Dampproof and anti-cracking PVC wood plastic door plank and preparation method thereof

A PVC resin powder and door panel technology, applied in the field of new energy-saving door panel production, can solve the problems of poor waterproof, moisture-proof and corrosion resistance of door panels, unusable recycled waste plastics, low strength and toughness, etc., so as to achieve less physical harm to workers, Improving impermeability and waterproof performance, good effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

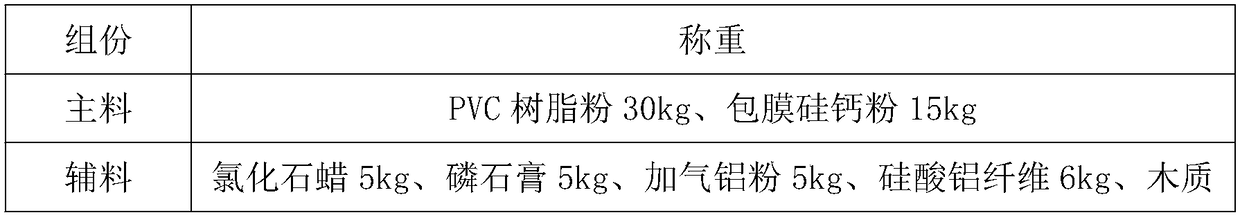

[0028] A moisture-proof and crack-proof PVC wood-plastic door panel, the raw materials in the following table 2 are weighed:

[0029] Table 2

[0030]

[0031]

[0032] The above-mentioned coated silicon-calcium powder is obtained by the following method: the silicon-calcium powder is ball-milled and dispersed with alcohol for 4 hours, the obtained slurry is dried and sintered at 380°C for 1 hour, cooled to room temperature, and then added to it equivalent to its weight 1 % of ammonium stearate, 1% of coconut oil fatty acid diethanolamide and 10% of deionized water, ultrasonically oscillated for 20 minutes, then stirred in a constant temperature water bath at 55°C for 35 minutes to obtain a modified compound solution; The concentration of 20% Al(NO 3 ) 3 At the same time, add an appropriate amount of ammonia water to adjust the pH to 8, stir for 30 minutes, let stand for 1 hour, filter, wash, and dry to obtain the coated silicon-calcium powder required by the raw mater...

Embodiment 2

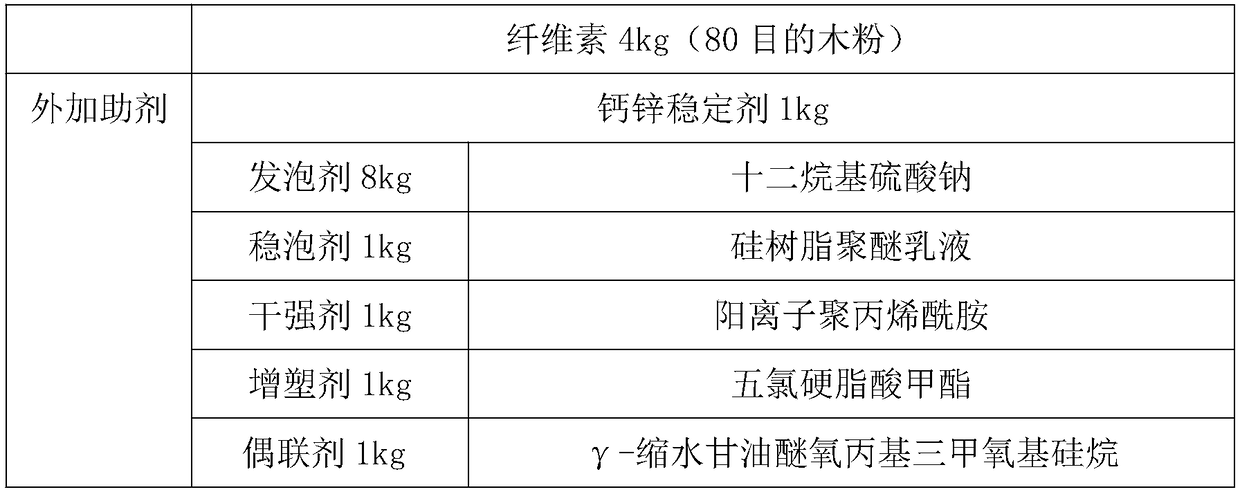

[0037] A moisture-proof and crack-proof PVC wood-plastic door panel, the raw materials in the following table 3 are weighed:

[0038] table 3

[0039]

[0040]

[0041] The above-mentioned coated silicon-calcium powder is obtained by the following method: the silicon-calcium powder is ball-milled and dispersed with alcohol for 5 hours, and the obtained slurry is dried and sintered at 400°C for 1.5 hours, cooled to room temperature, and then added to it by an amount equivalent to its weight 2% of ammonium stearate, 1.5% of coconut oil fatty acid diethanolamide and 12% of deionized water, ultrasonically oscillated for 25 minutes, then stirred in a constant temperature water bath at 60°C for 40 minutes to obtain a modified compound solution; Add the concentration that is 20% Al(NO 3 ) 3 solution, while adding an appropriate amount of ammonia water to adjust the pH value to 9, stirring for 35 minutes, standing for 1.5 hours, filtering, washing, and drying to obtain the coa...

Embodiment 3

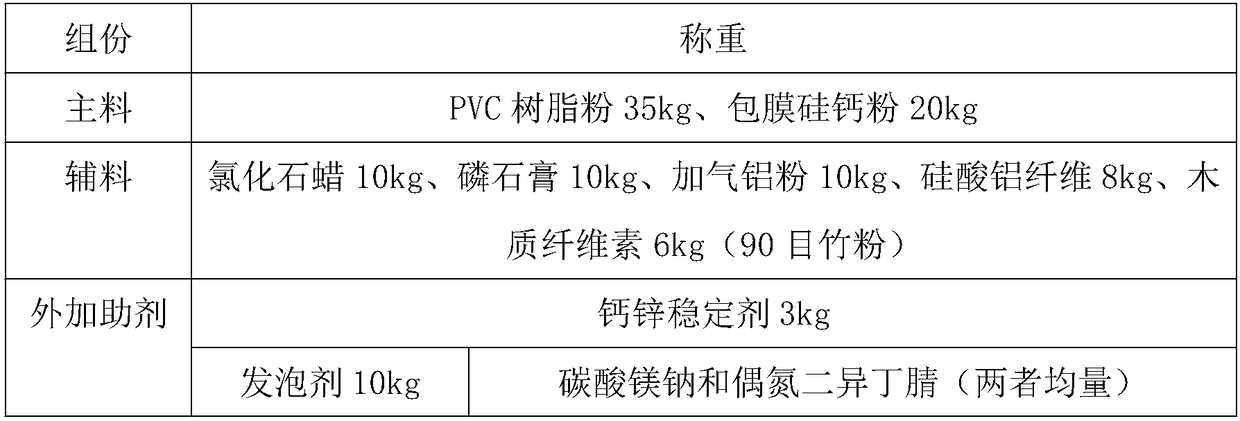

[0046] A moisture-proof and crack-proof PVC wood-plastic door panel, the raw materials in the following table 4 are weighed:

[0047] Table 4

[0048]

[0049]

[0050] The above-mentioned coated silicon-calcium powder is obtained by the following method: ball-milling and dispersing the silicon-calcium powder with alcohol for 6 hours, drying the obtained slurry and sintering at 420°C for 2 hours, cooling to room temperature, and then adding 3 % of ammonium stearate, 2% of coconut oil fatty acid diethanolamide and 15% of deionized water, ultrasonically oscillated for 30 minutes, then stirred in a constant temperature water bath at 65°C for 45 minutes to obtain a modified compound solution; Add the concentration of 20% Al(NO 3 ) 3 At the same time, add an appropriate amount of ammonia water to adjust the pH to 11, stir for 40 minutes, let stand for 2 hours, filter, wash and dry to obtain the coated silicon-calcium powder required by the raw material of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com