Polyester polyamide amphoteric charge composite nanofiltration membrane and preparation method thereof

A technology of polyester polyamide and charge recombination, which is applied in the field of membrane separation, can solve problems such as complex water quality components, and achieve good retention performance and high permeation flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

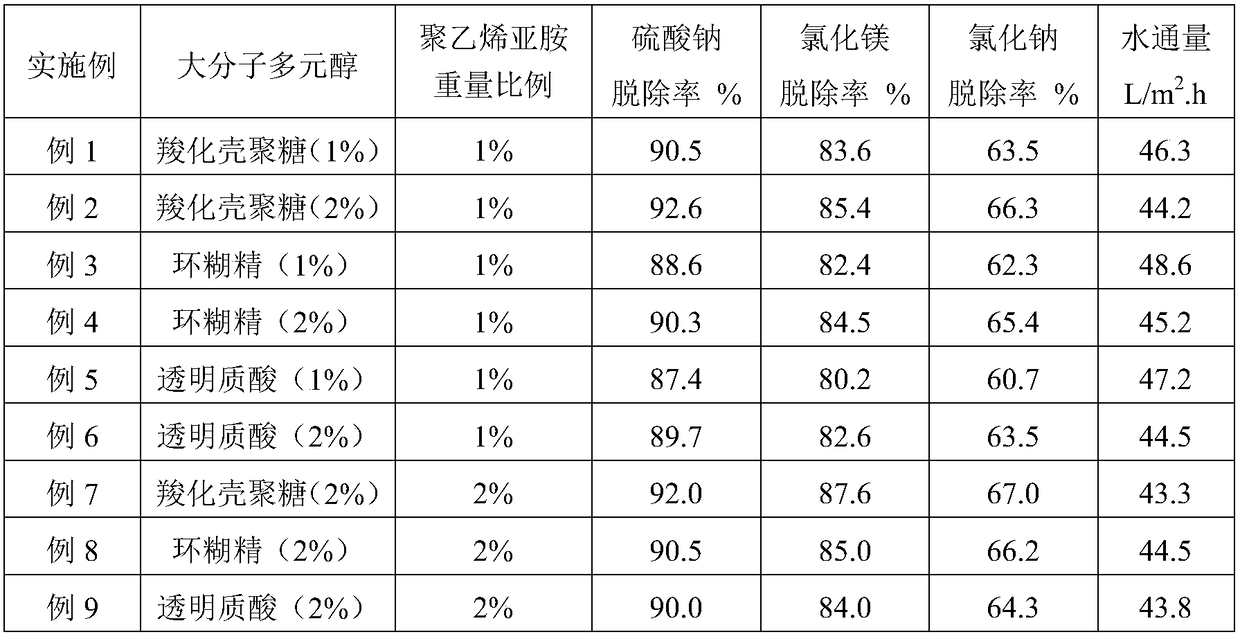

Embodiment 1-9

[0036] Immerse one side of the wet polysulfone microporous support membrane in an aqueous solution containing 1.0% to 3.0% of macromolecular polyols (respectively carboxylated chitosan, or cyclodextrin, or hyaluronic acid) for 10 minutes, and take out Afterwards, rinse with deionized water, dry in the air for 15 minutes, contact with n-hexane solution containing 0.2% trimesoyl chloride on one side for interfacial polymerization reaction for 10 minutes, and then react with polyethyleneimine containing 1.0% to 3.0% The aqueous solution is contacted for 10 minutes, and finally heat-treated in an oven at 50° C. for 10 minutes to obtain a polyester polyamide amphoteric charge composite nanofiltration membrane. The solute desalination rate and water flux of the membrane were tested with 500 mg / L sodium sulfate aqueous solution, magnesium chloride aqueous solution and sodium chloride aqueous solution at 0.6MPa, 25°C and pH 6.8 respectively. These several examples are to investigate t...

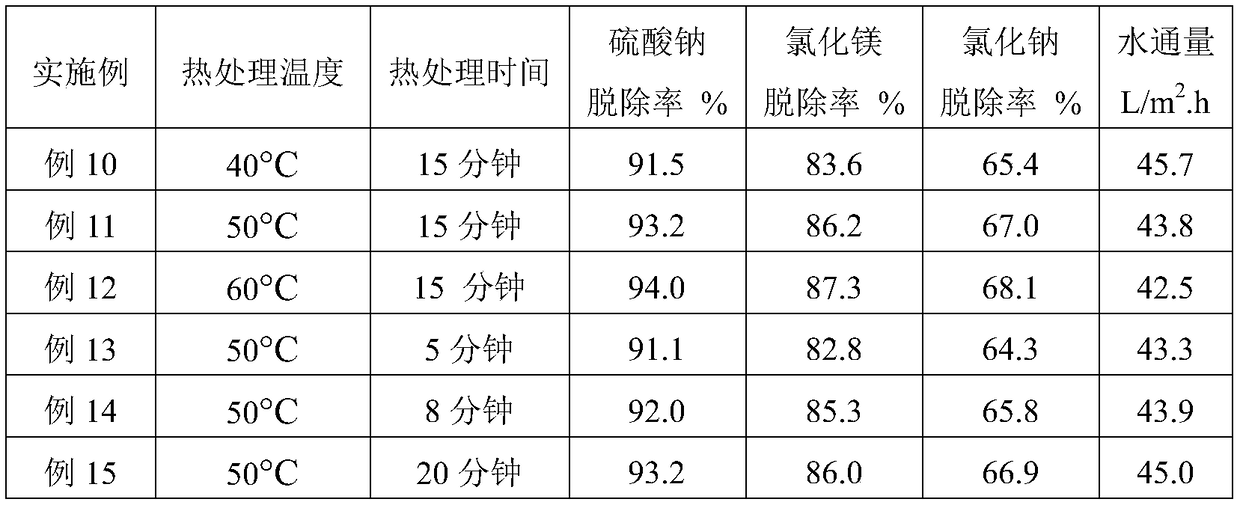

Embodiment 10-15

[0041] As in the previous example, according to the above method, 2.0% carboxylated chitosan aqueous solution and 1.0% polyethyleneimine aqueous solution were used to treat at 40-60° C. for 5-20 minutes. These examples are to investigate the influence of heat treatment temperature and time on the film performance, the results are shown in Table 2.

[0042] The performance measurement result of the composite nanofiltration membrane of table 2 embodiment 10-15

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com