Method for preparing hydrophobic microporous membrane and membrane prepared by method

A microporous membrane and hydrophobic technology is applied in the field of preparation of hydrophobic microporous membranes to achieve the effects of good thermal stability, good retention effect and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

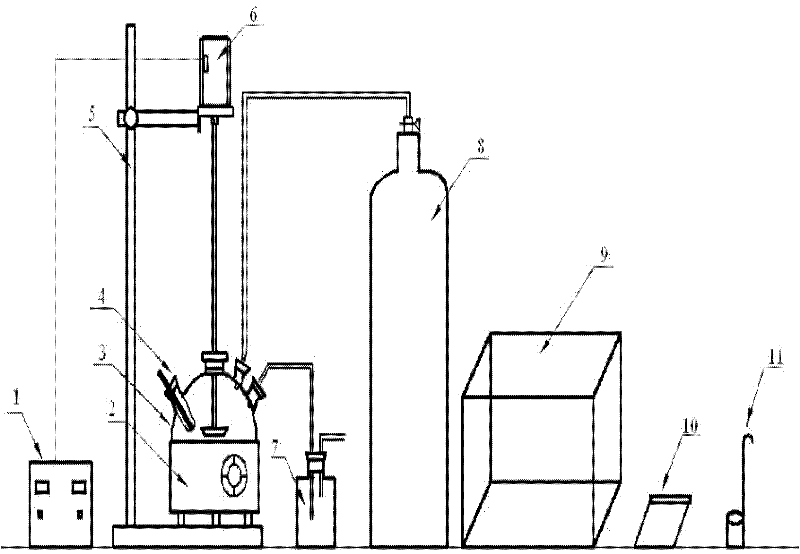

[0036] A method for preparing a hydrophobic microporous membrane, the steps are as follows:

[0037] (1) Add polypropylene (iPP) granules and high-density polyethylene (HDPE) granules, diluent soybean oil and nucleating agent adipic acid into a four-necked flask, nitrogen as a protective gas, at a temperature of 190°C to 200°C, and stir Heat the casting solution until it becomes a homogeneous solution, and the optimum heating time is 6 hours to obtain the casting solution;

[0038] Among them, the mass ratio of iPP / HDPE is 6:1, and the weight percent of each raw material is: the sum of iPP / HDPE is 30wt.%, the nucleating agent is 0.5wt.%, and the diluent is 69.5wt.%.

[0039] (2) The casting liquid system is degassed under 0.02MPa, and the best time is 2h;

[0040] (3) Preheat the scraper, scraper, and sampler in an oven at a temperature of 210°C to 220°C;

[0041] (4) Use a sampler to move 10g to 15g of the casting solution to the scraper, and use a scraper to quickly scrape...

Embodiment 2

[0046] A method for preparing a hydrophobic microporous membrane, the steps are as follows:

[0047] (1) Add polypropylene (iPP) particles and high-density polyethylene (HDPE) particles, diluents are esters or liquid paraffin and nucleating agent adipic acid in a four-necked flask, nitrogen is used as a protective gas, and the temperature is 190 ℃~200℃, stir and heat the casting solution until it becomes a homogeneous solution, and the best heating time is 5h~8h to obtain the casting solution;

[0048] Among them, the mass ratio of iPP / HDPE is 4:1~7:1, the weight percentage of each raw material is: the sum of iPP / HDPE is 25wt.%~38wt.%, adipic acid is 0.5wt.%, soybean oil is supplemented to 100%.

[0049] (2) The casting liquid system is degassed under 0.02MPa, and the degassing time is 2h to 4h;

[0050] (3) Preheat the scraper, scraper, and sampler in an oven at a temperature of 210°C to 220°C;

[0051] (4) Use a sampler to move 10g to 15g of the casting solution to the sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com