Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

A technology of composite processing and spraying liquid, applied in the field of structure, to achieve the effect of promoting electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

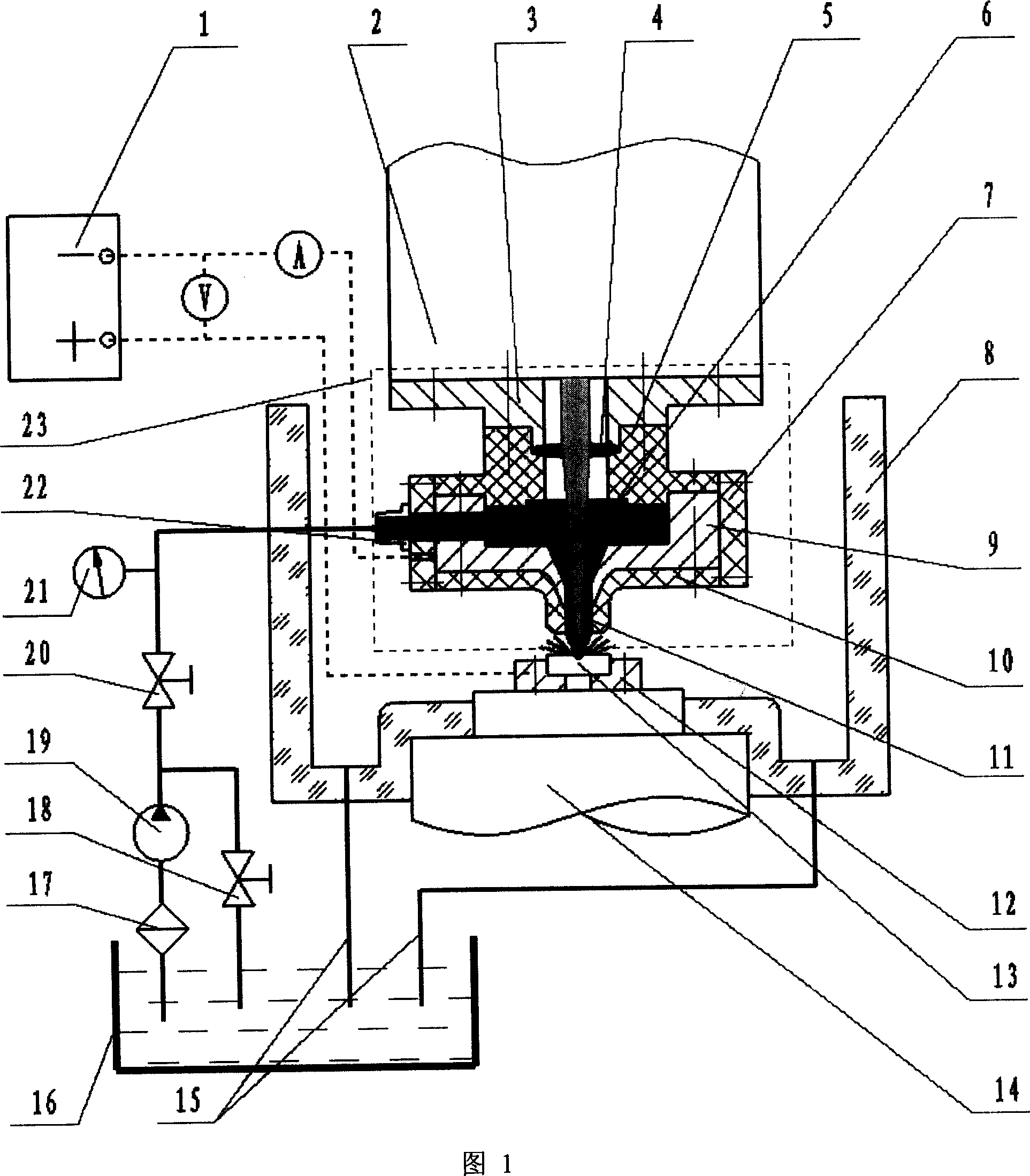

[0020] Embodiment 1: This embodiment is a jetted liquid beam electrolysis-laser composite processing method. First, a laser beam generator is used to generate a laser beam to process holes on a workpiece. At the same time, a jetted liquid beam device is used to generate a high-speed coaxial with the laser beam. The jet liquid beam, the laser beam removes the material under the guidance of the jet liquid beam. While the jet liquid beam cools and flushes the laser processing area, it also performs electrochemical anode dissolution, which can effectively thin the recast layer to less than 0.01mm, even Completely eliminated.

[0021] The spray liquid is ultrapure water, and a neutral salt solution can also be used; the ultrapure water is deionized water or distilled water; the neutral salt solution is a low-concentration neutral salt solution with a concentration of 3%-15% .

Embodiment 2

[0022] Embodiment 2: This embodiment is a jet beam electrolysis-laser composite processing device, which includes a laser 2 and a workpiece mounting fixture 12, and also includes a DC power supply 1 and a jet jet device 23, where the jet jet device 23 includes a jet device installation Base 3, insulating adapter 5, cathode 9, focusing lens 4, protective mirror 6, insulating jacket 7 and nozzle 11, spray device mounting base 3 is connected to laser 2 and insulating adapter 5 respectively; cathode 9 is connected to insulating adapter The base 5 is connected, the hollow part of the cathode 9 forms a liquid jet cavity, the cathode 9 and the laser beam generated by the laser 2 are installed coaxially; the focusing lens 4 and the protective mirror 6 are respectively fixed on the upper and lower ends of the insulating adapter 5; the cathode 9 is equipped with an insulating jacket 7, the nozzle 11 is fixed at the lower end of the insulating jacket 7, the laser beam generated by the laser ...

Embodiment 3

[0026] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, and the power supply 1 is a DC pulse power supply.

[0027] When the devices of Example 2 and Example 3 work, first connect the clamp 12 to the positive electrode of the power source 1 through a conductive block to make the workpiece 13 positively charged, and connect the cathode 9 coaxially installed with the laser beam to the negative electrode of the power source 1 to spray liquid The beam charging is "cathodicized" and coaxial with the laser beam and jetting at a certain speed. The jet speed can be adjusted by the overflow pressure regulating valve 18; the laser 2 emits the laser light which is focused on the surface processing position of the workpiece by the focusing lens 4 for laser drilling. At the same time, the cooling and scouring effect of the jetted liquid beam on the laser processing area, and the "cathodicized" jetted electrolyte beam will cause the electrolysis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com