Preparation method of grading magnesium and aluminum hydrotalcite capable of adsorbing Cr(VI)

A magnesium aluminum hydrotalcite and adsorbent technology, which is applied in the direction of separation methods, adsorption water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex preparation process and difficult control of magnesium aluminum hydrotalcite morphology, and achieve simple process , Good recycling ability, high adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

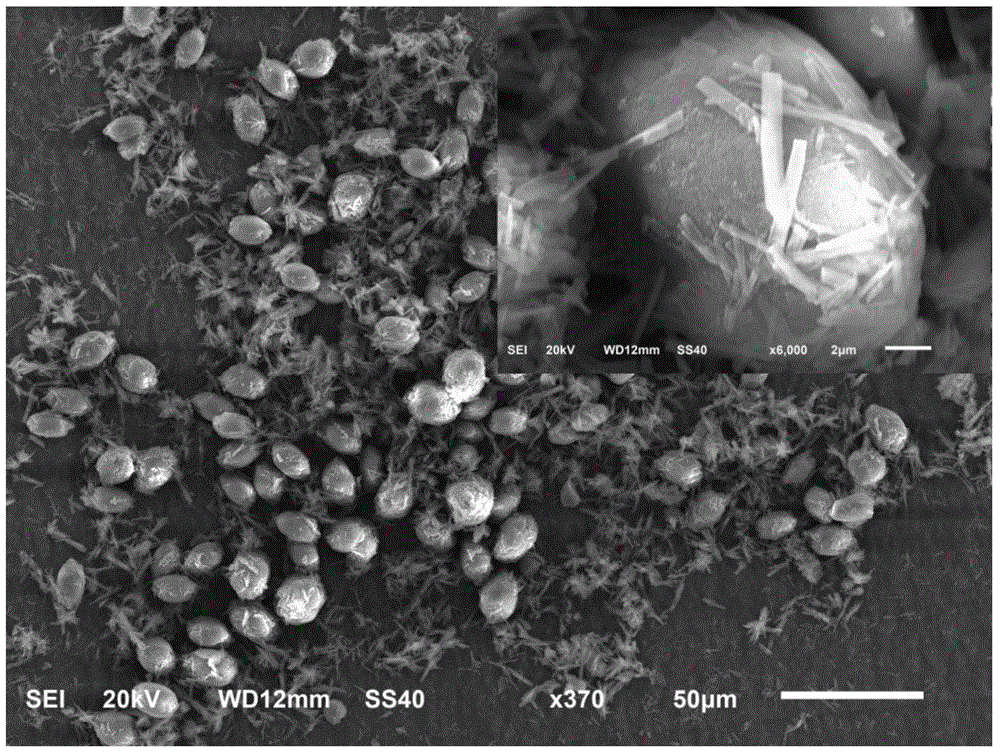

[0024] Embodiment 1: First, 6.14g magnesium nitrate hexahydrate and 3.0g aluminum nitrate nonahydrate are dissolved in 60ml distilled water (Mg 2+ The concentration is 0.4mol / L, Mg 2+ and Al 3+ The concentration ratio is 3), then add 21.6g urea and stir until dissolved (urea and Mg 2+ The molar ratio is 15.0), then 1.2 g of P123 (mass concentration: 2%) was added to the above solution, and stirred at room temperature until it was completely dissolved. Then, the above solution was transferred to a hydrothermal kettle and reacted at 140° C. for 24 h. The hydrothermal product is naturally cooled to room temperature, filtered, washed with distilled water until neutral, dispersed and washed with absolute ethanol and filtered, the obtained filter cake is vacuum-dried at 80°C for 12h, and roasted in a static air atmosphere at 500°C for 6h , the obtained sample is an adsorbent, that is, graded magnesium aluminum hydrotalcite, and its morphology is characterized by the coexistence o...

Embodiment 2

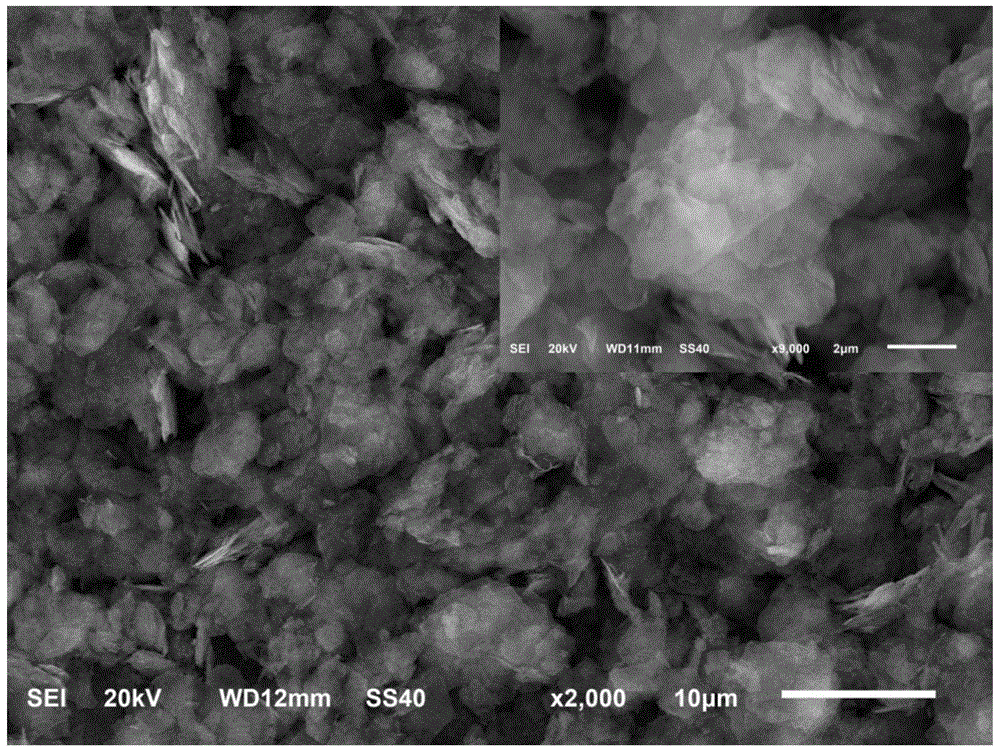

[0027] Embodiment 2: First, 2.44g magnesium chloride hexahydrate and 1.45g aluminum chloride hexahydrate are dissolved in 60ml distilled water (Mg 2+ The concentration is 0.2mol / L, Mg 2+ and Al 3+ The concentration ratio is 2), then add 7.2g urea and stir until dissolved (urea and Mg 2+ The molar ratio is 10.0), then 3.0 g of P123 (mass concentration: 5%) was added to the above solution, and stirred at room temperature until it was completely dissolved. Then, the above solution was transferred to a hydrothermal kettle and reacted at 140° C. for 36 h. The hydrothermal product is naturally cooled to room temperature, filtered, washed with distilled water until neutral, dispersed and washed with absolute ethanol and filtered, the resulting filter cake is vacuum-dried at 100°C for 4 hours, and roasted in a static air atmosphere at 600°C for 2 hours , the obtained sample is an adsorbent, that is, graded magnesium aluminum hydrotalcite, and its morphology is a sheet-like particle...

Embodiment 3

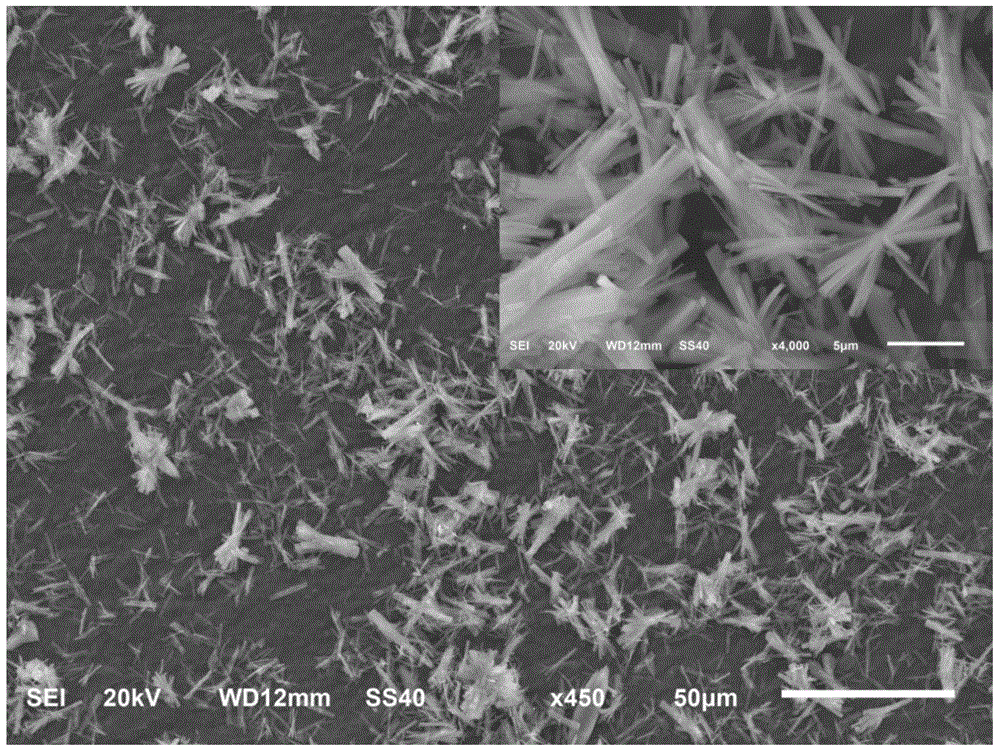

[0030] Example 3: First, 5.76g of anhydrous magnesium sulfate and 7.99g of aluminum sulfate octadecahydrate were dissolved in 60ml of distilled water (Mg 2+ The concentration is 0.8mol / L, Mg 2+ and Al 3+ The concentration ratio is 4), then add 28.8g urea and stir until dissolved (urea and Mg 2+ The molar ratio is 10.0), and then 6.0 g of P123 (mass concentration: 10%) was added to the above solution, and stirred at room temperature until it was completely dissolved. Then, the above solution was transferred to a hydrothermal kettle and reacted at 100° C. for 48 h. The hydrothermal product is naturally cooled to room temperature, filtered, washed with distilled water until neutral, dispersed and washed with absolute ethanol and filtered, the obtained filter cake is vacuum-dried at 60°C for 16h, and roasted at 400°C under a static air atmosphere for 8h The obtained sample is an adsorbent, that is, graded magnesium aluminum hydrotalcite, and its morphology is a bundle structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com