Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

A technology of ultra-high strength and manufacturing method, applied in the field of aluminum alloy processing, can solve the problems of difficulty in forming large-sized flat ingots, low yield, and thick surface shell of flat ingots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

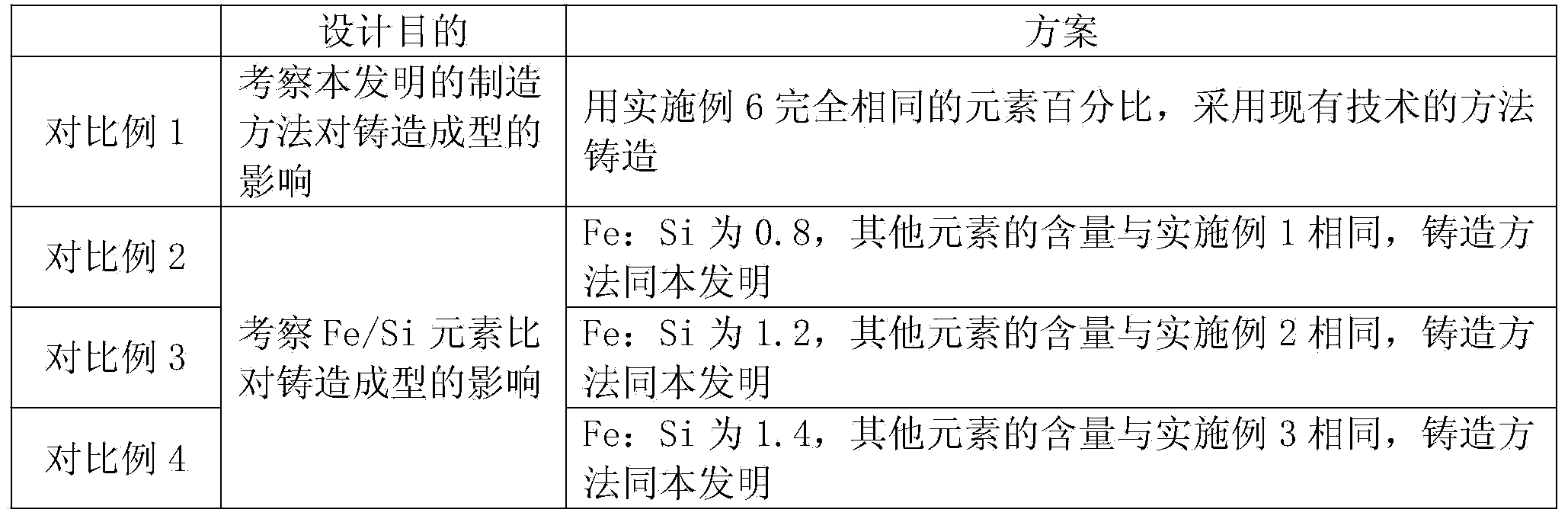

[0057] Table 3 shows the chemical composition and content (by weight percentage) of an ultrahigh-strength Al-Zn-Mg-Cu aluminum alloy large-scale slab ingot of the present invention.

[0058]Examples 1-6 The method of the present invention is used to prepare Al-Zn-Mg-Cu aluminum alloy slab ingot, its chemical composition and content (by weight percentage) are shown in Table 3, and the raw material selected is aluminum for remelting Ingots, pure magnesium ingots, pure zinc ingots, copper cathodes, aluminum-titanium master alloys, aluminum-zirconium master alloys, aluminum-chromium master alloys, aluminum-manganese master alloys, aluminum-beryllium master alloys, melting furnaces and holding furnaces are gas-fired reverberatory furnaces, The casting machine is a vertical semi-continuous casting machine. The manufacture method of a kind of ultra-high strength Al-Zn-Mg-Cu series aluminum alloy large size slab ingot of the present invention is as follows:

[0059] (1) Raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com