Patents

Literature

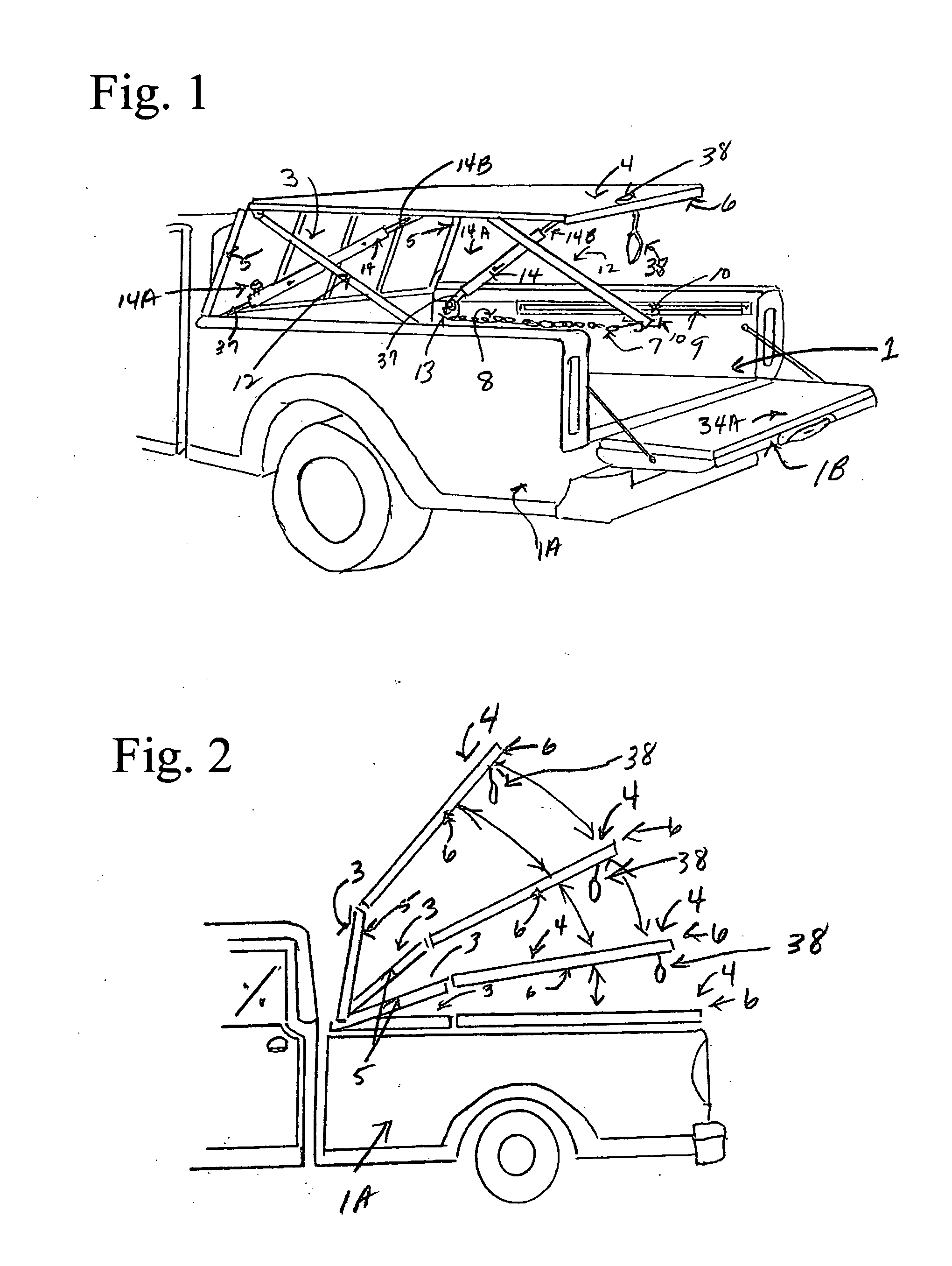

138 results about "Frame and panel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Frame and panel construction, also called rail and stile, is a woodworking technique often used in the making of doors, wainscoting, and other decorative features for cabinets, furniture, and homes. The basic idea is to capture a 'floating' panel within a sturdy frame, as opposed to techniques used in making a slab solid wood cabinet door or drawer front, the door is constructed of several solid wood pieces running in a vertical or horizontal direction with exposed endgrains. Usually, the panel is not glued to the frame but is left to 'float' within it so that seasonal movement of the wood comprising the panel does not distort the frame.

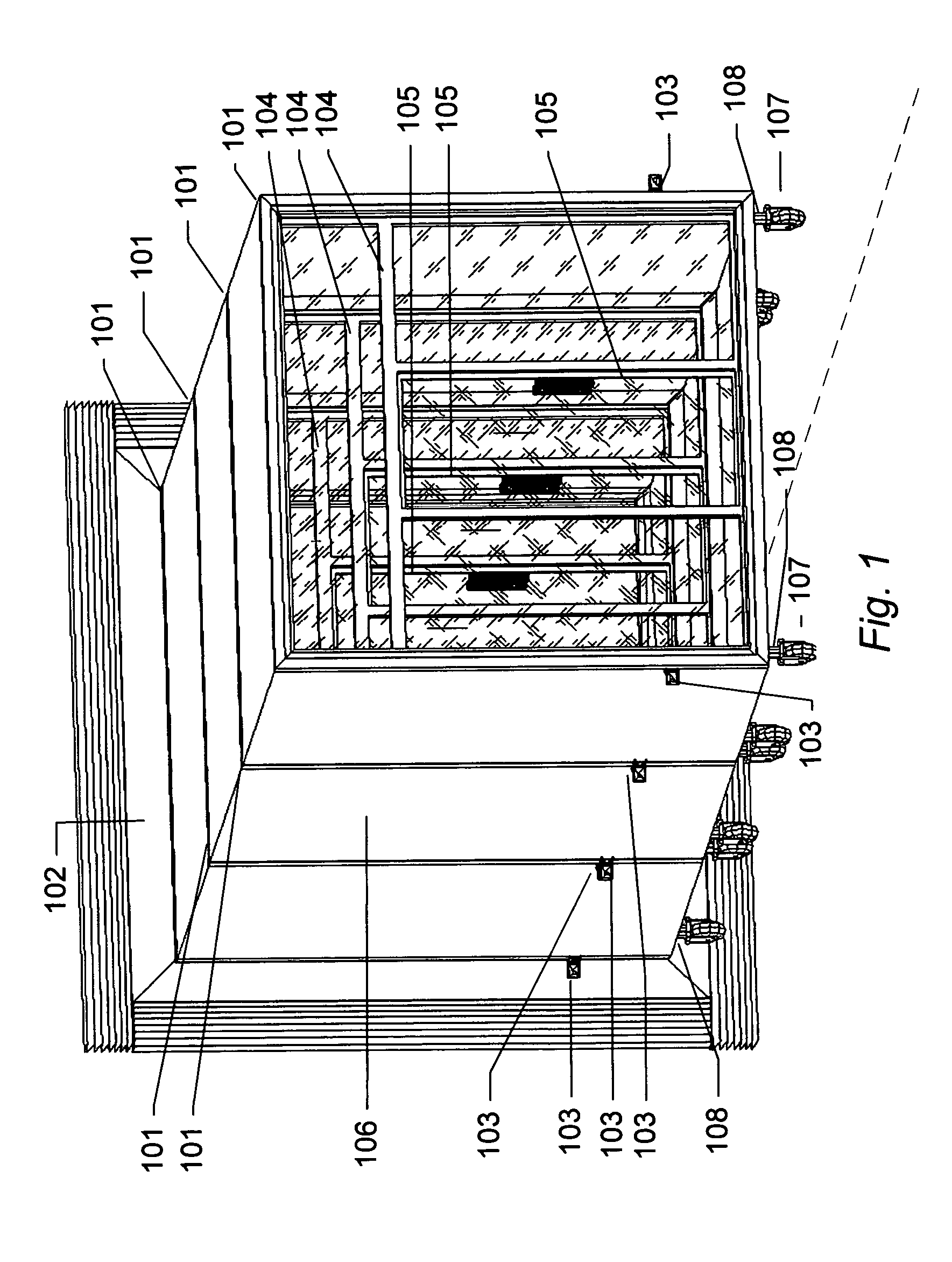

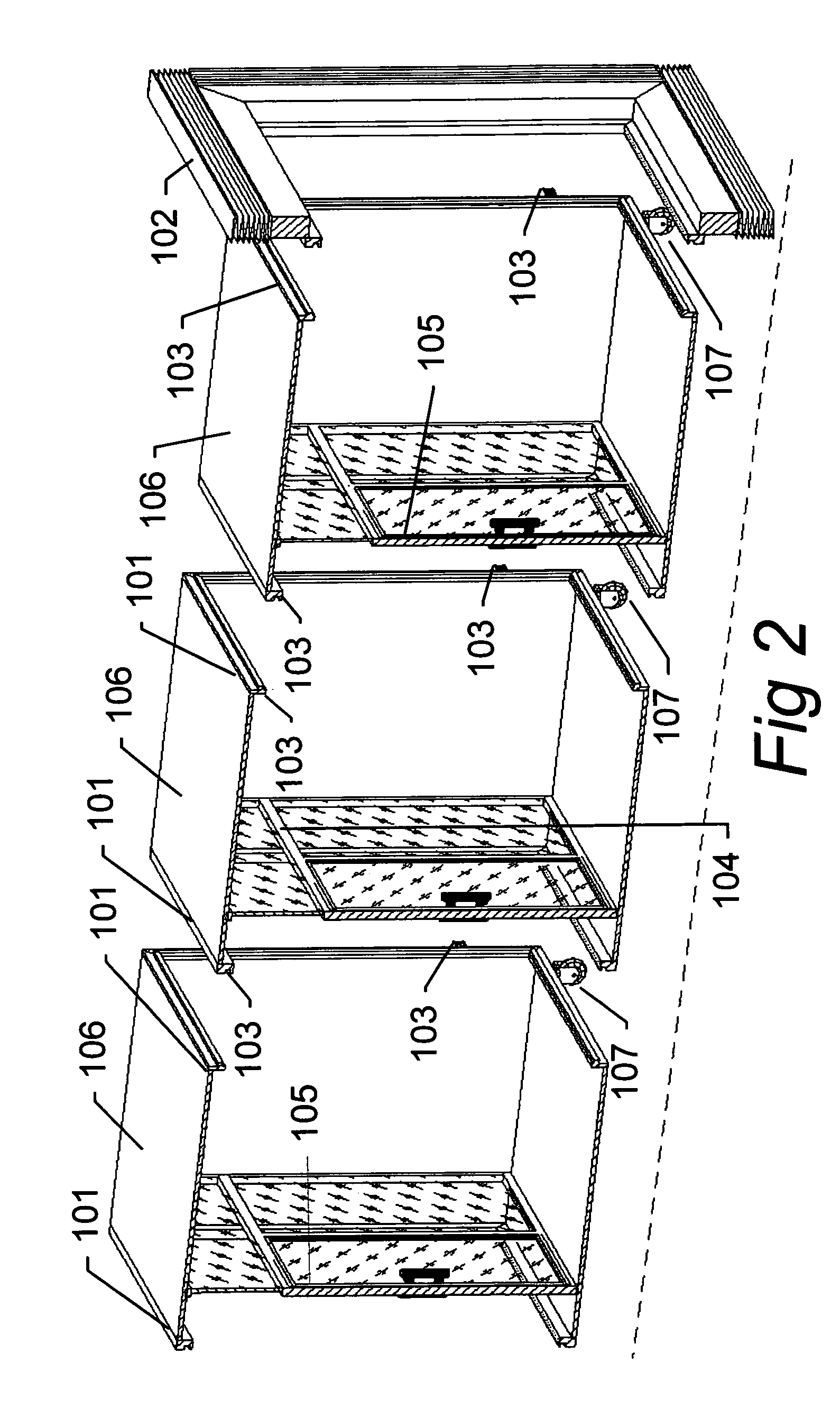

Modular assembly

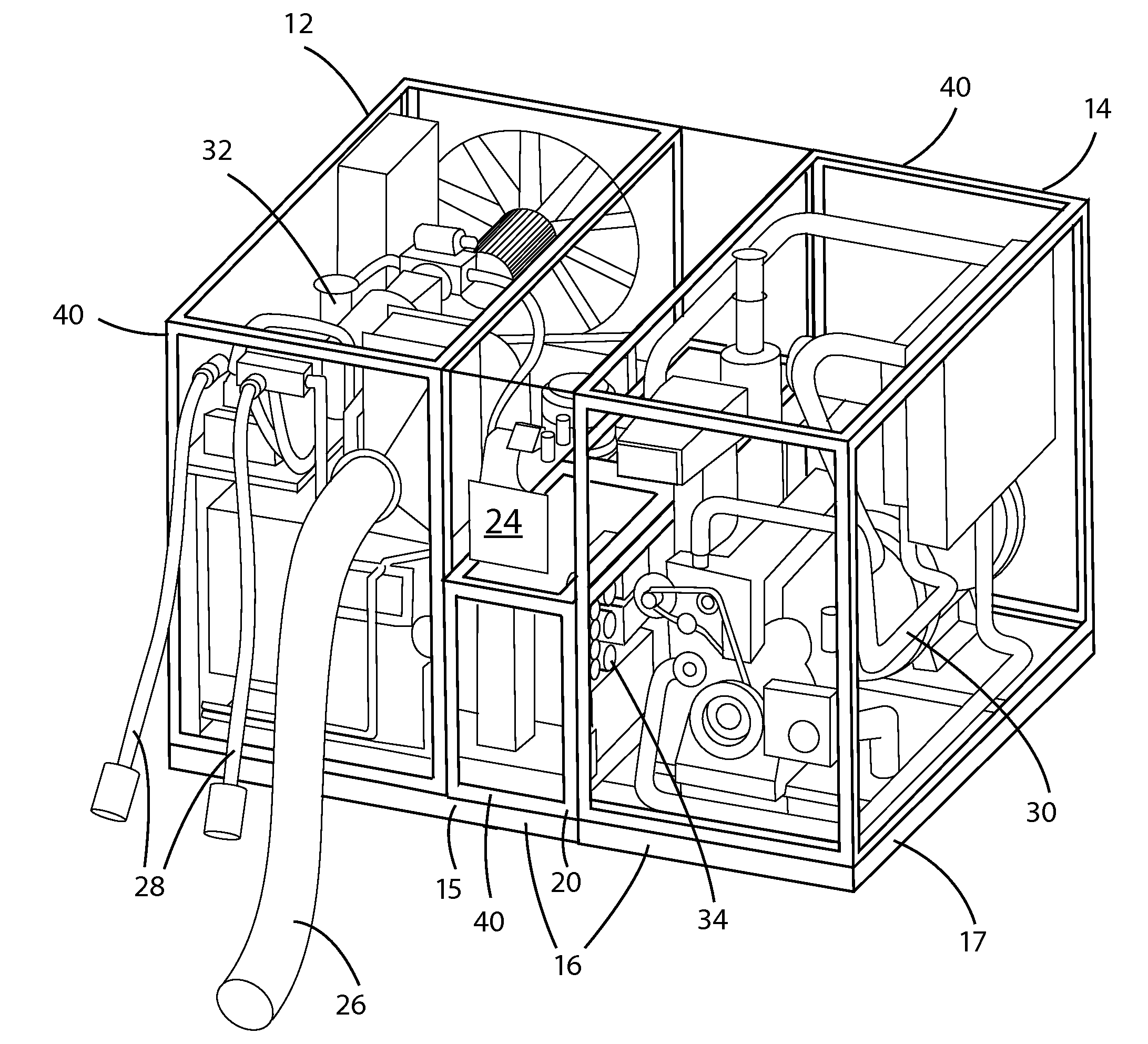

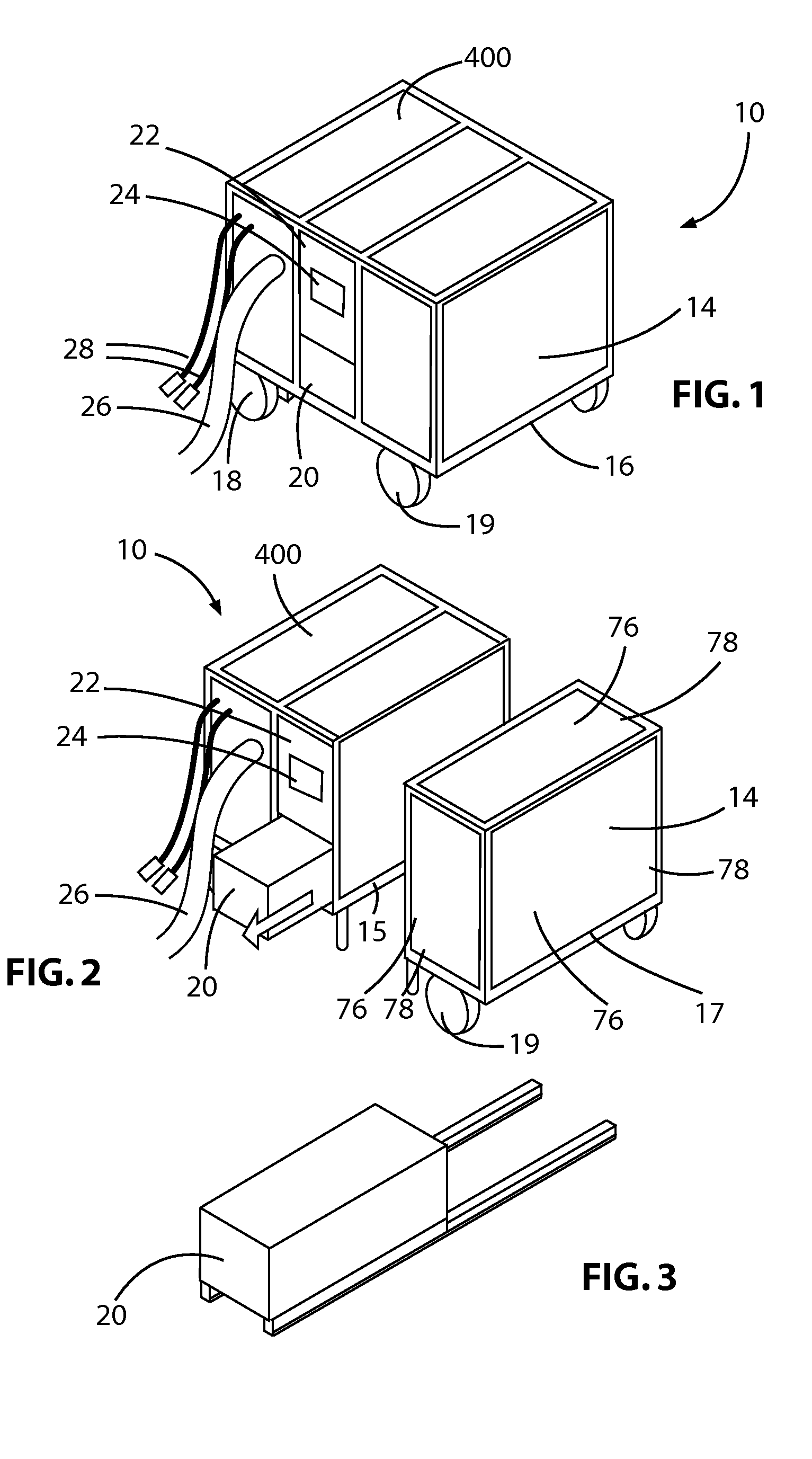

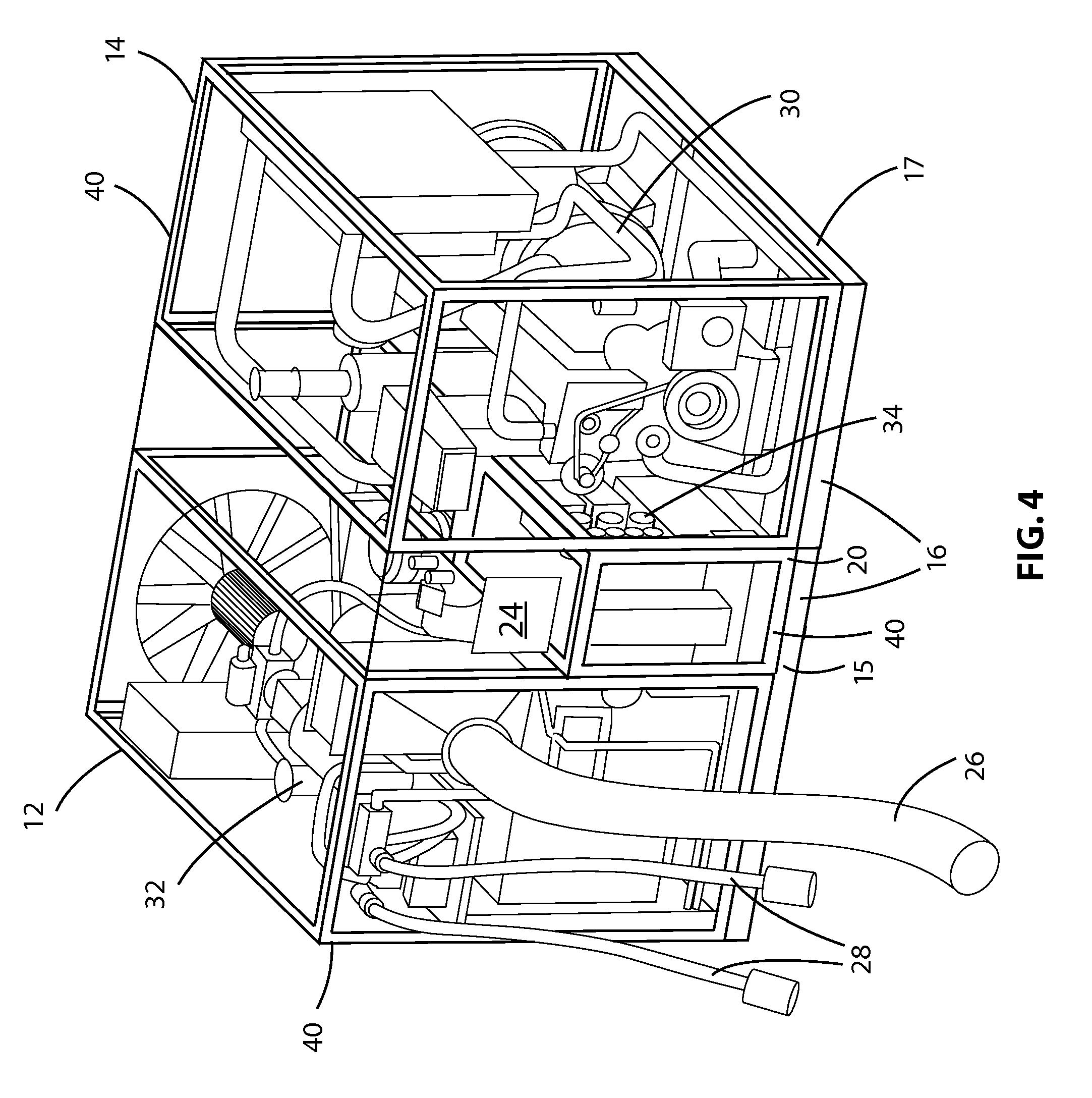

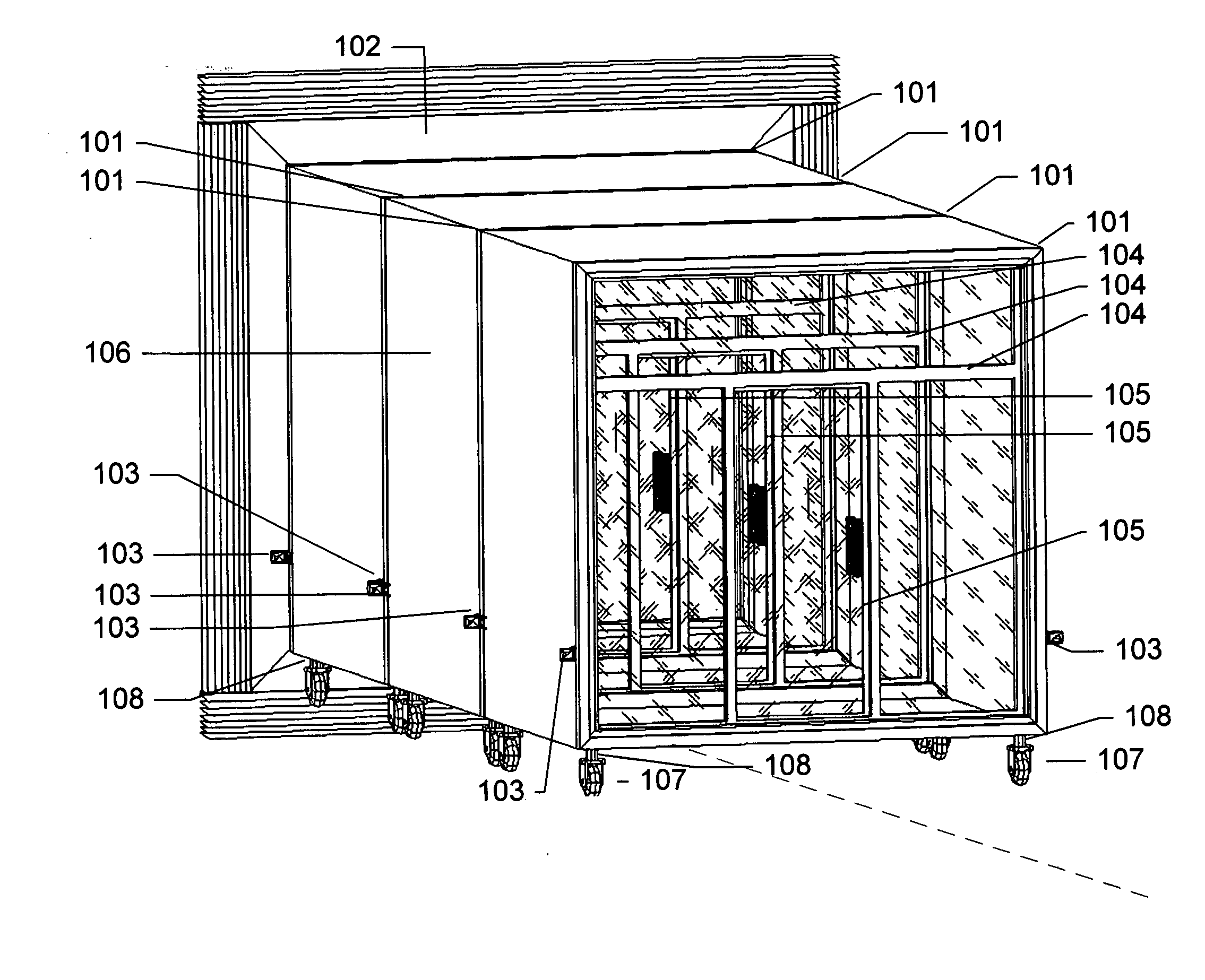

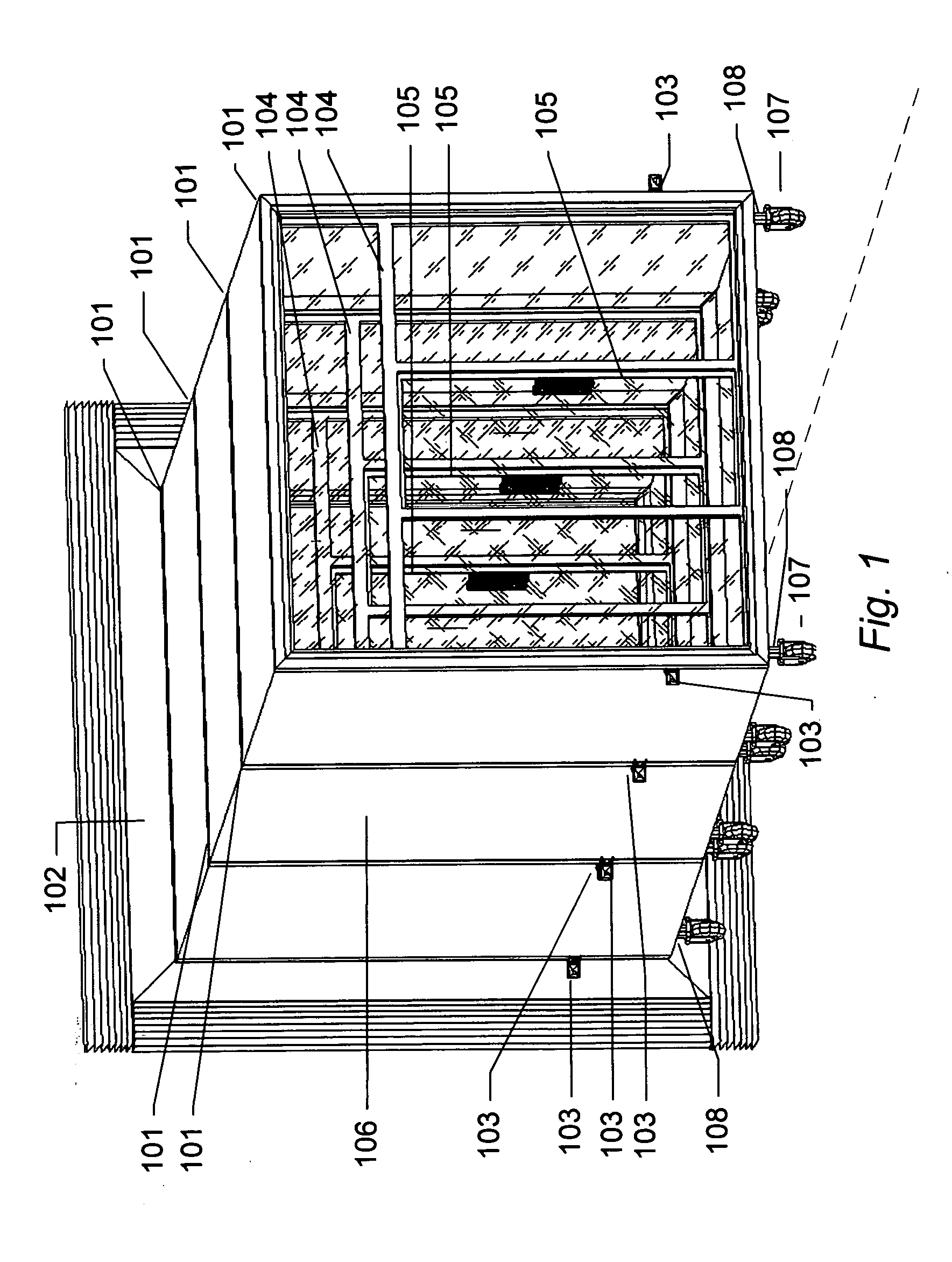

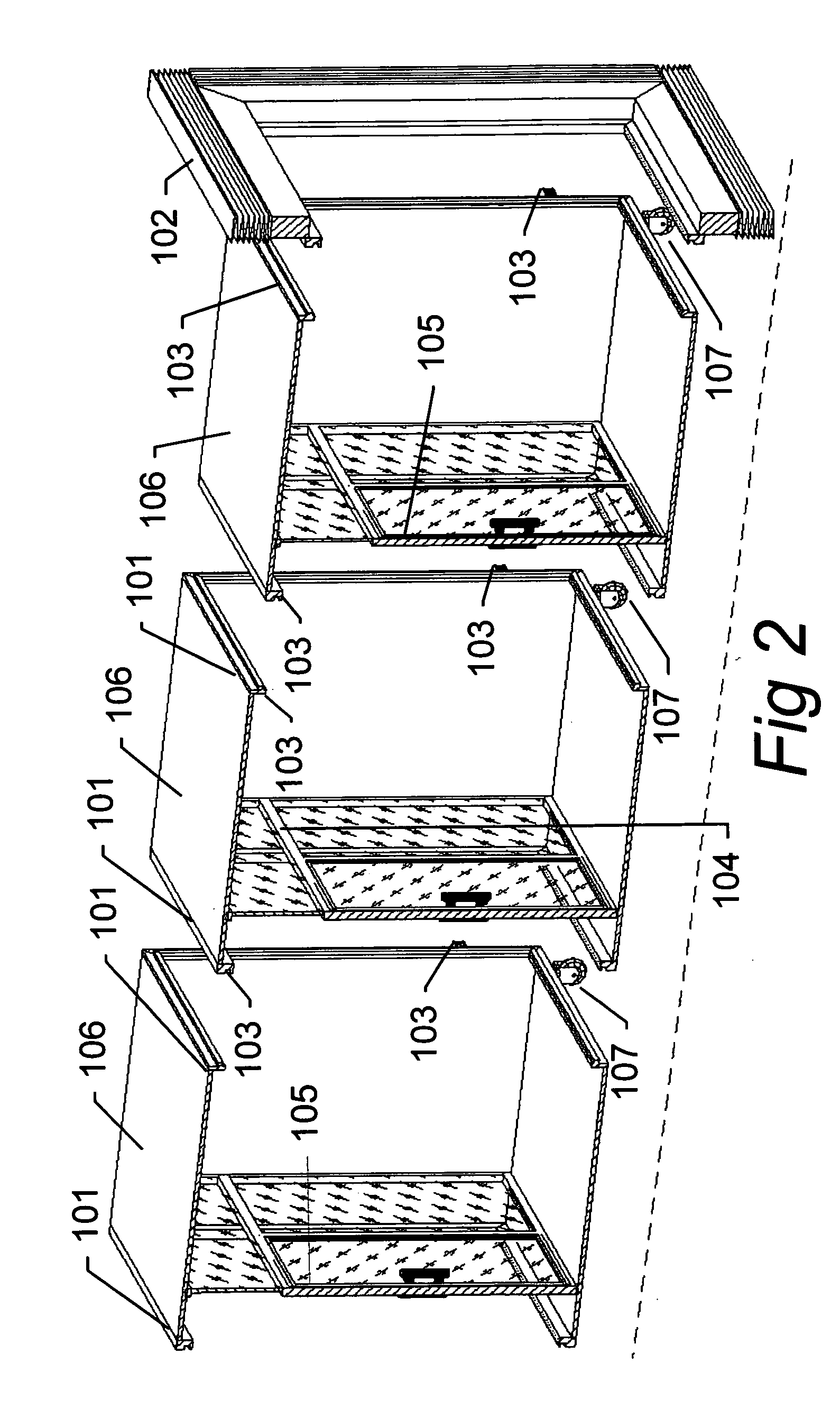

InactiveUS20100269419A1Promote conversionPrevent sinkingRoof covering using slabs/sheetsRoof covering using tiles/slatesElectricityModularity

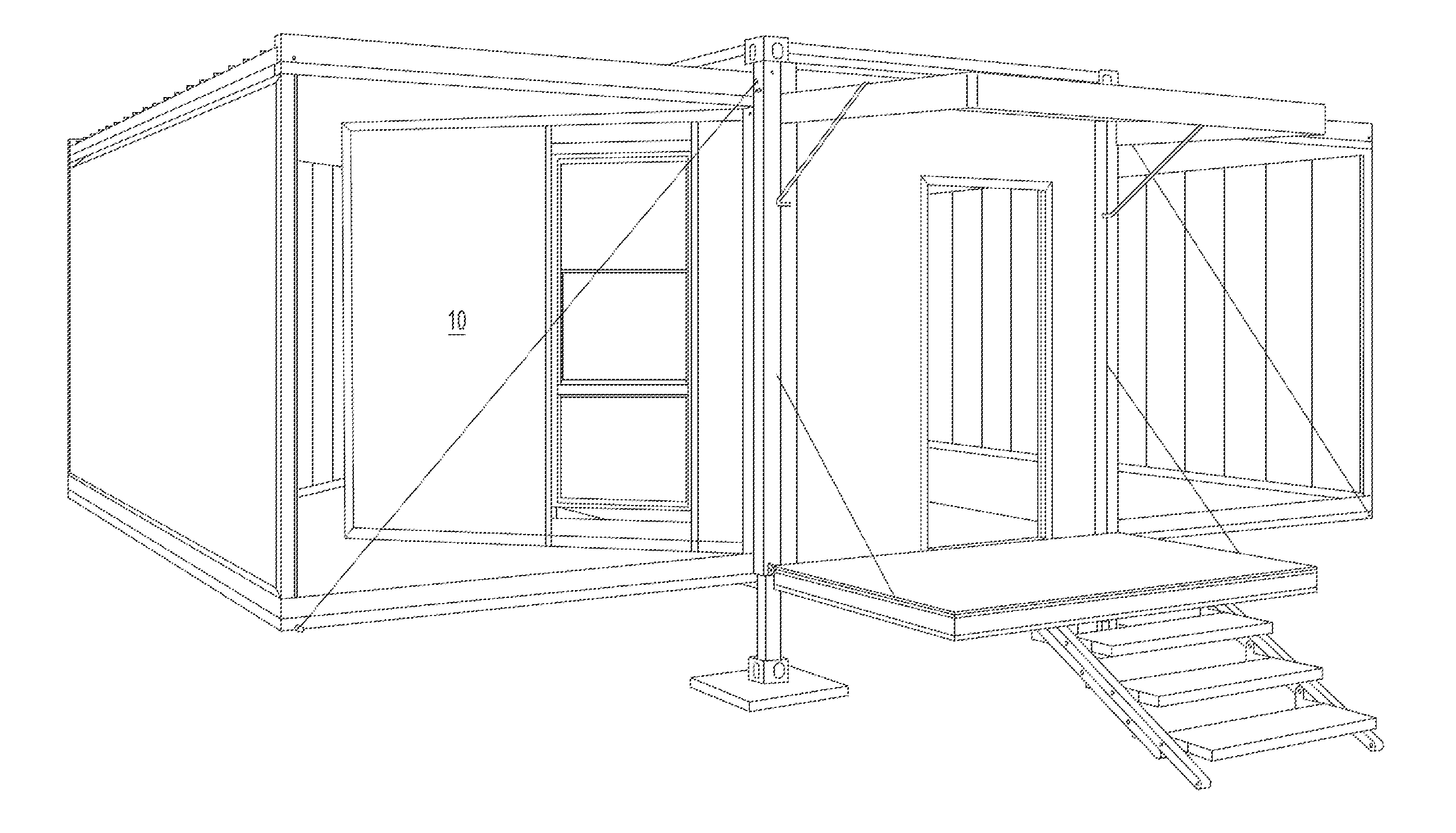

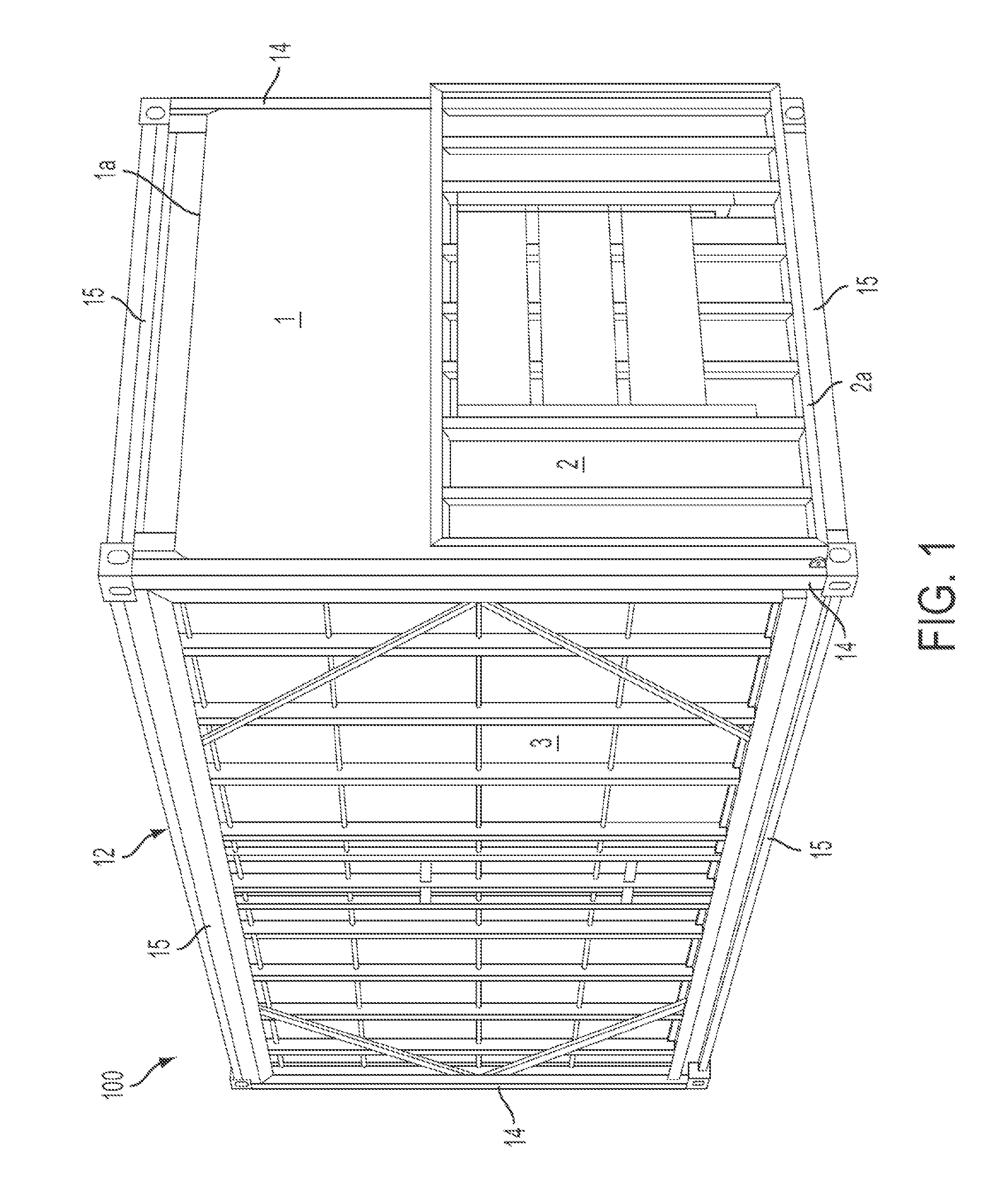

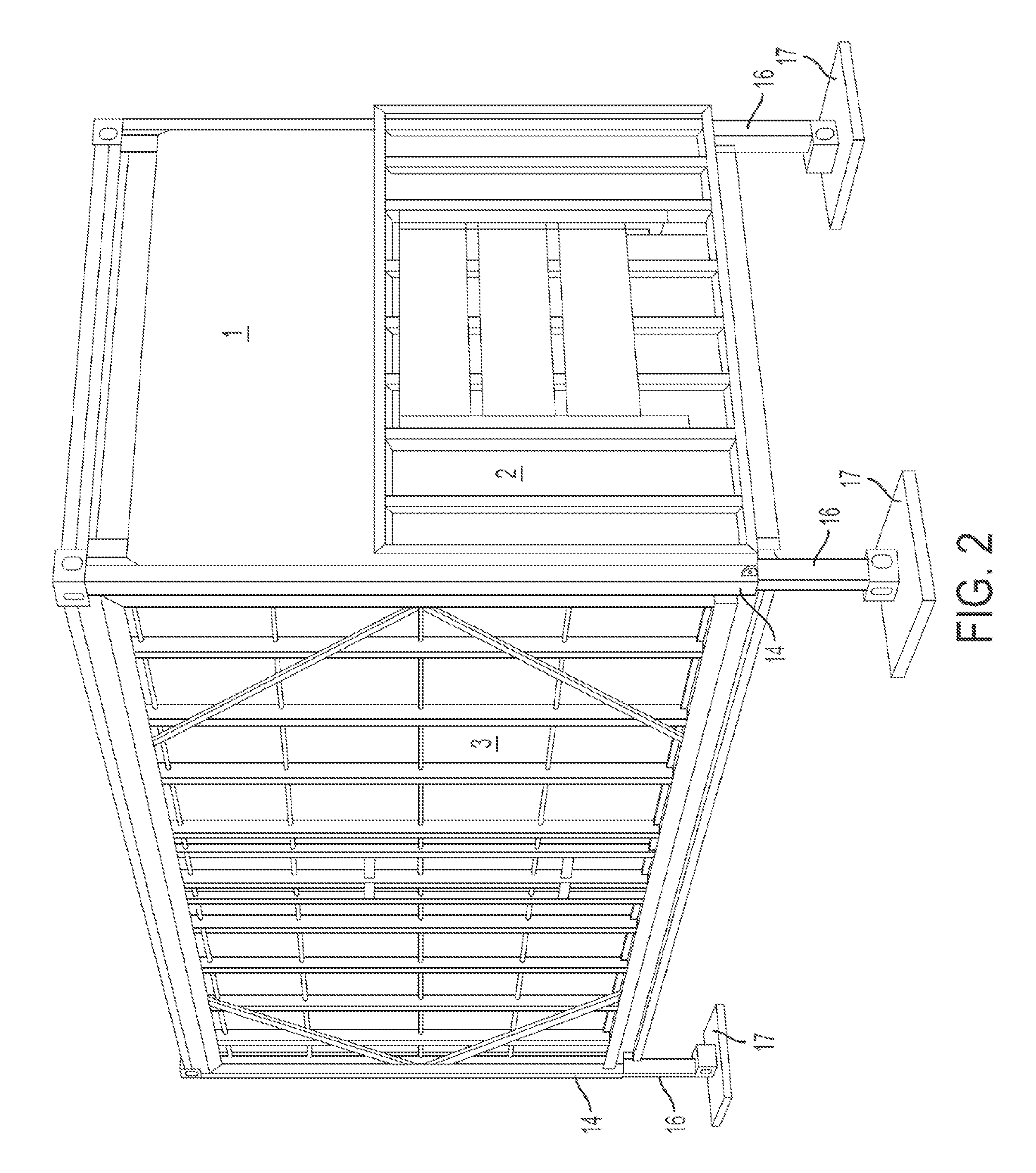

A modular assembly capable of converting from a shipping container configuration into a building unit, and from a building unit into a shipping container configuration. From the shipping container configuration, a plurality of frame panels and unit panels moveably connected to a frame of the modular assembly are selectively positioned to form the floors, walls, and ceilings of the building unit configuration thereby forming a living and / or commercial structure complete with electrical, water and sewage connections. The assembly may include an automated erection system, which may include a system of electric motors, gears, pulleys, cables, automated mechanical arms and electronic controls, located within the container structure of the modular assembly, and which interact with a plurality of frame panels and unit panels to deploy and retract the plurality of frame panels and unit panels for constructing the shipping container configuration and building unit configuration.

Owner:MODULAR CONTAINER SOLUTIONS

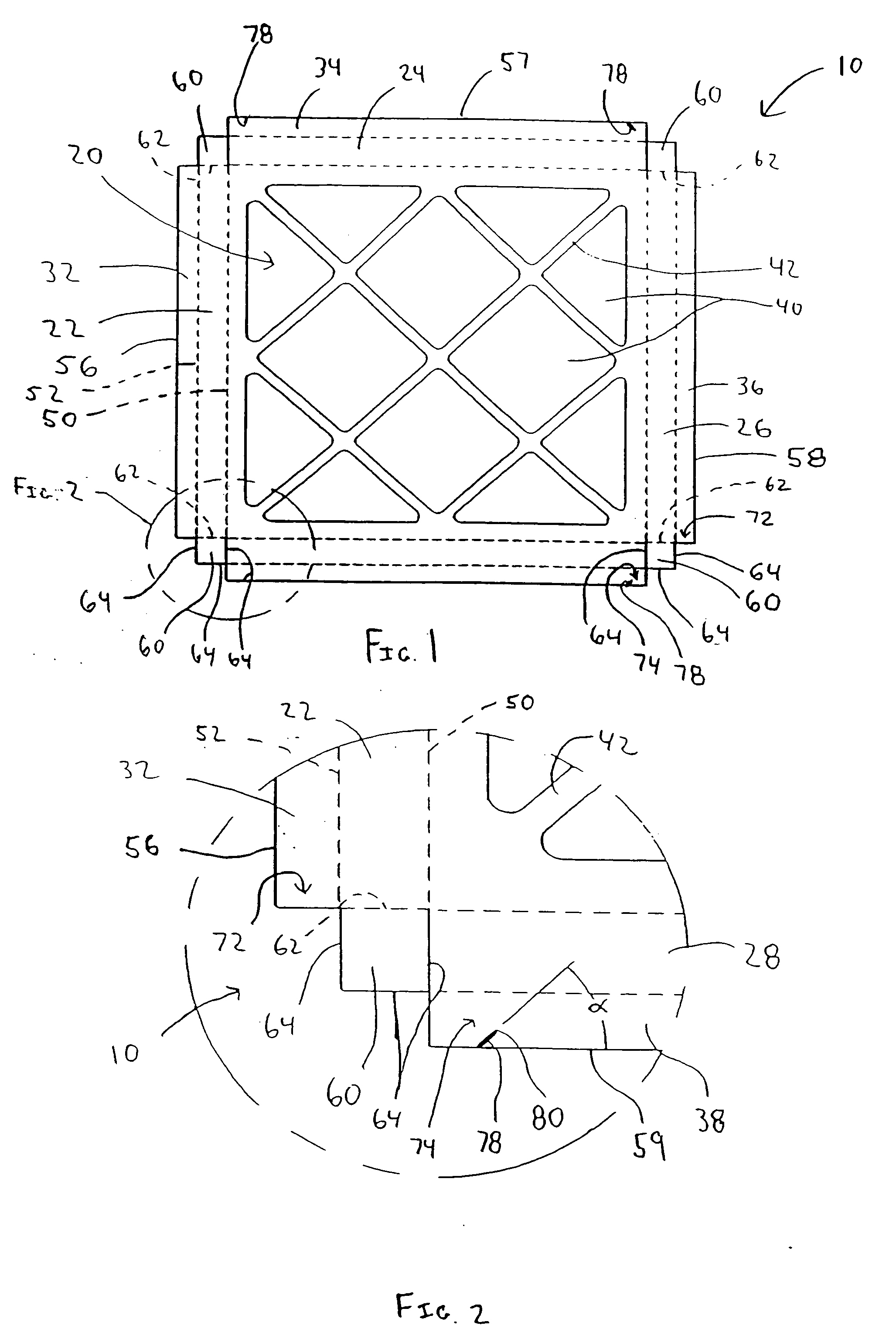

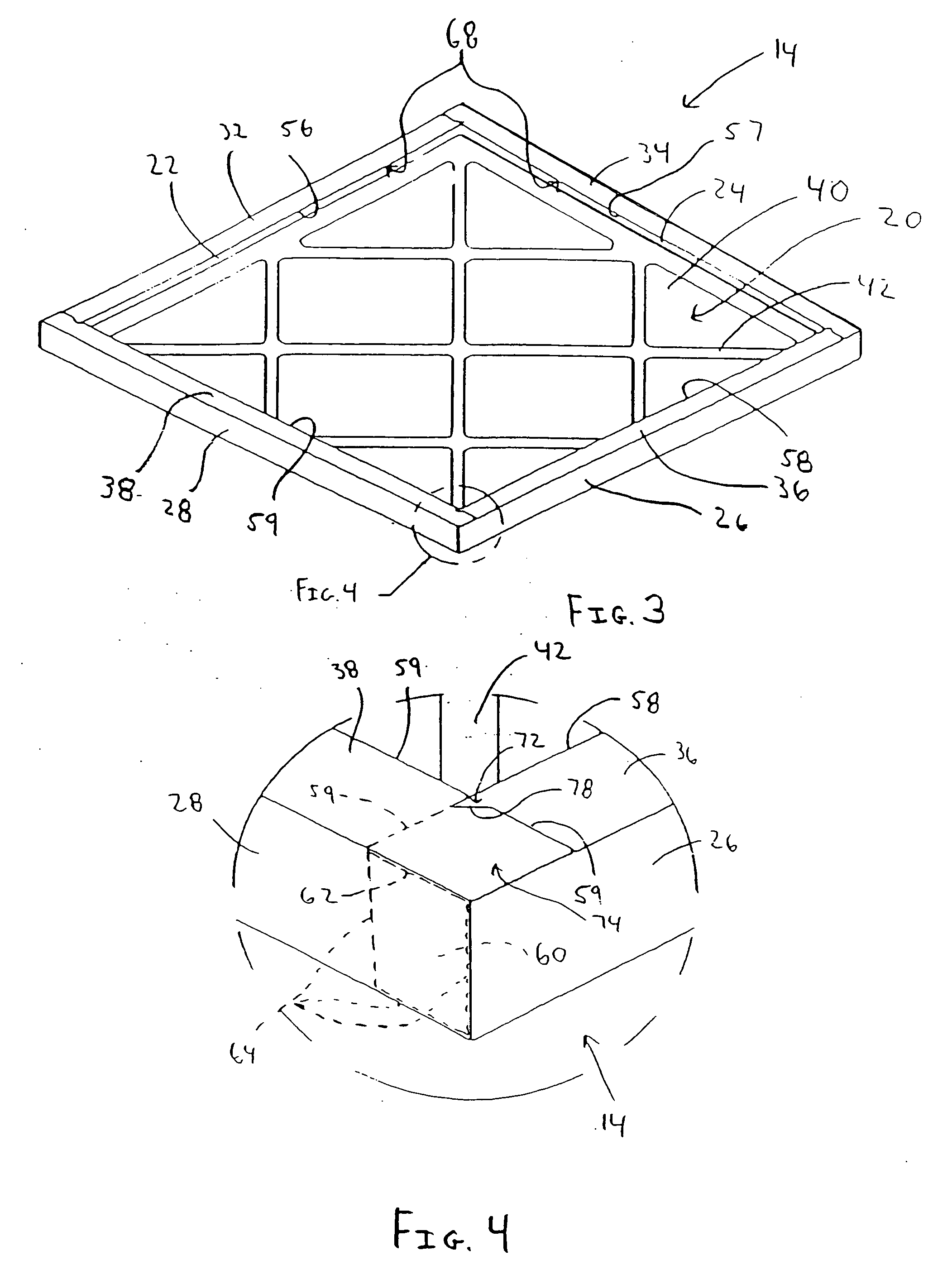

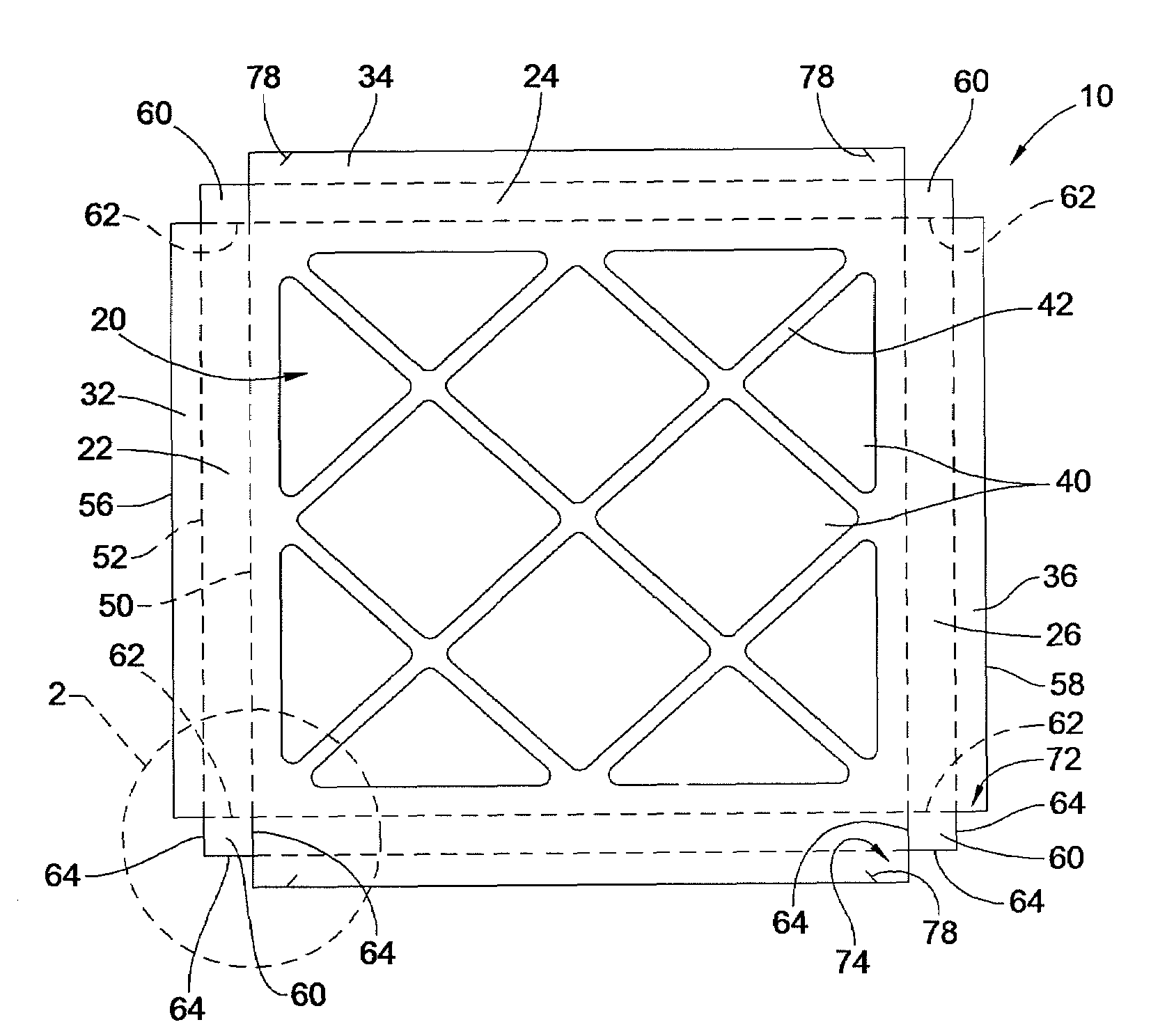

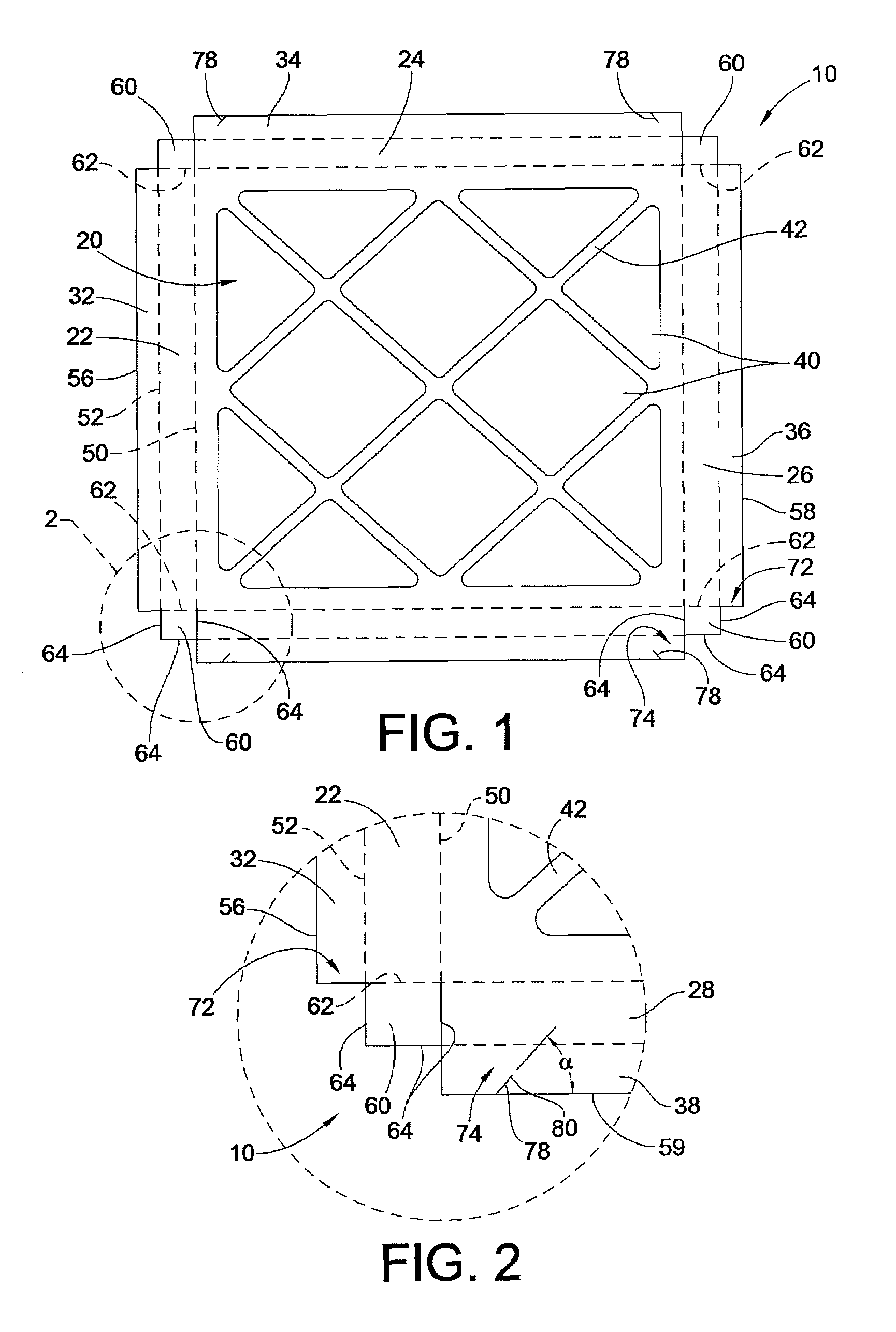

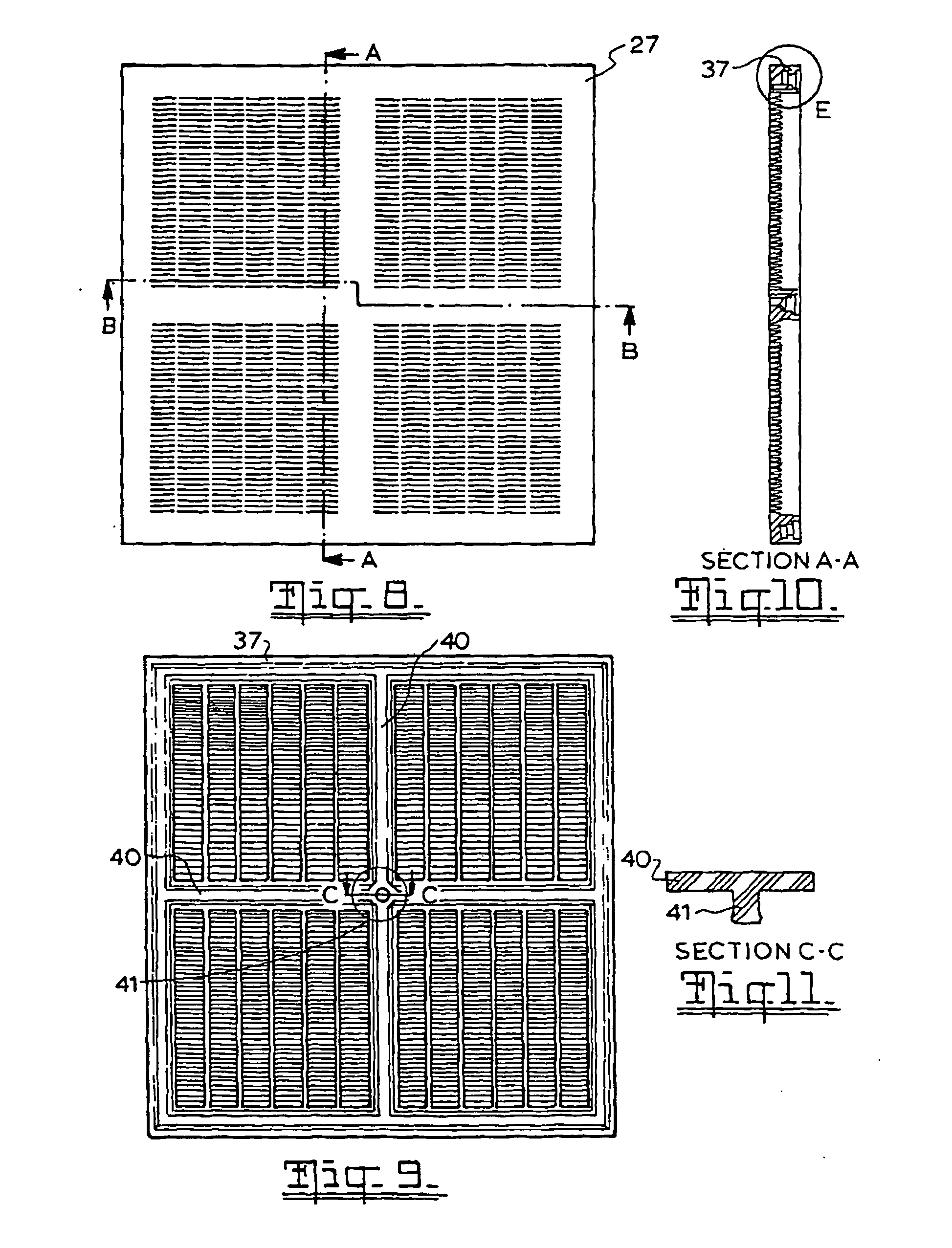

Panel filter with frame

ActiveUS20070294988A1Minimal modificationSimple materialDispersed particle filtrationFiltration separationEngineeringMechanical engineering

A panel filter frame and panel filter are provided. The panel filter frame is made from a one-piece die-cut blank of material. The die-cut blank includes a grill portion, four sidewall portions and four flap portions all integrally connected. Individual sidewall portions are interposed between a side of the grill portion and one of the four flap portions. The plurality of portions of the die-cut blank are interconnected at fold lines. The frame is formed when the die-cut blank is folded about the fold lines and the portions are secured in the folded position by at least a plurality of interlock receptacles formed in the terminating folded portion of the die-cut blank.

Owner:PARKER HANNIFIN CORP

Panel filter with frame

ActiveUS7537632B2Dispersed particle filtrationFiltration separationEngineeringMechanical engineering

A panel filter frame and panel filter are provided. The panel filter frame is made from a one-piece die-cut blank of material. The die-cut blank includes a grill portion, four sidewall portions and four flap portions all integrally connected. Individual sidewall portions are interposed between a side of the grill portion and one of the four flap portions. The plurality of portions of the die-cut blank are interconnected at fold lines. The frame is formed when the die-cut blank is folded about the fold lines and the portions are secured in the folded position by at least a plurality of interlock receptacles formed in the terminating folded portion of the die-cut blank.

Owner:PARKER HANNIFIN CORP

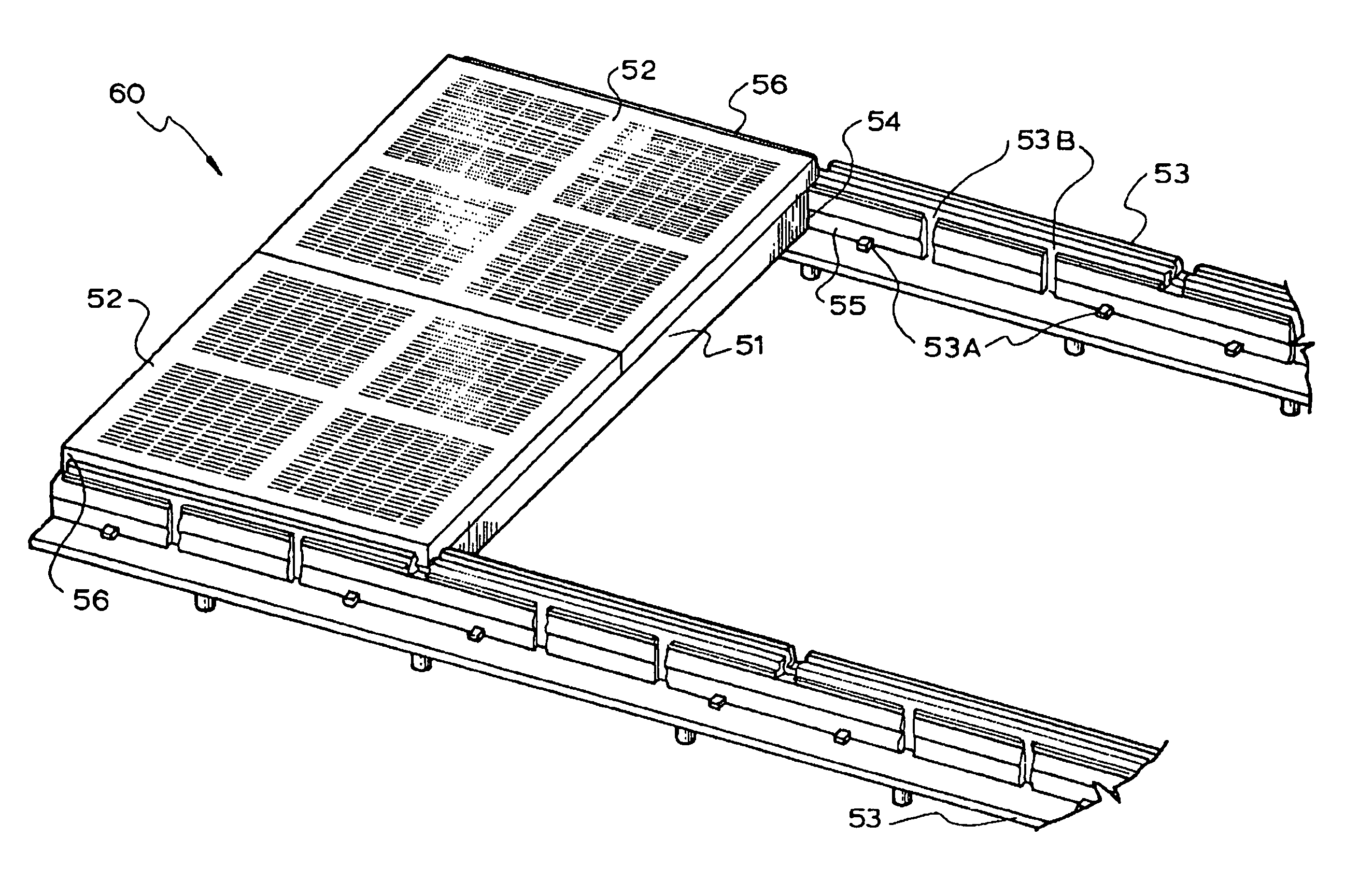

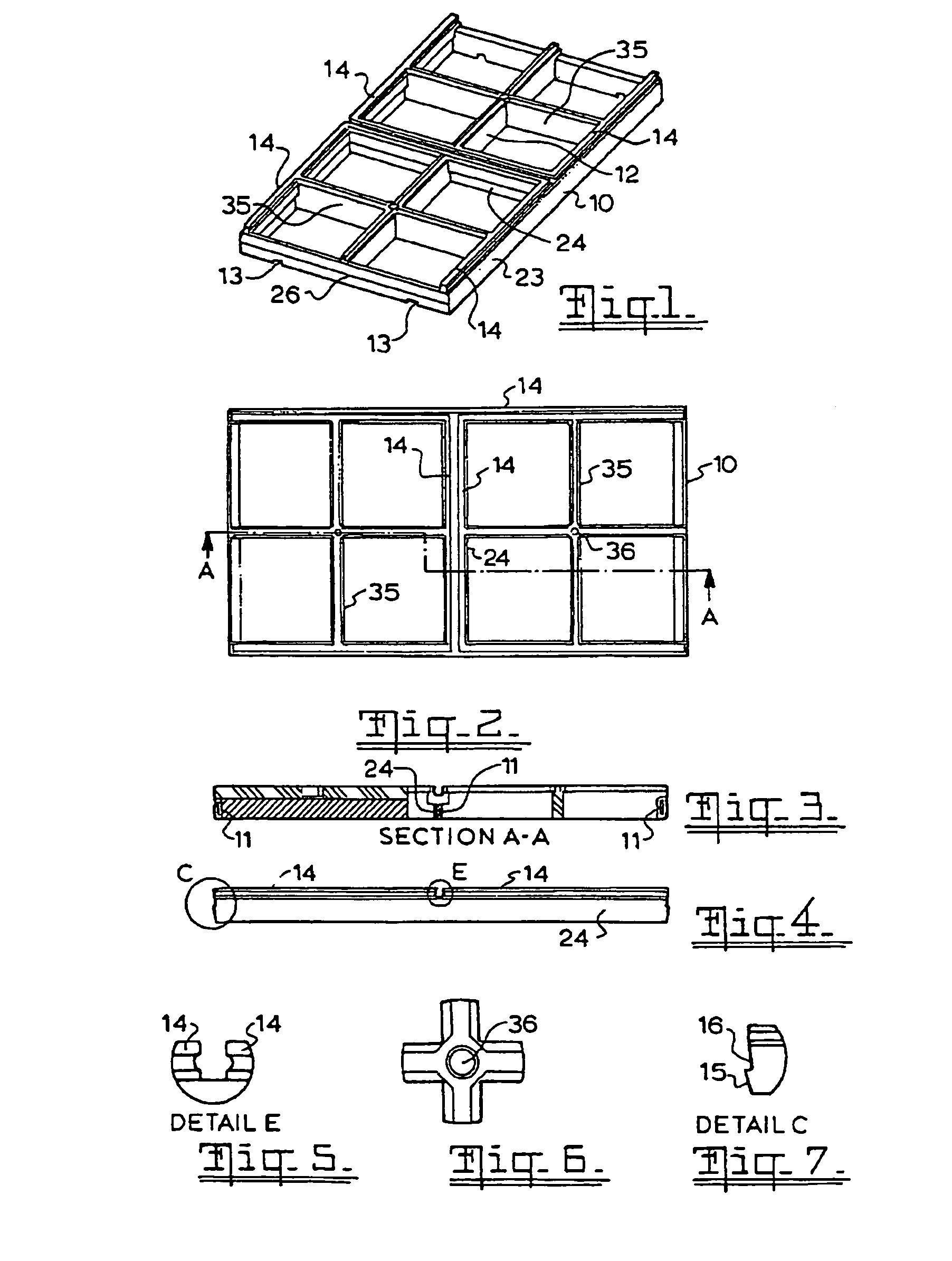

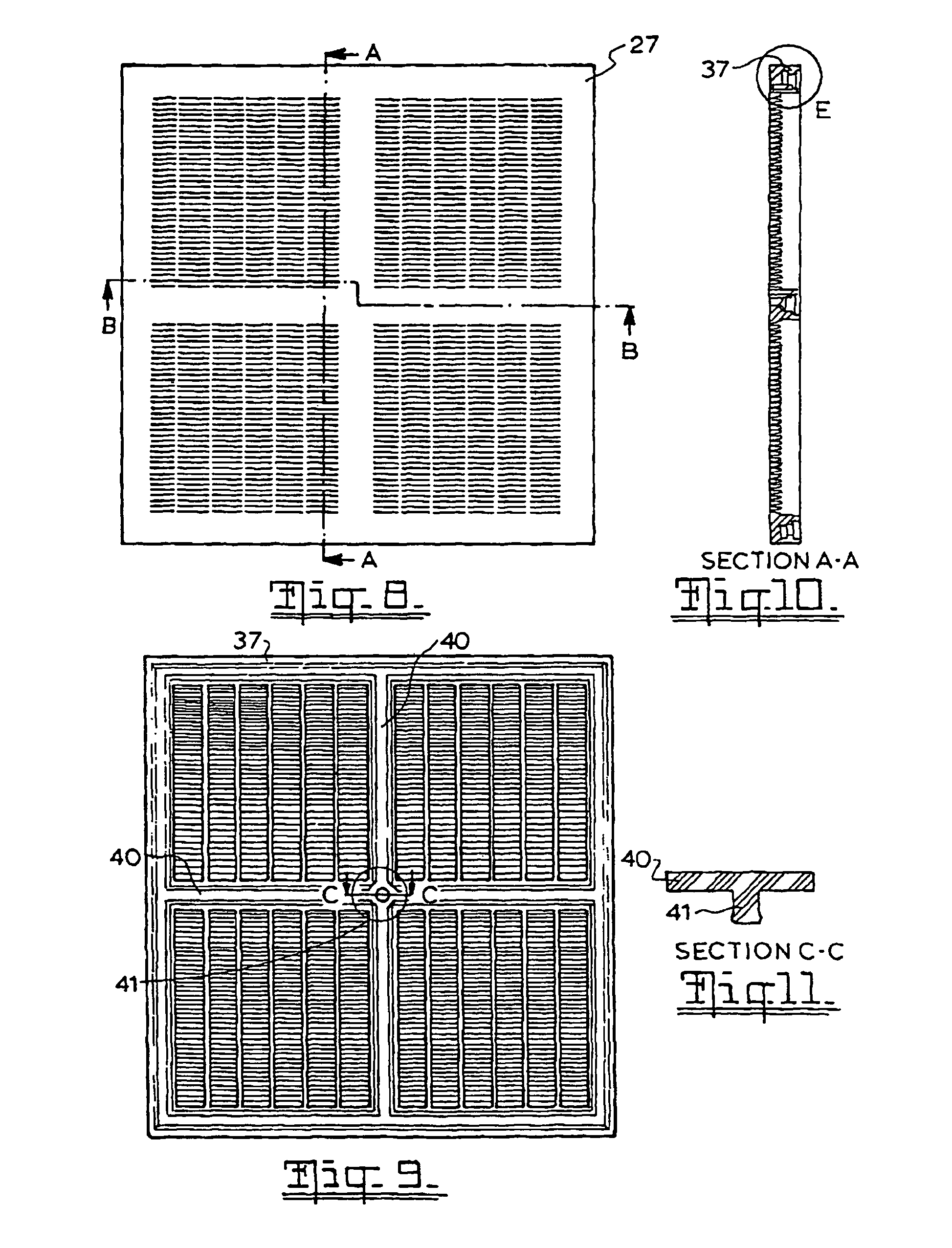

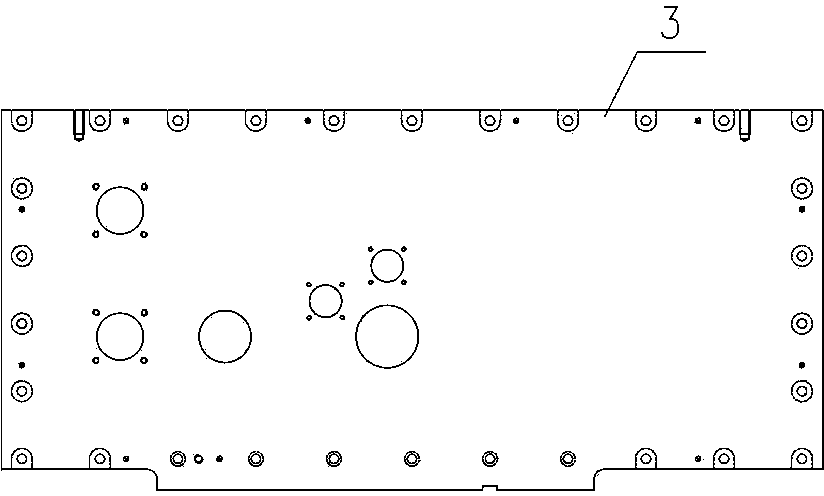

Screen module for vibratory screening apparatus

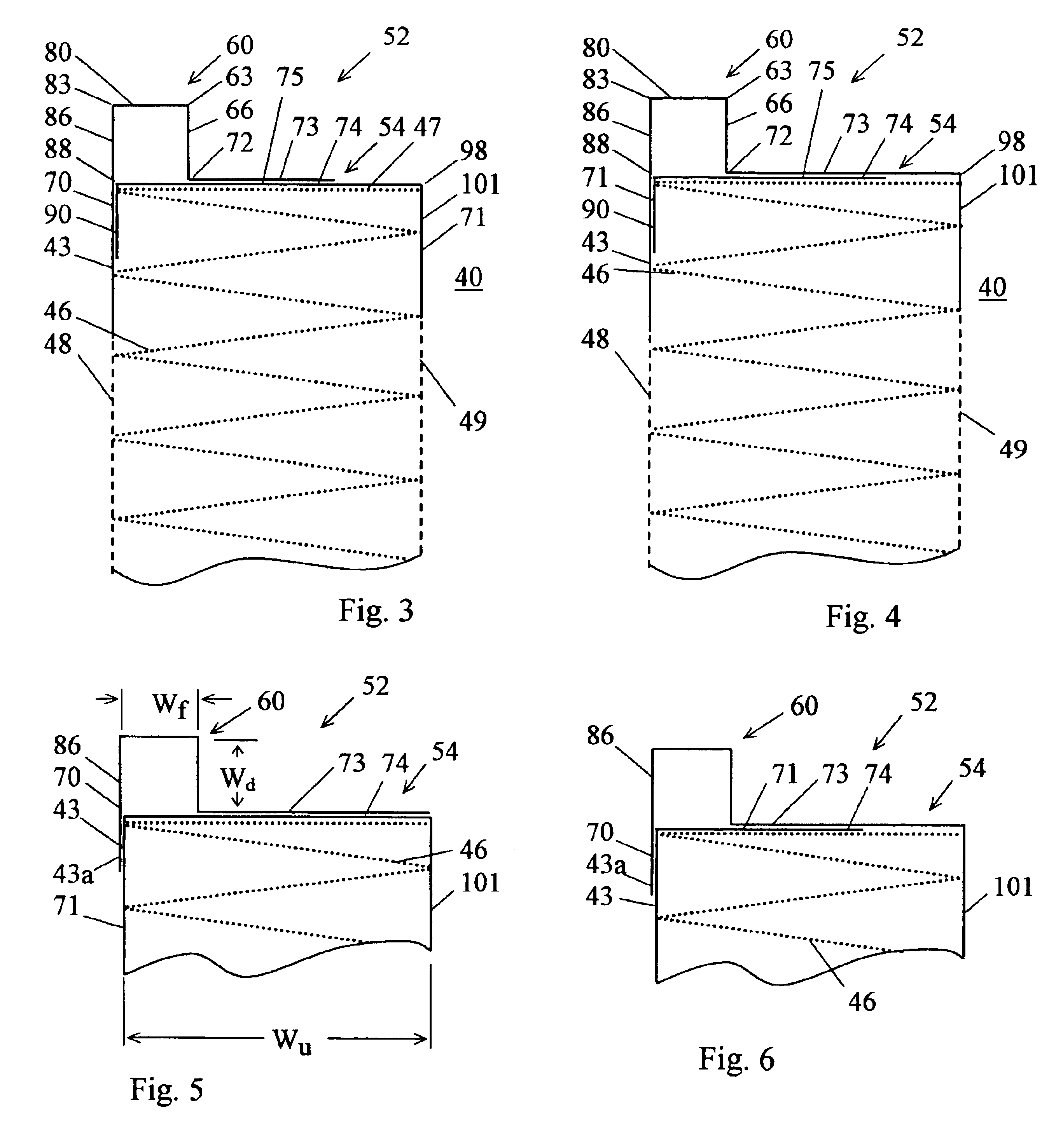

ActiveUS20090301945A1Alleviates excessive flexIncrease the degree of bendingSievingScreeningEngineeringFrame and panel

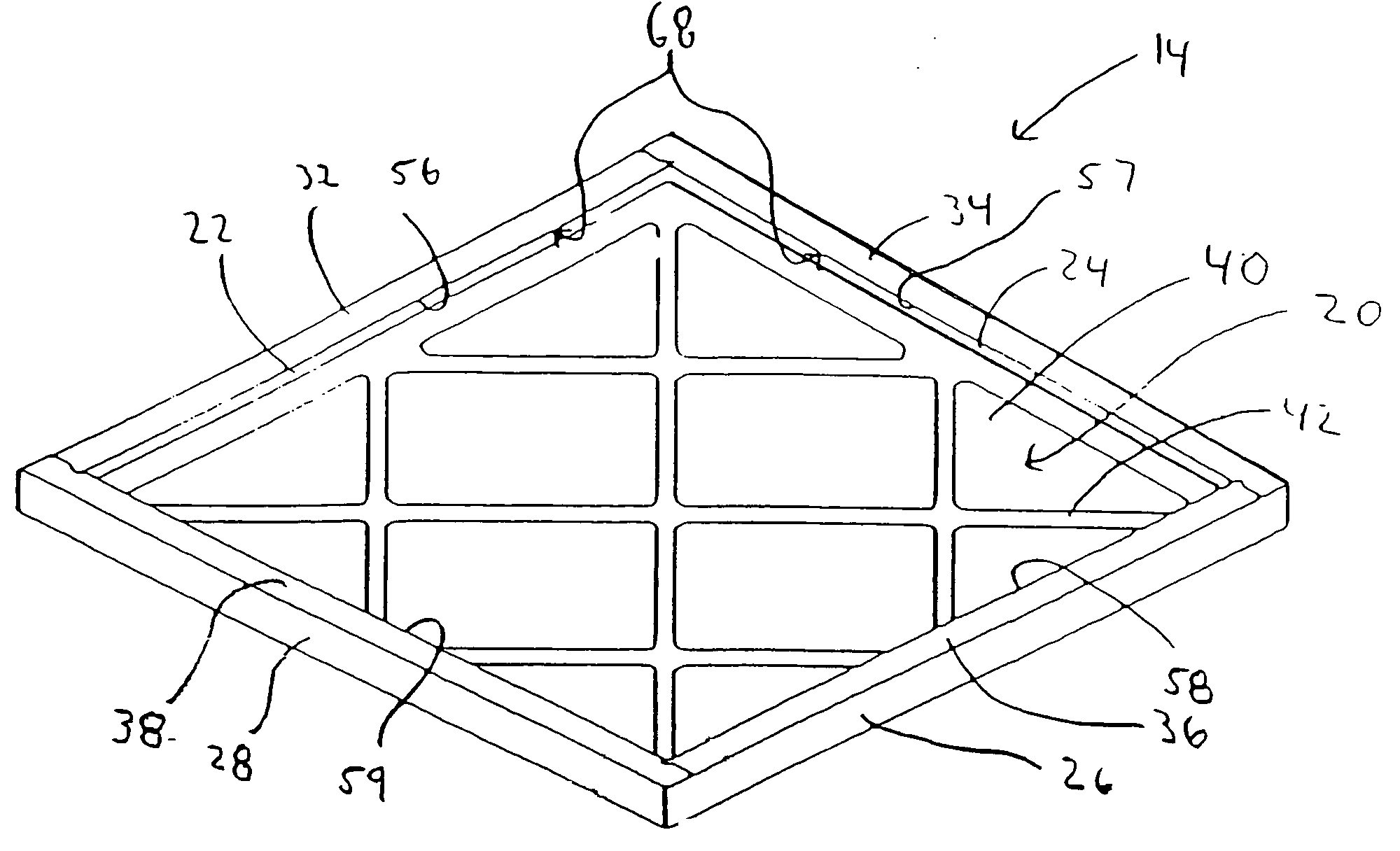

The invention provides a screen module for use on vibratory screening apparatus. The screen module includes: a panel frame having opposed side portions joined by opposed end portions, the end portions being configured for locating the panel frame between spaced panel support rails of the vibratory screening apparatus; at least one intermediate portion extending between the opposed side portions and / or opposed end portions and dividing the panel frame into panel portions; the side portions and said at least one intermediate portion having engagement formations provided on upper surfaces thereof that, together with engagement formations provided on each of the panel support rails of the vibratory screening apparatus, in use, form peripheral panel engagement formations about the panel portions; and at least one pair of screen panels, said screen panels overlying respective panel portions of the panel frame and including complementary engagement formations on an underside periphery thereof for engagement with the peripheral panel engagement formations, defined by the engagement formations of the panel frame and panel support rails.

Owner:F L SMIDTH & CO AS

Screen module for vibratory screening apparatus

ActiveUS8127932B2Alleviates excessive flexFacilitates easy assembly of moduleSievingScreeningEngineeringFrame and panel

The invention provides a screen module for use on vibratory screening apparatus. The screen module includes: a panel frame having opposed side portions joined by opposed end portions, the end portions being configured for locating the panel frame between spaced panel support rails of the vibratory screening apparatus; at least one intermediate portion extending between the opposed side portions and / or opposed end portions and dividing the panel frame into panel portions; the side portions and said at least one intermediate portion having engagement formations provided on upper surfaces thereof that, together with engagement formations provided on each of the panel support rails of the vibratory screening apparatus, in use, form peripheral panel engagement formations about the panel portions; and at least one pair of screen panels, said screen panels overlying respective panel portions of the panel frame and including complementary engagement formations on an underside periphery thereof for engagement with the peripheral panel engagement formations, defined by the engagement formations of the panel frame and panel support rails.

Owner:F L SMIDTH & CO AS

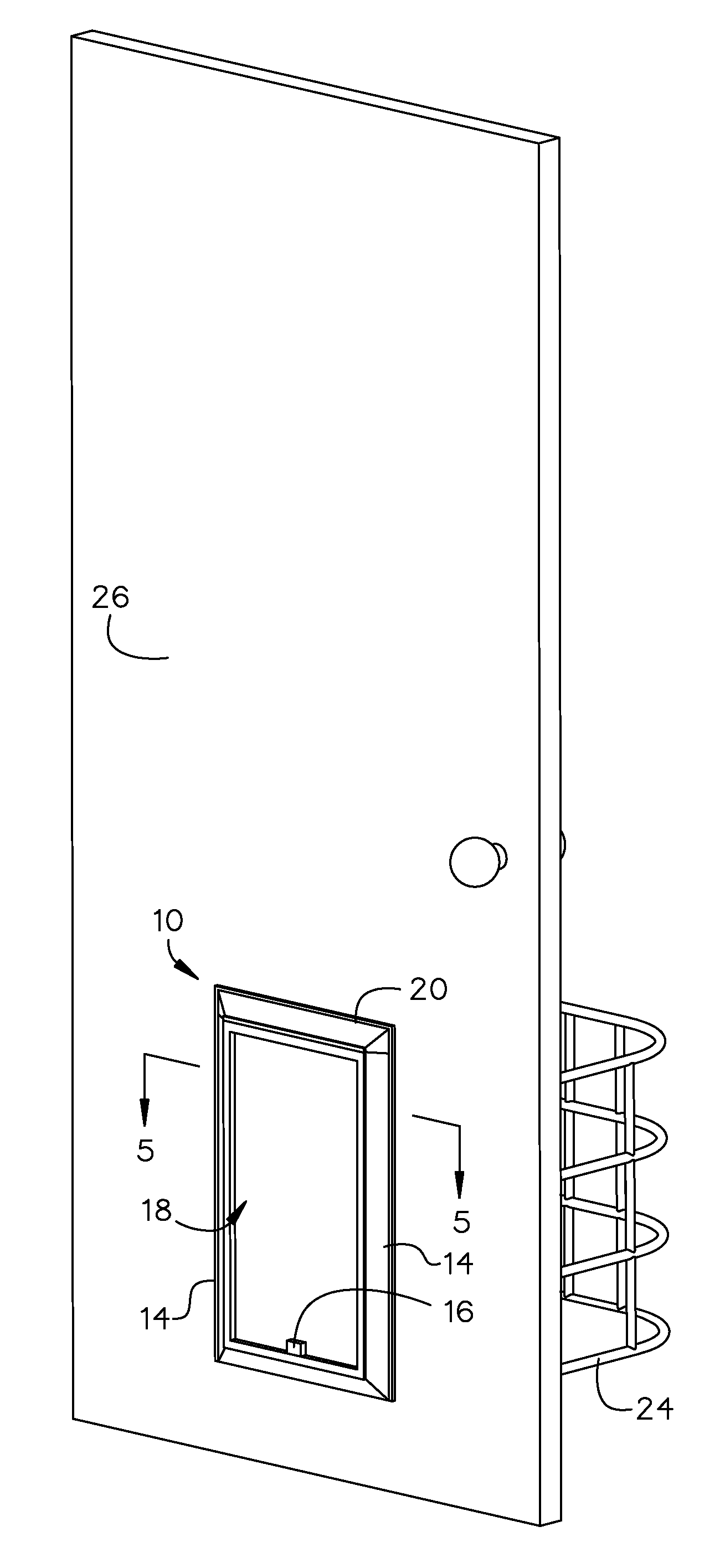

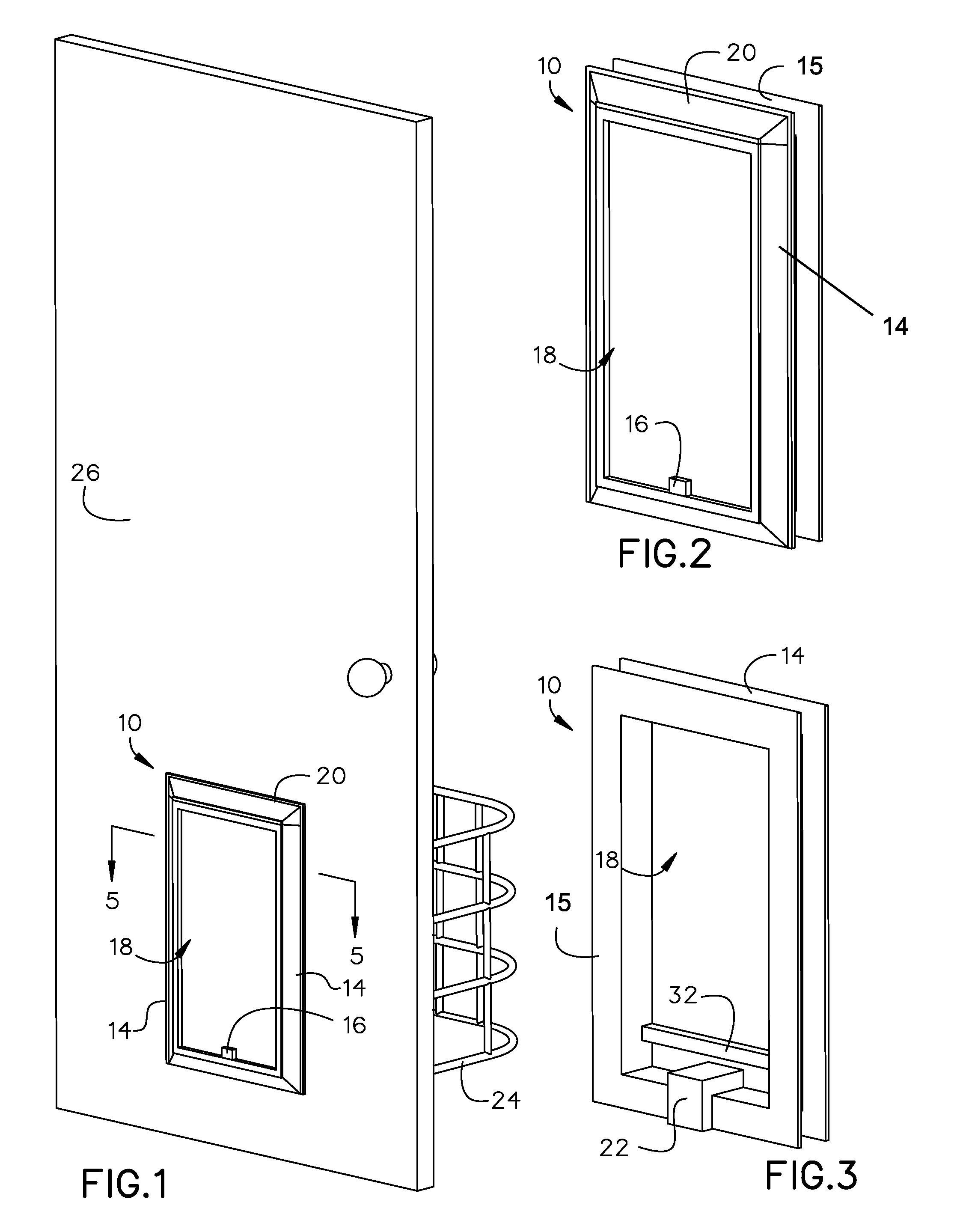

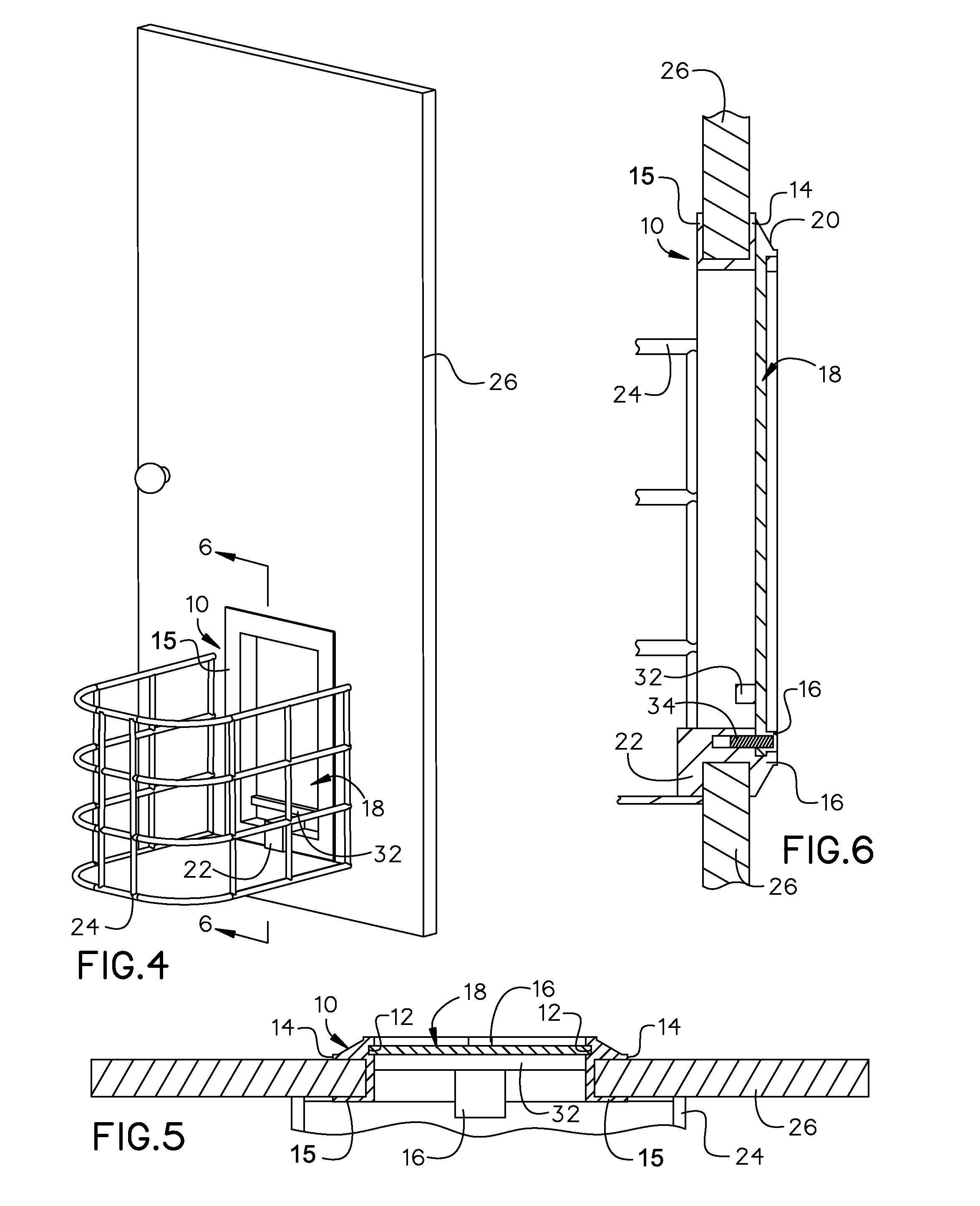

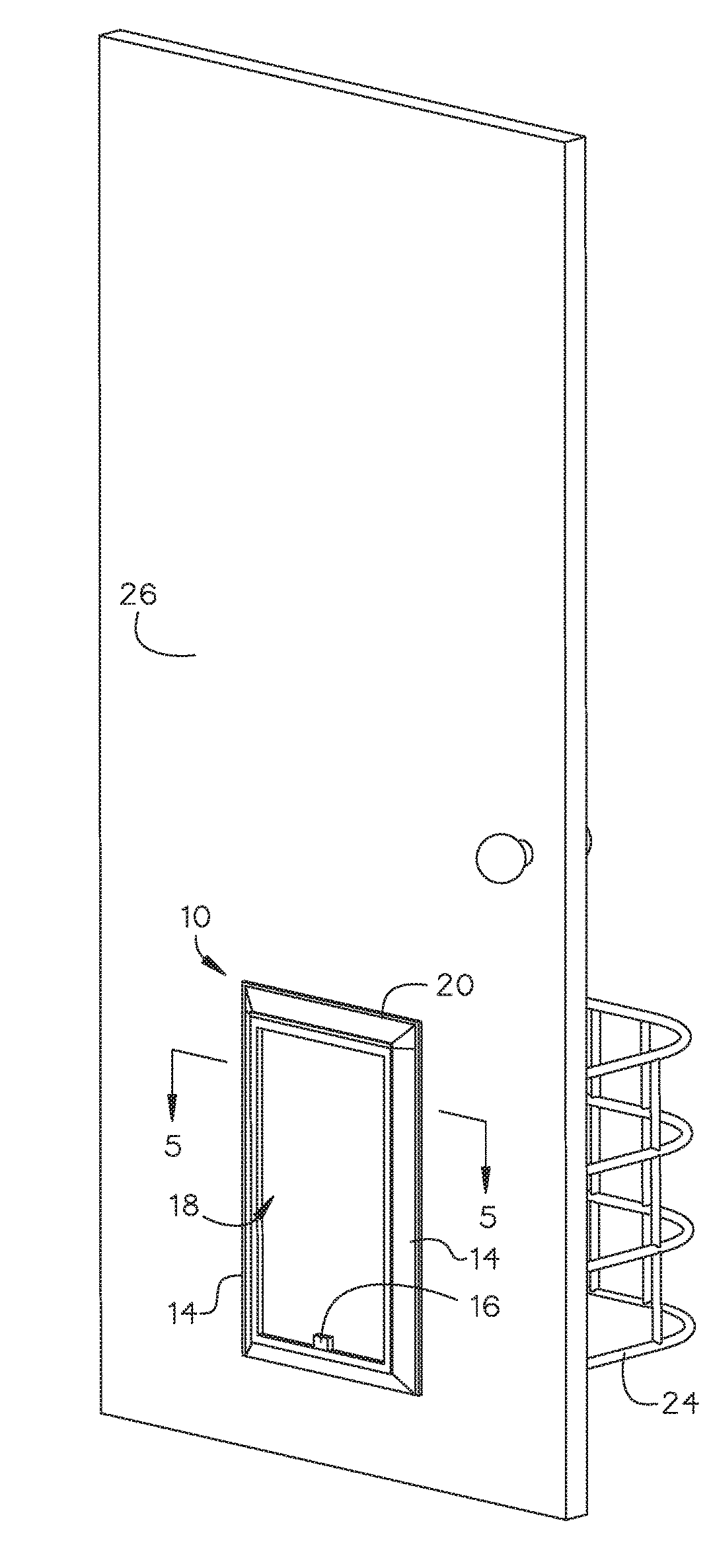

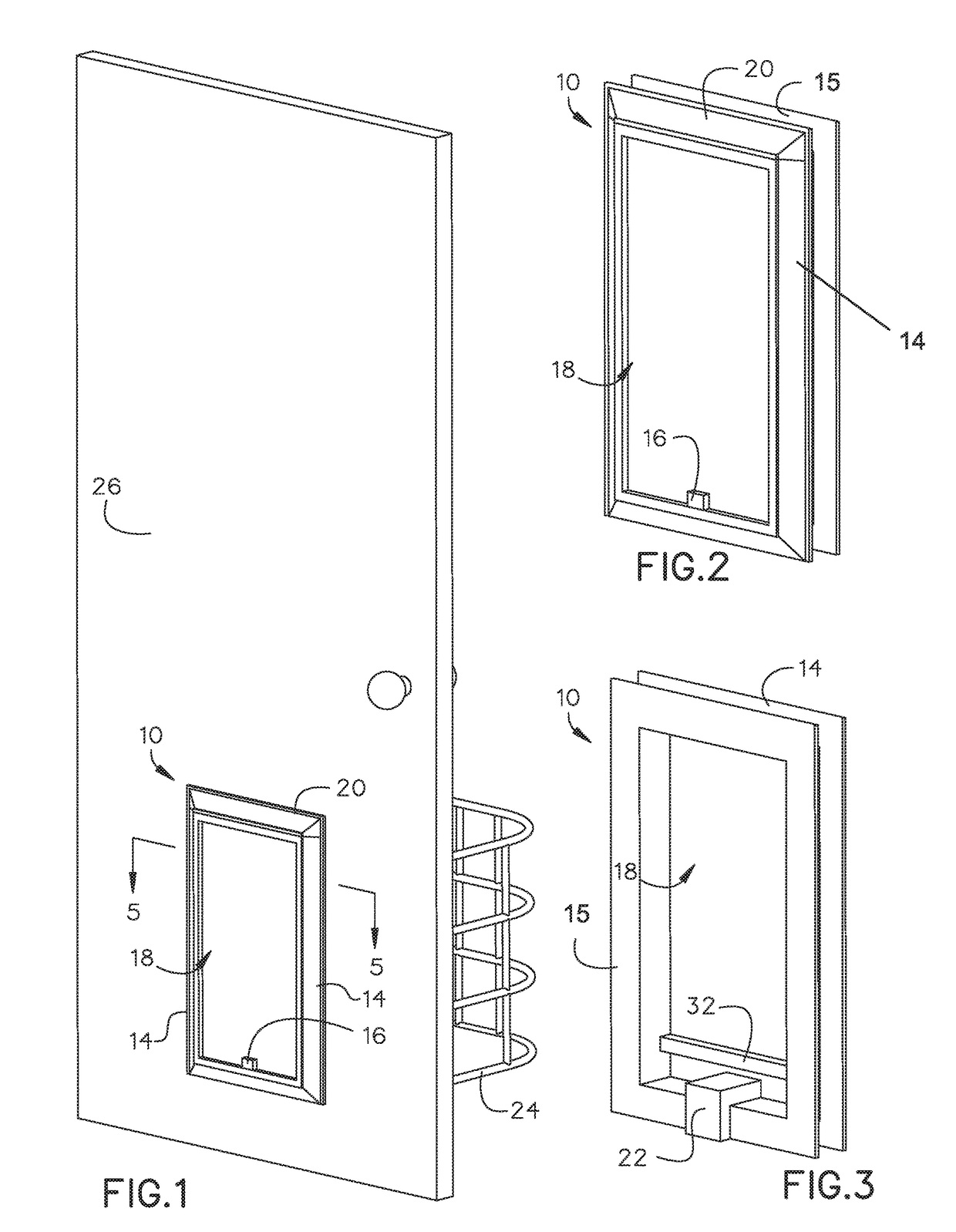

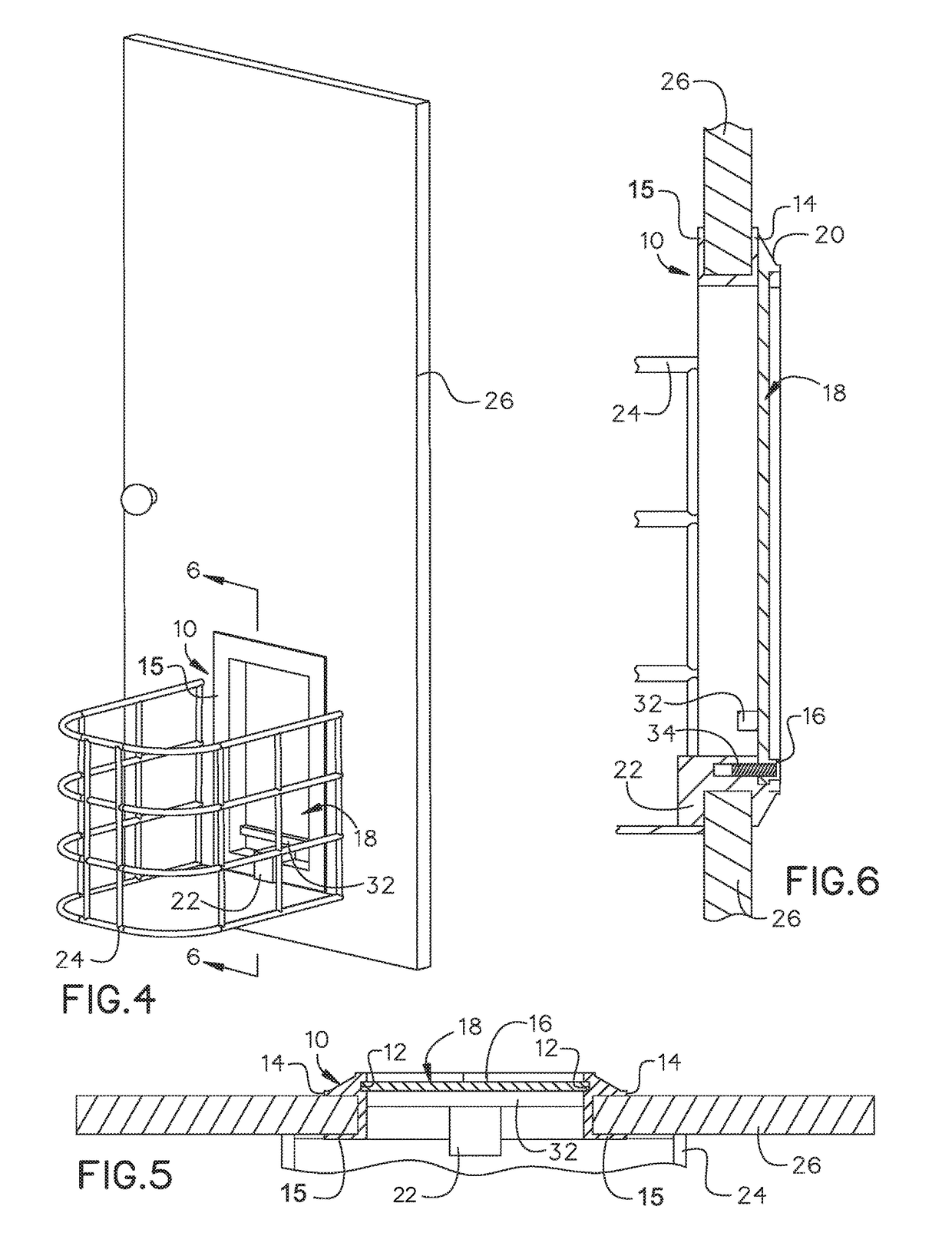

Delivery door

A delivery door may include a frame having a slot, an interior flange and an exterior flange. A panel may be attached to the frame and comprise a closed configuration and an open configuration. A securing device may be connected to the frame and the panel. The securing device may be a remote accessed internet enabled lock assembly. In certain embodiments, the panel may have a handle and a stopper. The panel may also be motorized. The delivery door may include a receptacle attached to the internal flange and the frame. The delivery door may be attached to a cut out portion of the structure. The securing device may be controlled from a wireless device.

Owner:WANJOHI SAMUEL SOLOMON

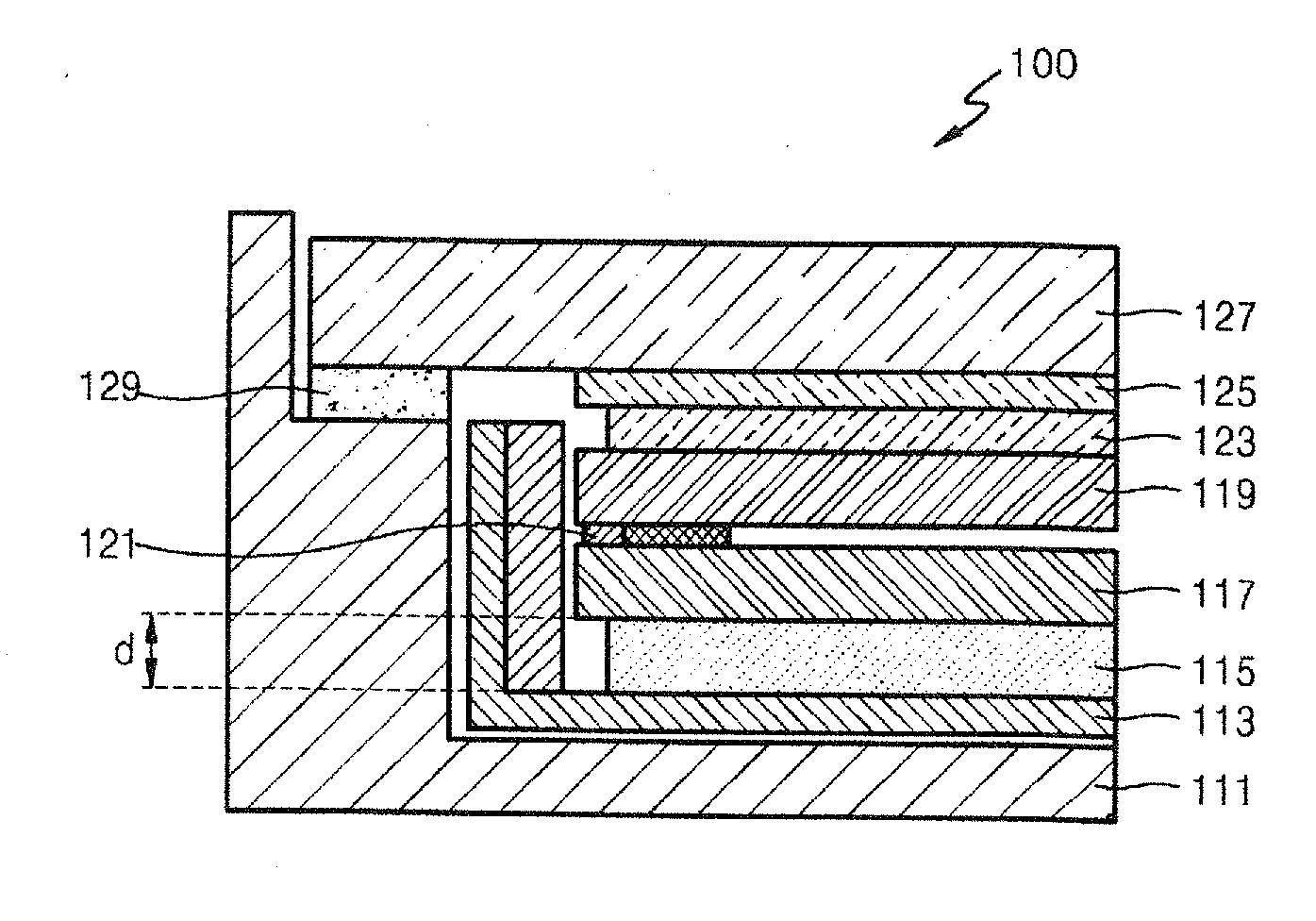

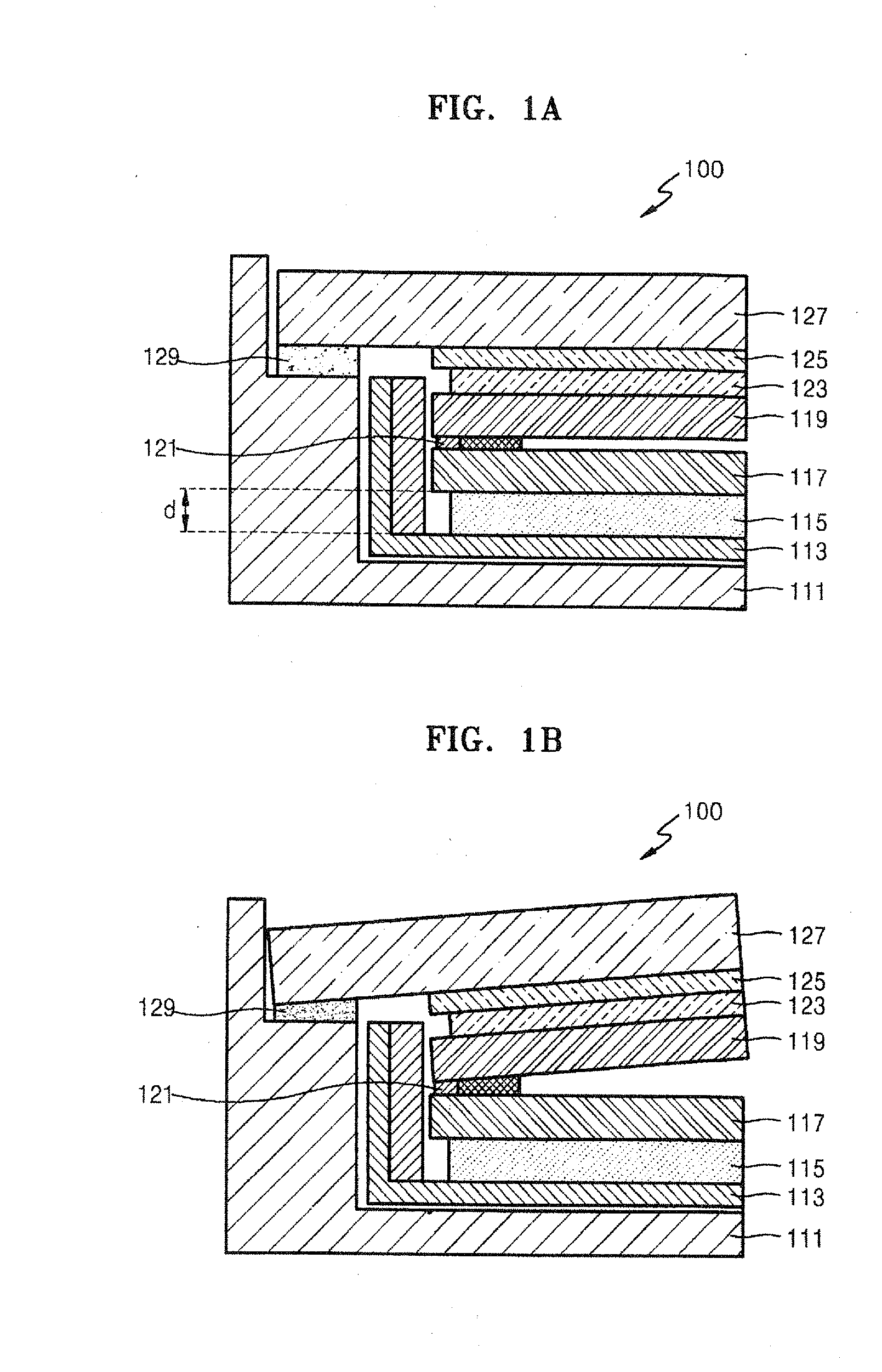

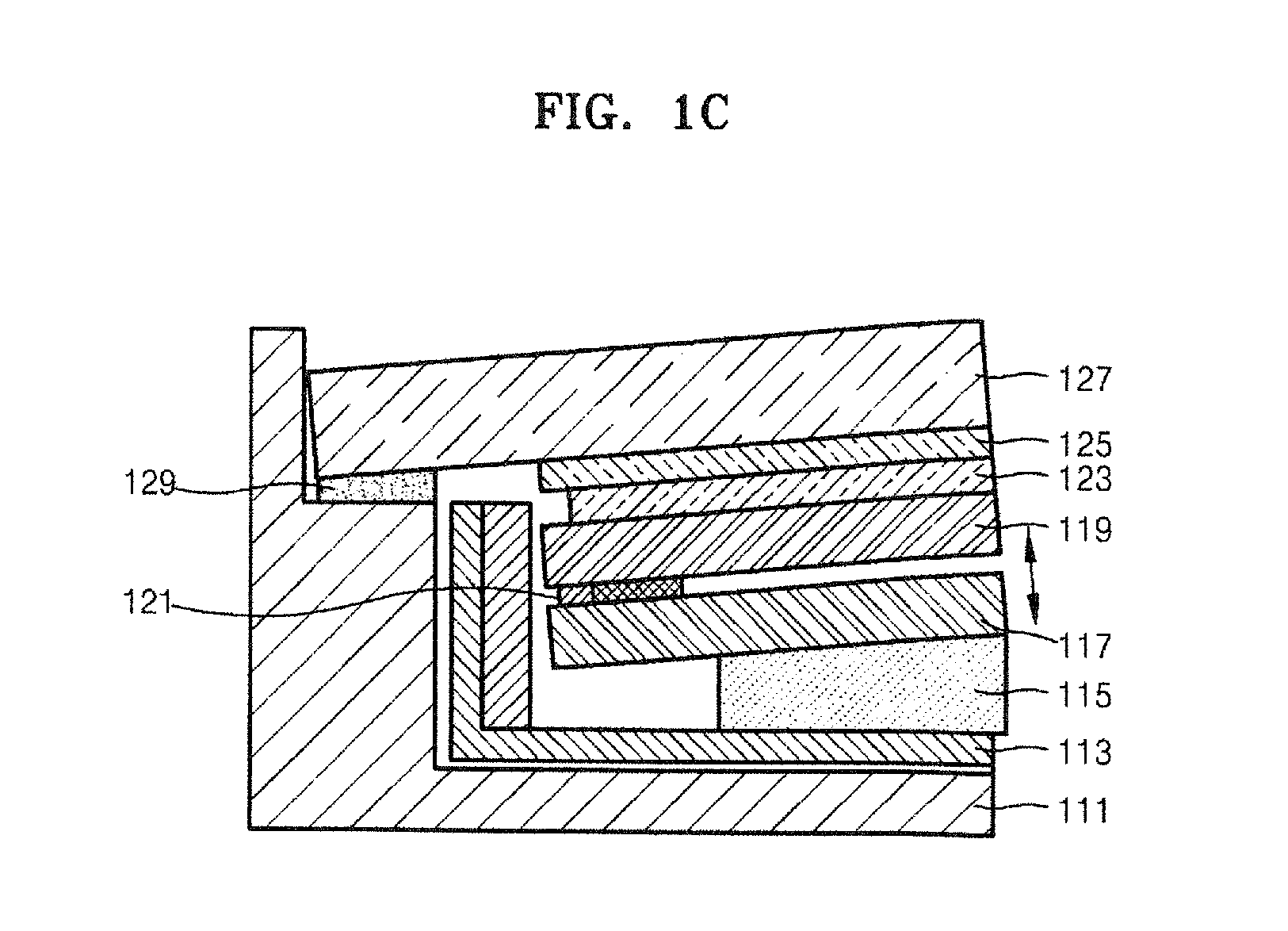

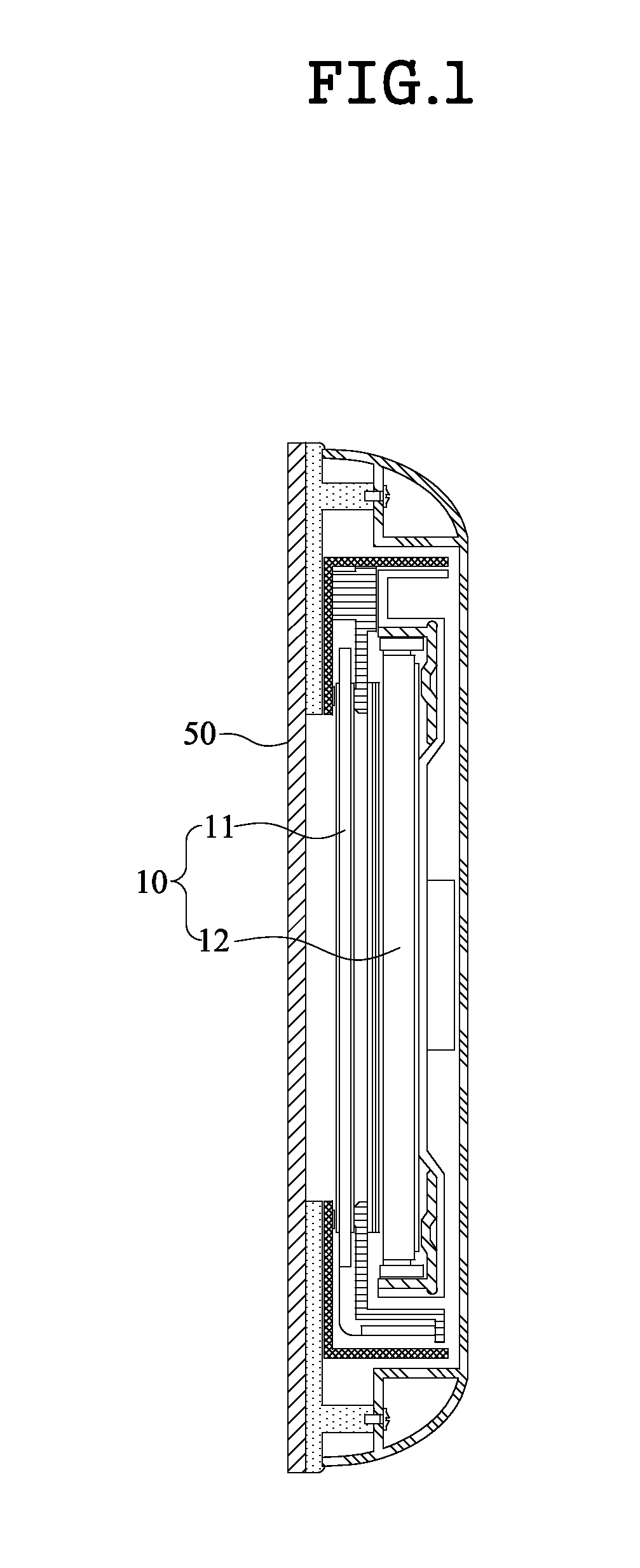

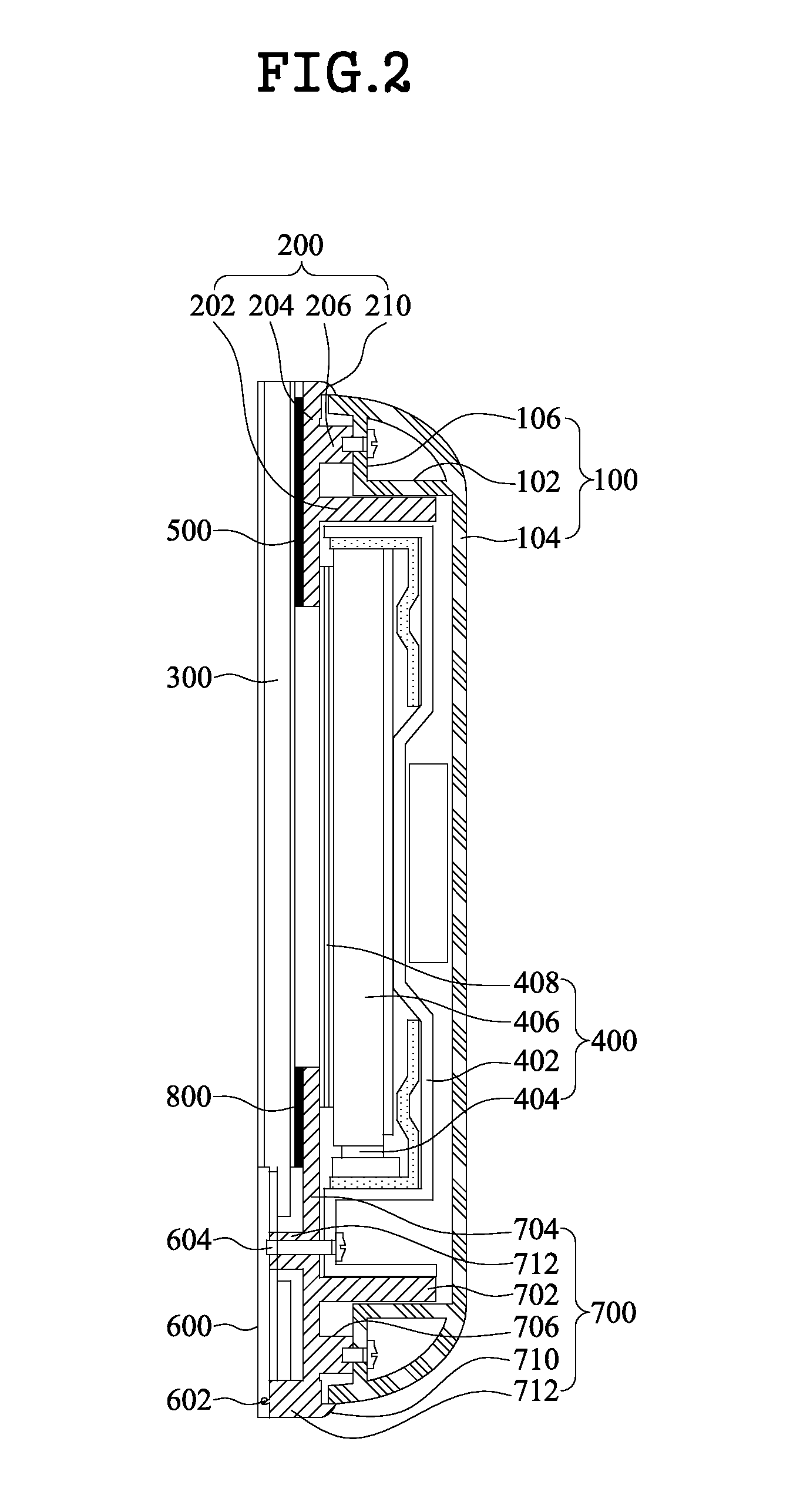

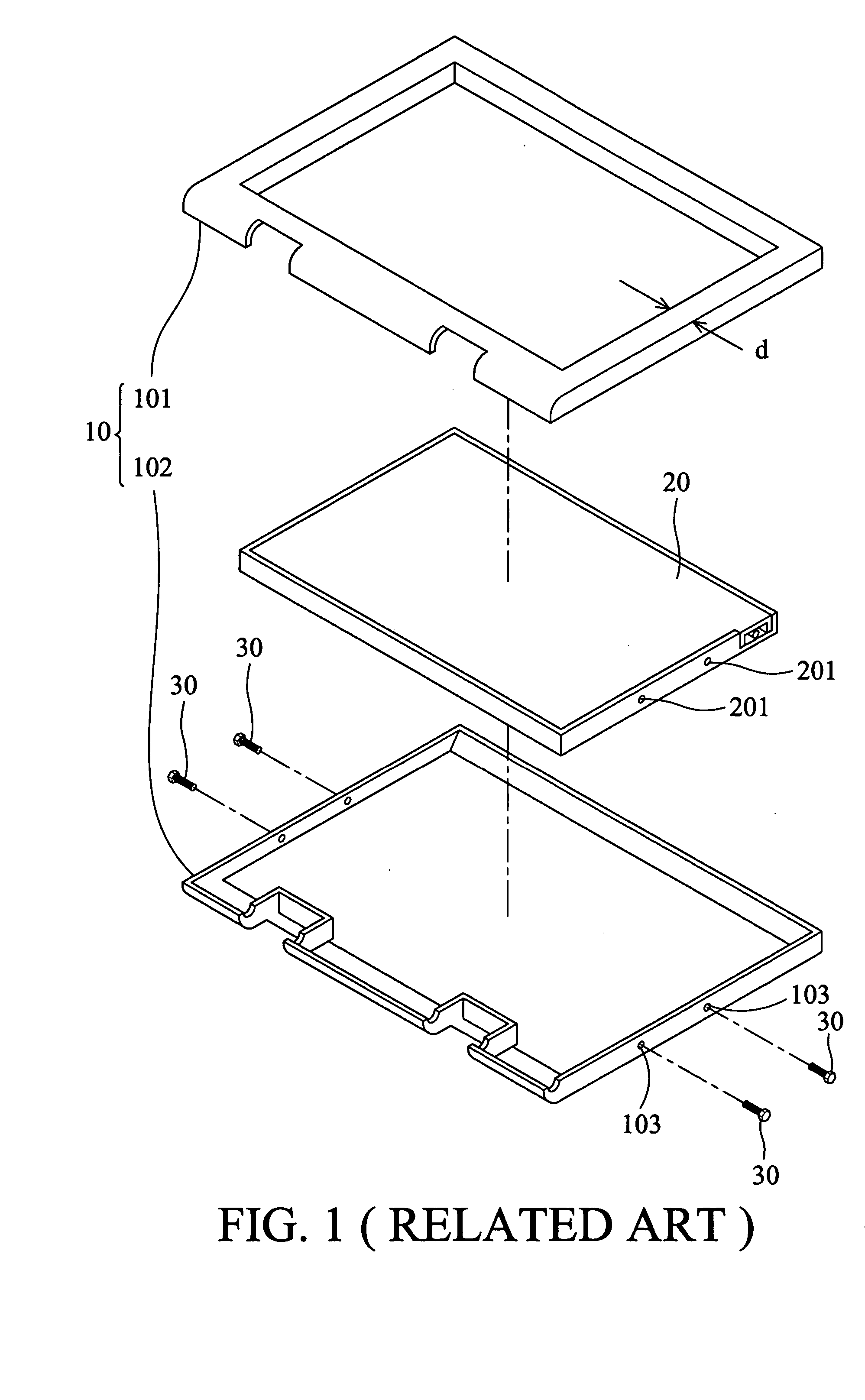

Organic light-emitting display device and electronic equipment including the same

ActiveUS20110242743A1Improve impact resistanceReduce external impactCasings/cabinets/drawers detailsElectrical apparatus contructional detailsDisplay deviceEngineering

An organic light-emitting display device having improved impact resistance by including a buffer member for reducing an external impact, and electronic equipment including the organic light-emitting display device. The organic light-emitting display device includes a frame, a panel assembly and a compression buffer tape arranged between the frame and the panel assembly, wherein the panel assembly includes a first substrate, a display unit arranged on a surface of the first substrate, a second substrate arranged to face the first substrate and a sealant arranged along edges of the first substrate and the second substrate to attach the second substrate to the first substrate.

Owner:SAMSUNG DISPLAY CO LTD

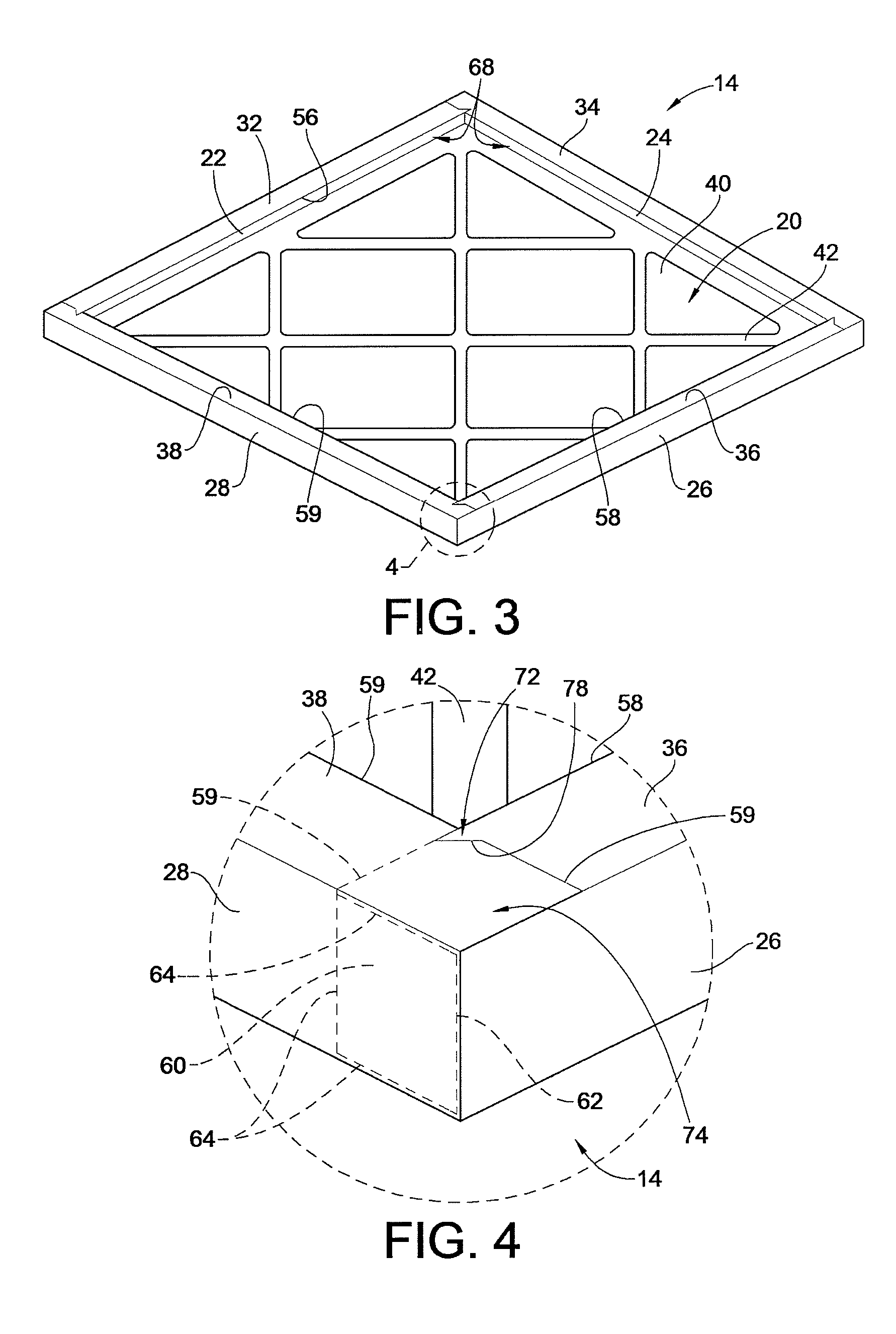

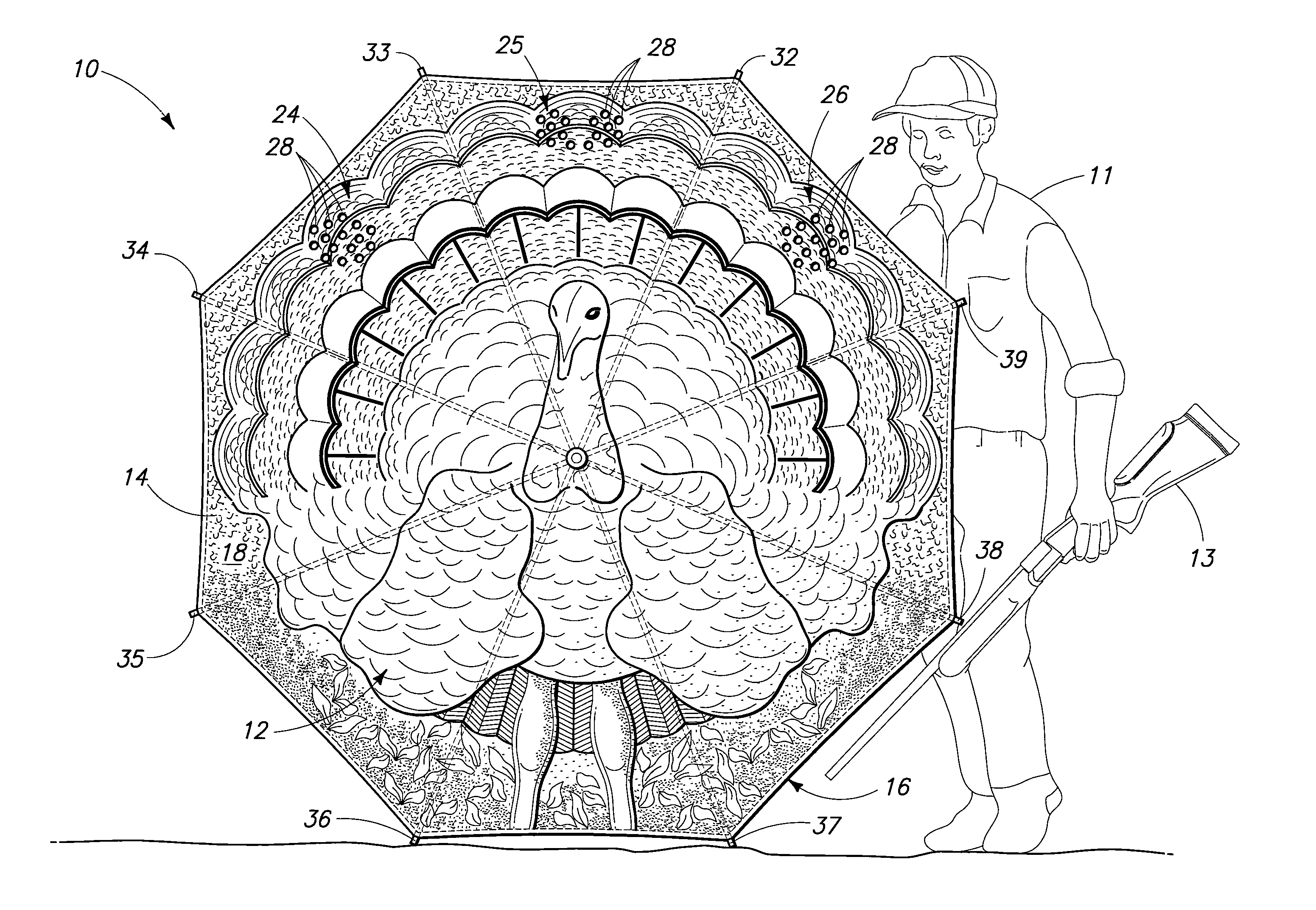

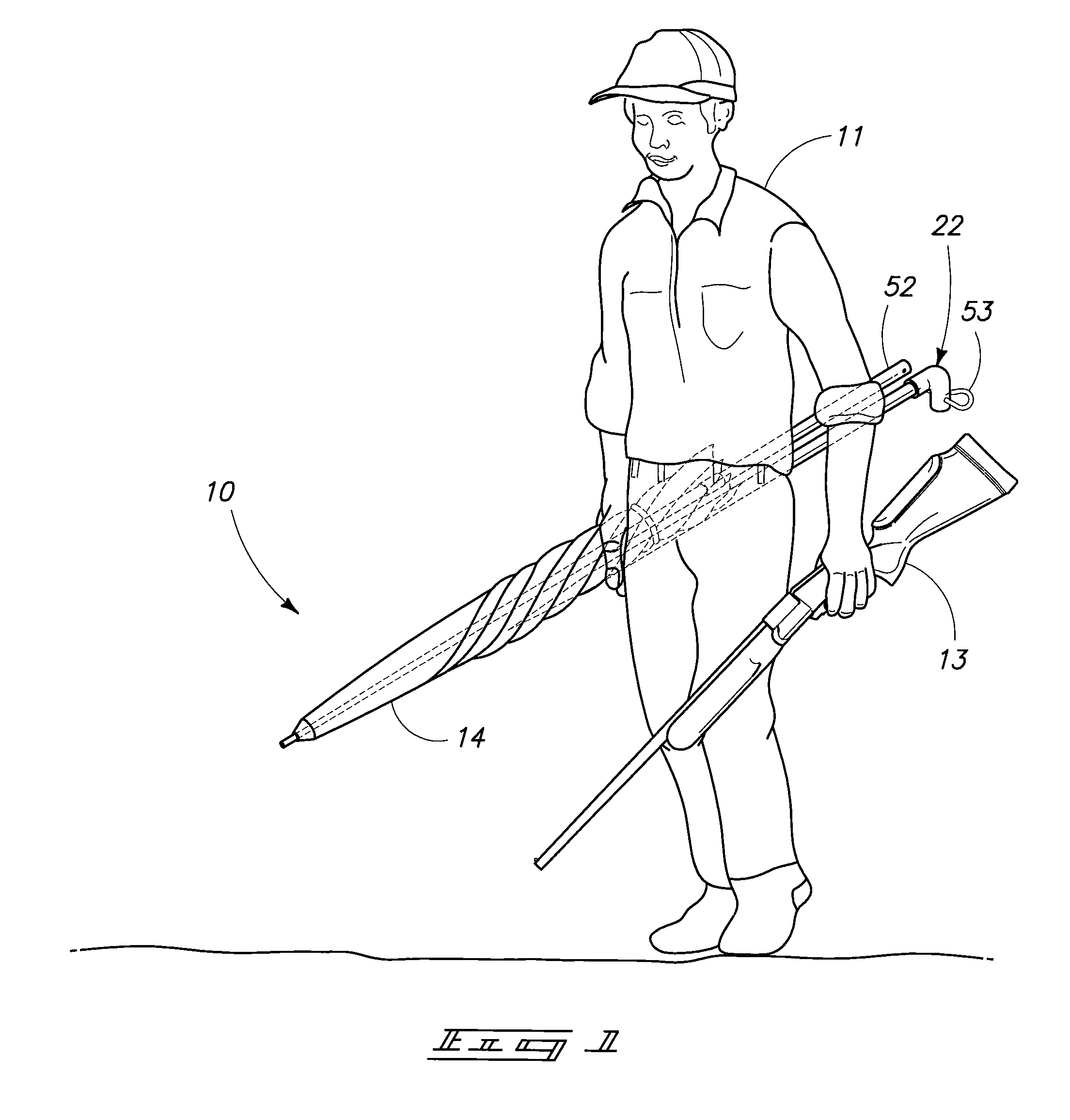

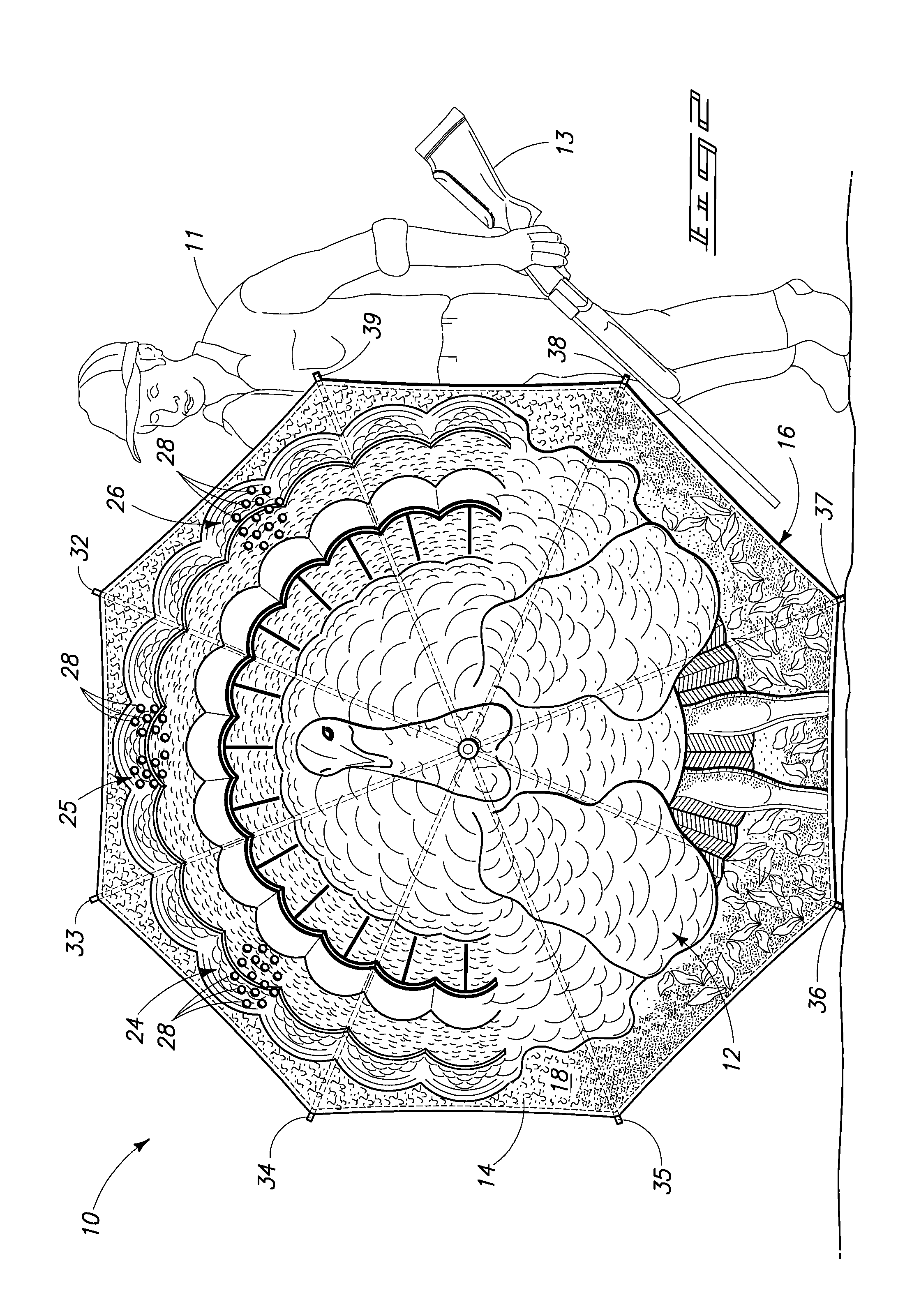

Collapsible hunting blind

Owner:MONTECUCCO TOM

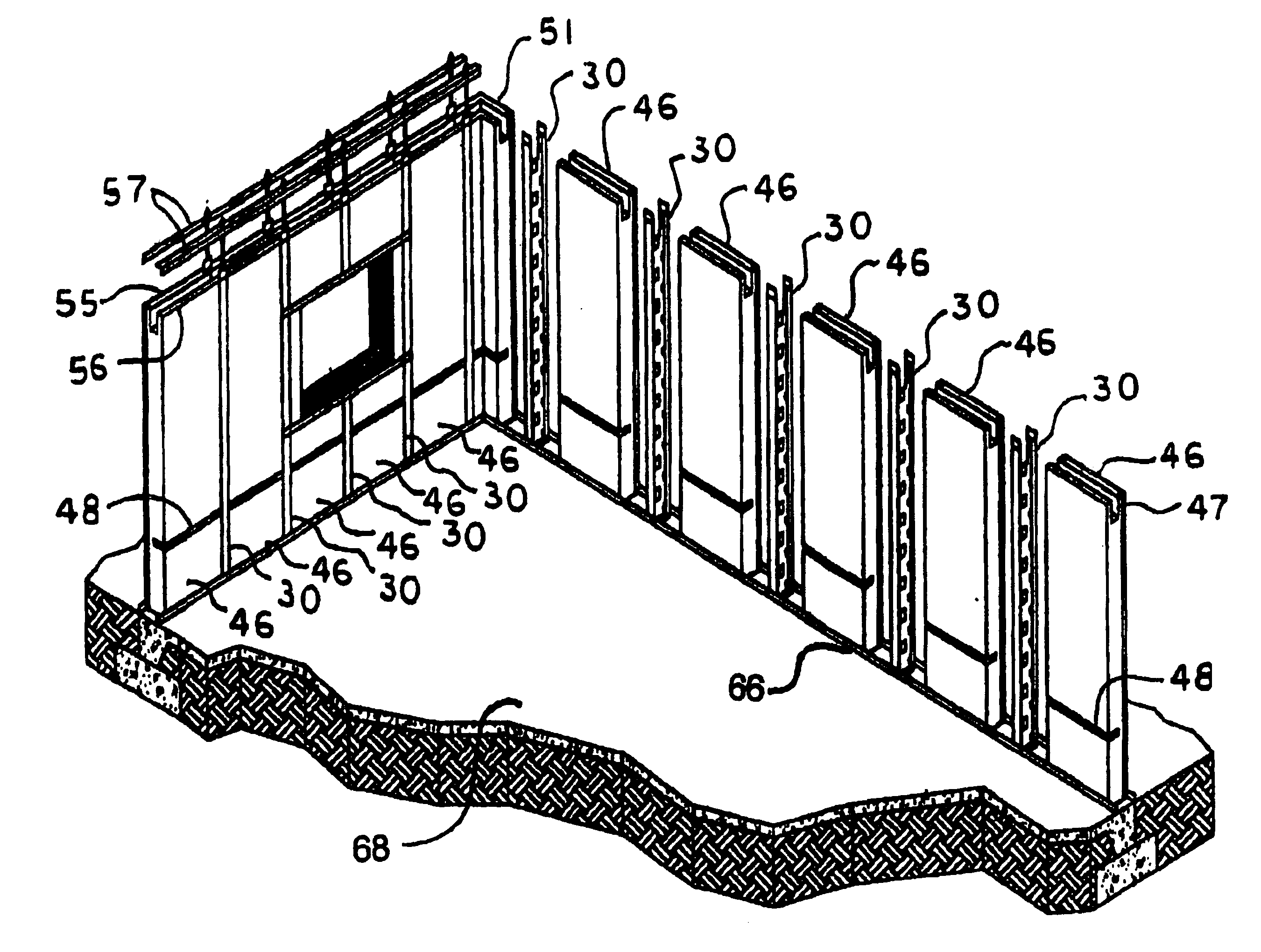

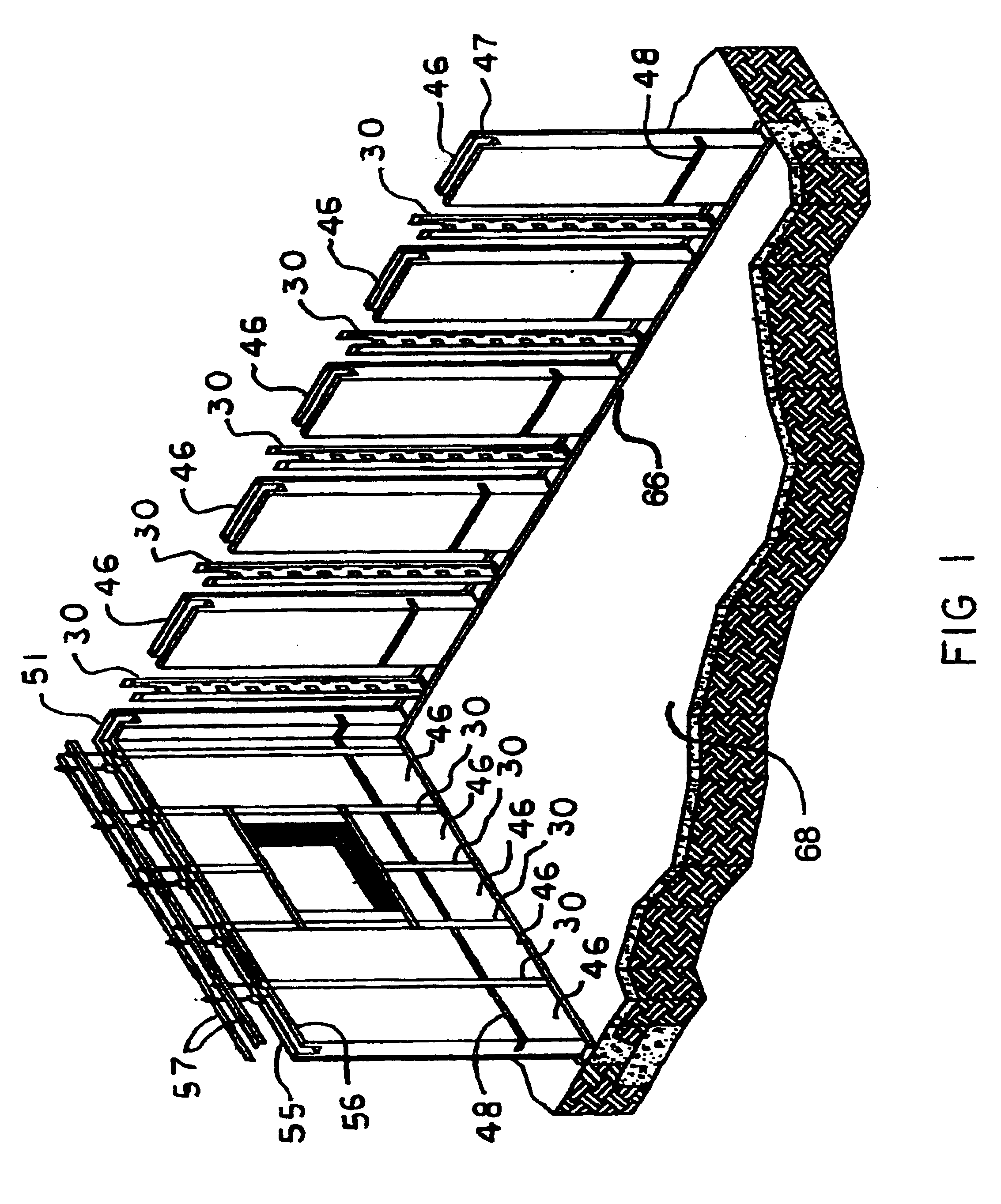

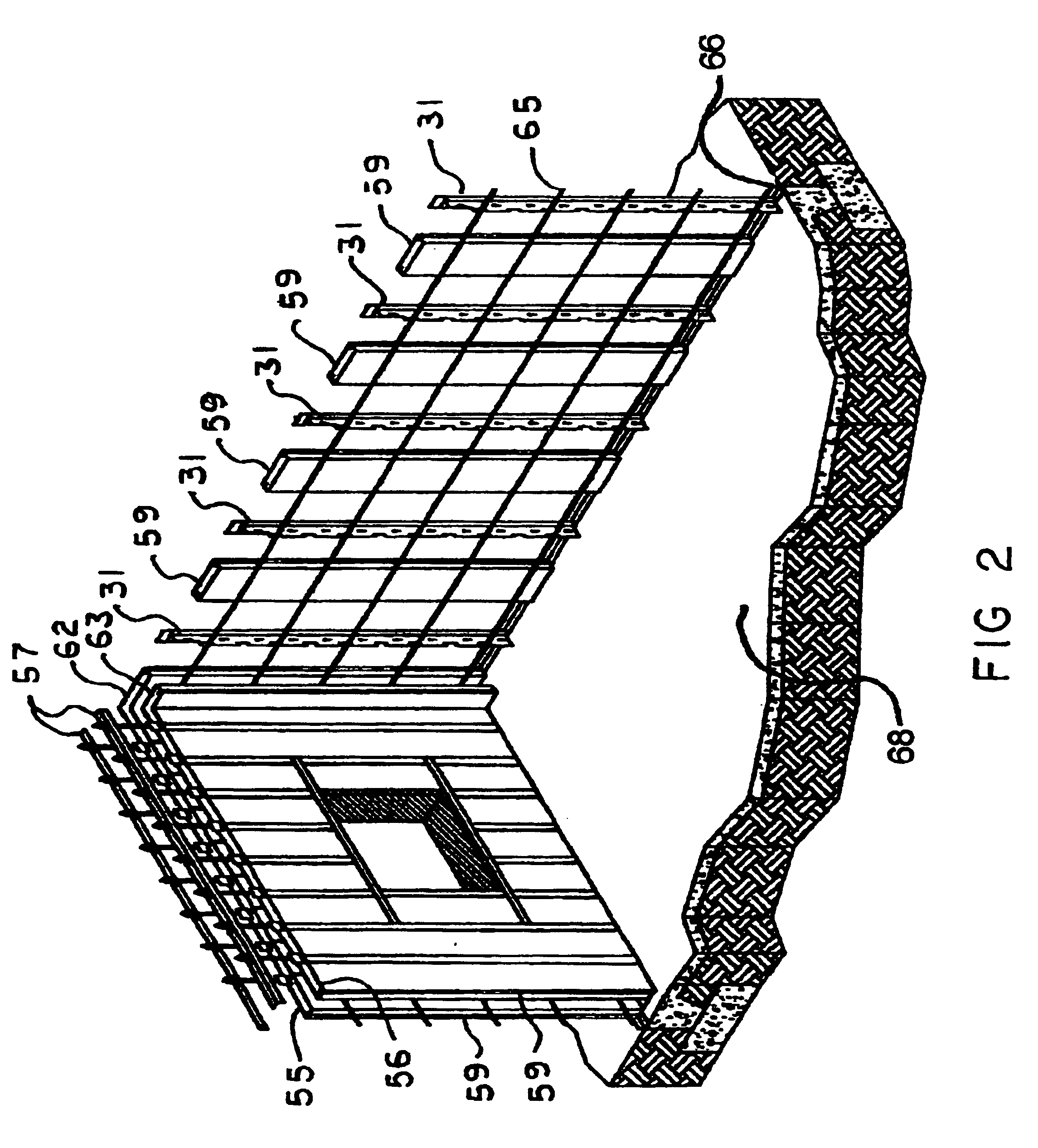

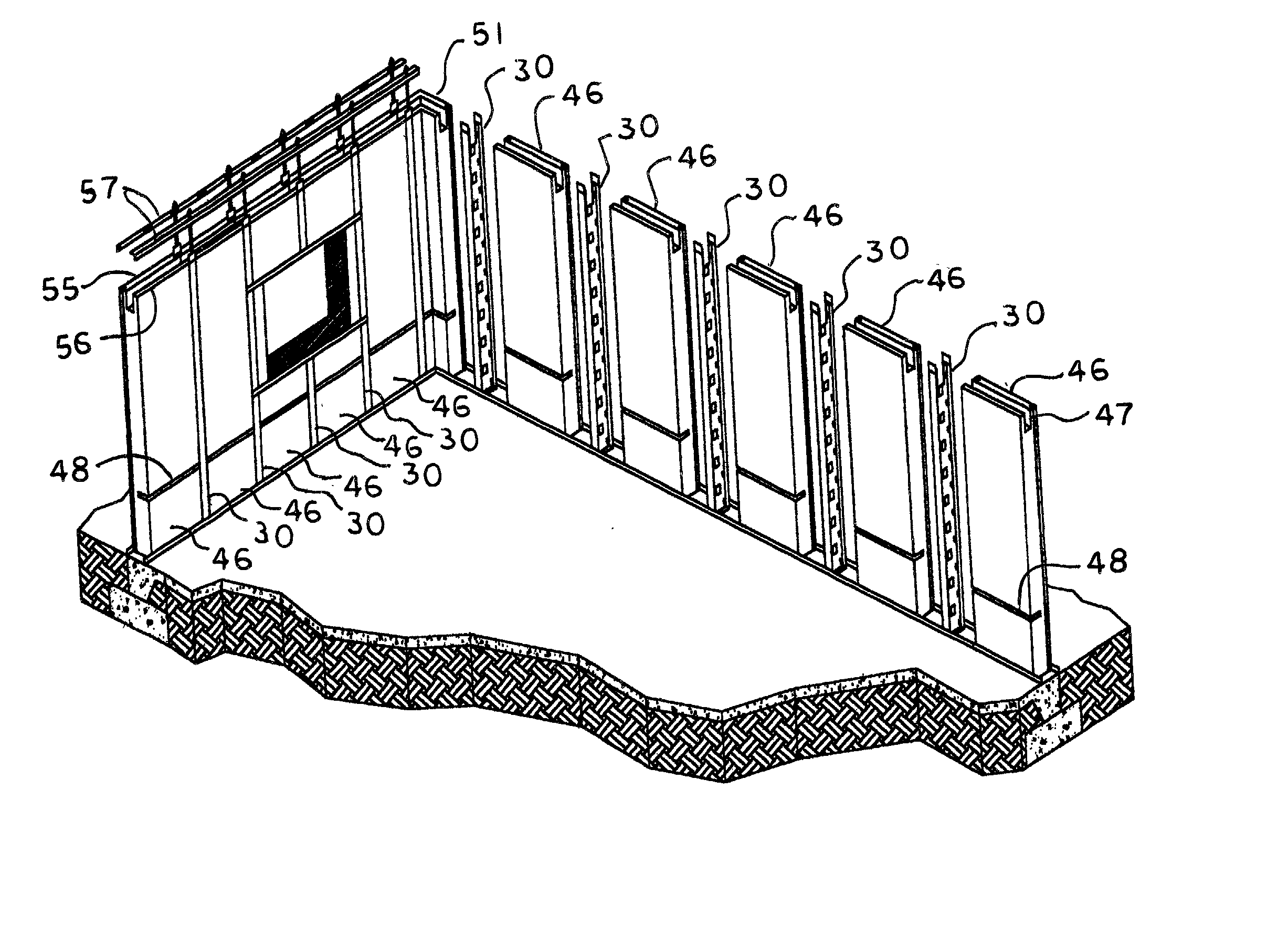

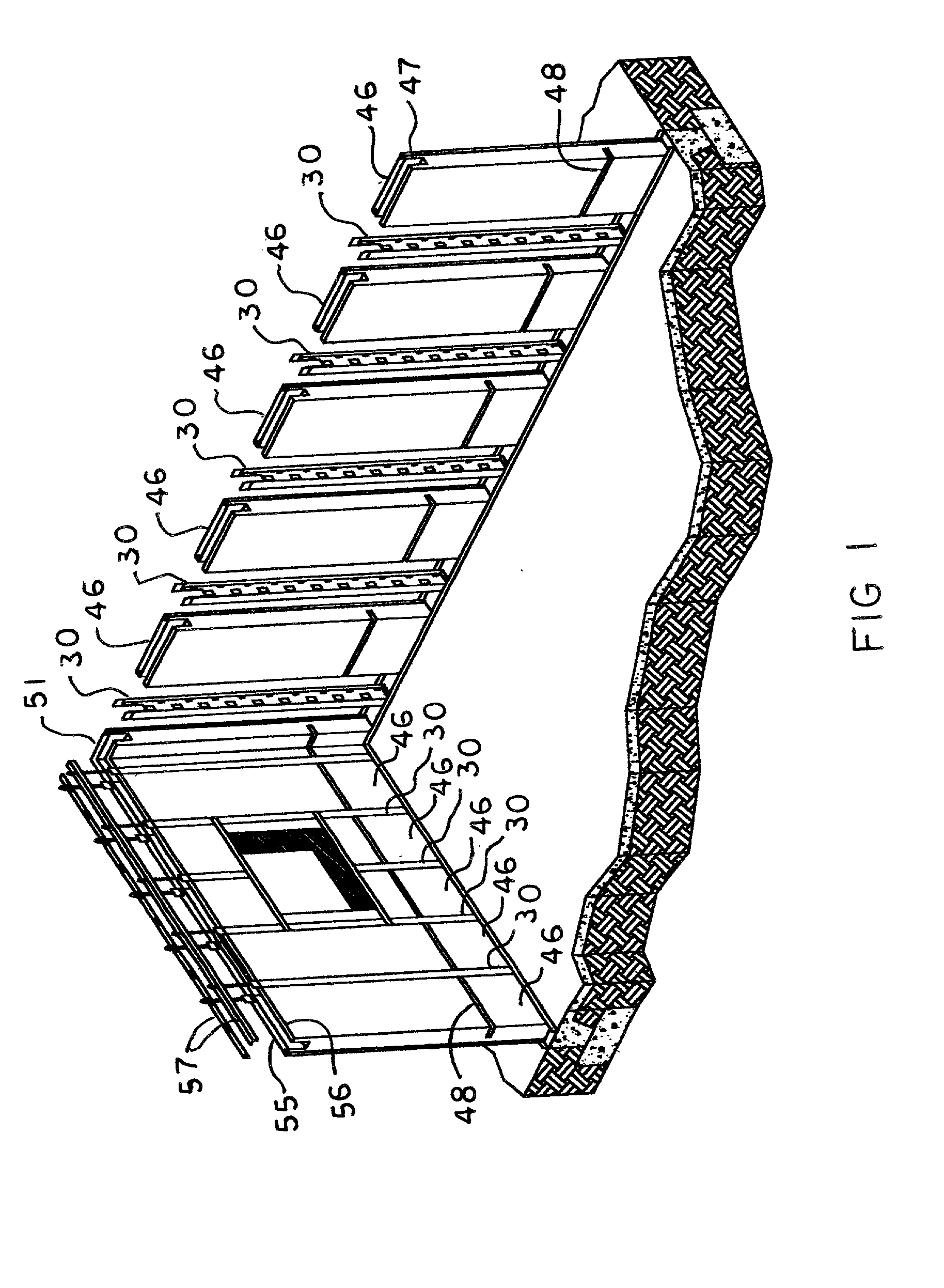

Structural thermal framing and panel system for assembling finished or unfinished walls with multiple panel combinations for poured and nonpoured walls

A novel structural thermal framing and panel system for assembling finished or unfinished walls with multiple combinations for poured and nonpoured walls comprising of a permanent structural framing stud which can be adjusted to different wall thickness, a plurality of permanent forms, wherein the pluralities of permanent forms are interchangeable with various other permanent panel forms with or without defined spaces for receiving filler, and wherein the framing stud substantially conforms to a portion of the pluralities of panel forms and resists bending in the panel forms. The framing stud is the main structural element in the wall. A structural framing system in combination with insulated panel forms with various defined spaces for receiving filler, and wherein panels may not be prefinished to form a rigid substrate. A method or forming a combination of various poured or nonpoured filler walls to form a structural, solid filled wall, post and beam filled wall, or a solid insulated structurally framed nonfilled wall. A structural framing element with multiple usage for forming walls, a process for forming structural framed walls. A method of forming variable configuration key grooved panel forms to form a variety of different wall thickness and pour configurations to form post and beam, post and beam matrix, solid poured walls, and solid nonpoured walls. An economical multiple use building system with extremely high R values.

Owner:JENTEC INDS

Structural thermal framing and panel system for assembling finished or unfinished walls with multiple panel combinations for poured and nonpoured walls

A novel structural thermal framing and panel system for assembling finished or unfinished walls with multiple combinations for poured and nonpoured walls comprising of a permanent structural framing stud which can be adjusted to different wall thickness, a plurality of permanent forms, wherein the pluralities of permanent forms are interchangeable with various other permanent panel forms with or without defined spaces for receiving filler, and wherein the framing stud substantially conforms to a portion of the pluralities of panel forms and resists bending in the panel forms. The framing stud is the main structural element in the wall. A structural framing system in combination with insulated panel forms with various defined spaces for receiving filler, and wherein panels may not be prefinished to form a rigid substrate. A method of forming a combination of various poured or nonpoured filler walls to form a structural, solid filled wall, post and beam filled wall, or a solid insulated structurally framed nonfilled wall. A structural framing element with multiple usage for forming walls, a process for forming structural framed walls. A method of forming variable configuration key grooved panel forms to form a variety of different wall thickness and pour configurations to form post and beam, post and beam matrix, solid poured walls, and solid nonpoured walls. An economical multiple use building system with extremely high R values.

Owner:JENTEC INDS

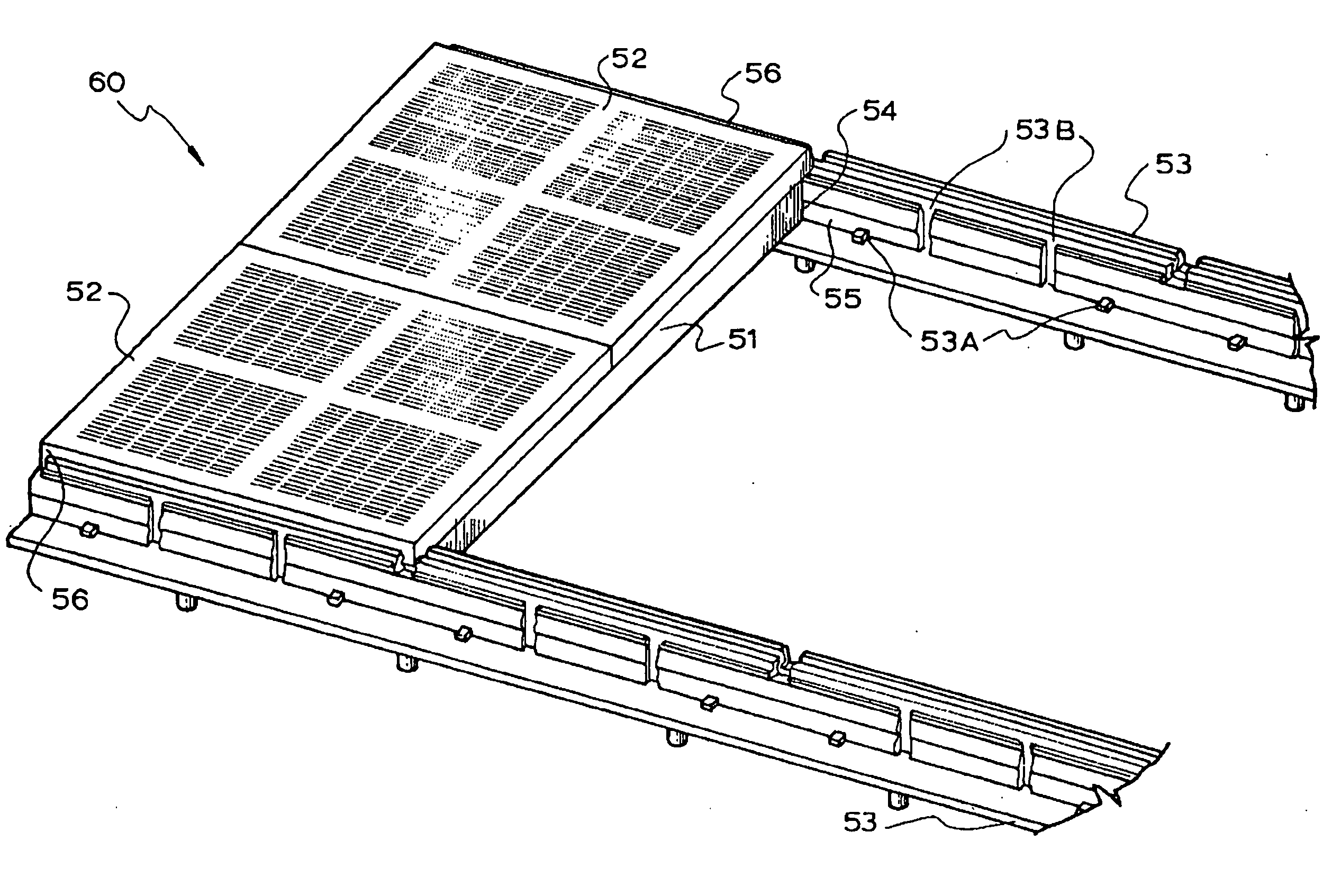

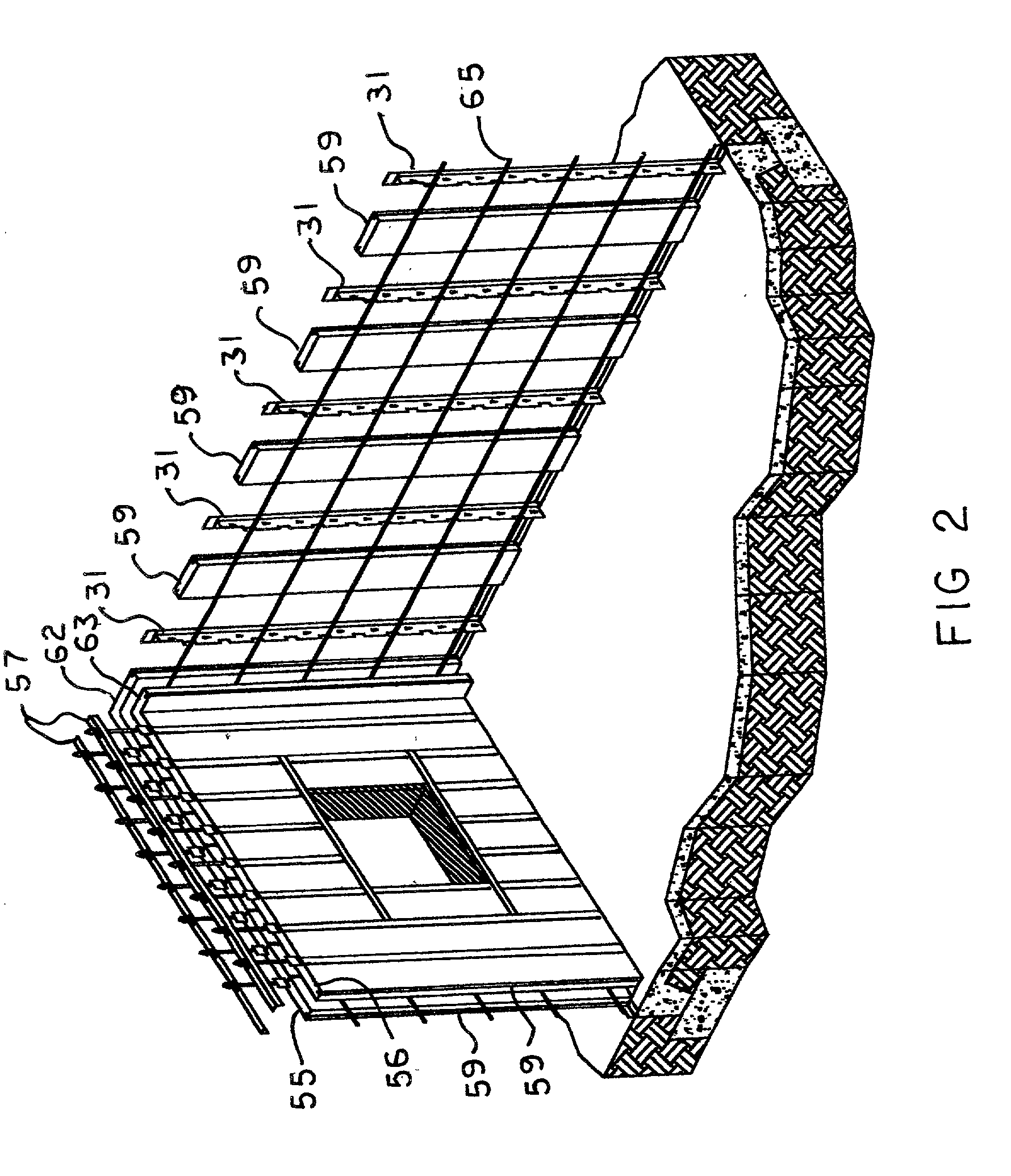

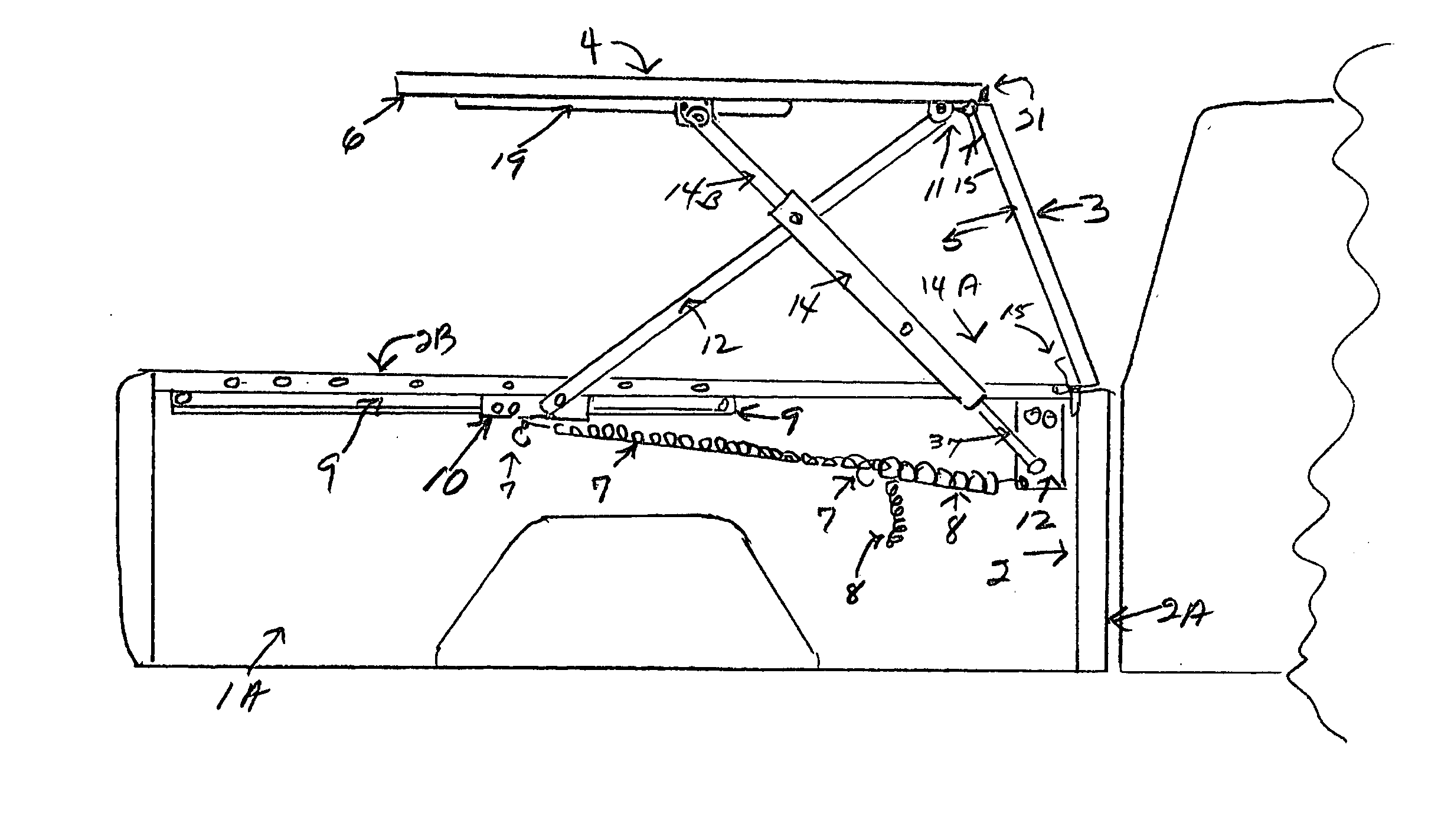

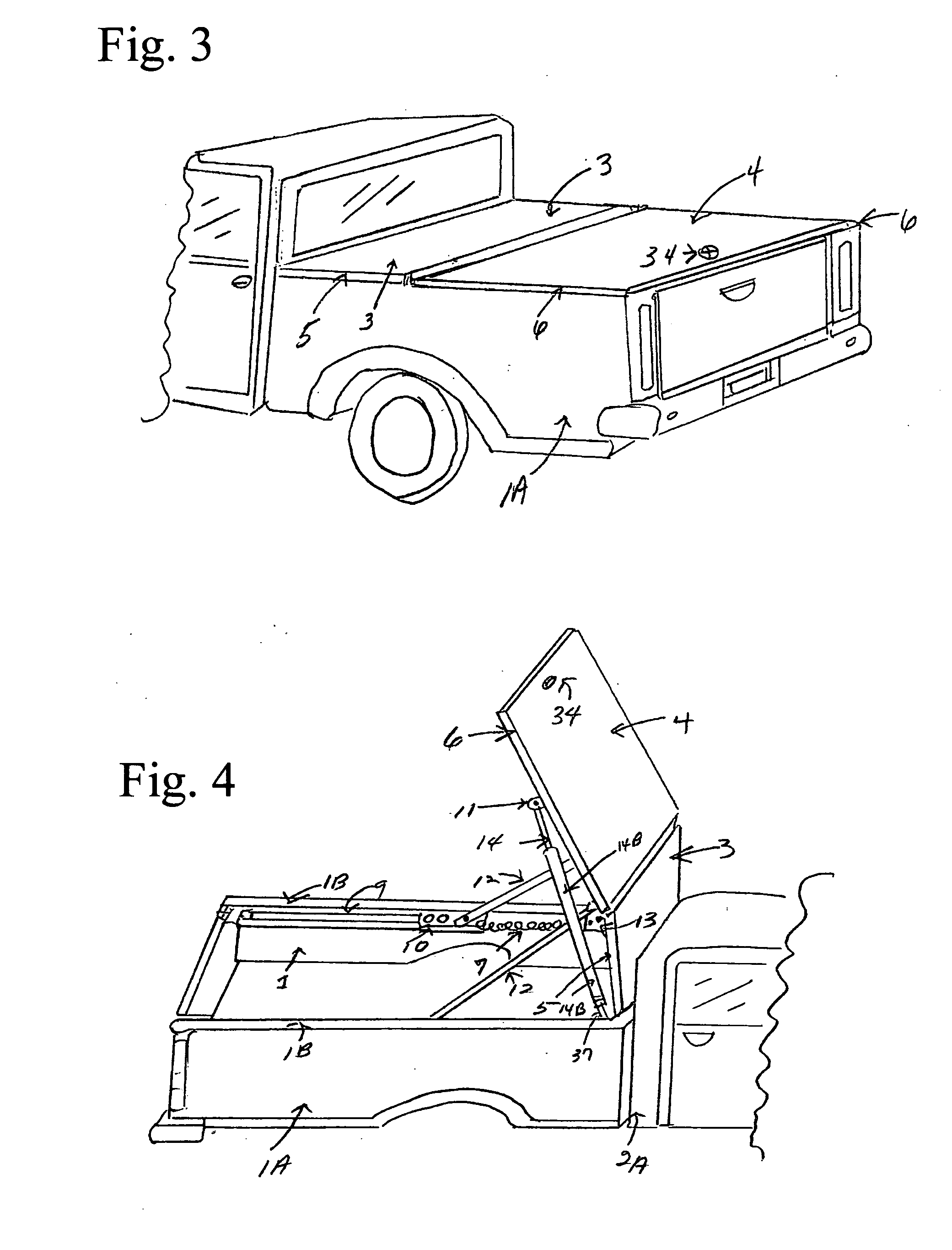

Adjustable height horizontal lockable frame method to attach and to lift a truck bed cover

InactiveUS20110309651A1Easy to lifted lid coverCheap manufacturingLoad coveringRoofsGlass fiberVehicle frame

An adjustable hold height lockable horizontal the two-piece member frame assembly method to attach and to lift a truck bed cover truck bed cover has a two-piece frame structure including front and rear frame members and front and rear cover panels secured thereon, the frame members hinged connected to move between a flat horizontal closed position covering the truck bed and an adjustable open position wherein the front frame and front panel is disposed adjacent to the truck cab and the rear frame and rear panel is disposed horizontally at selected hold heights above the bed, or extending angularly upward from the front frame and front panel. The cover can be adjusted and locked as option at selected hold positions between the closed and open positions. The two-piece frame and panel members where the rear frame has a elongate L-shape bracket attach onto inside interior of the front rear frame rail and where the top end of gas strut support assembly is attach onto and bottom end of gas strut support assembly with a locking device is attach to a bracket support that is attach on the truck bed inside corner which support rear cover and facilitate lifting and locking the rear cover in various positions also in the combination with on the rear cover a L-shaped bracket members attach to inside rear frame with selected longitudinally spaced holes which thereof can be adjusted to different length of rear cover which is attach to top end member of a tubular support member assembly and bottom end gas tubular support attached to back bracket support attached to the opposed inner sides of the truck bed and also the lockable slide rails assembly also link to a chain onto a tension springs provided a pull when attach to interior insides of the truck bed corner end which facilitate lifting and able to lock the rear cover in various positions. The front and rear cover panels may be made of a hard rigid material or a soft flexible heavyweight fabric material separately or the two piece frame assembly can be molded on to with fiberglass material or with other hard material separately.

Owner:HERNANDEZ JOSE ENRIQUE +1

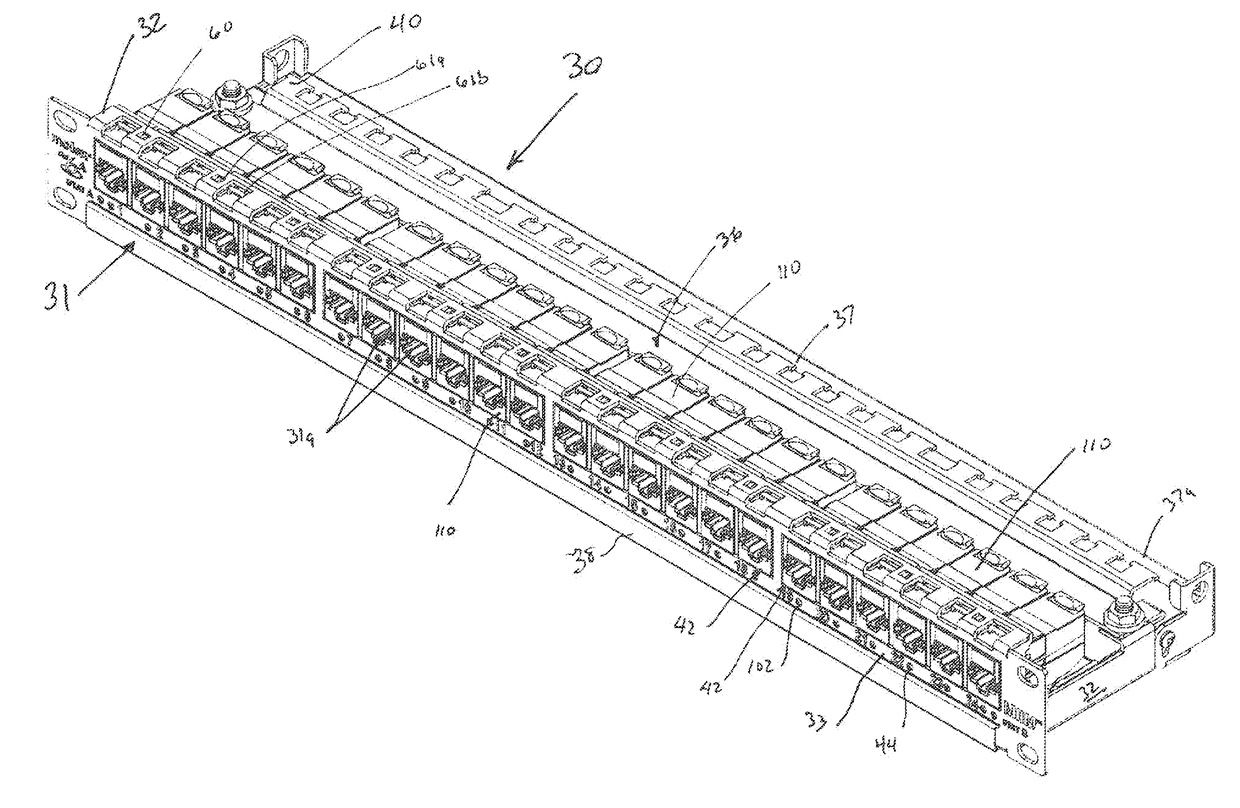

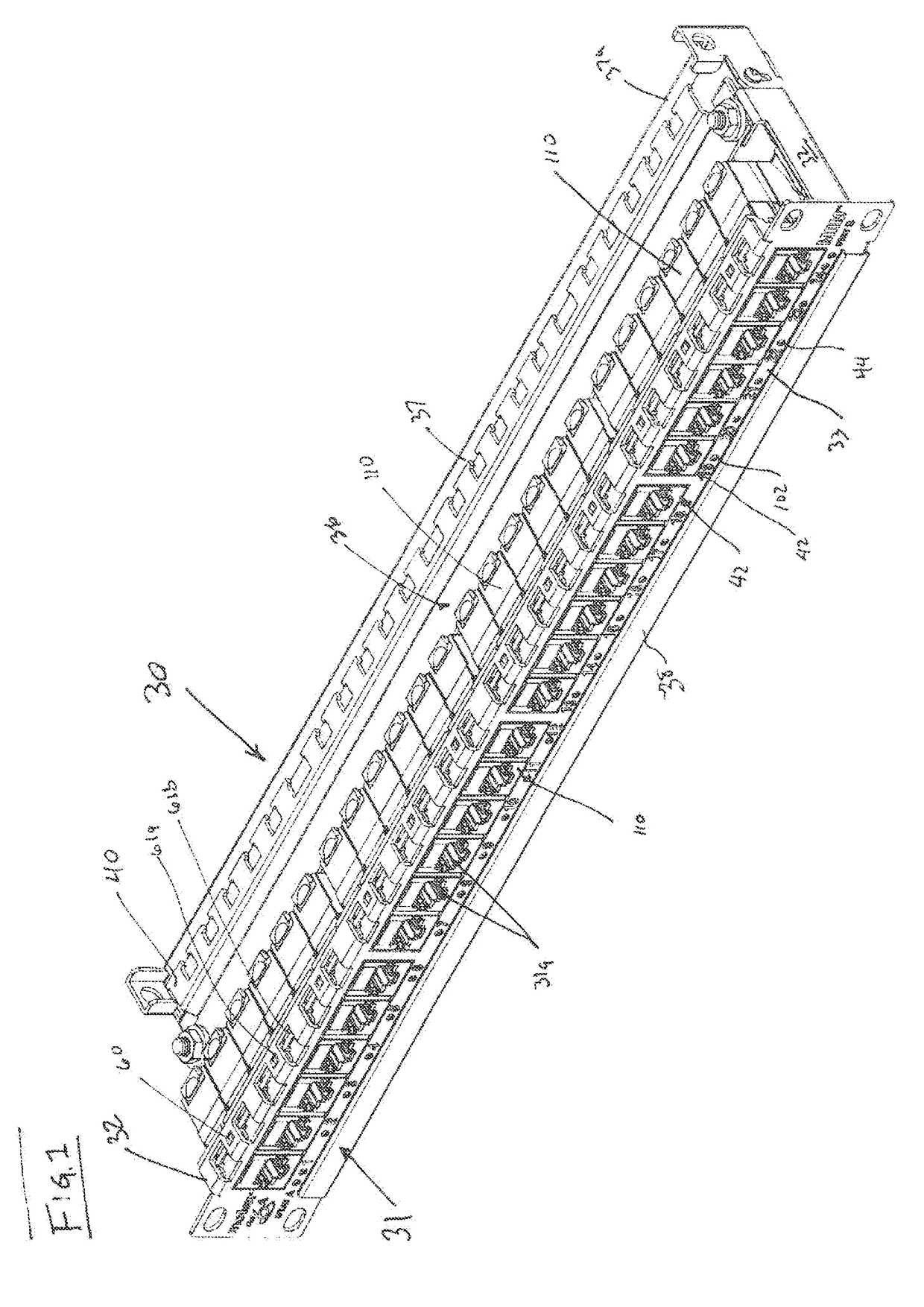

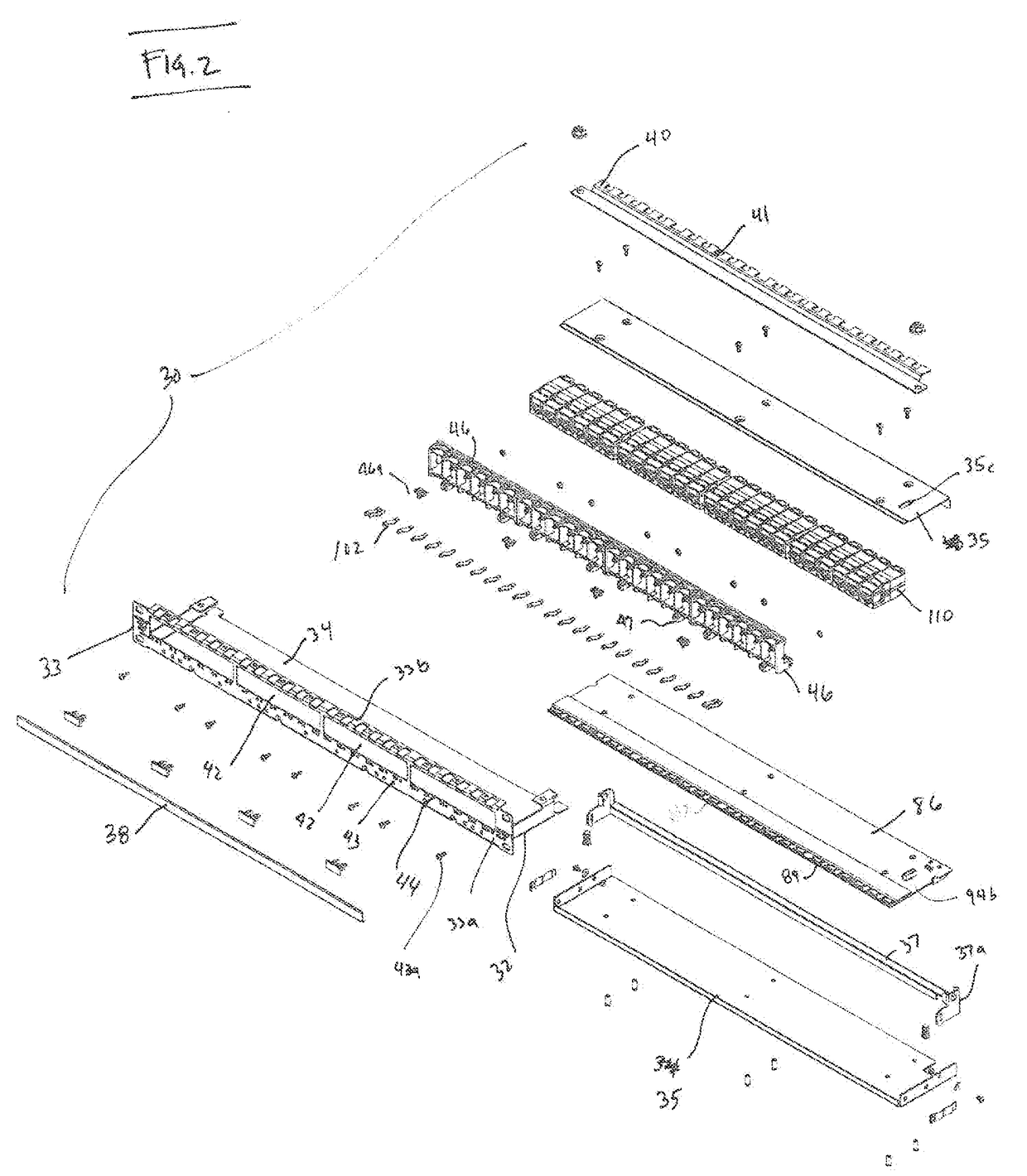

Patch panel frame for circuit board module

ActiveUS20170229825A1Easy to upgradePromote repairTwo-part coupling devicesCoupling parts mountingPatch panelComputer module

An improved patch panel assembly includes a frame and faceplate that mate with a housing, and the housing defines a plurality of individual communication ports. The housing is mounted to the patch panel frame and includes jack openings that accommodate data jacks and circuit board openings that accommodate mating blades of circuit boards. The two sets of openings are separated on the housing by an intervening spacing and interposer terminal sets are provided to electrically interconnect the jacks with circuits on the circuit boards. The patch panel housings may be formed in discrete groupings so that, if desired, the patch panels may have ports that are grouped together by bandwidth, storage capability and the like. Inasmuch as the housings are mounted to the patch panel frames, the jacks and the circuit boards can be easily and individually replaced, repaired or upgraded with similar components without requiring disassembly of the patch panel.

Owner:MOLEX INC

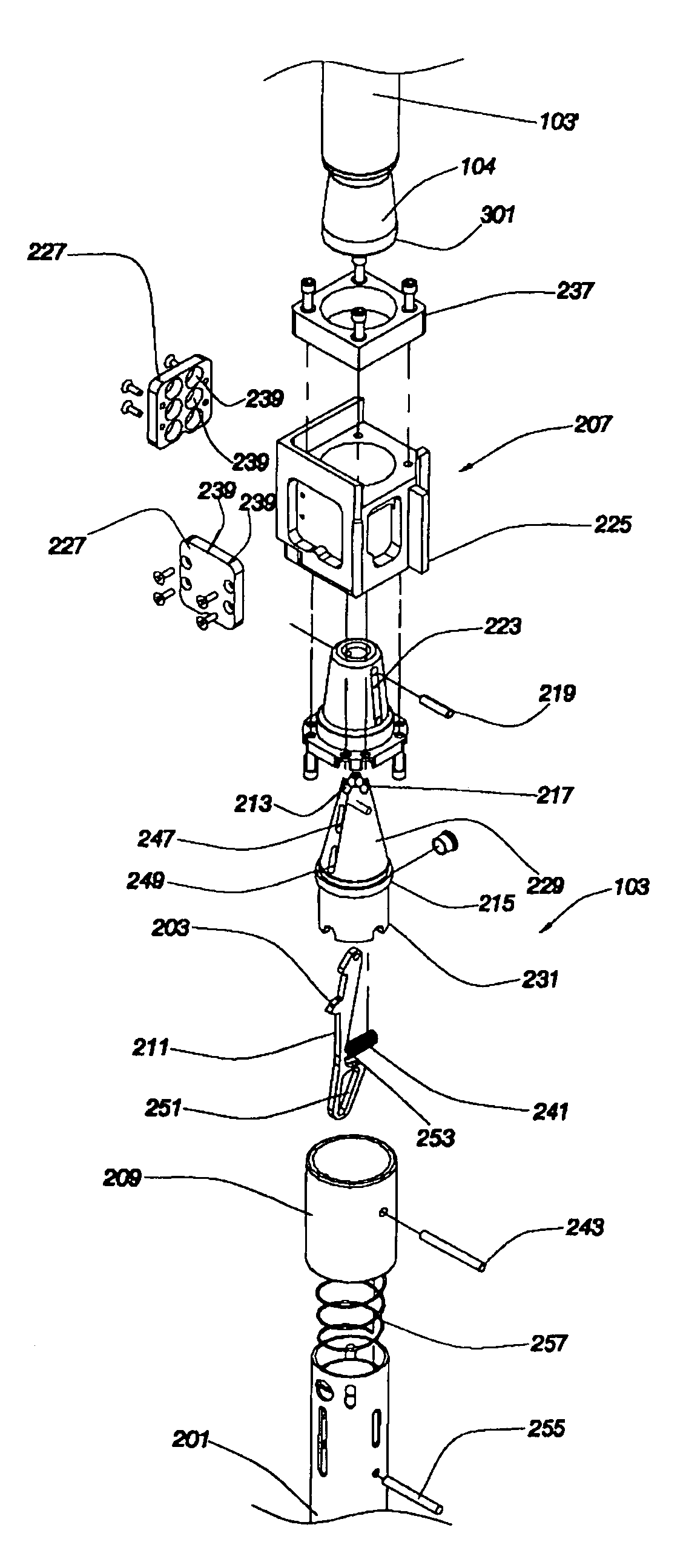

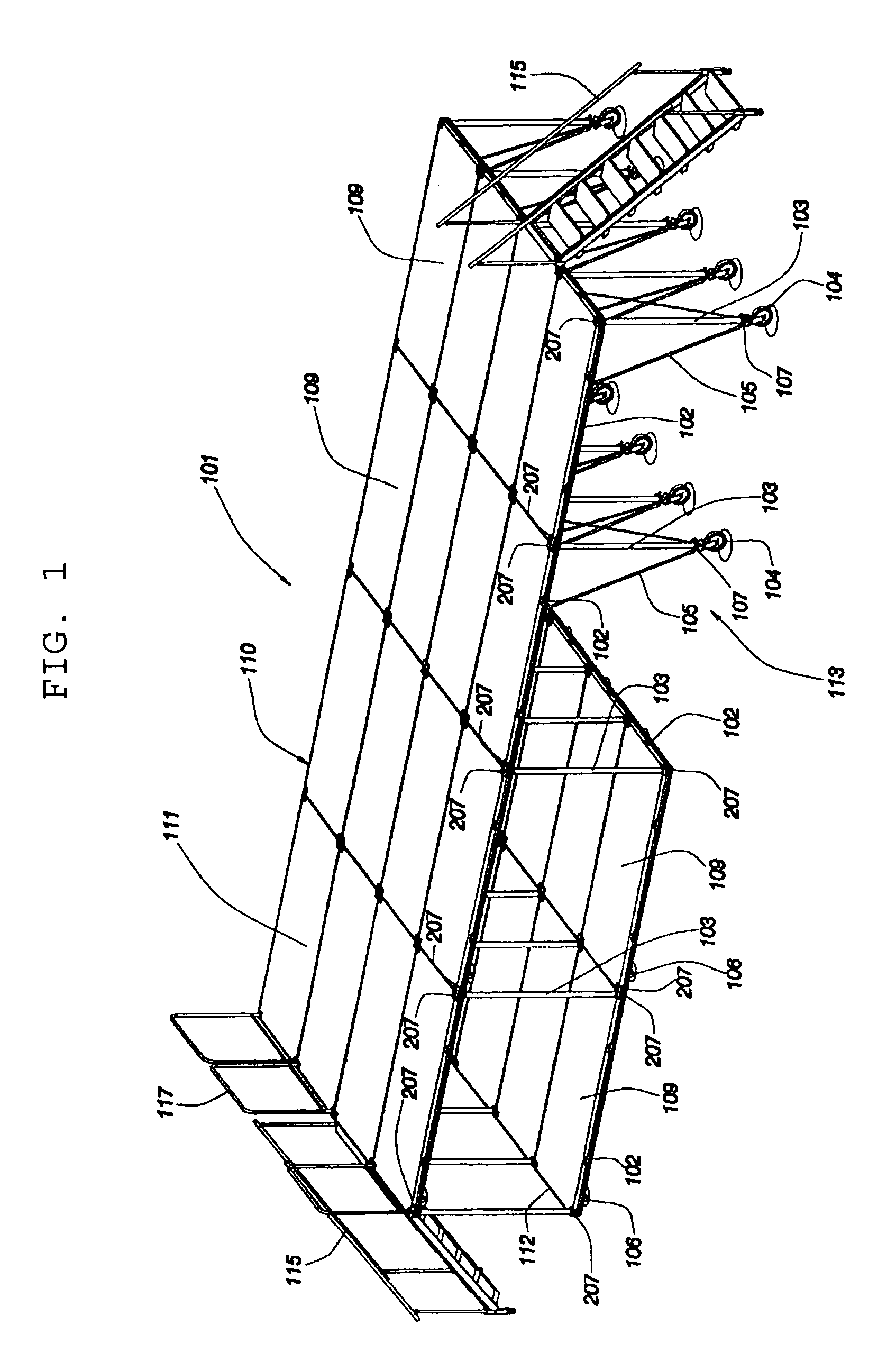

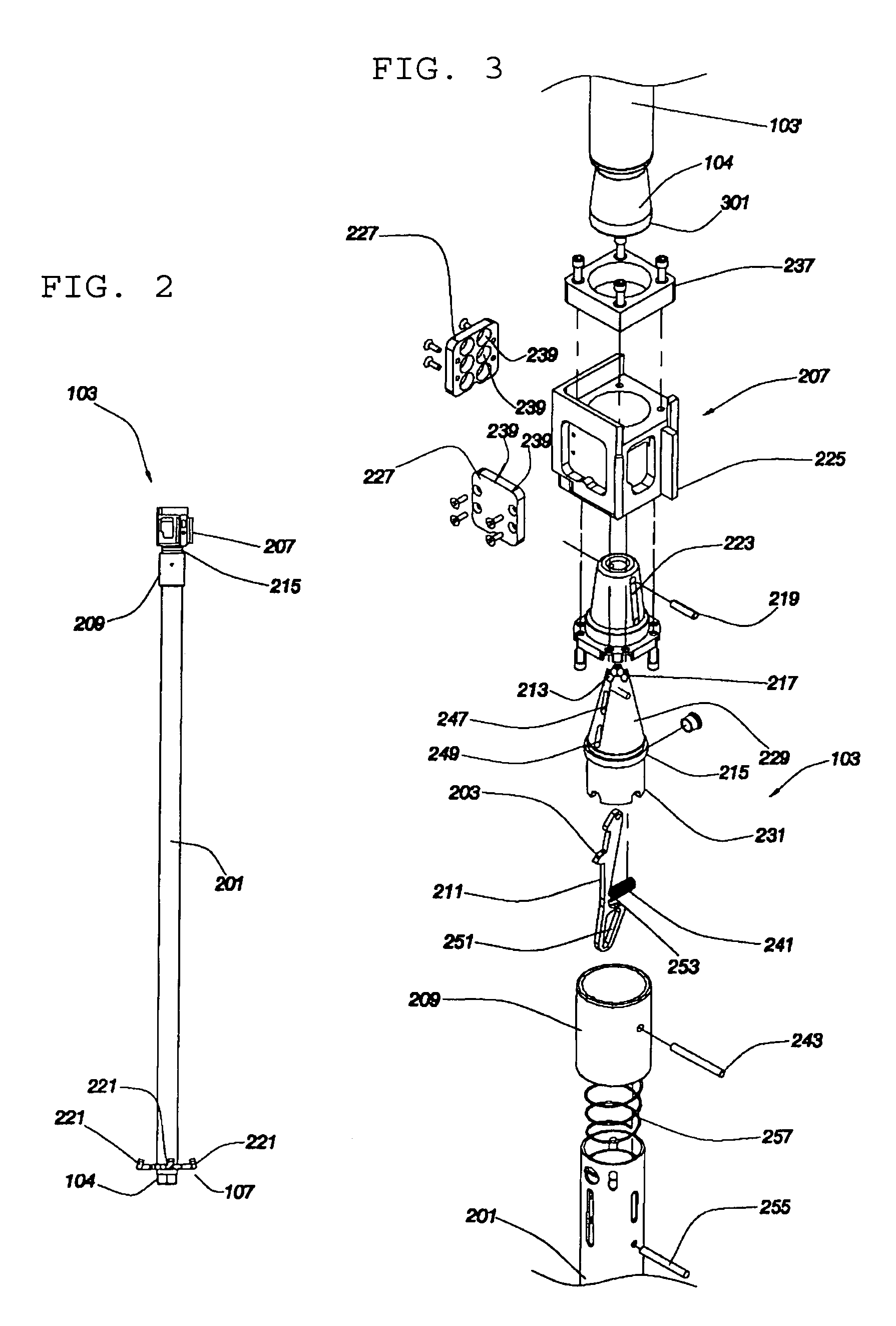

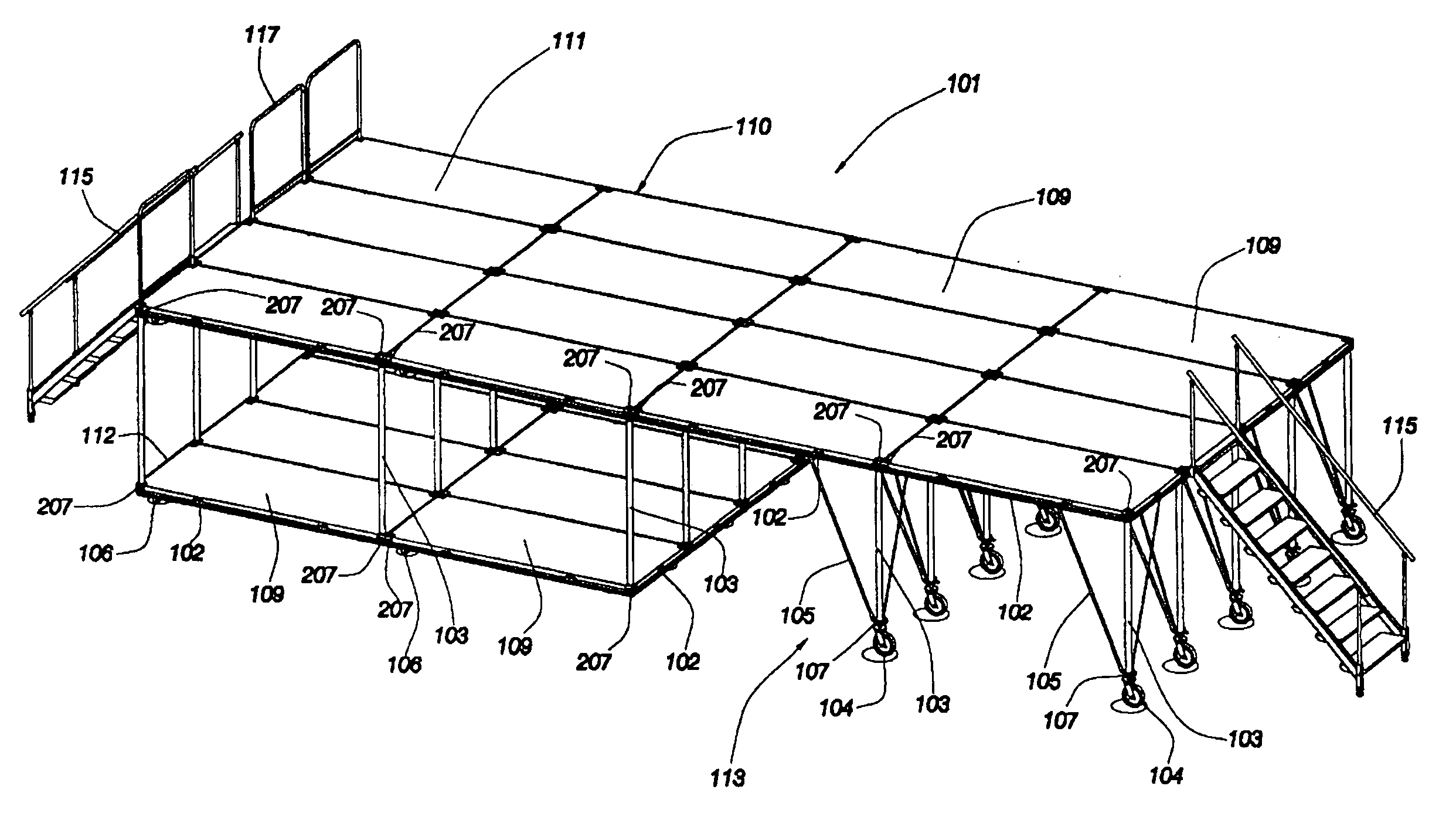

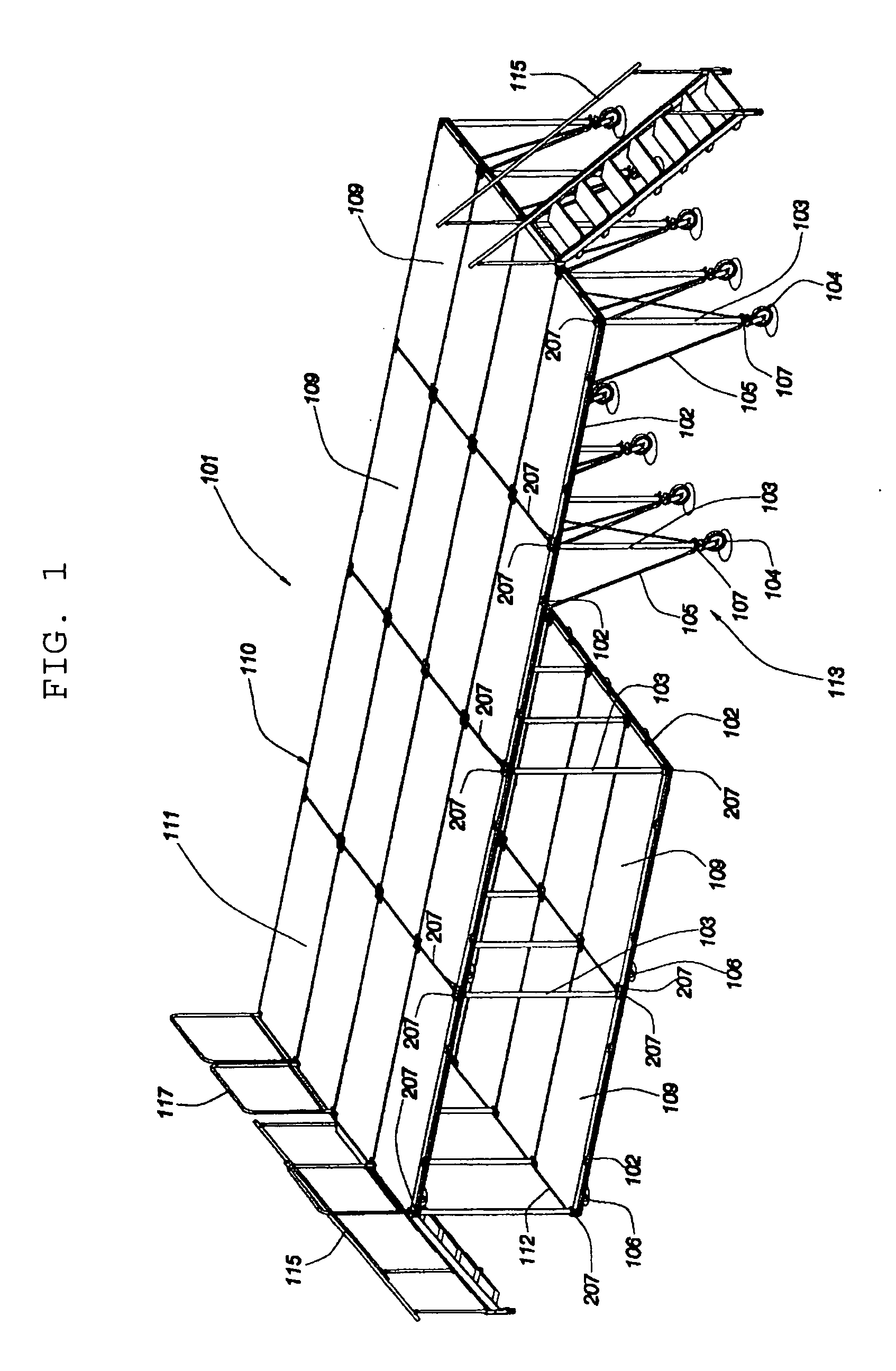

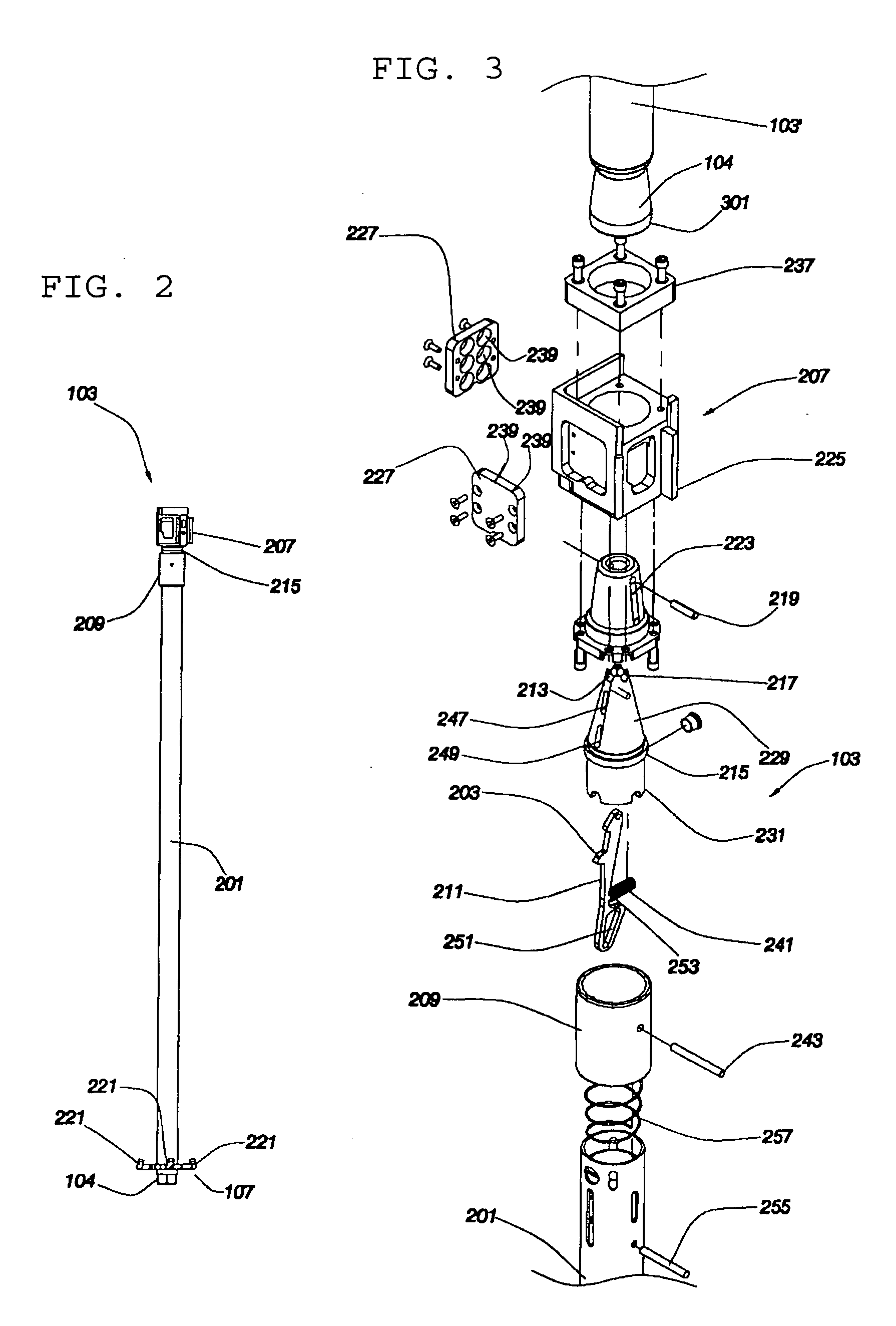

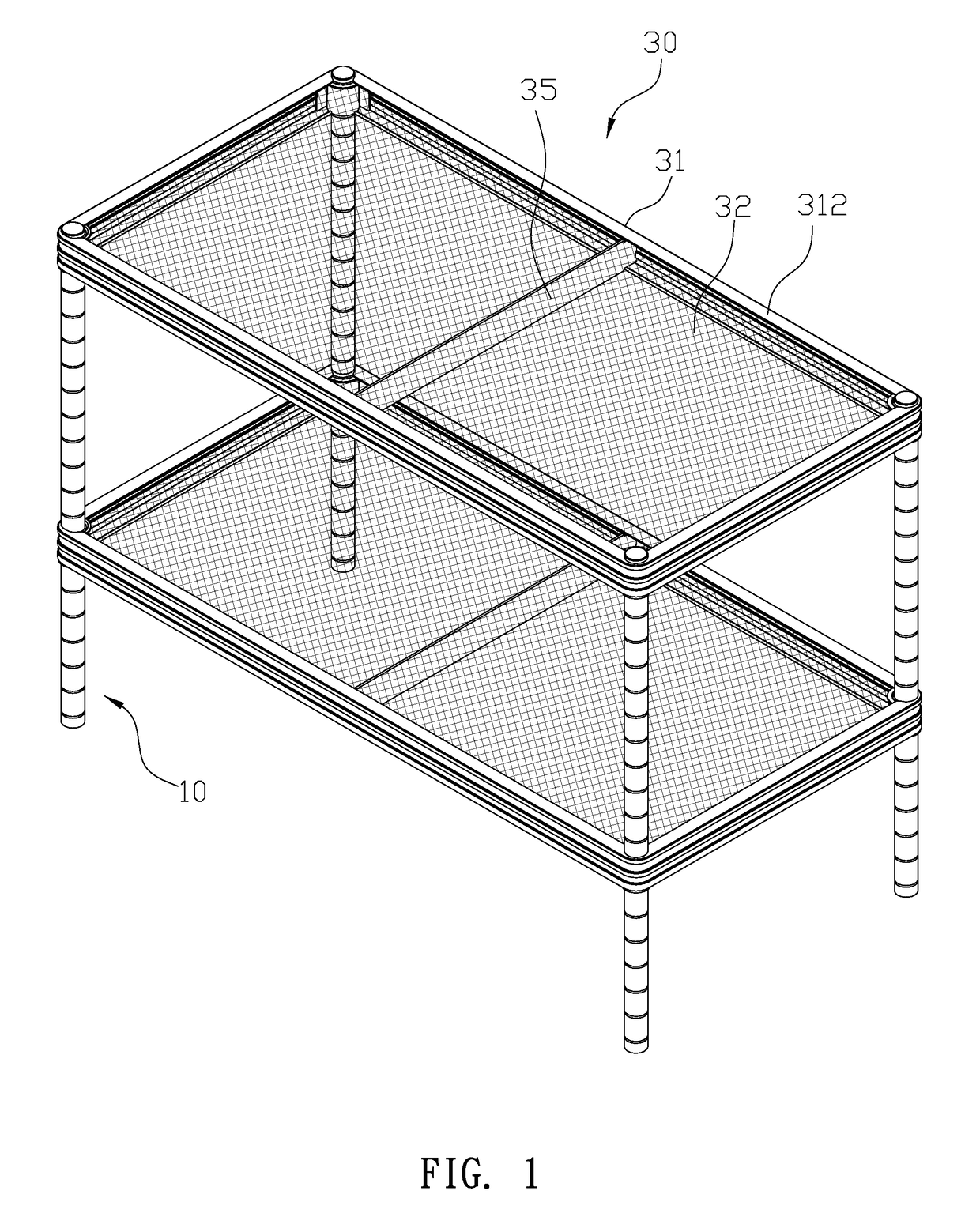

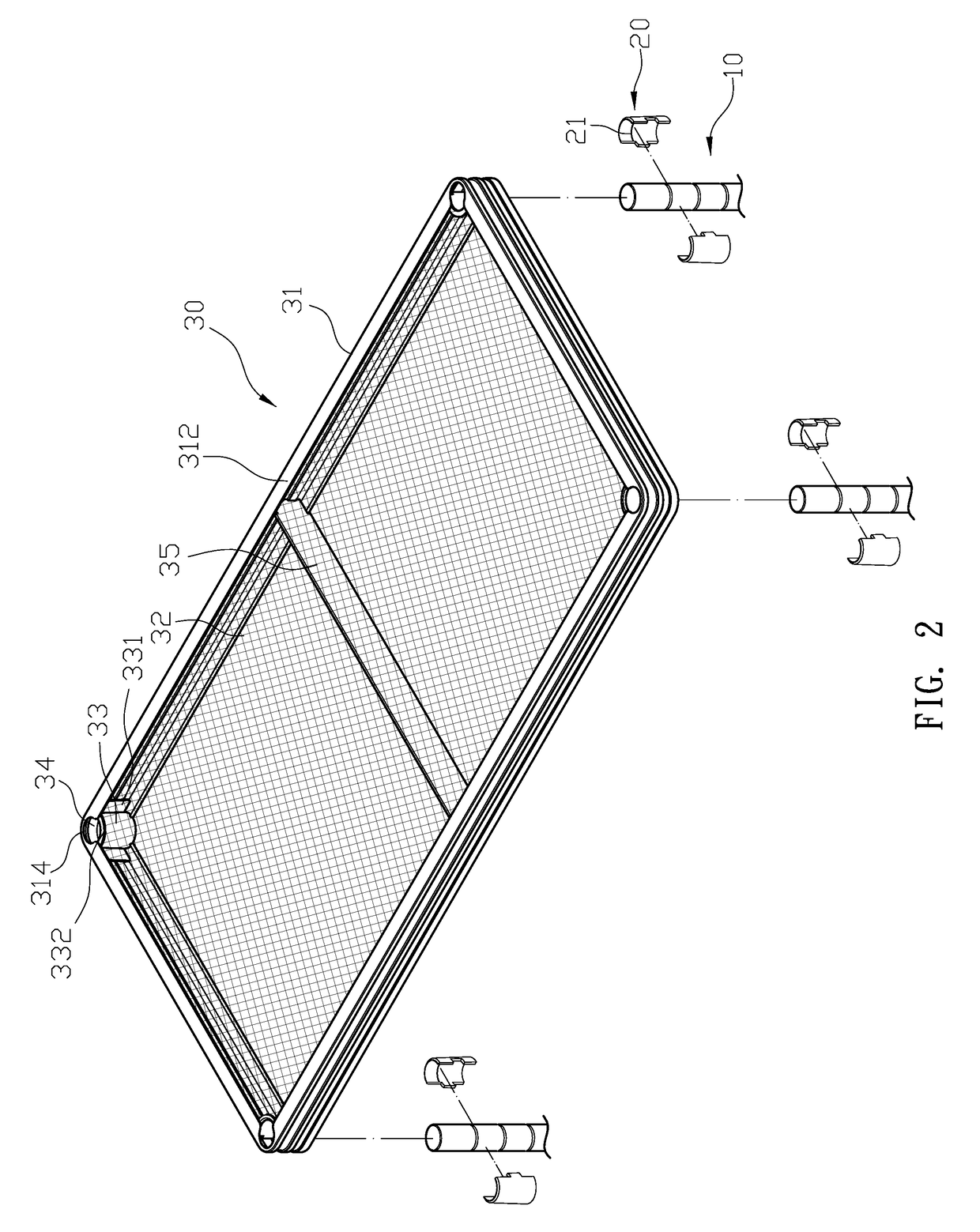

Portable locking support and platform system

ActiveUS8136460B2Reduce the possibilityAssembly of portableRod connectionsFoldable tablesSupporting systemSupport system

A portable support system having a portable support having a first end and a second end. The first end includes a tapered portion, and the second end includes a footing structure. The system also includes a receiving member having a support cone configured to receive the tapered portion. The support cone has a tapered inner surface and a tapered outer surface. The inner surface and outer surface are engagable with mating tapered surfaces. The receiving member is capable of attachment to one or both of a frame and a panel for use as a platform.

Owner:TAIT TOWERS

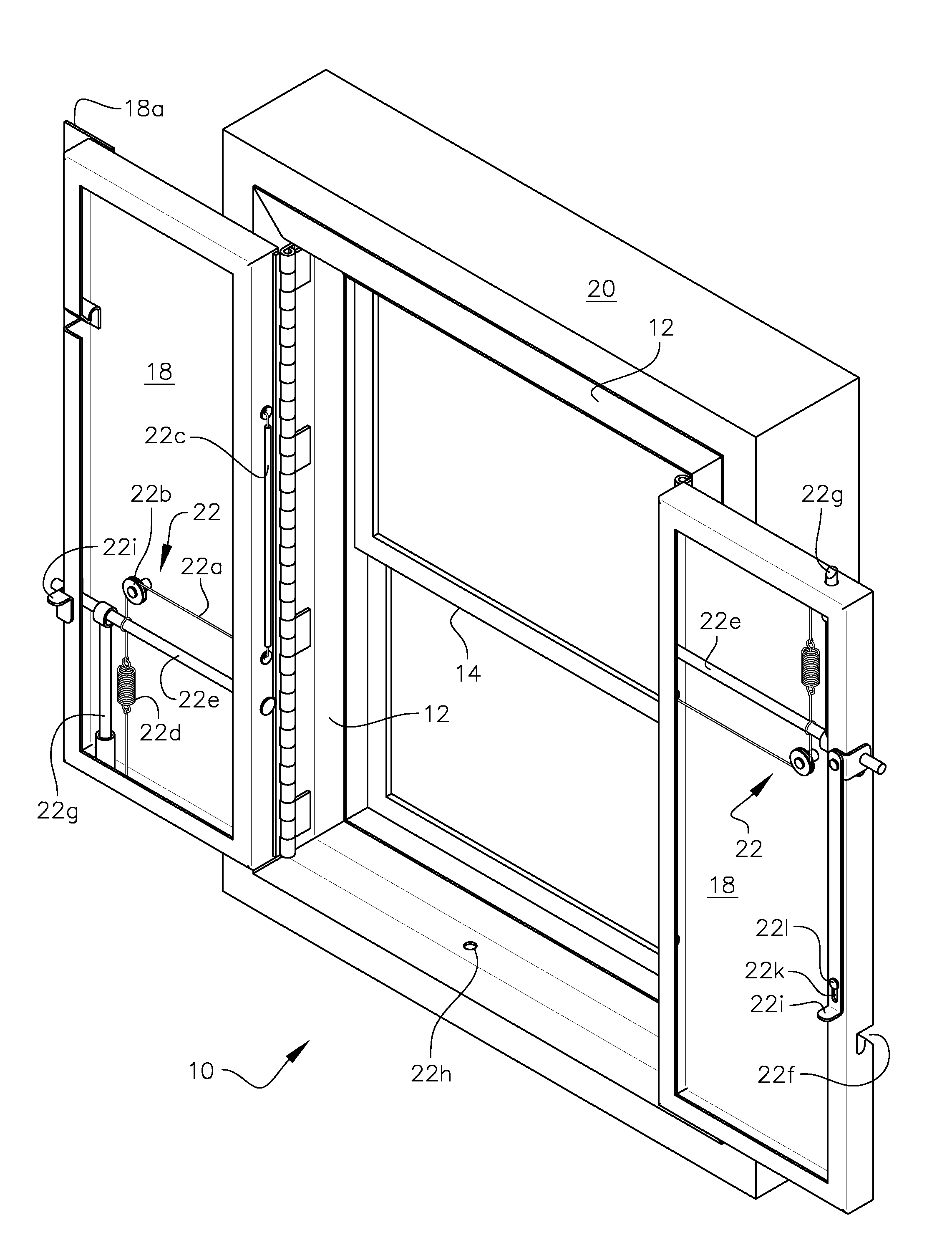

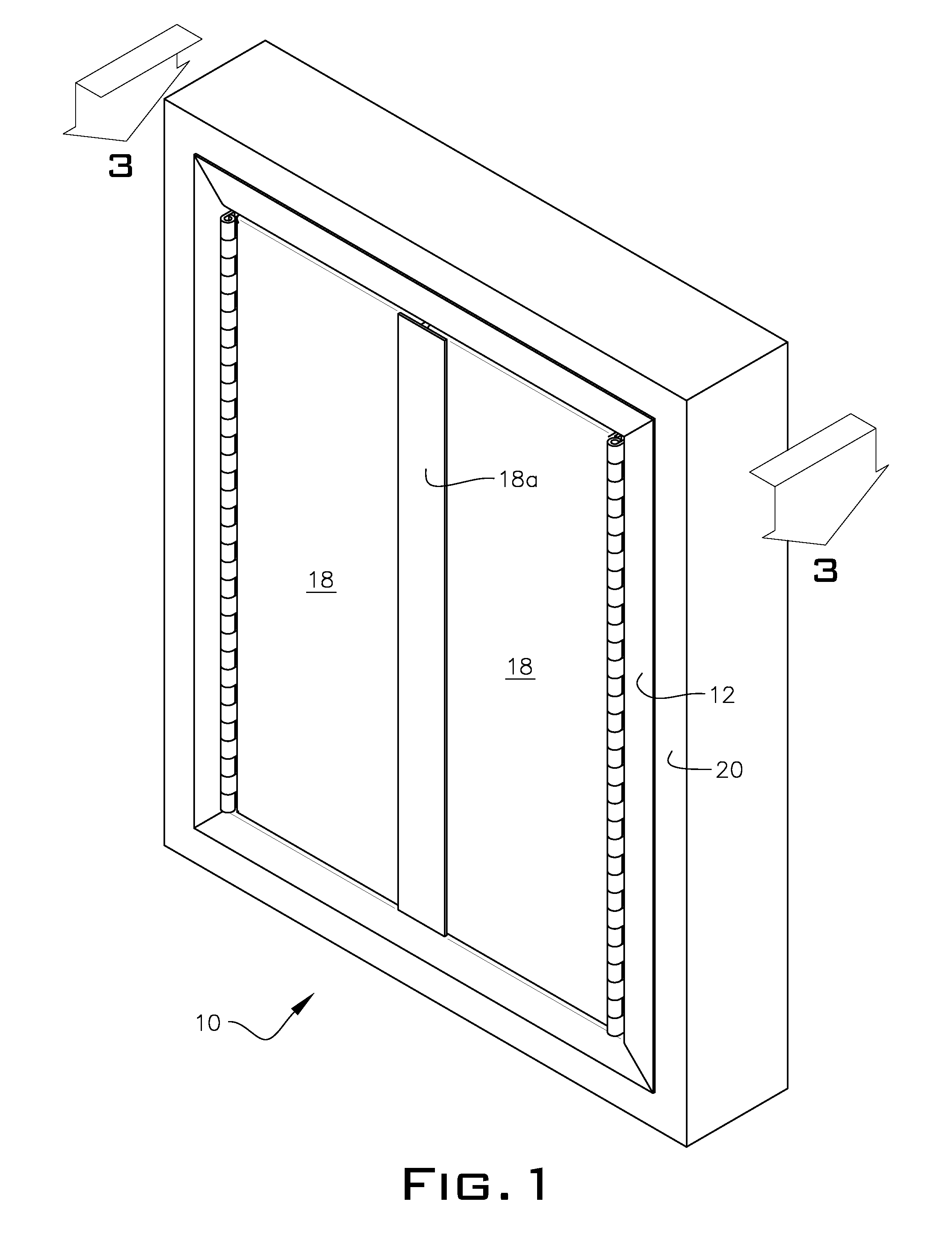

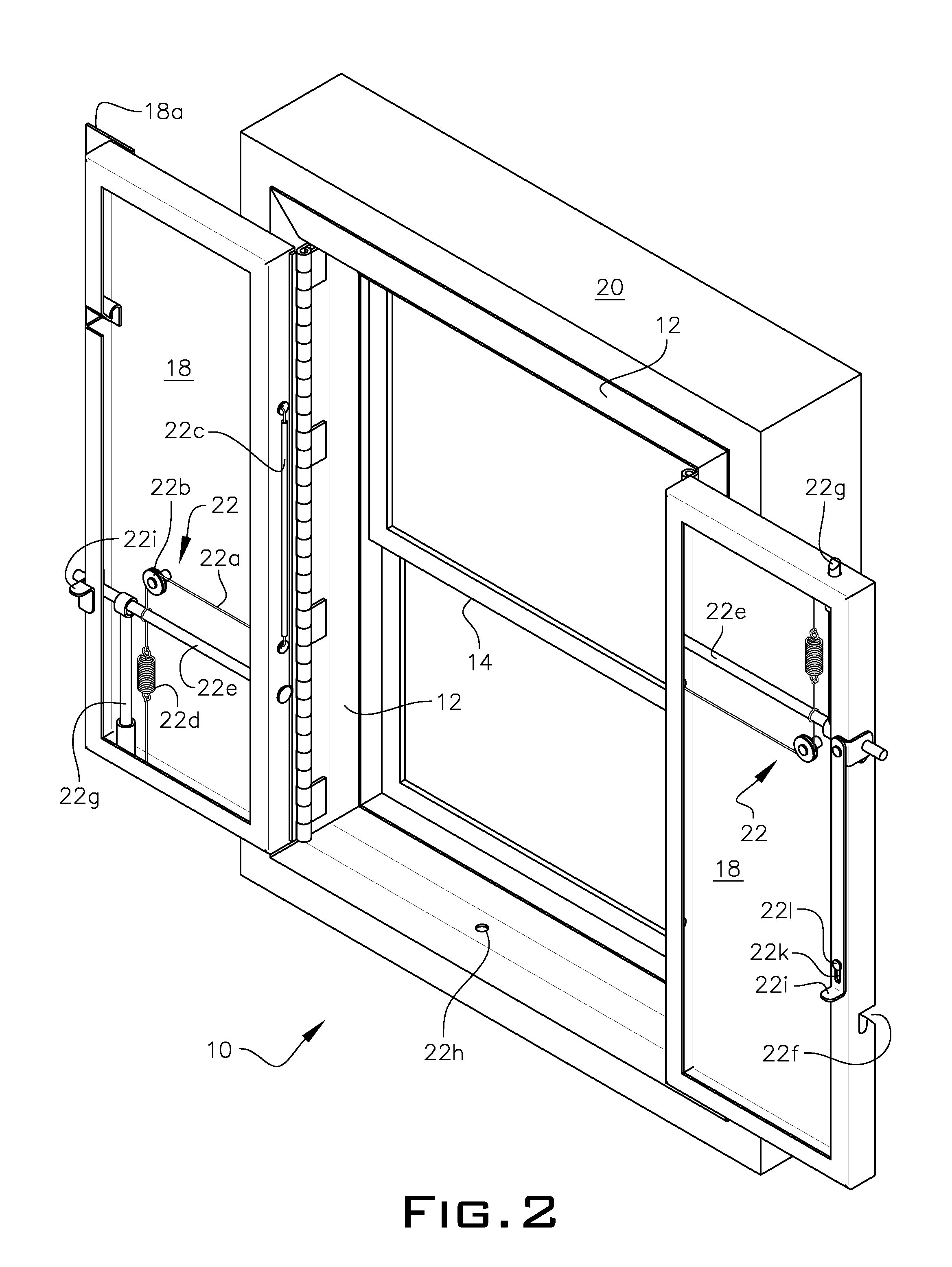

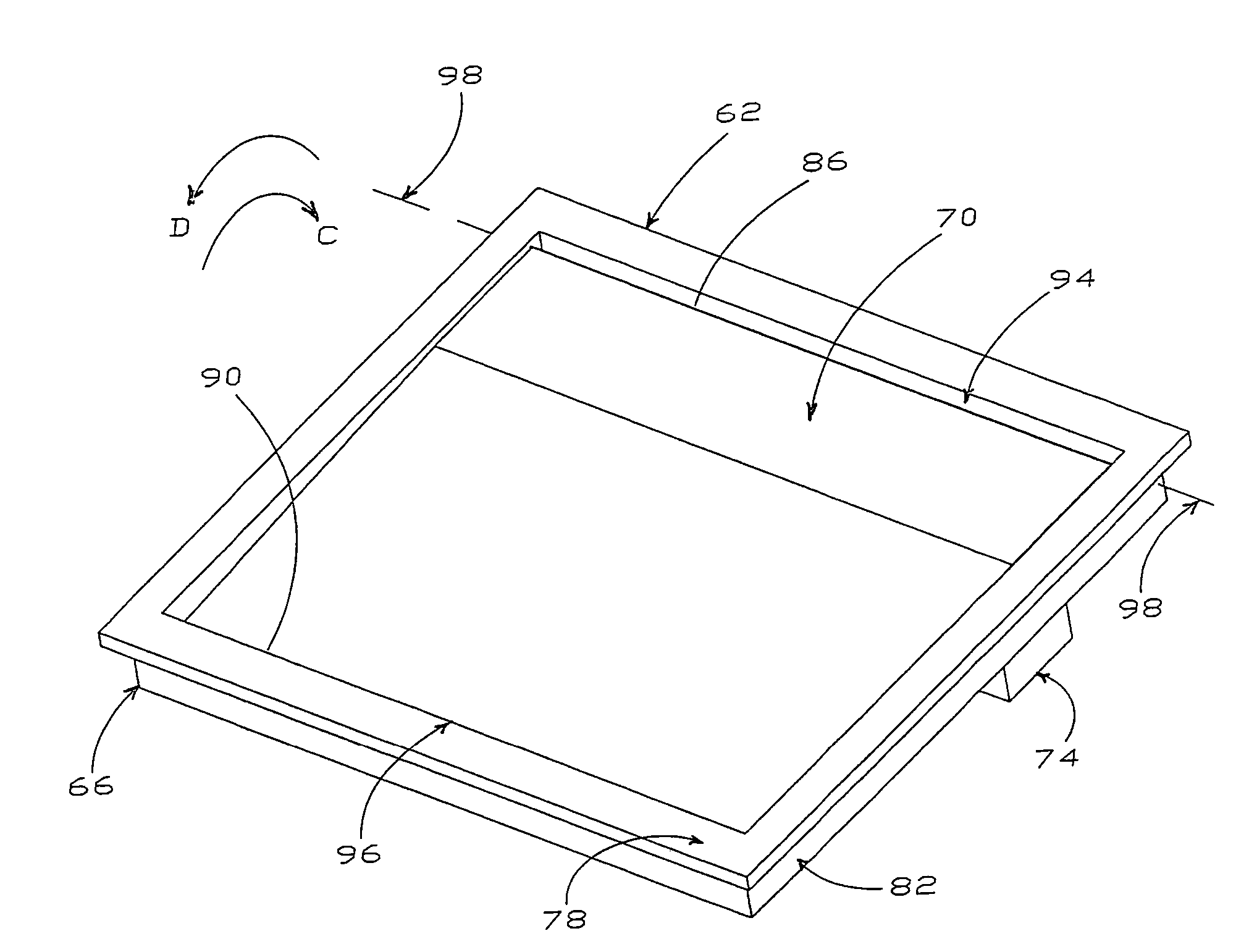

Storm protection and security window shutter system

InactiveUS20090090062A1Avoid damageProvide securityHurricane shuttersShutters/ movable grillesWindow shutterWindow opening

A combination window frame and panel or shutter door system to provide security to premises and to protect the windows from storm wind damage. The frame and shutter door combination is configured to be installed over existing pre-installed windows or configured to be combined as a single window shutter door frame combination to install in window openings on a wall. In an alternative design, the window has a frame adapted to receive a storm panel that covers the window during storms.

Owner:PANDORF BRIAN

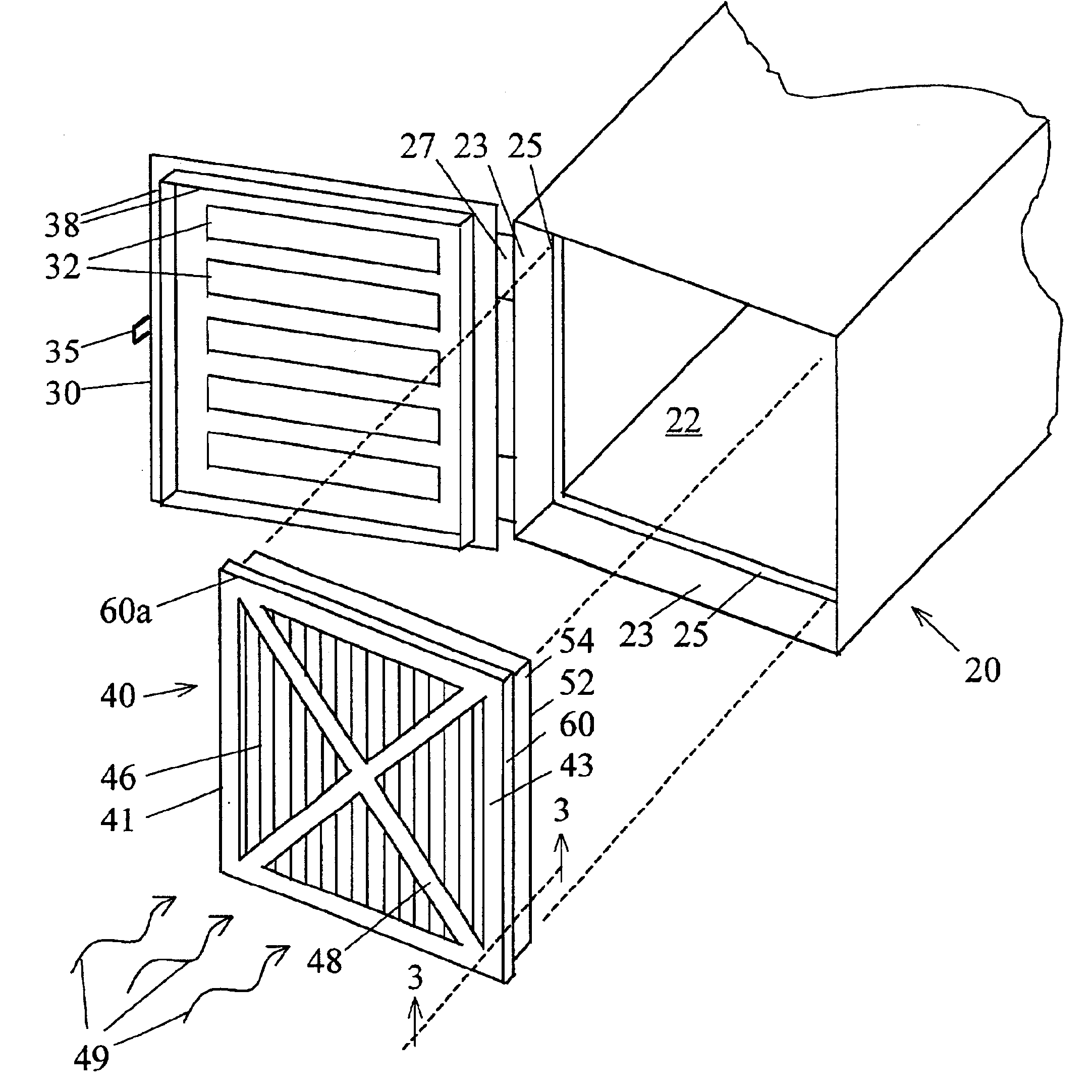

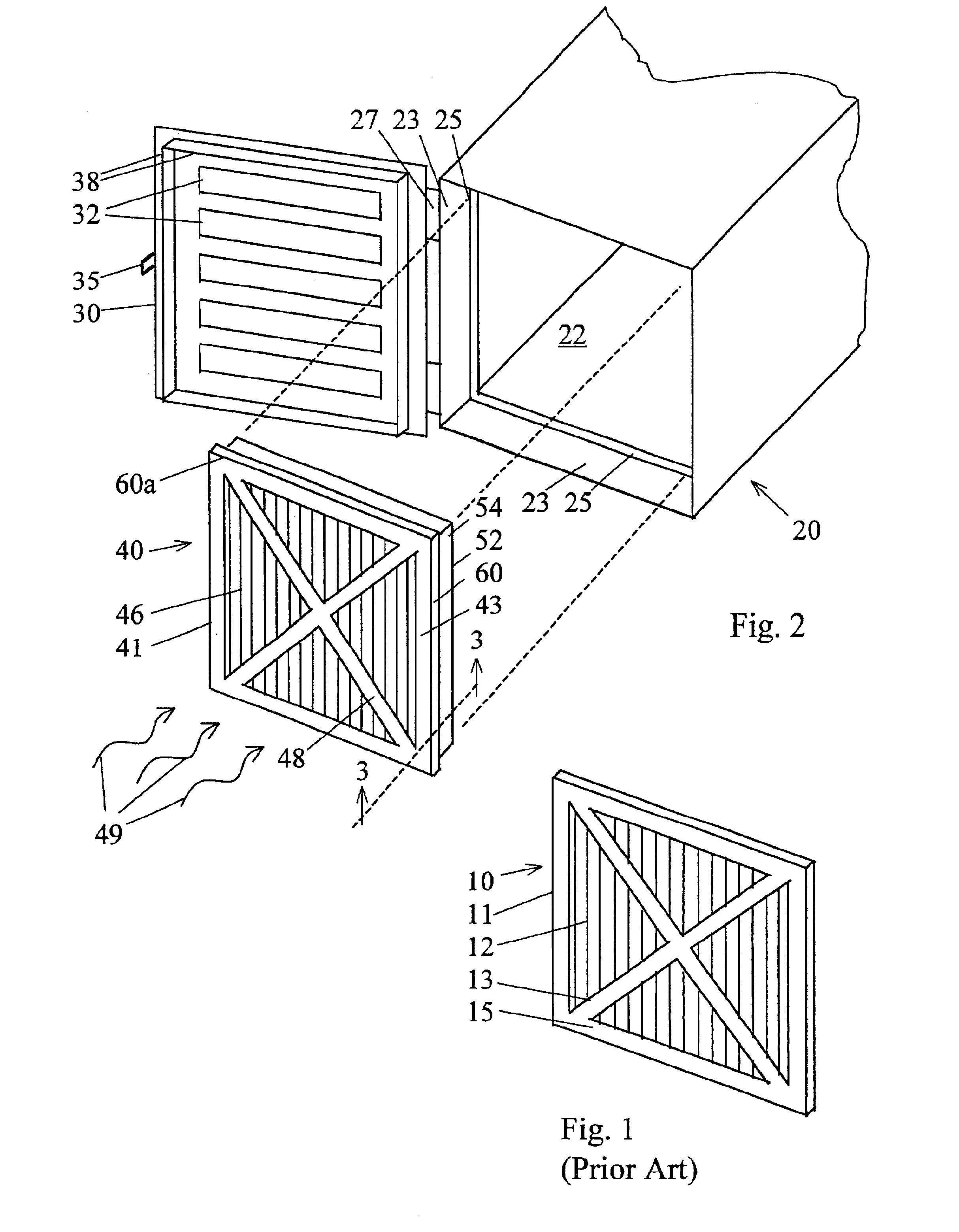

Deep filter element suitable for replacing a shallow filter element and having a support frame made from thin stock

InactiveUS6875250B2Efficient assemblyImprove rigidityDispersed particle filtrationFiltration separationCardboardEngineering

A deep format filter element has a peripheral frame with outwardly protruding mounting flanges. The mounting flanges simulate the periphery of a shallow format filter element to allow the deep format filter element to replace the shallow format filter element in many situations. The frame design allows the entire frame to be formed of cardboard and still provide adequate rigidity and strength. The frame includes first and second cardboard sheets forming individual sides of the frame and panels of the mounting flange. The first cardboard sheet includes for each mounting flange at least three folds defining edges of the mounting flange's first end panel and first and second side panels. The second cardboard sheet forms the second end panel of the mounting flange.

Owner:ADEMCO INC

Fully enclosed, folding, expandable multi-antechamber for emergencies

Compacting, fully enclosed, floored combination multi-antechamber and ramp system for emergency and civil defense use providing, when expanded, means of ingress and egress for the general population including the infected, wounded and handicapped to and from buildings or other folding structures via portals to which its adapter may be securely attached or retrofit while passing through a series of two or more antechambers so as to prevent spreading contamination and allow for various decontamination protocols to be conducted in separate chambers. Compacting is achieved by modularity in some embodiments, and folding in other embodiments, in both framed and panel versions, providing important advantages for transport, pre-positioning, storage, and warehousing.

Owner:KALNAY PETER ANDRES

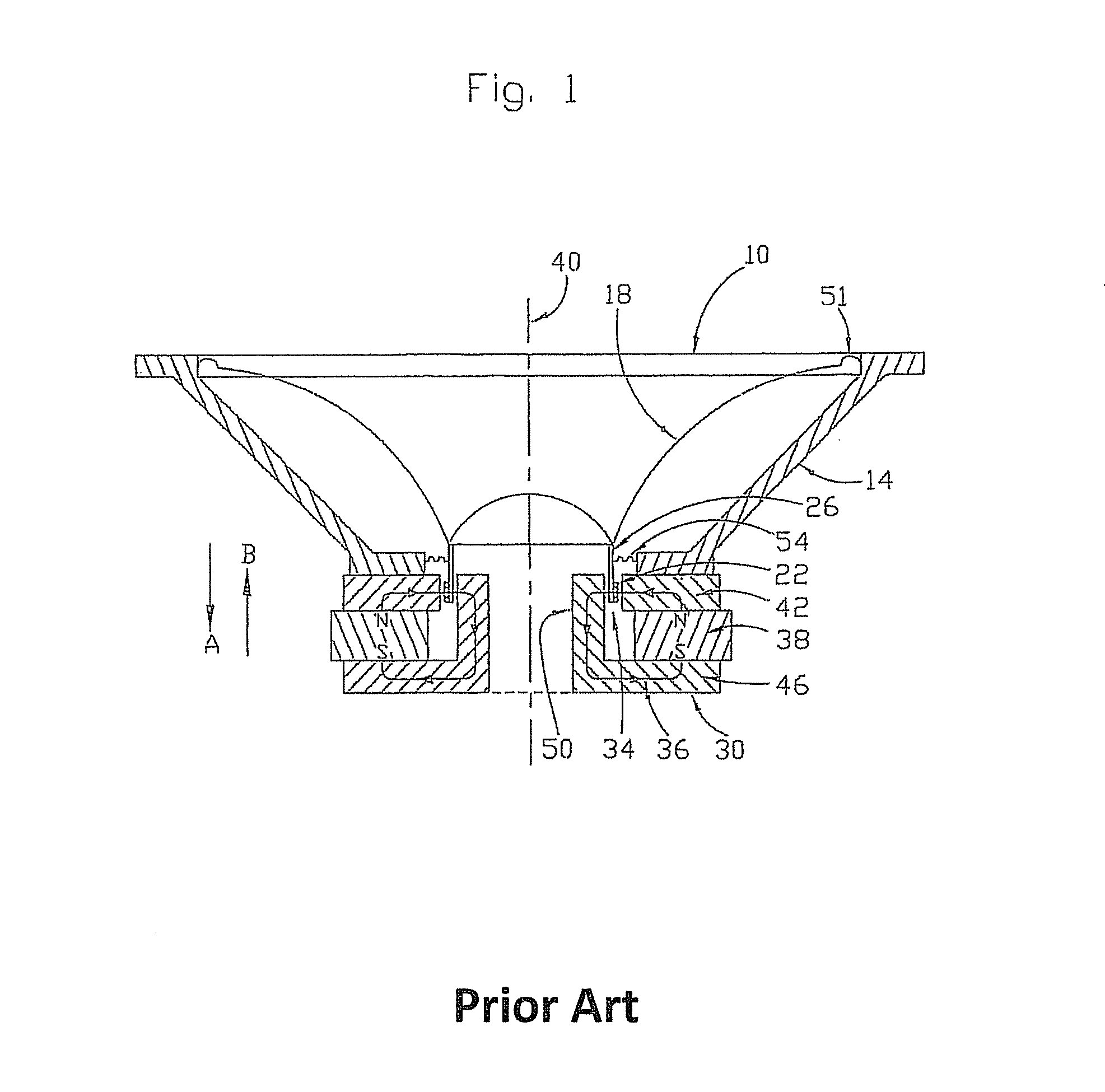

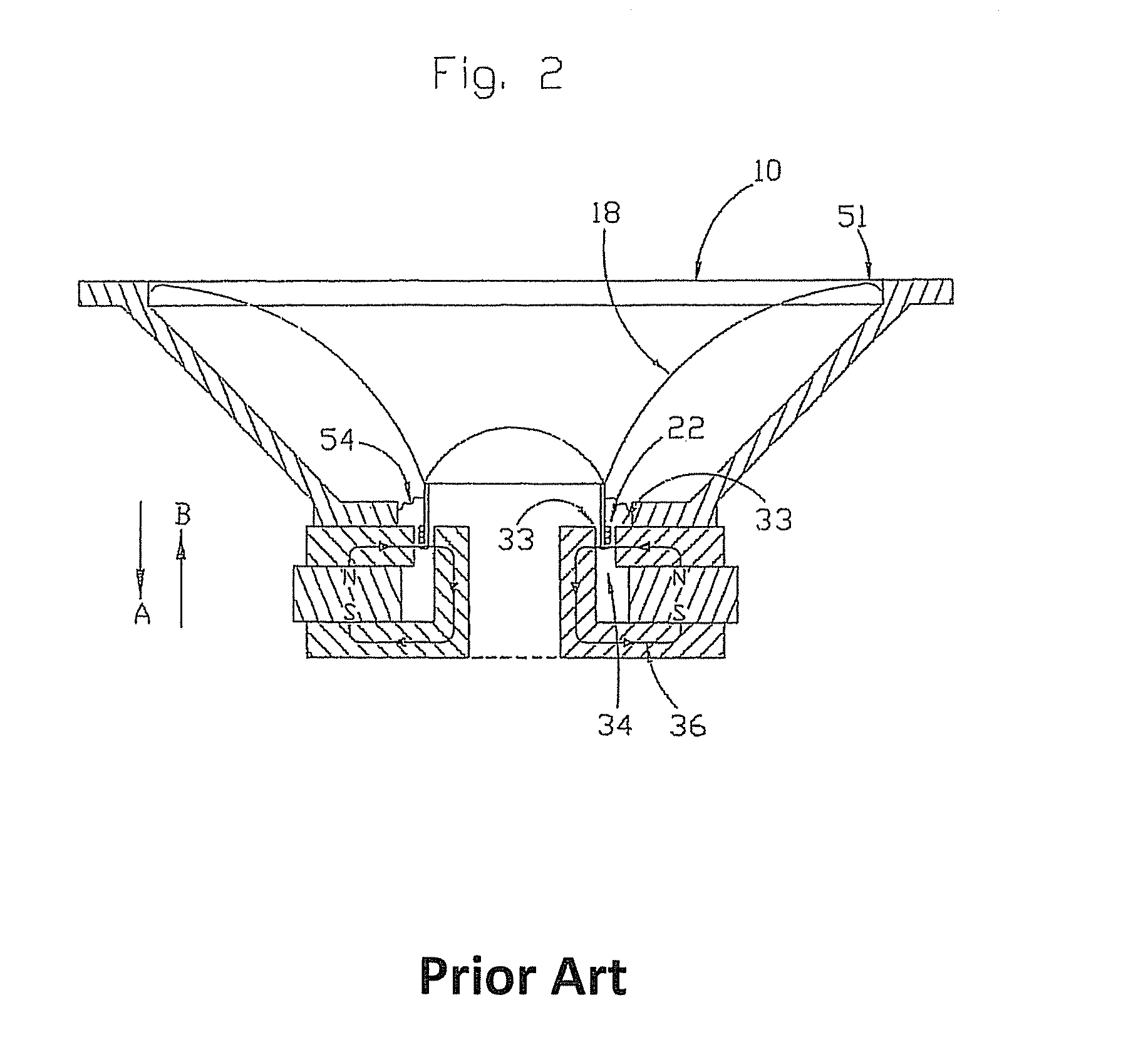

Electromagnetic lever diaphragm audio transducer

A transducer including a frame and a panel disposed within the frame and coupled to the frame such that the panel may rotate relative to the frame about a rotational axis. The transducer includes an actuator positioned to engage the panel such that the panel rotates about the rotational axis.

Owner:HENRY TODD

Frame and panel system for constructing modules to be installed on an airplane ground support equipment cart

A frame, panel, and fastener system for use in constructing modules that are to be installed on a ground support equipment cart. The modules have a rectangular frame that is constructed primarily by connecting together members constructed as folded sheet metal tubes substantially rectangular in cross section but, on two adjoining sides, bent perpendicularly outwards to form a first shelf perforated with fastener mounting holes, these frame members having ends that may be fastened to pairs of ends of other like frame members at perpendicular angles to form the corners of the rectangular frame and of the modules. Panels having edges bent over to form stand-offs and perforated with fastener mounting holes are sized so the stand-offs rest upon the first shelves on plural sides of the rectangular frame. Plural fasteners have first fastener parts that are attached to the shelf fastener mounting holes and second fastener parts that are attached to the panel fastener mounting holes, with the fasteners aligned to join and to detachably hold the panels upon the first shelves to form removable side panels for the modules.

Owner:ILLINOIS TOOL WORKS INC

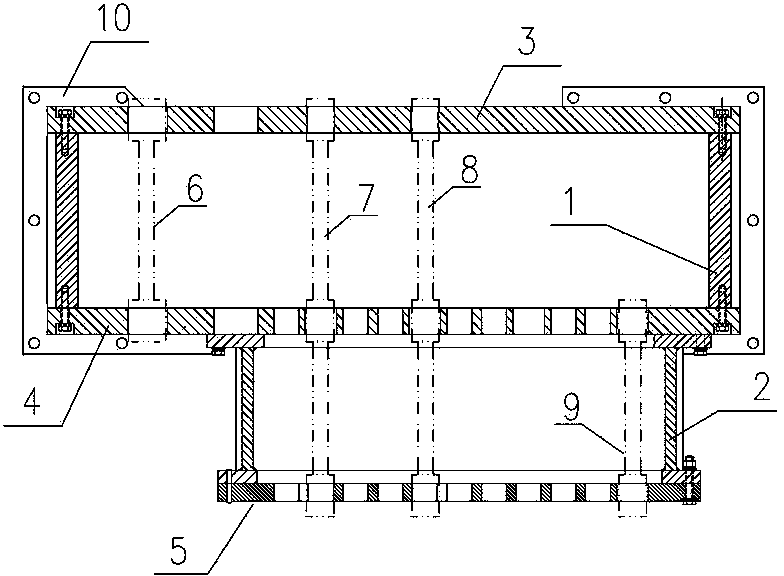

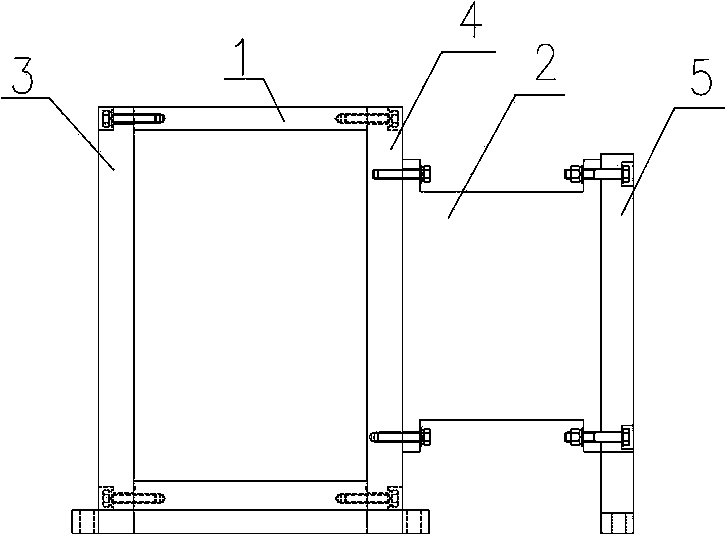

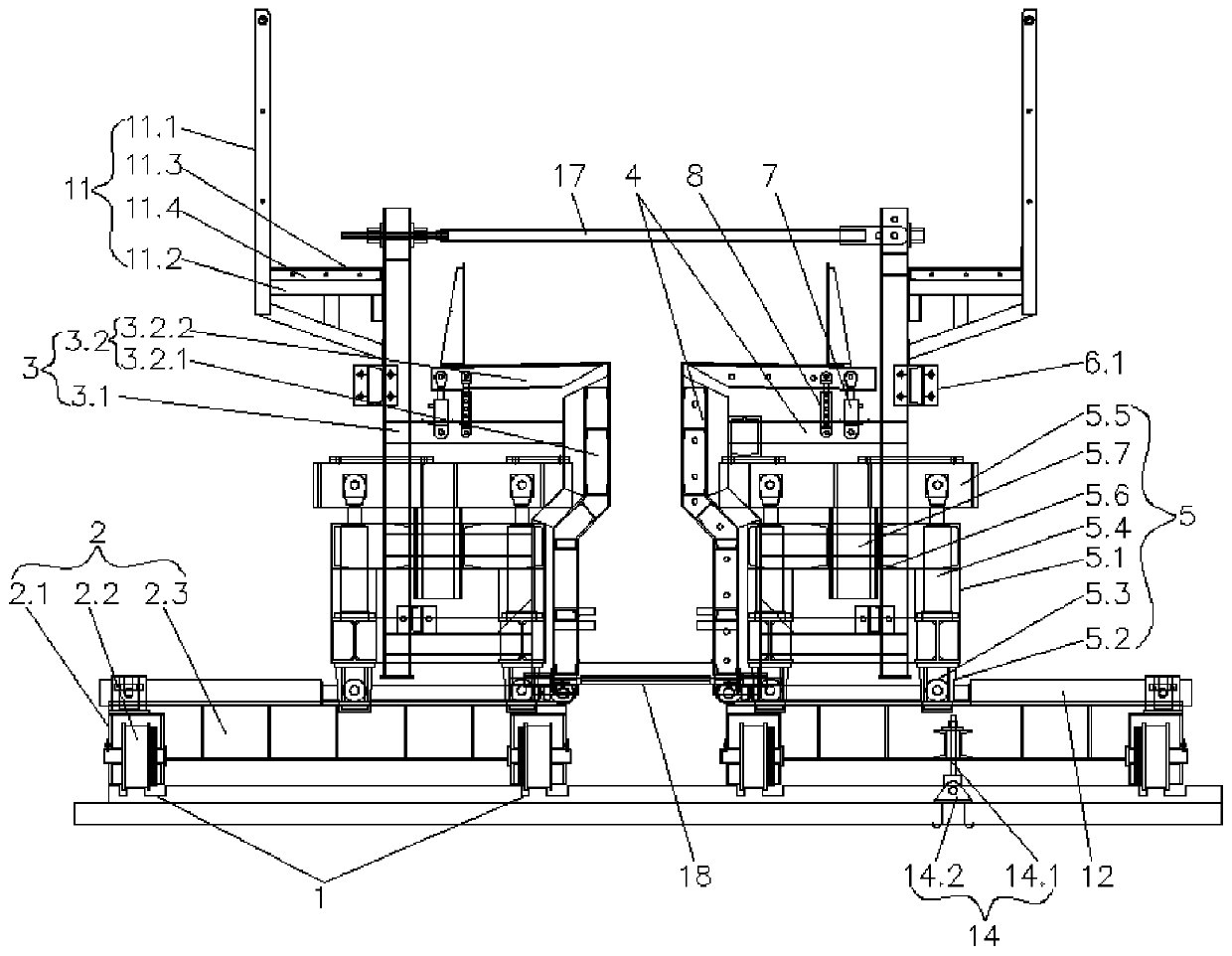

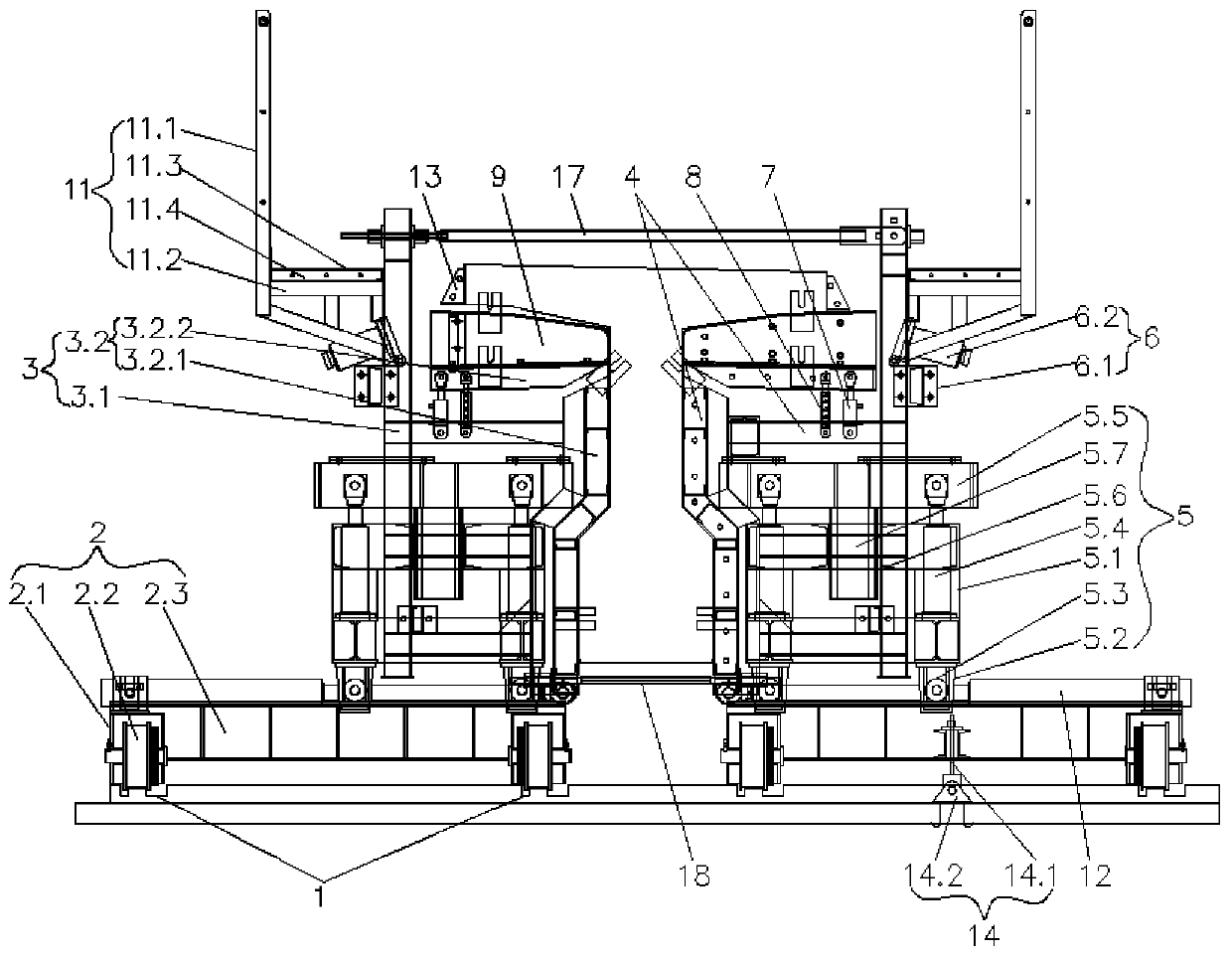

Machining process of multiple frame and panel combined parallel shaft gear box body

The invention discloses a machining process of a multiple frame and panel combined parallel shaft gear box body. The machining process includes that step 1, panel combined parts and frame combined parts of the box body are machined separately according to the design drawing; when panels and frames are machined, the panels are milled first, then bearing seat holes are bored, and bolt holes and positioning pin holes are drilled at last; the positioning pin holes which are formed in the panels are drilled into positioning pin holes for preassembly when being machined, the diameter of the positioning pin holes for the preassembly is smaller than the size of the design drawing, and the positioning pin holes are to be assembled and reamed in step 3 and drilled and reamed to meet the requirements of the size of the design drawing in step 4; step 2, pin shafts are assembled according to the box body bearing seat holes in the design drawing; step 3, gear shaft systems are replaced by the pin shafts which are assembled in the step 2 according to the design drawing to preassemble frame assemblies and panel assemblies and connecting bolt holes which are formed in the combined surfaces of the frame assemblies and the panel assemblies are assembled and drilled and the positioning pin holes for the preassembly are assembled, drilled and reamed; step 4, the box body which is preassembled in the step 3 is disassembled, the pin shafts which are matched with the bearing seat holes are taken out, and gear shafts and bearing parts are assembled in the box body. The machining process of the multiple frame and panel combined parallel shaft gear box body has the advantage of saving the cost.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Portable locking support and platform system

ActiveUS20090301359A1Improve stabilityMinimizing swayingRod connectionsFoldable tablesSupporting systemEngineering

A portable support system having a portable support having a first end and a second end. The first end includes a tapered portion, and the second end includes a footing structure. The system also includes a receiving member having a support cone configured to receive the tapered portion. The support cone has a tapered inner surface and a tapered outer surface. The inner surface and outer surface are engagable with mating tapered surfaces. The receiving member is capable of attachment to one or both of a frame and a panel for use as a platform.

Owner:TAIT TOWERS

Fully enclosed, folding, expandable multi-antechamber for emergencies

Compacting, fully enclosed, floored combination multi-antechamber and ramp system for emergency and civil defense use providing, when expanded, means of ingress and egress for the general population including the infected, wounded and handicapped to and from buildings or other folding structures via portals to which its adapter may be securely attached or retrofit while passing through a series of two or more antechambers so as to prevent spreading contamination and allow for various decontamination protocols to be conducted in separate chambers. Compacting is achieved by modularity in some embodiments, and folding in other embodiments, in both framed and panel versions, providing important advantages for transport, pre-positioning, storage, and warehousing.

Owner:KALNAY PETER ANDRES

Delivery door

A delivery door may include a frame having a slot, an interior flange and an exterior flange. A panel may be attached to the frame and comprise a closed configuration and an open configuration. A securing device may be connected to the frame and the panel. The securing device may be a remote accessed internet enabled lock assembly. In certain embodiments, the panel may have a handle and a stopper. The panel may also be motorized. The delivery door may include a receptacle attached to the internal flange and the frame. The delivery door may be attached to a cut out portion of the structure. The securing device may be controlled from a wireless device.

Owner:WANJOHI SAMUEL SOLOMON

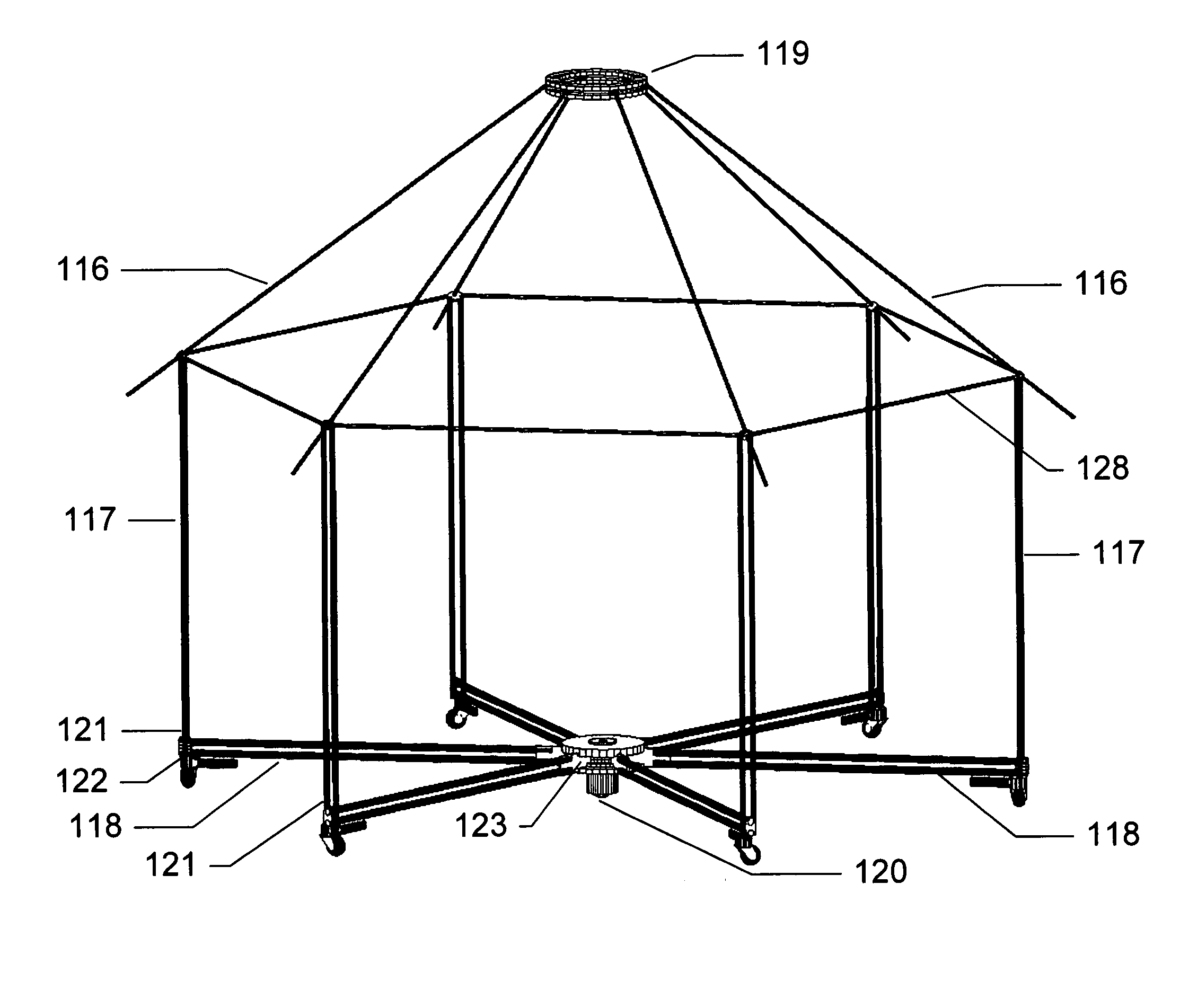

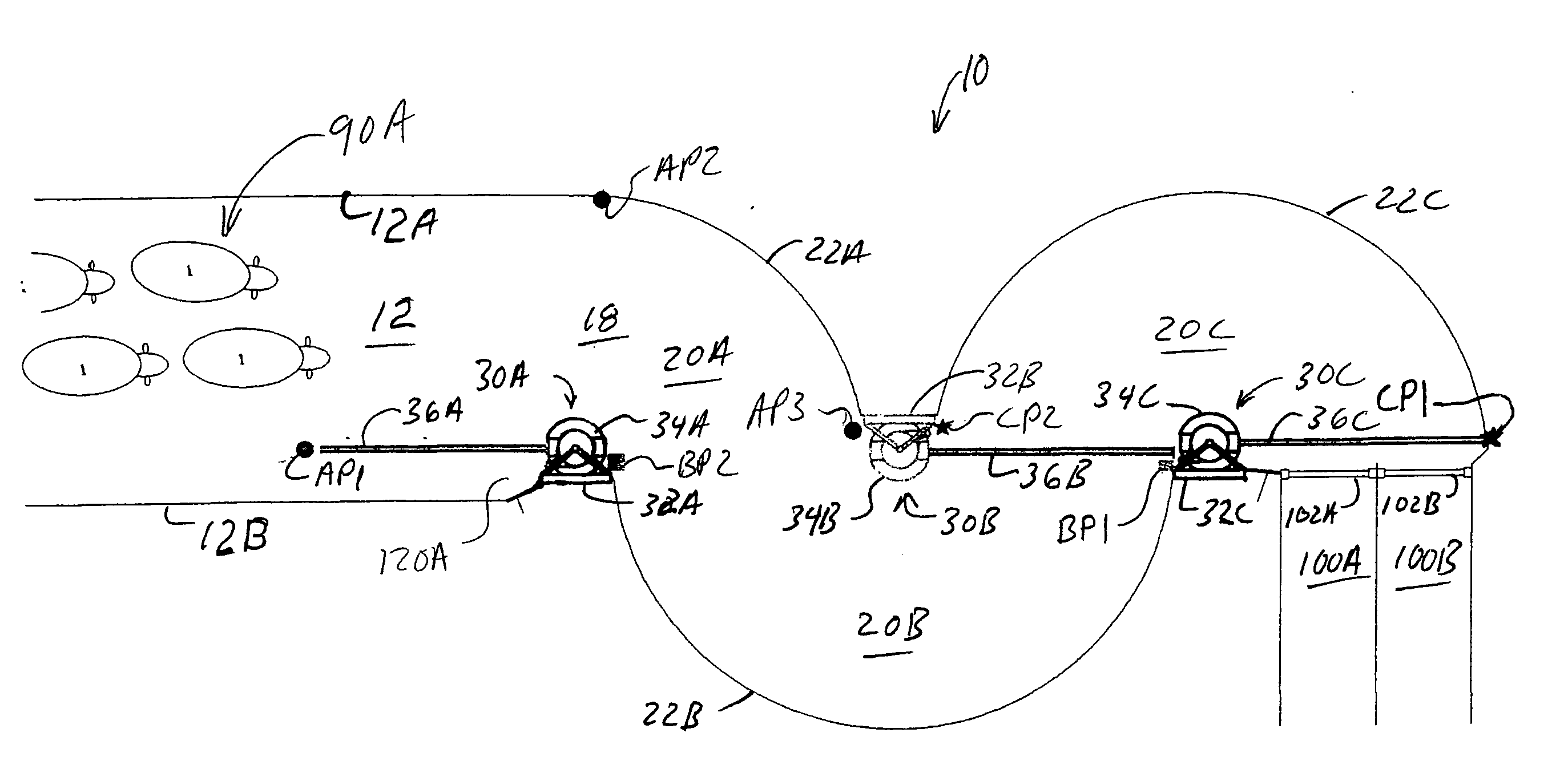

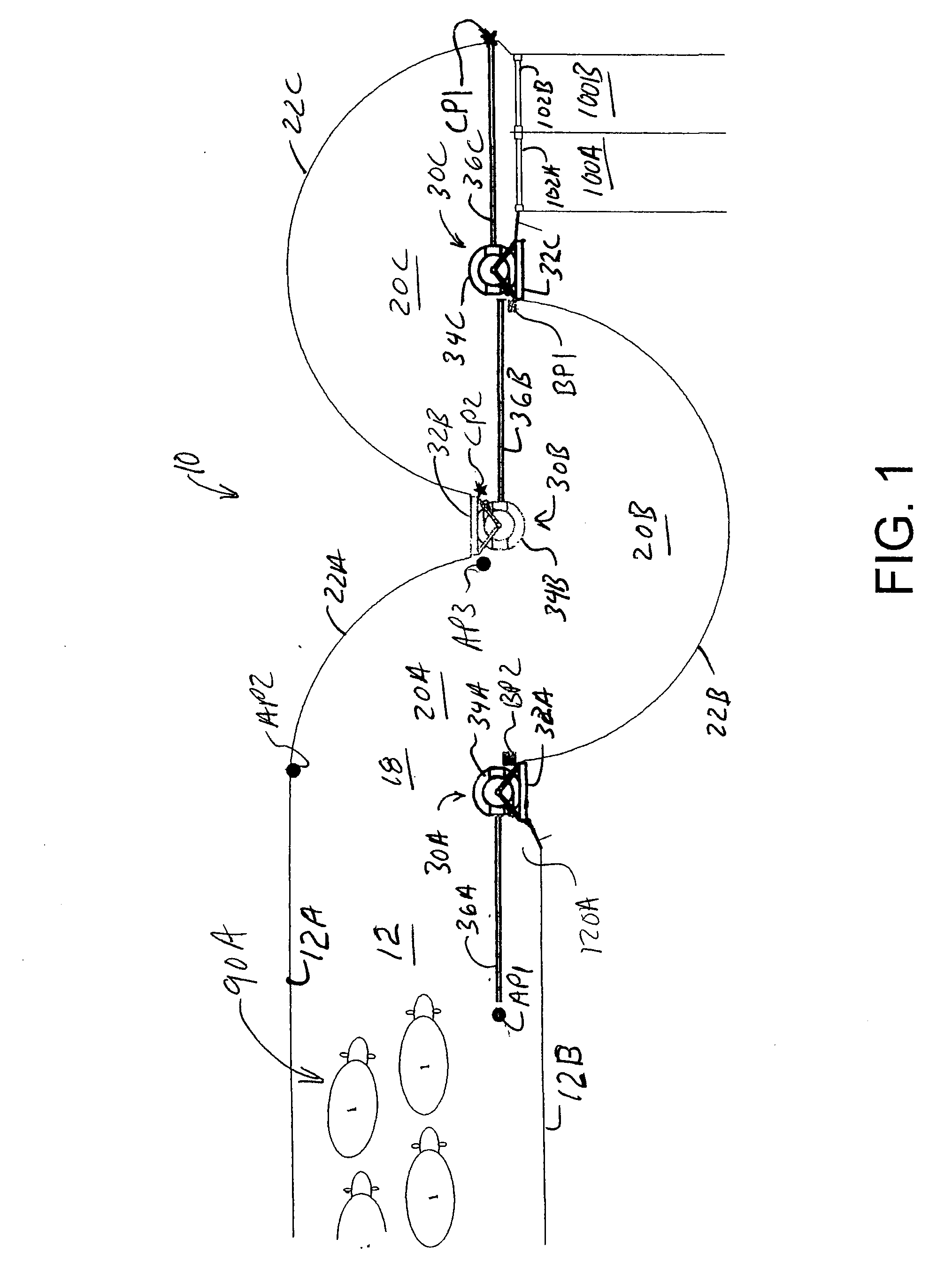

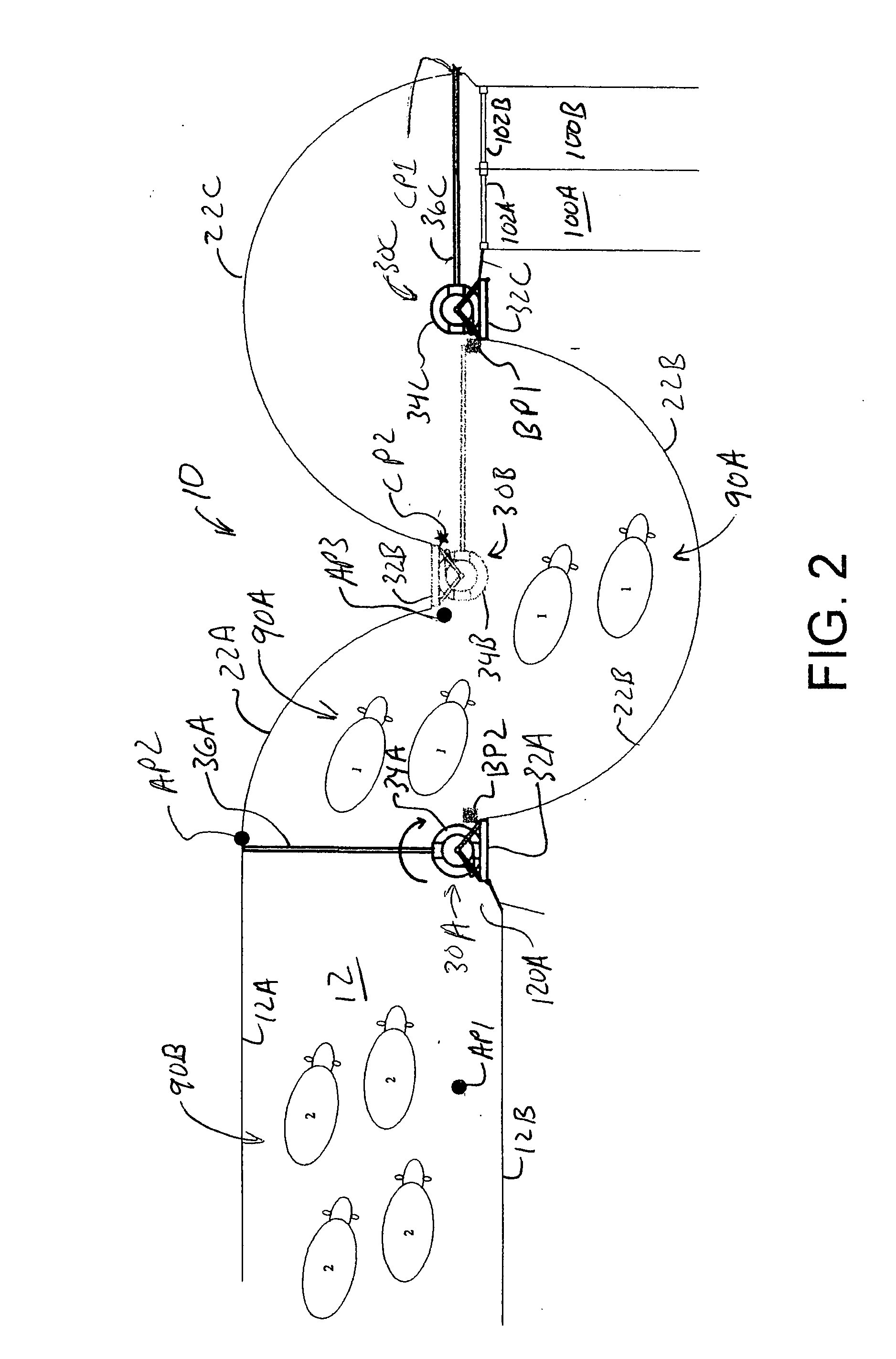

Livestock moving system and method

A system and method for moving livestock includes a sequence of interconnected enclosures in which the periphery of each enclosure extends generally to the center of the next enclosure. At the center of each enclosure is a turret unit including a support frame, a turret frame and a panel. The panel extends generally to the edge of the enclosure. The turret frame and panel are capable of two modes of movement: a sweeping mode and a shuttle mode. In the sweeping mode, the turret frame rotates the extended panel as the panel sweeps around the semicircular enclosure. In the shuttle mode the panel is translated across the enclosure from one side of the turret frame to the other side of the turret frame. Panels can thus be alternately swept around their respective enclosures and shuttled across their respective enclosures to present translating enclosed areas for livestock as the livestock progress through a series of interconnected semicircular enclosures.

Owner:MOLLHAGEN JON DAVIS

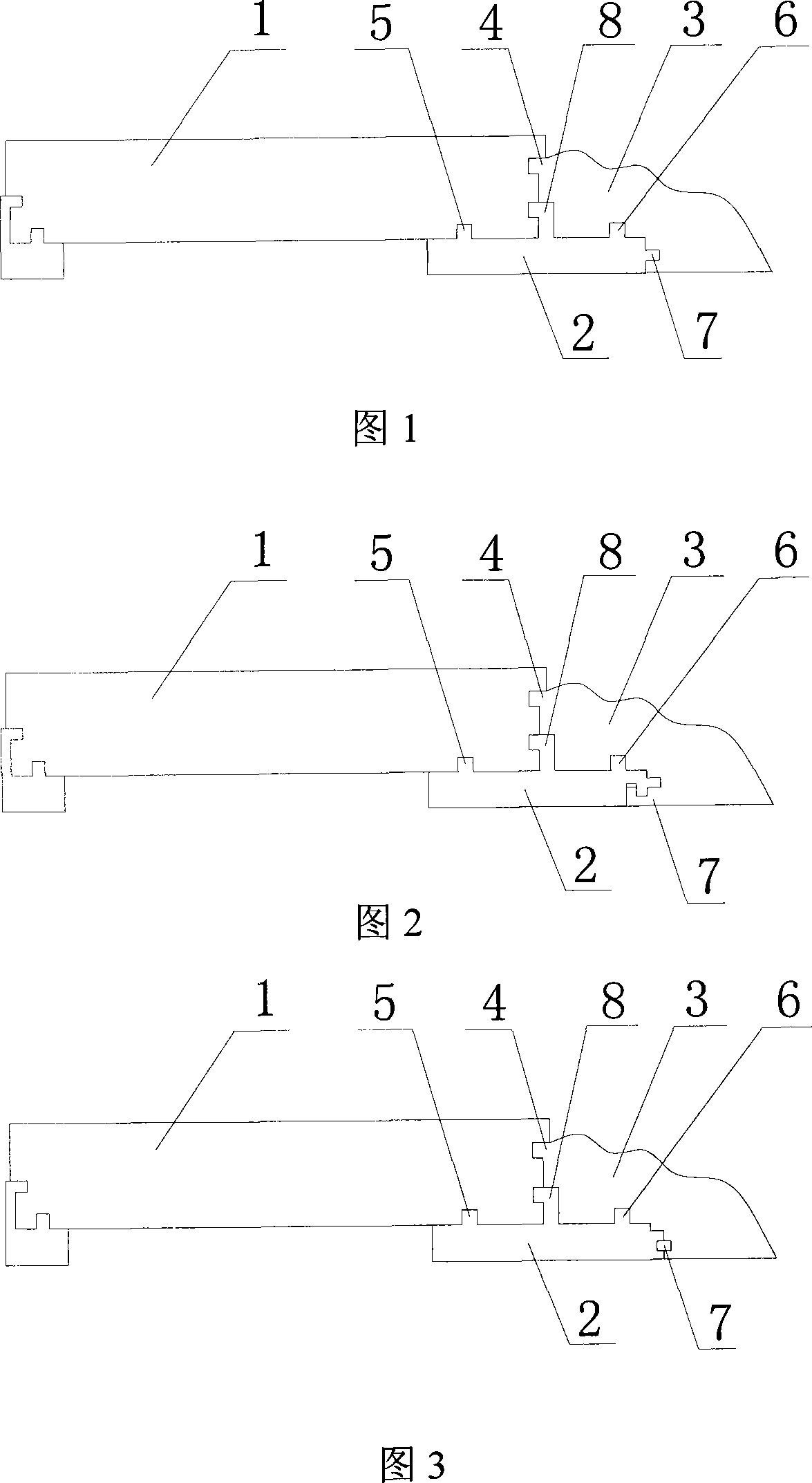

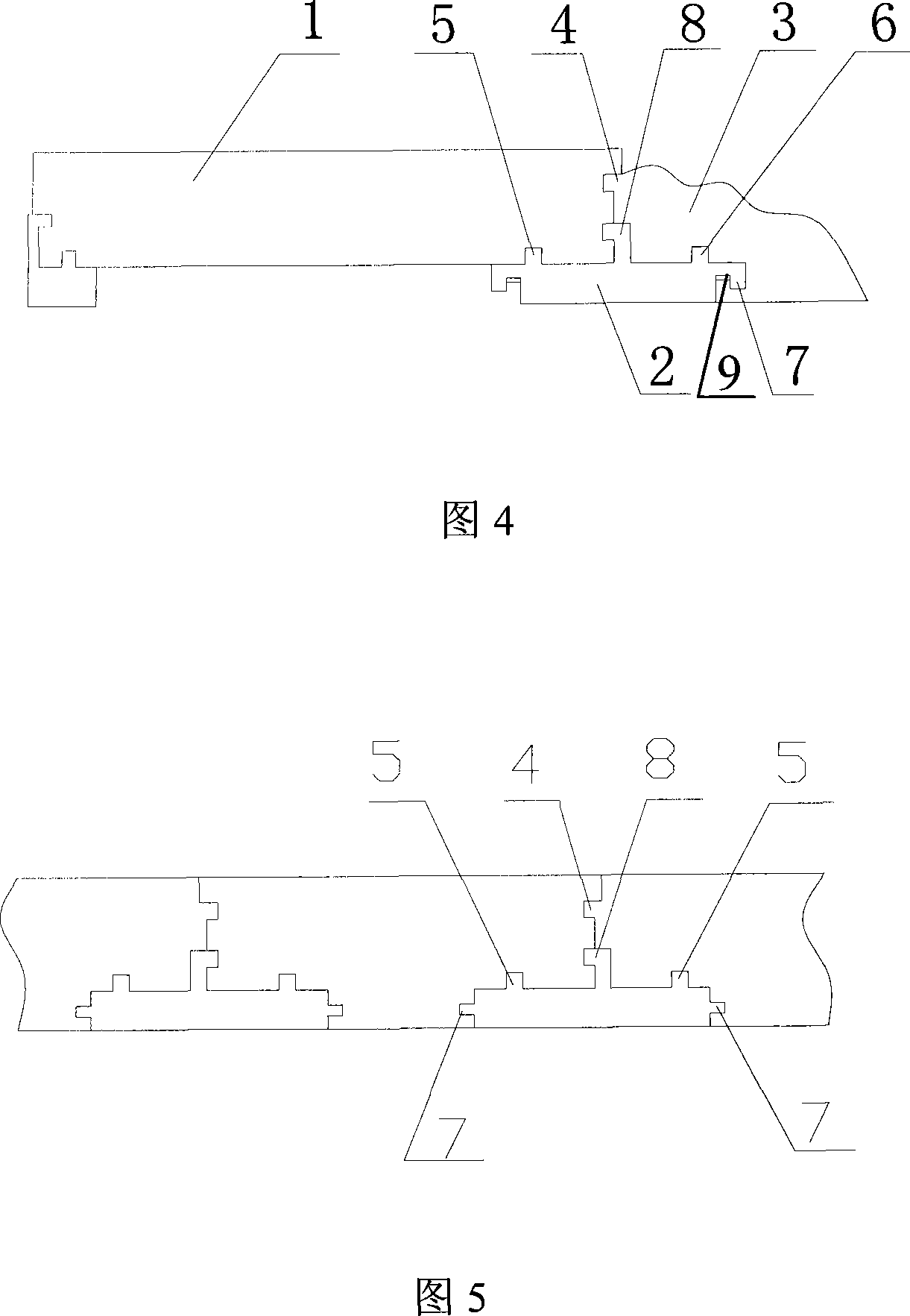

Split joint type decorated sheet

InactiveCN101235935ASimple structureEasy to splice and installCovering/liningsSheets/panelsKeelJoist

Owner:李新发

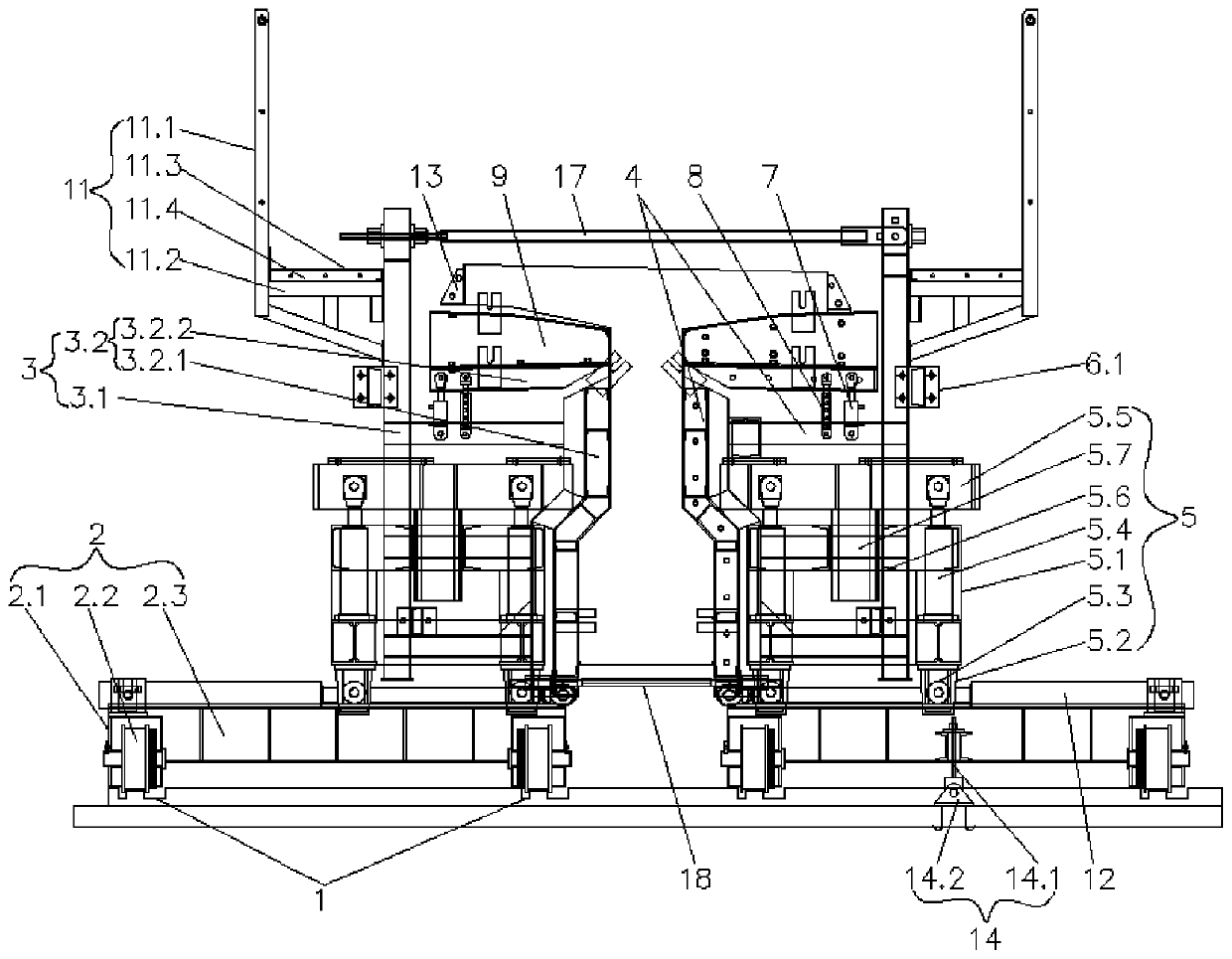

T-shaped beam casting special mold and using method thereof

PendingCN109968499AQuality improvementHigh quality, high market application prospectsDischarging arrangementMouldsShaped beamT-beam

The invention discloses a T-shaped beam casting special mold and a using method thereof, and relates to the technical field of T-shaped beam manufacturing. The T-shaped beam casting special die comprises a guide rail, wherein a walking trolley is arranged on the sliding rail in a sliding mode, a left mold and a right mold are symmetrically arranged on the walking trolley, the left mold comprises frames and panels connected to the inner side of the frames, the walking trolley is provided with mold guide devices which are positioned at the outer side ends of the two frames and provided with high-stroke spaces, the outer side ends of the two frames are provided with overturning type demolding mechanisms, an automatic slope adjusting mechanism and a locking mechanism are arranged on each frame, the tops of the automatic slope adjusting mechanisms and the tops of the locking mechanisms are hinged to the bottom of rotatable parts of the panels, combined adjusting mechanisms for adjusting theheight of the left mold and the bottom of the right mold are arranged at the bottom of the left mold and the bottom of the right mold, and supporting columns which are convenient to assemble and disassemble are arranged on the outer sides of the tops of the two frames, and during use, the supporting columns are subjected to mold closing and grouting, demoulding. The T-shaped beam casting specialmold has the advantages of being complete in function and good in T-shaped beam forming quality.

Owner:SICHUAN EAST SPRING MACHINERY EQUIP MFG CO LTD

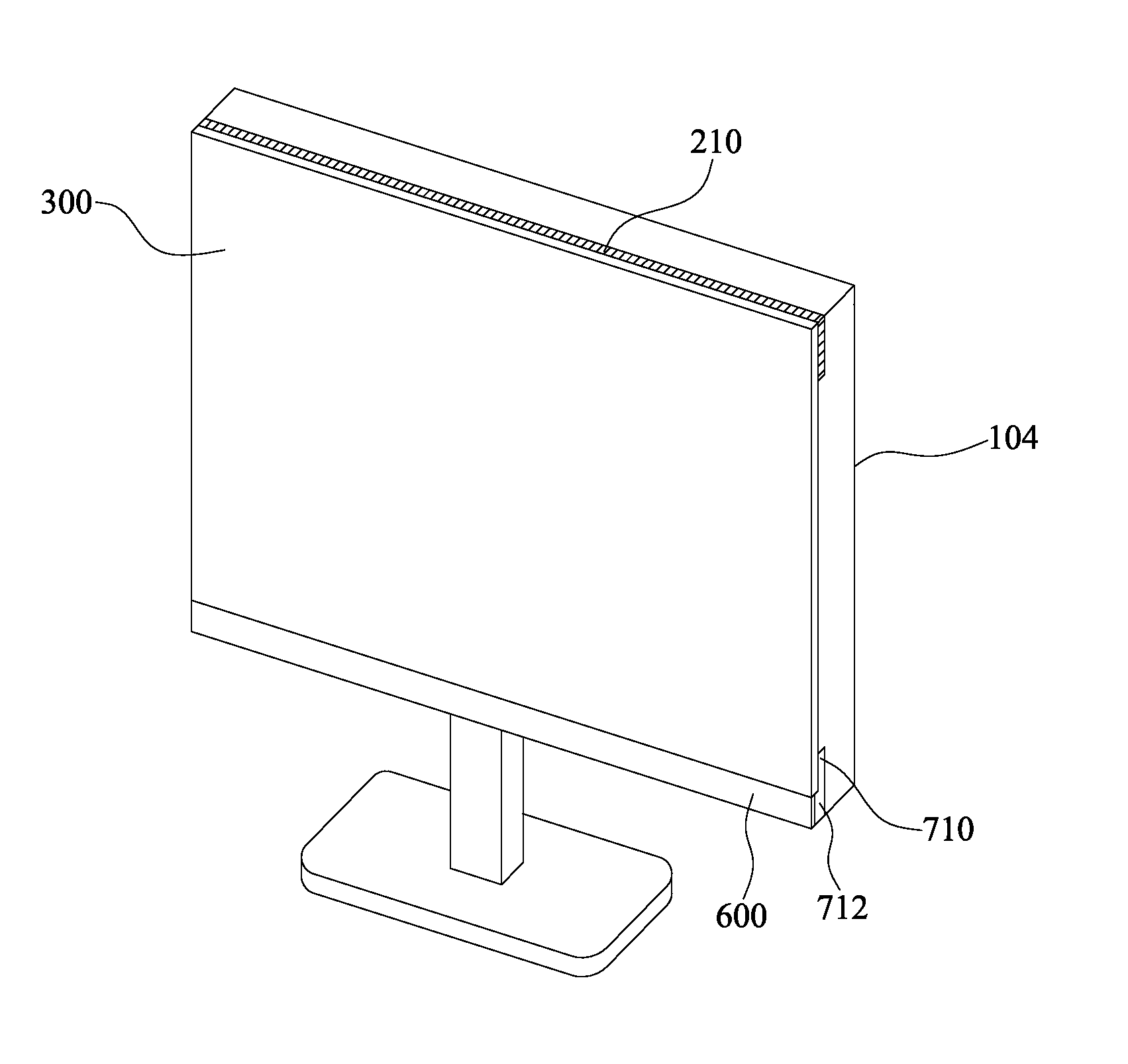

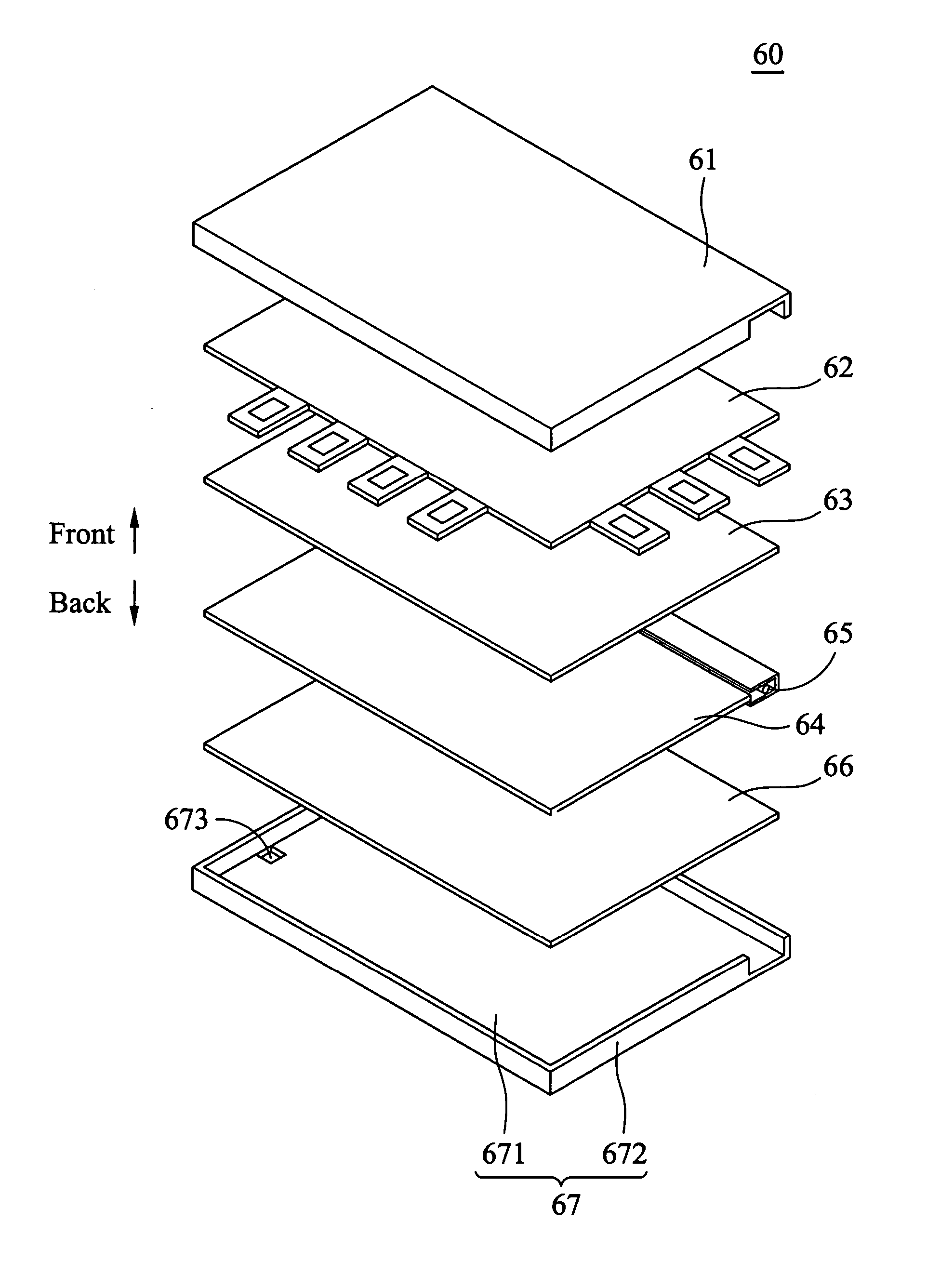

Display device

ActiveUS20120099259A1Eliminate the problemDigital data processing detailsElectrical apparatus contructional detailsDisplay deviceEngineering

A display device includes a rear set cover, an upper end guide frame, a lower end guide frame, a panel, a first adhesive member, a second adhesive member, a panel driver, and a lower finishing material. The upper end guide frame is secured to an upper end portion inside the rear set cover, and coupled to the rear set cover. The lower end guide frame is secured to a lower end portion inside the rear set cover, and coupled to the rear set cover. The panel is secured to the upper end guide frame and lower end guide frame. The first adhesive member couples the upper end guide frame and panel. The second adhesive member couples the lower end guide frame and panel. The panel driver is placed inside the rear set cover, and drives the panel.

Owner:LG DISPLAY CO LTD

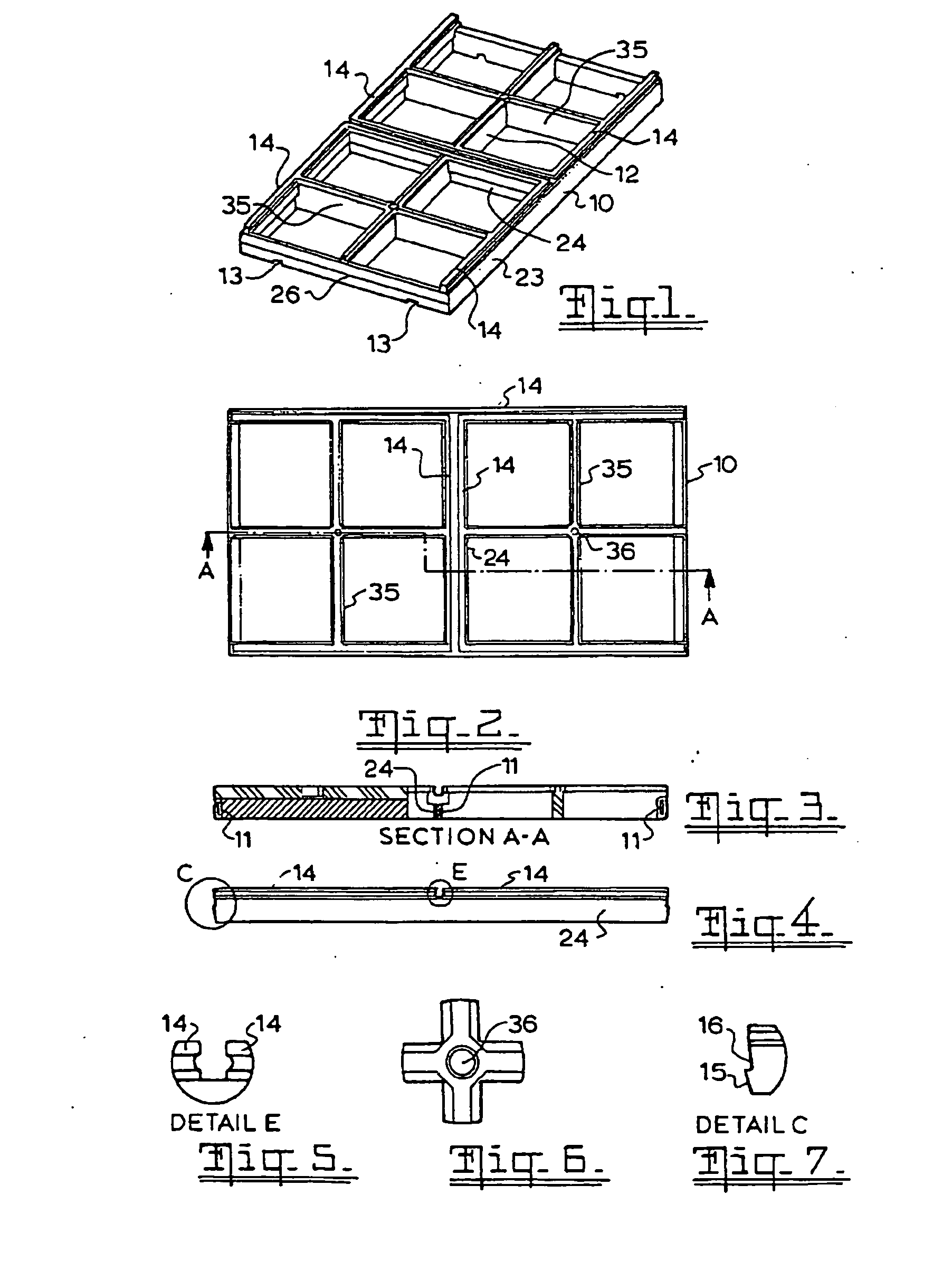

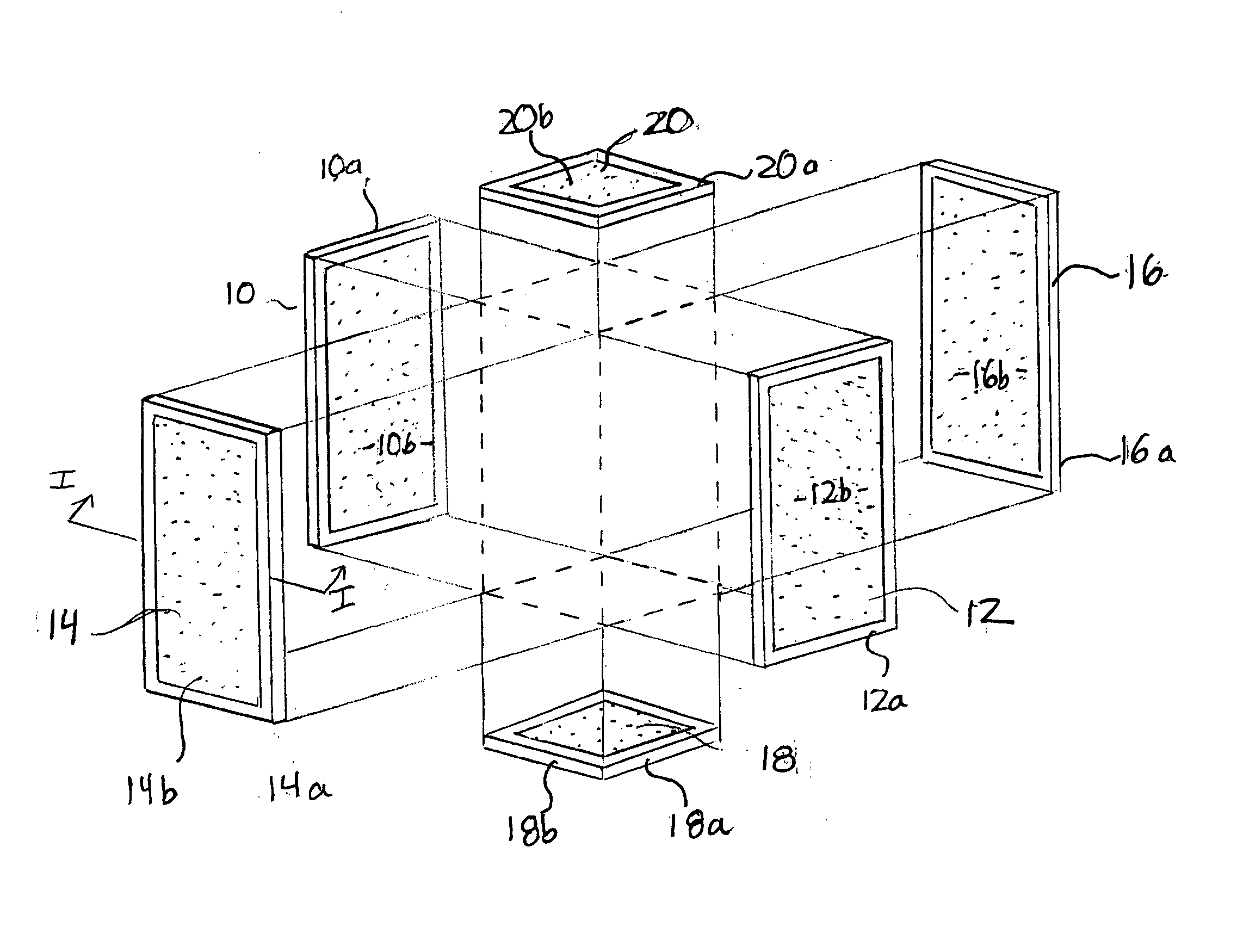

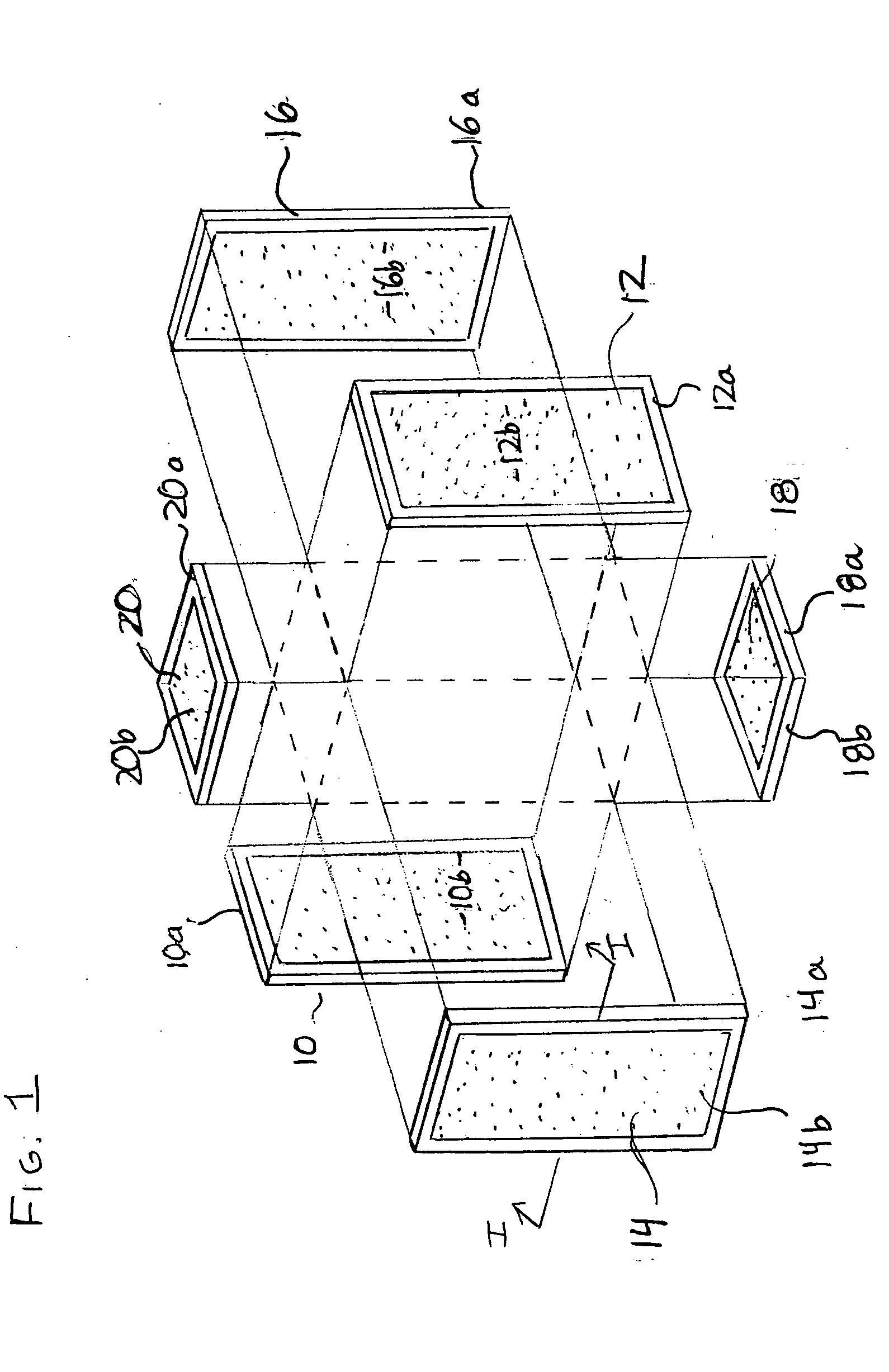

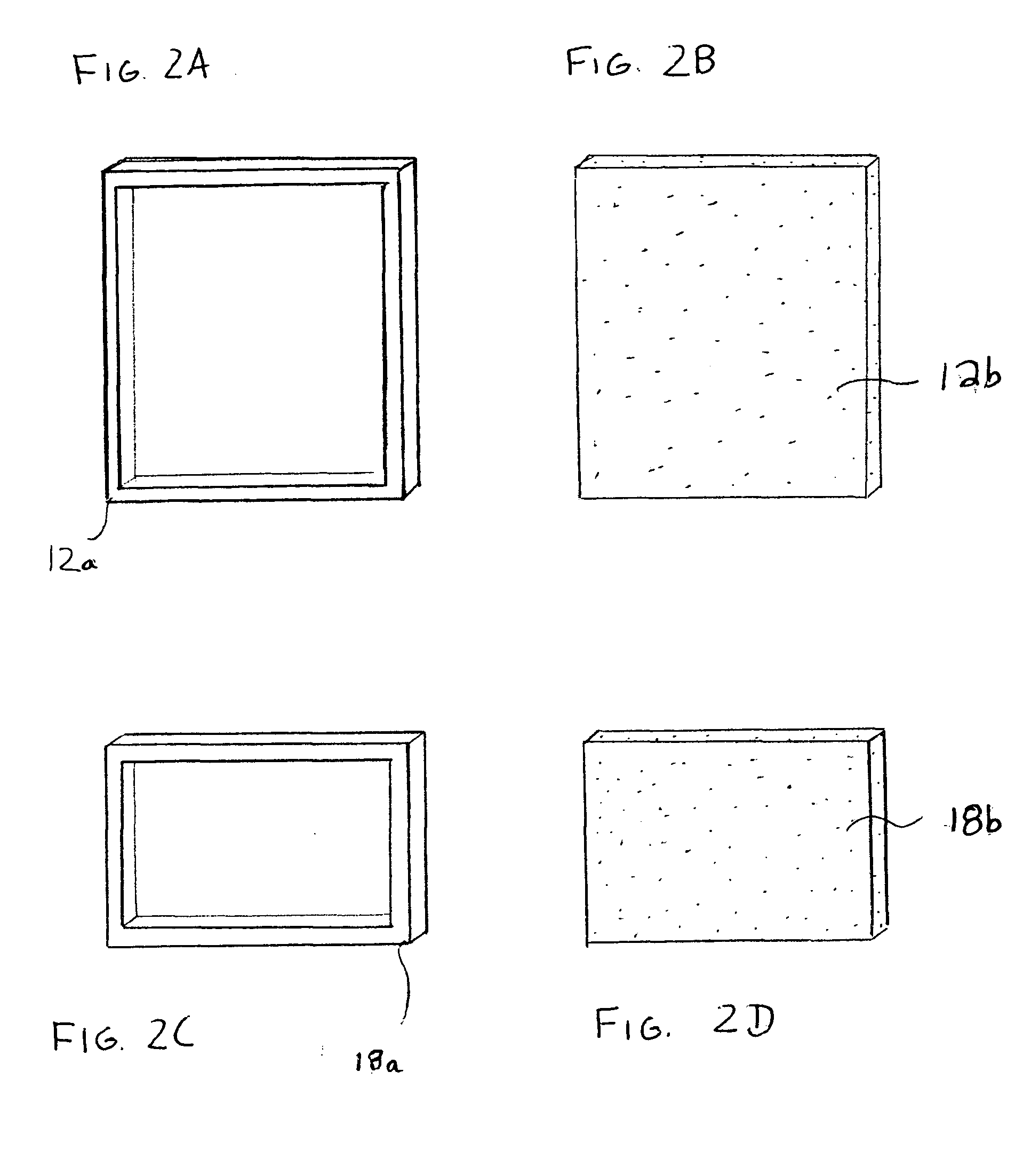

Interlocking component assembly system

InactiveUS20050023944A1Reduce inventory levelsLow investment costChestsDressing tablesEngineeringAssembly systems

An interlocking component assembly is made of a plurality of frame components and a plurality of panels. One panel is formed integrally with a respective frame to form a frame and panel component. A channel formed along the entire periphery of each of the frame components enables each of the frame and panel components to be interconnected. During assembly the channel of one frame component is inserted within a channel of another frame component to lock the components together along the length thereof. A plurality of locking tabs are disposed within the channel of each of the plurality of frame components. A plurality of apertures are also disposed within the channel of each of the plurality of frame components, wherein when the channel of a frame component is inserted within the channel of another frame component at least one locking tab is received within a corresponding aperture. This process is repeated until a three-dimensional unit is formed.

Owner:THAI UNIVERSAL OFFICE PRODS

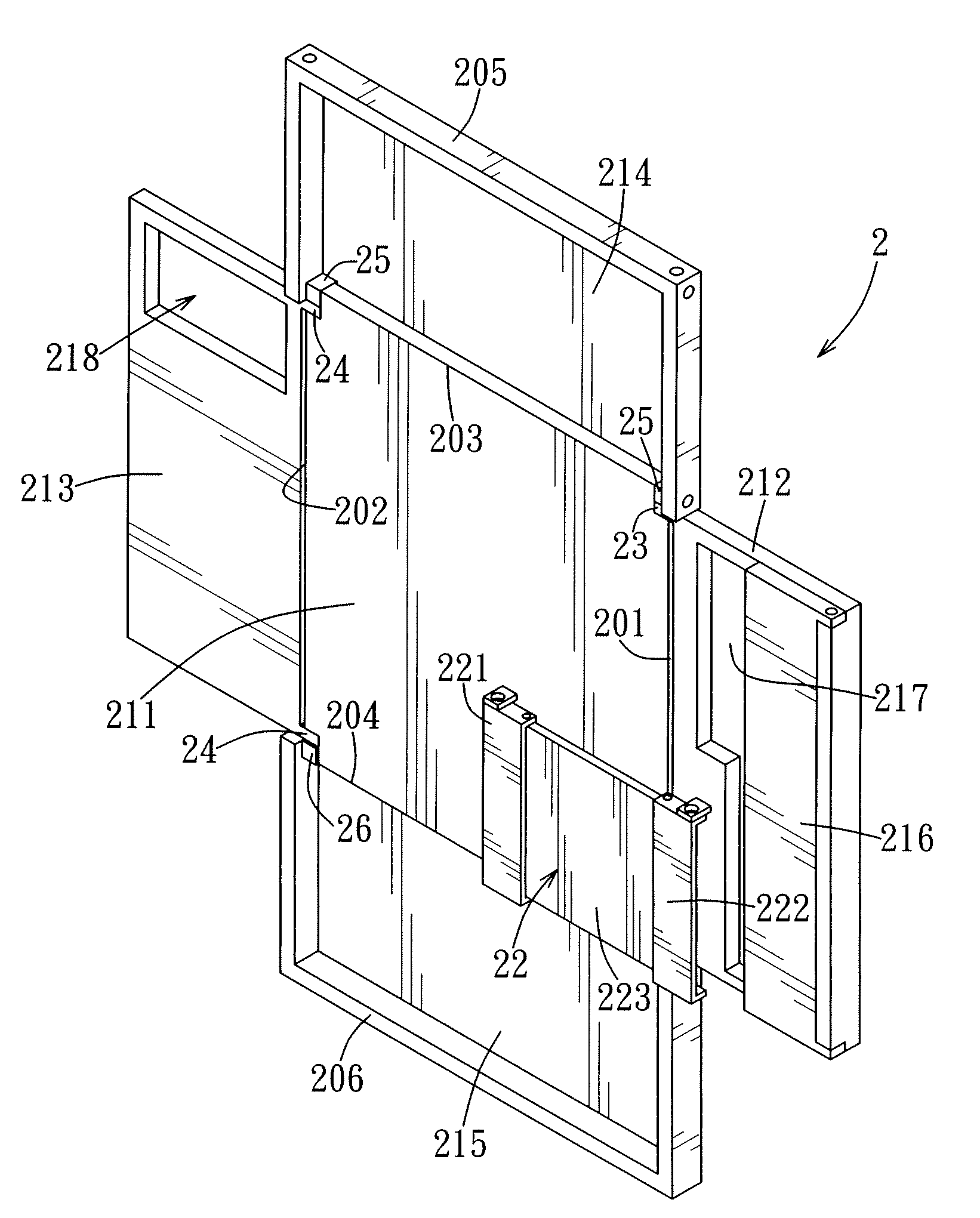

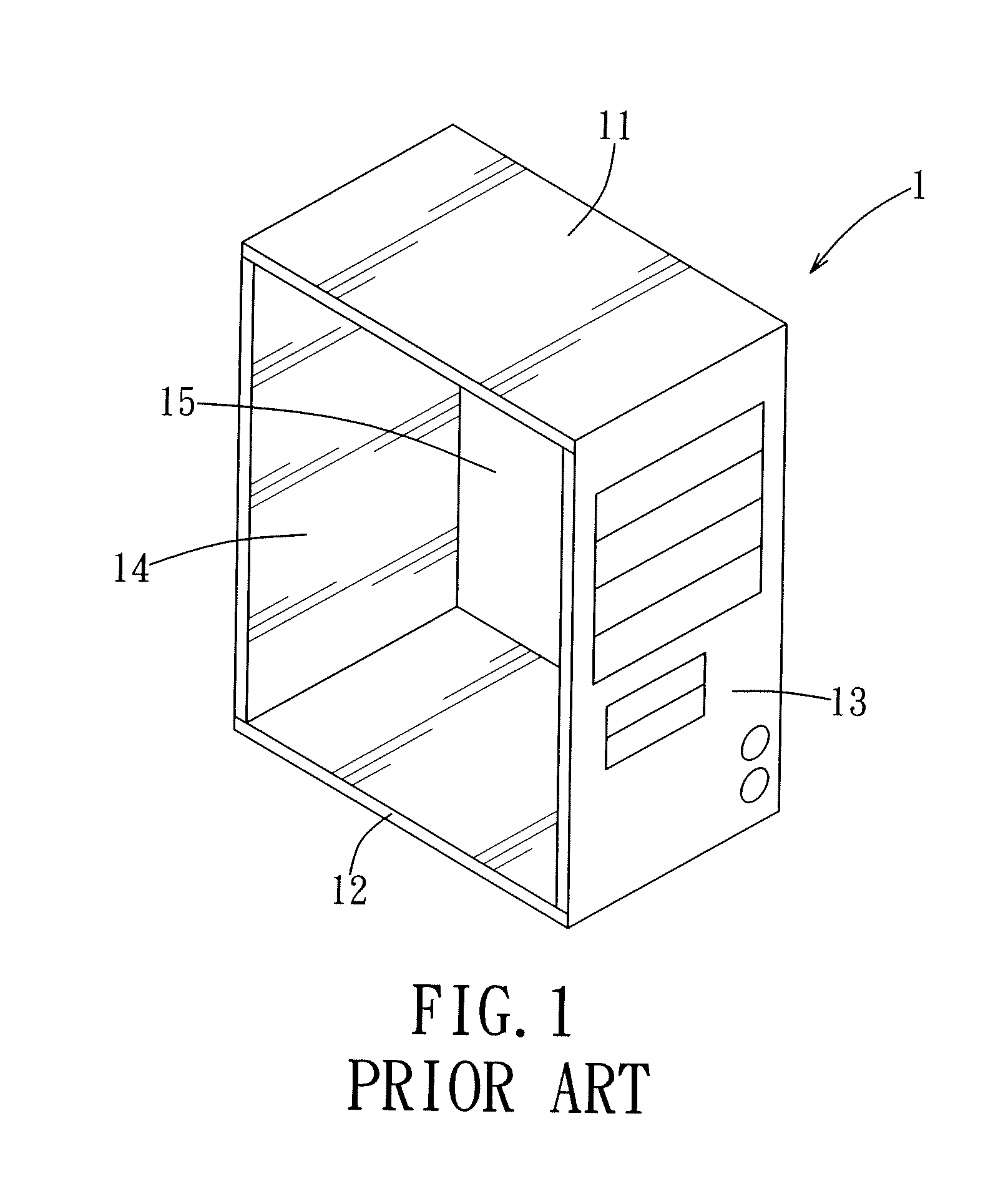

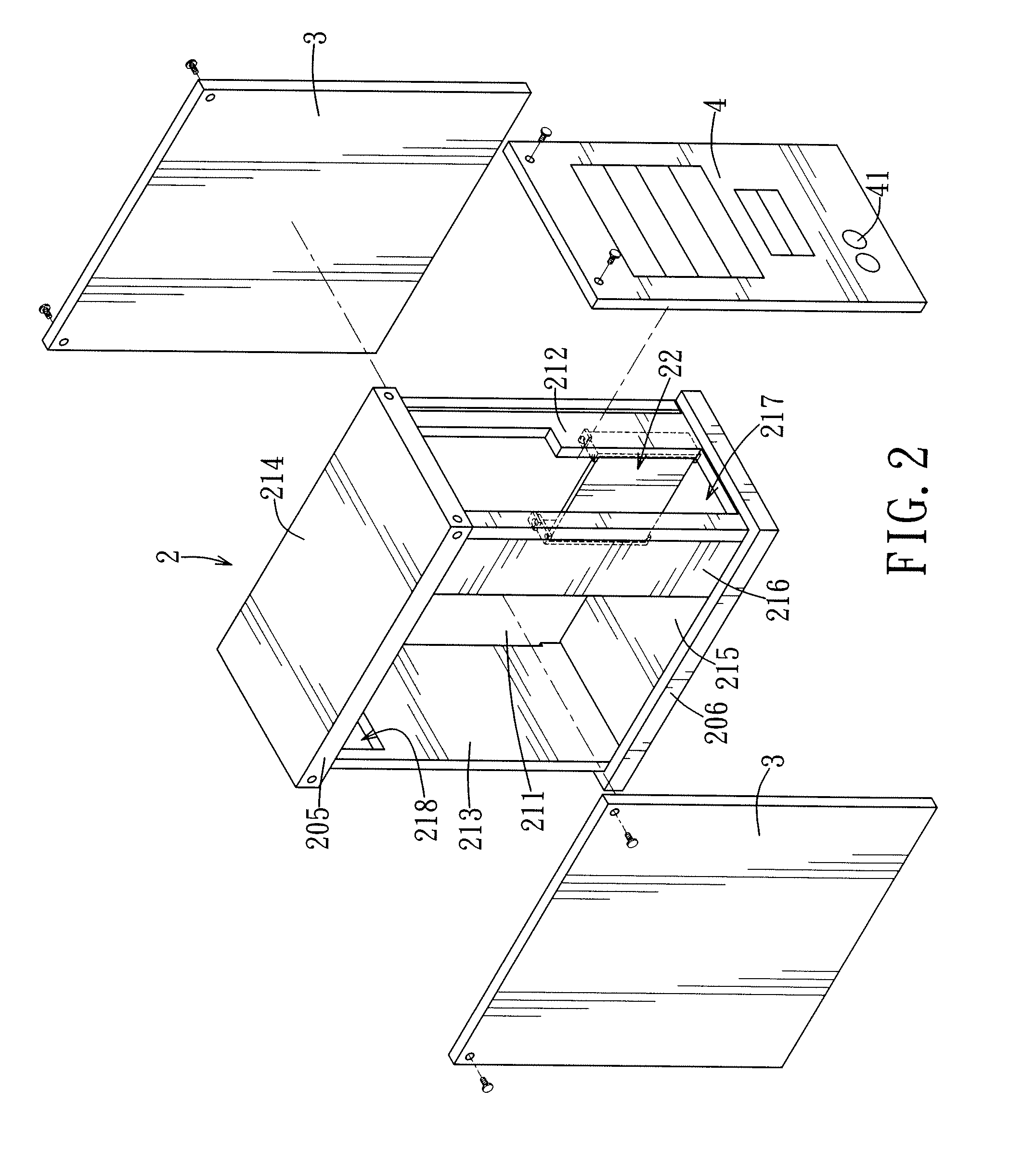

Computer housing and flattenable frame for the computer housing

InactiveUS20080002349A1Reduce storage space costsLow transportation costSubstation/switching arrangement detailsDigital data processing detailsElectronic componentMotherboard

A computer housing includes a frame and a face panel. The frame includes a plurality of pivotally interconnected frame panels such that the frame is convertible between an assembled state and a flattened state. In the assembled state, the frame panels form a rectangular frame for mounting electronic components, such as a motherboard, a disk drive and a hard disk. In the flattened state, the frame can be flattened out so that the frame panels lie in substantially the same plane, thereby reducing the space occupied by the frame.

Owner:AOPEN

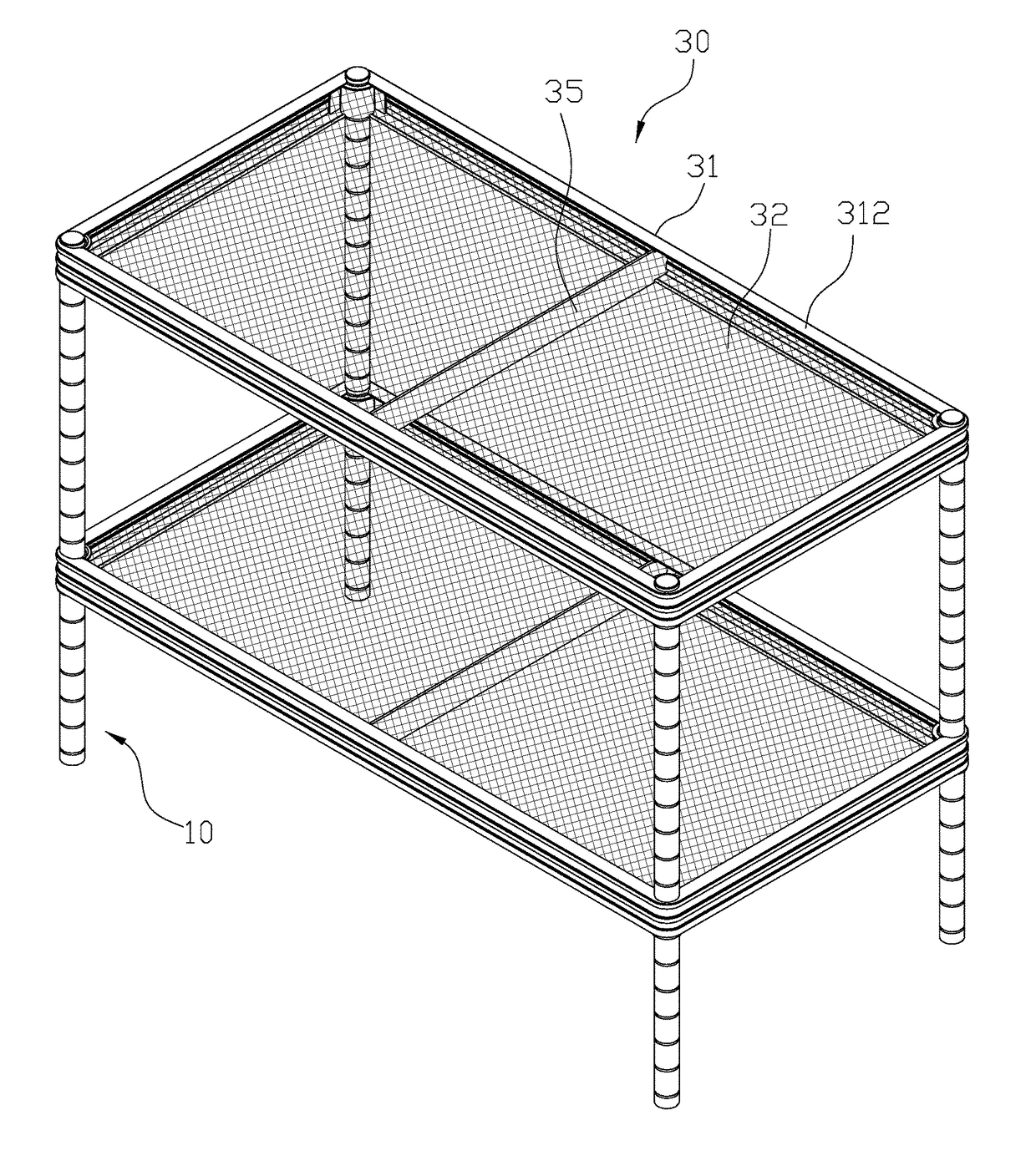

Shelving structure

ActiveUS9854906B1Reduce manufacturing costHigh strengthFurniture partsDismountable cabinetsEngineeringFrame and panel

Owner:KE CHIA NAN

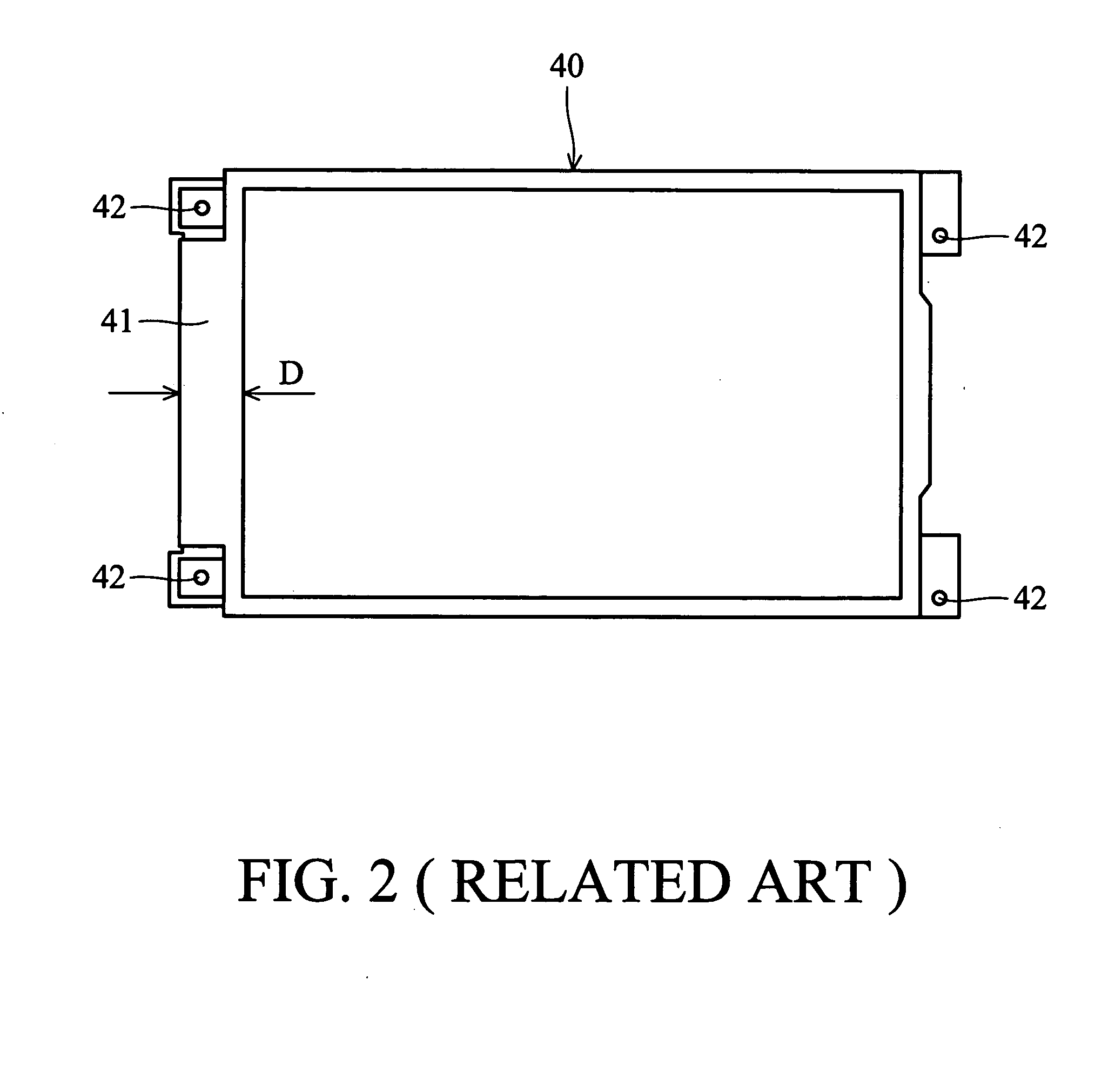

Flat panel display and panel module thereof

InactiveUS20050073623A1Reduce thicknessImprove efficiencyStatic indicating devicesDetails for portable computersVehicle frameDisplay device

A flat panel display and panel module thereof. The flat panel display includes a housing, a panel module and a main bracket. The panel module, contained in the housing, includes a front frame, a rear frame, and a panel. The front frame and the rear frame are assembled to encase the panel. The rear frame has at least one connecting portion, covered by the encased panel. The main bracket is disposed in the housing to connect the housing and the connecting portion of the rear frame.

Owner:QUISDA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com