Method and device for performing electric magnetization resistance welding-braze welding compounding on dissimilar materials

An electromagnetic excitation, dissimilar material technology, applied in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of short liquid molten pool retention time, easy defects in joints, and unfavorable liquid solder to fully spread and base metal mutual diffusion and other problems , to improve the connection quality, inhibit the formation of harmful substances, and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

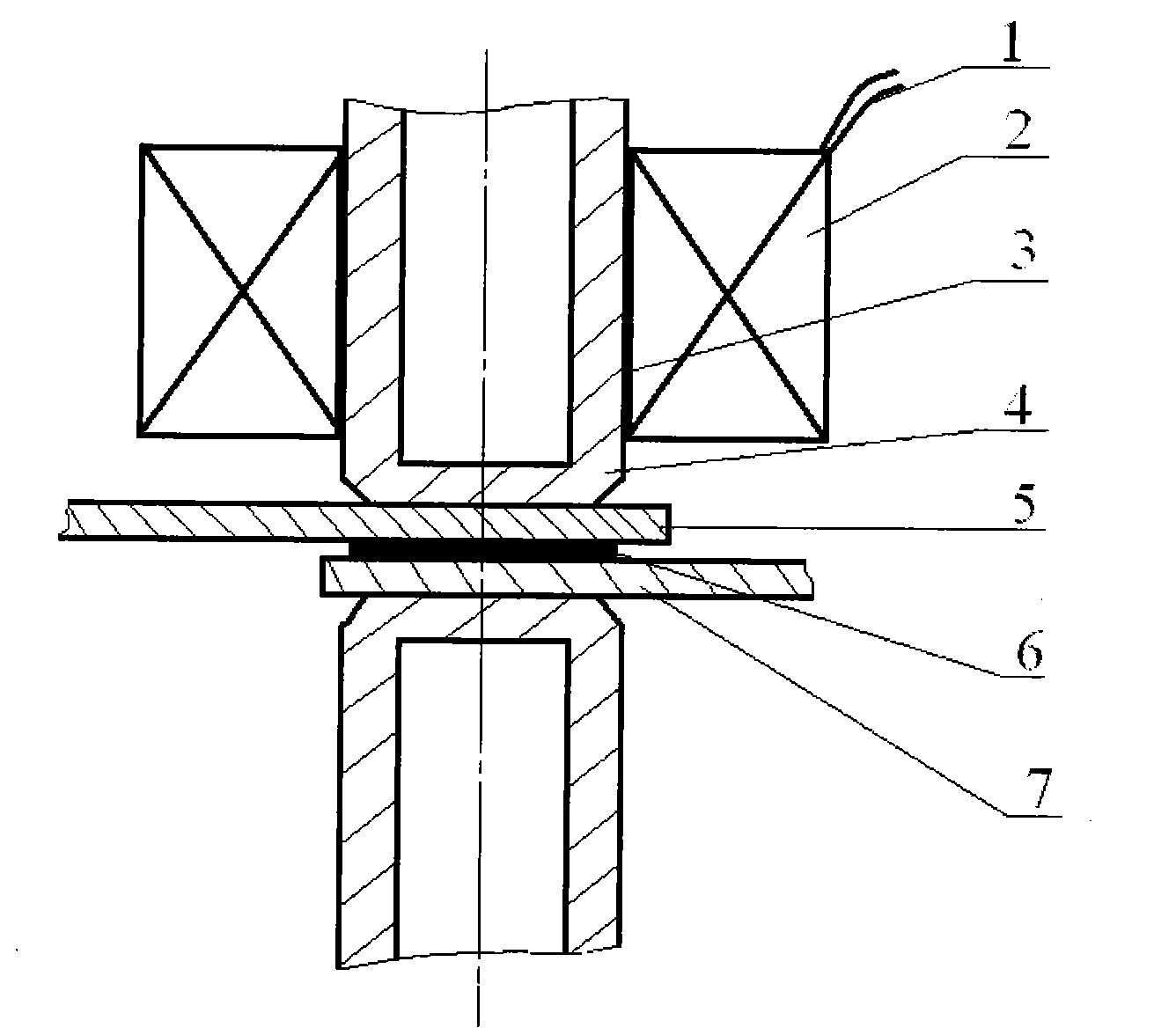

[0035] 1.2mm and ZK60 magnesium alloy workpiece overlap electromagnetic excitation resistance melting-brazing, welding process parameters are: the size of the upper and lower electrodes are Φ16mm and Φ8mm respectively, 42CrMnSi steel is placed on the lower electrode, and the flux and solder are placed on 42CrMnSi Between the steel and the ZK60 magnesium alloy workpiece, the ZK60 magnesium alloy workpiece is located on the upper electrode; the welding current is 12KA; the auxiliary magnetic field strength is 800Gs; the welding time is 0.2-0.6s; the electrode pressure is 2.4-3.7KN. Through parameter optimization, the required resistance fusion-brazing structure and performance can be achieved.

Embodiment 2

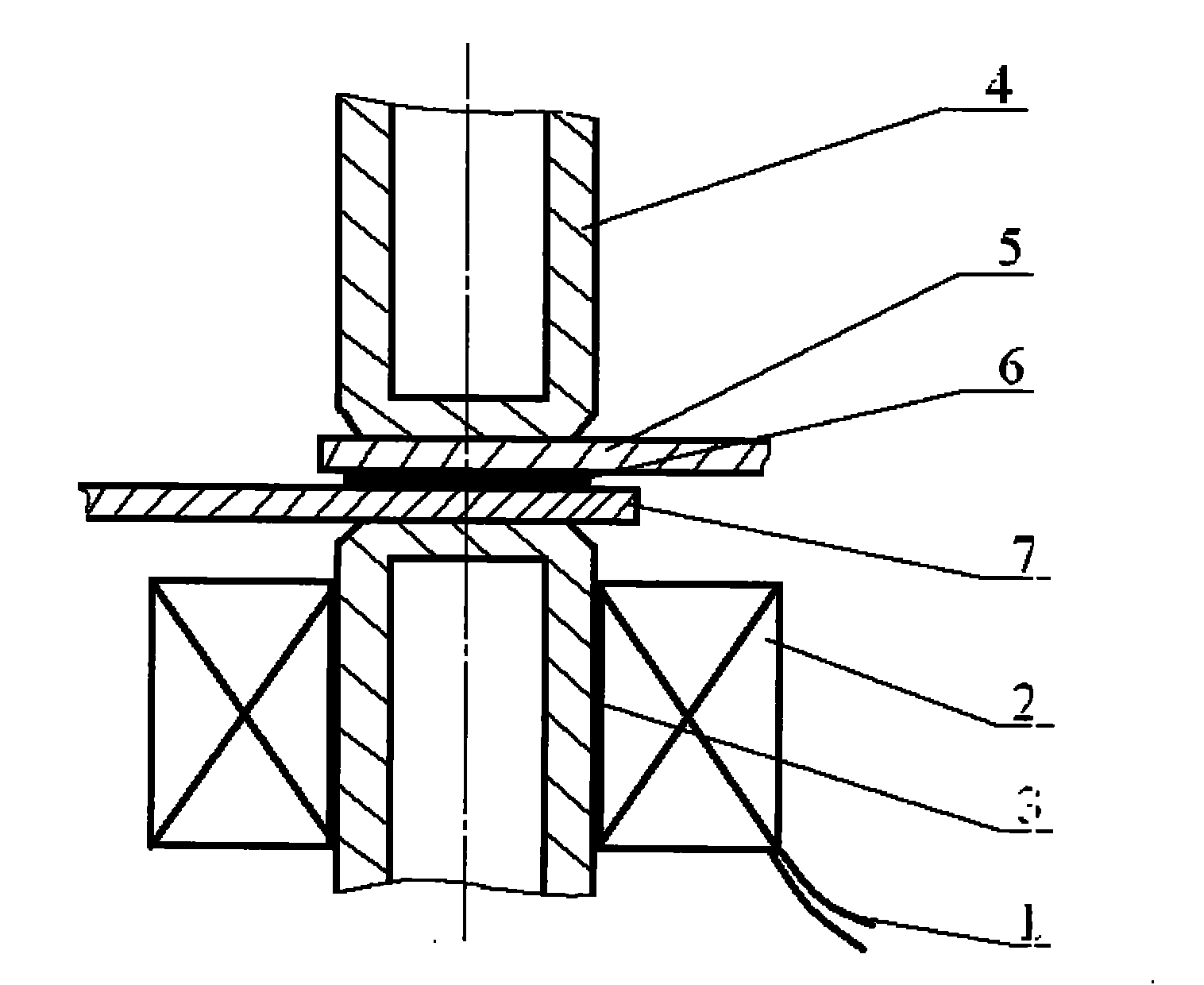

[0037] 1.6mm 7075 aluminum alloy and AZ31B magnesium alloy workpiece are electromagnetically excited resistance seam welding and melting-brazing. The welding process parameters are: the arc radius of the roller is 100mm; the welding current is 36KA; the auxiliary magnetic field strength is 800Gs; the number of points per minute is 120-150 point; electrode pressure 5.2-8.7KN. Flux and solder are placed between the 7075 aluminum alloy and the AZ31B magnesium alloy workpiece, and the welding of high-quality resistance fusion-brazing joints is realized through parameter optimization.

Embodiment 3

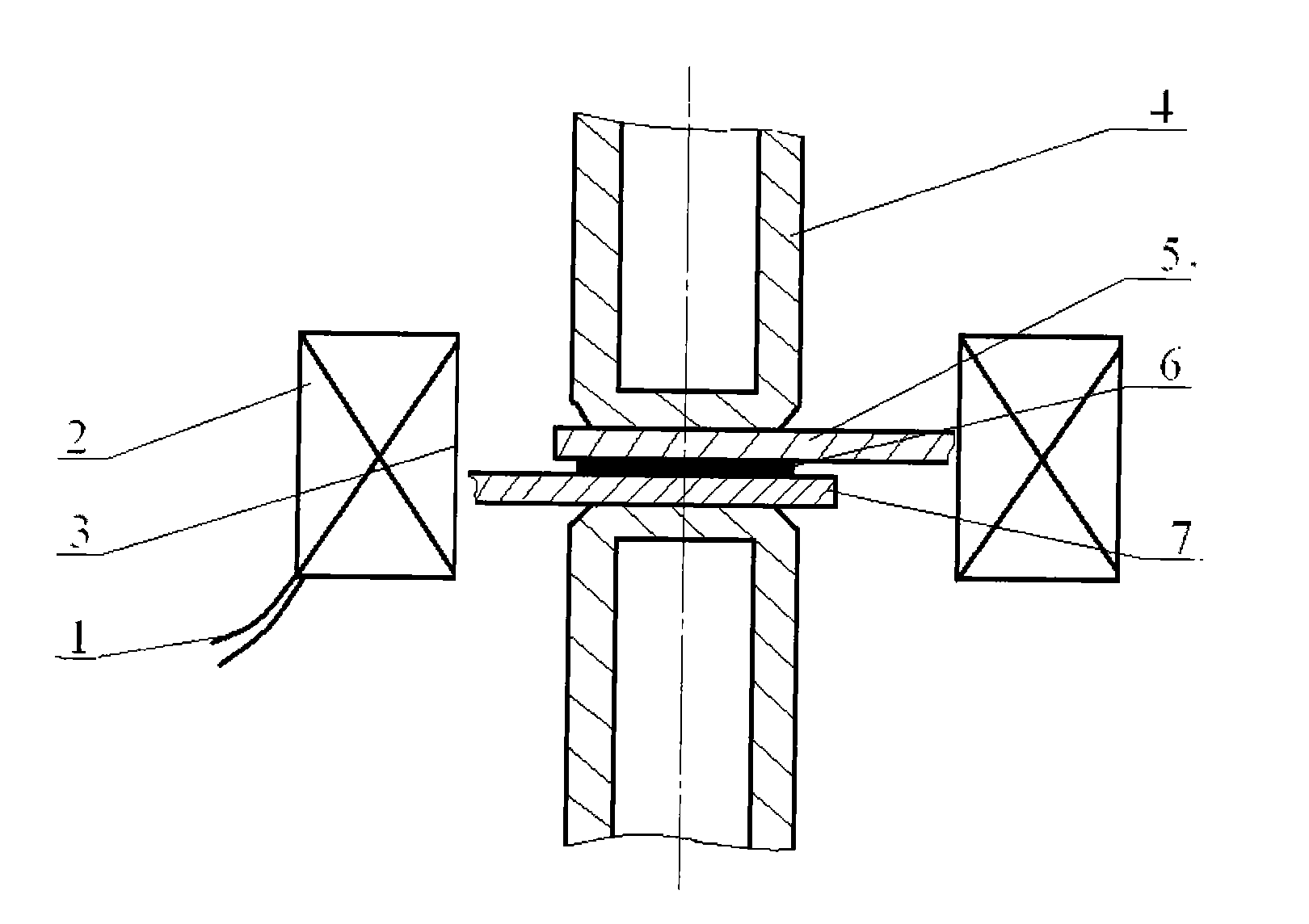

[0039] 3mm thick AZ91 magnesium alloy electromagnetic excitation resistance spot welding fusion-brazing, welding process parameters are: the upper and lower electrodes have the same size, the electrode spherical radius is 200mm; the welding current is 12-32KA; the auxiliary magnetic field strength is 1200Gs, and the direction is a transverse magnetic field ; The electrode pressure is 3.6-5.8KN, the brazing material is Zn-Al-Cu eutectic composition, and the brazing flux is chloride brazing flux prepared from KCl, NaCl, LiCl and NaF. Through parameter optimization, the welding of high-quality resistance fusion-brazing joints is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com