Method for preparing liposoluble tea polyphenol

A technology of fat-soluble tea polyphenols and tea polyphenols, which is applied in the direction of chemical instruments and methods, fat production, and chemical change-inhibiting compositions, etc., which can solve the problems of reduced antioxidant effect and loss of antioxidant active phenolic hydroxyl groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

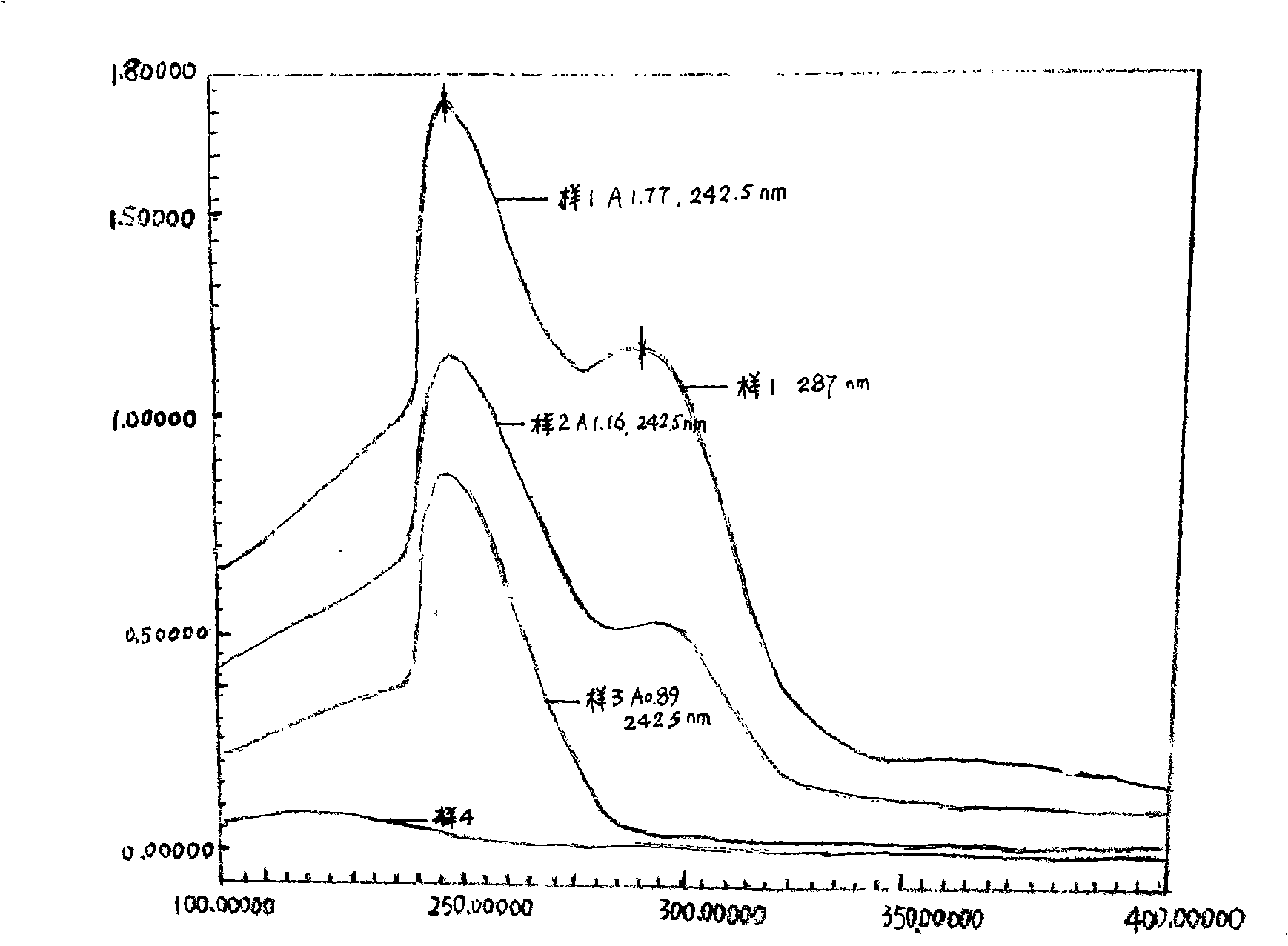

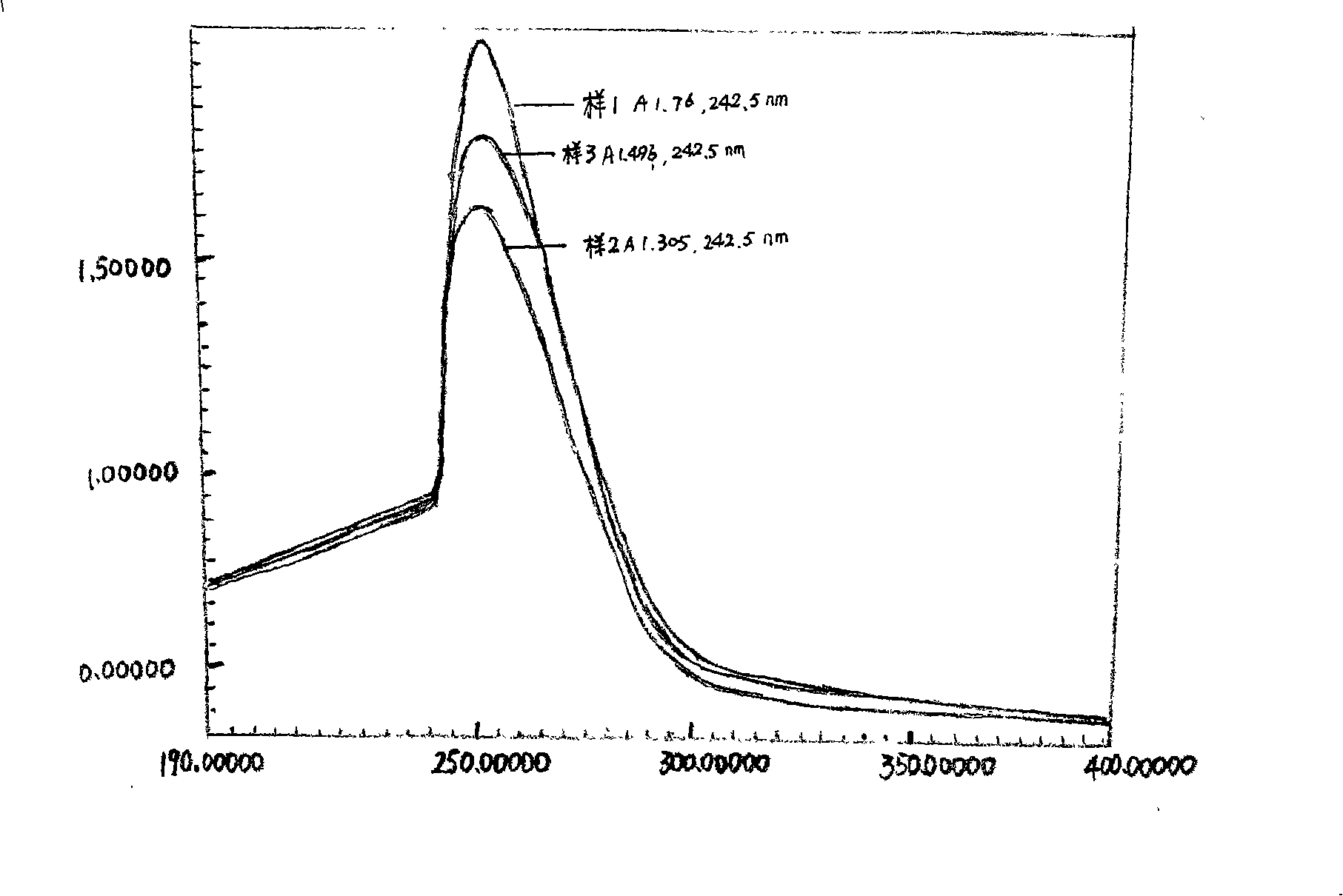

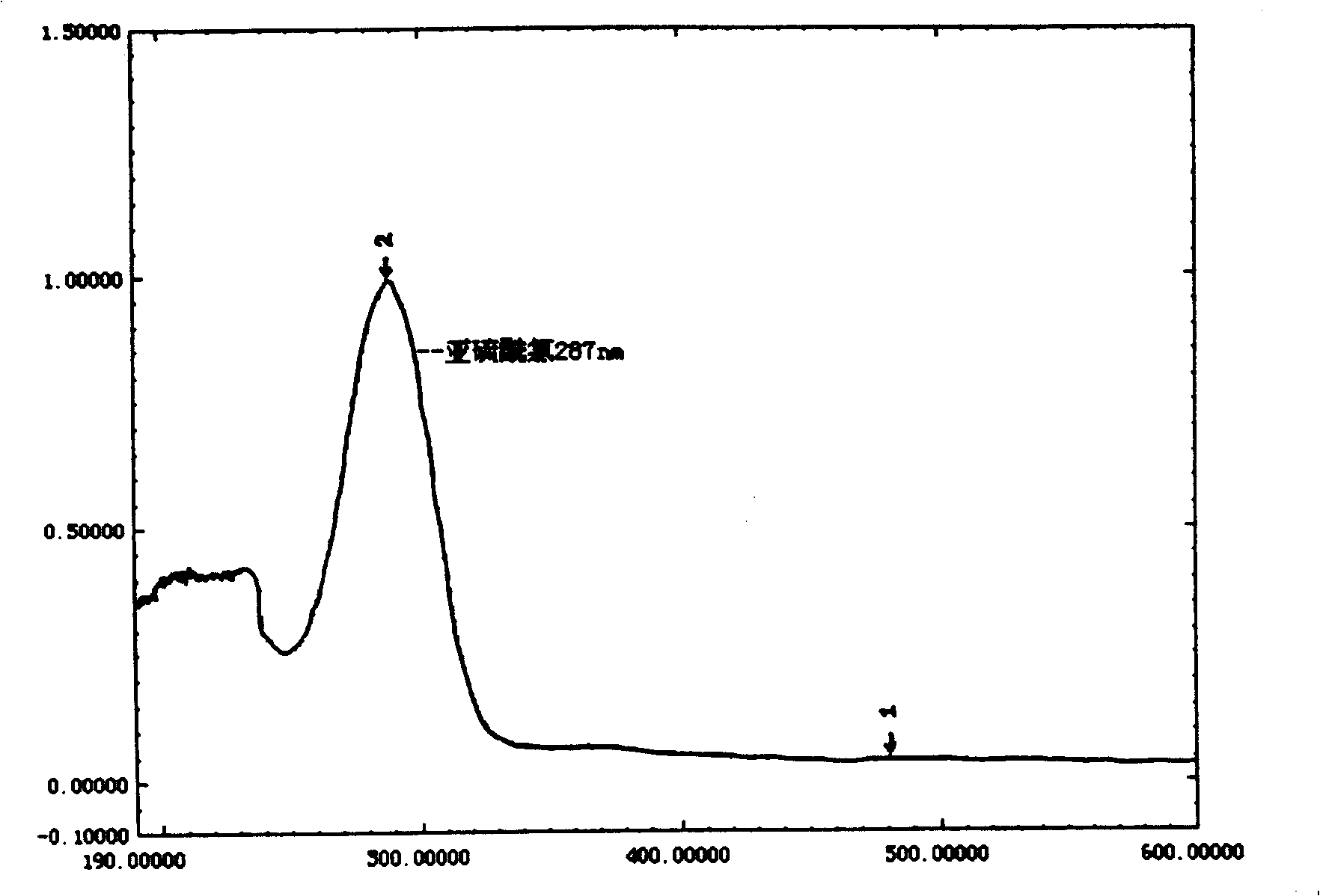

[0077] Weigh 104 grams (0.4mol) of palmitic acid, put it in a 250ml three-necked bottle (with stirring, feeding port, and condenser), and then add 36ml (0.49mol) of thionyl chloride. Repeatedly raise and lower the temperature between 20°C and 50°C, and at the same time stir the reaction until no bubbles are generated, and repeat the temperature rise and fall about 5 to 8 times. The reaction time is about 7 hours. After cooling, add 1.2ml DMF (0.0156mol), then gradually raise the temperature to 50°C, and react until there are no HCL bubbles (about 2 hours). After cooling, the reaction solution is a transparent solution without solids. Scanning (400nm ~ 200nm), there is no thionyl chloride absorption peak around 280nm.

[0078] Get 160ml of nitrobenzene and put it in a 500ml three-necked bottle (with stirring, feeding port, and condensation drying tube), while stirring, add 8.05 grams (0.061mol) of aluminum trichloride successively and the above reaction to obtain 18.88ml (0.061...

Embodiment 2

[0080] Weigh 104 grams (0.4mol) of palmitic acid, put it in a 250ml three-necked bottle (with stirring, feeding port, condenser), and then add 38.2ml (0.52mol) of thionyl chloride. Repeatedly raise and lower the temperature between 20°C and 50°C, and at the same time stir the reaction until no bubbles are generated, and repeat the temperature rise and fall about 5 to 8 times. The reaction time is about 5 hours. After cooling, add 1.6ml of DMF (0.021mol), then gradually raise the temperature to 50°C, and react until there are no bubbles (about 2 hours). After cooling, the reaction solution is a transparent solution without solids. Scan by UV (400nm~200nm) There is no thionyl chloride absorption peak around 280nm.

[0081] Get 180ml of nitrobenzene and put it in a 500ml three-necked bottle (with stirring, feeding port, and condensation drying tube), while stirring, add 9.71 grams of aluminum trichloride (0.074mol) and the above reaction to obtain 22.89ml (0.074mol) of palmitoyl ...

Embodiment 3

[0083]Weigh 104 grams (0.4mol) of palmitic acid, put it in a 250ml three-necked bottle (with stirring, feeding port, condenser), and then add 32.3ml (0.44mol) of thionyl chloride. Repeatedly raise and lower the temperature between 20°C and 50°C, and at the same time stir the reaction until no bubbles are generated, and repeat the temperature rise and fall about 5 to 8 times. The reaction time is about 10 hours. After cooling, add 2.6ml DMF (0.035mol), then gradually raise the temperature to 50°C, and react until there are no HCL bubbles (about 3 hours). After cooling, the reaction solution is a transparent solution without solids. Scanning (400nm~200nm) has no thionyl chloride absorption peak around 280nm.

[0084] Get 200ml of nitrobenzene and put it in a 500ml three-necked bottle (with stirring, feeding port, and condensation drying tube), while stirring, add 12.9 grams (0.098mol) of aluminum trichloride and the above reaction to obtain 30.3ml (0.098mol) of palmitoyl chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com