Patents

Literature

701results about How to "Does not affect mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

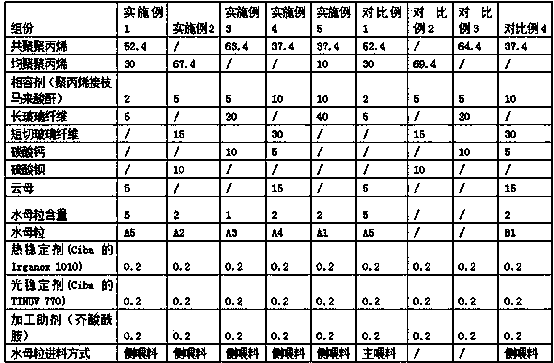

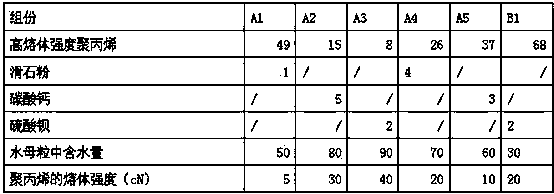

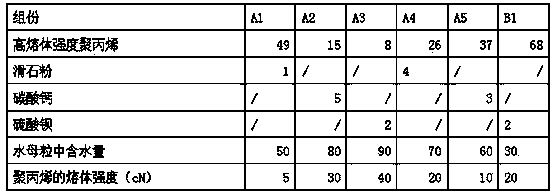

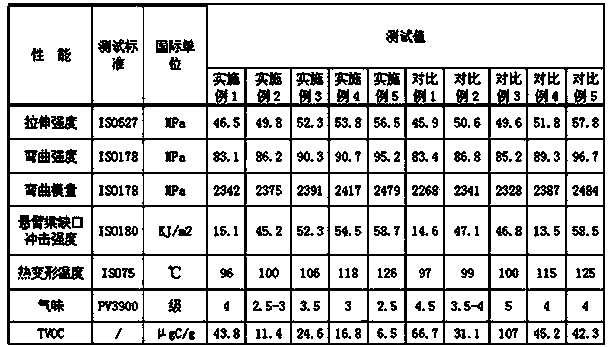

Polypropylene combination with low smell and diffusion and preparation method thereof

The invention discloses a polypropylene combination with low smell and diffusion and a preparation method thereof. The polypropylene combination with the low smell and diffusion comprises the compositions as follows: 37-88 percent of polypropylene resin, 5-30 percent of a toughener, 0-40 percent of mineral filler, 0.5-5 percent of medusa particle and 0.1-3 percent of an assistant. The preparation method comprises the steps as follows: the polypropylene resin, the toughener, the mineral filler and the assistant are uniformly mixed in a high mixing machine for 1-3 minutes, places in a main feeding hole of an dual-screw extruder, added with the medusa particles from a side feeding hole, molten, extruded, pelletized and dried at a temperature controlled within 200-215 DEG C and under the rotation speed condition of 450 round / minute, so that the polypropylene combination with the low smell and diffusion is obtained. According to the invention, the medusa particles adopting high-melts foamed PP as a carrier is used as a stripping agent, various kinds of volatile small molecules and organic compounds which are generated during processing can be effectively removed, the prepared polypropylene combination has the characteristics of low smell and diffusion, and can satisfies the demand of automobile for inner decoration.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Non-halogen flame-proof urethane elastomer flame resisting agent and method of preparing the same

ActiveCN101108914ADoes not affect mechanical propertiesGood compatibilityPolyurethane elastomerPolymer science

The invention relates to a halogen-free flame retardant polyurethane elastomer flame retardant and the preparation method. The flame retardant comprises the following components and contents (weight per cent): melamine-formaldehyde coating ammonium phosphate 30 per cent to 70 per cent, triethylol isocyanurate 10 per cent to 35 per cent, melamine cyanurate 5 per cent to 20 per cent, phosphonate 10 per cent to 20 per cent, organic silane coupling agent 0.1 per cent to 0.5 per cent and antioxidant 0.1 per cent to 0.8 per cent. The preparation method of the flame retardant comprises the process steps such as the mixture of the melamine-formaldehyde coating ammonium phosphate. Compared with the prior art, the invention overcomes the defect of harm of halogen flame retardant polyurethane elastomer on the environment and the human body, endows the materials with certain difficult-flammability, has good compatibility with the polyurethane and has no effect on the mechanical properties of the polyurethane.

Owner:SHANGHAI RES INST OF CHEM IND

Laser repairing process for automobile mold

ActiveCN102732831ADoes not affect mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingHardnessAlloy

The invention relates to a laser repairing process for an automobile mold. The repairing process comprises the following steps of: (A) processing the surface of the mold, and carrying out detection and analysis on the mold; (B) heating the mold at a low temperature; (C) programming a cavity of a worn part of the mold according to a detection and analysis result of the mold, setting process parameters, and sequentially carrying out laser cladding on edges and corners of the mold and plane parts and step parts on the mold; and (D) detecting, wherein alloy powder adopted by the process comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 2.5-15% of TiO and the balance of Fe. The laser repairing process for the automobile mold can be used for carrying out laser cladding on the worn parts and enabling the surface hardness and the sizes of the worn parts to meet a using requirement.

Owner:中科恩吉瑞特(烟台)科技发展有限公司

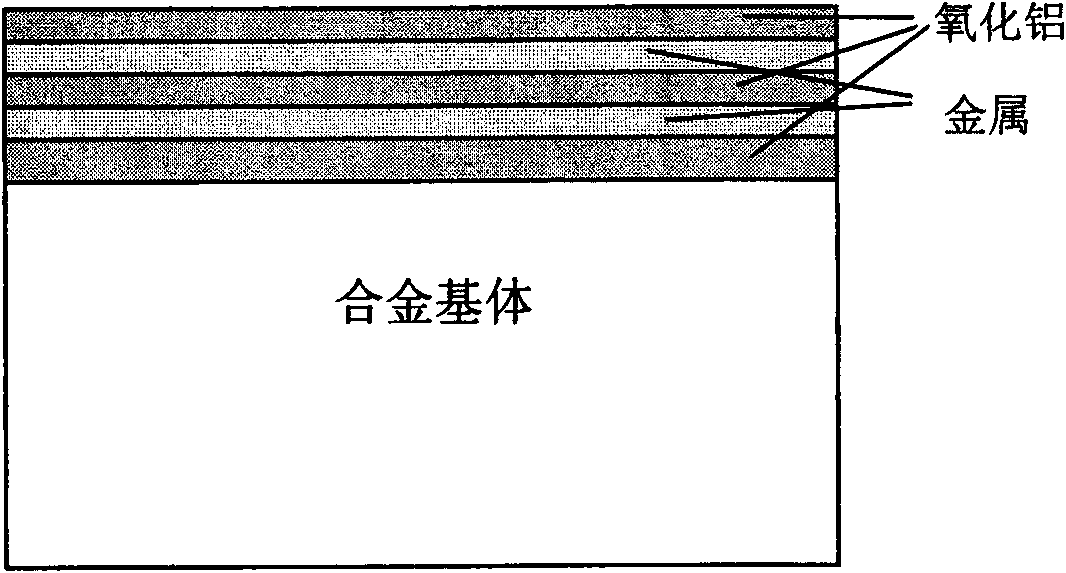

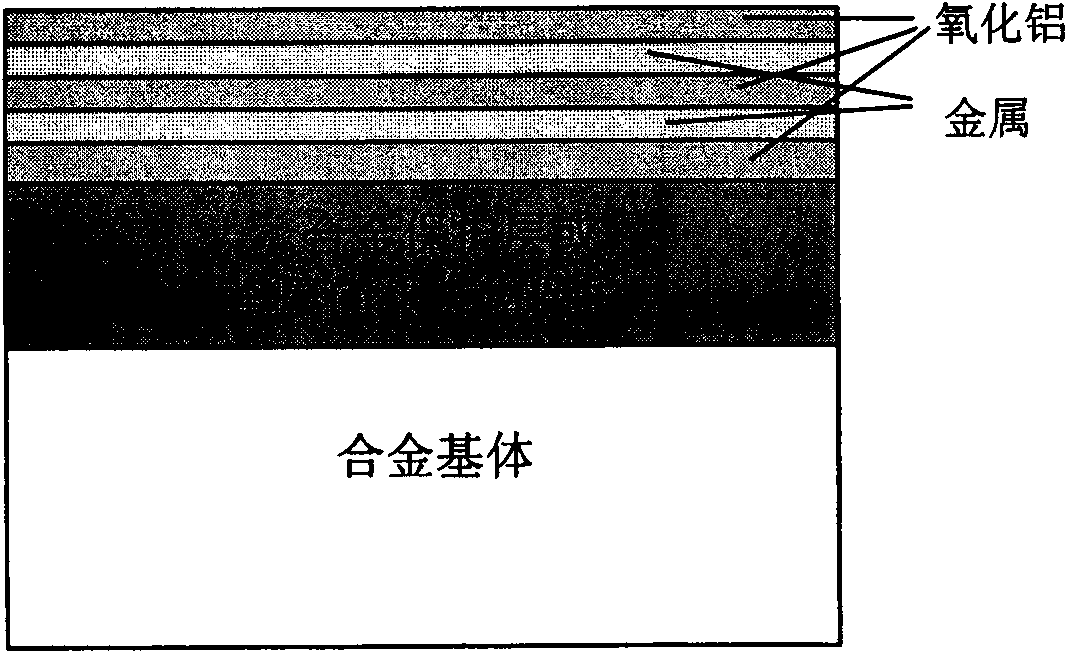

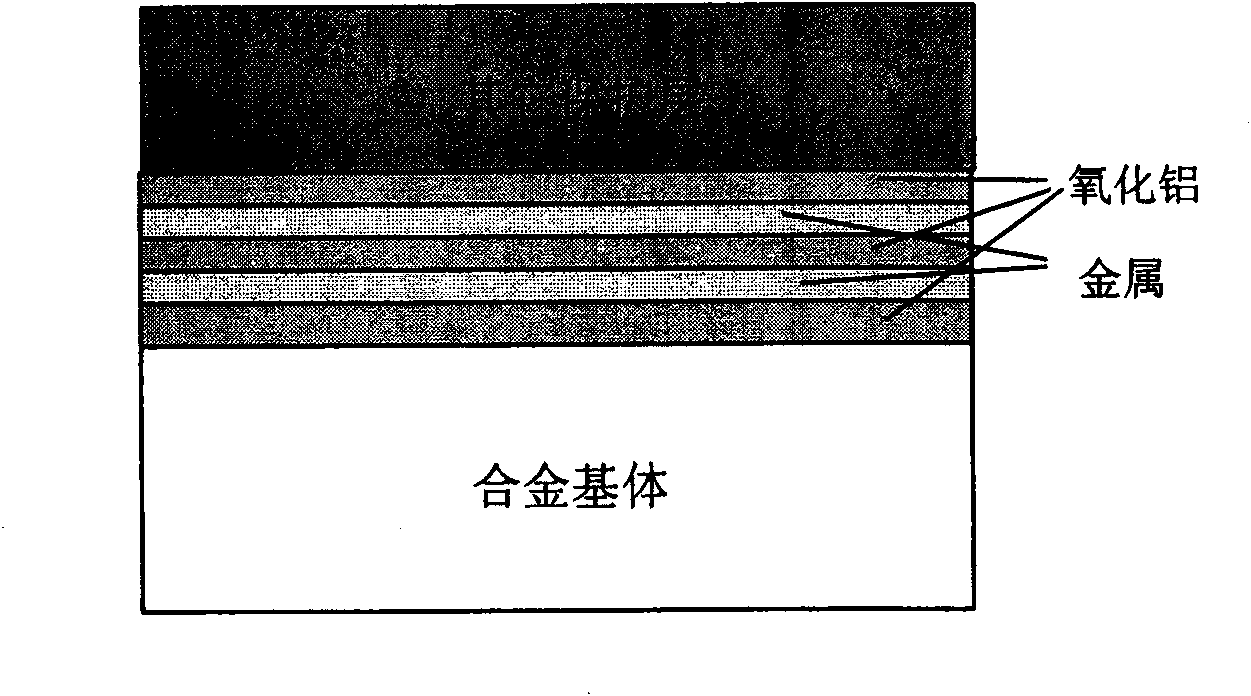

Multifunctional alumina/metal micro-laminated coating

The invention provides a multifunctional alumina / metal micro-laminated coating, which belongs to composite material made from metals and ceramic and coating technology thereof and is used for high-temperature protection, anti-tritium permeation, and anti-hydrogen damage of alloys with wide temperature scope. The micro-laminated coating adopts a high-pure alumina or alumina doped with a small amount of rear earth oxide, or alumina doped with a small amount of zirconia as an alumina coating, wherein the metals can be Pt, or Rh, or Ir, or Au, or alloys of all, or M-Cr-Al-rare earth alloy, or Fe, Co, Ni-based aluminum-containing alloy. The thickness of each laminated coating is 20-1000nm. The micro-laminated coating can be obtained by adopting a plurality of methods through the alternative sedimentation of the alumina coating and a metal coating. The micro-laminated coating has the following characteristics: (1) excellent binding force with the alloy substrate; (2) excellent high-temperature protection performance and anti-tritium penetration performance, and anti-hydrogen damage performance; (3) wide operating temperature range from room temperature to 2000 DEG C; (4) the evaporation inhibition of precious metal coatings at high temperature; and (5) and synergistic protective effect with other coatings.

Owner:UNIV OF SCI & TECH BEIJING

Rapid crystallization polylactic acid composite material and preparation method thereof

InactiveCN101544813AIncrease the rate of crystallizationImprove mechanical propertiesNatural mineralMechanical property

The invention relates to a rapid crystallization polylactic acid composite material and a preparation technique thereof. The composite material comprises the following components in portion by weight: 59 to 98 portions of hypocrystalline poly-L-lactic acid, 1 to 40 portions of organic modified natural mineral, 1 to 20 portions of organic crystallization promoter, 0.1 to 1.0 portion of heat stabilizer, and 0.05 to 1.0 portion of lubricant. The sum of the mass percentage of the components is 100 percent. The preparation method for the material comprises the following steps: firstly preparing the modified natural mineral; then mixing the components according to the components of the composite material; agitating and mixing the raw materials evenly through a high-speed agitator; and adding the co-mixture into a twin screw extruder for extrusion and granulation. The method improves the crystallization rate of a polylactic acid matrix through the synergistic action of organized mineral and the crystallization promoter. Due to the addition of the organic crystallization promoter, the method strengthens the mechanical properties of the polylactic acid composite material, while simultaneously quickening the crystallization rate of polylactic acid, thereby avoiding the defect of greatly reducing the mechanical properties of the polylactic acid composite material caused by the addition of a single inorganic mineral nucleating agent. The price of adopted fillers is low; and the whole preparation method has a simple technological process and less consuming time of the technological process, and can realize the large-scale industrialized production.

Owner:SHANGHAI UNIV

Method for preparing ultra-high molecular weight polyethylene/polyaniline composite conductive fibre

InactiveCN102720066ADoes not affect mechanical propertiesImprove conductivityPhysical treatmentPolymer scienceOxygen plasma

The invention discloses a method for preparing ultra-high molecular weight polyethylene / polyaniline composite conductive fibre, comprising the steps of: performing low-temperature oxygen plasma treatment on ultra-high molecular weight polyethylene fibre, wherein surface impurities of the fibre are removed, the treatment time is 0.5-1.5 minutes, the reaction power is 50-80W and the oxygen pressure is 30-50Pa; placing the fibre in aniline monomers for 0.5-2 hours, uniformly extruding the fibre after taking out the fibre, and controlling the mass ratio of the fibre and the aniline monomer at 1:1 to 1:1.3; and placing the fibre in a reaction solution at 10-35 DEG C for 0.5-3 hours, so that the fibre containing a uniform and continuous polyaniline conductive layer is obtained. By the method disclosed by the invention, the composite fibre with good conductivity is obtained, textiles or fibre reinforced composites with antistatic, conductive and electromagnetic shielding functions can be prepared, and are applied to fields of individual protection, military industry, electric products, petrochemical industry, machineries and the like.

Owner:SUZHOU UNIV

Novel compound brazed aluminum alloy material for heat exchanger of automobile

ActiveCN101927588AImprove stabilityImprove mechanical propertiesMetal layered productsPlate heat exchangerImpurity

The invention relates to a novel compound brazed aluminum alloy material for a heat exchanger of an automobile, which comprises an upper layer leather material, a core material and a lower layer leather material, wherein the upper layer leather material is coated on the upper surface of the core material. The novel compound brazed aluminum alloy material is characterized in that: the lower surface f the core material is coated with an alloy leather material; the lower layer leather material is coated outside the alloy leather material; the core material comprises the following components in percentage by weight: 0.15 to 0.25 percent of Si, 0.35 to 0.50 percent of Fe, 0.08 to 0.15 percent of Cu, 1.10 to 1.20 percent of Mn, less than or equal to 0.10 percent of Zn, less than or equal to 0.03 percent of Ti, less than or equal to 0.05 percent of impurities, and the balance of aluminum; and the AA7072 alloy leather material comprises the following components in percentage by weight: 0.10 to 0.30 percent of Si, 0.20 to 0.40 percent of Fe, less than or equal to 0.1 percent of Cu, less than or equal to 0.07 percent of Mn, less than or equal to 0.01 percent of Mg, 0.90 to 1.20 percent of Zn, less than or equal to 0.05 percent of individual impurity, and the balance of aluminum. The novel compound brazed aluminum alloy material for the heat exchanger of the automobile has the advantages of increasing the AA7072 alloy leather material, improving the corrosion resistance of the four-layer compound material by 30 percent compared with that of the traditional three-layer compound material, and keeping identical intensity, plasticity and structural homogeneity.

Owner:NANTONG HENGJIN COMPOSITE MATERIALS

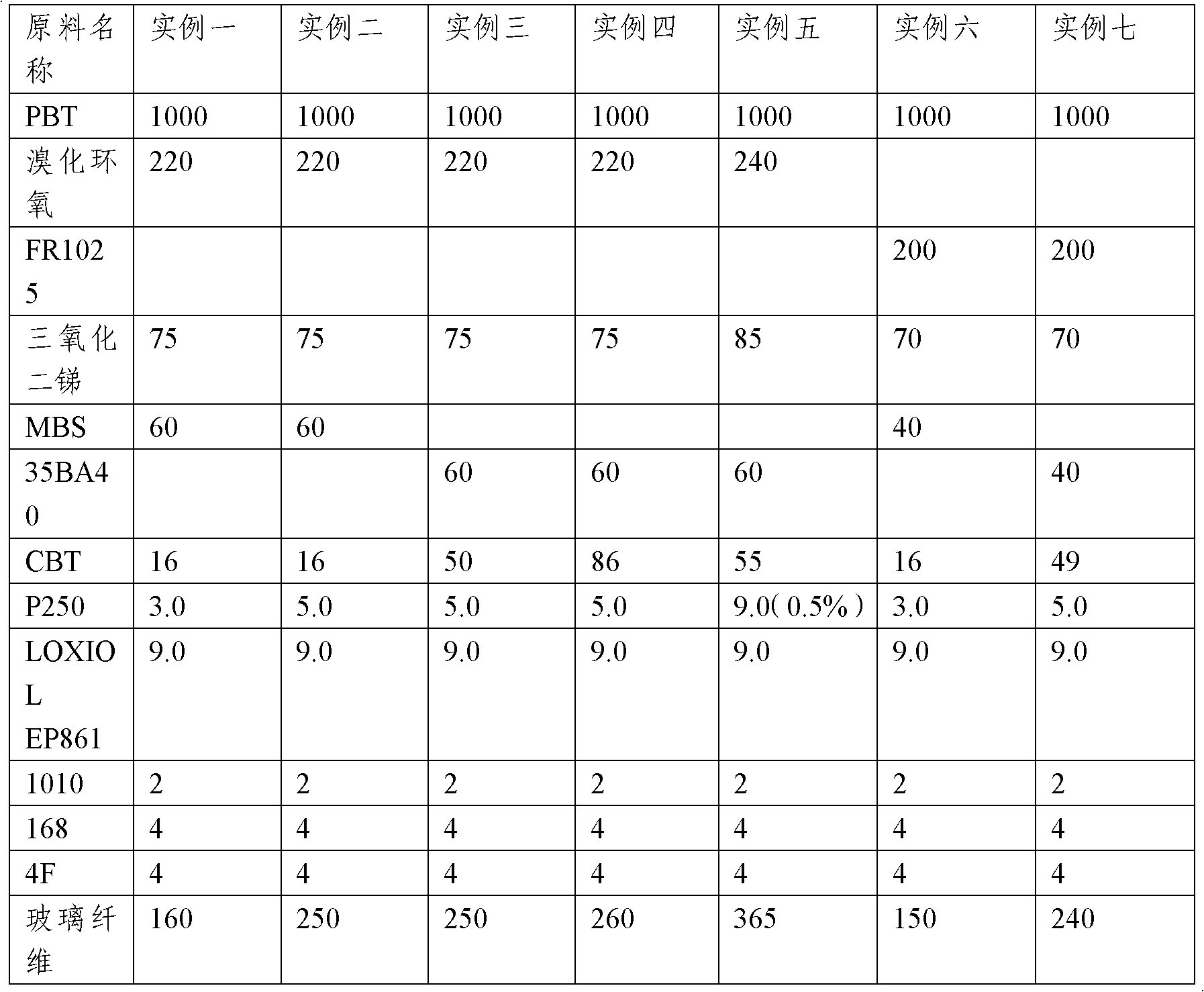

Reinforced flame retardant polyester with high molding rate and fluidity and production method thereof

The invention discloses a reinforced flame retardant polyester with high molding rate and fluidity and a production method thereof. The reinforced flame retardant polyester is prepared from the components of a half crystalloid thermoplastic polyester, a main flame retardant, a flame retardant synergist, a flexibilizer, a low-viscosity cyclic polyester, an antioxygen, a nucleating agent, a lubricant, a filling modifier and other auxiliaries. The reinforced flame retardant polyester with high molding rate and fluidity provided by the invention has the advantages of rapid molding period, high fluidity, fine demoulding efficacy, energy conservation, good mechanical property and the like.

Owner:NANTONG DONGFANG PLASTIC CO LTD

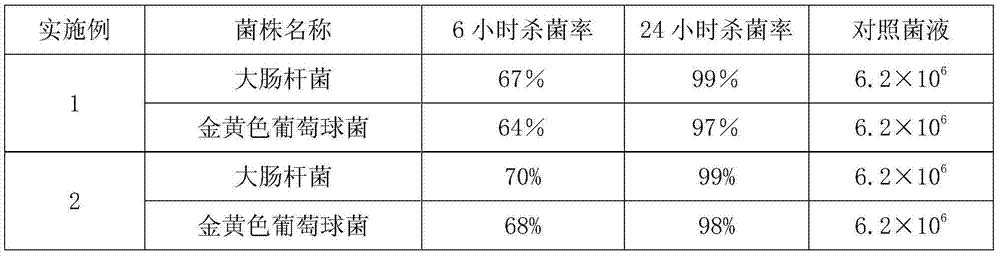

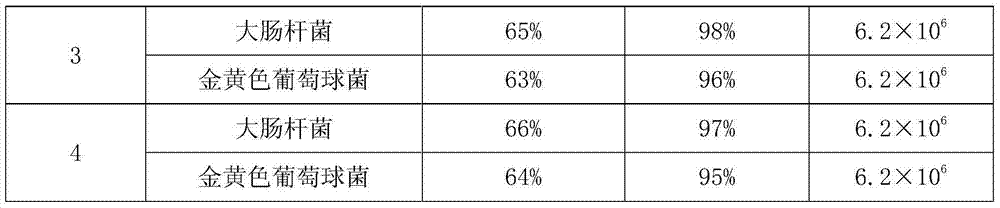

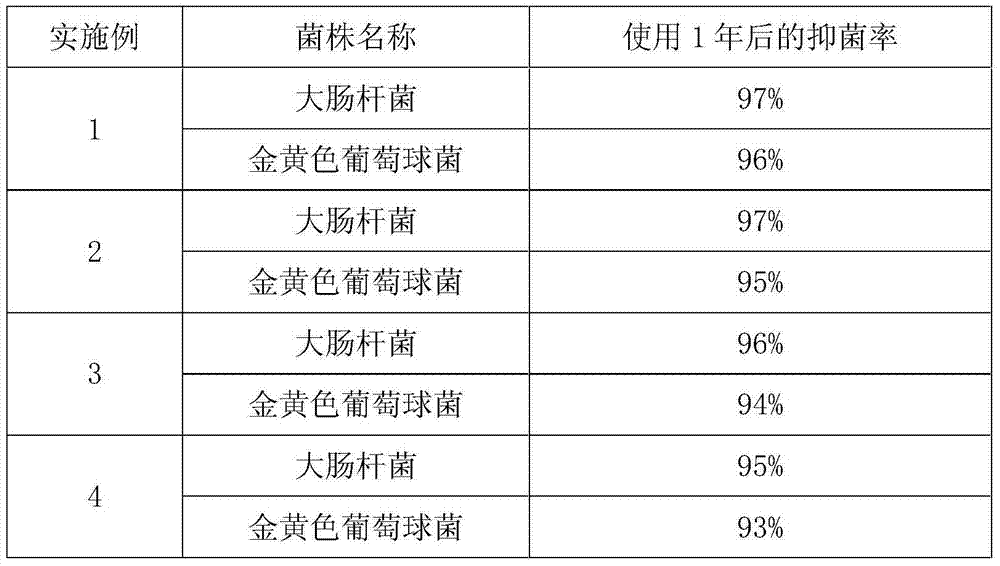

Antibacterial plastic master batch, and preparation method and antibacterial plastic thereof

InactiveCN103571055AImprove general performanceGood dispersionTemperature resistanceMechanical property

The invention relates to an antibacterial plastic master batch, and a preparation method and an antibacterial plastic thereof. The antibacterial plastic master batch comprises the following components in parts by mass: 0.1-5 parts of coupling agent, 0.1-5 parts of dispersant, 2-8 parts of polyethylene wax, 50-65 parts of nanometer titania antibacterial agent, and 20-40 parts of plastic resin. The preparation method comprises the following steps: burdening, stirring, extruding and pelletizing. The antibacterial plastic master batch disclosed by the invention has the characteristics of being strong in versatility, good in dispersibility, simple in process, good in machinability, good in temperature resistance, good in antibacterial property, free of environmental pollution and the like; continuous large-scale industrial production can be achieved; the obtained plastic product has excellent performance of long-acting and rapid antibacterial property; the mechanical property of the plastic product is not affected by adding of the antibacterial plastic master batch.

Owner:安徽纽麦特新材料科技股份有限公司

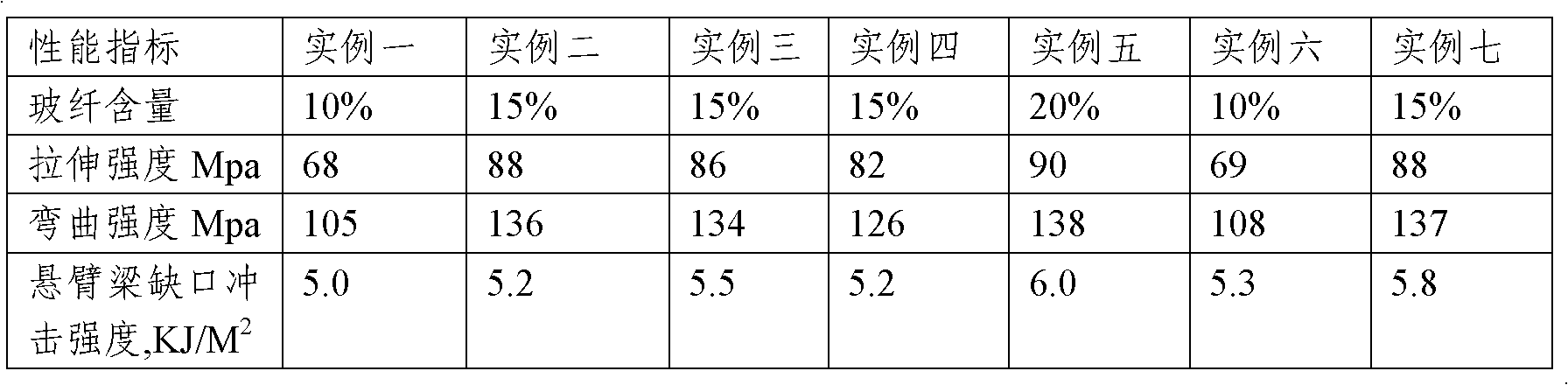

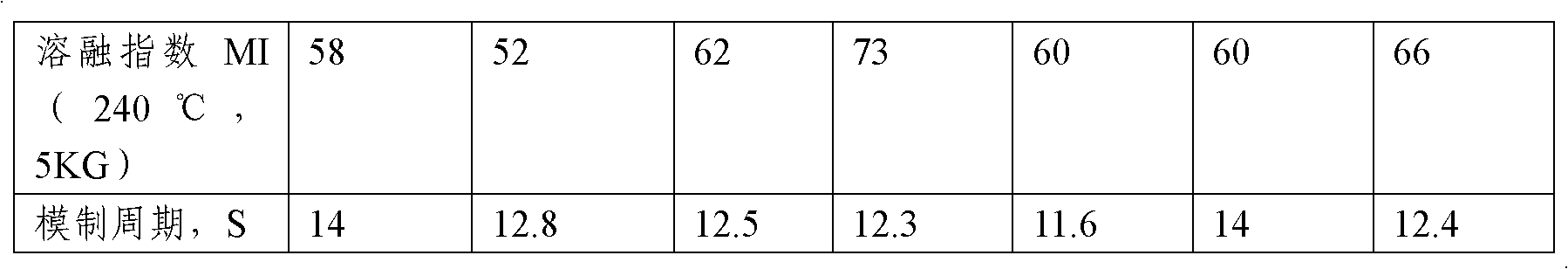

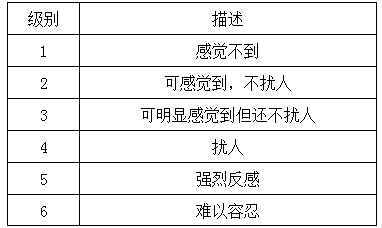

Low-odour glass-fiber-enhanced polypropylene composite material and preparation method thereof

ActiveCN103739944AAvoid the problem of premature evaporation of moistureEfficient removalPolypropylene compositesGlass fiber

The invention discloses a low-odor glass-fiber-enhanced polypropylene composite material comprising the following components: 37-83% of polypropylene resin, 2-10% of a compatilizer, 5-40% of glass fiber, 0-20% of a mineral filler, 0.5-5% of jellyfish grains and 0.1-3% of an assistant; the preparation method is as follows: mixing the polypropylene resin, the compatibilizer, the mineral filler and the assistant in a high mixing machine for 1-3min; evenly mixing, putting the mixture into a main feeding port of a double screw extruder, adding the jellyfish grains from a side feeding port, and then adding the glass fiber from the side feeding port of the extruder for melt extrusion and drying granulation to obtain the low-odor glass-fiber-enhanced polypropylene composite material. The low-odor glass-fiber-enhanced polypropylene composite material uses the jellyfish grains, using high-melt foaming PP (polypropylene) as a carrier, as a stripping agent for effective removal of various volatile small molecules and organic compounds produced in the machining process, and the prepared glass-fiber-enhanced polypropylene composite material has the characteristics of low odor, excellent mechanical properties and the like.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Nanometer composite powder zinc impregnation processing method

ActiveCN1730727AMeeting Corrosion Protection NeedsDoes not affect mechanical propertiesHeat inorganic powder coatingCooling downZinc

The invention provides a process for nanometer composite powder zinc impregnation processing method, which comprises metal member pretreatment, powder zinc impregnation processing and metal member post-treatment. The powder zinc impregnation processing comprises formulation of nano composite powder zinc impregnation agent, a zinc impregnation procedure and a cooling down separation process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

Method for preparing polyurethane medical anti-infectious interventional catheter

InactiveCN1528470ADoes not affect smoothnessIncrease loading capacityCatheterGuide tubeBiomedical engineering

The invention relates to a polyurethane medical anti-infection insertion guide tube preparing method, preparing antimicrobial-containing antibacterial mother material to mix with the polyurethane raw material, and extruding to shape so as to obtain the guide tube, its antimicrobial loadage high and its antibacterial effect more permanent; its inner and outer walls has the same antibacterial effect; the technique is simple, the operation is convenient and the cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Intergranular corrosion resistant high-strength full austenite welding rod

InactiveCN1927528ADoes not affect mechanical propertiesReduce manufacturing costWelding/cutting media/materialsSoldering mediaSlag (welding)Adhesive

The invention relates to an anti-inter-crystal-corrosion high-strength austenite welding bar. Wherein, it is formed by CaO-CaF2-SiO2 alkali coat slag and Cr-Ni-Mo-Mn-N alloy austenite coat, while its coat comprises marble at 45-55%, 45-55% at 16-25%, ferrotitanium at 8-12%, ferrosilicium at 1-5%, manganese metal at 2-8%, titanium dioxide at 1-6%, soda at 1-3% and fluoride rare earth at 0.5-2.0%; and the welding bar comprises C at 0.03-0.12%, Si at 0.2-0.7%, Mn at 2.0-7.0%, S and P<=0.030%, Cr at 15.0-19.5%, Ni at 20-25%, Mo at 4.0-7.0%, N at 0.15-0.25%, V at 0.15-0.3%, and the left is iron, then the mixed powder is coated on the welding core via soldium-water glass as adhesive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

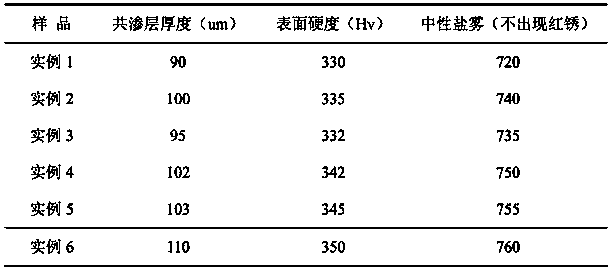

Multicomponent alloy co-permeation anticorrosive coating on surface of steel and co-permeation method thereof

ActiveCN103726009AImprove anti-corrosion performanceGood value for moneySolid state diffusion coatingRare earthAlloy

The invention discloses a multicomponent alloy co-permeation anticorrosive coating on the surface of steel. A preparation method of the coating comprises the following steps of carrying out co-permeation treatment on a clean steel part under the action of a dispersant (quartz sand) and a permeation promoter (NH4Cl or H2NCONH2) in a co-permeation furnace at the temperature of 400-460 DEG C and under the pressure of 0.08-0.15MP by using multicomponent alloy power so as to form a Zn-Ni light rare earth multicomponent alloy co-permeation coating with a certain thickness and excellent anticorrosive performance on the surface of the steel, wherein the multicomponent alloy power is formed by mixing 100 parts of zinc powder, 10-20 parts of nickel powder and 5-10 parts of a light rare earth oxide (La2O3, Ce2O3 or Nd2O3); the thickness of the co-permeation coating is between 90 micrometers and 110 micrometers; the hardness of the co-permeation coating is greater than 330Hv; the neutral salt spray resisting time (red rust does not appear) is greater than 720 hours.

Owner:安徽瑞合铁路紧固件科技有限公司

Tri-axial testing device for testing water content distribution of soil sample

ActiveCN103743787AImprove test accuracyFlexible control of relative positionMaterial resistancePhysicsWater content

The invention discloses a tri-axial testing device for testing the water content distribution of a soil sample. The device comprises a constant current alternating current source, a dynamic voltage tester, a computer and a plurality of groups of sheet electrodes, wherein the sheet electrodes correspond to the layers of the columnar tri-axial soil sample; each group comprises four sheet electrodes which are sequentially adhered to the corresponding layer of the soil sample and a tri-axial membrane at an interval of 45 degrees along the circumferential direction of the corresponding layer of the soil sample; the farthest two sheet electrodes and the middle two sheet electrodes in each group are alternately connected with the two electrodes of the constant current alternating current source and the two input ends of the dynamic voltage tester; the output end of the dynamic voltage tester is connected with the computer. According to the device, the van der Pauw principle is used for dynamically measuring the water content of the soil sample in real time; due to the adoption of the flexible sheet electrodes, the influence on the mechanical properties of the soil sample is avoided, and the testing accuracy of the water content of the soil sample is greatly improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

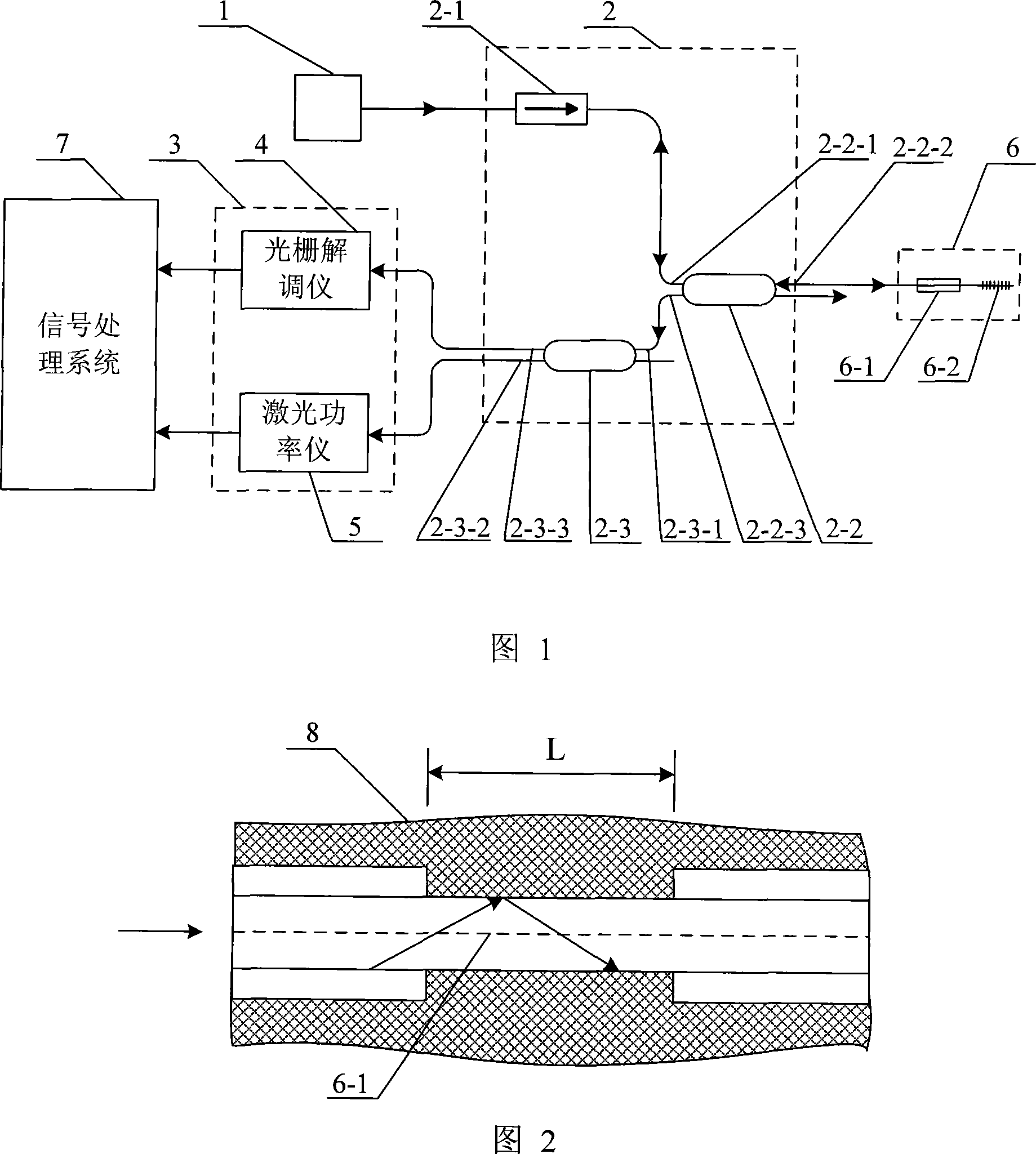

Temperature and solidification rate real-time monitoring device for polymer based composite material forming process

InactiveCN101105452ADoes not affect mechanical propertiesImprove performancePhase-affecting property measurementsThermometers using physical/chemical changesGratingRefractive index

The invention relates to a real-time synchronization monitoring device for monitoring the temperature solidification in the formation process of polymer base compound materials. The invention relates to a material formation monitoring device, which solved the problem of the prior technology that only the off-line measuring of the small test sample can be taken and the precision is low and the cost is high, and the real-time synchronous measuring can not be taken. The output terminal of the laser of the invention is connected with the first terminal port of the first coupler through an isolator, the second terminal port of the first coupler is connected with the terminal port of a sensing module, the third terminal port of the first coupler is connected with the first terminal port of the second coupler, and the second terminal port and the third terminal port are separately connected with an optical receiver and two input terminals, the two output terminals of the optical receiver are separately connected with the two input terminals of a signal processing system. One terminal of the optical fiber refractive index sensor in a sensing module is connected with the second terminal port of the first coupler, and the other terminal is connected with the Bragg optical grating. And the sensing module is buried in the material. Online inspecting is adopted, and the heating temperature and the heating time are adjusted according to the solidification; and the product performance and the productivity are enhanced, the production cycle is reduced and the energy is saved and the cost is reduced.

Owner:HARBIN INST OF TECH

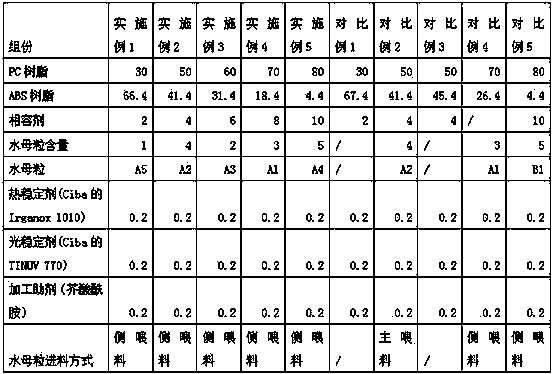

PC/ABS (Polycarbonate/Acrylonitrile-Butadiene-Styrene) alloy with low odor and low emission and preparation method of PC/ABS alloy

The invention discloses PC / ABS (Polycarbonate / Acrylonitrile-Butadiene-Styrene) alloy with low odor and low emission and a preparation method of the PC / ABS alloy. The PC / ABS alloy contains the following components: 30%-80% of PC resin, 4%-66.4% of ABS resin, 2%-10% of a compatibilizer, 1%-5% of aqueous master batch, and 0.1%-3% of an assistant. The preparation method of the PC / ABS alloy comprises the following steps: mixing the PC resin, the ABS resin, the compatibilizer and the assistant in a high mixing machine for 1-3 minutes; and after mixing evenly, placing in a main feeding port of a twin-screw extruder, adding the aqueous master batch from a side feeding port, melting and extruding, granulating and drying to obtain the PC / ABS alloy. According to the PC / ABS alloy and the preparation method, by using maleic anhydride grafted polymer as the compatilizer, the compatibility of a composite material can be greatly improved, by taking the aqueous master batch with high-melt foamed PP (Polypropylene) as a carrier as a gas stripping agent, various volatile small molecules and organic compounds generated during a machining process can be effectively removed, while mechanical properties are also not affected, and the prepared PC / ABS alloy has the characteristics of low odor and low emission.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Method for preparing antibiosis ABS products

A process for preparing antibiotic ABS product includes bal-grinding inorganic antibiotic powder containing nanosilicon dioxide and silver chloride as well as cladded by titanium dioxide with polymethyl methyl acrylate for obtaining inorganic antibiotic composite micropowder, adding prepared composite micropowder into ABS resin for producing antibiotic high polymer product through mixing and processing.

Owner:EAST CHINA UNIV OF SCI & TECH

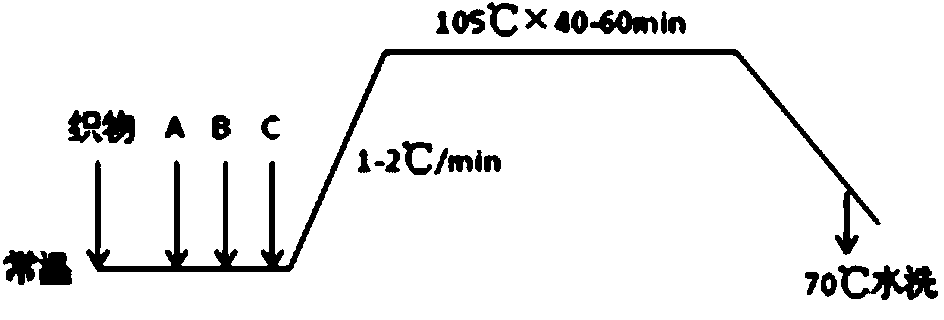

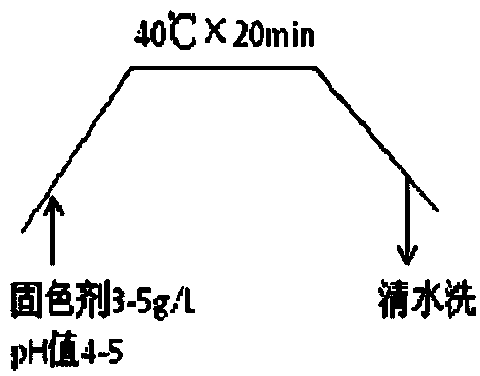

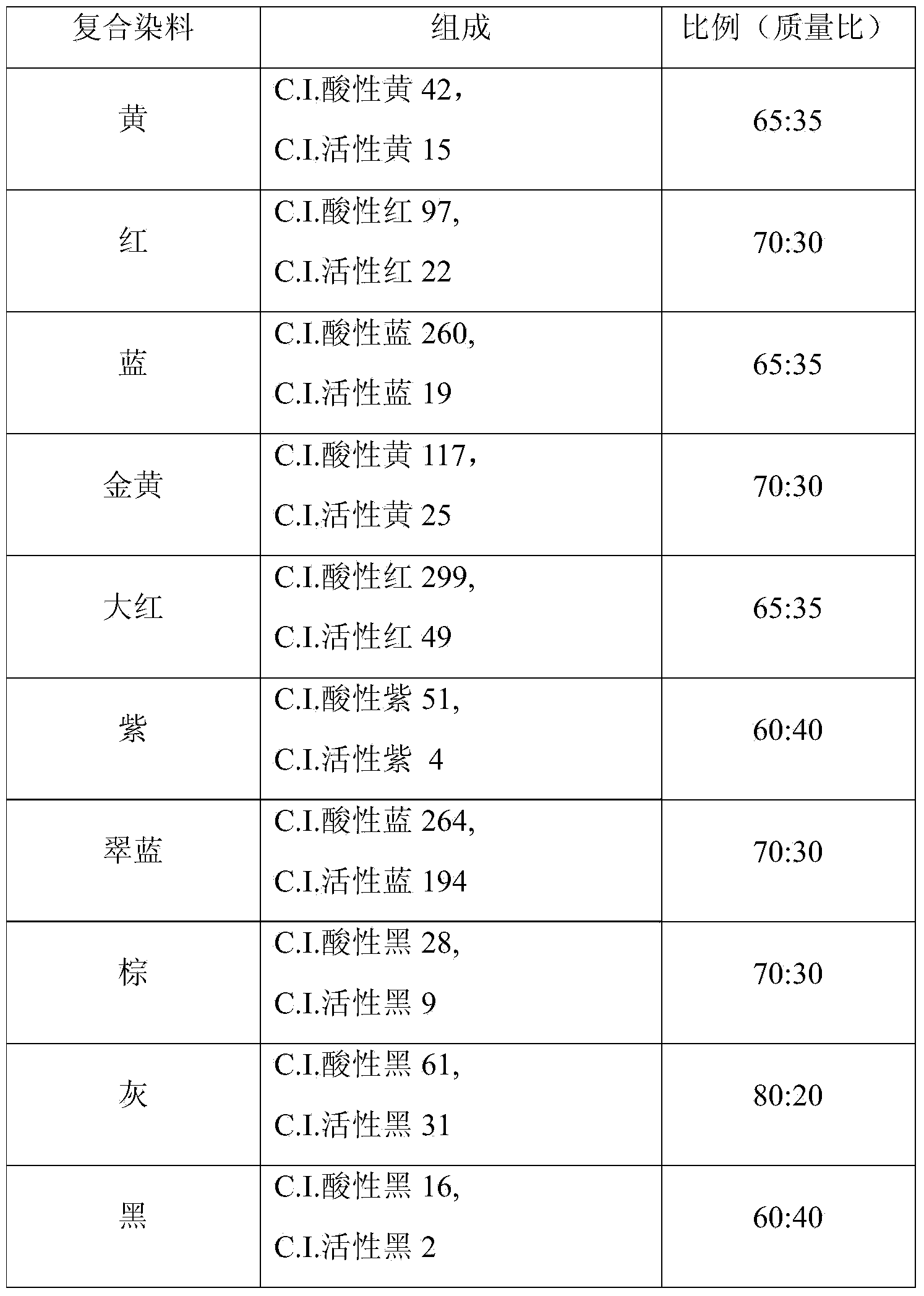

Nylon sea-island microfiber leather fabric composite dye and application thereof

ActiveCN103525123AConsistent dyeingApplicable dyeingOrganic dyesDyeing processAcid dyeIncrease temperature

The invention relates to nylon sea-island microfiber leather fabric composite dye and application thereof. The dye is formed by combining acid dye and active dye. The application is as follows: at normal temperature, sequentially adding an acid level dyeing penetrating agent and composite dye to a dye bath, regulating pH value to 5-6, soaking a fabric in the dye bath, increasing temperature to 105-110 DEG C, preserving for 40-60min, and completely washing at 70-80 DEG C to obtain the dyed fabric; soaking the dyed fabric in a fixation bath, increasing temperature to 40-50 DEG C, preserving for 20-30min and washing. The composite dye formed by combining the acid dye and the active dye, is free from components violating against national technical standard for safety, can consistently dye poly urethane (PU) and nylon superfine fiber, and in particular can dye nylon microfiber leather. The composite dye is complete in chromatography, good in compatibility, synchronous to dye and easy to control quality.

Owner:DONGHUA UNIV +1

Surface treatment method for neodymium iron boron permanent magnetic material by organic aluminum plating

The present invention provides an organic aluminum plating method for a neodymium iron boron permanent magnetic material. The method comprises the following steps: (1) carrying out chamfering and polishing; (2) carrying out degreasing and deoiling; (3) carrying out pickling and derusting; (4) carrying out organic aluminum plating: adopting an aluminum plating solution to carry out aluminum layer plating on the surface of the neodymium iron boron permanent magnetic material under the protection of inert gas, wherein the aluminum plating solution comprises AlCl3, LiAlH4 and tetrahydrofuran; (5) passivating the aluminum plating layer. With the organic aluminum plating method of the present invention, the neodymium iron boron permanent magnetic material can have the excellent corrosion resistance.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

Flame-retardant decorative plate, preparation method thereof and flame-retardant material comprising flame-retardant decorative plate

ActiveCN102756404AImprove flame retardant performanceGood gluing propertiesFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesAdhesivePyrophosphate

The invention provides a flame-retardant decorative plate and a preparation method thereof. The flame-retardant decorative plate comprises a plate component and a flame-retardant adhesive layer which is at least attached on at least one side surface of the plate component in the thickness direction and formed by an adhesive containing a flame-retardant adhesive, the plate component at least comprises a layer of wood veneer, the flame-retardant adhesive contains water-soluble amine resin, a dehydration catalyst, a char forming agent and auxiliaries, and the flame-retardant adhesive contains water or does not contain the water; the dehydration catalyst is selected from one or more of ammonium polyphosphate, melamine orthophosphate and melamine pyrophosphate; and the degree of polymerization of the ammonium polyphosphate is above 20. The invention further provides a flame-retardant material. The gluing performance of the flame-retardant decorative plate prepared by the method disclosed by the invention can meet the requirements of national standard and the flame retardance can be given to a base material; furthermore, the mechanical properties of the base material can not be affected, the formaldehyde release amount is also above E1 grade, and the flame-retardant decorative plate is safe and environment-friendly; and simultaneously, the natural texture of wood is kept and the decorative effect is good.

Owner:固安盛辉阻燃材料有限公司

Electrostatic-proofing polyvinyl chloride compeosite material and preparation process thereof

InactiveCN1861676AImprove ductilityImprove mechanical propertiesOther chemical processesSurface resistivityNanometre

This invention relates to a type of anti-static polychlorovinyl composite material and the method. Compounding include PVC resin, lasticizer, stabilizer, packing matetial. The feature is the formula also includes electric conductive mica, coupling agent of organic titanate and a little of nanometer sliver line power. It uses electric conductive mica and sliver line power which has been processed by coupling agent of organic titanate as the conductive packing material, surface resistivity reach to 106-107omega after film coating. The coupling agent of organic titanate disperses sliver line power well-distributed in PVC resin, solves the problem of agglomeration of nanometer power efficaciously.

Owner:JUNJIANG SCI & TECH CO LTD SHANGHAI

Method for compounding functional nanoparticles on surfaces of polymer filaments

ActiveCN103556451ADoes not affect mechanical propertiesRetain mechanical propertiesVegetal fibresFiberPolymer science

The invention relates to a method for compounding functional nanoparticles on surfaces of polymer filaments, belonging to the technical field of new fiber materials. The method comprises the steps of protein-based modification on surfaces of functional nanoparticles, preparation of a blended solution, formation of polymer filaments with surfaces compounded with the blended solution and control of thickness, phase inversion primary formation of the polymer filaments with surfaces compounded with the blended solution and thermosetting formation of the polymer filaments with surfaces compounded with the blended solution, thus obtaining the polymer filaments with surfaces compounded with the functional nanoparticles. In the preparation method, carbon nano tubes, graphene, carbon black, titanium dioxide, zinc dioxide, iron particles, iron oxide, aluminium oxide, silver particles and other nanoparticles can be compounded on the surfaces of the polymer filaments. The polymer filaments after compounding have good mechanical properties and functionality. The preparation method is simple to operate, dispenses with special equipment and achieves industrial production easily.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

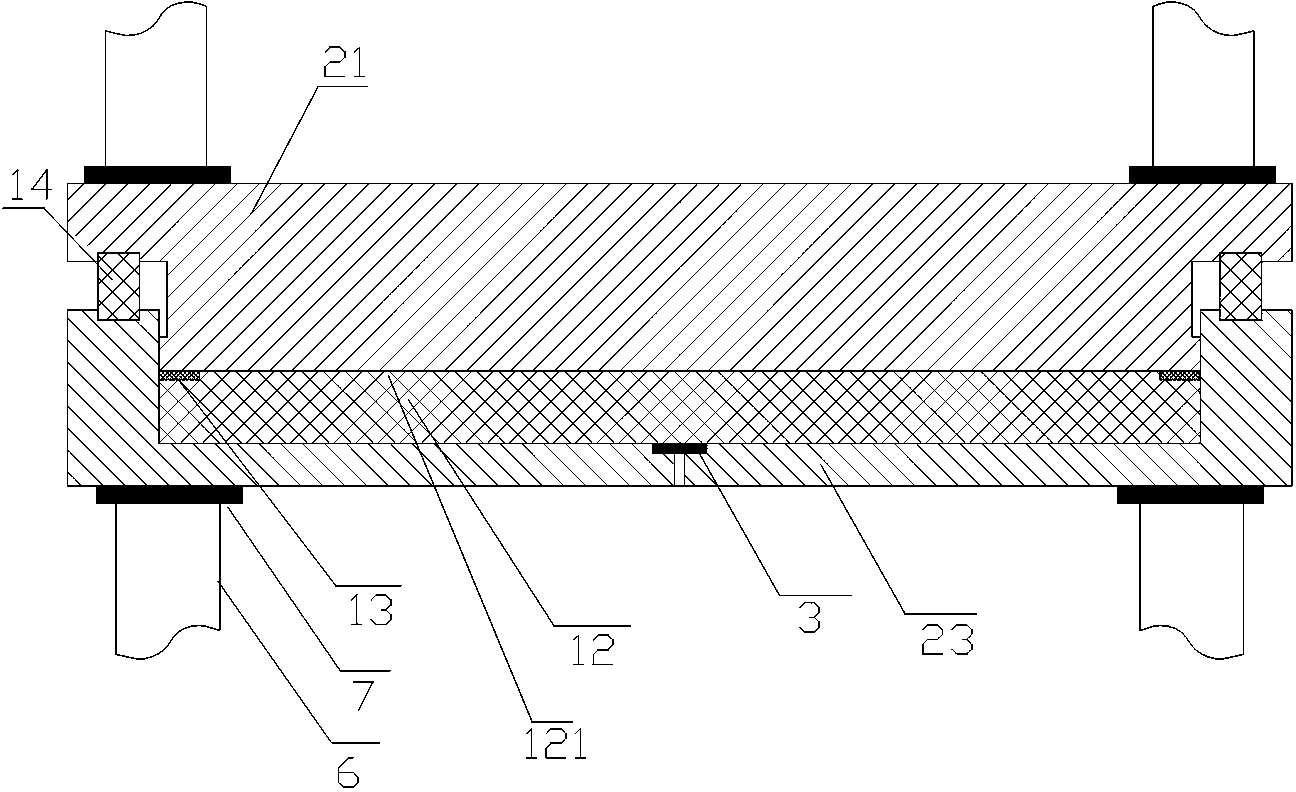

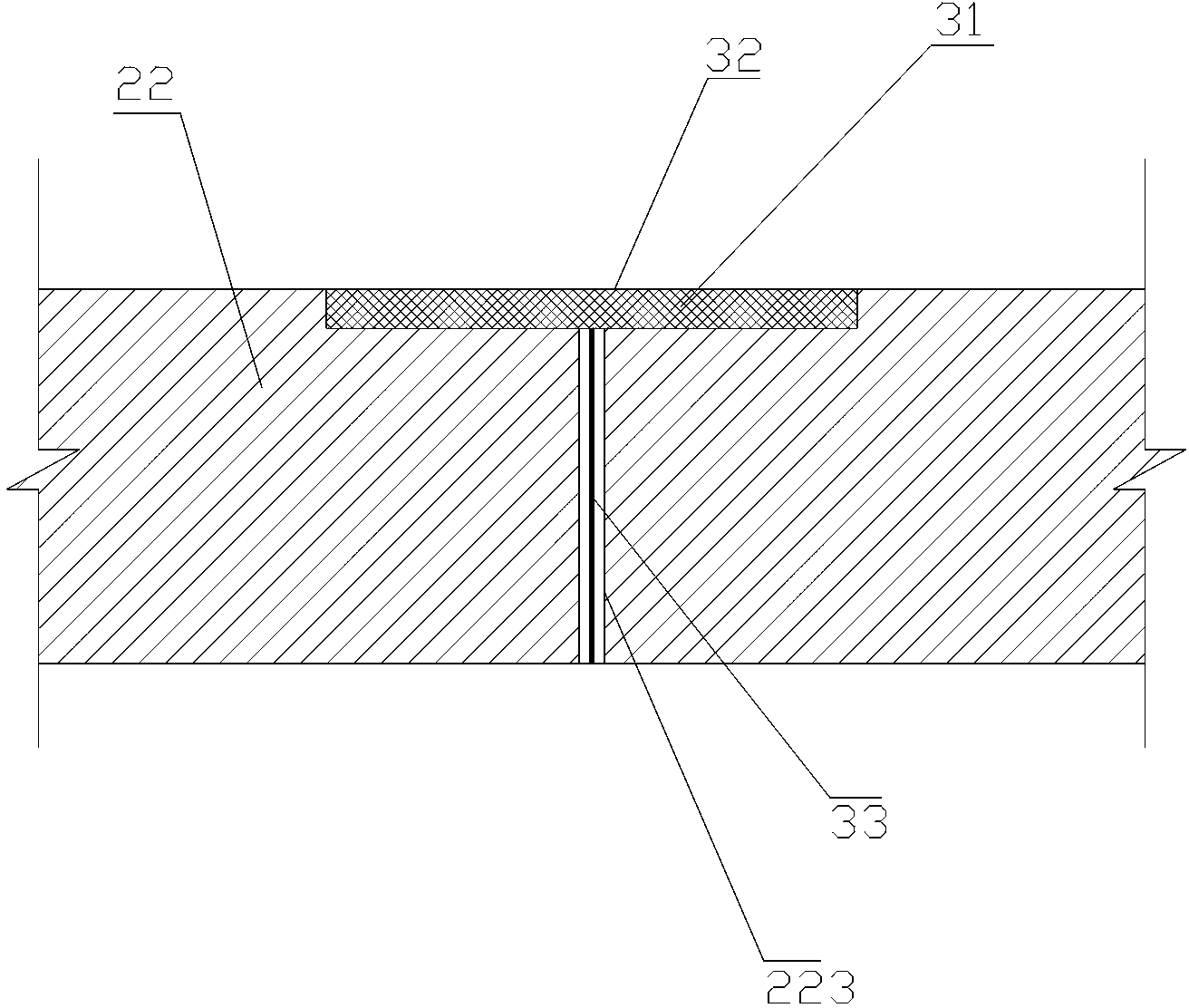

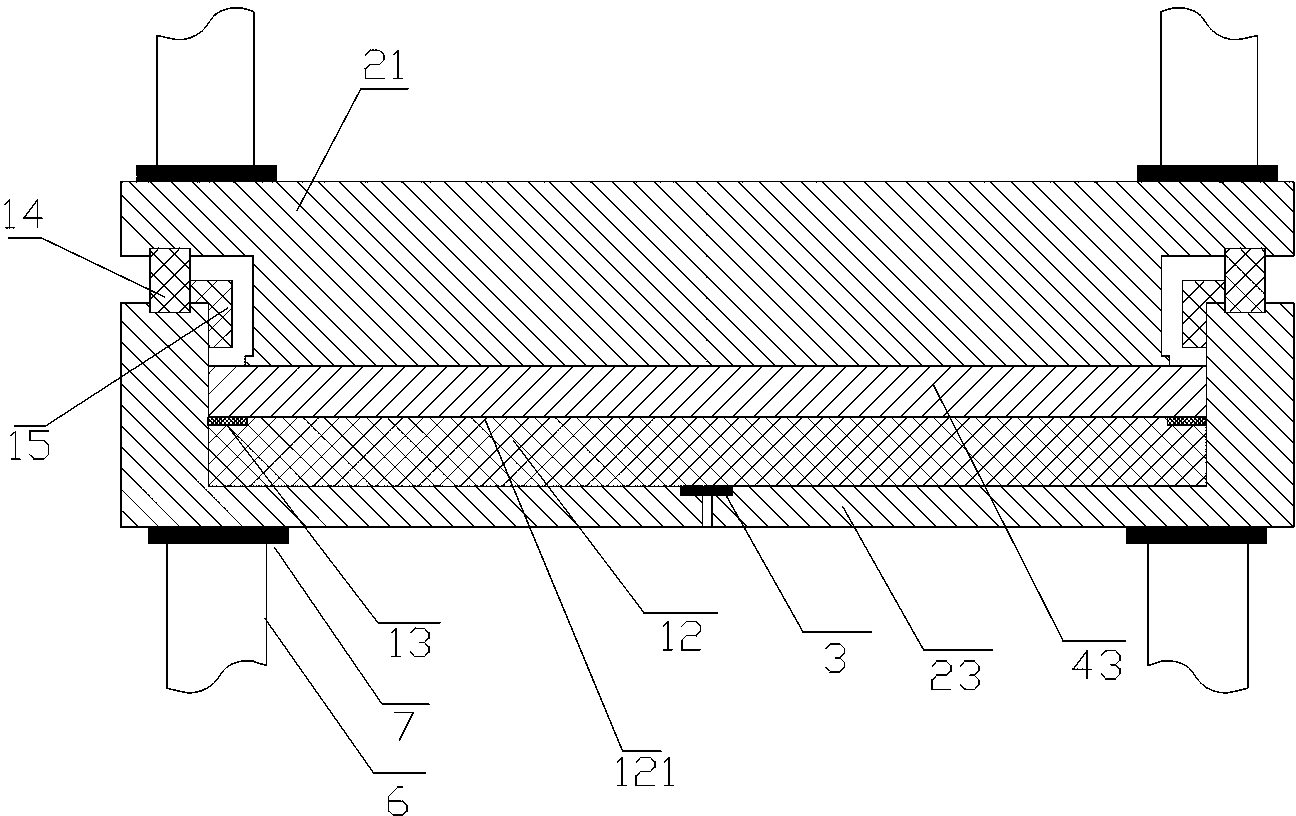

Pot type rubber support

ActiveCN104343081AReal-time monitoring of stressJudgment of healthBridge structural detailsBridge materialsStress conditionsEngineering

The invention discloses a pot type rubber support. The pot type rubber support comprises a top support plate, a steel pot and a rubber plate, wherein the rubber plate can be fastened between the top support plate and the steel pot; a side edge of the steel pot is higher than the top surface of the rubber plate; a sealing piece is arranged on a portion, which is in contact with the steel pot, of the rubber plate; a stainless steel diaphragm is inserted in one side, which faces the rubber plate, of the steel pot; an alloy resistor is assembled on the stainless steel diaphragm and is integrally connected with the stainless steel diaphragm through molecular bonds, so that an alloy film strain unit, which is used for inducing the vertical pressure of a support, of a Wheatstone bridge is formed; and an external load acts on the pot type rubber support, and the alloy film strain unit deforms and generates a voltage signal for monitoring the vertical pressure of the pot type rubber support. The stress condition of the pot type rubber support can be monitored in real time, so that the health condition of the pot type rubber support can be judged; the pot type rubber support is high in fatigue resistance, high in stability and small in size; and influence on the mechanical property of the pot type rubber support is low.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

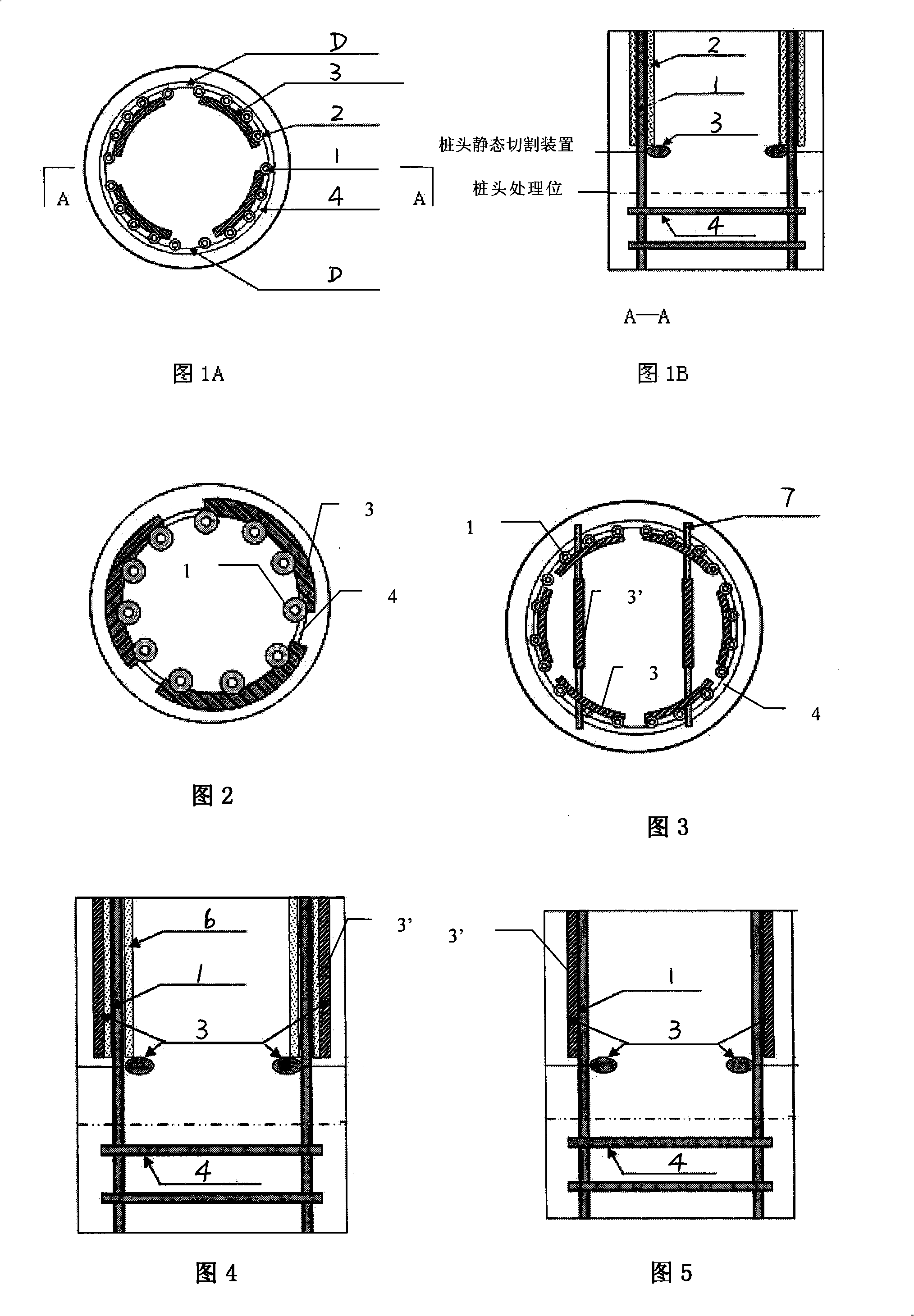

Concrete filling pile head static cutting and crushing method

ActiveCN101333811AEasy to operateLow construction costStone-like material working toolsBulkheads/pilesRebarUltimate tensile strength

The invention discloses a pile head static cutting crushing method for a bored concrete pile; a plurality of cutting bodies are evenly and horizontally fixed around the vertical steel ribs of a steel reinforcement cage of the bored pile on the position where the concrete needs to be removed; the concrete is poured after the steel reinforcement cage is hung into the pile hole; the pile head concrete is pulled out by a hoisting device or is cleaned manually after the concrete hardens; the pile head static cutting crushing method is characterized in that the number and the distribution form of the cutting pieces are designed according the diameter of the bored pile; for the bored pile with the diameter less than 1000mm, the cutting pieces are distributed outside the vertical steel ribs; for the bored pile with the diameter more than 1600mm, the cutting pieces are distributed inside the vertical steel ribs and at least a support steel rib is arranged in the pile parallel to the cutting pieces; each support steel rib is fixed bound with a cutting body; besides, a cutting piece can be vertically fixed outside each vertical steel rib to realize the bidirectional cutting. The pile head static cutting crushing method for the bored concrete pile has the advantages of obviously reducing the construction cost and the labor intensity, shortening the construction period, preventing the vibration noise and the dust in the construction process, being applicable to the popularization and application of the construction industry.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

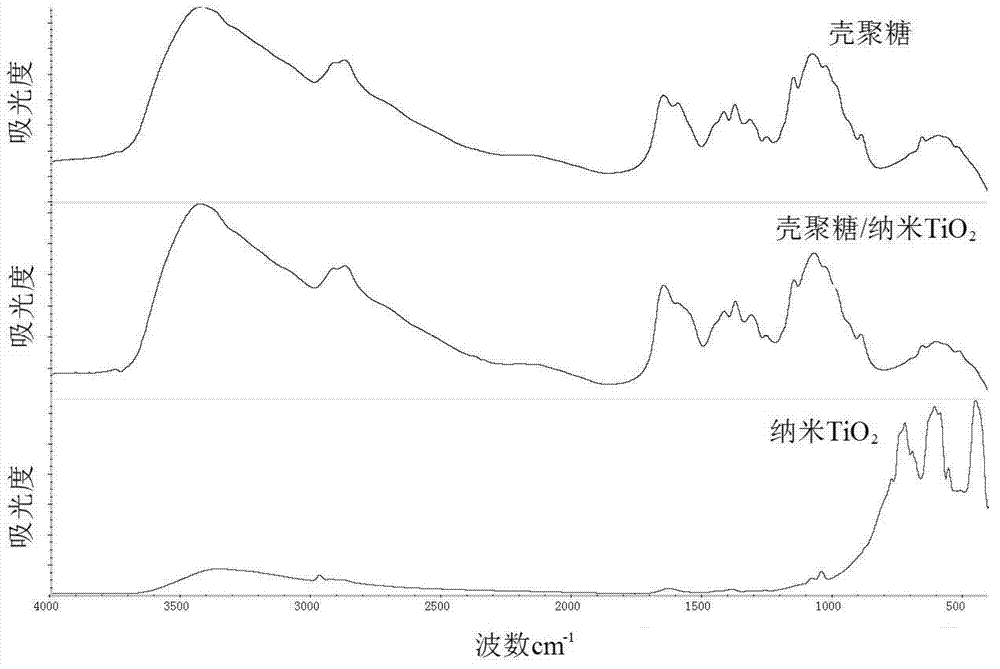

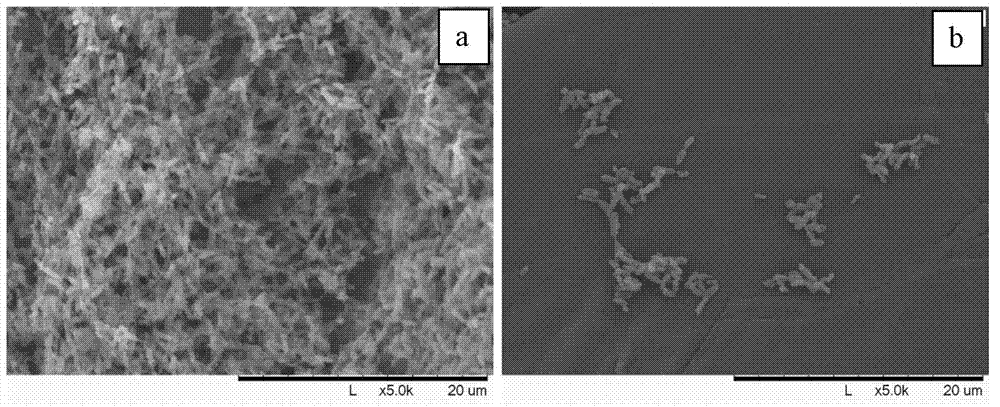

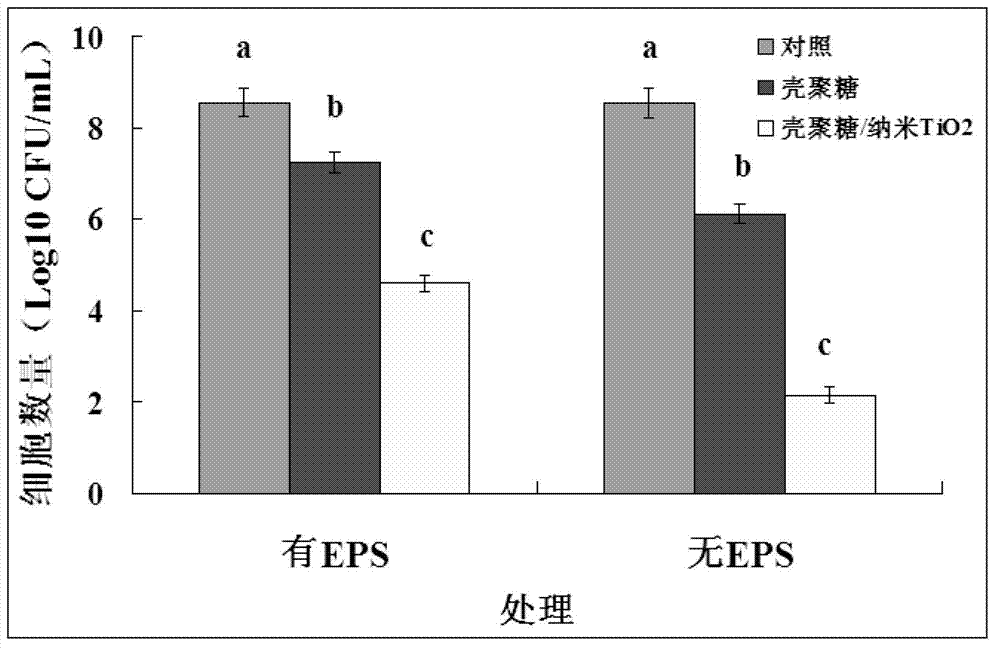

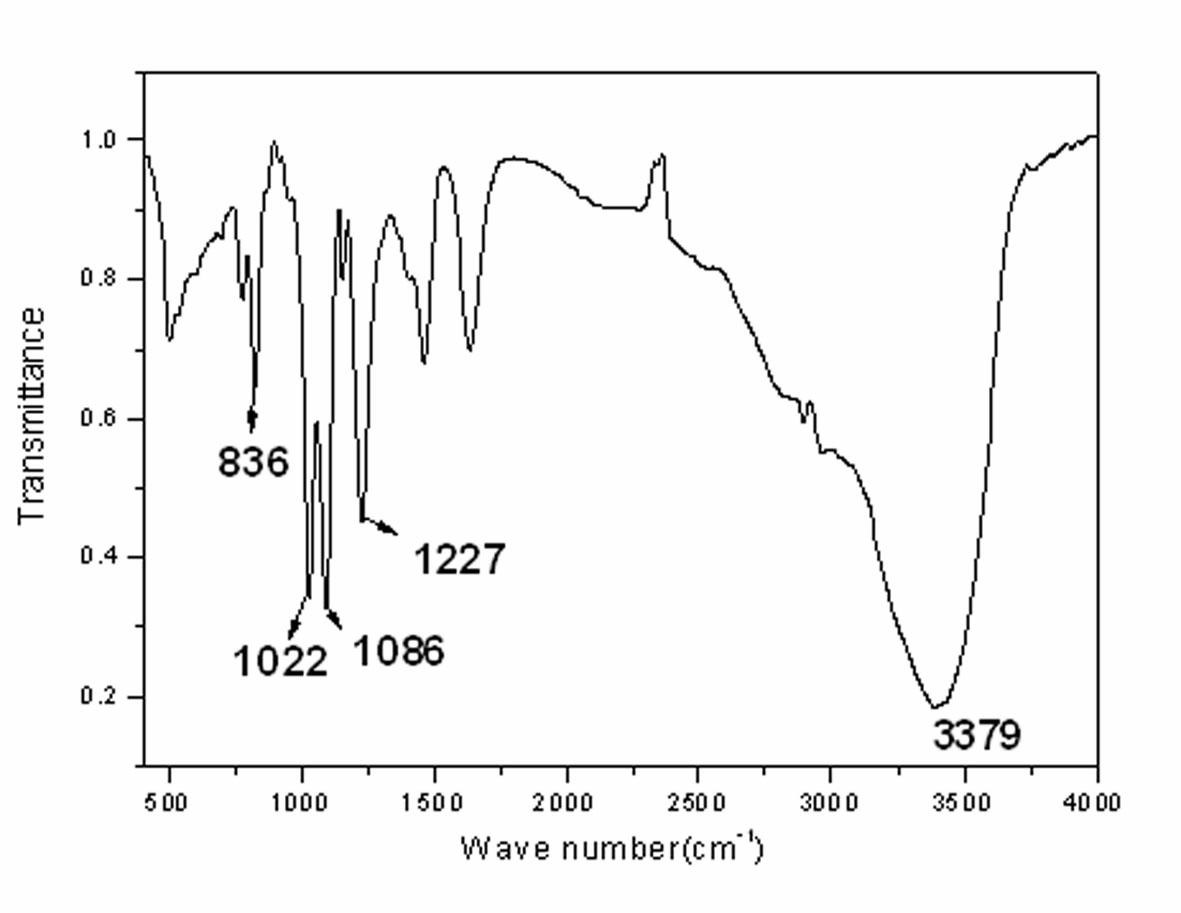

Chitosan/nano-TiO2 composite material and preparation method and application thereof

ActiveCN102816349AAppropriate degree of compoundingEvenly dispersedBiocideDisinfectantsFiberAntibacterial activity

The invention discloses a chitosan / nano-TiO2 composite material and a preparation method and application thereof. The preparation method comprises the following steps that a chitosan solution is mixed with nano-TiO2 powder, the chitosan solution and the nano-TiO2 powder are dispersed by ultrasonic waves and reacted at a temperature of 160-180 DEG C for 1-2h to obtain the chitosan / nano-TiO2 composite material, wherein the concentration of the chitosan solution is 0.05 to 0.2 g / L, and the addition amount of the nano-TiO2 powder is 0.1 to 1.0g / L. The preparation method provided by the invention is simple to operate and good in safety, and nano-TiO2 can be uniformly dispersed in chitosan. The chitosan / nano-TiO2 composite material prepared by the method has a stable structure, better mechanical properties and processing properties, and can be used for preparing a fiber material; and the composite material can effectively decompose exopolysaccharides of rice bacterial blight pathogens, has antibacterial activity against the rice bacterial blight pathogens, and high photocatalytic efficiency, and is used for rice cultivation to effectively prevent and treat the rice bacterial blight.

Owner:ZHEJIANG UNIV

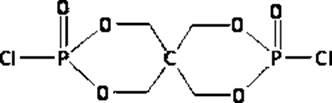

Reactive intumescent flame retardant for polyurethane and synthesis method of reactive intumescent flame retardant

InactiveCN102585135ADoes not affect mechanical propertiesHigh phosphorus and nitrogen flame retardant ingredientsGroup 5/15 element organic compoundsHalogenHigh carbon

The invention discloses a reactive intumescent flame retardant for polyurethane and a synthesis method of the reactive intumescent flame retardant, relates to a flame retardant technology, in particular to a novel intumescent flame retardant which contains an acid source, a carbon source and a gas source simultaneously and contains a hydroxyl group serving as an active group. The chemical name ofthe reactive intumescent flame retardant for polyurethane is 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane. The structure of the reactive intumescent flame retardant is shown as a formula (I). The synthesis method comprises the following steps of: adding 3,9-di{N,N-di(2-ethoxyl)-amino}-2,4,8,10-4-oxo-3,9-diphosphate spiro-3,9-dioxo-[5,5]-undecane into water; dropwise adding diethanolameine and triethylamine at the temperature of 0-5 DEG C; reacting at the temperature of 50-60 DEG C for 4-6 hours; concentrating under reduced pressure; purifying; and performing vacuum drying to obtain the flame retardant. The flame retardant and the synthesis method of the reactive intumescent flame retardant have the advantages of integration of phosphorus, nitrogen and carbon, high phosphorus and nitrogen flame-retardant ingredients, no containing of halogen, nontoxicity, environmental friendliness, high carbon forming property, high compatibility with apolyurethane system, simple process, mild synthesis condition and suitability for industrial implementation.

Owner:ZHONGBEI UNIV

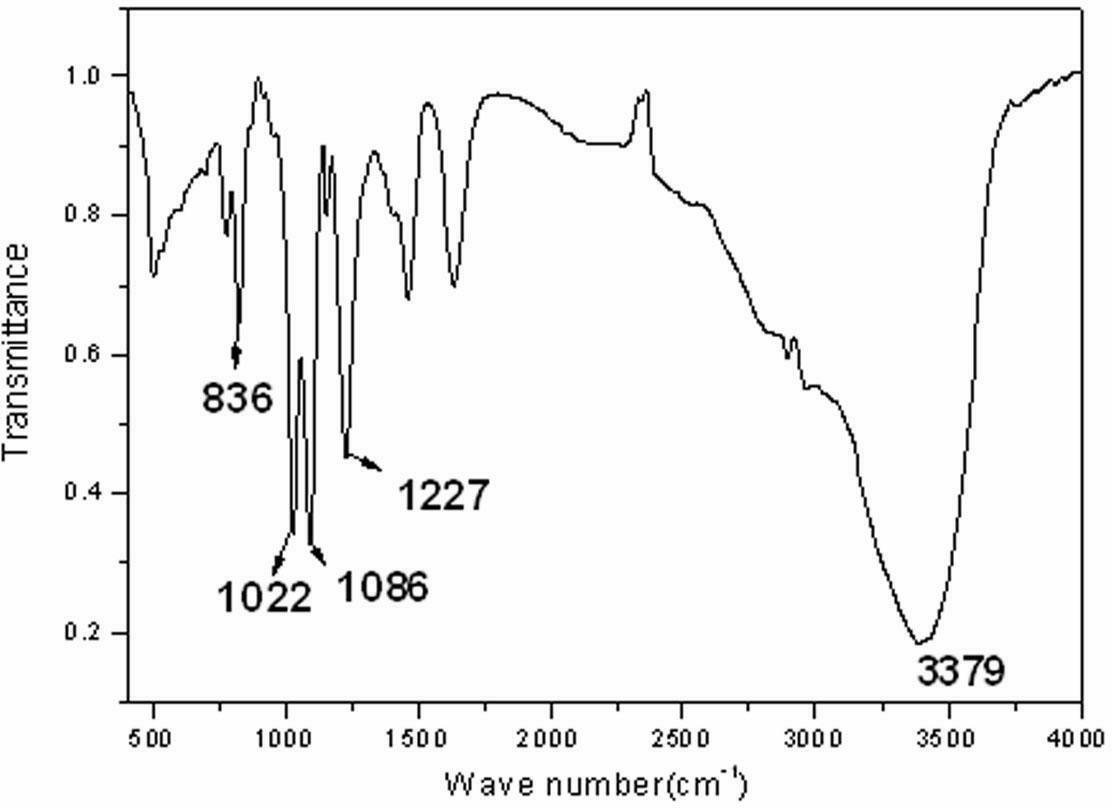

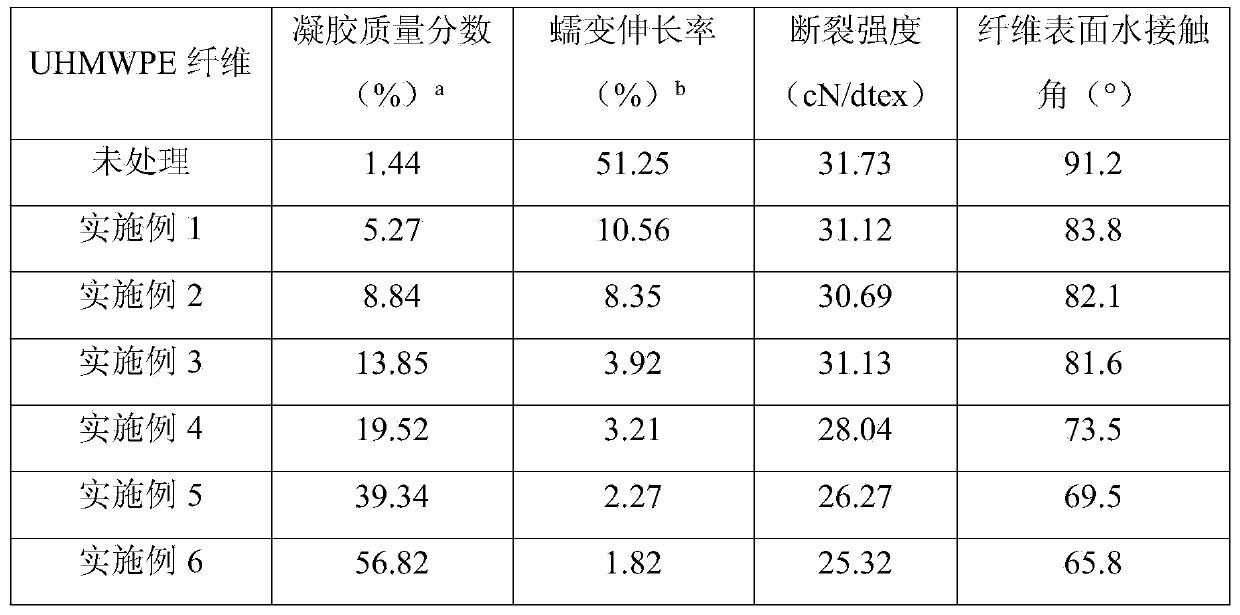

Silane cross-linking modified ultra-high molecular weight polyethylene fiber preparation method

The present invention relates to a silane cross-linking modified ultra-high molecular weight polyethylene fiber preparation method, which comprises: placing ultra-high molecular weight polyethylene UHMWPE gel fibers with no drying treatment into a modified solution, carrying out an ultrasonic treatment, and carrying out multi-stage hot stretching to obtain the finished product. According to the present invention, the fibers have excellent creep resistance and high surface adhesion property, the mechanical property of the modified fibers is basically not reduced, and the method can directly utilize the existing UHMWPE fiber production line to directly prepare the cross-linking modified UHMWPE fibers, has characteristics of simple process and easy operation, and easily achieves industrial continuous treatment.

Owner:JIANGSU SHENTAI SCI & TECH DEV

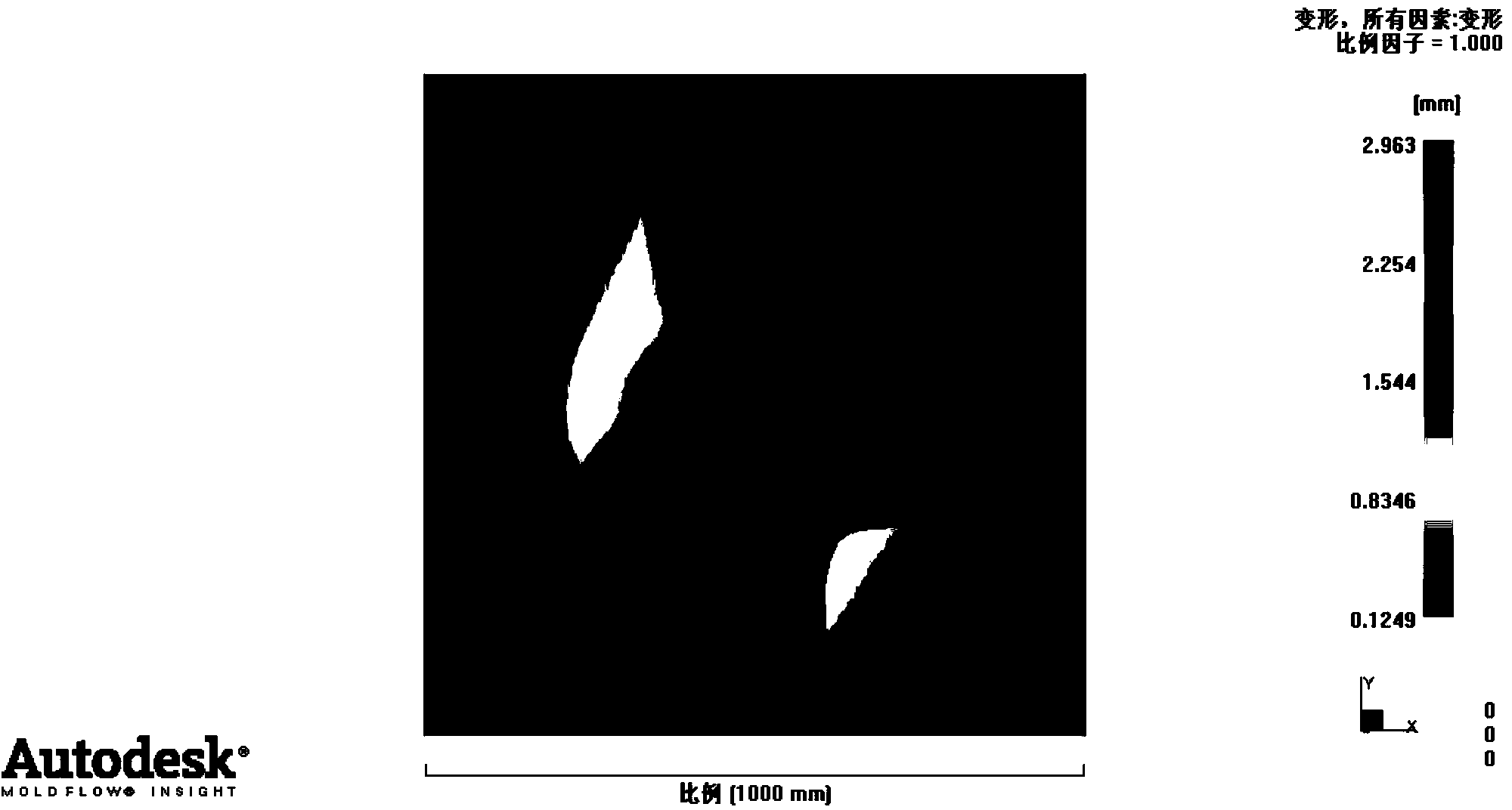

Injection-molding polyamide composite material and preparation method thereof

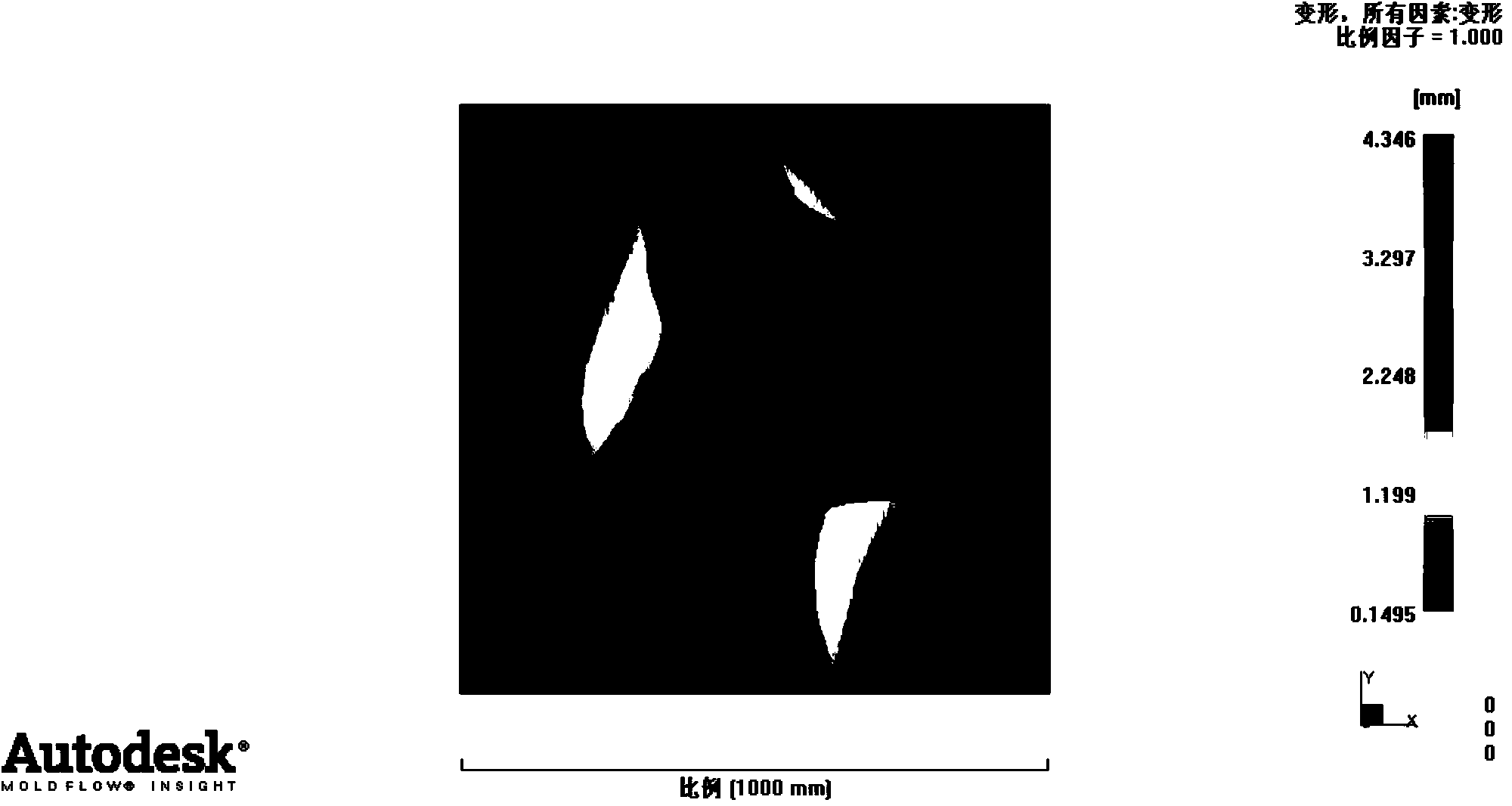

The invention relates to an injection-molding polyamide composite material and a preparation method thereof, belonging to the technical field of materials. The common glass fiber used as the reinforcer of the polyamide material can improve the appearance of the product and lower the buckling deformation of the product on the basis of not influencing the mechanical properties of the product; the coupling agent, lubricant and mineral are added to enhance the binding property between the polyamide material and glass fiber and improve the dispersity of the glass fiber in the polyamide material, so that the glass fiber can not be easily exposed to the surface, and the polyamide material has a favorable surface; and the nucleating agent is added to enhance the crystallization rate and crystallization temperature, reduce the after shrinkage and lower the buckling deformation. Simulation software MOLDFLOW is utilized to evaluate the buckling deformation of the material on the part, thereby being more beneficial to material development. On the premise of reducing the consumption of the nylon resin, increasing the consumption of the cheaper mineral and glass fiber and lowering the material cost, all the properties of the material are not lowered, and especially the appearance and warpage of the injection-molding part are not lowered.

Owner:NANJING JULONG SCI&TECH CO LTD

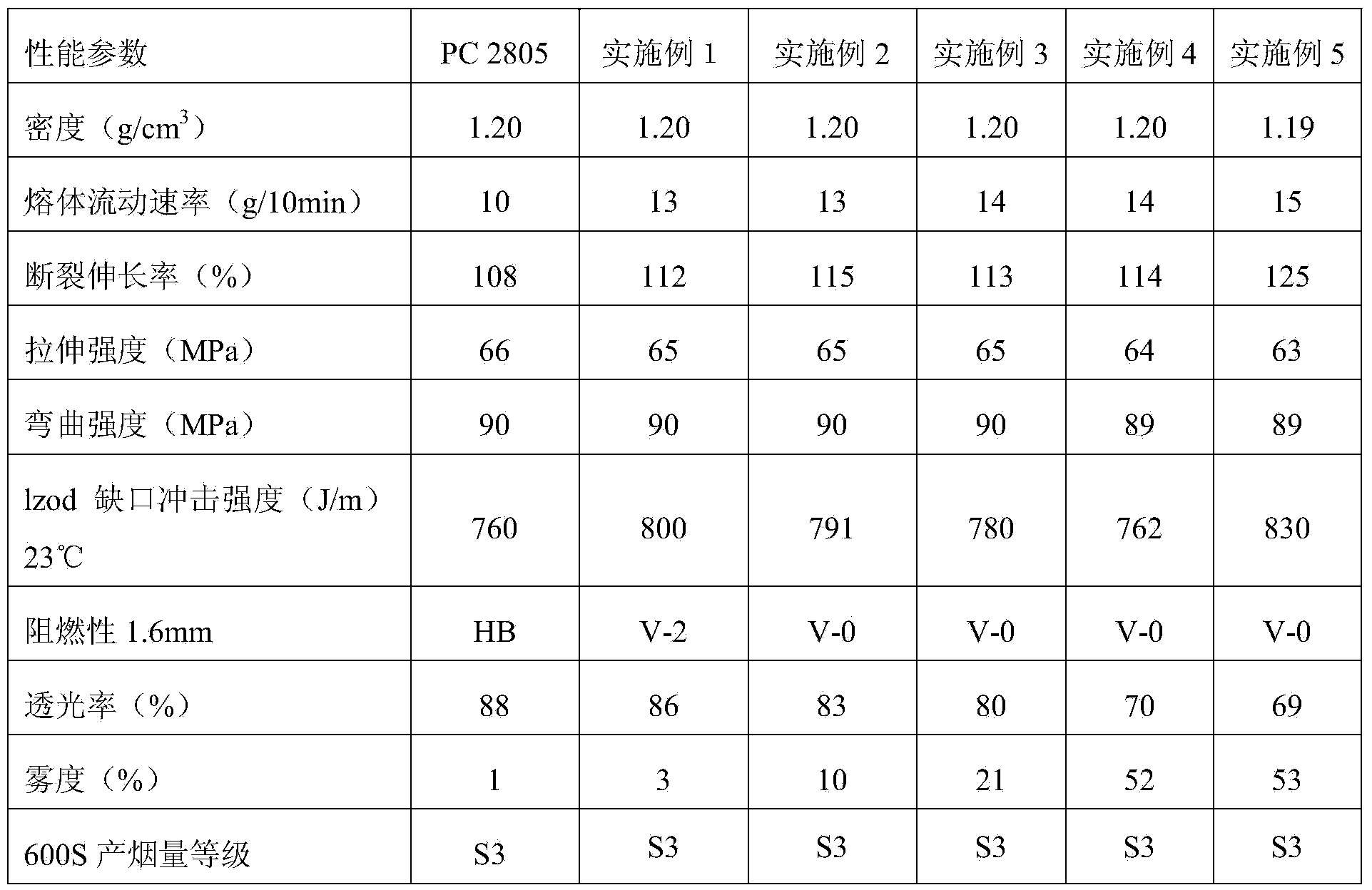

Transparent halogen-free low smoke antiflaming polycarbonate composite material and preparation method thereof

The invention discloses a transparent halogen-free low smoke antiflaming polycarbonate composite material and a preparation method thereof. The polycarbonate composite material comprises the following components in parts by weight: 900-980 parts of polycarbonate resin, 5-50 parts of polysiloxane fire retardant, 1-10 parts of sulfonate fire retardant, and 5-50 parts of additive. The preparation method comprises the following steps of mixing the polycarbonate resin, polysiloxane fire retardant, sulfonate fire retardant and additive in a highly mixing machine, then pelletizing through twin screw extrusion, drying and injection molding so as to obtain the transparent halogen-free low smoke antiflaming polycarbonate composite material. On one hand, the hazard that bromine antiflaming polycarbonate material generates carcinogen such as 4-bromo-dibenzdioxan and 4-bromo-dibenzofuran is avoided; on the other hand, the transparent halogen-free low smoke antiflaming polycarbonate composite material has excellent antiflaming performance, reaches the US standard of UL94V-0, also has high grade of transparency and excellent mechanical property, thermal property, low temperature performance and low smoke performance, and remarkably improves the processibility of the material.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com