Method for filtering and separating suspended maters from water and filtering device used in method

A technology of filtration separation and filtration device, which is applied in the field of filtration and separation of suspended solids in water bodies and the field of filtration devices used, which can solve the problems of high filtration energy consumption, inability to increase filtration pressure, high investment and use costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

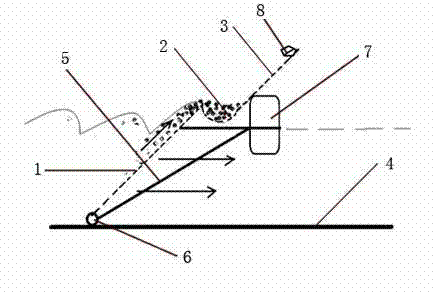

[0064] Embodiment 1: underwater sloping plate filter screen filter device

[0065] Equipment structure: Such as figure 1 As shown, the underwater inclined plate filter screen filter device includes a combined filter screen, a bracket, an air bag and a rotating shaft. The combined filter consists of filter a (1), filter b (2) and filter c (3), filter a (1) and filter c (3) are flat, filter b (2) It is groove-shaped, filter screen a (1) and filter screen c (3) are connected to filter screen b (2) and then connected through a frame to form a combined filter screen; the bracket is composed of a bottom bracket (4) and an airbag bracket (5) , the bottom bracket (4) and the combined filter screen are connected by a rotating shaft (6), so that the combined filter screen can be rotated to adjust the angle between the combined filter screen and the direction of water flow, and one end of the air bag bracket (5) is connected to the bottom The bracket (4) is connected, and the othe...

Embodiment 2

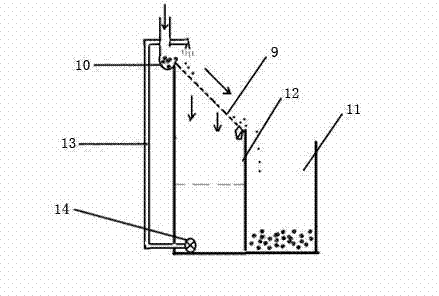

[0073] Example 2: Fecal-water separation system for water flushing inclined plate filter screen

[0074] Equipment structure: Such as figure 2 As shown, the excrement and water separation system is composed of a plate filter, a water flow distributor, a urine collection tank, a feces collection box, a sprayer and a vibrator. The water flow distributor (10) is connected with the defecation pipe in a groove shape, the upper end of the plate filter (9) is connected with the groove opening of the water flow distributor (10), and the lower end is connected with the feces collection box (11) to form an obtuse angle. A urine collection tank (12) is arranged below the plate filter screen (9), and a shower (13) is established at the upper end of the joint of the plate filter screen (9) and the water flow distributor (10). In the urine collection tank (12) Establish water pump (14), sprinkler (13) and water pump (14) are connected by pipeline.

[0075] A vibrator (8) can be set o...

Embodiment 3

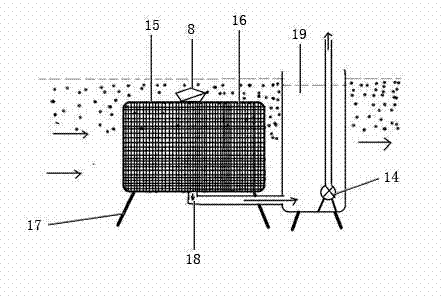

[0082] Embodiment 3: honeycomb plate type algae water collection device

[0083] Equipment structure: The honeycomb plate type algae separation and water collection device is composed of a board box filter assembly, a water collector, a support bracket and a vibrator. The box-shaped filter screen assembly is composed of a hollow box-shaped filter screen support (15) and a soft filter screen (16), and the soft filter screen (16) covers the hollow box-shaped filter screen support (15). The box-type filter screen assembly is installed on the support bracket (17), and there is a water collection outlet (18) at the bottom. Establish water pump (14).

[0084] A vibrator (8) can be arranged on the board box type filter screen assembly to shake the firmly attached blue algae from the combined filter screen.

[0085] Instructions: Place the support bracket (17) at the bottom of the algae-containing river, one end of the box-type filter screen assembly faces the direction of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com