End vinylsiloxane rubber cold curing method with controllable time of operation

An operation time and vinyl-terminated technology, applied in the field of room temperature curing of vinyl-terminated silicone rubber, can solve the problems that the vulcanization process cannot be carried out normally, reduce the comprehensive performance of silicone rubber, and the curing speed cannot be controlled, so as to improve storage stability and delay. Curing time, easy design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

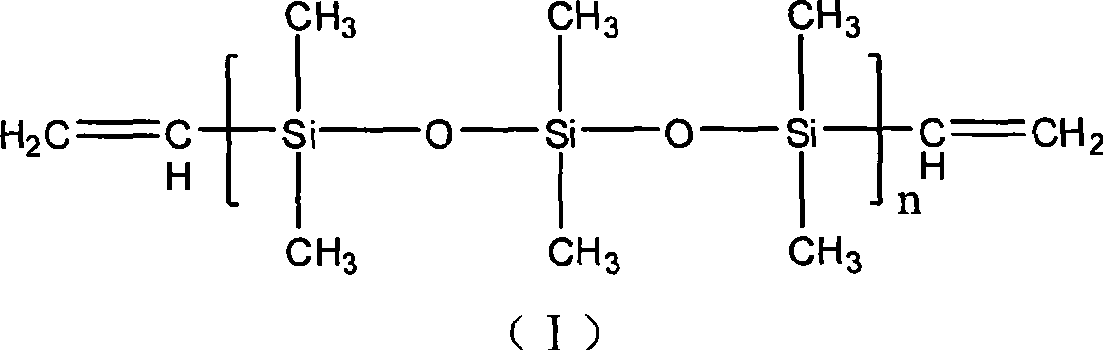

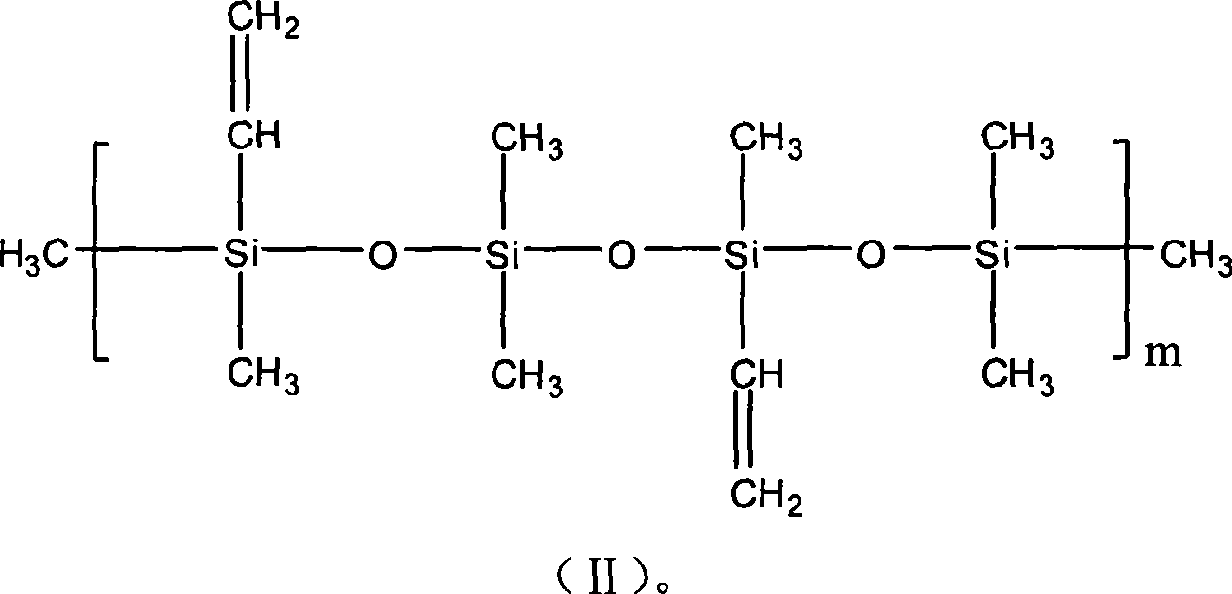

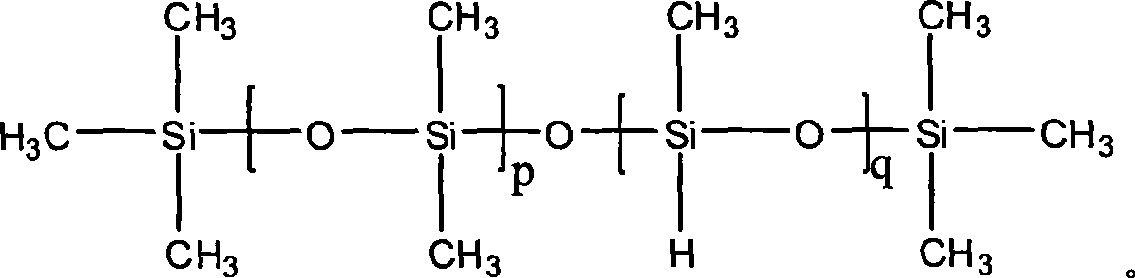

[0031] The base glue is selected from low-viscosity vinyl-terminated polysiloxane with a viscosity of 1800mPa s, branched-chain vinyl polysiloxane with a viscosity of 4000mPa s and high-viscosity vinyl-terminated polysiloxane with a viscosity of 7000mPa s. :107-Vi glue with moderate viscosity obtained by compounding at a mass ratio of 1:2, adding hexamethylsilazane to 15g of precipitated white carbon black for every 100g of 1800mPa·s low-viscosity vinyl-terminated polysiloxane And 2g high hydrogen-containing silicone oil, hydrogen content 1.58%wt. Mix the base rubber, filler, and crosslinking agent according to the formula ratio, first manually stir to make the filler and the base rubber preliminarily mix, then grind the rubber material through a three-roll mill for 3 to 4 times, so that the filler is evenly dispersed in the base rubber, and take it out Standby to obtain component A with a viscosity of 18000mPa·s.

[0032] The synthesis of the catalyst is to add a solution of...

Embodiment 2

[0035] A component is the same as Example 1, and the viscosity is 18000mPa·s.

[0036] The preparation of the toluene solution of platinum tetravinyl tetramethylcyclotetrasiloxane complex was the same as in Example 1. Take out 8g of the toluene solution of the platinum complex and add 2.74g of tetramethyltetravinylcyclotetrasiloxane, which is component B.

[0037] Mix component A and component B at a mass ratio of 500:1, stir, vacuumize to remove air bubbles, cure at 40°C for 8 hours, and then release the mold. The operation time is respectively: the scorch time T10 is 2396s, the positive vulcanization time T90 is 3360s, and the curing reaction time ΔT is 964s. The mechanical properties of the product are tensile strength of 1.85MPa, elongation at break of 120%, Shore A hardness of 35, and permanent deformation of 2%.

Embodiment 3

[0039] The base glue for component A is low-viscosity vinyl-terminated polysiloxane with a viscosity of 1500mPa s, branched-chain vinyl polysiloxane with a viscosity of 4000mPa s and high-viscosity vinyl-terminated polysiloxane with a viscosity of 7000mPa s. 107-Vi glue with moderate viscosity obtained by compounding oxane in a mass ratio of 7:1:2, adding hexamethylsilazane to every 100g of 1500mPa·s low-viscosity vinyl-terminated polysiloxane to treat precipitation method White carbon black 15g and hydrogen-containing silicone oil 5g, hydrogen content 1.0%wt. Mix the base rubber, filler, and crosslinking agent according to the formula ratio, first manually stir to make the filler and the base rubber preliminarily mix, then grind the rubber material through a three-roll mill for 3 to 4 times, so that the filler is evenly dispersed in the base rubber, and take it out Standby to obtain component A with a viscosity of 15000mPa·s.

[0040] The preparation of the toluene solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com