Cross flow fan

a technology of cross-flow fan and fan body, which is applied in the direction of machines/engines, threshers, liquid fuel engines, etc., can solve the problems of increasing power and output demands, and increasing the width of the combin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

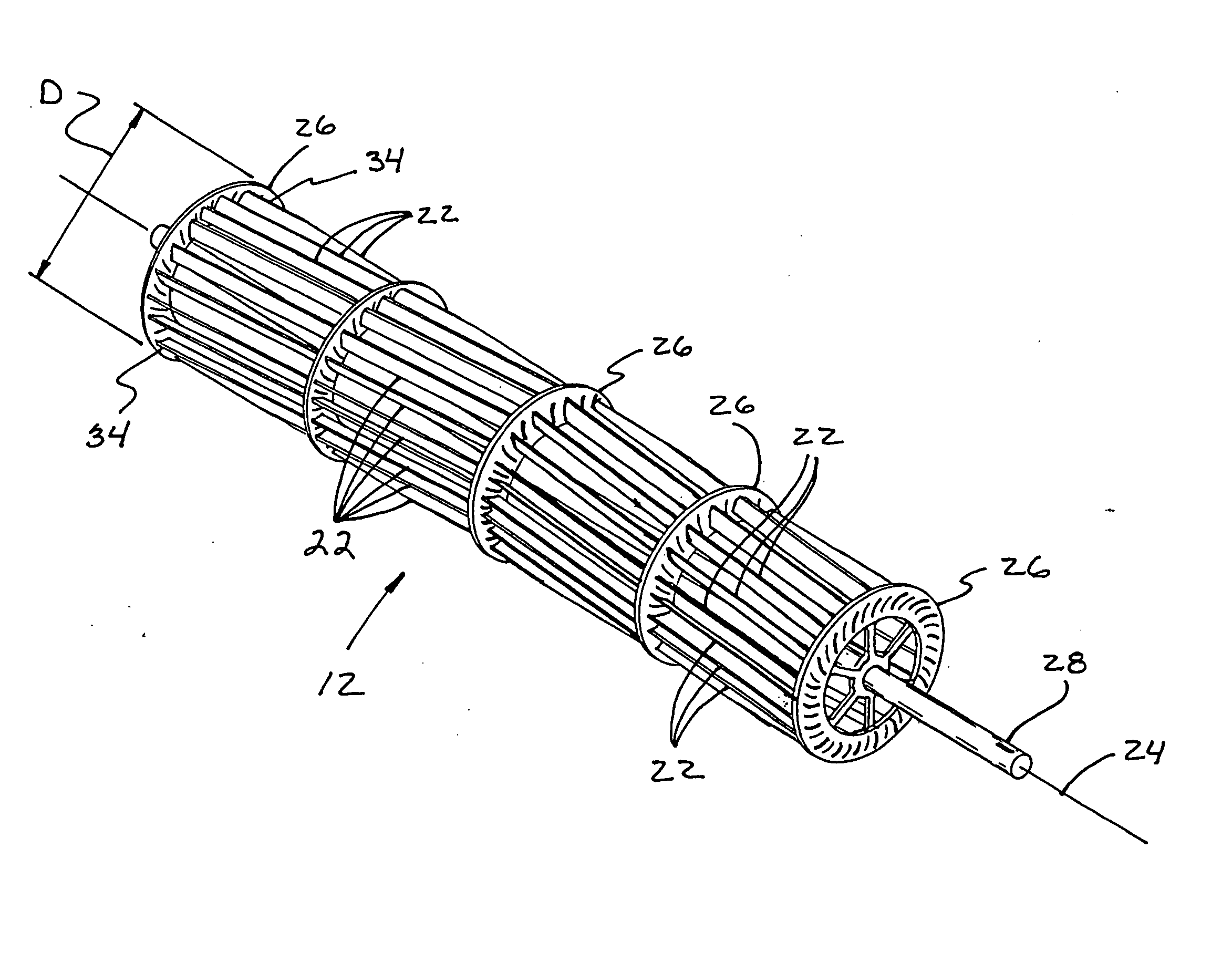

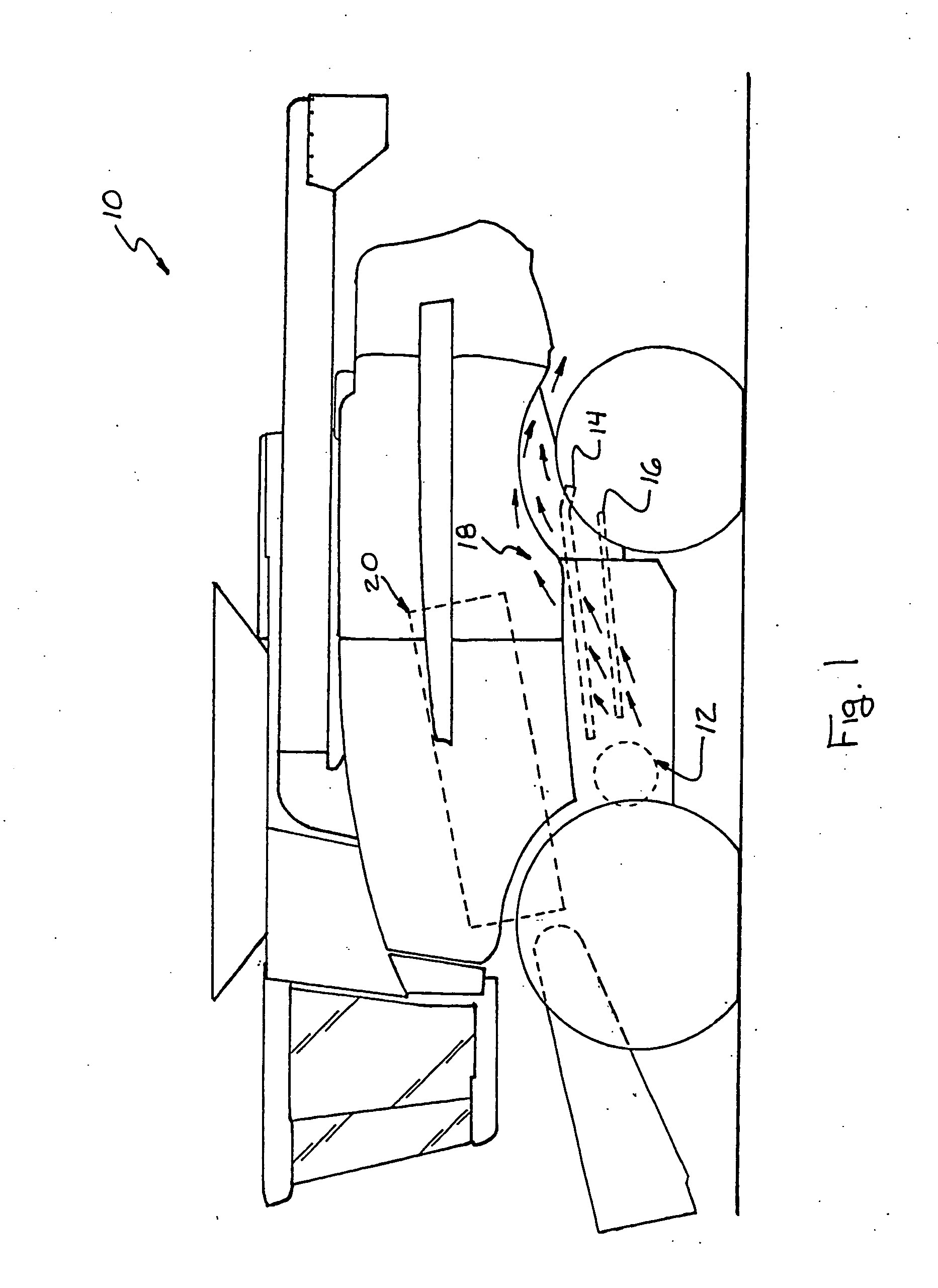

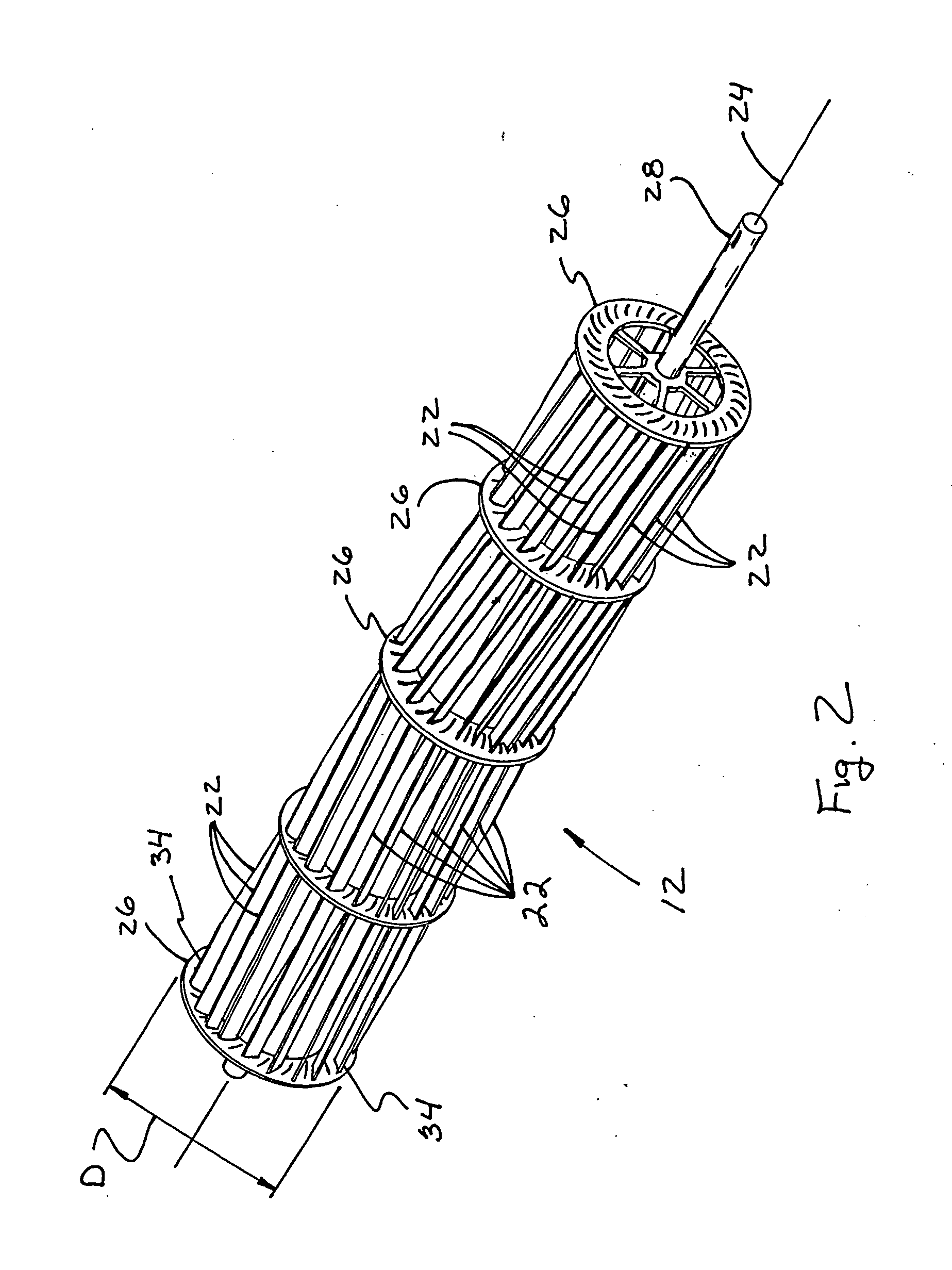

[0013] Referring now to the drawings, in FIG. 1, a representative agricultural combine 10 including a cross flow fan 12 constructed and operable according to the teachings of the present invention, for directing a flow of air, denoted by the arrows, upwardly through sieves 14 and 16 of a cleaning system 18, is shown. Cross flow fan 12 is located in a lower region of a chassis or frame of combine 10, generally beneath a threshing system 20, and the flow of air is directed toward sieves 14 and 16 by guides of sheet metal or other material (not shown) in the well known manner.

[0014] Referring also to FIG. 2, cross flow fan 12 includes a plurality of elongate fan blades 22 supported and held in an axial cylindrical, skewed pattern about a central rotational axis 24, by a plurality of axially spaced disk shape fan blade mounting members 26, supported on an axially extending shaft 28.

[0015] Referring also to FIG. 3, each fan blade mounting member 26 is preferably of molded construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com