Patents

Literature

140results about How to "No residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Laminated titanium-alloy thin-plate assembled connecting method

ActiveCN101028686AConsistent physical propertiesAvoid intensityOther manufacturing equipments/toolsNon-electric welding apparatusTectorial membraneAcid washing

A technology for combining multiple layers of Ti-alloy sheet includes such steps as blanking, acid washing, baking, sticking protective film, coating welding inhibitor, removing said protective film, welding technological edges, installing die set, heating the forming apparatus, diffusion joining, pneumatic expansion shaping, cooling and removing said technological edges. Its product can be used for wing, fin, or blade.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

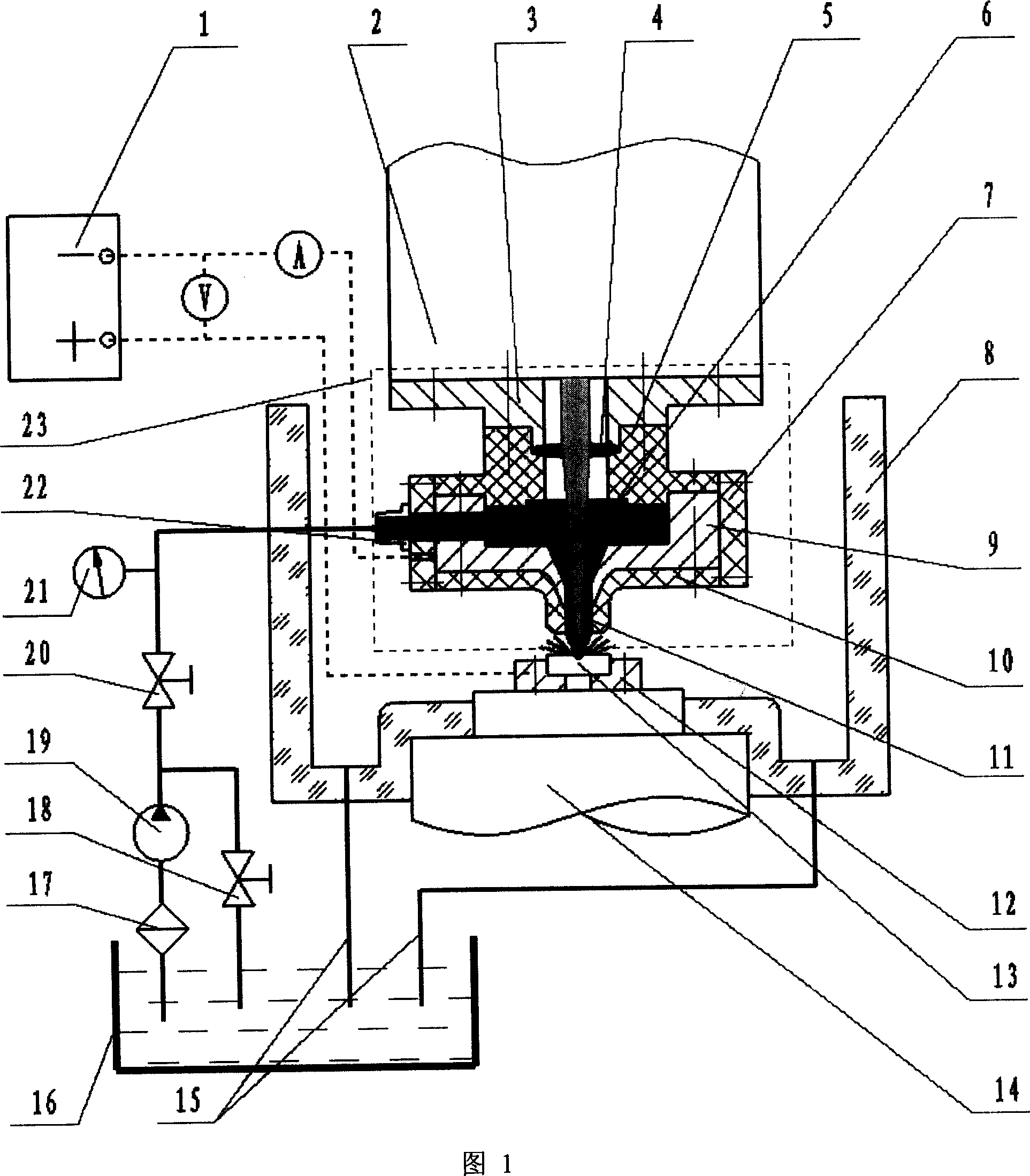

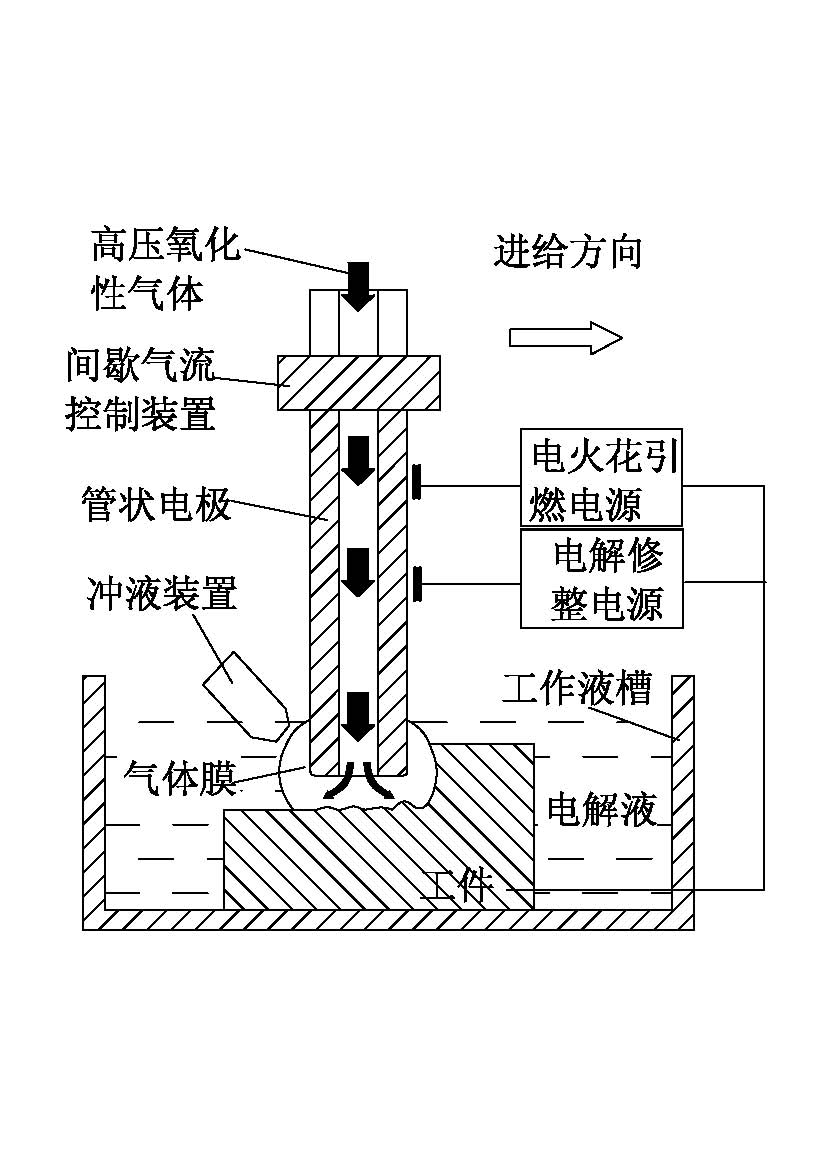

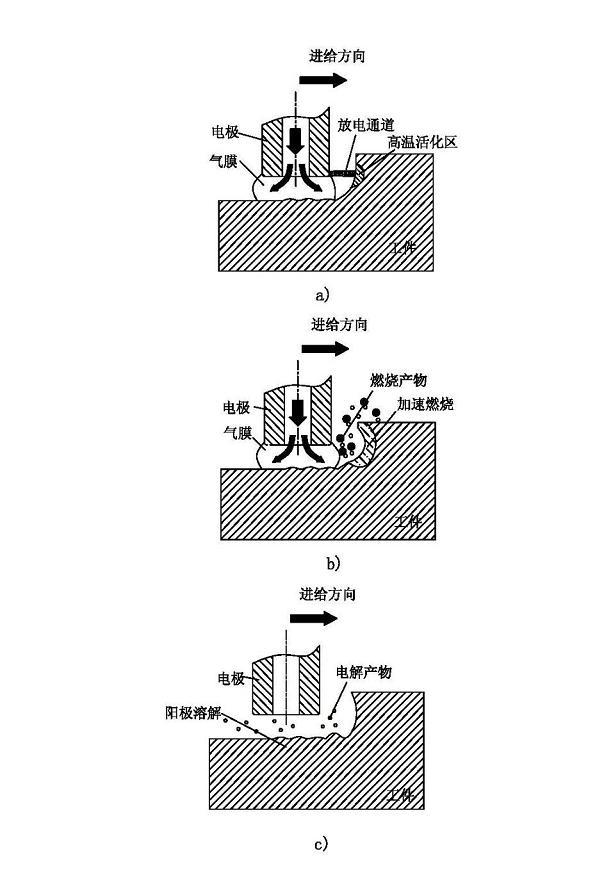

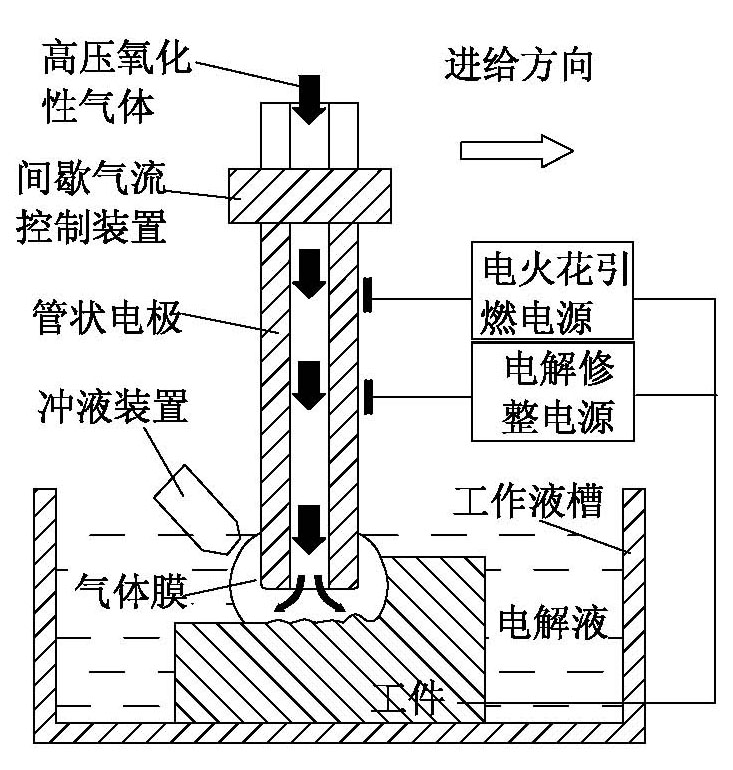

Electric spark induction controllable erosion and electrolysis compound efficient machining method

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mixture of grafted polyamide-block and flexible polyolefin copolymers

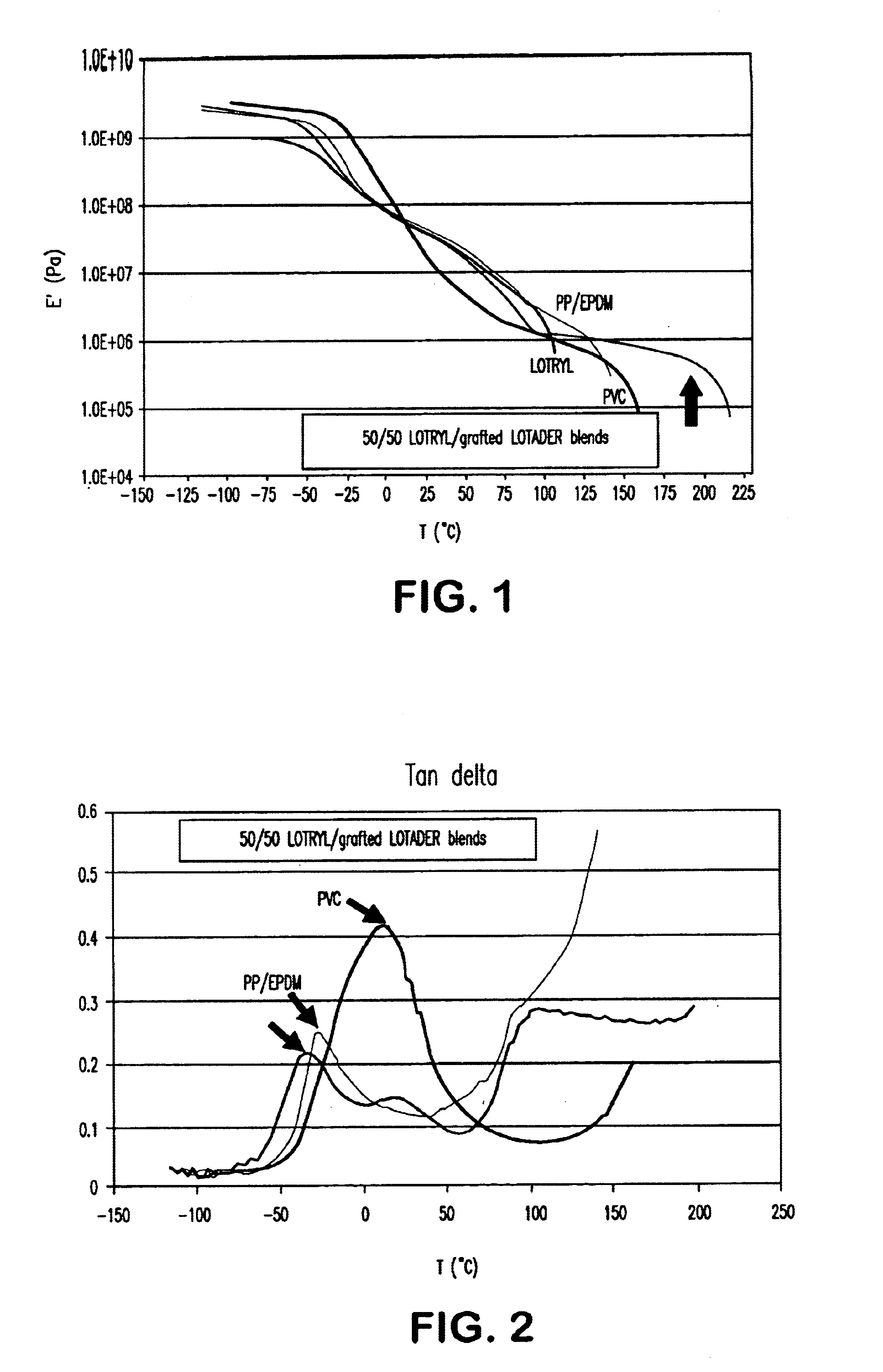

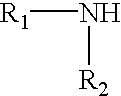

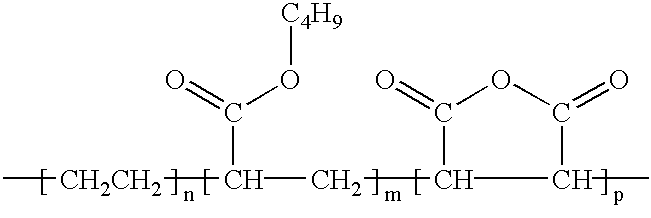

InactiveUS6875520B2Soft touchResidual stressSynthetic resin layered productsInsulated cablesPolyolefinGeomembrane

The invention concerns a mixture comprising by weight, the total being 100%, 1 to 100% if a polyamide block copolymer consisting of a basic polyolefin chain and on an average at least a polyamide graft wherein: the grafts are fixed to the basic chain by the radicals of an unsaturated monomer (X) having a function capable of reacting with a polyamide with amine terminal, the radicals of the unsaturated monomer (X) are fixed to the basic chain by grafting or copolymerization from its double bond; 99 to 0% of a flexible polyolefin with elastic modulus in flexure less than 50 MPa at 23° C. and having a crystalline melting point ranging between 60° C. and 100° C. Said mixtures are useful for making films, tanks, geomembrane protective fabrics produced by extrusion, products obtained by calendering, thermocladding / forming, protective films for electric cables and skins using slush molding technique.

Owner:ATOFINA

Sulfamic acid nickel plating solution and method

The invention relates to a nickel sulfamate electroplating solution which comprises nickel sulfamate, boric acid and nickelous chloride. A formed nickel-plated layer which has favorable stability and is continuous and complete without pinholes, bubble shedding and residual stress is formed after a metal surface is plated by the electroplating solution. The smoothness and the brightness of the obtained plated layer are improved after a certain amount of brightener is added to the electroplating solution so that the metal surface is smoother and more attractive.

Owner:嘉兴中科亚美合金技术有限责任公司

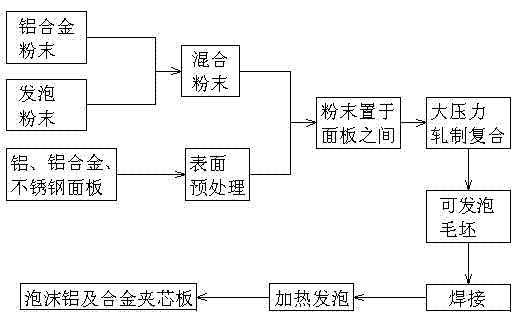

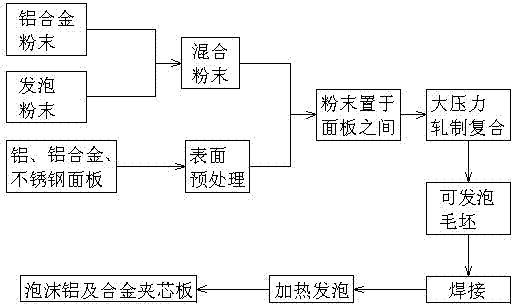

Preparation method of foamed aluminum and alloy sandwich plate

The invention discloses a preparation method of a foamed aluminum and alloy sandwich plate, which is characterized by comprising the following steps: (1) coating: selecting an aluminum and alloy panel, and compressing the aluminum and alloy panel and foaming powder to prepare a foamed aluminum and alloy sandwich plate blank; (2) welding: sanding and cleaning the welding surface of the foamed aluminum and alloy sandwich plate blank, clamping and positioning the foamed aluminum and alloy sandwich plate blank, and welding to obtain the foamed aluminum and alloy sandwich plate blank satisfying the specification and dimension requirements; (3) foaming: heating the welded foamed aluminum and alloy sandwich plate blank in a heating furnace at 300-600 DEG C for 10-40 minutes; and (4) cooling: cooling the heated foamed aluminum and alloy sandwich plate in the heating furnace, thus obtaining the well-welded foamed aluminum and alloy sandwich plate satisfying the specification and dimension requirements. The preparation method has the advantages of convenient preparation process and low processing cost; and the obtained foamed aluminum and alloy sandwich plate has fine performance.

Owner:SUZHOU UNIV

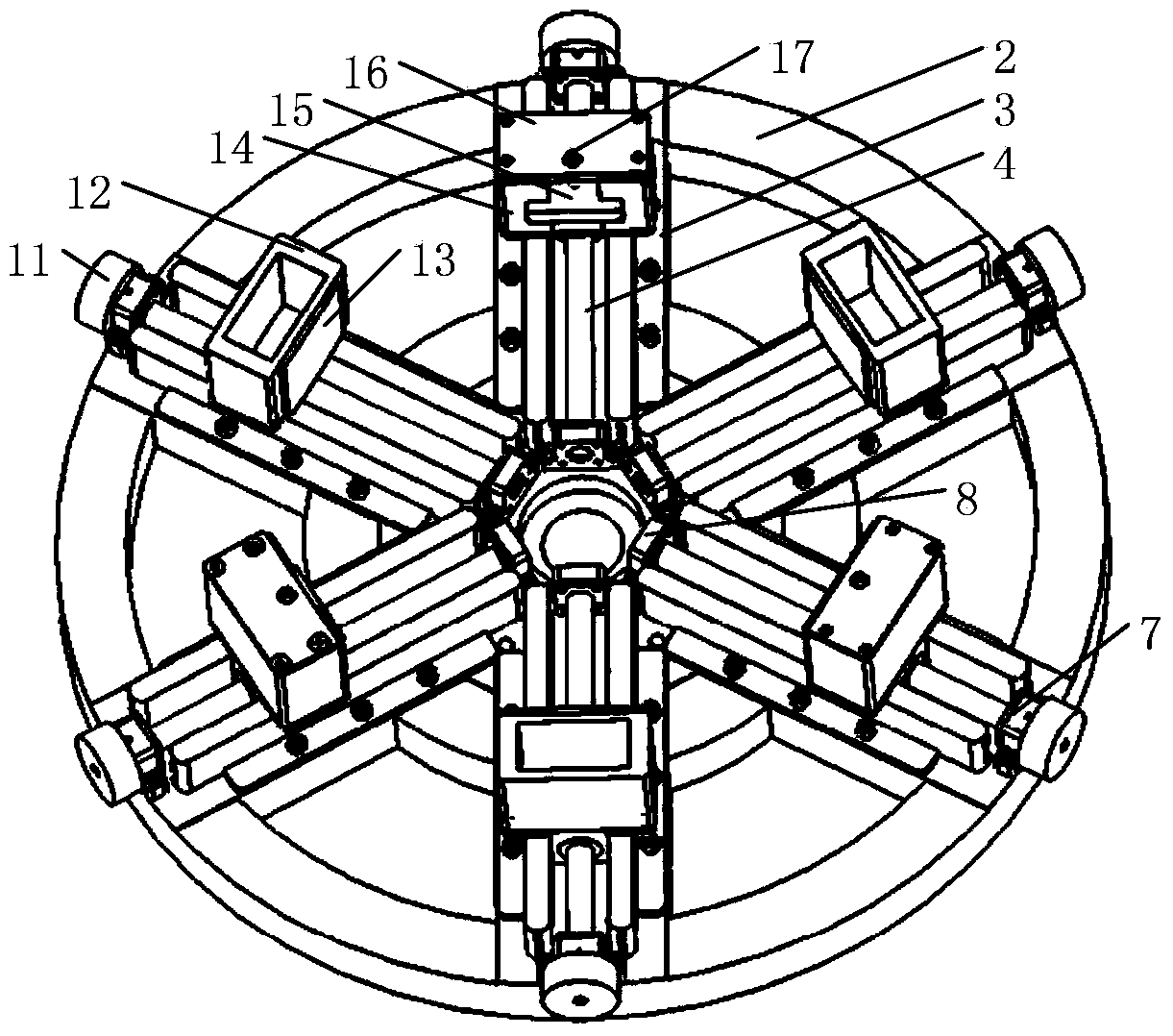

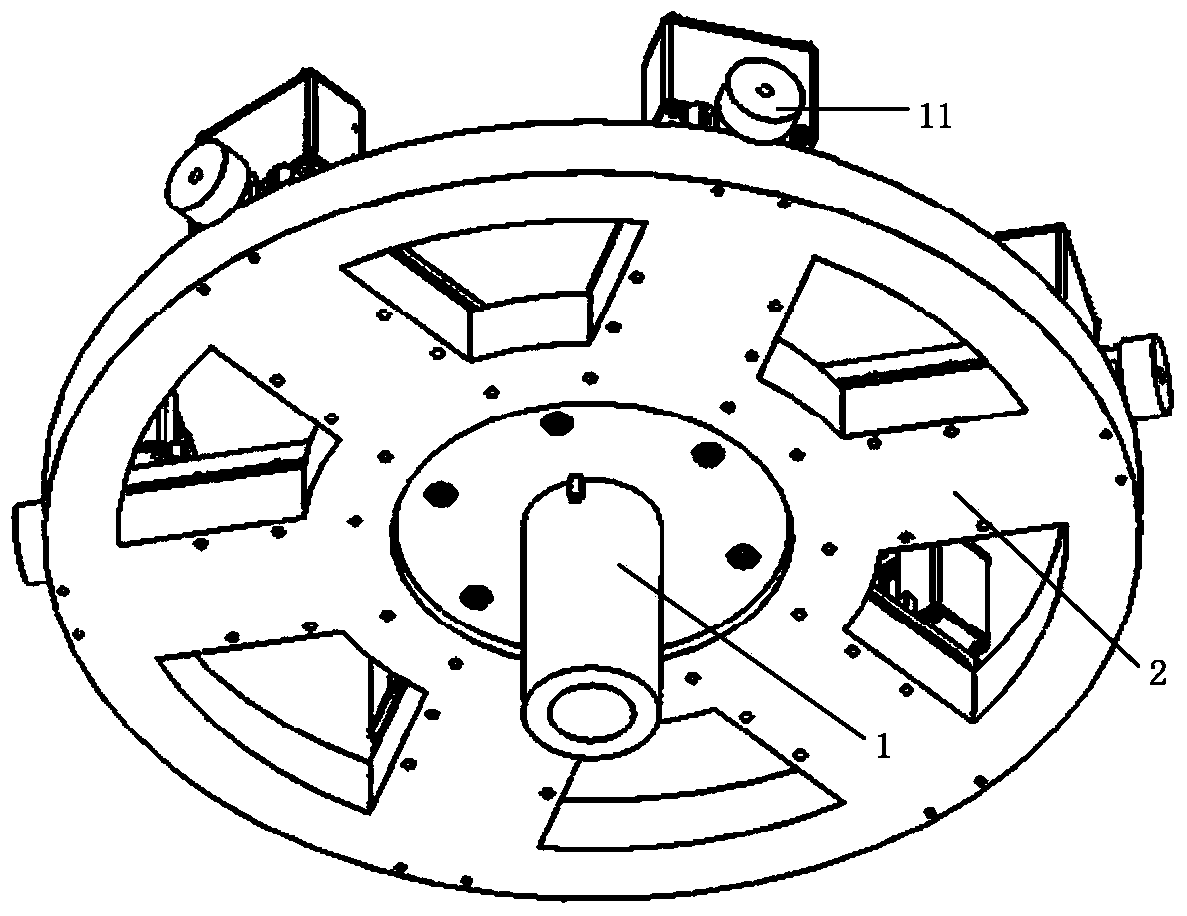

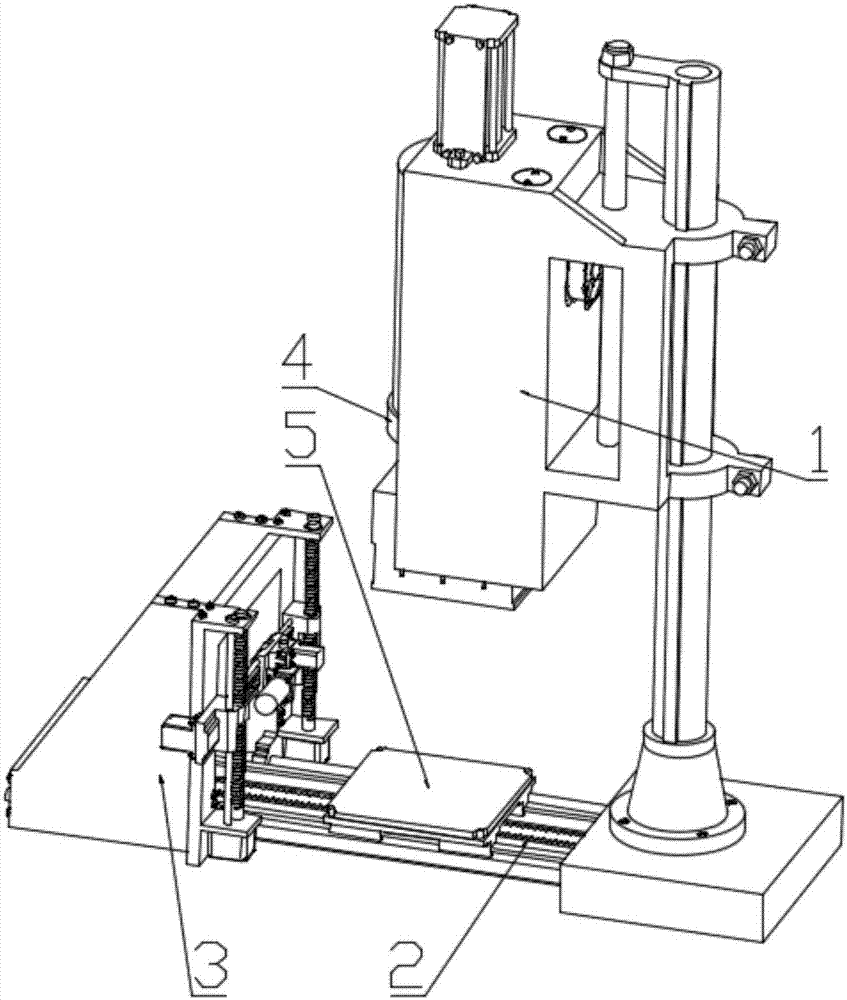

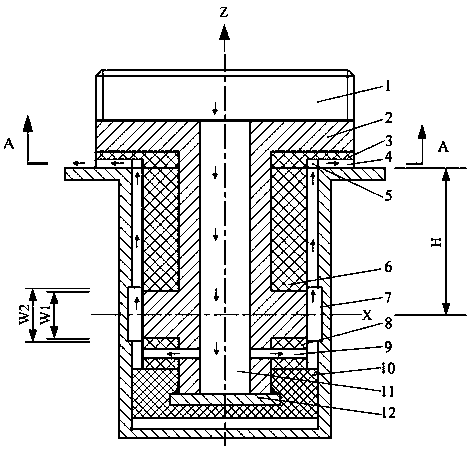

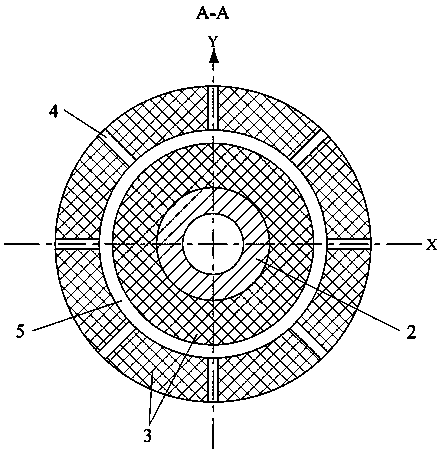

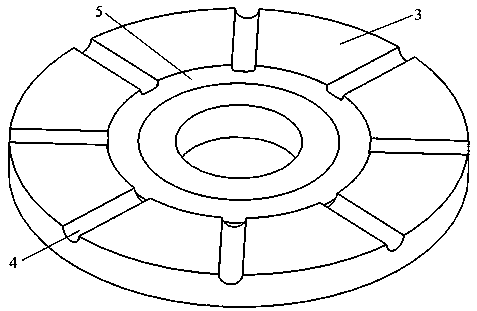

Magneto-rheological high-precision positioning device and magneto-rheological removing function transformation method

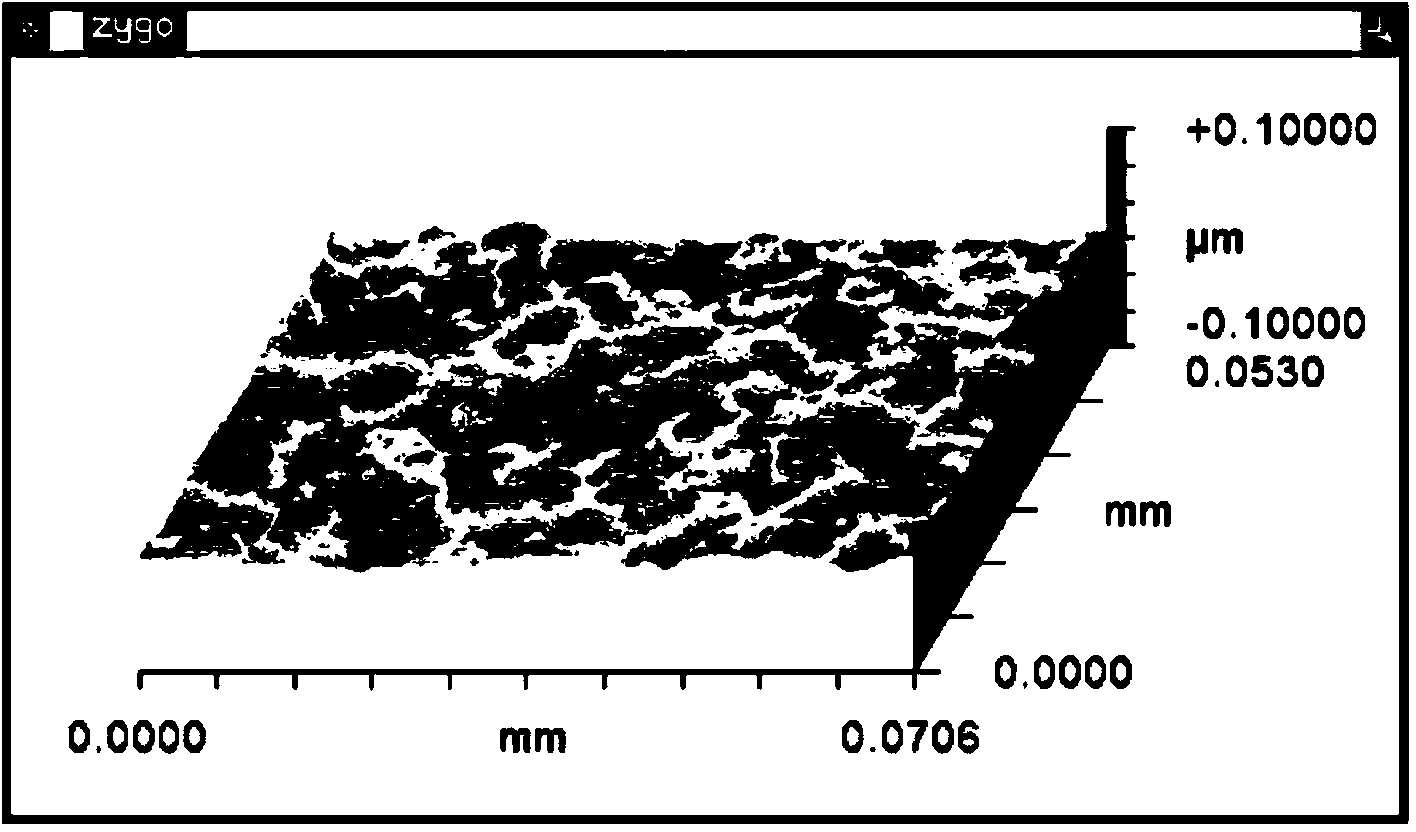

InactiveCN103447891AGood positioning accuracyNo residual stressGrinding machine componentsSingle pointEngineering

The invention discloses a magneto-rheological high-precision positioning device and a magneto-rheological removing function transformation method. The device comprises a fixed supporting mechanism, an excircle positioning mechanism and an end surface positioning mechanism. The method comprises the following steps of selecting an optical element substrate which is conventionally processed to measure single point removing efficiency, establishing a removing efficiency contrast coefficient library, measuring the removing efficiency of four points by using a microcrystal material, converting the removing efficiency into the removing efficiency of a workpiece to be processed, adjusting the positions of the excircle positioning mechanism, the end surface positioning mechanism and a slide block through a hand wheel and a screw rod, placing the workpiece, performing emulating calculation on the workpiece surface error through the converted removing efficiency of the workpiece to be processed, and fitting a production machine tool code to perform numerical control machining. The magneto-rheological high-precision positioning device has the advantages of high integration level and high positioning precision as well as improving removing function accuracy, shortening measuring time, improving processing efficiency, reducing processing material cost and the like and can be used for quickly processing plane and high-gradient spherical surface, non-spherical surface and free spherical surface optical elements.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

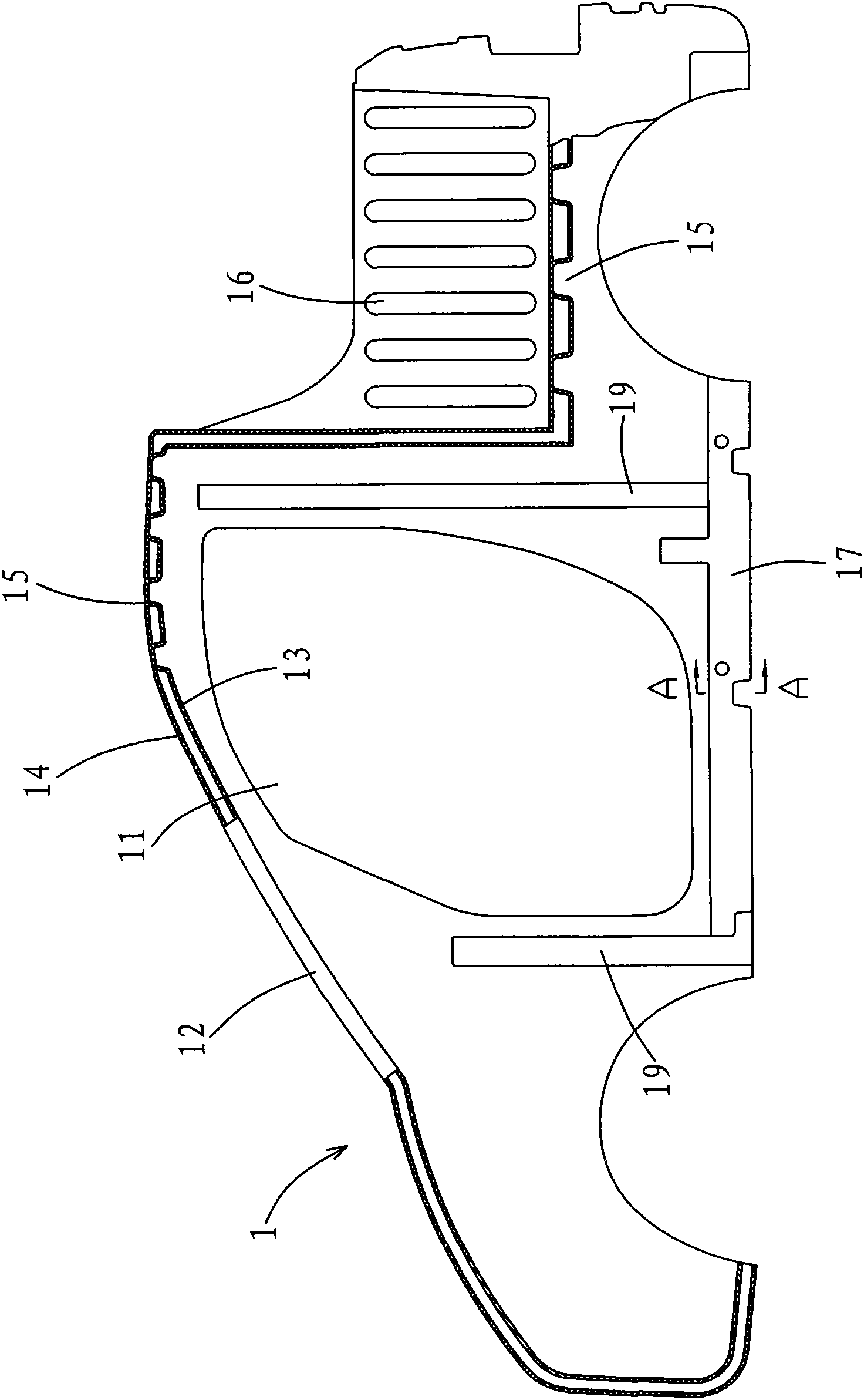

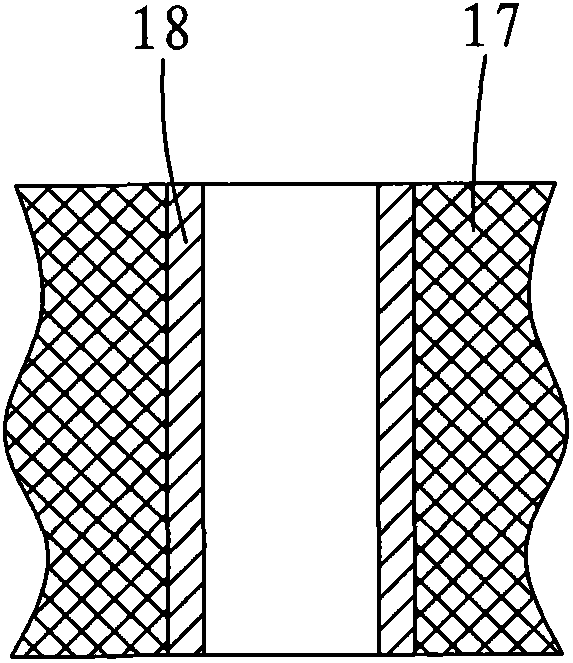

Automobile with one-time formed plastic shell

InactiveCN102328702ASimple manufacturing processIncrease productivitySuperstructure subunitsSuperstructure connectionsEngineeringBody weight

The invention relates to an automobile with a one-time formed plastic shell. The automobile comprises an automobile body and a chassis, wherein the automobile body is a hollow double-layer plastic shell which is integrally formed at one time by a rotational molding process and is provided with an automobile door installation hole and an automobile window installation hole in advance; a plurality of contact reinforcing ribs are formed between an inner-layer wall body and an outer-layer wall body of the hollow double-layer plastic shell; a plurality of convex reinforcing ribs are formed on the external surface of the outer-layer wall body or the inner-layer wall body of the hollow double-layer plastic shell; a chassis embedding groove is formed at the lower end of the external surface of the inner-layer wall body of the hollow double-layer plastic shell; a plurality of threaded sleeves are embedded into the chassis embedding groove; the chassis is embedded into and in threaded connection with the chassis embedding groove; the external surface of the inner-layer wall body of the hollow double-layer plastic shell is provided with door post embedding grooves on two sides of the automobile door installation hole; and the upper end of the chassis is fixedly provided with door posts inserted into the door post embedding grooves. The automobile has the advantages of high strength and surface performance, light body weight, low cost and the like, and is easy to manufacture and convenient to assemble.

Owner:应革

Device for high-frequency induction cladding with assistance with ultrasonic vibration and working method for device

PendingCN109811339AReduced crack susceptibilityImprove densification performanceMetallic material coating processesIncreasing energy efficiencyEngineeringUltrasonic generator

The invention relates to a device for high-frequency induction cladding with assistance with ultrasonic vibration and a working method for the device and particularly aims at surface treatment and reinforcement of a workpiece. The device comprises a horizontal machine tool, a PLC, a slide carriage tank, a triangular chuck, a power supply controller, a smoke removal system, an induction power supply, an infrared thermometer, an industrial water cooling circulation system, a guide rail, a ball screw, a nozzle, an ejector pin, an induction coil, an amplitude-change pole, a bracket and an ultrasonic generator. In the process of starting the induction coil for heating, and the PLC is used for controlling a motor to enable the workpiece to rotate at a certain speed (a specific speed value is obtained according to the fluidity of a molten pool in a state with assistance of ultrasonic vibration and the diameter of the workpiece), and unevenness in thickness of upper and lower cladding layers of the workpiece caused by the fact that the molten metal flows downwards due to gravity in the cladding process can be avoided. A gas protection device needs to be started before induction heating, sothat the workpiece is in an argon environment before being heated, injection of argon is stopped after the workpiece is thoroughly cooled, and the cladding layers and cladding layer influence regionscan be well prevented from being oxidized. By adding ultrasonic assistance equipment in the high-frequency induction cladding process, the quality of a bonding layer is improved to the maximum, generation of bubbles and cracks is reduced, the residual stress is eliminated, the comprehensive properties of the cladding layers are improved, the service life of the workpiece is prolonged, the production efficiency is improved, and the cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Compound ultrasonic fusion deposition additive-manufacturing device and compound ultrasonic fusion deposition additive-manufacturing method

ActiveCN107244072AHigh mechanical strengthImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringUltrasonic vibration

The invention relates to a compound ultrasonic fusion deposition additive-manufacturing device and a compound ultrasonic fusion deposition additive-manufacturing method, and belongs to the technical field of additive manufacturing. An ultrasonic enhancement device is fixed to a guide rod I and a guide rod II of an ultrasonic support platform; a moving base plate is installed on a guide rail I and a guide rail II of an X-directional guide connection system, and fixed to a synchronous belt simultaneously; the moving base plate is driven to move through an X-directional motor; and a fusion deposition additive-manufacturing system and the ultrasonic support platform are connected through a connection rod I and a connection rod II in the X-directional guide connection system. Parts with poor adhesion among fusion deposition wire materials and between the deposition wire materials and a deposition layer can be re-melted by virtue of ultrasonic vibration, and the deposition wire materials in formed parts are compounded into one piece, so that the comprehensive mechanical property of fusion deposition additive-manufactured parts, and in particular, the mechanical strength in the vertical direction of a forming axis, is remarkably improved.

Owner:李桂伟

Process for manufacturing and molding double-layer plastic vehicle body

The invention relates to a process for manufacturing and molding a double-layer plastic vehicle body, which comprises the following steps: (1) according to the profile of the vehicle body, manufacturing a concave die and a convex die respectively, and arranging outer edges on the bottoms of the concave die and the convex die respectively; (2) adding a plastic raw material into the concave die or the convex die, locking the concave die and the convex die through the outer edges on the bottoms thereof, performing heating, rotation, cooling and other steps, rotationally molding to form a hollow plastic vehicle body shell, and positioning the hollow plastic vehicle body shell in a shaping mould for shaping; and (3) foaming a hollow part of the hollow plastic vehicle body shell to form a middle foam plastic layer. The process adopts rotational molding to integrally shape the vehicle body shell, which can reduce the working procedures and simplify the process on one hand and makes the mould have simple structure, convenient processing and low manufacturing cost on the other hand; and meanwhile, a vehicle body product has the advantages of even wall thickness, no joint, difficult deformation and the like.

Owner:应革

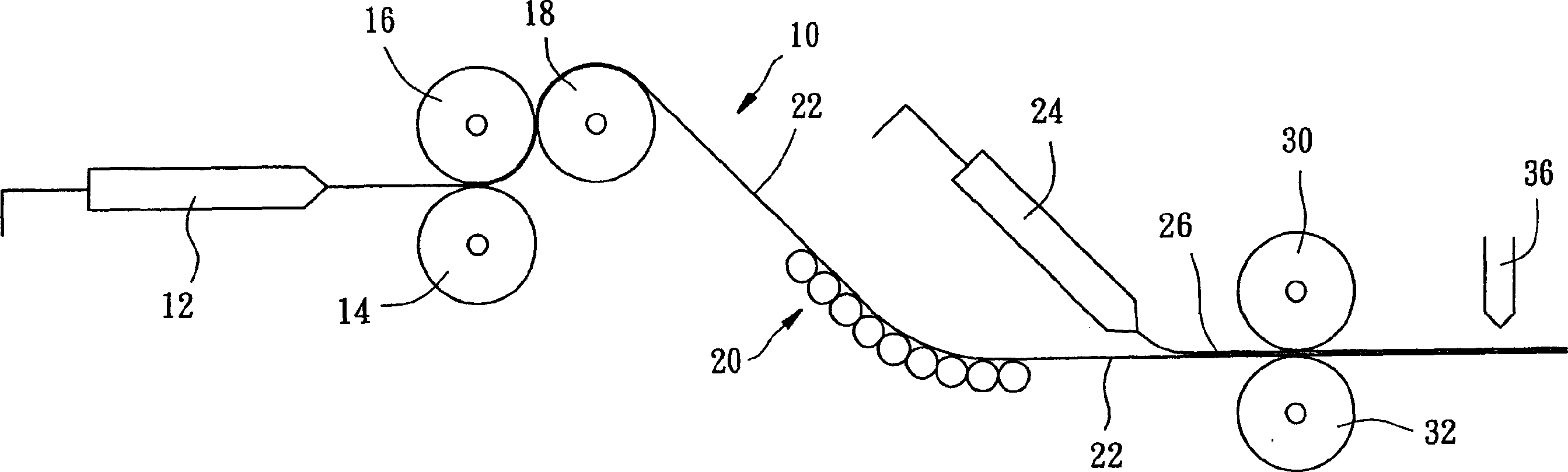

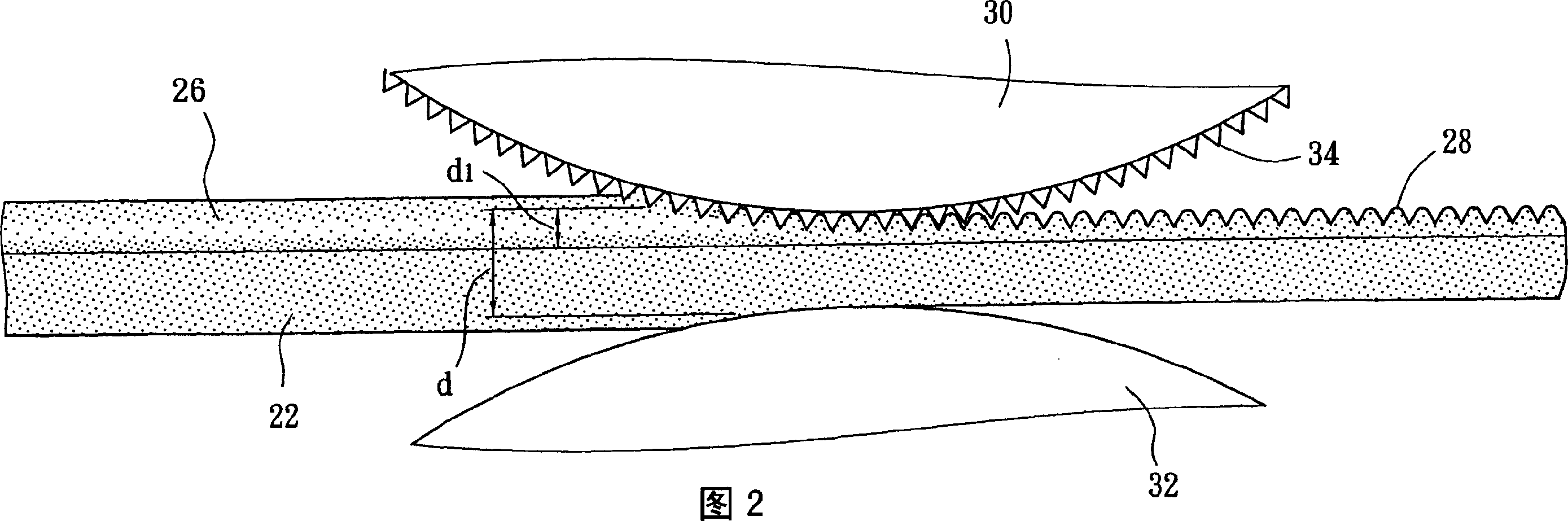

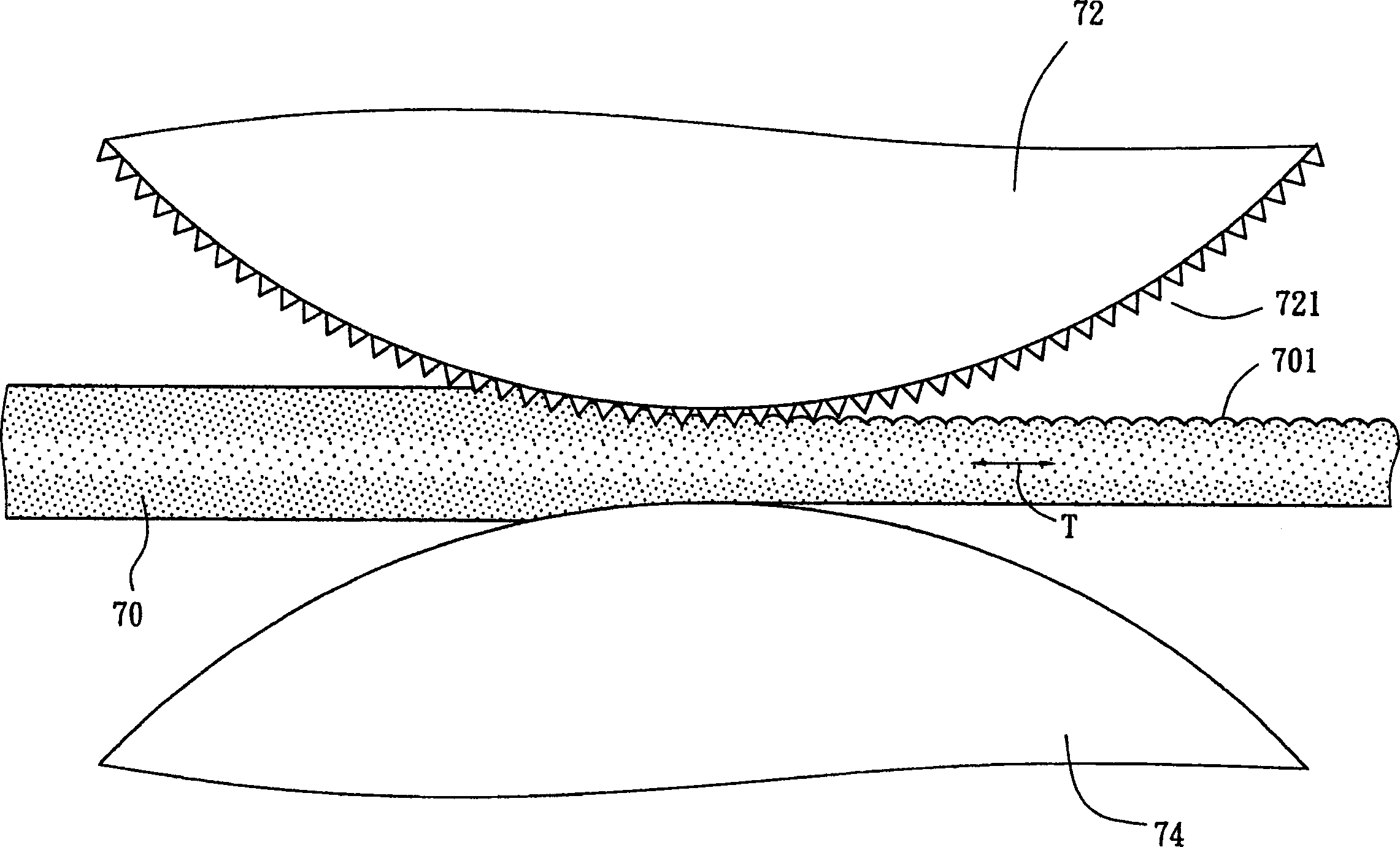

Device and method for manufacturing panel with embossing on surface

The invention relates to a device for producing the plate with figure on surface and relative method, which comprises: a basic material supplier, a condenser, a surface layer supplier, a rolling compression device, and a slicing device. Wherein, the basic material supplier provides basic material in fusing condition; said condenser cools said basic material to solid state; said surface layer supplier supplies a surface layer in fusion state on said basic material, then via said roller compression device to emboss said basic material and surface layer, to form a figure on said surface; and the slicing device slices the basic material and surface layer to attain the sheets in dual number.

Owner:FORHOUSE CORPORATION

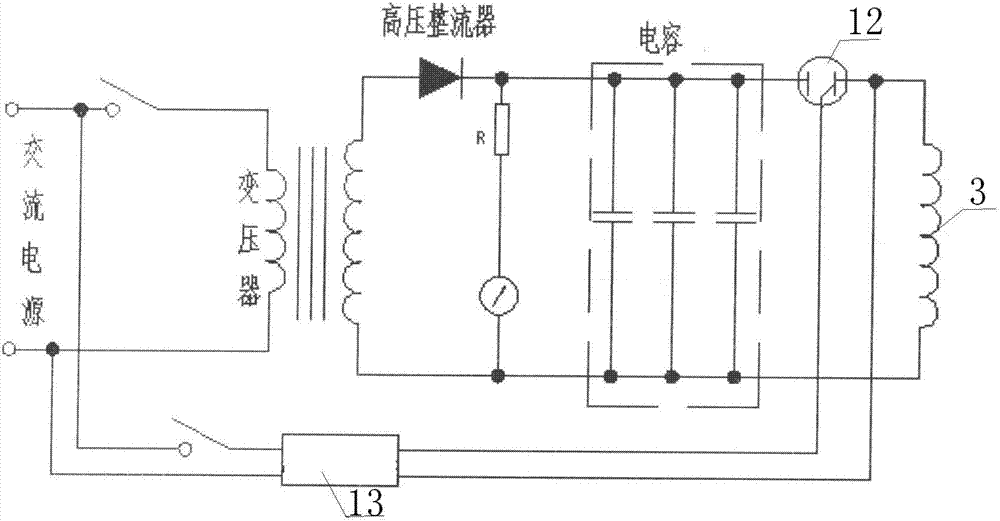

Device used for welding copper tube and aluminum tube in refrigeration equipment and welding method thereof

ActiveCN104191081ANo consumptionNice appearanceHigh frequency current welding apparatusWelding/soldering/cutting articlesMagnetic tension forceTransformer

The invention discloses a device used for welding a copper tube and an aluminum tube in refrigeration equipment and a welding method of the device. The device comprises a main device body and a working table, wherein the main device body comprises a main box, an alternating-current power source, a transformer, a high-voltage rectifier, a capacitor set, vacuum switches and a triggering device; the working table comprises a rack and a welding head, the welding head comprises an electric conducting coil and a magnetic flux concentrator, and the electric conduction coil is connected with all the vacuum switches through coaxial cables. The welding method includes the following steps that (1), one end of an outer tube is inserted in the magnetic flux concentrator, and one end of an inner tube is inserted into the magnetic flux concentrator; (2), a pulser is started, when a charging voltage reaches a set value, the system control triggering device turns on a discharging switch, and the outer tube and the inner tube are welded through magnetic force in the magnetic flux concentrator. The device used for welding the copper tube and the aluminum tube in the refrigeration equipment achieves normal-temperature welding, and is more convenient and faster to use, more environmentally friendly and lower in welding cost.

Owner:CHONGQING PULSAR TECH

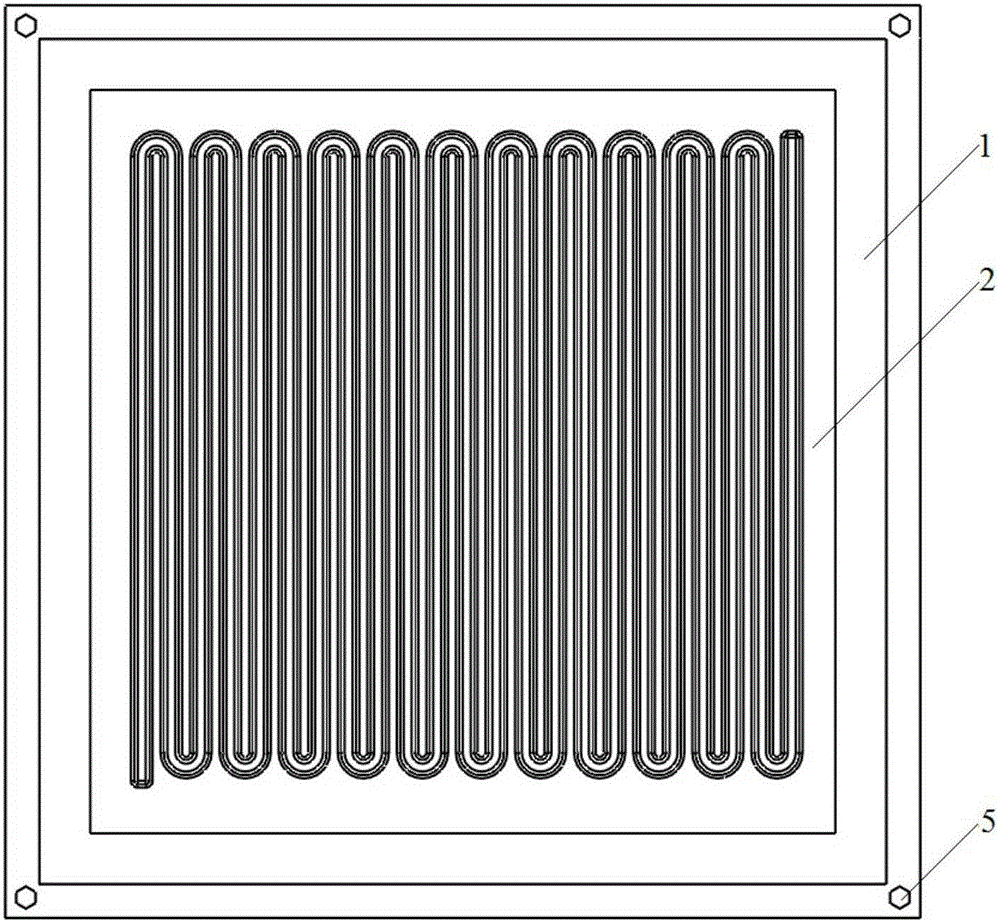

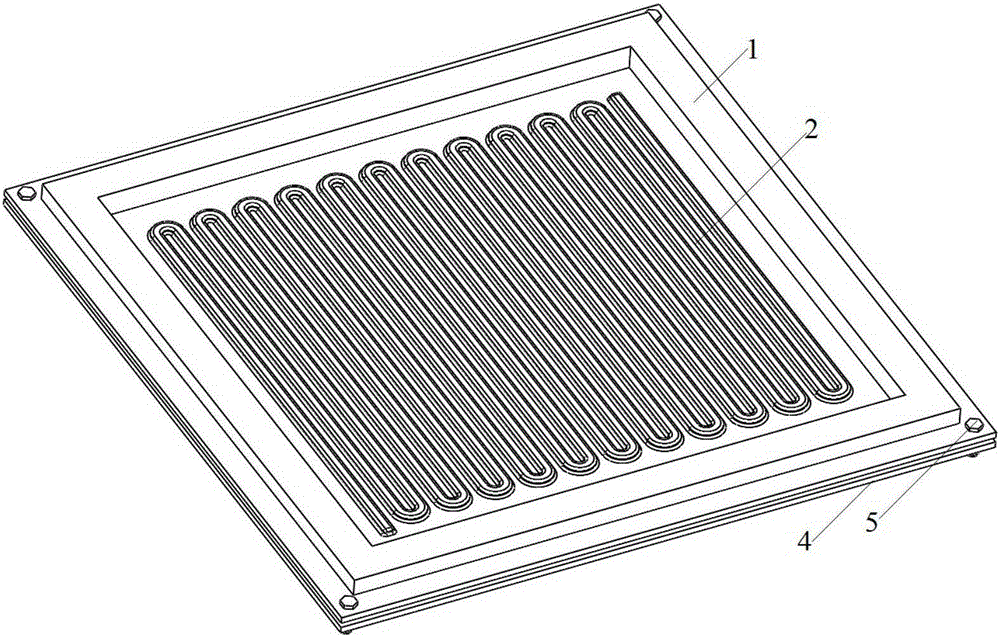

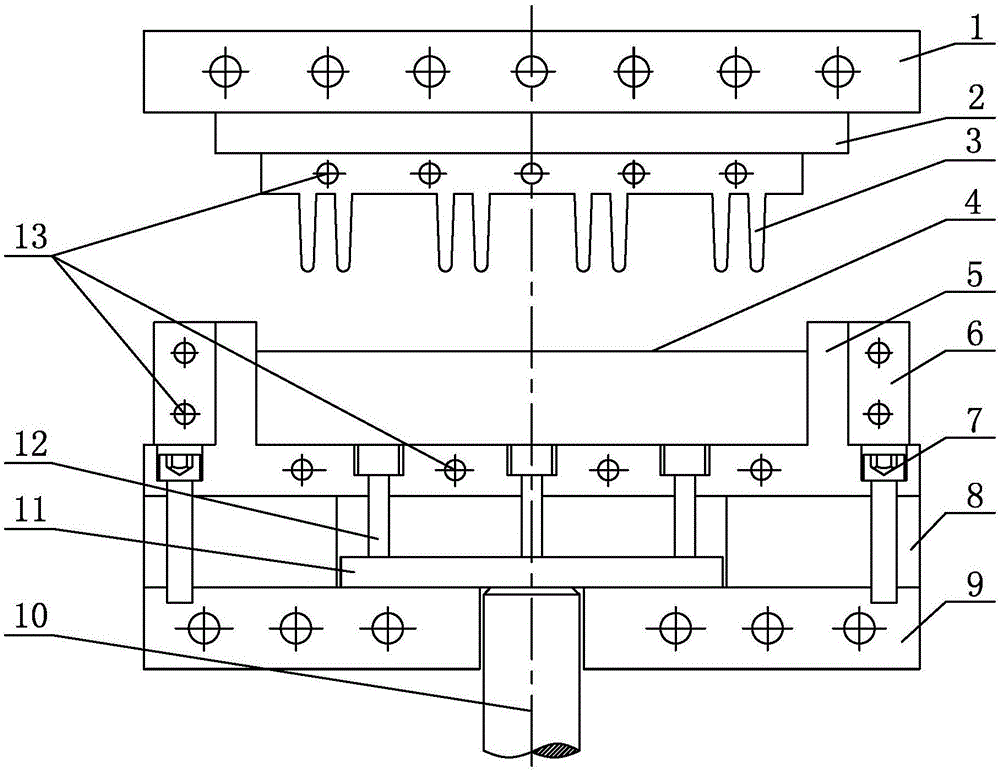

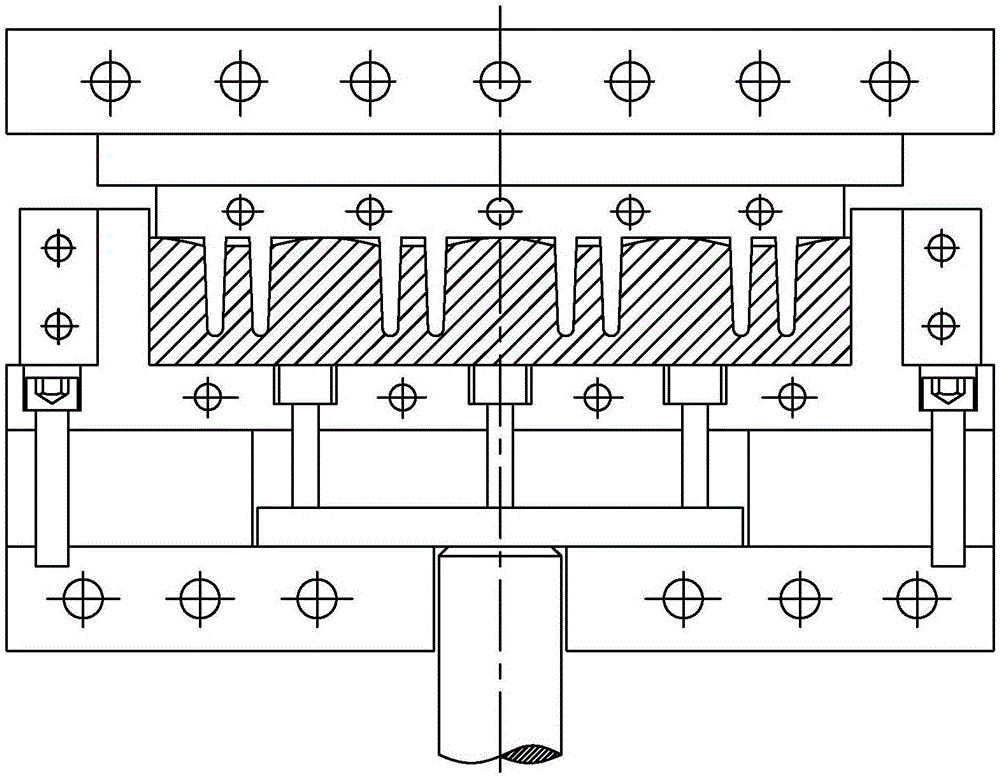

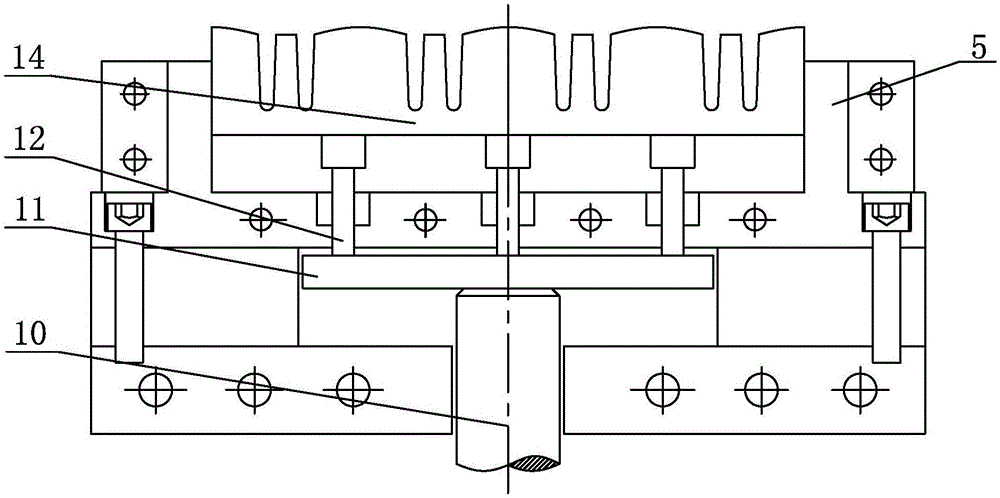

Super-plasticity diffusion connecting clamp and technology for metal bipolar plate

InactiveCN105328328AEasy to disassembleReduce processing costsNon-electric welding apparatusEngineeringHeating furnace

The invention relates to a clamp and technology for connecting metal unipolar plates made of materials with superplasticity performance into a bipolar plate in a diffusion manner. The clamp is composed of an upper pressing plate, a lower pressing plate, bolts and nuts. The technology for conducting super-plasticity connection on the bipolar plate through the clamp comprises the steps that firstly, the two metal unipolar plates are arranged between the upper pressing plate and the lower pressing plate, and the part, to be connected, of the metal bipolar plate is pressed through the upper pressing plate and the lower pressing plate via the fastening nuts; secondly, the clamp and the two metal unipolar plates which are fixed are put into a vacuum heating furnace, heat preservation is conducted for a certain time under the diffusion connection temperature, and the two metal unipolar plates are connected into one metal bipolar plate; and thirdly, the clamp and the metal bipolar plate are taken out of the vacuum heating furnace and cooled until the temperature in the furnace is lower than 50 DEG C, then the nuts are demounted, and the bipolar plate is taken out. According to the technology the metal bipolar plate made of the materials with the superplasticity performance is connected in the one-time heating and pressing process, the connector quality is high, and a connecting area is flat.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing poly(trimethylene terephthalate) fibre having shape memory characteristic

InactiveCN101200821ANo residual stressStable unwindingMelt spinning methodsMonocomponent polyesters artificial filamentPolymer sciencePolyethylene terephthalate

The invention discloses a preparation method of polytrimethylene terephthalate fiber with shape memory characteristics, including: firstly, selected polyester polymer is provided with at least 0.8dL / g of intrinsic viscosity and contains at least 85mol percent of polytrimethylene terephthalate, wherein, at least 85mol percent of the repeating unit is composed of three-methylene; secondly, the polyester polymer is melted and transported through a screw melting extruder, the melting body is metered through a metering pump and is extruded out through a spinneret, and as-spun fibers are drafted successively through a pair of drafting hot rollers after being cooled through lateral blowing; thirdly, the drafted fibers are introduced into a group of grouping roller stereotype boxes with steam; fourthly, tow is introduced into a winding head to be winded into mold. The fiber made through the invention has the advantages of good packaging appearance forming, good structural stability and soft handle. And with lower modulus, the fiber is still provided with good elasticity and tensile recoverability. The textiles made of the fiber which are produced through the process are provided with good shape memory characteristics.

Owner:方圆化纤有限公司

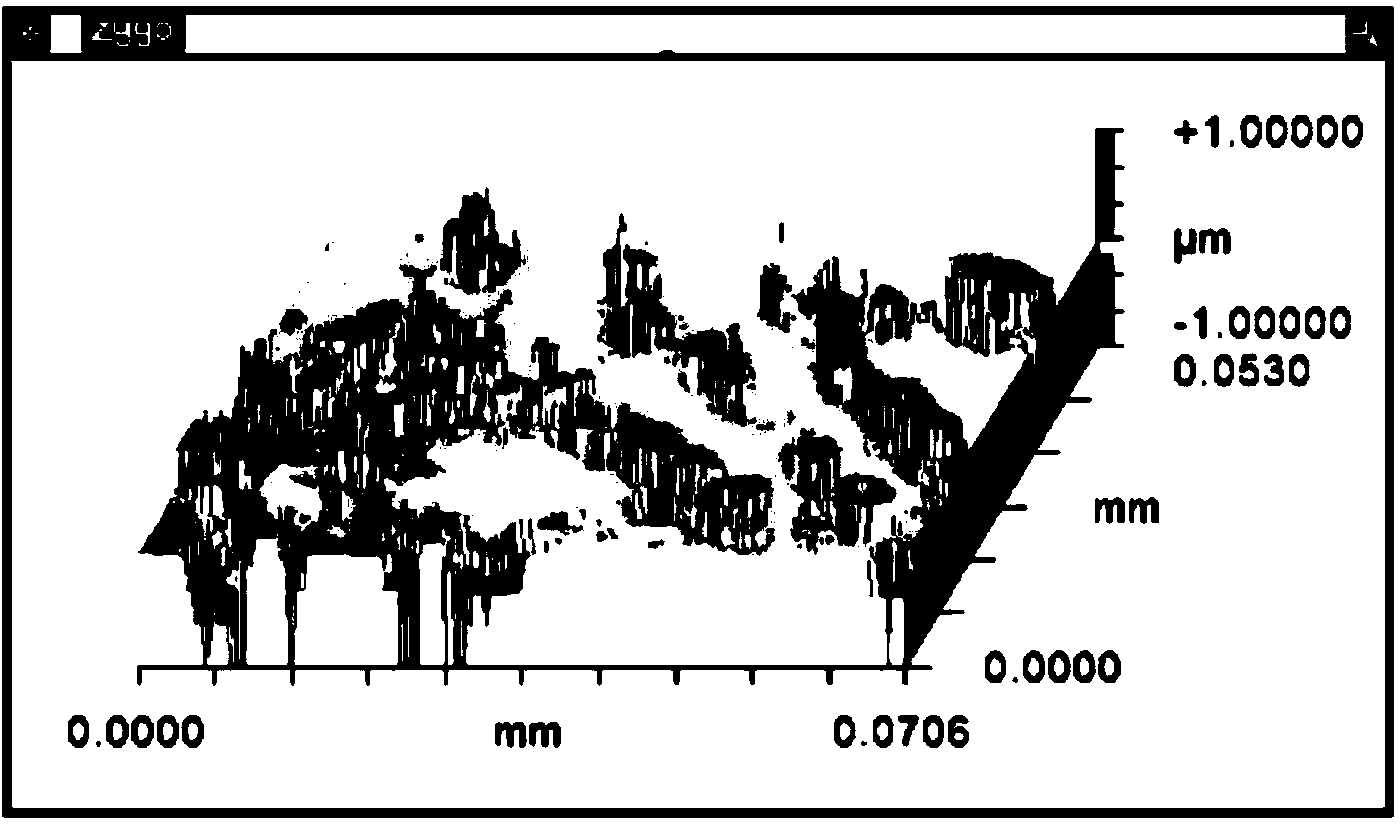

Electrogenerated chemical polishing method

ActiveCN103924287AAbility to selectively removeMethod steps scienceSemiconductor/solid-state device manufacturingMicro nanoElectrochemical response

The invention provides an electrogenerated chemical polishing method which comprises the following steps: preparing a working solution which contains an electroactive mediator, a pH regulating agent, a viscosity regulating agent and an inhibiting agent; parallelly and oppositely arranging the working surface of a working electrode and the surface of a workpiece, wherein the working surface of the working electrode has smoothness less than 1 micrometer; and immersing the working surface of the working electrode and the surface of the workpiece into the working solution, and regulating the spacing between the working surface of the working electrode and the surface of the workpiece to 0.05-20 micrometers through a micro-nano composite feeding mechanism. According to the method, a power supply is started to electrify the working electrode and an auxiliary electrode, the electroactive mediator near the working surface of the working electrode generates an etching agent through electrochemical reaction, and a local high point positioned on the surface of the workpiece is selectively etched in such a way that the etching agent is dispersed to the surface of the workpiece and generates diffusion controlled etching reaction, so that the unstressed polishing on the surface of the workpiece is realized.

Owner:DALIAN UNIV OF TECH +1

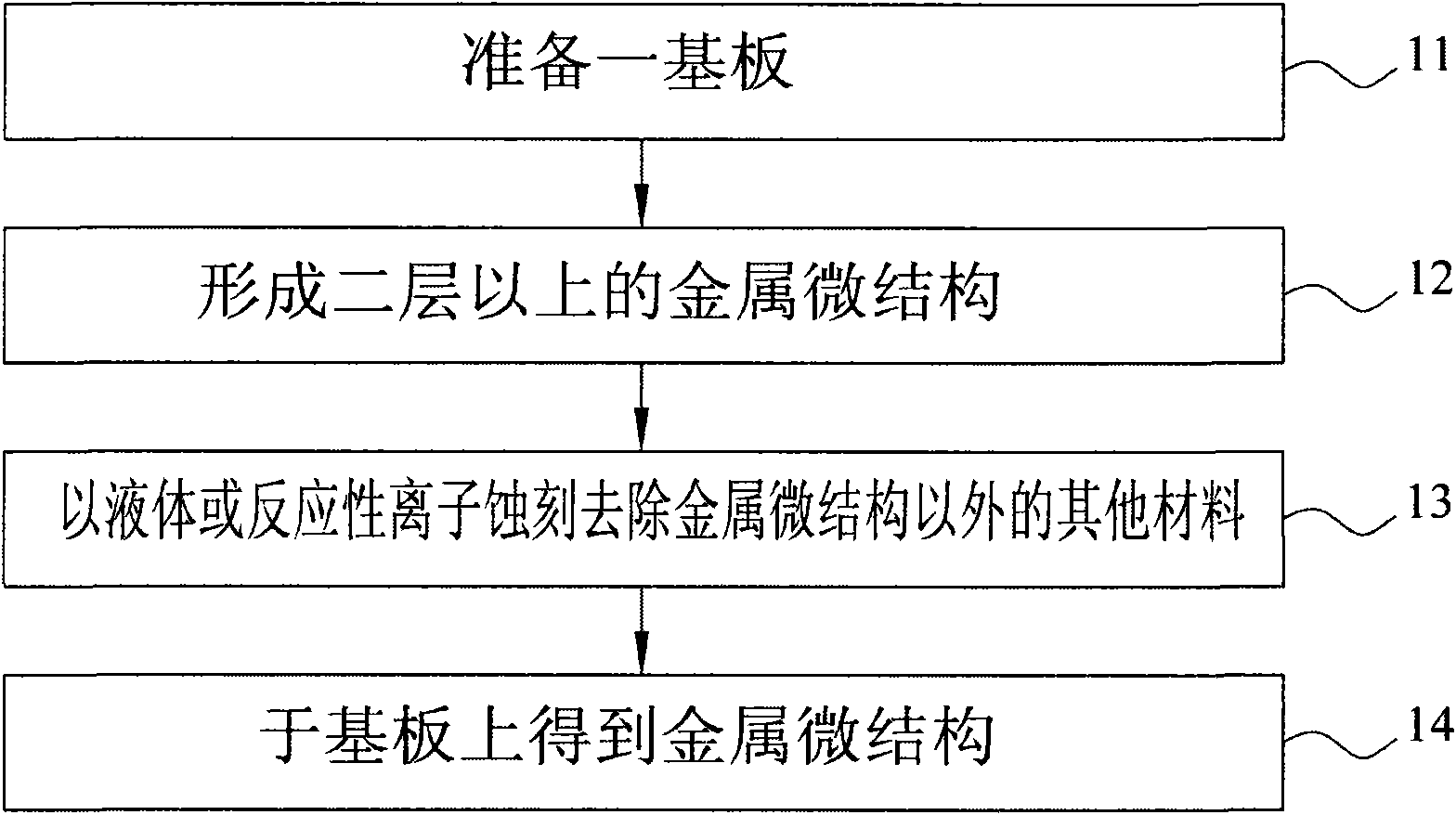

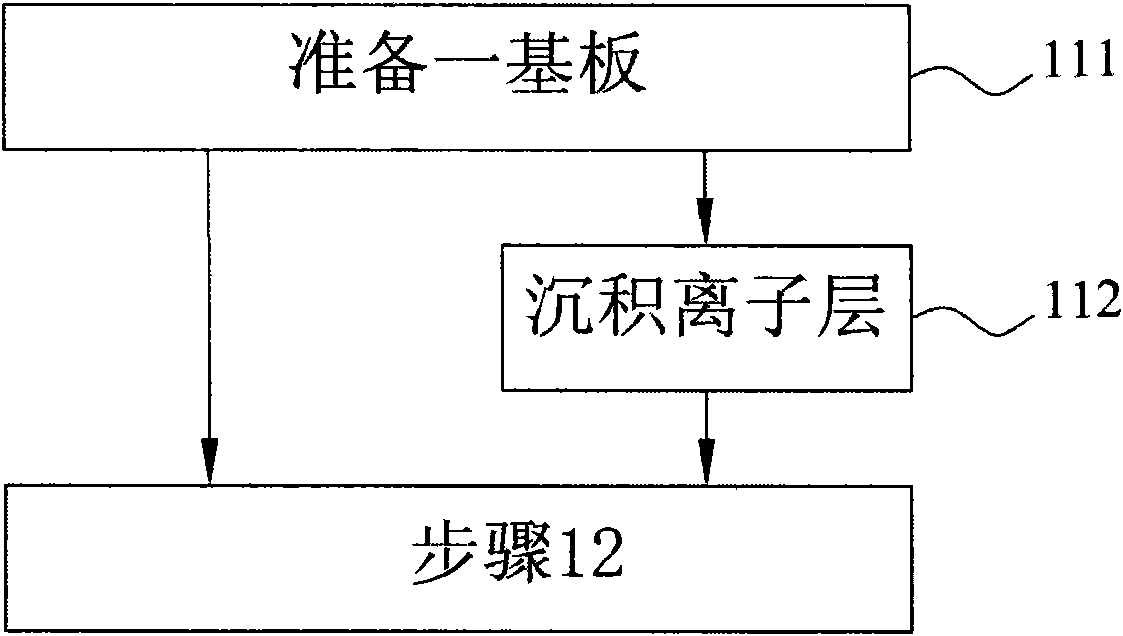

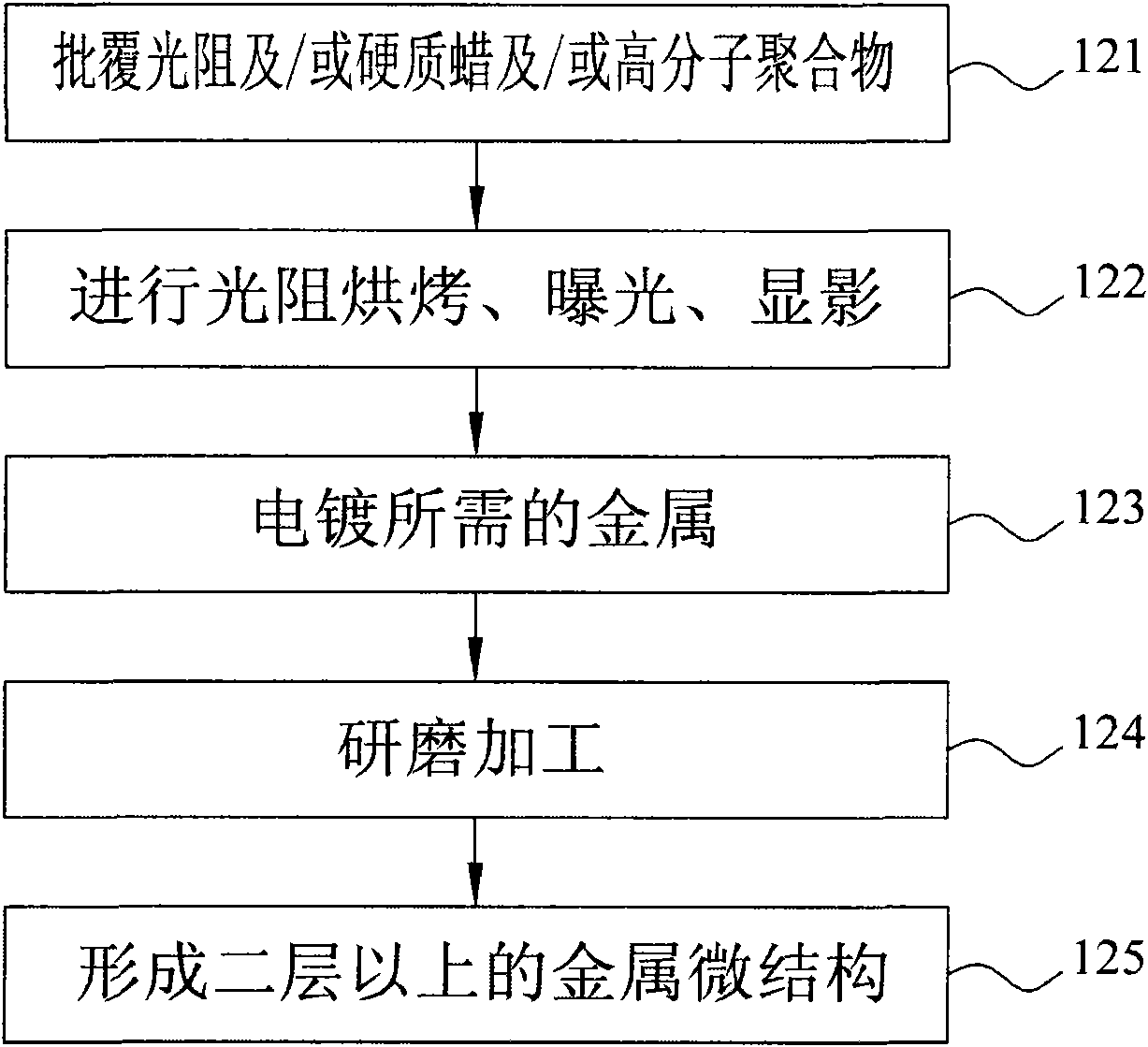

Metal microstructure forming method

InactiveCN101995766ANo residual stressReduce residual stressPhotomechanical apparatusMetal microstructureElectroplating

The invention discloses a metal microstructure forming method which is applied to the manufacturing process of a microstructure component; by utilizing the metal microstructure forming method, a second type of metal is not needed to be electric-plated to surround the periphery of the metal and the second type of metal is not needed to be etched when a three-dimensional metal microstructure of the microstructure component is formed, therefore, the residual stress caused by electric-plating is reduced, no residual stress exists among the metal layers, a base plate attached by the metal is not deformed and the implementing of the follow-up manufacturing process of the microstructure component is not affected; in addition, as the second type of metal is not needed to be etched, the problem that etchants are permeated to the interface at each layer does not exist, adhesive force reduction at each layer can not caused, so as not to affect the functions of the microstructure component.

Owner:PREMTEK INT

Manufacturing method for integrated panel with thin-wall ultrahigh reinforcing rib

The invention provides a manufacturing method for an integrated panel with a thin-wall ultrahigh reinforcing rib. The invention relates to the manufacturing method for a thin-wall integrated panel, in order to solve the problem that an integrated panel component with a thin-wall ultrahigh reinforcing rib structure cannot be manufactured using the present welding, casting, forging and machining method. The manufacturing method comprises the following steps: 1) manufacturing a required panel blank using cutting and blanking methods; 2) preheating the panel blank and causing the internal temperature of the panel blank to be uniform; 3) preheating and lubricating a mold; 4) transferring the preheated panel blank onto a lower mold and positioning, and then utilizing an upper mold for pressure forming on the panel blank; 5) opening the upper mold, taking out the pressure formed panel-shaped part and cooling to room temperature; 6) machining, removing the material in a material storage area on the panel-shaped part by using a cutting processing method to obtain the final integrated panel with the thin-wall ultrahigh reinforcing rib. The method provided by the invention is used for manufacturing the integrated panel with the thin-wall ultrahigh reinforcing rib.

Owner:HARBIN INST OF TECH

Preparation method of magnesium matrix composite bone implant and product thereof

InactiveCN109364292AEffective control of corrosion resistanceImprove corrosion resistanceAdditive manufacturing apparatusPharmaceutical delivery mechanismMagnesium matrix compositeAdhesive

The invention belongs to the field of bio-implant materials and discloses a preparation method of a magnesium matrix composite bone implant and a product thereof. The preparation method of the magnesium matrix composite bone implant comprises (a) structuring a three-dimensional structure of the bone implant, selecting spherical magnesium alloy powder and nano-hydroxyapatite (HA) as raw materials,ball-milling the two materials to prepare uniformly-mixed magnesium matrix composite powder; (b) performing shaping treatment on the magnesium matrix composite powder according to the three-dimensional structure through a three-dimensional jet printing process to obtain a green body of the bone implant; (c) vacuum-sintering the green body to evaporate adhesives inside the green body to obtain therequired customized bone implant with a porous structure. The preparation method of the magnesium matrix composite bone implant saves additional support and is low in requirements on printing environment, capable of avoiding burning loss of powder elements, few in impurities, high in efficiency and low in cost.

Owner:HUAZHONG UNIV OF SCI & TECH

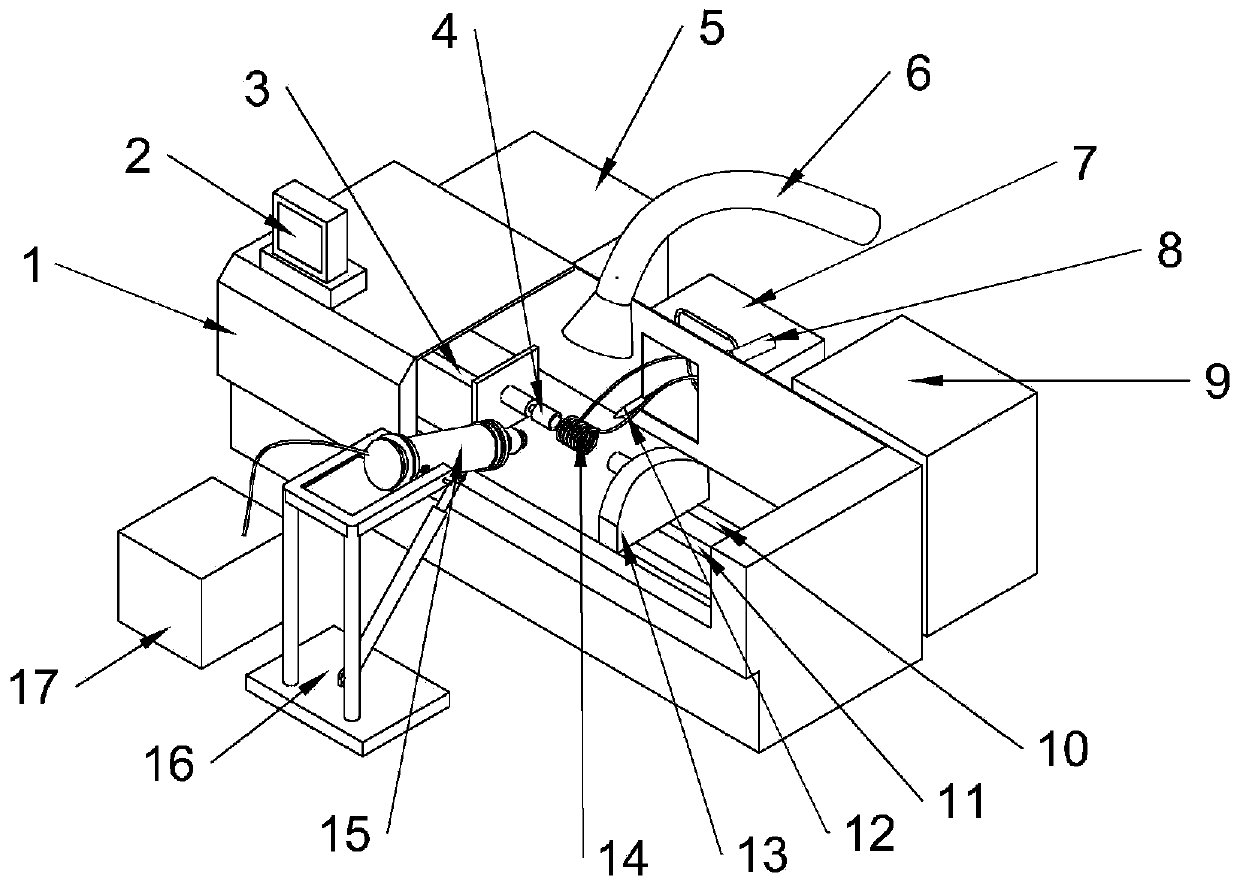

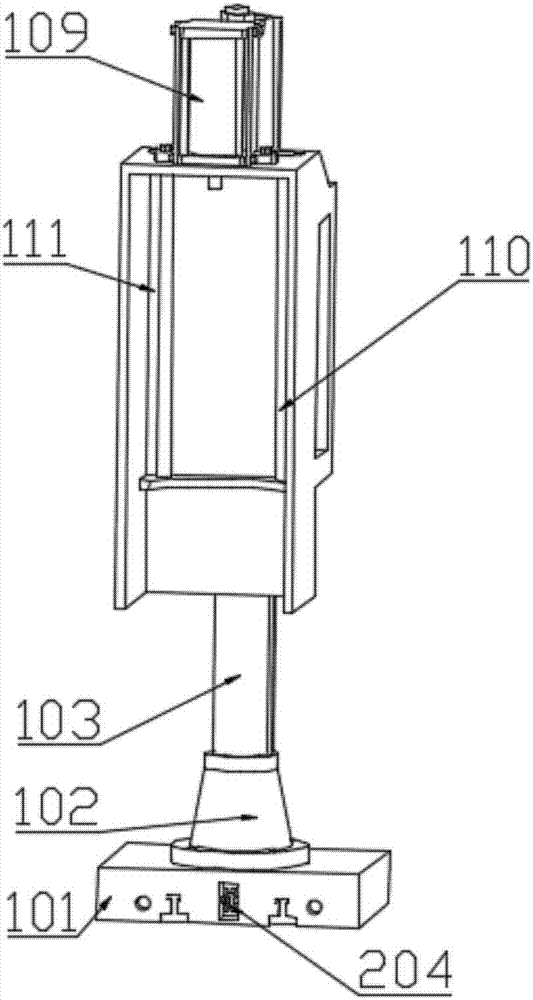

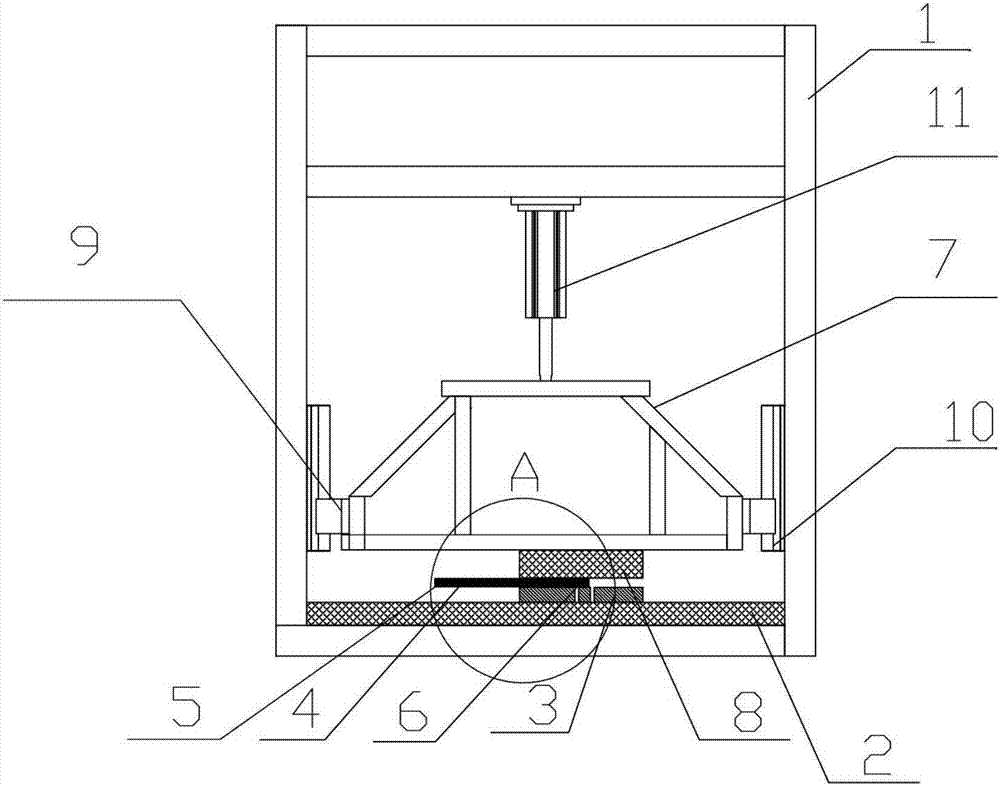

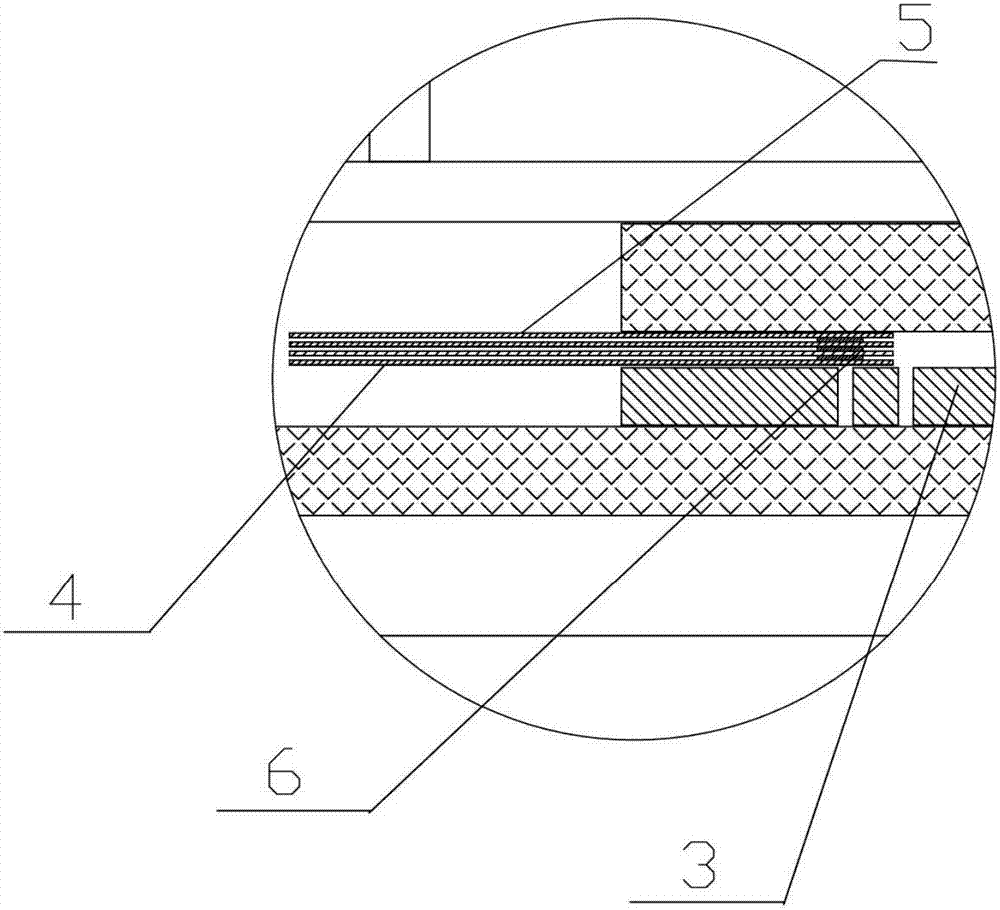

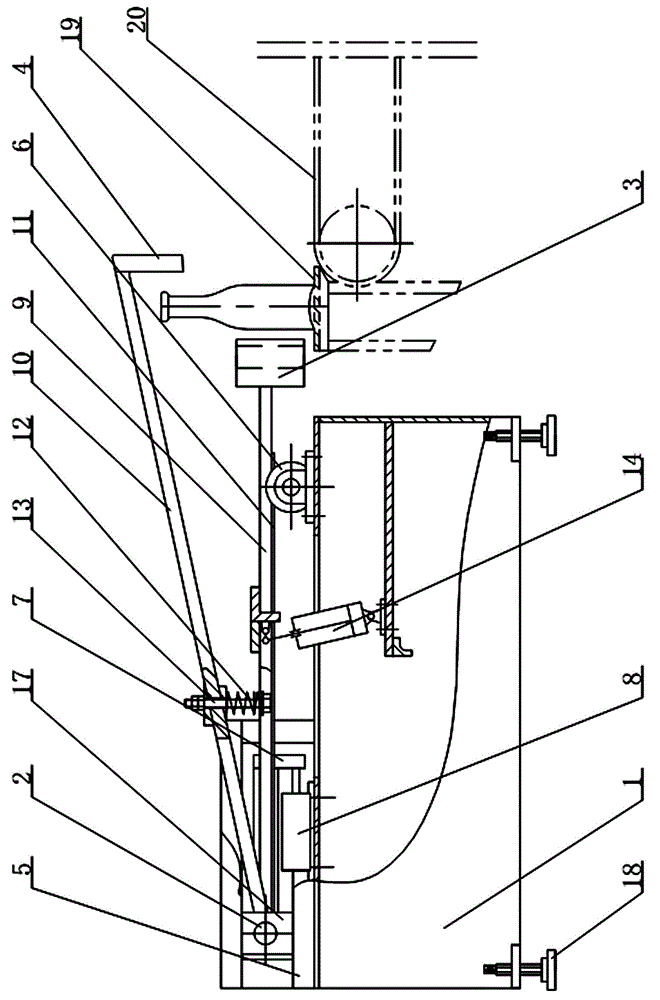

Spherical cathode numerical control electrochemical machining machine tool

InactiveCN104741712AAvoid designAvoid makingMachining electrodesMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a spherical cathode numerical control electrochemical machining machine tool which comprises a machine tool body. The machine tool body is provided with a linear circular rail. The machine tool body is provided with a workbench. The workbench is provided with an insulating plate. The insulating plate is connected with a machining box in a closed mode. The linear circular rail is provided with a three-axis movement mechanism. A Z-direction movement mechanism and a C-direction rotating mechanism in the three-axis movement mechanism are fixedly connected. The C-direction rotating mechanism is provided with a spherical cathode through a fixture in a clamped mode. The spherical cathode is of a round-rod-shaped structure with a spherical head. The spherical head end of the spherical cathode is provided with a plurality of small holes. The spherical cathode is internally provided with through holes communicated with the small holes. One side of the machine tool body is provided with an electrolyte storage mechanism and a pumping mechanism. The pumping mechanism pumps the electrolyte in the electrolyte storage mechanism to the through holes in the spherical cathode, and then the electrolyte flows out of the small holes. In the flowing out process of the electrolyte, the spherical cathode is driven by the three-axis movement mechanism and the C-direction rotating mechanism to finish machining of workpieces.

Owner:SHANDONG UNIV

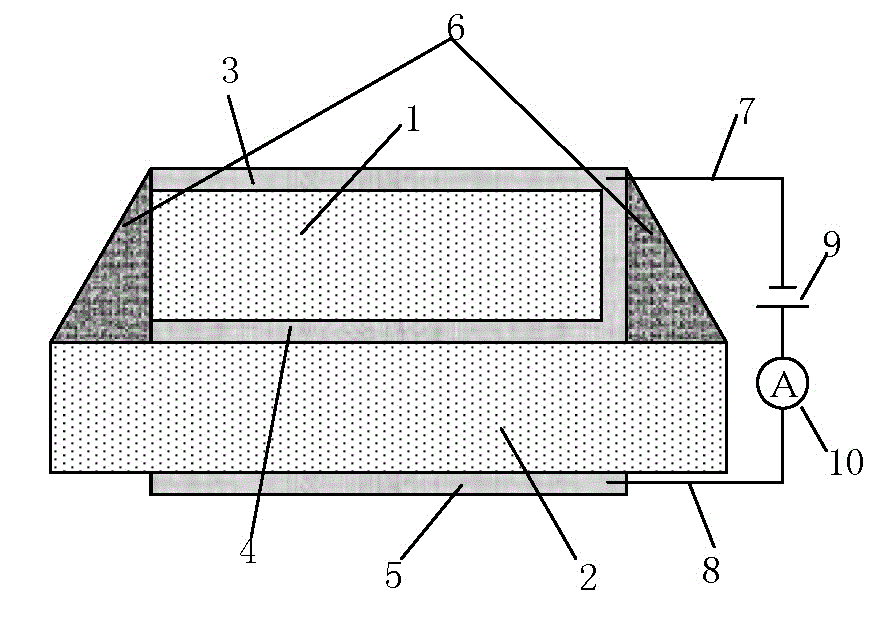

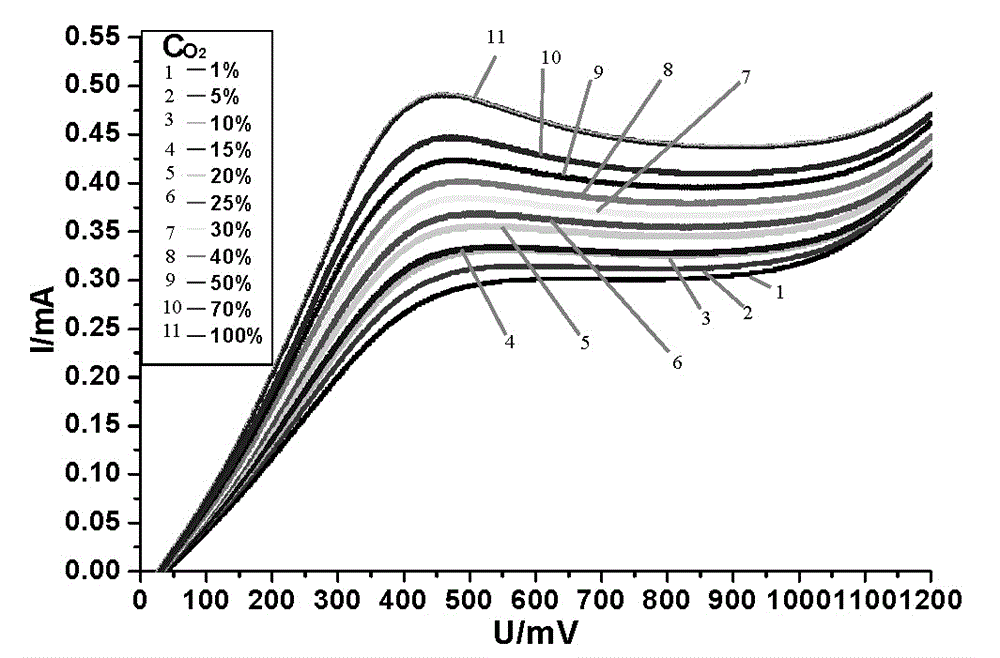

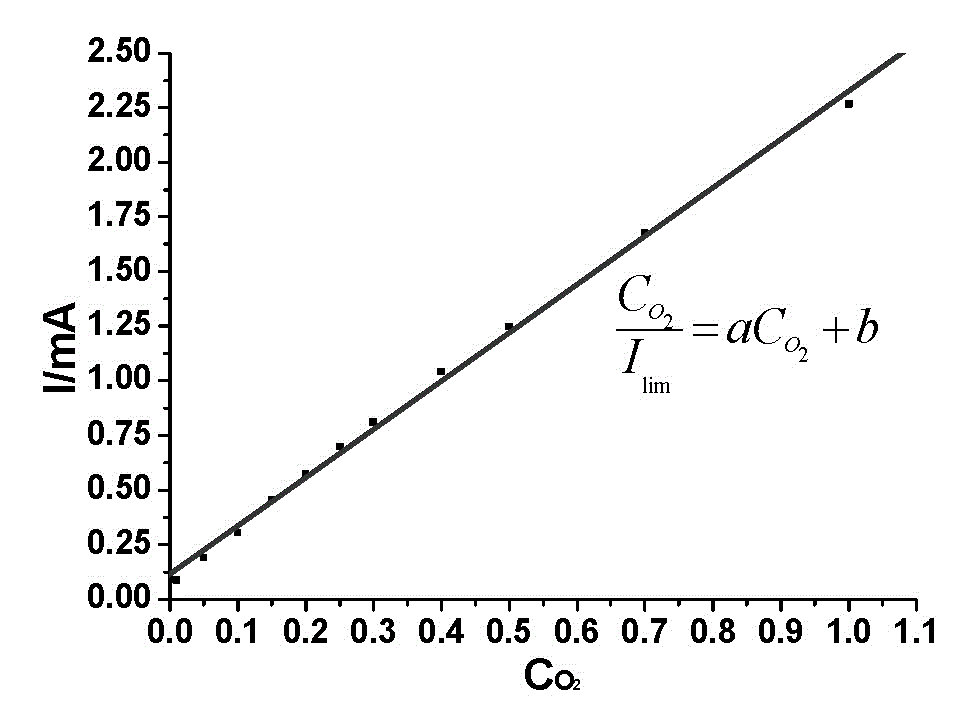

Limited current type oxygen sensor

InactiveCN102944600APerformance impactImprove long-term stabilityMaterial analysis by electric/magnetic meansOxygen sensorDiffusion barrier

The invention relates to a limited current type oxygen sensor which comprises an electrolyte layer and a compact diffusion barrier layer. The electrolyte layer and the compact diffusion barrier layer are both made of La1-xSrxGal-yMgyO3-delta, wherein 0.1<=x<=0.2, 0.1<=y<=0.2, and 0.1<=delta<=0.2. The sensor has good long-term stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

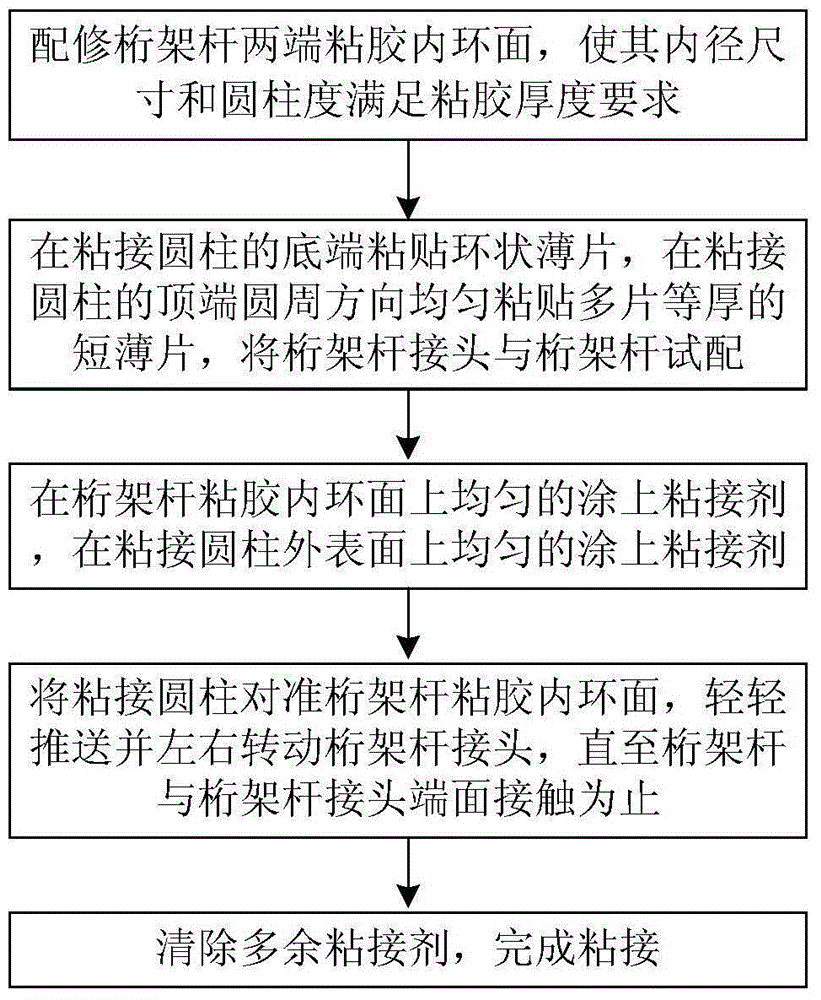

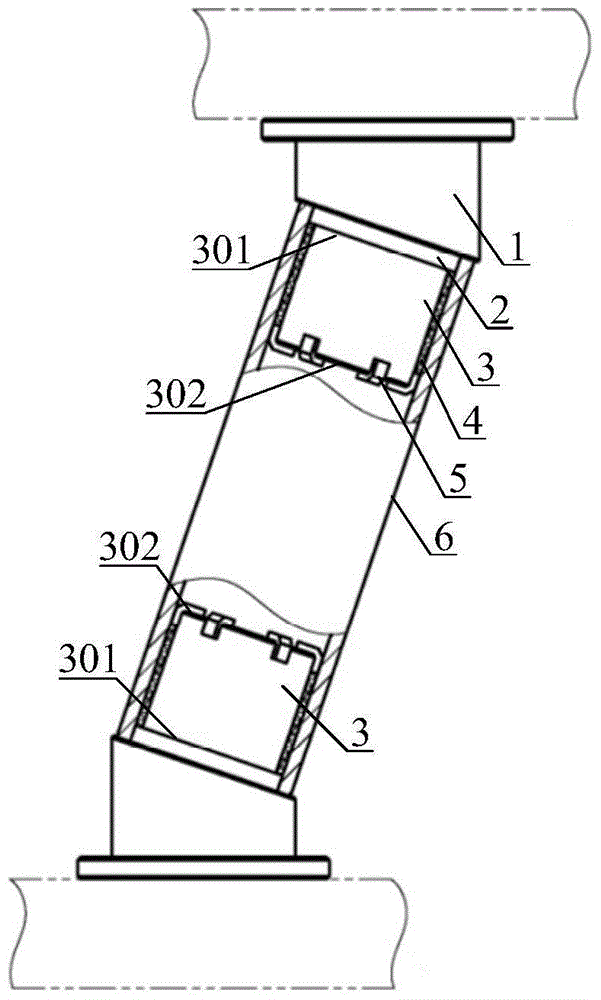

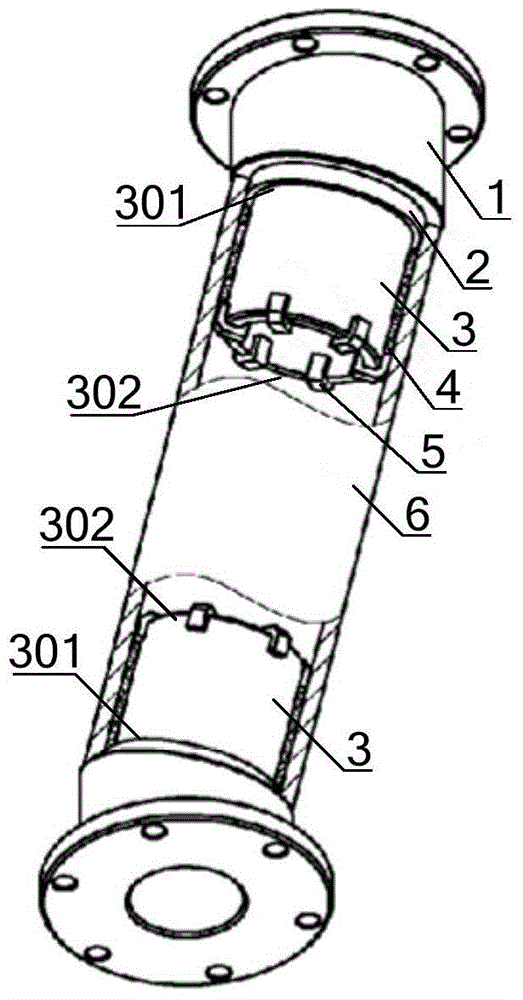

Method for controlling thickness of optical remote sensor space truss rod adhesive glue layer

ActiveCN104832511AEnsure thickness uniformity requirementsEnsure the bond strength requirementsMaterial gluingAdhesive glueEngineering

The invention provides a method for controlling thickness of an optical remote sensor space truss rod adhesive glue layer, and belongs to the field of space optical remote sensor space truss structure integration. The method comprises the following steps that adhesive glue internal annular surfaces of the two ends of a truss rod are configured and trimmed so that the size of internal diameter and cylindricity are enabled to meet the requirement of thickness of adhesive glue; an annular thin sheet is adhered at the bottom end of an adhesive cylinder, multiple equal-thickness short thin sheets are evenly adhered at the top end of the adhesive cylinder in a circumferential direction, and a truss rod connector and the truss rod are matched until the truss rod connector can smoothly rotate a circle at constant speed in the truss rod without waggling; an adhesive agent is uniformly coated on the adhesive glue internal annular surfaces of the truss rod, and the adhesive agent is uniformly coated on the external surface of the adhesive cylinder so that thickness of the adhesive agent of both parts is enabled to be greater than 2 / 3 of the required adhesive thickness; the adhesive cylinder is aligned with the adhesive glue internal annular surfaces of the truss rod, and the truss rod connector is slightly pushed and leftward and rightward rotated until the truss rod and the end surface of the truss rod connector are contacted; and the residual adhesive agent is removed so that adhesion is completed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

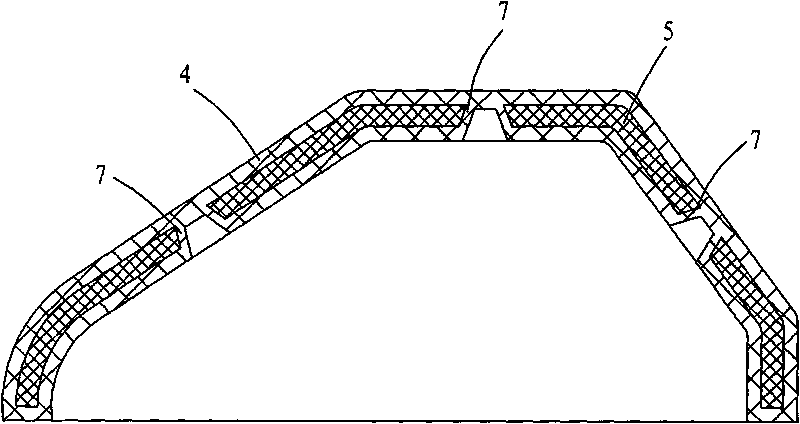

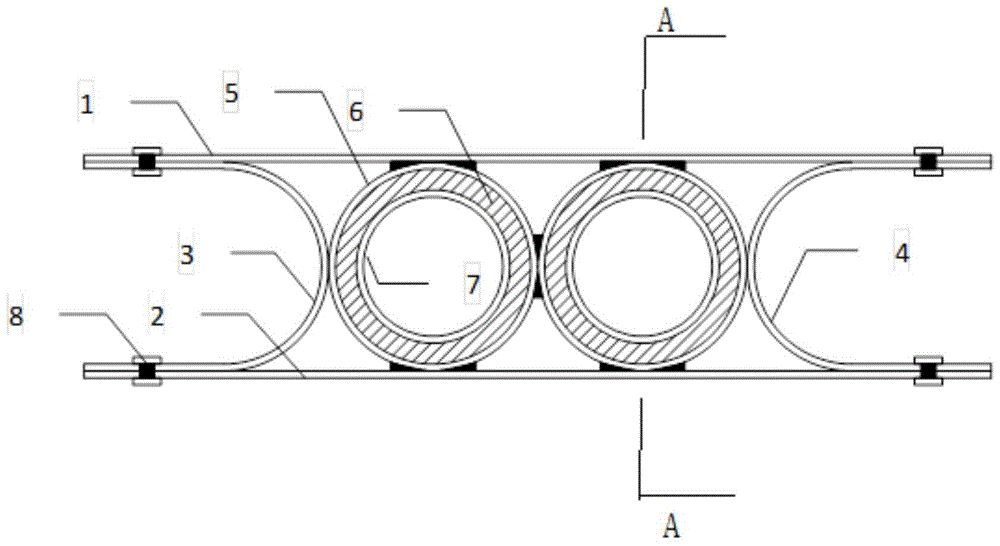

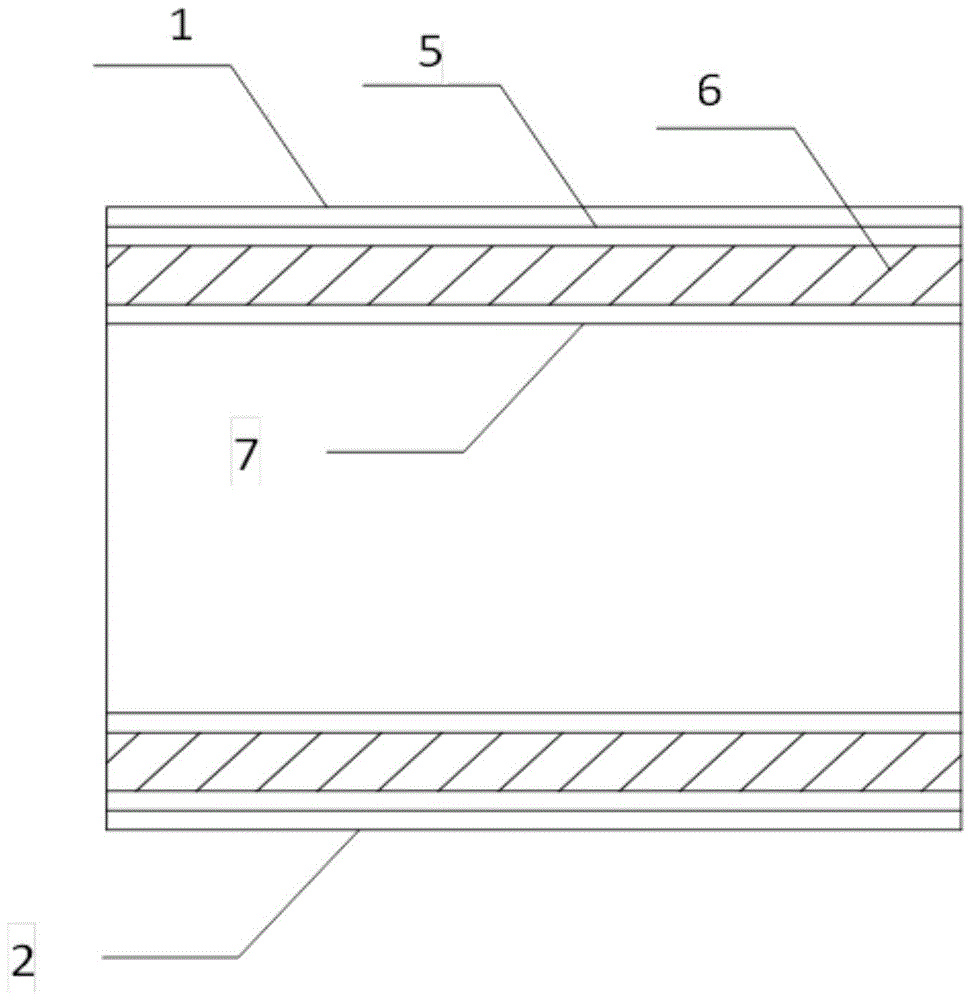

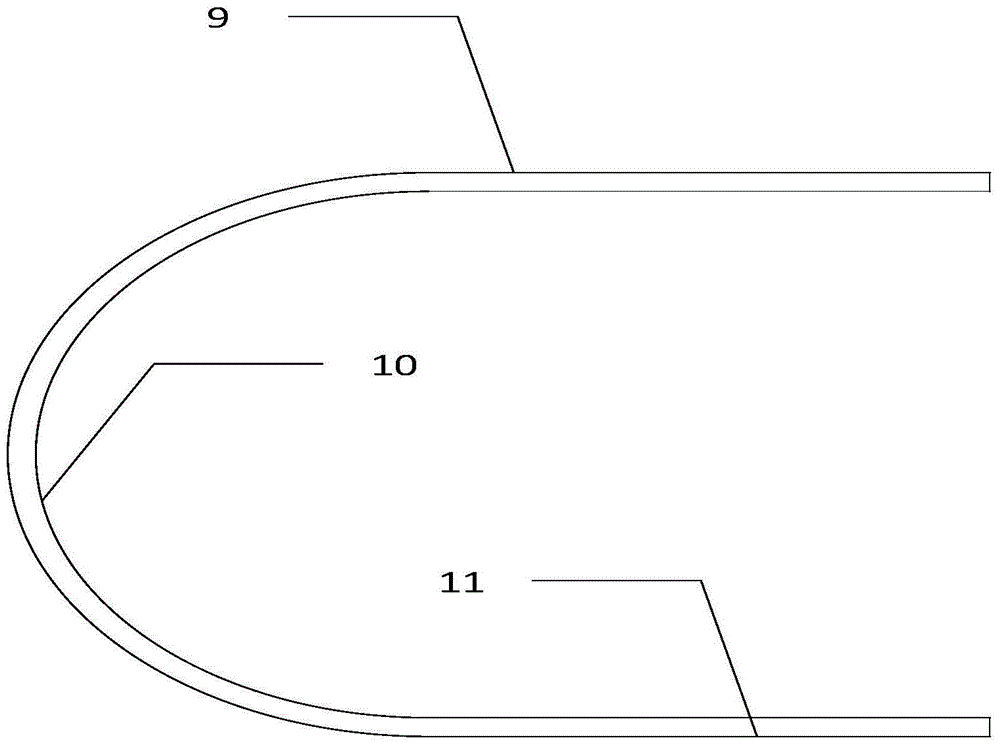

Novel lead core steel pipe U-shaped damper

ActiveCN105696454AImprove plastic deformation abilityImprove flexibilityBridge structural detailsSheet steelEngineering structures

The invention provides a novel lead core steel pipe U-shaped damper and belongs to the technical field of civil engineering structure damping. The novel lead core steel pipe U-shaped damper is mainly composed of an upper cover board, a lower cover board, U-shaped metal boards, lead core filling steel pipes and connecting bolts. Each lead core filling steel pipe is composed of an outer-layer steel pipe, a lead core filling layer and an inner-layer steel pipe. Each U-shaped metal board is composed of an upper straight section, a middle arc section and a lower straight section. Each middle arc section is semicircular, and the outer diameter of each middle arc section is the same as that of the corresponding outer-layer steel pipe. Each lead core filling steel pipe comprises the outer-layer steel pipe, the lead core filling layer and the inner-layer steel pipe from outside to inside. The placing direction of energy consumption components between the upper cover board and the lower cover board is set in the manner that the axis direction of the arc section of each U-shaped metal board is parallel to the width direction of the upper cover board and the lower cover board; the lead core filling steel pipes are located between the left U-shaped metal board and the right U-shaped metal board and are tangent to the arc sections of the two U-shaped metal boards; and the axis direction of each lead core filling steel pipe is parallel to the width direction of the upper cover board and the lower cover board. By the adoption of the damper, the double energy consumption effects of the U-shaped steel boards and the lead core steel pipes are used so that the earthquake action of a bridge and a structure can be effectively reduced.

Owner:BEIJING UNIV OF TECH

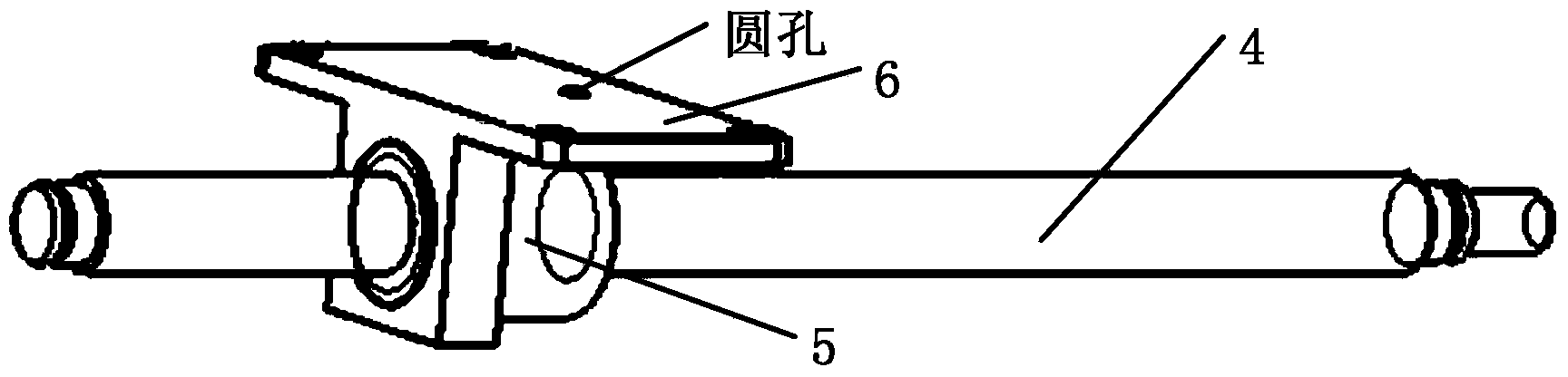

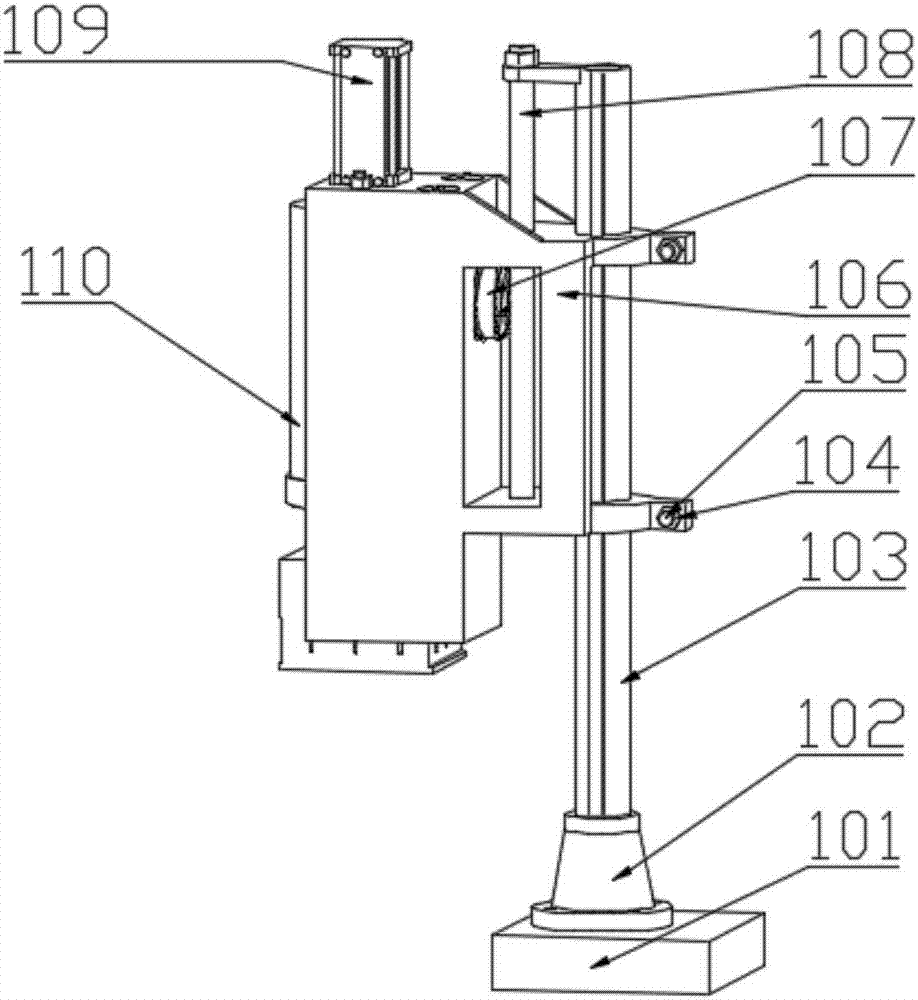

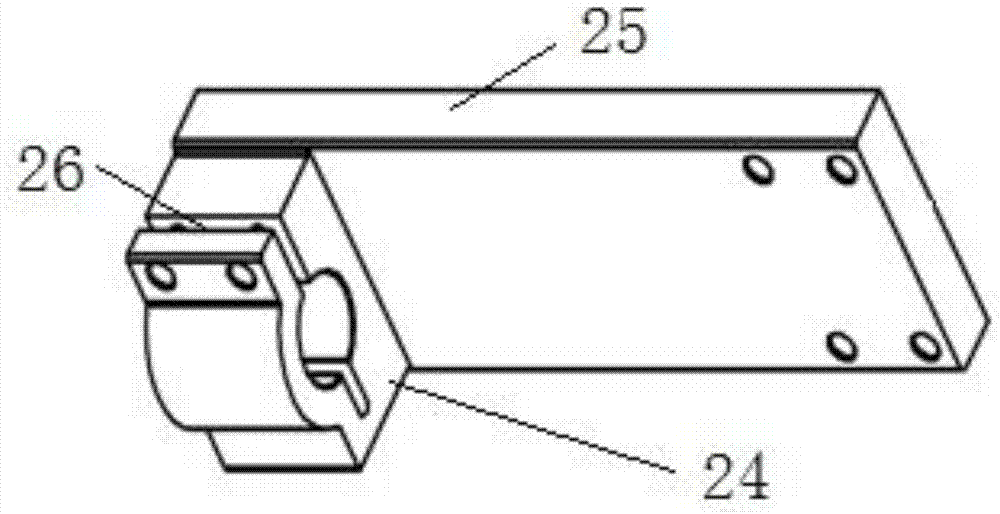

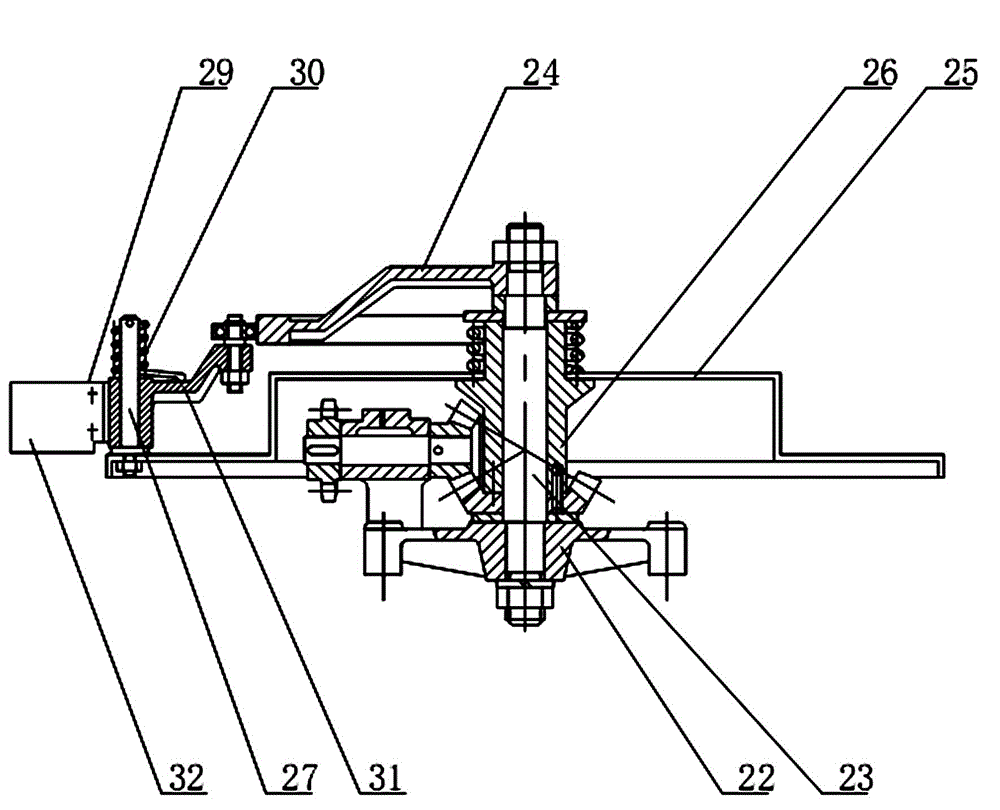

Cathode for electrolytic machining of small-size inner wall annular groove and using method thereof

PendingCN108480804ASimple structureEasy to implementMachining electrodesElectrical-based machining electrodesCorrosionEngineering

The invention relates to a cathode for electrolytic machining of a small-size inner wall annular groove and a using method thereof, and belongs to the field of electrolytic machining and manufacturing. The cathode mainly comprises an external thread joint, a tool cathode base body, a hard insulation layer, a side wall insulation layer, a lubricating insulation layer, a metal plug, a main flow channel and branch flow channels; the interior of the tool cathode base body is of a through hole structure, and the bottom of the base body and the metal plug are welded into a whole; an annular groove structure and circular groove structures uniformly distributed in the circumference are formed in the hard insulation layer so that an electrolyte can be conveniently discharged; and the side wall insulation layer plays a role in reducing stray corrosion. According to the cathode and the using method thereof, through the transition fit between the bottom insulation layer and the inner wall of a round pipe workpiece, automatic alignment and horizontal positioning of the tool cathode and the inner wall of the round pipe workpiece are achieved; through the close fit between the lower end surface of the upper insulation ring and the upper end surface of the workpiece, automatic positioning of the tool cathode in the axis direction is achieved; and then, concentric and coaxial effects between the tool cathode and the inner wall of the round pipe workpiece are achieved, and the machining precision of the inner wall annular groove is improved.

Owner:XIAN TECHNOLOGICAL UNIV

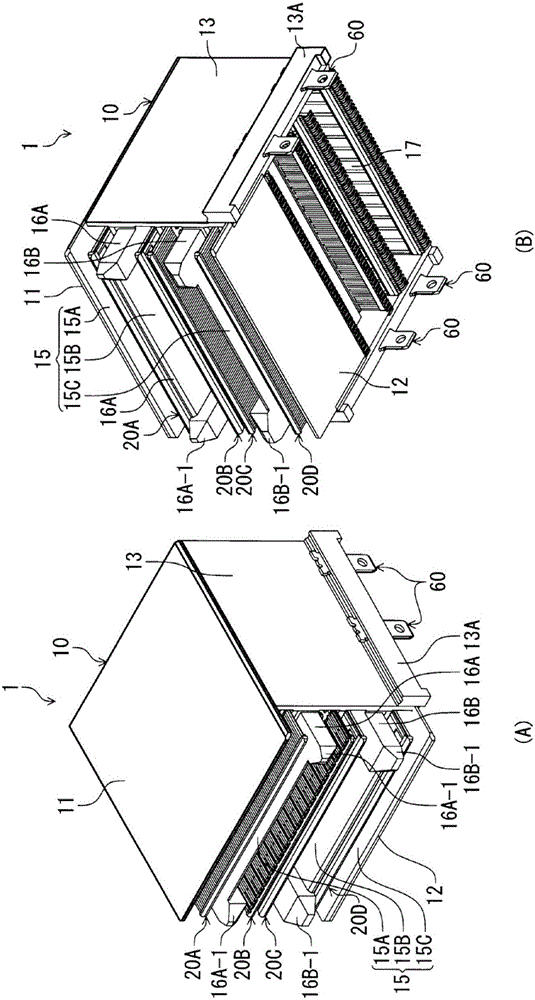

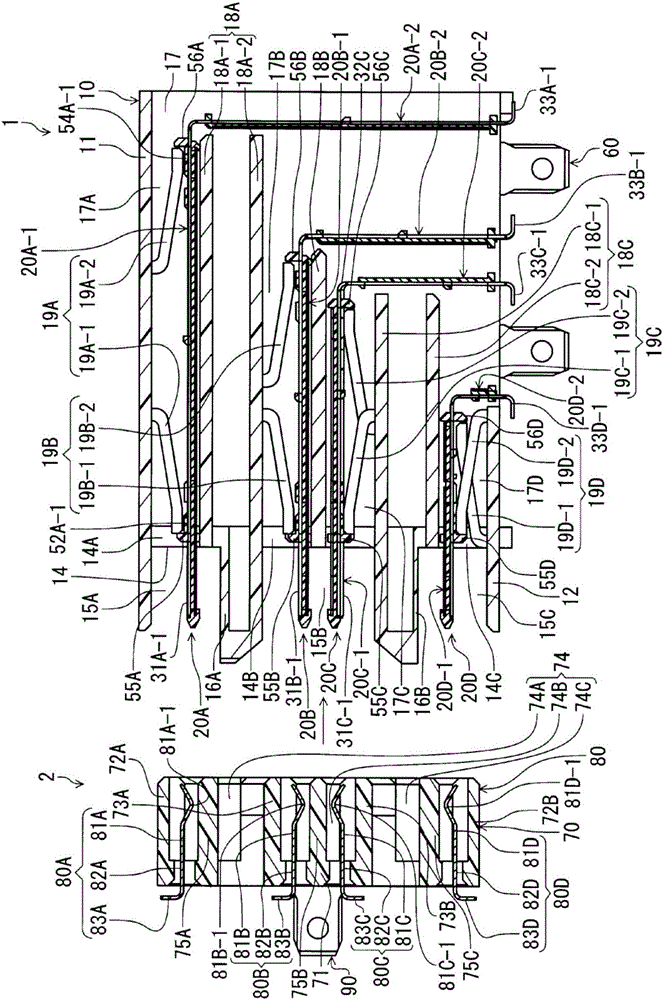

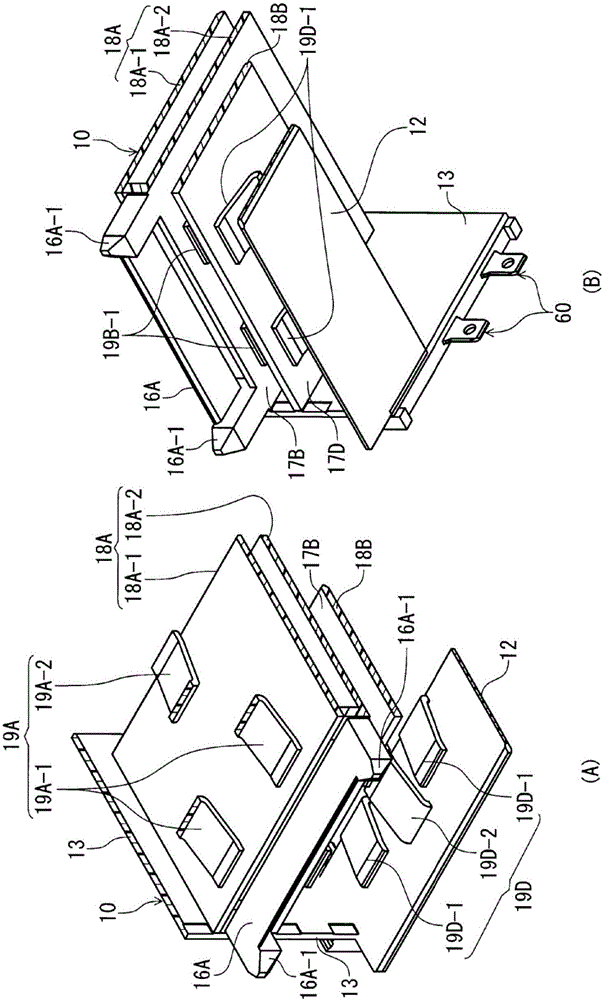

Right-angle electrical connector

ActiveCN106099449AEfficient weldingNo residual stressCoupling contact membersCouplings bases/casesElectrical connectorMechanical engineering

The invention discloses a right-angle electrical connector with which the problem is not encountered even when the positions of the connection components of different types of terminals are not aligned in the vertical direction with respect to the circtui board prior to mounting. In a housing (10) are formed holding grooves (17A to 17D) that permit arm-use blades (20A-1 to 20D-1) of various types of blades (20A to 20D) to be inserted from the rear, connection components (33A-1 to 33D-1) provided to the lower ends of legs (33A to 33D) of conductive bar members (30A to 30D) of the various types of blades (20A to 20D) are located outside the housing (10), the arm-use blades (20A-1 to 20D-1) of the various types of blades (20A to 20D) are able to move in the vertical direction over a specific range within the corresponding holding grooves (17A to 17D), and the various types of blades (20A to 20D) are able to move within a holding space 17.

Owner:HIROSE ELECTRIC GROUP

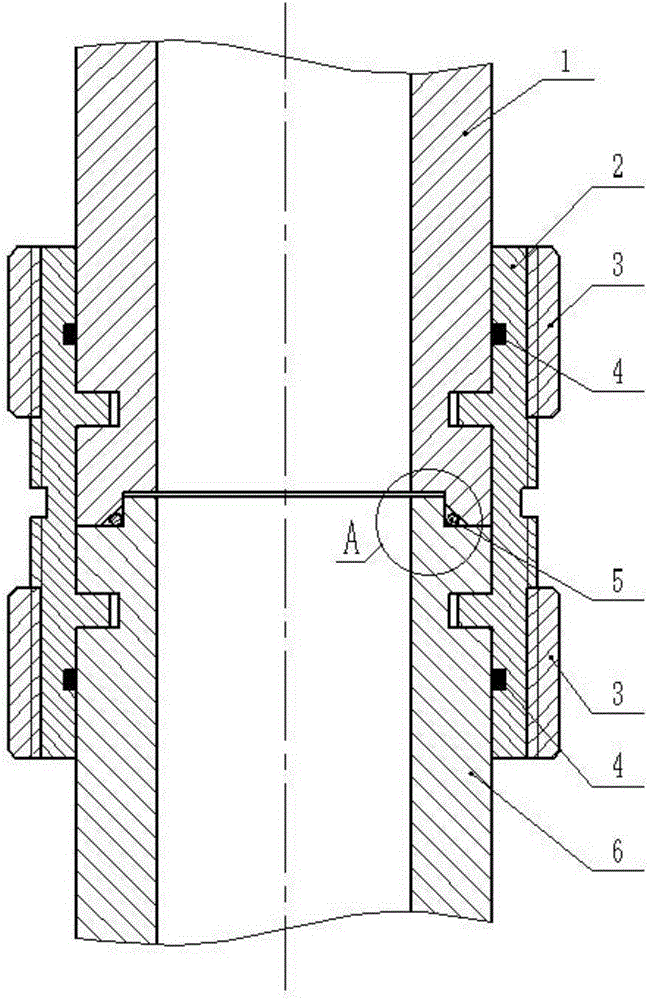

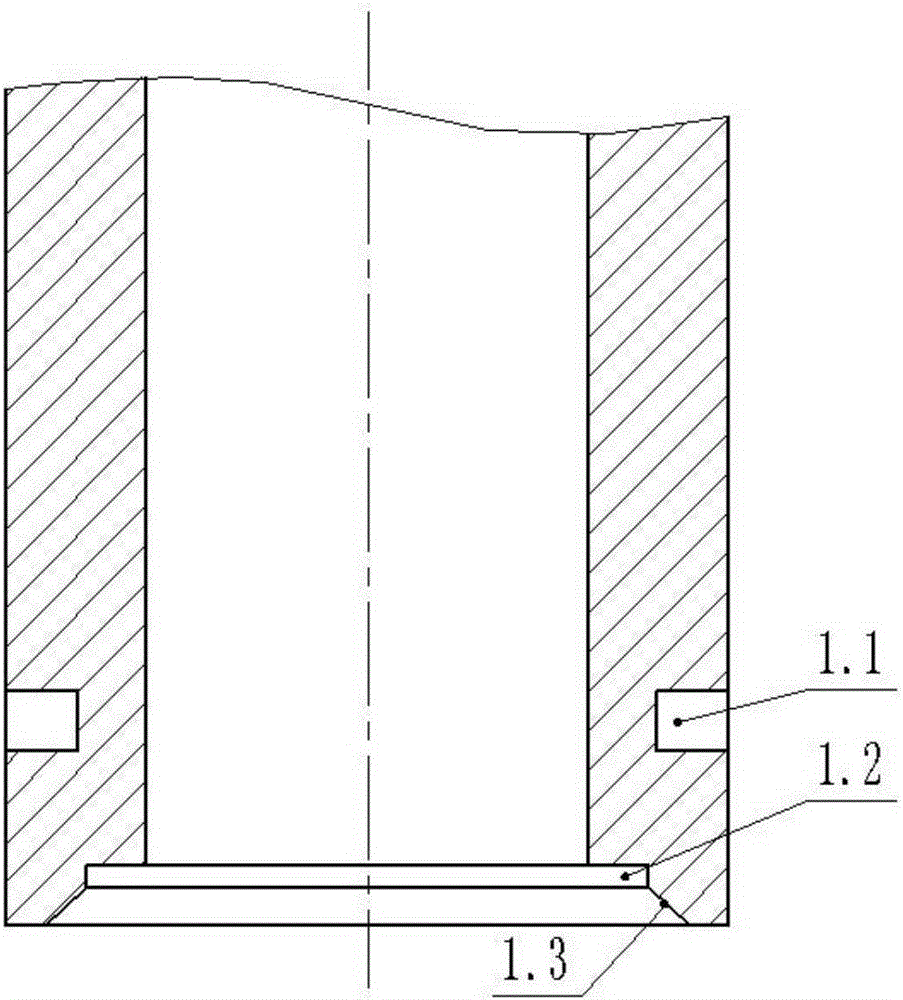

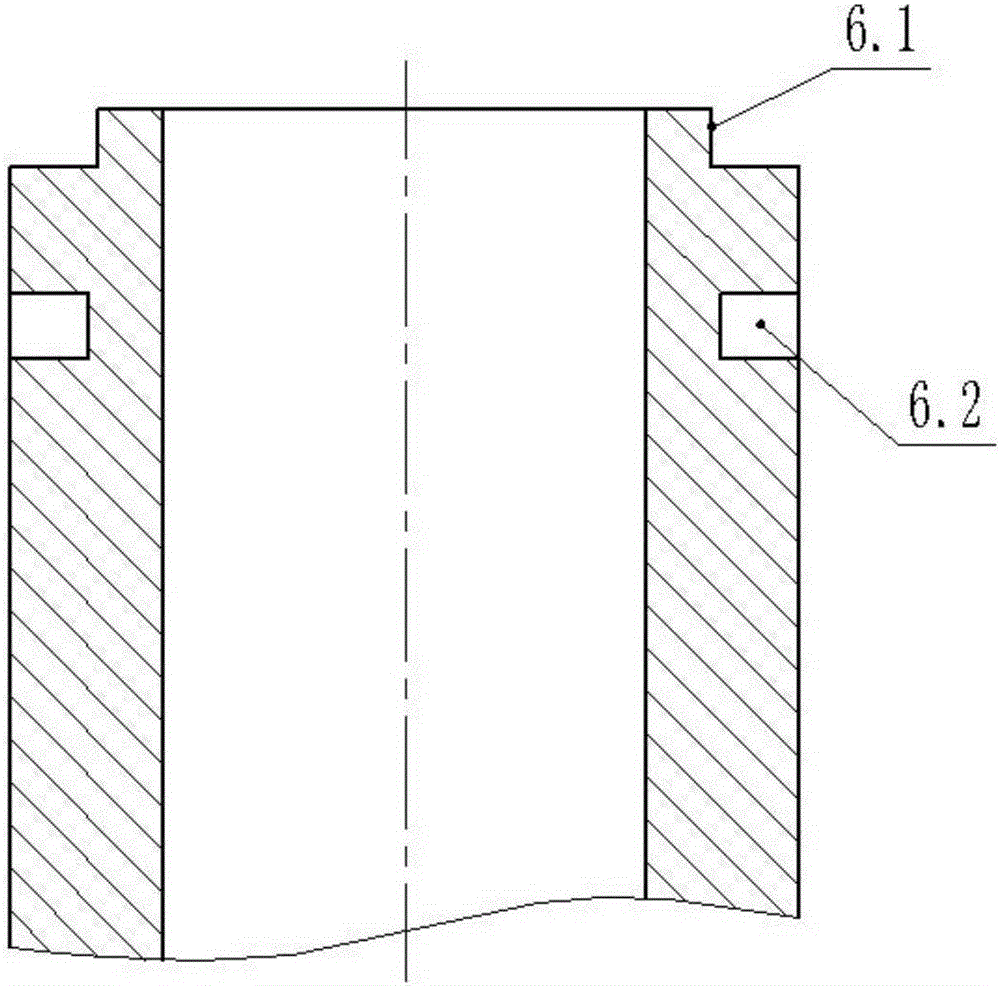

Drill rod connector

ActiveCN105298410ABurst evenlyReliable sealingDrilling rodsDrilling casingsDrill pipePetroleum engineering

The invention discloses a drill rod connector which comprises a male drill rod, a female drill rod, a snap ring and nuts. An inner spigot is arranged on the lower end face of the male drill rod, chamfers are formed in orifices of the inner spigot, grooves are formed in the outer wall of the periphery of the male drill rod, an outer spigot matched with the inner spigot of the male drill rod is arranged on the upper end face of the female drill rod, grooves which are the same as those formed in the male drill rod are formed in the outer wall of the periphery of the female drill rod, two outer threads are formed in the outer wall of the periphery of the snap ring, the inner wall of the periphery of the snap ring is provided with sealing grooves and protruding blocks which are both symmetric up and down, the male drill rod is in location fit with the female drill rod through the inner spigot and the outer spigot, the snap ring is inserted into the grooves formed in the outer wall of the periphery of the male drill rod and the grooves formed in the outer wall of the periphery of the female drill rod through the protruding blocks, the male drill rod, the female drill rod and the snap ring are connected into a whole, and the two nuts are installed on the two outer threads of the outer wall of the periphery of the snap ring. The drill rod connector has the advantages of being reliable in sealing, capable of bearing forward and reverse rotating torque and convenient to assemble and disassemble.

Owner:CHTC JOVE HEAVY IND

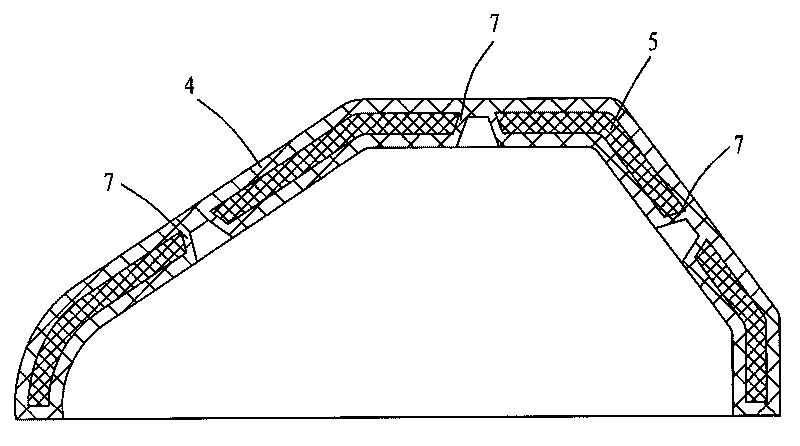

Bidirectional torsional lead shear damper

InactiveCN102535671AAmplify the degree of torsional deformationNo residual stressShock proofingSolid massTorsional deformation

The invention relates to a bidirectional torsional lead shear damper, and belongs to the technical field of seismic resistance and wind resistance of civil engineering. The bidirectional torsional lead shear damper is mainly characterized in that: a metal material such as lead or a high damping solid material is filled among sleeved steel hollow cylinders and is used as a damping layer; a large amount of lead is embedded into a hollow part between two layers of cylinders; the upper and lower ends of the steel hollow cylinders are fixed together with a bearing plate through bolts; a hollow part between an inner steel hollow cylinder and an outer steel hollow cylinder is a spiral part which forms opposite spiral angles; the inner and outer steel hollow cylinders can be reversely rotated in opposite directions, namely can generate relatively-torsional deformation according to loads along the axial directions of the steel hollow cylinders, so that a lead damping layer which is embedded into the hollow part between the inner and outer steel hollow cylinders is sheared; and hollow constraint steel is designed according to opposite angles, so that the relatively-torsional deformation degree of the damper under the action of axial loads can be amplified, and input vibration energy can be dissipated effectively.

Owner:YANGZHOU UNIV

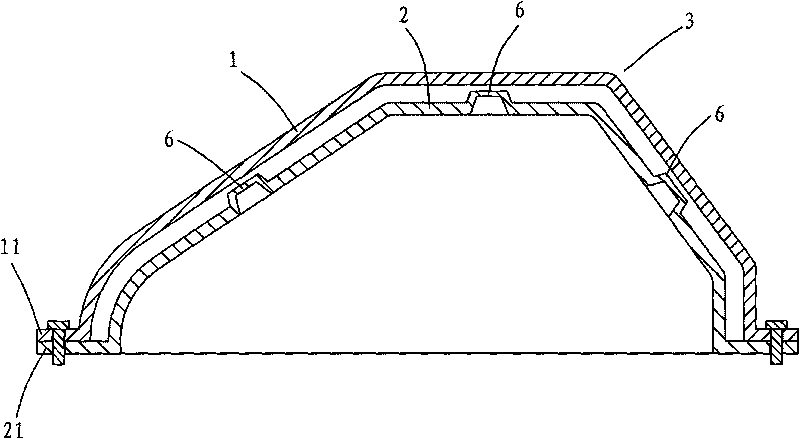

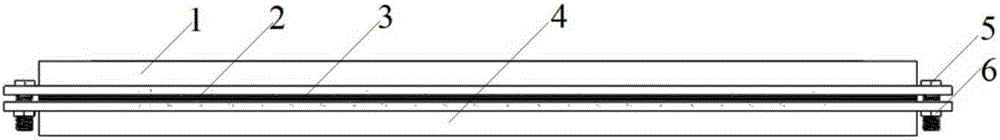

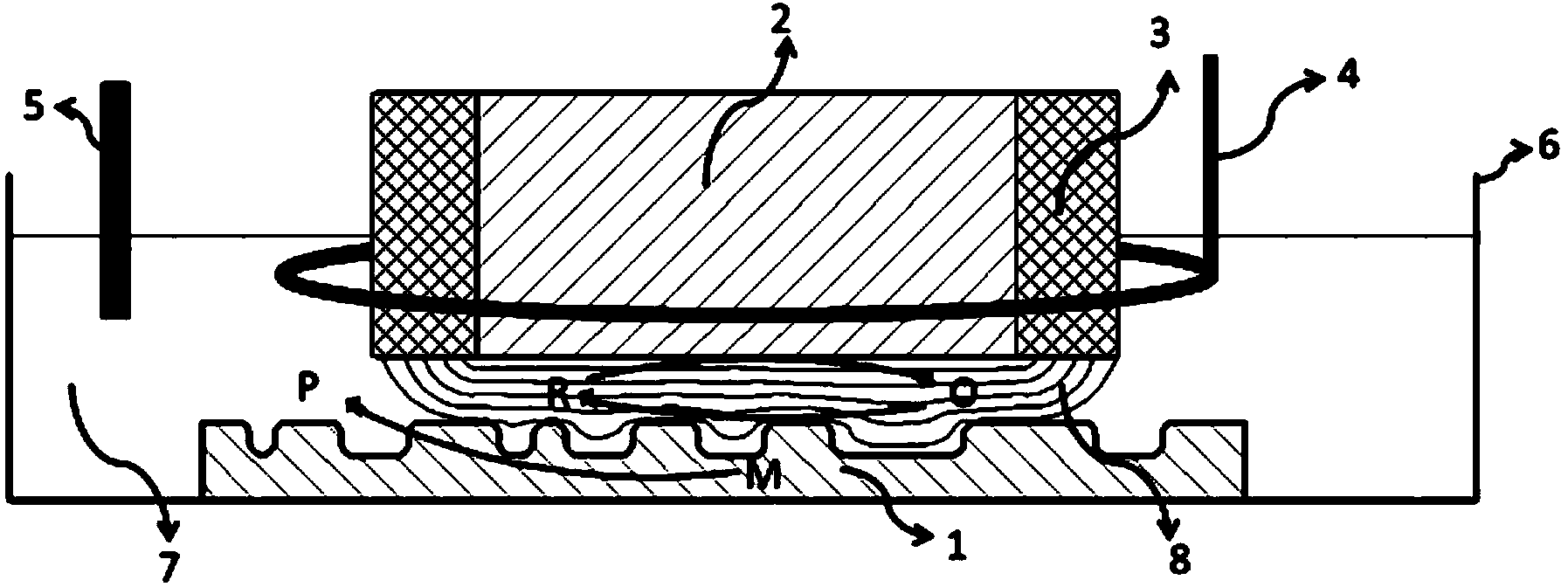

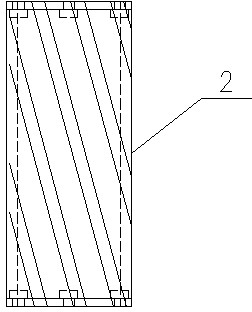

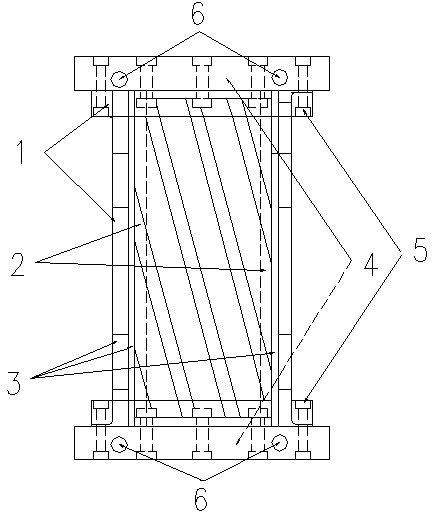

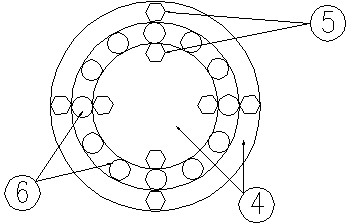

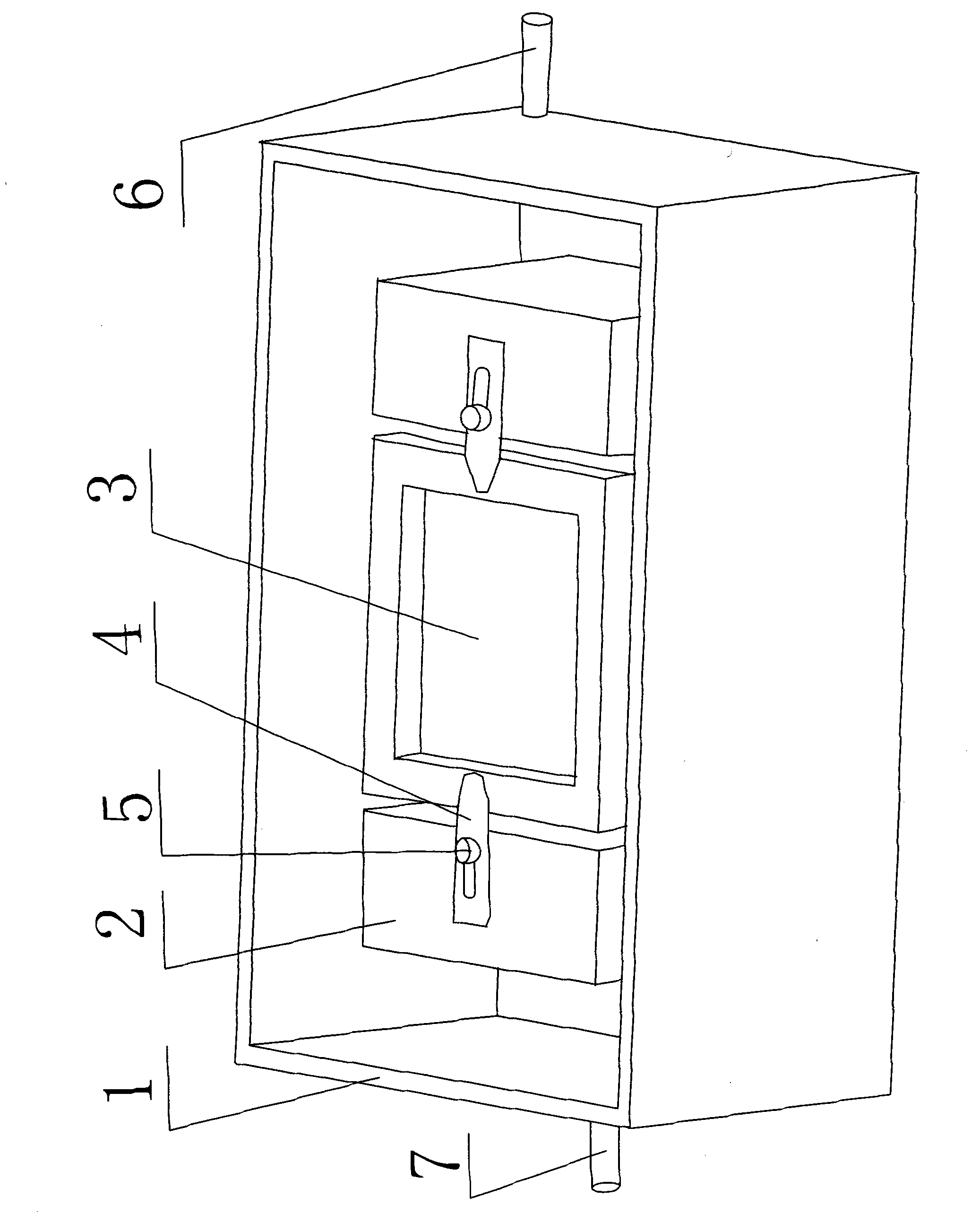

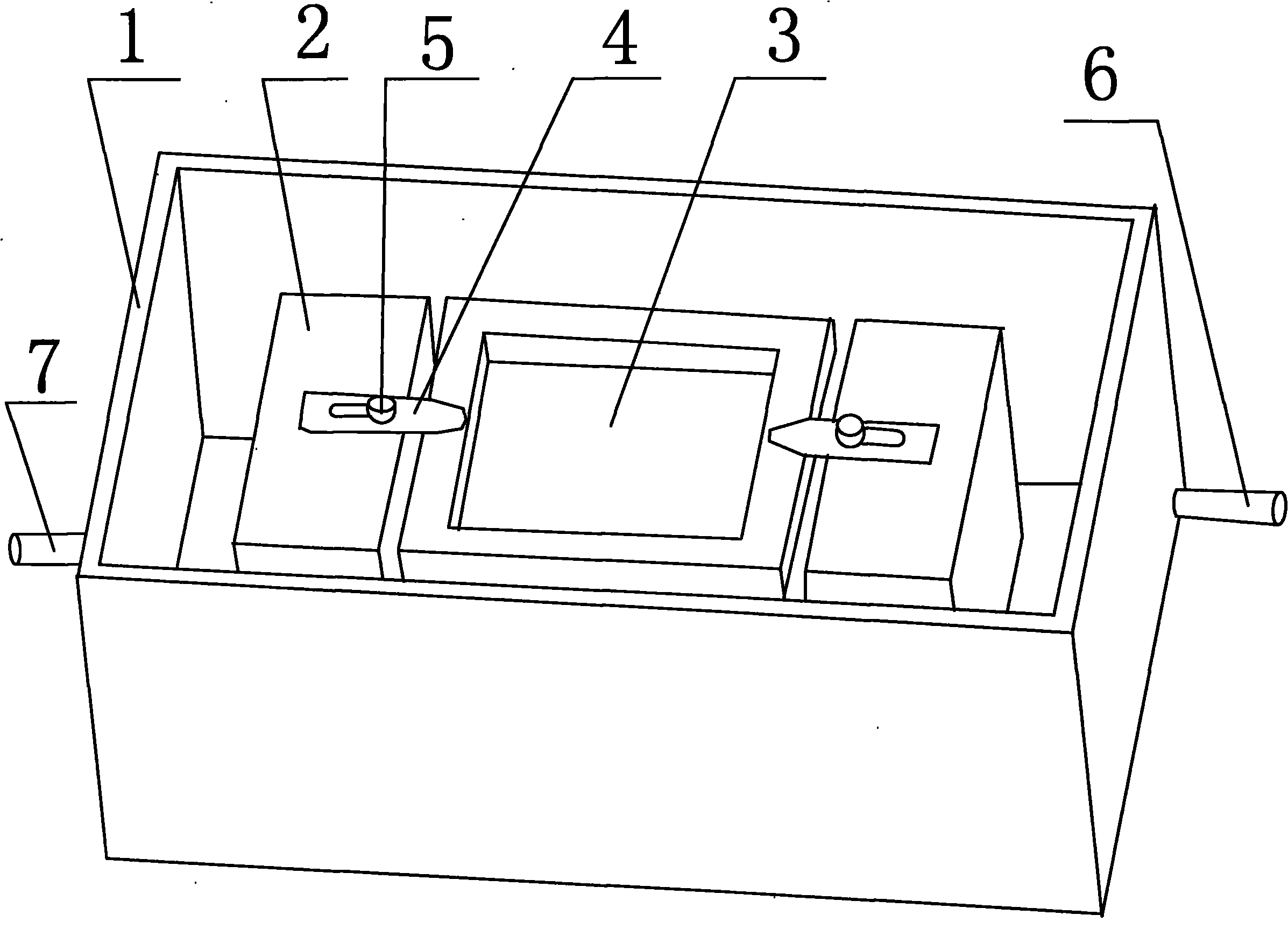

Mechanical processing device and method of ceramic-based complex curved surface parts with wave transmissivity

The invention relates to a mechanical processing device and a method of ceramic-based complex curved surface parts with wave transmissivity. Most of parts of an aircraft are products with complex curved surfaces, the design and production cycle is long, and the processing workload accounts for more than 65% of that of the whole system; and a wave-transmitting radome has the characteristics of small dimension, compact structure and the like as a key part of a fairing of the aircraft, thereby affecting the flight performance of the aircraft. The device comprises a water storage tank (1), wherein a padding block (2) is arranged in the water storage tank, a workpiece (3) is mounted in the middle of the padding block, a fire poker (4) with a long circular hole is arranged on the padding block (2), the fire poker is fixed on the padding block by using a bolt (5) when pressing the processed workpiece, a water outlet (6) is formed below one side outside the water storage tank, and a water inlet (7) is formed above one side outside the water storage tank. The device is used for SiO2 fiber- toughened SiO2 ceramic-based composite materials, in particular to mechanical processing of the ceramic-based complex curved surface parts with the wave transmissivity.

Owner:航天科工哈尔滨风华有限公司

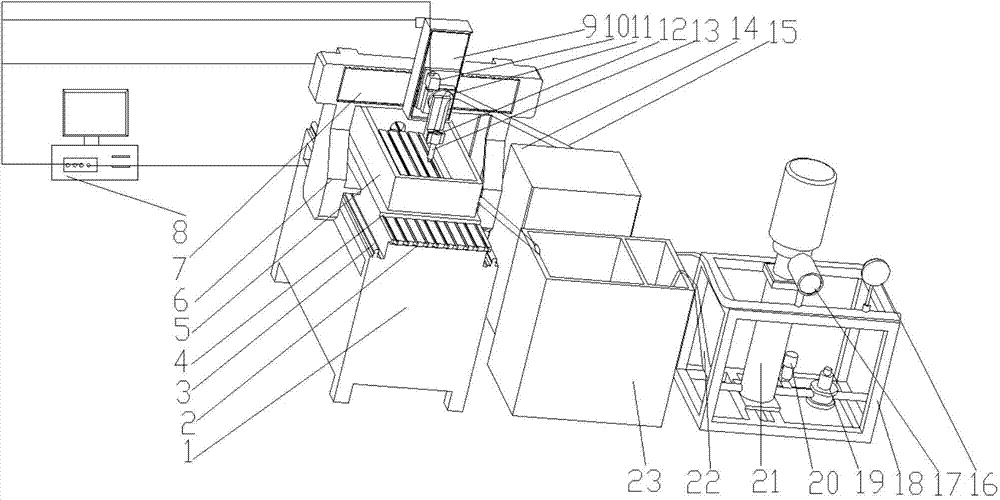

Electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs

InactiveCN107081513AReduce labor intensityIncrease productivityHigh frequency current welding apparatusWelding/soldering/cutting articlesCapacitanceElectrical battery

The invention discloses an electromagnetic pulse welding method of multilayer battery aluminum plate lugs and copper pole lugs. The aluminum plate lugs and the copper pole lugs are fixed on a welding device; the welding device comprises a rack; a cushion plate is arranged on the rack; an electromagnetic coil is arranged on the cushion plate; welding areas of the multilayer aluminum plate lugs are placed on the electromagnetic coil; the copper pole lugs are placed on the upper portion of the aluminum plate lug at the uppermost layer; interval pieces are arranged between the welding areas of the aluminum plate lugs as well as the welding areas of the aluminum plate lugs and the copper pole lugs; the aluminum plate lugs and the copper pole lugs are fixed through a pressing plate; the electromagnetic coil is connected with a capacitance switch of a capacitance power supply device; the capacitance switch is controlled by a pulse generator to be switched on and switched off; and the pulse generator is started to charge a capacitor of the capacitance power supply device, when the charging voltage reaches the set value, the capacitance switch is turned on, and the capacitor quickly discharges, so that welding of the battery aluminum plate lugs and the copper pole lugs is achieved. The welding efficiency is improved, the welding quality is improved, energy consumption is reduced, auxiliary materials are not consumed, and energy saving and environmental friendliness are achieved.

Owner:INST OF OPTICAL MASCH CHONGQING CITY +1

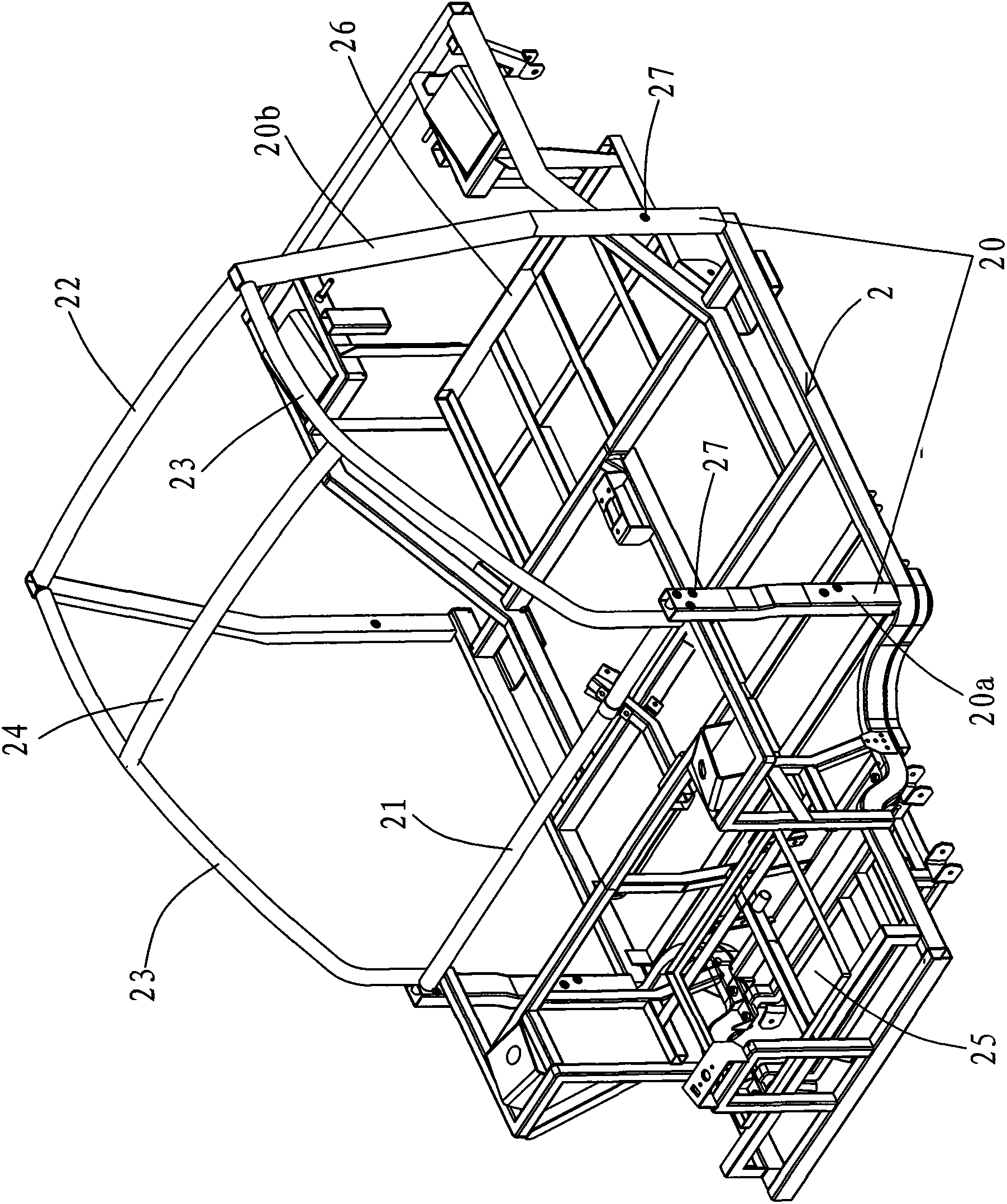

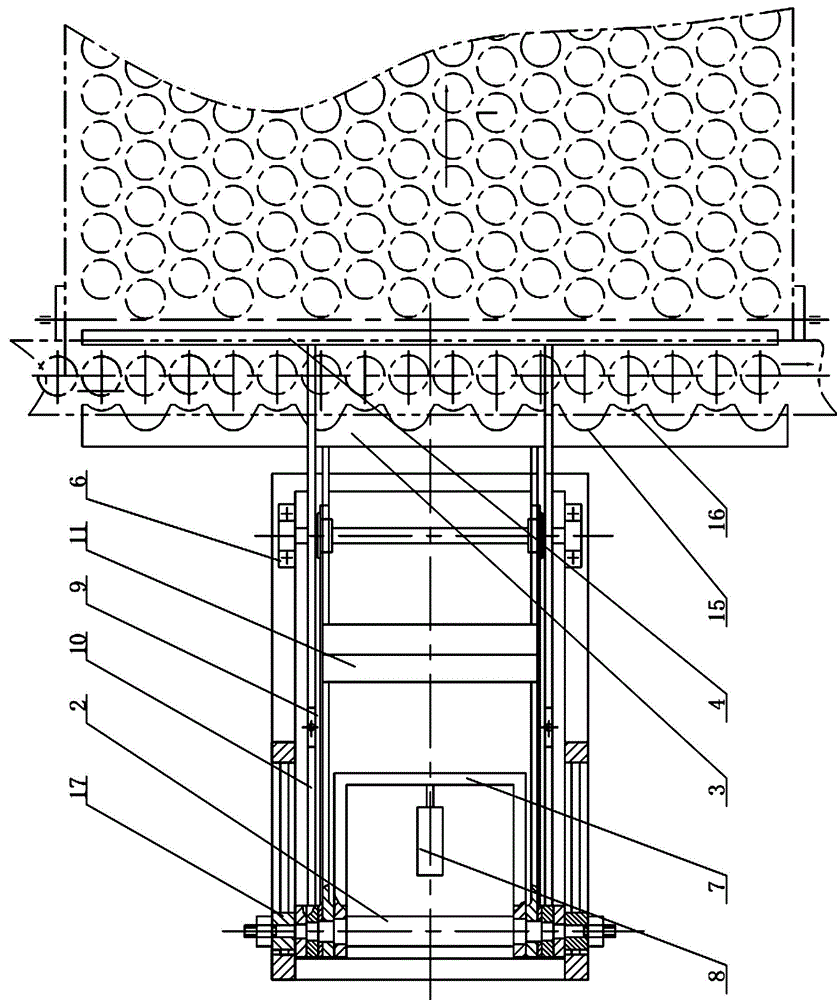

Automatic arranging and conveying system for glass containers

The invention relates to an automatic arranging and conveying system for glass containers. The system mainly solves the problems that due to uneven intervals of the glass containers on an annealing kiln mesh belt, in the annealing process, container exploding easily happens, consequently, the finished product rate of the glass containers is low, and residual stress and poor quality exist in the glass containers. The system is characterized in that an automatic arranging device is located between an output conveying belt (21) and a transition conveying belt (19) of a bottle producing molding machine; and one end of the transition conveying belt (19) is located on the annealing kiln mesh belt (20), and a pneumatic bottle pushing machine is placed on one side of the transition conveying belt (19) and corresponds to the annealing kiln mesh belt (20). According to the automatic arranging and conveying system for the glass containers, the glass containers are pushed to the middle transition conveying belt through the disc type automatic arranging device, and the pneumatic bottle pushing machine pushes the glass containers to the annealing kiln mesh belt; the glass containers can be in the ideal staggering arranging state on the annealing kiln mesh, and the intervals of the glass containers are even; in the annealing process of the glass containers, the glass containers are evenly heated; and the quality of glass bottle tanks is effectively improved.

Owner:广东亿方包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com