Patents

Literature

741results about How to "Reduce thermal effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

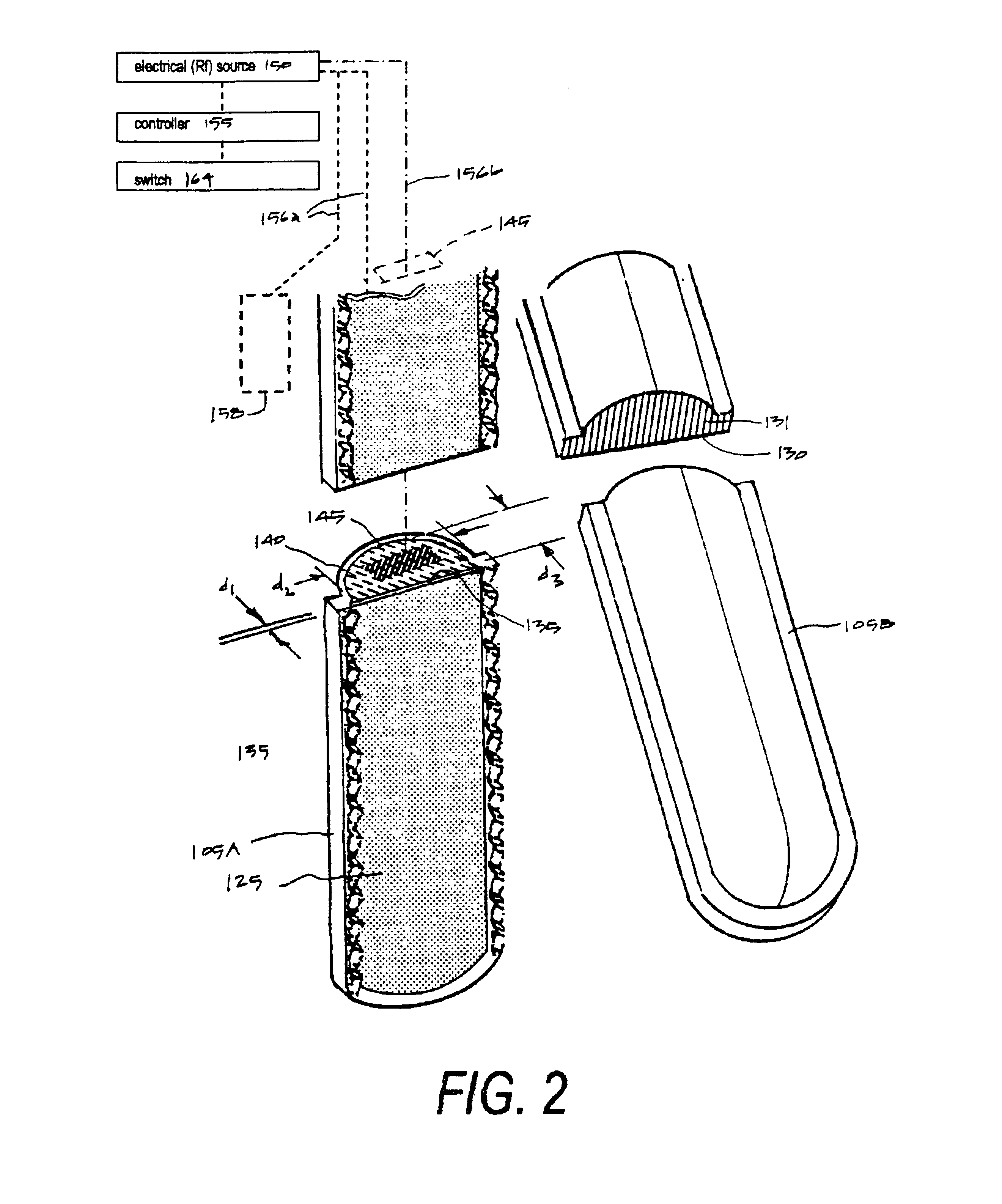

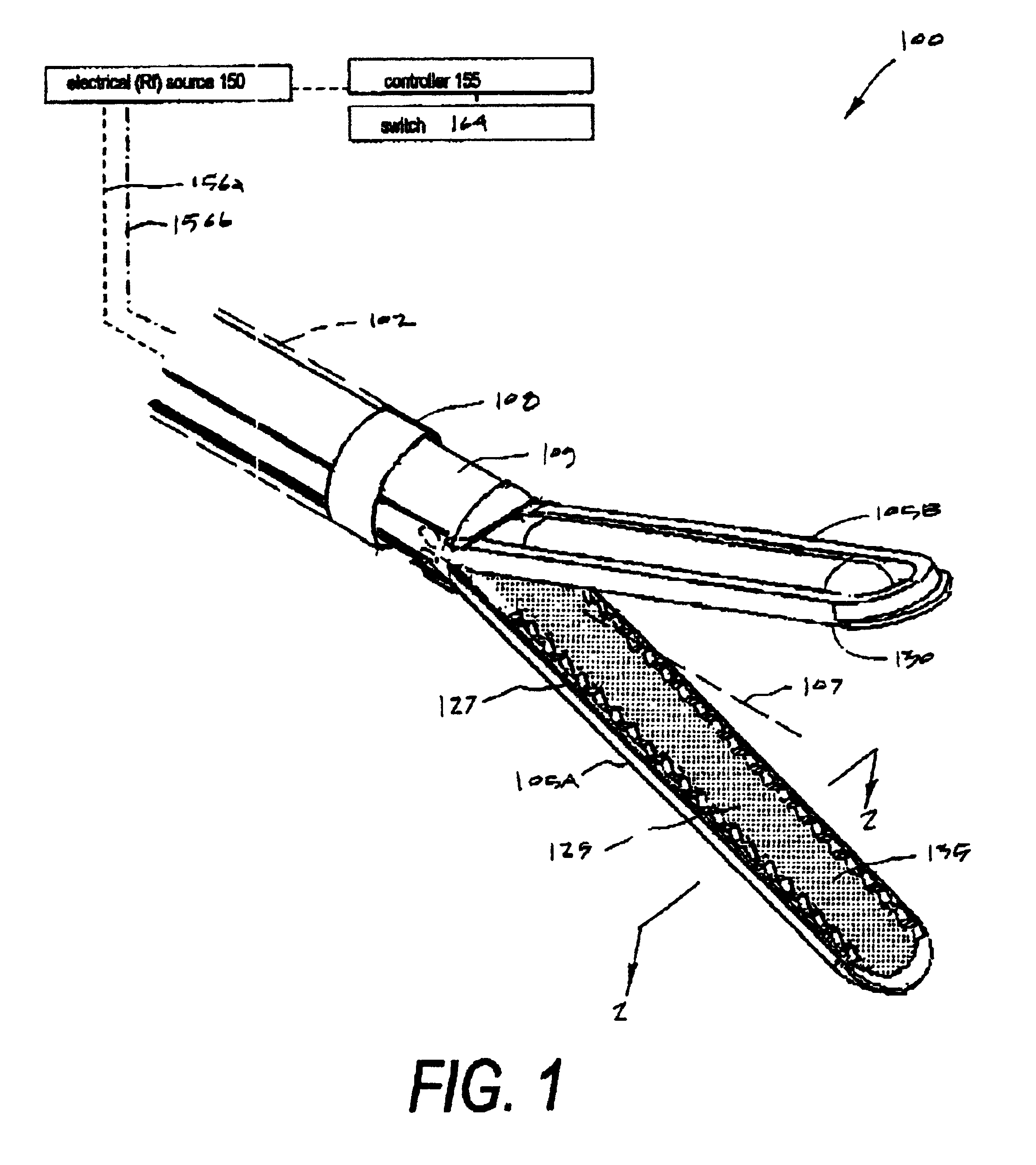

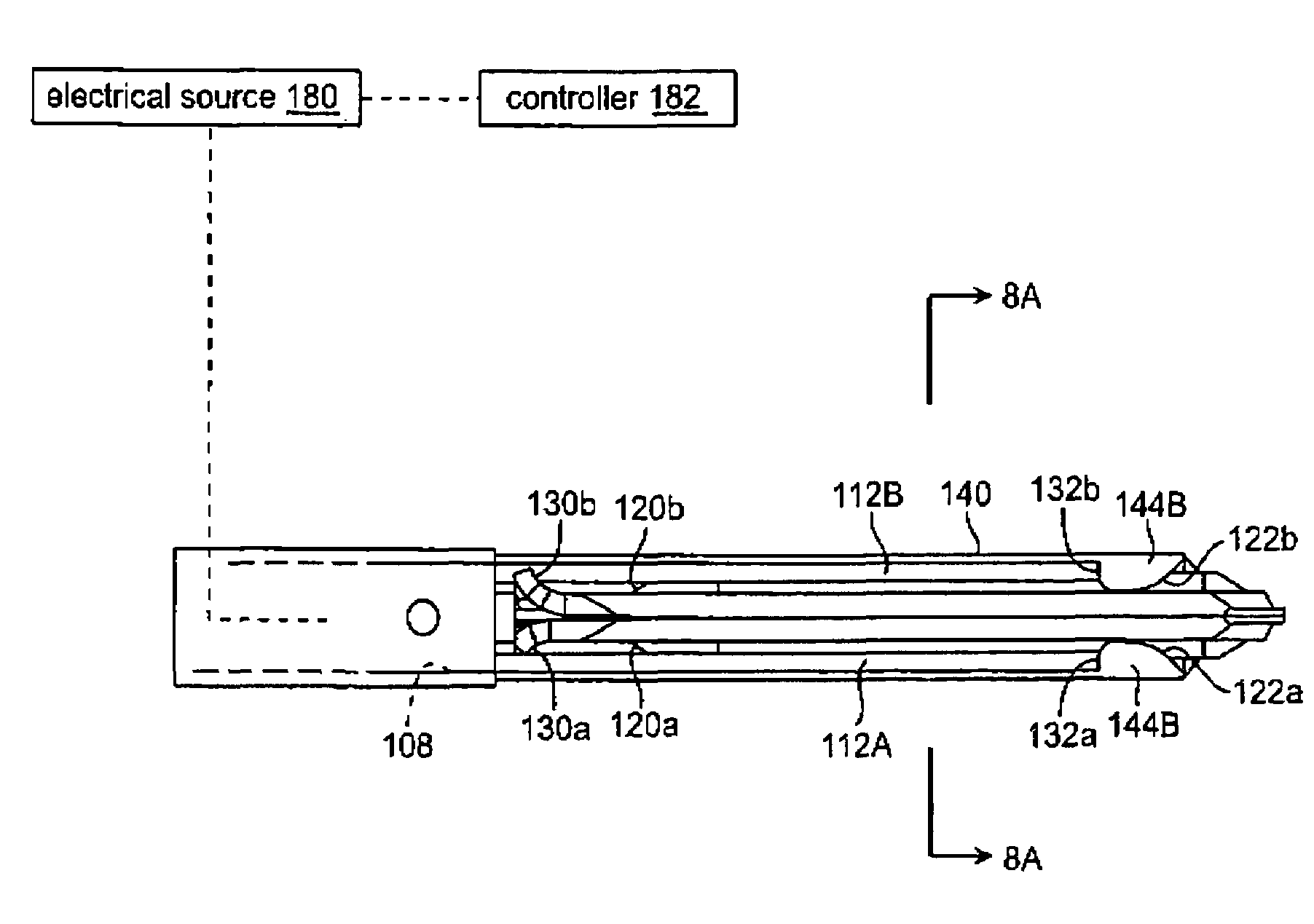

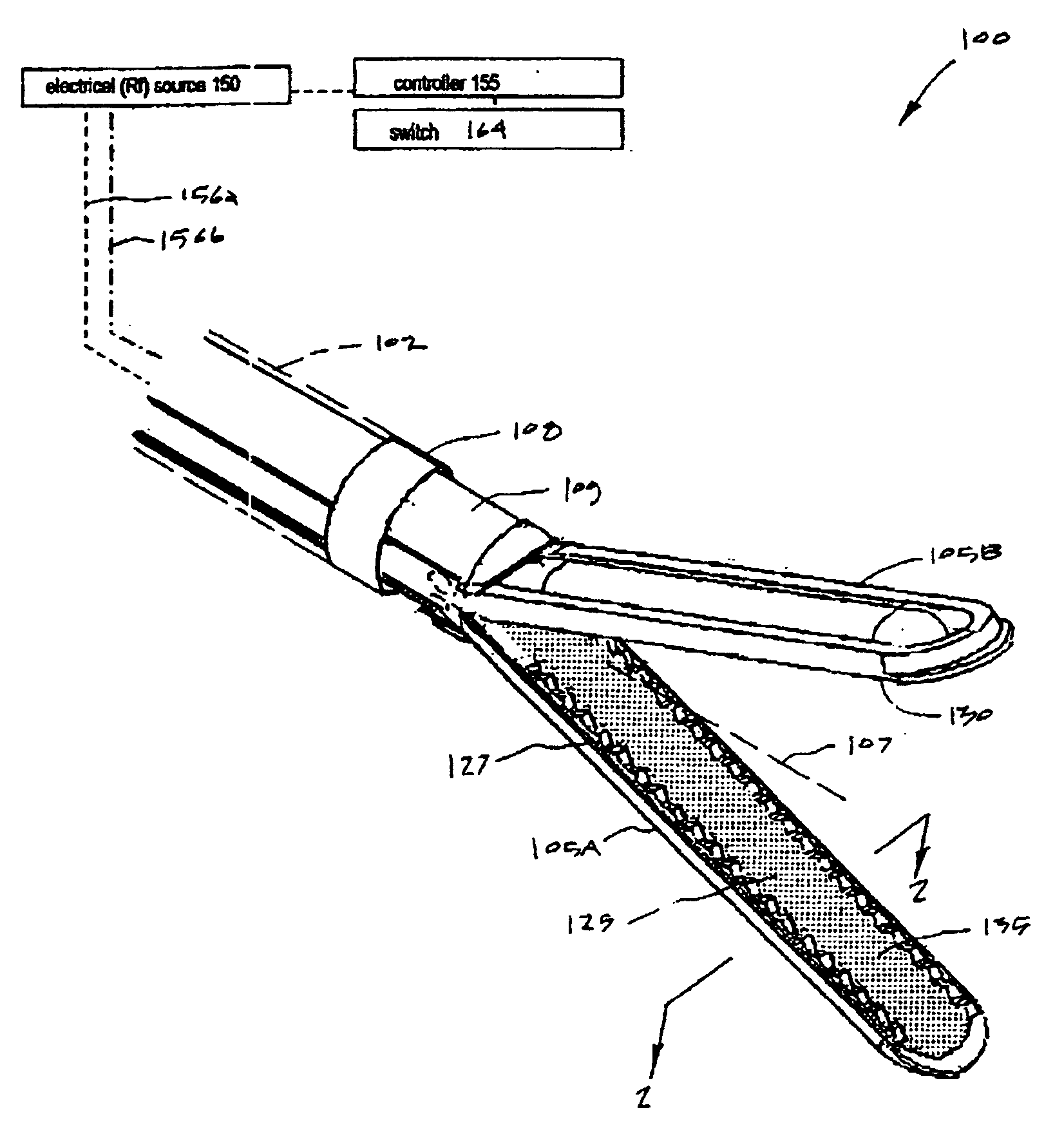

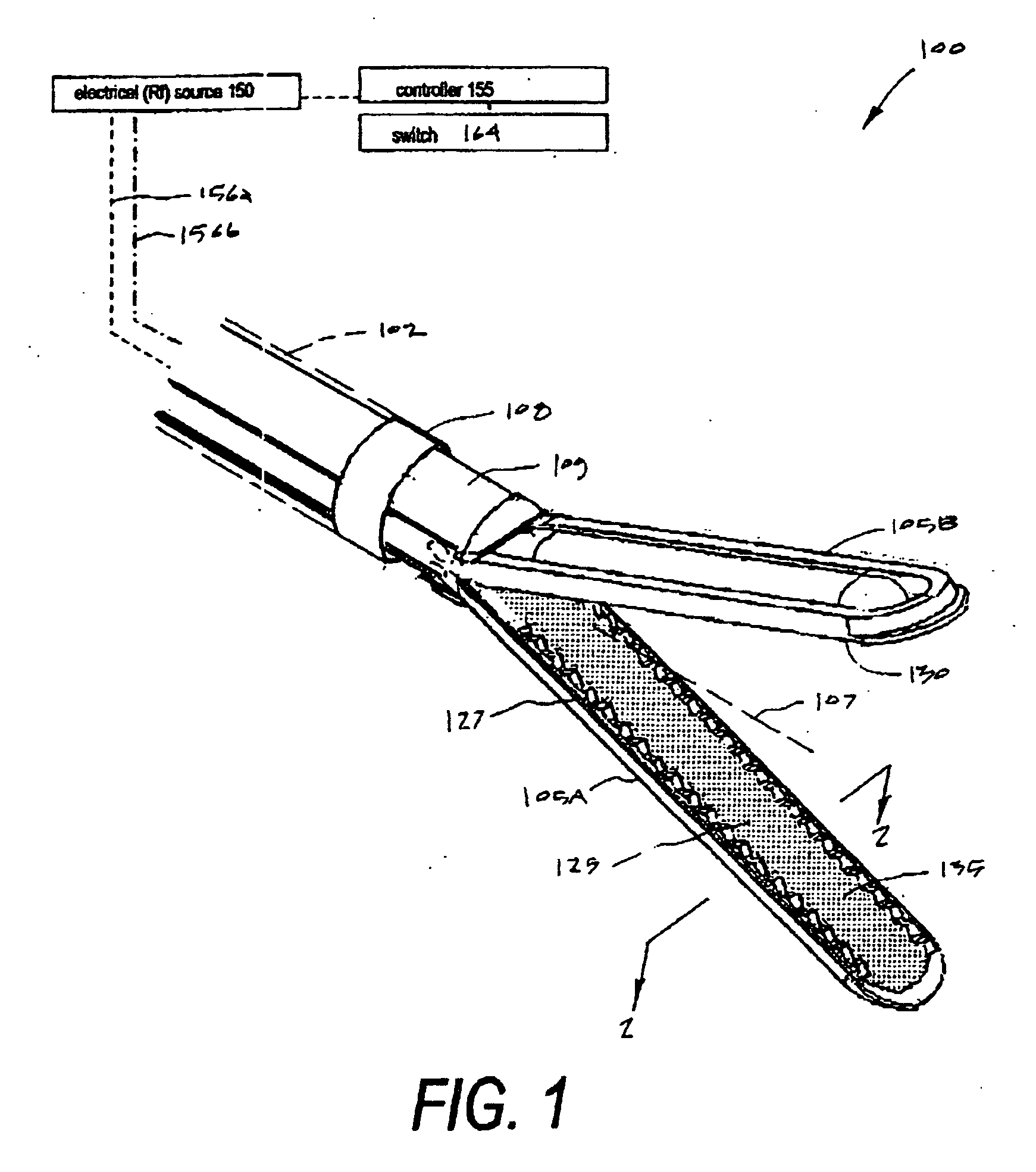

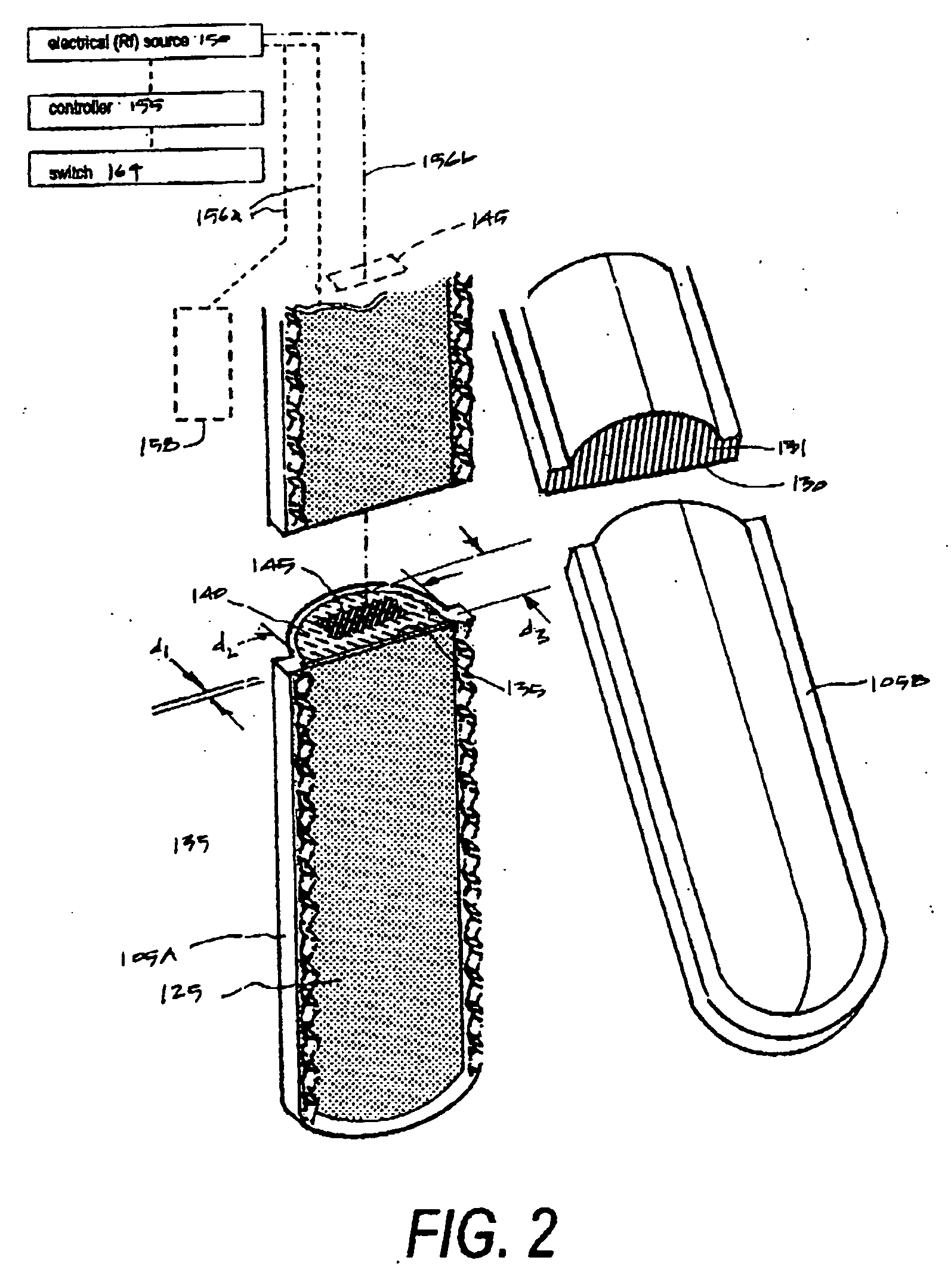

Electrosurgical instrument

InactiveUS6926716B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingSurgical forcepsElectrical resistance and conductanceVoltage source

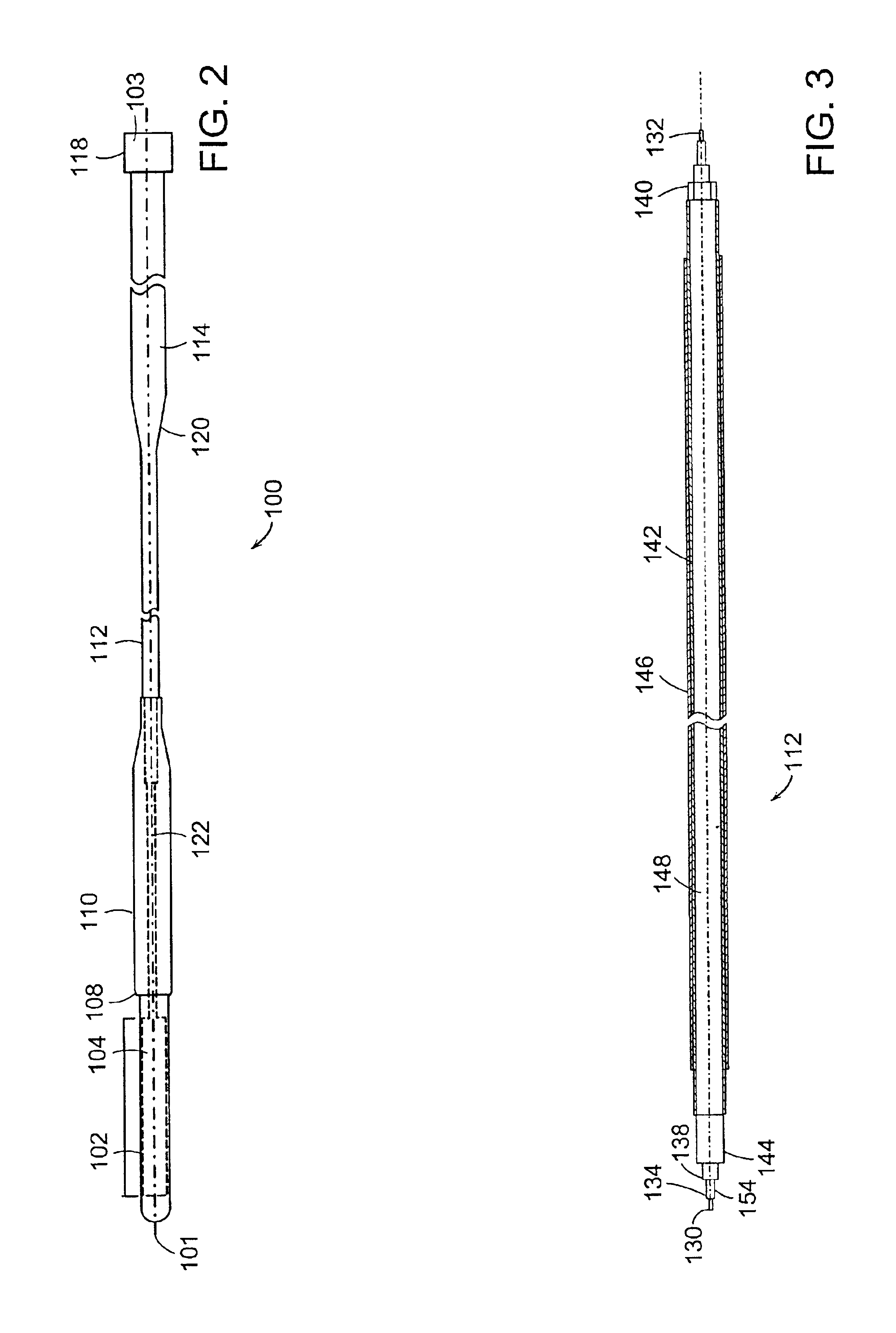

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines (i) a first surface conductive portion or a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material, and (ii) a second surface portion coupled to a fixed resistive material that coupled in series or parallel to a voltage source together with the first portion. In use, the engagement plane will apply active Rf energy to ohmically heat the captured tissue until the point in time that a controller senses an electrical parameter of the tissue such as impedance. Thereafter, the controller switches energy delivery to the second surface portion that is resistively heated to thereby apply energy to tissue by conductive heat transfer.

Owner:ETHICON ENDO SURGERY INC

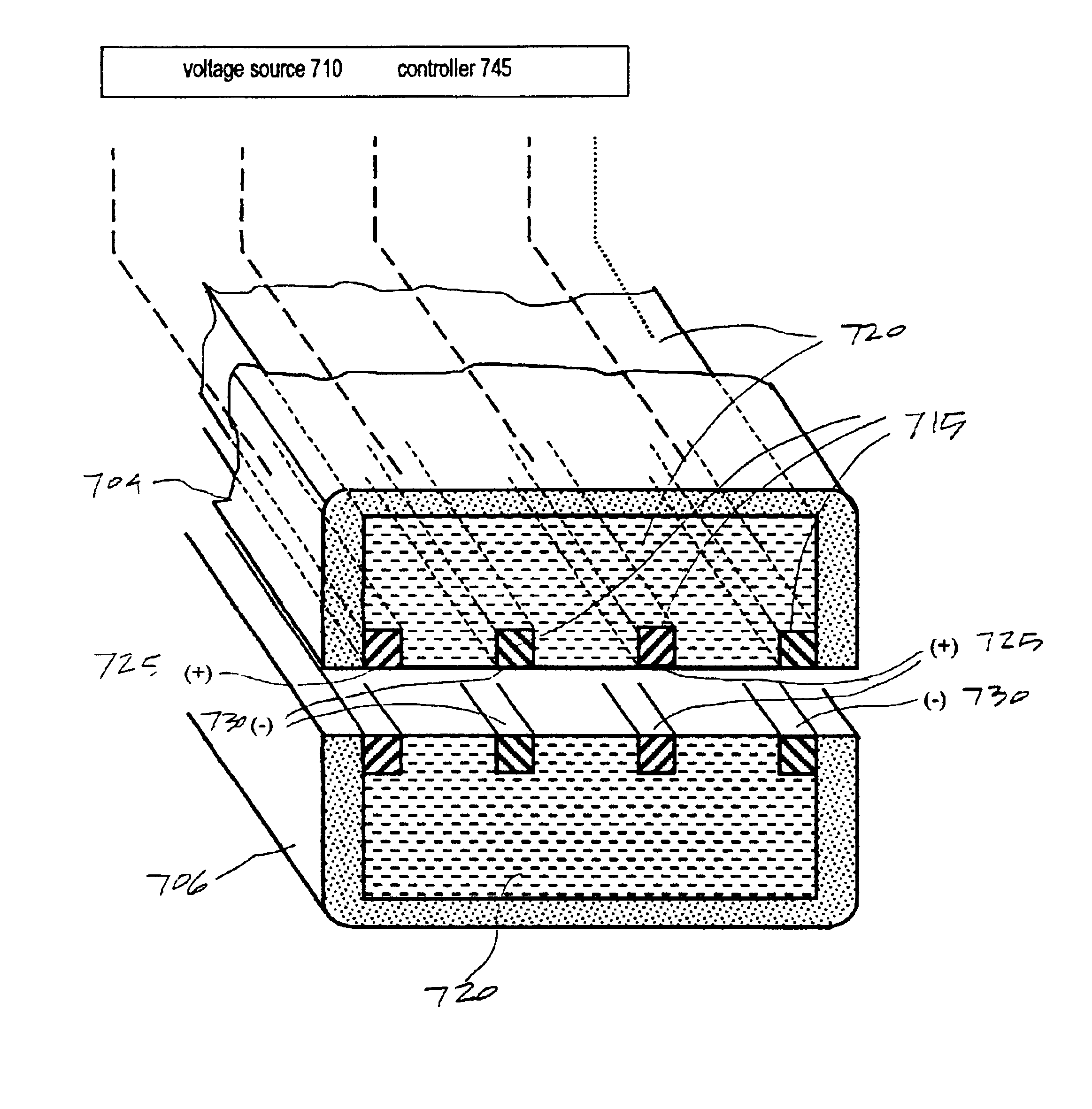

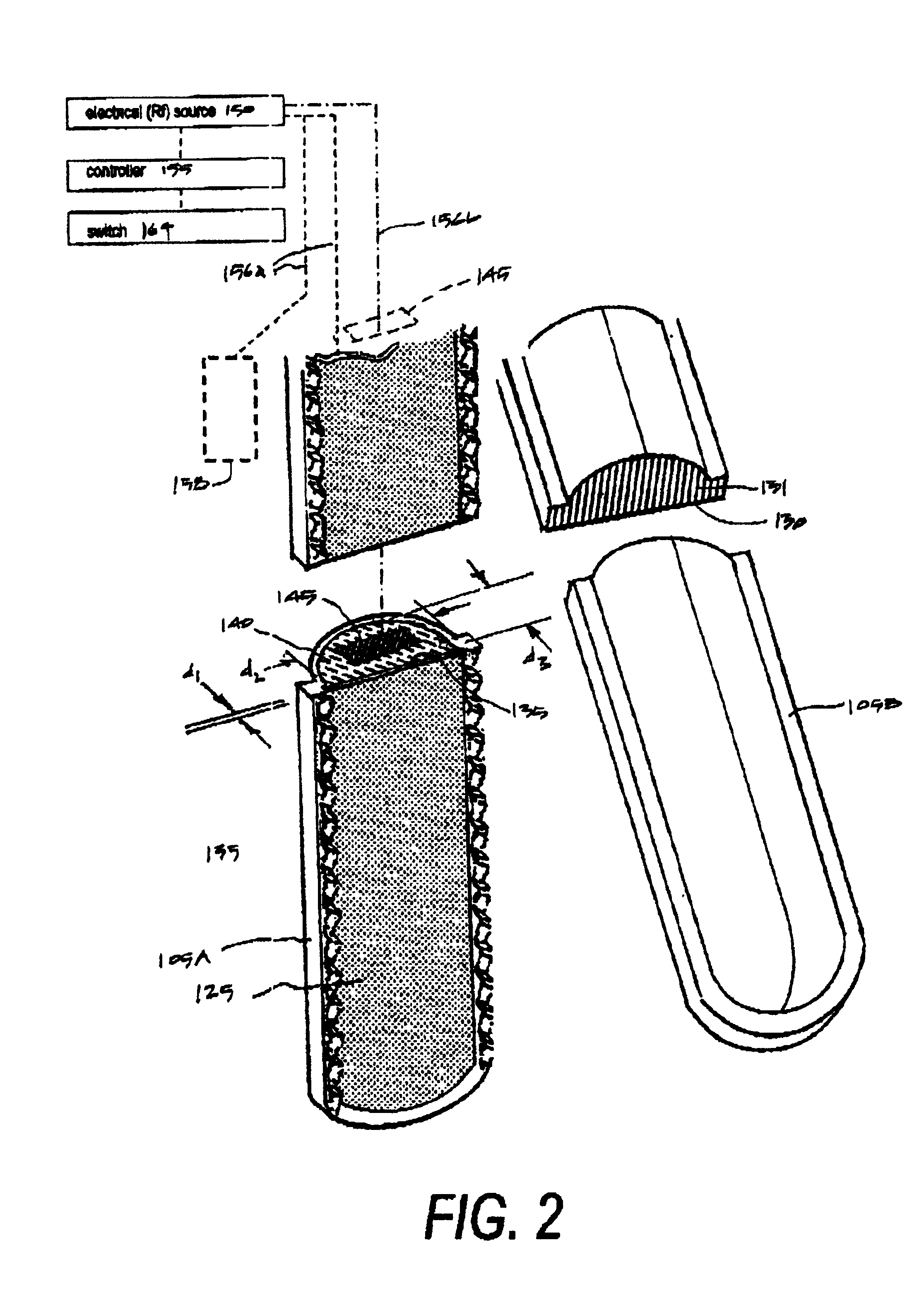

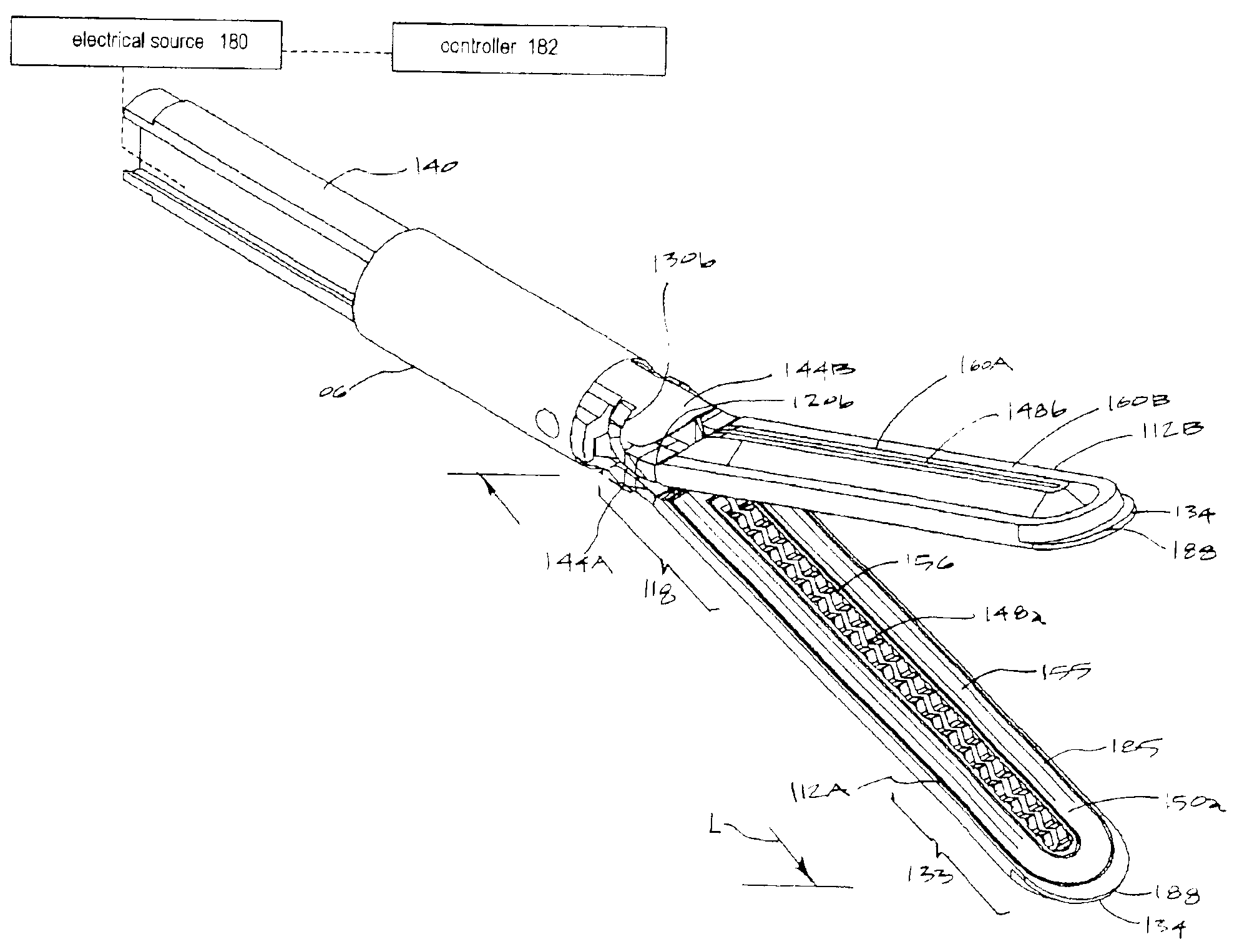

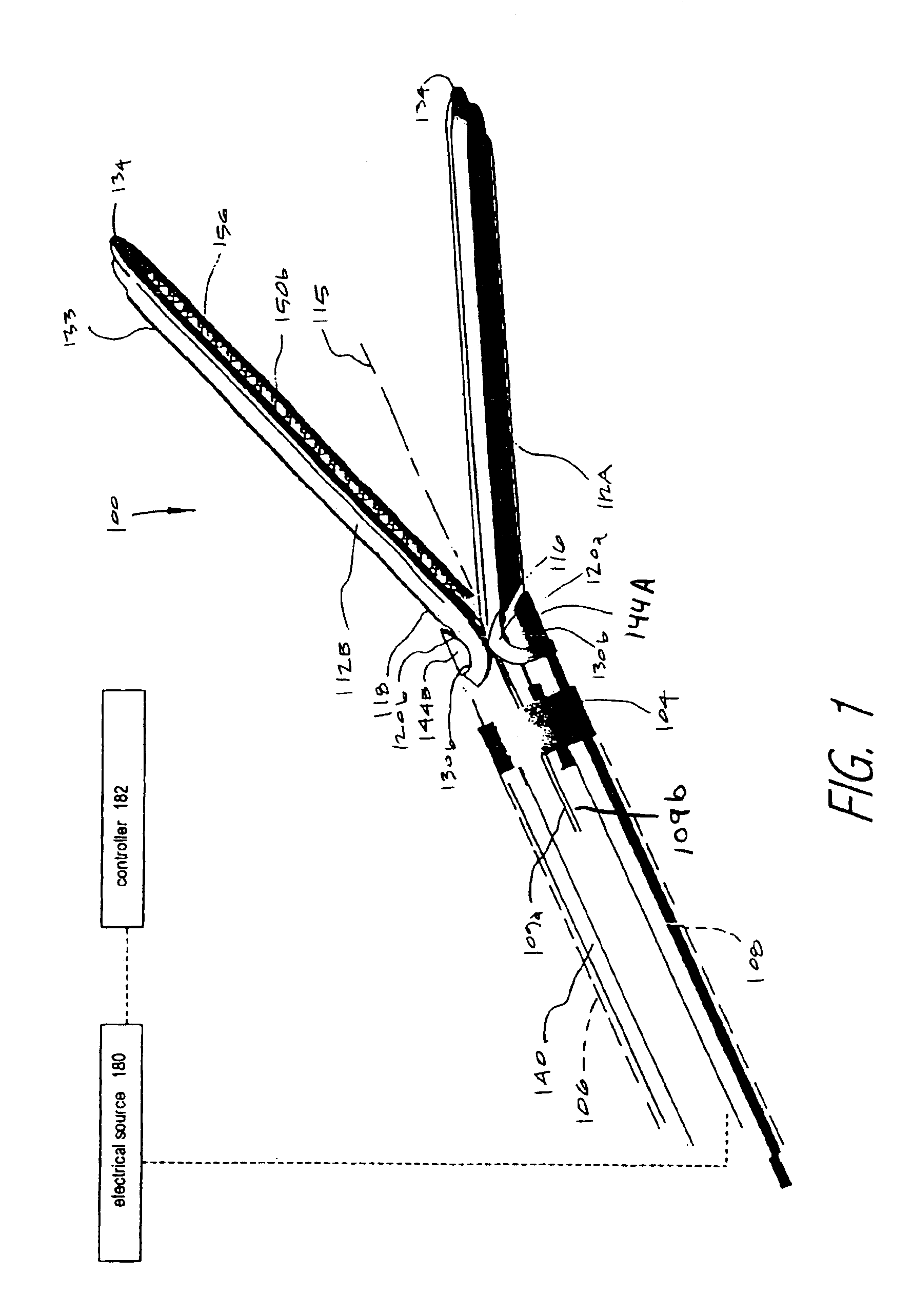

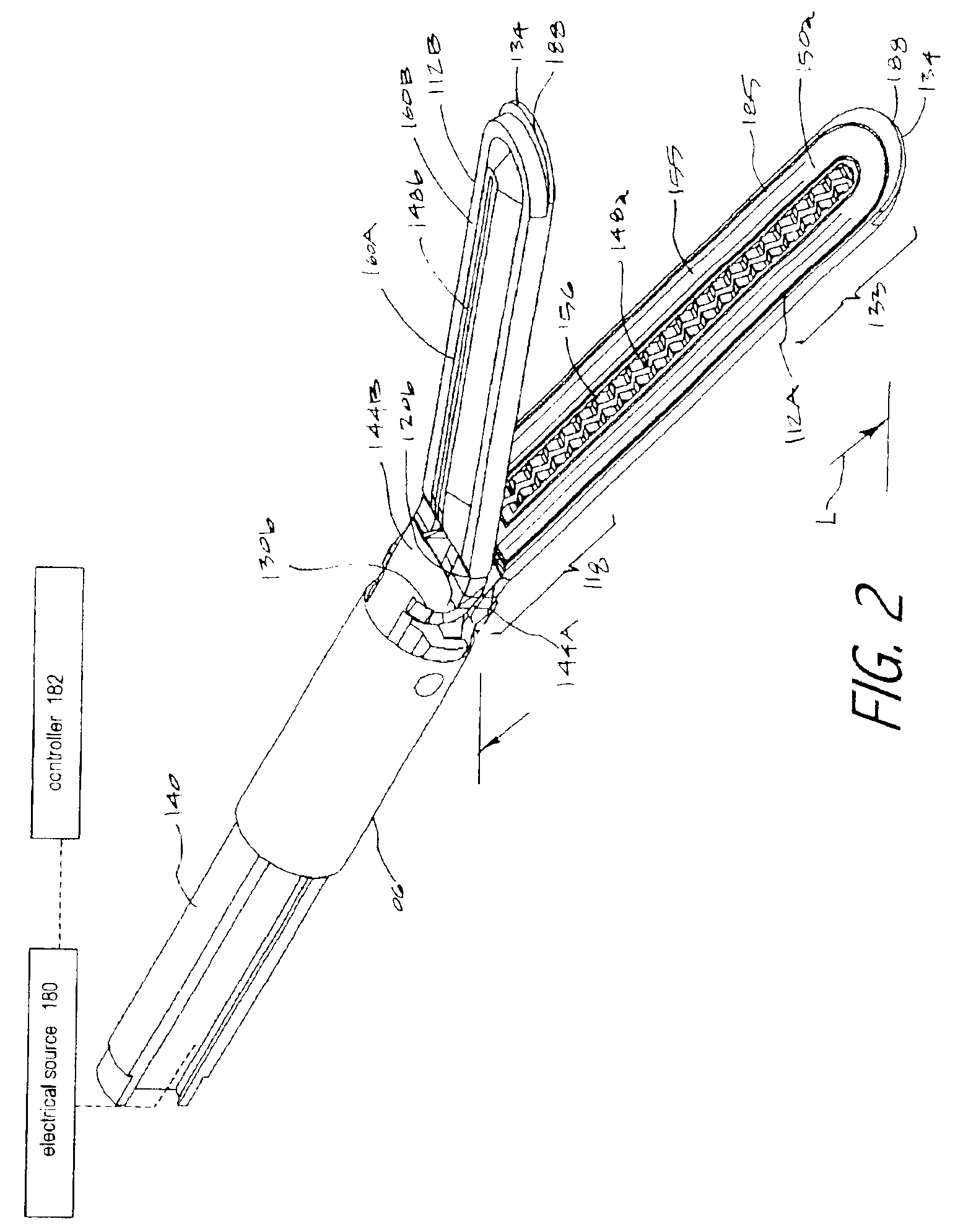

Electrosurgical jaw structure for controlled energy delivery

InactiveUS6929644B2Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsThermal energyConductive materials

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material. In use, the engagement plane will apply active Rf energy to captured tissue until the point in time that the variably resistive matrix is heated to its selected switching range. Thereafter, current flow from the conductive electrode through the engagement surface will be terminated due to the exponential increase in the resistance of variably resistive matrix to provide instant and automatic reduction of Rf energy application. Further, the variably resistive matrix can effectively function as a resistive electrode to thereafter conduct thermal energy to the engaged tissue volume. Thus, the jaw structure can automatically modulate the application of energy to tissue between active Rf heating and passive conductive heating of captured tissue to maintain a target temperature level.

Owner:ETHICON ENDO SURGERY INC

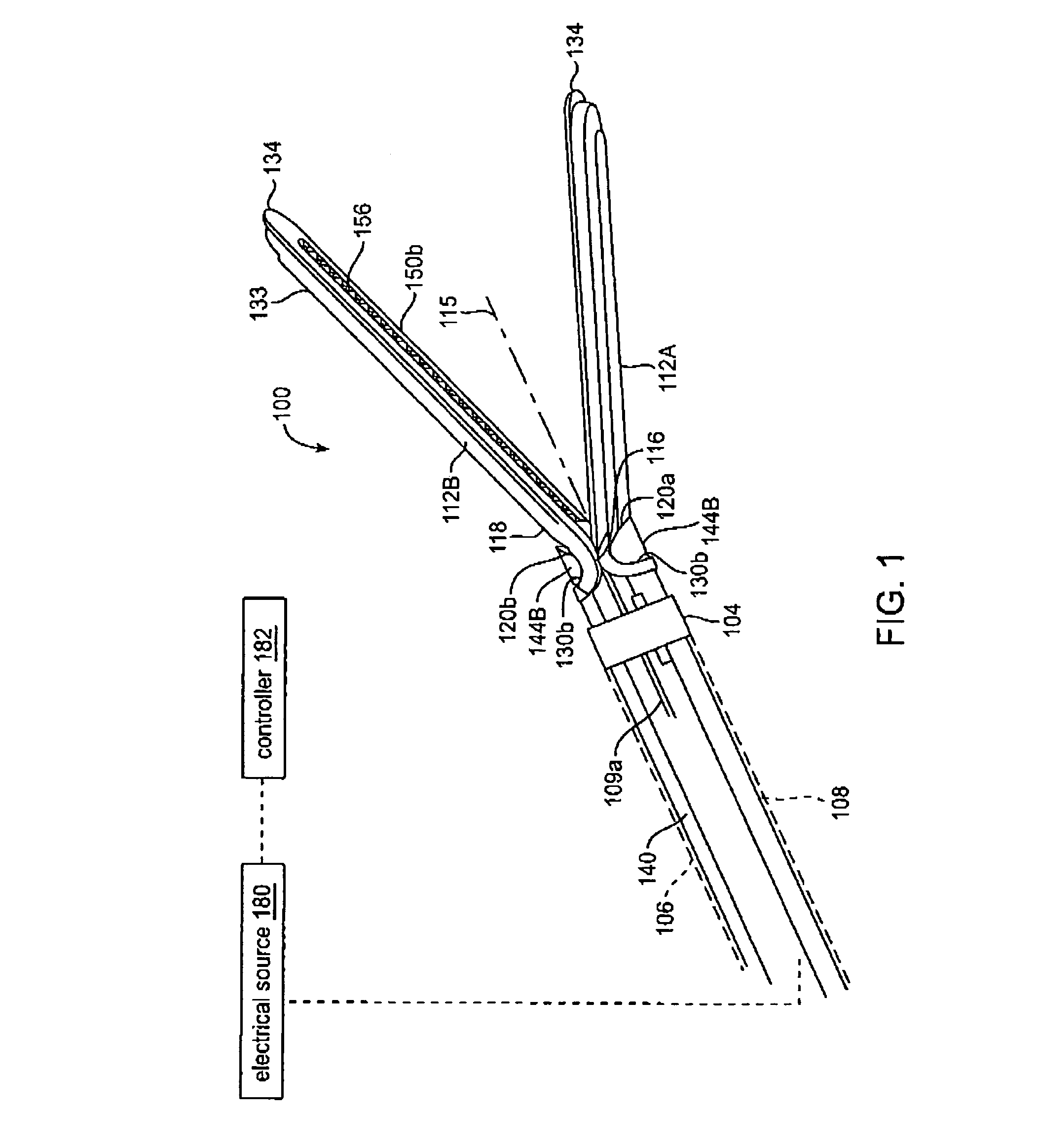

Jaw structure for electrosurgical instrument and method of use

InactiveUS7011657B2Improve the immunityEfficient weldingElectrotherapySurgical instruments for heatingTissue heatingVolumetric Mass Density

An electrosurgical medical device and technique for creating thermal welds in engaged tissue that provides very high compressive forces. In one exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying first and second surface portions that comprise (i) an electrically conductive material and (ii) a positive temperature coefficient (PTC) material having a selected increased resistance that differs at each selected increased temperature over a targeted treatment range. One type of PTC material is a doped ceramic that can be engineered to exhibit a selected positively sloped temperature-resistance curve over about 37° C. to 100° C. The 70° C. to 100° C. range can bracket a targeted “thermal treatment range” at which tissue welded can be accomplished. The engineered resistance of the PTC matrix at the upper end of the temperature range will terminate current flow through the matrix. In one mode of operation, the engagement plane cause ohmic heating within tissue from Rf energy delivery tissue PTC matrix is heated to exceed the treatment range. Thereafter, energy density in the engaged tissue will be modulated as the conductivity of the second portion hovers within the targeted treatment range to thereby provide optical tissue heating for purposes of tissue welding.

Owner:ETHICON ENDO SURGERY INC

Jaw structure for electrosurgical instrument

InactiveUS6905497B2Efficient weldingPrevent any substantial dehydrationSurgical instruments for heatingCoatingsBiomedical engineeringInstrumentation

An electrosurgical medical device for creating thermal welds in engaged tissue that provides general grasping and dissecting functionality. In an exemplary embodiment, at least one jaw of the instrument defines a tissue engagement plane carrying electrosurgical energy delivery means. The jaw assembly, in one mode of operation, can be used for general grasping and dissecting purposes wherein the jaws close in a non-parallel manner so that the distalmost jaw tip only engage tissue with little movement of the actuator lever in the handle of the instrument. In another mode of operation, the jaw assembly closes close in a parallel manner under very high compression to enable tissue welding.

Owner:ETHICON ENDO SURGERY INC

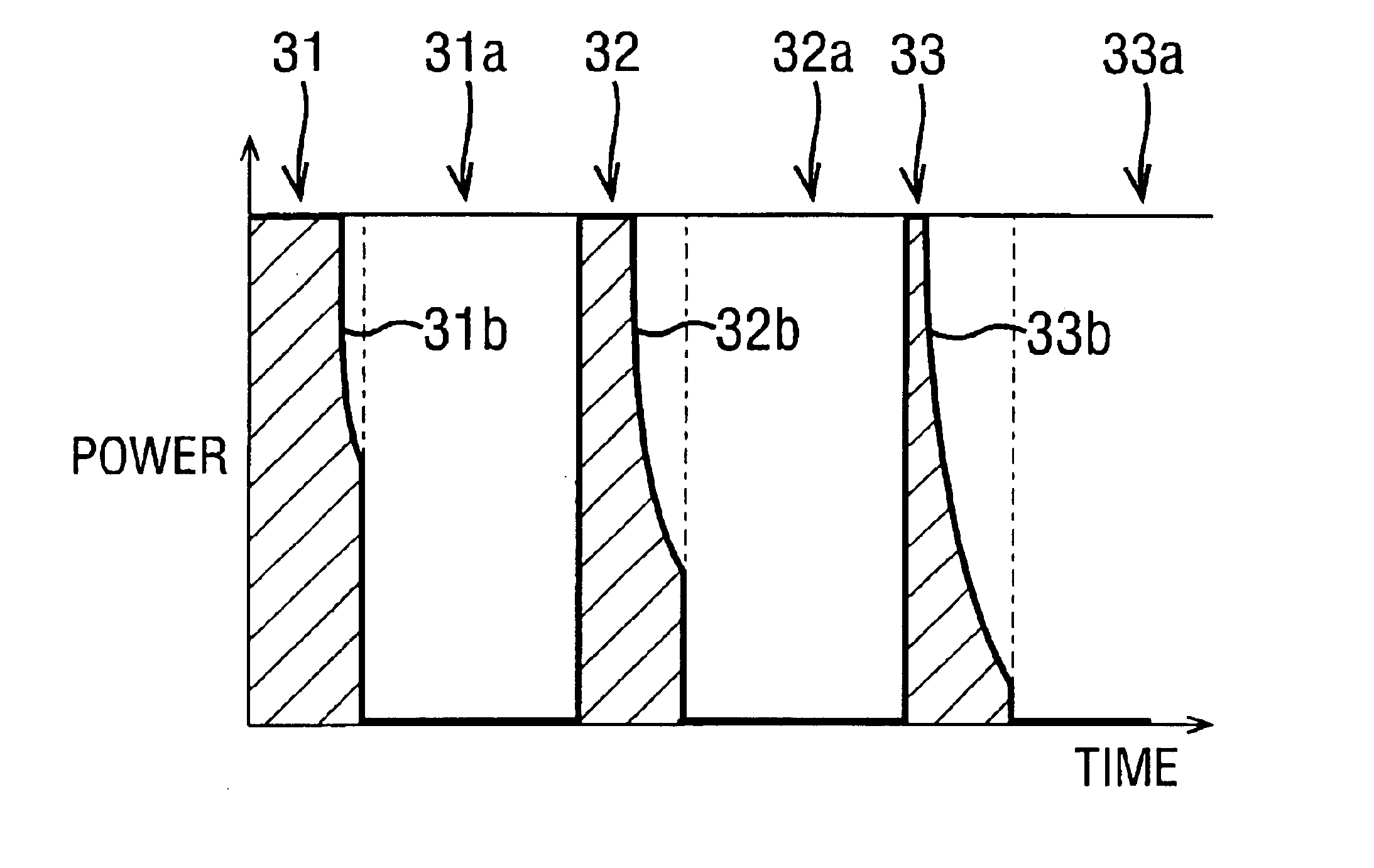

Electrosurgical system

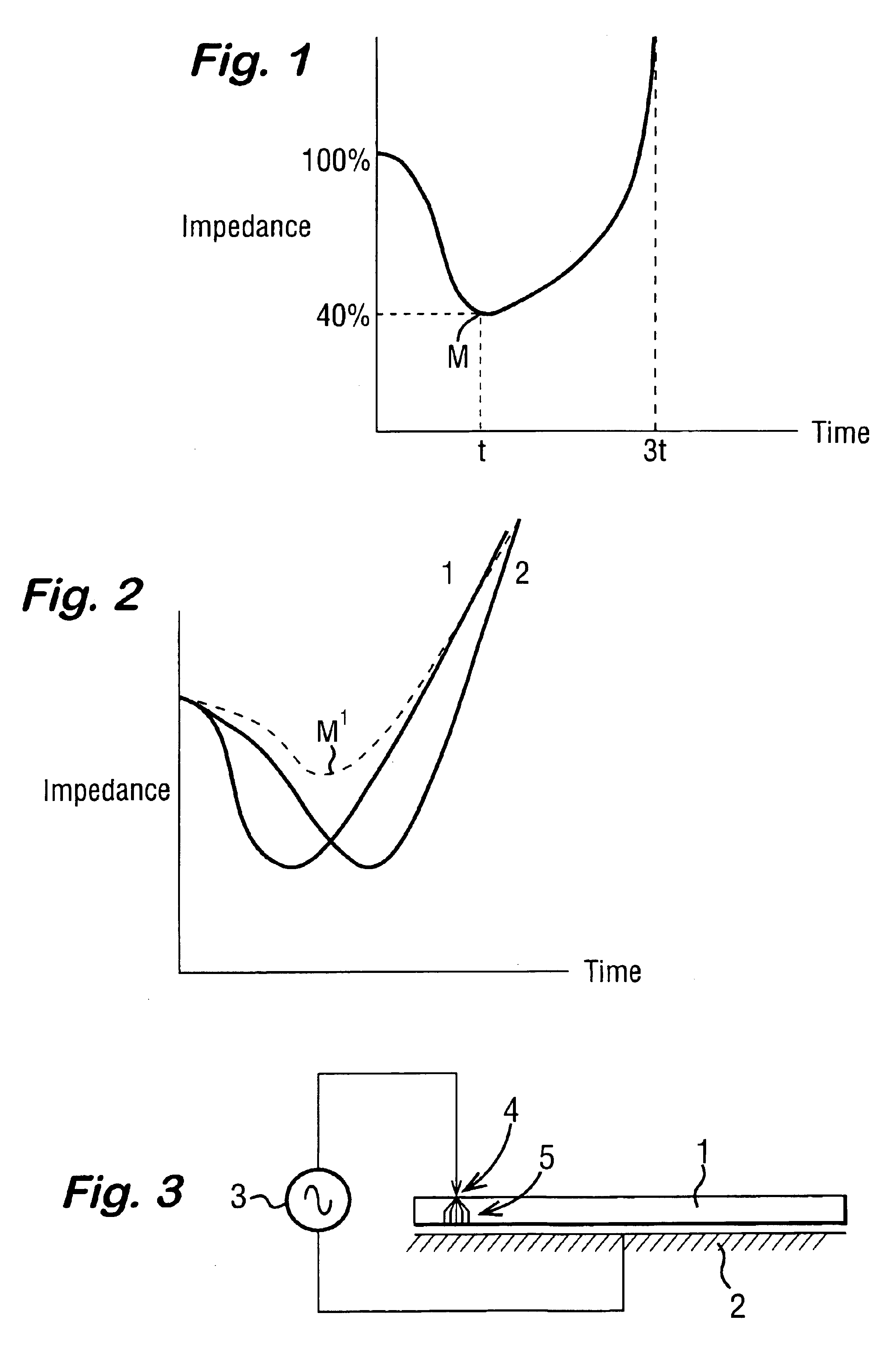

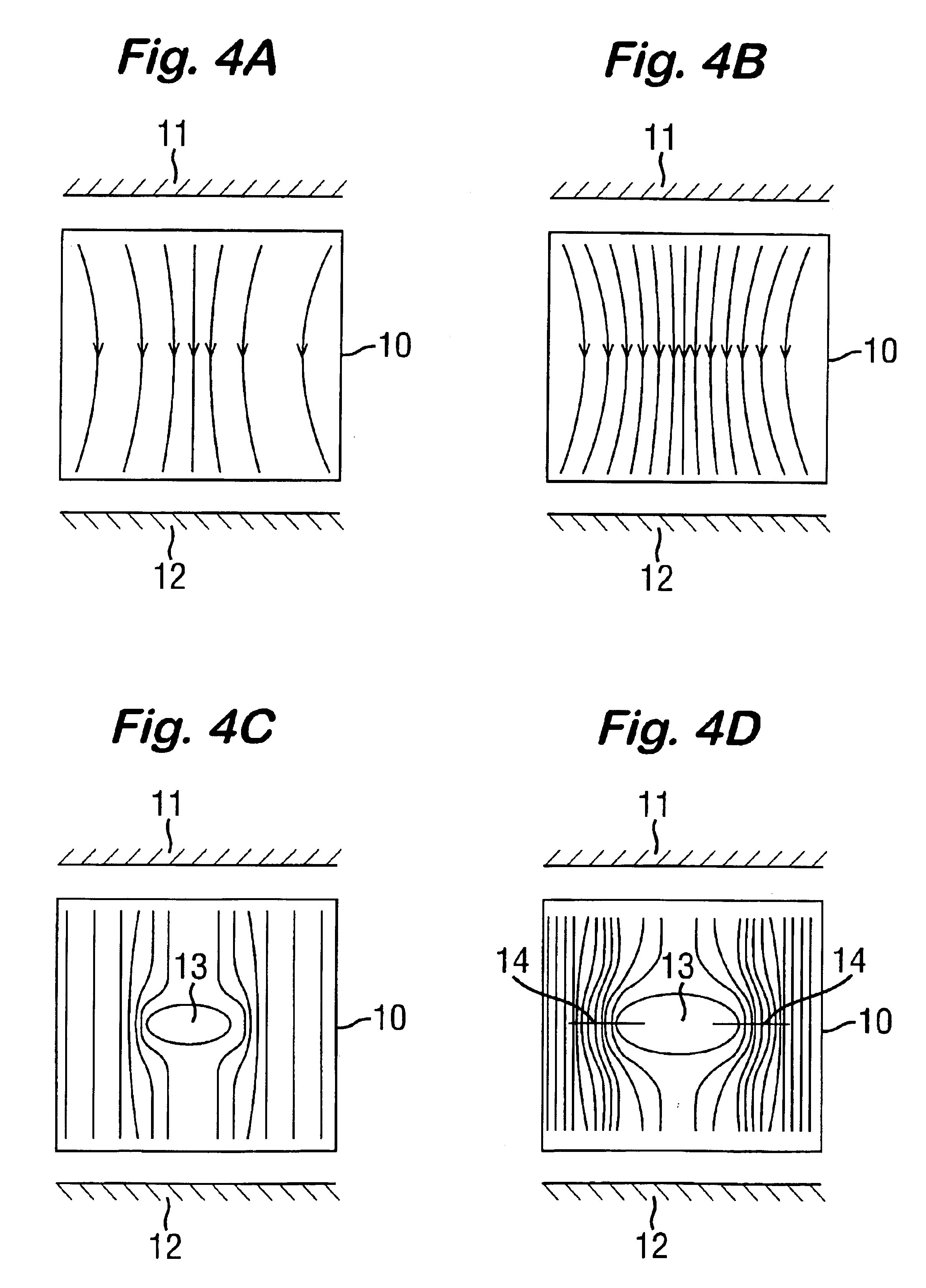

InactiveUS6893435B2Sufficient powerImproving impedanceSurgical instruments for heatingSurgical forcepsEngineeringRadio frequency

An electrosurgical system has an electrosurgical generator and a bipolar electrosurgical instrument, the generator being arranged to perform a treatment cycle in which radio frequency energy is delivered to the instrument as an amplitude-modulated radio frequency power signal in the form of a succession of pulses characterized by periods of a least 100 milliseconds between successive pulses and by a predetermined pulse mark-to-space ratio. Energy delivery between pulses is substantially zero and the mark-to-space ratio is typically 1:4 or less. Each burst is of sufficiently high power to form vapor bubbles within tissue being treated and the time between successive pulses is sufficiently long to permit condensation of the vapor. The treatment cycles may each include an initial period and a subsequent period, the pulse duty cycle being increased or energy being delivered continuously in the subsequent period in order that tissue coagulation can be achieved quickly despite increasing tissue impedance.

Owner:GYRUS MEDICAL LTD

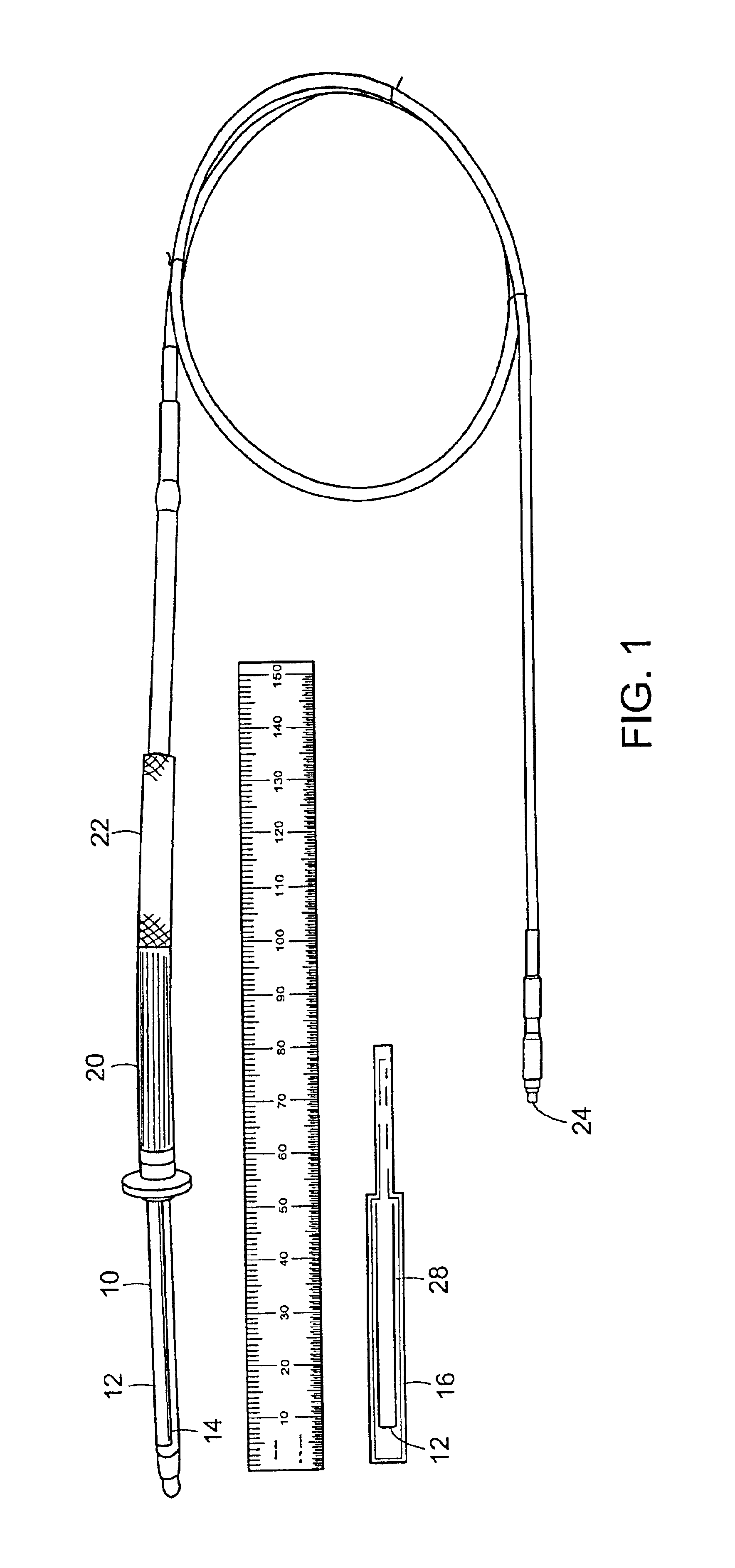

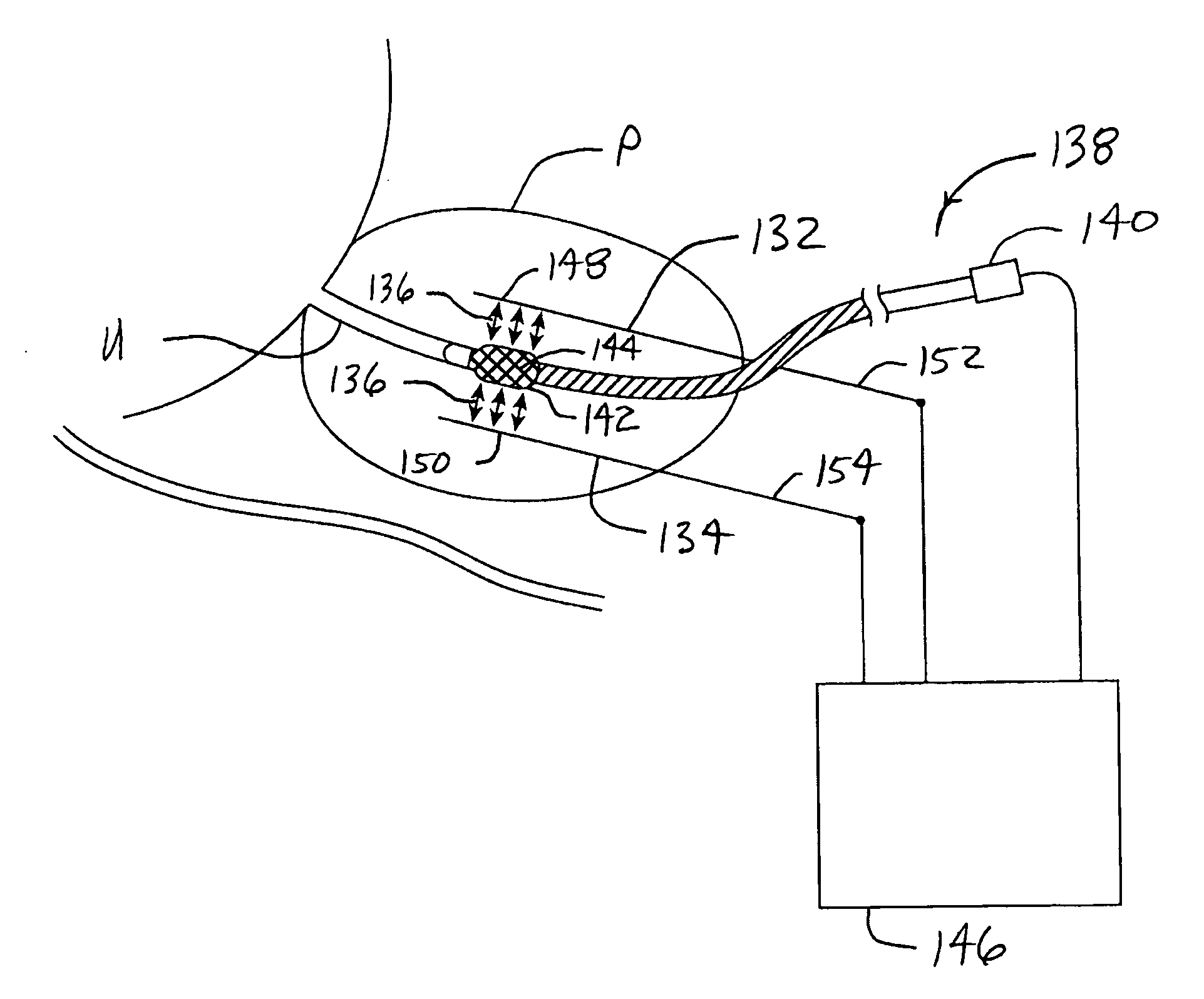

Systems and methods for evaluating the urethra and the periurethral tissues

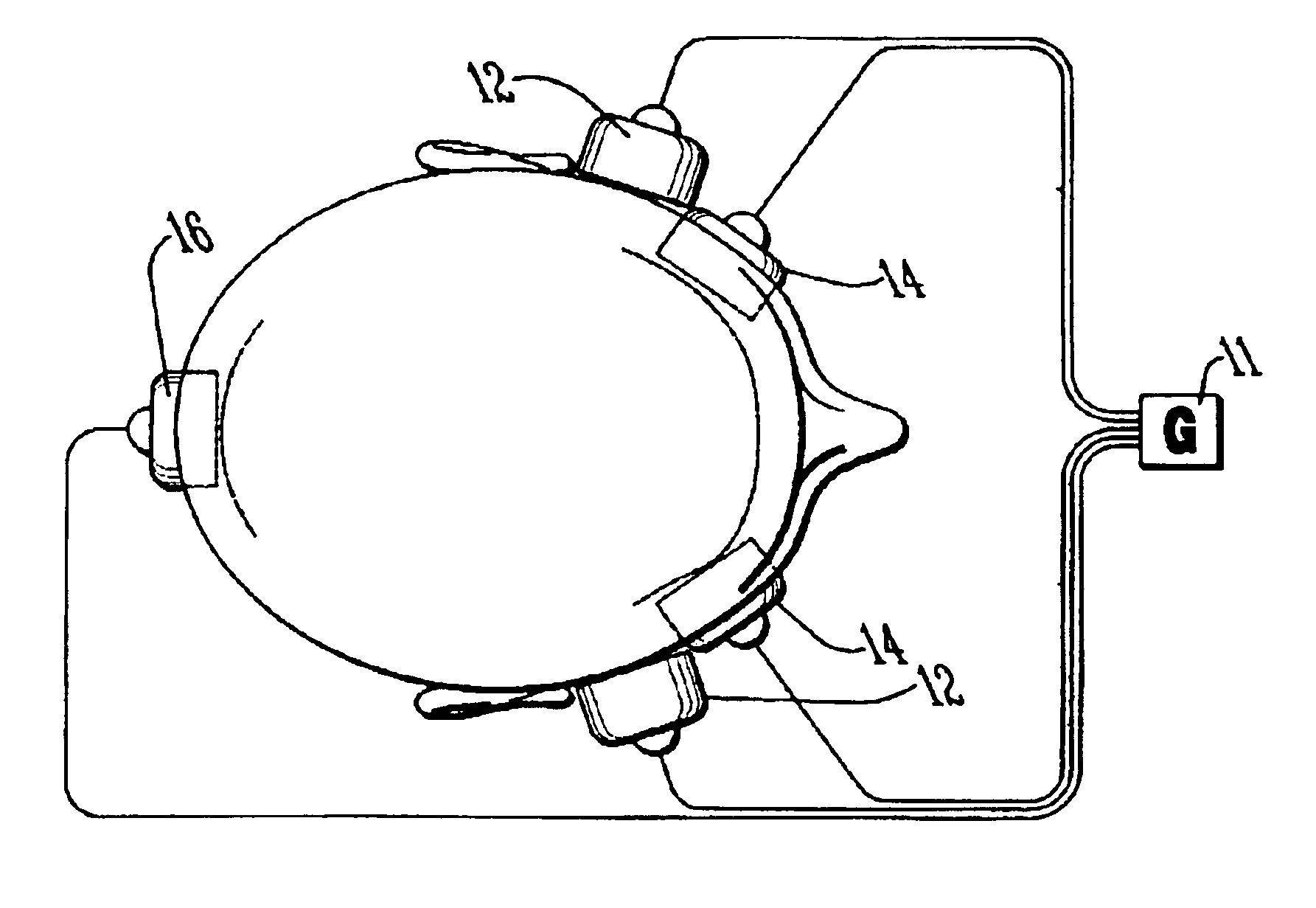

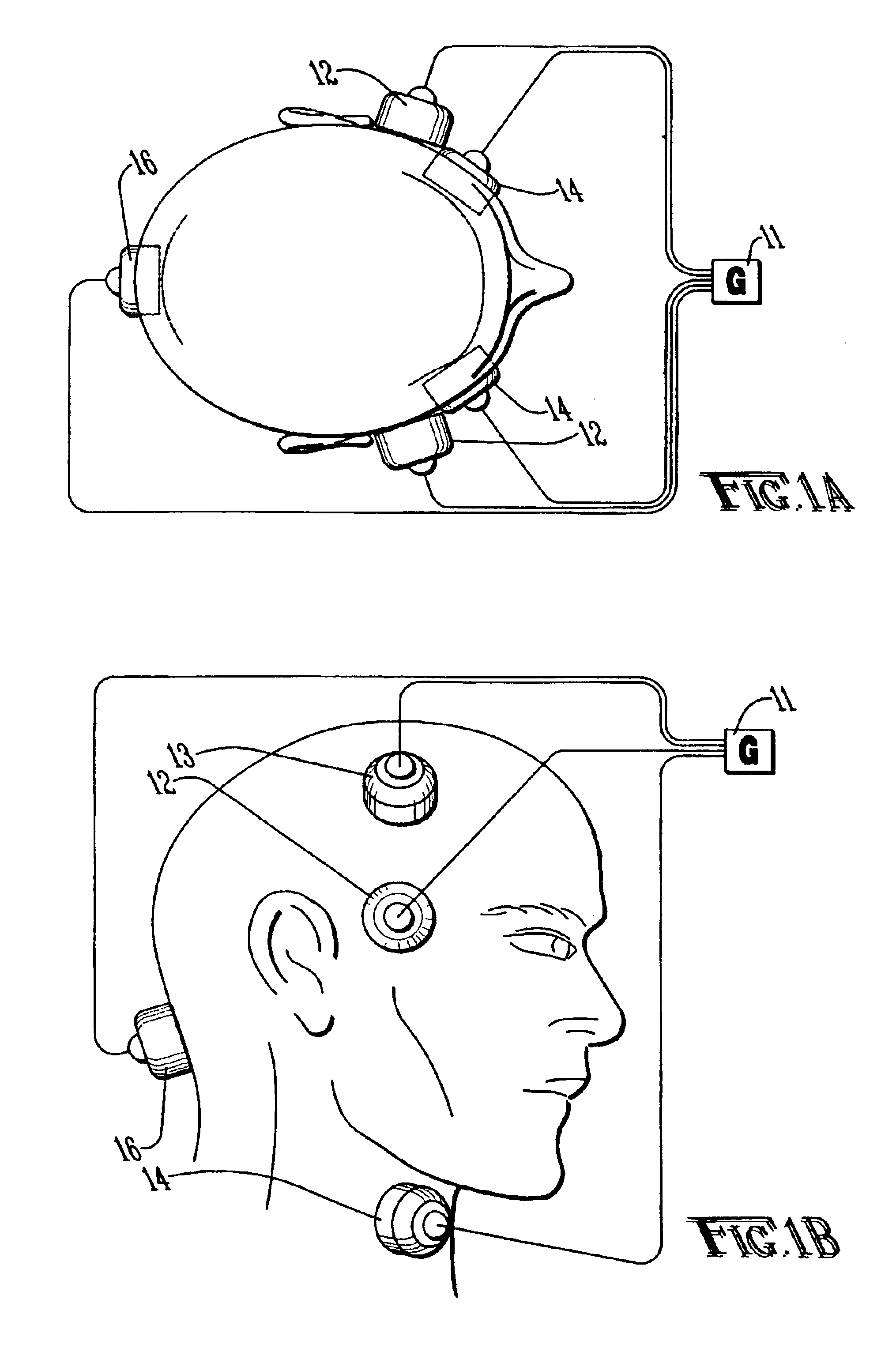

InactiveUS6898454B2Reduce thermal effectsImprove performanceGastroscopesOesophagoscopesDiseaseUrethra

The present invention provides systems and methods for the evaluation of the urethra and periurethral tissues using an MRI coil adapted for insertion into the male, female or pediatric urethra. The MRI coil may be in electrical communication with an interface circuit made up of a tuning-matching circuit, a decoupling circuit and a balun circuit. The interface circuit may also be in electrical communication with a MRI machine. In certain practices, the present invention provides methods for the diagnosis and treatment of conditions involving the urethra and periurethral tissues, including disorders of the female pelvic floor, conditions of the prostate and anomalies of the pediatric pelvis.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE +1

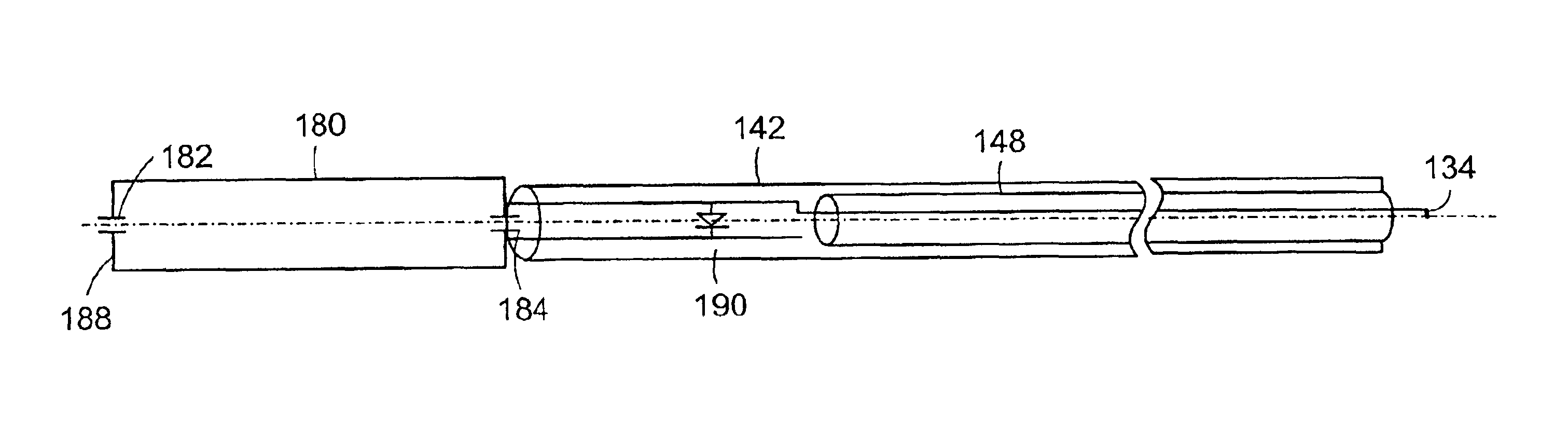

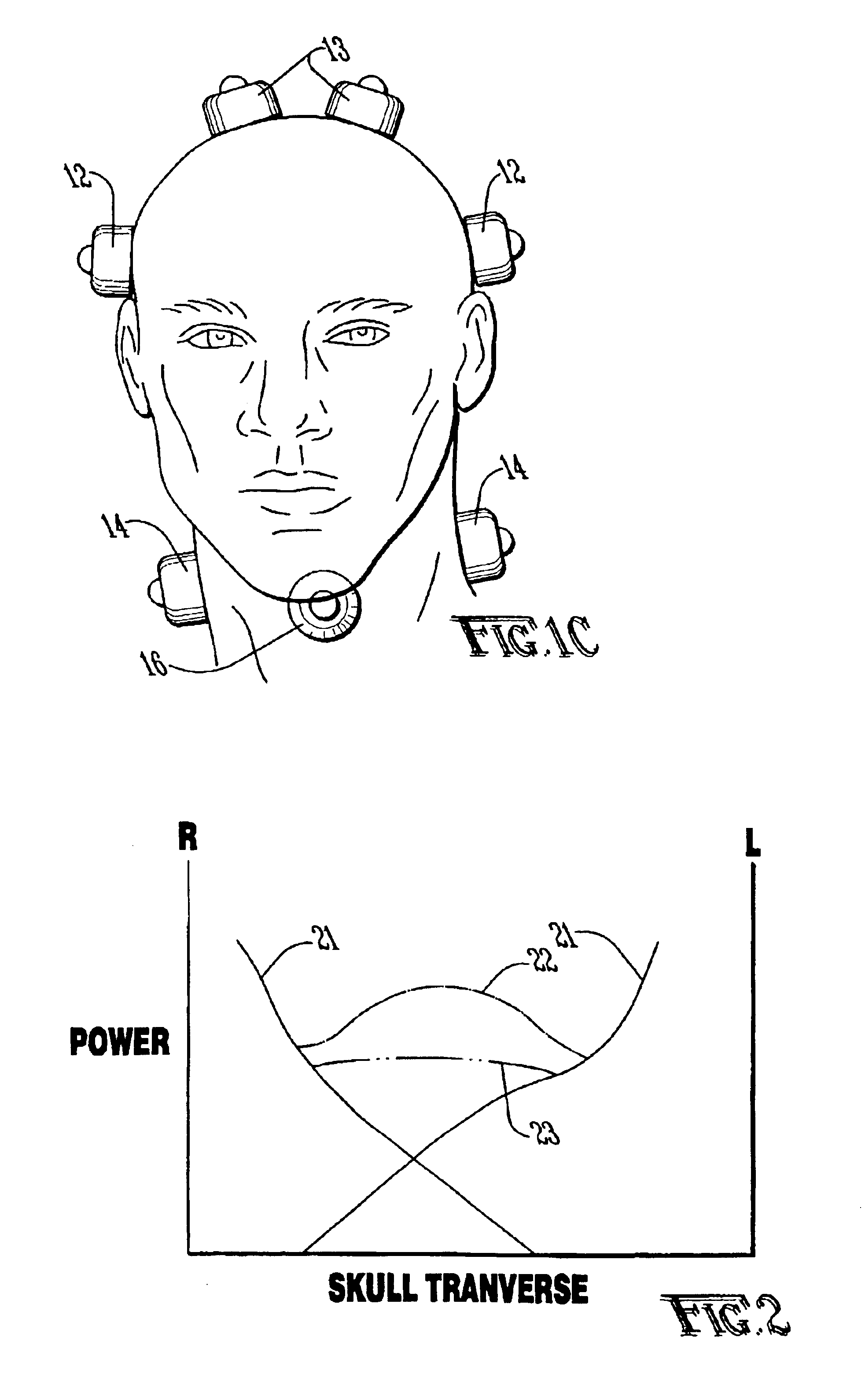

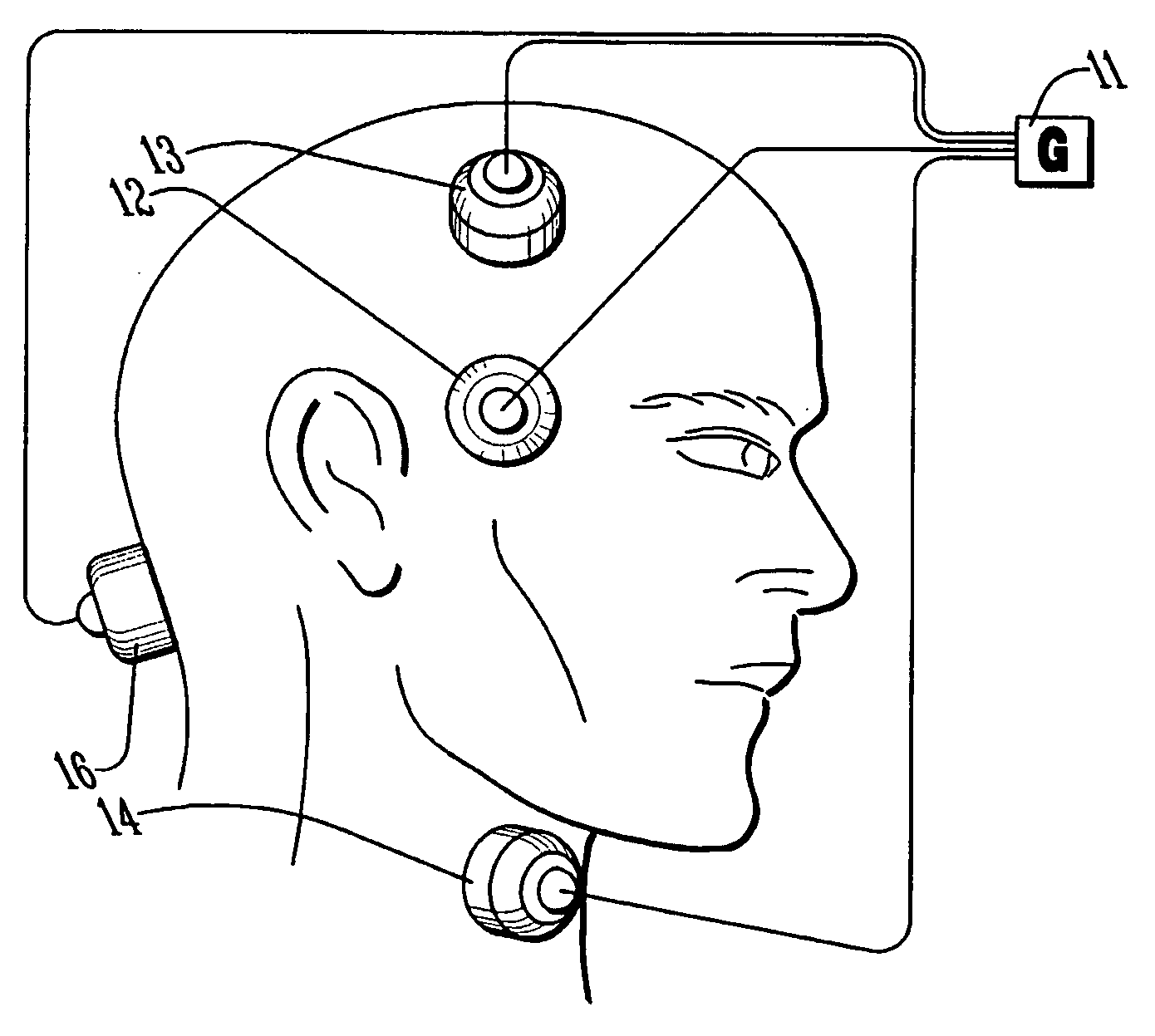

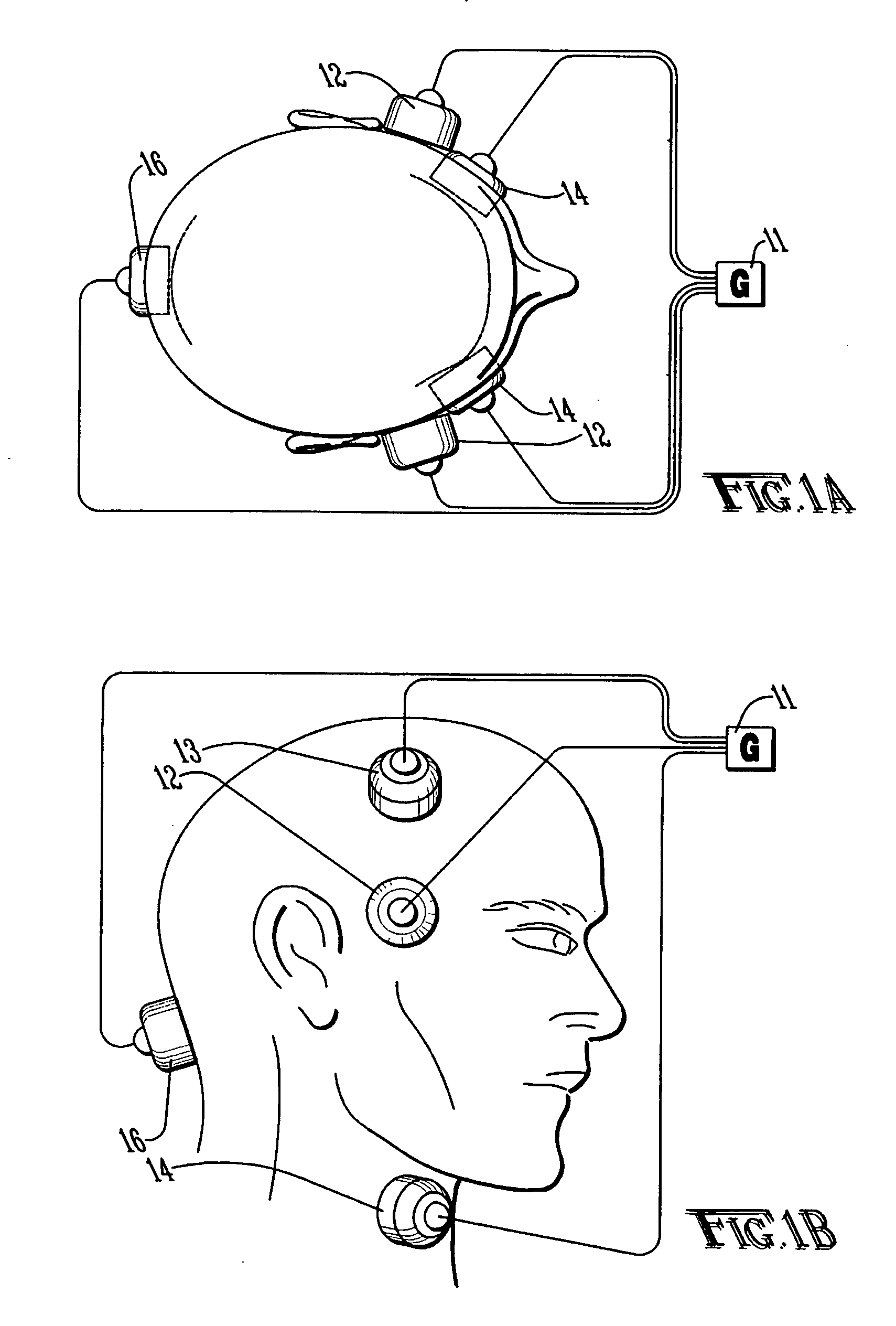

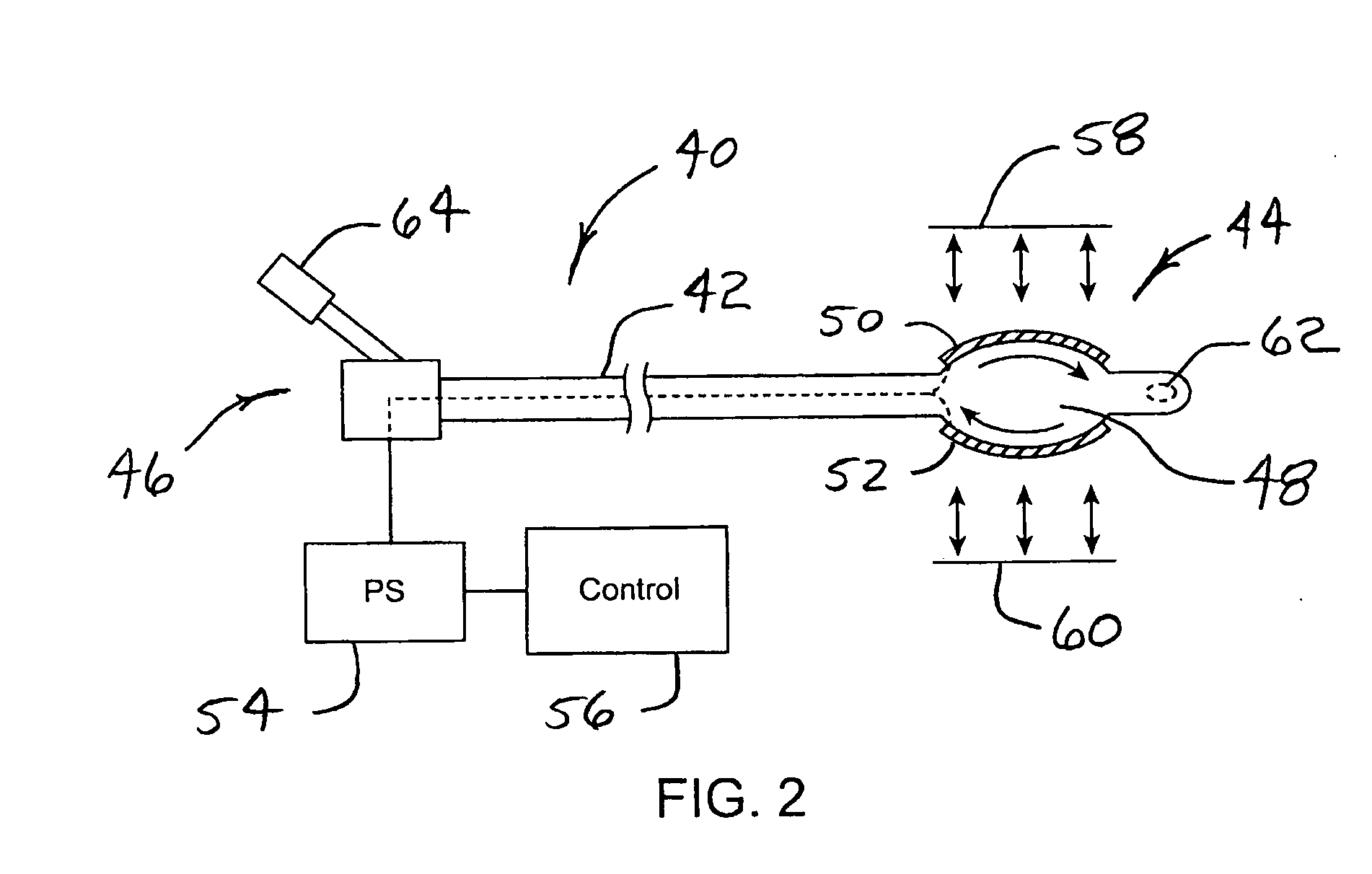

Ultrasound apparatus and method for augmented clot lysis

ActiveUS6945937B2Overcome problemsReduce thermal effectsUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic sensor

An apparatus and method for using ultrasound augmented with microbubbles, thrombolytic drugs or other agents for clot lysis wherein at least one ultrasound transducer generates a plurality of acoustic signals and time, amplitude, phase and frequency modulation of the signals provide more uniform power delivery with fewer gaps in the ultrasound field. Interference patterns from one or multiple transducers are constantly shifted in position. A phased array of transducers may generate a beam that is swept over the area to be treated. In another embodiment, an array of transducers may generate ultrasound at a number of slightly varying frequencies to produce an interference pattern that sweeps in and out through the targeted tissue. A single array may be used to produce both effects simultaneously or separately.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Method for producing aromatic hydrocarbon by adopting raw materials containing methanol

InactiveCN102199446ABoost octaneImprove conversion rateHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionNaphthaAromatic hydrocarbon

The invention discloses a method for producing aromatic hydrocarbon by adopting raw materials containing methanol. The raw material containing methanol comprises the methanol and Fischer-Tropsch synthesis naphtha. In the method, the raw materials containing methanol and a catalyst undergo a contact reaction under the condition of producing the aromatic hydrocarbon by using the methanol. By adopting the method disclosed by the invention, the problem that great removed heat is needed to be adopted in the prior art is solved; and the method has the advantages of simple flow and simpleness and convenience for operation. By adopting the method provided by the invention and a good method for processing and utilizing Fischer-Tropsch synthesis naphtha components, aromatic hydrocarbon products are produced or the octane value of the Fischer-Tropsch synthesis naphtha components is increased to gasoline mediated components with a high octane value.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ultrasound apparatus and method for augmented clot lysis

ActiveUS20050085748A1Limited rangeOvercome problemsUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic sensor

An apparatus and method for using ultrasound augmented with microbubbles, thrombolytic drugs or other agents for clot lysis wherein at least one ultrasound transducer generates a plurality of acoustic signals and time, amplitude, phase and frequency modulation of the signals provide more uniform power delivery with fewer gaps in the ultrasound field. Interference patterns from one or multiple transducers are constantly shifted in position. A phased array of transducers may generate a beam that is swept over the area to be treated. In another embodiment, an array of transducers may generate ultrasound at a number of slightly varying frequencies to produce an interference pattern that sweeps in and out through the targeted tissue. A single array may be used to produce both effects simultaneously or separately.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Method for preparing aromatic hydrocarbons by methanol-containing raw materials

InactiveCN102199069AHigh yieldAvoid inactivationHydrocarbon from oxygen organic compoundsAromatic hydrocarbonChemistry

A method for preparing aromatic hydrocarbons by methanol-containing raw materials. The methanol-containing raw materials comprise methanol and distilled gasoline. The method comprises that the methanol-containing raw materials and catalysts undergo a reaction under conditions of preparing aromatic hydrocarbons by methanol. The method provided by the invention solves the problems that in the prior arts, heat in a reactor is removed through an intermediate cooler and a multitubular reactor is utilized for heat removal or cold product gas is transmitted back to a raw material inlet to remove heat or a diluting material is added to control reaction heat. The method has the advantages of simple processes, and simple and convenient operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

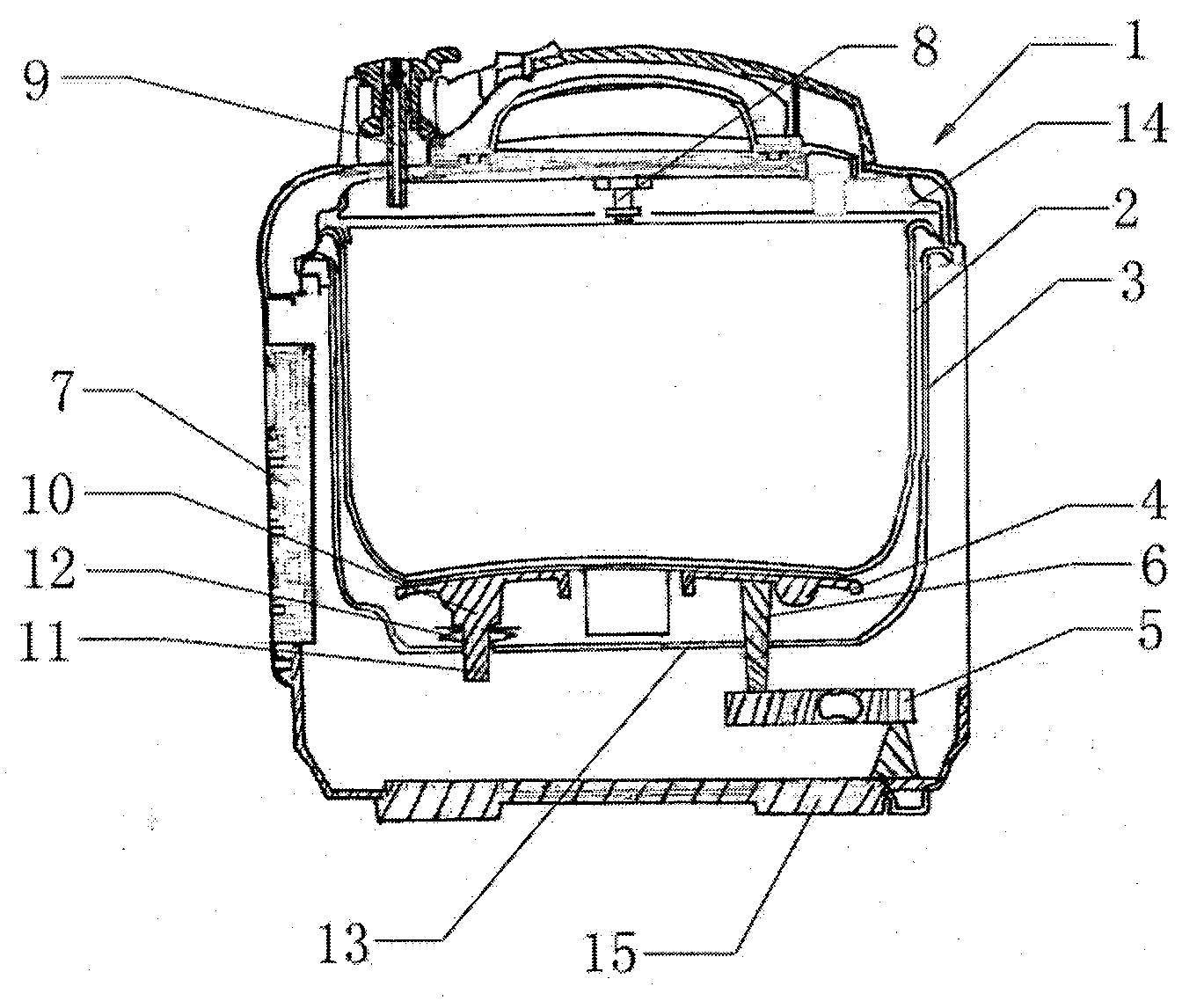

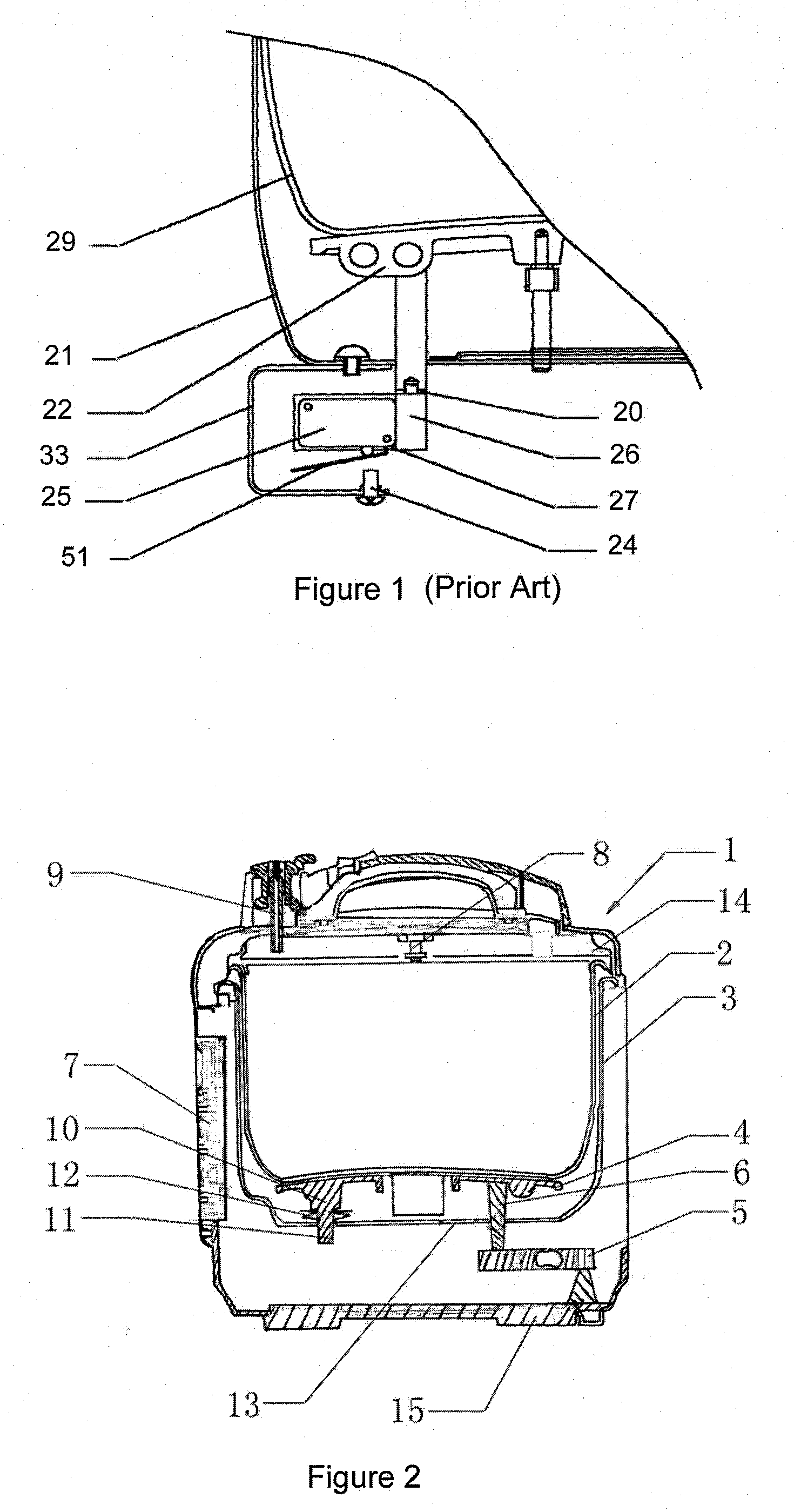

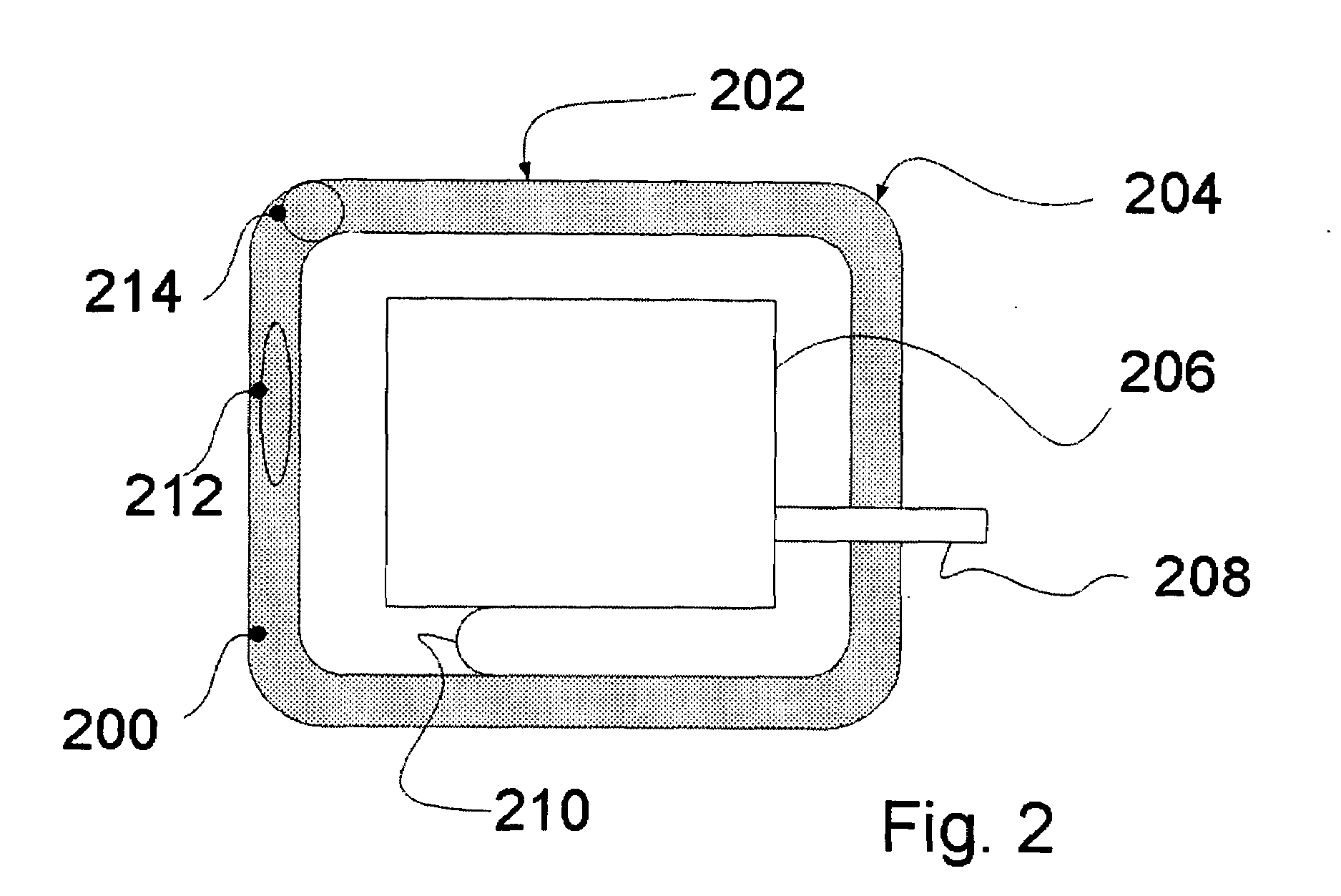

Pressure-detection method and a detection device for an electric pressure cooker

InactiveUS20090095166A1Detect and controlEasy to detectFluid heatersBoiling over preventionElectricityElastomer

A pressure-detection method and detection device for electric pressure cooker is used for detecting continuously and accurately to control the pressure in the electric pressure cooker. The method comprises that a strainometer is provided on the periphery of a cooking pot of the electric pressure cooker, and a transmission arm is utilized to sense the expanding amount of the cooking pot and converts the expanding amount into a displacement, then makes the elastomer of the strainometer distorting; the distorting elastomer generates subsequently a controllable electric signal due to the electric characteristic of a sensitive foil, and the controllable electric signal is delivered to a central control unit, then control signals and display signals are outputted by the central control unit. The detection device comprises a strainometer, a transmission arm, a central control unit and the like. The strainometer is provided on the periphery of the cooking pot of the electric pressure cooker and is fixed by a proper way. The present invention can be used not only to detect and control the pressure of the electric pressure cooker and can be used for the household appliances also, such as electric iron, electric water heater and the like, the temperature and pressure of which need to be detected.

Owner:JIAN WEI WEN

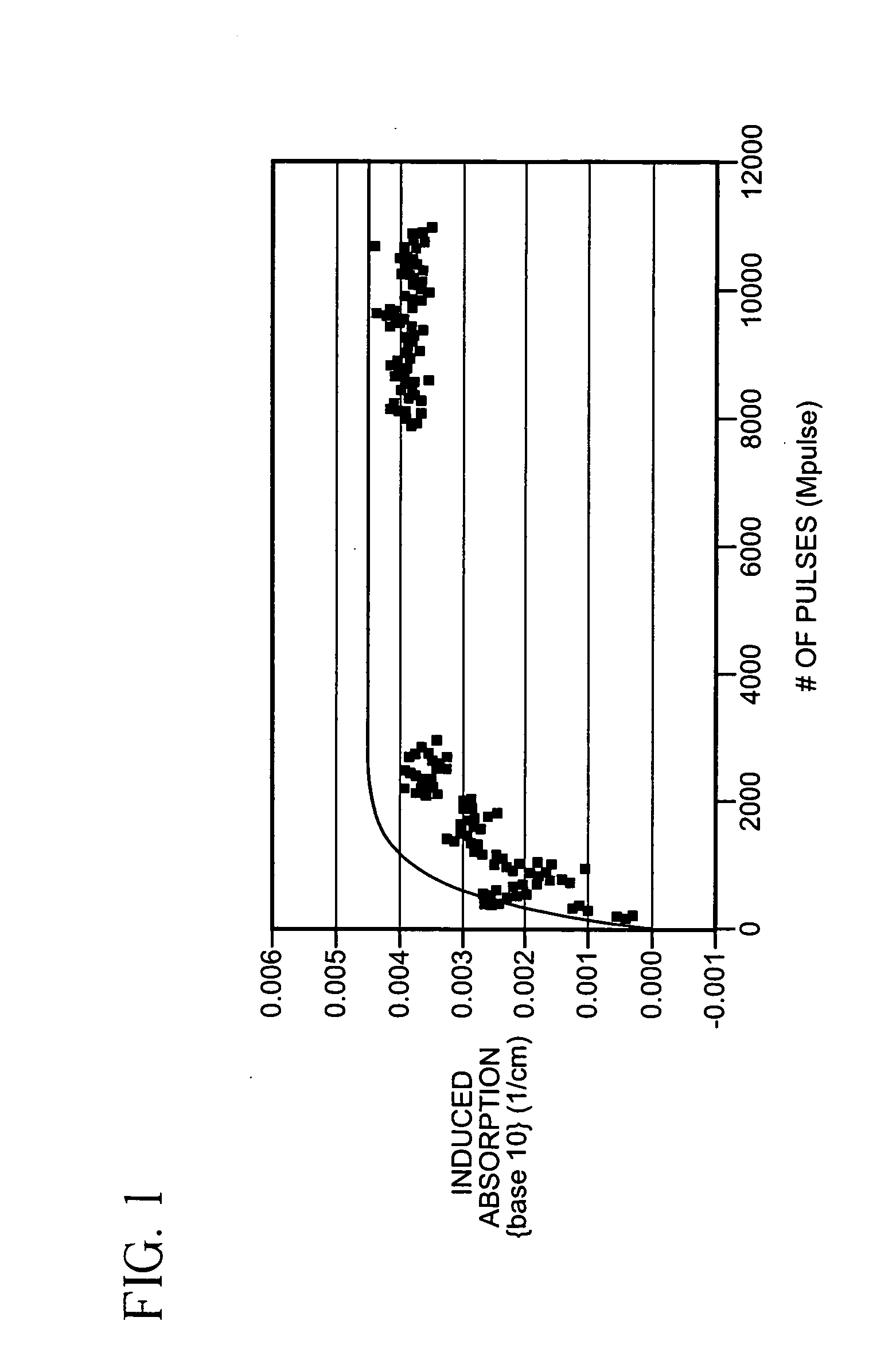

Fused silica having high internal transmission and low birefringence

InactiveUS20040162211A1Increase transmissionLow absolute maximum birefringencePhotomechanical exposure apparatusMicrolithography exposure apparatusTransmittancePolymer chemistry

Fused silica members having high internal transmission and low birefringence are disclosed. Methods of making such fused silica members are also disclosed. According to the present invention, fused silica members having an internal transmission equal to or greater than 99.65% / cm at 193 nm and having an absolute maximum birefringence along the use axis of less than or equal to 0.75 nm / cm are provided.

Owner:DOMEY JEFFREY J +7

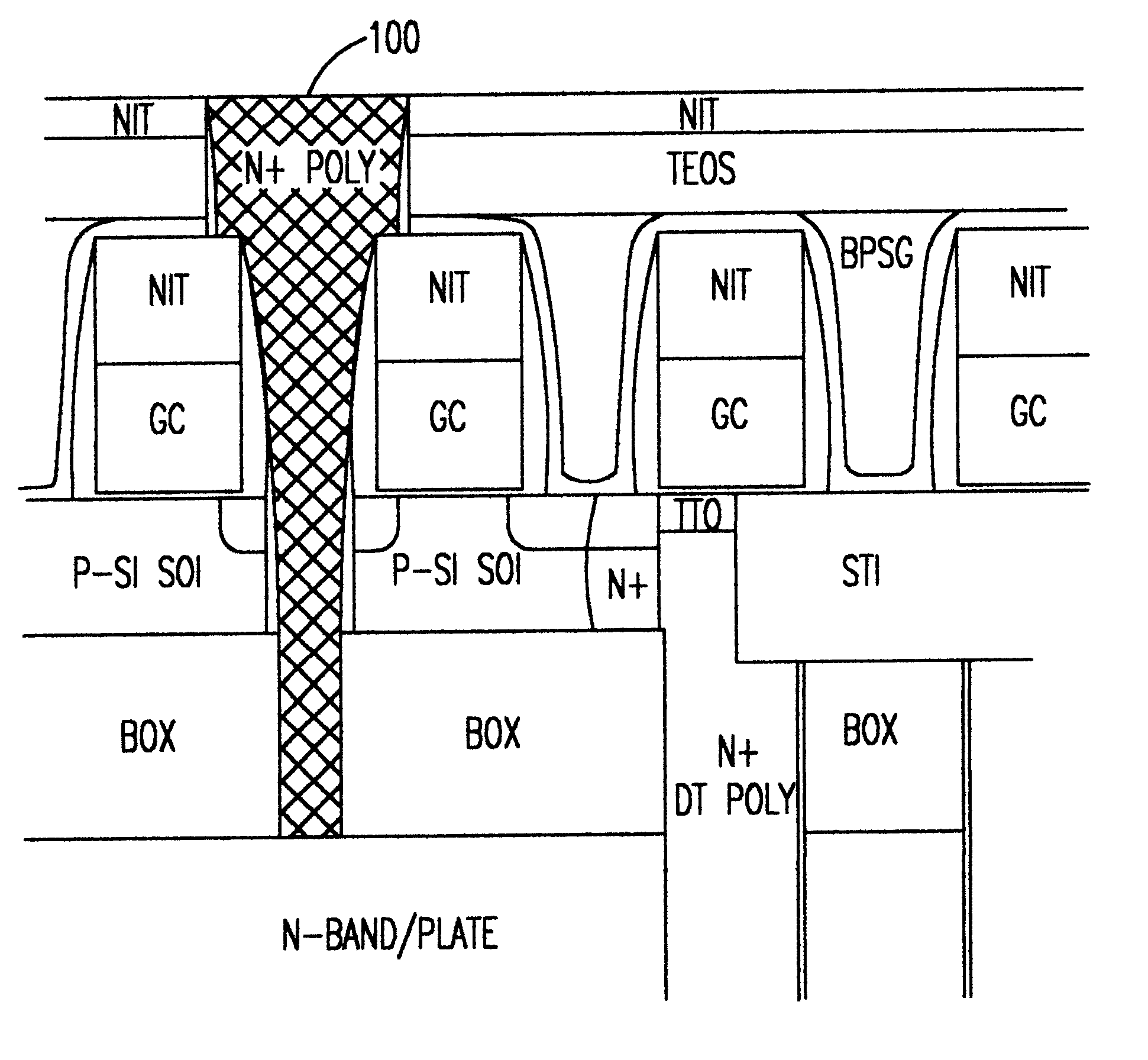

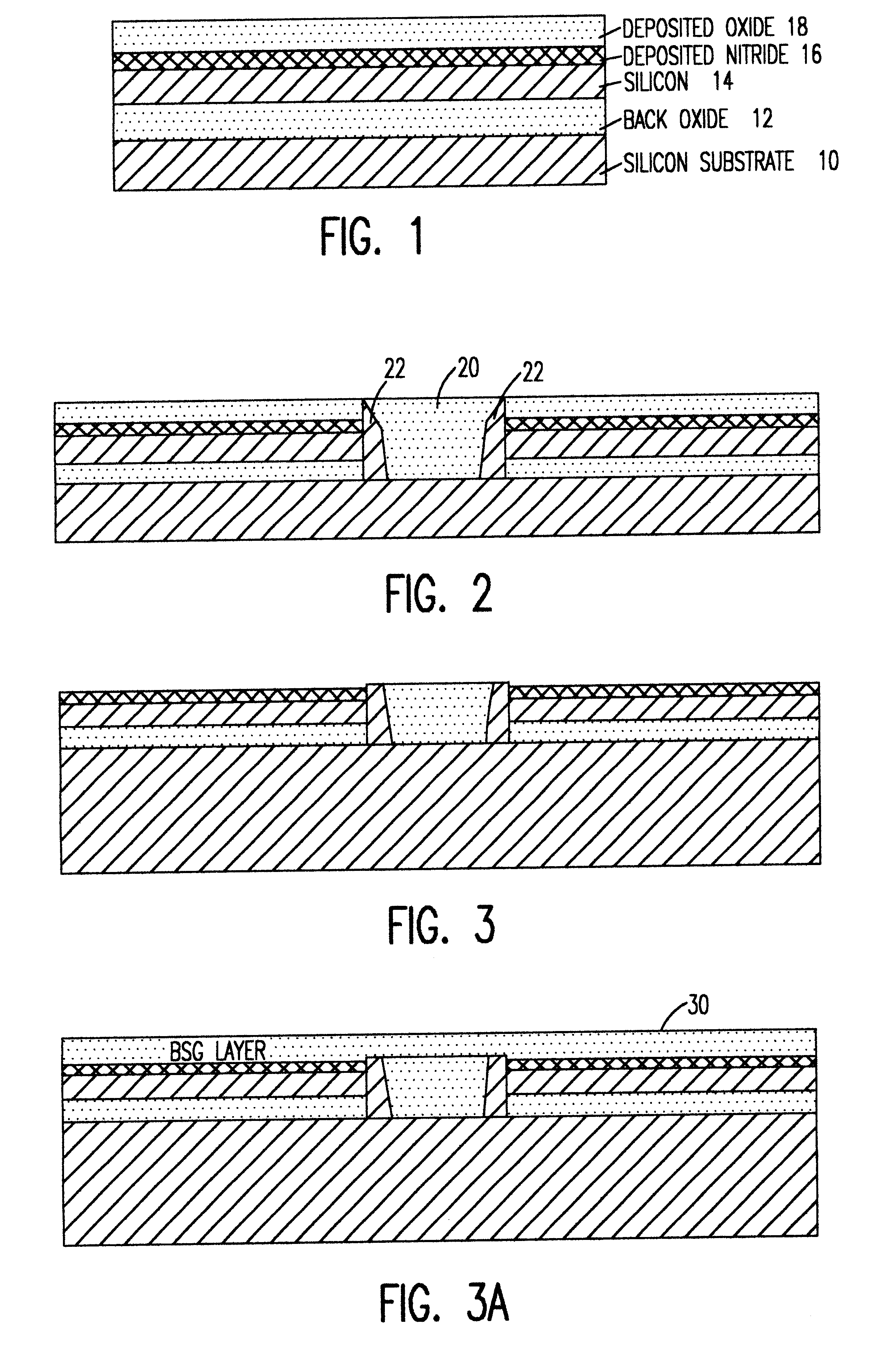

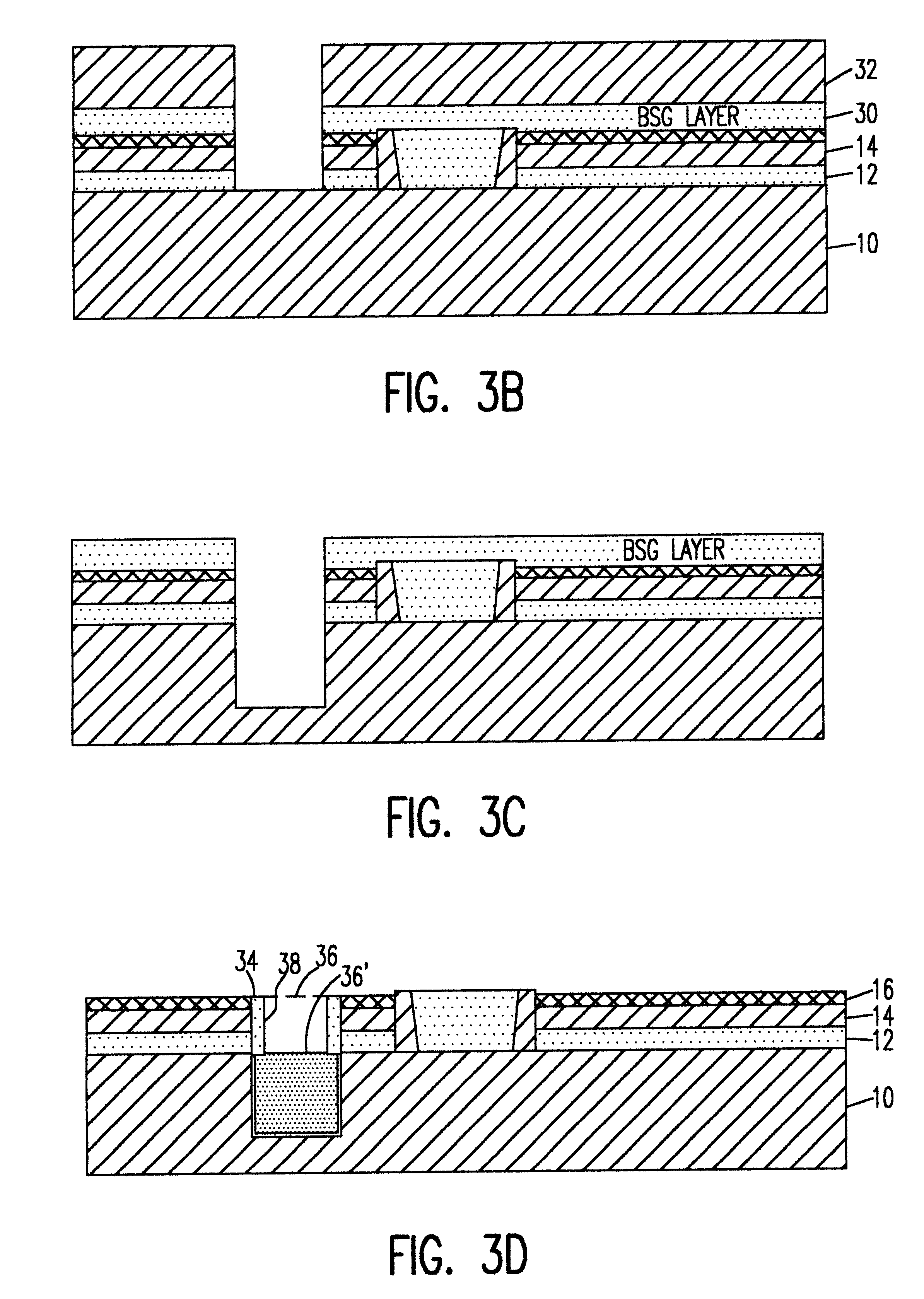

Structures and methods of anti-fuse formation in SOI

InactiveUS6396121B1Low programming voltage and currentReduce thermal effectsTransistorSemiconductor/solid-state device detailsDielectricElement space

An anti-fuse structure that can be programmed at low voltage and current and which potentially consumes very little chip spaces and can be formed interstitially between elements spaced by a minimum lithographic feature size is formed on a composite substrate such as a silicon-on-insulator wafer by etching a contact through an insulator to a support semiconductor layer, preferably in combination with formation of a capacitor-like structure reaching to or into the support layer. The anti-fuse may be programmed either by the selected location of conductor formation and / or damaging a dielectric of the capacitor-like structure. An insulating collar is used to surround a portion of either the conductor or the capacitor-like structure to confine damage to the desired location. Heating effects voltage and noise due to programming currents are effectively isolated to the bulk silicon layer, permitting programming during normal operation of the device. Thus the potential for self-repair without interruption of operation is realized.

Owner:IBM CORP

Method and apparatus for frit sealing with a variable laser beam

InactiveUS20090086325A1Uniform temperature distributionImprove overall utilizationDiffusing elementsElectroluminescent light sourcesFritLight beam

A beam shaper is implemented to seal an OLED. The beam shaper comprises a first and second lens and a beam shaper. Changing the relative position of the first, second lens and beam shaper relative to each other enables the beam shaper to generate laser beams with different shapes and intensity profiles.

Owner:CORNING INC

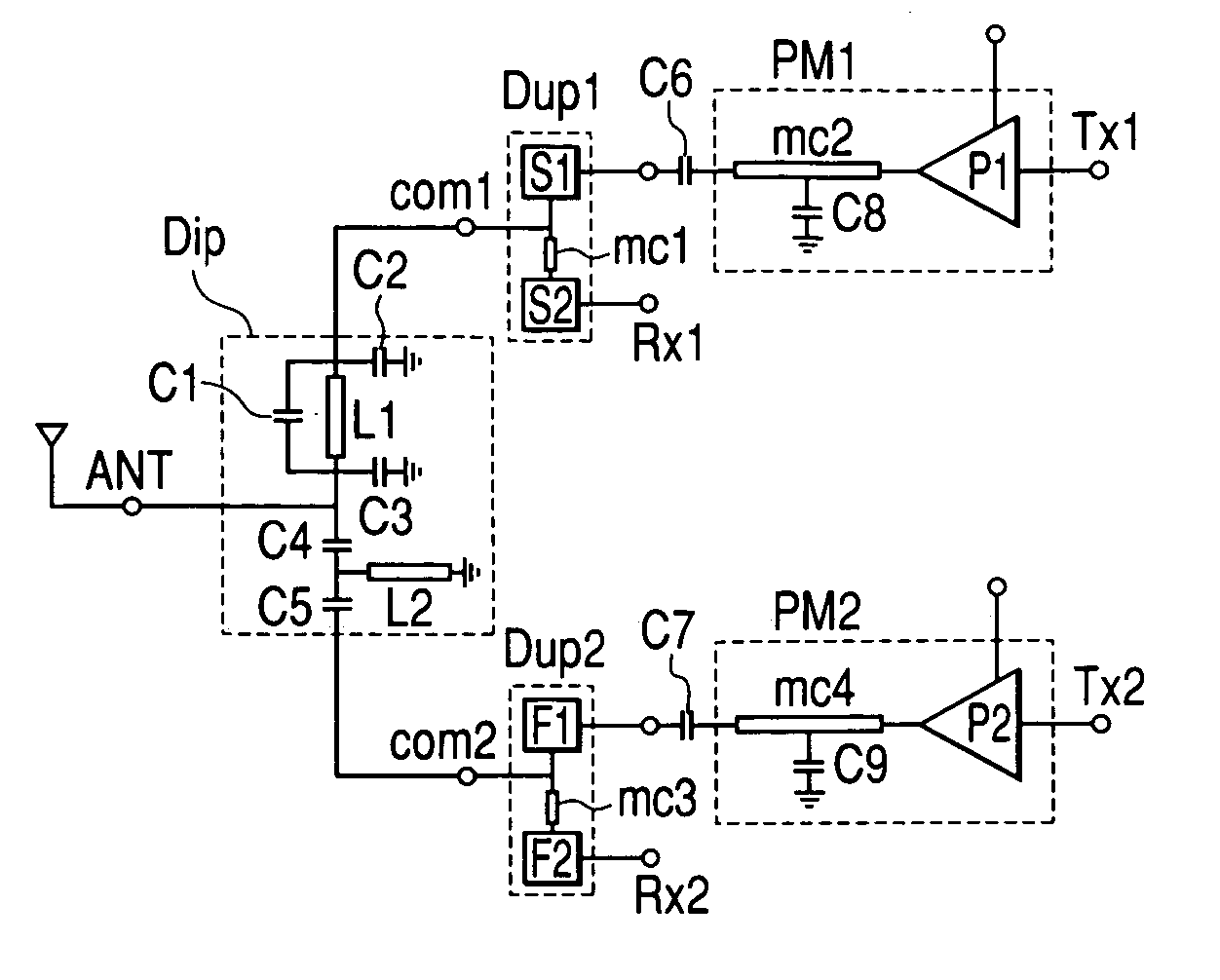

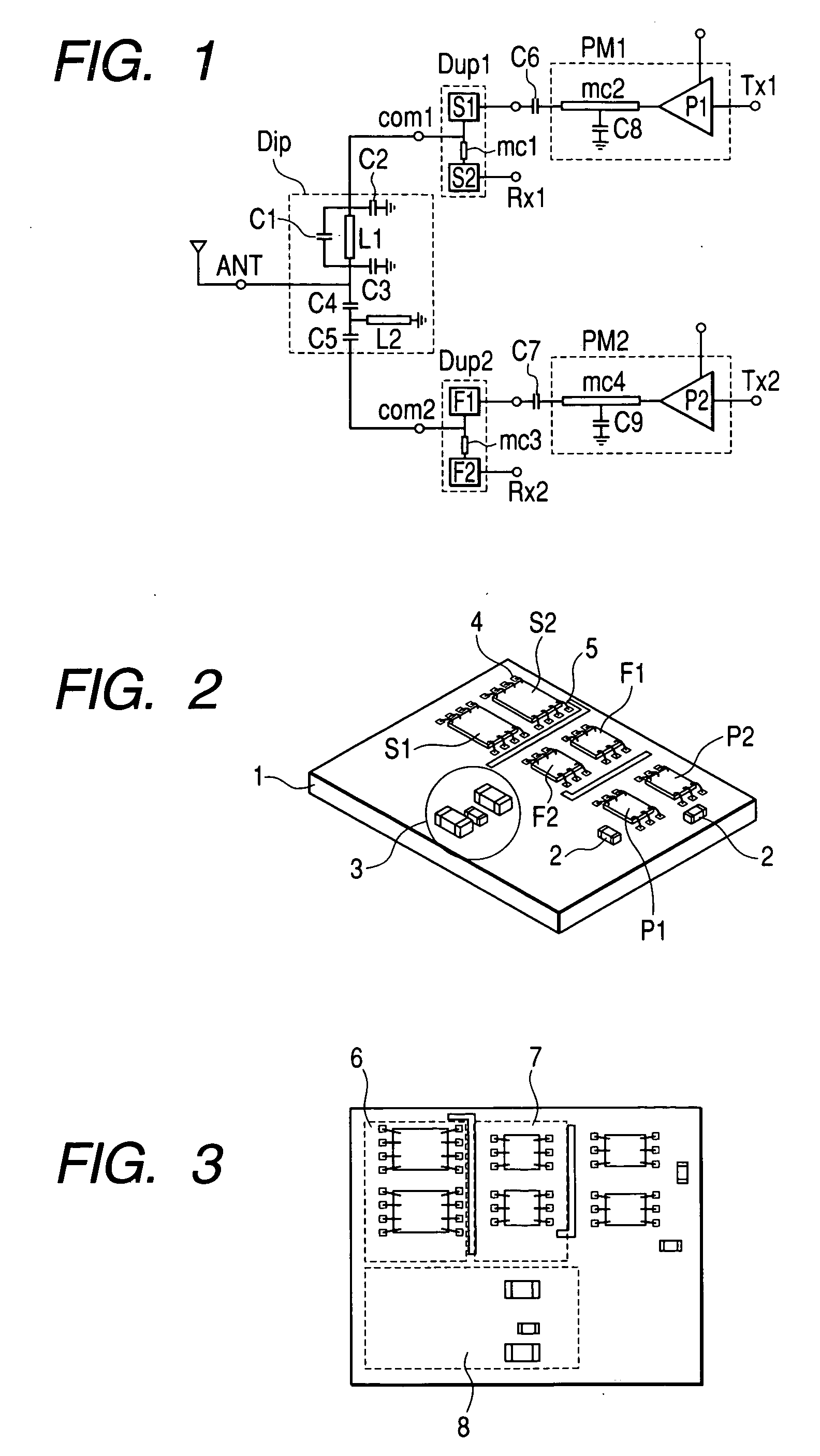

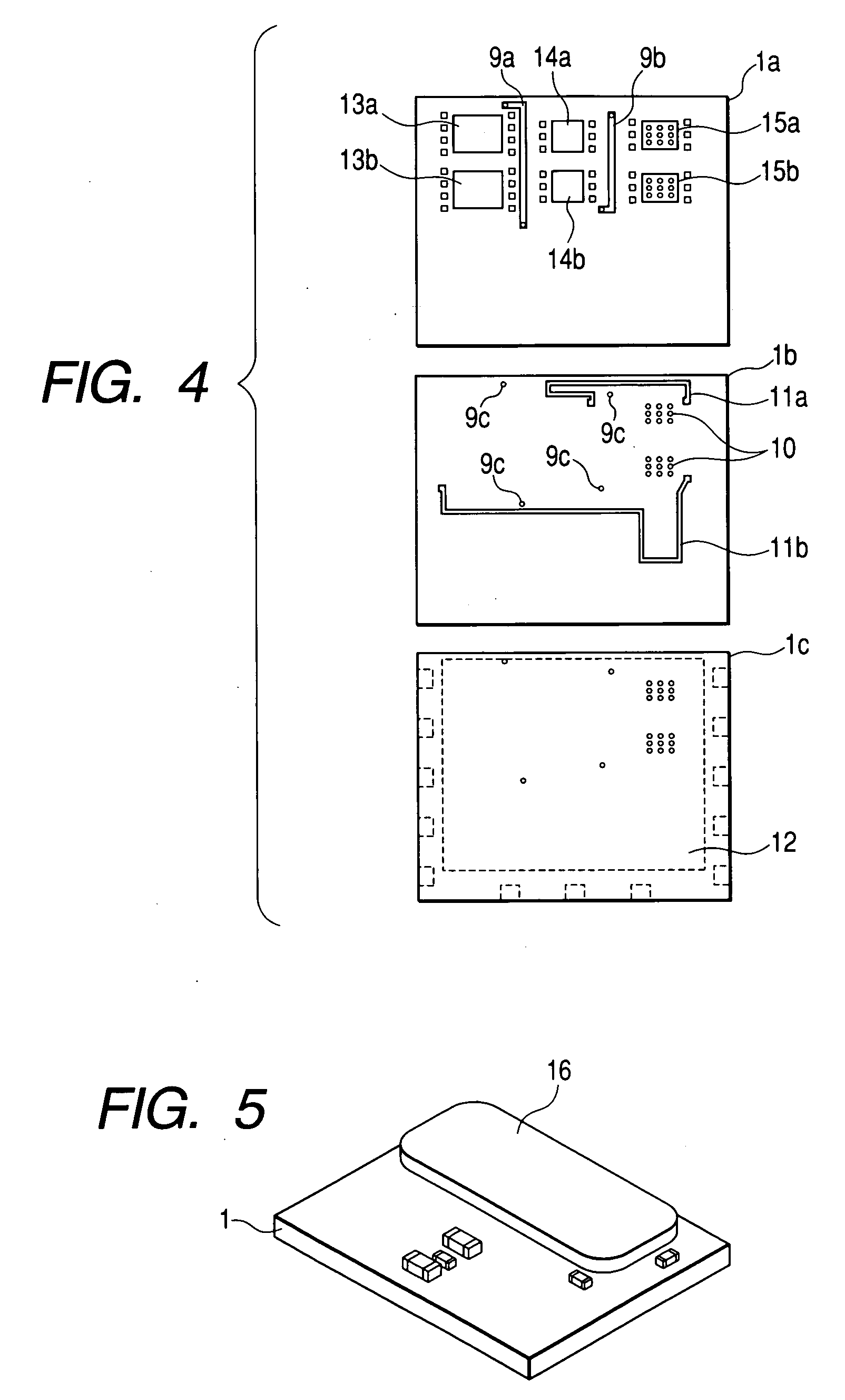

Multi-band transceiver and radio communication device using the transceiver

ActiveUS20050003855A1Improve performanceEliminate the effects ofMultiple-port networksSolid-state devicesMulti bandTransceiver

A multi-band transceiver has a function of sharing transmitted and received signals of multiple frequency bands by the same antenna. The multi-band transceiver mounts multiple filters that correspond to the multiple frequency bands and multiple amplifiers for amplifying the transmitted signals on the same substrate, and arranges the multiple filters in close vicinity to the amplifier in the order where the multiple filters are excellent in their temperature characteristic.

Owner:HITACHI METALS LTD

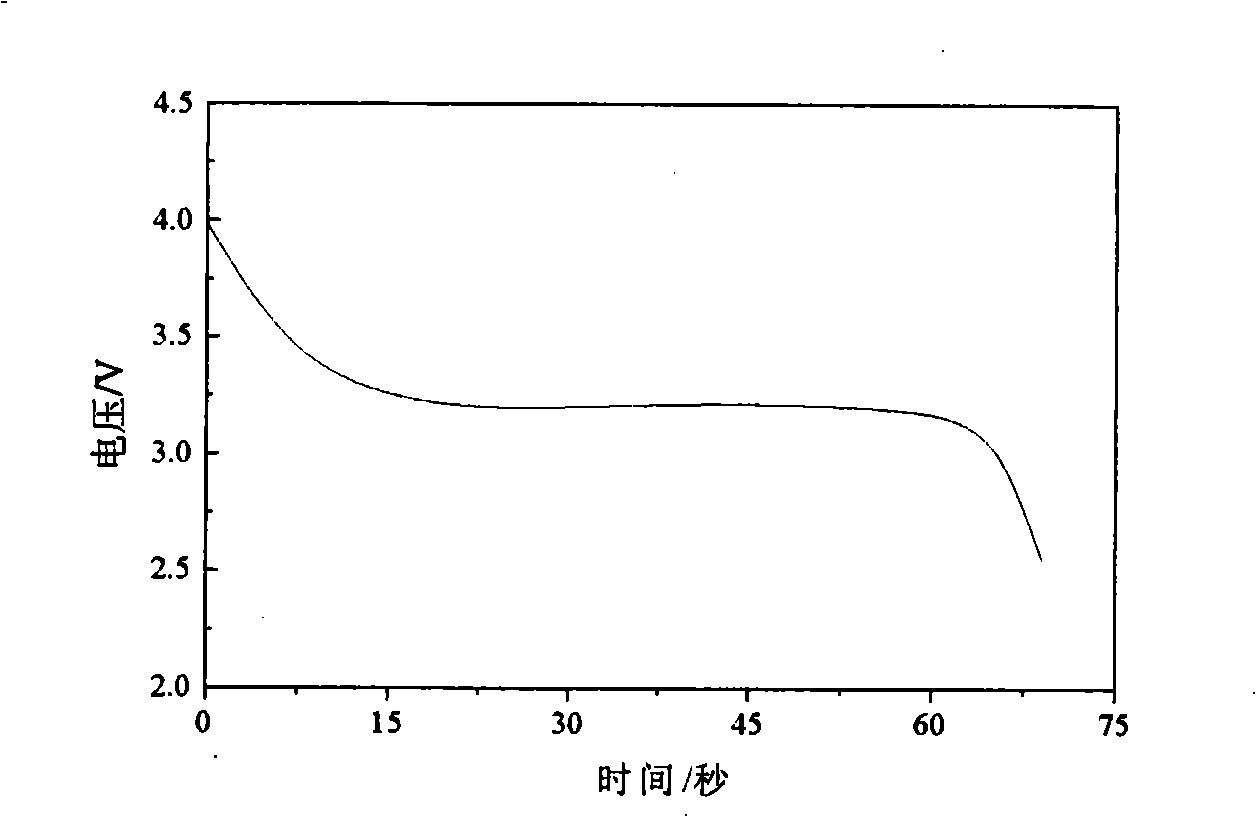

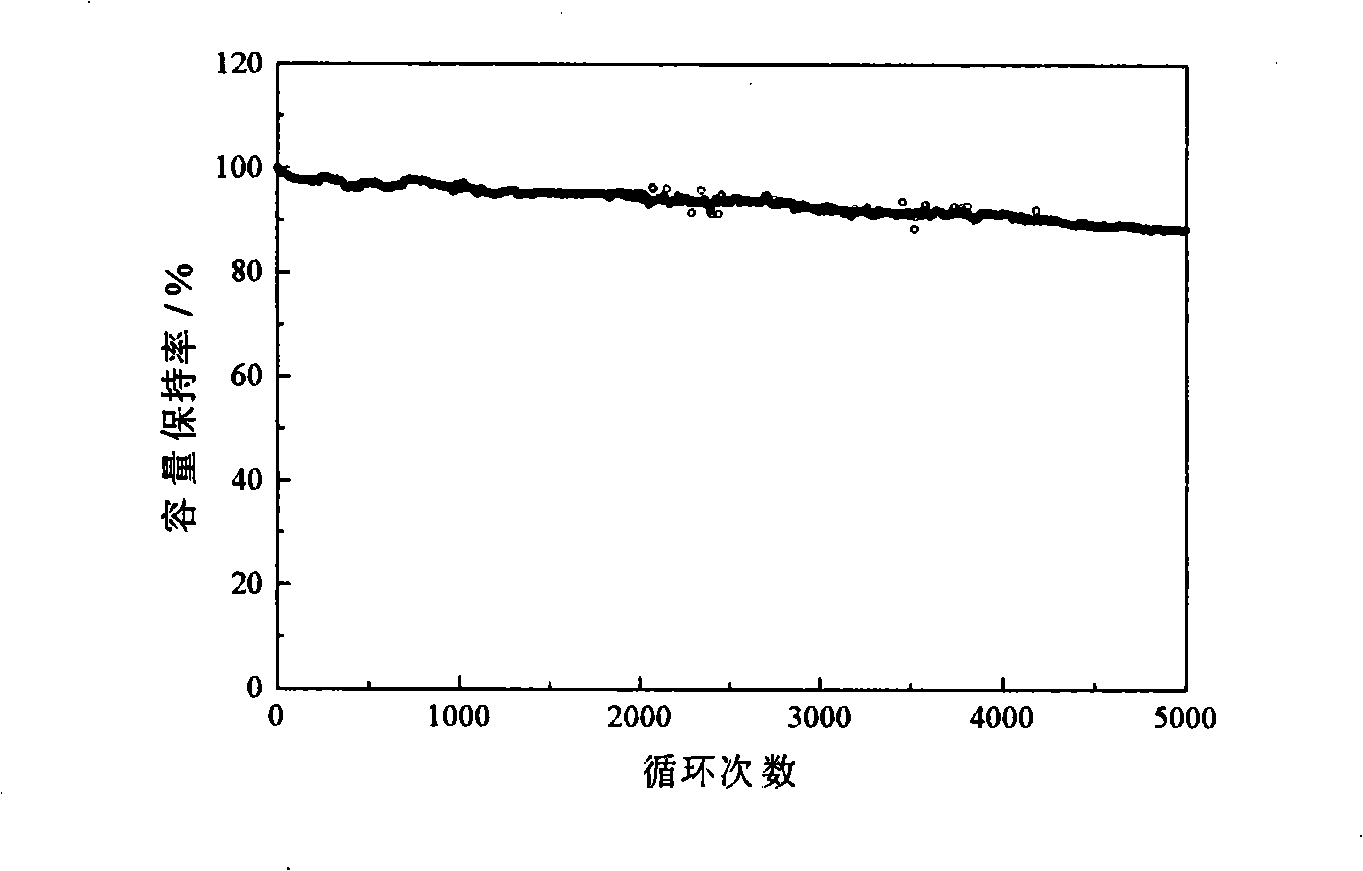

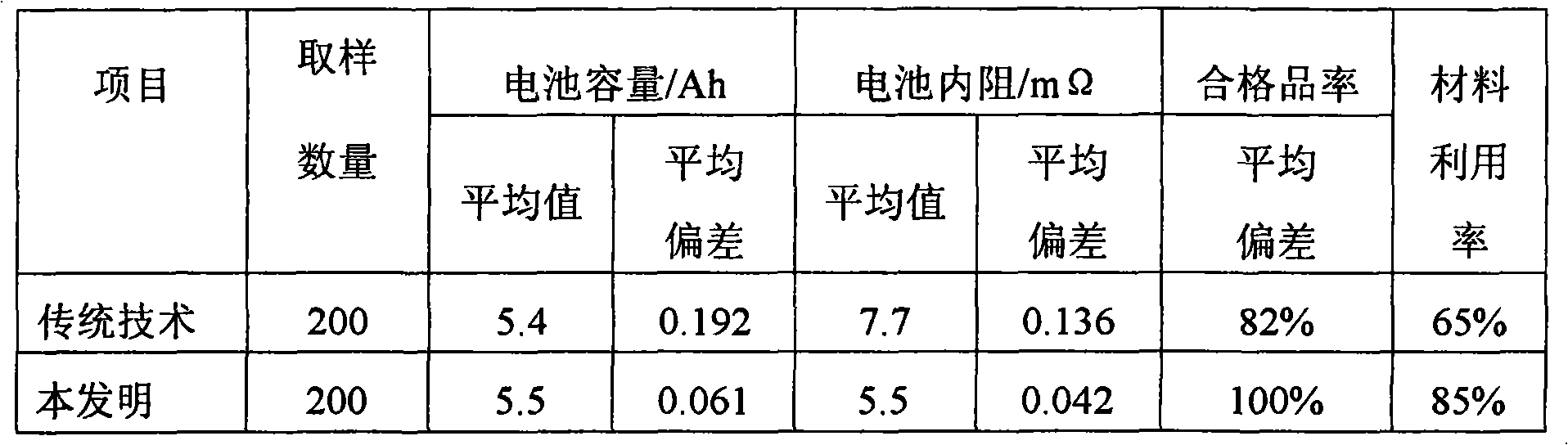

Energy storage device with both capacitor and lithium ion battery characteristics and manufacturing method thereof

InactiveCN101320821AIncrease energy densityImprove power densityFinal product manufactureActive material electrodesCapacitanceHigh energy

An energy storage device having both characteristics of super capacitor and lithium ion battery and manufacturing method thereof are provided. The invention adopts the mixture of anode material of lithium ion battery and electrode material of super capacitor or composite material as anode active substance, and uses the mixture of cathode material of the lithium ion battery and electrode material of the super capacitor or composite material as cathode active substance. In the electrode active substance, the electrode material of the lithium ion battery has a content of 20% to 95%; the electrode material of the super capacitor has a content of 5% to 80%. The electrode active substance is mixed with the bonder, conducting agent, additive and solvent etc to prepare slurry, then experience steps of coating, drying, roll forming, parting, so that the anode sheet and cathode sheet of the super capacitance battery are produced. By adopting multi-core winding parallel connection and the assembling technology of the winded wore parallel to the narrow arrangement, the anode sheet, the cathode sheet and the membrane are loaded in the battery shell and then welded, dried, dehydrated, and injected with electrolyte, then activated by electricity to obtain super capacitance battery with high energy density and high power density.

Owner:CENT SOUTH UNIV

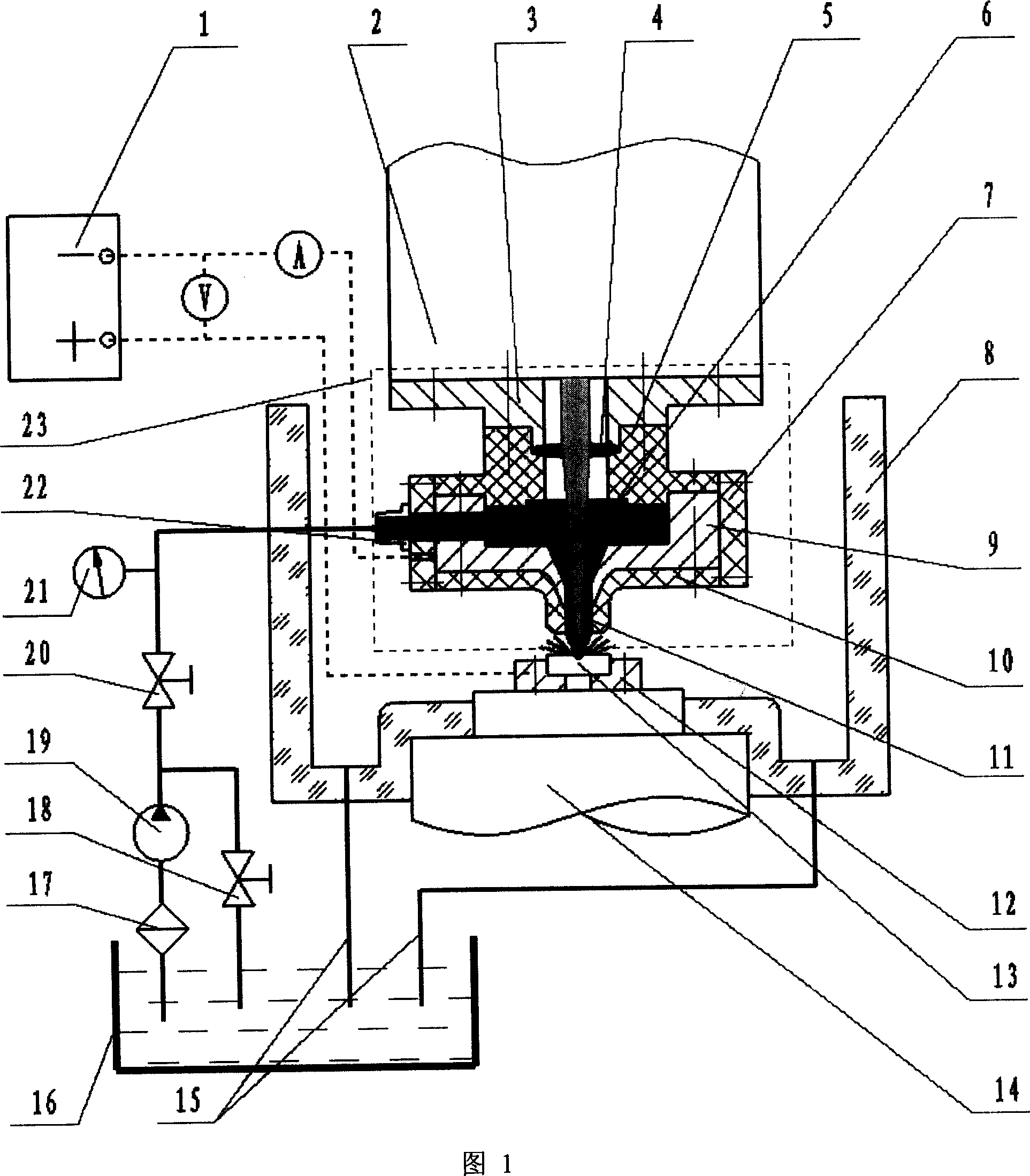

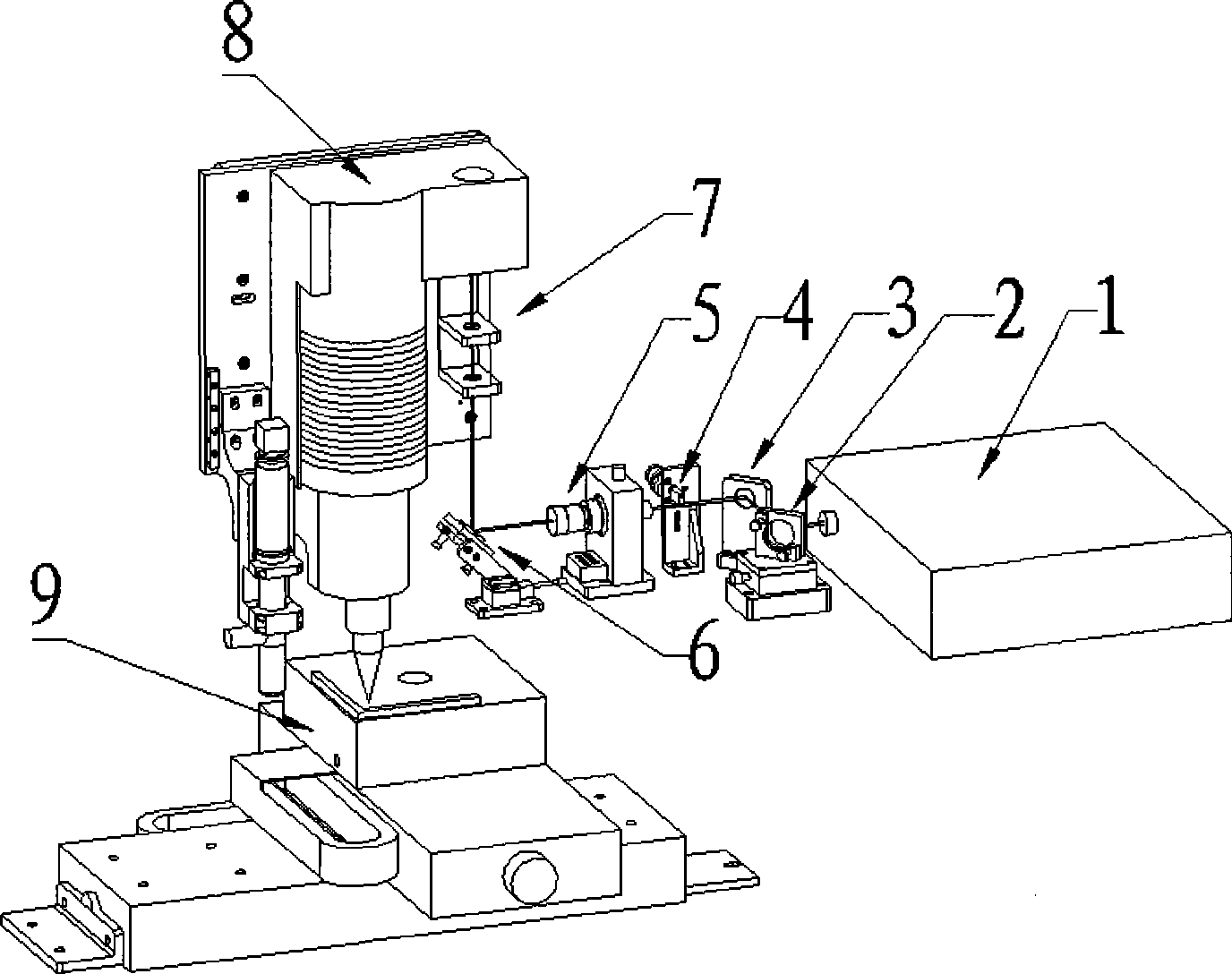

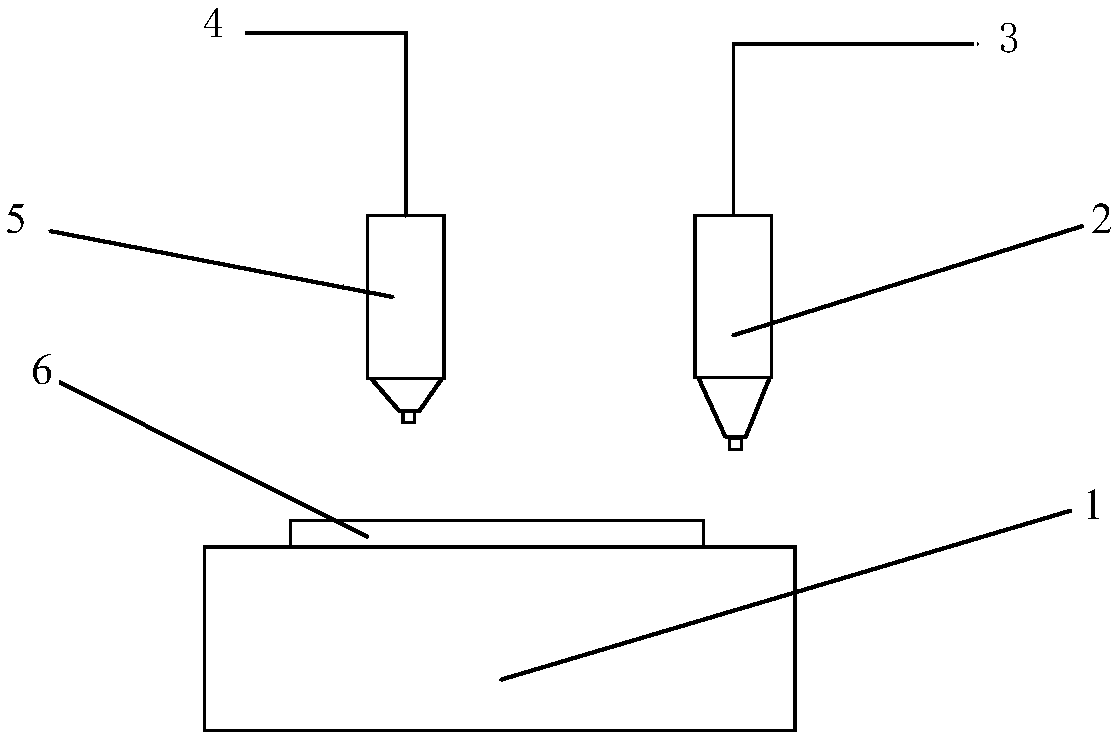

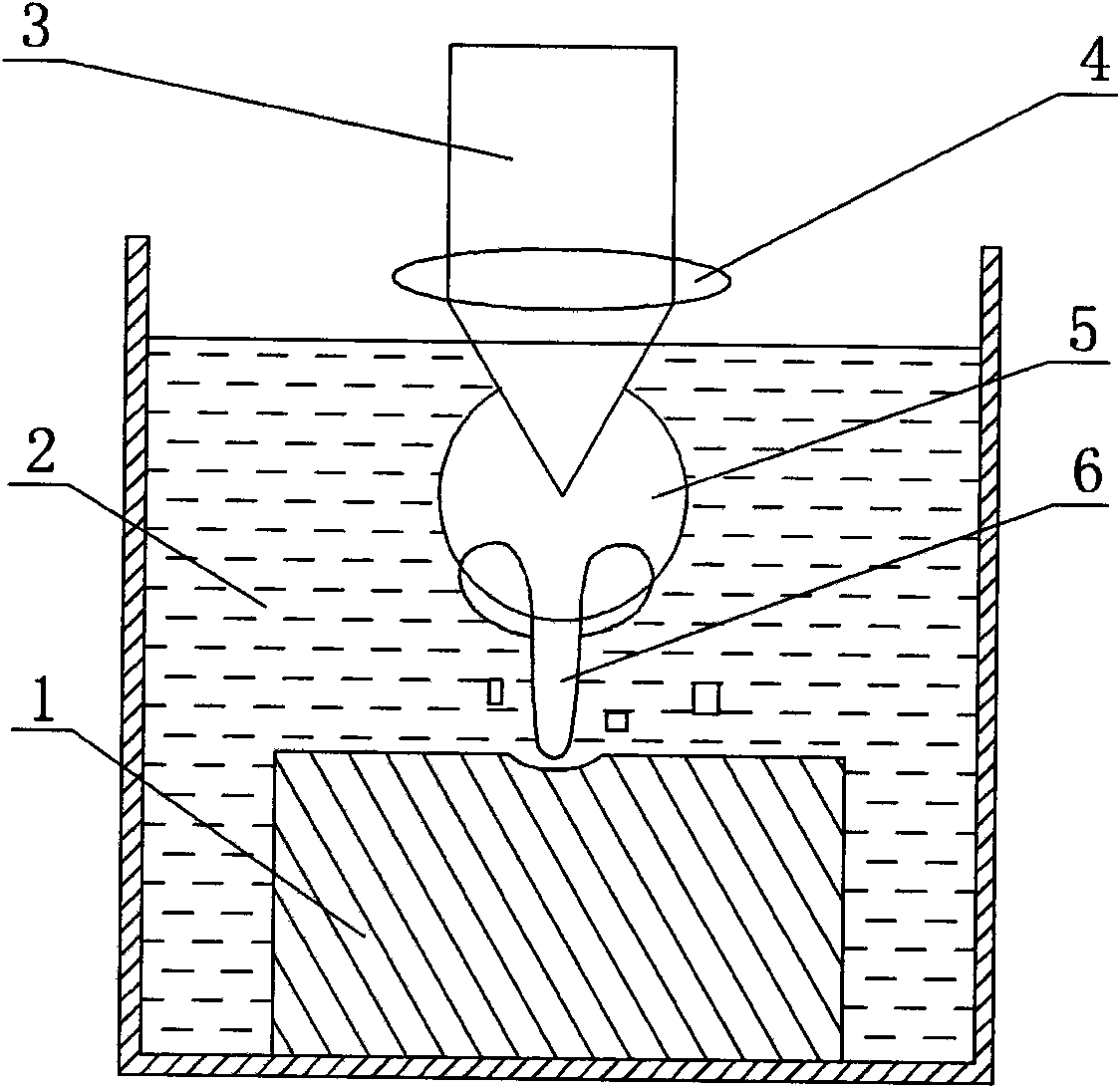

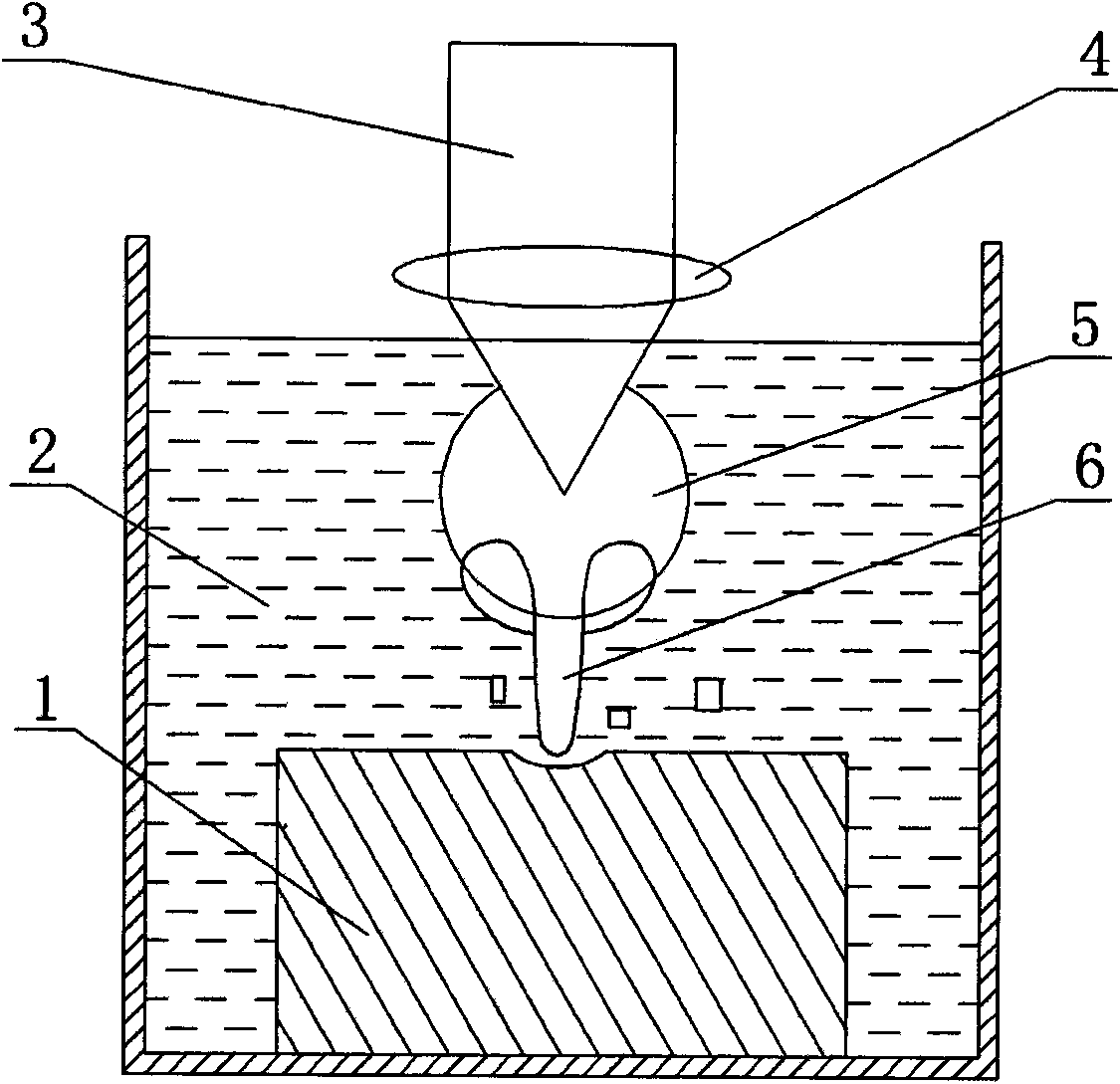

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

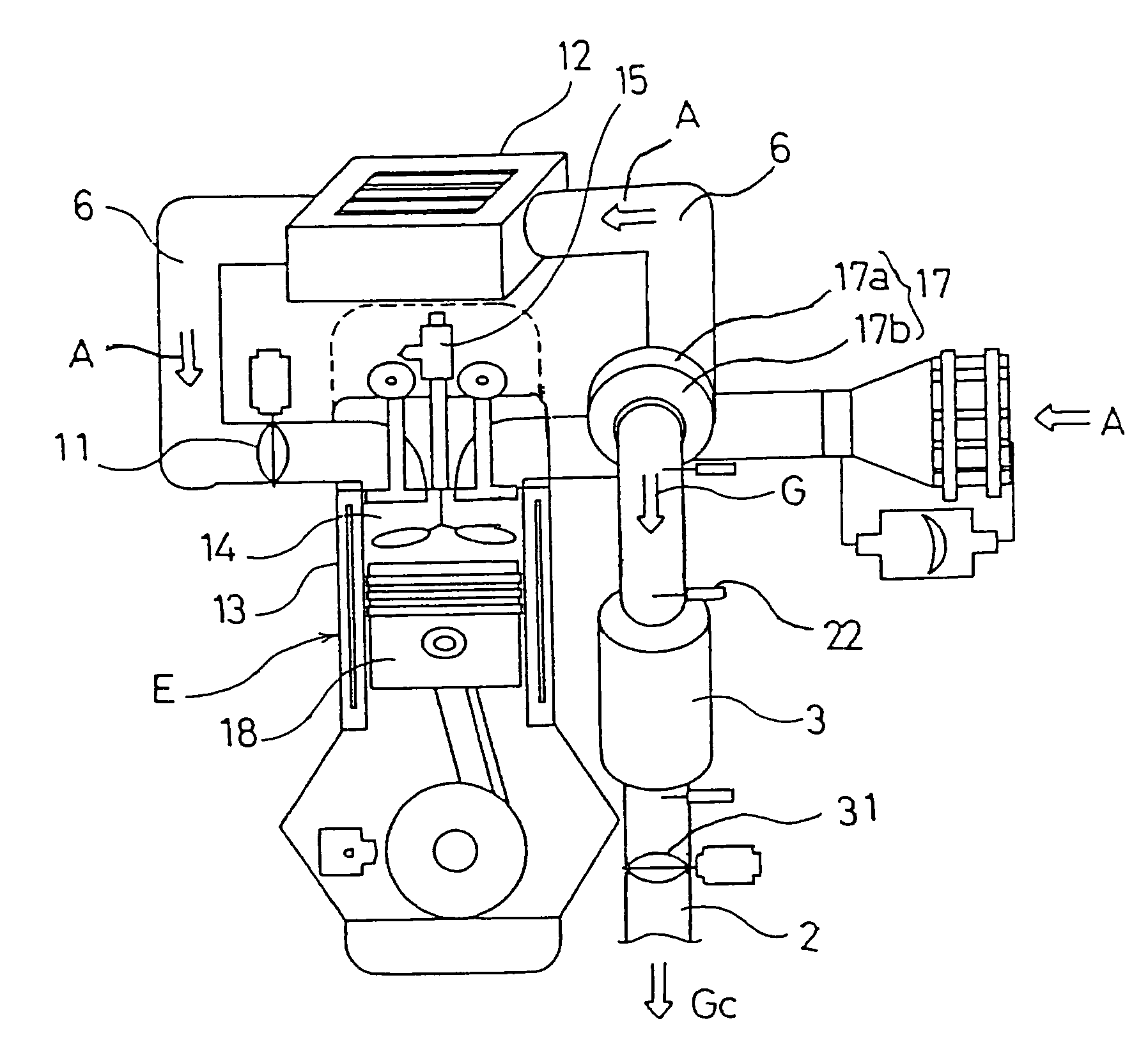

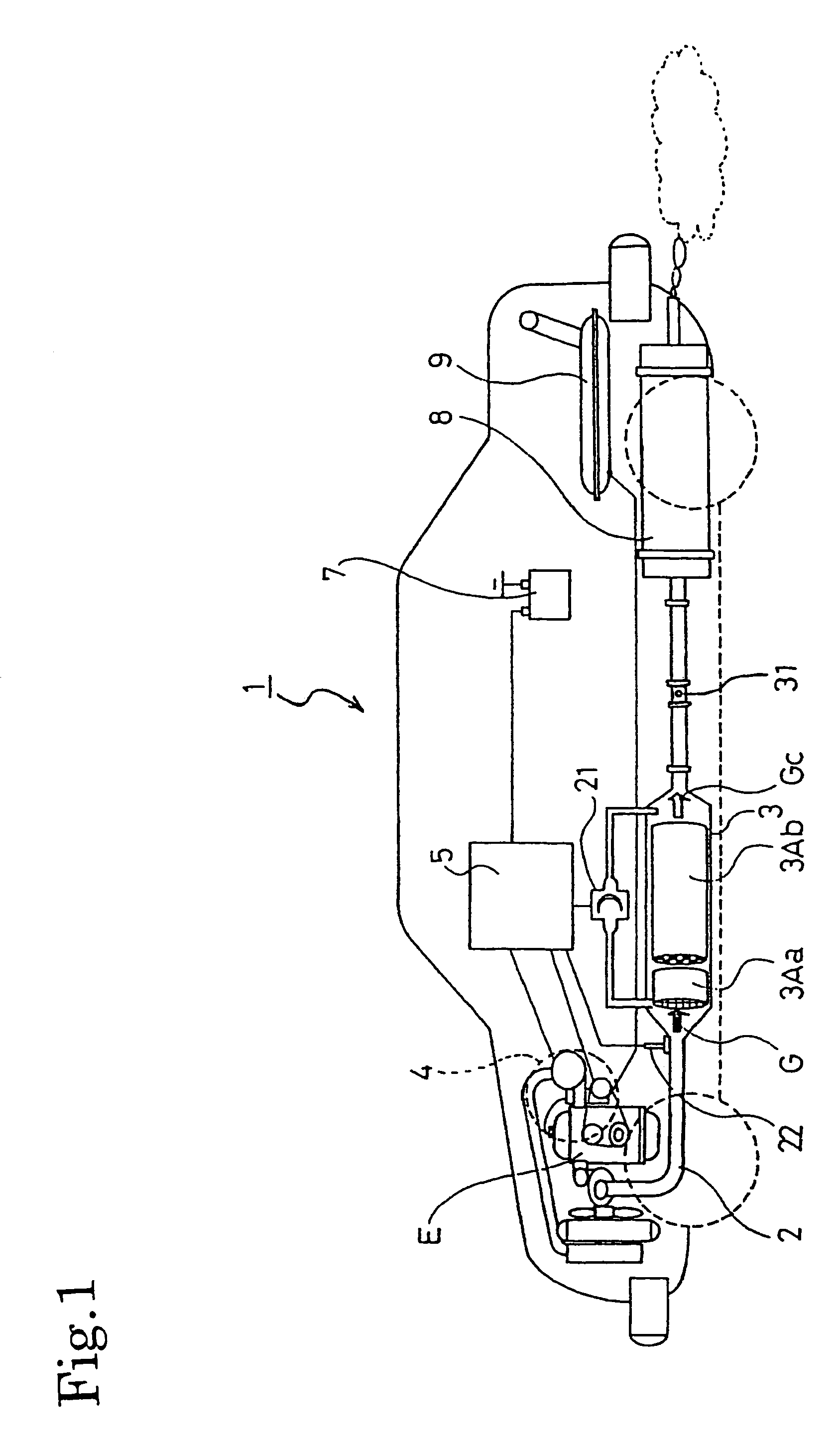

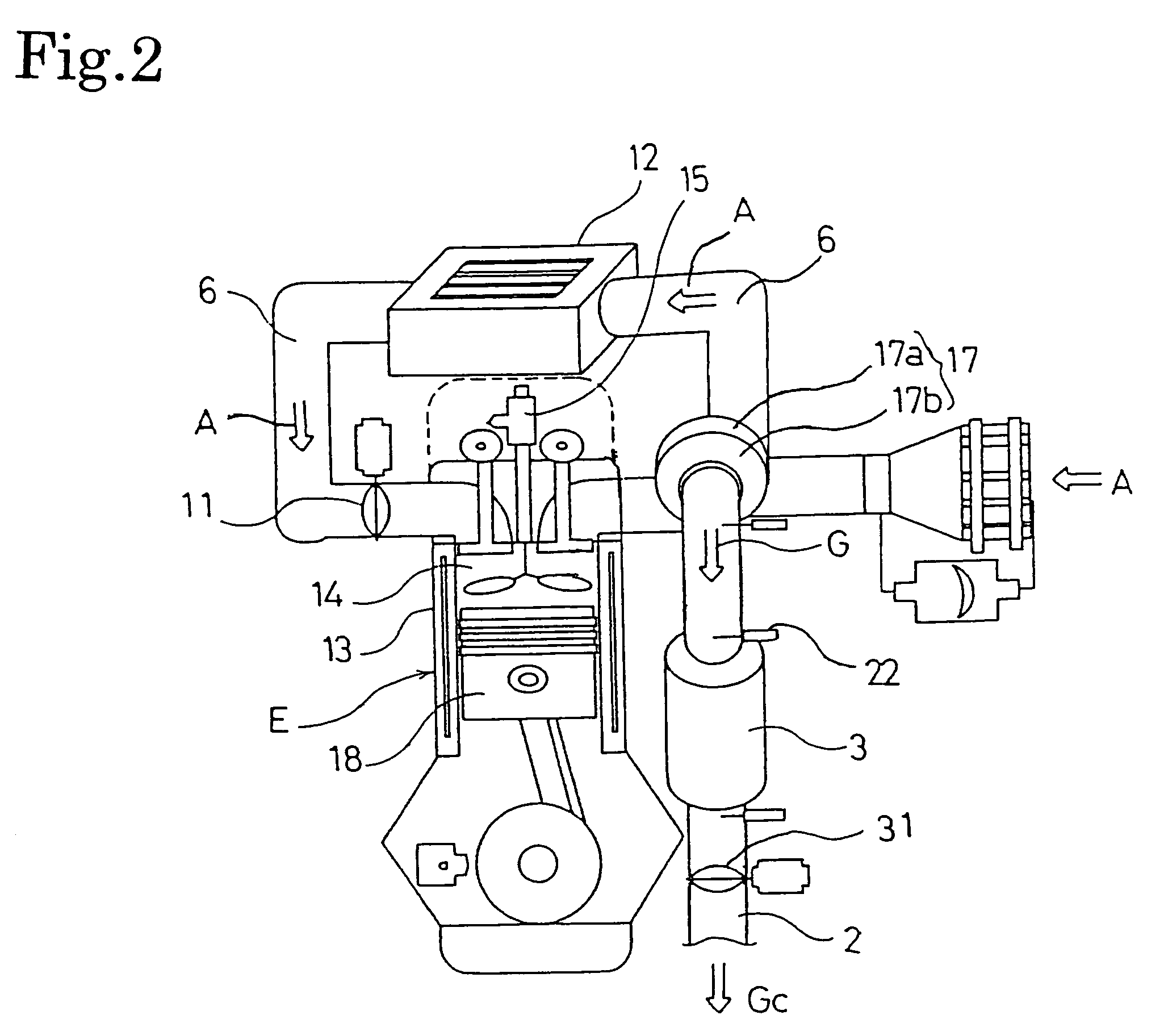

Exhaust gas purifying system

ActiveUS6966179B2Efficiently raising temperature of exhaust gasLower outlet temperatureElectrical controlInternal combustion piston enginesThrottle controlLow load

To provide an exhaust gas purifying system capable of forcibly regenerating DPF by efficiently raising the temperature of exhaust gas even when an exhaust gas temperature is very low at the time of low load and low engine speed such as an idling operation. In an exhaust purifying system (1) having an exhaust throttling valve (31) and a DPF (3) in an exhaust passage and having regeneration control means (P1) for regenerating the DPF (3), the regeneration control means (P1) is provided with an exhaust gas temperature detection means (P22), a fuel injection control means (P11), and an exhaust throttling control means (P12) and includes regeneration control for performing the exhaust gas temperature raising control through the multistage delay injection by the fuel injection control means (P11) and through the exhaust throttling of the exhaust throttling valve (31).

Owner:ISUZU MOTORS LTD

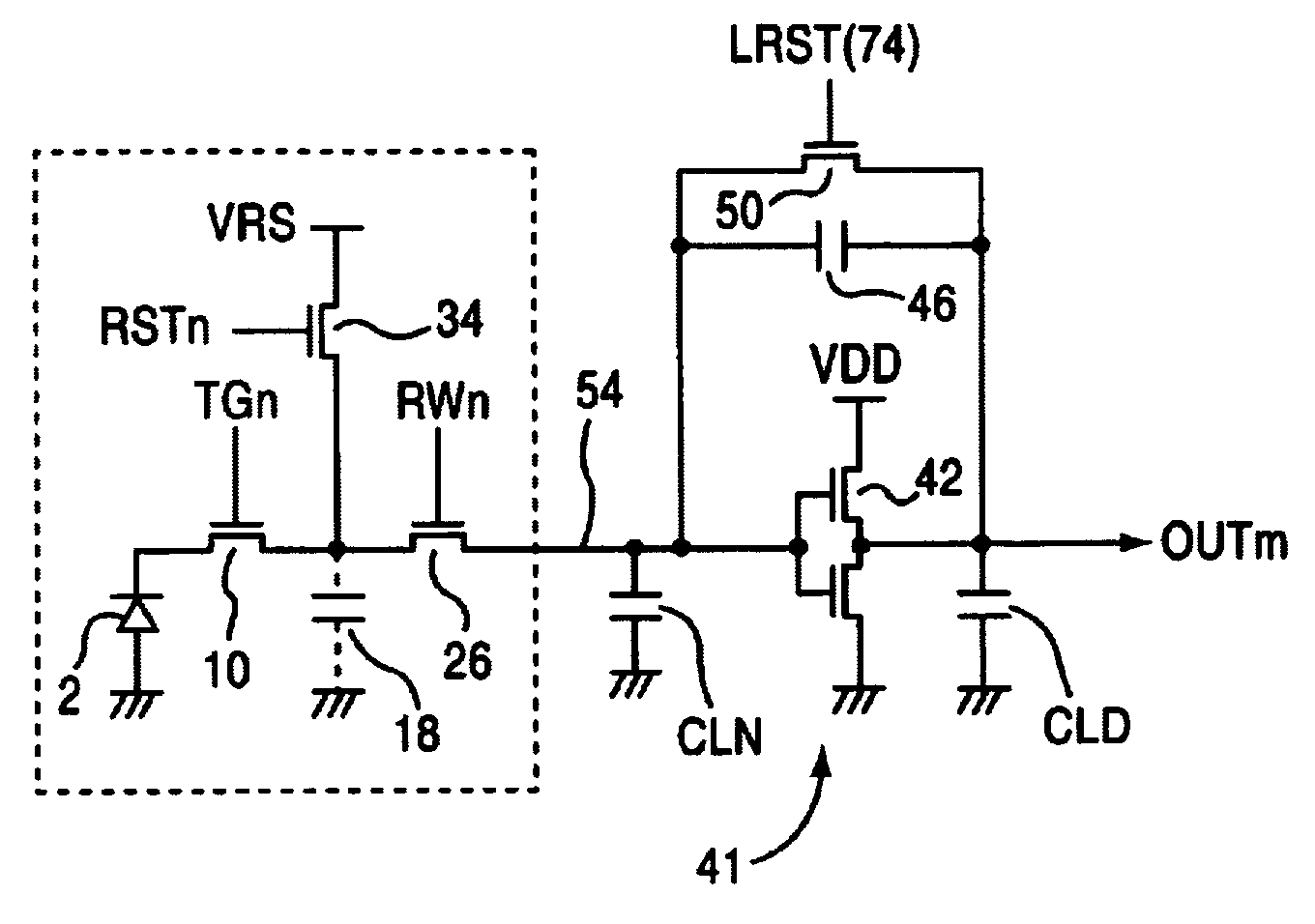

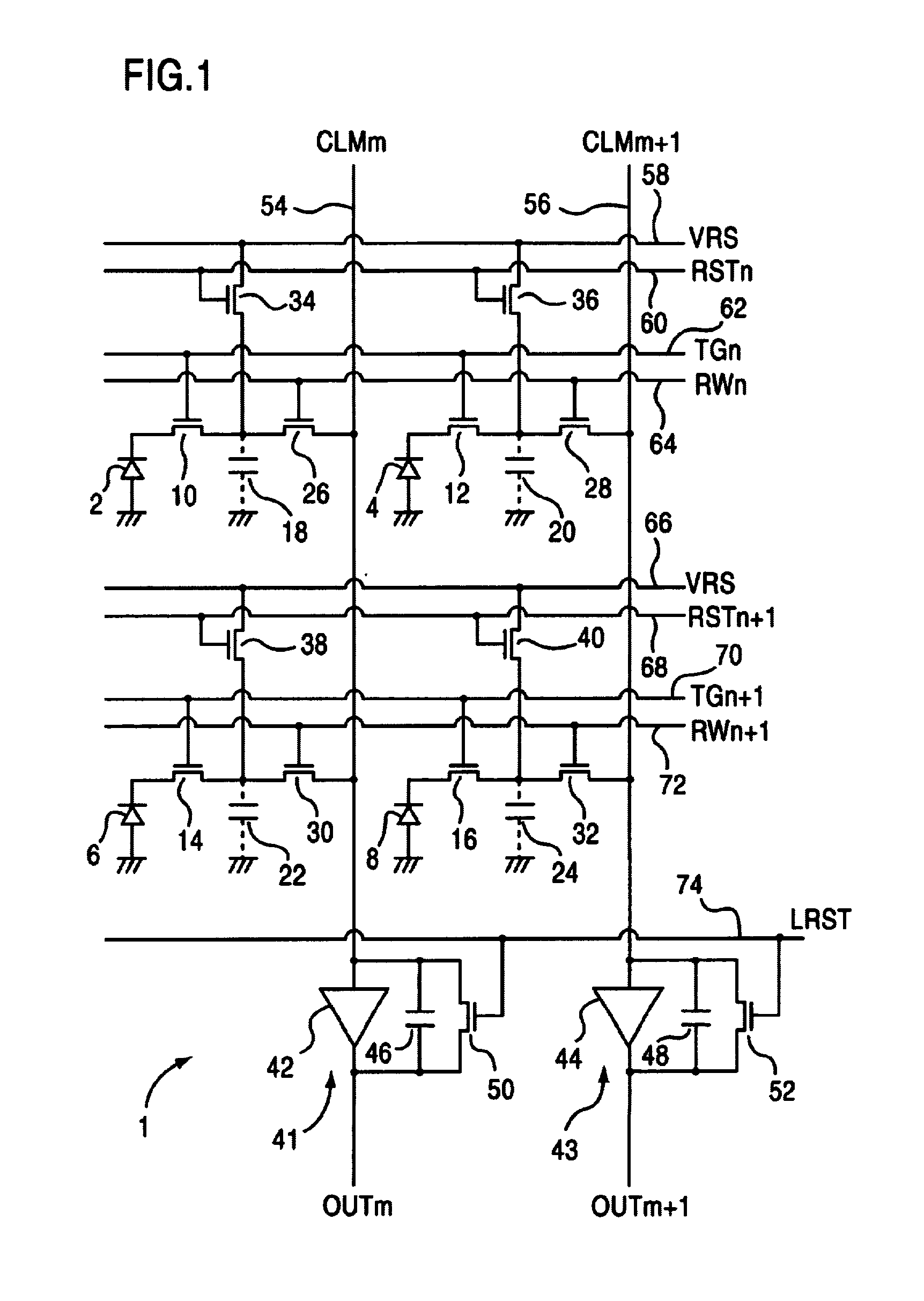

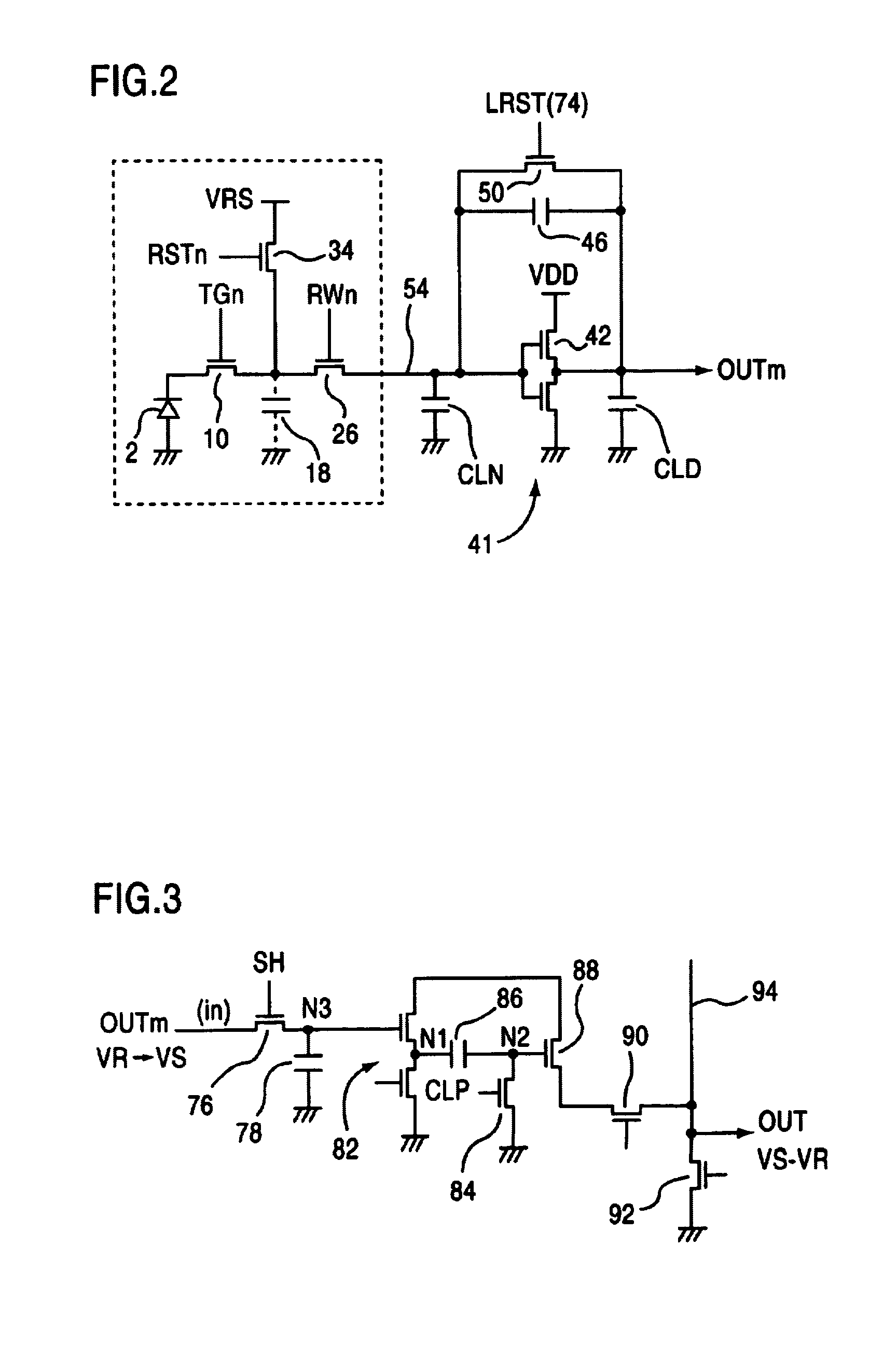

Solid-state imaging device with the elimination of thermal noise

InactiveUS6975356B1Reduce the impactReduce noiseTelevision system detailsTelevision system scanning detailsAudio power amplifierCapacitor

A solid-state imaging device comprises: a plurality of pixels including a light-sensitive portion (2) for photoelectrically converting incident light, a transfer gate (10) for transferring a charge stored in the light-sensitive portion, a resettable detection capacitor (18) for storing the charge transferred from the transfer gate, and a selection switch (26) for outputting a charge of the detection capacitor according to a selection signal RWn; a charge amplifier (41) for converting the detection capacitor charge, which is outputted from the pixels, to a voltage; and a correlated double sampling circuit (86) for obtaining a voltage difference between a reset level and a detected level converted by the charge amplifier. According to the above device, a thermal noise is eliminated due to the correlated double sampling circuit. Further, a fixed pattern noise is not generated due to the pixel circuit structure.

Owner:FUJITSU LTD

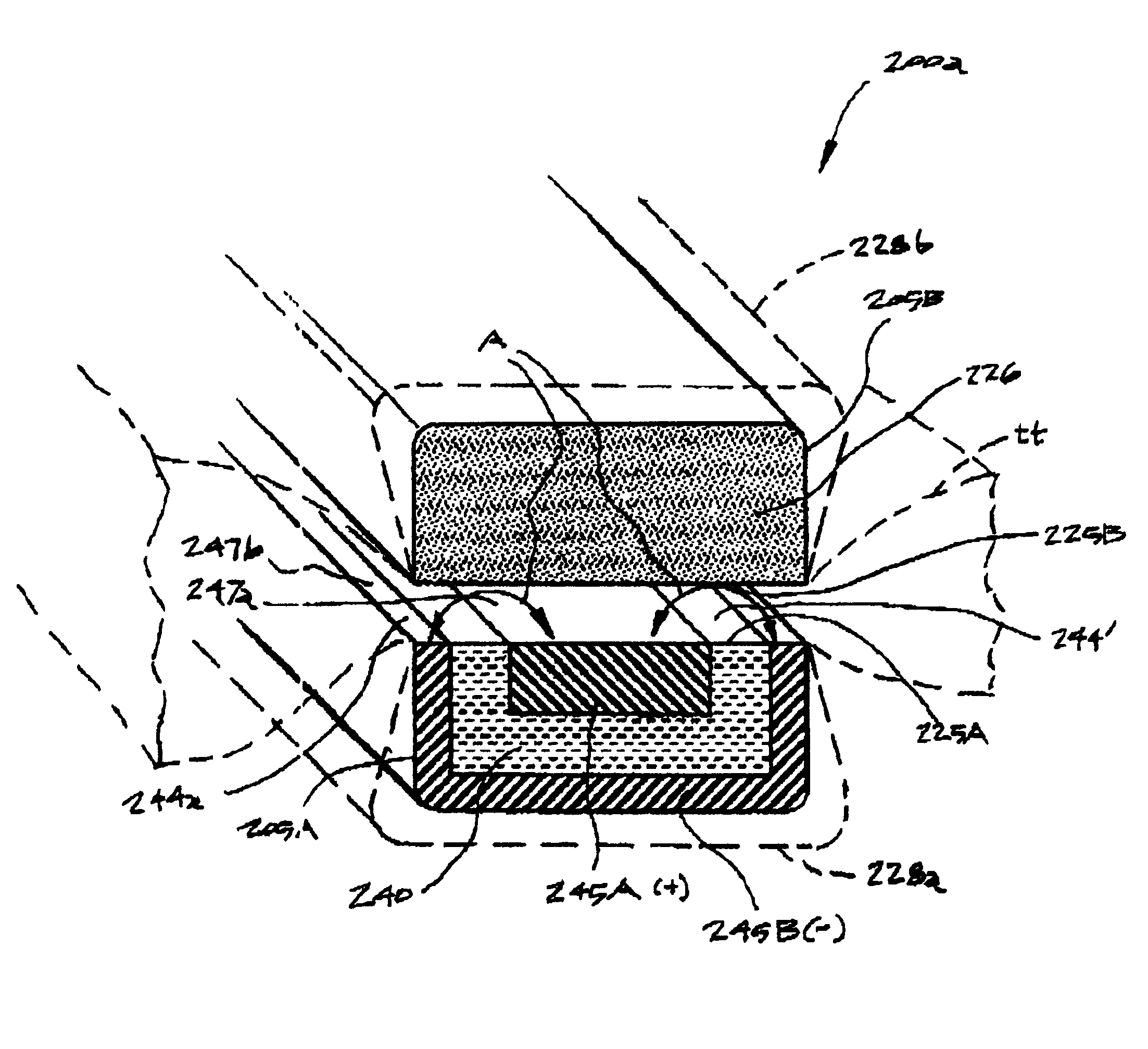

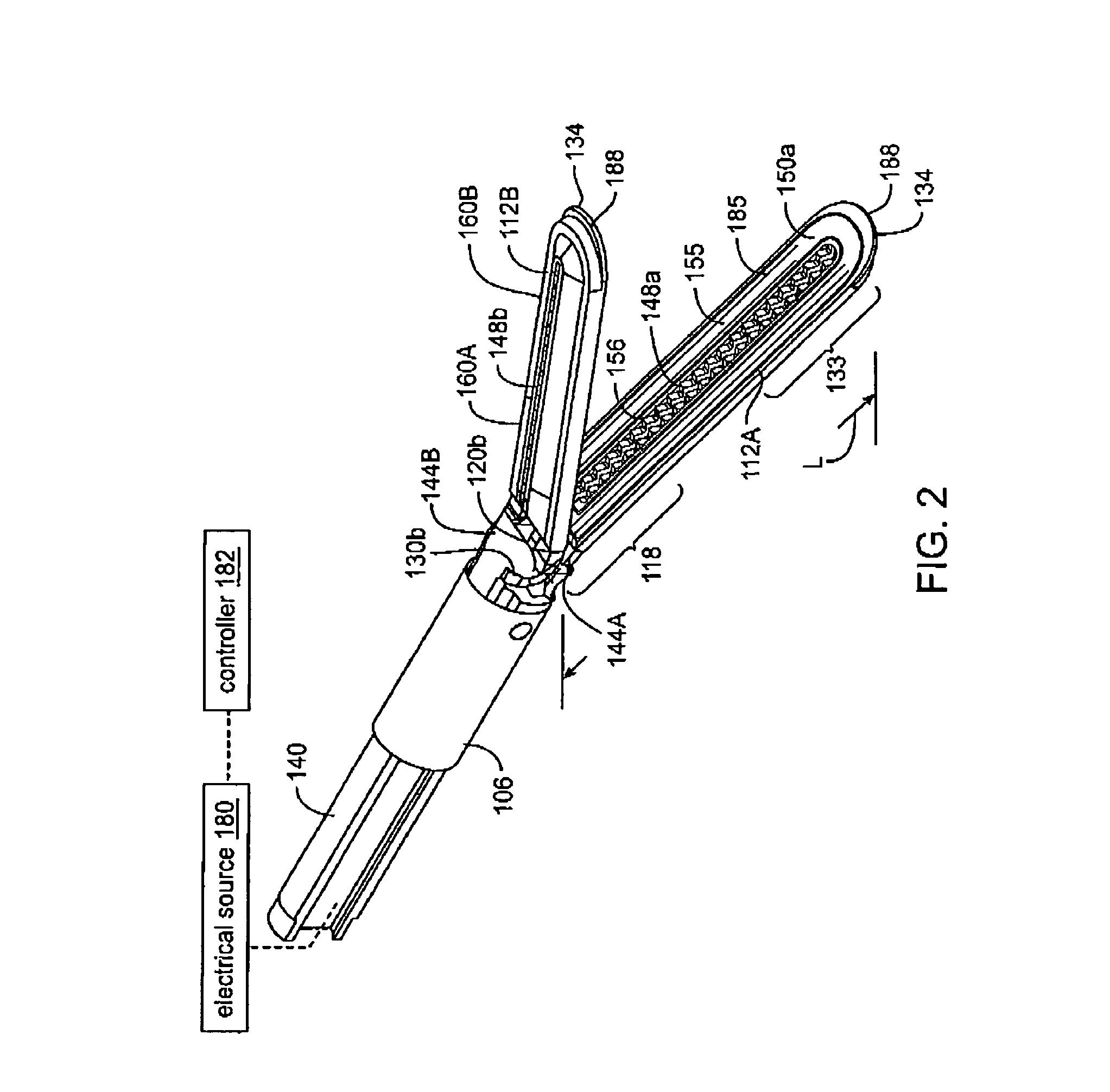

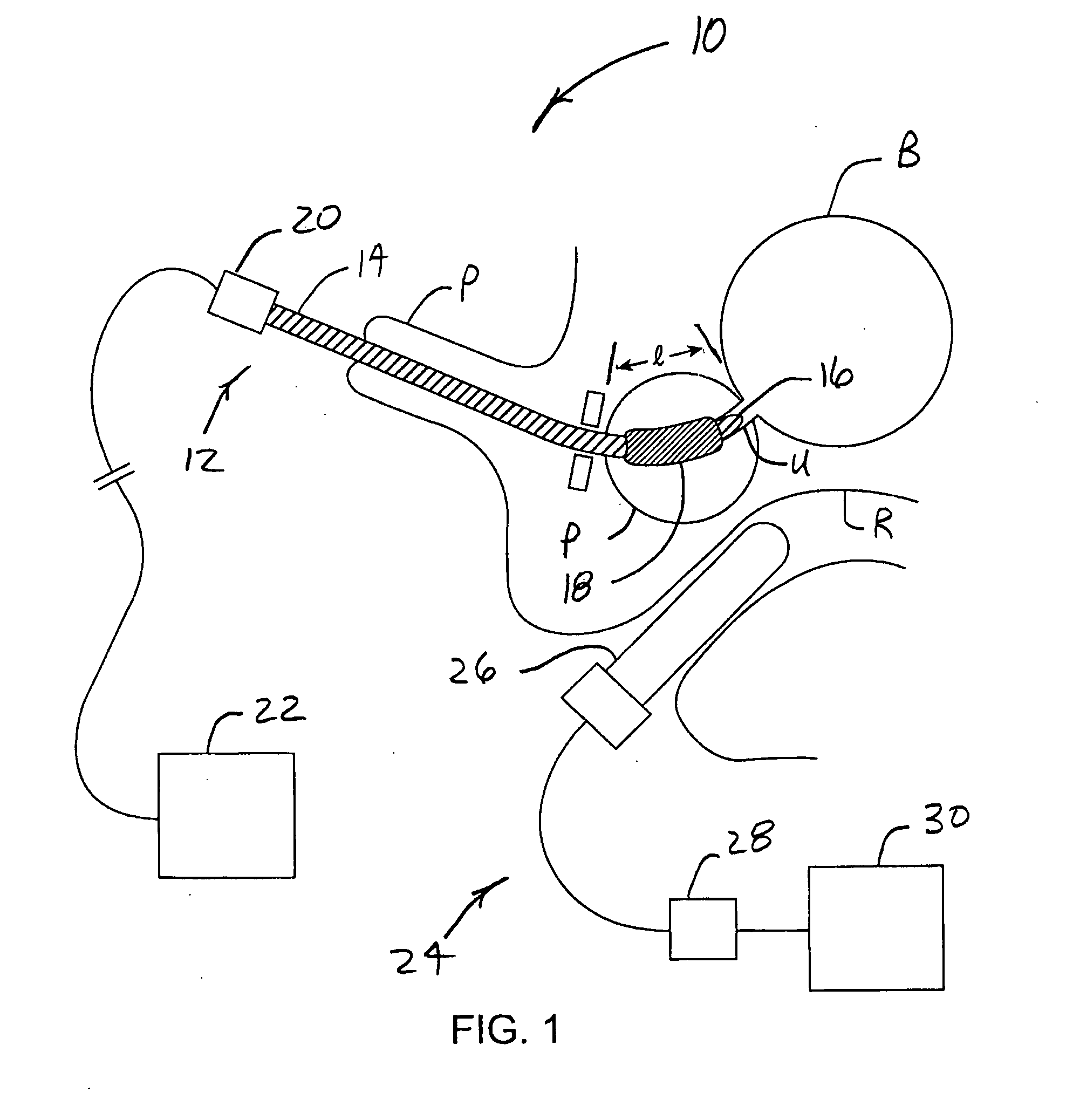

Transurethral systems and methods for ablation treatment of prostate tissue

Transurethral systems and methods for delivering electrical energy and controlled, mild heating to a prostate tissue of a patient for destruction of cancerous and / or hyperplastic tissue. A method includes positioning an elongate urethral probe having an expandable member with electrode elements at a target location in the patient's urethra, and inflating or expanding at the target location. Secondary electrodes are positioned within or adjacent to the prostate tissue and spaced from the electrode elements of the expandable member, and an alternating electrical current flow is established between the electrode elements of the expandable member and the one or more secondary electrodes. Current delivery can be selected so as to destroy or ablate cancerous cells of the prostate tissue.

Owner:LAZURE SCI

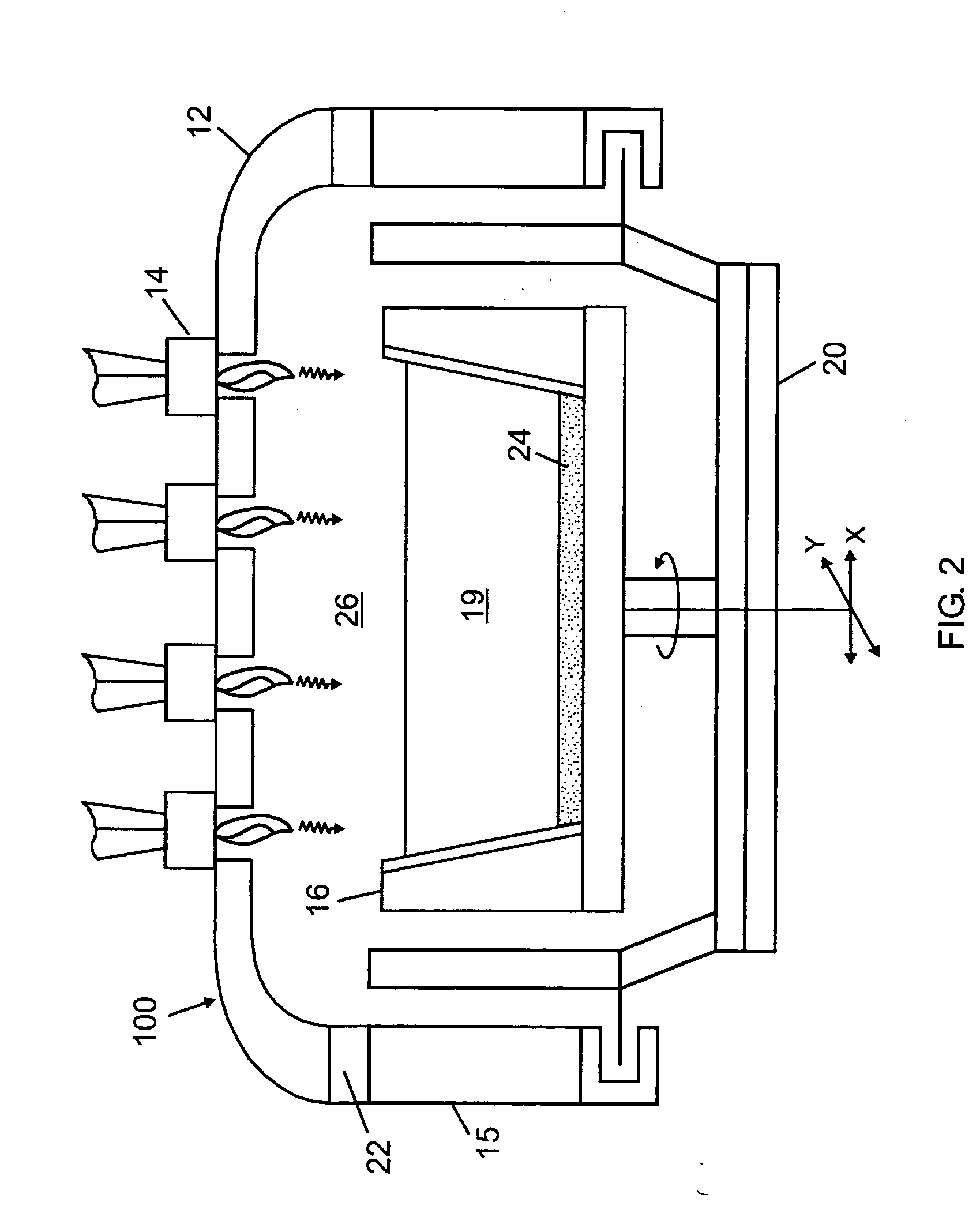

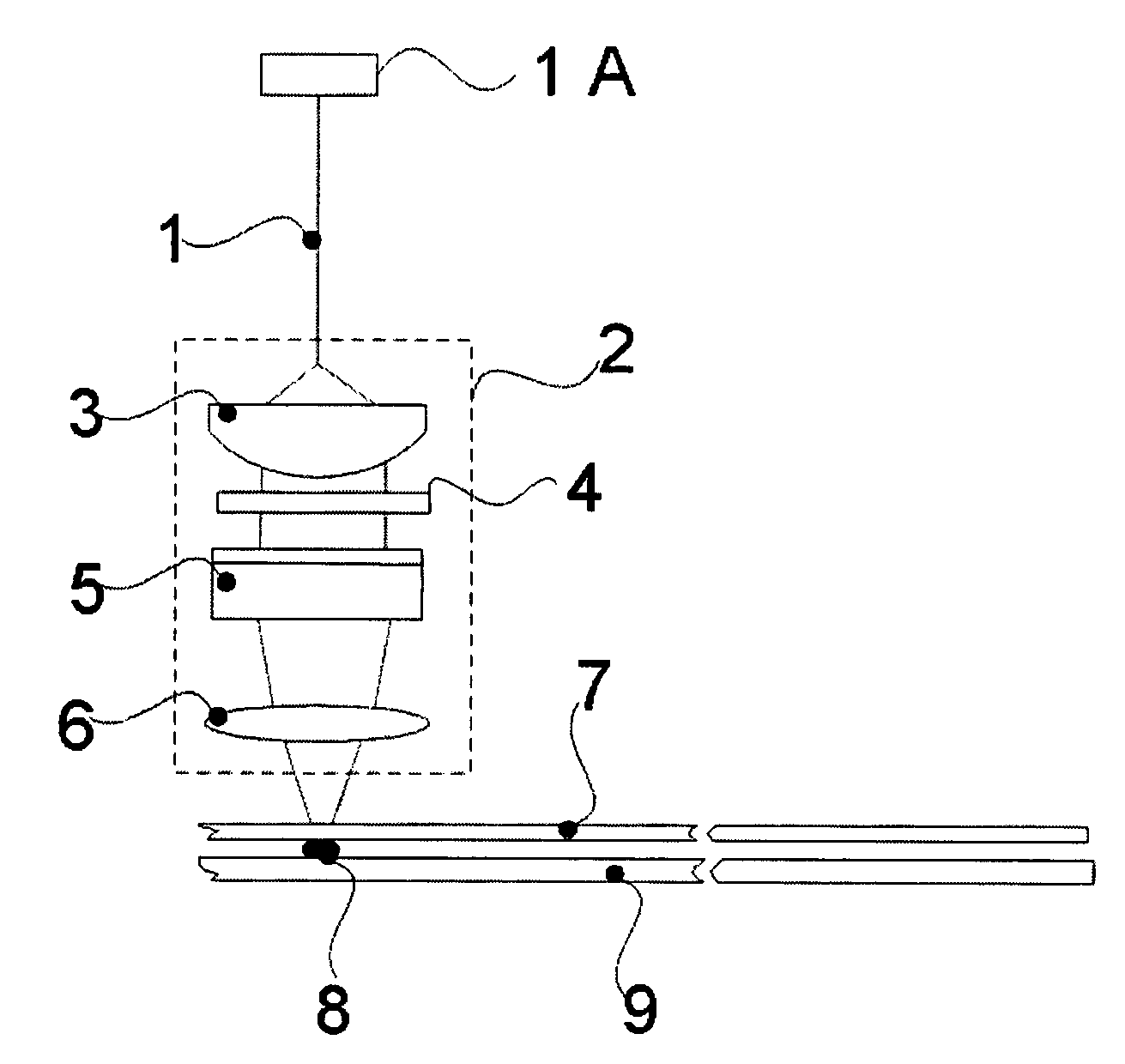

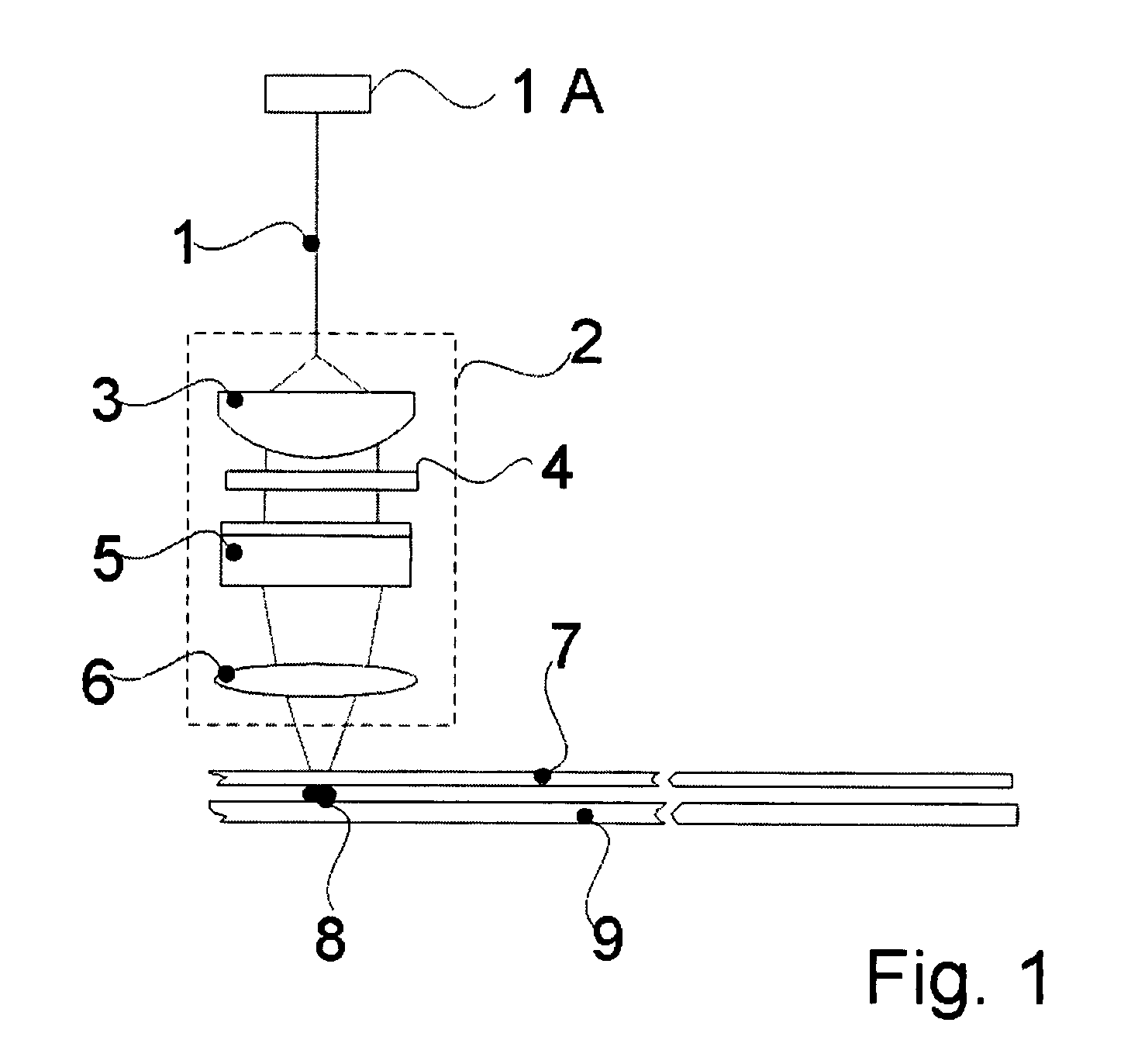

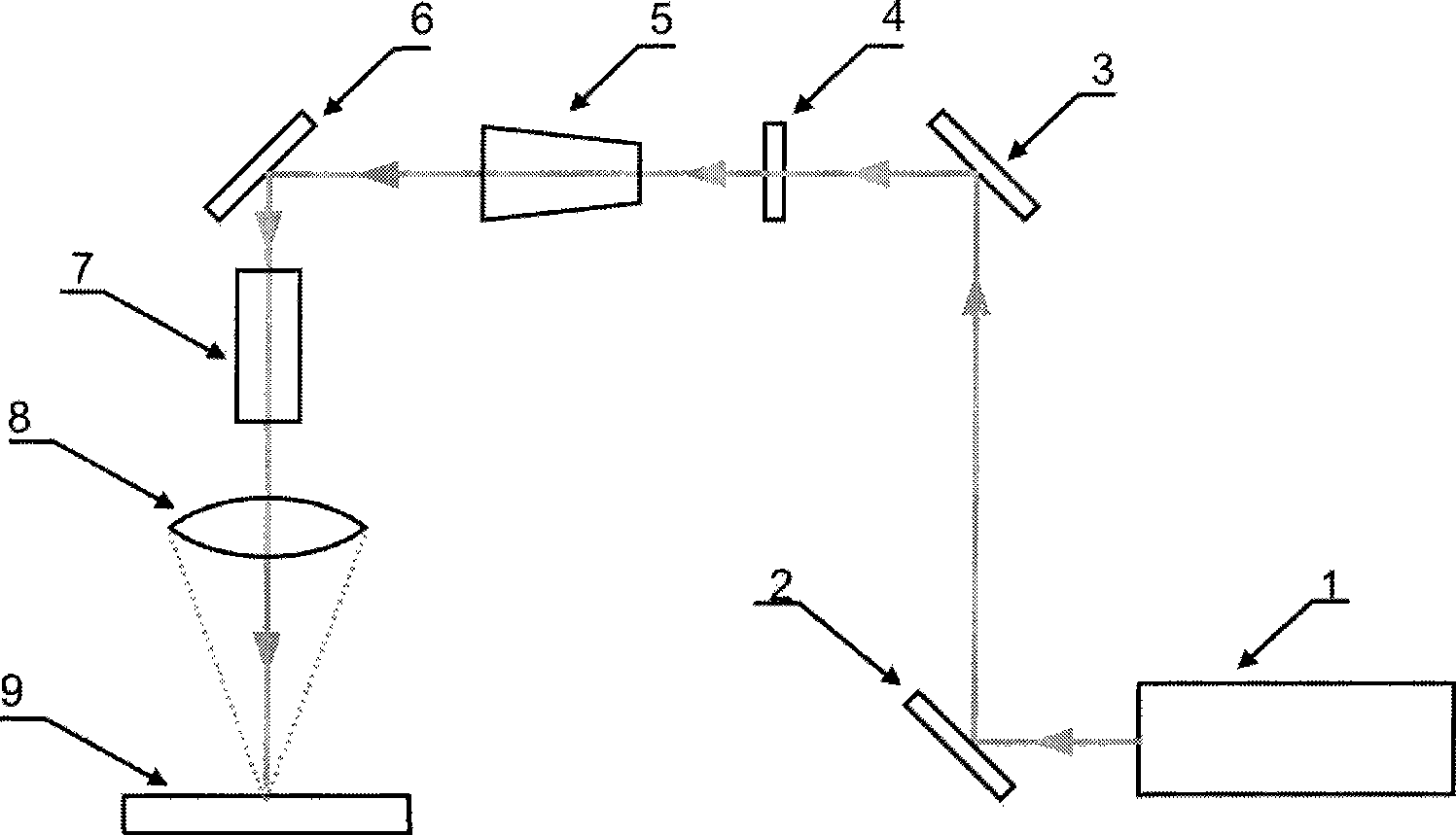

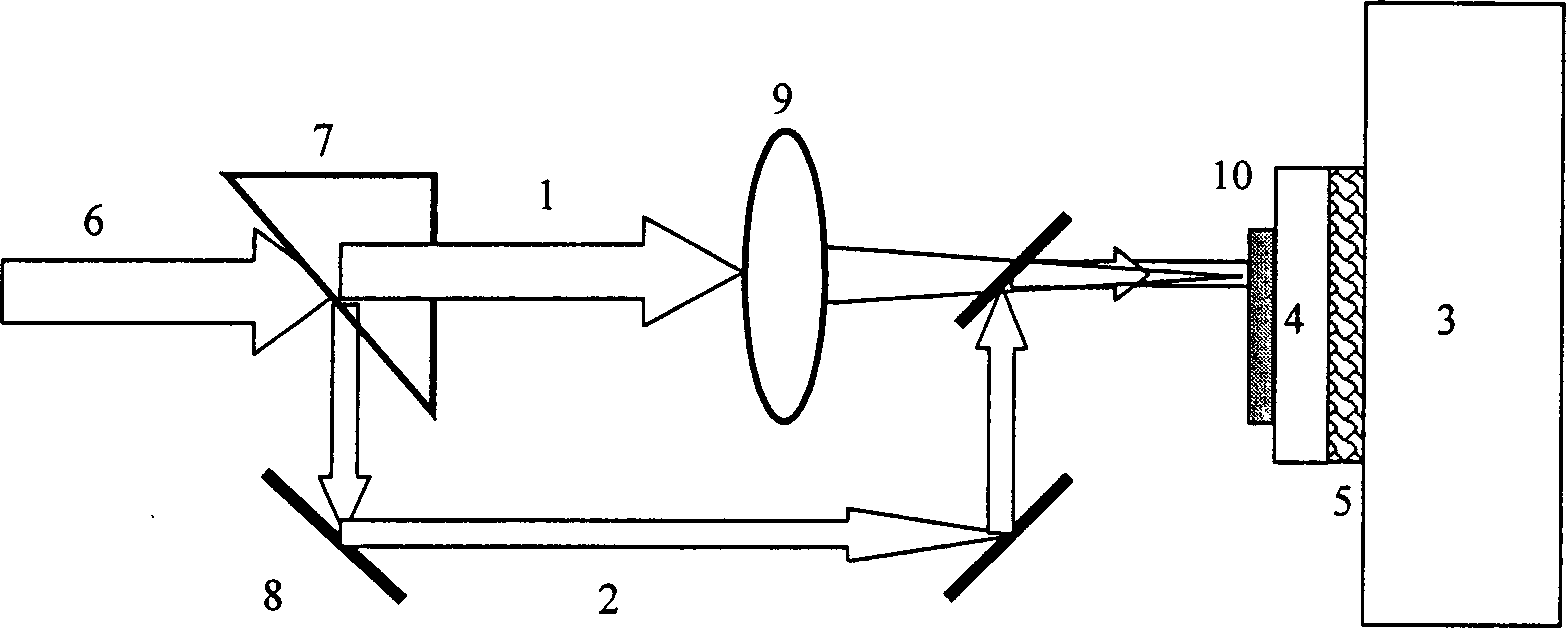

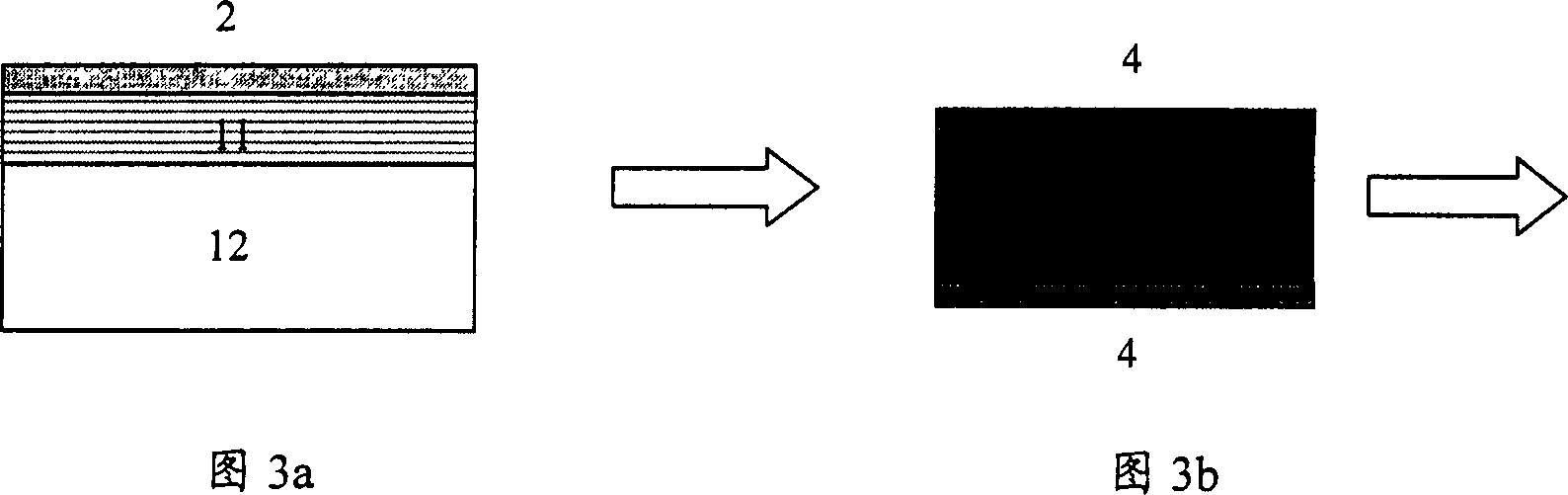

Picosecond laser machining apparatus for processing nozzle micropore

InactiveCN101502914AReduce thermal effectsImprove processing efficiencyLaser beam welding apparatusProcessing accuracyOptical processing

The invention provides a picosecond laser processing device for fuel nozzle microporous processing, which consists of a picosecond laser, a calibrating system and helical optical processing system. An output terminal of the picosecond laser is provided with a first reflecting mirror and the first reflecting mirror is connected with a second reflecting mirror; an output terminal of the second reflecting mirror is provided with an optical gate and an output terminal of the optical gate is connected with a beam extending lens; an output terminal of the beam extending lens is connected with a third reflecting mirror which is connected with the helical optical processing system through the calibrating system. The device is applicable to the fuel nozzle microporous processing and has the advantages of small thermal effect produced in the processing, smooth nozzle edge, no burr on the internal wall and high processing efficiency and accuracy; the diameter of the nozzle can be adjusted and the minimum is up to 60 um; the shape can be ensured to be cylindrical and the diameter depth ratio is up to 1:20, thus greatly increasing the processing accuracy and quality of the nozzle.

Owner:SUZHOU DELPHI LASER

Electrosurgical jaw structure for controlled energy delivery

InactiveUS20050192568A1Prevent any substantial dehydrationEnergy efficiencySurgical instruments for heatingCoatingsElectrical resistance and conductanceConductive materials

A working end of a surgical instrument that carries first and second jaws for delivering energy to tissue. In a preferred embodiment, at least one jaw of the working end defines a tissue-engagement plane that contacts the targeted tissue. The cross-section of the engagement plane reveals that it defines a surface conductive portion that overlies a variably resistive matrix of a temperature-sensitive resistive material or a pressure-sensitive resistive material. An interior of the jaw carries a conductive material or electrode that is coupled to an Rf source and controller. In an exemplary embodiment, the variably resistive matrix can comprise a positive temperature coefficient (PTC) material, such as a ceramic, that is engineered to exhibit a dramatically increasing resistance (i.e., several orders of magnitude) above a specific temperature of the material.

Owner:ETHICON ENDO SURGERY INC

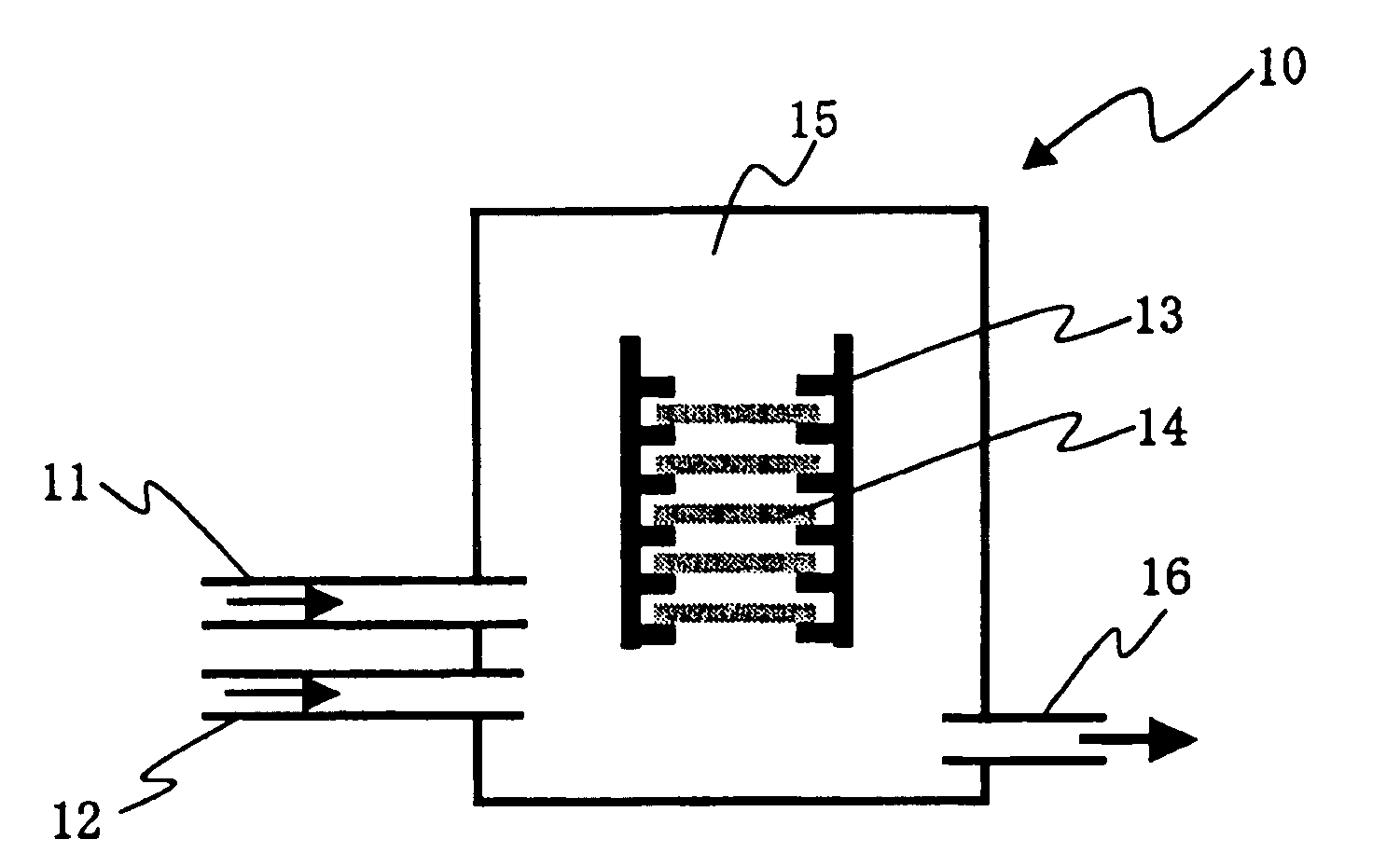

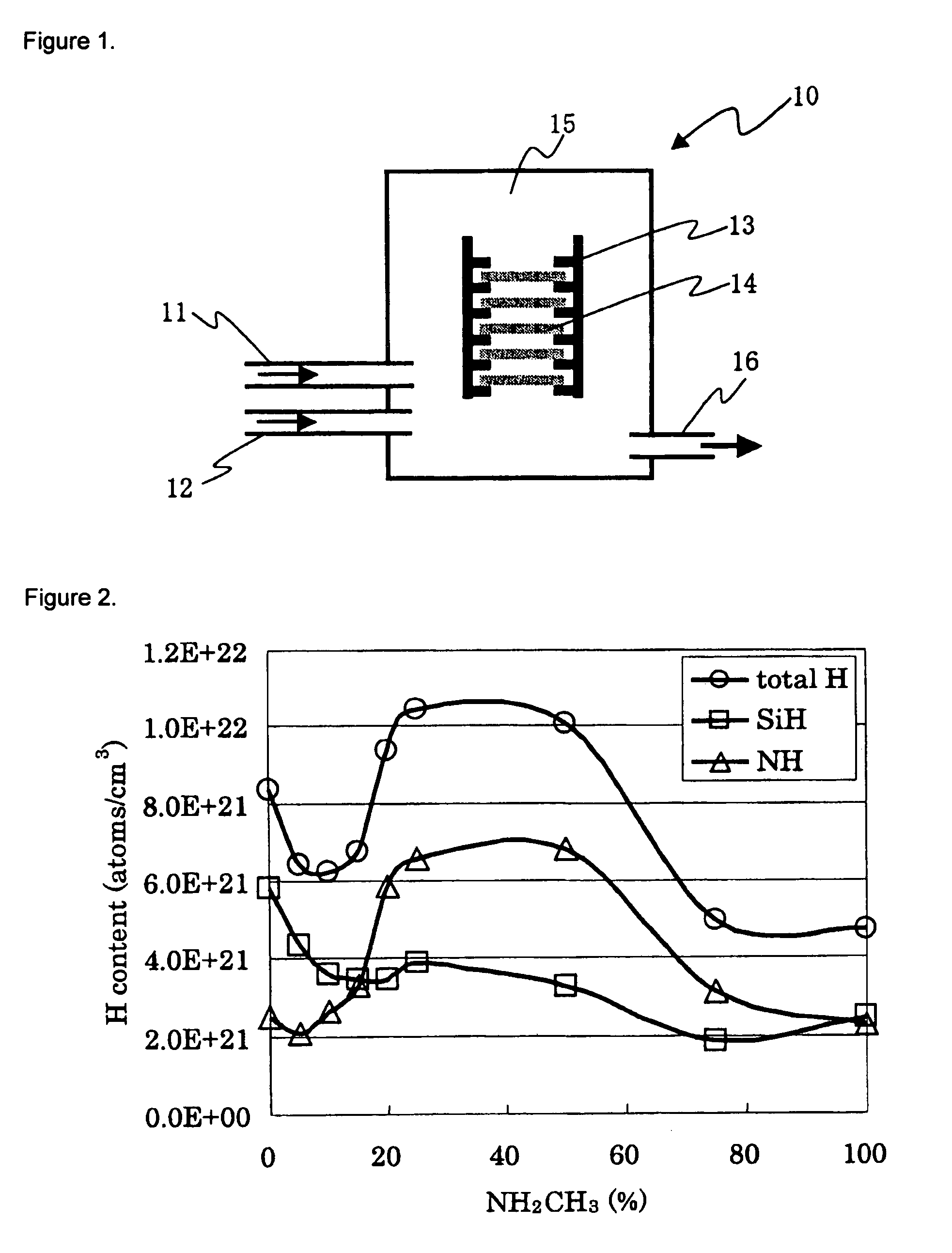

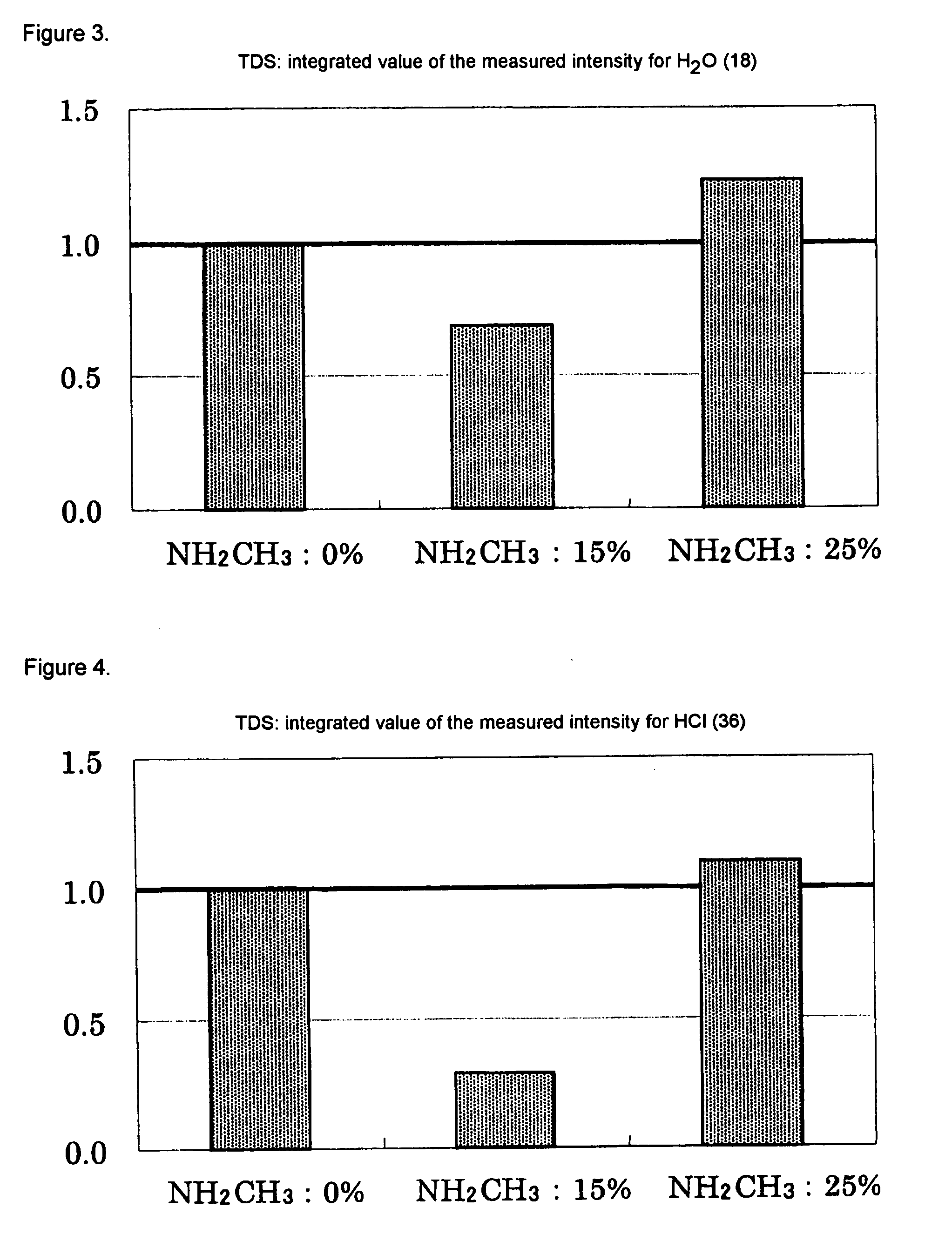

Method for producing silicon nitride films and process for fabricating semiconductor devices using said method

InactiveUS20050158983A1Reduction in thermal budgetImprove film propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceAmmonia

Silicon nitride film is formed on a silicon wafer mounted in a boat in an LPCVD tool by feeding a silicon source (SiH2Cl2, SiCl4, Si2Cl6, etc.) from an injector and feeding a mixed gas of monomethylamine (CH3NH2) and ammonia (NH3) as the nitrogen source from an injector. This addition of monomethylamine to the source substances for film production makes it possible to provide an improved film quality and improved leakage characteristics even at low temperatures (450-600° C.).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

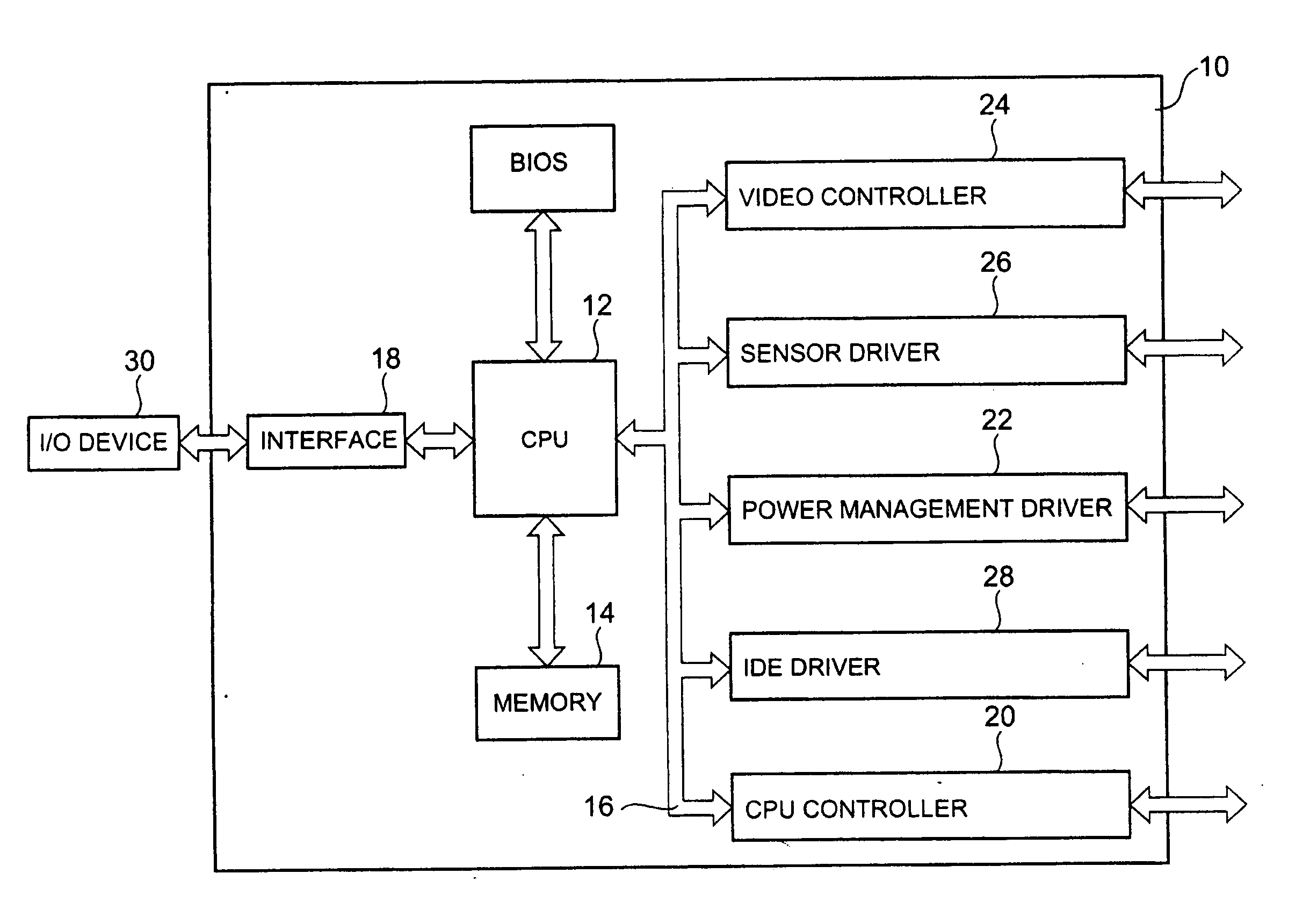

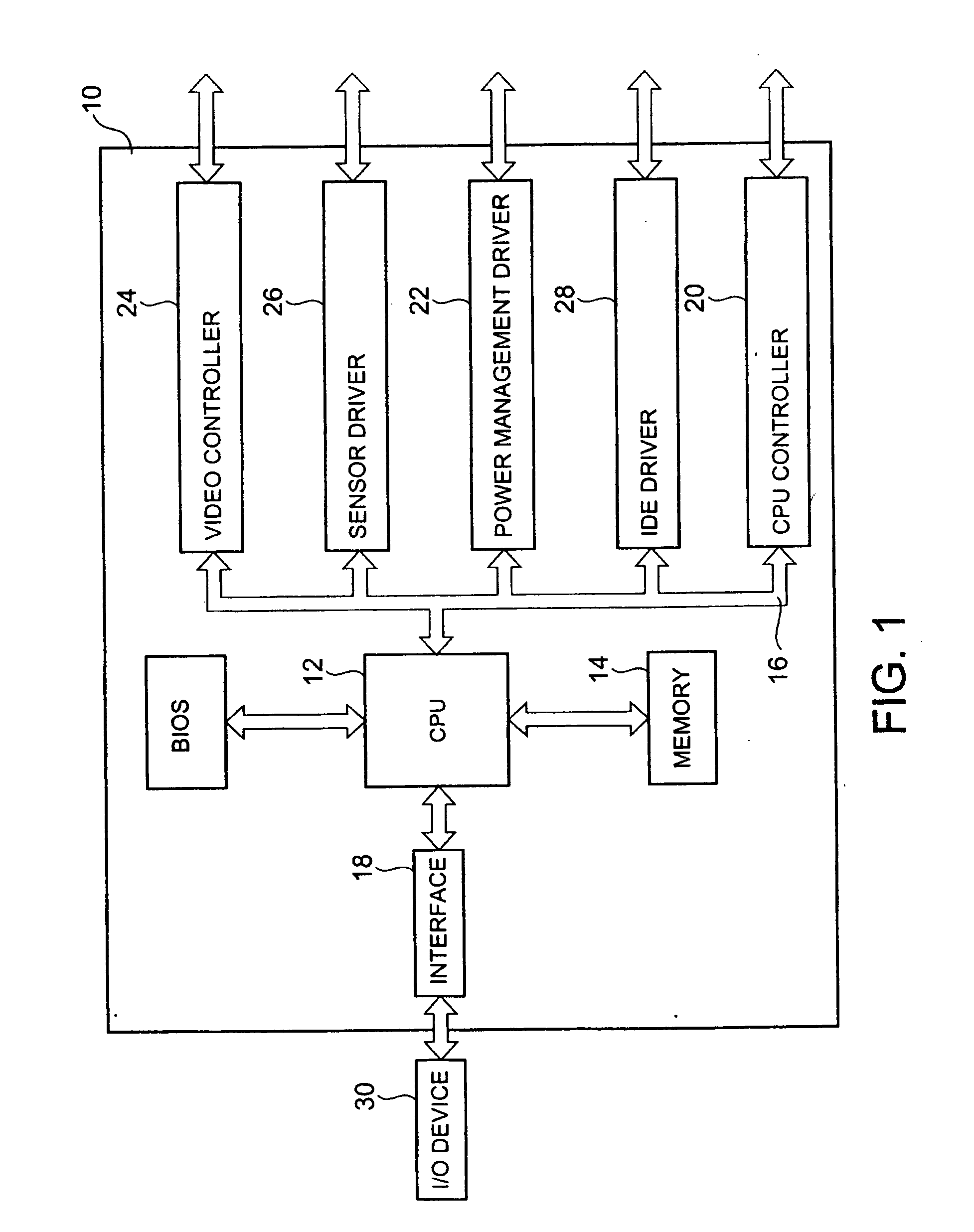

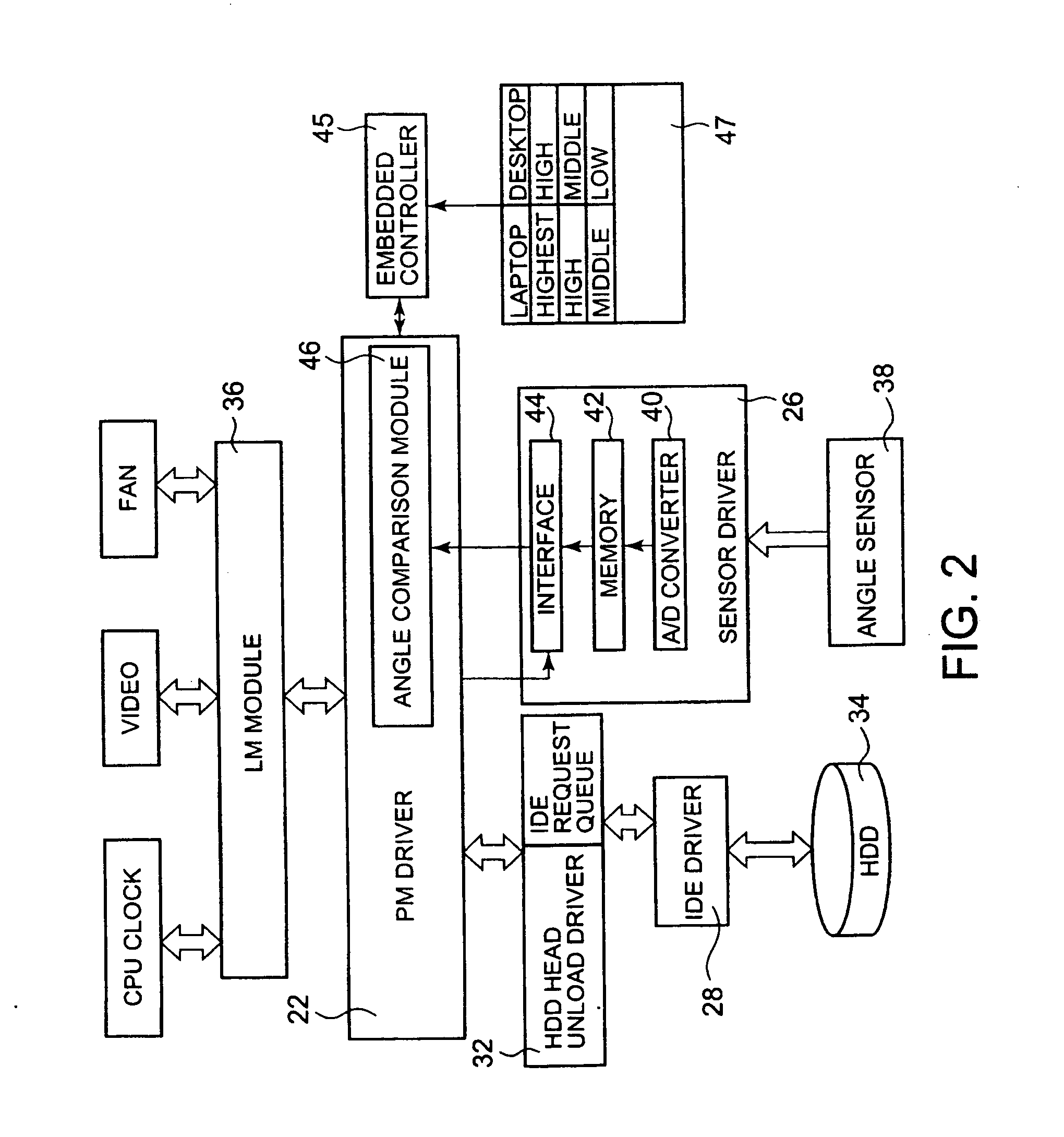

Managing laptop power based on display angle

ActiveUS20060139326A1Precise managementComfortable mobile environmentEnergy efficient ICTCathode-ray tube indicatorsEmbedded systemPower management

A notebook type of computer of one embodiment includes a display unit, a housing to which the display unit is pivotally attached, an angle sensor which detects an opening angle between the display unit and the housing, a sensor driver which A / D converts an output from the angle sensor and passes the result to a power management driver, and an angle comparison module which reads a setting value as to the opening angle and determines whether the opening angle is within a range of a predetermined angle. If the opening angle is within the predetermined range, a user is presumed to be using the notebook computer on a lap and the power management operation is performed per that presumption.

Owner:LENOVO PC INT

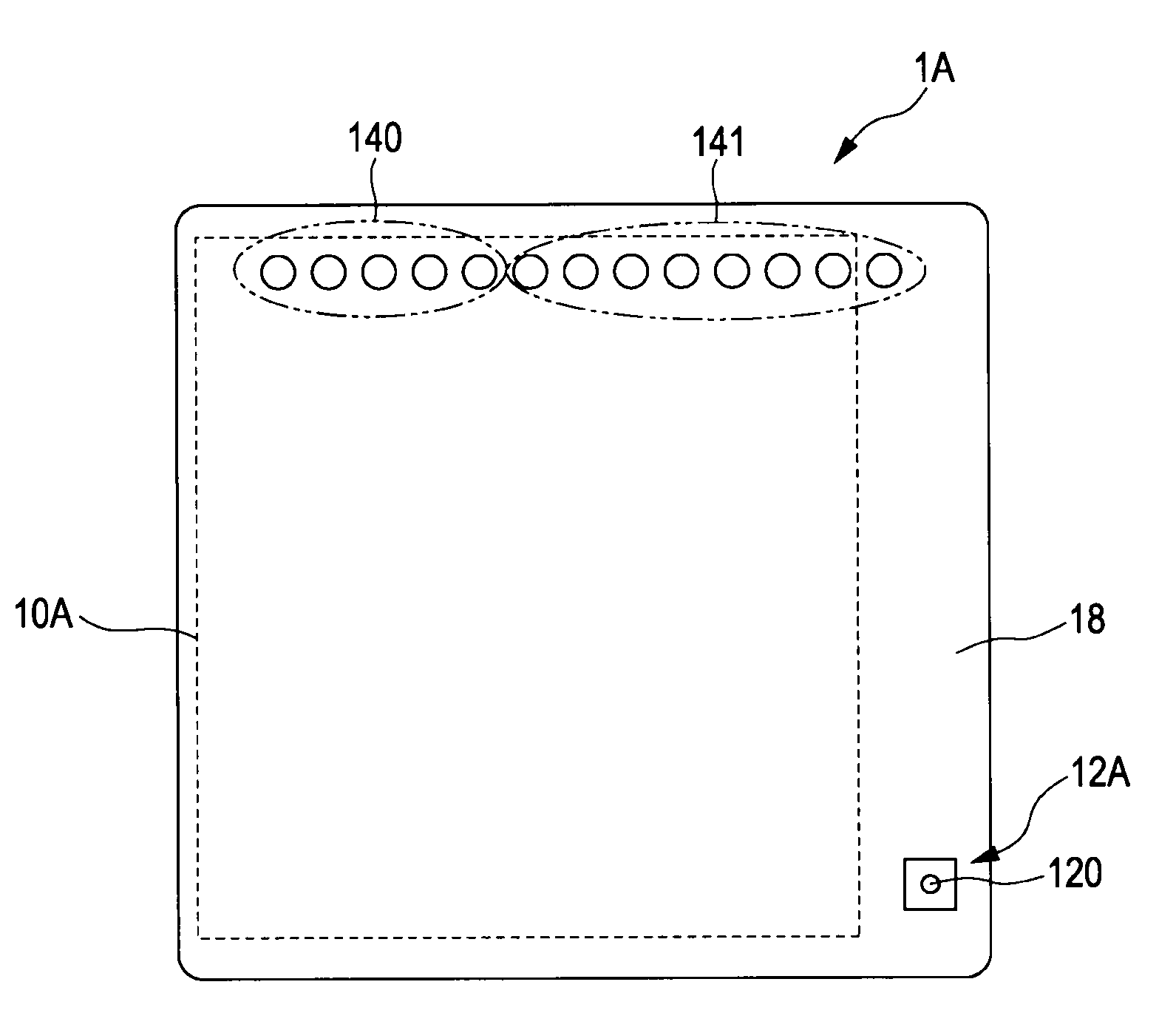

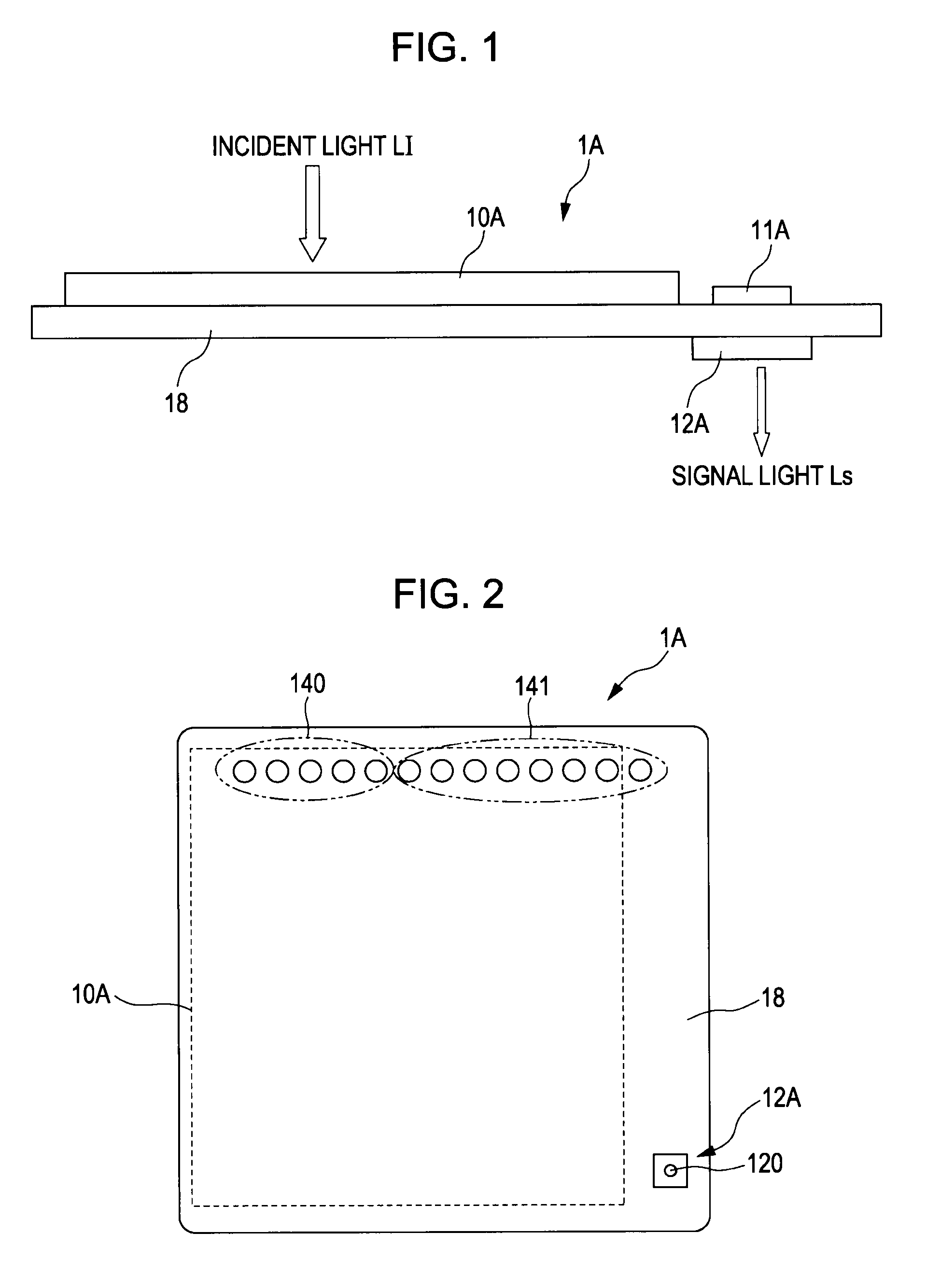

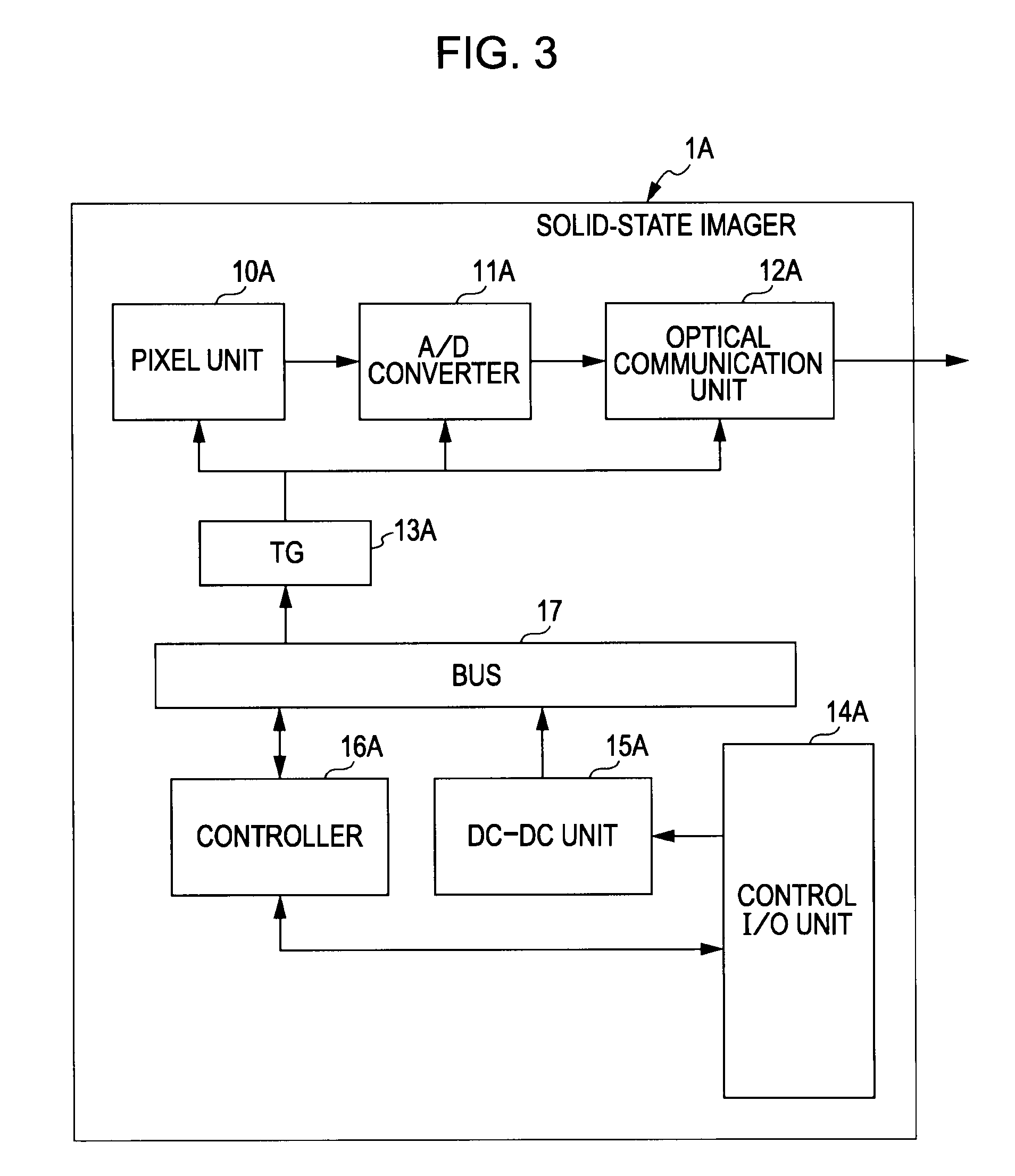

Solid-state imager and signal processing system

InactiveUS20100091128A1Improve layout freedomReduce thermal effectsTelevision system detailsTelevision system scanning detailsEngineeringLight signal

A solid-state imager includes a pixel unit for converting incident light into an electrical signal, a substrate bearing the pixel unit formed thereon, an analog-to-digital converter, formed on the substrate, for converting a signal read from the pixel unit into a digital signal, an optical communication unit, arranged on the bottom surface of the substrate opposite the surface of the substrate bearing opposite the top surface of the substrate bearing the pixel unit receiving the incident light, for converting the digital signal converted by the analog-to-digital converter into a light signal and outputting the light signal, and a signal line for transferring the digital signal, converted by the analog-to-digital converter, to the optical communication unit arranged on the bottom surface of the substrate.

Owner:SONY CORP

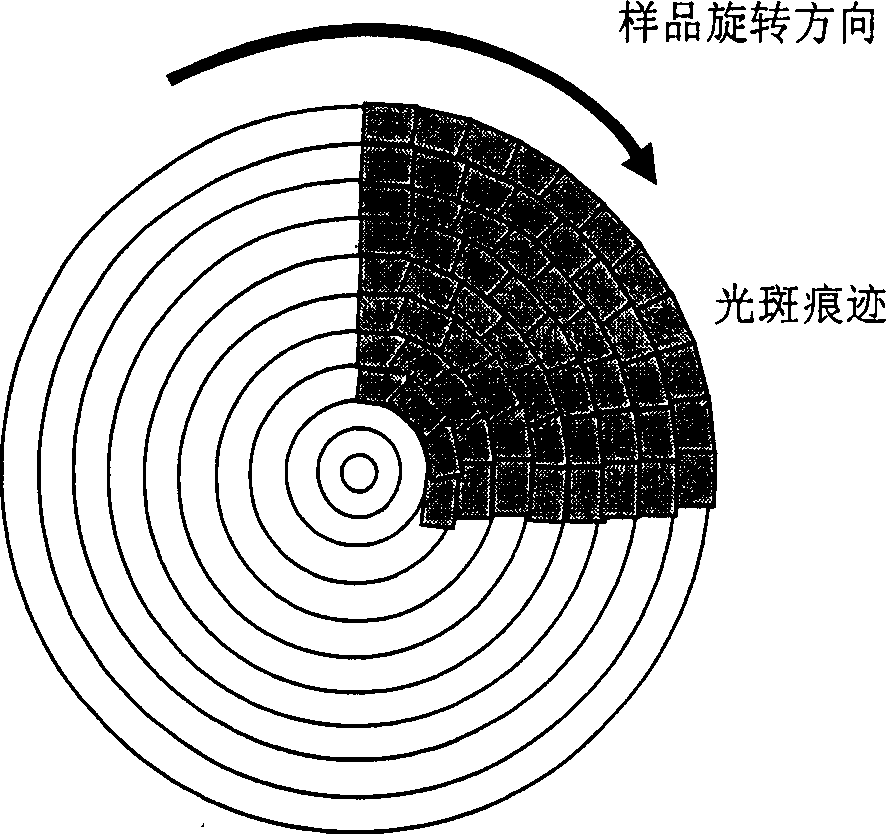

Large-area and low-power laser stripping method for GaN-base epitaxial layer

ActiveCN1779900AAvoid damageSmooth releaseLaser detailsFinal product manufactureOptoelectronicsPulsed laser beam

Owner:SINO NITRIDE SEMICON

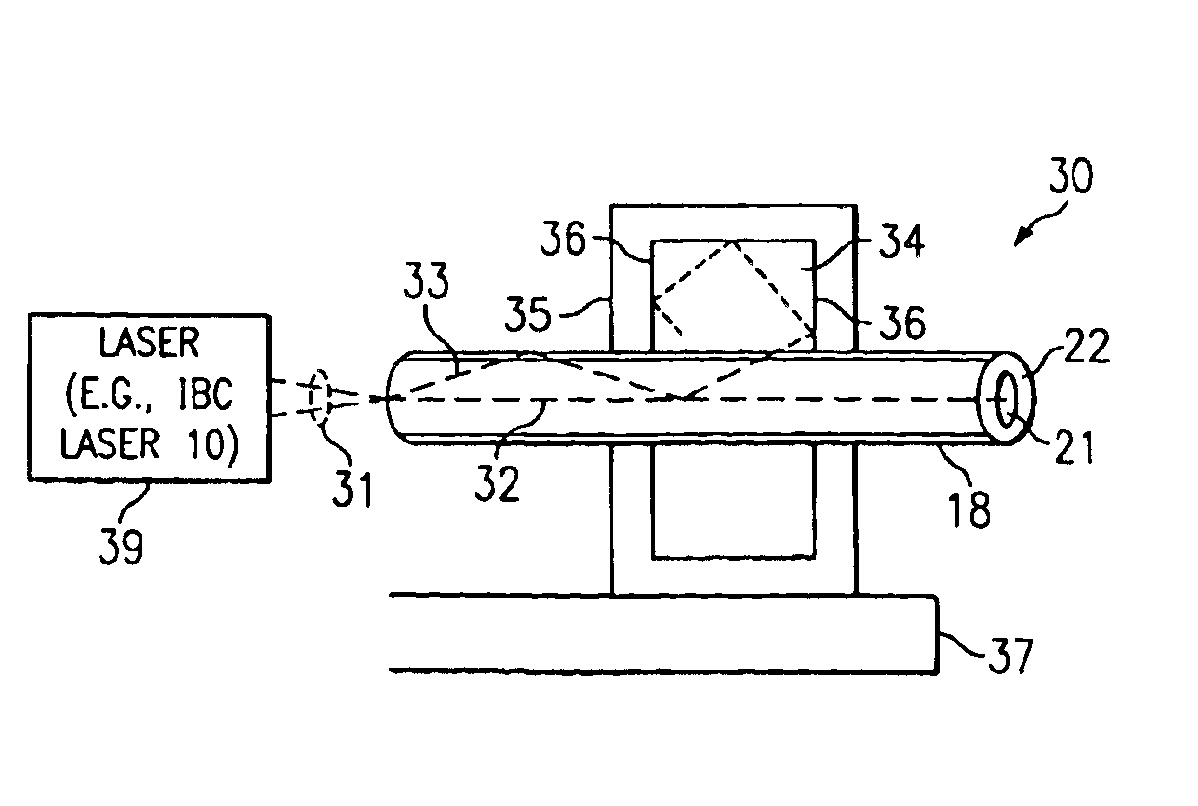

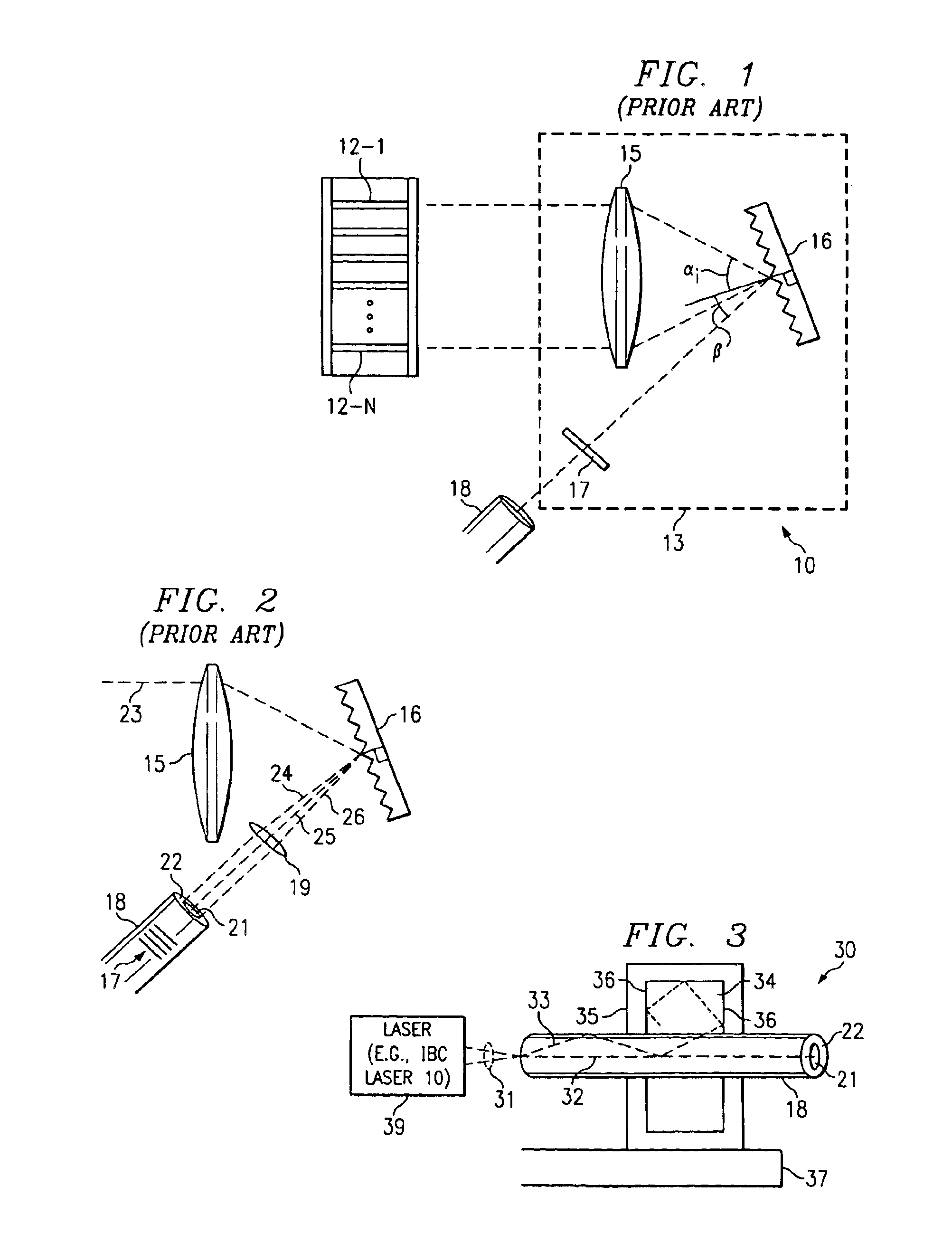

System and method of operating low coupling efficiency optical source by dissipating cladding modes

InactiveUS6865316B1Reduce thermal effectsDissipate optical powerCoupling light guidesOptical powerCladding mode

An embodiment is directed to a system for dissipating cladding modes of an optical fiber. In the system, a high power light source couples optical power into the optical fiber at a fiber coupling point thereby producing the cladding modes; material is indexed-matched to the optical fiber and is optically contacted to the optical fiber near the fiber coupling point; and a substrate layer is operable to provide a thermal sink for heat generated from dissipation of cladding modes of the optical fiber.

Owner:NLIGHT INC

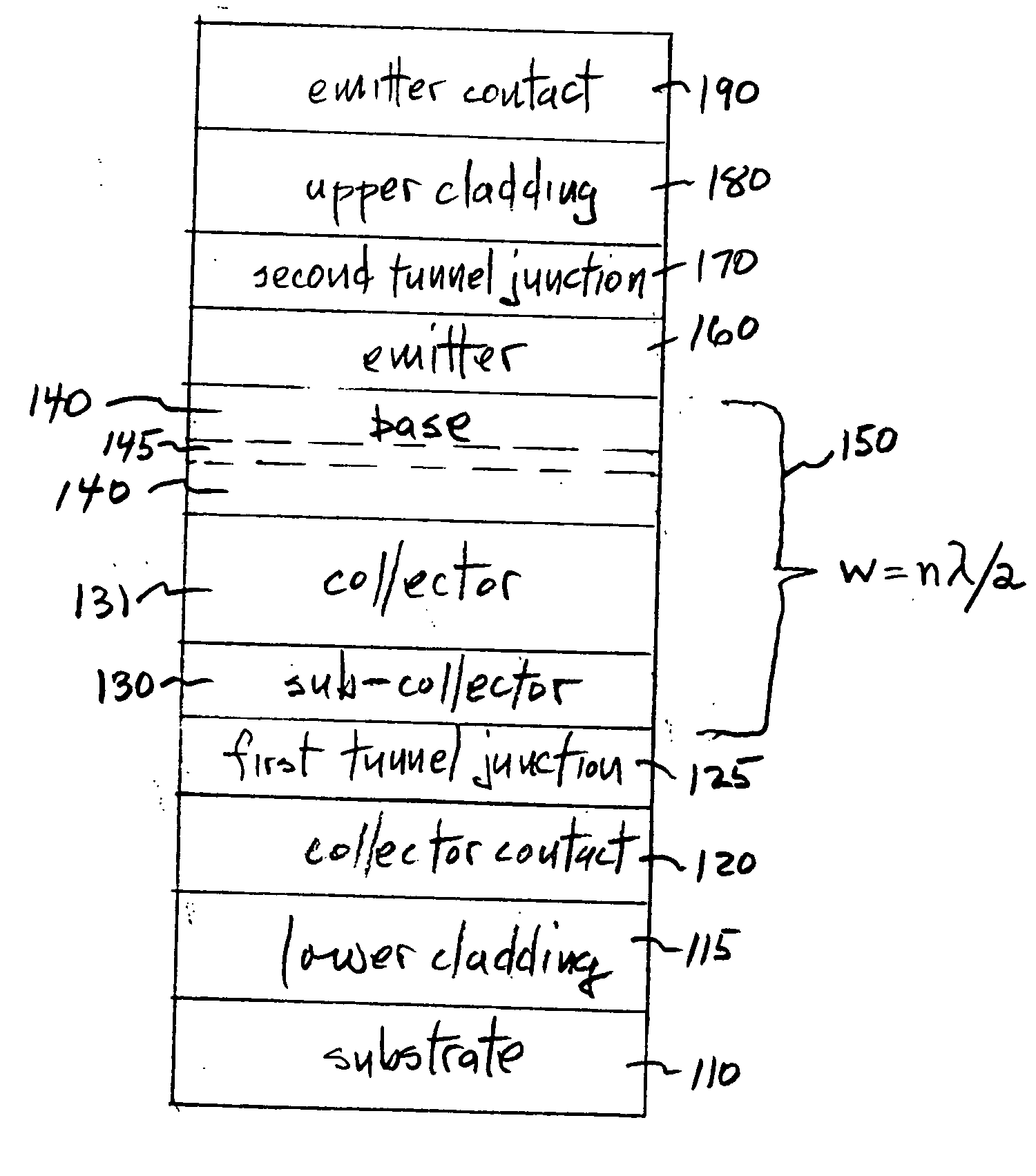

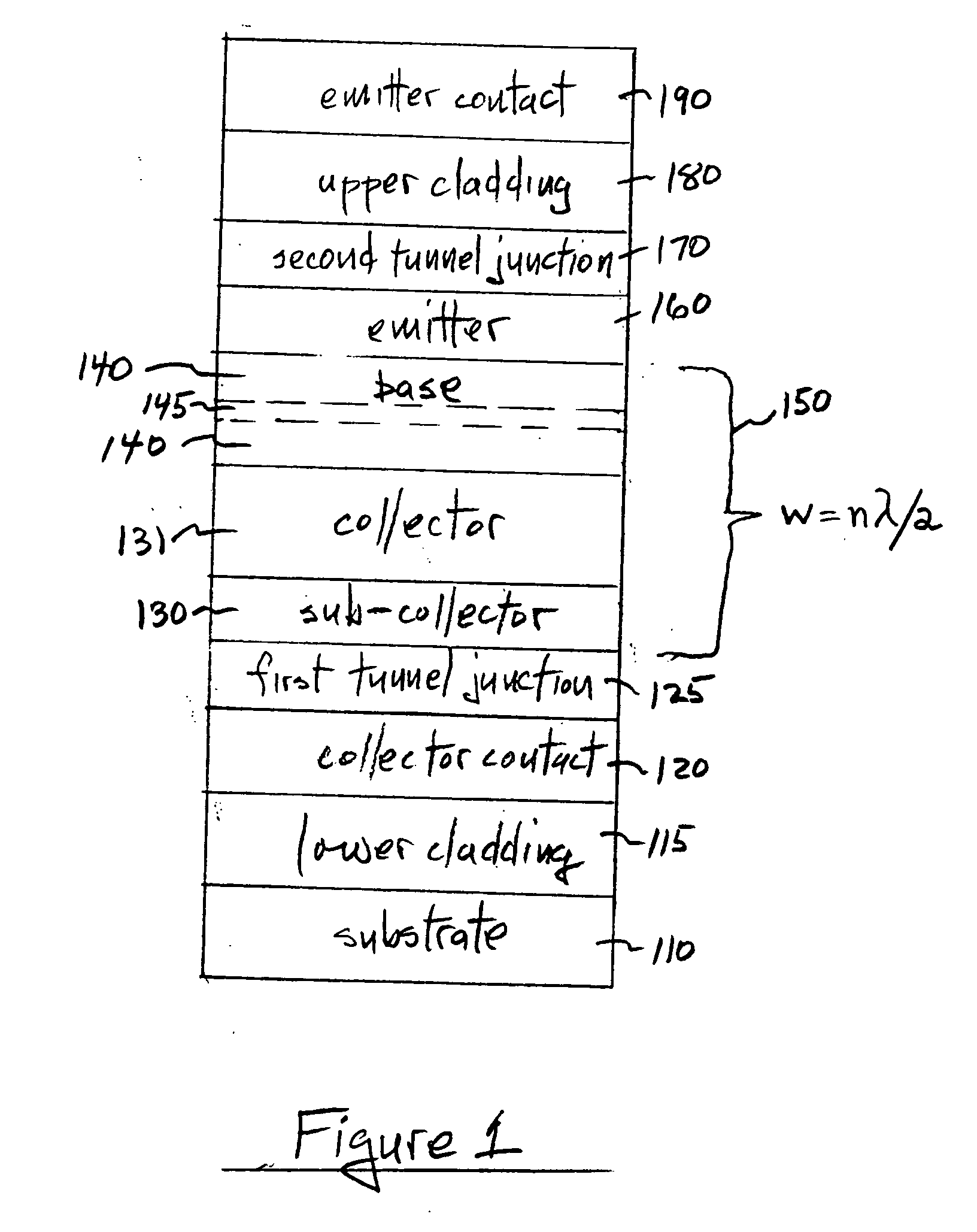

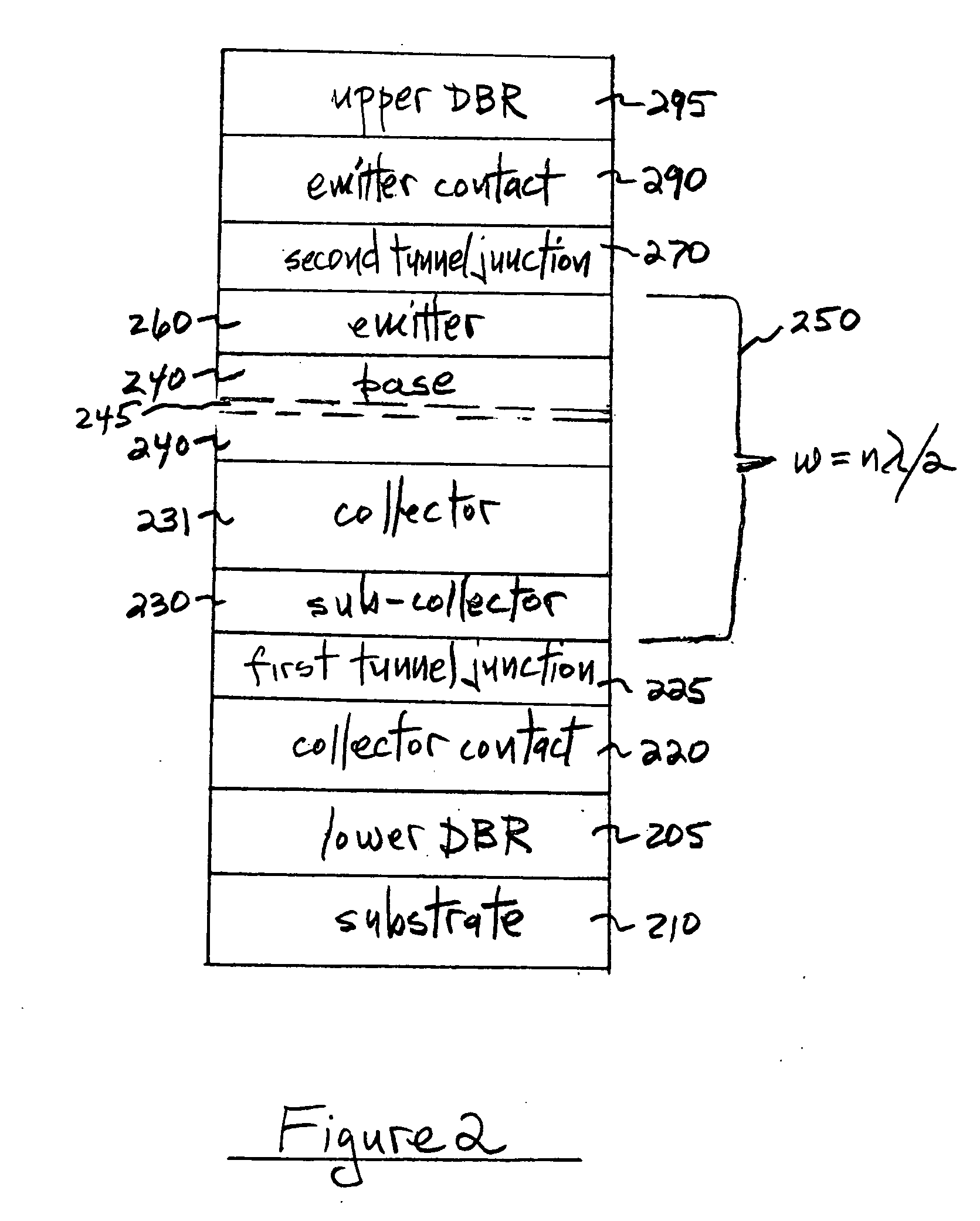

PNP light emitting transistor and method

ActiveUS20070201523A1Quantity minimizationThickness minimizationSemiconductor lasersLaser cooling arrangementsLight emissionSemiconductor

A semiconductor light-emitting transistor device, including: a bipolar pnp transistor structure having a p-type collector, an n-type base, and a p-type emitter; a first tunnel junction coupled with the collector, and a second tunnel junction coupled with the emitter; and a collector contact coupled with the first tunnel junction, an emitter contact coupled with the second tunnel junction, and a base contact coupled with the base; whereby, signals applied with respect to the collector, base, and emitter contacts causes light emission from the base by radiative recombination in the base.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Aluminum alloy workpiece additive manufacturing method implemented through friction stir welding

InactiveCN109108505AImprove mechanical propertiesElimination of internal tissue for refinementWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingVolumetric Mass Density

The invention discloses an aluminum alloy workpiece additive manufacturing method implemented through friction stir welding. On the basis of an existing electric arc additive manufacturing aluminum alloy workpiece, the characteristic that aluminum alloy is soft in property is combined, after an aluminum alloy workpiece is manufactured from electric arc additives layer by layer, friction stir welding intensification treatment is conducted on each layer, and therefore, defects such as pass gaps, interlayer incomplete fusion, air holes and the like can be eliminated through friction stir weldingwhen each layer is manufactured. Compared with the pure electric arc additive manufacturing aluminum alloy workpiece, by means of the method, the structural state of the aluminum alloy workpiece obtained through additive manufacturing can be improved; the grains can be finer; second-phase grains are finer and are distributed more uniformly; and the dislocation density achieved in the aluminum alloy additive manufacturing workpiece is increased. Compared with existing friction stir welding intensification, grain refining and defect elimination are conducted on each layer of the workpiece so that the strength of the whole workpiece can be improved rather than only surface modification, namely surface intensification, is conducted.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

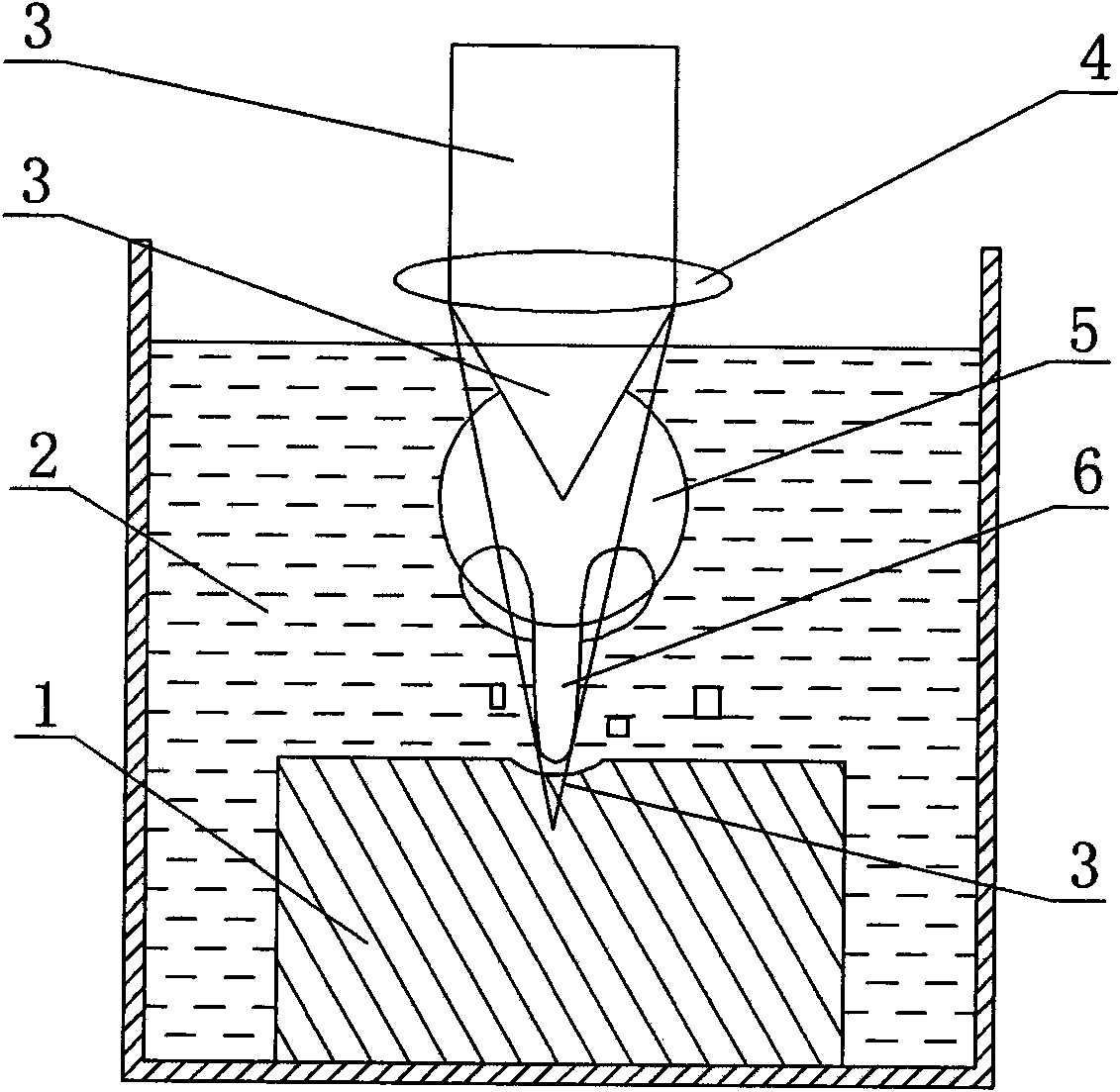

Method for performing microprocessing by utilizing laser cavitation micro jet flow

InactiveCN102248308AAvoid heat damageNo redepositionLaser beam welding apparatusShock waveLaser etching

The invention discloses a method for performing microprocessing by utilizing laser cavitation micro jet flow. The method comprises the following steps of: 1) placing a workpiece to be processed into liquid; 2) focusing laser beams in liquid near the workpiece through a lens group and generating cavitation effect at the focal point; 3) triggering high-speed microjet flow pointing to the workpiece by the cavitation effect and generating high-strength micro shock wave; 4) impacting the high-speed micro jet flow to the surface of the workpiece to form extremely high pressure intensity to damage a material on the surface of the workpiece and removing the material on the surface of the workpiece under the synergism of the high-speed microjet flow and micro shock wave; and 5) processing a fine surface structure on the workpiece under the action of continuous laser pulse and longitudinal or transverse feed of a laser head. Compared with the laser etching technique in the prior art, the method has the advantages of avoiding thermal damage of the workpiece due to low heat effect, not generating phenomenon of depositing processing splash again in the processing process, achieving higher processing precision and contributing to improving processing efficiency.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com