Patents

Literature

489 results about "Cross-flow filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemical engineering, biochemical engineering and protein purification, crossflow filtration (also known as tangential flow filtration) is a type of filtration (a particular unit operation). Crossflow filtration is different from dead-end filtration in which the feed is passed through a membrane or bed, the solids being trapped in the filter and the filtrate being released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially across the surface of the filter, rather than into the filter. The principal advantage of this is that the filter cake (which can blind the filter) is substantially washed away during the filtration process, increasing the length of time that a filter unit can be operational. It can be a continuous process, unlike batch-wise dead-end filtration.

Cross flow filtration materials and cartridges

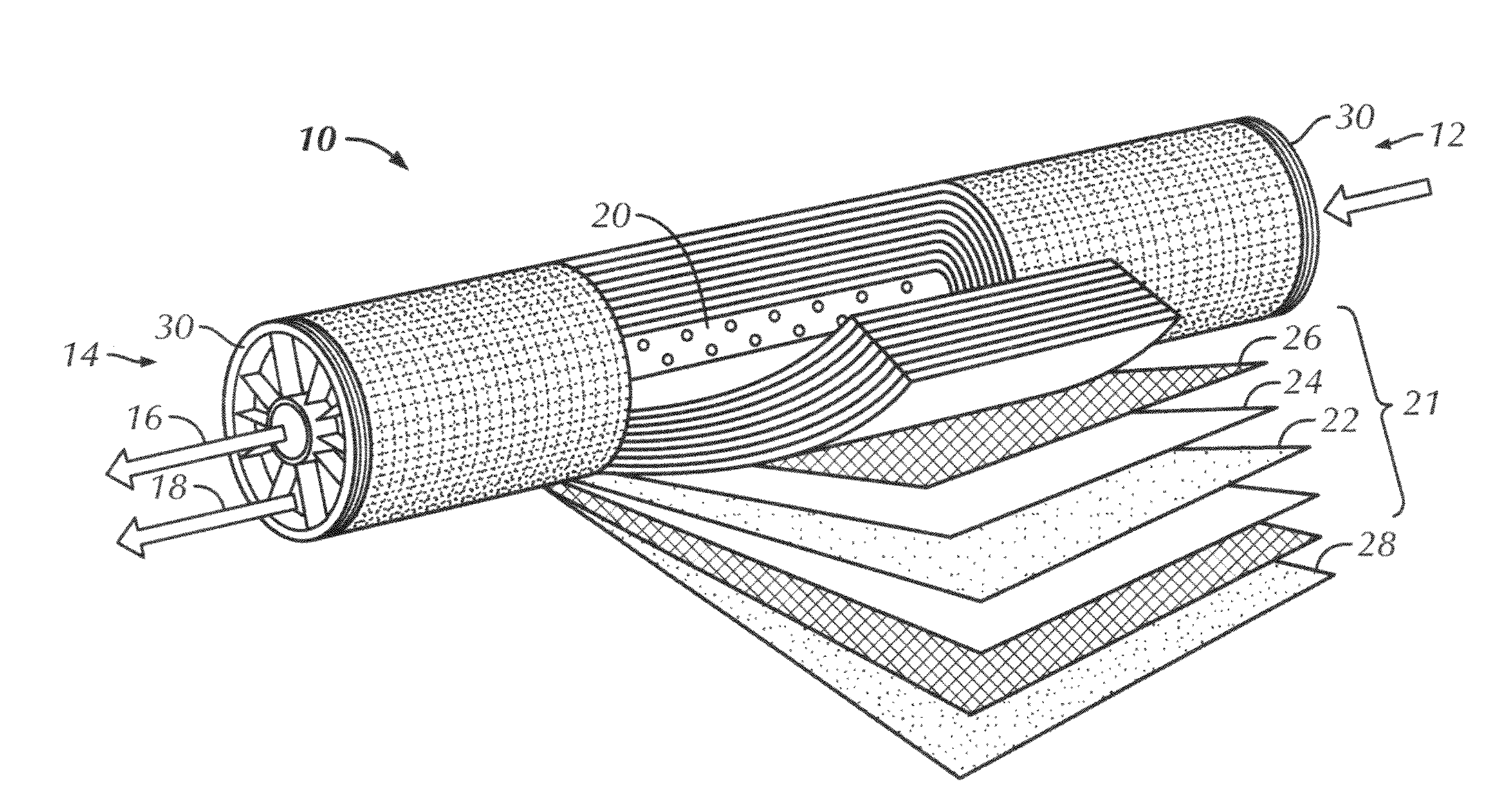

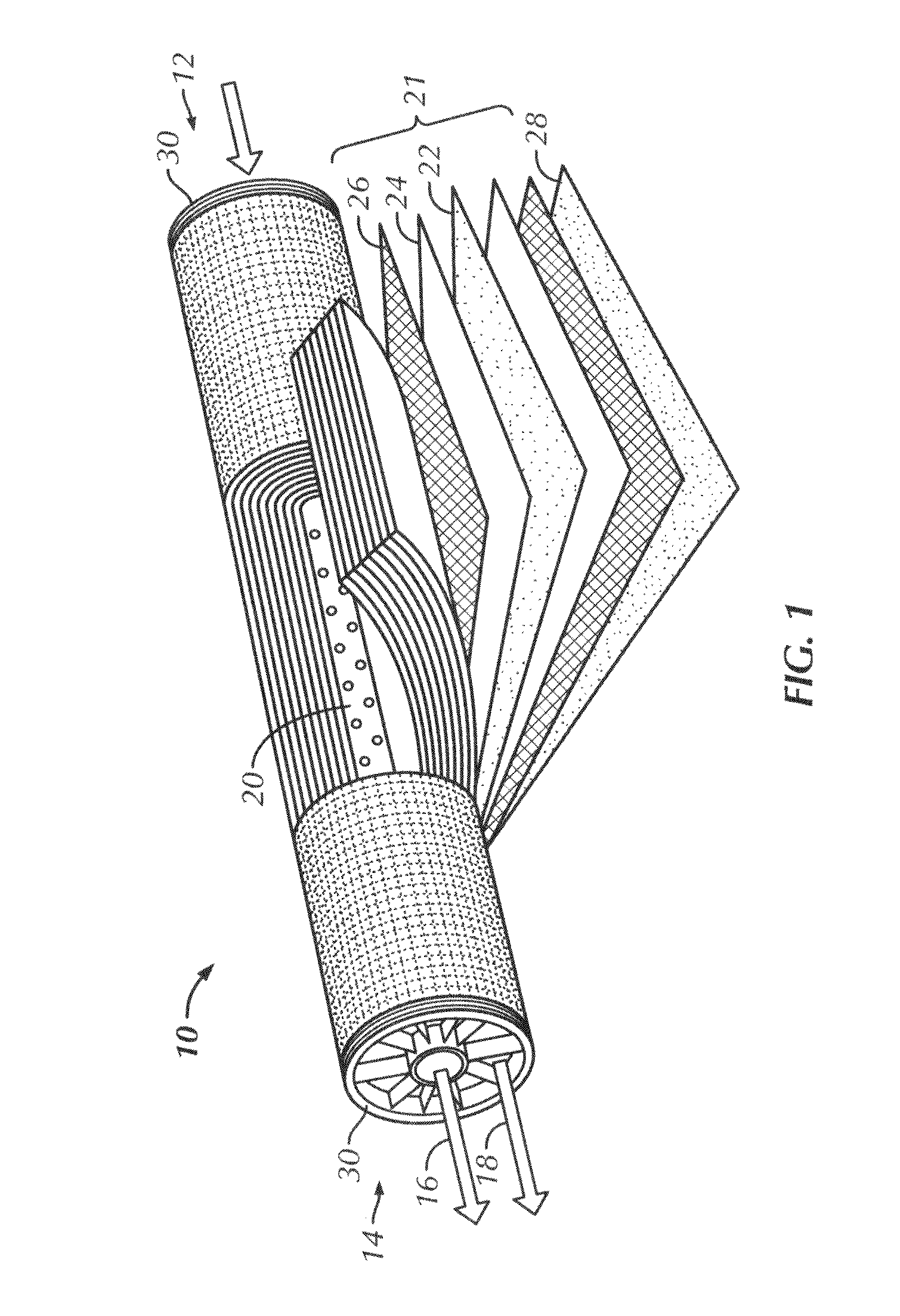

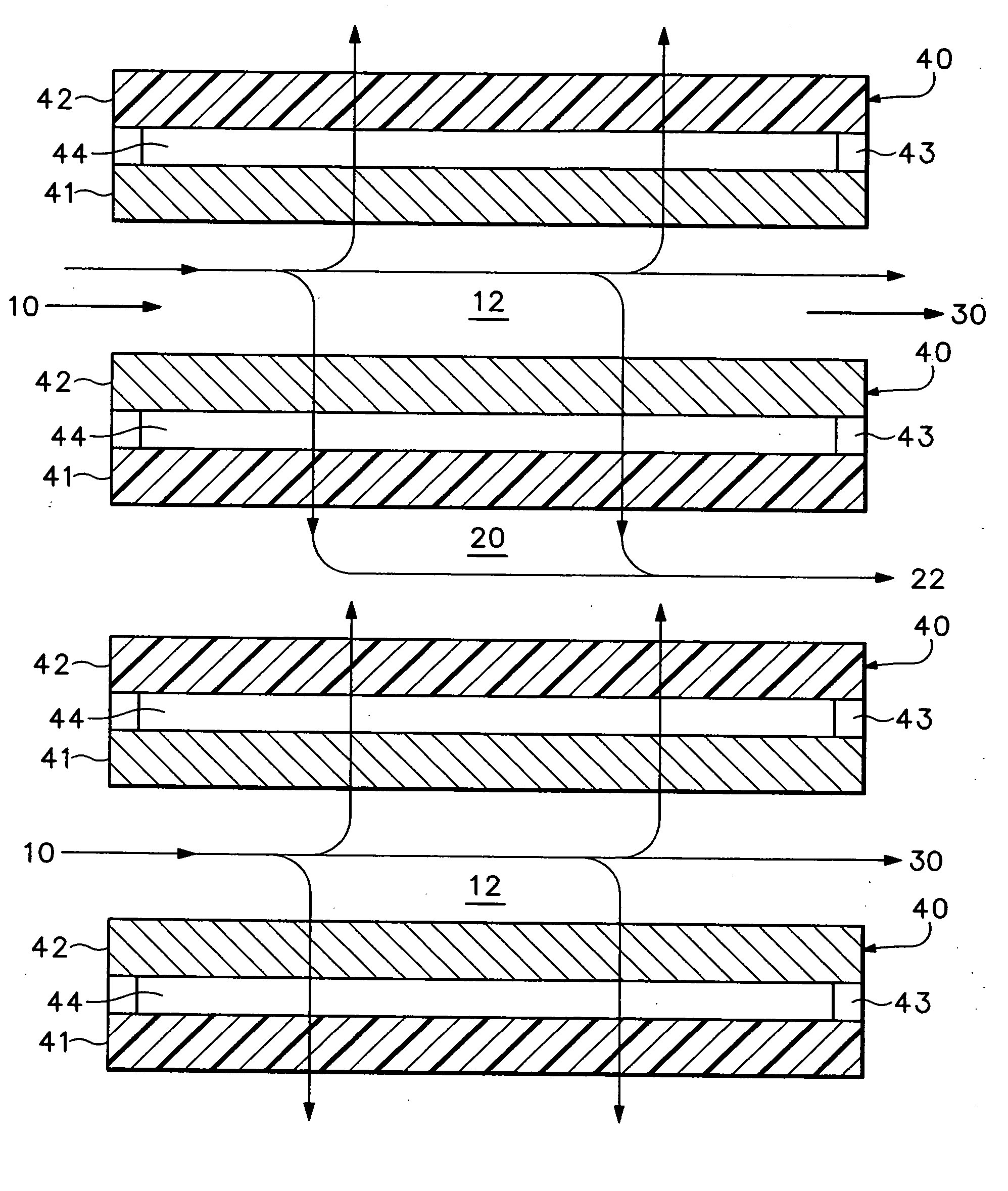

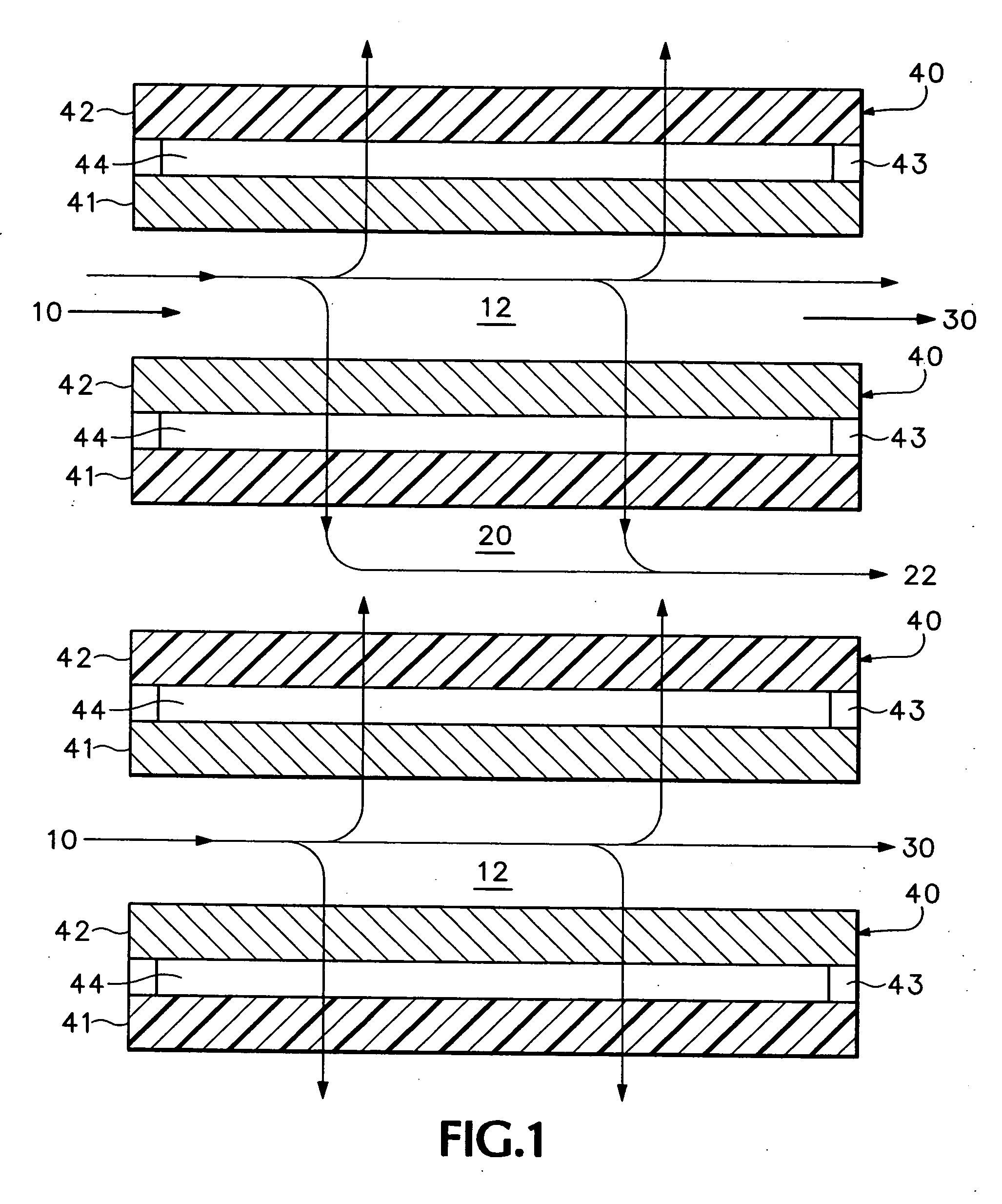

InactiveUS7048855B2Reduced operating requirementsAvoid problemsSemi-permeable membranesOther chemical processesFiberCross-flow filtration

Cross flow filtration cartridges are made using semipermeable membrane of sheet formation that was cast upon an integral polymeric fibrous support material which exhibits excellent permeate flow in the plane thereof and serves as both backing material and permeate carrier. A fibrous support having a thickness between about 0.4 mm and about 2 mm and at least one surface region with a mean pore size no greater than about 300 microns has a semipermeable membrane cast in situ thereupon from a liquid solution. After gelling to form a polymeric semipermeable membrane, the product is spirally wound about a porous tube in association with feed-passageway-providing sheet material, but in the absence of any separate permeate carrier, to form an effective cross-flow filtration cartridge wherein the feed flow may be spiral and the permeate discharge through one of the side edges.

Owner:GE OSMONICS INC

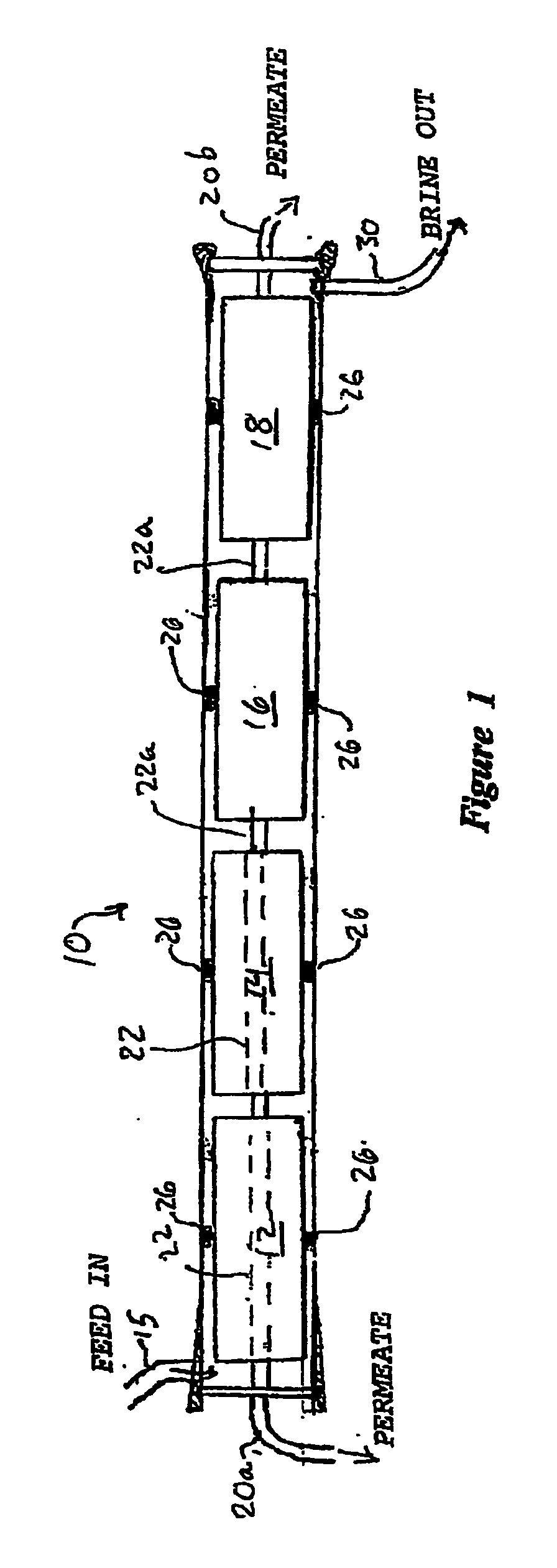

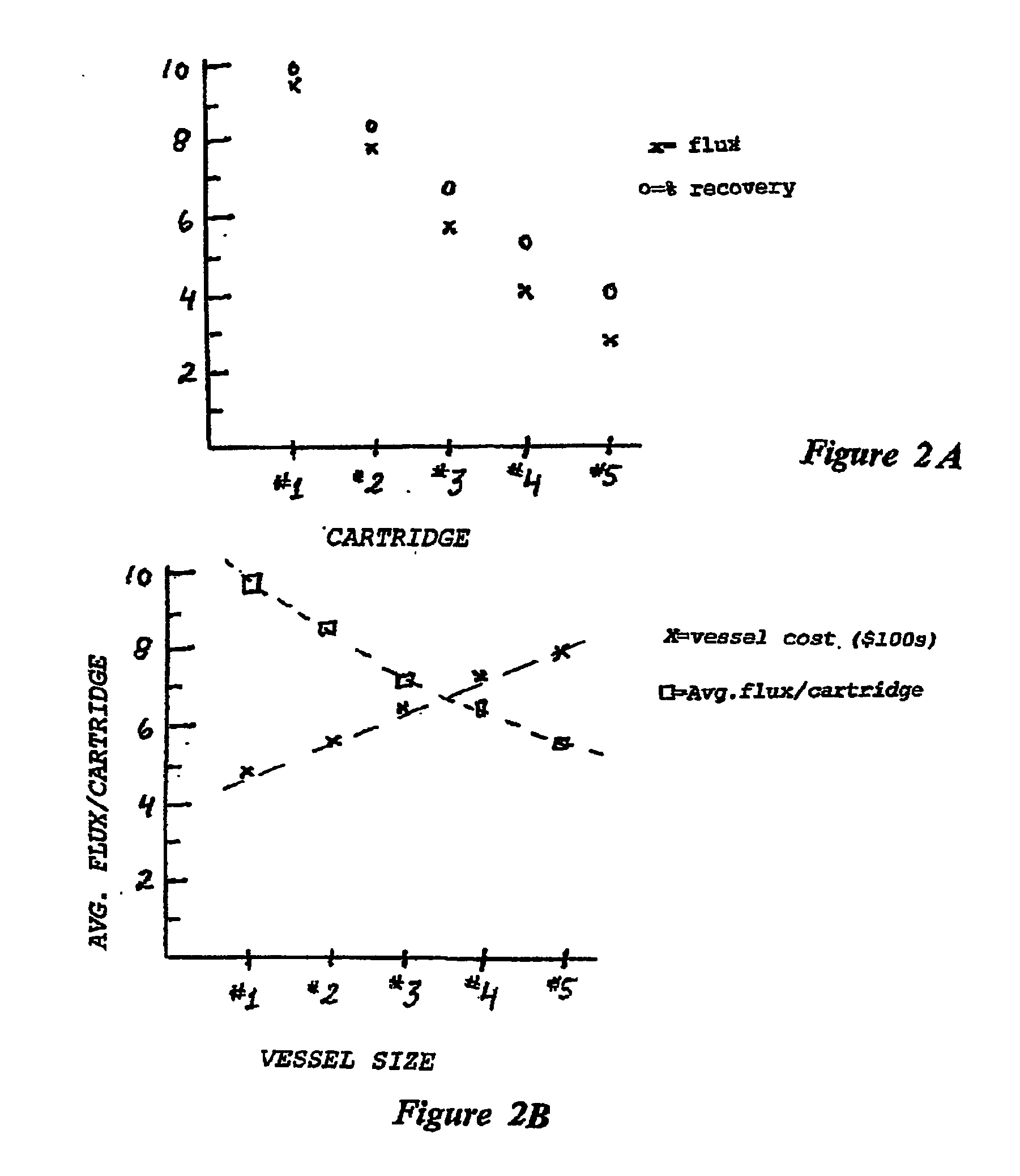

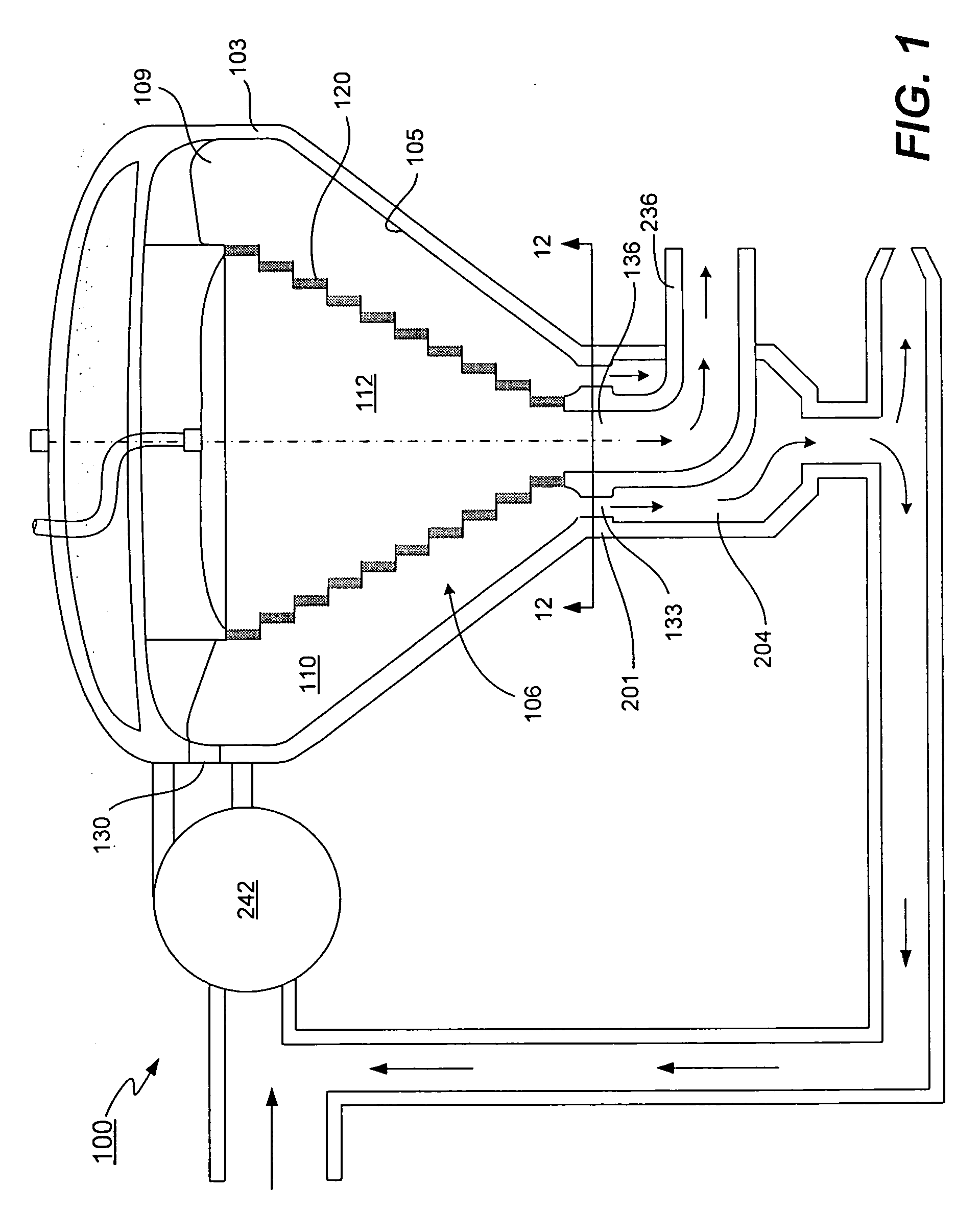

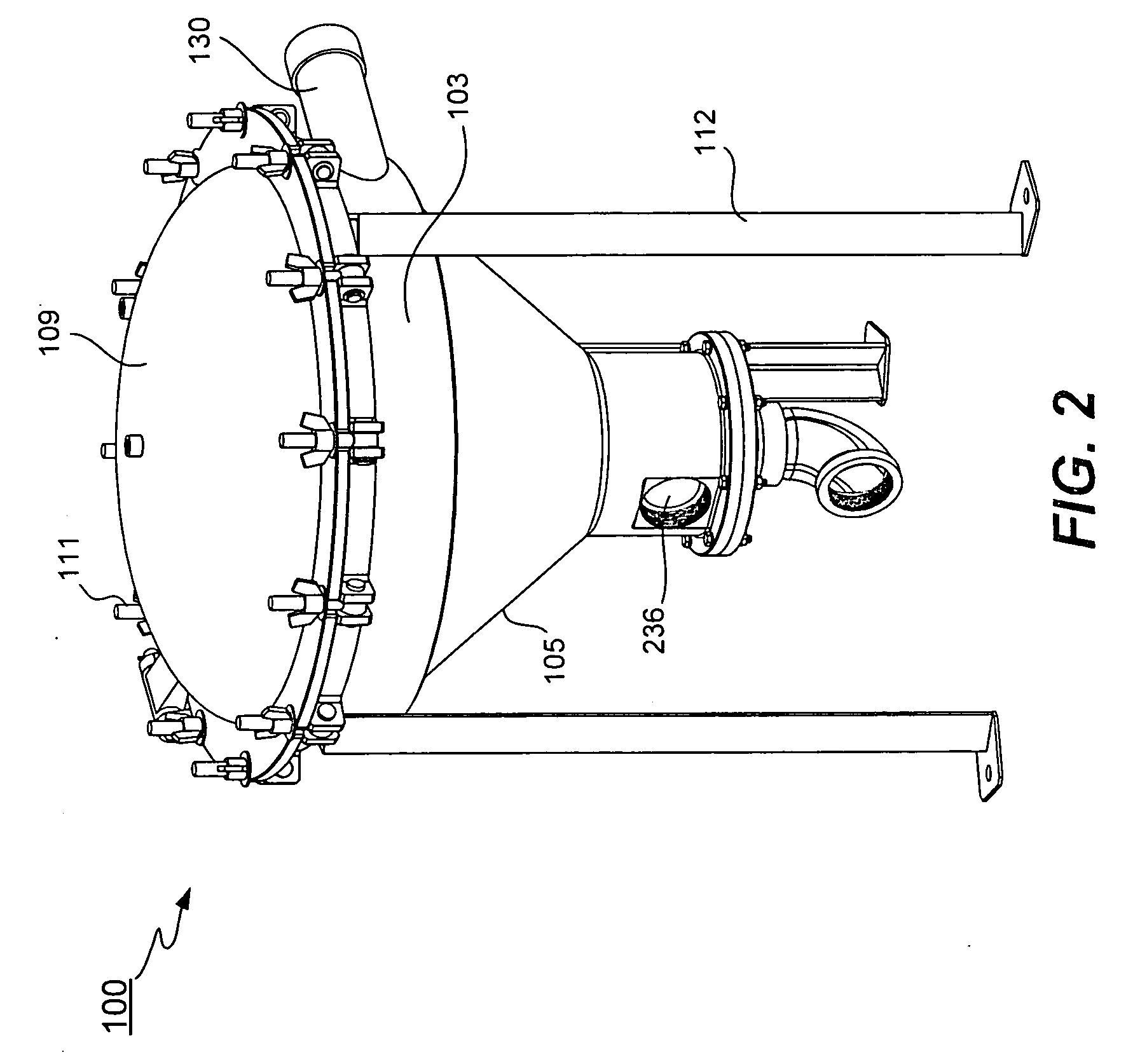

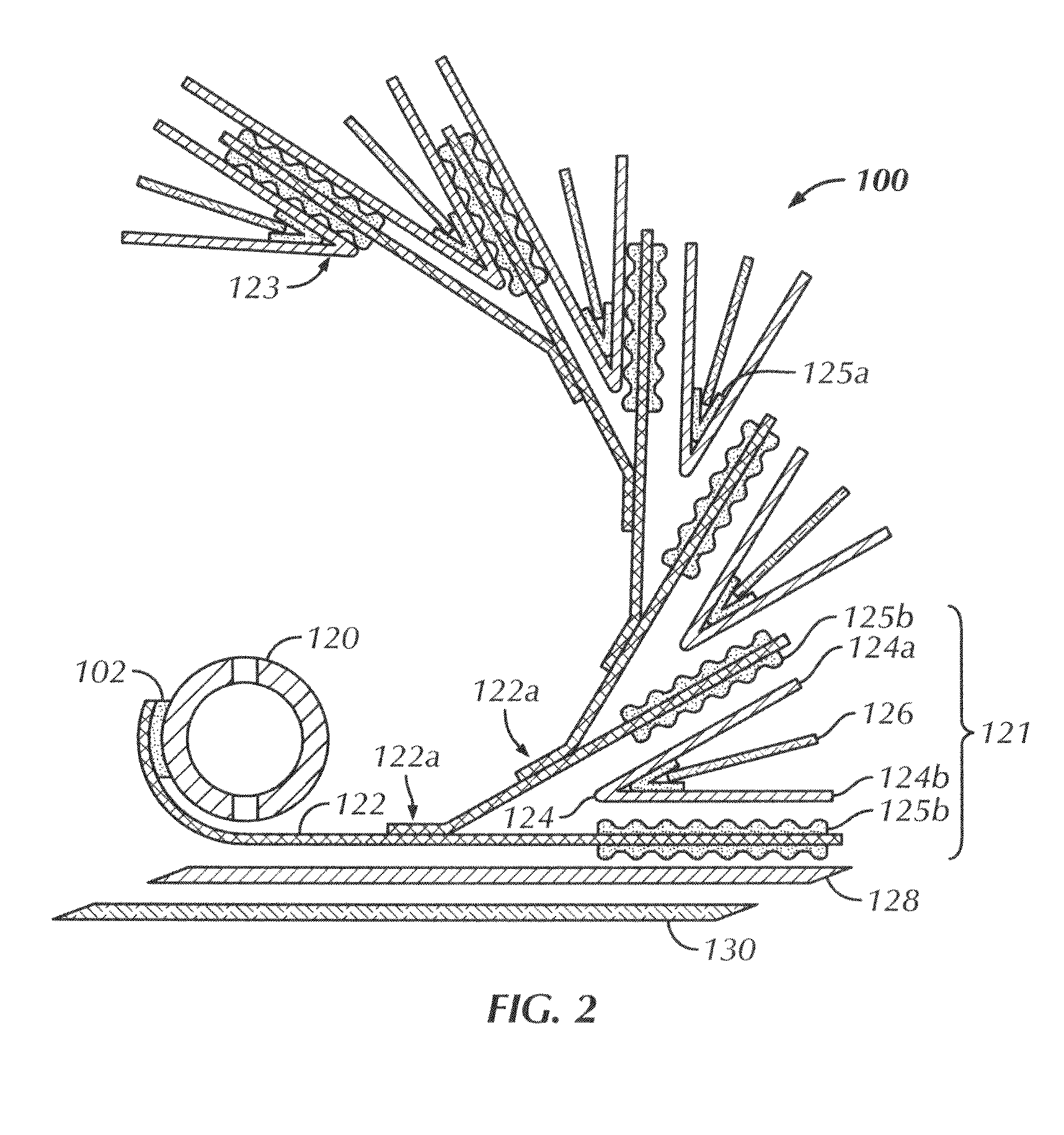

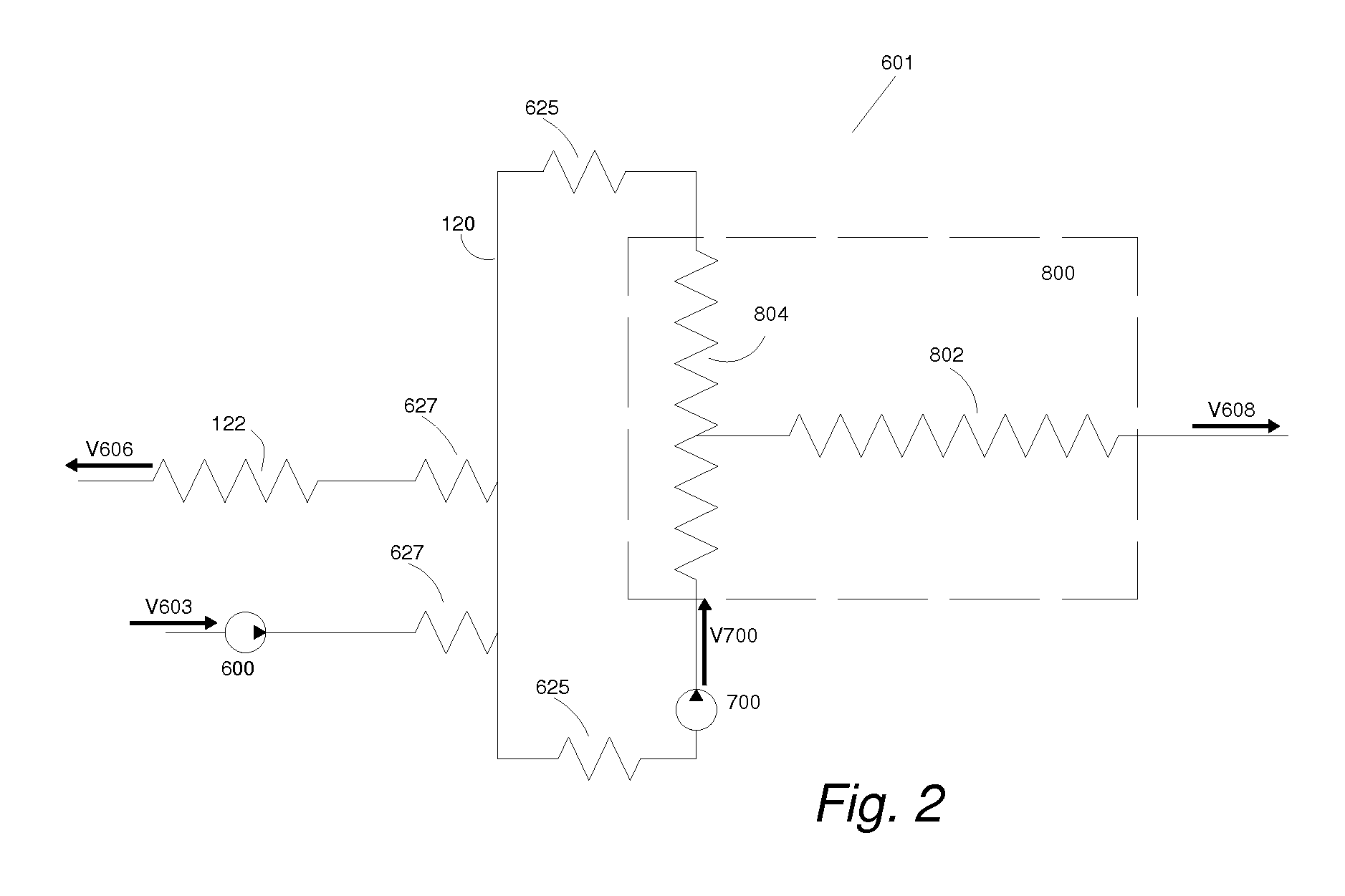

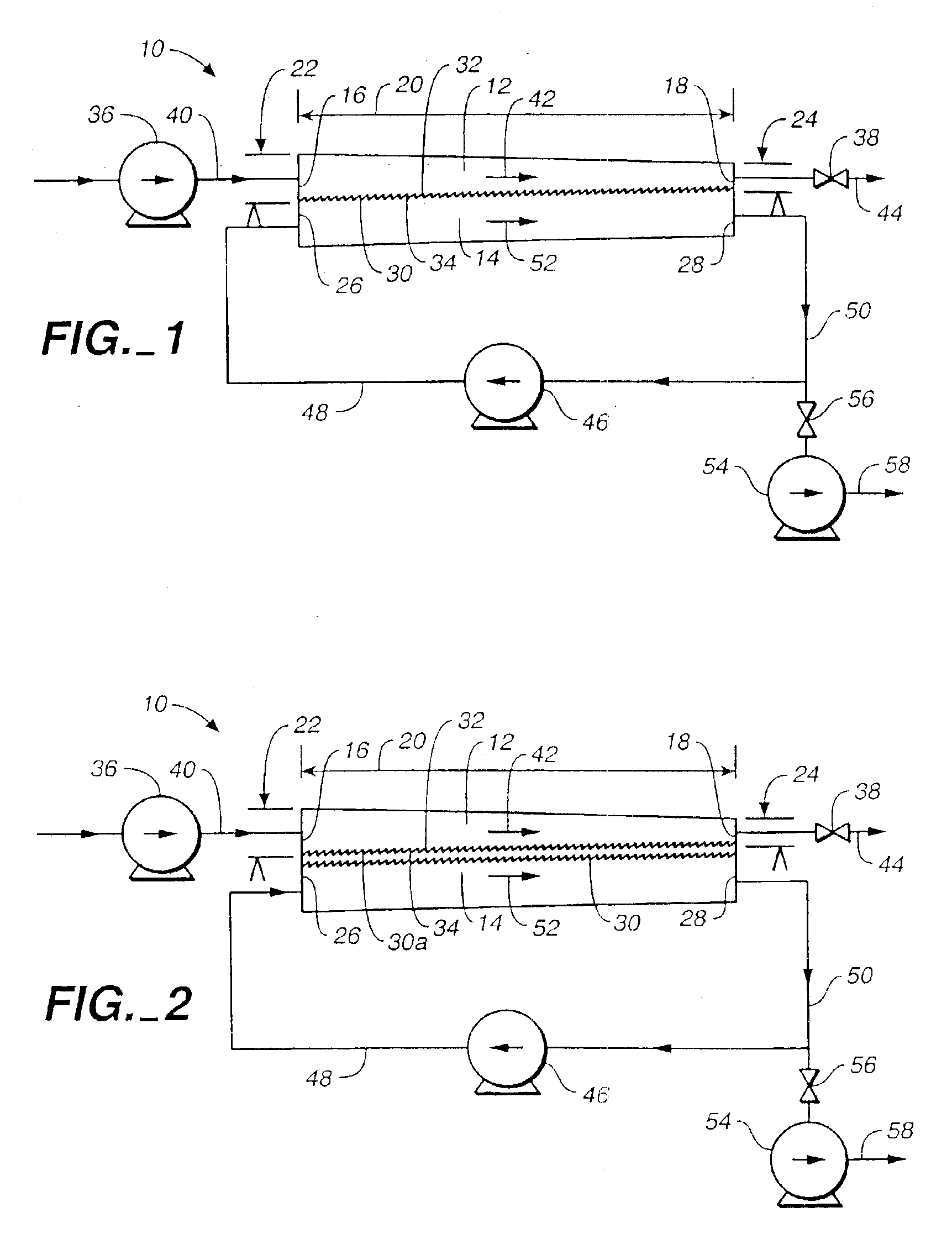

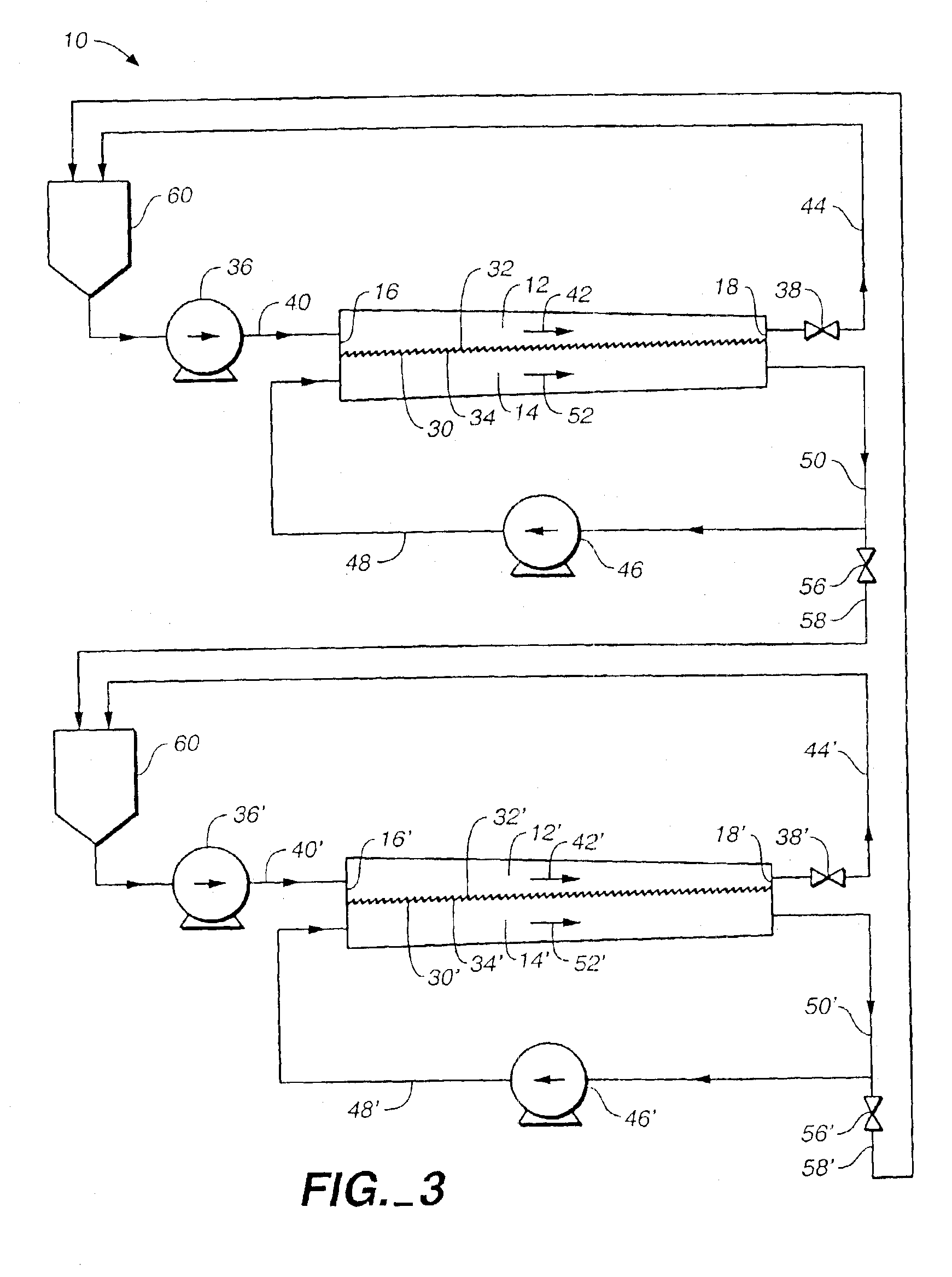

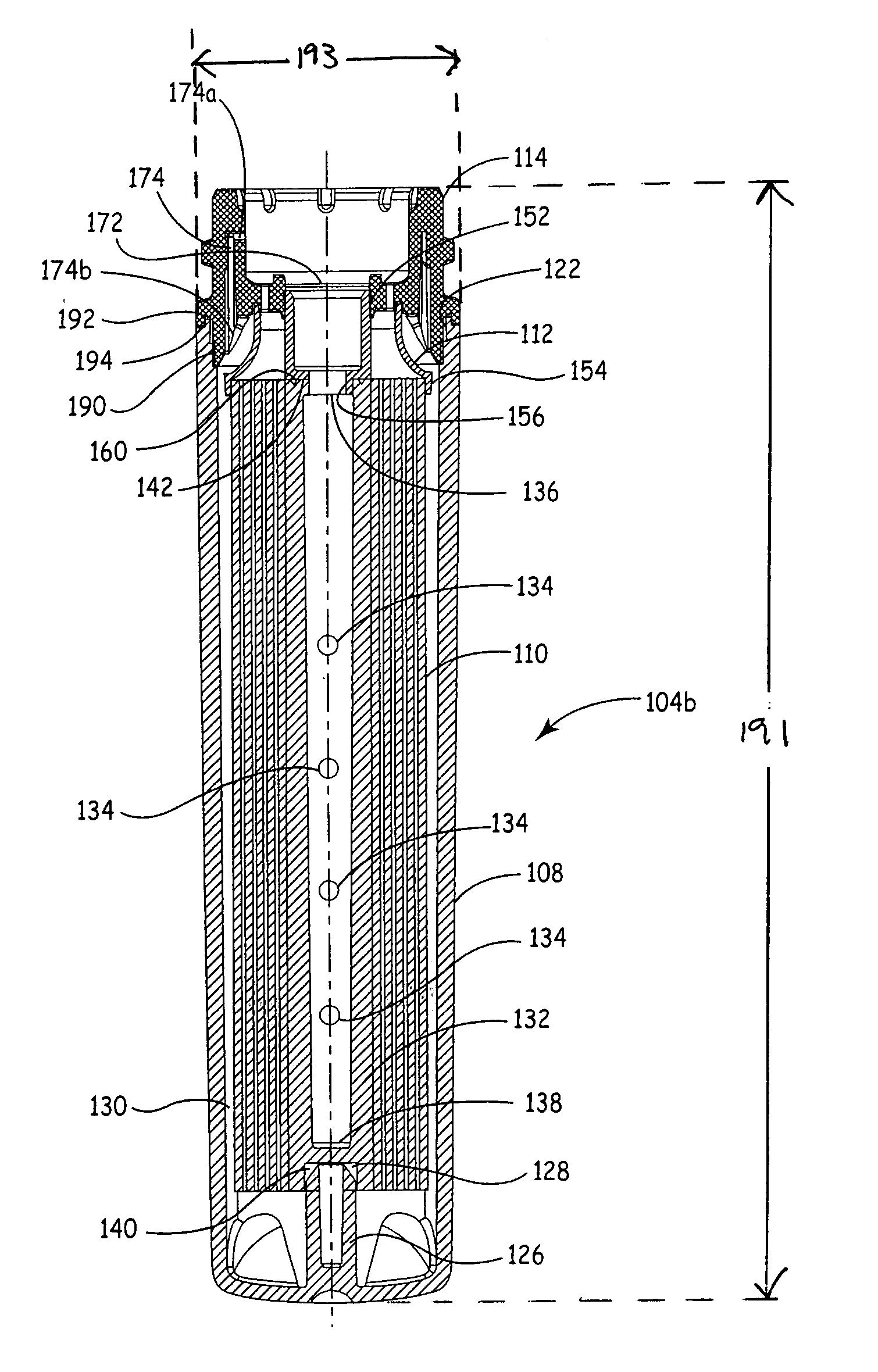

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

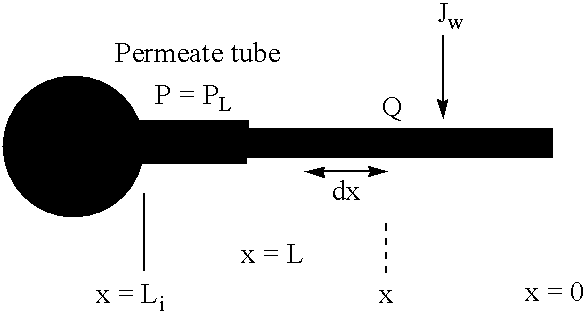

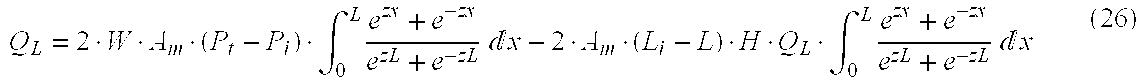

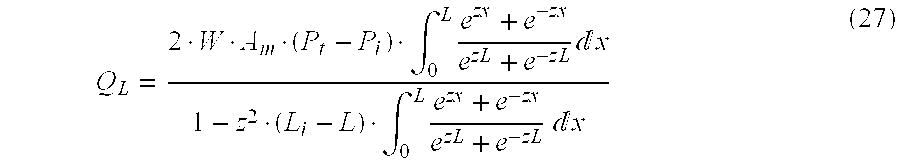

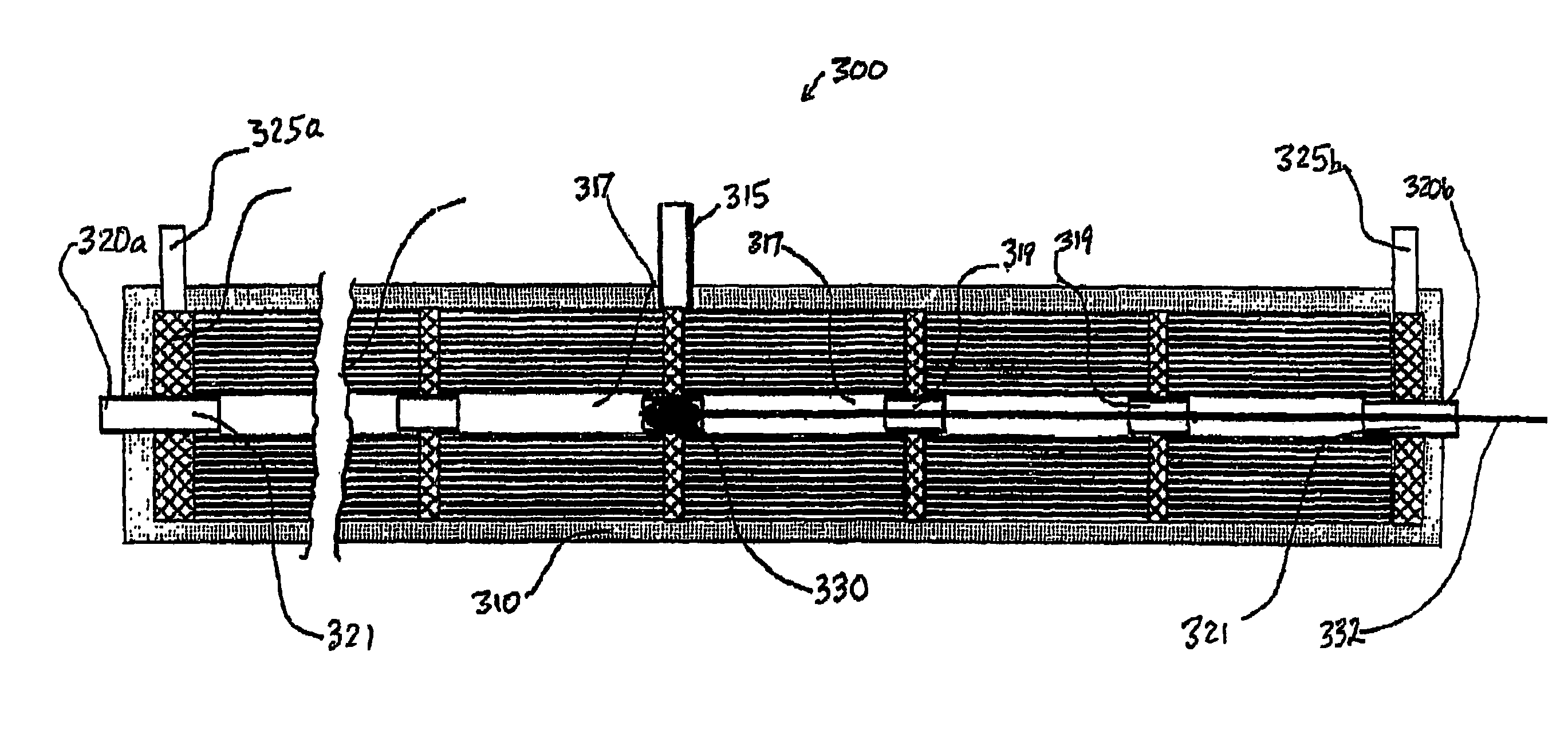

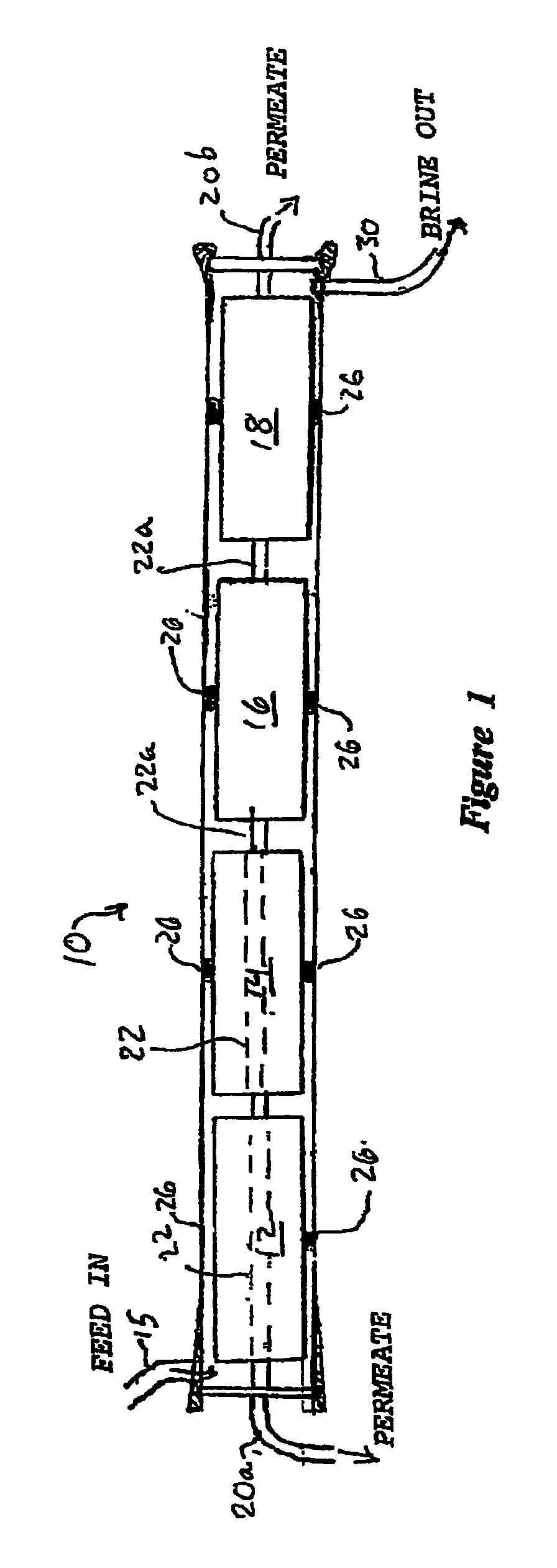

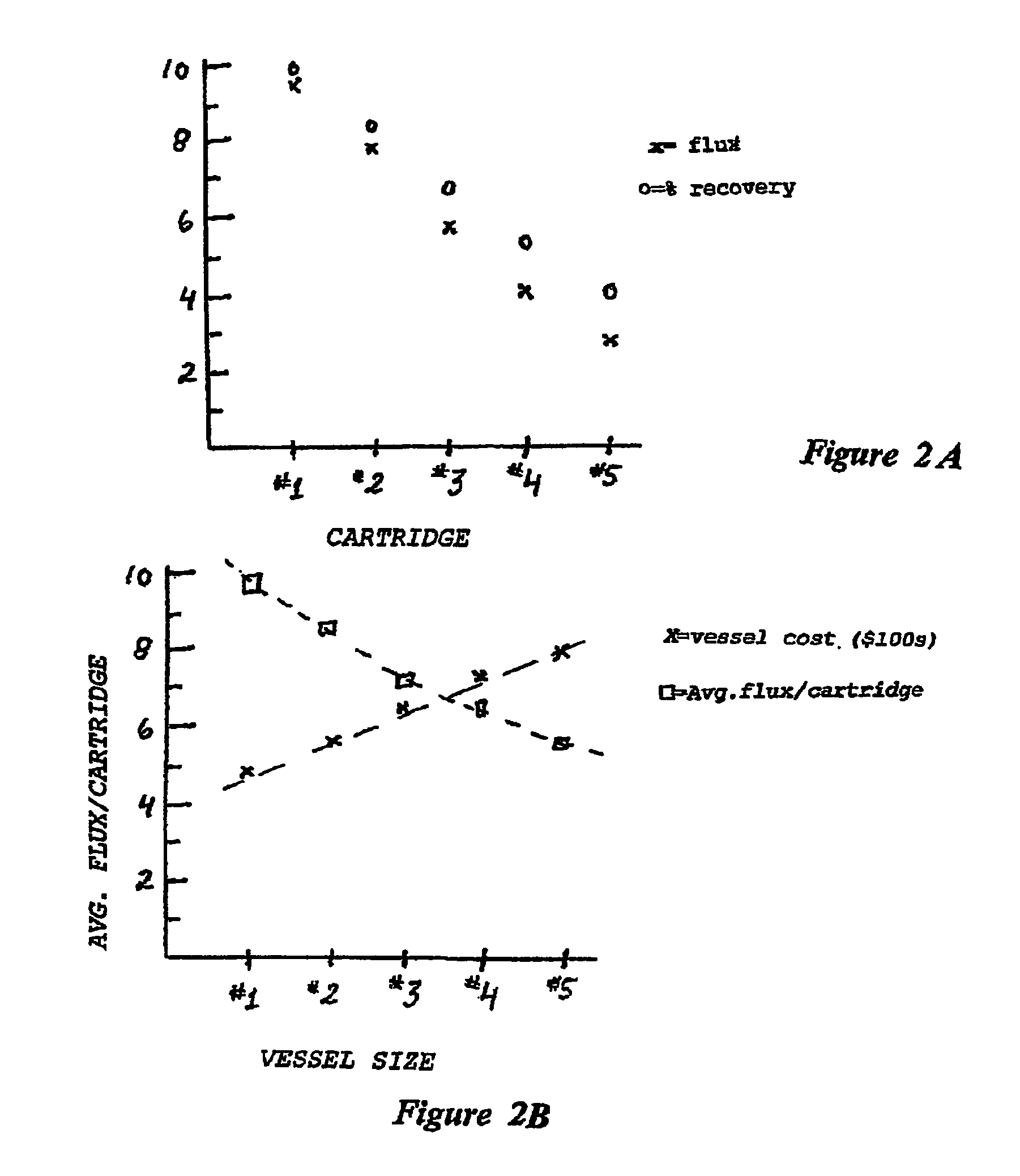

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

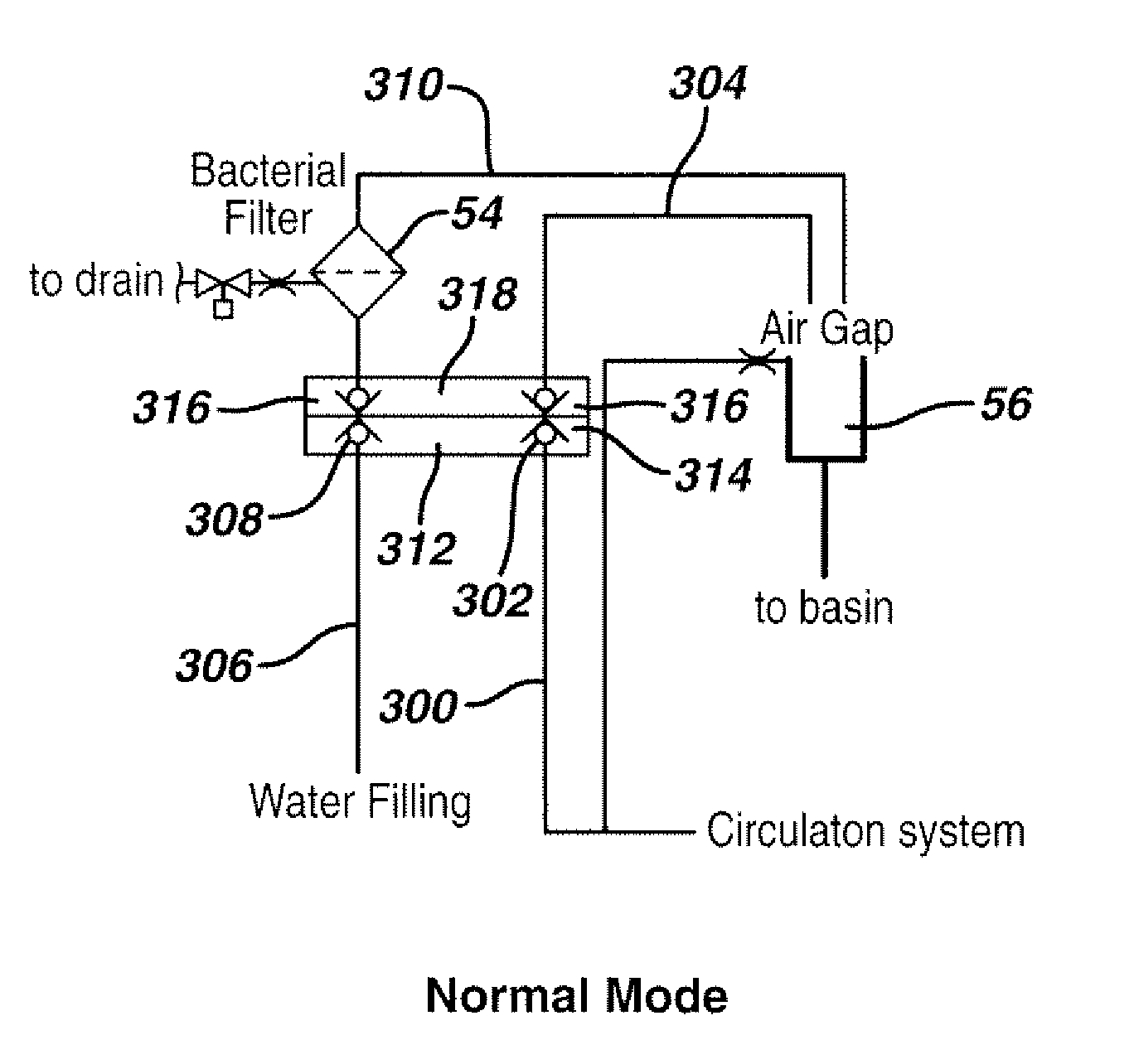

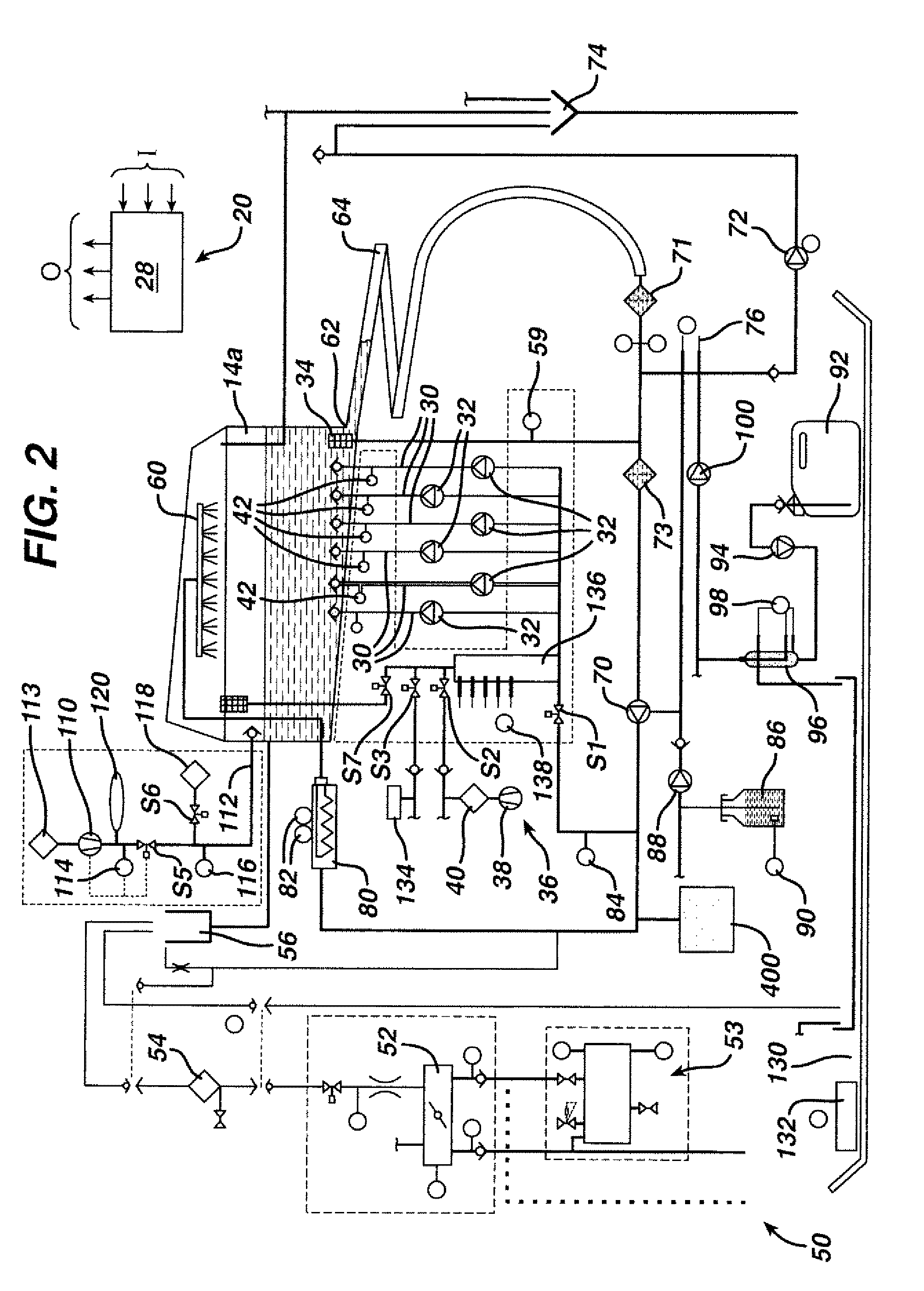

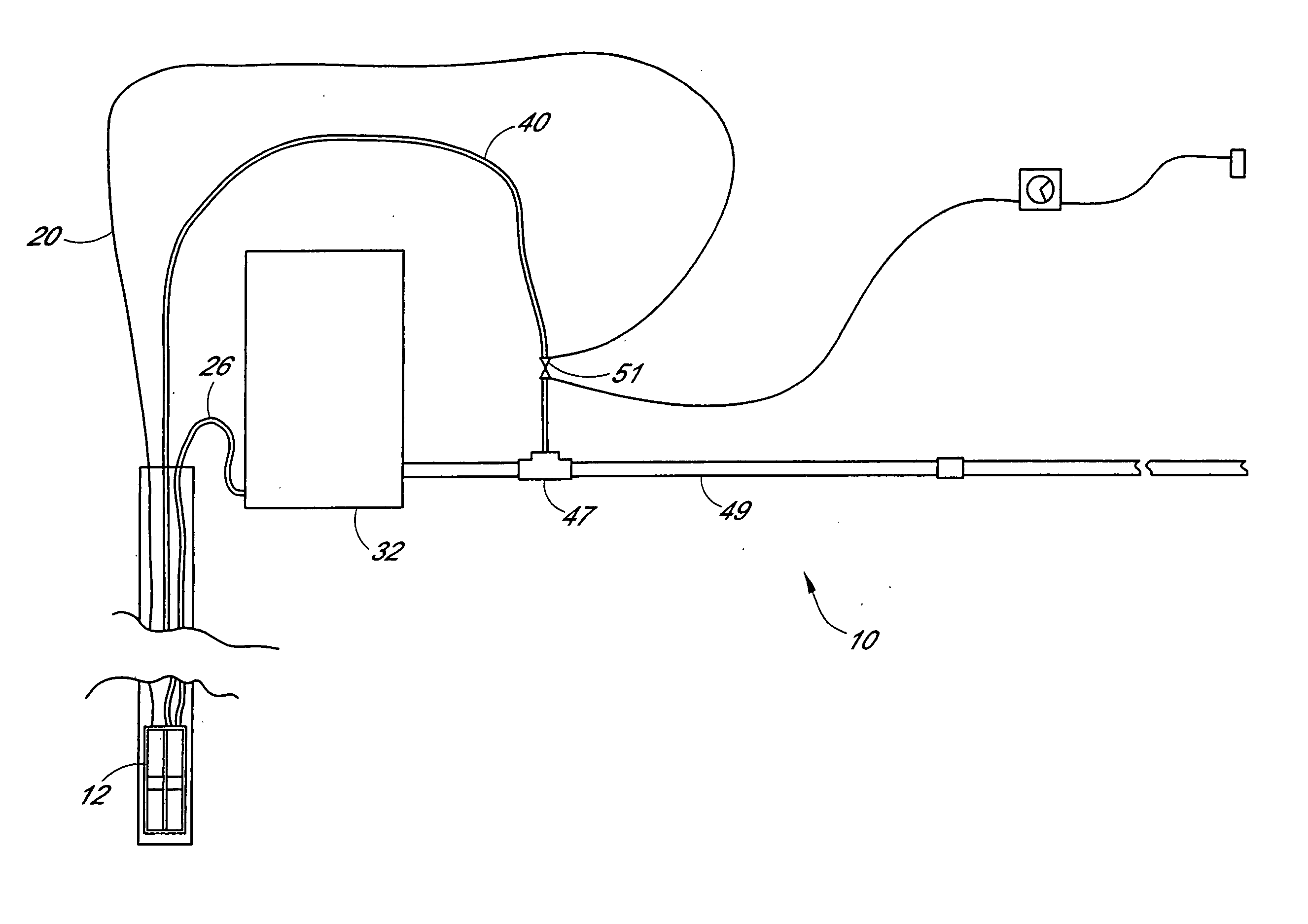

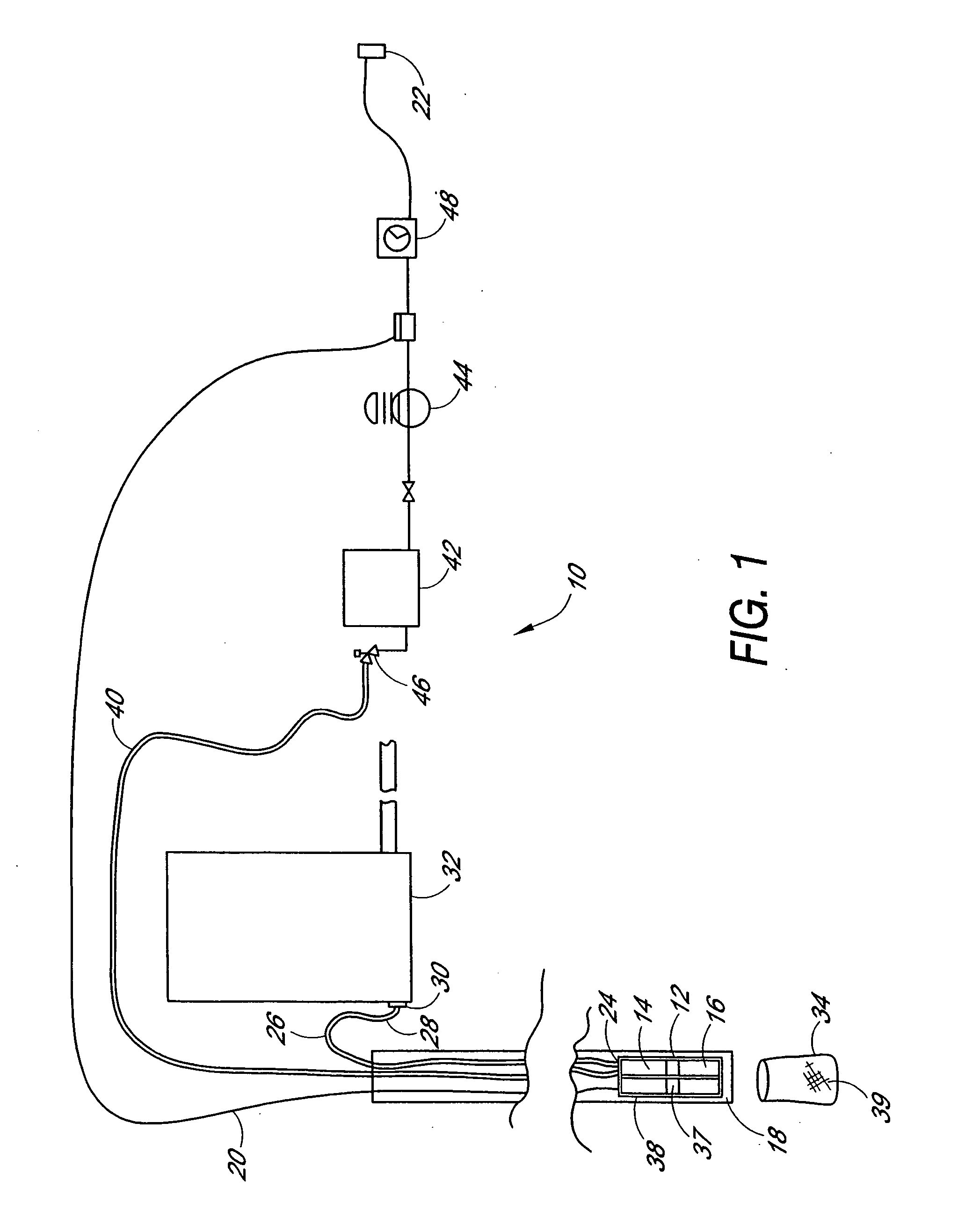

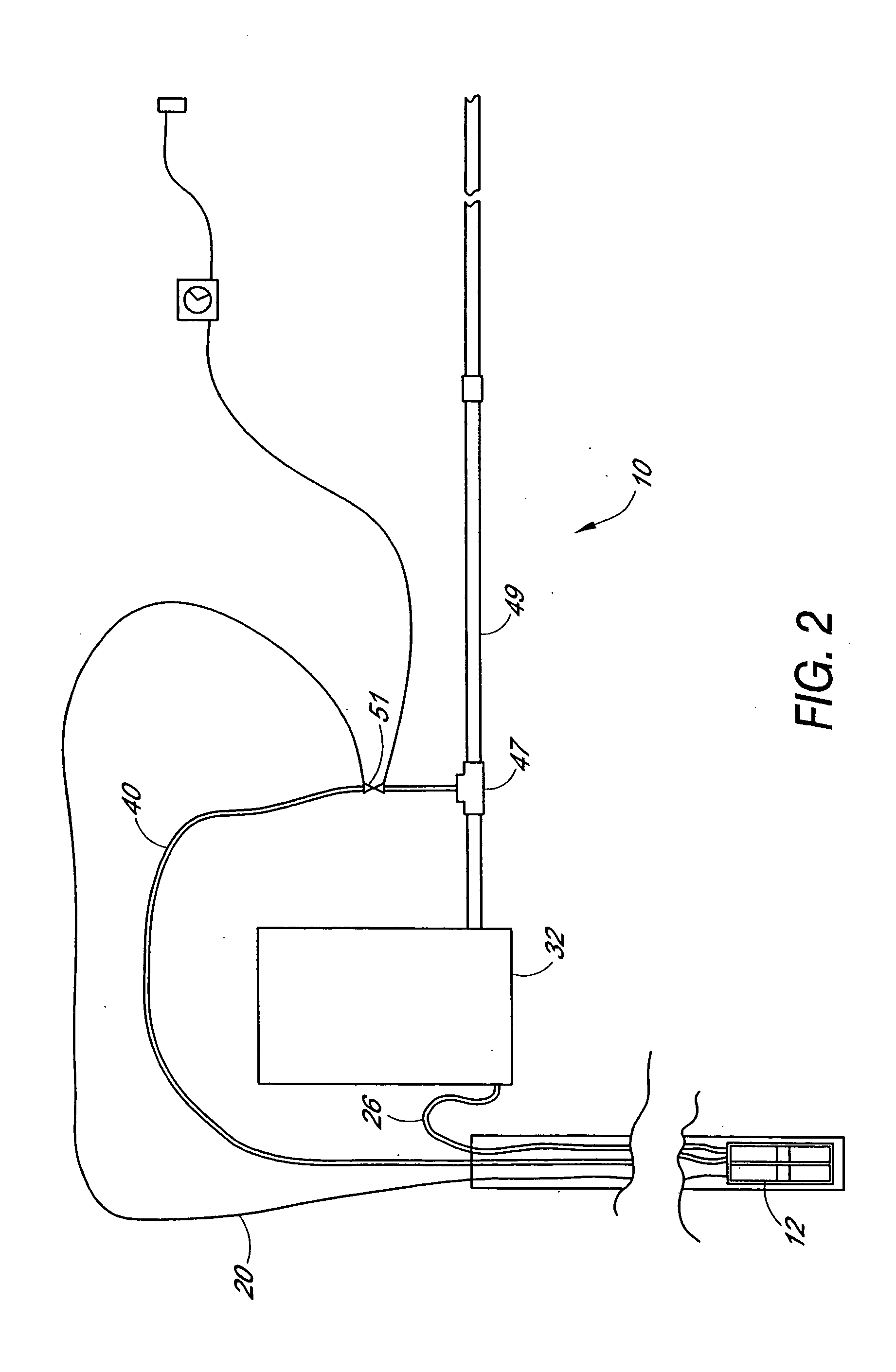

Automated endoscope reprocessor germicide concentration monitoring system and method

ActiveUS8246909B2Avoid accumulationOptical radiation measurementDispersed particle filtrationCuvetteReprocessor

A method measures a property of a germicidal solution in an endoscope processor spectroscopically by placing a quantity of the solution into a cuvette and passing a light therethrough. A reservoir receives a quantity of the solution and bubbles are filtered out via a cross-flow filter prior to putting a sample therefrom into the cuvette for measuring.

Owner:ASP GLOBAL MFG GMBH

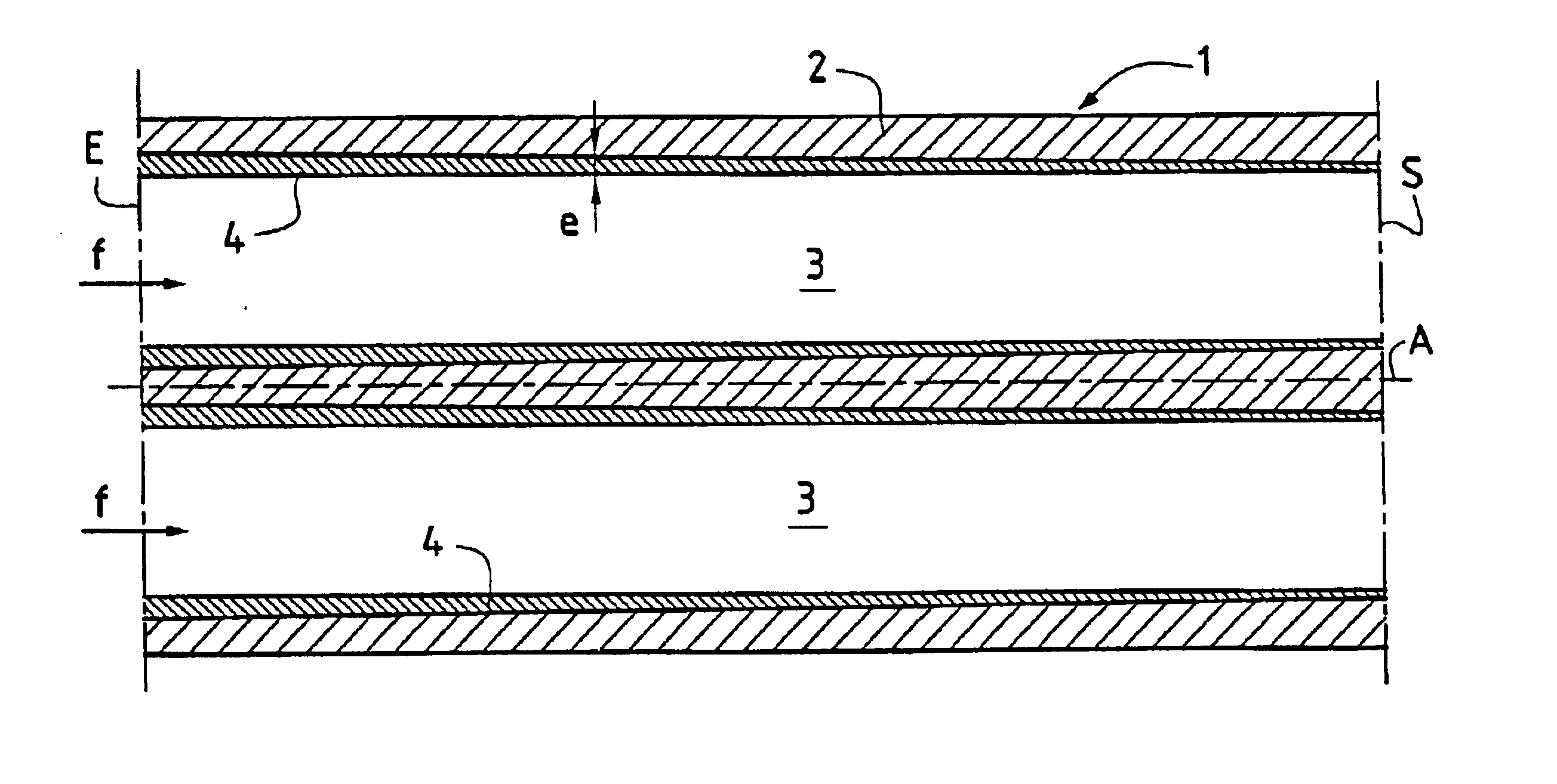

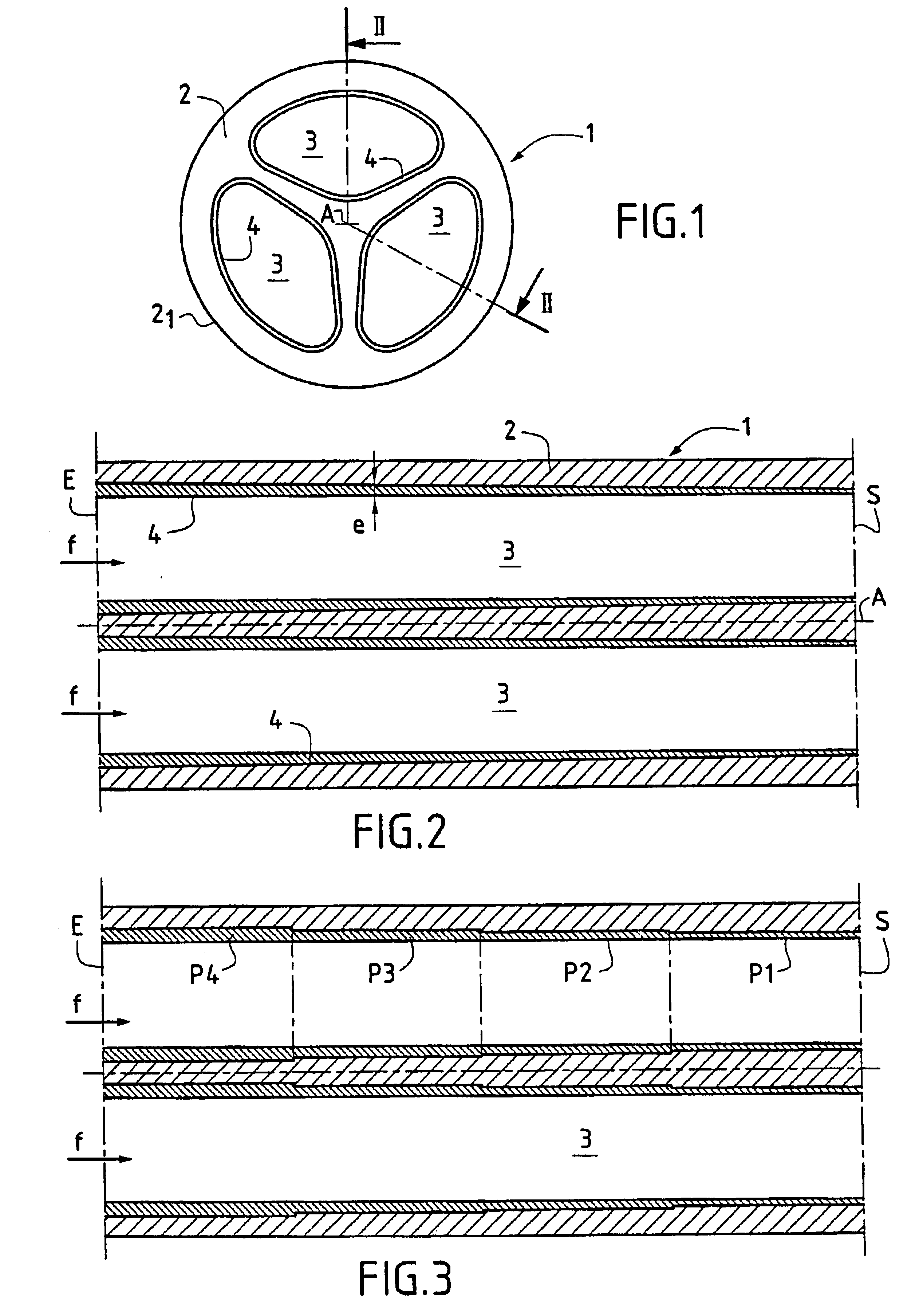

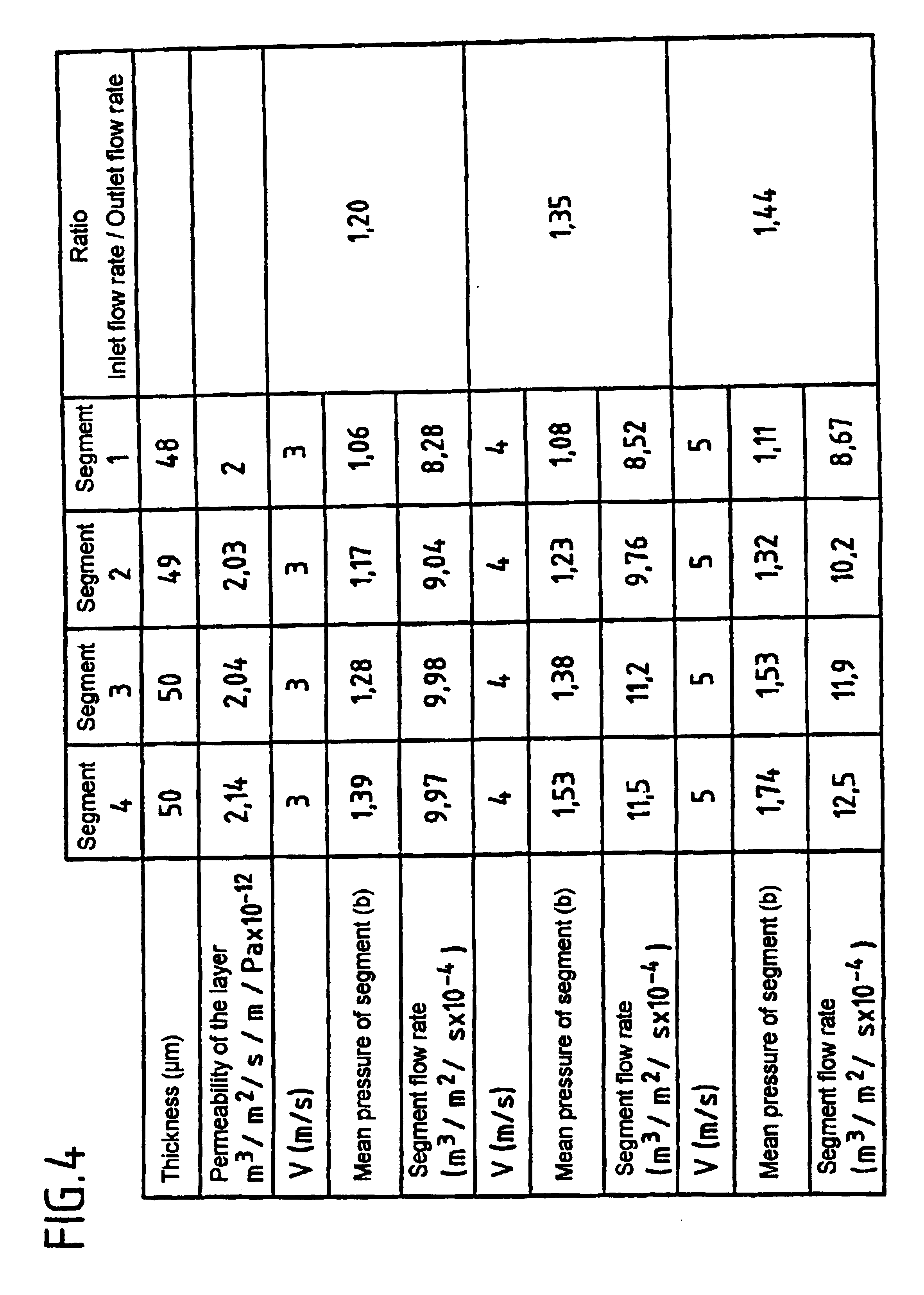

Cross-flow filter membrane and method of manufacturing it

Owner:TECH AVANCEES & MEMBRANES INDS

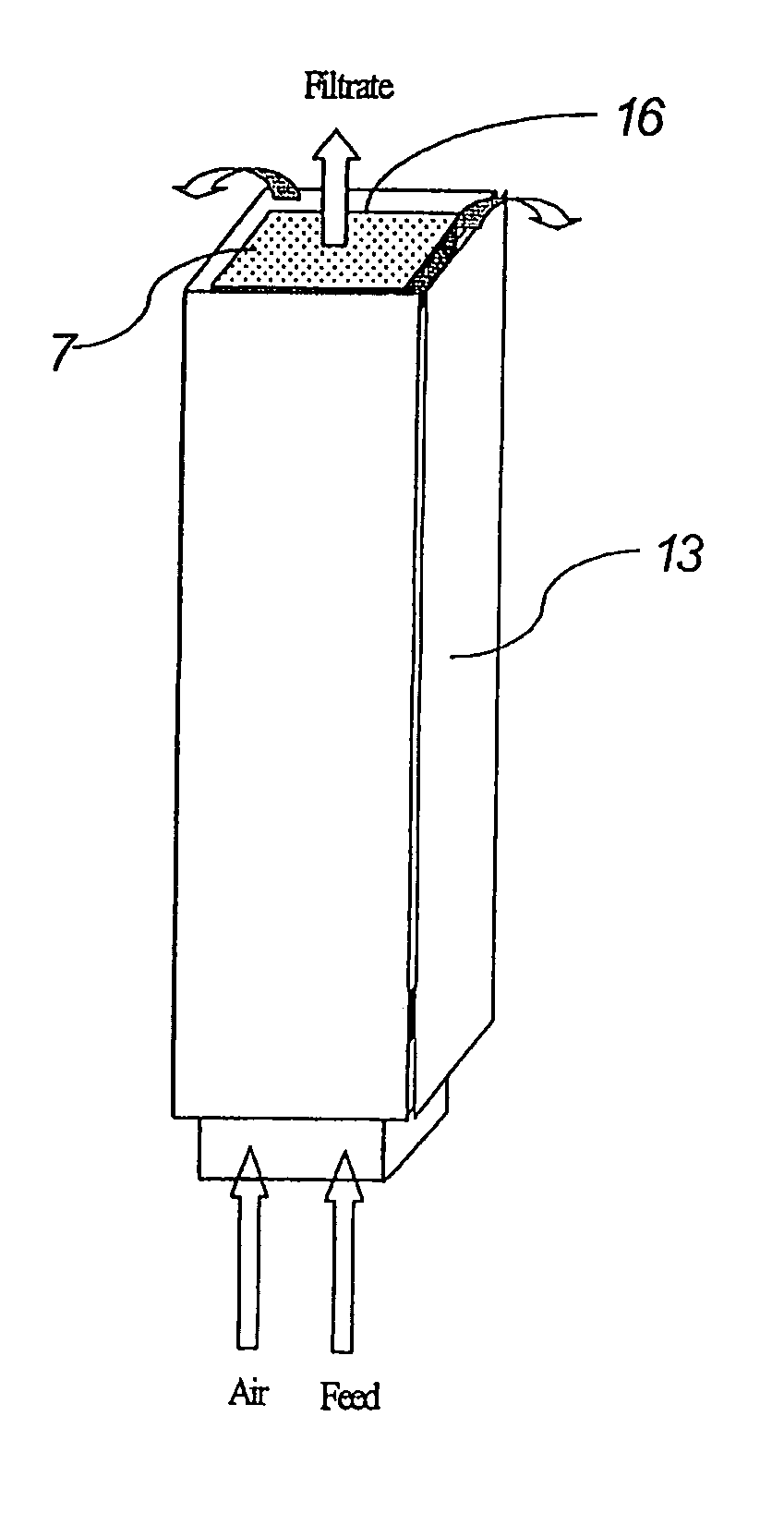

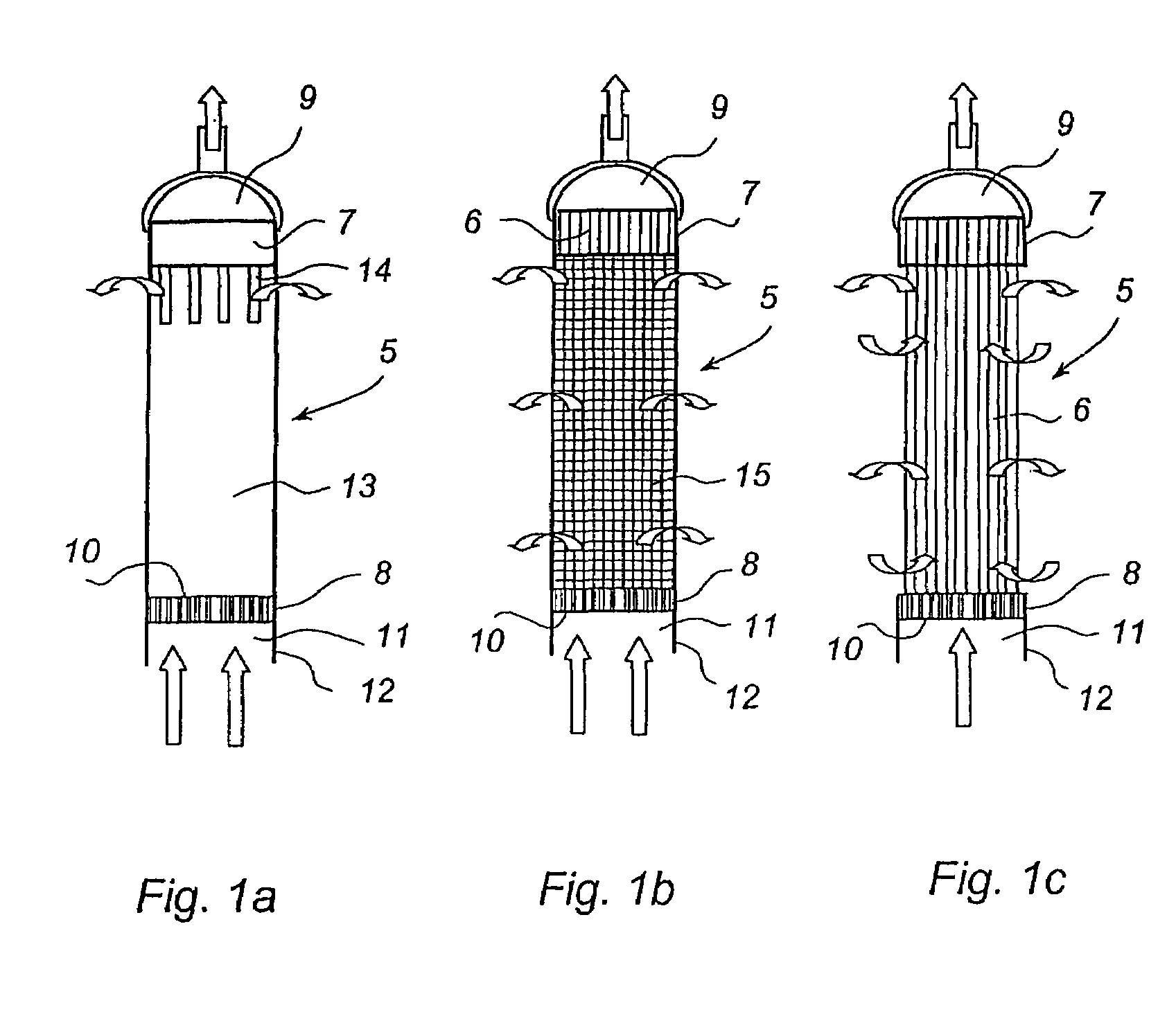

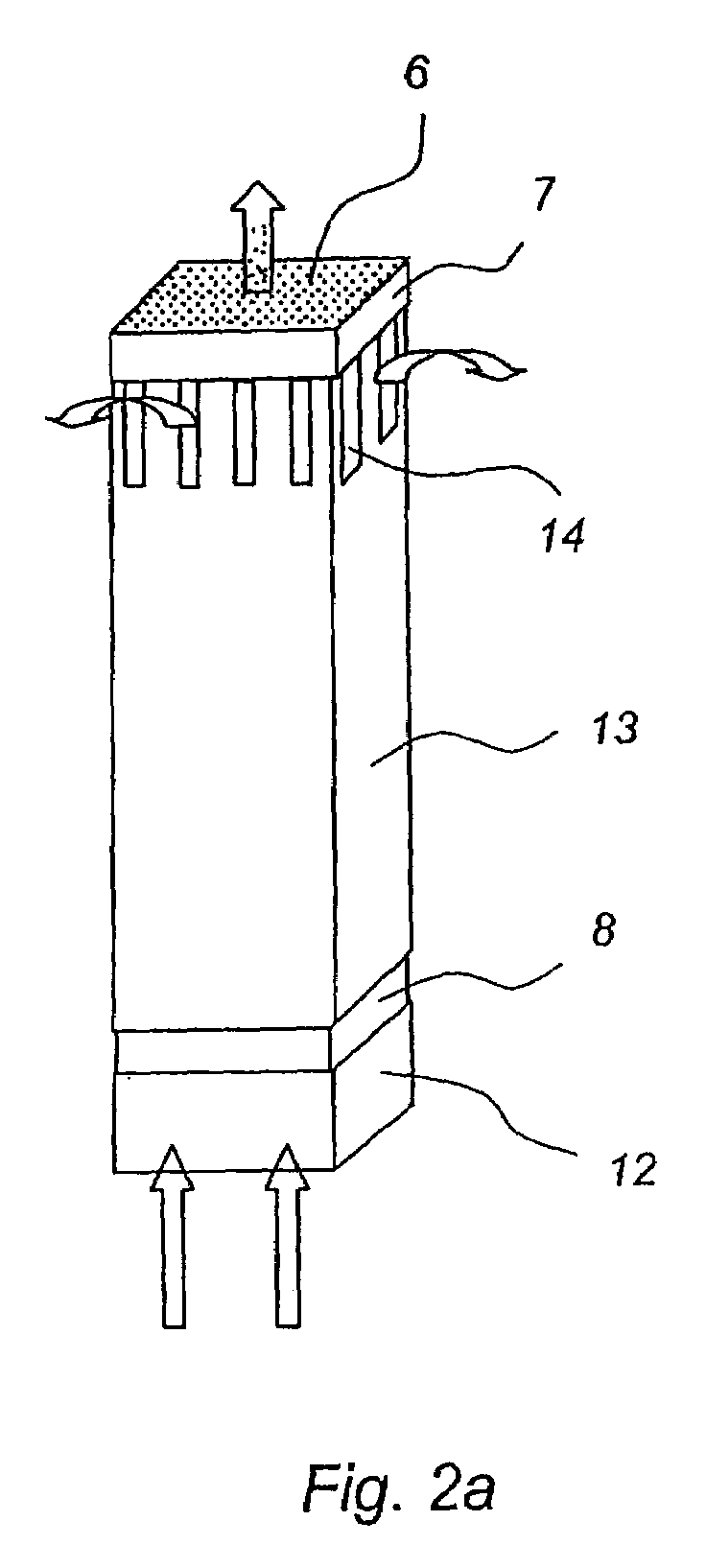

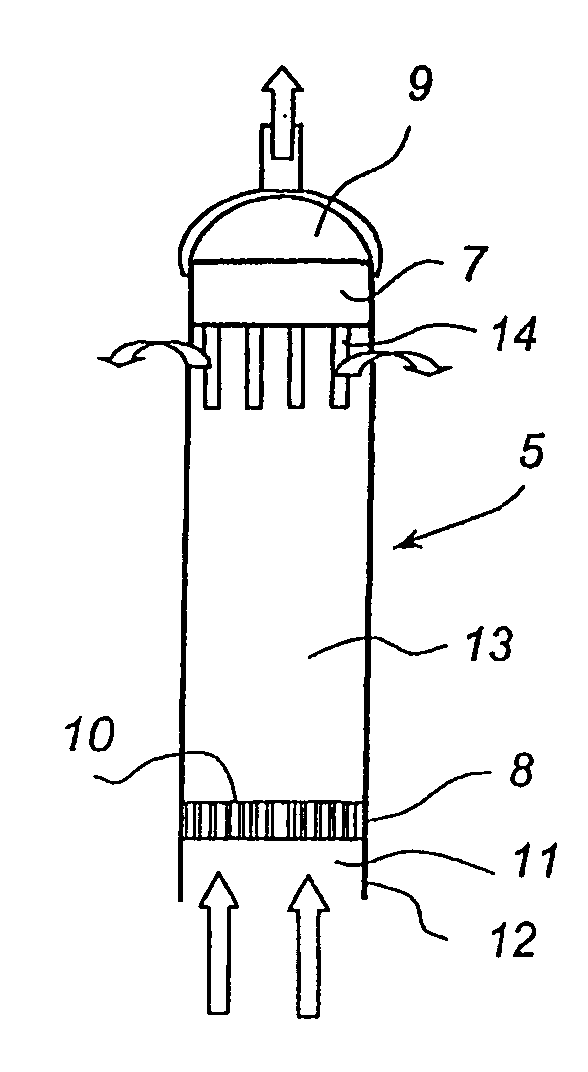

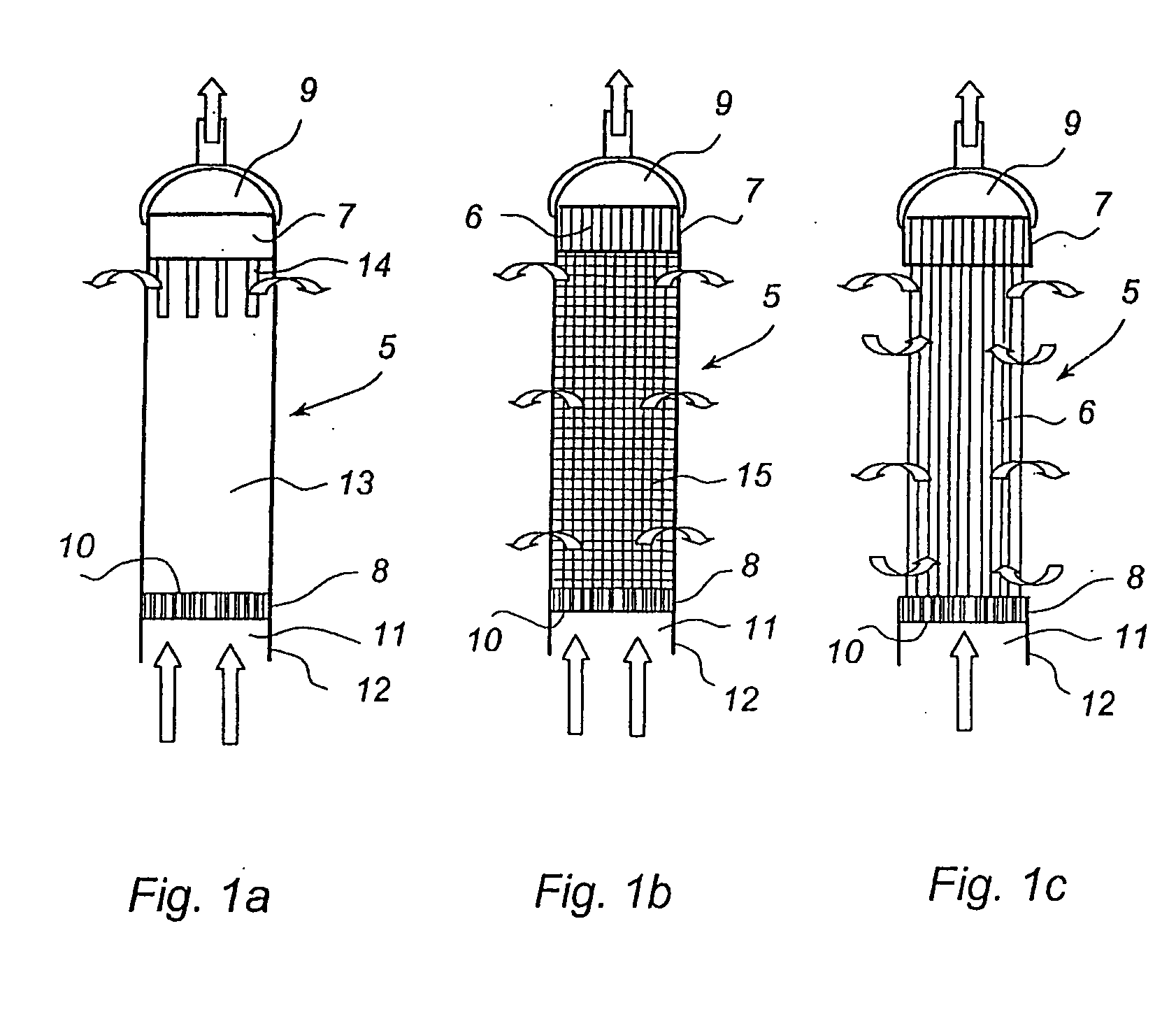

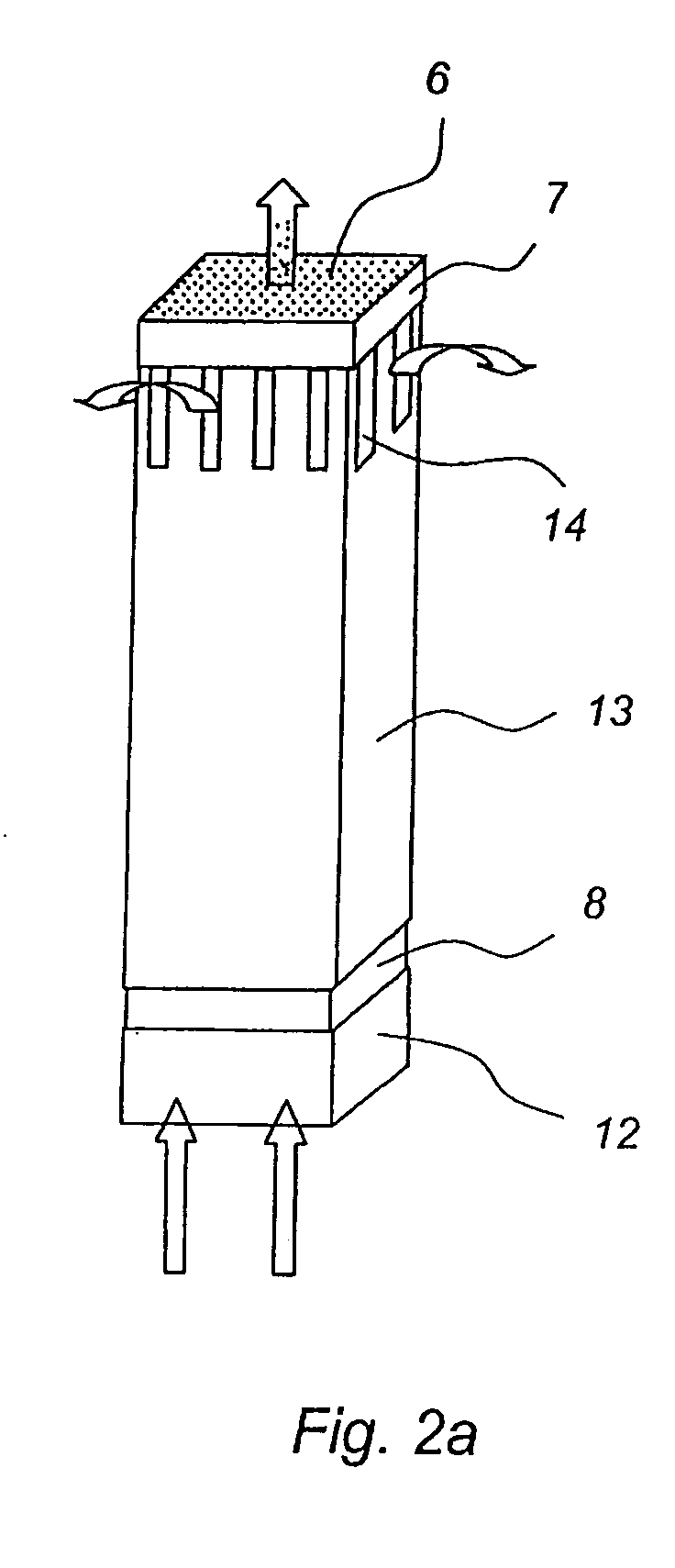

Submerged cross-flow filtration

A membrane filtration module having a plurality of permeable, hollow membranes is disclosed. In use, a pressure differential is applied across the walls of the permeable, hollow membranes when immersed in a liquid suspension containing suspended solids. Some of the liquid suspension passes through the walls of the membranes to be drawn off as clarified liquid or permeate, and at least some of the solids are retained on or in the permeable, hollow membranes or otherwise as suspended solids within the liquid suspension. The module has a shell or similar structure that at least partially surrounds the membrane module and substantially effects retaining at least portion of fluid flowed into the membrane module.

Owner:EVOQUA WATER TECH LLC

Submerged cross-flow filtration

A membrane filtration module having a plurality of permeable, hollow membranes is disclosed. In use, a pressure differential is applied across the walls of the permeable, hollow membranes when immersed in a liquid suspension containing suspended solids. Some of the liquid suspension passes through the walls of the membranes to be drawn off as clarified liquid or permeate, and at least some of the solids are retained on or in the permeable, hollow membranes or otherwise as suspended solids within the liquid suspension. The module has a shell or similar structure that at least partially surrounds the membrane module and substantially effects retaining at least portion of fluid flowed into the membrane module.

Owner:EVOQUA WATER TECH LLC

Method for separation of immunoglobulin monomers

InactiveUS20100190965A1Efficient collectionEasy to operateMembranesUltrafiltrationImmunoglobulin monomerIntravenous gammaglobulin

A method of accurately separating immunoglobulin monomers by subjecting an immunoglobulin solution containing at least immunoglobulin monomers and immunoglobulin aggregates to cross-flow filtration using an ultrafiltration membrane, an ultrafiltration membrane module, and a cross-flow filtration apparatus. The method can separate immunoglobulin monomers by subjecting an immunoglobulin solution containing at least immunoglobulin monomers and immunoglobulin aggregates and having an immunoglobulin concentration of 1 to 150 g / L to cross-flow filtration using an ultrafiltration membrane having a molecular weight cut-off of 100,000 or more and less than 500,000 so that immunoglobulin monomers passes through the ultrafiltration membrane with a permeability of 80% or more while achieving a fractionation performance in which the permeability ratio of immunoglobulin dimers to immunoglobulin monomers that pass through the ultrafiltration membrane is 0.20 or less.

Owner:ASAHI KASEI KK

Branched flow filtration and system

InactiveUS7410581B2Improve operationImprove performanceMembranesReverse osmosisCross-flow filtrationReverse osmosis

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

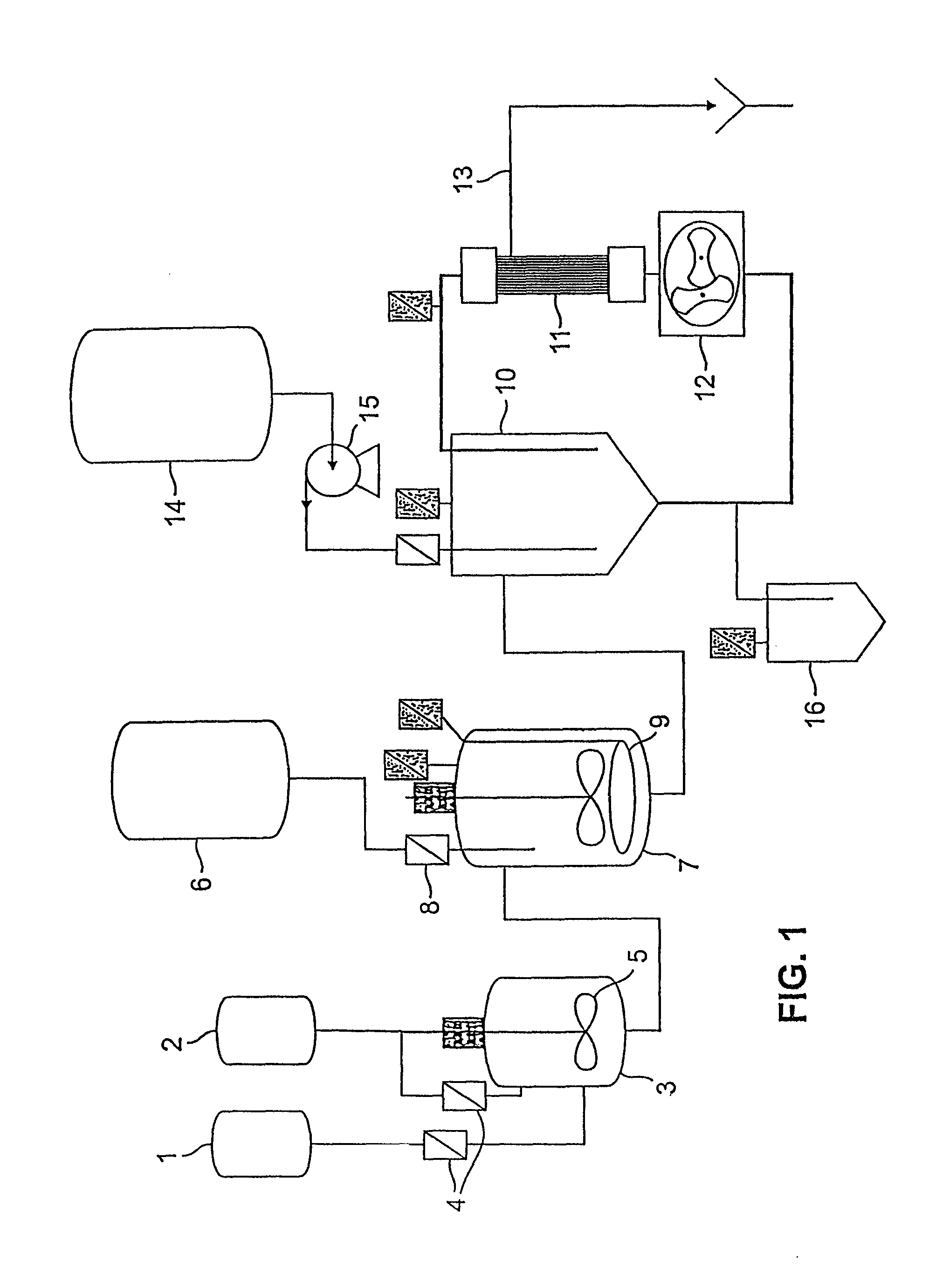

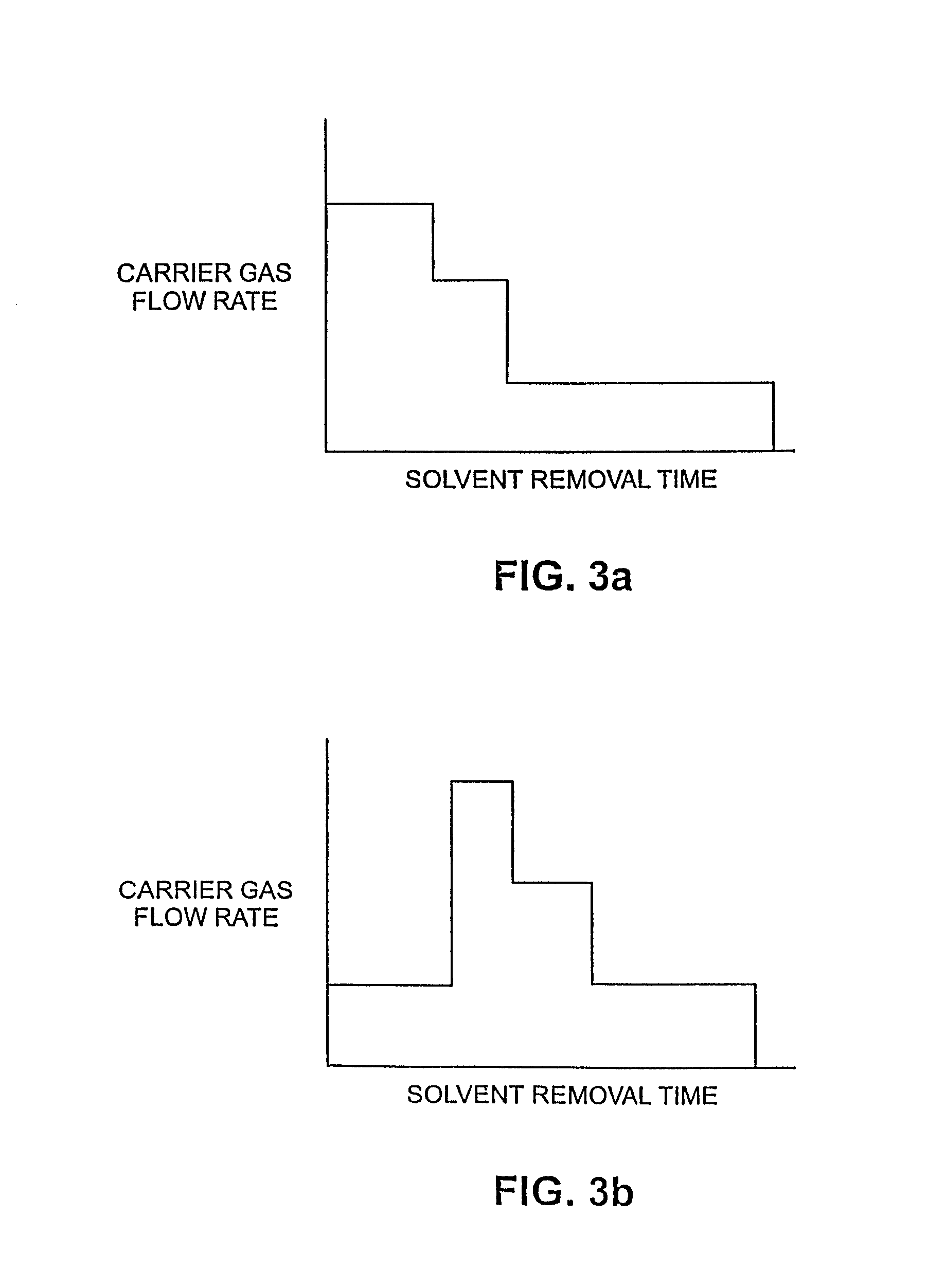

Production of multivesicular liposomes

InactiveUS20070235889A1Accurately and quickly scale up reactionAccurately and quickly up reactionOrganic active ingredientsPeptide/protein ingredientsEmulsionCross-flow filtration

Multivesicular liposomes are prepared at commercial scales by combining a first w / o emulsion with a second aqueous solution to form a w / o / w emulsion using a static mixer. Solvent is removed from the resulting emulsion to form multivesicular liposome-containing compositions. Further optional process steps include primary filtration and secondary cross-flow filtration. The products produced according to the processes of the invention can be produced through a series of aseptic steps.

Owner:PACIRA PHARMA INC

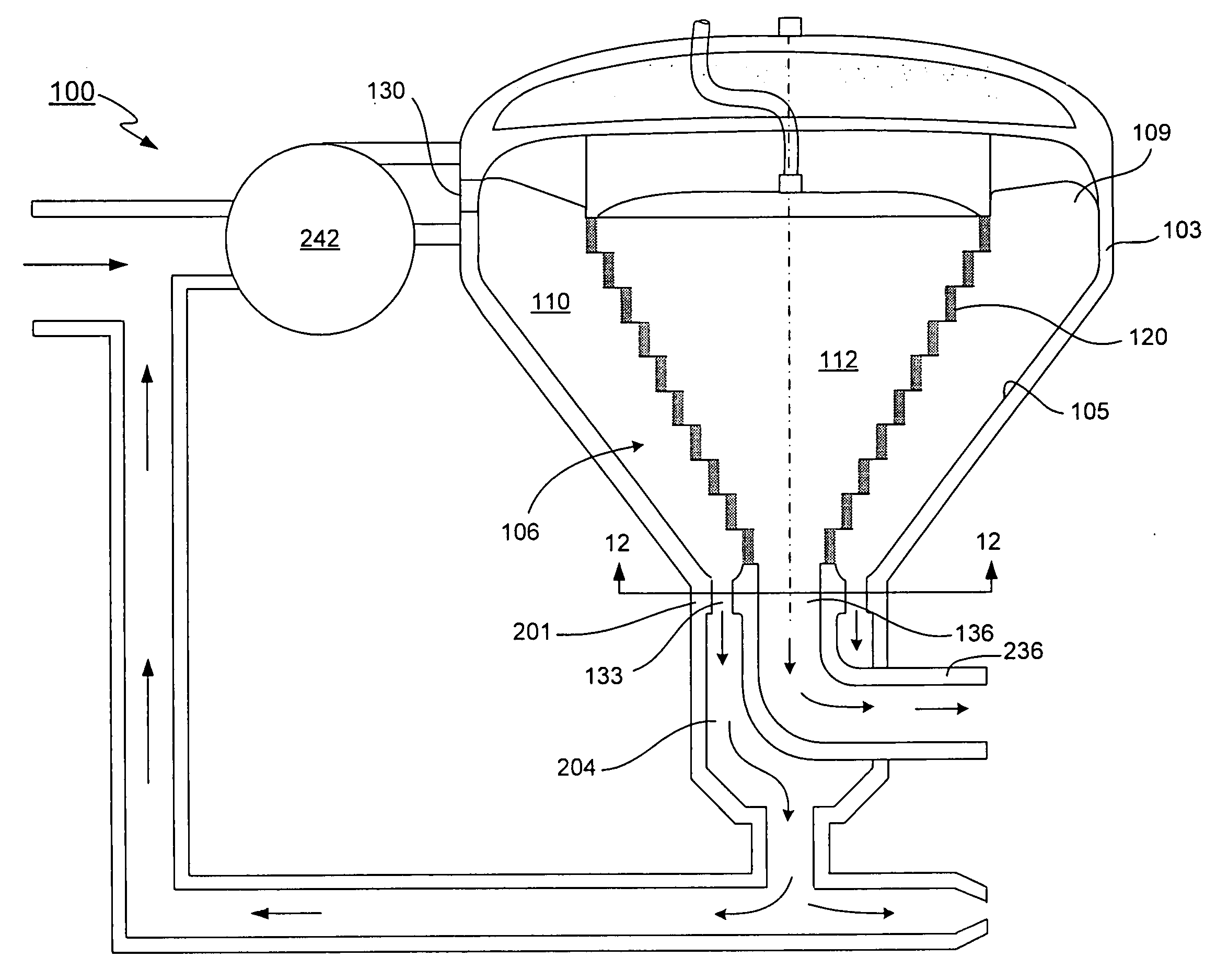

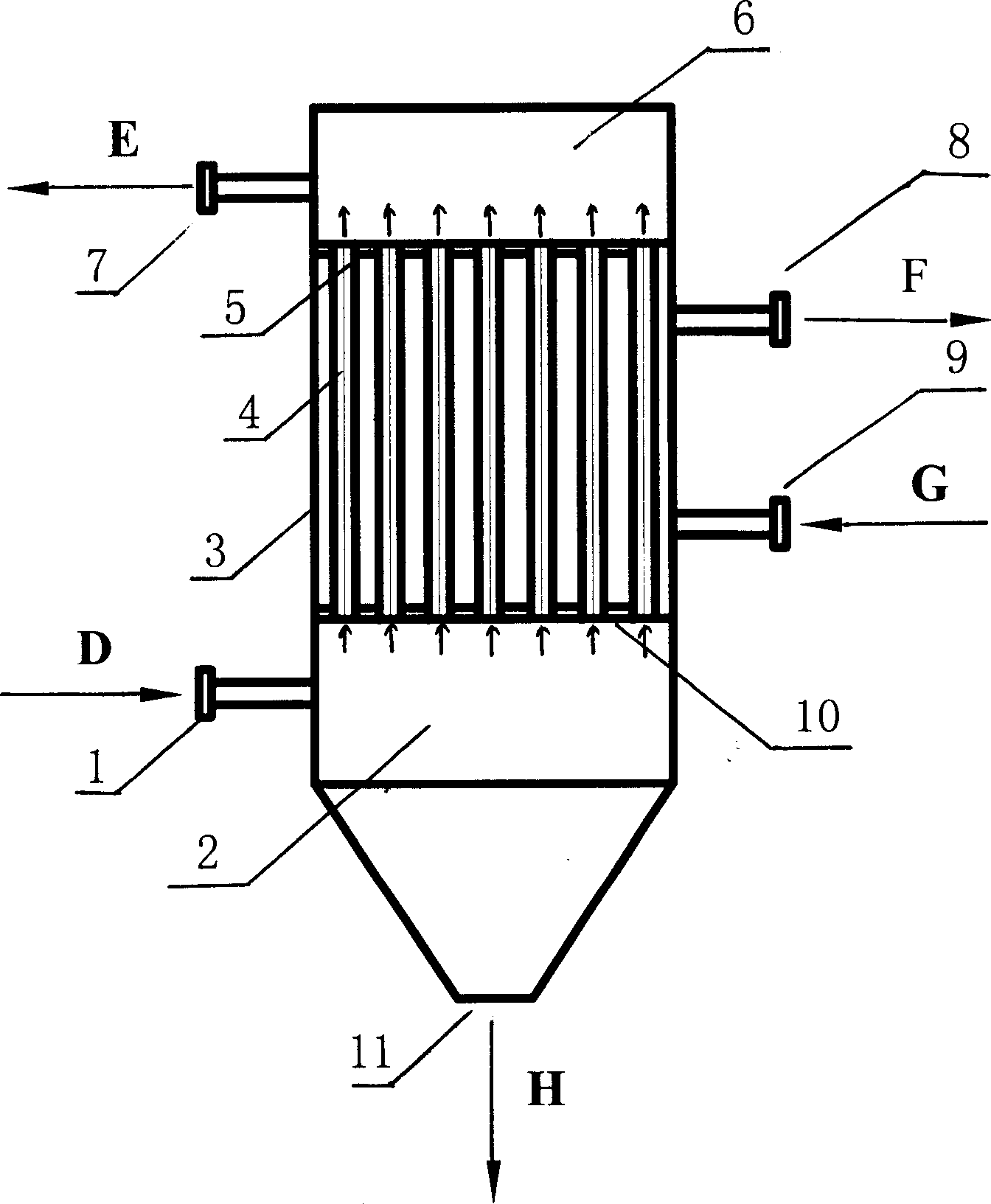

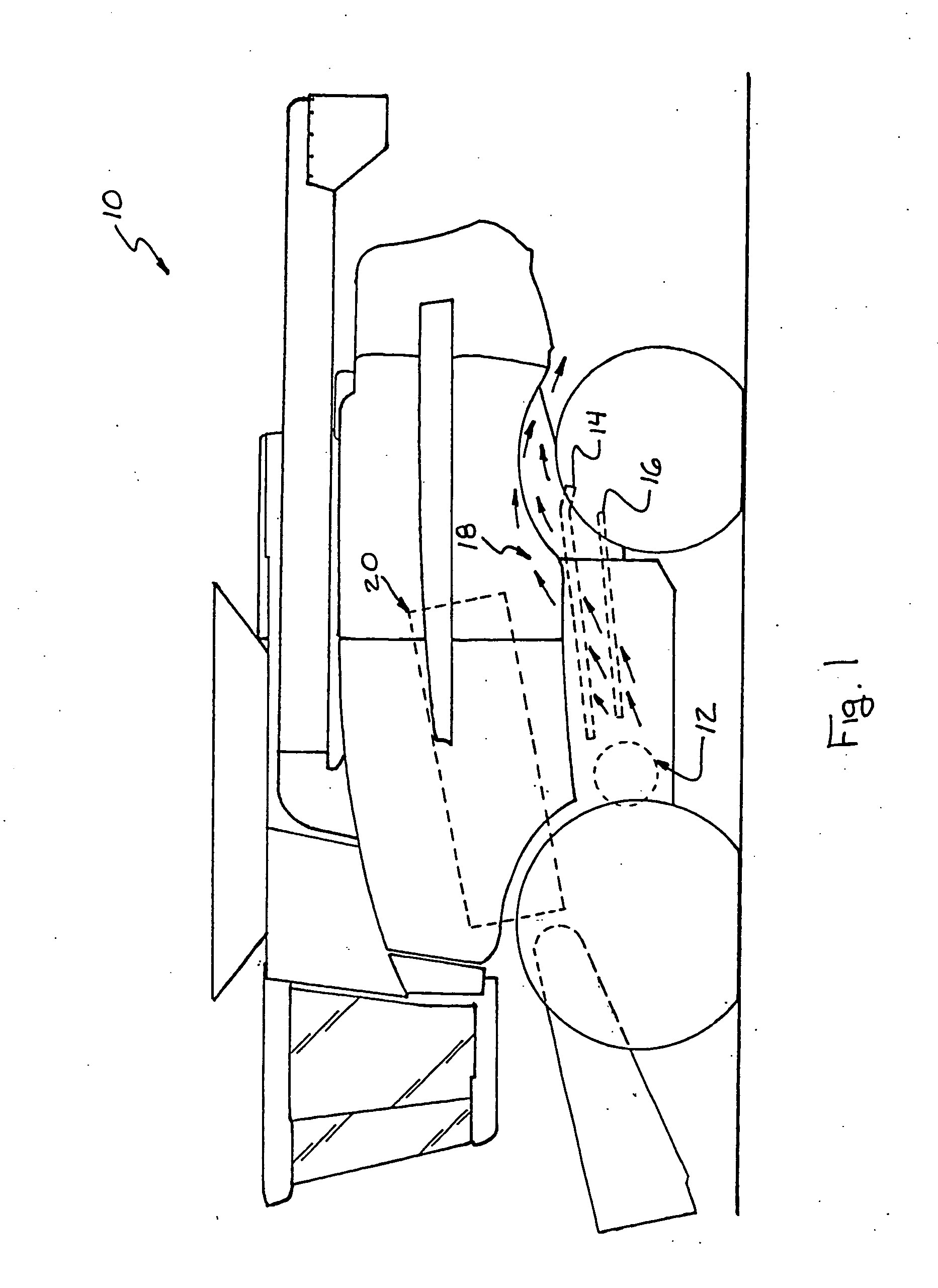

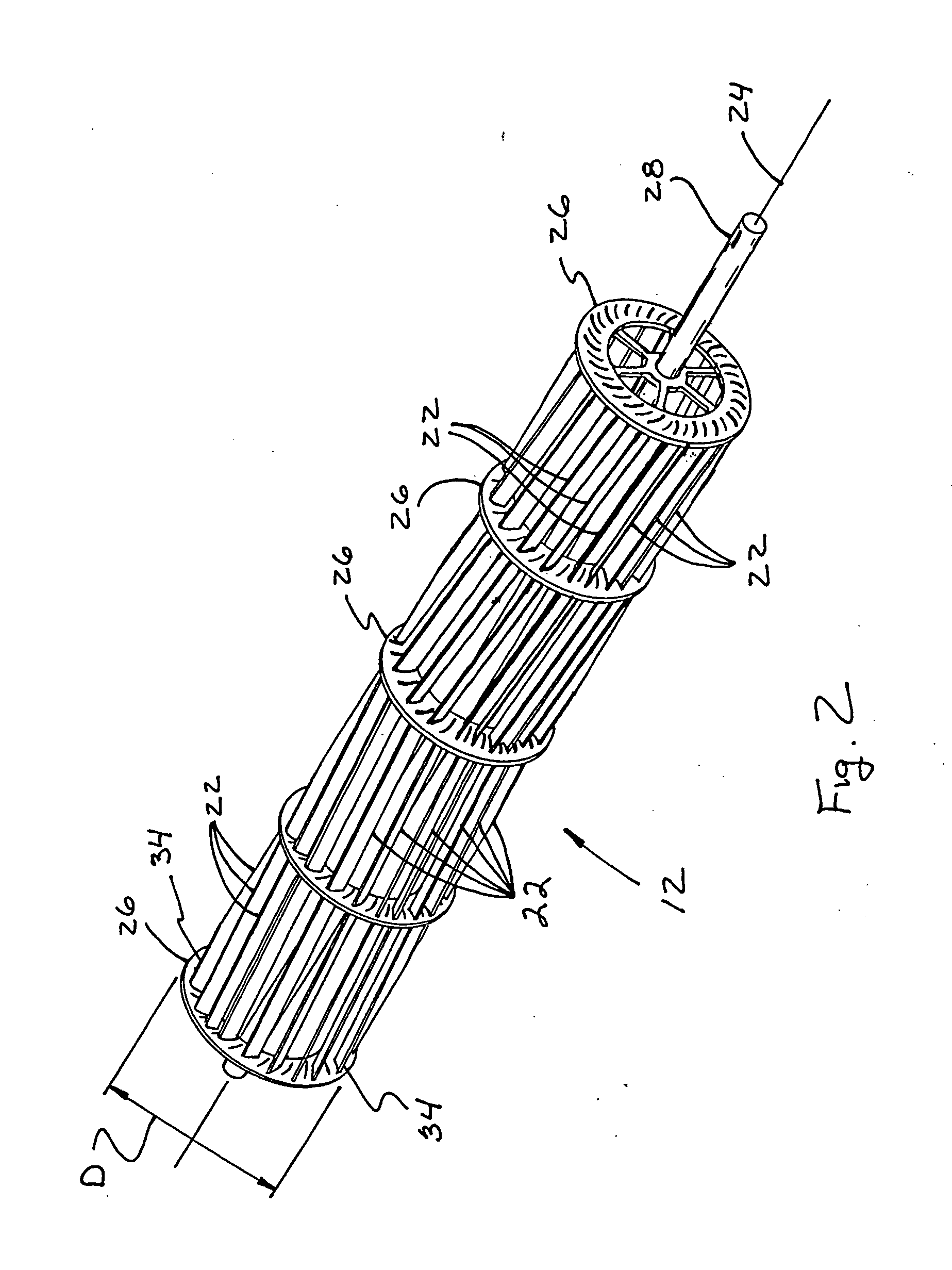

Hydroclone based fluid filtration system

ActiveUS20070039900A1Reduce morbiditySmall diameterLiquid separation auxillary apparatusReversed direction vortexCross-flow filtrationFluid filtration

A variety of improved hydroclone based fluid filtering systems are described. The hydroclones generally include a tank having an internal chamber and a filter (preferably a surface filter) that is positioned within the internal chamber. The filter defines a filtered fluid chamber within the internal chamber of the tank. The hydroclone may be operated such that a vortex of flowing fluid is formed between the chamber wall and the filter with the filter being located in the center of the vortex. With this arrangement, the filter acts as a cross-flow filter. In one aspect of the invention, the filter is a stepped filter. In another aspect of the invention, the filter is an surface filter, as for example, an electroformed metal surface filter. In some preferred embodiments, the openings in the filter are arranged as slots that extend substantially vertically so that they are oriented substantially perpendicular to the flow path of fluid flowing in the adjacent portion of the vortex. In another aspect of the invention, a circulating cleaning assembly is provided in the hydroclone region. The cleaning assembly is arranged to help clean the filter and is driven by the vortex of flowing fluid formed in the hydroclone region of the internal chamber. In yet another aspect of the invention, improved hydroclone intake structures are described. The described hydroclones may be used to filter water and other fluids in a wide variety of applications.

Owner:ACCELERATED FILTRATION INC

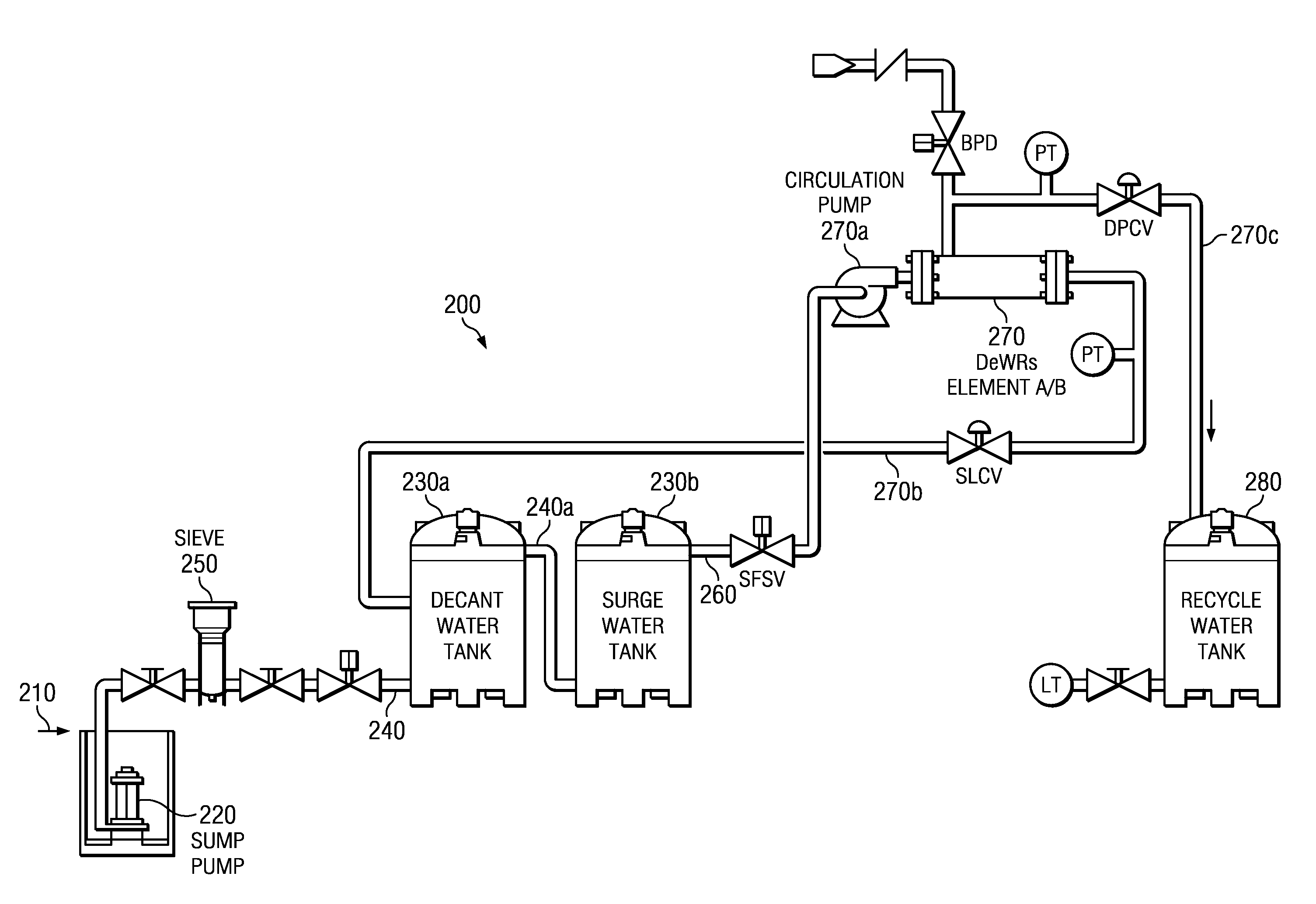

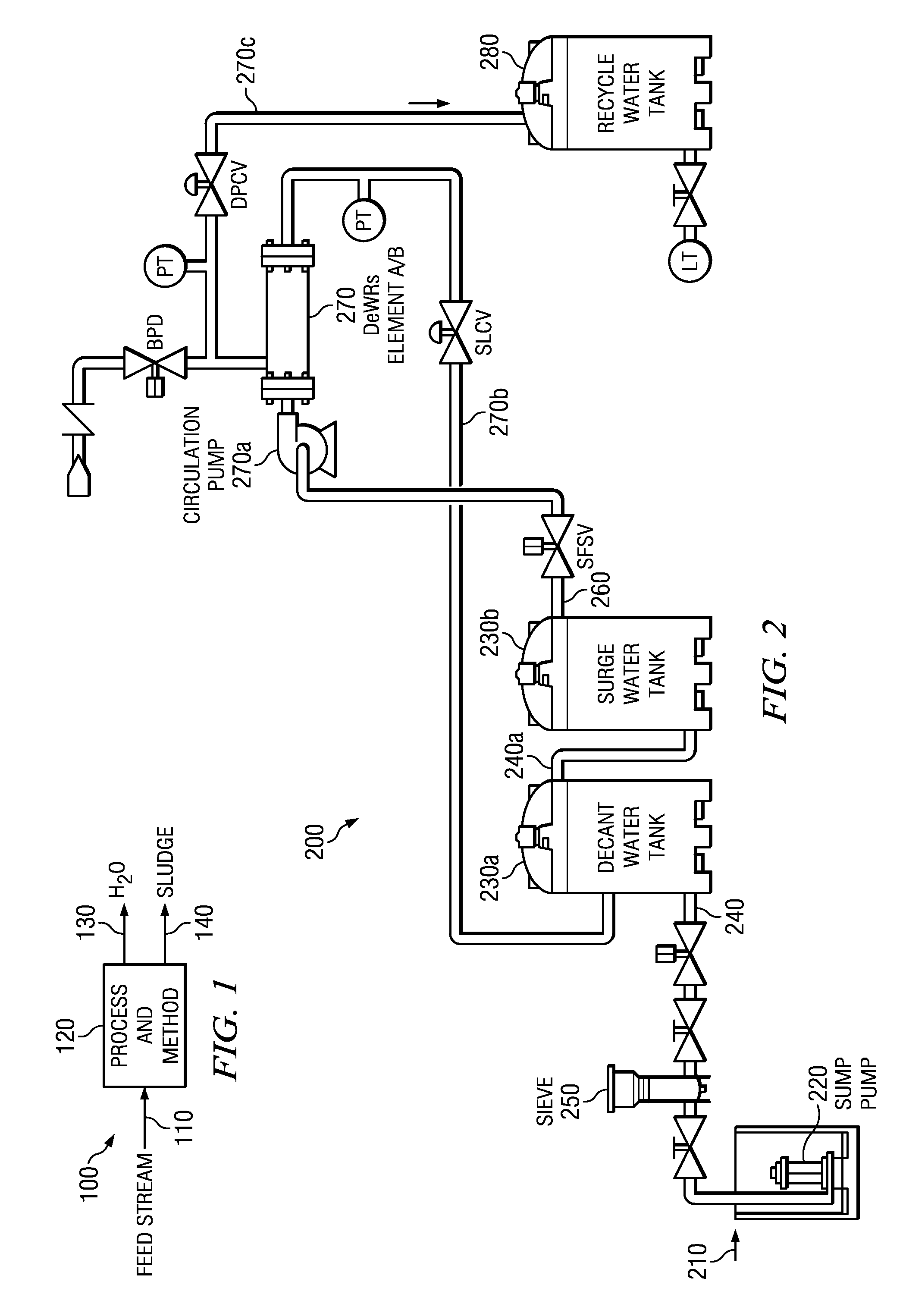

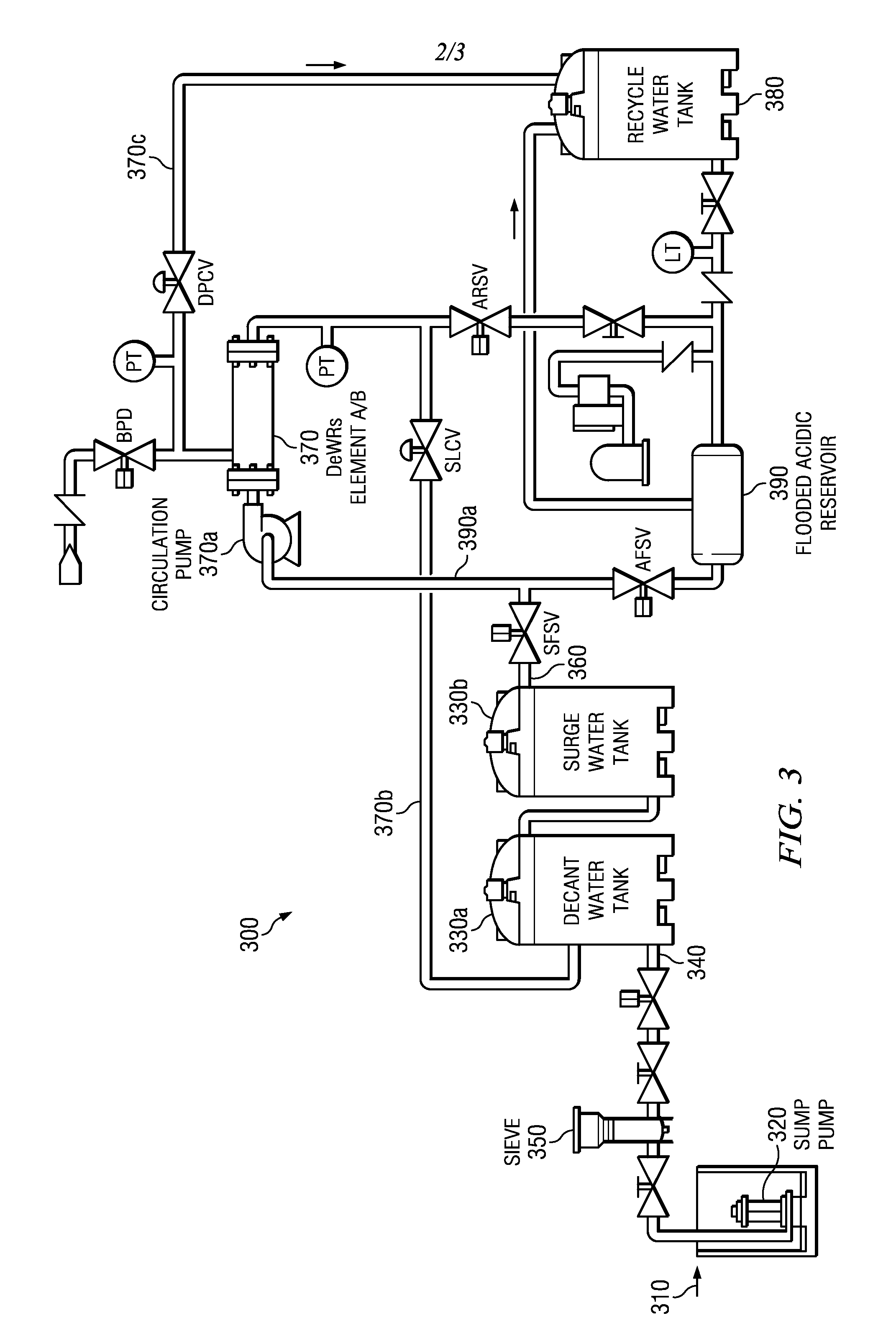

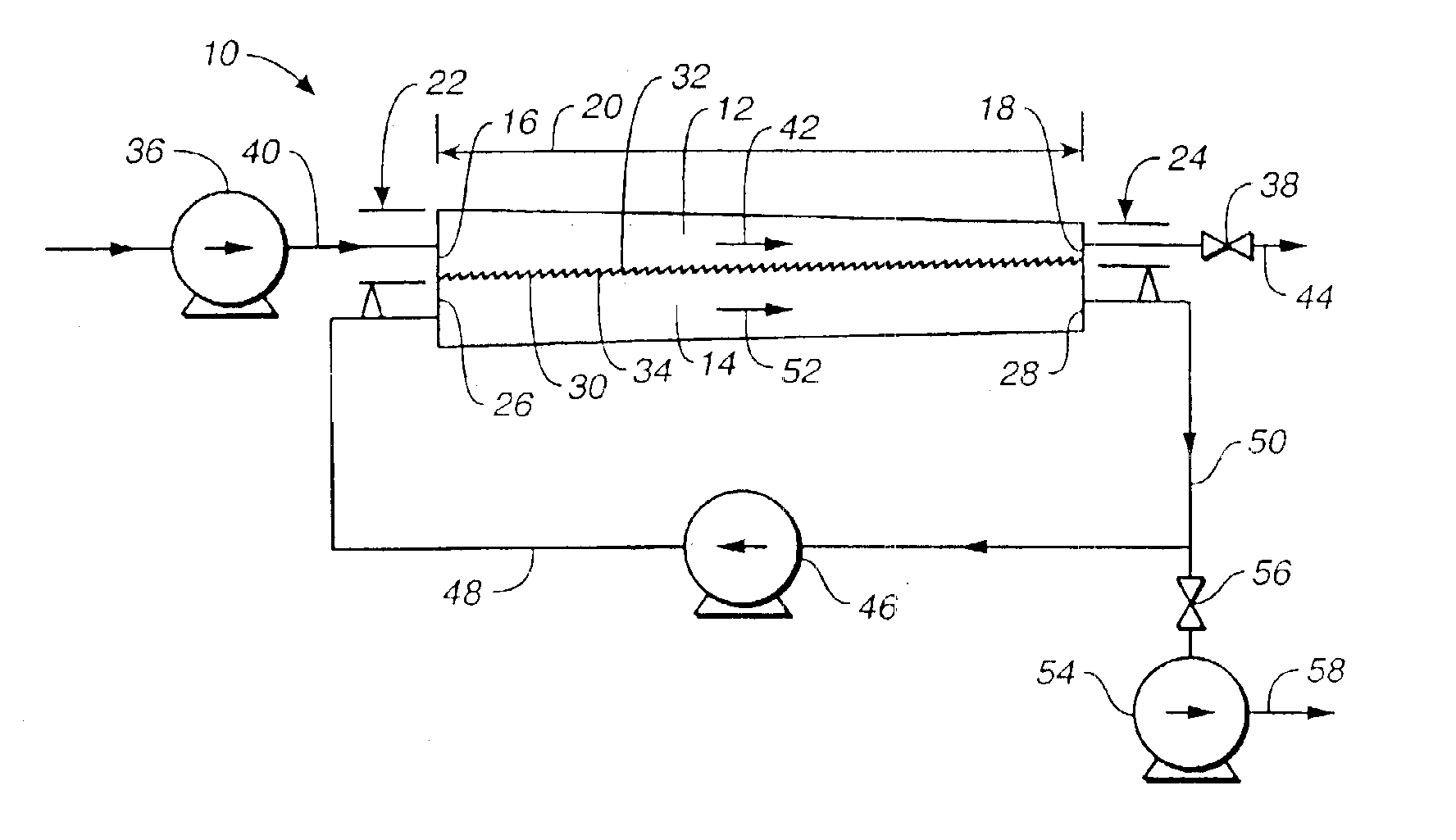

Integrated particulate filtration and dewatering system

The disclosed principles for providing a chemical-free filtering of particulate down below sub-micron levels, while concentrating the particulate into a sludge. The disclosed principles integrate cross-flow filtration (i.e., micro-filtration or ultra-filtration) with a settling tank (or “weir”) to provide sequential filtration and dewatering of an aqueous media. The disclosed technique operates chemical-free and is continuous. Applications for systems and processes in accordance with the disclosed technique are wide, and include aggregate fines removal, sediment removal, replacement for clarifiers, etc.

Owner:PURIFICS ENVIRONMENTAL TECH

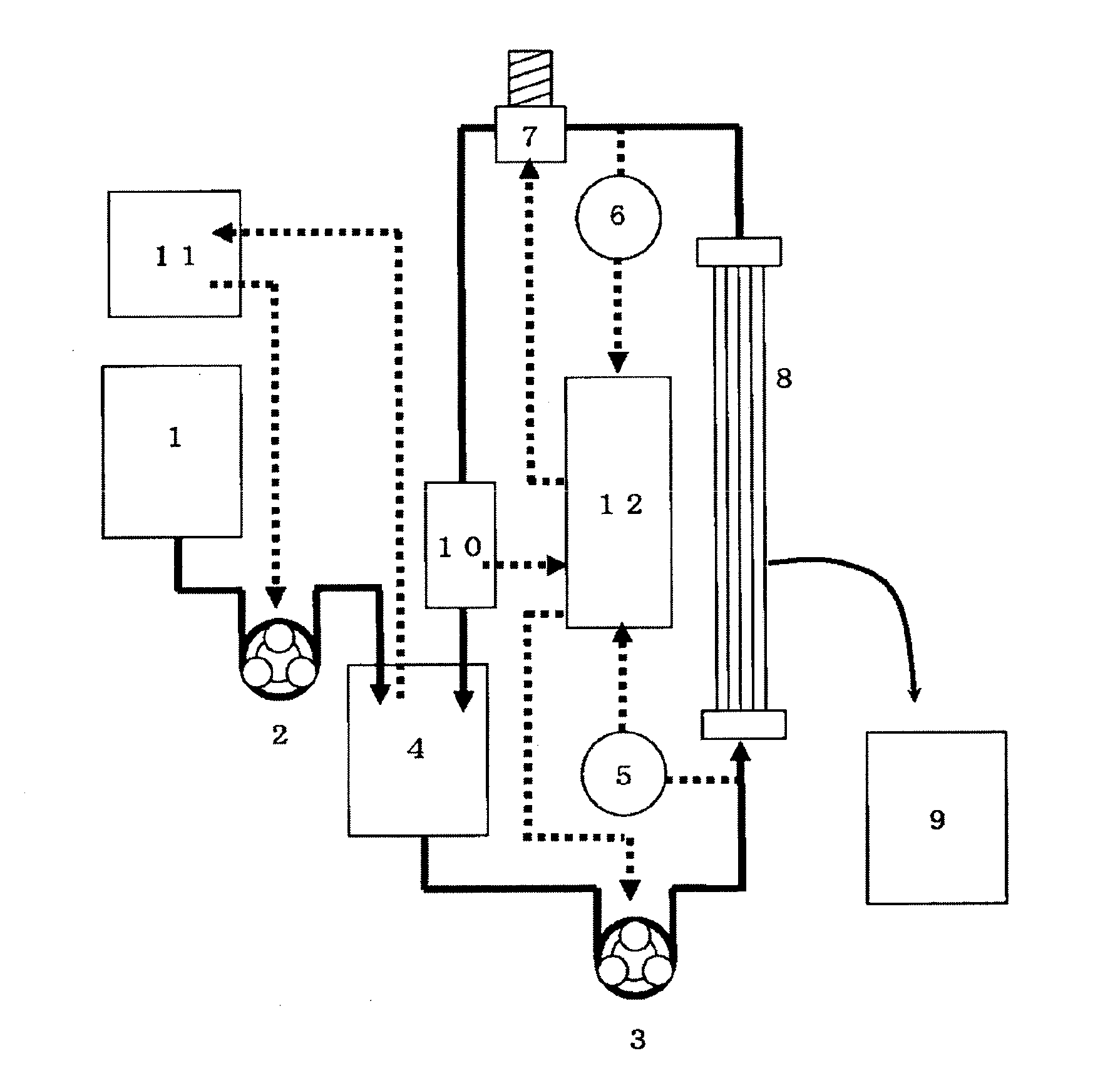

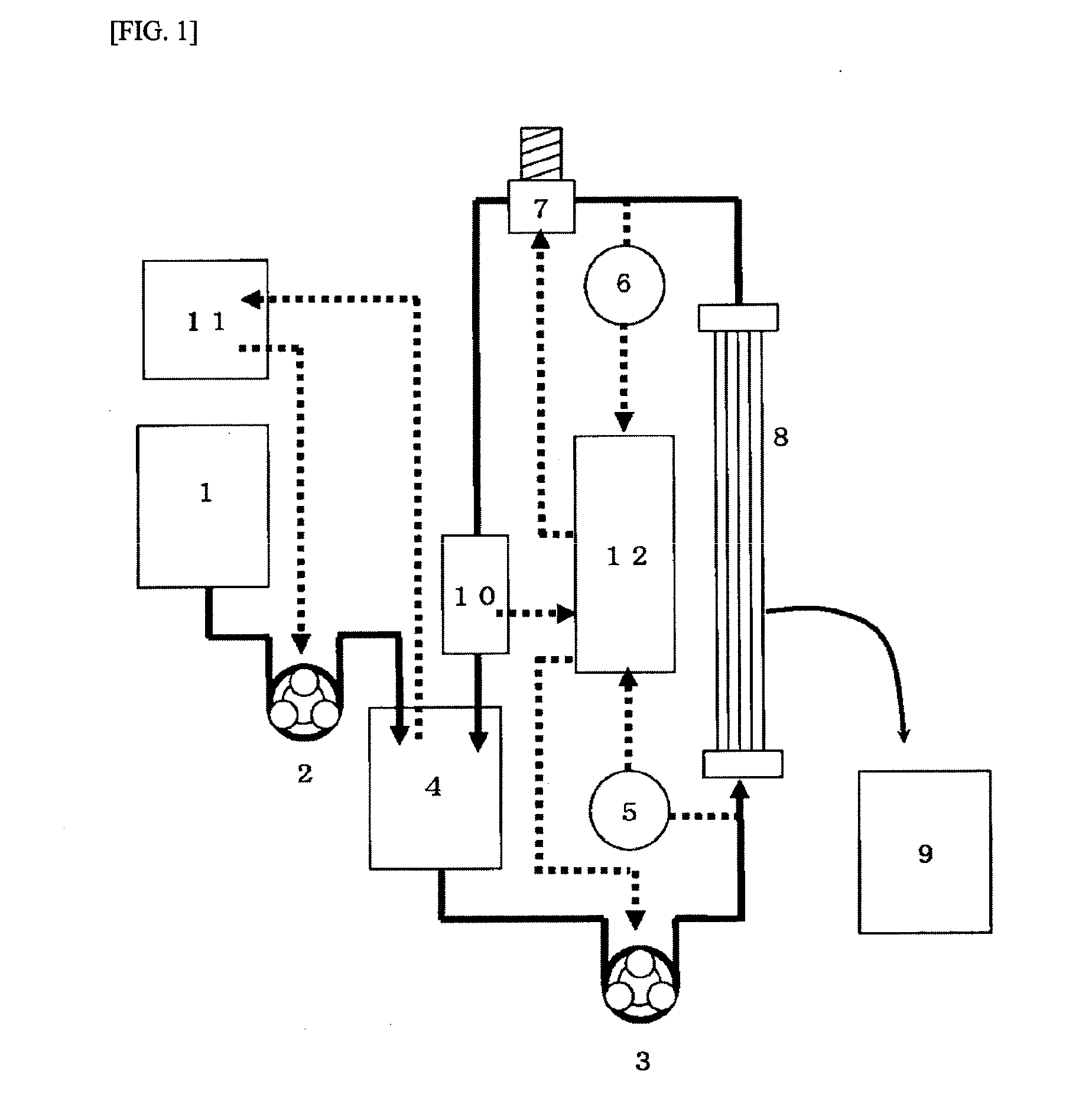

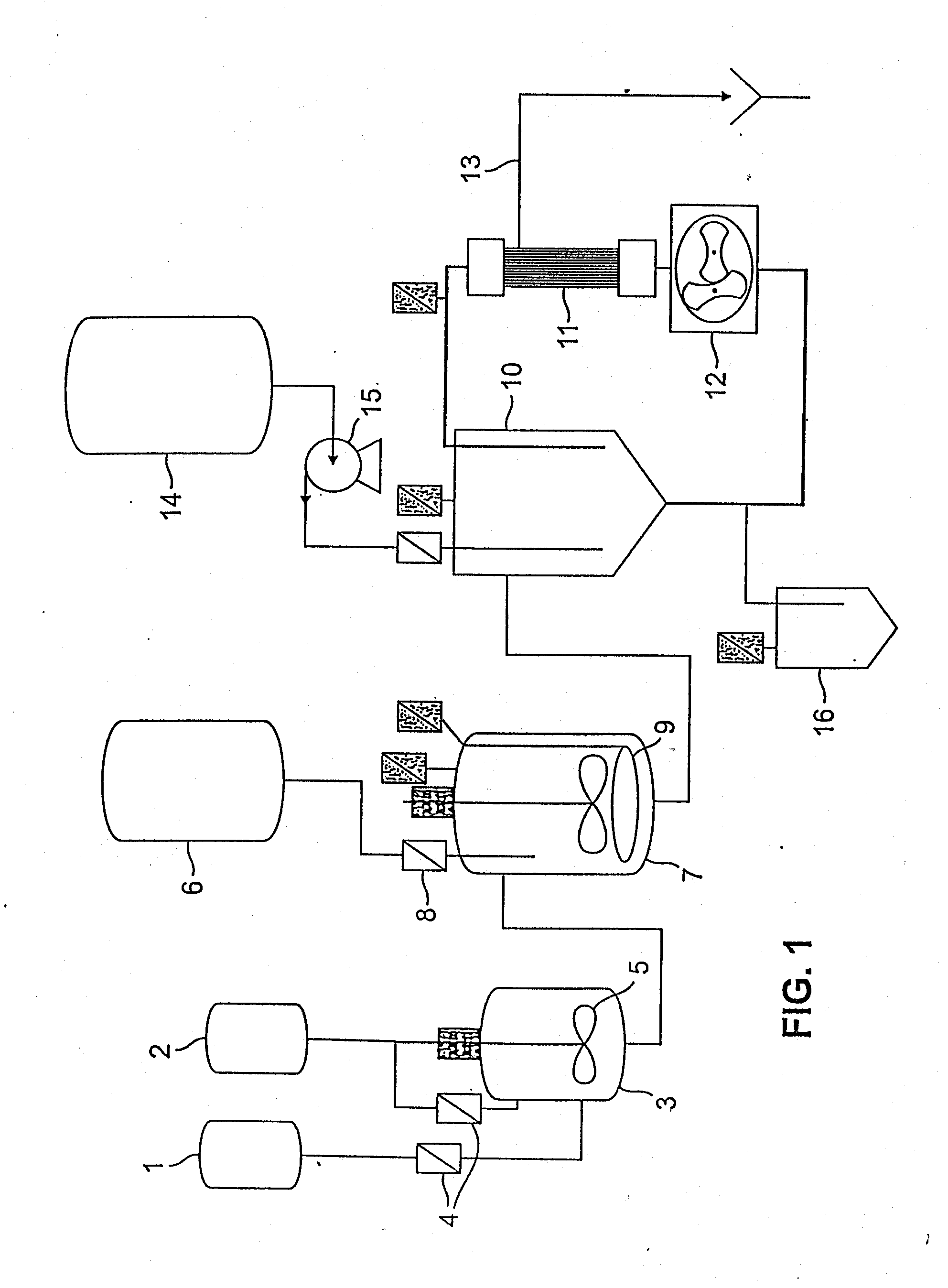

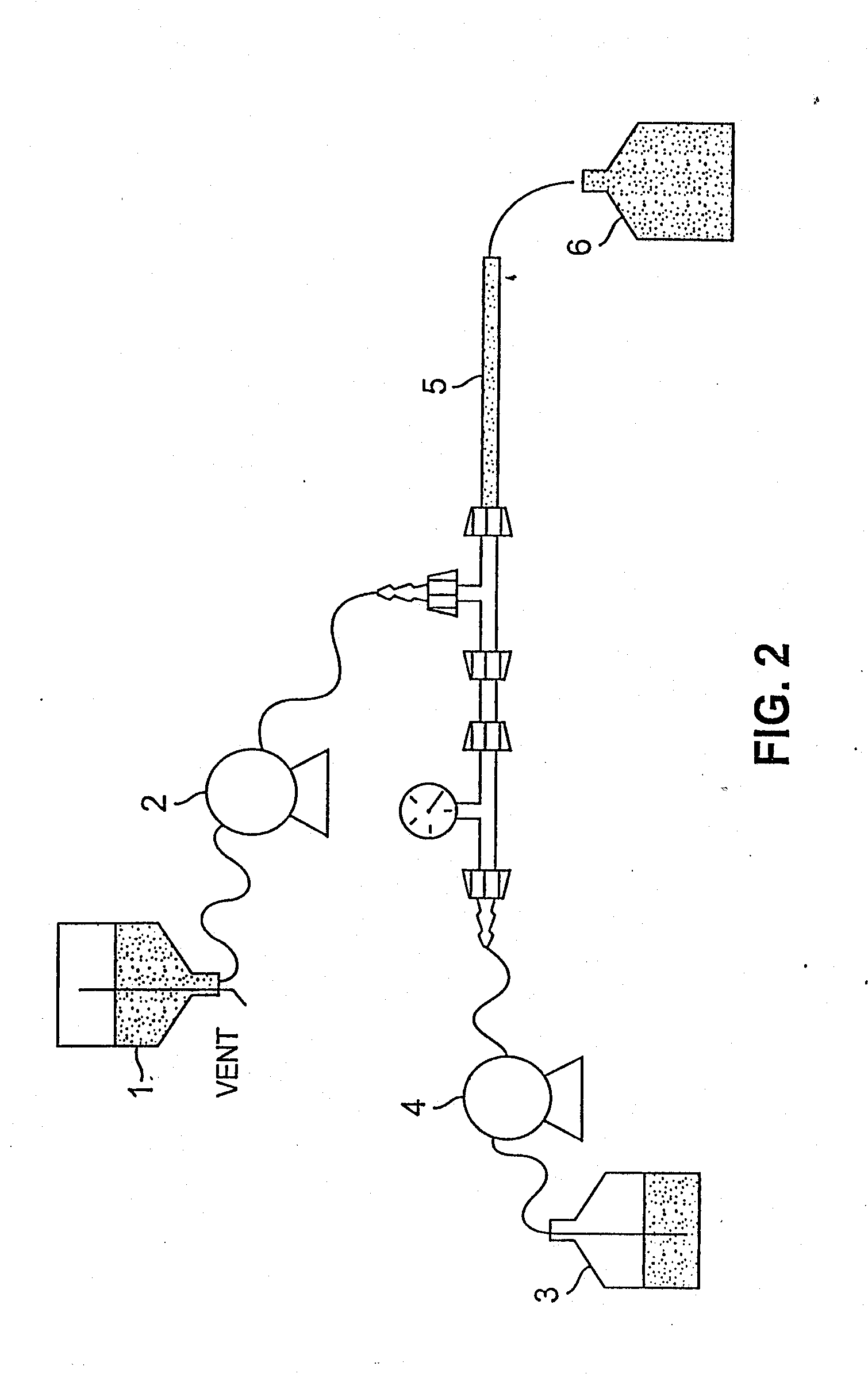

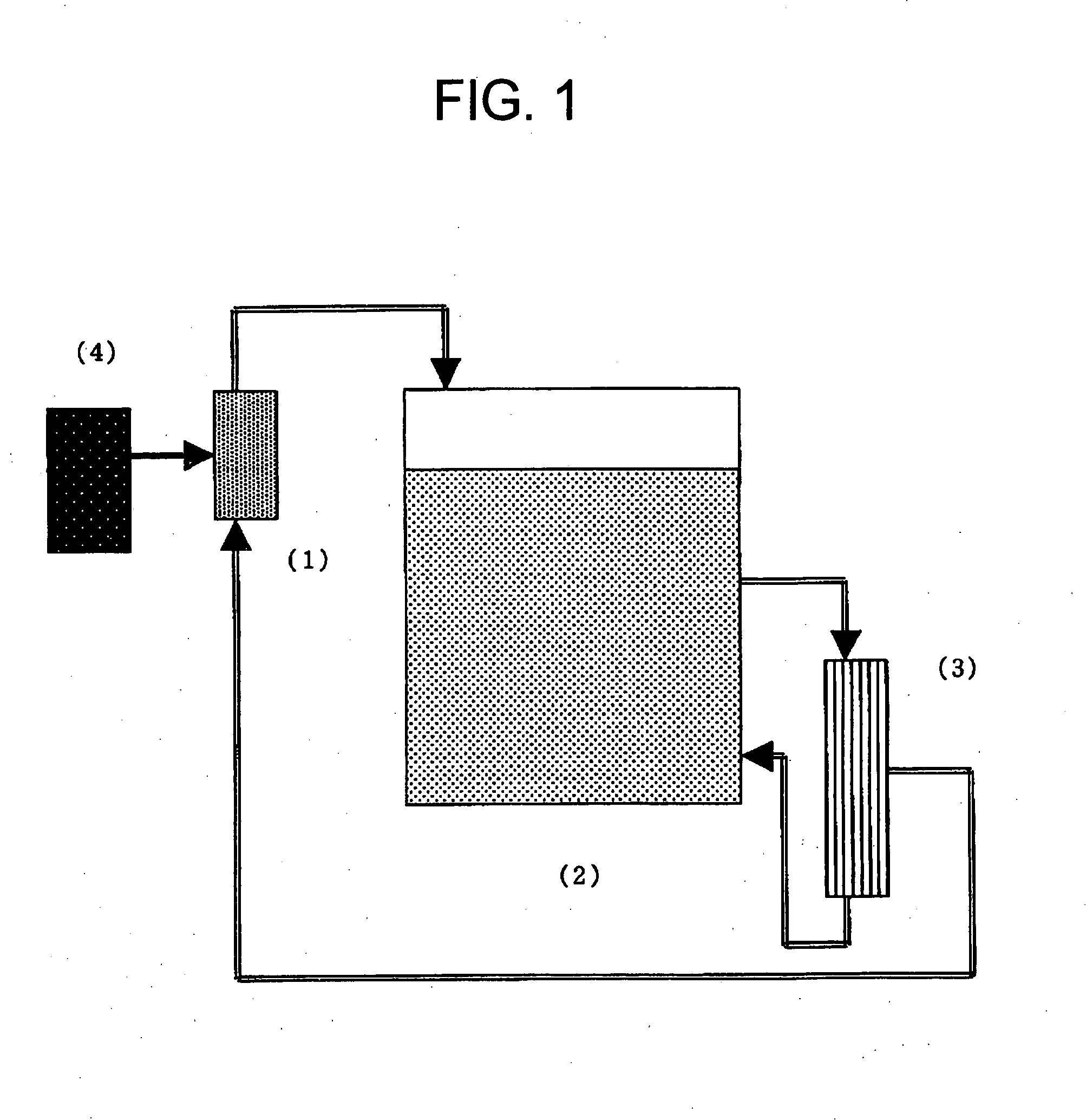

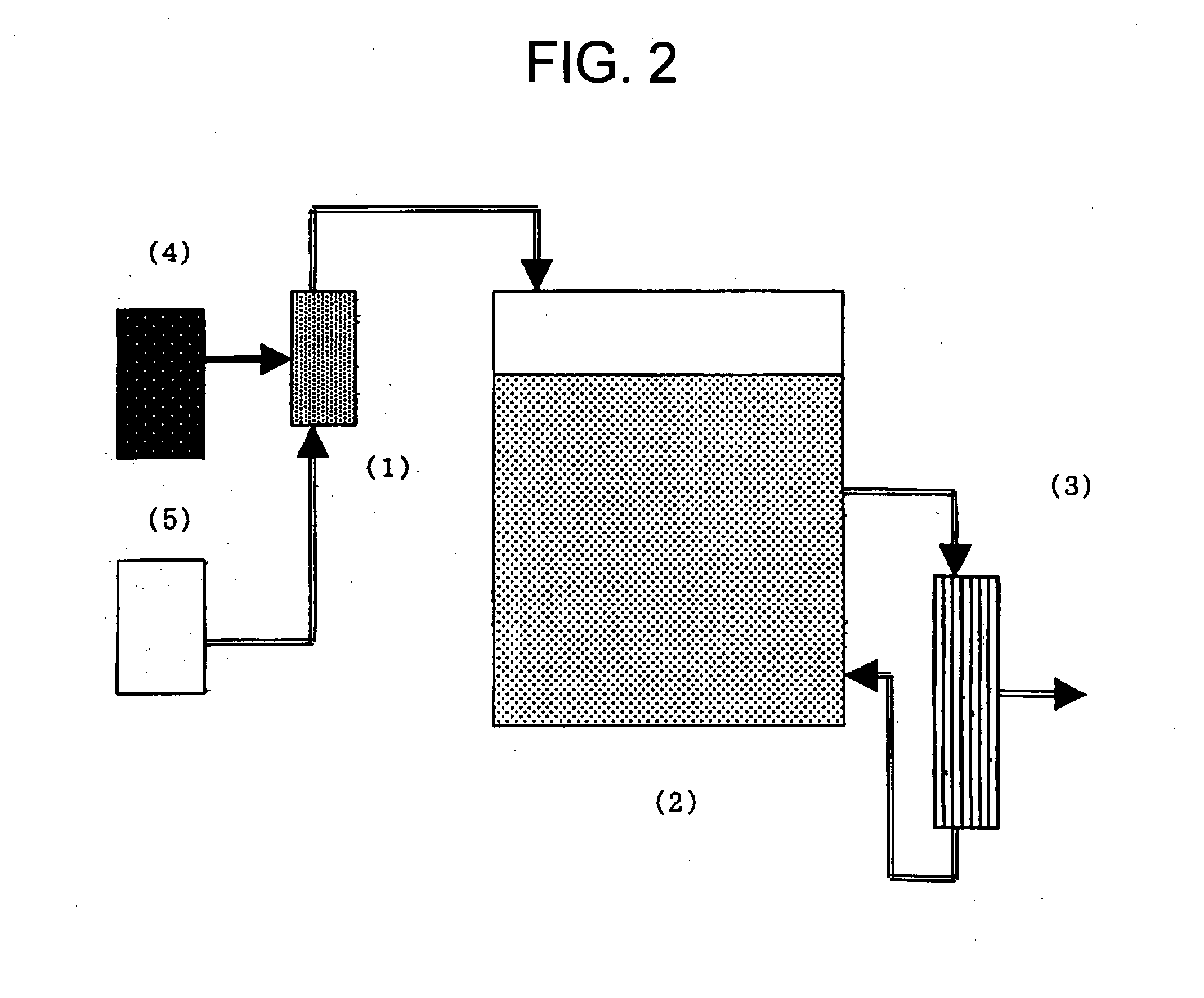

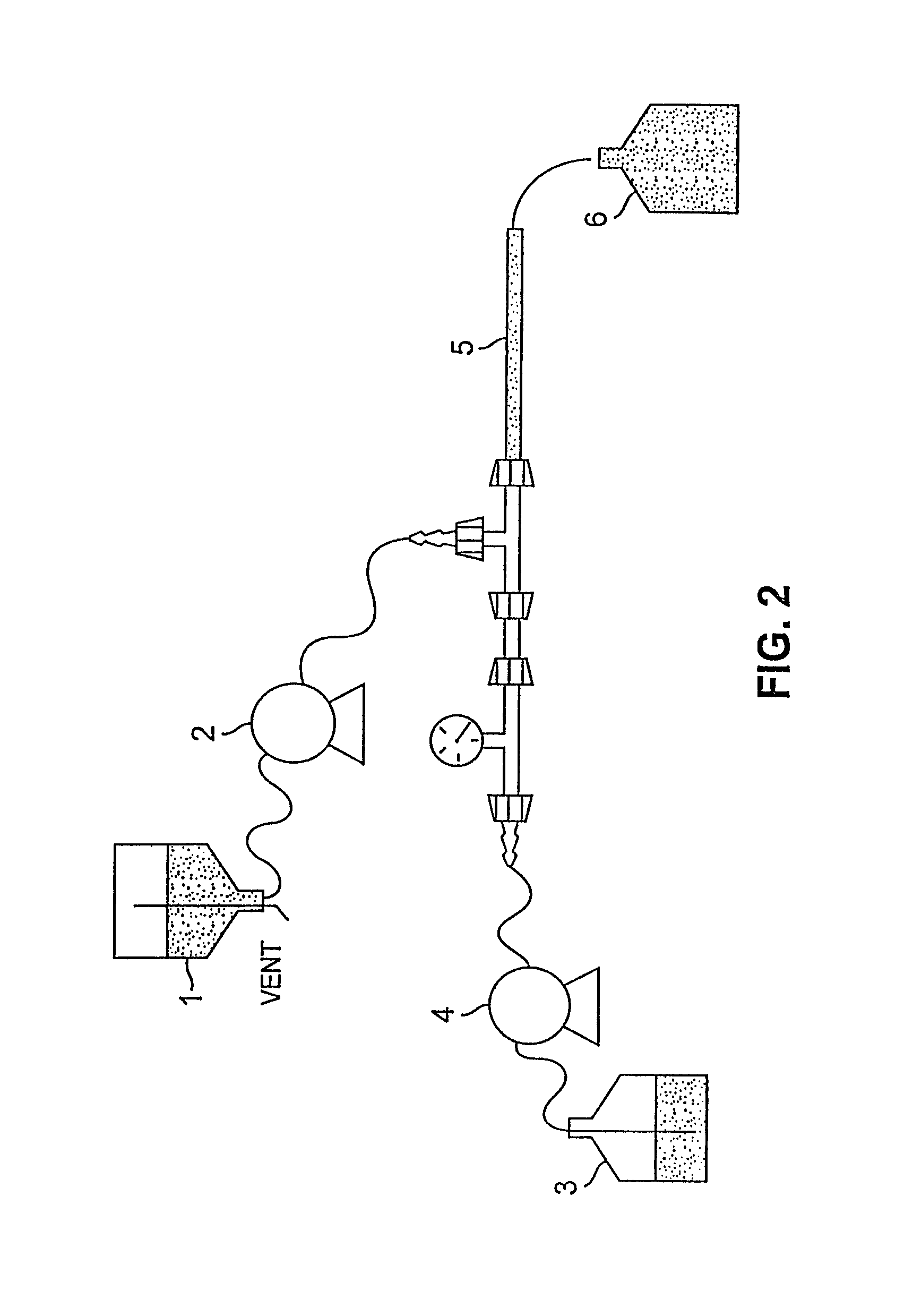

Method for preparation of microsphere and apparatus therefor

InactiveUS20070182040A1Avoid pollutionQuality improvementPowder deliveryGranular deliveryOrganic solventEmulsion

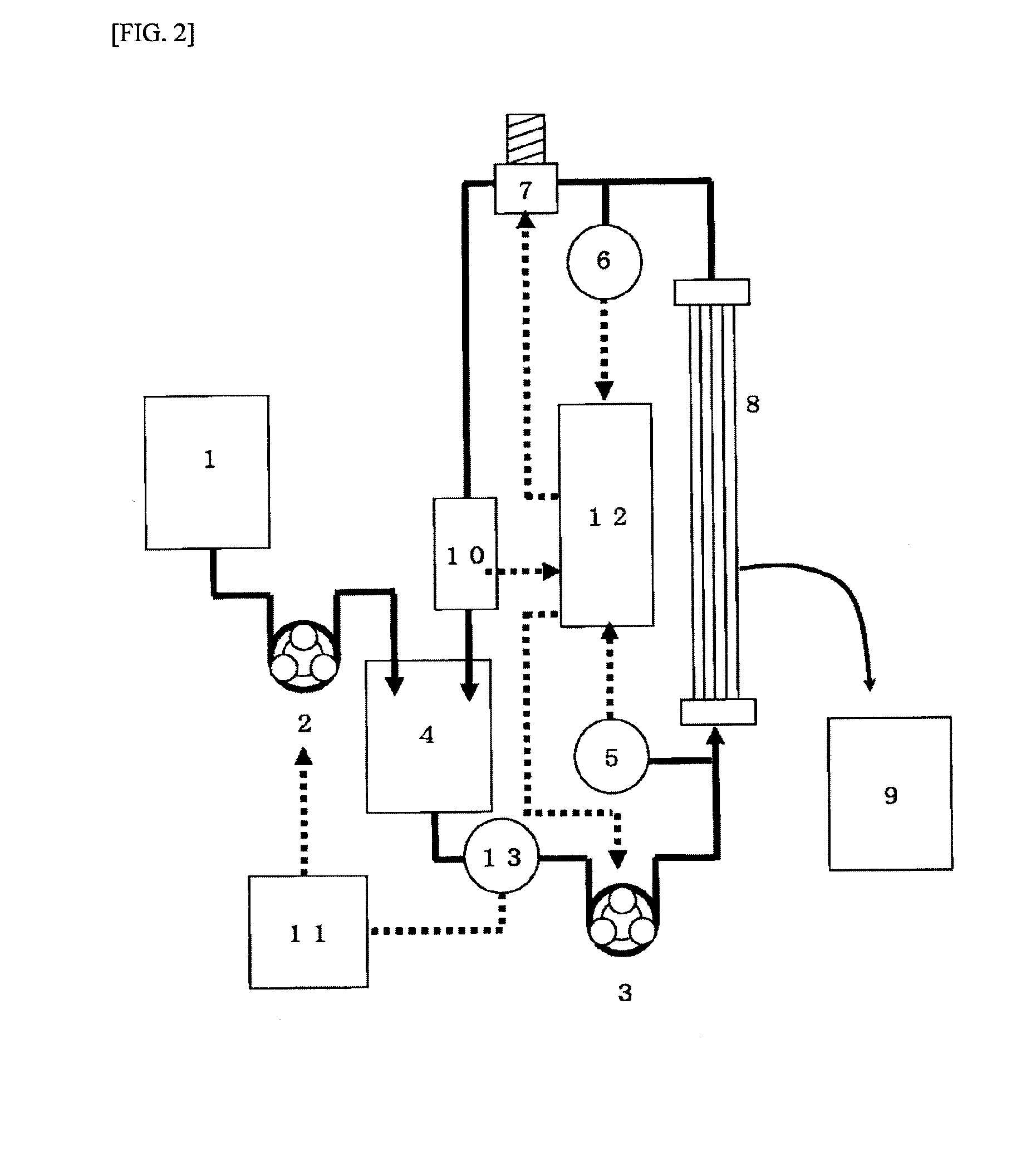

In the method for preparation of microspheres by in-water drying method, an iterative process is employed, which comprises emulsifying a medicament-containing polymer solution (4) containing an organic solvent in an emulsifying device (1) to form an emulsion; transferring this emulsion into a microsphere storage tank (2); introducing a part of said emulsion to a cross flow filter (3) from the microsphere storage tank; and returning a liquid passing over the cross flow filter to the microsphere storage tank (2). Since a small amount of microsphere is repeatedly produced, this process permits the downsizing and airtight closing of an apparatus therefor, and further makes it possible to freely control the production scale of microsphere.

Owner:MITSUBISHI TANABE PHARMA CORP

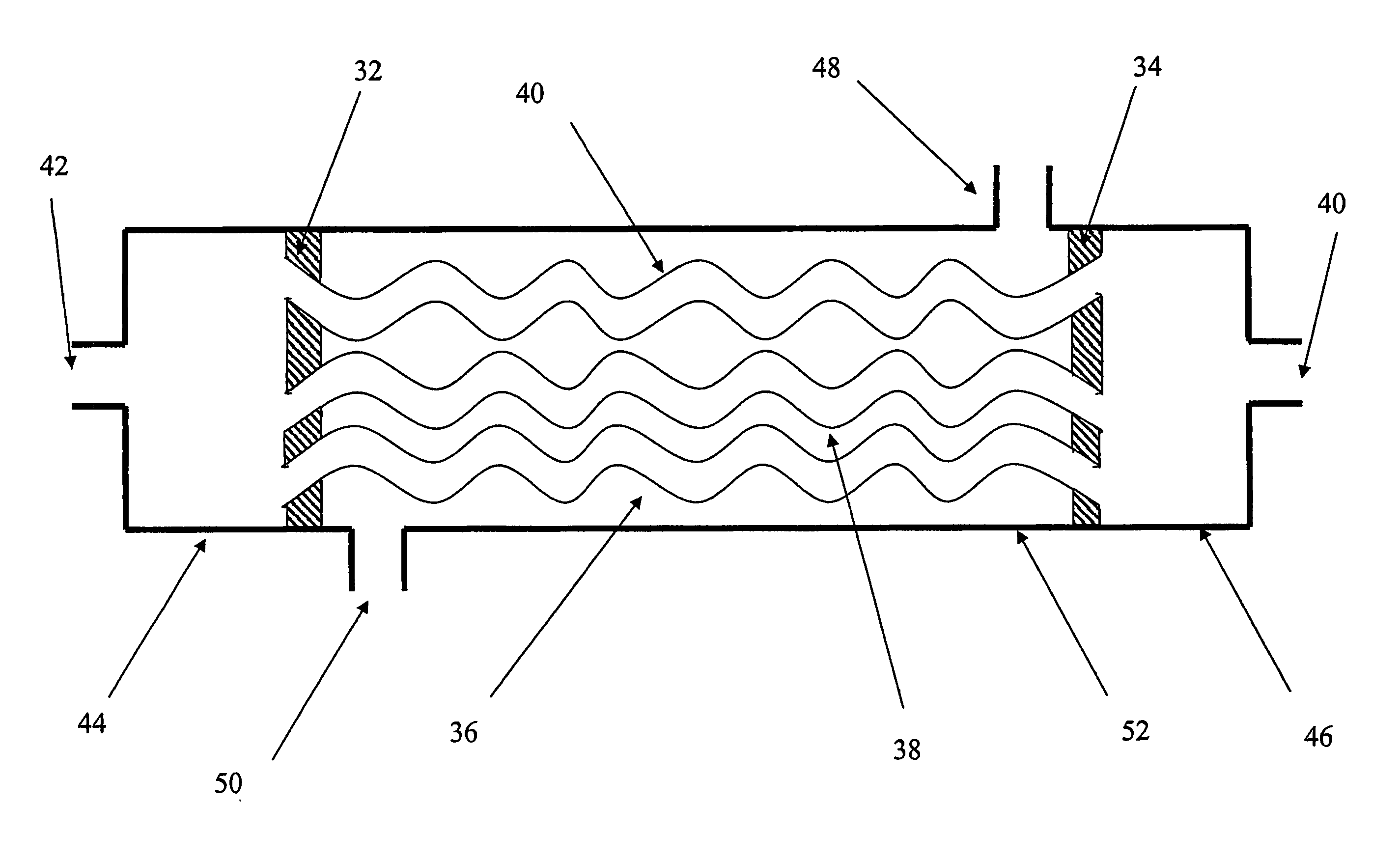

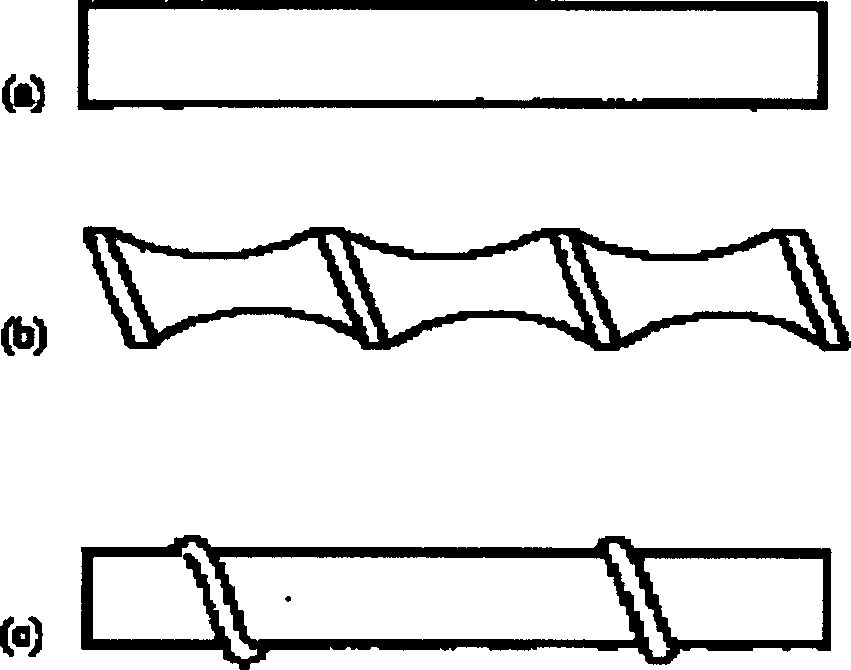

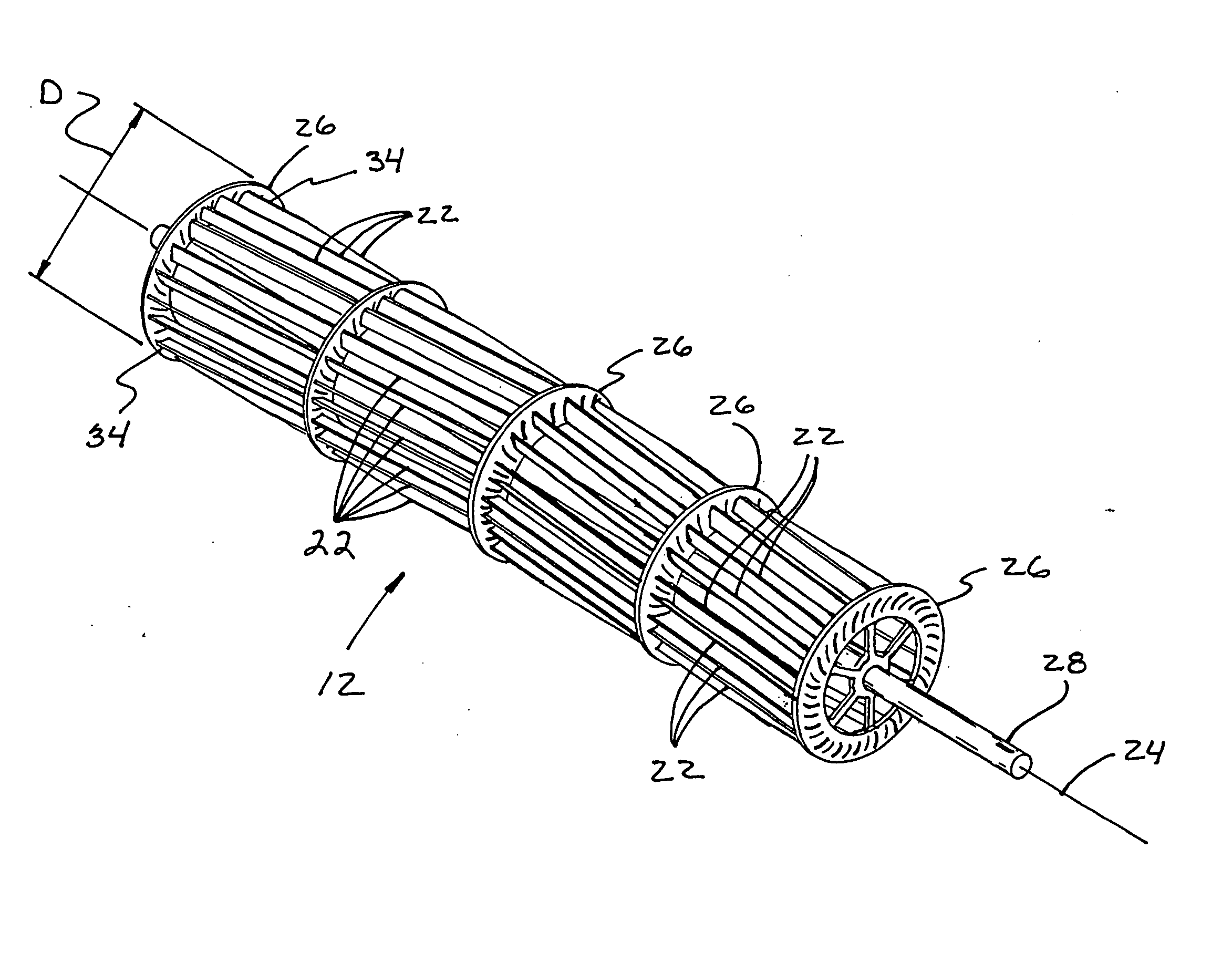

Exchange apparatus

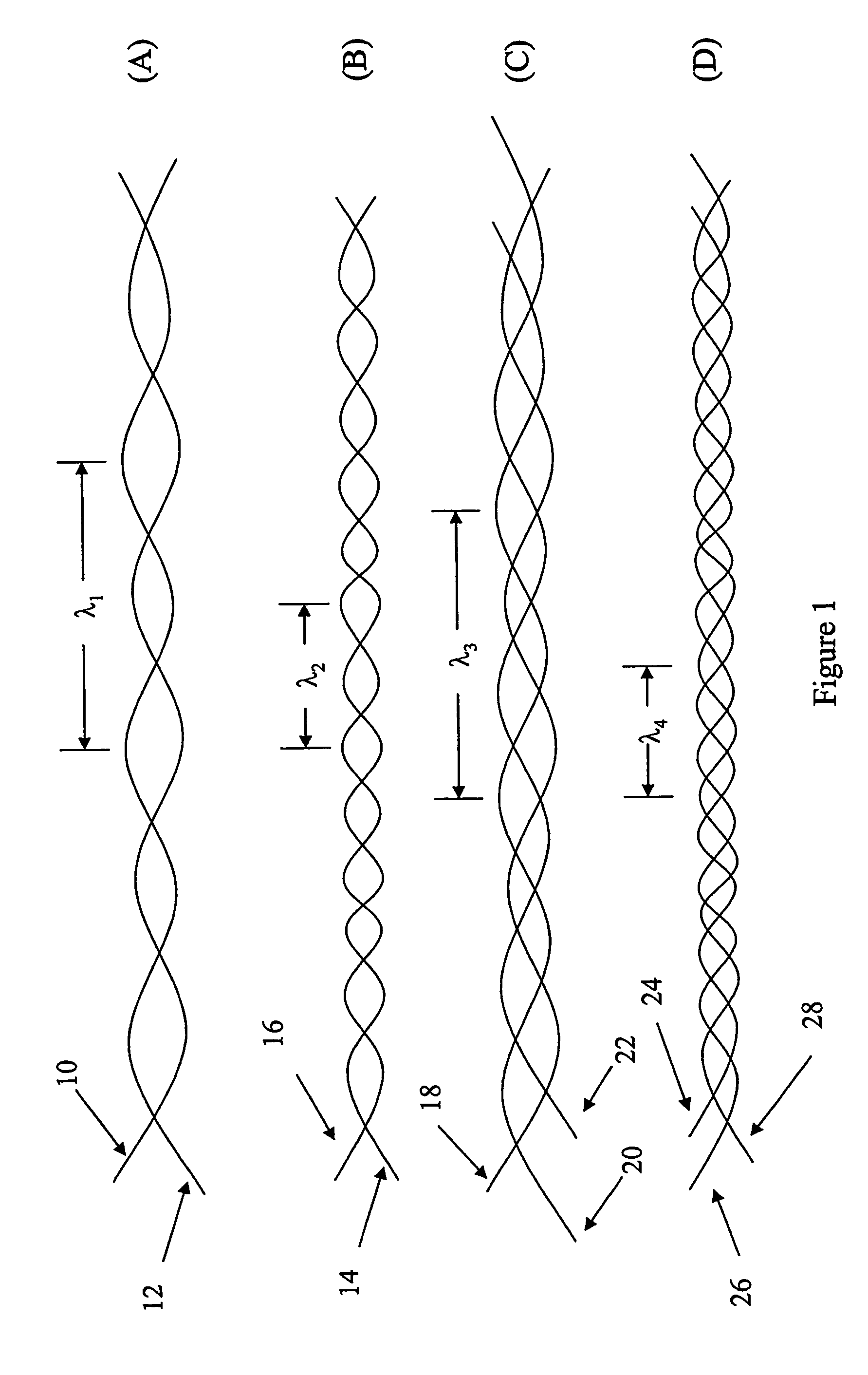

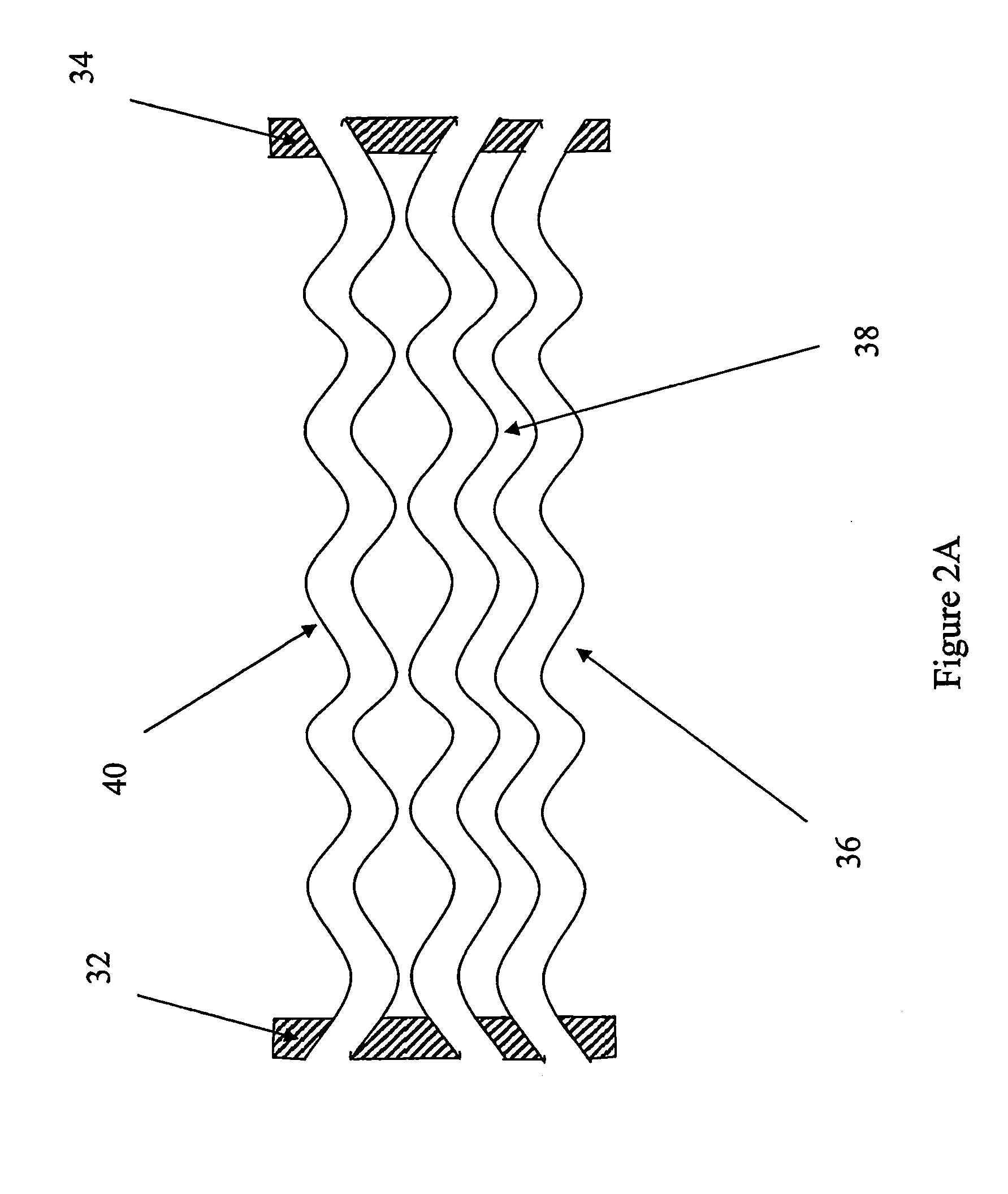

ActiveUS7308932B2Improve traffic distributionHigh bulk densityMembranesUltrafiltrationCross-flow filtrationEngineering

An exchange apparatus comprised of hollow thermoplastic tubes infusion bonded into a thermoplastic material is disclosed. In a preferred embodiment the hollow tubes are shaped by plaiting the tubes into cords and then thermally annealing the cords to set the crests and bends of the plait. The cords provide improved flow distribution of fluid about the hollow tube tubes in the exchange apparatus. The exchange apparatus is chemically inert and is useful for cross flow filtration, as well as heat and mass transfer in harsh chemical environments.

Owner:ENTEGRIS INC

Method and system for filtering sediment-bearing fluids

InactiveUS20050199551A1Reduce maintenance costsMembranesSemi-permeable membranesFilter systemCross-flow filtration

A self-cleaning, back-washable filter apparatus and method for use with a pumping apparatus which is at least partially immersed in fluid. A sediment removal system is disclosed for removing sediment from around a filter apparatus. The sediment removal system comprises a plurality of venturi jets configured to force sediment particles through a discharge line and away from the inlet to a filter apparatus. A filtering system is configured to direct a flow of fluid generally parallel to the surface of the filter, which may be a cross-flow filter, to prevent clogging or fouling. A method for filtering a flow of fluid comprises directing a flow of fluid generally parallel to the surface of a filter to prevent clogging or fouling of the filter. A method for filtering a flow of fluid is also disclosed, comprising vibrating a filter by applying a flow of fluid to the filter.

Owner:GORDON CONSTR INC

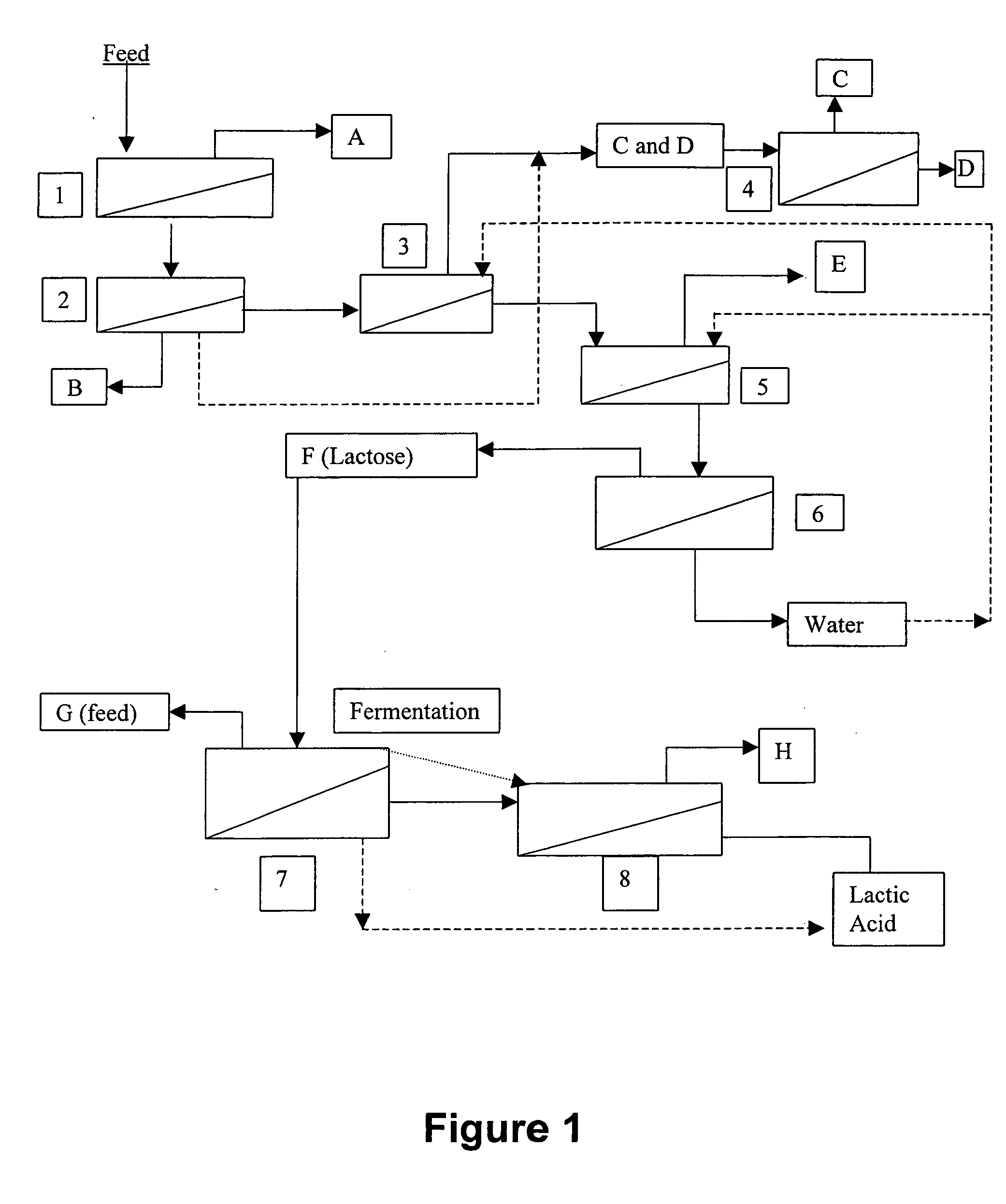

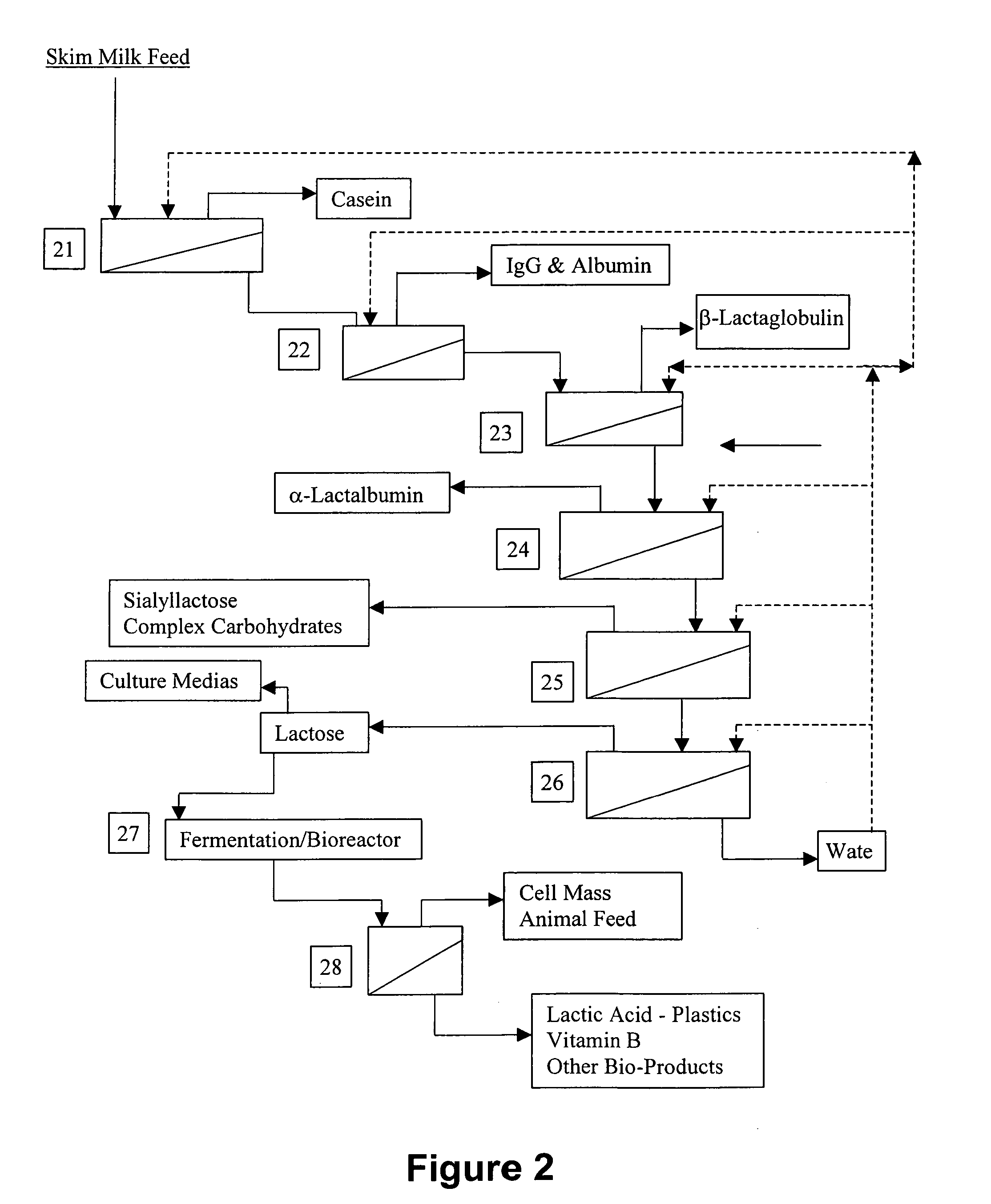

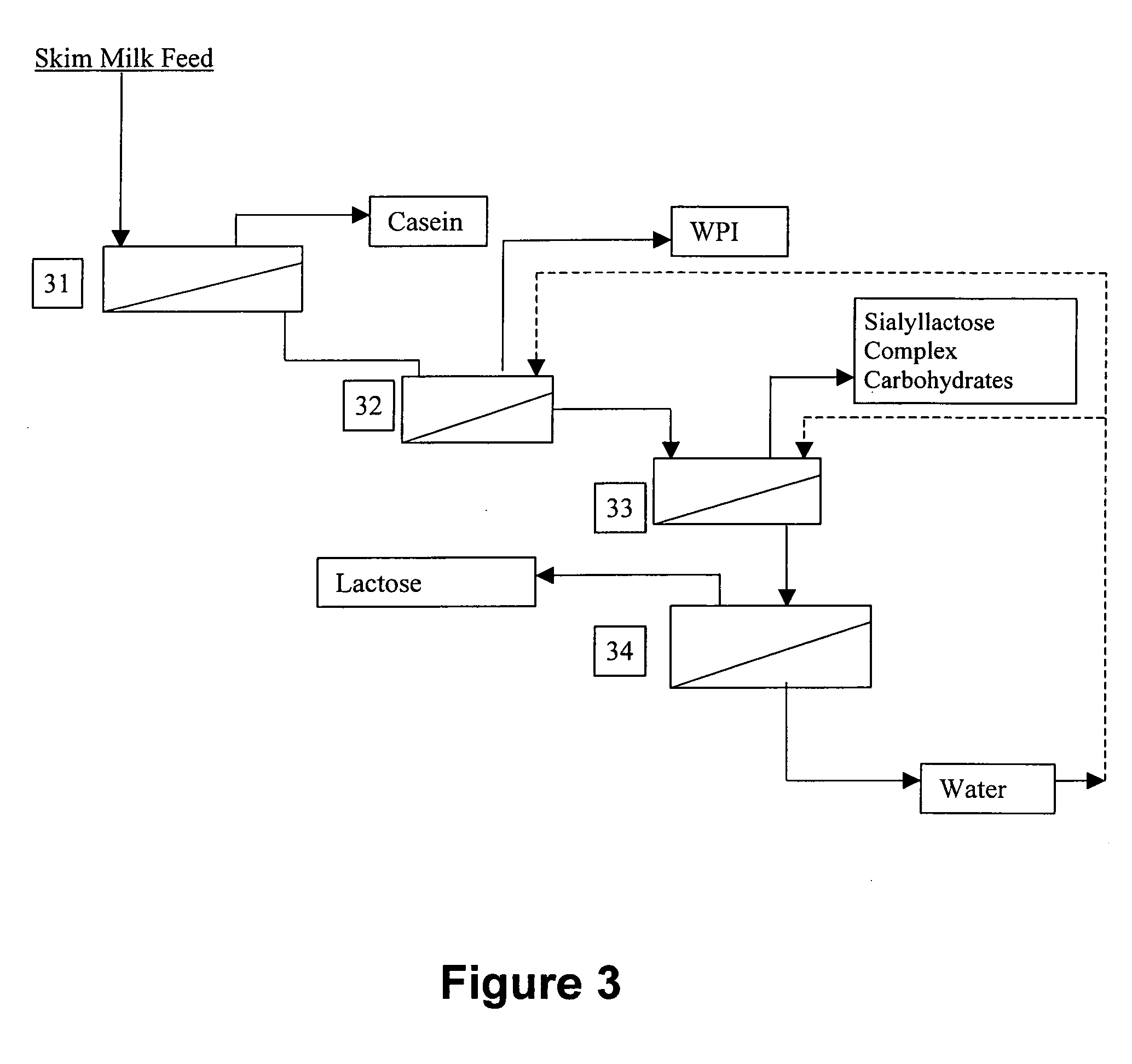

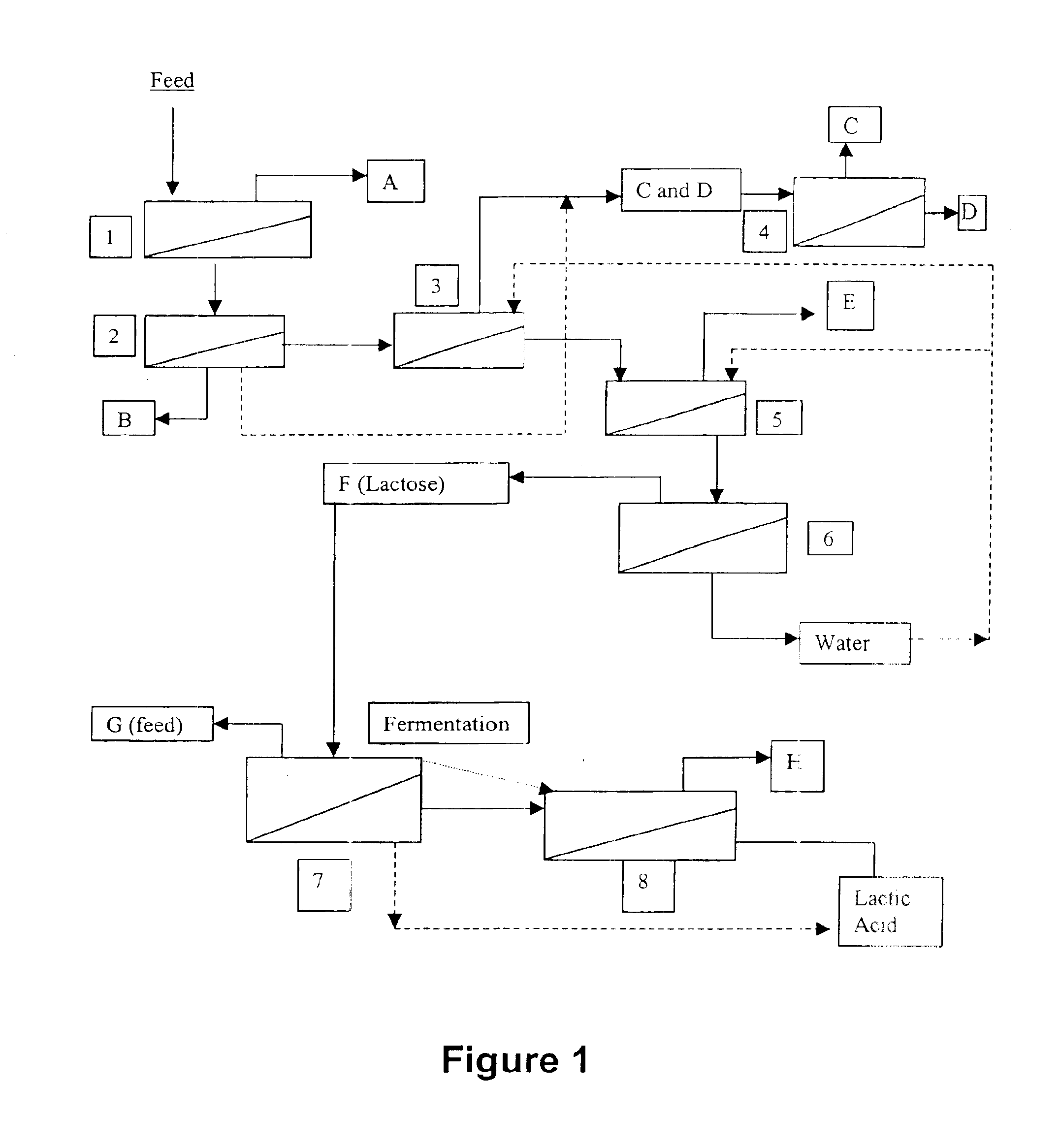

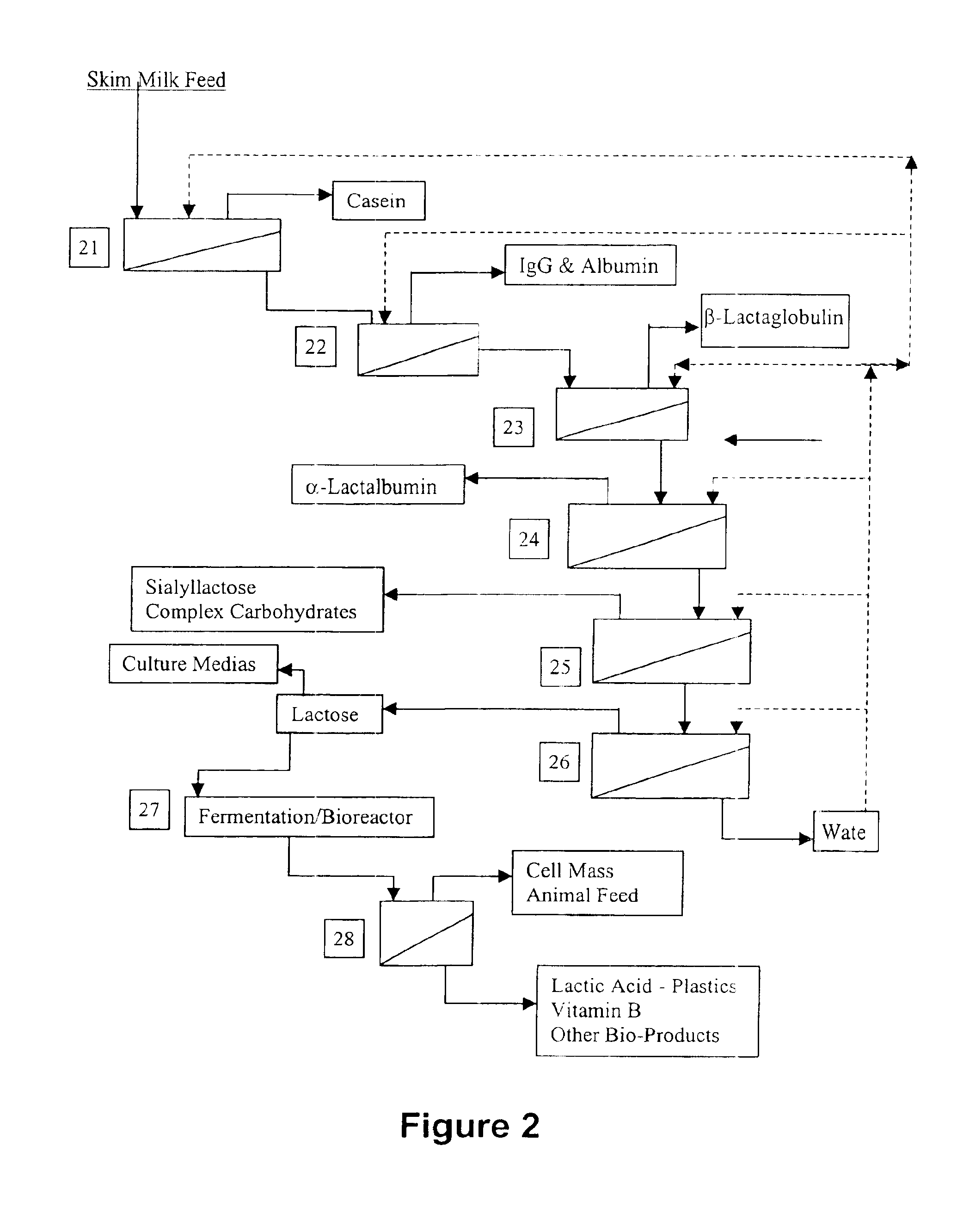

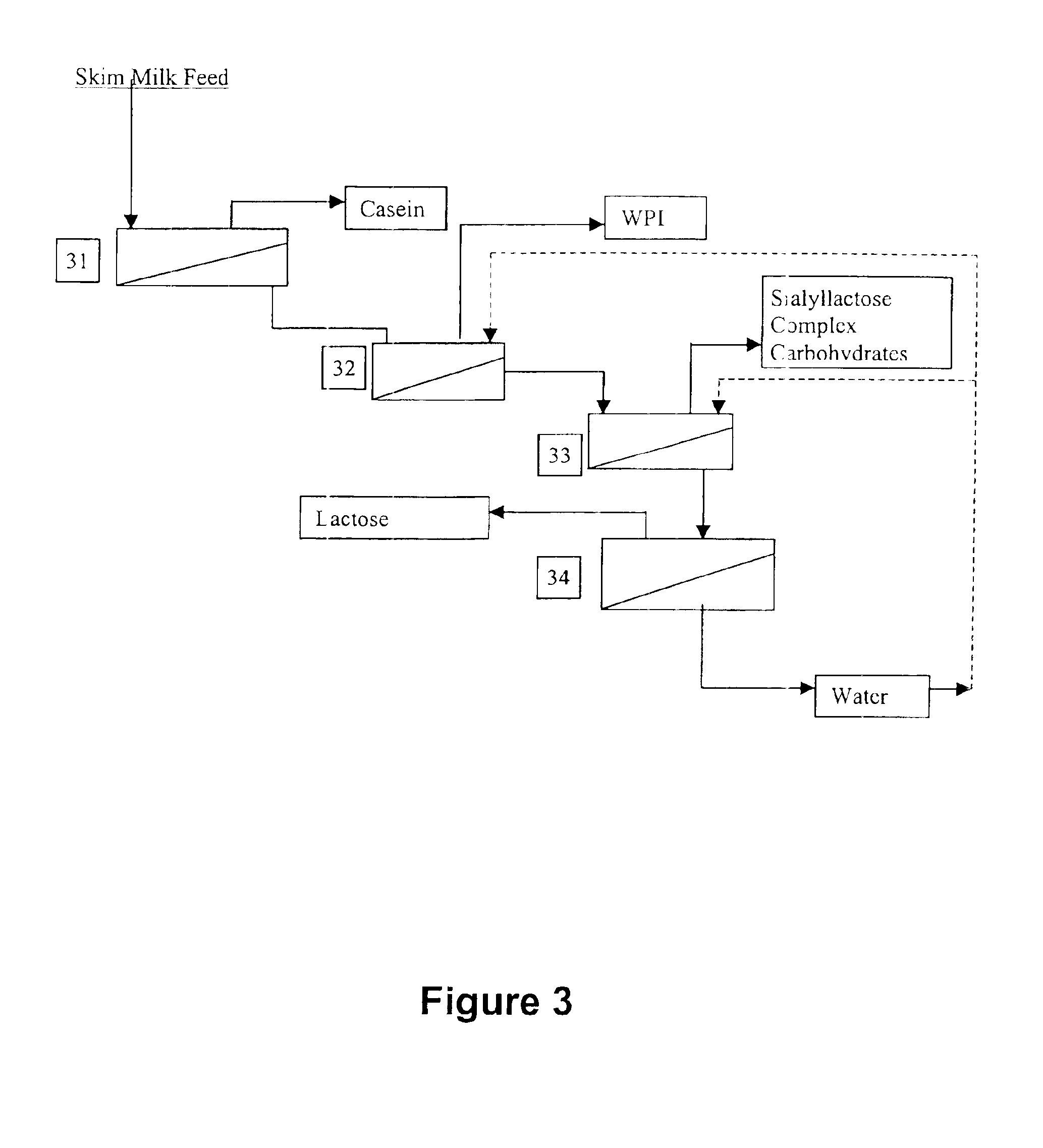

Method and apparatus for separation of milk, colostrum, and whey

InactiveUS20050053707A1Reduce quality and nutritional valueFacilitate efficient usMilk preparationMembranesMilk SerumDairy foods

Apparatus and method for separation of milk and milk products, e.g., involving sequential separation of milk, colostrum, and whey components by cross-flow filtration. The apparatus and method in a preferred aspect employ cross-flow filtration, chromatography and fermentation to separate and fully utilize the components of milk, colostrum, and whey to generate numerous individual components, minimize waste, lower adverse environmental issues and provide enhanced economic benefits to dairy producers. A wide variety of consumer and nutraceutical products can be produced from the fractions and / or sub-fractions of milk products obtained from such separation. The invention further contemplates a methodology for selecting optimum membrane, device, and operating conditions to achieve a desired separation.

Owner:SMARTFLOW TECH

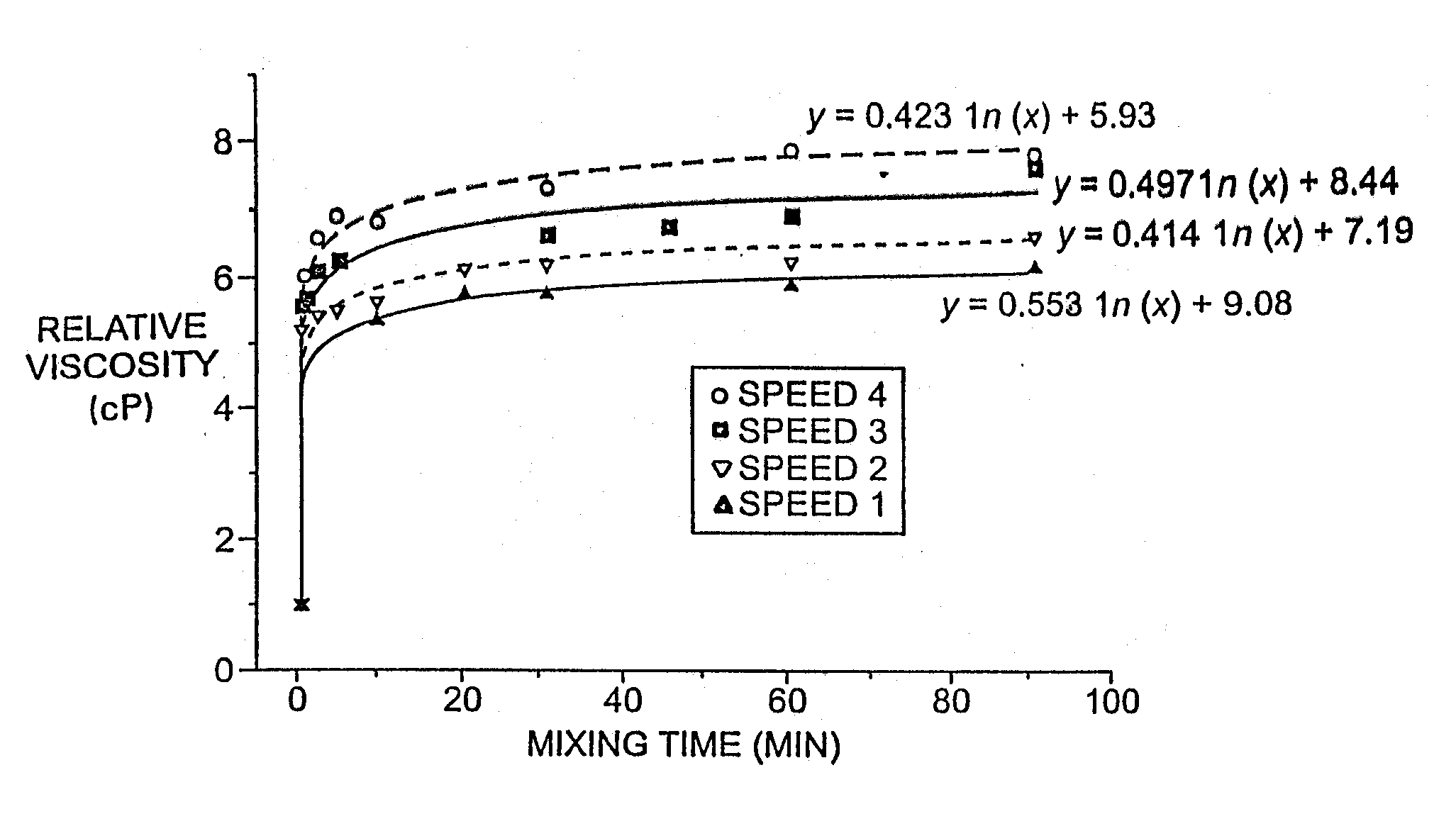

Optimization of separation for viscous suspensions

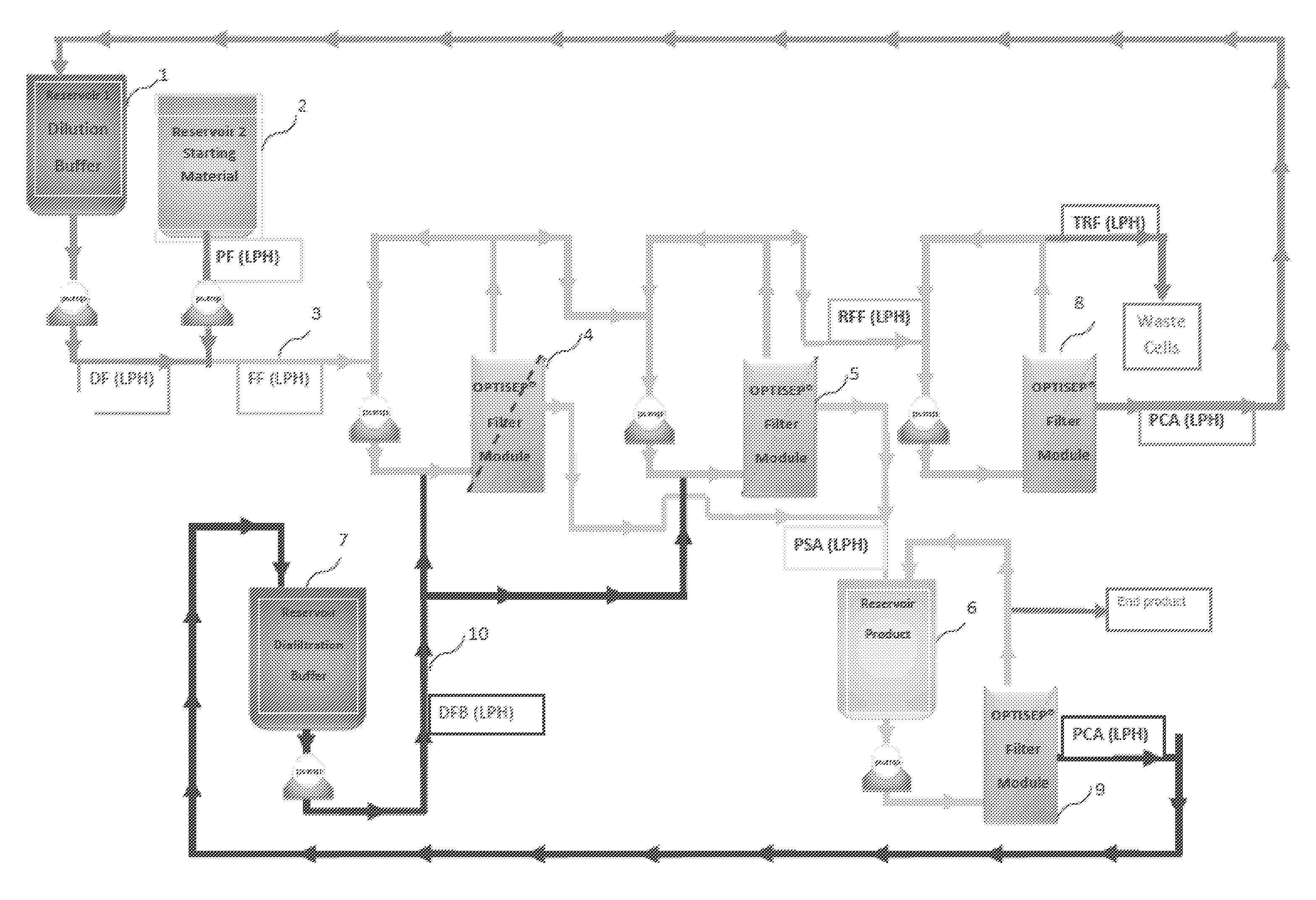

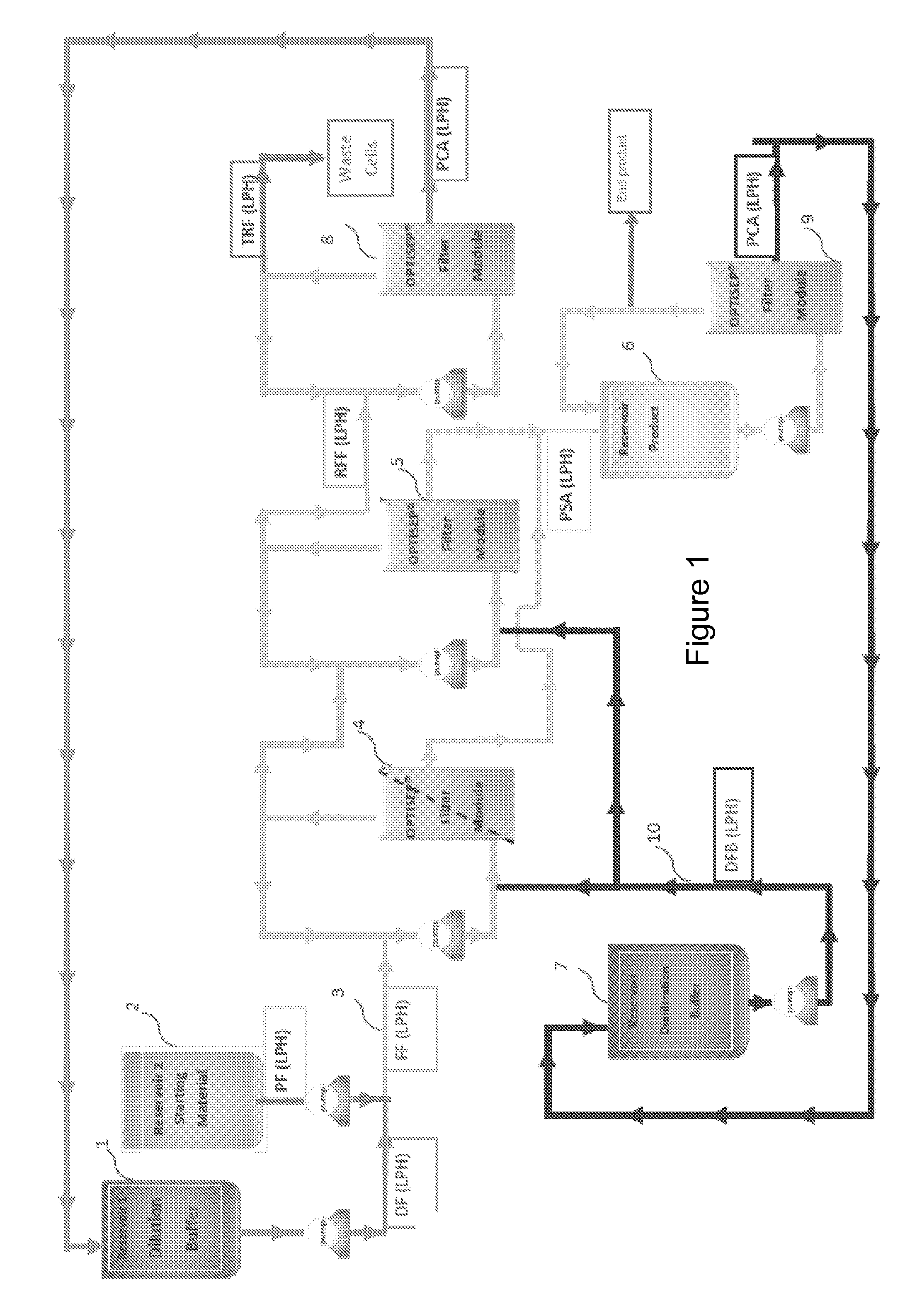

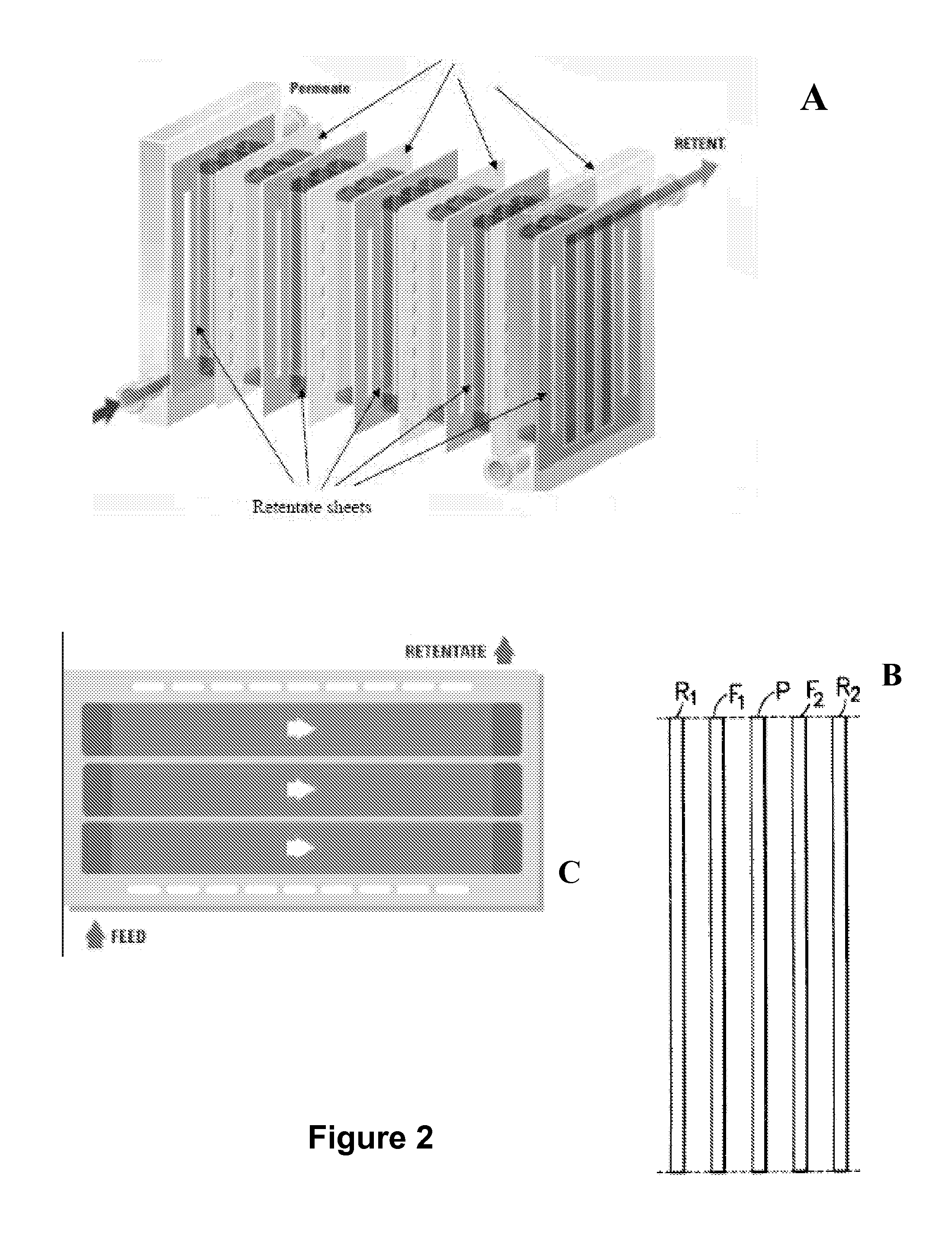

ActiveUS20110309018A1Low costYield maximizationSemi-permeable membranesMembranesSource materialWaste stream

The present invention relates to methods and systems for optimization of dilution of a viscous starting material to isolate and / or concentrate the product of interest from the starting source material such that the process minimizes the volume of diluent and the total volume of the waste stream generated during the process as well as maximizing the yield of desired product. The system employs cross-flow filtration modules with sub-channels that are equidistant to the inlet and outlet of said modules and such modules are characterized by optimal channel height, optimal transmembrane pressure, etc., which are selected in order to achieve the best combination of product quality and production yield.

Owner:SMARTFLOW TECH

Cross-flow filtration apparatus with biocidal feed spacer

InactiveUS20090314713A1Reduce the amount requiredReduce amount of biofoulingMembranesSemi-permeable membranesSpiral woundCross-flow filtration

A cross-flow filtration apparatus is provided. The cross-flow filter is a spiral wound filter that includes a semi-permeable membrane wrapped around a perforated central tube. The semi-permeable membrane includes a feed spacer and a membrane. The feed spacer is a biocidal feed spacer with a biocidal agent impregnated within the feed spacer to prevent biofouling of the feed spacer and the membrane.

Owner:HYDRANAUTICS

Litchi fruit vinegar beverage and production method thereof

ActiveCN101904525ARich tasteRich in nutritional valueVinegar preparationFood preparationFruit juiceUltrafiltration

The invention relates to a litchi fruit vinegar beverage and a production method thereof. The production method comprises the following steps of: removing shells and kernels of fresh litchis, and crushing the pulp to squeeze a juice; defecating the juice at a low temperature; separating the litchi juice; adding lactic acid bacteria into the litchi juice to perform fermentation for the first time; performing cross flow filtration to remove the lactic acid bacteria, and adding wine yeast into the litchi juice to perform fermentation for the second time; adding acetic acid bacteria into the litchi juice to perform fermentation for the third time to obtain a litchi raw vinegar; mixing the raw vinegar with a fruit juice, fructo-oligose (prebiotics), honey, purified water and the like in certain proportion; and filtering the mixture through an ultrafiltration membrane and performing aseptic canning to obtain the litchi fermented vinegar beverage. The litchi fruit vinegar beverage has a unique production process, and after multi-bacteria, low-temperature and long-time fermentations, the produced vinegar beverage has strong litchi fruit aroma and thick mouthfeel integrates nutritional and health-care functions, and is a novel nutritious, cosmetic and pollution-free green beverage.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

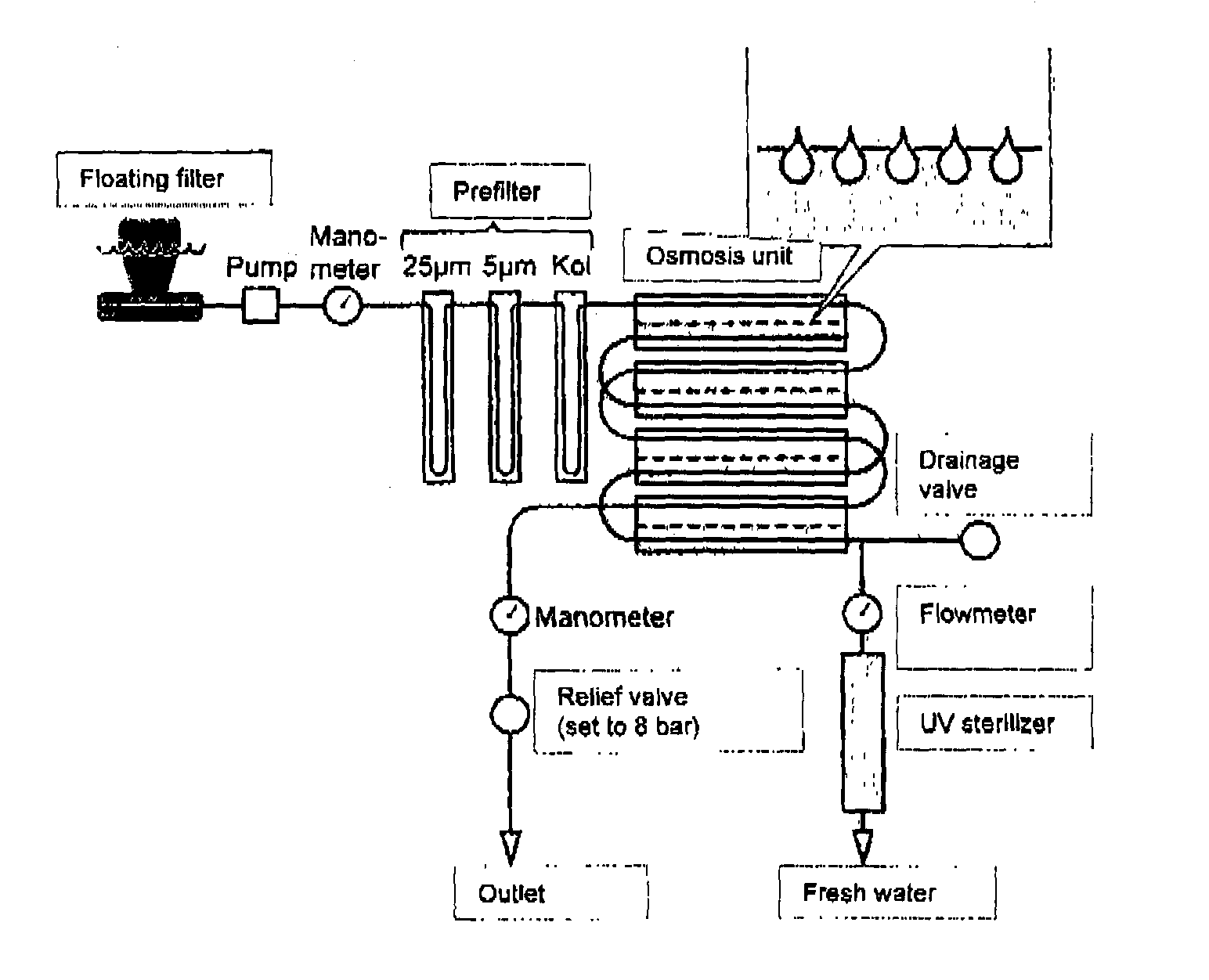

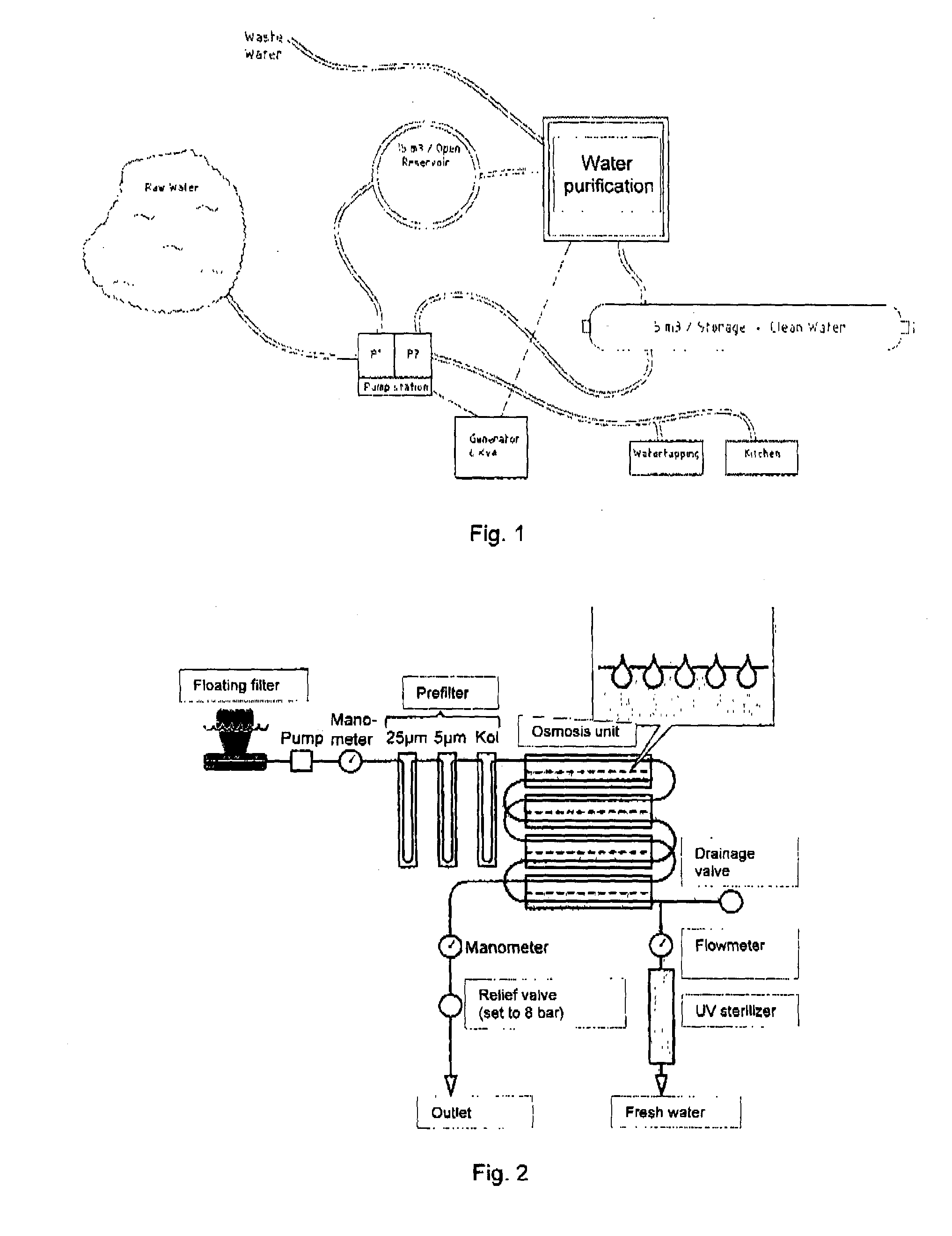

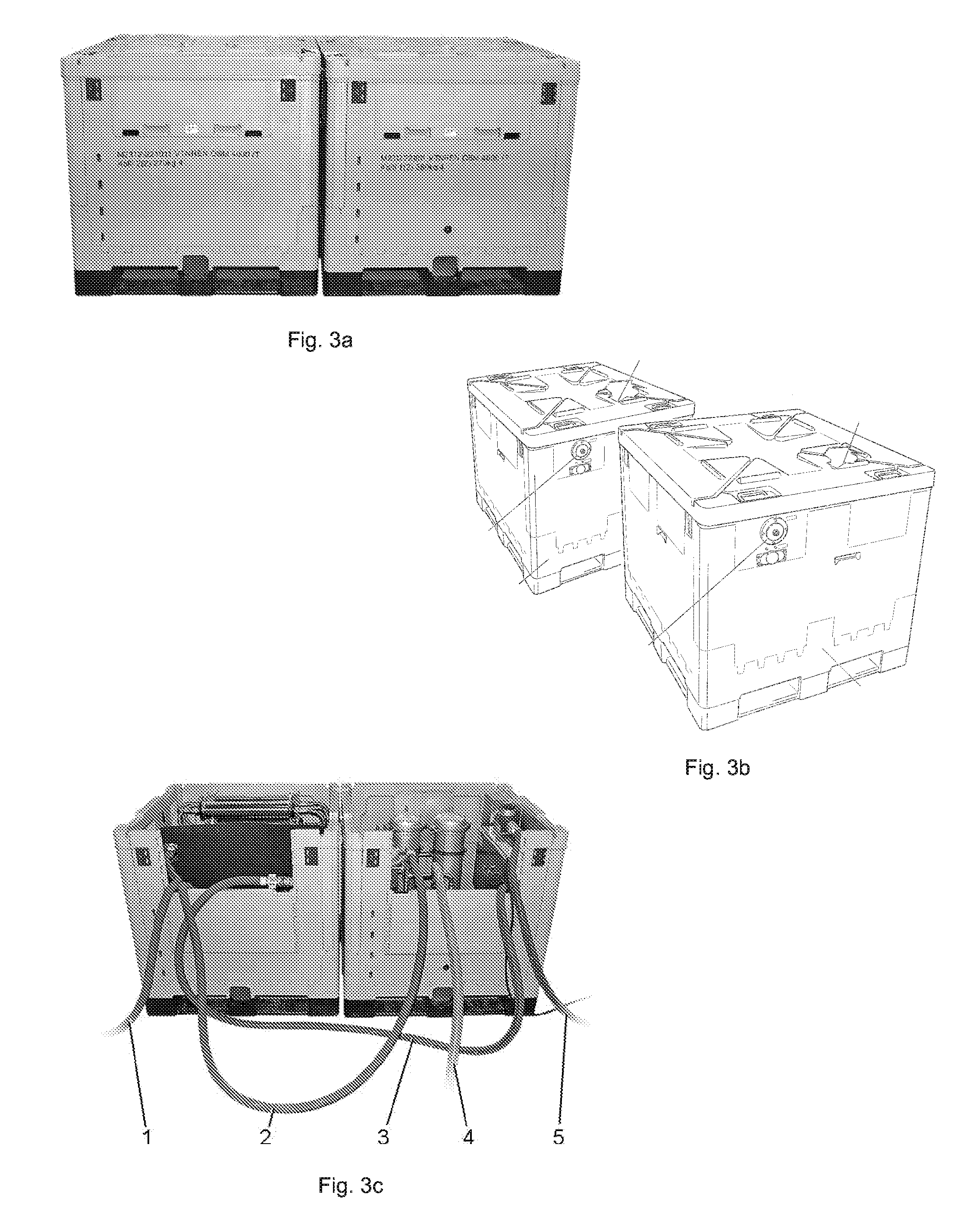

Mobile Water Purification System

InactiveUS20140021115A1Increase productionHigh energy consumptionWater/sewage treatment by irradiationGeneral water supply conservationReverse osmosisCross-flow filtration

The present invention relates to a mobile water purification system employing crossflow filtration, such as reverse osmosis filtration. One embodiment of the invention discloses a mobile water purification system comprising a housing, a pump unit and a piping system for providing fluid communication between a water inlet, a pre-filtration unit, a crossflow filtration unit, a disinfection unit and an outlet for supply of purified water, wherein the pre-filtration unit comprises sediment / cartridge filtrations means and dechlorination means, the cross-flow filtration unit comprises a plurality of parallel and / or sequentially arranged membrane filters, and the piping system is reconfigurable such that the crossflow filtration unit can be bypassed. The present water purification system is adapted to be deployed in remote areas substantially anywhere in the world.

Owner:PURE H2O

Method of refining salt by membrane filtration

ActiveCN1868878AReduce processing loadImprove permeabilitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisIon exchangeCross-flow filtration

A membrane filter process for refining saline includes such steps as dissolving salt to obtain saturated solution, adding sodium hydroxide, sodium carbonate and barium chloride, reaction to generate magnesium hydroxide, calcium carbonate and barium sulfate, adding coagulating precipitant and oxidant for pre-treating, adsorbing and depositing to remove magnesium hydroxide colloid and part of particles, cross-flow filtering by inorganic membrane, and ion exchange.

Owner:JIANGSU JIUWU HITECH

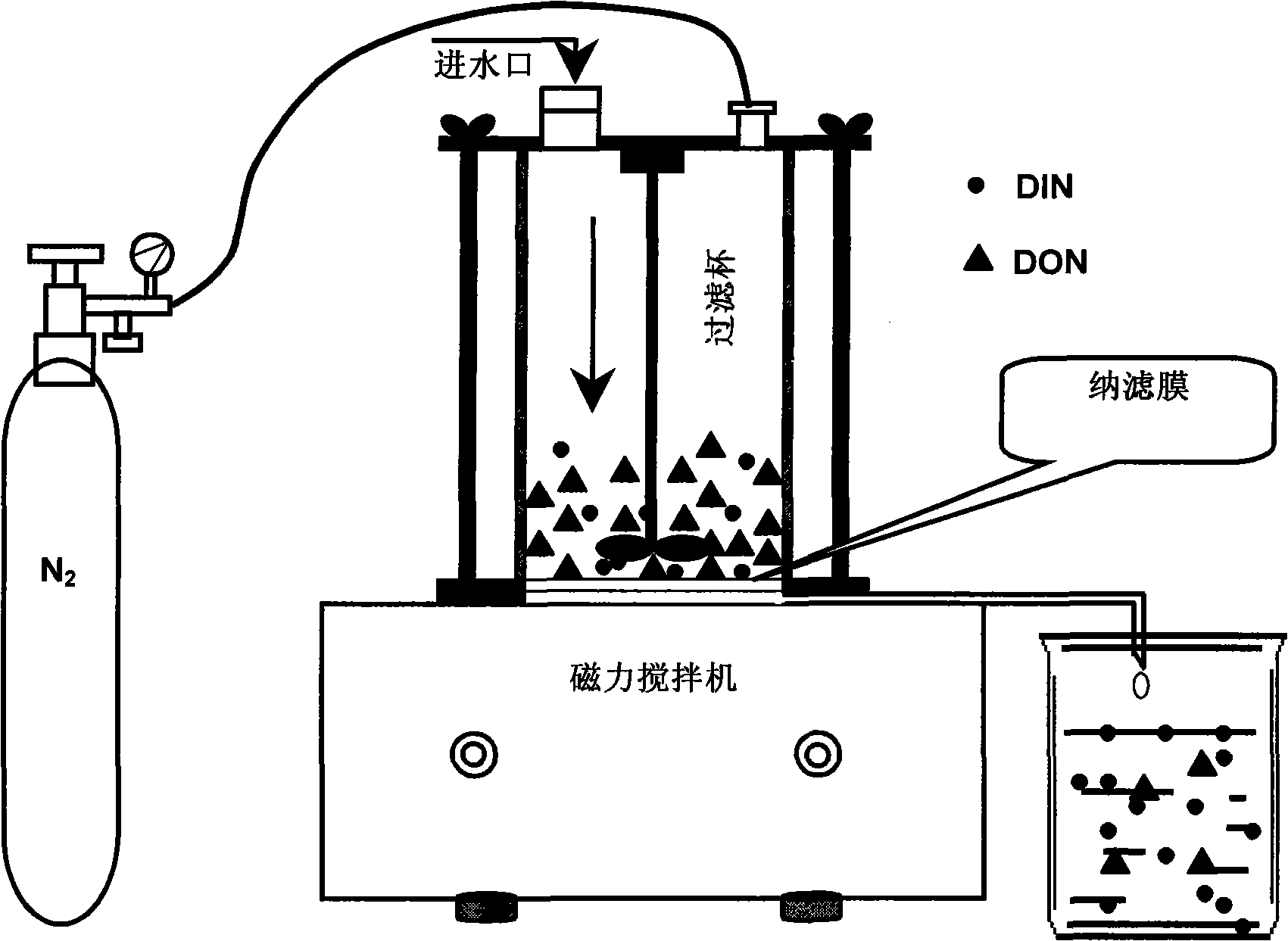

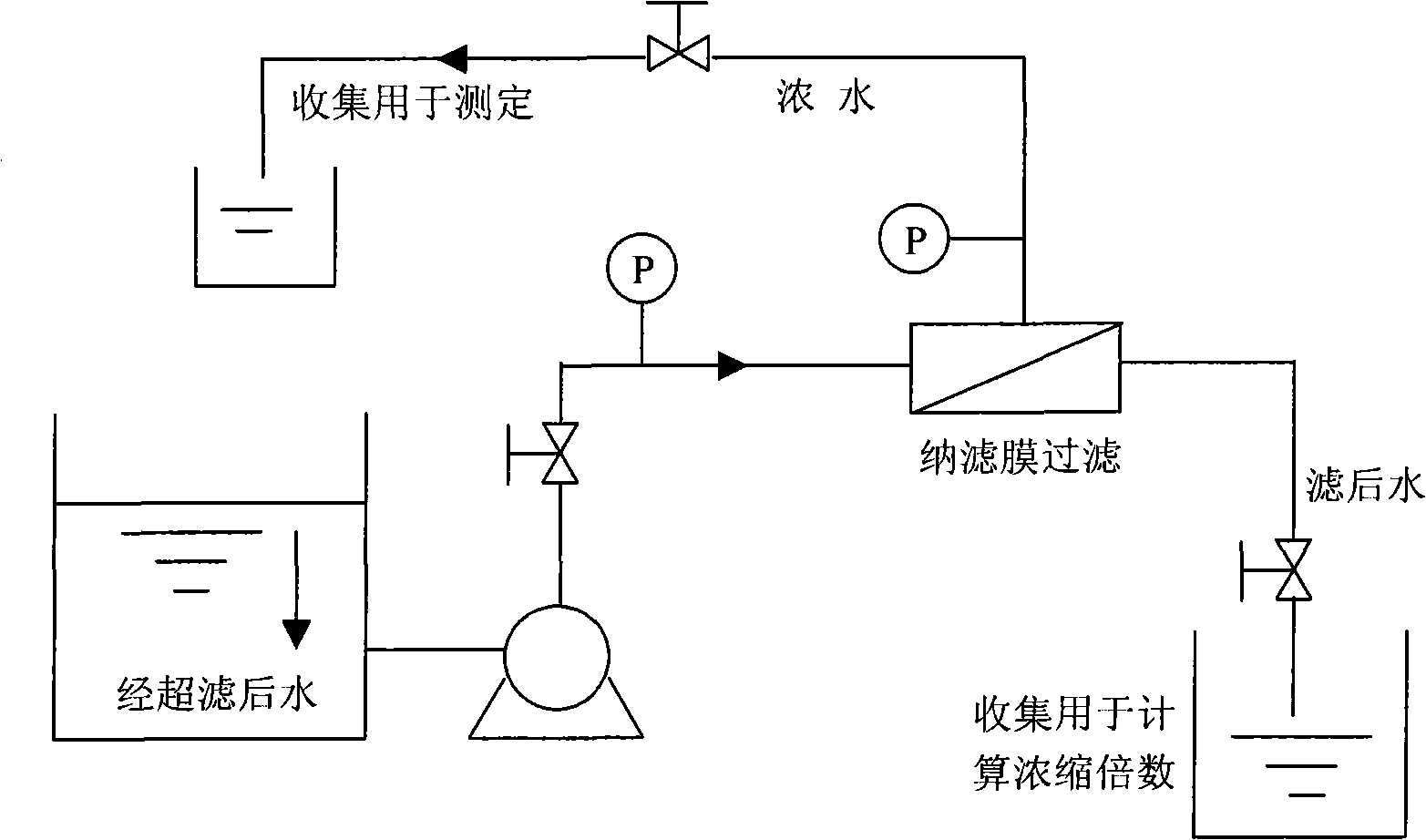

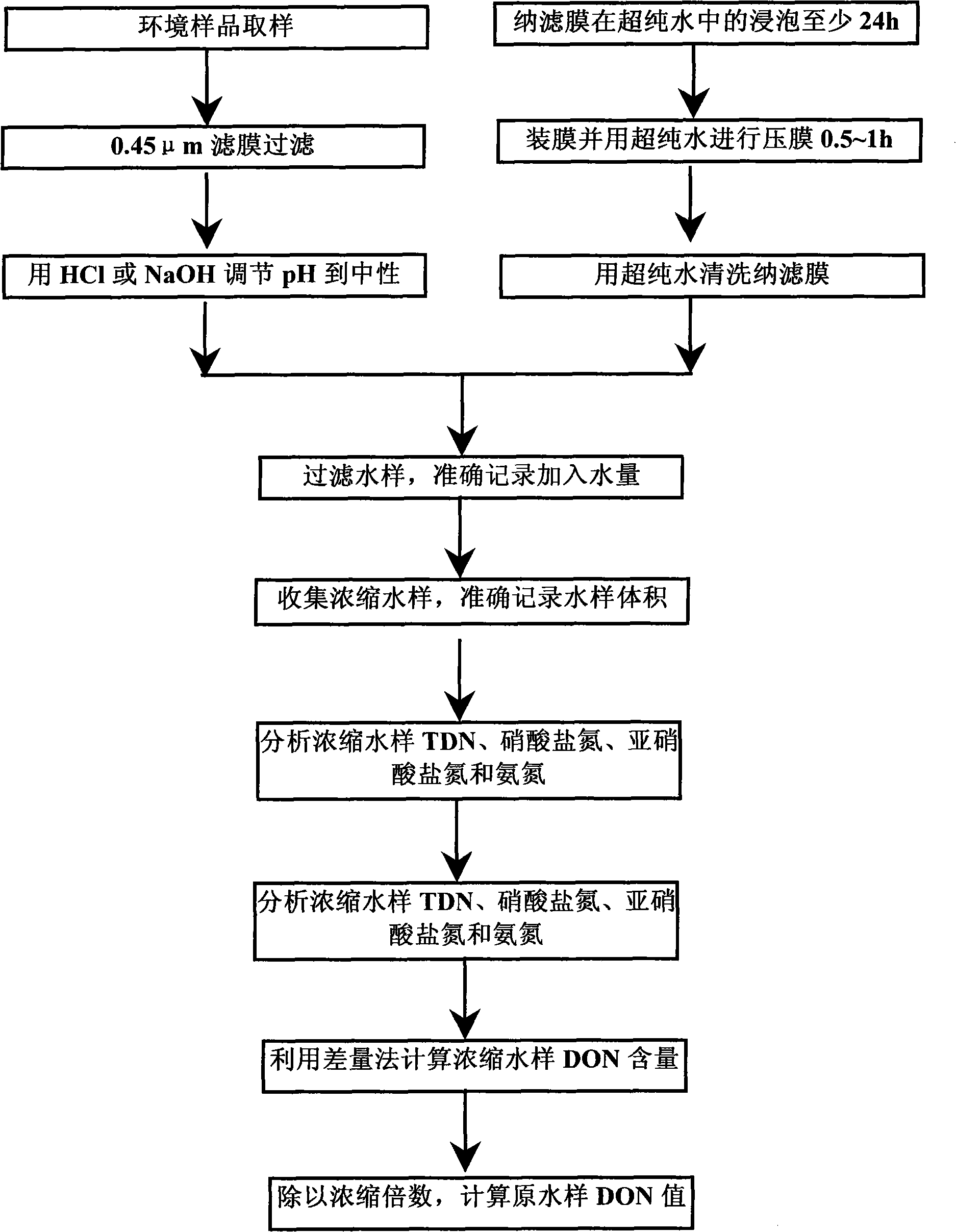

Method for measuring concentration of low-concentration soluble organic nitrogen in water

ActiveCN101782566AReduce the ratioIncrease contentComponent separationPreparing sample for investigationSolubilityFiltration membrane

The invention relates to a method for measuring concentration of low-concentration soluble organic nitrogen in water, in which the nano filtration membrane separation technology is employed to accurately measure concentration of soluble organic nitrogen. In the preparation process before pretreatment, membrane with a pore diameter being more than or equal to 0.22mu m and less than or equal to 0.45mu m is employed to remove particle impurities of a water sample.300-500mL of filtered water sample is taken, pH value is adjusted to 6.0-9.0; in the process of pretreatment, selective nano filtration membrane with a cut-off molecular weight being 150-500 Dalton is adopted for dead-end or cross flow filtration; so that 6-15 times of concentration and enrichment of DON in the water sample can be achieved; the DON content is obtained by using the total nitrogen to reduce other forms of nitrogen content of other measurements and then dividing actual concentration times. In the invention, accuracy and precision of DON measurement are greatly improved, so that the problems that negative values often appear in the direct water sample determination method and concentration standard deviation is large are solved; in addition, the whole measurement process of the measurement method is simple and effective, easy to operate, low in cost, so that the measurement method can be widely applied to surface water and ground watermonitoring and monitoring and analysis of small, medium and large waterplants.

Owner:TONGJI UNIV

Cross flow fan

InactiveUS20050013685A1Pump componentsCircumferential flow pumpsRotational axisCross-flow filtration

A fan for a cross flow fan assembly, including a plurality of elongate fan blades supported in an axial cylindrical pattern about a rotational axis by disk shape fan blade mounting members located adjacent ends of the blades. The fan blades have radial outer end portions defining an outer diameter of the fan, radial inner end portions opposite the radial outer end portions, and curved intermediate portions between the radial outer end portions and the radial inner end portions, respectively. Each of the fan blades is oriented such that the radial outer end is at about a 28° angle to a line tangent to the fan diameter at the outer end portion thereof, and the radial inner end portion is directed radially inwardly directly toward the axis or such that a line tangential to the radial inner end portion will pass through the axis.

Owner:CNH IND AMERICA LLC

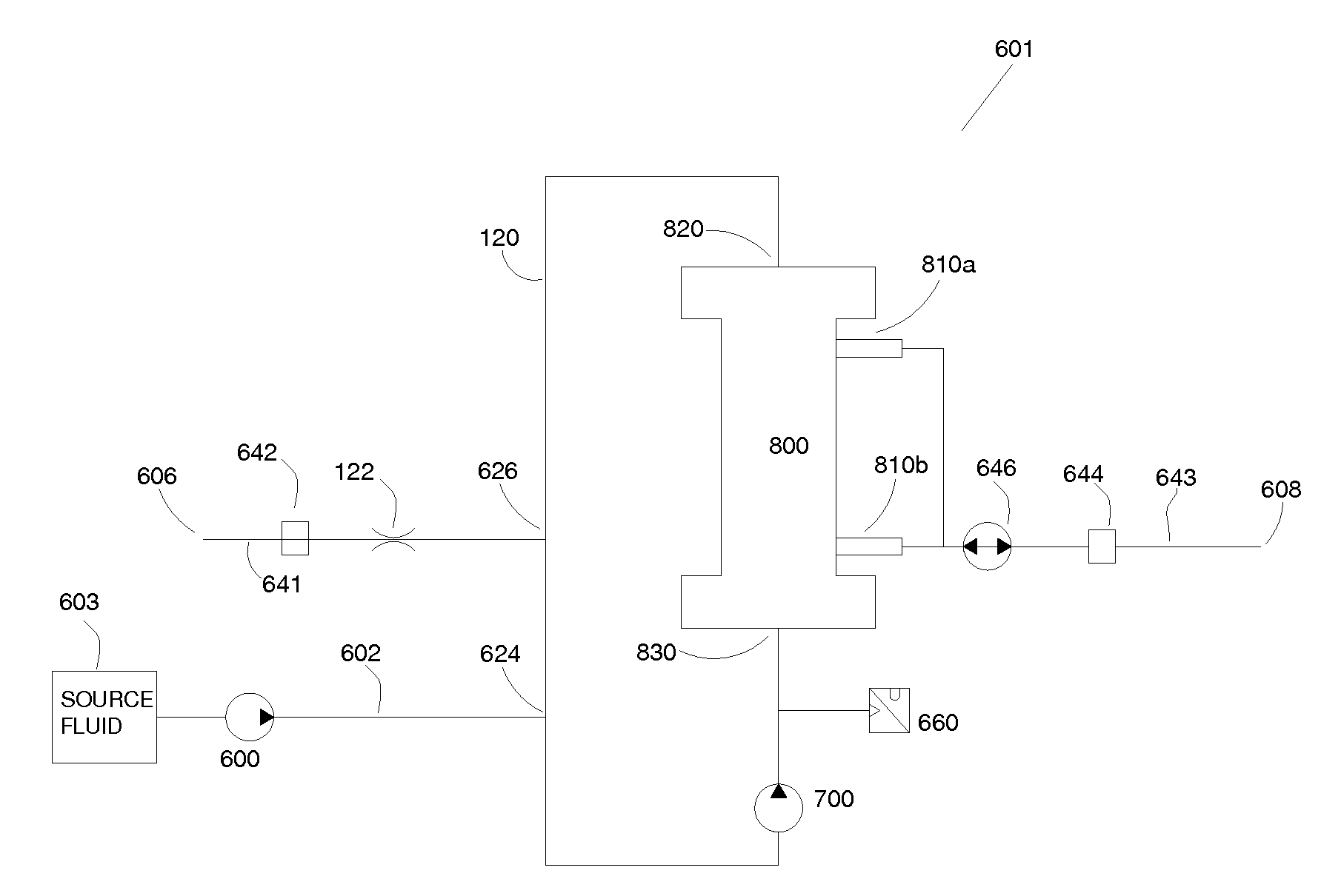

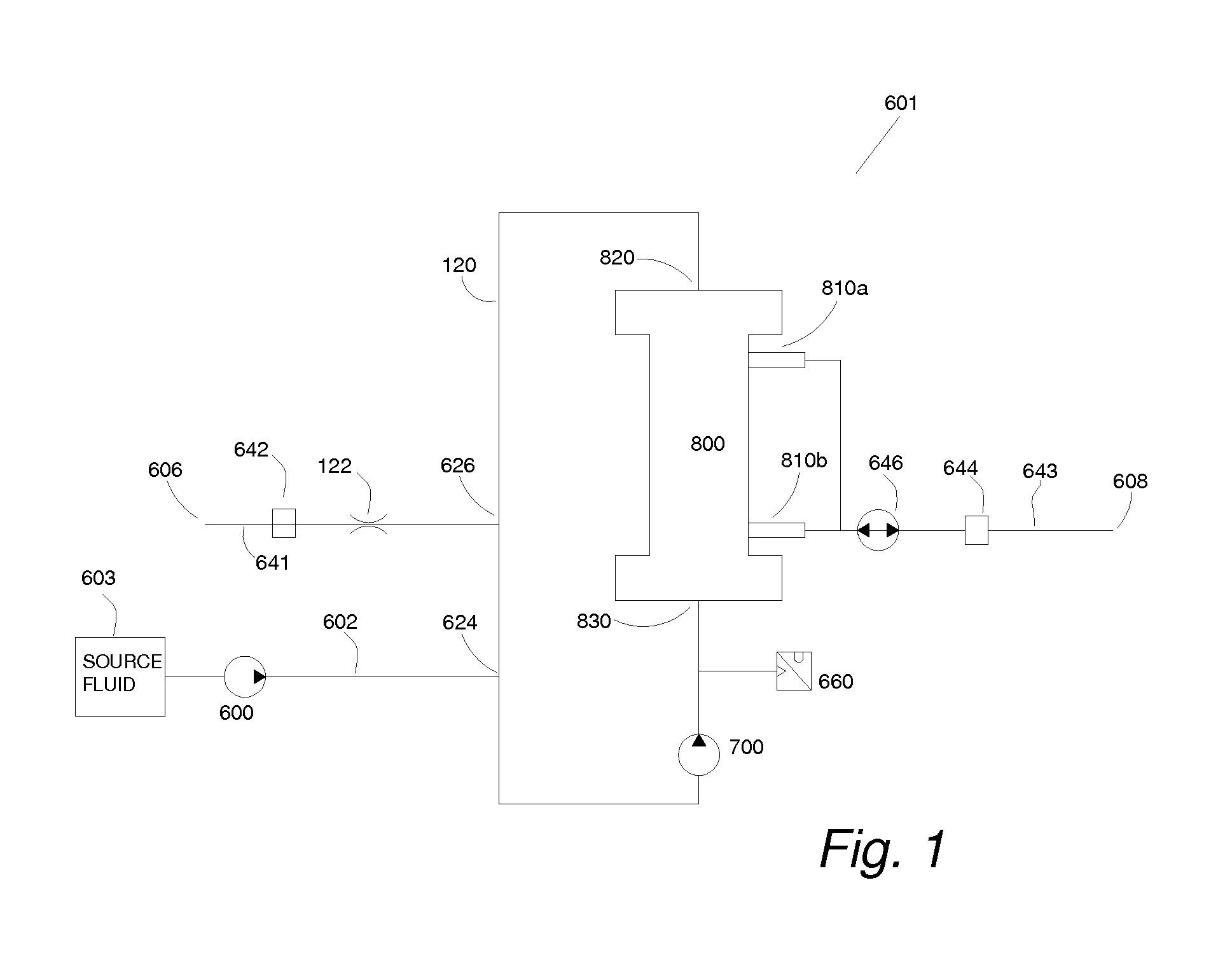

Recirculating fluid filtration system

ActiveUS20130248450A1Easy to operateKeep the pressureSemi-permeable membranesIon-exchanger regenerationHazardous substanceCross-flow filtration

A fluid filtration system comprising a cross-flow filter is arranged to permit a first pump to recirculate part of the retentate of the filter to the inlet of the cross-flow filter and a second pump to return part of the permeate to the inlet of the cross-flow filter. A third pump is configured supply source fluid to the inlet of the filter. The flow path between the second pump and the cross-flow filter inlet may include an adsorption filter that may selectively remove contaminants, toxins, or pathogens in the permeate. A controller may control the first, second and third pumps to provide predetermined flow ratios among the fluid flow paths of the system in order to achieve a desired filtration level. This system may be applicable to the removal of harmful substances from blood, by first separating the plasma from the blood and then removing harmful substances from the plasma.

Owner:DEKA PROD LLP

Cross-flow filter cassette

InactiveUS20070062856A1MembranesGeneral water supply conservationCross-flow filtrationMembrane configuration

Owner:SARTORIUS STEDIM BIOTECH GMBH

Tangential-flow filtration system

InactiveUS6926833B2Improve abilitiesDegrading directionUltrafiltrationDialysis systemsPorous membraneCross-flow filtration

The present invention includes a system and method for transferring a selected solute species from a fluid mixture to a fluid media. The system of the present invention includes a convergent channel for passing a fluid mixture containing a selected species tangentially across the first surface of a porous membrane. A fluid media is directed to flow tangentially over the second surface of the membrane. As the fluid mixture and the fluid media flow on opposite sides of the membrane, the selected species traverses the membrane leaving the fluid mixture and entering the fluid media. The volumetric loss to the fluid mixture associated with the loss of the selected species is compensated for by the convergency of the channel. As a result a constant velocity is maintained over the membrane, maximizing the selectivity of the filtration process.

Owner:GENENTECH INC

Method and apparatus for separation of milk, colostrum, and whey

InactiveUS6852352B2Reduce quality and nutritional valueFacilitate efficient usMilk immunoglobulinsUltrafiltrationMilk SerumCross-flow filtration

Apparatus and method for separation of milk and milk products, e.g., involving sequential separation of milk, clostrum, and whey components by cross-flow filtration. The apparatus and method in a preferred aspect employ cross-flow filtration, chromatography and fermentation to separate and fully utilize the components of milk, clostrum, and whey to generate numerous individual components, minimize waste, lower adverse environmental issues and provide enhanced economic benefits to dairy producers. A wide variety of consumer and nutraceutical products can be produced from the fractions and / or sub-fractions of milk products obtained from such separation. The invention further contemplates a methodology for selecting optimum membrane, device, and operating conditions to achieve a desired separation.

Owner:SMARTFLOW TECH

Production of multivesicular liposomes

InactiveUS9585838B2Accurately and quickly up reactionOrganic active ingredientsPeptide/protein ingredientsEmulsionCross-flow filtration

Multivesicular liposomes are prepared at commercial scales by combining a first w / o emulsion with a second aqueous solution to form a w / o / w emulsion using a static mixer. Solvent is removed from the resulting emulsion to form multivesicular liposome-containing compositions. Further optional process steps include primary filtration and secondary cross-flow filtration. The products produced according to the processes of the invention can be produced through a series of aseptic steps.

Owner:PACIRA PHARMA INC

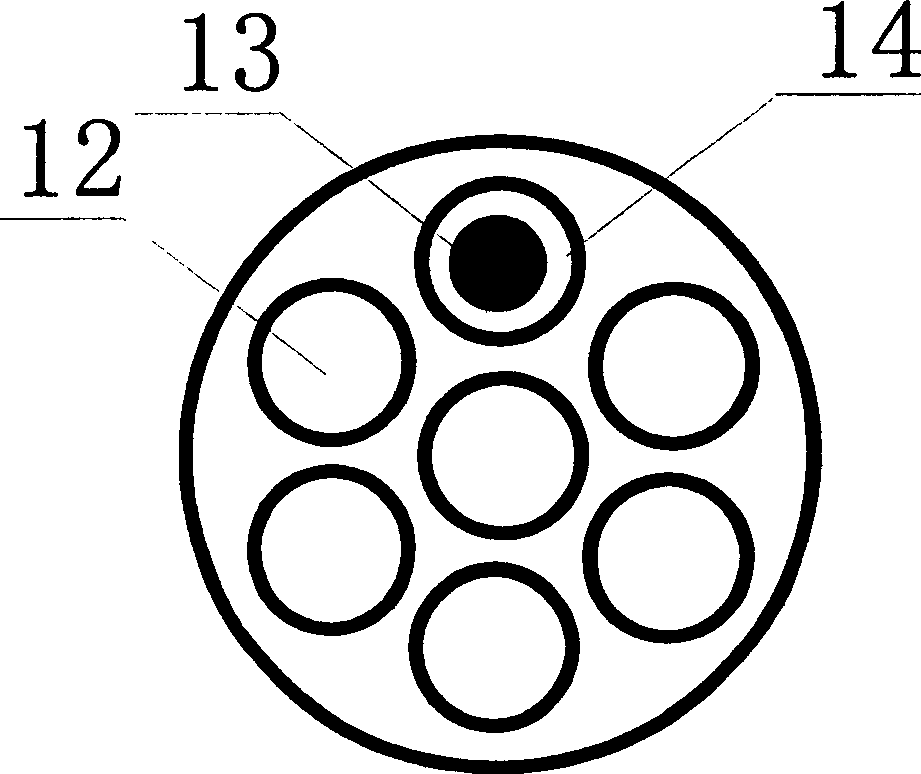

Polyolefine hollow fiber micro-filtration film with permanent hydrophilicity, and its prepn. method

A micro-filter membrane made of hollow polyolefin fibers and with permanent hydrophilicity is prepared from the ordinary basic membrane of hollow polyolefin fibers through immersing in alcohol or surfactant, filtering aldehyde solution and filming liquid containing PVA and / or polyethandiol or polyvinyl pyrrolidone, cross-linking reaction, immersing in deionized water and drying.

Owner:OCEAN UNIV OF CHINA

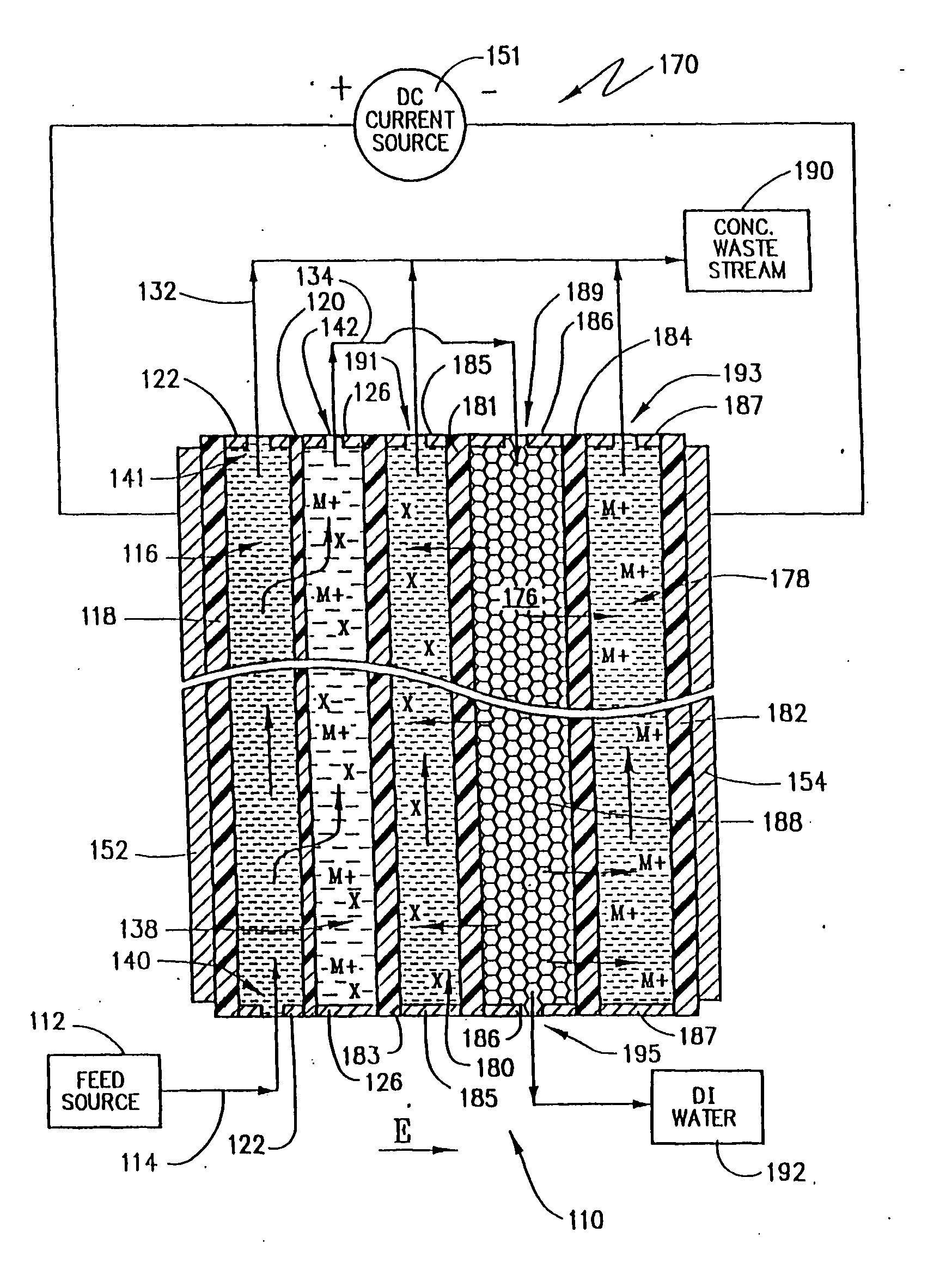

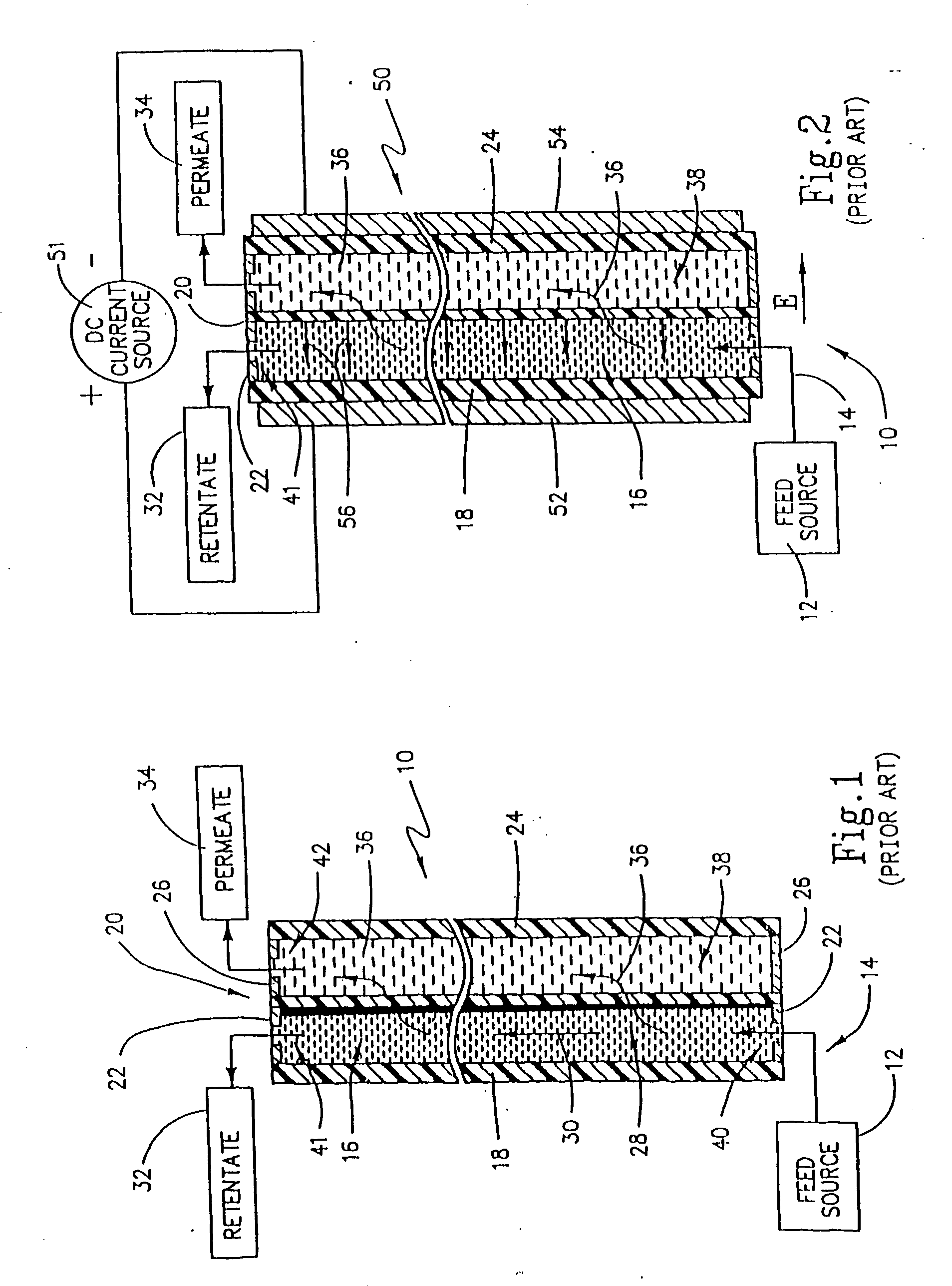

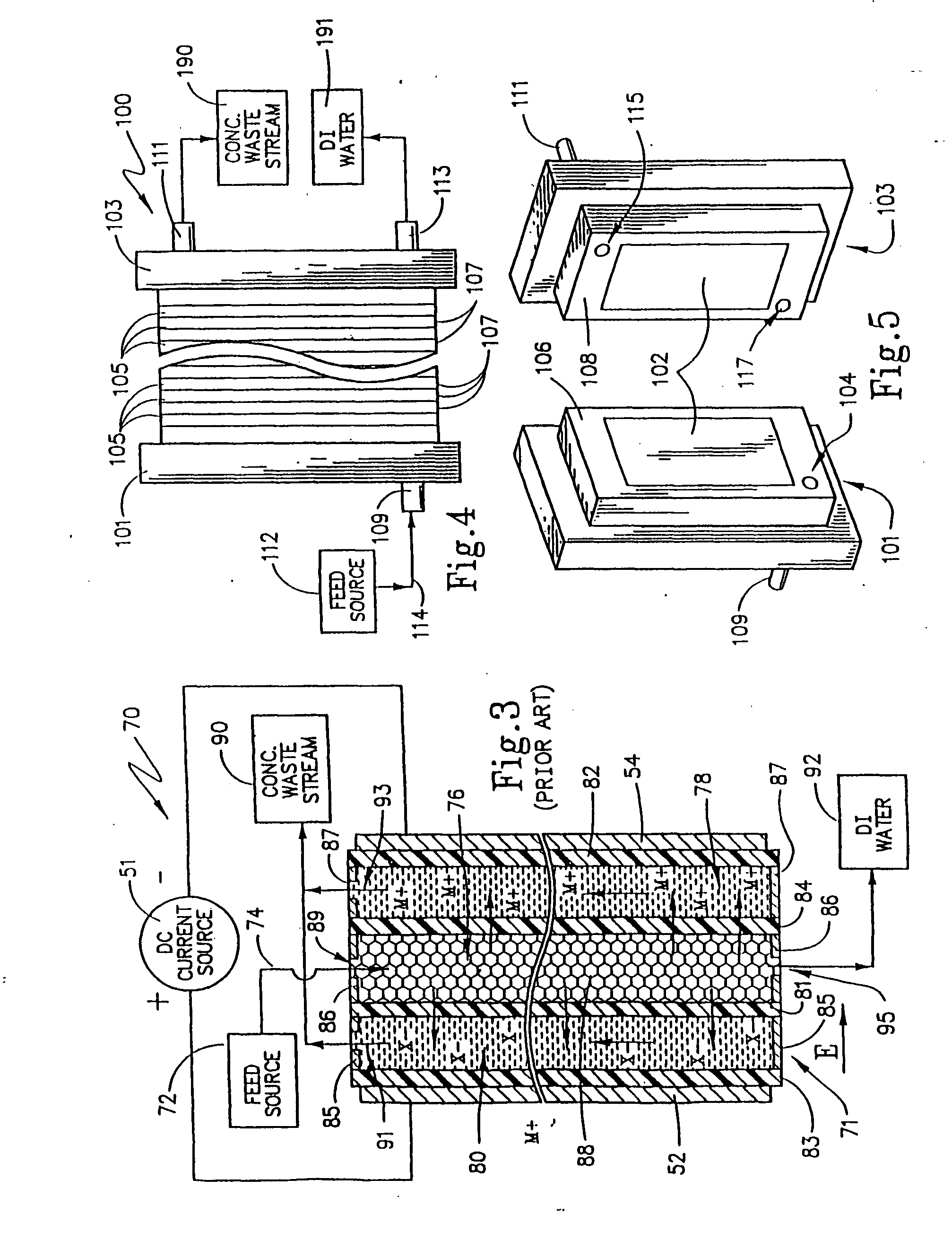

Electrophoretic cross-flow filtration and electrodeionization method for treating effluent waste and apparatus for use therewith

InactiveUS20060254919A1Efficient purificationEfficient methodSludge treatmentVolume/mass flow measurementSuspended particlesElectrophoresis

The present invention provides a method and apparatus for purifying effluent wastewater utilizing electrophoretic cross-flow filtration and electrode ionization. The method first comprises filtering the water in a cross-flow direction with a filter membrane in the presence of an electric field that is operative to drive suspended particles away from a surface of the filter membrane. The permeate containing dissolved solids is next passed through a mixture of at least one cation-exchange resin and at least one anion-exchange resin disposed between a cation-selective membrane and an anion-selective membrane in the presence of an electric field. The electric field drives cations in the permeate through the cation-selective membrane, and drives anions in the permeate through the anion-selective membrane, thereby to form deionized water. The apparatus includes cell modules adapted to be used in plate-and-frame or radial flow configurations.

Owner:EDWARDS VACUUM INC

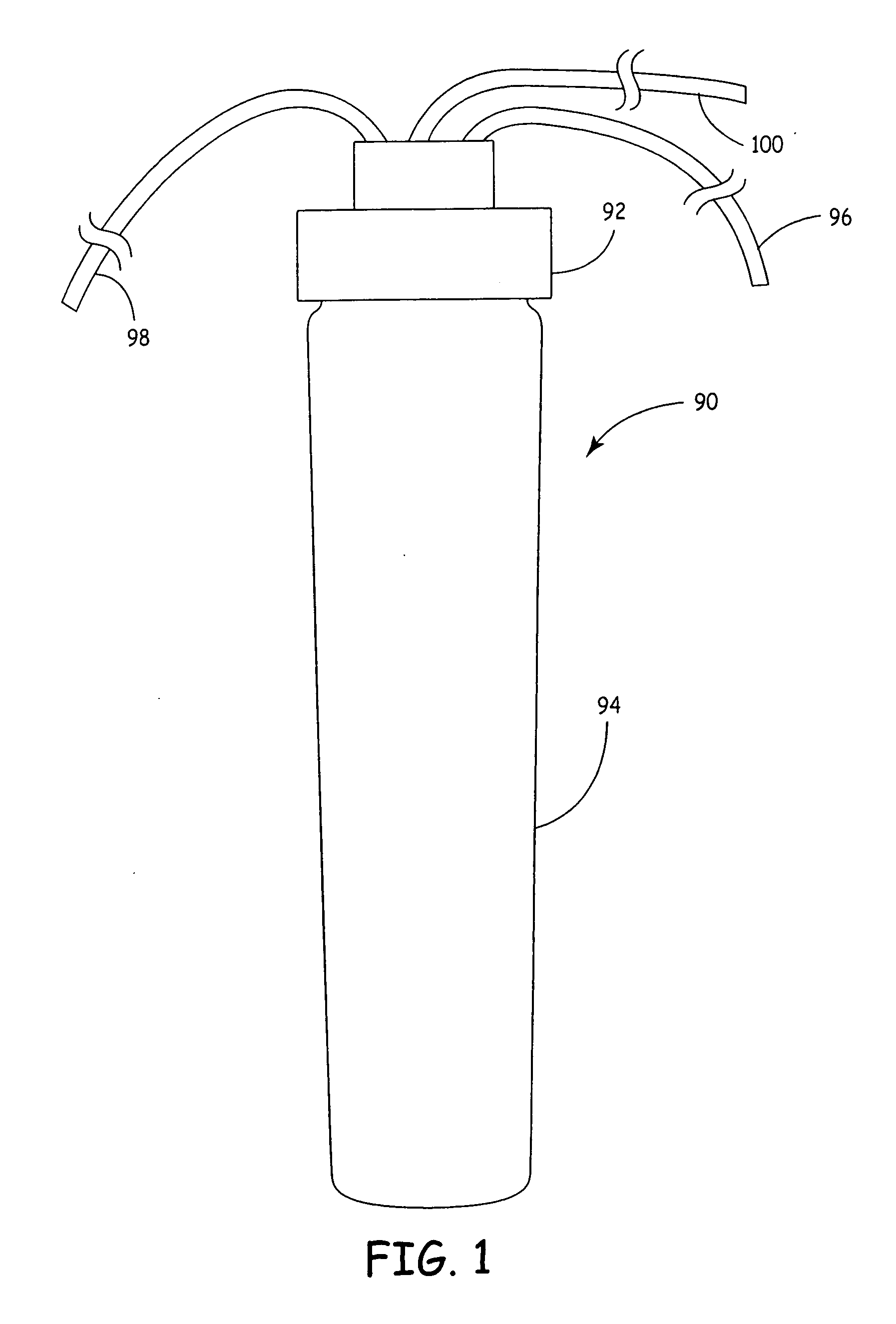

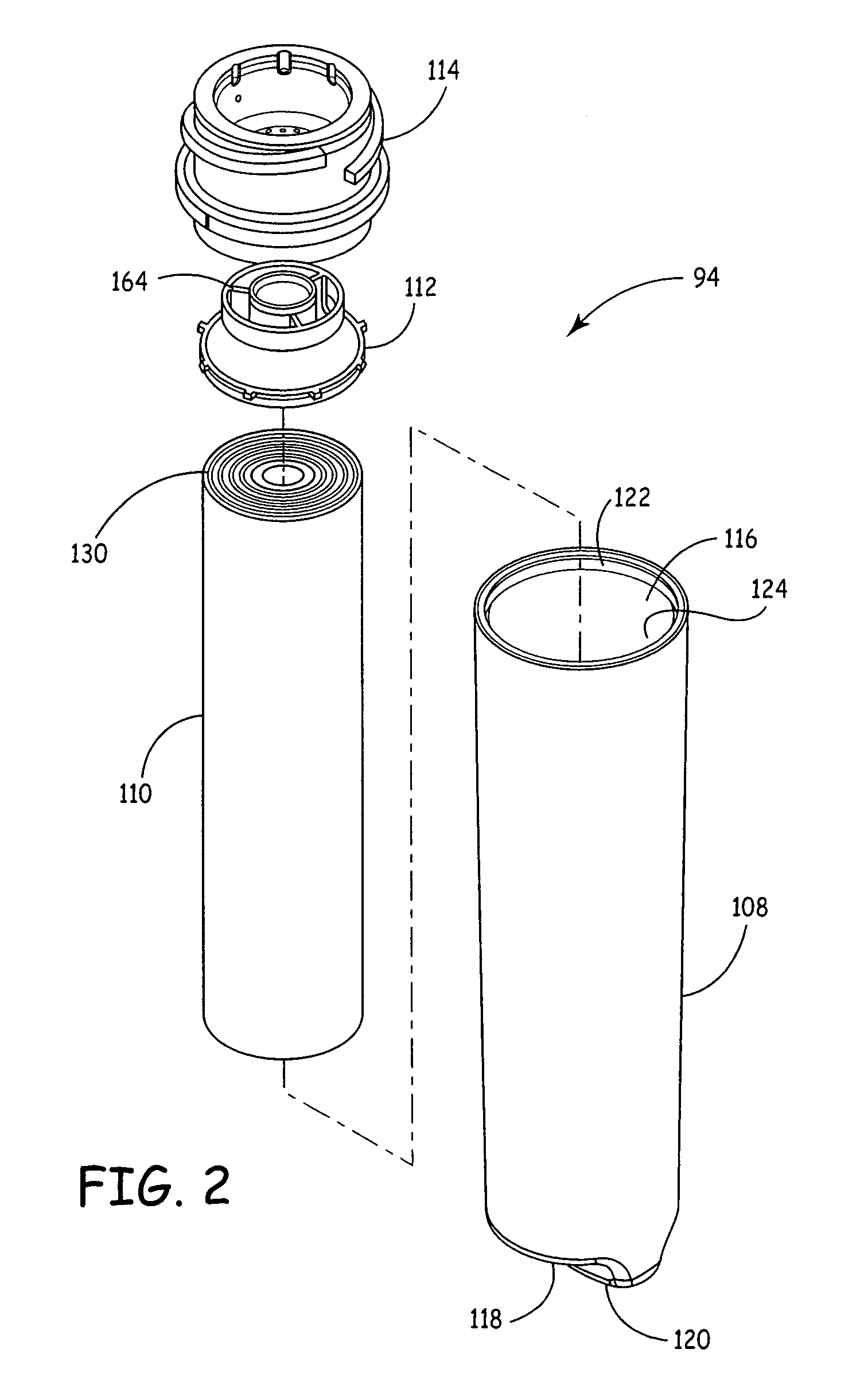

Crossflow filtration system with quick dry change elements

InactiveUS20050173319A1For quick replacementFiltering characteristics of the crossflow filtration system can be adjustablyUltrafiltrationSedimentation separationMicrofiltration membraneUltrafiltration

A crossflow filtration system including at least one quick dry change crossflow filtration cartridge designed to rotatably interface with a manifold assembly. The quick dry change crossflow filtration cartridge can comprise a membrane element, for example an ultrafiltration membrane, microfiltration membrane, nanofiltration membrane or high-flux reverse osmosis membrane element enclosed within a housing. The quick dry change cartridge includes an inlet stream, a permeate stream and a concentrate stream. The manifold assembly includes three similar flow paths; an inlet stream, a permeate stream and a concentrate stream. When engaged, the cartridge and manifold assembly define continuous inlet flow paths, permeate flow paths and concentrate flow paths that connect across the interface. Thus, all of the connections to the water filtration system can be made onto the manifold, and the resulting connected system is compact and easy to connect.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com