Patents

Literature

4967results about How to "No crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Attapulgite argil powder with air purifying function

ActiveCN102173743BImprove adhesionImprove plasticityDispersed particle separationDeodrantsFiberHazardous substance

The invention discloses an attapulgite argil powder with an air purifying function. The technical scheme is as follows: the attapulgite argil powder with an air purifying function is prepared from high-viscosity attapulgite clay, an attapulgite constant-humidity conditioner, a natural mineral adsorbing / filtering agent, Cacumen Biotae, aluminum silicate fiber and polyacrylamide. The attapulgite argil powder is prepared by the following steps: pulverizing the materials, soaking and aging to obtain a wet mixture, extruding the wet mixture into a strip, airing the strip, pulverizing to obtain powder, and packaging to obtain the finished product. The attapulgite argil powder has favorable cohesive property, plasticity, thixotropy, fire resistance and thermal stability; the pottery prepared from the attapulgite argil powder with an air purifying function contains a great deal of micropores and activated carbon, thus, has the characteristics of low shrinkage, no cracking or deformation and favorable adsorbability, and can effectively adsorb formaldehyde, ammonia, benzene and other harmful substances in the air, thereby protecting the environment and improving good health of people. The invention is suitable for producing pottery artware with an air purifying function.

Owner:江苏世澳非金属应用科技有限公司

Method for depositing paint-coat of metal surface, especially for gradient paint-coat

InactiveCN1405355ASimple production processLow costMetallic material coating processesAlloyIonization

The invention refers to a method of melting-covering coating of metal surface, especially a method of gradient coating. The steps: 1, pre-smear the mixing pwoder of Fe-, Co- or Ni-group alloying powder and ceramic powder; 2, use plasm produced by ionizing non-oxidizing gas in plasm moment to scan metal surface in order to produce melting-covering layer or gradient cost. It has positive effects.

Owner:山东科技大学机械电子工程学院

Drug-eluting stent (DES) with multicoating

The present invention discloses a Drug-eluting stent (DES) with multiple coating layer, its preparation method and application. Said stent consisting stent and coating layer convered on the stent surface. It is characterized by that the surface of the stent has 1-4 layers of coating layers, in which at least two layers are medicine-carried layer, and said medicine-carried layer is composed of (wt%) 0.5-99% of polymer, 0-10% of additive and 0.5-99% of active component, and between the medicine-carried layer and stent a base layer can be set so as to raise the anchoring force of medicine-carried layer and stent, and the surface of medicine-carried layer also can be more coated with a surface layer.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

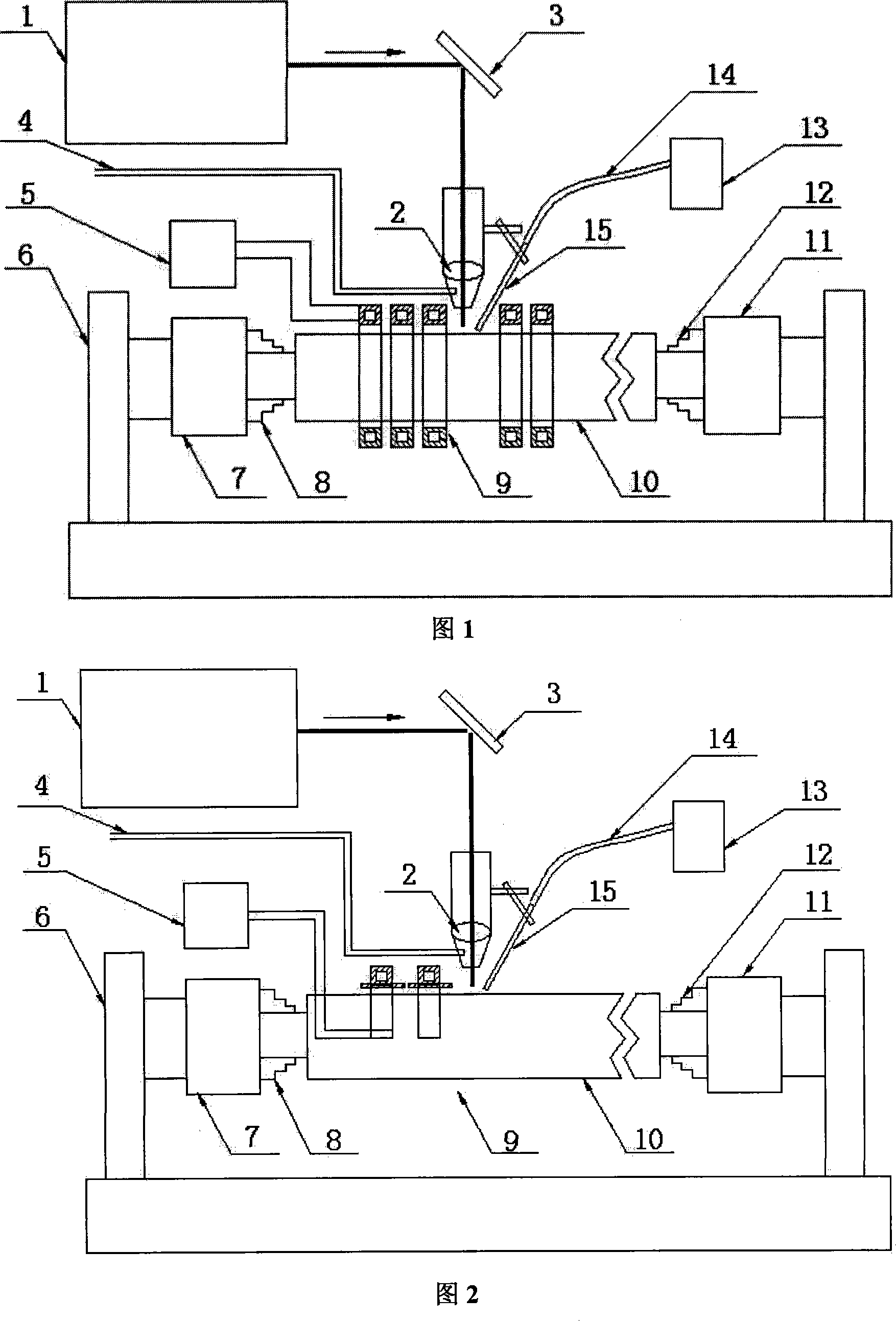

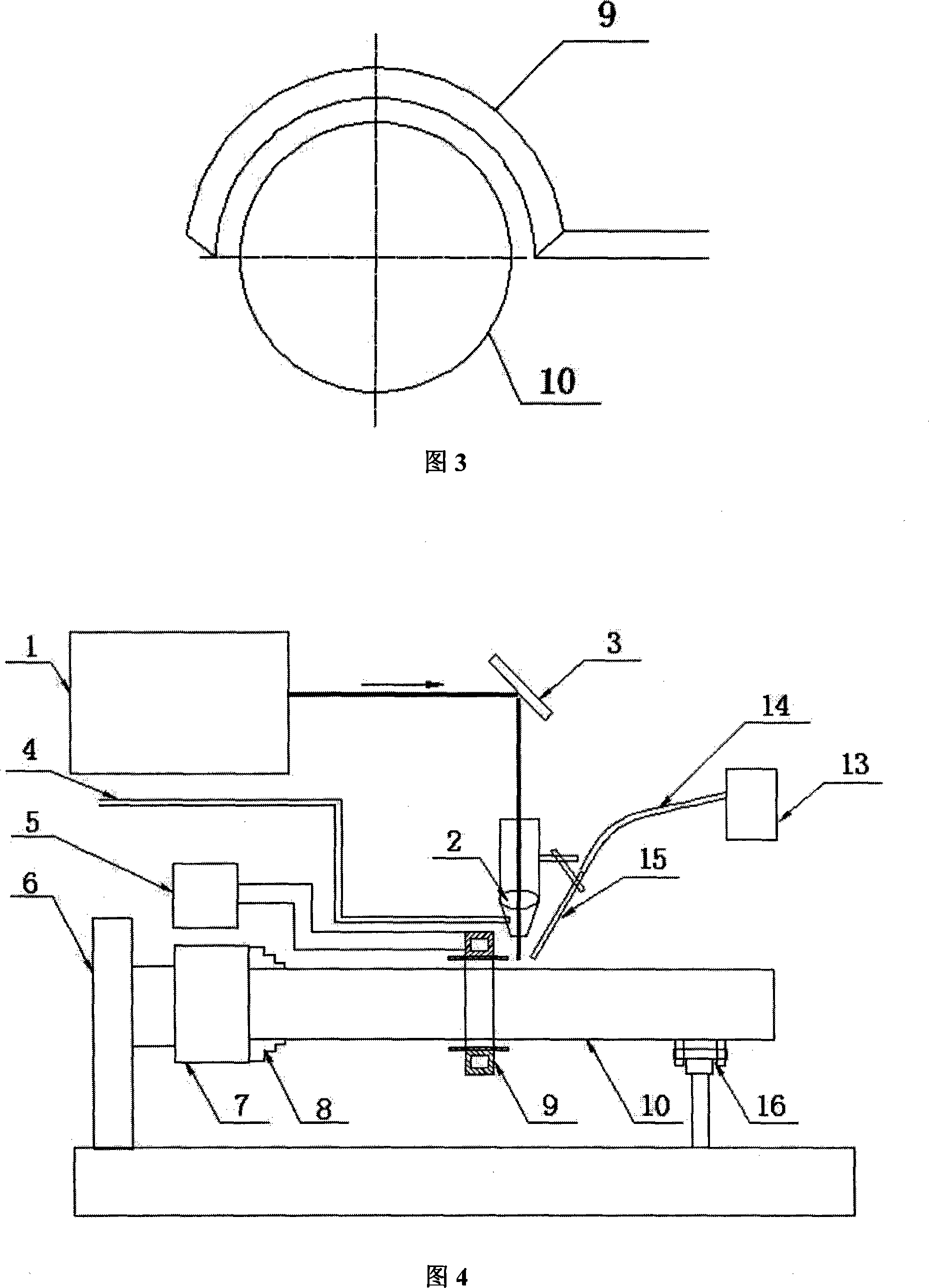

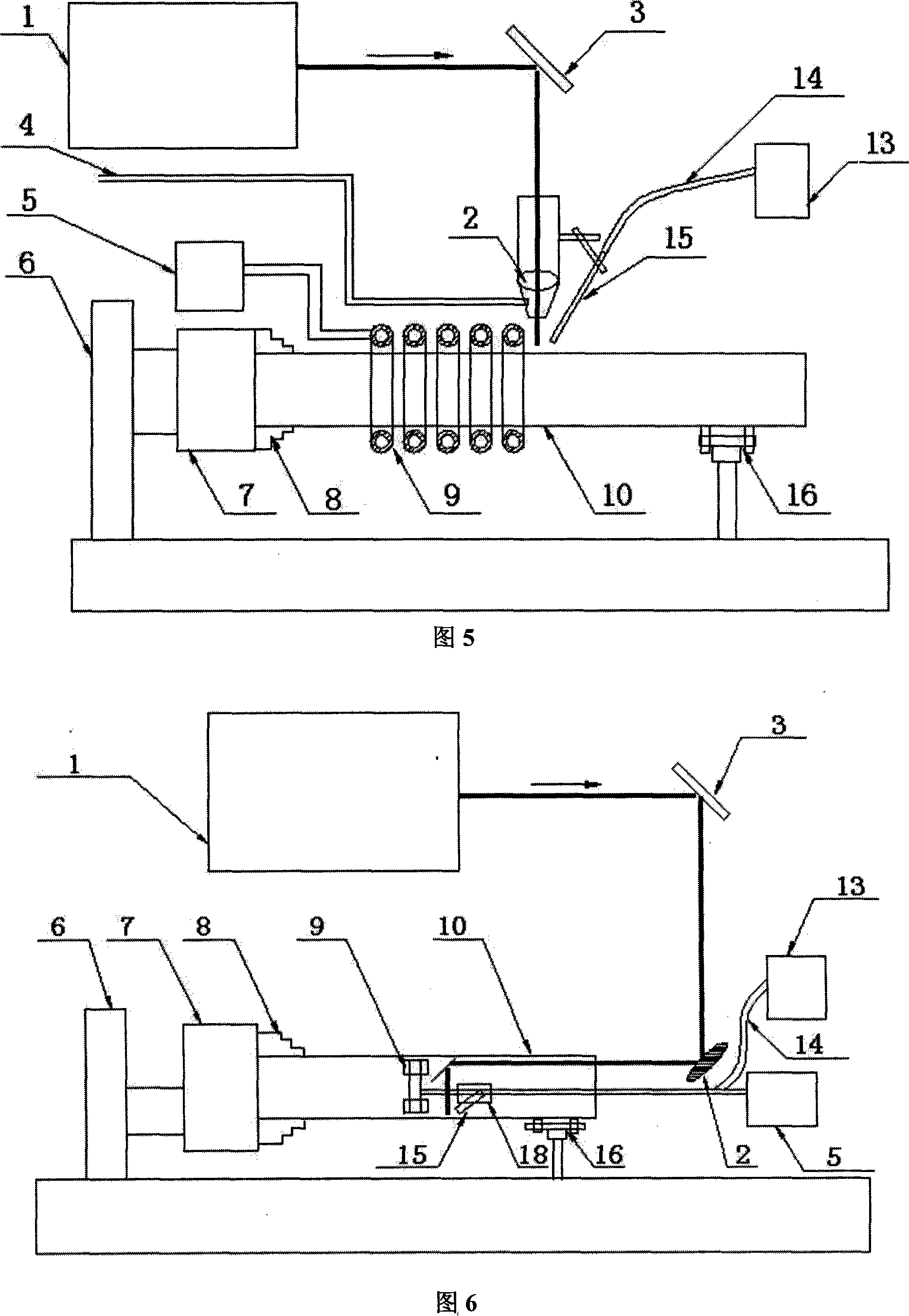

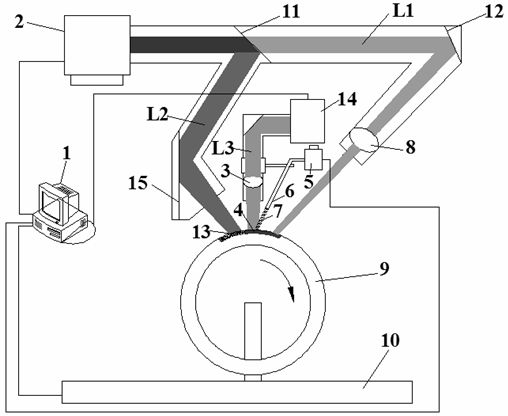

Automatic powder feeding laser induction composite coating method and device

ActiveCN101125394AImprove deposition efficiencyEasy to locate and installLaser beam welding apparatusHeat inorganic powder coatingSolid componentNumerical control

The present invention discloses a laser induced composite cladding measure and device for the automatic powder feeder. The present invention couples the laser beam and the high frequency electromagnetic induction heating so as to realize the composite cladding between the laser and the induction heating. The device comprises a laser, a laser light guide device, a laser gathering system, a high frequency induction heater, a digital control machine tool and a workpiece holding device. In work, the distance between the surface of workpiece under treatment and the induction heating coil is 1 to 10 mm. The present invention has a strong commonality and can conduct surface treatment of laser induced composite cladding high performance material coat toward the surface of the solid components in various materials and the inner and outer surfaces of the tubular spare parts. The cladding measure is characterized in that: the high frequency induction heater heats up the workpieces simultaneously and the automatic power feeder is applied to deliver the cladding powder to the laser irradiation area on the surface of the workpiece, so the alloy powder is instantaneously melted under the action of laser beam to form an alloy layer; and the maximum cladding speed reaches 10 m / min and the cladding efficiency is improved by one to ten times than the regular laser cladding and the powder utilization rate exceeds 90 percent; the applicable cladding materials have a wide range, comprising various wear resistant, corrosion resistant materials or high temperature resistant oxidizing materials as well as the composite materials; moreover, the cladding layer has no pores and crackles.

Owner:WUHAN HIVALUE INTELASER LTD

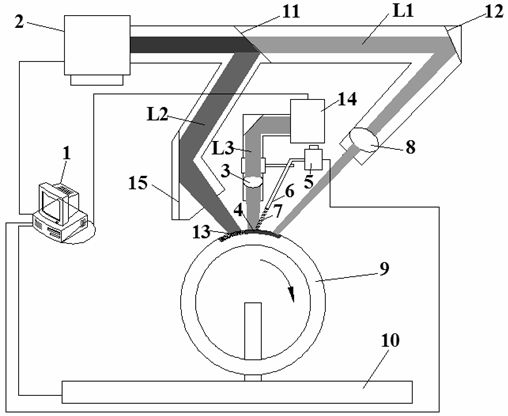

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

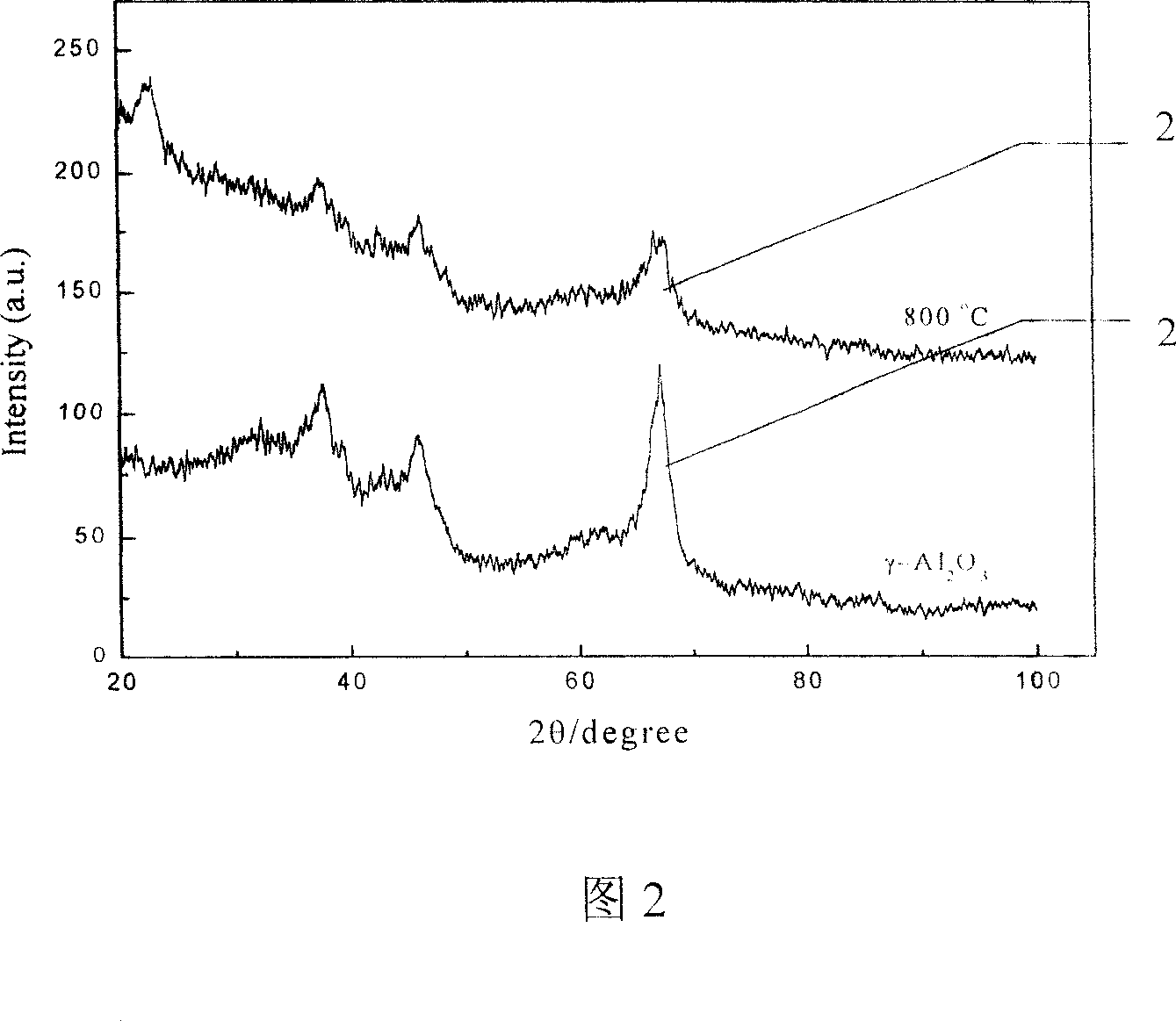

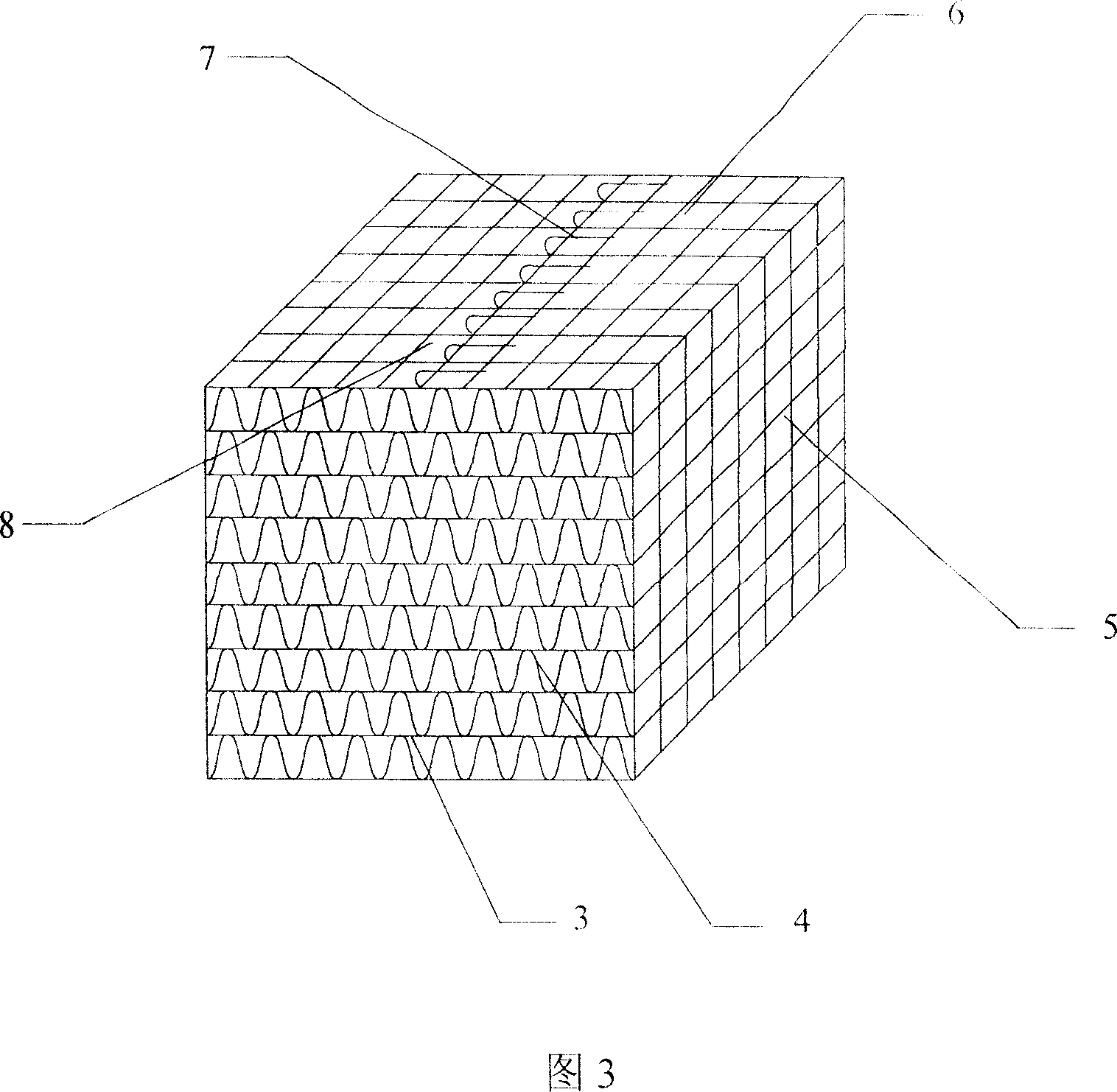

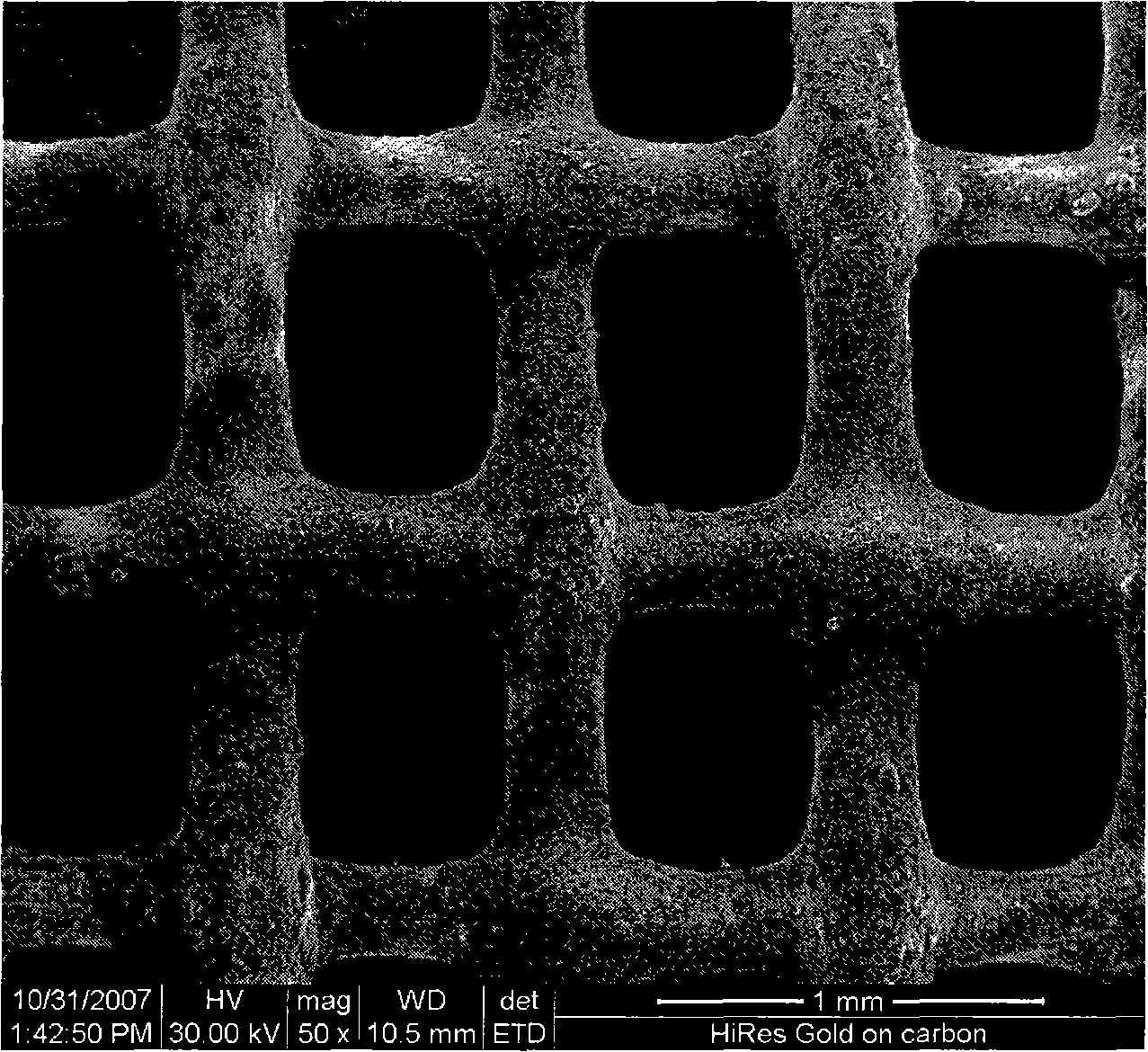

Cellulated wiremesh carrier with alumina coat, and preparation method

InactiveCN101049577AImprove thermal shock resistanceImprove mechanical propertiesCatalyst carriersHoneycomb likeStainless steel wire

A cellular metallic wire net carrier with coated aluminum oxide layer is composed of a metallic carrier and a coated layer and has an internal 3D through structure. Its preparing process includes such steps as preparing the planar metallic wire nets and corrugated metallic wire nets from stainless steel wire, pre-treating, preparing electric depositing liquid from gamma-Al2O3 powder, electric depositing to form a coated aluminum oxide layer on said metallic wire nets, stacking them in stagger mode, and binding them together by the strips of metallic wire net.

Owner:DALIAN UNIV OF TECH

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

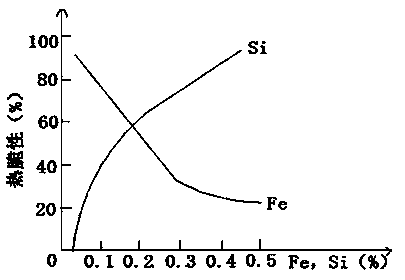

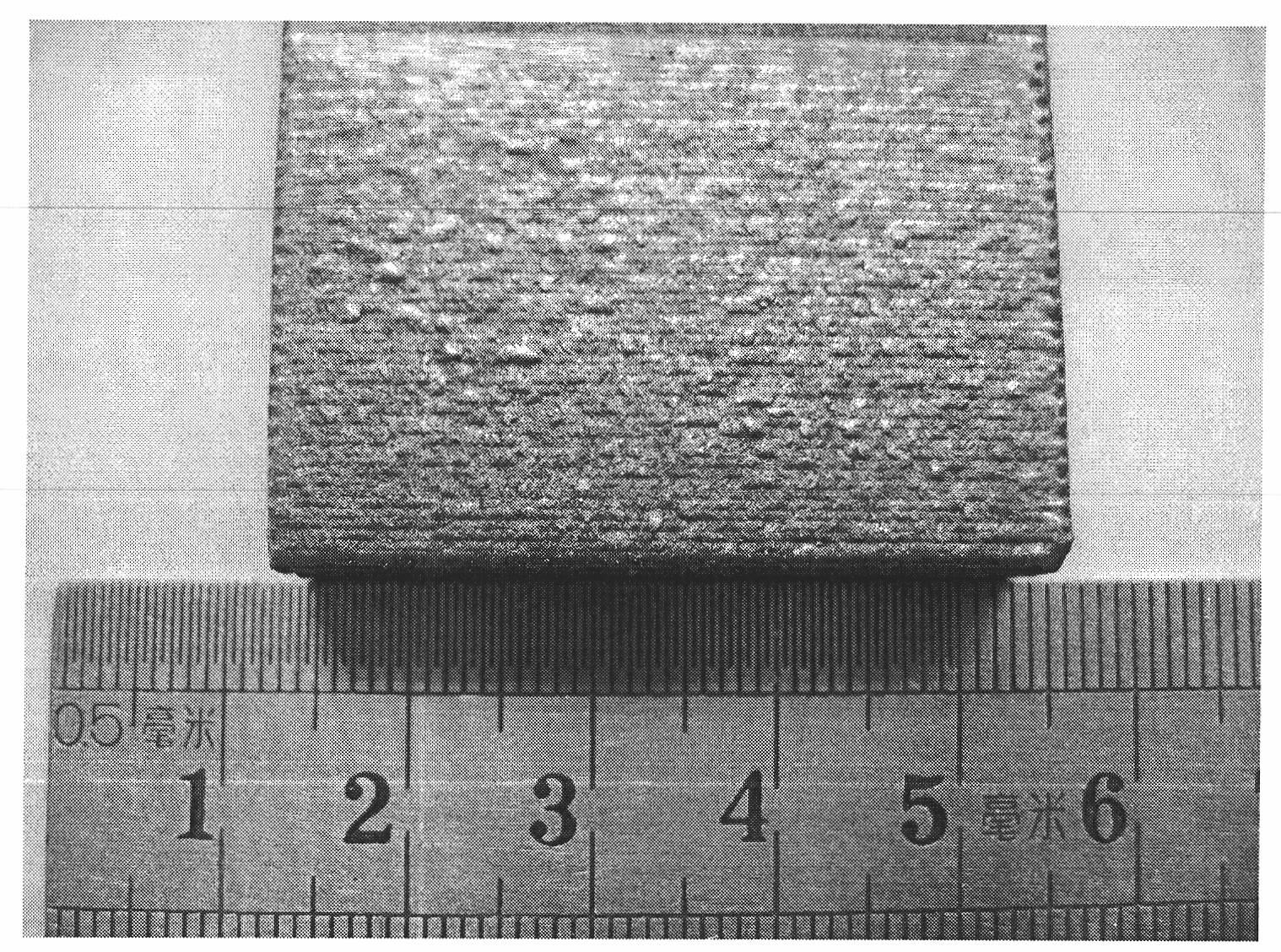

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

Laser-cladded composite wear-resisting layer on surfaces of copper and copper alloys and preparation method

InactiveCN102041503ADense tissueReduce energy consumptionMetallic material coating processesCobalt based alloyCopper alloy

The invention relates to a laser-cladded composite wear-resisting layer on the surfaces of copper and copper alloys and a preparation method. The composite wearing layer is a multi-layered laser cladding layer comprising at least two or more than two layers, wherein the coating connected with a substrate is the first layer, which is also called as a transition layer and is a copper-based alloy prepared from the following components in percentage by weight: 20.0-30.0 percent of Cu, 6.0-8.0 percent of Al, 0.3-0.6 percent of Si, 1.7-2.4 percent of Zr and the balance of Ni; and the rest layer is a cobalt-based alloy prepared from the following components in percentage by weight: 1.0-1.5 percent of C, 25-30 percent of Cr, 2-4 percent of Fe, 10-15 percent of W, 0.8-1.2 percent of Si, 3-4 percent of B, 8-12 percent of Ti, 10-12 percent of Ni and the balance of Co. The composite wear-resisting layer provided by the invention has compact tissues without cracks or pores and forms favorable metallurgy combination with the surfaces of copper and copper alloys. The preparation method provided by the invention can be used for accurately controlling the thickness of the composite wear-resisting layer and automatically controlling the whole process, and has the advantages of low energy consumption, no pollution, high efficiency and low cost.

Owner:HUAZHONG UNIV OF SCI & TECH

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

Construction method of anti-plastering putty for concrete structure wall

InactiveCN101363269AThin thickness and small weightLight weightCovering/liningsResource consumptionPutty

The invention discloses a construction method of a wall putty of a plaster-free concrete structure. The construction method comprises the following steps: construction preparation, base course treatment, concave-convex line construction, a first full application of wall putty, flattening, a second full application of wall putty and flattening. The construction method has the advantages of less workload, short construction time, little resource consumption, no hollow drum and crack of the floated coat, no crack at the joint of the primary structure and the secondary structure.

Owner:中建五局第三建设有限公司 +1

High-polymer modified pitch, its water-proof roll material and use thereof

ActiveCN101070434AImprove standardsHigh standard waterproof functionOther chemical processesRoof covering using flexible materialsPolymer modifiedCrack resistance

The invention provides a polymer modified asphalt, and the weight of the components comprising as follows :45-55% matrix asphalt, 4 - 8% blend oil, 12 - 14% of SBS ,5-9 % APAO, 2-7% of High-temperature improvement and 15-20% filler. It also offers polymer modified asphalt, which made of waterproof membrane and the railway bridge, highway bridge deck waterproofing project applications. The invention of these waterproofing membrane have a high standard of waterproof function, it can withstand high intensity of railway bridge and particularly high stress dynamic load .It also have excellent performance on water-resistance, high and low temperature resistance, adhesion, crack resistance, fatigue resistance and other aspects .it can be used for railway bridge and the road deck waterproofing works.

Owner:JINZHOU DONGFANG YUHONG BUILDING MATERIALS +1

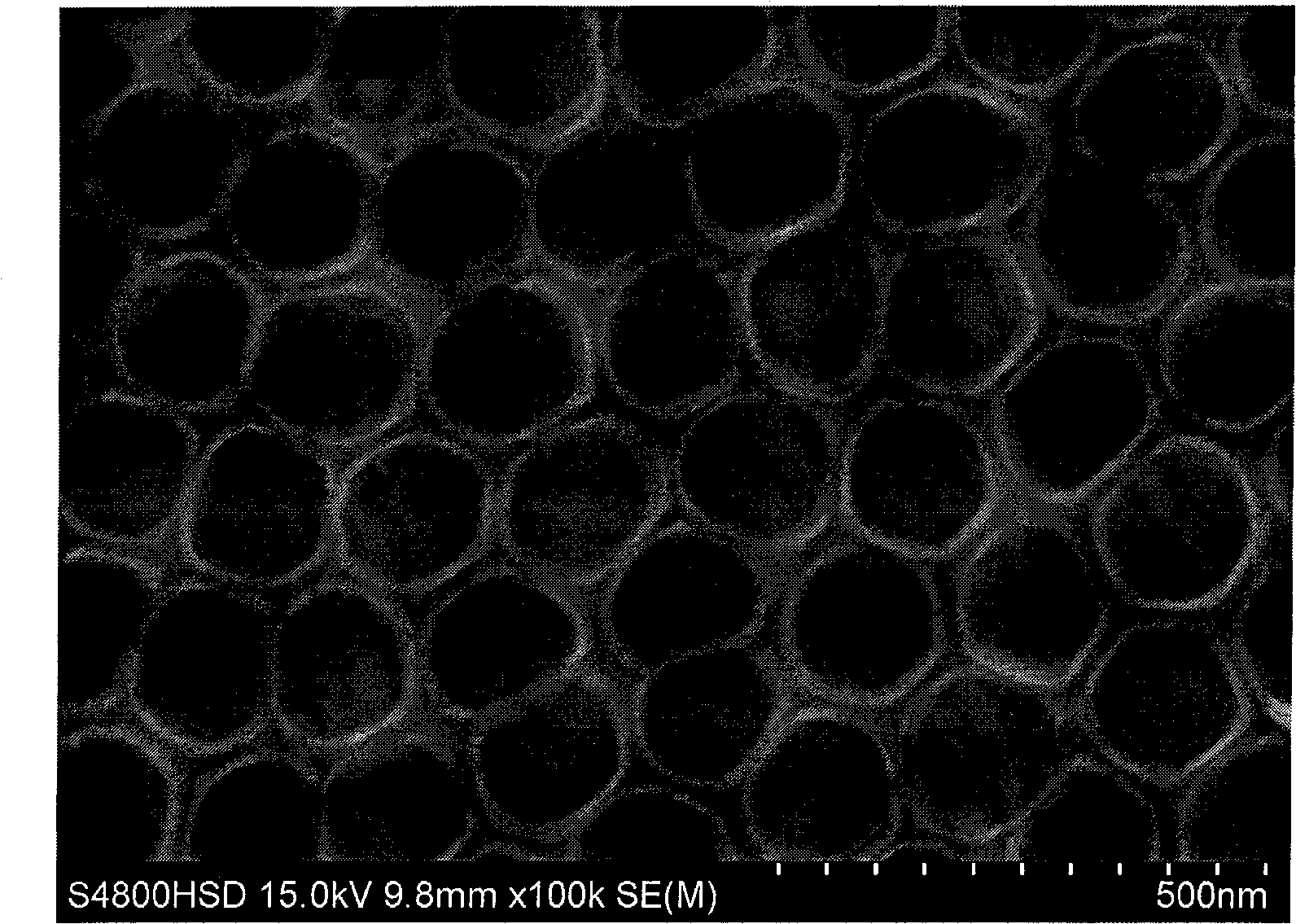

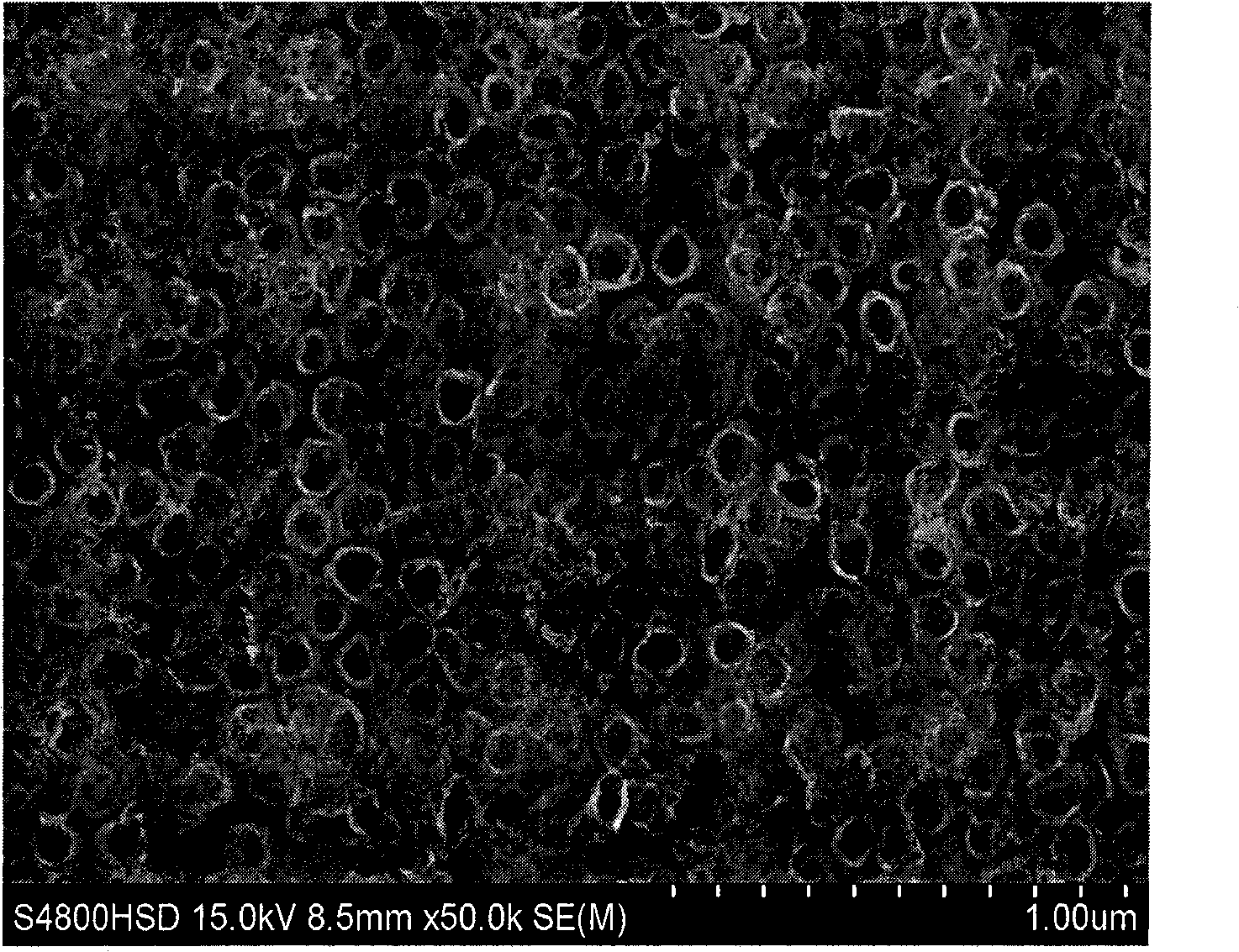

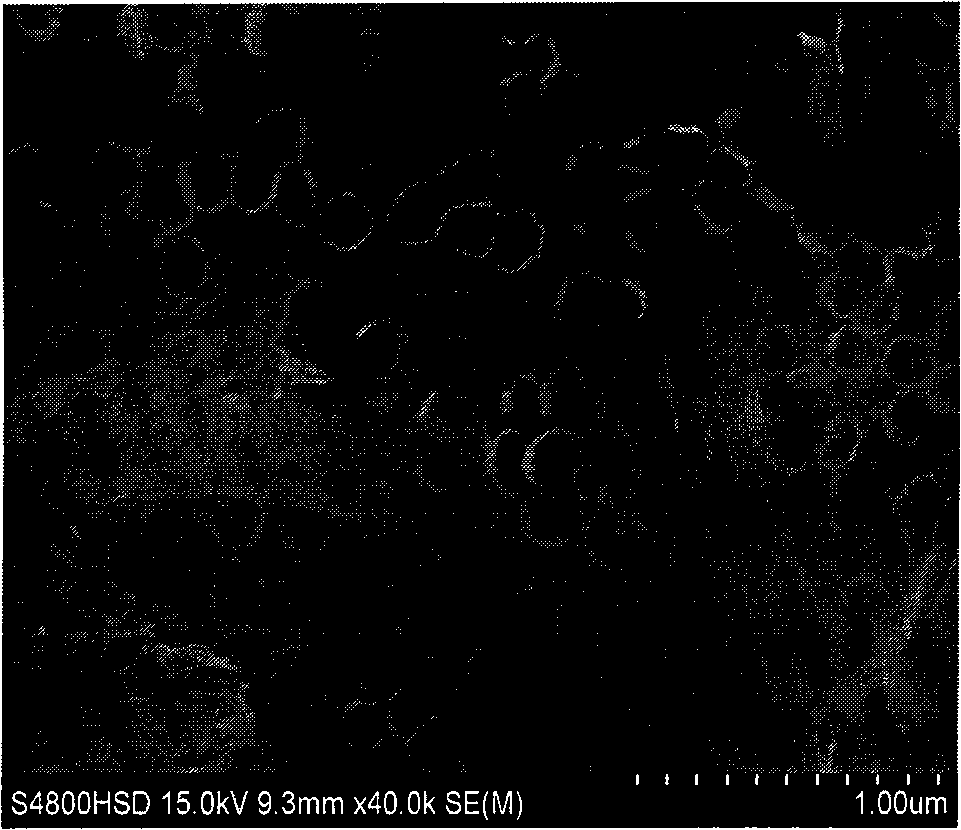

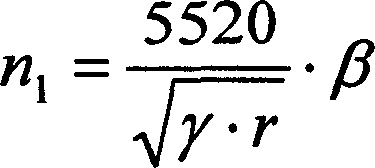

Method for preparing TiO2 nanotube array film

InactiveCN101514471ARegular microscopic morphologyNo reunionPolycrystalline material growthSurface reaction electrolytic coatingTio2 nanotubeTitanium

The invention provides a method for a preparing TiO2 nanotube array film, relating to a method for preparing a nanotube film. The method solves the problems of the prior art that the prepared nanotube array film features thin film, irregular micro appearance, heterogeneous length of nanotubes, reunion of tube orifice and cracking of the film. The preparation method comprises: 1. a titanium plate is cut into two titanium sheets of the same size, and polishing, ultrasound processing and washing are carried out on the two titanium sheets; 2. electrolyte is prepared; 3. primary anodic oxidation is carried out on the titanium sheets; 4. demoulding is carried out; 5. secondary anodic oxidation is carried out on the titanium sheets; 6. the titanium sheets are dried after ultrasonic processing; and 7. calcination treatment is carried out, thus obtaining the TiO2 nanotube array film. In the invention, twice anodic oxidations are carried out on the titanium sheets, thus producing the TiO2 nanotube array film featuring regular micro appearance, homogeneous, smoothness, thick film layer, reunion-free tube orifice and no cracking. The preparation method of the invention features simple technique and equipment and controllable thickness of the nanotube film.

Owner:HARBIN INST OF TECH

High hardness ferritic stainless steel wearable surfacing flux-cored wire

InactiveCN101224527AOvercome the disadvantage of poor wear resistanceHigh hardnessWelding/cutting media/materialsSoldering mediaHigh carbonBoron carbide

The invention provides a high hardness ferrite stainless steel wearable flux-cored wire, which takes a low carbon steel H08A cold rolling thin steel strip as an external wrapper; furthermore, the wrapper is internally provided with a powder core which is composed of graphite, metal and alloy powder; the weight percentages of all ingredients of the powder core are 50-75% of high carbon ferrochrome, 10-16% of ferrovanadium, 6-10% of ferrotitanium, 2-10% of tungsten carbide, 2-3% of nickel powder, 1.5-2.5% of silver graphite, 1-3.5% of boron carbide, 1-2% of aluminium magnesium powder, 0-10% of metallic chromium, and the residual quantity of reduced iron powder; the filling proportion of the powder core is 46-50%; the invention adopts the technical proposal that high-content ferrovanadium and adequate alloy powders such as tungsten carbide and boron carbide, etc. are added into the flux-cored wire, changes the microstructure of the existing ferrite stainless steel flux-cored wire surfacing alloy, overcomes the shortages of poor wearability and ductility, and can be applied to submerged arc bead weld manufacture or repair of the parts which has high requirement of abrasion and the corrosion resistance of the wearable grain.

Owner:XIANGTAN UNIV

Compound high speed steel roll and its making process

InactiveCN1846887AImprove efficiencySimple production processFurnace typesRollsChemical compositionHigh intensity

The present invention discloses compound high speed steel roll and its making process. The compound high speed steel roll consists of roll body and roll core compounded through central casting. The roll body is made of high speed steel comprising chemically C 1.8-2.8 (in wt%, same as below), Mo 4.0-8.0, V 3.0-7.0, Nb 1.5-4.0, Cr 6.0-12.0, RE 0.1-0.25, Ti 0.15-0.40, N 0.08-0.20, K 0.06-0.18, Si<2.0, Mn<2.0, S<0.05 and P<0.05, except Fe and inevitable impurity. The roll core is made of high strength nodular cast iron comprising chemically C 3.2-3.6 (in wt%, same as below), Si 1.8-2.4, Mn 0.4-0.8, Ni 0.3-1.2, Cr 0.3-0.8, Mo 0.2-0.5, Mg 0.03-0.08, RE 0.05-0.14, P<0.08 and S<0.03, except Fe and inevitable impurity. The compound high speed steel roll has high wear resistance, simple making process and high production efficiency.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

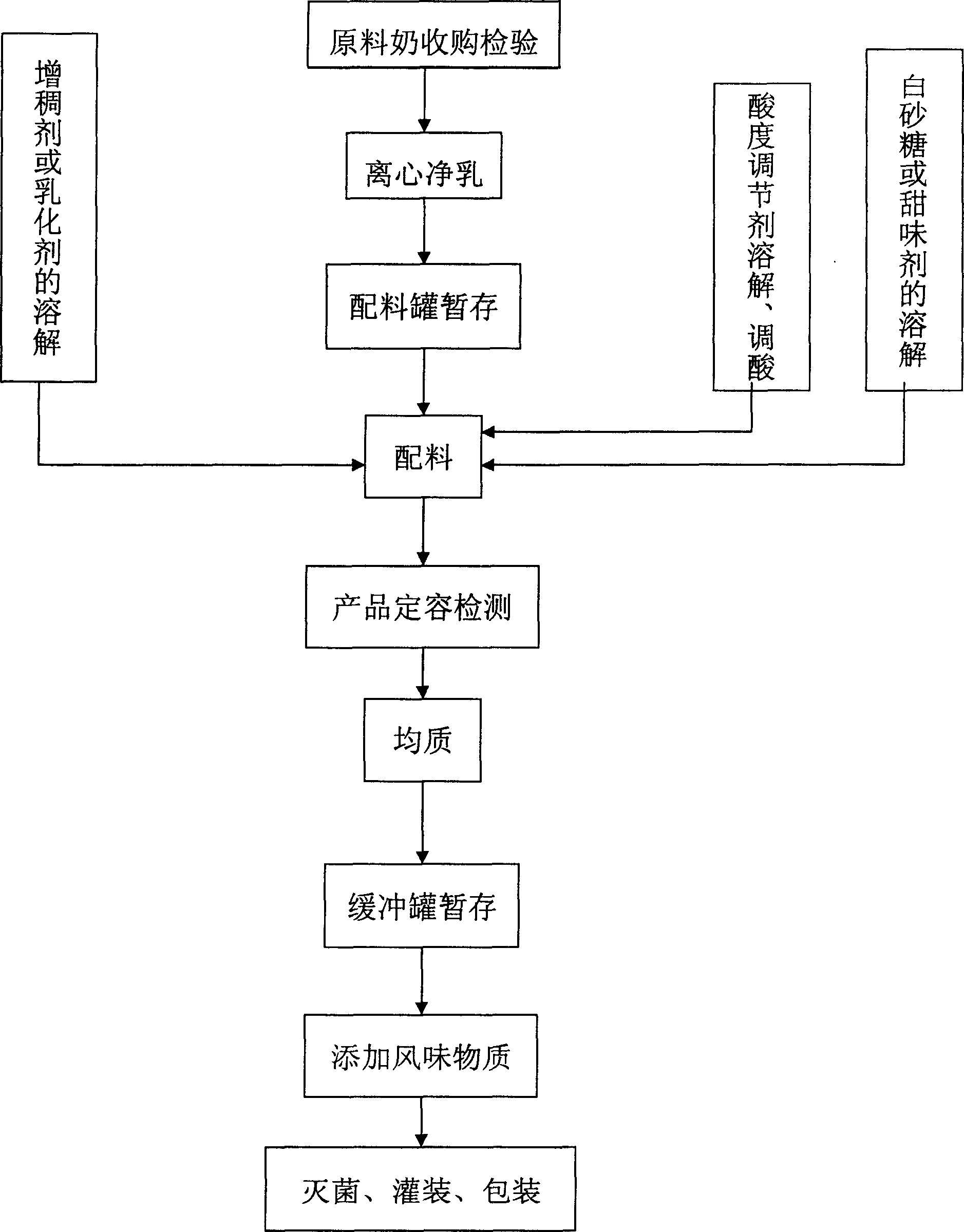

Milk containing jelly and method for its manufacture

InactiveCN1907094AReduce intensityHas a comprehensive nutritional effectMilk preparationFood preparationFlavoring essencesAdditive ingredient

The invention discloses a jelly and its preparing method, wherein each 100g of the jelly comprises the following constituents: milk 30-60g, sugar 6.0-12.0g, stabilizing agent 0.06-0.15g, acidness modifier 0.2-0.5g, edible flavoring essence 0.04-0.2g, and balancing water.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

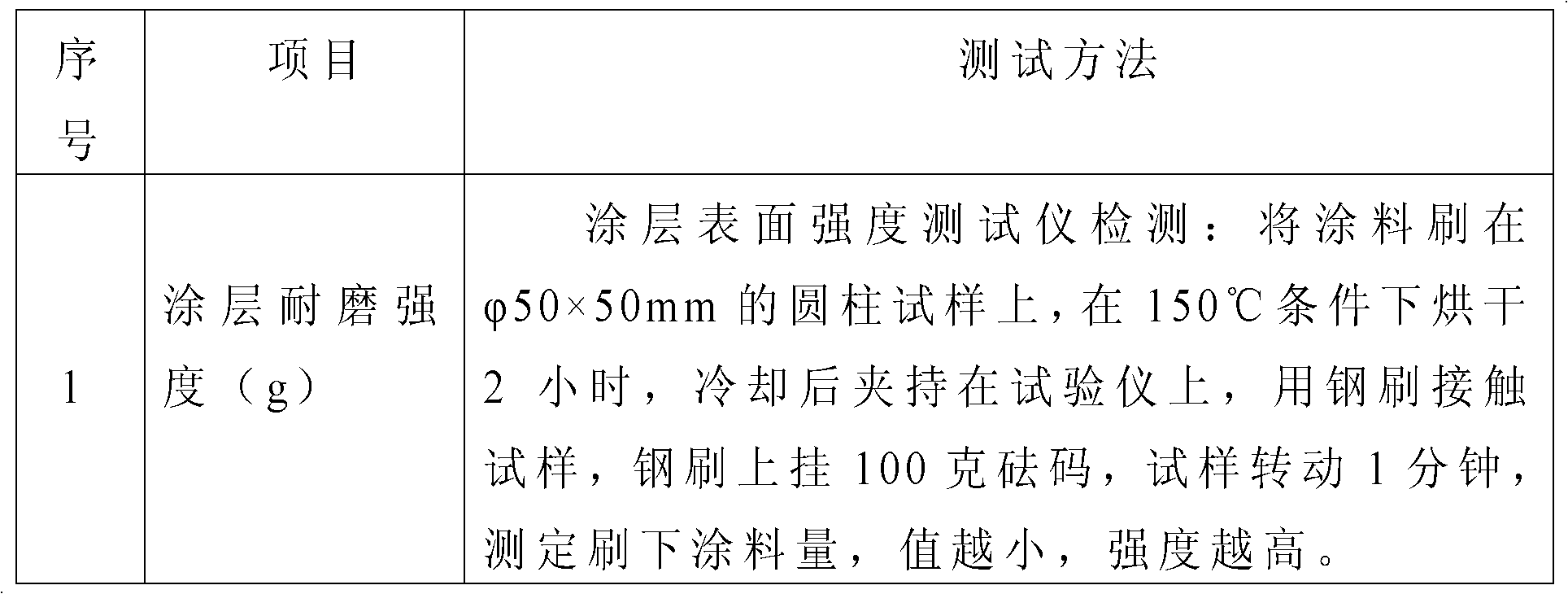

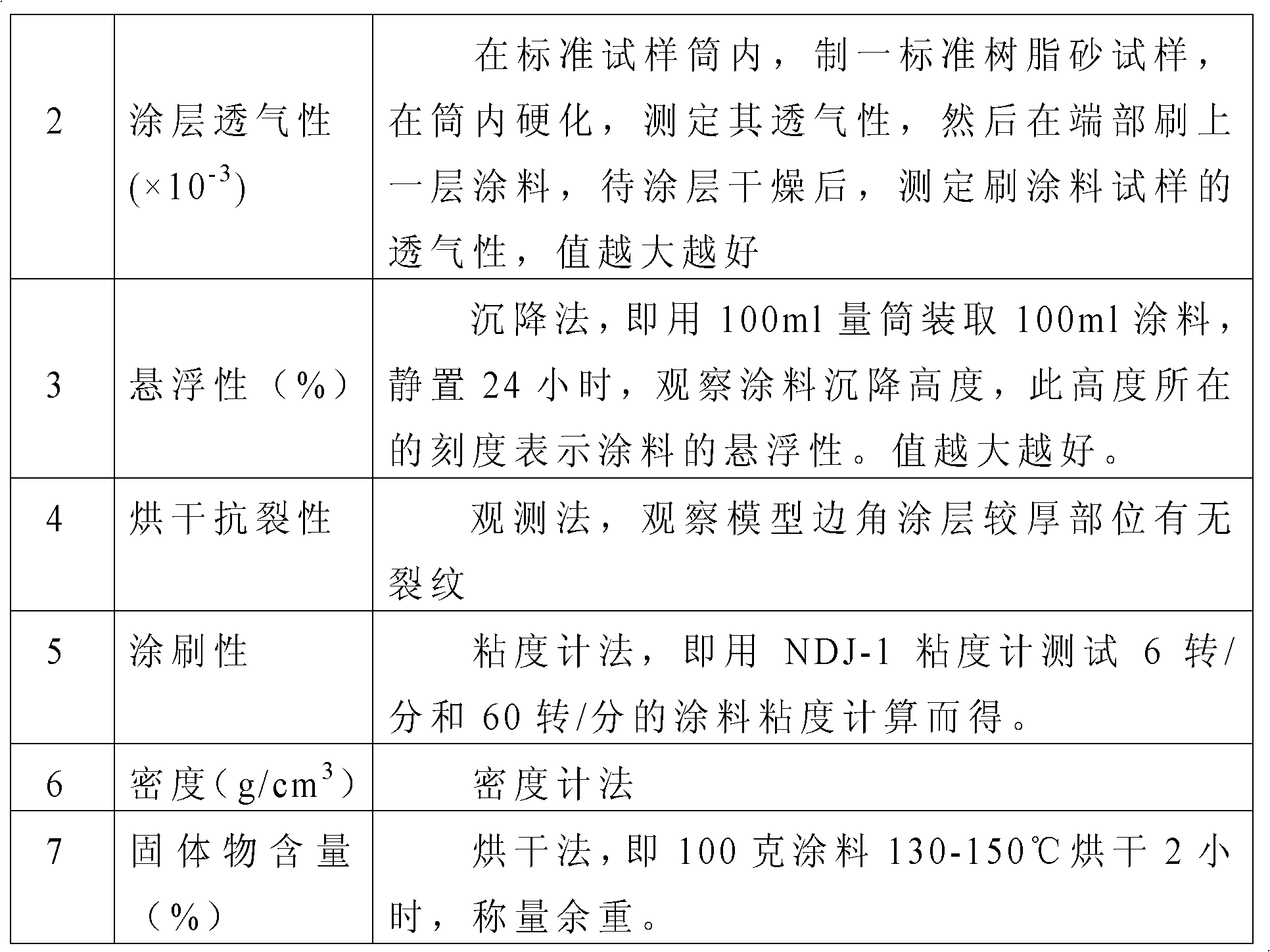

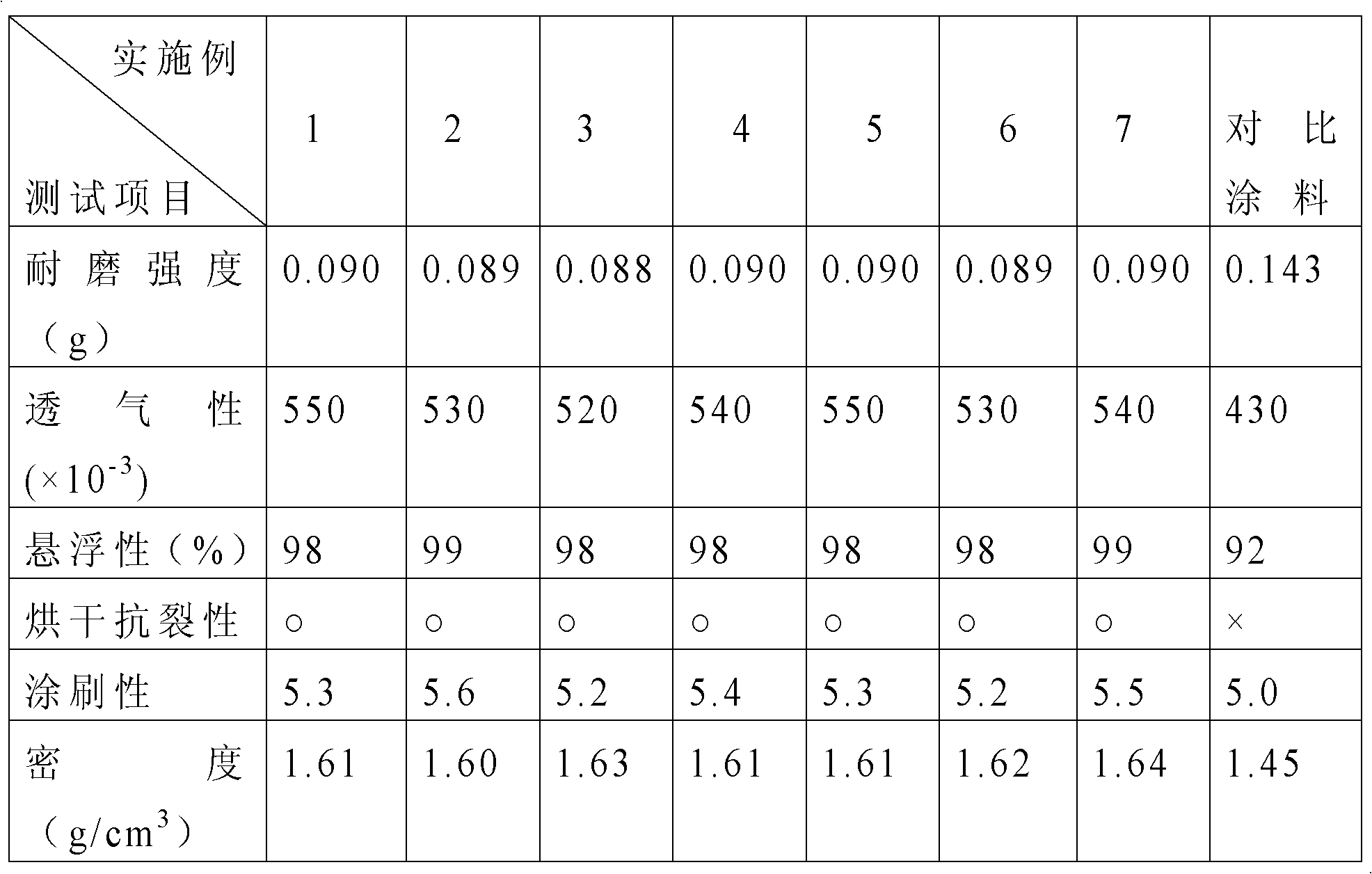

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing and transferring graphene transparent film

ActiveCN102719803AIncrease contactNo crackGrapheneChemical vapor deposition coatingElectrochemistryCvd graphene

The invention discloses a method for preparing and transferring a graphene transparent film. The technical problem required be solved is that impurities, cracks and bumps after the graphene transparent film is transferred are required to be reduced. The preparing and transferring method disclosed by the invention comprises the steps of: carrying out chemical vapor deposition on the graphene film on a metal substrate, coating methyl methacrylate or photoresist to form a support layer; electrolyzing the graphene film and separating the metal substrate; and coating the methyl methacrylate or photoresist on the support layer, putting the support layer into acetone solution, and attaching the graphene film to an appointed substrate. Compared with the prior art, the film composed of the graphene film and the support layer is separated from the metal substrate by an electrochemical foaming method; the graphene film is transferred to an appointed substrate and then the graphene film well contacts the plane of the appointed substrate without the cracks by spin coating for second time; the metal substrate can be repeatedly used, and the cost of preparation of the graphene transparent film is reduced; the transferred graphene film is well contacted with the substrate, and the impurities are relatively few.

Owner:BTR NEW MATERIAL GRP CO LTD

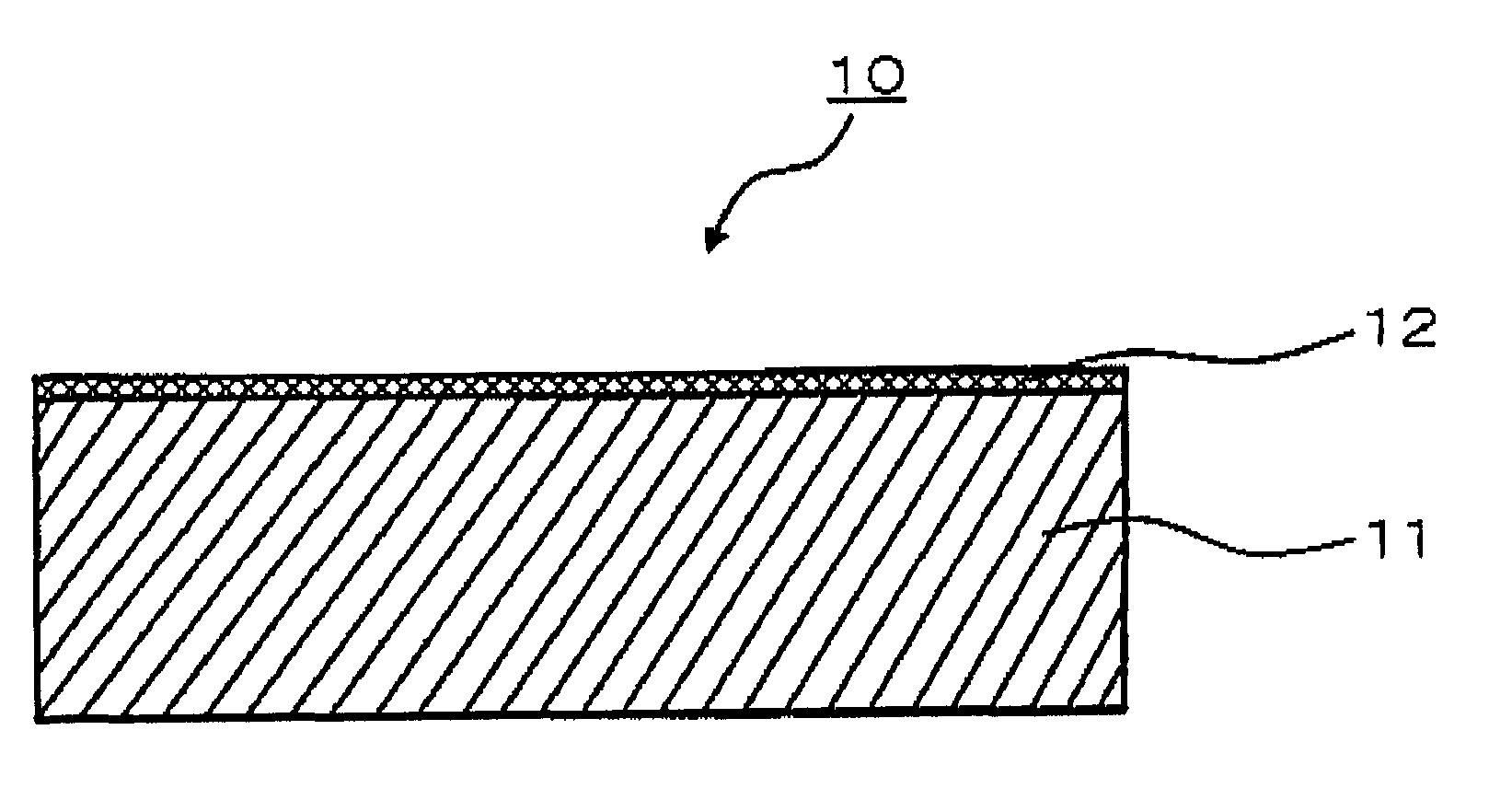

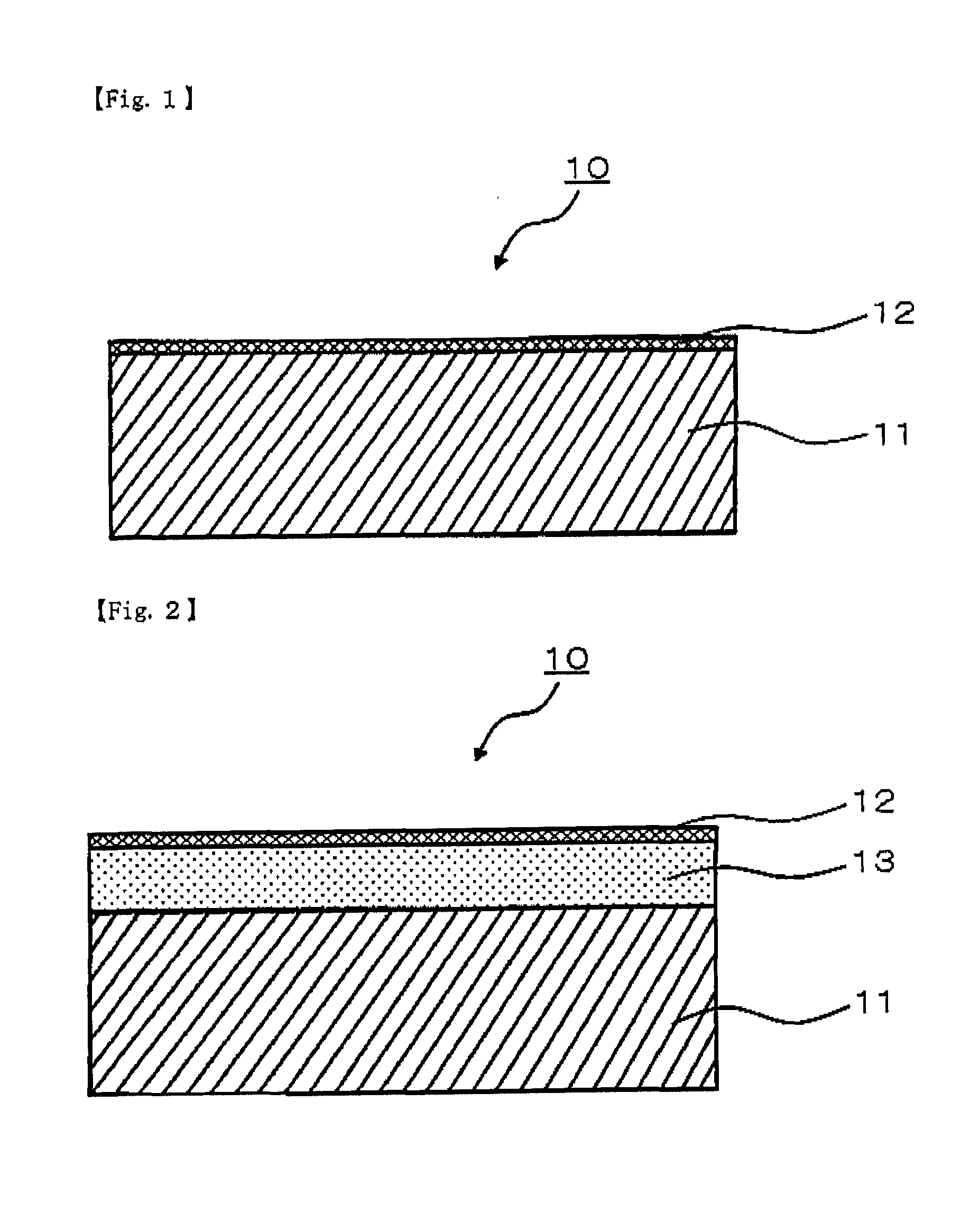

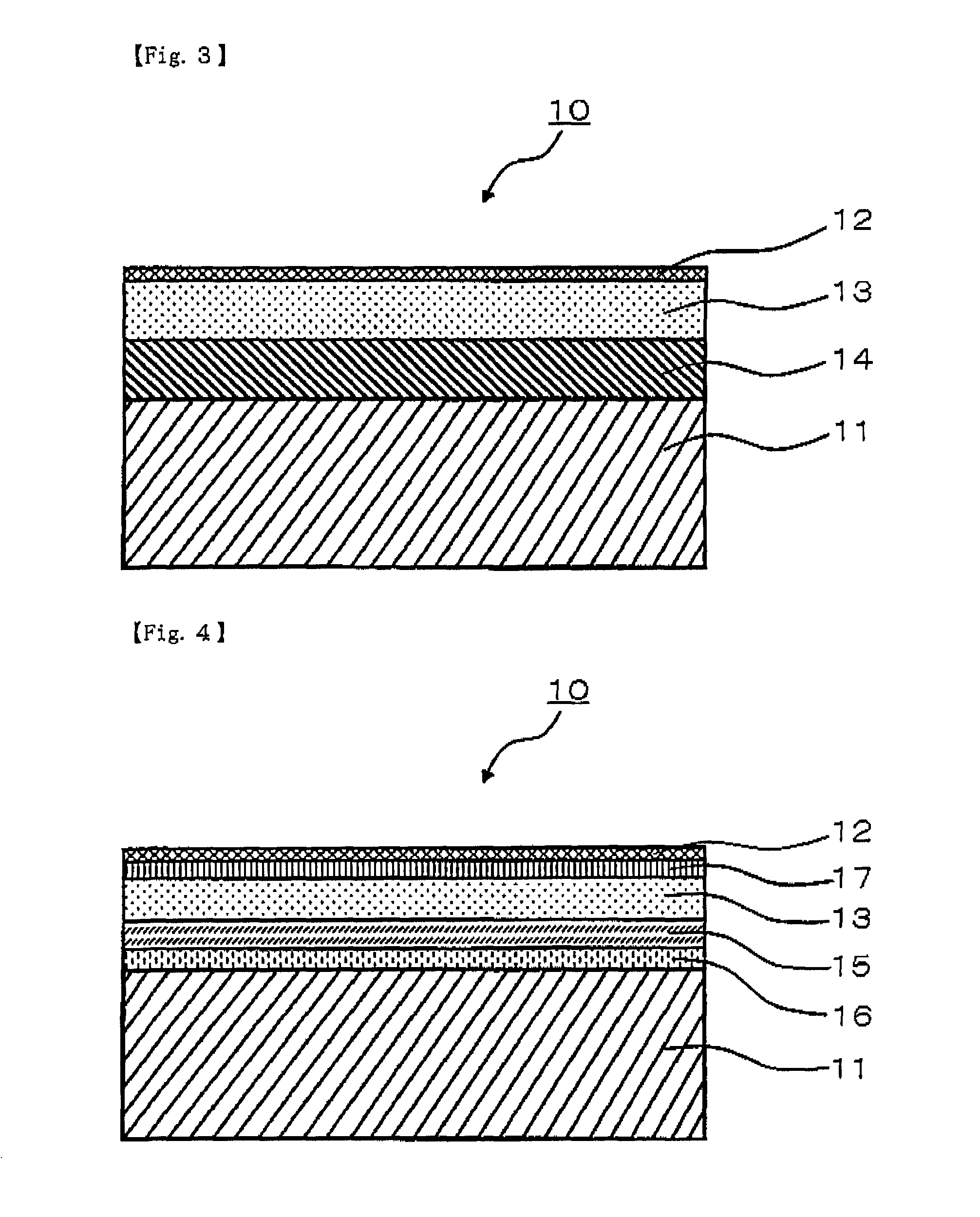

Decorative sheet for three-dimensional work

ActiveUS20110045284A1Good molding effectGood die releaseDecorative surface effectsSynthetic resin layered productsCross-linkHeat deflection temperature

Provided is a decorative sheet for three-dimensional processing comprising a support and at least a surface protective layer laminated thereon, wherein the above decorative sheet for three-dimensional processing has a breaking elongation (according to JIS K 7127) exceeding 300% at temperature higher by 40° C. than a thermal deformation temperature of the above support measured by an ASTM D648 method, and the above surface protective layer is obtained by cross-linking and curing an ionizing radiation curable resin composition and has a film thickness of 0.2 to 6.0 μm.Capable of being provided is a decorative sheet for three-dimensional processing which is improved in a molding property and has good die release and does not produce cracks and scratches on a surface in molding and which is improved as well in an abrasion resistance and a solvent resistance.

Owner:DAI NIPPON PRINTING CO LTD

Method for covering aluminum oxide coating on honeycomb shaped wire mesh carrier

InactiveCN101274291AStrong adhesionNo crackCatalyst carriersCatalyst activation/preparationHoneycomb likeThermal shock

The invention discloses a method for coating an alumina coating layer on a faviform metal wire mesh carrier, which belongs to the technical field of the preparation of the coating layers of metal carriers, and is characterized in that after the faviform metal wire mesh carrier is molded, a pretreatment is implemented on the metal surface, and then the faviform metal wire mesh carrier is soaked in a sizing agent that contains Gamma-Al2O3 powder and aluminum powder, the Gamma-Al2O3 powder and the aluminum powder are sedimentated on the surface of the faviform metal wire mesh carrier through the electrolytic deposition method, and finally the faviform metal wire mesh carrier coated with the coating layer is roasted, wherein, the faviform metal wire mesh carrier takes the material of a stainless metal wire mesh that contains aluminum, the coating layer is distributed evenly on the surface of the faviform metal wire mesh carrier and does not chap, the thickness of the coating layer is 30 to 80Mum; the addition of the aluminum powder improves the thermal shock resistance and the mechanical vibration resistance of the coating layer, as well as the conglutination degree between the coating layer and the faviform metal wire mesh. The method for coating the alumina coating layer on the faviform metal wire mesh carrier of the invention has the advantages that the method is applicable to the preparation of the coating layers of the catalyst carriers which are used in the gas-solid catalytic reactions that are related to the environmental protection field such as the fields of the tail gas burning of motor vehicles and fixed sources and catalytic burning.

Owner:DALIAN UNIV OF TECH

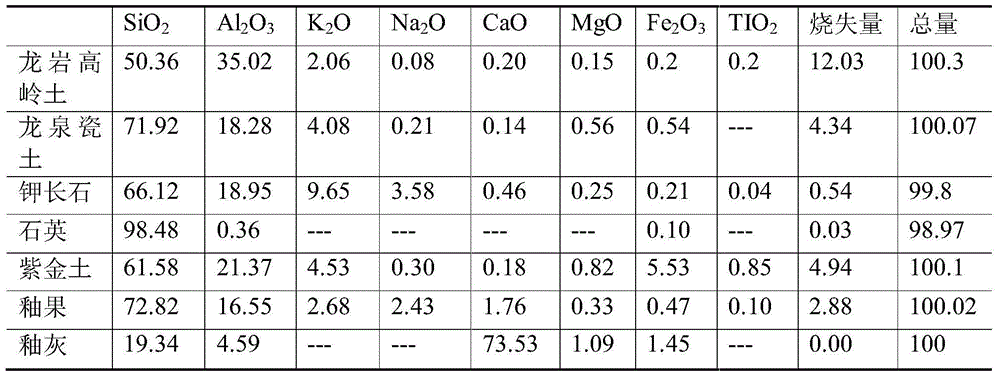

Longquan celadon crackle glaze wine bottle and preparation method thereof

ActiveCN104150873ANovel preparation methodSatisfy the wine storage functionClaywaresPotassiumWine bottle

The invention relates to a longquan celadon crackle glaze wine bottle and a preparation method thereof. Raw material proportions of a blank material, an internal glaze and an external glaze of the bottle are respectively described as follows: the blank material comprises: 40-55% of Longyan kaolin, 15-25% of Longquan china clay, 8-20% of potassium feldspar, 7-15% of quartz and 5-10% of zijin clay; the internal glaze comprises: 65-70% of glaze fruit, 12-25% of glaze ash and 5-10% of zijin clay; and the external glaze comprises: 60-70% of potassium feldspar, 8-15% of quartz, 8-13% of Longyan kaolin, 8-15% of glaze ash, 5-13% of zijin clay and 0.2-0.4% of Fe2O3. On the basis of above raw materials, the longquan celadon crackle glaze wine bottle is prepared by following steps: preparing slurry, performing an injection moulding process to obtain a wet blank; performing a drying process, a trimming process and a biscuiting process to complete a blank manufacturing process; and finally applying the internal glaze and the external glaze and performing a glazing firing process to obtain a finished product of the longquan celadon crackle glaze wine bottle. The bottle is free of stripes on the internal glaze. The external glaze is decorated through crackles. The bottle is good in quality and is free of internal leakage of wine. The method is low in cost and good in effect.

Owner:龙泉市尚唐瓷艺发展有限公司 +1

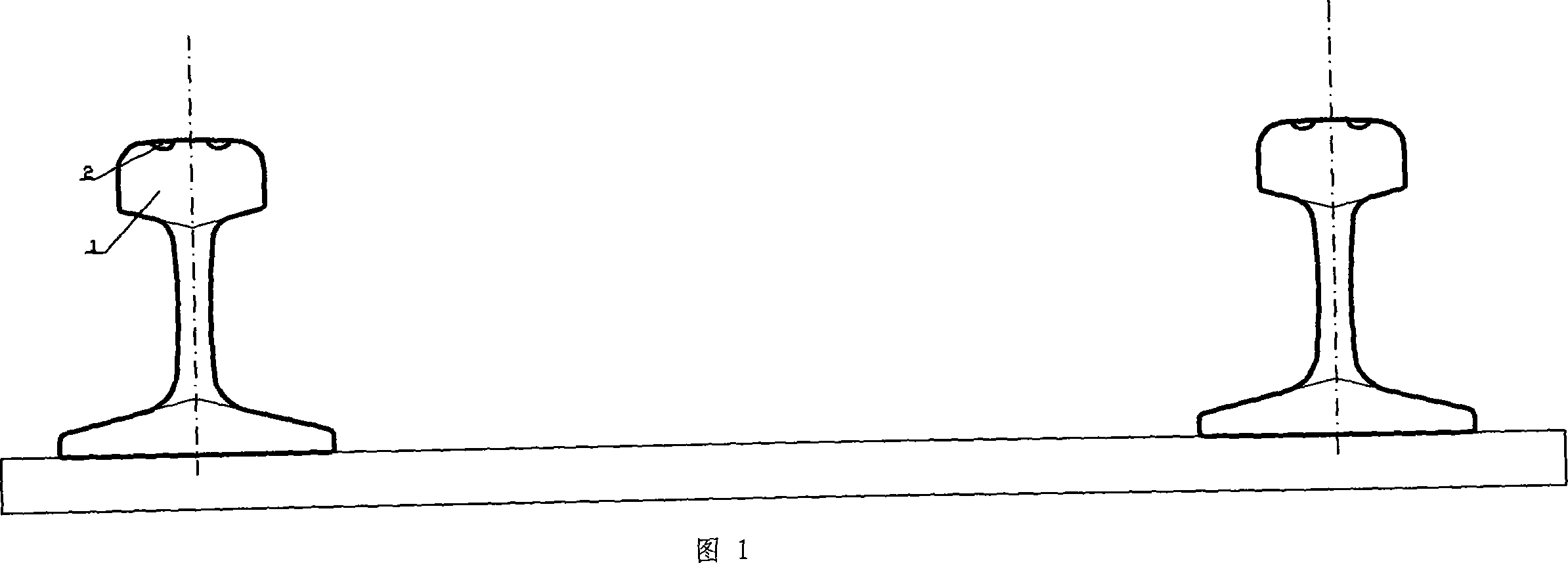

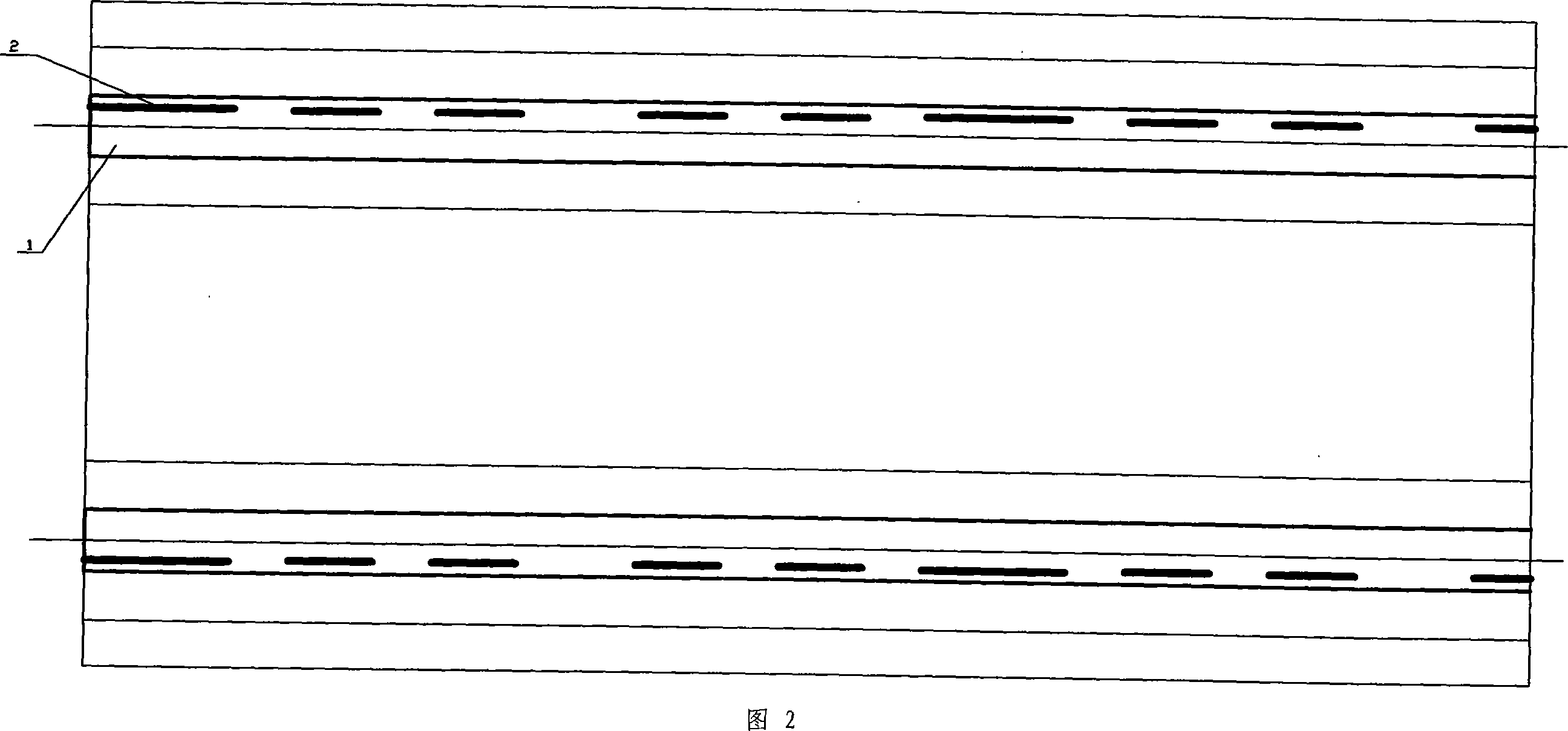

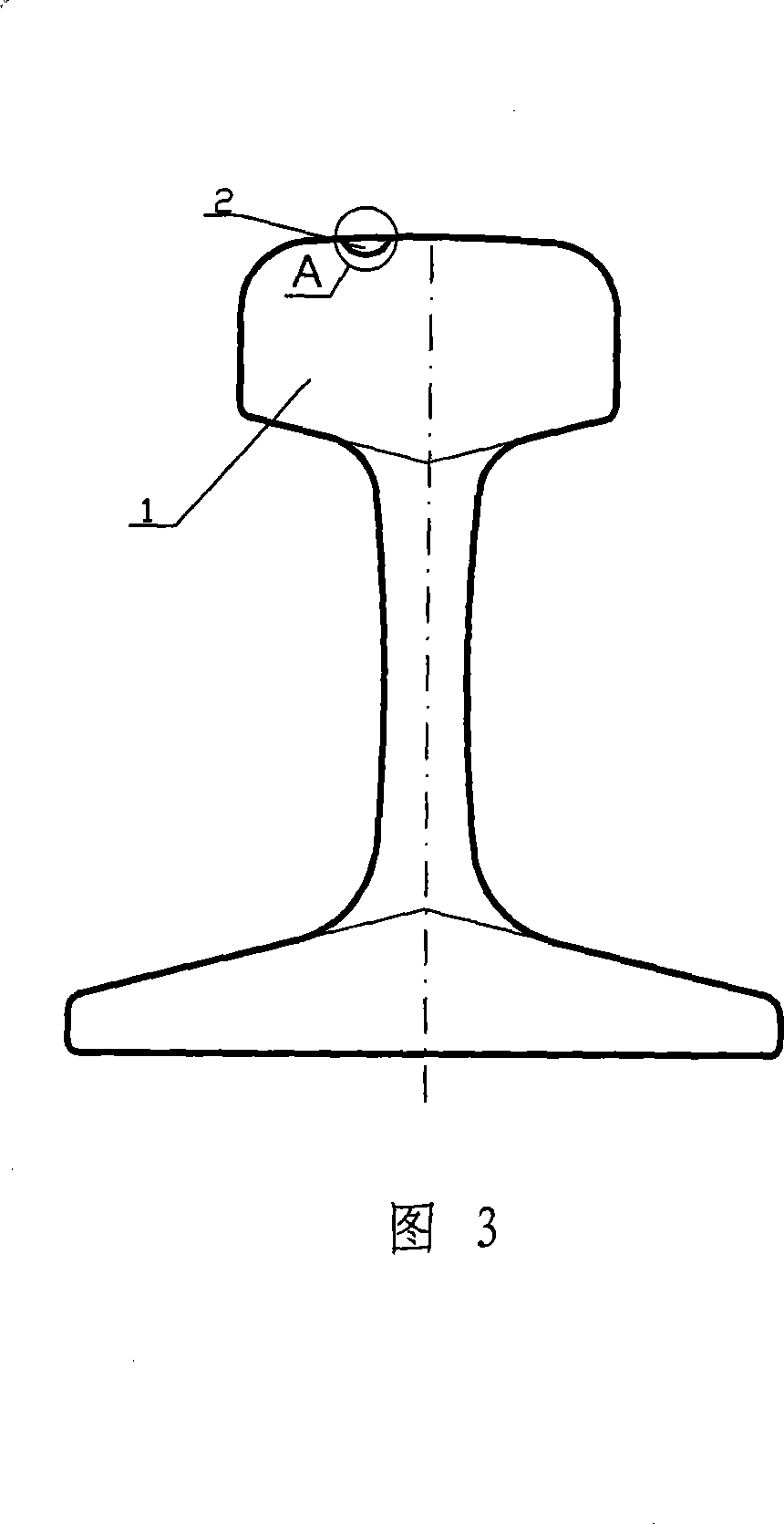

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

High abrasion-proof laser cladding nickel-base alloy powder and preparation method thereof

InactiveCN102943267AHigh hardnessImprove wear resistanceMetallic material coating processesCarbideAlloy

The invention relates to a high abrasion-proof laser cladding nickel-base alloy powder and a preparation method of the alloy powder. The high abrasion-proof laser cladding nickel-base alloy powder is characterized by comprising matrix alloy powder, hard carbide particles and a bonding agent; and the combined powder comprises 50-98% of matrix alloy powder, 1-45% of WC or TiC or mixed powder of WC and TiC, and 1-5% of bonding agent. The preparation method comprises the following steps of: preparing the matrix alloy powder, adding the carbide particles into the prepared matrix alloy powder, adding the bonding agent into the mixture, stirring, ball milling, combining the powder, drying, crushing and screening. The high abrasion-proof laser cladding nickel-base alloy powder not only is high in hardness, but also has excellent wear resistance and corrosion resistance, thus being especially suitable for laser cladding of alloy workpieces with high surface hardness and high wear resistance. Furthermore, the phenomenon of segregation caused by great differences among the specific gravities of all components in the processes of storage, transportation and using can be effectively prevented.

Owner:江苏新亚特钢锻造有限公司

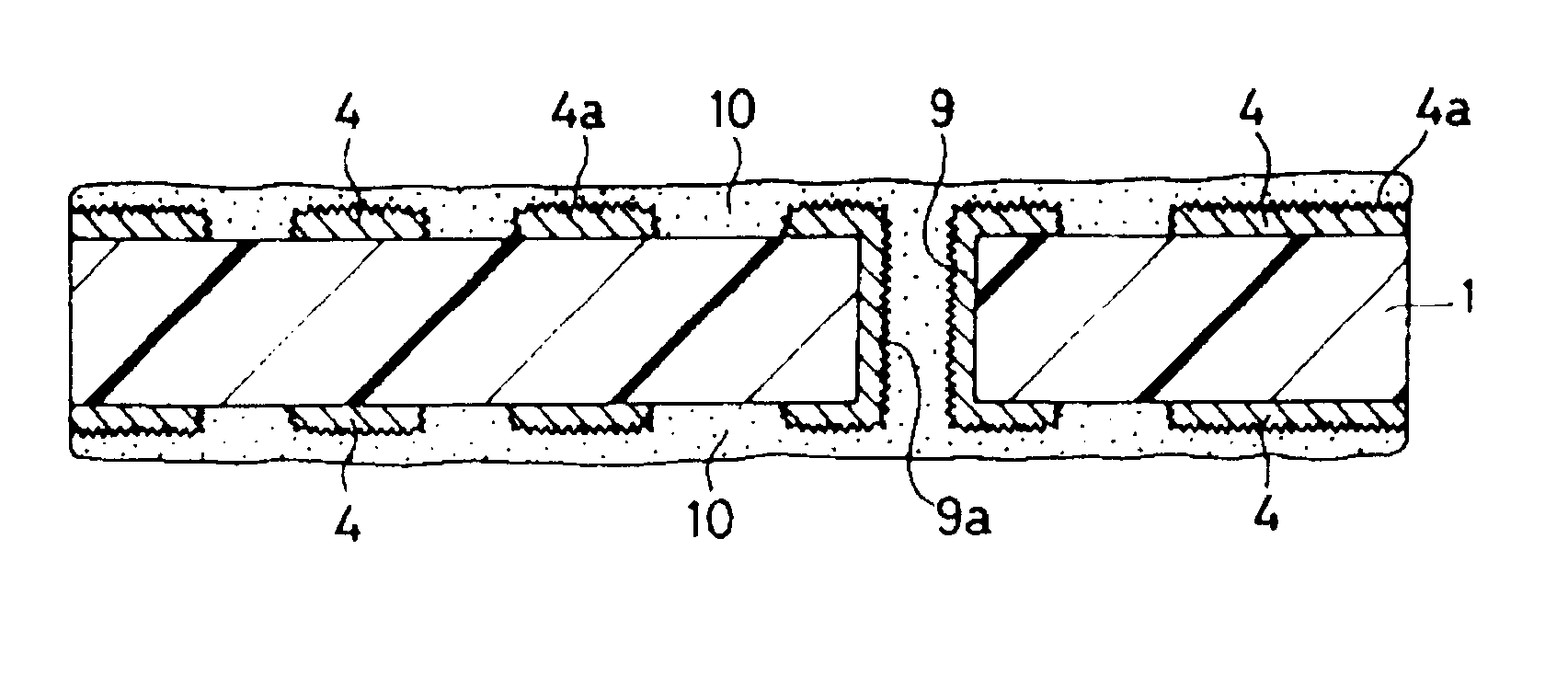

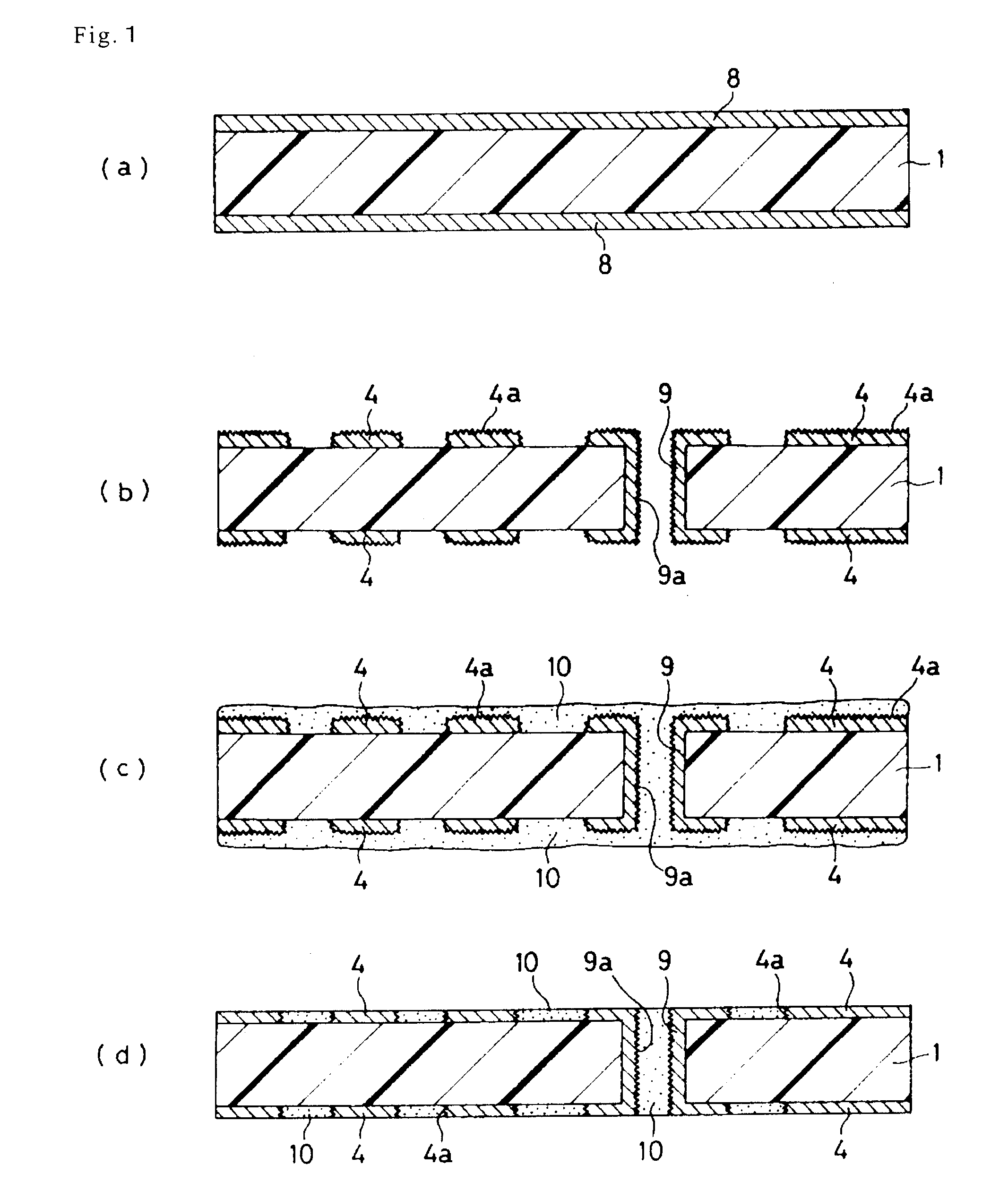

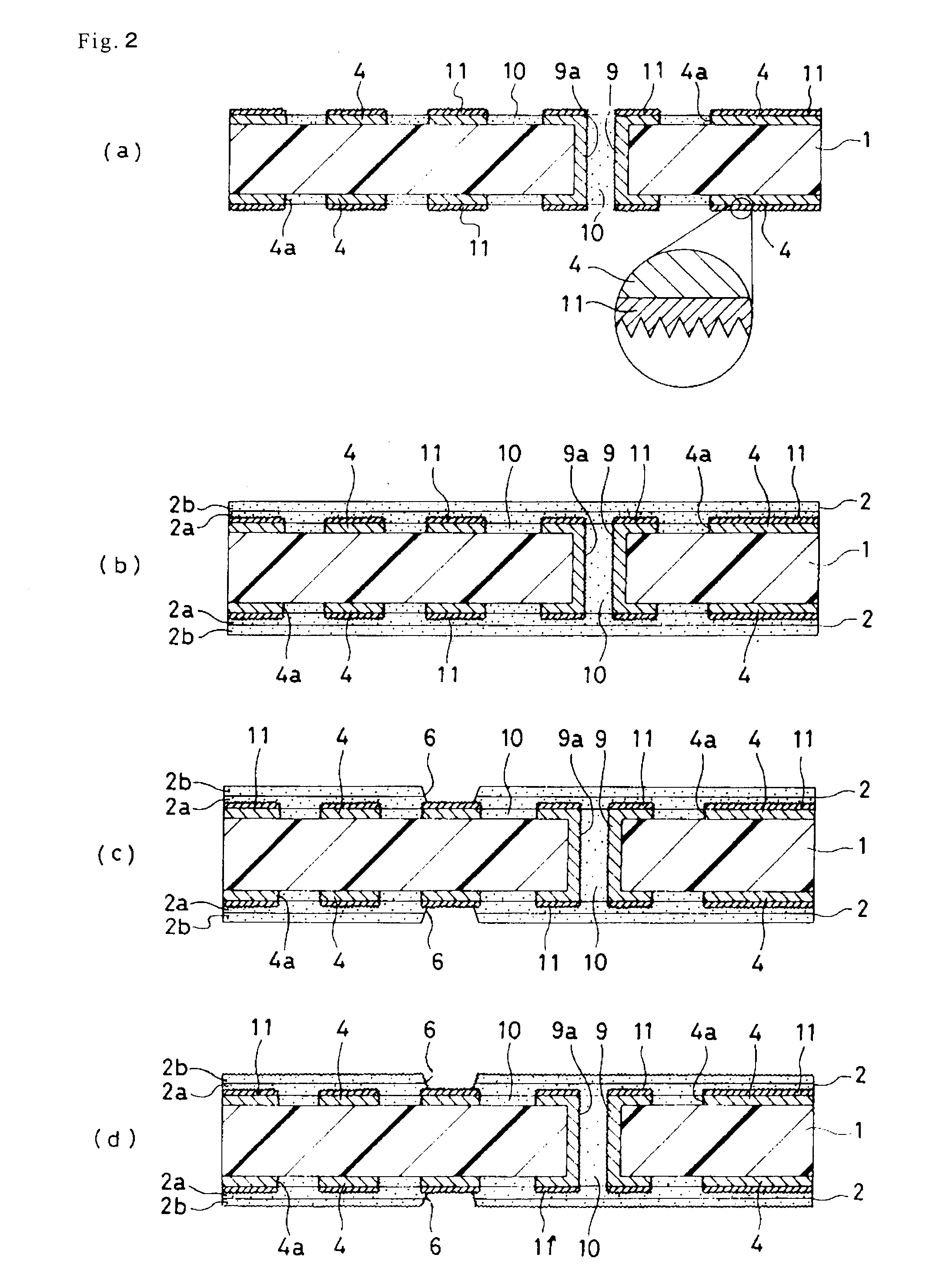

Multilayered printed circuit board, solder resist composition, multilayered printed circuit board manufacturing method, and semiconductor device

InactiveUS20080041615A1No crackImprove flame retardant performanceSolid-state devicesCircuit susbtrate materialsResistElectrical conductor

The present invention is to provide a multilayered printed circuit board free from cracks attributed to thermal expansion difference between a solder resist layer and another part and a multilayered printed circuit board of the present invention comprises a conductor circuit and a resin insulating layer serially formed on a substrate in an alternate fashion and in repetition and a solder resist layer formed as an outermost layer, and the solder resist layer contains an inorganic filler.

Owner:IBIDEN CO LTD

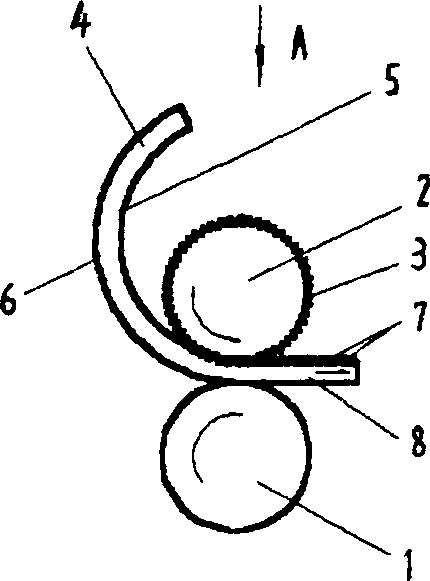

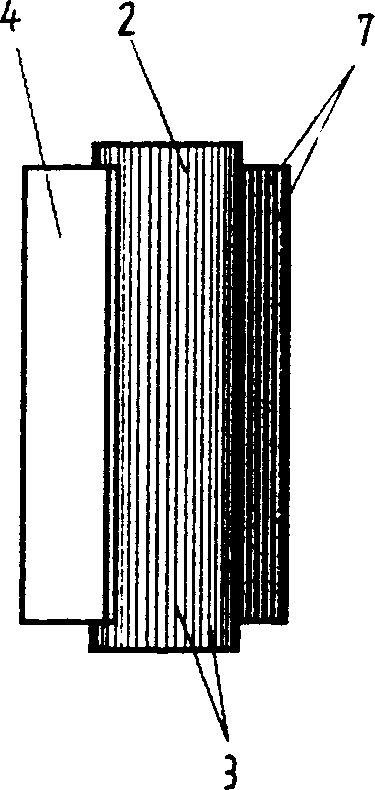

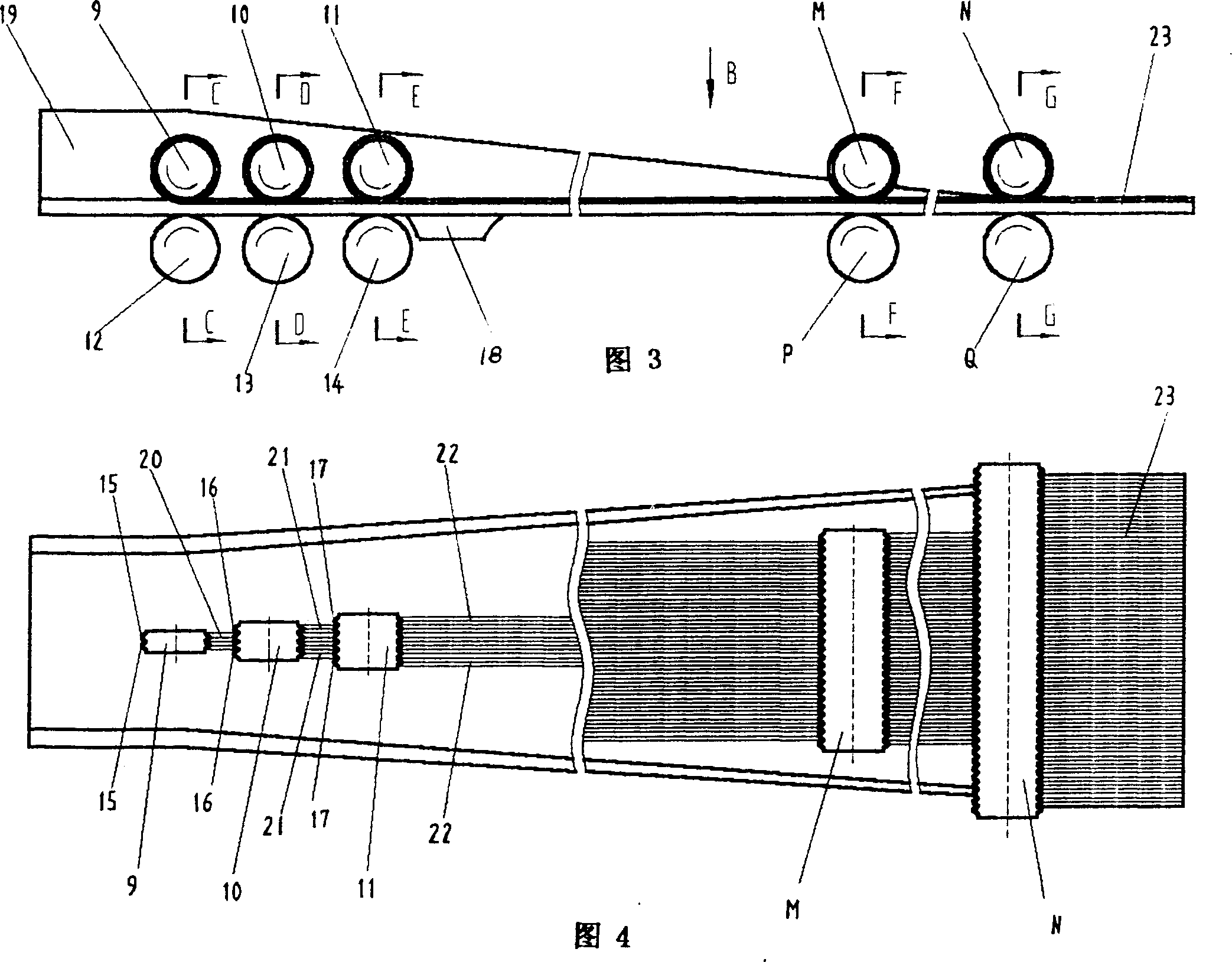

Method and apparatus for flattening bamboo wood without flaws

InactiveCN1485182AAvoid stretchingAvoid crackingOther plywood/veneer working apparatusWood treatment detailsEngineering

A method of spreading bamboo material without cracks and its device. First, remove bamboo green portion and outside nodes, cut open the bamboo sections, remove bamboo yellow portion and inner nodes, preheat to make bamboo sections soft, apply rollers with teeth to press and roll longitude grooves in the inner wall of bamboo material, to extend the arc length of bamboo material, thus flat bamboo material. The bamboo material could be fed along circumference of bamboo or in longitude direction, so there have two kinds of flatting devices: one has a smooth roller, a longitude toothed roller parallel to the smooth roller; another has two rows of rollers, each roller on one of rows has at least two teeth along the circumference, each end of the next roller have at least one more tooth than that of the former roller. when spreading bamboo material with more than 180íÒ,there wouldn't have cracks, then a flat bamboo plate is obtained.

Owner:刘觉春

Nutritional health bread rich in wheat bran dietary fiber and preparation method of nutritional health bread

The invention discloses a nutritional health bread rich in wheat bran dietary fiber and a preparation method of the nutritional health bread. The bread is light brown, full in appearance, smooth in surface and normal in size, and does not have cracks and is not deformed. The internal structure is uniformly spongy, fine, soft and flexible, and the bread has light fresh scent and sweet taste of wheat bran, does not have pungent smell, and is good in palatability. The bread has the advantages as follows: 1 the dietary fiber prepared from the raw material of wheat bran through compound enzymolysis is added into the bread, and the dietary fiber has the functions of moistening lung, moisturizing skin, preventing and resisting cancer, strengthening the spleen and harmonizing the stomach, blackening and strengthening hair and clearing intestines and stomach, so that the nutrition and functionality of the nutritional bread are improved; 2 the bran is soaked, washed and rinsed so as to remove protein, starch and phytic acid, so that the palatability of the bread is improved; 3 the water-soluble dietary fiber is added in raw materials of the bread, so that the rheological property and nutritional property of the bread are changed, and the nutrition arrangement of the bread is scientific and reasonable.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

Method for preparation of Yt-containing TiAl intermetallic compound plate material

InactiveCN101011705AImprove rolling deformation abilityUniform deformationTemperature control deviceFurnace typesYttriumHeating furnace

The invention discloses a making method of TiAl metal compound board with yttrium, which comprises the following steps: 1. fusing TiAl metal block with 0.01-0.6at.% yttrium; 2. making jacket through stainless steel or titanium alloy; 3. placing block in the jacket after heating; 4. placing TiAl metal compound block in the heating furnace to 950-1320 deg.c; rolling; cooling to indoor temperature; 5. removing jacket; obtaining the product.

Owner:HARBIN INST OF TECH

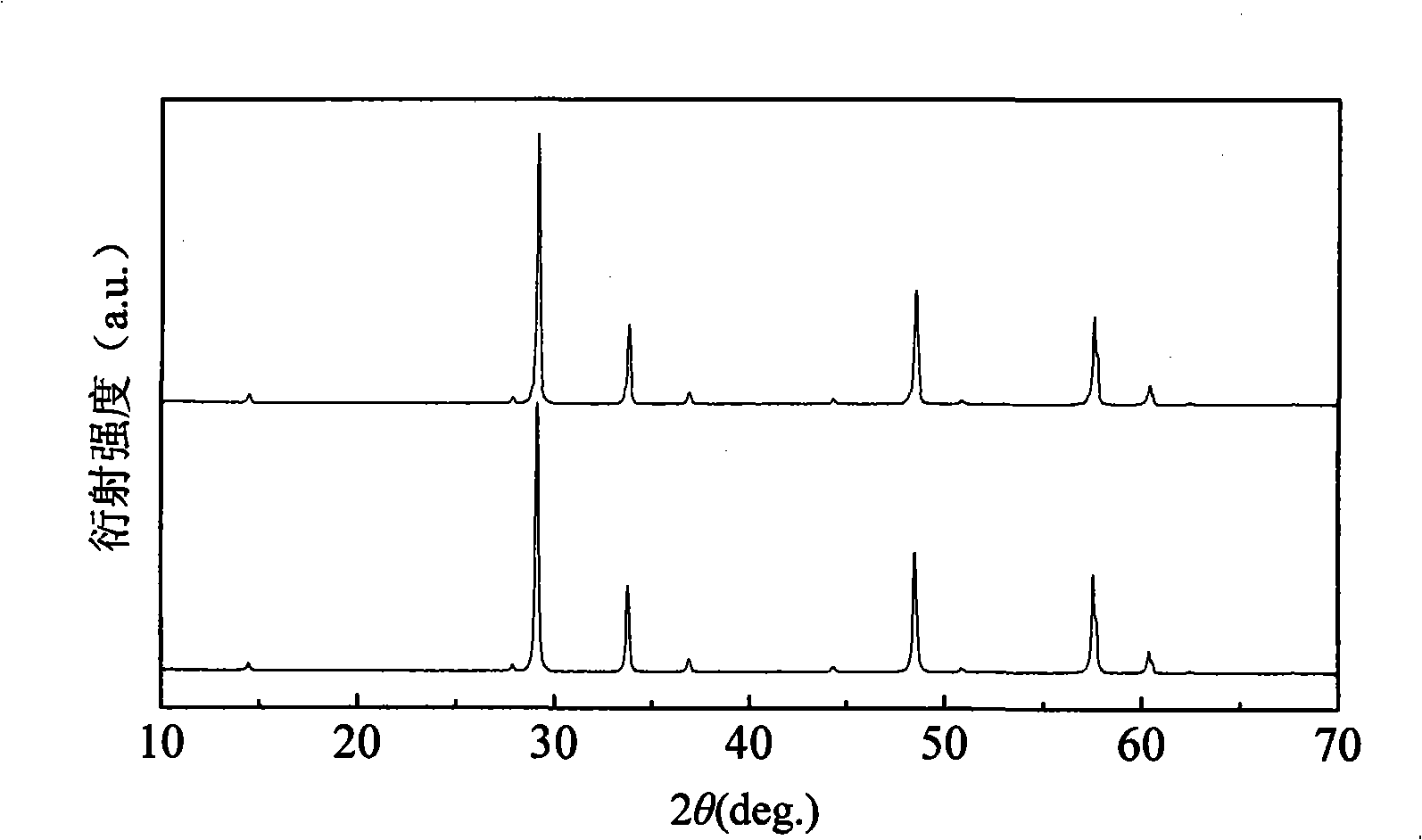

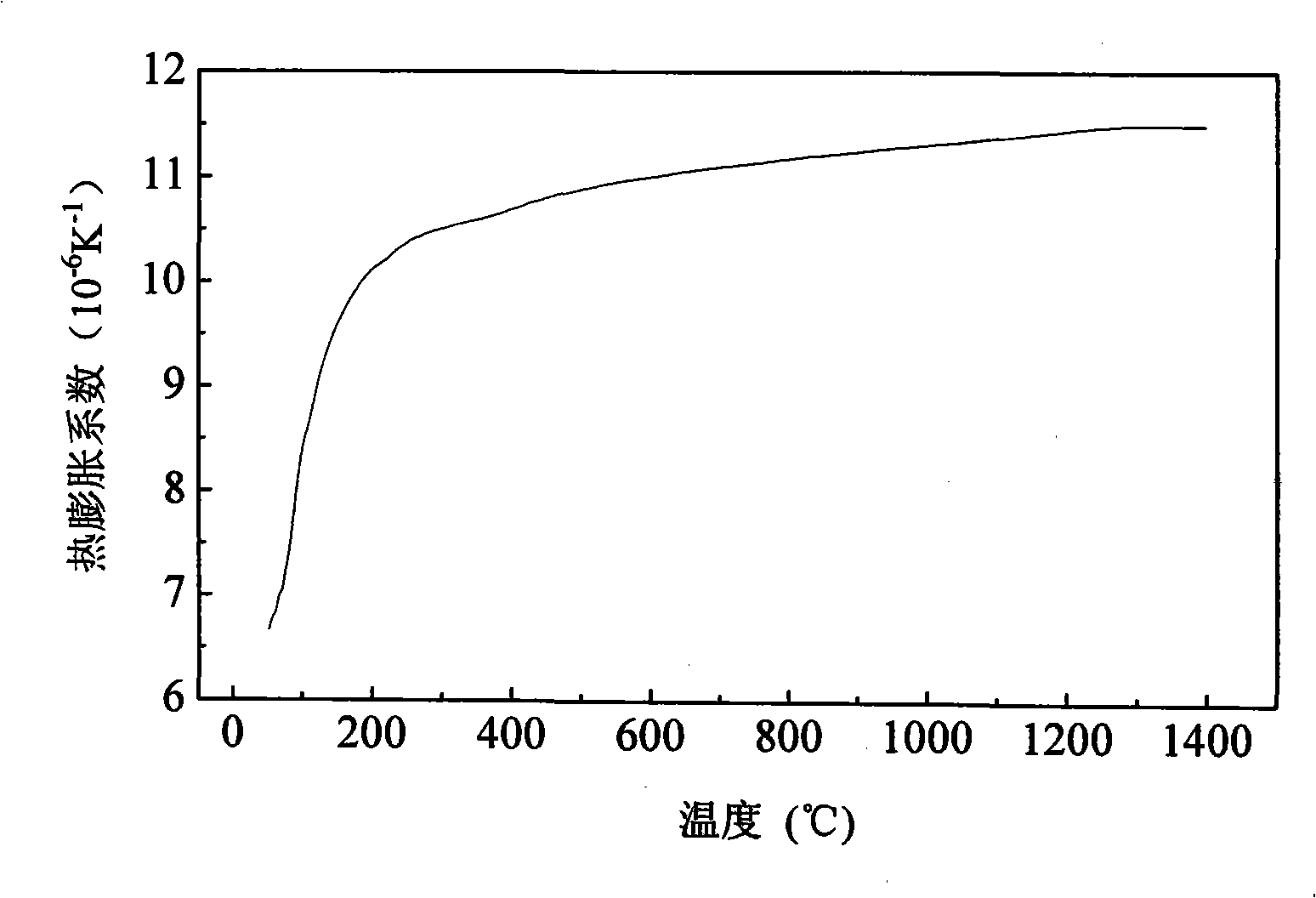

Composite rare earth zirconate thermal barrier coating ceramic material and preparation method thereof

The present invention provides composite rare earth zirconate thermal barrier ceramic material and a preparation method thereof, and relates to the thermal barrier coating ceramic material and the preparation method. The preparation method solves the problems of the complex process, the high costs, the serious phase change at the temperature above 1200 DEG C, the high thermal conductivity, the low coefficient of thermal expansion and so on in the existing preparation method of the thermal barrier coating ceramic material. The composite rare earth zirconate thermal barrier ceramic material is made of zirconia, rare earth oxide Ln2O3 and rare earth oxide Yb2O3. The preparation method comprises the following steps: 1, the zirconia, the rare earth oxide Ln2O3 and the rare earth oxide Yb2O3 are mixed; 2, deionized water is added for ball milling and the dried mixed powder can be prepared after drying; 3, powder C can be prepared after a plurality of processing steps; 4, the powder C is cooled and molded by isostatic pressing to prepare a green body; 5, the green body is sintered to prepare the composite rare earth zirconate thermal barrier ceramic material. The preparation method has the advantages of simple process, low cost, no phase change of the product at high temperature, low thermal conductivity and high coefficient of thermal expansion.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com