Patents

Literature

153 results about "Permeate flux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permeation Flux. The membrane permeation flux is defined as the volume flowing through the membrane per unit area per unit time. The SI unit used is m3/m2.s although other are often used as well. For the case of transport of gases and vapors, the volume is strongly dependent on pressure and temperature.

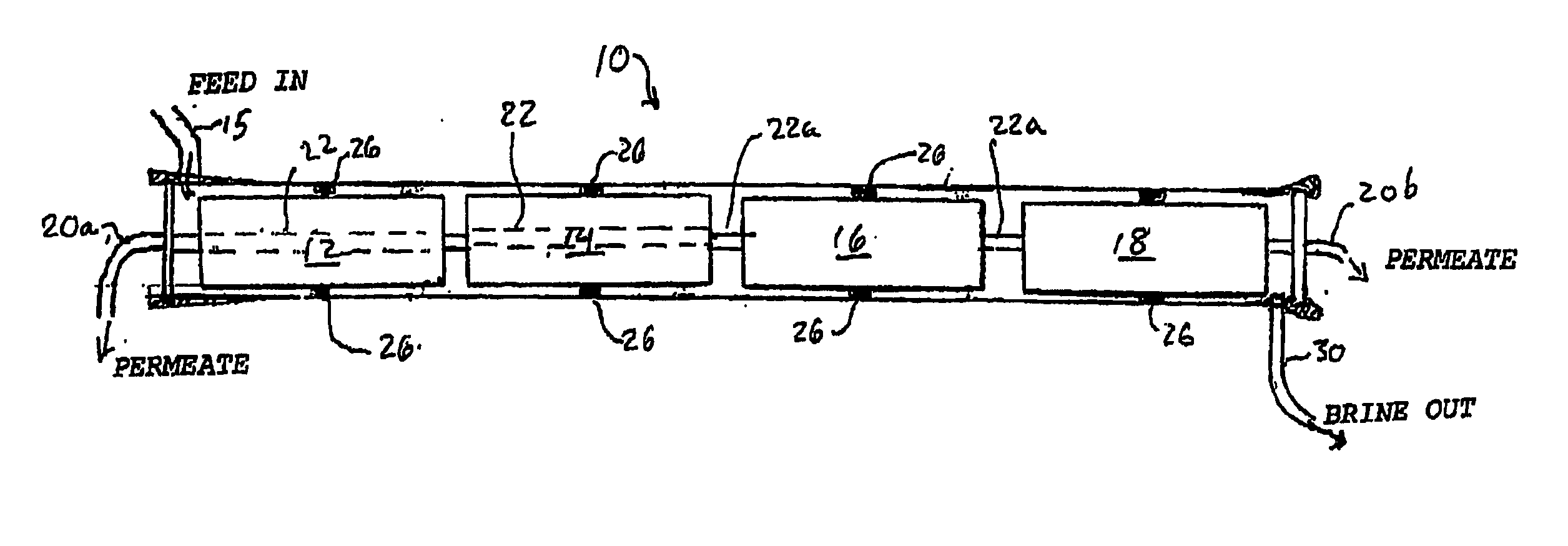

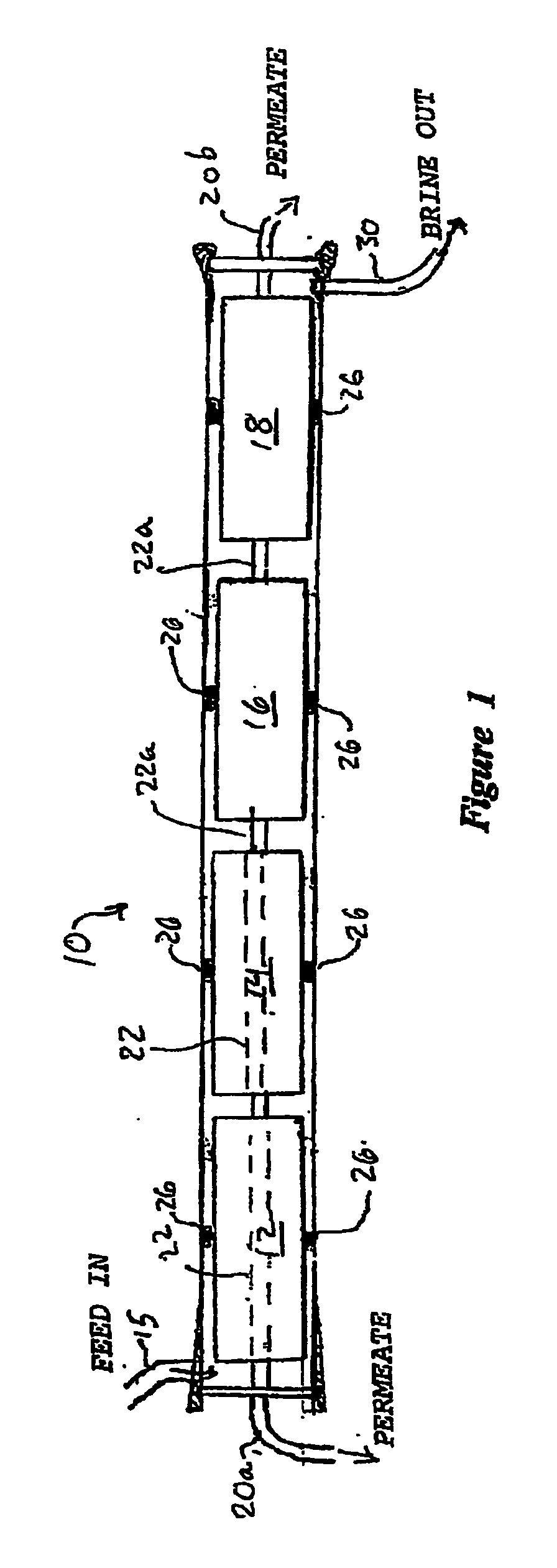

Branched flow filtraction and system

InactiveUS20050029192A1Improve operationImprove performanceMembranesWater/sewage treatment bu osmosis/dialysisReverse osmosisCross-flow filtration

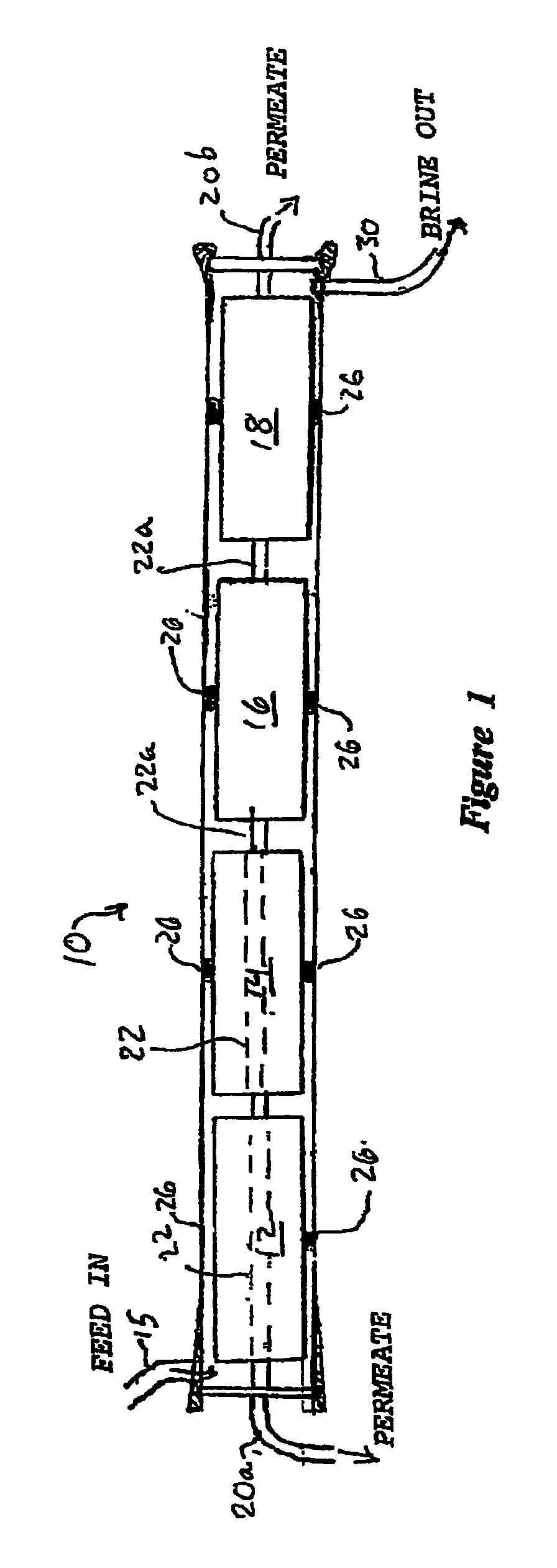

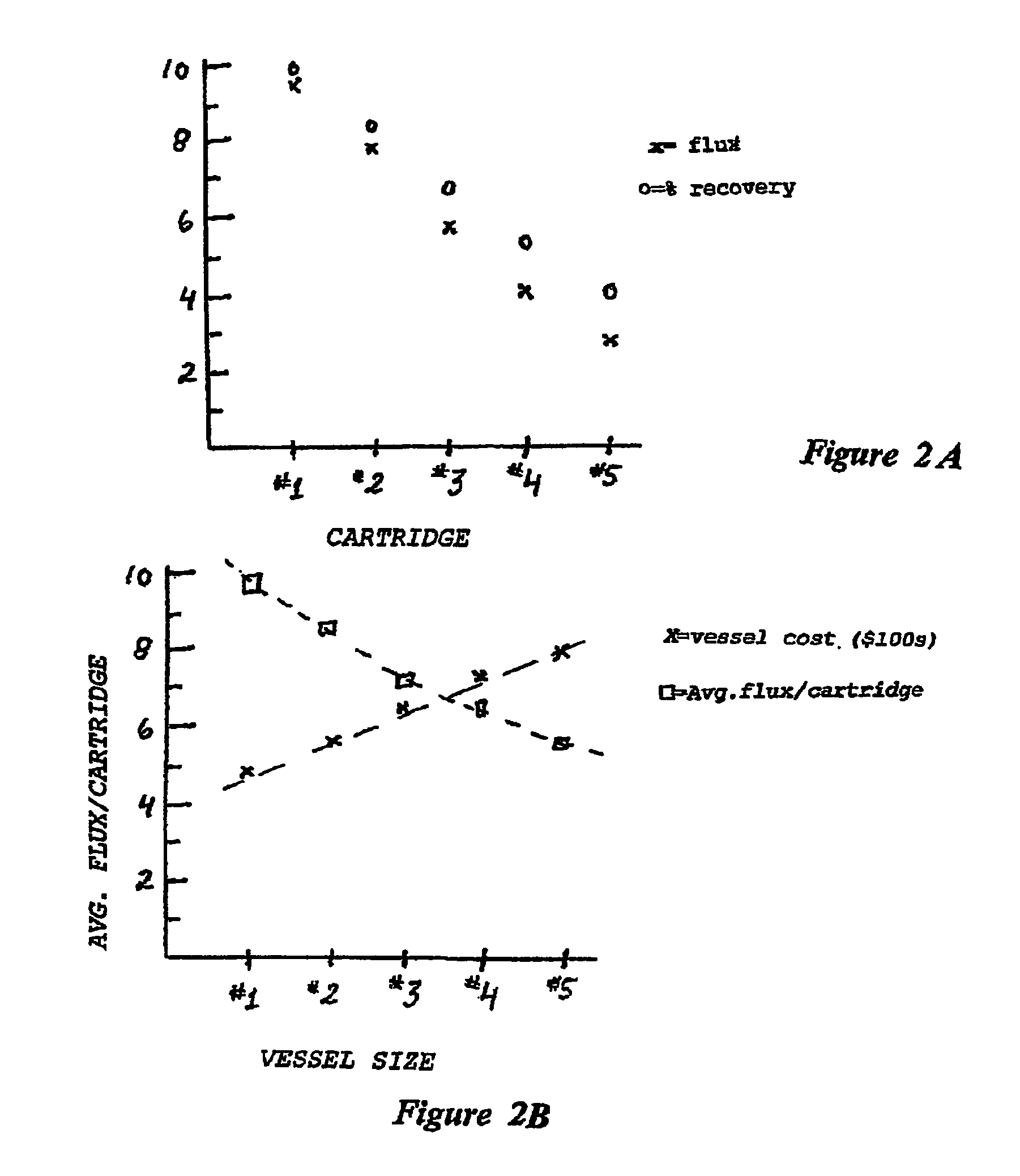

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

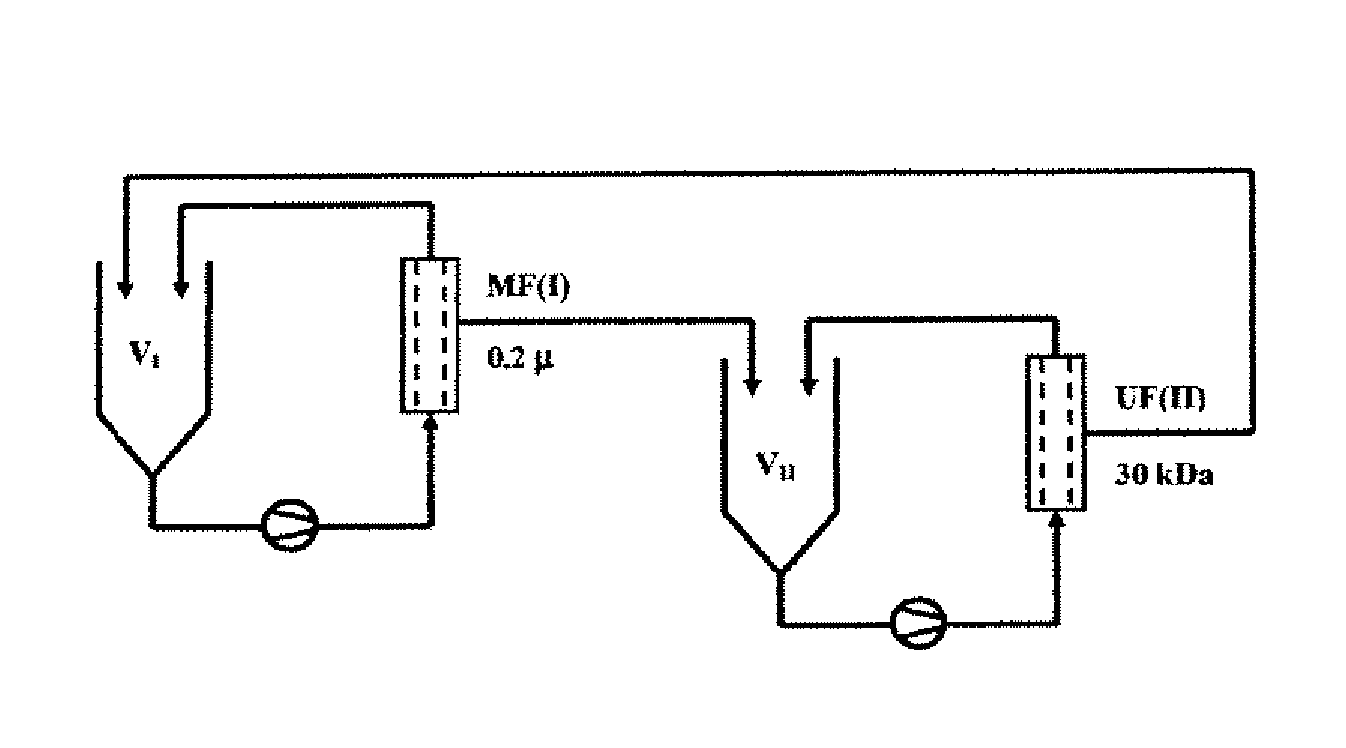

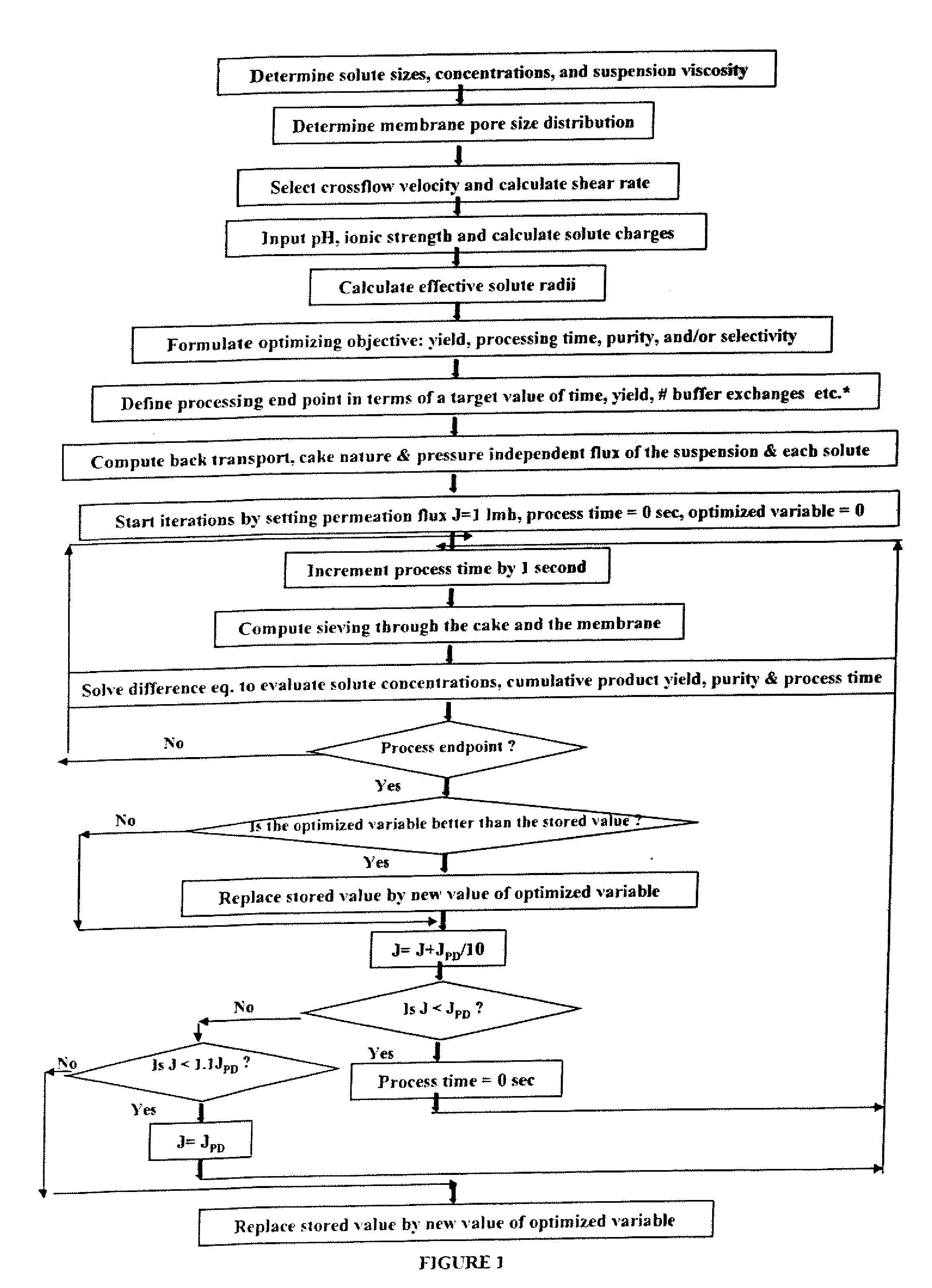

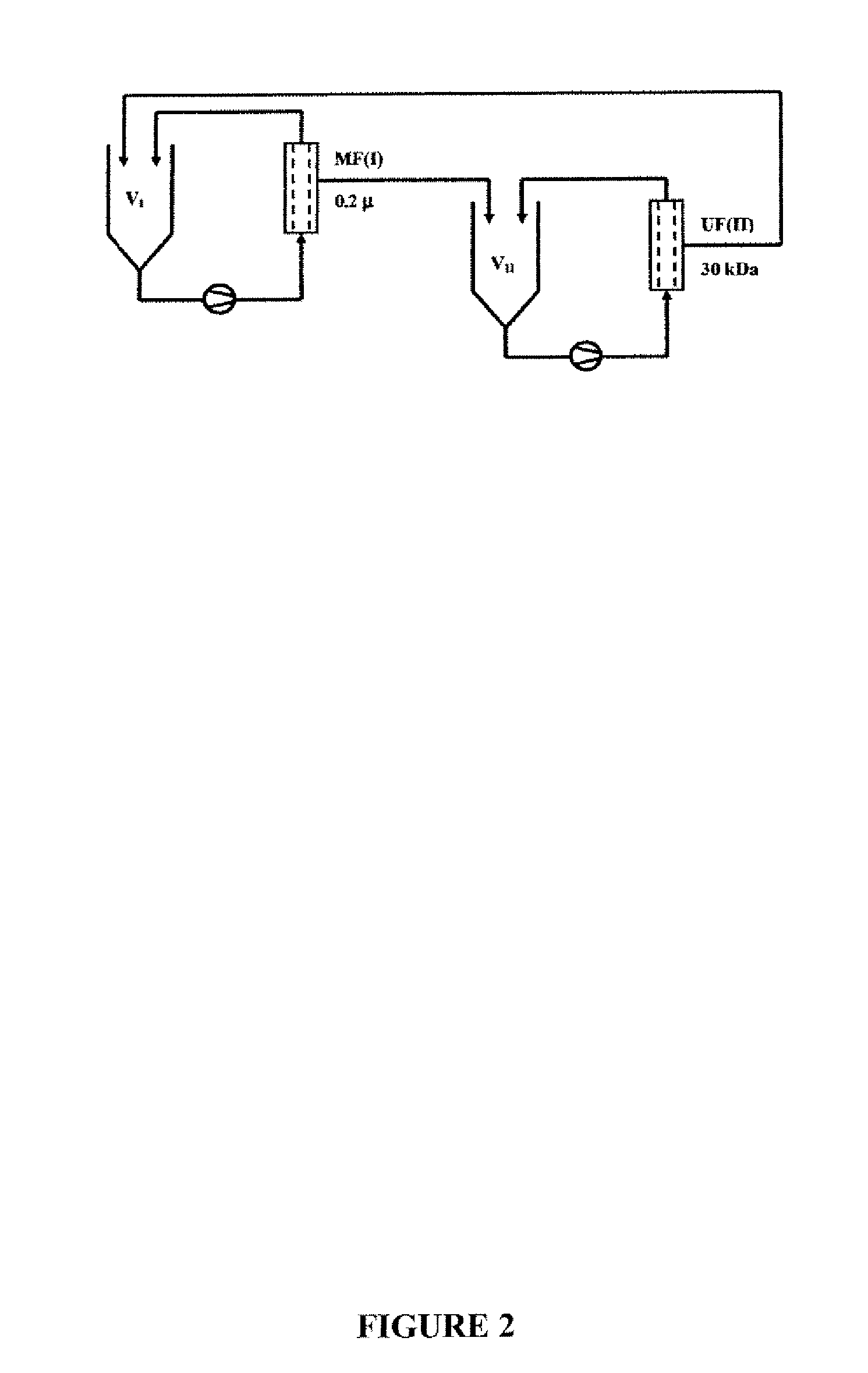

Global model for optimizing crossflow microfiltration and ultrafiltration processes

InactiveUS20080017576A1Realistic and rapid in silico MF/UF optimizationFill in the blanksMembranesUltrafiltrationChemical physicsSieving coefficient

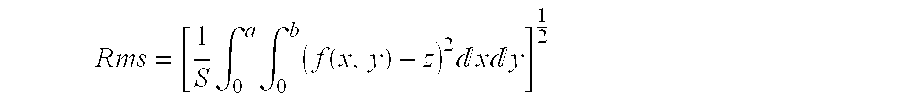

The present invention is a method for optimizing operating conditions for yield, purity, or selectivity of target species, and / or processing time for crossflow membrane filtration of target species in feed suspensions. This involves providing as input parameters: size distribution and concentration of particles and solutes in the suspension; suspension pH and temperature; physical and operating properties of membranes, and number and volume of reservoirs. The method also involves determining effective membrane pore size distribution; suspension viscosity, hydrodynamics, and electrostatics; pressure-independent permeation flux of the suspension and cake composition; pressure-independent permeation flux for each particle and overall observed sieving coefficient of each target species through cake deposit and pores; solving mass balance equations for all solutes; and iterating the mass balance equation for each solute at all possible permeation fluxes, thereby optimizing operating conditions. The invention also provides a computer readable medium for carrying out the method of the present invention.

Owner:RENESSELAER POLYTECHNIC INST

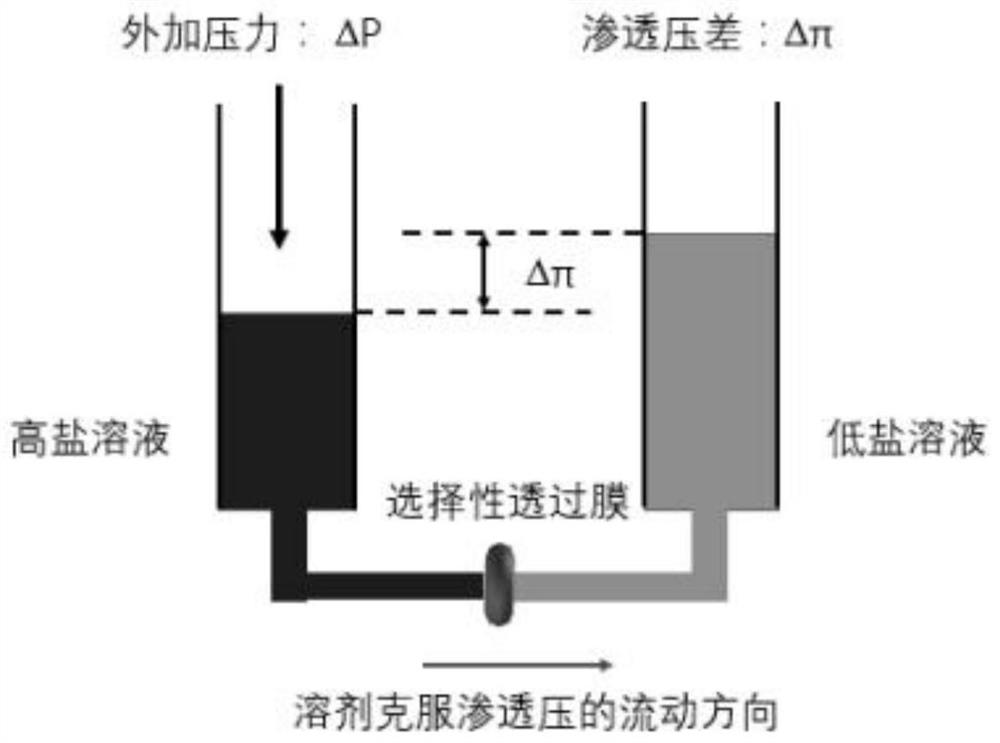

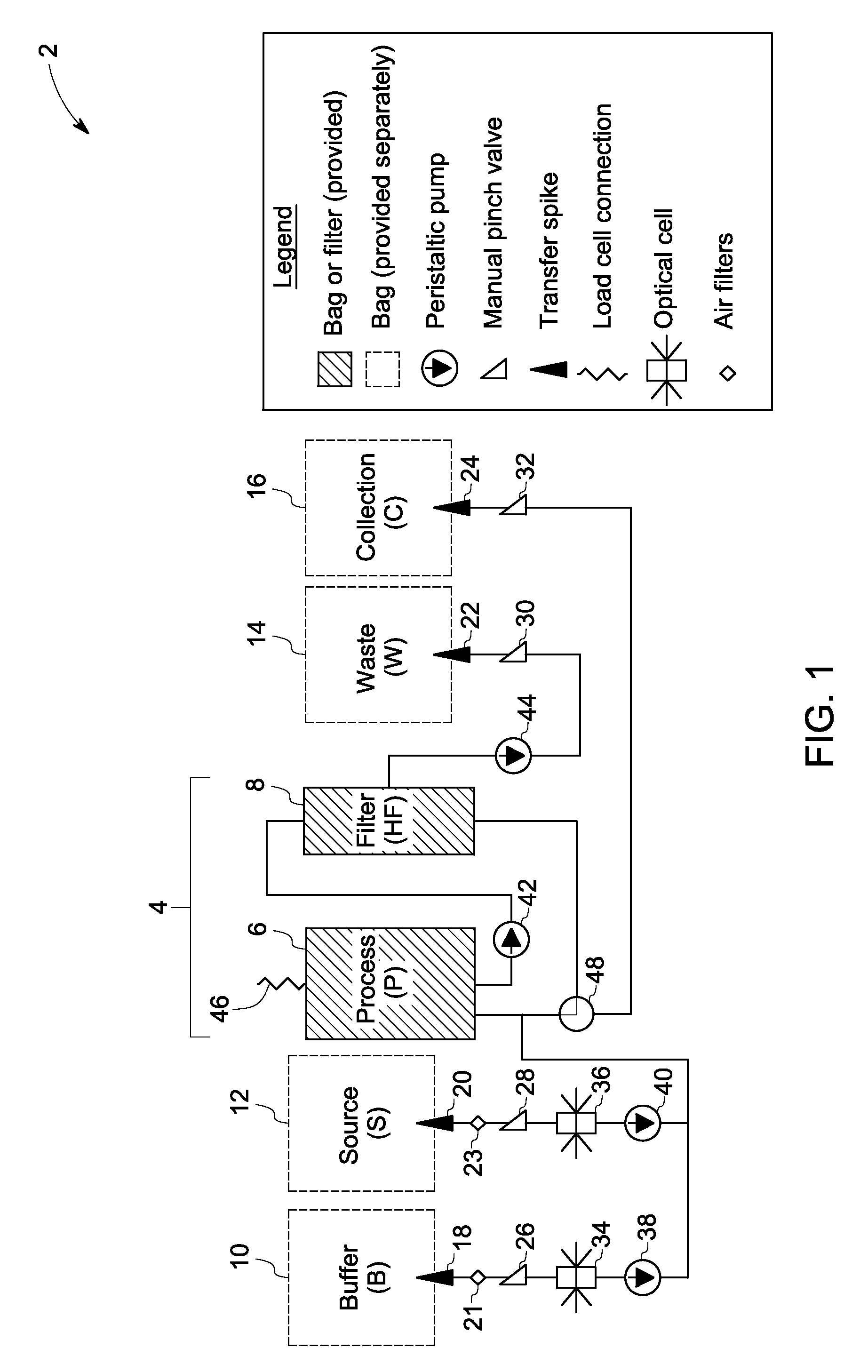

Induced symbiotic osmosis [iso] for salinity power generation

ActiveUS20110044824A1Reduce excessive wasteMaximizing membrane efficiencyFlexible member pumpsServomotorsHigh concentrationConcentration ratio

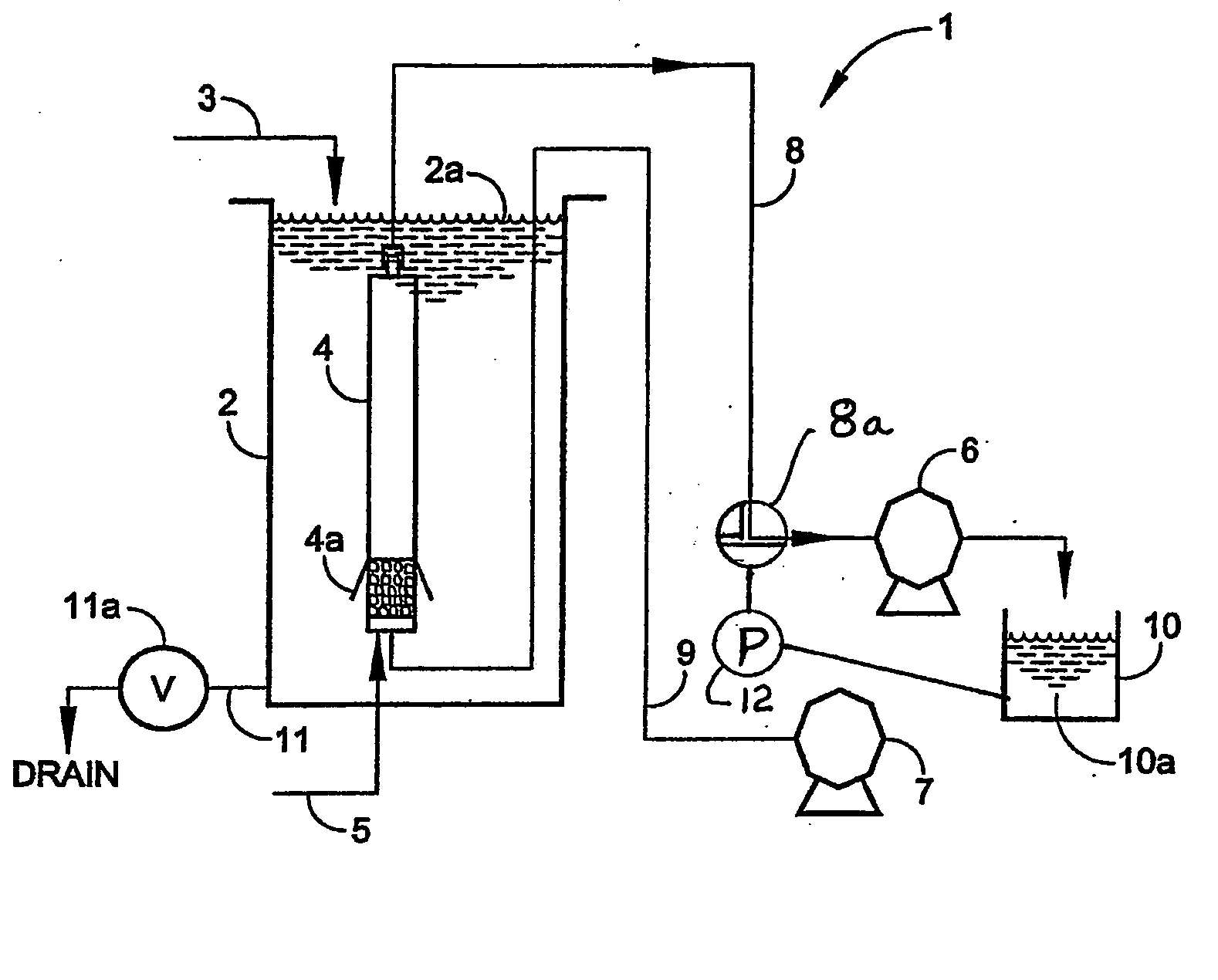

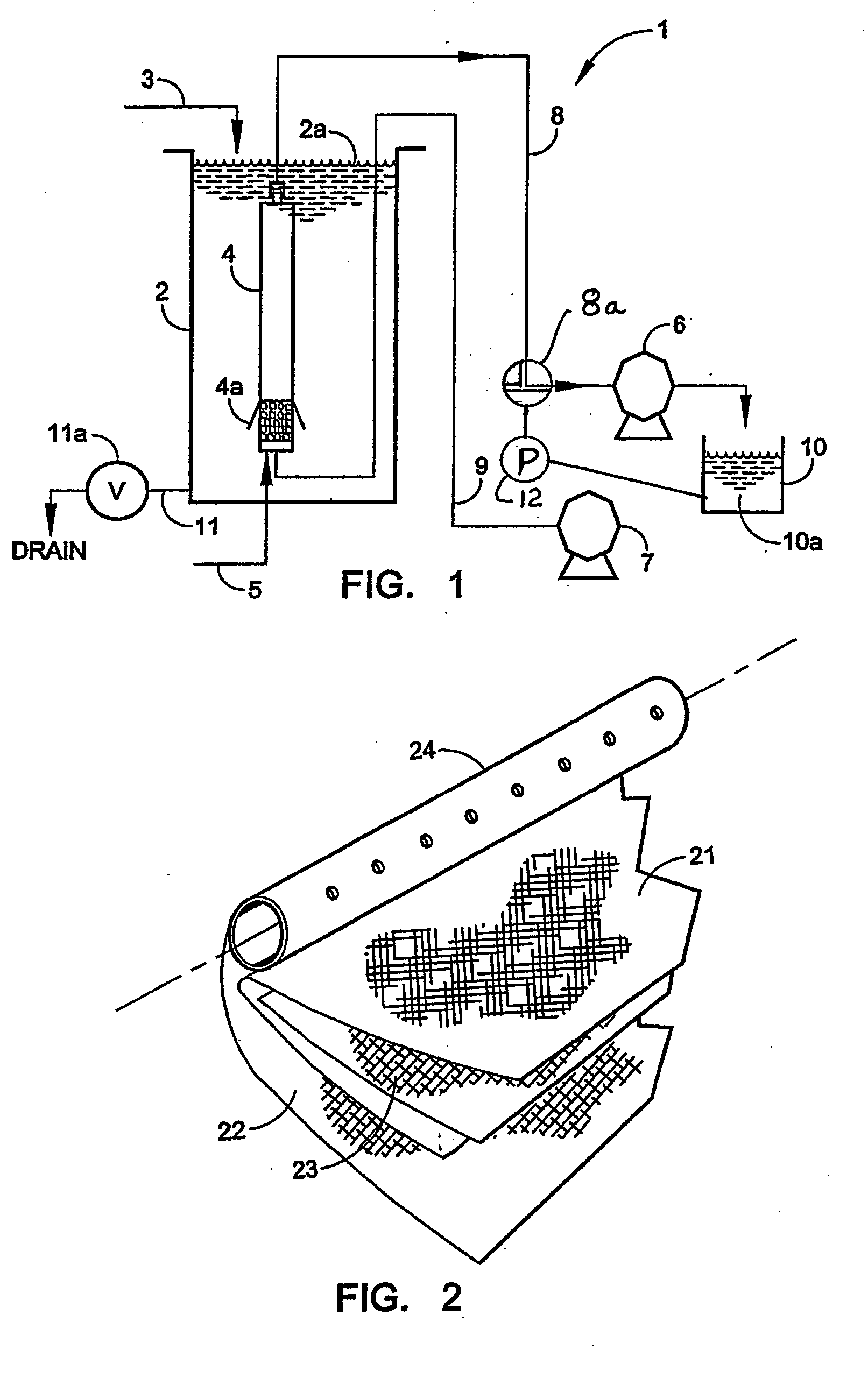

A method and apparatus for renewable power generation utilizes the chemical potential dissimilarity between solutions of differing ionic formulations. A train is formed by a sequentially ordered set of a plurality of cells in which each successive cell is related to the preceding cell. Each cell has pumping means and hydro-power generation turbine means to form a closed hydraulic loop configured for specified volumetric and flow capacity. Adjacent cells share semipermeable membranes. Each cell is charged with a brine of specified ionizable inorganic salt quantity and type with the brine being cycled in a controlled concentration-pressure loop, with each of the cells operating at progressively increasing concentration and osmotic pressure ratio. A continuous and constant flow rate of substantially salt-free permeate flux is maintained across each cell, the flux being osmotically induced from low salt concentration water being fed at the first cell in the train and exiting at the last cell along with the discarded high concentration water brine. The salt-free permeate flux is continuously induced, in symbiotic mode, through the shared membranes, driven by the chemical influence of concentration potential field bounded by water of low to no salt concentration on one end of the train and by brine of high salt concentration on the other end of the train with sufficient concentration difference to provide driving force for said plurality of cells, while maintaining adequate concentration difference between adjacent cells to enhance osmosis function, as well as defining a concentration ratio within each cell to ensure a net positive power generation.

Owner:KELADA MAHER ISAAC

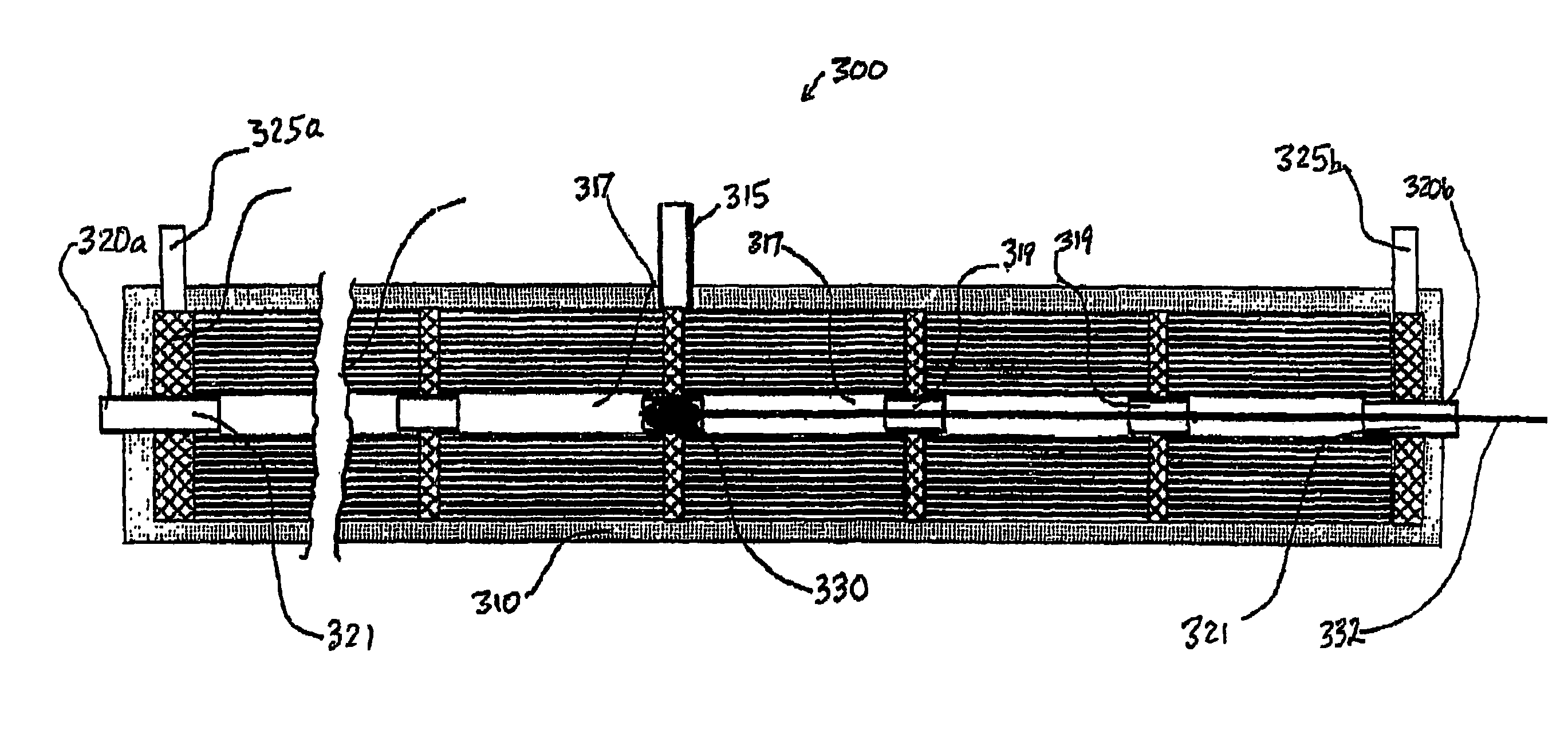

Branched flow filtration and system

InactiveUS7410581B2Improve operationImprove performanceMembranesReverse osmosisCross-flow filtrationReverse osmosis

A cross flow filtration apparatus for nanofiltration or reverse osmosis has pressure vessels with a plurality of filter cartridges in each vessel. A feed port is provided at an intermediate position on the side of the vessel, and two permeate flows or branches exit opposite ends of the vessel, and the first branch has a characteristically high “upstream” flux and quality, while the second is of lesser flux and / or quality. The system provides a high degree of moduarity, enhancing flux or yield at a reduced driving pressure or overall pressure drop. Centered or off-center port, and a stop or valve in the permeate stream may apportion flows between the two outlets. Staged systems may employ a first stage bypass to achieve a target quality with increased yield. A flow divider or adaptor permits the cartridges to fit and seal in the vessel and an installation tool or sleeve may facilitate installation or replacement of cartridges having a directional perimeter seal. A tool permits modules to be bi-directional installed in the pressure vessel. Other embodiments involve adapting a conventional vessel designed for end-to-end feed flow utilizing a restrictor, obstruction or valve inside the filter cartridge to bifurcate or otherwise split or apportion the permeate. RO elements may be modified to movably position an obstruction or valve along a string of the elements and vary the take-off to two or more permeate outlets, or to provide pressure relief valves that present different pressure conditions for different elements of a string. A pressure vessel may have an intermediate inlet, with symmetric or asymmetric branching of permeate flow to opposed ends of the vessel, enhancing permeate flux, permeate quality and / or energy efficiency.

Owner:IONICS INC

Low pressure filtration

ActiveUS20070131614A1Produced economicallyReduce energy consumptionMembranesUltrafiltrationFiltrationStreamflow

High flow, low-pressure ultrafiltration or microfiltration spiral wound membrane cartridges are used in filtration of liquid feedstocks having high suspended solids. Applications may utilize either vacuum or pumping for transmembrane drive pressure (TMP), and gas may optionally be bubbled up through the cartridges with certain feedstocks. Water permeate flux rates as high as 90 gallons per square foot per day (gfd) can be obtained at TMPs below 5 pounds per square inch. By locating each spiral wound cartridge in its own casing and supplying liquid feedstock to an open lower end of the casing, as opposed to submerging such cartridges in a tank filled with feedstock, overall low pressure performance is greatly improved. High permeate flow can be maintained for long periods of time between shutdowns for intensive cleaning. TMP is gradually increased to maintain a substantially constant rate of permeate discharge until a target is reached, indicative of solids accumulation on the membrane surface to an undesirable extent; then backflushing is effected for a short time. Discarding the hold-up volume of feedstock in the cartridge, the backflushing fluid and dislodged solids, allows production to be promptly resumed with fresh feedstock at performance at near original levels.

Owner:MANNHUMMEL WATER & FLUID SOLUTIONS GMBH

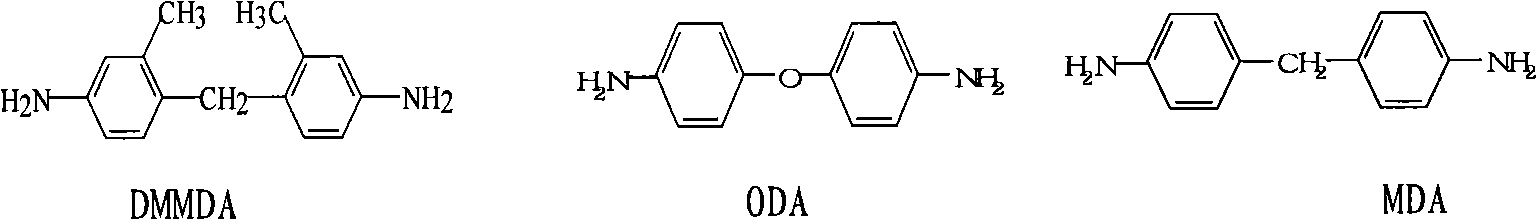

Polysulfonamide matrices

InactiveUS6837996B2Semi-permeable membranesLoose filtering material filtersSemipermeable membranePermeate flux

Sulfonamide polymer matrices and their various uses are disclosed. Among the uses is the configuration of the matrix with a porous support membrane to form a semipermeable membrane of the invention. The matrix of the invention is ultrathin, dense and substantially free of defects. The matrix configuration as the semipermeable membrane shows improved permeate flux and retention values.

Owner:GE OSMONICS INC

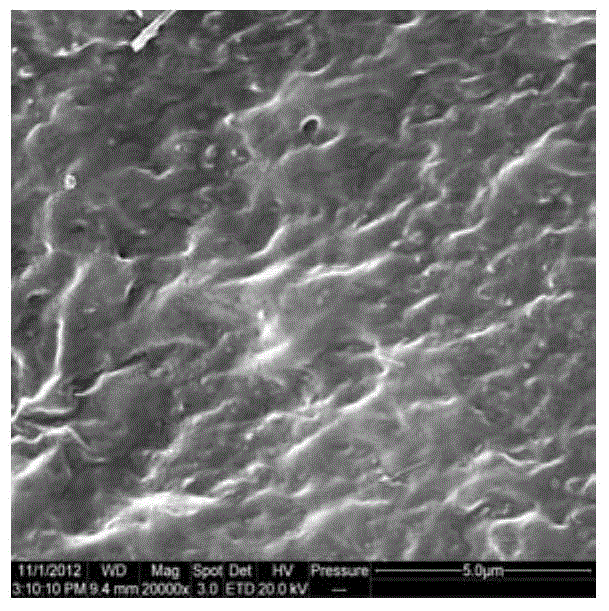

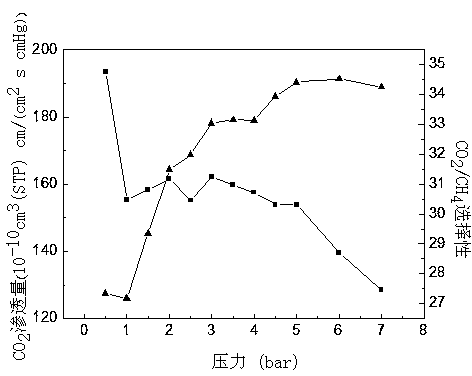

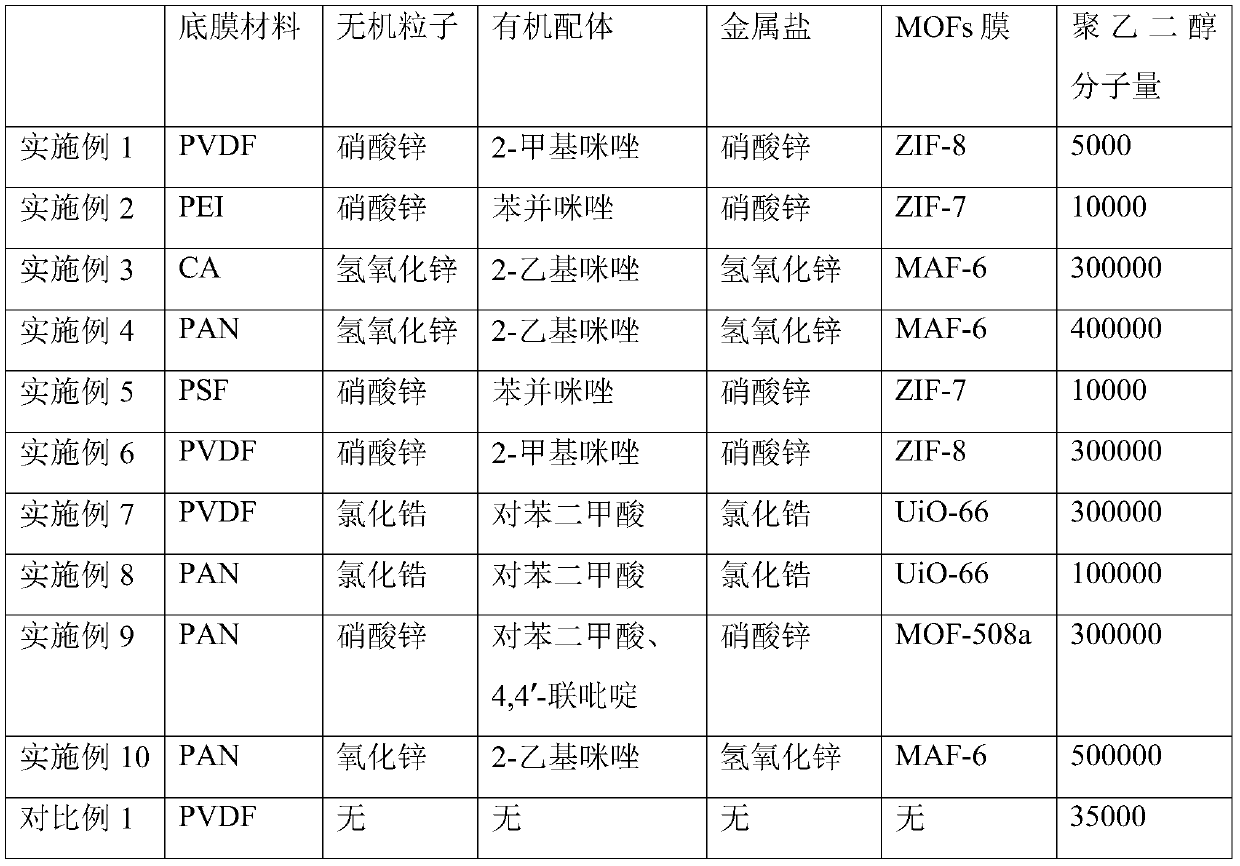

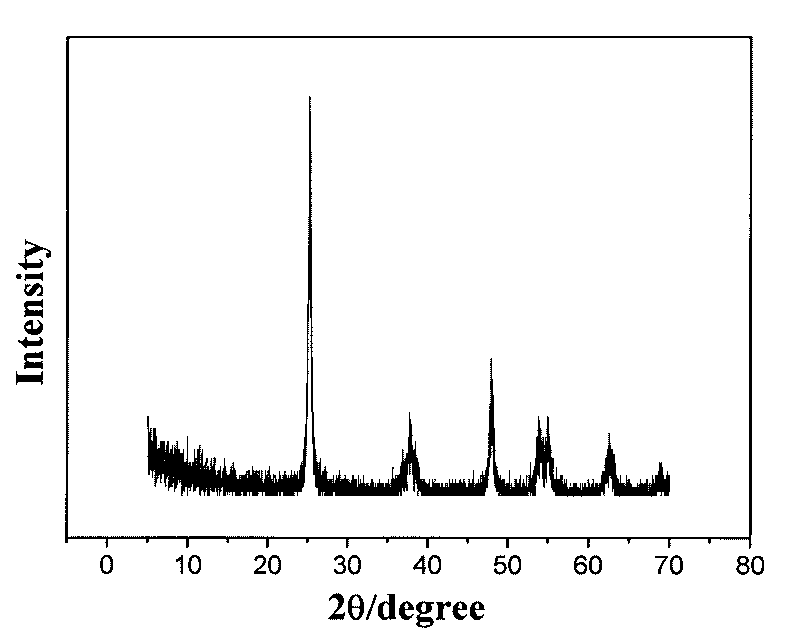

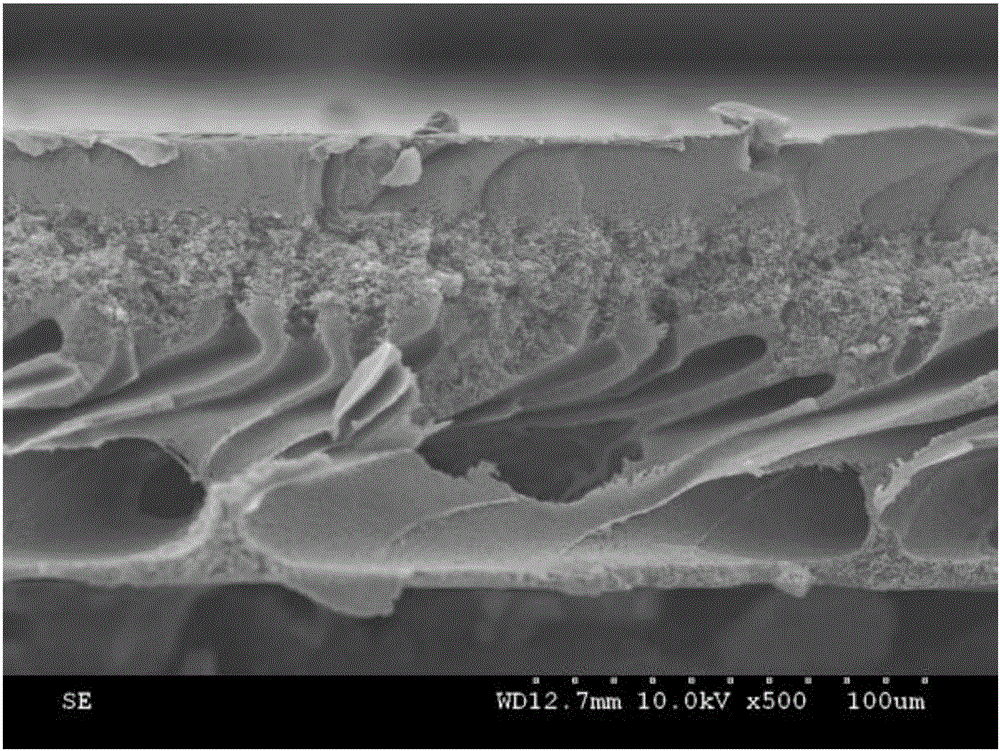

Preparation method and application of graphene oxide composite membrane

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

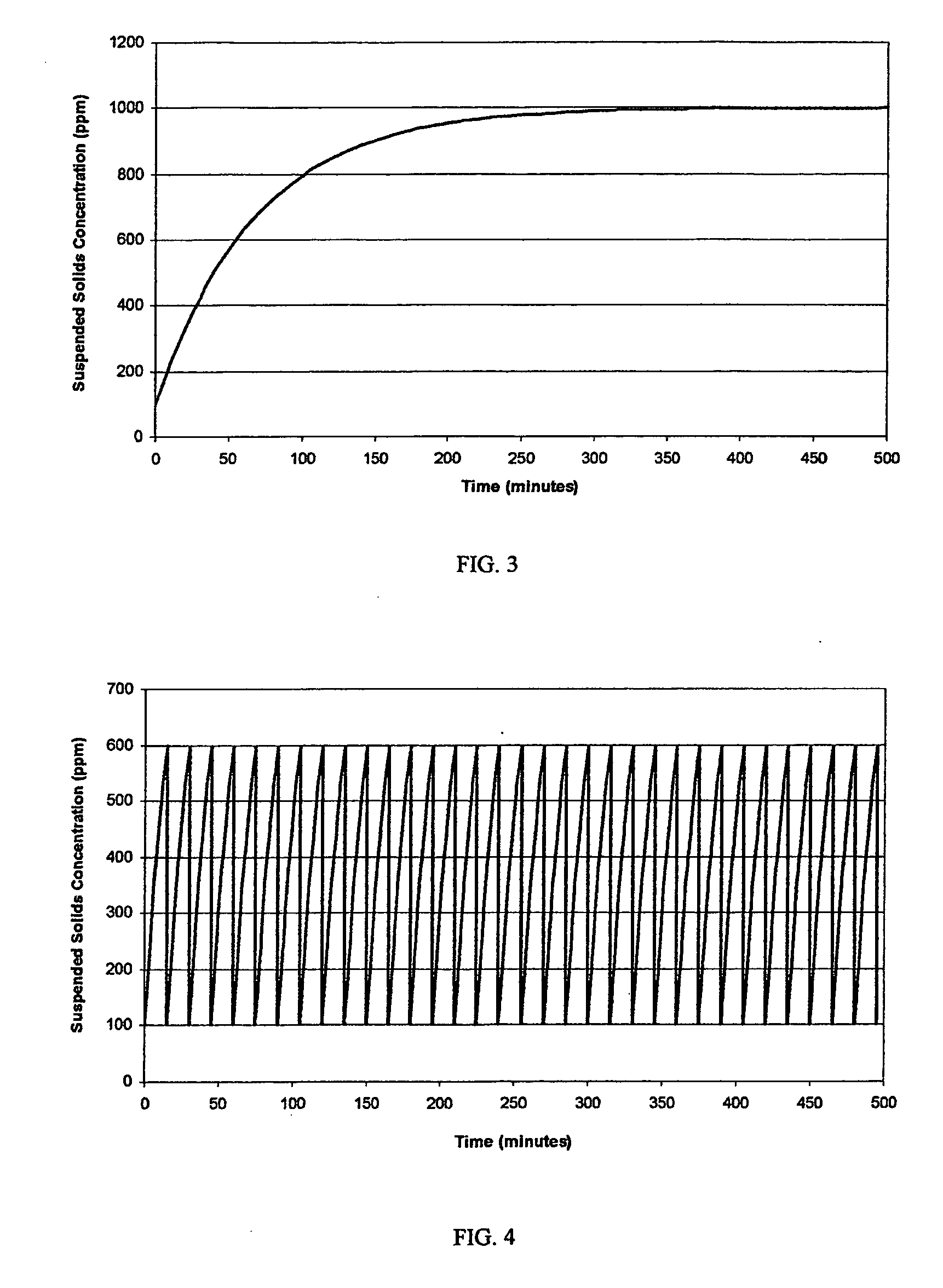

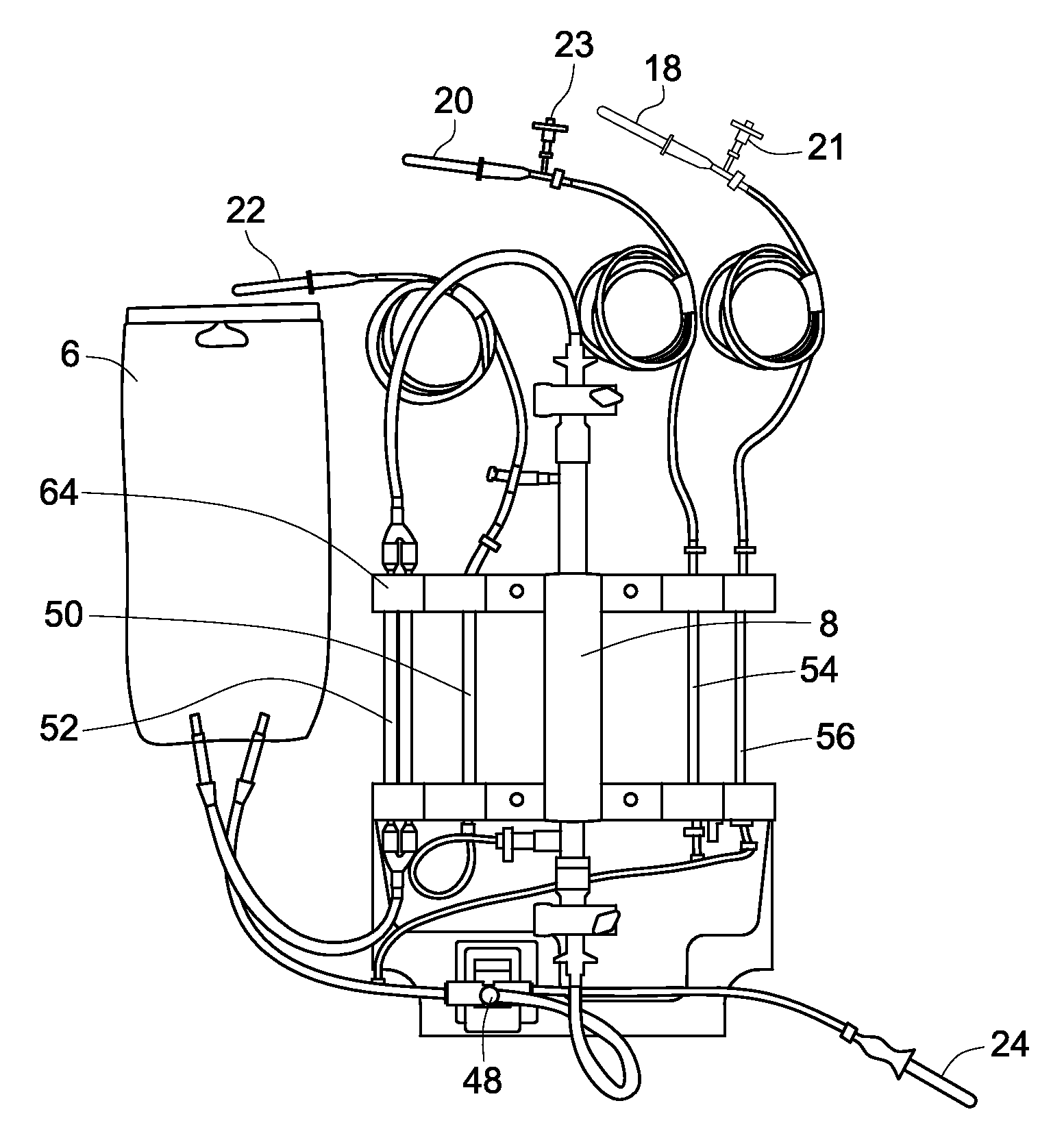

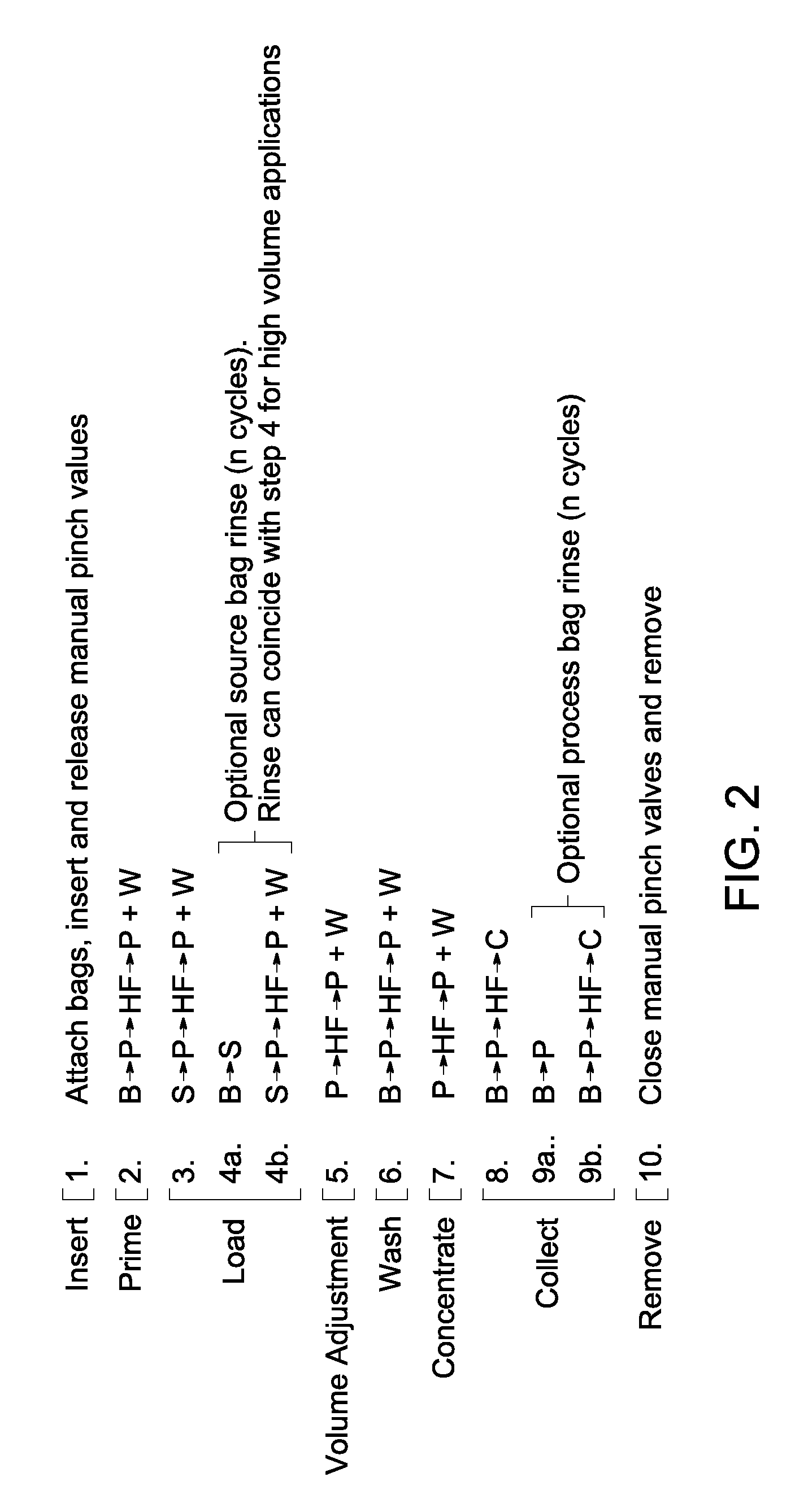

Systems, methods and control laws for cell harvesting

ActiveUS20130029411A1Quality improvementBioreactor/fermenter combinationsBiological substance pretreatmentsSource materialParallel computing

The methods of harvesting cells are provided, wherein the methods comprise introducing a processing material and a source material into a processing loop. The processing loop comprises a processing chamber and a filtering device. The processing material and the source material are circulating through the processing chamber and the filtering device, wherein the processing chamber has a mass; balancing an influx of the processing material into the processing chamber with a permeate flux of the filtering device to maintain the mass of the processing chamber at a constant value; and collecting the cells in a collection chamber. Cell harvesting devices are also provided for processing and harvesting cells using a control law to balance the mass of the processing chamber through the entire process.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

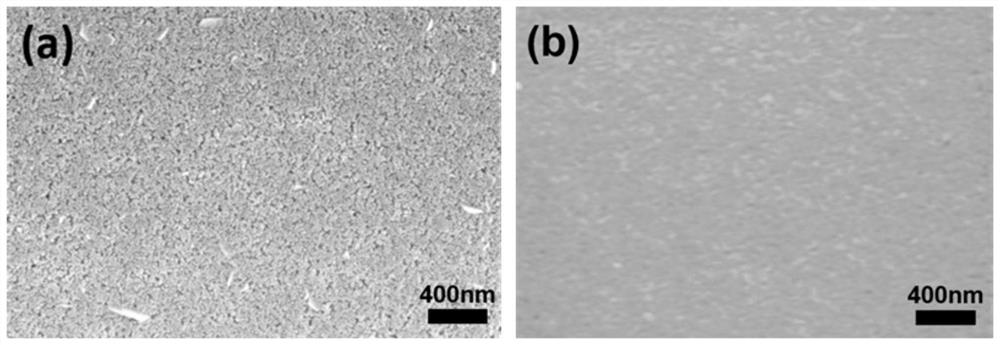

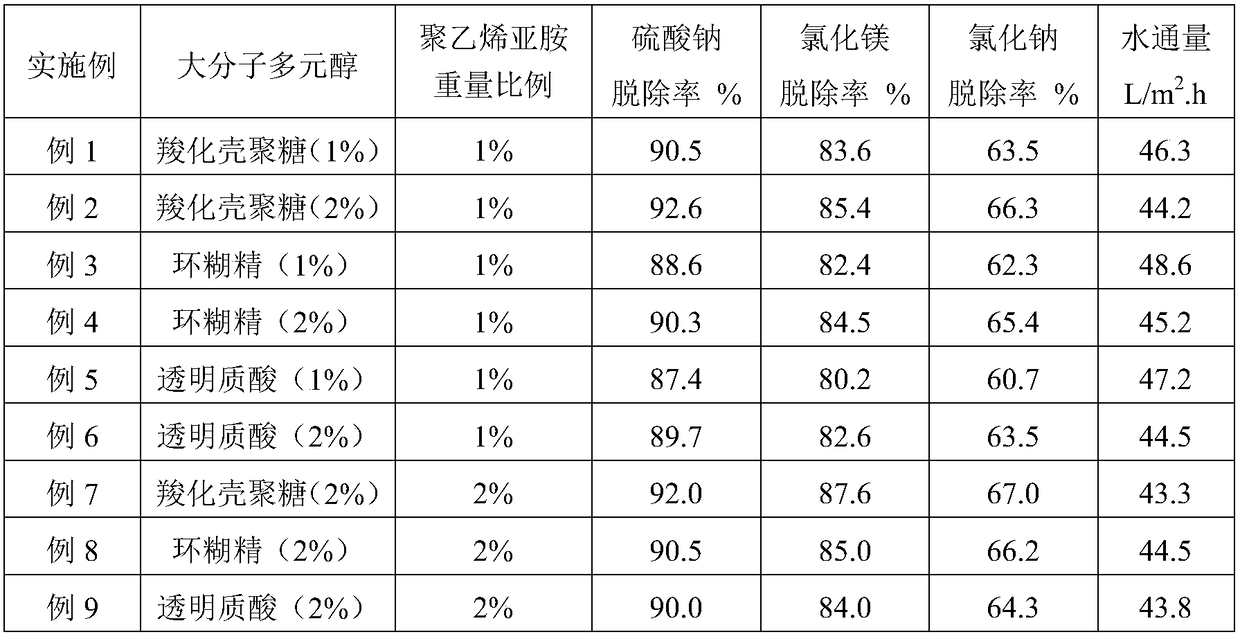

Polyester polyamide amphoteric charge composite nanofiltration membrane and preparation method thereof

The invention discloses a polyester polyamide amphoteric charge composite nanofiltration membrane and a preparation method thereof. The method comprises the following steps: firstly, enabling a polysulfone microporous support membrane to make contact with a macromolecular polyol aqueous solution, washing the surface and then drying in the air; secondly, enabling the dried polysulfone microporous support membrane to make contact with a trimesoyl chloride organic phase solution and carrying out single-sided interface polymerization reaction to form a composite membrane with an ultra-thin polyester layer; thirdly, enabling the composite membrane to make contact with a polyethylene imide aqueous solution, carrying out secondary interfacial polymerization reaction by utilizing residual acyl chloride to form an ultra-thin polyamide layer; fourthly, successively carrying out surface washing, drying and heat treatment to obtain the amphoteric charge composite nanofiltration membrane. The composite nanofiltration membrane disclosed by the invention has high permeate flux and retention rate; in addition, the preparation method has the advantages of simplicity, controllable reaction and capability of adjusting the separation performance of the membrane in a wider range.

Owner:HUNAN KEENSEN TECH CO LTD

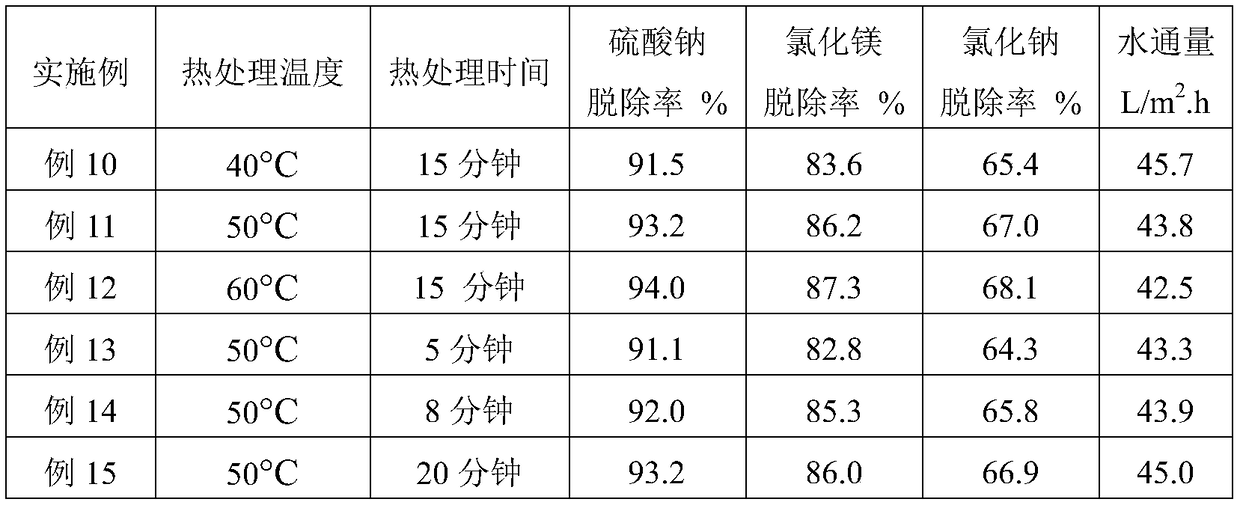

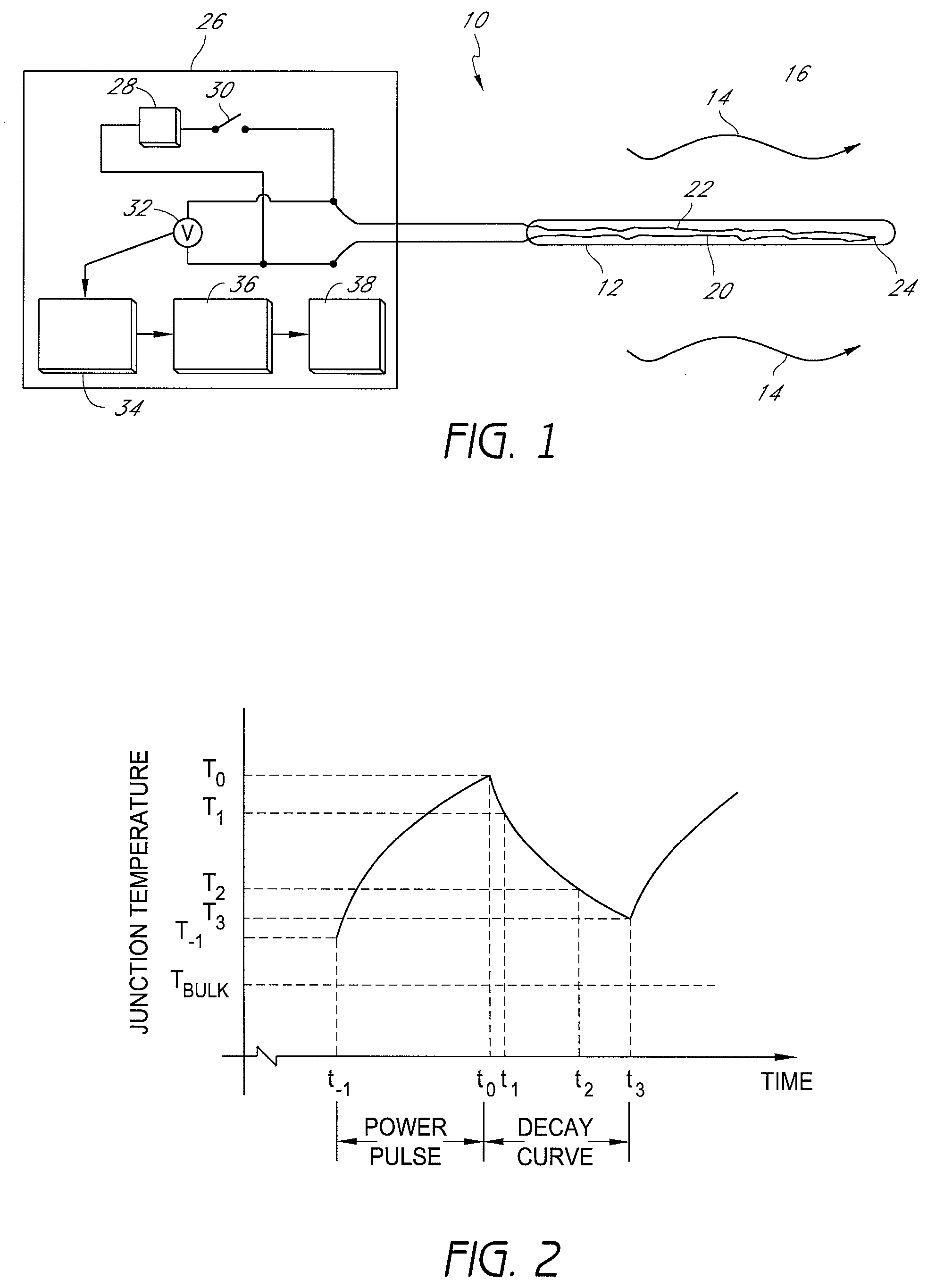

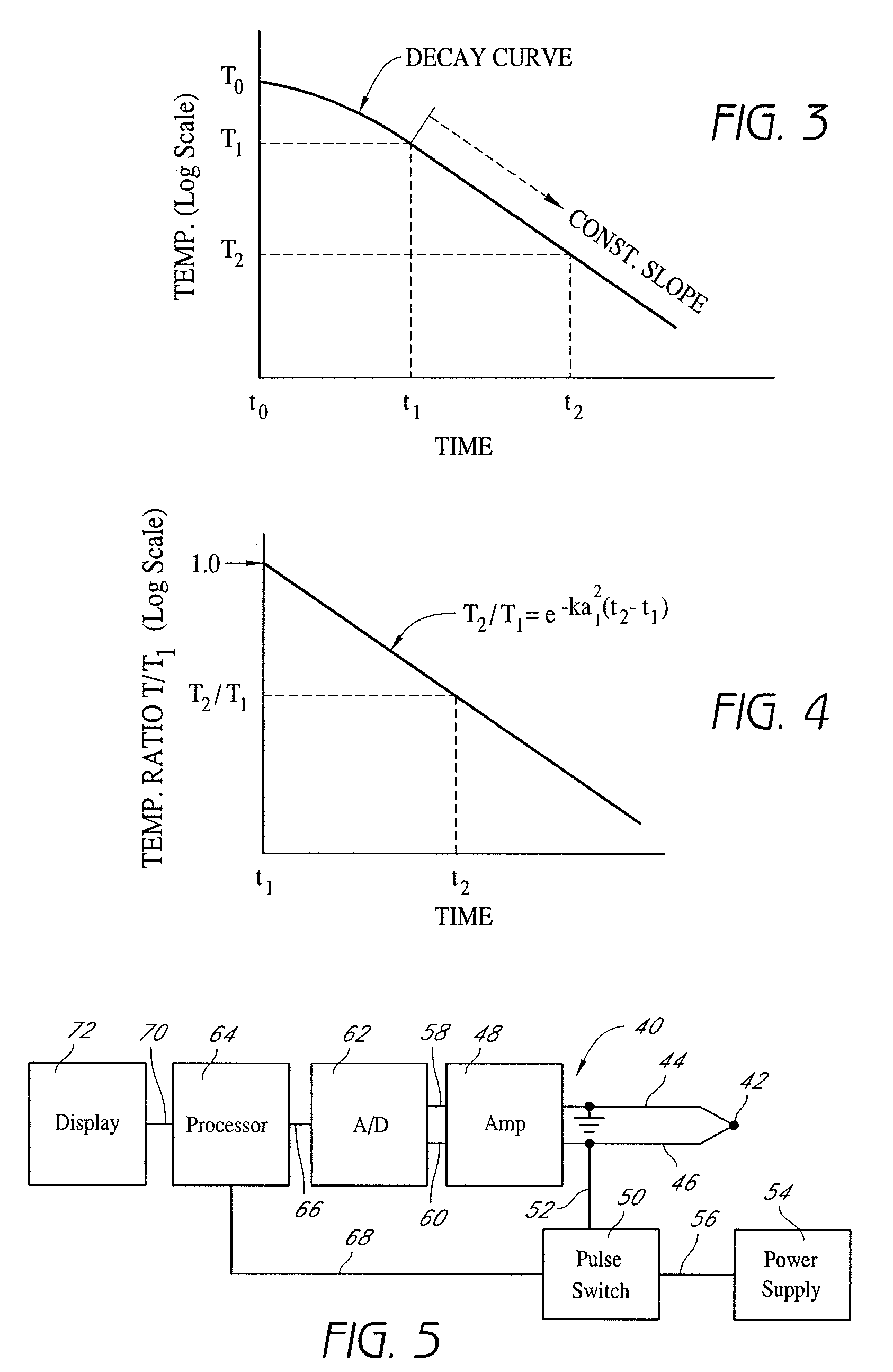

Device for measuring permeate flow and permeate conductivity of individual reverse osmosis membrane elements

InactiveUS7584061B2Improve system performancePlug gaugesMembranesWireless transmissionReverse osmosis

The present disclosure relates to a system comprising an integrated sensor for measurement of permeate flow and permeate conductivity of individual membrane elements while they are in operation in an RO unit. The flow and conductivity measuring integrated sensor is of a small size that enables it to be inserted into the permeate tube of connected membrane elements during RO unit operation. Measured flow and conductivity information is transferred to the recording device through electric wires or through wireless transmission.

Owner:NITTO DENKO CORP +1

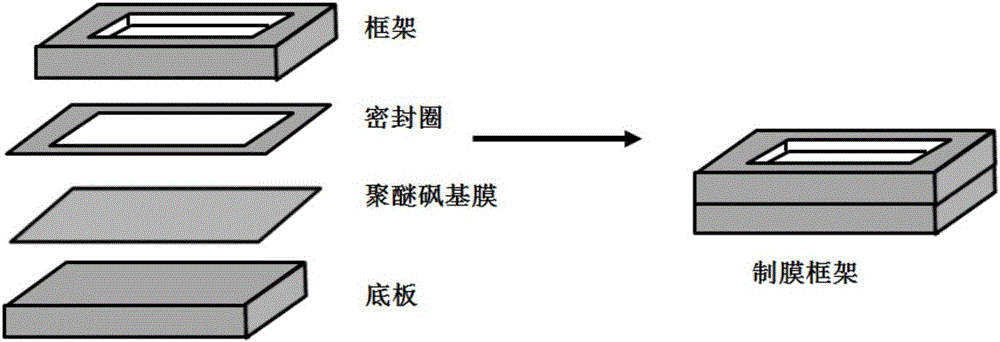

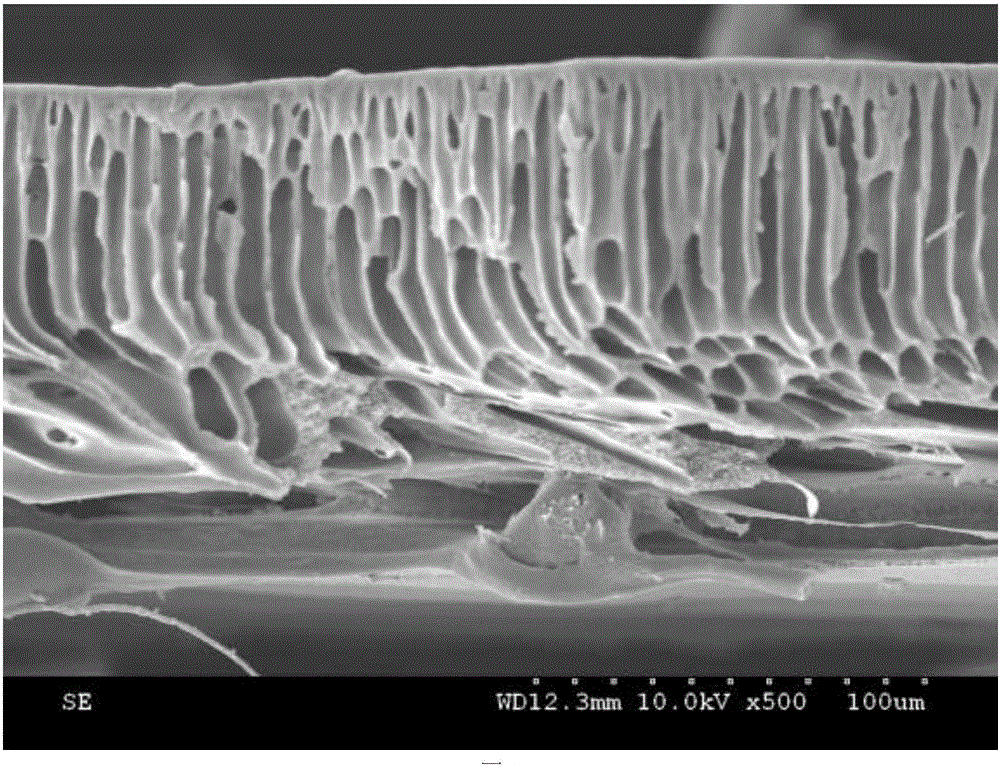

Preparation method of polyethersulfone-based composite positive permeable membrane

InactiveCN105771703AHigh porosityImprove hydrophilicitySemi-permeable membranesMembranesPorosityPolyethylene glycol

The invention discloses a preparation method of a polyethersulfone-based positive permeable membrane, and relates to the field of membrane separation. The method comprises the following steps: dissolving polyethersulfone and polyethylene glycol in a solvent; coating membrane casting fluid on a low-temperature glass plate; leaving the membrane casting fluid to stand on the glass plate, and enabling the membrane casting fluid to generate thermally induced phase separation; finally immersing the glass plate into water, and enabling the solvent to be removed. The prepared base membrane is prepared into a polyamide separating layer by an interfacial polymerization method, the base membrane is sequentially immersed into an m-phenylene diamine-aqueous solution of which the percentage by weight is 1.0-4.0wt% and a trimesoyl chloride-hexane solution of which the percentage by weight is 0.05-0.2wt%, and finally heat treatment is performed at 60 DEG C for 300 s so that the polyethersulfone-based composite positive permeable membrane is obtained. The polyethersulfone-based composite positive permeable membrane prepared by the method disclosed by the invention has high hydrophilicity and porosity, and besides, a fault surface adopts a perforated finger shaped structure. Tests on properties of the composite membrane indicate that the composite membrane prepared by the method disclosed by the invention has a high permeation flux and a high interception rate.

Owner:BEIJING UNIV OF TECH

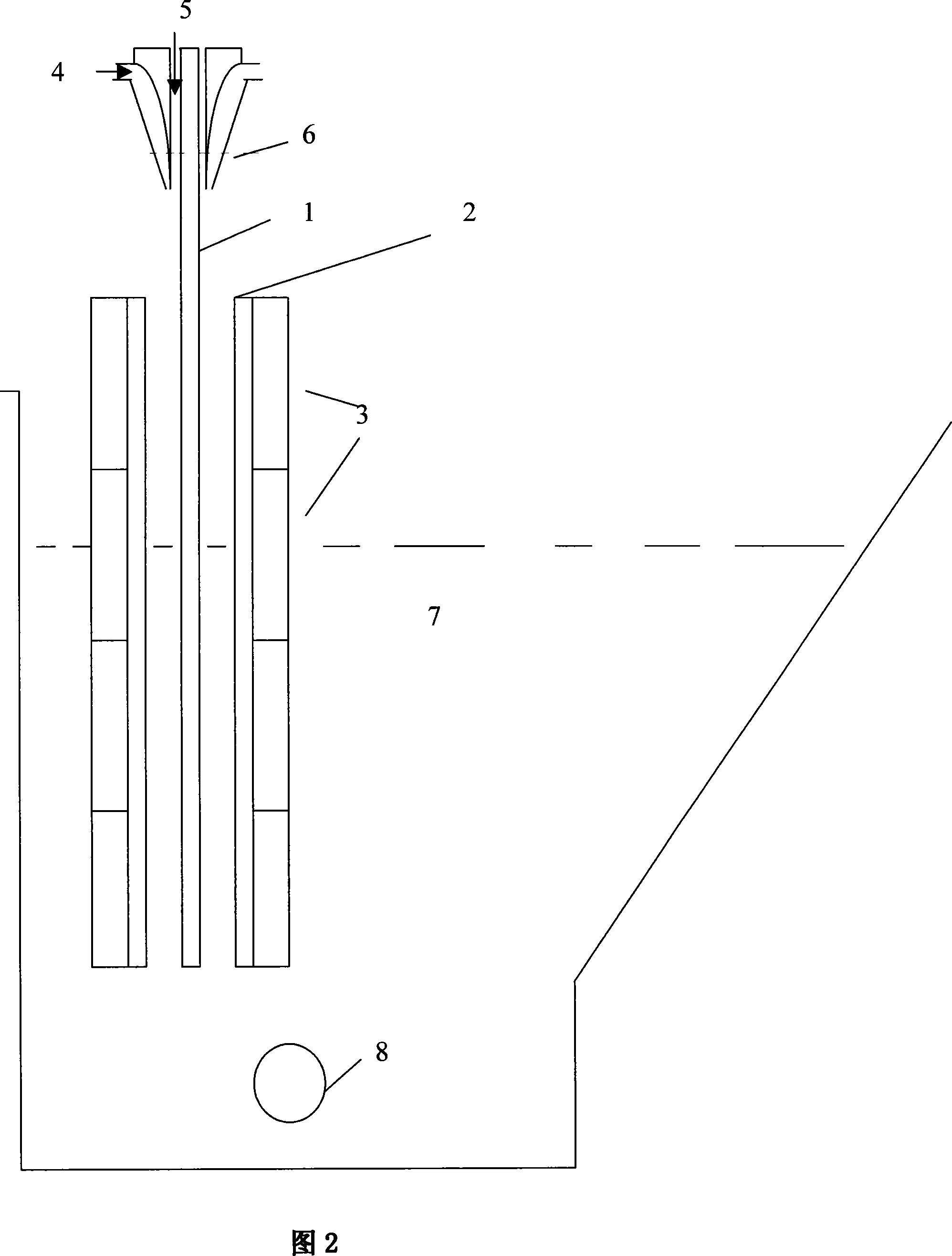

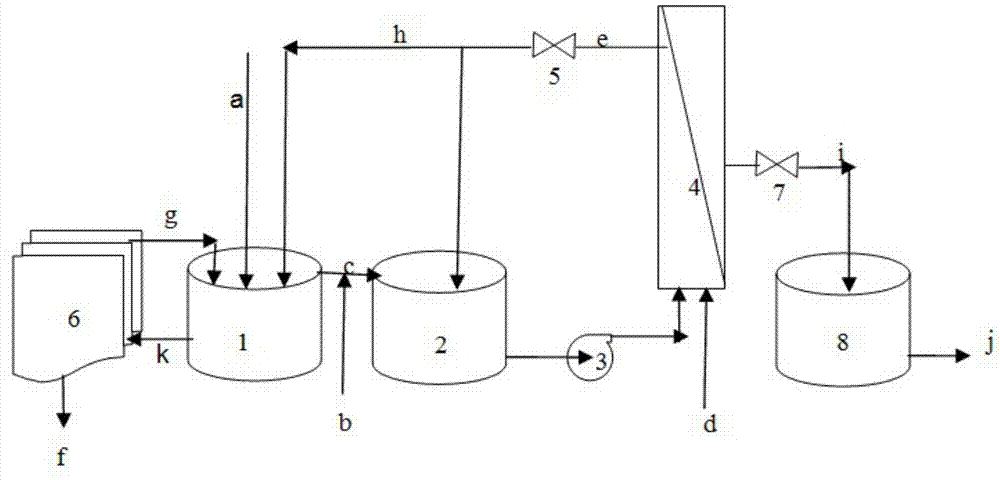

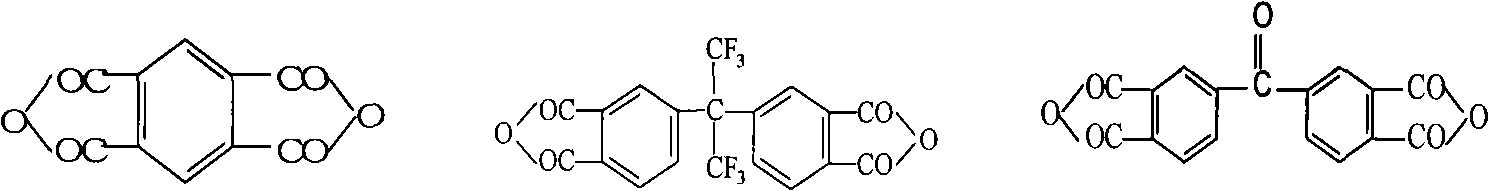

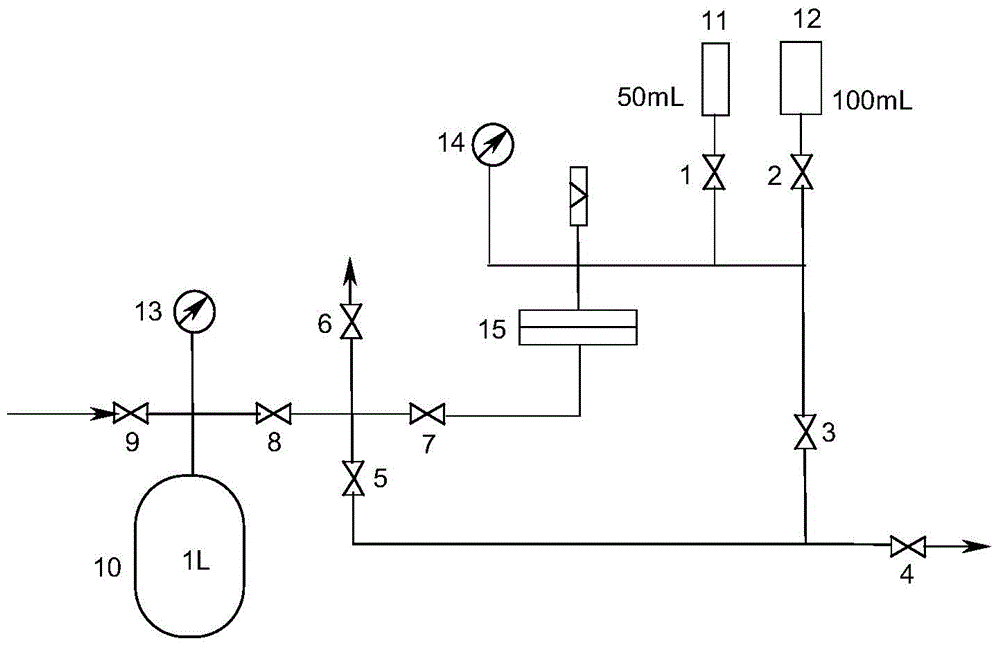

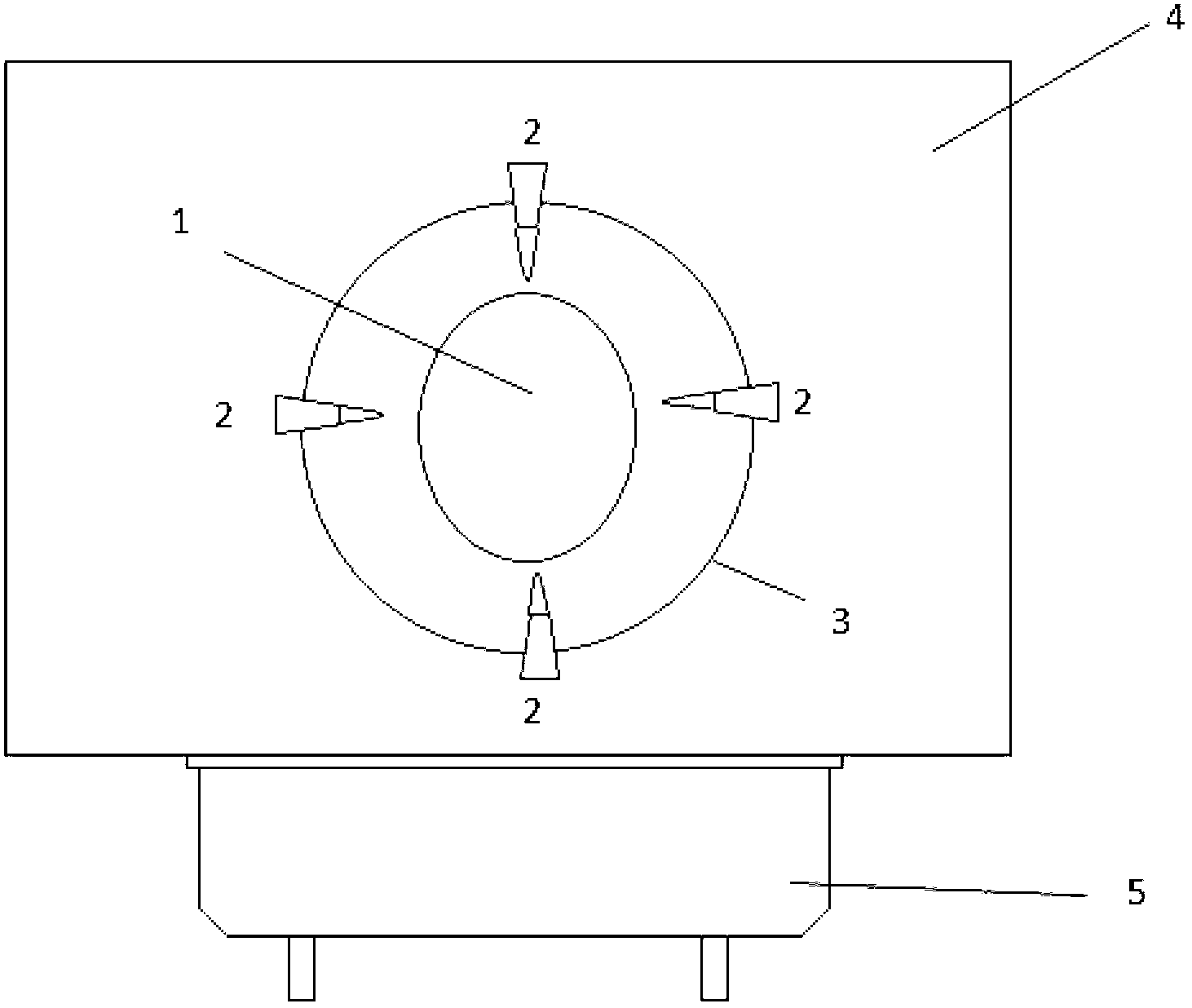

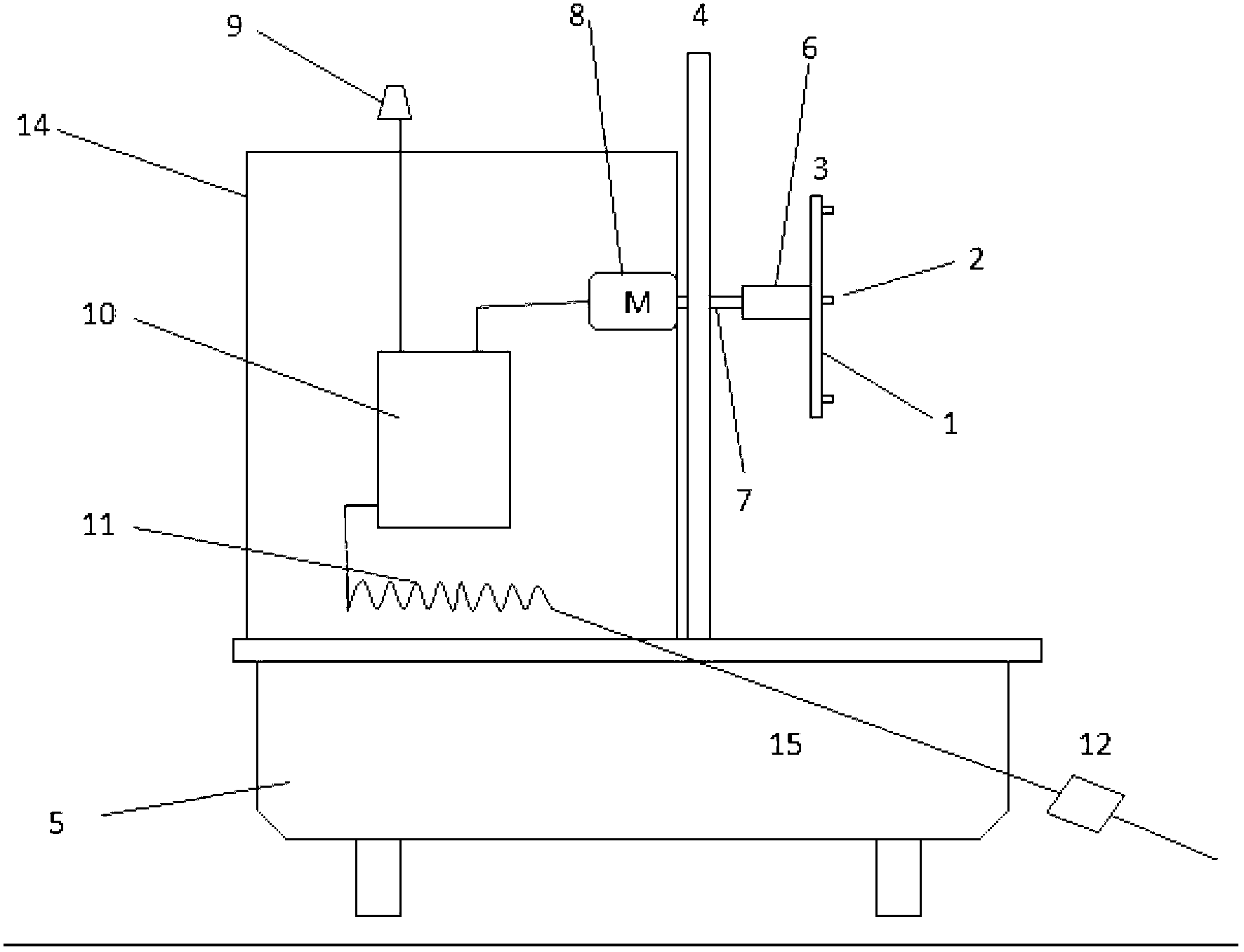

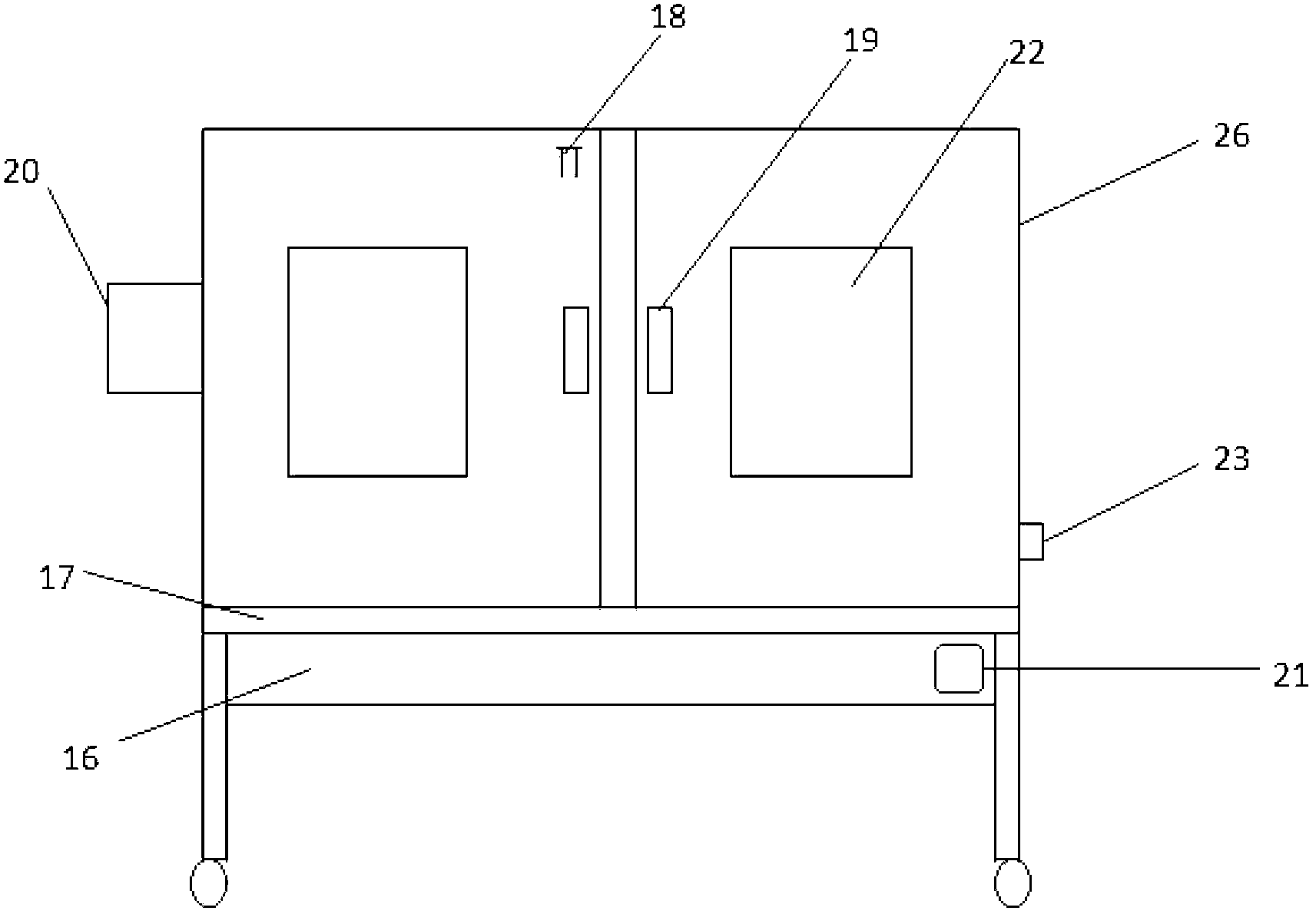

Automatic device and method for preparing prior-alcohol-permeable composite membrane

The invention provides an automatic device and a method for preparing a prior-alcohol-permeable composite membrane, belonging to the field of membrane separation technology. The automatic device for preparing the alcohol-permeation-prior composite membrane comprises a constant-temperature low-temperature drying oven, an air compressor, a filtering pressure-reducing valve, a three-way valve, an atomizing nozzle, an electromagnetic valve, a loading tray, a baking lamp, an electrical box, a motor, and a membrane loader; a macromolecular polymer solution is spayed on the surface of a porous support body; a cross-linker agent and a catalyst solution are sprayed to the surface of the membrane on the support body and react with the macromolecular polymer on the surface of the membrane by chemical crosslinking action to form the dense prior-alcohol-permeable composite membrane; a plurality of separation layers can form on the surface of the support body by alternative repetition of the above operations. The automatic device and the method provided by the invention automatically finishes spaying and crosslinking of a membrane casting solution with different components, effectively overcomes the problem of large thickness of the existing dipping composite membrane, greatly increases permeation flux and also improves the membrane forming stability.

Owner:BEIJING UNIV OF TECH

Novel polyether copolyamide gel membrane and preparation method thereof

InactiveCN103599712AImprove permeabilityHigh separation selectivitySemi-permeable membranesSeparation technologySolvent

The invention relates to a preparation method of a novel polyether copolyamide gel membrane, belonging to the field of membrane separation technologies. The preparation method of the gel membrane comprises the following steps of mixing and stirring polyether copolyamide, surfactant and solvent at a certain temperature so as to obtain casting film liquor, coating the casting film liquor on a teflon plate, standing in air for a while, then drying in a vacuum drying oven for several hours, and obtaining the polyether copolyamide gel membrane. The polyether copolyamide gel membrane prepared by the method not only has excellent tensile strength and elongation at break, but also has high permeation flux and separation factor, and is especially suitable for separation of carbon dioxide and hydrogen and recycling of organic steam such as benzene and methane.

Owner:JIANGNAN UNIV

Induced symbiotic osmosis [ISO] for salinity power generation

ActiveUS8545701B2High energyCompetitive costFlexible member pumpsReverse osmosisHydrologyPermeate flux

A method comprising providing a power train comprising a plurality of cells, each cell forming a hydraulic loop; producing a power train cycle comprising a controlled concentration-pressure loop wherein the concentration field: (a) osmotically induces a continuous and constant flow rate of substantially salt-free permeate flux throughout the power train; (b) maintains a salt concentration difference across the semipermeable membrane shared by the adjacent cells in the plurality of cells; (c) defines a salt concentration ratio within each cell that ensures a net positive power generation; and, (d) discharges the concentrated brine at the opposing end cell; and operating the power train under conditions effective to generate net positive power at an efficiency of 35% or more.

Owner:KELADA MAHER ISAAC

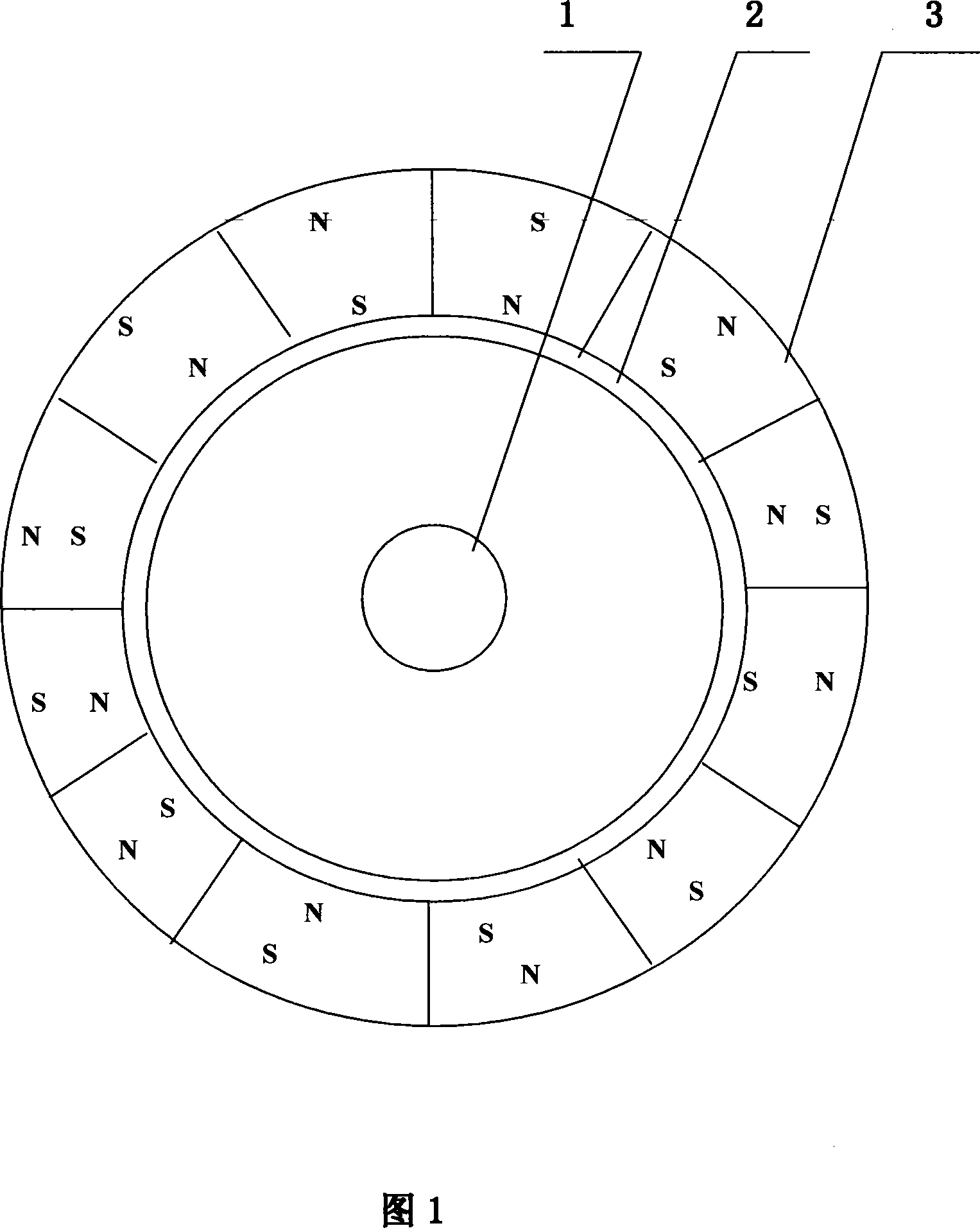

Process of preparing tubular porous membrane with high permeating flux

The present invention is process of preparing tubular porous membrane with high permeating flux. The process includes the following steps: mixing certain amount of additive, solvent, polymer and magnetic material through vibrating in certain temperature to compound homogeneous suspension; defoaming; wet or dry spinning to form capillary membrane or wet and dry phase converting to coat porous pipe to form membrane; and applying 100-18000 gauss cross magnetic field during evaporating and coagulating to form membrane. The tubular porous membrane with high permeating flux may be applied alone or as the porous support material for composite membrane.

Owner:HUBEI UNIV OF TECH

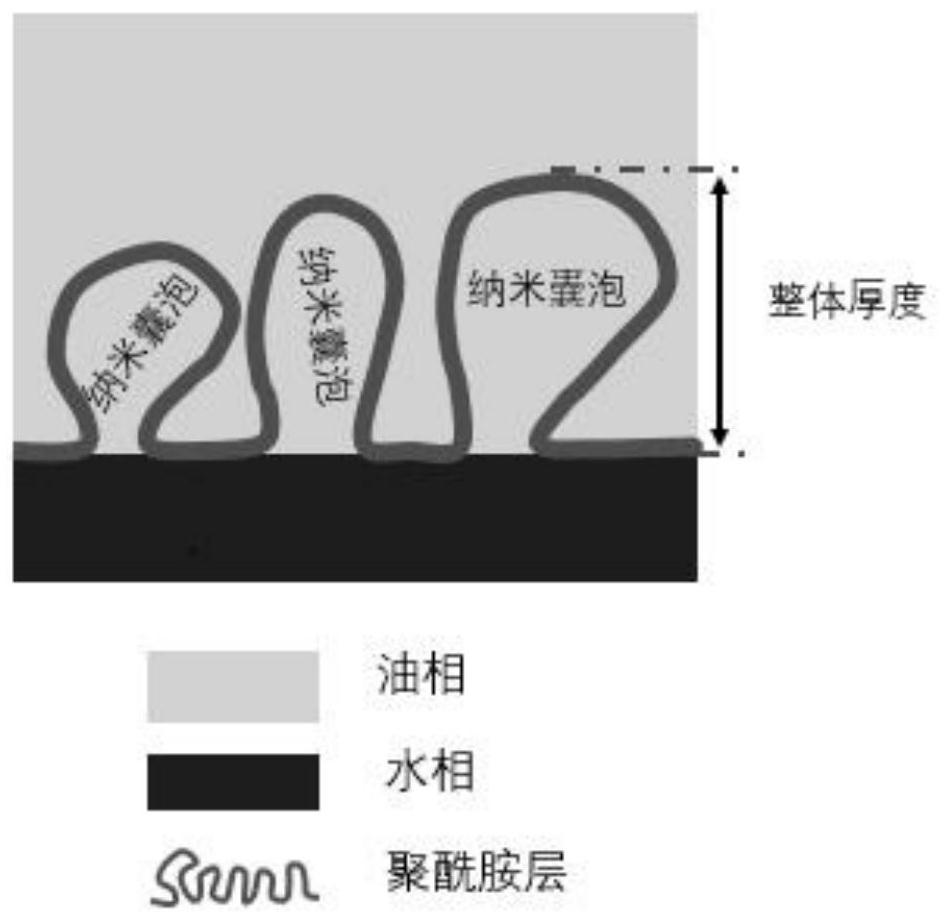

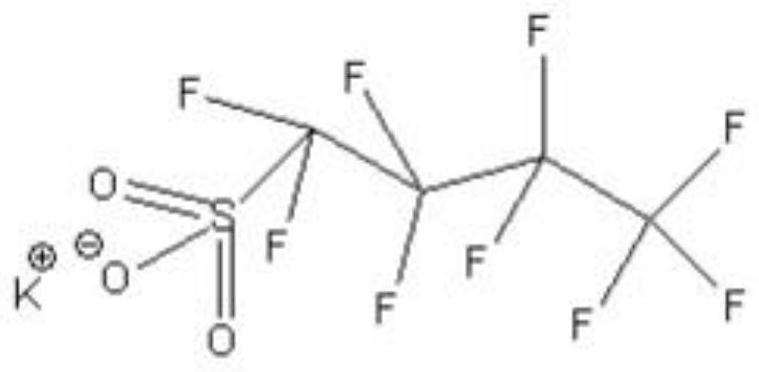

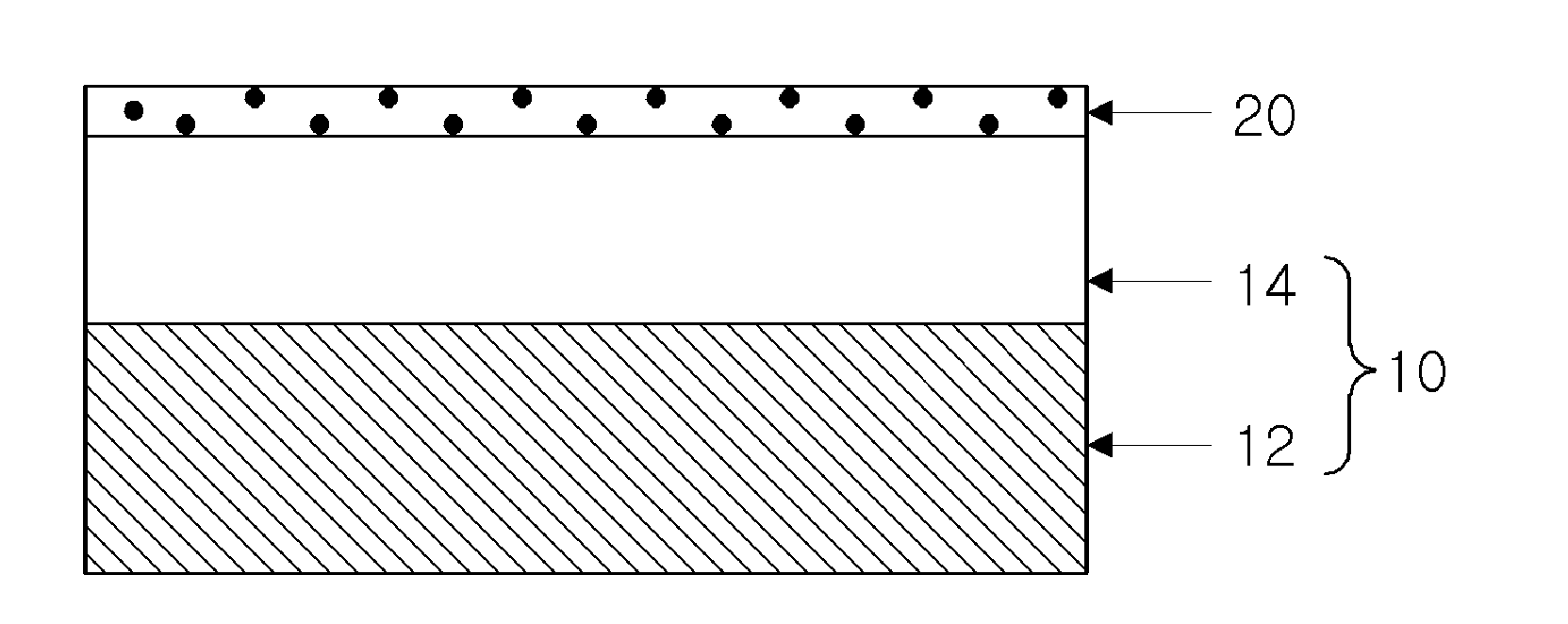

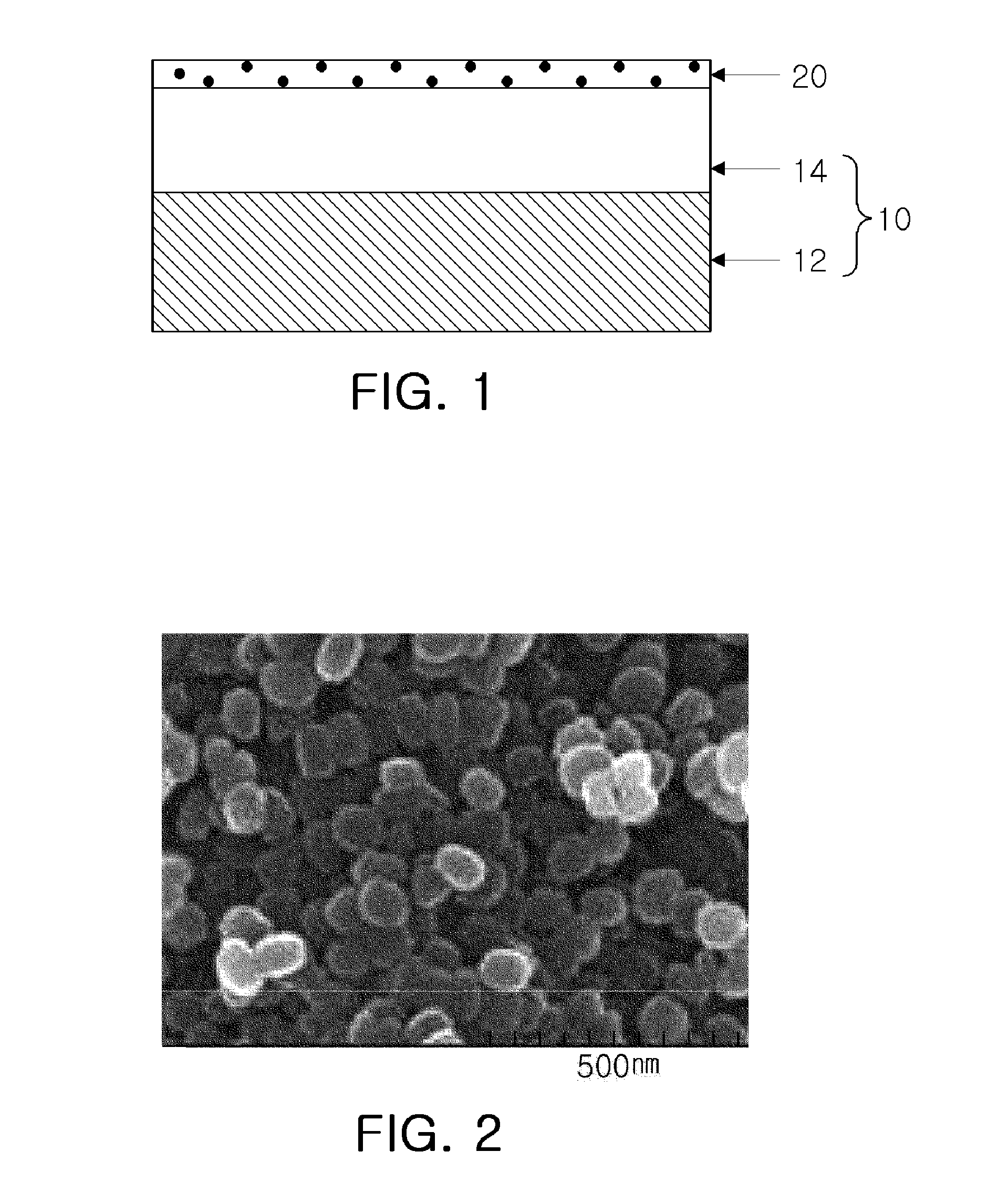

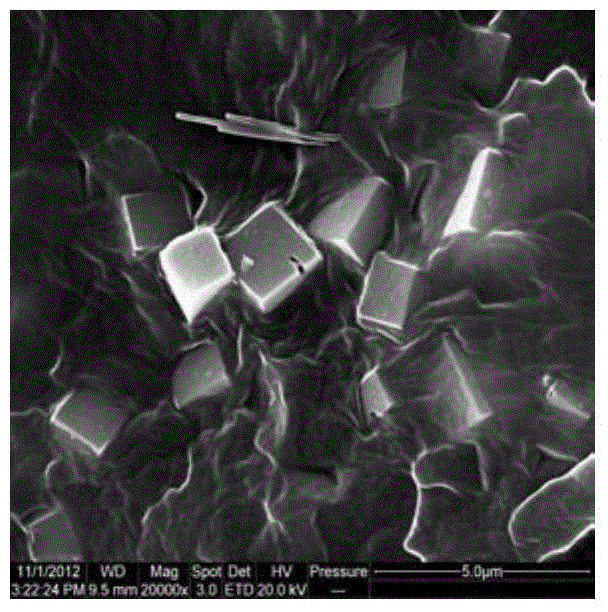

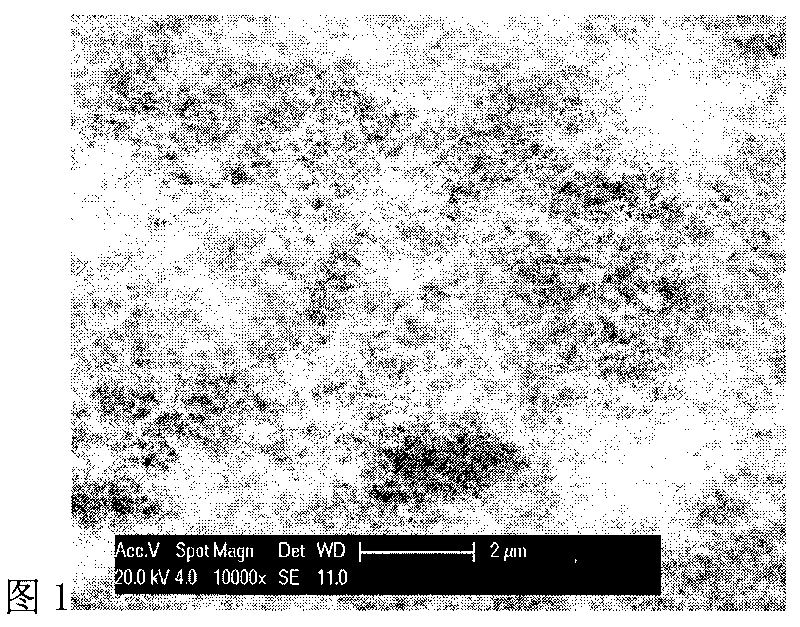

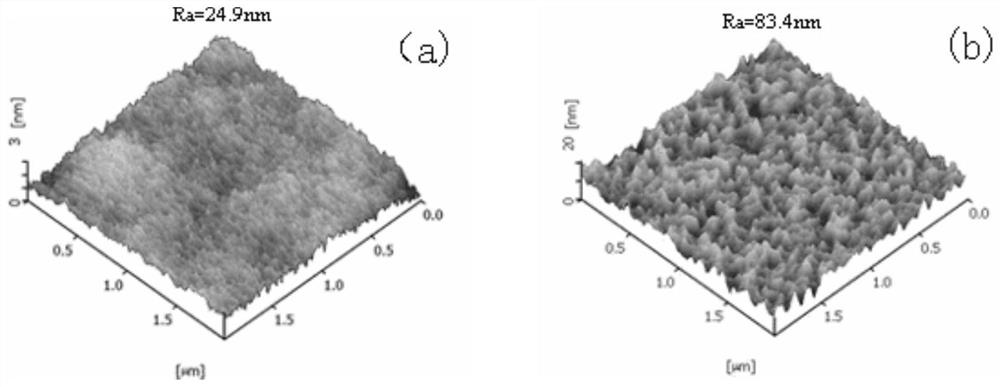

Preparation method of high-performance reverse osmosis membrane for promoting growth of polyamide nano vesicles

ActiveCN111790277AWeakened permeabilityAvoid situations prone to shrinkageMembranesReverse osmosisSulfonateReverse osmosis

The invention discloses a preparation method of a high-performance reverse osmosis membrane for promoting the growth of polyamide nano vesicles. A polysulfone ultrafiltration membrane is selected as asupport bottom membrane, and interfacial polymerization reaction of a water-phase amine monomer and an oil-phase polybasic acyl chloride monomer is carried on the surface of the support bottom membrane to compound with a polyamide ultrathin layer, thereby forming a reverse osmosis membrane; and the permeation selectivity of the reverse osmosis membrane is optimized by regulating and controlling parameter conditions in the interfacial polymerization process. On the basis, potassium perfluorobutyl sulfonate is introduced into an aqueous phase solution to promote the growth of polyamide nano vesicles supporting the surface of the bottom membrane and increase the surface roughness of the membrane, so that the permeation flux of the membrane is improved, and the performance of the reverse osmosis membrane is further optimized. According to the reverse osmosis membrane prepared by the method, the permeation flux of the membrane can be remarkably improved while the salt rejection rate is notlost. The invention provides a new reference way for development of a polyamide reverse osmosis membrane with high rejection rate and high flux.

Owner:ZHEJIANG UNIV OF TECH

Technology for efficiently treating mine water by using ceramic membrane

InactiveCN103708581AReduce pollutionFacilitate ultrafiltrationWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by neutralisationSludgeEconomic benefits

The invention relates to a technology for efficiently treating mine water by using a ceramic membrane, and belongs to the water treatment field. The technology comprises the following steps: 1, carrying out homogenous and equal quantity adjustment treatment of mine water for treatment; 2, adding an acid to the supernatant obtained in step 1, allowing the acid added supernatant to enter a ceramic membrane ultrafiltration system for ultrafiltration, and introducing a gas in the ultrafiltration process to carry out reinforced filtration; and 3, directly reusing or carrying out depth treatment of the above obtained ceramic membrane clear liquid after the clear liquid reaches standards, discharging an ultrafiltation ceramic membrane liquid concentrate to an adjustment pool after the ultrafiltation ceramic membrane liquid concentrate is concentrated to a certain concentration in order to carry out settlement separation, carrying out frame press filtration of precipitated sludge, discharging the filtered sludge, and allowing the clear liquid obtained after the sludge press filtration to enter the adjustment pool for circulation treatment. The ceramic membrane ultrafiltration system is the core and ensures the continuity of the process and the standard reaching discharge of produced water, and a gas feeding and acid feeding system is the characteristic of the technology in the invention different from other mine water membrane treatment technologies, greatly improves the penetration flux and the water recovery rate of the ceramic membrane, improves the mine water treatment efficiency of the ceramic membrane, reduces the investment and the running cost, and has substantial environmental and economic benefits.

Owner:JIANGSU JIUWU HITECH

High permeate flux reverse osmosis membrane including surface-treated zeolite and method of manufacturing the same

ActiveUS20150321151A1Prevents reduction in permeation fluxIncrease permeation fluxMembranesReverse osmosisReverse osmosisCompound (substance)

The present invention relates to a reverse osmosis membrane including: a porous support; and a polyamide active layer formed on the porous support and including zeolite, surface-treated with a compound having at least one functional group selected from a group consisting of an amino group and a glycidyl group, and a method of manufacturing the same.

Owner:LG CHEM LTD +1

Method of preparing composite membrane for gasoline desulphurization

The present invention provides a method for manufacturing a composite membrane for gasoline desulfurization. The composite membrane is manufactured by compounding an epidermal layer membrane material and a support layer membrane material. The epidermal layer membrane material is polyethylene glycol or polyethylene oxide, which has strong permselectivity of sulfide in the gasoline; the support layer adopts a sodium polyimide filter membrane or an ultrafiltration membrane with temperature resistance and organic solvent resistance, which can resist complicated components of the gasoline and 150 DEG C high temperature. Adopting the appropriate composite membrane preparation can prepare a composite membrane with ultrathin epidermal layer and no defect which can resist high temperature and hydrocarbon. The composite membrane can be used to for gasoline desulfurization. Under the condition of 110 DEG C feeding temperature and 1.5KPa membrane posterior pressure, the sulfur enrichment factor of the prepared composite membrane for the gasoline with 1000 Mu g / g sulfur content is larger than 4 and the permeation flux is larger than 40kg.Mu m / m< 2 >h.

Owner:PETROCHINA CO LTD +1

Preparation method and application of mixed matrix membrane with thermoplastic elastomer as matrix

ActiveCN104689730AIncrease the permeability coefficientAvoid influenceSemi-permeable membranesDispersed particle separationMolecular sieveThermoplastic elastomer

The invention relates to a preparation method and application of a mixed matrix membrane with a thermoplastic elastomer as the matrix. An unconventional solvent (acid) is employed to prepare a casting solution, and casting is carried out to prepare the mixed matrix membrane. When the molecular sieve content reaches certain degree, a layered structure similar to a composite membrane is formed, under the circumstance of substantial increase of the permeation flux, the selectivity remains unchanged, and the compromise relationship between traditional permeability / selectivity can be overcome. The method has a simple process and is convenient, and the obtained membrane can be used for gas separation, especially CO2 / light gas (N2, CH4, H2, O2) separation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

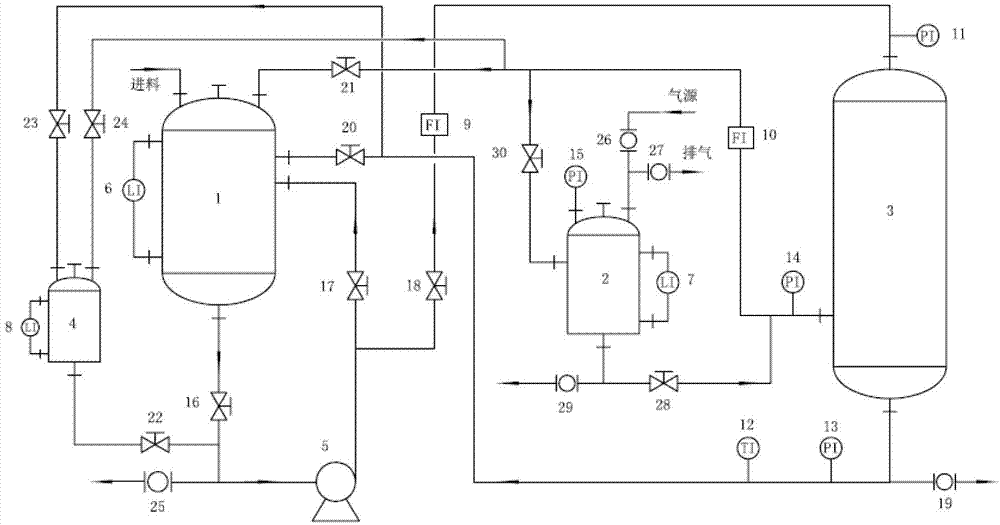

Membrane device for treating oilfield produced water for reinjection and treating method

ActiveCN103030193AGuaranteed qualityHD Liquid Side FluxFatty/oily/floating substances removal devicesUltrafiltrationWater qualityFilter system

The invention relates to a membrane device for treating oilfield produced water for reinjection and a treating method. The device comprises a feed liquid tank, a series of separator main bodies, built-in membrane separation elements of the separator main bodies, a backlash tank, a cleaning tank and a pump. The oilfield produced water with oil spots enters separating devices through a precipitation tank and the pump; a clear liquid after membrane separation is in accordance with a reinjection index of oilfield reinjection water, and used for the reinjection; and waste water with the oil spots on the concentrated liquid side returns to the precipitation tank. When a permeating flux decline of a filtering unit module is set to be 80% of an initial value, the backlash course is started. A whole system is totally enclosed so as to prevent the water from being contacted with the outside to bring in new pollution; the quality of dischargws products on the clear liquid side can be ensured; the products are high-temperature resistant and acid and alkali resistant; the clear liquid side of a ceramic membrane is high in flux; the treating capacity is high; the separating effect is good; the effluent quality is stable; a ceramic membrane filtering system is easy to operate, short in technological process and high in automation degree, and lowers the cost and investment; a cleaning period is long; and a flux restoration ratio can reach above 90% after cleaning.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

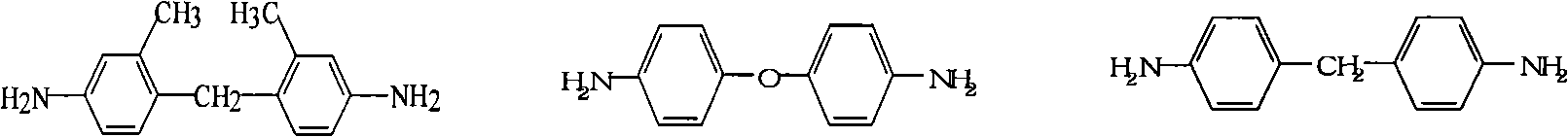

Preparation and application of polyimide-imidazole micro-capsule hybrid membrane

InactiveCN103537206AImprove water retentionChange the crystallization regionProductsSemi-permeable membranesImidePermeate flux

The invention discloses preparation and application of a polyimide-imidazole micro-capsule hybrid membrane. The preparation comprises the following process steps of: preparing silicon dioxide balls, preparing imidazole micro-capsules, filling the imidazole micro-capsules in a polyimide solution to obtain a membrane casting solution, standing, filtering and defoaming the membrane casting solution, and then carrying out curtain coating, drying and annealing to form a membrane. The hybrid membrane is used as a separation membrane for removing carbon dioxide gas out of natural gas. The polyimide-imidazole micro-capsule hybrid membrane has the advantages that the preparation method is simple, the nano-scale imidazole micro-capsules in the prepared membrane are distributed evenly, the addition of the imidazole micro-capsules greatly promotes transfer of carbon dioxide in the membrane, the hybrid membrane has high carbon dioxide permeation flux and carbon dioxide-to-methane selectivity, and the hybrid membrane also has excellent mechanical stability and thermal stability.

Owner:TIANJIN UNIV

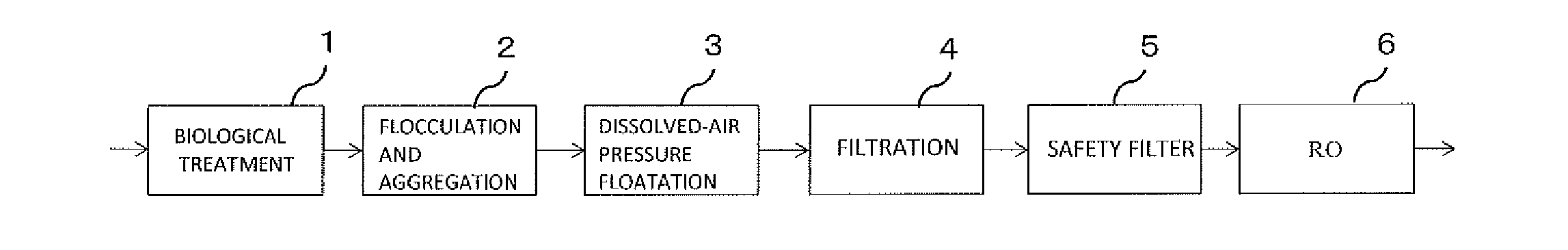

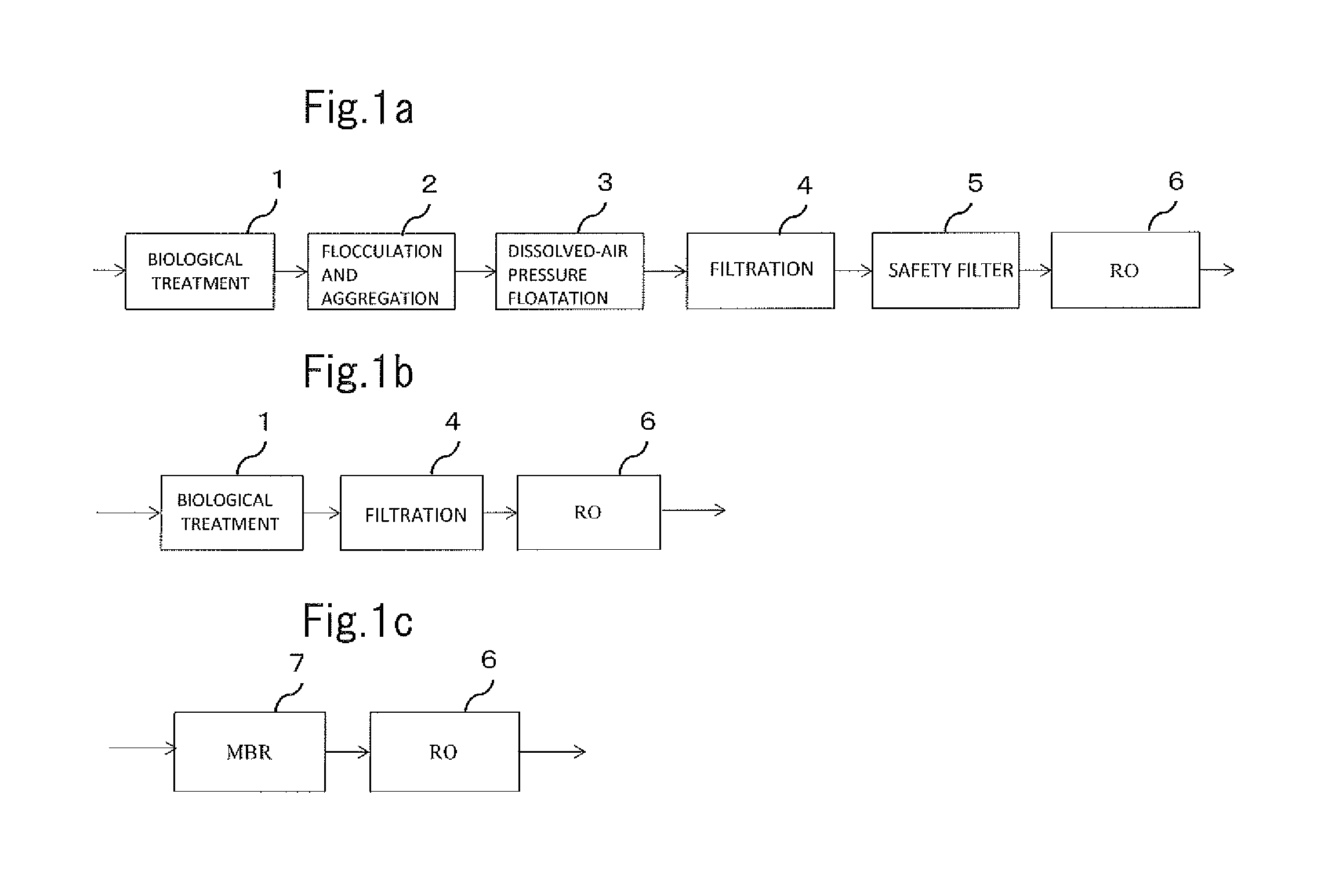

Method for operating reverse osmosis membrane device, and reverse osmosis membrane device

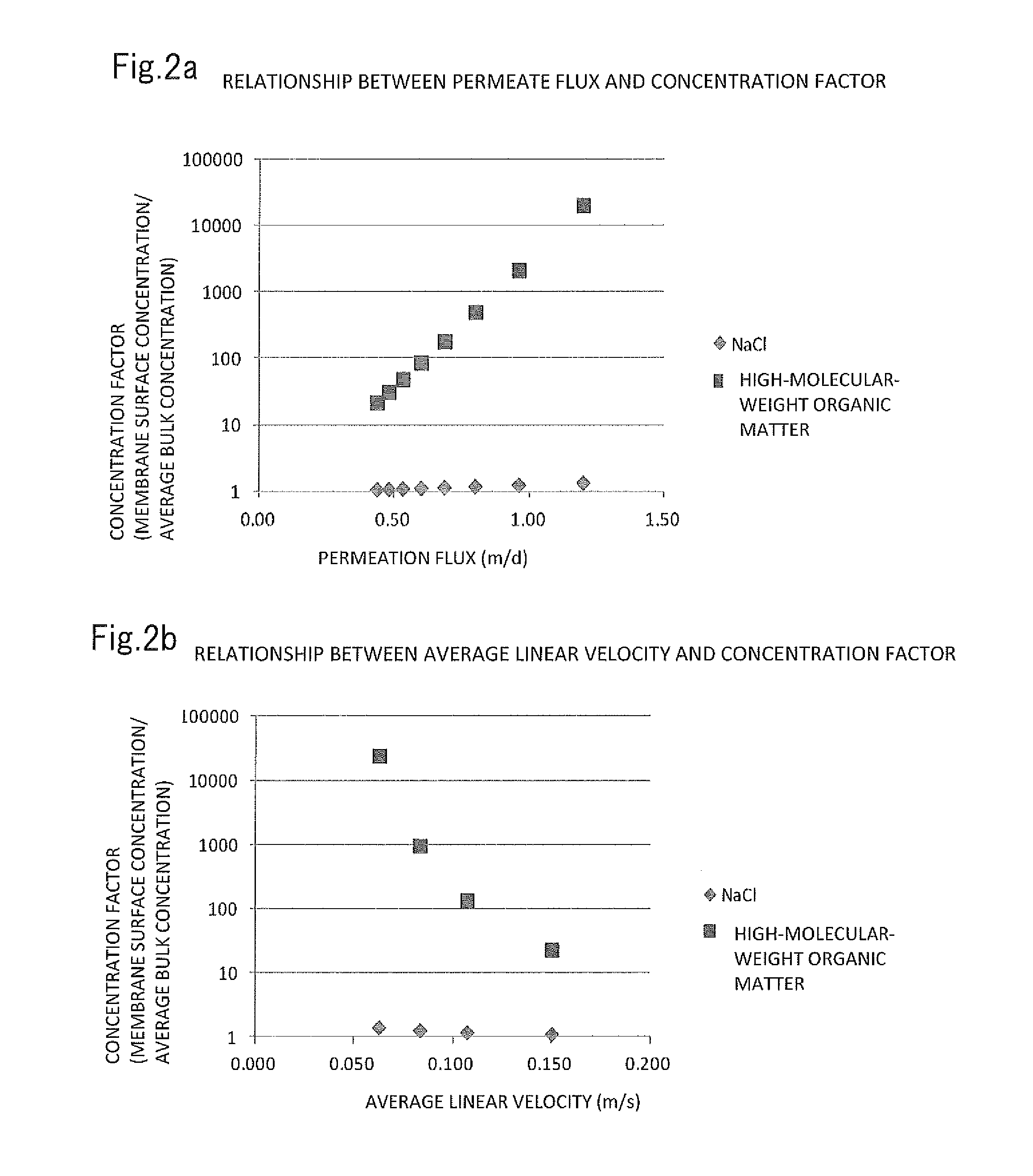

ActiveUS20160016122A1Preventing decrease in permeate flow rateSuppressing decrease in permeate flow rateGeneral water supply conservationSeawater treatmentMembrane surfaceReverse osmosis

Provide is a reverse osmosis membrane device that is capable of treating raw water containing membrane-fouling substance in large quantities, such as MBR-treated water, in a stable manner while preventing decreases in permeate flow rate, and a method for operating thereof. A method for operating a reverse osmosis membrane device that treats raw water containing high-molecular-weight organic matter, wherein the raw water contains high-molecular-weight organic matter having a molecular weight of 10,000 or more at a concentration of 0.01 ppm or more, wherein the reverse osmosis membrane device is equipped with a spiral-type reverse osmosis membrane element that has a membrane surface area satisfying the below formula (1), and wherein the reverse osmosis membrane device is operated at a permeate flux of 0.6 m / d or less:membrane surface area (m2)≧n2×(11 / 16) (1)wherein n represents a diameter (inches) of the reverse osmosis membrane element.

Owner:KURITA WATER INDUSTRIES LTD

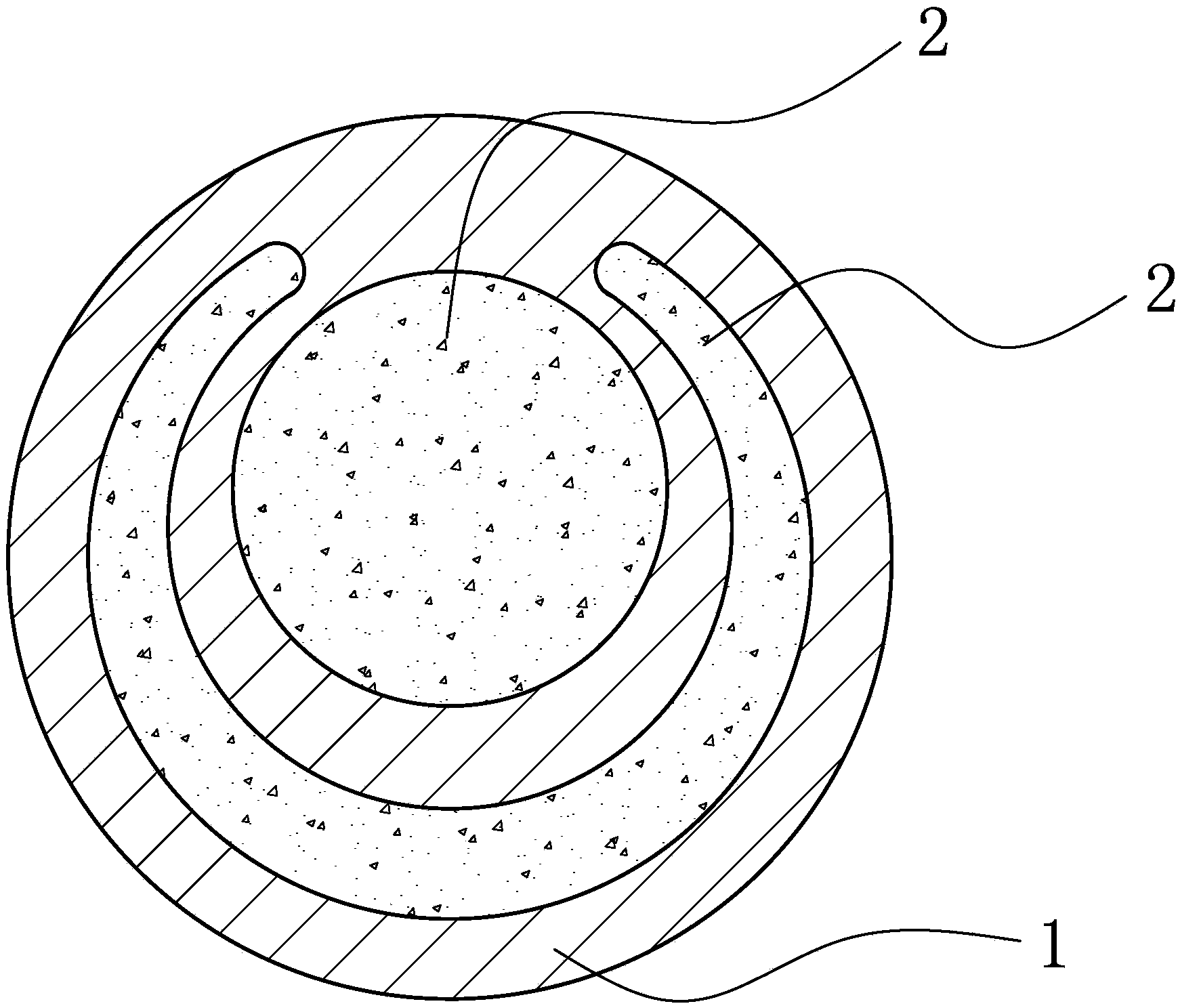

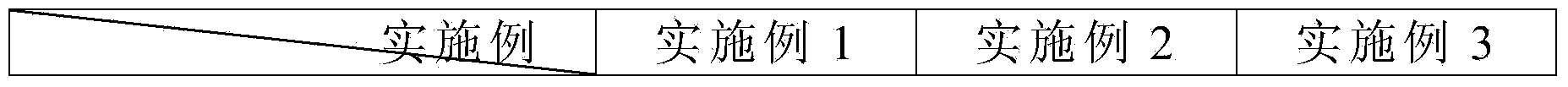

Nickelic and chrome welding permeating flux-cored wire and preparing method

ActiveCN103659049AFusion beautifulEasy to weldWelding/cutting media/materialsSoldering mediaPermeate fluxMetal powder

The invention relates to a nickelic and chrome welding permeating flux-cored wire and a preparing method. The flux-cored wire comprises an outer shell, and the outer shell is internally provided with a through hole and an arc hole, wherein the through hole penetrates through the outer shell in the axial direction, and the arc hole is formed in the periphery of the through hole in a surrounding mode. The through hole and the arc hole are filled with the materials, by weight, 20-35 parts of metal powder, 35-65 parts of alloyed powder and 8-18 parts of mineral powder. The preparing method of the flux-cored wire comprises the steps that the powder is baked into the flux-cored powder, a cold-rolled steel strip is rolled two times into a U-shaped groove structure, the flux-cored powder accounting for 8%-10% of the total weight of the flux-cored wire is added into a U-shaped groove in twice, the U-shaped groove is sealed through a forming machine, the through hole and the arc hole penetrating through the cold-rolled steel strip are formed in the axial direction of the cold-rolled steel strip, the flux-cored powder is filled in the through hole and the arc hole, the cold-rolled steel strip is drawn through a drawbench in each welding pass, the diameter of the cold-rolled steel strip is reduced in each welding pass, and therefore the nickelic and chrome welding permeating flux-cored wire is obtained. The nickelic and chrome welding permeating flux-cored wire can be perfectly welded on nickelic and chrome products, and the fusion of the welding passes is very attractive.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Preparation method of pervaporation layer-by-layer assembled membrane for gasoline desulfurization

ActiveCN110327782AEasy to separateSimple structureRefining by dialysisDistillationComposite filmInorganic particle

The invention provides a preparation method of a pervaporation layer-by-layer assembled membrane for gasoline desulfurization. The layer-by-layer assembled film is a multilayer composite film including three or more layers. The preparation method of the layer-by-layer assembled membrane comprises the following steps: S1, preparing a porous supporting bottom membrane; S2, forming a metal organic framework membrane, namely an MOFs membrane, on the bottom membrane in situ; and S3, coating the surface of the MOFs film with polyethylene glycol to form the composite film, namely the MOFs / PEG layer-by-layer assembled film. The metal elements contained in the inorganic particles used in step S1 are the same as the metal elements contained in the metal salt in step S2. The layer-by-layer assembledmembrane has a good sulfur-rich effect reaching 19.5 at most on sulfur-containing gasoline, is high in sulfur-rich factor and good in permeation flux being 3.583 kg / m<2>*h, and has a good industrial application prospect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

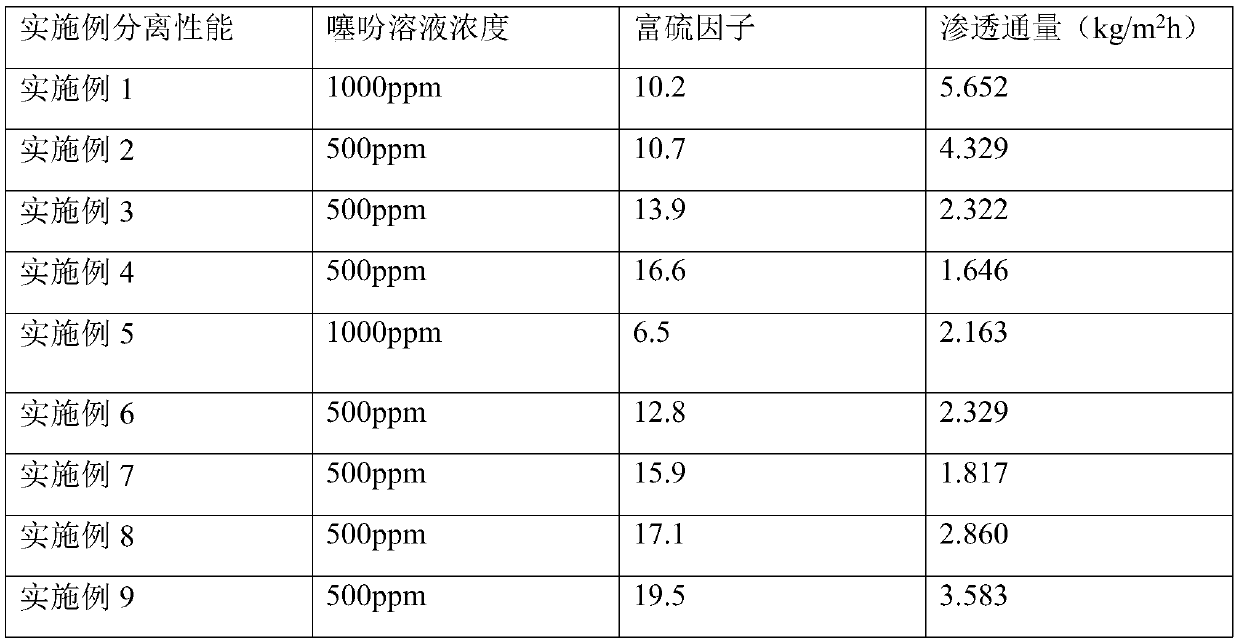

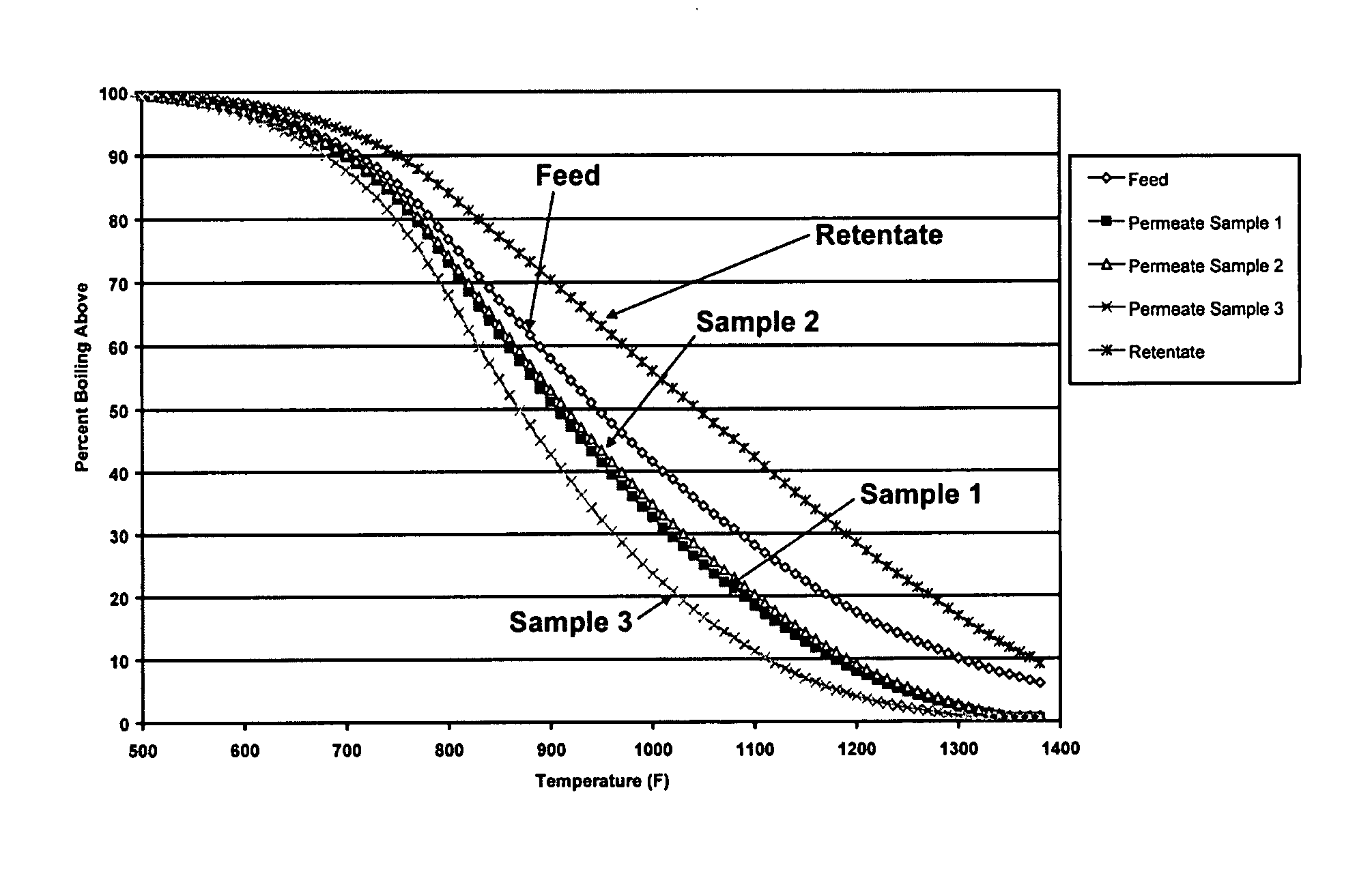

Reduction of conradson carbon residue and average boiling points utilizing high pressure ultrafiltration

InactiveUS8864996B2Improved low energy membrane separations processReduce contentMembranesGas treatmentBoiling pointTar

This invention relates to a process for producing a product stream with improved reduction of Conradson Carbon Residue (“CCR”) and a reduced average boiling point from a heavy hydrocarbon feedstream utilizing a high-pressure, low-energy separation process. The invention may be utilized to reduce the CCR content and reduce the average boiling point in heavy hydrocarbon feedstreams, such as whole crudes, topped crudes, synthetic crude blends, shale oils, bitumen, oil from tar sands, atmospheric resids, vacuum resids, or other heavy hydrocarbon streams. This invention also results in a process with an improved CCR separation efficiency while maintaining permeate flux rates.

Owner:EXXON RES & ENG CO

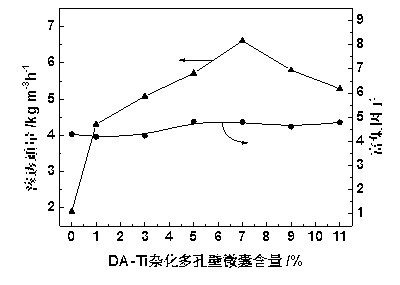

High-permeation flux polydimethylsiloxane porous-wall micro-capsule hybrid membrane and preparation method

InactiveCN103285750AEasy to separateHigh reactivityRefining by dialysisDistillationRoom temperatureGasoline

The invention relates to a high-permeation flux polydimethylsiloxane porous-wall micro-capsule hybrid membrane and a preparation method. The preparation method comprises the following steps of: preparing a DA-Ti hybrid porous-wall micro-capsule by using a template method and the process of biological mineralization in a restricted space; dissolving polydimethylsiloxane with a certain mass ratio in normal heptane at room temperature so as to form a homogeneous solution, and then adding the DA-Ti hybrid porous-wall micro-capsule into the solution; stirring and dispersing the suspension liquid; then adding a certain quantity of crosslinking agent and catalyst, and stirring, standing and defoaming to obtain a membrane casting solution; and then casting the membrane casting solution on a dry polysulfone basic membrane, and drying and treating to obtain the membrane. The hybrid membrane is used for simulating gasoline desulfurization, the enrichment factor of the thiophene is 4.29 to 5.89, and the permeation flux is 1.90 to 8.09 kg / (m<2>h). The preparation conditions of the hybrid membrane are mild, and raw materials are abundant and controllable.

Owner:TIANJIN UNIV

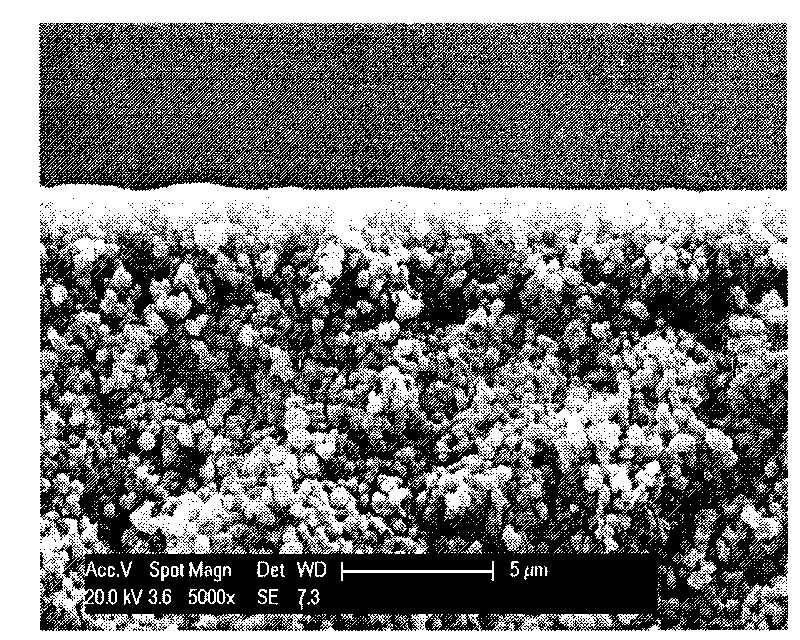

Method for preparing TiO2/Al2O3 composite film

InactiveCN101721918AHigh selectivityImprove permeabilitySemi-permeable membranesCatalyst carriersComposite filmPore distribution

The invention relates to a method for preparing a TiO2 / Al2O3 composite film, which takes chitosan derivative as organic additive, adopts organic titanium salt as titanium source and uses water as solvent to prepare colloidal sol. The method comprises: taking alpha-Al2O3 as carrier, and preparing the TiO2 / Al2O3 composite film by film coating, drying and calcining. The film material prepared by the method is thin in film layer, large in porosity, narrow in pore distribution, high in permeation flux and good in separating performance. Furthermore, the preparation method is simple in technique, has higher repeatability, improves the utilization rate of raw materials, is beneficial to reducing the cost and is suitable for industrial amplification.

Owner:TAIYUAN UNIV OF TECH

Ceramic composite nanofiltration membrane for dye removal and preparation method thereof

ActiveCN111672339AImprove performanceImprove interception effectSemi-permeable membranesGeneral water supply conservationPolymer scienceCeramic composite

The invention relates to a preparation method of a ceramic composite nanofiltration membrane for dye removal, and belongs to the field of membrane separation. A tubular or flaky ceramic substrate is used as a carrier, a dopamine compound and polyethyleneimine form a co-deposition layer on the surface of the carrier, TiO2 is loaded on the co-deposition layer, and finally, gallic acid is used for crosslinking to obtain the composite nanofiltration membrane. The preparation process is simple, the reaction conditions are mild, and the prepared ceramic composite nanofiltration membrane is high in mechanical strength, good in stability, large in permeation flux and high in rejection rate, is suitable for removal of dyes in wastewater and is also suitable for removal of dyes in organic solvents.

Owner:CHONGQING UNIV OF TECH

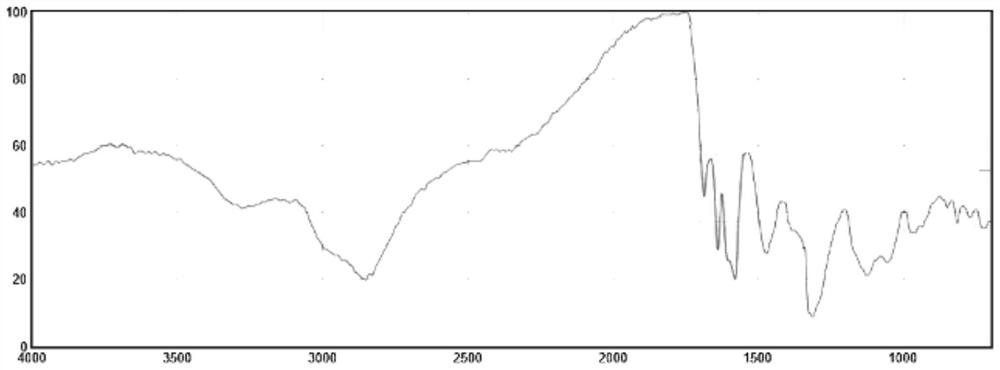

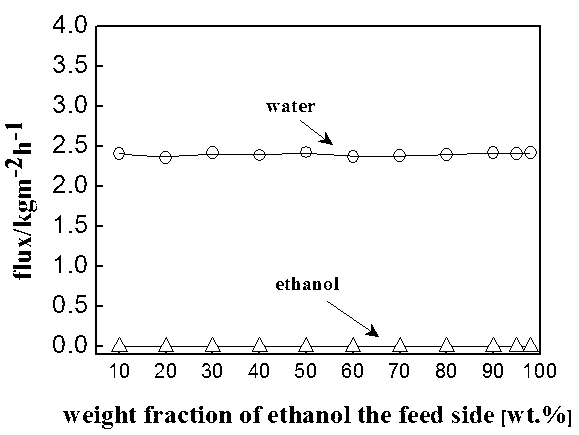

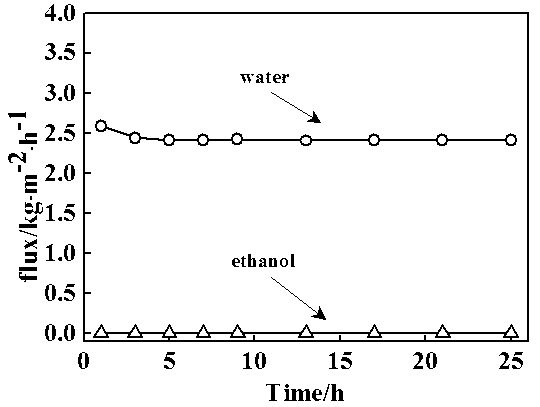

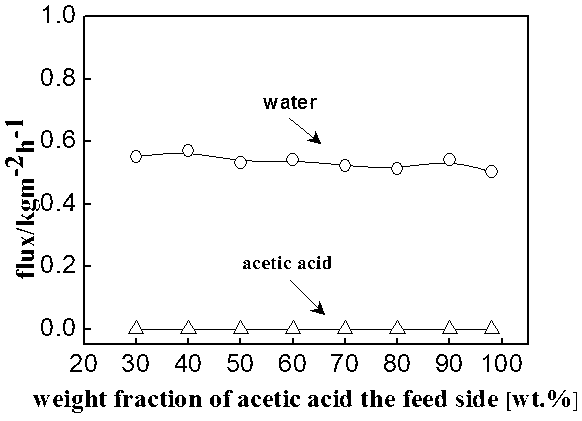

Application of hydrophilic Ge-ZSM-5 molecular sieve membrane to separation of organics/water system

InactiveCN102701327AStable applicationHigh separation factorSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPervaporationChemistry

The invention discloses an application of a hydrophilic Ge-ZSM-5 molecular sieve membrane to separation of an organics / water system. The alpha-Al2O3 is taken as a carrier, the hydrophilic Ge-ZSM-5 molecular sieve membrane prepared by an in-situ hydrothermal crystallization method is adopted as a separation material, and water in the organics / water system is separated through the pervaporation effect so as to obtain the organics. When the molecular sieve membrane is applied to an ethanol-water system of 343 K, 10 to 98 wt% and an acetic acid-water system of 353 K, 30 to 98 wt%, the separating factor reaches infinity, the permeation flux reaches 2.4 kg / m2.h and 0.57 kg / m2.h, both the permeation flux and the separating factor of the membrane are kept constant in the pervaporation process of 25 h, and the membrane shows excellent stability. The application is simple and easy to operate, and the hydrophilic Ge-ZSM-5 molecular sieve membrane is suitable for industrial production.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00000.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00001.png)

![Induced symbiotic osmosis [iso] for salinity power generation Induced symbiotic osmosis [iso] for salinity power generation](https://images-eureka.patsnap.com/patent_img/b4b27964-7dda-4348-9317-116c9790f6a1/US20110044824A1-20110224-D00002.png)

![Induced symbiotic osmosis [ISO] for salinity power generation Induced symbiotic osmosis [ISO] for salinity power generation](https://images-eureka.patsnap.com/patent_img/bd122305-095f-4cab-8085-426f2dae8871/US08545701-20131001-D00000.png)

![Induced symbiotic osmosis [ISO] for salinity power generation Induced symbiotic osmosis [ISO] for salinity power generation](https://images-eureka.patsnap.com/patent_img/bd122305-095f-4cab-8085-426f2dae8871/US08545701-20131001-D00001.png)

![Induced symbiotic osmosis [ISO] for salinity power generation Induced symbiotic osmosis [ISO] for salinity power generation](https://images-eureka.patsnap.com/patent_img/bd122305-095f-4cab-8085-426f2dae8871/US08545701-20131001-D00002.png)