Profile extrusion assembly and extrusion equipment

A component and profile technology, applied in the field of profile processing equipment, can solve the problem of single shape of profile products and achieve the effect of excellent product performance and rich shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

[0017] The most critical idea of the present invention is that a dynamic slider is set on the extrusion head of the extrusion assembly to change the solidification form of the molded product, so that the extruded profile can also have a rich shape.

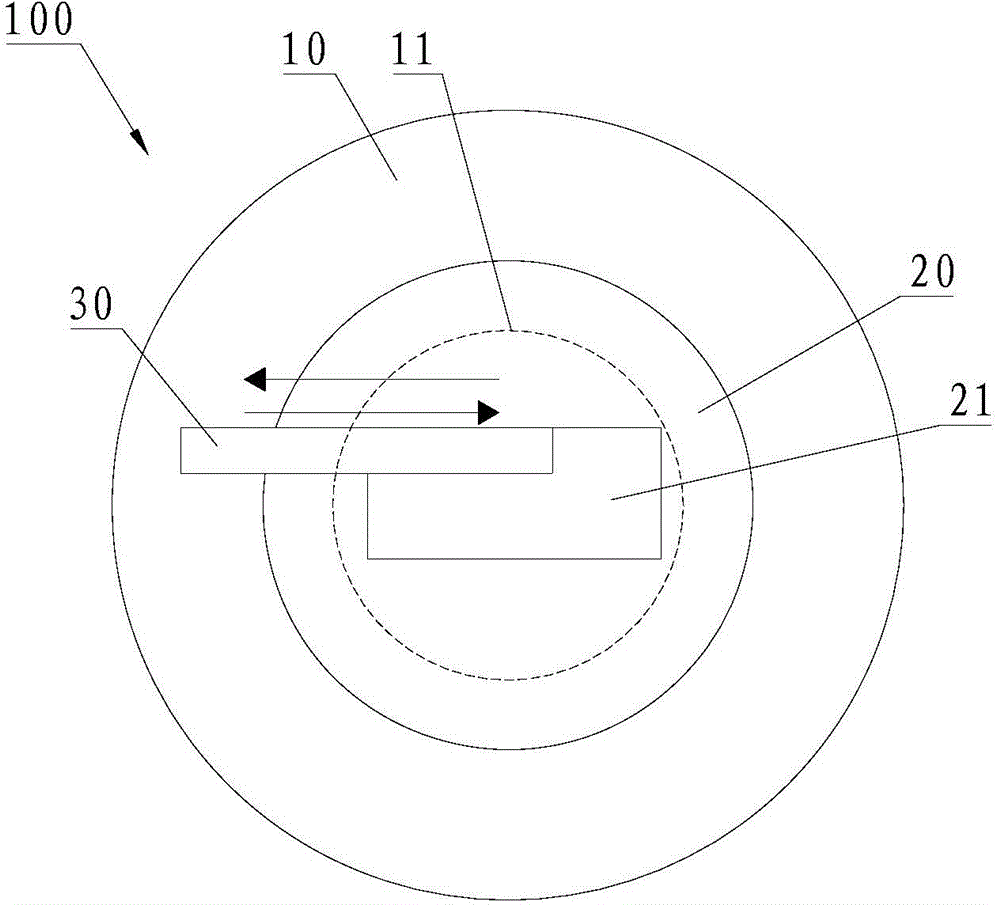

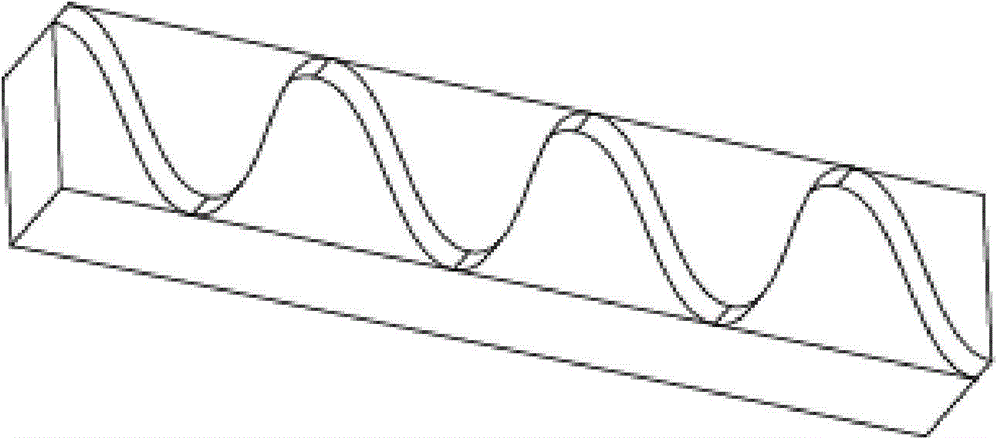

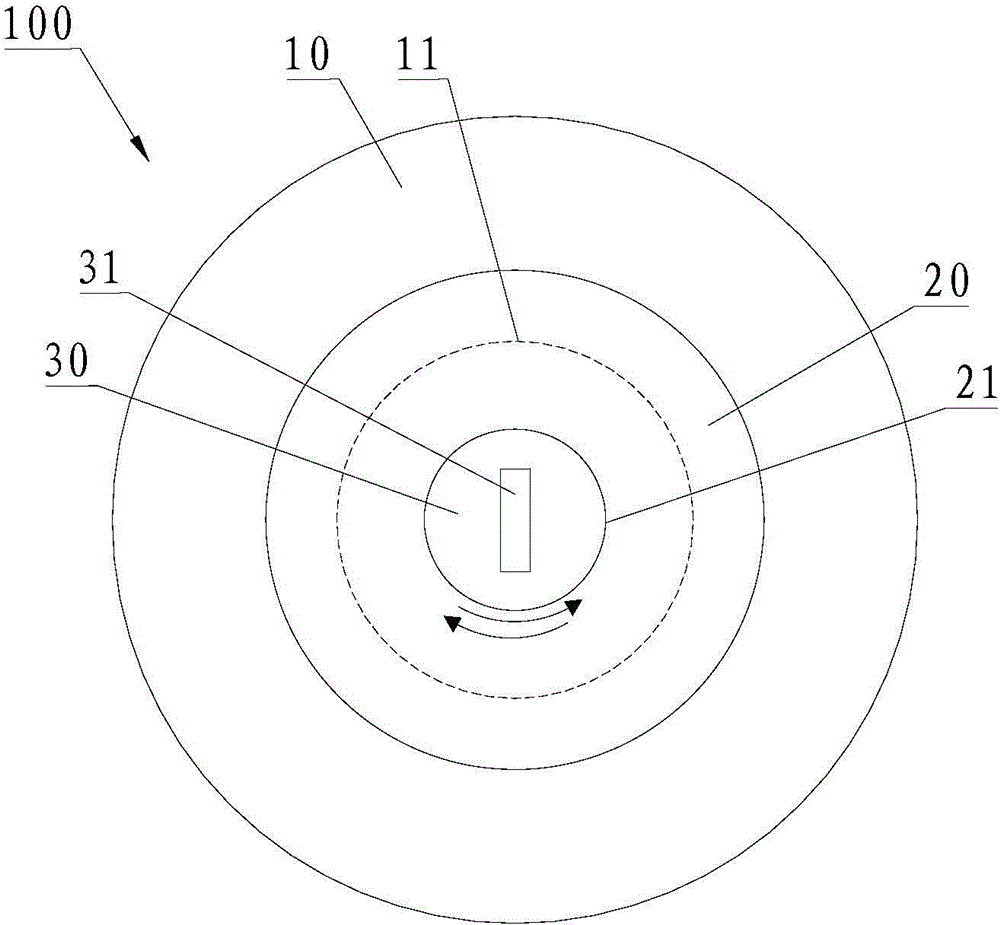

[0018] See figure 1 , image 3 with Figure 5 , A profile extrusion assembly 100, including an extrusion head 10, the extrusion head 10 includes a runner 11, further includes a molding part 20 and at least one slider 30, the molding part 20 is provided with a molding cavity 21 , The molding part 20 is connected with the extrusion head 10, the molding cavity 21 is in communication with the flow channel 11, and the slider 30 can be rotated (such as image 3 ) Or movable (e.g. figure 1 with Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com