Patents

Literature

703 results about "Electrochemical machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical machining (ECM) is a method of removing metal by an electrochemical process. It is normally used for mass production and is used for working extremely hard materials or materials that are difficult to machine using conventional methods. Its use is limited to electrically conductive materials. ECM can cut small or odd-shaped angles, intricate contours or cavities in hard and exotic metals, such as titanium aluminides, Inconel, Waspaloy, and high nickel, cobalt, and rhenium alloys. Both external and internal geometries can be machined.

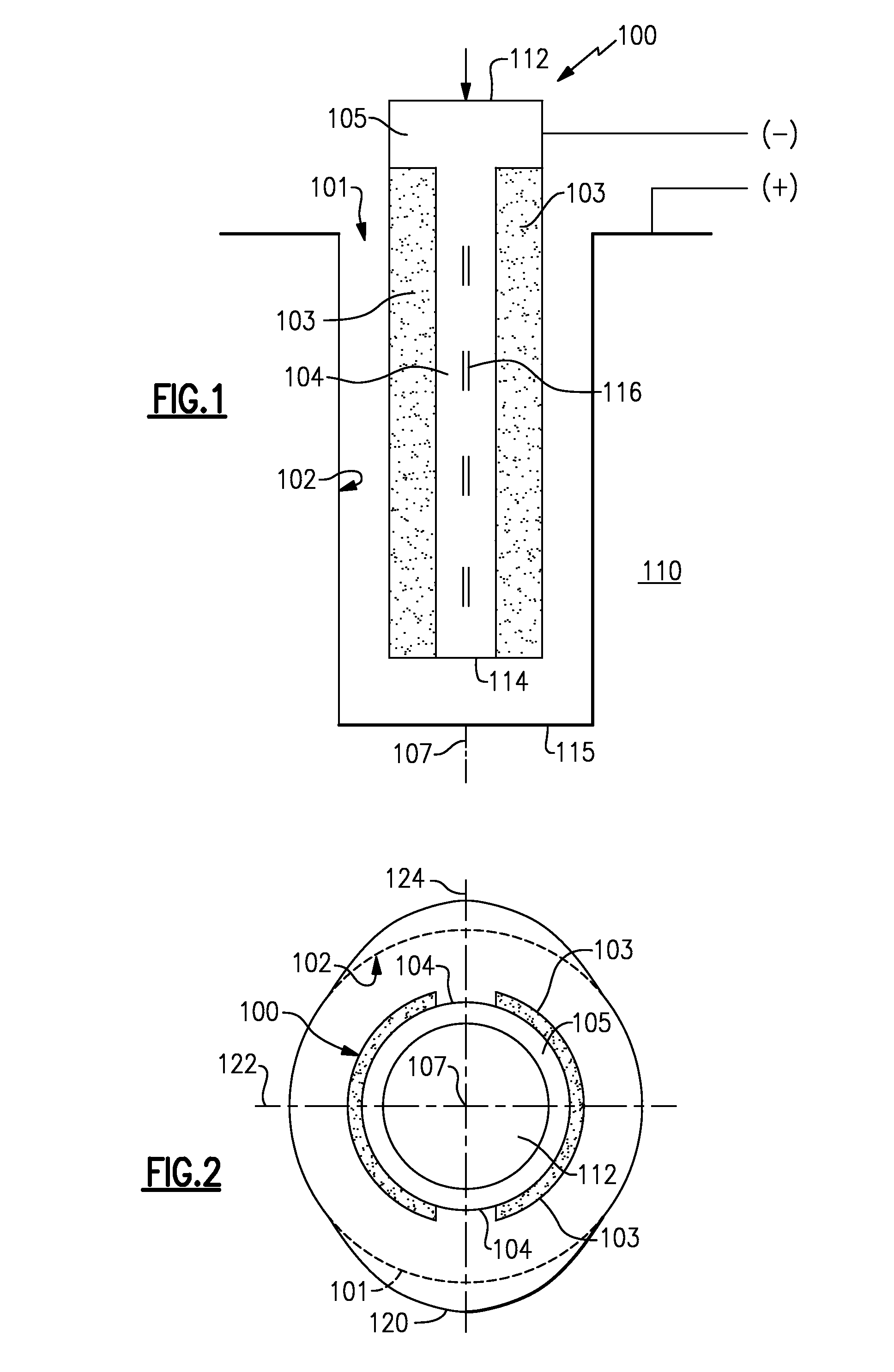

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

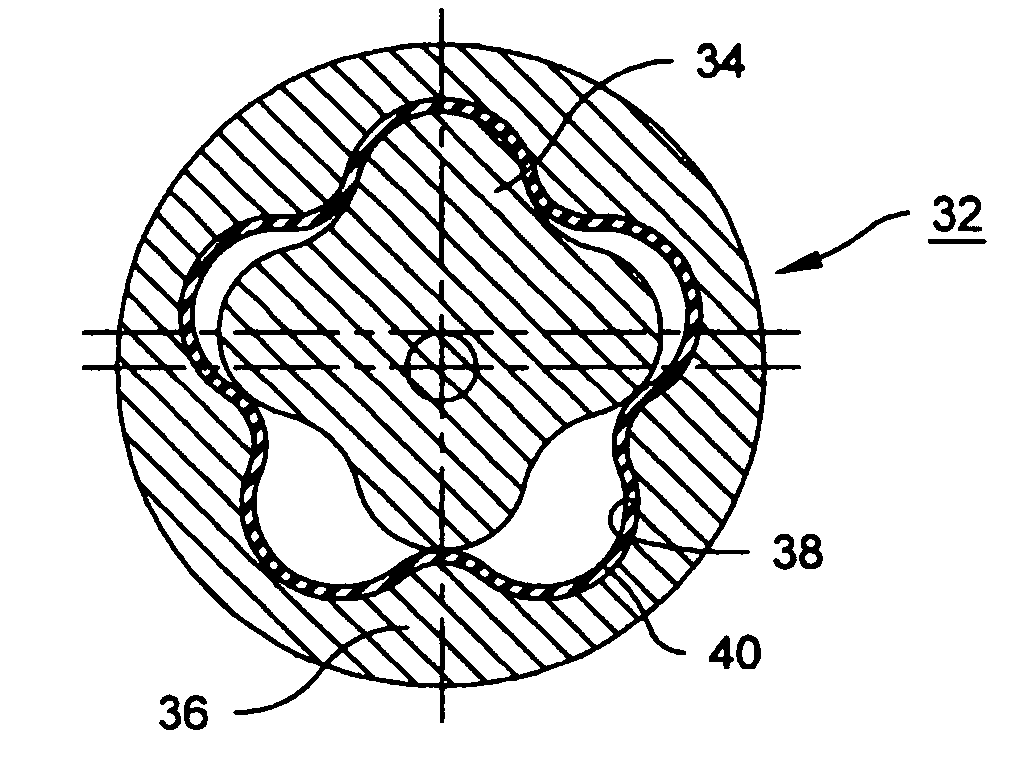

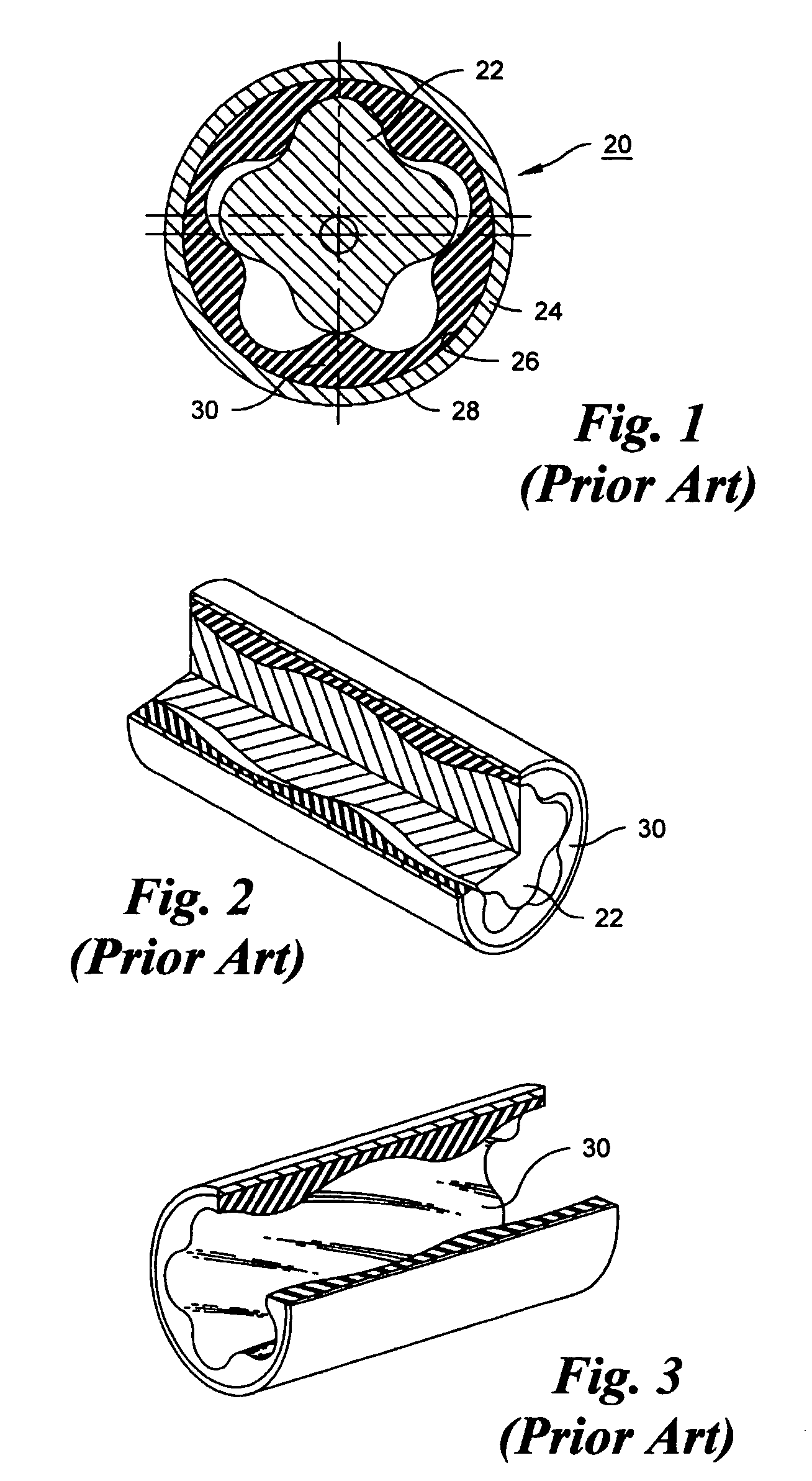

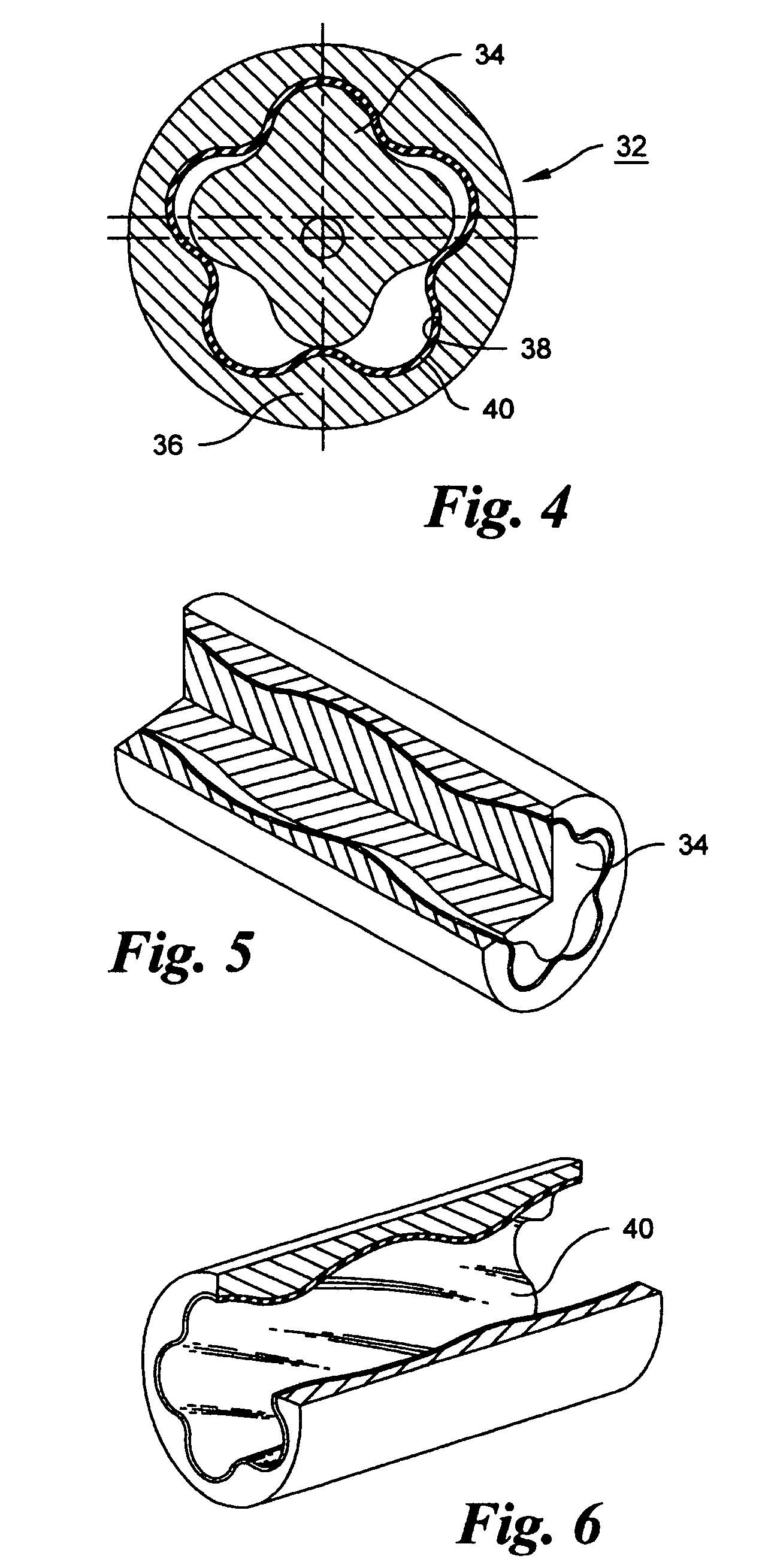

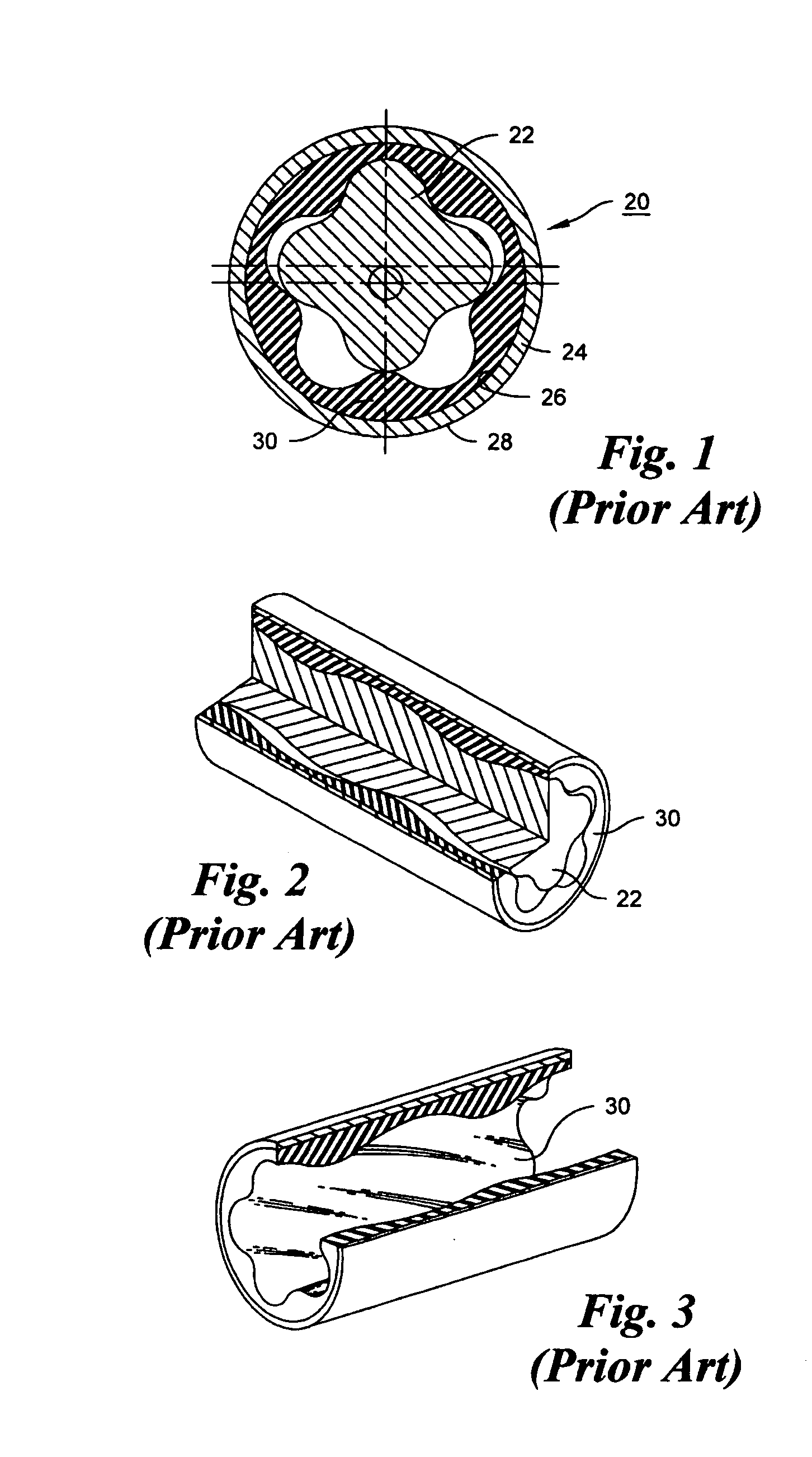

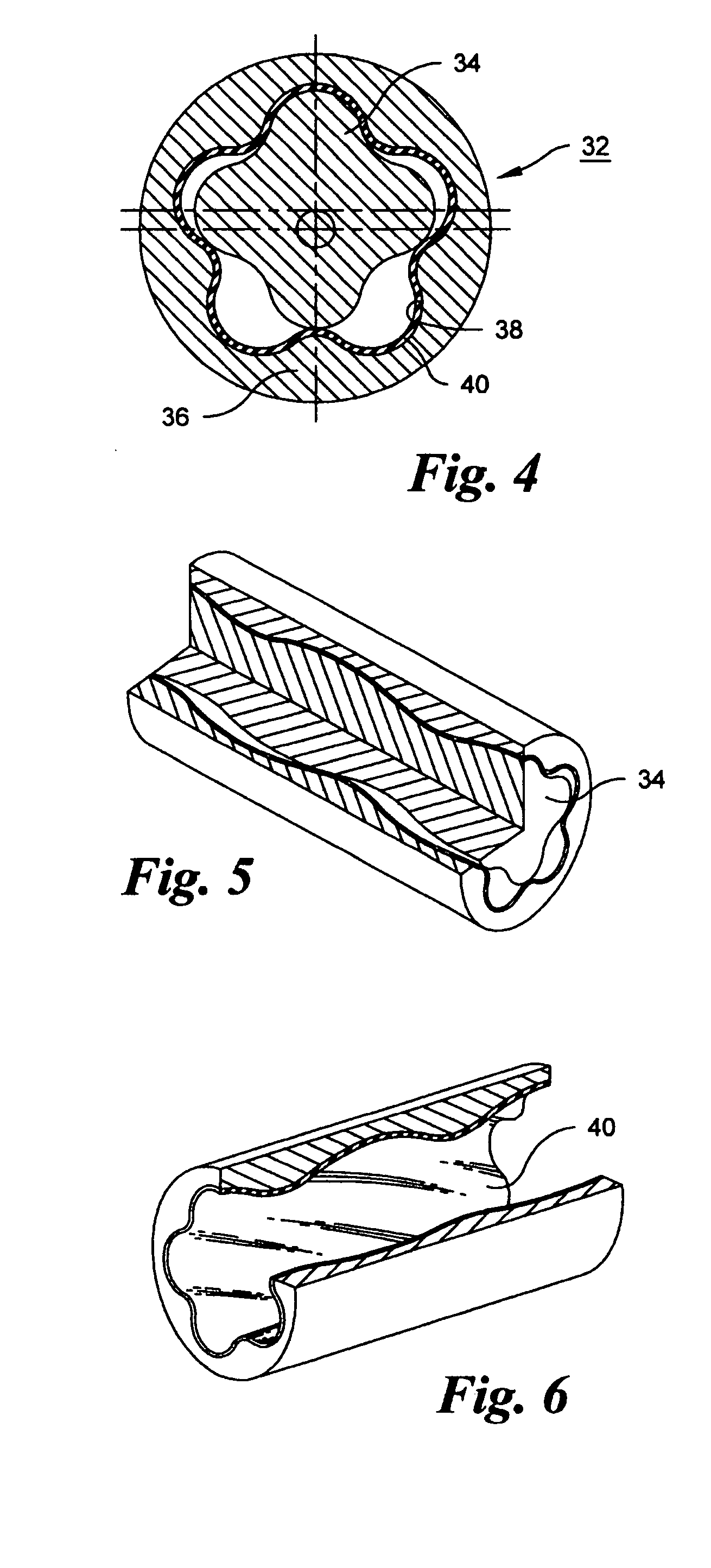

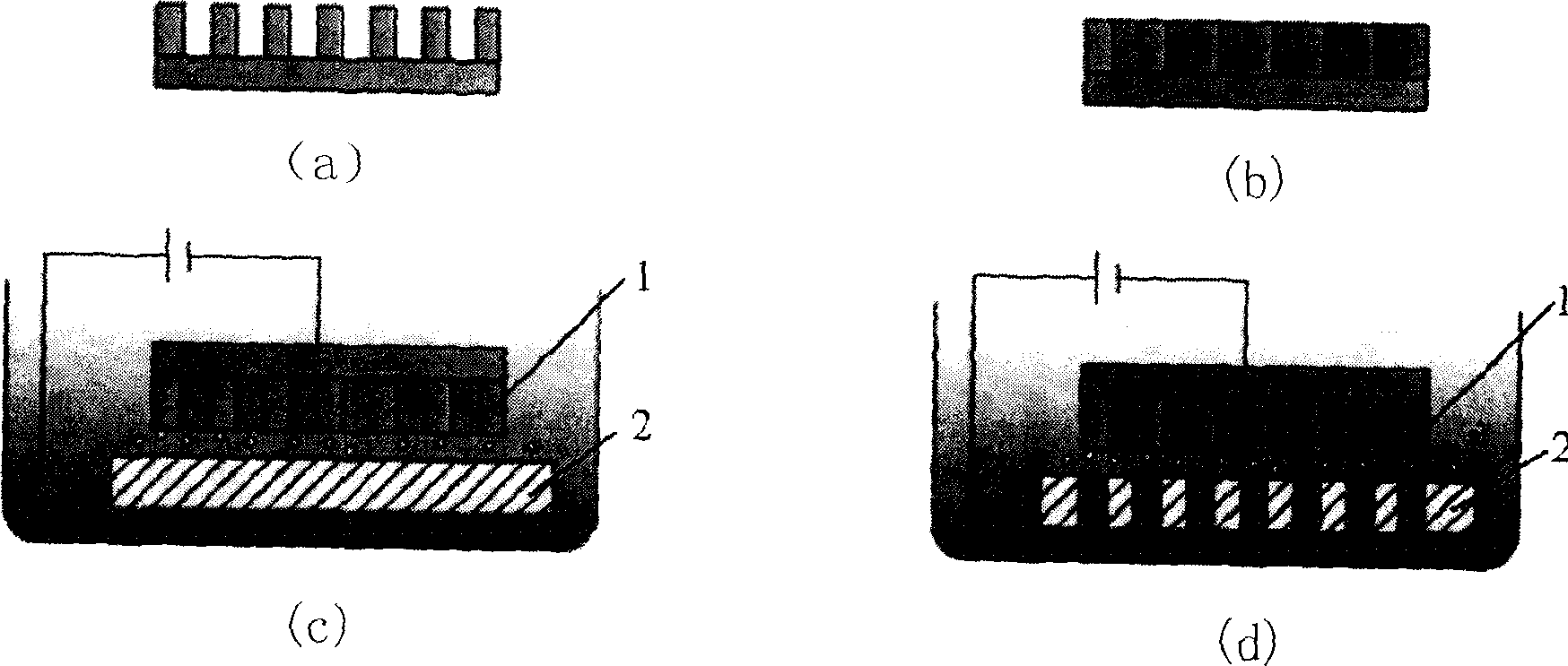

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Applications of laser-processed substrate for molecular diagnostics

ActiveUS20070115469A1Facilitate SERS analysisMaterial nanotechnologyRadiation pyrometryChemical reactionPhotonics

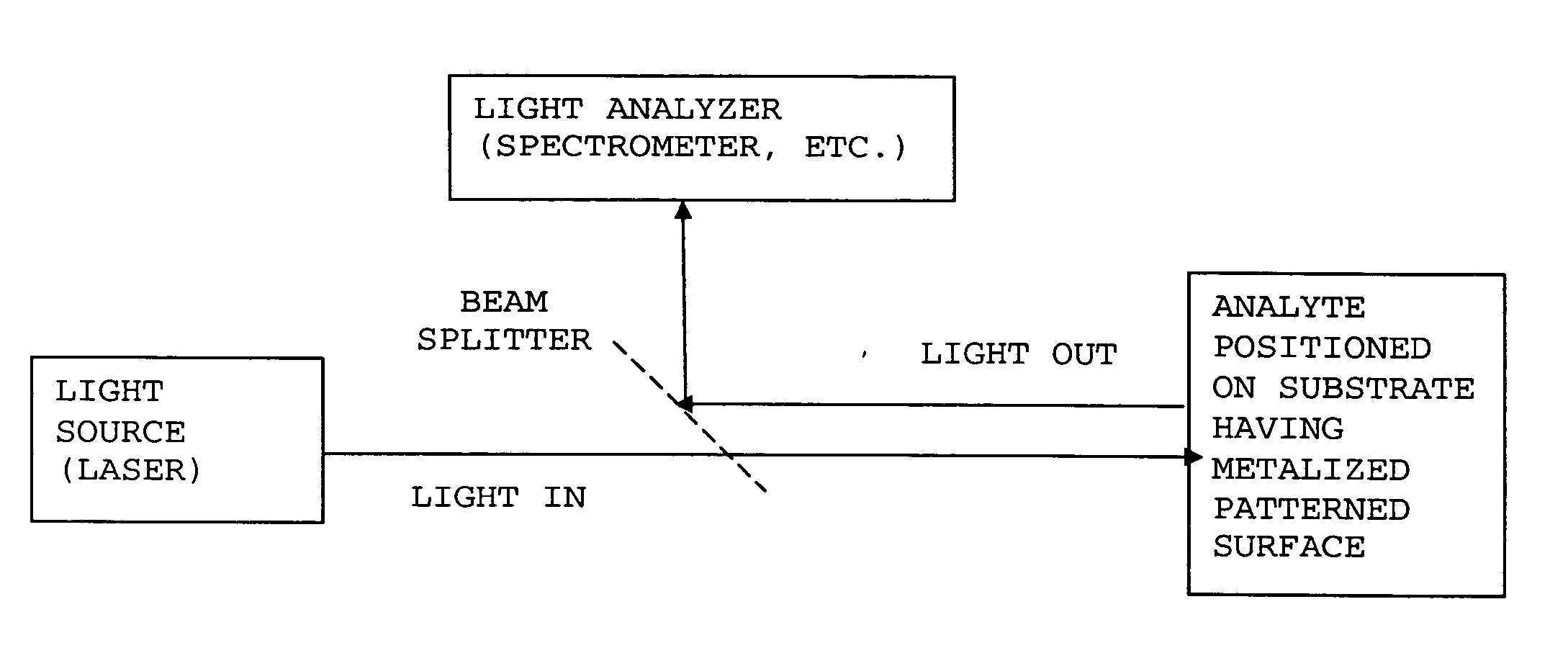

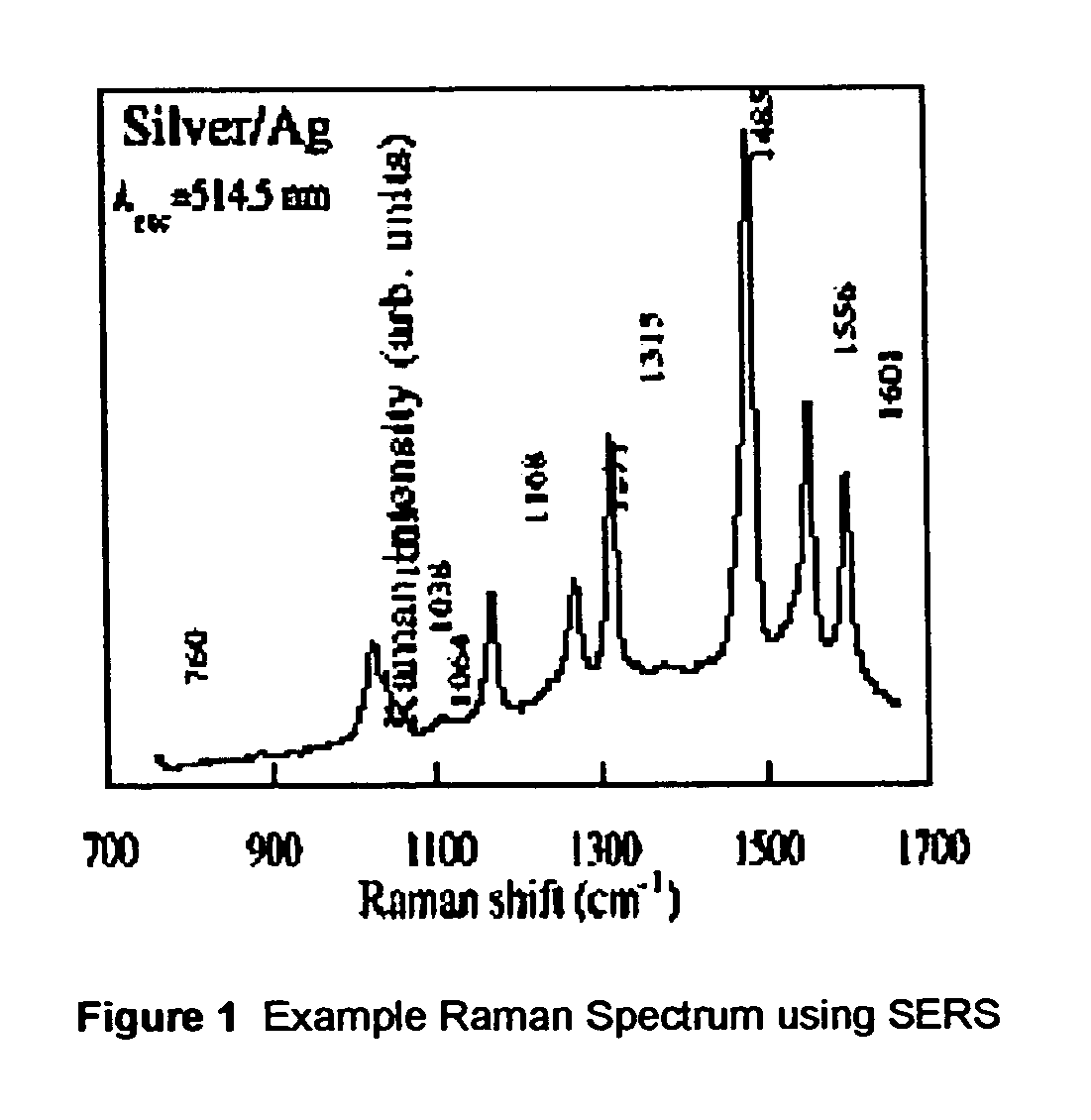

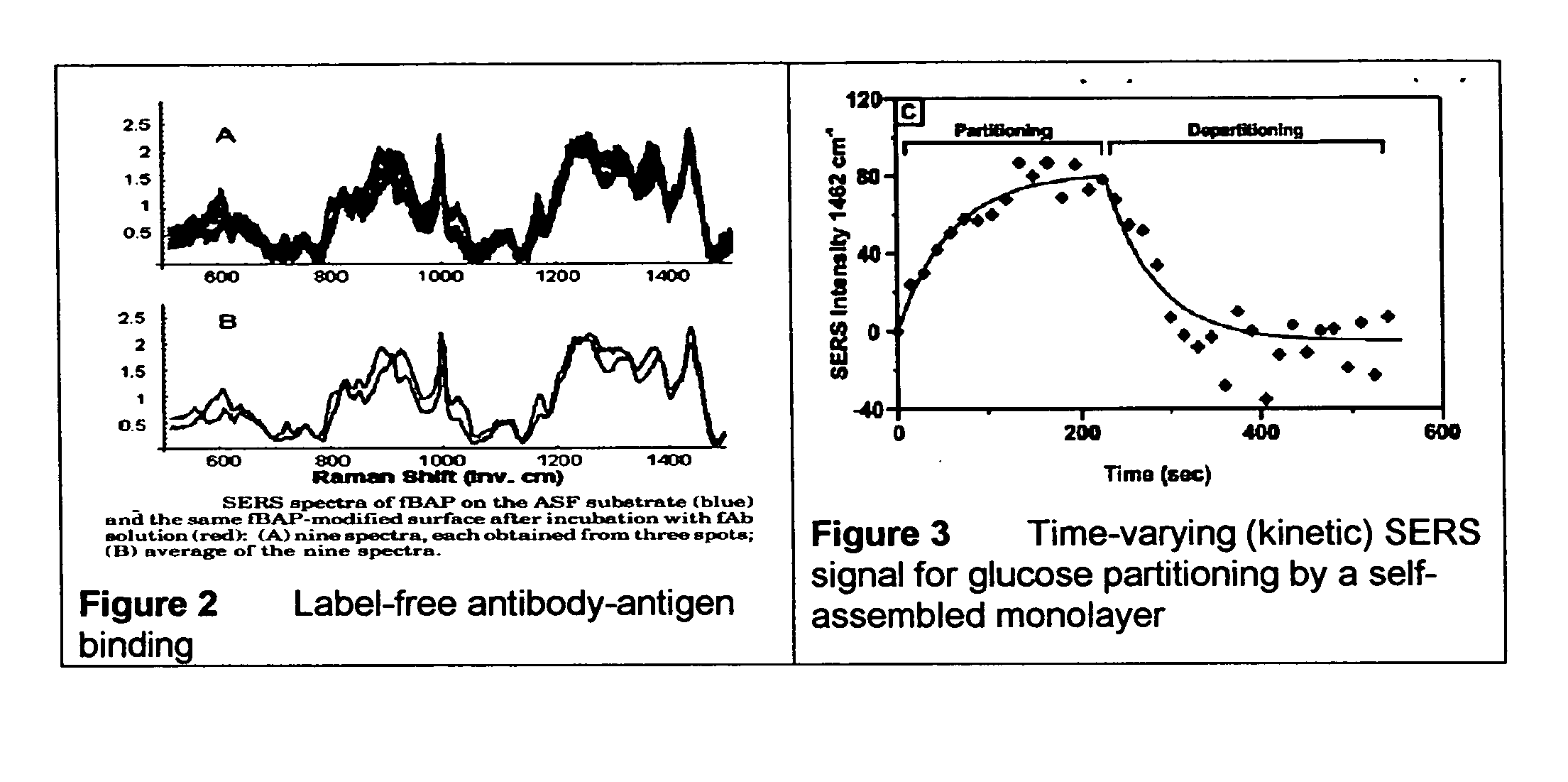

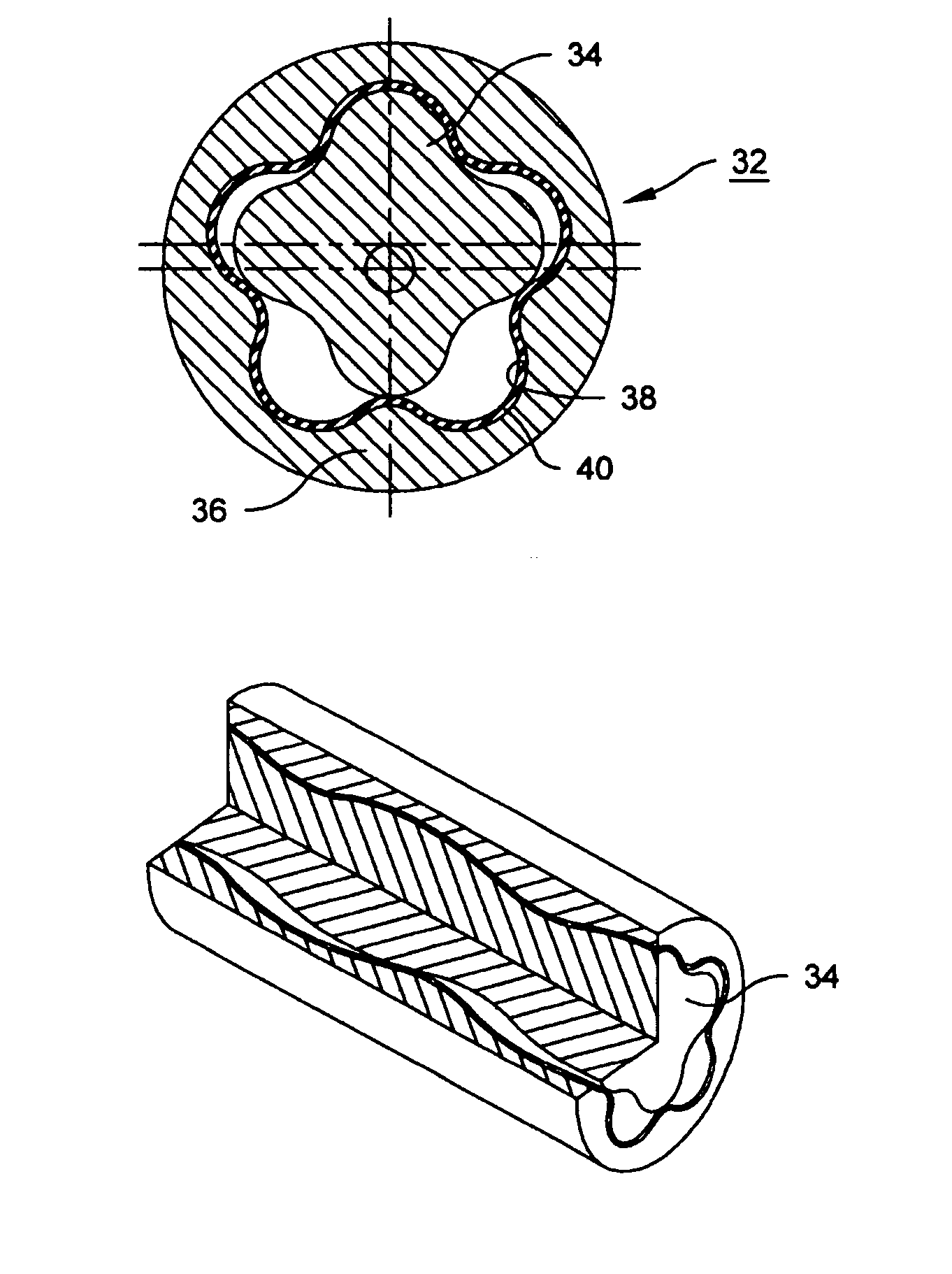

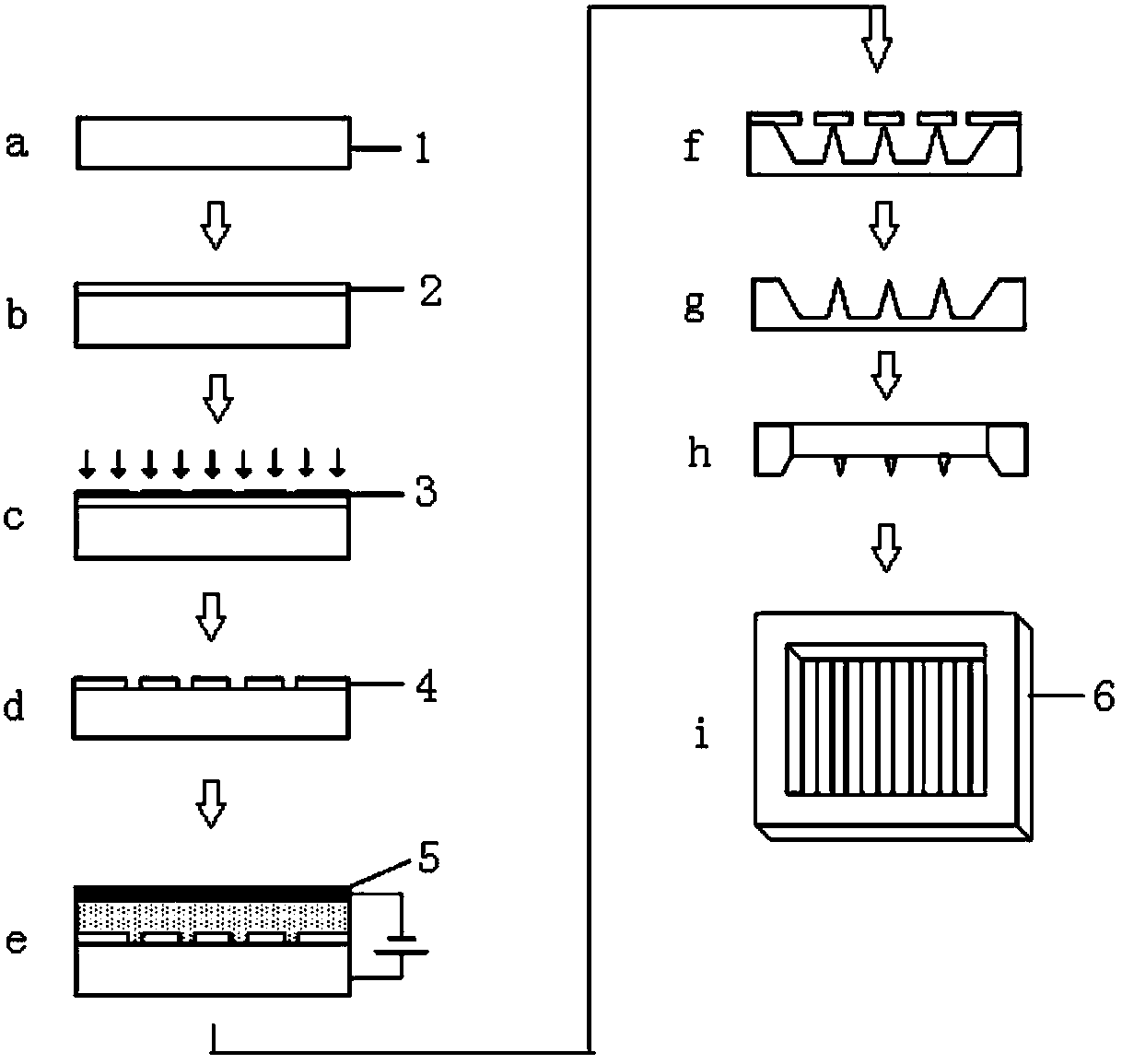

Surface enhanced Raman Scattering (SERS) and related modalities offer greatly enhanced sensitivity and selectivity for detection of molecular species through the excitation of plasmon modes and their coupling to molecular vibrational modes. One of the chief obstacles to widespread application is the availability of suitable nanostructured materials that exhibit strong enhancement of Raman scattering, are inexpensive to fabricate, and are reproducible. I describe nanostructured surfaces for SERS and other photonic sensing that use semiconductor and metal surfaces fabricated using femtosecond laser processing. A noble metal film (e.g., silver or gold) is evaporated onto the resulting nanostructured surfaces for use as a substrate for SERS. These surfaces are inexpensive to produce and can have their statistical properties precisely tailored by varying the laser processing. Surfaces can be readily micropatterned and both stochastic and self-organized structures can be fabricated. This material has application to a variety of genomic, proteomic, and biosensing applications including label free applications including binding detection. Using this material, monolithic or arrayed substrates can be designed. Substrates for cell culture and microlabs incorporating microfluidics and electrochemical processing can be fabricated as well. Laser processing can be used to form channels in the substrate or a material sandwiched onto it in order to introduce reagents and drive chemical reactions. The substrate can be fabricated so application of an electric potential enables separation of materials by electrophoresis or electro-osmosis.

Owner:EBSTEIN STEVEN M

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS20050079083A1Improve heat transfer performanceReduce adverse effectsOscillating piston enginesEngine of intermeshing engagement typeRough surfaceElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

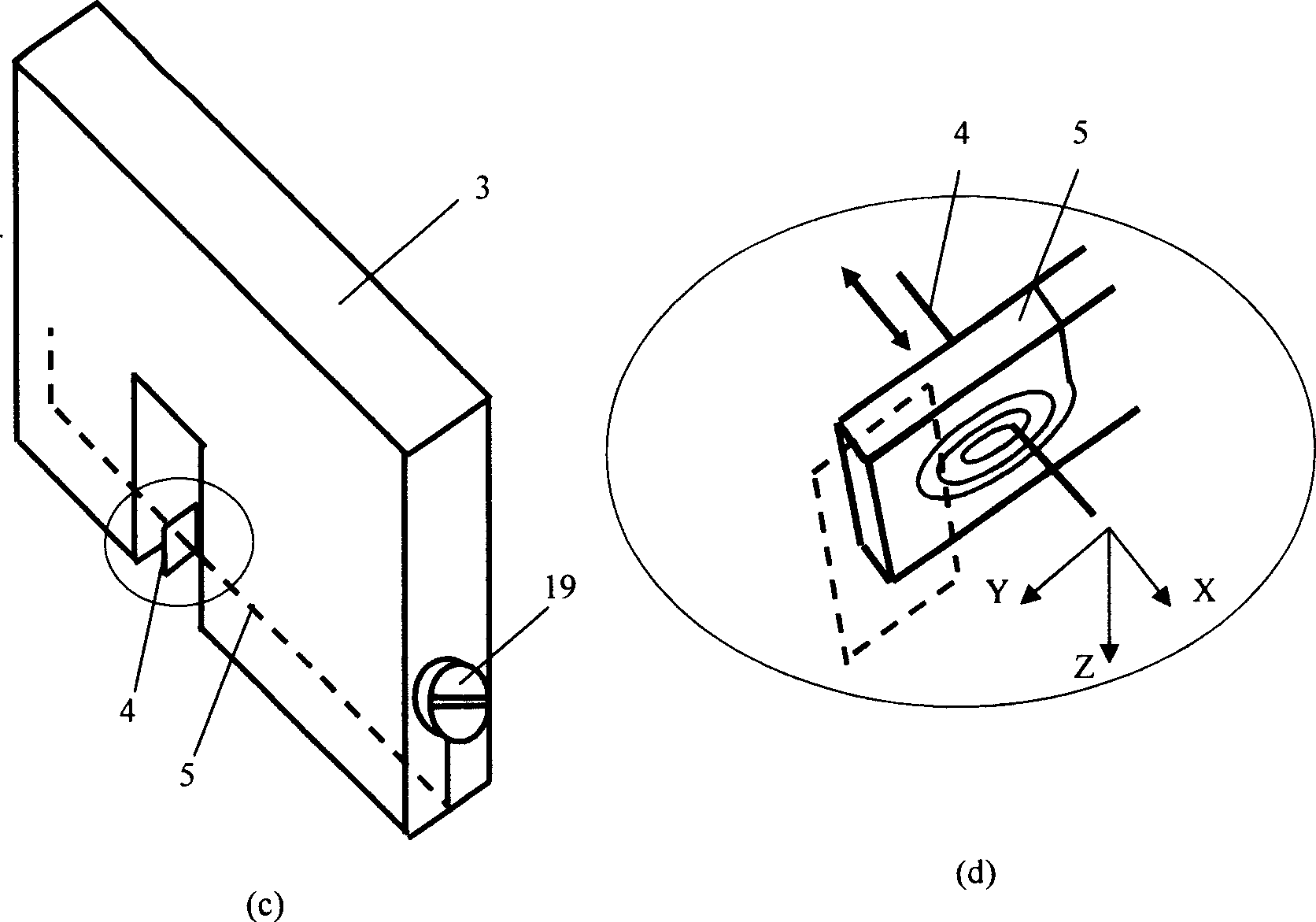

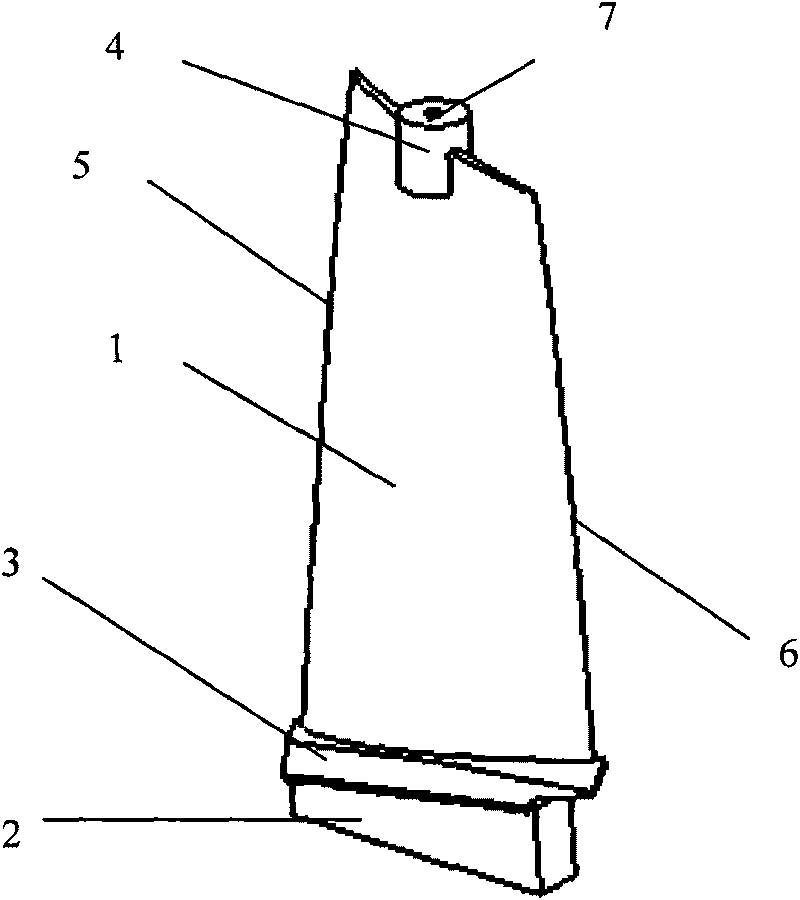

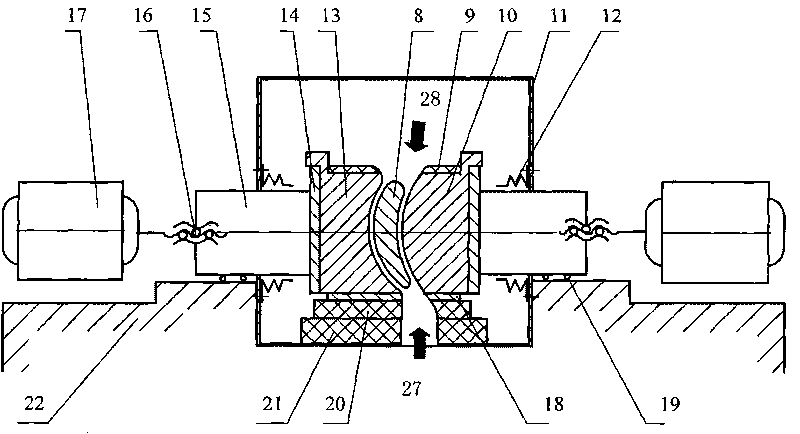

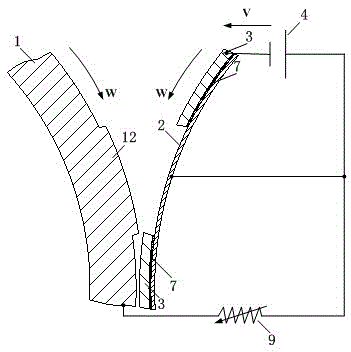

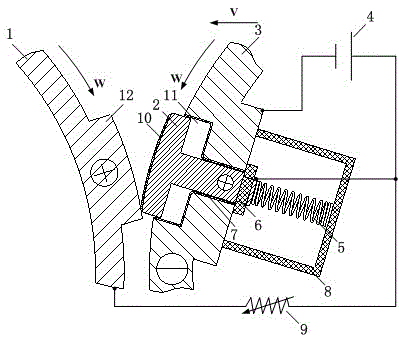

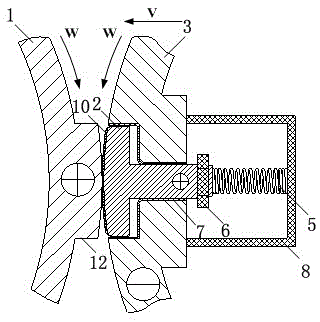

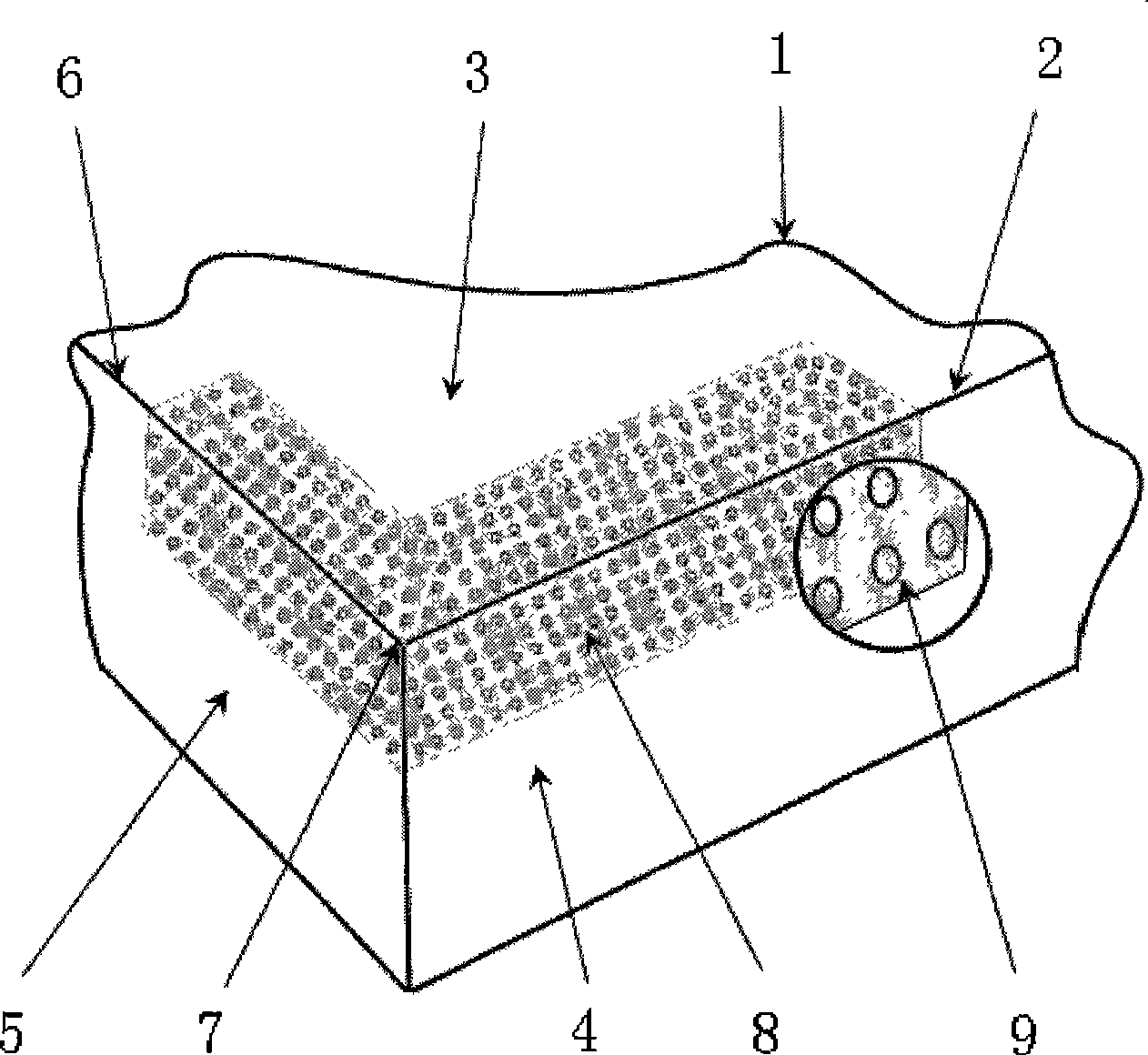

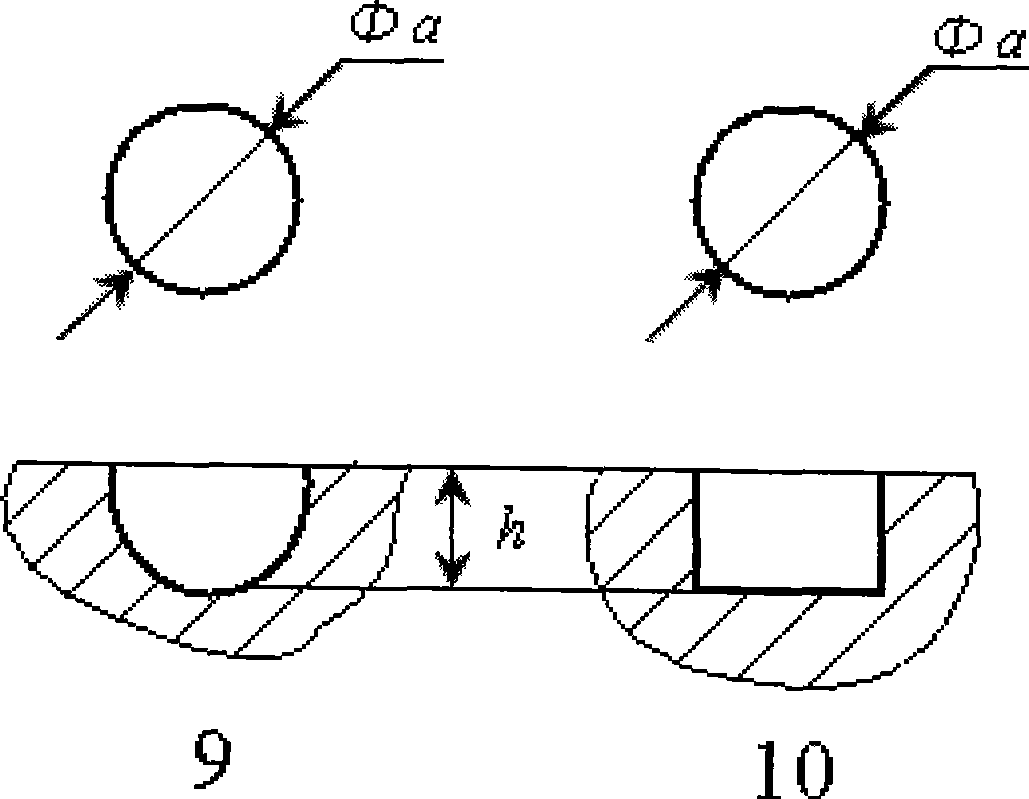

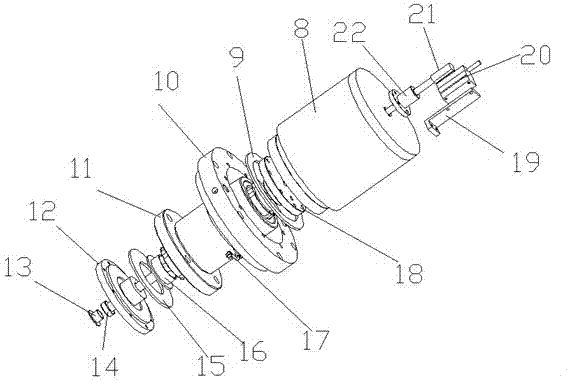

Blisk blade profile subtle electrochemical machining electrode and machining method

ActiveCN102794516AImprove processing efficiencyElectrochemical machining apparatusElectrolysisAgricultural engineering

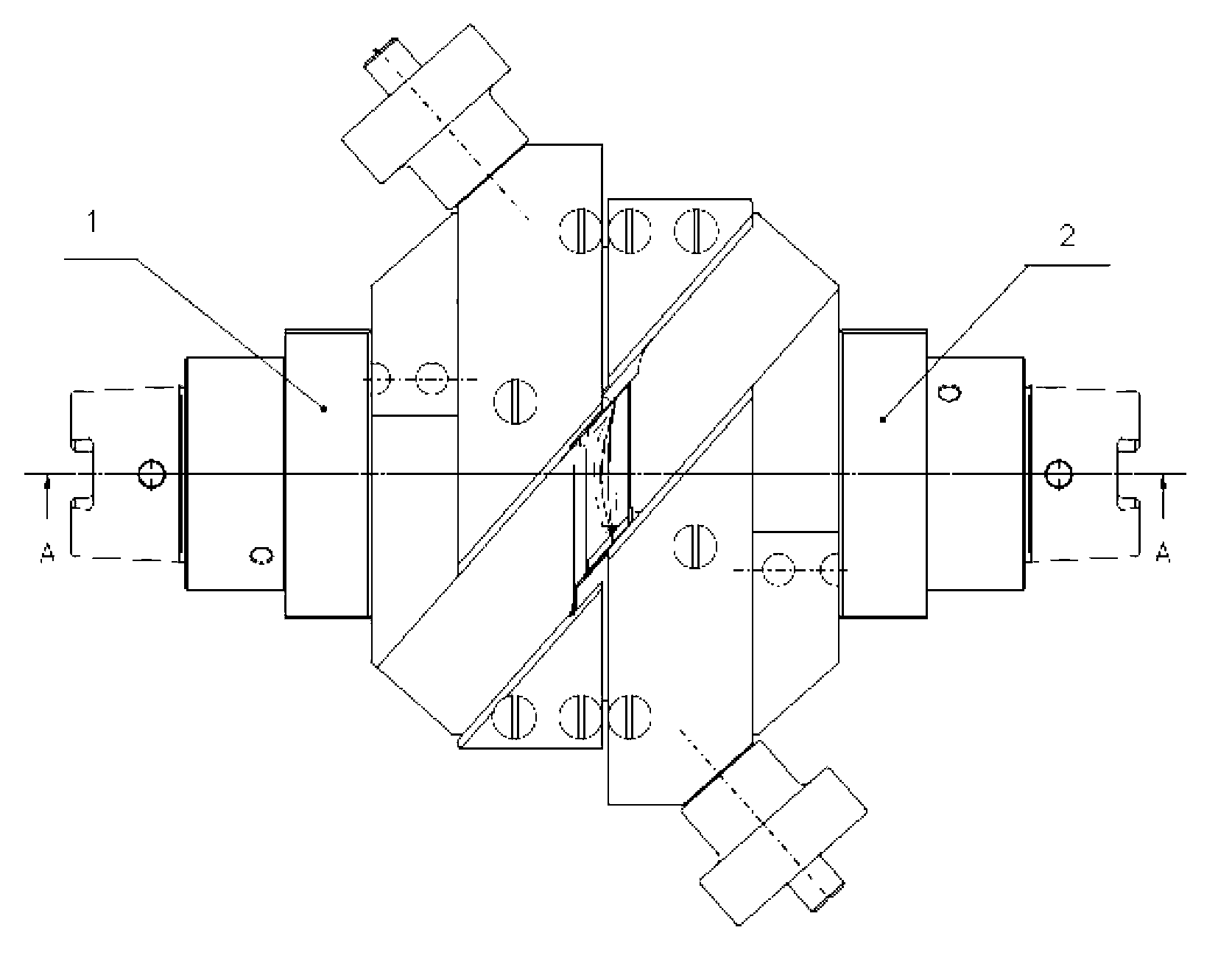

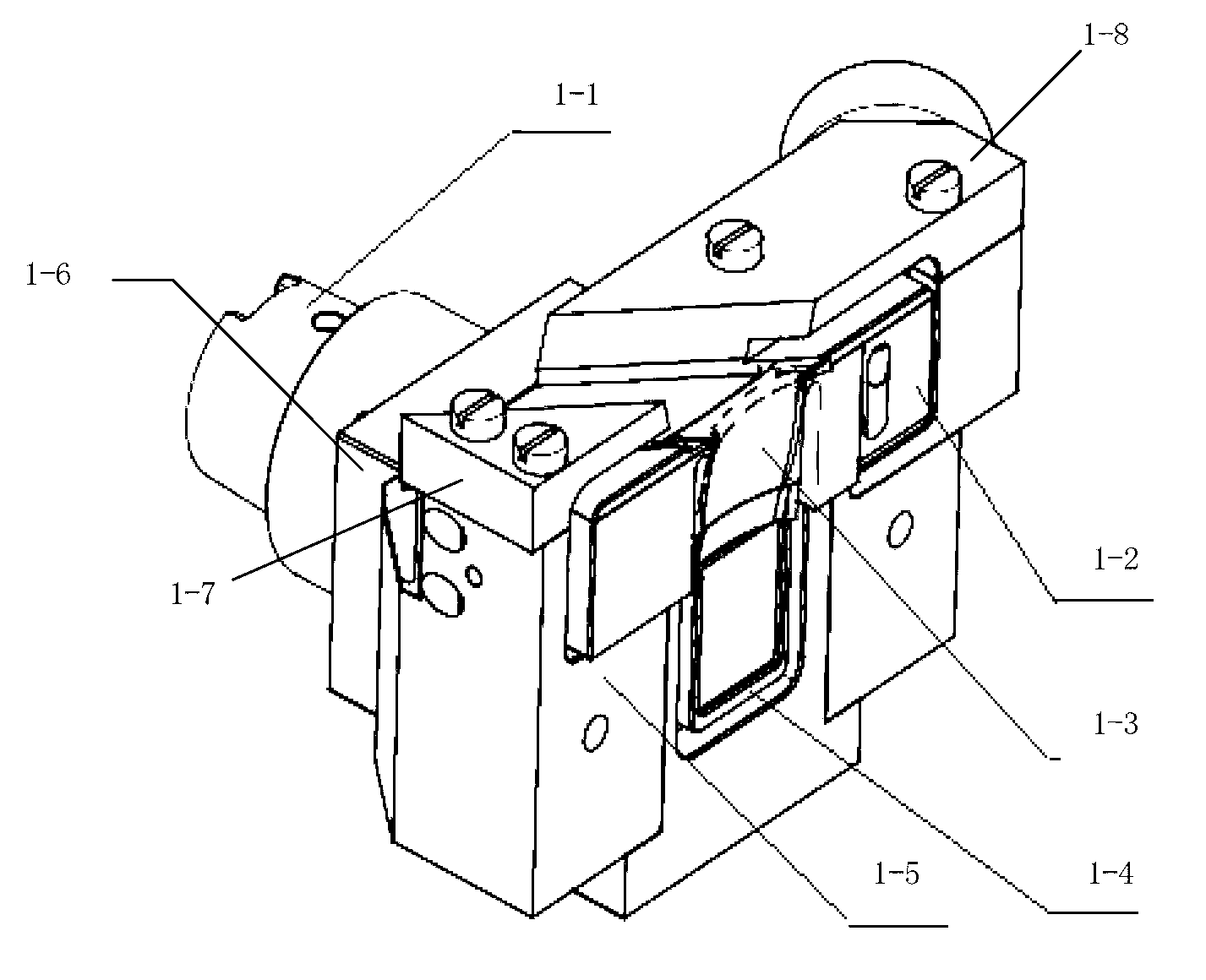

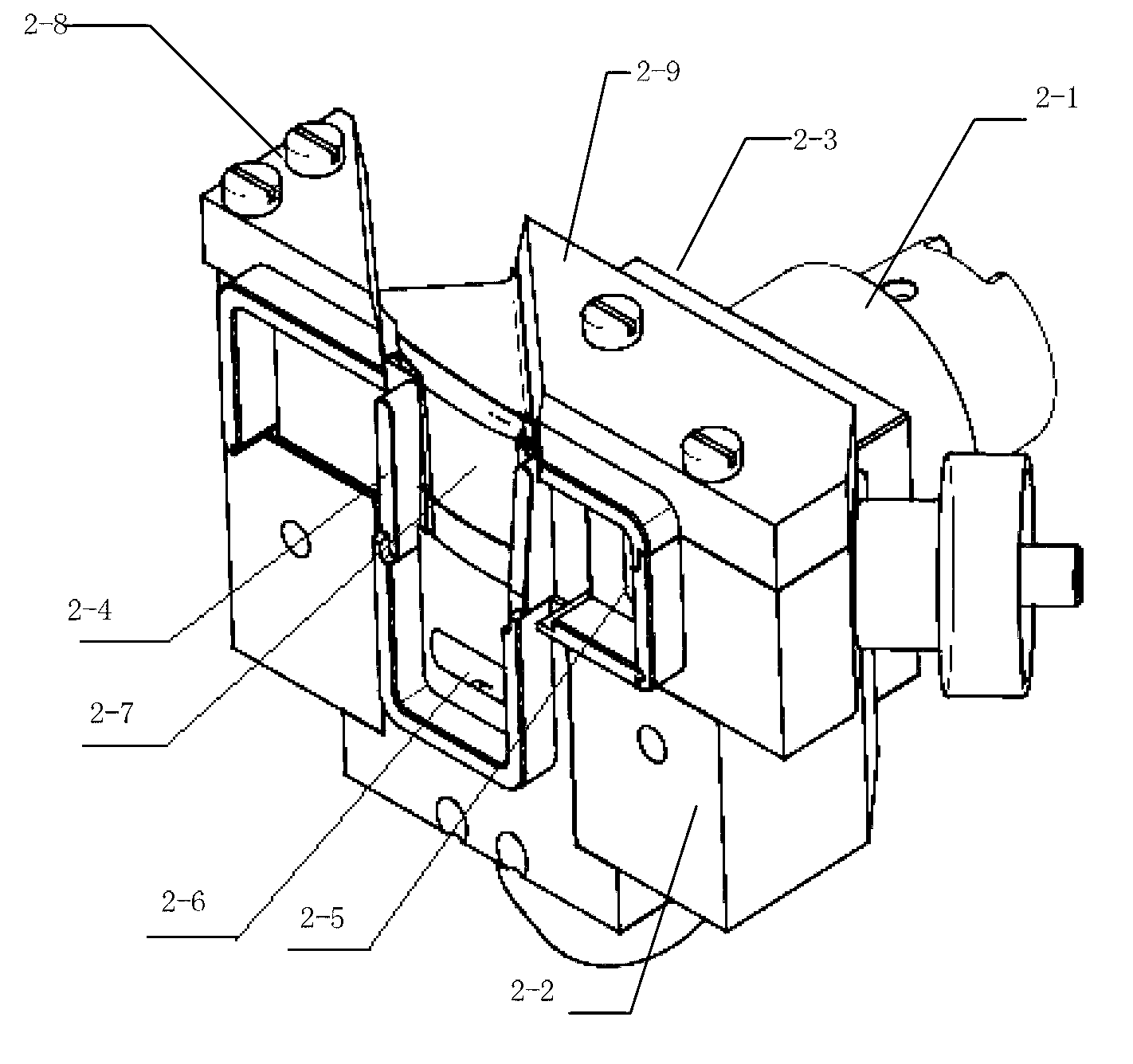

The invention discloses a blisk blade profile subtle electrochemical machining electrode and a machining method. The device comprises a left electrode device and a right electrode device, wherein the left electrode device comprises an HSK high-precision hydraulic chuck, a first auxiliary liquid supply module, a blade back working cathode, a lower insulating baffle, an electrode base, a transfer base and an upper insulating baffle; and the right electrode device comprises an HSK high-precision hydraulic chuck, an electrode base, a transfer base, a sealing baffle, a second auxiliary liquid supply module, a main liquid supply module, a blade basin working cathode and an upper insulating baffle. According to the invention, through the vibrating electrochemical machining of the left and right electrodes, the final machine shaping of the blisk blade profile surface is finished, the machining efficiency can be improved by 50% compared with that of the traditional machining method, and allowance-free shaping is realized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

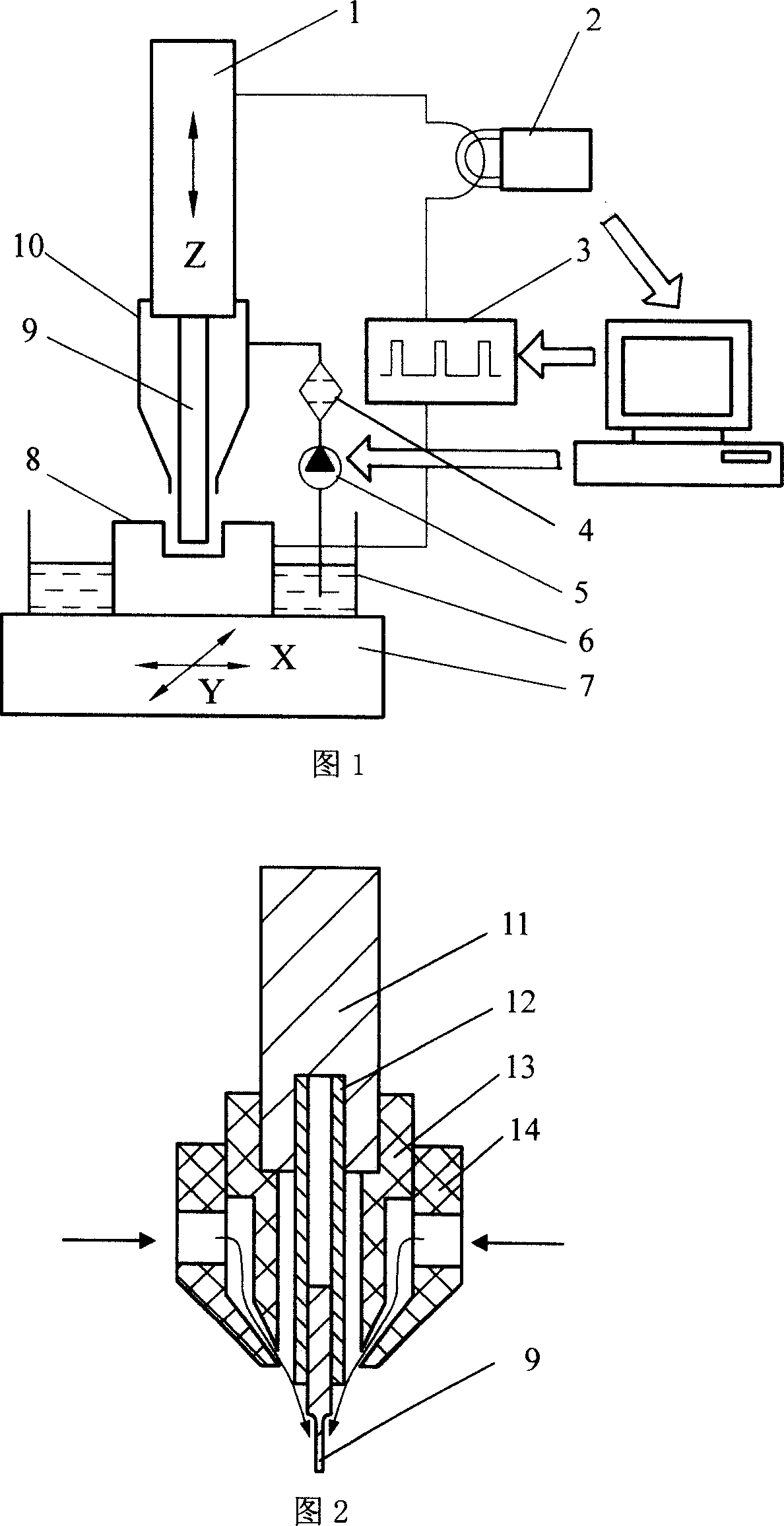

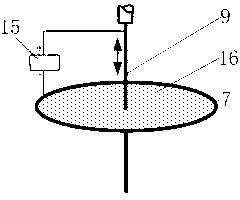

Subtly processing method of electrolyte axial flow and special electrode nozzle therefor

InactiveCN101011765AShorten the timeReduced areaMachining working media supply/regenerationElectrolysisEngineering

The invention relates to trickle electrochemical machining. The liquid level of the electrolyte cell is lower than the machining surface, extracting electrolyte form the cell using its pump, using special electrode nozzle to introduce the electrolyte flowing slowly to the machining area along the radial of the tool electrode and finally returning back to the electrolyte cell from the machining area. The special electrode is made of nozzle clamper, electrode annular tube, nozzle liner and nozzle bushing. It can improve the machining stability, machining precision and micro degree.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

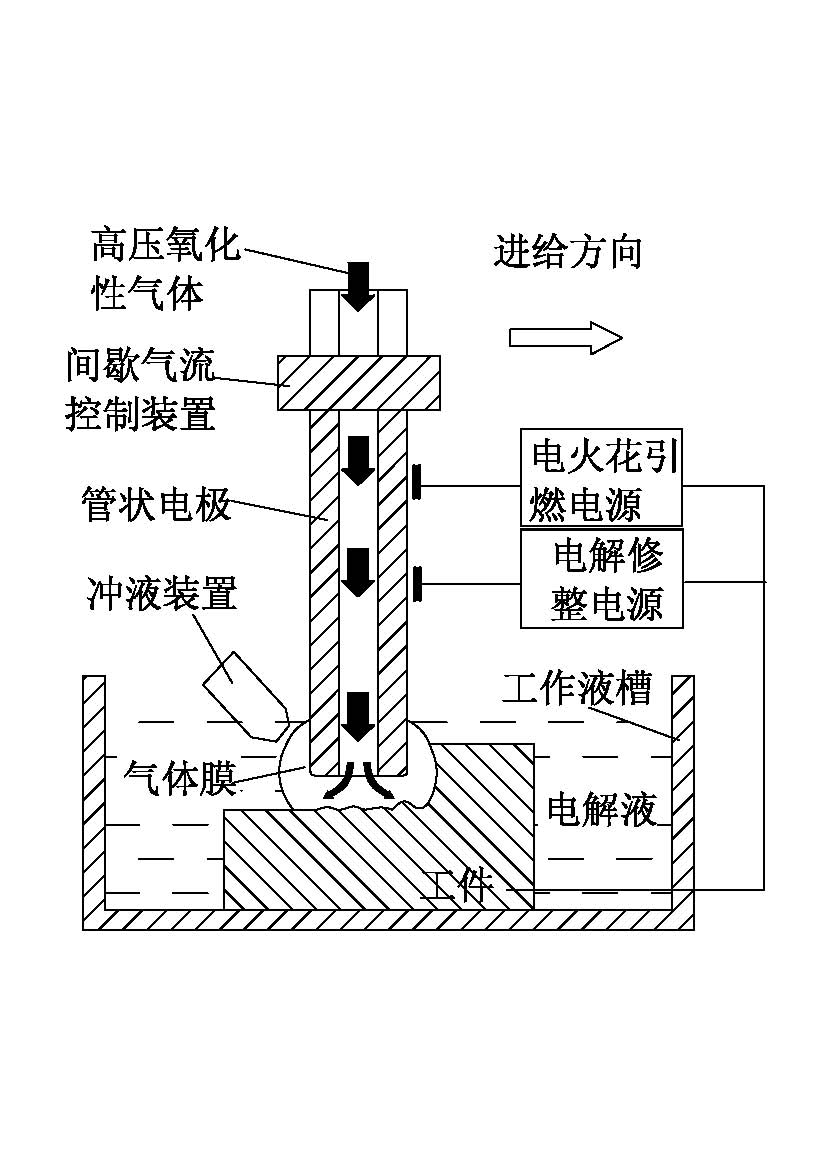

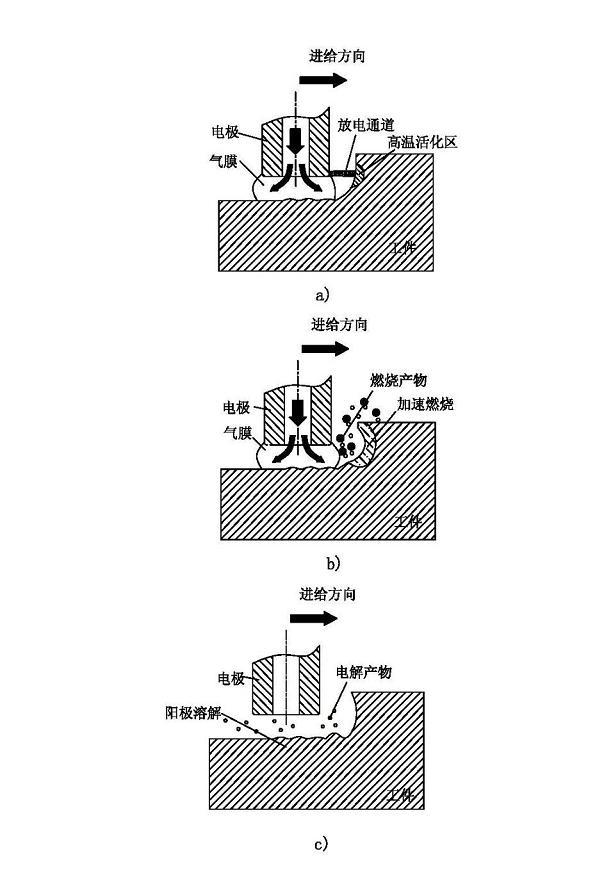

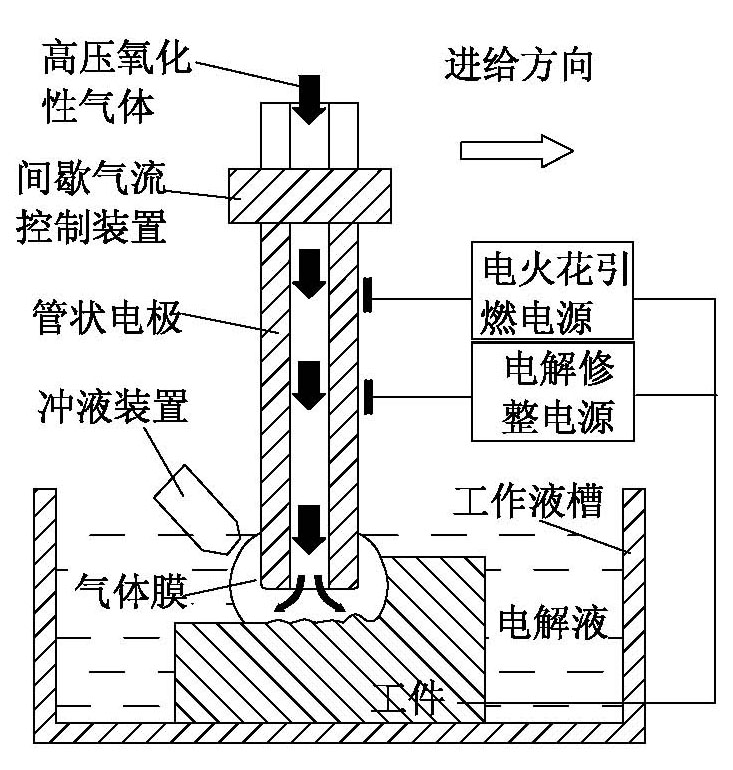

Electric spark induction controllable erosion and electrolysis compound efficient machining method

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

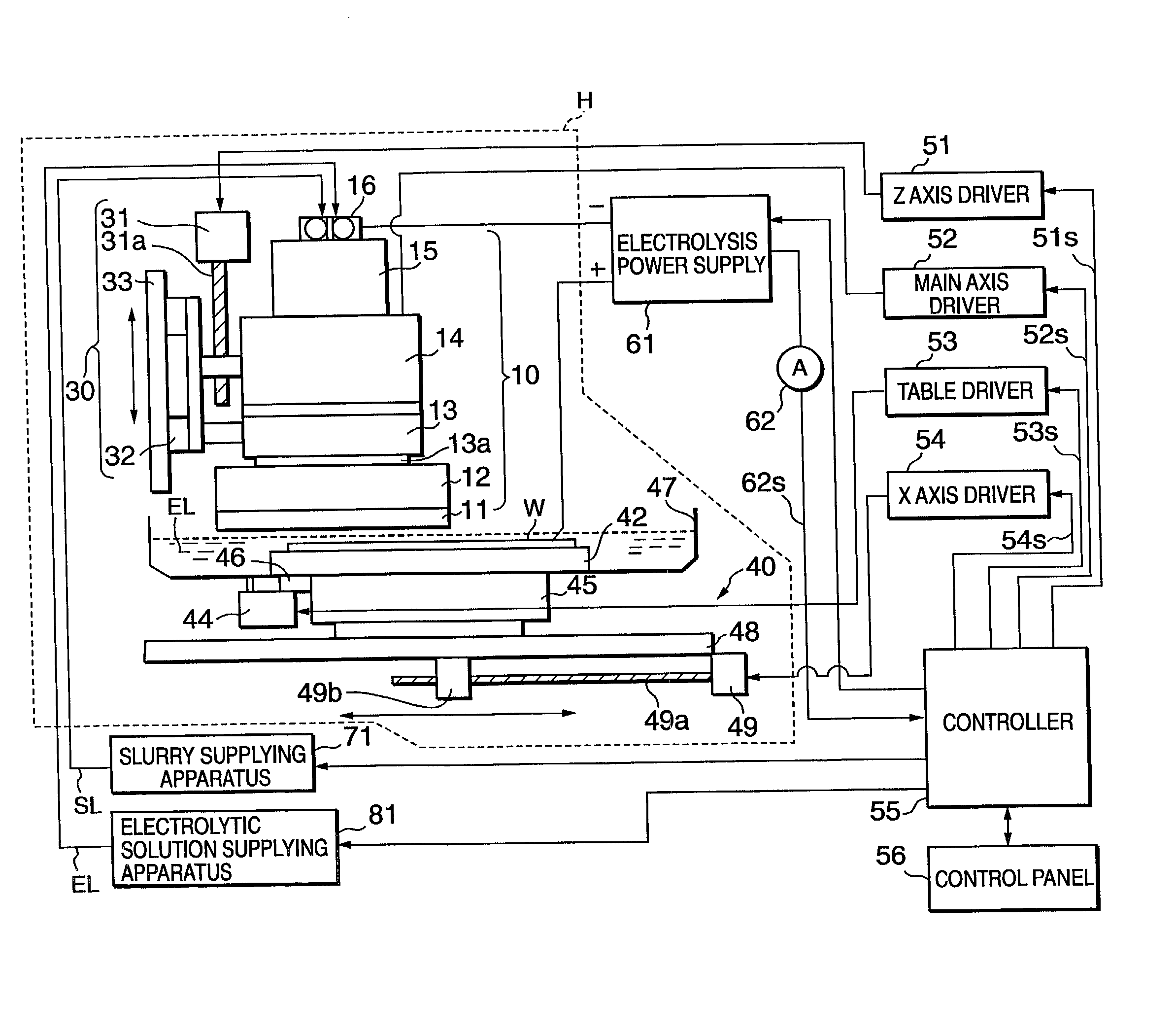

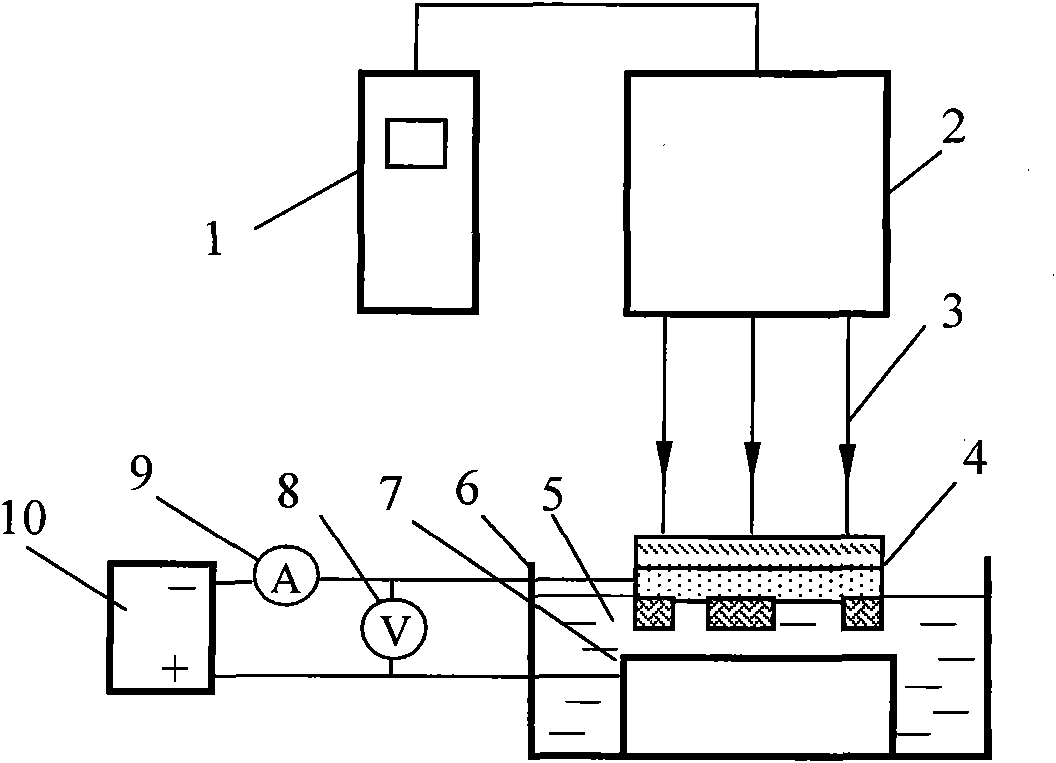

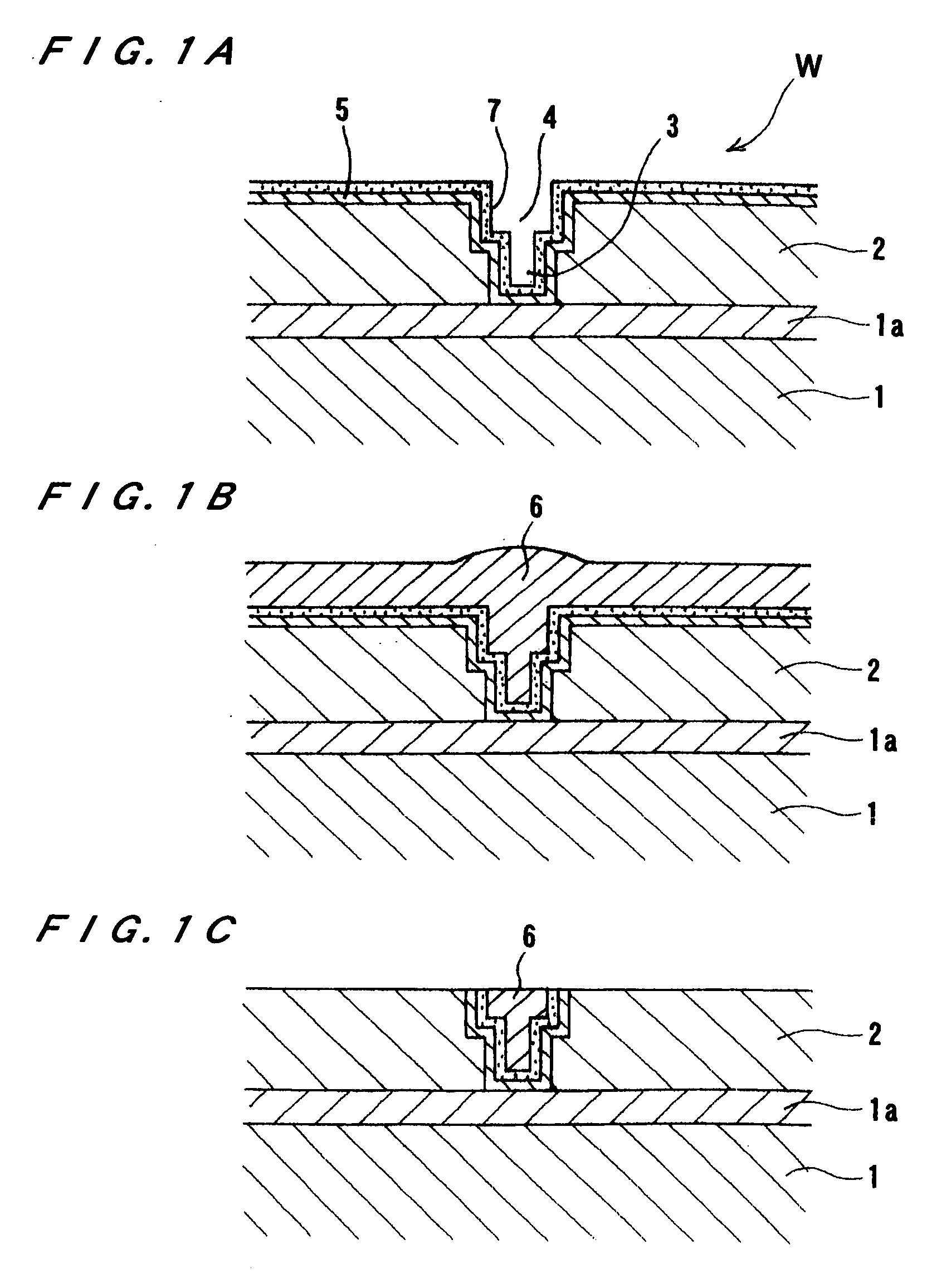

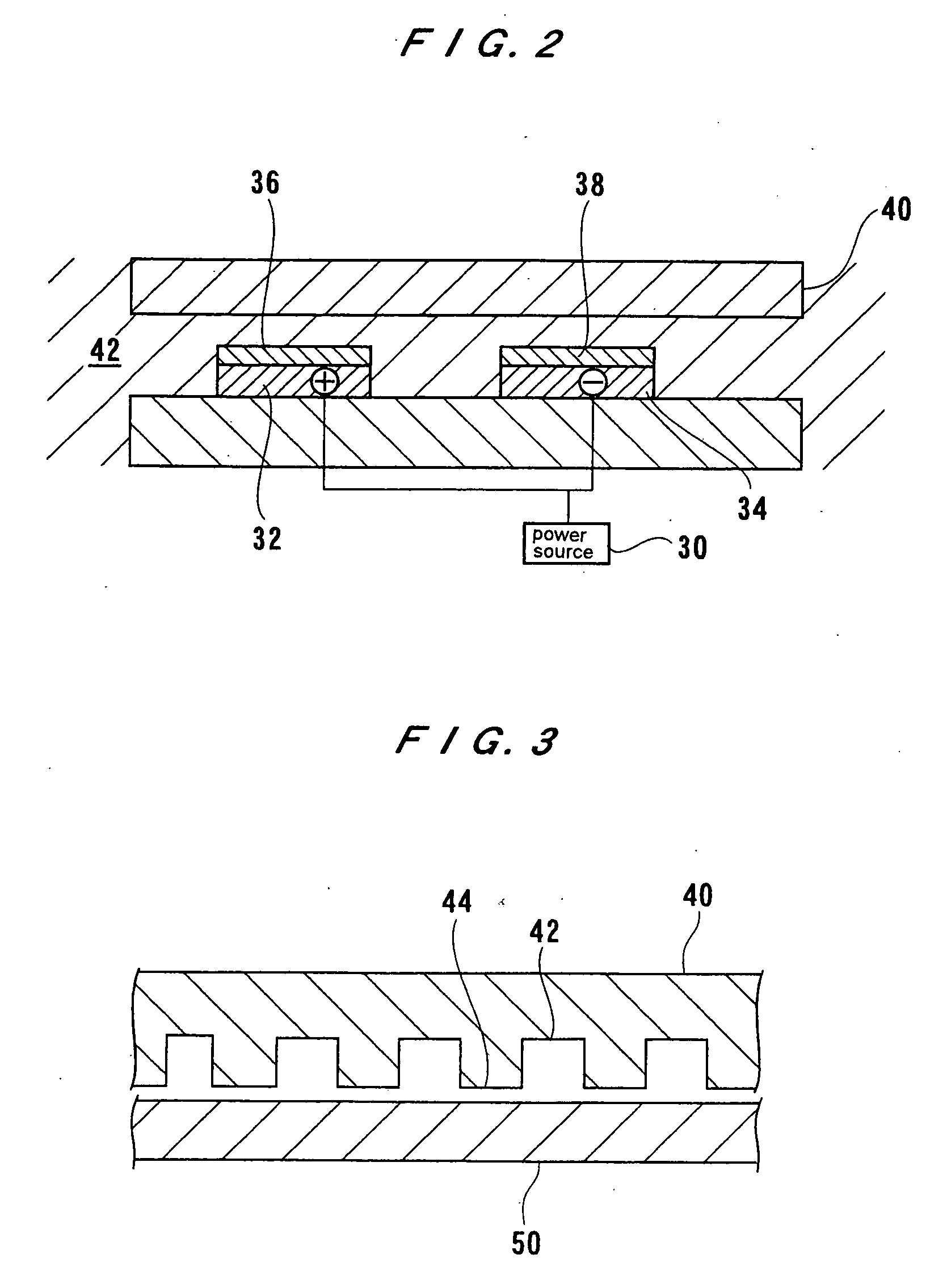

Electro-chemical machining apparatus

The electro-chemical machining apparatus of this invention is designed to smoothing a metal film by efficiently reducing initial rough surface and removing excessive metal film with reduced damages to the metal film. For this end, the electro-chemical machining apparatus performs electro-chemical machining of an object to be machined having a metal film on the surface to be machined. Such apparatus has a means for holding the object to be machined, a wiper for wiping the surface of the object to be machined, a means for supplying electrolytic solution onto the surface of the object to be machined, a first electrode disposed at a position opposed to the surface of the object to be machined, a second electrode disposed at a peripheral portion on the surface of the object to be machined, and a power supply for causing electrical current to flow between the second electrode on the surface of the object to be machined and the first electrode.

Owner:SONY CORP

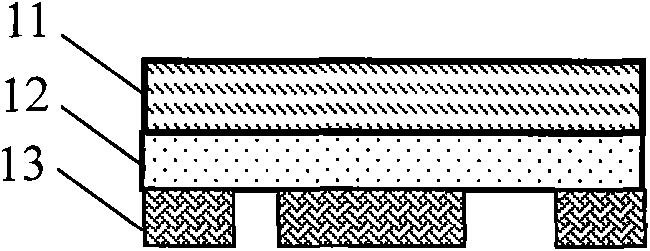

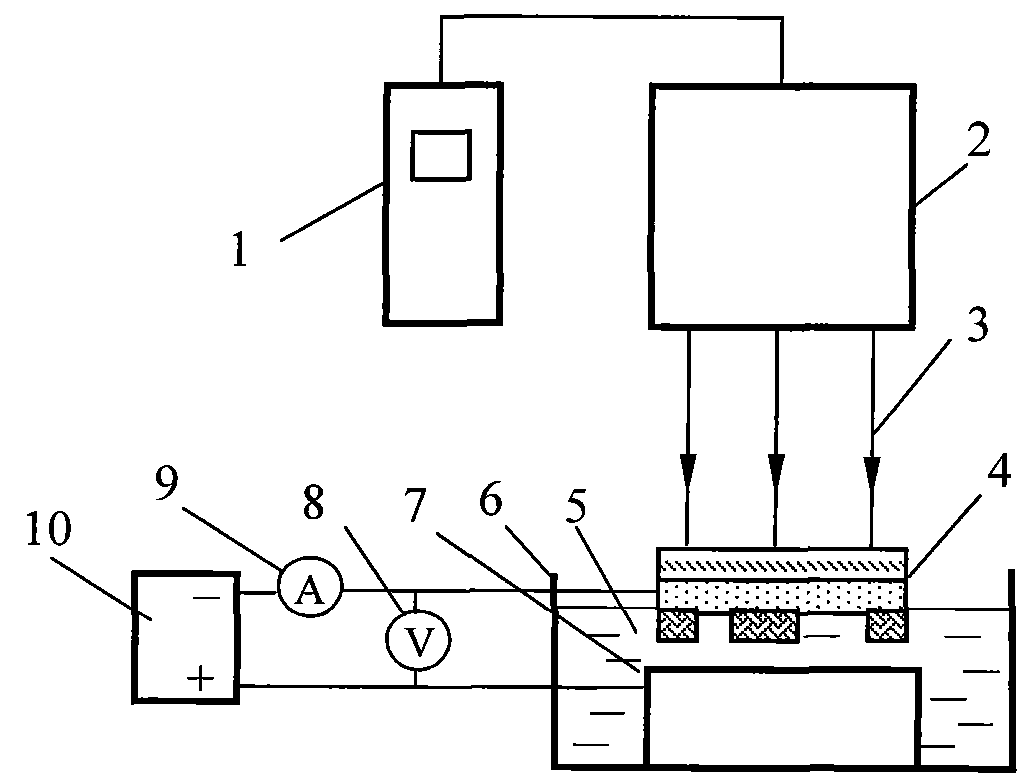

Method and device for realizing photoelectrochemical micro-etch processing of masked electrode

The invention provides a method and a device for realizing the photoelectrochemical micro-etch processing of a masked electrode, and relates to the micro processing field in the manufacturing technology. A masked electrode used by the invention comprises a glass substrate, an indium tin oxide (ITO) layer and a photoresist mask layer, wherein the conductive light-permeable ITO layer is used as a tool electrode for electrochemical processing and can be permeated by a laser beam, and the photoresist mask layer can limit the action zones of the laser beam and the electrochemical electrode to achieve the double effects of a beam mask and an electric field mask. When the laser beam permeates the masked electrode, a mask pattern is imaged on the surface of a workpiece, the force effect of a shock wave generated by the irradiation of the laser between the workpiece and the electrolyte enables the passivation layer to be removed by the generation of stress corrosion. Meanwhile, the workpiece material at the laser-irradiated part is removed by etching under the action of the photoelectrochemical reaction. The invention can effectively enhance the processing efficiency, the micro processing degree and the processing precision of the complex pattern, and is applicable to the micro processing of the conductive metal material.

Owner:JIANGSU UNIV

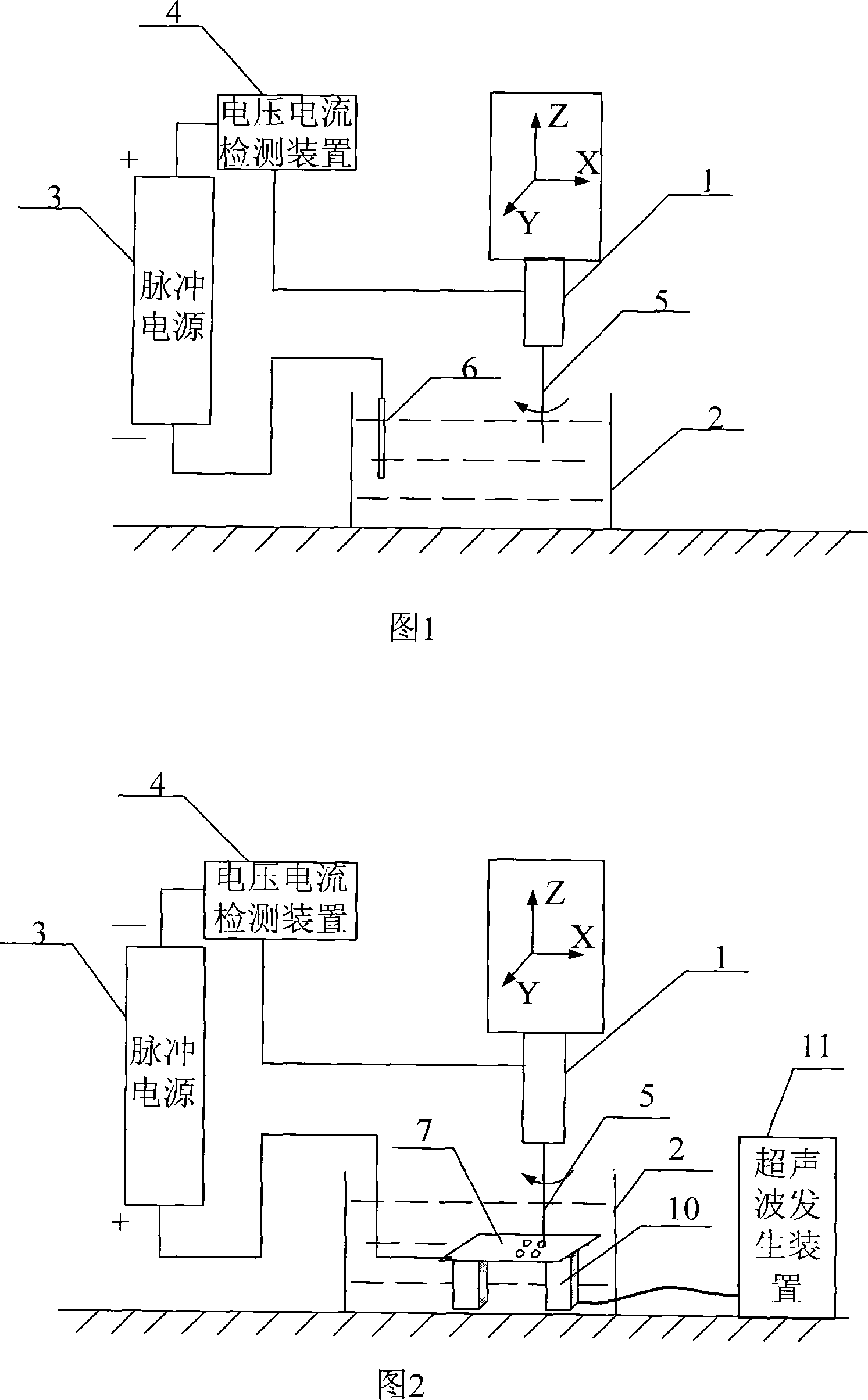

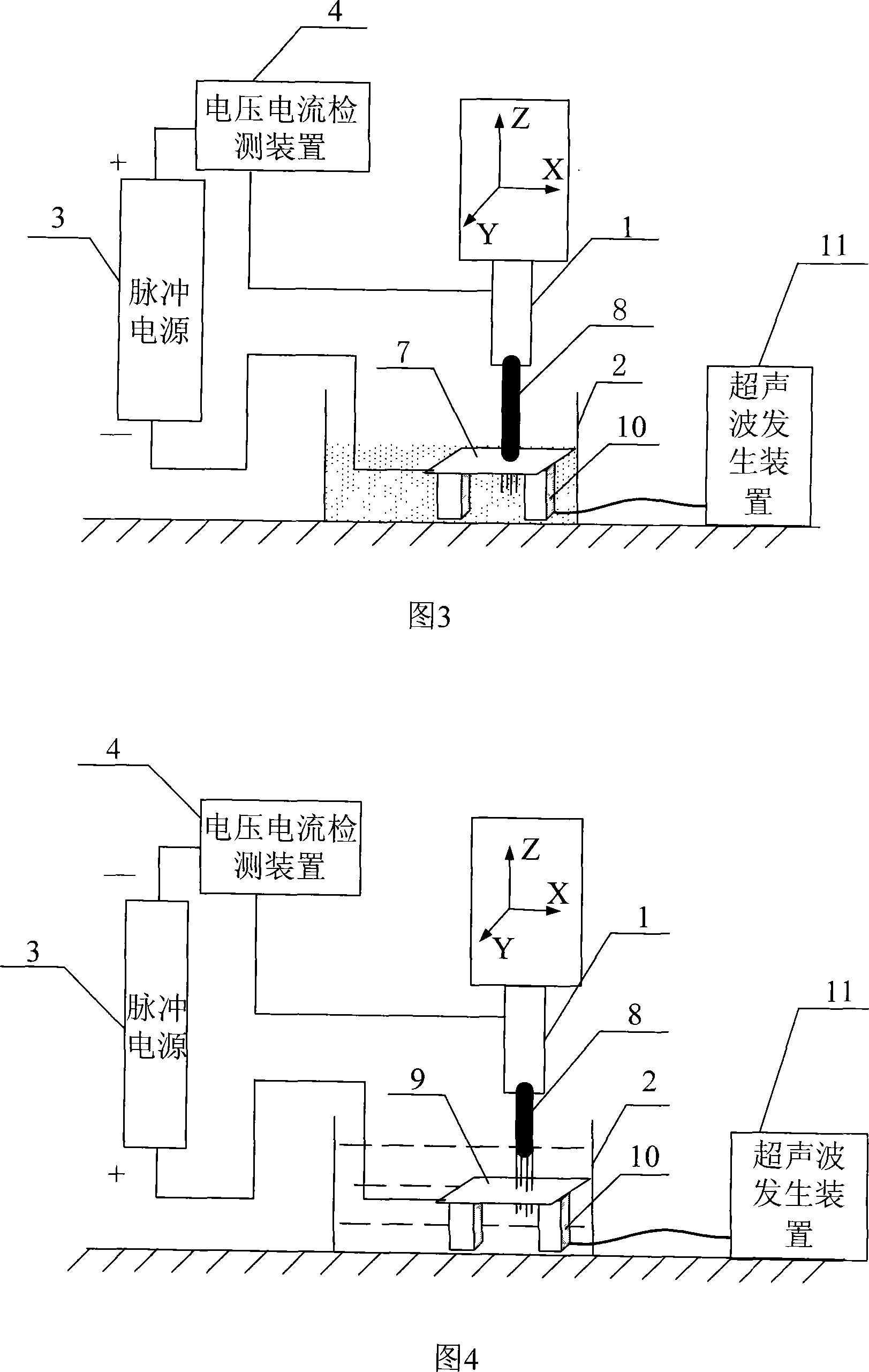

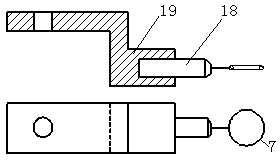

Micro-scale line electrode electrolysis machining method and micro-vibration line electrode system

InactiveCN1850411AEasy to excludeAvoid short circuitMechanical vibrations separationElectrical-based machining electrodesNumerical controlElectrolysis

The present invention relates to a microdimesion wire electrode electrolytic machining method. It is characterized by that in the course of electrolytically microcutting metal material by using wire electrode it utilizes a microvibration device to make the wire electrode produce microvibration perpendicular to its feeding direction, so that it is favourable for discharging electrolytic product from machining gap so as to prevent the short circuit from producing and greatly raise electrolytic quality. Said microvibration wire electrode system is mounted on the Z-axis of numerical control machine tool and is formed from wire electrode frame, microdimension wire electrode mounted on the wire electrode frame and microvibation device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

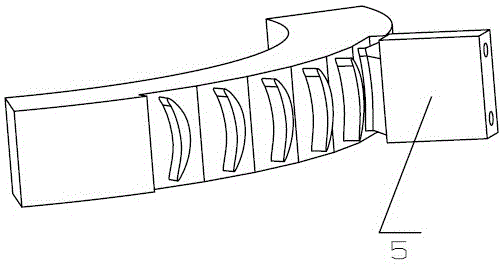

Overall process linear flow flexible protection sleeve material electrochemical machining device and method

ActiveCN106141343AImprove stabilityImprove machining accuracyMachining electrodesElectrical-based machining electrodesElectrolysisMachined surface

The invention relates to an overall process linear flow flexible protection sleeve material electrochemical machining device and method, and belongs to the field of electrochemical machining. The device is formed by a cathode assembly and an auxiliary assembly. The flow mode of the electrochemical machining method is an overall process linear flow manner, electrolyte flows from the front edge of a blade to the back edge of the blade, and a flow field is in a convergence state; the cathode assembly moves and drives the auxiliary assembly to move at the same time, the electrolyte is supplied in a manner of aligning at a machining area all the time, and it is ensured that the flow field is stable; and in the electrochemical machining process, a flexible insulation block seals a machined area, and scattered corrosion caused by the fact that the electrolyte flows to the machined surface is effectively reduced. By means of the overall process linear flow flexible protection sleeve material electrochemical machining device and method, the sleeve material electrochemical machining flow field stability is better improved; the taper of the blade is reduced, and the machining accuracy is improved; and the surface quality is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

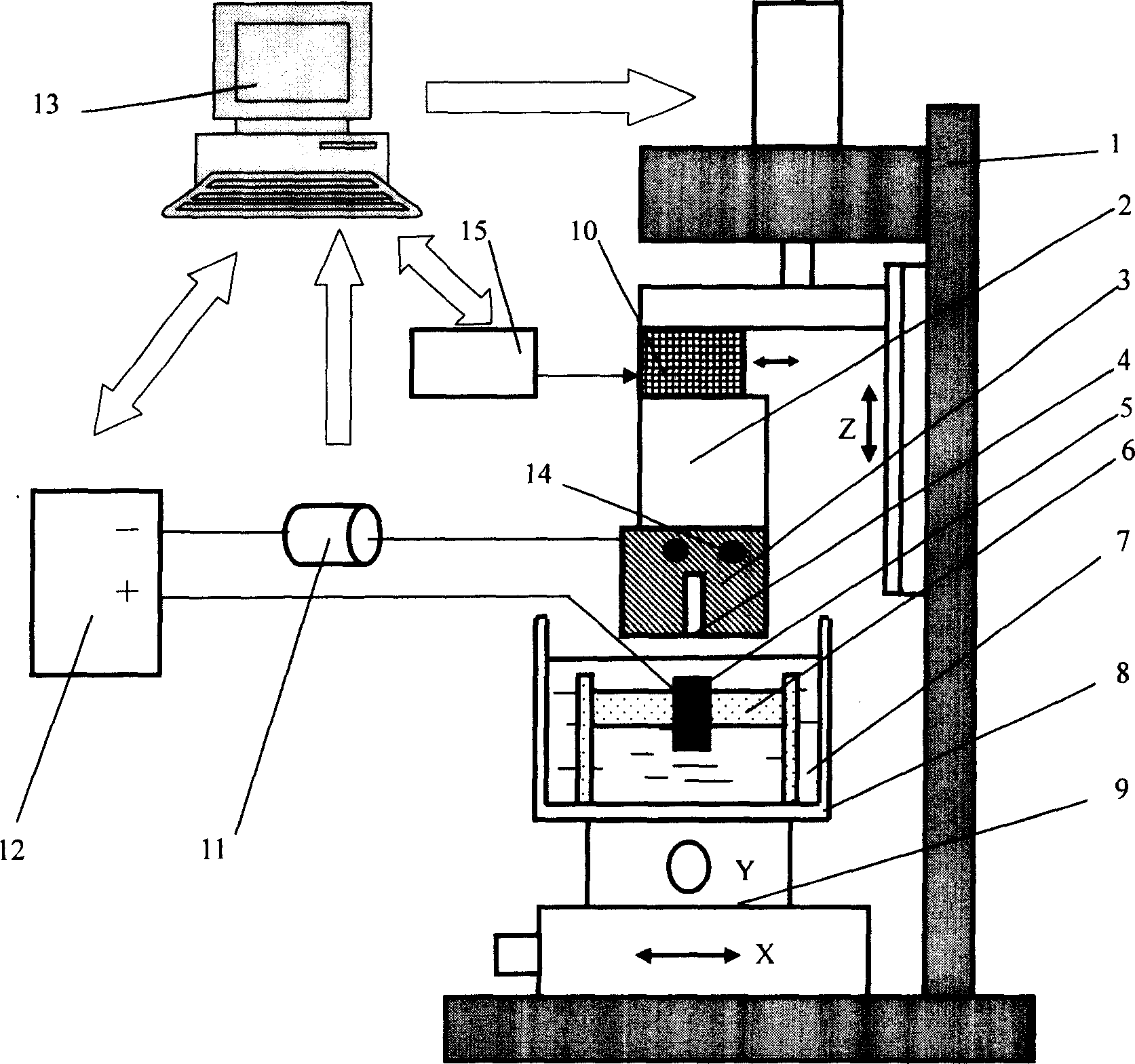

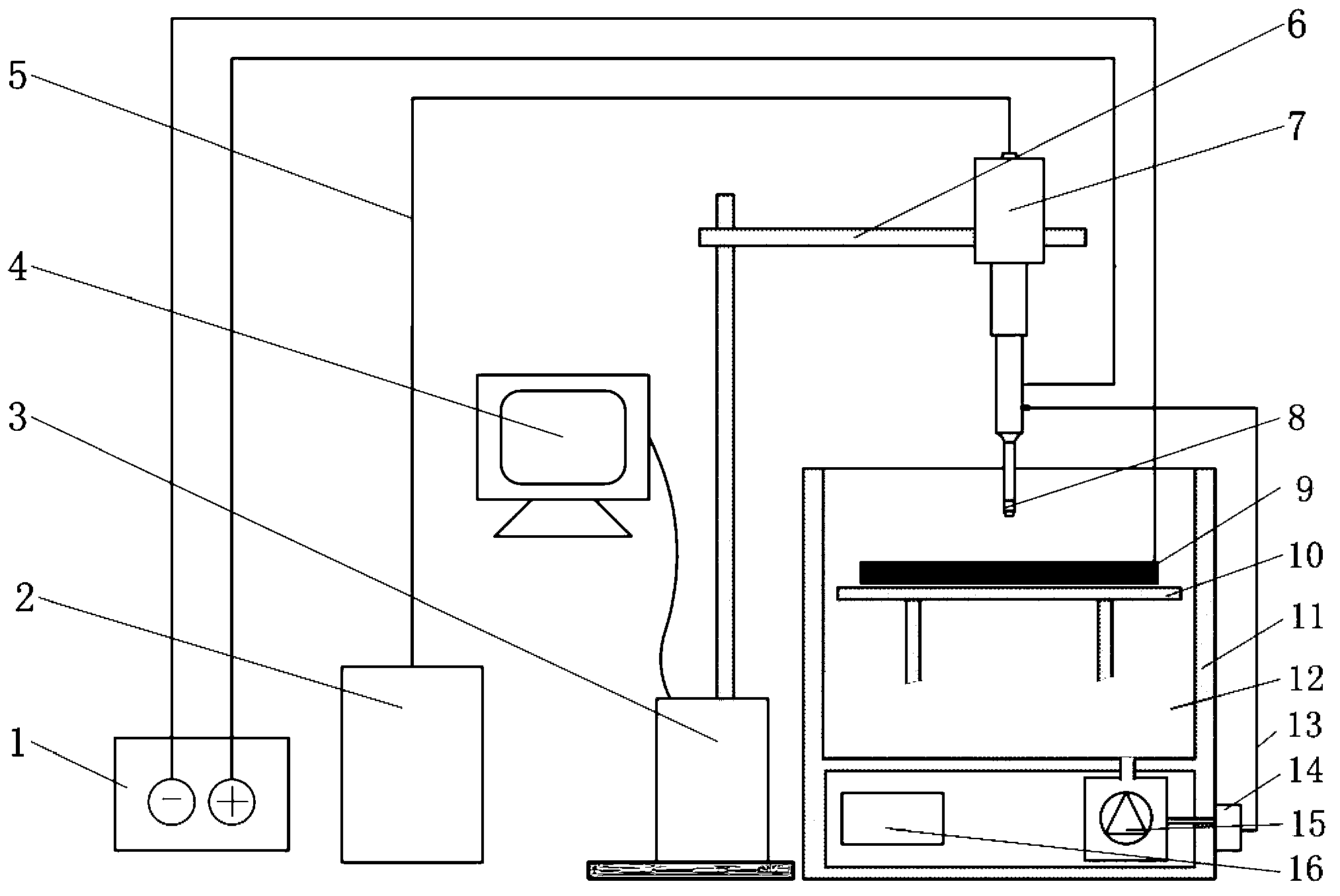

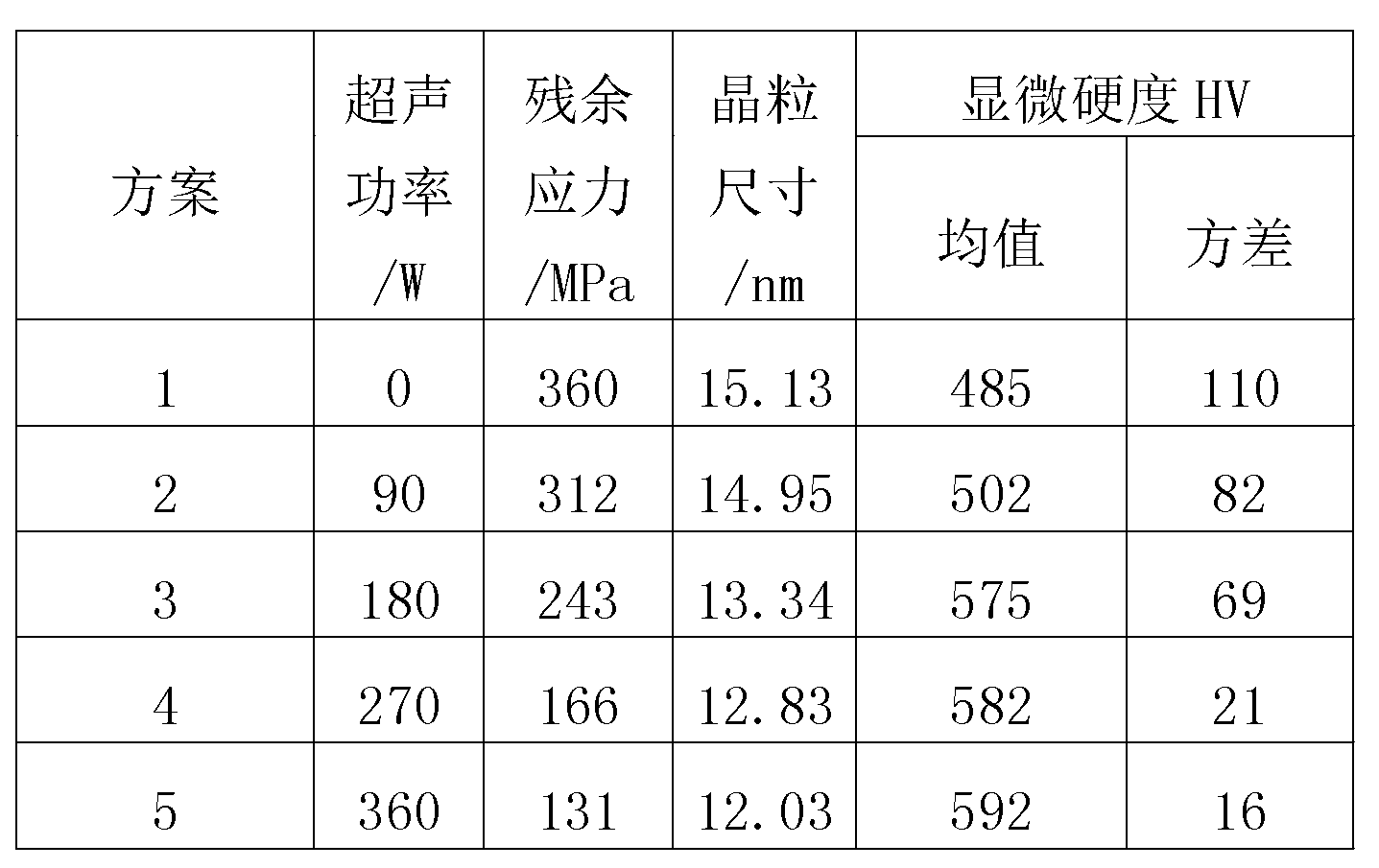

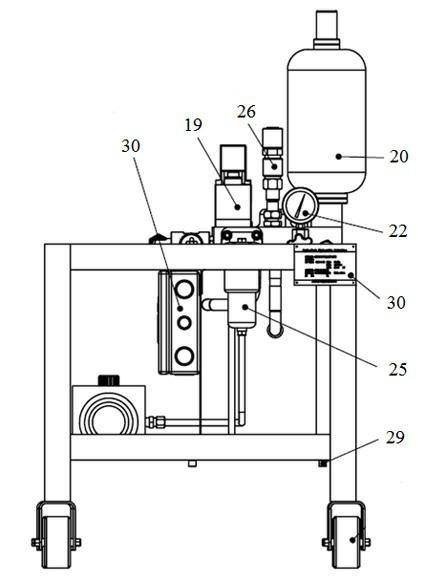

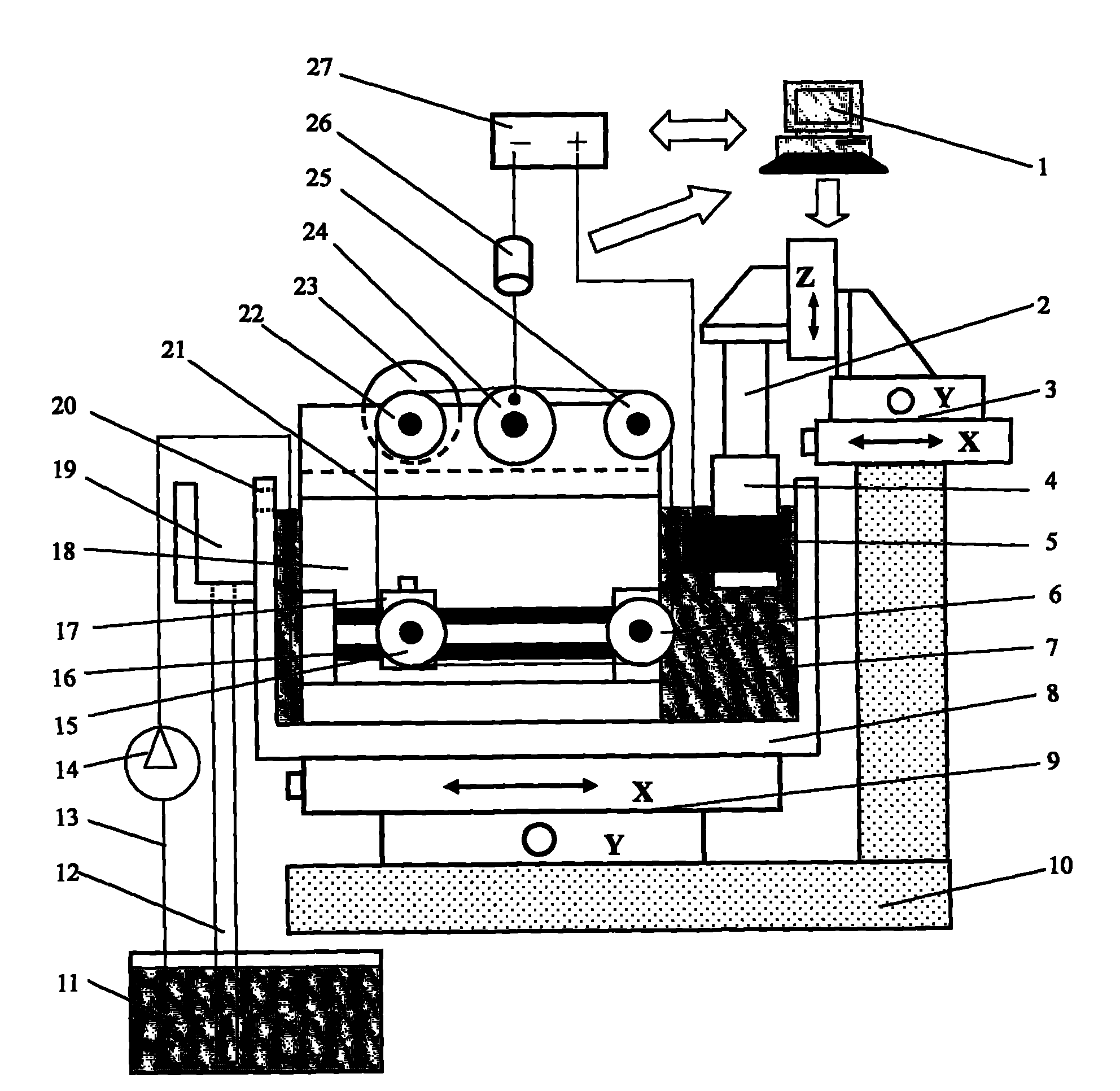

Selective metal electro-deposition device and application thereof

ActiveCN103255452AConducive to precise formingPromote precipitationPeristaltic pumpNumerical control

The invention belongs to the field of electrochemical process technology and relates to a selective metal electro-deposition device and application thereof. The metal electro-deposition device is characterized by comprising a liquid storage tank for containing electrolyte, a power supply namely an ultrasonic power supply electrically connected with a cathode and an anode correspondingly in electro-deposition process, an ultrasonic assistant jet apparatus supported by a rack and a three-dimensional numerical control platform which comprises a motion actuator, the rack and a computer, wherein the liquid storage tank is also externally provided with a peristaltic pump for supplying jet pressure for the electrolyte and a control valve for controlling the flow of the electrolyte, the liquid storage tank is internally provided with a temperature controller for keeping the temperature of the electrolyte, and an electrolyte nozzle is arranged at the bottom of the ultrasonic assistant jet apparatus. The selective metal electro-deposition device can improve the hardness, compactness and electro-deposition speed of a settled layer in the existing electro-deposition technology, lower the residual stress of a clad layer, and realize the selectivity of an electro-deposition area and the electro-deposition forming of parts of simple shape.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for electrochemically machining titanium alloy large-scale blades

The invention relates to a method for electrochemically machining titanium alloy large-scale blades, which comprises the following steps of: arranging a convex plate on a blade blank when preparing the blade blank; performing electrochemical machining on the blade blank by using an electrochemical machine, wherein the height of the convex plate is 20 to 40mm; the clamped area of a clamp and the convex plate is not less than 98 percent of the overall area of the side of the blade; pressing force at the tip is 3,000 to 4,000N; and the width of an inlet of an electrolyte is 2 to 3 times of the thickness of the blade; and symmetrically arranging the inlet of the electrolyte along an inlet edge of the blade blank, wherein machining parameters include the electrode feeding speed of 0.25 to 0.4 mm / min, before-machining time delay of 3 to 5s, after-machining time delay of 3 to 5s, electrolyte temperature of 35-45 DEG C, the hydraulic pressure of the electrolyte of 0.3 to 0.5MPa, and compressed air pressure of 0.4 to 0.6MPa. The method can be used for machining the titanium alloy blade with the blade profile area of more than 700cm2; and the technique can be widely applied to the machining of the profile area of the titanium alloy blade, such as heavy duty gas turbines, a large-scale aero-engines and the like, and also has an extensive application prospect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Electrochemical machining method for auxiliary anode tube electrode

ActiveCN103317196AInhibition of stray corrosionReduce sensitivityElectrochemical machining apparatusElectrolysisElectronic load

The invention relates to an electrochemical machining method for an auxiliary anode tube electrode and belongs to the technical field of electrochemical machining. The electrochemical machining method includes the following processes: 1, manufacturing a perforated plate (5); 2, positioning and clamping a workpiece anode (4), the perforated plate (5) and an auxiliary anode (6); 3, connecting the positive pole of a power source (2) with one end of a substrate clamp (7) and one end of the workpiece anode (4), connecting the negative pole of the power source (2) with a tube electrode (1), and connecting the other end of the electronic load (3) with the workpiece anode (4); 4, leading in electrolyte, setting a constant voltage working mode of the electronic load (3) to achieve voltage drop, starting the power source, and performing electromechanical machining on the tube electrode when the potential of the workpiece anode (4) is lower than that of the auxiliary anode; 5, separating and cleaning the workpiece anode (4), the perforated plate (5) and the auxiliary anode (6). The electrochemical machining method for the auxiliary anode tube electrode has important meaning in improving aperture outlet accuracy of tube electrode electrochemical machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Combinational processing method for micro-array axle hole

The invention relates to the micro matrix shaft hole combination machining method with the combination of electrochemical machining, electrical spark machining, and hypersonic recombination, to solve the difficulties of un-assured precision, low machining efficiency, and complex shape hard to machining. It makes single micro electrode through electrochemical machining, machining micro matrix master hole on the flat electrodes, making micro matrix shaft through electrical spark machining and complex supersonic vibration, and using micro matrix shaft and electrochemical machining to make the micro matrix shaft hole. It has high machining precision, high in efficiency and convenient.

Owner:HARBIN INST OF TECH

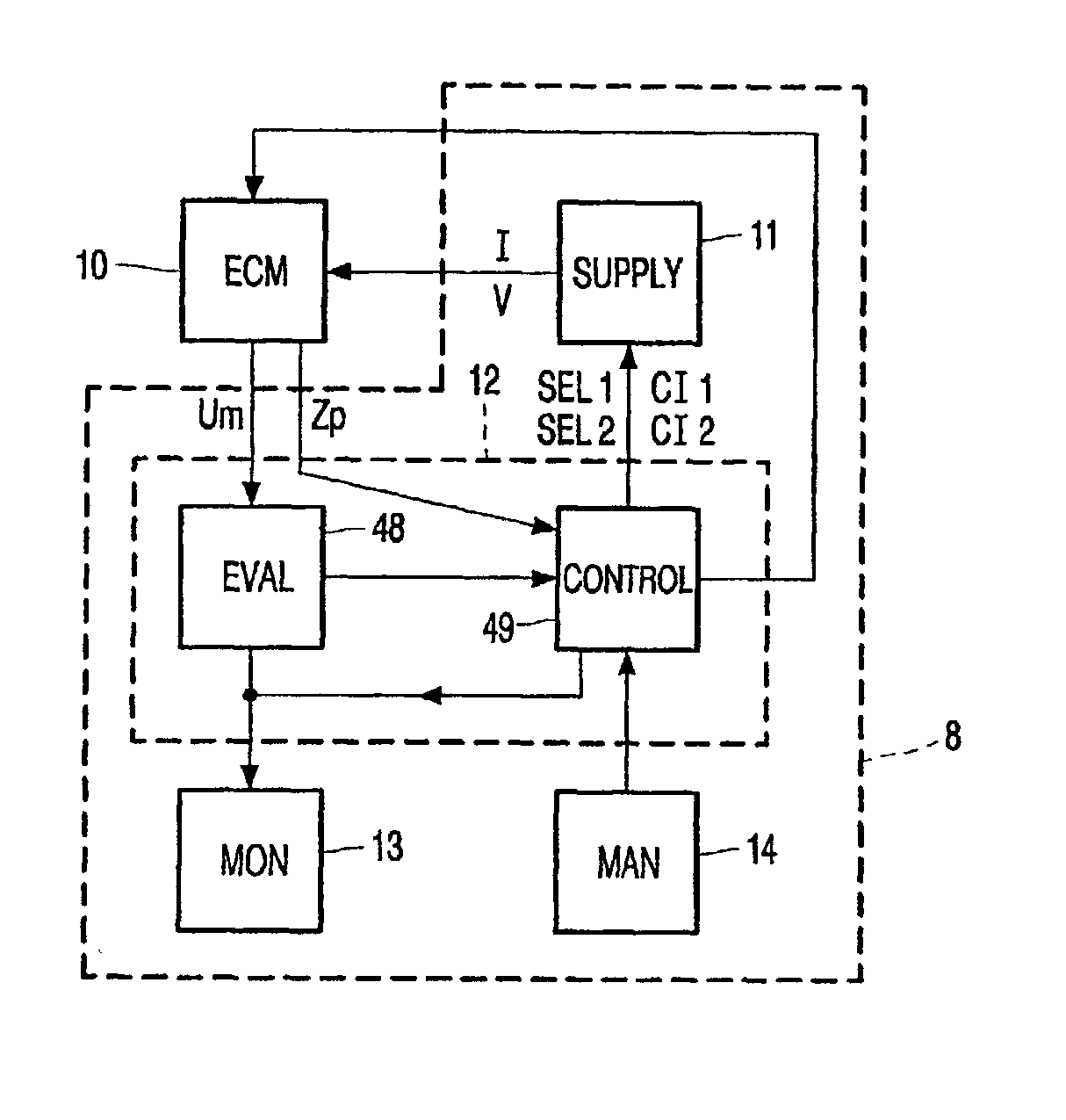

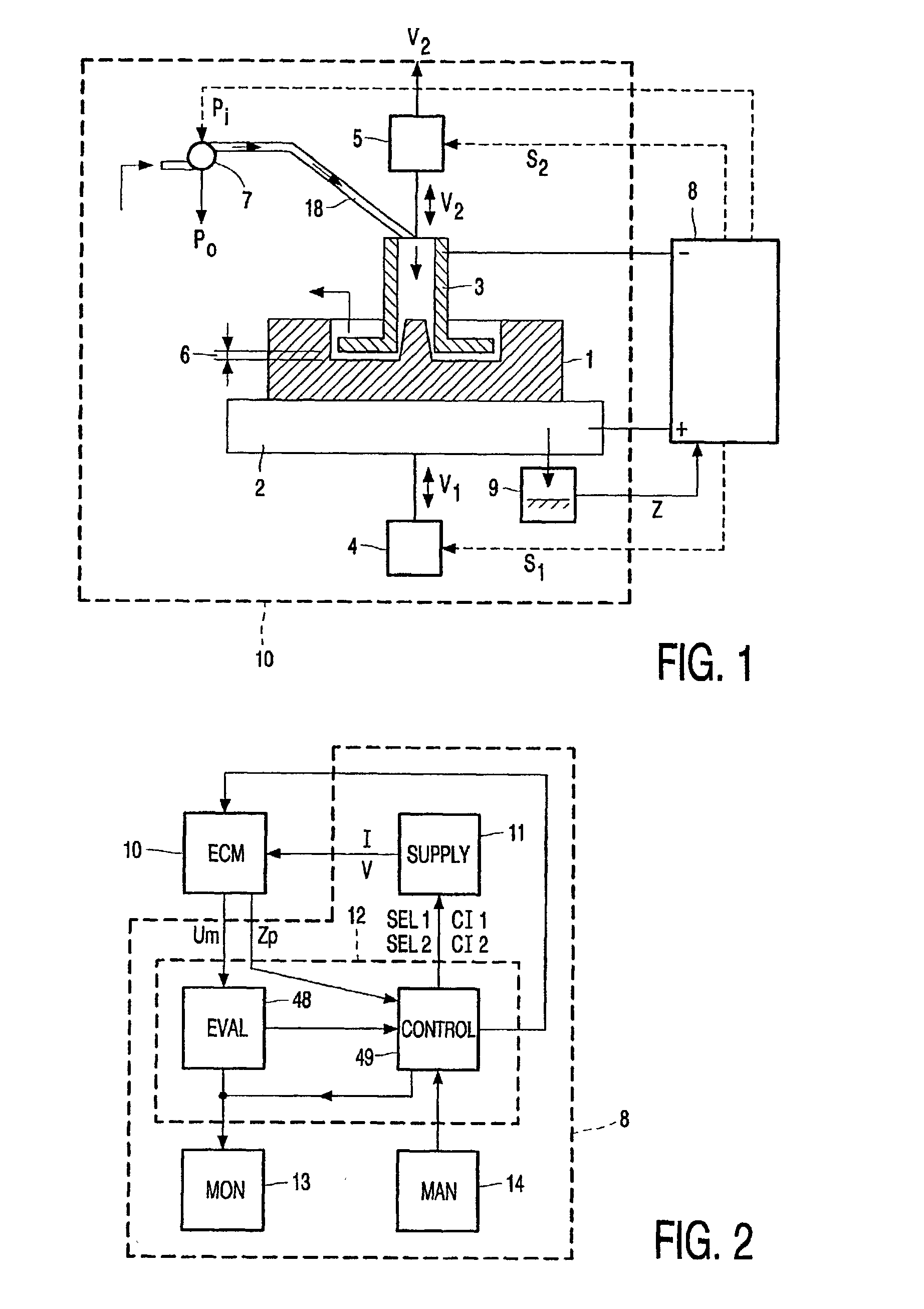

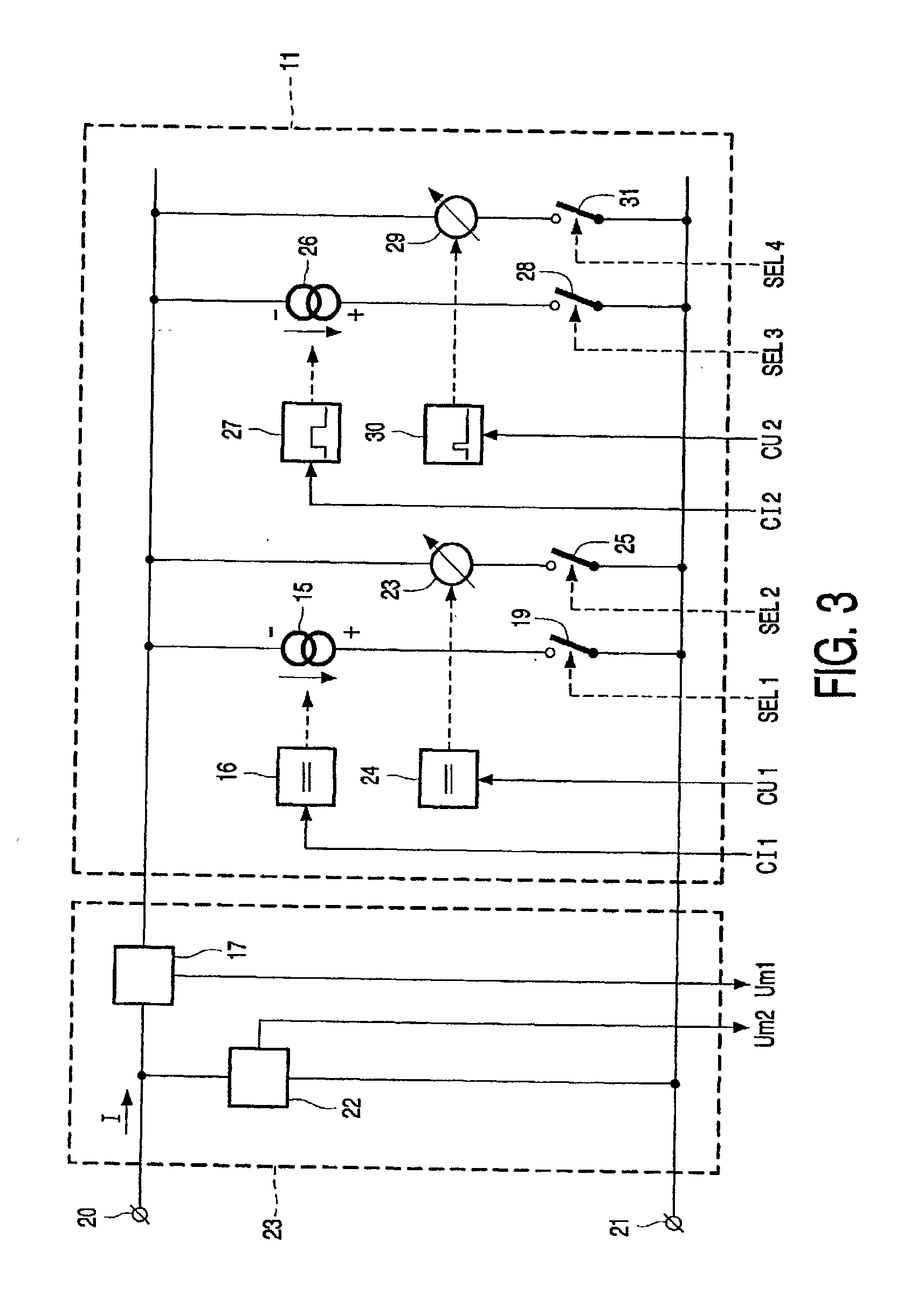

Method of controlling an electrochemical machining process

InactiveUS20020169516A1Improve machining accuracyAvoid large gapsMachining electric circuitsElectric circuitsElectrochemistryElectrochemical machining

A method of controlling a process of electrochemically machining an electrically conductive workpiece employing the spectral composition of the measured voltage within a predetermined measuring period such as induced by an applied current between the electrically conductive workpiece and an electrode tool. A process of electrochemically machining employing a material removing step with electric current supplied continuously and an a workpiece shaping step with electric current supplied intermittently. An advantageous embodiment employs extreme short pulses.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV +1

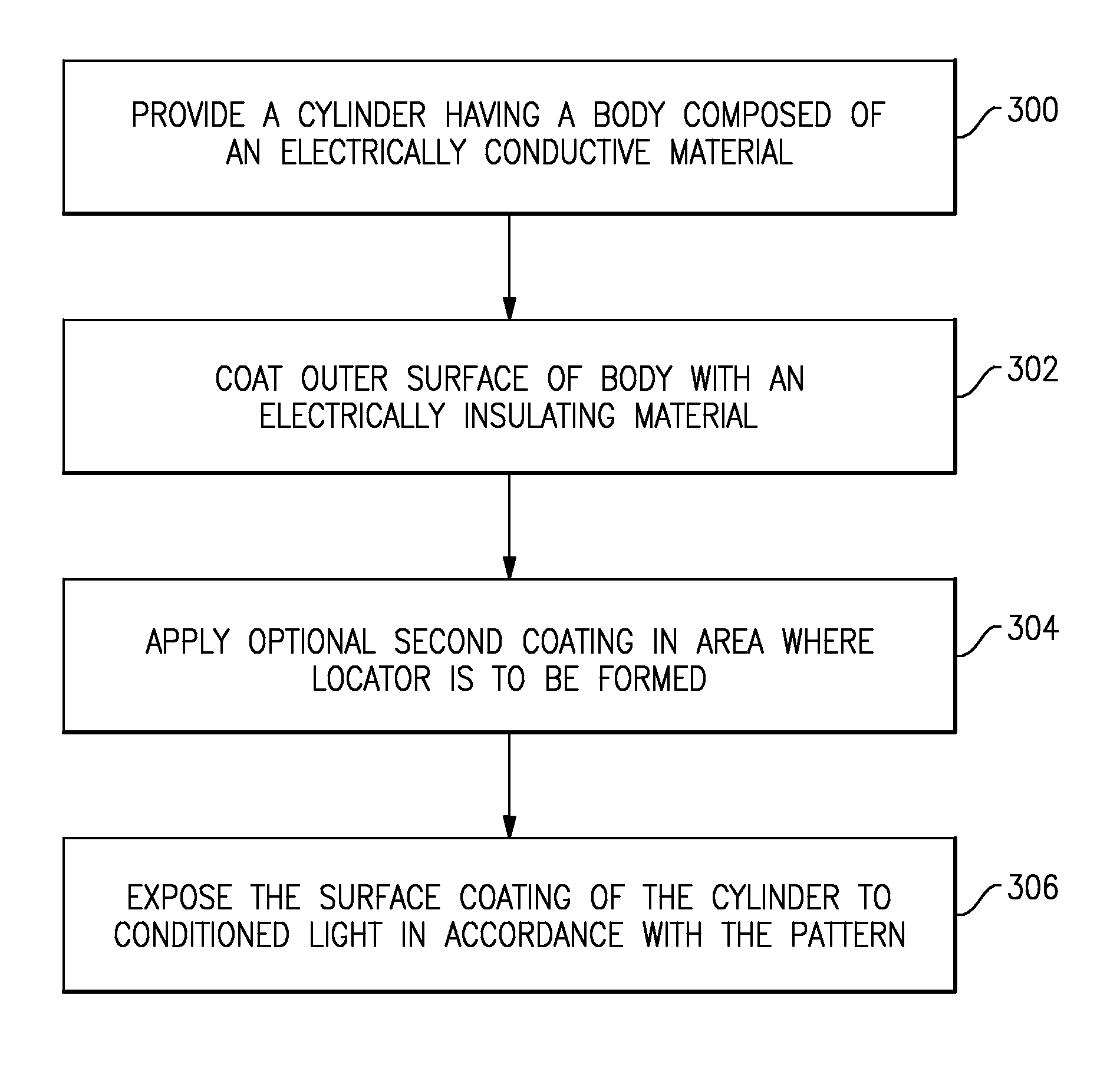

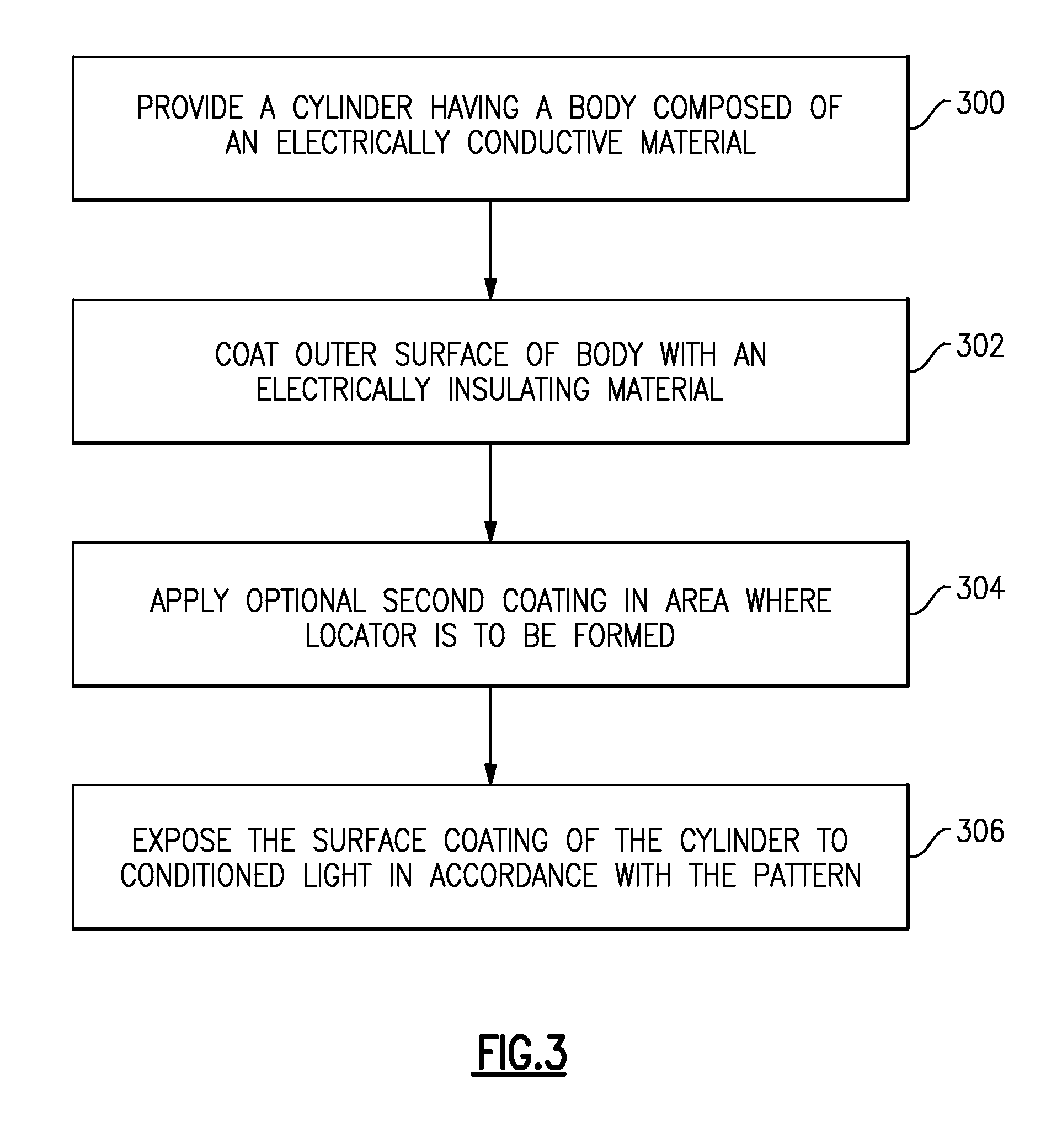

Method and tool for forming non-circular holes using a selectively coated electrode

An electrochemical machining process for forming a non-circular hole from a substantially circular hole within a workpiece using an electrode. The electrode is made of an electrically conductive material and has insulated areas in which the electrically conductive material is coated with an insulating material, and exposed areas of metal or conductive material. The insulated areas and exposed areas extending in rows substantially along a longitudinal axis of the electrode. The electrode is first positioned in a substantially circular hole. An electric current is then applied to the electrode to electrochemically remove a predetermined amount of material from the substantially circular hole to form a non-circular hole. A variety of different non-circular shapes are achievable using the process.

Owner:GENERAL ELECTRIC CO

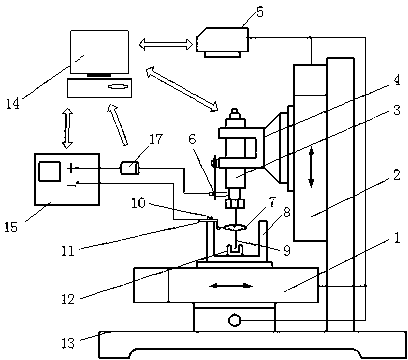

Online preparing system and method for electrochemical grinding micro tool for line electrode

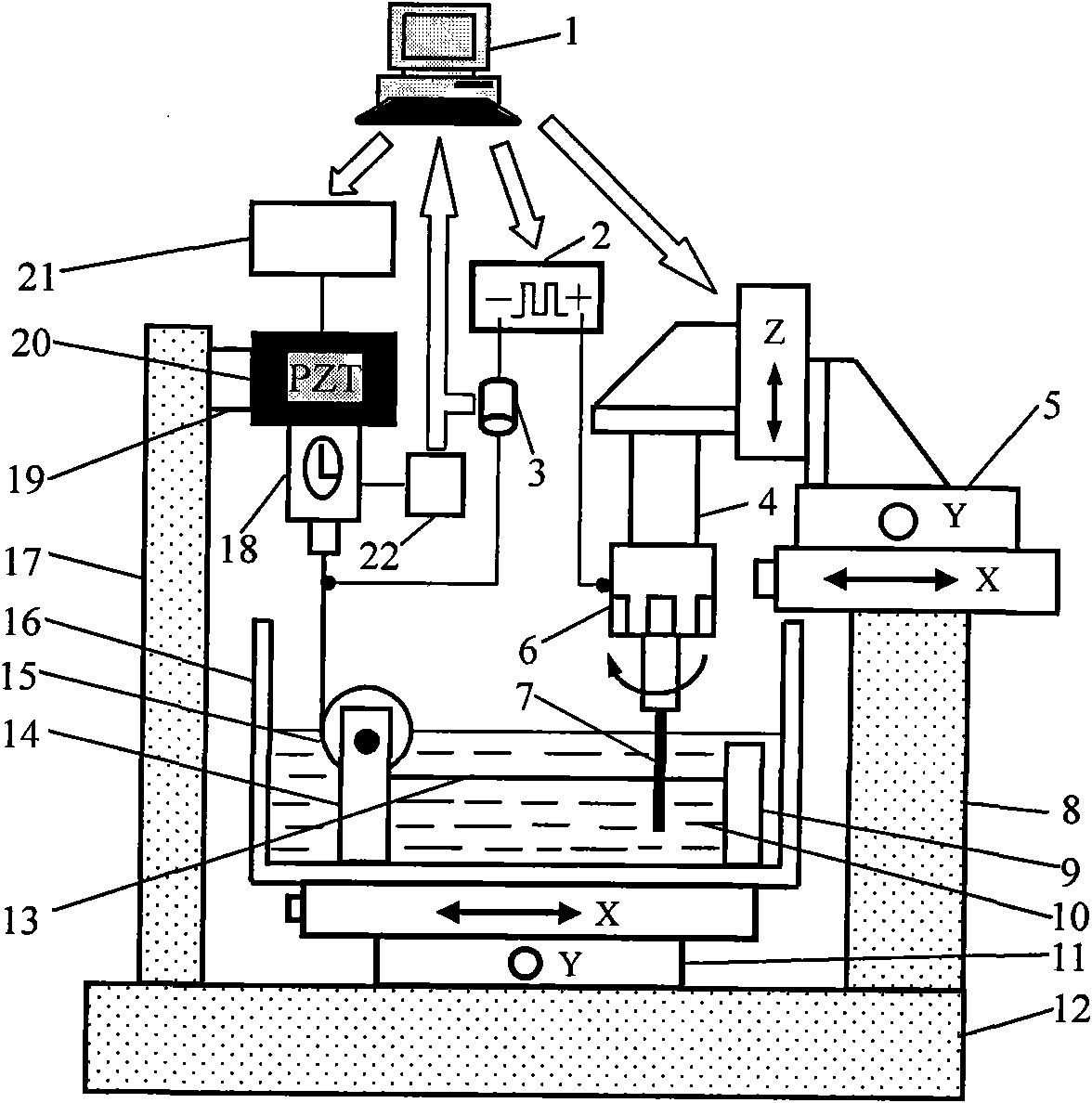

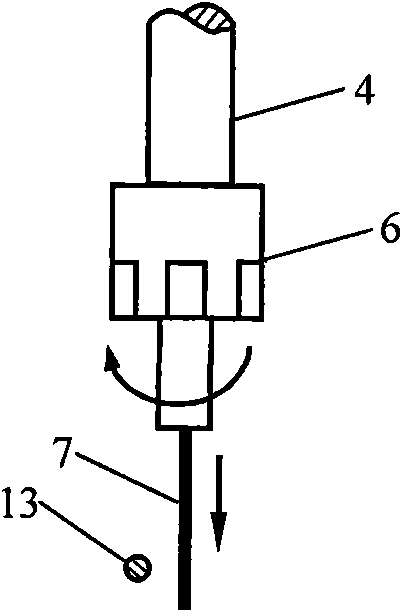

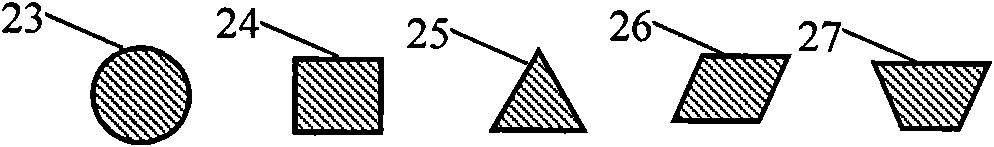

ActiveCN102019474AStrong processing localization abilityGood process compatibilityElectrolytic agentNumerical control

The invention relates to online preparing system and method for an electrochemical grinding micro tool for a line electrode, belonging to the field of micro electrochemical machining. A microscale line electrode is fixed in an electrolyte tank and is tensioned by a micro tension device, and a tool electrode is connected onto a numerical-control rotary main shaft; the electrolyte tank is filled with electrolyte, the microscale line electrode and the tool electrode are immersed in the electrolyte, both the microscale line electrode and the tool electrode maintain a machining gap, and a pulse width power supply is connected; and by utilizing a principle that metal generates electrochemical anodic dissolution in the electrolyte, the tool electrode is corroded for molding. In the machining process, the numerical-control rotary main shaft is utilized to enable the tool electrode to generate rotation of certain angular speed or perform indexing, meanwhile a three-axis motion platform is utilized to generate uniform-speed feeding in a Z-axis direction so as to obtain the micro tool with a needed section shape. In size control, a current sensor is used for collecting and machining current in a loop, the size change of tungsten filaments in the corrosion process is reflected by utilizing the corresponding relationship of machining current and tungsten filament resistance, and therefore the size is accurately controlled.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

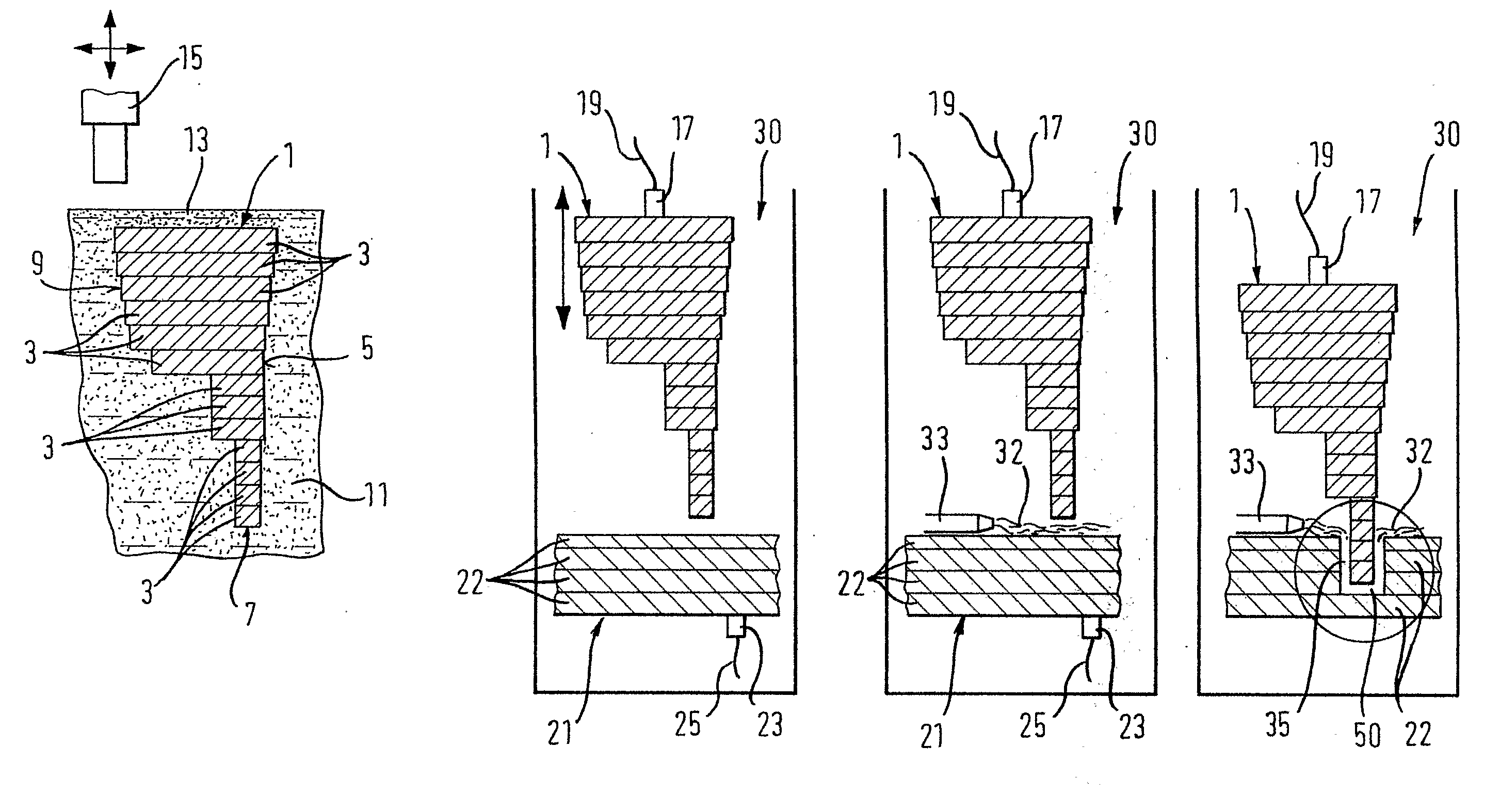

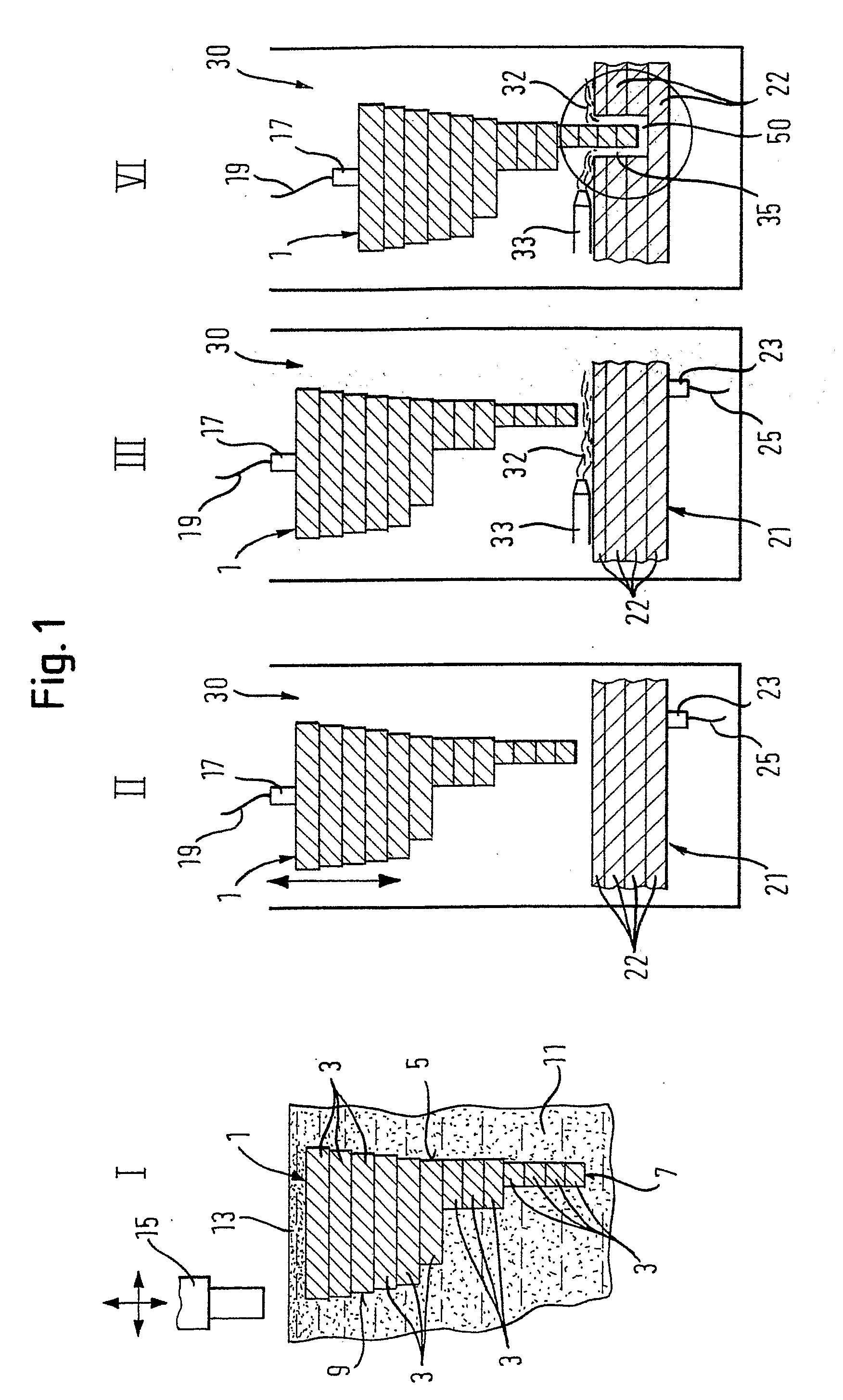

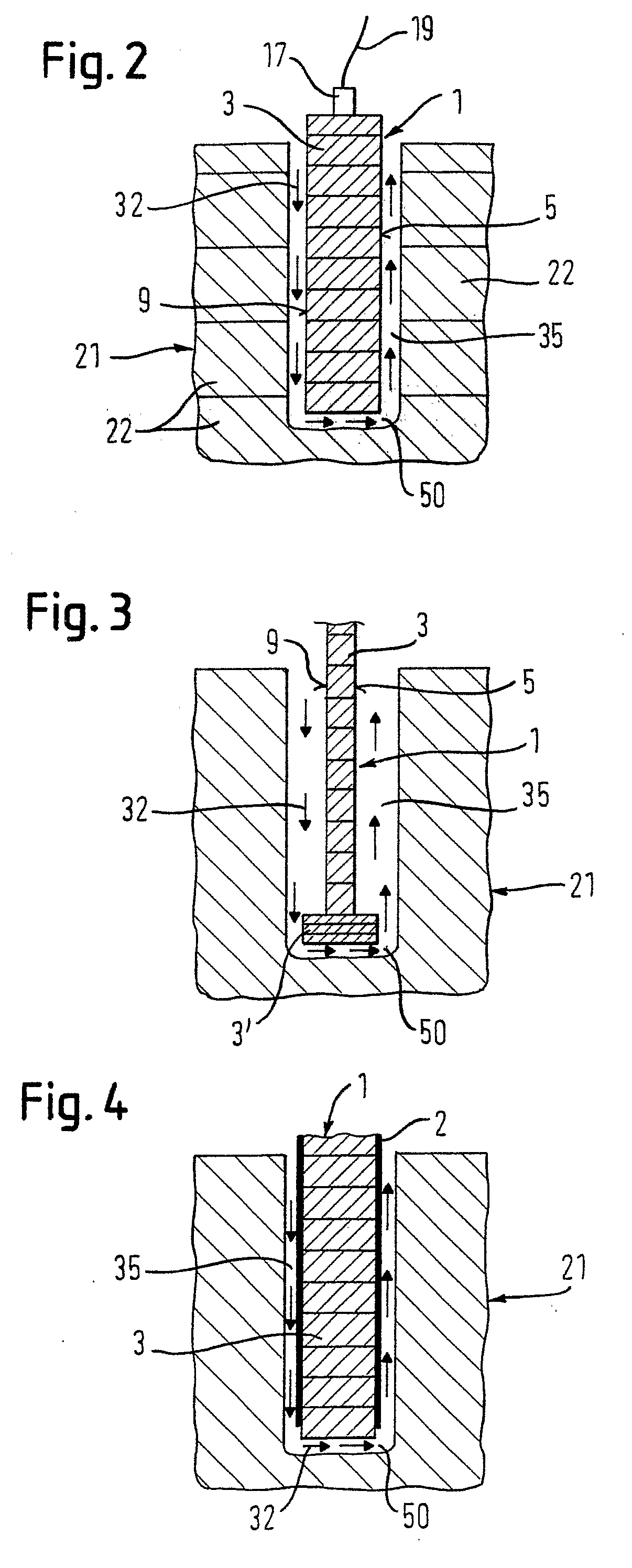

Method for Electro-Chemical Processing of a Work Piece and Electrode for Such a Method

InactiveUS20070256938A1Improve washing effectPrecision of material removalMachining electrodesAdditive manufacturing apparatusElectrolysisRp-process

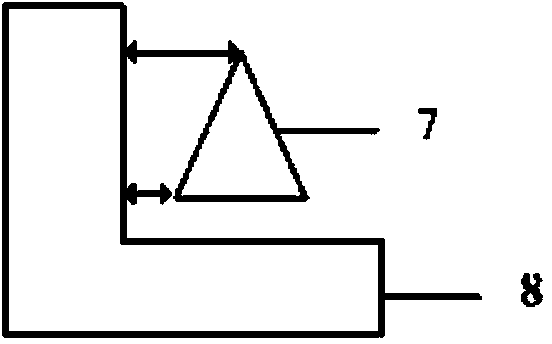

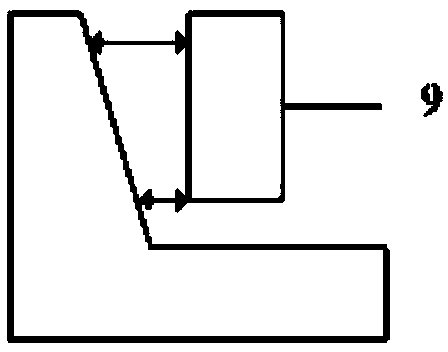

The invention concerns a method for processing a work piece (21), in which a work piece (21) is constructed in layers (3) from a conductive material using a rapid prototyping process. The work piece (21) constructed in layers (3) is contacted in an anodic manner. Then, a tool (1) is disposed opposite to a to-be-processed site of the work piece (21) such that a gap (50) remains therebetween. The tool (1) is contacted in a cathodic manner and a conductive medium (32) is brought into the gap (50) so that current flows by applying an electronic voltage and metal ions are dissolved from the work piece (21) by electrolysis, whereby a defined removal of material from the work piece (21) takes place. The invention further concerns a method for producing a tool to be utilized as an electrode (1) in an ECM method and an electrode (1) for usage in an ECM method for electro-chemical processing of a work piece (21).

Owner:FRUTH CARL JOHANNES

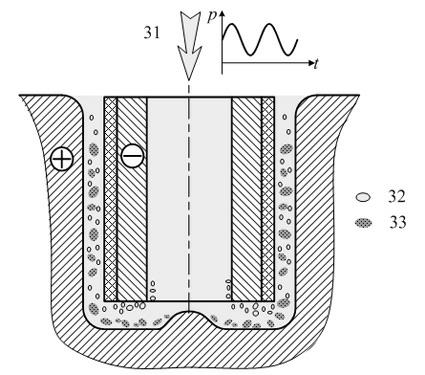

Electrochemical machining method and device for pulsating flow field tube electrode

ActiveCN102198549AReduce the "holding effect"Reduce the "squeeze effect"Machining working media supply/regenerationVoltage pulseElectrolysis

The invention relates to an electrochemical machining method and an electrochemical machining device for a pulsating flow field tube electrode, and belongs to the technical field of electrochemical machining. The method comprises the following steps of: 1, adjusting the flow and the pressure by controlling an action of a spool of a servo valve (9) by a pressure servo execution module (4), and outputting a pulsating electrolyte solution to an electrochemical machining area; 2, modulating a control instruction phase by using a control system of an electrochemical machining machine tool according to a pressure and voltage feedback signal, so that the pressure of the machining area is matched with the voltage pulse rhythm; and 3, dynamically adjusting a feeding speed and the machining voltage by using the control system of the electrochemical machining machine tool so as to machine a hole with a variable section in regular change. The method and the device provided by the invention have important meaning for increasing the flocculent product discharge rate and the machining stability of the electrochemical machining of a neutral saline solution deep hole tube electrode.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

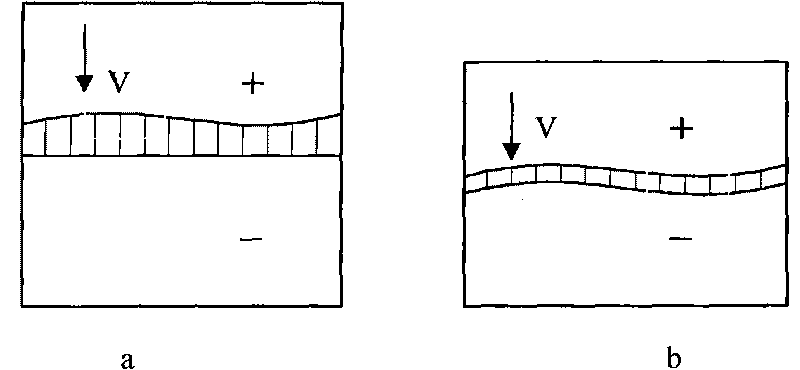

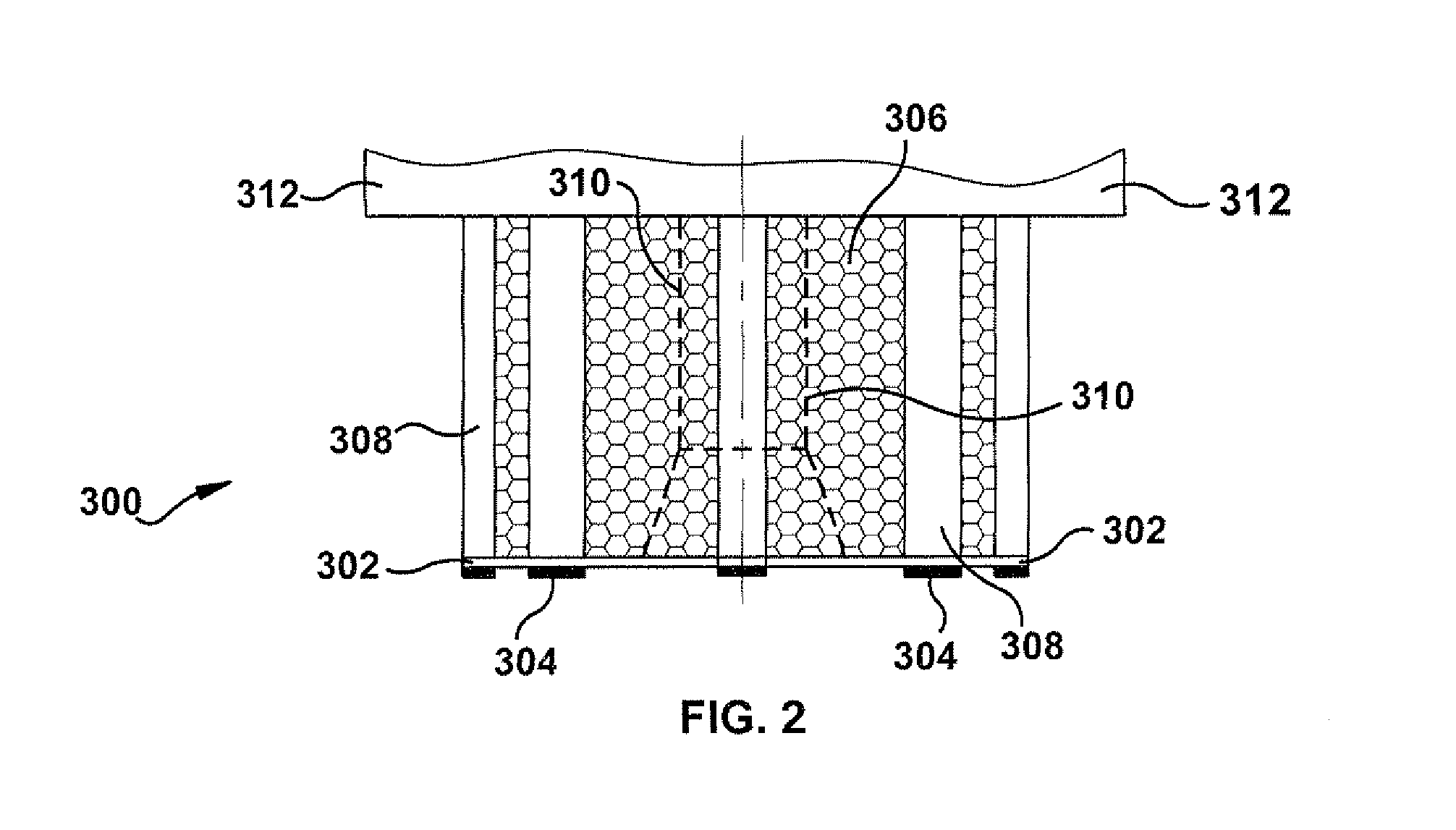

Method, apparatus and system for flexible electrochemical processing

Conventional electrochemical machining process requires fixed shaped tool cathodes, which makes retooling time consuming and expensive. Flexible tool cathodes include elastically deformable cathodes that can deform in two or three dimensions and can adapt to the contour of the workpiece while the workpiece is moving relative to the flexible tool cathode. That is, the flexible tool cathode can perform tracing. Certain flexible tool cathodes can be also used for special configurations such corners and edges. The flexible tool cathodes can be used to polish, finish, or shape the workpiece through electrochemical processes.

Owner:GENERAL ELECTRIC CO

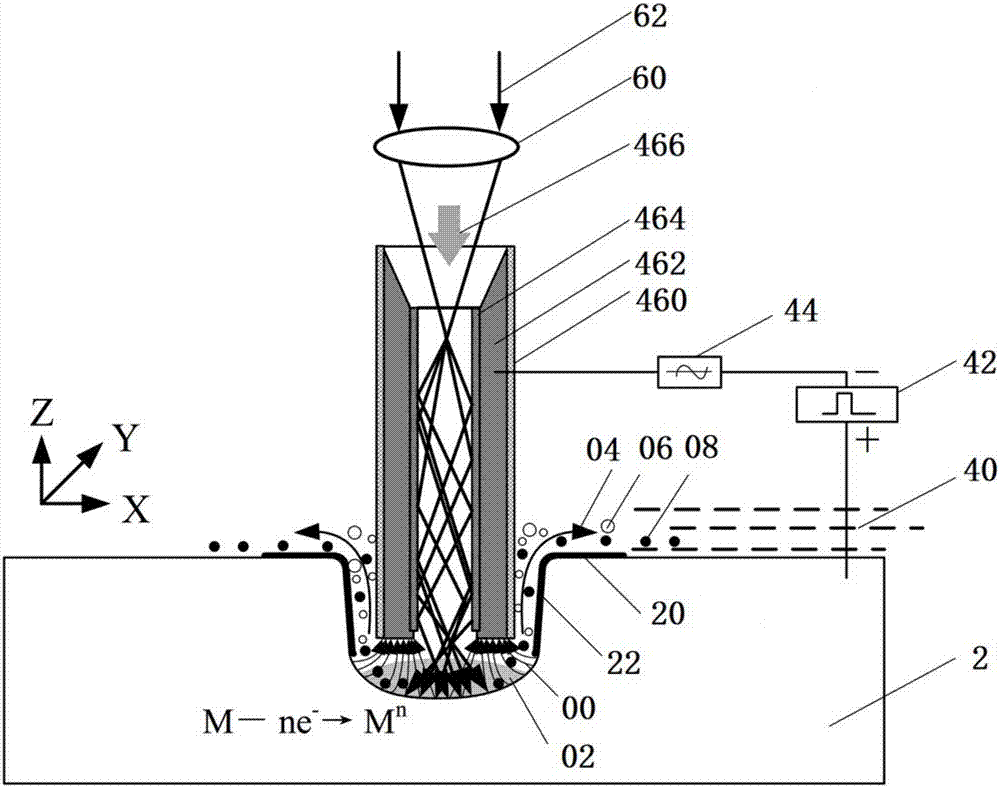

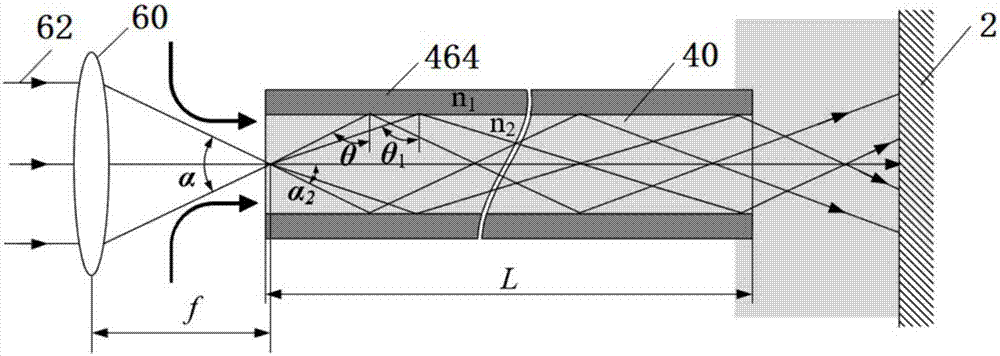

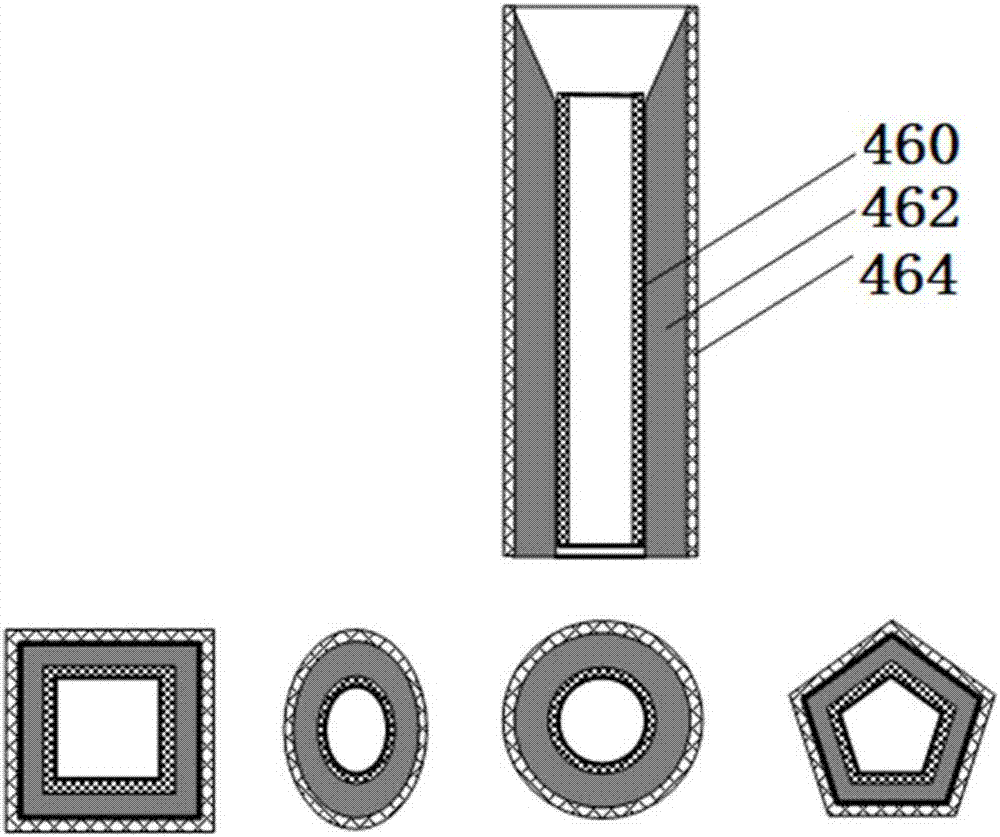

Laser-intervening micro-electrochemical machining method and device

The invention discloses a laser-intervening micro-electrochemical machining method. The laser-intervening micro-electrochemical machining method comprises at least the following steps that a tool electrode and a to-be-machined workpiece are connected with a negative electrode and a positive electrode of a power supply correspondingly; lasers and an electrolyte are transmitted through the tool electrode to a machining area of the to-be-machined workpiece; and after the power supply is switched on, micro-electrochemical machining is conducted, the tool electrode is fed towards the to-be-machinedworkpiece, and a target structure is obtained. In the laser-intervening micro-electrochemical machining method and a laser-intervening micro-electrochemical machining device, laser beams are transmitted through liquid core optical fibers to the deep machining area in a full reflection mode, large-depth coupling of a laser energy field and electrochemical machining is achieved, and efficient machining of a micro-structure with the large depth-diameter ratio can be achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

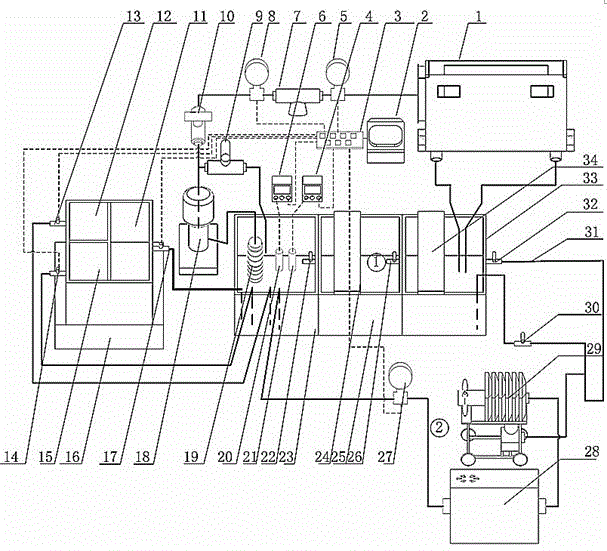

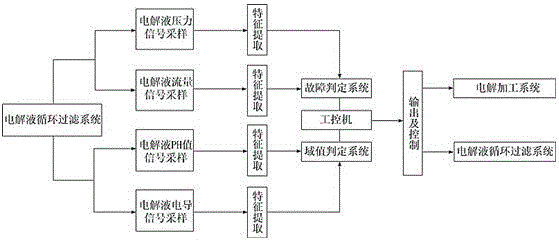

Circulating filtration system for electrochemical machining electrolyte and control method thereof

InactiveCN102873418AImprove cleanlinessImprove operational reliabilityMachining electric circuitsMachining working media supply/regenerationElectrolytic agentSolenoid valve

The invention discloses a circulating filtration system for electrochemical machining electrolyte and a control method thereof, and belongs to the technical field of electrochemical machining. The circulating filtration system for the electrochemical machining electrolyte comprises an electrolyte tank, an electrolyte circulating device, an electrolyte filtering device, an electrolyte filtering and monitoring device and an electrolyte component control device. According to the circulating filtration system for the electrochemical machining electrolyte, which is disclosed by the invention, two loops are connected in parallel to filter the electrolyte, the electrolyte input to a processing area has a high cleanliness; the electrolyte filtering and monitoring device is adopted to monitor a secondary filter and a plate-and-frame filter press in real time; in an electrolysis processing process, the circulating filtration system for the electrolyte has a high reliability; the electrolyte component control device is used for monitoring the pH (potential of hydrogen) value and the conductivity of the electrolyte in real time; and an industrial personal computer controls a liquid regulation tank to correspond to the on and off of a solenoid valve so as to guarantee the stability of the pH value and the conductivity of the electrolyte in the electrolysis processing process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

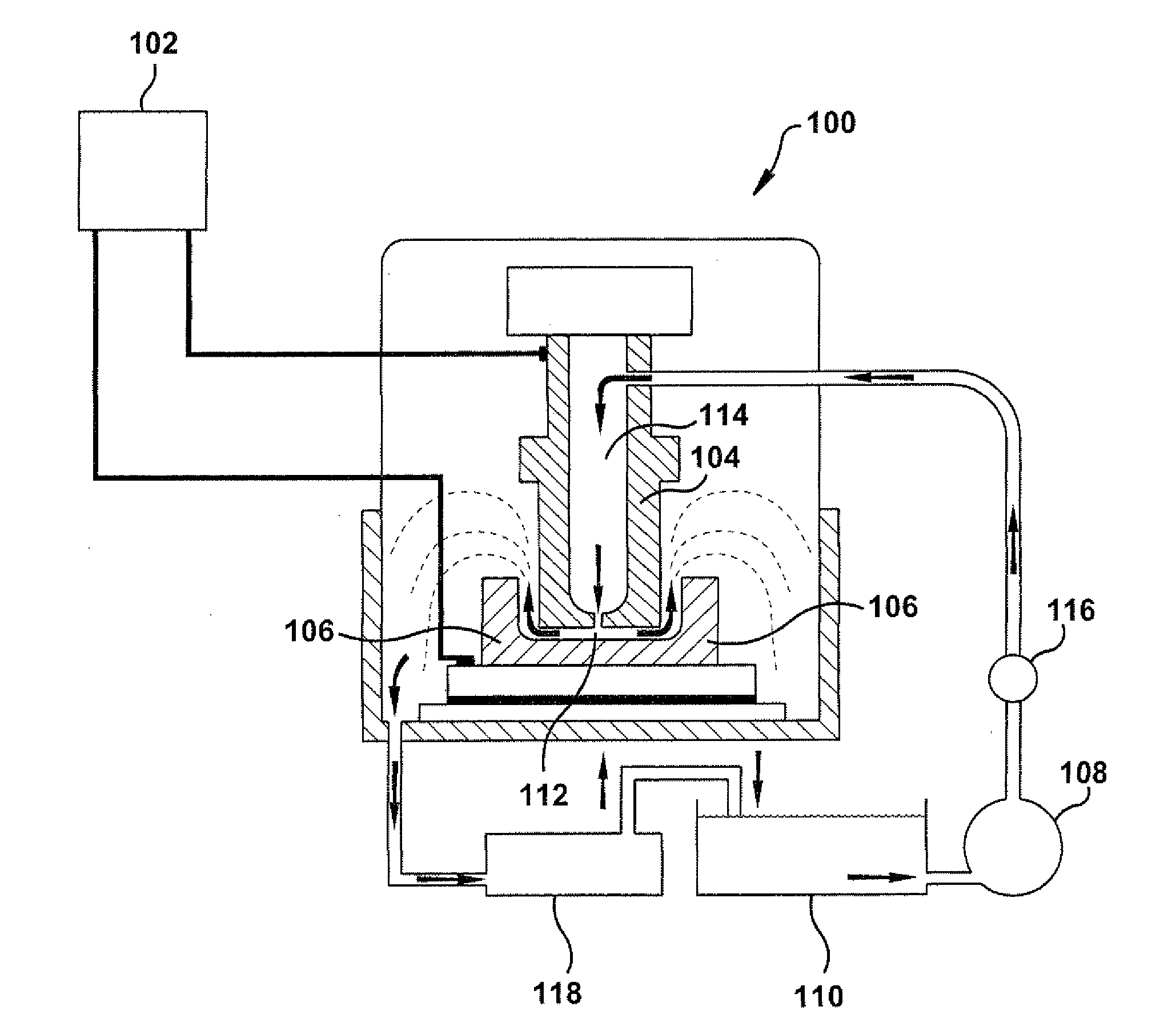

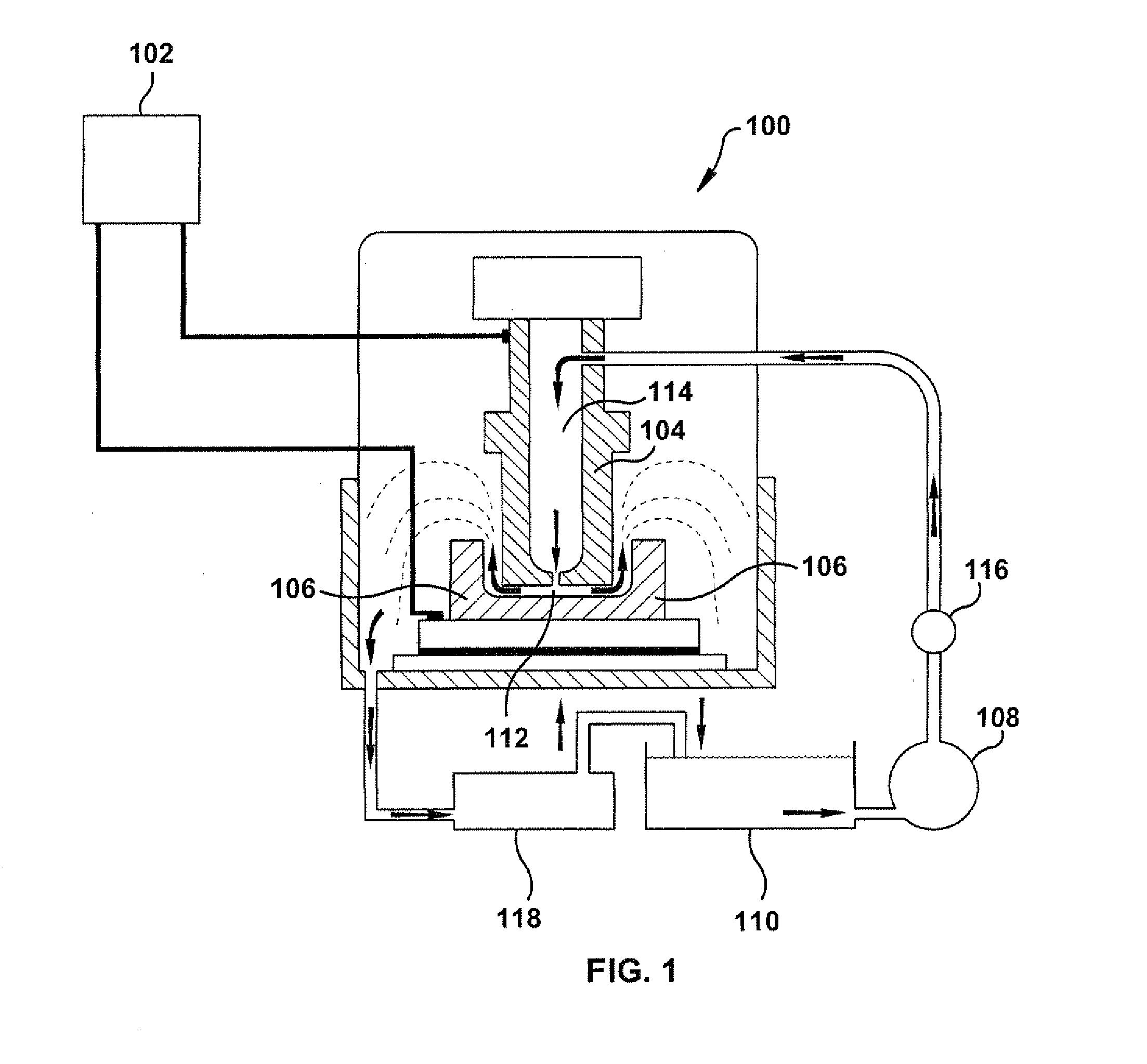

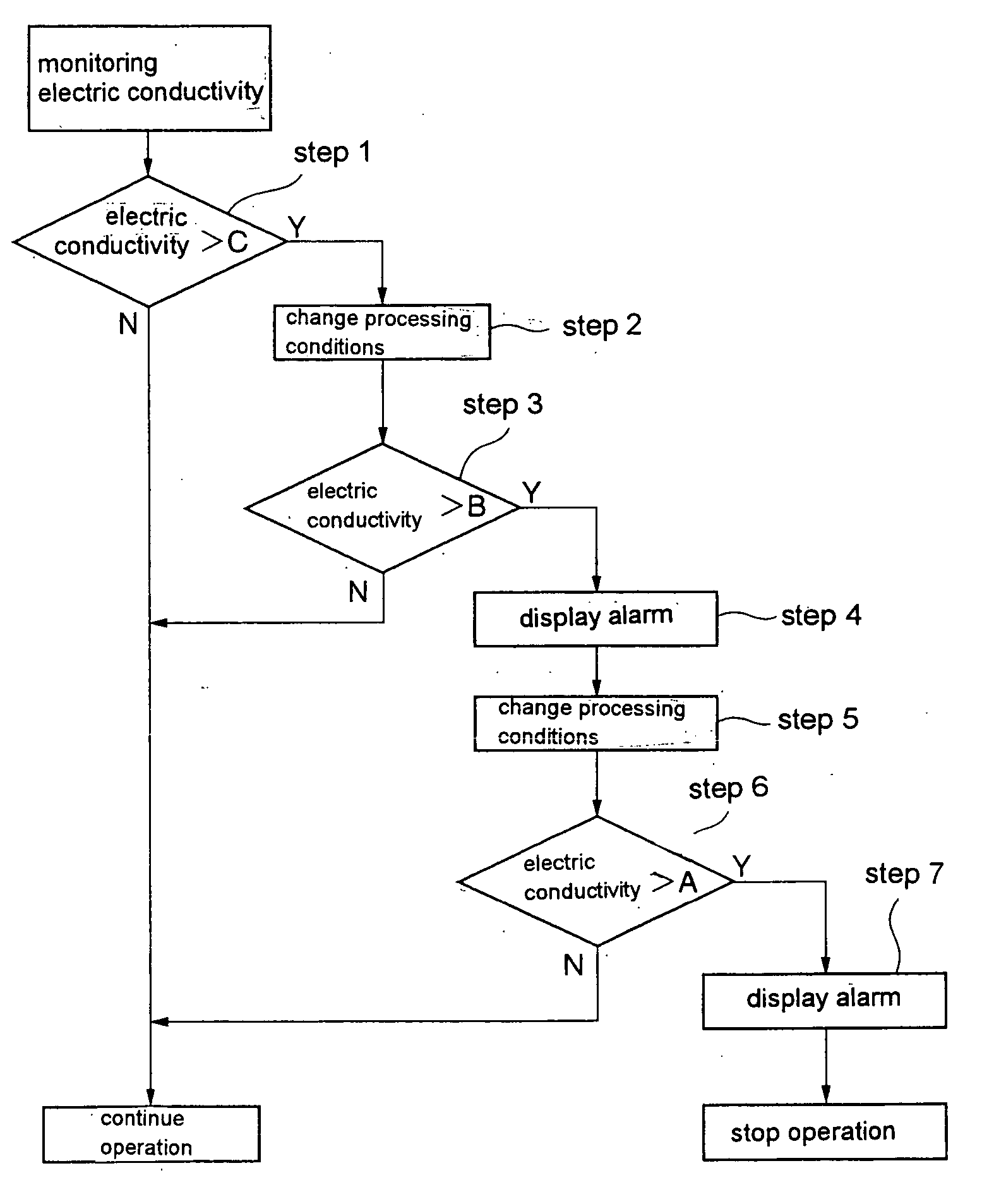

Electrochemical machining device and electrochemical machining method

InactiveUS20060144711A1Suppress change in electric conductivityImprove flattening effectCellsMachining electric circuitsElectricityElectrolysis

A object of this invention is to provide an electrolytic processing method and apparatus that can suppress a change in the electric conductivity of a fluid due to contaminants, such as processing products produced in electrolytic processing, so that the fluid can maintain good flattening properties. The electrolytic processing apparatus of this invention includes: a processing electrode (42) that can come into contact with a workpiece (W); a feeding electrode (44) for feeding electricity to the workpiece (W); a holder (22) for holding the workpiece (W); a power source (26) for applying a voltage between the processing electrode (42) and the feeding electrode (44); a fluid supply section (50) for supplying a fluid between the workpiece (W) and at least one of the processing electrode (42) and the feeding electrode (44); a sensor (80) for measuring the electric conductivity of the fluid; and a control section (84) for changing the processing conditions based on the electric conductivity measured by the sensor (80).

Owner:EBARA CORP

Electrochemical machining bipolar electrode of revolution body surface boss structure and electrochemical machining method of electrochemical machining bipolar electrode

ActiveCN105522239AElimination of surface stray corrosionEliminate stray currentMachining electrodesElectrical-based machining electrodesElectronic loadElectrolysis

The invention relates to an electrochemical machining bipolar electrode of a revolution body surface boss structure and the electrochemical machining method of the electrochemical machining bipolar electrode, and belongs to the technical field of electrochemical machining. The method is characterized in that a tool electrode is the bipolar electrode, according to different boss heights, an auxiliary electrode is arranged to be in a fixed and reciprocating motion manner, and a constant positive potential difference is applied to the auxiliary electrode and a workpiece positive pole through an electronic load in the machining process; and as the distance between the auxiliary electrode and a boss is short, according to the electric field distribution principle, the auxiliary electrode with the higher potential can effectively change electric field distribution on the surface of the boss in a machining zone, stray current on the surface of the boss is eliminated, and the effect of protecting the surface of the boss from dispersive corrosion is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

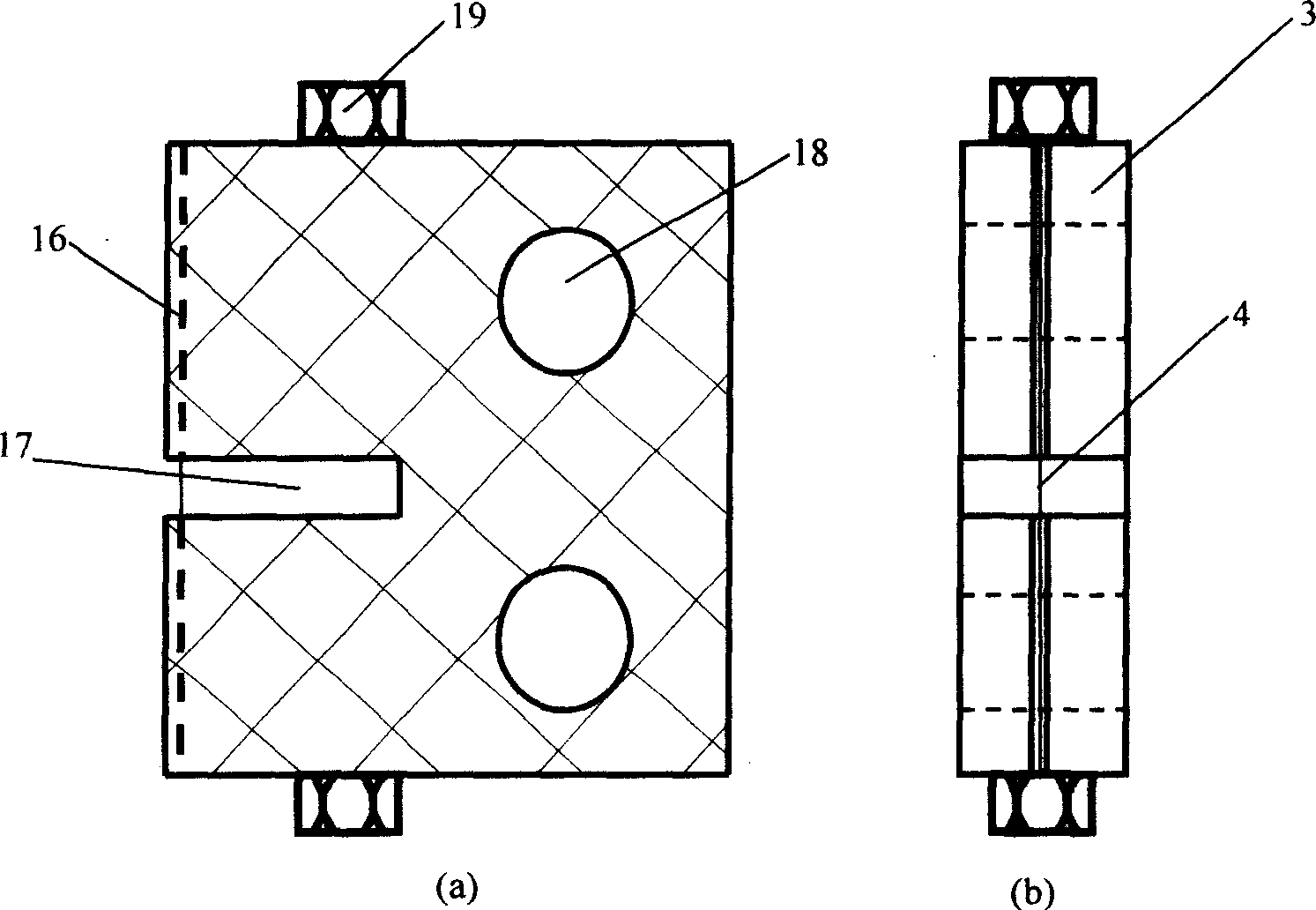

Circulating wire cutting electrode system and processing method for electrolytic wire cutting

InactiveCN101774050ASimple structureLow costMachining electrodesElectrical-based machining electrodesElectrochemical responseElectrolysis

The invention relates to a circulating wire cutting electrode system and a processing method for electrolytic wire cutting, which belong to the field of electrochemical processing. The electrode system comprises a wire cutting frame (18), a driving guide wheel (22), a conductance guide wheel (24) and a positioning guide wheel arranged on the wire cutting frame (18), and a tension guide wheel (15) with adjustable positions; the conductance guide wheel (24) is connected with the negative pole of a power supply (24); and the system also comprises electrode wires (21) which are wound on the four guide wheels and are butted end to end, and a micro variable speed motor (23) connected with the driving guide wheel (22) through a transmission gear group (29). In an electrolysis process, circulating wire cutting motion is realized with the electrode wires so as to eliminate electrolytic products, so that novel electrochemical reaction ions are timely supplemented to a processing area. The invention can greatly improve the processing efficiency and the processing quality, and reduce the processing cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

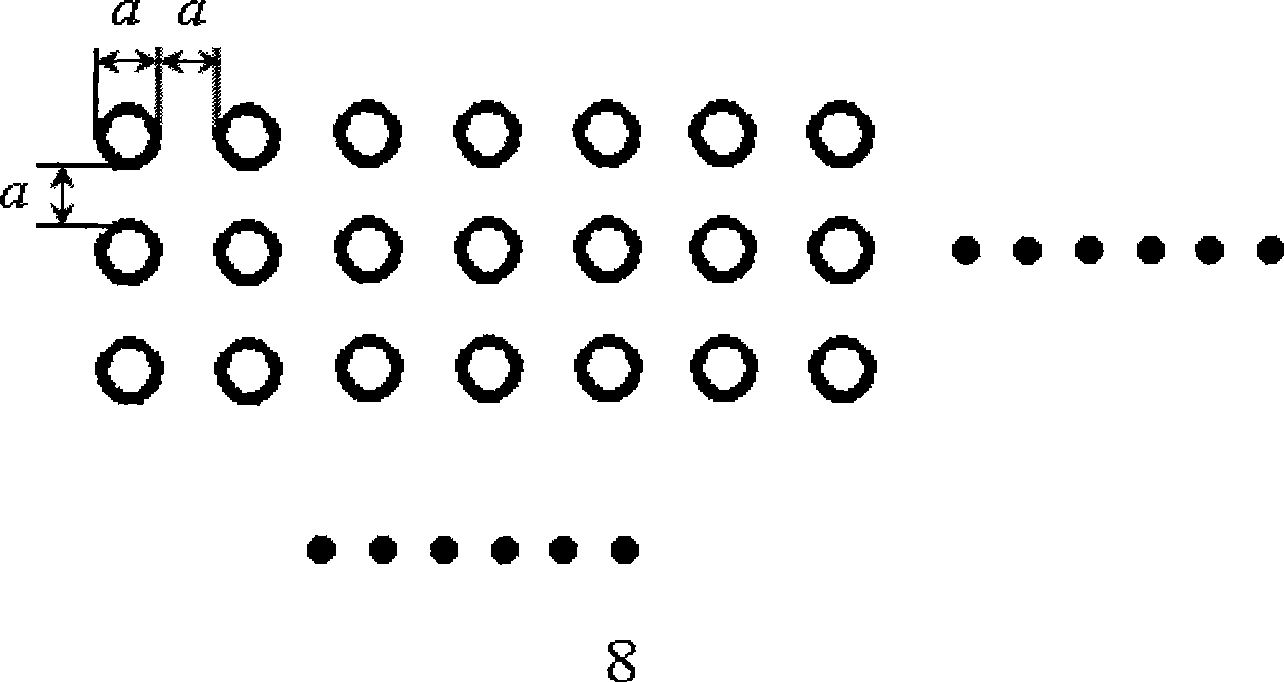

Electrochemical machining process for array micro type hole

InactiveCN1699006ALow costGood repeatabilityMachining electrodesElectrical-based machining electrodesElectrolysisMetal alloy

This invention discloses an electrochemical process method for processing array micropore of metal alloy material, combining photolithagraphic process, electric casting technique and precise electrospark wire-electrode cutting technique, which comprises the following steps: a) applying wire-electrode cutting or photolithographic electric casting technology to make array micropore; b) electrochemical expelling machining the metal alloy material; when processing array micropore with small form ratio, the space between said array micropore is filled with insulation paste; when processing micropore with big form ratio, there is no insulation paste filled, but the electrode side wall is covered with insulating film. The insulation process decreases the disadvantage of stray electric field in electrochemical machining.

Owner:TSINGHUA UNIV

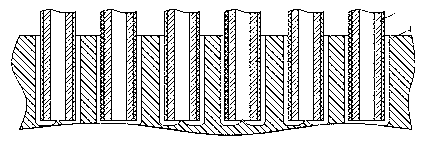

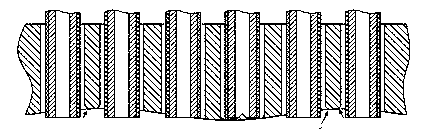

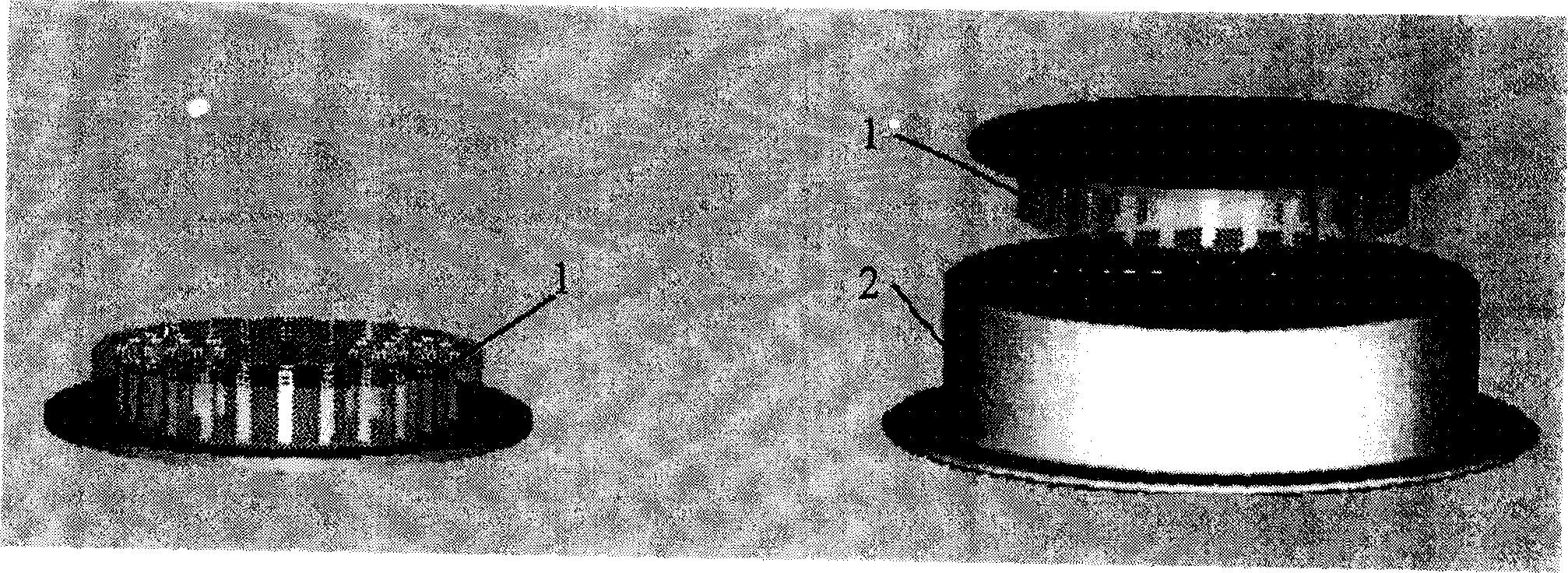

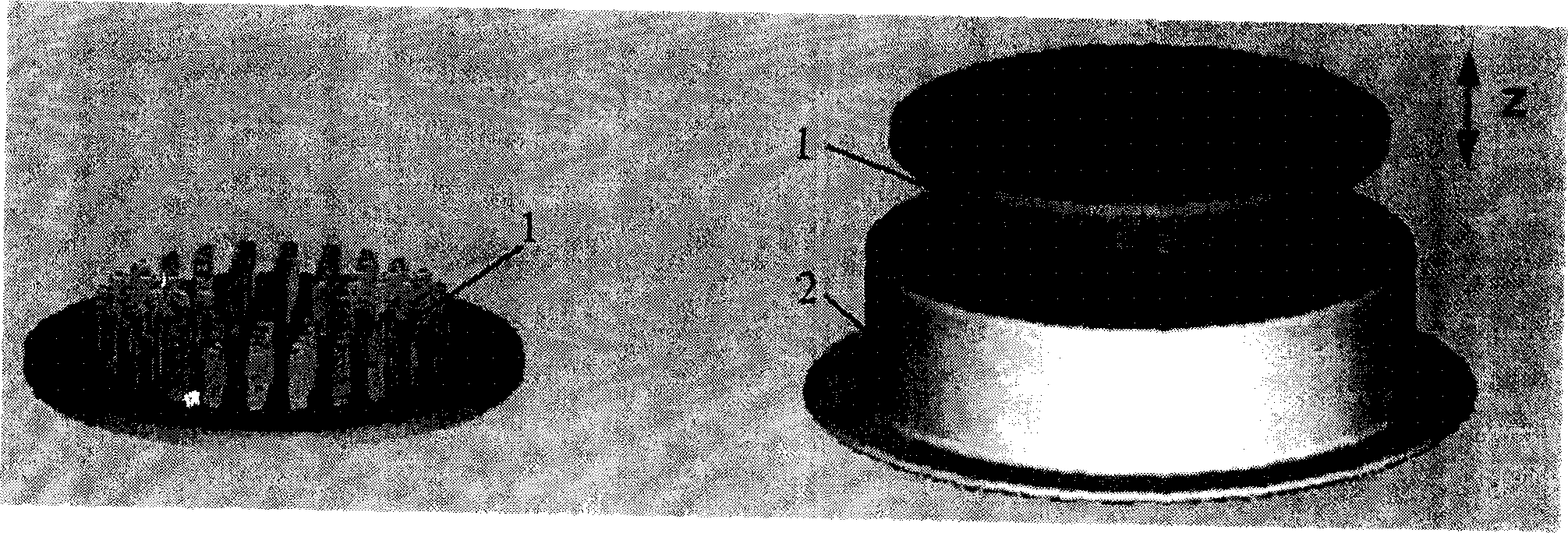

Wire electrode array structure preparation method for micro-electrochemical machining

ActiveCN103706899AEfficient preparationReduce the impactMachining electrodesElectrical-based machining electrodesElectrolysisElectrode array

The invention discloses a wire electrode array structure preparation method for micro-electrochemical machining. The wire electrode array structure preparation method includes the steps of 1), pretreating a metal base; 2), manufacturing a graphical masking film; 3), subjecting the masking film to profound electrolytic corrosion, namely taking the metal base with the graphical surface as a positive electrode for electrolytic machining to obtain a tool negative electrode in a wire electrode template machined and manufactured in the profound electrolytic corrosion, and determining electrolytic corrosion time according to photoresist pattern width and electrolysis current density till to obtain a metal gate line array pattern with the point top; 4), removing back materials, namely removing the back materials corresponding to the manufactured metal gate lines to obtain a wire electrode array integrated with a frame. By means of the method, the metal microstructure array with cross sections different in shapes like square, rectangle and rhombus can be manufactured, so that the metal microstructure array with large depth-to-width ratio, high density and high machining quality can be efficiently realized.

Owner:江苏蔚之领域智能科技有限公司

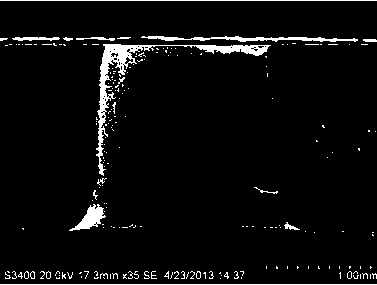

Anti-adhering knife/blade with surface micromoulding

InactiveCN101480783AReduce wearIncreased durabilityMaintainance and safety accessoriesWorkpiecesManufacturing technologyLaser processing

The invention relates to a cutter / cutter blade with a slightly formative surface, which has bonding resistance and abrasion resistance and belongs to the filed of the mechanical manufacture of mechanical engineering. The invention is characterized in that a plurality of dimple array structures are distributed in an area which is easy to generate abrasion, such as a front tool face and a rear tool face which are near the neighborhood of a cutting edge, and the dimple array structures are processed by adopting a minuteness manufacturing technique, such as electrochemical processing or laser processing, and the like so as to improve the contact situation of the cutter, cuttings and workpieces during cutting processing and prevent workpiece materials from bonding the cutter. The invention is suitable for various processing methods of the cutting processing, such as turning, milling, drilling, boring, broaching, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

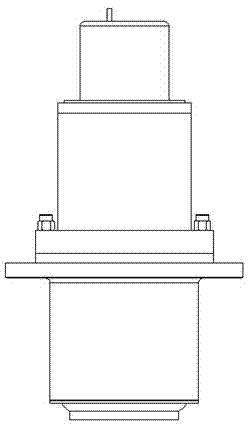

Device and method for manufacturing large-length-diameter-ratio nanoscale shafts

InactiveCN103252541ALight in massLow costElectrochemical machining apparatusElectricityDiameter ratio

The invention relates to a device and method for manufacturing large-length-diameter-ratio nanoscale shafts and belongs to the field of precise micro electrochemical machining. The device comprises a locating piece (8) installed on an X-Y-axis mobile platform (1), a cathode fixture (11) fixed on the locating piece (8), and a cathode horizontal ring (7) clamped by the cathode fixture (11), and further comprises a rotary main shaft fixture (4) installed on a Z-axis precise displacement platform (2), an electricity leading device (6) fixed on the rotary main shaft fixture (4), and a rotary main shaft (3) fixed on the rotary main shaft fixture (4). The positive electrode and the negative electrode of a power supply (15) are connected with the electricity leading device (6) and the cathode fixture (11) respectively. With the method and device, the nanoscale thin and long shafts with large length-diameter ratios can be machined, and the method and device has the advantages of being strong in repeatability, high in success rate, low in cost and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

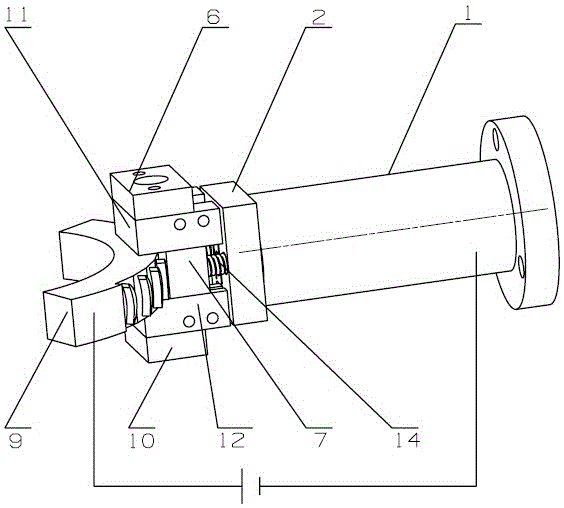

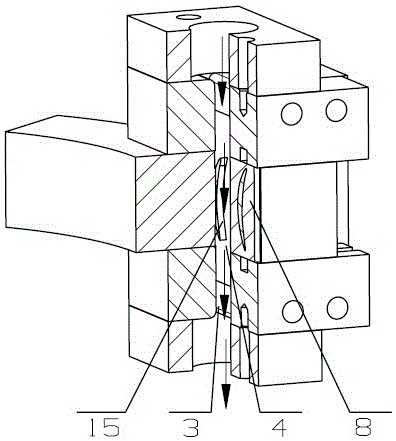

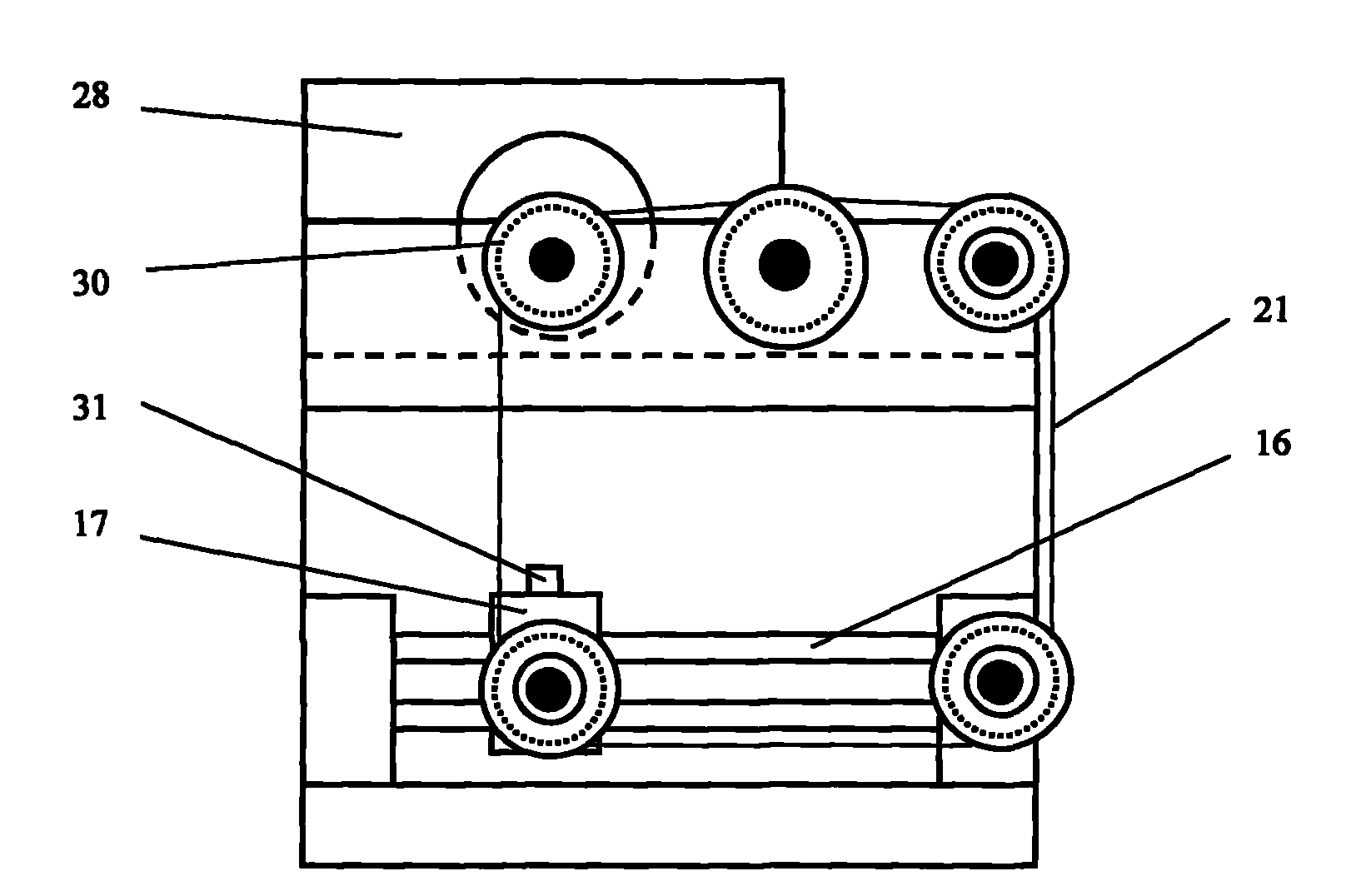

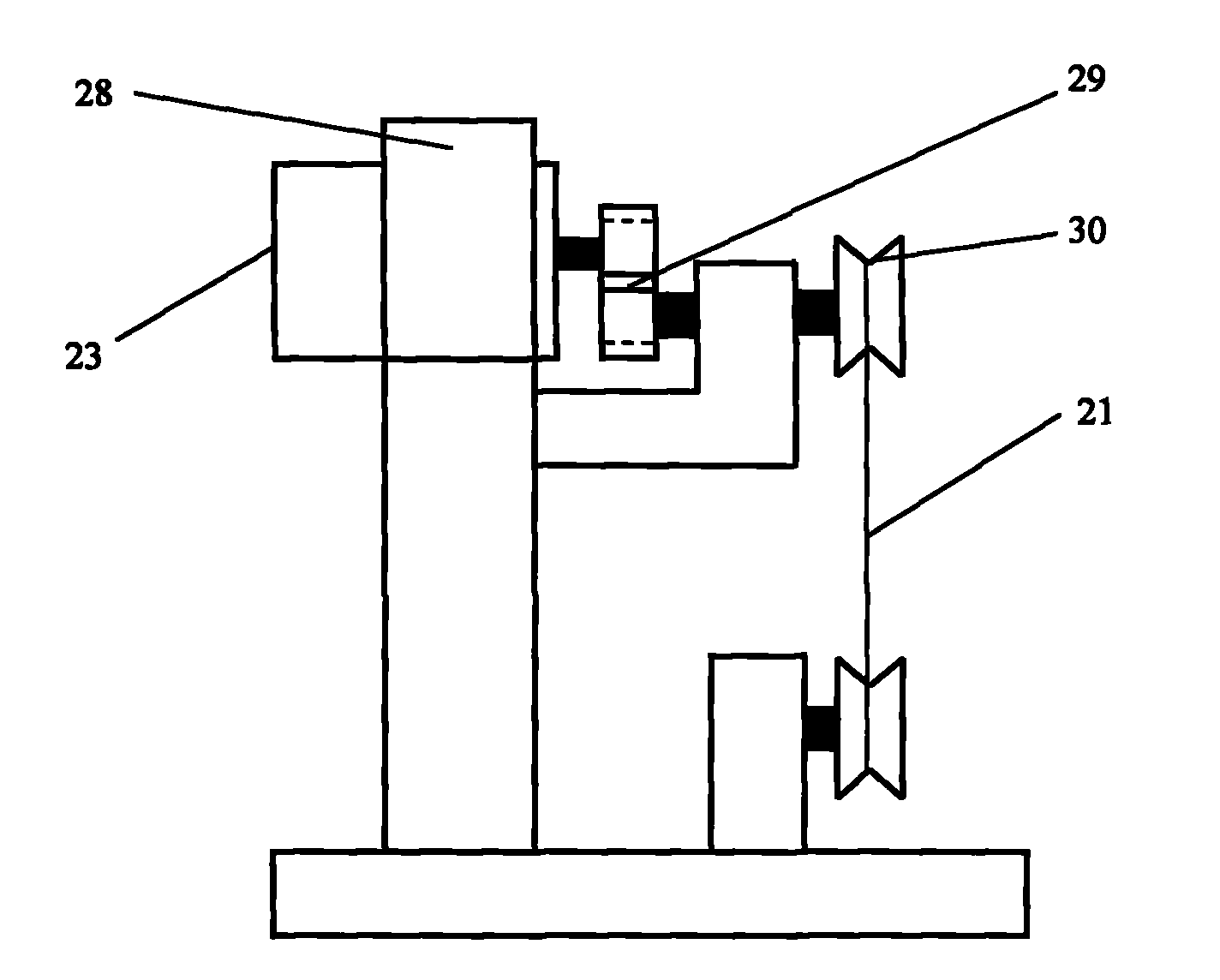

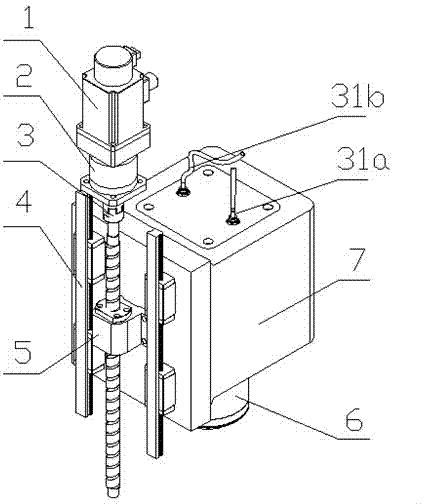

Electrochemical machining vibro-feed movement implementation device

InactiveCN103028795AHigh vibration frequencySteplessly adjustable vibration amplitudeElectrochemical machining apparatusElectrical-based auxillary apparatusMachining vibrationsElectric machine

The invention discloses an electrochemical machining vibro-feed movement implementation device, which belongs to the electrochemical machining field. The device comprises a servo feed movement device and a vibration device, wherein the vibration device is installed on the servo feed movement device via a sliding seat; the vibration device comprises a voice coil motor; the top end of a voice coil motor rotor is fixedly provided with a connecting block; the connecting block is connected with an electric conduction block via a transmission mechanism; and the electric conduction block is used for clamping a tool cathode. According to the electrochemical machining vibro-feed movement implementation device disclosed by the invention, the feed movement is realized by a servo motor, a lead screw and a guide rail pair, the voice coil motor is used for driving so as to realize the vibro-movement, and the two mutually-parallel movements are compounded to realize the vibro-feed movement of the tool cathode. According to the movement implementation device, the electrolysate discharge problem in the electrochemical machining process can be effectively solved, an electrolysate flow field is effectively improved so as to easily realize small-gap electrochemical machining, and a purpose of improving the electrochemical machining precision and stability is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com