytie polycondensation of tetraethoxysilane by using tetraethoxysilane as a precursor, a nonionic surfactant P123 as a template agent and trimethylbenzene as aswelling agent; hydro-thermally treating the silica powder so as to ensure that Si-OH in pore walls is completely polycondensed; coating the hydro-thermally treated silica powder with sol, and preparing the silica-based porous bulk for a heat insulating material by using the dry pressing method. The silica-based porous bulk is obtained by sintering the porous silica powder with oxide coated surface, wherein the oxide is alumina or titania. The mesoporous aperture of the silica-based porous bulk prepared by using the method is 21-35 nm, the mesoporous window is 10-18 nm, the total porosity is 65-82%, the mesoporosity is 80-99%, and the tensile strength is 45-180 MPa.

Owner:BEIHANG UNIV

Similar bone biology medical material for slow releasing bioactivity factor as well as its preparing method

InactiveCN101156964AEasy to introduceImprove biological activityCoatingsProsthesisApatiteDrug biological activity

The invention discloses bone-like bio-medical material of a slow-release bioactive factor, the bone-like bio-medical material consists of a medical metal transplant body and the bone-like bioactive coating of the slow-release bioactive factor, and the bone-like bioactive coating is coated on the surface of the medical metal transplant body. The invention adopts an electrolytic deposition method to prepare, electrolyte solution contains calcium, a phosphorous compound, bone matrix collagen and the bioactive factor, the medical metal transplant body is taken as a working electrode, platinum is taken as a reference electrode, through the electrode reaction, the bone-like bioactive coating of the slow-release bioactive factor is deposited on the surface of the medical metal transplant body. Compared with the pure inorganic coating, through the adoption of the invention method, the bioactive coating acquired on the surface of the metal transplant body is similar to a natural bone in the component and the structure, and can control the slow-release bioactive factor, adjust, control and promote the growth of bones. The disadvantages that the biological activity of the business use hydroxyapatite coating is limited, the growth of bones cannot be promoted, the required curing time is long, etc. are solved. The preparation process of the invention is simple, highly effective and easy to be industrialized.

Owner:ZHEJIANG UNIV

Phenylboronic acid hydrogel-based sugar-sensitive microneedle pad and preparation method thereof

InactiveCN109675185AImprove sugar sensitivityPerformance can be adjustedPeptide/protein ingredientsMetabolism disorderConcentrations glucoseN isopropyl acrylamide

The invention discloses a phenylboronic acid hydrogel-based sugar-sensitive microneedle pad and a preparation method thereof. The phenylboronic acid hydrogel-based sugar-sensitive microneedle pad comprises a base and a microneedle array which is located on the base, wherein the base and microneedles are mainly prepared from a vinyl phenylboronic acid monomer and a vinyl monomer through free radical copolymerization; microneedle bodies and the base can both be used for embedding insulin drugs; the phenylboronic acid monomer is selected from 3-acrylamidophenylboronic acid, and the vinyl monomeris selected from N-isopropyl acrylamide and N-vinyl pyrrolidone. The preparation method disclosed by the invention is simple; the obtained phenylboronic acid hydrogel-based sugar-sensitive microneedlepad is regular in structure, has good mechanical performance, is capable of effectively piercing the skin, has stimulus responsiveness to glucose concentration, and is capable of regulating the release rate and the dosage of insulin according to blood sugar concentrations and effectively preventing a risk of hypoglycemia caused by excessive release of the insulin.

Owner:ZHEJIANG UNIV

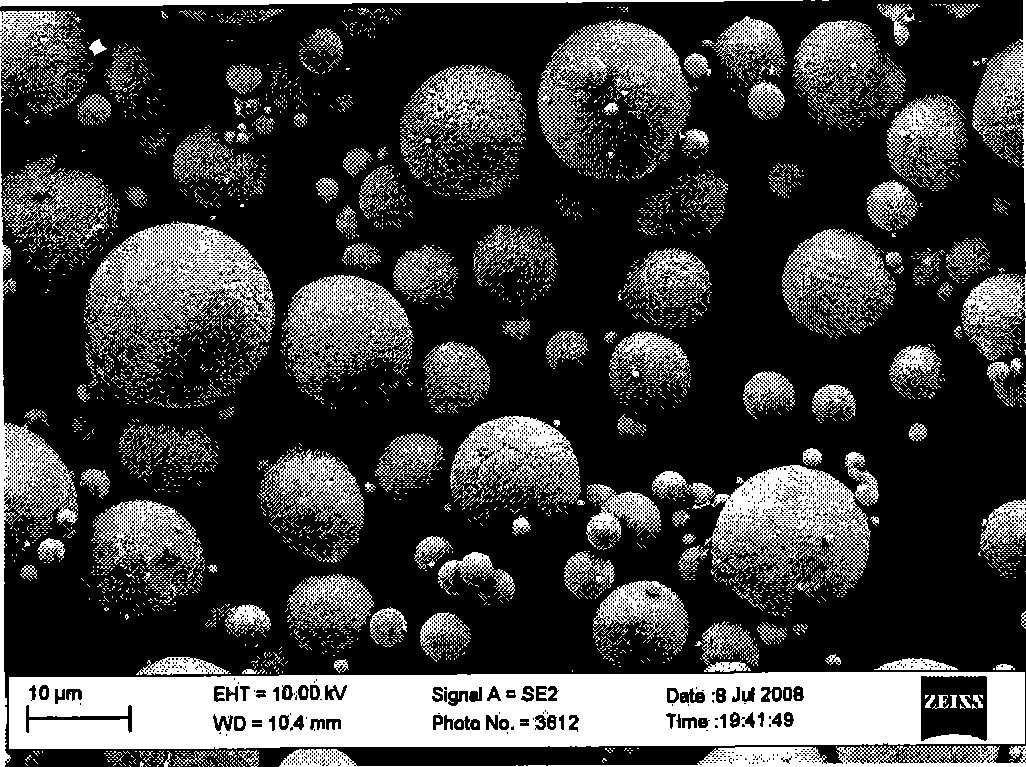

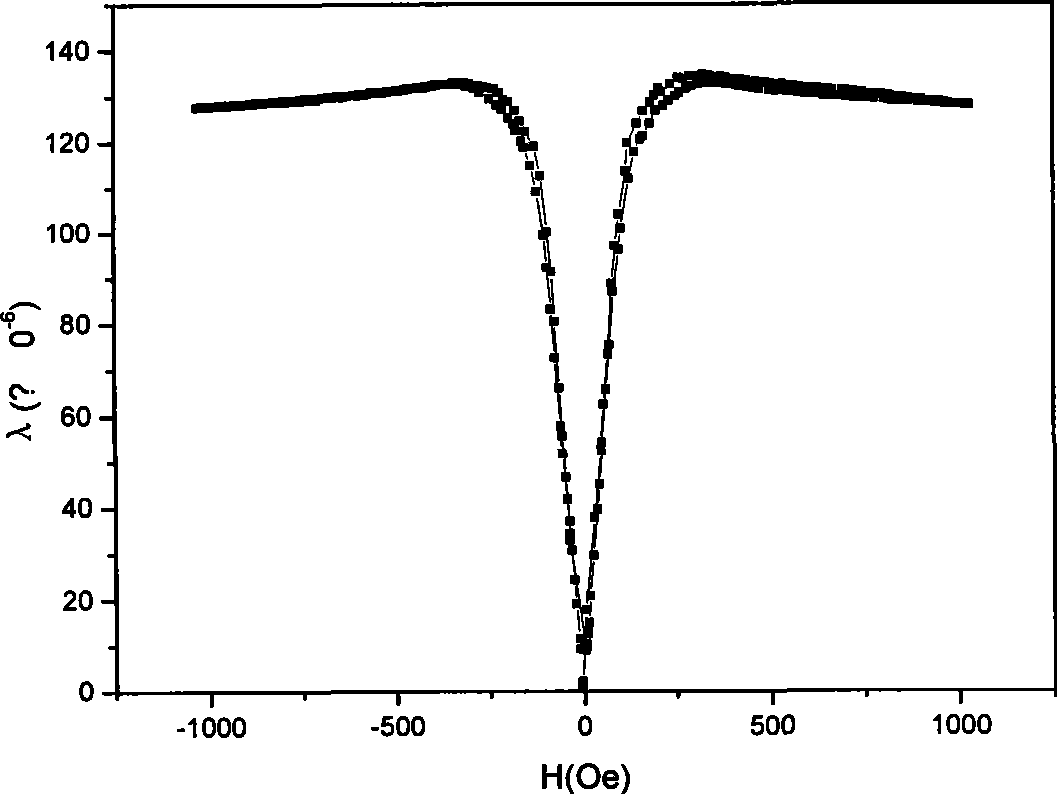

High specific resistance magnetic striction composite material and preparation

InactiveCN101476079AIncrease resistanceHigh magnetostrictive performanceElectrical resistance and conductanceGranularity

The invention provides a high-resistivity supermagnetostrictive composite material and a method of preparing the same and relates to the components of supermagnetostrictive material and a manufacturing process. The composite material consists of a powdered alloy and a binder, wherein, the component of the powdered alloy is Fe1-x and x is 10-30at%, the binder is a non-metal material. The method comprises steps of smelting the master alloy according to the component of the material, pulverizing the master alloy into powder with the granularity from micrometer to hundreds of micrometers by using gas flow grinding, air atomizing or other methods; mixing the obtained power with a certain amount of binder uniformly, then pressing the mixture for forming.The composite material prepared by a powdered alloy and a binder through an agglutinating technique has a high resistivity which can be up to 48.8 omega*m and a high supermagnetostrictive value and the maximum supermagnetostrictive coefficient can be over 130*10 6.

Owner:UNIV OF SCI & TECH BEIJING

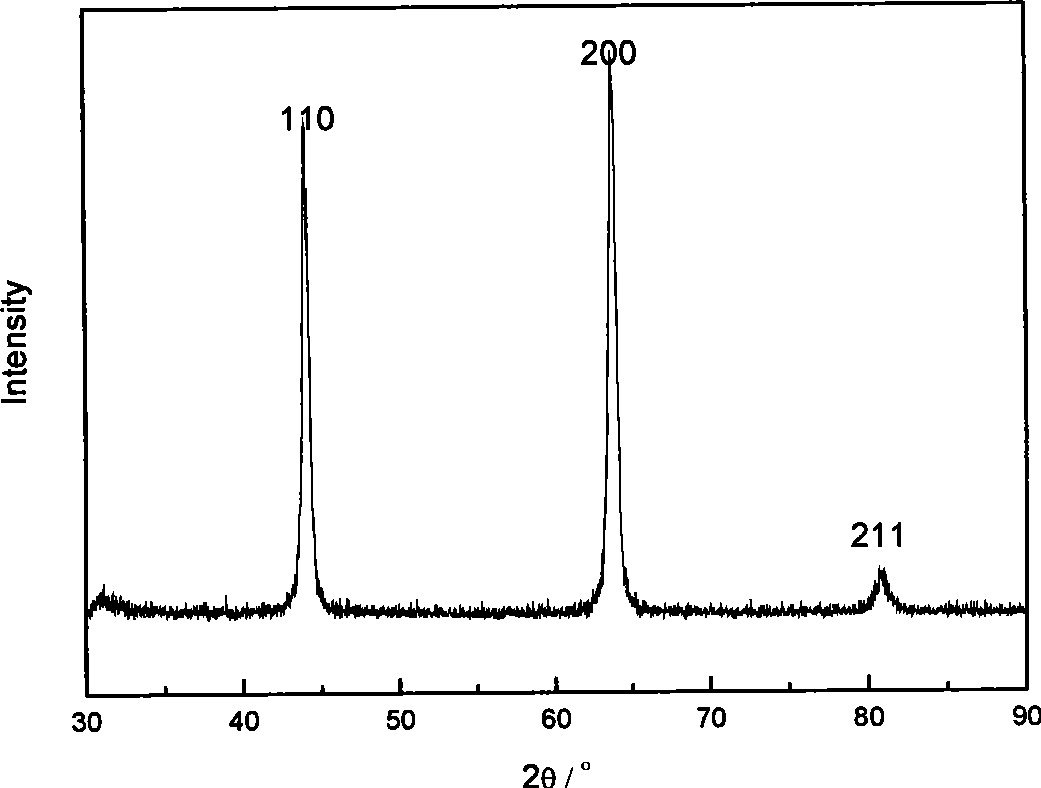

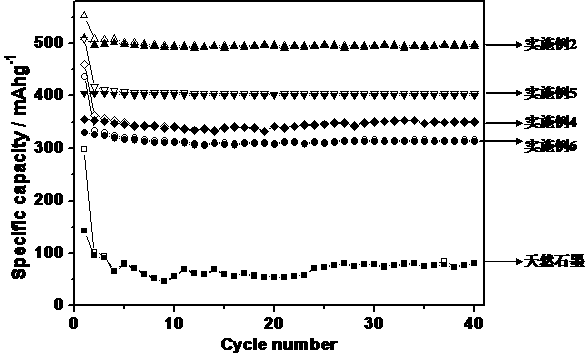

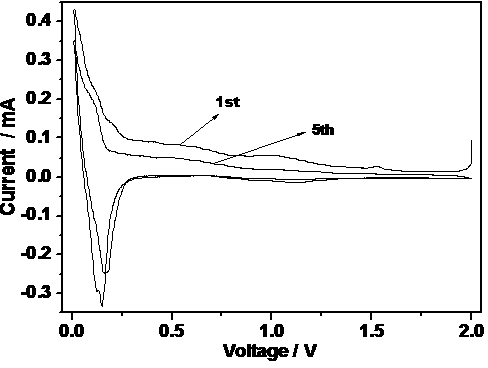

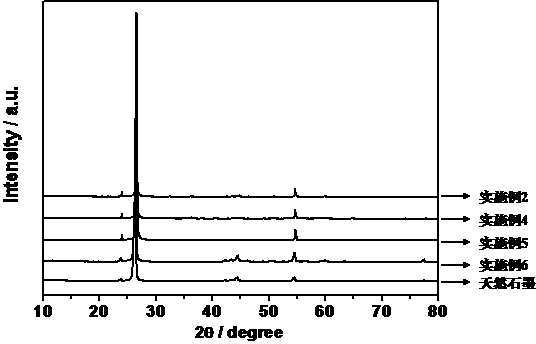

High-performance natural graphite-MnO composite electrode material and preparation method thereof

ActiveCN104022269AHigh tap densityImprove charge and discharge efficiencyCell electrodesSecondary cellsComposite electrodeElectrode material

The invention relates to a high-performance natural graphite-MnO composite electrode material and a preparation method of the high-performance natural graphite-MnO composite electrode material. The preparation method comprises the following steps that: a mixture of MnO2 and natural graphite is generated by virtue of reaction between KMnO4 solution and the natural graphite, wherein one part of the generated MnO2 goes into the natural graphite to form an intercalated structure, while the other part of the MnO2 is deposited on the surface of the natural graphite; next, the mixture is calcined in an inert atmosphere, and the MnO2 is reduced into MnO by utilizing the reducing property of the natural graphite, and therefore, the natural graphite-MnO composite material is formed. In the preparation method, the natural graphite is used as either a main body material or a reducing agent, the process is simplified, and the obtained composite material is excellent in properties. The natural graphite layers do not collapse as being supported by MnO among the natural graphite layers, the interlayer spacing of the natural graphite is expanded, so that lithium ions can be deintercalated quickly without affecting the structure of the natural graphite, and therefore, the cycle performance of the natural graphite composite electrode material can be improved favorably; the MnO deposited on the surface of the natural graphite is helpful to capacity improvement. The natural graphite composite electrode material with high capacity and good cycle performance can be obtained by combining the natural graphite and MnO.

Owner:HUBEI ZHONGYI TECH

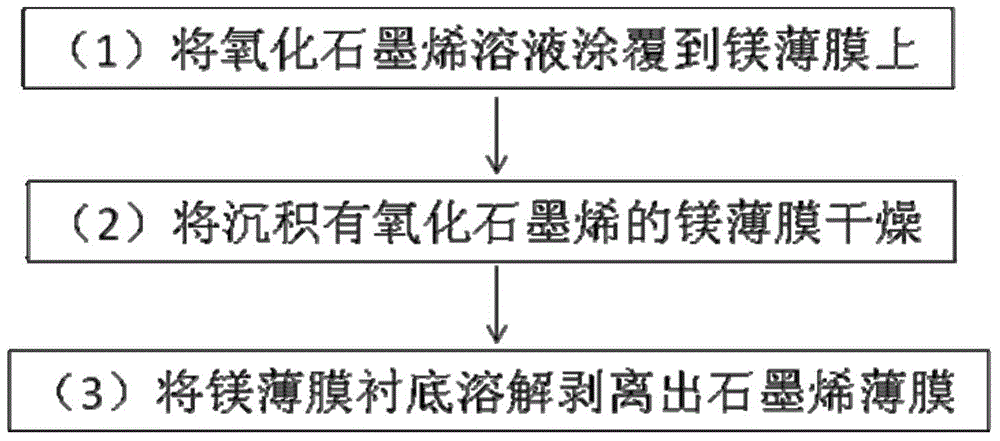

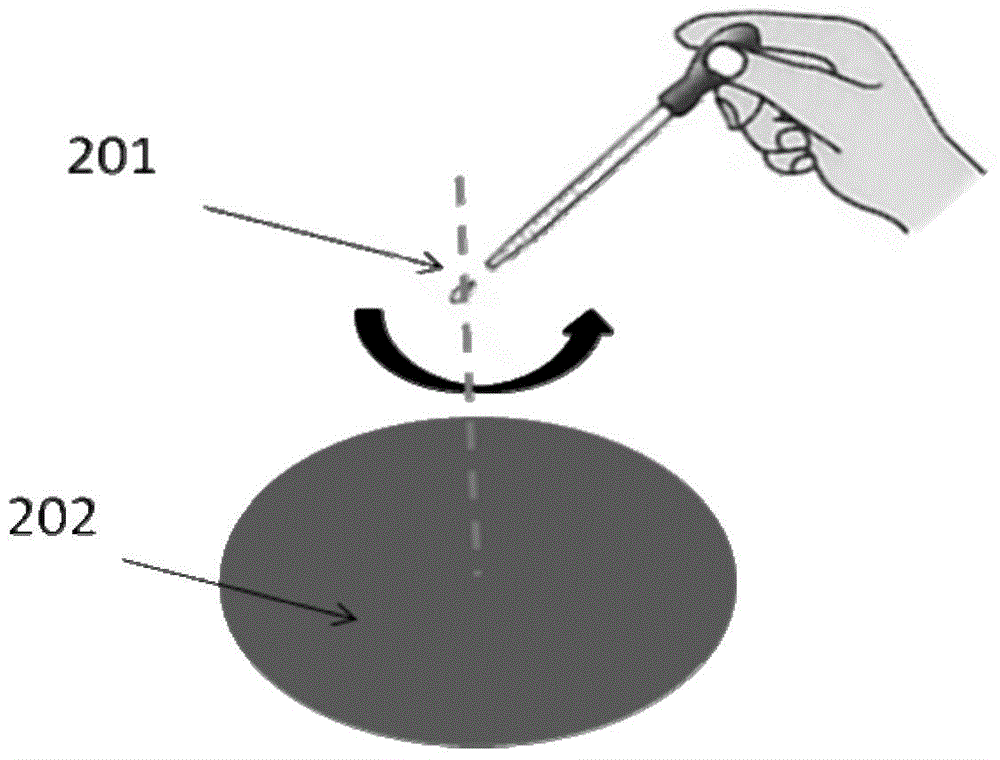

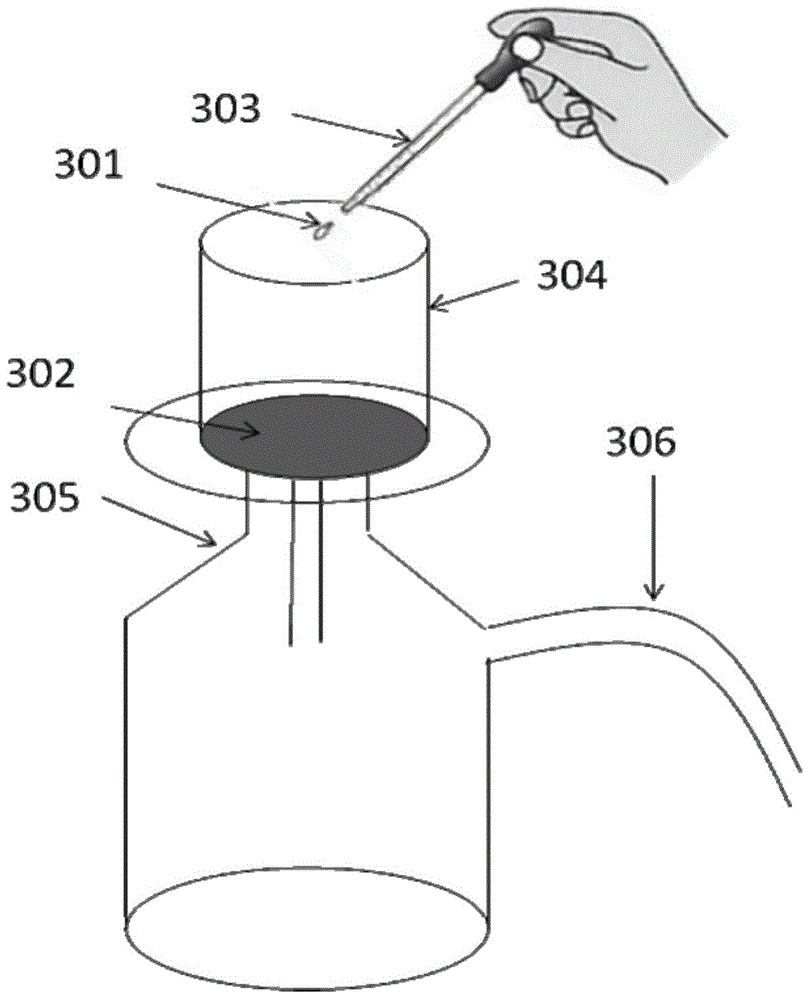

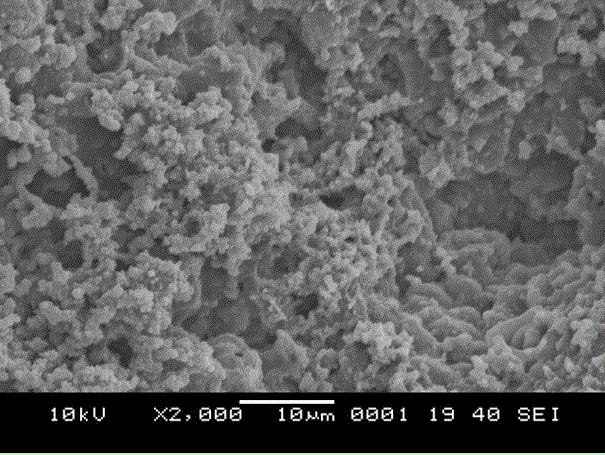

Method for preparing graphene film

InactiveCN104445170AGood for mass manufacturingThe preparation process conditions are simpleProcess conditionsCvd graphene

The invention relates to a method for preparing a graphene film. The method comprises the following steps: coating a graphene oxide acid solution on a magnesium film, drying the magnesium film deposited with graphene oxide, and dissolving the magnesium film by using diluted acid, thereby obtaining the graphene film. The method is simple in process condition, environmental friendly, low in cost and beneficial for large-scale preparation of the graphene film.

Owner:BOE TECH GRP CO LTD

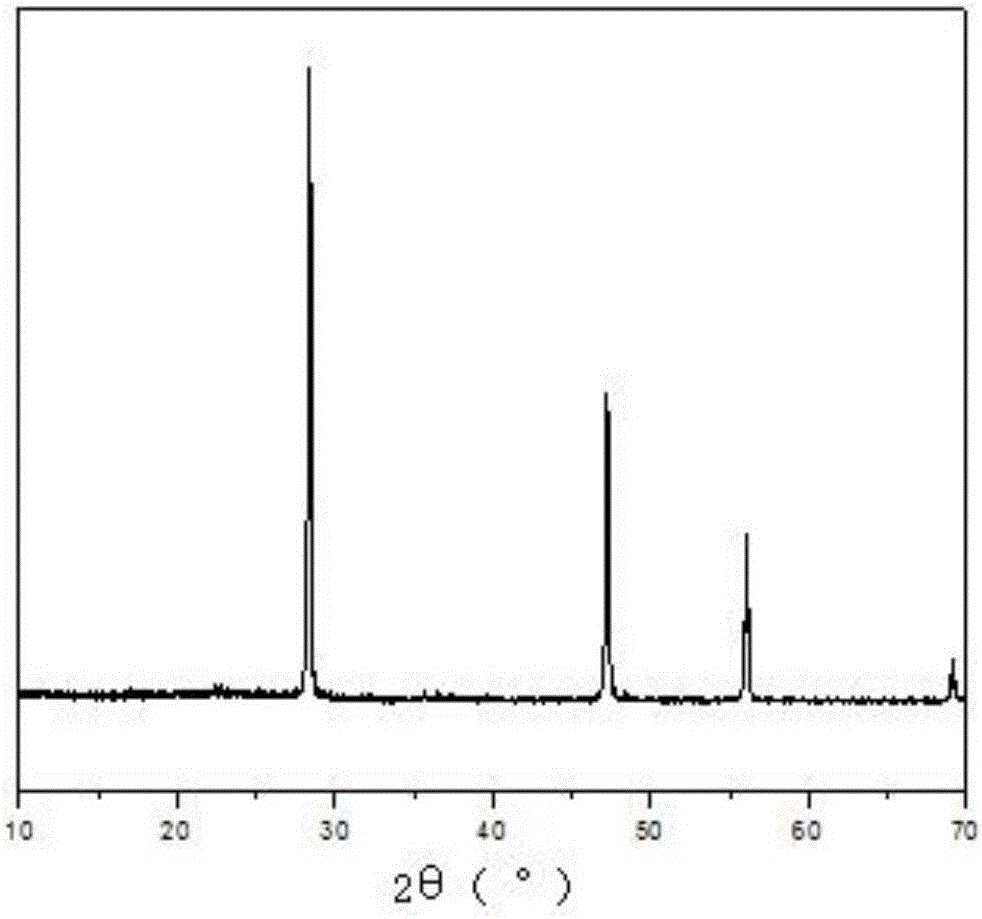

Calcium phosphate composite powder and preparing method thereof

InactiveCN1488680AUniform size distributionEasy to operatePigment treatment with macromolecular organic compoundsCalcium biphosphateApatite

The present invention discloses a kind of calcium phosphate composite powder and its preparation method. Adopting wet chemical method and controlling technological condition to synthesize calcium phosphate precursor with different Ca / P ratios, then through heat treatment to obtain the hydroxyapatite and / or alpha-phase tricalcium phosphate composite powder, hydroxyapatite and / or beta-phase tricalcium phospate composite powder or alpha-phase tricalcium phosphate composite powder and / or beta-phase tricalcium phosphate composite powder whose ratios can be arbitrarily regulated. The invented granule distribution is uniform, and its granule size is 50nm-500nm, it can be used in the bio-medicinal material field extensively.

Owner:ZHEJIANG UNIV

Ethylene-vinyl acetate copolymer/polyaniline composite conductive material and preparation method thereof

The invention belongs to the technical field of composite conductive materials and particularly relates to an ethylene-vinyl acetate copolymer / polyaniline composite conductive material and a preparation method thereof. The preparation method comprises the steps of firstly preparing an ethylene-vinyl acetate copolymer porous membrane, and then carrying out in situ polymerization on the ethylene-vinyl acetate copolymer porous membrane and aniline so as to prepare the ethylene-vinyl acetate copolymer / polyaniline composite conductive material. According to the preparation method, the problem that conductive polyaniline is absorbed by an EVA matrix is thoroughly solved. The preparation method has the advantages that the preparation process condition is easily realized, the cost is saved, and the conductivity of the ethylene-vinyl acetate copolymer / polyaniline composite conductive material is excellent.

Owner:HENAN UNIV OF URBAN CONSTR

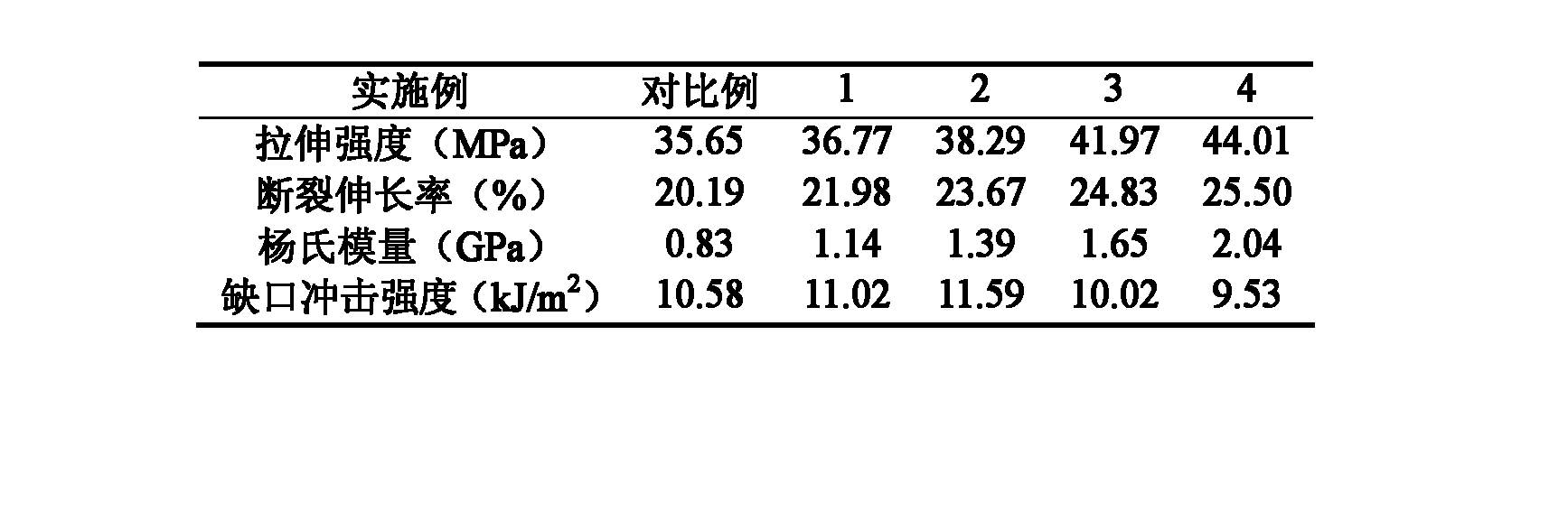

Preparation method of modified magnesium borate whisker/PP (propene polymer) composite material

InactiveCN102504414AImprove mechanical propertiesThe preparation process conditions are simpleMolding machineCoupling

The invention relates to a preparation method of a modified magnesium borate whisker / PP (propene polymer) composite material. In the method, a PP material is used as a matrix, and a borate coupling agent modified magnesium borate whisker is used as reinforcement. The preparation method comprises the following steps of: (1) sufficiently dissolving 1 to 3 parts by mass of borate coupling agent with a proper amount of absolute ethanol at a temperature of between 30 and 50 DEG C, and uniformly mixing for 0.5 to 1 hour with 97 to 99 parts by mass of magnesium borate whisker which is dried for 4 hours at a temperature of between 120 and 140 DEG C, filtering, cleaning, and baking at a temperature of between 90 and 120 DEG C for 4 to 6 hours to obtain a surface modified whisker; (2) preheating a mixing mill to a temperature of between 180 and 200 DEG C, adding a PP base material to melt for 3 to 5 minutes, and adding the borate coupling agent modified magnesium borate whisker which is prepared in the step (1) according to a proportion to mix for 8 to 10 minutes to prepare a semifinished product; and (3) molding the semifinished product prepared in the step (2) for 6 to 8 minutes in a molding machine at a pressure of 10MPa and a temperature of between 180 and 185 DEG C to prepare the modified magnesium borate whisker / PP composite material. The preparation method of the invention has the advantages of simple conditions and low cost; and the mechanical performance of the modified magnesium borate whisker / PP composite material is remarkably improved, and the application prospect is wide.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Prepn process of nanometer tricalcium phosphate powder with slowly released metal ion

InactiveCN1772603AHigh activityUniform particle distributionPhosphorus compoundsProsthesisPolyethylene glycolTri calcium phosphate

The present invention discloses the preparation process of nanometer tricalcium phosphate powder with slowly released metal ion. The preparation process adopts metal ion compound, calcium containing compound and phosphide as main material, and polyglycol as stabilizer, and includes reaction inside water solution at 0-5 deg.c to produce amorphous calcium phosphate containing metal ion, and the subsequent sintering at 800-1100 deg.c. The said preparation process can obtain nanometer tricalcium phosphate powder with controllable metal ion releasing rate and small particle size, and the nanometer tricalcium phosphate powder is used as bioactive material capable of promoting bone growth and inhibiting bone absorption. The preparation process is simple, feasible, simple in operation, low in cost and easy for industrial production.

Owner:ZHEJIANG UNIV

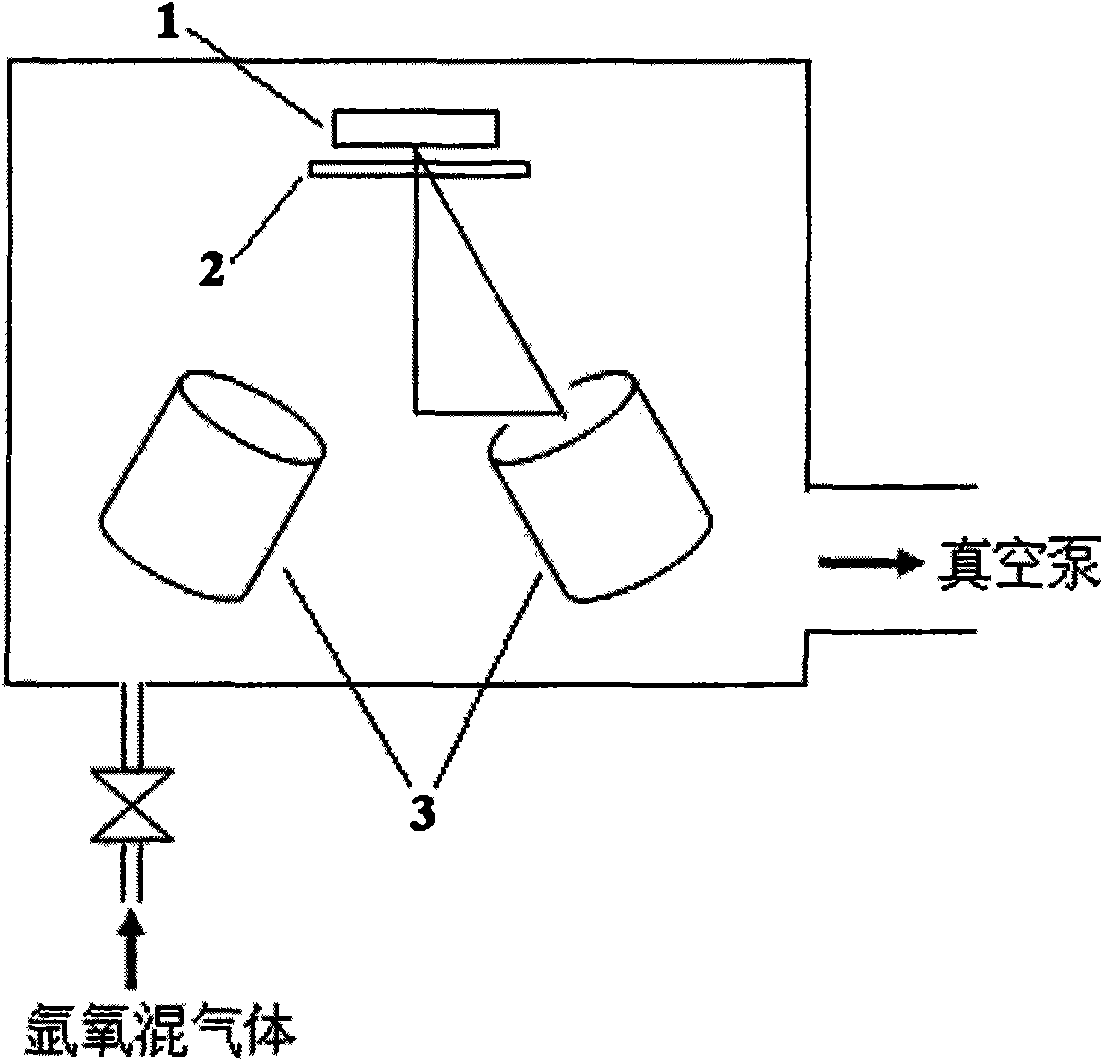

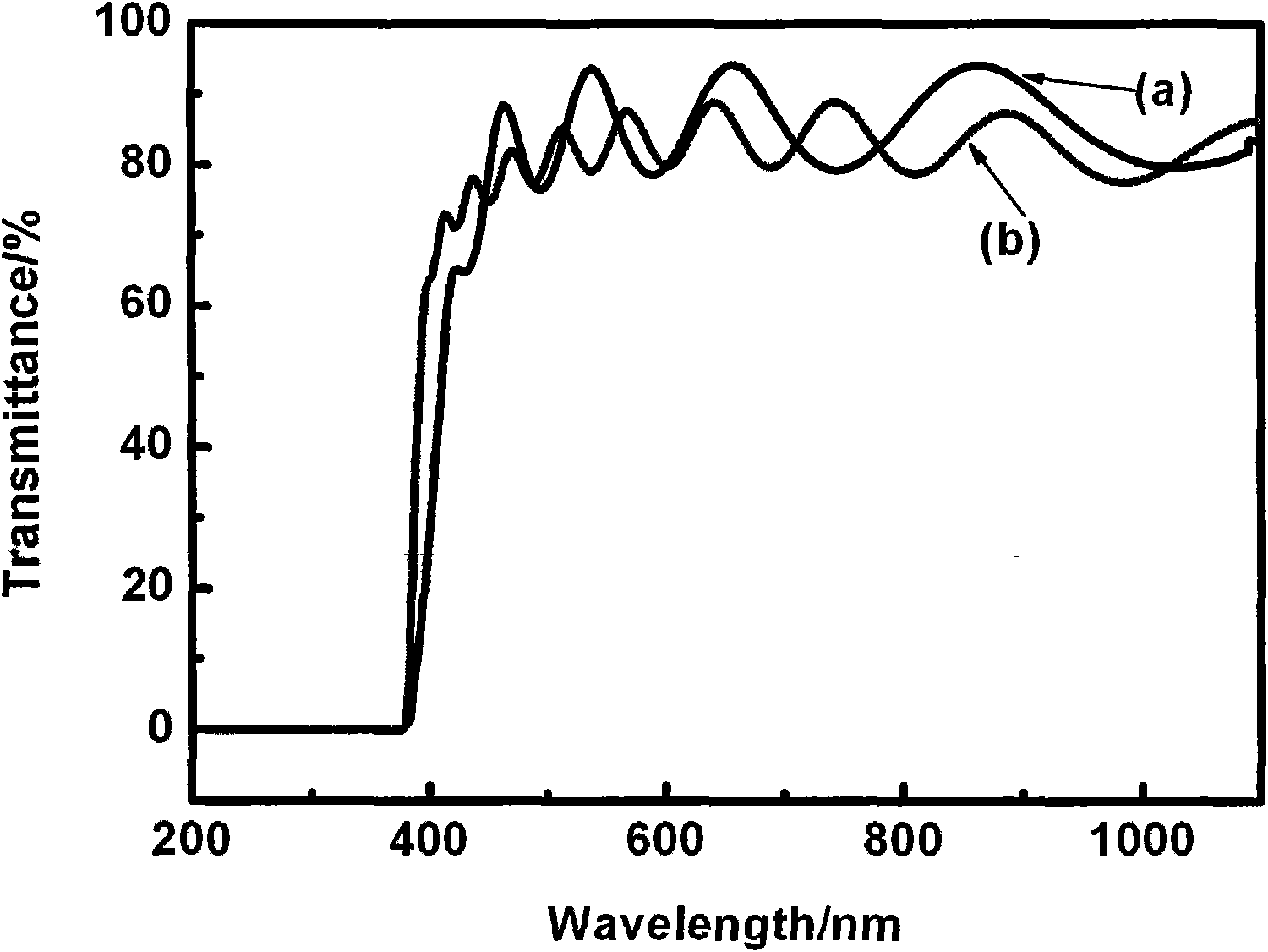

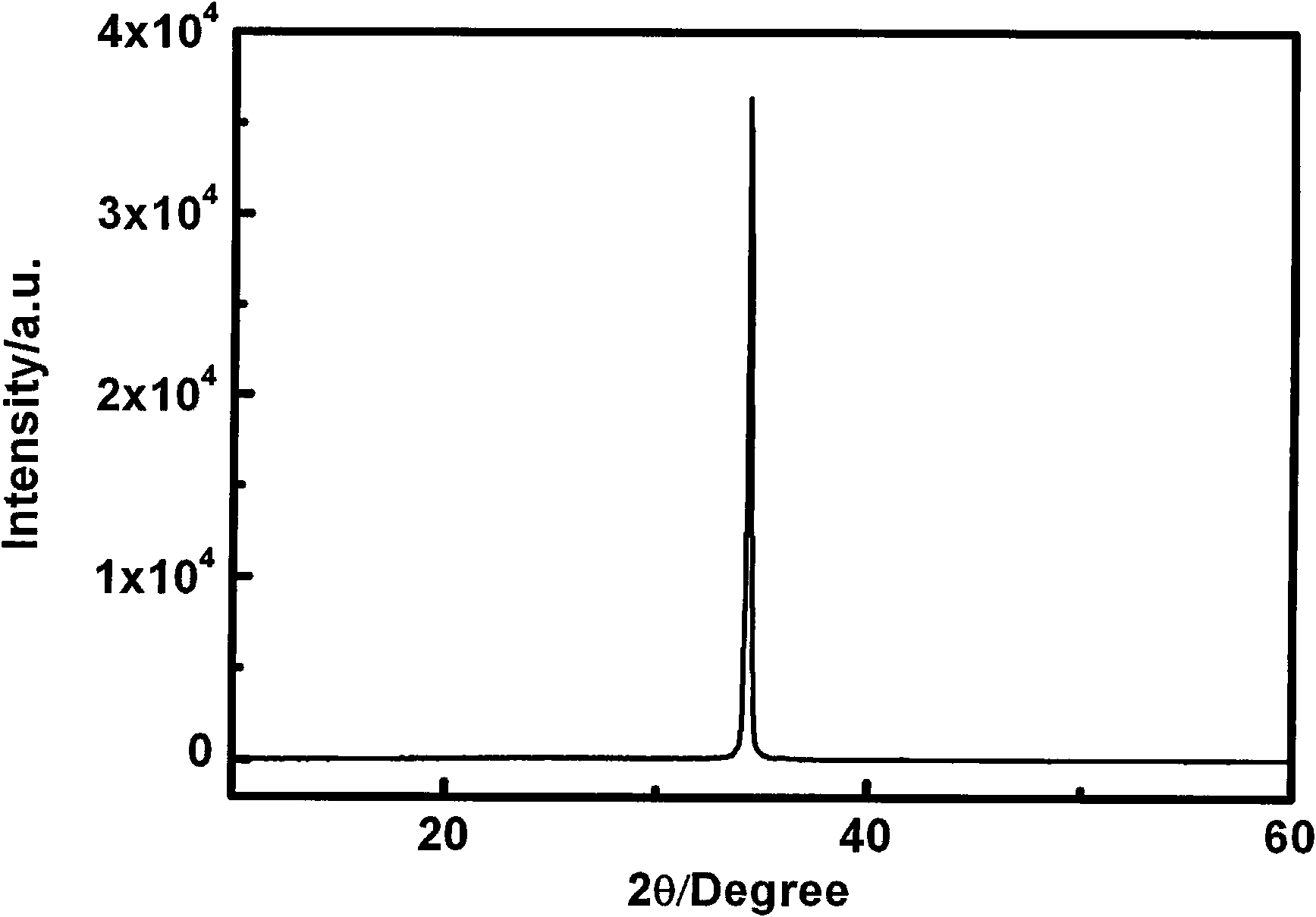

Low-indium doping amount zinc oxide transparent conducting film and preparation method thereof

ActiveCN101834009AImprove transmittanceThe preparation process conditions are simpleConductive layers on insulating-supportsConductive materialOxide ceramicOxygen

The invention relates to an indium doped zinc oxide transparent conducting film and a preparation method thereof. In the method, a ZnO:In transparent conducting film with a polycrystal structure is prepared on a common alkali glass and quartz glass substrate by adopting a multitarget co-sputtering magnetron sputtering technology and adopting a zinc oxide ceramic target and indium metal target co-sputtering method. In the process condition, the pressure of the argon and oxygen mixed working gas is 0.2-2.0Pa; the volume ratio of the oxygen to the argon is 0-0.2; the sputtering power of a zinc oxide target and an indium target are respectively 50-200W and 5-40W; the substrate temperature is room temperature-500 DEG C; and the bias voltage is 0-negative 200V. The prepared transparent conducting film reduces indium atomic number content to 2 percent, has favorable conducting performance, transmissivity larger than 90 percent at 400-1,100nm and can be widely applied to the fields of solar batteries, panel display, and the like instead of ITO (Indium Tin Oxide).

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

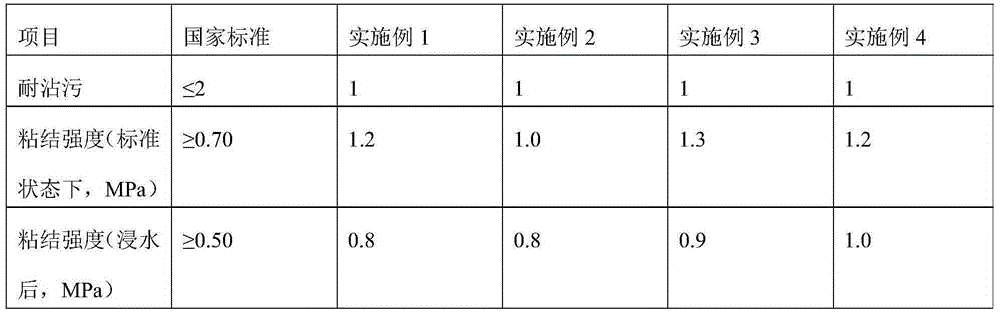

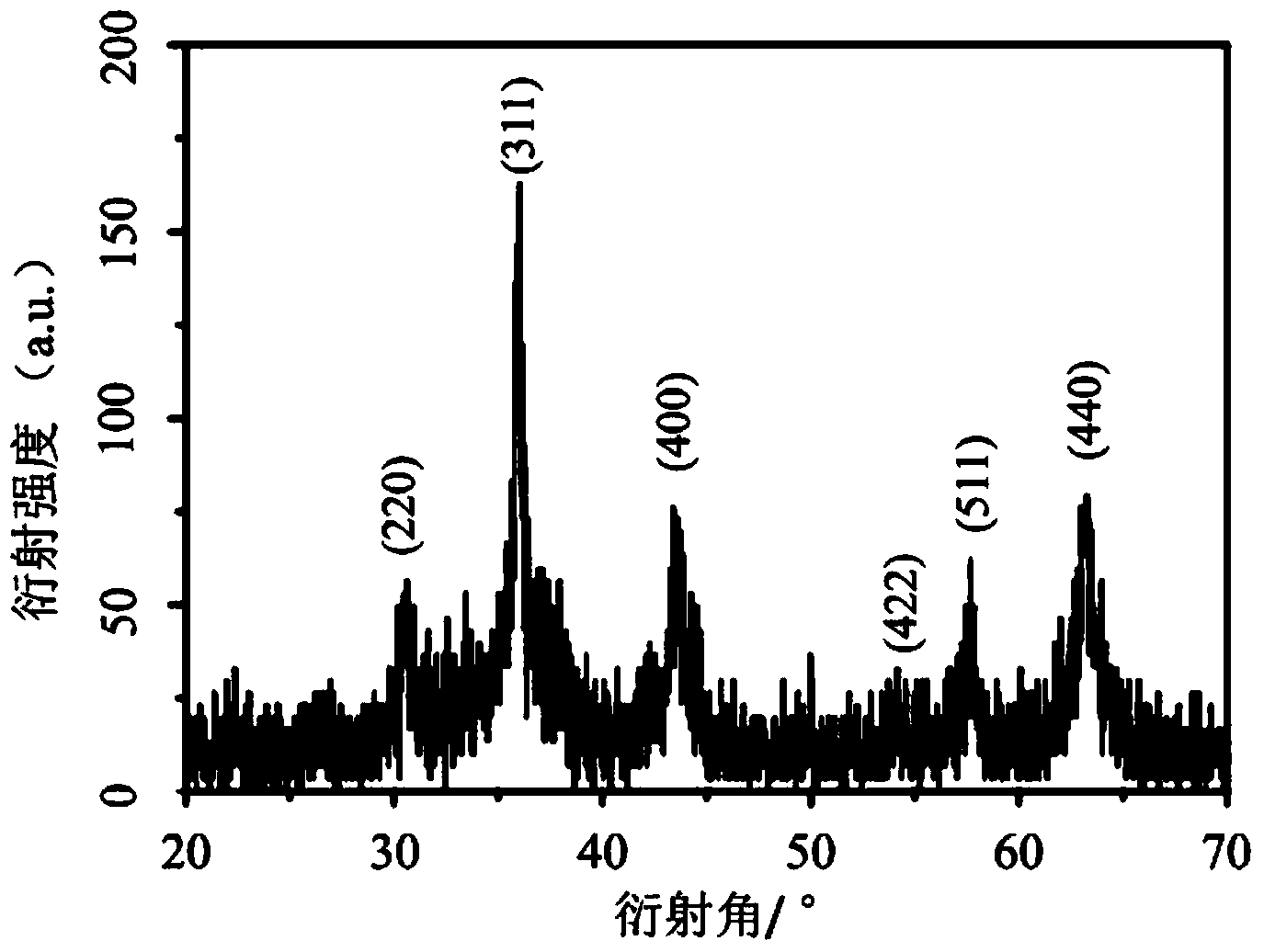

Water-coating-sand colorful paint and preparation method thereof

InactiveCN106752482AHigh elongationImprove water resistanceAnti-corrosive paintsCelluloseAluminum magnesium silicate

The invention relates to a water-coating-sand colorful paint and a preparation method thereof. The paint includes, by weight, 15-20 parts of a resin compound emulsion, 30-45 parts of compound powder, 3-5 parts of an additive, 30-50 parts of color sands, and 20-30 parts of water, wherein the resin compound emulsion is prepared by mixing acrylic pure acrylic emulsion and silicone acrylic emulsion. The additive includes, by weight, 0.3-0.5 parts of dodecanoate, 0.8-1.2 parts of propylene glycol, 0.2-0.4 parts of a wetting agent X-405, 0.2-0.4 parts AMP-95 neutralizing amine, 0.5-0.8 parts of an ammonium salt dispersant, 0.2-0.4 parts of a defoamer, 0.7-1 part of a DR-72 alkali swelling thickener, 1-1.2 parts of aluminum-magnesium silicate, 0.3-0.5 parts of cellulose, and 0.5-1 part of a liquid stabilizer. Compared with the prior art, the paint has good water resistance, extensibility and stain resistance, is low in preparation cost, is good in storage stability, is easy to construct and saves labor hour.

Owner:BNSA NEW MATERIAL SHANGHAI CO LTD

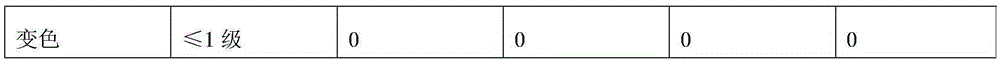

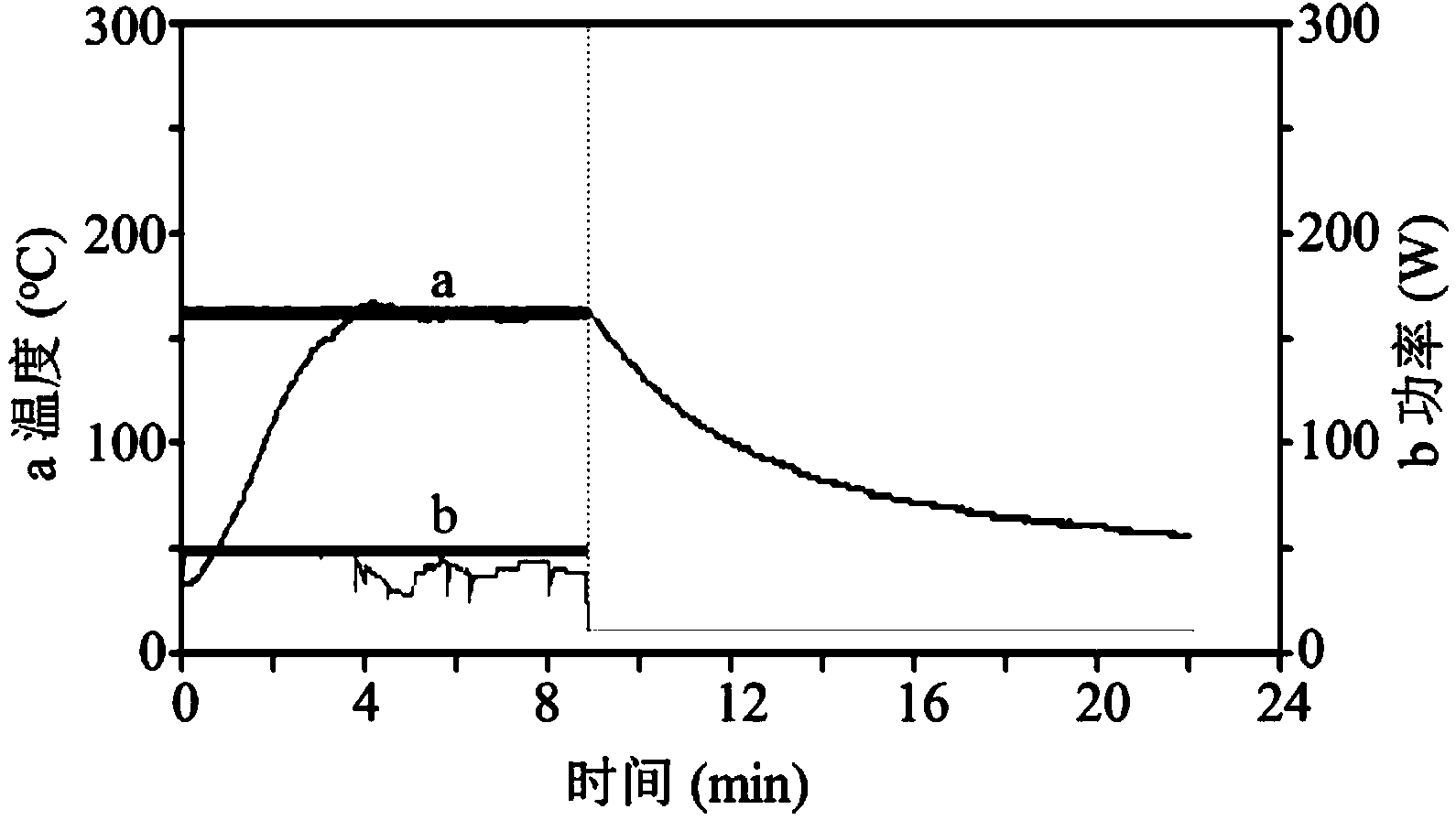

Preparation method for superparamagnetism ferrite nano particles

InactiveCN103818971AImprove efficiencyImprove energy efficiency utilizationFerric oxidesSuperparamagnetismReaction tube

The invention discloses a preparation method for superparamagnetism ferrite nano particles, relates to nanometer materials and provides a quick, environment-friendly and convenient preparation method for the superparamagnetism ferrite nano particles. The preparation method comprises the following steps: adding a sodium hydroxide solution into oleinic acid, stirring so as to obtain a white sodium oleate solid; then utilizing absolute ethyl alcohol to dissolute the sodium oleate solid during the stirring process and obtaining a homogeneous and transparent solution A; adding a hydrazine hydrate solution into the solution A during the stirring process; continuously stirring, enabling reactants to be well mixed and obtaining a homogeneous and transparent solution B; sequentially adding a Fe <3+> salt solution and a M<2+> salt solution into the solution B, stirring, enabling reactants to be well mixed and obtaining a solution C; transferring the solution C to a quartz reaction tube of a microwave synthesizer; sealing the solution C, packing the solution C into the microwave synthesizer and conducting a microwave synthesis; when the reaction stops, taking out the reaction vessel and adding the absolute ethyl alcohol; conducting an ultrasonic washing or centrifugal separation on the products; obtaining the superparamagnetism ferrite nano particles after the drying.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com