Preparation method for superparamagnetism ferrite nano particles

A nanoparticle and superparamagnetic technology, which is applied in the field of nanomaterials, can solve the problems of high energy consumption, uneven particle size distribution, and low purity of nanoparticles in the production process, and achieve high energy efficiency, high saturation magnetization, and high product quality. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

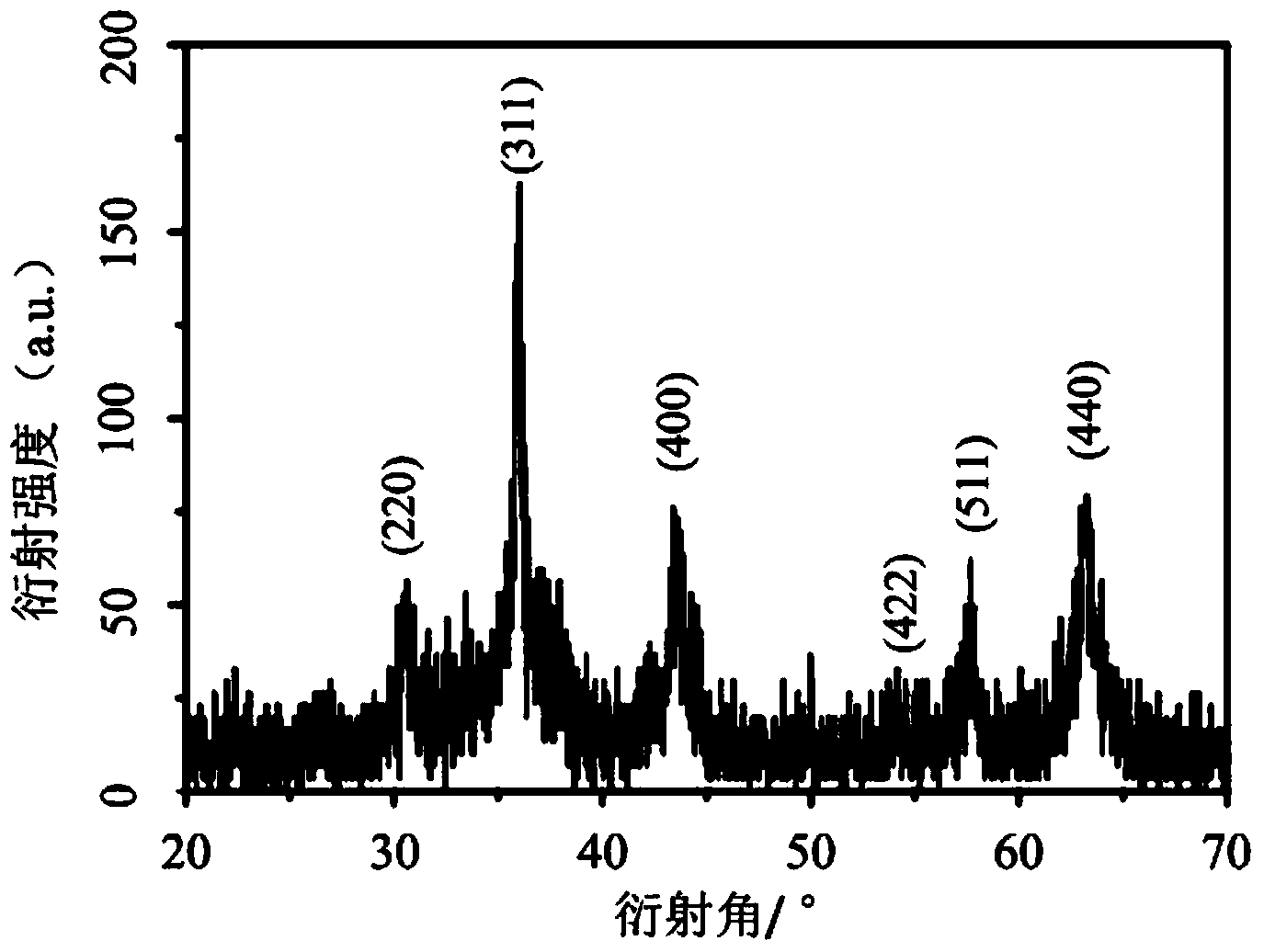

Embodiment 1

[0031] (a) Dissolve 0.4g NaOH in 1mL H 2 O, and then mixed with 6mL oleic acid and 3mL absolute ethanol in the process of stirring to obtain a homogeneous transparent solution A.

[0032] (b) Add 50 μL of 80% hydrazine hydrate to solution A, and continue stirring for 5 minutes to obtain homogeneous solution B.

[0033] (c) Prepare 0.5mM ferric ammonium sulfate aqueous solution C and 0.25mM ferrous sulfate aqueous solution D for later use.

[0034] (d) Add 1mL of C solution and 1mL of D solution to solution B in turn, stir quickly and mix well to obtain solution E.

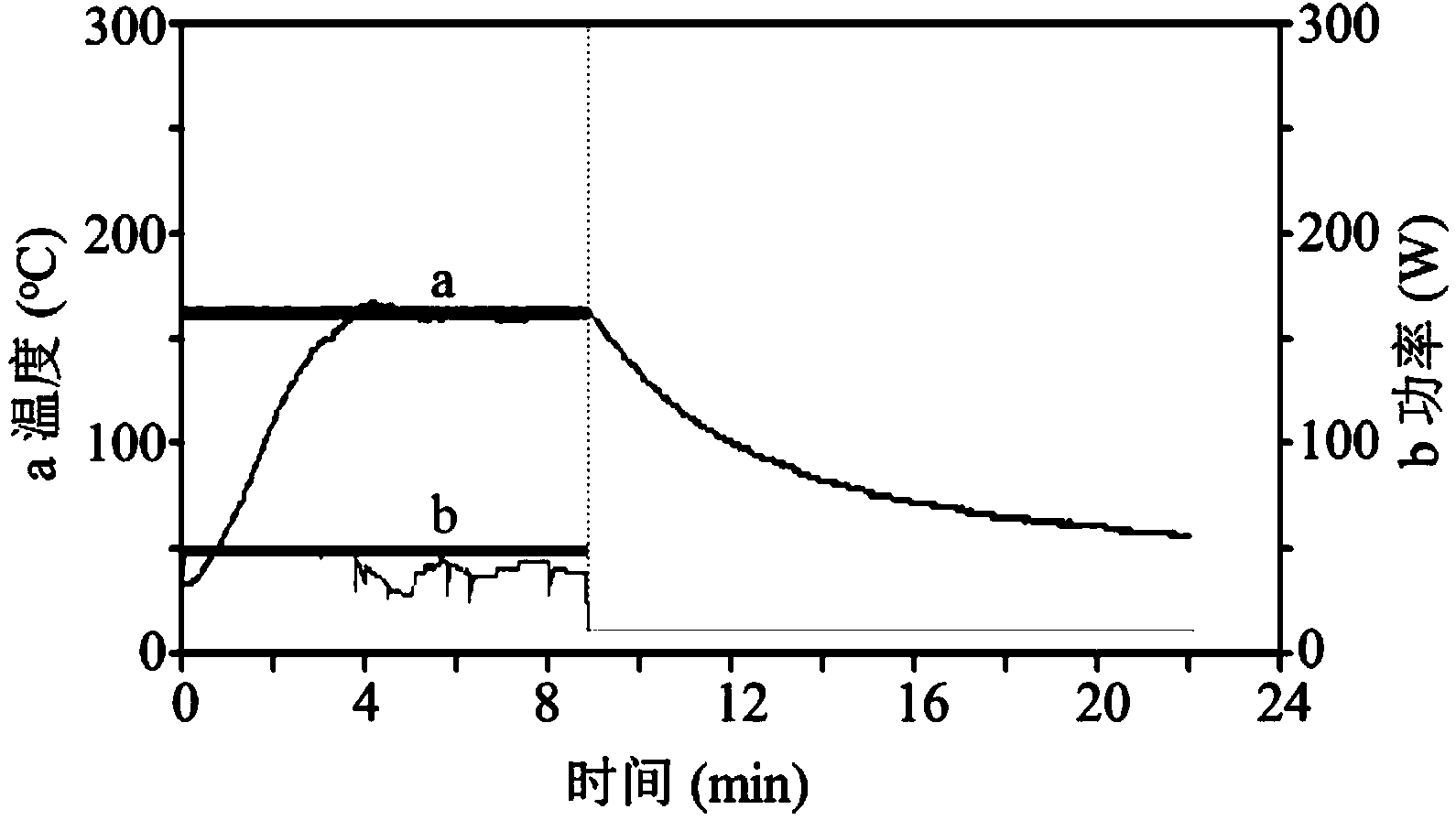

[0035] (e) Transfer the solution E into the quartz reaction tube of the microwave synthesizer, seal it with a matching rubber stopper, put it into the microwave synthesizer, and set the microwave synthesis parameters: power 40W, keep temperature 160°C, keep time 5min. Start the program for microwave synthesis.

[0036] (f) After the reaction stops, take out the reaction tube, add 10mL of absolute ethanol for ult...

Embodiment 2

[0043] (a) Dissolve 0.4g NaOH in 1mL H 2 O, and then mixed with 6mL oleic acid and 3mL absolute ethanol in the process of stirring to obtain a homogeneous transparent solution A.

[0044] (b) Add 50 μL of 80% hydrazine hydrate to solution A, and continue stirring for 5 minutes to obtain homogeneous solution B.

[0045] (c) Prepare 0.5mM ferric chloride aqueous solution C and 0.25mM manganese acetate aqueous solution D for later use.

[0046] (d) Add 1mL of C solution and 1mL of D solution to solution B in turn, stir quickly and mix well to obtain solution E.

[0047] (e) Transfer the solution E into the quartz reaction tube of the microwave synthesizer, seal it with the matching rubber stopper, put it into the microwave synthesizer, and set the microwave synthesis parameters: power 40W, keep temperature 160°C, keep time 1min. Start the program for microwave synthesis.

[0048] (f) After the reaction stops, take out the reaction tube, add 10mL of absolute ethanol for ultraso...

Embodiment 3

[0053] (a) Dissolve 0.4g NaOH in 1mL H 2 O, and then mixed with 6mL oleic acid and 3mL absolute ethanol in the process of stirring to obtain a homogeneous transparent solution A.

[0054] (b) Add 100 μL of 80% hydrazine hydrate to solution A, and continue stirring for 5 minutes to obtain homogeneous solution B.

[0055] (c) Prepare 0.25mM ferric ammonium sulfate aqueous solution C and 0.125mM cobalt acetate aqueous solution D for later use.

[0056] (d) Add 1mL of C solution and 1mL of D solution to solution B in turn, stir quickly and mix well to obtain solution E.

[0057] (e) Transfer the solution E into the quartz reaction tube of the microwave synthesizer, seal it with a matching rubber stopper, put it into the microwave synthesizer, and set the microwave synthesis parameters: power 20W, keep temperature 120°C, keep time 5min. Start the program for microwave synthesis.

[0058] (f) After the reaction stops, take out the reaction tube, add 10mL of absolute ethanol for u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com