Drill rod connector

A technology for drill pipe joints and drill pipes, which is applied in the direction of drill pipes, drill pipes, and drilling equipment. Uniform seam and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

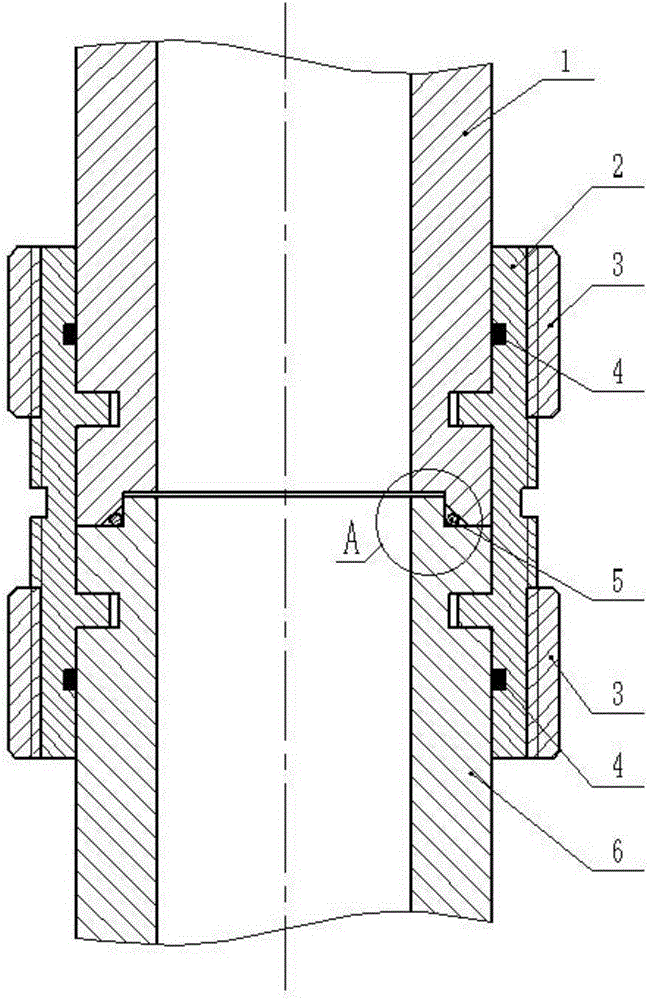

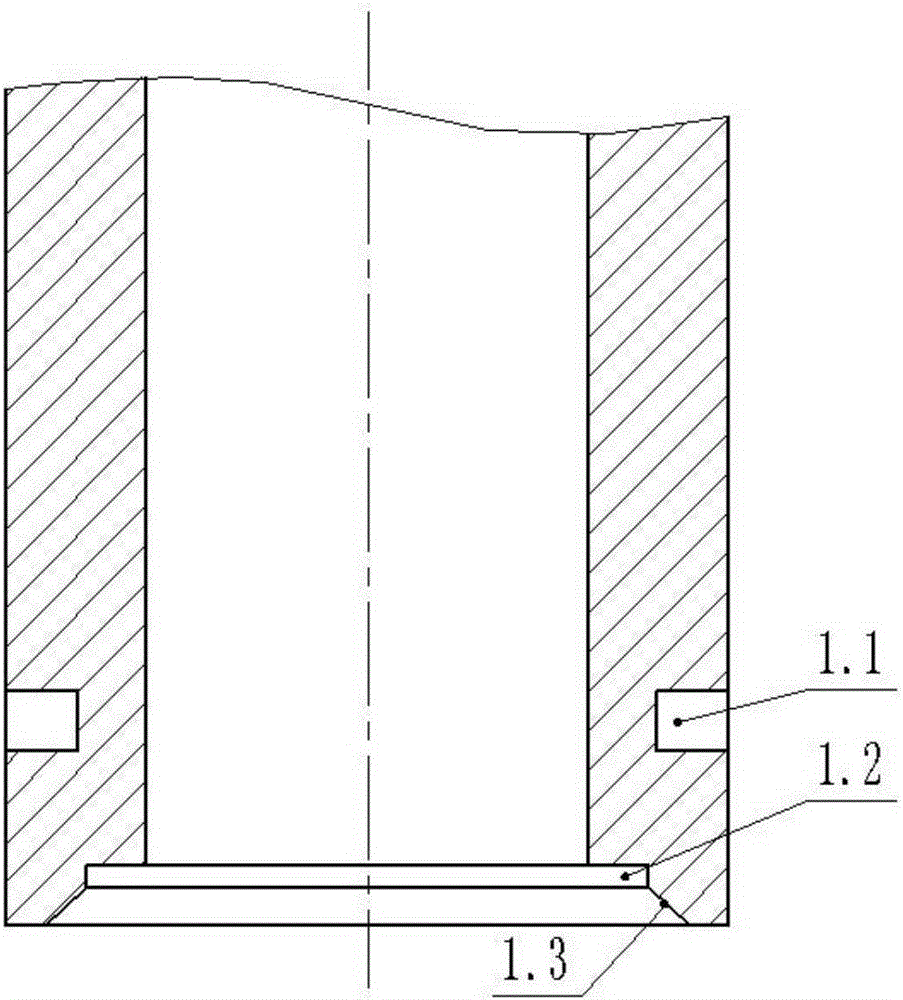

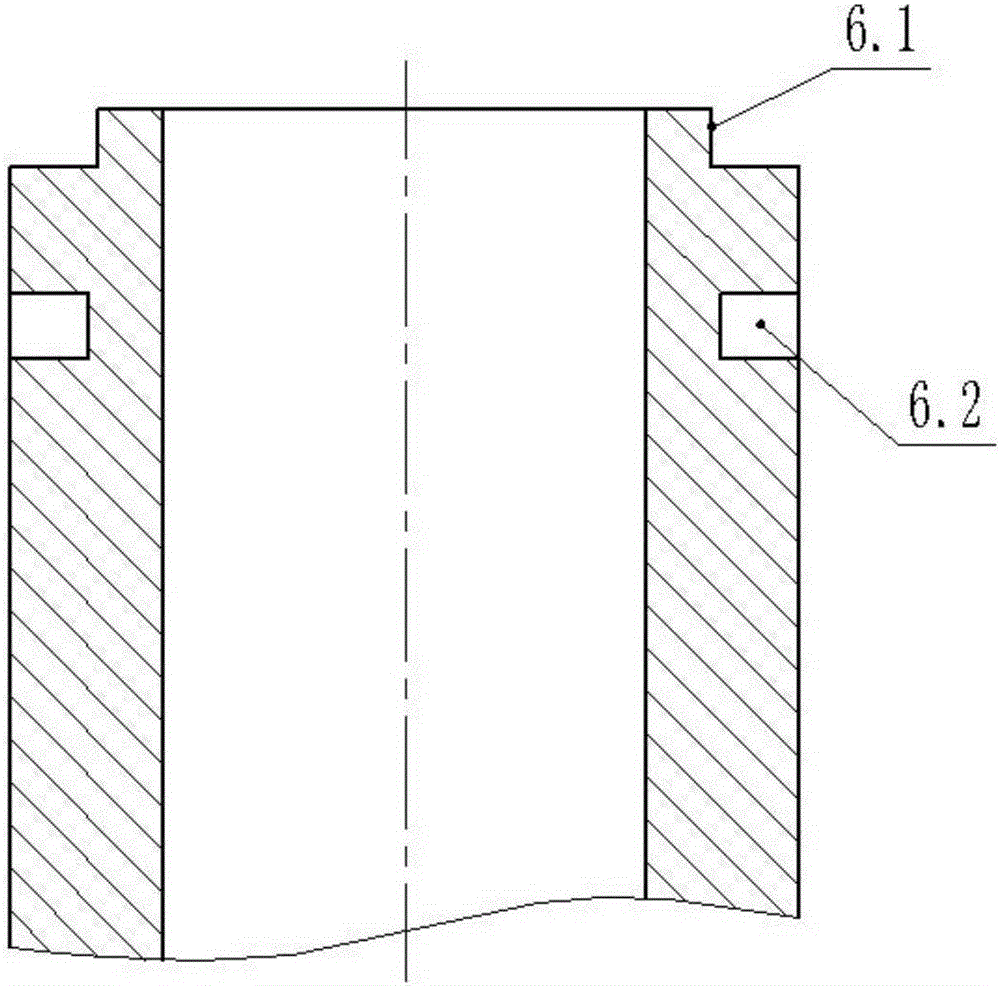

[0035] Such as Figure 1~6 As shown, a drill pipe joint provided by the present invention includes a male drill pipe 1, a female drill pipe 6, a snap ring 2 and a nut 3, the lower end surface of the male drill pipe 1 is provided with an inner stop 1.2, and the inner The opening of the spigot 1.2 is provided with a chamfer 1.3, the outer wall of the male drill rod 1 is provided with a groove 1.1, and the upper end surface of the female drill rod 6 is provided with a groove corresponding to the inner spigot 1.2 of the male drill rod. Matched outer stop 6.1, the peripheral outer wall of the female drill pipe 6 is provided with the same groove 6.2 as the male drill pipe groove 1.1, the snap ring 2 has a symmetrical structure up and down, and the snap ring 2 The outer wall of the circumference is provided with two external threads, and a tool relief groove 2.3 is provided between the two external threads, and the inner wall of the circumference of the snap ring 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com