Patents

Literature

20446results about How to "Improve the immunity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

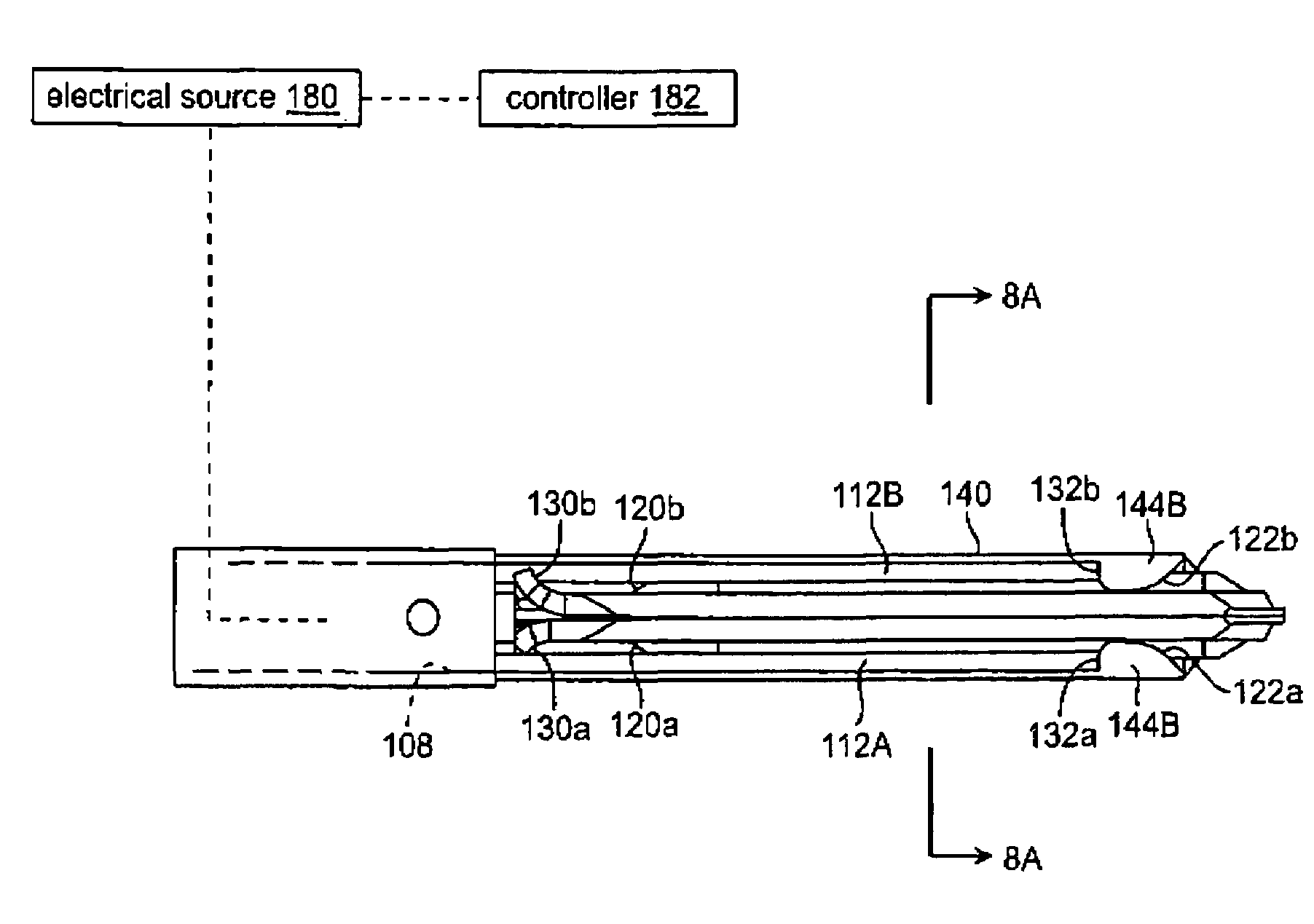

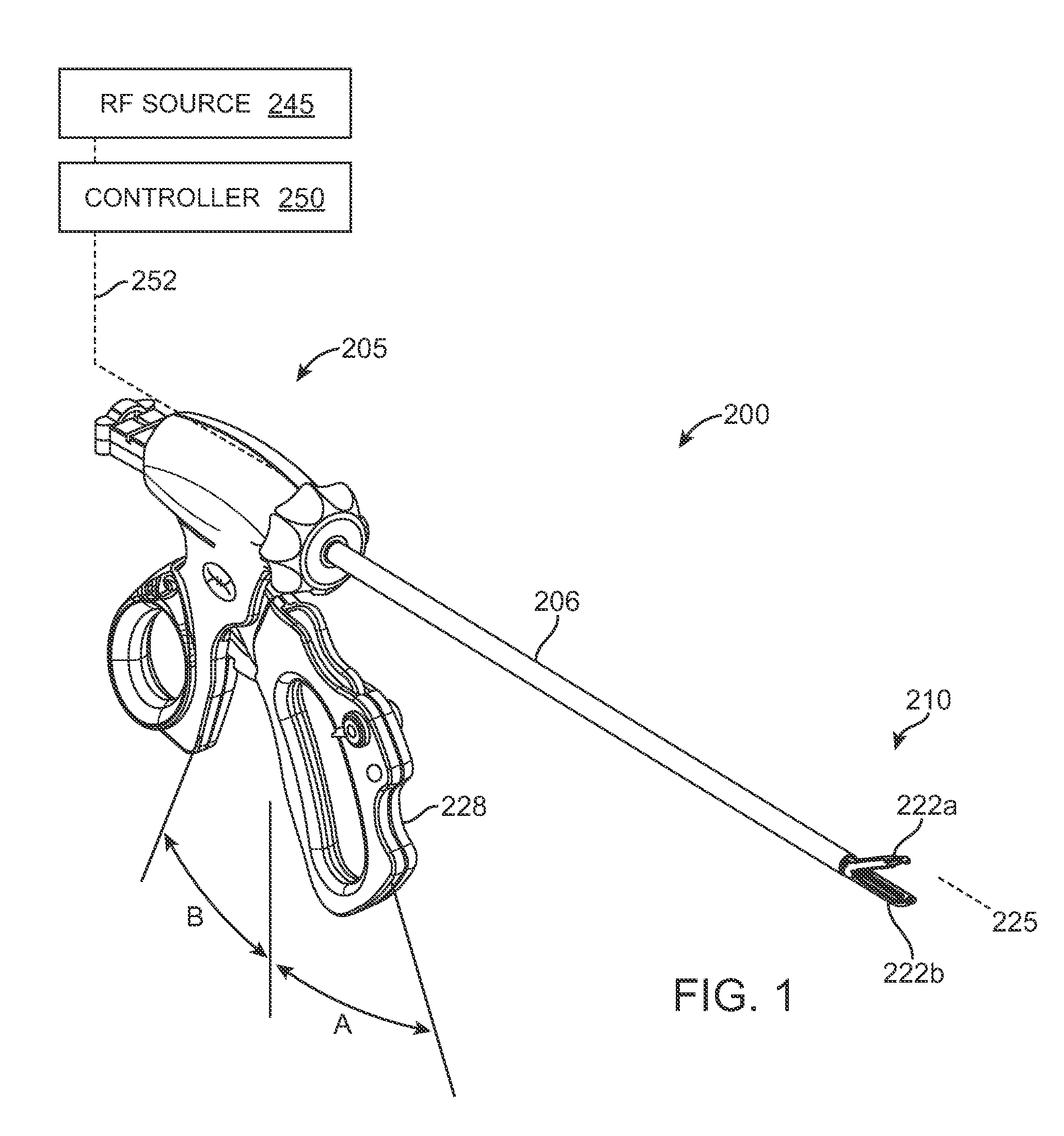

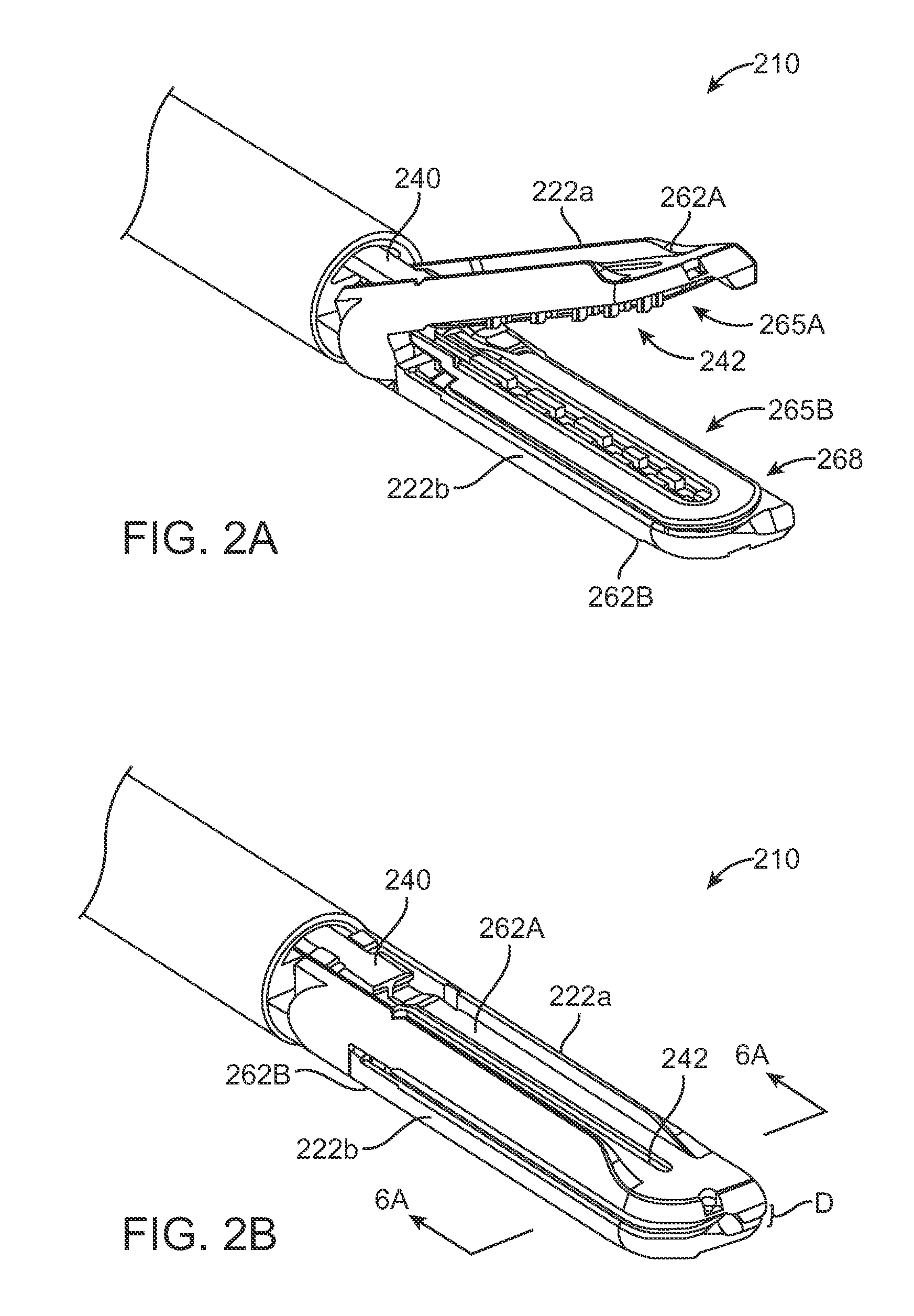

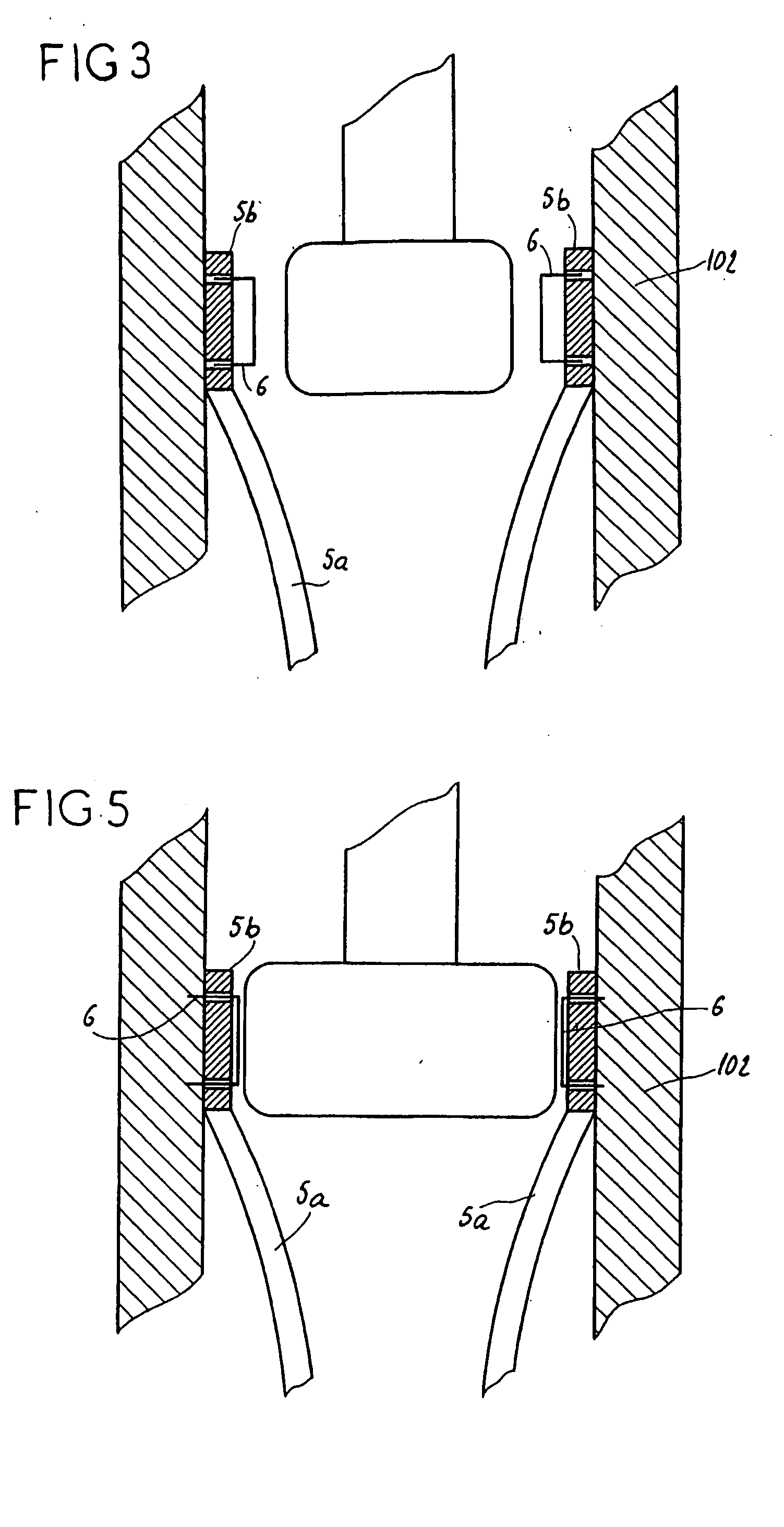

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

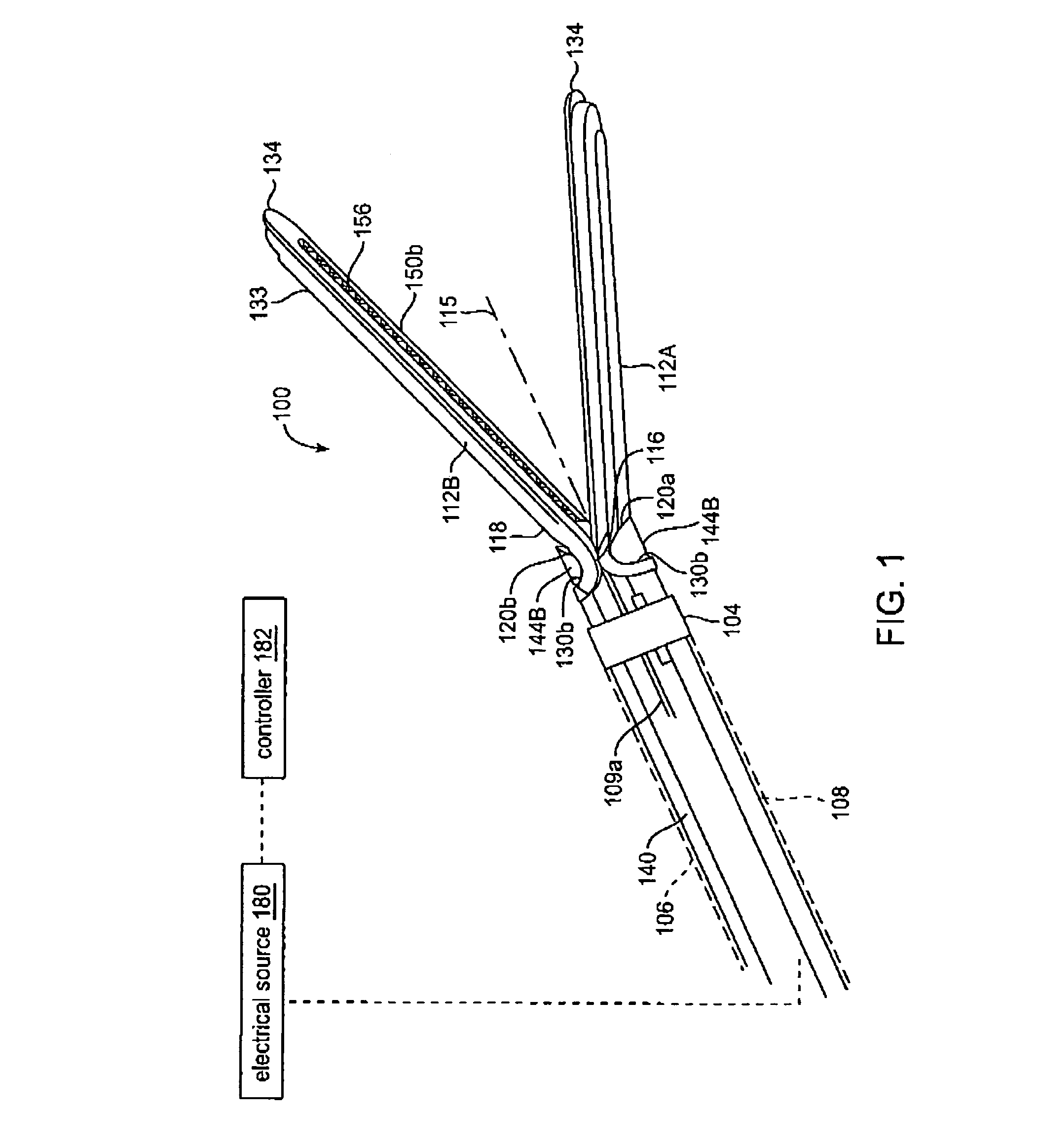

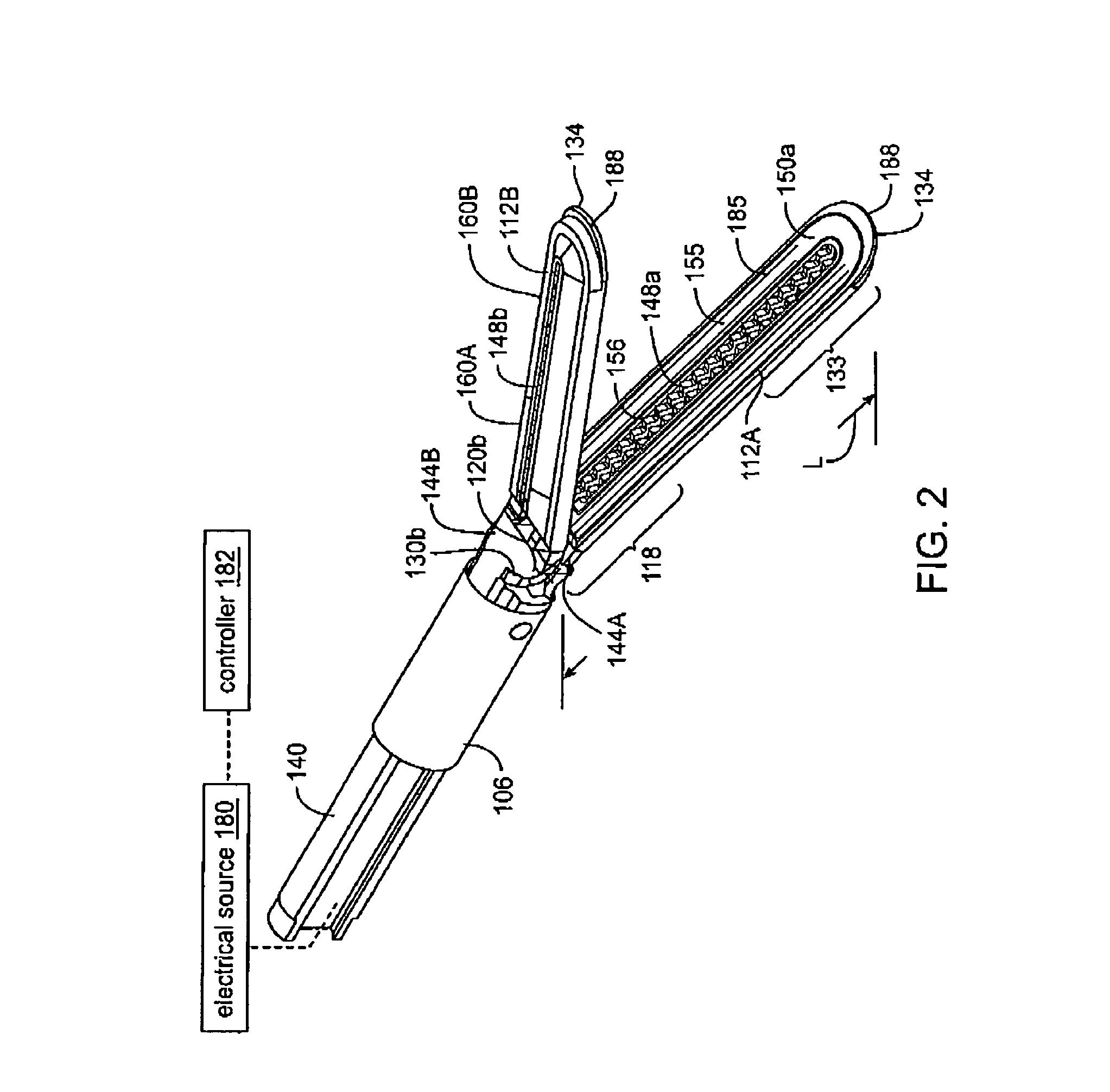

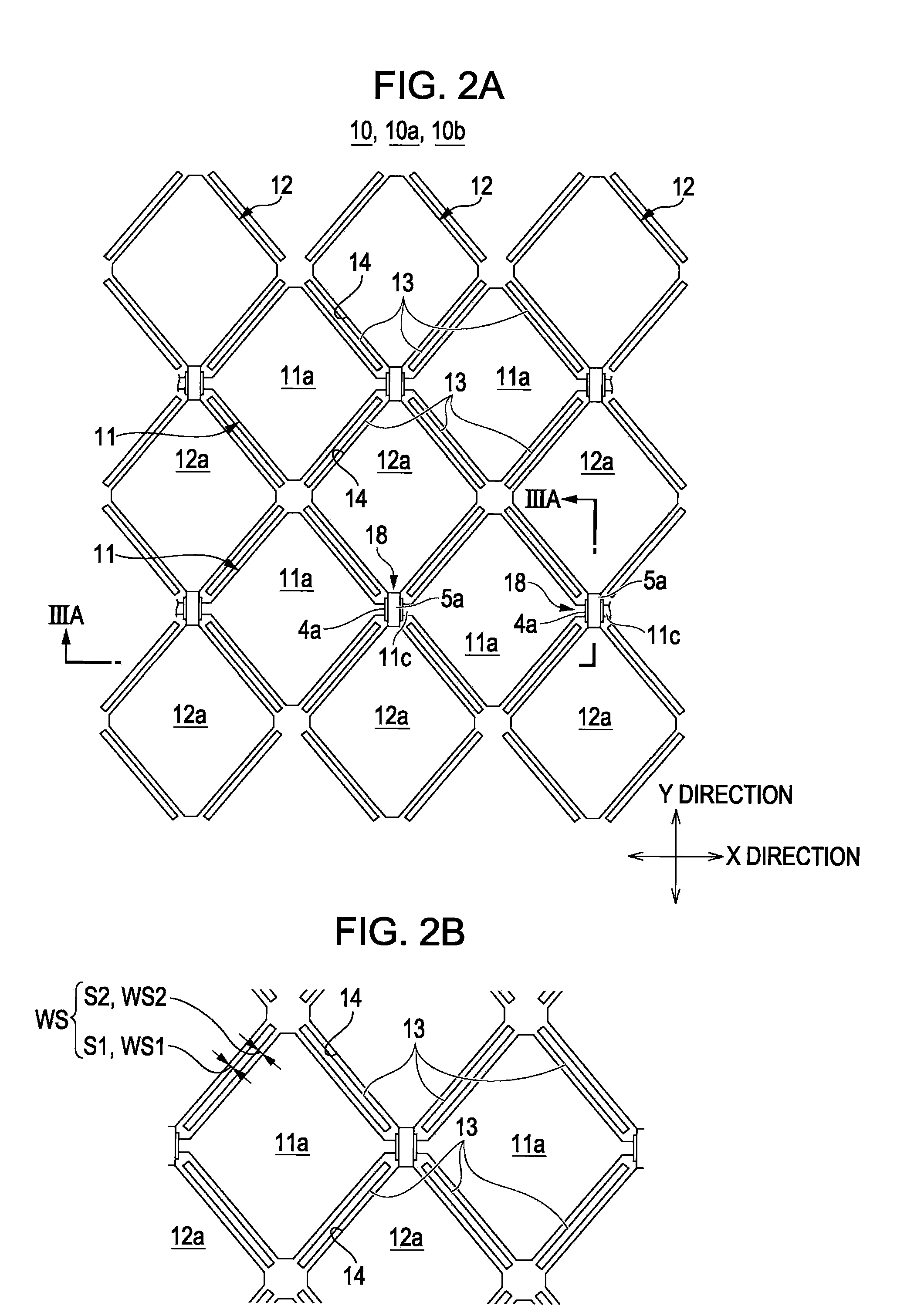

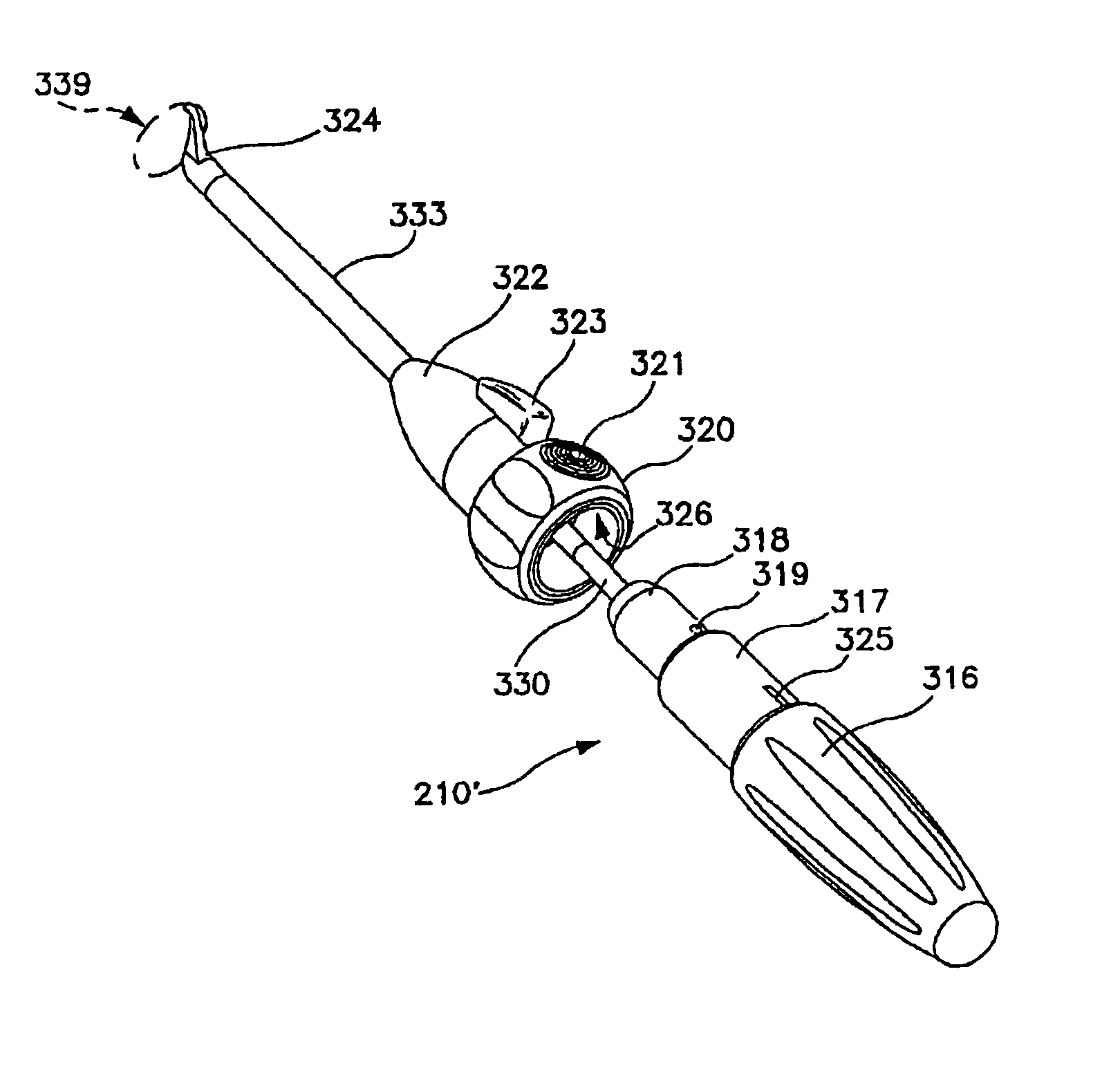

Electrosurgical instrument and method

InactiveUS20090076506A1Controllably seal the tissueImprove the immunitySurgical instruments for heatingSurgical forcepsTissue volume

An electrosurgical working end and method for sealing and transecting tissue are provided. An exemplary electrosurgical working end has openable-closeable first and second jaws for progressively clamping a selected tissue volume. A method of the invention comprises applying electrosurgical energy to the tissue in either a first mode or a second mode based on the degree of jaw closure.

Owner:ETHICON ENDO SURGERY INC

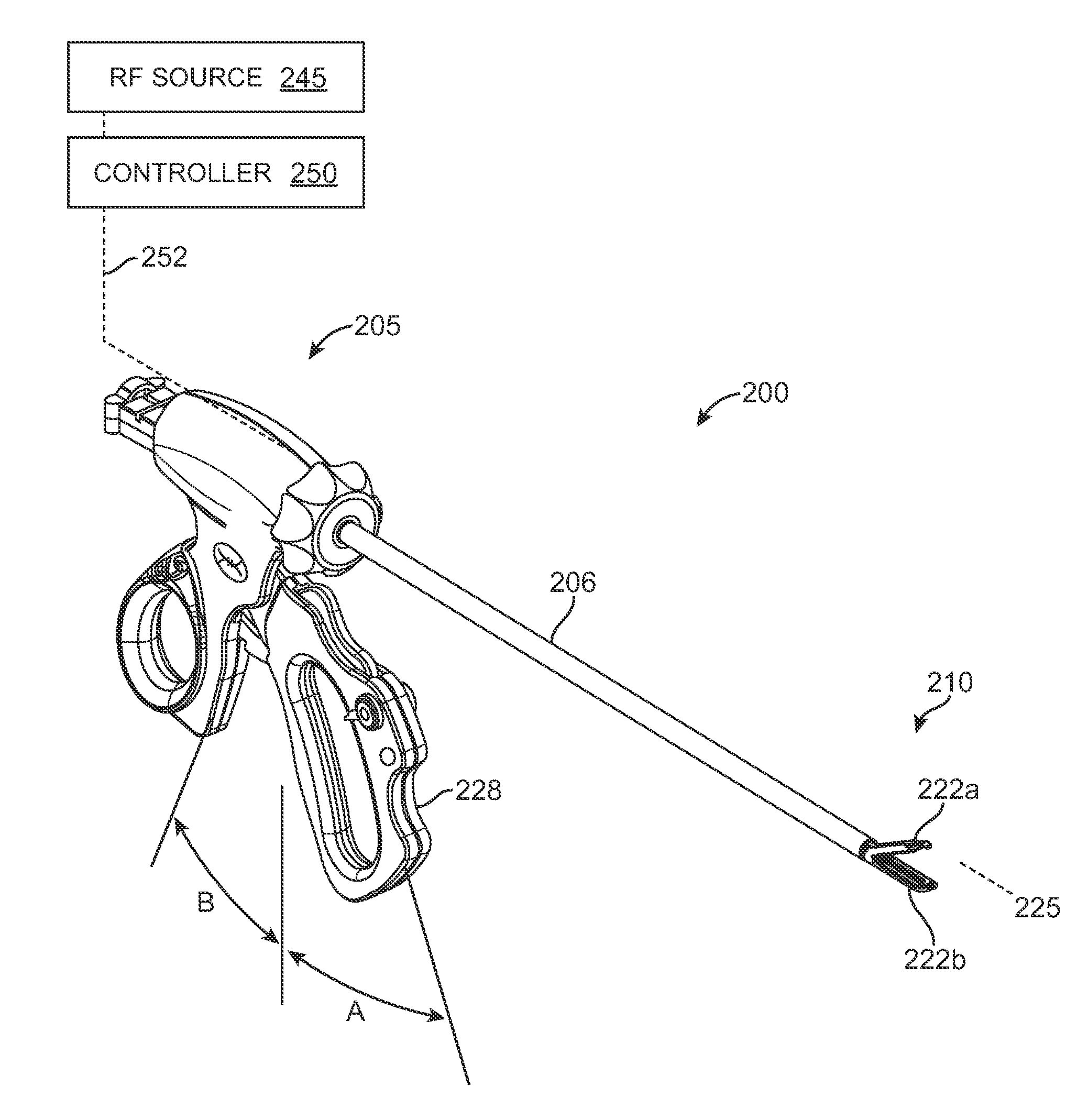

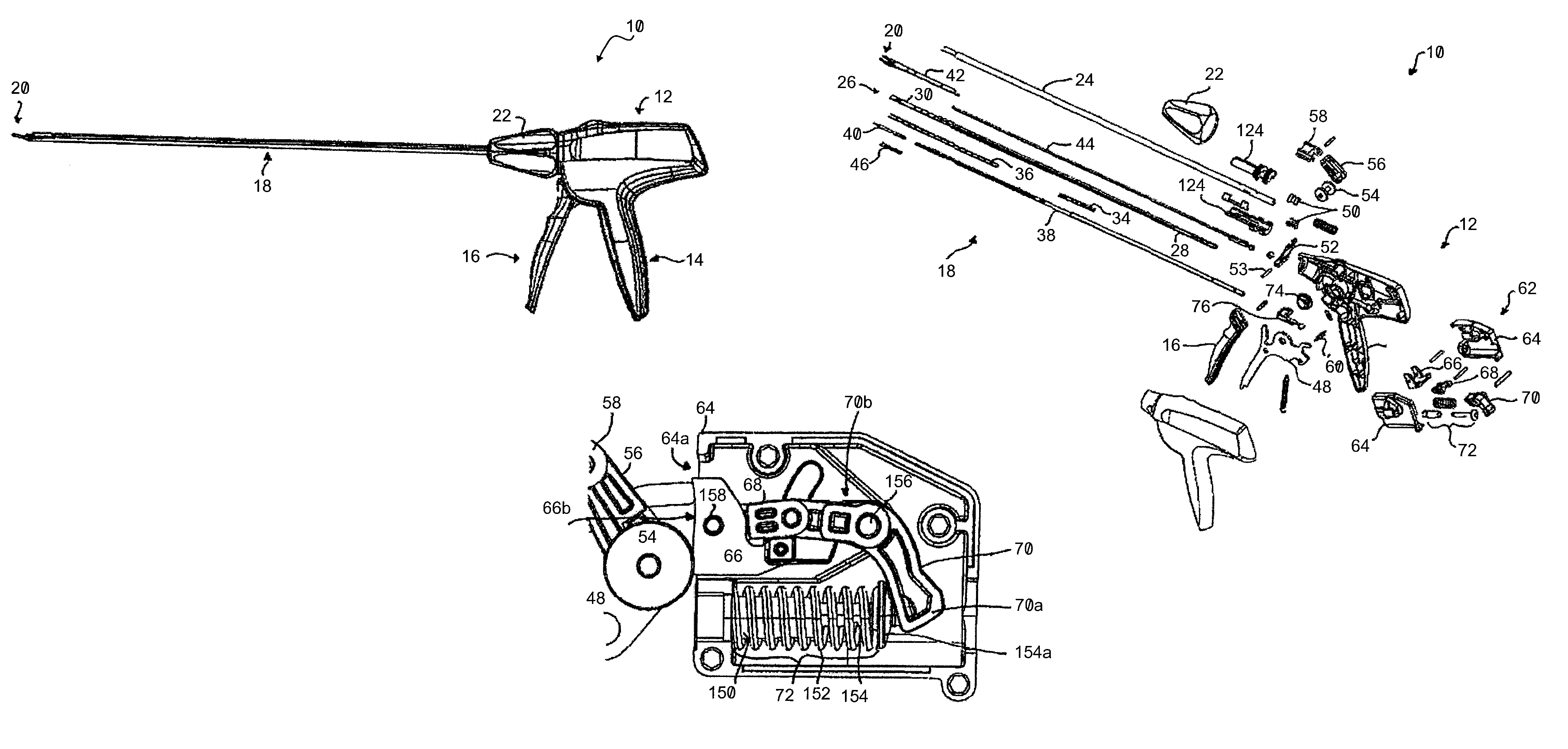

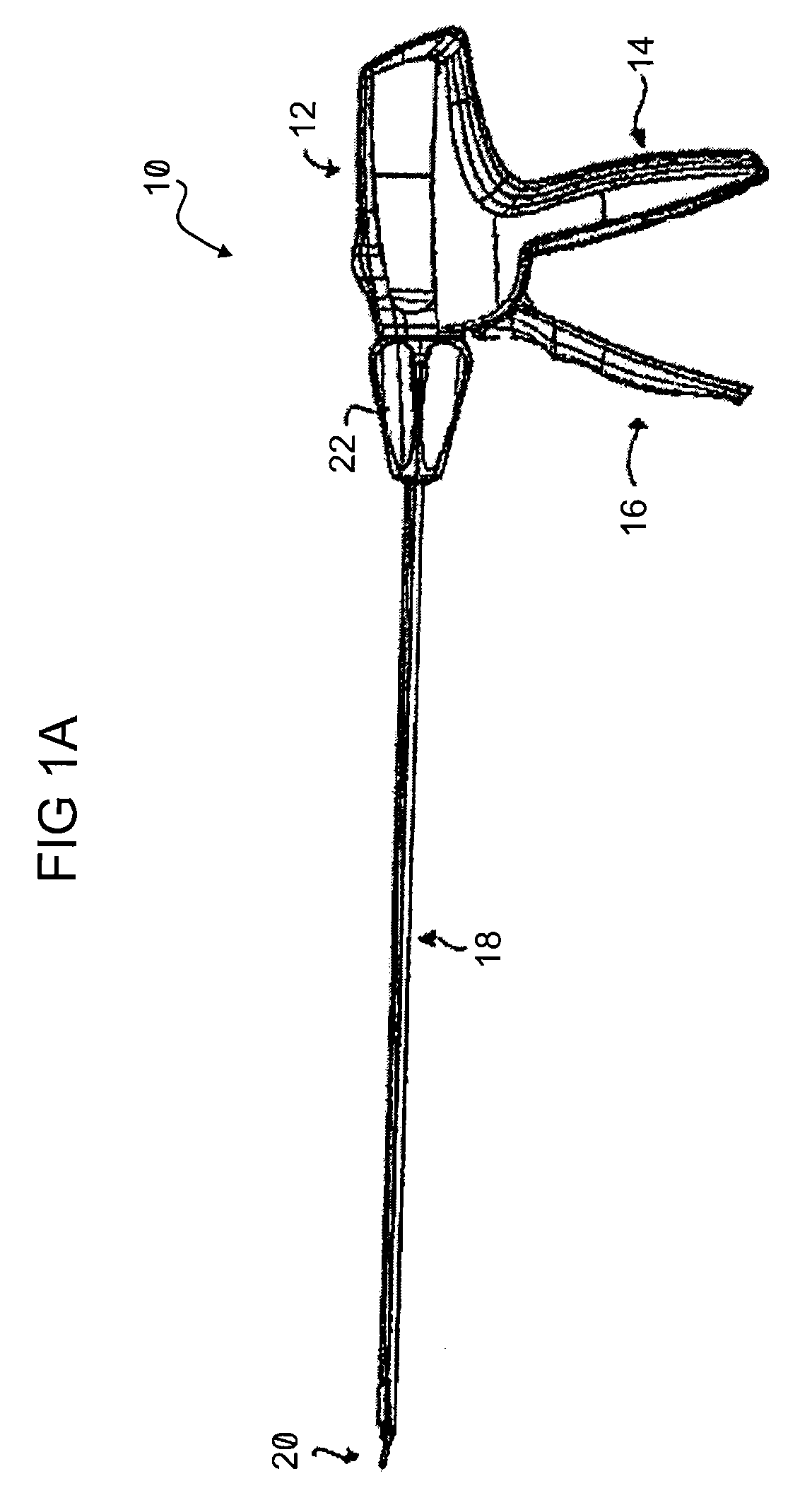

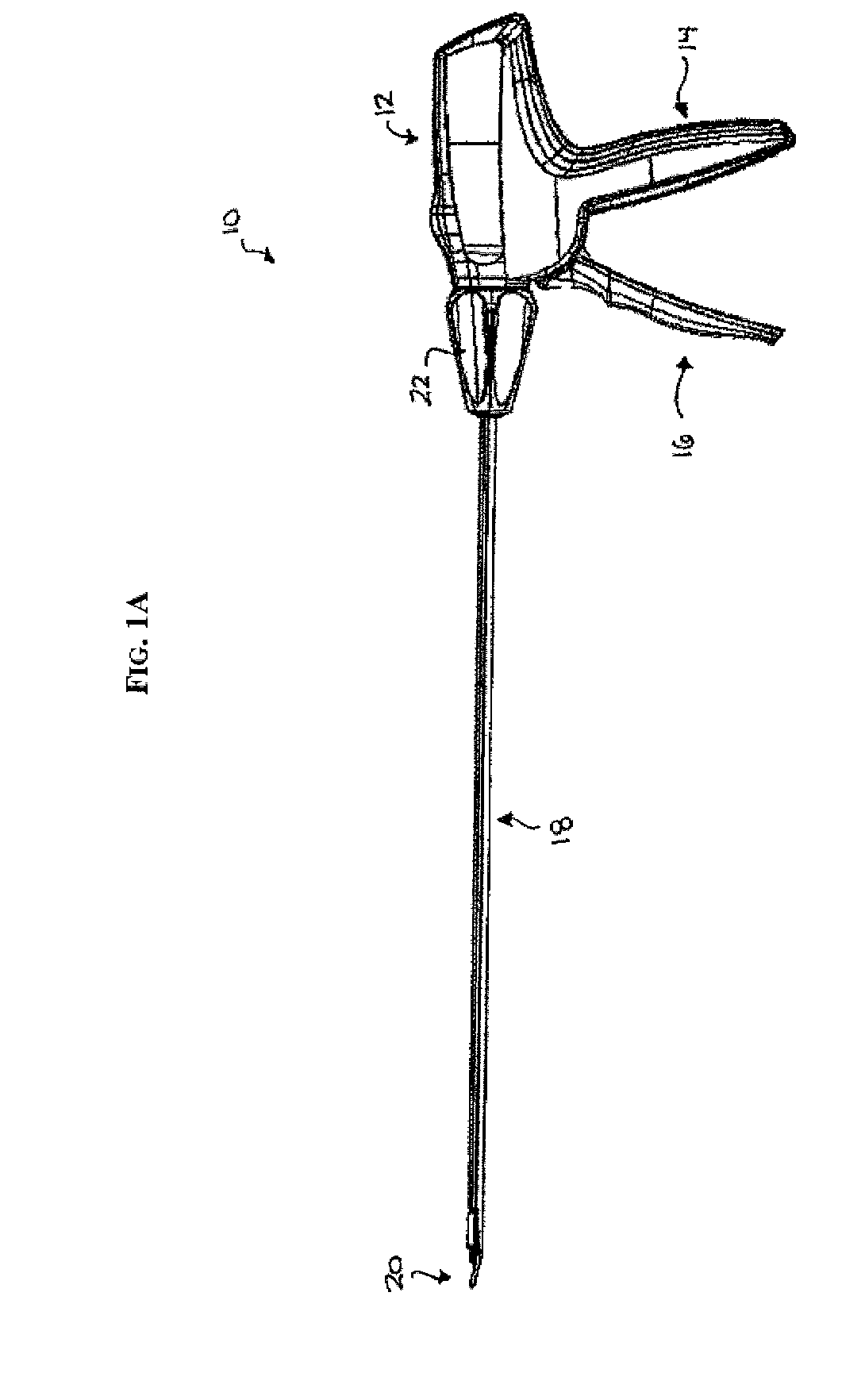

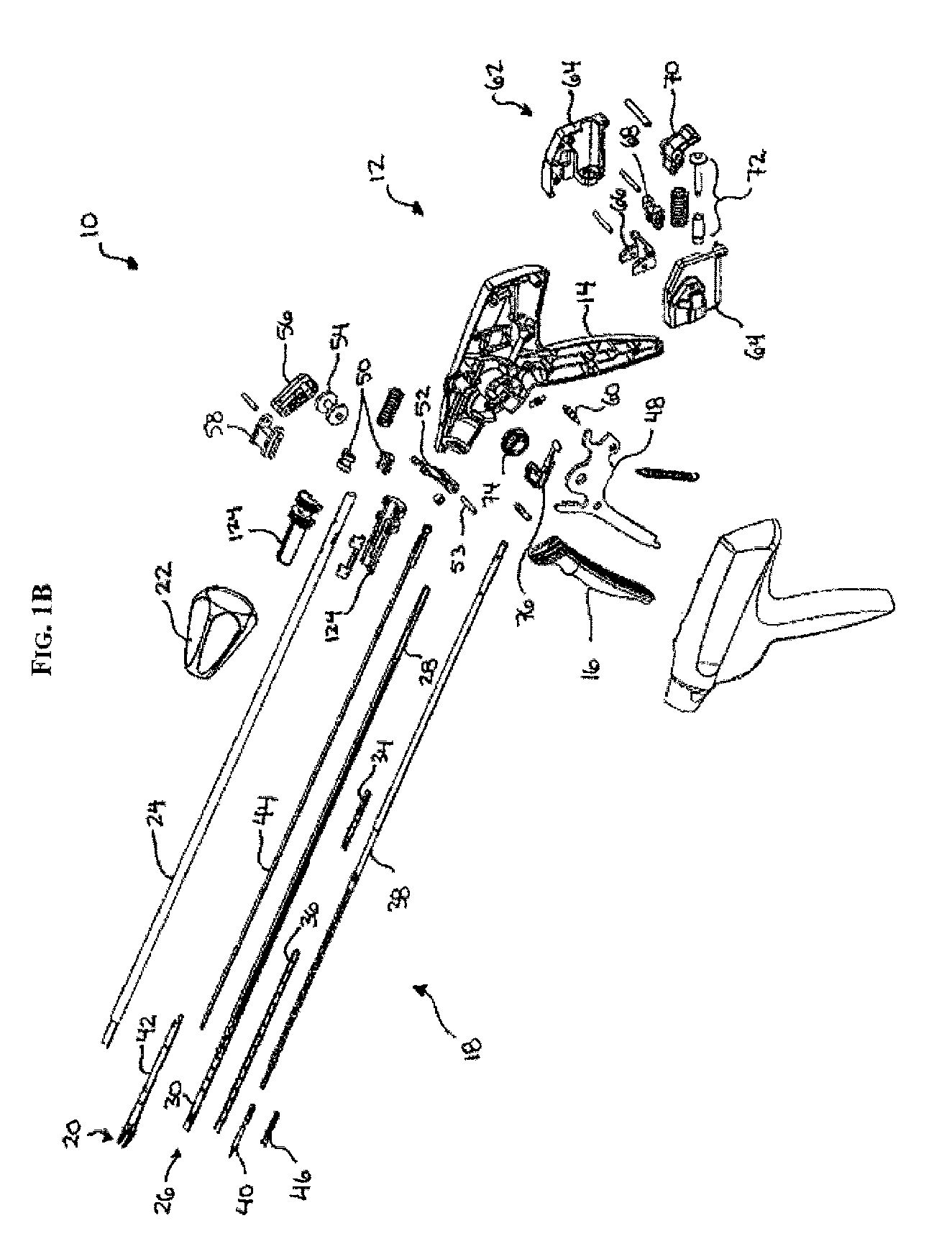

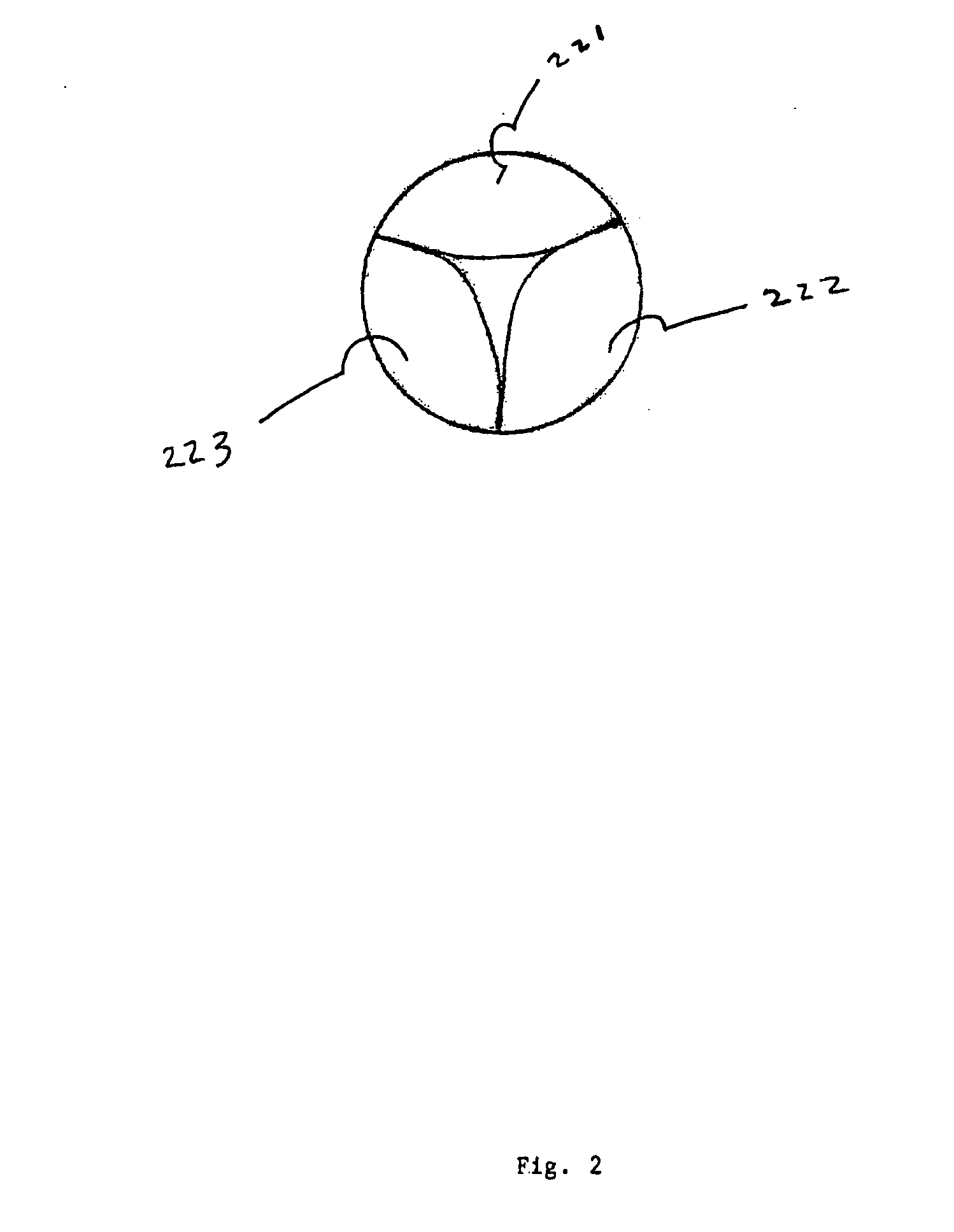

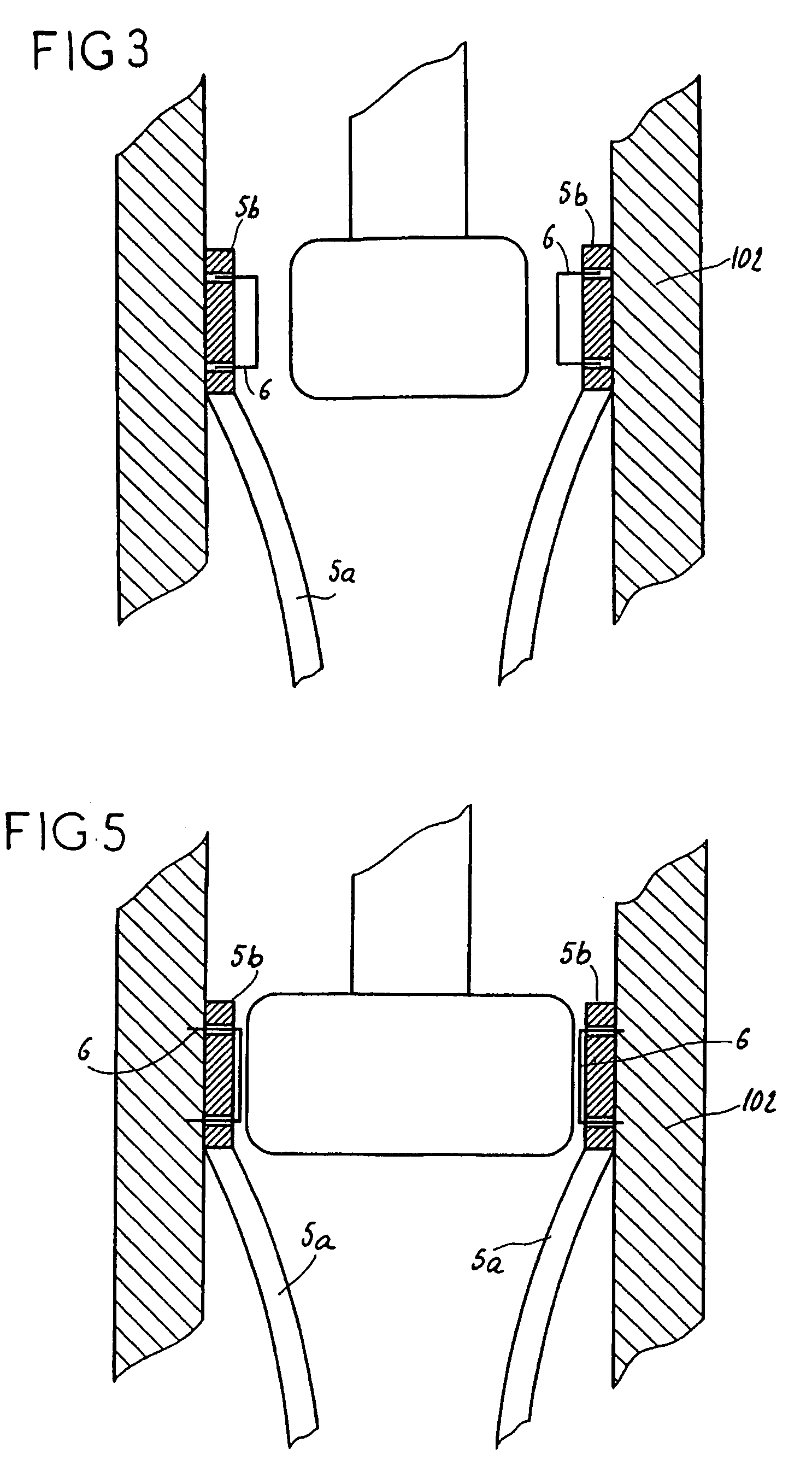

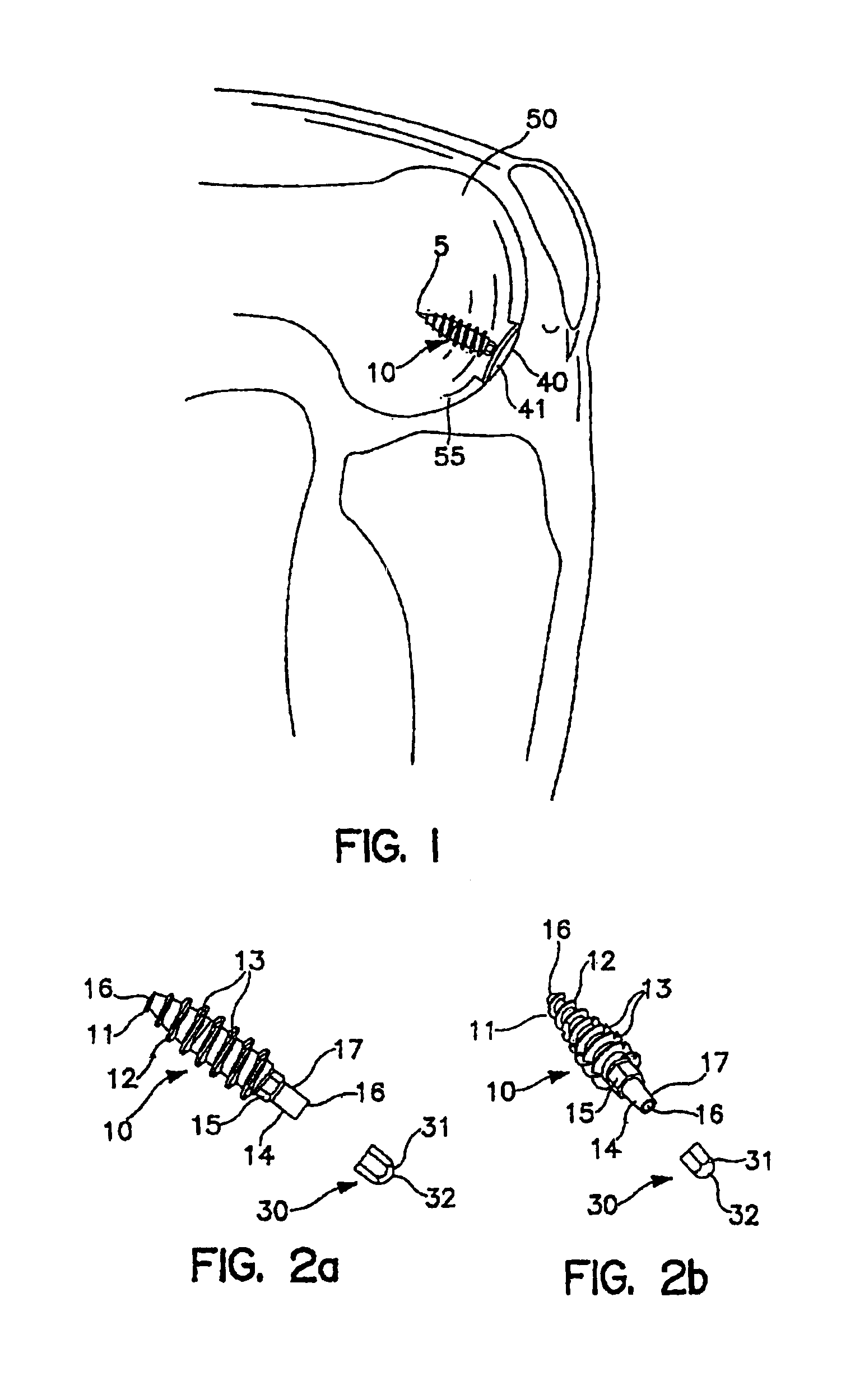

Surgical clip applier methods

ActiveUS7297149B2Facilitate advancementFacilitate formationDiagnosticsWound clampsEngineeringSurgical Clips

A surgical clip applier and methods for applying surgical clips to a vessel, duct, shunt, etc., during a surgical procedure are provided. In one exemplary embodiment, a surgical clip applier is provided having a housing with a trigger movably coupled thereto and an elongate shaft extending therefrom with opposed jaws formed on a distal end thereof. The trigger is adapted to advance a clip to position the clip between the jaws, and to move the jaws from an open position to a closed position to crimp the clip positioned therebetween.

Owner:CILAG GMBH INT

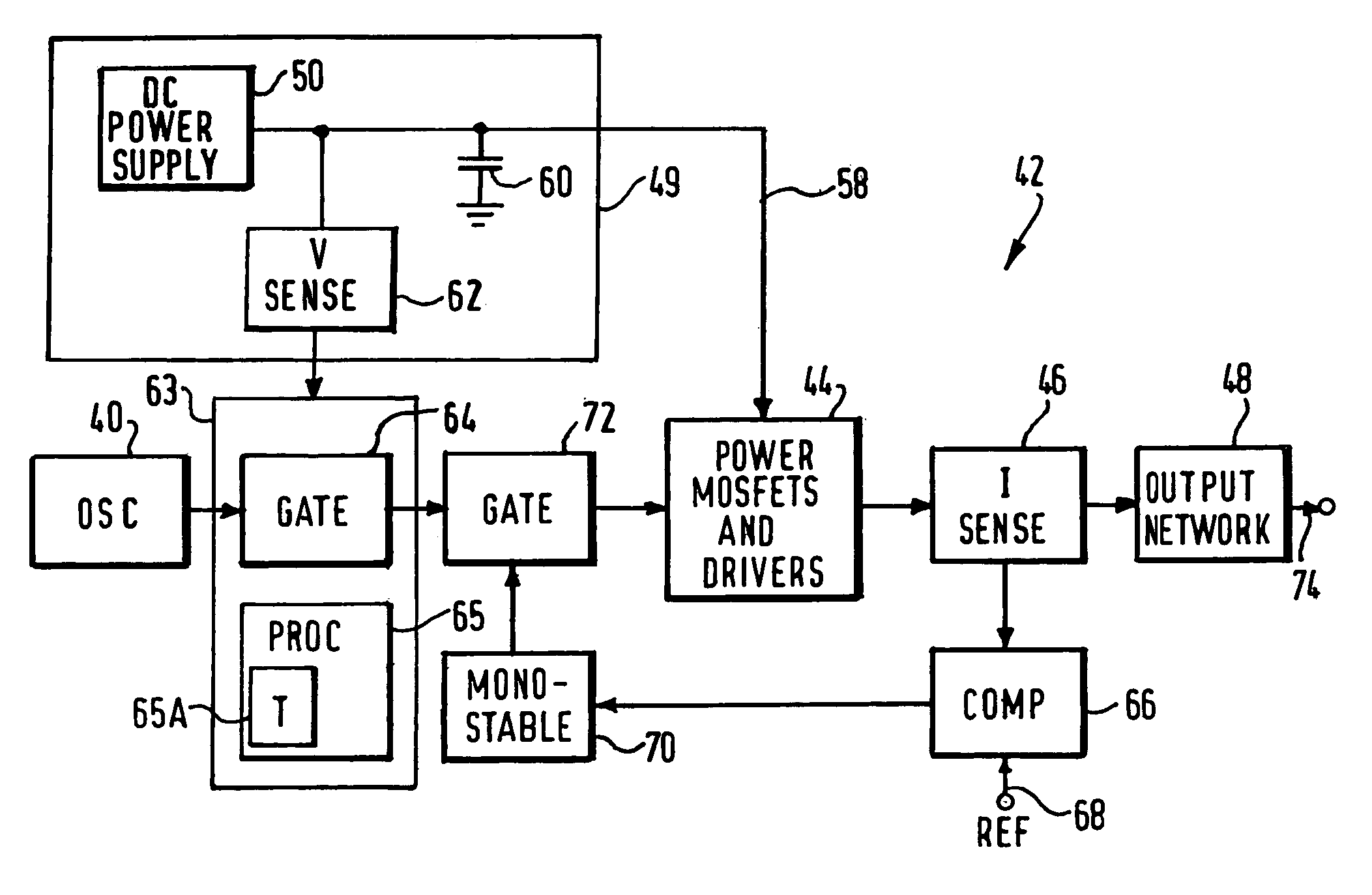

Electrosurgical generator

ActiveUS7195627B2High peak power capabilityReduces delay and unwanted coagulation effectSurgical instruments for heatingPeak valueContinuous wave

An electrosurgical generator for supplying RF power to an electrosurgical instrument for cutting or vaporising tissue has an RF output stage with RF output devices, a series-resonant output network and an RF output. The generator offers improved cutting and vaporising performance, especially in relation to the reliability with which an arc can be struck when presented with an initial load impedance load. This is achieved by virtue of the output stage being capable of maintaining output pulses of at least 1 kW peak by supplying the RF output devices from a large reservoir capacitor. An appropriate combination of cutting performance and haemostasis is provided by allowing for pulsed or continuous wave operation once an arc has been established, according to whether or not a surplus energy condition exists, as indicated by the voltage across the reservoir capacitor.

Owner:GYRUS MEDICAL LTD

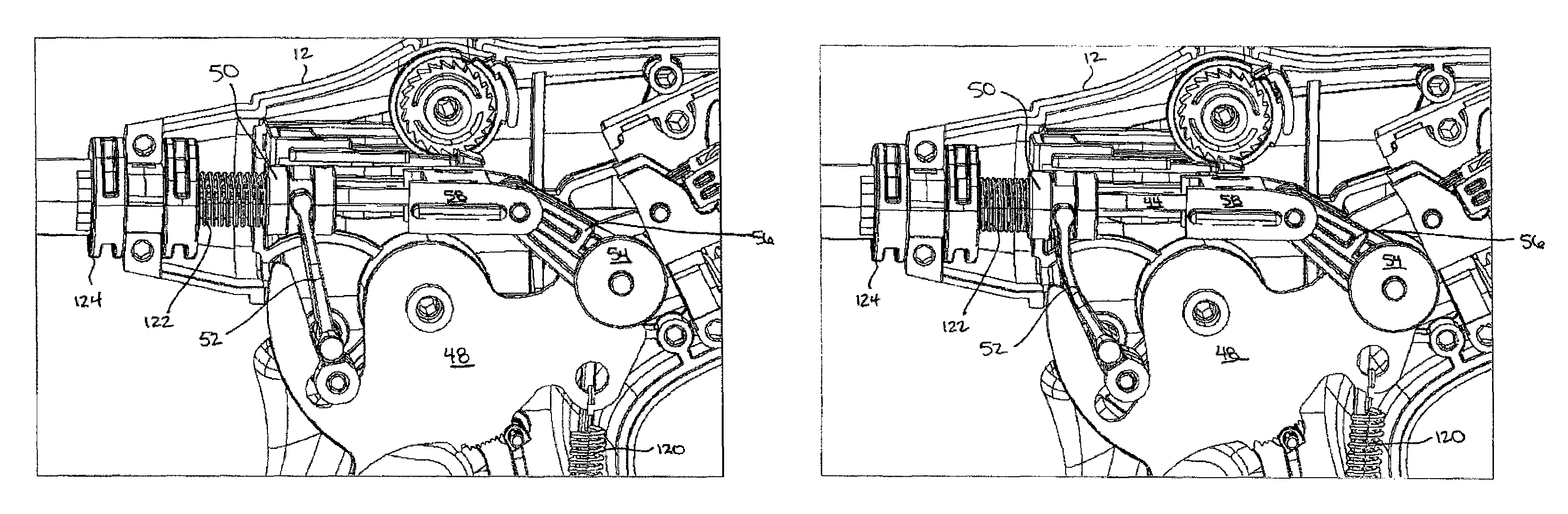

Surgical clip advancement and alignment mechanism

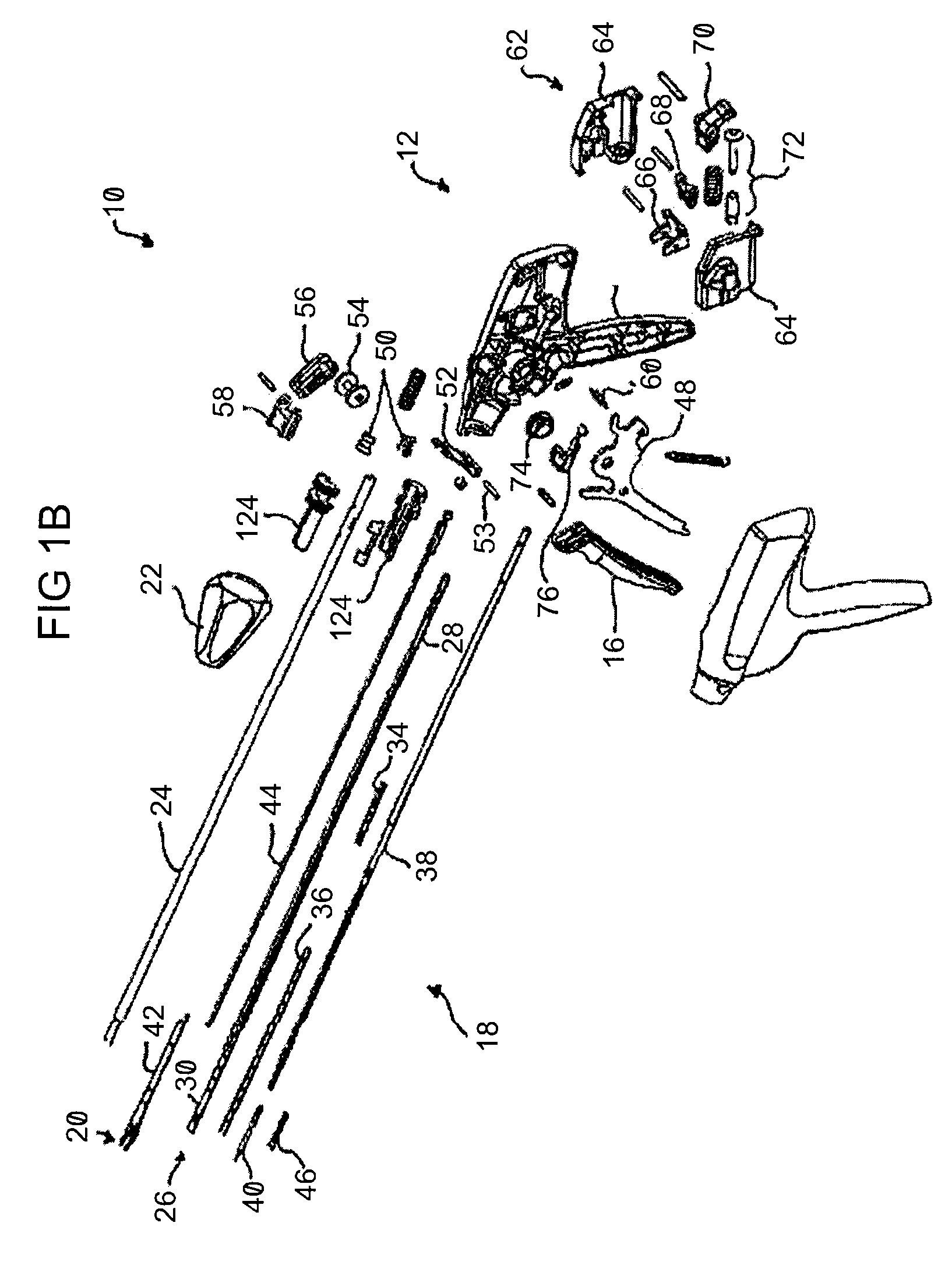

ActiveUS7731724B2Facilitate advancementFacilitate formationSurgical staplesWound clampsEngineeringSurgical Clips

A surgical clip applier and methods for applying surgical clips to a vessel, duct, shunt, etc., during a surgical procedure are provided. In one exemplary embodiment, a surgical clip applier is provided having a housing with a trigger movably coupled thereto and an elongate shaft extending therefrom with opposed jaws formed on a distal end thereof. The trigger is adapted to advance a clip to position the clip between the jaws, and to move the jaws from an open position to a closed position to crimp the clip positioned therebetween.

Owner:CILAG GMBH INT

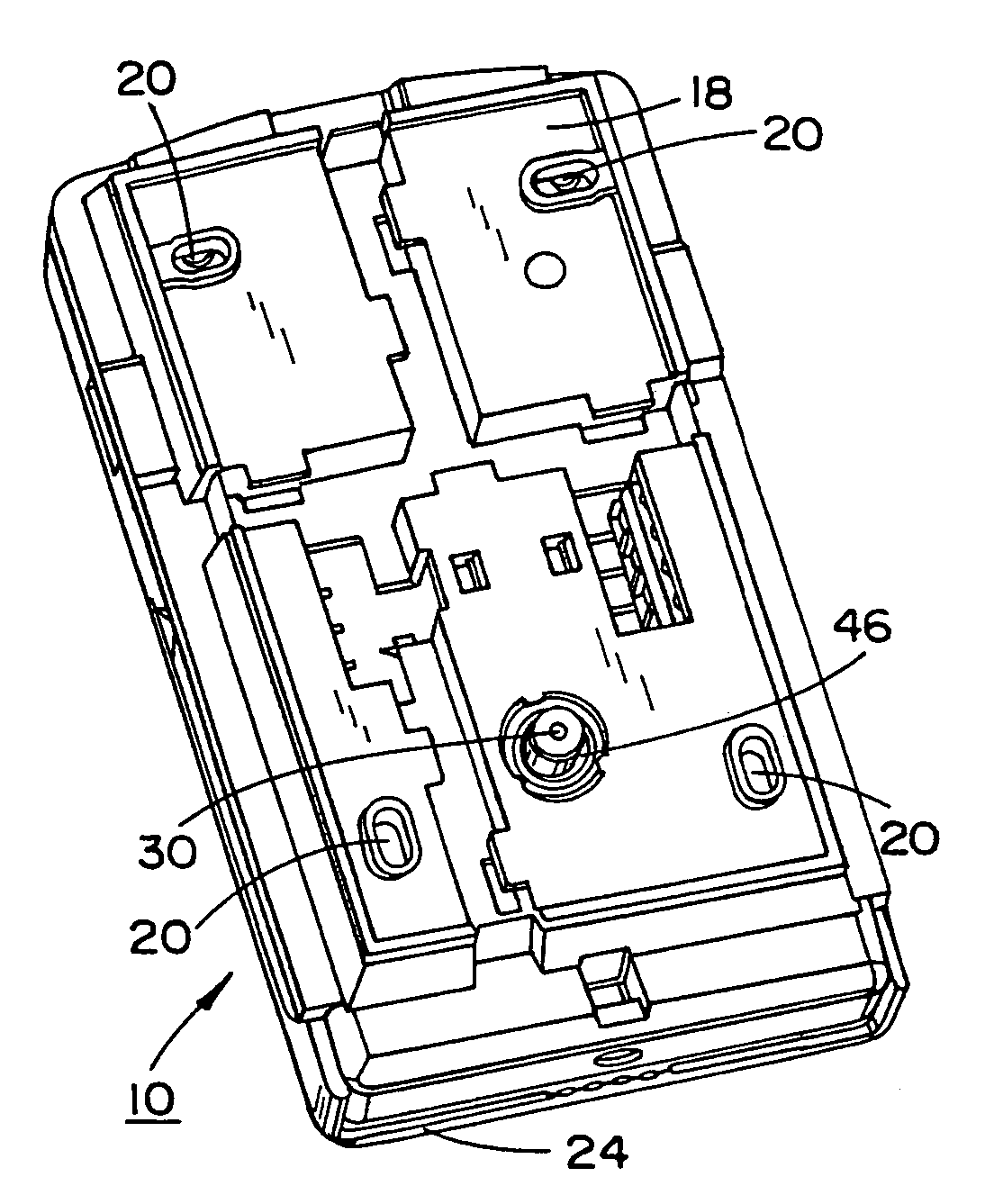

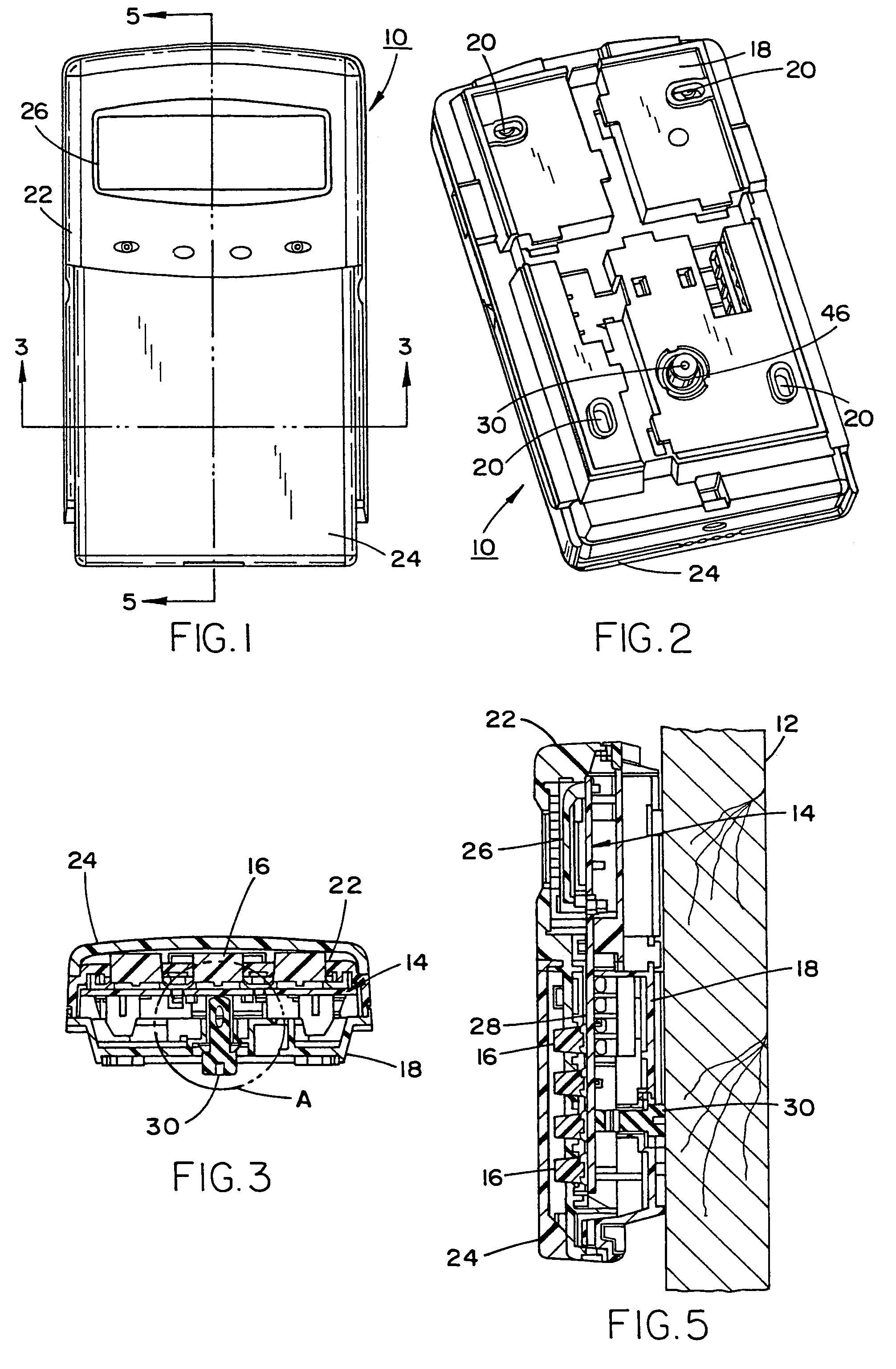

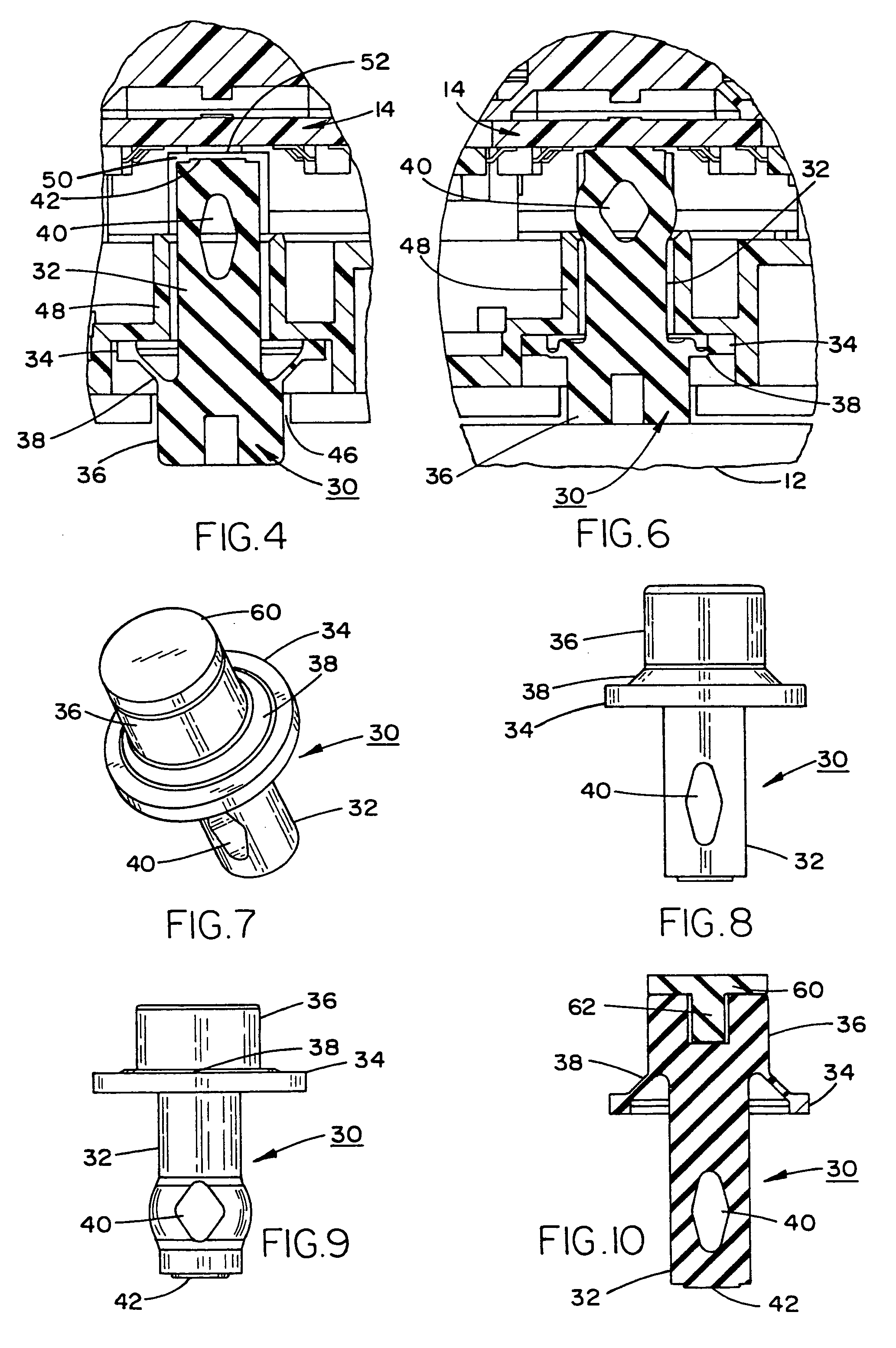

Conductive tamper switch for security devices

InactiveUS7388484B2Highly efficient and reliable in operationCost-effectively mountedInternal/peripheral component protectionRadio/inductive link selection arrangementsMonitoring siteFire alarm system

A tamper switch mechanism utilized in security interface devices such as keypad installations to render them tamper-resistant, wherein the devices are generally connected to burglar alarm and fire alarm systems. More particularly, provided is a conductive tamper switch which is installed in a security interface device, such as a keypad, which upon an unauthorized attempt to dislodge the device or keypad from a wall or surface on which it is mounted, will trigger an alarm or generate a warning signal at a monitoring site indicative that an effort at tampering with the device has been effected. Also disclosed is a method of providing the tamper switch mechanism in a security interface device, such as a keypad installation.

Owner:HONEYWELL INT INC

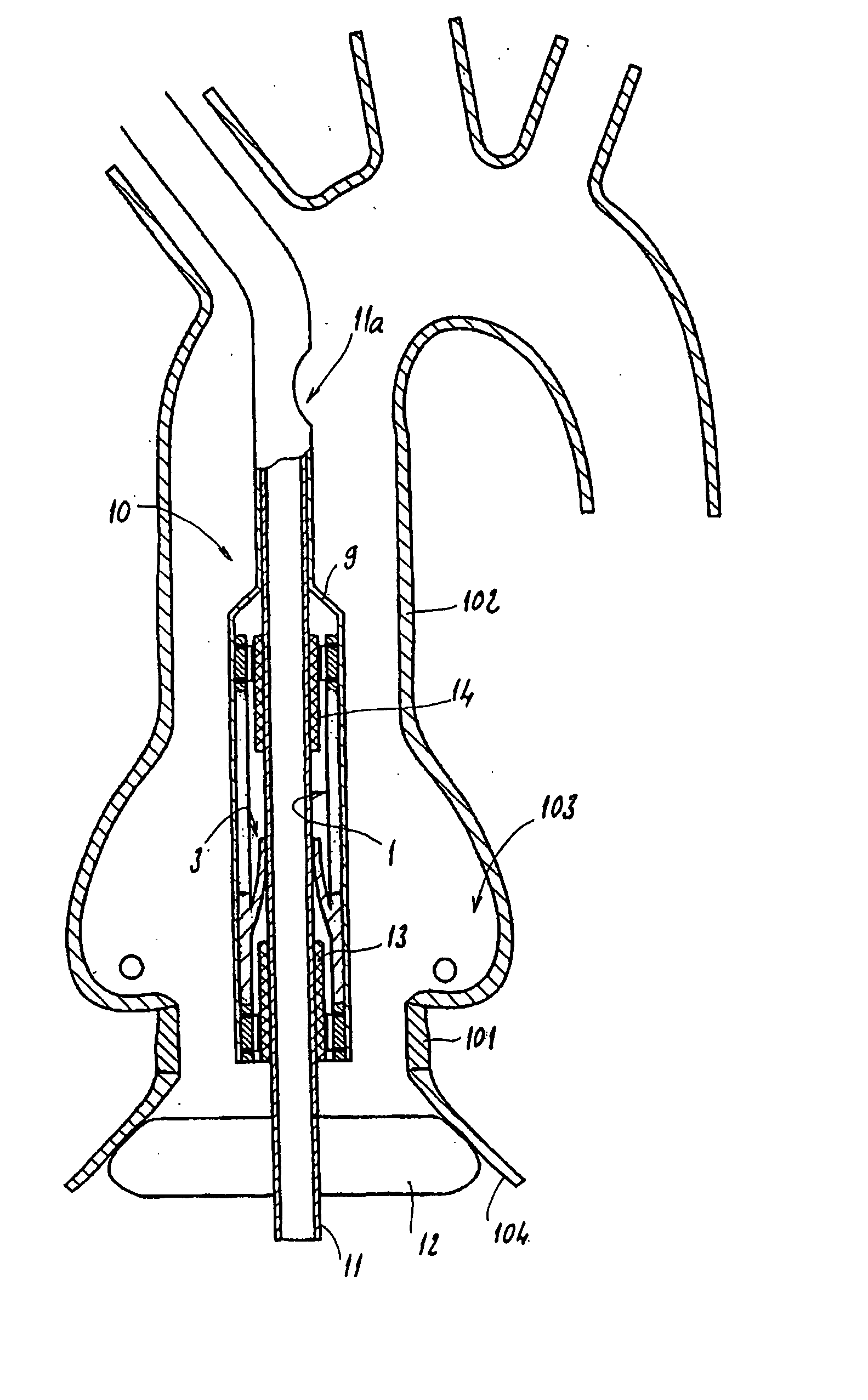

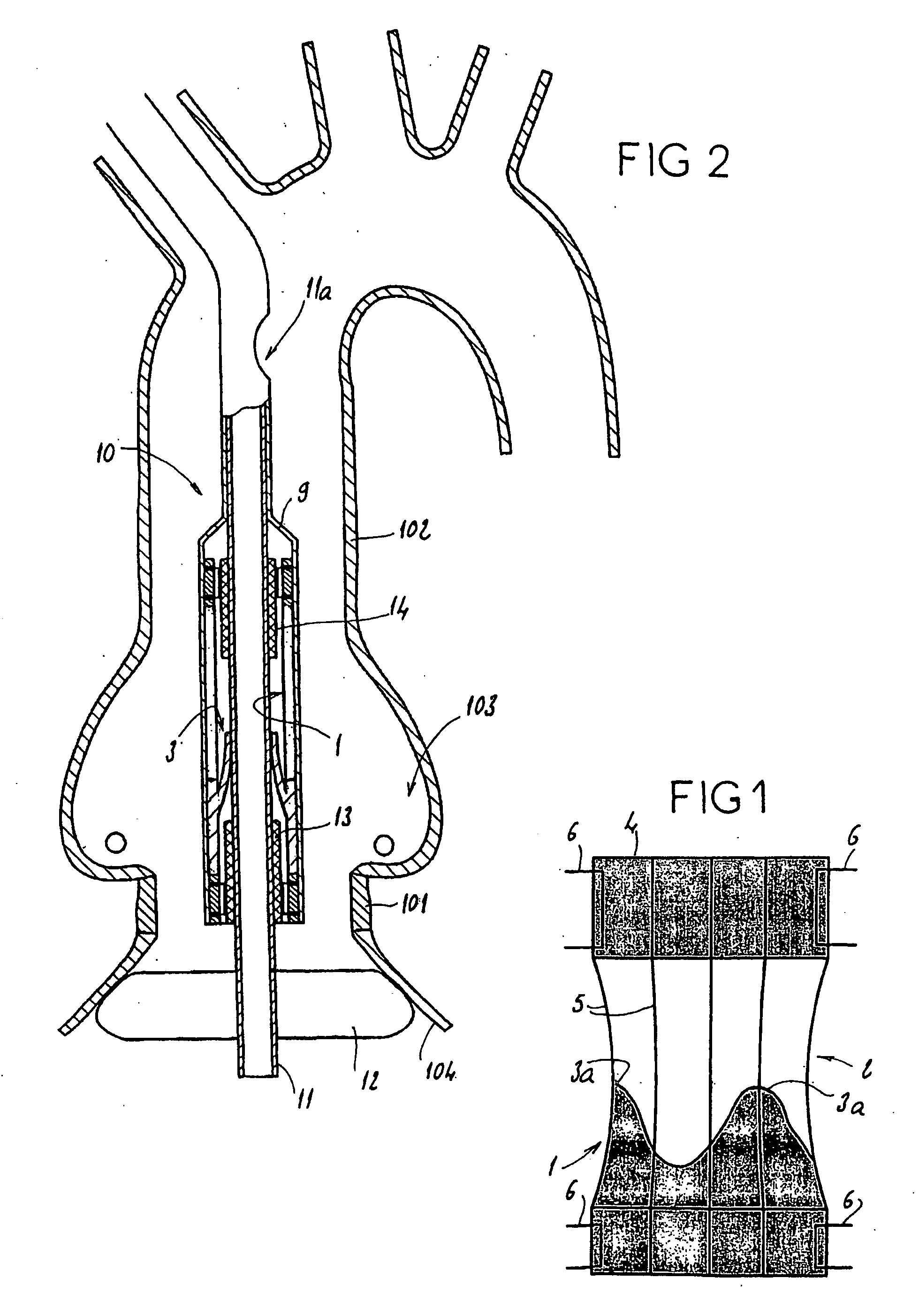

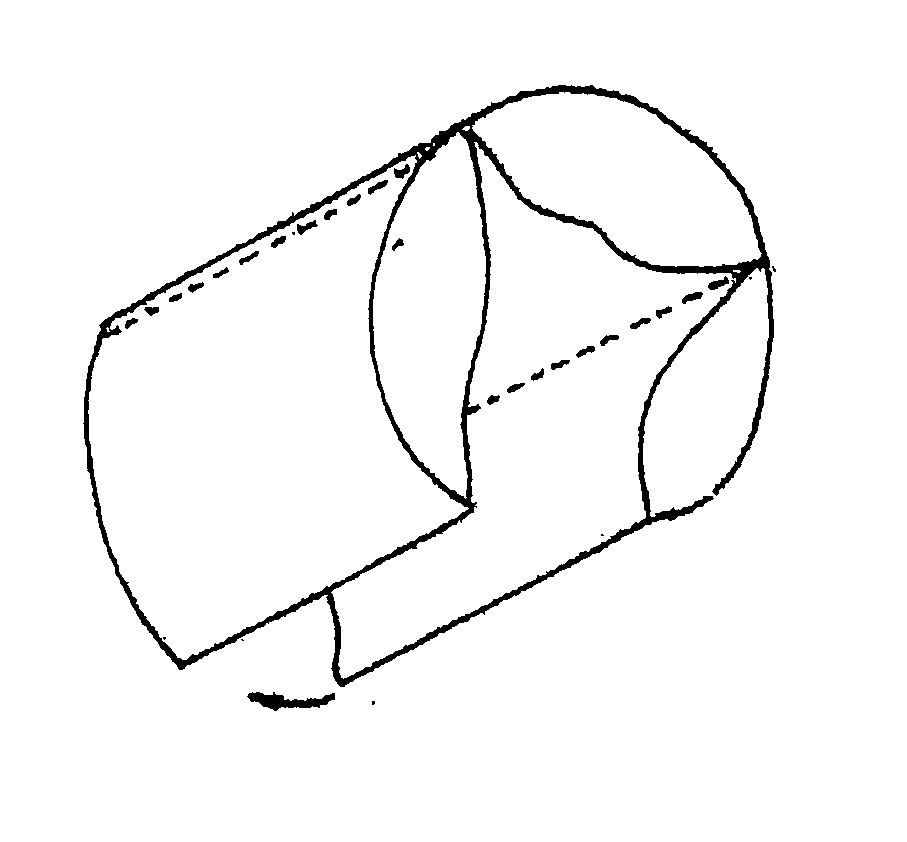

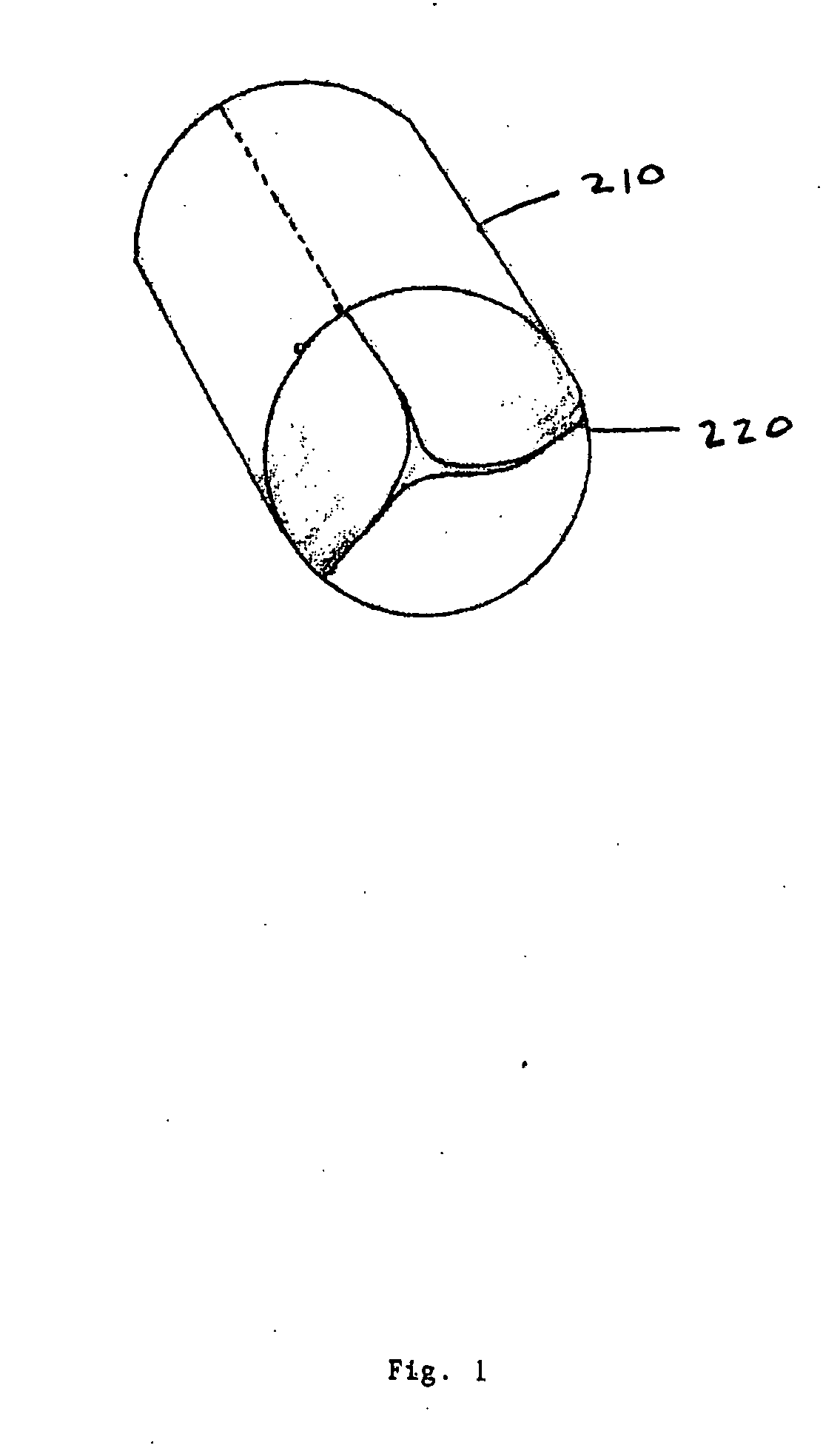

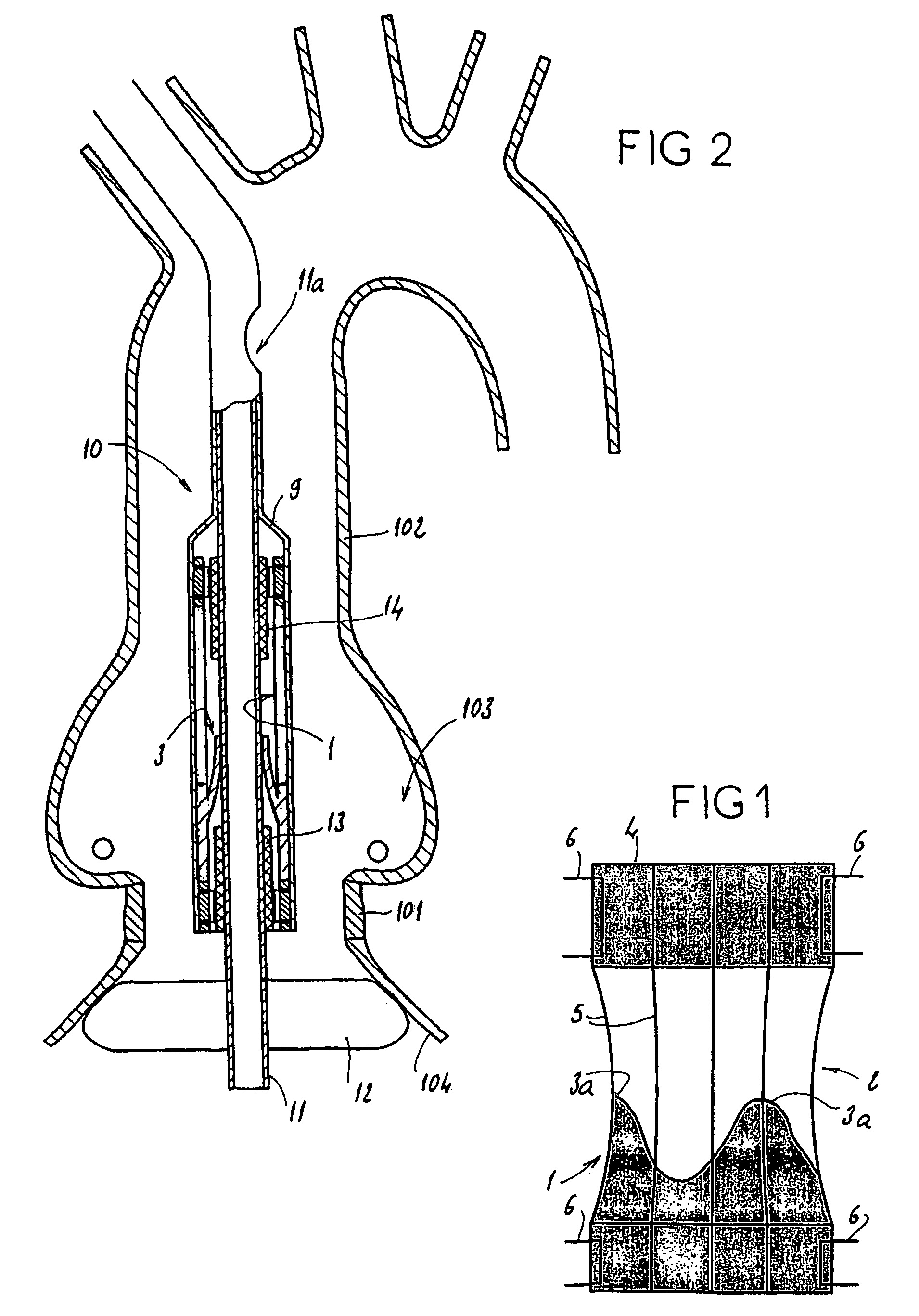

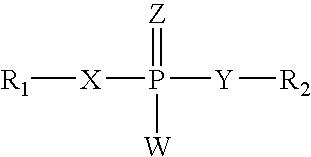

Assembly for setting a valve prosthesis in a corporeal duct

The invention concerns an assembly comprising a valve prosthesis to be implanted and a support receiving said valve. The support comprises: at least a tubular portion made of a pliable material slightly stretchable in the circumferential direction; means for fixing said tubular portion to the wall of the corporeal duct; and a plurality of elongated reinforcing elements, arranged on the circumference of said tubular portion and linked to said tubular portion independently of one another; the valve is linked at least partly to said elongated reinforcing elements, in particular at the commissures of its leaflets, and said elongated reinforcing elements jointly form, in extended position, a structure having a predetermined diameter that ensures sufficient extension of said valve.

Owner:MEDTRONIC COREVALVE

Percutaneously implantable replacement heart valve device and method of making same

The present invention comprises a percutaneously implantable replacement heart valve device and a method of making same. The replacement heart valve device comprises a stent member made of stainless steel or self-expanding nitinol, a biological tissue artificial valve means disposed within the inner space of the stent member. An implantation and delivery system having a central part which consists of a flexible hollow tube catheter that allows a metallic wire guide to be advanced inside it. The endovascular stented-valve is created from a glutaraldehyde fixed biocompatible tissue material which has two or three cusps that open distally to permit unidirectional blood flow. The present invention also comprises a novel method of making a replacement heart valve by taking a fragment of biocompatible tissue material and treating, drying, folding and rehydrating it in such a way that forms a two- or three-leaflet / cusp valve with the leaflets / cusps formed by folding, thereby eliminating the extent of suturing required, providing improved durability and function.

Owner:COLIBRI HEART VALVE

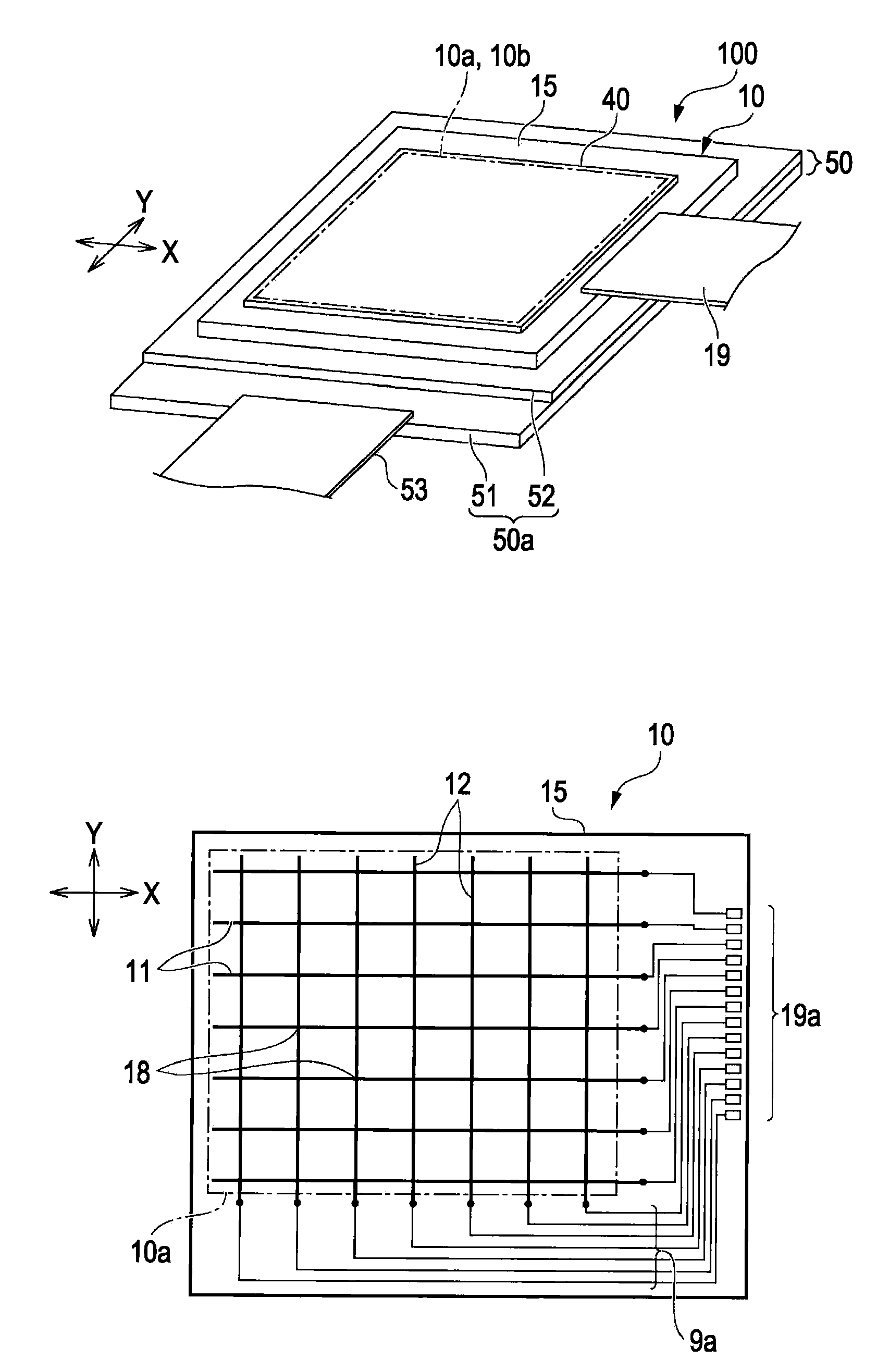

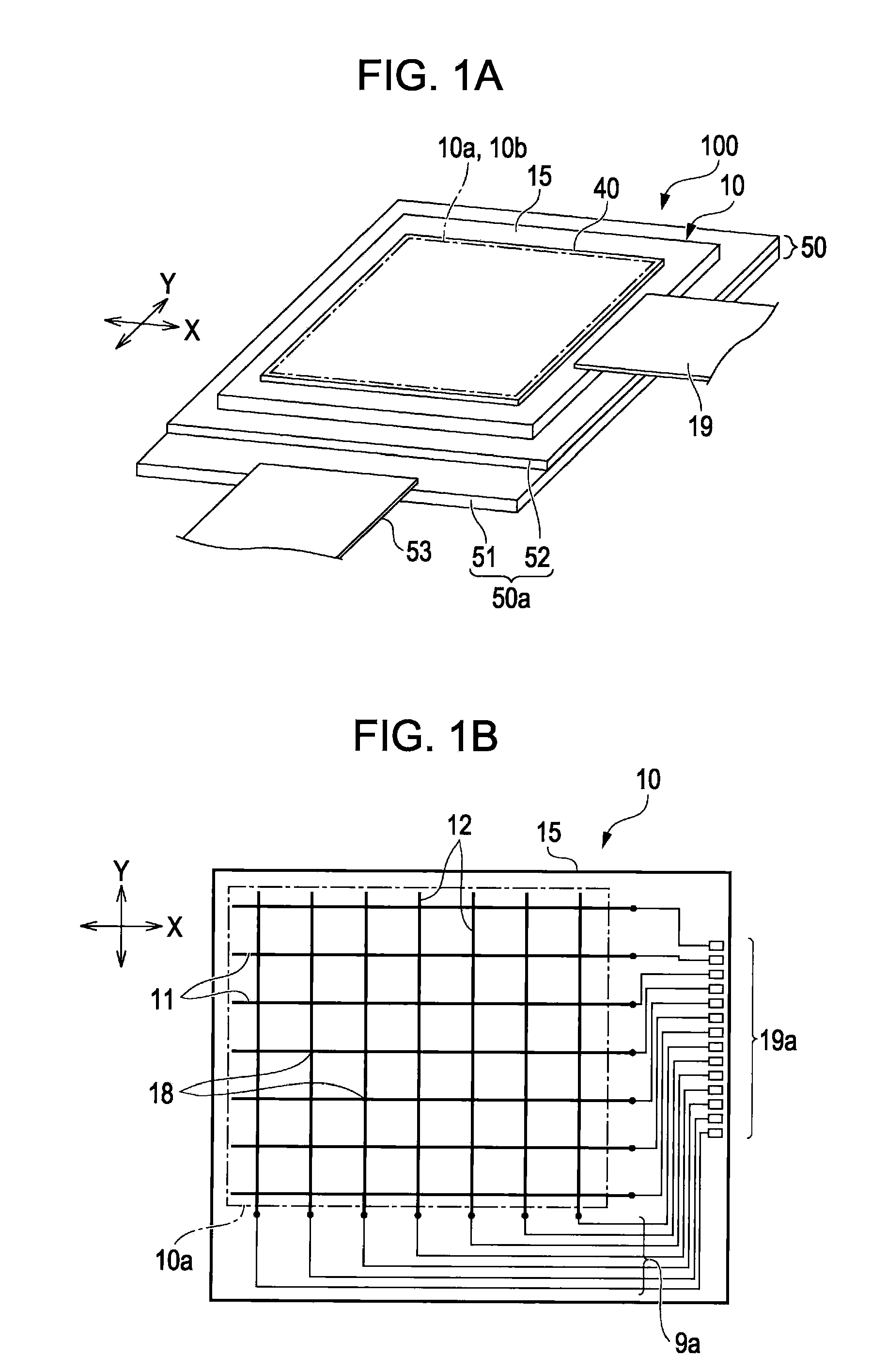

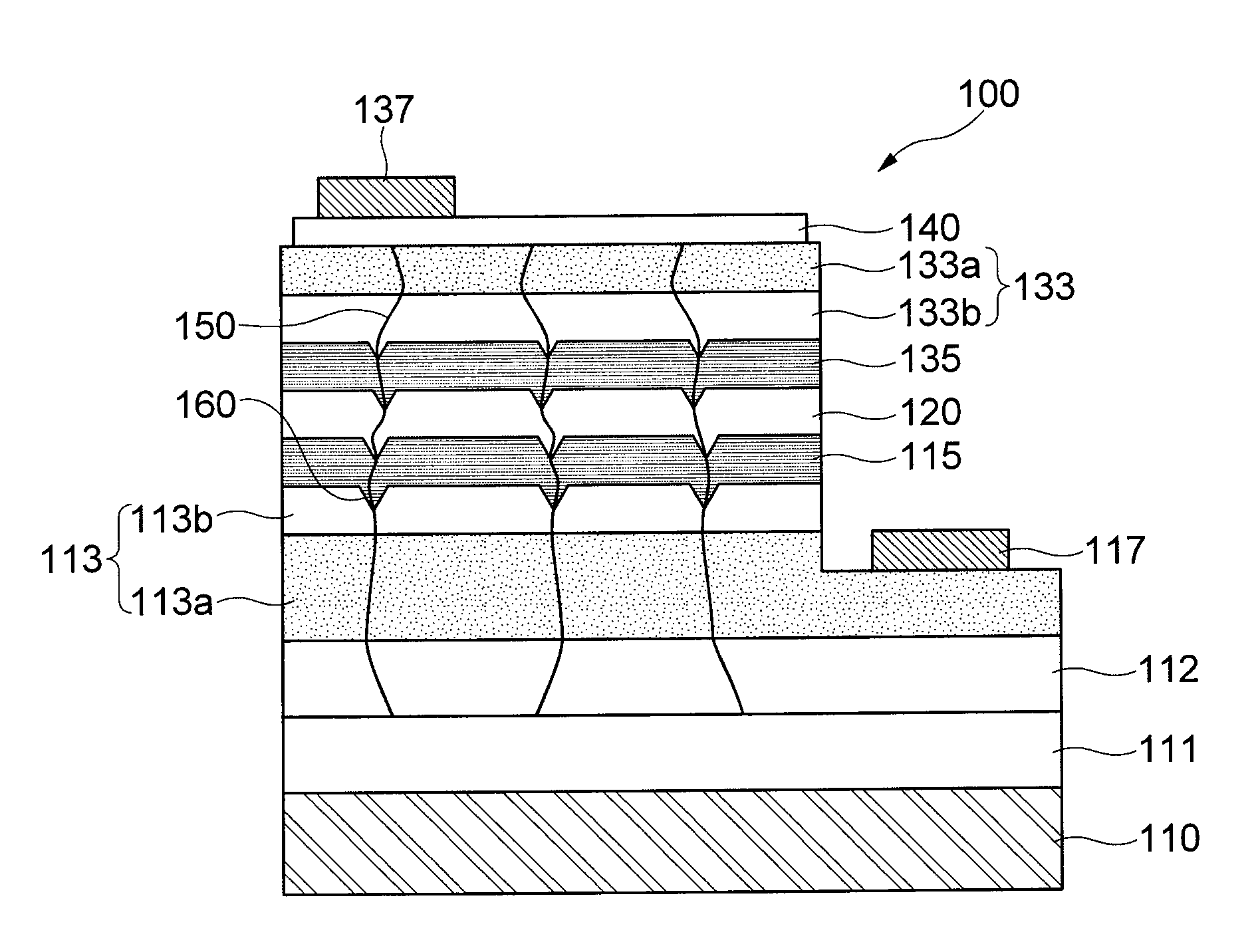

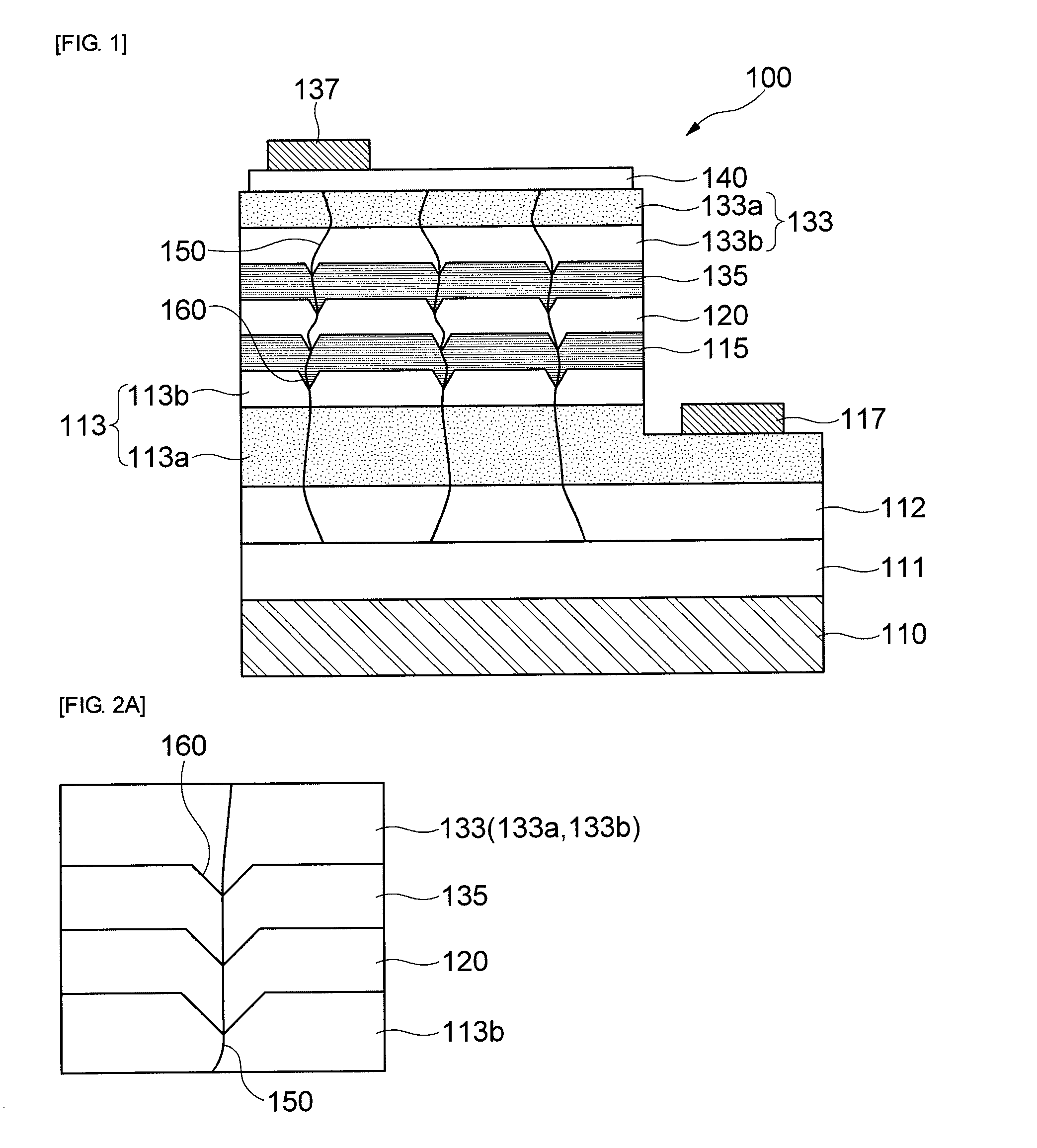

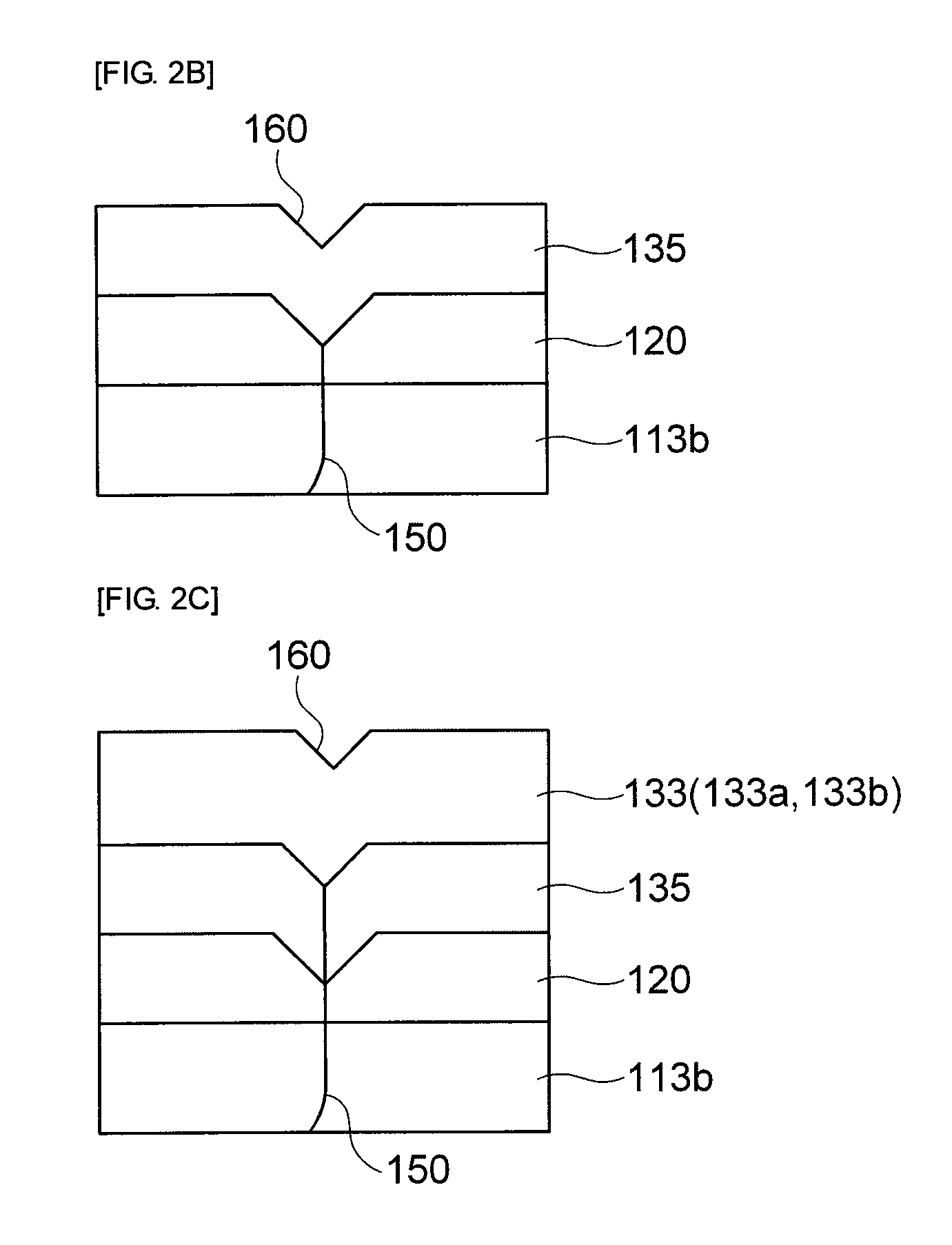

Capacitance type input device and display device with input function

ActiveUS20090315854A1Simple configurationResistance of light lightInput/output processes for data processingCapacitanceDisplay device

Provided is a capacitance type input device, in which a plurality of first light transmission electrodes extending in a first direction and a plurality of second light transmission electrodes extending in a second direction crossing the first direction are formed in an input region of a light transmission substrate, wherein, when the light transmission substrate is viewed from the top, dummy patterns formed of the same light transmission conductive film as the first light transmission electrodes and the second light transmission electrodes are formed in regions sandwiched between the first light transmission electrodes and the second light transmission electrodes.

Owner:JAPAN DISPLAY WEST

Assembly for setting a valve prosthesis in a corporeal duct

InactiveUS7682390B2Eliminate riskRisk is exacerbatedBalloon catheterHeart valvesCommissureBiomedical engineering

The invention concerns an assembly comprising a valve prosthesis to be implanted and a support receiving said valve. The support comprises: at least a tubular portion made of a pliable material slightly stretchable in the circumferential direction; means for fixing said tubular portion to the wall of the corporeal duct; and a plurality of elongated reinforcing elements, arranged on the circumference of said tubular portion and linked to said tubular portion independently of one another; the valve is linked at least partly to said elongated reinforcing elements, in particular at the commissures of its leaflets, and said elongated reinforcing elements jointly form, in extended position, a structure having a predetermined diameter that ensures sufficient extension of said valve.

Owner:MEDTRONIC COREVALVE

Nitride semiconductor light emitting device and fabrication method thereof

ActiveUS8129711B2Good effectReduce leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerLight emitting device

The present invention relates to a GaN based nitride based light emitting device improved in Electrostatic Discharge (ESD) tolerance (withstanding property) and a method for fabricating the same including a substrate and a V-shaped distortion structure made of an n-type nitride semiconductor layer, an active layer and a p-type nitride semiconductor layer on the substrate and formed with reference to the n-type nitride semiconductor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

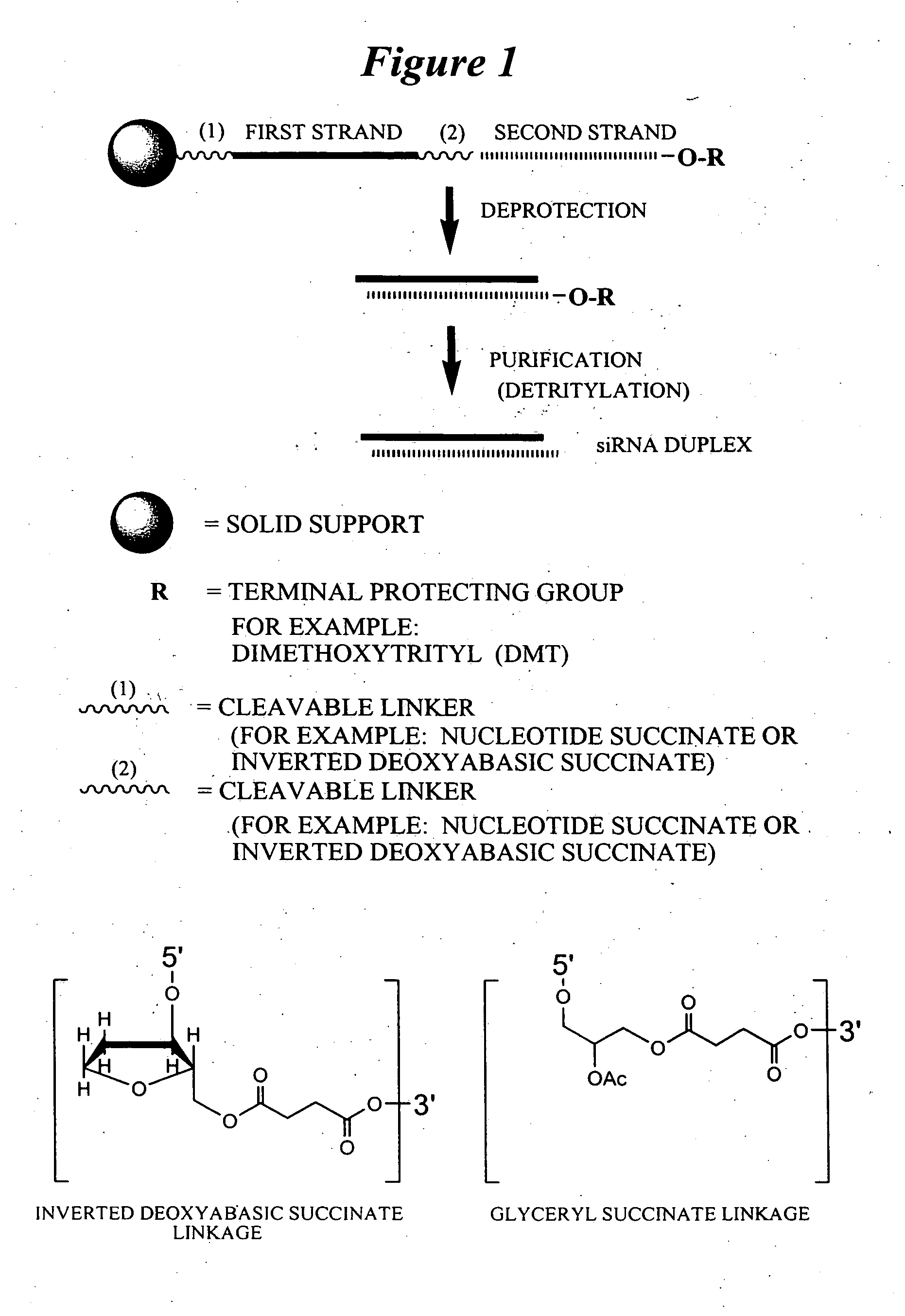

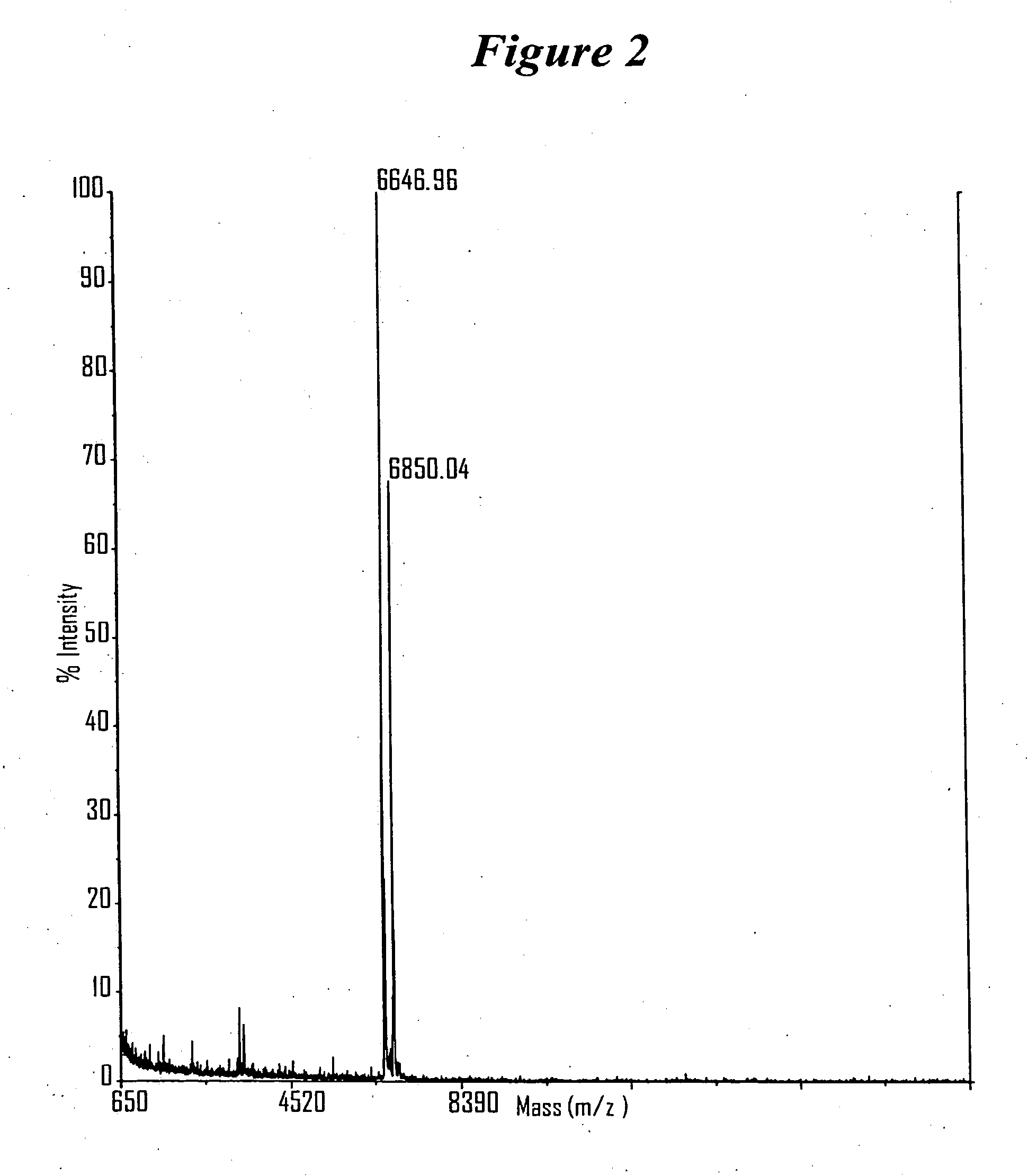

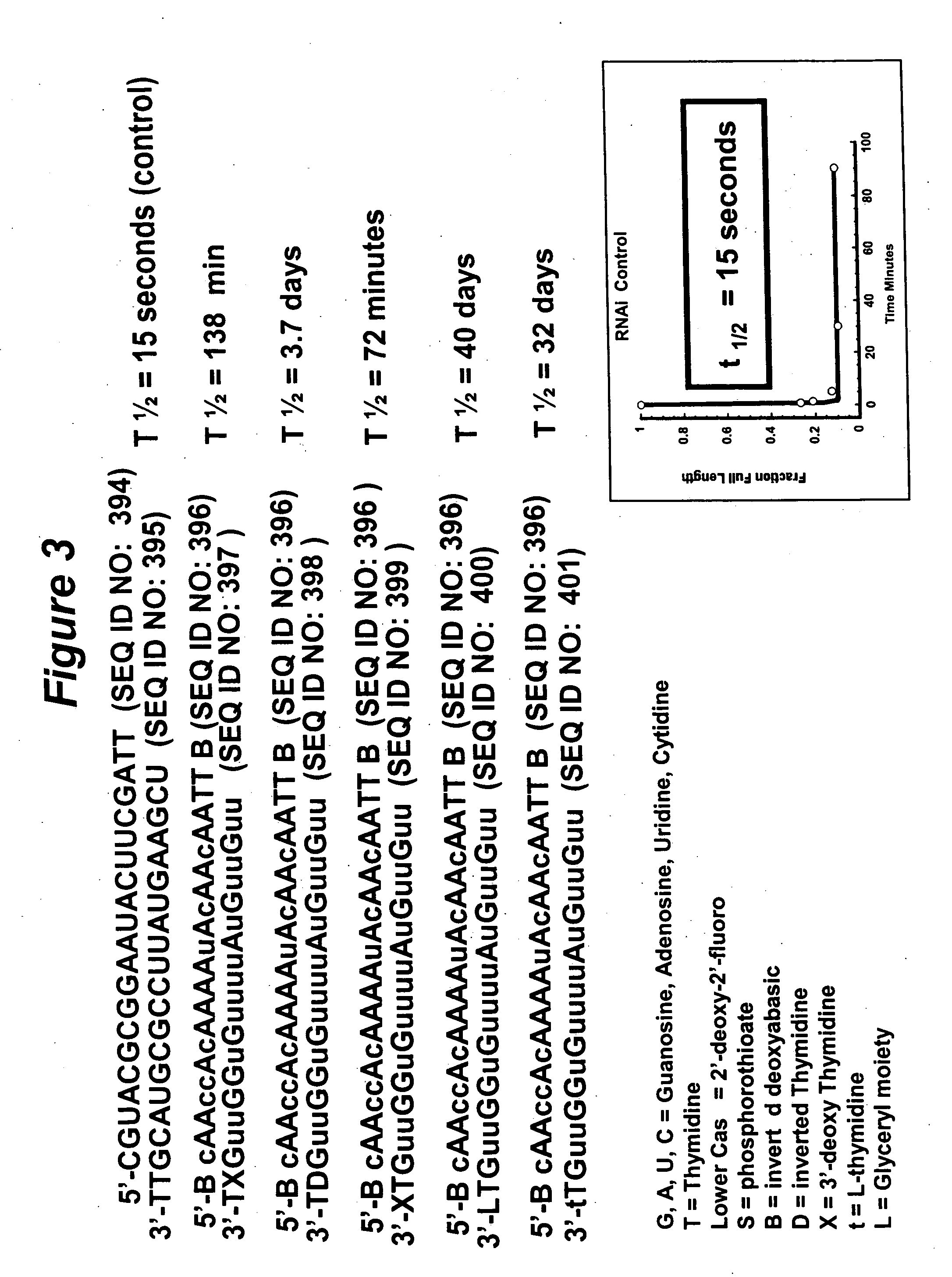

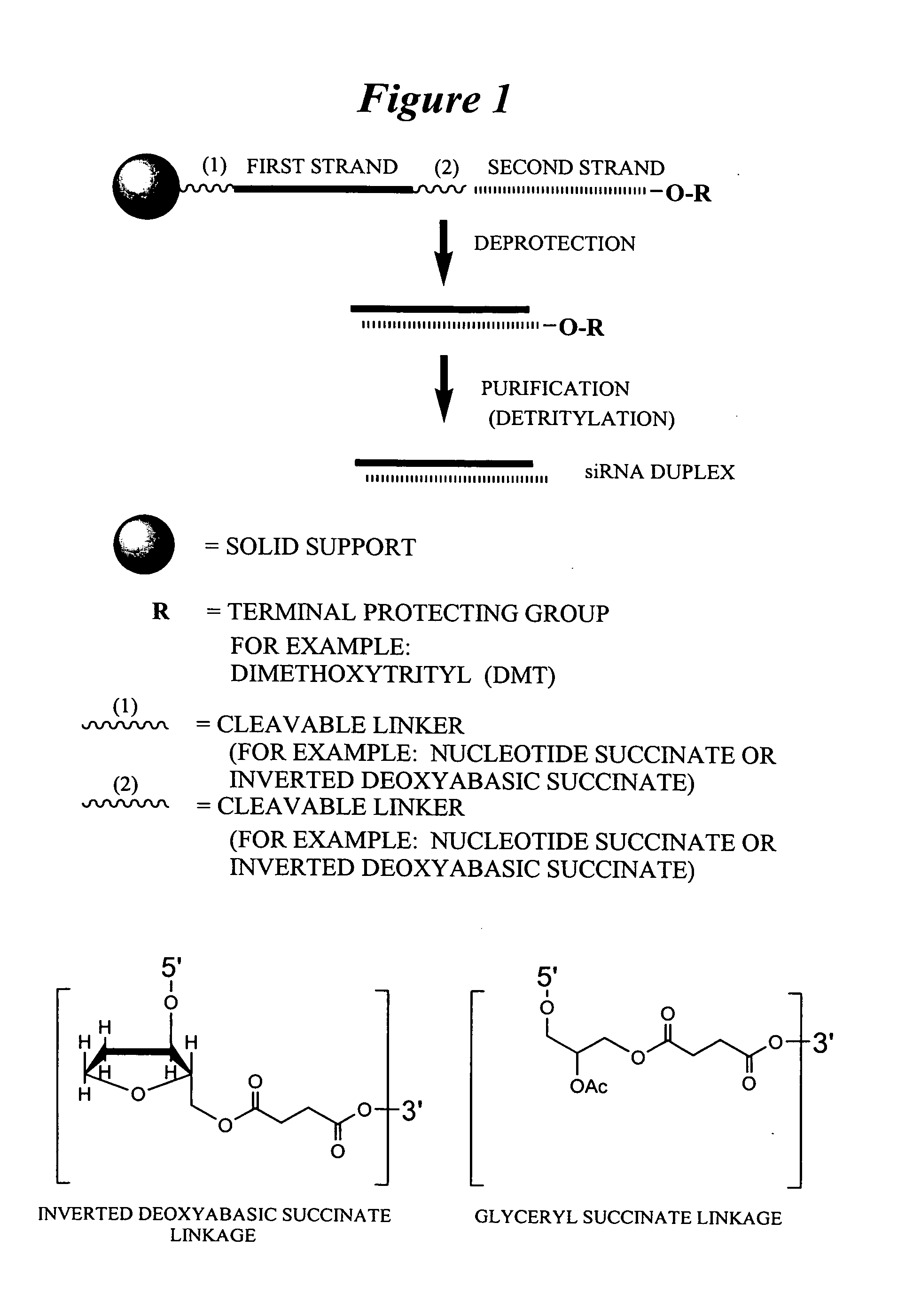

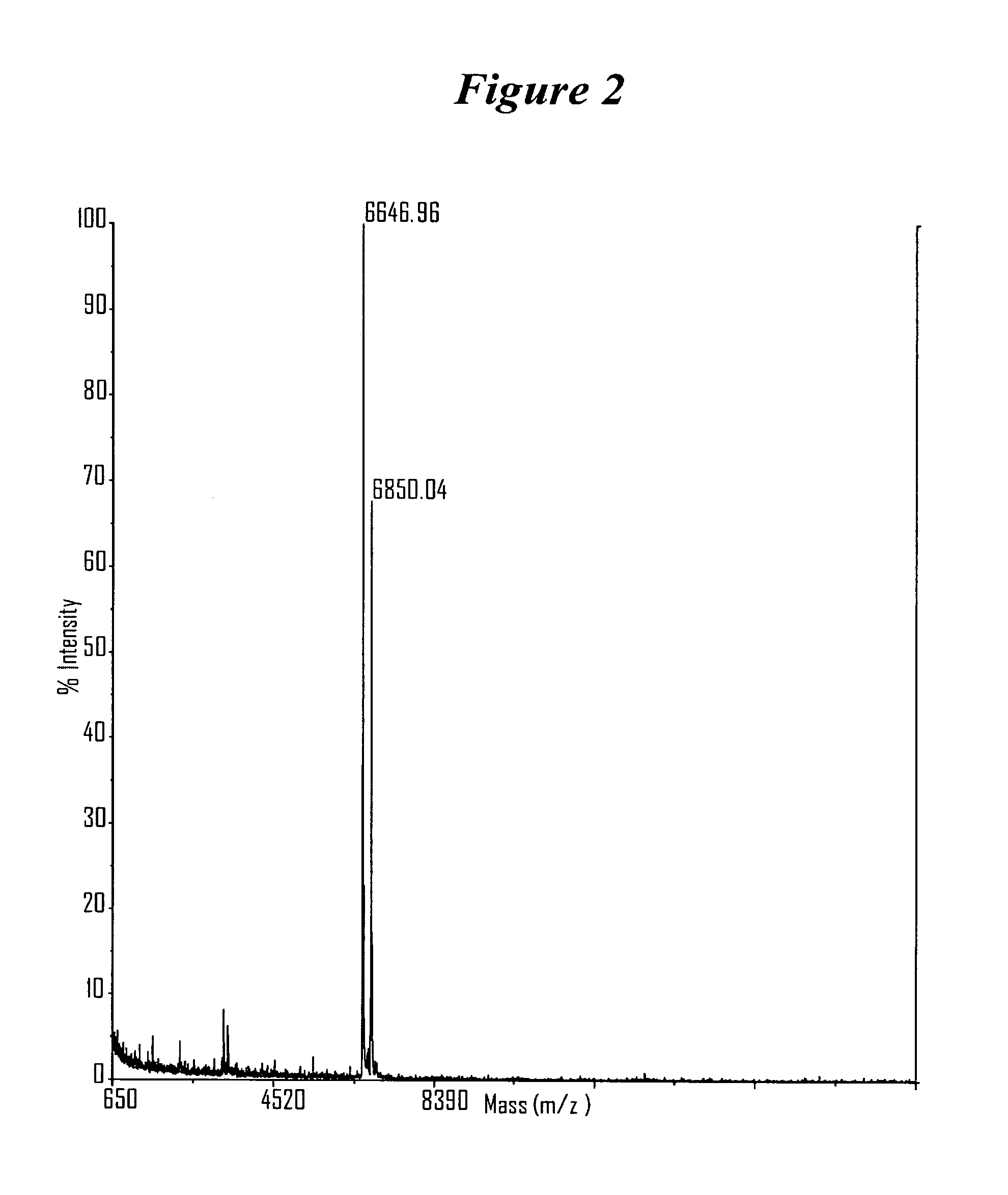

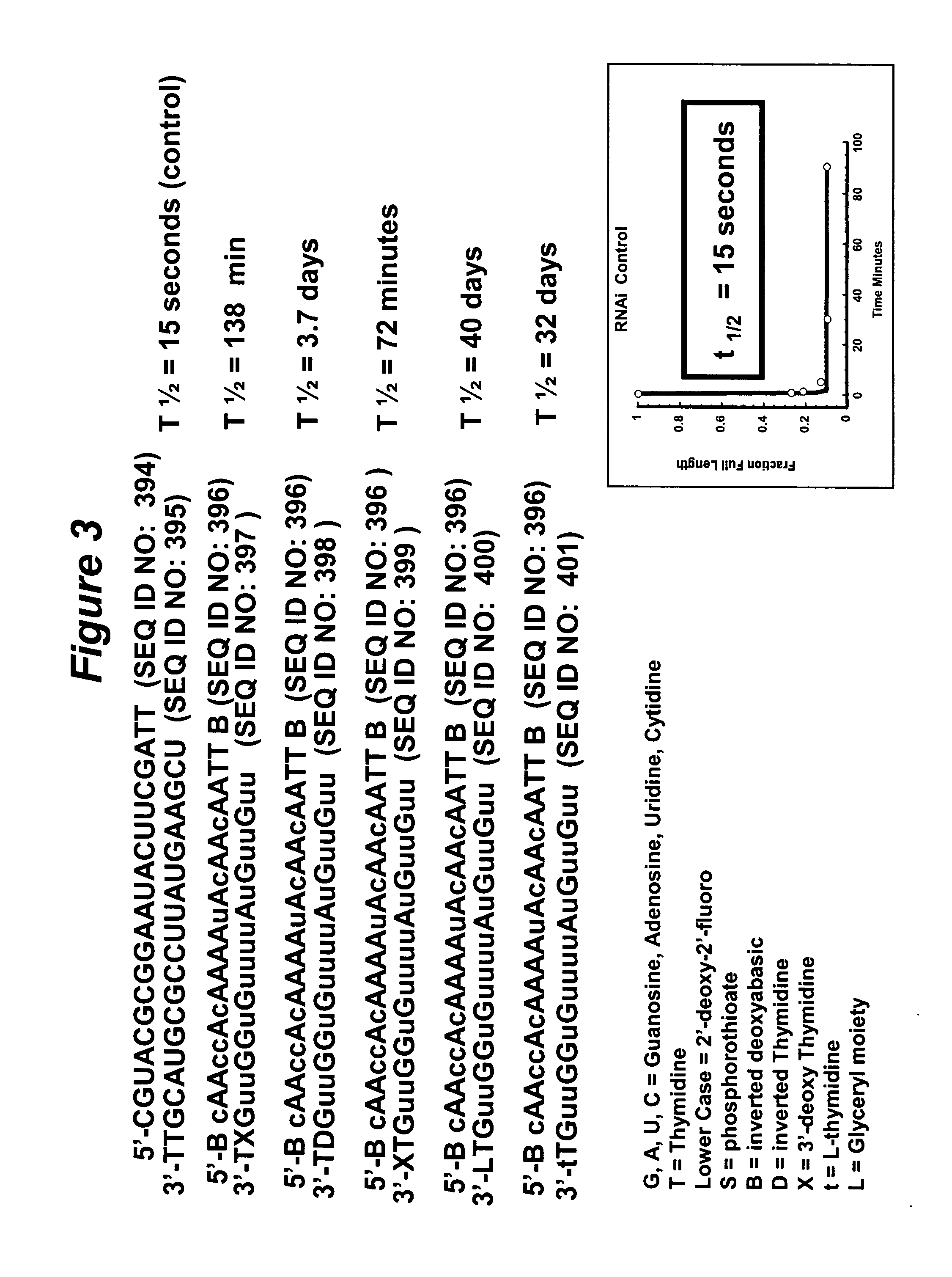

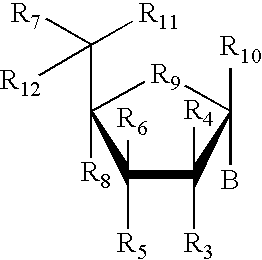

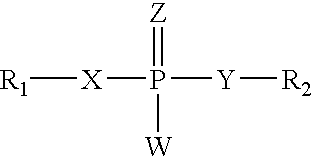

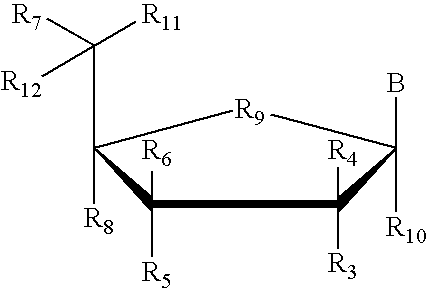

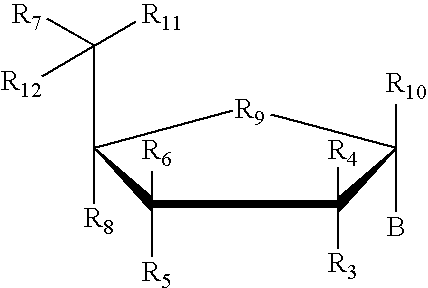

RNA interference mediated inhibition of gene expression using chemically modified short interfering nucleic acid (siNA)

InactiveUS20050020525A1Improve various propertyModulate its functionCompounds screening/testingSugar derivativesDouble strandOrganism

The present invention concerns methods and reagents useful in modulating gene expression in a variety of applications, including use in therapeutic, diagnostic, target validation, and genomic discovery applications. Specifically, the invention relates to synthetic chemically modified small nucleic acid molecules, such as short interfering nucleic acid (siNA), short interfering RNA (siRNA), double-stranded RNA (dsRNA), micro-RNA (miRNA), and short hairpin RNA (shRNA) molecules capable of mediating RNA interference (RNAi) against target nucleic acid sequences. The small nucleic acid molecules are useful in the treatment of any disease or condition that responds to modulation of gene expression or activity in a cell, tissue, or organism.

Owner:SIMA THERAPEUTICS ICN

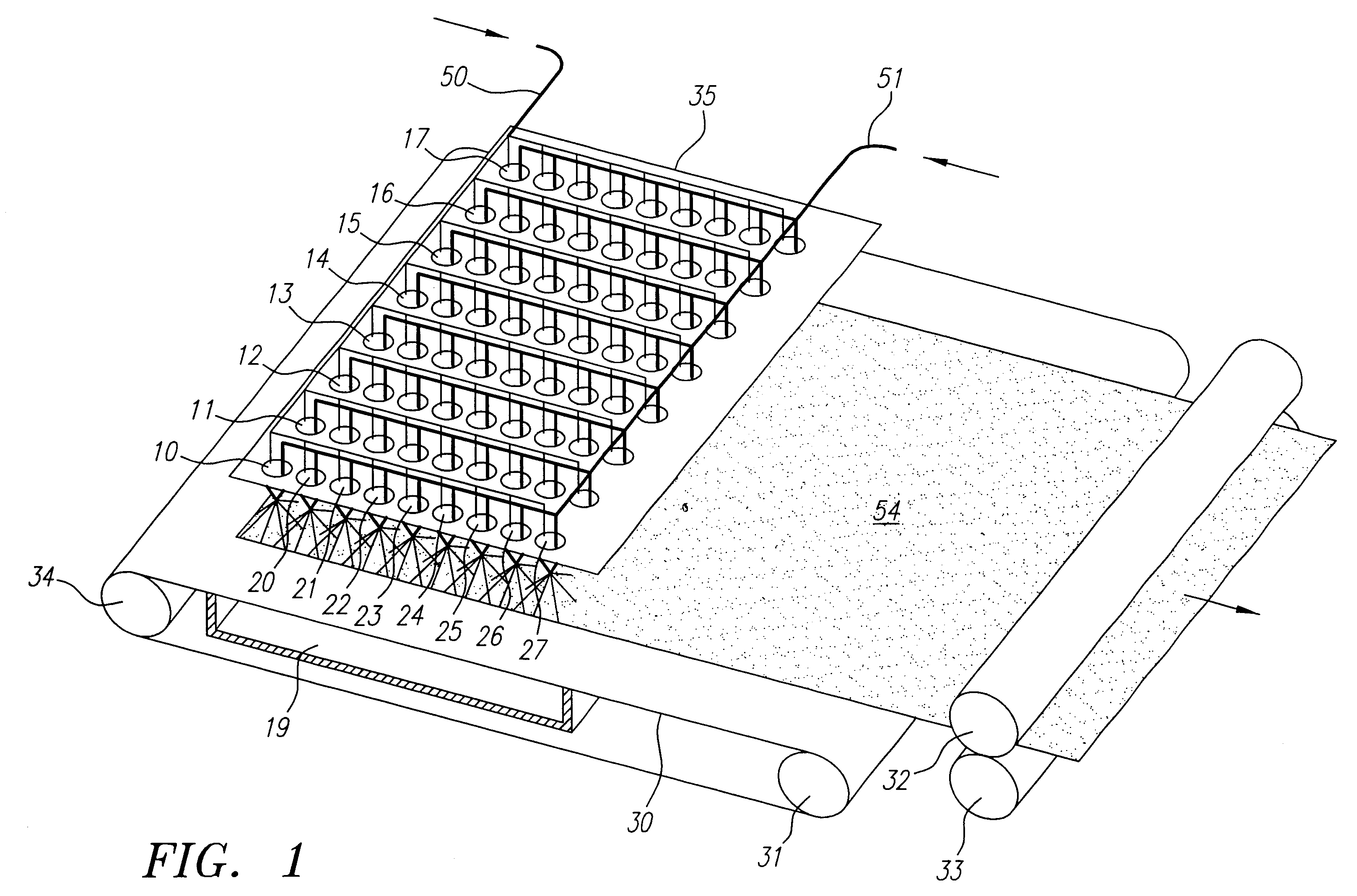

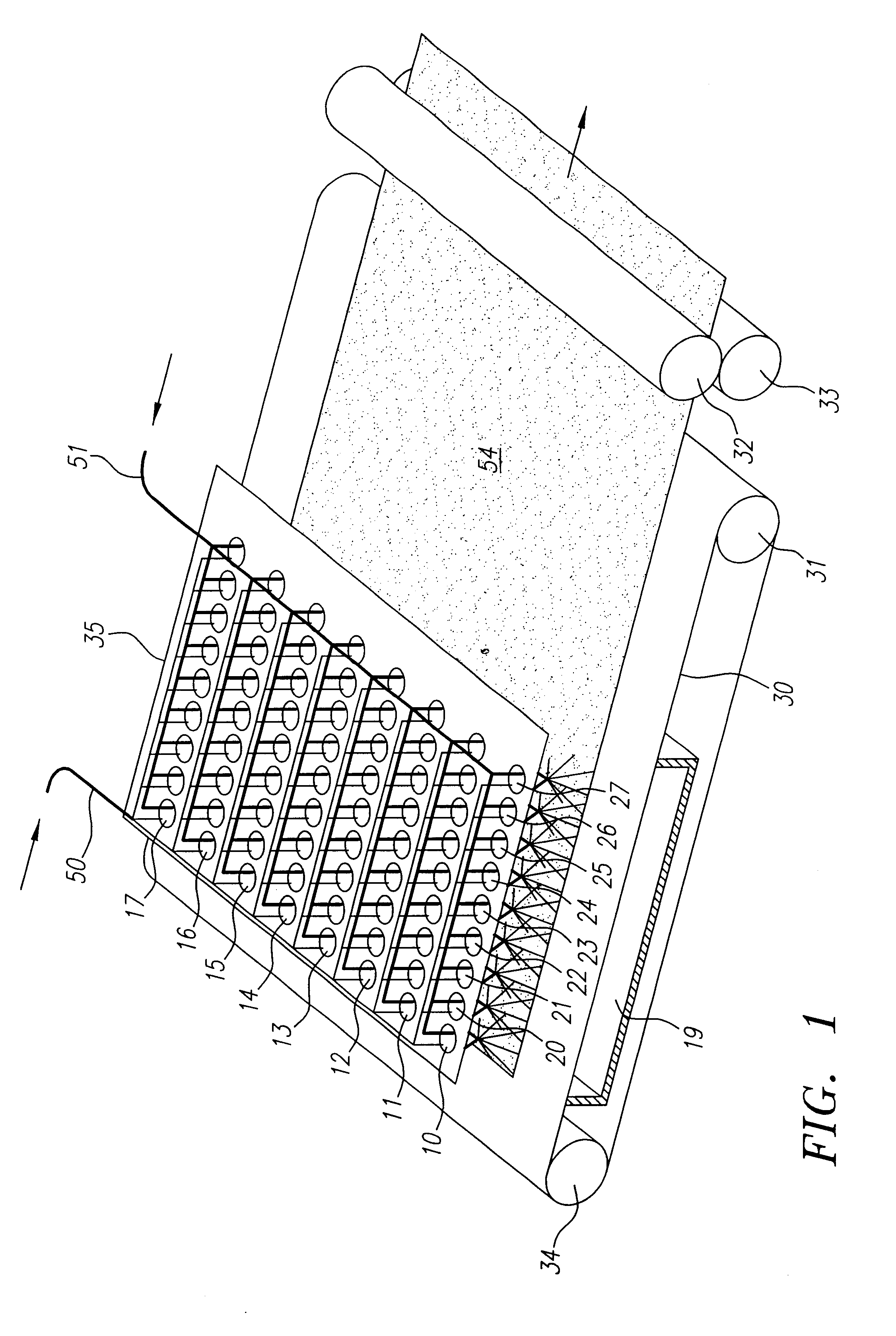

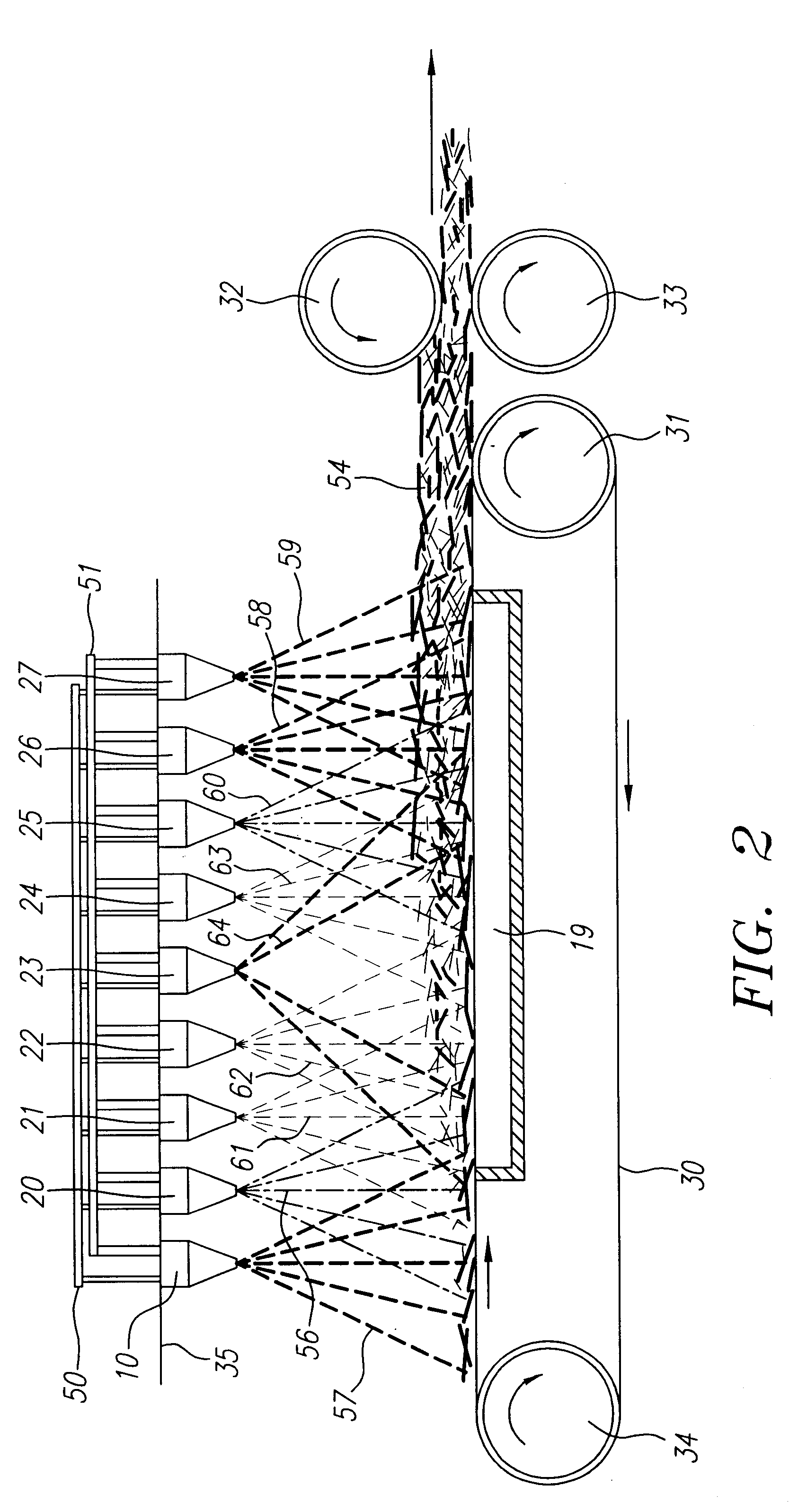

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

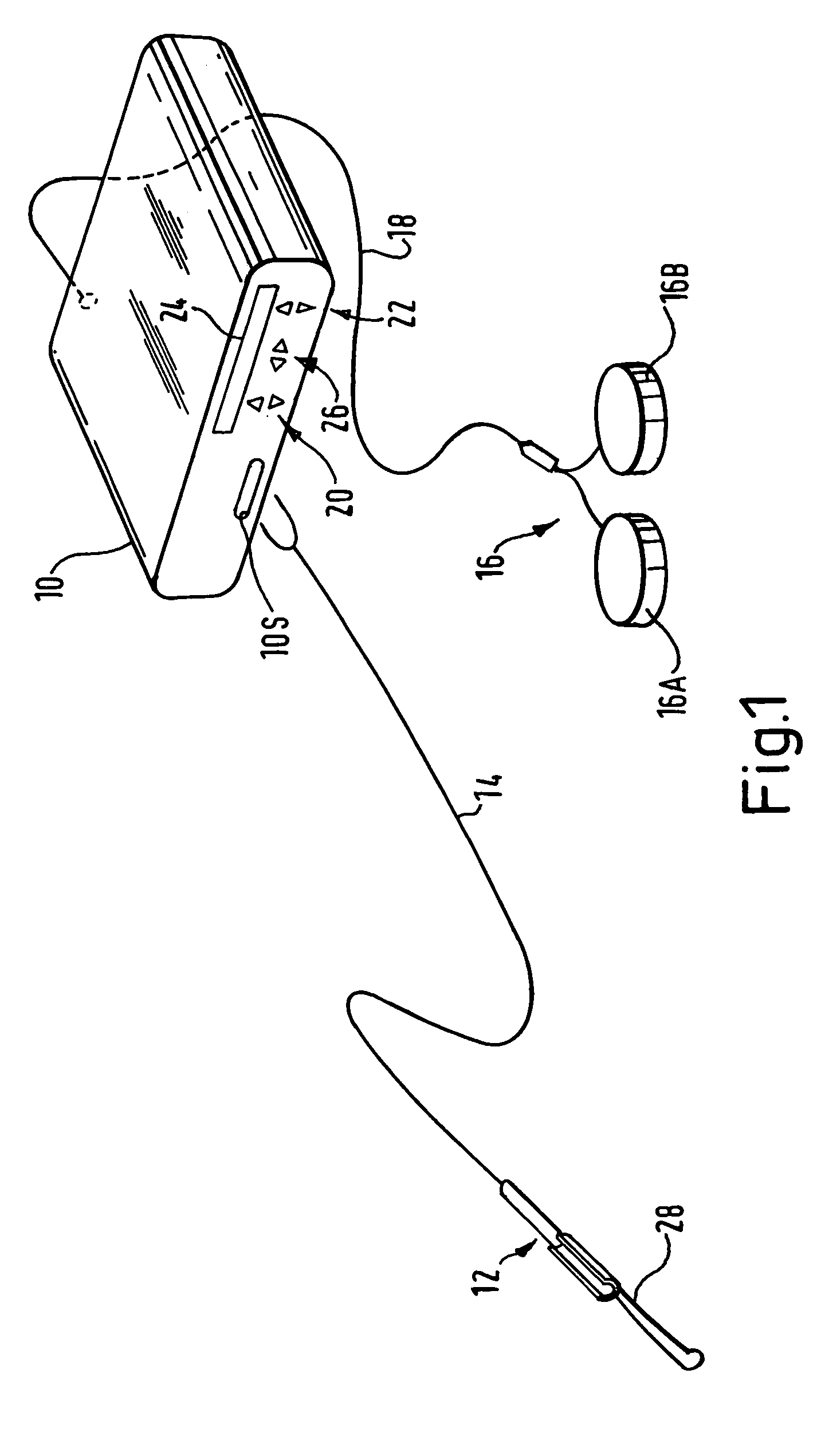

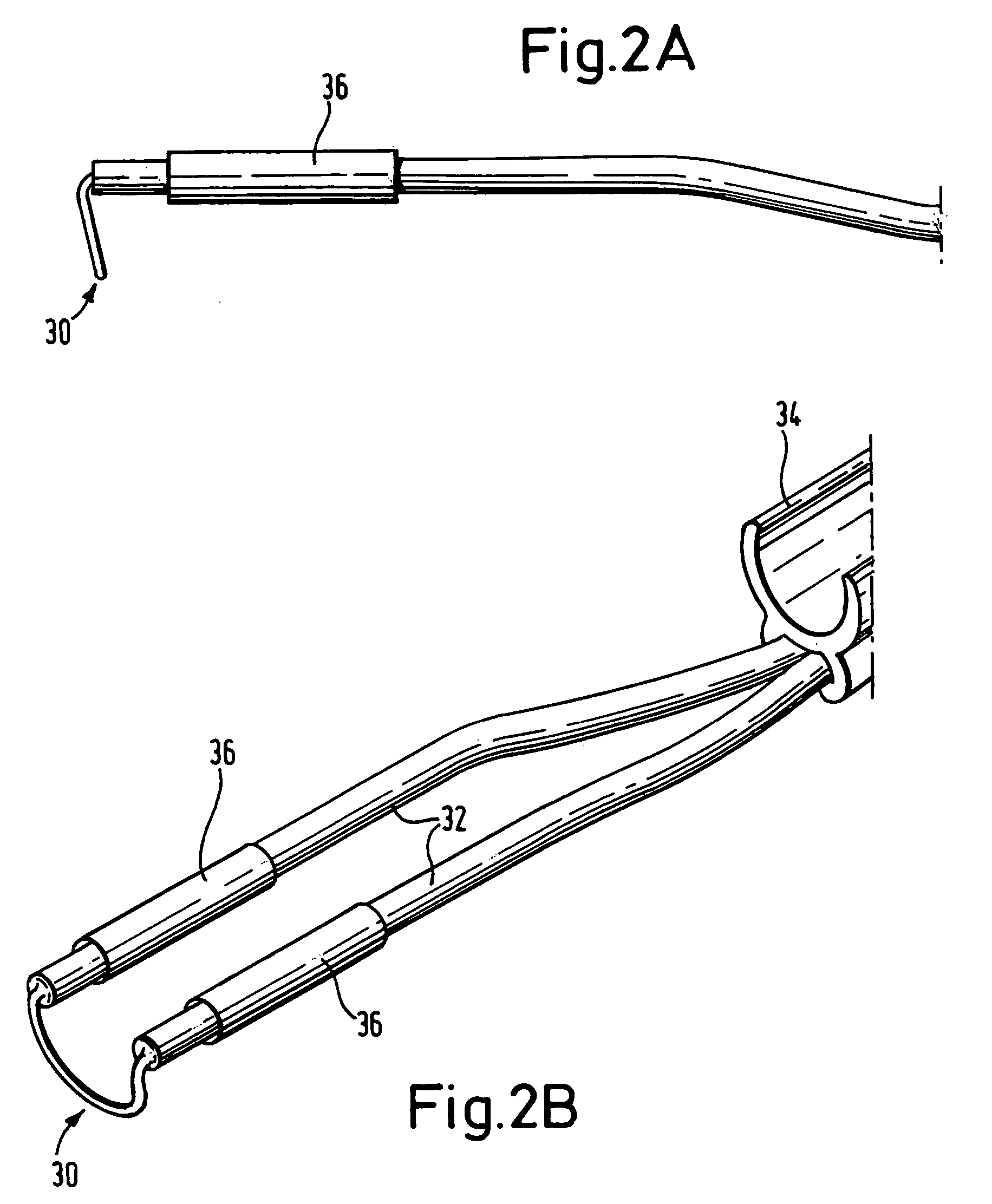

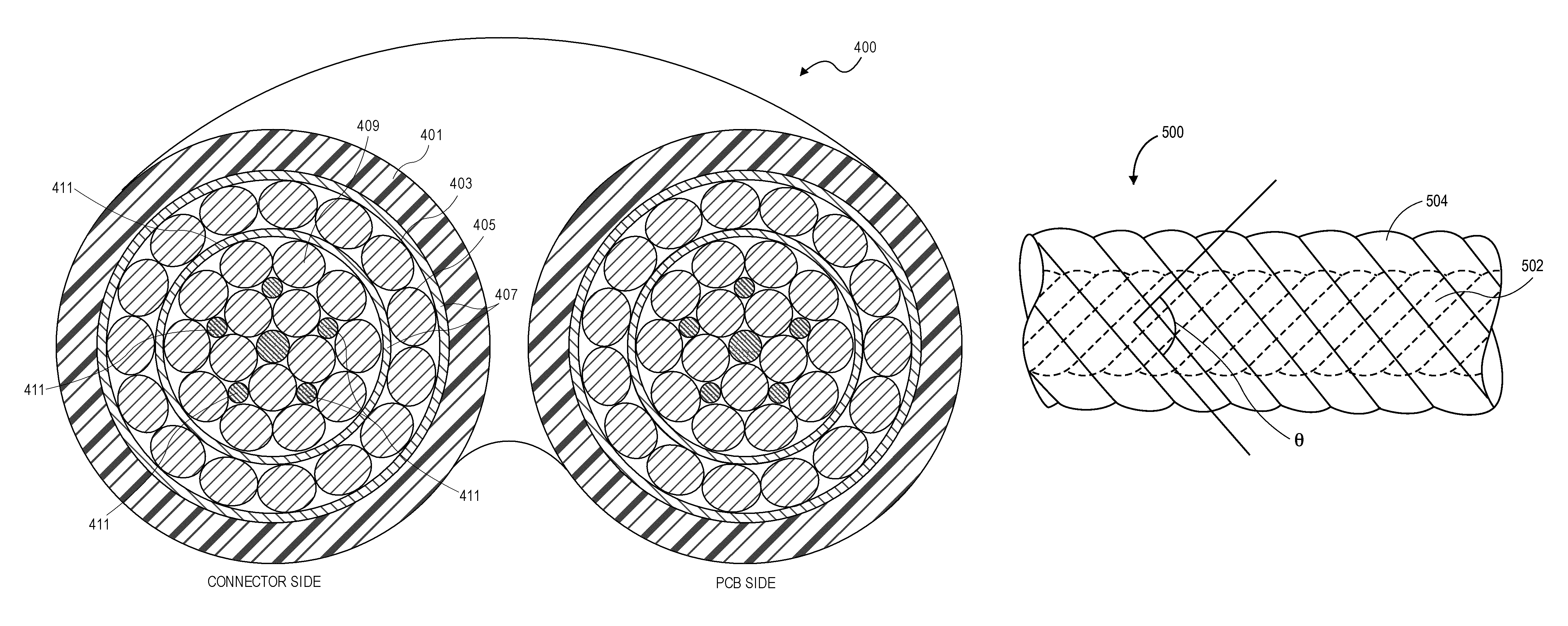

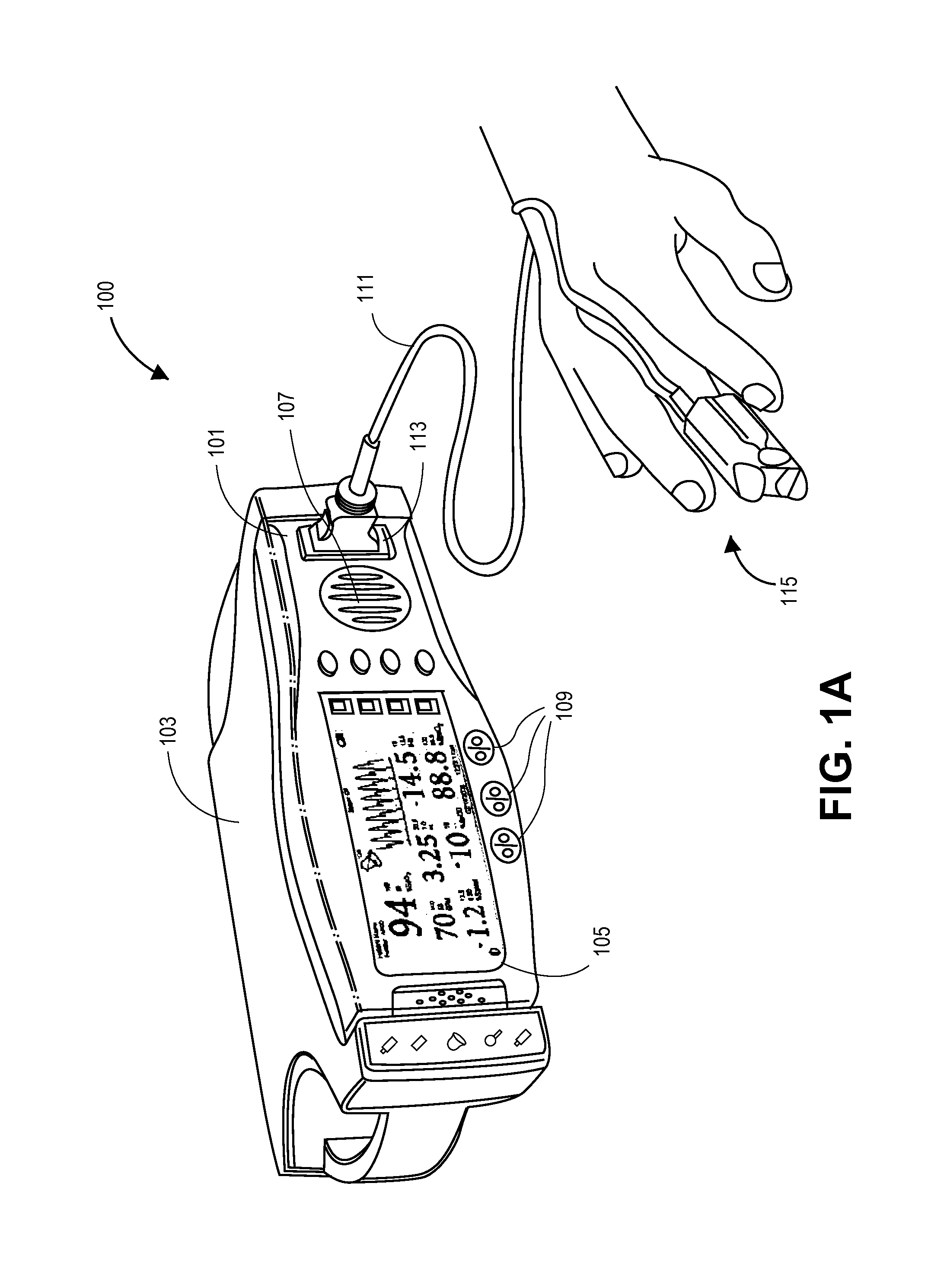

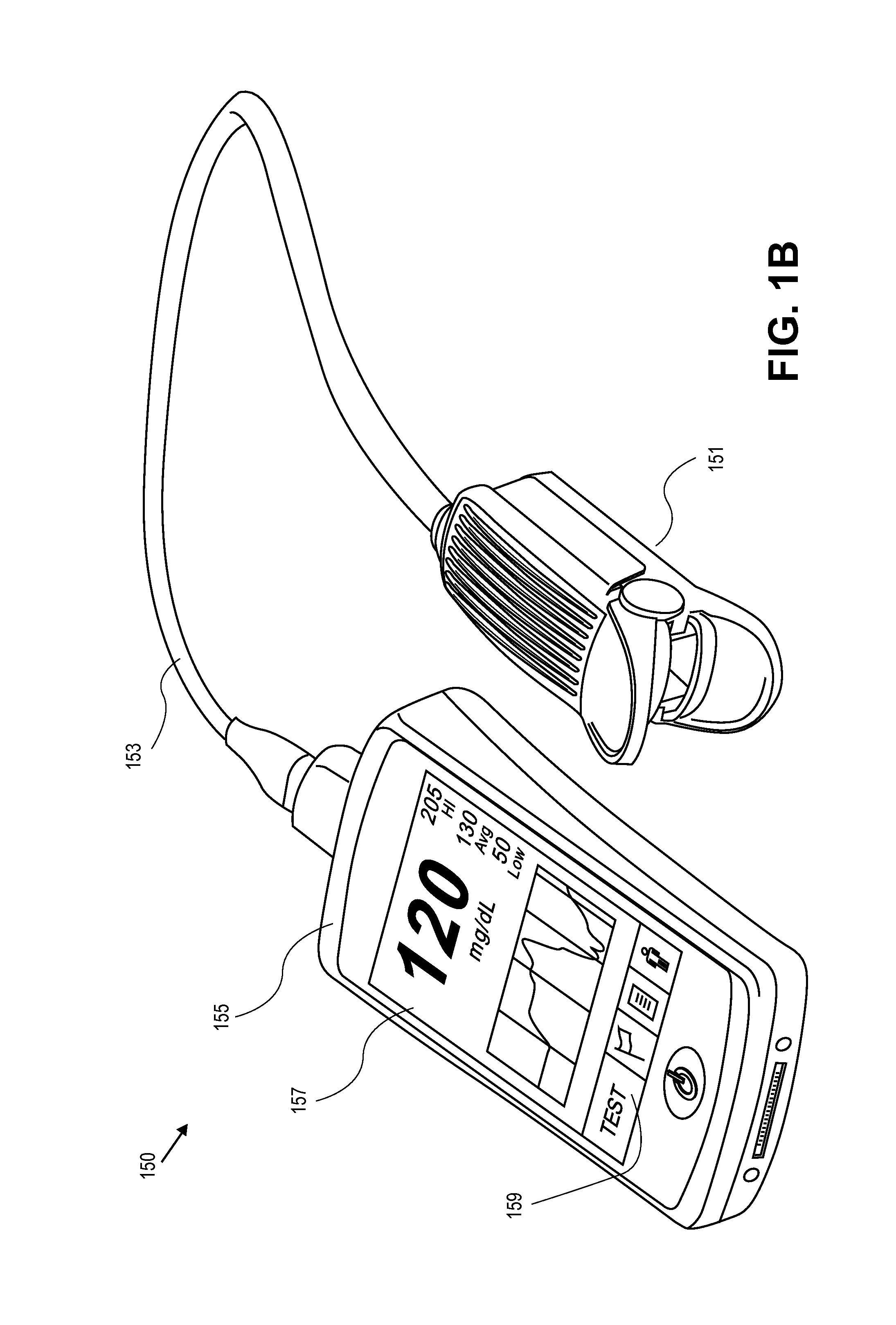

Low noise cable providing communication between electronic sensor components and patient monitor

ActiveUS9245668B1Reduce crosstalkNot hindering sensor placementDiagnostics using lightConductive materialLow noiseEngineering

A physiological measurement system can include a low noise patient cable that connects a monitor and a noninvasive optical sensor. The cable has a plurality of emitter wires configured to communicate a drive signal between the monitor and at least one emitter. The cable also has a plurality of detector wires configured to communicate a physiological signal between at least one detector responsive to the emitter and the monitor. The emitter and detector wires are orthogonally disposed so that crosstalk between the two functionally different wires is mitigated.

Owner:MASIMO CORP

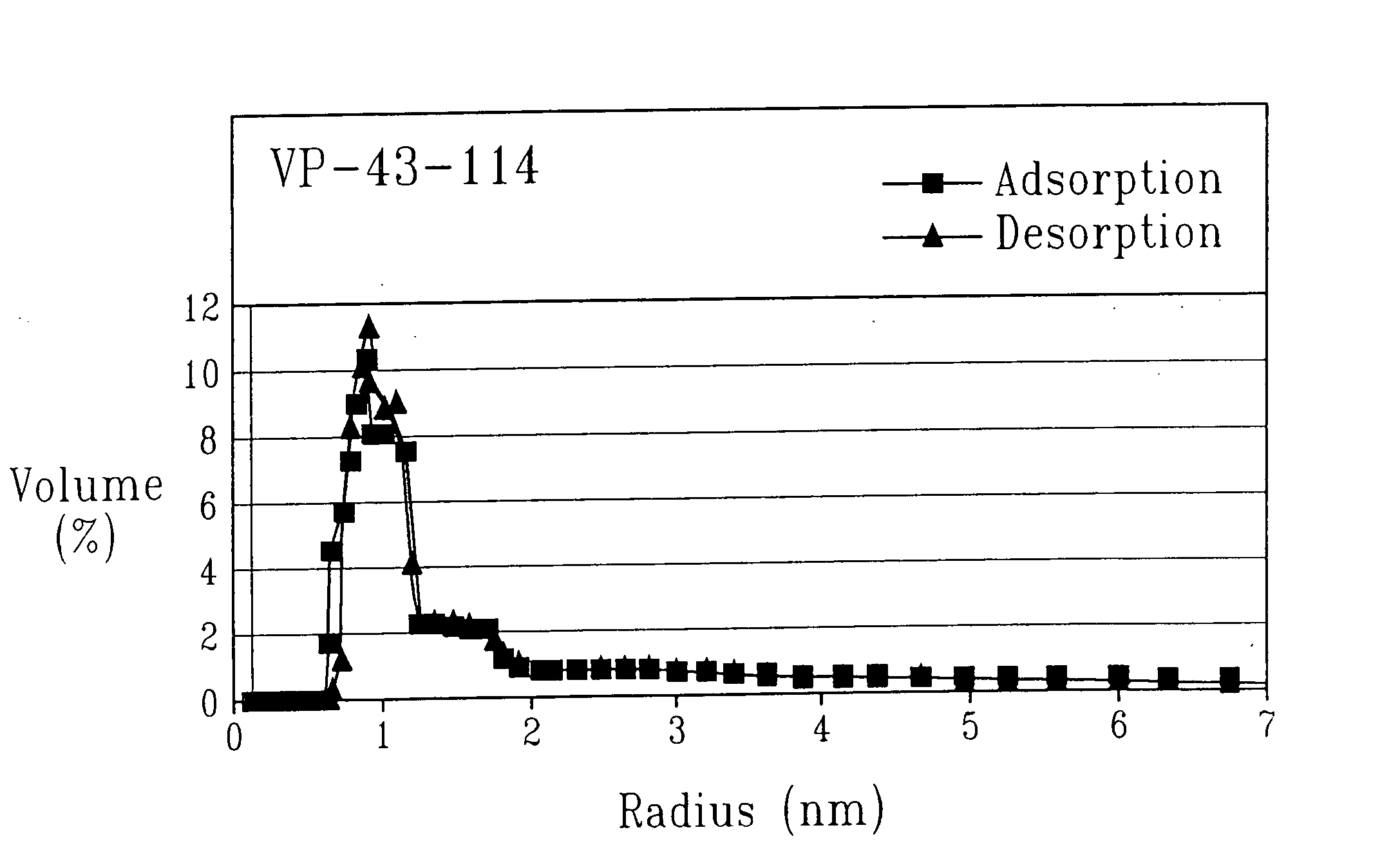

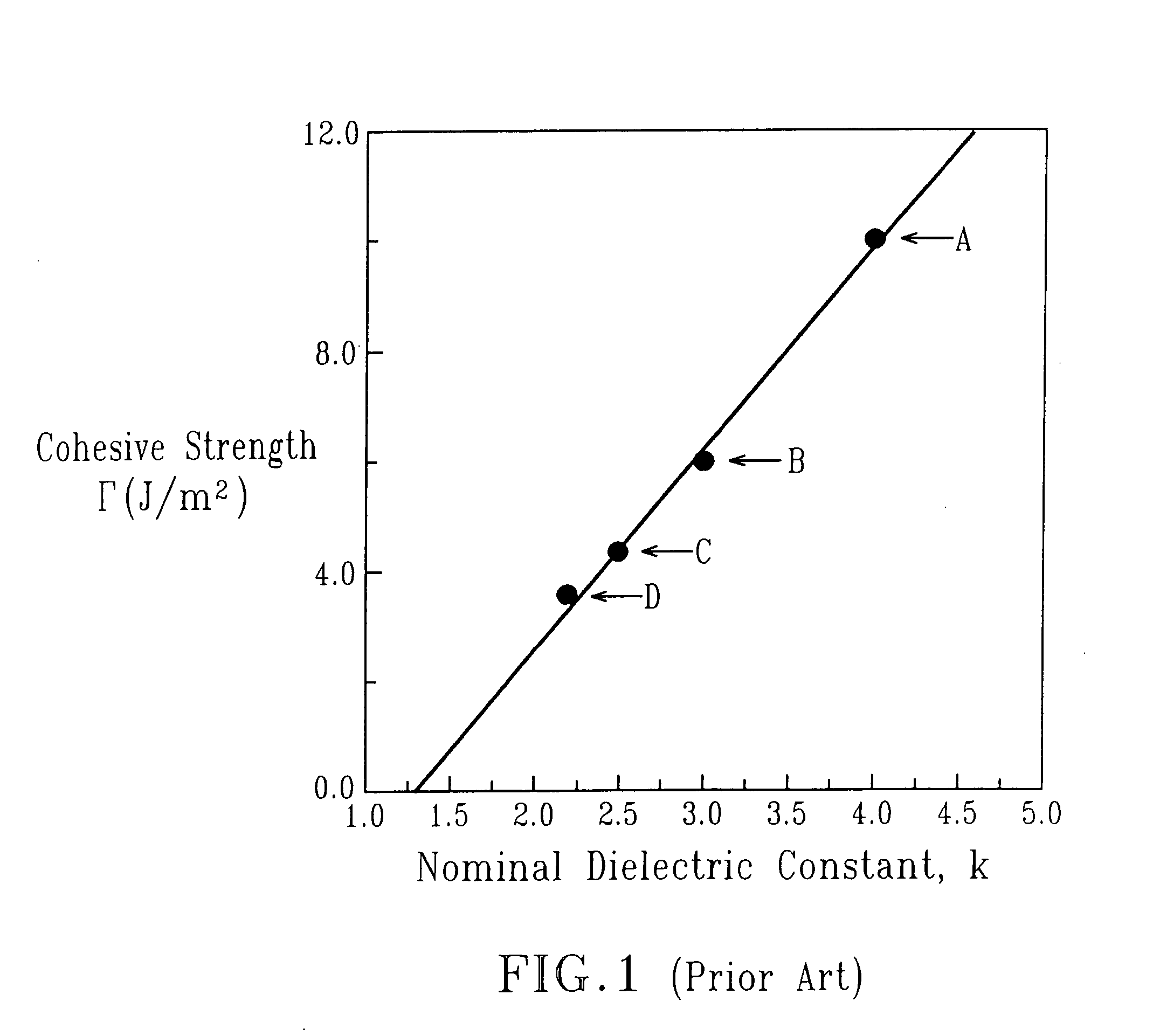

SiCOH dielectric

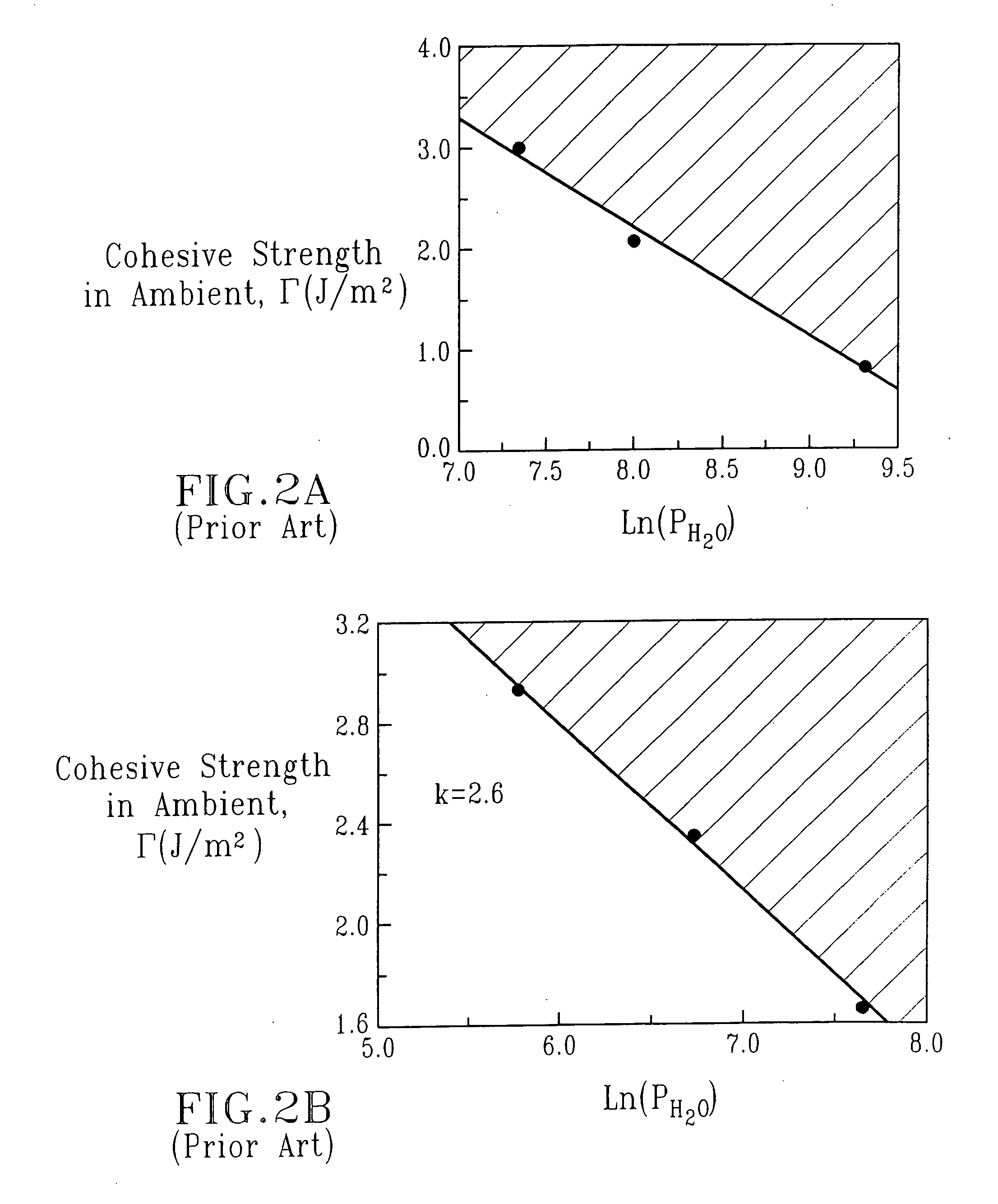

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

RNA interference mediated inhibition of gene expression using chemically modified short interfering nucleic acid (SiNA)

InactiveUS20050032733A1Improve various propertyModulate its functionCompounds screening/testingSpecial deliveryBiological bodyNucleic acid sequencing

The present invention concerns methods and reagents useful in modulating gene expression in a variety of applications, including use in therapeutic, diagnostic, target validation, and genomic discovery applications. Specifically, the invention relates to synthetic chemically modified small nucleic acid molecules, such as short interfering nucleic acid (siNA), short interfering RNA (siRNA), double-stranded RNA (dsRNA), micro-RNA (miRNA), and short hairpin RNA (shRNA) molecules capable of mediating RNA interference (RNAi) against target nucleic acid sequences. The small nucleic acid molecules are useful in the treatment of any disease or condition that responds to modulation of gene expression or activity in a cell, tissue, or organism.

Owner:SIRNA THERAPEUTICS INC

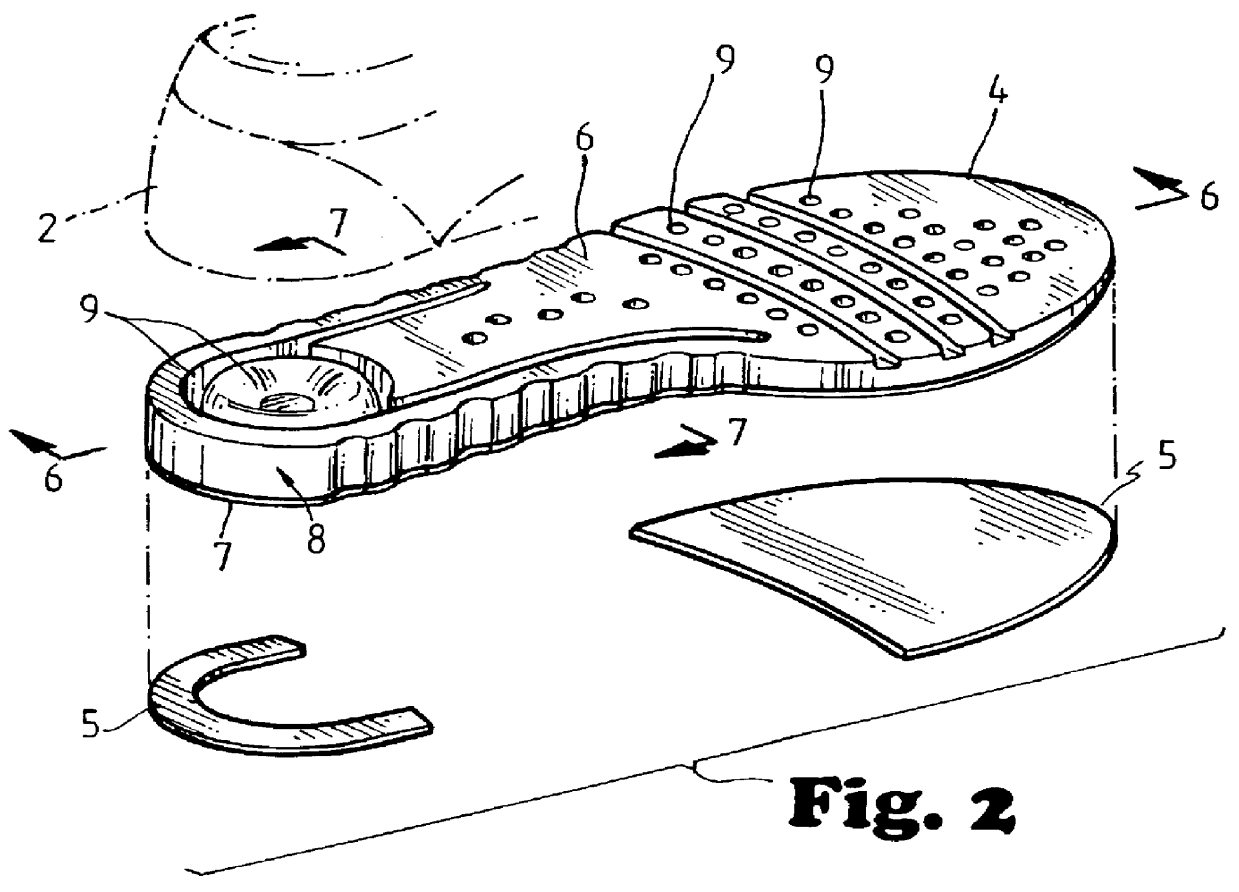

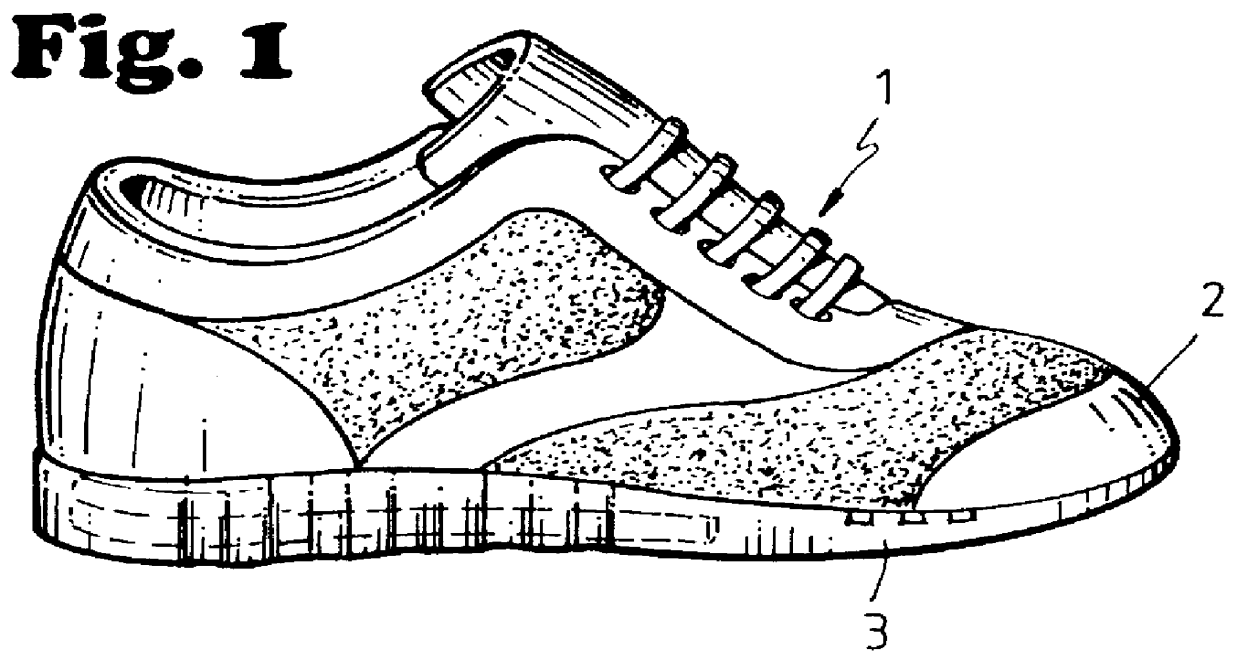

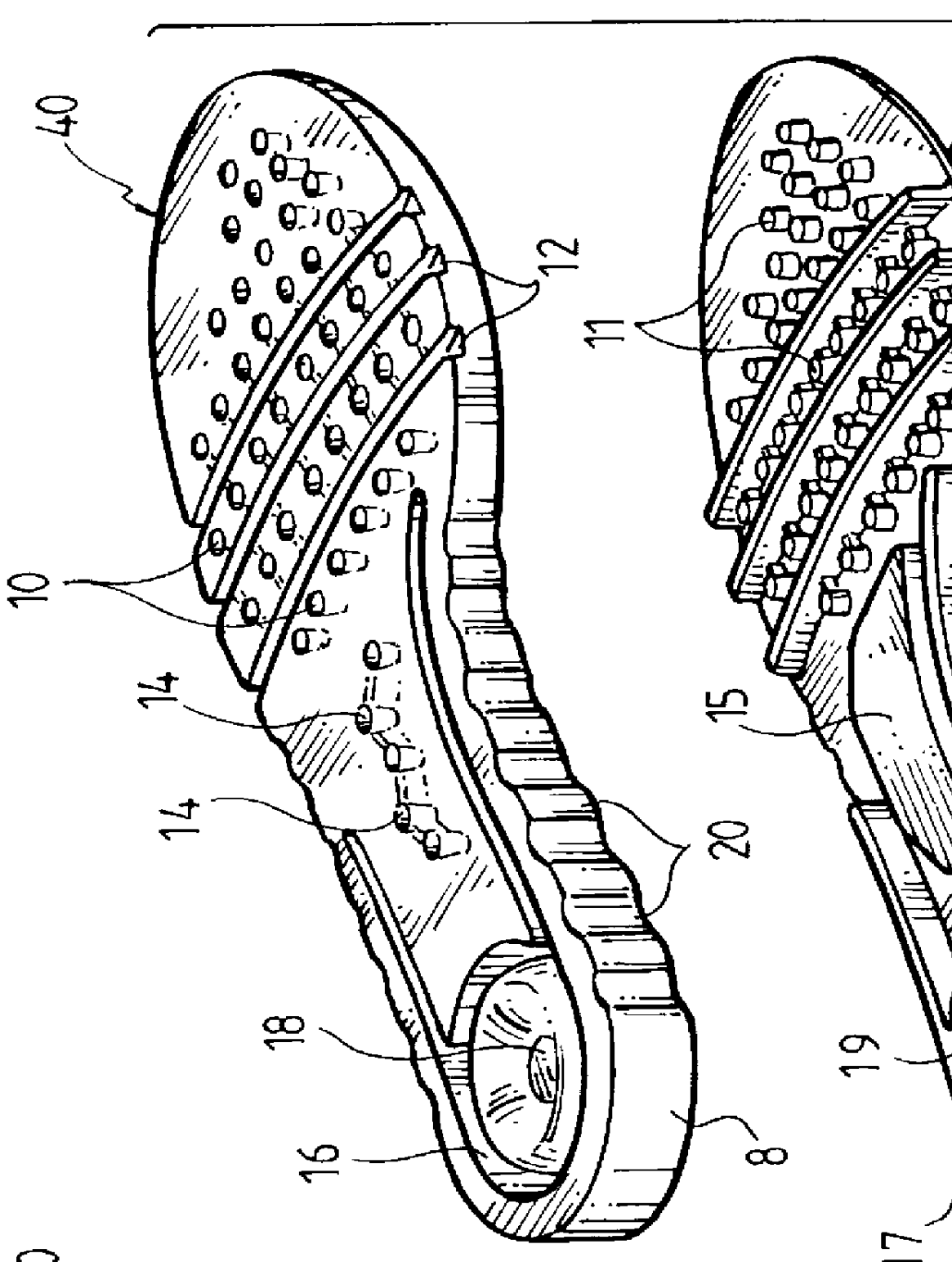

Shoe sole component and shoe sole component construction method

A high polymer resin material is configured into a shoe sole component having a plurality of inwardly extending indentations in one or both of the top and bottom members of the component. The indentations extend into the interval between the members and adjacent to the opposite member to provide support members for the sole component. The sole component can be constructed by molding upper and lower sole component halves wherein the molds are configured to provide indentations in the top and bottom members. The upper and lower sole component halves are then joined to complete the sole component.

Owner:LIESENFELD MARY C +1

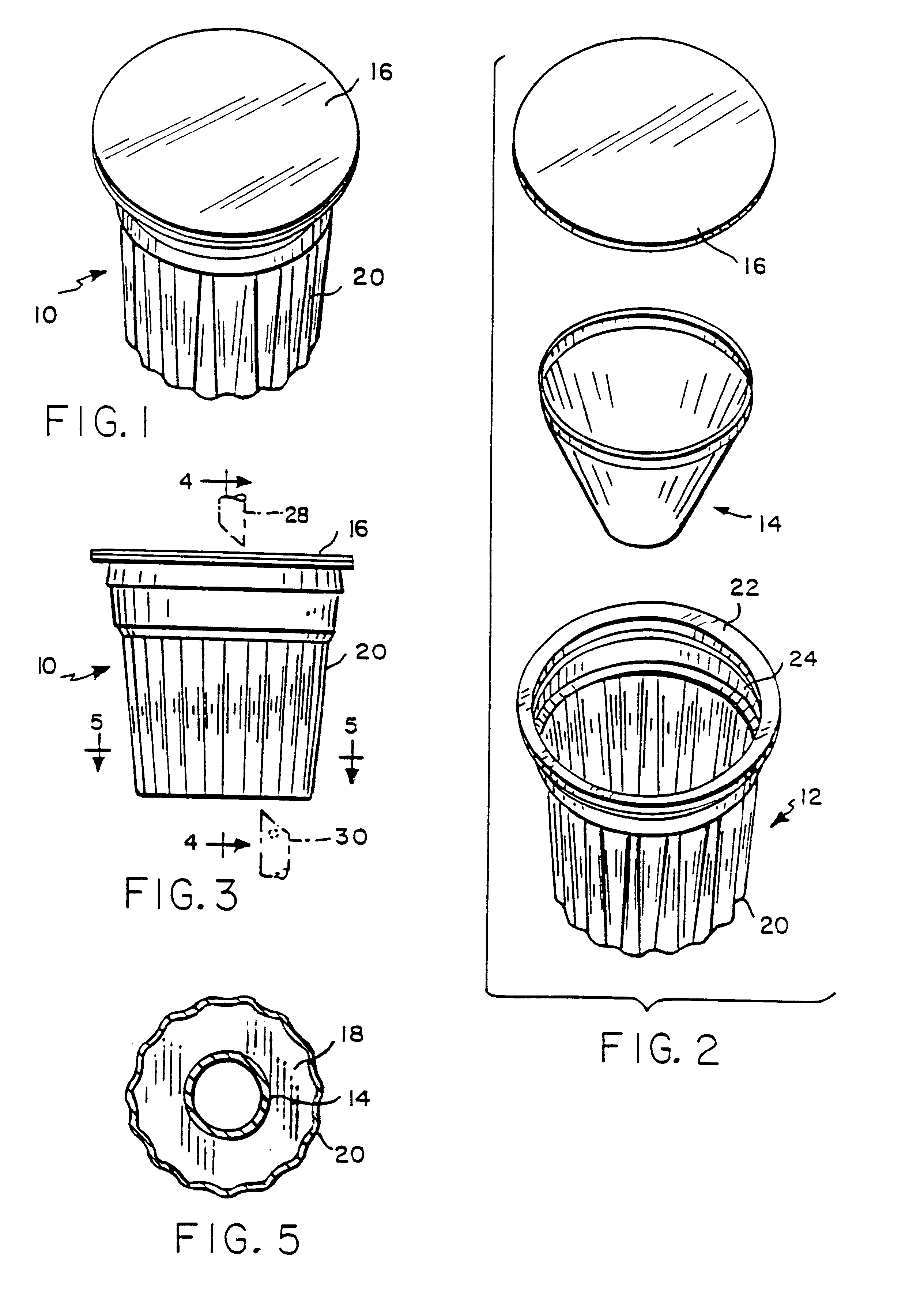

Beverage filter cartridge

InactiveUS6645537B2Increase storage capacityImprove the immunityReady-for-oven doughsBeverage vesselsMechanical engineeringEngineering

Owner:KEURIG GREEN MOUNTAIN INC

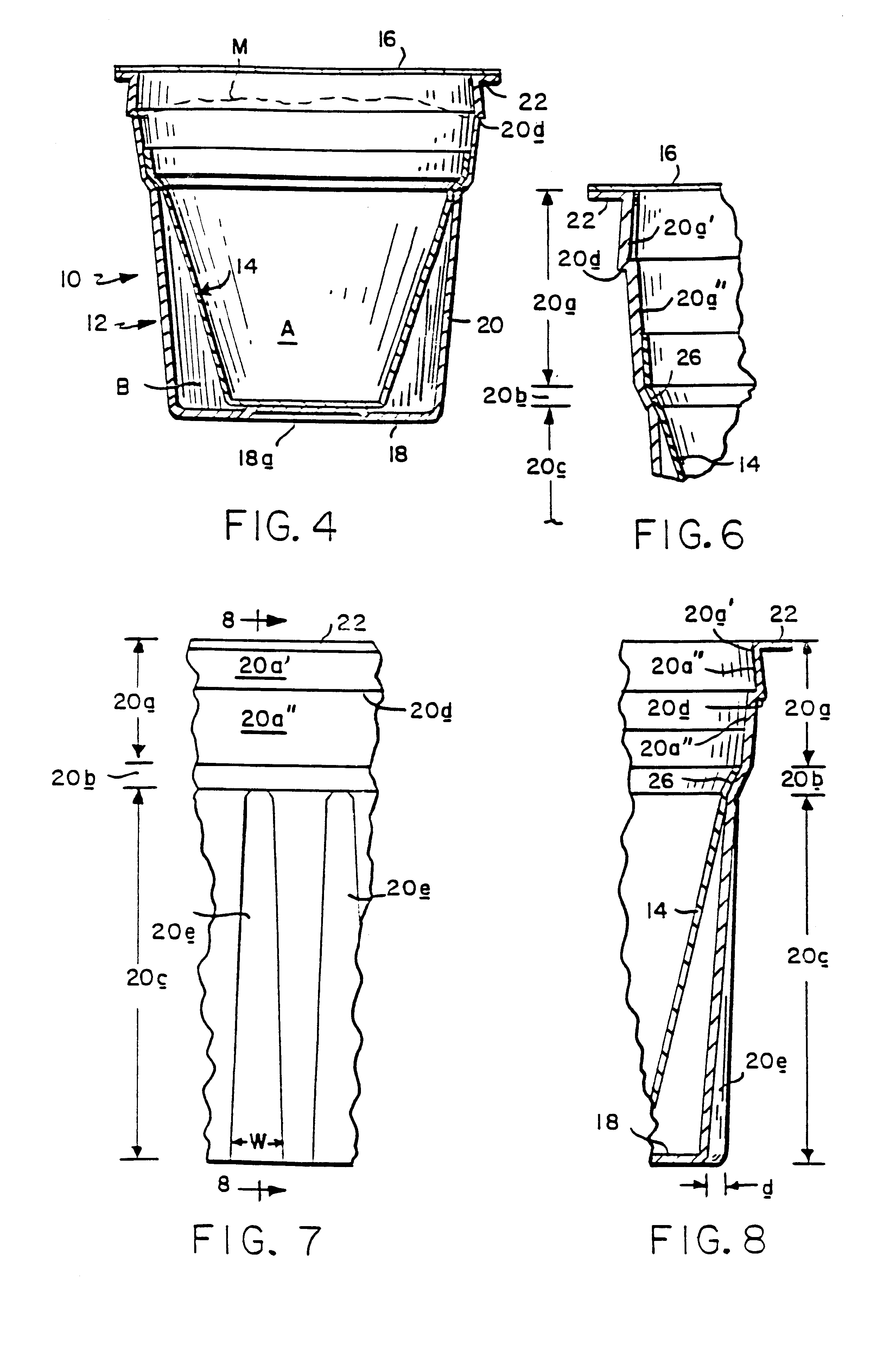

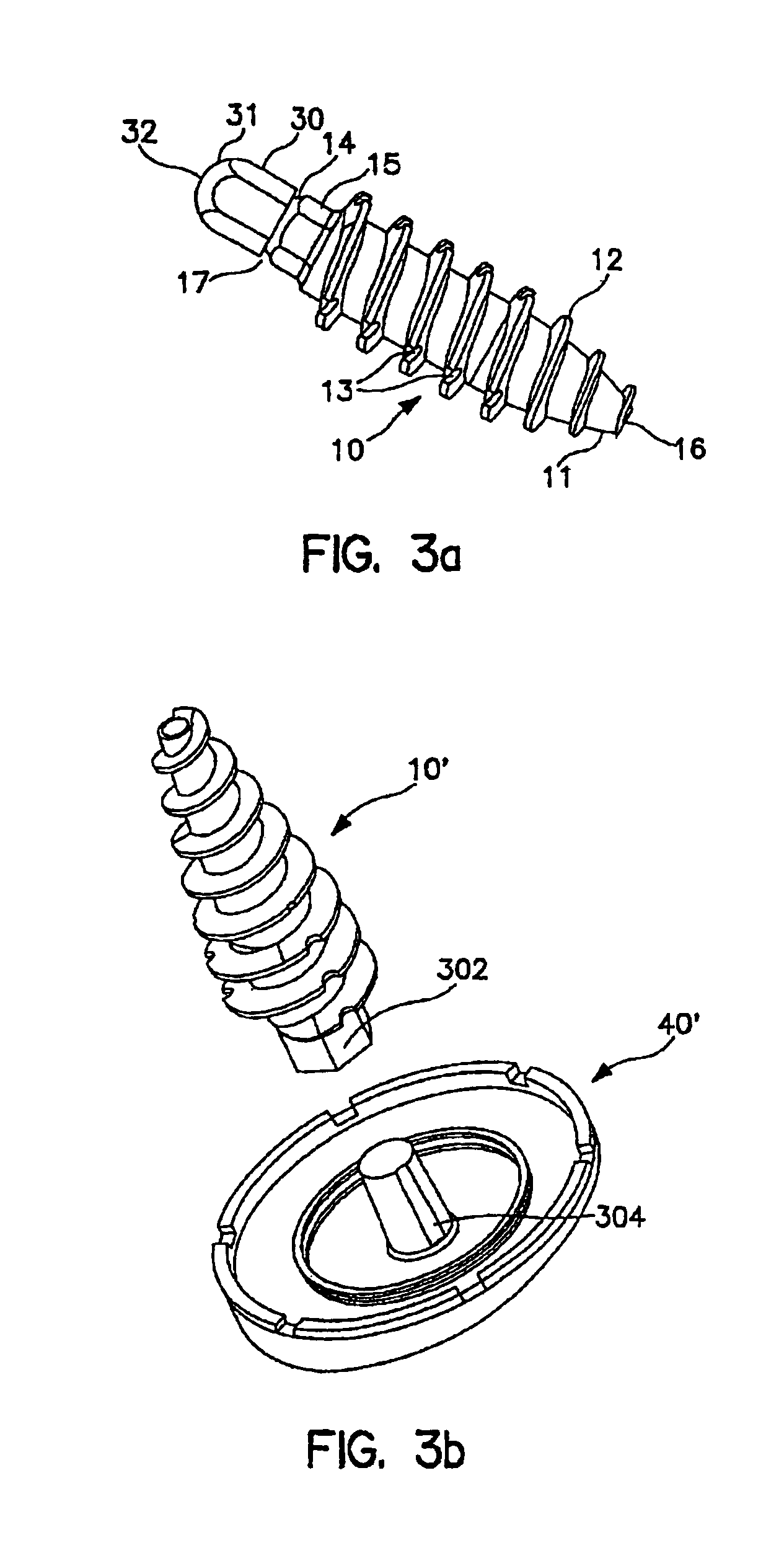

System and method for joint resurface repair

InactiveUS7029479B2Enhance transfer of loadIncrease rotational forceSuture equipmentsInternal osteosythesisBearing surfaceSacroiliac joint

The present invention provides tools and methods for mapping and measuring the articular surface of a joint (or of any bony surface) and for fabricating a prosthetic device based on this recorded data. In one embodiment, once the defect of the chondral surface has been identified, a guide pin is inserted arthroscopically. A fixation screw is driven into the subchondral bone in relation to a reference axis that is approximately central to the defect, the fixation device also serving to define a tangent point to the surrounding articular surface. A further cylindrical proximal extension of the screw that eventually serves as a fixation element for the surface prosthetic is concealed with a cover or plug. The depth positioning of the cover or plug establishes an origin or reference point for all future measuring, cutting, and prosthetic machining operations. A measuring tool having a static post that establishes the axial location of origin is inserted on the reference axis. By rotating the outer arm or outrigger of the measuring tool relative to the static post while also maintaining contact with the articular surface, an axial displacement or Z dimension is established relative to the origin for any point along the known radial sweep of the outrigger to determine the final geometry of the prosthetic surface which fits within the defect. Data recorded during the mapping procedure is entered into parametric engineering design software or similar algorithm to define a three dimensional surface matched to the bearing surface geometry to be implanted and reproduce the anatomic contours mapped.

Owner:ARTHROSURFACE

RNA interference mediated inhibition of B-cell CLL/Lymphoma-2 (BCL-2) gene expression using short interfering nucleic acid (siNA)

InactiveUS20050176025A1Improves various propertyImprove the immunityCompounds screening/testingSpecial deliveryAutoimmune conditionAutoimmune disease

This invention relates to compounds, compositions, and methods useful for modulating BCL2 gene expression using short interfering nucleic acid (siNA) molecules. This invention also relates to compounds, compositions, and methods useful for modulating the expression and activity of other genes involved in pathways of BCL2 gene expression and / or activity by RNA interference (RNAi) using small nucleic acid molecules. In particular, the instant invention features small nucleic acid molecules, such as short interfering nucleic acid (siNA), short interfering RNA (siRNA), double-stranded RNA (dsRNA), micro-RNA (miRNA), and short hairpin RNA (shRNA) molecules and methods used to modulate the expression of BCL2 genes (e.g., BCL2, BCL-XL, BCL2-L1, MCL-1 CED-9, BAG-1, E1B-194 and / or BCL-A1). The small nucleic acid molecules are useful in the treatment of cancer, malignant blood disease, polycytemia vera, idiopathic myelofibrosis, essential thrombocythemia, myelodysplastic syndromes, autoimmune disease, viral infection, and proliferative diseases and conditions

Owner:SIRNA THERAPEUTICS INC

Electrosurgical instrument and method

InactiveUS7517349B2Lower base resistanceRule out the possibilityDiagnosticsSurgical instruments for heatingElectrical resistance and conductanceVaricose veins

Owner:TYCO HEALTHCARE GRP LP

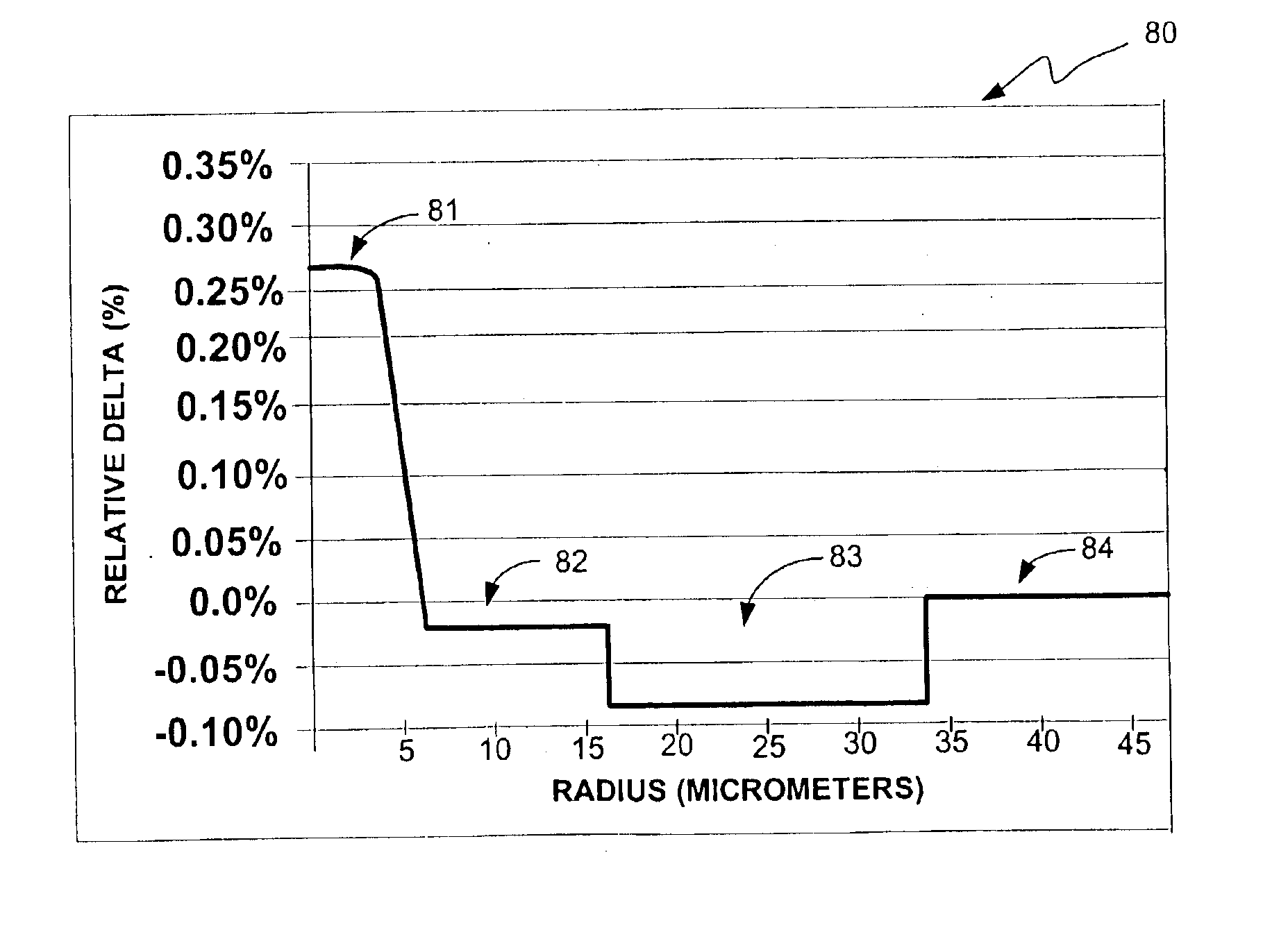

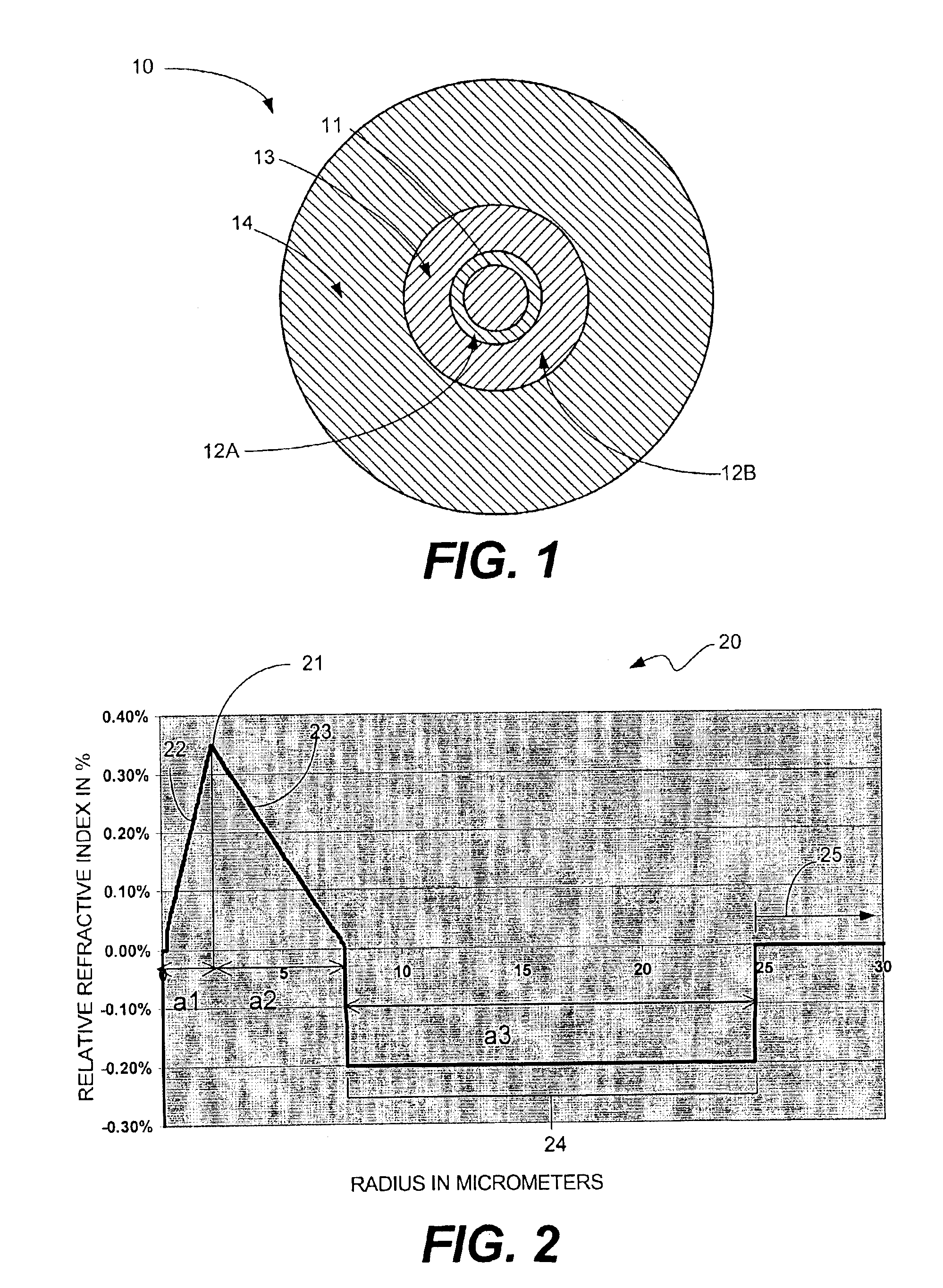

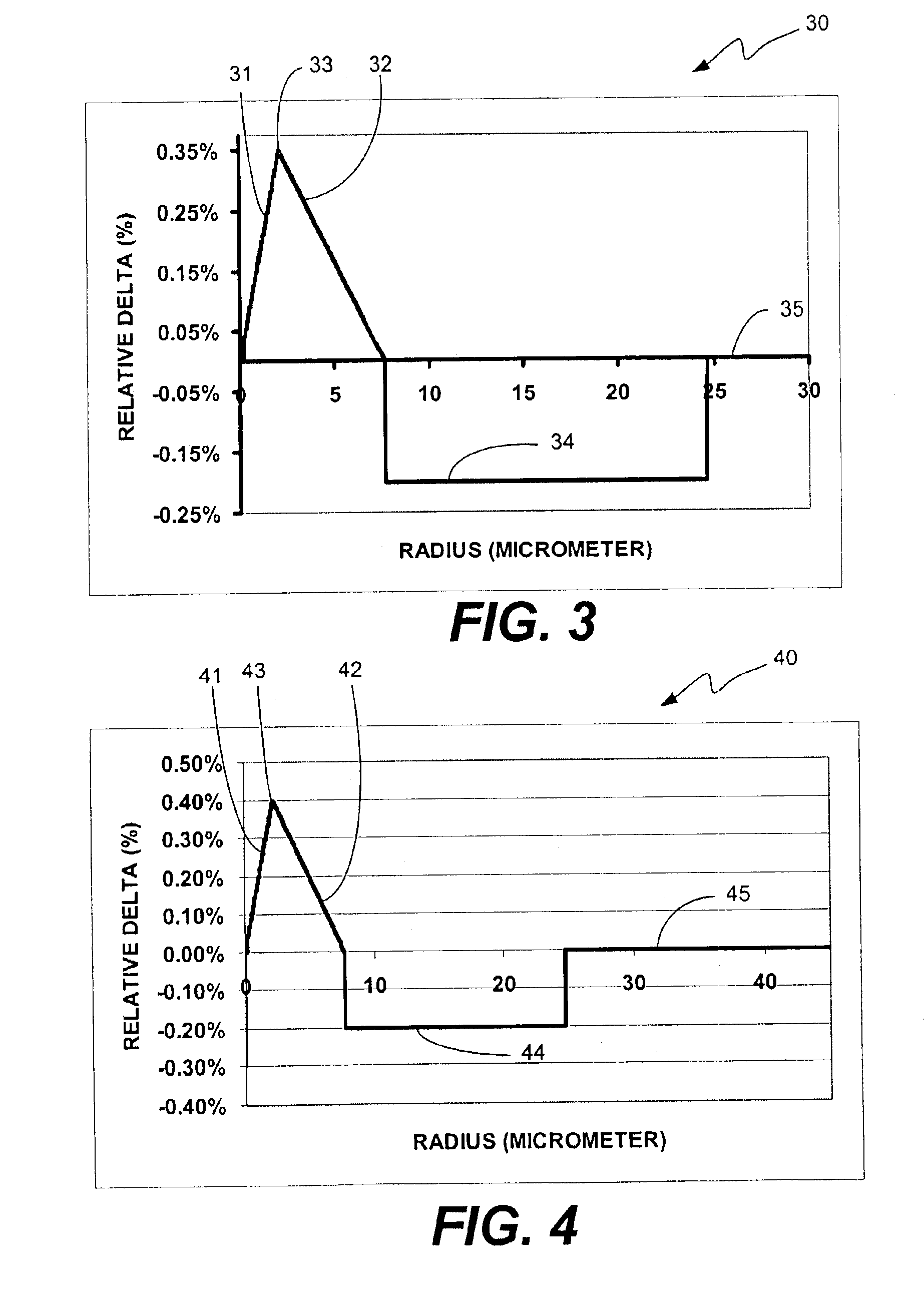

Super-large-effective-area (SLA) optical fiber and communication system incorporating the same

ActiveUS6904218B2Increase the effective areaLow cutoff wavelengthOptical fibre with multilayer core/claddingOptical waveguide light guideFiberUltrasound attenuation

A super-large-effective-area (SLA) optical fiber that is suitable for communicating over a wide wavelength range and that, because of its large effective area, suppresses nonlinear effects that typically result from interaction between signal channels. The effective area, Aeff, of the SLA fiber of the present invention preferably is equal to or greater than approximately 80 μm2 at a wavelength window around 1310 nm. The cutoff wavelength of the SLA fiber of the present invention preferably is less than 1310 nm. Thus, the SLA fiber of the present invention has a very large effective area and a very low cutoff wavelength. In accordance with the present invention, a variety of SLA fibers are provided that all have very large effective areas and desirable transmission properties. The large effective areas of the SLA fibers of the present invention enable nonlinear effects to be suppressed, as well as Stimulated Brillouin Scattering in analog transmission. The large effective areas also enable attenuation to be reduced. The result of suppressing nonlinear effects and reducing attenuation enable signals to be transmitted over long distances and over a broad bandwidth.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

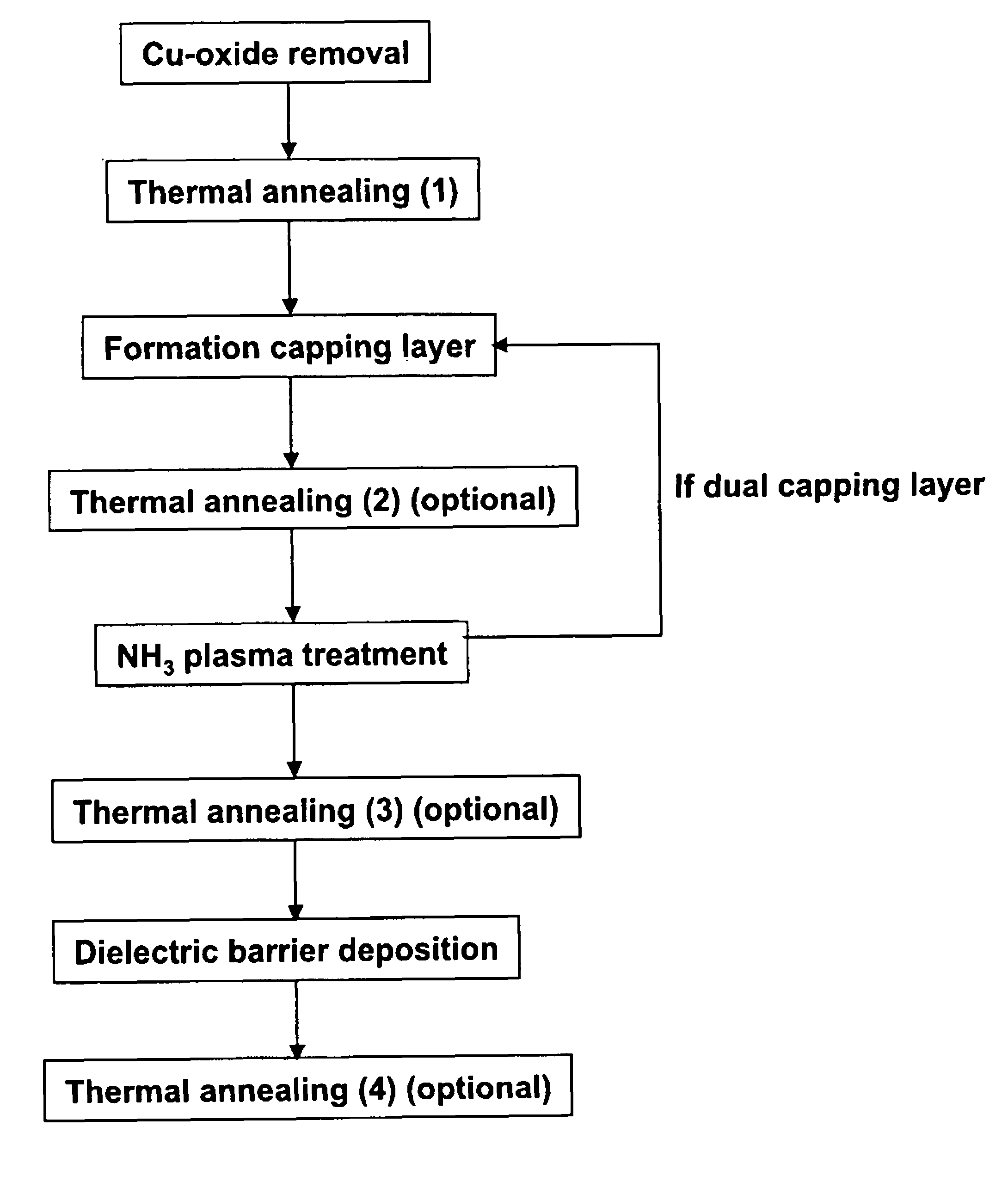

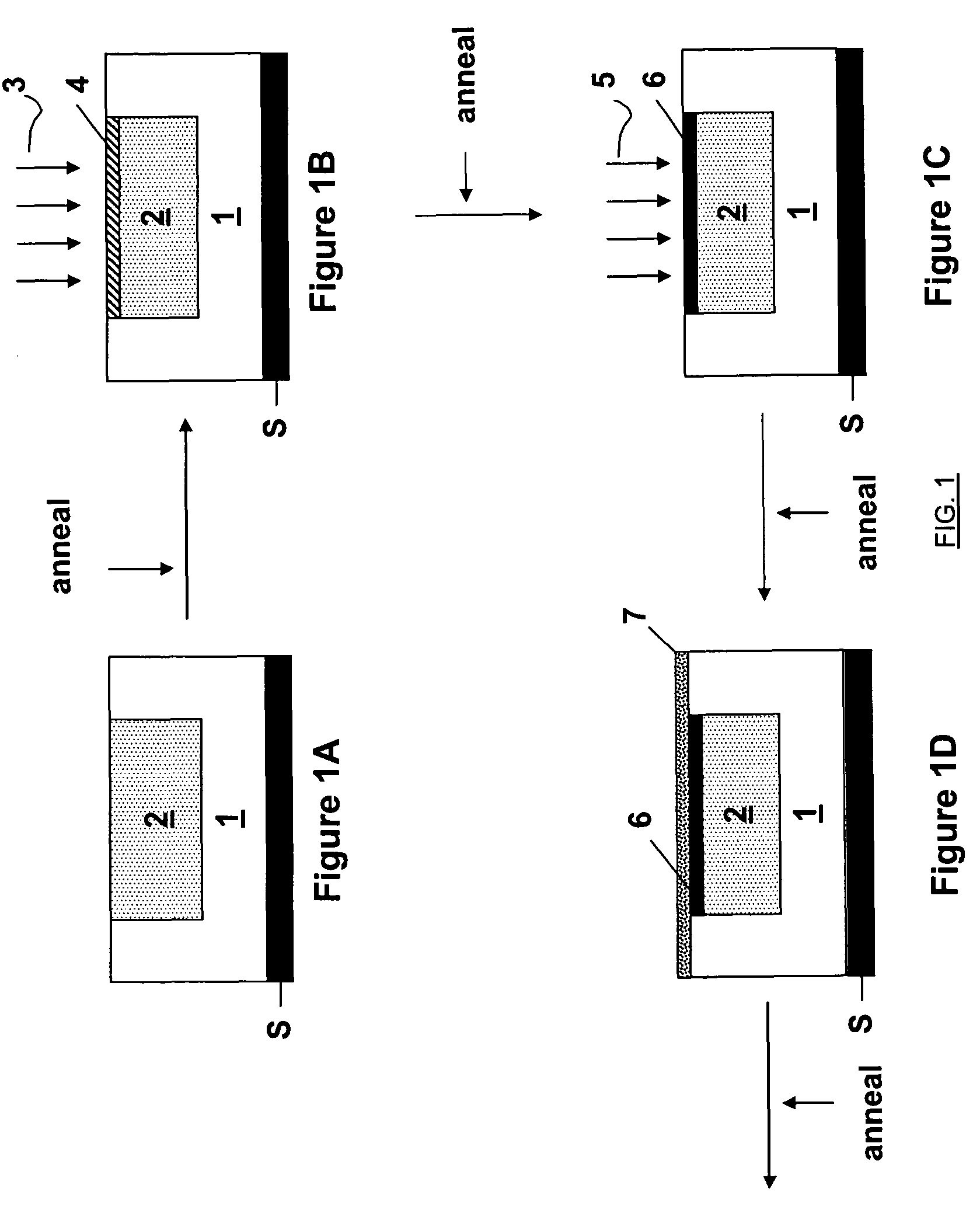

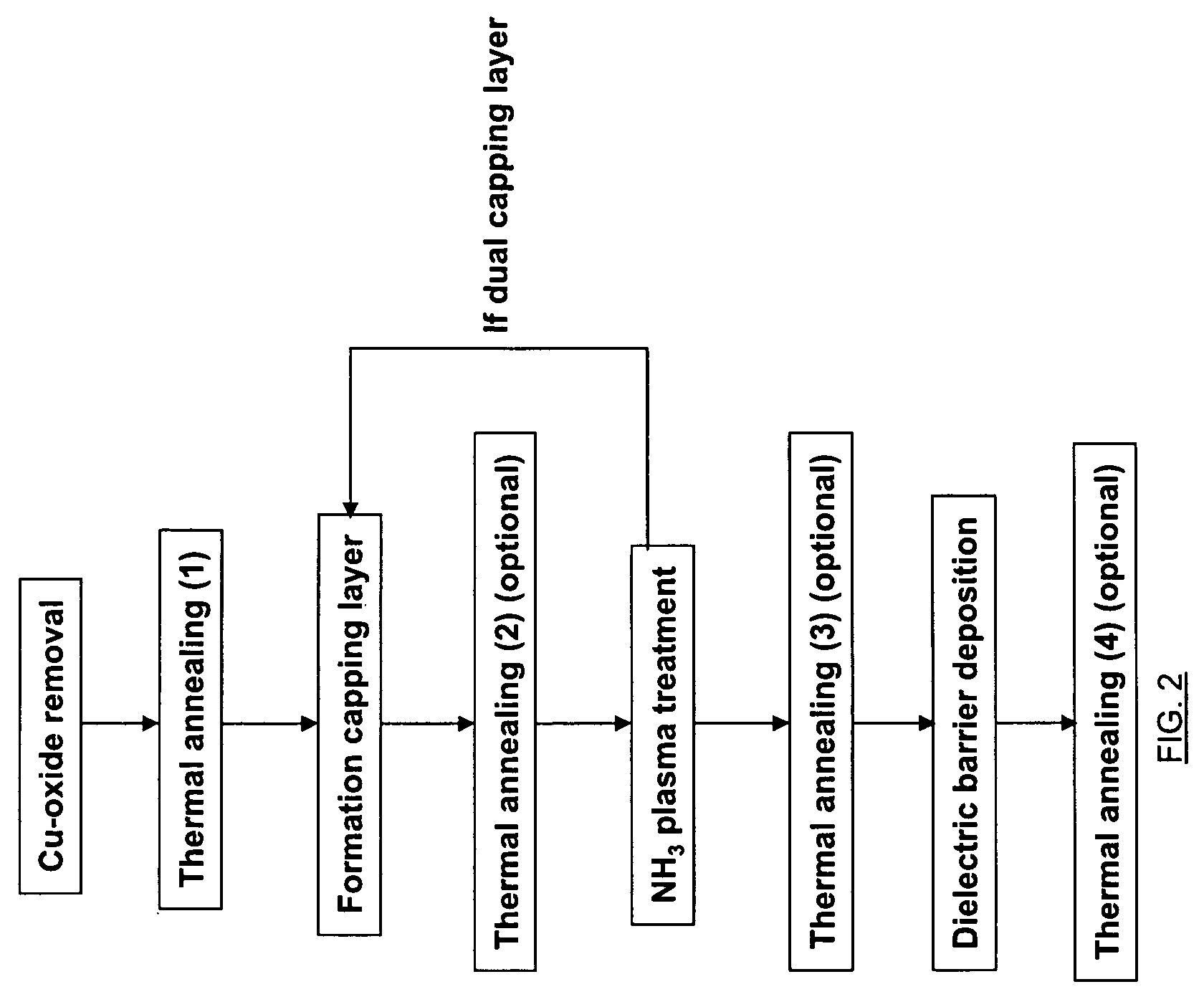

Integrated circuit and manufacturing method of copper germanide and copper silicide as copper capping layer

ActiveUS7858519B2Improve barrier propertiesAvoiding Cu out diffusingSemiconductor/solid-state device detailsSolid-state devicesGermanideCopper silicide

A method is provided for forming a capping layer comprising Cu, N, and also Si and / or Ge onto a copper conductive structure, said method comprising the sequential steps of: forming, at a temperature range between 200° C. up to 400° C., at least one capping layer onto said copper conductive structure by exposing said structure to a GeH4 and / or a SiH4 comprising ambient, performing a NH3 plasma treatment thereby forming an at least partly nitrided capping layer, forming a dielectric barrier layer onto said at least partly nitrided capping layer, wherein prior to said step of forming said at least one capping layer a pre-annealing step of said copper conductive structure is performed at a temperature range between 250° C. up to 450° C.

Owner:TAIWAN SEMICON MFG CO LTD +1

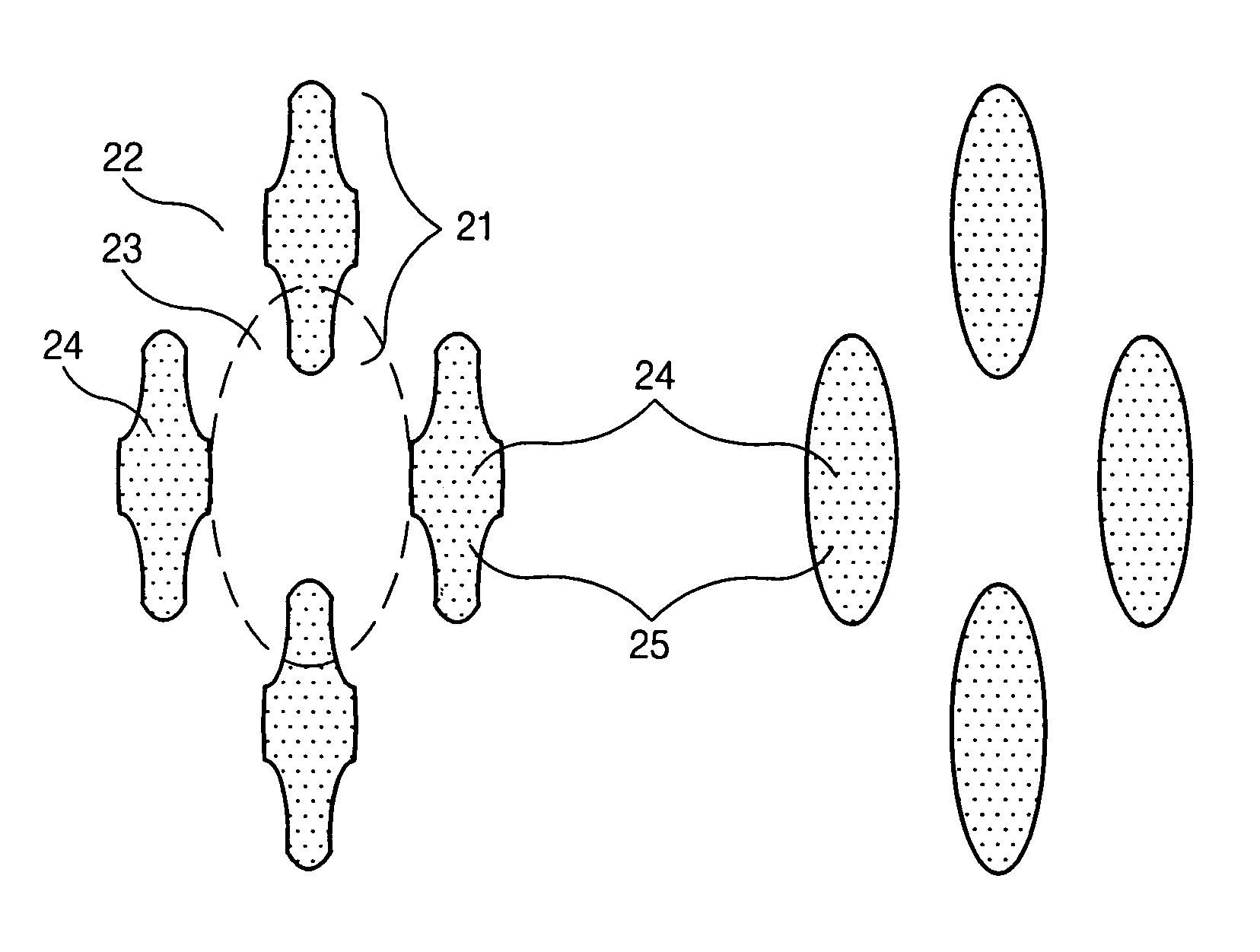

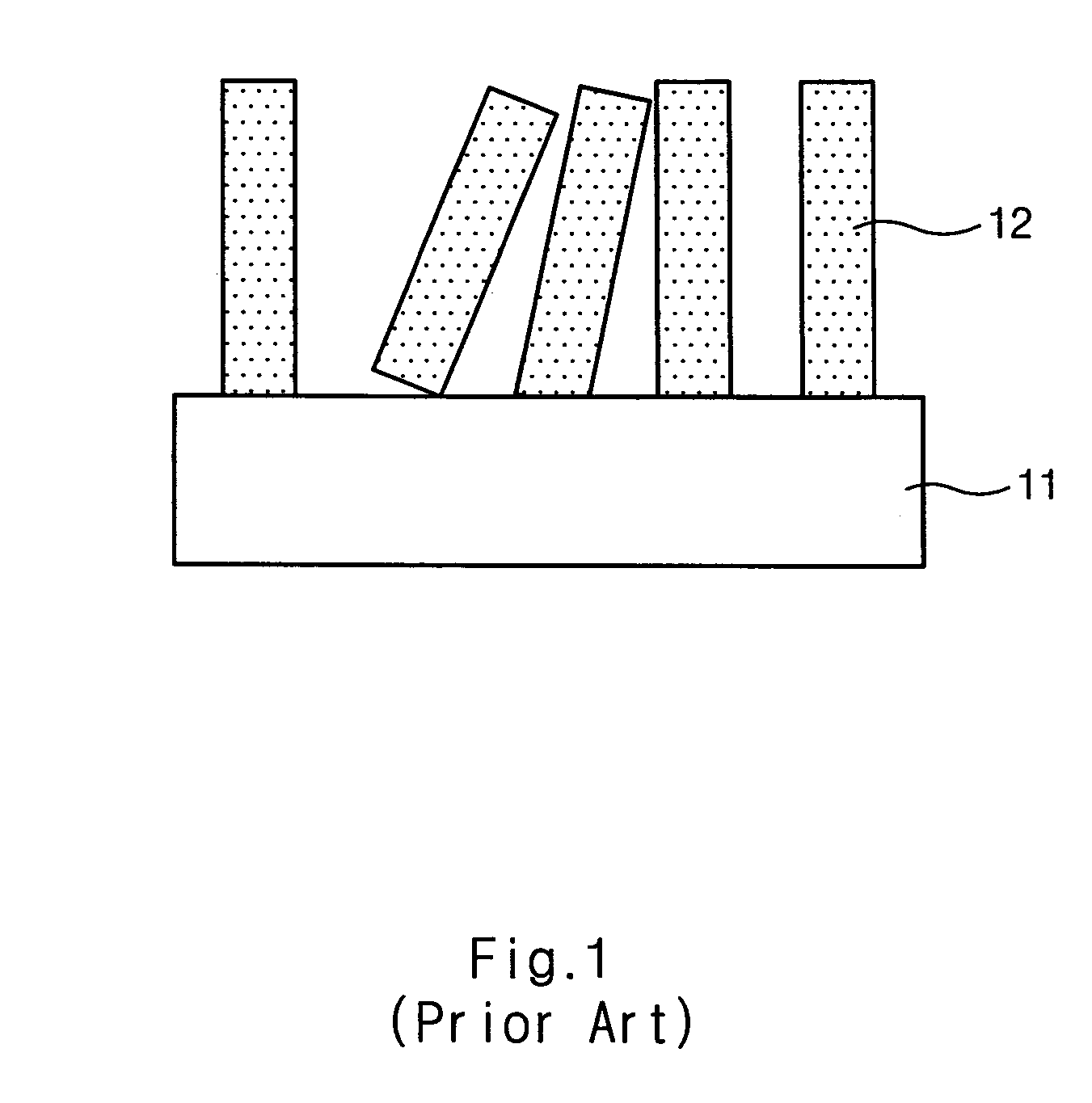

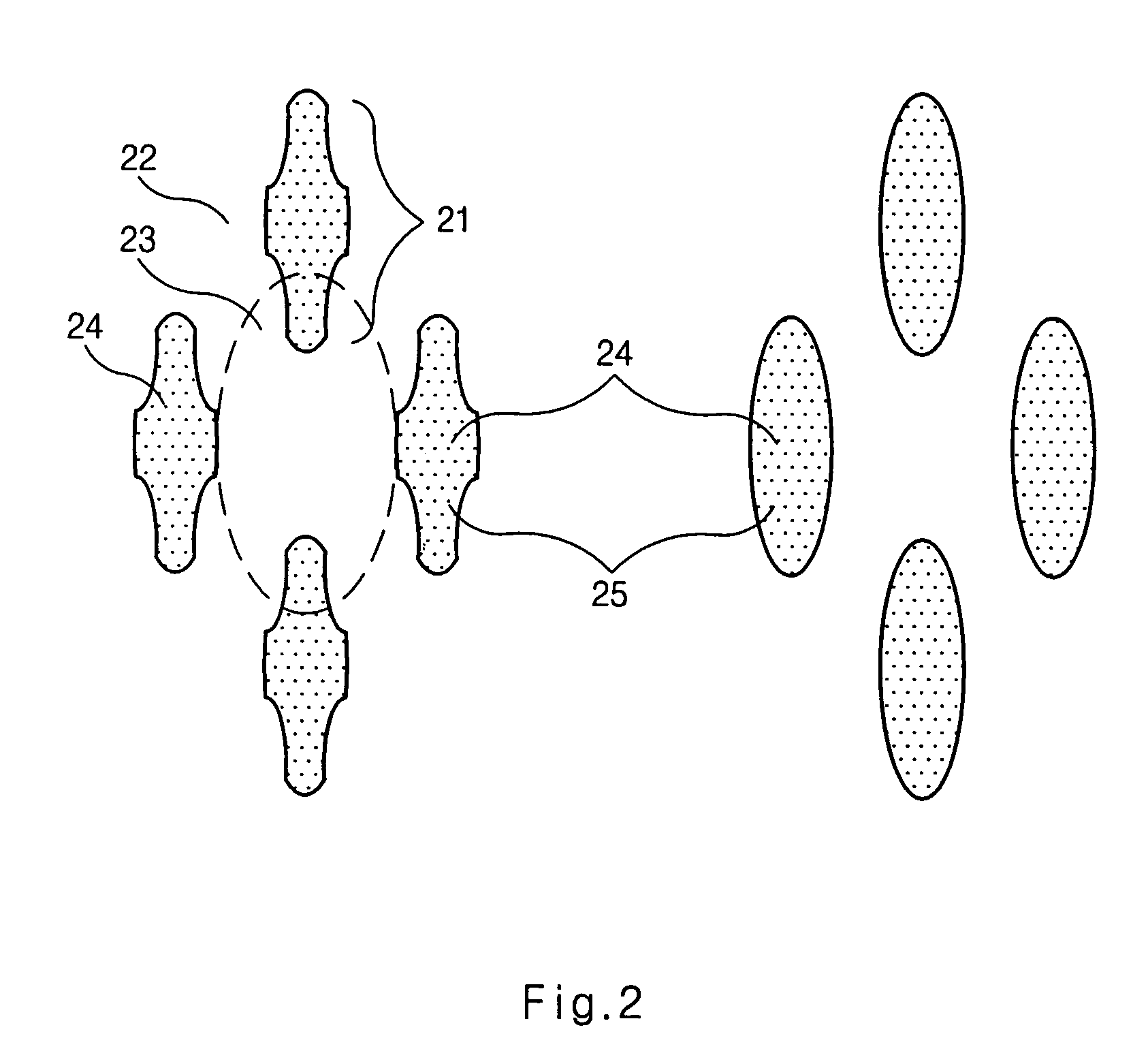

Photoresist polymer and photoresist composition containing the same

InactiveUS7279256B2Enhance the imageImprove the immunityPhotosensitive materialsRadiation applicationsResistEnergy variation

Photoresist polymers and photoresist compositions are disclosed. A photoresist polymer comprising a polymerization repeating unit represented by Formula I is less sensitive to change in the amount of energy due to its higher active energy than that of a conventional photoresist polymer. As a result, a phenomenon where the portion of the pattern for the storage electrode contact region that receives relatively large amount of light becomes too thin is avoided when the device isolation film pattern is formed, and wherein pattern collapse caused by a high aspect ratio due to high etching resistance is prevented or avoided.whereinR1–R10, a, b, c and d are as defined in the description.

Owner:SK HYNIX INC

RNA interference mediated inhibition of MAP kinase gene expression using short interfering nucleic acid (siNA)

InactiveUS20050239731A1Improve bioavailabilityMinimize the possibilityBiocideSugar derivativesMAP Kinase GeneMitogen-activated protein

This invention relates to compounds, compositions, and methods useful for modulating mitogen activated protein kinase (MAP kinase) gene expression using short interfering nucleic acid (siNA) molecules. This invention also relates to compounds, compositions, and methods useful for modulating the expression and activity of other genes involved in pathways of MAP kinase gene expression and / or activity by RNA interference (RNAi) using small nucleic acid molecules. In particular, the instant invention features small nucleic acid molecules, such as short interfering nucleic acid (siNA), short interfering RNA (siRNA), double-stranded RNA (dsRNA), micro-RNA (miRNA), and short hairpin RNA (shRNA) molecules and methods used to modulate the expression of MAP kinase genes, such as Jun amino-terminal kinase (e.g., JNK-1, JNK-2), p38 (MAPK 14), ERK (e.g., ERK-1, ERK-2) and / or c-Jun.

Owner:SIRNA THERAPEUTICS INC

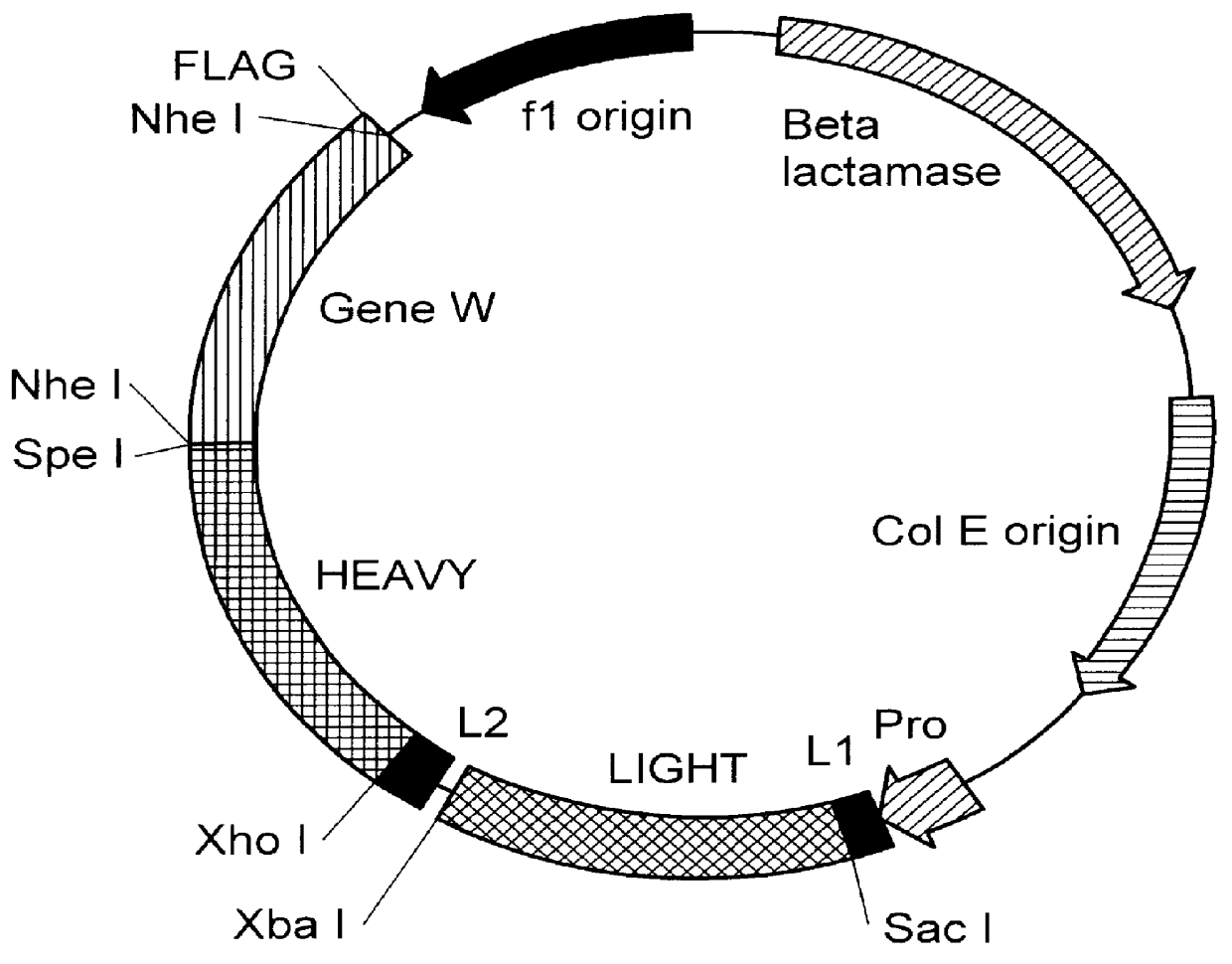

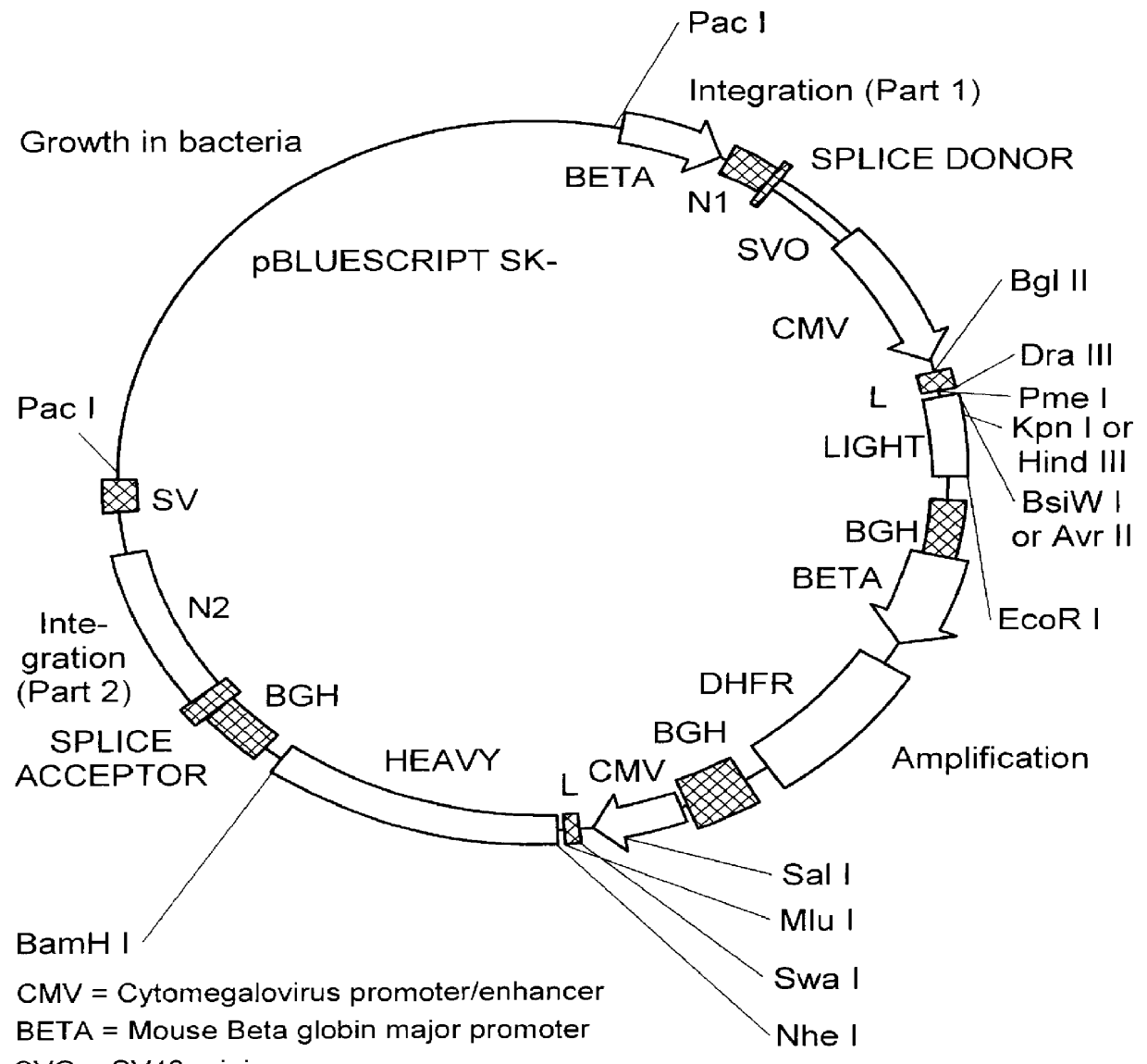

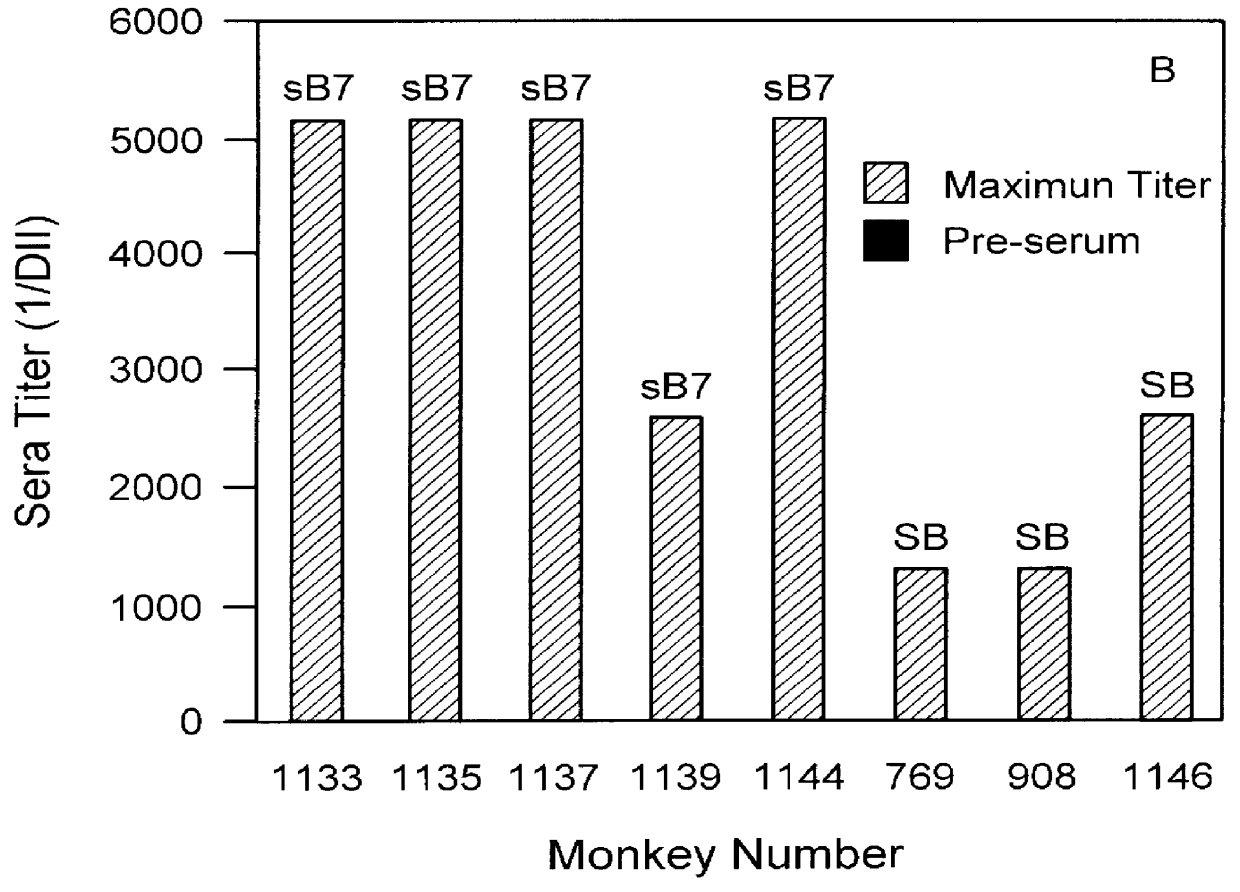

Human B7.1-specific primatized antibodies and transfectomas expressing said antibodies

InactiveUS6113898AShrink tumorInhibit tumor growthPeptide/protein ingredientsAntipyreticDiseaseOrgan transplant rejection

The present invention relates to the identification of macaque antibodies to human B7.1 and B7.2 by screening of phage display libraries or monkey heterohybridomas obtained using B lymphocytes from B7.1 and / or B7.2 immunized monkeys. More specifically, the invention provides four monkey monoclonal antibodies 7B6, 16C10, 7C10 and 20C9 which inhibit the B7:CD28 pathway and thereby function as effective immunosuppressants. The invention further provides the complete DNA and amino acid sequences of the light and heavy chain of three primatized antibodies derived from those monkey monoclonal antibodies which bind B7.1 and possibly B7.2, primatized 7C10, primatized 7B6 and primatized 16C10. These primatized and monkey antibodies may be used as specific immunosuppressants, e.g., for the treatment of autoimmune diseases and to prevent organ transplant rejection.

Owner:BIOGEN INC

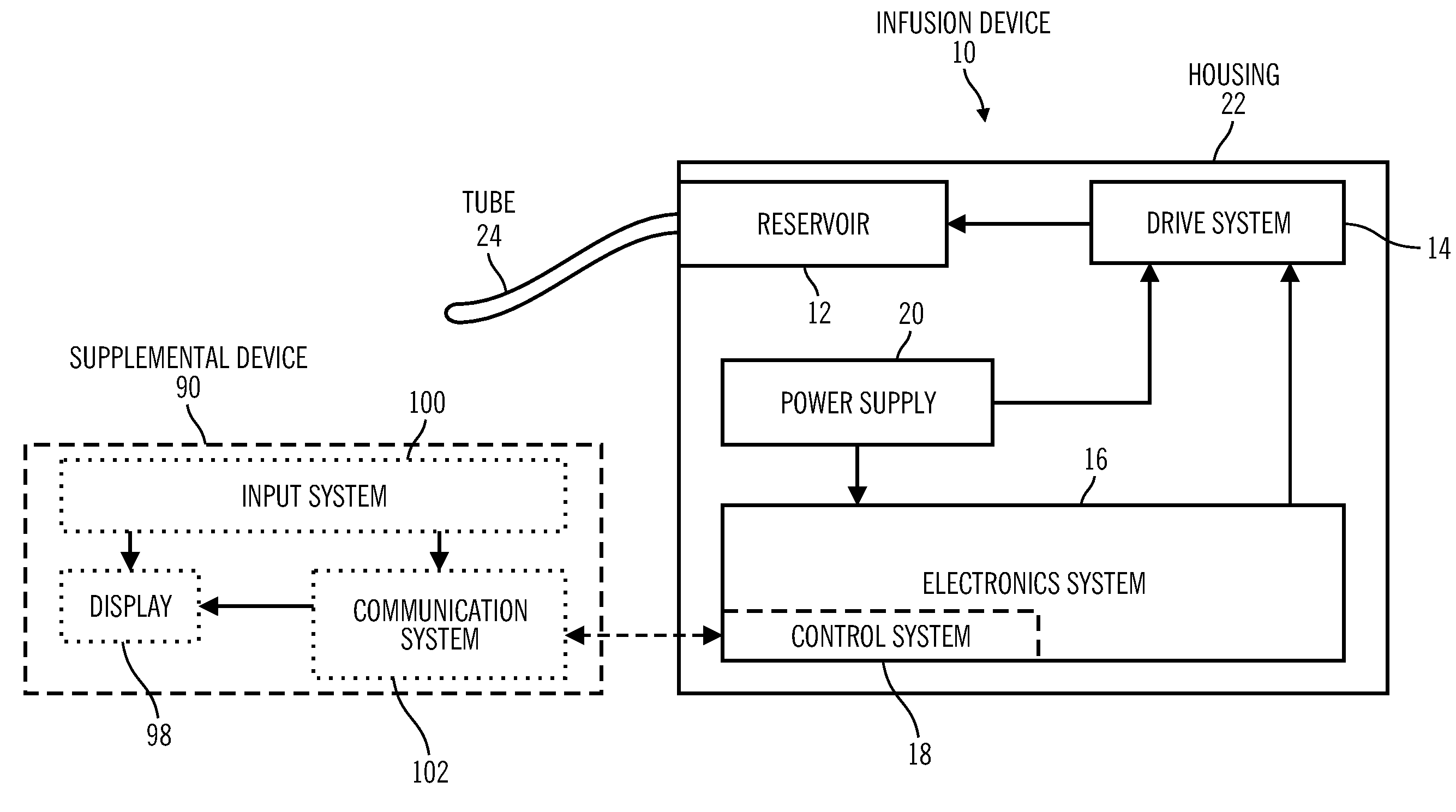

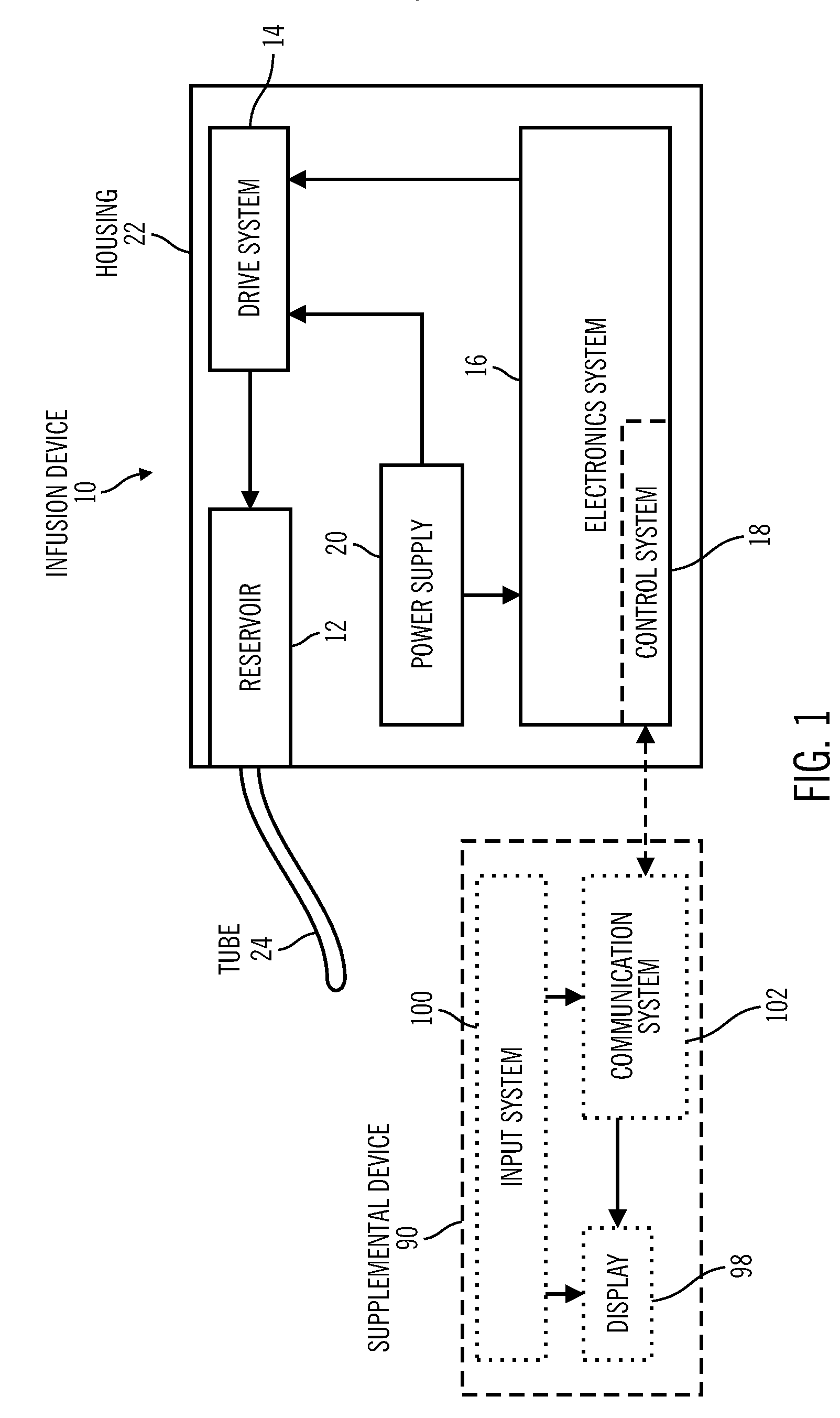

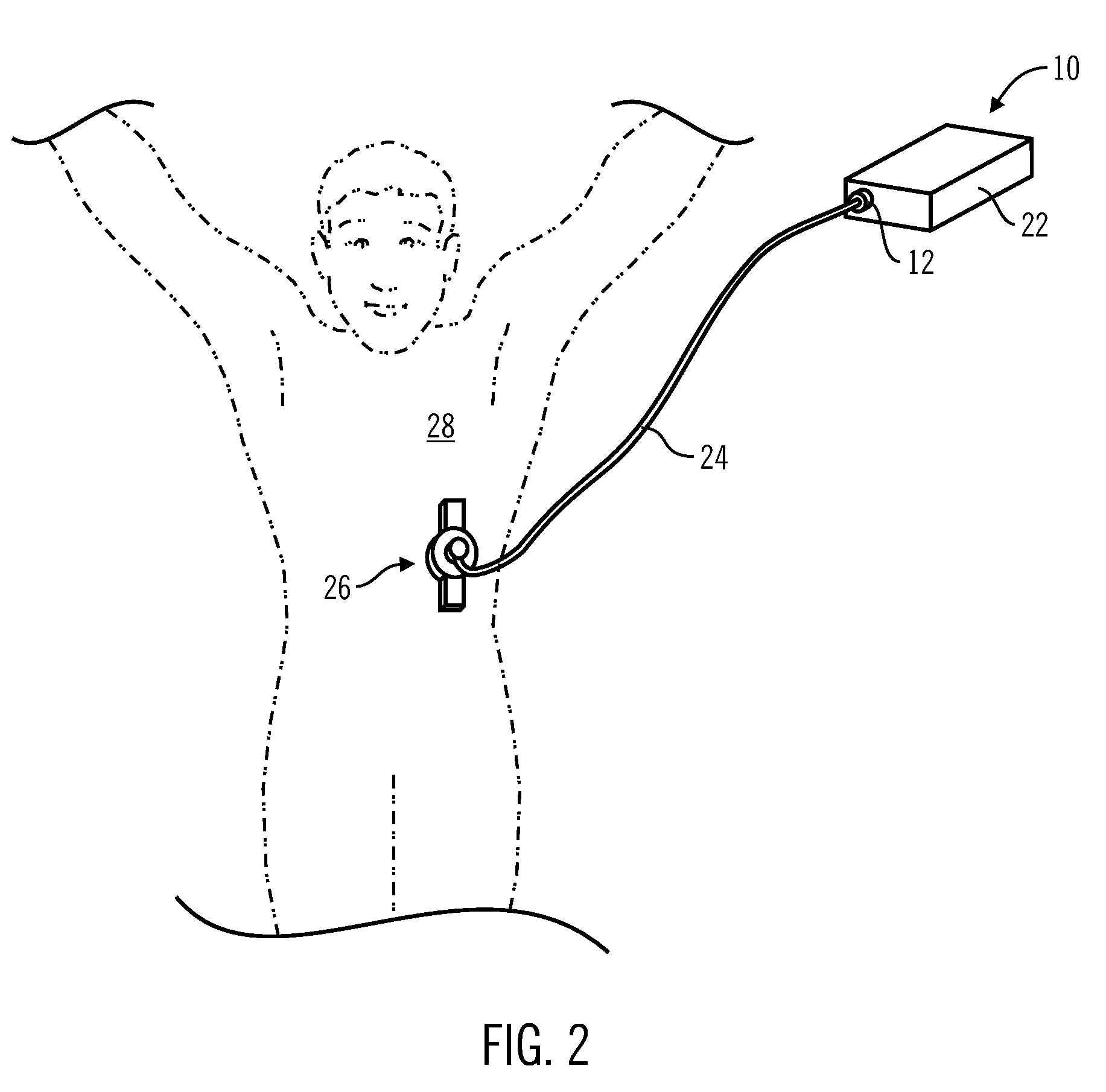

Control Tabs for Infusion Devices and Methods of Using the Same

InactiveUS20100160861A1Improve water resistanceImprove the immunityOther blood circulation devicesMedical devicesBiomedical engineeringElectrical element

An external infusion device that infuses a fluid into an individual's body includes a housing, a reservoir, a drive system, a power supply, electrical elements, and a tab. The reservoir contains the fluid, and the drive system forces the fluid from the reservoir. The electrical elements control the power to the drive system to regulate the rate that fluid is forced from the reservoir. The tab mates with the housing, and contains at least one electrical element. The tab is removable, and may be replaced with a different tab. The different tab may change the rate fluid is forced from the reservoir. A tab may be removed from one external infusion device and installed in a different external infusion device. The tab may be limited to use in a predetermined number of external infusion devices and may include a power supply.

Owner:MEDTRONIC MIMIMED INC

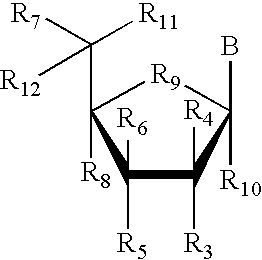

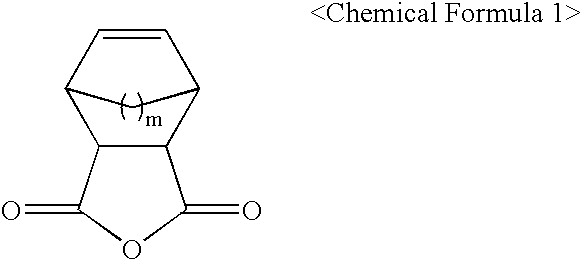

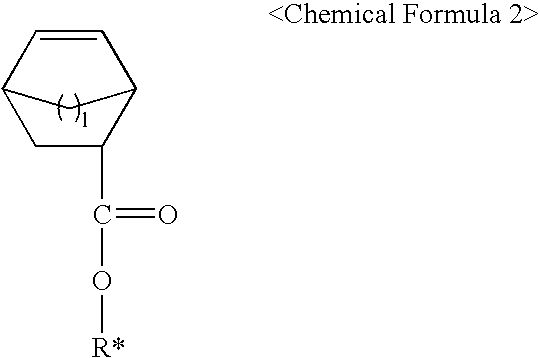

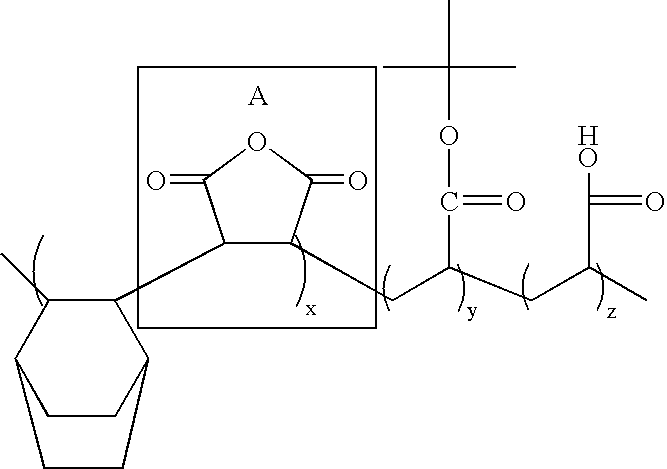

Polymers for photoresist and photoresist compositions using the same

InactiveUS6987155B2Improve the immunityExcellent etching resistance and adhesiveness and photosensitivityElectric discharge tubesPhotomechanical exposure apparatusResistX-ray

The present invention relates to photoresist monomers, polymers formed therefrom and photoresist compositions suitable for photolithography processes employing a DUV light source, such as KrF (249 nm) and ArF(193 nm); EUV; VUV; E-beam; ion-beam; and X-ray. Photoresist monomers of the present invention are represented by the following Chemical Formula 1: wherein, m is 1 or 2.Polymers of the present invention comprise repeating units derived from the comonomer of Chemical Formula 1, preferably together with monomers of the following Chemical Formula 2: wherein,R* is an acid-labile group, andl is 1 or 2.

Owner:HYUNDAI ELECTRONICS IND CO LTD

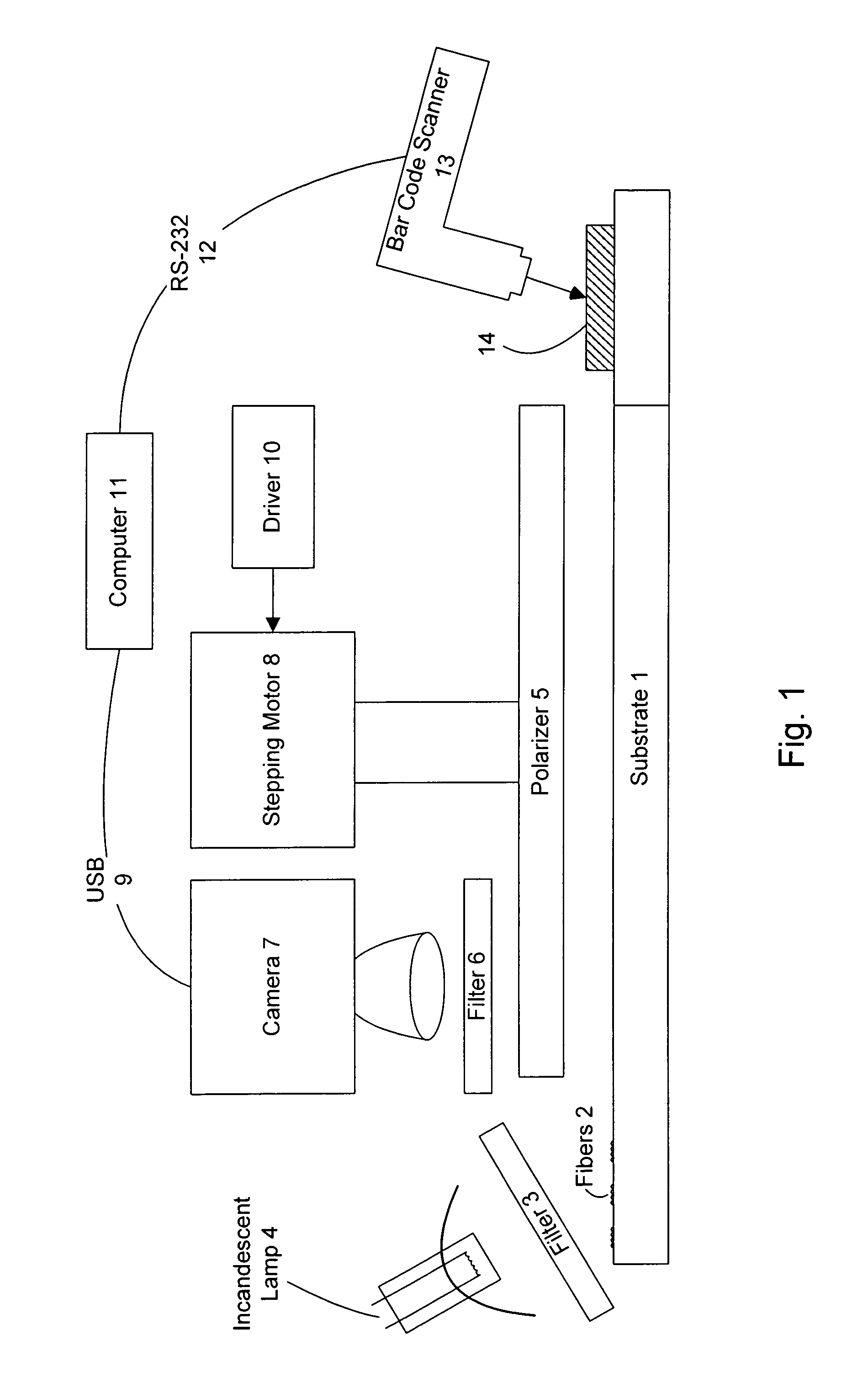

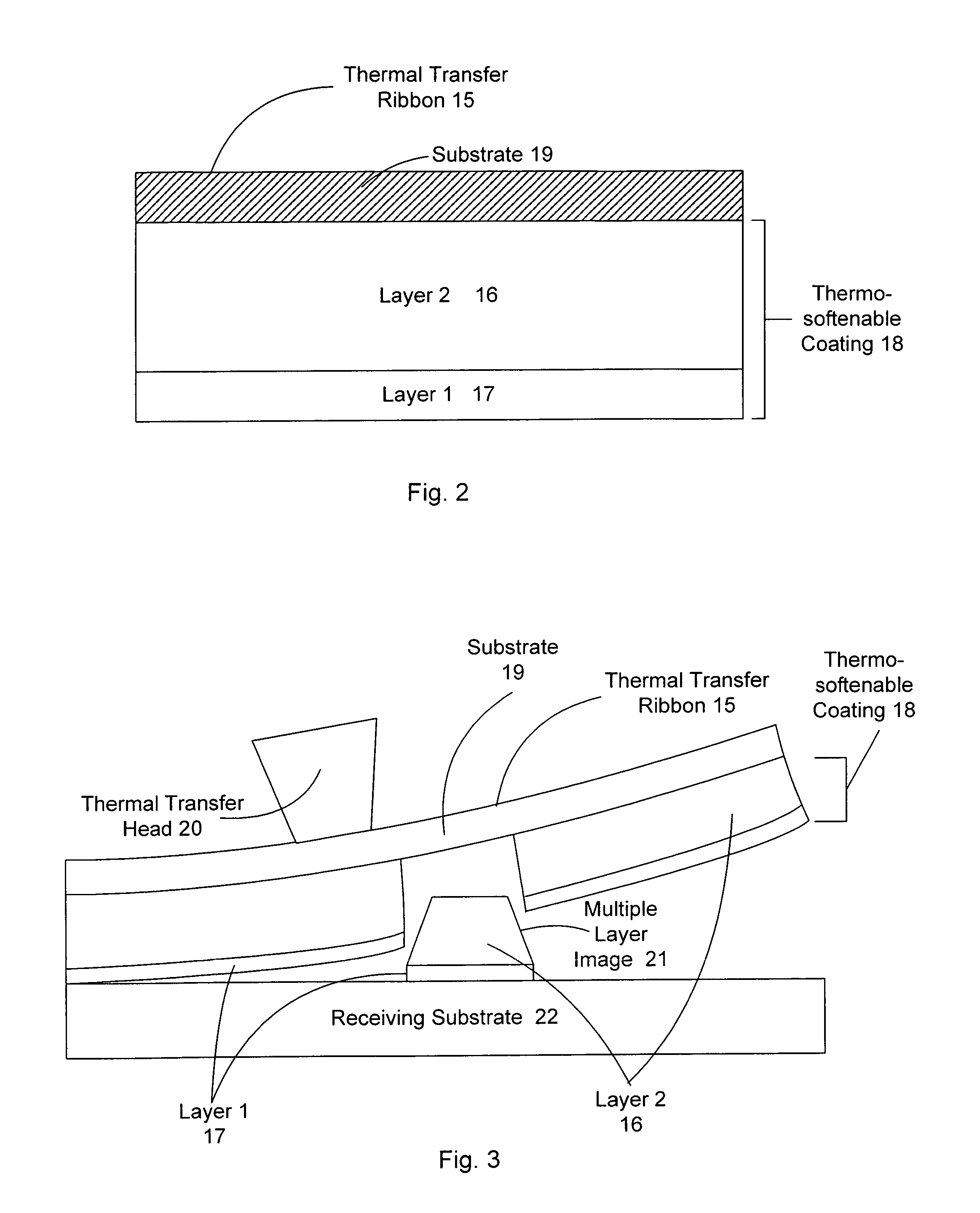

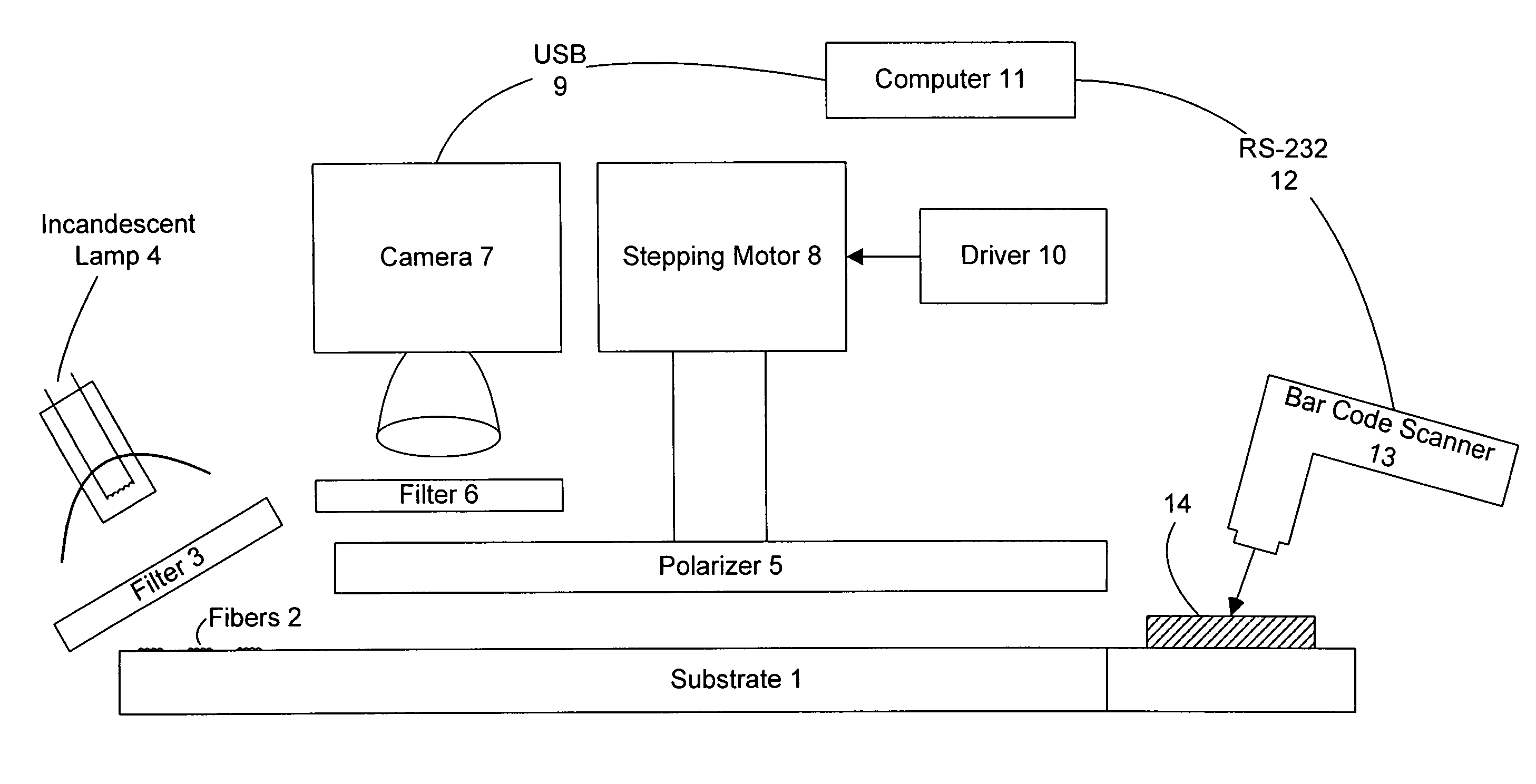

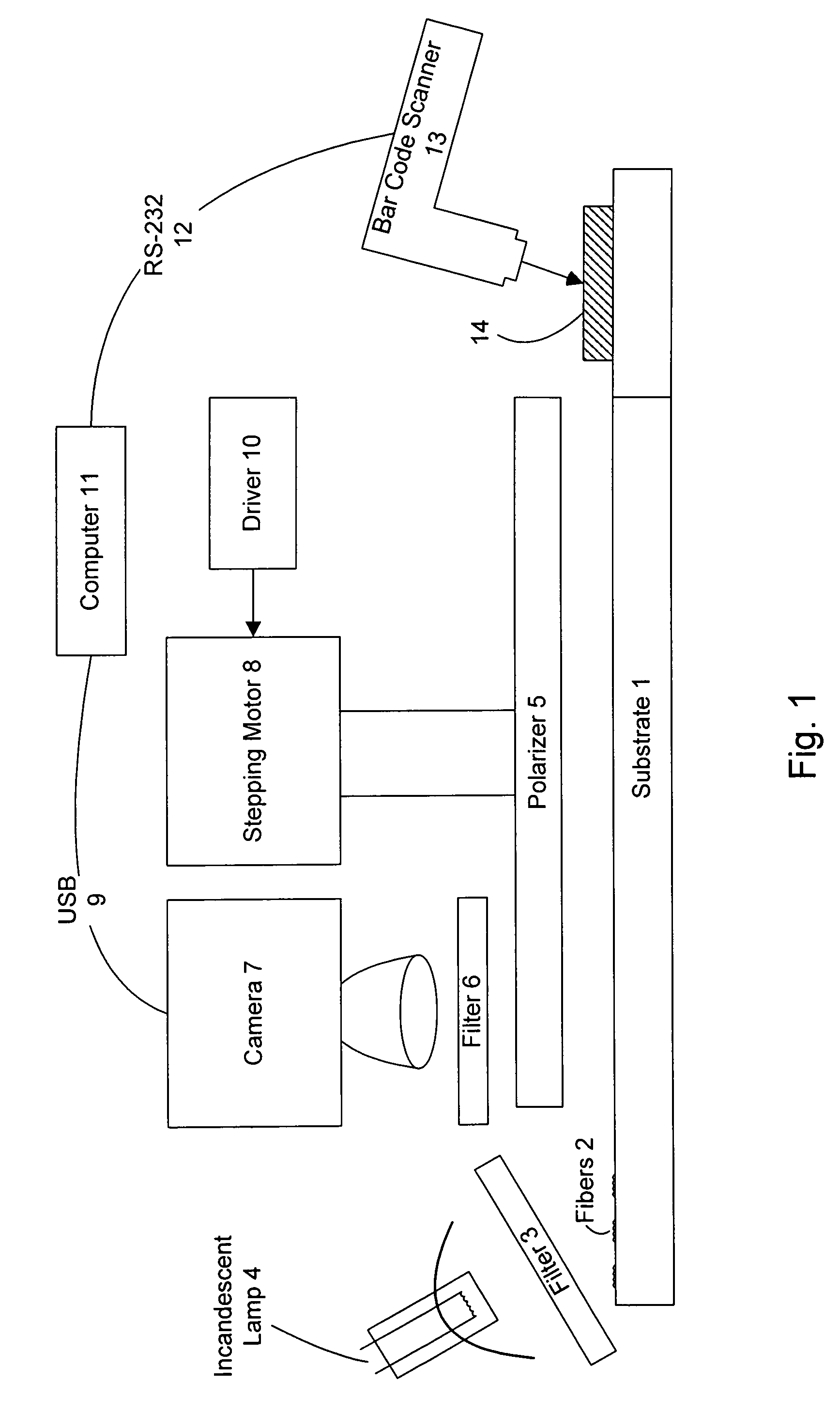

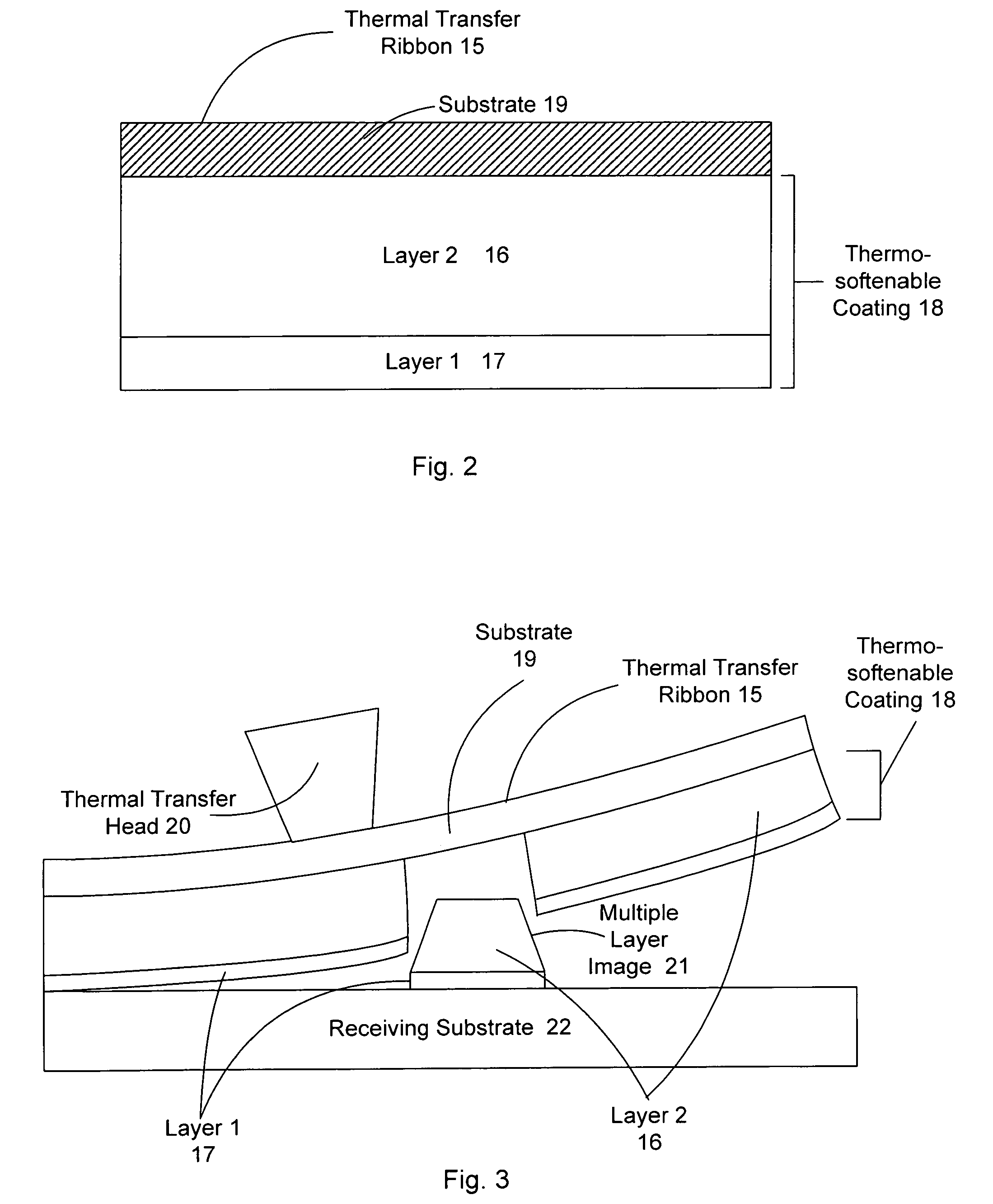

Authentication method and system

InactiveUS7089420B1Great difficultyEfficient codingOther printing matterUser identity/authority verificationComputer hardwareOptical property

The present invention provides a method and apparatus for the production and labeling of objects in a manner suitable for the prevention and detection of counterfeiting. Thus, the system incorporates a variety of features that make unauthorized reproduction difficult. In addition, the present invention provides an efficient means for the production of labels and verification of authenticity, whereby a recording apparatus which includes a recording medium, having anisotrophic optical domains, along with a means for transferring a portion of the recording medium to a carrier, wherein a bulk portion of the recording medium has macroscopically detectable anisotrophic optical properties and the detecting apparatus thereon.

Owner:COPILOT VENTURES FUND III

Authentication method and system

InactiveUS7162035B1Great difficultyEfficient codingUser identity/authority verificationComputer security arrangementsComputer hardwareOptical property

The present invention provides a method and apparatus for the production and labeling of objects in a manner suitable for the prevention and detection of counterfeiting. Thus, the system incorporates a variety of features that make unauthorized reproduction difficult. In addition, the present invention provides an efficient means for the production of labels and verification of authenticity, whereby a recording apparatus which includes a recording medium, having anisotrophic optical domains, along with a means for transferring a portion of the recording medium to a carrier, wherein a bulk portion of the recording medium has macroscopically detectable anisotrophic optical properties and the detecting apparatus thereon.

Owner:COPILOT VENTURES FUND III

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com