Patents

Literature

153 results about "Plank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plank is timber that is flat, elongated, and rectangular with parallel faces that are higher and longer than wide. Used primarily in carpentry, planks are critical in the construction of ships, houses, bridges, and many other structures. Planks also serve as supports to form shelves and tables.

Design internal stress analyzing method for hinged hollow plank girder bridge with reinforced transverse prestress

InactiveCN102953347AAvoid analysisSimulation is accurateBridge erection/assemblyBridge strengtheningPlankPre stress

The invention discloses a design internal stress analyzing method for a hinged hollow plank girder bridge with reinforced transverse prestress. Transverse prestress is applied to reinforce a hollow plank girder bridge with a hinged joint, and the reinforcing mode is one of effective measures for solving the single-plate force applying and the crack along the hinged joint of the hinged hollow plank girder bridge. The patent aims at the characteristics that the plank girder reinforced by the reinforcing method can bear bending bidirectional stress in the longitudinal and transverse directions, and simulates the reinforced hollow plank girder bridge to an orthotropic anisotropic plate and adopts a corresponding longitudinal-transverse rigidity hypothesis to propose an internal stress analyzing method for designing the bridges with the reinforced transverse prestress, so that the problem that no practical design calculation methods are available for the internal stress analysis of the hinged hollow plank girder bridge is solved, and meanwhile, the complexity and time consumption of the modeling calculation in the finite element software calculation are avoided.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

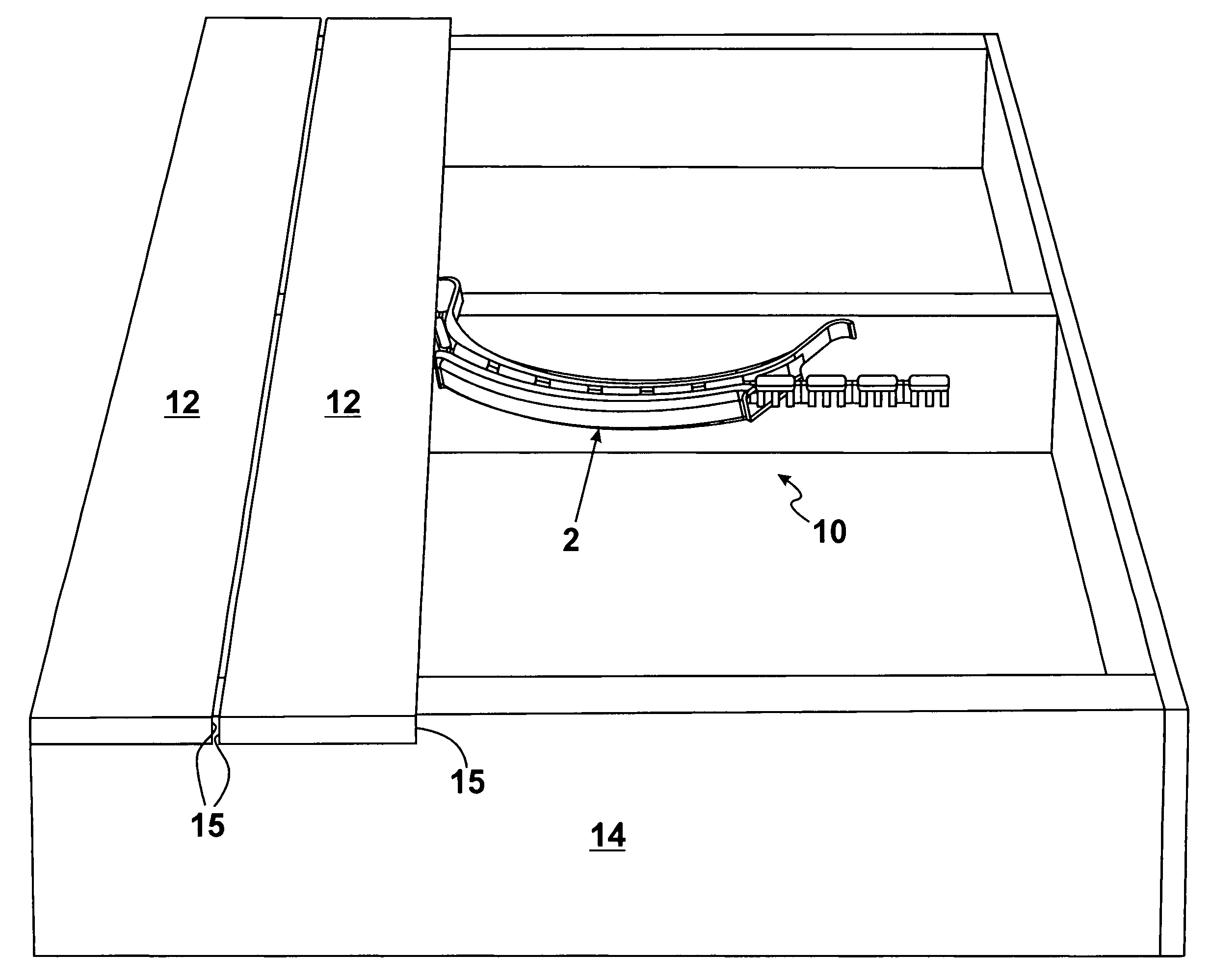

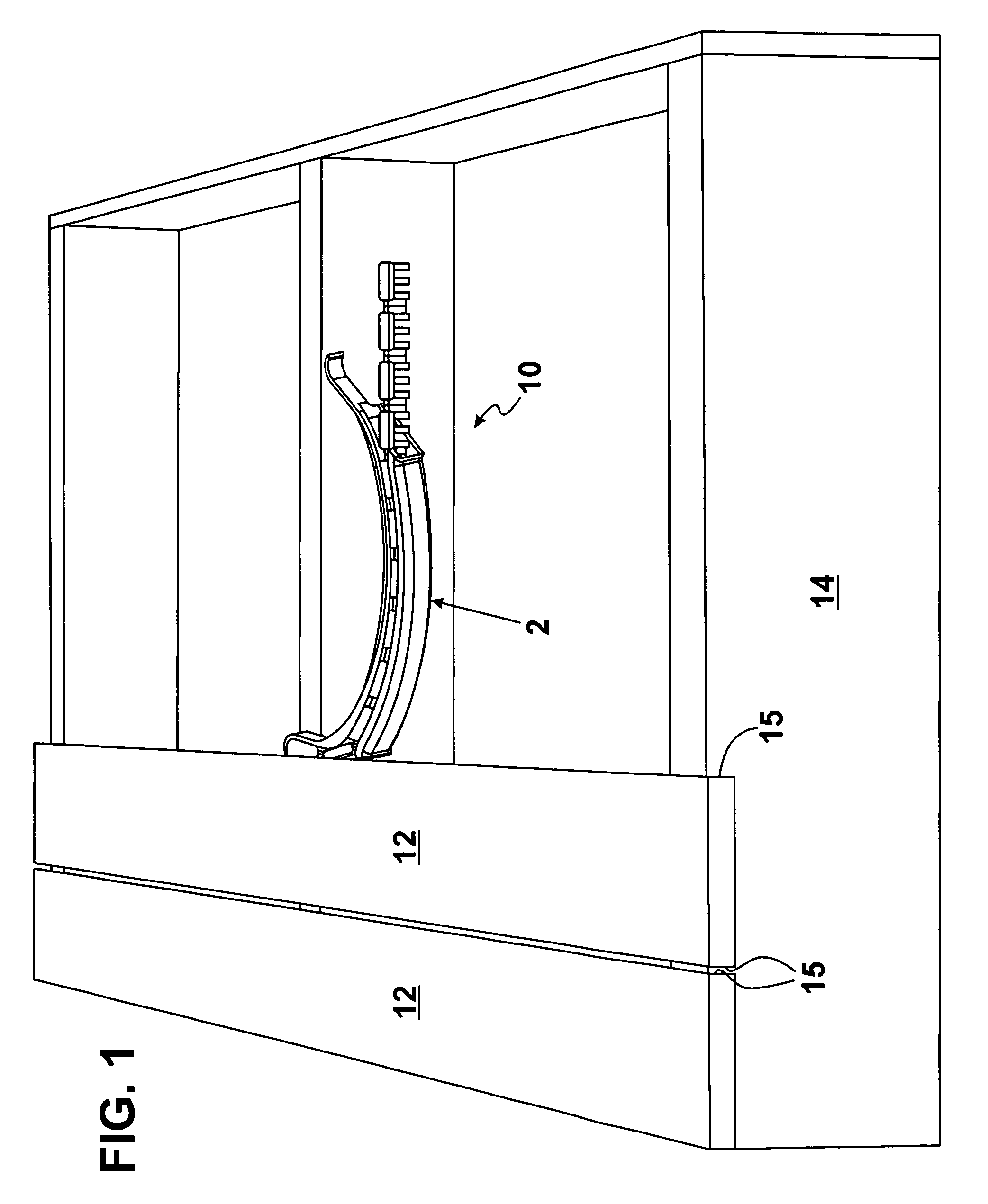

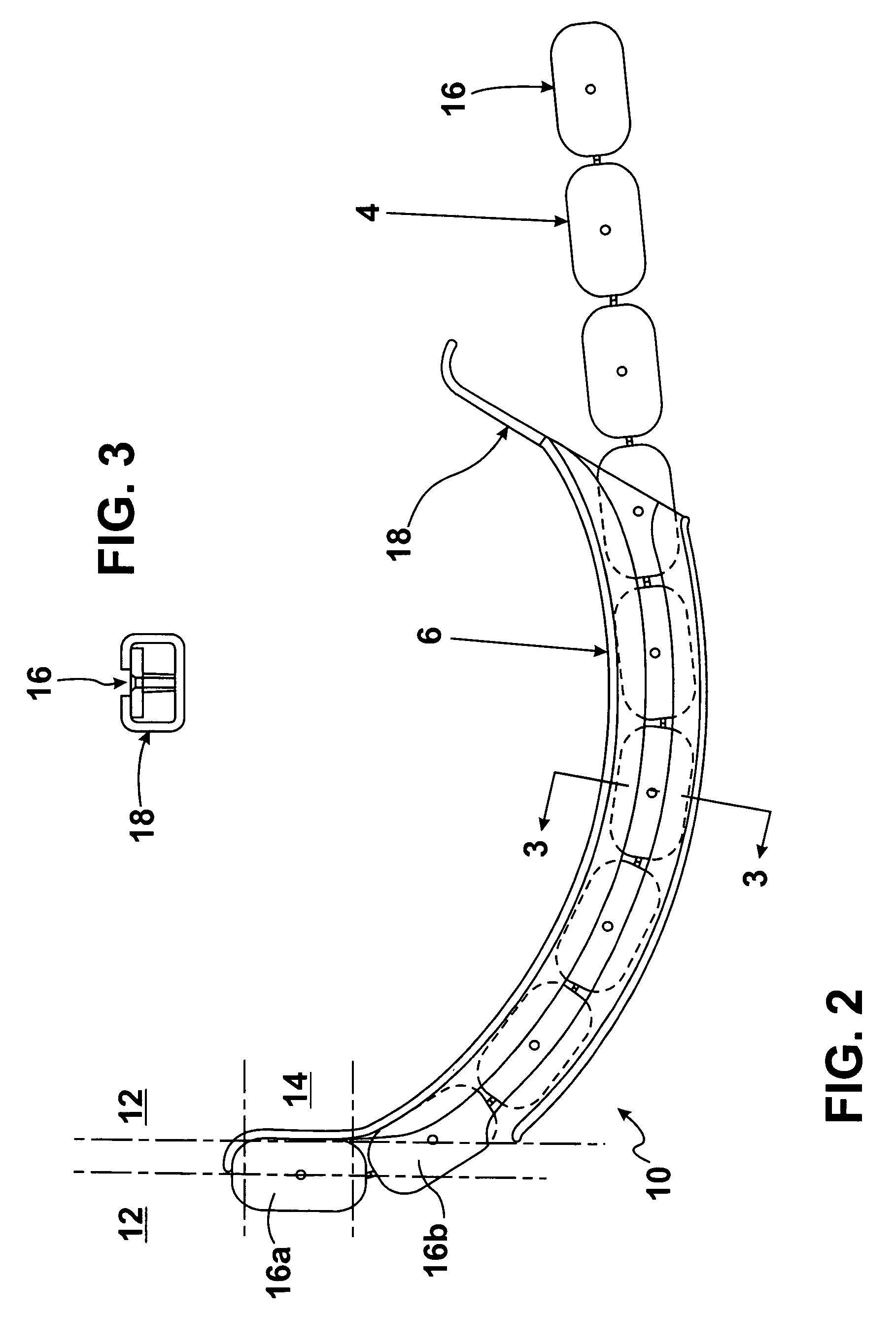

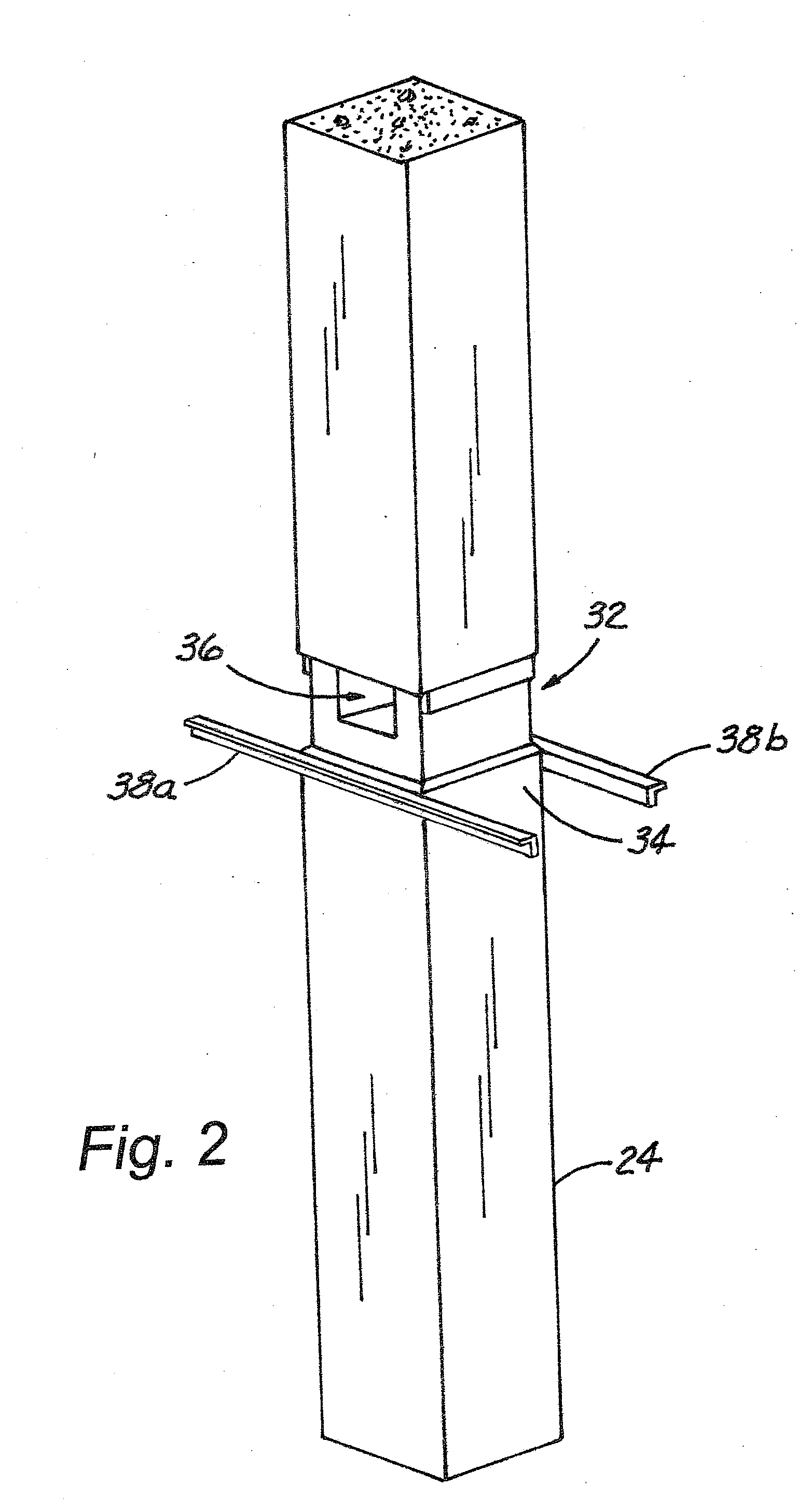

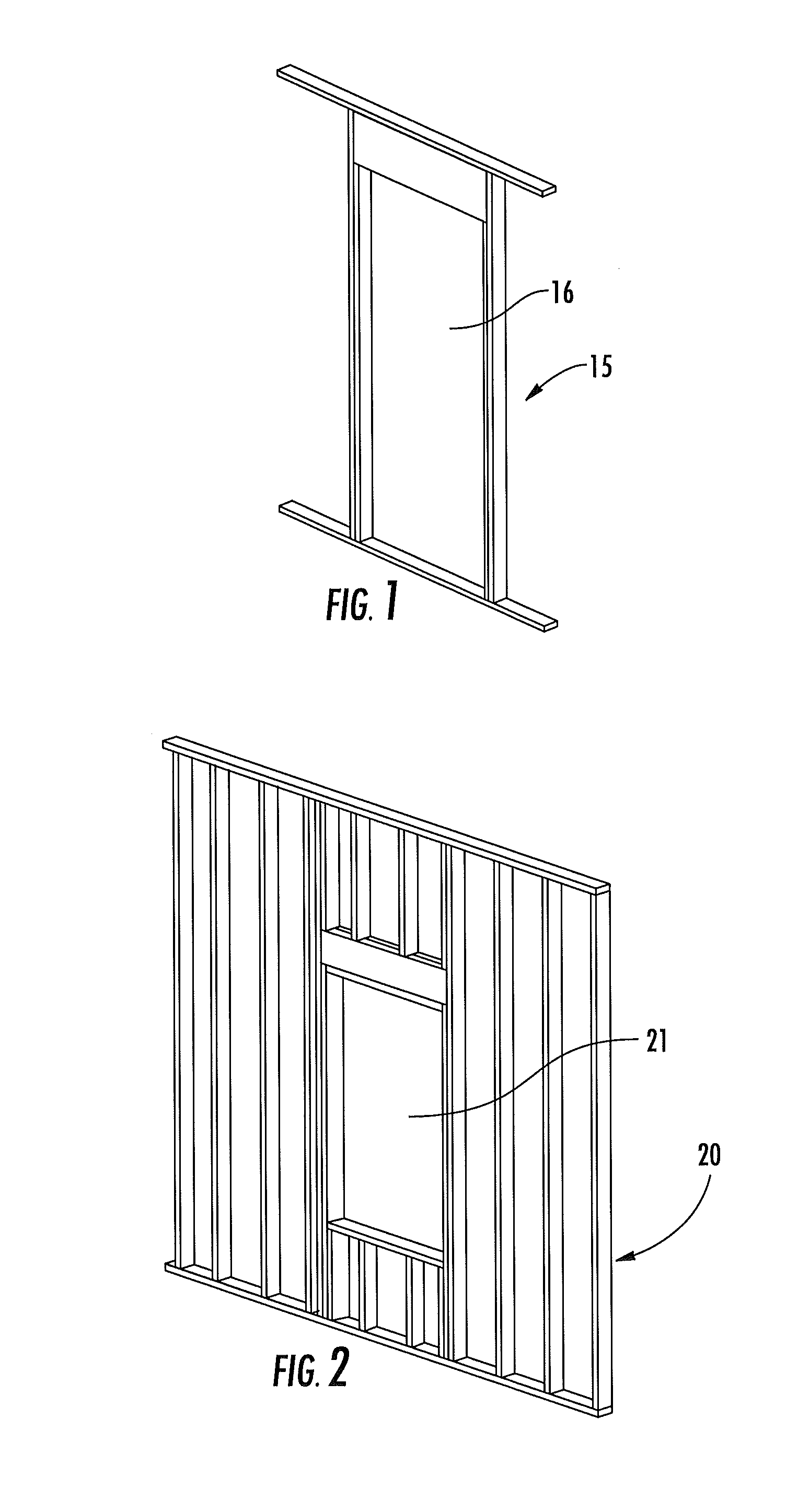

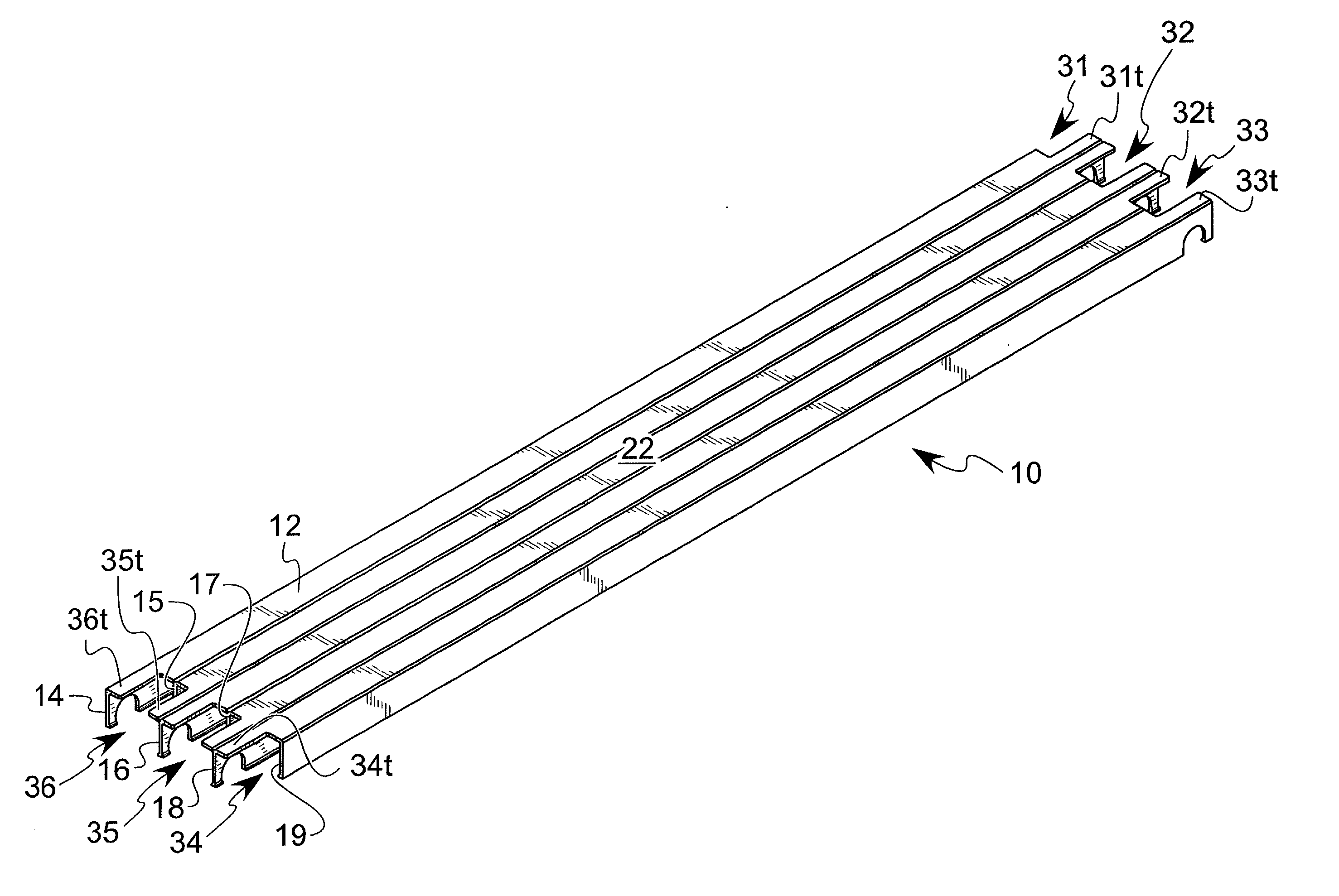

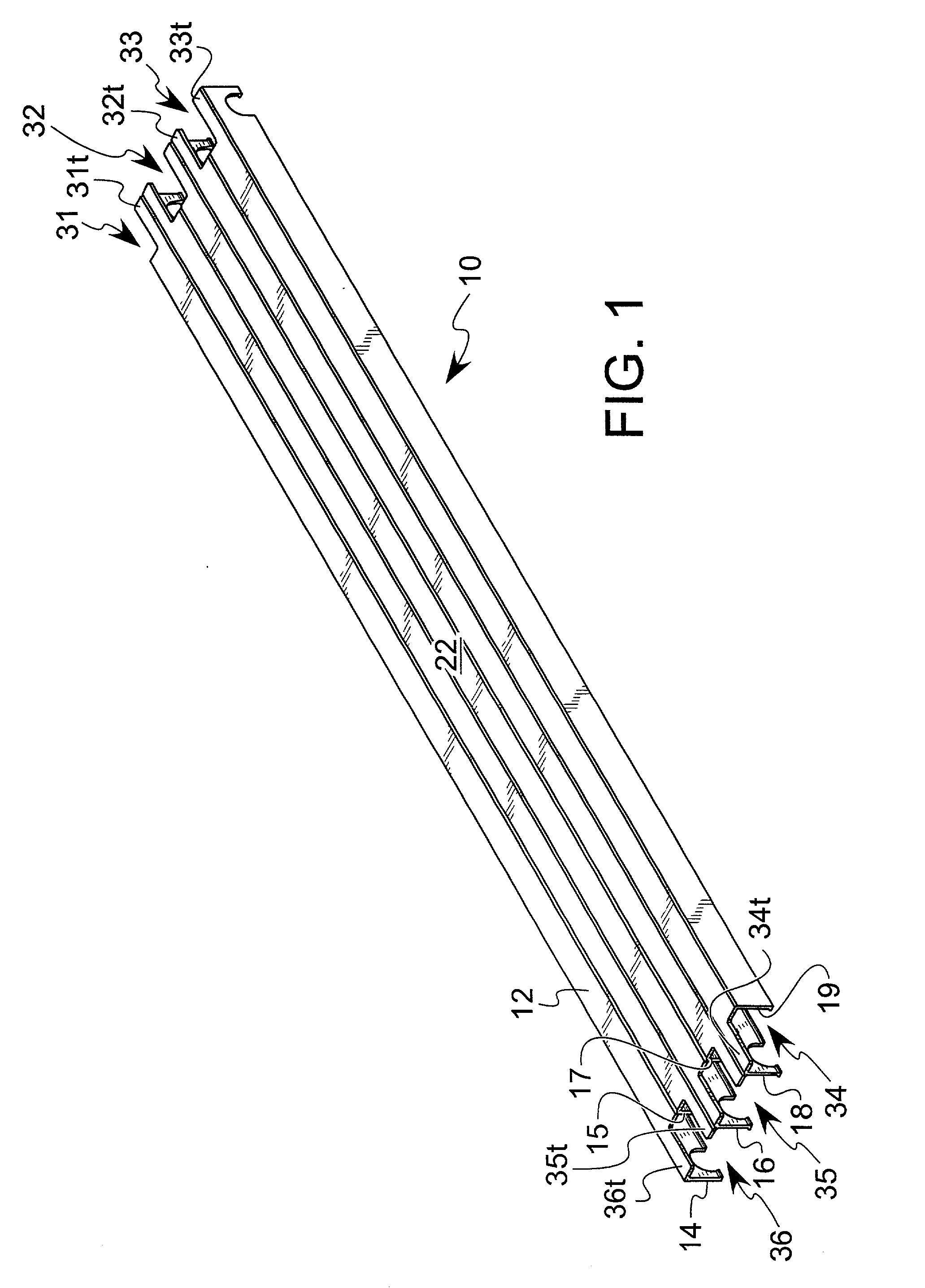

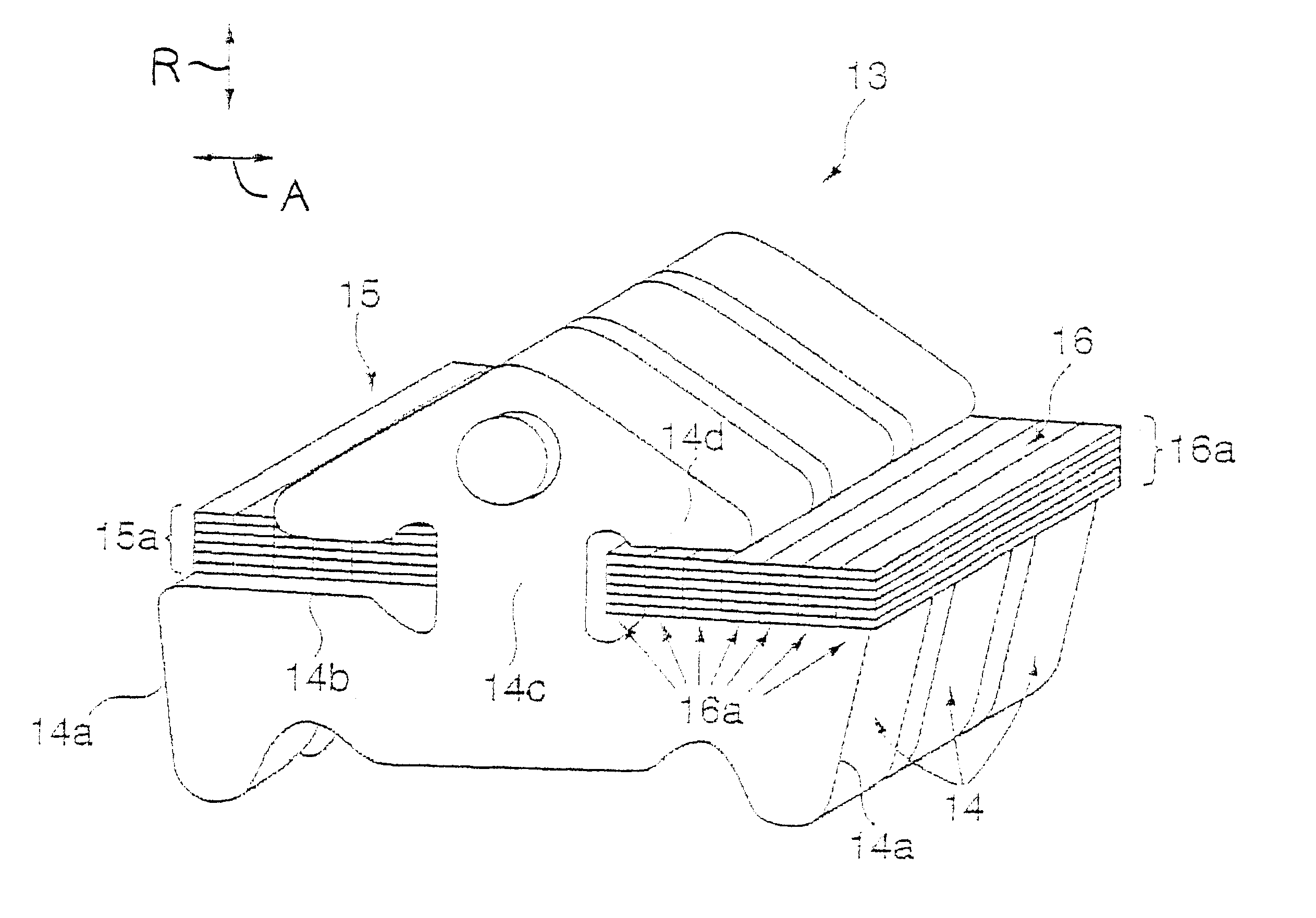

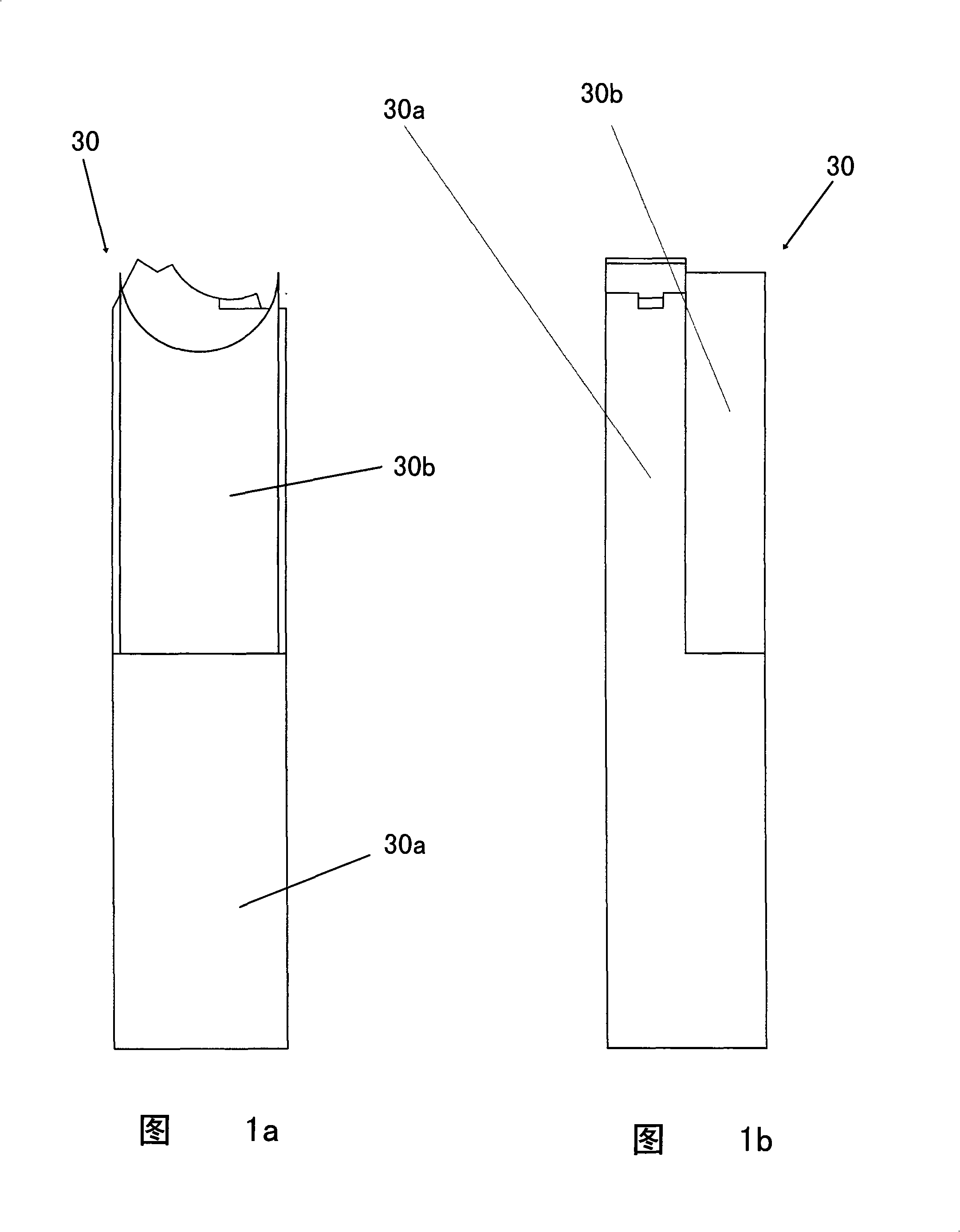

Interconnected and on-site severable deck clips with cooperating installation tool for joining two adjacent decking planks to an underlying support structure

Interconnected and on-site severable deck clips with cooperating installation tool for joining two adjacent decking planks to an underlying support structure. The deck clips are interconnected and on-site severable, are attached to the underlying support structure, and engage the two adjacent decking planks so as to fasten the two adjacent decking planks to the underlying support structure without a need for nails or screws to pass through the two adjacent decking planks. The installation tool is hand-held, removably receives a number of the deck clips, and feeds the deck clips one at a time to fasten to the underlying support structure, and when a deck clip is fastened to the underlying support structure, the deck clip is severed from the other deck clips in the installation tool and a next deck clip is feed by way of the installation tool and attached to the underlying support structure to engage the two adjacent decking planks.

Owner:SIMPSON STRONG TIE

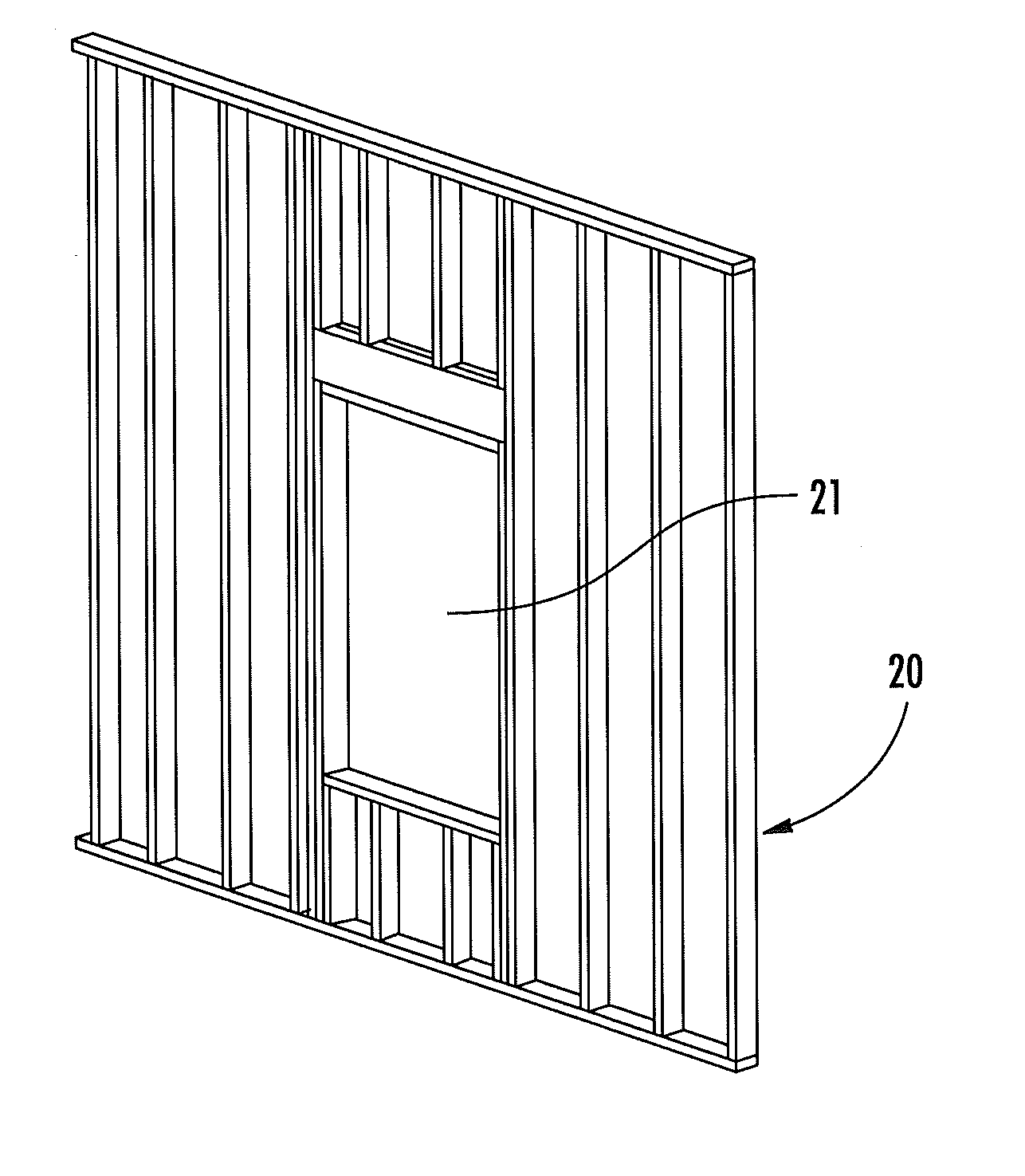

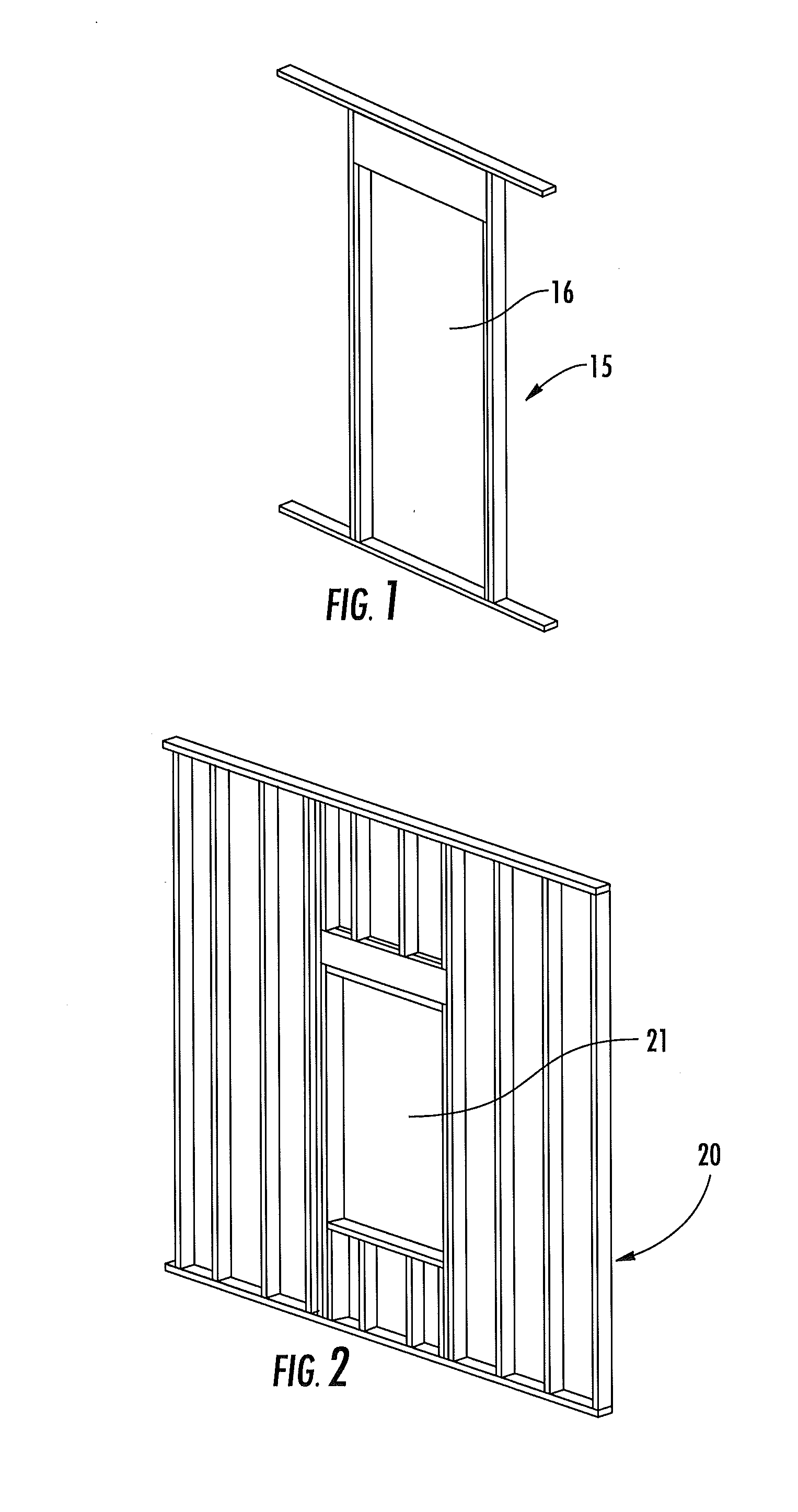

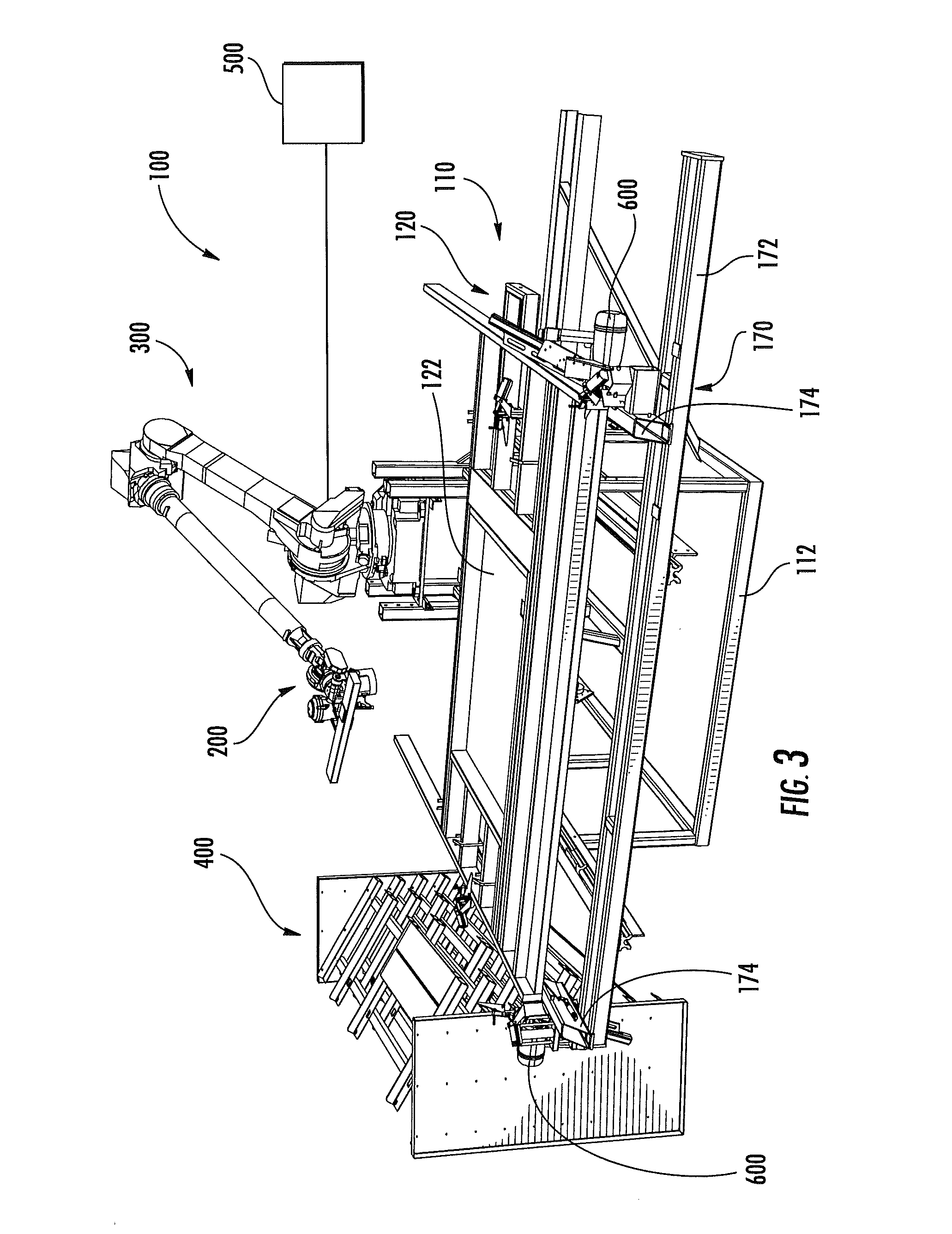

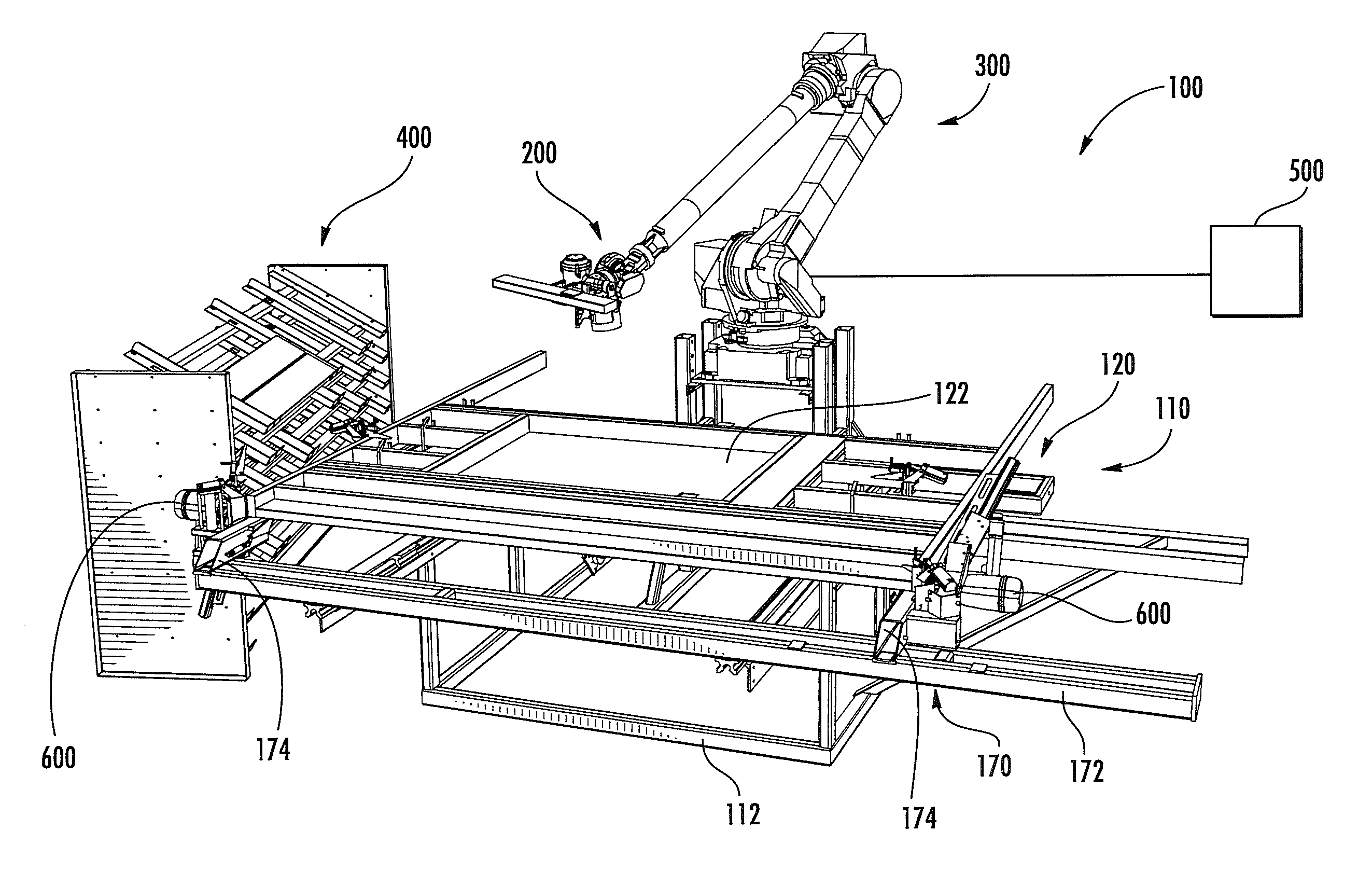

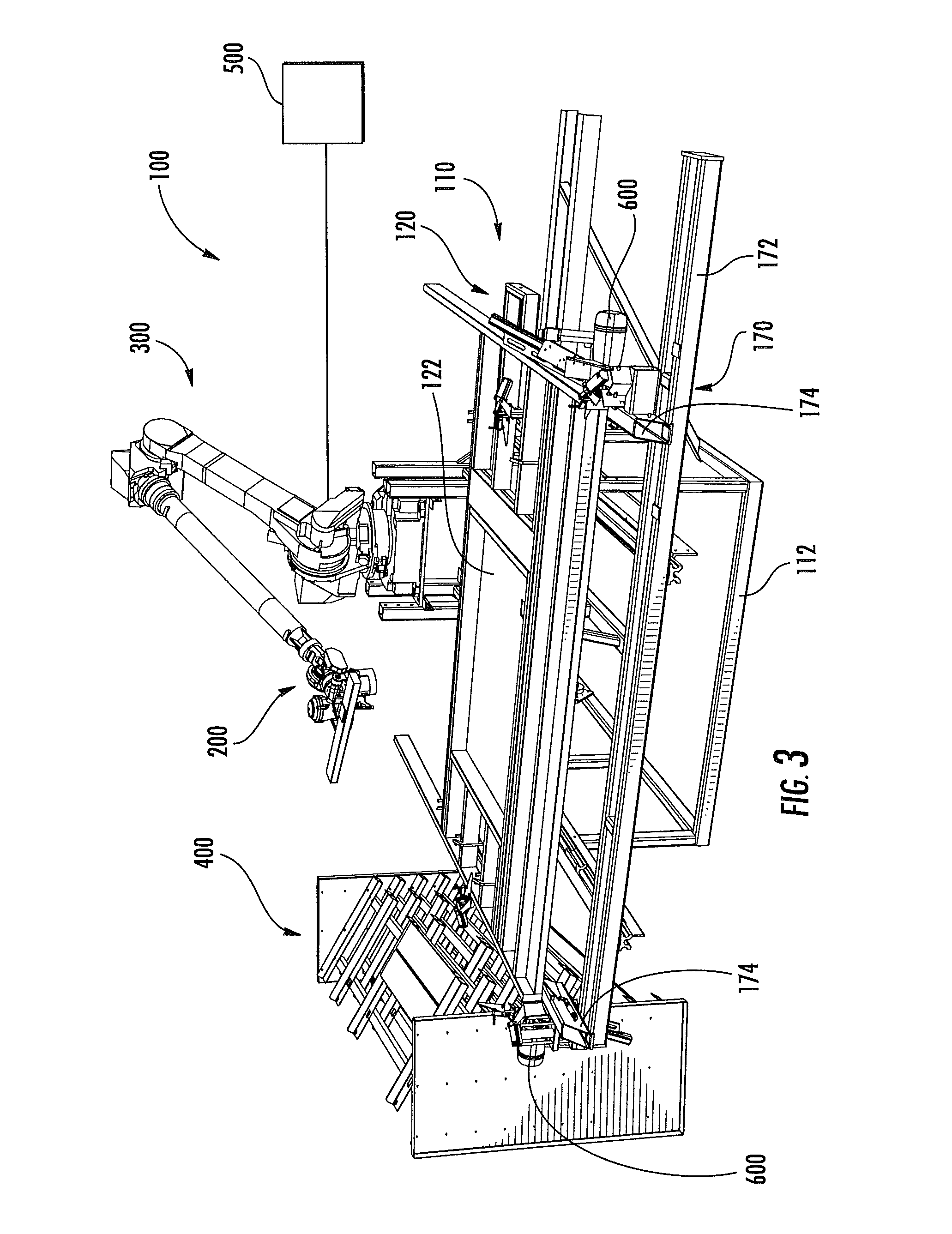

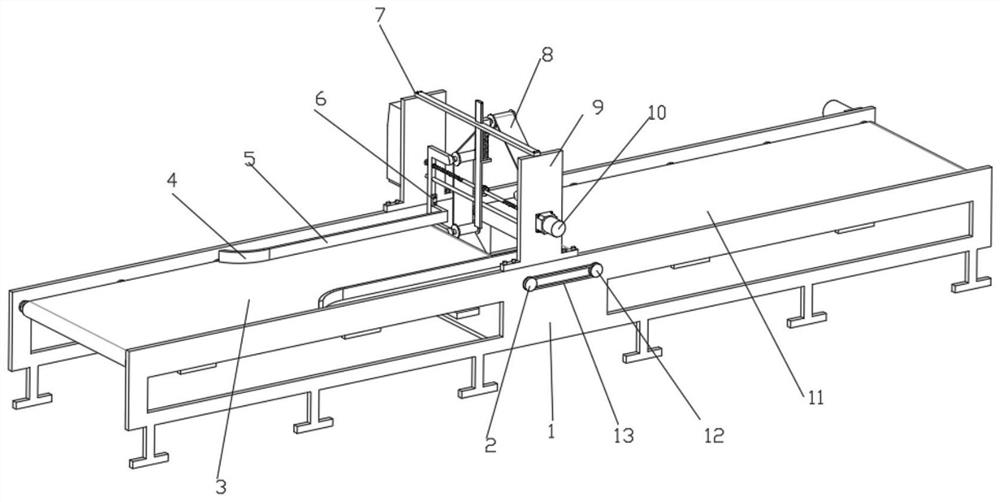

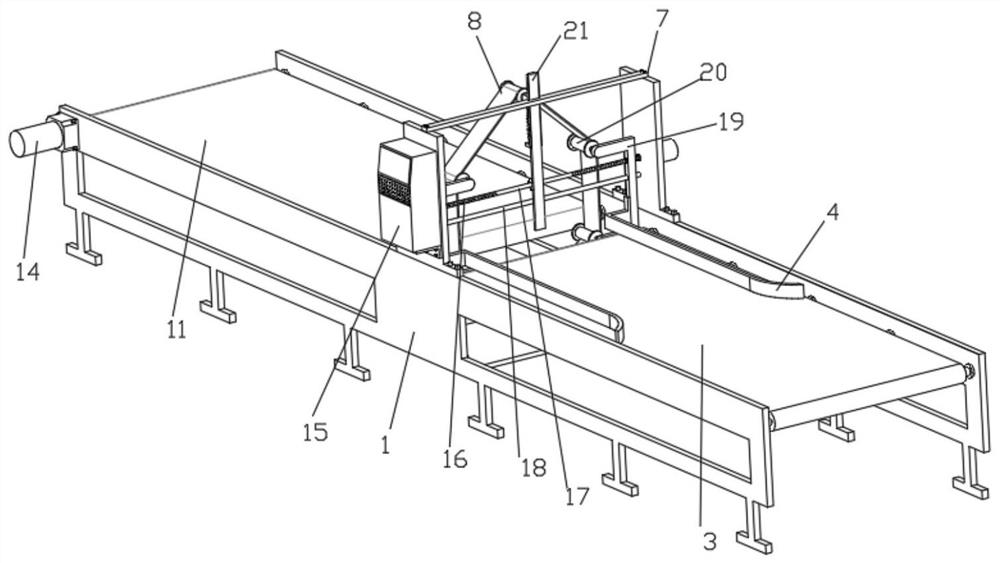

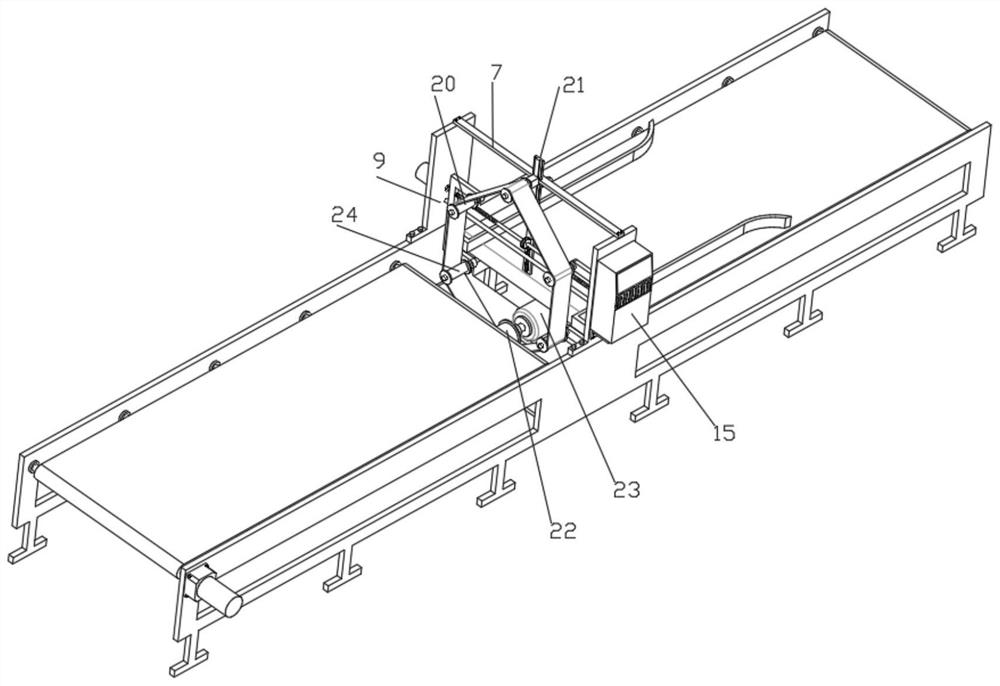

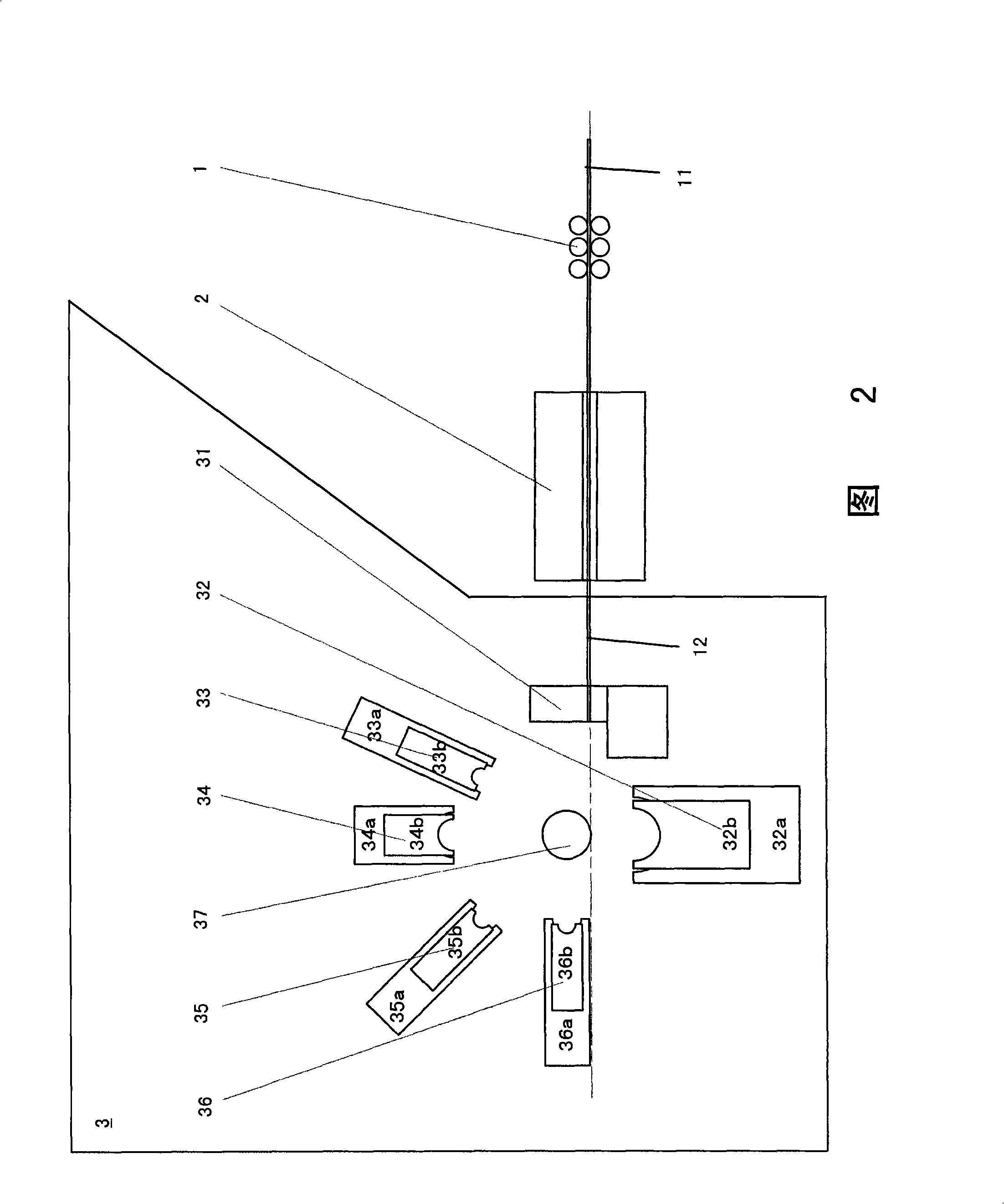

Automated apparatus for constructing assemblies of building components

ActiveUS20130283618A1Easy to installSimplify the build processStapling toolsProgramme-controlled manipulatorEngineeringMechanical engineering

A system for constructing wall panels comprising a plurality of structural members includes: a source of structural members of predetermined size; a horizontal table configured to support planks as they are being formed into a wall panel, the table including a stationary section and a movable carriage that is configured to move in a longitudinal direction toward and away from the stationary section; an articulated arm unit having a gripper, the articulating arm unit positioned to retrieve boards from the source with the gripper and place them on the table; at least one first clamping unit mounted to the stationary section for clamping structural members thereto; at least one second clamping unit mounted to the movable carriage for clamping structural members thereto; and a controller that controls the movement of the articulating arm unit and the movable carriage.

Owner:WILLIAMS ROBOTICS

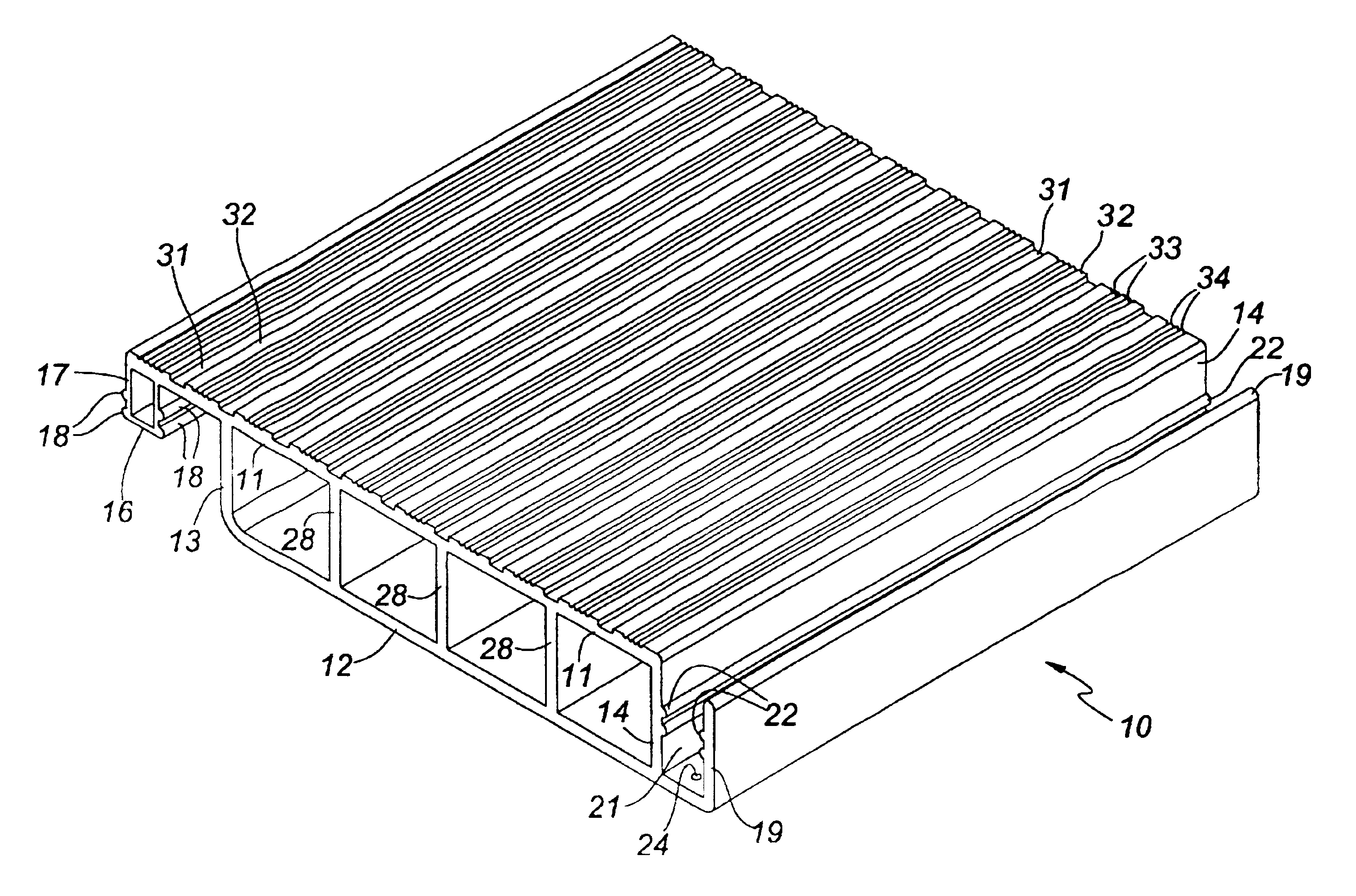

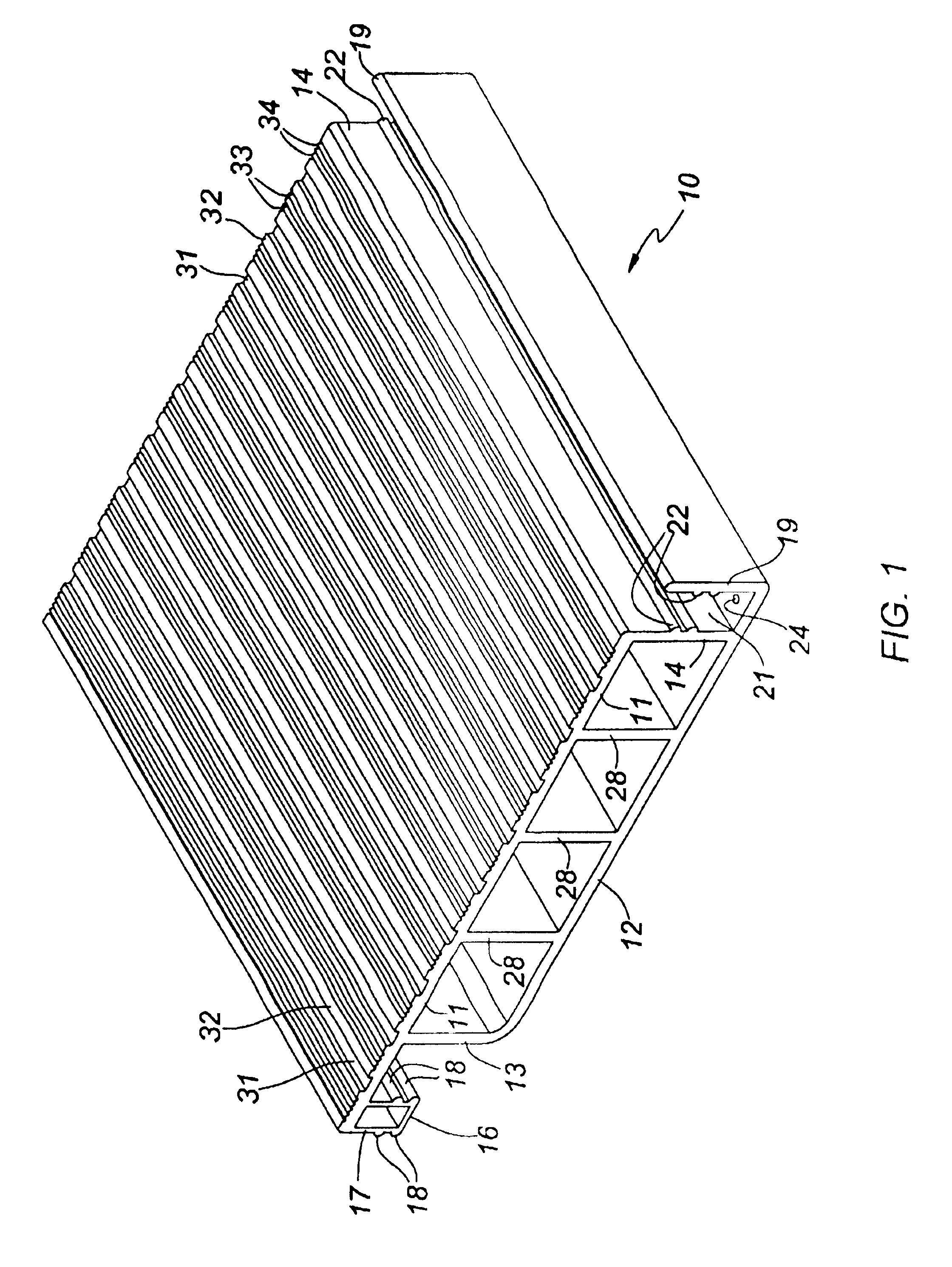

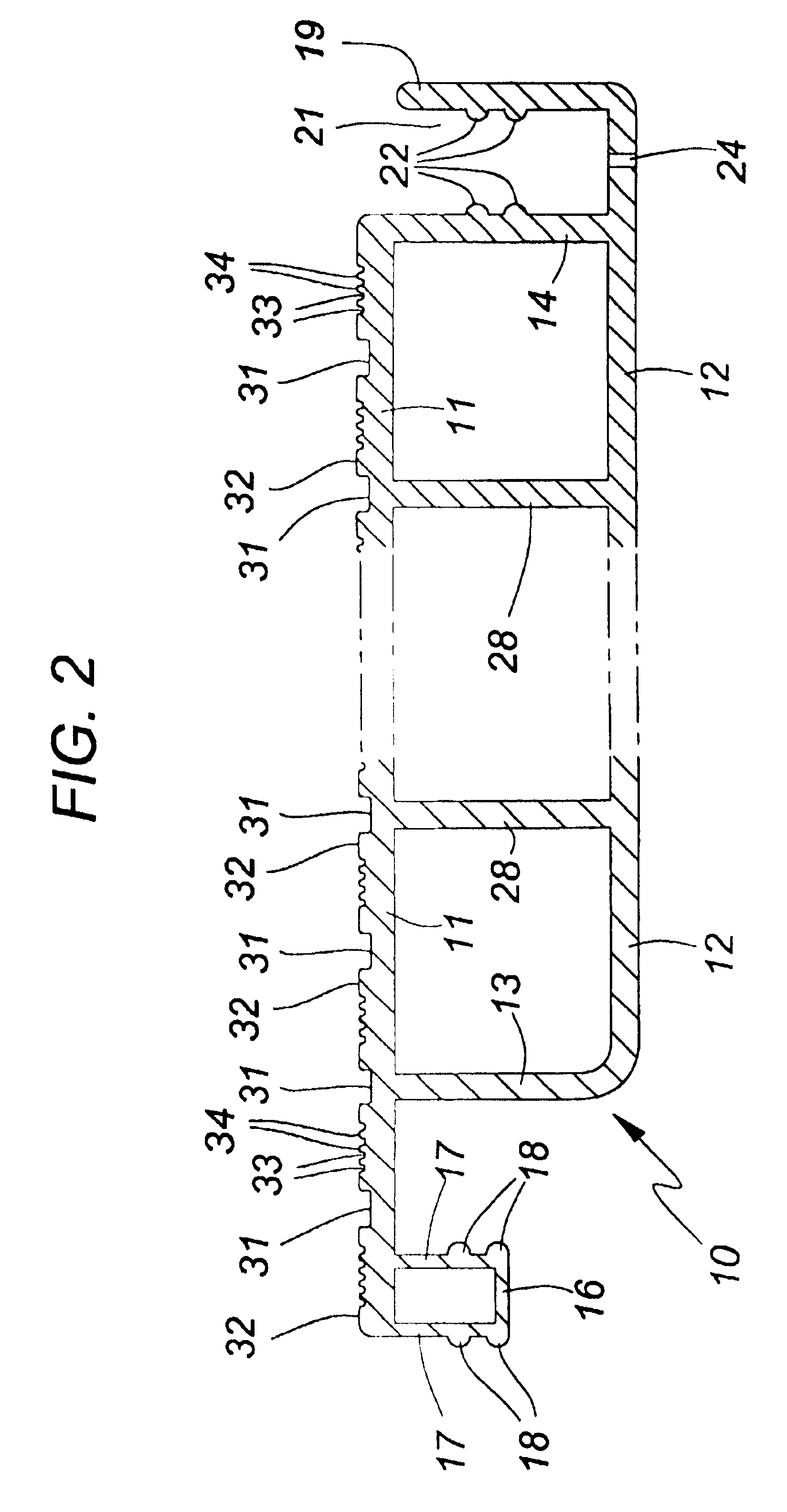

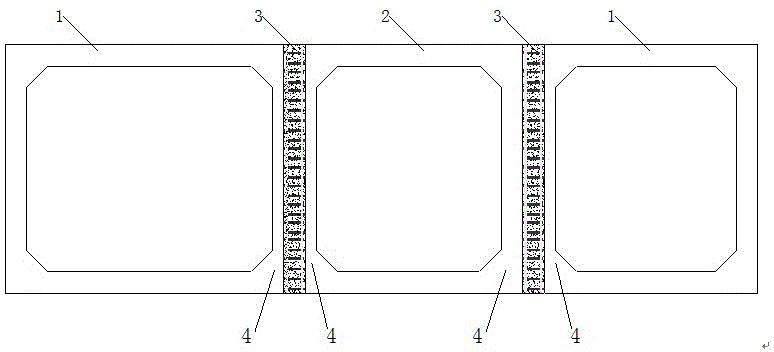

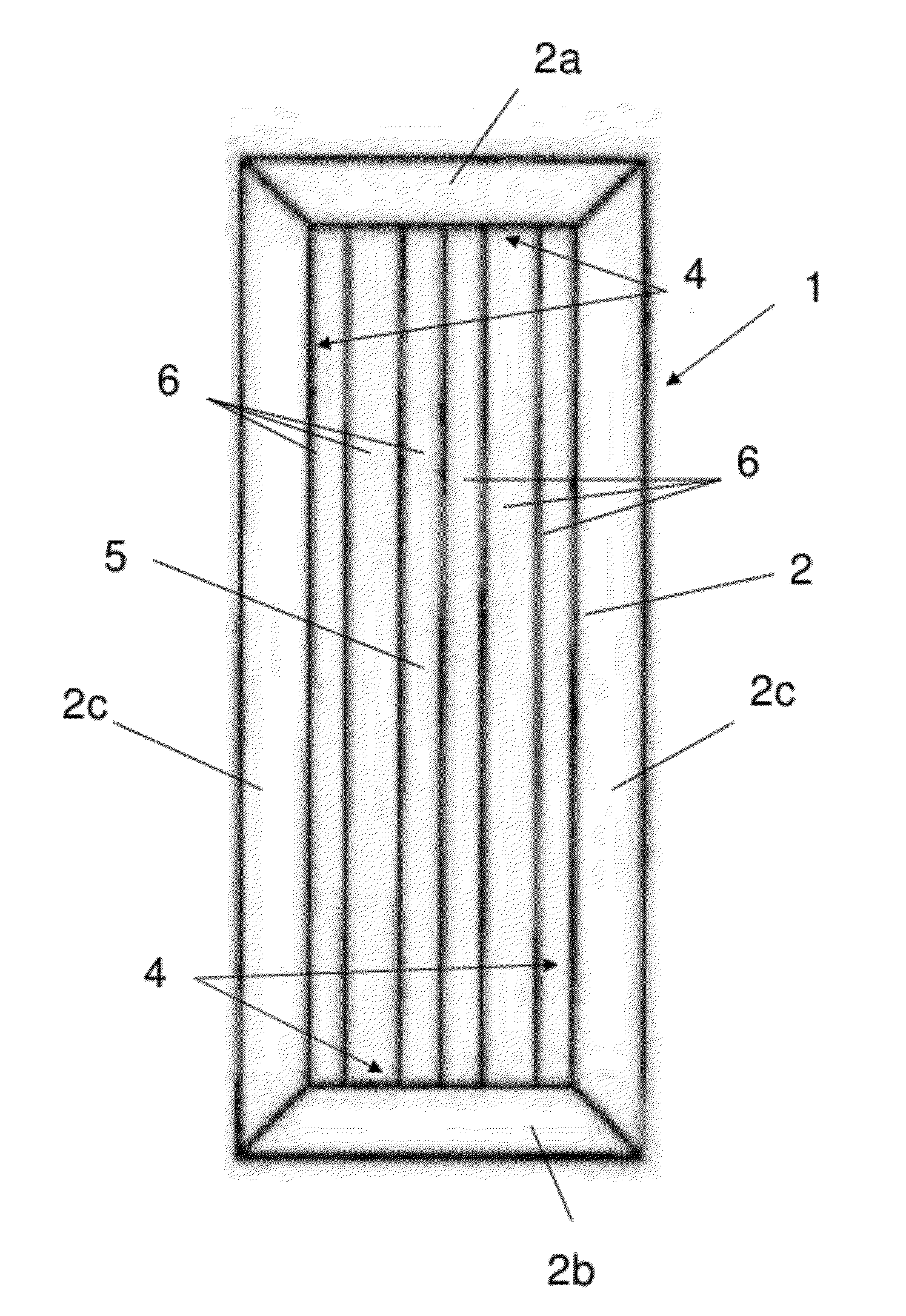

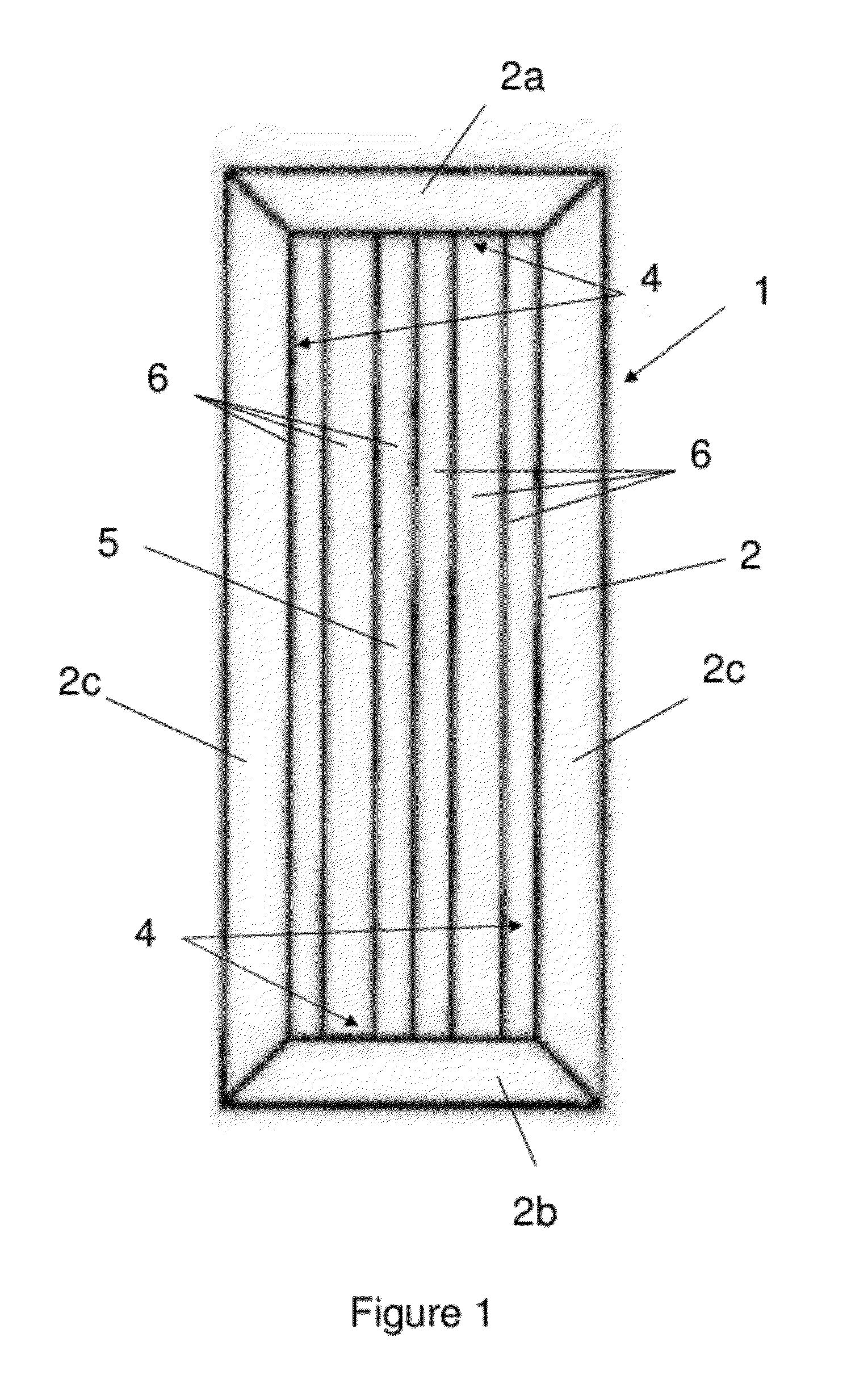

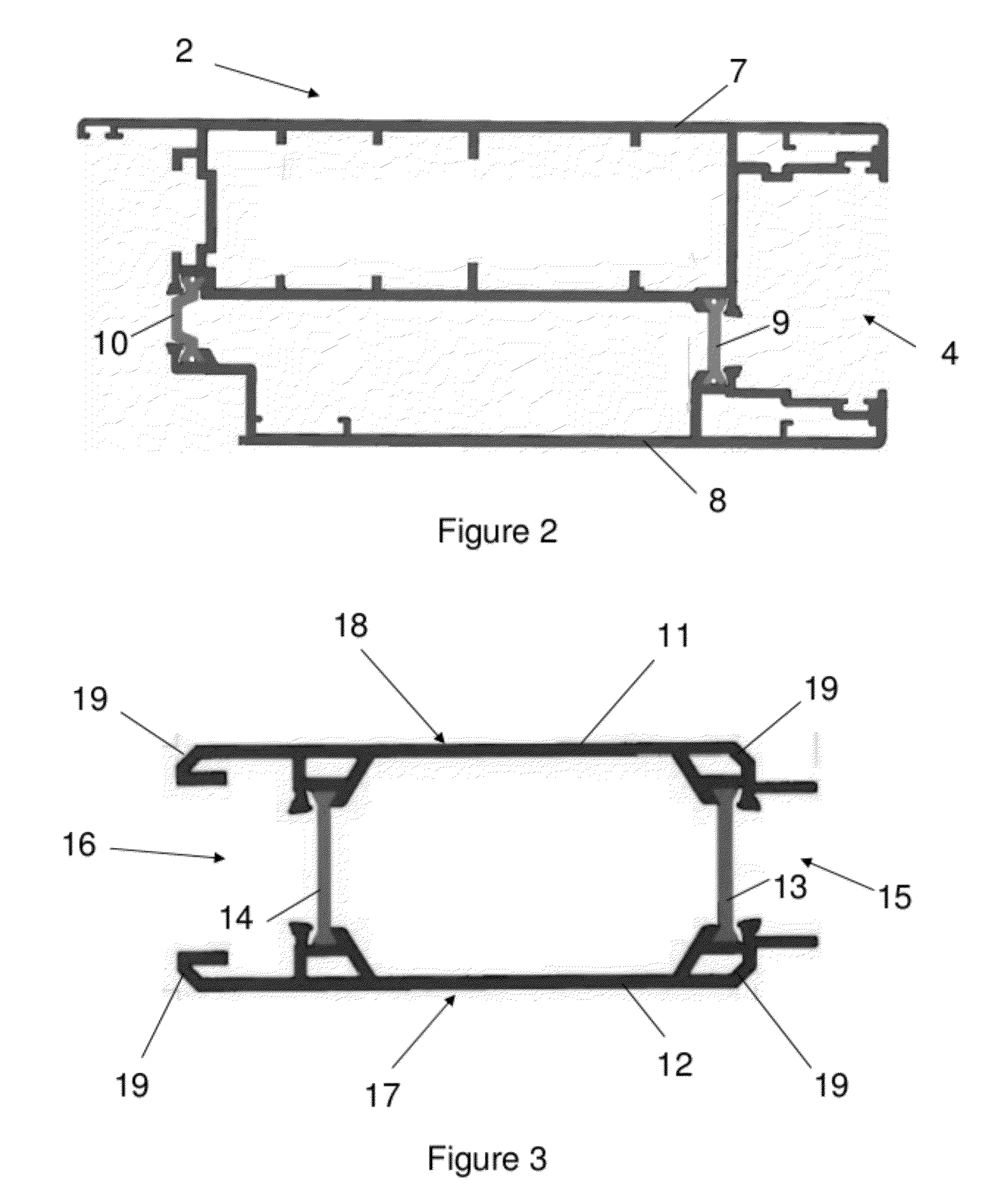

Modular decking planks

InactiveUSRE41140E1Easily assembled togetherReduce manufacturing costTreadsConstruction materialJoistEngineering

A decking system for placement on a subassembly having at least two spaced apart joists. A plurality of elongated tubular elements for placement in lateral interlocking engagement with each other transversely of and spanning the distance between the joists. Each of said plurality of elements having a top portion, a bottom portion, and first and second side walls connecting said top and bottom portions. The top portion extends laterally beyond the first side wall and has formed thereon a downwardly extending longitudinal flange. The bottom portion extends laterally beyond the second side wall and has formed thereon an upwardly extending longitudinal wall defining an upwardly opening channel adjacent the second side wall adapted to receive therein a watertight relation the downwardly extending longitudinal flange. The bottom portion having formed therein a plurality of apertures intermediate the second side wall and the upwardly extending longitudinal wall, adapted for the insertion of fasteners therethrough for engagement with the joists.

Owner:HOMELAND VINYL PRODS

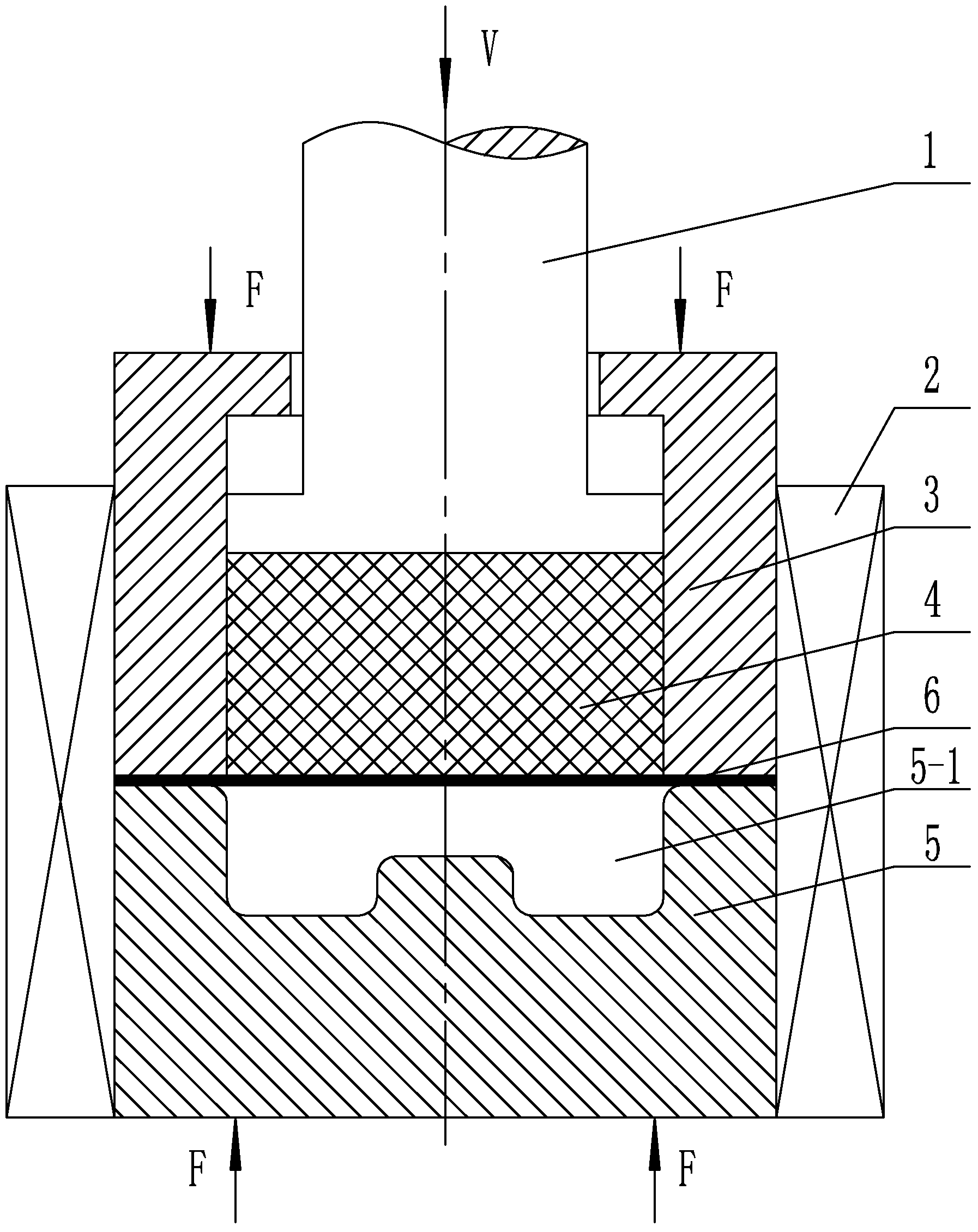

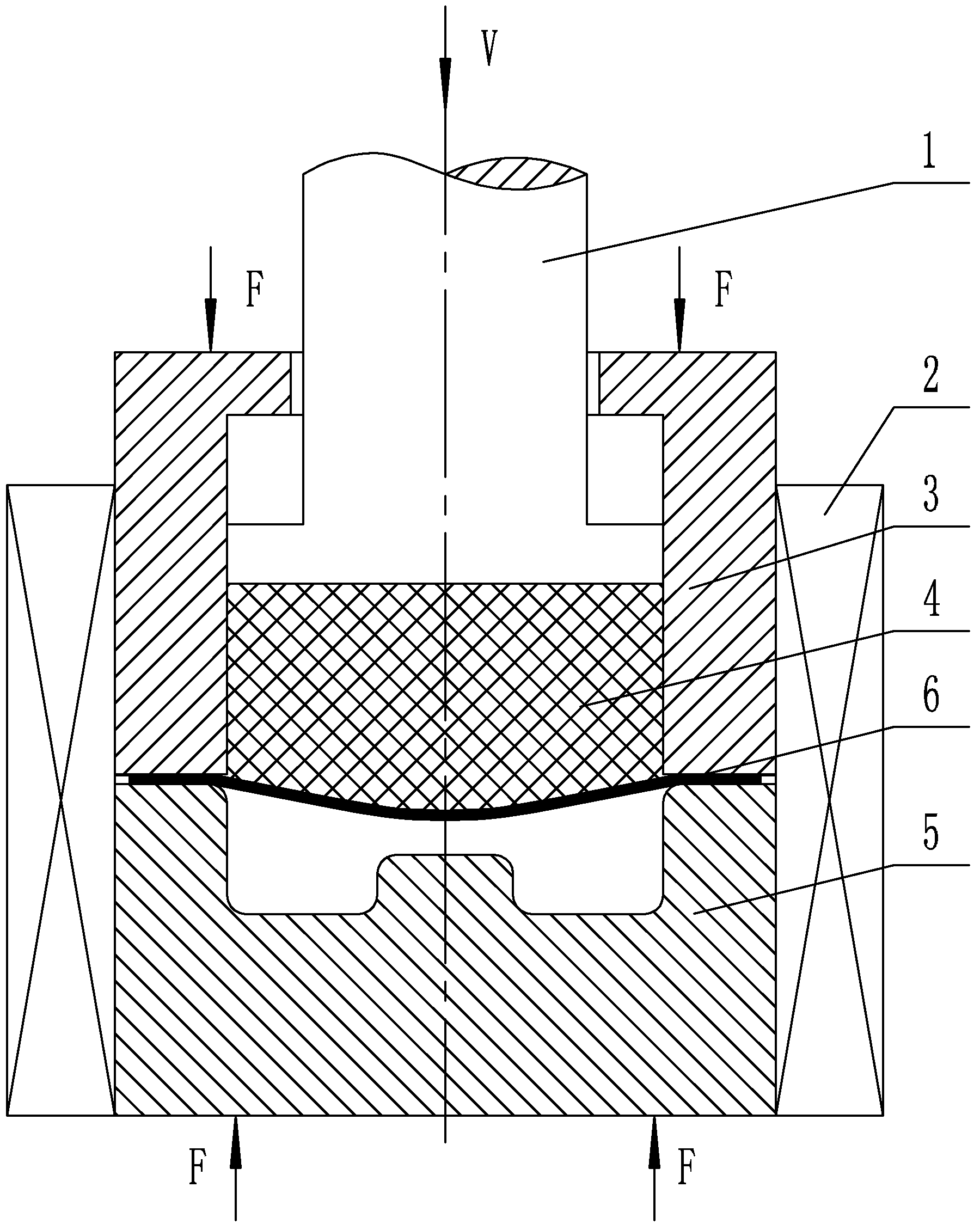

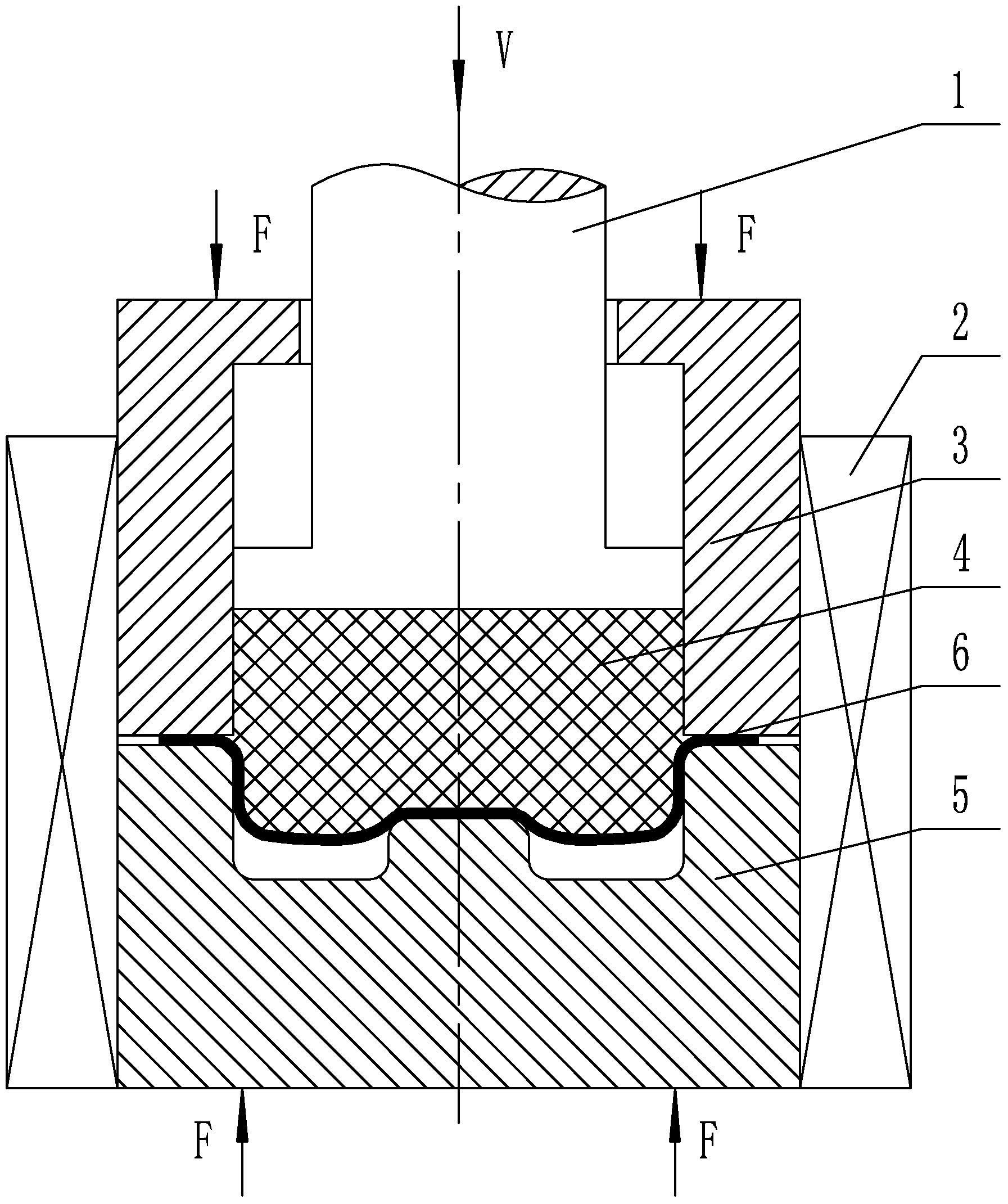

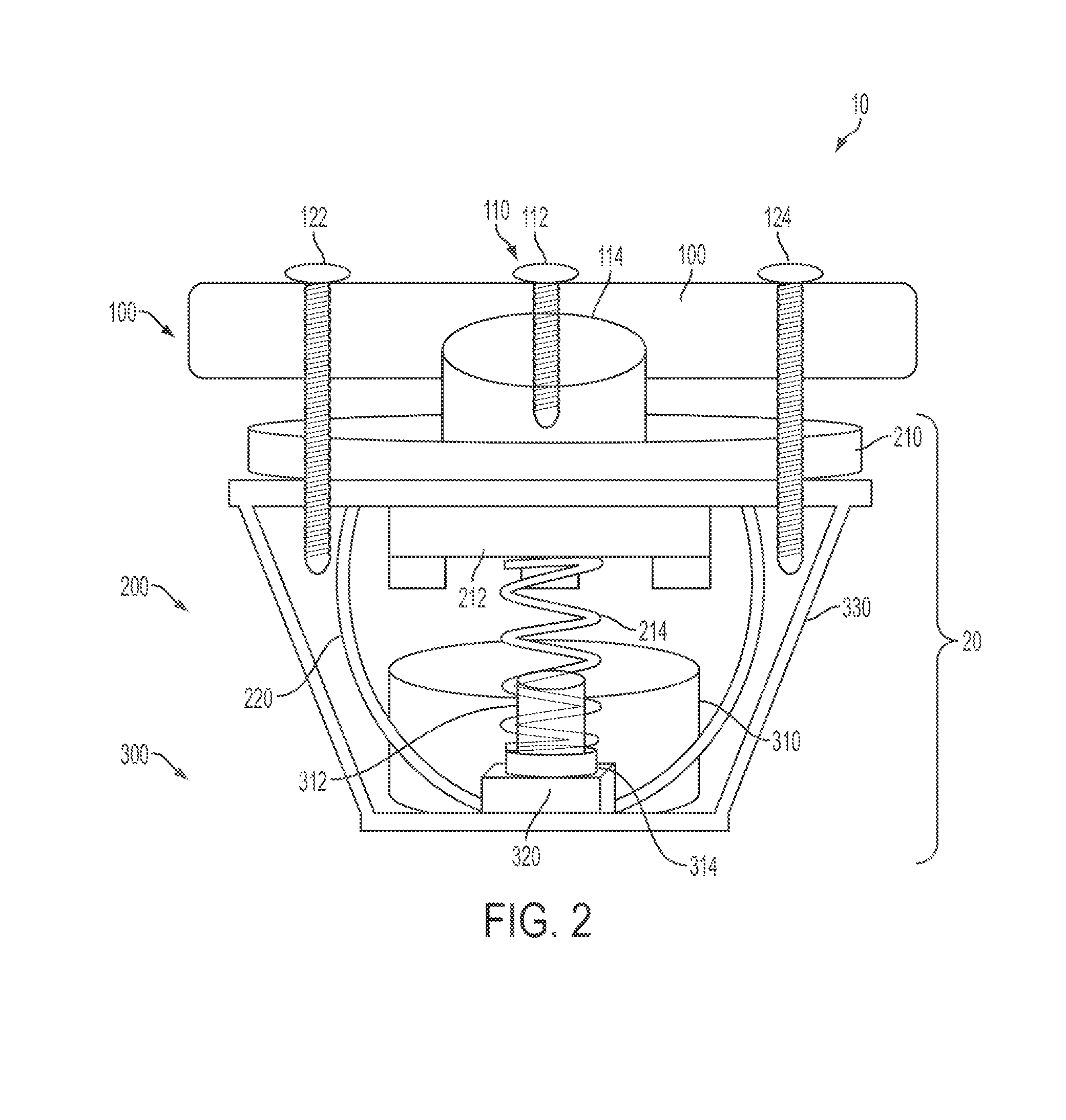

Plank soft mode forming device and method based on magnetorheological elastomers

The invention peovides a plank soft mode forming device and method based on magnetorheological elastomers, relates to a plank soft mode forming device and method, and solves the problem that the rubber performance of the conventional rubber soft mode can not be changed during forming process. The device provided by the invention is characterized in that a holding frame is arranged opposite to a die in an up and down manner, the head of a plunger piston is positioned in the inner cavity of the holding frame, the lower surface of the plunger piston is filled with a magnetorheological elastomer, and the outer sidewalls of the holding frame and the die are sleeved and mounted with coils. The method provided by the invention comprises the following steps: firstly, placing the to-be-formed plank between the lower surface of the holding frame and the die; secondly, determining the magnetic field strength B in work area according to the shape of the to-be-formed plank and the size of the elastic modulus of magnetorheological elastomer needed at each stage in forming; thirdly, connecting the coil with a direct current, enabling the magnetic field strength of the magnetorheological elastomer area to be changed by adjusting the current, and enabling the to-be-formed plank to form the needed shape under proper elasticity modulus of the magnetorheological elastomer; and fourthly, taking out the formed parts. The method provided by the invention is used for plank soft mode forming.

Owner:HARBIN INST OF TECH

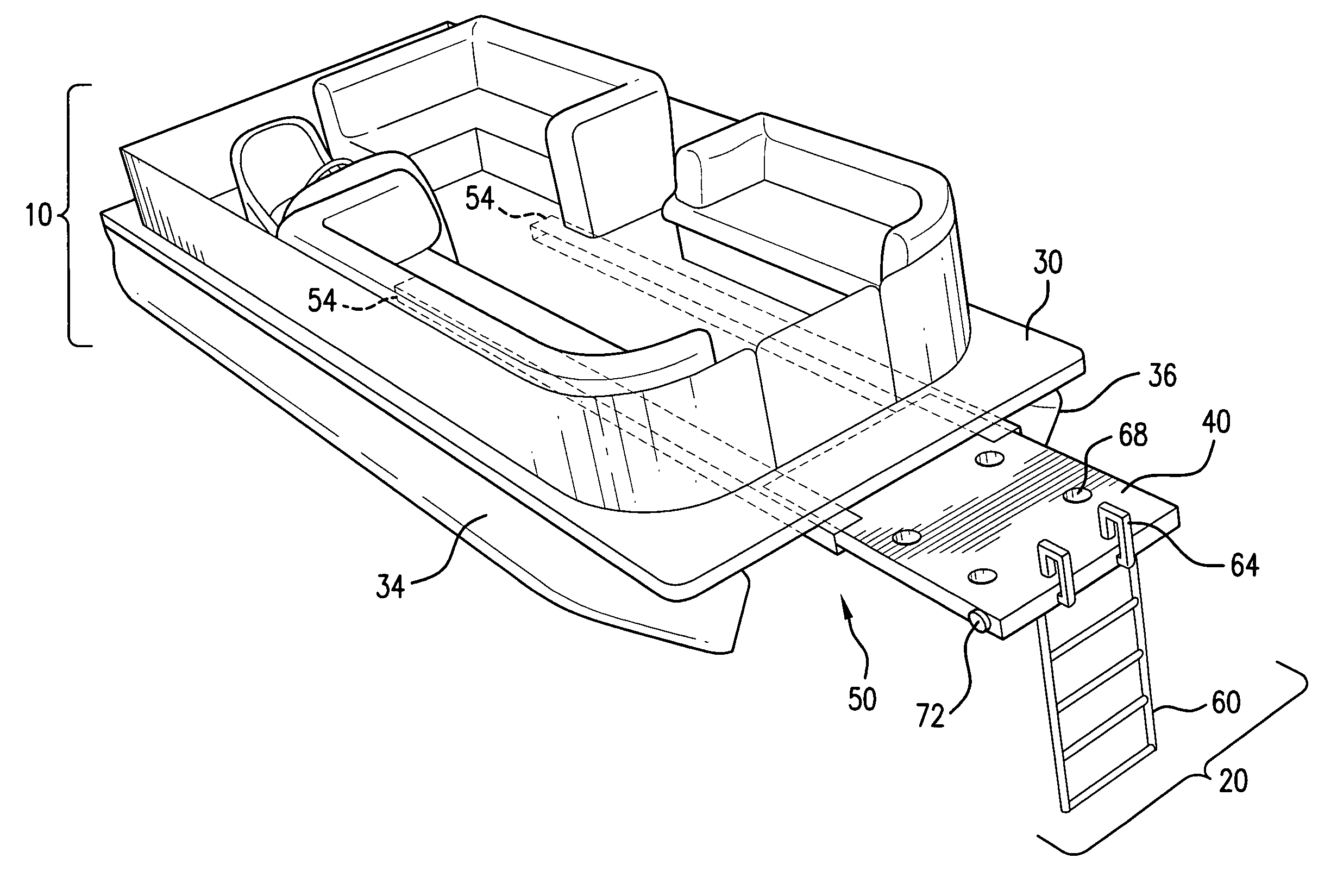

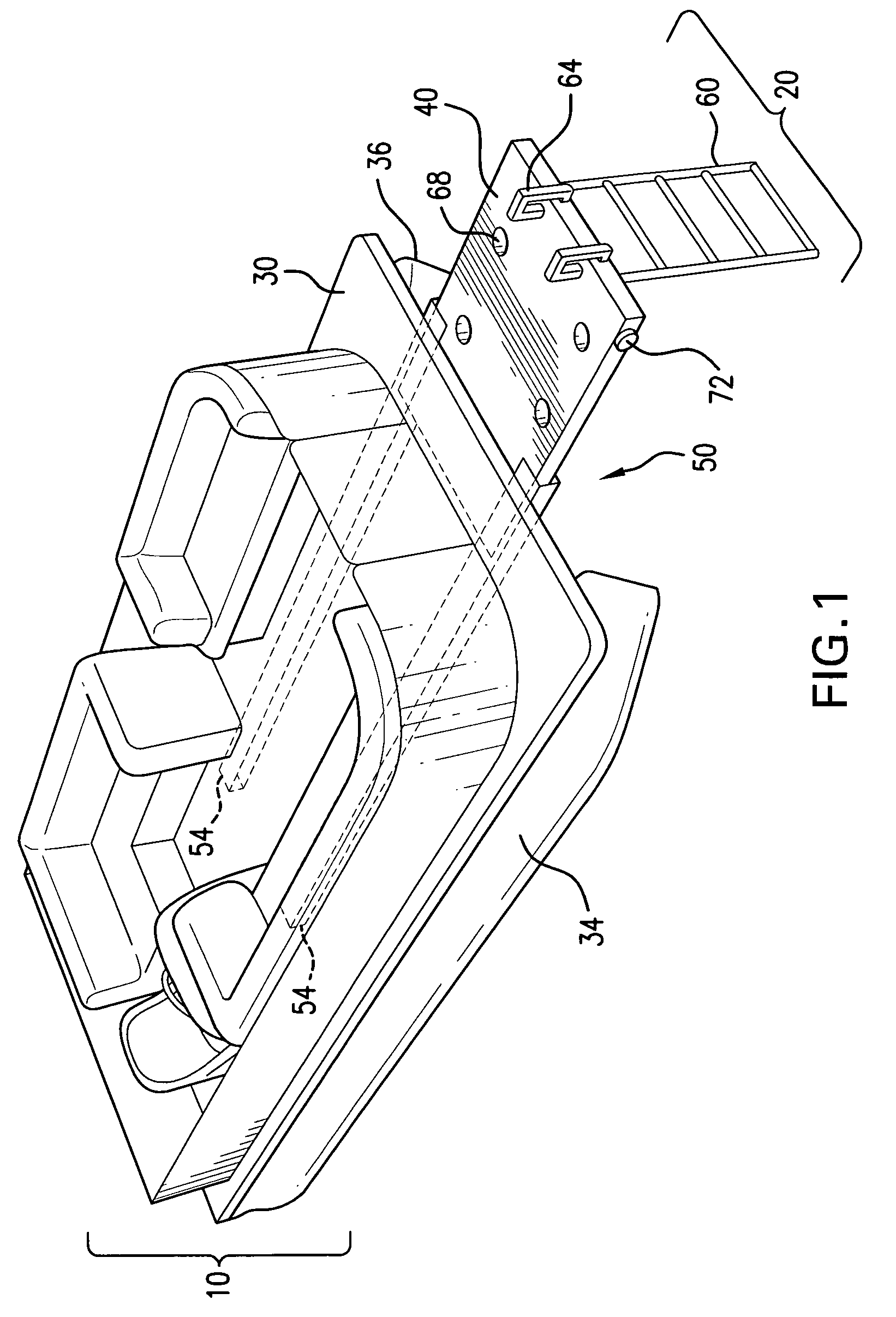

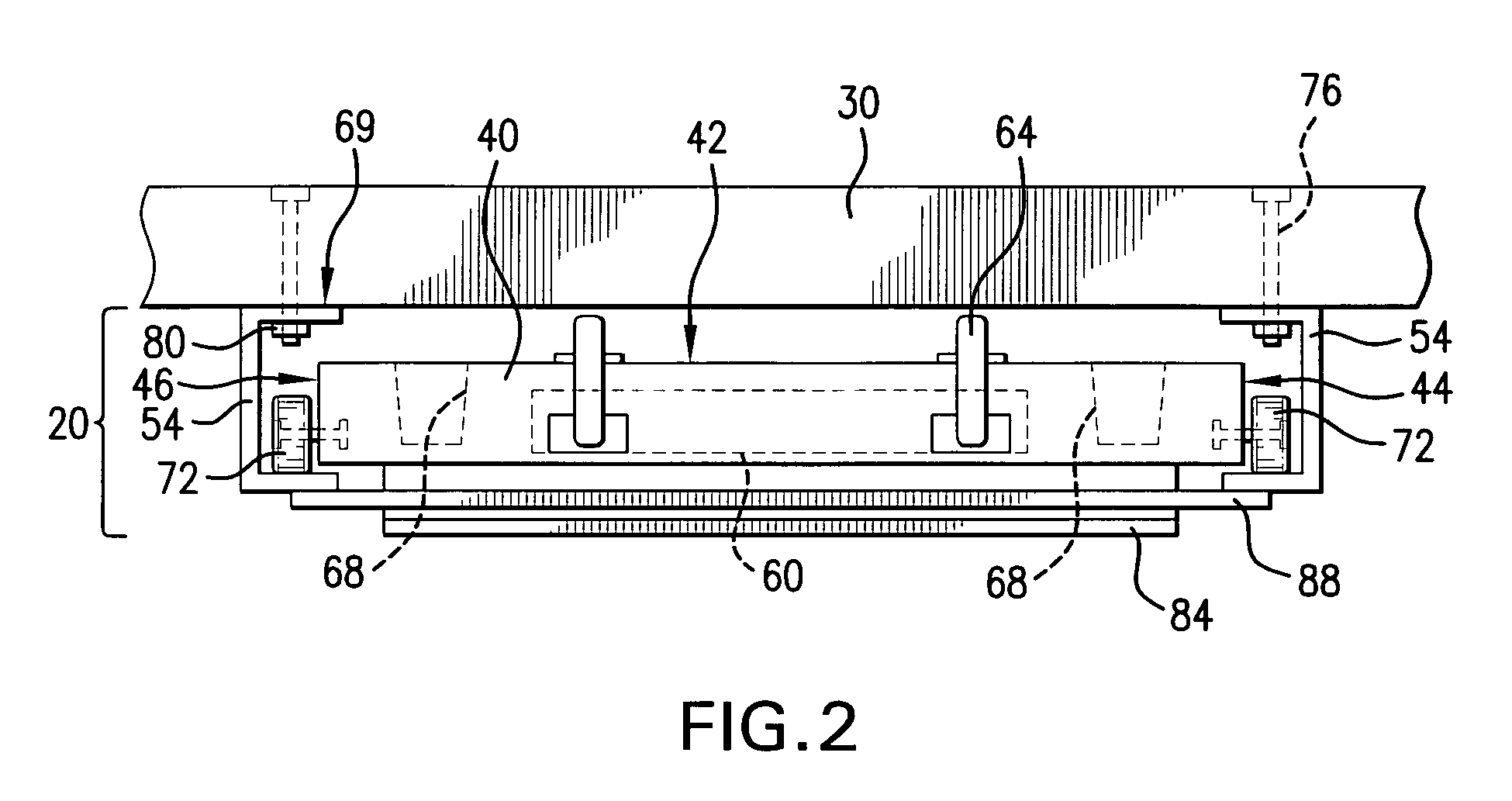

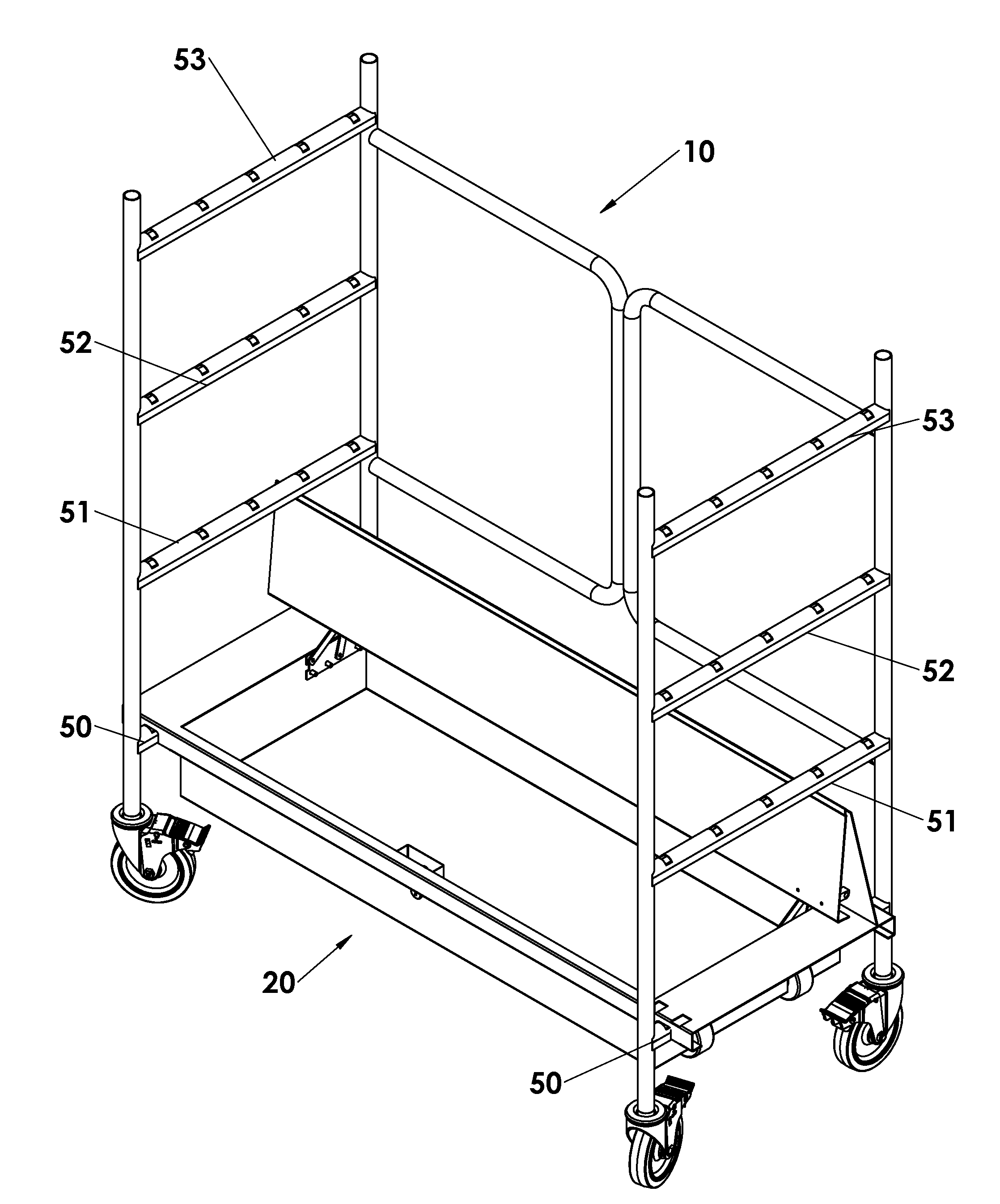

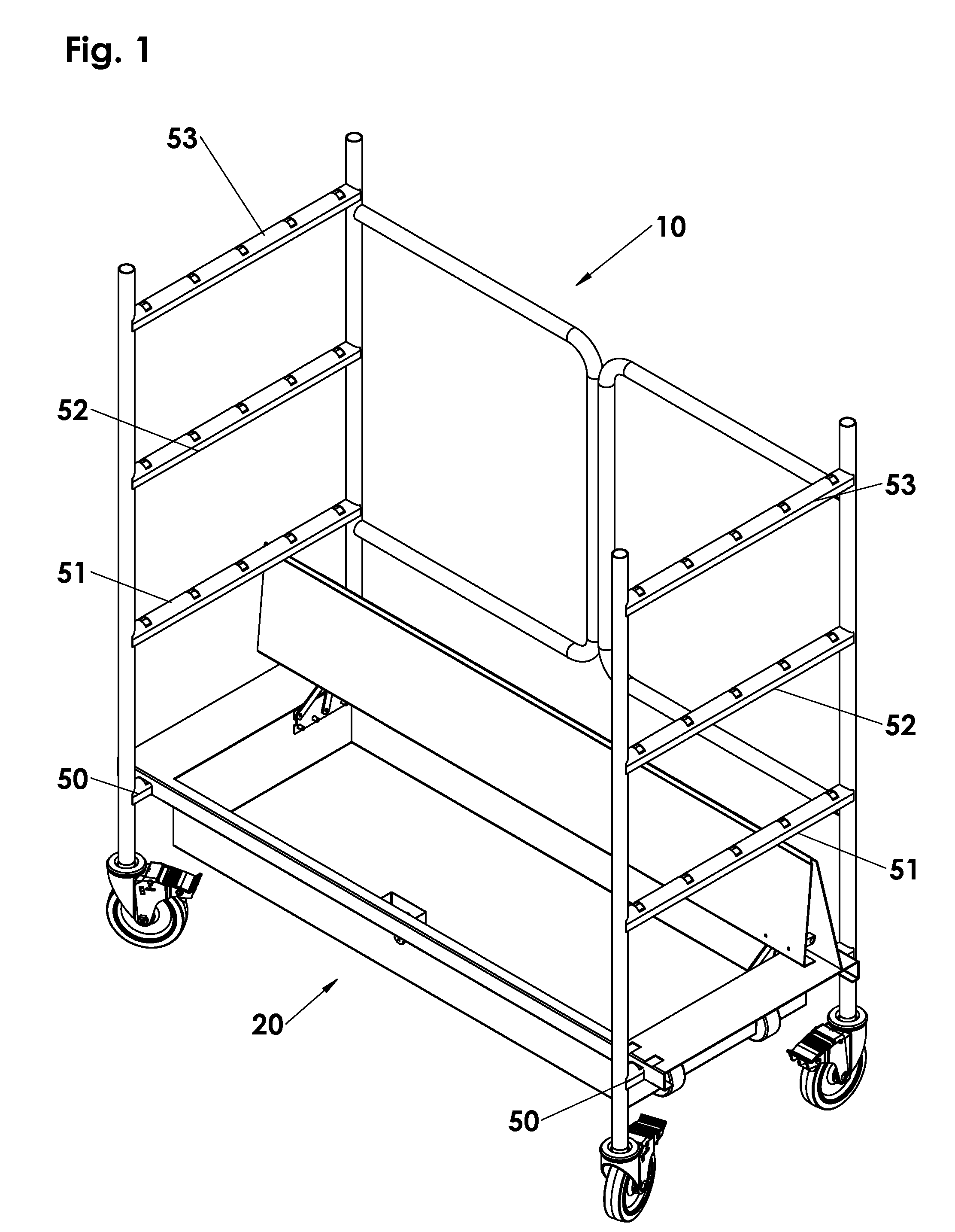

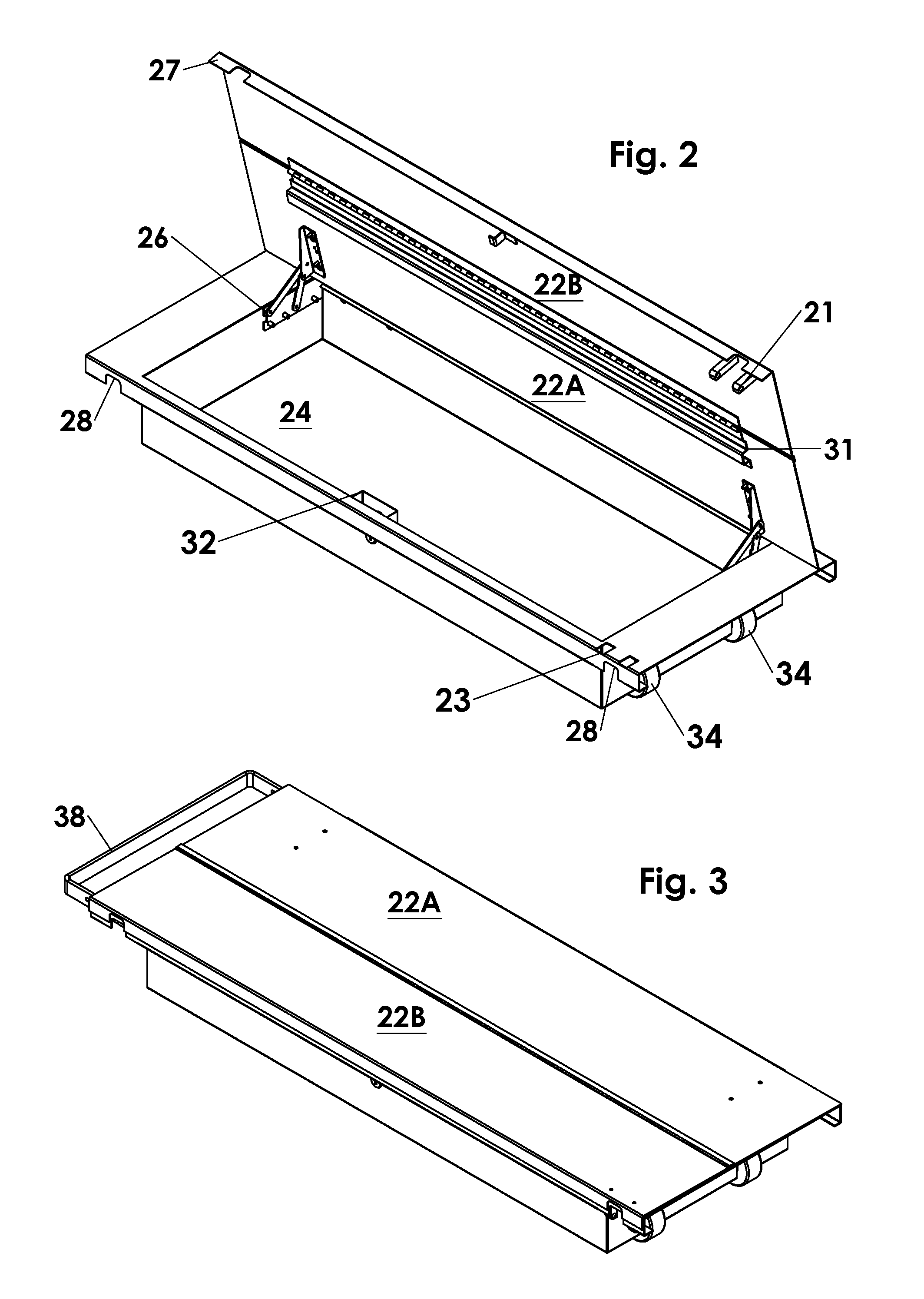

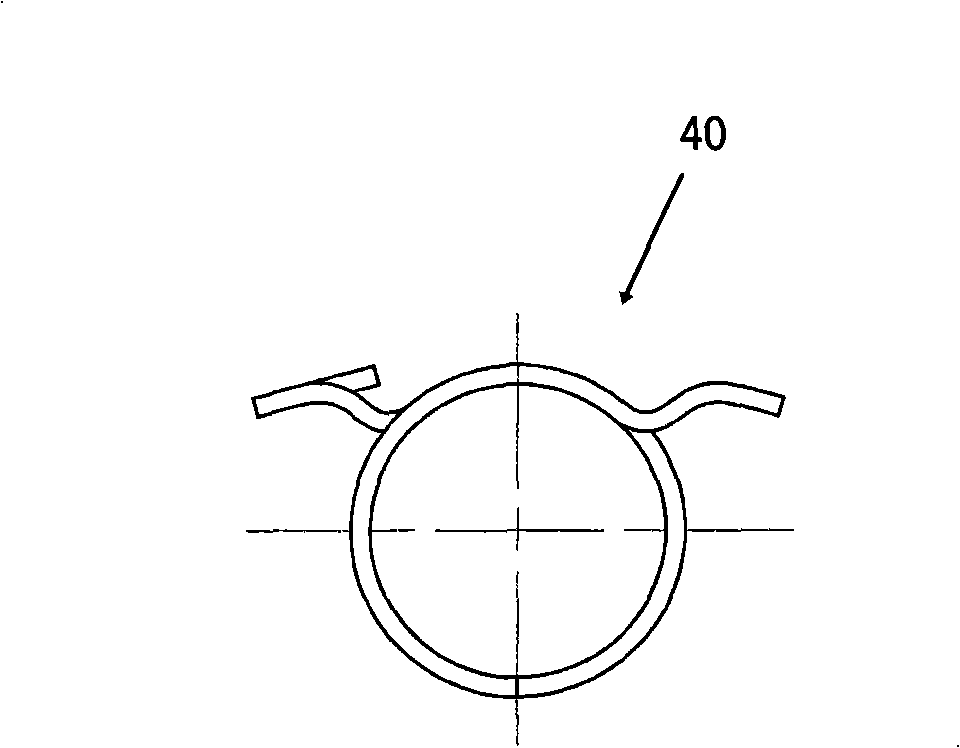

Floating deck apparatus for a pontoon boat

ActiveUS8056496B1Easy to manufactureEasy accessCargo handling apparatusRaftsEngineeringMarine engineering

A floating deck apparatus (20) includes a plank (40), a pair of tracks (54), a ladder (60), and a pair of handles (64). Each track (54) is coupled to the underside of a boat platform. The pair of tracks rollingly supports the plank (1) in a storage position, (2) in a deck position, and (3) in a ramp position. A proximal stop (88) across the proximal ends (62) of the tracks (54) stops the plank (40) in the ramp position. A distal stop bar (89) across the distal ends (66) of the tracks (54) stops the plank (40) in the storage position. The ladder (64) is movably coupled to the bottom (105) of the plank (40) and pivots from (1) a swimming position to (2) a storage position. The pair of handles (64) is mounted to the plank top (42) or to the plank proximal end (48).

Owner:BUSSA PATTI

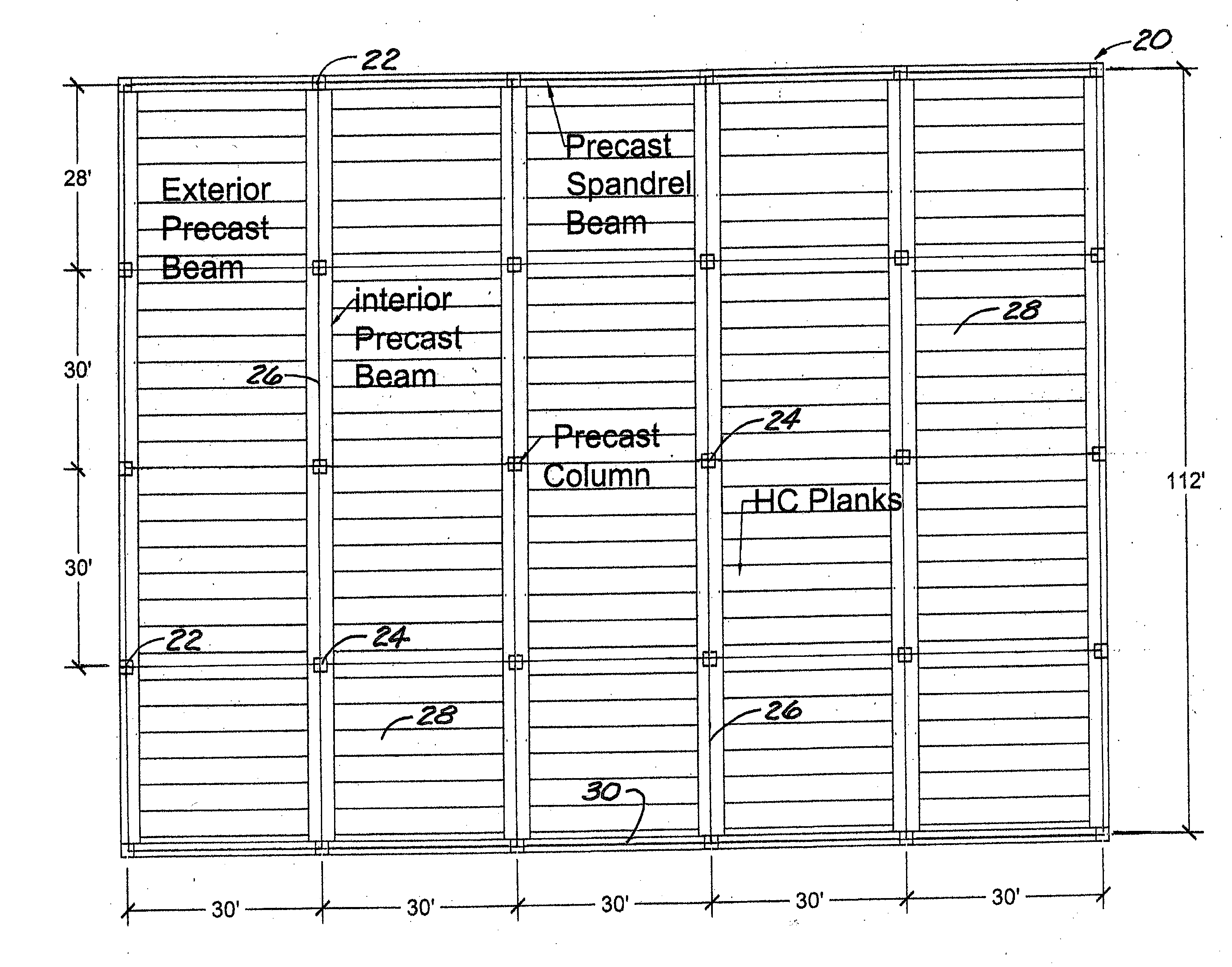

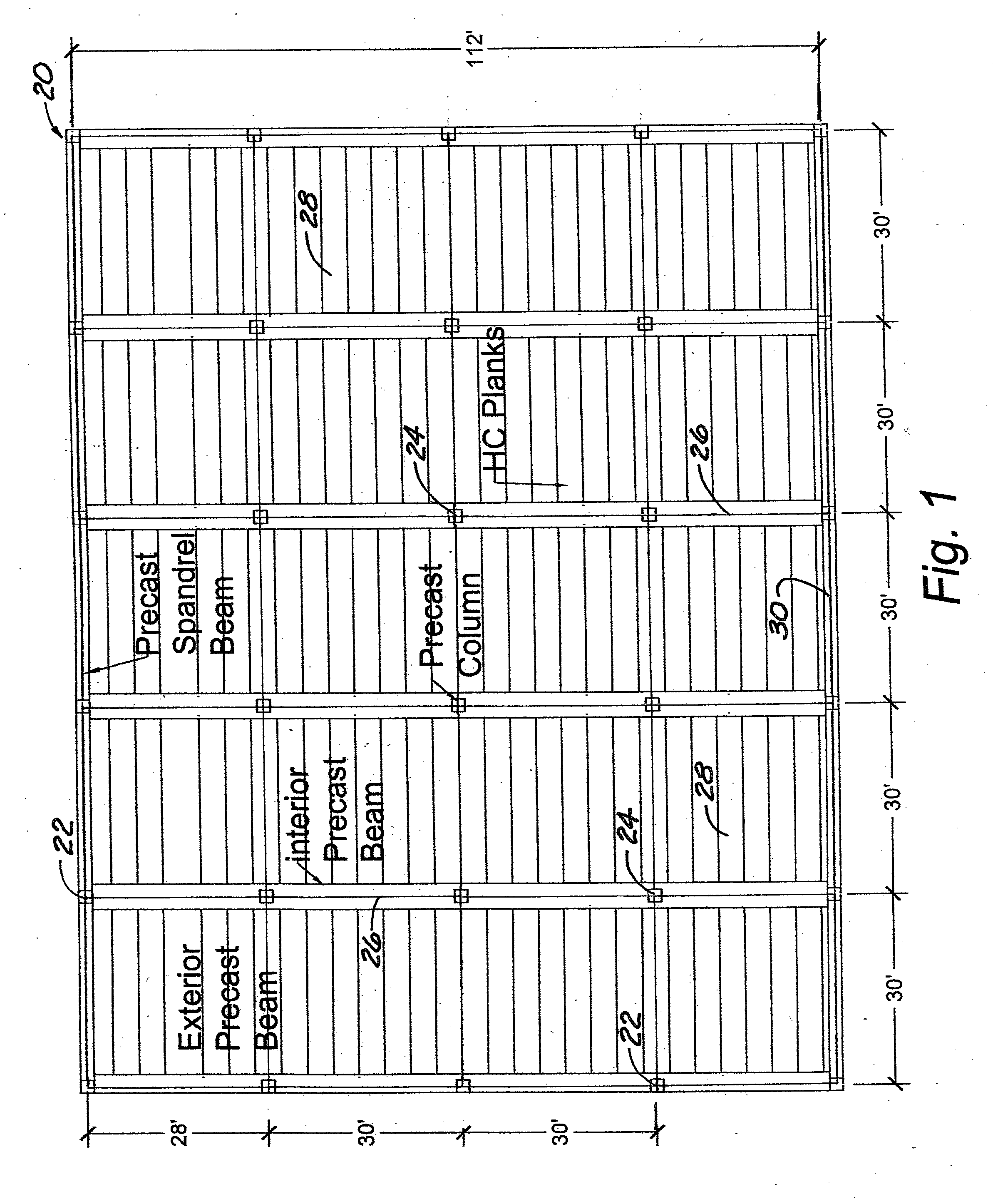

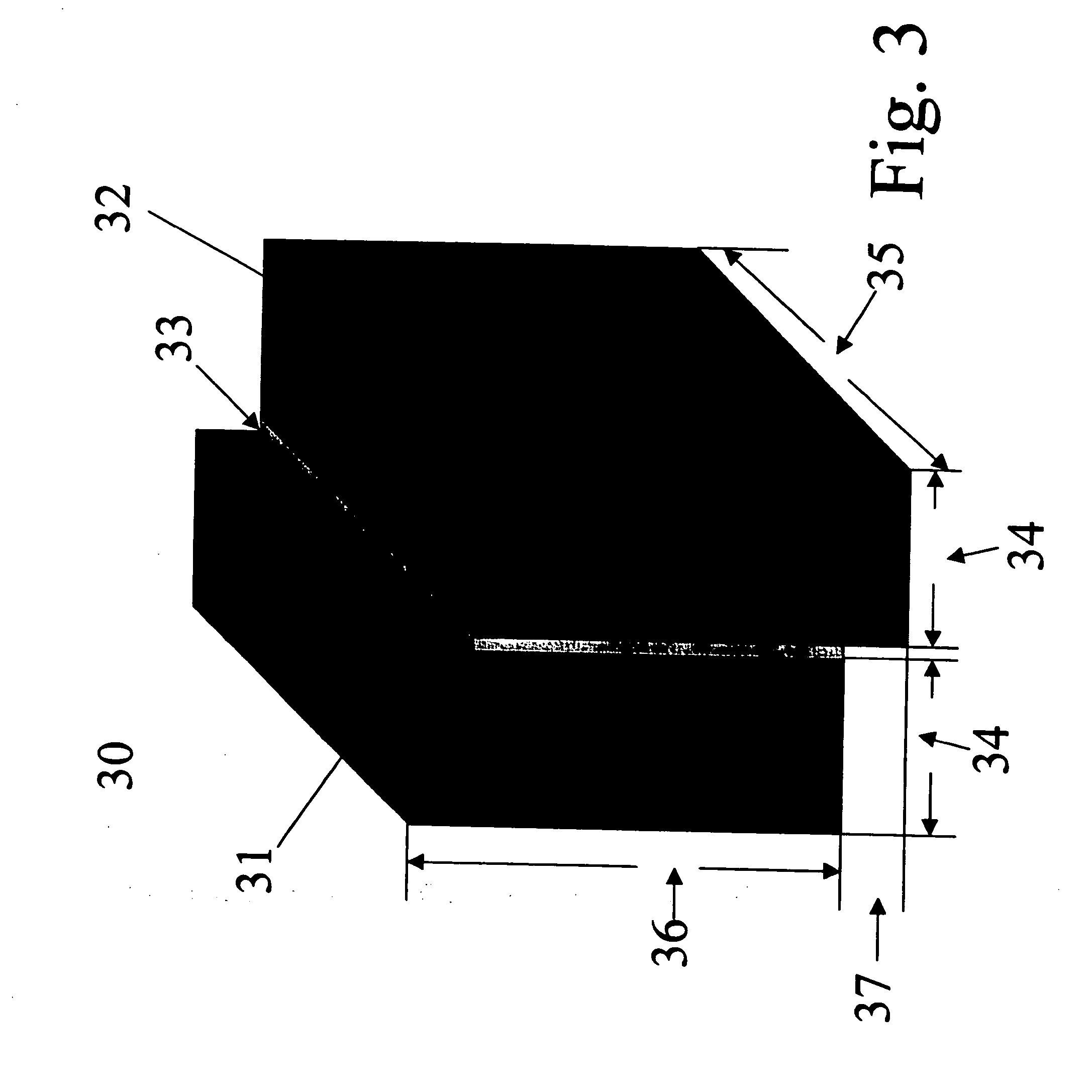

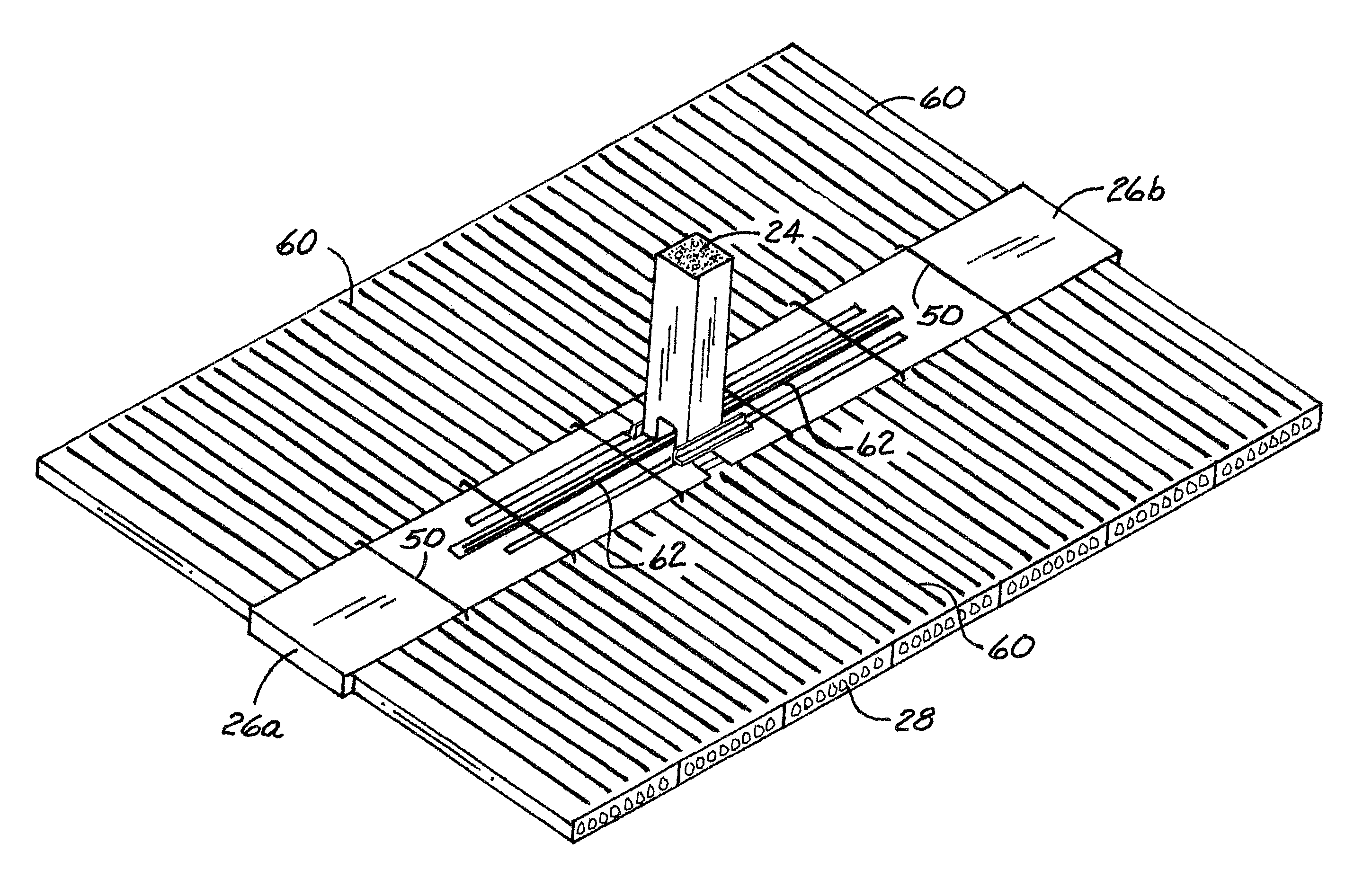

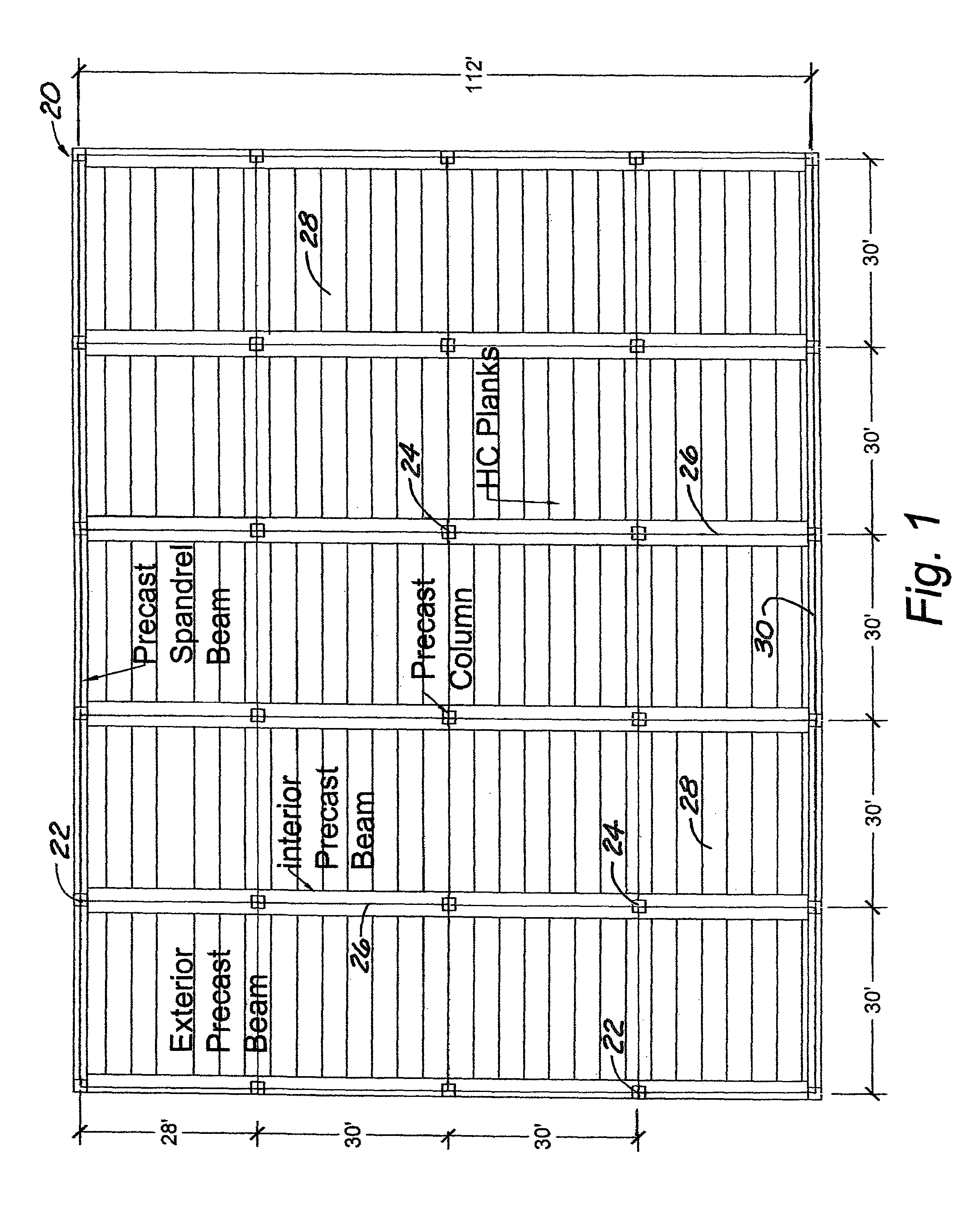

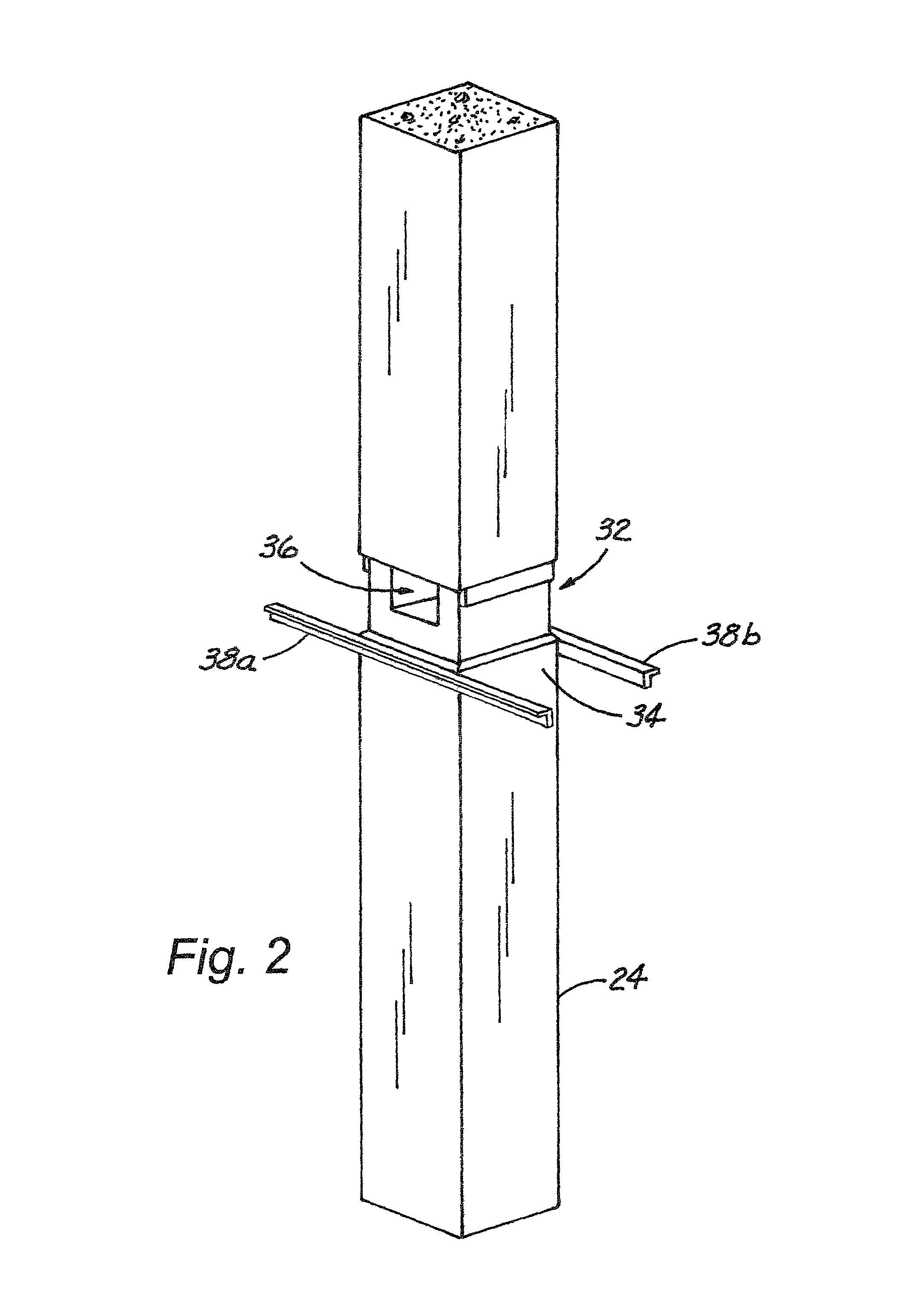

Shallow Flat Soffit Precast Concrete Floor System

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

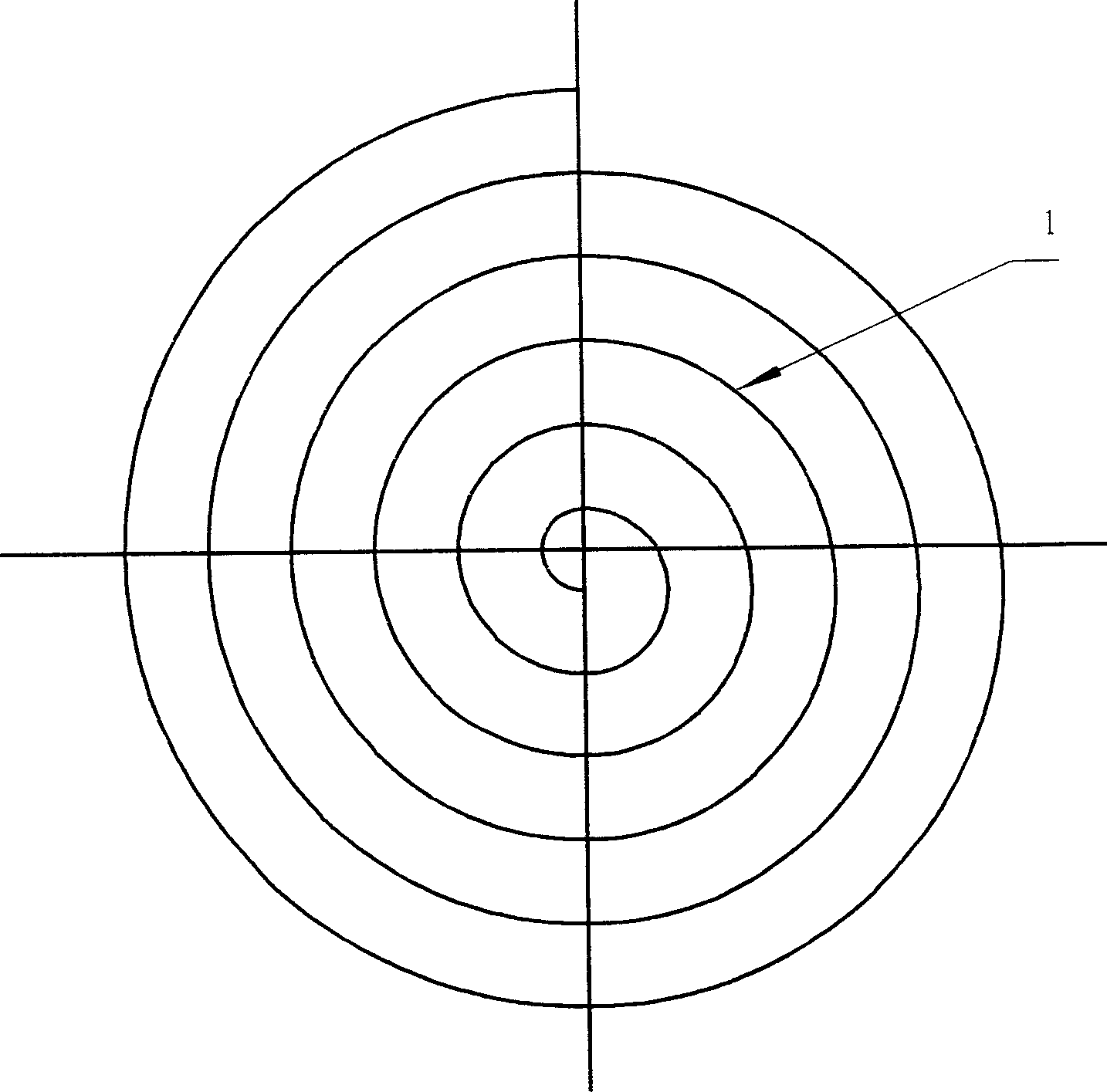

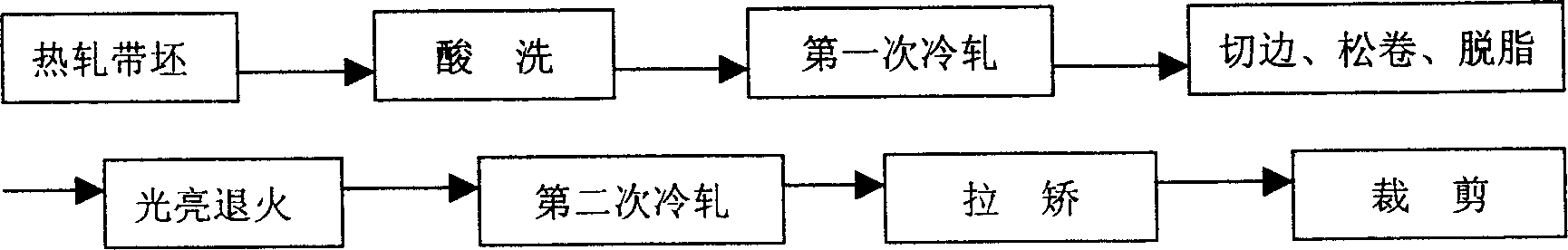

High-precision very-thin special-wide cold-rolled steel band and its working process

This present invention relates to a craftwork of very thin and very wide cold rolling steel band with high precision and its application. It belongs to a battery pole base plank material field. The acid cleaned hot steel rolling is cold rolled by the first rolling, then cut margin, degrease and anneal heat treatment. After cold rolled to 0.035-0.055mm by the second rolling and extended, bended, it can be cut out to finished product with client's demand. This invention has the virtues of simple and low cost. The latter disposal is simple and easy to master for company.

Owner:YONGXIN PRECISION MATERIAL WUXI

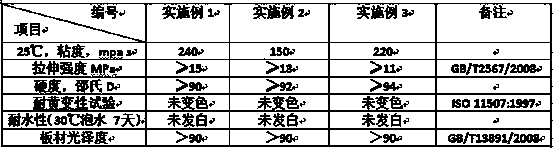

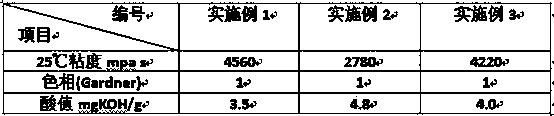

Photo-curable resin composition for repairing facing marble plank and preparation and using method of photo-curable resin composition

InactiveCN104212396ACuring reaction is gentleRealize energy savingPolyureas/polyurethane adhesivesModified epoxy resin adhesivesPolymer sciencePlasticizer

The invention relates to a photo-curable resin composition for repairing a facing marble plank. The photo-curable resin composition comprises the following components in percentage by total weight being 100%: 70-92% of epoxy acrylate or modified epoxy acrylate, 5-30% of reactive diluent, 0-10% of plasticizer, 0.1-3% of photoinitiator and 0-20% of filler The composition is used for spraying or scraping the surface of the plank, can be fast cured by being irradiated by an ultraviolet light source or sunlight to realize repair enhancement and has the characteristics of fast construction speed, energy conservation, good grinding and polishing effects and the like.

Owner:HUNAN KOSEN NEW MATERIAL

Structural building elements having pressure-sensitive adhesive

A building element having pressure-sensitive adhesive coating layer having a low initial bond strength, to permit a substrate to be repositioned without destroying the integrity of the adhesive, and a long term bond strength, which occurs after the building element is mechanically fastened to another building element. This allows wood deck components, flooring planks, roofing tiles, and other building material components to be fastened together conveniently while securing a waterproofing and / or sound-deadening effect.

Owner:WR GRACE & CO CONN

Floating island on sea and detachable hanging bridge and plank house affiliated thereto

InactiveCN101992841AReduce construction costsVessels for aircraftPublic buildingsShoreFloating island

The invention provides a 'floating island on the sea and a detachable hanging bridge and a plank house affiliated thereto', which is characterized in that the floating island is composed of floating island units, the facilities such as the hanging bridge and the plank house can be installed, exchanged and detached on the floating island, the inventive product carries large weight, and does not limit laying positions, has wide application field (such as installing and detaching the lank house with various functions, and satisfying demands of humans in resident and exercise aspects). The technology of the invention has wide market prospect and important application value in the technology files of management and improvement of nearshore water area zoology environment, laying 'land above sea' of a shore city, laying 'land above sea' of sea water area, load connection over gully and fast construction of simple houses, especially national military logistics and military equipment in the spratly dispute.

Owner:谭健苗

Automated apparatus for constructing assemblies of building components

ActiveUS9353519B2Stapling toolsProgramme-controlled manipulatorMechanical engineeringStructural element

A system for constructing wall panels comprising a plurality of structural members includes: a source of structural members of predetermined size; a horizontal table configured to support planks as they are being formed into a wall panel, the table including a stationary section and a movable carriage that is configured to move in a longitudinal direction toward and away from the stationary section; an articulated arm unit having a gripper, the articulating arm unit positioned to retrieve boards from the source with the gripper and place them on the table; at least one first clamping unit mounted to the stationary section for clamping structural members thereto; at least one second clamping unit mounted to the movable carriage for clamping structural members thereto; and a controller that controls the movement of the articulating arm unit and the movable carriage.

Owner:WILLIAMS ROBOTICS

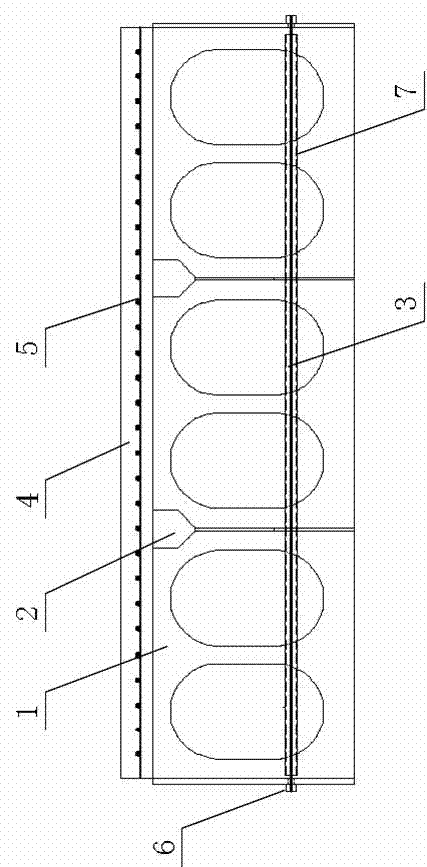

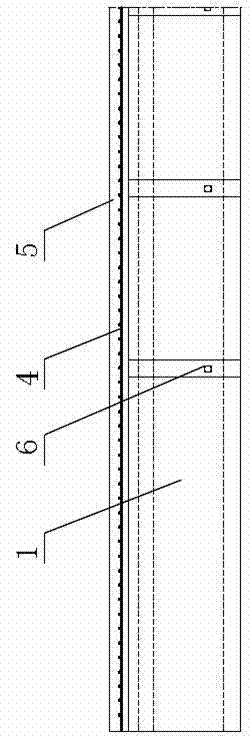

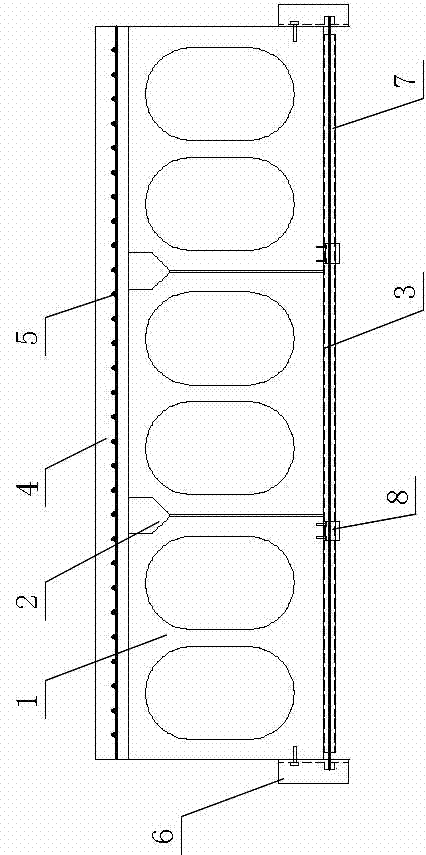

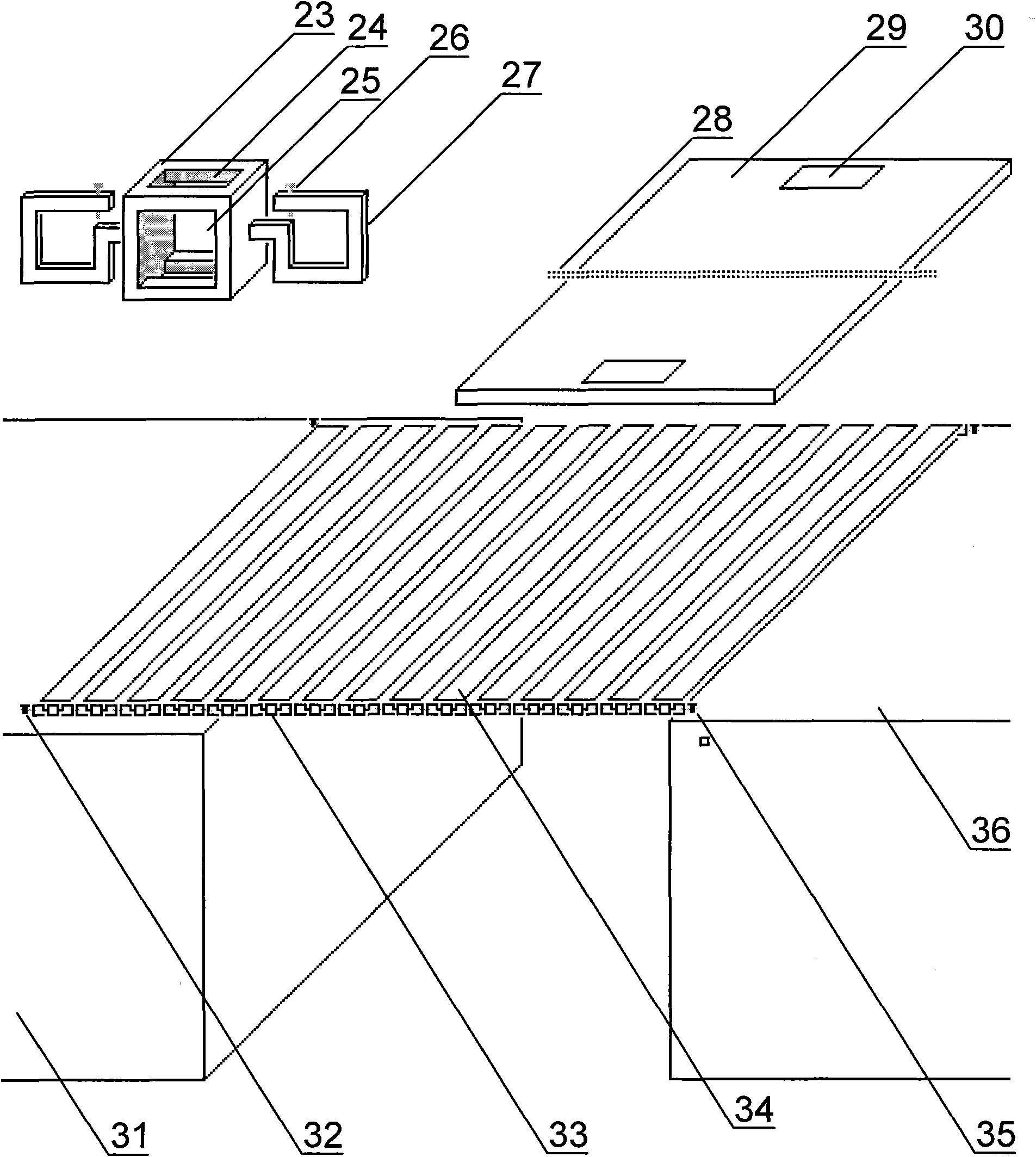

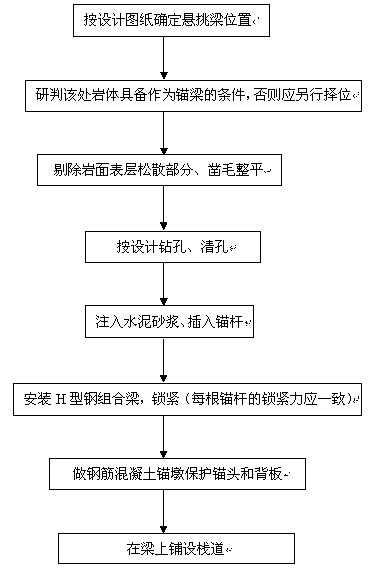

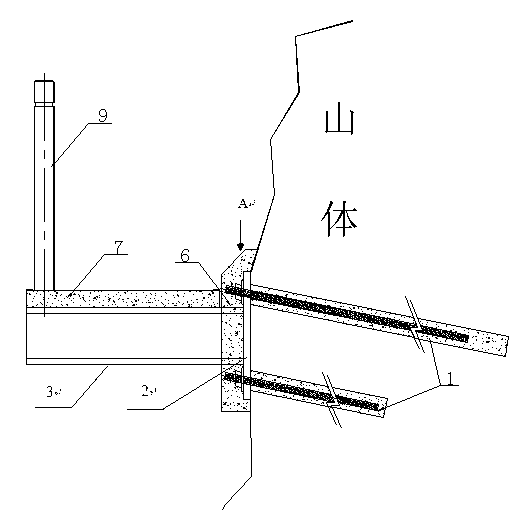

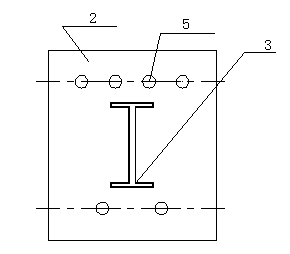

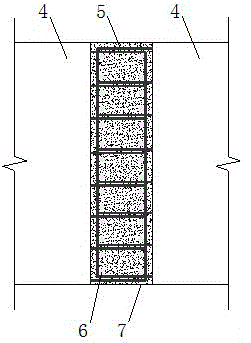

Cantilever beam structure of antique plank road along cliff and construction technology thereof

The invention discloses a cantilever beam structure of an antique plank road along a cliff and a construction technology thereof. The cantilever beam structure is formed by an H-type steel assembly, and a rock bolt assembly fixedly anchored on the rock wall of a mountain in a combining way, wherein the H-type steel assembly is formed by the combination of a steel backing plate (2) and H-type steel (3); the H-type steel (3) is welded on the steel backing plate (2) vertically and serves as the supporting beam of a road panel (7) of the antique plank road along the cliff; the rock bolt assembly is formed by the connection of rock bolts (1), bolts and nuts; and the rock bolts (1) are welded with the bolts in a surfacing manner. The construction technology of the cantilever beam structure is as follows: ensuring the position of the cantilever beam according to the design graph paper; eliminating the weathering surface and fractured rock mass of the locating-point rock surface, and scabbling and leveling; ensuring the length of the rock bolts (1) and drilling holes in the rock bolts; filling cement mortar into the rock bolt holes and inserting the rock bolts (1) welded with anchor heads; mounting the H-type steel assembly on the rock bolts after the cement mortar is solidified to a degree of the designed strength; and fastening with bolts. The cantilever beam structure is safe and reliable in structure, simple and convenient in construction technology, quick in speed, low in engineering cost, and good in simulating of the style of the antique, and is suitable for application along the cliff.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Shallow flat soffit precast concrete floor system

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Interlocking scaffold plank

A composite scaffold plank for resting on two spaced, substantially parallel horizontal scaffold support members. The plank has an elongated planar panel with elongated reinforcing ribs mounted at a lateral edge substantially perpendicularly to the second major surface of the planar panel. The reinforcing ribs are substantially parallel and equally spaced from one another. There are notches defining tabs at each end of the planar panel that form a finger joint with another similar plank abutting the plank's end. Transverse channels formed in the ribs fit over the frame's horizontal support members.

Owner:PALLTECH IND

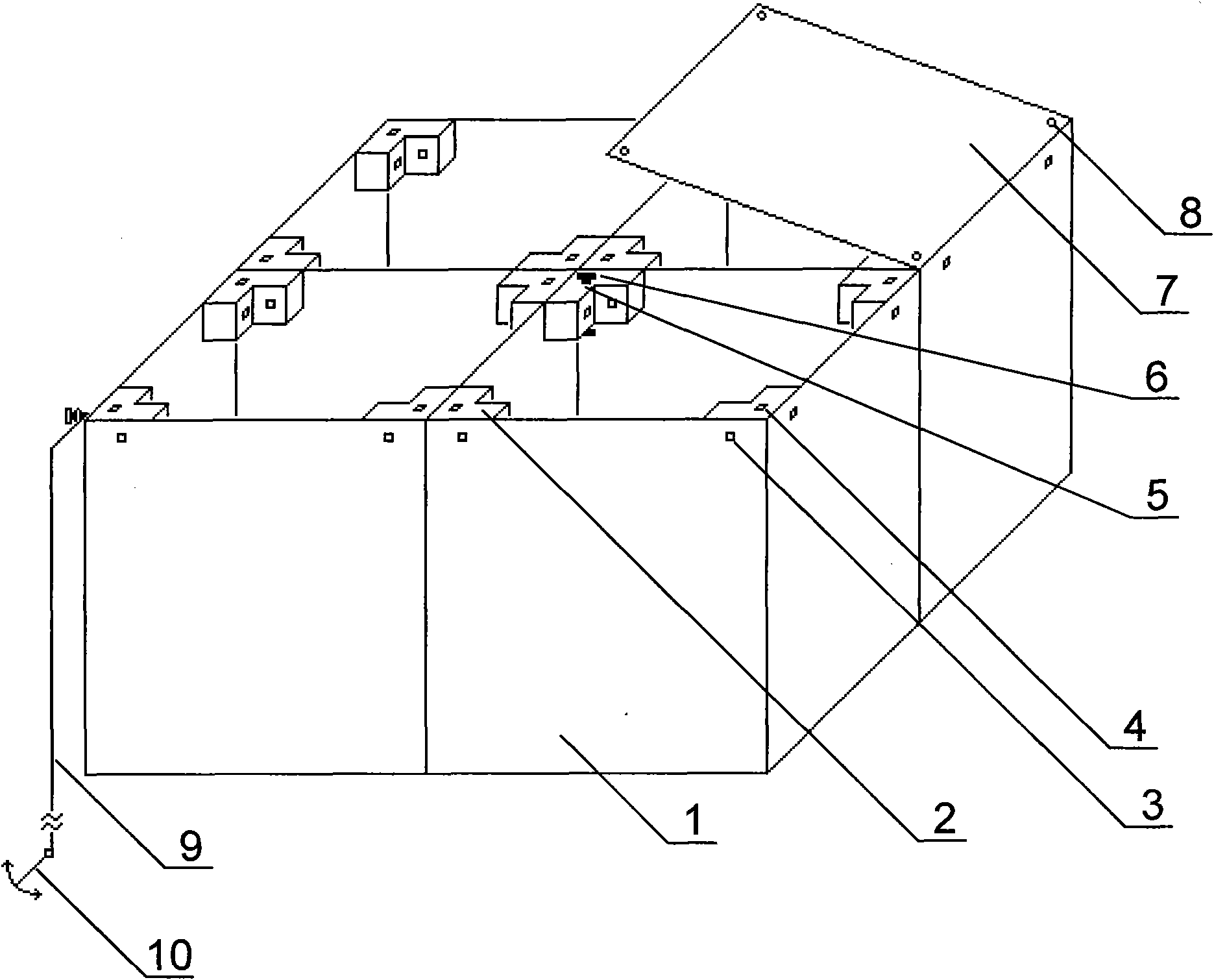

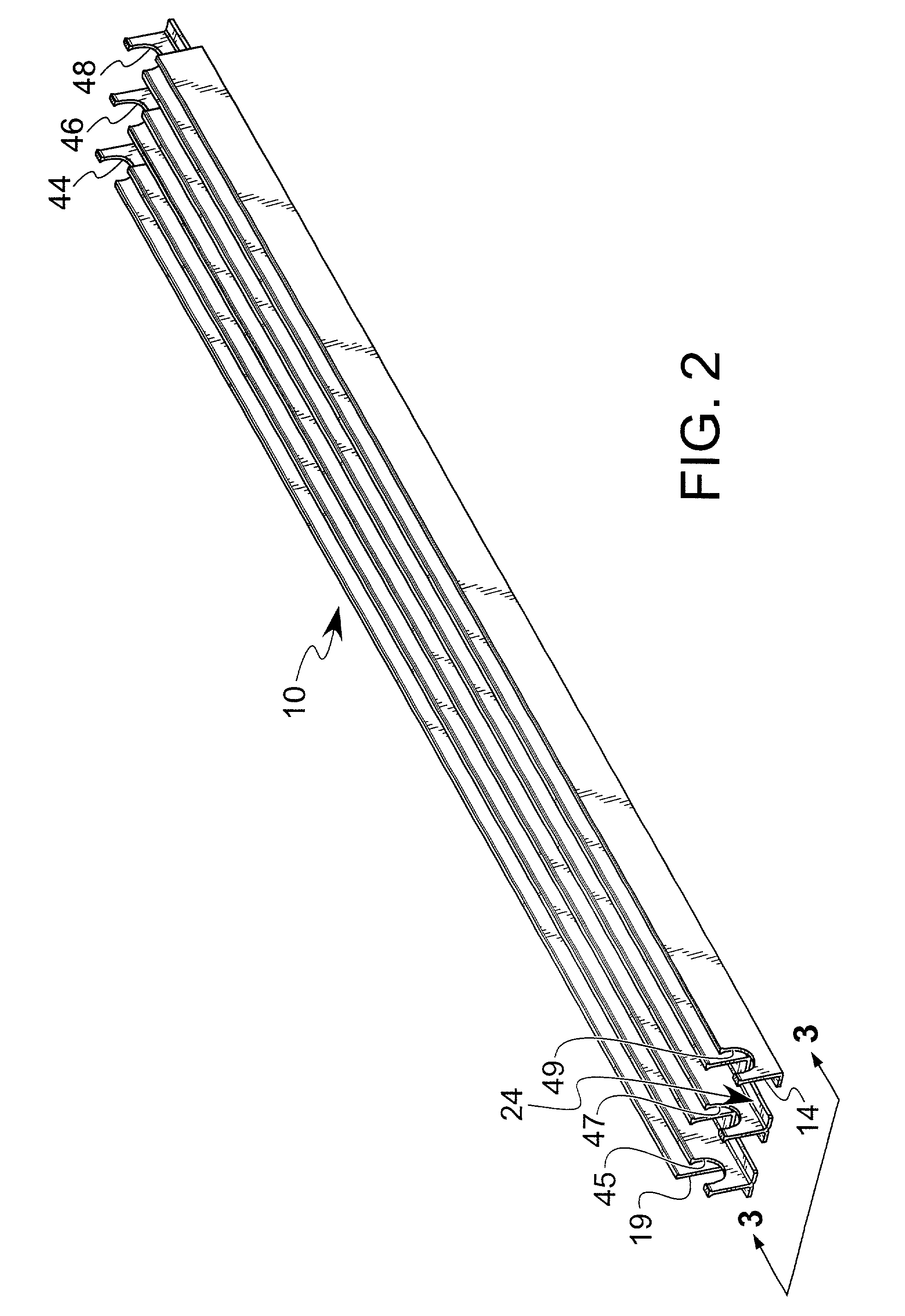

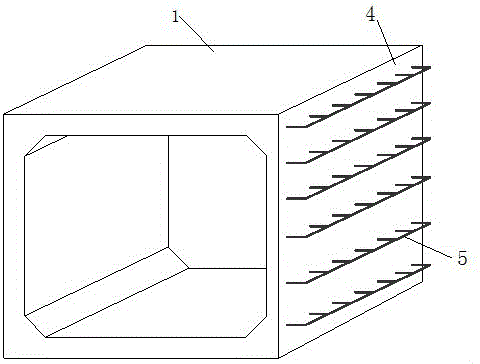

Transverse laminated connection type single compartment precast multiple-compartment assembled comprehensive pipe gallery

InactiveCN105756089AImprove integrityImprove waterproof performanceArtificial islandsUnderwater structuresPre stressPlank

The invention relates to a precast concrete plank type comprehensive pipe gallery used in urban municipal engineering. The precast concrete plank type comprehensive pipe gallery is composed of a side-span precast concrete cabin 1, a mid-span precast concrete cabin 2 and a laminated side wall 3. According to the comprehensive pipe gallery, after each precast cabin is fastened by a bolt in the longitudinal direction or subjected to prestressed tension shaping and is connected into a whole in the transverse direction through the laminated side wall 3. According to the side spans and mid-spans of different sizes and different numbers, the precast concrete cabins can be combined to form the multi-compartment comprehensive pipe gallery meeting different requirements.

Owner:上海同预建筑科技有限公司

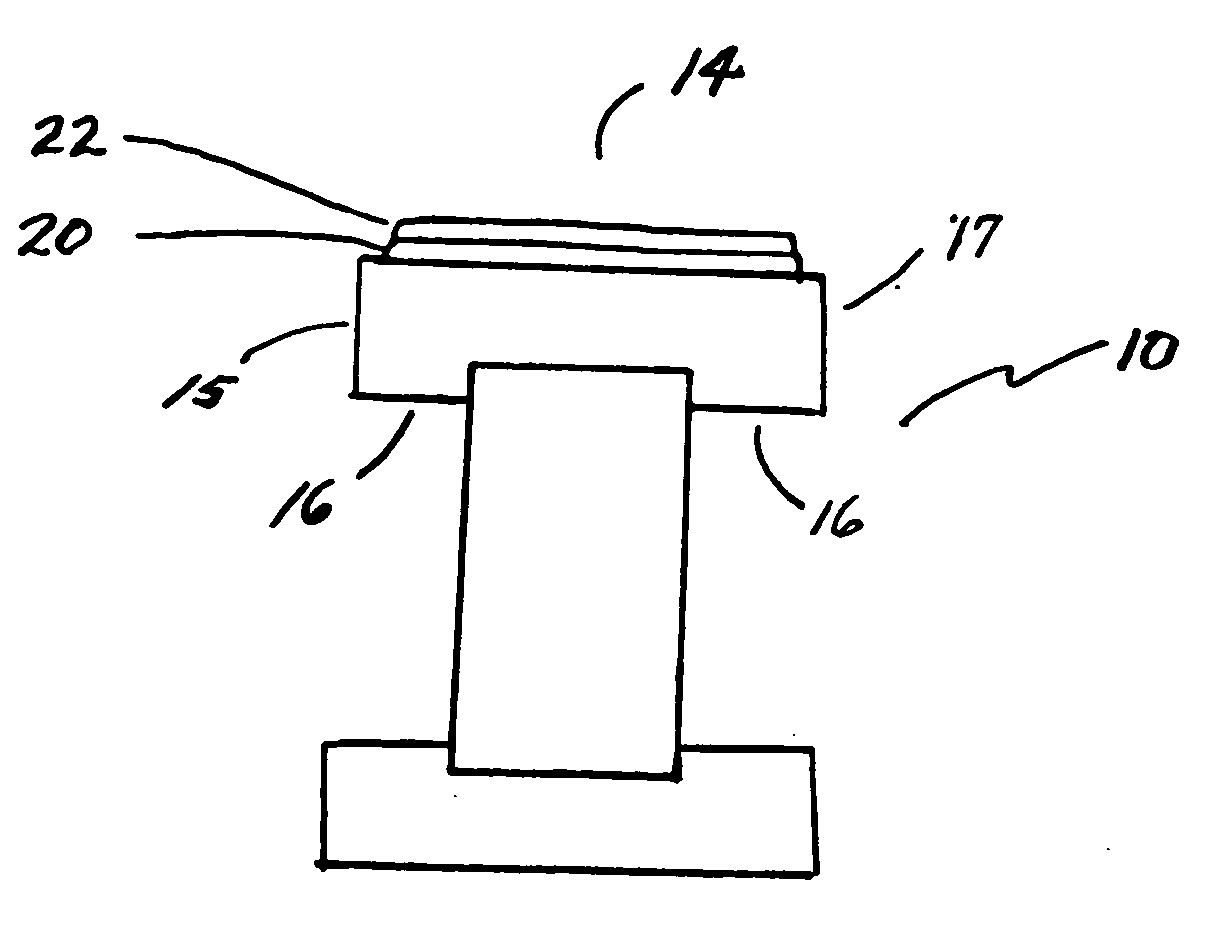

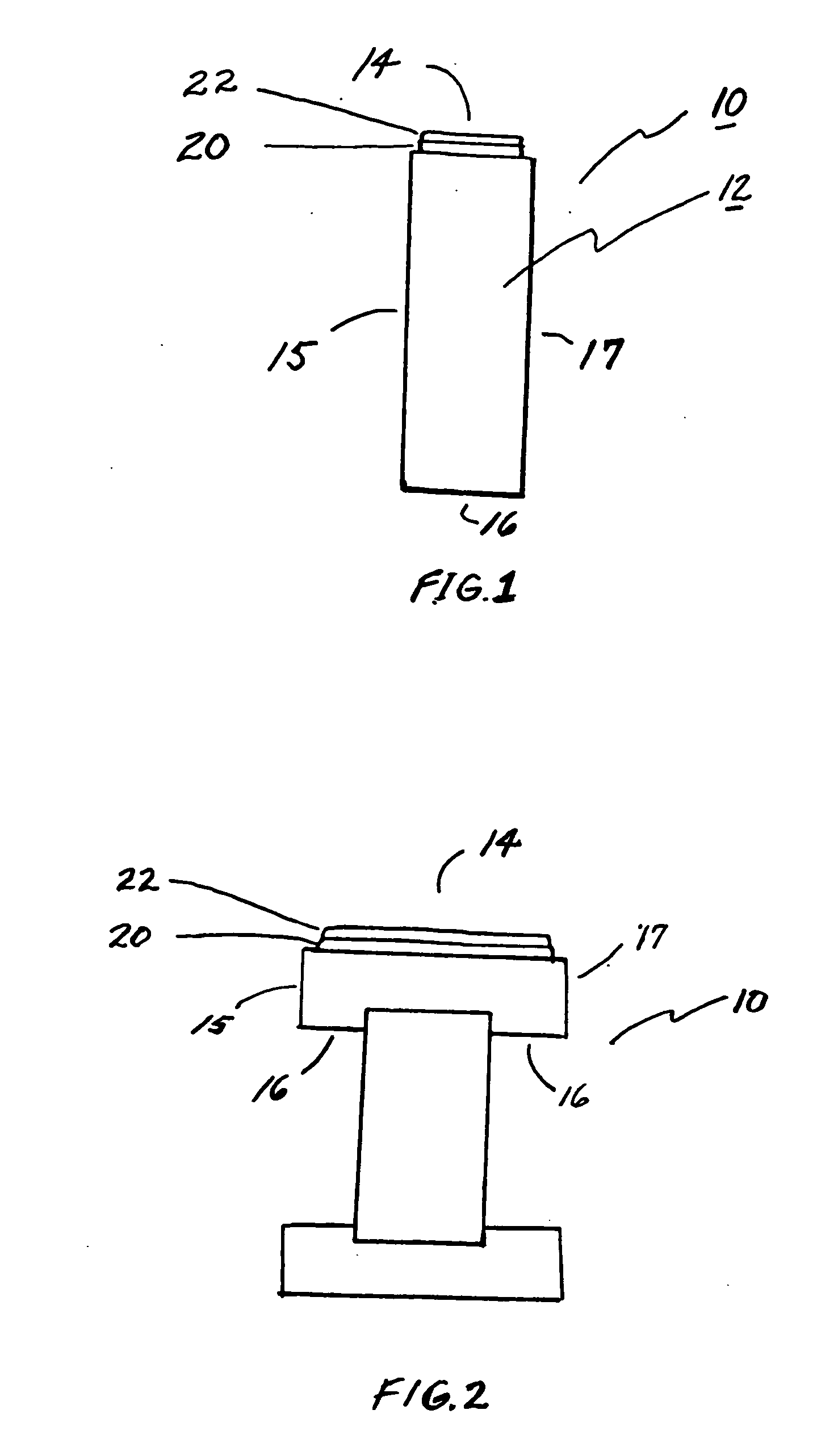

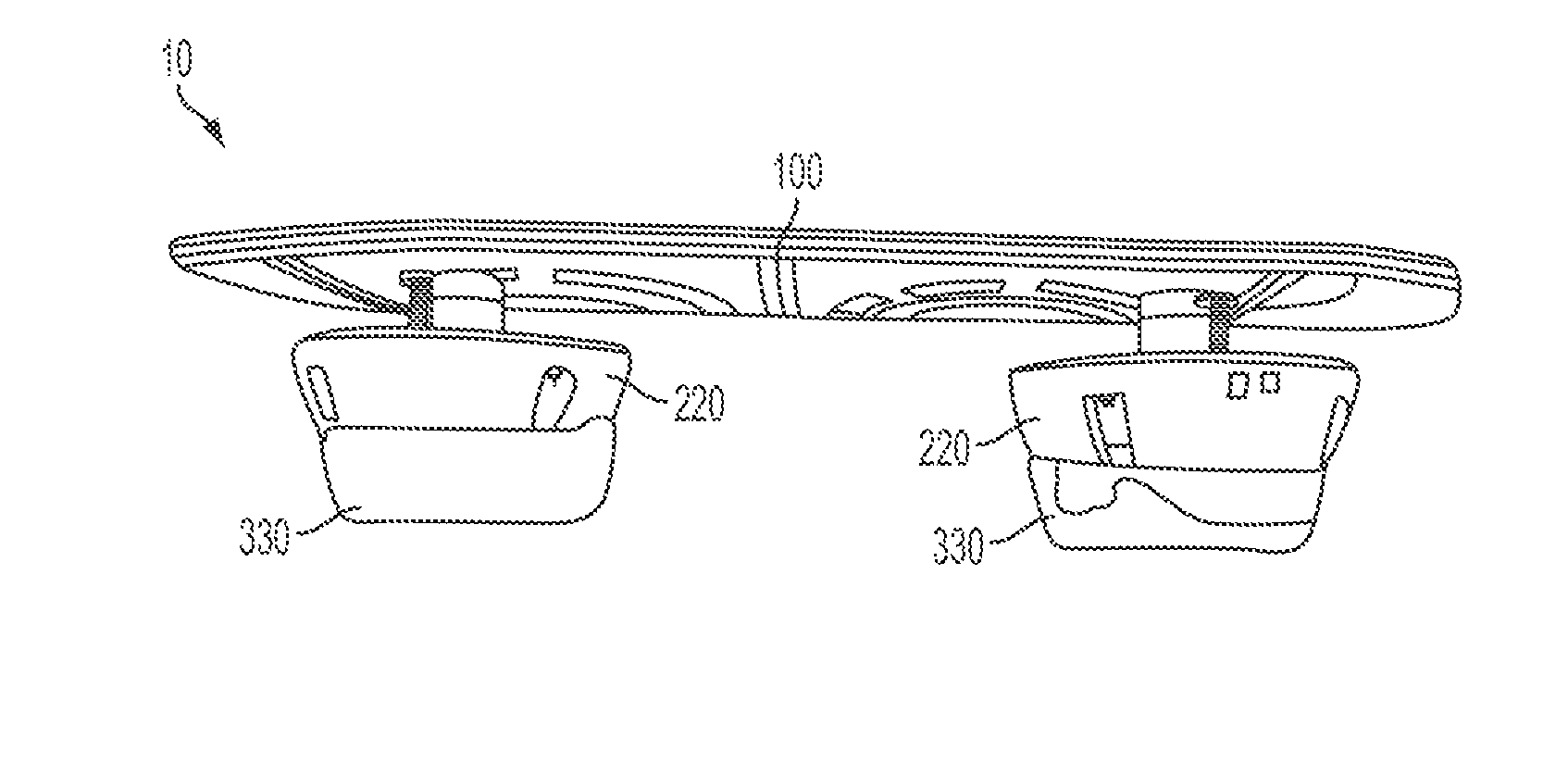

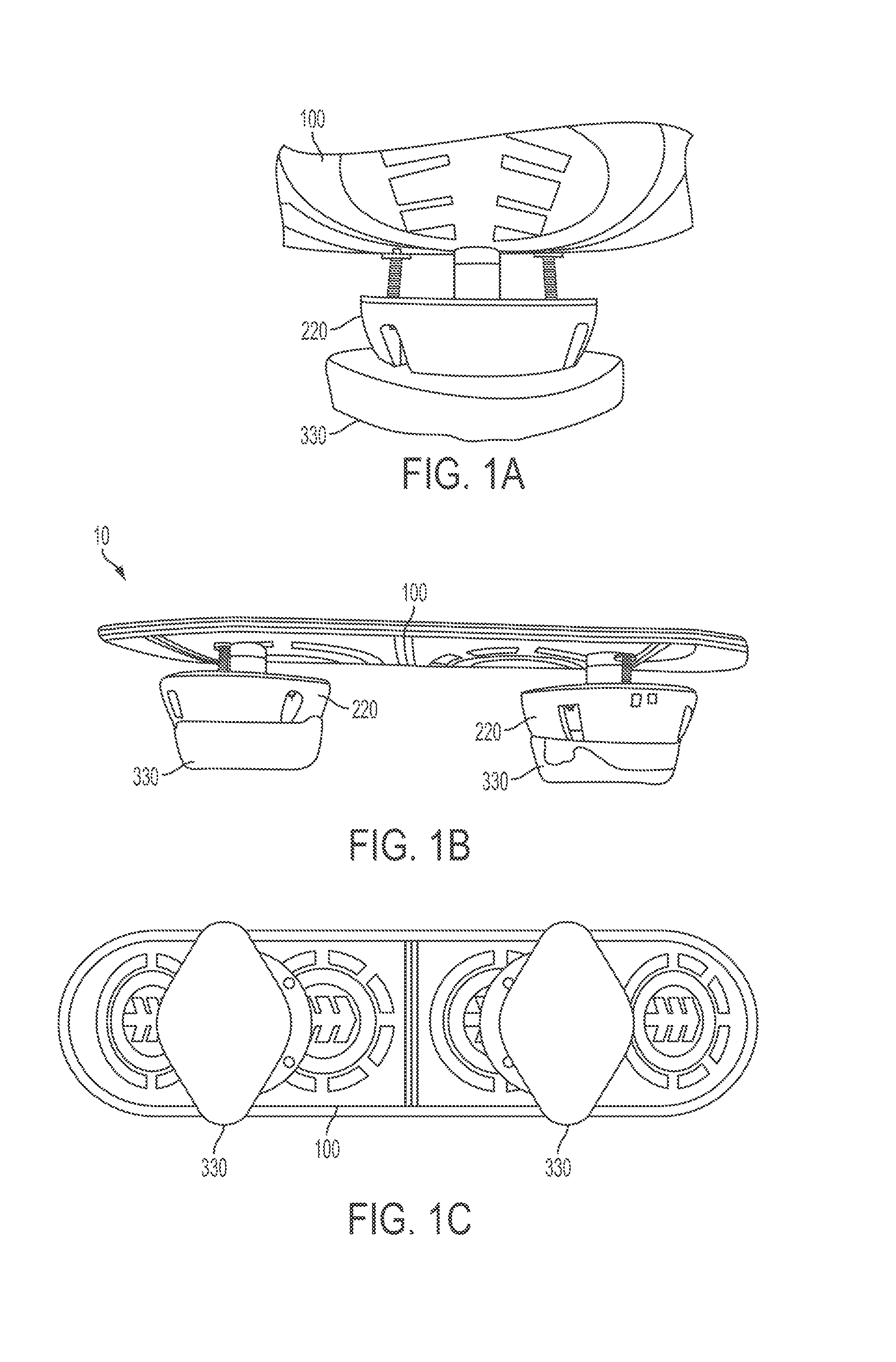

Exercise device and method of using same

ActiveUS20140005018A1Promote balance between supply and demandQuickens reflex timeStiltsMovement coordination devicesRotational axisEngineering

A system and method are disclosed which may include a training board including a plank made of wood (or other material such as metal, rubber or plastic) and deformable or non-deformable structures coupled to a bottom thereof, thereby enabling the board to rotate about as many as three rotational axes upon having force applied thereto by a user. The training board may enable a user to use to the board for training purposes or recreational activities using structures having a range of properties.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

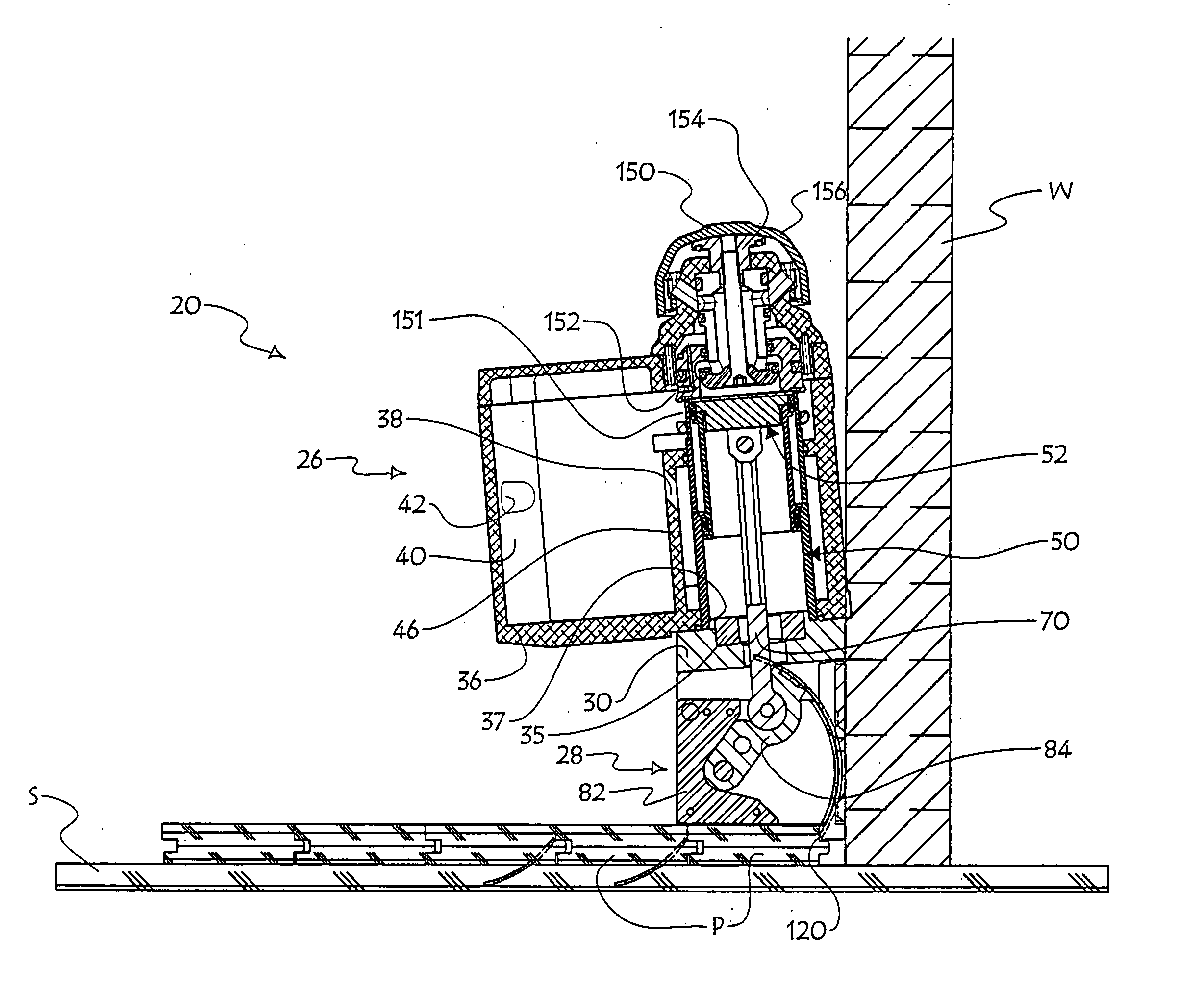

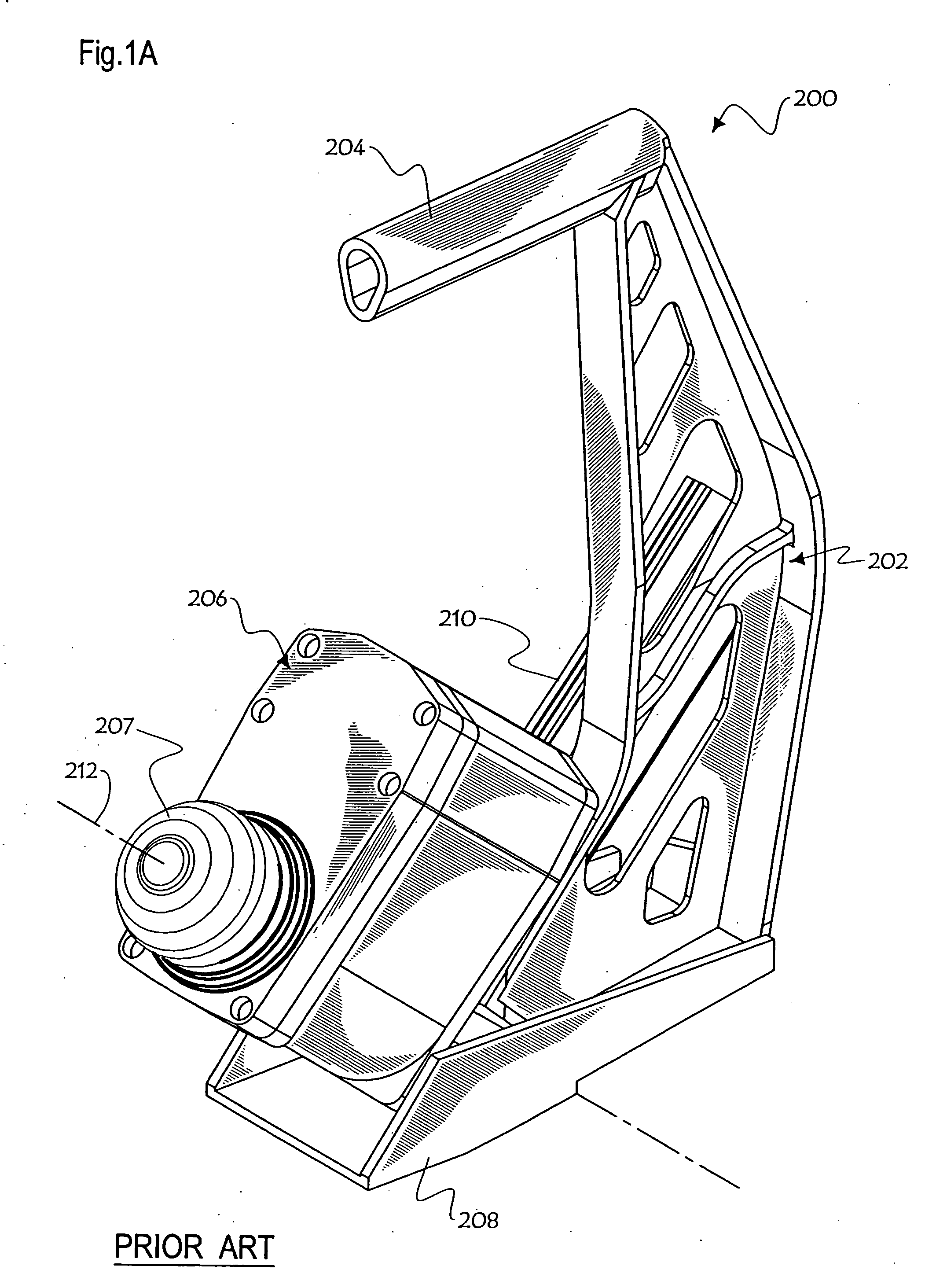

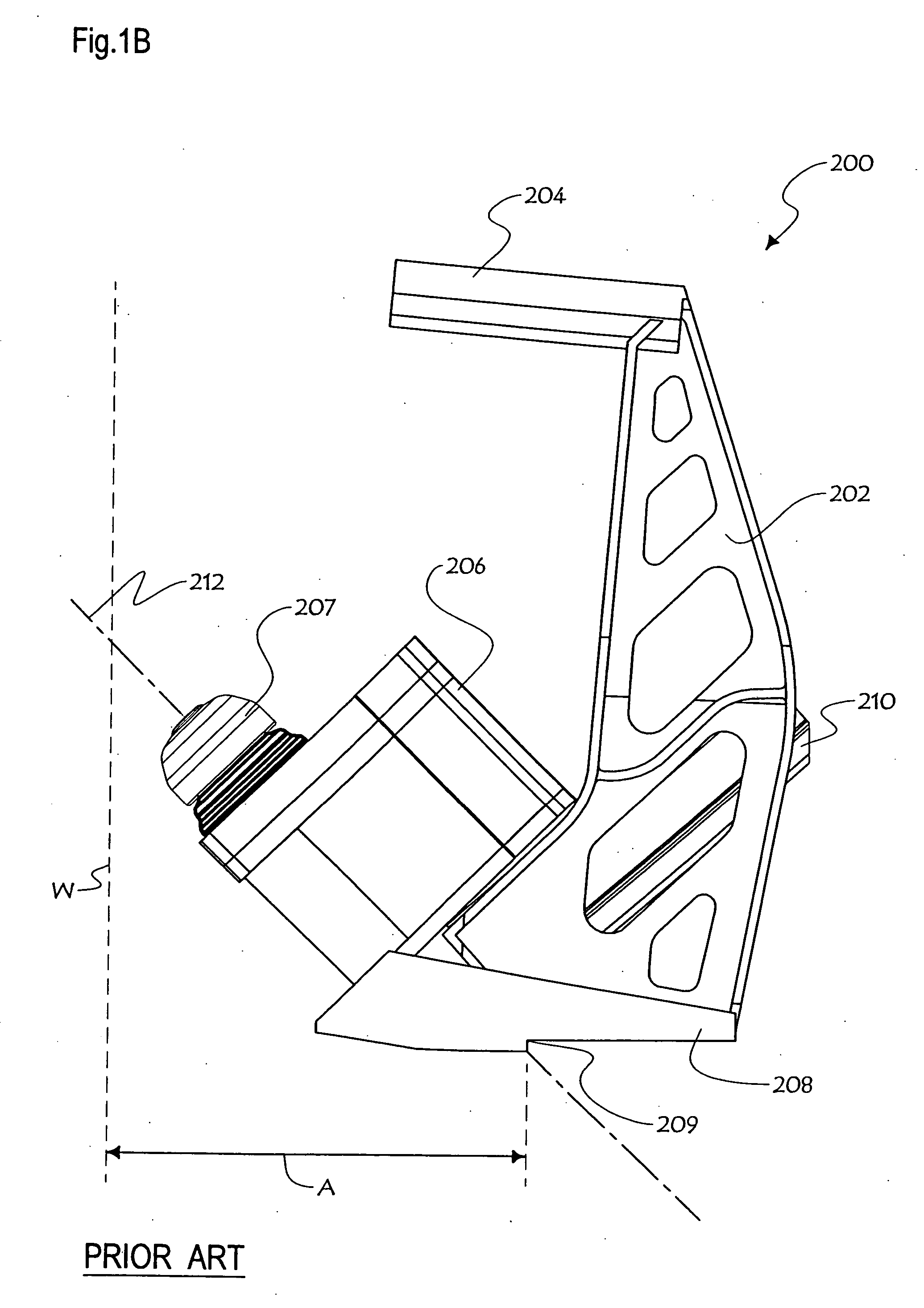

Arcuate fastener nailing device for hardwood flooring

InactiveUS20070017954A1Reduce performanceLower performance requirementsStapling toolsPortable percussive toolsArcuate shapeActuator

A nailing device used for securing hardwood flooring planks to a subfloor using arcuate fasteners. The nailing device comprises a main body in turn defining a fastener discharge opening. The nailing device also comprises an arcuate fastener ejection channel made in the main body and destined to accommodate an arcuate fastener, the arcuate fastener ejection channel opening outwardly of the nailing device at the fastener discharge opening. The nailing device further comprises an arcuate plunger at least partially nested in the arcuate fastener ejection channel and movable along the arcuate fastener ejection channel between first and second limit positions. Moreover, the nailing device comprises a plunger actuator nested in the main body and connected to the arcuate plunger, which can be selectively activated for moving the arcuate plunger between its first and second limit positions. Upon activation of the plunger actuator, the plunger will move along the fastener ejection channel from its first limit position towards its second limit position to forcibly strike the arcuate fastener located in the fastener ejection channel and eject it out of the nailing device through the fastener discharge opening and into a subjacent workpiece.

Owner:LABE PRIMATECH

Package box plate material and its making method

InactiveCN101152729AIncrease elasticityEasy to carryFlat articlesDomestic articlesEngineeringUltimate tensile strength

The present invention discloses a packing chest plank stuff and a manufacturing method. The packing chest plank stuff consists of a middle layer, an upper strengthen layer and a lower strengthen layer. A structure layer is made of crop leftover and glue composition. The upper and the lower sides use poplar veneer skin and are processed through material mixing, glue stirring, paving, pressing and curing, stripping and trimming and other steps. The plank stuff has the advantages of high strength, light weight, good flexible, convenient transport and good processing performance and so on. Crop leftover is used as the main raw material, which has extensive source and low price, saves a lot of timber and belongs to environmentally-friendly plank stuff.

Owner:海门市三阳镇飞鸿包装箱厂

Frame and Panel Door

InactiveUS20120272601A1Highly customizableReduce maintenanceWing arrangementsWing suspension devicesPlankArchitectural engineering

A door having a frame and panel construction, wherein the panel comprises a plurality of planks received in a rebate formed in the surrounding frame, and the planks include extruded aluminum profiles. Also, a door unit, and a method of constructing the door.

Owner:MUSKITA ALUMINUM INDS

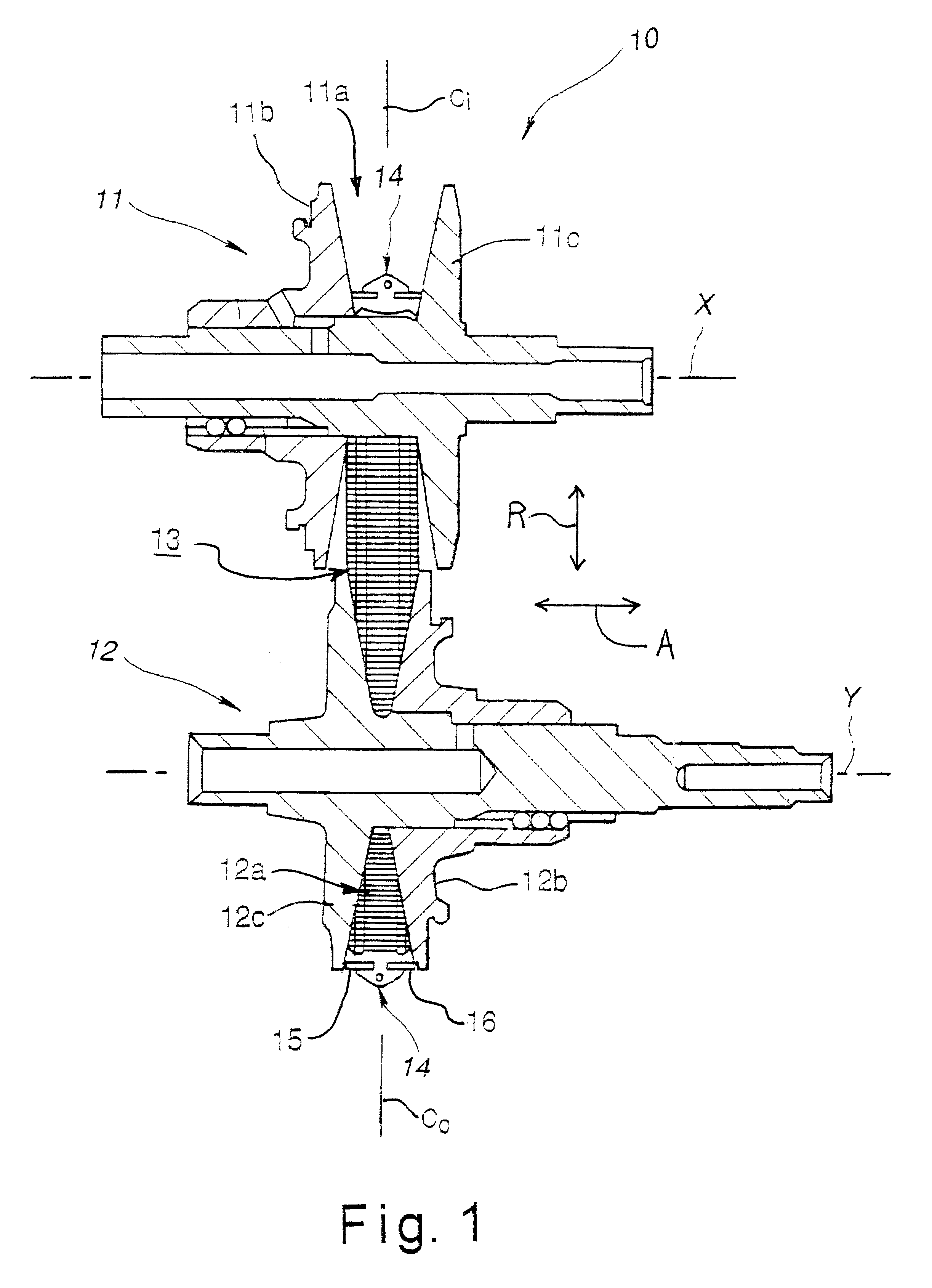

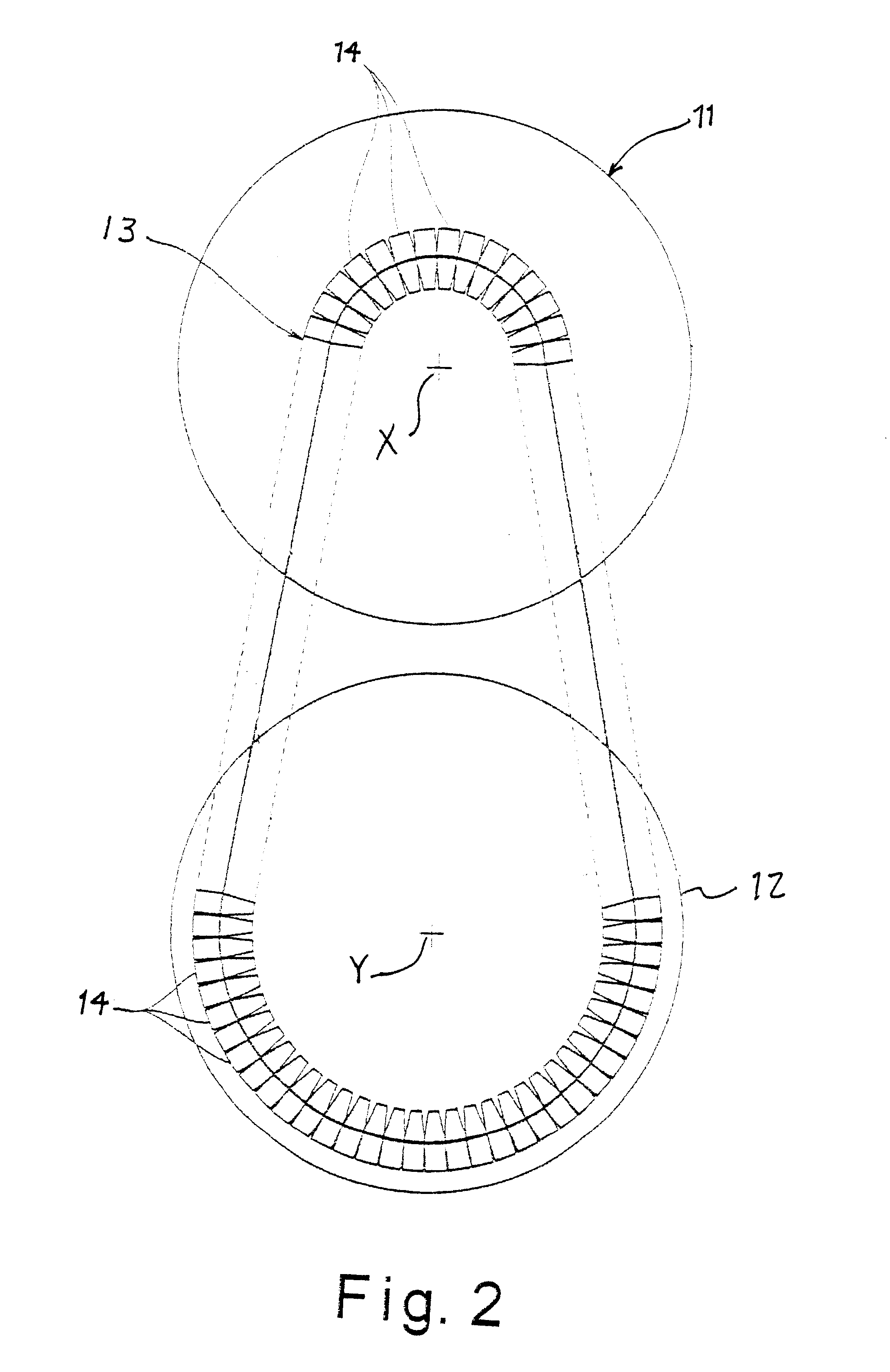

Drive belt for continuously variable transmission

Owner:NISSAN MOTOR CO LTD

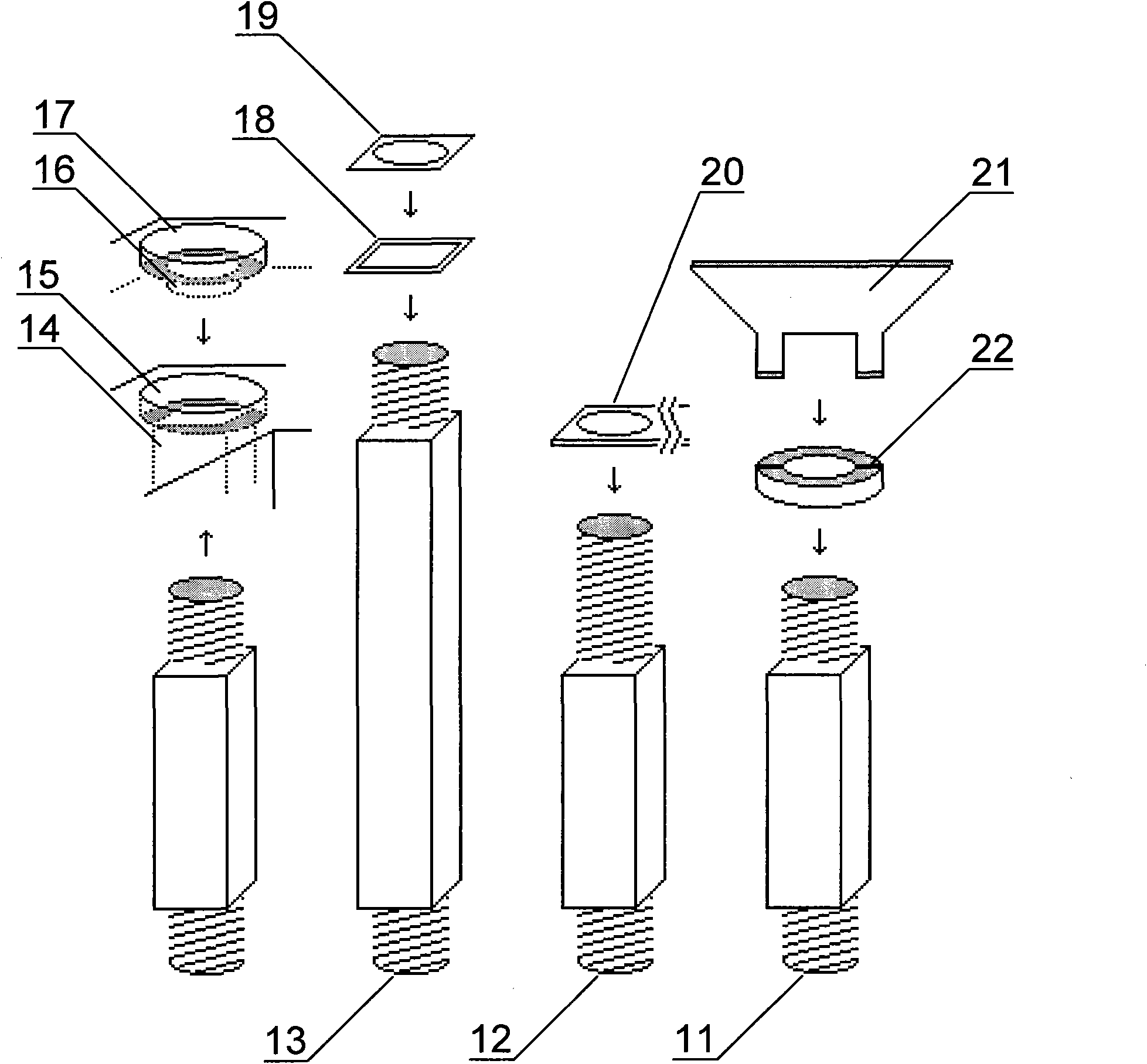

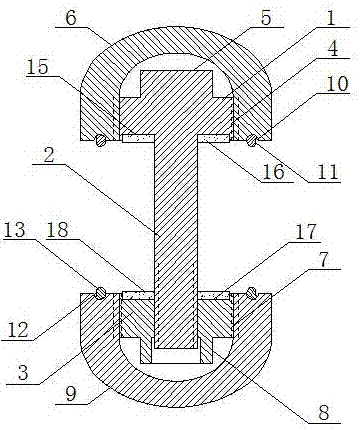

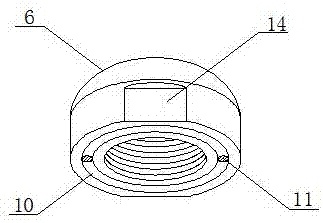

Rust-proof metal door plank fastener

The invention discloses a rust-proof metal door plank fastener, and relates to the field of decoration. The fastener comprises screw heads, a screw rod and nuts, threads I are arranged on the periphery of the screw heads, the inner end of each screw head is fixedly connected with one end of the screw rod, the other end of the screw rod is matched with the screw port of each nut for use, and an outer hexagonal bulge is arranged on the outer end of each screw head; each screw head is externally connected with a cap body I through the corresponding thread I, a thread II is arranged on the periphery of each nut, and an outer hexagonal extension part is arranged on the outer end of each nut; the nuts are connected with a cap body II through the threads II, the inner rim of the cap body I is provided with grooves I, rubber rings I are arranged inside the grooves I, and the inner rim of the cap body II is provided with grooves II internally provided with rubber rings II. According to the rust-roof metal door plank fastener, tiny structures of bolts and the nuts are improved, decorative caps are arranged on the bolts and the nuts, and moreover, the rubber rings are installed on the bottoms of the decorative caps to insulate connecting parts of all screw ports, and the problem that normal bolts and nuts are easy to oxidize and erode is overcome.

Owner:HUZHOU GUANJU METAL DECORATION MATERIALS CO LTD

Decorative plate and its shaping process

InactiveCN1641129ALow costReduce weightConstruction materialCovering/liningsFiberglass meshGlass fiber

The invention discloses a kind of adornment material and it's moulding craft, it is maked up of the oxidize magnesium, chlorination magnesium, grind pearl coating etc., draw on the 2-16 layer glass fiber net cloths equality, after model, aridity we can get the plank material. The plank material thickness can be a 2-30 mm, can decorate the plank for the flat surface; Also can take as various different shape and flower veins of the adornment plank, decorate lines, the corner line...etc., can also make into the acoustic board, heat preservation, set fire, effective acoustic board. The plank material can use for mechanize and industrialization production, also can make by hand operation. This kind of plank material, cost is low, the weight is light, the strength is high, constant form, bear wait good,contaim nothing poison material toward human body, harmful material, and can defend tidewater, defend fire, soundproof, heat preservation, construction convenience, can carry on various process like drill, saw, plane, can replace the aluminum mold plank and the other various existing adornment plank materials, is the ideal material do various public appearance to repair, family repair.

Owner:周新春

Scaffold Storage Plank

ActiveUS20120043161A1Easy accessOther accessoriesContainer/bottle contructionFalseworkInsertion stent

The present invention comprises a scaffolding system with scaffolding frames and at least one scaffold storage plank. The scaffold storage plank comprises of a body that contains a storage reservoir capable of holding tools or equipment. The scaffold storage plank further comprises a folding sectional cover to the storage reservoir and allows assess to the storage reservoir when the cover is in its open position. When the cover is in its closed position the scaffold storage plank functions as a means of support. The scaffold storage plank may be locked to the scaffolding structure in the closed position so that tools and equipment stored within the scaffolding system are secure.

Owner:RENISH LANCE

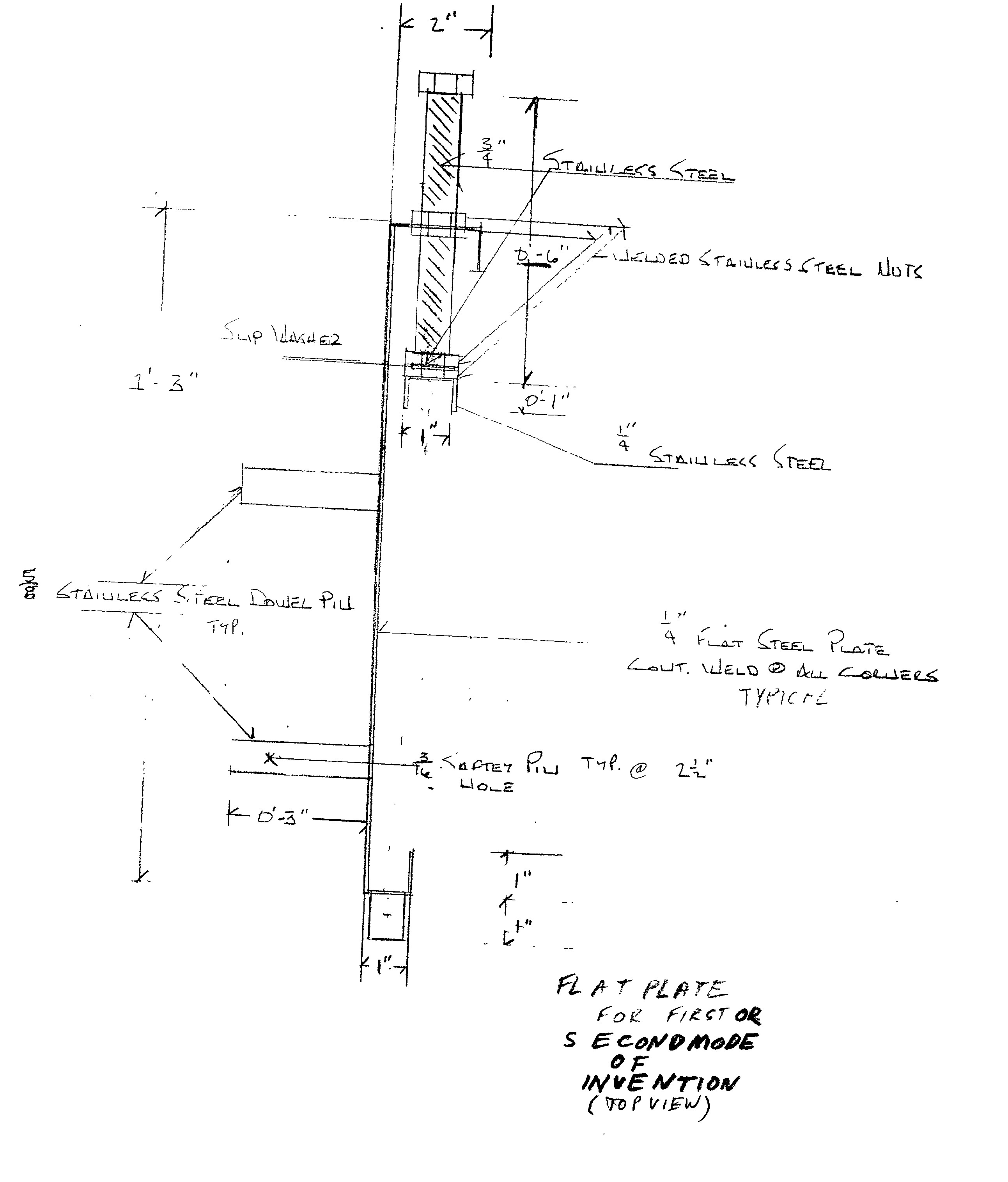

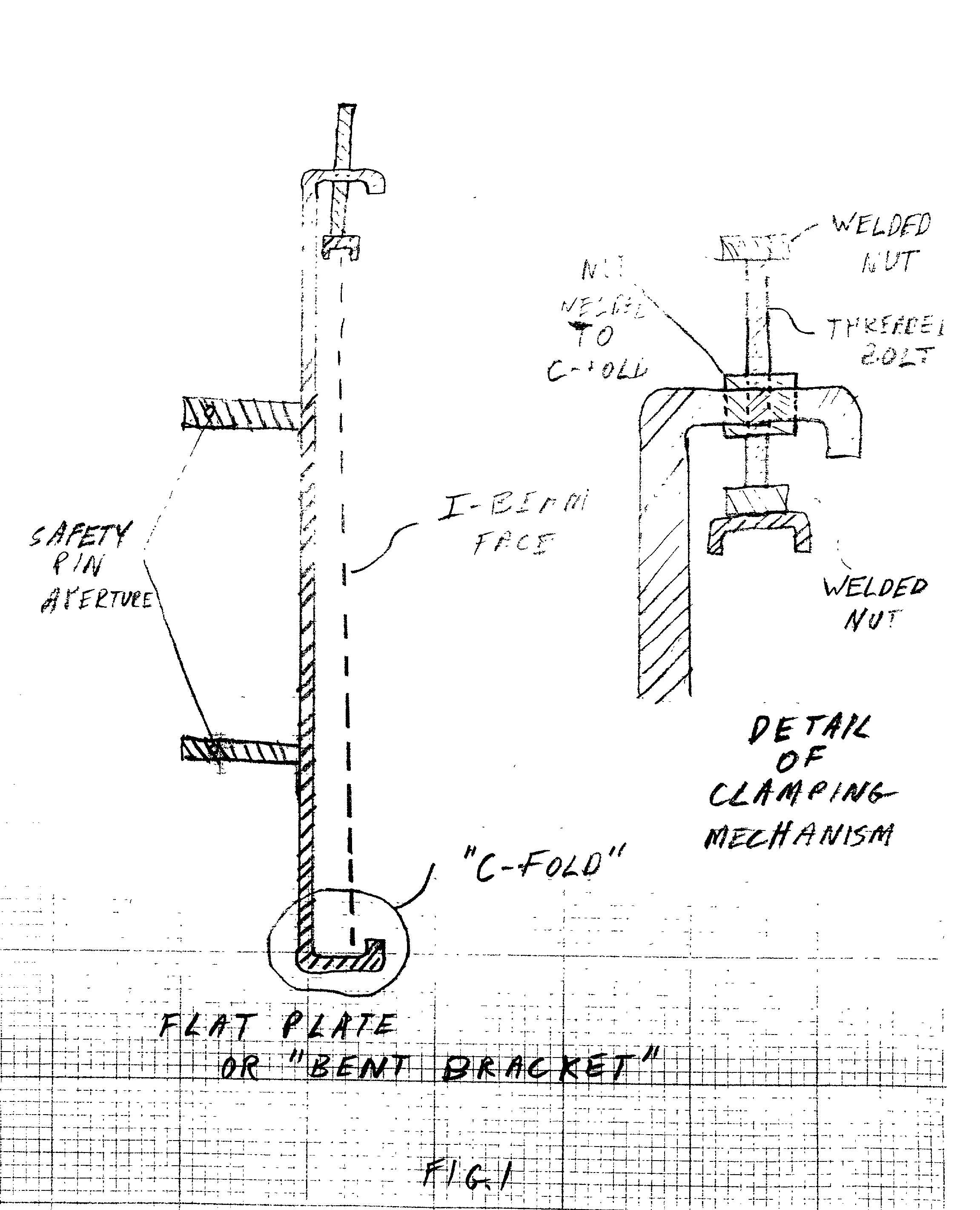

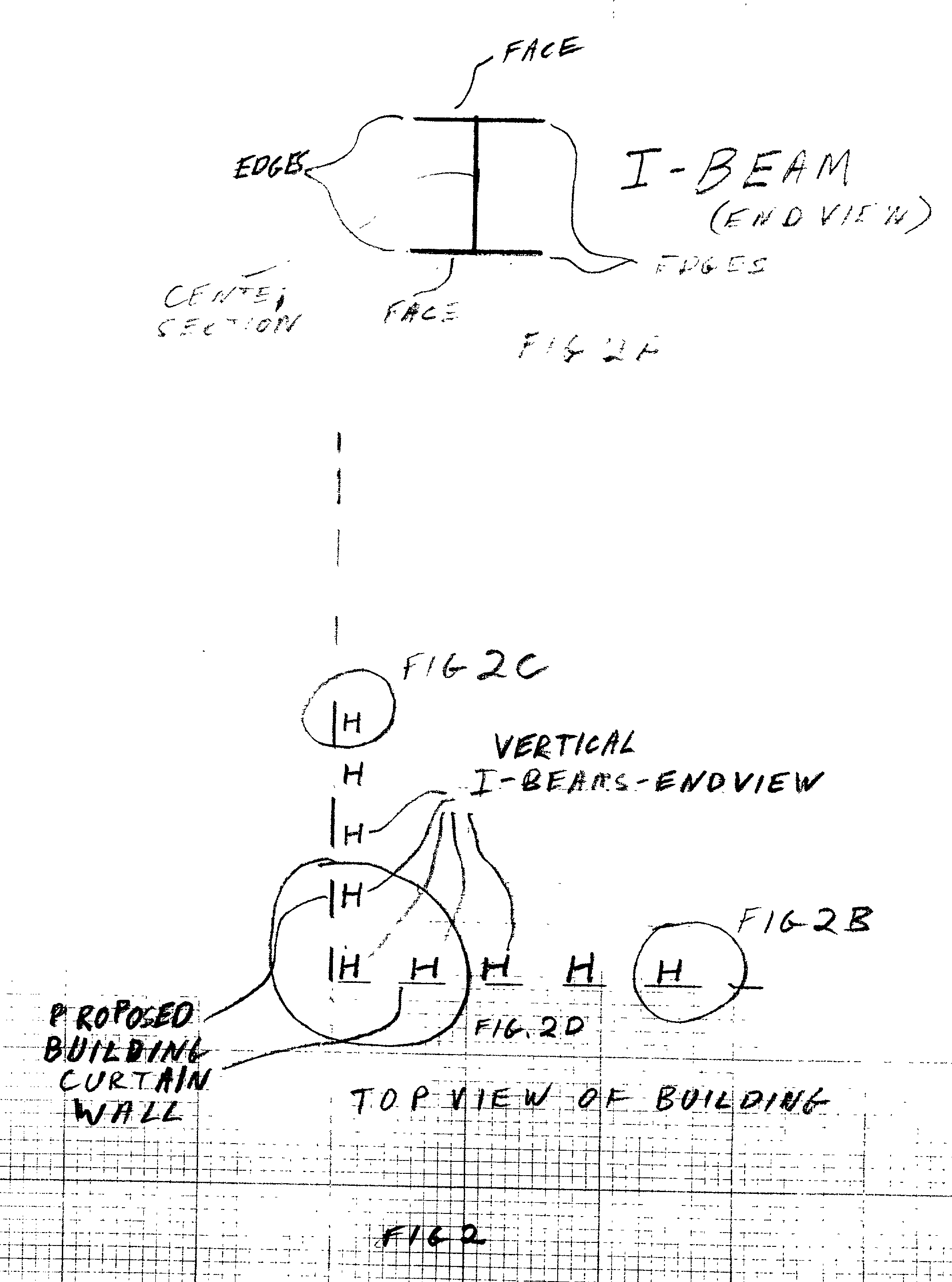

Mobile outrigger scaffolding system

This invention contemplates a combination and method involving mounting specially designed plates and / or mounting apparatus against and on the standard vertical column used in construction of office structures or other structures including bridges. The plates have a clamping mechanism designed to fit around or on the vertical column. A lower and upper plate are mounted. The plates have a protrusions onto which are mounted a bracket with holes fitting on the protrusions. The bracket is secured with a cotter pin. The brackets project outside the eventual skin of a building and deck planks or pics can be mounted on the brackets. The mobile outrigger scaffolding system allows workmen to safely walk and work on the deck planks to perform work on a floor-by-floor basis. The system can be dissembled quickly and moved to another part of the same floor, to a new floor, and can be used around the outside corner of a structure or from an overhang or from a horizontal beam. The invention is uniquely designed for steel tube construction. A small part of fireproofing can be removed, the invention utilized and the fireproofing replaced.

Owner:COGAR TERRY L

Intelligent numerical control machining equipment for wooden door machining

ActiveCN113601337AImprove adaptabilityEasy to moveBelt grinding machinesGrinding feedersNumerical controlPlank

The invention discloses intelligent numerical control machining equipment for wooden door machining, and relates to the technical field of wooden door machining. The intelligent numerical control machining equipment comprises a supporting frame and a numerical control box, the supporting frame is connected with a moving structure used for driving a wooden door to move, the top of the supporting frame is fixedly connected with a straight block, the outer wall of the straight block is connected with the numerical control box, the straight block is connected with a polishing structure used for polishing the side edge of the wooden door, the structural shape of the polishing structure is adjusted according to the width of the wooden door, and the polishing structure is connected with a guiding and righting structure used for guiding the wooden door. The intelligent numerical control machining equipment ensures that a polishing belt is in a tensioning state, is suitable for machining door planks with different widths, and improves the adaptability.

Owner:JIANGSU GUOQUAN AUTOMATION TECH CO LTD

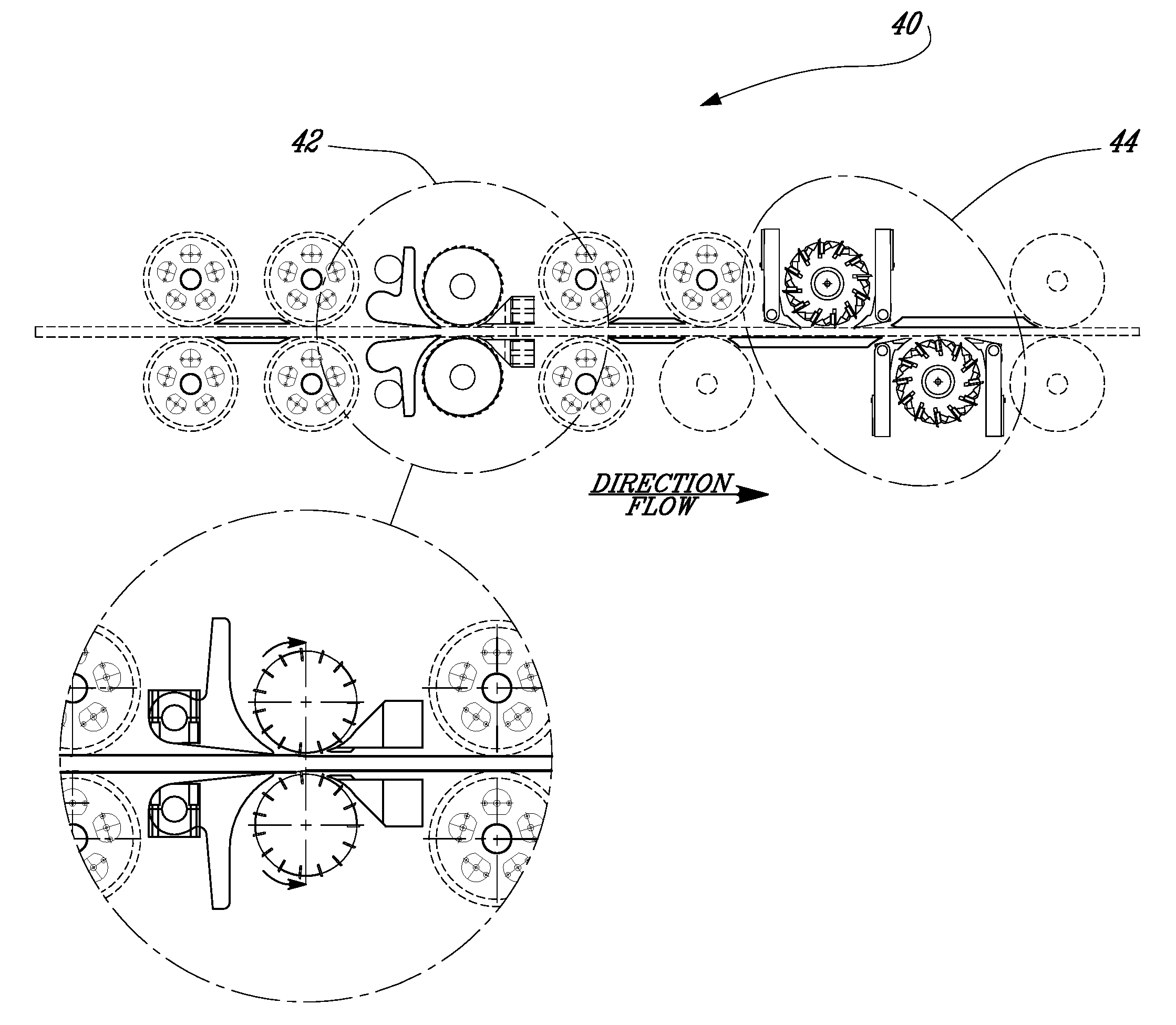

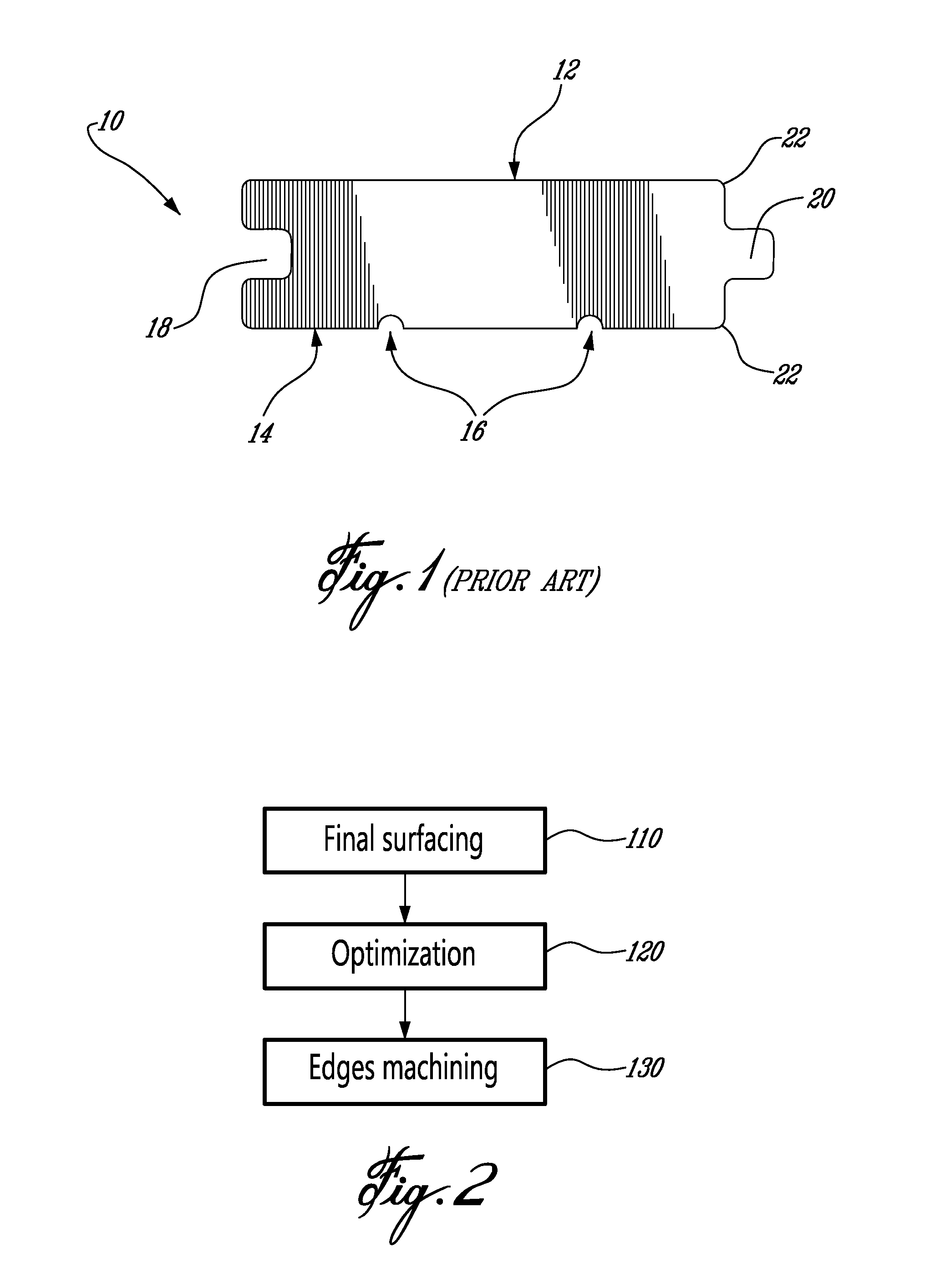

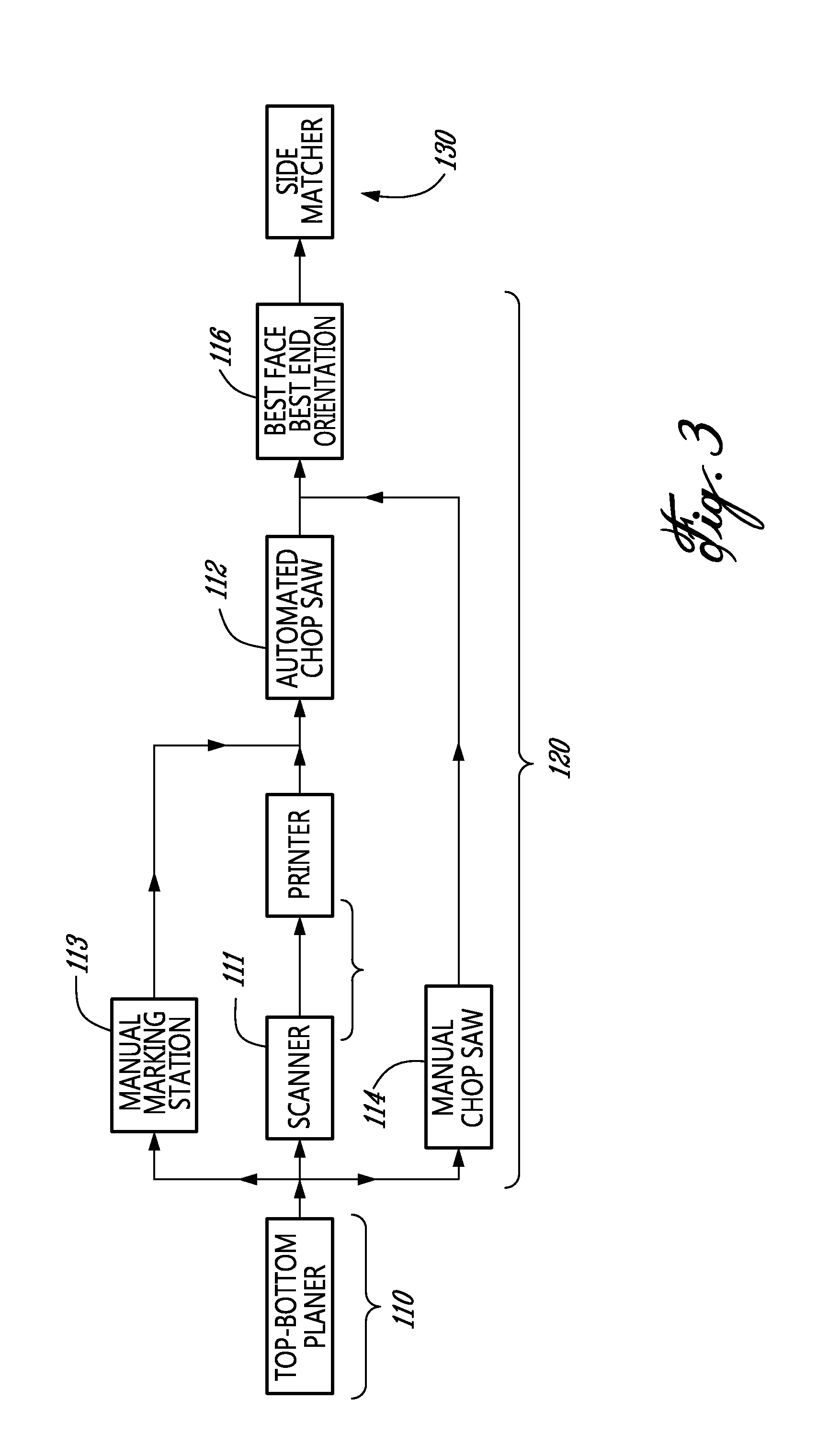

Floor planks production machines and method

A floor planks production method, for producing wood flooring from raw lumbers, by surfacing top and lower faces of the lumbers to a final thickness of the lumbers; optimizing the lumbers along a length thereof to determine lengths of best faces; and profiling edges of the optimized lumbers. The system comprises a surfacing unit processing both top and lower faces of each lumber to final dimensions; an optimizing unit receiving lumbers from the surfacing unit; and a profiling unit processing edges of each length of best faces positioned by the optimizing unit.

Owner:OSI MACHINERIE

One-step molding technique of carbon stirrup and used stirrup-molding mould thereof

ActiveCN101327503AOne-time forming process is simpleImprove forming qualityMetal-working apparatusEngineeringStirrup

The invention discloses a one step forming process of carbon clip and a clip resizer adopting the method. The method is a one step clip forming technique with simple process, high forming quality and high forming speed. The invention forms a clip at one step by lowering a plurality of clip forming cutters in the clip resizer on a sheet-forming machine. The method includes the following steps: the first step: the feed wheels of a sheet-forming machine deliver the blanks of carbon strips to perforating dies; the second step: the perforating dies punch the blanks, thus producing a plurality of holes simultaneously; the third step: the feed wheels continue to deliver the blanks, wherein, the blanks with holes punched by the perforating dies are delivered into the clip resizer to process the blanks with holes into formed clips at one step. The one step forming process of carbon clip provided by the invention is characterized by simple process, high forming quality and rapid forming speed, and the inside diameter of the formed clips and the thickness and the width of the plank stuff are changeable. The invention plays a good role in improving the highly efficient mass production of comparable products.

Owner:SHANGHAI SPRING CORP

Method of using additive containing lignin to prepare cottonwood plank stuff

InactiveCN101229647AGood dimensional stabilityImprove physical and mechanical propertiesWood compressionPressure impregnationChemistryHot press

The invention relates to a method of preparing polar planks with additive containing lignin. Material preparation comprises the following steps: mixed solution of lignin solution and formaldehyde solution is prepared; liquor immersion of slabs is carried out: the prepared polar slabs are immersed in a sealed tank with the mixed solution of lignin and formaldehyde for vacuum treatment; the slabs are compressed: the obtained polar slabs are then placed in a hot press provided with a steam generating device for hot pressing; post treatment of slabs is carried out: the slabs after treated through the former steps are then piled up for 14 days and then made into polar compression planks. By adopting the method, the dimensional stability of the compression planks is greatly improved; the production technique is simple and the product performance index can achieve the performance index of the domestic like products. Meanwhile, the planks produced by the method of the invention have better dimensional stability under the precondition of good physical and mechanical property and produce no free formaldehyde.

Owner:广西林安木业有限公司

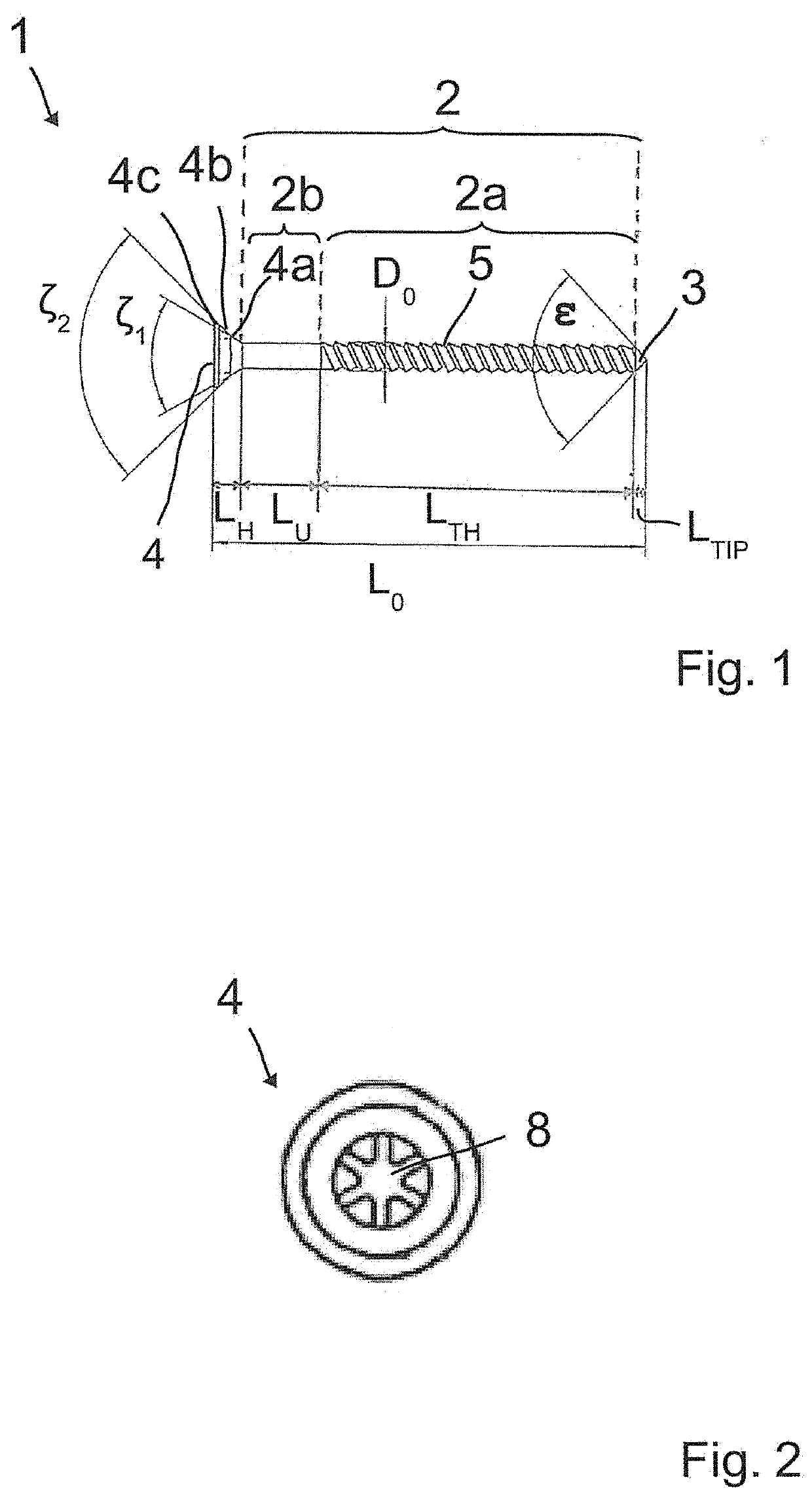

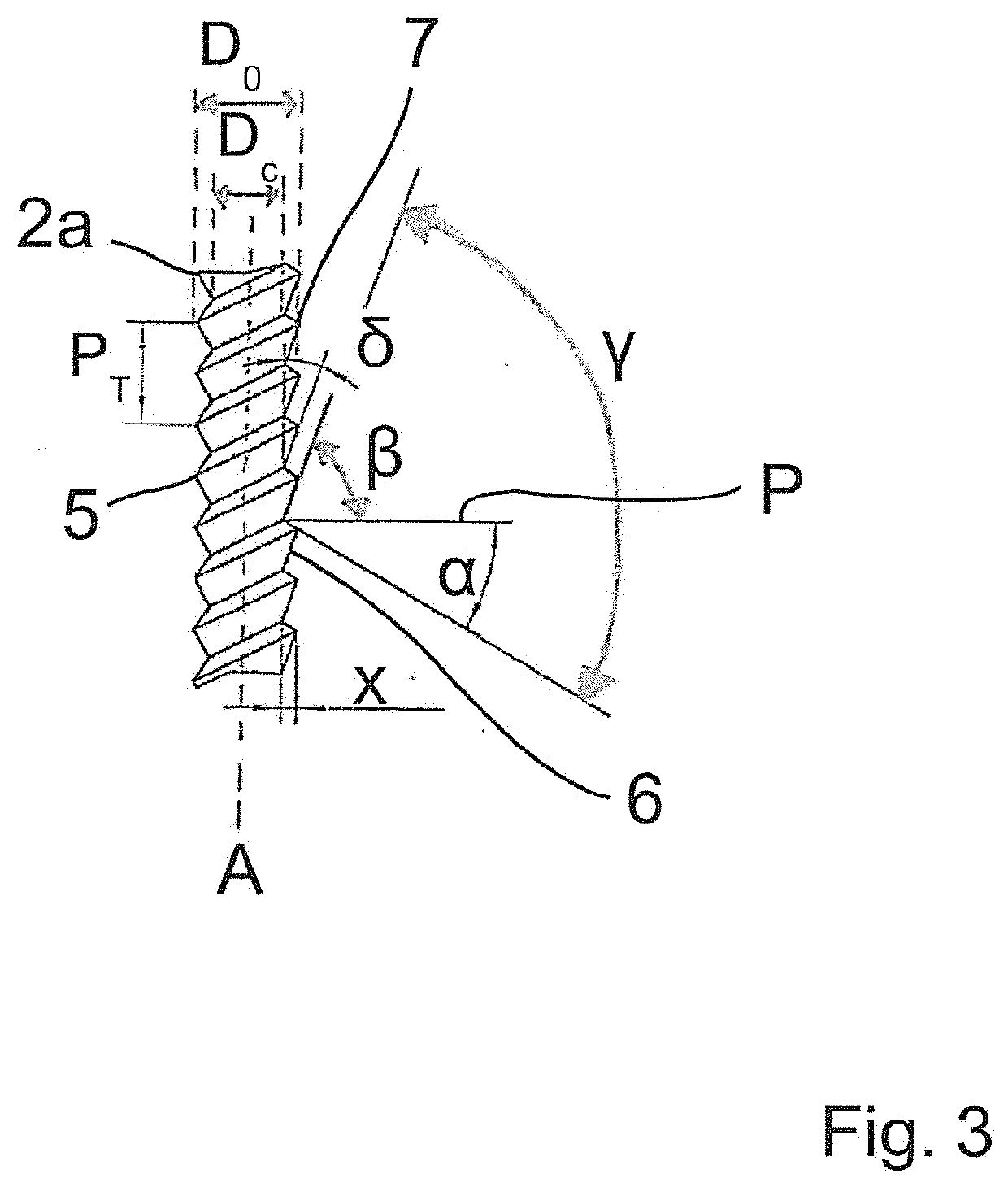

Nail screw

A nail screw, in particular for connecting facade boards or terrace planks made of wood, especially real wood, has a shaft, a conical tip formed at the front end region of the shaft and a head formed at the rear end region of the shaft. A thread has a forward facing insertion flank and a rearward facing grip flank between the conical tip and the head. The thread is a double thread, wherein a grip flank angle (α) measured between the grip flank and a plane perpendicular to the longitudinal axis of the nail screw is between 25 and 35 degrees, more preferably between 28 and 32 degrees, most preferably 30 degrees. The conical tip has a tip angle (ε) between 80 and 120 degrees, more preferably between 90 and 110 degrees, most preferably of 80, 90 or 100 degrees.

Owner:RAIMUND BECK NAGELTECHNIK GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com