Electric spark induction controllable erosion and electrolysis compound efficient machining method

A processing method, EDM technology, applied in the field of high-efficiency composite machining, EDM-induced controllable ablation and electrolytic composite high-efficiency processing, can solve the problems of residual tensile stress and metamorphic layer, low EDM efficiency, etc., and achieve the elimination of surface Effects of residual stress, improved material removal efficiency, good surface quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

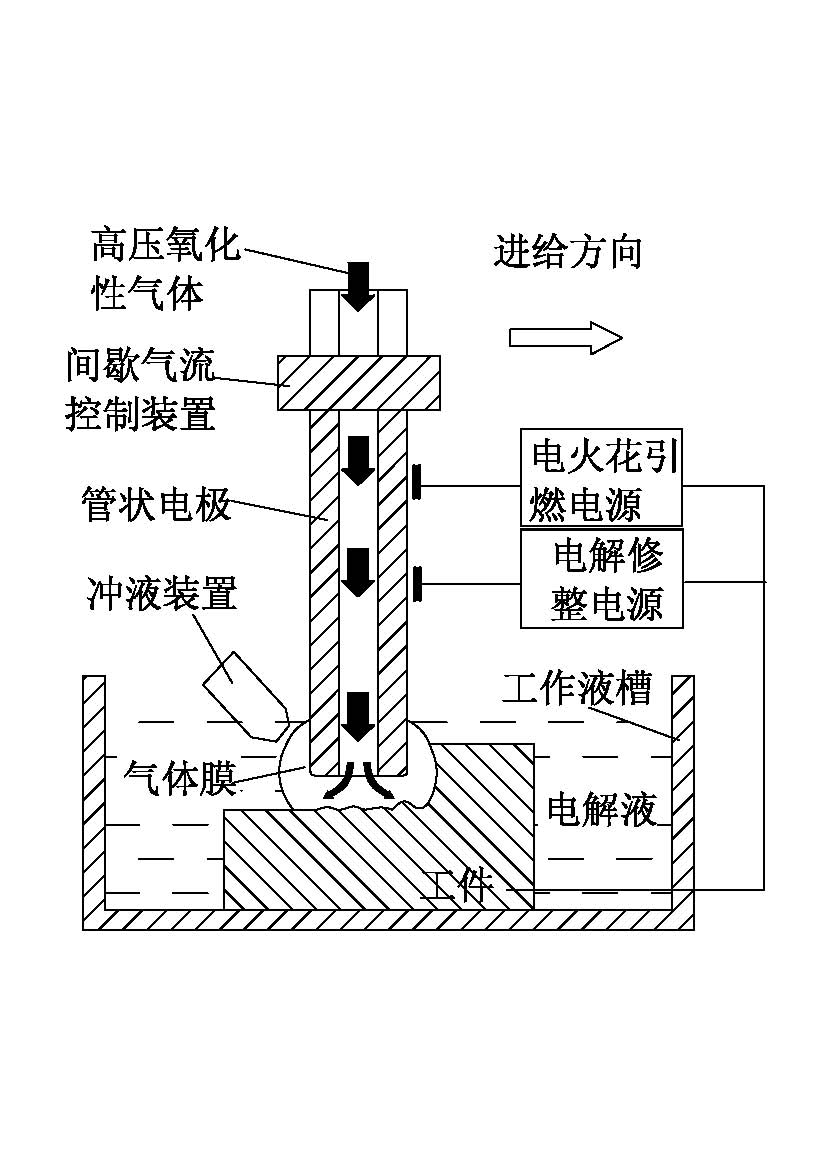

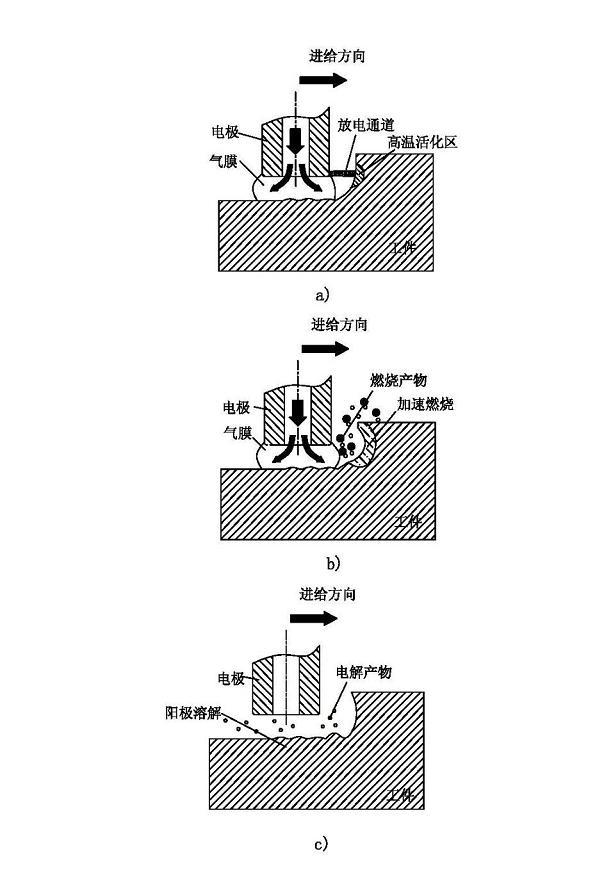

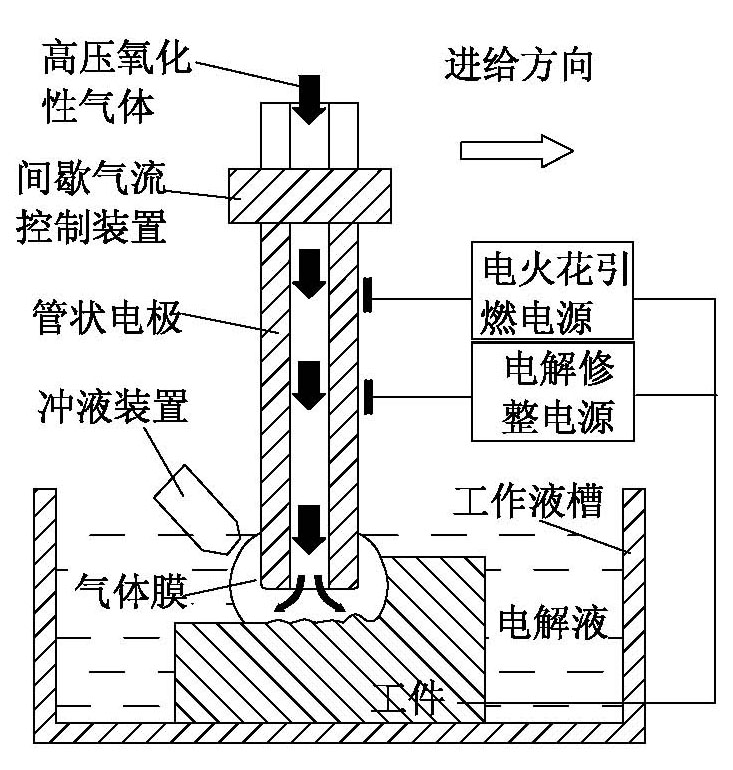

[0039] Such as Figure 1-2 shown.

[0040] The invention relates to an electric spark induced controllable ablation and electrolytic composite high-efficiency processing method, which belongs to the category of special processing. The processing is always in the state of EDM-induced controllable ablation and electrolytic composite trimming. Using the electrolyte as the working medium, immerse one end of the workpiece electrode and the tool electrode in the working medium, intermittently inject gas into the processing area and form a gas film between the electrodes of the workpiece electrode to be processed and the tool electrode, such as figure 1 As shown; under the action of the electric spark power supply, an electric spark discharge is generated between the electrode of the workpiece to be processed and the tool electrode, so that the workpiece to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com