Patents

Literature

510results about How to "Reduced tendency to crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and making method thereof

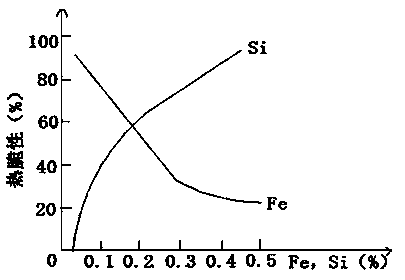

The invention discloses an ultrahigh-strength Al-Zn-Mg-Cu system aluminum alloy large-size flat cast ingot and a making method thereof, and belongs to the aluminum alloy making field. The flat cast ingot comprises, by mass, 2.0-2.4% of Cu, 1.95-2.5% of Mg, 5.5-9.0% of Zn, 0.08-0.15% of Zr, 0.0003-0.0015% of Be, below 0.06% of Ti, below 0.04% of Cr, below 0.10% of Mn, 0.085% or less of Si, 0.14% or less of Fe, and the balance Al and inevitable elements, wherein the content of each of the inevitable elements is lower than 0.05%, the total amount of the inevitable elements is lower than 0.15%, and a content ratio of Fe to Si is not less than 1.6. The making method disclosed in the invention improves traditional making methods, and does not need pure aluminum bottoming, and the flat cast ingot made in the invention has the advantages of large size, high strength, no cracks, and high casting success rate.

Owner:广西南南铝加工有限公司

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

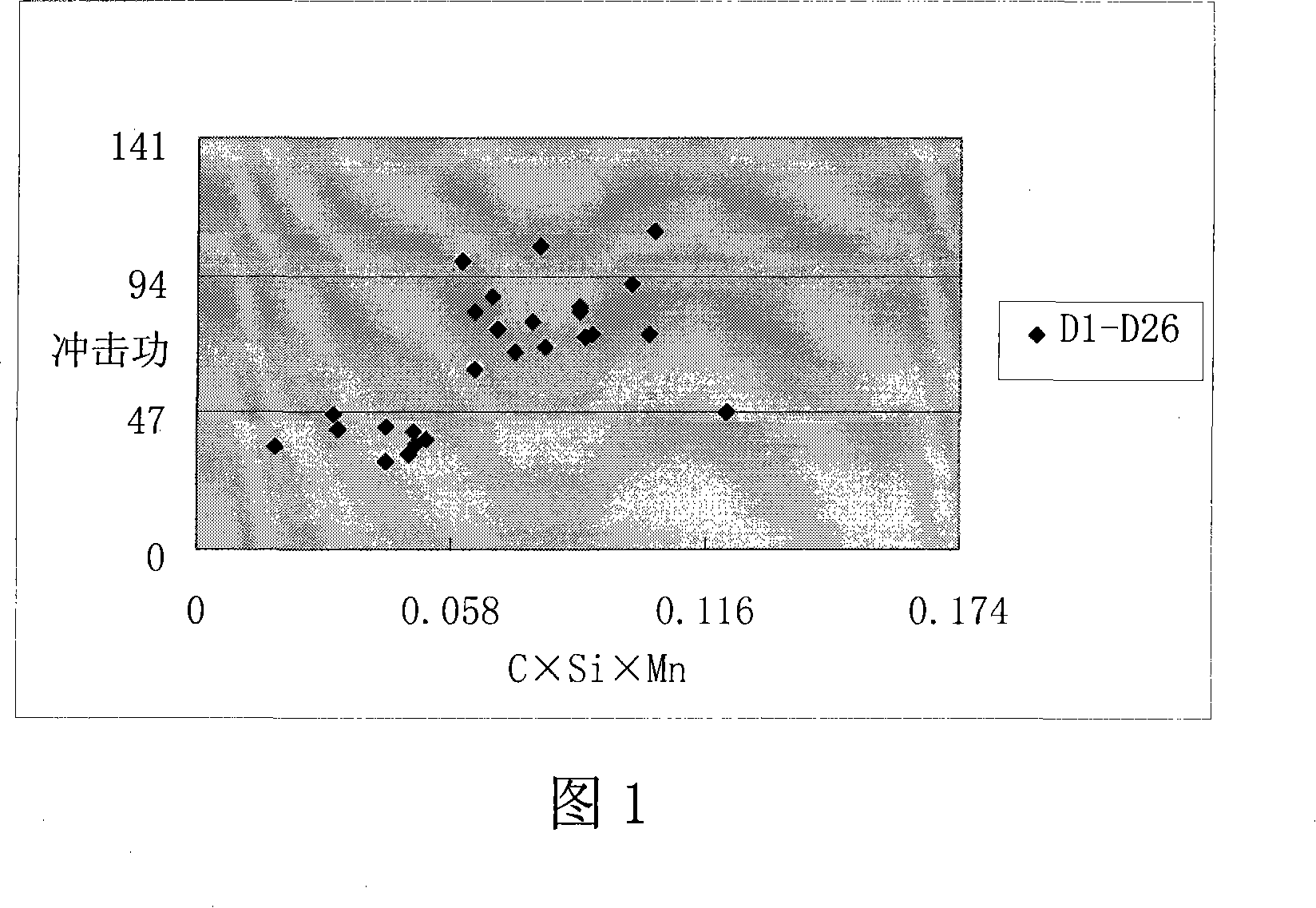

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

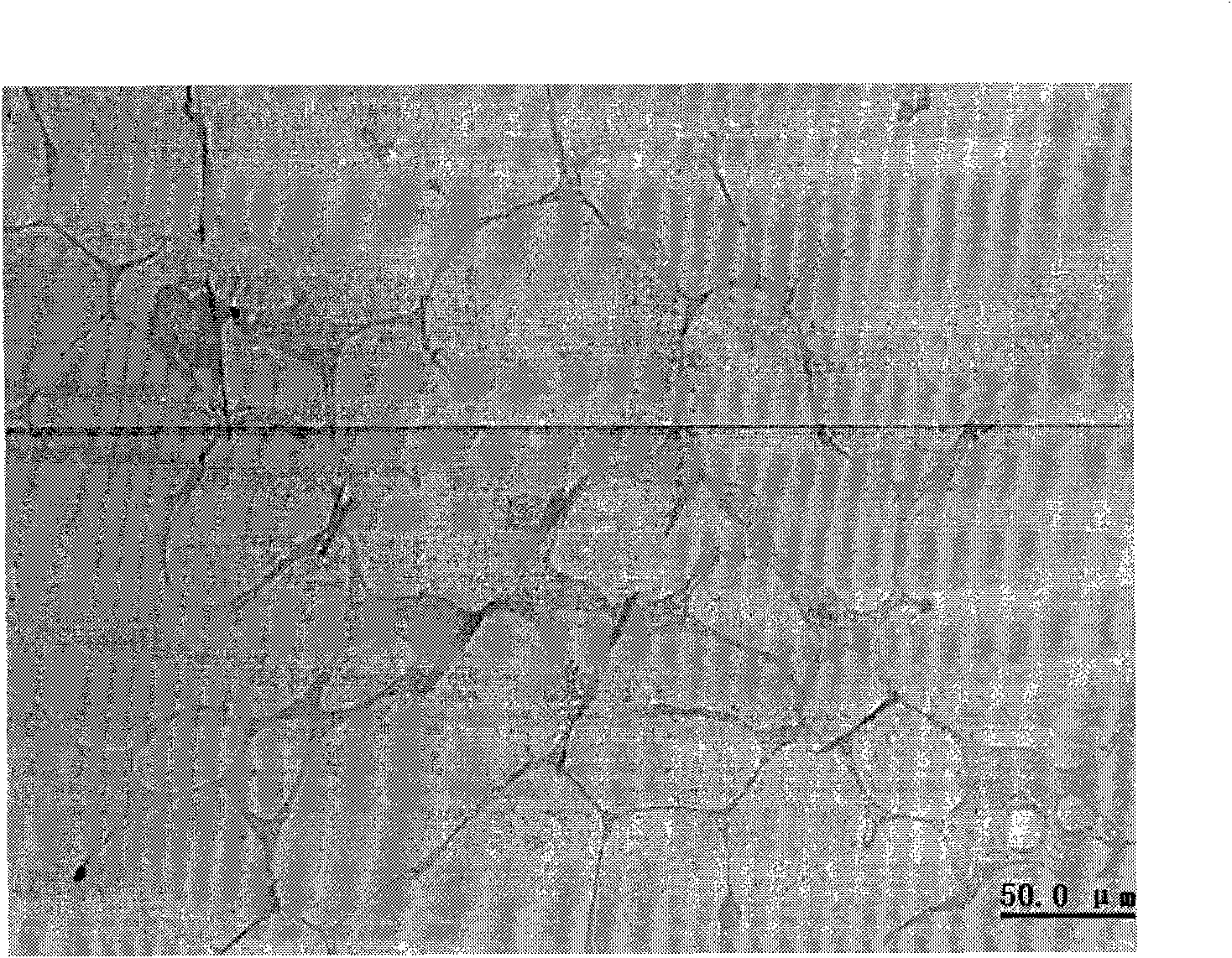

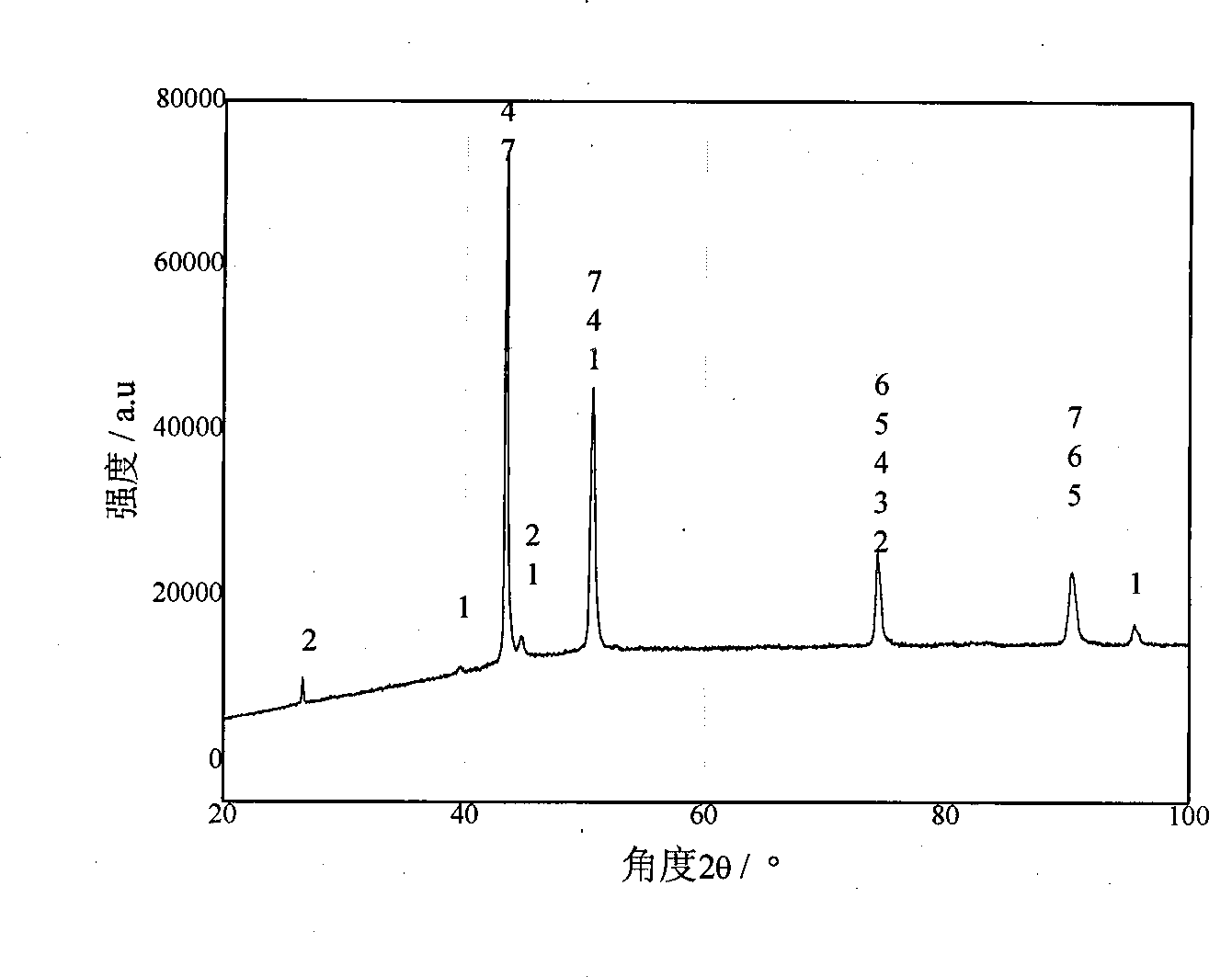

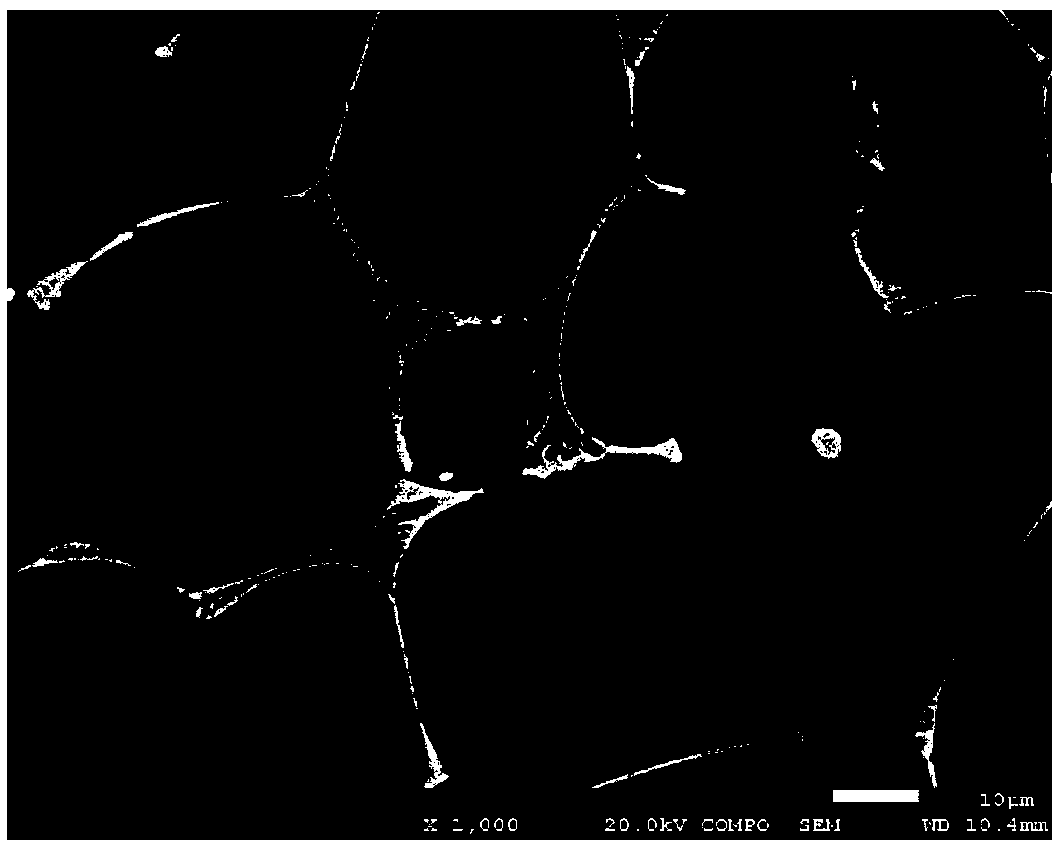

Method for acquiring highly-adaptive abrasion-proof titanium-based composite material on titanium alloy surface

InactiveCN101139709AReduce stressReduced tendency to crackMetallic material coating processesLaser beam welding apparatusIn situ reactionHigh power lasers

The invention discloses a method for preparing a Ti-based composite with high adaptability on a Ti-alloy surface, which pertains to the field of surface modification of metallic materials. The method comprises such procedures as: weighing by certain proportion spherical Ti alloy powder particles in proper particle sizes (45-150 micro meter) and TiB2, Cr3C2, TiC or B4C powder particles (3.4-30vol%, particle size 38-106 micrometer); mixing the powder evenly by a mechanical way; sending at the set powder-feeding rate the mixed powder by a powder feeder and coaxial powder-feeding nozzles into a molten bath formed by a high-power laser at the surface of a Ti-alloy substrate; the mixed powder carrying out in-situ reaction by the high temperature from the molten bath, and forming such steady and dispersion reinforced phases as in-situ self-grown TiC or TiB. The reinforced phases are featured by small particle size, steady thermal and mechanical properties, free pollution in interfaces, and high bond strength with the substrate. The method can substantially improve the hardness and wear resistance of Ti alloy surfaces, guarantees the high adaptability between the surface modified layer and the substrate, can be used for repairing and surface reinforcing treatment of Ti alloy parts bearing impact vibration load and thermal fatigue, etc.

Owner:有研科技集团有限公司

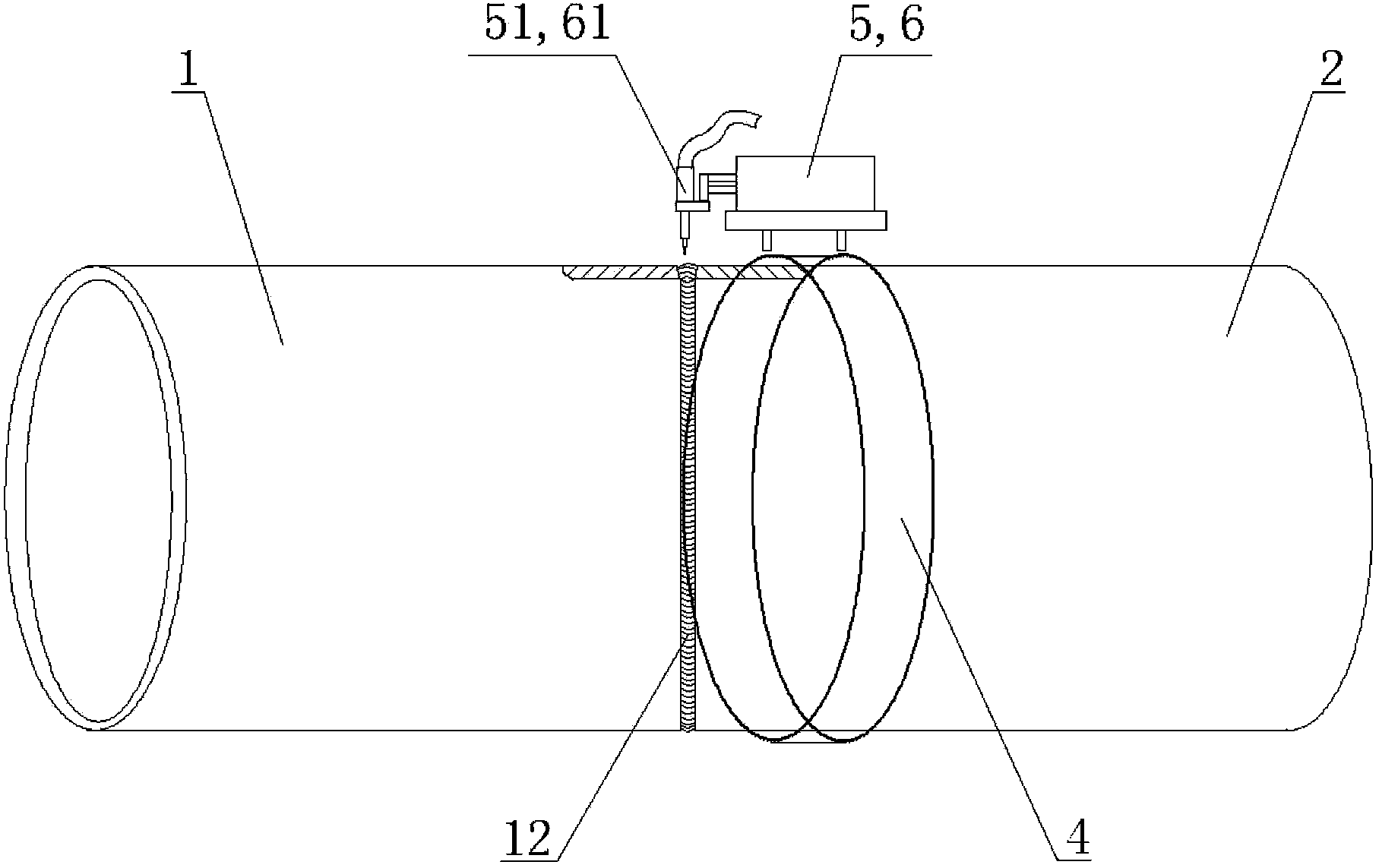

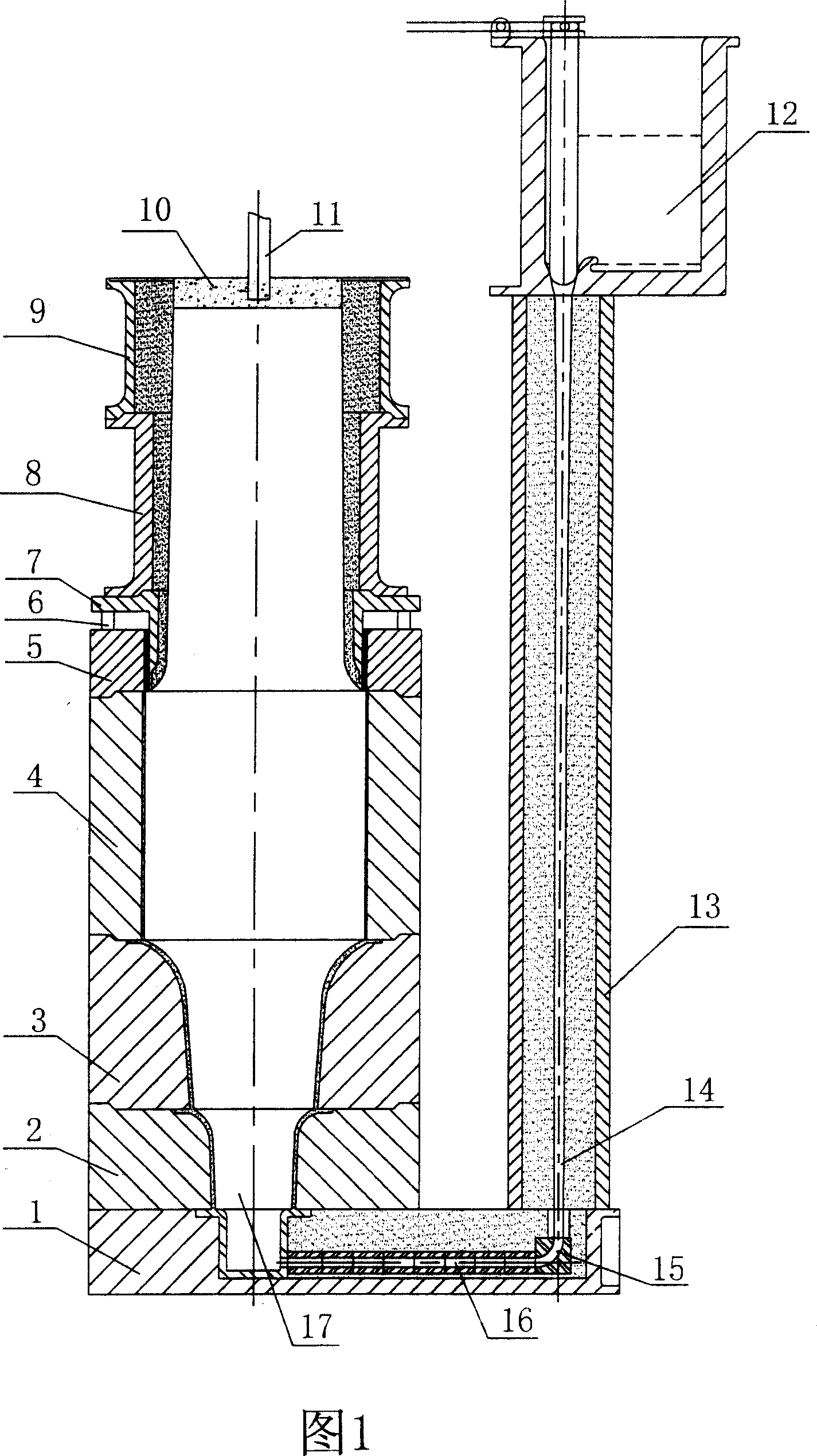

Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

ActiveCN102554402AReduce labor intensityEnsure continuous weldingArc welding apparatusFurnace typesNuclear technologyNuclear engineering

The invention discloses welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes, which are suitable for welding and heat treatment of large-diameter and thick-wall pipes. The pipes welded by the welding and heat treatment processes are steady and reliable in the quality of welding lines, and can completely meet the quality requirement of nuclear technology.

Owner:江苏利柏特股份有限公司

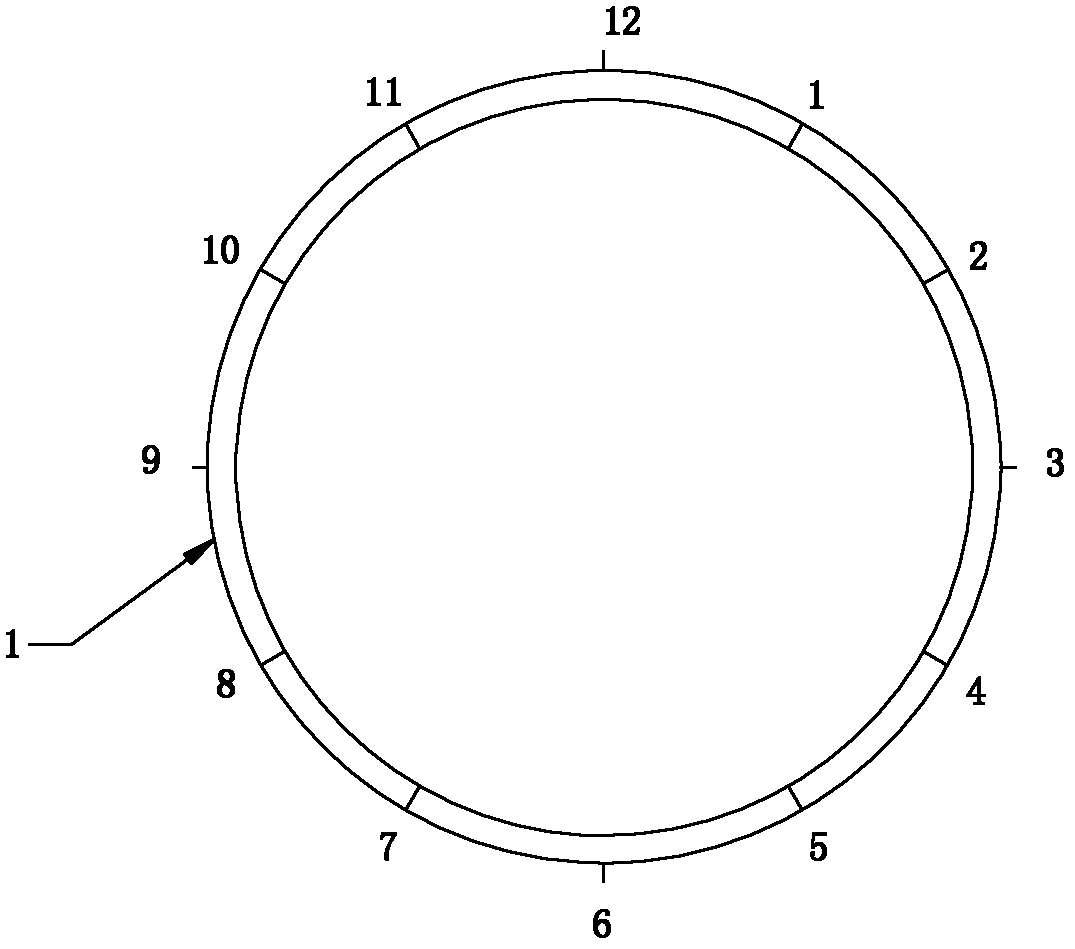

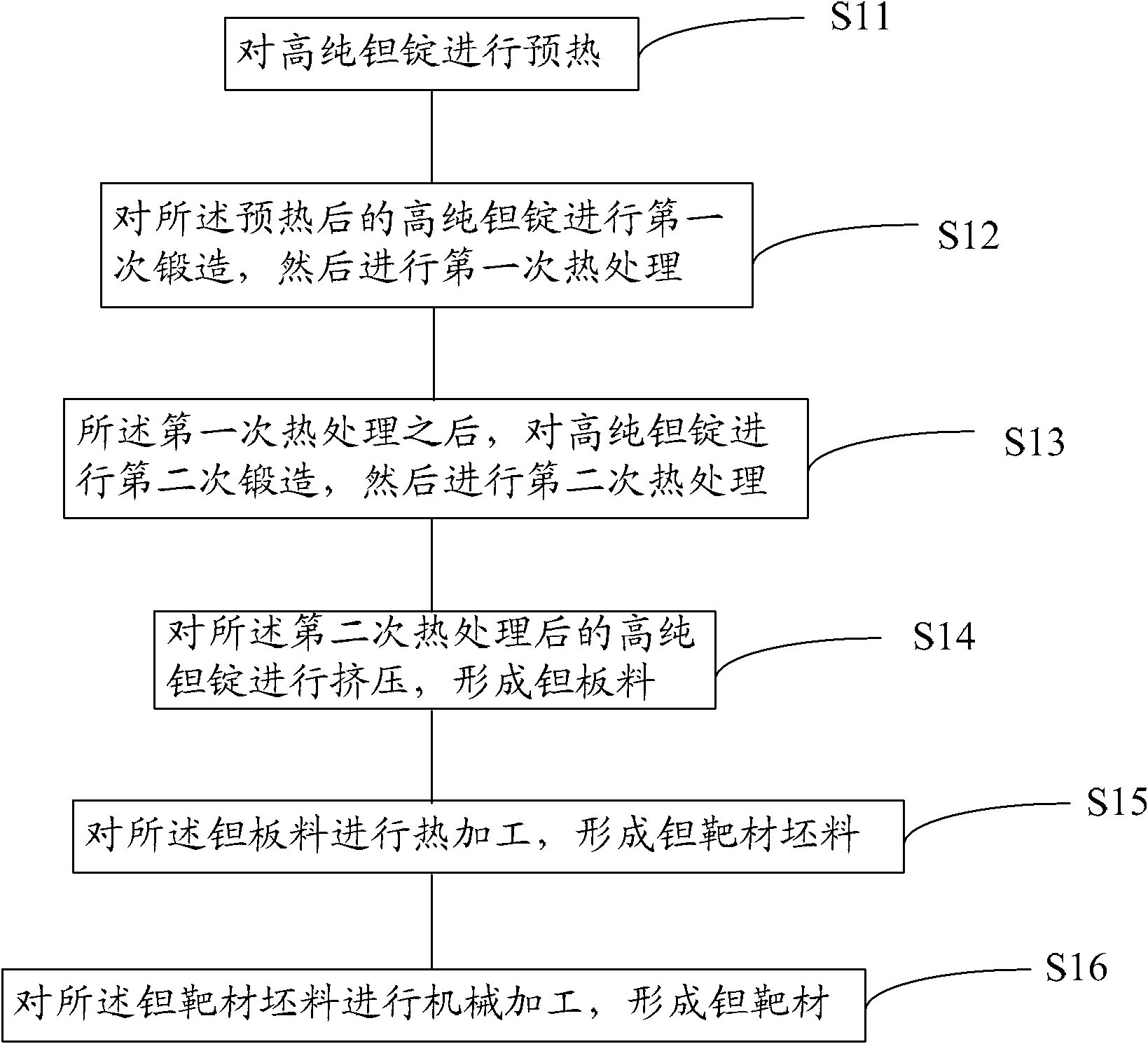

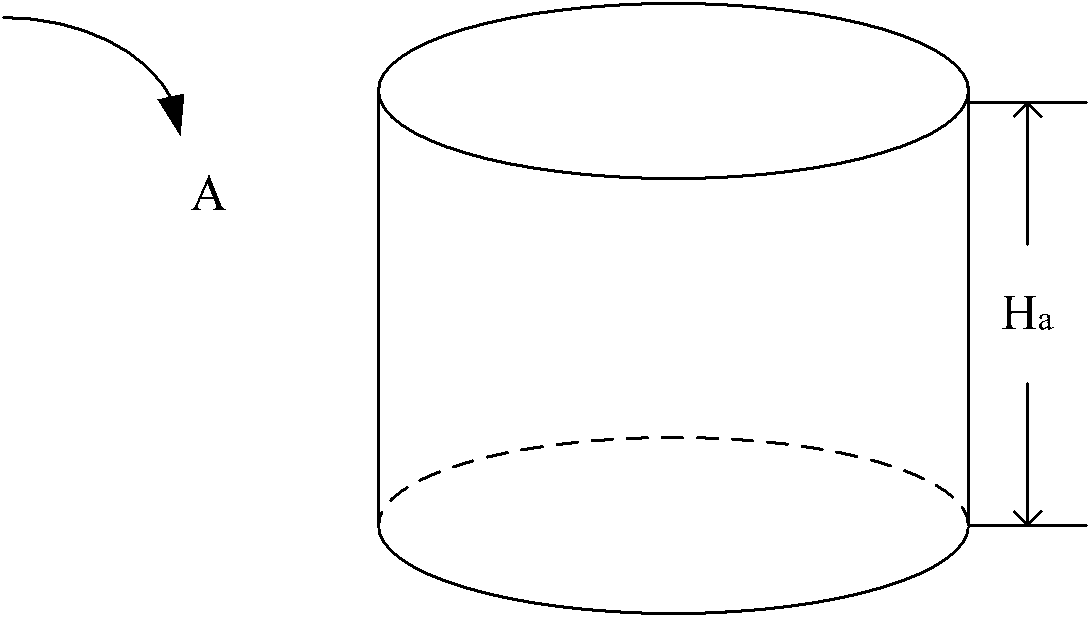

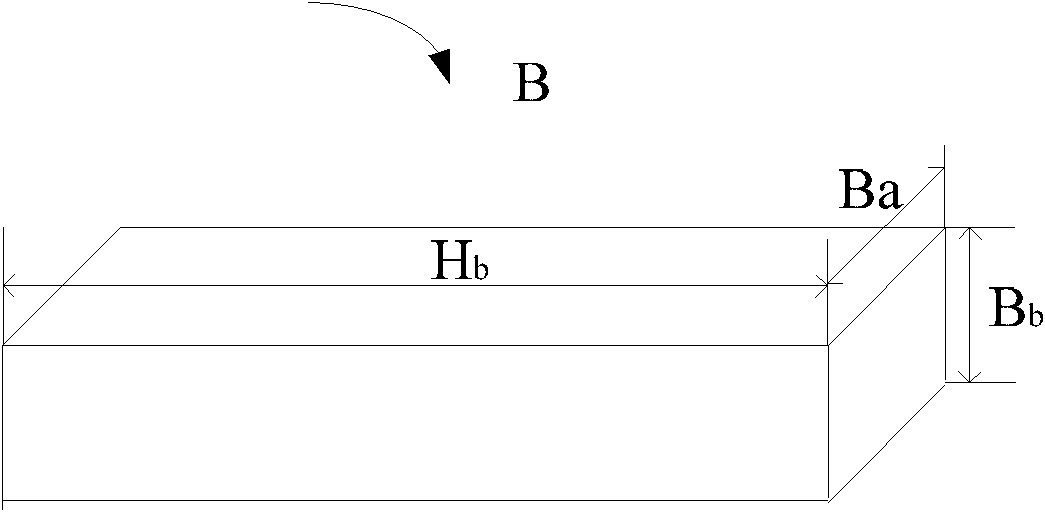

Method for preparing high-purity tantalum target

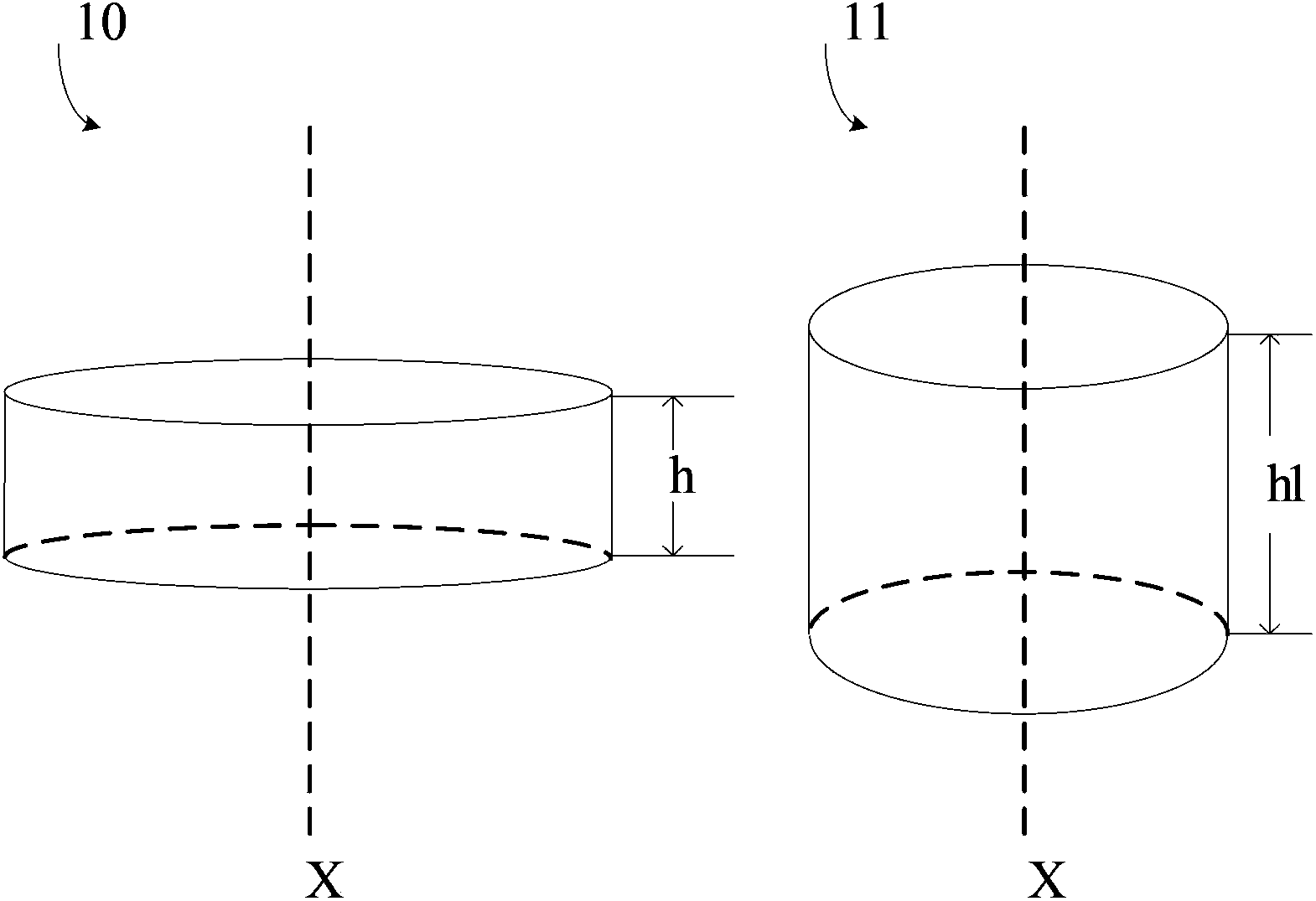

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

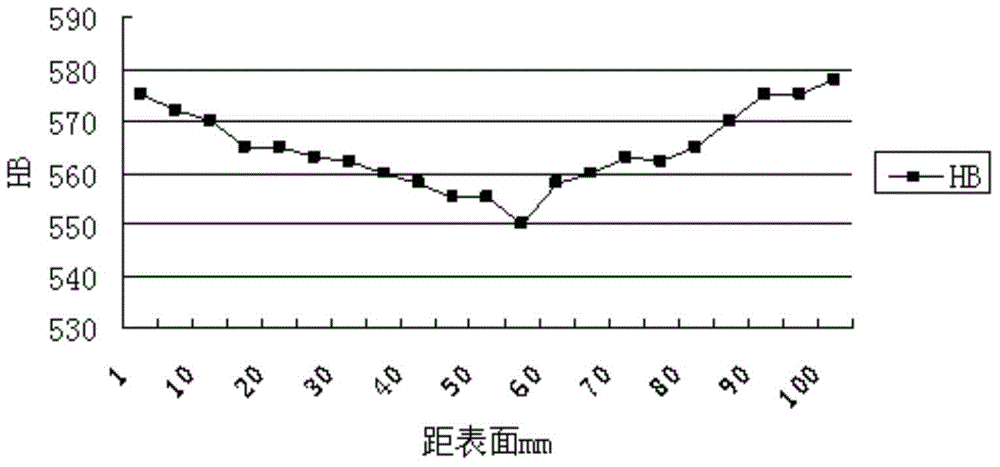

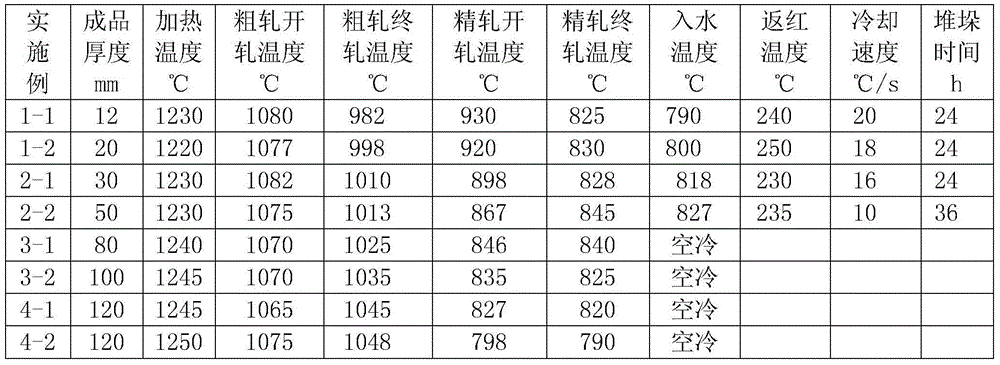

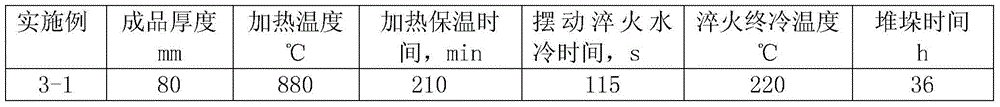

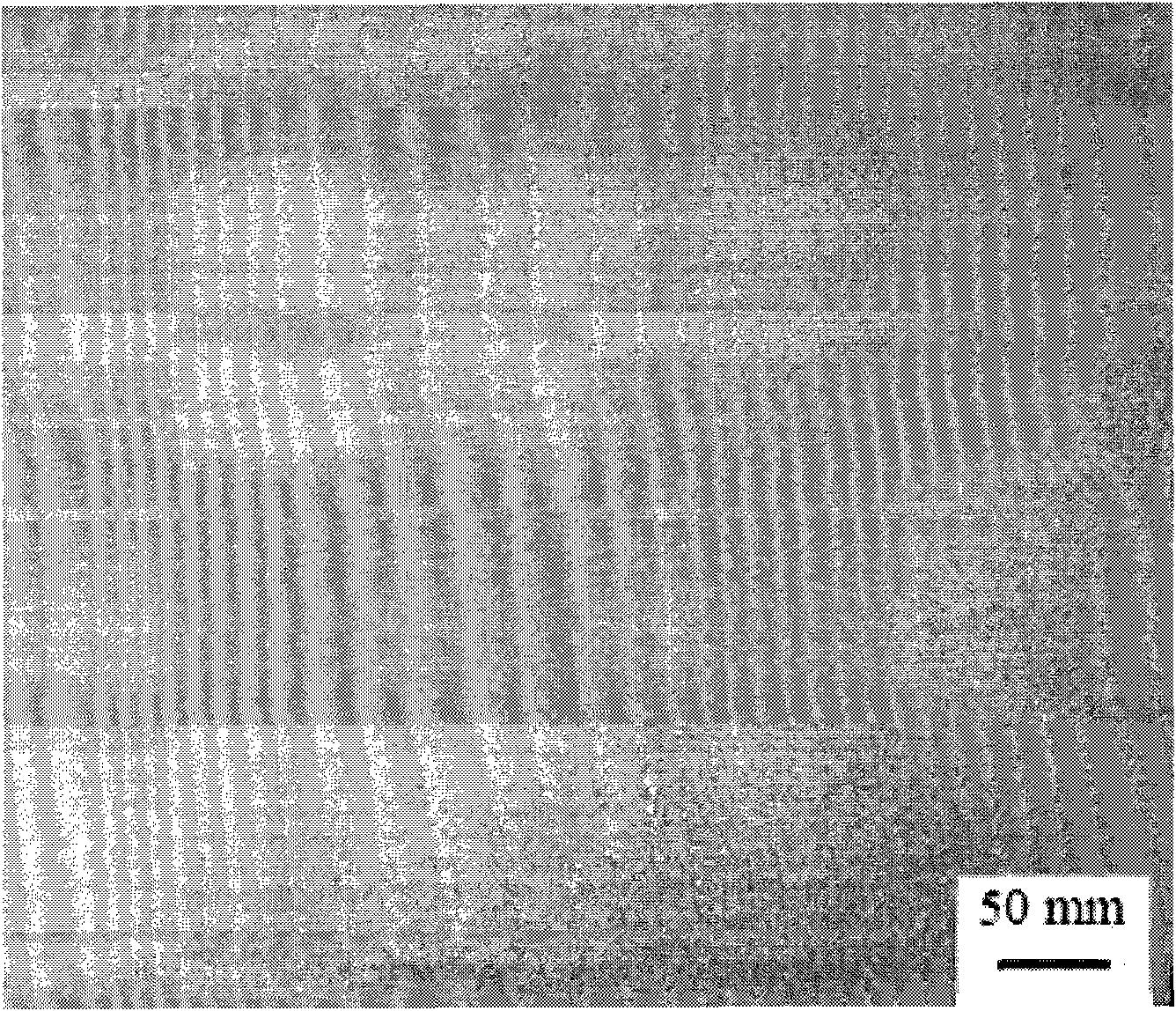

High-strength abrasion-resisting steel plate and production method thereof

The invention provides a high-strength abrasion-resisting steel plate and a production method thereof. The chemical components of the high-strength abrasion-resisting steel plate include, by weight, 0.25-0.30% of C, 0.3-0.5% of Si, 0.40-1.00% of Mn, 0.6-1.2% of Cr, 0.15-0.4% of Mo, 0.01-0.03% of Nb, smaller than or equal to 0.50% of Ni, smaller than or equal to 0.50% of Cu, 0.0005-0.0022% of B, 0.025-0.04% of Ti, 0.020-0.045% of Als, smaller than or equal to 0.015% of P and smaller than or equal to 0.005% of S, wherein Ti / N is greater than or equal to 3.4. During refining, molten steel [N] is controlled to be smaller than or equal to 0.0080%, [O] is controlled to be smaller than or equal to 0.0020%, it is ensured that the effective boron content is 0.0010-0.0020%, and stacking for slow-cooling is performed for 48 hours or more after continuous casting. Two-stage rolling control is adopted, the finish rolling temperature at the first stage is 980-1050 DEG C, out-line quenching is conducted on plate blanks with the thickness greater than 50 mm at the second stage, swinging is performed at the low-pressure section of a quenching machine, on-line quenching is conducted on plate blanks with the thickness smaller than or equal to 50 mm, and residual heat is utilized to perform self tempering. The high-strength abrasion-resisting steel plate has lower carbon and manganese contents and good weldability, the surface hardness is greater than 550 HB, and the toughness at the low temperature of -40 DEG C is greater than 30 J, and the maximum thickness can be up to 120 mm.

Owner:ANGANG STEEL CO LTD

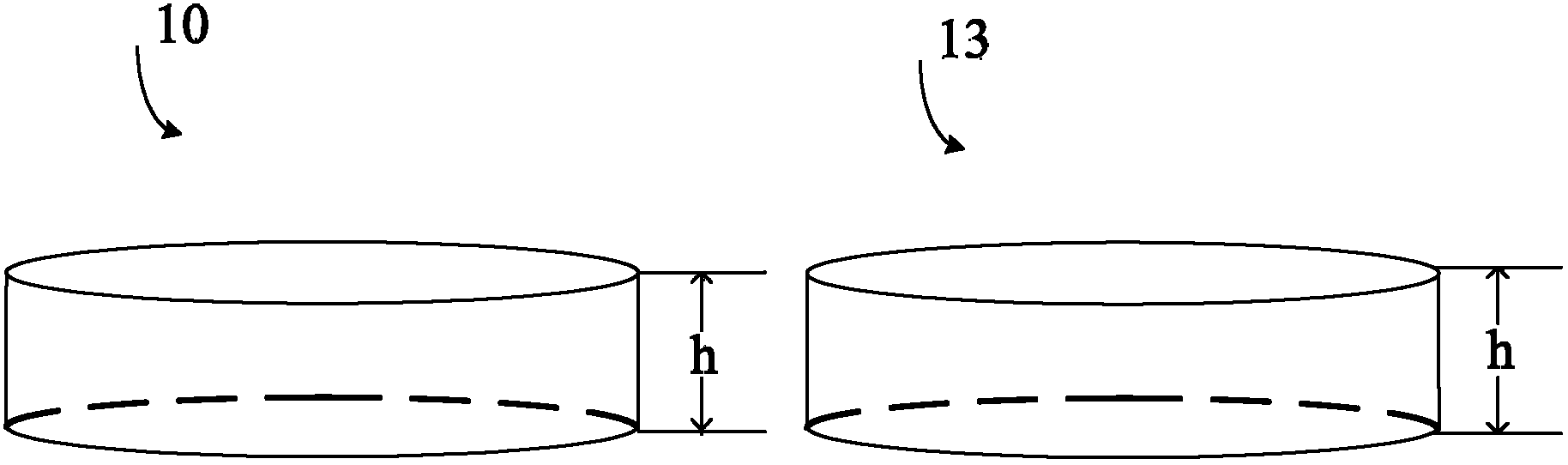

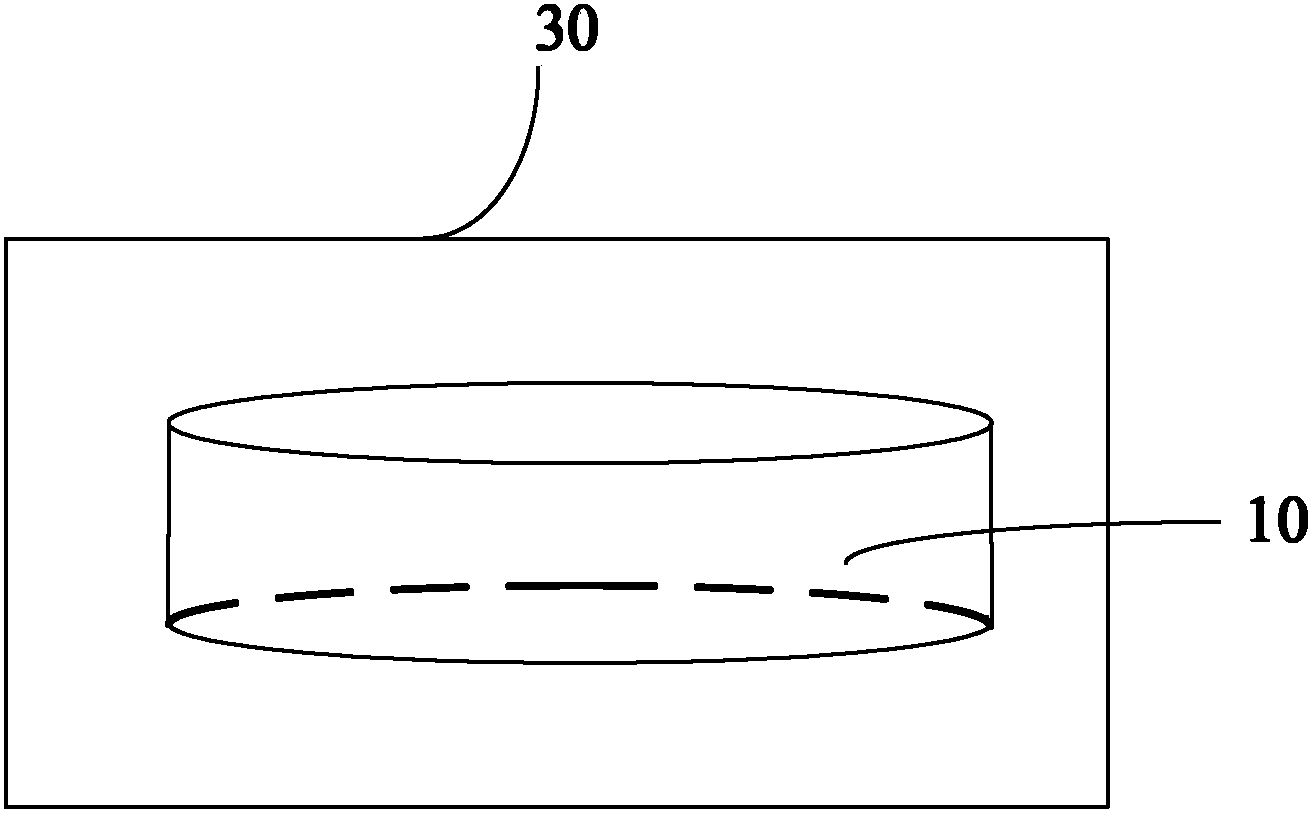

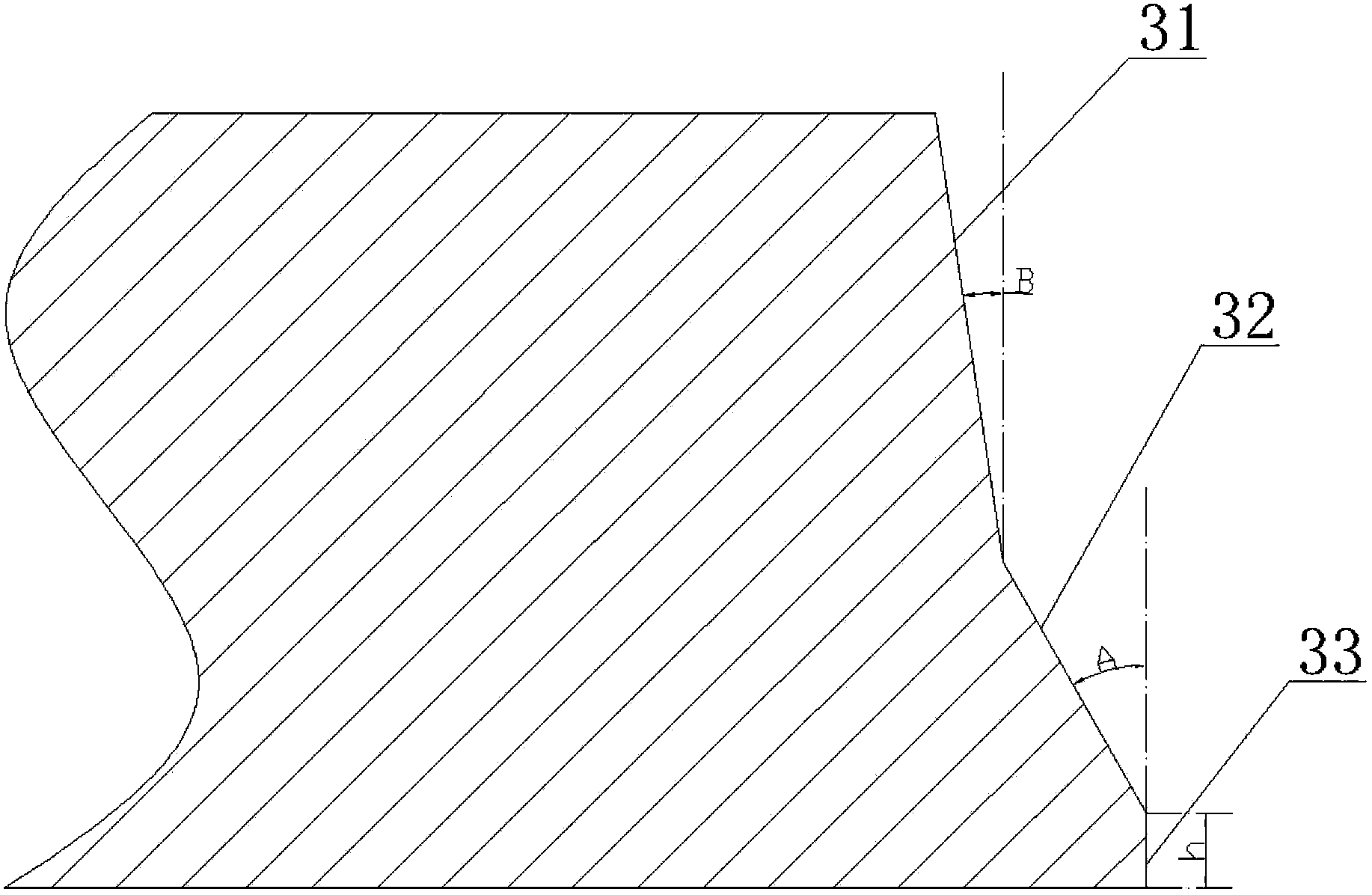

Preparation method of large-size aluminum alloy ingot

The invention discloses a preparation method of a large-size aluminum alloy ingot, relating to a preparation method of aluminum alloy ingots, and the provided preparation method of a large-size aluminum alloy ingot solves the problem of easy cracking during preparing the large-size aluminum alloy ingots by the traditional aluminum alloy ingot preparation method. The method comprises the following steps of: spreading and scattering a NO. flux at the bottom of a smelting furnace; adding aluminum ingots, electrolytic copper, zinc ingots, aluminum-silicon intermediate alloy, aluminum-iron intermediate alloy, aluminum-manganese intermediate alloy, aluminum-chromium intermediate alloy and aluminum-titanium intermediate alloy into the smelting furnace and spreading and scattering a covering agent; heating to ensure that the materials are smelted, sequentially adding a zirconium composite salt and magnesium ingots as well as smelting and refining to obtain an aluminum alloy melt; filtering the aluminum alloy melt and then pouring into a crystallizer; and finally, obtaining the large-size aluminum alloy ingot through casting. The thickness of the ingot prepared by using the method is 500-600mm, the width is 1,600mm, and the length is 1,500-2,500mm. The ingot has no cracks, good surface quality and uniform internal grains, and the yield is not smaller than 65 percent.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Wear resistant coating for brush seal applications

InactiveUS6186508B1Less stressReduced tendency to crackEngine sealsMolten spray coatingWear resistantCarbide

A metallic coating containing hard carbide particles is described. The coating is applied by an HVOF process using powder particles whose size ranges from about 15 to about 44 microns. The carbide particles are held in a 80% nickel-20% chromium matrix. The coating has a reduced tensile compressive stress relative to similar plasma sprayed coatings and exhibits a high strain to cracking value.

Owner:UNITED TECH CORP

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

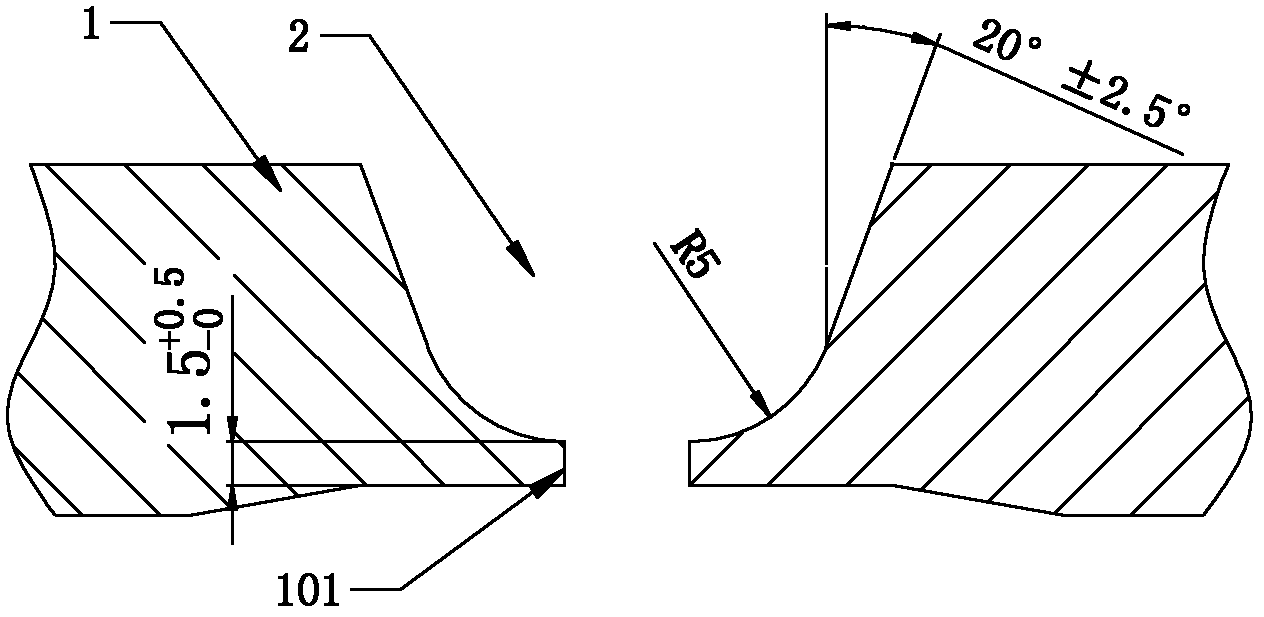

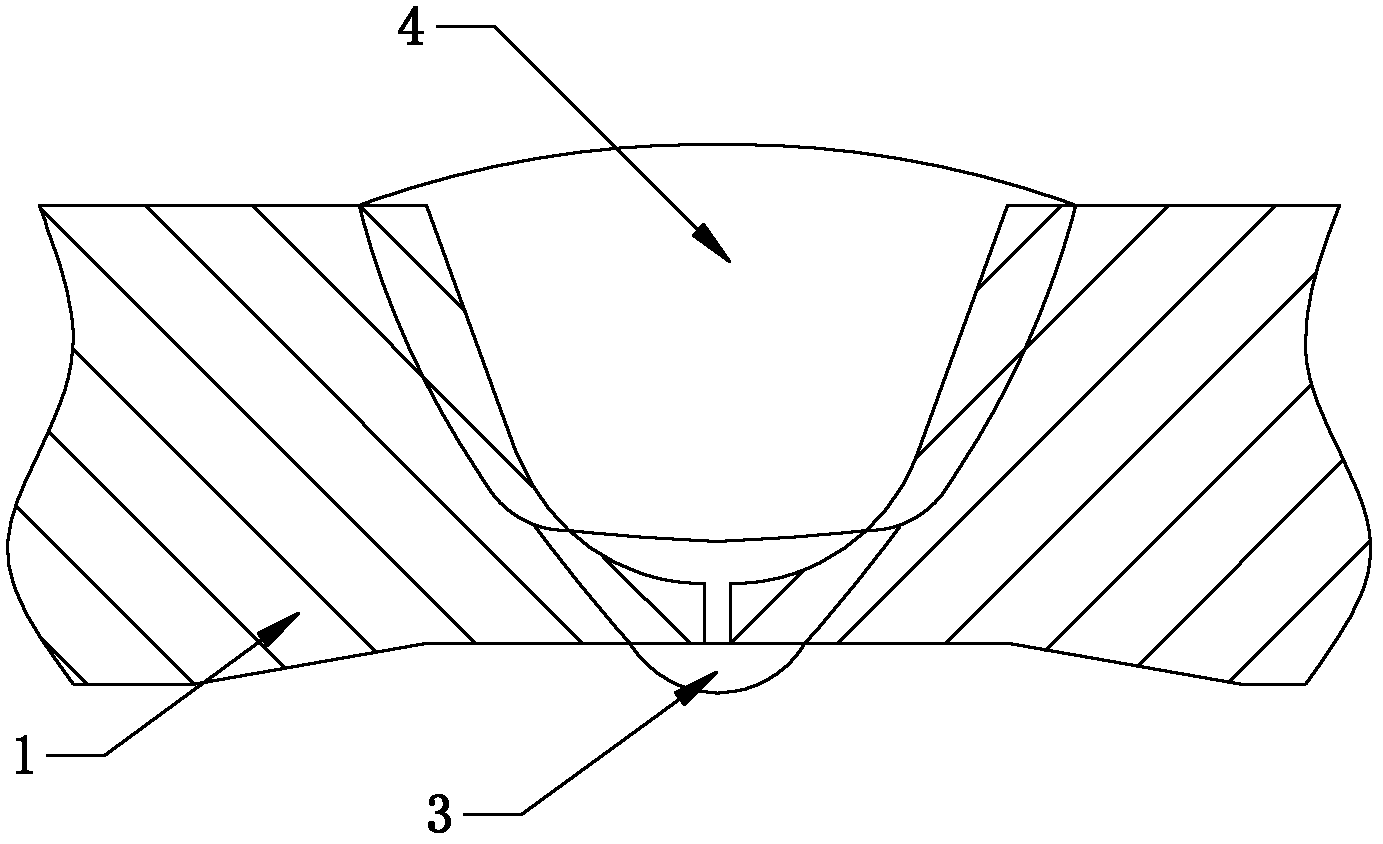

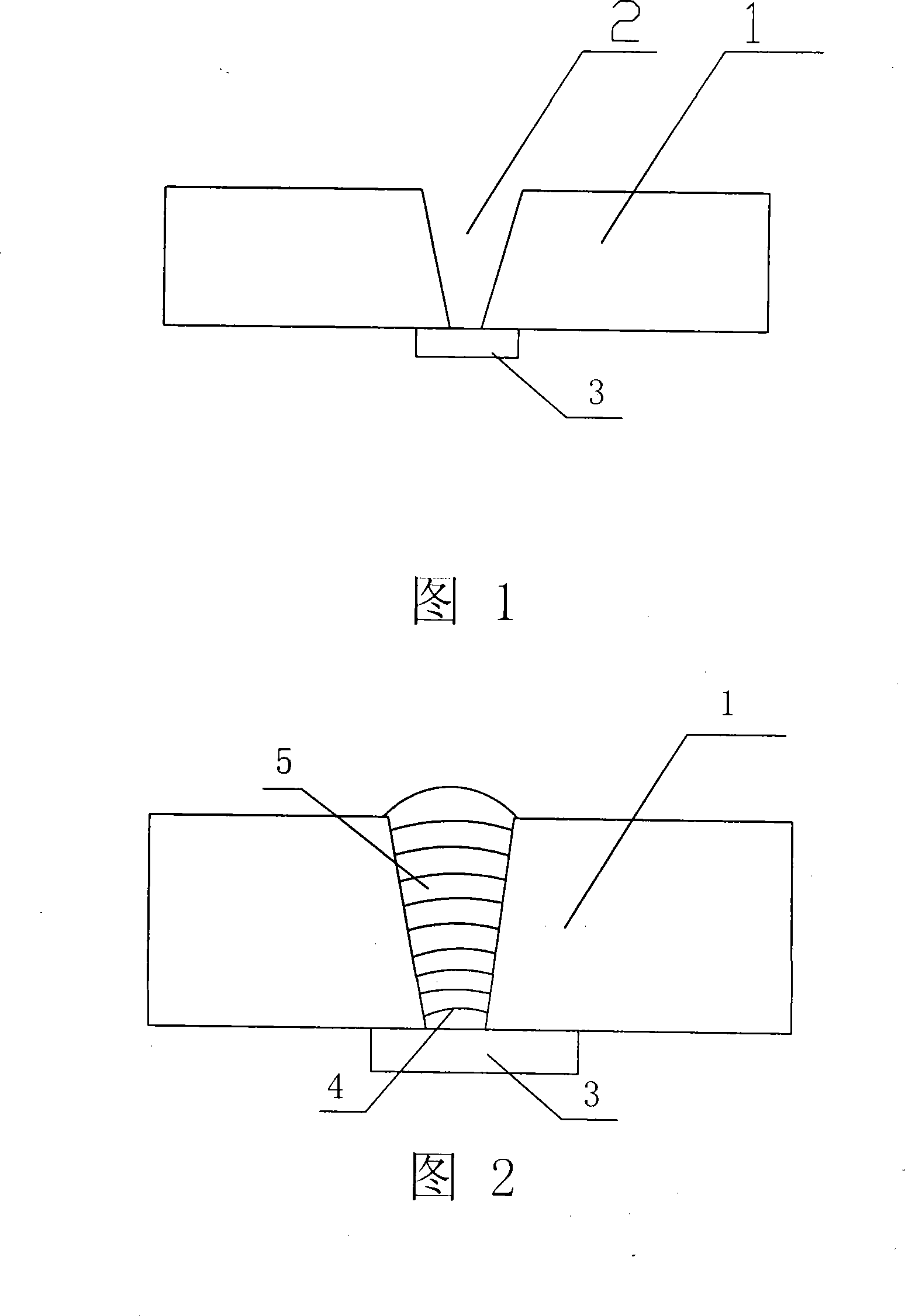

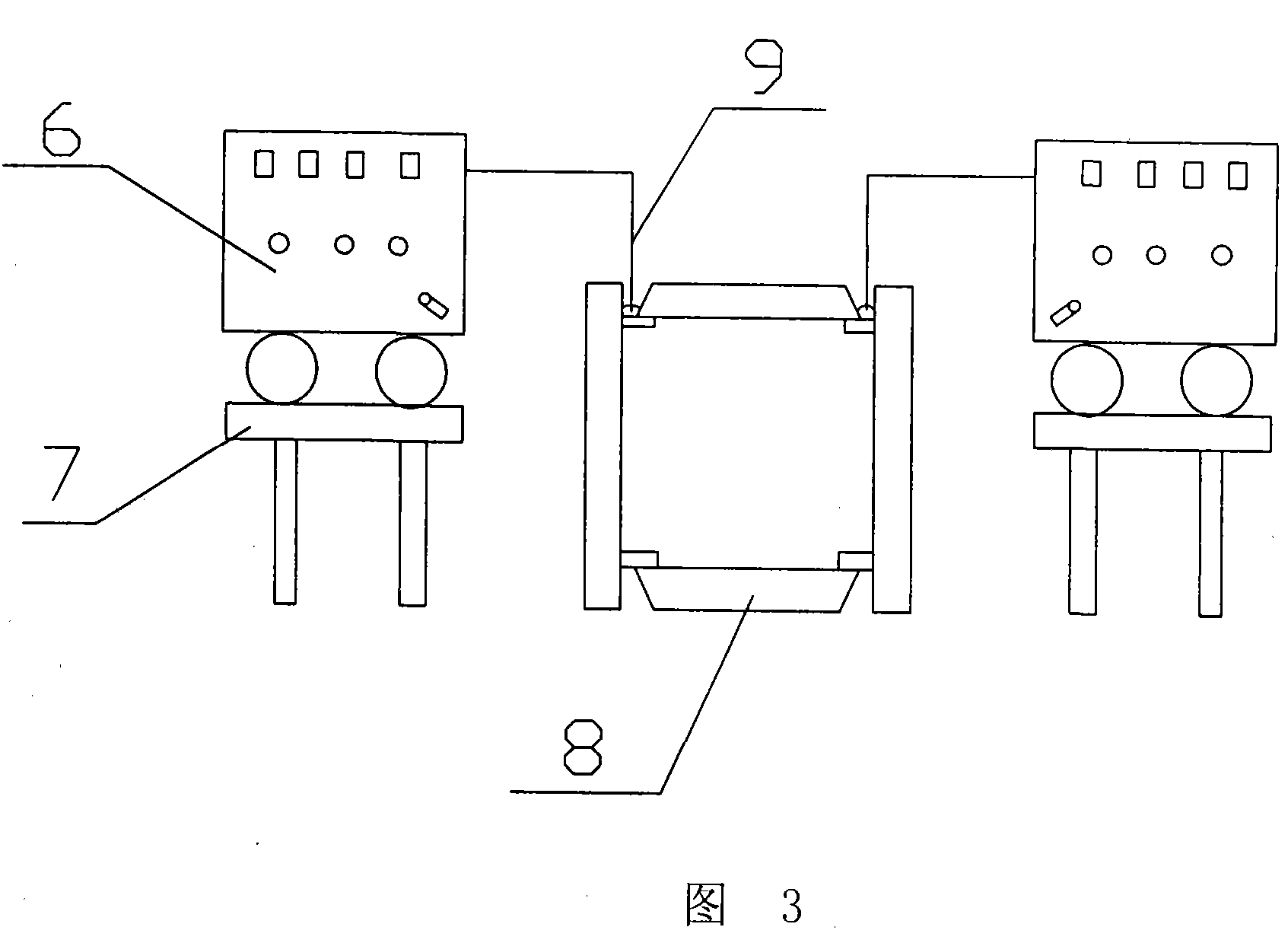

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

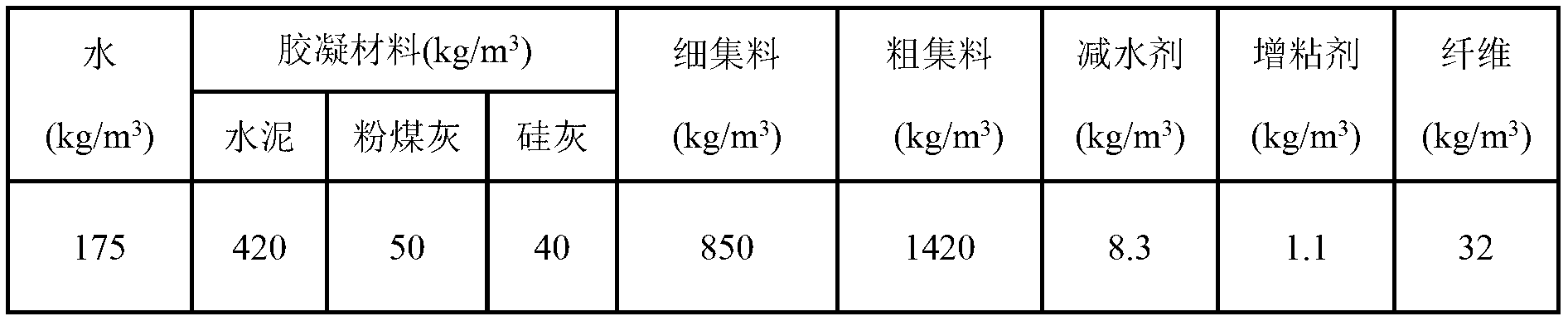

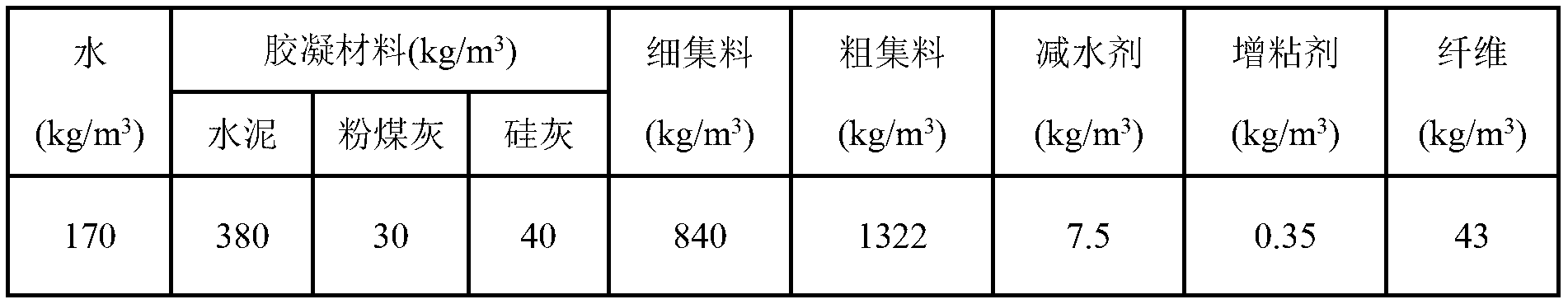

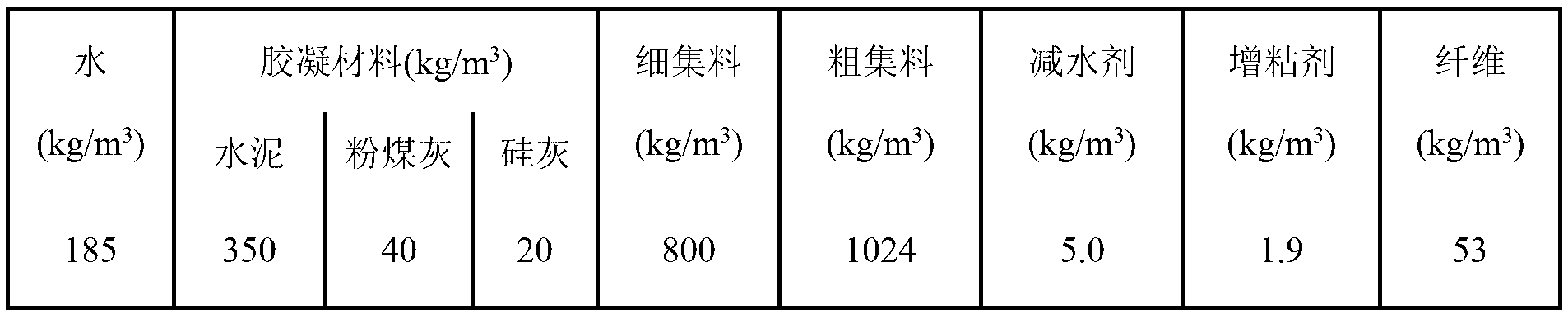

Anti-radiation concrete produced from slag aggregate, and production method thereof

InactiveCN103224369ATotal momentum downReduce the degree of stratificationSolid waste managementSlagTackifier

The invention relates to anti-radiation concrete produced from slag aggregate, and a production method thereof so as to effectively consume and utilize mineral waste, and improve an anti-radiation performance and durability of concrete. The anti-radiation concrete produced from slag aggregate comprises the following raw materials, by weight, 140-190 parts of water, 350-630 parts of a cementing material, 750-850 parts of a fine aggregate, 1000-1500 parts of a coarse aggregate, 0.35-1.9 parts of a tackifier, 2.1-7.5 parts of a water reducing agent, and 30-70 parts of fibers, wherein the cementing material comprises cement and a mineral admixture, the mineral admixture comprises silicon ash and fly ash, the cementing material comprises 300-500 parts by weight of the cement, 20-60 parts by weight of the silicon ash and 30-70 parts by weight of the fly ash, the coarse aggregate is a high titanium heavy slag coarse aggregate, the fine aggregate comprises high titanium heavy slag sand and lead powder according to a mass ratio of 1:0.2-3.0, the tackifier is methyl cellulose ether, and the fibers are one or a plurality of material selected from polypropylene fibers, steel fibers and lead fibers.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

InactiveCN101362253ALess loss of shape memory propertiesSmall organizationWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneSurface cleaning

The invention relates to a method for transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel, which belongs to the technical field of the connection of dissimilar materials. In the prior art, the technology of the connection between TiNi shape memory alloy and stainless steel has the problems of welding crack, large crystal grains in the heat affected zone and poor mechanical properties. The transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel is realized through the following steps: after the surfaces of TiNi shape memory alloy and stainless steel to be welded and the surface of AgCuTi foil is cleaned and dried, a TiNi shape memory alloy / AgCuTi metallic foil / stainless steel structure is formed, fixed through a welding clip, and then positioned in a vacuum diffusion oven, and welding pressure and temperature are applied to the structure. The method has the advantages that the welding temperature is low (relative to fusion welding), the influence to the base material is small, the connector has no welding defect, the shearing strength of the connector in the room temperature reaches 250 MPa, and the microhardness of the area near the seam section can reach 670 Hv.

Owner:BEIJING UNIV OF TECH

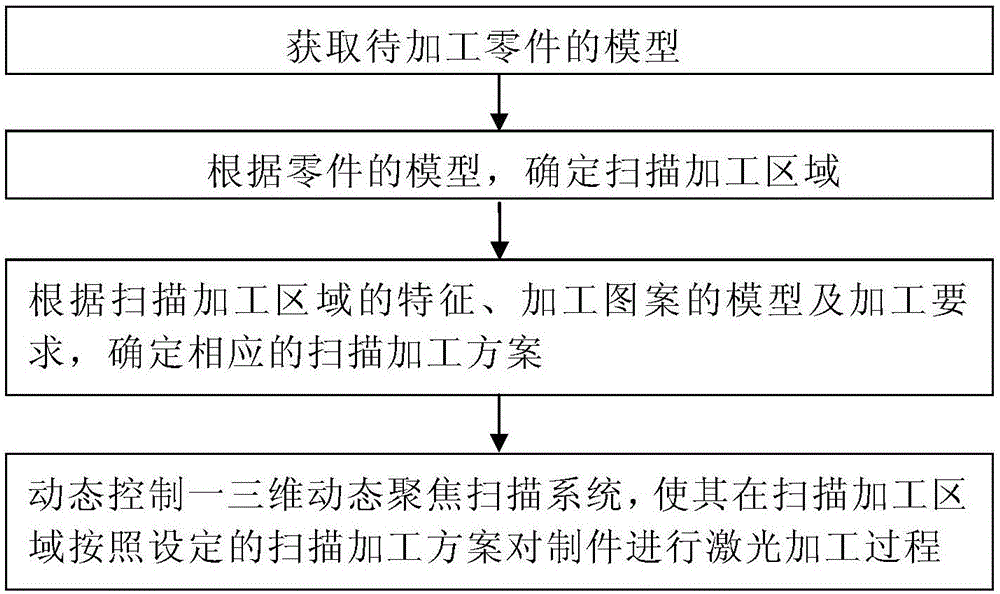

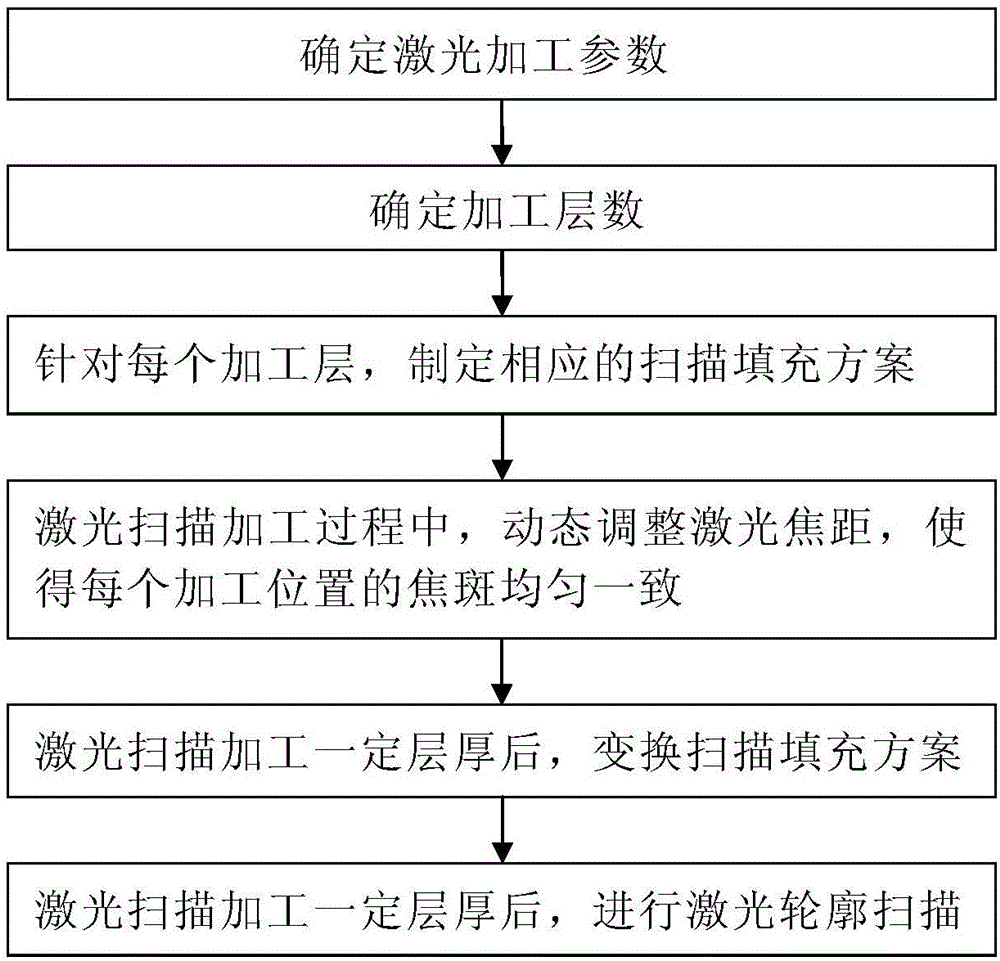

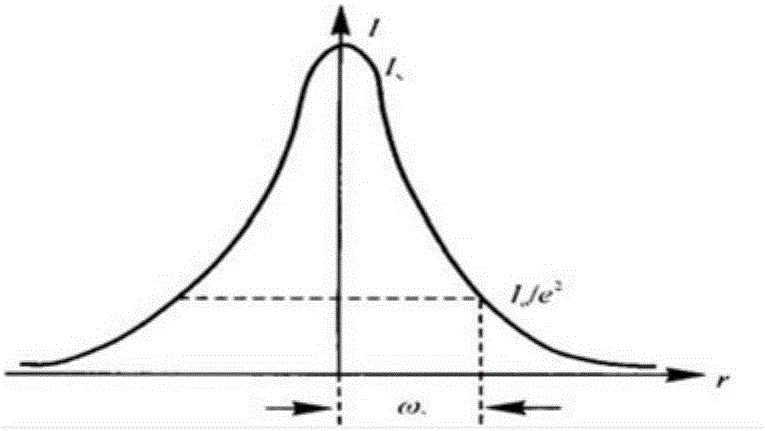

Three-dimension laser fine machining system and method for crisp and hard materials

InactiveCN107175409AGuaranteed uniformityUniform focal spotLaser beam welding apparatusLaser scanningMachining process

The invention provides a three-dimension laser fine machining system and method for crisp and hard materials. The method comprises the steps that a laser scanning machining scheme according to the model of a to-be-machined part, the model of a machining pattern and the machining requirements, specifically, the scheme comprises the process of determining the laser machining parameters and the process of determining the number of machining layers; scanning filling schemes corresponding to the machining layers are made in the pattern filling area; the laser focus is adjusted dynamically in the machining process, light spots are made to keep focusing in each machining position, and focus spots are uniform and coincident; the laser scanning filling schemes are changed every time one or more layers of materials are scanned and removed; and after one or more layers are scanned in the pattern filling area, laser contour scanning is conducted in the pattern contour area one or more times. The three-dimension laser fine machining system and method for the crisp and hard materials can achieve high-precision and efficient machining of the crisp and hard materials by making full use of the various advantages of fine light spot laser scanning machining.

Owner:苏州菲镭泰克激光技术有限公司

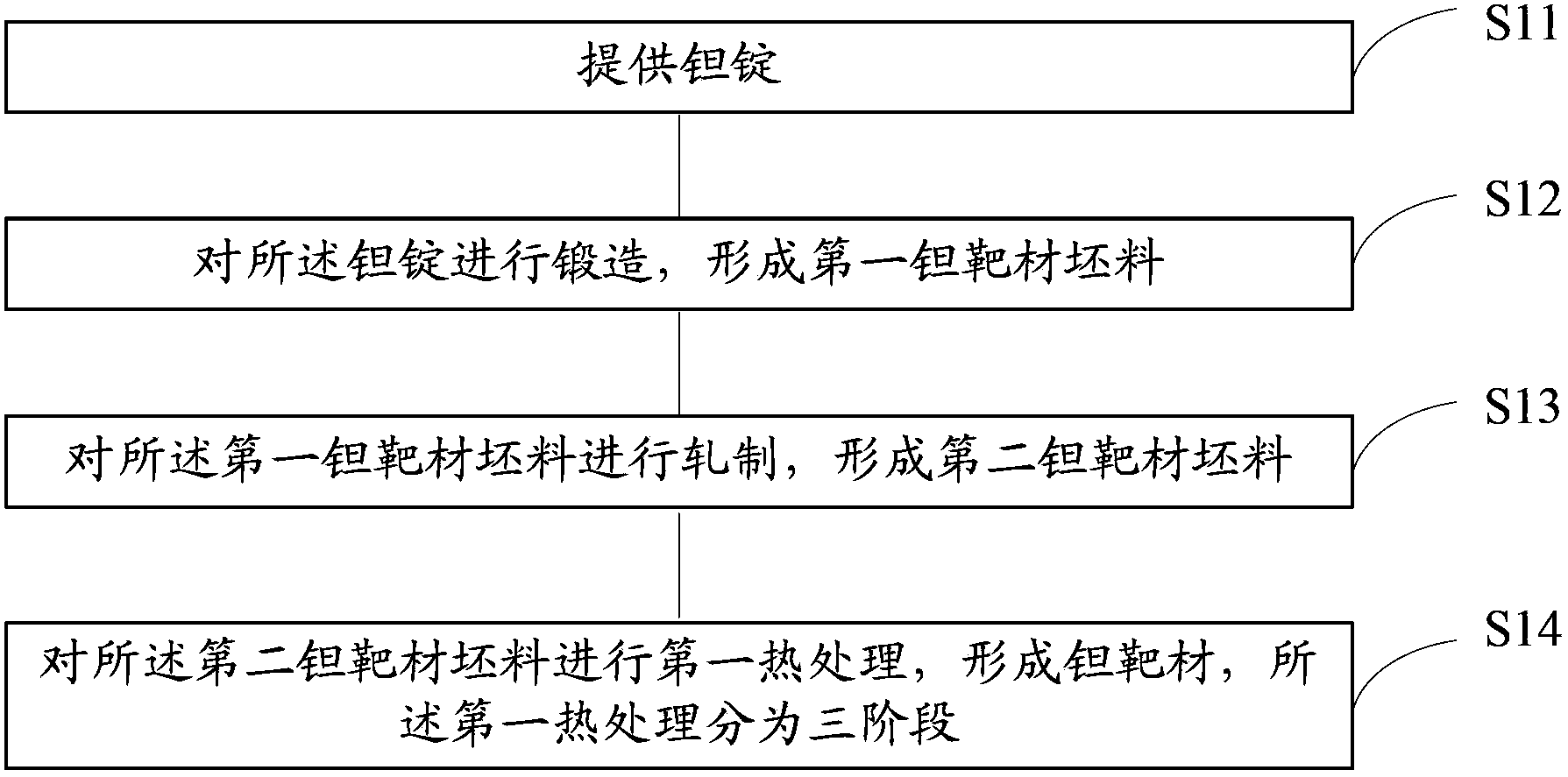

Production method of tantalum target and tantalum target component

ActiveCN103572223AReduce residual stressUniform crystal orientationVacuum evaporation coatingSputtering coatingCrystalliteHolding time

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; forging the tantalum ingot to form a first tantalum target blank; rolling the first tantalum target blank to form a second tantalum target blank; performing first heat treatment on the second tantalum target blank to form the tantalum target, wherein the first heat treatment is divided into three stages: the temperature of the first stage of heat treatment is 550-750 DEG C, and the temperature is maintained for 30-90 minutes; the temperature of the second stage of heat treatment is 750-950 DEG C, and the temperature is maintained for 30-90 minutes; the temperature of the third stage of heat treatment is 950-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the main crystal orientation of the obtained tantalum target is (100), and the crystal orientation on the cross section is uniform; moreover, the tantalum target with fine grain and uniform internal organization also can be obtained.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

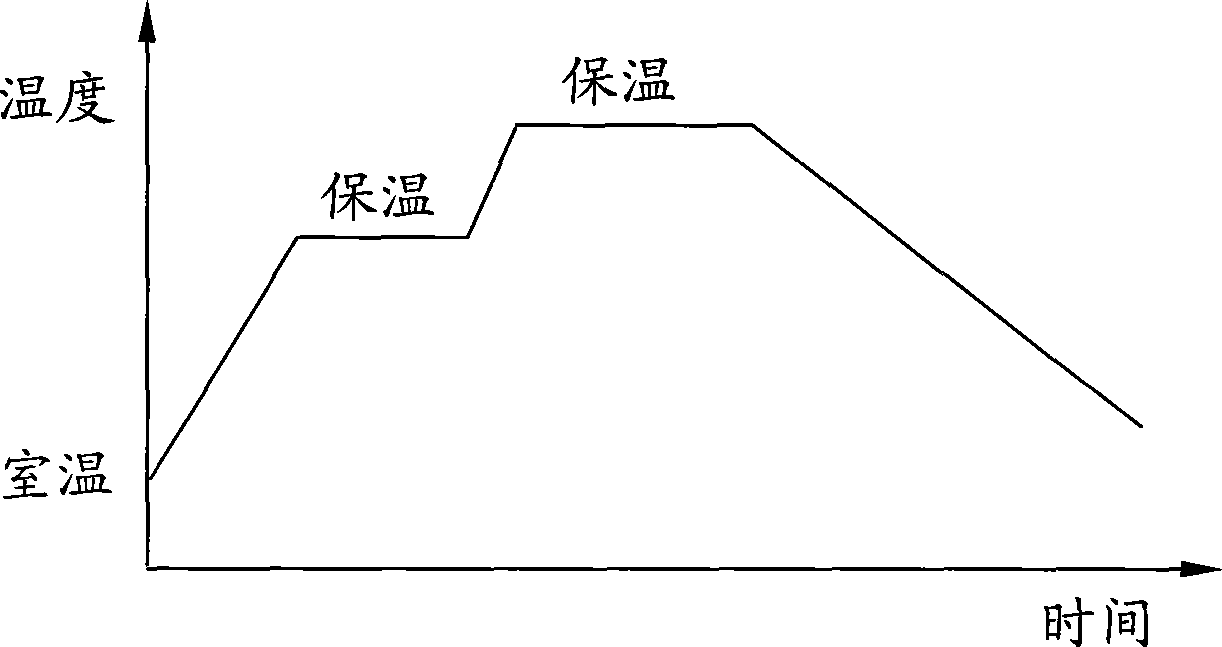

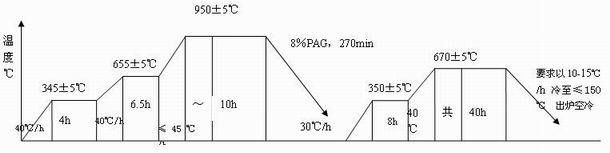

Environment-friendly heat treatment process for large shaft forgings

InactiveCN102115809AUniformly hardenedReduce cleaning costsFurnace typesHeat treatment process controlWater solubleLaser cooling

The invention discloses an environment-friendly heat treatment process for large shaft forgings. According to the heat treatment process, the traditional oil and tap water are substituted by a commercial water soluble quenching medium PAG (poly alkylene glycol) or BW, the concentration of the quenching medium PAG or BW is adjusted, and the process parameters such as the heating speed, holding time, quenching temperature, quenching time, tempering temperature, cooling speed and the like are strictly controlled, thereby solving the problems of deformation and even defects liable to occur by water cooling of large shaft parts and lower rigidity, environmental pollution and the like liable to occur by oil cooling of large shaft parts, and simultaneously solving the problems of heavy weight, great change of sectional dimension, uneven performance after heat treatment and the like of large shaft parts.

Owner:HENAN UNIV OF SCI & TECH

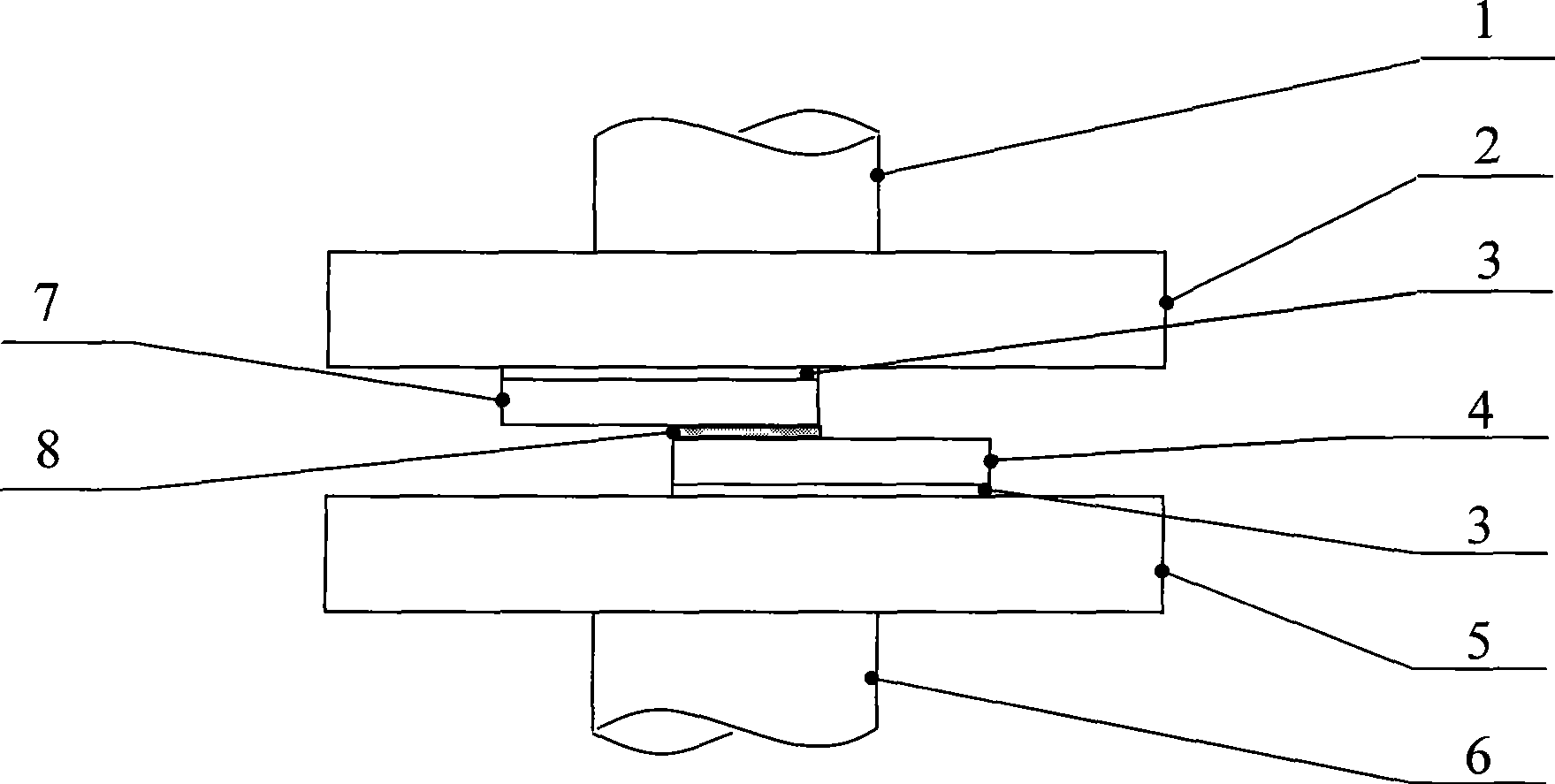

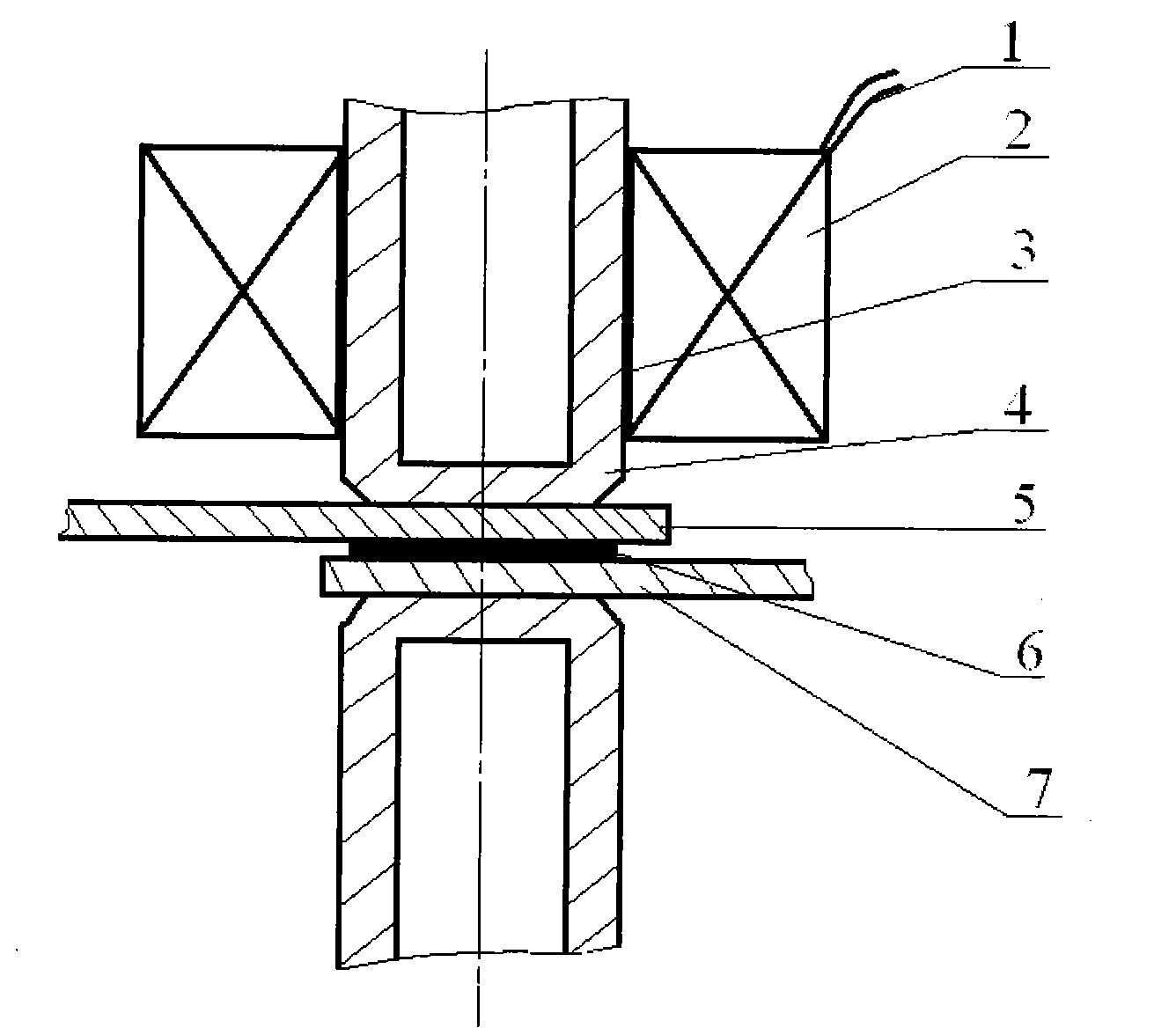

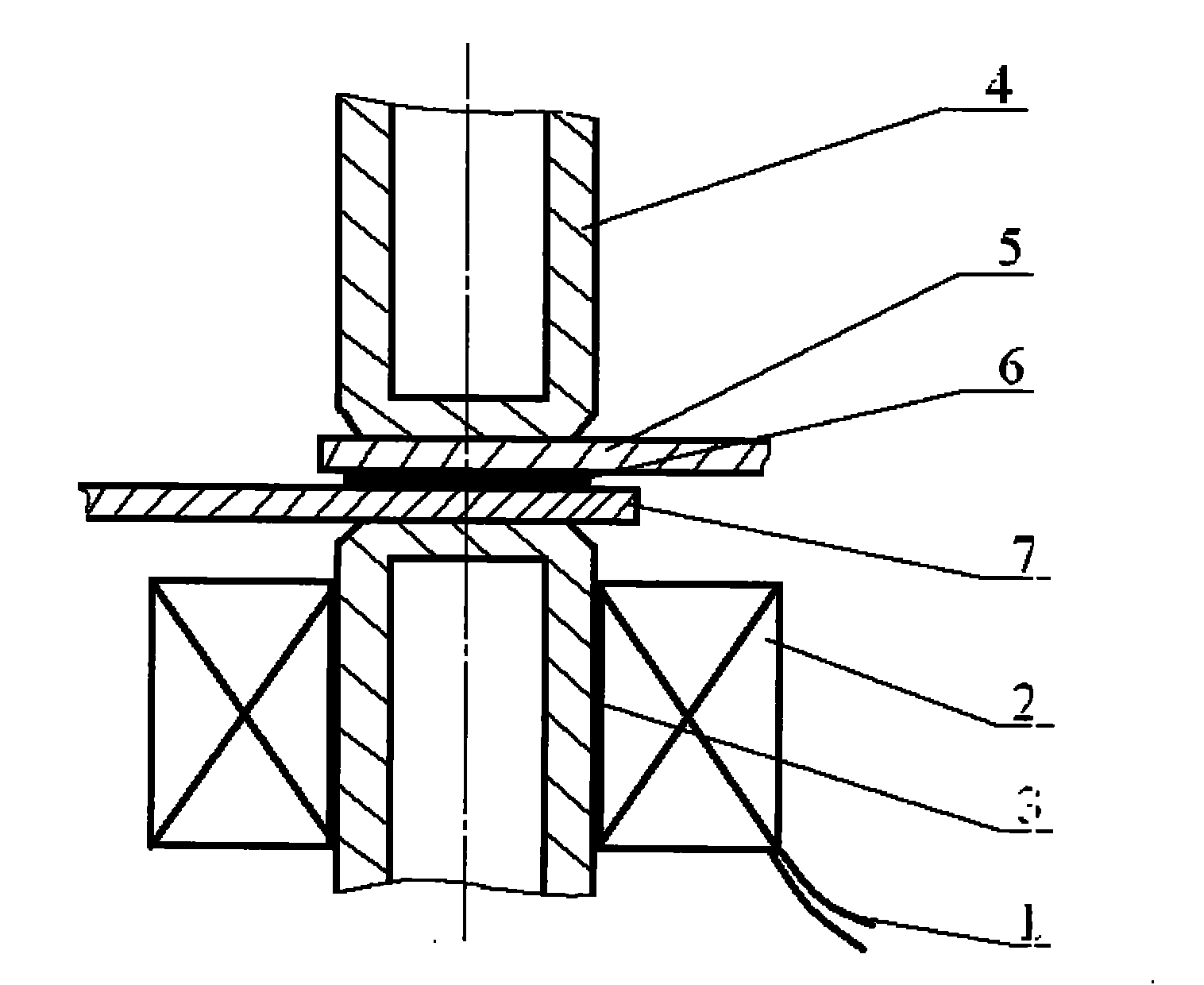

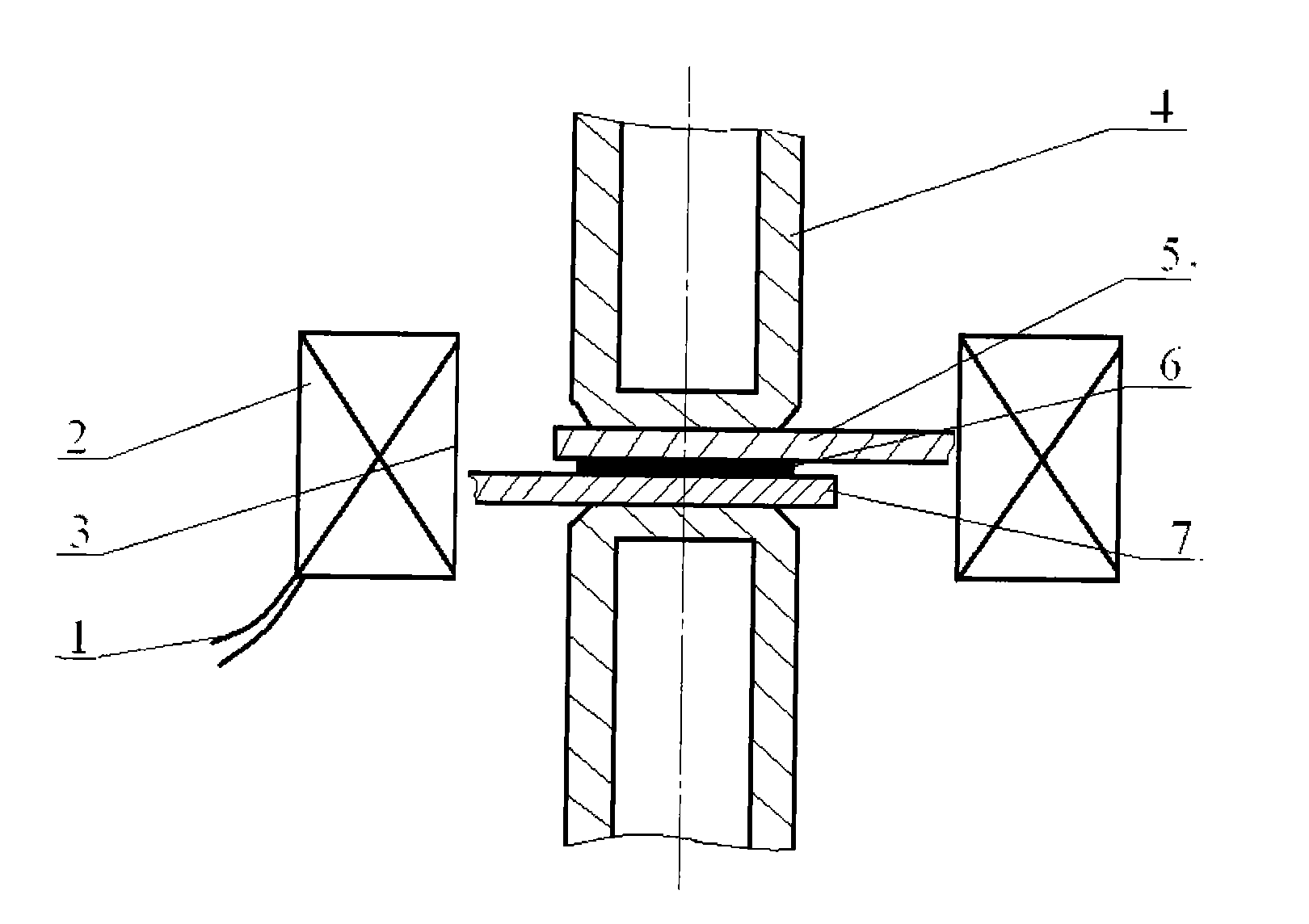

Method and device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials

InactiveCN101844260AImprove connection qualityFully moistenedSoldering apparatusMetal working apparatusMagnetizationMetallic materials

The invention discloses a method and a device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials by assistance of an applied magnetic field. In the process of performing resistance welding-braze welding on the dissimilar metal material, a liquid solder is subjected to auxiliary electromagnetic stirring and ordered control, and the molten liquid solder is subjected to the reinforced booster action of electromagnetic stirring and electric magnetization by using an external applied alternating magnetic field which is generated by a magnet exciting coil in a welding area so as to promote directional flow of the liquid solder, and rupture of membranes, wetting, spreading and diffusion of the liquid solder on the surface of the metal material with a higher melting point, promote the liquid solder and a base metal which is molten by the metal material with a lower melting point to be mixed fully, promote interdiffusion of elements and compositions between the solder and the base metal and alloying between the two, improve uniformity of compositions of a soldered seam, reduce the weld defects, optimize the texture and the performance of the soldered seam, and improve the resistance soldered joint; and the device has the advantages of simple structure, flexible application, lower cost, good effect, and easy implementation.

Owner:CHONGQING UNIV

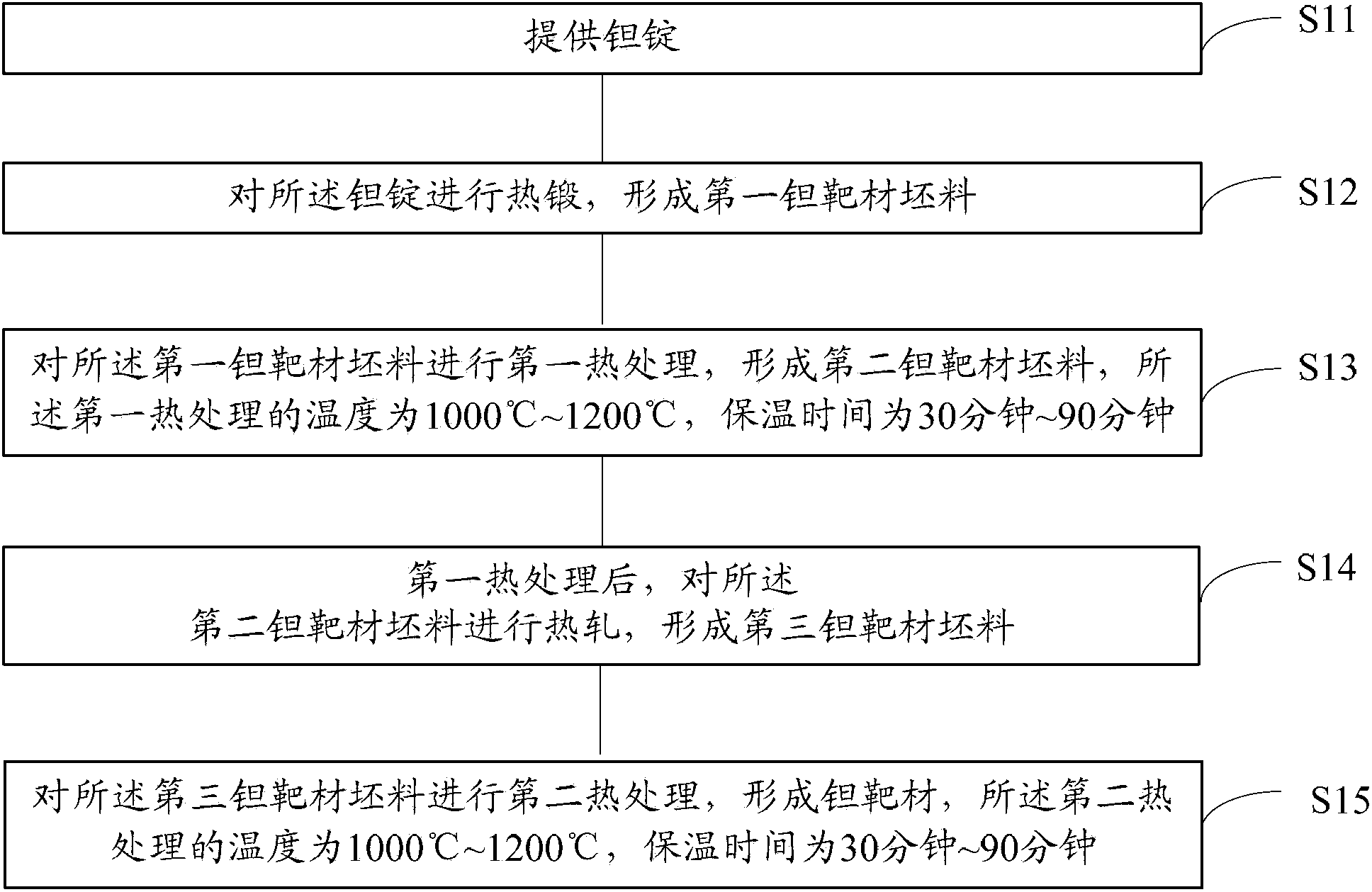

Production method of tantalum target and tantalum target component

ActiveCN103572225ADense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

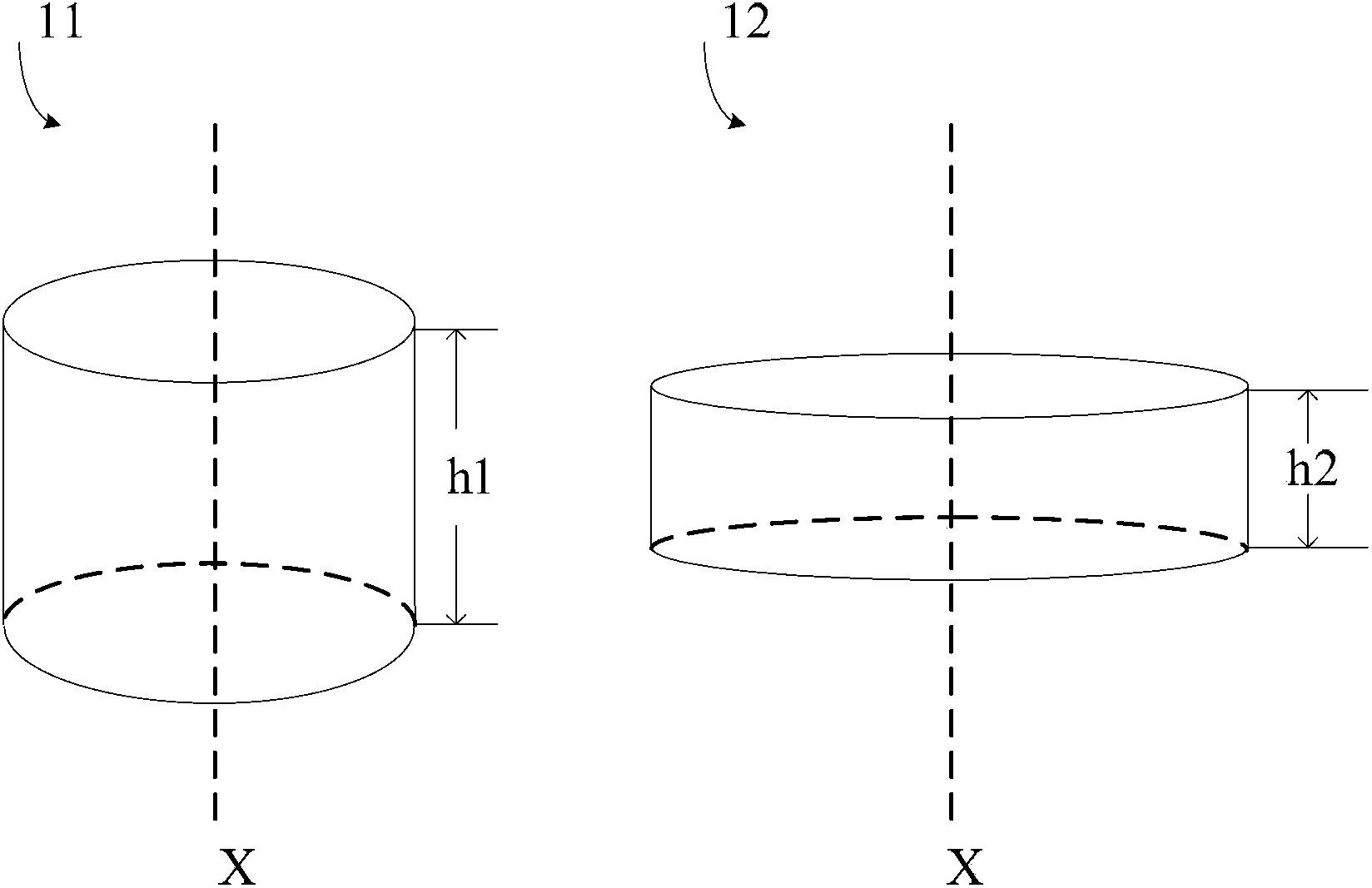

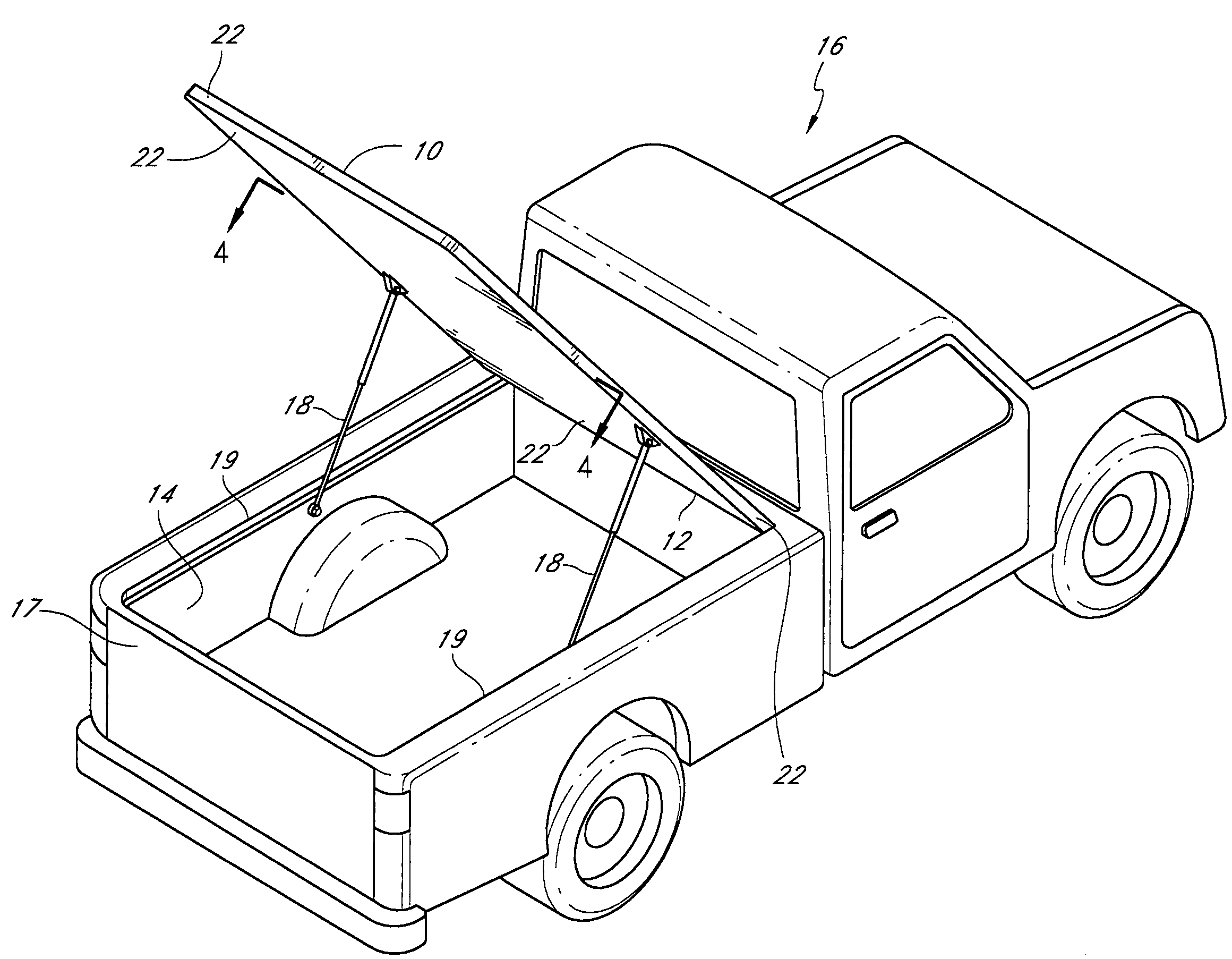

Reinforced tonneau cover

Owner:CYC ENG

Process for preparing large cast steel support roller

The process of making cast steel supported roller is suitable for integral casting of cast steel supported roller of 5-100 ton weight. The present invention has adopts computer simulation, coating iron mold with sand, rotary cavity filling, heat insulating casting head technology, electrically casting head heating technology and sliding roller neck technology; and designs pouring system and casting mold design by means of new design principle and successive solidification principle. Adopting sliding roller neck technology and electrically casting head heating technology can avoid cracking in the cast steel supported roller.

Owner:CHANGSHU LONGTENG SPECIAL STEEL

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

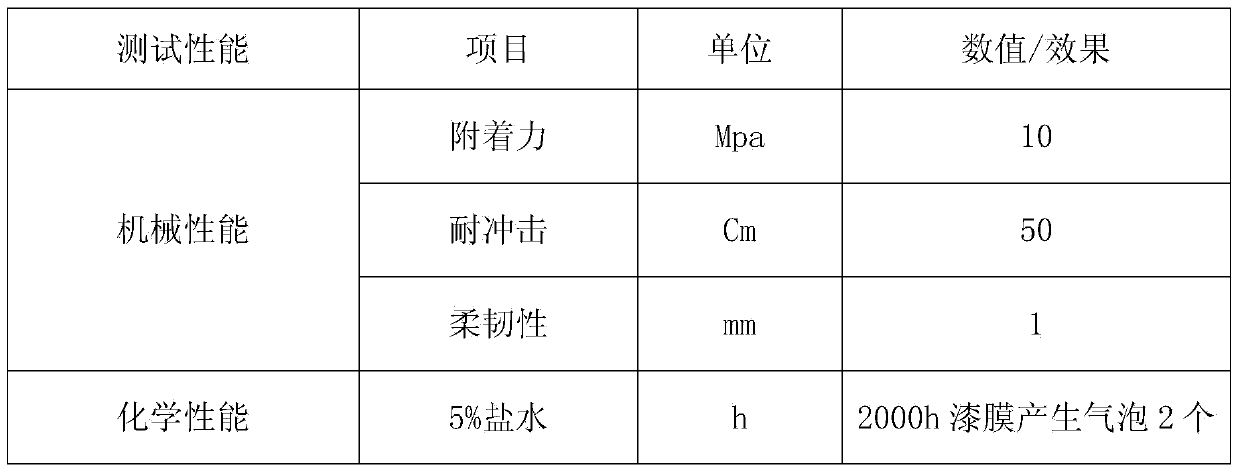

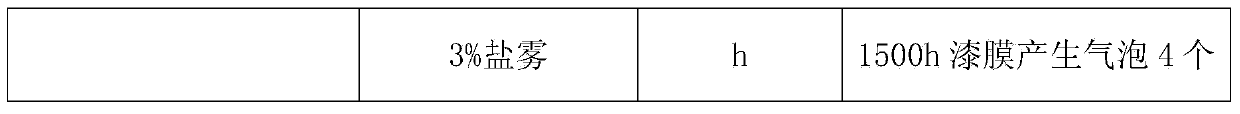

Tetraethylorthosilicate inorganic high-temperature-resistant coating and preparation method thereof

InactiveCN104212206AReduced tendency to crackReduce uneven evaporationAnti-corrosive paintsNanometreAluminium

The invention discloses a tetraethylorthosilicate inorganic high-temperature-resistant coating. The tetraethylorthosilicate inorganic high-temperature-resistant coating comprises the following components in percentage by mass: 28-35% of tetraethylorthosilicate, 35-50% of heat-resistant pigment and filler, 2%-4% of additives and 13-18% of dimethylformamide, wherein the heat-resistant pigment and filler comprises nano-silicon dioxide, a blocking type functional filler and aluminum powder in the mass ratio of 1.5 to 1 to 1. The invention further designs a preparation method of the tetraethylorthosilicate inorganic high-temperature-resistant coating. According to the tetraethylorthosilicate inorganic high-temperature-resistant coating and the preparation method thereof designed by the invention, the adhesion and the hardness of a cured film formed after heat curing of the coating can be significantly improved along with increase in temperature, the adhesion achieves grade one, the pencil hardness is more than 6H, the high temperature above 800 DEG C can be resisted and the cracking tendency of the coated film is greatly reduced.

Owner:JIANGSU MARINE VICTORY COATING

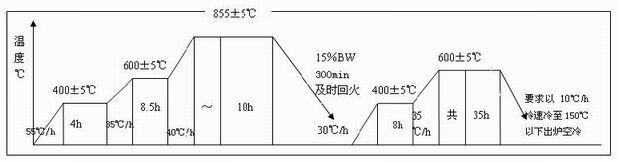

Steel suitable for drill rod joint in low-temperature environment and heat treatment process of steel

InactiveCN102140610AOvercome shortcomingsIncrease low temperature toughness reserveDrilling rodsDrilling casingsFiberTrace element

The invention relates to steel suitable for a drill rod joint in a low-temperature environment and a heat treatment process of the steel. The steel used for a drill rod joint comprises the following components by weight percent: C 0.25-0.35%, Mn 0.50-1.00%, P<=0.015%, S<=0.008%, Mo 0.15-1.00%, Ni 0.75-1.50%, Cr 0.80-1.50%, two or more of Si<=0.30%, Al<=0.03%, V<=0.10%, Ti<=0.03% and Re<=0.005%, and the balance of Fe and inevitable trace elements. The heat treatment process of the steel suitable for a drill rod joint is as follows: heating the steel in a furnace to 900-960 DEG C; carrying out heat insulation for 1.0-1.5 hours; putting the steel into a quenching medium and cooling down completely; tempering at the temperature of 660-690 DEG C; carrying out heat insulation for about 2.0-2.5 hours; and then taking the steel out of the furnace. After the steel is treated according to the process, when the yield strength of the steel is 905MPa, longitudinal and full-size charpy impact power average value at -60 DEG C is 110J, the fracture fiber rate is 100% on the average, and the ductile-brittle transition temperature is -85 DEG C.

Owner:SHANGHAI HILONG DRILL PIPE MATERIALS INST +1

Wear resistant coating for brush seal applications

InactiveUS6815099B1Less stressReduced tendency to crackEngine sealsMolten spray coatingWear resistantCarbide

A metallic coating containing hard carbide particles is described. The coating is applied by an HVOF process using powder particles whose size ranges from about 15 to about 44 microns. The carbide particles are held in a 80% nickel-20% chromium matrix. The coating has a reduced tensile compressive stress relative to similar plasma sprayed coatings and exhibits a high strain to cracking value.

Owner:UNITED TECH CORP

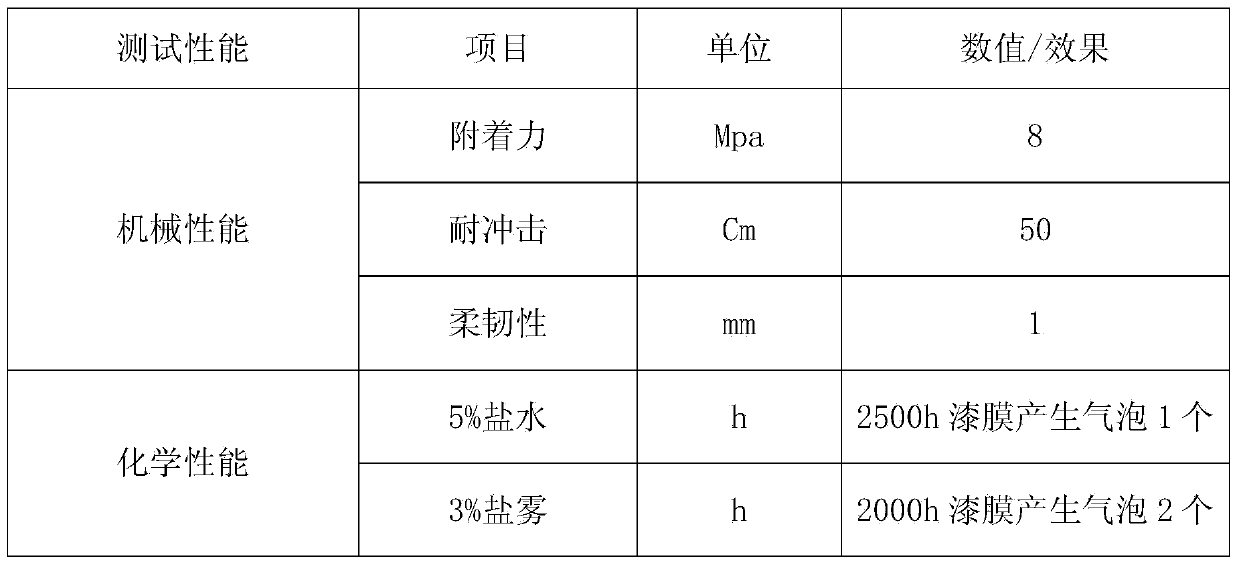

Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy

InactiveCN103911612ADense tissueSmall heat affected zoneMetallic material coating processesAlloyOptoelectronics

The invention discloses a Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy. The Cr12MoV cold stamping mold laser repair technology comprises the following steps: (1) cleaning defects on the surface of a cold stamping mold, and removing grinding racks, oil stains and microcracks on the surface; (2) using Fe316 alloy powder as a bottoming layer, and carrying out laser bottoming fusion covering; (3) using Co06+WC alloy powder as a covering layer, and after cooling the mold to 300-600 DEG C, carrying out laser fusion covering on the covering layer; and (4) carrying out mechanical machining on the surface of the fusion covering layer. According to the technology, the fusion covering layer with high interface bonding strength and compact structure and without cracks is obtained without preheating, the microhardness of the fusion covering layer reaches 58-62HRC9.8N, particularly the fusion covering layer has good abrasive resistance and can meet the production requirements, and the service life of the cold stamping mold can be prolonged.

Owner:SHANDONG UNIV

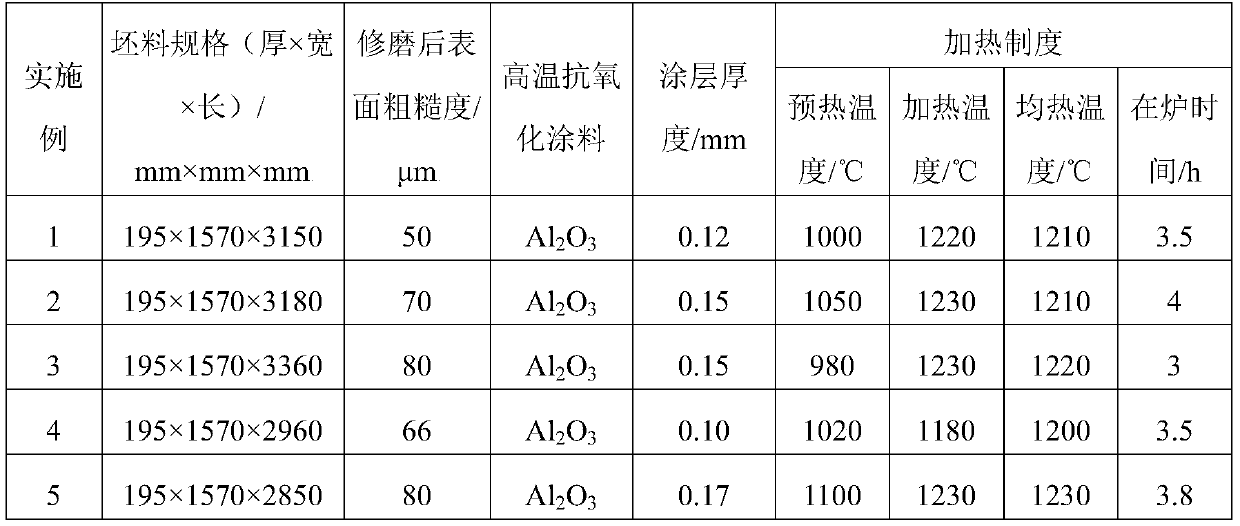

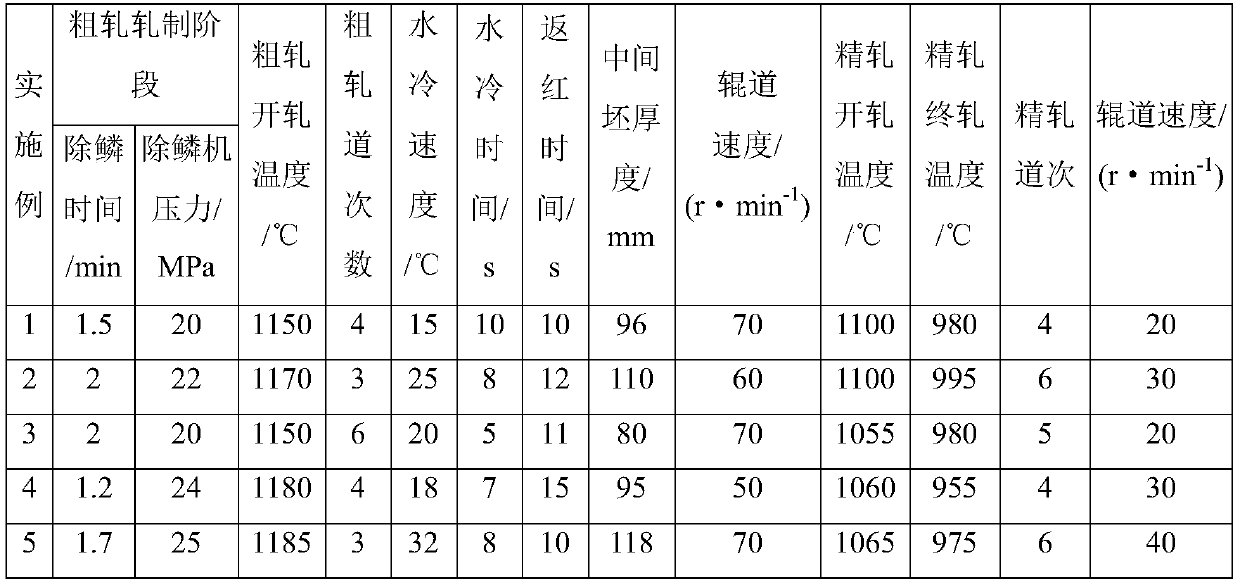

Method for eliminating surface cracks of ultra-wide ferrite stainless steel middle-thick plate

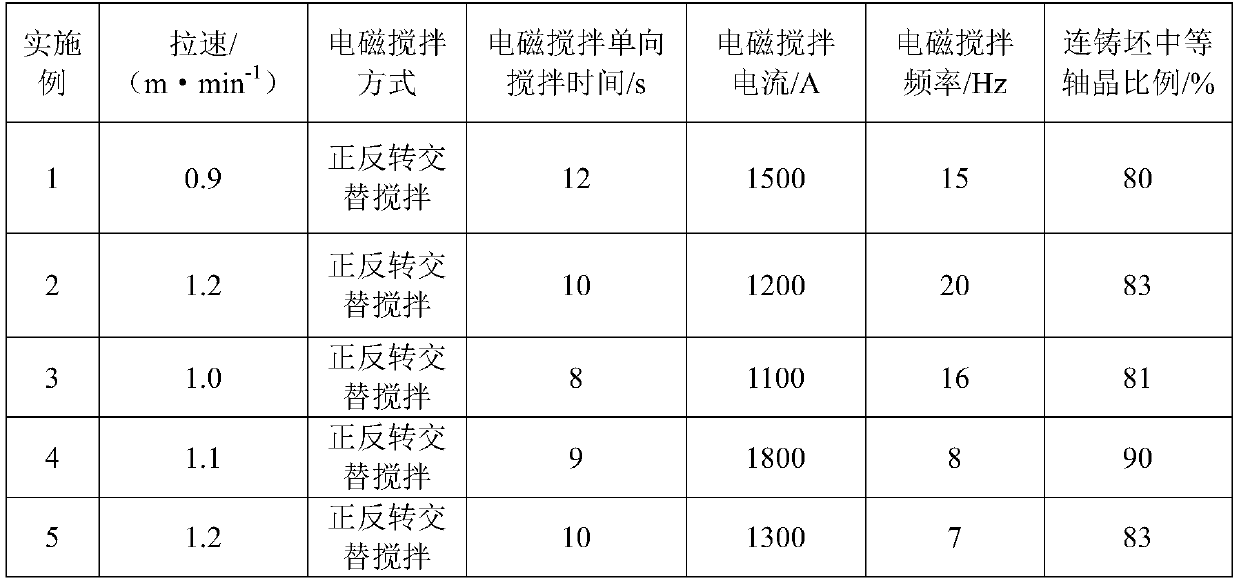

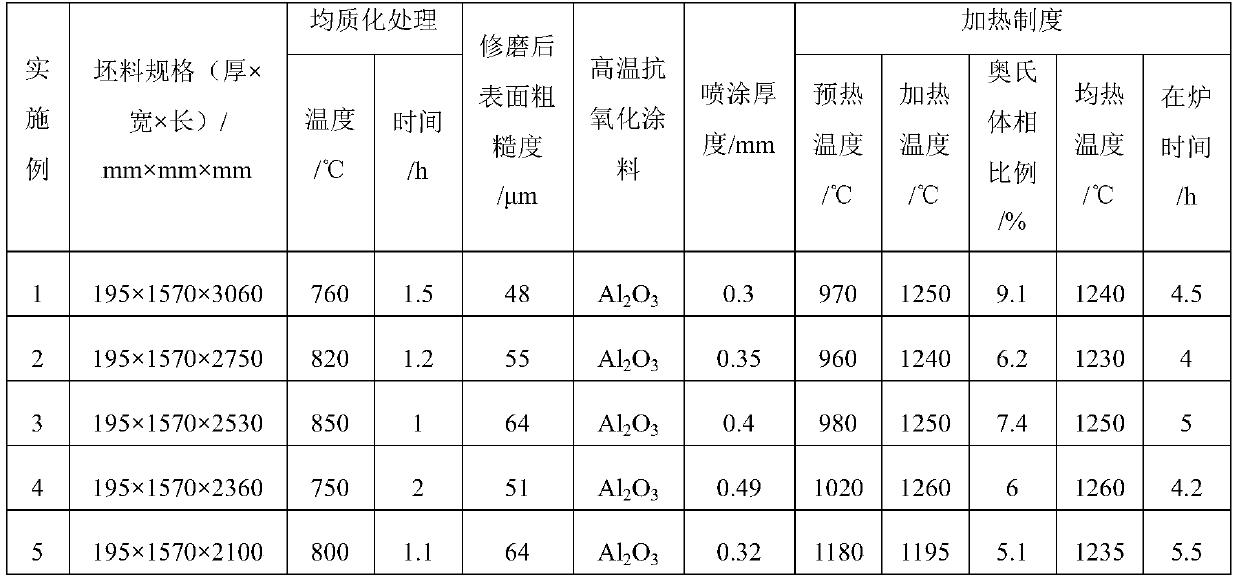

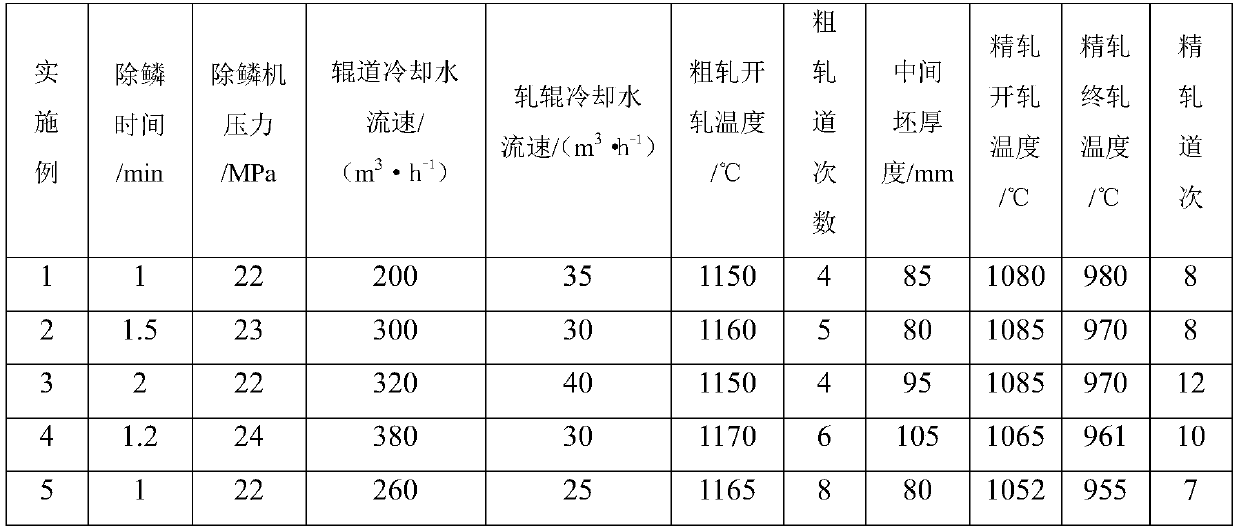

ActiveCN110438414AIncrease equiaxed crystal ratioShorten the forming intervalProcess efficiency improvementWork heating devicesSingle passThick plate

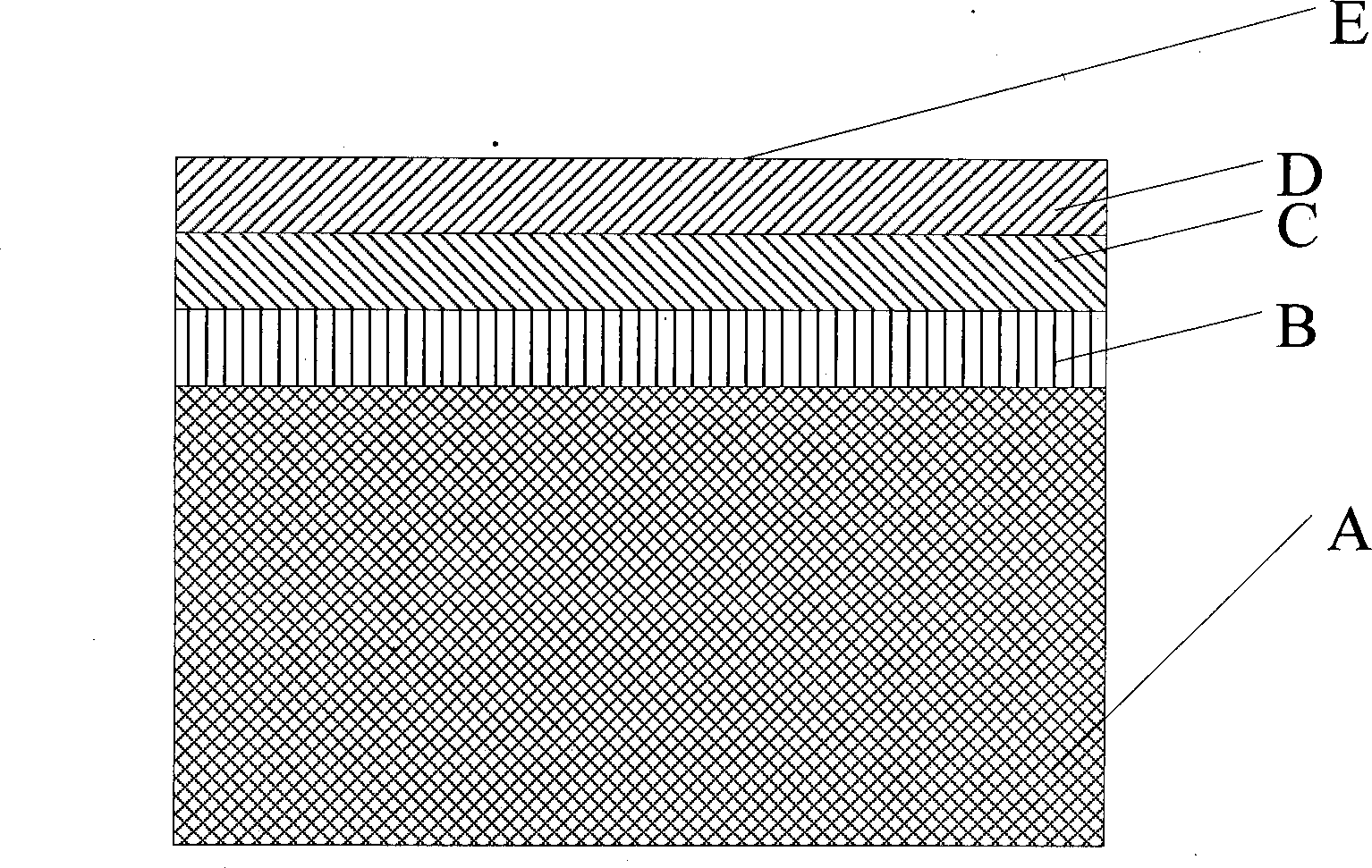

The invention discloses a method for eliminating surface cracks of an ultra-wide ferrite stainless steel middle-thick plate. The proportion of the medium axis crystal of a continuous cast blank is notlower than 75%; the homogenization temperature of the cast blank is 750-850 DEG C, the duration in the furnace is 1-2 hours, and water cooling is carried out to the room temperature; the surface roughness Ra of the cast blank after grinding is less than or equal to 70 microns, and high-temperature antioxidant coating is sprayed; the cast blank is processed by a preheating section, a heating section and a soaking section in sequence, and then is discharged from the furnace; the temperature of the preheating section is 950-1180 DEG C, the temperature of the heating section is 1180-1260 DEG C, the temperature of the soaking section is 1220-1250 DEG C, and the furnace time is 4-5.5 hours; the rough rolling temperature is larger than or equal to 1150 DEG C; the finish rolling temperature is larger than or equal to 1150 DEG C, the final rolling temperature is larger than or equal to 950 DEG C, the rolling single-pass pressing rate is less than or equal to 20%, the annealing temperature is 750-880 DEG C, the furnace time is 2-5 min / mm, and air cooling is carried out. The product width is 2500-4000 mm and the thickness is 8-30 mm. The rejection rate of the surface cracks is reduced from 6% or above to 0.5% or below.

Owner:ANGANG STEEL CO LTD

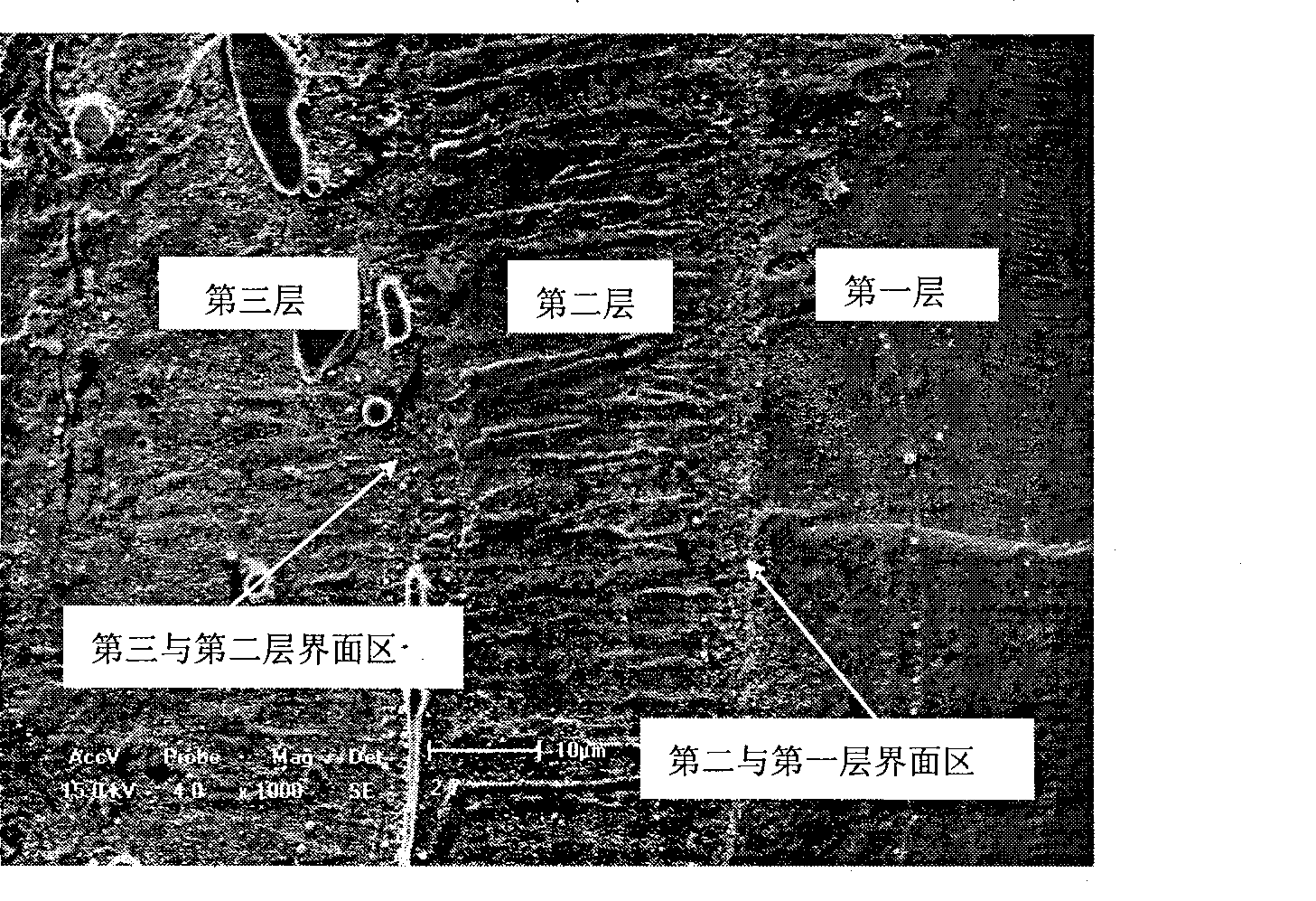

In-situ preparation of cobalt-base alloy gradient coating on aldary surface through laser induction, and method thereof

InactiveCN101444981AIncreased average microhardnessHigh hardnessMetallic material coating processesMetal layered productsWear resistantCeramic particle

The invention relates to in-situ preparation of a cobalt-base alloy gradient coating on an aldary surface through laser induction and a method thereof, and belongs to the material technical field. The gradient coating comprises a first coating, a second coating and a third coating, and the thickness of each coating is 0.04 to 0.10mm, 0.03 to 0.08mm and 0.07 to 0.13mm respectively. The preparation method comprises the steps as follows: the aldary surface is processed through activating treatment, Al, Co, C, Ni, Cr, Fe, Si, CrO3, Y2O3, Mo, W, MgO, B2O3 and graphite nodule milling are mixed and are prepared into a mixed materiel for the three coatings respectively; and the mixed materiel for the three coatings is spread on the aldary surface; and the ceramic particle reinforced cobalt-base alloy gradient coating is prepared through laser induction in-situ. The invention adopts the advanced technology for preparing an advanced heatproof wear-resistant gradient coating on the aldary surface, and has good application prospect and important economic significance.

Owner:XINGKE MEDIUM & SMALL ENTERPRISES SERVICE CENT OF NORTHEASTERN UNIV

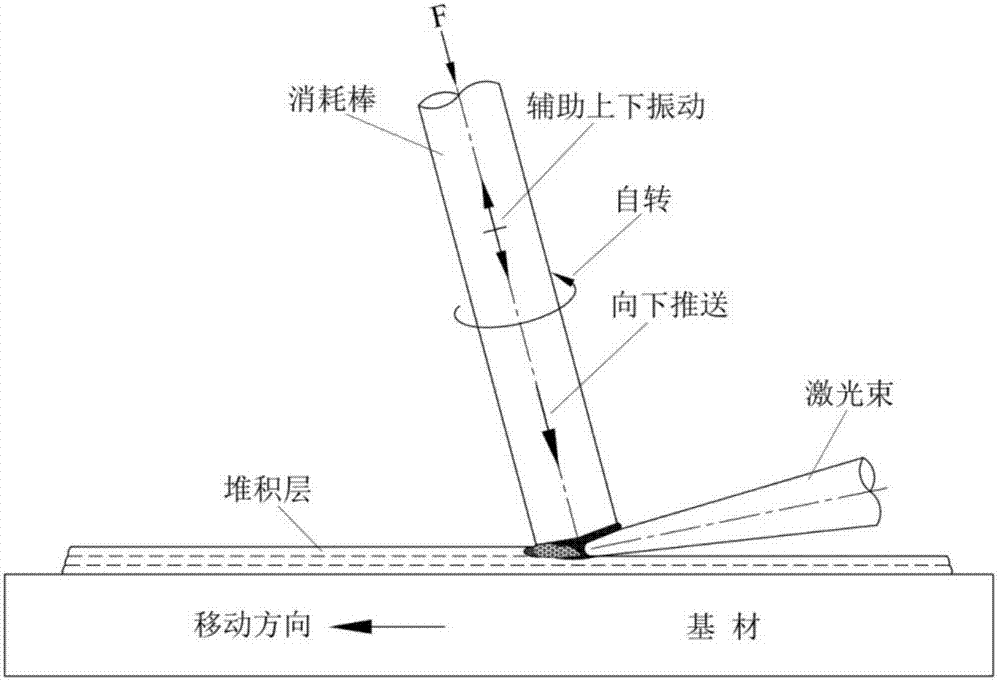

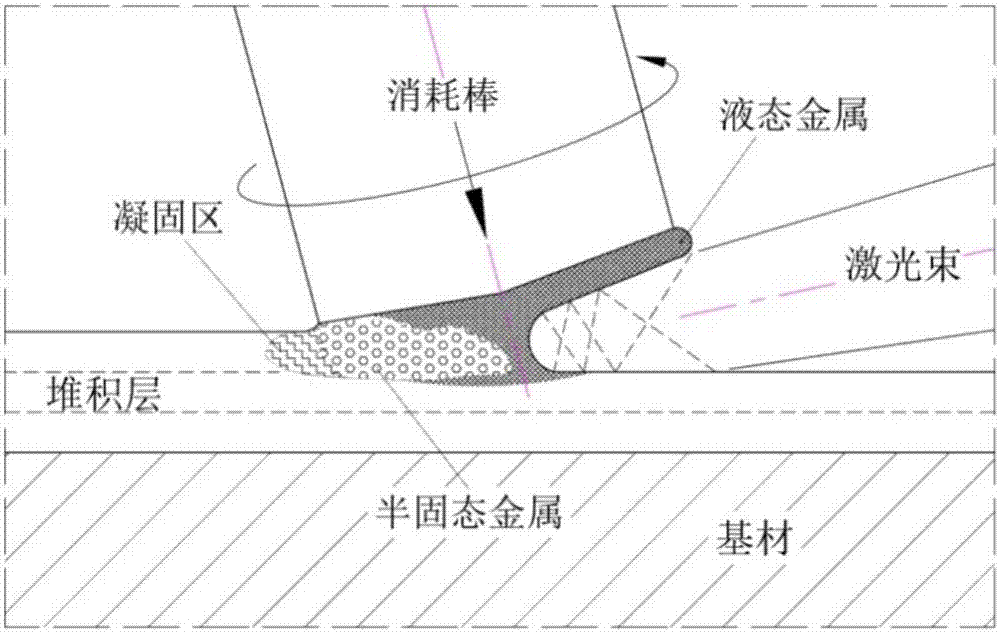

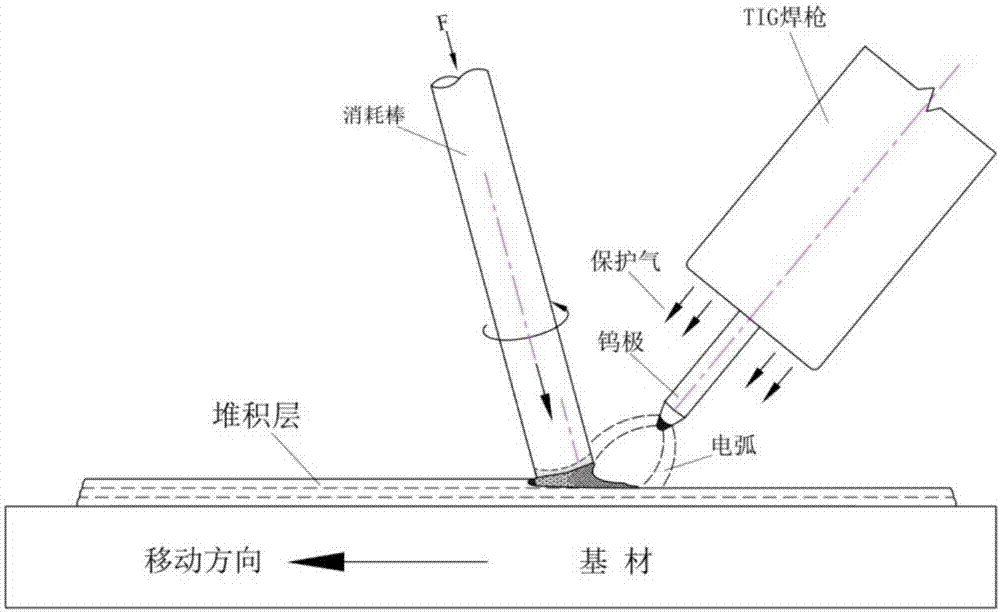

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

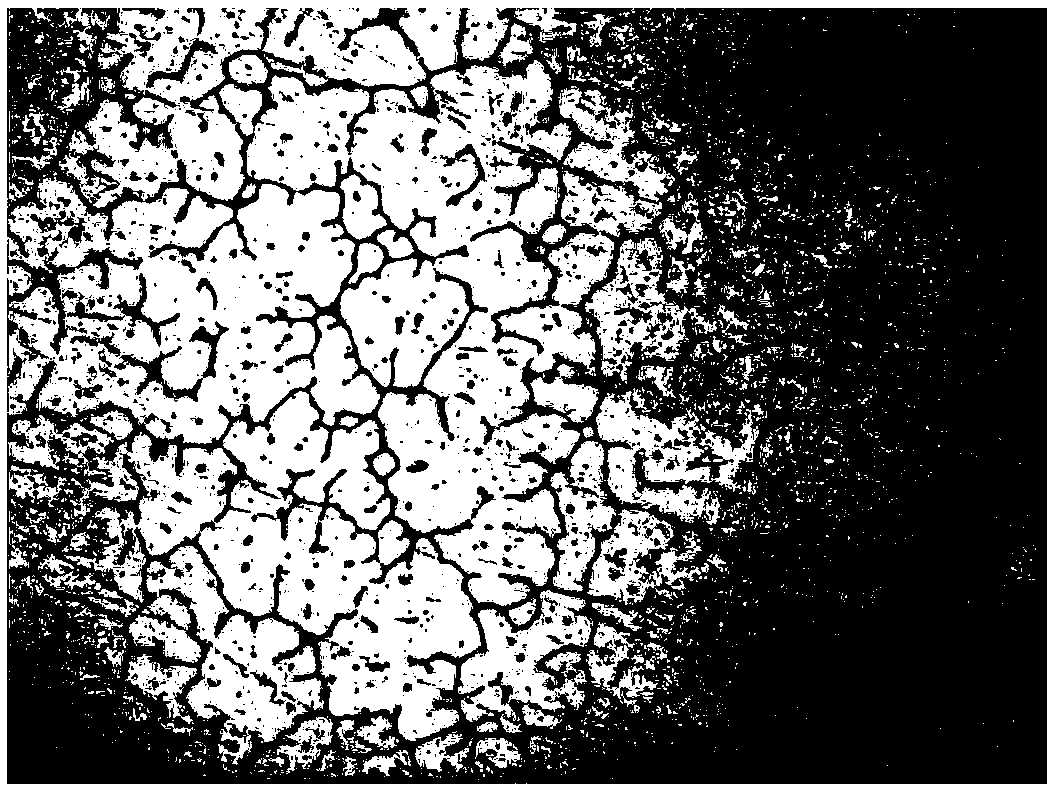

Excellent-performance high-N austenitic stainless steel medium-thick plate and manufacturing method thereof

ActiveCN110499448AIncrease the axial grain rateQuality improvementProcess efficiency improvementReduction rateThick plate

The invention discloses an excellent-performance high-N austenitic stainless steel medium-thick plate and a manufacturing method thereof. The continuous casting slab medium axialite ratio is higher than or equal to 80%; the casting blank surface roughness is smaller than or equal to 100 microns; the casting blank preheating section temperature is 980 DEG C to 1100 DEG C, the heating section temperature is 1160 DEG C to 1230 DEG C, the soaking section temperature is 1200 DEG C to 1230 DEG C, and the in-furnace time is 3 h-4 h; the rough rolling starting temperature is higher than or equal to 1150 DEG C, the first-two gate rolling reduction rate is higher than or equal to 20%, the rough rolling follow-up gate reduction rate is smaller than or equal to 15%, and the intermediate blank thickness is 80 mm to 120 mm; the finish rolling start temperature is higher than or equal to 1050 DEG C, the final rolling temperature is higher than or equal to 950 DEG C, and the rolling reduction rate issmaller than or equal to 20%; and the solution temperature is 980 DEG C to 1050 DEG C, and the in-furnace time is 2 min / mm to 5 min / mm. The product width is 2200 mm to 4000 mm, and the product thickness is 30 mm to 60 mm. The -196 DEG C yield strength is larger than or equal to 350 MPa, the tensile strength is larger than or equal to 1250 MPa, the elongation is larger than or equal to 40%, and thesurface crack rejection rate drops from more than 15% to less than 5%.

Owner:ANGANG STEEL CO LTD

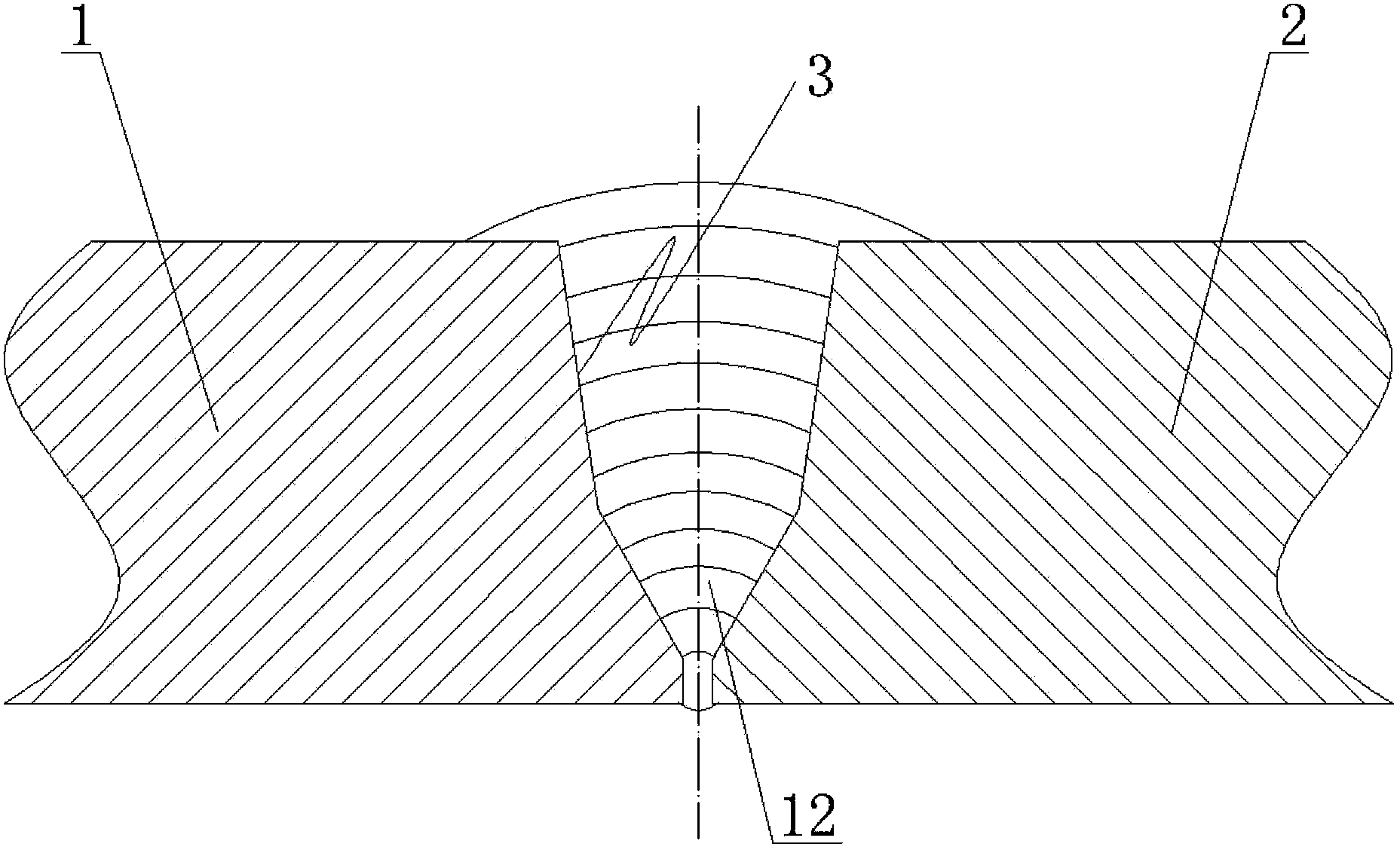

Large-sized, high-strength and high-toughness 7000 series aluminum alloy round cast ingot and preparation method thereof

The invention relates to a large-sized, high-strength and high-toughness 7000 series aluminum alloy round cast ingot and a preparation method thereof to solve the problems of low strength and low fracture toughness property of an existing large-sized 7000 series aluminum alloy round cast ingot. The aluminum alloy round cast ingot is manufactured by Si, Fe, Cu, Mn, Mg, Cr, Zn, Ti, Zr, Sb, Be, Na, Li, K and the balance Al. The preparation method comprises the following steps that step 1, that raw materials are weighed; step 2, a smelt agent is laid at the bottom of a furnace before raw materialfeeding, the raw materials are added into the smelting furnace, and then the smelt agent is laid on the surface after raw material feeding; step 3, heating is conducted until the raw materials in thefurnace smelt, and then a copper plate and zinc ingot are added; step 4, smelting is carried out, and dross on the surface is removed; step 5, refining is carried out; step 6, turning down is carriedout; step 7, casting is carried out; step 8, saw cutting is carried out, and step 9, homogenizing annealing is carried out. The aluminum cast ingot manufactured section steel has high tensile strength, compression-resisting yield strength and high fracture toughness property, and is used in the field of aluminum alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com