Patents

Literature

50results about How to "Good product performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process method of producing high-grade TC4 alloy hot rolled plate with high material-obtaining rate and low cost

ActiveCN103045906ANovel process routeGood product performanceMetal rolling arrangementsHot rolledAtmosphere

The invention presents a process method of producing a high-grade TC4 alloy hot rolled plate with a high material-obtaining rate and low cost, which comprises the following steps: slab ingot preparation through an EB, grinding, heat rolling, atmosphere annealing, sand blasting, pickling, grinding and sizing to obtain an annealed TC4 hot rolled plate, wherein a coloring and inspection technology is applied for the surface detection of a cogging bland and for the surface quality detection of a fire rolling blank. According to the invention, the EB is adopted to smelt and roll blank; the material-obtaining rate from the raw materials to slabs is improved to 92 percent, and the material-obtaining rate from the raw materials to finished products is improved to 69-73.6 percent; cracks are ensured to be removed completely, so as to achieve the purpose of no grinding or less grinding in follow-up rolling, and accordingly the labor and material cost for grinding is greatly reduced; and the prepared plate has the tensile strength of 950-1100 MPa, the yield strength of 880-980 MPa, and the elongation percentage among 14-20 percent, and meets the standard requirements of GB / T3621-2007, GT / B14845-2007 and ASTMB265-2006.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

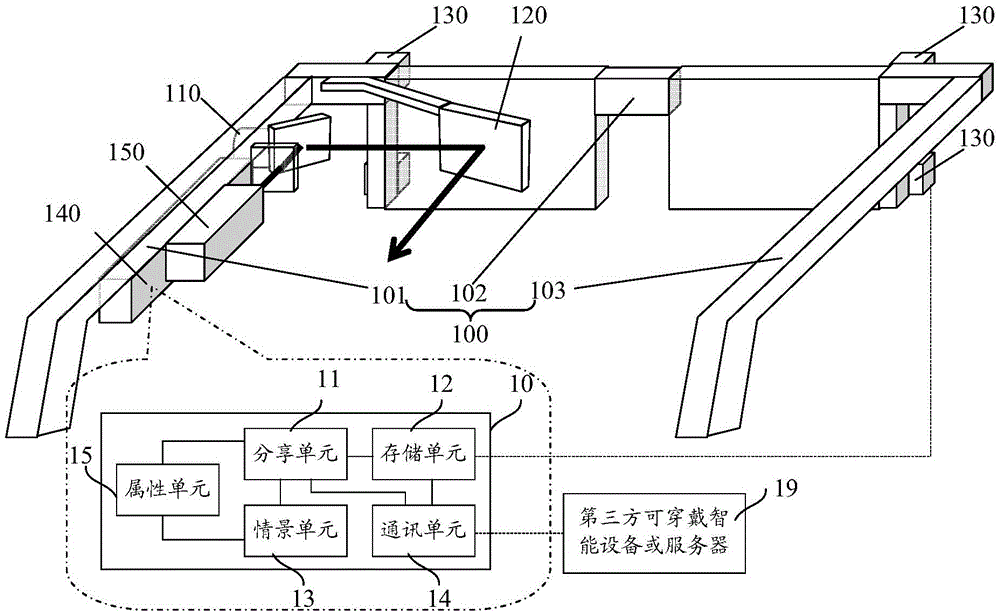

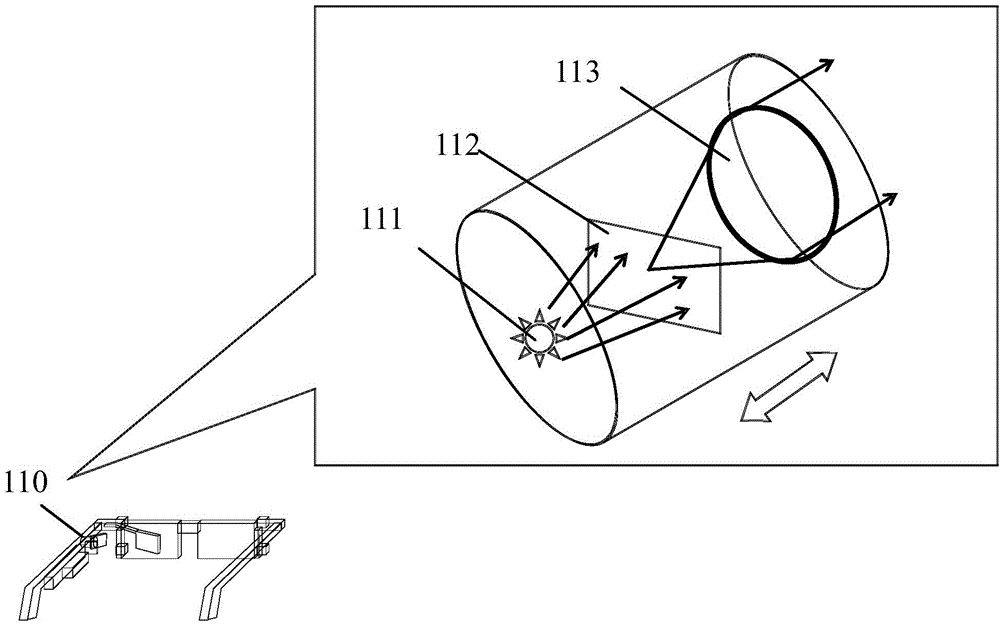

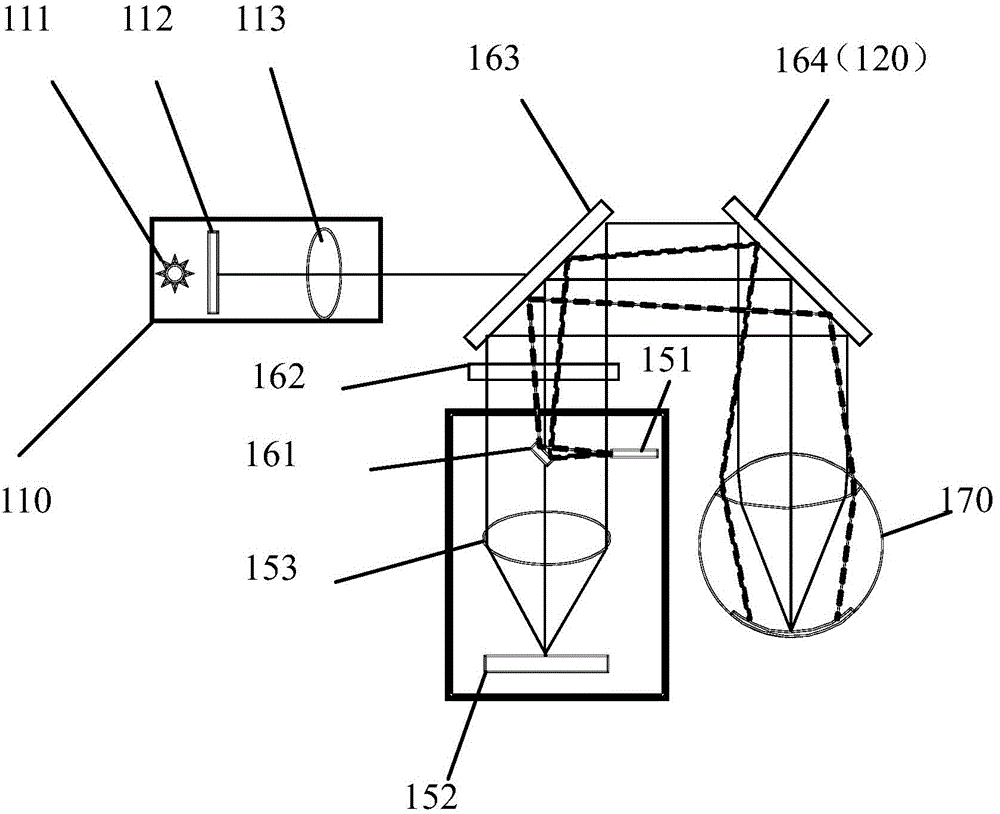

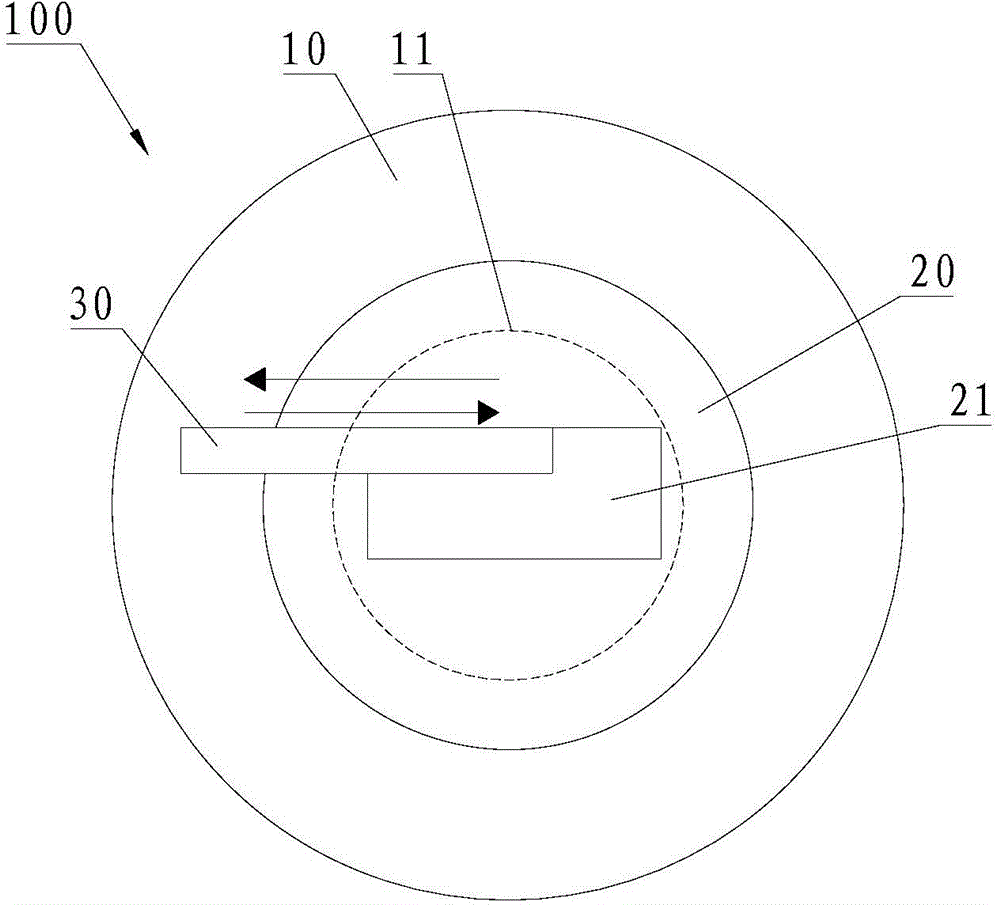

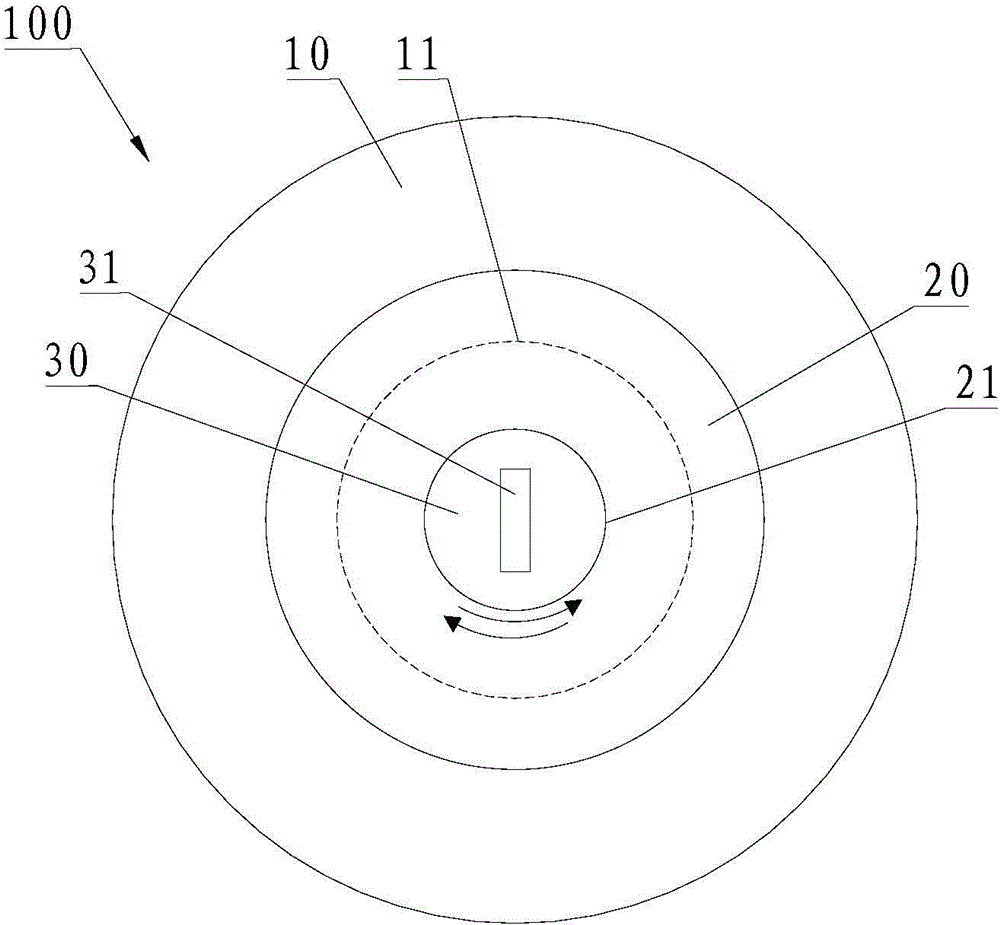

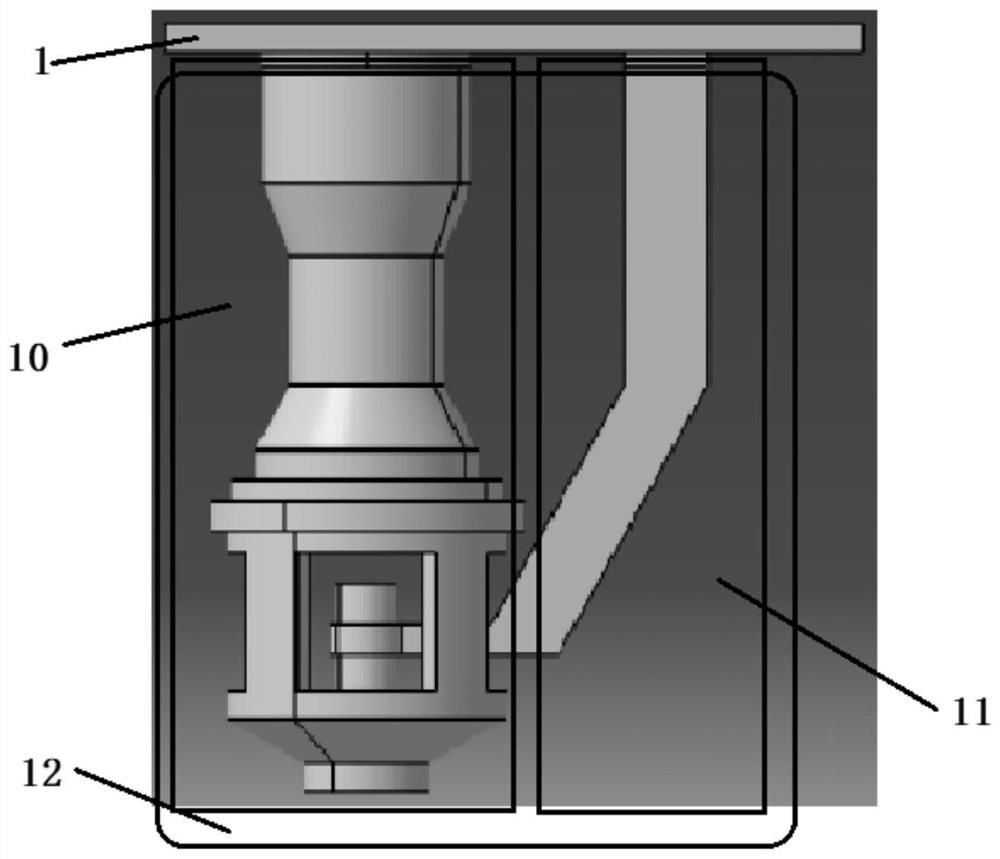

Wearable intelligent device, interaction method of wearable intelligent device and wearable intelligent device system

ActiveCN105446474AOptimizing light pathGood product performanceInput/output for user-computer interactionGraph readingHuman eyeThird party

The invention relates to a wearable intelligent device, an interaction method of the wearable intelligent device and a wearable intelligent device system. The wearable intelligent device comprises a device frame, a micro projector, a spectroscope, an image sensing unit, a retina position sensing unit, and a central data center, wherein the micro projector is suitable for projecting a graphic interface to the spectroscope; the spectroscope is suitable for receiving the projected graphic interface and forming a real image of the graphic interface in human eyes; the image sensing unit is suitable for sensing external scene information, and converting the external scene information into scene image data; the retina position sensing unit is suitable for sensing positions of the eyes and a changing mode of the positions along with time, and converting the positions into position data; the central data center is at least suitable for converting the changing mode of the positions along with time and the position data into corresponding operation instructions; the central data center further comprises a sharing module; and the sharing module is at least suitable for receiving the operation instructions, and executing an operation of sharing the scene image data to a third-party wearable intelligent device. According to the wearable intelligent device disclosed by the invention, rapid sharing of data is achieved, and user experience is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Hard medicine capsule

InactiveCN100998572AGood product performanceStable in naturePharmaceutical non-active ingredientsCapsule deliveryAqueous solutionBiomedical engineering

An empty capsule for medicines is proportionally prepared from hydroxypropyl methylcellulose, hydroxypropyl starch and chitin through preparing aqueous solution, immersing die in it, baking, removing die and trimming. It has bactericiding action.

Owner:刘杰

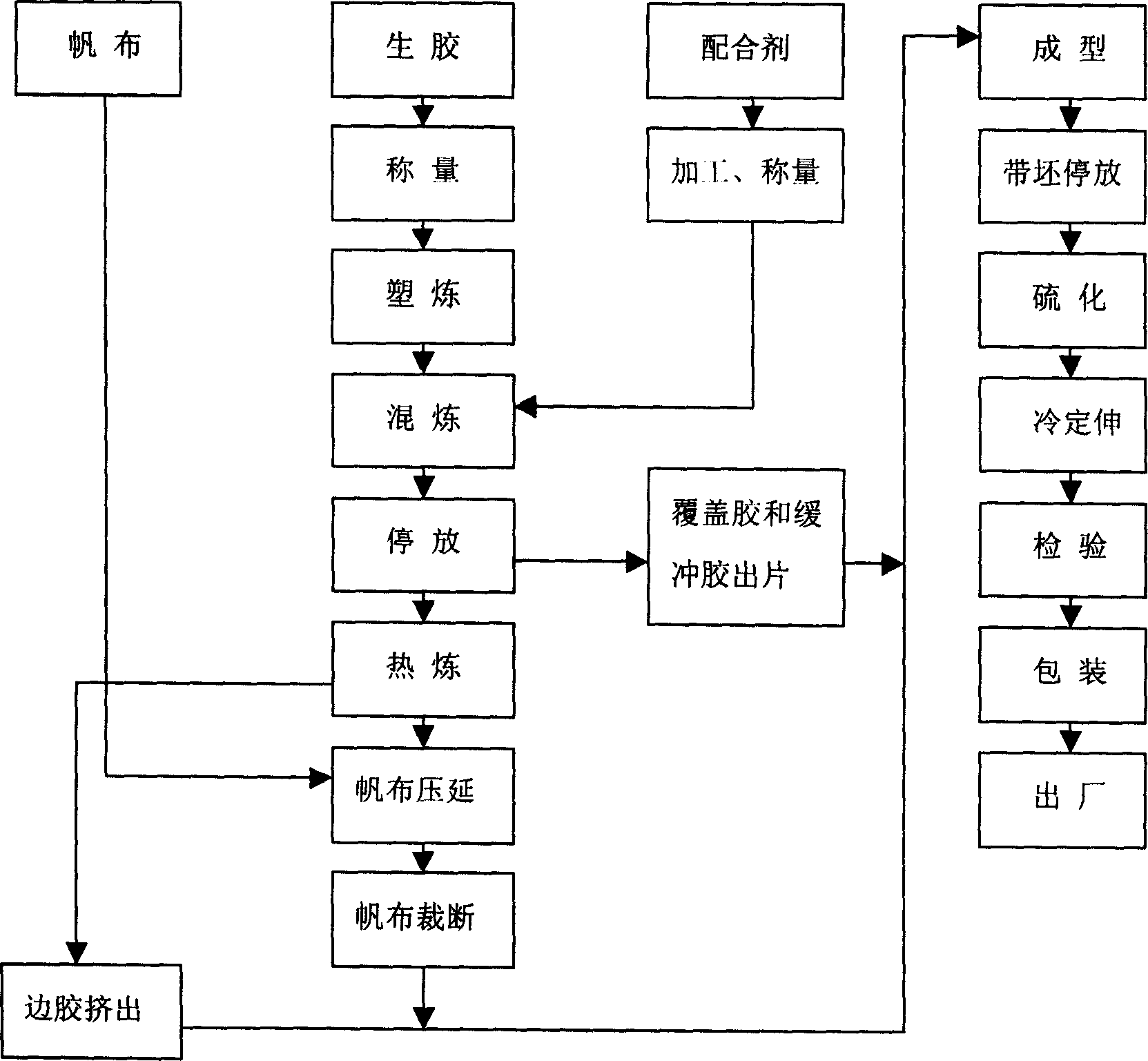

Impact resistance high wearing-proof conveyer belt

An anti-impact and anti-wear conveying belt features that the rubber layer covered on its surface is proportionally prepared from natural rubber, synthetic rubber, sulfur, zinc oxide, stearic acid, promoter, reinforcing agent, softening agent and anti-ageing agent.

Owner:阳江市北山胶化有限公司

Production and processing process of ultra-coarse denier polyester filament yarn

InactiveCN101302671AGood product performanceGood spinnabilityTextiles and paperHot boxMachining process

The invention relates to a production process technique for super-coarse denier polyester filament. The POY processed by spun yarn is submitted for false twist after inspection and equilibration. The precursor fiber is fed by a first roller and enters the twist stop for stop twisting; after being drawn in a first thermal chamber, the fiber is cooled by a cooling plate, then enters the false twister for false-twist texturing, and then enters a network machine to allow the fiber to form a network; after directly passing a second thermal chamber (the temperature of the thermal chamber is closed) and a third roller, the fiber is winded into a spinning cake after oiling in an oiling roller, finally, the whole process is finished after inspecting and packaging the spinning cake obtained. The spun yarn is processed into 400-denier POY by a single spinneret, and then processed into 800-denier DTY by false-twist and bunching combination. The second thermal chamber is closed during the process to provide the finished DTY with high elastic property.

Owner:许燕红

Production method of hydraulic hose wound by four layers of steel wires

InactiveCN109454842ALow raw material costGood product performancePolyamide coatingsTubular articlesEngineeringConductor Coil

The invention relates to a production method of a hydraulic hose wound by four layers of steel wires. The production method includes the following steps of (1) batching, (2) internal mixing, (3) openmixing, (4) medium film calendering, (5) inner tube extruding, (6) winding, (7) external glue coating, (8) water cloth winding, (9) vulcanizing, (10) water cloth opening, (11) decoring and pressure testing, and (12) inspecting, packaging and warehousing. According to the production method of the hydraulic hose wound by the four layers of steel wires, in the production process, a raw material adopts a special material formula, the raw material cost is low, produced product performance is excellent, the good acid and alkali resistant and anti-corrosion effects are achieved, oil-resistant, heat-resistant and ageing-resistant properties are good, the four layers of steel wires are used for winding, a binder is used for bonding, the structure is compact, the bonding effect is good, service performance of the hydraulic hose is enhanced, and the service life of the hydraulic hose is prolonged; and in the technological process, heating treatment is conducted in a special mode, and circulationsupply of cooling water is realized, so that the production cost is lowered.

Owner:宣祖成

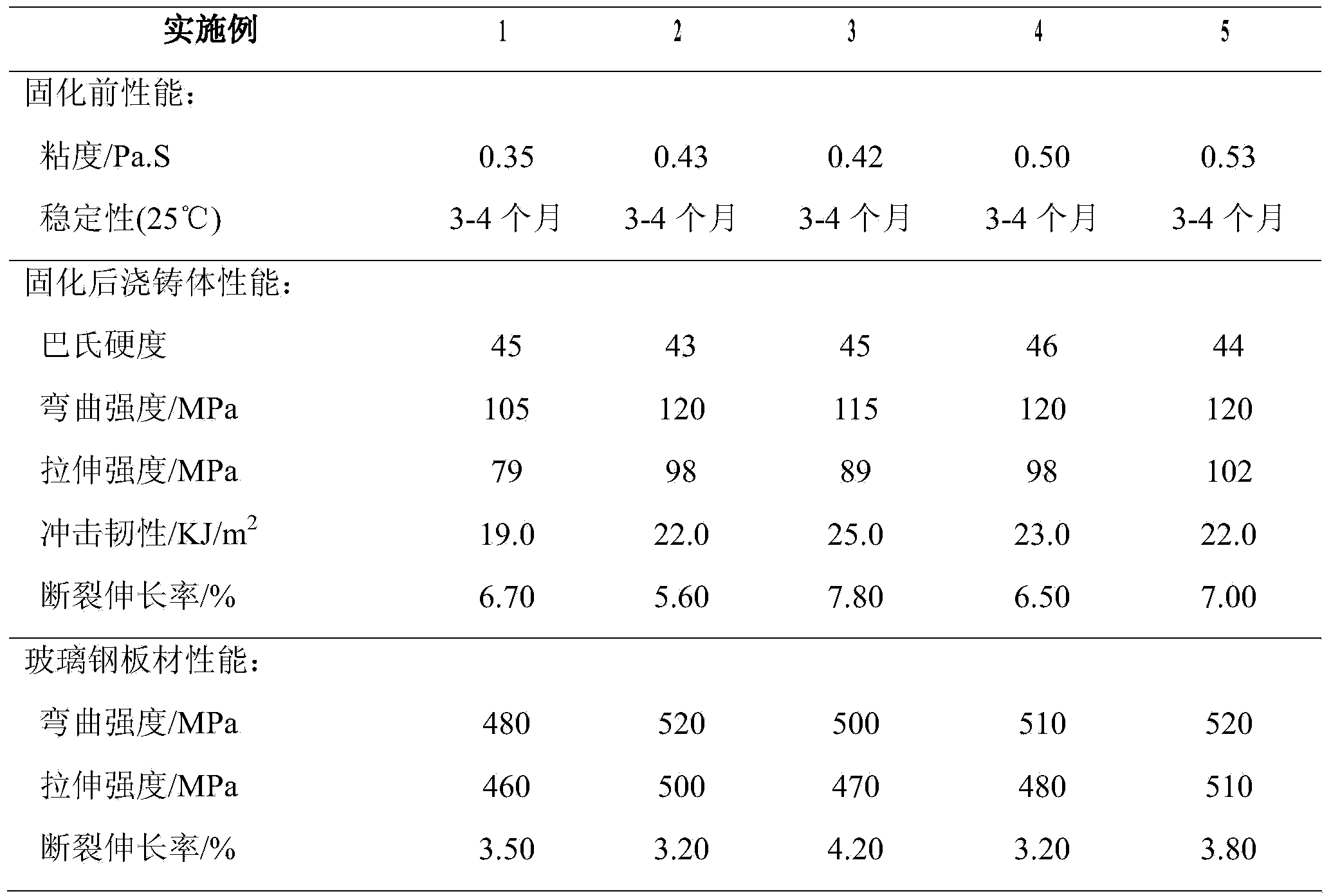

Modified polyurethane/unsaturated polyester resin dibasic alcohol preparation method

The invention relates to a modified polyurethane / unsaturated polyester resin dibasic alcohol preparation method belonging to the field of high molecular polymerization. By synthesizing flexible unsaturated polyester dibasic alcohol through multi-step polymerization, the flexible group proportion and the hydroxyl value are controllable; a flexible unsaturated polyester dibasic alcohol, isocyanate and diluter blending method is easy to implement in the production process; the curing process is controllable, and room-temperature curing can be realized; and modified polyurethane / unsaturated polyester resin cured products are excellent in performance. The invention can be widely used in industrial, agricultural and transportation occasions as well as some occasions of special applications.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Co-extrusion production method for deeply-embossed composite plastic-wood plate with mixed color

ActiveCN104004369ARaw material formula is reasonableGood product performanceSynthetic resin layered productsWood layered productsMaleic anhydrideVacuum pumping

The invention provides a co-extrusion production method for a deeply-embossed composite plastic-wood plate with a mixed color, and relates to the technical field of plastic-wood material production. The production method mainly comprises a pelleting process, a co-extrusion process and a deep-embossing process. Needed raw materials comprise 40-60% of bamboo / wood powder, 15-30% of PE, 4-10% of talcum powder, 10-15% of toner, 2-5% of a coupling agent and 3-5% of a maleic anhydride grafted mateiral. The extrusion process comprises mixing material particles obtained in the pelleting process with color masterbatch with stirring, then adding into an extruder for extruding to obtain plates, and controlling the pressure in a cylinder of the extruder to be 0.06 MPa by utilizing vacuum-pumping equipment connected with the cylinder. By utilizing the provided co-extrusion production method for the deeply-embossed composite plastic-wood plate with mixed color, the raw-material formula is reasonable, the product performances are good, the plastic-wood plate with mixed color is produced and possesses patterns with different colors, and the variety of products is improved; and after extrusion molding and hot embossing are continuously performed on the composite plastic-wood plate, cooling and once-more heating are not needed, the production process reaches the purpose of saving energy, and the embossing depth reaches 0.4-0.8 mm, so that the lines are not easy to rub down.

Owner:ANHUI SENTAI WPC GRP CO LTD

Production technology for plastic-wood plate with mixed color

ActiveCN104004370ARaw material formula is reasonableGood product performanceMaleic anhydrideFlue gas

The invention provides a production technology for a plastic-wood plate with mixed color, and relates to the technical field of plastic-wood material production. The production technology mainly comprises a pelleting process and an extrusion process. In the pelleting process, needed raw materials comprise 40-60% of bamboo / wood powder, 15-30% of PE, 4-10% of talcum powder, 10-15% of toner, 2-5% of a coupling agent and 3-5% of a maleic anhydride grafted material. The extrusion process comprises: mixing material particles obtained in the pelleting process with color masterbatch with stirring, then adding into an extruder for extruding to obtain plates, and controlling the pressure in a cylinder of the extruder to be 0.06 MPa by utilizing vacuum-pumping equipment connected with the cylinder. By utilizing the production technology for plastic-wood plate with mixed color, the raw-material formula is reasonable, the product performances are good, the plastic-wood plate with mixed color is produced and possesses patterns with different colors, and the variety of products is improved; and the extruder cylinder is connected with the vacuum-pumping equipment in the extrusion process, so that the interior of the cylinder is a low-pressure environment, moisture, flue gas and air in the cylinder are timely exhausted, and thus the product performances are improved.

Owner:ANHUI SENTAI WPC GRP CO LTD

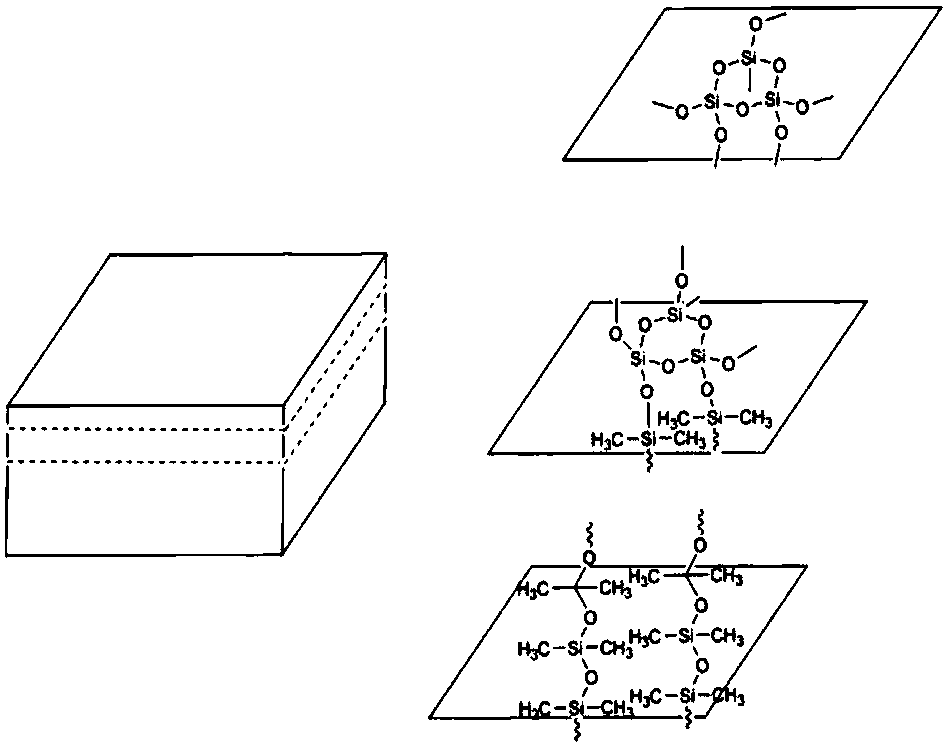

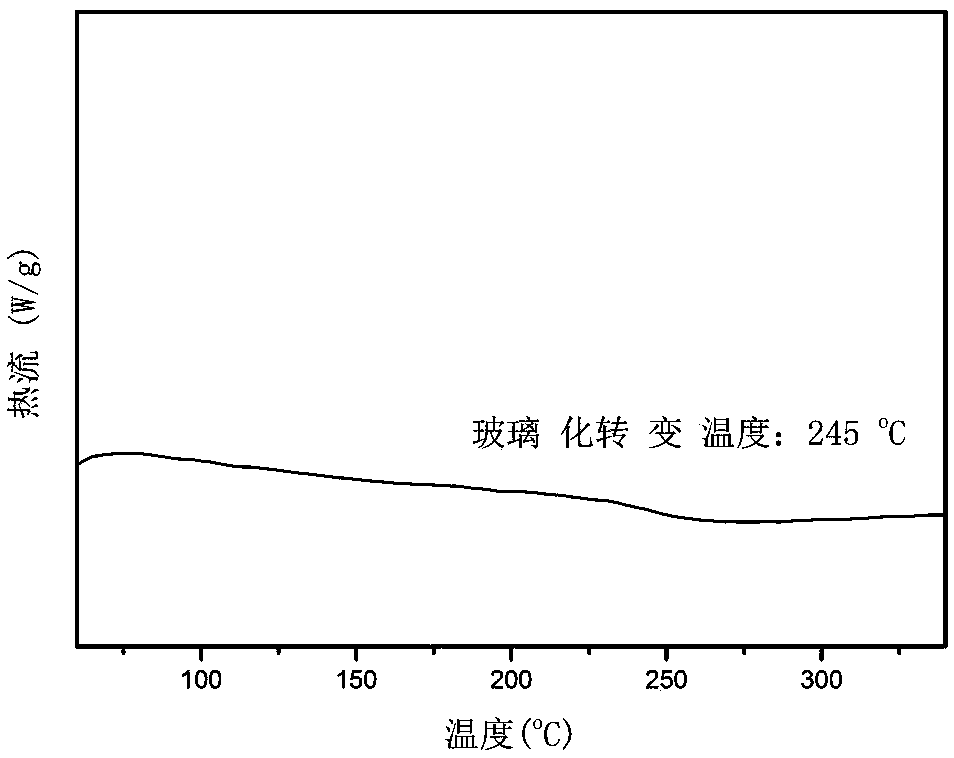

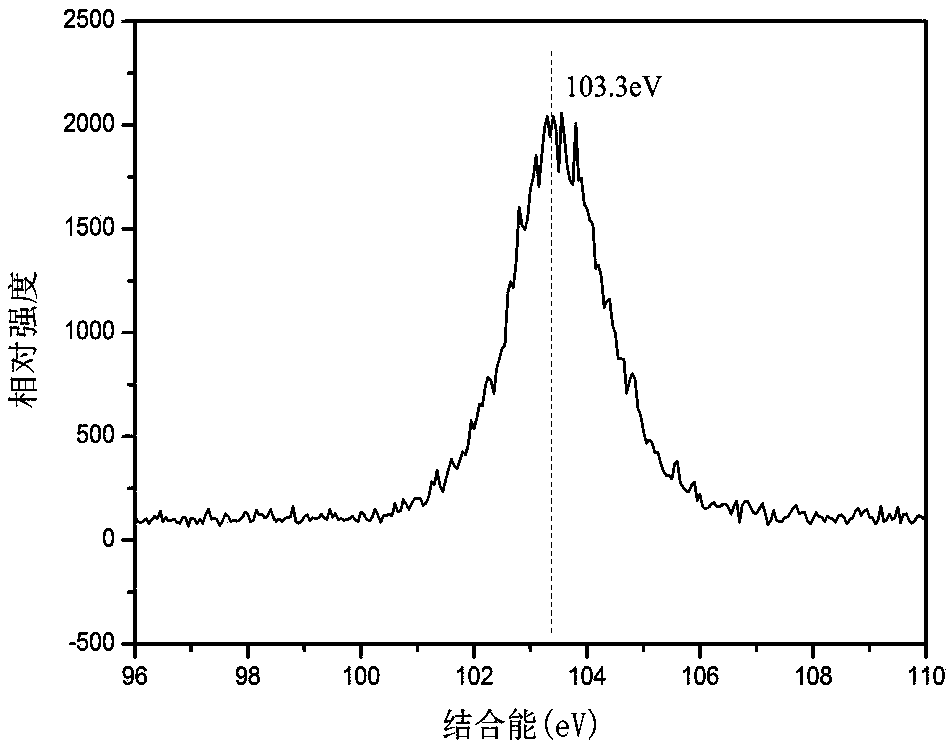

Surface silicon oxidation polyimide-co-silane thin film and preparation method thereof

ActiveCN107757015AGood product performanceControllable process conditionsSynthetic resin layered productsGlass/slag layered productsAtomic oxygenSilicon oxygen

The invention discloses a surface silicon oxidation polyimide-co-silane thin film and a preparation method and belongs to the technical field of polyimide preparation. The invention provides the surface silicon oxidation polyimide-co-silane thin film. The preparation method comprises the following steps: firstly, preparing polyimide-co-silane by adopting a temperature raising and pressurizing method on the basis of a traditional two-step preparation method; and secondly, forming a glass-like functional layer on the surface by controlling conditions and adopting atomic oxygen equipment. The surface silicon oxidation polyimide-co-silane thin film consists of three parts, namely a glass layer, a transition layer and a substrate layer, wherein the glass layer consists of a silicon-oxygen structure, the transition layer consists of the silicon-oxygen structure and the polyimide-co-silane and the substrate layer consists of the polyimide-co-silane. The surface silicon oxidation polyimide-co-silane thin film, disclosed by the invention, has the advantages of excellent atomic oxygen resistance and capability of self-healing. The glass-like functional layer avoids the occurrence of a cold welding phenomenon.

Owner:JILIN UNIV

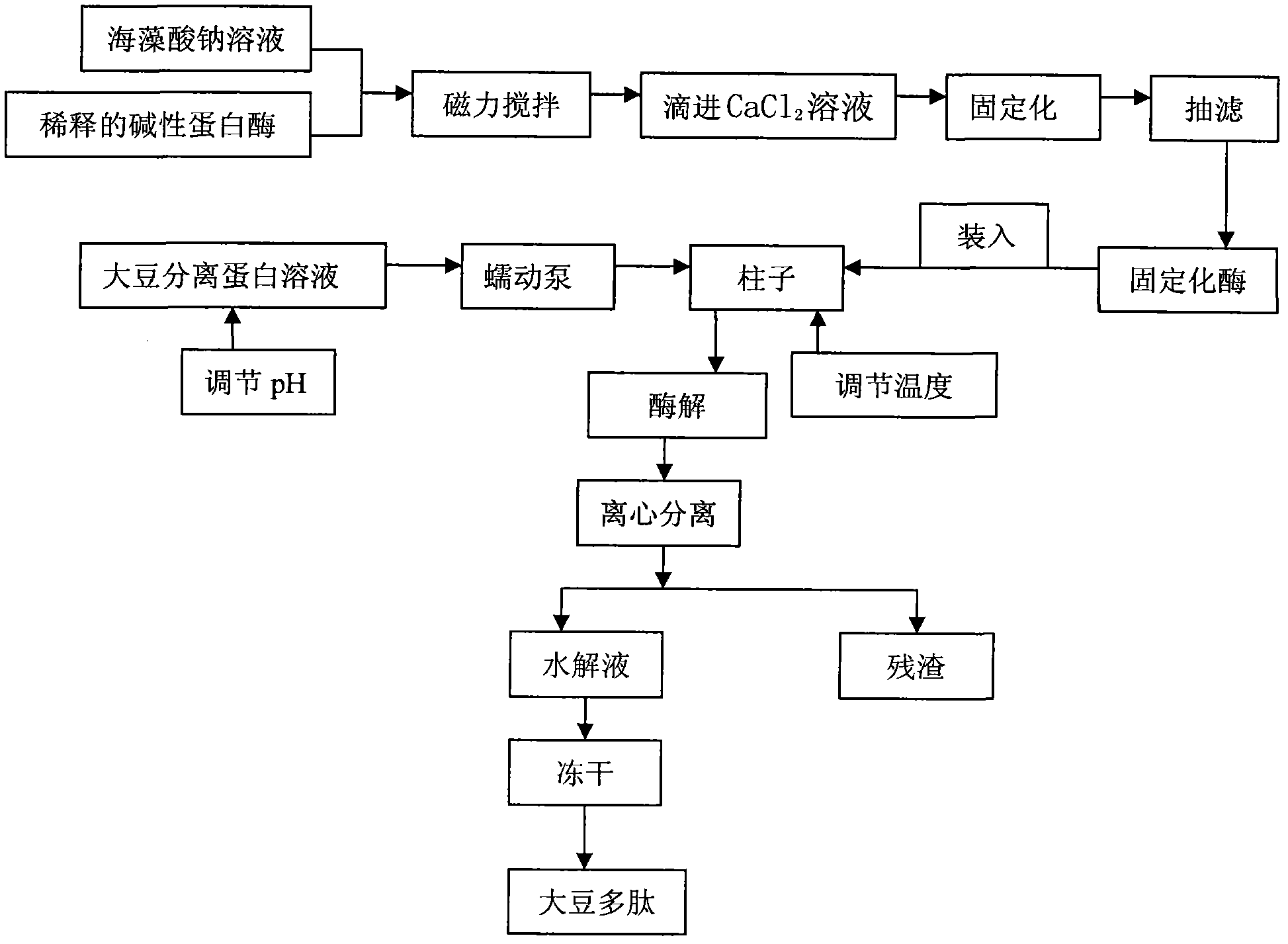

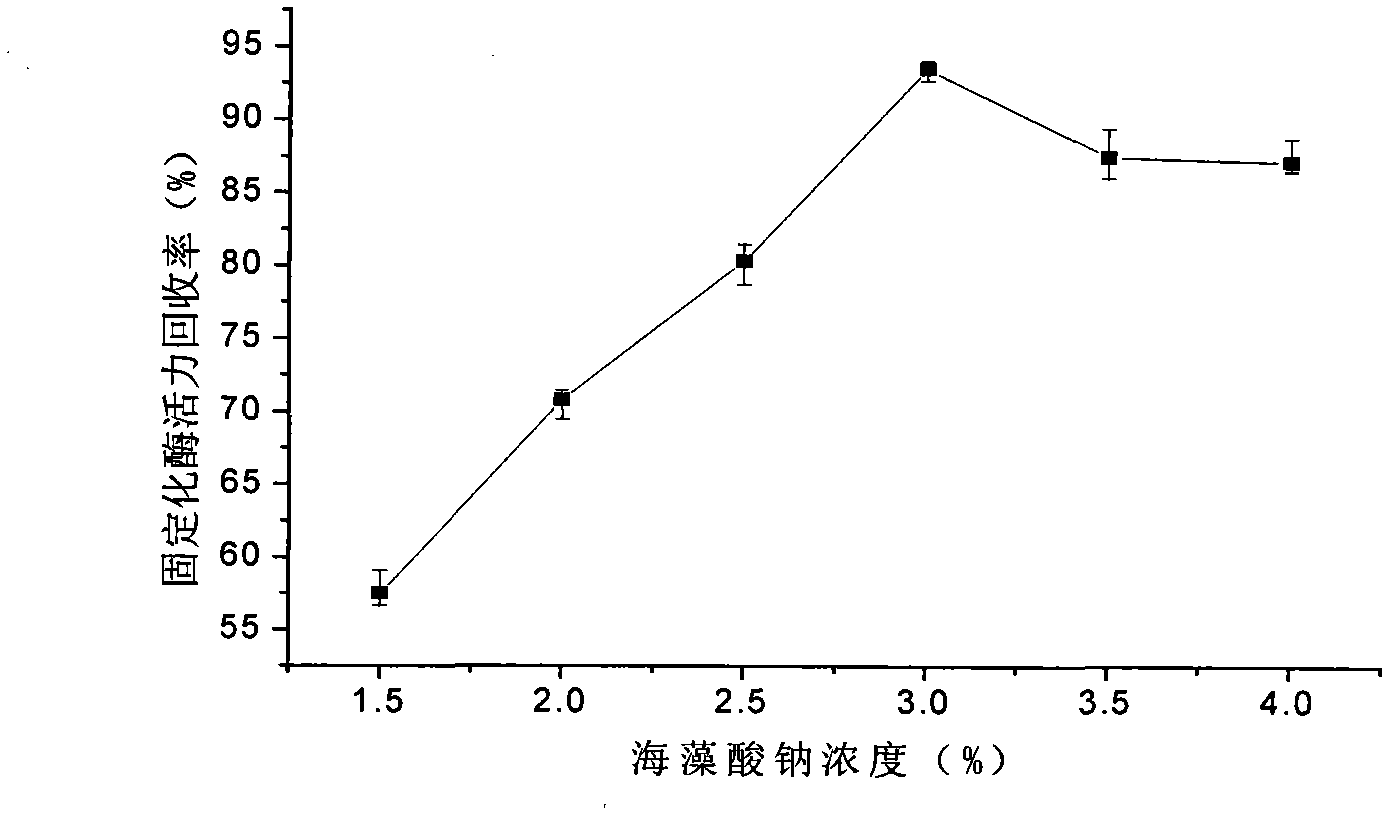

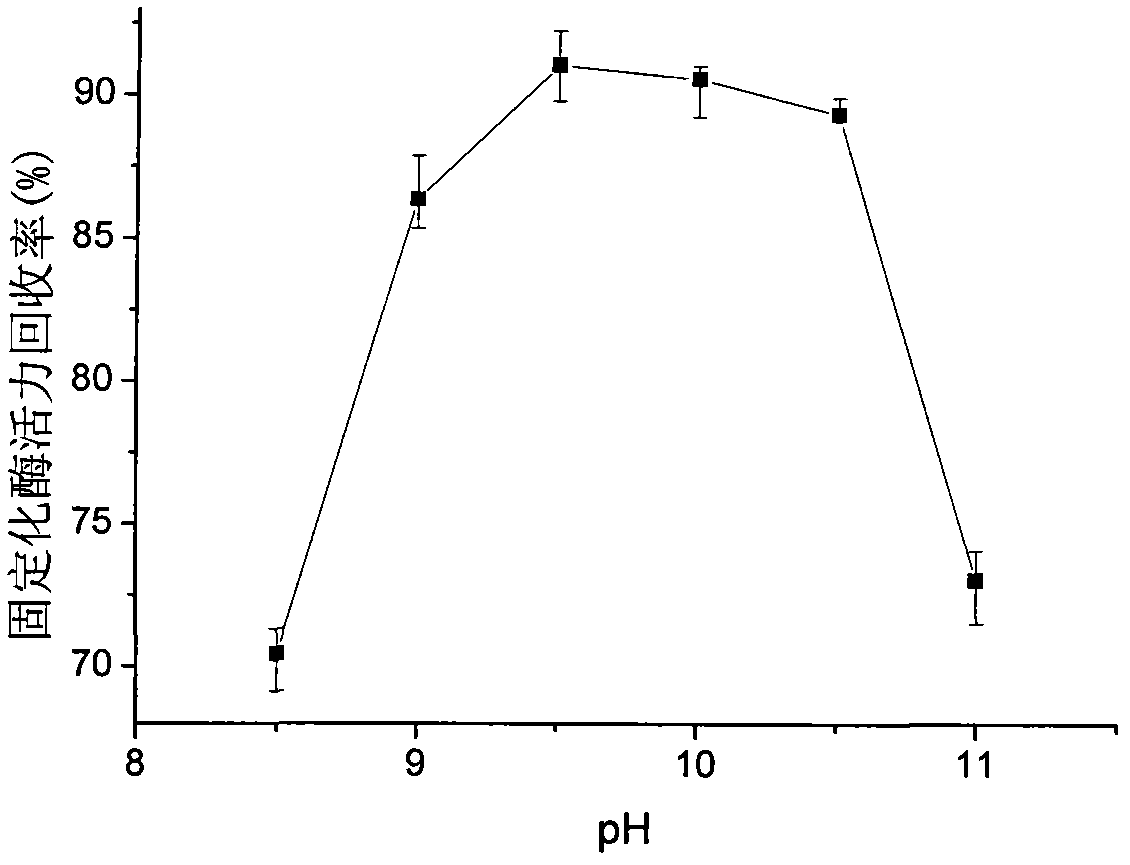

Method for preparing soybean peptide by immobilized alkaline protease

InactiveCN102613387AEasy to useExtended shelf lifeVegetable proteins working-upAlkaline proteaseSoybean Proteins

A method for preparing soybean peptide by immobilized alkaline protease belongs to soybean peptide extraction technology. The method includes steps of adding self-regulated immobilized alkaline protease into a packed bed reactor; and filling soy protein isolate liquor into the packed bed reactor to realize enzymolysis and obtaining a soybean peptide product after purification and lyophilization. Soybean protein isolates are in enzymolysis by the aid of immobilized enzyme and the bioreactor, an enzymolysis process is continuous without enzyme inactivation, and continuous production is realized. The method has the advantages of mild reaction conditions, low energy consumption, good product performance, low production cost, and the like. Besides, the immobilized enzyme can be reused, and further, the high-quality soybean peptide can be obtained.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Extra-deep drawing IF steel and annealing process thereof

InactiveCN102586679AIncrease productivityGood product performanceFurnace typesHeat treatment furnacesChemical compositionDeep drawing

Extra-deep drawing IF steel and an annealing process thereof belong to the technical field of metallurgy. The extra-deep drawing IF steel is characterized that the chemical components and the weight percentage content should conform to: C<=0.008%, Si<=0.015%, Mn<=0.15, P<=0.01%, S<=0.005%, Alt>=0.015%, Ti=0.01-0.07%, Nb=0.01-0.02%, and the balance Fe and trace impurities which cannot be detected. In the annealing process, continuous heating is adopted, the heating rate is 4-8 DEG C / min, the intermediate annealing temperature is 700 DEG C to 750 DEG C, the heat-preserving time is 1-50h, and cooling is performed along with a furnace. The second annealing temperature is 700 DEG C to 750 DEG, the heat-preserving time is 1-10h, and cooling is performed along with the furnace to 400 DEG C-450 DEG C, and discharging and air cooling are performed. The IF steel having excellent deep drawing performance can be obtained by the method, an IF steel sample processed by the process has excellent deep drawing performance, the tensile strength is 290-320MPa, the yield strength is 95-145MPa, the elongation is 45-65%, the plastic strain ratio n is not smaller than 0.27, and the plastic strain ratio r is not smaller than 2.0.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

4140 plastic die steel plate with delivery in annealed state and production method of 4140 plastic die steel plate

The invention discloses a 4140 plastic die steel plate with delivery in an annealed state and a production method of the 4140 plastic die steel plate. The plastic die steel plate is prepared from thefollowing chemical compositions in percentage by mass: 0.38-0.43 percent of C, 0.75-1.00 percent of Mn, 0.15-0.35 percent of Si, smaller than or equal to 0.015 percent of S, smaller than or equal to 0.020 percent of P, 0.80-1.10 percent of Cr, 0.15-0.25 percent of Mo, 0.005-0.025 percent of Al and the balance of iron and inevitable impurities. The production method comprises the following procedures of converter smelting, LF furnace refining, RH vacuum refining, continuous casting slab, controlled rolling and cooling rolling and high-temperature tempering heat treatment. According to the production method provided by the invention, the Al content is controlled to be 0.005-0.025 percent, other precious alloying elements such as Nb, Ti and V are not added, and the hardness of the steel plateis smaller than or equal to 230HB by adopting a high-temperature tempering heat treatment technology, so that the technology is simple, and the production cost is effectively lowered.

Owner:TANGSHAN IRON & STEEL GROUP +1

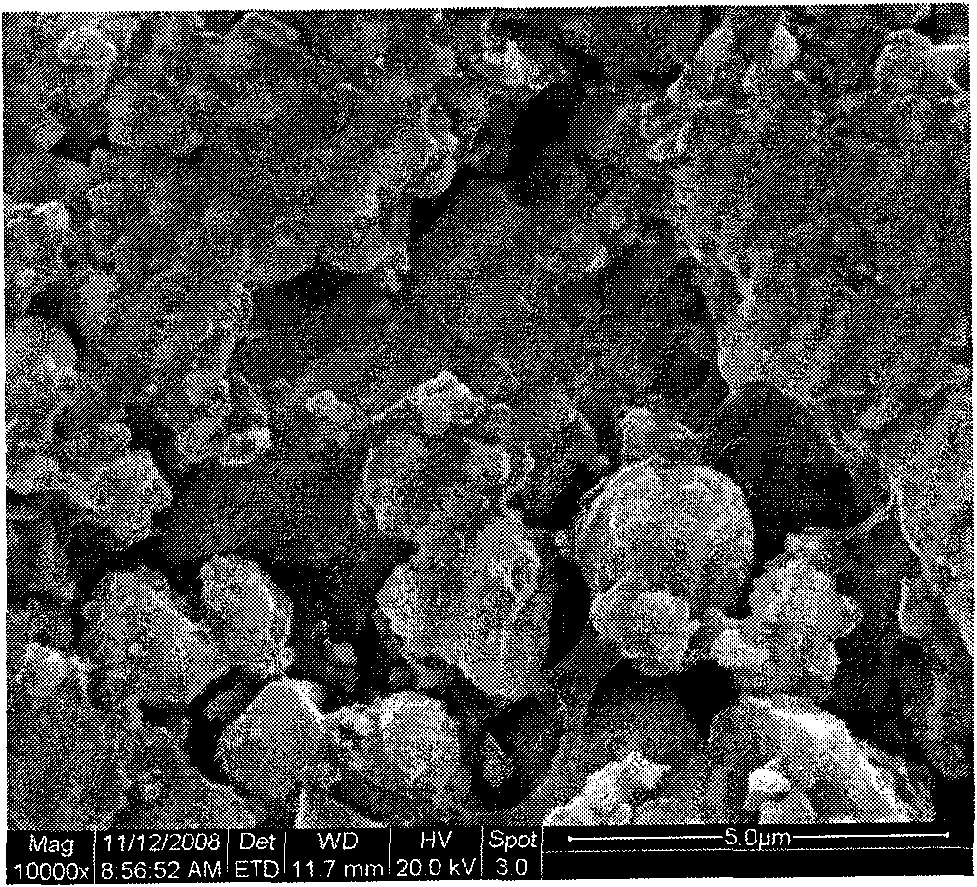

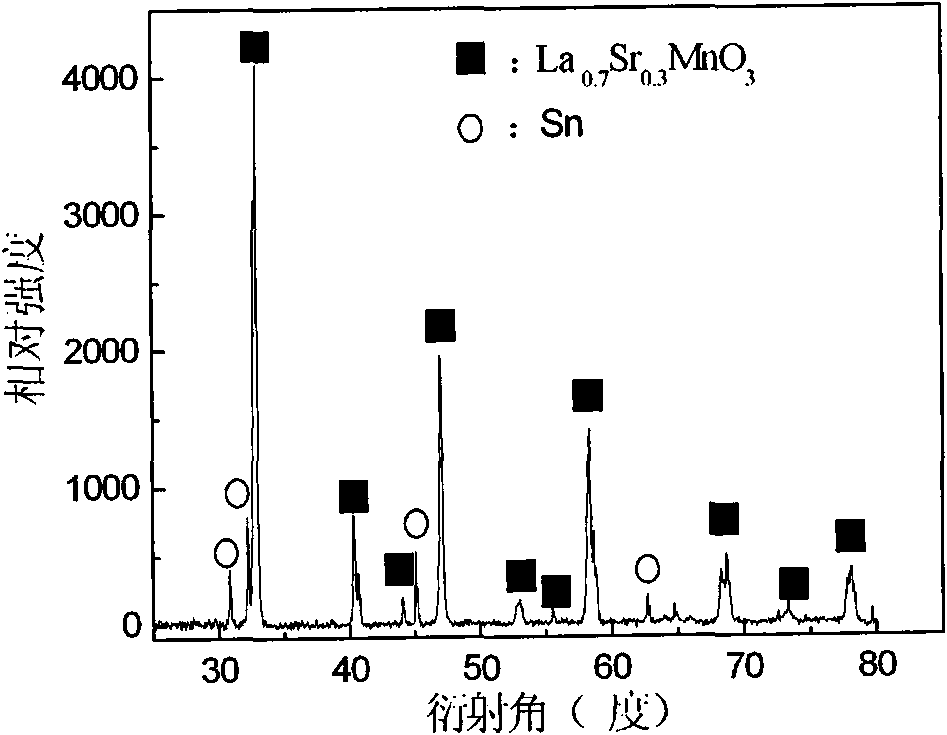

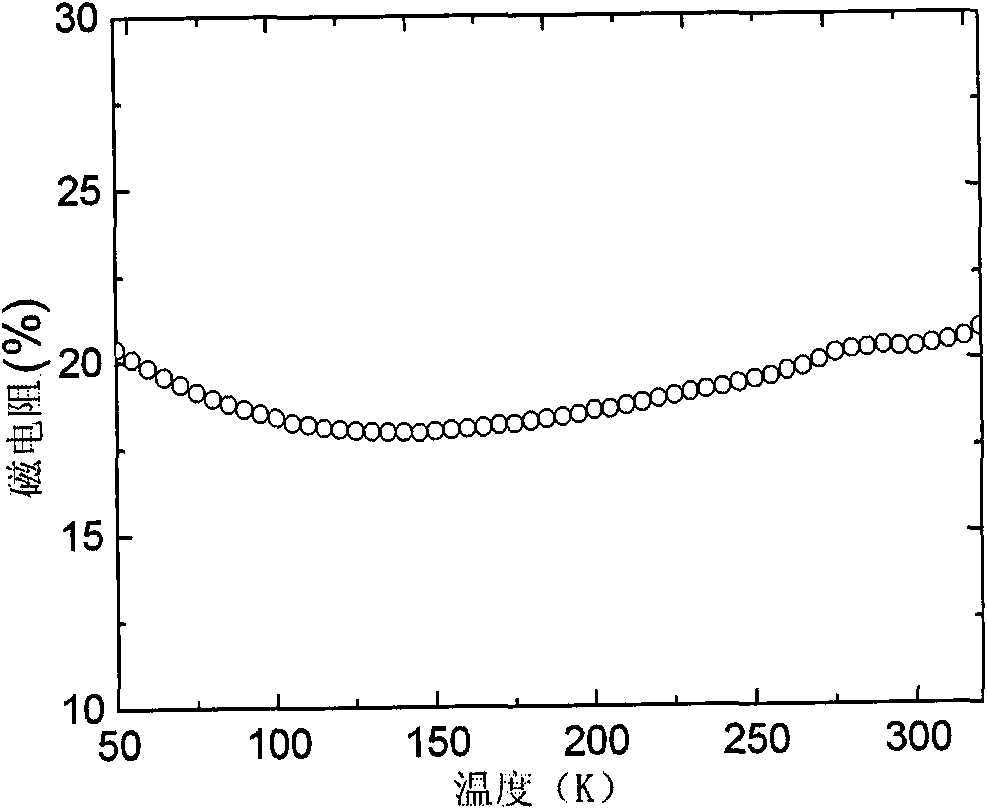

Preparation method of non temperature-sensibility manganese oxide magneto-resistor material

The invention relates to a preparation method of non temperature-sensibility manganese oxide magneto-resistor material, the specific steps are as follows: a. La2O3, SrCO3 and MnO2 are prepared according to atomic ratio of La0.7Sr0.3MnO3, the raw material is ground, three-time calcination and the grinding after calcination are carried out to obtain precursor powder; b. 5-15 percent of metal tin powder is added in the precursor powder to obtain mixed powder; c. the mixed powder is mixed with coupling agents of which the weight is 1 percent of the precursor powder; d. binding material which is 4 percent of the precursor powder by weight and curing agents are sequentially dissolved in acetone, the mixed powder is added, evenly mixed and then the mixture is dried and is formed by pressing at 100-800MPa, and is solidified at 120-160 DEG C. The preparation method has simple preparation process, low energy consumption and low cost, and the prepared manganese oxide magneto-resistor material has high magneto-electricity resistance in the wide temperature range and downfield, and the magneto-electricity resistance is insensitive to the temperature.

Owner:SOUTHWEST JIAOTONG UNIV

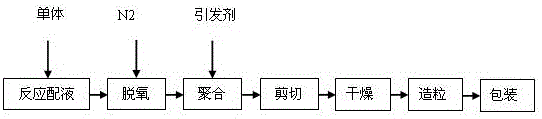

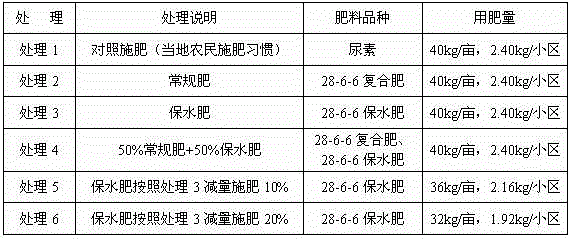

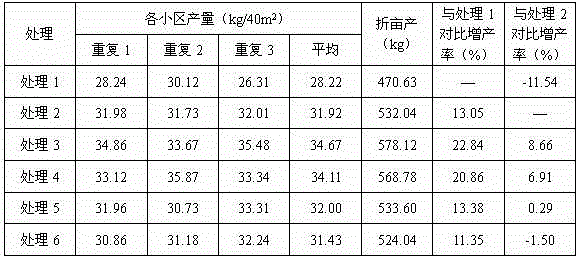

Water-retaining agent and compound functional fertilizer thereof

InactiveCN105732225AGood product performanceImprove water and fertilizer use efficiencyMagnesium fertilisersAlkali orthophosphate fertiliserChemistryPhosphate

The invention discloses a water-retaining agent and a compound functional fertilizer thereof, and belongs to the technical field of agricultural fertilizers. The water-retaining agent takes acrylamide, acrylic acid, 2-acrylamide octa-alkyl sulphonic acid and dimethyl diallyl ammonium chloride as monomers, takes potassium persulfate and sodium hydrogen sulfite as initiators and is a polypropylene acid amide polymer formed through polymerization; the compound functional fertilizer is prepared from urea, monoammonium phosphate, potassium sulfate, the water-retaining agent, potassium humate, magnesium sulfate, borax and ammonium molybdate. By means of the water-retaining agent and the compound functional fertilizer thereof, complex integration of the fertilizer and the water-retaining is achieved, the water-retaining fertilizer capable of increasing the water and fertilizer utilization rate is developed, and the water-retaining agent and the compound functional fertilizer thereof have the advantages that the environment is protected, the oil structure is improved, the crop stress-resistance capacity is enhanced, and the product quality is improved.

Owner:STANLEY AGRI GRP CO LTD

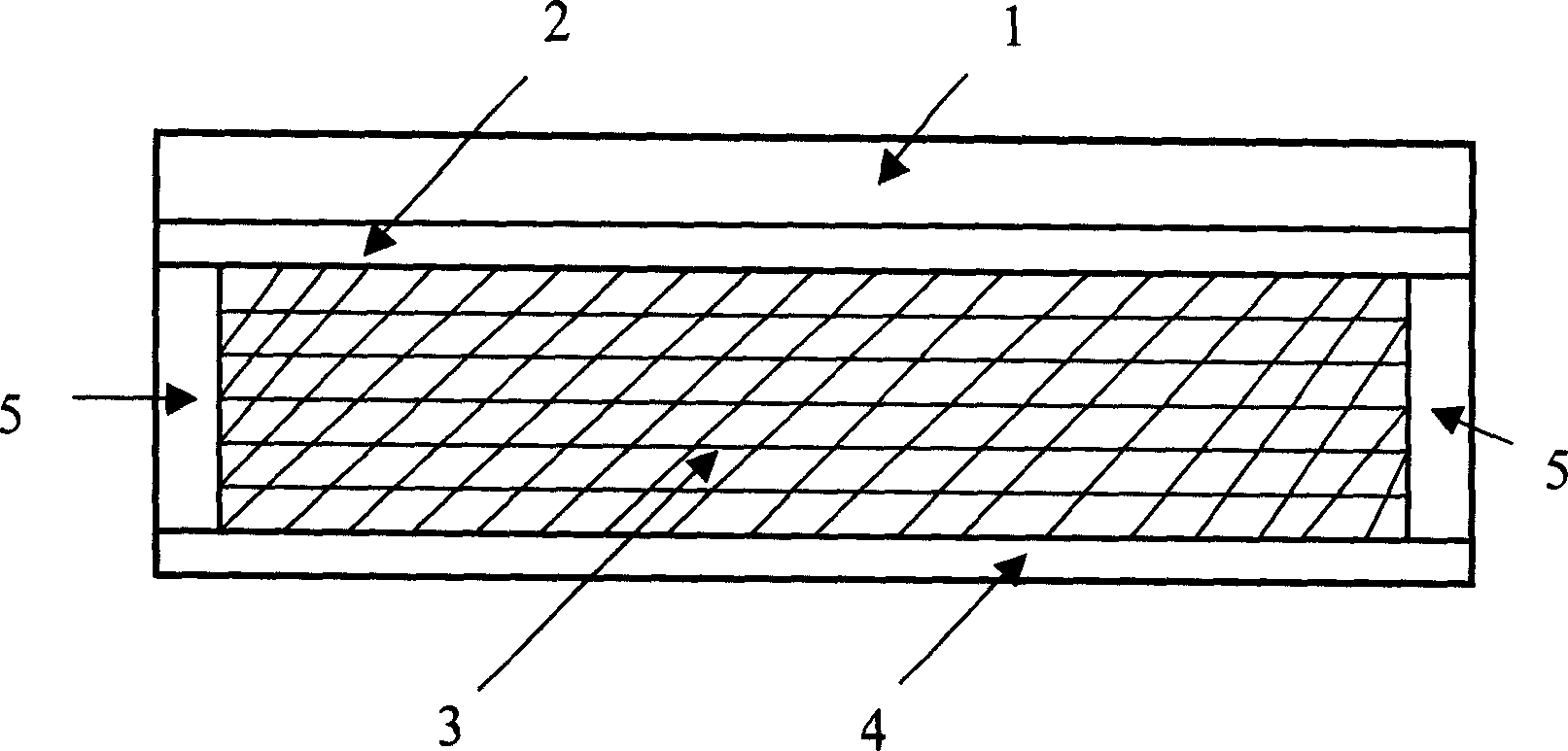

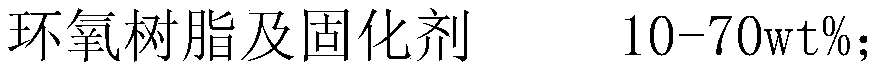

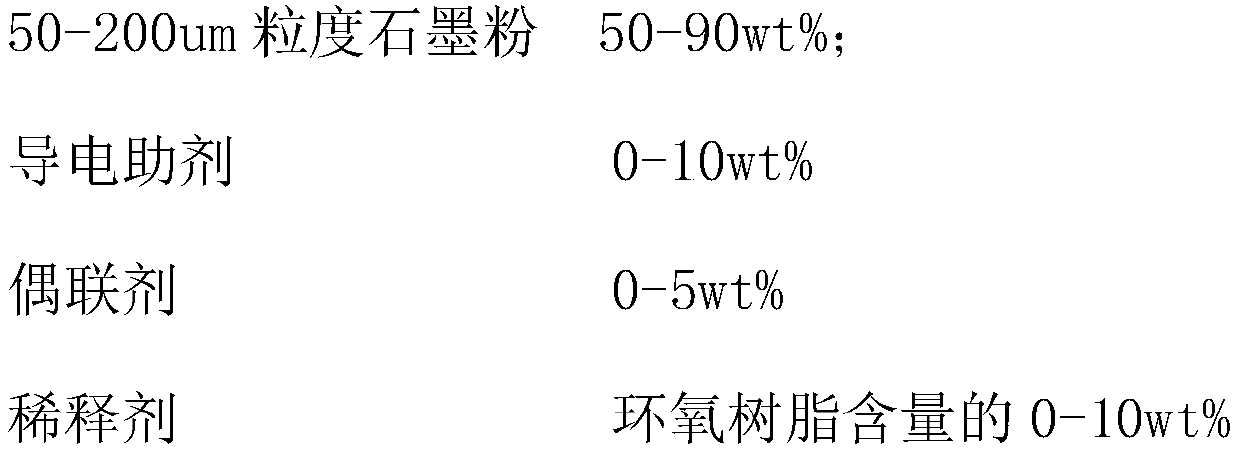

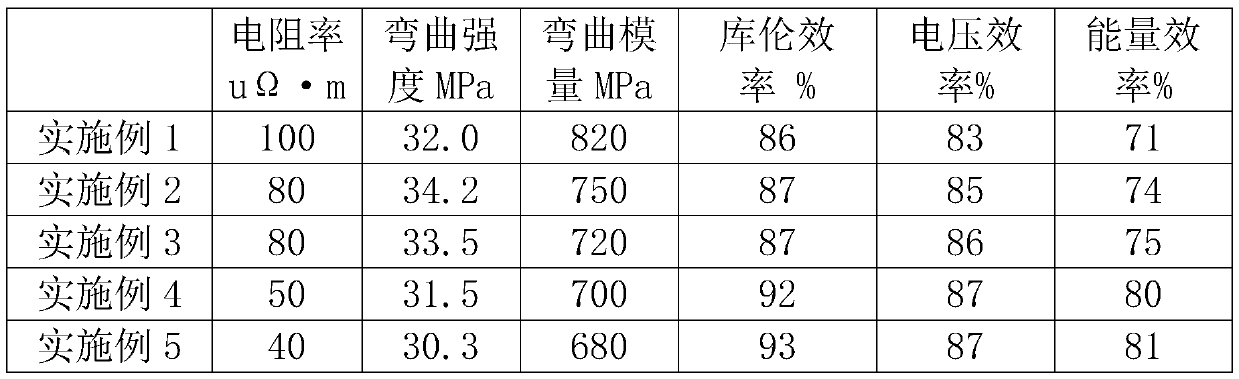

All-vanadium redox flow battery bipolar plate and preparation process thereof

ActiveCN109768296AGood product performanceImprove conductivityRegenerative fuel cellsElectro conductivityCorrosion

An all-vanadium redox flow battery bipolar plate and a preparation process thereof. The all-vanadium redox flow battery bipolar plate comprises a silane coupling agent solution, mesh carbon cloth treated with the silane coupling agent solution, a flexible graphite plate and a conductive adhesive. The conductive adhesive is a graphite-filled conductive adhesive. The bipolar plate is prepared by heating and pressing the flexible graphite plate, the graphite-filled conductive adhesive, the mesh carbon cloth, the graphite-filled conductive adhesive and the flexible graphite plate in sequence withthe vacuum molding technology; and the graphite-filled conductive adhesive is used as a binder. The invention reduces the use of an organic solvent; the preparation process adopts an internal mixer and a open mill for the conductive adhesive preparation and the vacuum molding for the composite bipolar plate preparation so that the operation process is more automatic and the product performance isbetter and more stable; the prepared vanadium battery composite bipolar plate material has the advantages of high electrical conductivity, good corrosion resistance, excellent mechanical properties and good product stability; and the defects of pure graphite plate and conductive plastic as a bipolar plate material in a vanadium battery are solved.

Owner:杭州德海艾科能源科技有限公司

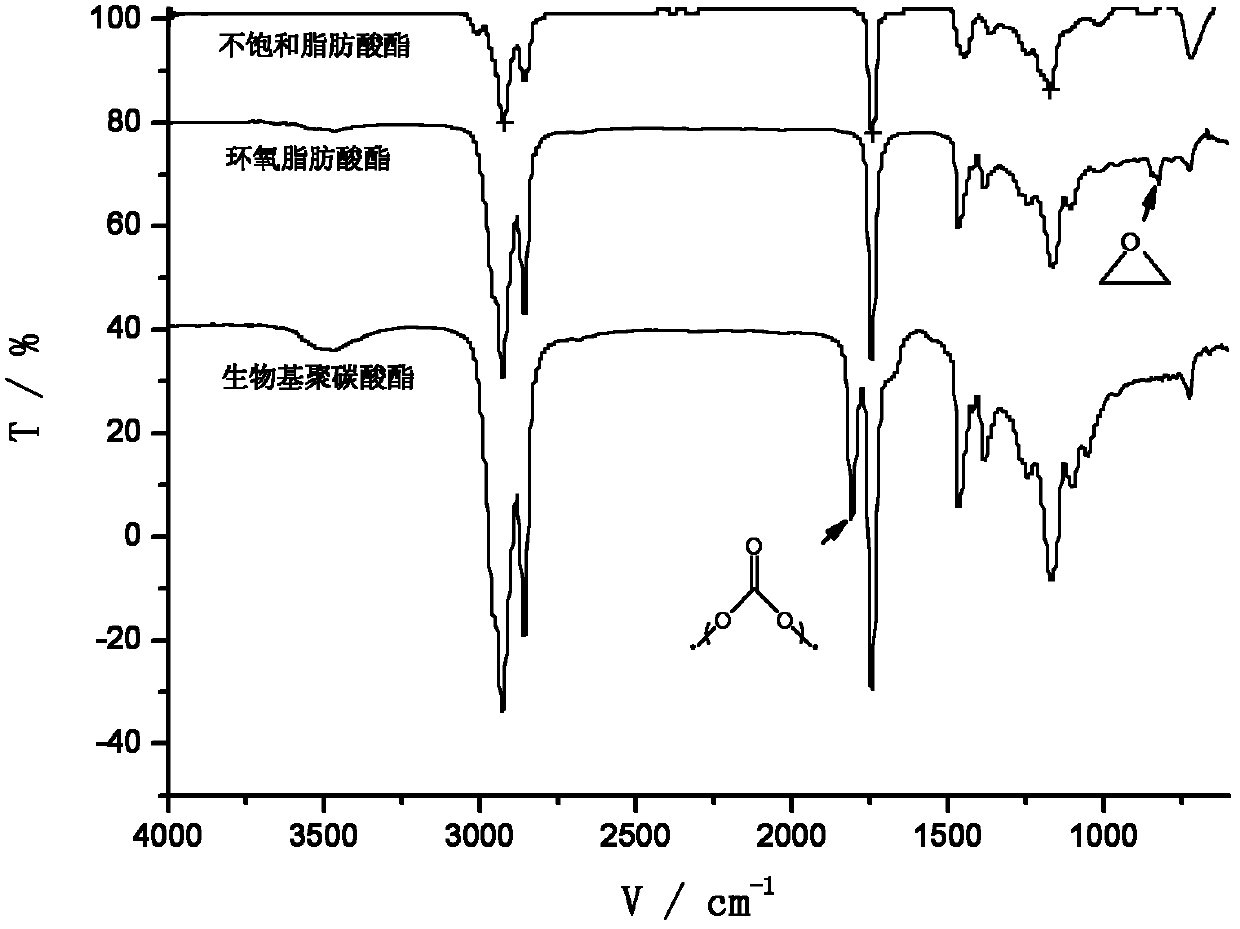

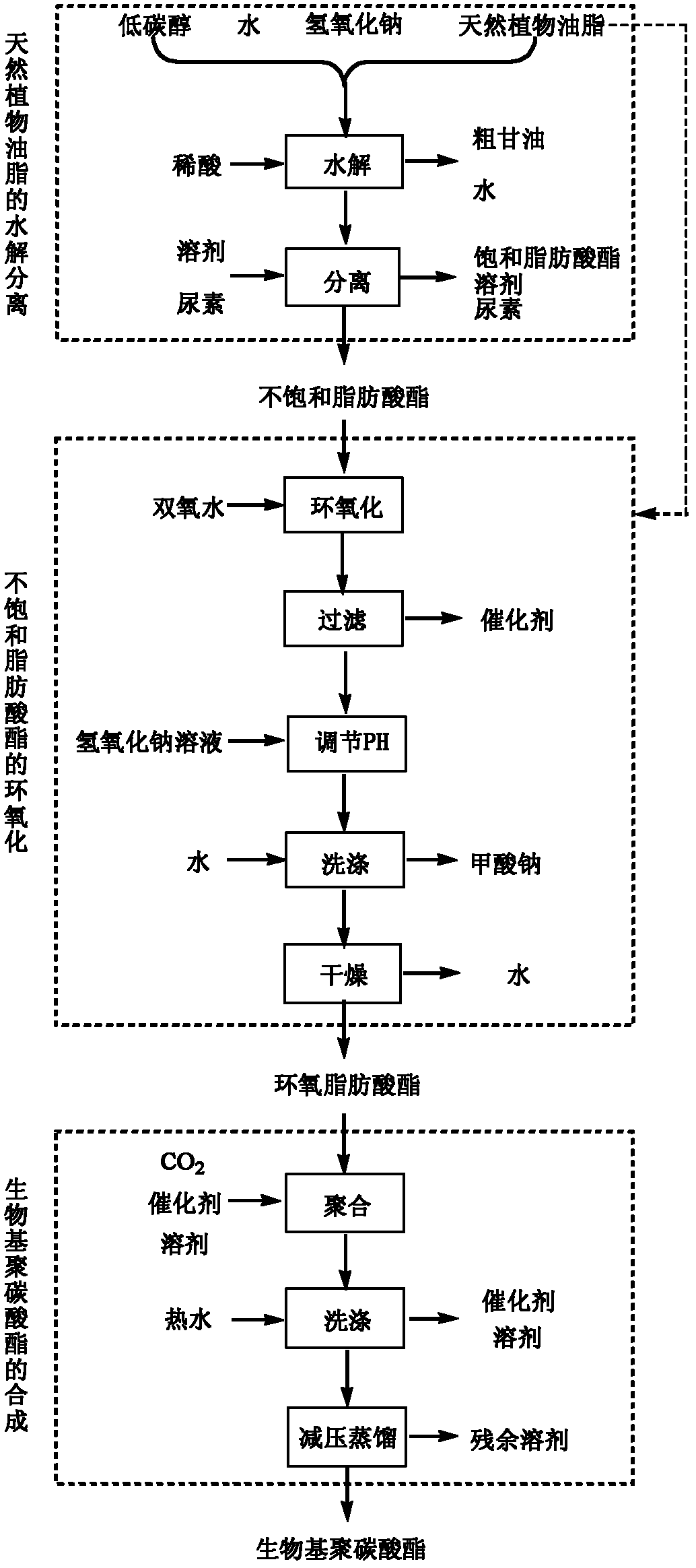

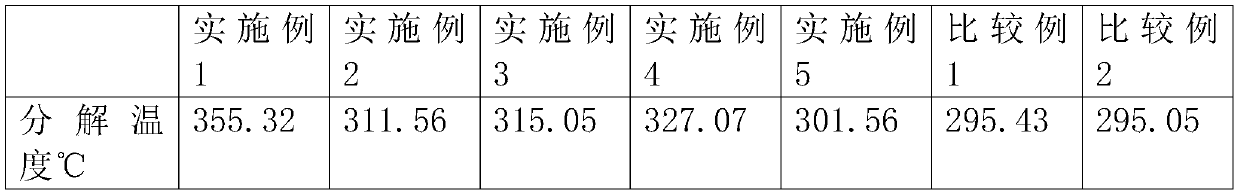

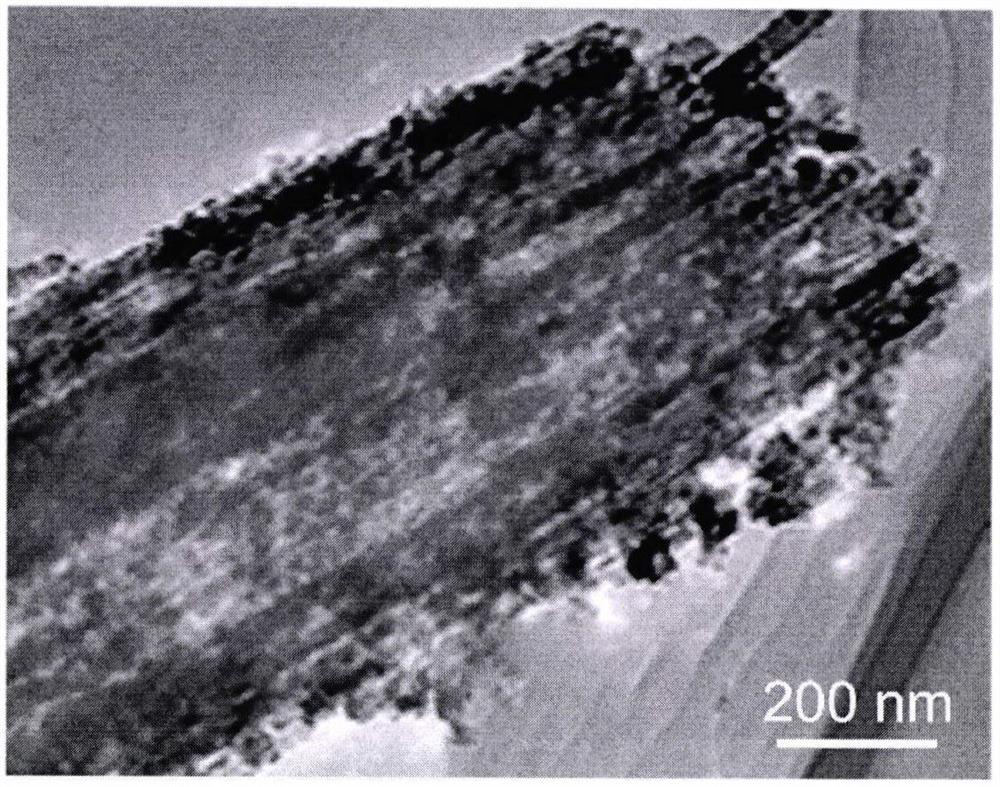

Biologic polycarbonate and preparation method thereof

InactiveCN102585192ALow costGood product performanceFatty acid esterificationFatty acids production/refiningPolycarbonateFatty acid ester

The invention provides a biologic polycarbonate and a preparation method thereof. The biologic polycarbonate is obtained by polymerizing biologic epoxy fatty acid ester serving as a raw material and CO2 gas, the yield is more than or equal to 70 percent, the number-average molecular weight is 11,000 to 30,000, and the molecular weight distribution is 1.10 to 1.74; and the biologic epoxy fatty acid ester is obtained by hydrolyzing, freezing and separating unsaturated fatty acid ester from natural vegetable fat and then performing epoxidation, or obtained by direct epoxidation of the natural vegetable fat. The renewable natural vegetable fat and the greenhouse gas CO2 are used as raw materials, so the method is environment-friendly, low in cost and simple and feasible in process operation, the solvent and the catalyst can be efficiently recycled, and the method is environment-friendly and suitable for industrialized production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Ultra-high molecular weight polysiloxane synthesis method

The invention relates to the technical field of high molecular materials. Unbalanced arrangement of vinyl groups, wide molecular weight distribution and many low molecular polymers will influence performance of the final product. In allusion to the problem, the invention provides an ultra-high molecular weight polysiloxane synthesis method. The technical scheme is as follows: the ultra-high molecular weight polysiloxane synthesis method comprises the following steps: carrying out dehydration treatment on 100 parts by weight of hydroxyl-terminated polydimethyl siloxane, adding 0.01-0.015 partsby weight of a linear phosphonitrilic chloride silicone oil solution containing 20-30 ppm of linear phosphonitrilic chloride and stirring for 5-10 min until viscosity starts to rise, controlling temperature to 100-130 DEG C at negative pressure and stirring and reacting for 2-4 h, recovering normal pressure, continuously heating to 230-250 DEG C, reacting for 2-3 h, decomposing linear phosphonitrilic chloride, and terminating the reaction. By using the linear phosphonitrilic chloride, the arrangement of vinyl groups is ordered, molecular weight distribution is narrow, the content of low molecular volatile cyclosiloxane is low, and the performance of the final product is excellent.

Owner:烟台隆达树脂有限公司

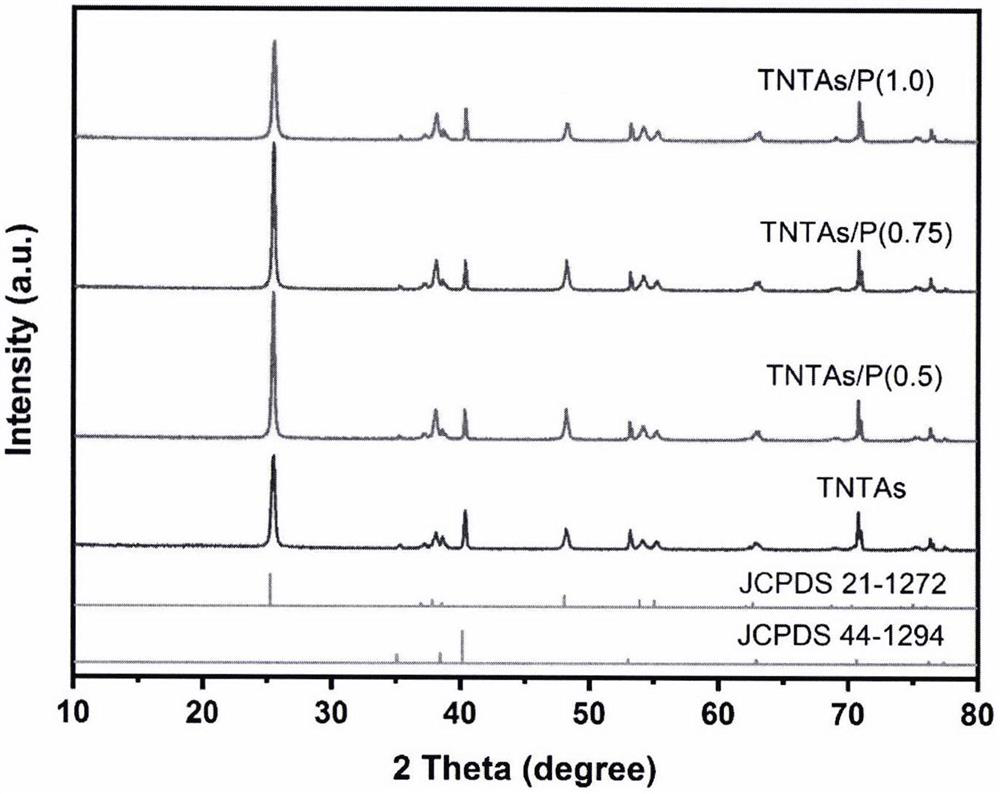

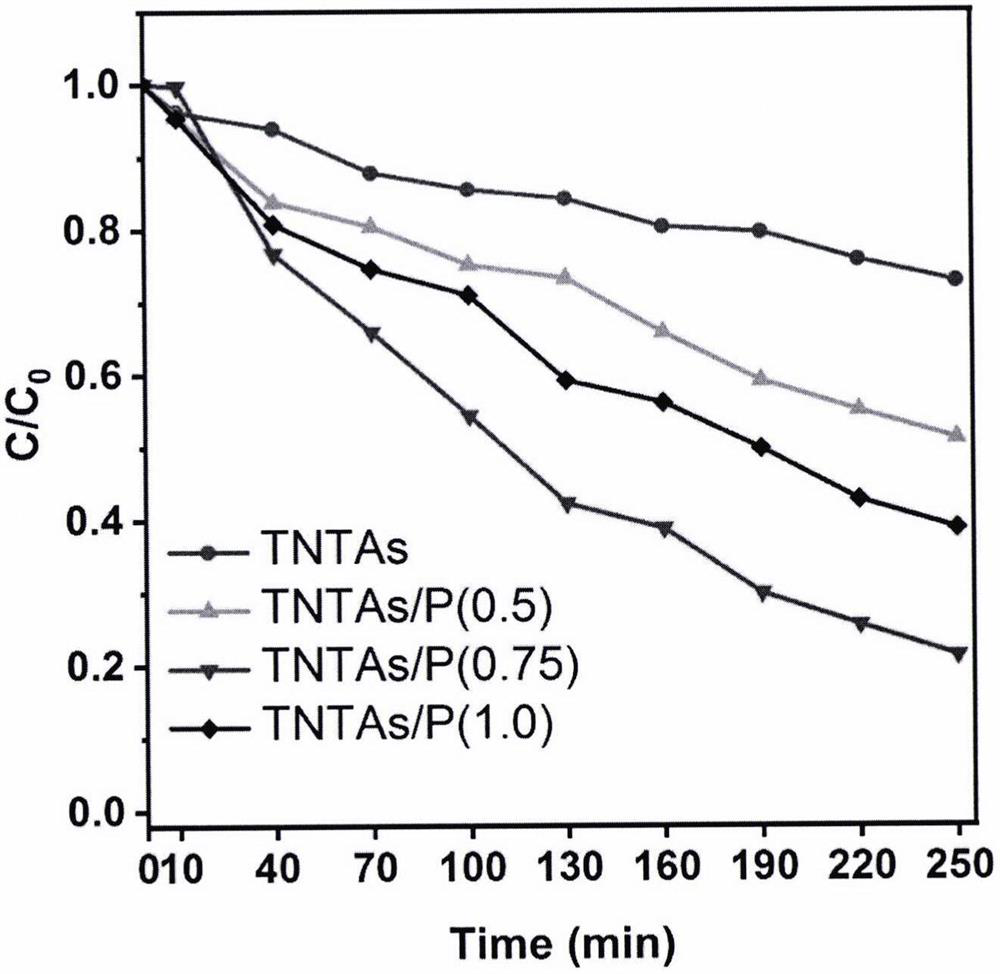

Application of phosphorus-doped titanium dioxide nanotube array catalyst in photoelectrocatalytic degradation of tylosin

ActiveCN112266044AEasy to prepareGood product performancePhysical/chemical process catalystsWater/sewage treatment by irradiationTitanium dioxideCyclic stability

The invention discloses an application of a phosphorus-doped titanium dioxide nanotube array catalyst in photoelectrocatalytic degradation of tylosin, and belongs to the field of photoelectrocatalysis. According to the titanium dioxide nanotube array catalyst, a titanium sheet, red phosphorus and ethylene glycol are adopted as raw materials, a titanium dioxide nanotube array is prepared through ananodic oxidation method, then an ampoule bottle is sealed, and the titanium dioxide nanotube array is calcined with amorphous red phosphorus to prepare the phosphorus-doped titanium dioxide nanotubearray. According to the invention, the catalyst has excellent performance of photoelectrocatalytic degradation of tylosin (80% of tylosin can be removed after four hours of illumination) and good cycling stability (78% of tylosin can still be removed after four cycling tests); at present, a plurality of methods are used for removing tylosin, such as physical adsorption, biodegradation, chemical oxidation, photocatalysis technology and the like, but the methods have the defects of high energy consumption, poor tylosin removal effect under low pollutant concentration and the like to different extents, so that the photoelectrocatalysis technology with the help of the phosphorus-doped titanium dioxide nanotube array catalyst has certain significance; and the titanium sheet and the red phosphorus are rich in reserves in nature, non-toxic, low in price and environment-friendly, and are environment-friendly catalysts with very good prospects.

Owner:QINGDAO UNIV

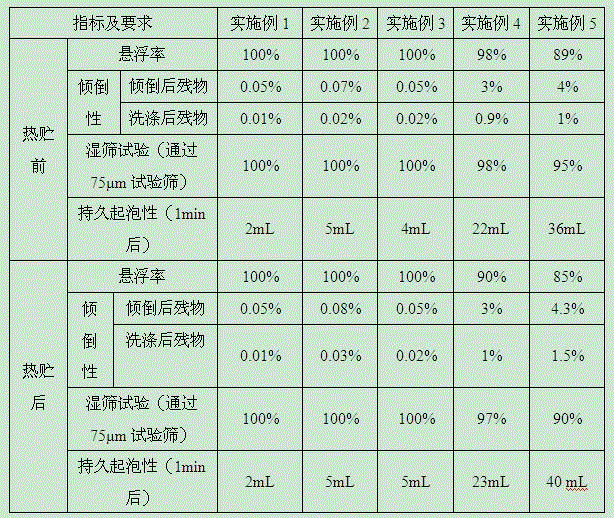

Continuous pyraclostrobin suspending agent preparation method

The invention belongs to the technical field of suspending agent preparation, and particularly relates to a continuous pyraclostrobin suspending agent preparation method and application of the same in plant protection. The preparation method includes dissolving pyraclostrobin in an alcohol-water solution, wherein alcohols solvents are methanol, alcohol, propanol and isopropanol, weight ratio of alcohol and water is 100:1-10, and quantity of added alcohol-water meets the condition that pyraclostrobin can be dissolved completely at temperature of 40-64 DEG C. Utilization rate of currently-commercial pyraclostrobin which is input reaches 100%, so that freeness of loss is realized, and utilization rate is high. The pyraclostrobin suspending agent prepared by the method is good in performance and low in cost.

Owner:SHANDONG UNITED PESTICIDE IND CO LTD

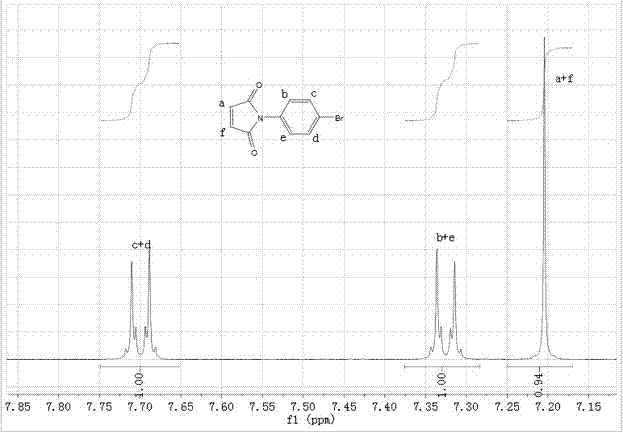

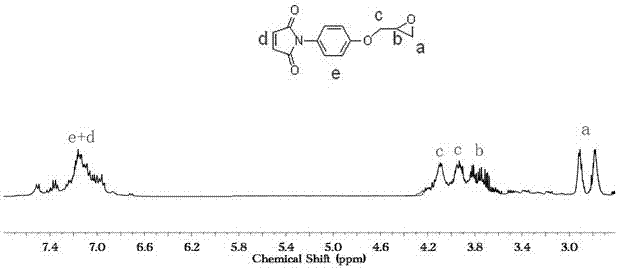

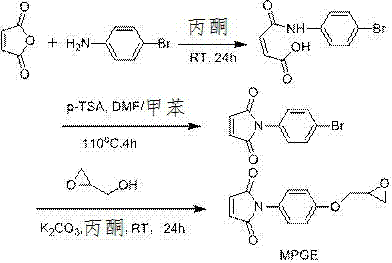

Leadless high-heat resistance glue solution for producing copper-clad plates

ActiveCN107245221ASimple preparation processGood product performanceLamination ancillary operationsLaminationMaleic anhydrideSilane coupling

The invention relates to a leadless high-heat resistance glue solution for producing copper-clad plates. Main raw materials of the glue solution include 30-60 parts of low brominated epoxy resin, 10-30 parts of high brominated epoxy resin, 5-10 parts of tetrafunctional epoxy resin, 20-40 parts of 4-(N-maleimido)phenol glycidyl ether, 2.5-4 parts of dicyandiamide, 0.05-0.2 parts of a curing accelerator, 20-50 parts of an inorganic filler and 0.5-2 parts of a silane coupling agent KH560, wherein the 4-(N-maleimido)phenol glycidyl ether is prepared from maleic anhydride, p-bromoaniline and glycidol. The FR-4 CCL copper-clad plates made by using the glue solution have excellent comprehensive performances and meet requirements of high-end PCB.

Owner:建滔电子材料(江阴)有限公司

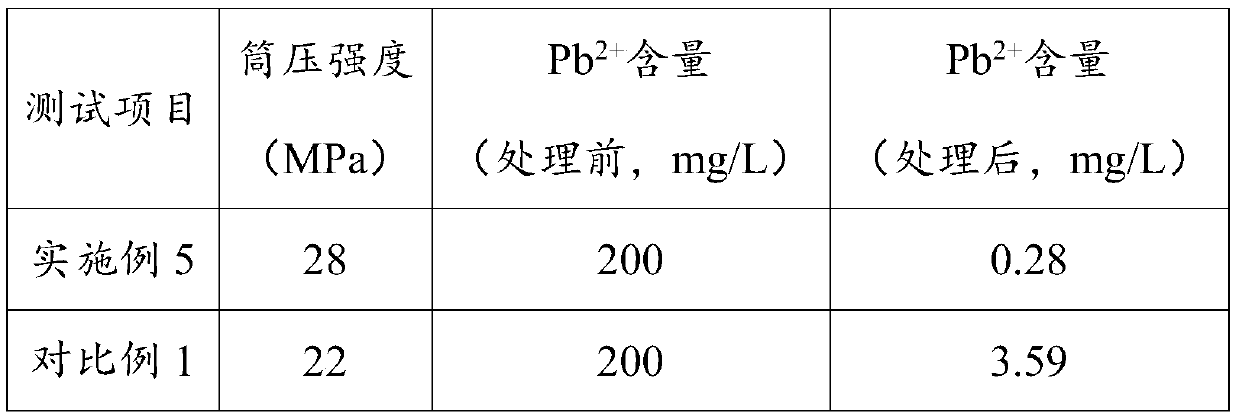

Biomass sludge ceramsite as well as preparation method and application thereof

InactiveCN111393142AUniform pore sizeLow water absorptionWater contaminantsCeramic materials productionSludgeKaolin clay

The invention is applicable to the field of waste utilization and sewage treatment, and provides biomass sludge ceramsite as well as a preparation method and an application thereof. The biomass sludgeceramsite comprises the following components in parts by weight: 60-80 parts of biomass co-fired ash, 10-30 parts of sludge powder and 5-15 parts of fly ash; the biomass co-fired ash comprises the following components in parts by weight: 25-45 parts of rice hull powder, 10-20 parts of sawdust powder and 40-60 parts of sludge powder. The biomass sludge ceramsite provided by the invention does notconsume any non-renewable natural resources such as shale, kaolin, clay and the like, is uniform in pore size, has relatively low water absorption and a relatively good adsorption effect, and is a very good heavy metal sewage treatment material.

Owner:海南普尔顿环境科技有限公司

Profile extrusion assembly and extrusion equipment

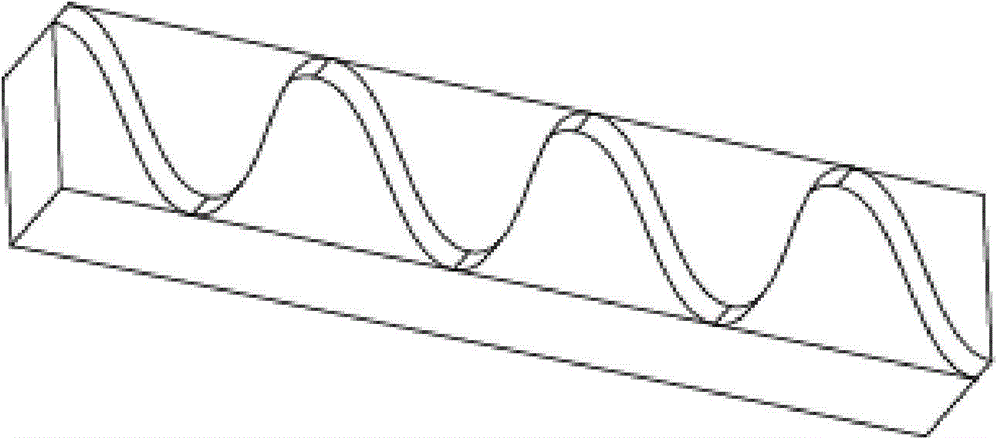

The invention discloses a profile extrusion assembly, which comprises an extrusion head, wherein the extrusion head comprises a runner, and also comprises a molding part and at least one sliding block, and a molding cavity is arranged in the molding part; the molding part is connected with the extrusion head, and the molding cavity is communicated with the runner; the sliding block is rotatably or movably arranged in the molding cavity. The invention also discloses profile extrusion equipment with the extrusion assembly. The profile extrusion assembly and extrusion equipment provided by the invention have the beneficial effects that when the profile extrusion equipment is used, a raw material in a molten state flows through the runner and flows into the molding cavity, and the sliding block in the molding cavity is in a state of rotating or moving dynamic change when the raw material passes, so that the raw material is distorted or changed in a section shape before being solidified along with the rotation or movement of the sliding block, and the non-linear shape and / or changed section of a profile extrusion product are / is realized, and thus the shape of the profile extrusion product is relatively rich, the product performance is relatively excellent, and the blank of the industry can be filled up by a rich product line.

Owner:FUJIAN HONGBO OPTO ELECTRONICS TECH CO LTD

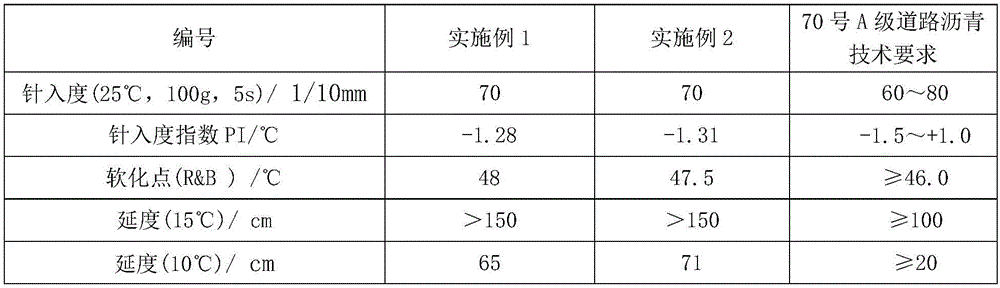

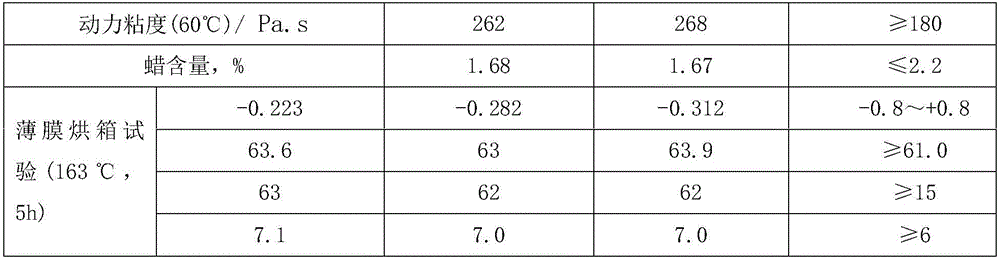

Raw materials and technological method for producing No. 70 asphalt with mixed crude of Venezuelan Boscan crude and Venezuelan Merey-16 crude

InactiveCN105778967ASimple production processGood product performanceWorking-up pitch/asphalt/bitumen by distillationBuilding insulationsPetroleumRoad construction

The invention discloses raw materials and a technological method for producing No. 70 asphalt with mixed crude of Venezuelan Boscan crude and Venezuelan Merey-16 crude. The raw materials are characterized by comprising the Venezuelan Boscan crude and the Venezuelan Merey-16 crude. The No. 70 heavy traffic road asphalt produced by the technological method disclosed by the invention conforms to the indexes of No. 70 A-level road petroleum asphalt formulated in 'Technical Specifications for Construction of Asphalt Road Surfaces of Roads by Ministry of Communications' JTGF40-2004, and the indexes of the No. 70 heavy traffic road asphalt are better than indexes of Chinese national standard (GB50092-96). The high-grade road asphalt is produced by straight distillation of an atmospheric and vacuum distillation unit, and the production process is simple, so that the method is the most economic and convenient method for producing the asphalt; besides, the produced products are excellent in properties, and can completely replace imported high-grade road asphalt, so that needs for high speed development of road construction and high speed development of national economy in China can be met.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

SiO2 artificial quartz stone plate with fish belly white pattern and preparation method thereof

The invention provides a SiO2 artificial quartz stone plate with a fish belly white pattern and a preparation method thereof. The SiO2 artificial quartz plate with the fish belly white pattern is prepared from (1) main materials including quartz sand with the size of 40 meshes to 70 meshes, quartz stone with the size of 70 meshes to 120 meshes, ultra-white quartz powder with the size of 500 meshes and quartz powder with the size of 275 meshes; (2) auxiliary materials including the quartz sand with the size of 40 meshes to 70 meshes, the quartz stone with the size of 70 meshes to 120 meshes, the ultra-white quartz powder with the size of 500 meshes and the quartz powder with the size of 275 meshes; (3) A-colored gas-phase SiO2, B-colored gas-phase SiO2 and C-colored gas-phase SiO2; (4) D-colored mixed color paste; (5) colored pigment, a silane coupling agent, unsaturated polyester resin and a curing agent. According to the SiO2 artificial quartz plate with the fish belly white pattern and the preparation method thereof, prepared artificial quartz stone has an attractive appearance, a bright figure, a unique color and unique pattern formation; the types and patterns of the artificial quartz stone are enriched by utilizing a similar fish-belly-shaped pattern, and random patterns can be made through molds with different shapes; staggered combinations are produced, so that the production efficiency is high, the reject ratio of products is effectively reduced, and the products can be produced in a large batch.

Owner:GUANGDONG BANNER NEW MATERIAL TECH

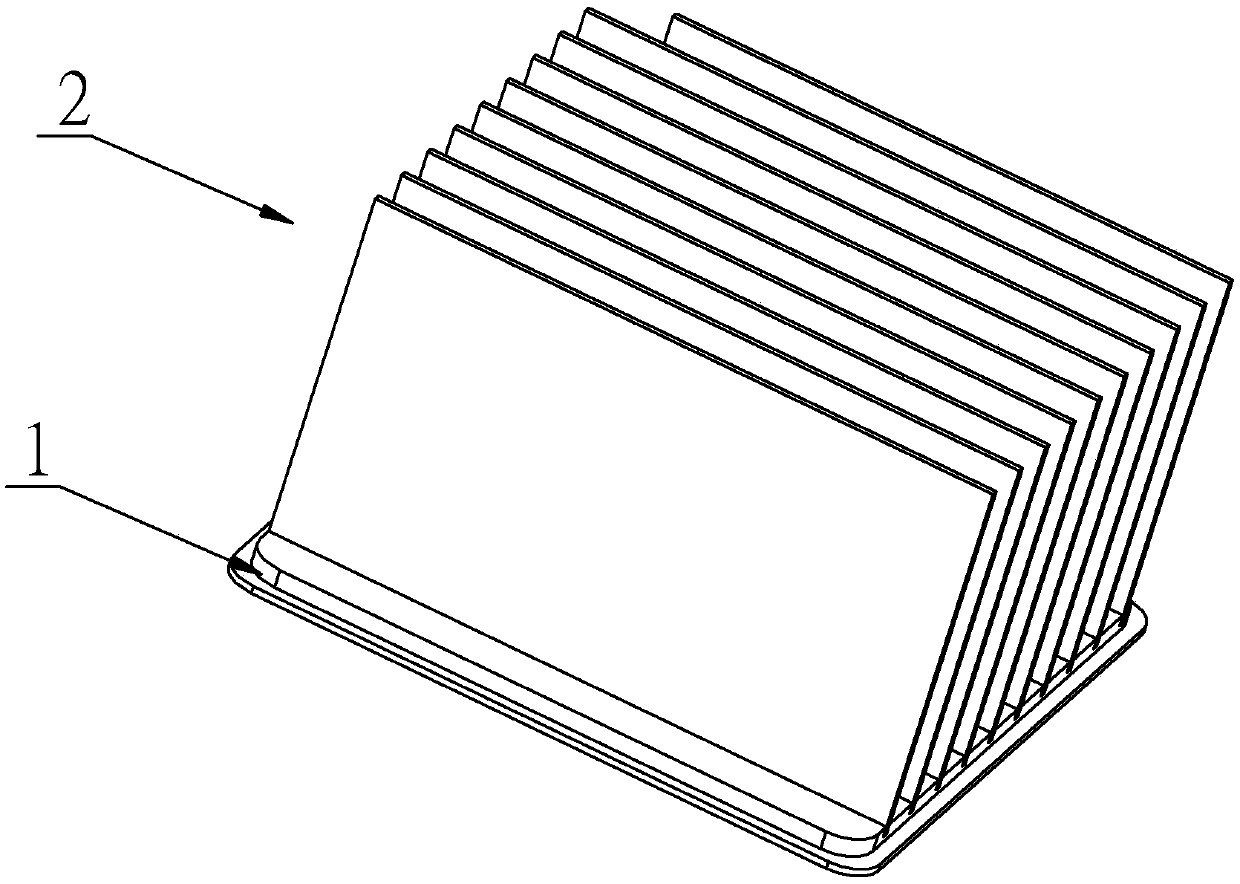

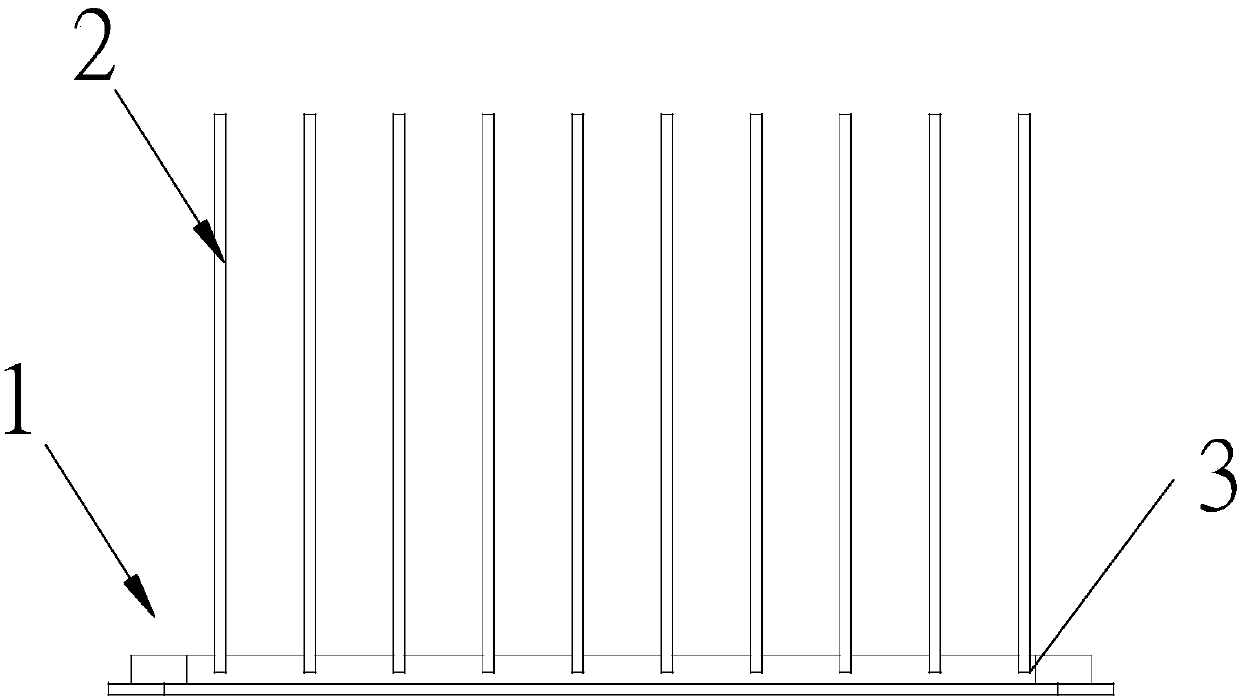

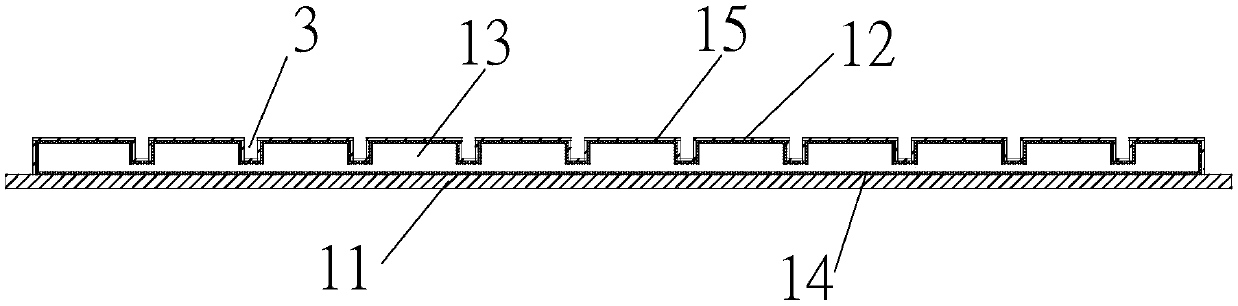

Clamping type radiator

InactiveCN109996424AThe production process is simpleGood product performanceModifications by conduction heat transferEnergy consumption

The invention discloses a clamping type radiator, and aims to provide the clamping type radiator convenient to machine and capable of reducing energy consumption; according to the technical scheme, the clamping type radiator comprises a heat-equalizing plate, wherein the heat-equalizing plate is connected with fins; a plurality of connecting pieces arranged in parallel are arranged on the heat-equalizing plate; a plurality of connecting parts matched with the connecting pieces are arranged on the fins; and the connecting pieces are clamped with the connecting parts.

Owner:GUANGZHOU HUAZUAN ELECTRONICS TECH

Novel putty for wood floors

InactiveCN103819958AGood product performanceSimple preparation processFilling pastesProduct propertyPolyvinyl alcohol

The invention discloses novel putty for wood floors. The putty comprises the following components in parts by weight: 3-8 parts of polyvinyl alcohol, 10-20 parts of kaolin, 20-40 parts of talcum powder, 1-3 parts of hydroxymethyl cellulose, 6-9 parts of nano silicon dioxide and 30-50 parts of water. In the technical scheme, a preparation process of the putty used for filling gaps of the wood floors is characterized by mixing all the components according to the formula, and stirring the components uniformly, thus obtaining a finished product. Compared with the prior art, the putty has the beneficial effects of good product properties, simple preparation process, low cost and the like.

Owner:广州耐威建材有限公司

Water-containing porous granular ammonium nitrate fuel oil (ANFO) explosive

InactiveCN107746362AGood product performanceReduce consumptionNon-explosive/non-thermic compositionsAir quality improvementANFOFuel oil

For overcoming defects in the prior art, the invention provides a water-containing porous granular (ANFO) explosive, which is high in explosive power and is greatly reduced in quantity of generated toxic gas under the same conditions, so that pollution on atmospheric environment due to blasting operation can be reduced. For solving the technical problems, the water-containing porous granular ANFOexplosive includes porous granular ammonium nitrate, dimethylacetamide and water, wherein the porous granular ammonium nitrate is used as an oxidant, the dimethylacetamide is used as a combustible, and the water is used as a catalyst; the weight ratio of the porous granular ammonium nitrate is 94-95%, the weight ratio of the dimethylacetamide is 3.9-4.2% and the weight ratio of the water is 1.4-1.7%. The water-containing porous granular ANFO explosive can be widely applied to the field of explosion for civil use.

Owner:祁茂富

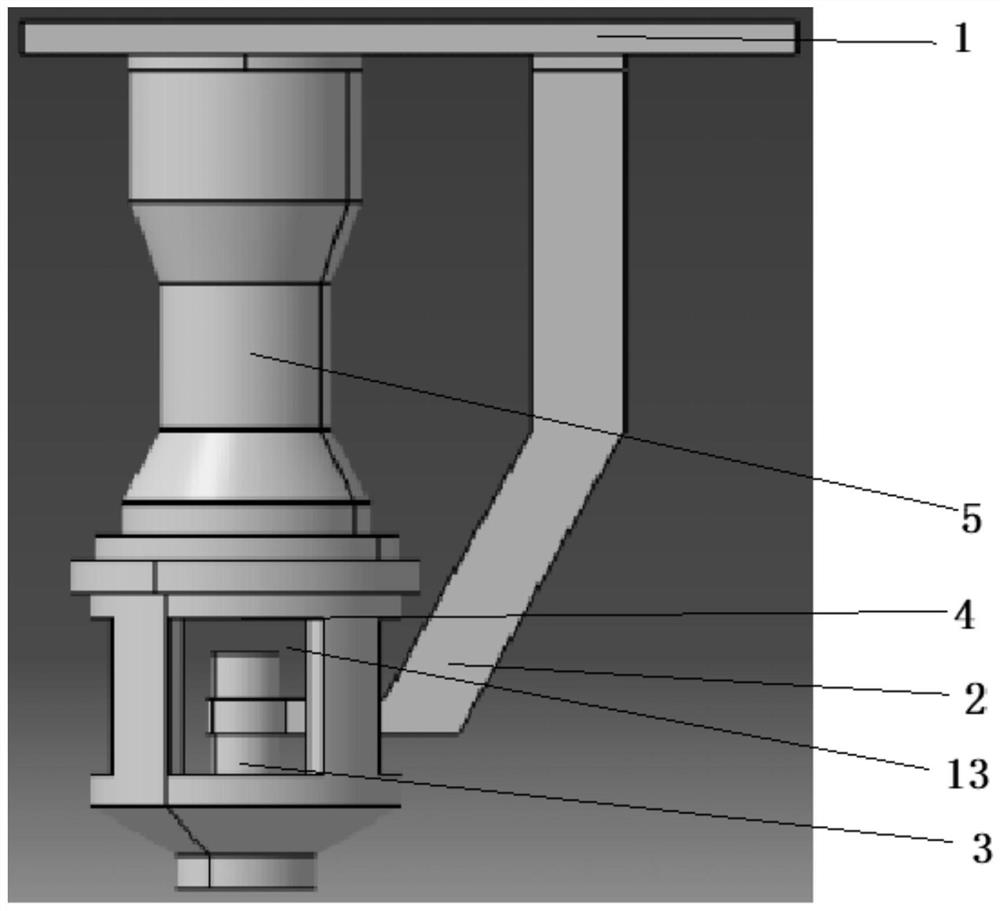

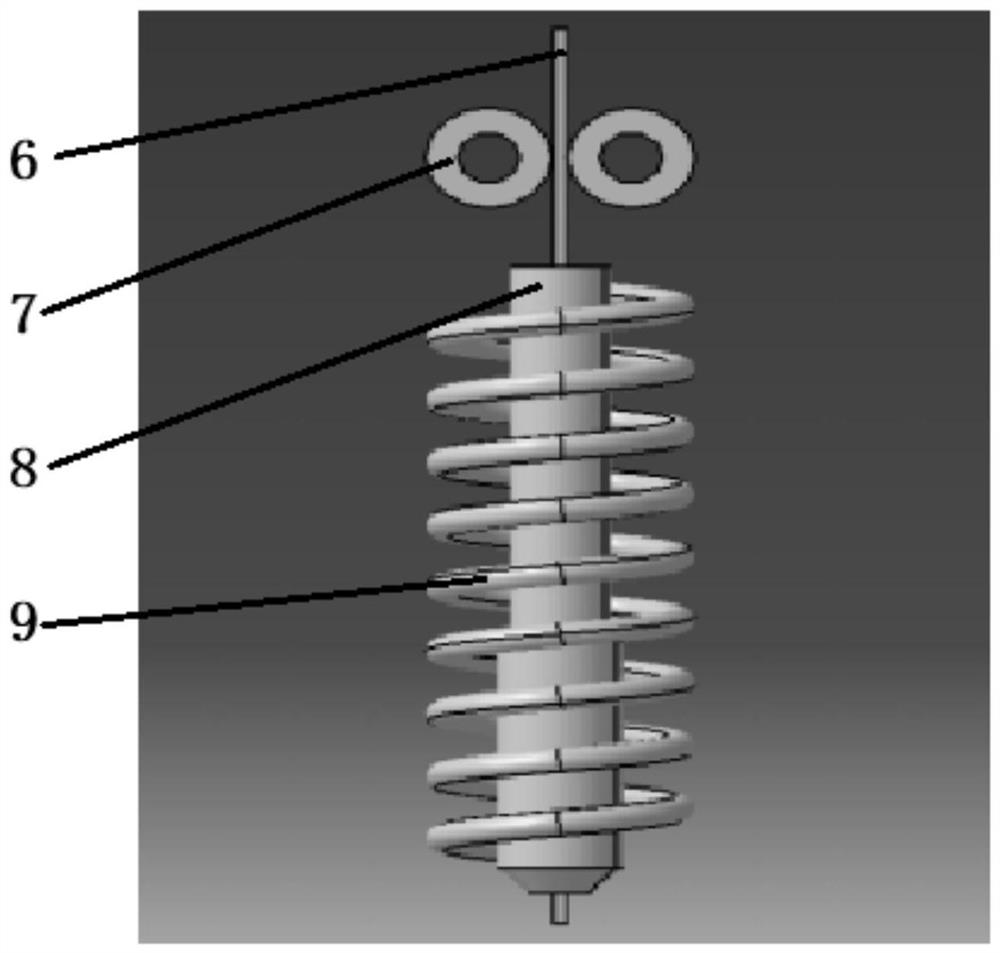

Additive manufacturing equipment and manufacturing method for titanium alloy structural part

ActiveCN112427649AImprove efficiencyGood product performanceAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing engineeringMechanical engineering

The invention relates to additive manufacturing equipment and a method for a titanium alloy structural part. The additive manufacturing equipment adopts an integrated printing head and comprises a metal laying part and a forging part, and the metal laying part and the forging part are fixed to a numerical control sliding rail; the metal laying part comprises a heating wire feeding device and a heating wire feeding device bracket; the forging part comprises an air hammer and a forging head; and the heating wire feeding device comprises a metal wire, wire feeding rollers, a guide sleeve and an induction heating coil. According to the additive manufacturing equipment and method, the forging technology is introduced into the additive manufacturing process, additive manufactured parts with theforging mechanical property are achieved in the two states of fusion-cladding and solid plastic deformation-laying, and the problems existing in an existing additive manufacturing technique based on the fusion cladding and friction welding technologies are effectively solved; and the mechanical property of the parts produced in an additive manufacturing mode is improved, introduced impurities arereduced, the production capacity of part products with complex structures is improved, meanwhile, the cost can be reduced, and the efficiency is improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

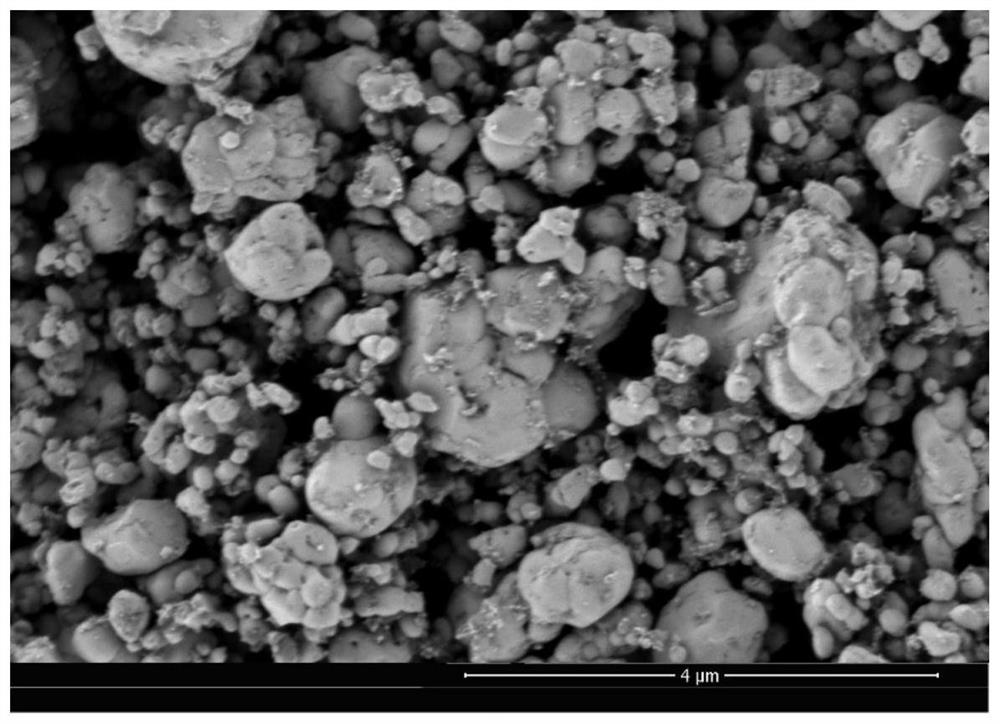

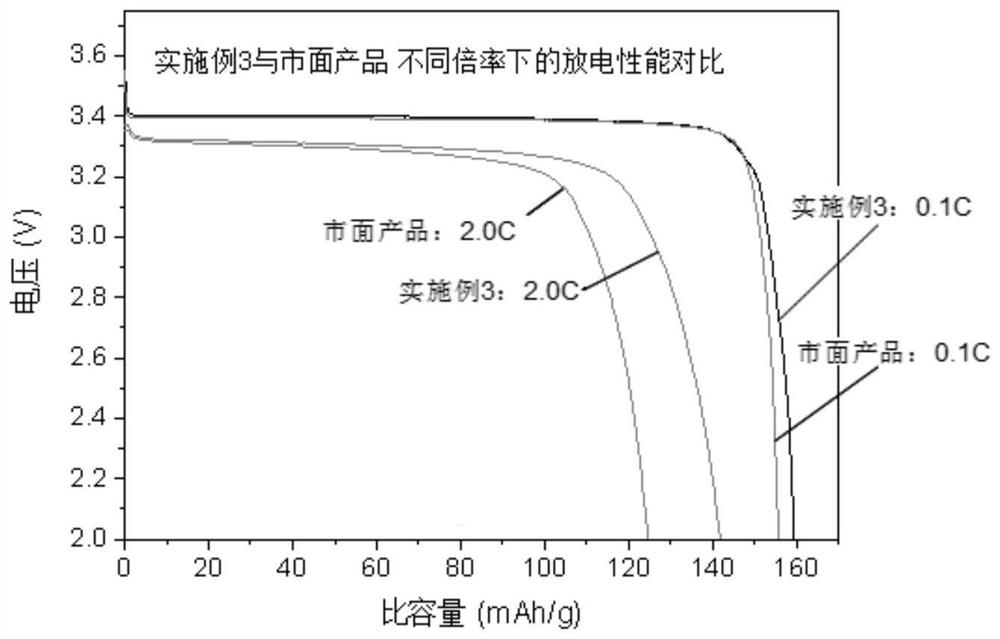

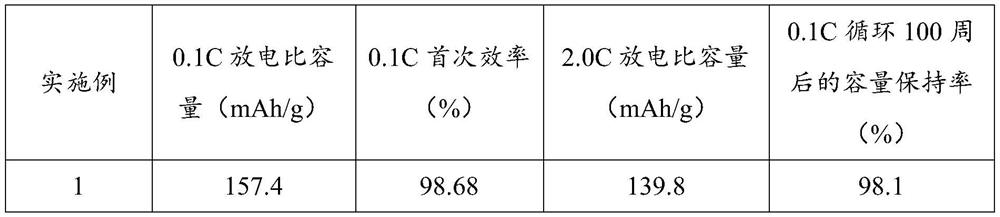

Preparation method and application of lithium iron phosphate positive electrode material

ActiveCN112897491AGood product performanceSimple preparation processSecondary cellsPositive electrodesCarbon coatingCarbon source

The invention belongs to the technical field of lithium ion battery material preparation, and provides a preparation method and application of a lithium iron phosphate positive electrode material, and the preparation method comprises the following steps: (1) mixing and refining an iron source, a phosphorus source, a lithium source, a carbon source and an additive by a dry method to obtain a mixed material; (2) sintering the mixed material for the first time, and then crushing to obtain a crushed material; and (3) sintering the crushed material for the second time, introducing a gasifiable organic carbon source during sintering, and then cooling to obtain the lithium iron phosphate positive electrode material. According to the invention, high-efficiency mixing equipment is used for carrying out one-step mixing refining, sintering and crushing on the raw materials, then secondary sintering is carried out, and a gasifiable organic carbon source is used for supplementing carbon coating, so that the material has better carbon coating layer and particle morphology, the obtained product has better performance, the performance is greatly improved compared with the same type of products on the market, the cycling stability is good, and the general requirements of high-performance lithium iron phosphate batteries can be met.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com