Concrete filling pile head static cutting and crushing method

A technology of static cutting and crushing method, which is applied to sheet pile walls, stone processing tools, manufacturing tools, etc. It can solve the problems that concrete cannot be cut into small blocks and is not suitable for cast-in-place piles, so as to reduce construction costs and labor intensity. Effects of shortening the construction period and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

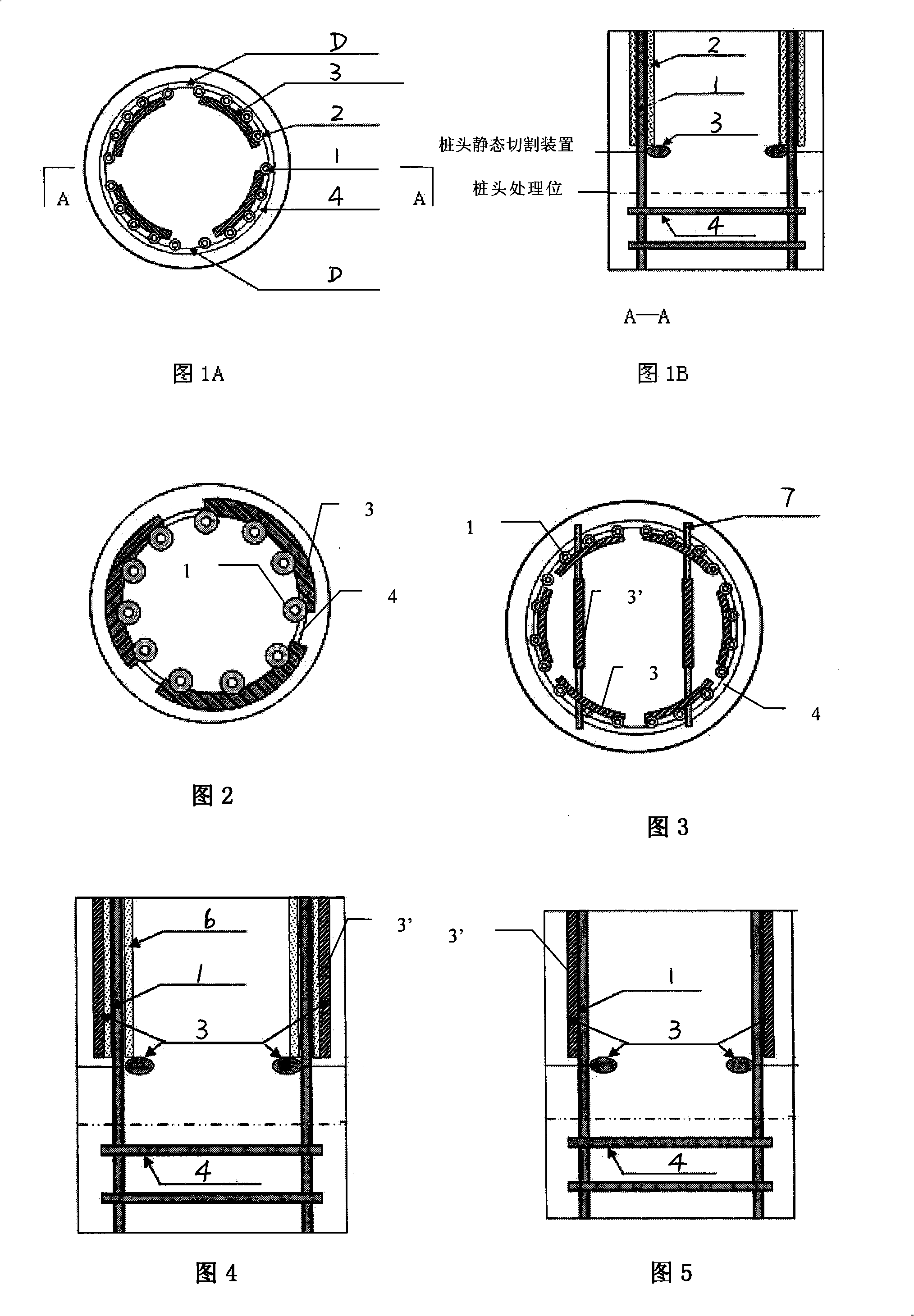

[0032] Example 1: Horizontal cutting of pile heads of cast-in-situ piles with a diameter less than 1000mm

[0033] The other steps are the same as those of the comparative example, except that three cutting bodies 3 are used in step 2), and the cutting bodies are arranged outside the vertical steel bars 1 (see FIG. 2 ). In this case, the cutting force of the cutting part is sufficient to cross the resistance of the steel bar, and the concrete of the cast-in-place pile is cut off along the predetermined position, and the cutting body is arranged outside the vertical steel bar 1, which can prevent the small-diameter pile from falling down during the pouring of concrete. The barrel touches the cut piece.

Embodiment 2

[0034] Example 2: Horizontal cutting of pile heads of cast-in-situ piles with a diameter greater than 1600mm

[0035] The other steps are the same as those of the comparative example, except that six or more cutting bodies 3 are used in step 2), and the cutting bodies are arranged in the vertical reinforcement 1, and at least one A supporting steel bar 7, the supporting steel bar 7 is in the same horizontal plane as other cutting bodies 3, and another cutting body 3' is also bound to the supporting steel bar 7. As shown in Figure 3, it shows that two support bars 7 and cutting body 3' have been added in addition. Like this, the cutting body 3 ' on the supporting steel bar 7 can produce horizontal cracks when the concrete in the middle of the reinforcement cage hardens, thereby also producing cutting action to this part concrete, so that the hoisting of step 4) is easier. If no support reinforcement is provided for auxiliary cutting, the large-diameter pile cannot be cut off b...

Embodiment 3

[0036] Example 3: Two-way cutting of cast-in-situ pile head

[0037] 1) Wrap or put isolation material 6 on each vertical steel bar 1 reserved for the reinforcement cage of cast-in-situ pile (belt-shaped isolation material for wrapping, tubular isolation material for wrapping, foam plastic, rubber-plastic material for isolation material) , paper products, etc.) to prevent concrete from bonding to vertical reinforcement.

[0038] 2) Fix multiple cutting parts 3 with metal, plastic, cotton or other materials horizontally and uniformly distributed in a circle on the vertical reinforcement of the reinforcement cage at the design site where the concrete needs to be removed from the cast-in-place pile (the Generally, each vertical steel bar is a binding point; at the same time, outside the isolation material 6 of each vertical steel bar 1, a cutting piece 3' is vertically fixed with a binding wire, see FIG. 4 .

[0039] 3) After hoisting the reinforcement cage with the cutting part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com