Patents

Literature

90results about How to "Dust free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

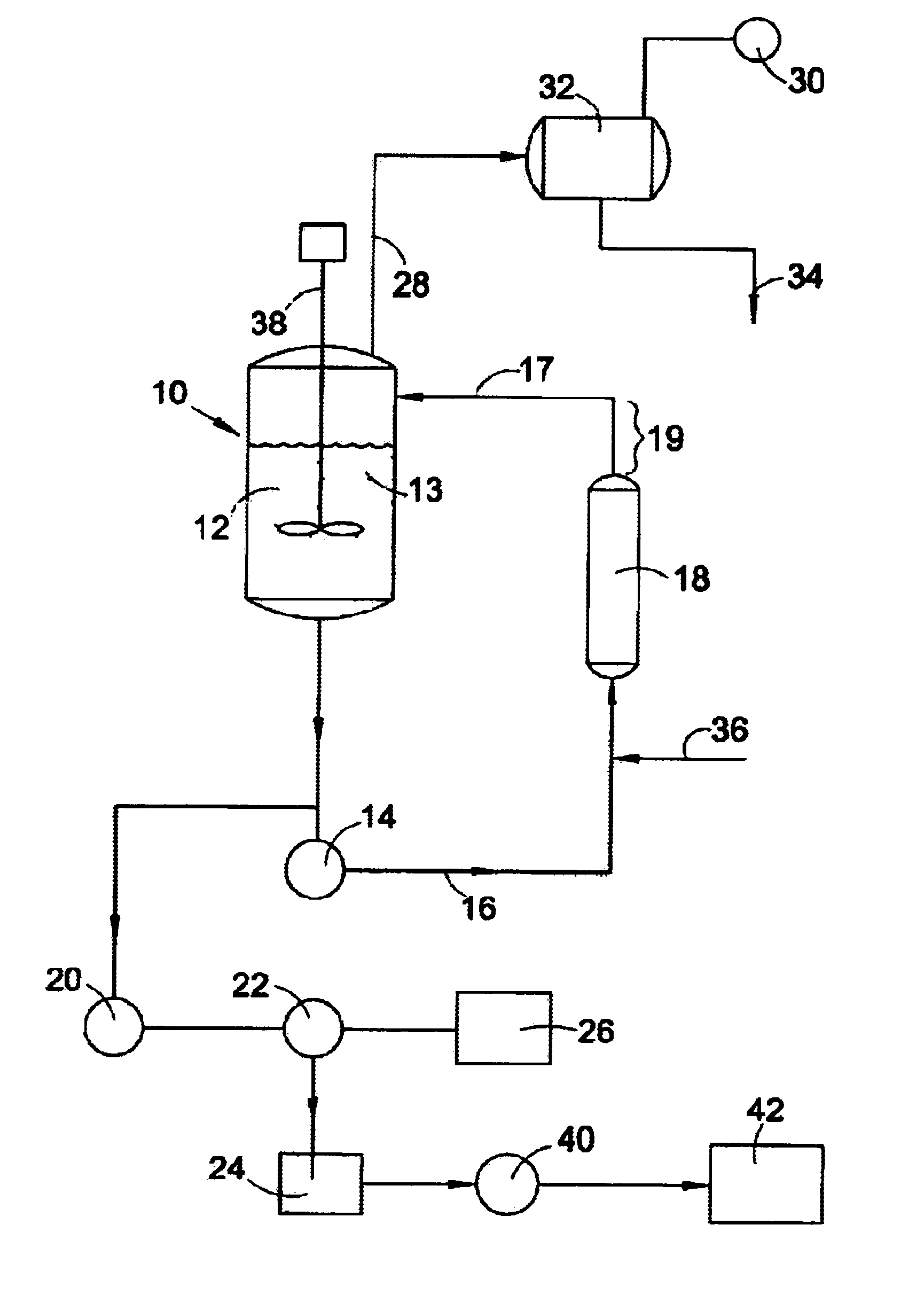

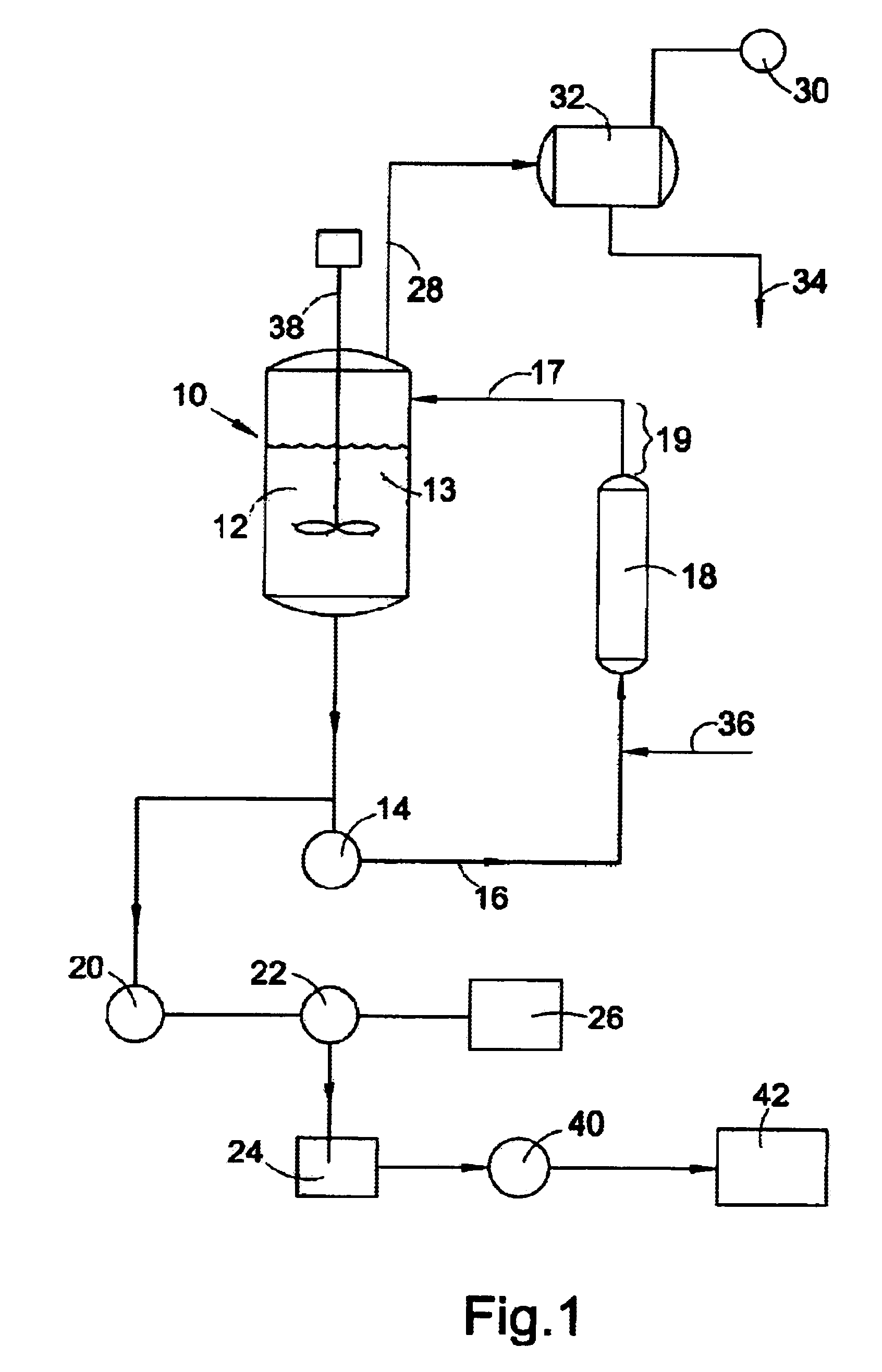

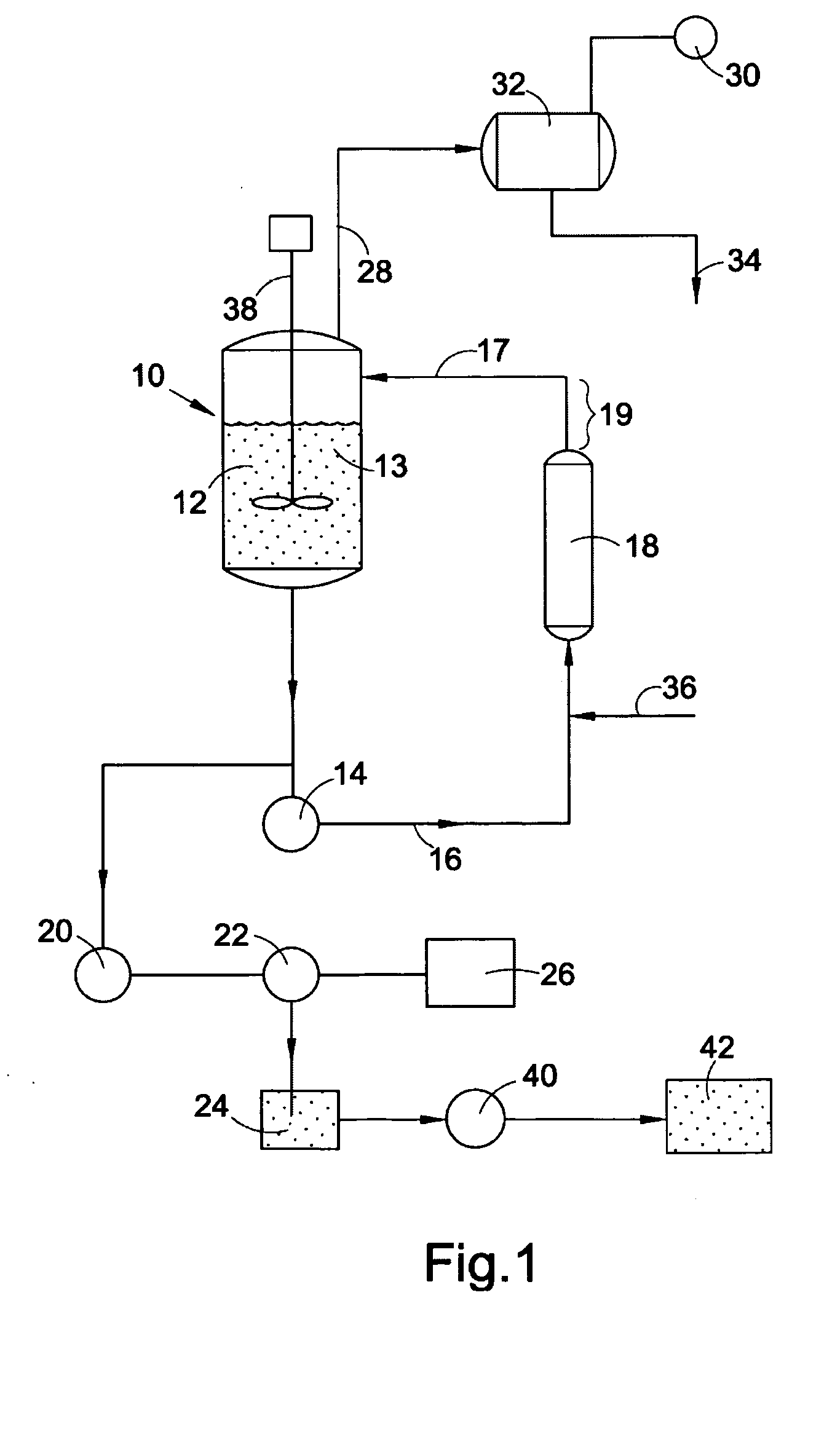

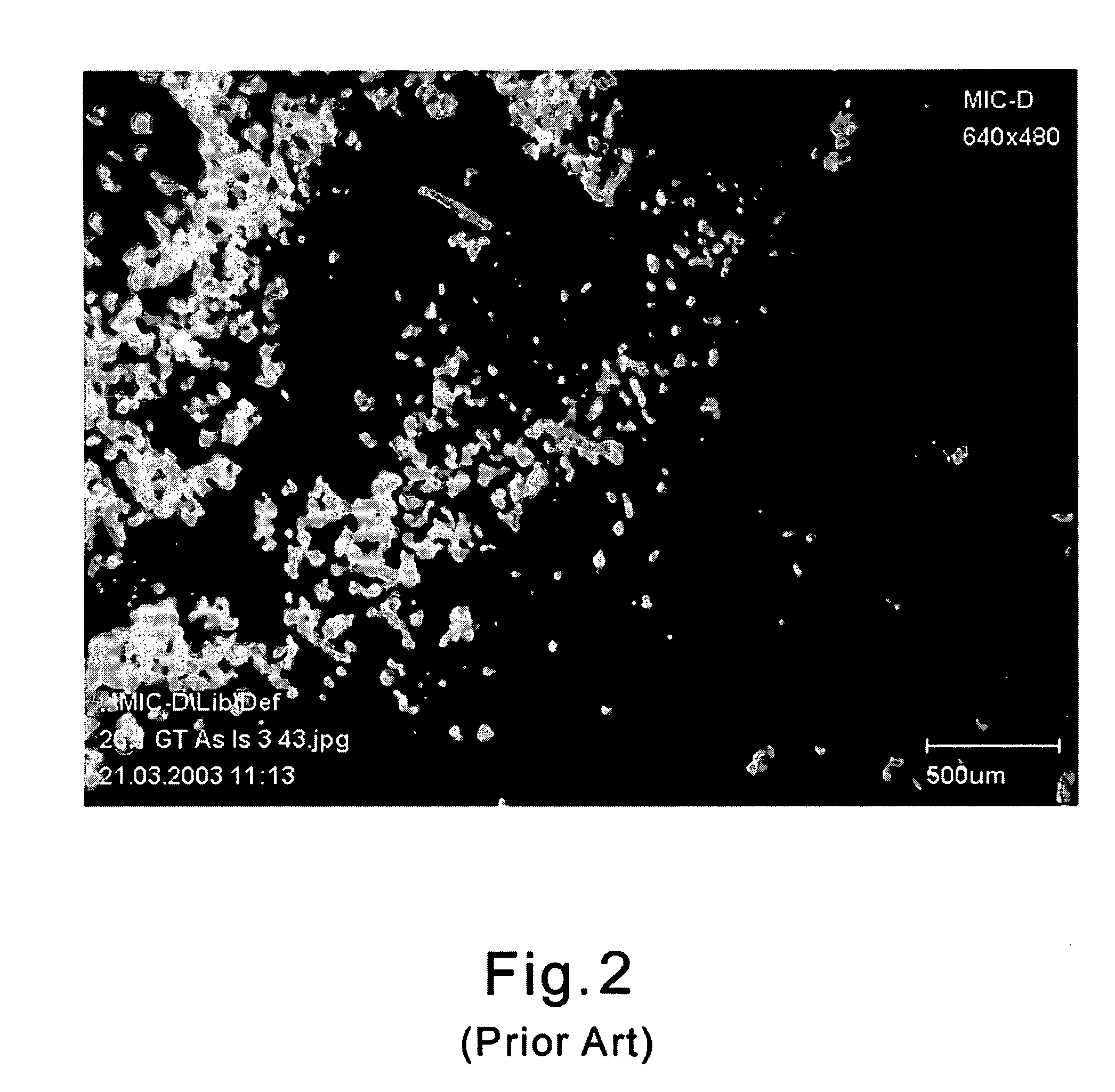

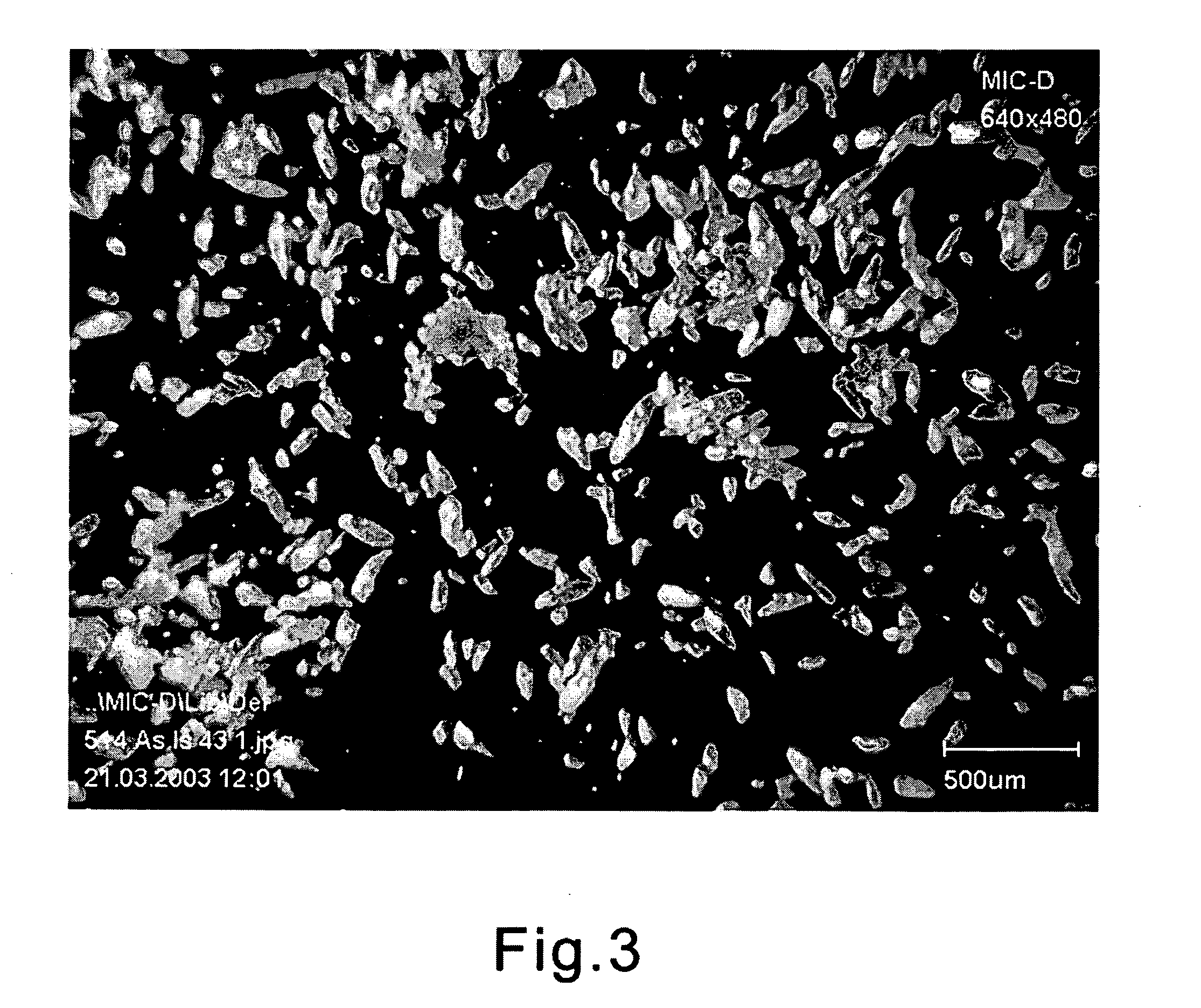

Crystalline form of sucralose, and method for producing it

A crystalline form of sucralose, and a method of making it. The method involves continuously crystallizing sucralose from an aqueous solution by a process providing continuous removal and recirculation of the vessel contents, and providing a long residence time for sucralose in the system. The crystals thus formed are of a relatively low length / diameter ratio, have an unsymmetrical shape, and exhibit good stability. The larger crystals in particular are tapered as compared to the rod-like larger crystals in prior art product.

Owner:TATE & LYLE TECH LTD

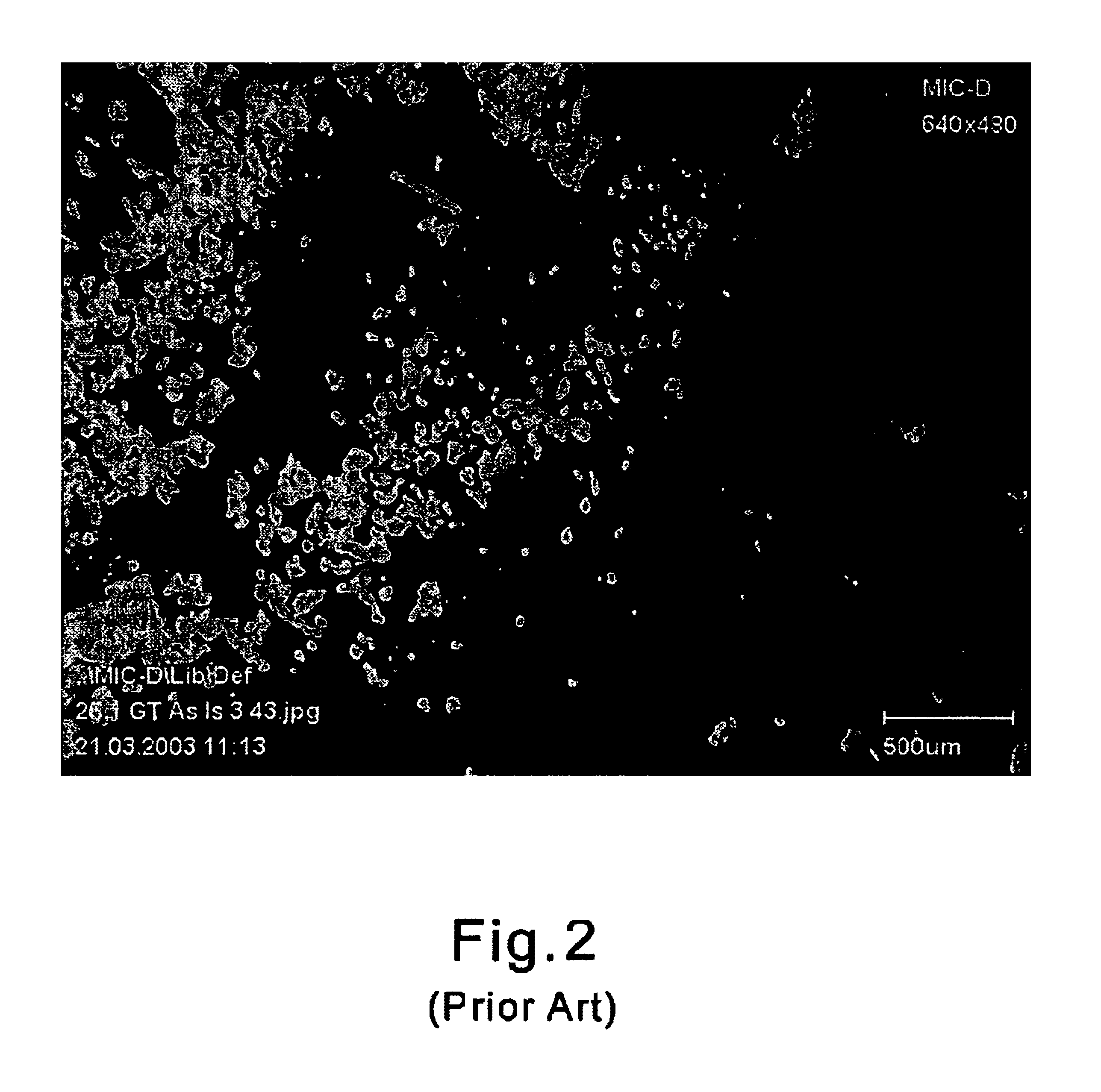

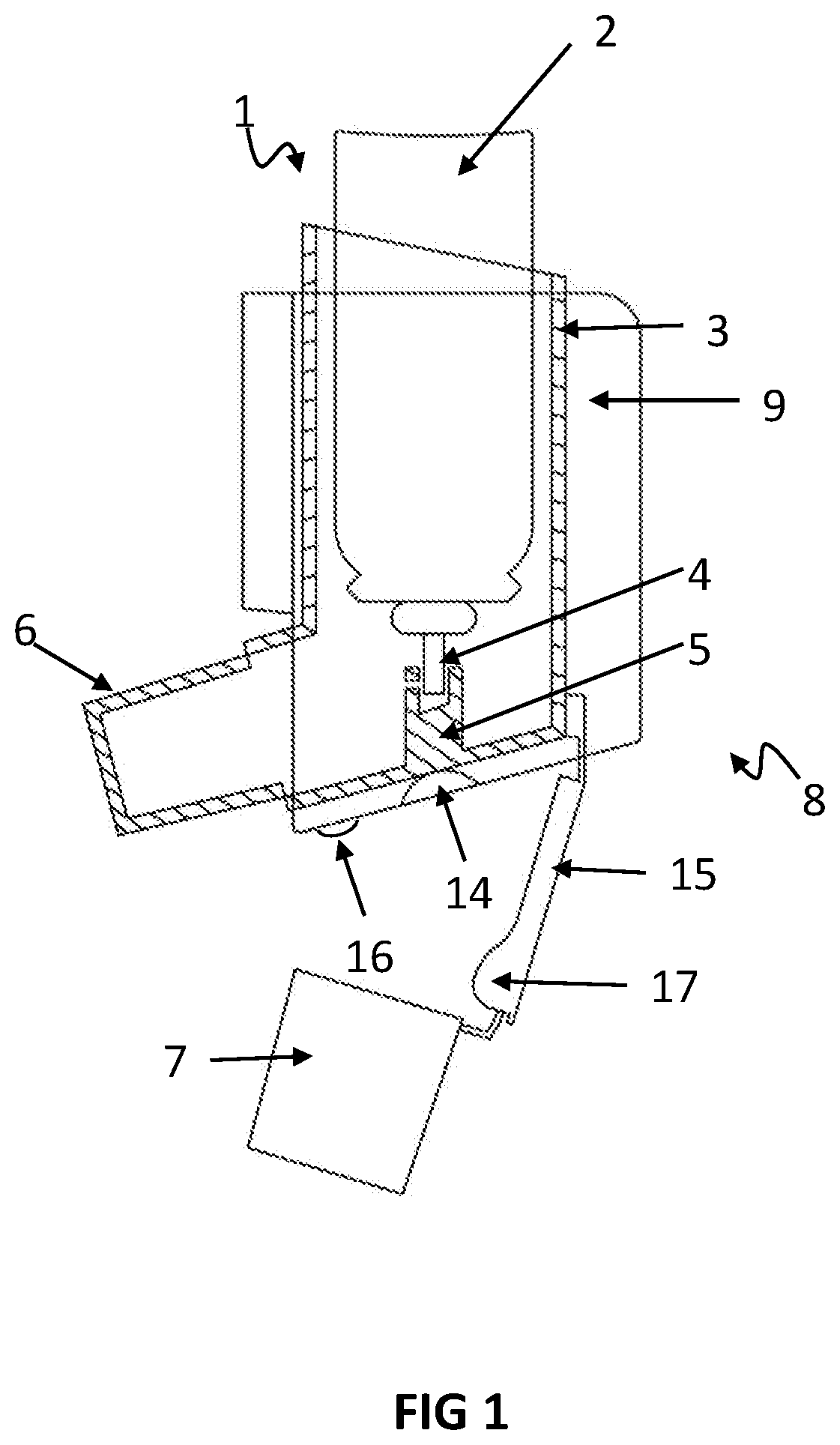

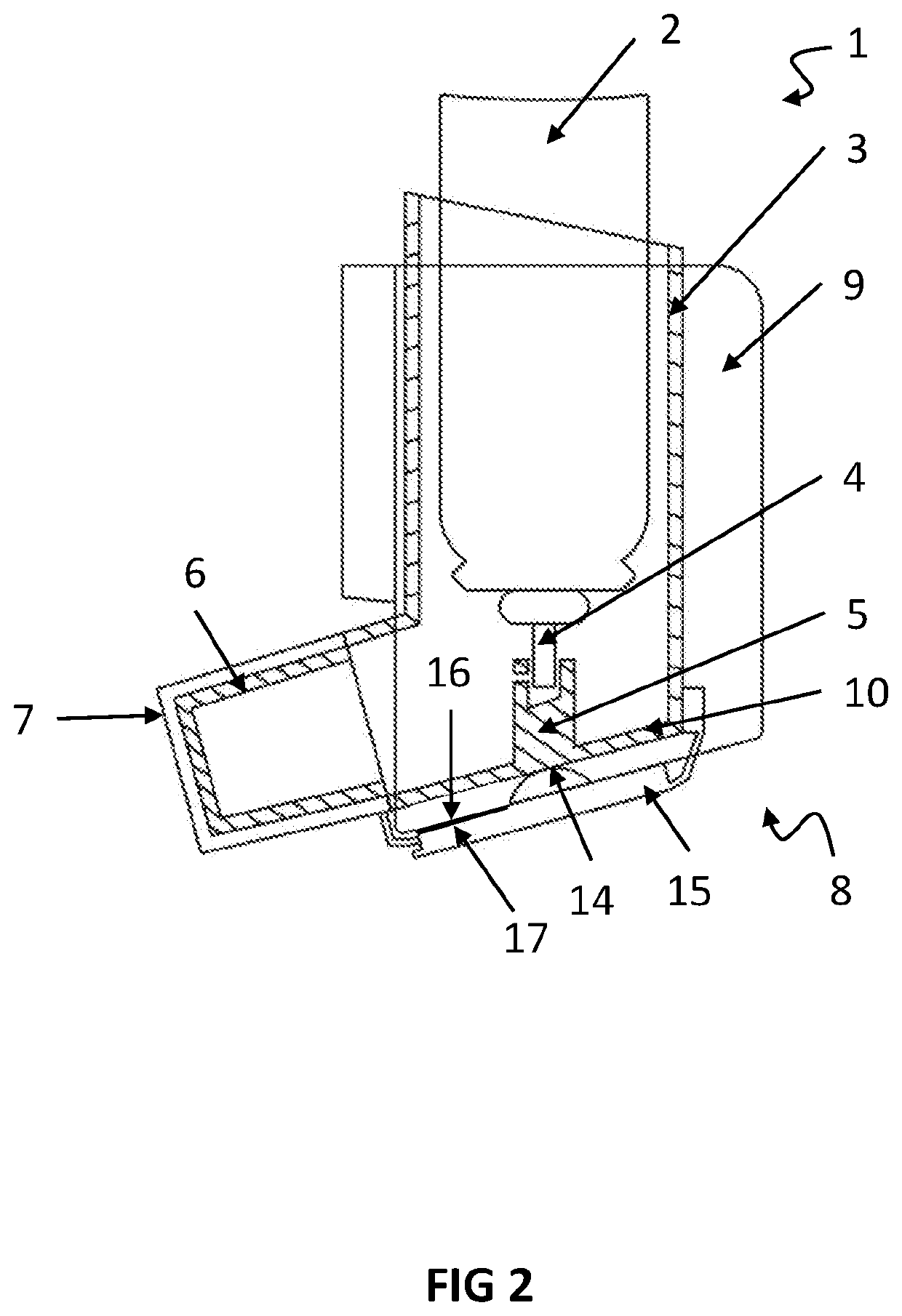

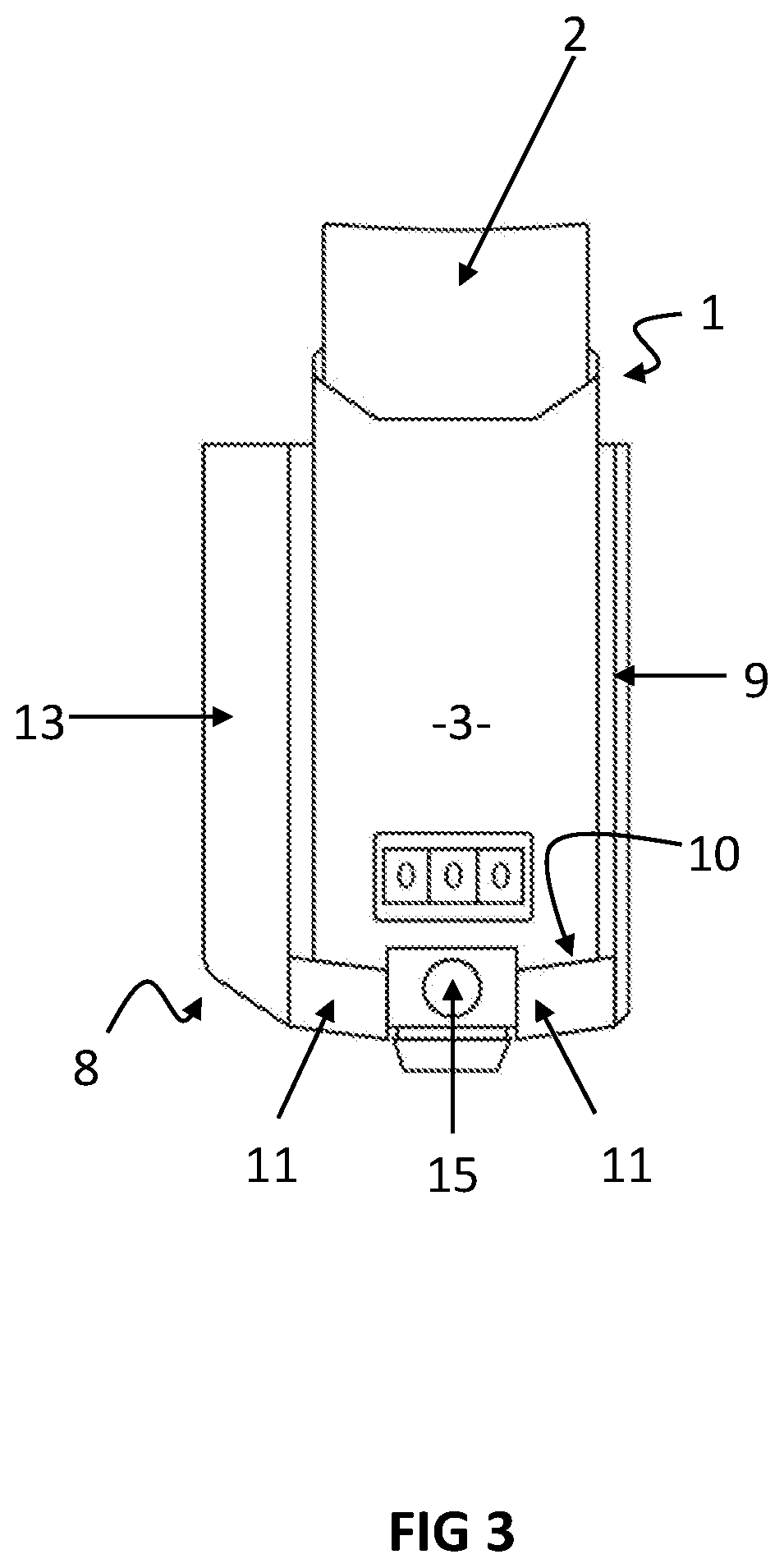

A compliance monitor for a medicament inhaler

ActiveUS20160228657A1Problem be addressEasy to cleanMedical devicesMedical atomisersDrug StorageBiomedical engineering

This invention relates to a compliance monitor for monitoring patient usage of a medicament inhaler. The medicament inhaler includes a store of medicament, a first housing for housing the store of medicament, a medicament dispensing means for delivering a dose of medicament, a mouthpiece for directing the dose of medicament into the mouth of a user, and a removable and replaceable cap for the mouthpiece. The compliance monitor includes a cap detection means for determining when the cap is covering the mouthpiece and / or for determining that the cap is being removed or replaced, with respect to the mouthpiece. The compliance monitor may also include a dose detection means for determining that a dose of medicament has been dispensed.

Owner:ADHERIUM (NZ) LTD

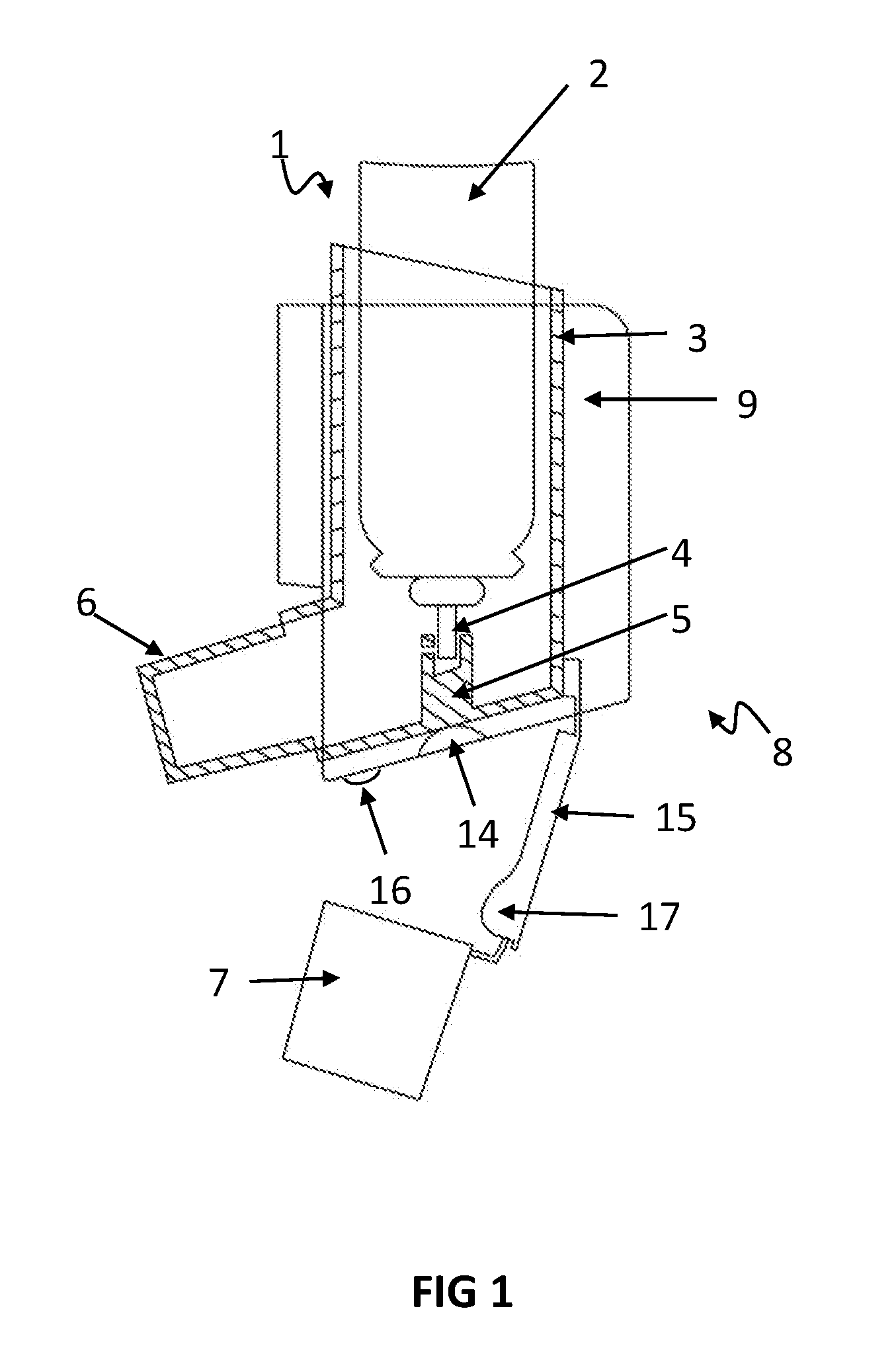

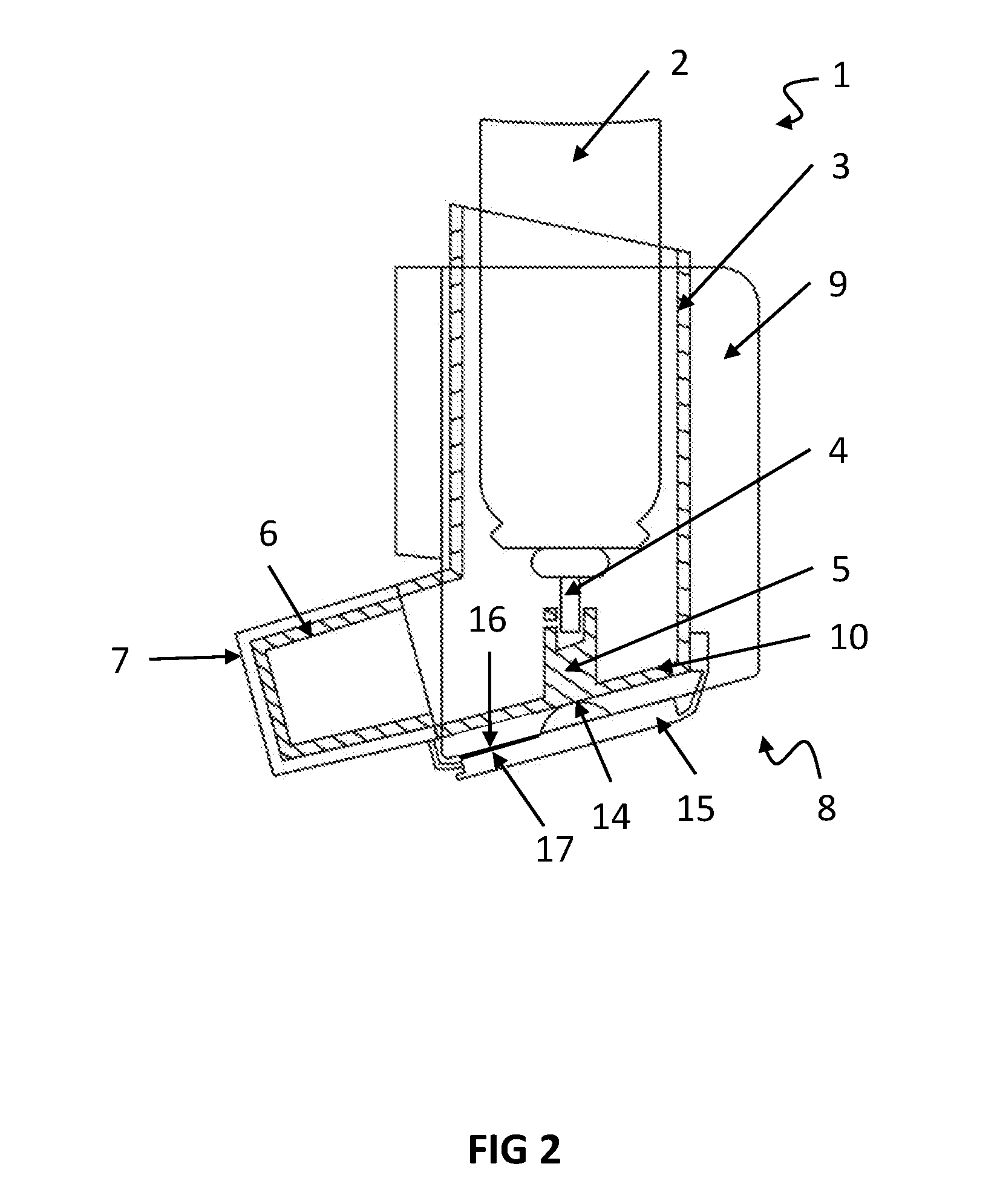

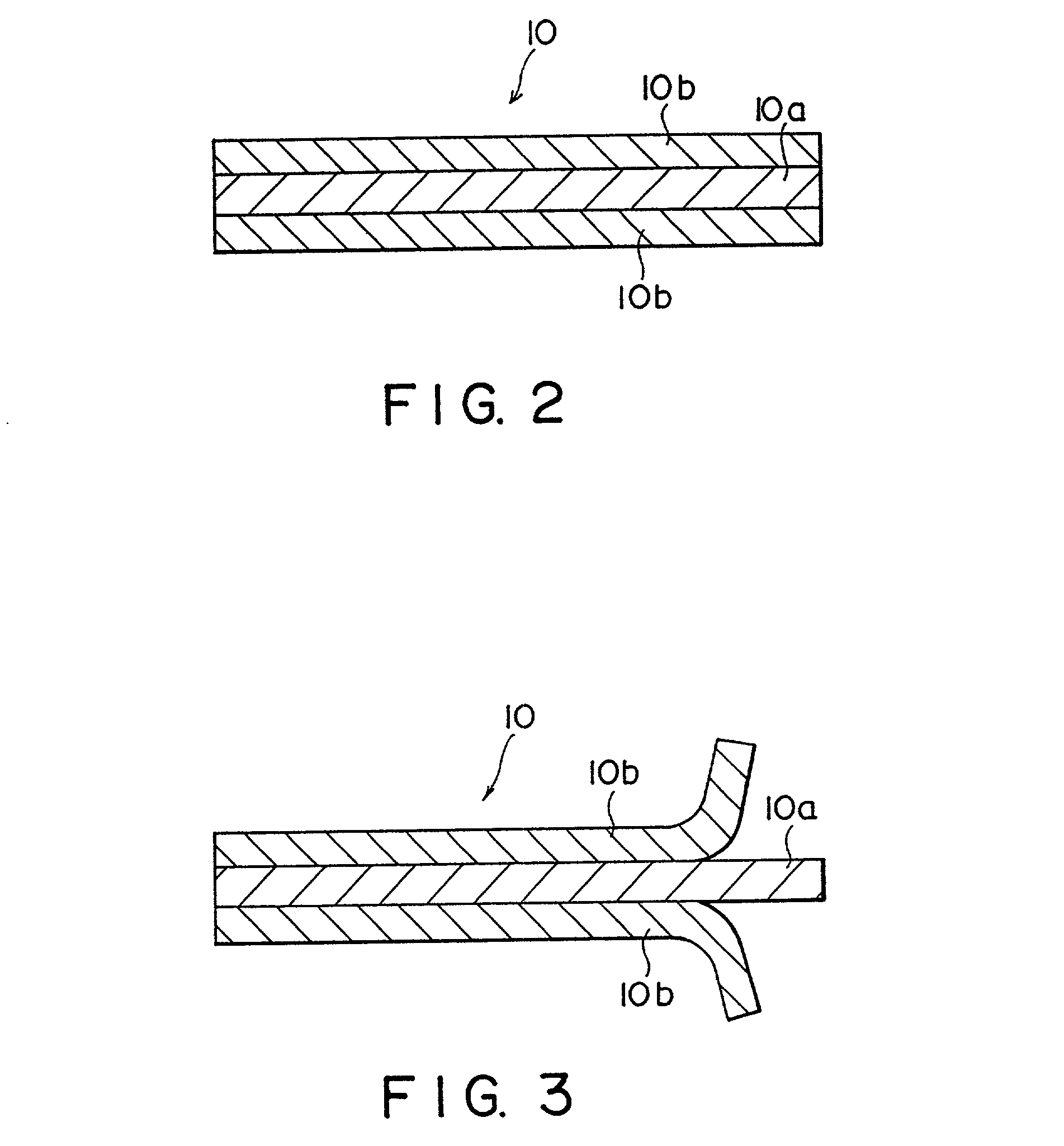

Dustfree filling and sealing apparatus, dustfree container and wrapping clean film producing method

InactiveUS20030062114A1Dust freeDeteriorating peeling propertyAdhesive processesFlexible coversEngineeringMechanical engineering

Owner:DAI NIPPON PRINTING CO LTD

Soil conditioner and preparation and application methods thereof

InactiveCN106995342AGood physical propertiesDust freeAgriculture tools and machinesOther chemical processesNutrientSoil acidification

The invention relates to a soil conditioner and preparation and application methods thereof. The soil conditioner is prepared from the following ingredients in percentage by weight: 30% to 35% of overrotten organic fertilizer, 35% to 40% of fruit tree branch charcoal, 14.5% to 19.5% of oyster shell powder, 8% of pyroligneous liquor, 6.0% of natural humus acid, and 1.5% of titanium oxide. The conditioner has effects of loosening soil, improving soil acidification and removing soil hardening, and has effects of improving water and nutrient retention capacity of soil, supplementing trace elements in soil calcium and magnesium and reducing crop diseases and pests. The soil conditioner can replace slaked lime, an organic fertilizer and the like as the soil conditioner to be applied to the planting industry.

Owner:山东安绿能源科技有限公司

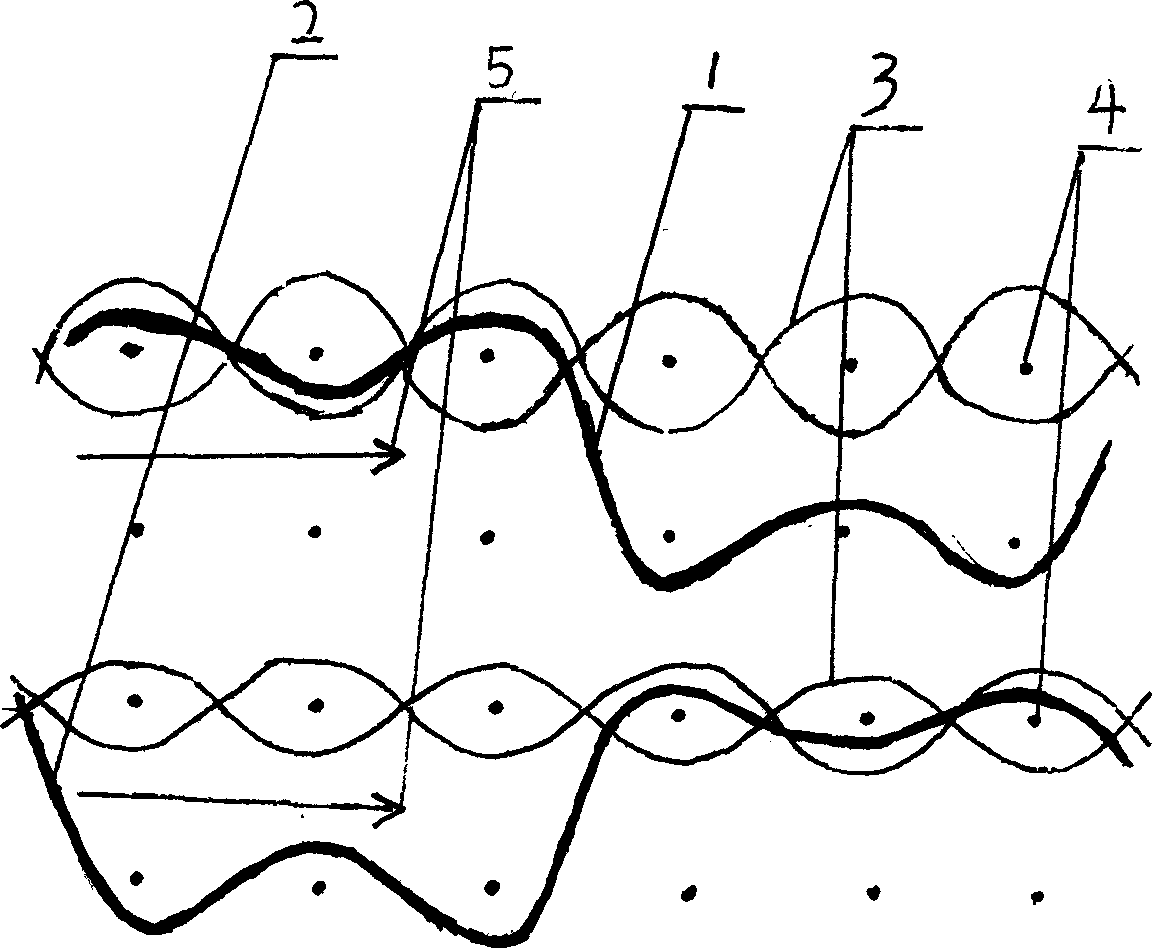

Clean wiping cloth and its producing process

The clean wiping cloth and its production process belong to the field of weaving technology. The clean wiping cloth is produced with composite polyester-Jinlun yarn as material and through the steps of compounding twisting, warping, weaving, opening, and gluing to set. In the opening step, the composite polyester-Jinlun yarn is soaked in sodium hydroxide solution of concentration 6-8 g / L at 98-105 or 1 hr. The high efficiency clean wiping cloth made of superfine fiber has fine fuzzy fibers in much greater quantity than that in common fabric, high dirt holding capacity, no dust, high hygroscopicity and high cleaning power.

Owner:沂水恒泰纺园有限公司

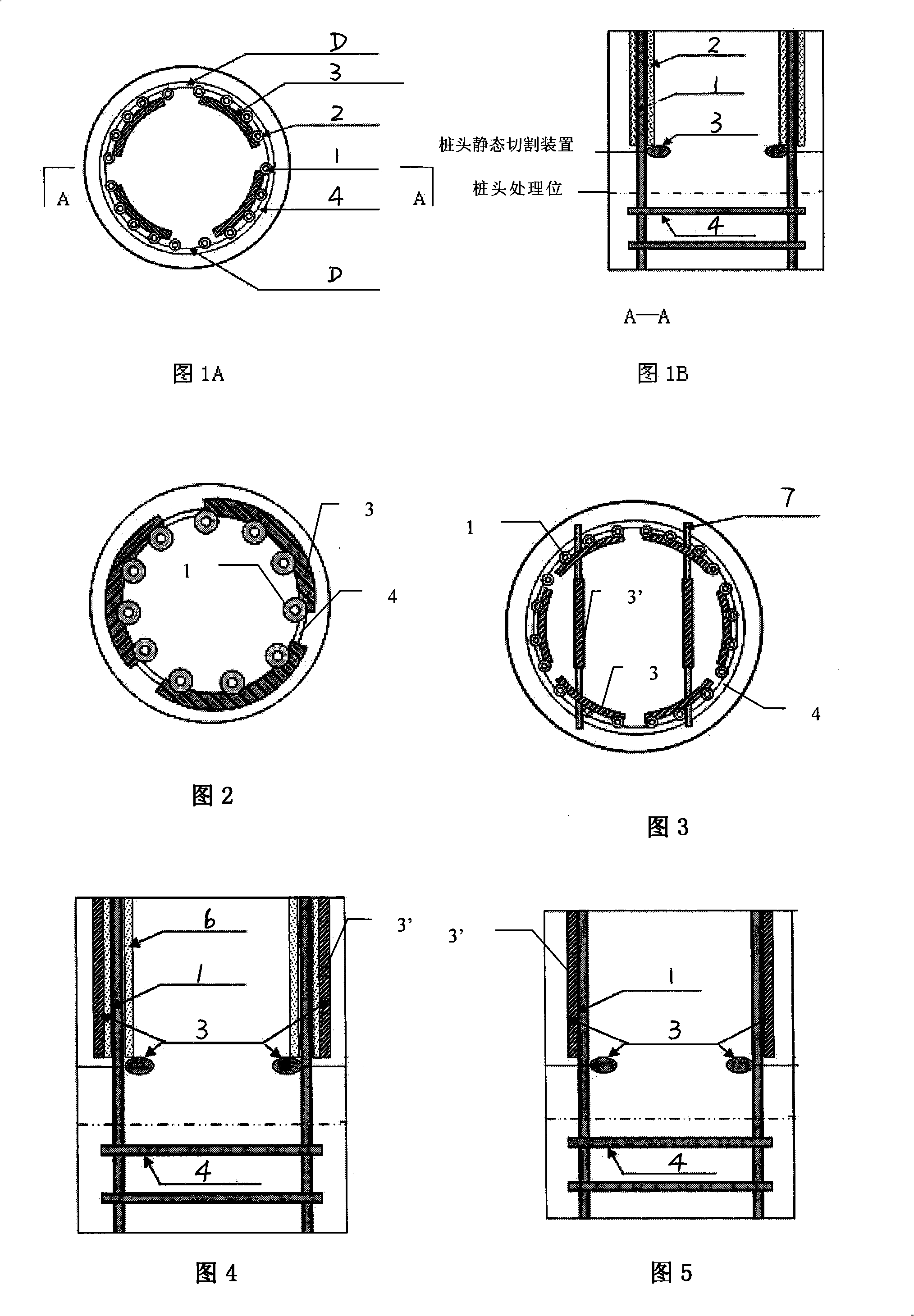

Concrete filling pile head static cutting and crushing method

ActiveCN101333811AEasy to operateLow construction costStone-like material working toolsBulkheads/pilesRebarUltimate tensile strength

The invention discloses a pile head static cutting crushing method for a bored concrete pile; a plurality of cutting bodies are evenly and horizontally fixed around the vertical steel ribs of a steel reinforcement cage of the bored pile on the position where the concrete needs to be removed; the concrete is poured after the steel reinforcement cage is hung into the pile hole; the pile head concrete is pulled out by a hoisting device or is cleaned manually after the concrete hardens; the pile head static cutting crushing method is characterized in that the number and the distribution form of the cutting pieces are designed according the diameter of the bored pile; for the bored pile with the diameter less than 1000mm, the cutting pieces are distributed outside the vertical steel ribs; for the bored pile with the diameter more than 1600mm, the cutting pieces are distributed inside the vertical steel ribs and at least a support steel rib is arranged in the pile parallel to the cutting pieces; each support steel rib is fixed bound with a cutting body; besides, a cutting piece can be vertically fixed outside each vertical steel rib to realize the bidirectional cutting. The pile head static cutting crushing method for the bored concrete pile has the advantages of obviously reducing the construction cost and the labor intensity, shortening the construction period, preventing the vibration noise and the dust in the construction process, being applicable to the popularization and application of the construction industry.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

Preparation method of electroconductive silicone rubber

The invention discloses a preparation method of electroconductive silicone rubber. Acetylene black, aluminum oxide, hydroxyl silicone oil and water accounting for 1% of the acetylene black by weight are mixed and added into a granulator to be produced into acetylene black and aluminum oxide particles for mixing. The silicone rubber has the advantages of high heat conductivity, heat resistance and low compressibility, the tensile strength is larger than 9.6 MPa, the tear strength is above 36 N / mm, and the volume resistivity is smaller than 45 omega.cm.

Owner:广东长博电子绝缘材料有限公司

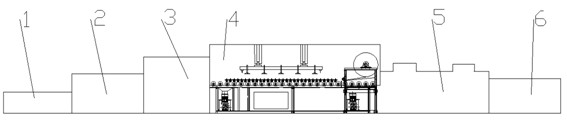

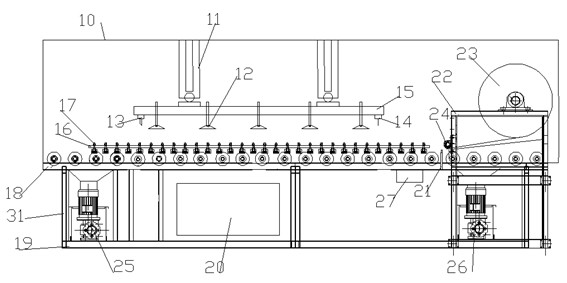

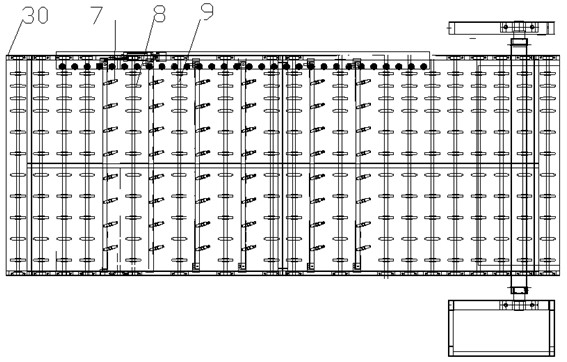

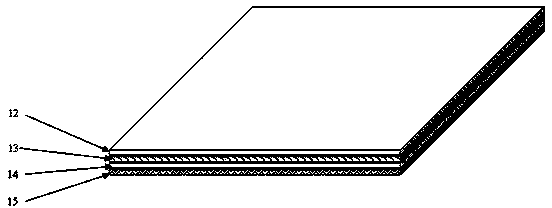

Full-automatic laminated glass production system and process thereof

ActiveCN102659325AImprove safety performance and production efficiencySmall footprintFilm frameAgricultural engineering

The invention discloses a full-automatic laminated glass production system and a process thereof. According to the full-automatic laminated glass production system, a sheet assembly table, a cleaning machine, an air drying machine, a positioning film paving sheet closing table, a rolling machine and a sheet disassembly table are connected sequentially; an integrated air purification device, a glue film frame, a first motor and a second motor are arranged on a base; the base is connected with a positioning platform by a support; a transmission shaft, a positioning plate, a glue film clamp, a third motor and a third guide rail are arranged on the positioning platform; an inclined transmission wheel and a horizontal transmission wheel are arranged on the transmission shaft; a positioning pulley is arranged on the positioning plate; a sucker frame is arranged on the positioning platform; two air cylinders are hung on the sucker frame; a sucker plate is arranged at the lower ends of the two air cylinders; vacuum suckers, a transverse film cutting mechanism, a longitudinal film cutting mechanism, a first guide rail and a second guide rail are arranged on the sucker plate; and a glue film spreading machine and a glue outlet are formed on the glue film frame. The full-automatic laminated glass production system is high in automated degree, and manual operation is replaced, so that the production efficiency, product quality and safety are improved greatly, and the field cost and labor cost are saved greatly.

Owner:广西远大玻璃节能科技股份有限公司

Crystalline form of sucralose, and method for producing it

InactiveUS20050203290A1Dust freeSugar derivativesSugar derivatives preparationState of artDiameter ratio

A crystalline form of sucralose, and a method of making it. The method involves continuously crystallizing sucralose from an aqueous solution by a process providing continuous removal and recirculation of the vessel contents, and providing a long residence time for sucralose in the system. The crystals thus formed are of a relatively low length / diameter ratio, have an unsymmetrical shape, and exhibit good stability. The larger crystals in particular are tapered as compared to the rod-like larger crystals in prior art product.

Owner:CATANI STEVEN J +2

Ultra lightweight clay and polymer high performance clumping cat litter

ActiveUS20160044891A1Shorten the trackComparable clumping performanceBiocideAnimal housingLitterAbsorbent material

This invention relates to a formulation and process for making a lightweight, clumping absorbent material with virtually no dust, low tracking, superior clumping and odor control. The formulations described herein may utilize a tackifying agent to attach the clumping additive to the surface of the absorbent material.

Owner:OIL DRI OF AMERICA

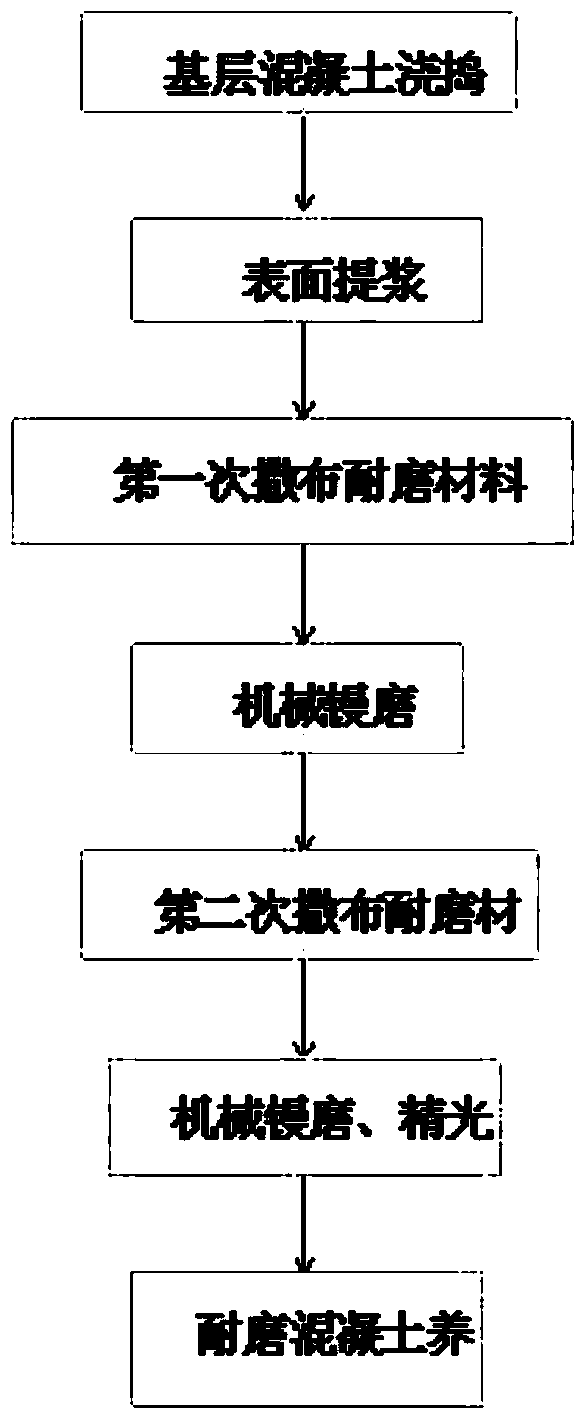

Wear-resisting concrete terrace overall molding construction method

The invention discloses a wear-resisting concrete terrace overall molding construction method, and the method comprises the steps as follows: casting and compacting the base layer concrete, purifying syrup for the surface, spreading the wear-resisting material for the first time, grinding via machine, spreading the wear-resisting material for the second time, grinding via machine, polishing, curing the wear-resisting concrete and cutting. The wear-resisting concrete terrace prepared by the method has integrated surface layer and concrete base layer for eliminating the crack and empty drum quality defects caused by bad combination.

Owner:GUANGXI METALLURGICAL CONSTR

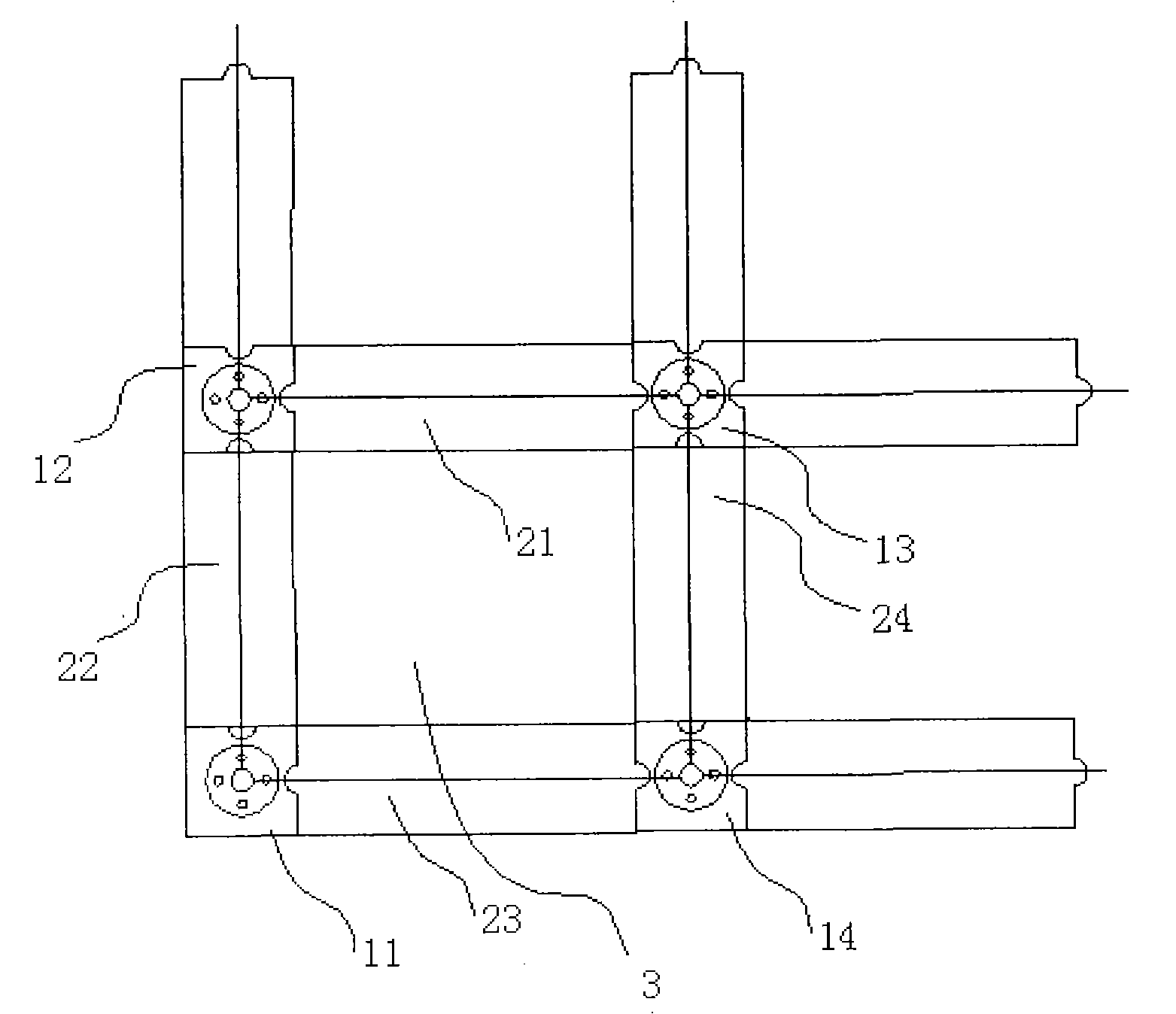

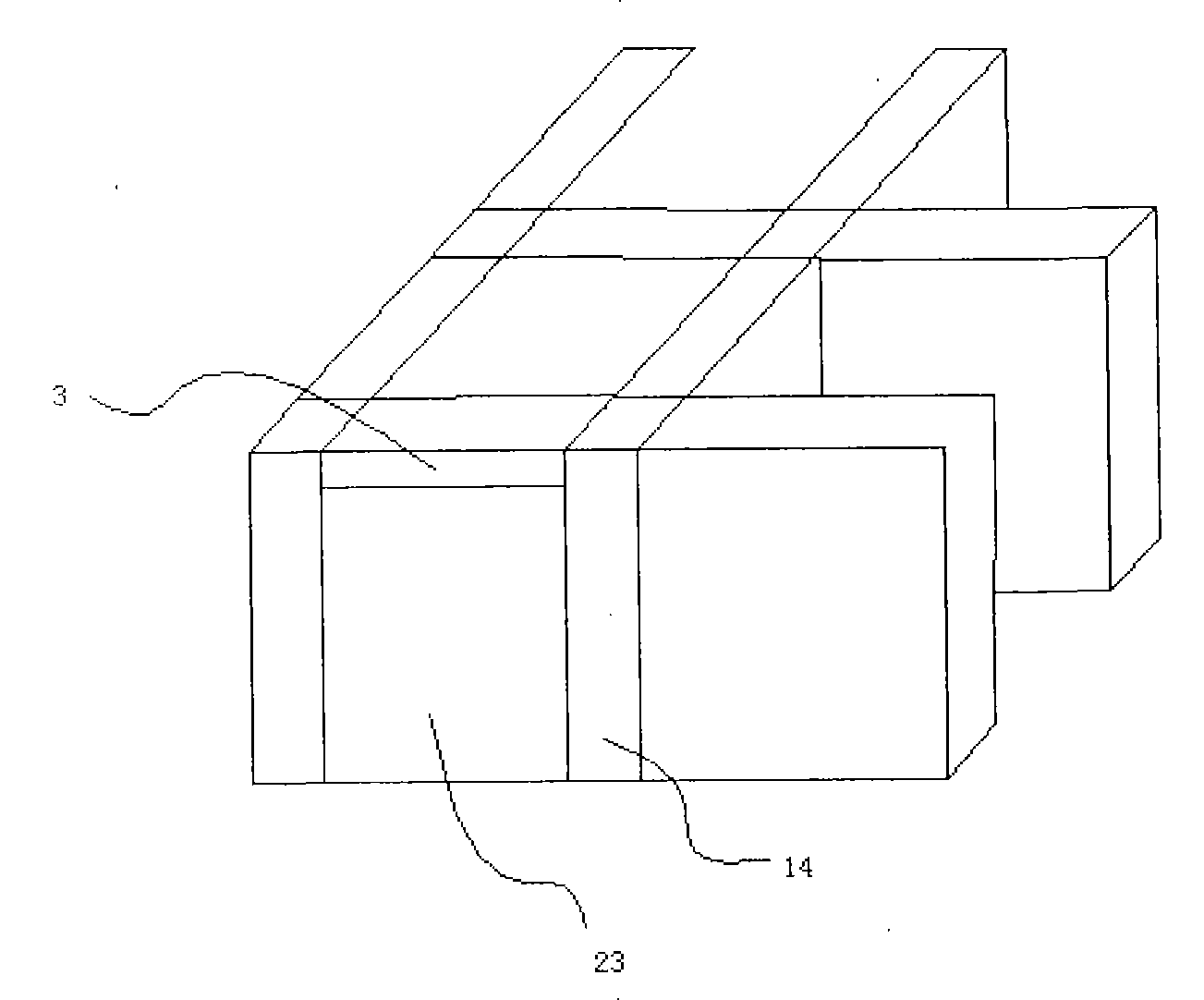

Fully-fabricated building system with grid steel structure

InactiveCN102174858AMeet different energy saving requirementsMeet energy saving requirementsWallsFloorsSteel frameWall plate

The invention discloses a fully-fabricated building system with a grid steel structure. The system comprises wall plates, a floor plate and load bearing combination columns, wherein each wall plate comprises a grid steel frame and gelatine powder granular layers pressed on the two side faces of the grid steel frame in a casting way; both ends of the wall plate are provided with a bulged clamping head; a door opening is formed on the wall plate on one side; each load bearing combination column comprises a connecting column and a gelatine powder granular layer; the gelatine powder granular layer is arranged adjacent to the outer side at the periphery of the connecting column through press casting to make the cross section of the load bearing combination column rectangular; slots matched with clamping heads at the two ends of the wall plate are formed on two, three or four side faces of the load bearing combination column; the wall plates are clamped together through the load bearing combination columns to form a building; and the floor plate is arranged on the top surfaces of the wall plates. The fully-fabricated building system with the grid steel structure has an environment-friendly building structure which has light weight and is heat-preserving, sound-proof, fire-resistant, rust-proof, load-bearing and quake-proof, has high construction efficiency, saves labor hours, has small construction floor area, does not have dust in a site environment and contributes to civilized construction.

Owner:黄志元

High-concentration colored master batch and preparation method thereof

The invention discloses a high-concentration colored master batch. The high-concentration colored master batch is composed of, by mass, 50-70% of colored pigment, 5-15% of a dispersing agent, 20-39% of resin and 0.5-1% of a processing aid. The invention further discloses a preparation method of the high-concentration colored master batch. The preparation method comprises the following steps of 1, weighing the colored pigment, the dispersing agent, the resin and the processing aid according to the mass percentage compounding ratio of the constitute raw materials, and mixing the raw materials in a high-and-low-speed blender mixer till the raw materials are caked; 2, adding the mixed raw materials into a three-roller grinding machine, and conducting grinding till the raw materials are dispersed uniformly; 3, adding the ground raw materials into a single-screw or a double-screw extruder for extrusion and granule cutting. The high-concentration colored master batch and the preparation method thereof have the advantages that the pigment is dispersed uniformly; the surface of the master batch is smooth and free of pores; black spots or toner points do not appear; the preparation method is simple; dispersity is good; consumption of the pigment is saved; no dust is generated in the processing process; a processed product is free of dust or pollution.

Owner:OPTA POLYMER JIANGSU

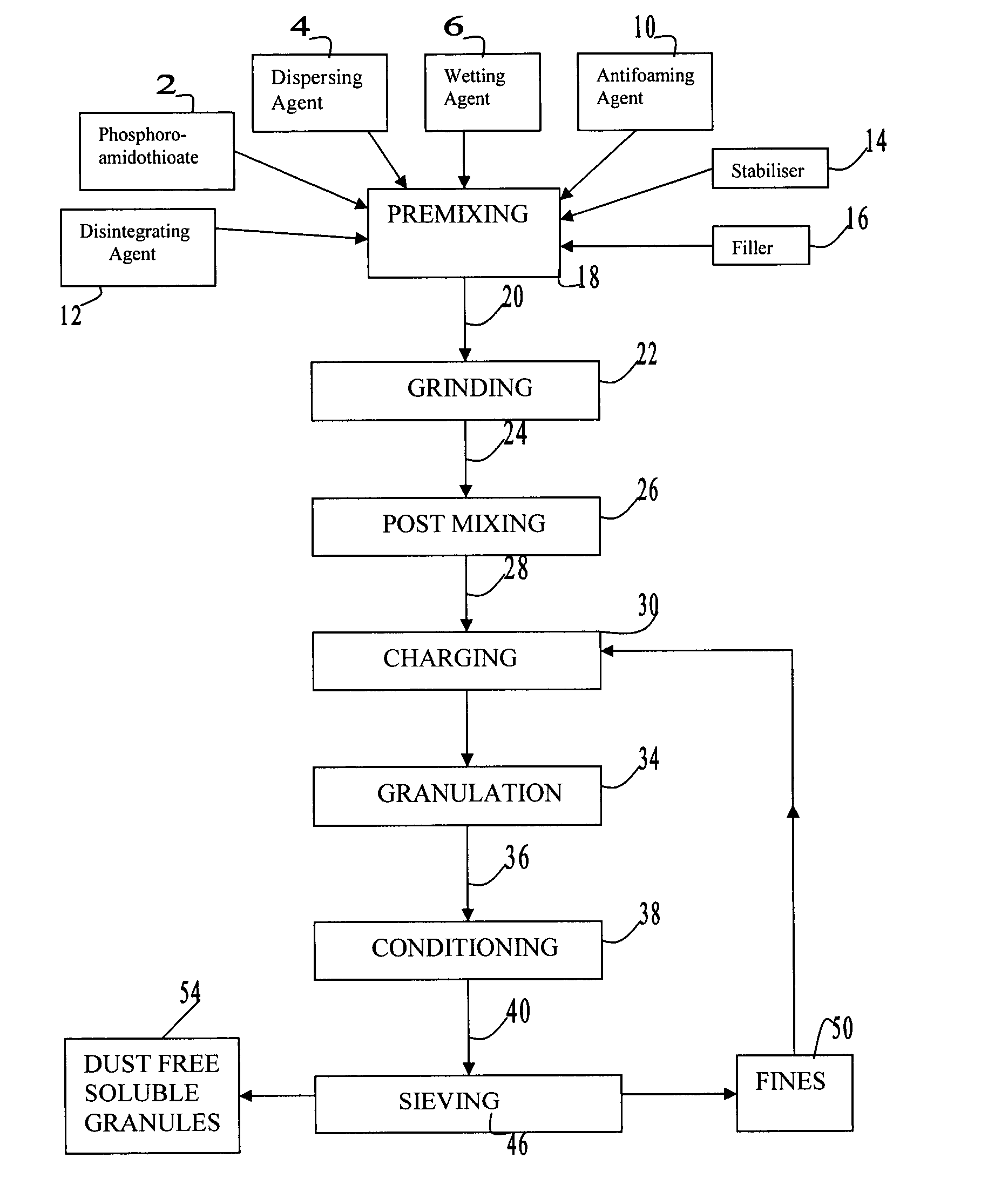

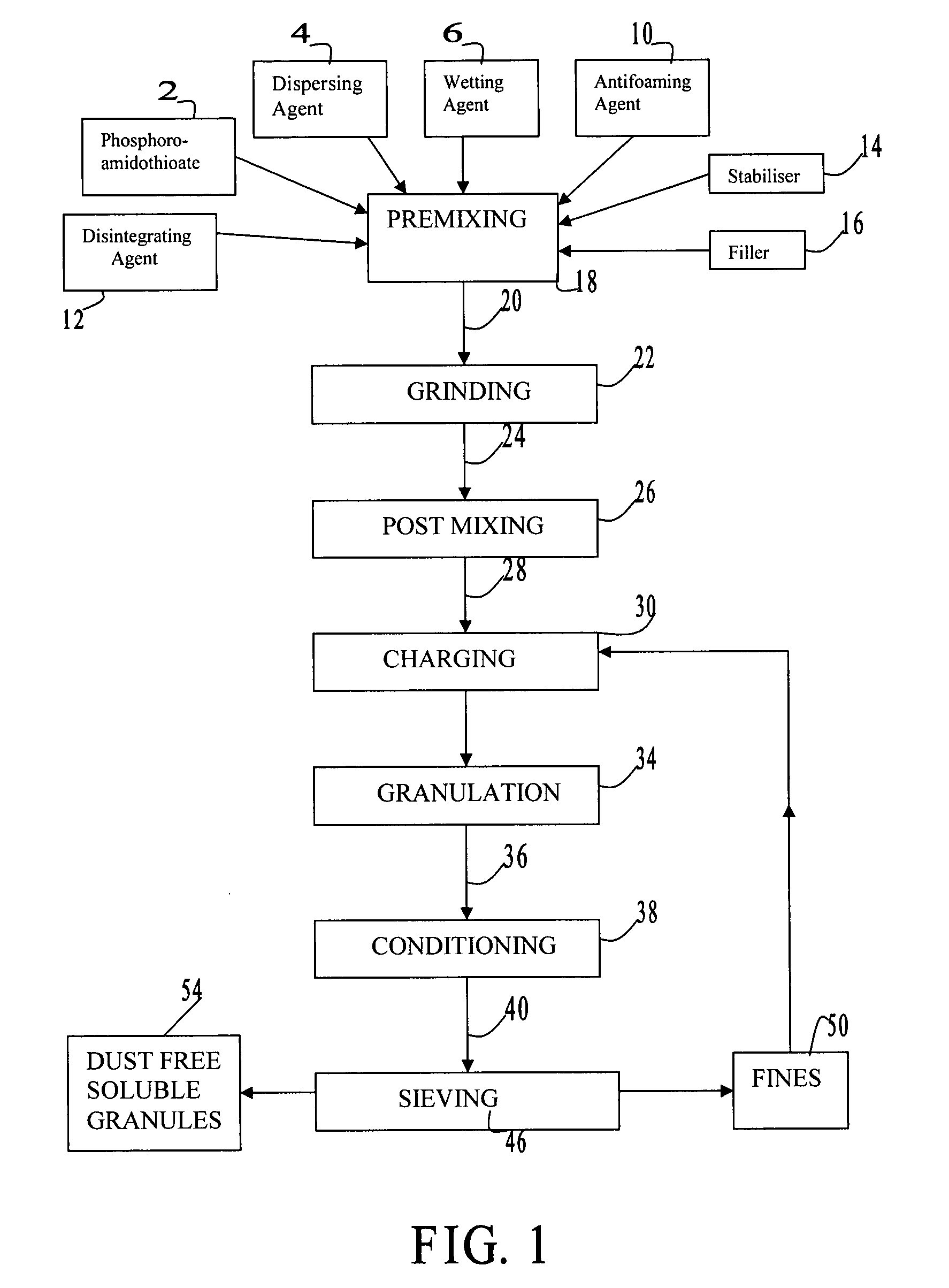

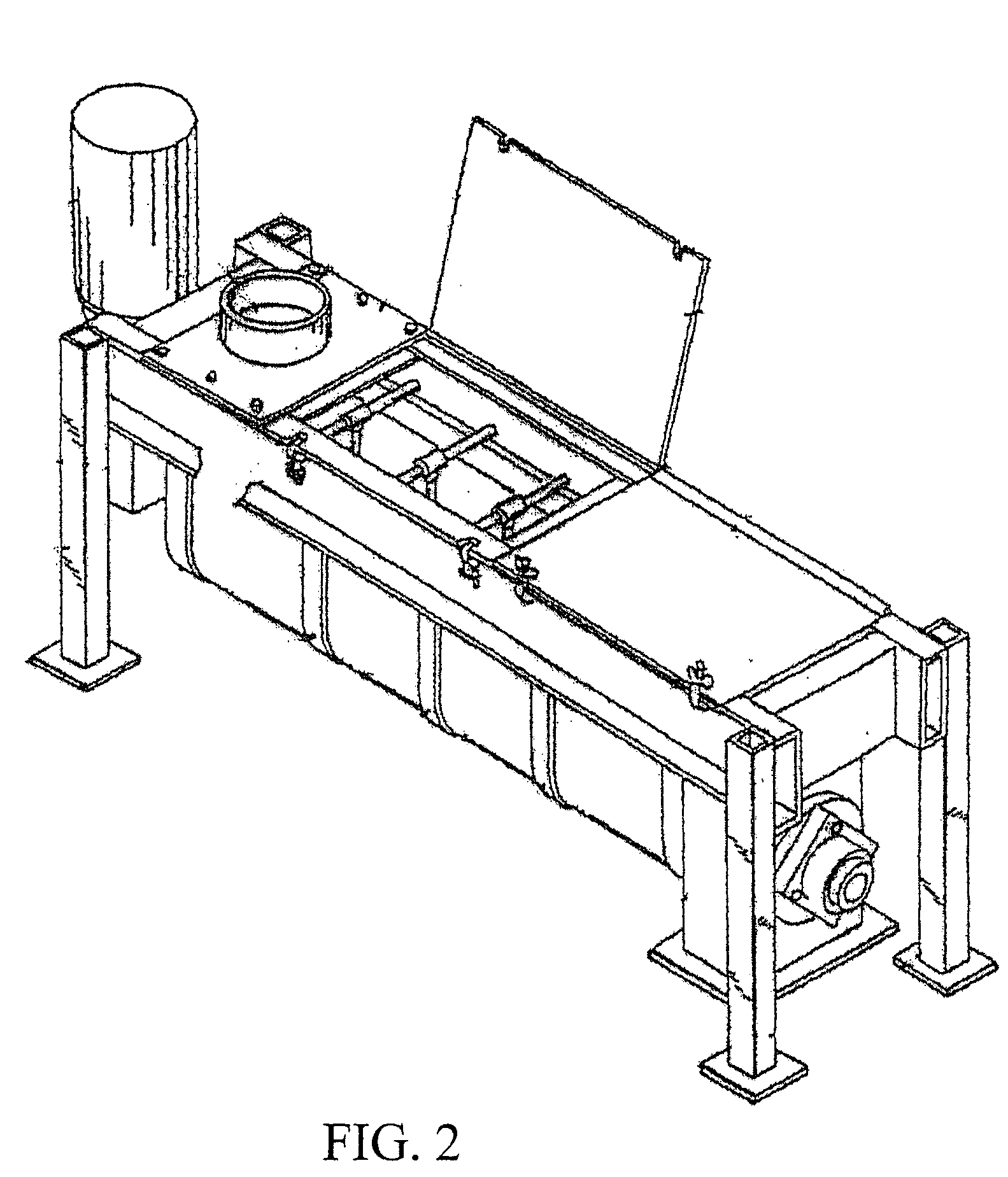

Process for dry granulation by agitative balling for the preparation of chemically stable, dry-flow, low compact, dust free, soluble spherical granules of phosphoroamidothioate

InactiveUS20050048094A1High surface finishReduce compactionPigmenting treatmentBiocideSpherical granuleSolvent

Chemically stable, dry-flow, low compact, dust free, soluble granules of phosphoroamidothioate are prepared using a substantially dry granulation process including an agitative balling process. In a preferred embodiment, spherically shaped acephate granules are produces without the intentional addition of water and / or solvents.

Owner:UNITED PHOSPHORUS LTD

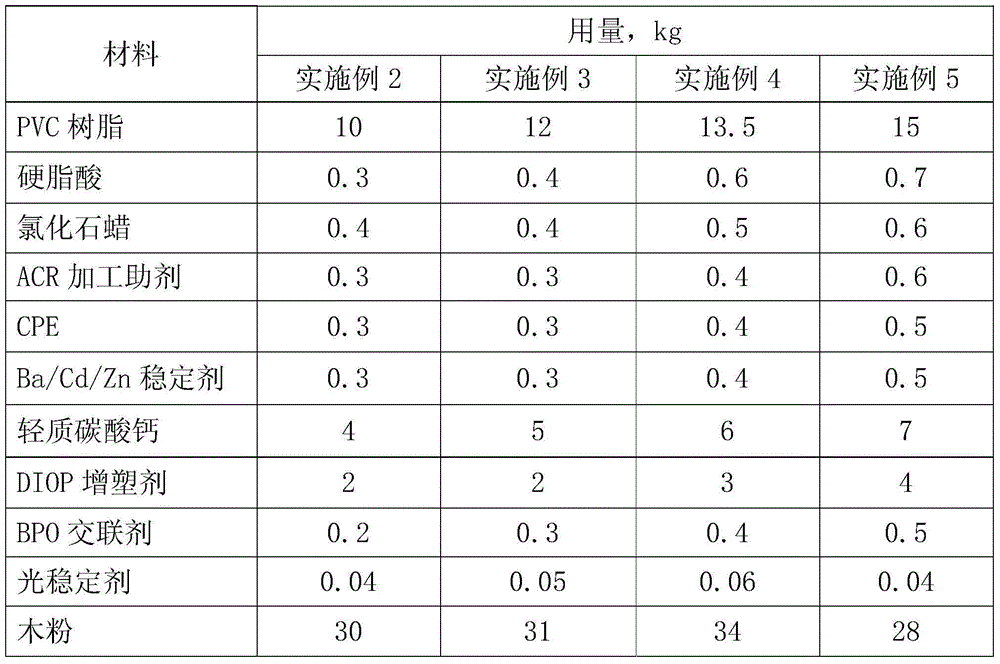

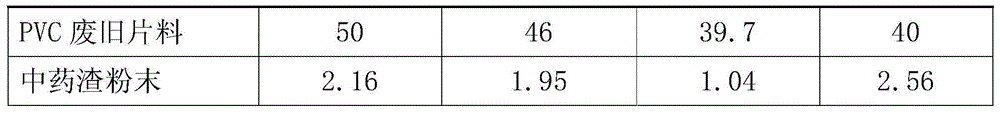

Insect prevention wood plastic interior door and preparation method thereof

The invention discloses an insect prevention wood plastic interior door and a preparation method of the insect prevention wood plastic interior door. The interior door is prepared from the following raw materials in percent by weight: 10-15 percent of PVC resins, 0.3-0.7 percent of stearic acid, 0.4-0.6 percent of chlorinated paraffin, 0.3-0.6 percent of ACR processing agent, 0.3-0.5 percent of CPE, 0.3-0.5 percent of Ba / Cd / Zn stabilizing agent, 4-7 percent of light calcium carbonate, 2-4 percent of DIOP plasticizers, 0.2-0.5 percent of BPO cross-linking agents, 0.04-0.06 percent of light stabilizers, 28-35 percent of wood powder, 38-50 percent of PVC waste strips, and 1-3 percent of Chinese medicine residue powder. According to the insect prevention wood plastic interior door, the Chinese medicine residue powder having an effect of desinsectization or insect protection is added into a formula, so that a door plate can keep in a good condition in a moist or bad-illumination room, the breakage and the crevice are avoided, and the service life is prolonged under a moist condition.

Owner:许冰

Method for preparing fire-resistant conductive silicone rubber

InactiveCN103665888AImprove thermal conductivityImprove conductivityUltimate tensile strengthAcetylene

The invention discloses a method for preparing fire-resistant conductive silicone rubber. The method comprises the steps as follows: acetylene black is pretreated firstly, then raw silicone rubber is mixed with other additives, and the temperature is adjusted for kneading. According to the method, the silicone rubber can be resistant to the high temperature of 360 DEG C, the tensile strength can be up to 8.5 MPa, the tearing strength is 33 N / mm, the volume resistivity can be up to 50 omega.cm, the silicone rubber is free from deformation and embrittlement in case of fire for a long time, physical properties of the silicone rubber are not changed, and the good flame retardant effect can be realized.

Owner:SHANDONG YONGTAI CHEM GROUP

Resin concrete

The invention provides a resin concrete, comprising a component A, a component B and a component C, wherein component A comprises cement, paint and sand-gravel filler, component B comprises water, water-based liquid resin and wetting agent, and component C comprises water and water-based curing agent. The method for preparing resin concrete comprises the following steps: adding cement and paint into a double helix cone-shaped mixer, starting the mixer, adding the sand-gravel filler and continuing the mixing process until colour and interface are mixed evenly, weighing and packaging the mixture to obtain component A; adding water, water-based liquid resin and wetting agent into a dispersing vat in sequence, dispersing in high speed and packaging to obtain component B; and adding water and water-based curing agent into the dispersing vat in sequence, dispersing in high speed and packaging to obtain component C. The resin concrete has the advantages of good adhesive power, abrasive resistance, chemical resistance and steam resistance, no dusting and no pollution, and can restrain the bacteria growth effectively. In addition, the intensity of the resin concrete is twice higher than the intensity of the traditional concrete.

Owner:武汉菲凡士建材有限公司

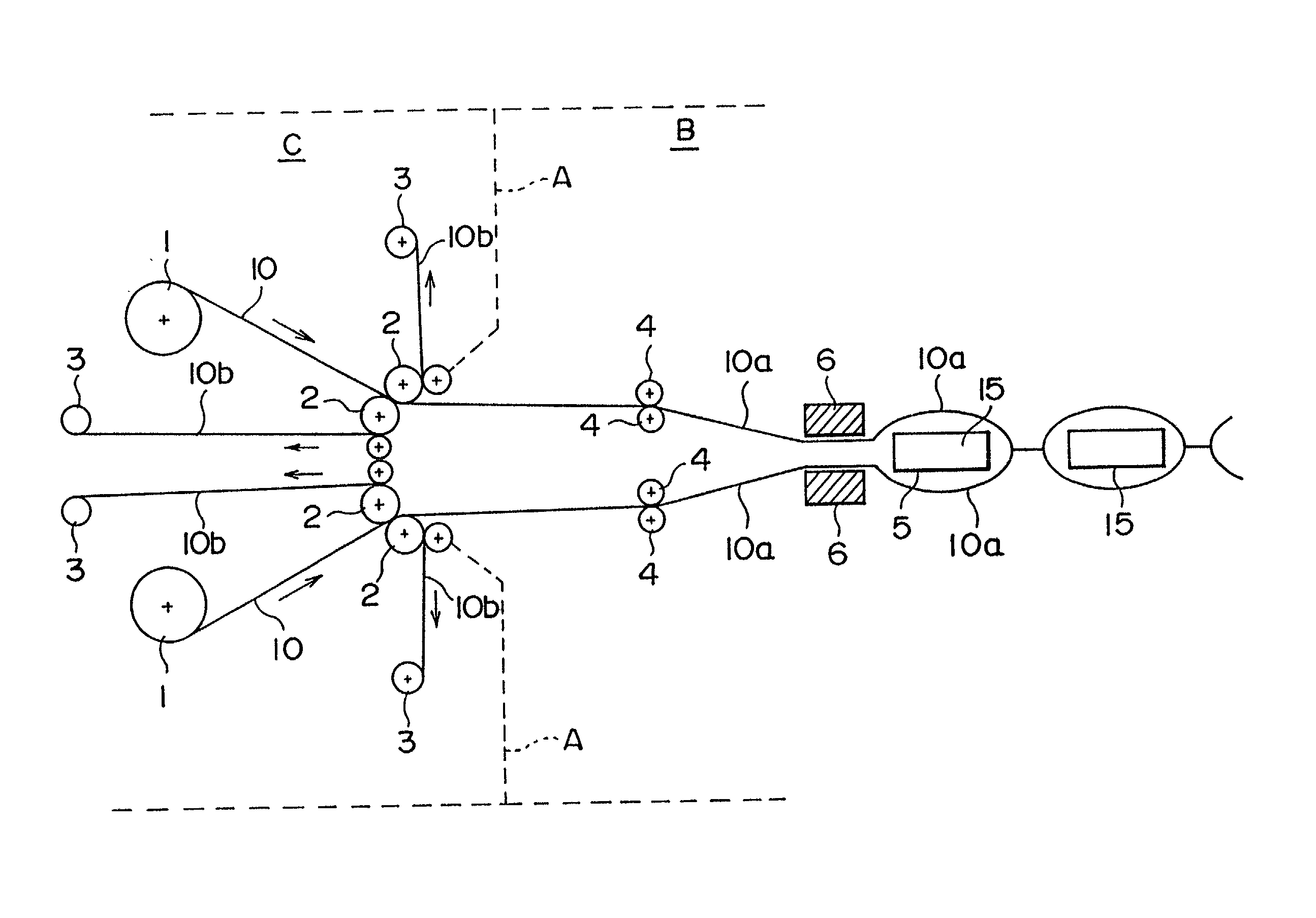

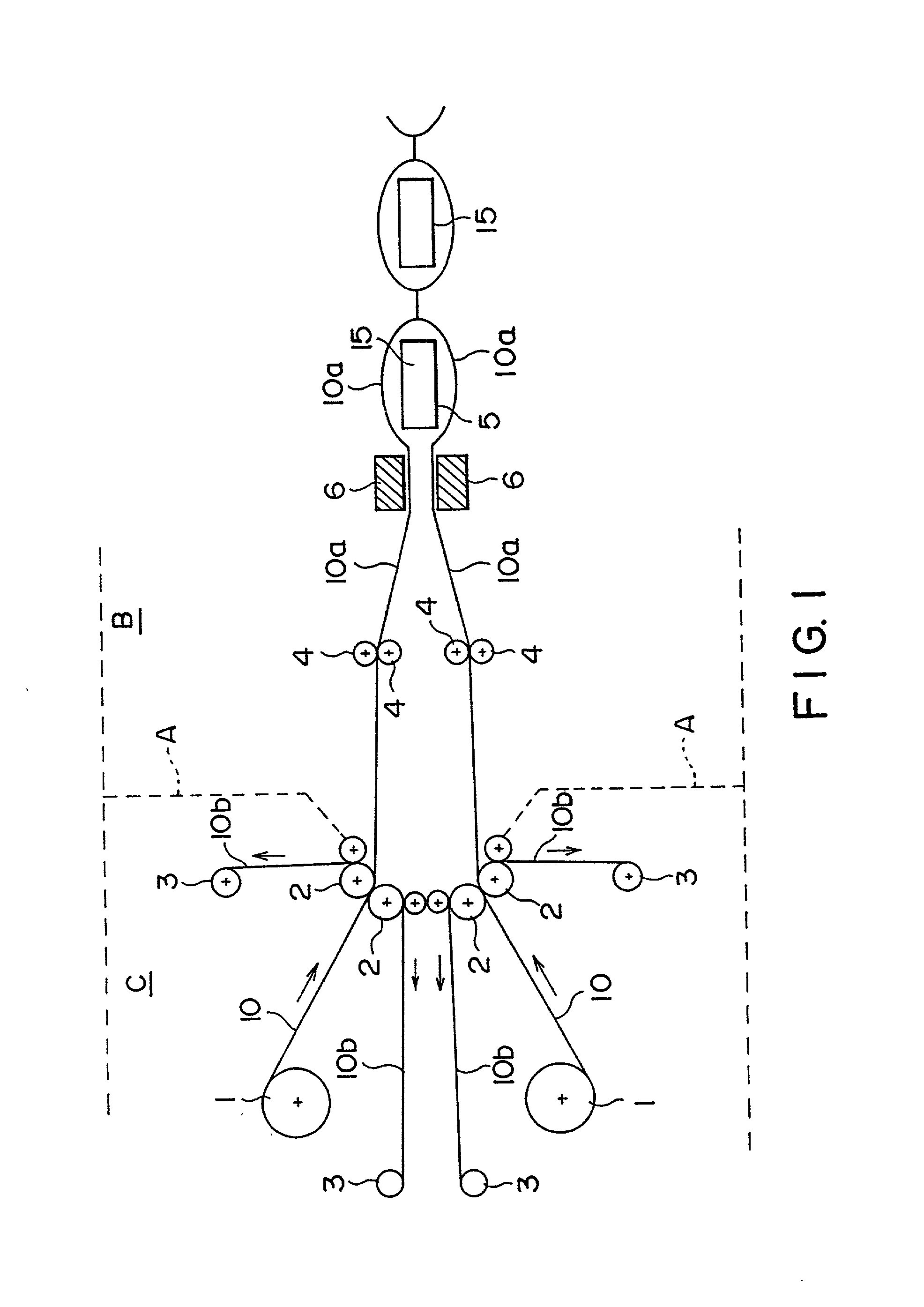

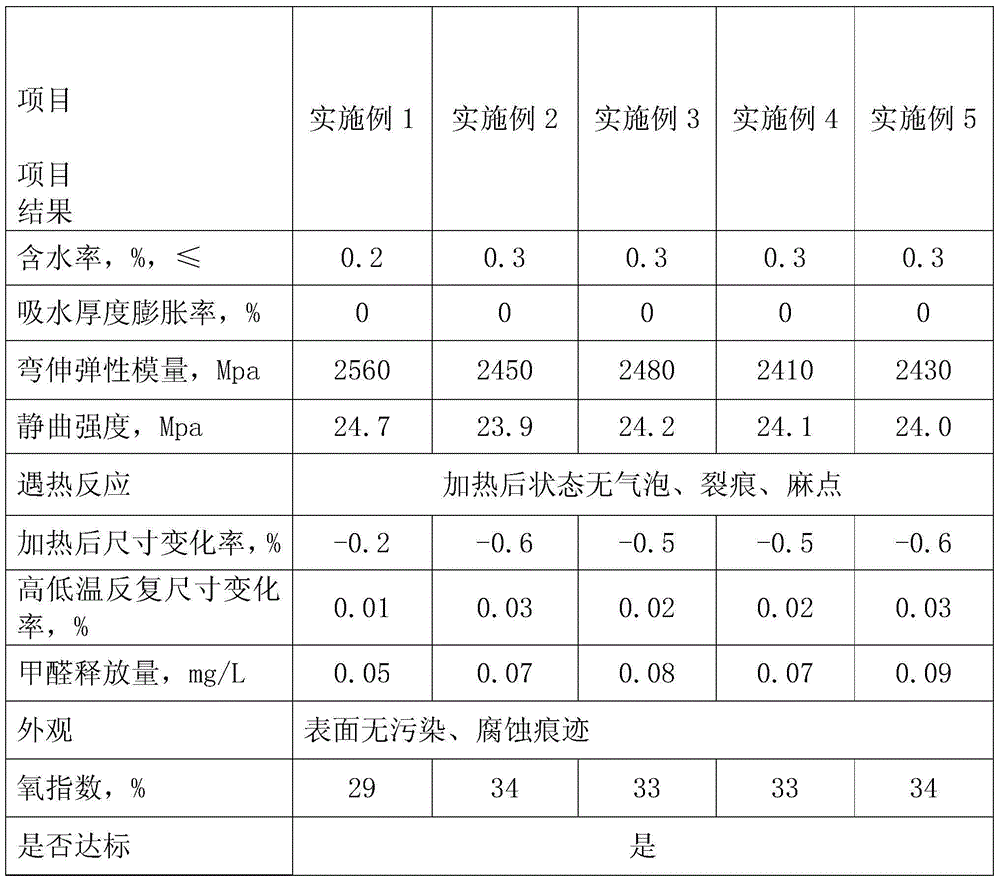

Method for forming image and image forming apparatus

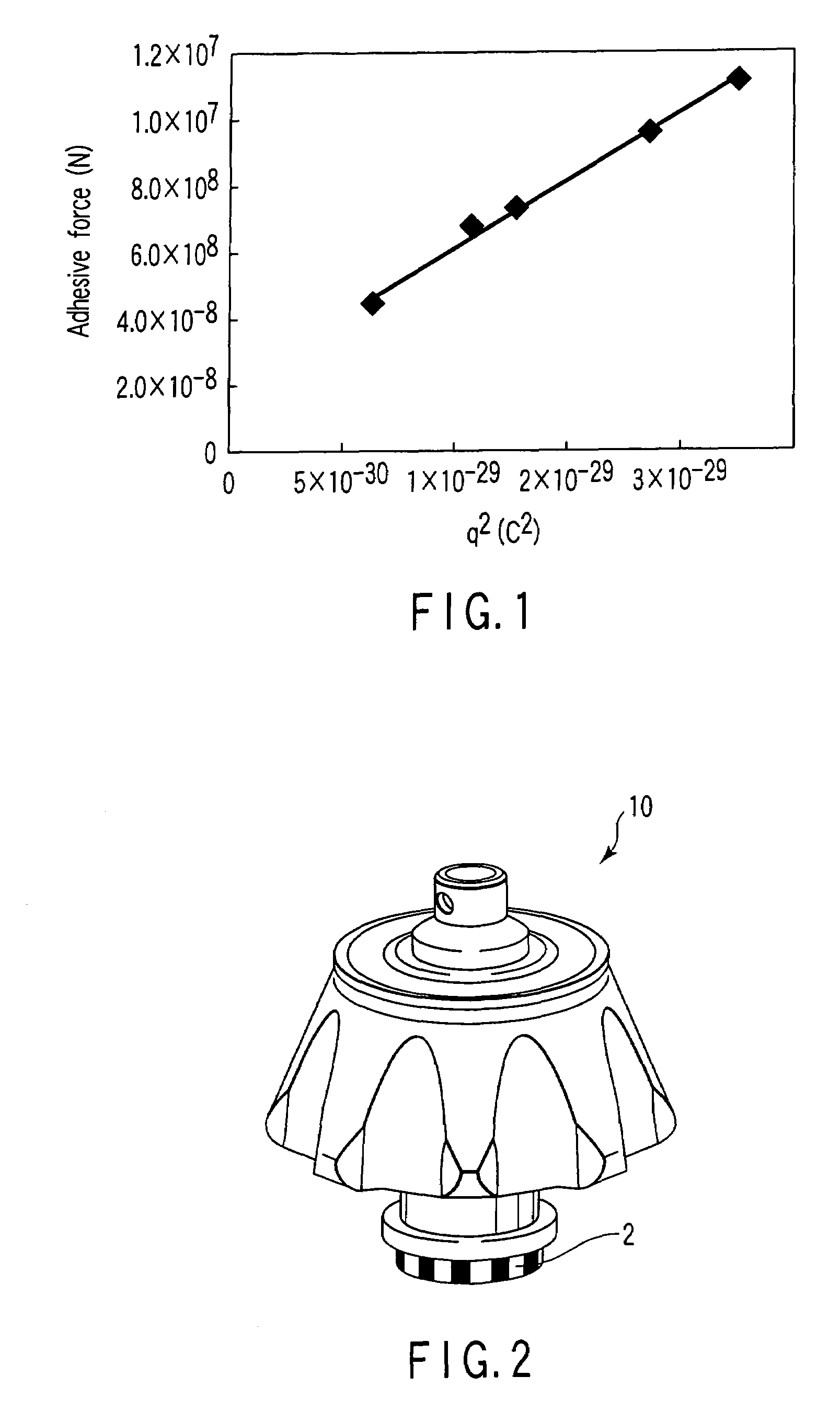

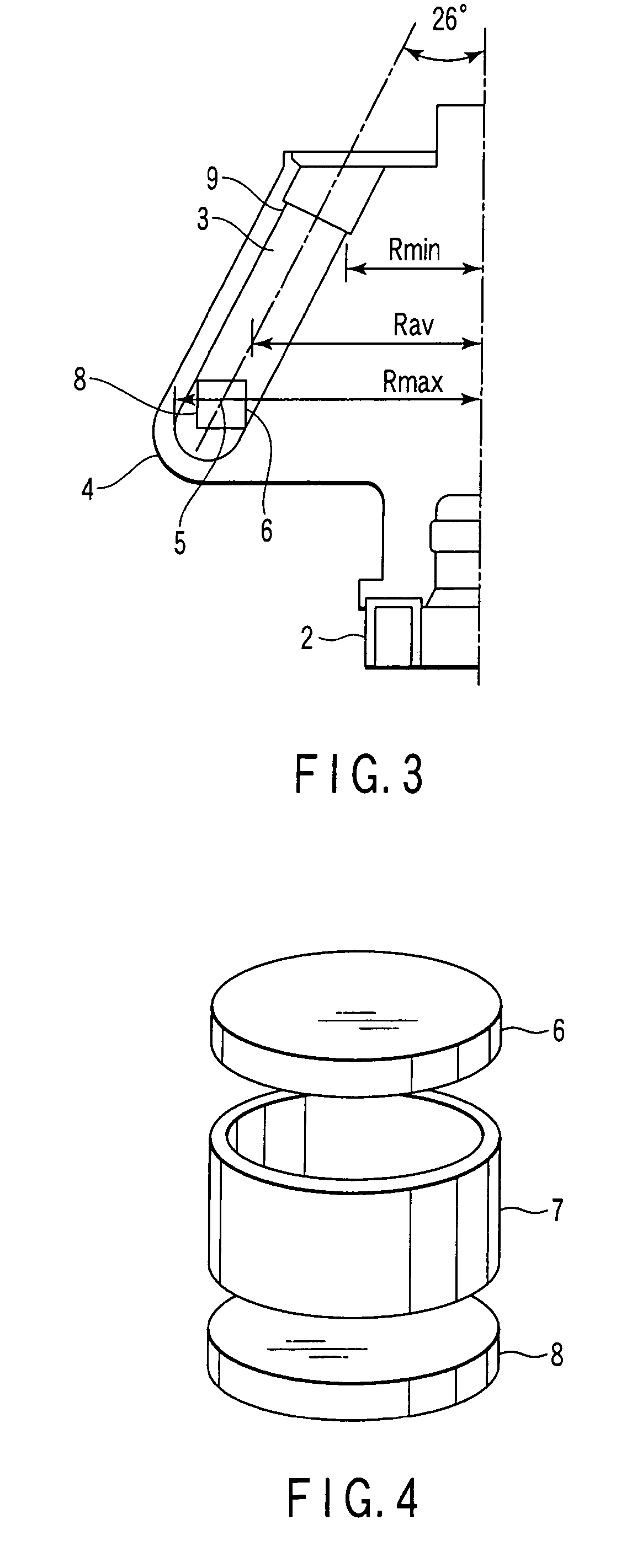

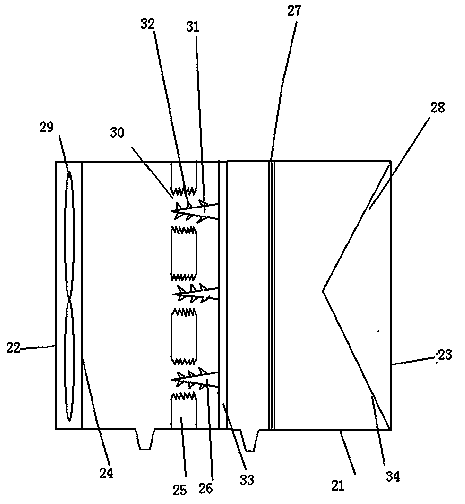

ActiveUS7236724B2Improve transmission efficiencyAccurate imagingElectrographic process apparatusDevelopersEngineeringResultant force

The developing agent is selected to have a distribution of adhesive force to the surface of an image carrier, which is configured such that the ratio of the developing agent having an adhesive force which is not less than 2.5 times as high as an average value of a distribution of adhesive force is 3% by weight or less based on an entire weight of the developing agent.

Owner:KK TOSHIBA +1

Reinforced dedusting device for coal min safety

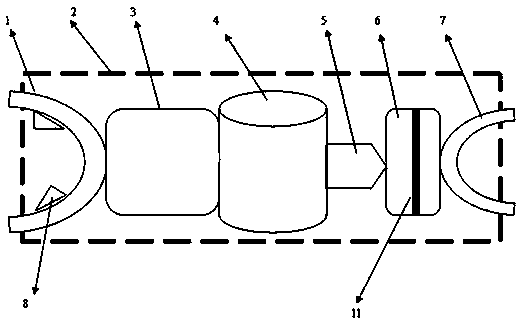

InactiveCN103410554AAvoid cloggingEnsure safetyMining devicesDust removalMining engineeringWater vapor

The invention discloses a reinforced dedusting device for coal mine safety. The reinforced dedusting device comprises a fan, a shell, an adsorption filtering part, a water vapor dedusting part, a bag-type dedusting part and a dust inlet, wherein the water vapor dedusting part, the bag-type dedusting part, the fan and the adsorption filtering part are sequentially arranged behind the dust inlet, the shell is located on the outer side of the whole dedusting device, dust particles of various particle sizes are eliminated in sequence, coal mine safety is guaranteed, and the working gas environment of coal mine workers is optimized.

Owner:王业常

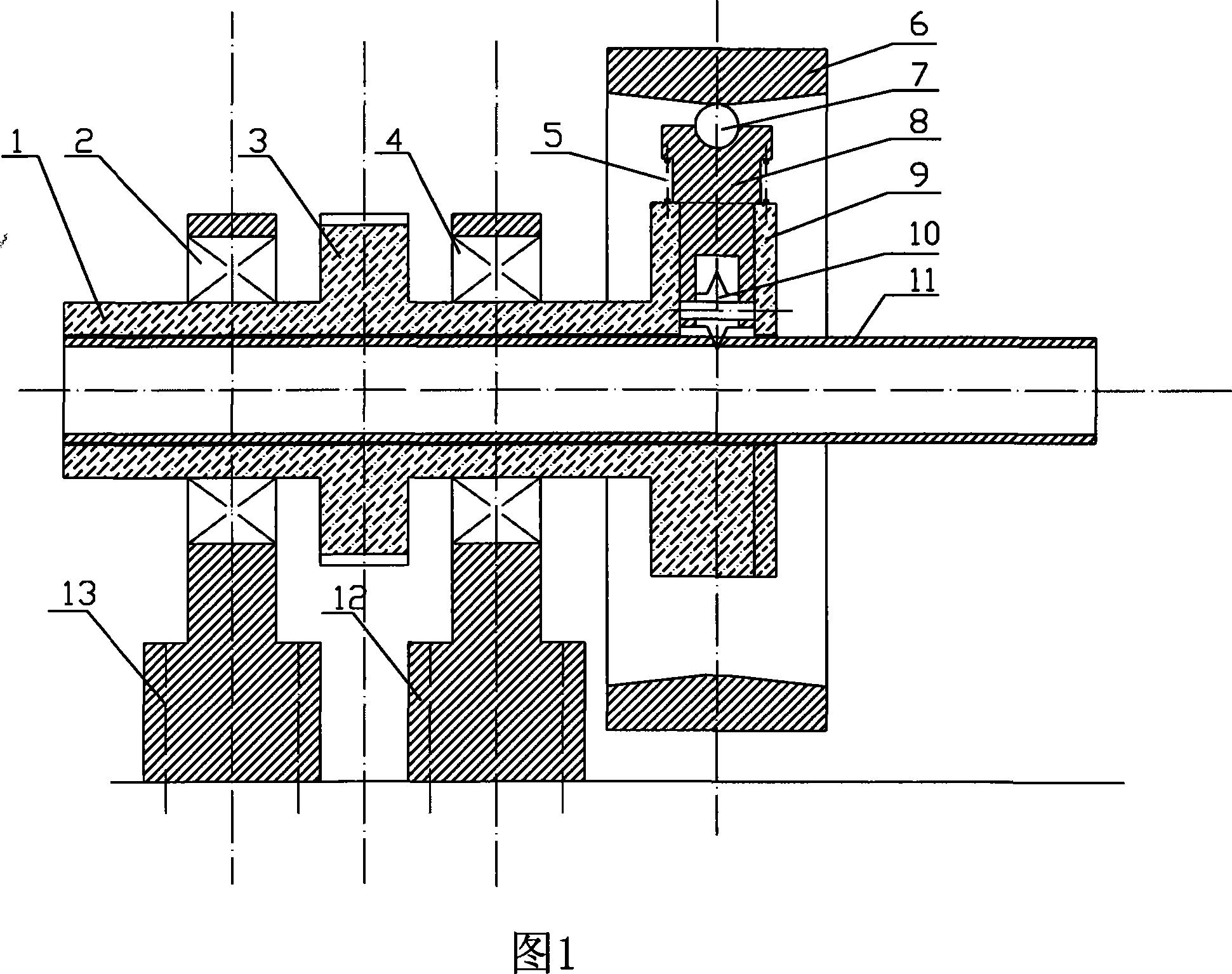

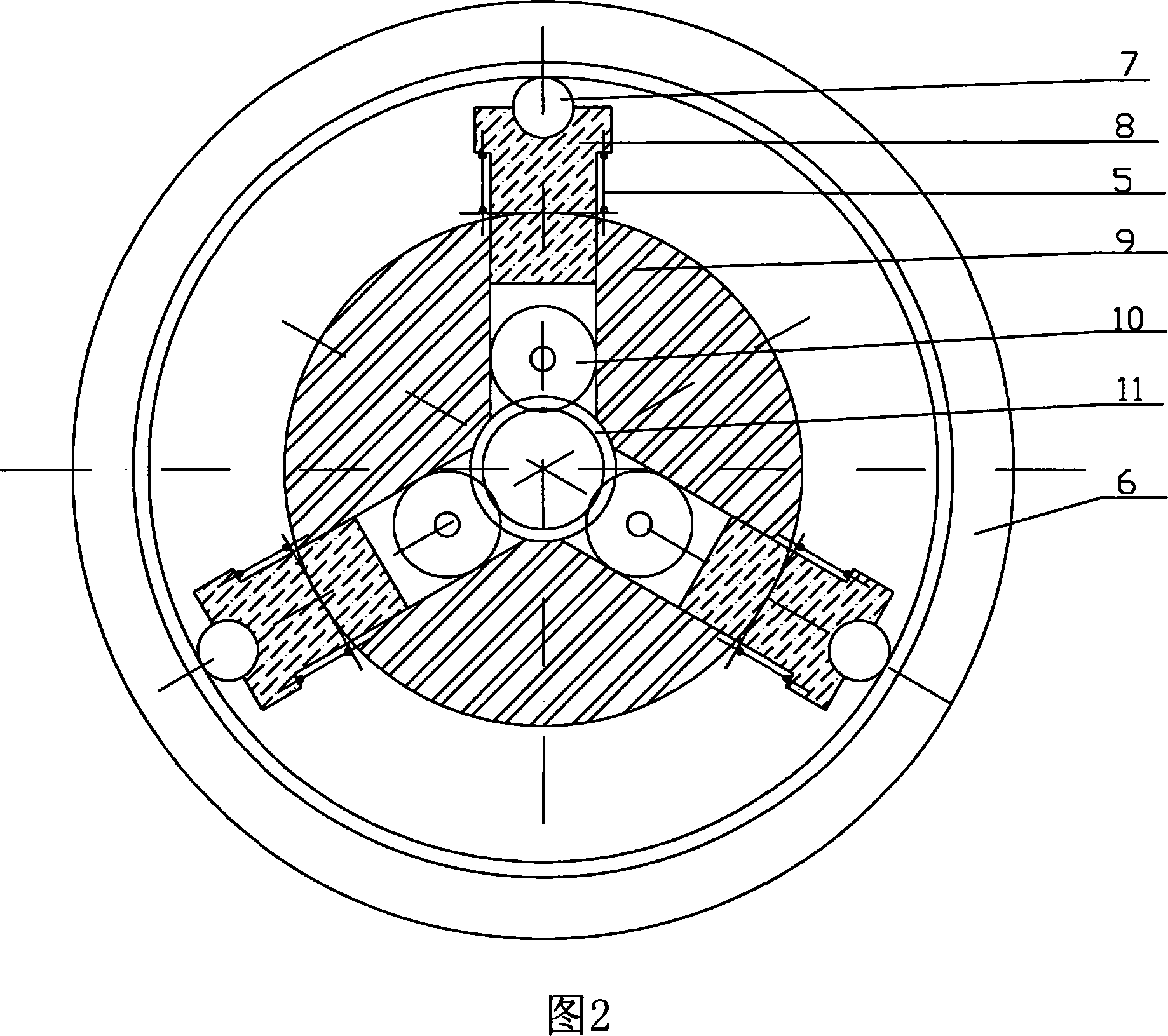

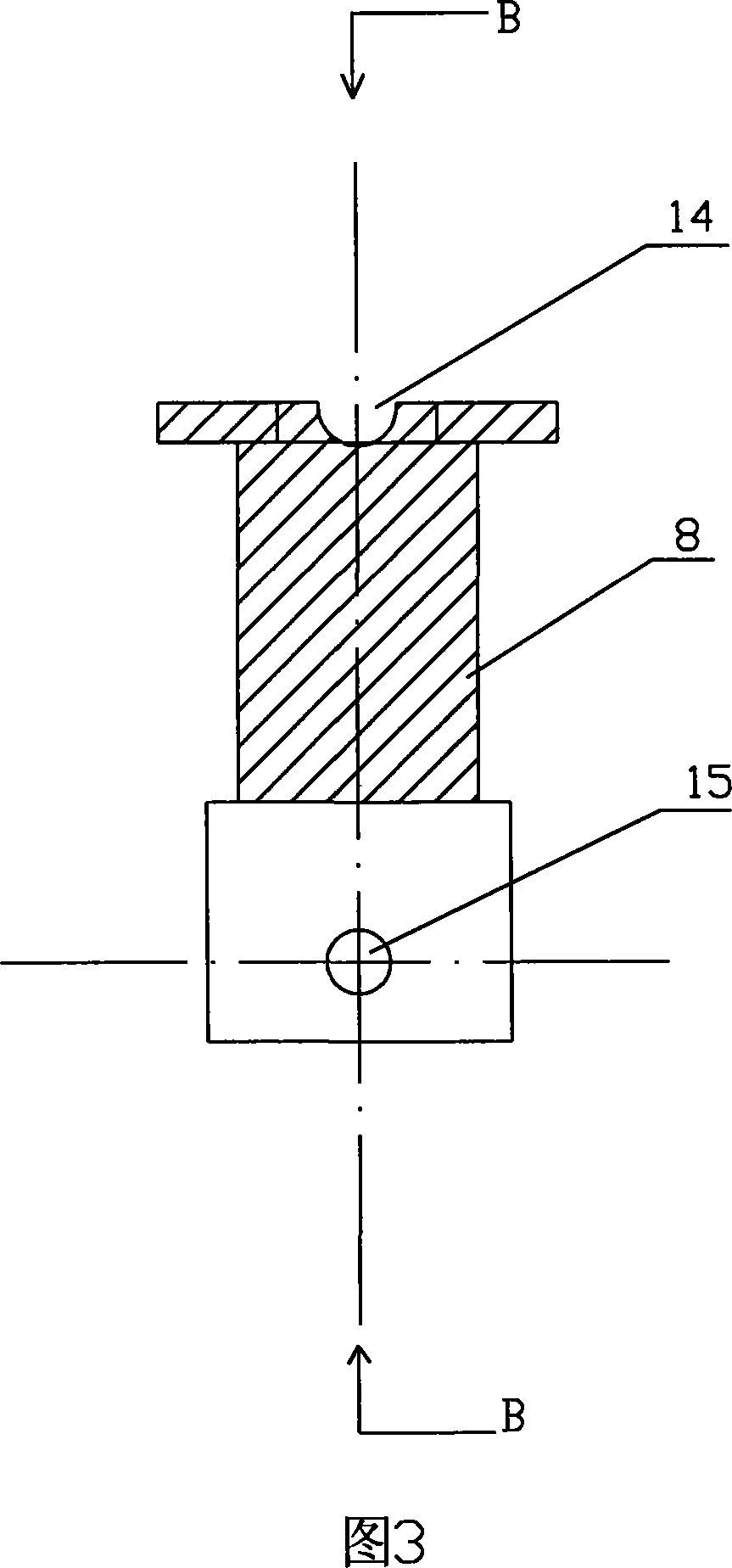

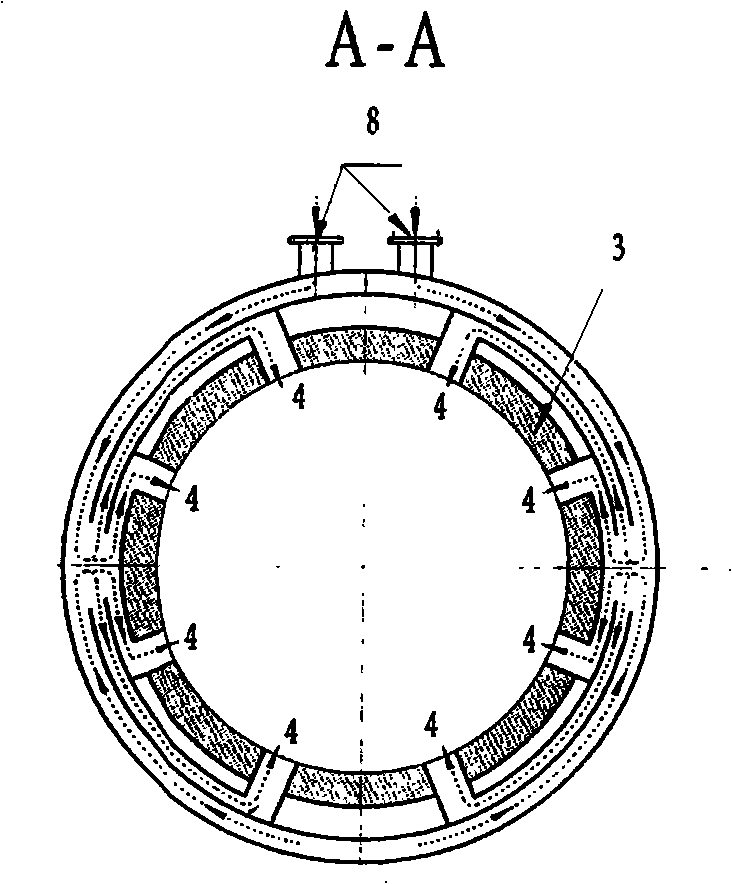

Tool type steel pipe cutting machine

InactiveCN101053911AExtended service lifeNot easy to damageTube shearing machinesShearing control devicesBarrel ShapedEngineering

The invention discloses a tool type steel tube cutter comprising: a mechanical drive device essentially composed of bearings and bearing supports which are fixed on both ends of a barrel-shaped tool post, a driving belt pulley disposed on the middle of the tool post and a drive motor; a tool post part essentially composed of the barrel-shaped tool post, a lathe chuck disposed on one end of the tool post, a movable cutter head positioned within three grooves of the chuck, and a hob disposed in inner end of the chuck and radially fixed via a shaft. A groove for receiving balls is provided in an outer end face of the cutter head, which outer end part has a reset spring. The steel tube is fixed within a central hole of the tool post and the chuck via a fixing fixture on both ends. The invention further includes a cutter feed device with an annular wall in arc structure protruding along axial central part. Three balls arranged on outer end of the three cutter heads contact with the annular wall of the cutter feed device. Compared with traditional tube cutter, the invention has advantages of low use cost, enhanced work efficiency, basically neither noise nor dust pollution.

Owner:北京城建建设工程有限公司

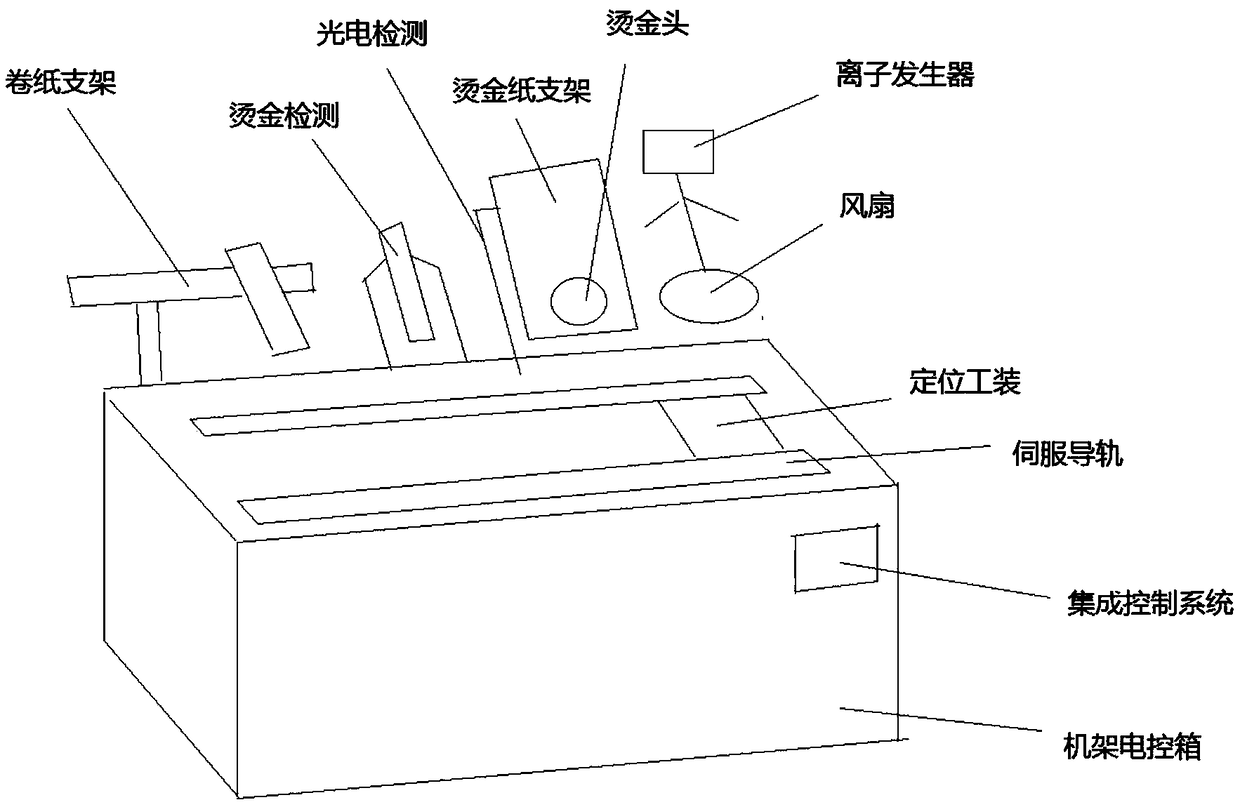

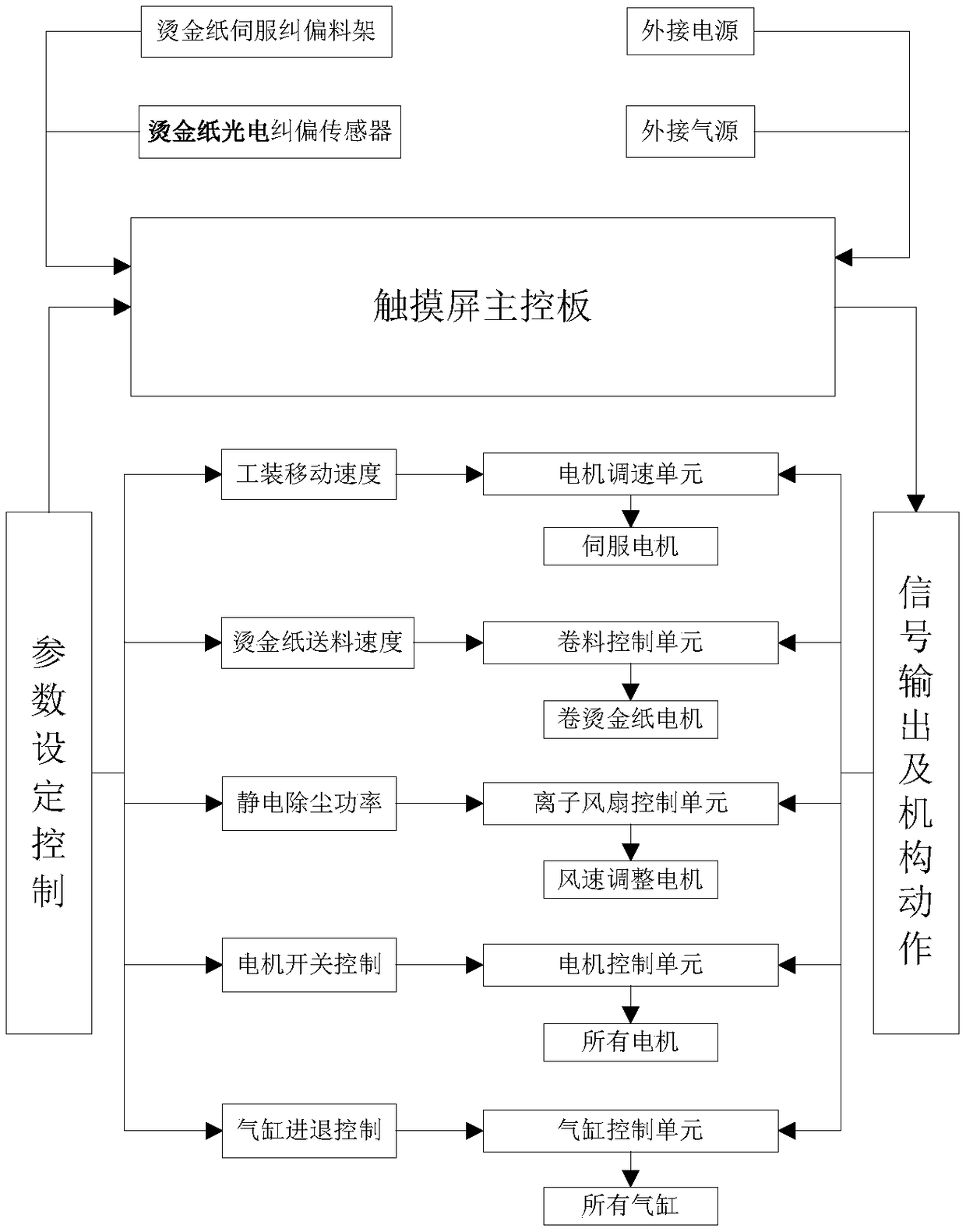

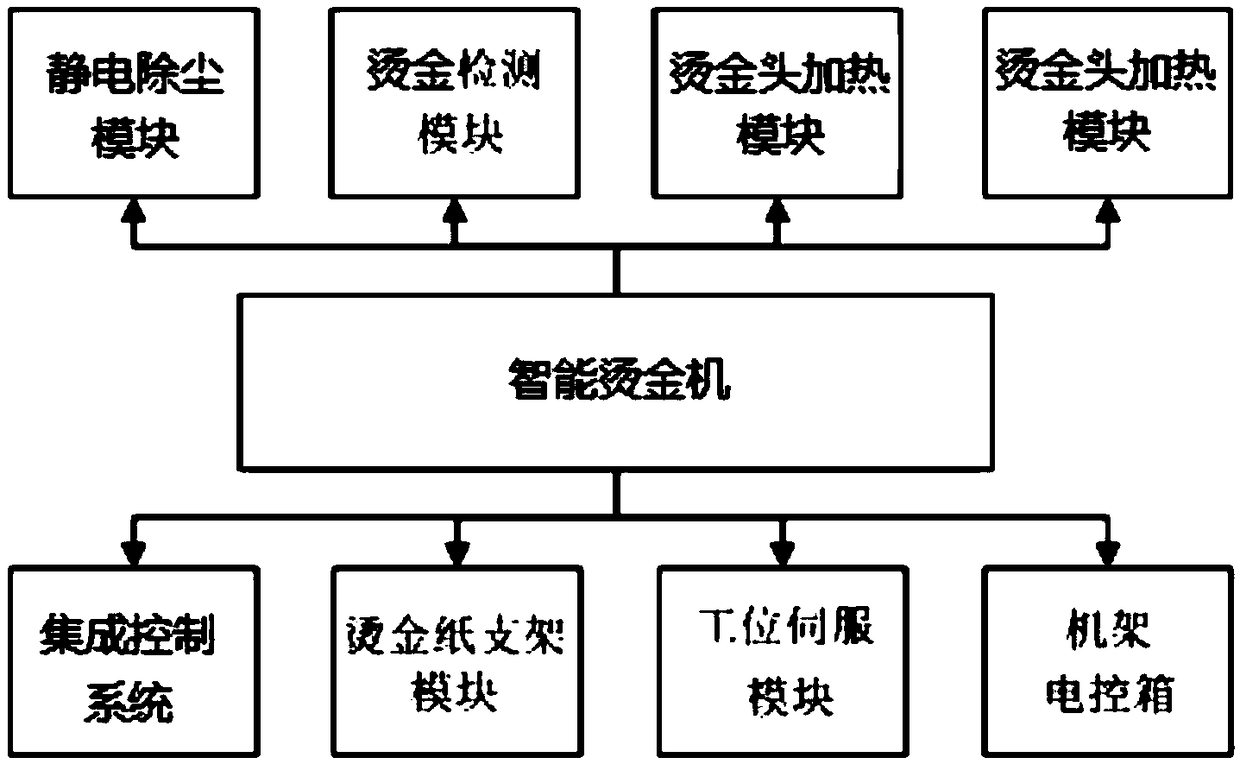

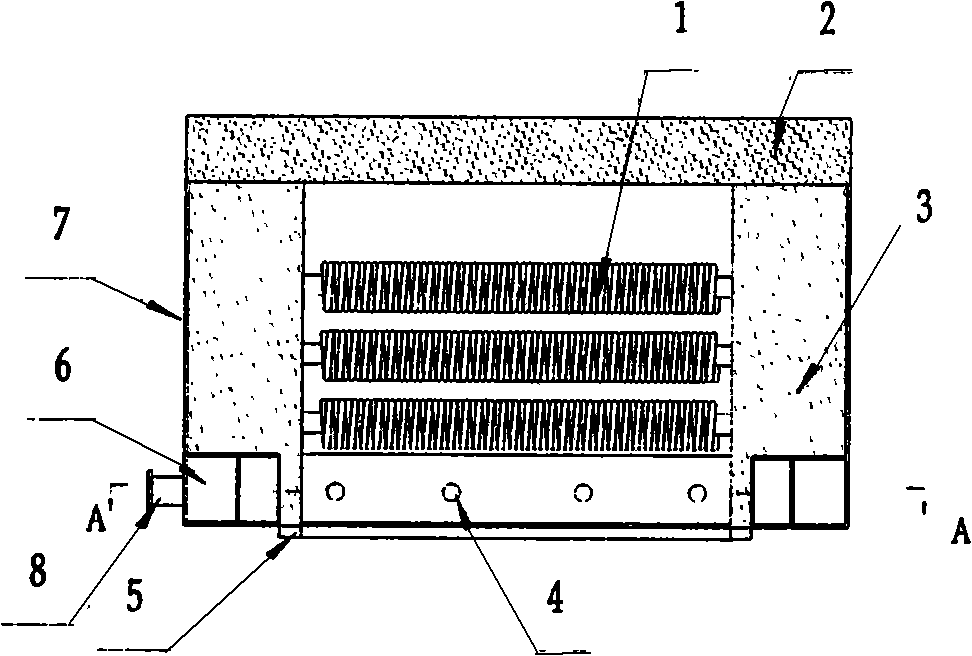

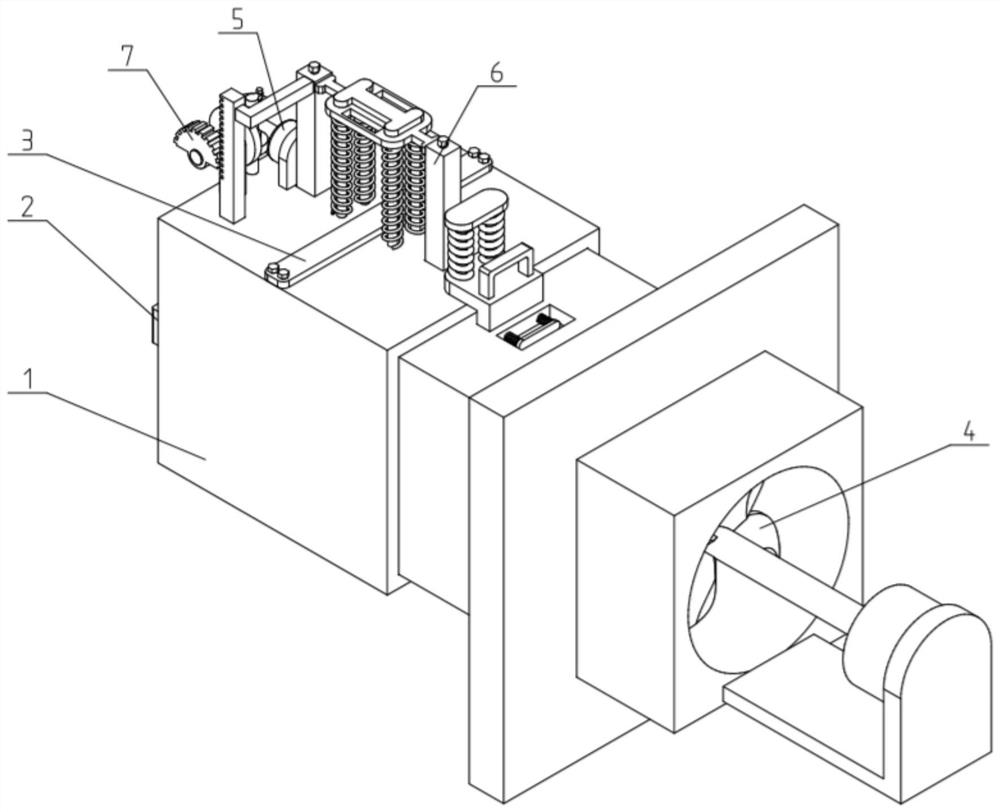

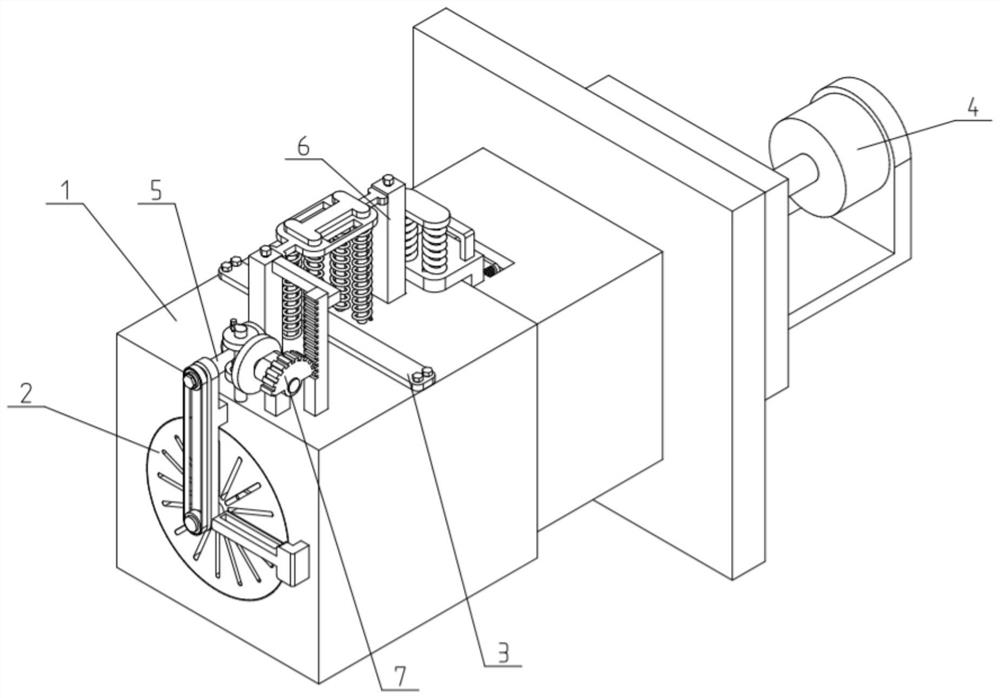

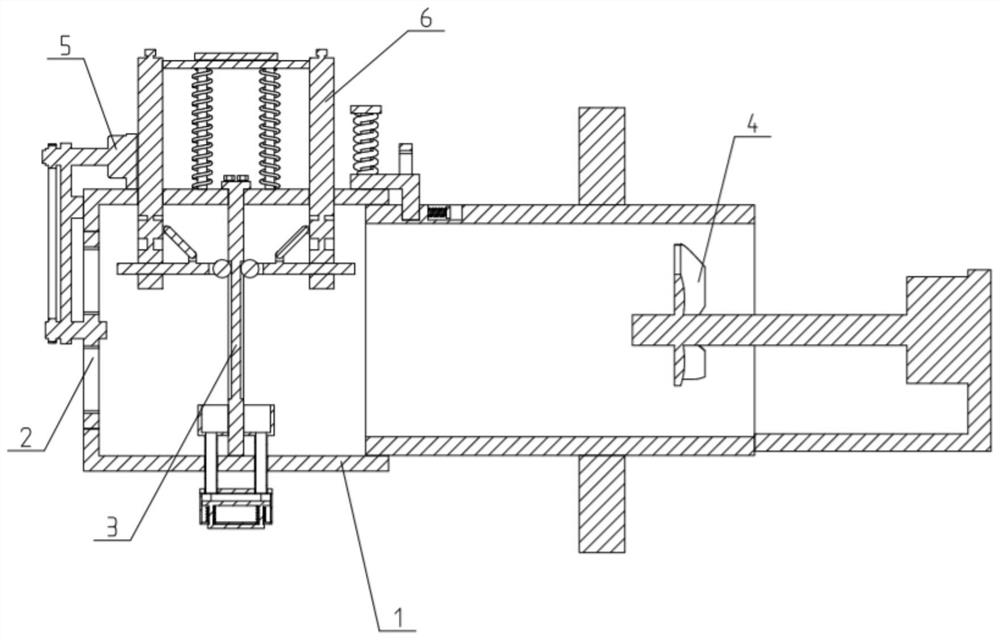

Intelligent gold stamping method of intelligent gold stamping machine

PendingCN109177473ADust freeImprove securityRotary pressesPrinting press partsControl systemEngineering

The invention discloses an intelligent gold stamping machine which comprises a rack, an electric control box, a station servo module, a gold stamping paper support module, a gold stamping head heatingmodule, an electrostatic dust removing module, a gold stamping detection module and an integrated control system. Meanwhile, the invention discloses an intelligent gold stamping method, equipment needed by gold stamping is installed in the rack, unified power and gas supply and distribution are achieved, the whole gold stamping process is automatically conducted, halt alarming is conducted when abnormal conditions happen, and manual intervention is adopted at anytime. By means of the intelligent gold stamping method, the equipment needed by gold stamping is integrated, and overall moving, installing and debugging are facilitated; the position of a gold stamping part is adjusted according to gold stamping needs, and the gold stamping needs are met flexibly; electrostatic dust removing is conducted before gold stamping, and the surface of the gold stamping part is maintained free of dust; automatic deviation correction of gold stamping paper is conducted, and the gold stamping process is accurate; the displacement and temperature of the gold stamping head are monitored, and the safety of the gold stamping machine is improved; patterns are checked after gold stamping, and wrong stamping and missed stamping are avoided; and the whole gold stamping process is controlled through a system and can be completed in a full automatic manner, and manual intervention can also be conducted at any time.

Owner:GREE ELECTRIC APPLIANCES INC

Smokeless emission chemical for fireworks

The invention relates to a smokeless emission chemical for fireworks. The smokeless emission chemical consists of the following components in parts by weight: 20-120 parts of nitrocellulose, 5-10 parts of graphite, 5-25 parts of carboxymethylcellulose, 3-40 parts of charcoaled hemp stalk powder, 3-40 parts of charcoaled fir powder, 2-30 parts of ammonium dichromate, 10-30 parts of barium nitrate and 5-40 parts of potassium perchlorate. The smokeless emission chemical produces smoke only after being burnt, which is 80% less than that of fireworks made from conventional materials; the smokeless emission chemical is free from sulfur dioxide, and the riction sensitivity, collision degree, heat absorption, wet absorption and compatibility are superior to those of the common military saltpeter.

Owner:杨培江

Ignition method and apparatus of product line for sintering porcelain granule

InactiveCN101269949AImprove ignition efficiencySimple structureClaywaresProduction lineThermal energy

The present invention relates to an ignition method and an ignition device, which are applied to the baking porcelain grain production line. The ignition method: the temperature of the ignition device is increased to pre-determined temperature, generally 800 to 1350 DEG C, a baking box that is fully provided with the baking raw materials is close to the ignition device at high temperature to reach the closed state, and then to be preheated; the baking box is ventilated with air or other combustion-assistant gas to assist the combustion, so that the surface of the raw materials can be combusted adequately; the temperature in the ignition device is introduced downwards by the guiding air so as to increase the thickness of the ignition layer; the air introduction is stopped after the ignition, and the ignited baking box is moved to a next position, and simultaneously the next baking box that is fully provided with the baked raw materials is moved to the ignition position. With the present invention, the ignition efficiency at the surface of the baking box is high, thereby greatly reducing the heat waste and shortening the ignition time; moreover, the porcelain grain that is arranged on the surface of the baking box is combusted adequately without breaking or dust; the particle is complete, thus improving the rate of the finished product of the production line. The ignition device has simple structure, not only has low production cost, but also greatly reduces the running operation compared with the traditional ignition system.

Owner:BEIJING SIDIQI SCI & TECH

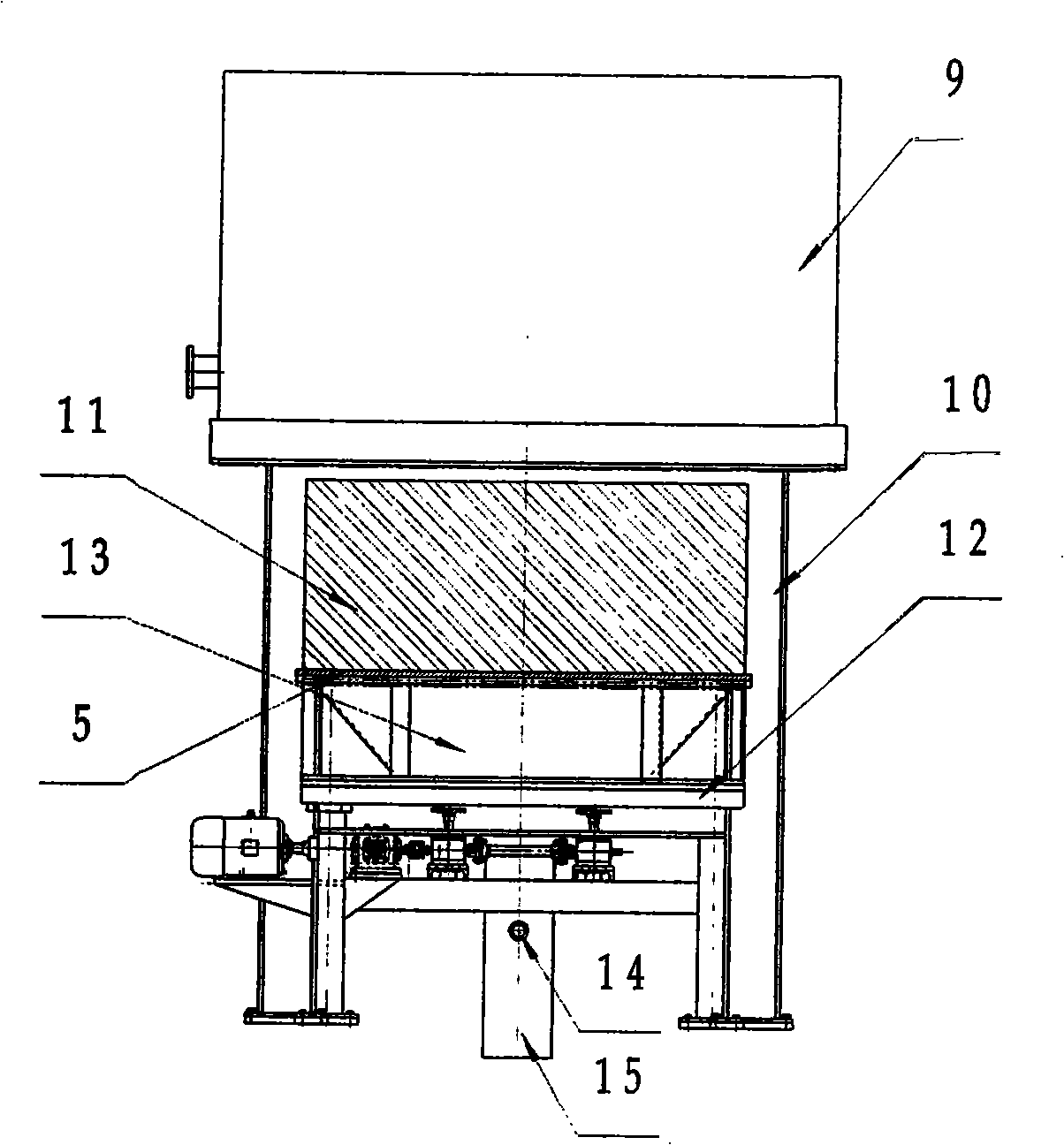

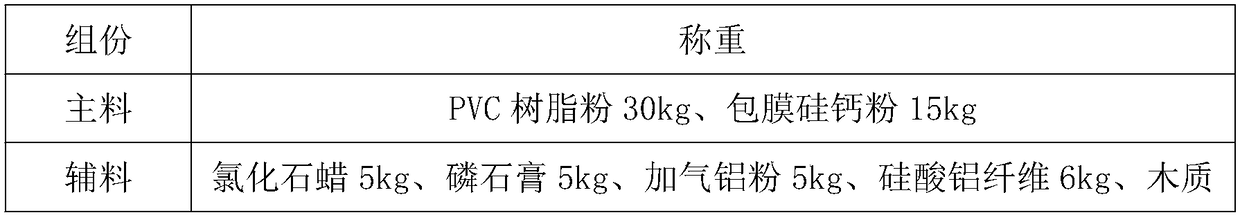

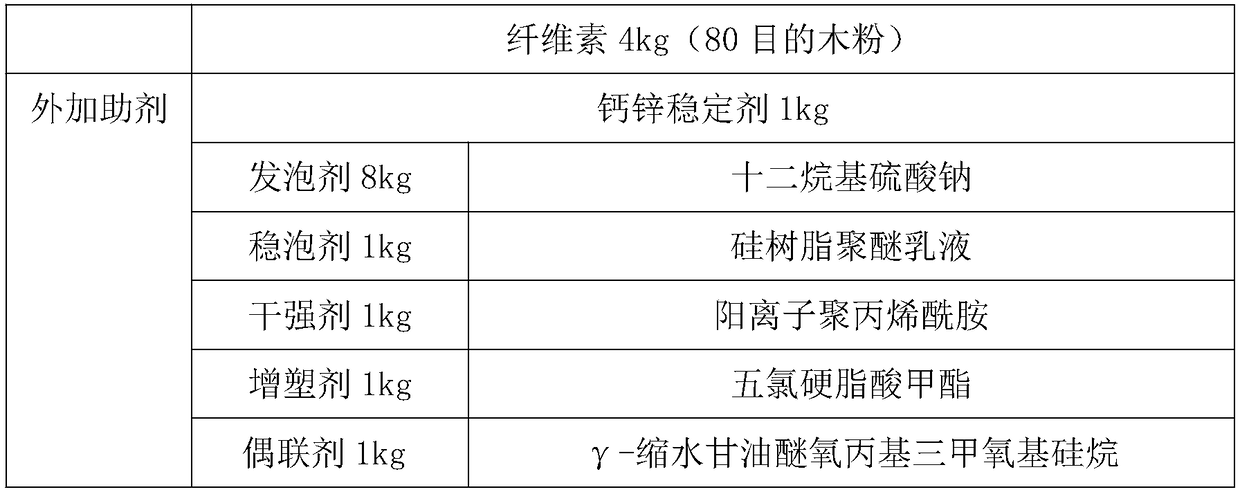

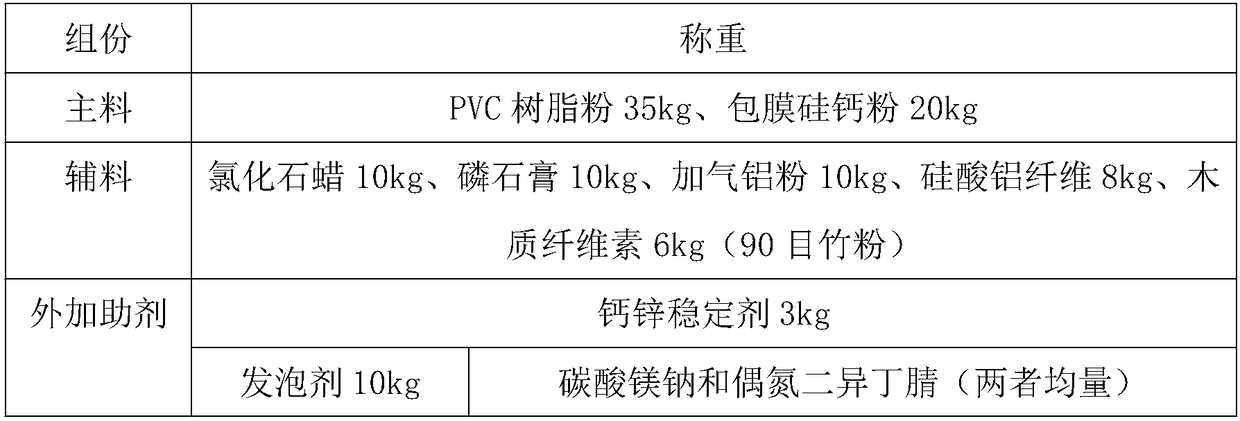

Dampproof and anti-cracking PVC wood plastic door plank and preparation method thereof

InactiveCN108084611AImprove corrosion resistanceImprove waterproof and anti-seepage performanceFiberEnvironmental resistance

The invention discloses a dampproof and anti-cracking PVC wood plastic door plank and a preparation method thereof, and relates to the technical field of novel energy-saving door plank production. Thewood plastic door plank is prepared from the following raw materials of PVC resin powder, enveloped calcium silicon powder, chlorcosane, ardealite, aerated aluminum powder, aluminum silicate fiber, lignocellulose, a calcium-zinc stabilizer, a foaming agent, a foam stabilizer, a dry strength agent, a plasticizer and a coupling agent. The preparation method of the PVC wood plastic door plank comprises the steps of uniform mixing of the raw materials, extrusion, modeling, cutting, engraving, deburring, transfer printing, stoving varnish, solidifying, inspecting and the like. The PVC wood plasticdoor plank is simple in preparation technology and low in raw material cost, has the properties of environmental protection, watertightness and moisture resistance, corrosion crack resistance and high strength and toughness, and is long in service life and wide in application range.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Ventilation device of underground substation

ActiveCN112398026AGuaranteed dust-free and dryReduce the probability of cloggingEnclosed substationsSubstation/switching arrangement cooling/ventilationStructural engineeringDust control

The invention discloses a ventilation device of a underground substation. The ventilation device comprises an air inlet pipeline, an air inlet in one end of the air inlet pipeline is connected with adraught fan unit, an air inlet in the other end of the air inlet pipeline is connected with a filtering unit, and a dehumidification unit is fixedly arranged in the air inlet pipeline; the air inlet pipeline is movably connected with an extrusion dewatering unit for rolling and extruding the dehumidification unit, the center of the filtering unit is rotatably connected with a cleaning driving unit, and the cleaning driving unit is in engaged transmission connection with an extrusion linkage unit; and one end of extrusion linkage unit is fixedly connected with an extrusion dehydration unit, andother end is movably connected with the air inlet pipeline. In a conventional state, an outer pipeline and an inner pipeline are in a state of being fixedly connected through a disassembly and assembly locking piece, external air enters a substation after being filtered and dedusted by the filtering unit and dehumidified by the dehumidification unit, and dust-free and dry power transformation equipment rooms can be ensured.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

Clean wiping cloth and its producing process

InactiveCN100585042CImprove water absorptionSolve the fiber opening problemCarpet cleanersFloor cleanersYarnTextile technology

The clean wiping cloth and its production process belong to the field of weaving technology. The clean wiping cloth is produced with composite polyester-Jinlun yarn as material and through the steps of compounding twisting, warping, weaving, opening, and gluing to set. In the opening step, the composite polyester-Jinlun yarn is soaked in sodium hydroxide solution of concentration 6-8 g / L at 98-105 or 1 hr. The high efficiency clean wiping cloth made of superfine fiber has fine fuzzy fibers in much greater quantity than that in common fabric, high dirt holding capacity, no dust, high hygroscopicity and high cleaning power.

Owner:沂水恒泰纺园有限公司

High performance environment-friendly metal polishing agent and preparation method thereof

The invention discloses a high performance environment-friendly metal polishing agent which is prepared from the following raw materials in parts by weight: 10-14 parts of organic acid, 2-4 parts of inorganic acid, 0.7-0.9 part of a bright adjuvant, 5-7 parts of glycerinum, 8-12 parts of calcium carbonate, 3-5 parts of an antirust agent, 2-4 parts of acetyl monoethanolamine, 1-3 parts of stearate,10-12 parts of a wax emulsion, 5-10 parts of triethanolamine, 0.5-1.5 parts of a surfactant, 1-3 parts of sodium nitrite, 2-4 parts of a stabilizer, 1-3 parts of nano silicon dioxide, 5-7 parts of zinc sulfate, 0.1-0.3 part of a corrosion inhibitor and 35-45 parts of distilled water. The high performance environment-friendly metal polishing agent disclosed by the invention has the characteristicsof being good in polishing quality, convenient to use, high in efficiency and the like, the surface brightness of a metal can be enhanced, and in the polishing process, no corrosive gas, dust and chromic anhydride harmful substances are available. The demand on wastewater treatment condition is low, and the high performance environment-friendly metal polishing agent is good in abrasive dispersityand relatively good in stability of composition, and has a remarkable effect on surface evenness of the metal and micro-puncture phenomenon.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

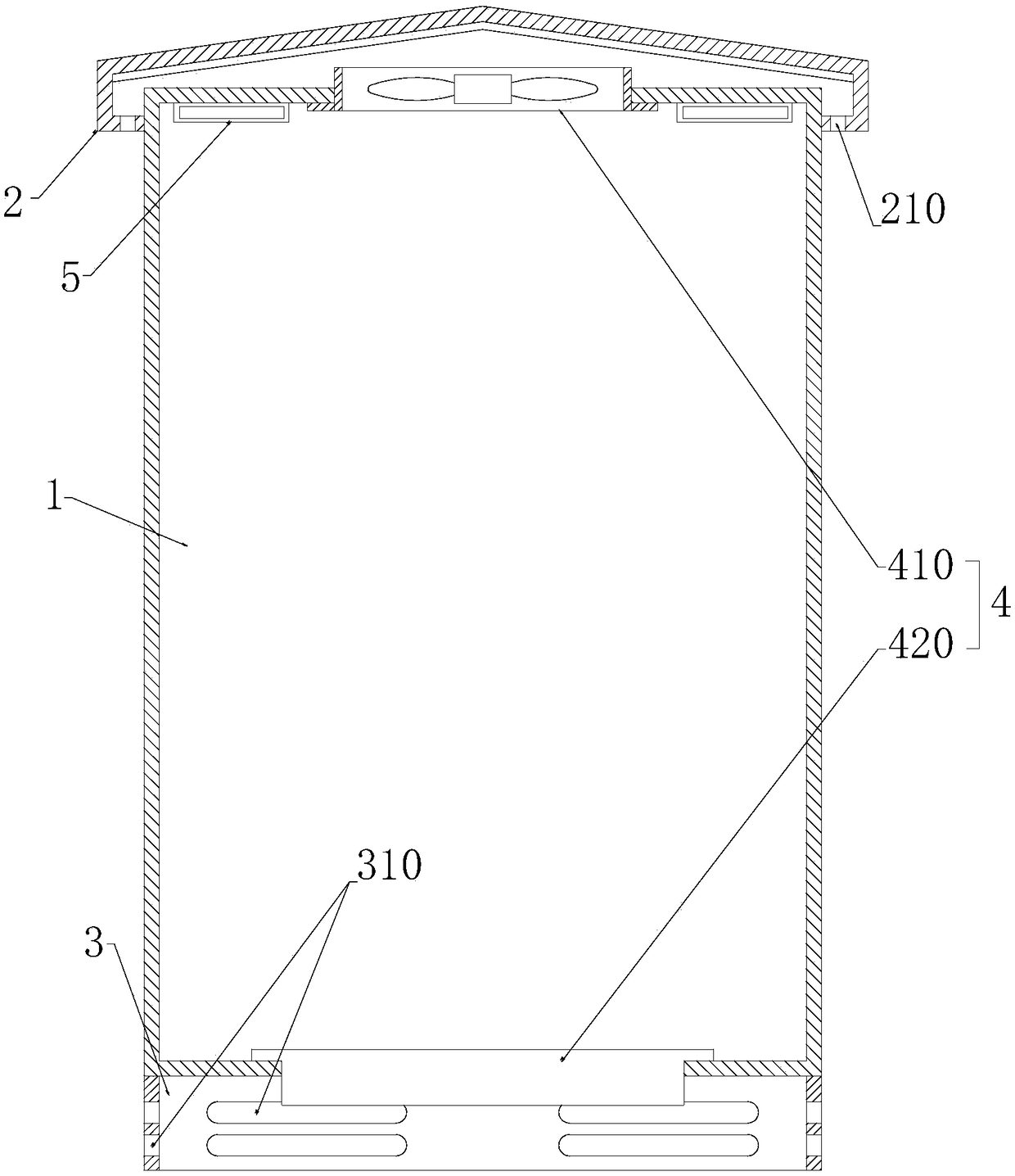

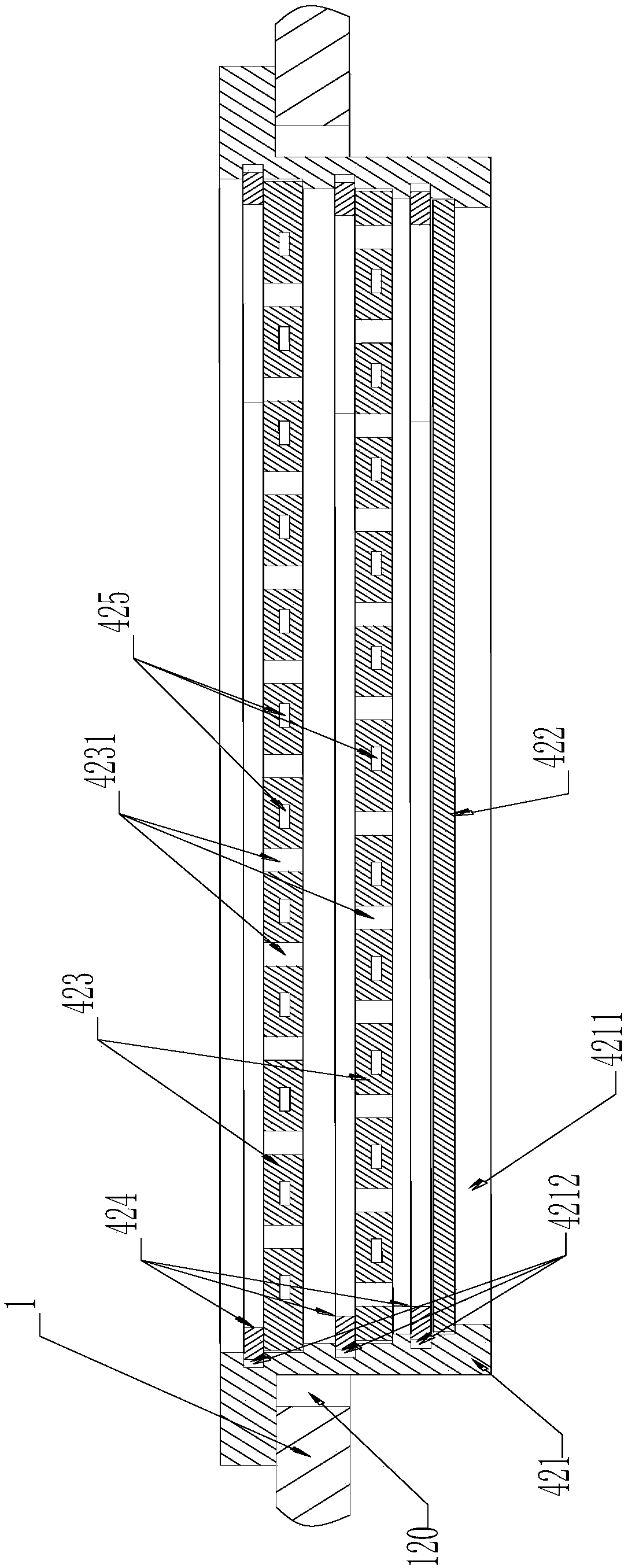

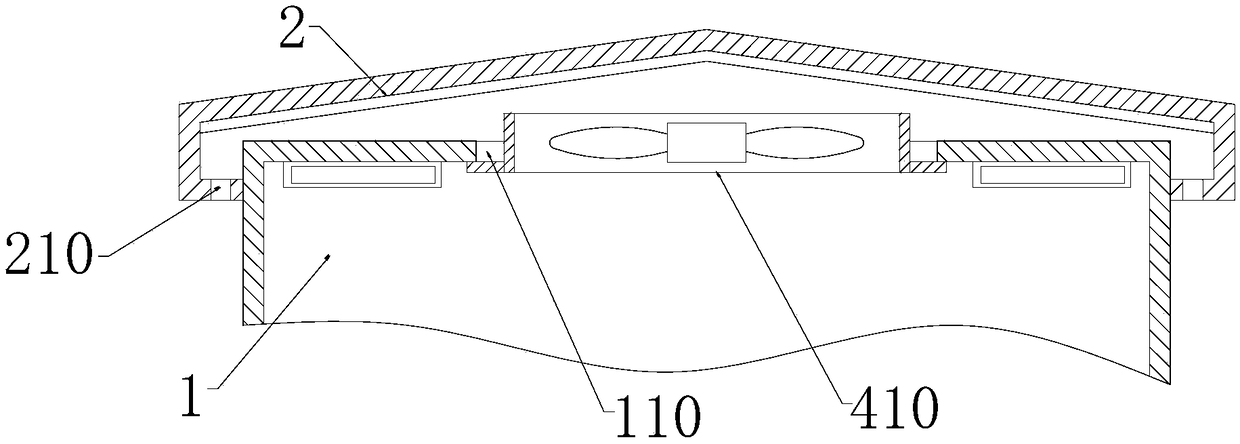

Novel PLC control box

InactiveCN108174578AConvenience to workDust freeDispersed particle filtrationCasings/cabinets/drawers detailsMoisture absorptionComputer engineering

The invention relates to a novel PLC control box comprising a box body, a top cover, a base, and a heat dissipation device. The base is arranged at the bottom of the box body; and the top cover is arranged on the top of the box body. An upper mounting opening is formed in the top wall of the box body; and a lower mounting opening is formed in the bottom wall of the box body. The heat dissipation device consists of a cooling fan and a dust removing and moisture absorption part; the cooling fan is arranged in the upper mounting opening; and the dust removing and moisture absorption part is arranged in the lower mounting opening. Air inlet holes are formed in side walls of all sides of the base; and an air outlet is formed in the downward end surface of the top cover. The dust removing and moisture absorption part includes a frame, a dustproof net, and a plurality of moisture absorption plates; a mounting hole is formed in the frame; the dustproof net and the plurality of moisture absorption plates are arranged in the mounting hole successively from bottom to top; and vent holes are formed in the moisture absorption plates, wherein projections of all vent holes of each two adjacent moisture absorption plates are not overlapped. The novel PLC control box has the following beneficial effects: the heat dissipation performance of the control box is improved; and dust removing and moisture absorption are carried out on air entering the box body while heat is dissipated.

Owner:瑞鸿电控设备(武汉)有限公司

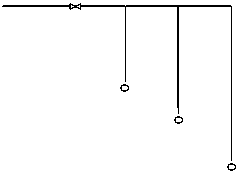

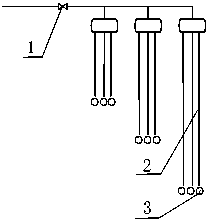

Ammonia injection grid for thermal power plant denitration unit

InactiveCN107456869AImprove uniformityReduce dust accumulationDispersed particle separationFlue gasEngineering

The invention discloses an ammonia injection grid for a thermal power plant denitration unit. The ammonia injection grid comprises a valve 1, ammonia injection branch pipes 2 and ammonia injection nozzles 3, wherein the valve 1 is arranged on an ammonia injection pipeline; multiple ammonia injection branch pipes 2 are arranged on the pipeline, and the bottom ends of the ammonia injection branch pipes 2 are connected with the ammonia injection nozzles 3; the distance between two adjacent ammonia injection branch pipes is 150mm; and the quantity of the ammonia injection nozzles 3 is 144. According to the ammonia injection grid disclosed by the invention, the uniformity of ammonia in flue gas at the denitration inlet is greatly improved, conversion of sulfur trioxide in the local flue gas is effectively reduced, dust deposited on a flow equalizing grid at the denitration inlet is obviously decreased, the dust is not deposited on the denitration catalyst, the problems of the flow equalizing grid at the denitration inlet, the deposited the catalyst and the damaged denitration catalyst are effectively avoided, the denitration efficiency is greatly improved, the denitration ammonia consumption is reduced from 12kg per 10000 kWh to 9kg per 10000 kWh, and the cost of liquid ammonia is saved by about **yuan per year.

Owner:贵州黔西中水发电有限公司

Compliance monitor for a medicament inhaler

ActiveUS10828434B2Easy to cleanDust freeMedical devicesMedical atomisersMedication DispenserPharmacy medicine

Owner:ADHERIUM (NZ) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com