Fabricated shear wall and assembly method thereof

An assembly method and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of complex assembly of prefabricated shear walls, influence of mechanical properties of shear walls, and difficulty in inspection of assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

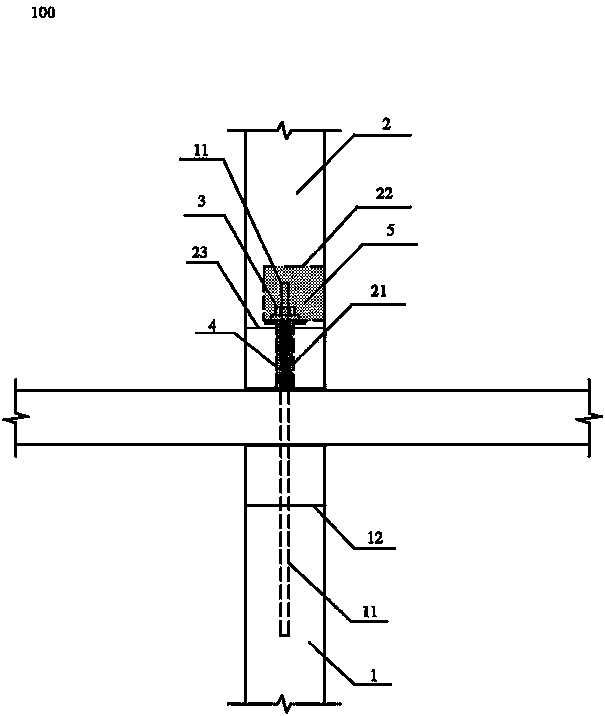

[0038] like figure 1 As shown, the prefabricated shear wall 100 of this embodiment includes at least one lower prefabricated shear wall panel 1 and at least one upper prefabricated shear wall panel 2, and the upper end of the lower prefabricated shear wall panel 1 is pre-embedded with multiple Steel bar connecting bolts 11, the lower end of the upper prefabricated shear wall panel 2 is provided with a plurality of bolt holes 21 corresponding to the steel bar connecting bolts 11; each of the reinforcing bar connecting bolts 11 is inserted into one of the bolt holes 21 and fastened by a nut 3 , each of the bolt holes 21 communicates with a mounting hole 22 .

[0039] continue to refer figure 1 , the lower prefabricated shear wall panel 1 and the upper prefabricated shear wall panel 2 are fixedly connected through the reinforcement connecting bolts 11 and nuts 3 to form an integral prefabricated shear wall 100 . Compared with the vertical connection method of prefabricated shea...

Embodiment 2

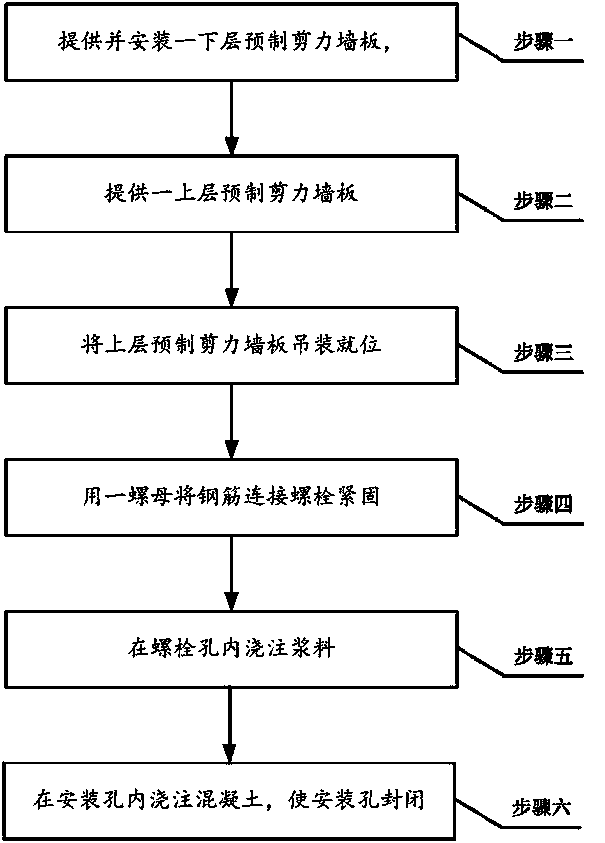

[0045] figure 2 Be the flow chart of the assembly method of the prefabricated shear wall of this embodiment, below in conjunction with Figure 2 to Figure 7 The assembly method of the prefabricated shear wall of this implementation will be described in detail.

[0046] The assembly method of the prefabricated shear wall of the present embodiment comprises:

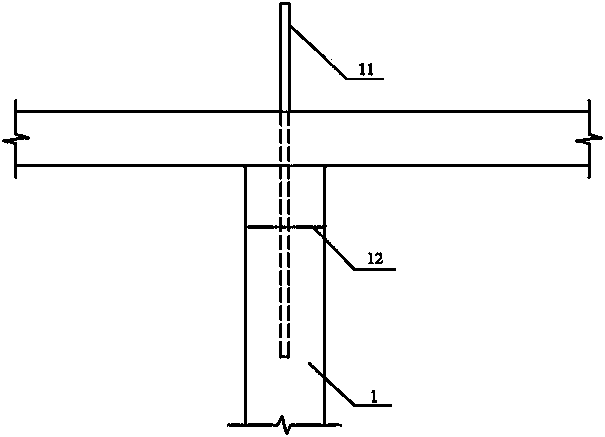

[0047] Step 1: providing the prefabricated shear wall panel 1 of the lower floor, and installing the prefabricated shear wall panel 1 of the lower floor;

[0048] Such as image 3 As shown, the upper end of the lower prefabricated shear wall panel 1 is pre-embedded with a plurality of reinforcement bolts 11 . Preferably, the reinforcing bar connecting bolts 11 are arranged in a single row at equal intervals, for example, the distance between two adjacent reinforcing bar connecting bolts 11 is 400mm~600mm.

[0049] Step 2: providing an upper prefabricated shear wall panel 2;

[0050] Such as Figure 4 As shown, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com